Samsung SH09AWH, SH09AWHX, SH09ZWH, SH09ZWHX, AQ09WHWE Service manual

...

ROOM AIR CONDITIONER

INDOOR UNIT

SH09AWH

SH09ZWH

AQ09WHWE

KFR-25G/SWA

SH12AWH

SH12ZWH

AQ12WHWE

KFR-35G/SWA

SERVICE

OUTDOOR UNIT

SH09AWHX

SH09ZWHX

UQ09WHWE

KFR-25W/SWA

SH12AWHX

SH12ZWHX

UQ12WHWE

KFR-35W/SWA

Manual

CONTENTSAIR CONDITIONER

1. Product Specifications

2. Disassembly and Reassembly

3. Refrigerating Cycle Diagram

4. Set Up the Model Option

5. T roubleshooting

6. Exploded Views and Parts List

7. Block Diagram

8. Wiring Diagram

9. Schematic Diagram

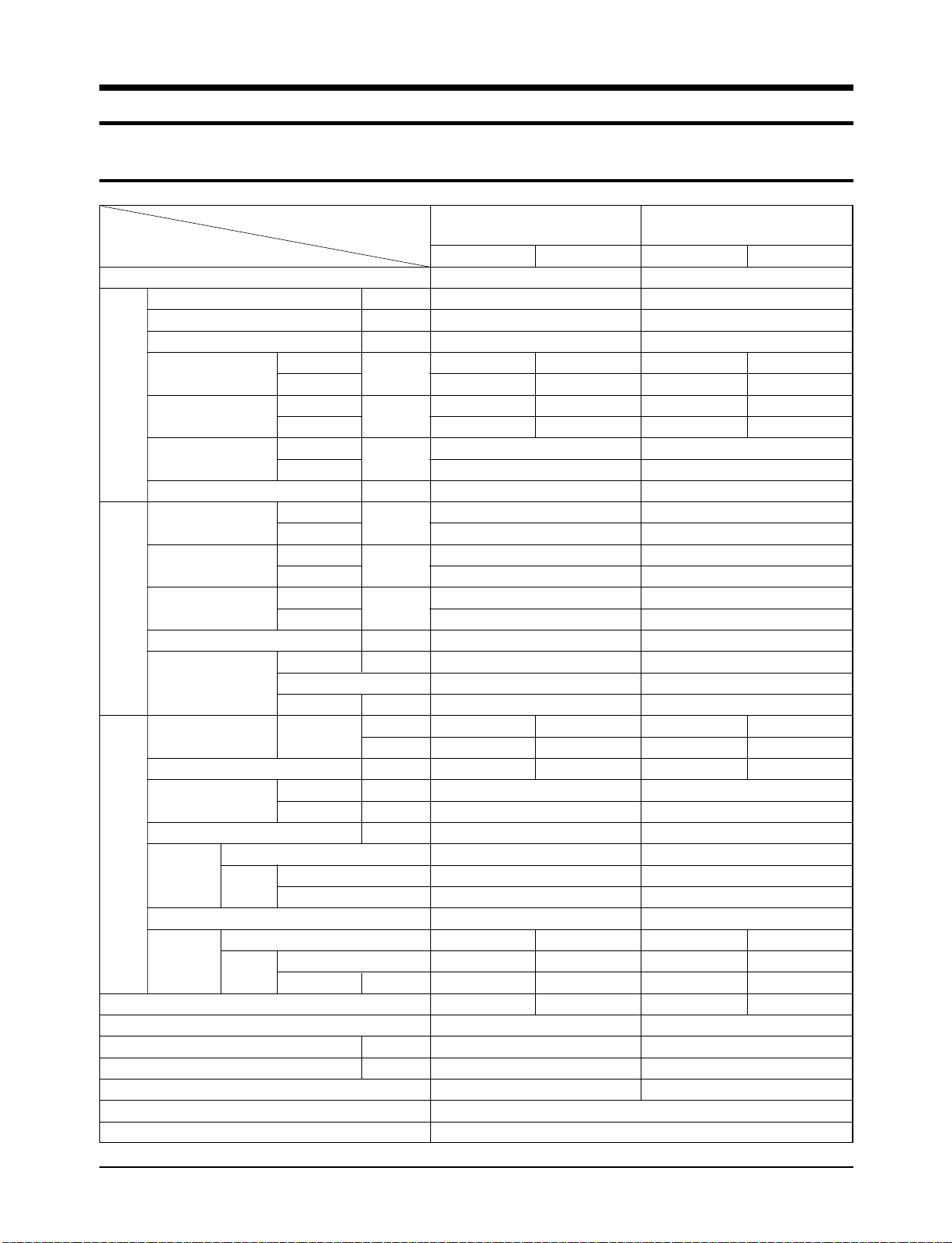

1. Product Specifications

1-1 Table

Item

Type

Cooling kW

Heating kW

Dehumidifying |/h

Air Volume

Performance

Noise

Energy Efficiency Ratio

Power V-Hz

Power Consumption

Operating Current

Power

Power Factor

Starting Current A

Power Cord Number of Core Wire

Outer Dimension

Weight(Net) kg

Refrigerant Pipe

Drain Hose D x L(mm)

Size

Compressor Motor Type

Oil Type

Blower Motor Type

Heat Exchanger

Refrigerant Control Unit

Freezer Oil Capacity cc

Refrigerant to Change(R410A) g

Protection Device(OLP)

Cooling Test Condition

Maximum Operation Condition

Type

Type

Cooling

Heating

Cooling

Heating

Cooling

Heating

Cooling

Heating

Cooling

Heating

Cooling

Heating

Length m

Capacity A

Width x Height

x Depth

Liquid mm x L(m)

GAS mm x L(m)

Rated Output

Rated Output W

Model

m3/min

dB

W/W

W

A

%

mm

inch

SH09AWH SH12AWH

Indoor unit Outdoor unit

Wall-mounted

2.75

2.90

1.0

7.3 25

8.0 25

38 / 36 / 34 51 / 51

38 / 36 / 34 51 / 51

2.81

3.22

1-220 / 240-50

980

900

4.5

4.5

96.5

95.5

21.0

