SANDVIK Silent Tools Plus TA50D, Silent Tools TA51D, Silent Tools TA60D, Silent Tools TA61D General User Manual

Silent Tools™ Plus

Cylindrical turning

adaptor

TA50 D

TA51D

TA6 0 D

TA61D

General user manual version 1.0

© 2018 Sandv ik Coroma nt AB. All r ights rese rved. T his docume nt may not be c opied or

reprod uced in wh ole or in par t, or tran sferred to a ny other me dia or lang uage, by an y means,

without the prior written permission of Sandvik Coromant AB.

2

Introduction

Purchase

Congratulations on your purchase of a Silent Tools™ Plus Cylindrical

turning adaptor.

This m anual contains important safety directions and instructions for

product setup and operation.

Keep for further reference

Product identification

Product type and ar ticle numbers are printed on the product .

Refer to this when contacting Sandvik Coromant.

Validity of this manual

This m anual applies to the Silent Tools™ Plus adapter type: TA50D,

TA51D, TA60D and TA61D, chapter 2 describe naming rules.

Available documents

Silent Tools™ Plus Cylindrical Turning adaptor user manual and other

documents can be dow nloaded from t he Sandvik Coromant website:

http://www.sandvik.coromant.com

3

4

Introduction 3

1 Safety 6

1.1 General 6

1.2 Purpose 8

1.3 Limits of use 8

1.4 Areas of responsibility 9

1.5 Hazards of use 10

1.6 Unpacking 12

2 Product description 13

3 Description of the system 15

3.1 System components adaptor 15

3.2 System components charger kit 17

4 Operation 18

4.1 Setting up dampened turning adaptor 18

4.2 Mounting of the electronic unit to tool post 21

4.3 Connect coolant 22

4.4 Connecting cables 23

4.5 Start ing up 24

4.6 Updating the firmware 24

5 The sensors 25

6 Care and transport 27

6.1 Transport 27

6.2 Storage 27

6.3 Cleaning and dr ying 28

6.4 Modify tool 28

6.5 Conformity 29

6.6 FCC statement, applicable in U.S. 30

7 Warranty 32

8 Technical data 33

5

1 Safety

1.1 General

Description

The following instructions should enable the person responsible

for the product and the person w ho actuall y uses the equipment to

anticipate and avoid o perat ional hazards. The person responsible for

the product must ensure that all users understand these instructions

and adhere to them.

About warning messages

Warning messages are an essential part of product safet y. They

appear wherever hazards or hazardous situations can occur.

For use r safet y, all safety instructions and safety mes sages shall be

strictly observed and followed. Therefore, the manual must a lways be

available to all product users.

DANGER, WARNING, CAUTION and NOTICE are standardized sign al

words for identify ing levels of hazards and risks related to personal

injury and proper ty damage. For your safet y it is impor tant to read

and fully underst and the table below with the different signal words

and their definitions. Supplementary safety information symbols

may be placed within a warning message. as well as supplementary

information.

6

Danger Indicates an imminently hazardous situation

Warning Indicates a potentially hazardous situation or

Caution Indicates a potentially hazardous situation or

Notice Important information which must be adhered

which, if not avoided, will result in death or

serious injury.

an unintended use which, if not avoided, could

resul t in deat h or serious injur y.

an unintended use which, if not avoided, may

resul t in minor or moderate injury.

to in practice as it enables the product to be

used in a technically correct and ef ficient

manner.

7

1.2 Purpose

Permitted use

Prepare Silent Tools™ Plus Cylindrical Turning adaptor for work.

Adverse use

- Use of the product without instruction.

- Use outside of t he intended limits.

- Disabling safety systems.

- Removal of haz ard notices.

- Opening the product using tools, e.g., screwdriver, unless

specifically instructed for certain functions.

- Modification or conversion of the product.

- Use after misappropriation.

- Use of products with obviously recognizable damages or defect s.

- Use with accessories from other manufacturers without the prior

explicit approval of Sandvik Coromant.

Warning

Adverse use can lead to i njur y, malfunction and damage. It is the

task of the person responsible for the equipment to inform the user

about hazards and how to counteract them. T he product is not to be

operated unt il the user has been instructed on how to work with it.

1.3 Limits of use

Environment

Suitable for use under rough conditions, ref. technical data.

Not sui table for use in agressive or explosive environments.

8

1.4 Areas of responsibility

Manufacturer of the product

Sandvik Coromant is responsible for supplying the product, including

the user manual and original accessories, in a completely safe

condition.

