Samsung WF-F1256, WF-F1056 YLP, WF-F1256/YLP, WF-F856, WF-F856/YLP Service Manual

1. Memory Washing

2. Add Washing Clothes

3. Calm Wash

4. Child Lock

5. Prewash

WF-F1256/YLP

F1056/YLP

F856/YLP

BASIC MODEL

F1245AVGW/YLP

SERVICE

Manual

F1256

THE FEATURE OF PRODUCT

Refer to the service manual in the itself (http://itself.sec.samsung.co.kr/) for the more information.

1. PRECAUTION

1-1. SAFETY PRECAUTIONS

1-2. PRECAUTIONS UPON INSTALLATION

2.THE FEATURE OF PRODUCT

5041

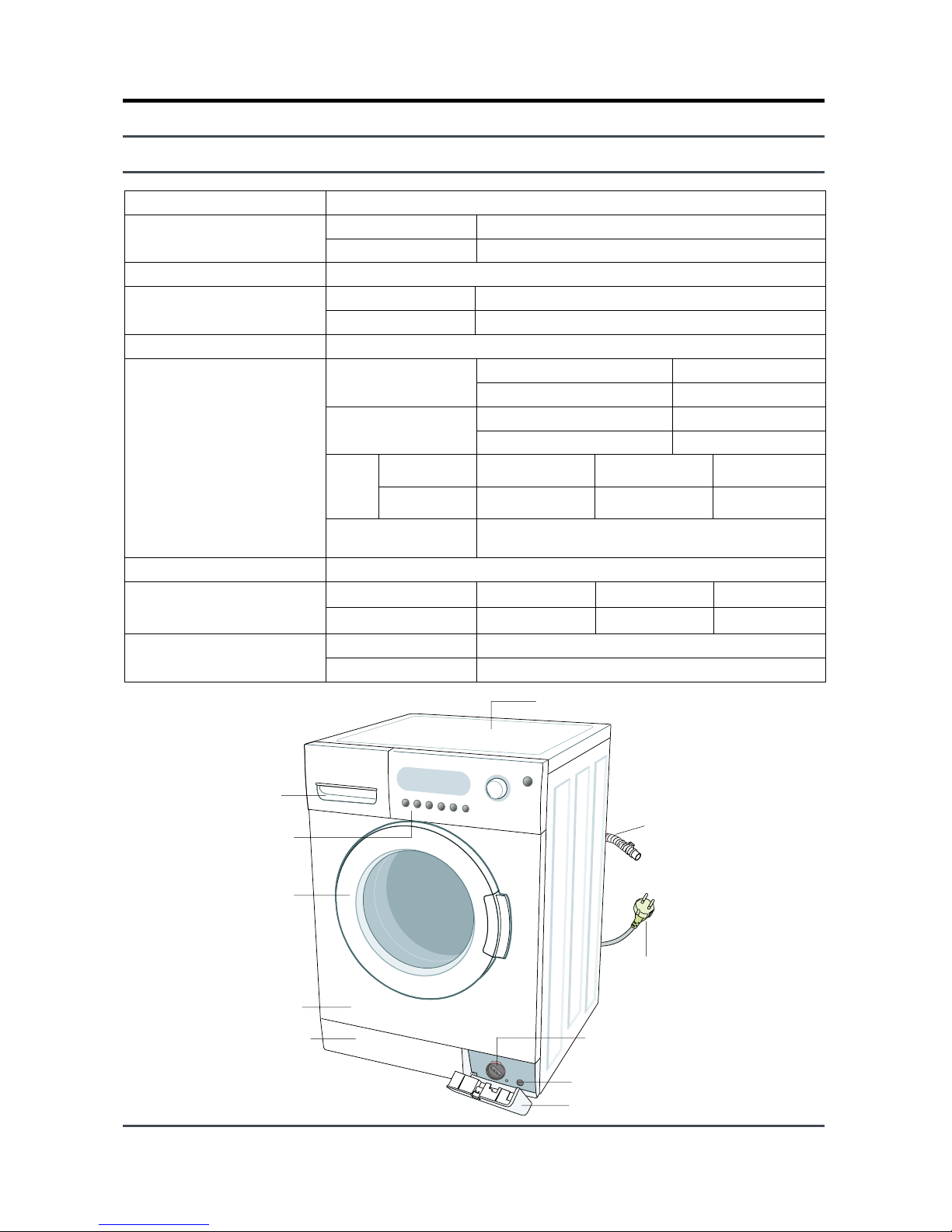

SPECIFICATIONS

5051

OVERVIEW OF THE WASHING MACHINE

506

.

