Instruction Manual

5 Burner Gas Hob

S5GONGW13/S5GONGB13

2

Contents

Safety Warnings ...................................................................................................................... 4

Unpacking ................................................................................................................................ 6

Product Overview ................................................................................................................... 7

Main Unit ............................................................................................................................................ 7

Control Panel .................................................................................................................................... 7

Before Using Your New Hob ................................................................................................. 8

Lighting the Hob ..................................................................................................................... 8

Manual Ignition (in case of electricity failure) ............................................................................8

Flame Failure Safety Feature ......................................................................................................... 9

If the Burner Does Not Light ......................................................................................................... 9

If the Flame is Irregular .................................................................................................................. 9

Cookware Guidelines ..................................................................................................................... 10

Cleaning and Maintenance ....................................................................................................11

Cleaning Burner Parts and Pan Supports ..................................................................................12

Replacing the Burners....................................................................................................................12

Hob Controls ....................................................................................................................................12

Hints and Tips .........................................................................................................................13

Specifications .........................................................................................................................14

Nominal Heat Input Chart ....................................................................................................14

Installation ..............................................................................................................................15

Ventilation ............................................................................................................................... 15

Location ...................................................................................................................................16

When the Hob is First Installed ........................................................................................... 17

Fitting ................................................................................................................................................17

Fitting the Hob into the Worktop ............................................................................................... 18

Electrical Connection ............................................................................................................19

Gas Connection .....................................................................................................................20

Check the Hob After Installation & Before Using ................................................................... 20

3

Conversion from NG to LPG or from LPG to NG ..............................................................21

Method ..............................................................................................................................................21

Adjusting the Gas Rate .................................................................................................................21

Burner Configuration Table ......................................................................................................... 22

4

Safety Warnings

IMPORTANT SAFETY INSTRUCTIONS

READ CAREFULLY AND KEEP FOR FUTURE REFERENCE

• This appliance must be installed by a qualified Gas Safe registered

engineer. The manufacturer is not responsible for any damage caused

by incorrect installation.

• Check whether there is any damage to the appliance after you have

unpacked it. If any damage is found, do not use the appliance and

contact the store where you purchased it.

• This appliance is for indoor domestic use only.

• This appliance is for cooking purposes only. It must not be used for

other purposes, for example room heating.

• The hob is fitted with a moulded mains plug. The mains plug must

remain accessible or a switch providing full disconnection incorporated

in the fixed wiring.

• If the mains cable gets damaged, it should be replaced by an authorized

service agent or qualified electrician in order to avoid a hazard.

• The hob must be used in a well ventilated location and installed on

a flat/level surface.

• Only operate your appliance in a dry atmosphere.

• Keep the electrical cables of your other appliances away from hot

areas; do not let them touch the appliance.

• Ensure that the appliance is switched off at the mains supply switch

and allowed to completely cool down before cleaning or performing any

maintenance to avoid the possibility of an electric shock or burns.

• The use of a gas cooking appliance results in the production of heat,

moisture and products of combustion in the room in which it is

installed. Ensure that the kitchen is well ventilated especially when the

appliance is in use. Keep natural ventilation holes open or install a

mechanical ventilation device (mechanical extractor hood).

5

• Prolonged intensive use of the appliance may call for additional

ventilation, for example opening of a window, or more effective

ventilation, for example increasing the level of mechanical ventilation

where present.

• This appliance is not intended for use by persons (including children)

with reduced physical, sensory and mental capabilities, or lack of

experience and knowledge, unless they have been given supervision or

instruction concerning the use of the appliance by a person responsible

for their safety.

• Cleaning and user maintenance shall not be made by children without

supervision.

• Children should be supervised to ensure that they do not play with

the appliance.

• The appliance and its accessible parts become hot during use. Young

children should be kept away.

• Unattended cooking on a hob with fat or oil can be dangerous and may

result in fire. NEVER try to extinguish a fire with water, but switch off

the appliance and then cover the flame e.g. with a lid or a fire blanket.

• Danger of fire: Do not store items on the cooking surfaces.

• When the hob is hot never touch any parts that get hot. Allow the hob

to cool before touching these parts.

• Before starting to use your appliance, keep curtains, tulle/netting,

paper or flammable materials away from your appliance.

• Do not keep combustible or flammable things on or near the appliance.

• Do not use steam cleaners for cleaning the appliance.

• The appliance is not intended to be operated by means of an external

timer or separate remote-control system.