-

-

250V-10A

825x 285x 189 720x548 x265

32.5x 11.2 x 7.44 28.4x21.6 x10.4

8.2 31.3

ø6.35 x 7.5

ø9.52 x 7.5

ø18 x 550

Rotary

Induction Motor(PSC)

900

DAPHNE FV68S(PVE)

Cross-flow Propeller

steel steel

15 50

2ROW 14STEP 1ROW 24STEP

CAPILLARY TUBE

350

650

MRA99134-9201

INDOOR UNIT : DB27˚C WB19˚C OUTDOOR UNIT : DB35˚C WB24˚C

INDOOR UNIT : DB32˚C WB23˚C OUTDOOR UNIT : DB43˚C WB26˚C

Indoor unit Outdoor unit

Wall-mounted

3.5

4.2

1.4

8.3 25

9.0 25

41 / 39 / 37 53 / 53

41 / 39 / 37 53 / 53

2.82

3.23

1-220 / 240-50

1,240

1,300

5.7

5.7

98.3

98.0

30.0

-

-

250V-10A

825x 285x 189 720x548 x265

32.5x 11.2 x 7.44 28.4 x 21.6x 10.4

8.4 33.8

ø6.35 x 7.5

ø9.52 x 7.5

ø18 x 550

Rotary

Induction Motor(PSC)

1,075

DAPHNE FV68S(PVE)

Cross-flow Propeller

steel steel

15 50

2ROW 14STEP 2ROW 24STEP

CAPILLARY TUBE

520

1,020

MRA99908-9201

1Samsung Electronics

Table(cont.)

Item

Type

Cooling kW

Heating kW

Dehumidifying |/h

Air Volume

Perfor-

mance

Noise

Energy Efficiency Ratio

Power V-Hz

Power Consumption

Operating Current

Power

Power Factor

Starting Current A

Power Cord Number of Core Wire

Outer Dimension

Weight(Net) kg

Refrigerant Pipe

Drain Hose D x L(mm)

Size

Compressor Motor Type

Oil Type

Blower Motor Type

Heat Exchanger

Refrigerant Control Unit

Freezer Oil Capacity cc

Refrigerant to Change(R22) g

Protection Device(OLP)

Cooling Test Condition

Maximum Operation Condition

Type

Type

Cooling

Heating

Cooling

Heating

Cooling

Heating

Cooling

Heating

Cooling

Heating

Cooling

Heating

Length m

Capacity A

Width x Height

x Depth

Liquid mm x L(m)

GAS mm x L(m)