THE COMPARATIVE SPECIFICATIONS OF PRODUCT

3. PRODUCT SPECIFICATIONS

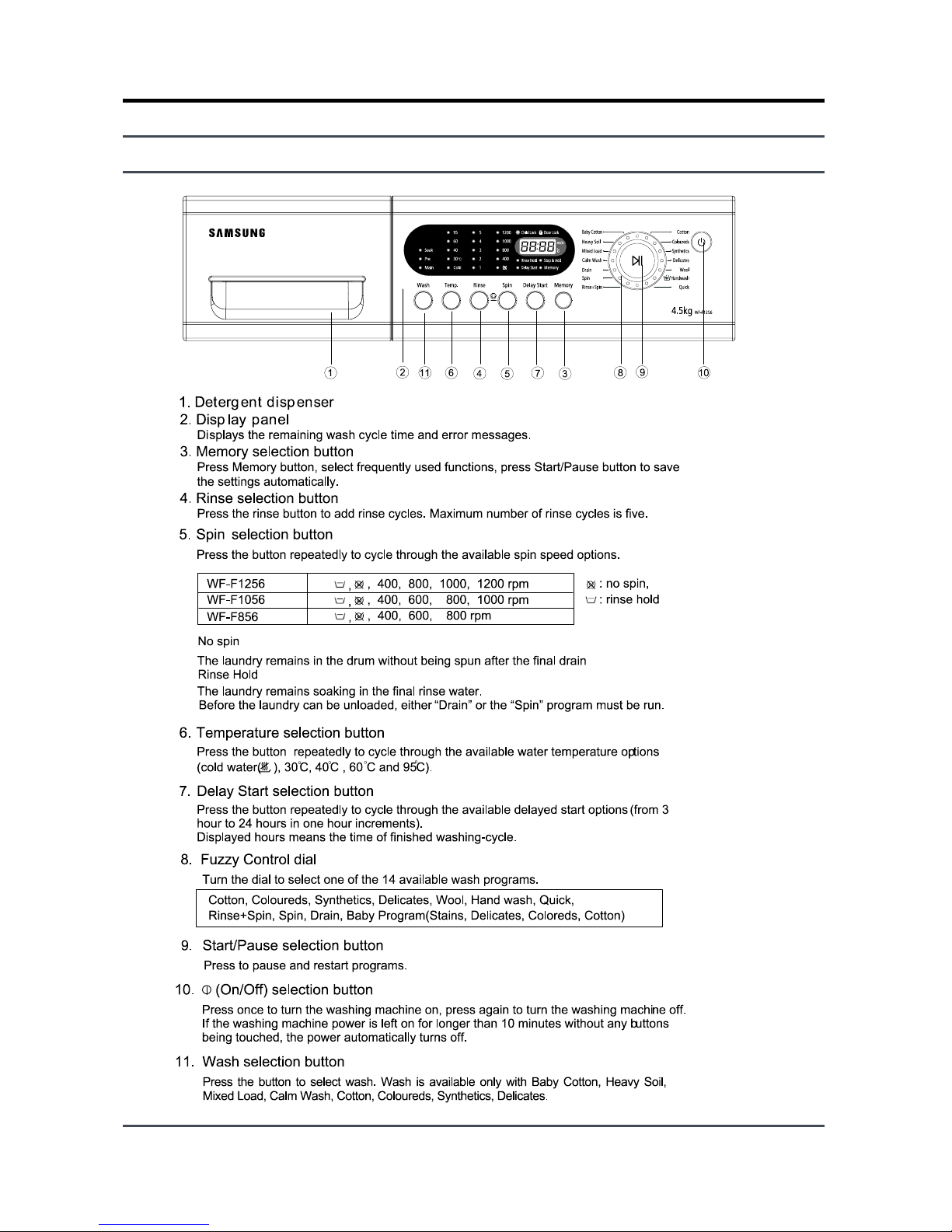

3-1. OVERVIEW OF THE CONTROL PANEL

3-2. MAIN FUNCTION

3-3. MAIN FUNCTION

3-4. TECHNICAL POINT

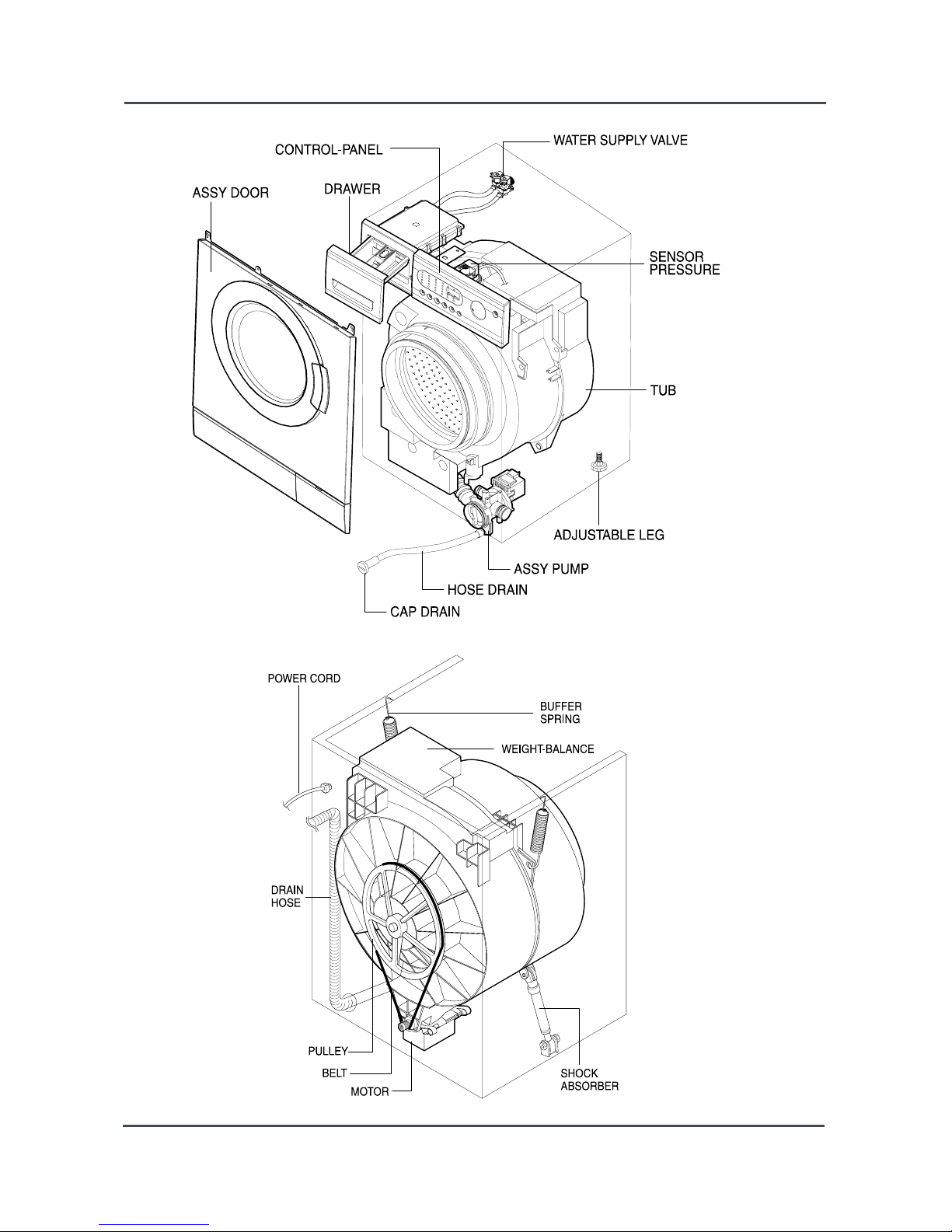

3-5. DESIGNATION OF MAIN COMPONENTS

4. ALIGNMENT AND ADJUSTMENTS

4-1. GENERAL ERROR FUNCTION

4-2. TEST MODE

5. ASSEMBLE AND DISASSEMBLE

5-1. TOOLS FOR DISASSEMBLY AND ASSEMBLY

5-2. ASSEMBLE AND DISASSEMBLE

6. TROUBLE DIAGNOSIS

6-1. TROUBLE DIAGNOSIS

6-2. PROBLEM CHECKING AND METHOD OF PCB

6-3. DETAILED DIAGNOSIS

7. EXPLODED VIEWS AND PARTS LIST

7-1. EXPLODED VIEWS OF T OP(FRONT)

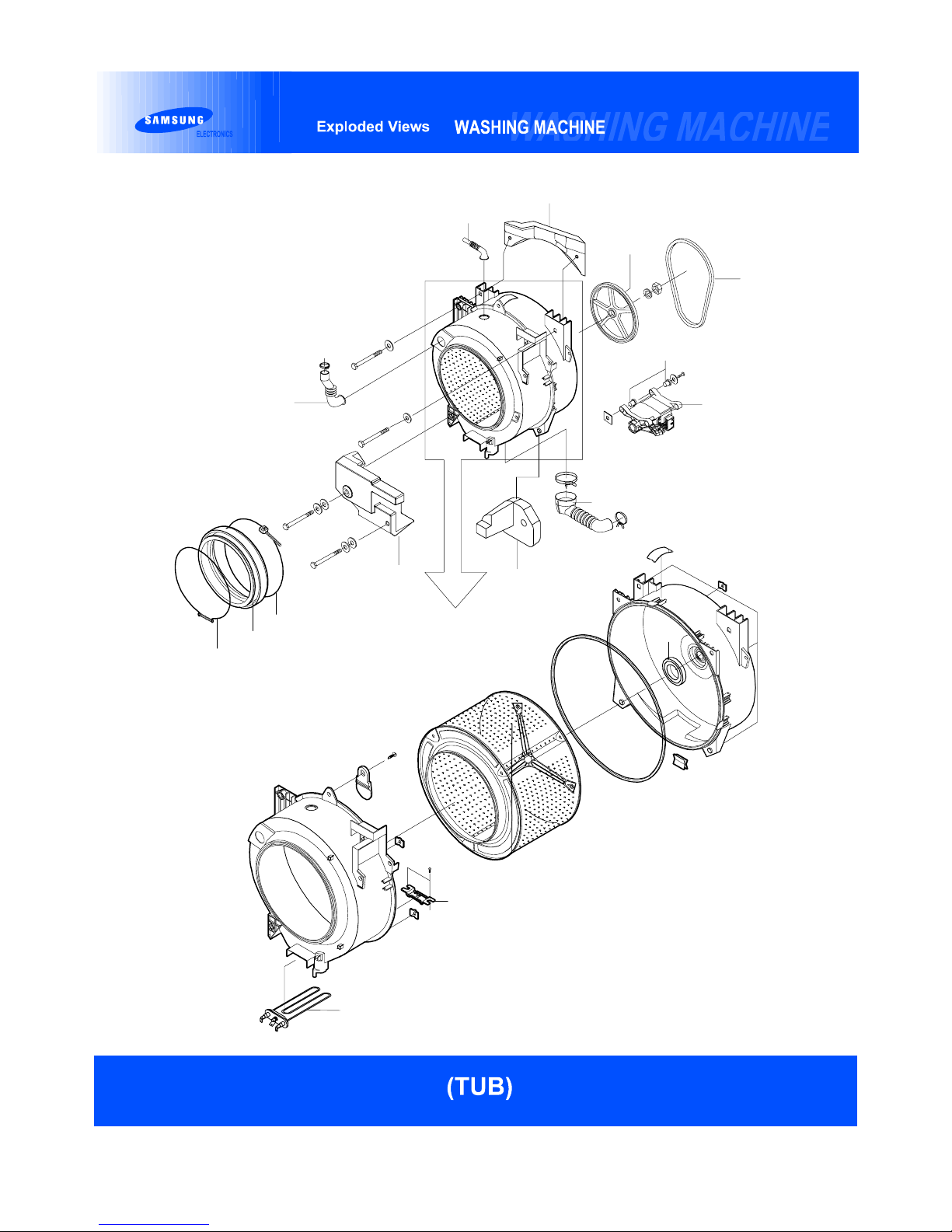

7-2. EXPLODED VIEWS OF T UB

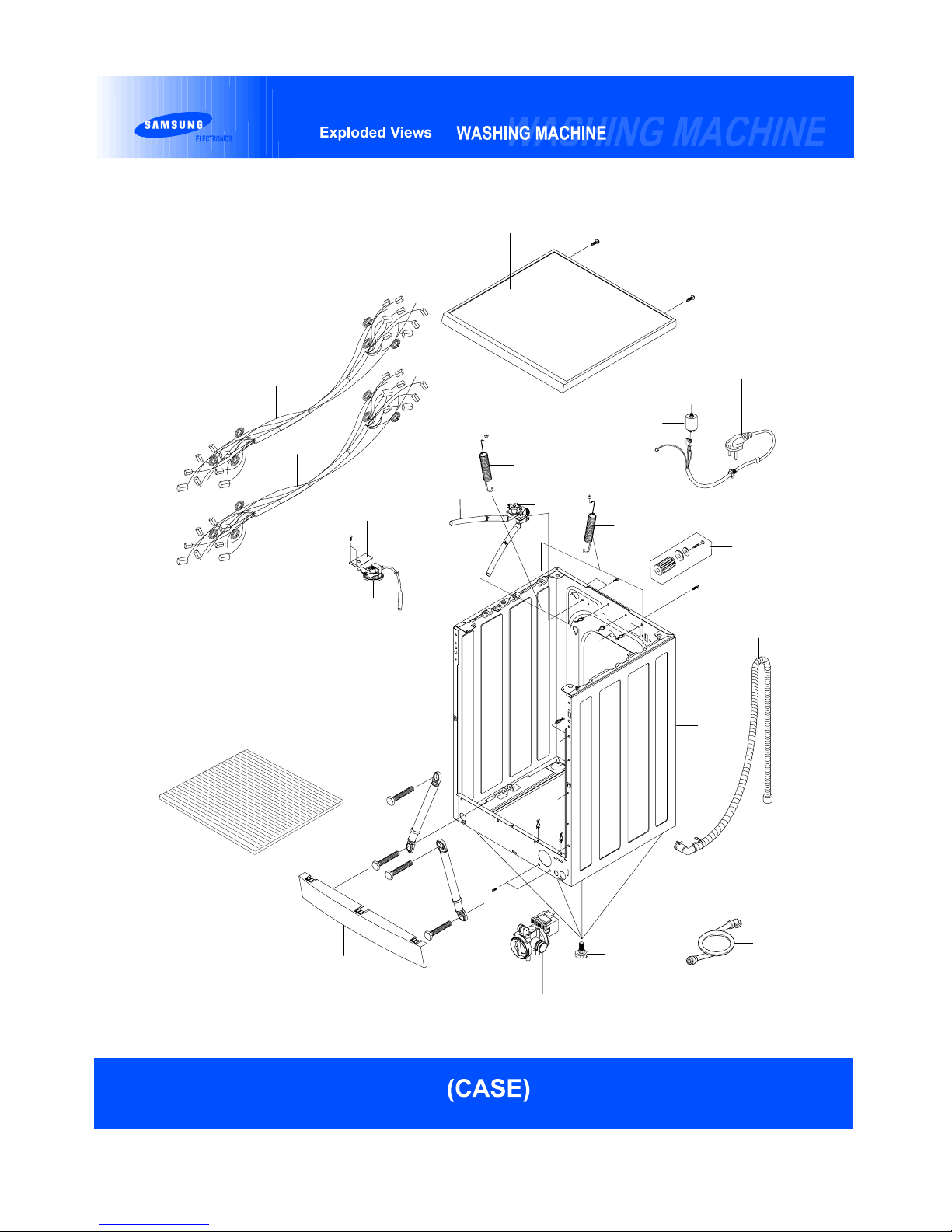

7-3. EXPLODED VIEWS OF CASE

7-4. PARTS LIST

CONTENTS

2

1

5

6

7

9

10

19

22

24

25

43

45

44

35

26

37

12

16

47

46

8. BLOCK DIAGRAM

9. SCHEMATIC-DIAGRAM

9-1. EMZ (F1256~F1056)

9-2. ROLD (F856)

