Page 1

WASHING MACHINE

DRUM TYPE

Basic Model : Q1657

(TS EURO PROJECT)

Model Name : WF8800*

SERVICE

WASHING MACHINE (DRUM) CONTENTS

WF8700*

WF8802*

WF8804*

WF8814* WF8714*

WF8754*

(HEBA PROJECT)

WF8702*

WF8704*

Manual

WF8802DPF WF8702LSV

1. Safety Instructions

2. Features and Specifications

3. Disassembly and Reassembly

4. Troubleshooting

5. PCB Diagram

6. Wiring Diagram

7. Schematic Diagram

8. Reference Information

Refer to the service manual in the GSPN (see the rear cover) for the more information.

Page 2

CONTENTS

1. Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1. Safety instructions for service engineers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

2. Features and Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2-1. Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2-2. Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2-3. Comparing specifications with existing models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2-4. Options specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3. Disassembly and Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3-1. Tools for disassembly and reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3-2. Standard disassembly drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

4. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4-1. Error modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

4-2. Corrective actions for each error code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

5. PCB diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

5-1. Main PCB (Best: WF880*P* / WF870*P*) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

5-2. Main PCB (Better: WF880*S* / WF870*S*) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

5-3. Circuit diagrams of main parts (Best: WF880*P* / WF870*P*) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

5-4. Circuit diagrams of main parts (Better: WF880*S* / WF870*S*) . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

5-5. Sub PCB (Best: WF880*P* / WF870*P*) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

5-6. Sub PCB (Better: WF880*S* / WF870*S*) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

5-7. Detailed descriptions of contact terminals (sub PCB-Best: WF880*P* / WF870*P*) . . . . . . . . . . . . .41

5-8. Detailed descriptions of contact terminals (sub PCB-Better: WF880*S* / WF870*S*) . . . . . . . . . . . .42

6. Wiring diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

6-1. Wiring diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

7. Schematic diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

7-1. Main control (Best: WF880*P* / WF870*P*) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

7-2. Main control (Better: WF880*S* / WF870*S*) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

7-3. Sub control (Best: WF880*P* / WF870*P*) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

7-4. Sub control (Better: WF880*S* / WF870*S*) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

8. Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

8-1. HEBA Project name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Page 3

1. SAFETY INSTRUCTIONS

1-1. SAFETY INSTRUCTIONS FOR SERVICE ENGINEERS

► Make sure to observe the following instructions to operate the product correctly and safely and prevent possible

accidents and hazards while servicing.

► Two types of safety symbols, Warning and Caution, are used in the safety instructions.

Hazards or unsafe practices that may result in severe personal injury or death.

WARNING

Hazards or unsafe practices that may result in minor personal injury or property damage.

CAUTION

WARNING

• (When servicing electrical parts or harnesses) Make sure to disconnect the power plug before servicing.

Failing to do so may result in a risk of electric shock.

• Do not allow consumers to connect several appliances to a single power outlet at the

same time.

There is a risk of fire due to overheating.

• When removing the power cord, make sure to hold the power plug when pulling the plug

from the outlet.

Failing to do so may damage the plug and result in fire or electric shock.

• When the washing machine is not being used, make sure to disconnect the power plug

from the power outlet.

Failing to do so may result in electric shock or fire due to lightning.

BEFORE SERVICING

• Do not place or use gasoline, thinners, alcohol, or other fl

machine.

There is a risk of explosion and fire caused from electric sparks.

ammable or explosive substances near the washing

Safety Instructions _ 1

Page 4

2 _ Safety Instructions

WARNING

• Check if the power plug and outlet are damaged, flattened, cut or otherwise degraded.

If faulty, replace it immediately.

Failing to do so may result in electric shock or fire.

• Completely remove any dust or foreign material from the housing, wiring and connection parts.

This will prevent a risk of fire due to tracking and shorts in advance.

When connecting wires, make sure to connect them using the relevant connectors and check that they are

•

completely connected.

If tape is used instead of the connectors, it may cause fire due to tracking.

WHILE SERVICING

• Make sure to discharge the PBA

Failing to do so may result in a high voltage electric shock.

• When replacing the heater

If not inserted into the bracket-heater, it touches the drum and causes noise and electric leakage.

WARNING

• Check the wiring.

Ensure that no wire touches a rotating part or a sharpened part of the electrical harness.

• Check for any water leakage.

Perform a test run for the washing machine using the standard course and check whether there is any water

leakage through the floor section or the pipes.

• Do not allow consumers to repair or service any part of the washing machine

themselves.

This may result in personal injury and shorten the product lifetime.

AFTER SERVICING

power terminals before starting the service.

, make sure to fasten the nut after ensuring that it is inserted into the bracket-heater.

• If it seems that grounding is needed due to water or moisture, make sure to run

grounding wires.

(Check the grounding of the power outlet, and additionally ground it to a metallic water

pipe.)

Failing to do so may result in electric shock due to electric leakage.

[Running a grounding wire]

Twist a grounding wire (copper wire) two or three times around the tap.

-

- If you connect the grounding wire to a copperplate, bury it 75 cm under the earth in a

place with a lot of moisture.

Do not connect the grounding wire to a gas pipe, plastic water pipe or telephone

wire. There is a risk of electric shock or explosion.

Grounding

terminal

75 cm

Copperplate

Page 5

CAUTION

• Do not sprinkle water onto the washing machine directly when cleaning it.

This may result in electric shock or fire, and may shorten the product lifetime.

• Do not place any containers with water on the washing machine.

If the water is spilled, it may result in electric shock or fire. This will also shorten the

product lifetime.

Do not install the washing machine in a location exposed to snow or rain.

•

This may result in electric shock or fire, and shorten the product lifetime.

BEFORE SERVICING

• Do not press a control button using a sharp tool or object.

This may result in electric shock or damage to the product.

CAUTION

• When wiring a harness, make sure to seal it completely so no liquid can enter.

Make sure that they do not break when force is exerted.

• Check if there is any residue that shows that liquid entered the electric parts or harnesses.

If any liquid has entered into a part, replace it or completely remove any remaining moisture from it.

WHILE SERVICING

• If you need to place the washing machine on its back for servicing purposes, place a support(s) on the floor and lay it

down carefully so its side is on the floor

Do not lay it down on its front.

.

This may result in the inside tub damaging parts.

Safety Instructions _ 3

Page 6

CAUTION

• Check the assembled status of the parts.

They must be the same as before servicing.

• Check the insulation resistance.

Disconnect the power cord from the power outlet and measure the insulation resistance between the power plug

and the grounding wire of the washing machine. The value must be greater than 10MΩ when measured with a

500V DC Megger

AFTER SERVICING

• Check whether the washing machine is level in relationship with the floor

it is installed firmly on the floor.

Vibrations can shorten the lifetime of the product.

. Check whether

4 _ Safety Instructions

Page 7

2. FEATURES AND SPECIFICATIONS

2-1. FEATURES

COMMON FEATURES

Features Description

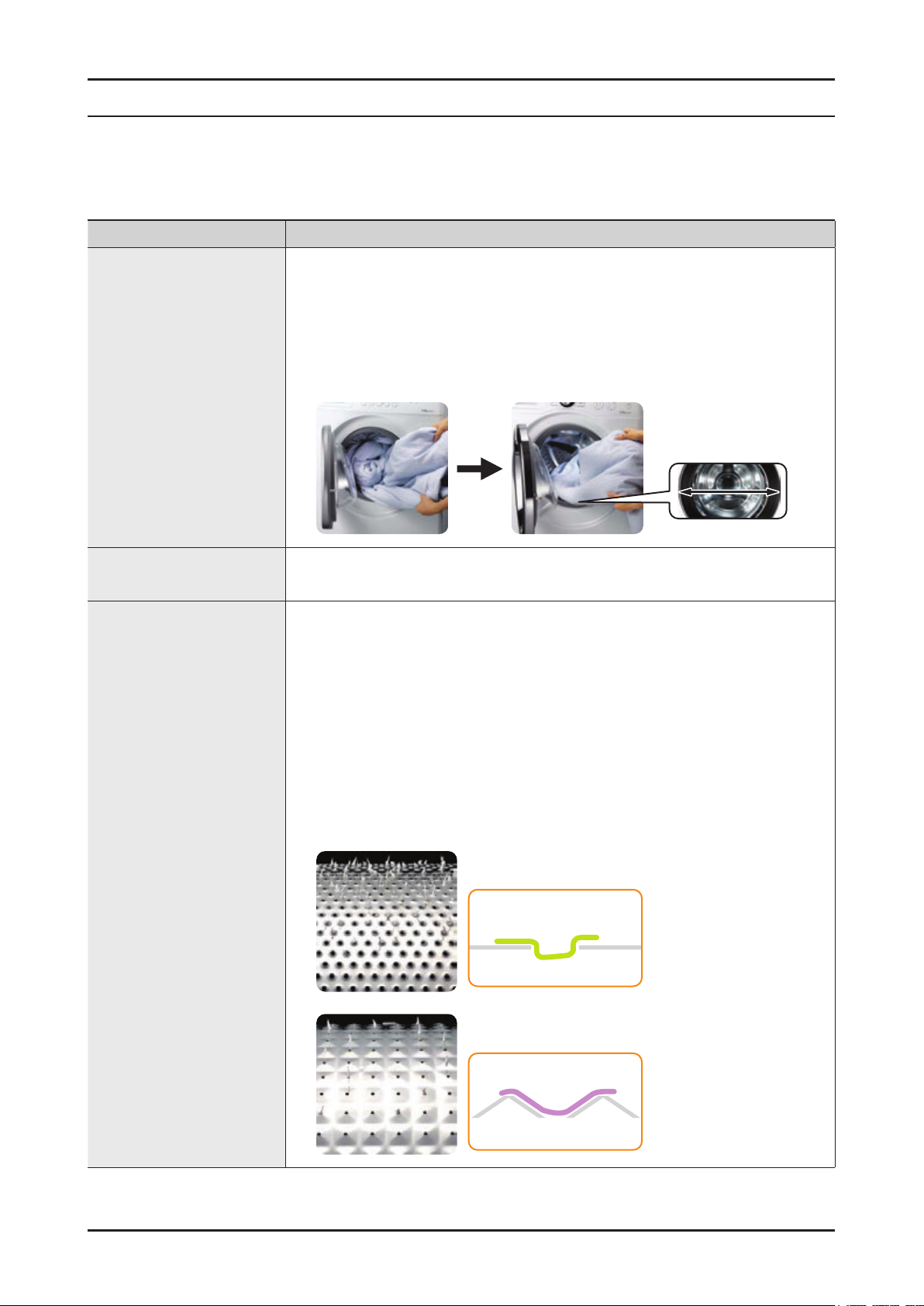

Implementing 8 kg in the

Standard Size

Addition of a Liquid

Detergent Tray

Diamond Drum • The washing performance has increased but potential damage to the washing has

• This is the maximum capacity to be implemented at the standard 60 cm depth.

- The benefits for customers have been greatly increased due to the efficient

use of limited space.

- Usability has been improved due to the easier loading and removing of the

laundry.

• The size of the loading entry has increased: 300 mm → 330 mm (Wide)

A lot more washing can be conveniently added and removed.

-

330 mm

• Usability has been improved due to the newly added Liquid Detergent Tray.

been minimized. (The size of the holes on the diamond drum has been reduced

for minimizing damage to the washing.)

- The embossed wall of the drum serves as a washboard, dramatically

increasing the washing performance compared with existing drum washing

machines, which use the power of the difference in elevation only

- The size of holes has been reduced drastically, maintaining the optimal wash

performance (Washing Cost 1.0) while saving on water and electricity required

for washing.

- The structure of the holes on the diamond drum has been changed minimizing

potential damage to the washing since it is difficult for strands to enter the

holes.

.

Conventional

Diamond Drum

Fabric

Fabric

Features and Specifi cations _ 5

Page 8

6 _ Features and Specifi cations

OPTIONAL FEATURES

► The features below depend on the model.

