Samsung WF350ANP User Manual

WASHING MACHINE

Technical Information

• Due to possibility of personal injury or property damage, always contact an authorized

technician for servicing or repair of this unit.

• Refer to Service Manual for detailed installation, operating, testing, troubleshooting, and

disassembly instructions.

CAUTION

All safety information must be followed as provided in Service Manual.

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to washer

before servicing, unless testing requires power.

Code No. : DC68-02834A-02_EN

1

ALIGNMENT AND ADJUSTMENTS

2

To avoid risk of electrical shock, personal injury or death; disconnect power to washer

before servicing, unless testing requires power.

WARNING

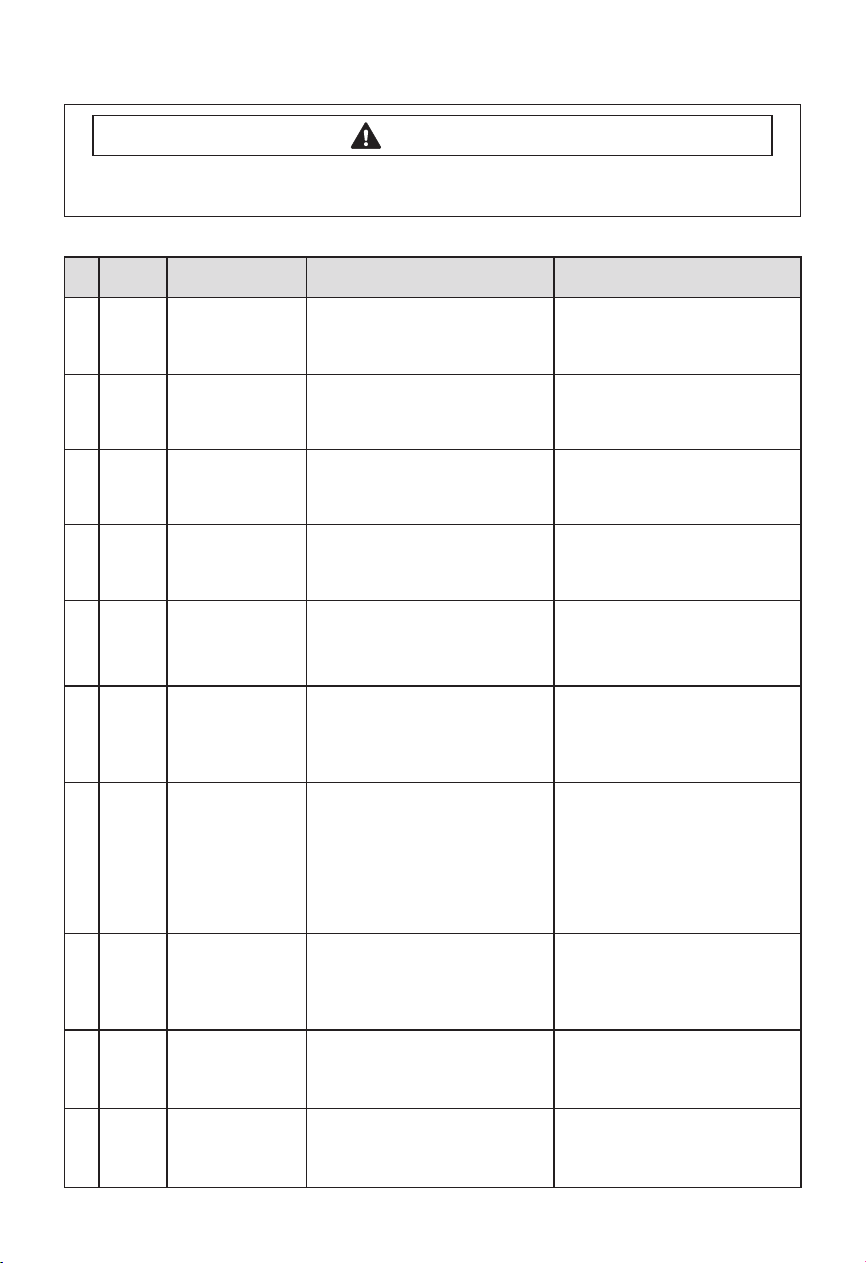

GENERAL ERROR FUNCTION

Error

NO

1 nd 1

Diagnostic Code

Code

Error Image

Description Corrective Action

The water level fails to drop below

the Reset Water Level within 15

minutes.

Go to “ Will Not Drain”

Troubleshooting Section.

2 LO 2

3 nF 3

4 FL 4

5 LE 8

6 LE 8

7 OE E

8 dc 10

9 E2 15

10 dL 18

Door fails to Unlock After 7

attempts.