Rated Output

Rated Output W

Model

m3/min

dB

W/W

W

A

%

mm

inch

SH12ZWHSH09ZWH

Indoor unit Outdoor unit

Wall-mounted

2.70

2.90

1.0

7.3 25

8.0 25

38 / 36 / 34 51 / 51

38 / 36 / 34 51 / 51

2.70

3.22

1-220 / 240-50

1,000

900

4.5

4.0

98.2

99.1

21.0

-

-

250V-10A

825x 285x 189 720x548 x265

32.5x 11.2 x 7.44 28.4 x 21.6x 10.4

8.2 31.3

ø6.35 x 5.0

ø9.52 x 5.0

ø18 x 550

Rotary

Induction Motor(PSC)

1,005

SUNISO-4GSD

Cross-flow Propeller

steel steel

15 50

2ROW 14STEP 1ROW 24STEP

CAPILLARY TUBE

360

580

RAC12110-9622

INDOOR UNIT : DB27˚C WB19˚C OUTDOOR UNIT : DB35˚C WB24˚C

INDOOR UNIT : DB32˚C WB23˚C OUTDOOR UNIT : DB43˚C WB26˚C

Indoor unit Outdoor unit

Wall-mounted

3.5

4.0

1.4

8.3 25

9.0 25

41 / 39 / 37 53 / 53

41 / 39 / 37 53 / 53

2.99

3.48

1-220 / 240-50

1,170

1,150

5.2

5.2

96.9

96.2

30.0

-

-

250V-10A

825x 285x 189 720x 548x 265

32.5x 11.2 x 7.44 28.4 x21.6 x 10.4

8.4 33.8

ø6.35 x 5.0

ø12.70 x 5.0

ø18 x 550

Rotary

Induction Motor(PSC)

1,206

SUNISO-4GSD

Cross-flow Propeller

steel steel

15 50

2ROW 14STEP 2ROW 24STEP

CAPILLARY TUBE

600

980

RAC12074-9622

Samsung Electronics2

Model

AQ12WHWEAQ09WHWE

Item

Type

Cooling kW

Heating kW

Dehumidifying |/h

Air Volume

Performance

Noise

Energy Efficiency Ratio

Power V-Hz

Power Consumption

Operating Current

Power

Power Factor

Starting Current A

Power Cord Number of Core Wire

Outer Dimension

Weight(Net) kg

Refrigerant Pipe

Drain Hose D x L(mm)

Size

Compressor Motor Type

Oil Type

Blower Motor Type

Heat Exchanger

Refrigerant Control Unit

Freezer Oil Capacity cc

Refrigerant to Change(R22) g

Protection Device(OLP)

Cooling Test Condition

Maximum Operation Condition

Type

Type

Cooling

Heating

Cooling

Heating

Cooling

Heating

Cooling

Heating

Cooling

Heating

Cooling

Heating

Length m

Capacity A

Width x Height

x Depth

Liquid mm x L(m)

GAS mm x L(m)

Rated Output

Rated Output W

m3/min

dB

W/W

W

A

%

mm

inch

Indoor unit Outdoor unit

Wall-mounted

2.70

2.90

1.0

7.3 25

8.0 25

38 / 36 / 34 51 / 51

38 / 36 / 34 51 / 51

2.70

3.22

1-220 / 240-50

1,000

900

4.5

4.0

98.2

99.1

21.0

-

-

250V-10A

825x 285x 189 720x548 x265

32.5x 11.2 x 7.44 28.4 x 21.6x 10.4

8.2 33.0

ø6.35 x 5.0

ø9.52 x 5.0

ø18 x 550

Rotary

Induction Motor(PSC)

1,005

SUNISO-4GSD

Cross-flow Propeller

steel steel

15 50

2ROW 14STEP 1ROW 24STEP

CAPILLARY TUBE

360

580

RAC12110-9622

INDOOR UNIT : DB27˚C WB19˚C OUTDOOR UNIT : DB35˚C WB24˚C

INDOOR UNIT : DB32˚C WB23˚C OUTDOOR UNIT : DB43˚C WB26˚C

Indoor unit Outdoor unit

Wall-mounted

3.5

4.0

1.4

8.3 25

9.0 25

41 / 39 / 37 53 / 53

41 / 39 / 37 53 / 53

2.99

3.48

1-220 / 240-50

1,170

1,150

5.2

5.2

96.9

96.2

30.0

-

-

250V-10A

825x 285x 189 720x 548x 265

32.5x 11.2 x 7.44 28.4 x21.6 x 10.4

8.4 33.8

ø6.35 x 5.0

ø12.70 x 5.0

ø18 x 550

Rotary

Induction Motor(PSC)

1,206

SUNISO-4GSD

Cross-flow Propeller

steel steel

15 50

2ROW 14STEP 2ROW 24STEP

CAPILLARY TUBE

600

980

RAC12074-9622

3Samsung Electronics

Table(cont.)

