Samsung WF8800, WF8802, WF8700, WF8714 Schematic

WASHING MACHINE

DRUM TYPE

Basic Model : Q1657

(TS EURO PROJECT)

Model Name : WF8800*

SERVICE

WASHING MACHINE (DRUM) CONTENTS

WF8700*

WF8802*

WF8804*

WF8814* WF8714*

WF8754*

(HEBA PROJECT)

WF8702*

WF8704*

Manual

WF8802DPF WF8702LSV

1. Safety Instructions

2. Features and Specifications

3. Disassembly and Reassembly

4. Troubleshooting

5. PCB Diagram

6. Wiring Diagram

7. Schematic Diagram

8. Reference Information

Refer to the service manual in the GSPN (see the rear cover) for the more information.

CONTENTS

1. Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1. Safety instructions for service engineers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

2. Features and Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2-1. Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2-2. Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2-3. Comparing specifications with existing models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2-4. Options specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3. Disassembly and Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3-1. Tools for disassembly and reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3-2. Standard disassembly drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

4. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4-1. Error modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

4-2. Corrective actions for each error code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

5. PCB diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

5-1. Main PCB (Best: WF880*P* / WF870*P*) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

5-2. Main PCB (Better: WF880*S* / WF870*S*) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

5-3. Circuit diagrams of main parts (Best: WF880*P* / WF870*P*) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

5-4. Circuit diagrams of main parts (Better: WF880*S* / WF870*S*) . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

5-5. Sub PCB (Best: WF880*P* / WF870*P*) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

5-6. Sub PCB (Better: WF880*S* / WF870*S*) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

5-7. Detailed descriptions of contact terminals (sub PCB-Best: WF880*P* / WF870*P*) . . . . . . . . . . . . .41

5-8. Detailed descriptions of contact terminals (sub PCB-Better: WF880*S* / WF870*S*) . . . . . . . . . . . .42

6. Wiring diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

6-1. Wiring diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

7. Schematic diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

7-1. Main control (Best: WF880*P* / WF870*P*) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

7-2. Main control (Better: WF880*S* / WF870*S*) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

7-3. Sub control (Best: WF880*P* / WF870*P*) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

7-4. Sub control (Better: WF880*S* / WF870*S*) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

8. Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

8-1. HEBA Project name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

1. SAFETY INSTRUCTIONS

1-1. SAFETY INSTRUCTIONS FOR SERVICE ENGINEERS

► Make sure to observe the following instructions to operate the product correctly and safely and prevent possible

accidents and hazards while servicing.

► Two types of safety symbols, Warning and Caution, are used in the safety instructions.

Hazards or unsafe practices that may result in severe personal injury or death.

WARNING

Hazards or unsafe practices that may result in minor personal injury or property damage.

CAUTION

WARNING

• (When servicing electrical parts or harnesses) Make sure to disconnect the power plug before servicing.

Failing to do so may result in a risk of electric shock.

• Do not allow consumers to connect several appliances to a single power outlet at the

same time.

There is a risk of fire due to overheating.

• When removing the power cord, make sure to hold the power plug when pulling the plug

from the outlet.

Failing to do so may damage the plug and result in fire or electric shock.

• When the washing machine is not being used, make sure to disconnect the power plug

from the power outlet.

Failing to do so may result in electric shock or fire due to lightning.

BEFORE SERVICING

• Do not place or use gasoline, thinners, alcohol, or other fl

machine.

There is a risk of explosion and fire caused from electric sparks.

ammable or explosive substances near the washing

Safety Instructions _ 1

2 _ Safety Instructions

WARNING

• Check if the power plug and outlet are damaged, flattened, cut or otherwise degraded.

If faulty, replace it immediately.

Failing to do so may result in electric shock or fire.

• Completely remove any dust or foreign material from the housing, wiring and connection parts.

This will prevent a risk of fire due to tracking and shorts in advance.

When connecting wires, make sure to connect them using the relevant connectors and check that they are

•

completely connected.

If tape is used instead of the connectors, it may cause fire due to tracking.

WHILE SERVICING

• Make sure to discharge the PBA

Failing to do so may result in a high voltage electric shock.

• When replacing the heater

If not inserted into the bracket-heater, it touches the drum and causes noise and electric leakage.

WARNING

• Check the wiring.

Ensure that no wire touches a rotating part or a sharpened part of the electrical harness.

• Check for any water leakage.

Perform a test run for the washing machine using the standard course and check whether there is any water

leakage through the floor section or the pipes.

• Do not allow consumers to repair or service any part of the washing machine

themselves.

This may result in personal injury and shorten the product lifetime.

AFTER SERVICING

power terminals before starting the service.

, make sure to fasten the nut after ensuring that it is inserted into the bracket-heater.

• If it seems that grounding is needed due to water or moisture, make sure to run

grounding wires.

(Check the grounding of the power outlet, and additionally ground it to a metallic water

pipe.)

Failing to do so may result in electric shock due to electric leakage.

[Running a grounding wire]

Twist a grounding wire (copper wire) two or three times around the tap.

-

- If you connect the grounding wire to a copperplate, bury it 75 cm under the earth in a

place with a lot of moisture.

Do not connect the grounding wire to a gas pipe, plastic water pipe or telephone

wire. There is a risk of electric shock or explosion.

Grounding

terminal

75 cm

Copperplate

CAUTION

• Do not sprinkle water onto the washing machine directly when cleaning it.

This may result in electric shock or fire, and may shorten the product lifetime.

• Do not place any containers with water on the washing machine.

If the water is spilled, it may result in electric shock or fire. This will also shorten the

product lifetime.

Do not install the washing machine in a location exposed to snow or rain.

•

This may result in electric shock or fire, and shorten the product lifetime.

BEFORE SERVICING

• Do not press a control button using a sharp tool or object.

This may result in electric shock or damage to the product.

CAUTION

• When wiring a harness, make sure to seal it completely so no liquid can enter.

