Page 1

Chip Resistor

Page 2

Chip Resistor

■

INTRODUCTION

Chip resistors are general passive component which is useful for derating voltage, current

controlling in circuit and surface mounting is available.

Samsung electro mechanics also manufactures a wide range of chip resistors such as general,

precision, trimmable and low ohms and so on.

Production is increasing with demand for small size & light weight of set product. We provide

ultra-small, high-reliability, high-stability resistors.

We have obtained ISO-9002 and QS-9000 certification.

■

FEATURE AND APPLICATION

●

Feature

- Very small, thin, and light weight.

- Both flow and reflow soldering are applicable.

- Owing to the reduced lead inductance, the high frequency characteristic is excellent.

- Suitable size and packaging for surface mount assembly.

- Reel type and Bulk type Packaging are applicable.

●

Application

- General purpose.

- Home Appliances.

(DVD, Digital TV, Camcorder, VTR, Digital Camera, Audio, Tunner)

- For Computers & Communication Devices.

(Notebook, Memory Module, Mobile, Network Equipment, etc)

- 1 -

Page 3

Chip Resistor

■

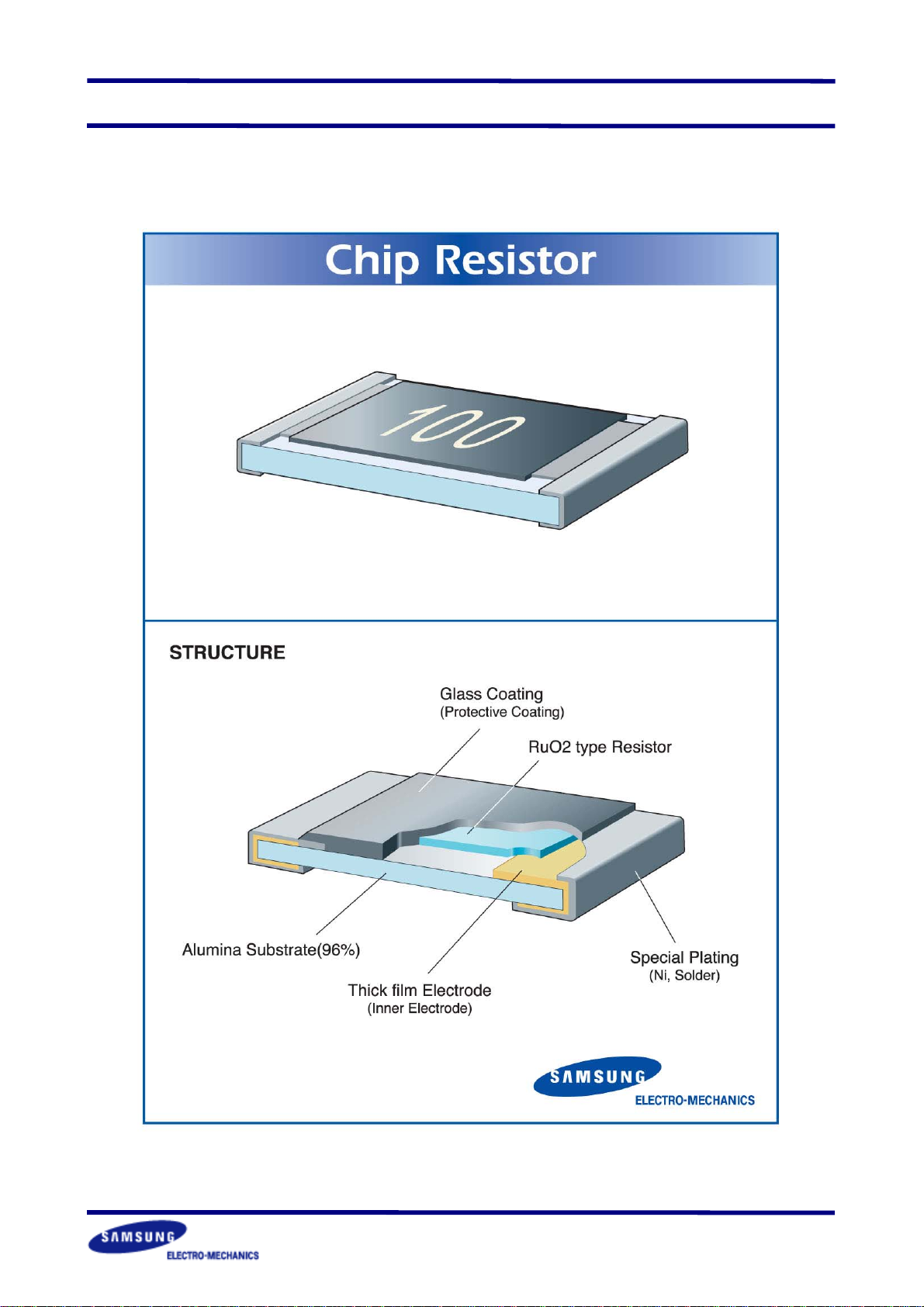

STRUCTURE

- 2 -

Page 4

Chip Resistor

■

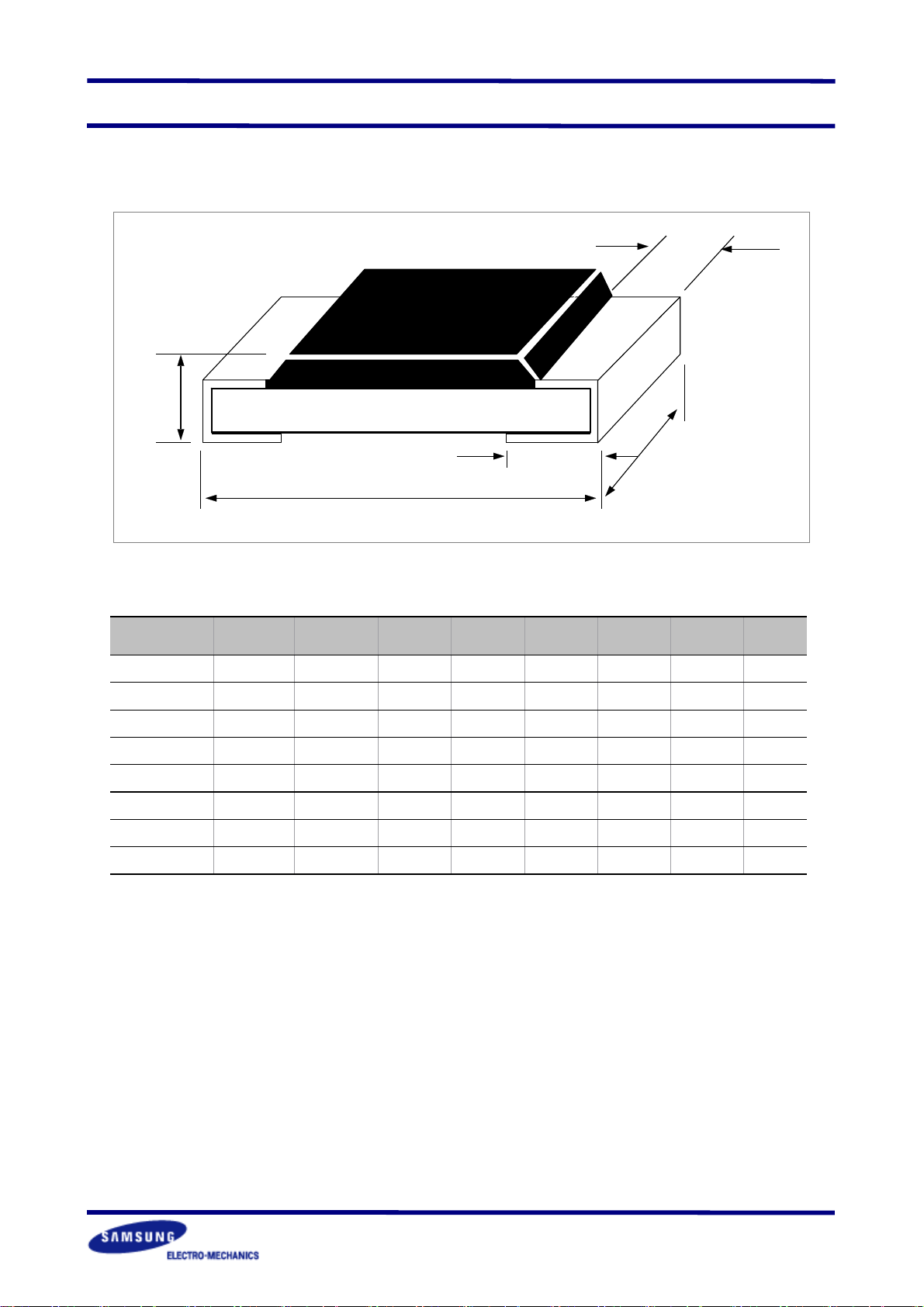

APPEARANCE AND DIMENSION

H

l

1

l

2

L

TYPE inch Power (W) L W H I

0603

1005

1608

2012

3216

3225

5025

6432

0201

0402

0603

0805

1206

1210

2010

2512

1/20 0.60±0.03 0.30±0.03 0.23±0.05 0.15±0.05 0.15±0.05 0.16

1/16 1.00±0.05 0.50±0.05 0.35±0.05 0.20±0.10 0.25±0.10 0.6

1/10 1.60±0.10 0.80±0.15 0.45±0.10 0.30±0.20 0.35±0.20 2.1

1/8 2.00±0.20 1.25±0.15 0.50±0.10 0.40±0.20 0.35±0.20 4.9

1/4 3.20±0.20 1.60±0.15 0.55±0.10 0.45±0.20 0.40±0.20 9.5

1/4 3.20±0.20 2.55±0.20 0.55±0.10 0.45±0.20 0.40±0.20 16

1/2 5.00±0.15 2.50±0.15 0.55±0.15 0.60±0.20 0.60±0.20 26

1 6.30±0.15 3.20±0.15 0.55±0.15 0.60±0.20 0.60±0.20 41

W

[Unit:㎜]