10. PCB CIRCUIT DIAGRAM

10-1. PCB CIRCUIT DIAGRAM

11. REFERENCE INFORMATION

44041 PRGHO QDPH

44051 WHUPLQRORJ\

44061 IDEULF FDUH FKDUW

44071 HOHFWULFDO ZDUQLQJV

44081 T)D

CONTENTS

50

51

49

53

54

52

56

56

57

52

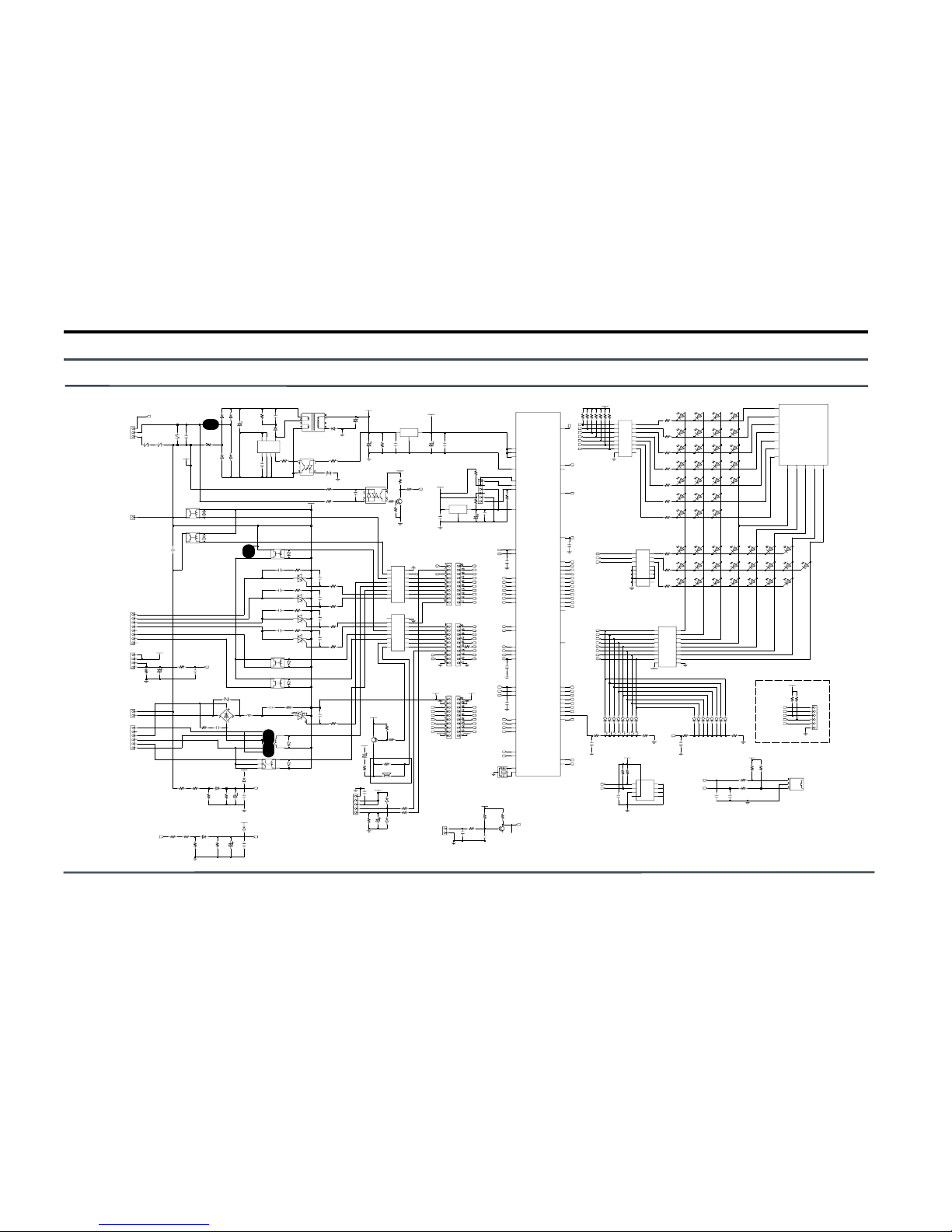

10. PCB CIRCUIT DIAGRAM

This Document can not be used without Samsung's authorization.

10-1. PCB CIRCUIT DIAGRAM

AG SIG-A

TACHO

Motor

D_PUMP

DIGIT-LED

1

N

4

1

4

8

X

8

AG SIG-A

SCAN-LED KEY

BIMETAL(LOCK) DOOR-UNLOCK

AG_KIT CURCIRT

Door_Com

AG-IH

AG SIG-B

AG SIG-B

DIAL-B

DOOR-LOCK

PRE

CW/CCW

D

I

G

I

T

-

L

E

D

270KOHM 1/2W X 2

MAIN(COLD)

330OHM 1/2W X 10

DIGIT-LED

DIAL-2

620OHM 1W X 4

180OHM 2W

W/L SENSOR

AG-IL

G

R

N

S

C

A

N

-

L

E

D

K

E

Y

DIGIT-LED

zero cross

270KOHM 1/2W X 2

(JOG DIAL CURCIRT)

AG-IH

SCAN-LED KEY

THERMISTOR

OPTION

THERMISTOR

DIGIT-LED

W_HEATER

MR1000

HOT

EEPROM1

AG-IL

CHIP X 7

BUZZER

KEY_SCAN

EEPROM2

BUZZER

DOOR-SIG IN

DIGIT-LED

300OHM 2W

100OHM 2W

HIGH SPEED

1N4007 X 4

PWM_AG

1

N

4

1

4

8

X

8

Controll

WHT

DOOR-SIG IN

POWER_RELAY

BLUE_LED

LED48

R65 1K

CE1

10uF

G

MT1

MT2

RY?

OMIF-S-112LM

1

5

0

R

5

4

TRIAC2 SM2LZ47

R

4

9

1

5

0

R

5

6

6

2

0

MMBT3904

TR1

LVT1

T-PJT

1

0

0

n

F

DGND

4

.

7

n

F

C

5

C

2

CN9

S

M

W

4

2

0

A

-

0

8

1

2

3

4

5

6

7

8

C26

10nF

PC1

LTV817B

R41

47K

+5V

R44

1K

C24

10nF

DGND

LED11

1

2

3

4

5

6

+5V

R

2

7

1

0

0

K

4

.

7

K

R

2

CN8

LED17

C

1

1

1

0

0

n

F

T

N

Y

2

6

6

P

I

C

3

1

B

Y

P

5

D

R

E

N

4

S

1

2

3

S

2

S

3

8

7

S

4

330 R8

BD1

10nF

C20

LED31

LED5

DGND

C

E

3

D

1

7

R20 4.7K

2

2

0

0

u

10nF

C14

LED13

GND

IN

OUT

S

W

5

R

3

IC4

KA7805A

1N4007

D25

4

.

7

K

4.7K

R47

R68 1K

D

1

0

100 R24

+12V

C30

10nF

R28

10K

6

5

4

3

2

1

10

11

12

13

14

15

16

9

VCC

C3

IC1

KID65003AP

8

GND

7

1

5

0

R

7

0

2.2NF

LED35

R

6

3

1

5

0

D

1

6

FTR-F3AA012E

RELAY6

LED29

LED23

R39

270K

100nF

C23

1

A

2

B

1K R62

CN1

MMBT3904

TR2

C

8

1

0

0

n

F

100K R22

DGND

C

1

1

0

0

n

F

+5V

DGND

DGND

1

2

3

4

5

6

7

8

LED41

12

13

14

15

16

9

VCC

RTE24012

RELAY3

GND

8

7

6

5

4

3

2

1

10

11

LED7

KID65003AP

IC7

LED10

DGND

LED39

11

12

13

14

15

16

9

VCC

2

0

D

5

6

1

V

A

R

4

8

GND

7

6

5

4

3

2

1

10

LED14

IC9

KID65003AP

RELAY7

FTR-F3AA012E

4.7K R21

LED30

D22

J

U

M

P

O

J

2

4

.

7

K

R

6

330 R9

R13 330

DGND

LED12

4

.

7

K

R

7

D

3

2

1

0

0

n

F

10nF

C4

+5V

C

9

OUT

D

1

5

7533

IC8

GND

IN

4.7K

R60

+5V

LED25

UF4007 D23

DGND

100nF

CM1

14D561K

VAR1

+5V

JUMP

L1

10uF

CE7

D

3

R

3

3

4

.

7

K

RESO1

16MHZ

S

W

6

OMIF-S-112LM

RY?

1

0

0

R

2

6

+12V

LED43

R35 1K

1

A

2

B

D

1

9

CN10

C

1

6

flat_wire_2x10p

F2

4

.

7

n

F

SM10LZ47

TRIAC1

LED1

LED37

1

A0

A1

2

3

A2 SCL

6

5

SDA

VCC

8

4

VSS

7

WP

1

2

3

IC5

24LC04B

330

9

0

0

1

9

W

S

-

0

3

W

H

T

CN3

R52 1K

R14

BLUE_LED

LED28

R66

4.7K

C29

100nF

WILL BUZZER1

LED9

DGND

LED19

D

1

2

DGND

D

1

8

D

5

D

6

D11

1N4148

R51 1K

+5V

PTC?

270M

1

N

4

1

4

8

270K

R40

D30

D33

1N4148

LED15

10K

R38

R32

270K

+5V

100nF

C19

D

3

1

LED34 LED38

S

W

4

+5V

C10

100nF

ZD1

R16 100K

D29

1N4007

MTZJ11B

10uF

+12V

1

2

3

4

CE8

330 R43

DGND

+5V

CN6

S

M

W

B

2

5

0

-

0

4

V

W

H

T

+5V

PC2

LTV814

LED24

LED22

1

2

3

4

5

6

+12V

D

1

3

S

M

W

4

2

0

-

0

6

CN4

CN5

1

2

3

4

5

6

3

3

K

R

3

4

R30

LED2

LED16

10K

F1

flat_wire_2x10p

330 R11

C7

1nF

CE6

DGND

6

2

0

R

6

1

10nF

C27

10uF

CE5

1uF

D

2

0

DGND

F3

flat_wire_2x10p

330 R71

DGND

15

14

13

12

11

9

VCC

DGND

1

2

3

4

5

6

7

8

18

17

16

C22

IC2

KID65783AP

GND

10

10nF

100nF

C32

BLUE_LED

LED6

100nF

C15

10

9

VCC

6

2

0

R

5

8

GND

8

1

2

3

4

5

6

7

16

15

14

13

12

11

KID65003AP

IC6

R46

47K

LED27

DGND

RELAY4

OMIH_SH_112L

LED46

+5V

4

.

7

K

R

1

S

W

7

MT1

MT2

10nF

C28

TRIAC3 SM2LZ47

G

TRIAC5

G

MT1

MT2

C

C

1

6

8

0

n

F

D

9

SM2LZ47

R

5

4

.

7

K

C

1

7

4

.

7

n

F

D

1

4

10K

R45

LED36

1

2

3

4

5

6

7

8 9 10 11 12

D

7

CSQ-4744G

DSP1

D

8

100nF

LED3

1K R50

C21

BLUE_LED

LED18

C25

10nF

52

53

VAREF

18

5

VDD

1

VSS

XIN

2

3

XOUT

14D911D

VAR2

22

23

24

25

26

27

28

29

30

31

32

33

34

35

8

RESET

62

63

64

36

37

38

39

40

41

42

43

54

55

56

51

20

21

17

44

45

46

47

48

49

50

9

6

7

57

58

59

60

61

TMP86FS49FG

MICOM1

19

AVDD

ISP_RX

11

ISP_TEST

4

12

ISP_TX

10

13

14

15

16

+5V

S

W

8

R17 100

1

LED8

YDW236-01BLK

CN2

1N4148

D1

TR3

K

S

A

9

2

8

A

-

Y

LED4

R29

10K

R25

100

1N4148

D35

LED42

R

5

7

6

2

0

R23 100

270K

R31

R42

33K

330 R12

LED47

DGND

D

2

DGND

CE2

470uF

CM3

100nF

S

W

1

R74

4.7K

DGND

+12V

4.7K

R53

4.7K

R67

DGND

R

4

4

.

7

K

R69

4.7K

DGND

DGND

4

7

0

u

F

C

E

4

14D182

VAR3

R75

220

D34

1N4148

LED44

+5V

R55 330

D

4

DGND

+12V

LED32

DGND

D21

U

F

4

0

0

7

180

4.7K

+12V

+12V

R15

DGND

R59

1

N

4

1

4

8

D

2

7

DGND

C

6

4

.