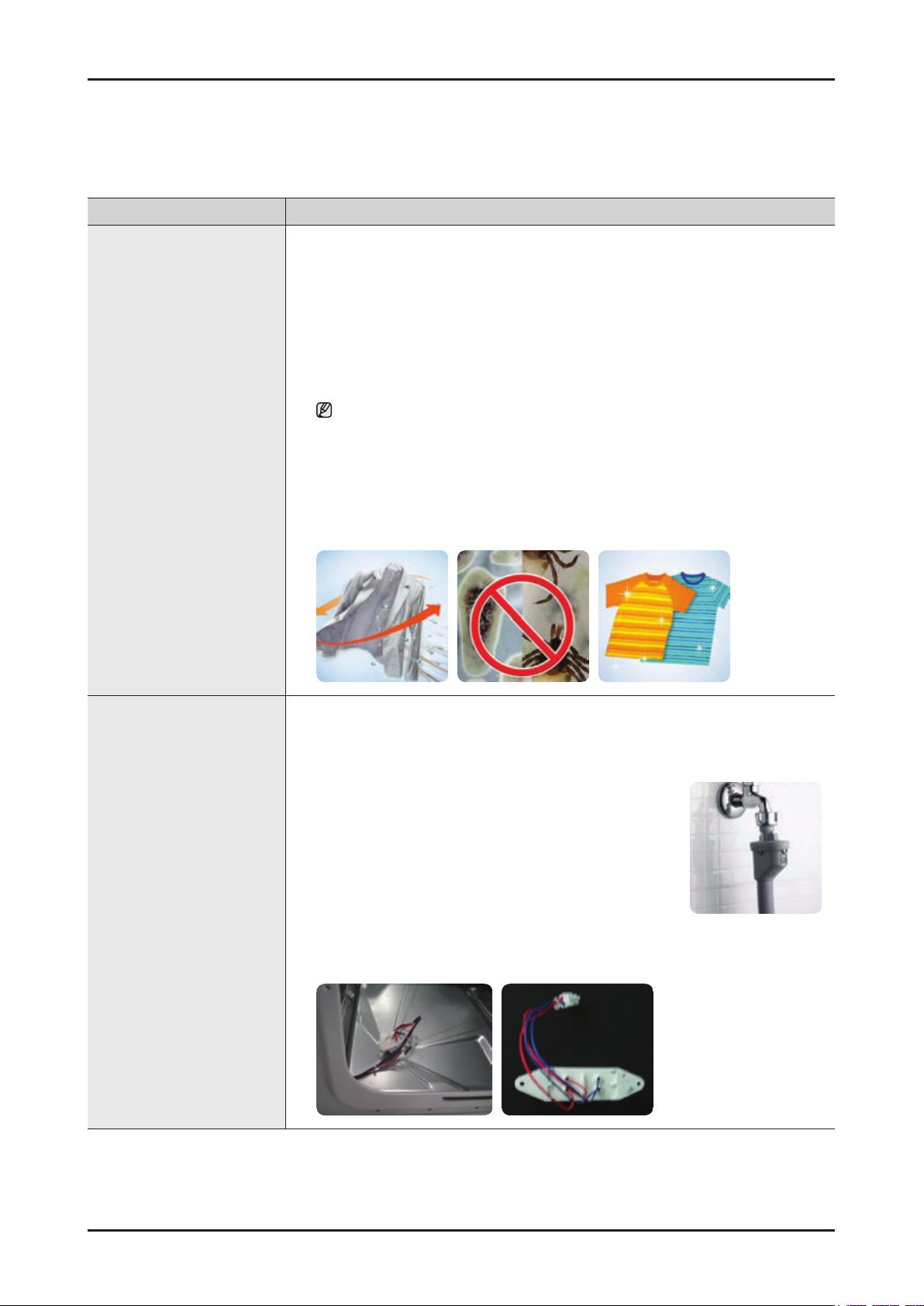

Features Description

Air Refresh System • Sterilization/Deodorization/Removal of Ticks without Water Washing (Air Washing

Using Air and Heating)

Destroying bacteria and ticks without the use of water

-

- Removing the sweat and dirt odors

- Maintaining the shape and color of the washing without dry-cleaning

• Washing with air.

- Removing odors by heating, keeping the washing as new.

- Washing with air conveniently, compared with dry-cleaning

The goal of deodorization is 60 percent. (40-minute cycle)

• Washing one or two shirts in 30 minutes

- If a piece of clothes is not completely dry when it is humid, the machine can

dry it within 30 minutes

• Preventing bio-film caused by humidity from occurring

- You do not need to worry about the humidity inside the drum.

- The drum is dried regularly, preventing bio-film.

Water Safety System • The Water Safety System has invented for perfect leakage protection. The double

safety valve connects directly to the water faucet. In the event of a leakage,

the built-in sensor immediately detects the leak within a few short seconds,

automatically turning off both the water supply and the washing machine.

- Inlet hose

It attached to the water supply hose and automatically

cuts off water flow when hose damaged. It also

displays a warning indicator.

- Leakage Sensor

A water leakage sensor attached at the bottom of the washing machine to

cutoff the power automatically if a leakage occurs, to prevent danger of a fire.

Page 9

► The features below depend on the model.

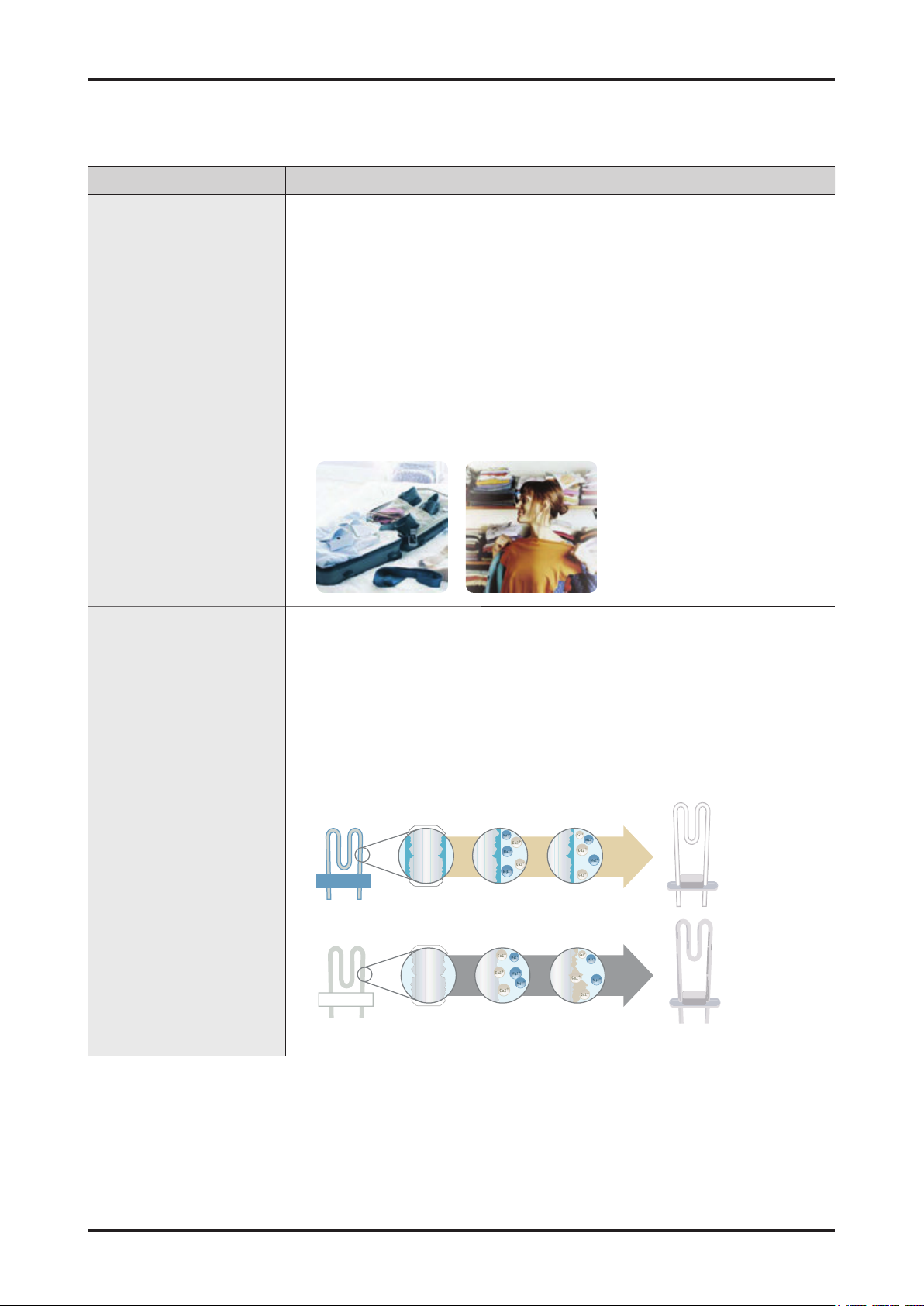

Features Description

Silver Wash System • Samsung’s unique technology generates silver ions that remove bacteria and

fungi, and create an invisible shield that protects your clothes from unwanted

odors until your next wash. Using an ancient and proven purification technique so

simple, yet so advanced it removes microbes even in cold water.

• Effect of Silver W

ash System

- Keeps Stored Clothes Fresh

Ag+ Silver (Nano) Technology anti-bacterial effect keeps fabric free from

The

odor-causing micro-organisms for up to one month, without the use of strong

chemical cleaners. There’s no need to worry about musty-smelling clothes

even if they remain unused for a long period.

- Makes Shapeless Garments a

Thing of the Past

High temperatures and harsh bleaches can damage and discolor your clothes.

The Ag+ Silver (Nano) Technology helps your clothes last longer, without

stretching, shrinking, pilling or fading.

Ceramic Heater • The ceramic heater in Samsung washing machine prevents metals in hard water

from being attach to the heater, which may cause a reduction in heater efficiency.

It saves energy, time and costs.

- Energy Savings

Over time, conventional heaters increase their power consumption an average

of 5.8 percent, while ceramic heaters only become 1.8 percent less efficient.

- Time Savings

After three years, conventional heaters take 7.5 percent longer to heat up,

whereas ceramic only lose 2.5 percent longer to heat up, whereas ceramic

only lose 2.5 percent of their ability to heat up.