6

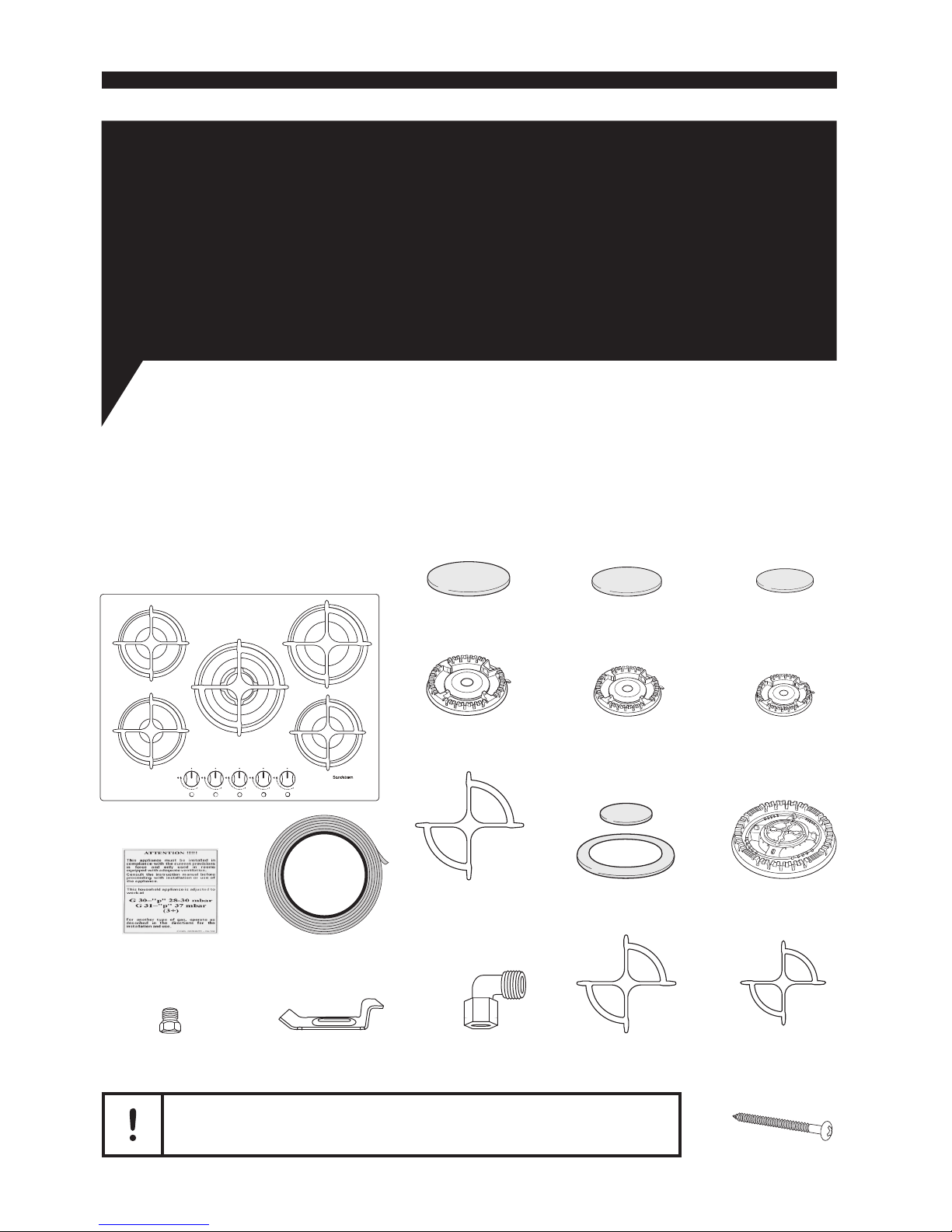

Unpacking

Remove all packaging from the unit. Retain the packaging. If you dispose of it, please do so according

to local regulations.

The following items are included:

Thank you

Thank you for purchasing your new Sandstrøm Gas Hob. Like all Sandstrøm products

our gas hobs take inspiration from traditional Scandinavian values of quality and

functionality, combined with modern innovations and a flair for simply looking good.

These operating instructions will help you use it properly and safely. You must spend

some time reading this manual in order that you fully understand all the operational

features it offers. Read all the safety instructions carefully before use and keep this

manual for future reference.

Screws x4

If items are missing or damaged, please contact Partmaster (UK only).

Tel: 0844 800 3456 for assistance.