Make sure that they do not break when force is exerted.

• Check if there is any residue that shows that liquid entered the electric parts or harnesses.

If any liquid has entered into a part, replace it or completely remove any remaining moisture from it.

WHILE SERVICING

• If you need to place the washing machine on its back for servicing purposes, place a support(s) on the floor and lay it

down carefully so its side is on the floor

Do not lay it down on its front.

.

This may result in the inside tub damaging parts.

Safety Instructions _ 3

CAUTION

• Check the assembled status of the parts.

They must be the same as before servicing.

• Check the insulation resistance.

Disconnect the power cord from the power outlet and measure the insulation resistance between the power plug

and the grounding wire of the washing machine. The value must be greater than 10MΩ when measured with a

500V DC Megger

AFTER SERVICING

• Check whether the washing machine is level in relationship with the floor

it is installed firmly on the floor.

Vibrations can shorten the lifetime of the product.

. Check whether

4 _ Safety Instructions

2. FEATURES AND SPECIFICATIONS

2-1. FEATURES

COMMON FEATURES

Features Description

Implementing 8 kg in the

Standard Size

Addition of a Liquid

Detergent Tray

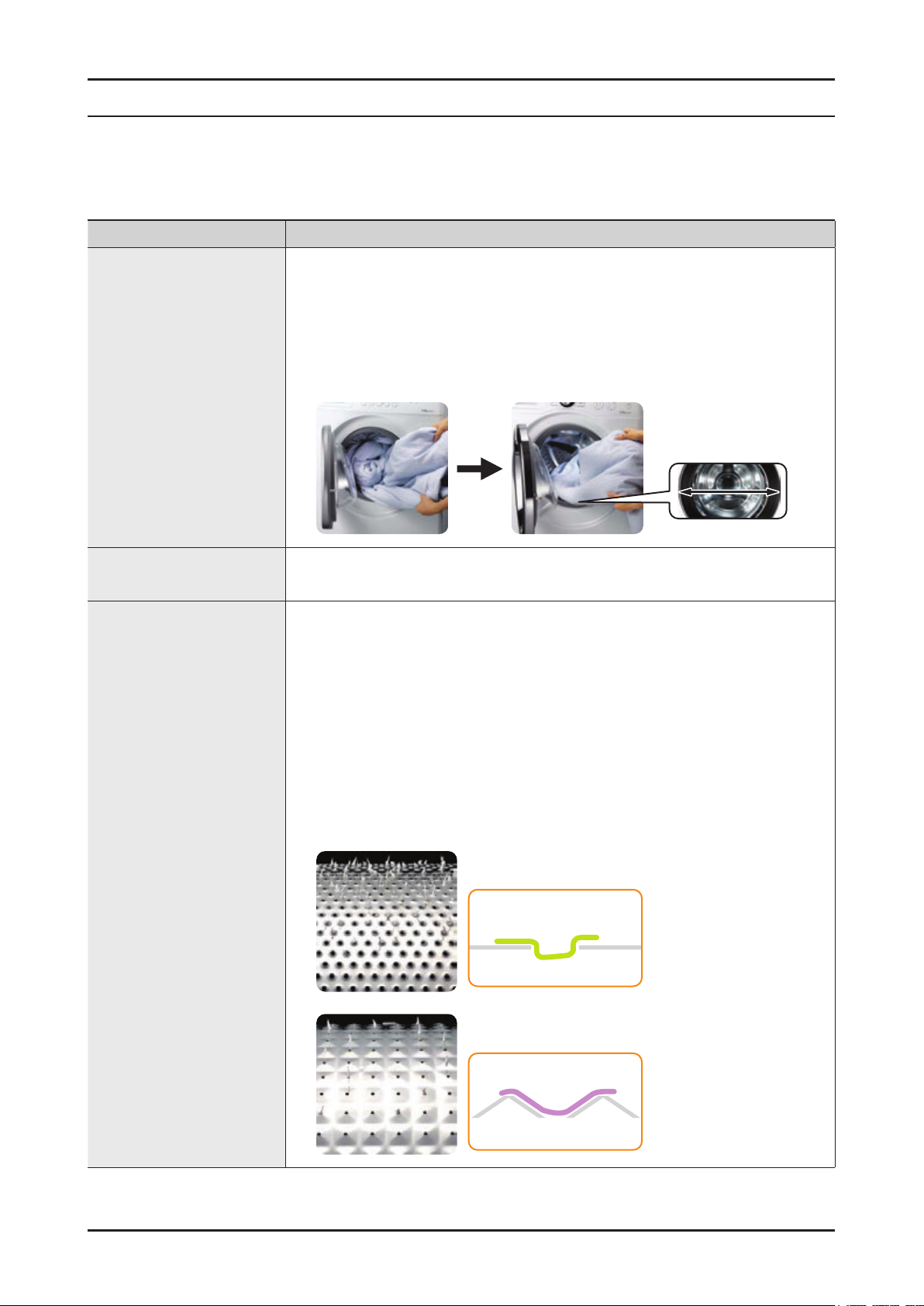

Diamond Drum • The washing performance has increased but potential damage to the washing has

• This is the maximum capacity to be implemented at the standard 60 cm depth.

- The benefits for customers have been greatly increased due to the efficient

use of limited space.

- Usability has been improved due to the easier loading and removing of the

laundry.

• The size of the loading entry has increased: 300 mm → 330 mm (Wide)

A lot more washing can be conveniently added and removed.

-

330 mm

• Usability has been improved due to the newly added Liquid Detergent Tray.

been minimized. (The size of the holes on the diamond drum has been reduced

for minimizing damage to the washing.)

- The embossed wall of the drum serves as a washboard, dramatically

increasing the washing performance compared with existing drum washing

machines, which use the power of the difference in elevation only

- The size of holes has been reduced drastically, maintaining the optimal wash

performance (Washing Cost 1.0) while saving on water and electricity required

for washing.