7

n

F

S

M

W

B

2

5

0

-

0

5

W

H

T

CN7

1

2

3

4

5

10uF

CE9

47K

R36

COIL1

NV2-08730

DGND

DGND

100nF

C12

DGND

D28

1

N

4

1

4

8

LED26

LED45

1K R72

S

W

2

LED33

CE10

47uF

C18

LED40

10nF

D24

S

W

3

R19

100K

DGND

JES1424GS

JOG1

R73 2.2K

LED20

FTR-F3AA012E

RELAY5

R37

10K

27K

R48 300

100nF

CM2

R64

G

MT1

MT2

D26

1

N

4

1

4

8

C

1

3

SM2LZ47 TRIAC4

DGND

1

0

0

n

F

LED21

R10 330

35

25

25 PWM_AG

47

35

EX_INT

30

33

32

31

34

9

63

58

62

44

46

45

63

61

62

60

10

17

22

51

EX_INT

26

51

24

23

22

50

49

48

57

59

15

14

20

16

21 21_1

THER

F

G

29

28

27

13

49

14_1

15_1

16_1

20_1

TACHO

2

0

57

56

58

59

60

61

36

37

38

39

40

27

46

24

38

39

40

41

26

55

45

23

29

30

31

32

33

34

55

52

28

53

41

42

43

F

14_1

20_1

21_1

15_1

TACHO

10

53

52

13

14

15

16

17

44

47

48

50

9

36

37

42

43

21

16_1

G

PWM_AG

D_CHK

D_CHK

THER

44

R0019

D0003

R0036

C0002

C0115

F0125

D0081

D0061

D0112

D0075

D0046

C0058

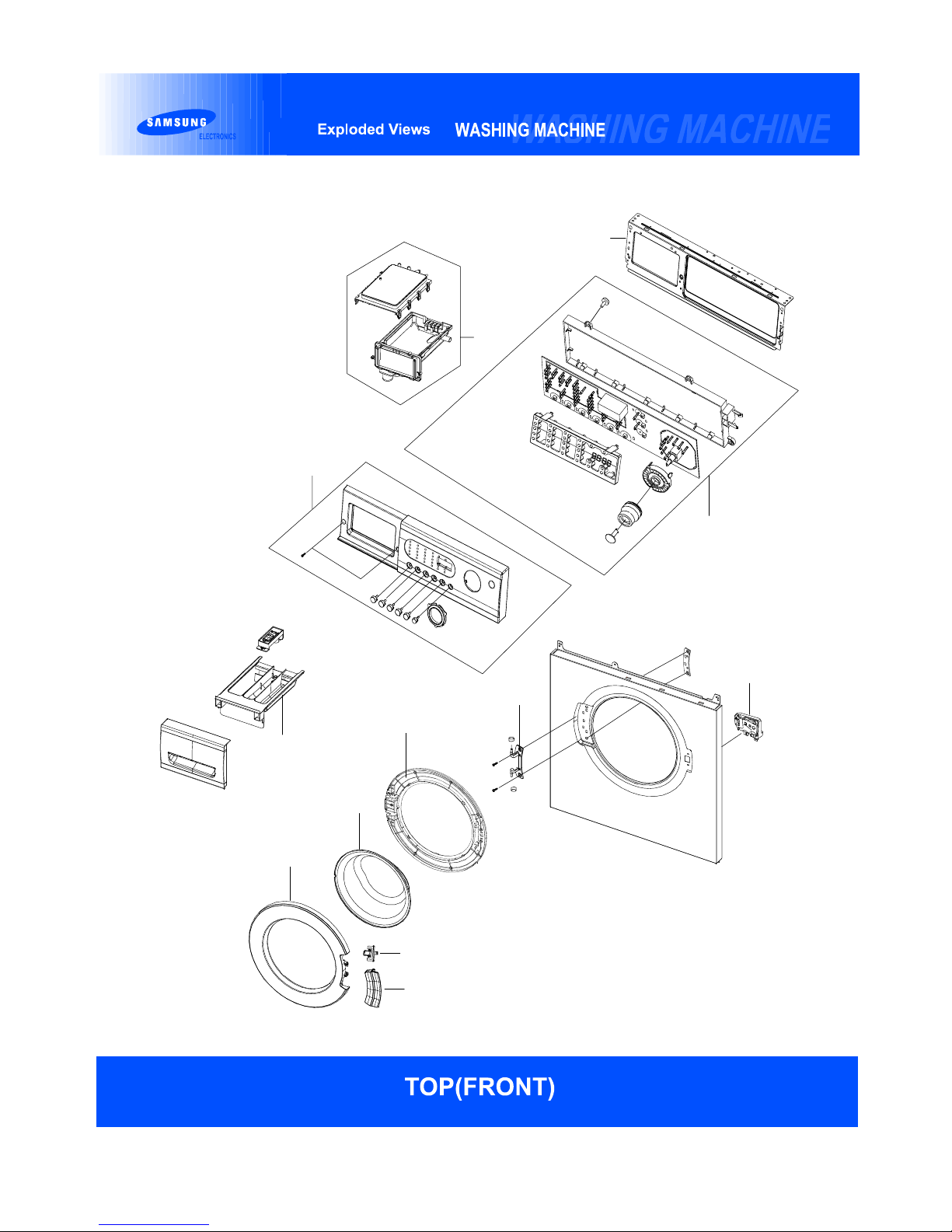

7.

EXPLODED VIEWS AND PARTS LIST

45

R0158

I0043

U0355

U0095

U0010

U0015

U0307

U0033

U0016

U0018

D0048

R0030

U0029

U0038

U0355

U0355

46

W0004

W0001

R0148

R0027

P0001

Y0040

W0002

I0022

F0027

B0070

I0003

A0006

J0013

A0025

R0159

R0159

W0032

R0158

47

NO. CODE NO. DESCRIPTION;SPECIFICATION QTY SA/SNA REMARK

A0004 DC63-00609A COVER-FILTER;F125AV-B145AV,ABS 1 SA

A0006 DC63-00608A COVER-FRONT(L);F125AV-B145AV,ABS 1 SA

A0025 DC97-02106A ASSY-FIXER TUB;S1005J,SLIM-PJT 5 SA

A0034 DC60-40146A BOLT-SPANER;OD36,T2.5,L52,FE,FZY,P 1 SA

A0043 DC61-10688A CAP-FIXER;SWF-P12,PP(TB53),WHT, 5 SA

A0043 DC61-10688A CAP-FIXER;SWF-P12,PP(TB53),WHT, 1 SA

A0115 DC61-60180A SLEEVE-PLUG;NYLON#6,SEW-720DR,NTR 4 SA

A0242 DC64-00945B INLAY-PANEL;WF-R1256/TROIKA,ACRYL,T1.5 1 SA

A0359 DA69-90141A BAND-PP;GB-SPEC,PP,T1.0,W13,W14.5,RE 7.5 SA

A0362 DC61-40081A HOLDER-WIRE;DAWH-2NC,NYLON66,NTR 6 SA

A0365 DC69-90008A TAPE-OPP;W50,YEL/WHT 0.8 SA

A0365 DC69-90008A TAPE-OPP;W50,YEL/WHT 2.8 SA

B0070 DC97-02079D ASSY-LEG;SBP2,SD455,SD405,FLANG TYPE/25M 4 SA

C0002 DC97-09209N ASSY-PANEL CONTROL;WF-F1256/YLP,NEAT-WHT 1 SA WF-F1256

C0002 DC97-09209P

ASSY-PANEL CONTROL;WF-F1056/YLP,NEATWHT/RUS/4.5KG

SA WF-F1056

C0002 DC97-09209Q

ASSY-PANEL CONTROL;WF-F856/YLP,NEATWHT/RUS/4.5KG

SA WF-F856

C0058 DC64-00652A

DOOR-LOCK S/W;38.0092,PA-GF,-,H107,W60,L30,,250V50/60HZ/EMZ(S)

