Samsung AQ07A1VE, AQ09B1VE, SH12YAB, UQ09B2VE, AQ12A1VE Service Manual

...

SERVICE

Manual

CONTENTSAIR CONDITIONER

1. Precautions

2. Product Specifications

3. Operating Instructions and

Installation

4. Disassembly and Reassembly

5. Troubleshooting

6. Exploded Views and Parts List

7. Block Diagrams

8. PCB Diagrams

9. Wiring Diagrams

10. Schematic Diagrams

ROOM AIR CONDITIONER

INDOOR UNIT OUTDOOR UNIT

AQ07A1VE

AQ07A2VE

AQ07B1VE

AQ07B2VE

AQ09A1VE

AQ09A2VE

AQ09B1VE

AQ09B2VE

AQ12A1VE

AQ12A2VE

AQ12B1VE

AQ12B2VE

SH09ZV

SH12ZV

SH09YAO

SH12YAO

SH07YAB

SH09YAB

SH12YAB

UQ07A1VE

UQ07A2VE

UQ07B1VE

UQ07B2VE

UQ09A1VE

UQ09A2VE

UQ09B1VE

UQ09B2VE

UQ12A1VE

UQ12A2VE

UQ12B1VE

UQ12B2VE

XSH09ZV

XSH12ZV

SH09YAOX

SH12YAOX

SH07YABX

SH09YABX

SH12YABX

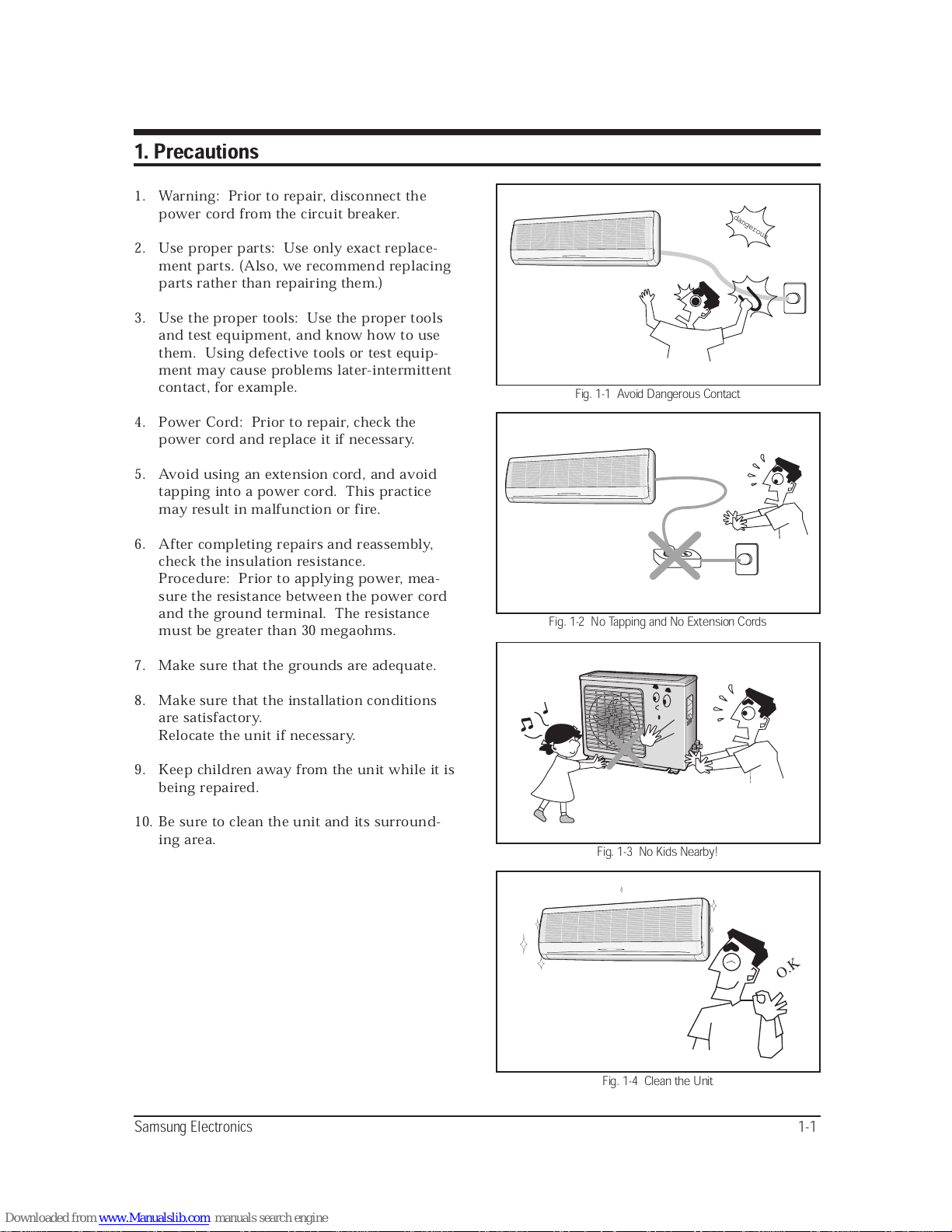

1. Precautions

Samsung Electronics 1-1

1. Warning: Prior to repair, disconnect the

power cord from the circuit breaker.