1

I

2

Unit

Weight

㎎

㎎

㎎

㎎

㎎

㎎

㎎

㎎

- 3 -

Page 5

Chip Resistor

■

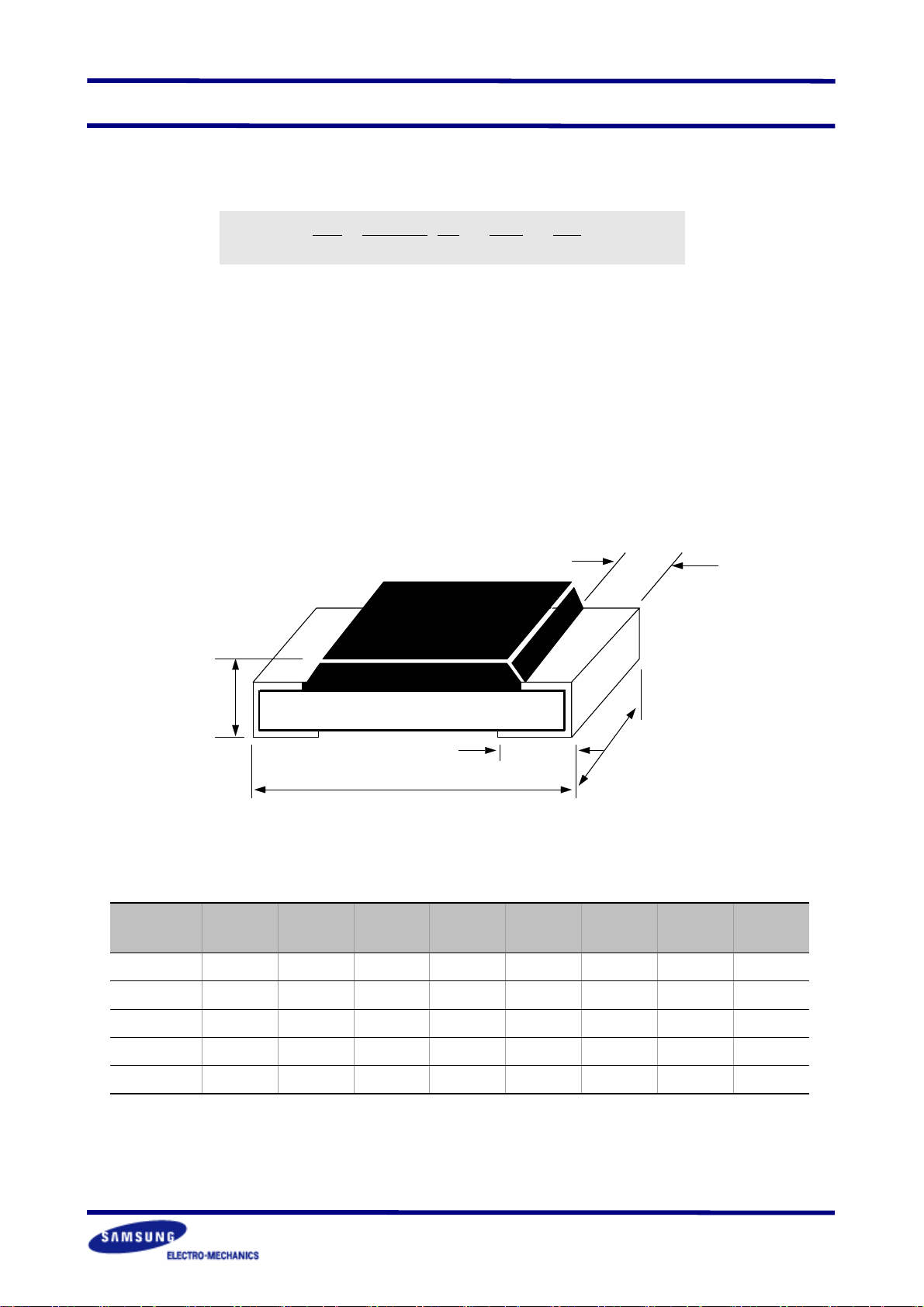

PART NUMBERING

RC 2012 J 100 CS

1

●

1

●

CODE DESIGNATION

RC : This code expresses the Resistor that i s produced by Samsung Electro-Mechanics

CO.LTD. (with the exception of Trimmable Chip Resistor(RT))

2

●

DIMENSION

The dimension is expressed as 4 digits number by SI unit (mm). <Table 1>

Left 2 digits are length of resistor, and the other 2 digits are width. <Fig 1>

2

●

3

●

4

●

5

●

<Fig 1>

<Table 1>

Dimension

(inch)

L

W

H

l

1

l

2

l

1

H

l

L

0603 1005 1608 2012 3216 3225 5025 6432

(0201) (0402) (0603) (0805) (1206) (1210) (2010) (2512)

0.60±0.03 1.00±0.05 1.60±0.10 2.00±0.20 3.20±0.20 3.20±0.20 5.00±0.15 6.30±0.15

0.30±0.03 0.50±0.05 0.80±0.15 1.25±0.15 1.60±0.15 2.55±0.20 2.50±0.15 3.20±0.15

0.23±0.05 0.35±0.05 0.45±0.10 0.50±0.10 0.55±0.10 0.55±0.10 0.55±0.10 0.55±0.10

0.15±0.05 0.20±0.10 0.30±0.20 0.40±0.20 0.45±0.20 0.45±0.20 0.60±0.20 0.60±0.20

0.15±0.05 0.25±0.10 0.35±0.10 0.35±0.20 0.40±0.20 0.40±0.20 0.60±0.20 0.60±0.20

2

W

[Unit:㎜]

- 4 -

Page 6

Chip Resistor

3

●

RESISTANCE TOLERANCE

The Resistance Tolerance is expressed as 1 digit alphabet by EIAJ standard. <Table 2>

<Table 2>

Item F G J K L M

Tolerance (%)

Producing Series E-24, E-96 E-48 E-24 E-12 E-9 E-6

Type P, L G, L G, L G, L, T T T

±

1

±

2

±

5

±

10

±

15

±

Type Representation : G(General), P(Precision), L(Low ohms), T(Trimmable)

4

●

NOMINAL RESISTANCE VALUE

The Nominal Resistance Value is expressed as 3 or 4 digits by EIAJ standard. <Table 3>

<Table 3>

Item 3 Digits mark 4 Digits mark

Resistance

Tolerance

Only number

Number &

alphabet "R"

Example

F, G, J, K, L, M

Left 2 digits : Resistance value

Right 1 digit : Exponential number of 10.

Read alphabet "R" as decimal point.

1) 101 : 10×10

2)7R5:7.5=7.5

3) R75 : 0.75

1

=10×10 = 100

Ω

Ω

Ω

Left 3 digits : Resistance value

Right 1 digit : Exponential number of 10.

Read alphabet "R" as decimal point.

1) 1001 : 100×101= 100×10 = 1

2) 9R09 : 9.09 = 9.09

F, G

Ω

20

㏀

If resistance value in E-96 is same resistance value in E-24, we mark 3 or 4 digits on the

resistor.

In case of JUMPER(0 ohm), '000' is marked on that resistor.