Fixing Bracket x4

Elbow Connector

with Washer x1

Main Unit

Self Adhesive

Sealing Tape x1

LPG Nozzle x4

90 mm

Burner Cap x1

125 mm Inner &

Outer Cap x1

90 mm

Burner Ring x1

90 mm

Pan Support x1

65/45 mm

Pan Support

125 mm

Pan Support x1

65 mm

Burner Cap x2

45 mm

Burner Cap x1

65 mm

Burner Ring x2

45 mm

Burner Ring x1

125 mm

Burner Ring x1

LPG Replacement

Plate Sticker x4

7

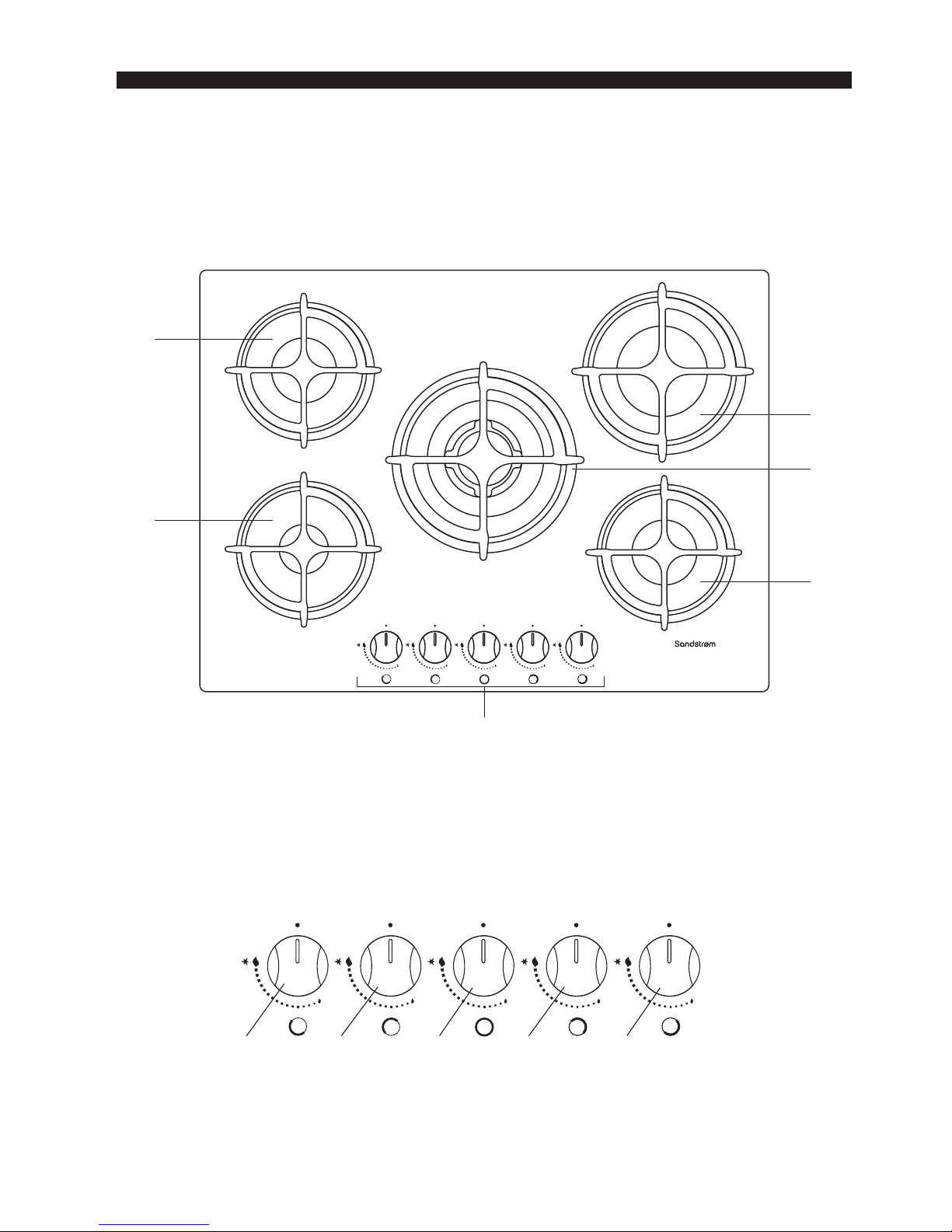

Product Overview

Main Unit

Control Panel

1. Standard Burner (65 mm)

2. Small Burner (45 mm)

3. Large Burner (90 mm)

4. Extra Large Burner (125 mm)

5. Standard Burner (65 mm)

6. Control Panel

1. Selects front left burner

2. Selects back left burner

3. Selects centre burner

4. Selects back right burner

5. Selects front right burner

1

2

5

3

4

6

1 2 43 5

8

Before Using Your New Hob

Before using your new hob, please:

• Read this manual fully, taking special note of the ‘Safety Warnings’ section.

• Plug the hob into the electricity supply and turn it on so that the ignition circuit will work.

• This appliance is for cooking purposes only. It must not be used for other purposes,

for example room heating.

• The use of a gas cooking appliance results in the production of heat, moisture and products

of combustion in the room in which it is installed. Ensure that the kitchen is well ventilated

especially when the appliance is in use: keep natural ventilation holes open or install a

mechanical ventilation device (mechanical extractor hood). Prolonged intensive use of the

appliance may call for additional ventilation, e.g. opening of a window, or more effective

ventilation, e.g. increasing the level of mechanical ventilation where present.

Lighting the Hob

1. Choose the control for the burner you intend using.

2. Press the burner control in lightly and turn anti-clockwise to the large flame symbol

.

3. Press the burner control in fully. The spark ignition will operate and gas will be released whilst you

hold in the control.

Continue to hold the control in for approximately 5 – 10 seconds after the burner has lit before

adjusting to the desired setting. Releasing the control too soon will extinguish the flame due to the

flame failure safety feature.