1SA

WF-F1256

WF-F1056

C0058 DC64-00653A

DOOR-LOCK S/W;DA,PA6-G,-,H82,W50,,BLK,250V/16A/ROLD

1 SA WF-F856

C0115 MFS-T1F12NS-00 ASSY PCB PARTS(M);MFS-T1F12NS-; 1 SA WF-F1256

C0115 MFS-T1F10NS-00 ASSY PCB PARTS(M);MFS-T1F10NS-00 SA WF-F1056

C0115 MFS-T1F08NB-00 ASSY PCB PARTS(M);MFS-T1F08NB-00 SA WF-F856

C0116 DC66-00333A LEVER;Q1636GW/XEU,PE,TS-2 PJT 1 SA

D0003 DC61-00932A HINGE-DOOR;Q1636GW/XEU,ZN DC,TS 1 SA

D0046 DC97-05111A ASSY-LEVER DOOR;Q1636GW/XEU,TS-2 PJT 1 SA

D0048 DC61-00933A BRACKET-HIN GE;Q1636GW/XEU,SBHG,T 1 SA

D0061 DC64-00920A DOOR-GLASS;R831,GLASS,NTR,CKD /C 1 SA

D0072 DC61-00891A GUIDE-HINGE;HAUZEN(DOM),POM,WHT,HI 2 SA

D0075 DC64-00773B HANDLE-DOOR;WF-F85A,ABS,NEAT WHT 1 SA

D0076 DC64-00564A HANDLE-PIN;Q1636GW/XEU,STS,TS- 2 SA

D0081 DC61-01144A HOLDER-GLASS;SEW-3HR109BT,PP(TB53) 1 SA

D0112 DC63-00506B COVER-DOOR;WF-F85A/R85A/B85A,ABS 1 SA

F0027 DC99-00638A ASSY-PAINT FRAME;WF-F1256,T1.0/NEAT-WHT 1 SA

F0064 DC97-09198A ASSY-FRAME FRONT;TROIKA-PJT,ROUND/NEAT W 1 SA

F0125 DC61-01397A FRAME-PLATE(U);T-PJT,EGI,NTR,T0.8, 1 SA

I0003 DC62-10289C HOSE-WATER(C);RUSSIA,PVC+NYLON,ID10.3, 1 SA

I0022 DC97-00139E ASSY-HOSE DRAIN(O);SB-PJT,PP/L1770/CHINA 1 SA

I0030 DC62-10278A HOSE-HANGER;PP(JS20),NTR 1 SA

I0043 DC62-10303A HOSE-AIR;EPDM,ID24,L130,BLK,SWF-P1 1 SA

J0013 DC96-00859A ASSY-PUMP DRAIN;R1245A/XSC,220V~240V/50H 1 SA

J0019 DC61-10652C CASE-PUMP;PP(5113MF6),SWT50B1P,GRY 1 SA

J0024 DC62-00187A SEAL-WASHER;SW80ASPIW/YMI,NBR,BLK, 1 SA

J0025 DC31-00056A PUMP-DRAIN;220~240V,50Hz,30W/3000RPM 1 SA

P0001 DC97-09278A ASSY-COVER TOP;WF-F125A/WHT/WOOD,TROIKA- 1 SA

P0082 DC97-05973A ASSY-HOSE PRESSURE;5.2kg/SD455/SD405,PVC 1 SA

R0019 DC97-04748T ASSY-HOUSING DRAWER;F1033,1WAY(COLD) 1 SA

R0019 DC97-02132C ASSY-HOUSING DRAWER;S1093~S6093/2-WAY,SL 1 SA

R0025 DC97-09333A ASSY-PANEL DRAWER;WF-F125AV~B85A/YLP,NEA 1 SA

R0027 DC97-00731A ASSY-SENSOR PRESSURE;P1091,S-PRE+BRAKET+ 1 SA

R0030 DC91-12078A ASSY-WIRE DIAPHRAGM;SWF-P12,FRAME-FRONT 1 SA

R0036 DC61-01395A BODY-DRAWER;WF -R125,PP,NTR,5.2KG 1 SA

R0047 DC67-00114A CAP-FILTER;SW80ASPIW/YMI,P.P,BLK 1 SA

R0096 DC63-00143A HOUSING-DRAWER(L);PP(TB-53),SL-600,WHT 1 SA

7

. PARTS LIST

48

7

. PARTS LIST

NO. CODE NO. DESCRIPTION;SPECIFICATION QTY SA/SNA REMARK

R0097 DC61-00686A HOUSING-DRAWER(M);F1225J,TB53,WHT, 1 SA

R0098 DC61-00685A HOUSING-DRAWER(U);F1225J,TB53,WHT, 1 SA

R0147 6011-001421 BOLT-FLANGE;M7,L61(29.4),ZPC(YEL),SWRCH1 1 SA

R0147 6011-001421 BOLT-FLANGE;M7,L61(29.4),ZPC(YEL),SWRCH1 5 SA

R0148 DC61-40345A BRACKET-PRESSURE;GI or GA,SWK-P12,T1.0 1 SA

R0158 DC62-10305A HOSE-DRAWER TUB;EPDM,ID35,L158,BLK 1 SA

R0158 DC67-00051D HOSE-DRAWER;S1093~S6093,EPDM,BLK 0.38 SA

R0159 DC61-01279A SPRING-HANGER;5.2KG(F631/F831),HSWR,CD2. 2 SA

R0159 DC61-01280A SPRING-HANGER;5.2KG(F631/F831),HSWR,CD2. 2 SA

U0003 DC60-60044A WASHER-PLAIN;ID10.5,OD30,T3,ST S 304 2 SA

U0003 DC60-60044B WASHER-PLAIN;SBC,ID8.4,OD30,T3 5 SA

U0005 DC60-60040A WASHER-NYLON;ID10.5,OD32,T2,PBSP-1/2 5 SA

U0010 DC66-10176B PULLEY;ALDC,D297,P12 91,ID12.5 1 SA

U0015 DC31-00002H MOTOR-DRUM;HXGP2I,S803J,50HZ,LOW-R 1 SA

U0016 DC62-00007A SEAL-OIL;NBR(SD25),BLK,P6091/NBU 1 SA

U0018 DC47-00006B HEATER;KAWAI,P-SLIM MODEL,SUS316L,23 1 SA

U0023 DC61-00201A BRACKET- NUT;SBHG-R,P1291,T3,NO-PAI 1 SA

U0023 DC61-00201A BRACKET- NUT;SBHG-R,P1291,T3,NO-PAI 1 SA

U0029 DC61-20219E DOOR-DIAPHRA GM;SEW-HW107,EPDM,GR 1 SA

U0033 DC62-00121A HOSE-FILTER TUB;S1005J,EPDM,ID65 1 SA

U0038 DC91-12077A ASSY-CLAMP DIAPHGRAM;SWF-P12,TUB 1 SA

U0082 DC62-00116A FILTER-NET;P1205J,EPDM+STS304,OD25,ID9 1 SA

U0095 6602-001072 BELT-TIMING GEAR;POLYURETHAN,L1270,J5,ME 1 SA

U0307 DC61-00041A CUSHION-MOTOR;SWF-6V,BUTYL,ID16/OD 1 SA

U0320 6011-001447 BOLT-HEX;M8,L123(25),ZPC(YEL),SWRCH18A,W 1 SA

U0320 6011-001448 BOLT-HEX;M8,L170(25),ZPC(YEL),SWRCH18A,W 1 SA

U0320 DC60-40141A BOLT-HEX;SM10C/DAMPER,HEX,M8,L66,ZPC2( 2 SA

U0320 DC60-40144A BOLT-HEX;M10,L41,ZPC2(YEL),SM10C/DAMPER 2 SA

U0353 DC61-60359E CLAMPER HOSE;F1235AS/F1035AS,ID7.8,Y 1 SA

U0353 DC61-60497A CLAMPER HOSE;SWF-P12,HSWR,ID70/OD75.8, 1 S A

U0353 DC65-00008A CLAMPER HOSE;SEW-DR605,SK5,YEL,ID14. 1 SA

U0353 DC61-60359E CLAMPER HOSE;F1235AS/F1035AS,ID7.8,Y 1 SA

U0353 DC61-00118A CLAMPER HOSE;P1291,LYLON6/6,ID27,OD30, 1 SA

U0353 DC61-60359F CLAMPER HOSE;F1235AS/F1035AS,ID15 .7, 4 SA

U0353 DC61-00133A CLAMPER HOSE;P1291,PP(BJ-730),ID24.5,OD2 1 SA

U0354 DC97-06393J ASSY-SEMI TUB DRUM;WF-F125AC/YLP,SSEC 1 SA

U0355 DC67-00038A WEIGHT-BALANCER;F-PJT(40CM),CONCREET 1 SA

U0355 DC67-00042B WEIGHT-BALANCER;F1215,GC-150(CHINA), 1 SA

U0355 DC67-00050B WEIGHT-BALANCER;F-1215,GC-150,F- 1 SA

U0356 DC65-10001A CABLE TIE;DA-140 6 SA

U0359 DC62-00066A FILTER-CASE;PP,BLK/SW90V2 1 SA

U0360 DC61-60499B CLIP-TUB;HSWR,P1291,NO/PAINT, 6 SA

U0360 DC61-60520A CLIP-TUB;SK5,SWF-P12,PLATE-TYPE, 2 SA

W0001 DC96-00990A ASSY-WIRE HARNESS;TROIKA-PJT,SUB/WIRE (R 1 SA

W0002 DC96-00146A asSY POWER CORD;UCP2,250V/16A, 1 SA

W0004 DC96-00951A ASSY-M.WIRE HARNESS;WF-F1256V,TROIKA-PJT 1 SA

WF-F1256

WF-F1056

W0004 DC96-00955A ASSY-M.WIRE HARNESS;WF-F856,TROIKA-PJT 1 SA WF-F856

W0032 DC62-00024F VALVE-WATER;B1215J,NYLON66/250TRMN,N 1 SA

Y0040 DC29-00006A FILTER-EMI;DFC-2712R,P/PV/SLIM,250V,12A, 1 SA

Z0006 DC97-02412A ASSY-BOLT;SWF-P12,MOTOR, M8*L62 2 SA

Z0006 DC97-02412H ASSY-BOLT;Q1657 1 SA

DC66-10003A WIRE-VINYL;SEW-100 JL,PVC,T2.0 0.56 SA

DC66-10003A WIRE-VINYL;SEW-100 JL,PVC,T2.0 0.15 SA

DC66-10003A WIRE-VINYL;SEW-100 JL,PVC,T2.0 0.4 SA

49

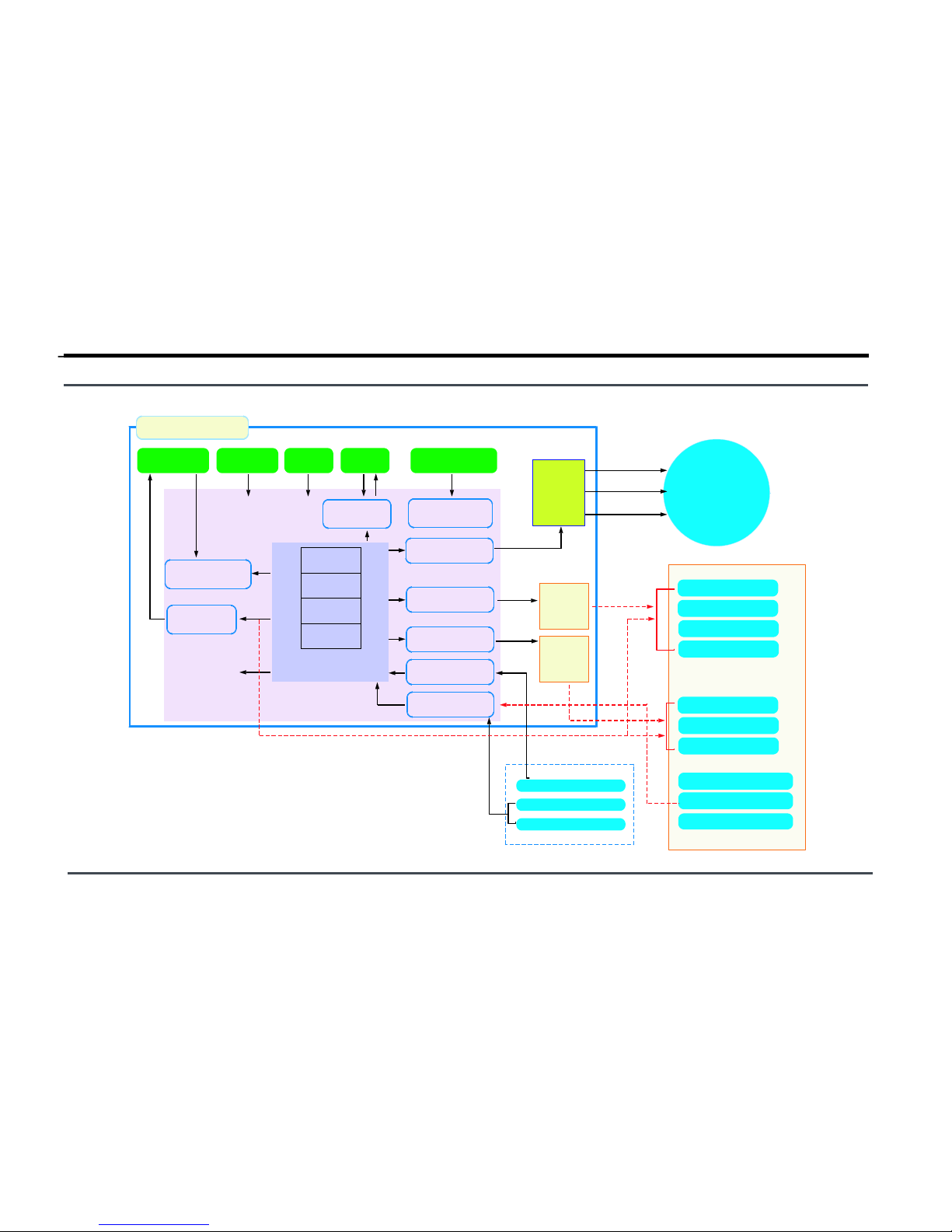

8.