- The structure of the holes on the diamond drum has been changed minimizing

potential damage to the washing since it is difficult for strands to enter the

holes.

.

Conventional

Diamond Drum

Fabric

Fabric

Features and Specifi cations _ 5

6 _ Features and Specifi cations

OPTIONAL FEATURES

► The features below depend on the model.

Features Description

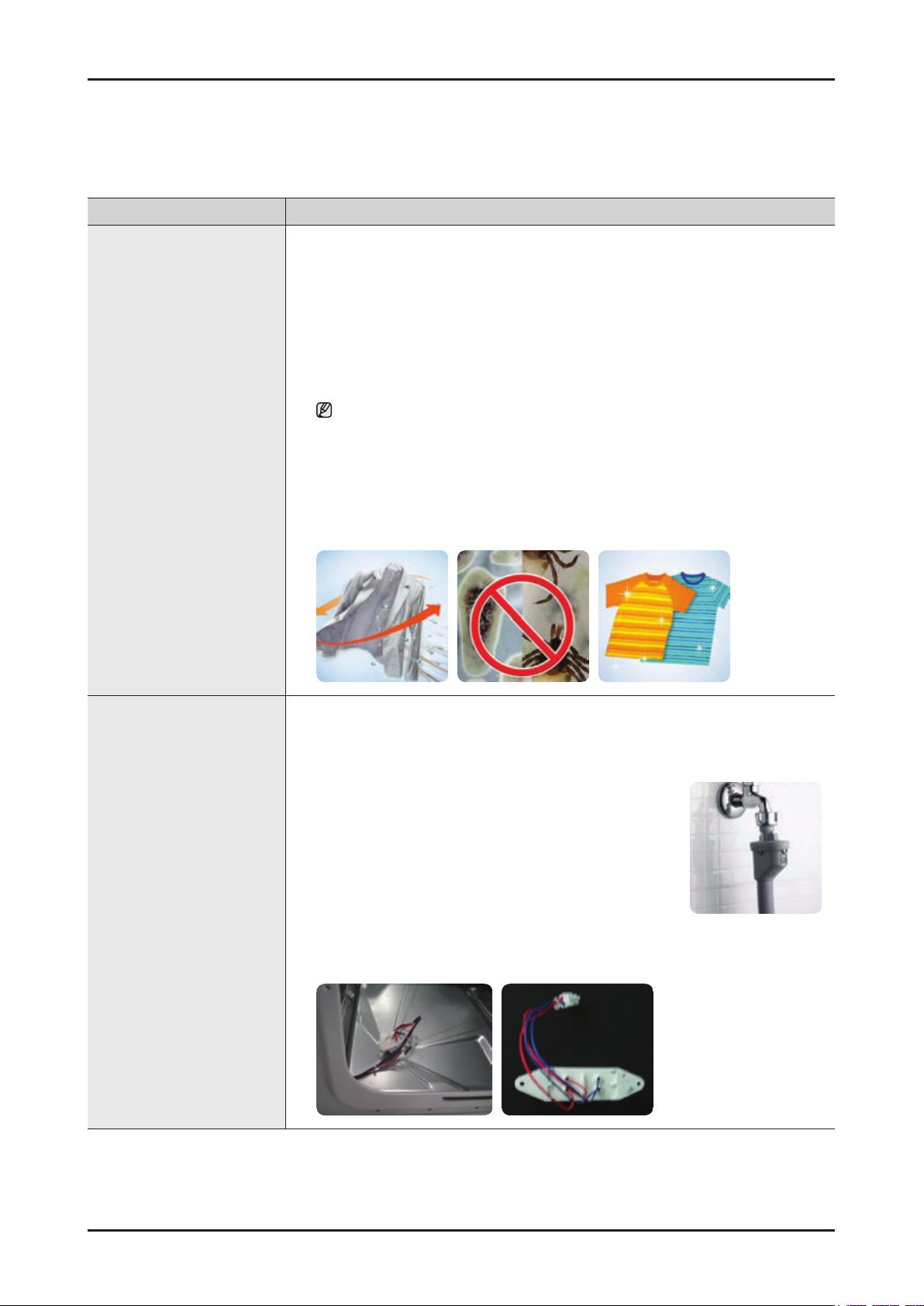

Air Refresh System • Sterilization/Deodorization/Removal of Ticks without Water Washing (Air Washing

Using Air and Heating)

Destroying bacteria and ticks without the use of water

-

- Removing the sweat and dirt odors

- Maintaining the shape and color of the washing without dry-cleaning

• Washing with air.

- Removing odors by heating, keeping the washing as new.

- Washing with air conveniently, compared with dry-cleaning

The goal of deodorization is 60 percent. (40-minute cycle)

• Washing one or two shirts in 30 minutes

- If a piece of clothes is not completely dry when it is humid, the machine can

dry it within 30 minutes

• Preventing bio-film caused by humidity from occurring

- You do not need to worry about the humidity inside the drum.

- The drum is dried regularly, preventing bio-film.

Water Safety System • The Water Safety System has invented for perfect leakage protection. The double

safety valve connects directly to the water faucet. In the event of a leakage,

the built-in sensor immediately detects the leak within a few short seconds,

automatically turning off both the water supply and the washing machine.

- Inlet hose

It attached to the water supply hose and automatically

cuts off water flow when hose damaged. It also

displays a warning indicator.

- Leakage Sensor

A water leakage sensor attached at the bottom of the washing machine to

cutoff the power automatically if a leakage occurs, to prevent danger of a fire.

► The features below depend on the model.

Features Description

Silver Wash System • Samsung’s unique technology generates silver ions that remove bacteria and

fungi, and create an invisible shield that protects your clothes from unwanted

odors until your next wash. Using an ancient and proven purification technique so

simple, yet so advanced it removes microbes even in cold water.