2. Use proper parts: Use only exact replace-

ment parts. (Also, we recommend replacing

parts rather than repairing them.)

3. Use the proper tools: Use the proper tools

and test equipment, and know how to use

them. Using defective tools or test equip-

ment may cause problems later-intermittent

contact, for example.

4. Power Cord: Prior to repair, check the

power cord and replace it if necessary.

5. Avoid using an extension cord, and avoid

tapping into a power cord. This practice

may result in malfunction or fire.

6. After completing repairs and reassembly,

check the insulation resistance.

Procedure: Prior to applying power, mea-

sure the resistance between the power cord

and the ground terminal. The resistance

must be greater than 30 megaohms.

7. Make sure that the grounds are adequate.

8. Make sure that the installation conditions

are satisfactory.

Relocate the unit if necessary.

9. Keep children away from the unit while it is

being repaired.

10. Be sure to clean the unit and its surround-

ing area.

dangerous

Fig. 1-1 Avoid Dangerous Contact

Fig. 1-2 No Tapping and No Extension Cords

Fig. 1-3 No Kids Nearby!

O.K

Fig. 1-4 Clean the Unit

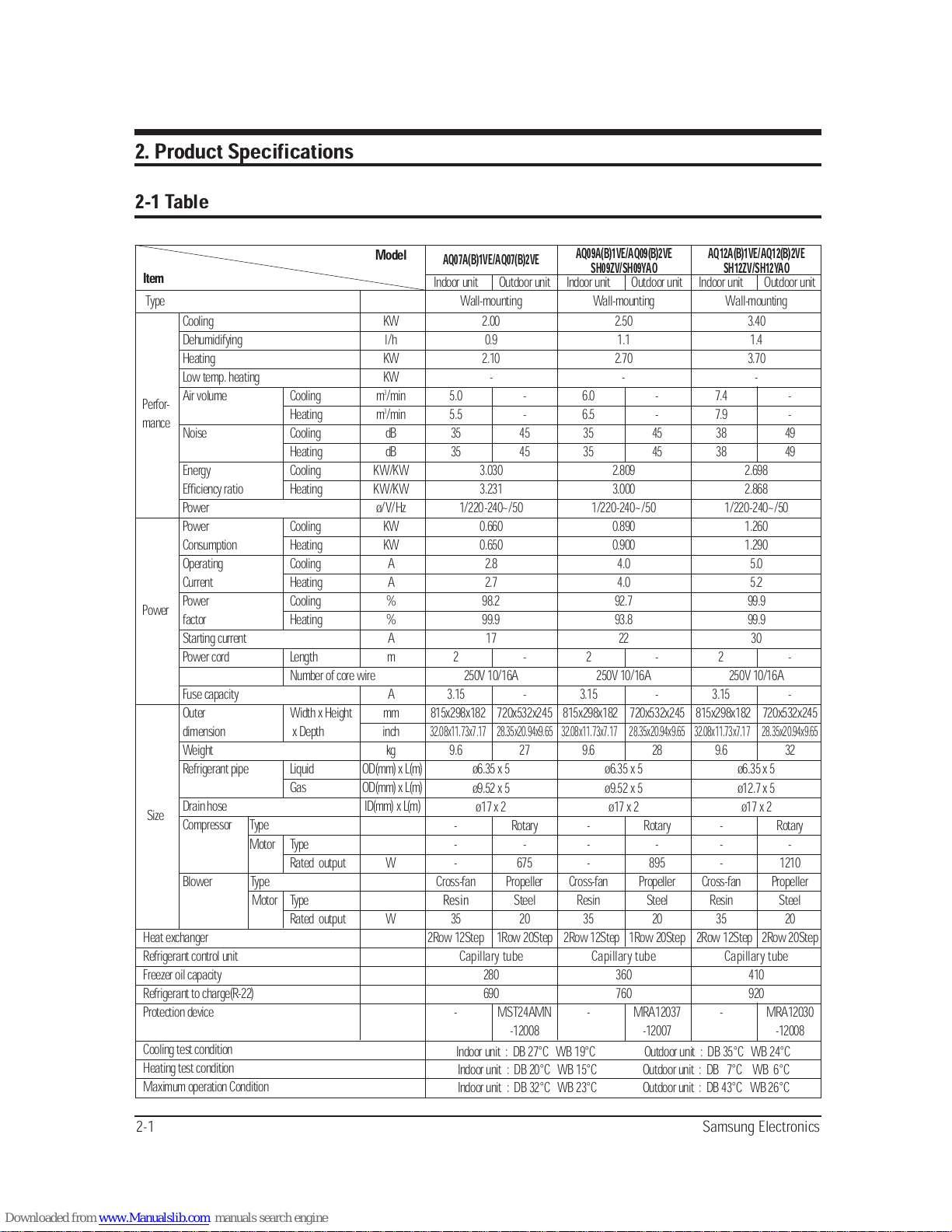

2. Product Specifications

2-1 Table

2-1 Samsung Electronics

Model

Item

Type

Cooling KW

Dehumidifying l/h

Heating KW

Low temp. heating KW

Air volume Cooling m

3

/min

Heating m3/min

Noise Cooling dB

Heating dB

Energy Cooling KW/KW

Efficiency ratio Heating KW/KW

Power ø/V/Hz

Power Cooling KW

Consumption Heating KW

Operating Cooling A

Current Heating A

Power Cooling %

factor Heating %

Starting current A

Power cord Length m

Number of core wire

Fuse capacity A

Outer Width x Height mm

dimension x Depth inch

Weight kg

Refrigerant pipe Liquid OD(mm) x L(m)

Gas OD(mm) x L(m)

Drain hose ID(mm) x L(m)

Compressor Type

Motor Type

Rated output W

Blower Type

Motor Type

Rated output W

Heat exchanger

Refrigerant control unit

Freezer oil capacity

Refrigerant to charge(R-22)

