Page 1

FCC Class B Test Report

For A Class B Digital Device

Client:

SanDisk Corporation

7 Atir Yeda Street

Kfar Saba, Israel

Phone 972-9-7644908

Device Under Test:

SanDisk SSD SATA 5000 2.5”

Document Number: 2007160

Reference Number: QRTL07-033

This report may not be reproduced, except in full, without the written approval of Rhein Tech Laboratories, Inc.

Page 2

Test Overview:

Model No.:

Manufacturer’s

Name:

Manufacturer’s

Address:

Manufacturer’s

Contact:

Type of Equipment:

Serial No.:

Year of Manufacture:

Location of Testing:

Date of Receipt:

Date(s) of Testing:

Purpose of Testing:

SanDisk SSD SATA 5000 2.5”

SanDisk Corporation

7 Atir Yeda Street

Kfar Saba, Israel

Eitan Chalfon

ITE

713050010

2007

Rhein Tech Laboratories, Inc., Herndon, VA

February 5, 2007

April 10, 2007

FCC Class B Compliance

Standard(s) to which device was tested:

STANDARDS SPECIFIC TESTS

APPLICABILITY

Tested

Not Tested

CFR47 Parts 15.109 and

15.107

Radiated and Conducted Emissions

Test Engineer:

Jon Wilson

Signature:

Report Written By:

Jon Wilson

Signature:

Report Approved By:

Desmond Fraser

Signature:

Report Number:

Report Date:

®

Accredited by the National Voluntary Accreditation Program for the specific scope of accreditation under

Lab Code 20061-0.

Note: This report may not be used by the client to claim product endorsement by NVLAP or any agency of the U.S. Government.

2007160

April 27, 2007

Page 3

Suite 1400

Herndon, VA 20170

http://www.rheintech.com

360 Herndon Parkway

TABLE OF CONTENTS

1 GENERAL INFORMATION.............................................................................................................................4

1.1 DEVIATIONS ................................................................................................................................................4

1.2 ACCREDITATION STATEMENTS ..................................................................................................................... 4

2 TEST DETAILS................................................................................................................................................ 5

2.1 PRODUCT DESCRIPTION .............................................................................................................................. 5

2.2 MODIFICATIONS...........................................................................................................................................5

2.3 EUT EXERCISE DESCRIPTION...................................................................................................................... 5

2.4 EQUIPMENT UNDER TEST ............................................................................................................................6

2.5 CONFIGURAT I ON OF TESTED SYSTEM...........................................................................................................7

3 PRODUCT LABELLING/ INFORMATION TO THE USER.............................................................................8

3.1 DOC LABEL ON DEVICE...............................................................................................................................8

3.2 DOC STATEMENT IN USER’S MANUAL........................................................................................................... 8

3.3 LOCATION OF LABEL ON EUT....................................................................................................................... 8

4 CONDUCTED EMISSIONS.............................................................................................................................9

4.1 SITE AND TEST DESCRIPTION....................................................................................................................... 9

4.2 CONDUCTED EMISSIONS TEST DATA..........................................................................................................10

4.3 CONDUCTED TEST PHOTOGRAPHS.............................................................................................................11

5 RADIATED EMISSIONS................................................................................................................................12

5.1 SITE AND TEST DESCRIPTION..................................................................................................................... 12

5.2 FIELD STRENGTH CALCULATION.................................................................................................................13

5.3 RADIATED EMISSIONS TEST DATA..............................................................................................................14

5.4 RADIATED TEST PHOTOGRAPHS ................................................................................................................ 15

6 EMISSIONS EQUIPMENT LIST....................................................................................................................16

7 MANUFACTURER’S EQUIPMENT FILE CHECKLIST (PER FCC RULES §2.1075)..................................17

SanDisk Corporation Page 3 of 17

DoC Report

2006137

04/27/07

Page 4

Suite 1400

Herndon, VA 20170

http://www.rheintech.com

360 Herndon Parkway

1 GENERAL INFORMATION

The following test report for a Class B digital device is prepared on behalf of SanDisk Corporation in

accordance with Part 2, and Part 15, Subparts A and B of the Federal Communications Commissions Rules and

Regulations. The Equipment Under Test (EUT) was the SanDisk SSD SATA 5000 2.5”. The test results

reported in this document relate only to the items that were tested.