Manufacturers of non Sandvik Coromant Accessories

The manufacturers of non-Sandvik Coromant accessories are

responsible for developing, implementing and communicating

safet y concepts for their products, and are also responsible for the

effectiveness of those safety concepts in combination with the

Sandvik Coromant product.

Person in charge of the product

The person in charge of t he product has the following duties:

• To understand the safety instructions on the product and the

instructions in the user manual

• To be familiar wit h local regulations relating to safety and accident

prevention

• To inform Sandvik Coromant immediately if the product becomes

unsafe

9

1.5 Hazard of use

Warning

The absence of instruction, or the inadequate imparting of

instruction, can lead to incorrect or adverse use, and can give

rise to accidents with far-reaching human, material, f inancial and

environmental consequences.

Precautions: All users m ust follow the safety instructions given by

the manufacturer and the directions of the person responsible for the

product.

Warning

This tool is intended for use by skilled persons and knowledge on the

use of this tool and have understood the resulting risks.

Precautions: Read all instructions before using the tool system.

Warning

Use all appropriate safety guards or machine encapsulations to

securely collect particles such as chips or cutting elements that may

spin off.

10

Precautions: Always use appropriate personal protective

equipment.

Caution

The user must u se the tool as inte nded.

Precautions: Only Sandvik Coromant authorized serv ice

workshops are entitled to repair these products.

Caution

Check important components for damage prior to every operation.

Precautions: DO NOT USE or ope rate damaged tool or product.

Retur n the product to the appropriate location for repair, replacement

or recycling.

11

1.6 Unpacking

When u npacking the product, make sure that no accessories are

missing and that none of the package contents have been damaged.

If you detect any t ransport damages please contact your sales

representatives.

Warning

For safety reasons it is recommend to use lifting eq uipment for

lifting damped boring adaptors heavier than 18kg/40lb.

(BD x L > Ø60x800mm/Ø2,5”x31”). Lifting slings are

recommended.

Warning

Do not use a magnet when lif ting carbide reinforced

boring adaptors.

Caution

The front of the dampened boring ada ptor may be heavier because

of the integrated damped system. Check the center of gravity before

lifting.

Warning

Keep the packaging for safe storage of tools.

12

2 Product description

Example: TA61D-CY50C865W4RB (kit), includes

- adapter TB61D-CY50C865W4RB (tested adapter type 160782)

- electronic u nit: ST+:BT A 2PP (160953) / ST+:BT A 1PP (157434)

- battery: ST+ A Bat9.6Wh (157432)

The adapter is delivered in ma ny design variants based on the family,

see naming description.

Product description

Product name See marking on turn ing adaptor

Product family TA TA... Kit structure with accessor y

TB... Turning adaptor

Product type 6 5… 4C dampened bars

(sensor embedded)

6… 3C dampened bars

(sensor embedded)

Product material group 1 0... Steel

1... Carbide reinforced

Design versions

Adaptor type D D… Damped

() … Not damped

Machine side coupling CY CY… Cylindrical

13

Bar diameter 50 40, 50, 60 … and other diameter

sizes in millimeter

A... Inch descript ion, bar diameter

given in 1/16 inch

Sensor type/

signal connection C A... Unsensored

B... 1 sensor, con nector type PP x1

C... 2 sensors, connector type PP x2

D... 2 sensors, connector ty pe PP x1

Funct ional length 865 400, 500, 865...1500 and ot her, in

mm (equ al to body length for CY)

Work side

coupling interface W W... Wedge lock

S... Serration Lock

Work side

coupling interface size 4 1... 16mm, 2... 25mm, 3... 32mm, 4... 40mm

6... 60mm, 8... 80mm, 0... 100mm

Work side

coupling position R R... Right

L... Left

N... Neutral

2... 2 couplings

Area code electronics B A... G lobal

B... CE and FCC/IC (Europe, Nor th America)

C... CCC (China)

D... PSE (Japan)

E... KC (Korea)

14

F... NOM (Mexico)