Protection device

Cooling test condition

Heating test condition

Maximum operation Condition

Indoor unit Outdoor unit

Wall-mounting

2.00

0.9

2.10

-

5.0 -

5.5 -

35 45

35 45

3.030

3.231

1/220-240~/50

0.660

0.650

2.8

2.7

98.2

99.9

17

2 -

250V 10/16A

3.15 -

815x298x182 720x532x245

32.08x11.73x7.17 28.35x20.94x9.65

9.6 27

ø6.35 x 5

ø9.52 x 5

ø17 x 2

- Rotary

- -

- 675

Cross-fan Propeller

Resin

Resin Steel

35 20

2Row 12Step 1Row 20Step

Capillary tube

280

690

- MST24AMN

-12008

AQ07A(B)1VE/AQ07(B)2VE

Perfor-

mance

Power

Size

Indoor unit : DB 27°C WB 19°C Outdoor unit : DB 35°C WB 24°C

Indoor unit : DB 20°C WB 15°C Outdoor unit : DB 7°C WB 6°C

Indoor unit : DB 32°C WB 23°C Outdoor unit : DB 43°C WB 26°C

Indoor unit Outdoor unit

Wall-mounting

2.50

1.1

2.70

-

6.0 -

6.5 -

35 45

35 45

2.809

3.000

1/220-240~/50

0.890

0.900

4.0

4.0

92.7

93.8

22

2 -

250V 10/16A

3.15 -

815x298x182 720x532x245

32.08x11.73x7.17 28.35x20.94x9.65

9.6 28

ø6.35 x 5

ø9.52 x 5

ø17 x 2

- Rotary

- -

- 895

Cross-fan Propeller

Resin Steel

35 20

2Row 12Step 1Row 20Step

Capillary tube

360

760

- MRA12037

-12007

Indoor unit Outdoor unit

Wall-mounting

3.40

1.4

3.70

-

7.4 -