Item

Type

Cooling kW

Heating kW

Dehumidifying |/h

Air Volume

Perfor-

mance

Noise

Energy Efficiency Ratio

Power V-Hz

Power Consumption

Operating Current

Power

Power Factor

Starting Current A

Power Cord Number of Core Wire

Outer Dimension

Weight(Net) kg

Refrigerant Pipe

Drain Hose D x L(mm)

Size

Compressor Motor Type

Oil Type

Blower Motor Type

Heat Exchanger

Refrigerant Control Unit

Freezer Oil Capacity cc

Refrigerant to Change(R22) g

Protection Device(OLP)

Cooling Test Condition

Maximum Operation Condition

Type

Type

Cooling

Heating

Cooling

Heating

Cooling

Heating

Cooling

Heating

Cooling

Heating

Cooling

Heating

Length m

Capacity A

Width x Height

x Depth

Liquid mm x L(m)

GAS mm x L(m)

Rated Output

Rated Output W

Model

m3/min

dB

W/W

W

A

%

mm

inch

KFR-25G/SWA KFR-35G/SWA

Indoor unit Outdoor unit

Wall-mounted

2.65

2.90

1.0

7.3 25

8.0 25

38 / 36 / 34 51 / 51

38 / 36 / 34 51 / 51

2.65

3.22

1-220-50

1,000

900

4.6

4.1

97

97

21.0

-

-

250V-10A

825x 285x 189 720x548 x265

32.5x 11.2 x 7.44 28.4 x 21.6x 10.4

8.2 31.3

ø6.35 x 4.0

ø9.52 x 4.0

ø18 x 550

Rotary(SAMSUNG)

Induction Motor(PSC)

990

SUNISO-4GSD/NOC

Cross-flow Propeller

steel steel

15 50

2ROW 14STEP 1ROW 24STEP

CAPILLARY TUBE

360

600

RAC12054-9622

INDOOR UNIT : DB27˚C WB19˚C OUTDOOR UNIT : DB35˚C WB24˚C

INDOOR UNIT : DB32˚C WB27.5˚C OUTDOOR UNIT : DB43˚C WB33˚C

Indoor unit Outdoor unit

Wall-mounted

3.5

4.0

1.4

8.3 25

9.0 25

41 / 39 / 37 53 / 53

41 / 39 / 37 53 / 53

2.99

3.48

1-220-50

1,170

1,150

5.8

5.8

92

92

30.0

-

-

250V-16A

825x 285x 189 720x548 x265

32.5x 11.2 x 7.44 28.4 x 21.6x 10.4

8.4 33.8

ø6.35 x 4.0

ø12.70 x 4.0

ø18 x 550

Rotary(SAMSUNG)

Induction Motor(PSC)