3 Description

of the system

3.1 System components adaptor

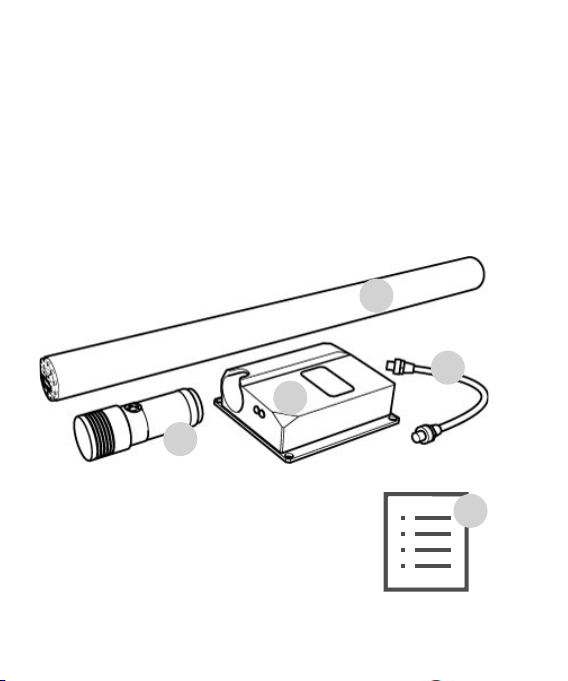

Main components

Component Description

1 Turning adaptor • A turning adaptor that can mount a cutting

head with an insert and per form metal

cutting

• Consists of various models with a range of

sizes in diameter and length

• Integrated w ith sensor(s)

• Electronic unit (2), a connecting cable

(3) and a batter y (4) to form a system*

for remote monitoring of the machining

process

2 Elect ronic unit • Provide a link to the tool, through the

connecting cable (3), type PP (Push-Pull)

• Provide communication to/from t he sensor

in the tool (1)

• Provide power to the sensor and the

transmitter

• Transmit the signal to the tablet (7)

15

3 Connecting cable • Connecting the turning adaptor (1) to the

• Cable with PP type connectors (push-pull)

• Length 300 mm or 500mm

4 Battery • Type-A Li-ion

5 User Manuals • Silent Tools™ Plus Turning adaptor

• Silent Tools™ Elect ronic unit

• Silent Tools™ Battery

electronic u nit (2)

1

3

2

4

5

16

3.2 System components charger kit

(if ordered together)

Component Description

6 Charger • Provide charging of Type-A Li-ion battery

7 AC power adaptor • Wall adaptor

8 AC socket • Socket for EU/UK /USA

9 User Manuals • Silent Tools™ Plus Charger

• AC power

6

7

9

8

17

4 Operation

Notice

If the equipm ent is used in a manner not specif ied, the protection

provided by the equipment may be impaired.

4.1 Setting up dampened turning

adaptor

Before use

Make sure that the machine side, coupling surfaces of the tool and

tool holder are free from dust or chips. If necessar y, clean with a wet /

dry cloth.

18

Setting up dampened adaptors

Two important factors for achieving the right dimensional tolerances

and surface finish of the component are clamping stability and

correct center height for the i nser t.

- Ensure that the length of the t urning adaptor allows for the

recommended clamping lengths. The clamping length is

recommended to be 4 times the diameter of the bar, minimum 3xd.

- Clamp in a split sleeve holder to achieve maximum contact area.

Recommended clamping tolerance is ISO H7. Recommended

bushing material w ith a minimum 45 HRC to avoid permanent

deformation.

- Never use screw s in direct contact with the bar shank as they may

damage the bar.

19

Orient tool

The tool must be rotated to the correct position (around center a xis),

for cor rect placement of the insert. This is done most easily with the

Silent Tools™ Plus sof tware. We recommend doing this when the

Silent Tools™ Plus sof tware is up and running.

A manu al lever can be used on slant bed machines.

Overhang (OHX)

The Silent Tools™ Plus Cylindrical Turning adaptor with Load Sensor

has a fixed overhang position. The sensor is placed at a specific

position inside the tool to ensure it functions as intended. Refer to t he

cata log drawing for the adaptor.

The Silent Tools™ Plus Cylindrical Turning adaptor with only Vi bration

Sensor can be used wit h overh ang bet ween OHN and OHX, as

specified in the catalog drawing for the adaptor.

20

4.2 Mounting of the electronic unit

to tool post

Mounting to tool post

4

Follow instruction in the user manual for

the electronic unit.

- Make threading holes on the machine tool holder (4).

- Fasten the electronic unit to the machine tool holder (4).

- Connect the dampened turning adaptor to the electronic unit using

connecting wire (1).

- Antenna lid (3) should be in front when fastening the electronic unit

to the tool holder.