4. Adjust the flame anywhere between the

and positions. Do not adjust the flame between the

and Off ‘

’ position.

5. After ignition, check the flames visually. If you see yellow tipped, lifted or unstable flames; turn the

control off, and check the assembly of the burner rings and caps. Allow these to cool before

touching. Also, make sure that no liquid has entered into the burner cups. If the burner flames go

out accidentally, turn the burners off, and do not try to light them again for at least one minute

(to allow the gas to disperse).

6. When turning the hob off, turn the control in a clockwise direction. If the control stops at the maximum

flame mark, push the control in slightly and continue turning clockwise to the off mark, ‘

’.

• If the burner does not light within 15 seconds, turn the control off

and wait for at least one minute before trying again.

• To switch the burner off, turn the control clockwise to the off position.

• After use, always turn the controls to the off position.

Manual Ignition (in case of electricity failure)

1. Choose the control for the burner you intend using.

2. Press the burner control in lightly and turn anti-clockwise to the large flame symbol

.

9

3. Hold an ignition source (e.g. candle lighter) close to the side of the burner and press the burner

control in fully to release and light the gas.

The control must still be held down for approximately 5 – 10 seconds after the burner has lit.

Releasing the controls too soon will extinguish the flame.

4. Adjust the controls as required.

Flame Failure Safety Feature

The flame supervision device (FSD) probe cuts off the gas supply to the burner within one minute if the

flame is extinguished.

If the flames are accidentally extinguished, turn off the burner and do not try to light it again for at

least one minute (to allow the gas to disperse).

When lighting the burner, hold down the control for approximately 5 – 10 seconds after the burner has

lit. Releasing the control too soon will extinguish the flame.

If the Burner Does Not Light

If the burner does not light, check that:

• The hob is connected to the electrical supply and the supply is switched on.

• The gas is turned on.

• You have held down the control for at least 5 – 10 seconds after the flame has been lit.

• The ignitors are sparking. If the ignitors are not sparking,

they may be dirty or wet. Clean them gently with a small nylon

brush such as a toothbrush as shown opposite and allow to

dry fully. Ensure the electrical supply has been

disconnected before cleaning.

To avoid damage to the ignition circuit

NEVER light the hob when the burners

are not in place.

If the Flame is Irregular

If the flame is yellow or irregular, check that the burner parts,

including the burner cap (allow this to cool before touching) are:

• Clean and dry.

• Positioned correctly. See ‘Replacing the Burners’.

• Also see ‘Hints and Tips’.

Ignitor

Flame failure

probe

Burner Cap

Electrode

Burner Ring

10

Cookware Guidelines

To get the best out of your hob, follow these simple suggestions:

• Use saucepans with thick flat bottoms. Food in a saucepan with an uneven bottom will take longer

to cook.

• Do not use large saucepans or frying pans that overlap the edges of your hob as this can deflect

heat onto your worktop and damage the surface, and may also cause a hazard.

• Always make sure saucepans are stable. Using very heavy saucepans may bend the trivet/pan

support or deflect the flame.

• Always lift the cookware when removing from the hob, do not drag.

• When you need to boil, simmer or fry food, first set the temperature to the High position.

Once the food is boiling, reduce the temperature to maintain a steady heat to cook your food

thoroughly. Doing this will reduce the cooking time and save energy.

• Pan sizes should be as per the table shown below.

Burners Minimum Diameter Maximum Diameter

Extra Large 24 cm 26 cm

Large 20 cm 22 cm

Standard 16 cm 18 cm

Small 10 cm 14 cm

Do not use cooking vessels on the hob

that overlap its edges.

• Using a lid will reduce cooking times and save energy.

• Choose cookware of the proper size, material and construction.

• Minimise the amount of liquid or fat to reduce cooking times.

• Select the proper temperature setting for the cooking task.

Avoid using pans of the maximum diameter on both the large and extra large burners

together as these sizes will not allow the pans to sit centrally above the gas flame.

11

Cleaning and Maintenance

• To avoid shock hazard, always disconnect the hob from the electrical supply.

• Steam Cleaners must not be used to clean this product.

Cooking Part Cleaning Method Important

Trivets/pan supports,

burner caps and

enamel surfaces

• Hot soapy water and nylon scourer

• Non-abrasive cream cleaners

• Always allow hob parts to cool

completely before cleaning them

• Always apply minimal pressure

with cleaners

• Remove spills as soon as the hob

is cool to avoid the spills becoming

burnt on

Burner parts • Hot soapy water

• To clear the holes use a stiff nylon

brush

• Non-abrasive cream cleaners

• Ensure burner parts are dry before

refitting

• Reassemble the burner parts

correctly

Controls • Hot soapy water and a soft cloth • Care must be taken if removing the

controls from the shafts

• If cleaning the controls whilst they

are attached to the shaft, ensure

liquid does not enter the appliance

Hob surfaces • Soak stains under a hot soapy cloth,

rinse and dry thoroughly

• Non-abrasive hob surface cleaners.