1,210

SUNISO-4GSD/NOC

Cross-flow Propeller

steel steel

15 50

2ROW 14STEP 2ROW 24STEP

CAPILLARY TUBE

600

950

RAC12074-9622

Samsung Electronics4

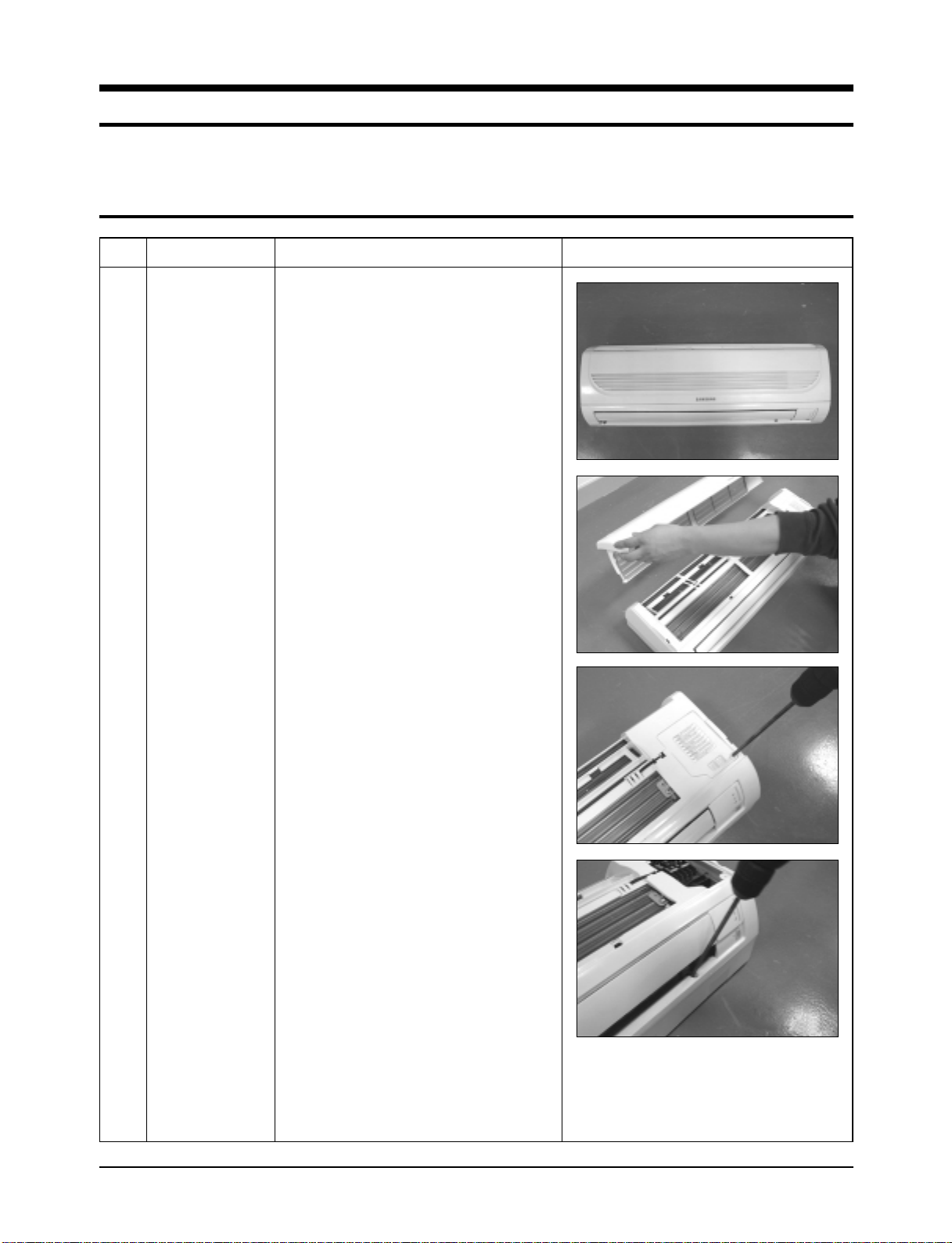

2. Disassembly and Reassembly

Stop operation of the air conditioner and remove the power cord before repairing the unit.

2-1 Indoor Unit

No Parts Procedure Remark

1 Front Grille

1) Stop the air conditioner operation and

block the main power.

2) Open the Front Grille by pulling right and

left sides of the hook.

3) Loosen 1 of the right screw and detach

the Terminal Cover.

4) Detach the thermistor from the Front

Grille.

5) Loosen 2 fixing screws of Front Grille.

5Samsung Electronics

Disassembly and Reassembly

No Parts Procedure Remark

6) Unlock 2 hooks to fix Panel Front and

Tray Drain.

7) Unlock 3 hooks to fix Panel Front and

Back-Body.

2

3

Control-In

(Main PCB)

Tray Drain

1) Take all the connector of PCB upper side

out. (Inclusion Power Cord)

2) Detach the outdoor unit connection wire

from the Terminal Block.

3) Loosen 4 fixing screws of Ass'y Control-In.

1) Pull Tray Drain out from the Back Body.

Samsung Electronics6

Disassembly and Reassembly

No Parts Procedure Remark

4

Heat Exchanger

1) Loosen 2 fixing earth screws of right side.

2) Detach the Connection Pipe.

3) Detach the Holder Pipe at the rear side.

4) Loosen the 3 fixing screws of right and left

side.

5) Lifting the Heat Exchanger up a little to

push the up side for separation from the

indoor unit.