All measurements contained in this Application were conducted in accordance with ANSI C63.4 Methods of

Measurement of Radio Noise Emissions, 2003. The instrumentation utilized for the measurements conforms to

the ANSI C63.4 standard for EMI and Field Strength Instrumentation. Some accessories are used to increase

sensitivity and prevent overloading of the measuring instrument. Calibration checks are performed regularly on

all test equipment.

All radiated and conducted emission measurements were performed manually at Rhein Tech Laboratories, Inc.

The radiated emissions measurements were performed on the (three/ten) meter, open field, test range

maintained by Rhein Tech Laboratories, Inc., 360 Herndon Parkway, Suite 1400, Herndon, Va., 20170.

Complete description and site attenuation measurement data has been placed on file with the Federal

Communications Commission. The power line conducted emission measurements were performed in a

shielded enclosure also located at the Herndon, Virginia facility. Rhein Tech Laboratories is accepted by the

FCC as a facility available to do measurement work for others on a contract basis.

1.1 DEVIATIONS

There were no deviations from the test standard(s) and/or methods.

1.2 ACCREDITATION STATEMENTS

• NVLAP (USA): Accreditation under NVLAP Lab Code: 200061-0

• US CAB: Recognition as of U.S. Conformity Assessment Body (CAB) for EMC testing under US-EU and

US-APEC MRA; IC accepted CAB under Phase I of APEC Telecommunication MRA. Identification

number US0079.

• FCC (USA): Listing of test sites, Registration # 90902

• IC (Canada): Listing of test sites, IC 2956-1 and IC 2956-2

• US TCB (ATCB): Certification of cooperation, granted in 2005

• CE Notified Body: Rhein Tech Laboratories, Inc. has been approved by TNO Certification B.V. to provide

EMC Test Reports and Technical Construction Files to TNO Certification B.V. Rheintech Certification

number: 10118957

• AUSTEL (Australia): Acceptance as of a Listed Test House, A97/TH/0107

• ANATEL (Brazil, telecommunication): NCC certification for performing tests

• Ministry of Commerce (New Zealand): Approval of a test laboratory: ECR 3-9 BAE

• VCCI (Japan): Approval and registration of RTL test sites as R-1113 and C-1172

SanDisk Corporation Page 4 of 17

DoC Report

2006137

04/27/07

Page 5

Suite 1400

Herndon, VA 20170

http://www.rheintech.com

360 Herndon Parkway

2 TEST DETAILS

2.1 PRODUCT DESCRIPTION

SanDisk SATA 5000 2.5” SSD is a drop-in replacement for the hard disk drive. It has no moving/ mechanical

parts.

Features

o 2.5" small form factor supporting unformatted capacity of 32GB

o 9.5mm case height

o SATA 7+15 pins combo connector

Interface to host

o Standards: SATA 1.0a 1.5Gb/s

High performance

o Host transfer rate: 150MB/s

o Internal transfer read rate: 67MB/s

o Internal transfer write rate: 47MB/s

o Random Read (4KB): 5350 IOPS

o Average access time: 0.11msec

Low power consumption

o Supply voltage: 5Vdc

o Typical read/write: 190mA

o Typical idle: 125mA

o Typical standby: 70mA

o Typical sleep: 60mA

Reliability

o Mean time between failure (MTBF): 2,000,000 hours, based on Part Stress Analysis

o Operating shock: 1,500G, 0.5msec half sine

o Operating vibration: 2.17G, 7-500 Hz

o Operating temperature: 0˚C to 70˚C

o Non operating temperature and storage: -55˚C to 95˚C

o Operating temperature: 0˚C to 70˚C

2.2 MODIFICATIONS

None

2.3 EUT EXERCISE DESCRIPTION

The SanDisk SSD SATA 5000 2.5” was installed in a Class B laptop personal computer which was running

Windows XP. The computer was programmed to transfer files continuously, to and from the device under test

using a software application provided by Dell. The SanDisk SSD SATA 5000 2.5” was tested as a

representative of the full line of available capacities. The only difference among the different sizes is the onboard flash memory. Otherwise, there are no physical, clock, or electronic changes. Determination of the 2.5

as the “worst case” test sample was determined by SanDisk based on preliminary scanning of the devices under

test and engineering judgement that: because of the small changes between the various capacities, any

changes in emission amplitudes or EMC susceptibility would be inconsequential.