When the filling Continues for

more than 40 minutes or there is no

change of water level for 6 minutes.

Door fails to lock after 7 attempts.

A water level lower than the Reset

water level (25.6Khz) is detected for

5 seconds during the Wash/Rinse

cycle.

Water Level Sensor Trouble. (When

the input signal from the water level

sensor is out of range, the unit will

send out beeping sounds and halts

the cycle.)

A fault is detected in the water level

sensor. Data (frequency) shows

the water level is at or above the

overflow water level. (When this

condition is detected, the machine

will automatically starts draining

water until the water level falls

below the overflow water level)

Unbalance or cabinet bump is

detected during final spin, which

prevents the drum from spinning

over 150 rpm. (Never exceeds 150

RPM due to unbalanced load)

Jammed Key.(When key input

signals are coming out for more

than 30 seconds, it is regarded as

a jam.)

Door is detected as open when the

motor is operating.

Go to “ Will Not Unlock”

Troubleshooting Section.

Go to “ No Water Fill”

Troubleshooting Section.

Go to “ Will Not Lock”

Troubleshooting Section.

Go to “No Water Fill”

Troubleshooting Section.

Go to “No Water Fill”

Troubleshooting Section

First check to see that all of water

valves are not stuck. If water valves

are OK, check water level sensor.

Go to “Wet Clothes” Troubleshooting

Section.

Check all of keys. If A key is sensed

to be pressed, all keys will do not

respond.

Check for loose wire connections. Go

to “Quick Test Mode” and then do Door

lock/Unlock Test and Motor Test.

ALIGNMENT AND ADJUSTMENTS

3

To avoid risk of electrical shock, personal injury or death; disconnect power to washer

before servicing, unless testing requires power.