Regular use of a polish designed for

use with glass hobs will reduce

fingerprints and other marks

• Never use harsh/abrasive cleaning

agents as they will damage the finish

• Chlorine or chlorine compounds in

some cleaners are corrosive to hob

surface and may damage the

appearance of your hob. Check the

label on the cleaner before using

Electrodes • Toothbrush • A dirty or wet electrode will prevent

the burner lighting efficiently. Ensure

the appliance has been disconnected

from the electrical supply before

cleaning or drying

Regular Maintenance

Daily

• Clean gas hob as per the instructions

Monthly

• Remove all burner parts, and clean using a non-abrasive detergent.

Rinse in cold water, dry thoroughly, and replace

• Clean the ignitor and probe carefully, using a toothbrush

Yearly

• Contact your local authorized gas Service Agent to perform a thorough check

on all gas components on the gas hob

12

Cleaning Burner Parts and Pan Supports

You can remove and clean these parts with hot soapy water or non-abrasive detergents.

Clean spills regularly before they become burnt on, especially spills of vinegar, coffee, milk, salt

water, lemon or tomato juice.

Do not wash these parts in a dishwasher.

After cleaning, check that the burner rings and burner caps are dry before replacing correctly.

It is very important to check that the burner rings and burner caps have been correctly positioned.

Failure to do so can cause serious problems.

To avoid damage to the ignition

circuit NEVER light the hob when

the burners are not in place.

Replacing the Burners

Check that:

• The ignitor is always clean to ensure trouble-free sparking.

• The FSD probe is always clean to ensure correct operation

of the safety valves.

• All the burner parts are assembled correctly.

• Both the ignitor and probe must be very carefully

cleaned using a toothbrush.

• When replacing the burner parts, ensure you do not

damage the ignitor or temperature probes.

Hob Controls

These parts are not user serviceable.

If you have problems with the hob controls (gas taps), call your Authorised Service Centre.

13

Hints and Tips

Problem Possible Solutions

My burner does not light • Check the hob is plugged in and the electricity is switched on

• Check the gas supply valve is turned on and the gas supply

to the house is working. You should hear the gas when you turn

a burner on

• Ensure the control is held down for 5 – 10 seconds after the burner

has lit, as releasing the control too soon will extinguish the flame

• The ignitors may be dirty. Clean gently with a small nylon brush

such as a toothbrush

• The burner parts may not be located properly. Check the assembly

and make sure the burner cap is sitting flat

My burner flames are yellow

or hard to start

• The burner parts may not be located properly. Check the assembly

and make sure the burner cap is sitting flat

• If you use bottled gas this may indicate you are getting near the

end of the bottle

• Check the burner parts are clean and dry

• The gas pressure may not be at the correct level. Check with your

approved service agent

• Your hob may not be set up for the gas you are using. Check this

with your approved service agent or installer

One of my burners has

an uneven flame

• Check the burner parts are clean and dry. Check the assembly and

make sure the burner cap is sitting flat

My burner goes out when

I let go of the control

• The hob has a safety feature called ‘Flame Supervision Device

(FSD)’. Hold down the control for approximately 5 – 10 seconds

after the burner has lit. Releasing the control too soon will

extinguish the flame. See the ‘Flame Failure Safety Feature’ section

The flame goes out at

low settings

• The gas supply pressure may be low. Check this with your

approved service agent

• The low setting may have been adjusted incorrectly.

Check this with your approved service agent

My burners do not turn down

much (when running on bottled

gas or LPG)

• Your burners may not have been adjusted correctly.

Check this with your approved service agent

The flame tips are very yellow • Call your approved service agent

There are objectionable odours • Ensure the hob and burners are clean and dry

• Call your approved service agent

The flame appears to lift off

the burner

• Call your approved service agent

There is an electricity failure • If there is an electricity failure, you can still use your hob.

See the ‘Manual Ignition’ section for more information

14

Specifications

Model No. S5GONGW13/S5GONGB13

Rated Voltage (V)

220 – 240

Rated Frequency (Hz)

50

Power Consumption (W)

1.1

Gas Type

NG or LPG (Default set to NG)

Net Weight (kg)

15

External Product Dimensions (cm)

Width x Depth

68 x 50

Internal Product Dimensions (cm)

Width x Depth

55 x 47

Features and specifications are subject to change without prior notice.

Nominal Heat Input Chart

Burner Power Output

Extra Large Burner (120 mm) 3100W

Large Burner (90 mm) 2800W

Standard Burner – back left (65 mm) 1750W

Standard Burner – front right (65 mm) 1400W

Small Burner (45 mm) 1000W

15

Installation

• This appliance must be installed and serviced only by a suitably qualified and Gas Safe

Registered engineer, and in accordance with the current editions of the following standards

and regulations or other locally applicable regulations:

Gas Safety (Installation and Use) Regulations

Building Regulations

British Standards (BS 5440, BS 6172 and BS 6891)

Regulations for Electrical Installation (BS 7671, (Latest Edition))

• Please, ensure that, once the hob is installed, it is easily accessible for the engineer in the

event of a breakdown

• This hob uses and is ready to use NATURAL GAS only and cannot be used with any other

gas without modification. This appliance is manufactured for conversion to LPG after fitting

new injectors and making adjustments. Refer to “replacement of burner injectors” section

for details.