SanDisk Corporation Page 5 of 17

DoC Report

2006137

04/27/07

Page 6

Suite 1400

Herndon, VA 20170

http://www.rheintech.com

360 Herndon Parkway

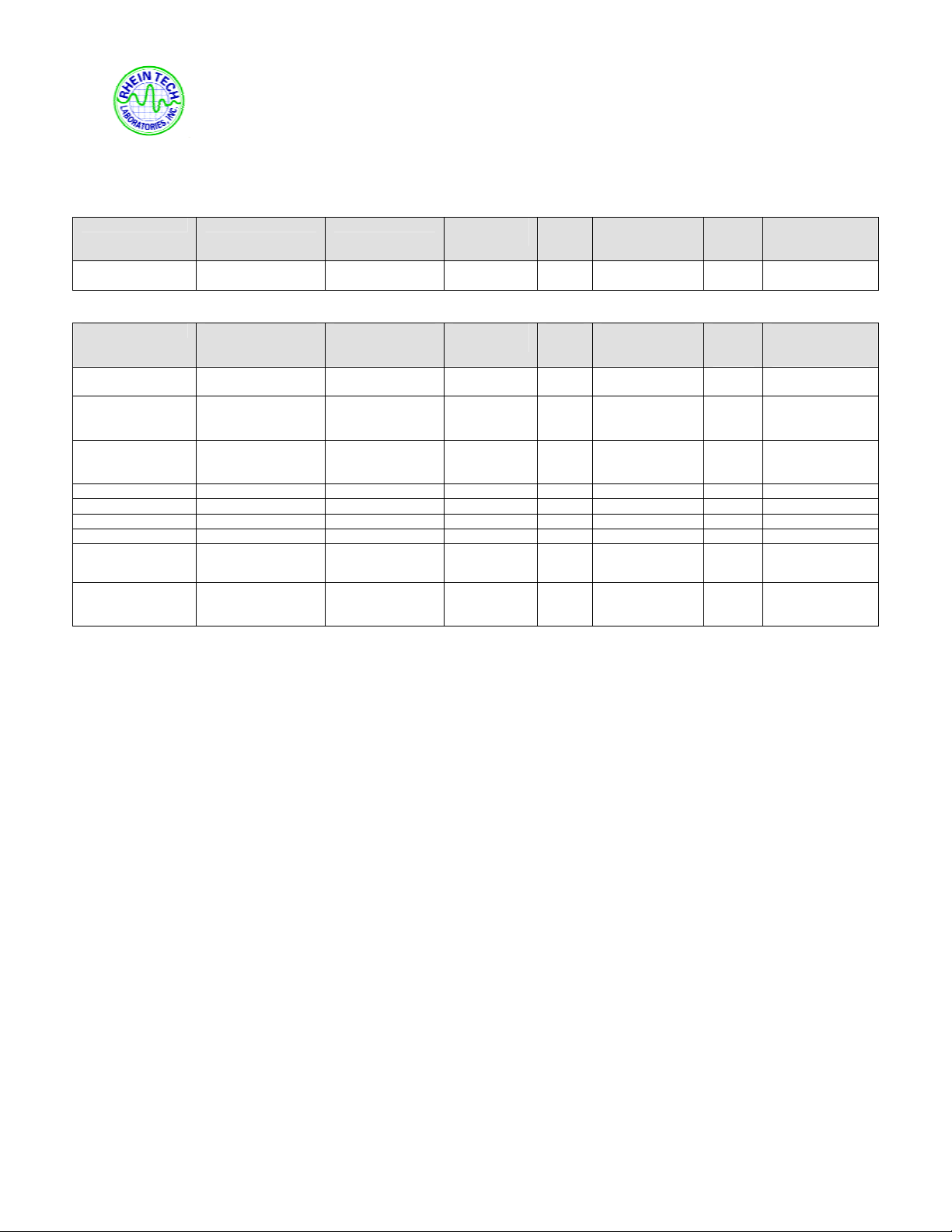

2.4 EQUIPMENT UNDER TEST

Listed below are the identifiers and descriptions of all equipment, cables, and internal devices used with the EUT for this test.