WARNING

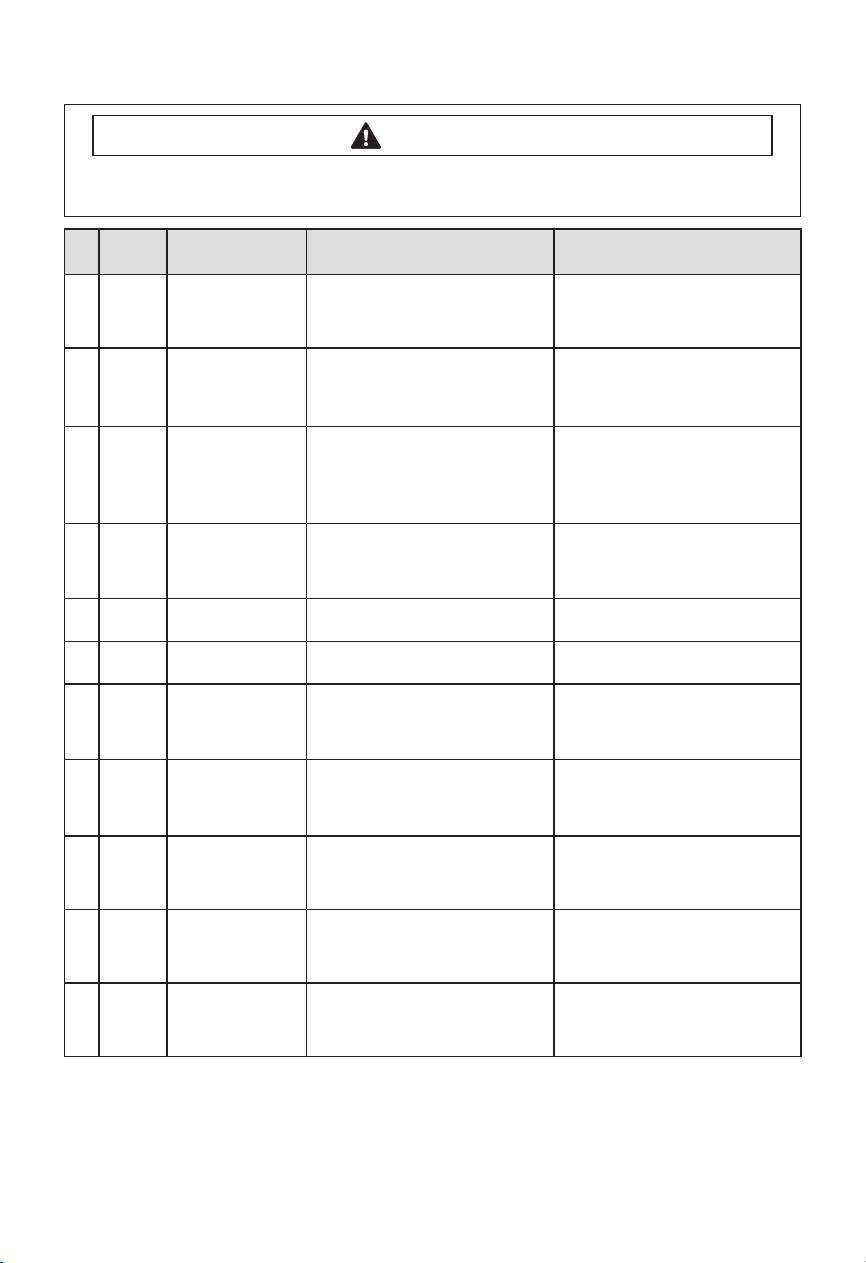

error

NO

Diagnostic Code

code

Error Image

Description Corrective Action

11 ds 22

12 tE 29

13

3E 2E

14

Sr 34

15

Hr 36

16

nF1 5

17 2E -

18 7E -

19 suds -

Door is detected as open while it is

trying to lock the door.

Abnormal high/low temperature or

resistance (Thermal sensor or PBA

resistance).

MICOM is attempting to drive the motor

but is not getting any response signals

from the hall sensor. Visual check shows

motor is not running. (Locked, Defective

Hall Sensor or Overload)

System Relay (Main Relay) Failure.

(PCB does not notice the relay

operation when there should be.)

Heater Relay Failure (No Heater

Relay Check Signal)

The hot/cold water hose connection

is not correct.

Voltage for motor control bus is

over or under specified limit.

Silver Care Kit (PCB) Failure.

Suds is detected during the washing

session. (“SUdS” is not an error. If the

washer is in suds period, “SUdS” will

light up instead of remaining time.)

Go to “Quick Test Mode” and then

do Door Lock/Unlock Test

Go to “ Board Input Test” and check

Water Temperature. Check loose

or pinched wires. Replace PCB or

thermistor.

Evaluate wire harness for loose or

unhooked connections. Go to “

Quick Test Mode” and test Motor.

Replace PCB.

Replace PCB

Please connect the hot/cold water

hose connection correctly.

Replace PCB

Check PCB ,Main PCB & Wireharness

Guide a user to reduce amount of

detergent usage.

20 AE

SF1,

21

SF2,

SF3

-

-

Communication error between SUB

PBA and MAIN PBA

System Error Replace PCB

Check Main PBA, SUB PBA & Wireharness. Replace PCB

ALIGNMENT AND ADJUSTMENTS

4

To avoid risk of electrical shock, personal injury or death; disconnect power to washer

before servicing, unless testing requires power.