BLOCK DIAGRAM

MAIN PBA

COLD-VALVE

PRE-VAL VE

DRAIN PUMP

HOT-VALV E

DOOR-COM

DOOR-UNLOCK

DOOR-LOCK

DOOR-CLOSE SIG

DOOR-LOCK SIG

DOOR-UNLOCK SIG

UNIVERSAL

MOTOR

MOTOR

CW/CCW

CONTROL

RELAY

ML

MR

MAIN MICOM

DRIVE

CONTROL

TRIAC

DRIVE

CONTROL

RELAY

WATER LEVEL SENSOR

WATER THERMISTOR

HEAT SINK THERMISTOR

OSCILLA TION

CIRCUIT

RESET

CIRCUIT

EEPROM

CIRCUIT

AC ZERO CROSSING

DETECT CIRCUIT

PRE WASH

WASH

RINSE

SPIN

ERROR

CONTROL

EEPROM

DRIVE

POWER

CONTROL DRIVE

AD COVERTER

CONTROL

FREQUENCY

CHECK DRIVE

DOOR CONTROL

DRIVE

ACTUATOR CONTROL

DRIVE

MAIN MOTOR

CONTROL DRIVE

DISPLAY

CONTROL DRIVE

CPU

DISPLAY

CIRCUIT

2

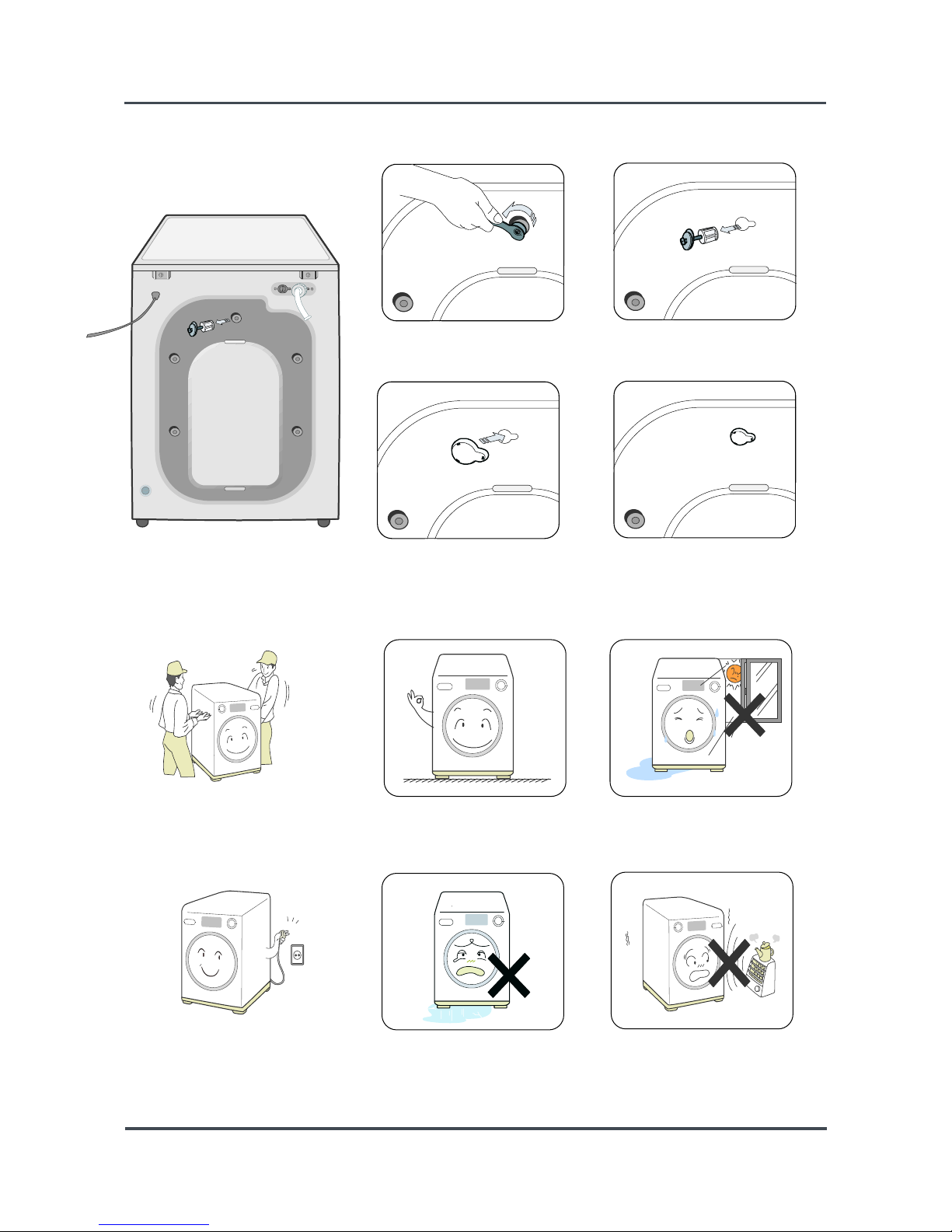

■

How to Remove Shipping Bolts

1. Remove the screws by using

the supplied spanner.

2. Remove the shipping bolts

from the back of the unit.

3. Fill the holes with the

supplied plastic caps.

4. Keep the shipping bolts and

screws for future use.

Make sure that the unit stands

on a firm and leveled floor.

Keep it away from direct sunlight

or high humidity, and install it

in a place with good ventilation.

Keep the unit away from places

in which it is freezing,

especially in winter.

Keep the unit away from heat

appliances such as a heater.

1-2.Precautions upon Installation

■ Precautions before

Installation

The unit is quite heavy. So,

make sure to have 2 or more

personnel move it.

Install the unit at a place

with a wall outlet easily

accessible.

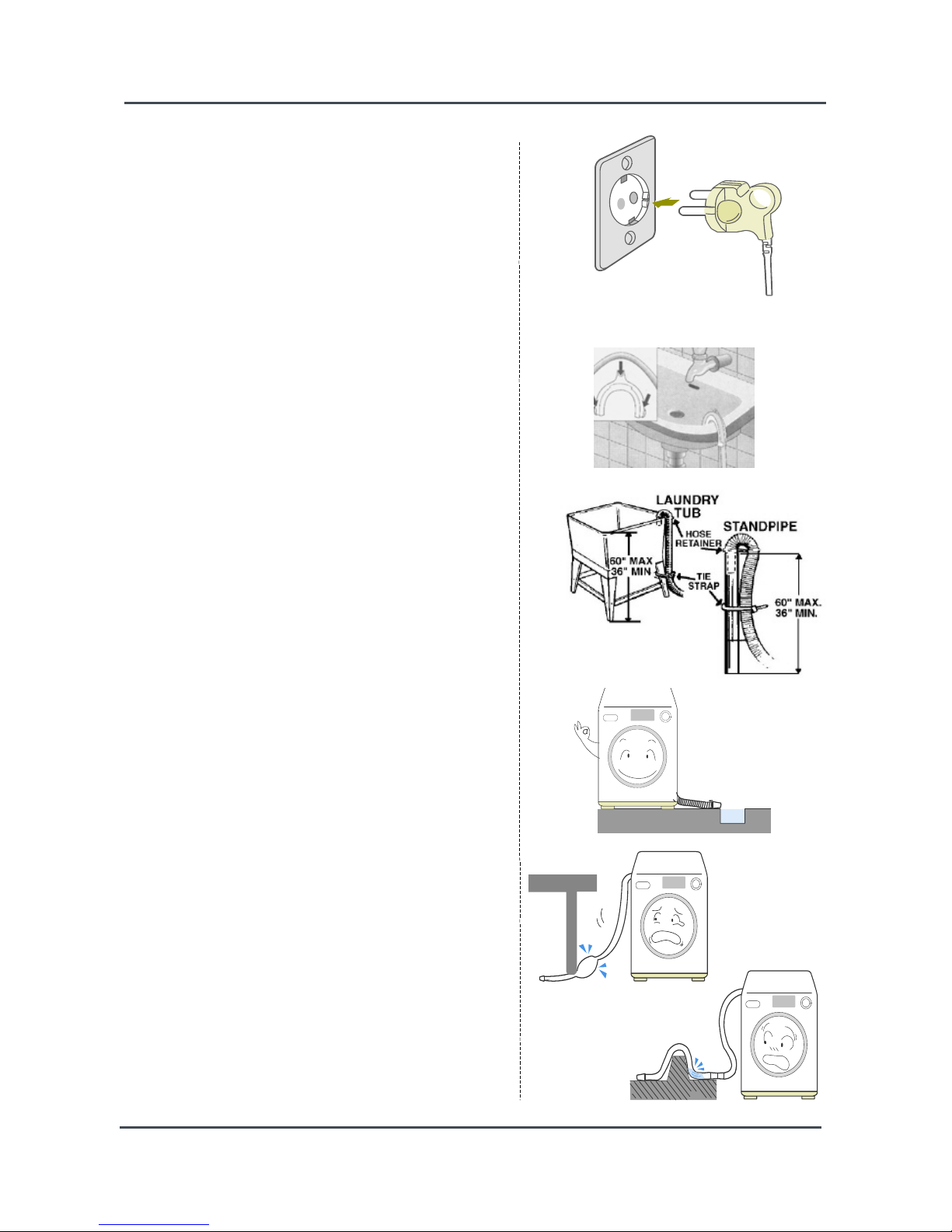

3

■ Grounding

※ Make sure to ground the unit to prevent

electric leakage or shock.

With a grounded receptacle

▶ It does not need an additional grounding.

■ Water Drainage

Note: Caution must always be exercised to

avoid collapsing or damaging the drain hose.

For best performance the drain hose should

not be restricted in any way, through elbows,

couplings or excessive lengths.

▶ Hook the drain hose over the Wash Basin or

Laundry Tub or plug the end of the drain hose

into the Standpipe

- The end of the drain hose must be passed

through the Hose Guide or secured as shown in

the picture to prevent it from popping up

during drainage of water.

- The outlet end of the drain hose must be at

least 60-90 cm above the base of the machine.

▶ Seal the drain pipe connections

- If not, it may cause water leakage.

▶ Prevent water from siphoning away

- If the end of the drain hose is put in water,

it could siphon away water during washing.

So, make sure that the end of the drain hose

is not put in water.