Equipment Under Test

Part Manufacturer Model Serial

SATA Storage

Device

SanDisk

Corporation

SanDisk SSD

SATA 5000 2.5”

Number

713050010 DoC Internal N/A 4/10/2007

Auxiliary Equipment

Part Manufacturer Model Serial

Laptop PC Dell

Laptop AC Adapter Dell LA65NS0-00

Monitor Mag Innovision LT716s 700P

Speaker Boston Acoustics BA265 7002305 N/A Unshielded 011966 09/22/1999

USB Termination Gateway, Inc. USB PCB Rev 1.0 N/A Shielded 008645 04/07/1997

USB Termination Gateway, Inc. USB PCB Rev 1.0 N/A Shielded 011726 05/09/1996

Microphone Gateway, Inc. Telex 700358 N/A Unshielded 016989 01/24/2006

Ethernet hub Flowpoint 134 F258219

Modem US Robotics

Latitude D620

PP18L

Sportster Model

0413

Number

N/A DoC

CN-0DF263-

716156822ED4

F6EQ581028

18U

8390364644

992

FCC

ID

FCC

ID

N/A Unshielded 017737 4/10/2007

DoC

Class

A

Device

DoC

Cable

Description

Cable

Description

Unshielded

Power

Unshielded

Power

Shielded I/O

Unshielded

Power

Unshielded

Power

Shielded I/O

RTL

Bar

Code

RTL

Bar

Code

N/A 4/10/2007

901427 12/15/2005

901278 10/04/2002

900427 11/13/1996

Equipment

Arrival

Date

Equipment

Arrival

Date

SanDisk Corporation Page 6 of 17

DoC Report

2006137

04/27/07

Page 7

Suite 1400

Herndon, VA 20170

http://www.rheintech.com

360 Herndon Parkway

2.5 CONFIGURATION OF TESTED SYSTEM

Modem

Speaker Microphone

Laptop PC with

SanDisk SSD

SATA 5000

USB

Termination

Monitor

SanDisk Corporation Page 7 of 17

DoC Report

2006137

04/27/07

Page 8

Suite 1400

Herndon, VA 20170

http://www.rheintech.com

360 Herndon Parkway

3 PRODUCT LABELLING/ INFORMATION TO THE USER

3.1 DOC LABEL ON DEVICE

The label shall be located in a conspicuous location on the device and shall contain the unique

identification described in FCC CFR 47; Section 2.1074 (the unique model name), and the

following DoC logo:

SanDisk Corporation SanDisk SSD SATA 5000 2.5”

3.2 DOC STATEMENT IN USER’S MANUAL

For a Class B digital device or peripheral, per FCC CFR 47; Section 15.105, the instructions

furnished the user shall include the following or similar statement, placed in a prominent location

in the text of the manual:

NOTE: This equipment has been tested and found to comp ly with the limits for a Class B di gital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection aga inst

harmful interference in a residential installation. This equipment generate s, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions, may cause harmful

interference to radio communications. However, there is no guarantee that interfere nce will not occur in a

particular installation. If this equipment does cause harmful interference to radio or televi sion reception,

which can be determined by turning the equipment off an d on, the user is encouraged to try to correct

the interference by one or more of the following measures:

—Reorient or relocate the receiving antenna.

—Increase the separation between the equipment and receiver.

—Connect the equipment into an outlet on a circuit different from that to which the receiver

is connected.

—Consult the dealer or an experienced radio/ TV technician for help.

3.3 LOCATION OF LABEL ON EUT

Label

SanDisk Corporation Page 8 of 17

DoC Report

2006137

04/27/07

Location

Page 9

Suite 1400

Herndon, VA 20170

http://www.rheintech.com

360 Herndon Parkway

4 CONDUCTED EMISSIONS

4.1 SITE AND TEST DESCRIPTION

The power line conducted emission measurements were performed in a Series 81 type shielded enclosure

manufactured by Rayproof. The EUT was assembled on a wooden table 80 centimeters high. Power was fed to

the EUT through a 50 ohm /50 microhenry Line Impedance Stabilization Network (EUT LISN). The EUT LISN

was fed power through an A.C. filter box on the outside of the shielded enclosure. The filter box and EUT LISN

housing are bonded to the ground plane of the shielded enclosure. A second LISN, the peripheral LISN,

provides isolation for the EUT test peripherals. This peripheral LISN was also fed A.C. power. A metal power

outlet box, which is bonded to the ground plane and electrically connected to the peripheral LISN, powers the

EUT host peripherals.