WARNING

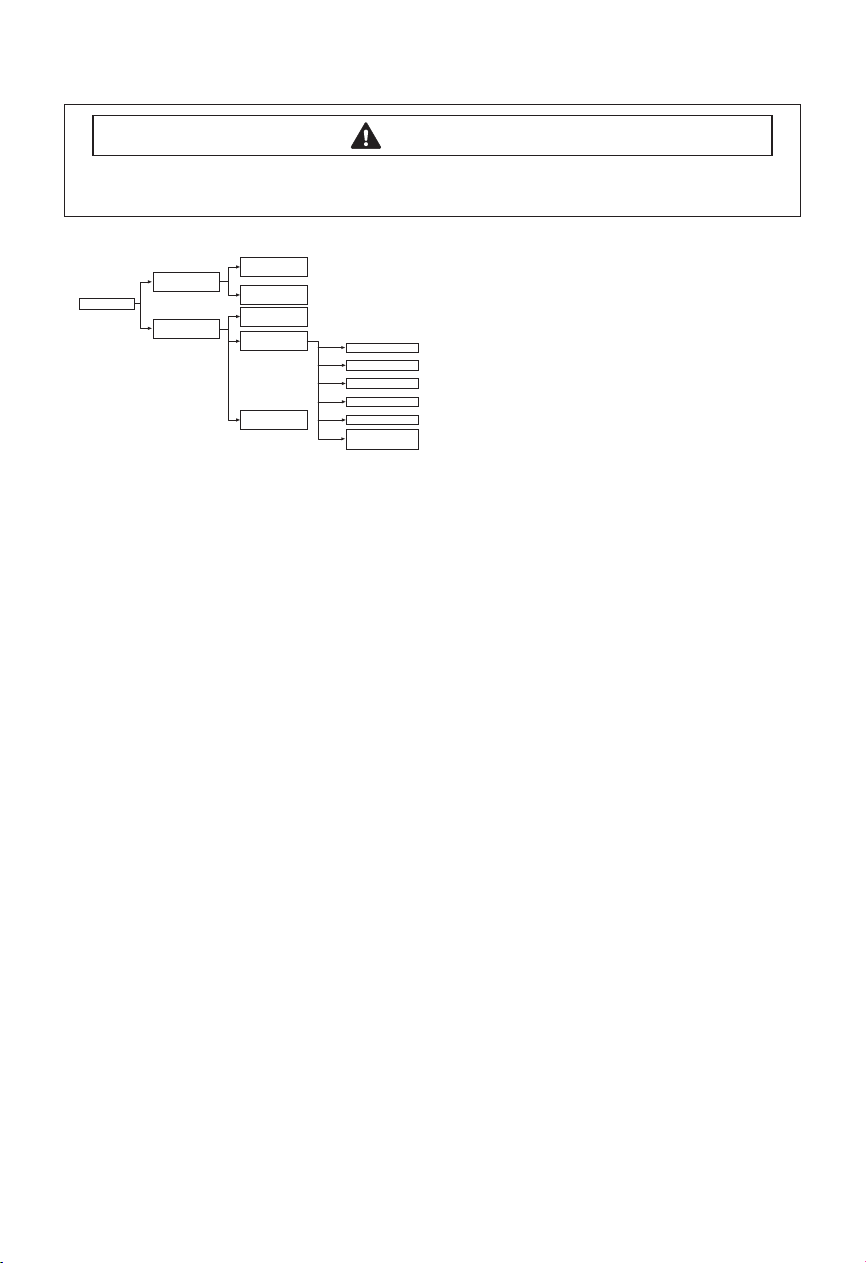

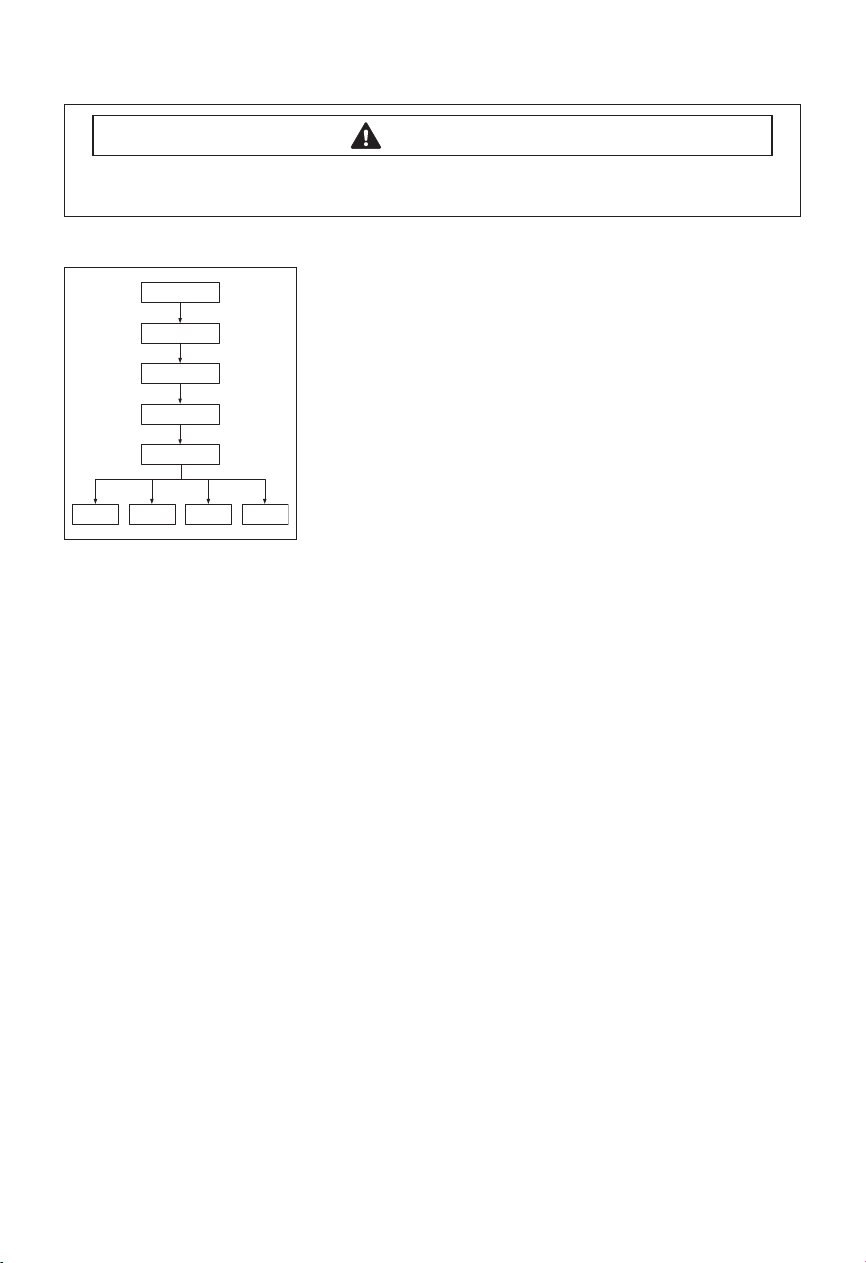

Special Test Mode

Power Off State

Quick Test Mode

EEPROM Clear

Mode

Continuous Cycle

Mode

Service Mode

Demo Mode

Quick Spin Test Mode

Cycle Count Check Mode

S/W Version Check Mode

Fast Time Down Test Mode

Board Input Test Mode

Diagnostic Code

CheckMode

Power On State

(Normal User Mode)

TEST MODE

Test Mode:

Each Test Mode for the Squall is as follows in the

coming pages. The test modes indicated by the

red arrows are modes unable to get an access

once the washing cycle has started due to safety

resons.

Quick Test Mode

Definition of Quick Test Mode:

- Check operation of all LED’s (Verify faulty LED).

- Check model and software version.

- Check different operating modes (e.g. water valve, motor, door, drain pump, etc.).

How to Enter:

- Plug in the unit.

- Press Soil Level Key + Signal Key and Power Key at the same Time.

Important. Once test mode is performed, all data including the diagnostic code saved in the

EEPROM will be erased.

ALIGNMENT AND ADJUSTMENTS

5

To avoid risk of electrical shock, personal injury or death; disconnect power to washer

before servicing, unless testing requires power.

WARNING

Quick Test Mode

All LEDs On for 1 sec

(include 7-Segment)

S/W version display

(7-Segment)

Turn the Jog-Dial

(S/W Version Disappeared)

All Devices Test using keys

Temp Key Soil Key Signal KeySpin Key

Quick Test Mode:

1. All LED’s light up and it sends out Beep Sound when it

enters into the Quick Test Mode. (Including 7-Segment)

2. Displays software version for a sec and Clear EEprom. (Ex. If

S/W Version is 49, 7-Segment will display E149)

3. When the version is displayed, turn the Jog-Dial so that

the version disappears. Press the following keys to test the

various components.

- Temp Key : Water Valve Test

- Spin Key : Door Lock/Unlock Test

- Soil Key : Water/Steam Heater Test(Steam Models)

Water Test(Non-Steam Models)

- Signal Key : Drain Pump Test

ALIGNMENT AND ADJUSTMENTS

6

To avoid risk of electrical shock, personal injury or death; disconnect power to washer

before servicing, unless testing requires power.