4

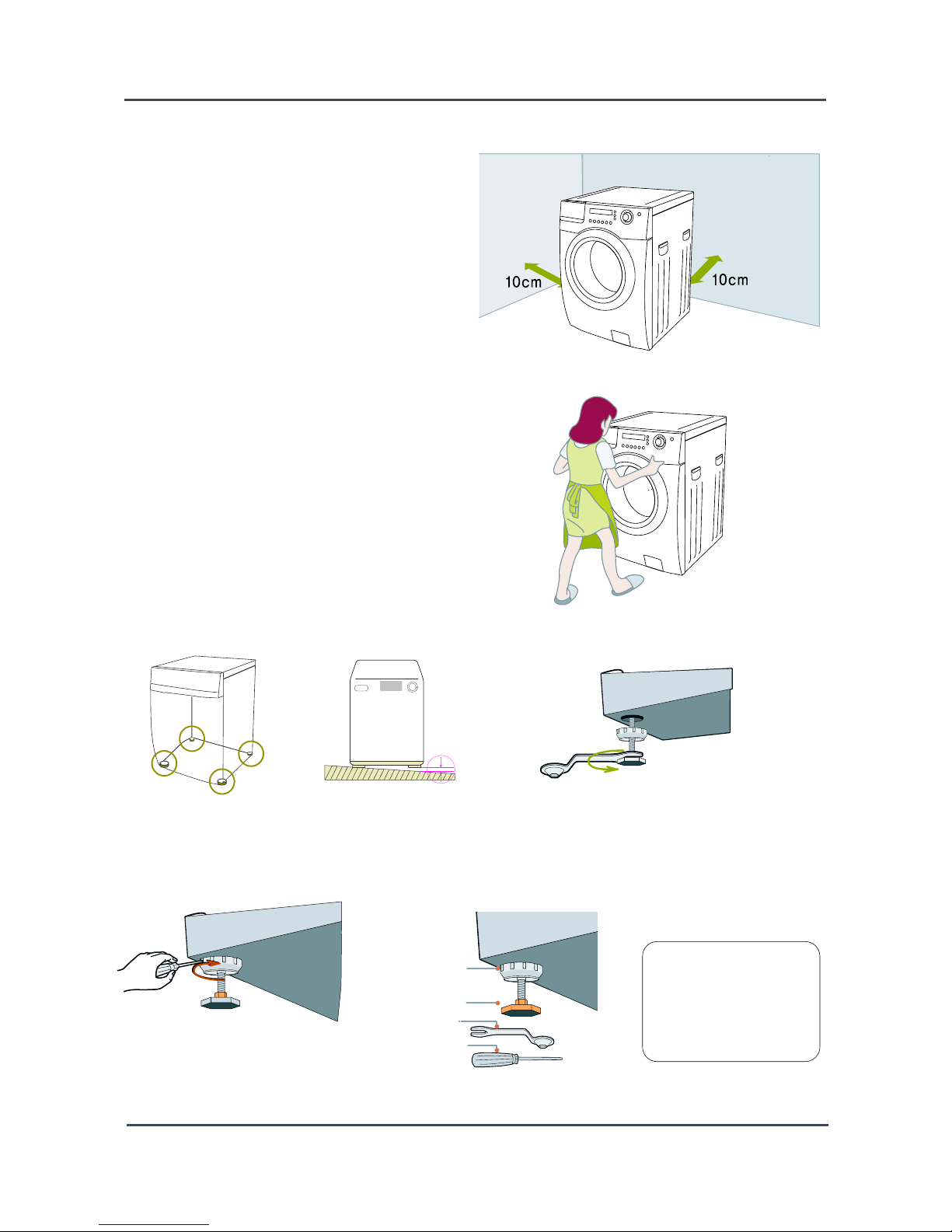

■ How to Level the Unit

1. Select an installation place.

▶Install the unit with 10cm or more

clearance from its surrounding walls.

▶The unit is also available for

alcove or closet installation.

2. Check if the unit is leveled.

▶If the unit wabbles, adjust the leveling

legs.

3. Adjust the leveling legs.

▶ The 4 leveling legs

should touch the floor

all together.

※ Caution ※

Tighten the lock nut after

the leveling. If not, it

could generate vibrations &

noises.

When the unit is not leveled

▶Lift up the unit a little bit and adjust the shortest.

▶Turn the leveling bolt counter clockwise as shown in the picture above

(The leveling leg gets longer.)

▶ After adjusting the leveling

bolt, tighten the lock nut by

turning it clockwise.

Lock Nut

Leveling Bolt

Spanner

Flat Head

Screwdriver

1

1. Do not allow the customer to repair the product.

☞

It may cause personal injury or product damage when the unit is serviced by unqualified personnel.

2. Disconnect power to the appliance before servicing.

☞

Be aware of the possibilities of an electric shock.

3. Do not use multi-plug.

☞

Power outlet may be overloaded causing the socket to overheat.

4. Check for any damage on power plug or power outlet.

☞

Replace it immediately if it has problem. (It may cause an electric shock or fire)

5. Make sure to earth the product.

☞

May cause electric shock.

6. Do not clean the product with water.

☞

May cause electric shock / fire or shorten product life.

7. The wiring harness should be free from moisture and connected properly during serving.

☞

It should be proof against any external force.

8. Remove any dust or dirt in the product, wiring section and connections during servicing.

☞

Protect against possibilities of fire due to tracking etc.

9. Check for any water trace on electrical parts, harness, etc.

☞

Replace the parts and /or wipe dry the water.

10. Check the assembled status of the parts after servicing.

☞

Check if the product is assembled in the same status as before servicing.

11. Be sure not to pull on the power cord but to unplug it by holding the plug.

☞

Beware of possibility of electric shock or fire when the power cord is damaged.

12. Unplug the powe r plug from the outlet when the washing machine is not used.

☞

Beware of possibility of electric shock or fire while lightening.

13. Do not use or put flammable materials (including gasoline, alcohol, thinner etc) around the

washing machine.

☞

Flammable materials may spark an explosion or fire.

14. Do not put a water containing bowl or wet laundry on the washing machine.

☞

It may cause an electric shock or fire, or shorten the product life when its water penetrates into the

washing machine.

15. Do not install the washing machine in a place where it is exposed to snow or rain etc.

☞

It may cause an electric shock or fire and shorten the product li fe.

16. Do not press control buttons with pointed objects such as pins, needles, etc.

☞

It may cause an electric shock or other problems.

17. Check the washing machine is leveled horizontally on the floor and is installed properly.

☞

Vibration may shorten the product life.

18. Make sure to use connectors when connecting wires.

☞

If wires are connected without connectors, it may cause a tracking fire.

19. When the washing machine is to be laid down for servicing, put a pad on the floor and lay the

product on its side slowly.

☞

If the wash machine is laid on its front, internal components may be damaged by the tub.

1. Precautions

1-1. Safety Precautions

5

2.

THE FEATURE OF PRODUCT

2-1. SPECIFICATIONS

WASH TYPE

FRONT LOADING TYPE

DIMENSION

NET W 598mm X D 404mm X H 844mm

GROSS W 668mm X D 530mm X H 890mm

WATER PRESSURE

50 kPa ~ 800 kPa

WEIGHT

NET 65 kg

GROSS 68 kg

WASH and SPIN CAPACITY

4.5 kg (DRY LAUNDRY)

POWER CONSUMPTION

WASHING

220V 180W

240V 180W

WASHING and

HEATING

220 V 1850 W

240 V 2150 W

SPIN

MODEL

WF-F1256 WF-F1056 WF-F856

220~240V 270 W 230 W 180 W

PUMPING 34 W

WATER CONSUMPTION

43

ℓ

(STANDARD COURSE)

SPIN REVOLUTION

MODEL

WF-F1256 WF-F1056 WF-F856

rpm 1200 1000 800

PACKAGE Wt

PAPER 2.5kg

PLASTIC 1.0kg

Filter-cover

Door

Detergent

drawer

Emergency drain

tube

Filter-cover

Debris filter

Plug

Drain Hose

Door

Worktop

Base cover

Adjustable feet

Control panel

Detergent

drawer

6

2-2. OVERVIEW OF THE WASHING MACHINE

7

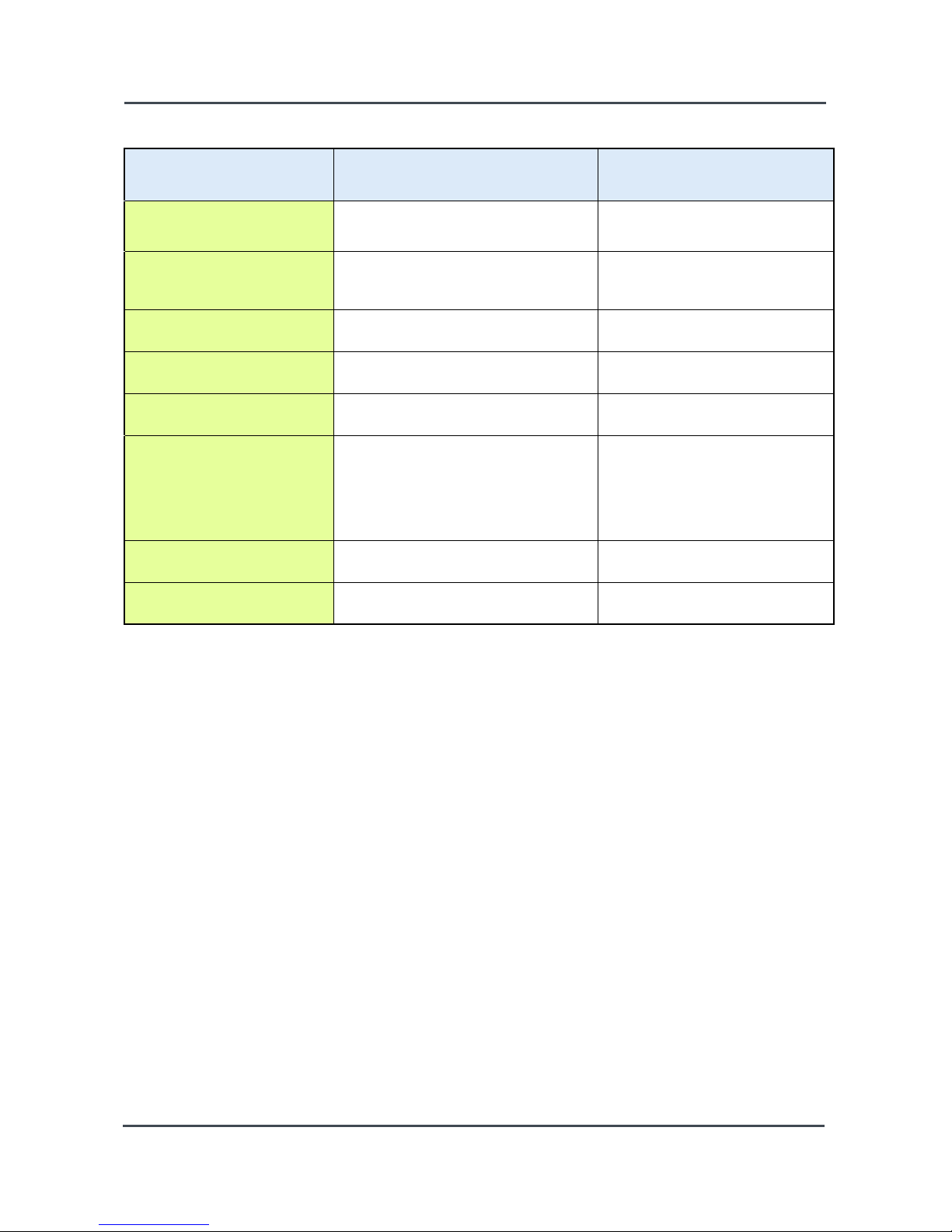

2-3. THE COMPARATIVE SPECIFICATIONS OF PRODUCT

Item 4.5kg Old (6.0kg)

Model Name

WF-F1256 F1245AVGW

Capacity (Washing)

4.5kg 4.5kg

Drum Capacity

43

ℓ

42

ℓ

Washing Motor

HXGP2I HXGN2I

Heater (220V)

1900W 1900W

Supply/Drain

All temperatures /Drain pump All temperature /Drain pump

Balancer

Weight Weight

SIZE(W*D*H)

598*404*844 598*404*844

8

2-3. THE COMPARATIVE SPECIFICATIONS OF PRODUCT

4.5kg

Model Name

WF-F1256 WF-F1056 WF-F856

Function

Water-level Control

OOO

Add Laundry

OOX

Exterior Replacement Part

Name

Specifications

Design

Cover Door

Neat-White Neat-White Neat-White

Handle Door

Neat-White Neat-White Neat-White

9

3.