- 5 -

Page 7

Chip Resistor

5

●

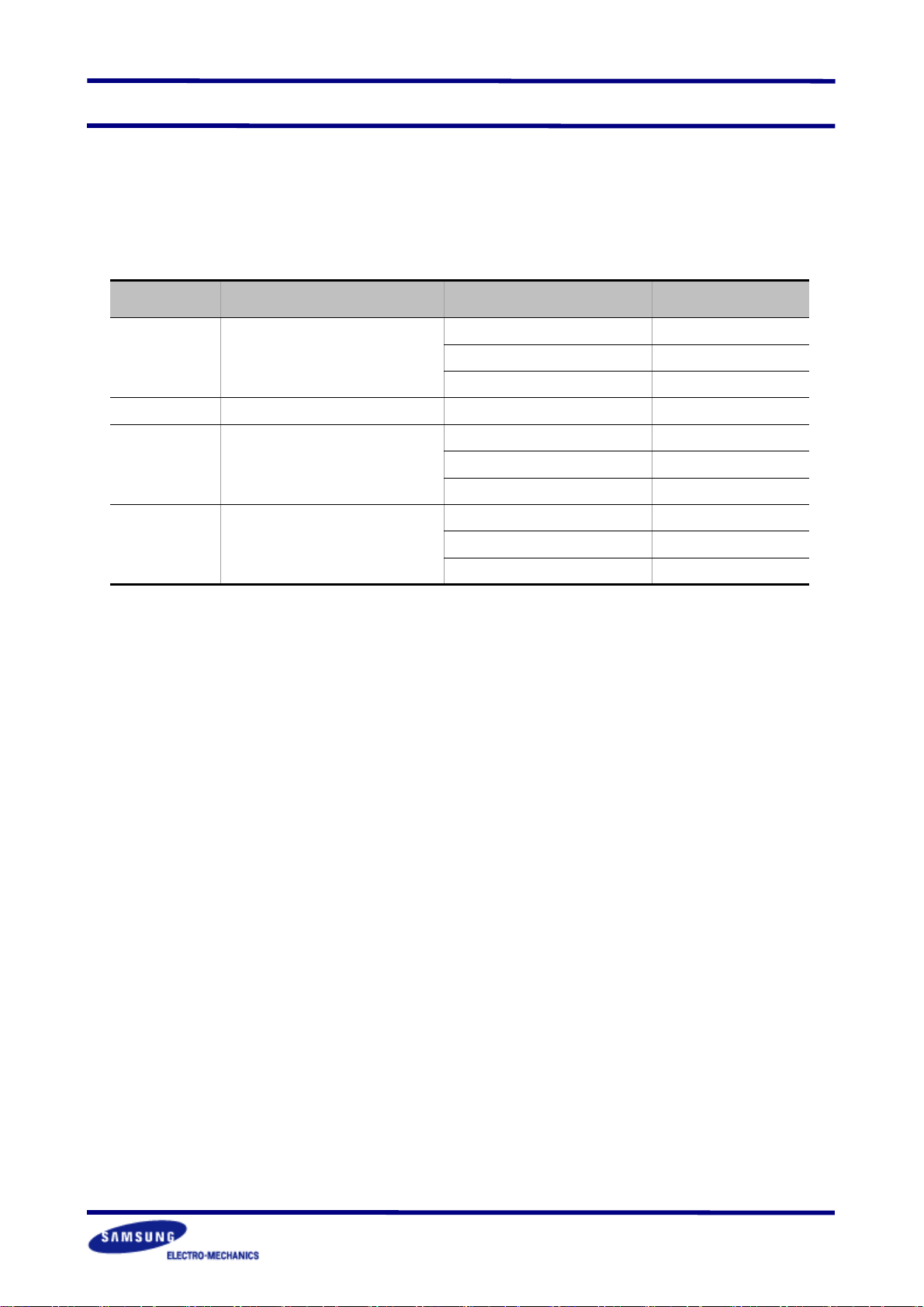

PACKAGING CODE

The Packaging Code is expressed as 2 digits alphabet. <Table 4>

<Table 4>

Packaging

Code

CS

ES

AS

GS

Description Dimension Packaging Q'ty

0603, 1005 10,000 PCS

7" REEL PACKAGING

10" REEL PACKAGING 1608, 2012, 3216 10,000 PCS

13" REEL PACKAGING

BULK CASE PACKAGING

1608, 2012, 3216, 3225 5,000 PCS

5025, 6432 4,000 PCS

0603, 1005 40,000 PCS

1608, 2012, 3216, 3225 20,000 PCS

5025, 6432 15,000 PCS

1608 25,000 PCS

2012 10,000 PCS

3216 5,000 PCS

- 6 -

Page 8

Chip Resistor

■

PACKAGING

●

PACKAGING METHOD

Packaging protects the resistor from damage during the shipping or storage.

There are two types of packaging method ; one is "Reel" type, and the other is "Bulk" type.

●

REEL TYPE PACKAGING SPECIFICATION

The packaging specification is based on the EIAJ RC-1009.

<Fig 2> is tape dimension For 0603, 1005 type. <Table 5> is for pocket sizes, A and B.

<Fig 2>

0.5 Max

1.0

Carrier Tape

Top Tape

4.0±0.1

2.0±0.05

0.1

±

1.5

0

B

A

Chip Resistor

1.75±0.1

3.5±0.05

8.0±0.1

0.5 Max

- 7 -

Page 9

Chip Resistor

<Fig 3> is tape dimension For 1608, 2012, 3216, 3225 type. <Table 5> is for pocket sizes,

AandB.

<Fig 3>

1.0 Max

1.0

Carrier Tape

4.0±0.1

2.0±0.05

Top Tape

4.0±0.1 A

Bottom Tape

0.1

0

±

1.5

B

Chip Resistor

1.75±0.1

3.5±0.05

8.0±0.1

1.0 Max

<Fig 4> is tape dimension For 5025, 6432 type. <Table 5> is for pocket sizes, A and B.

<Fig 4>

<Table 5>

Dimension

Symbol

A

B

tMAX=1.1

0603 1005 1608 2012 3216 3225 5025 6432

(0201) (0402) (0603) (0805) (1206) (1210) (2010) (2512)

0.65±0.10 0.70±0.10 1.10±0.20 1.65±0.20 2.00±0.20 2.90±0.20 2.80±0.10 3.50±0.10

1.15±0.10 1.20±0.10 1.90±0.20 2.40±0.20 3.60±0.20 3.60±0.20 5.30±0.20 6.75±0.10

- 8 -

Page 10

Chip Resistor

●

TAPING METHOD

There are empty holes at both start part and end part of carrier tape. <Fig 5>

<Fig 5>

Reel

Empty Portion Chips Empty Portion Lead Part

End

10 Pitches

or more

Packed Part Empty Part Lead Part

Adhesion Tape

*********

5,000 Pitches

or

20,000 Pitches

10 Pitches

or more

200~250 mm

Note

①

The resistor should move in the pocket freely.