WARNING

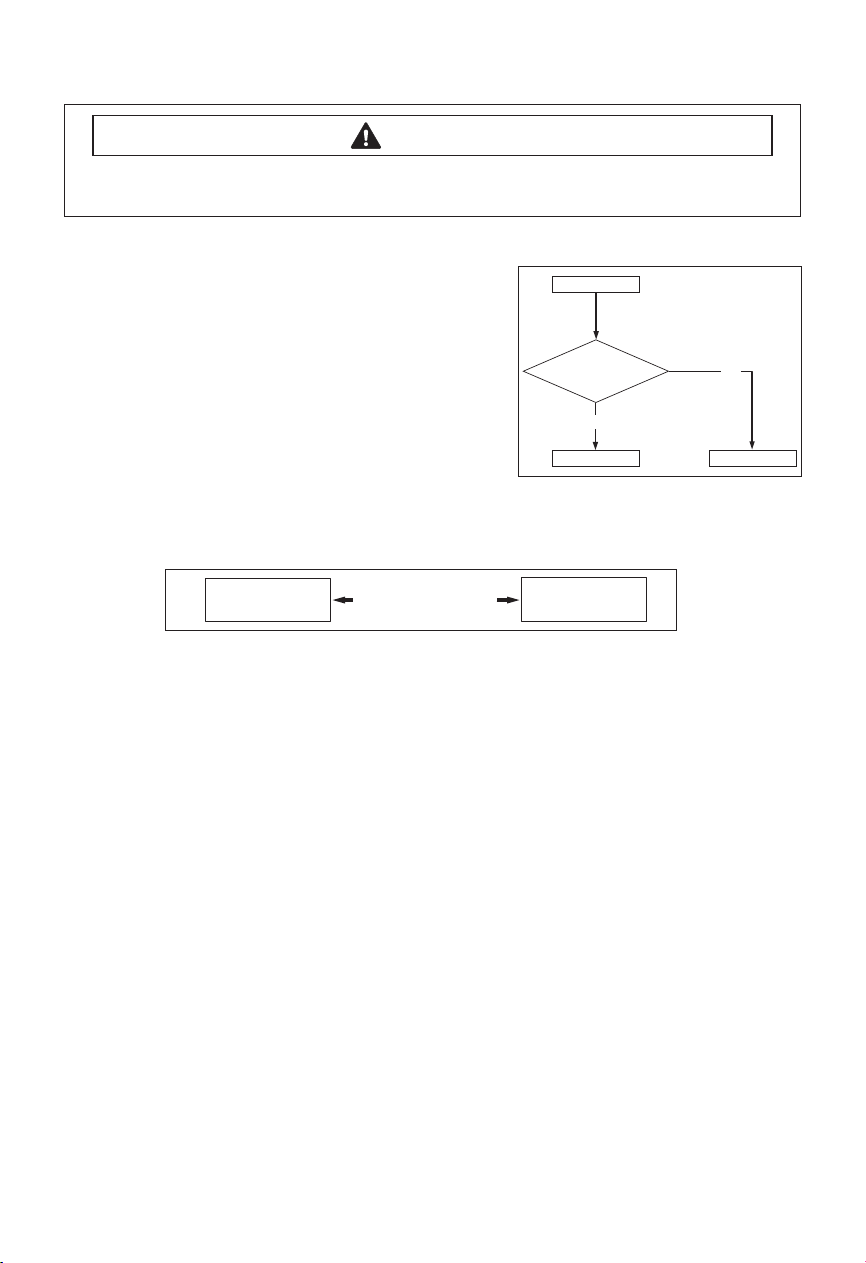

EEPROM Clear Mode

EEPROM check ?

Display "FAIL"Display "Good"

NO

YES

Pre Wash + Pure Cycle

3 sec

Power On State

(Normal User Mode)

Continuous Run Mode

EEPROM Clear Check

Definition of EEPROM Clear Mode:

- EEPROM initialization.

- All course/option settings are to be reset to default values

after EEPROM initialization.

- When Service arises and it needs PCB replacement,

EEPROM should be reset.

How to Enter:

- The unit needs to be on.

-

Press Delay Start Key, Signal Key, and Power Key at the same time.