7.9 -

38 49

38 49

2.698

2.868

1/220-240~/50

1.260

1.290

5.0

5.2

99.9

99.9

30

2 -

250V 10/16A

3.15 -

815x298x182 720x532x245

32.08x11.73x7.17 28.35x20.94x9.65

9.6 32

ø6.35 x 5

ø12.7 x 5

ø17 x 2

- Rotary

- -

- 1210

Cross-fan Propeller

Resin Steel

35 20

2Row 12Step 2Row 20Step

Capillary tube

410

920

- MRA12030

-12008

AQ09A(B)1VE/AQ09(B)2VE

SH09ZV/SH09YAO

AQ12A(B)1VE/AQ12(B)2VE

SH12ZV/SH12YAO

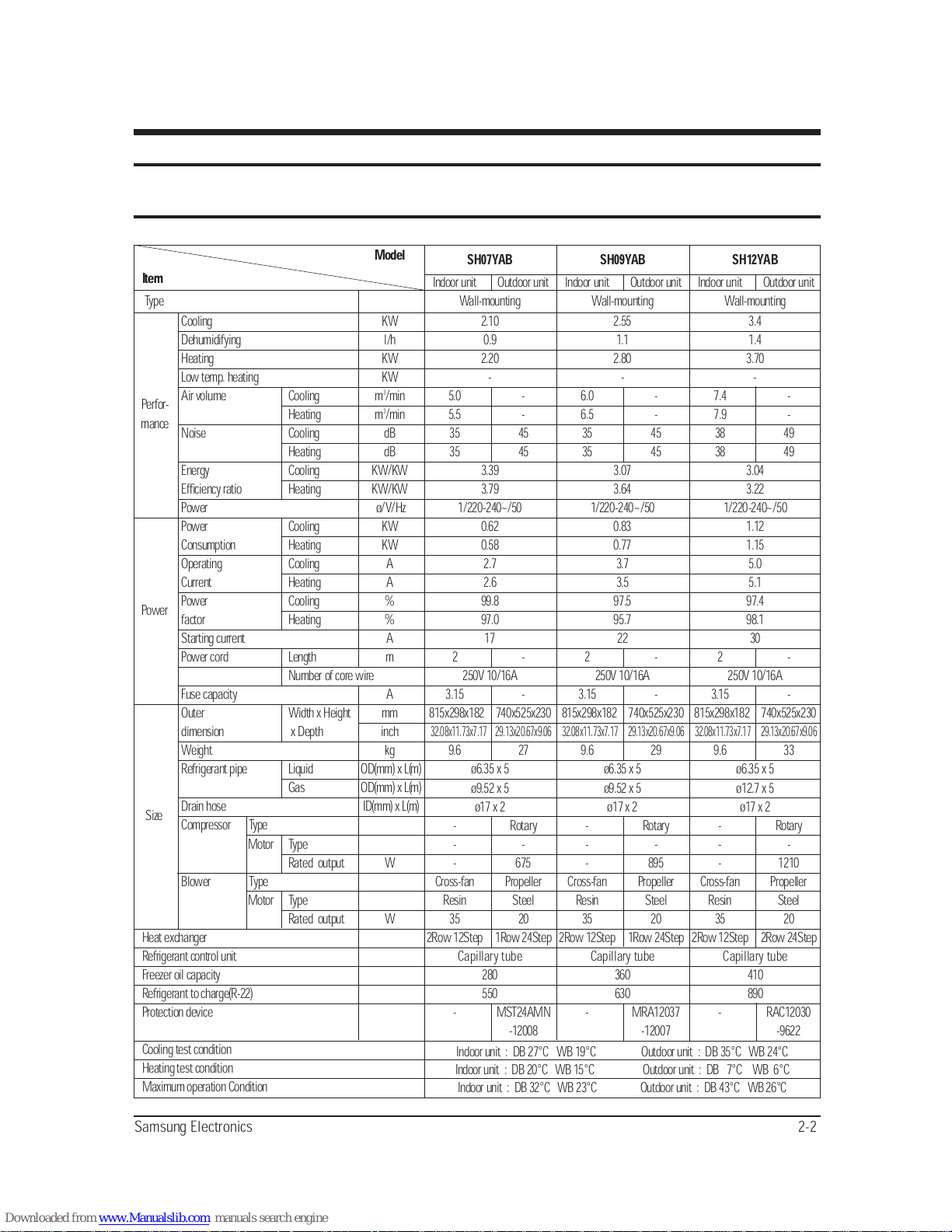

Samsung Electronics 2-2

Model

Item

Type

Cooling KW

Dehumidifying l/h

Heating KW

Low temp. heating KW

Air volume Cooling m

3

/min

Heating m3/min

Noise Cooling dB

Heating dB

Energy Cooling KW/KW

Efficiency ratio Heating KW/KW

Power ø/V/Hz

Power Cooling KW

Consumption Heating KW

Operating Cooling A

Current Heating A

Power Cooling %

factor Heating %

Starting current A

Power cord Length m

Number of core wire

Fuse capacity A

Outer Width x Height mm

dimension x Depth inch

Weight kg

Refrigerant pipe Liquid OD(mm) x L(m)

Gas OD(mm) x L(m)

Drain hose ID(mm) x L(m)

Compressor Type

Motor Type

Rated output W

Blower Type

Motor Type

Rated output W

Heat exchanger

Refrigerant control unit

Freezer oil capacity

Refrigerant to charge(R-22)