The spectrum analyzer was connected to the A.C. line through an isolation transformer. The 50-ohm output of

the EUT LISN was connected to the spectrum analyzer input through a Solar 7 kHz high-pass filter. The filter is

used to prevent overload of the spectrum analyzer from noise below 7 kHz. Conducted emission levels were

measured on each current-carrying line with the spectrum analyzer operating in the CISPR quasi-peak mode (or

average mode if applicable). The analyzer's 6 dB bandwidth was set to 9 kHz. No video filter less than 10 times

the resolution bandwidth was used. Average measurements are performed in linear mode using a 10 kHz

resolution bandwidth, a 1 Hz video bandwidth, and by increasing the sweep time in order to obtain a calibrated

measurement. The range of the frequency spectrum to be investigated is specified in FCC Part 15. The highest

emission amplitudes relative to the appropriate limit were measured and have been recorded in this report.

SanDisk Corporation Page 9 of 17

DoC Report

2006137

04/27/07

Page 10

Suite 1400

Herndon, VA 20170

http://www.rheintech.com

360 Herndon Parkway

4.2 CONDUCTED EMISSIONS TEST DATA

Mode: 115 vac, 60 Hz.

Neutral Conductor

Emission

Frequency

(MHz)

0.157 Qp 56.2 0.2 56.4 65.6 -9.2 55.6 Pass

0.157 Av 33.4 0.2 33.6 65.6 -32.0 55.6 -22.0 Pass

0.186 Qp 54.7 0.2 54.9 64.2 -9.3 54.2 Pass

0.186 Av 21.8 0.2 22.0 64.2 -42.2 54.2 -32.2 Pass

0.212 Qp 42.4 0.2 42.6 63.1 -20.5 53.1 -10.5 Pass

0.221 Qp 43.7 0.2 43.9 62.8 -18.9 52.8 -8.9 Pass

0.265 Qp 46.6 0.2 46.8 61.3 -14.5 51.3 -4.5 Pass

0.320 Qp 54.0 0.3 54.3 59.7 -5.4 49.7 Pass

0.320 Av 29.3 0.3 29.6 59.7 -30.1 49.7 -20.1 Pass

0.372 Qp 51.7 0.3 52.0 58.5 -6.5 48.5 Pass

0.372 Av 30.9 0.3 31.2 58.5 -27.3 48.5 -17.3 Pass

0.710 Pk 40.4 0.2 40.6 56.0 -15.4 46.0 -5.4 Pass

1.650 Pk 35.5 0.7 36.2 56.0 -19.8 46.0 -9.8 Pass

4.450 Pk 35.6 1.3 36.9 56.0 -19.1 46.0 -9.1 Pass

15.070 Pk 25.2 2.3 27.5 60.0 -32.5 50.0 -22.5 Pass

17.640 Pk 28.2 2.5 30.7 60.0 -29.3 50.0 -19.3 Pass

25.100 Pk 29.4 2.7 32.1 60.0 -27.9 50.0 -17.9 Pass

Phase Conductor

Emission

Frequency

(MHz)