②

The resistor should not adhere to the top or bottom tape.

③

There should be no vacant pocket.

④

Peeling strength of the top tape should be within 5g and 80g. <Fig 6>

Start

<Fig 6>

Chip Resistor

Carrier Tape

F

Top Tape

Peeling

°

10

Bottom Tape

- 9 -

Page 11

Chip Resistor

●

REEL DIMENSION

The Reel dimension is classified by the diameter of Reel. <Fig 7> <Table 6>

<Fig 7>

<Table6>

[Unit:mm]

Packaging Code Diameter A B C D

CS 7"

ES 10"

FS,AS 13"

●

BULK TYPE PACKAGING

178

258

330

Φ

70

Φ

80

Φ

80

9.5(13.0)±0.1 1.2±0.1

9.5±0.1 2.0±0.1

9.5±0.1 2.0±0.1

Bulk cassette specification is based on the EIAJ ET-7201. <Fig 8>

The standard packaging quantity depends on the dimension. <Table 7>

<Fig 8>

12

36

11

0

6.0±0.05

4.4±0.05

3.4±0.05

<Table 7>

Dimension Inch Standard packaging quantity Weight (g, avg.)

1608 0603 25,000 PCS 71

2012 0805 10,000 PCS 65

3216 1206 5,000 PCS 67

- 10 -

Page 12

Chip Resistor

●

LABELING

▶

Reel type Label

The reel type label includes following contents as <Fig 9>.

<Fig 9>

- Following -

①

Resistance Value

②

Tolerance, Marking

③

Part Number

④

Quantity

⑤

LOT Number

⑥

Bar-Code

⑦

Serial Number

③

④

⑤

⑥

100 J101

P/N : RC1608J101CS

QTY : 5000PCS

L/N : RMBA20630

①

Ohm

SAMSUNG ELECTRO-MECHANICS CO.,LTD.

②

007

V-2

⑦

▶

Bulk type Label

The bulk type label includes following contents as <Fig 10>.

<Fig 10>

- Following -

①

Part Number

②

Resistance Value

③

LOT Number

④

Quantity

⑤

Bar-Code

⑥

Serial Number

●

BOX PACKAGING METHOD

①

The bulk or reel type packaging is packaged twice by paper box, inner box and outer box.

②

The packaging should protect the resistor from damaging during shipping by vehicle, ship,

airplane and etc.

③

The information of contents is marked on both inner and outer box.

①

②

③

⑤

RC3216J100GS

10 ohm

RC3216J100GS

RMBA71025 ,5000pcs

SAMSUNG ELECTRO-MECHANICS CO.,LTD.

④

10 ohm

00

7

V-2

⑥

※

For other packaging methods, please contact us.

- 11 -

Page 13

Chip Resistor

●

BOX DIMENSION FOR REEL TYPE

①

Max 25,000 pcs ( 5 EA×7" )

30±1.0

185±1.0

185±1.0

③

Max 300,000 pcs ( 60 EA×7" )

215±5.0

②

Max 100,000 pcs ( 20 EA×7" )

195±5.0

66±1.0

285±5.0

(Unit:mm) (Unit:mm)

④

Max 400,000 pcs ( 20 EA×13" )

370±5.0

348±5.0

187±5.0

336±5.0

410±5.0

(Unit:mm)

●

BOX DIMENSION FOR BULK TYPE

①

Inner box ( Cassette×5EA)

41

116

(Unit:mm)

65

339±5.0

②

Outer box ( Inner box×20 EA )

215

242

(Unit:mm)

135

(Unit:mm)

- 12 -

Page 14

Chip Resistor

−

■

RELIABILITY TEST DATA

Jumper's reliability test data are only applied to General type resistor.

●

ELECTRICAL CHARACTERISTIC

The electrical characteristic test should satisfy the test method, procedure, and standard.

If there is no special comment, Each test performs in standard state.

(temperature 20℃, humidity 65%RH, pressure 1023mbar)

item

DC resistance

Temperature

Coefficient

of

Resistance

Permissible deviation

Resistor Jumper

DC resistance value

should be within the

specified resistance

tolerance.

Tolerance ppm/℃Type

100

F

200 L

G Table 9 G, P, L

J Table 9 G, L

K Table 9 G, L

L, M Table 9 G, L, T

<Table 9>

Range(Ω) ppm/

0.1 ≤ R < 1

1≤R<10

10 ≤ R < 1M ±

1M ≤ R < 10M ±

500(L-Type)

+300, -200

200

300

P

℃

Ω

50m

Maximum

-

Test method

묤

Standard : JIS C 5202 (5.1)

묤

Test voltage : <Table 8>

묤

Applying time : within 5 seconds.

묤

Test board : <Fig 11>

<Table 8>

Range (Ω) Voltage (V)

R<1 0.1

R < 10 0.1

10≤R<100 0.3

100≤R<1K 1.0

1K≤R<10K 3.0

10K≤R < 100K 10

100K≤R < 1M 25

1M≤R50

묤

Standard : JIS C 5202 (5.2)

묤

Temp. : 20

묤

Test board : <Fig 11>

묤

Calculation :

TCR(ppm/℃)=

T

R

℃→

℃

20

:20±2

0

:ResistanceatT0(Ω)

0

℃→20℃→

-55

RR

0

RTT

00

℃

℃→

125

1

×

6

10

×

−

T : Test temperature ( -55, 125℃)

R : Resistance at T (Ω)

묤

Standard : JIS C 5202. (5.5)

묤

Test voltage : 2.5 times of rated voltage Max.

surge current at the Jumper.