10 Years

Ceramic

Enlarged

iew

V

Producted

Surface

No Build-Up

2.7 Years

Normal

Enlarged

View

Molecules

binding

Scale

Formation

Features and Specifi cations _ 7

Page 10

8 _ Features and Specifi cations

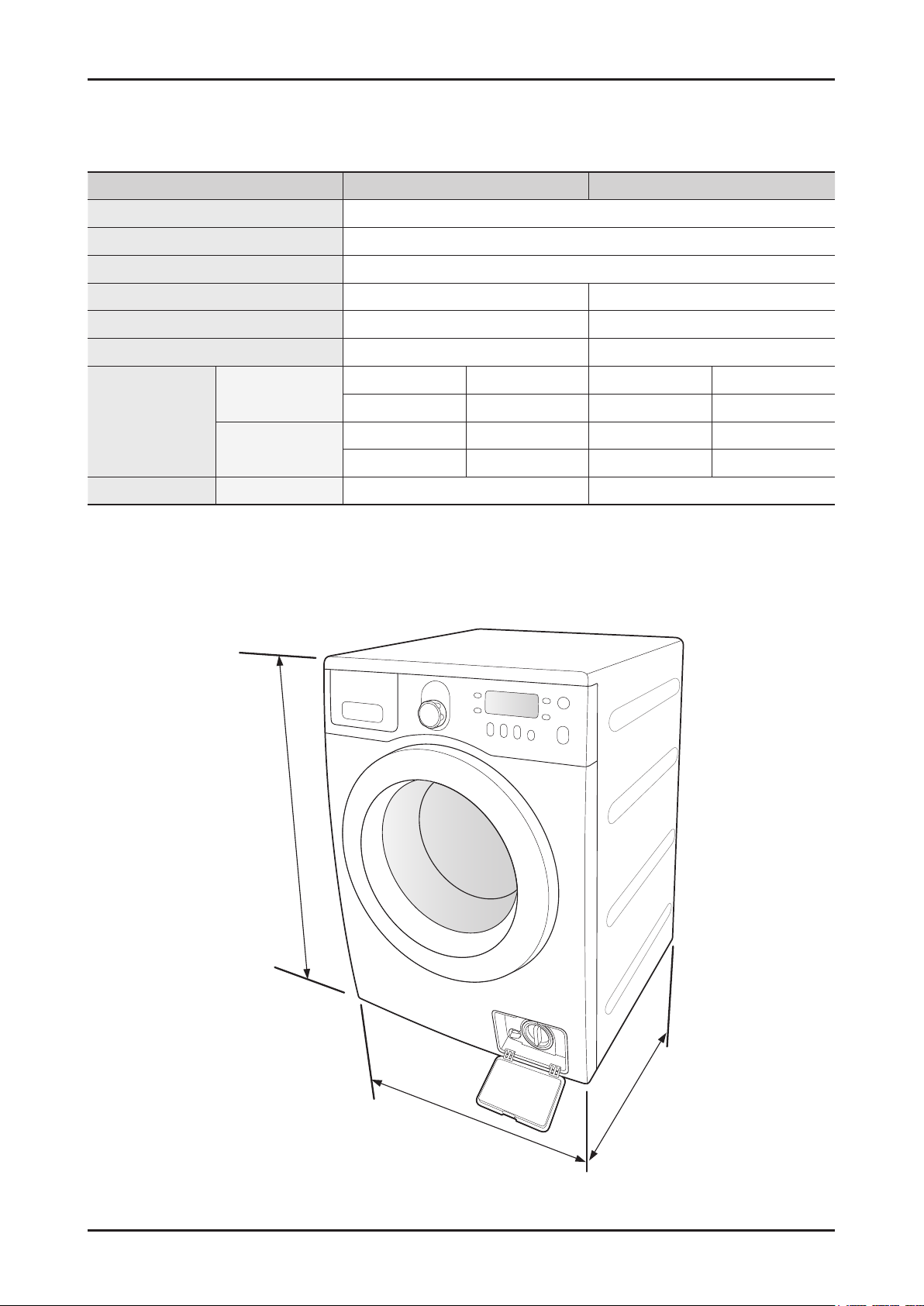

2-2. SPECIFICATIONS

Model WF8804*/WF8802*/WF8800* WF8704*/WF8702*/WF8700*

Wash Type FRONT LOADING TYPE

Dimension W 598 mm X D 600 mm X H 844 mm

Water Pressure 50 kPa ~ 800 kPa

Water Volume 64 ℓ 56 ℓ

Weight 74 kg / 73 kg / 72 kg 73 kg / 72 kg / 71 kg

Wash & Spin Capacity 8.0 kg 7.0 kg

WASHING

Power

Consumption

Spin Revolution rpm 1400 / 1200 / 1000 1400 / 1200 / 1000

WASHING and

TING

HEA

844

220 V 150 W 220 V 150 W

240 V 150 W 240 V 150 W

220 V 2000 W 220 V 2000 W

240 V 2400 W 240 V 2400 W

600

598

Page 11

2-3. COMPARING SPECIFICATIONS WITH EXISTING MODELS

() : Functions may be different depending on the model.

Grade Heba TS euro

Model Name

Image

WF8804*/

WF8802*/

WF8800*

WF8704*/ 8754*

WF8702*/

WF8700*

Q1657

Feature

Capacity 8.0 kg 7.0 kg/7.5Kg(WF8754*) 7.5 kg

Drum Volume 64 ℓ 56 ℓ 57 ℓ

Max rpm 1400 / 1200 / 1000 1400 / 1200 / 1000 1600

Motor Universal 3 phase inverter

Control Sys General General

eight Detection 3 Stages No

W

Main Spec

USP

Design

Dimension (W X D X H mm) 598 x 600 x 844 600 x 600 x 850

Heater Capacity 2000 W / 230 V 2400 W /230 V

Water Supply Cold Only Cold and Hot Cold Only

Drainage Pump Pump

Power-Outage

Compensation

Zero Standby Power Y

Air Refresh

Silver Wash

Water Safety

Ceramic Heater

Diamond Drum Yes No

Loading Entry Size Wide (330 mm) 300 mm

Detergent

Installation Handle No No

Center Jog Dial Yes No

Display

Tray Powder/Liquid Powder Only

Big Door Yes (480 mm) No (400 mm)

High G.LED

Mid Dot Display

Diamond drum

Big door design

Yes Yes

es (1W or Less) No

Yes ()

Y

es () Y

()

Yes

Y

es ()

Silver wash

Wide G.LED

es ()

G.LED

No

No

No

Features and Specifi cations _ 9

Page 12

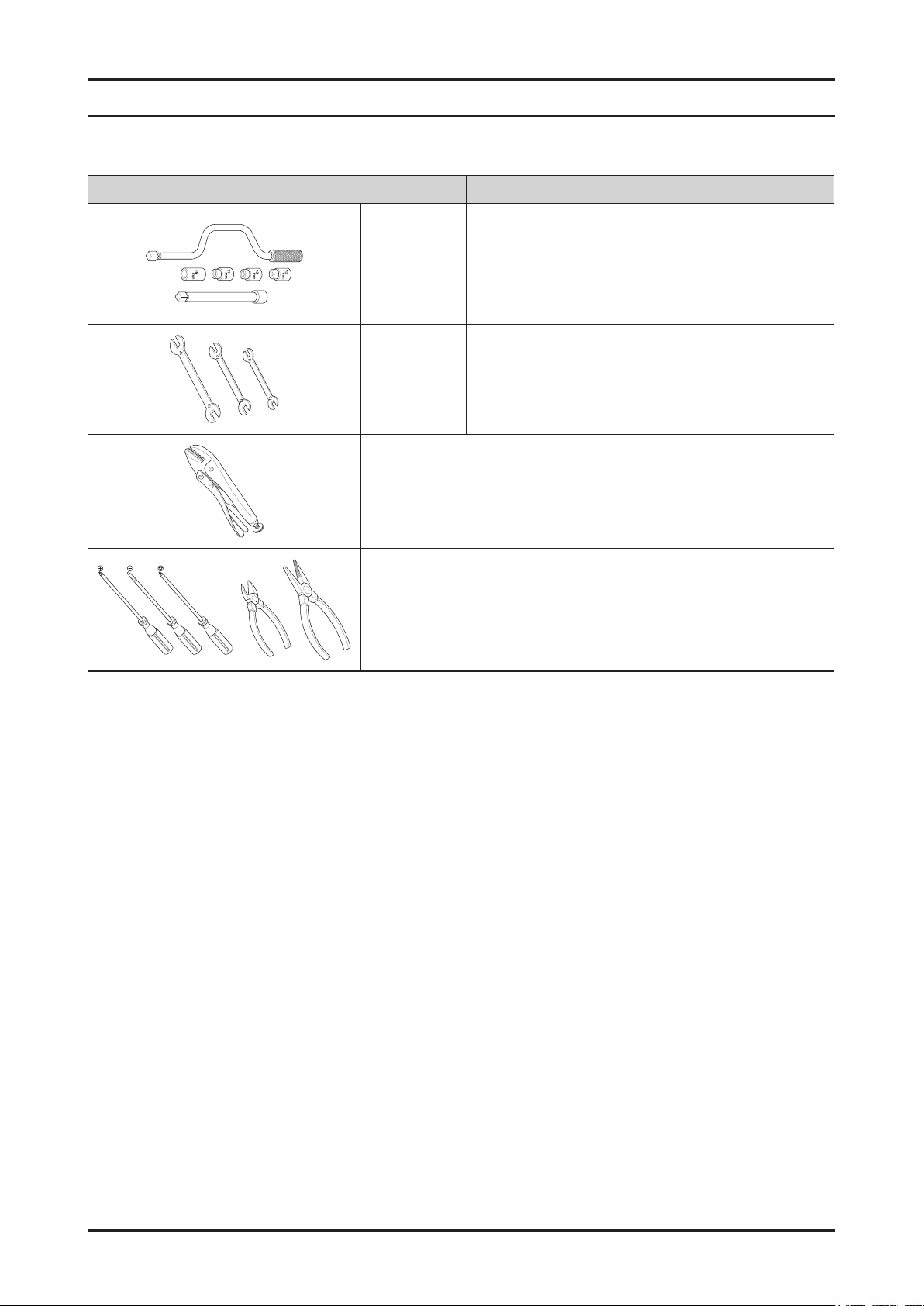

3. DISASSEMBLY AND REASSEMBLY

3-1. TOOLS FOR DISASSEMBLY AND REASSEMBLY

Tool Type Remarks

10mm

Box driver

Double-ended

spanner

Vice pliers

Others

(screwdriver, nipper,

long nose pliers)

13mm

19mm Pulley(1)

10mm

13mm

19mm

Heater(1),Tub(12), Fixer screw(5), Motor(2),

Balance(9)

Shock Absorber (2 holes each in left/right),

Damper(2), Damper(friction 2)