• Effect of Silver W

ash System

- Keeps Stored Clothes Fresh

Ag+ Silver (Nano) Technology anti-bacterial effect keeps fabric free from

The

odor-causing micro-organisms for up to one month, without the use of strong

chemical cleaners. There’s no need to worry about musty-smelling clothes

even if they remain unused for a long period.

- Makes Shapeless Garments a

Thing of the Past

High temperatures and harsh bleaches can damage and discolor your clothes.

The Ag+ Silver (Nano) Technology helps your clothes last longer, without

stretching, shrinking, pilling or fading.

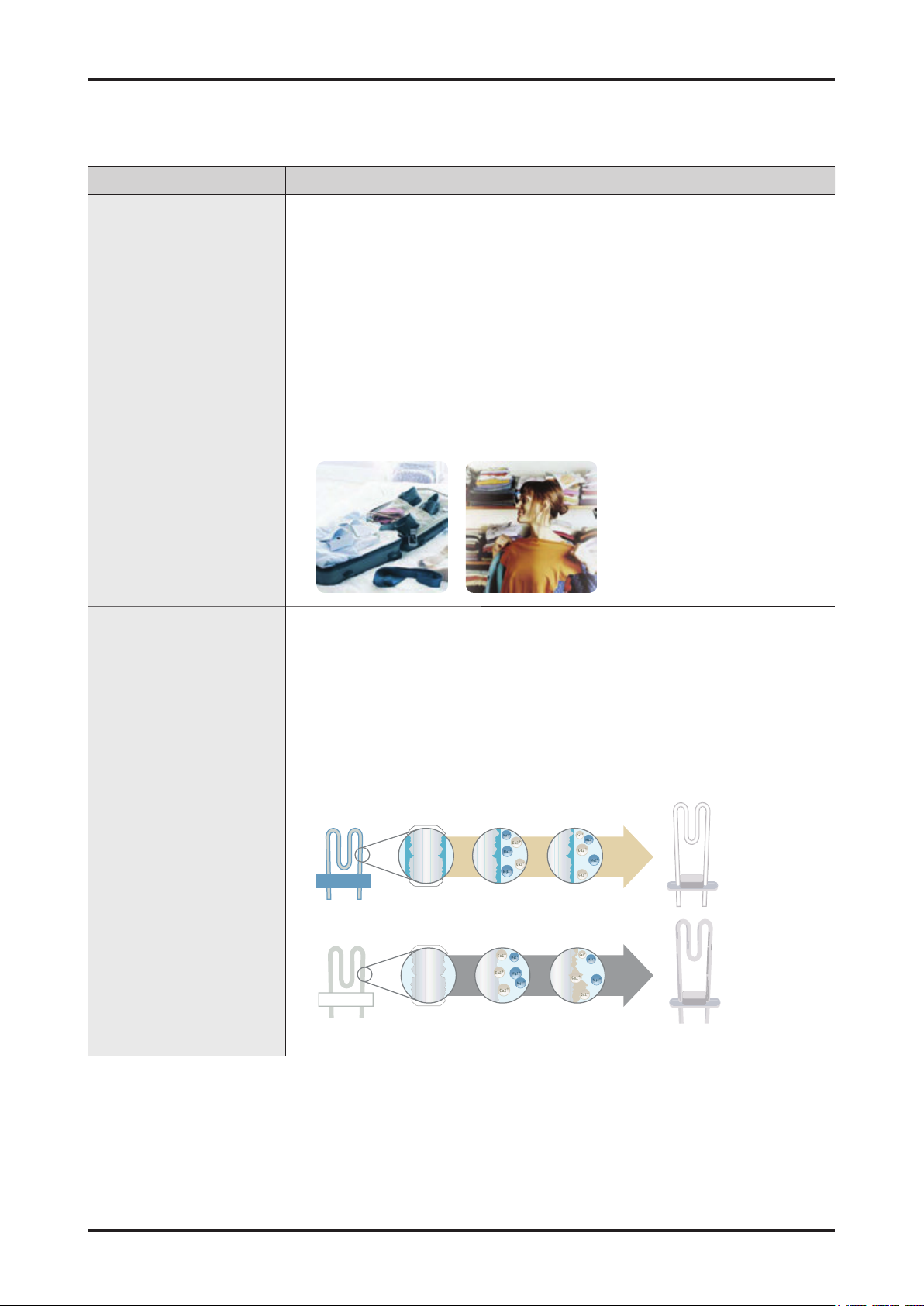

Ceramic Heater • The ceramic heater in Samsung washing machine prevents metals in hard water

from being attach to the heater, which may cause a reduction in heater efficiency.

It saves energy, time and costs.

- Energy Savings

Over time, conventional heaters increase their power consumption an average

of 5.8 percent, while ceramic heaters only become 1.8 percent less efficient.

- Time Savings

After three years, conventional heaters take 7.5 percent longer to heat up,

whereas ceramic only lose 2.5 percent longer to heat up, whereas ceramic

only lose 2.5 percent of their ability to heat up.