묤

Applying time : 5 seconds

묤

Test board : <Fig 11>

묤

Standard : JIS C 5202. (5.8)

묤

Test voltage : 2.5 times of rated voltage Max.

surge current at the Jumper.

묤

Test method : 1 sec ON, 25 sec OFF

+400

cycles

묤

Test board : <Fig 11>

10,000

Short time

overload

(STOL)

Intermittent

overload

(IOL)

1. No mechanical

damage

Δ

R should be

2.

within±(1%+0.1Ω)

1. No mechanical

damage

Δ

R should be

2.

within±(3%+0.1Ω)

Ω

50m

Maximum

Ω

50m

Maximum

- 13 -

Page 15

Chip Resistor

item

Withstanding

voltage

Insulation

resistance

Noise

Permissible deviation

Resistor Jumper

묤

No mechanical

damage, short circuit,

or disconnection.

묤

Shouldhavemore

than 1,000M

묤

Noise standard

Ω

<Table 10>

Range (Ω)dBMax.

0.1≤R<1

1≤R < 100

100≤R<1K

1K≤R < 100K

100K≤R<1M

1M≤R < 10M

-10(L-Type)

-10

0

15

20

30

Same as

left

Same as

left

-

Test method

묤

Standard : JIS C 5202. (5.7)

묤

Test voltage : 1005 1608 AC 100V,

others AC 500V

묤

Applying time : 60 +10/-0 seconds

묤

Test board : <Fig 13>

묤

Standard : JIS C 5202. (5.6)

묤

Test voltage : 1005 1608 DC 100V,

others DC 500V

묤

Applying time : 60 seconds

묤

Test pressure : 1.0±0.2 N

묤

Test board : <Fig 13>

묤

Standard : JIS C 5202. (5.9)

JIS appendix1 "Noise measure in

resistor"

묤

Measure equipment : QUAN-TECH NOISE

METER

(MODEL 315C)

●

MECHANICAL CHARACTERISTIC

The mechanical characteristic test should satisfy the test method, procedure, and standard.

If there is no special comment, Each test performs in standard state.

(temperature 20℃, humidity 65%RH, pressure 1023mbar)

item

Solderability

Bending

strength

Permissible deviation

Resistor Jumper

묤

New solder

coated more than

95% of termination

1. No mechanical

damage

Δ

R should be

2.

within±(0.5%+0.05Ω)

Same as

left

Same as

left

Test method

묤

Standard : JIS C 5202. (6.5)

묤

Test temperature : 235±5

묤

Test time : 2±0.5 sec (dipping both side)

묤

Standard : JIS C 5202. (6.1)

묤

Test board : <Fig 12>

묤

Test speed : 100mm/min

묤

Test procedure : press until 3mm,

℃

then keep 5 seconds <Fig 14>

<Fig 14>

20

R205

3

- 14 -

Page 16

Chip Resistor

item

Termination

strength

Withstanding

soldering heat

Vibration

Permissible deviation

Resistor Jumper

묤

No mechanical

damage, or sign of

disconnection

1. No mechanical

damage

Δ

R should be

2.

within±(1%+0.05Ω)

1. No mechanical

damage

Δ

R should be

2.

within±(1%+0.05Ω)

Same as

left

Ω

50m

Maximum

Ω

50m

Maximum

Test method

묤

Standard : JIS C 5202 (6.1)

묤

Test time : applying pressure for 10 seconds

묤

Test tension : 5 N (500g묤f)

1005, 1608 - 3 N (300g묤f)

묤

Standard : JIS C 5202 (6.4)

묤

Temperature : 260±5

묤

Test time : 10±1second (both side dipping)

묤

Test procedure : measures after 24 hours

묤

Standard : JIS C 5202 (6.3)

묤

Test amplitude : 1.5mm

묤

Test procedure : frequency 10Hz - 55Hz -

℃

10Hz each 2 hours in x, y, z direction.

●

ENVIRONMENTAL CHARACTERISTIC

The Environmental characteristic test should satisfy the test method, procedure, and standard.

If there is no special comment, Each test performs in standard state.

(temperature 20℃, humidity 65%RH, pressure 1023mbar)

item

Temperature

cycle

Moisture

resistance life

Permissible deviation

Resistor Jumper

1. No mechanical

damage

Δ

R should be

2.

within±(1%+0.1Ω)

1. No mechanical

damage

Δ

R should be

2.

within <Table 12>

<Table 12>

Range(Ω)

0.1≤R<1

1≤R<10

10≤R<1M

1M≤R < 10M

Δ

±

5%(L-Type)

±

(3%+0.1Ω)

RMAX

±

5%

±

5%

Ω

50m

Maximum

Ω

100m

Maximum

Test method

묤

Standard : JIS C 5202 (7.4)

묤

Test procedure : <Table 11>

묤

Measure : after 5 cycles of procedure

묤

Test board : <Fig 11>

<Table 11>

item 1 2 3 4

temp(℃)-55±2 5~35 125±2 5~35

time(min) 30 15 30 15

묤

Standard : JIS C 5202 (7.9)

묤

Test condition : temp 40±3℃, humid 90 ~

95%RH

묤

Test voltage : rated voltage

묤

Test time : repeat 90min ON, 30min OFF

+48

during 1000

묤

Test board : <Fig 11>

hours

- 15 -

Page 17

Chip Resistor

item

Low

temperature

exposure

High

temperatur

exposure

Load life

Permissible deviation

Resistor Jumper

1. No mechanical

damage

Δ

R should be

2.

within±(3%+0.1Ω)

1. No mechanical

damage

Δ

R should be

2.

within±(3%+0.1Ω)

1. No mechanical

damage

Δ

R should be

2.

within

<Table 13>

<Table 13>

Range(Ω)

0.1≤R<1

1≤R<10

10≤R<1M

1M≤R < 10M

Δ

±

5%(L-Type)

±

(3%+0.1Ω)

RMAX

±

5%

±

5%

Ω

50m

Maximum

Ω

50m

Maximum

Ω

100m

Maximum

Test method

묤

Standard : JIS C 5202 (7.1)

묤

Test temperature : -55±2

묤

Test time : 1000

묤

Measure : after 1 hour

묤

Test board : <Fig 11>

묤

Standard : JIS C 5202 (7.2)

묤

Test temperature : 1608,2012,3216 : 155

묤

Test time : 1000

묤

Measure : after 1 hour

묤

Test board : <Fig 11>

묤

Standard : JIS C 5202 (7.10)

묤

Test temperature : 70±2

묤

Test voltage : rated voltage

묤

Test time : repeat 90min ON, 30min OFF

+48

hours (without load)

2℃, others : 125±2

+48

hours (without load)

during 1000

묤

Test board : <Fig 11>.