Replaced by box driver

Leg

A Tool for protecting empty turning of bolt or

abrasion from using box driver

For disassembly of Spin drum

Common tools for servicing

Removal and Reassembly _ 11

Page 13

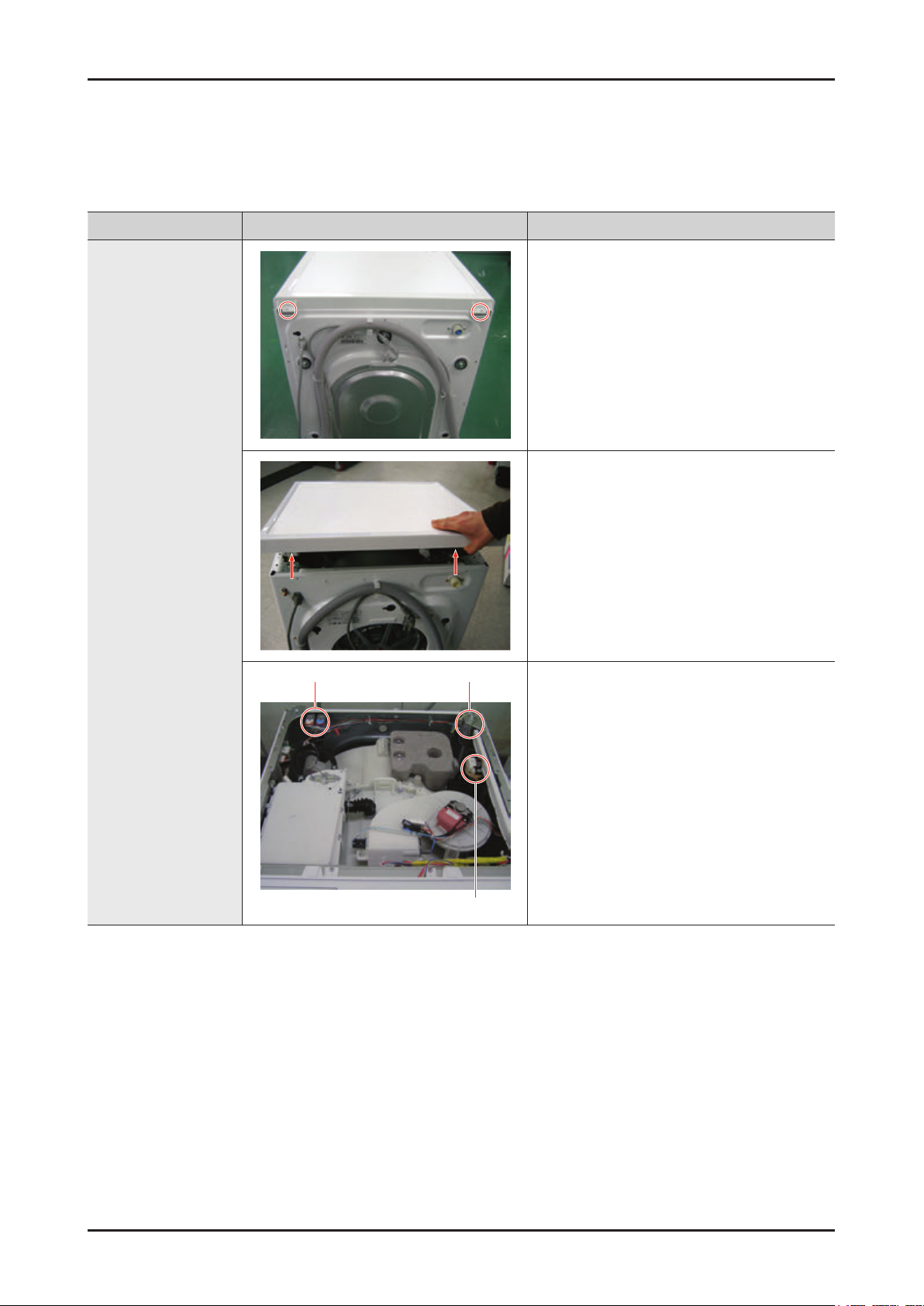

12 _ Removal and Reassembly

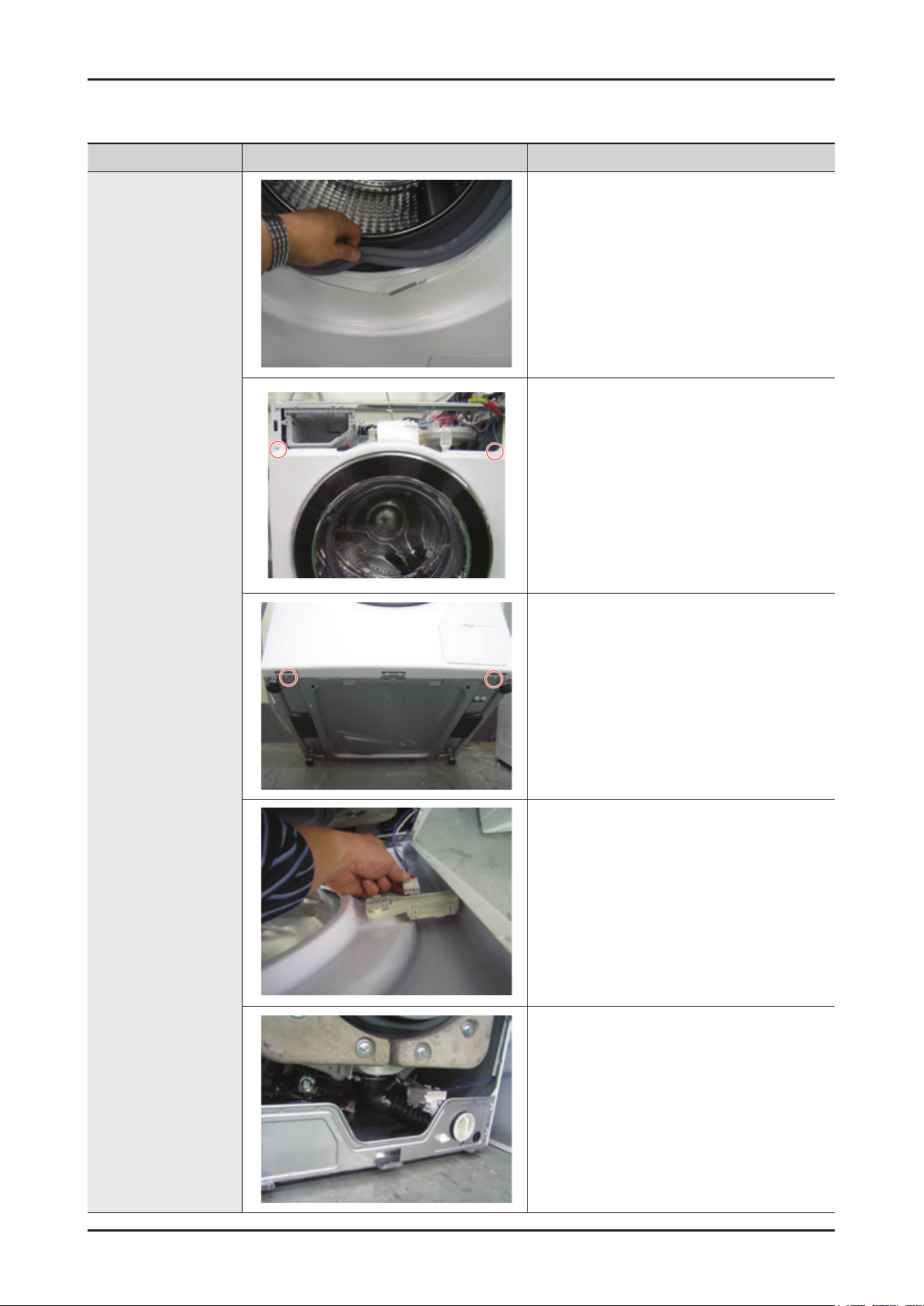

3-2. STANDARD DISASSEMBLY DRAWINGS

► This is a standard disassembly diagram and may differ from the actual product.

Use this material as a reference when disassembling and reassembling the product.

Part Figure Description

1. Remove the two screws holding the Top

Cover at the back of the unit.

2. Remove the top-cover by lifting it up after

pulling it back about 15mm.

ASSY COVER TOP

Water valve Noise filter

Sensor pressure

3. Then, the Water (Pressure) Sensor, Noise

Filter and Water Valve can be replaced.

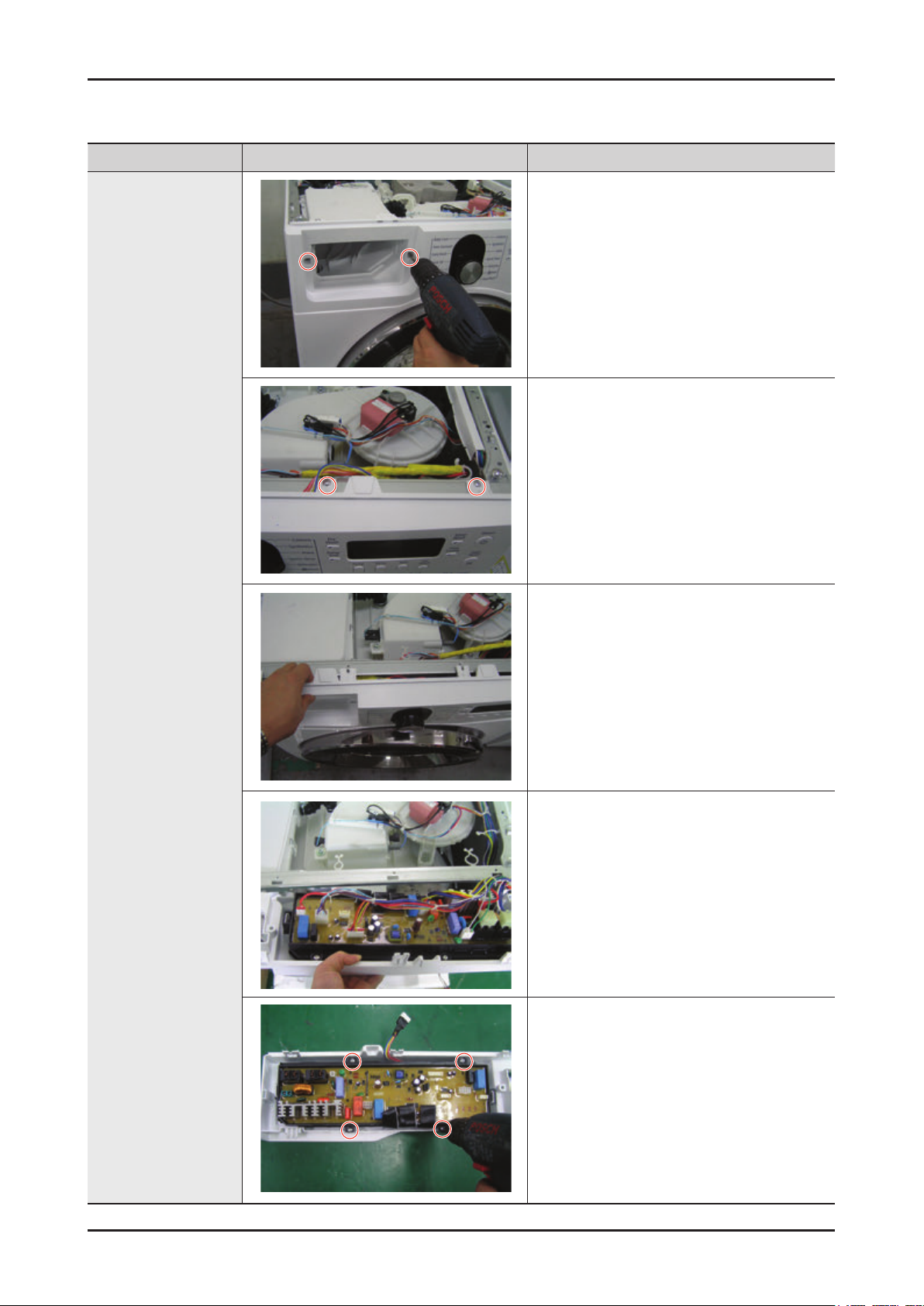

Page 14

Part Figure Description

1. Remove the 2 screws holding the front

operating panel.

Remove the four screws at the top of the

2.

ASSY-PANEL

CONTROL.

MAIN-PCB AND

SUB-PCB PANEL

Hold the

3.

pulling it upwards and release the hook to

remove it.

4. Disconnect the terminals connected to the

PCB by hand.

5. Remove the four screws holding the PCB

and release the hooks on both sides to

remove the PCB for repair / replacement.

ASSY-PANEL CONTROL while

Removal and Reassembly _ 13

Page 15

14 _ Removal and Reassembly

Part Figure Description

1. Separate the Wire-Diaphragm from the

Front-Frame and remove the Diaphragm.

2. Remove the two screws holding the

FRAME-FRONT

.

FRAME FRONT

3.

Remove the two screws holding the bottom

of the FRAME-FRONT

4.

Disconnect the terminal for the DOORLOCK switch.

The DOOR-DIAPHRAGM, HEATER, PUMP,

5.

SHOCK- DAMPER and DOOR LOCK

switch.

.

Page 16

Part Figure Description

COVER-BACK

BELT

• Remove the 4 screws holding the BackCover at the back of the washing machine.

1. Separate the belt and then assembly it.

2. Check if the belt position is at the center of

the Pulley.

Assembling the belt

Place the belt around the Motor-Pulley (

and then over the Pulley (

).

)

MOTOR

1. Separate the Wire Housing from the motor.

2. Remove the bolts holding the motor at the

back of the washing machine.

3.

Separate the motor.

When installing the Belt around the Motor

Pulley, the bottom of the belt must be

located on the second floor of the Motor

Pulley.

Removal and Reassembly _ 15

Page 17

16 _ Removal and Reassembly

Part Figure Description

1. Remove the three screws on the AIR WASH

fixed to the TUB.

AIR WASH

Terminals for

the Heater

Terminals for

the motor

2. Disconnect the terminals for the HEATER/

MOTOR/THERMISTOR.

Terminals for the thermistor

3. Remove the JOINT-DIAPHRAGM SCREW

assembled with the DIAPHRAGM.

Page 18

Part Figure Description

1. Remove the single HOUSING-AIR WASH

screw.

2. Release the six hooks by hand.

AIR WASH (Inside)

3. Remove the PTC-HEATER and

THERMISTOR for repair / replacement.