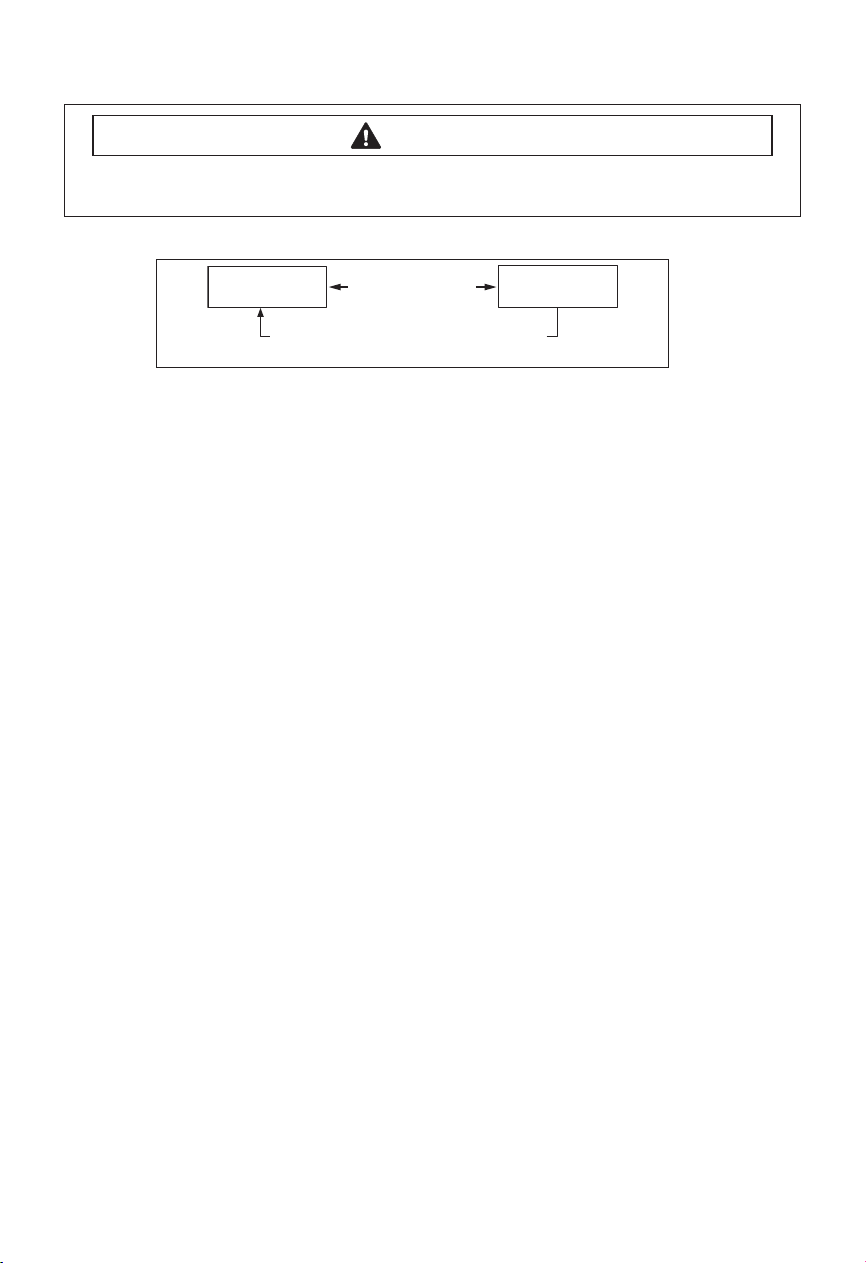

Continuous Run Mode

Definition of Continuous Run Mode:

- Will continuously repeat the current cycle until the Continuous Run Mode is cancelled.

How to Enter:

- Press Pre Wash Key and Pure Cycle Key together for 3 sec.

Continuous Run Mode:

1. Press

Pre Wash + Pure Cycle 3 sec

2.

Once in Continuous Run Mode, The seven segments will no longer display “0000” and will alternate

between displaying the number of cycles of the completed course and the remaining time of the course.

3. The Continuous Run Mode will repeat the previous cycle until continuous run mode is cancelled.

4.

During Continuous Run Mode, press Pre Wash + Pure Cycle 3 seconds to return to normal user

mode. The seven segments will no longer display the number of cycles and will display the

maintenance time only.

5. If you exit Service Mode after entering it from Continuous Mode, the washing machine returns

to Continuous Mode.

6. If power is lost in Continuous Run Mode (that is, when the power plug is disconnected or the

Power key is pressed turning the washing machine off), the mode is released when the washing

machine is turned on again.

during Power On State (Normal User Mode) .

ALIGNMENT AND ADJUSTMENTS

7

To avoid risk of electrical shock, personal injury or death; disconnect power to washer

before servicing, unless testing requires power.