- Risk for breakage: Make sure th at the connecting cable is not in

contact wit h machine or other par ts that may c ause damages by

running over, pinching, dragging or the like.

1

3

2

21

4.3 Connect coolant

Coolant flow

Make su re that t he coupling surfaces and threads of the fitting are

free from dust or particles. If necessary, clean with a cloth.

Thread type: G1/8 (1/8 BSP), Sealing is provided by an O-ring gasket

or a sealing washer. Torque according to fitting instructions.

Maximum pressure

The tool is design for a maximum coolant pressure of 150 PN (ba r).

Caution

Use fi ttings and tubing towards t he tool according to the maximum

coolant pressure used.

22

4.4 Connecting cables

Connect cable(s)

The adaptor sensor is connected to the radio module through a cable.

The adaptor may be equipped with one or two connector(s). The

connector is of a type PP (push -pull). Orient the cable as indicated by

the groove in the connector or N-mark. Push it in. Do not twist.

Removing cable(s)

Grasp the cable by the plug and pull out. Do not t wist.

Do not pull from the cable.

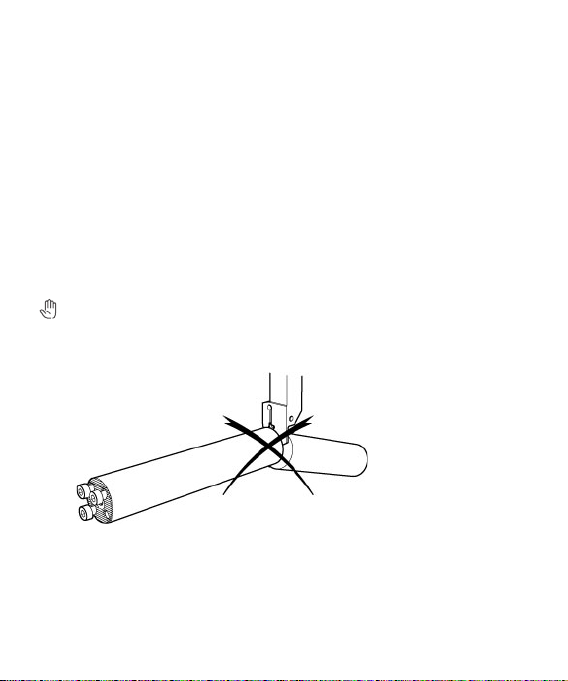

Caution

X

23

4.5 Starting up

Updating adaptor

See Use r Manual Silent Tools™ Plus Electronic Unit.

4.6 Updating the firmware

Firmware upload

Caution

Uploading f irmware can take some time. Ensure that the battery is at

least 75% charged before you star t the upload. Do not remove the

battery during t he upload process. Software is downloaded to the

tablet/PC.

When new application software is connected to the tools electronic

unit:

1) It will check if new firmware has been downloaded, compared to the

version used .

2) User will be prompted to update f irmware or postpone update.

3) When the update is complete, a message appears.

24

5 The sensors

Sensors

The Silent Tools™ Plus Cylindrical Turning adaptor can be equipped

with one or two senso r units.

Sensor 1, vibration

The vibration sensor is located just behind the cutting head interface.

It is positioned as close to the insert as possible, ensuring that the

vibr ation s that affect the sur face qualit y are monitored. The sensor

monitors vibration in three axes. The sensor monitors vibration values

from very small vibrations up to crash sit uations.

The algorithms in t he Silent Tools™ Plus softw are prov ide you w ith

analysis of the sensor information registrated during the machinging

process. The main functionsare in cut-, roughness- and vibration

monitoring. In the Silent Tools™ Plus software the algorithms are

anal yzed in more detail.

The temperature probe monitors the internal temperature in the

adaptor. Operating the adaptor within the specified temperature

range ensures optimal performance of the damping system.

The vibration sensor is calibrated from the factory.

25

Sensor 2, Load

The load sensor monitors the cutting forces and the bending of the

tool. It monitors the adaptors bending in two axes ( X and Y).

The sensor provides i nput to t he load and deflecton f unctions. It also

provides enhanced functions of the in cut and roughness functions.

More information about these funcions can be found in the Silent

Tools Plus software.

Caution

The sensor must be calibrated for best performance:

• Load function is factory calibrated, and can be f urther improved

• Deflection calibration must be done in the turning machine where

the tool is to be used

Calibration is done by a Sandvik Coromant technician or through a

specific test cut procedure. This w ill also enhance the tolerance of

the load function.