5

Fan Motor

&

Cross Fan

1) Loosen the fixing screw and detach the

Motor Holder.

2) Detach the Fan Motor from the Fan.

3) Detach the Fan From the left Holder

Bearing.

7Samsung Electronics

2-2 Outdoor Unit

No Parts Procedure Remark

1 Common Work

1) Loosen each 3 fixing screws on both right

and left Cabinet-Side edge and a fixing

screw on the Cabinet-Front lower to detach

the Cabinet-Front.

2) Loosen 2 fixing screws of the

Ass'y-Control.

3) Loosen 6 fixing screws of the Cabinet-Side

RH.

4) Loosen 2 fixing screws of the Cabinet-Side

LF.

Samsung Electronics8

Disassembly and Reassembly

No Parts Procedure Remark

2

3

Fan & Motor

Heat Exchanger

1) Detach the Nut Flange.(Turn counterclockwise because the screw is right-handed)

2) Detach the Fan.

3) Loosen 4 fixing screws to detach

the Motor.

1) Loosen 2 fixing screws on both sides.

2) Disassemble the pipe in both inlet and

outlet with welding torch.

3) Detach the Heat Exchanger.

4

Compressor

1) Loosen the Terminal Cover nut to open the

Terminal Cover.

2) Disassemble the cloth sound felt.

3) Disassemble the pipe in both inlet and

outlet of the Compressor with welding

torch.

4) Disassemble the pipe in both inlet and

outlet of the Condenser with welding torch.

5) Loosen the 3 bolts at the bottom.

6) Detach the Compressor.