WARNING

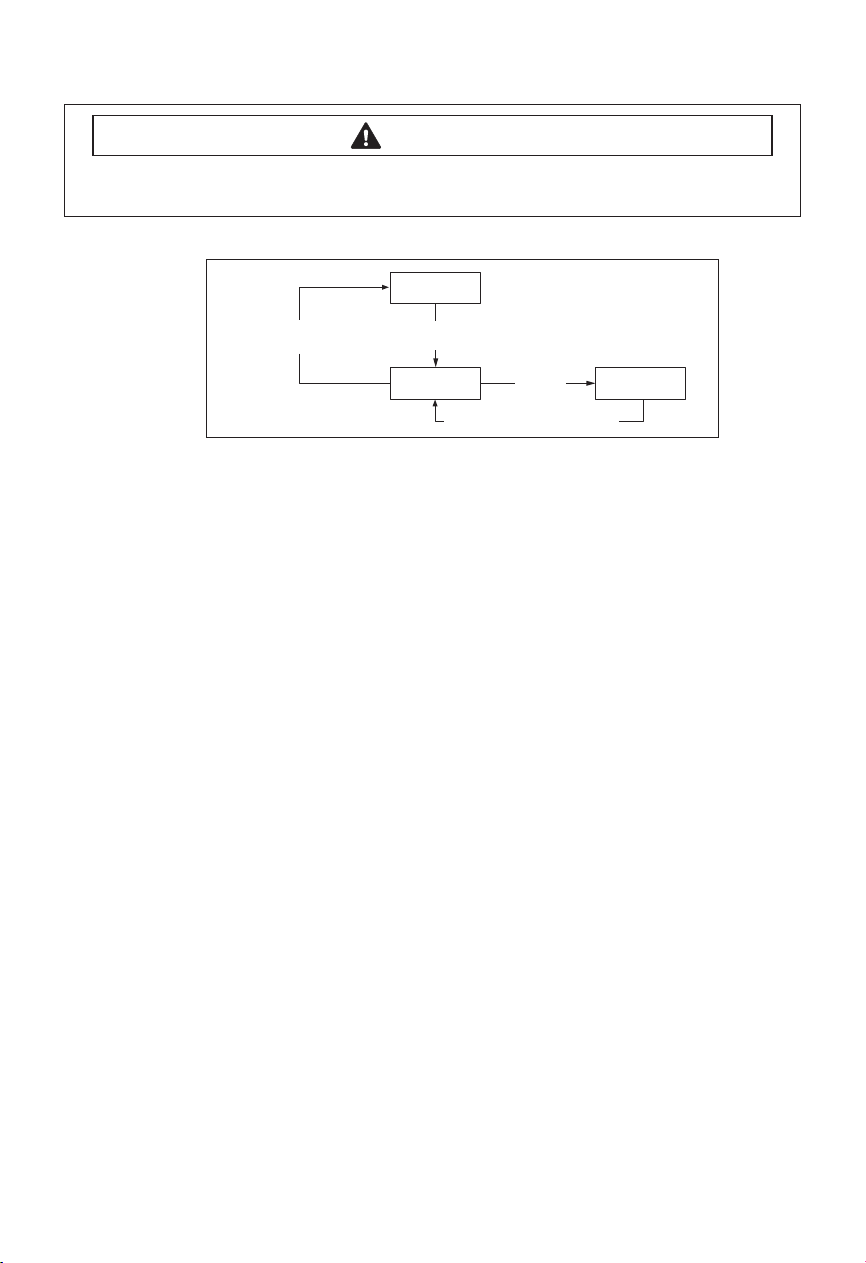

Signal + Delay Start

3 sec

Service Mode is canceled if no key is pressed for 5 minutes

before the washer operation begins. However, this is not true

when the washer operation has already started.

Power On State

(Normal User Mode)

Service Mode

Service Mode

Definition of Service Mode:

- Service Mode enables service technicians to verify the operation of the washing machine and

do troubleshooting.

- Service Mode can be entered during all washing cycle without interrupting the cycle except

some of test modes.

- Various tests can be done with Service Mode. So, troubleshooting can be done based on the

resulting diagnostic codes.

How to Enter:

- To enter the Service Mode, press the Signal and Delay Start Keys for 3 seconds or until the unit

sends out beeping sounds.

Service Mode:

1. The washer must be on to go into the Service Mode.

2. The motor speed will be displayed when started (It displays 0 when the motor does not spin).

3. The present state of the machine will not be changed.

(i.e., the current cycle in progress will not be interrupted and only the display will change)

4. To exit Service Mode, press Signal and Delay Start Keys for 3 second again, or Power Key.If no key

is operated during Service Mode for 5 minutes, the machine will return to normal user mode.

ALIGNMENT AND ADJUSTMENTS

8

To avoid risk of electrical shock, personal injury or death; disconnect power to washer

before servicing, unless testing requires power.

WARNING

Dealy Start + Pre Wash for 3sec or after 10 minutes

Dealy Start + Pre Wash

3 sec

While a cycle is not running

Dealy Start + Pre Wash

While it is not in Hold Speed Mode

Service Mode

Start/Pause

Quick Spin Test Mode Hold Speed Mode

Quick Spin Test Mode

Definition of Quick Spin Test Mode:

- Quick Spin Test Mode is to do Spin Check. (High RPM)

How to Enter:

- During Service Mode, press the Dealy Start and Pre Wash Keys for 3 seconds to enter Quick Spin

Test Mode. (Same for all Frontier 2 models.)

- Cannot enter once the washing cycle has started.

Quick Spin Test Mode:

As it enters into the Quick Spin Test Mode, it starts spinning and reaches to its maximum RPM.

Once the Spin speed reaches the maximum RPM, the speed drops immediately.

To hold Quick Spin Test Mode (entering Hold Speed Mode), press the Start/Pause button. If the

Start/Pause button is pressed during Quick Spin Test Mode, it will stop accelerating and hold its

spinning speed for 10 minutes before going back to Quick Spin Test Mode.

Also, to cancel the hold and allow Quick Spin Test Mode to continue, press the Dealy Start and Pre

Wash Keys together for 3 seconds.

If you hold down the Dealy Start and Pre Wash keys for three (3) seconds when the washing

machine is not in Hold Speed Mode, Quick Spin Mode is exited and Service Mode is restored.

Loading...

Loading...