4. Remove the Nut.

5. Remove the two screws holding the

MOTOR for repair / replacement.

Removal and Reassembly _ 17

Page 19

18 _ Removal and Reassembly

Part Figure Description

1. Separate the Top Assy-Plate.

2. Separate the water supply valve wire.

WATER SUPPLY

VALVE

3. Remove the 2 screws holding the water

supply valve.

Page 20

Part Figure Description

Water valve Noise filter

1. Separate the Top Assy-Plate.

Sensor pressure

WATER LEVEL

SENSOR

2. Remove the screw holding the water level

.

sensor

DOOR-HINGE

3. Disconnect the wire between the

PRESSURE HOSE and the water level

sensor for repair / replacement.

1. Remove the 2 screws holding the Door

Hinge and separate the door.

2. Remove the 11 screws holding the Holder

Glass, separate the Holder Glass and

replace the hinge.

Removal and Reassembly _ 19

Page 21

20 _ Removal and Reassembly

Part Figure Description

1. Insert the (-) screwdriver into the upper part

of the Filter Cover and push it downwards

to release the catch.

2. Remove the remaining water through the

drainage hose.

Place a bowl under the drainage hose,

or the remaining water may flow out.

DRAIN PUMP

3. Separate the Drain Filter by turning it

counterclockwise.

Since the remaining water may flow

out, place a bowl underneath it when

separating the filter..

4. Remove the 1 screws holding the Drain

Pump.

2. Remove the remaining water through the

drainage hose.

Page 22

Part Figure Description

6. Release the BAND RING (2EA) to remove

the HOSE (2EA).

DRAIN PUMP

7. Push the

the PUMP

Disconnect the wires (2EA).

8.

Check Points for Troubleshooting

1.

Separate the Drain Filter and check if any alien substances are inside the pump (e.g.

coins, buttons .., etc.) → Remove these if found.

2. Check if the wire driving the pump is has come loose → Take the relevant countermeasure

if necessary.

When water leaks, check the assembly status of the Clamp Hose, and Cap Drain → Take

3.

the relevant countermeasure if necessary.

Turn the filter counterclockwise to remove the remaining water.

TUB inwards slightly to remove

.

Removal and Reassembly _ 21

Page 23

22 _ Removal and Reassembly

Part Figure Description

1. Open the Door.

Remove the Wire Diaphragm and remove it

from The Front Frame.

For easier disassembly, remove the

spring from the lower part of the

Diaphragm with a (-) screwdriver.

Since the Diaphragm can be damaged

when removing it, remove it slowly in

one direction.

DOOR-LOCK S/W

2. Remove the two screws.

3. Remove the screw holding the Door-Lock

S/W.

Remove the Door-Lock S/W.

Remove the connection wire.

(Remove the connector after releasing it by

pressing the catch.)

Page 24

Part Figure Description

1. Separate the Back Cover.

2. Separate the Connection Housing (3).

HEATER

3. Remove the nut holding the heater and

separate the Heater.

4. Remove the Heater from the Tub.

Caution

Make sure to insert

the Heater into the

correct position of

the bracket inside

the Tub when

reassembling it.

Otherwise, there is

a danger of a fire.

Make sure to push it inwards until the

packing part comes into the Tub completely

when reassembling it so that the packing

part is completely stuck to the

Fasten the holding nut with a force of 5Kgf/

cm2.

If the nut is not fastened properly, there is a

danger of water leaking.

Tub.

Reassembly is in the reverse order of the removal.

Removal and Reassembly _ 23

Page 25

24 _ Troubleshooting

4. TROUBLESHOOTING

4-1. ERROR MODES

► This is a washer integrated error mode. For detailed information, refer to the general repair scripts.

Drum

Error Type

Water Level

Sensor

Motor Driving

Error and Hall

Sensor Error

Water Supply

Error

Error

mode

1E

3E

3E1 3E1

3E2

3E3 3E3

3E4

4E

4E1 4Ed -

4E2 E8

Old

error

mode

1E

E7

3E

EA

EB

8E

3E2

3E4

4E

E1

For USA

LE 1E

3E

E3

bE

nF

-

Fully

automatic

3E

4E

Causes Remarks

-

The part of the hose where the water level sensor

is located is damaged (punctured).

- The hose is clogged with foreign material.

The hose is folded.

-

- Too much lubricant has been applied to the

insertion part of the air hose.

- Hose engagement error (disengaged)

-

Part fault (Faulty internal soldering)

- The water level sensor terminal is disengaged.

- Main PBA fault.

-

The PBA

- The motor spin net is not engaged.

- The motor’

circuited or cut)

- The hall sensor terminal is not connected.

- Foreign material (a screw) has entered the motor.

Motor overloaded due to too much laundry (Non-

sensing)

-

The motor hall sensor terminal is not connected.

- PBA fault

- The motor driving error from the PBA is weak.

: Unstable relay operation, etc.

- This occurs due to erroneous operating signals

for the motor hall sensor

- The IPM terminal of the main PBA is not

connected.

- The DD motor cover is out of place.

- The PCB housing terminal is not connected.

- PBA

- DD motor fault

-

Foreign material is entering the water supply

valve.

The water supply valve terminal is not connected.

(Wire disconnected)

- The warm water and rinse connectors are wrongly

connected to each other

- This occurs if the PCB terminal from the drain

hose to the detergent drawer is not connected.

Check whether the transparent hose is folded or

torn.

- The cold and warm water supply hoses are

wrongly engaged into each other.

The temperature of the water supplied through

the dry valve during a dry cycle is sensed as

higher than 70 ˚C.

- The water temperature is sensed as higher than

50 ˚C in the Wool or Lingerie courses.

connector terminal is not connected.

s internal coil is damaged (short-

.

fault

.

For USA

products, this

error occurs

because of

restrained

revolutions

For USA

products, this

error occurs

when an

interference is

generated due

to too much

laundry, etc.

If this error

occurs in the

W

The water

supplied for 1

minute drying

the

is 0.3 ~ 0.4 L.

ool course

drying cycle

Page 26

Drum

Error Type

Drain Error 5E

Motor Error 8E - 3E

Power Error

Communication

Error

Switch Error

(Main Relay

Error)

Error

mode

9E1

9E2 Plo

AE 13E - -

bE1 12E

bE2 14E

bE3 18E

Old

error

mode

5E

E5

PH1

For USA

nd 5E

2E

PF

E2 -

Sr -

Fully

automatic

Causes Remarks

-

The pump motor impeller is damaged internally.

- The wrong voltage (220 V → 110 V) is supplied to

the parts.

- Part fault

This occurs due to freezing in the winter season

-

- The drain hose is clogged. (Injection error, foreign

material)

- Clogged with foreign material

The water pump terminal is not connected: rubber

band, bills, cotton, hair pins, coins

-

This occurs when motor driving is unstable

because the motor hall sensor does not work.

- This occurs when the PBA

unstable or the control circuit has an error.

- Check whether the wire connector is connected

correctly or whether there is a contact error

Check the consumer’s power conditions.

: Make sure to check the operating voltage.

Connect a tester to the internal power

terminals during the Boil or Dry operations

and observe the washing machine’s operation

carefully

.

: Check the voltages. (An error occurs when

under or over voltage is supplied.)

: Check whether a plug receptacle is used.

-

When the connecting wire is 1m, a momentary

low voltage may drop up to 10 V

- Main PBA

-

This error is not a fault but occurs during a

momentary power failure

: If started again when this error code is

: If the washing machine is not operating and

- The signals between the sub and main PBAs are

not sensed because of a communications error.

Check the connector connections between

the sub and main PBAs carefully. → Check for

incorrect or loose connections, etc.

- Remove the sub PBA

faulty soldering.

- The Power button is pressed continually (for more

than 12 seconds).

- The switch is pressed unevenly because of a

deformation of the control panel.

- This error may occur when the screws that hold

the sub PBA in place are tightened too much.

- A button other than the Power button is

continually pressed (for more than 30 seconds).

-

Deformation of an internal plastic injection part

- A screw for assembling the sub PBA is tightened

too much.

-

The main relay of the PBA is short-circuited.

- The main relay terminal is connected incorrectly.

(The terminal is bent and contact cannot be

made.)

fault (sometimes)

displayed, the operation restarts from the cycle

that was stopped due to the power failure.

this error code is displayed, it is displayed to

notify that a power failure has occurred.

IPM operation is

C/Panel and check for any

.

For Full

Automated

products, no

error code is

displayed for a

power error

When the

PBA

relay does not

operate

.

motor

Troubleshooting _ 25

Page 27

26 _ Troubleshooting

Error Type

Cooling Error CE

Door Error

Fan Error FE

Error

mode

dE

door

dE1 dE1

dE2 dE2

Drum

Old

error

mode

CE

cE

dE

Ed

door

F

FE

For USA

- -

dS

(Before

operation)

dL

(During

operation)

LO

(Unlock

Fail)

FL

(Lock Fail)

- -

- -

Fully

automatic

dE

-

Causes Remarks

-

occurs when the temperature of the washing

This

machine is more than 55 ˚C and no draining is

performed.

n: If hot water comes into contact with skin, it

(Reaso

may cause burns.)

- This occurs when the water temperature, for a

specific course, exceeds 55 ˚C. In that case, the

water will be drained to the Reset level.

- This represents a thermal sensor error or any

misuse of the unit.

-

A switch contact error because of a deformation

of the door hook

- When the door is pulled by force

-

This occurs in the Boil wash because the door is

pushed due to a pressure difference from internal

temperature changes

- The door lock switch terminal is connected

incorrectly.

The door lock switch terminal is broken.

-

- This occurs intermittently because of an electric

wire leakage

-

Main PCB fault

- This occurs if the Power switch is turned on/off

continually and too much heat is generated (This

error is difficult to be reproduced.)

-

The start condenser terminal comes out of place

when inserting the top cover

- The fan motor has a wire disconnected or the belt

is out of place. Therefore, the fan does not start.

- The cooling wings are restrained or stains have

developed on the bearings.

does not start.

-

Start condenser fault

→ In this case, you cannot detect it with a tester.

Always replace the start condenser

.

Therefore, the fan

If this error

occurs for

another

reason, it

is due to a

washing heater

sensor fault.

Replace it.

When the door

is not opened

after the door

open operation

When the door

is not locked

after the door

close operation

Page 28

Error Type

Heater Error

W

ater Leakage

Error

Overflow Error

Error

mode

HE

HE1

HE2 HE2

HE3 -

LE

LE1

OE

OF

Old

error

mode

HE1

11E

Drum

HE

E5

E1

Ec

E9

OE

OF

E3

For USA

Hr

(Heater

Relay)

LE LE

OE -

Fully

automatic

-

Causes Remarks

-

The washing heater is short-circuited or has a

wire disconnected.

- The washing heater in the tub has an error.

(Contact error, temperature sensor fault)

- If the water level sensor operates without water

because water is frozen or for any other reason

and the temperature sensor engaged at the

bottom to prevent overheating for the washing

heater detects a temperature of 100 to 150 ˚C,

the washing machine turns the input power off.

- This error occurs when the red temperature

sensor at the center of the dry heater operates (at

a temperature higher than 145 ˚C)

: Corrective action – Press the button at the

center lightly

operate normally.

Alternatively

the temperature sensing is unstable because of

functional degradation.

- This occurs when the steam function does not

operate normally.

- This error does not occur in existing drum

products. Check whether the product is a steam

model

Heater engagement fault (out of place)

-

- The air hose is out of place and water leakage

occurs during the spin cycle.

- The tub back at the safety bolts fixing part is

broken.

- W

ater leakage occurs at the front with foaming

because of too much detergent

- Water leakage occurs because the connecting

hose to the detergent drawer is connected

incorrectly.

- The drain pump filter cover is engaged incorrectly.

- W

ater leakage occurs at the drain hose.

- The duct condensing holding screws are worn.