• Prior to installation, ensure that the local distribution conditions (nature of gas and pressure) and

the adjustment of the product are compatible. The adjustment conditions for this product are stated

on the data plate.

• Ensure that there is a mains socket within reach of the hob cable (1500 mm from the rear left of the

product). This must be accessible after installation or an all-pole disconnection switch must be

provided in the fixed wiring in accordance with the local wiring regulations. The mains cable must

not touch any hot parts.

• Ensure that your kitchen worktop is designed for use in a kitchen.

Ventilation

• This appliance is not connected to a combustion products evacuation device. It should be installed

and connected in accordance with current installation regulations. Particular attention should be

given to the relevant requirements regarding ventilation.

• The appliance should be installed in a room or space with an air supply in accordance with the latest

edition of BS5440-2.

• For rooms with a volume of less than 5m

3

— permanent ventilation of 100cm2 free area will be required.

• For rooms with a volume of between 5m

3

and 10m3 a permanent ventilation of 50cm2 free area will

be required unless the room has a door which opens directly to the outside air in which case no

permanent ventilation is required.

• For rooms with a volume greater than 10m

3

— no permanent ventilation is required.

• Regardless of room size, all rooms containing the appliance must have direct access

to the outside air via a window that opens or equivalent.

• Where there are other fuel burning appliances in the same room, the latest edition

of BS 5440-2 should be consulted to determine the correct amount of free area

ventilation requirements.

16

Location

• The hob should be located in a kitchen or kitchen/diner, but not in a bathroom, shower room,

garage or a bed sitting room with a volume less than 20 cubic metres.

• Before making the cut out in the worktop ensure that there is a minimum distance of 50 mm

between the rear edge of the hob and the wall.

• A minimum distance of 175 mm must be left between the side edges of the hob and any adjacent

cabinets or walls.

• The minimum distance combustible material can be fitted above the hob in line with the edges of

the hob is 450 mm.

• The minimum distance combustible material can be fitted directly above the hob is 760 mm.

• The furniture walls adjacent to the cooker must be made of heat resistant material (check with your

furniture supplier). The veneered synthetic material and the glue used must be resistant to

a temperature of 150°C in order to avoid ungluing or deformations.

The use of a gas cooking appliance results in the production of heat, moisture and products

of combustion in the room in which it is installed. Ensure that the kitchen is well ventilated

especially when the appliance is in use: keep natural ventilation holes open or install a

mechanical ventilation device (mechanical extractor hood). Prolonged intensive use of the

appliance may call for additional ventilation, e.g. opening of a window, or more effective

ventilation, e.g. increasing the level of mechanical ventilation where present.

600 mm

40 mm

175 mm

65 mm

50 mm

450 mm

Curtains 2000 mm

760 mm

When fitting the hob with a cooker hood above

17

When the Hob is First Installed

Once the hob has been installed, it is important to remove any protective materials, which were put

on in the factory.

Any gas installation must be carried out by a Gas Safe Registered engineer.

The manufacturer will not accept liability, should the above instructions or any of the other safety

instructions incorporated in this manual are ignored.

Connect the threaded elbow to the gas supply input if required. The washer (supplied) must be fitted

between these components, if any adjustments are made ensure parts are screwed together without

using excessive force.

Fitting

The dimensions of the cut-out are given in the diagram.

Width: 553 mm Depth: 473 mm

Product Overall Dimensions

Width: 680 mm Depth: 500 mm

63.5mm

63.5mm

175mm

473mm

553mm

18

Fitting the Hob into the Worktop

When fitted, the metal base of the hob should rest against the worktop.

Do not allow the glass surface of the hob to rest against the worktop

as it could cause damage to the glass.

1. Remove all removeable parts from the hob.

2. Turn the hob upside down and place it on a soft surface to avoid scratching.

3. Measure the width and depth of the outer edge of the hob glass and cut the self adhesive sealing

tape (supplied) to the correct lengths.

4. Stick the sealing tape to the outer edge of the underside of the hob. Ensure the strips of tape fit

together at the corners but do not overlap.

5. Remove the backing strip from the sealing tape and carefully fit

the hob into the aperture.

6. Fit the four brackets to the underside of the hob. Insert the

hooked edge of the bracket into the slot on the underside of

the hob and secure the bracket in place with the screw. Replace

the procedure for the other three brackets.

7. Adjust the position of the brackets depending on the thickness of

the worktop as indicated below and tighten the screws evenly.

Worktop

Hob

If the appliance is to be installed above a cupboard or drawer it is absolutely essential that

you place a separating board between the base of the appliance and the drawer unit.