0.155 Qp 58.5 0.2 58.7 65.7 -7.0 55.7 Pass

0.155 Av 34.7 0.2 34.9 65.6 -30.7 55.6 -20.7 Pass

0.186 Qp 54.5 0.2 54.7 64.2 -9.5 54.2 Pass

0.186 Av 20.8 0.2 21.0 64.2 -43.2 54.2 -33.2 Pass

0.213 Qp 52.2 0.2 52.4 62.7 -10.3 52.7 Pass

0.213 Av 38.1 0.2 38.3 63.1 -24.8 53.1 -14.8 Pass

0.265 Qp 46.6 0.2 46.8 61.3 -14.5 51.3 -4.5 Pass

0.294 Qp 41.0 0.3 41.3 60.4 -19.1 50.4 -9.1 Pass

0.377 Qp 39.8 0.3 40.1 58.3 -18.2 48.3 -8.2 Pass

0.423 Qp 39.6 0.2 39.8 57.4 -17.6 47.4 -7.6 Pass

0.500 Pk 38.5 0.2 38.7 56.0 -17.3 46.0 -7.3 Pass

2.740 Pk 31.2 1.0 32.2 56.0 -23.8 46.0 -13.8 Pass

9.910 Pk 24.0 1.9 25.9 60.0 -34.1 50.0 -24.1 Pass

18.640 Pk 28.0 2.6 30.6 60.0 -29.4 50.0 -19.4 Pass

25.070 Pk 29.8 2.7 32.5 60.0 -27.5 50.0 -17.5 Pass

28.850 Pk 22.2 3.1 25.3 60.0 -34.7 50.0 -24.7 Pass

Result: PASS

Test Personnel:

Jon Wilson

Tester Signature Date of Test

Test

Detector

Test

Detector

Analyzer

Reading

(dBuV)

Analyzer

Reading

(dBuV)

Temperature: 75°F Humidity: 31%

Site

Correction

Factor

(dB)

Site

Correction

Factor

(dB)

Emission

Level

(dBuV)

Temperature: 75°F Humidity: 31%

Emission

Level

(dBuV)

CISPR B

QP

Limit

(dBuV)

CISPR B

QP

Limit

(dBuV)

CISPR B

QP

Margin

(dBuV)

CISPR B

QP

Margin

(dBuV)

CISPR B

AV

Limit

(dBuV)

CISPR B

AV

Limit

(dBuV)

CISPR B

AV

Margin

(dBuV)

CISPR B

AV

Margin

(dBuV)

Pass/

Pass/

Fail

Fail

April 10, 2007

SanDisk Corporation Page 10 of 17

DoC Report

2006137

04/27/07

Page 11

Suite 1400

Herndon, VA 20170

http://www.rheintech.com

360 Herndon Parkway

4.3 CONDUCTED TEST PHOTOGRAPHS

SanDisk Corporation Page 11 of 17

DoC Report

2006137

04/27/07

Page 12

Suite 1400

Herndon, VA 20170

http://www.rheintech.com

360 Herndon Parkway

5 RADIATED EMISSIONS

5.1 SITE AND TEST DESCRIPTION

Before final measurements of radiated emissions were made on the open-field three/ten meter range,

the EUT was scanned indoor at one and three meter distances. This was done in order to determine

its emissions spectrum signature. The physical arrangement of the test system and associated

cabling was varied in order to determine the effect on the EUT's emissions in amplitude, direction and

frequency. This process was repeated during final radiated emissions measurements on the openfield range, at each frequency, in order to insure that maximum emission amplitudes were attained.

Final radiated emissions measurements were made on the three/ten-meter, open-field test site. The

EUT was placed on a nonconductive turntable 0.8 meter above the ground plane. The spectrum was

examined as per FCC part 15 specifications.

At each frequency, the EUT was rotated 360°, and the antenna was raised and lowered from 1 to 4

meters in order to determine the emission’s maximum level. Measurements were taken using both

horizontal and vertical antenna polarizations. For frequencies between 30 and 1000 MHz, the

spectrum analyzer’s 6 dB bandwidth was set to 120 kHz, and the analyzer was operated in the CISPR

quasi-peak detection mode. For emissions above 1000 MHz, measurement use an average detector

function with a minimum resolution bandwidth of 1 MHz. No video filter less than 10 times the

resolution bandwidth was used. The highest emission amplitudes relative to the appropriate limit

were measured and recorded in this report.

Rhein Tech Laboratories, Inc. has implemented procedures to minimize errors that occur from test

instruments, calibration, procedures, and test setups. Test instrument and calibration errors are

documented from the manufacturer or calibration lab. Other errors have been defined and calculated

within the Rhein Tech quality manual, section 6.1. Rhein Tech implements the following procedures to

minimize errors that may occur: yearly as well as daily calibration methods, technician training, and

emphasis to employees on avoiding error.