10 Years

Ceramic

Enlarged

iew

V

Producted

Surface

No Build-Up

2.7 Years

Normal

Enlarged

View

Molecules

binding

Scale

Formation

Features and Specifi cations _ 7

8 _ Features and Specifi cations

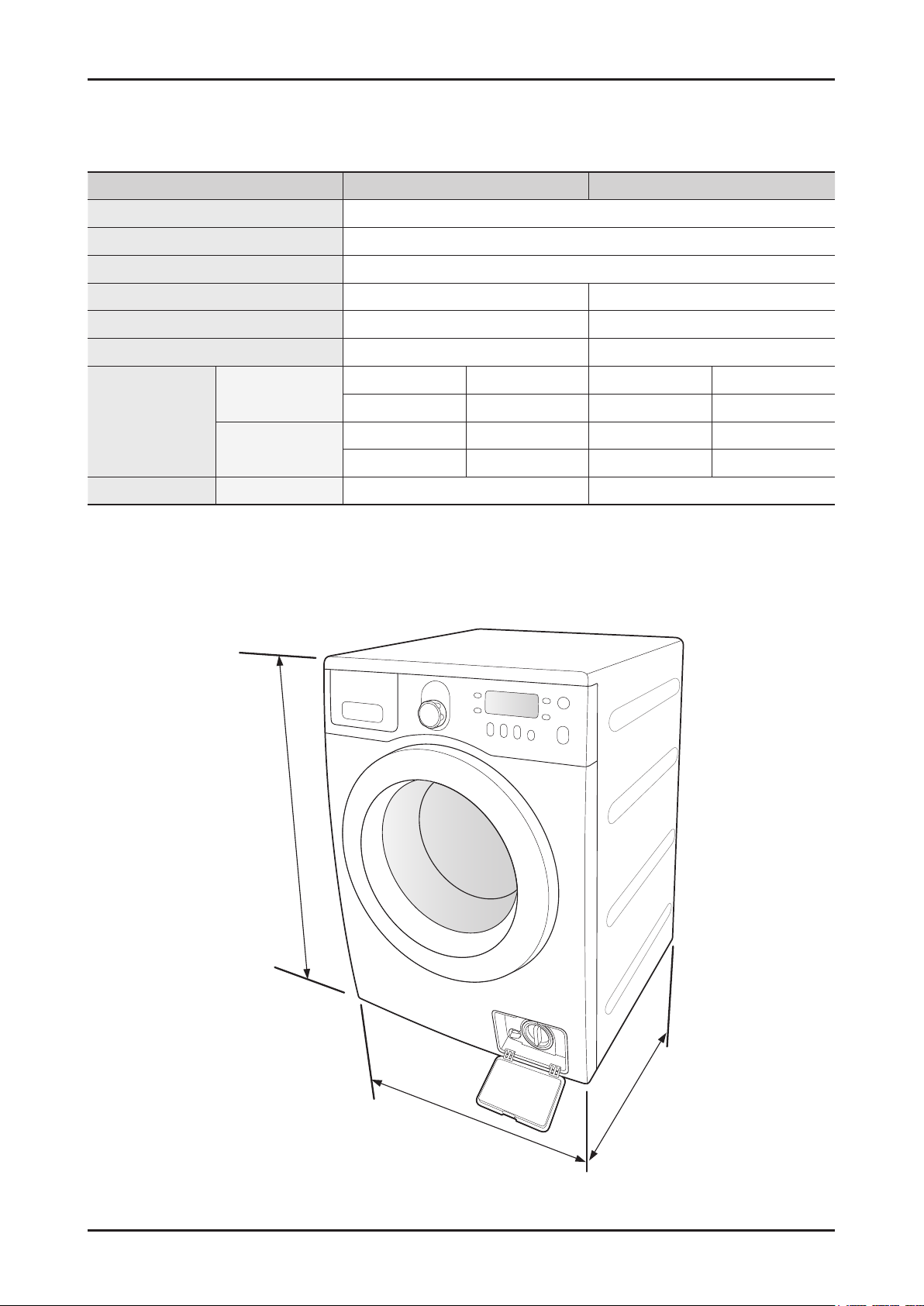

2-2. SPECIFICATIONS

Model WF8804*/WF8802*/WF8800* WF8704*/WF8702*/WF8700*

Wash Type FRONT LOADING TYPE

Dimension W 598 mm X D 600 mm X H 844 mm

Water Pressure 50 kPa ~ 800 kPa

Water Volume 64 ℓ 56 ℓ

Weight 74 kg / 73 kg / 72 kg 73 kg / 72 kg / 71 kg

Wash & Spin Capacity 8.0 kg 7.0 kg

WASHING

Power

Consumption

Spin Revolution rpm 1400 / 1200 / 1000 1400 / 1200 / 1000

WASHING and

TING

HEA

844

220 V 150 W 220 V 150 W

240 V 150 W 240 V 150 W

220 V 2000 W 220 V 2000 W

240 V 2400 W 240 V 2400 W

600

598

2-3. COMPARING SPECIFICATIONS WITH EXISTING MODELS

() : Functions may be different depending on the model.

Grade Heba TS euro

Model Name

Image

WF8804*/

WF8802*/

WF8800*

WF8704*/ 8754*

WF8702*/

WF8700*

Q1657

Feature

Capacity 8.0 kg 7.0 kg/7.5Kg(WF8754*) 7.5 kg

Drum Volume 64 ℓ 56 ℓ 57 ℓ

Max rpm 1400 / 1200 / 1000 1400 / 1200 / 1000 1600

Motor Universal 3 phase inverter

Control Sys General General

eight Detection 3 Stages No

W

Main Spec

USP

Design

Dimension (W X D X H mm) 598 x 600 x 844 600 x 600 x 850

Heater Capacity 2000 W / 230 V 2400 W /230 V

Water Supply Cold Only Cold and Hot Cold Only

Drainage Pump Pump

Power-Outage

Compensation

Zero Standby Power Y

Air Refresh

Silver Wash

Water Safety

Ceramic Heater

Diamond Drum Yes No

Loading Entry Size Wide (330 mm) 300 mm

Detergent

Installation Handle No No

Center Jog Dial Yes No

Display

Tray Powder/Liquid Powder Only

Big Door Yes (480 mm) No (400 mm)

High G.LED

Mid Dot Display

Diamond drum

Big door design

Yes Yes

es (1W or Less) No

Yes ()

Y

es () Y

()

Yes

Y

es ()

Silver wash

Wide G.LED

es ()