Protection device

Cooling test condition

Heating test condition

Maximum operation Condition

Indoor unit Outdoor unit

Wall-mounting

2.10

0.9

2.20

-

5.0 -

5.5 -

35 45

35 45

3.39

3.79

1/220-240~/50

0.62

0.58

2.7

2.6

99.8

97.0

17

2 -

250V 10/16A

3.15 -

815x298x182 740x525x230

32.08x11.73x7.17 29.13x20.67x9.06

9.6 27

ø6.35 x 5

ø9.52 x 5

ø17 x 2

- Rotary

- -

- 675

Cross-fan Propeller

Resin Steel

35 20

2Row 12Step 1Row 24Step

Capillary tube

280

550

- MST24AMN

-12008

SH07YAB

Perfor-

mance

Power

Size

Indoor unit : DB 27°C WB 19°C Outdoor unit : DB 35°C WB 24°C

Indoor unit : DB 20°C WB 15°C Outdoor unit : DB 7°C WB 6°C

Indoor unit : DB 32°C WB 23°C Outdoor unit : DB 43°C WB 26°C

Indoor unit Outdoor unit

Wall-mounting

2.55

1.1

2.80

-

6.0 -

6.5 -

35 45

35 45

3.07

3.64

1/220-240~/50

0.83

0.77

3.7

3.5

97.5

95.7

22

2 -

250V 10/16A

3.15 -

815x298x182 740x525x230

32.08x11.73x7.17 29.13x20.67x9.06

9.6 29

ø6.35 x 5