SanDisk Corporation Page 12 of 17

DoC Report

2006137

04/27/07

Page 13

Suite 1400

Herndon, VA 20170

http://www.rheintech.com

360 Herndon Parkway

5.2 FIELD STRENGTH CALCULATION

The field strength is calculated by adding the Antenna Factor and Cable Factor, and subtracting the

Amplifier Gain (if any) from the measured reading. The basic equation with a sample calculation is as

follows:

FI(dBuV/m) = SAR(dBuV) + SCF(dB/m)

FI = Field Intensity

SAR = Spectrum Analyzer Reading

SCF = Site Correction Factor

The Site Correction Factor (SCF) used in the above equation is determined empirically, and is

expressed in the following equation:

SCF(dB/m) = - PG(dB) + AF(dB/m) + CL(dB)

SCF = Site Correction Factor

PG = Pre-amplifier Gain

AF = Antenna Factor

CL = Cable Loss

The field intensity in microvolts per meter can then be determined according to the following equation:

FI(uV/m) = 10

For example, assume a signal at a frequency of 125 MHz has a received level measured as 49.3

dBuV. The total Site Correction Factor (antenna factor plus cable loss minus preamplifier gain) for

125 MHz is -11.5 dB/m. The actual radiated field strength is calculated as follows:

49.3 dBuV - 11.5 dB/m = 37.8 dBuV/m

10

37.8/20

= 10

1.89

= 77.6 uV/m

FI(dBuV/m)/20

SanDisk Corporation Page 13 of 17

DoC Report

2006137

04/27/07

Page 14

Suite 1400

Herndon, VA 20170

http://www.rheintech.com

360 Herndon Parkway

5.3 RADIATED EMISSIONS TEST DATA

Temperature: 48°F Humidity: 36%

Emission

Frequency

(MHz)

50.000 Qp H 200 3.0 38.4 -22.2 16.2 30.0 -13.8 Pass

73.800 Qp V 100 1.0 41.6 -23.5 18.1 30.0 -11.9 Pass

144.000 Qp V 5 1.0 40.1 -18.5 21.6 30.0 -8.4 Pass

191.992 Qp V 80 1.0 42.2 -19.4 22.8 30.0 -7.2 Pass

200.000 Qp V 190 1.0 35.3 -19.0 16.3 30.0 -13.7 Pass

225.000 Qp V 290 1.0 32.7 -18.5 14.2 30.0 -15.8 Pass

250.000 Qp H 160 4.0 44.2 -15.5 28.7 37.0 -8.3 Pass

369.340 Qp H 190 1.5 42.8 -12.1 30.7 37.0 -6.3 Pass

406.340 Qp V 270 1.0 32.9 -10.5 22.4 37.0 -14.6 Pass

463.850 Qp H 75 2.5 38.8 -9.5 29.3 37.0 -7.7 Pass

485.970 Qp V 190 1.0 29.4 -8.9 20.5 37.0 -16.5 Pass

631.945 Qp V 45 1.0 30.8 -6.2 24.6 37.0 -12.4 Pass

700.000 Qp V 5 1.0 30.4 -5.8 24.6 37.0 -12.4 Pass

Note:

The EUT was scanned from 30 MHz to 15,000 MHz. All emissions other than thos e listed in the tab les above were found to

have amplitudes attenuated by more than 20dB below the FCC limit.

Result: Pass

Test Personnel:

Test

Detector

Antenna

Polarity

(H/V)

Turntable

Azimuth

(deg)

Antenna

Height

(m)

Analyzer

Reading

(dBuV)

Site

Correction

Factor

(dB/m)

Emission

Level

(dBuV/m)

Limit

(dBuV/m)

Margin

(dB)

Pass/

Fail

Jon Wilson

EMC Test Engineer Signature Date Of Test

April 10, 2007

SanDisk Corporation Page 14 of 17

DoC Report

2006137

04/27/07

Page 15

Suite 1400

Herndon, VA 20170

http://www.rheintech.com

360 Herndon Parkway

5.4 RADIATED TEST PHOTOGRAPHS

SanDisk Corporation Page 15 of 17

DoC Report

2006137

04/27/07

Page 16

Suite 1400

Herndon, VA 20170

http://www.rheintech.com

360 Herndon Parkway

6 EMISSIONS EQUIPMENT LIST

The following is a list of equipment Rhein Tech uses to perform testing.