PRODUCT SPECIFICATIONS

3-1. OVERVIEW OF THE CONTROL PANEL

10

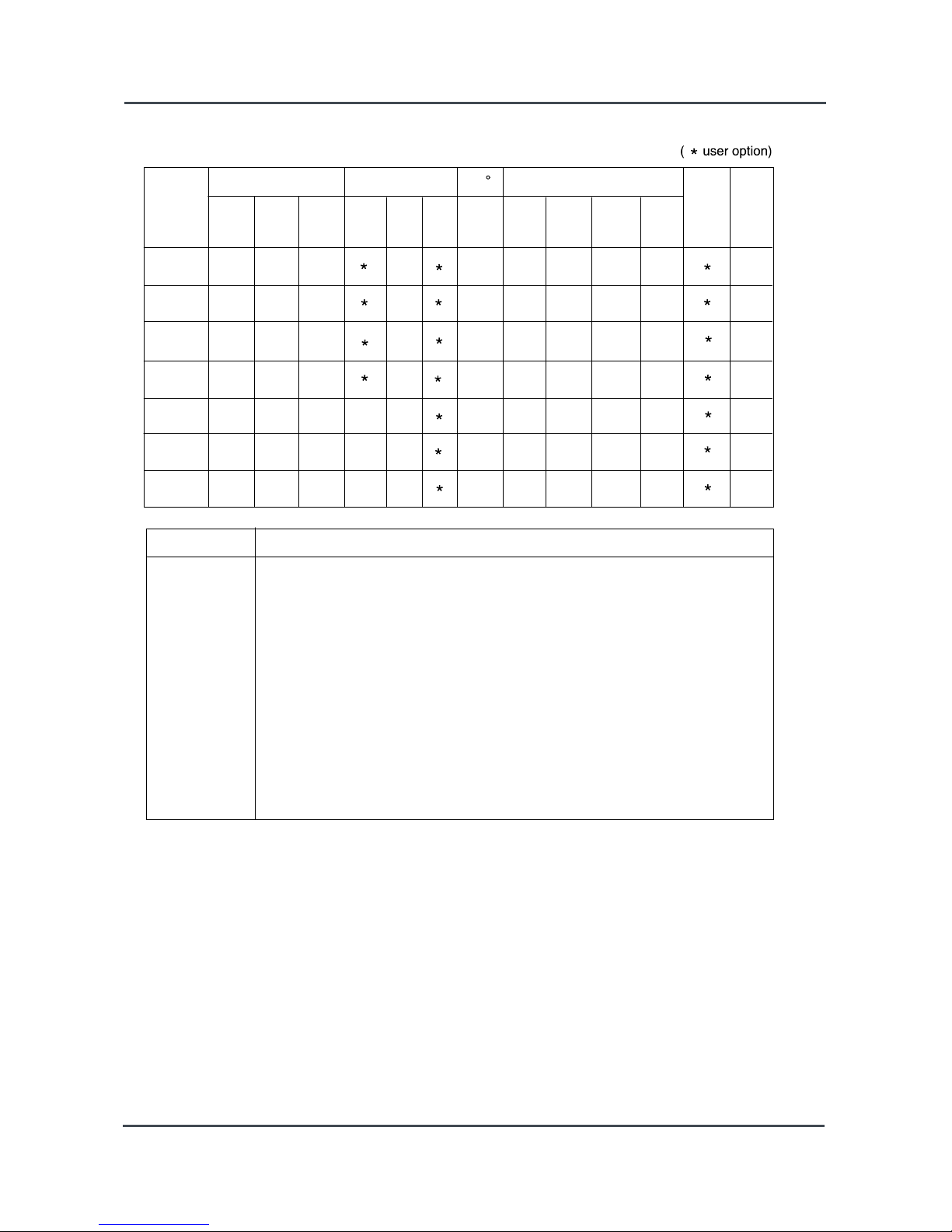

3-2. PROGRAMME CHART

PROGRAM

Type of WASH

Cotton Averagely or lightly soiled cottons, bed linen, table linen, underwear, towels,

shirts, etc.

Coloureds Averagely or lightly soiled cottons, bed linen, table linen, underwear, towels,

shirts, etc.

Synthetics Averagely or lightly soiled blouses, shirts, etc., Made of polyester

(diolen, trevira), polyamide (perlon, nylon) or other similar blends.

Delicates Delicate curtains, dresses, skirts, shirts and blouses.

Wool Only machine washable woolens with pure new wool label.

Handwash

Very light wash course like hand wash.

Quick

Lightly soiled cottons or linen blouses, shirts, dark coloured terry cloth,

coloured linen articles, jeans, etc.

Cotton 5.2

4.5

yes

95 1400 1200 1000 800

126

Coloureds 7.0

4.0

7.0

5.2 4.5

yes

60 1400 1200 1000 800

99

Synthetics 3.0 3.0

yes

60 800 800 800 800

72

Delicates 2.5 2.5

2.0

yes

40 800 800 600 600

55

Wool 2.0

2.0

1.5

1.5

1.5

1.5

- yes

40 400

400

400 400 400

40

Handwash - yes

yes

40 400 400 400

35

Quick

2.0 1.5

60 1400 1200 1000 800

47

PRO-

GRAM

DETERGENT

AND ADDITIVES

Spin Speed(MAX)rpm

Cycle

Time

(min)

Tem( C)

Max load(kg)

Prewash

Sof-

tener

Maxwash

Delay

start

WFJ1456C

J1256C

J1056

WFR1256

R1056

R856

WFJ1456C

WFJ1256C

R1256

F1256

WF-

J1056

R1056

F1056

WFF1256

F1056

F856

WFR856

F856

1. Programme with prewash lasts approx. 15 minutes longer.

2. The programme duration data has been measured under the conditions specified in

Standard IEC 456.

3. Consumption in individual homes may differ from the values given in the table

due to variations in the pressure and temperature of the water supply, the load and

the type of laundry.

1.5

-

11

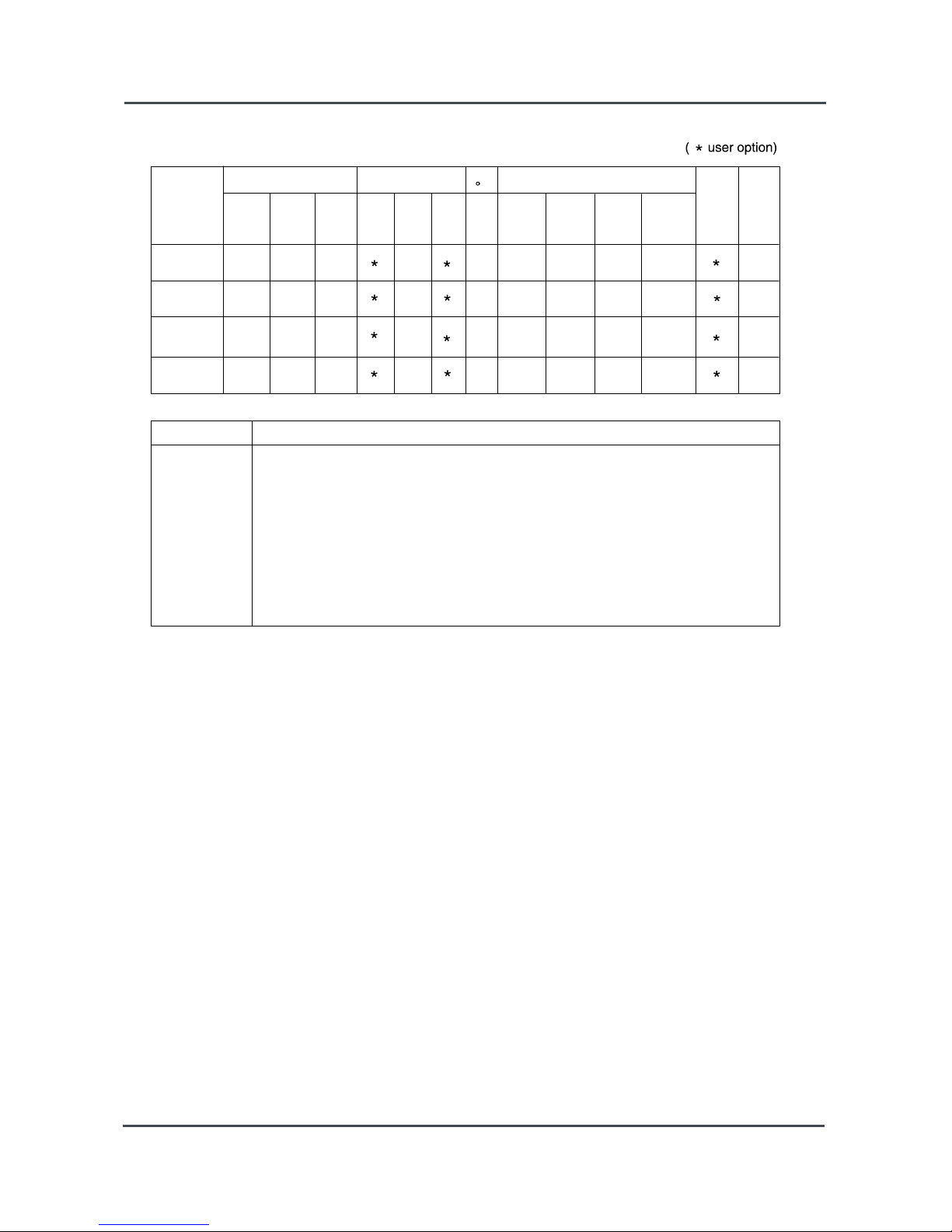

Baby Cotton

7.0 4.5 yes 95 1400 1200 1000 800 122

7.0 5.2

5.2

5.2

4.5 yes 60 1400 1200 1000 800 109

2.5 2.0

2.0

yes 60 800 800 600 400 77

Calm Wash

7.0 4.5 yes 40 1400 1200 1000 800 98

PROGRAM

DETERGENT

AND ADDITIVES

Spin Speed(MAX)rpm

Cycle

Time

(min)

Tem

( C)

Max load(kg)

Pre-

wash

Sof-

tener

Maxwash

Delay

start

Heavy Soil

Mixed Load

WFJ1456C

WFJ1056

R1056

F1056

WFR1256

R1056

R856

WFF1256

F1056

F856

WFR856

F856

WFJ1456C

J1256C

J1056

WFJ1256C

R1256

F1256

PROGRAM Type of WASH

Baby Cotton

Averagely or lightly soiled baby cottons, bed linen, table linen, underwear,

towels, shirts, etc.

Heavy Soil

Stained or heavy soiled cottons, bed linen, table linen, underwear,

towels, shirts, jeans, etc.

Mixed Load

A mix of lightly soiled cottons and synthetic fabrics.

Calm Wash

Extremely low noise level during the entire cycle and finish rinse hold.

Cottons, bed linen, table linen, underwear, towels, shirts.

Loading...

Loading...