26

6 Care and transport

6.1 Transport

Shipment

When t ransport ing the product by rail, air or sea, always use the

complete original Silent Tools™ Plus packaging, transport container

and cardboard box, or equivalent , to protect against shock and

vibration.

6.2 Storage

Product

When t he adaptor is stored in a wet e nvironment, i.e. in the machine,

keep the adaptor connected to the cable to protect the con nectors.

Caution

Respect the temperature limits when storing the product, particularly

in summer if the product is inside a vehicle. Refer to sect ion “7

Technical Data” for information about temperature limits.

Keep the packaging for safe storage of the tool.

27

6.3 Cleaning and drying

Product

Use a cle an, sof t, lint-free cloth for cleaning. Electrical contact

cleaner can be used in small amounts on cable connector(s).

Cables and plugs

Keep plugs clean and dr y. Blow away any dirt lodged in the plugs of

the connecting cables.

6.4 Modify tool

Modifying of damped boring adaptor

Caution

• Shortening the adaptors with integrated electronic data collecting

system is not allowed

28

6.5 Conformity

EU

Sand vik Coromant AB declares that the product Silent Tools™ Plus

Cylindrical Turning adaptor complies to the:

Safety:

• EN 61010-1

Electromagnetic Compability (EMC):

• EN 61000-6-2

• EN 61000-6-4

Following the provisions of EU-directives:

• 2014/35/EU (low voltage)

• 2014/30/EU (EMC)

• 2011/65/EU (Rohs2)

USA/Canada

Safety:

• UL 61010-1

• CS A-C2 2.2 #61010-1

29

6.6 FCC statement, applicable in U.S.

This product has been tested and found to comply with the limits for a

Class B digit al device, pursuant to part 15 of the FCC rules.

These limits are designed to provide reasonable protection against

harmful interference in a residential installation.

This equipment generates, uses and can radiate frequency energy

and, if not installed and used in accordance with the instructions, may

cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a

particular installation.

If this equip ment does cause harmful interference to radio or

telev ision reception, which can be determined by turning the

equipment off and on, the user is encouraged to tr y to eliminate the

interference by one or more of the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and the receiver.

- Connect the equipment to an outlet on a circui t different from that

to which the receiver is connected.

- Consult the dealer or an experienced radio/T V technician for help.

30

Labels

TB61D-XXXXXXXXXXX

TB61D-XXXXXXXXXXX

31

7 Warranty

Product

Sand vik Coromant AB warrants its equipment for a limited period of

two ye ars, from purchase date, provided that it is installed exactly as

defined in associated Sandvik Coromant documentation.

Failure to comply with this w ill inv alidate the Sa ndvik Coromant

warranty. Claims under warranty must be made from authorized

service/ sales personnel from Sandvik Coromant only.

For more information about Silent Tools damped adaptors please visit

www.sandvik.coromant.com (Application guide).

32

8 Technical data

Sensors

Sensor 1, Vibration Monitor vibrations from 0 -50 G

Monitor vibrations in 3 axes

(X-, Y- and Z-axis)

Temperature 0 – 120°

Sensor 2, Load Load, up to tools maximum load

(see label on tool)

Deflection in two directions

(X- and Y-axis)

Input / Output Signal

Vibration signal Signal cable, shielded 10 pin push-pull,

maximum 500 mm

Deflection signal Signal cable, shielded 10 pin push-pull,

maximum 500 mm

Input voltage 3.3v and 5.0\v

Power maximum 0.18W (3.3v) and 0.25W (5.0\v)

Operating environment IP56 according to IEC 60529

Indoor use in lathe/CNC machine,

closed or open , dry or wet machining

33

Temperature range Storage : - 40°C to +85°C

Operating: 0°C to +70°C

Relative humidity Use 10%-95%,

Storage recommended 10%- 50%

Maximum altitude 2000 m

Weight See adaptor catalog d rawing

(packaging not included).

Dimensions See adaptor catalog drawing.

34

35

Get started

To get star ted using Silent Tools™ Plus, please go to

the Sa ndvik Coromant website and activate the software using

the serial number.

www.sandvik.coromant.com/silentTools™ Plus/activate

Serial number:

Manufacturer:

Sandvik Teeness AS

Ranheimsveien 127

7053 Ranheim

Norway

92056

© AB Sandvik Coromant 2018.01

Loading...

Loading...