Part Type Manufacturer Model Serial Number Barcode Cal Due Date

Conducted Emissions (SR2, SA3)

Spectrum Analyzer (10kHz-1.5GHz) Hewlett Packard 8567A 2602A00160 900968 8/14/2007

Spectrum Analyzer Display Section Hewlett Packard 85662A 2542A11239 900970 8/14/2007

Quasi-Peak Adapter Hewlett Packard 85650A 2521A00743 900339 8/14/2007

Filter Solar 8130 947306 900729 N/A

16A LISN AFJ International LS16/110VAC 16010020080 901083 4/4/2008

16A LISN AFJ International LS16/110VAC 16010020081 901082 1/6/2008

Current Probe (Telecom conducted) Fischer Custom Communications F-14-1 33 901084 8/31/2007

Emissions testing software Rhein Tech Laboratories, Inc. Automated Emission Tester Rev. 14.0.2 N/A N/A

Radiated Emissions

EMI Receiver RF Section, 9 KHz - 6.5 GHz Hewlett Packard 85462A 3325A00159 900913 3/21/2008

RF Filter Section, 100 KHz to 6.5 GHz Hewlett Packard 85460A 3330A00107 900914 3/21/2008

Amplifier RTL PR-1040 1004 901281 1/19/2008

Bi-Log Antenna (20MHz-2GHz) Schaffner Chase CBL6112B 2648 901053 11/1/2007

Emissions testing software Rhein Tech Laboratories, Inc. Automated Emission Tester Rev. 14.0.2 N/A N/A

SanDisk Corporation Page 16 of 17

DoC Report

2006137

04/27/07

Page 17

Suite 1400

Herndon, VA 20170

http://www.rheintech.com

360 Herndon Parkway

7 MANUFACTURER’S EQUIPMENT FILE CHECKLIST (PER FCC RULES §2.1075)

This checklist shall be used by the manufacturer to verify the correct filing per FCC 2.1075 Retention of records

for products produced and marketed.

PRODUCT MODEL(s): Records Verified By:

SanDisk SSD SATA 5000 2.5”

A record of the original design drawings and specifications.

A record of all changes that have been made that would affect continued compliance

with the authorized unit (e.g., any changes which would require a Class I or Class II

permissive change).

A record of the procedures used for production inspection and testing (if tests were

performed) to ensure ongoing conformance.

A record of the measurements made on an appropriate (NVLAP-accredited) test site

that demonstrates compliance. The record shall contain:

• (i) The actual date or dates testing was performed;

• (ii) The name of the test laboratory, or individual performing the testing. (The

Commission may request additional information regarding the test site, the test

equipment or the qualifications of the Test laboratory from the client. or individual

performing the tests);

• (iii) A description of how the device was actually tested, identifying the measurement

procedure and test equipment that was used contained in the test report

• (iv) A description of the equipment under test (EUT) and support equipment

connected to, or installed within the EUT

• (v) The identification of the EUT and support equipment by trade name and model

number and, if appropriate, by FCC identifier and serial number;

• (vi) The types and lengths of connecting cables used and how they were arranged

or moved during testing;

• (vii) At least two photographs showing the test set-up for the highest line conducted

emission and showing the test set-up for the highest radiated emission. These

photographs must be focused originals which show enough detail to confirm other

information contained in the test report;

• (viii) A description of any modifications made to the EUT Client, or individual to

achieve compliance with the regulations;

• (ix) All of the data required to show compliance with the appropriate regulations;

• (x) The signature of the individual responsible for testing the product along with the

name and signature of an official of the responsible party

• (xi) A copy of the compliance information (i.e., the DoC), as described in §2.1077,

required to be provided with the equipment as follows:

(a) Identification of the product (name and model number);

(b) The unique model name and FCC DoC logo information as specified in

§15.19(b)(1) and §15.105, that the product complies with Part 15 of the FCC

Rules;

(c) Identification, by name, and address of the responsible party.

, as designated in §2.909;

SanDisk Corporation Page 17 of 17

DoC Report

2006137

04/27/07

Loading...

Loading...