ø9.52 x 5

ø17 x 2

- Rotary

- -

- 895

Cross-fan Propeller

Resin Steel

35 20

2Row 12Step 1Row 24Step

Capillary tube

360

630

- MRA12037

-12007

Indoor unit Outdoor unit

Wall-mounting

3.4

1.4

3.70

-

7.4 -

7.9 -

38 49

38 49

3.04

3.22

1/220-240~/50

1.12

1.15

5.0

5.1

97.4

98.1

30

2 -

250V 10/16A

3.15 -

815x298x182 740x525x230

32.08x11.73x7.17 29.13x20.67x9.06

9.6 33

ø6.35 x 5

ø12.7 x 5

ø17 x 2

- Rotary

- -

- 1210

Cross-fan Propeller

Resin Steel

35 20

2Row 12Step 2Row 24Step

Capillary tube

410

890

- RAC12030

-9622

SH09YAB SH12YAB

2-3 Samsung Electronics

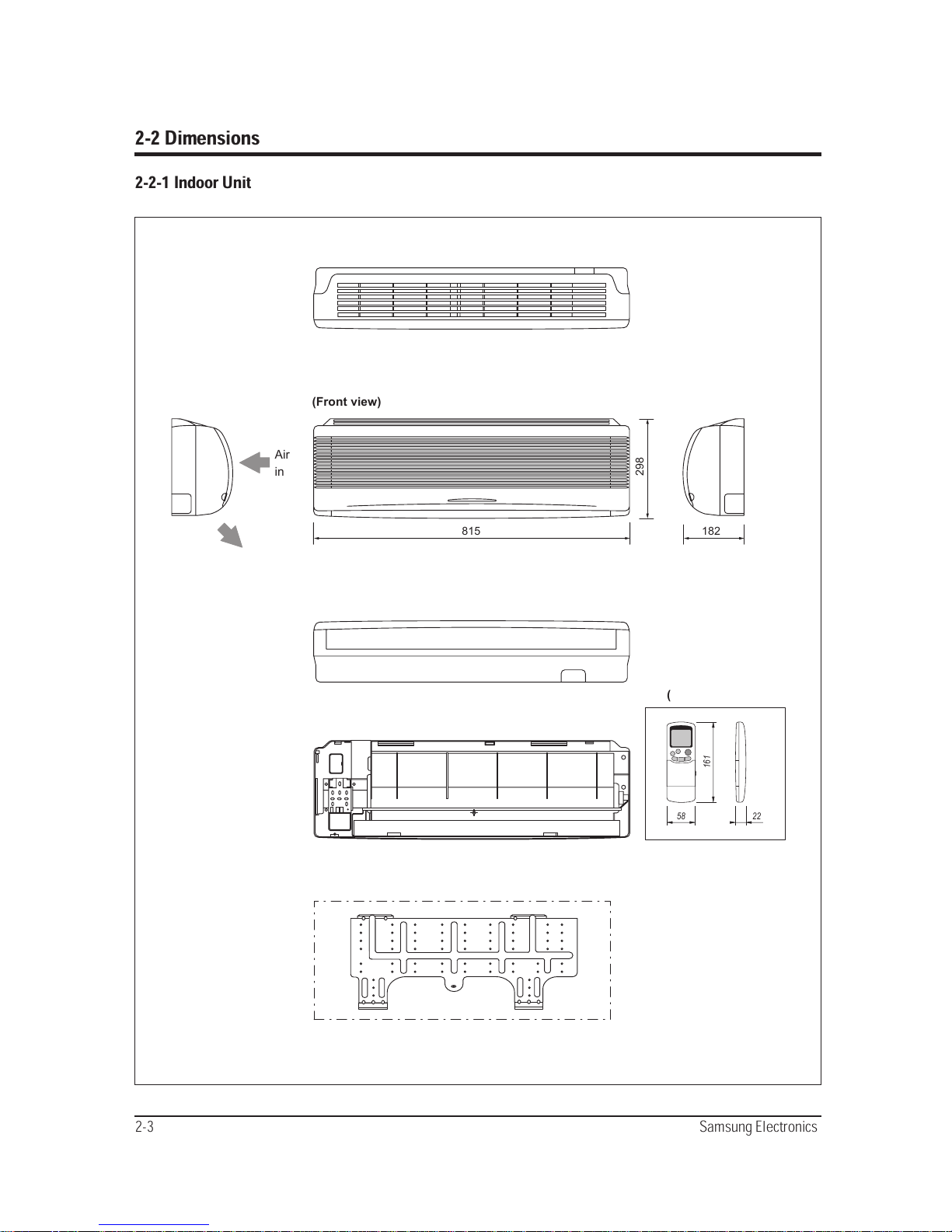

2-2 Dimensions

2-2-1 Indoor Unit

815 182

298

58 22

161

Air

in

(Front view)

(Remote control)

(Rear view)

Air out

Installation plate

Product Specifications

Samsung Electronics 2-4

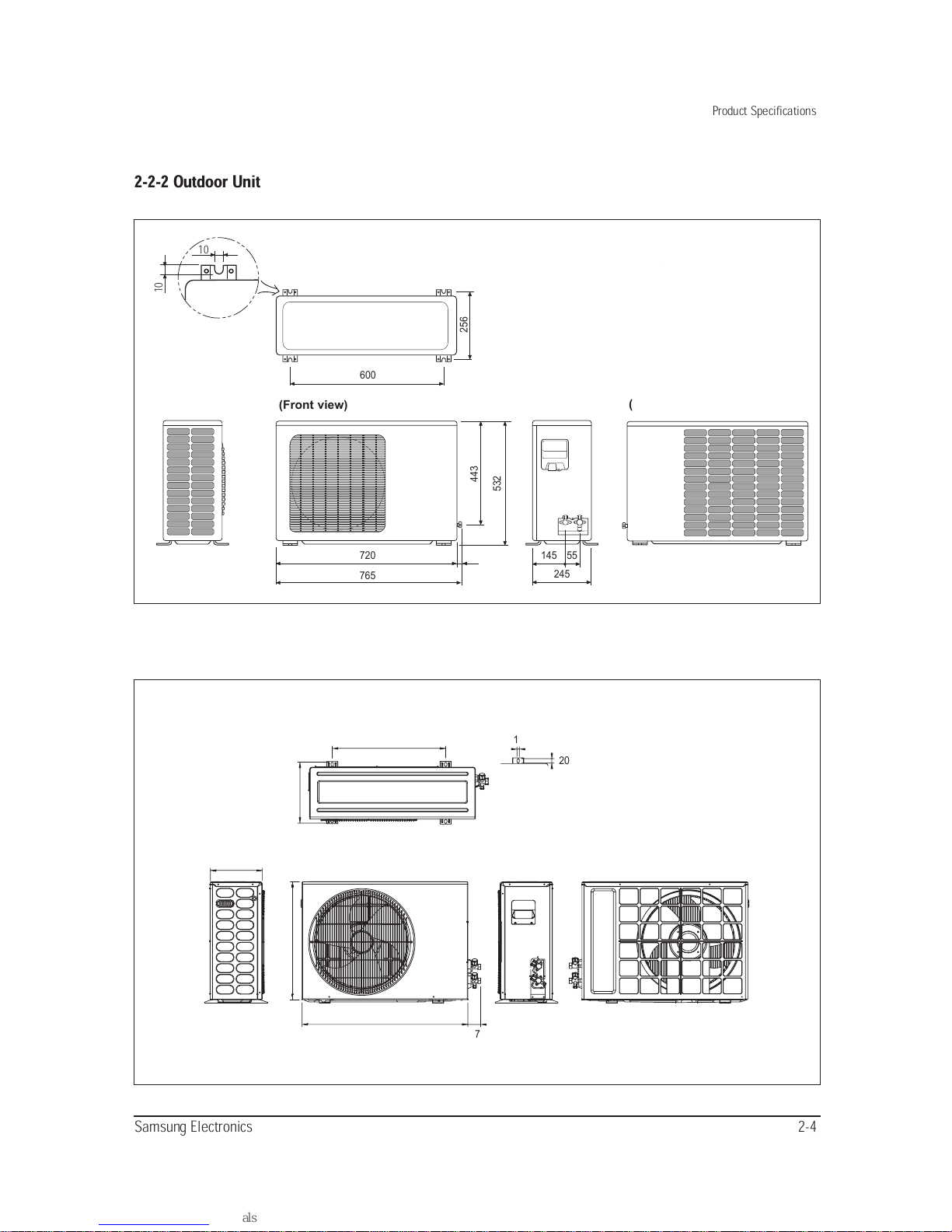

2-2-2 Outdoor Unit

(Front view)

720 145 55

245

600

10

10

765

443

256

532

(Rear view)