- The nozzle-diaphragm is engaged in the opposite

direction or the rubber packaging is omitted.

-

Water leakage occurs because the screws that

hold the tub back and front in place are fastened

incorrectly.

- The leakage sensor is faulty.

-

Water is supplied continually because the water

level detection does not work.

Because the drain hose is clogged and there

is an injection error (at a narrow section), the

water level detection does not work and water is

supplied continually.

- Water is supplied continually because of freezing

or because there is foreign material in the water

supply valve.

- This error may occur when the water level sensor

is degraded.

. The washing machine will

, replace the temperature sensor if

For USA

products, if

the heater

has no error,

this occurs

because of

a PBA relay

malfunction.

For USA

products, this

error occurs

because the

water level

sensor terminal

is out of place.

Troubleshooting _ 27

Page 29

28 _ Troubleshooting

Error Type

Temperature

Sensor Error

Unbalance

Error

Foaming

Detected

Mems PBA

Error Detected

Drum

Error

mode

tE1

tE2 tE2 - -

tE3 tE3 - -

UE

Sud -

Old

error

mode

tE1

- - E8

6E

UE

E4

For USA

tE -

dc UE

SUdS -

automatic

Fully

-

Causes Remarks

-

The washing heater in the tub has an error.

(Contact error, temperature sensor fault)

- The connector is connected incorrectly or is

disconnected.

- If the water level sensor operates without water

because the water is frozen or for any other

reason and the temperature sensor engaged at

the bottom to prevent overheating for the washing

heater detects a temperature of 100 to 150 ˚C,

the washing machine turns the input power of

- The temperature sensor for the duct assy fan

housing is faulty.

(A sensor fault such as an internal short-circuit or

wire disconnection)

- The connector is out of place or has a contact

error

.

- This occurs when the duct condensing

temperature sensor is open.

- This occurs when the duct condensing

temperature sensor has a wire disconnected or is

short-circuited.

- The connector is out of place or has a contact

error.

-

As laundry causes this error

- Find the reason for the unbalance and solve it as

directed in the user manual.

-

This occurs when too much foaming is detected.

It is also displayed while foaming is removed.

When the removal is finished, the normal cycle

proceeds. “Sud” or “SUdS” is displayed when too

much foaming is detected and “End” is displayed

when the removal of the foaming is finished.

(This is one of the normal operations. It is an error

for preventing non-sensing faults.)

- Error detected in the Mems PBA or data error

detected. Check the wire connections.

Replace if necessary.

1. Check the wire connections.

Replace the Mems PBA.

2.

3. Main PBA wire connection error or PBA

nano part malfunction. Replace if necessary.

, check the laundry.

f.

’s silver

Heater sensor

fault

: When the

connector is

connected

incorrectly or

has a wire

disconnected

or contact error

Duct

condensing

temperature

sensor

fault (for

models before

the silver nano

function was

applied)

Dry heater

temperature

sensor fault (for

models before

the silver nano

function was

applied)

Page 30

4-2. CORRECTIVE ACTIONS FOR EACH ERROR CODE

sensor and the connector

are connected.

KHz with no load

Check the water level sensor

frequency.

- Check it after the water level

- Frequency: Approx. 26.4

► DD MOTOR

Check the resistance on the

main PCB motor. (Between pins

1 and 3, and 1 and 4 of the four

MΩ

(4) pins)

- Resistance: Approx. 2 to 4

- Check the voltage when the

power is on.

► UNIVERSAL MOTOR

Check the Resistance of Nos.1

and 4 of the wire pin on the side

of the TACHO SENSOR.

40 to 45 Ω (Normal)

- Resistance: Approximately

needs to be reproduced.

(Turn the drum by hand.)

to 12V (Voltages may differ

depending on the speed of

the revolutions.)

► THREE PHASE MOTOR

Measure the Resistance of Nos.

2 and 3 of the wire pin on the

side of the HALL SENSOR.

- The revolution of the drum

- Resistance: Approximately 3

Check the water level sensor terminal

connections and contacts.

An error occurs if an incorrect water level

sensor is used. Make sure to check the

material code. (Abnormal operation)

If the error persists despite taking the action

above, replace the PBA.

•

•

• If the water level sensor is faulty, replace it.

•

level sensor terminal

sensor is folded.

• Water level sensor fault

• Incorrect connections of the water

• The hose part for the water level

• Main PCB fault

1E

control circuit is faulty, replace the

Check whether the stator of the motor cover is

damaged.

material.

connections and contacts.

due to too much laundry.

hall sensor.

• Check the motor connector terminal

• 3E1 is displayed because overloading occurs

• If the hall sensor terminal is faulty, replace the

Washing motor fault

•

washing motor/hall sensor

• Washing motor hall sensor fault

• Incorrect connections of the

3E

3E1

• Check for coil disconnections due to foreign

•

ashing motor rotor and stator

fault

connector

W

•

3E2

3E3

3E4

PBA.

• If the PBA

• Main PCB fault

Error Type Error Mode Causes Corrective Actions Description of Photo

Water Level

► These are common troubleshooting procedures for each drum-type washer error mode. For detailed information, refer to the general repair scripts.

Sensor

Washing Motor

Error and Hall

Sensor Error

Troubleshooting _ 29

Page 31

30 _ Troubleshooting

water supply valve.

between the terminals of the

water supply valve.

foreign material in the water

supply valve diaphragm.

1. Check the resistance for the

- Resistance: 4.0 to 5.0 Ω

2. Check whether there is

6.3 Ω between the Terminals

for the Water Supply Valve

► DRAIN MOTOR

Resistance: Approximately

174 Ω between the Terminals

for the Water Supply Valve

► DRAIN PUMP

Resistance: Approximately

-

s communication circuit is

disconnected, replace it.

• If the water supply valve has a wire

Error Type Error Mode Causes Corrective Actions Description of Photo

Check whether the water supply valve is

clogged with foreign material and whether

water is supplied continually.

of freezing in the winter season.

the PBA.

•

• Check whether no water is supplied because

• If the PBA relay operates abnormally, replace

• Water supply value fault

• Main PCB fault

• Freezing in the winter season

4E

4E1

4E2

Water Supply

Error

If the drain pump operates abnormally

intermittently when the temperature of the

water in the tub is high.

to freezing in the winter season, check the

method to remove the freezing and remove as

pump motor are restrained by foreign material.

process.

and if there is any wires disconnected.

• Check whether the revolutions of the drain

• Check the same thing for the natural drain

• Check whether the connections are correct

•

pump• Main PCB fault

• Drain pump fault

• Freezing in the winter season

• Foreign materials in the drain

Drain Error 5E

directed.

• If the motor revolutions are restrained due

contacts between the sub and main PBAs.

• Check the wire connections and terminal

• Check whether the sub PBA is short-circuited

• Check for disconnected wires.

main PBAs are not sensed.

• The signals between the sub and

AE

Communication

faulty, replace it.

because of moisture.

• If the main PBA’

between the sub and main PBAs.

• Incorrect wire connections

Error

Page 32

occurs after approx. 30

seconds has passed.

between a control panel

Check the contact between the

control panel buttons and their

corresponding tact switch.

- There must be a gap

Otherwise, an error

button and its corresponding

micro switch.

f error has

GAP

terminals and the voltage

of the Heater.

Check 27±10% on both

Check the resistance on the

Heater. (For faulty features)

Check the voltages on the red

/ blue terminals of the Heater

while washing.

.

tact switch is continually pressed.

• Check whether either the Power switch or a

Error Type Error Mode Causes Corrective Actions Description of Photo

screws are fastened too much. If they are

fastened too much, loosen them a little.

occurred, replace the main PBA.

connections are incorrect. Check the

connections. If there is no error in the

connections, replace the main PBA.

• Check whether the service PBA holding

• If the main PBA switching IC on/of

• The “bE3” error occurs if the main relay

button other than the Power

The Power button is continually

pressed.

button is continually pressed.

•

• A

• Main PCB relay fault

bE1

bE2

bE3

Switch Error

(Main Relay

Error)

This error occurs if the water temperature

•

is due to a temperature sensor fault. Replace

is more than 50 ˚C in draining. Check the

temperature.

• If the water temperature is normal, this error

• Washing temperature sensor fault

• Description of PL hazard

Cooling Error CE

to prevent water leakage.

the washing heater

When replacing the washing heater, take care

prevention

Troubleshooting _ 31

Page 33

32 _ Troubleshooting

► TYPE 1

Check the door switch voltage.

Check the voltage after the

power is on. (That is, check the

door switch when the power

button is turned on and no

operating key is pressed.)

.

during the Boil cycle.

If it is detected that the door is open, close the

door

Check and repair the power wire connections

• If a dE error occurs, check whether it occurs

-

• The 220V is directly connected to the door.

► TYPE 2

The resistance of Nos. 3 and 5

of the DOOR LOCK SWITCH

must be approximately 949 Ω.

.

and insulation state.

Replace if faulty.

• Check the main PBA door sensing circuit.

• Check the door switch. Replace if faulty

► TYPE 1

Check the dry fan motor

operation.

Check the motor voltage during

the dry cycle.

,

defects for the dry motor.

faults.• If the start condenser has a functional error

• Check for disconnected wires and insulation

• Check connector connections and contact

► TYPE 2

the motor rotates normally. However, because

the start condenser operates unstably, replace

it.

The resistance of both terminals

of the AIR WASH MOTOR must

be approximately 298 Ω.

Error Type Error Mode Causes Corrective Actions Description of Photo

• Door switch fault

• Drain pump fault

• Dry duct fan motor fault.

• Main PCB fault

dE

dE1

dE2

Door Error

• Main PCB fault

• Dry duct fan motor fault

FE

Dry Duct Fan

Error

Page 34

hose is folded, cut, or

material, such as

underwear wires or coins.

(Automatic Drainage)

-

► DRAIN PUMP TYPE

Check for any foreign

Check whether there is any

foreign material in the bellows.

ub connections and take any

► PUMP TYPE

Check for any leakage on the

base, Hose, Valve and Tub

connections.

Check the hose connected to

the water level sensor.

damaged.

Check whether the

An HE or HE1 error occurs.

overheating sensor is faulty, replace it.

- An HE2 error occurs.

Check for disconnected wires for the washing

heater. Replace if faulty.

-

•

• Because the dry heater or air refresh heater

Heater fault

sensor at the center of the dry

heater

•

• A fault of the red temperature

HE

HE1

HE2

- An HE3 error occurs.

• Check the steam heater. Replace if faulty.

• Steam function fault

• Freezing in the winter season

HE3

Error Type Error Mode Causes Corrective Actions Description of Photo

Heater Error

the drain bellows are clogged with foreign

material. Remove the foreign material.

Check the drain motor operation. Replace if it

Check for any leakage on the base, Hose,

Valve and T

required action.

•

• For natural draining, this error occurs because

Check for any leakage.

•

• Foreign material in the DV case

LE

ater Leakage

W

Error

does not operate normally.

•

engagement in the product

• Fault of a hose or incorrect part

LE1

Check the hose. This error occurs if it is torn

or has a hole.

winter season. Check the method to remove

replace it.

• If the water level sensor has a functional error,

•

Water level sensor fault

•

OE

Overflow Error

freezing and follow as directed.

• This error occurs if water is frozen in the

• Freezing in the winter season

OF

Troubleshooting _ 33

Page 35

-

, replace it.

- A tE1 error occurs.

temperature sensor connector.

functional error, replace it.

- A tE2 error occurs.

condensing temperature sensor connector.

has a functional error, replace it.

temperature sensor connector.

a functional error

• Check the connections for the dry heater

• Check the connections for the washing heater

• If the washing heater temperature sensor has

• If the dry heater temperature sensor has a

• Check the connections for the duct

- A tE3 error occurs.

• If the duct condensing temperature sensor

-

,

make sure to check and follow the related

directions in the user manual and follow

the directions.

they may cause an unbalanced situat ion.