9Samsung Electronics

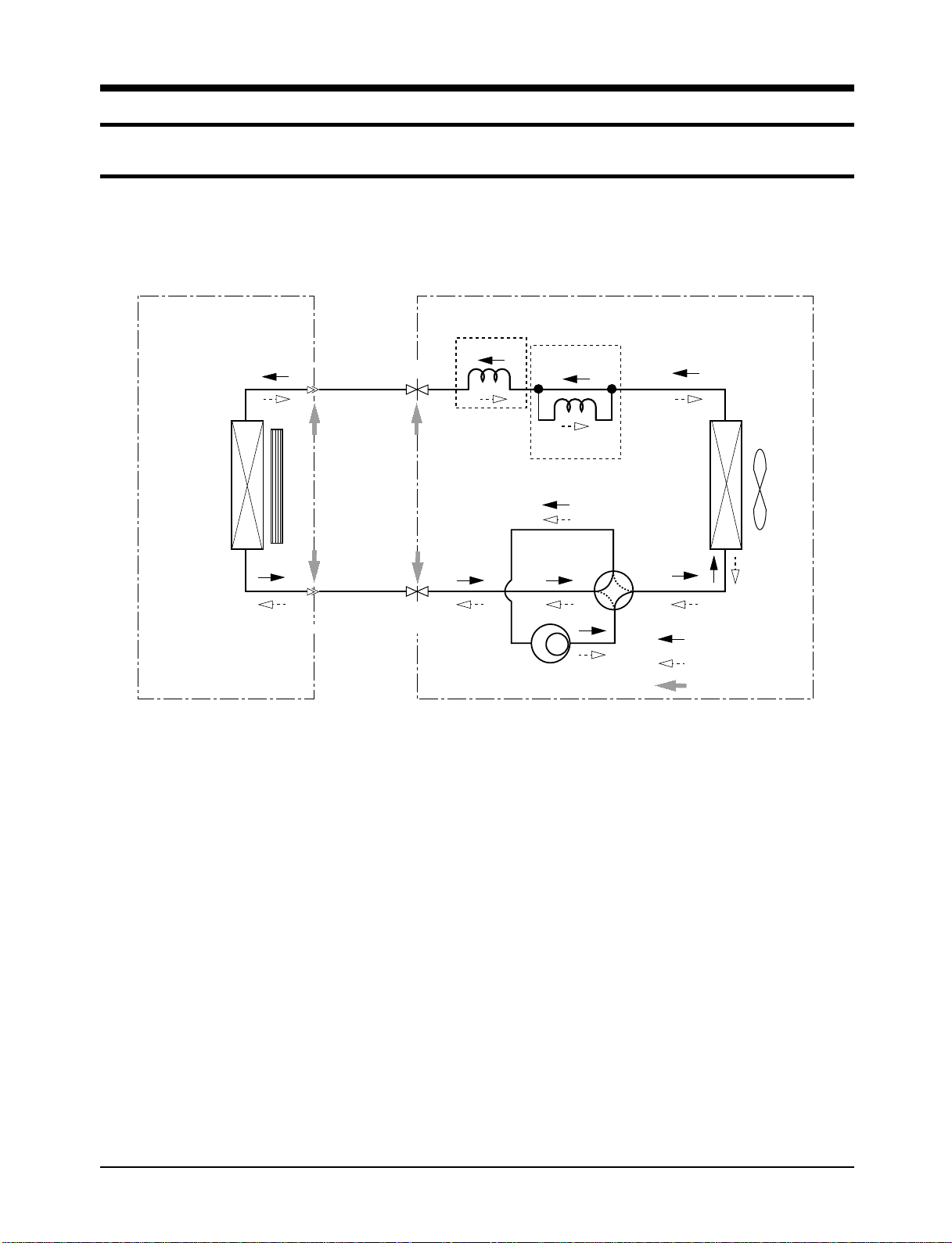

Cooling

Heating

Gas Leak Check Polnt

3. Refrigerating Cycle Diagram

3-1 Refrigerating Cycle Diagram

Indoor Unit

Heat

Exchanger

(Evaporator)

Outdoor Unit

T

1

Liquid side

Cross fan

T

2

Gas side

2-Way valve

3-Way valve

Capillary tube

✳Note

Check valve

Capillary tube

Heat

Exchanger

(Evaporator)

Propeller fan

4-Way valve

Compressor

Samsung Electronics10

DB15.0

DB20.0

DB25.0

Heating Capacity

Heating Capacity Distribution

6.00

5.00

4.00

3.00

2.00

1.00

0.00

1.0/0.0 7.0/6.0 20.0/15.0

Indoor Temp.( C)

Outdoor Temp.(DB/WB C)

3-2 Refrigerating Cycle Characteristic

3-2-1 Capacity Distributions

Capacity Distributions according to indoor and outdoor temperature variation.

- Indoor Temp. Variation : 15.0˚C ~ 25.0˚C

- Outdoor Temp. Variation: 1.0˚C ~ 20.0˚C

■ 9,000BTU

Heating Capacity Distribution

■ 12,000BTU

4.00

3.00

2.00

Heating Capacity(kW)

1.00

1.0/0.0 7.0/6.0 20.0/15.0

Outdoor Temp.(DB/WB C)

Indoor Temp.( C)

DB15.0

DB20.0

DB25.0

11Samsung Electronics

Refrigerating Cycle Diagram

Power consumption(W)

Power consumption Distribution(Heating mode)

1,600

1,500

1,400

1,300

1,200

1,100

1,000

25 35 45

DB25.0

DB20.0

DB15.0

Indoor Temp.( C)

Outdoor Temp.(DB/WB C)

3-2-2 Power Consumption Distributions

Power consumption distributions according to indoor and outdoor temperature variation.

- Indoor Temp. Variation : 15.0˚C ~ 25.0˚C

- Outdoor Temp. Variation: 1.0˚C ~ 20.0˚C

■ 9,000BTU

Power consumption Distribution(Heating mode)

■ 12,000BTU

1,100

1,000

900

800

Power consumption(W)

700

1.0/0.0 7.0/6.0 20.0/15.0

Indoor Temp.( C)

DB25.0

DB20.0

DB15.0

Outdoor Temp.(DB/WB C)

Samsung Electronics12

Refrigerating Cycle Diagram

3-2-3 Capacity and Power Consumption Distributions

Capacity and power consumption distributions according to the length of connecting pipe between indoor unit and

outdoor unit.

■ 9,000BTU

4.00

3.00

2.00

Heating Capacity(kW)

1.00

■ 12,000BTU

Heating Capacity

7.5 15.0

Length of Connecting Pipe(m)

Power consumption(Heating)

1,100

1,000

900

800

Power consumption(W)

700

7.5 15.0

Length of Connecting Pipe(m)

Heating Capacity

4.20

4.10

4.00

3.90

Heating Capacity(kW)

3.80

7.5 15.0

Length of Connecting Pipe(m)

Power consumption(Heating)

1,350

1,300

1,250

1,200

Power consumption(W)

1,150

7.5 15.0

Length of Connecting Pipe(m)

13Samsung Electronics

Loading...

Loading...