This must be fixed in place below the hob (at 70 mm measured from the top of the worktop)

to prevent accidental contact with the bottom of the hob which may be hot.

19

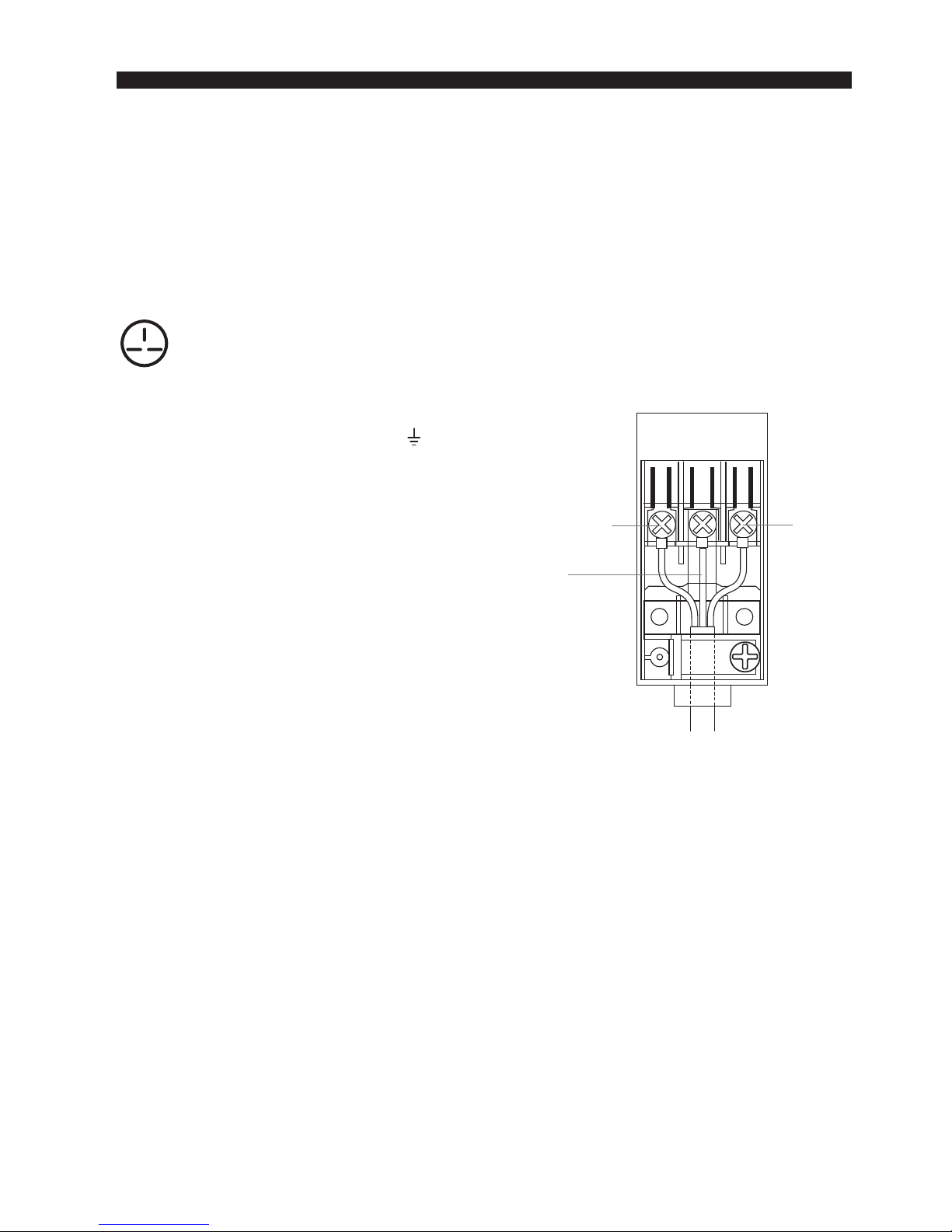

Electrical Connection

The flexible mains lead is supplied connected to a BS1363 fused plug, having a fuse of 3Amp capacity.

If this plug does not fit the socket in your home, it should be replaced with a suitable plug as outlined below.

Should the mains lead of the appliance ever require replacing, we recommend that this be carried out

by a qualified electrician who must replace it with a lead of the same size and temperature rating.

The wires in the mains lead are coloured in accordance with the following code:

The wire which is coloured green and yellow must

be connected to the terminal marked E (

) Earth.

The wire which is coloured blue must be connected

to the terminal marked N (Neutral).

The wire which is coloured brown must be connected

to the terminal marked L (Live).

Ensure all screws are adequately tightened.

Do not over tighten as you may risk damaging

the screw threads.

The plug and socket must be accessible after

installation, or an all-pole disconnection switch

provided in the fixed wiring in accordance with

the local wiring regulations.

Green & Yellow = Earth

Blue = Neutral

Brown = Live

Neutral

(Blue)

Live (Brown)

Earth

(Green/Yellow)

20

Gas Connection

Any gas installation must be carried out by a Gas Safe Registered engineer.