- If they are small but absorb a lot of water

• Check the type of laundry. Check whether

• Washing temperature sensor fault

• Dry temperature sensor fault

tE1

Error Type Error Mode Causes Corrective Actions Description of Photo

34 _ Troubleshooting

of the dry condensing sensor

Freezing in the winter season

• Faulty and incorrect connections

• Main PCB fault

•

tE2

tE3

Temperature

Sensor Error

Motor hall sensor fault

•

• Caused by the laundry

Unbalance Error UE

Page 36

. PCB DIAGRAM

-1. MAIN PCB (BEST: WF880*P* / WF870*P*)

Location Part No. Function Description

1 RY1 Main Relay Receives 220 ACV to operate the PBA.

2 RY3 Heater Relay For driving the heater power

3 CN9 Power Supply T

4 CN8 Water Level and Thermal Sensor Connection T

5 CN5 Motor Protector Connection Terminal Protects the motor against abnormal current.

6 CN4 Silver-Nano Control Connection

7 CN6 Terminal for Each Driving Section Locks the door, supplies cold/hot water

8 CN3 Motor Tacho Connection T

9 CN2 Motor Power Supply T

_ PCB Diagram

erminal Receives 220 ACV to operate the PBA.

erminal Detects the water supply / drainage and the heater operations.

Terminal Controls the behavior of the silver-nano control PBA.

, and operates the drain motor

erminal Controls the speed of the motor with the tachometer.

erminal Detects whether the motor is operating normally.

Page 37

-2. MAIN PCB (BETTER: WF880*S* / WF870*S*)

Location Part No. Function Description

1 RY1 Main Relay Receives 220 ACV to operate the PBA.

2 RY3 Heater Relay For driving the heater power

3 CN9 Power Supply T

4 CN8 Water Level and Thermal Sensor Connection T

5 CN5 Motor Protector Connection Terminal Protects the motor against abnormal current.

6 CN4 Silver-Nano Control Connection

7 CN6 Terminal for Each Driving Section Locks the door, supplies cold/hot water

8 CN3 Motor Tacho Connection T

9 CN2 Motor Power Supply T

erminal Receives 220 ACV to operate the PBA.

erminal Detects the water supply / drainage and the heater operations.

Terminal Controls the behavior of the silver-nano control PBA.

, and operates the drain motor

erminal Controls the speed of the motor with the tachometer.

erminal Detects whether the motor is operating normally.

PCB Diagram _ 6

Page 38

-3. CIRCUIT DIAGRAMS OF MAIN PARTS (BEST: WF880*P* / WF870*P*)

► CN4

► CN3

1. Motor Tachometer Connection

2. NC

3. NC

4. Motor Tachometer Connection

1. Silver-Nano Forward Current Control

2. Silver-Nano Backward Current Control

3. Silver-Nano Current Volume Control

4. Silver-Nano Activation On/Off

5. GND

► CN2

1. Motor-Driving Relay Connection

2. NC

3. Motor-Driving Power Connection

4. High Speed Relay Connection

5. High Speed Relay Connection

6. Motor-Driving Relay Connection

► CN5

1. Motor Protector Connection

2. Motor Protector Connection

_ PCB Diagram

► CN6

1. Air Wash FAN Connection

2. NC

3. Air Wash Heater Connection

4. Door Lock Relay Connection

5. Drain Pump Connection

6. Hot-Water Valve Connection

7. Spare Valve Connection

8. Cold-Water Valve Connection

► CN8

1. Heater Temperature Sensor

2. Heater Temperature Sensor

3. Water-Level Sensor Signal

4. 5V

5. GND

6. NC

7. Leakage Sensor

8. NC

► CN9

Power Supply

► Relay

RY1 Power Supply Relay

RY3 Heater Relay

Page 39

-4. CIRCUIT DIAGRAMS OF MAIN PARTS (BETTER: WF880*S* / WF870*S*)

► CN4

► CN3

1. Motor Tachometer Connection

2. NC

3. NC

4. Motor Tachometer Connection

1. Silver-Nano Forward Current Control

2. Silver-Nano Backward Current Control

3. Silver-Nano Current Volume Control

4. Silver-Nano Activation On/Off

5. GND

► CN2

1. Motor-Driving Relay Connection

2. NC

3. Motor-Driving Power Connection

4. High Speed Relay Connection

5. High Speed Relay Connection

6. Motor-Driving Relay Connection

► CN5

1. Motor Protector Connection

2. Motor Protector Connection

► CN6

1. Air Wash FAN Connection

2. NC

3. Air Wash Heater Connection

4. Door Lock Relay Connection

5. Drain Pump Connection

6. Hot-Water Valve Connection

7. Spare Valve Connection

8. Cold-Water Valve Connection

► CN8

1. Heater Temperature Sensor

2. Heater Temperature Sensor

3. Water-Level Sensor Signal

4. 5V

5. GND

6. NC

7. Leakage Sensor

8. NC

► CN9

Power Supply

► Relay

RY1 Power Supply Relay

RY3 Heater Relay

PCB Diagram _

Page 40

-5. SUB PCB (BEST: WF880*P* / WF870*P*)

Location Part No. Function Description

1 BUZZER1 BUZZER Circuitry Emits a sound when a menu key or encoder key is pressed or when a program is finished.

2 DSP1 Time Display Displays the remaining time of the selected cycle.

3 CN1 Program Writing Connected when writing a program for updating or modifying the software.

4 DSP2 Cycle Display Displays menus and the progress.

_ PCB Diagram

Page 41

-6. SUB PCB (BETTER: WF880*S* / WF870*S*)

Location Part No. Function Description

1 BUZZER1 BUZZER Circuitry Emits a sound when a menu key or encoder key is pressed or when a program is finished.

2 DSP1 Time Display Displays the remaining time of the selected cycle.

3 CN1 Program Writing Connected when writing a program for updating or modifying the software.

PCB Diagram _

Page 42

-7. DETAILED DESCRIPTIONS OF CONTACT TERMINALS (SUB PCB-BEST: WF880*P* / WF870*P*)

_ PCB Diagram

► CN1

1. Program Writing ISP_TEST Connection

2. GND

3. 5V

4. Program Writing RESET Connection

5 Program Writing TX Connection

6. Program Writing RX Connection

Page 43

-8. DETAILED DESCRIPTIONS OF CONTACT TERMINALS (SUB PCB-BETTER: WF880*S* / WF870*S*)

► CN1

1. Program Writing ISP_TEST Connection

2. GND

3. 5V

4. Program Writing RESET Connection

5 Program Writing TX Connection

6. Program Writing RX Connection

PCB Diagram _

Page 44

. WIRING DIAGRAM

-1. WIRING DIAGRAM

REFERENCE INFORMATION

BLK BLACK

BLU BLUE

GRN GREEN

GRY GRAY

NTR NATURAL

ORG ORANGE

PNK PINK

RED RED

SKYBLU SKYBLUE

VIO VIOLET

WHT WHITE

YEL YELLOW

4 _ Wiring Diagram

Page 45

. SCHEMATIC DIAGRAM

JUMP

AC1

AC2

(AC1)

(AC1)

GND_POWER

RY3(AC1)

7

1

SENSOR

8

ROTOR

LEAKAGE

NOISE

STATOR

AC100-120V

AC220-240V

DOOR SWITCH

6

STATOR

EEPROM

RESET

4

5

PROTECTOR

AG PCB

WATER

PRE VALVE

5V

W/L SENSOR

SCHEMATIC DIAGRAM

GND

L

N

HOT VALVE

COLD VALVE

FAN

THERMAL

CUT OFF

LEVEL

AIRWASH HEATER

FILTER

WASHING MOTOR

TACHO

AC DETECT

THERMISTOR

THERMISTOR

2

POWER_RELAY

HEATER_RELAY

RY1(AC2)