G.LED

No

No

No

Features and Specifi cations _ 9

3. DISASSEMBLY AND REASSEMBLY

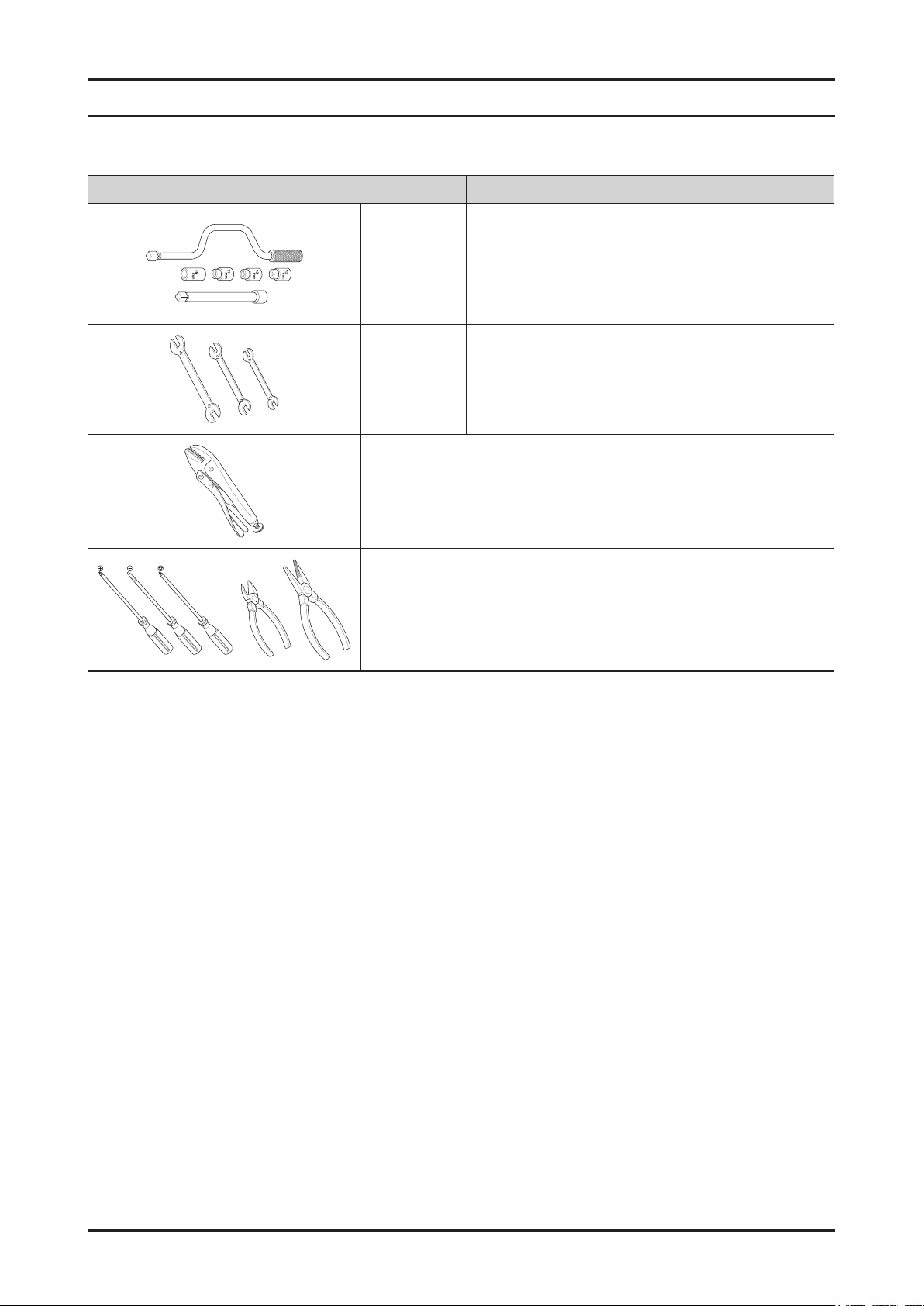

3-1. TOOLS FOR DISASSEMBLY AND REASSEMBLY

Tool Type Remarks

10mm

Box driver

Double-ended

spanner

Vice pliers

Others

(screwdriver, nipper,

long nose pliers)

13mm

19mm Pulley(1)

10mm

13mm

19mm

Heater(1),Tub(12), Fixer screw(5), Motor(2),

Balance(9)

Shock Absorber (2 holes each in left/right),

Damper(2), Damper(friction 2)