230

506

270

525

740

57

20

11

■ ✳✳

YABX

2-5 Samsung Electronics

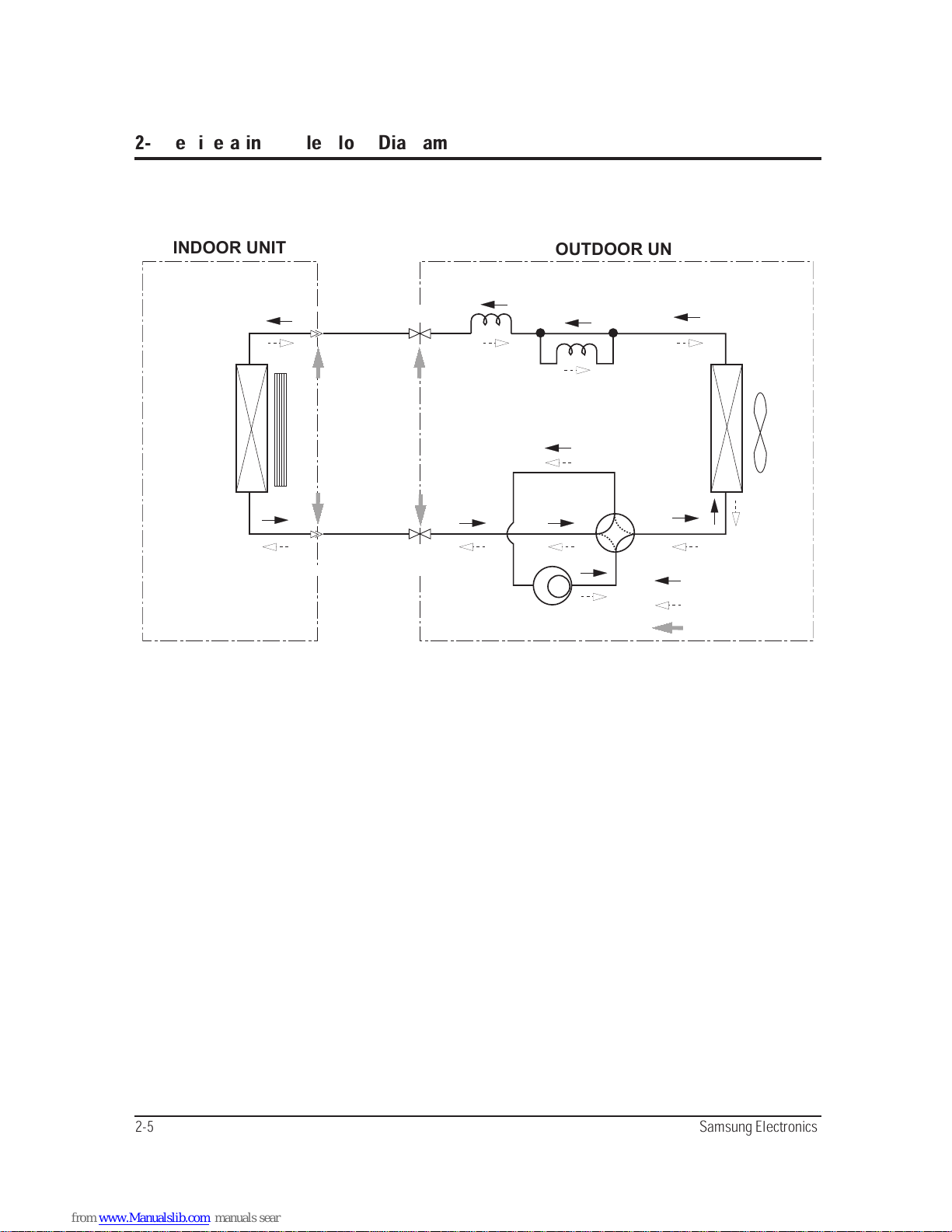

INDOOR UNIT

OUTDOOR UNIT

Heat

exchanger

(Evaporator)

Gas side

3-way valve

2-way valve

Liquid side

Capillary tube

Cooling

Gas leak check point

Cross fan

Heat

exchanger

(Condenser)