+48

℃

℃

hours

±

℃

●

TEST BOARD AND SPECIFICATION

▶

Soldering

▷

The resistor should be fixed on PCB(printed circuit board) for testing.

- Soldering specification : JIS C 5202 (6.2)

* Soldering method : Flow type(Dipping type), Reflow type

* Solder : H63A (JIS Z 3282)

* FLUX : ROSIN 25WT% (JIS K 5902), IPA 75WT% (JIS K 5901)

- Flow soldering condition

* FLUX dipping time : 5∼10 sec

* Pre-treatment : None

* Soldering temp. : 235℃±5

* Soldering time : 5±0.5 sec

* Temp. profile : <Fig 15>

- Reflow soldering condition

* Peak temp. : 230℃±5

* Duration over 220℃:15±5sec

* Solder Cream : Sn-Pb (63-37)

* Temp. Profile : <Fig 16>

℃

℃

- 16 -

Page 18

Chip Resistor

▶

Test board

▷

Test board

<Table 14>

item Dimension (mm)

Dimension Power

0603

1005

1608

2012

3216

3225

5025

1/20W

1/16W

1/10W

1/8W

1/4W

1/4W

1/2W

6432

▷

Bending Test Board

<Table 15>

item Dimension (mm)

Dimension Power

0603

1005

1608

2012

3216

3225

5025

6432

1/20W

1/16W

1/10W

1/8W

1/4W

1/4W

1/2W

1W

1W

a b c f

0.3 1.4 0.3 5.2

0.6 1.9 0.7 4.9

1.0 3.0 1.2 4.5

1.2 4.0 1.65 4.3

2.2 5.0 2.0 3.3

2.2 5.0 2.9 3.3

3.6 7.0 3.0 3.0

5.2 8.0 3.5 2.5

<Table 14>, <Fig 11> are dimensions of test board.

* Board material : epoxy JIS C 6484

* pattern material : pure copper 99.5% or above JIS C 6484

a b c f

0.3 1.4 0.3 5.2

0.6 1.9 0.7 4.9

1.0 3.0 1.2 4.5

1.2 4.0 1.65 4.3

2.2 5.0 2.0 3.3

2.2 5.0 2.9 3.3

3.6 7.0 3.0 3.0

5.2 8.0 3.5 2.5

<Fig 11>

b

<Fig 12>

10 -φ1.0

c

35.08

Connector

58.5

: COPPER PATTERN

:SOLDER-RESISTOR

af d=4.

c

b

100

: COPPER PATTERN

:SOLDER-RESISTOR

3

3.5

f

a

25

5.5

7.5

5

40

<Table 15>, <Fig 12> are dimensions of bending test board.

* Board material : epoxy JIS C 6484

* pattern material : pure copper 99.5% or above JIS C 6484

▶

Sketch of Withstanding voltage and Insulation resistance

<Fig 13>

Cu

P2

V

Cu

Cu

P1P1

Substrate

- 17 -

Page 19

Chip Resistor

■

CHARACTERISTIC GRAPH

●

RESISTANCE RANGE

The Resistance Range that we produce depends on the Dimension and the Resistance

Tolerance of the resistor. <Table 16>

<Table 16>

Dimension

Tolerance

F

G

J

K

L, M

0603 1005 1608 2012 3216 3225 5025 6432

(0201) (0402) (0603) (0805) (1206) (1210) (2010) (2512)

10Ω∼1MΩ10Ω∼1MΩ10Ω∼1MΩ10Ω∼1MΩ10Ω∼1MΩ10Ω∼1MΩ10Ω∼1M

0.1Ω∼1MΩ0.1Ω∼1MΩ0.1Ω∼1MΩ0.1Ω∼1MΩ0.1Ω∼1M

1Ω∼10MΩ1Ω∼10MΩ1Ω∼10MΩ1Ω∼10MΩ1Ω∼10MΩ1Ω∼10MΩ1Ω∼10MΩ1Ω∼10M

10Ω∼1MΩ10Ω∼1MΩ10Ω∼1MΩ10Ω∼1MΩ10Ω∼1MΩ10Ω∼1MΩ10Ω∼1M

0.1Ω∼1MΩ0.1Ω∼1MΩ0.1Ω∼1MΩ0.1Ω∼1MΩ0.1Ω∼1M

1Ω∼10MΩ1Ω∼10MΩ1Ω∼10MΩ1Ω∼10MΩ1Ω∼10MΩ1Ω∼10MΩ1Ω∼10MΩ1Ω∼10M

0.1Ω∼1MΩ0.1Ω∼1MΩ0.1Ω∼1MΩ0.1Ω∼1MΩ0.1Ω∼1M

1Ω∼10MΩ1Ω∼10MΩ1Ω∼10MΩ1Ω∼10MΩ1Ω∼10MΩ1Ω∼10MΩ1Ω∼10MΩ1Ω∼10M

0.1Ω∼1MΩ0.1Ω∼1MΩ0.1Ω∼1MΩ0.1Ω∼1MΩ0.1Ω∼1M

1Ω∼10MΩ1Ω∼10MΩ1Ω∼10MΩ1Ω∼10MΩ1Ω∼10MΩ1Ω∼10M

1Ω∼10MΩ1Ω∼10MΩ1Ω∼10MΩ1Ω∼10MΩ1Ω∼10MΩ1Ω∼10M

Type

Ω

P

Ω

L

Ω

G

Ω

P

Ω

L

Ω

G

Ω

L

Ω

G

Ω

L

Ω

T

Ω

T

Type Representation : G(General), P(Precision), L(Low ohms), T(Trimmable)