Replaced by box driver

Leg

A Tool for protecting empty turning of bolt or

abrasion from using box driver

For disassembly of Spin drum

Common tools for servicing

Removal and Reassembly _ 11

12 _ Removal and Reassembly

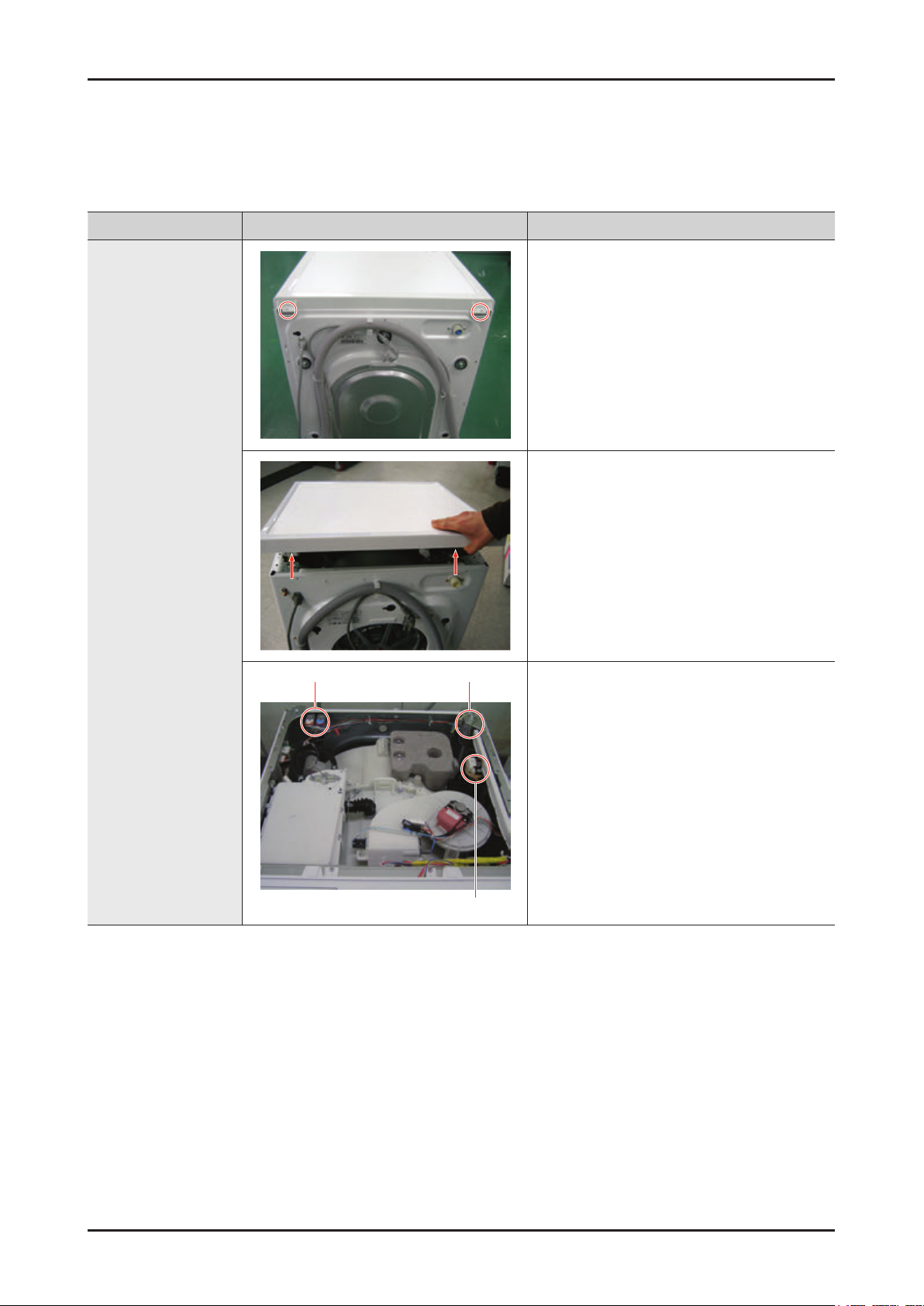

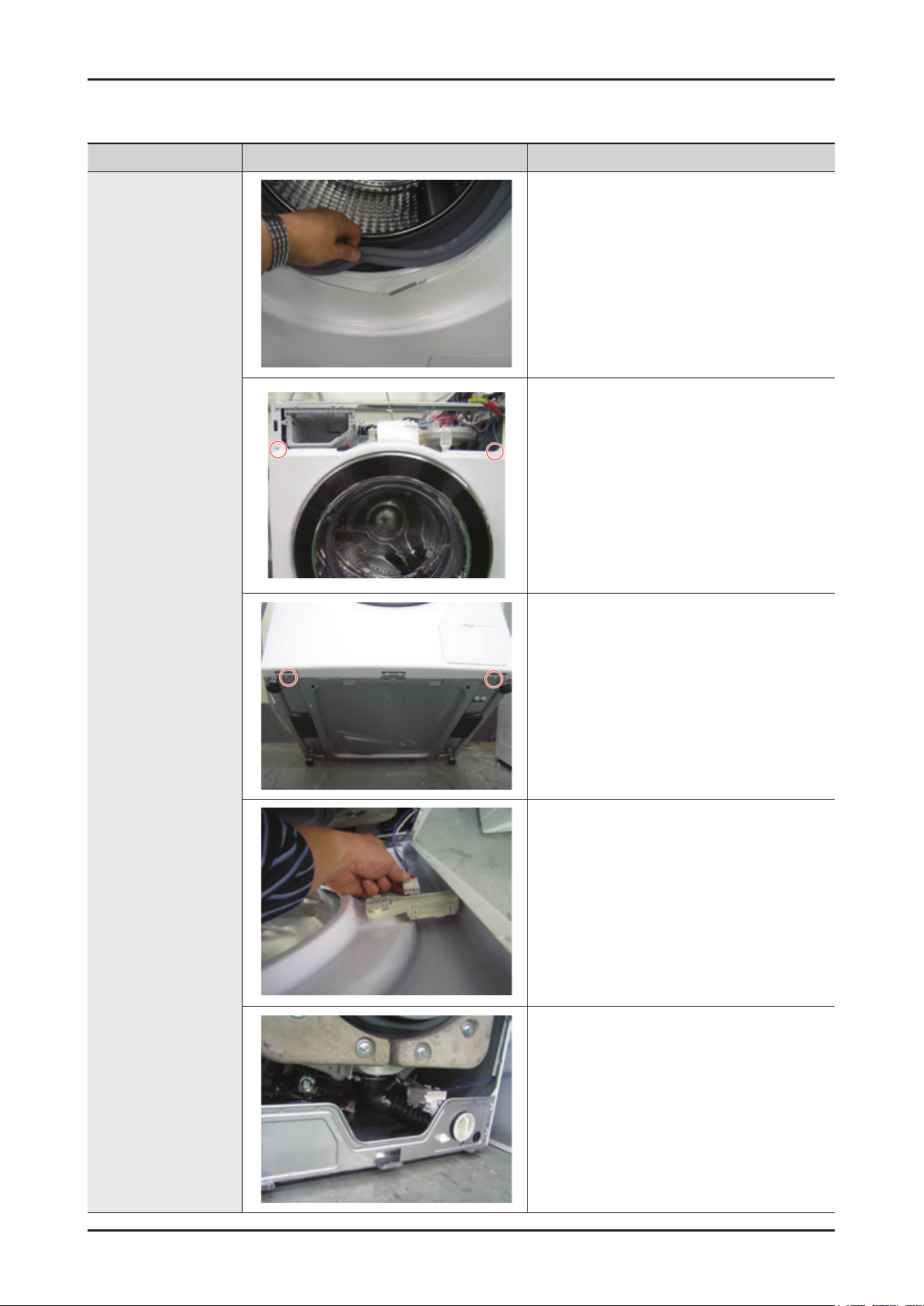

3-2. STANDARD DISASSEMBLY DRAWINGS

► This is a standard disassembly diagram and may differ from the actual product.