3

D-PUMP

2

i6

1

i7

8

GND

9

VCC

DGND

+12V

13

O4

12

O3

11

O2

10

O1

6

i2

5

i3

4

i4

3

i5

KID65003AP

IC8

7

i1

16

O7

15

O6

14

O5

SMW250-06DW,WHT

1

2

3

4

5

6

R83

2.7Kohm,J,0.5W

CN1

TR7

KRC246S,0.2W

I

1

G

2

3

O

C23

50V,1nF

+12V

C10

25V,10nF

123

DGND

CM1

630V,100nF

DGND

DGND

X1

CSTLS16M0X51,16MHz

2

3

4

CM2

250V,10nF

DGND

BD1

1

50V,100nF

C33

DGND

50V,100nF

CE10

35V,10uF

R65

10Kohm,J,0.125W

C18

DGND

DGND

CE3

50V,1uF

C19

50V,100nF

CE5

25V,470uF

R49

620ohm,J,1W

1KV,2.2nF

DGND

DGND

D21

BAV99

132

C21

1

ZNR1

460V

DE39-60001A

OJ1

CN9

YDW236-01,WHT

ACS108-5Sx

TRIAC4

1

OUT

2

COM13G

4

COM2

R38

10Kohm,J,0.125W

PC1

LTV817B

1

2

IN

1

GND

2

OUT

3

R59

10Kohm,J,0.125W

1

2

4

3

+12V

IC10

NJM7805

DGND

LTV817B

PC4

R19

10Kohm,J,0.125W

C29

50V,100nF

DGND

D30

UG2D

R75

100Kohm,J,2W

COM13G

4

COM2

D26

TRIAC3

ACS108-5Sx

1

OUT

2

DGND

CC1

275V,680nF

1KV,2.2nF

D28

4

GND

5

INB+

6

INB-

7

OUTB

8

VCC

AGND

C27

DGND

IC9

KA2904

1

OUTA

2

INA-

3

INA+

BP1S2S3EN_UV

4

D

5NC6S7S8

IC11

R46

620ohm,J,1W

R39

10Kohm,J,0.125W

R47

620ohm,J,1W

C26

25V,10nF

2

1 4

3

+12V

+5V

C22

50V,100nF

RY2

AJW2211

C15

50V,10nF

R69

1Kohm,J,0.125W

R18

10Kohm,J,0.125W

+5V

CE6

500V,10uF

R68

100Kohm,J,2W

R60

1Kohm,J,0.125W

2

E

C

3

DGND

+5V

R72

4.7Kohm,J,0.25W

50V,100nF

C28

TR5

MMBT3904,0.35W

1

B

T1T2

G

+12V

+5V

TRIAC5

12A

1

2 3

4

+12V

DGND DGND

R79

1Kohm,J,0.125W

PCF-112D2M-B

RY3

VAR1

460V

DGND

DGND

R45 220ohm,J,0.25W

R78

20Kohm,J,0.25W

1

B

2

E

C

3

D32

UF4007

4

3

DGND

DGND

TR4

MMBT3904,0.35W

RELAY3

PCJ-112D3MH

2

1

R58

620ohm,J,1W

C14

50V,100nF

+8V

C30

50V,10nF

R84

2.4Kohm,J,0.5W

R56

47Kohm,J,0.125W

R54

1Kohm,J,0.125W

27,1.5A

DGND

DGND

DGND

C11

50V,100nF

PTC1

9

P80

IC1

7042P

IN

1

GND

2

OUT

3

74

P6175P6276P6377P6478P6579P66

8

P75

80

P67

67

P5268P5369P54

7

P74

70

P5571P5672P5773P60

6

P73

60

P32

61

P33

62

PB0

63

PB1

64

PB2

65

P5066P51

52

P12

53

P13

54

P14

55

P15

56

P16

57

P17

58

P30

59

P31

45

P04

46

P05

47

P06

48

P07

49

DVSS

5

P72

50

P10

51

P11

38

P4239P43

4

P71

40

HV-Monitor

41

P00

42

P01

43

P02

44

P03

30

P9631P9732PA033PA134PA235PA336P4037P41

23

X2

24

DVSS

25X126

AM127RESET28P9429P95

3

P70

16

P87

17

P90

18

P91

19

P92

2

AVCC

20

P93

21

AM0

22

DVCC

1

AVSS

10

P81

11

P82

12

P83

13

P84

14

P85

15

P86

MICOM1

TMP91FU62FG

R43 220ohm,J,0.25W

R42

220ohm,J,0.25W

1000uH,ADR3102J

+12V

TR6

RN2427,0.2W

1

I

2

G

O

3

L1

DGND

R82

10Kohm,J,0.125W

AGND

123 4

5678

DGND

YDH236-01S,BLK

1

RTE24012

RELAY2

R48

620ohm,J,1W

DGND

CN7

730uH,NV2-08730

R67

100ohm,J,0.5W

COIL1

4

5

R74

100Kohm,J,0.5W

+12V

+12V

CN4

SMW250-05DW,WHT

1

2

3

LTV814

124

3

+5V

DGND

C8

50V,100nF

PC3

CE4

35V,10uF

+5V

AGND

D29

E2

4

VSS

5

SDA

6

SCL

7

NWC

8

VCC

C2

50V,100nF

24C04

IC2

1

E0

2

E1

3

6

7

8

9

R77

4.7Kohm,J,0.25W

14

15

16

17

18

192

20

3

4

5

F2

*

1

10 11

12

13

R76

100Kohm,J,2W

+5V

1

2 3

4

+5V

+12V

+12V

2

COM13G

4

COM2

+5V

DGND

RY1

PCF-112D2M-B

COM

1

OUT

2G3

TRIAC2

ACS108-5Sx

1

OUT

C13

50V,10nF

TRIAC1

ACS120-7Sx

50V,100nF

4

5

+5V

DGND

C24

RELAY1

OMIH-SS-112D

1

2

3

DGND

1N4007

D34

CE8

35V,10uF

R52

10Kohm,J,0.125W

+5V

D31

R40

27Kohm,J,0.25W

6

7

8

DGND

DGND

D24

1N4148

CN8

SMW250-08DW,WHT

1

2

3

4

5

3

DGND

C20

50V,100nF

ACS120-7Sx

TRIAC6

COM

1

OUT

2

G

D33 1N4007

+5V

+5V

DGND

R63

6.8Kohm,F,0.25W

R64

20Kohm,J,0.25W

10Kohm,J,0.125W

AGND

C1

50V,100nF

R81

100ohm,J,2W

R70

200Kohm,J,0.125W

4

R53

300ohm,J,2W

R50

8

CN3

SMW250-04DW,WHT

1

2

3

CN6

SMW420A-08,_

1

3

2

4 5

6

7

R73

1Kohm,J,0.125W

CE9

25V,470uF

DGND

10Kohm,J,0.125W

C32

50V,100nF

2

3 4

5

6

+5V

R80

CN2

SMW420-06,_

1

3

4 5

6

7

8

C25

50V,10nF

LVT1

EE1616-H

1

2

DGND

R51

1Kohm,J,0.25W

132

CE11

35V,10uF

R71

270kohm,F,1W

BAV99

D22

2

20

3

4

5

6

7

8

9

10 11

12

13

14

15

16

17

18

19

+12V

F1

*

1

3

i5

2

i6

1

i7

8

GND

9

VCC

DGND

DGND

14

O5

13

O4

12

O3

11

O2

10

O1

6

i2

5

i3

4

i4

IC7

KID65003AP

7

i1

16

O7

15

O6

R61

1Kohm,J,0.25W

DGND

+5V

R44 220ohm,J,0.25W

DGND

R66

100ohm,J,0.5W

R55

1Kohm,J,0.25W

C12

50V,100nF

DGND

C16

50V,10nF

CE1

50V,1uF

D27

C5

50V,100nF

+12V

+5V

DGND

19

2

20

3

4

5

6

7

8

9

1

10

11

12

13

14

15

16

17

18

F3

*

YDW236-02,GRN

1

2

R85

9.1Kohm,F,0.25W

CE7

25V,1000uF

CN5

D25

1N4148

D23

P6KE6.8A

10Kohm,J,0.125W

R62

270kohm,F,1W

25V,10nF

R12

+5V

+5V

DGND

DGND

C31

4.7Kohm,J,0.25W

C9

50V,100nF

A

2

C

3

+12V

+8V

R41

243

TL431

IC12

R1

LTV814

PC2

1

C17

50V,100nF

R57

180ohm,J,2W

MTZJ5.6B

ZD1

+5V

+12V

R2

10Kohm,J,0.125W

DGND

HEATER_RELAY

DOOR_LOCK

AC_DETECT_1

LED_DATA1

AC1

AC1

AC

DGND

VCC

VCC

GND

AIRWASH_HEATER

LED_DATA0

WATER_THERMISTER_1

TRIAC_THERMISTER_1

AIRWASH_THERMISTER_1

MOTOR_CWCCW

MOTOR_HSPEED

MAIN_RELAY

COLD_TRIAC

PRE_TRIAC

HOT_TRIAC

PUMP_TRIAC

VCC

BUZZER_ENVELOPE

BUZZER_FREQ

LEAKAGE_1

AG_B_1

AG_A_1

AG_IH_1

TX

JOG_DIAL_B

JOG_DIAL_A

AIRWASH_FAN

AG_PWM_1

MOTOR_PHASE

TACHO_1

ZEROCROSS_1

GND

DIGIT_4

DIGIT_3

DIGIT_2

DIGIT_1

DIGIT_0

LED_DATA9

LED_DATA8

LED_DATA7

LED_DATA6

LED_DATA5

LED_DATA4

LED_DATA3

LED_DATA2

STDBY_1

DOORLOCKSTATE_1

GND

RX

WATER_FREQ_1

OPTION_SCAN

KEY_SCAN

GND

SCL

SDA

DIGIT_12

DIGIT_11

DIGIT_10

DIGIT_9

DIGIT_8

DIGIT_7

DIGIT_6

DIGIT_5

GND

ZEROCROSS RX

TX

STDBY

ISP_TEST

RESET

WATER_FREQ

AC2

GND

STDBY_1

AC1

AC

AC

AG_IH

AG_A

TACHO

MOTOR_PHASE

AG_IH_1

AG_A_1

AC_DETECT

DOORLOCKSTATE

AG_B

AC2

DOORLOCKSTATE

AG_IH

AG_PWM

AIRWASH_HEATER

AG_PWM_1

DOORLOCKSTATE_1

AG_B_1

TACHO_1

WATER_FREQ_1

AG_PWM

AC_DETECT

TRIAC_THERMISTER

WATER_THERMISTER

AIRWASH_THERMISTER

HEATER_RELAY

AIRWASH_THERMISTER_1

WATER_THERMISTER_1

TRIAC_THERMISTER_1

AC_DETECT_1

ZEROCROSS_1ZEROCROSS

AIRWASH_FAN

PUMP_TRIAC

DOOR_LOCK

MOTOR_HSPEED

MOTOR_CWCCW

PRE_TRIAC

COLD_TRIAC

HOT_TRIAC

AC1 AC1

WATER_FREQ

LEAKAGE_1

LEAKAGE

ISP_TEST

RESETRESET

AC1

WATER_THERMISTER

AIRWASH_THERMISTER

LEAKAGE

AG_A

AG_B

VCC

MAIN_RELAY

STDBY

TACHO

SDA

SCL

VCC

TRIAC_THERMISTER

-1. MAIN CONTROL (BEST: WF880*P* / WF870*P*)

► This Document can not be used without Samsungs authorization.

Schematic Diagram _

Page 46

-2. MAIN CONTROL (BETTER: WF880*S* / WF870*S*)

JUMP

HOT VALVE

6

GND_POWER

HEATER_RELAY

6

AC100-120V

5

ROTOR

4

WASHING MOTOR

5

THERMAL

NOISE

PROTECTOR

RY1(AC2)

FAN

L

N

STATOR

3

CUT OFF

4

2

RY3(AC1)

LEVEL

SENSOR

8

7

FILTER

LEAKAGE

POWER_RELAY

1

5V

STANDBY

2

PRE VALVE

STATOR

D-PUMP

EEPROM

COLD VALVE

AG PCB

DOOR SWITCH

AIRWASH HEATER

AC220-240V

THERMISTOR

SCHEMATIC DIAGRAM

TACHO

WATER

W/L SENSOR

THERMISTOR

RESET

LEAKAGE

1

GND

3

2

P67

11

P80

75

P60

76

P6177P62

78

P63

79

P6480P65

1

P66

10

P75

68

P51

69

P52

70

P5371P54

9

P74

72

P5573P5674P57

61

P31

8

P73

62

P32

63

P33

64

PB0

65

PB166PB2

67

P50

53

P11

54

P12

55

P13

56

P14

57

P15

58

P16

59

P17

60

P30

46

P03

47

P04

48

P05

49

P06

50

P07

51

DVSS

7

P72

52

P10

39

P4140P42

41

P43

6

P71

42

EMU0

43

P00

44

P01

45

P02

5

P70

32

P9633P9734PA0

35

PA136PA237PA338P40

24

DVCC

25X226

DVSS27X128AM129nRESET30P94

31

P95

17

P86

18

P87

19

P90

20

P91

21

P92

4

AVCC

22

P93

23

AM0

3

AVSS

12

P81

13

P82

14

P83

15

P84

16

P85

ACS120-7Sx

COM

1

OUT2G

3

TMP91FU62DFG

MICOM1

27,1.5A

PTC1

TRIAC6

DGND

R58

620,J,1W

1KV,2.2nF

C21

5

6

D34

1N4007

3

2

SMW250-06DW,WHT

CN1

1

2

3

4

+12V

D22

BAV99

1

220,J,0.25WR42

1

i7

8

GND9VCC

220,J,0.25WR43

12

O3

11

O2

10

O1

6

i2

5

i3

4

i4

3

i5

2

i6

IC7

7

i1

16

O7

15

O6

14

O5

13

O4

50V,100nF

C20

KID65003AP

BD1

1

2

3

4

DGND

123

DGND

DGND

+5V

X1

CSTLS16M0X51,16MHz

D28

DGND

DGND

C10

25V,10nF

MMBT3904,0.35W

TR5

B

1

E

2

3

C

R71

270K,F,1W

DGND

4.7K,J,0.25W

R72

BP1S2S3EN_UV

4

D

5

6

NC

S7S

8

IC11

3

4 5

6

7

8

C28

50V,100nF

EE1616-H

LVT1

1

2

DGND

C17

50V,100nF

7042P

IC1

IN

1

GND

2

OUT

3

DGND

+5V

C24

50V,100nF

1K,J,0.25WR55

DGND

DGND

R61

1K,J,0.25W

9.1K,F,0.25W

R85

1

23

4

10K,J,0.125W

R1

C19

50V,100nF

RY3

PCF-112D2M-B

1N4148

D24

DGND

D26

220,J,0.25WR44

+12V

ACS108-5Sx

TRIAC3

1

OUT2COM13G

4

COM2

1

2

3

4 5

6

7

8

1

23

4

CN6

SMW420A-08,_

T1T2

G

+5V

PCF-112D2M-B

RY1

D27

TRIAC5

12A

50V,10nF

C16

+5V

DGND

CN7

YDH236-01S,BLK

1

R47

620,J,1W

1

OUT2COM13G

4

COM2

CE4

35V,10uF

C31

25V,10nF

DGND

ACS108-5Sx

TRIAC2

1K,J,0.125W

DGND

+12V

2.7K,J,0.5W

R83

R60

UF4007

D32

P6KE6.8A

D23

124

3

2

1 4

3

PC2

PS2565

3

5

DGND

OMI-SH-112LM

RY2

PCJ-112D3MH

RELAY3

2

1 4

C33

50V,100nF

2

4

3

R81

10K,J,0.125W

2

PC4

PS2561

1

DGND

PS2561

PC1

1

1 2 3 4

5678

620,J,1W

+5V

RELAY2

RTE24012

10K,J,0.125W

R38

DGND

R48

DGND

+5V

DGND

R69

DGND

50V,100nF

C11

1K,F,0.25W