- 18 -

Page 20

Chip Resistor

●

RATED POWER

The Rated Power is classified by the dimension of the resistor. <Table 17>

<Table 17>

Dimension

item

Rated Power

Working Volt.(Max.) 25 V 50 V 50 V 150 V 200 V 200 V 200 V 200 V

STOL, IOL Volt.(Max.) 50 V 100 V 100 V 300 V 400 V 400 V 400 V 400 V

※

The rated power is specified as continuous full loading power at the ambient temperature of 70

±2℃

.Incaseofthetemperatureexceeding70±2℃, the power should be derated in

0603 1005 1608 2012 3216 3225 5025 6432

(0201) (0402) (0603) (0805) (1206) (1210) (2010) (2512)

1/20 W

(0.05 W)

1/16 W

(0.063 W)

1/10 W

(0.100 W)

1/8 W

(0.125 W)

1/4 W

(0.25 W)

1/4 W

(0.25 W)

1/2 W

(0.5W)

1.0 W

accordance to <Fig 17>.

<Fig 17>

[0603, 1005, 3225, 5025, 6432]

Ratedloadpercent(%)

100

Ambient temperature (℃)

80

[1608, 2012, 3216]

Ratedloadpercent(%)

100

Ambient temperature (℃)

80

60

40

20

-55

0

-40

▶

Working Temperature

-55

-55

04080120

℃∼

+125℃: 0603, 1005, 3225, 5025, 6432

℃∼

+ 155

70

℃

: 1608, 2012, 3216

125

60

40

20

-55

0

0306090 150

-30

70

120

155

- 19 -

Page 21

Chip Resistor

■

APPLICATION MANUAL

●

Applications

Chip resistors are designed for general electronic devices such as home appliances, computer,

mobile communications, digital circuit, etc.

If you require our products with high reliability-performing at more than 125C or below -55C- for

medical equipments, aircraft, high speed machines, military usage, and items that can affect

human life or if you need to use in specific conditions (corrosive gas atmosphere), please contact

us beforehand.

▶

Normal Operation temperature ranges(℃)asfollows.

- 1608, 2012, 3216(general, precision) : -55℃ ~+155℃

- Others (rectangular, array, trimmable) : -55℃ ~+125℃

▶

Although resistor body is coated, sharp excessive impact should be avoided to prevent

damages and adverse effects on characteristics(resistor value, open circuited, T.C.R.).

●

Storage

To maintain proper quality of chip components, the following precautions are required for storage

environment, method and period.

▶

Storage Environment

- Chip components may be deformed, if the temperature of packaged components exceeds

40C.

- Do not store where the soldering properties can be deteriorated by harmful gas such as

sulphurous gas, chlorine gas, etc.

- Bulk packed chip components should be used as soon as the seal is opened, thus

preventing the solderability from deteriorating.

- The remaining unused chips should be put in the original bag and sealed again or store in

a desiccator containing a desiccating agent.

▶

Storage Time Period

- Stored chip components should be used within 12 months after receiving the components.

If 12 months or more have elapsed, please check the solderability before actually using.

●

Mounting

Please give more attention not to press the chip owing to the nozzle's improper height when it

is mounted on PCB.

(Excessive pressure may cause exterior damage, change in resistance, circuit open, etc.)

- 20 -

Page 22

Chip Resistor

●

Soldering

Our products have Ag electrodes protected by double layer.

▶

1st Ni Coating

- This prevents Ag electrode from leaching and enhance the bonding with Sn-Pb.

▶

2nd Sn-Pb Coating

- This is made of Sn 90% and Pb 10% with melting point 213℃ to prevent it from melting

when solder cream melts, and to enhance the bonding.

- Commercial solder creams are made of Sn 63% and Pb 37% with melting point 183℃.

●

Cleaning

After Soldering Cleaning, soldering flux & Ionic cleaning liquid should be avoided on product.

If any possibility on product, please take a test before usage.

●

Caution for chip resistor separation from PCB

Chip resistor installation on PCB is similar phenomenon on chocolate chip on top of cake.

PCB has enough flexibility on outer force but Chip resistor can be defected without any bending.

(By chip resistor use of Ceramic, solder, metal)

Therefore, when separate from Chip resistor on PCB, be ware of any crack of chip

●

Others

▶

Manual work

- Whenever separate chip resistor from PCB, do not re-use the chip resistor for circuit safety.

hip resistor can be electrical specification change by soldering Iron after separation.

C

Re-use of separated chip resistor should be prohibited.

▶

Do not use more than rated voltage.(check the contents on the file)

- 21 -

Page 23

Chip Resistor

■

NOTICE

●

Usage of the resistor

▶

Flow Soldering

After sticking the resistor to PCB with paste, dip the PCB into solder bath. <Fig 15>

<Fig 15>

▶

Reflow Soldering

Temp.

235±5

℃

Δ

T≤150

℃

Pre-heating

Soldering Cooling

within 5 sec

After printing solder c reams on PCB, place the resistor on the solder cream.

Then heat the PCB. <Fig 16>

<Fig 16>

Temp.

230±5

200

160

℃

℃

℃

Peak temp.

within 10 sec

Time

℃

130

●

Caution

▶

Storage condition

Pre-heating

within 120 sec

Soldering

within 20 sec

Cooling

Please make sure that keep the storage conditions.

* Temperature : 5

▶

Damage control

℃∼35℃

,*Humidity:45%RH∼85%RH

Please handle with care, to prevent damaging the resistor.

Specially, the excessive nozzles' height of SMD or the extreme touch with tweezers.

▶

Leaching prevention

It is important to keep the soldering conditions for prevent Ag leaching in Flow soldering.

Time

- 22 -

Loading...

Loading...