Use this material as a reference when disassembling and reassembling the product.

Part Figure Description

1. Remove the two screws holding the Top

Cover at the back of the unit.

2. Remove the top-cover by lifting it up after

pulling it back about 15mm.

ASSY COVER TOP

Water valve Noise filter

Sensor pressure

3. Then, the Water (Pressure) Sensor, Noise

Filter and Water Valve can be replaced.

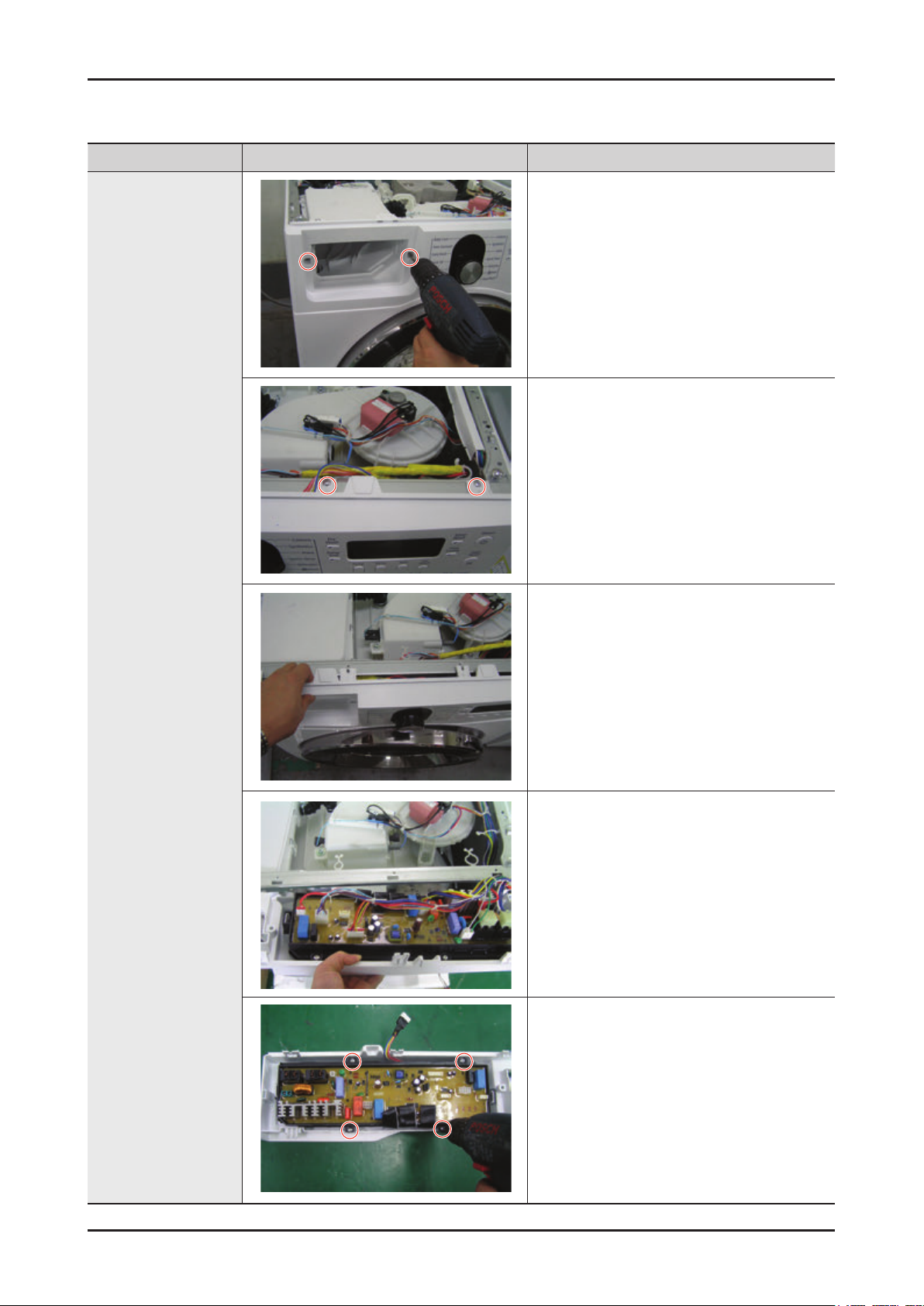

Part Figure Description

1. Remove the 2 screws holding the front

operating panel.

Remove the four screws at the top of the

2.

ASSY-PANEL

CONTROL.

MAIN-PCB AND

SUB-PCB PANEL

Hold the

3.

pulling it upwards and release the hook to

remove it.

4. Disconnect the terminals connected to the

PCB by hand.

5. Remove the four screws holding the PCB

and release the hooks on both sides to

remove the PCB for repair / replacement.

ASSY-PANEL CONTROL while

Removal and Reassembly _ 13

14 _ Removal and Reassembly

Part Figure Description

1. Separate the Wire-Diaphragm from the

Front-Frame and remove the Diaphragm.

2. Remove the two screws holding the

FRAME-FRONT

.

FRAME FRONT

3.

Remove the two screws holding the bottom

of the FRAME-FRONT

4.

Disconnect the terminal for the DOORLOCK switch.

The DOOR-DIAPHRAGM, HEATER, PUMP,

5.

SHOCK- DAMPER and DOOR LOCK

switch.

.

Loading...

Loading...