Connection to the gas supply should be with either rigid or semi-rigid pipe, i.e. steel or copper.

The connection should be suitable for connecting to 1/2 inch BSP male thread. When the final

connection has been made, it is essential that a thorough leak test is carried out on the hob and

installation. Ensure that the main connection pipe does not exert any strain on the hob.

It is important to install the elbow correctly, with the shoulder on the end of the thread, fitted to the

hob connecting pipe. Failure to ensure the correct assembly will cause leakage of gas.

1. 90 degree connection elbow

2. Washer

3. End of manifold with 1/2 inch BSP male thread

Check the Hob After Installation & Before Using

When the hob has been fully installed it will be necessary to check the minimum flame setting.

To do this, follow the step below,

1. Turn the gas tap to the maximum position and ignite

2. Set the gas tap to the minimum flame position then turn the control from minimum to maximum

several times. If the flame is unstable or is extinguished adjust the gas rate.

3. Perform a gas tightness test.

1 2 3

21

Conversion from NG to LPG or from LPG to NG

The replacement/conversion of the gas hob should only be undertaken by a Gas Safe

Registered Engineer. The hob is supplied for use with Natural Gas only and cannot be used

on any other gas without modification. It can be converted from NG to LPG or LPG to NG

providing the correct injectors are fitted and the gas rate is adjusted to suit.

Natural Gas

In the United Kingdom flexible connections must NOT be used for built in product, rigid or semi-rigid

pipework must be used.

LP Gas

In the United Kingdom flexible type hoses must NOT be used for built in products, rigid or semi-rigid

pipework must be used. Ensure it is suitable for use on LP Gas up to 50mbar pressure rise.

In all other countries this appliance must be installed in accordance with local regulations and standards.

Method

1. Ensure that the gas taps are in the Off ‘ ’ position

2. Isolate the hob from the electrical supply

3. Remove all pan supports, burner caps, rings, crowns and controls.

4. With the aid of a 7 mm box spanner the burner injectors can then be unscrewed and replaced by the

appropriate injectors. See the Burner Configuration Table for details. Note the size of the injector

being removed to ensure the corresponding size of the new injector is used, NG vs LPG.

Adjusting the Gas Rate

This unit has been set at the factory for NG but can be checked

after the correct pressure has been reached.

The bypass adjustment screw, which is located on the gas tap

body, can be adjusted with the aid of a thin bladed

screwdriver as follows:

1. Ignite the burner and set the control to its minimum position.

2. Remove the control. Also remove rubber seal if needed

to gain easier access.

3. FOR NG (G20 G25)

Rotate the screw slowly until a minimum regular flame is achieved.

(The flame will diminish when the screw is turned clockwise and

increase when turned anti-clockwise.

FOR LP Gas (G30 G31)

Rotate the screw fully clockwise – this is the fixed turn down position for LP Gas.

22

4. Upon completion stick the replacement rating plate sticker on the under side of the hob.

5. Replace the rubber seal (if removed) and the control.

When the setting is right check regulation by quickly rotating the control from the maximum to the

minimum delivery position. The flame must not go out and remain stable throughout the range.

Burner Configuration Table

Gas Category G30/31 G20

Normal Pressure (mbar) 28 – 30/37 20

Extra Large Burner

Injector Diameter (mm) 0.90 1.21

Nominal Rating (W) 3100 3100

Consumption 225/222 gr/h 295 lt/h

Large Burner

Injector Diameter (mm) 0.83 1.17

Nominal Rating (W) 2800 2800

Consumption 204/200 gr/h 267 lt/h

Standard Burner (front right)

Injector Diameter (mm) 0.58 0.85

Nominal Rating (W) 1400 1400

Consumption 102/100 gr/h 133 lt/h

Standard Burner (back left)

Injector Diameter (mm) 0.68 0.98

Nominal Rating (W) 1750 1750

Consumption 127/125 gr/h 167 lt/h

Small Burner

Injector Diameter (mm) 0.51 0.75

Nominal Rating (W) 1000 1000

Consumption 73/71 gr/h 95 lt/h

IB-S5GONGW_B13-130805V2

DSG Retail Limited (Registered in England No. 504877), Maylands Avenue,

Hemel Hempstead, Hertfordshire HP2 7TG. UK

This symbol on the product or in the instructions means that your electrical and electronic

equipment should be disposed at the end of its life separately from your household waste.

There are separate collection systems for recycling in the EU.

For more information, please contact the local authority or your retailer where you purchased

the product.

Visit Partmaster.co.uk today for the easiest way to buy electrical spares and accessories. With over

1 million spares and accessories available we can deliver direct to your door the very next day.

Visit www.partmaster.co.uk or call 0844 800 3456 (UK customers only)

Calls charged at National Rate.

For general information about this appliance

and handy hints and tips, please visit

www.knowhow.com/knowledgebank or call 0844 5611234.

Loading...

Loading...