Propeller fan

Heating

Capillary tube

Check valve

Compressor

4-way valve

T

1

T

2

2-3 Refrigerating Cycle Block Diagram

Samsung Electronics 3-1

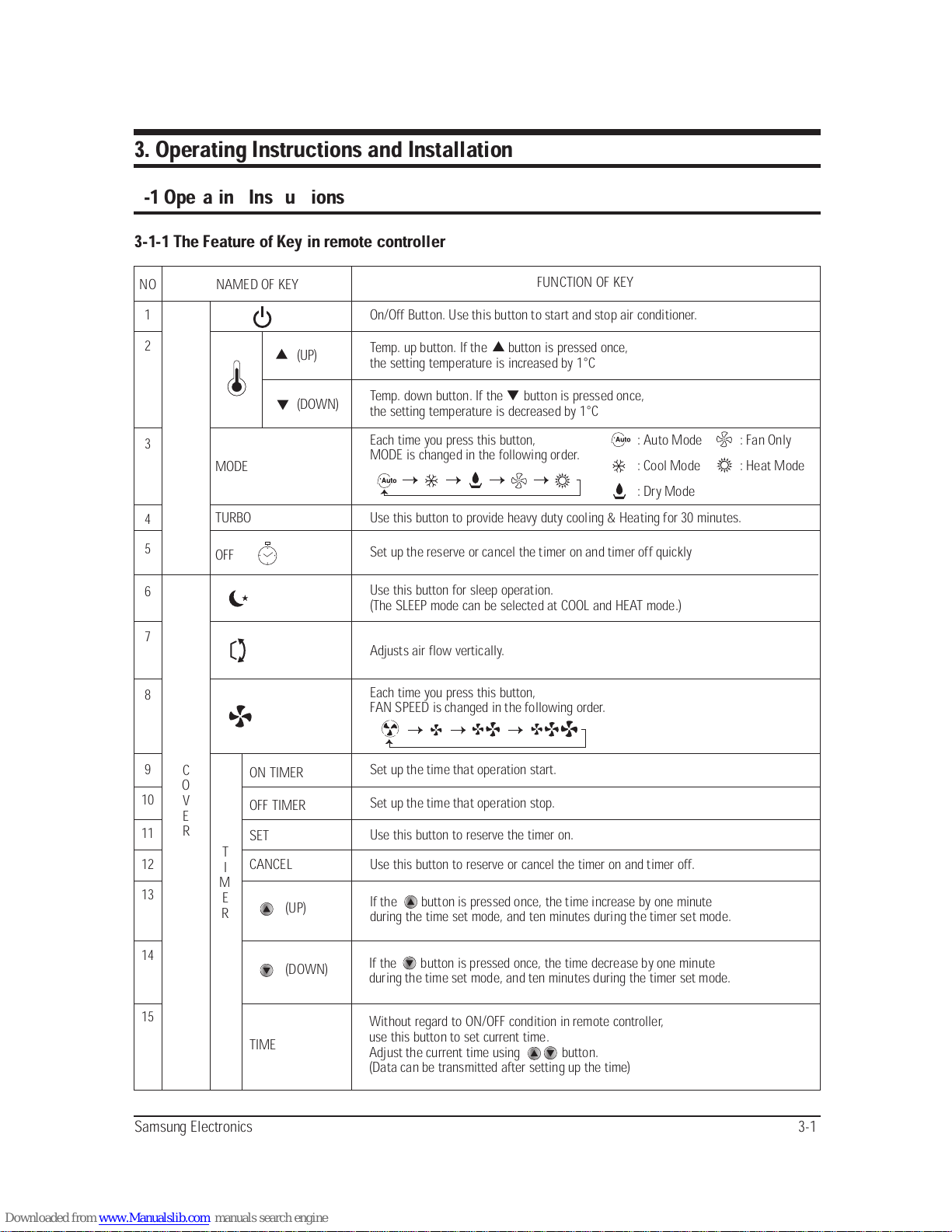

3. Operating Instructions and Installation

3-1 Operating Instructions

NO

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

NAMED OF KEY

MODE

(UP)

(DOWN)

TURBO

OFF

ON TIMER

OFF TIMER

SET

CANCEL

(UP)

Without regard to ON/OFF condition in remote controller,

use this button to set current time.

Adjust the current time using button.

(Data can be transmitted after setting up the time)

If the button is pressed once, the time decrease by one minute

during the time set mode, and ten minutes during the timer set mode.

If the button is pressed once, the time increase by one minute

during the time set mode, and ten minutes during the timer set mode.

Use this button to reserve or cancel the timer on and timer off.

Use this button to reserve the timer on.

Set up the time that operation stop.

Set up the time that operation start.

Each time you press this button,

FAN SPEED is changed in the following order.

Adjusts air flow vertically.

Use this button for sleep operation.

(The SLEEP mode can be selected at COOL and HEAT mode.)

Set up the reserve or cancel the timer on and timer off quickly

Use this button to provide heavy duty cooling & Heating for 30 minutes.

Each time you press this button,

MODE is changed in the following order.

Temp. down button. If the button is pressed once,

the setting temperature is decreased by 1°C

Temp. up button. If the button is pressed once,

the setting temperature is increased by 1°C

On/Off Button. Use this button to start and stop air conditioner.

FUNCTION OF KEY

(DOWN)

TIME

3-1-1 The Feature of Key in remote controller

C

O

V

E

R

T

I

M

E

R

: Auto Mode : Fan Only

: Cool Mode : Heat Mode

: Dry Mode

3-2 Samsung Electronics

Operating Instructions and Installation

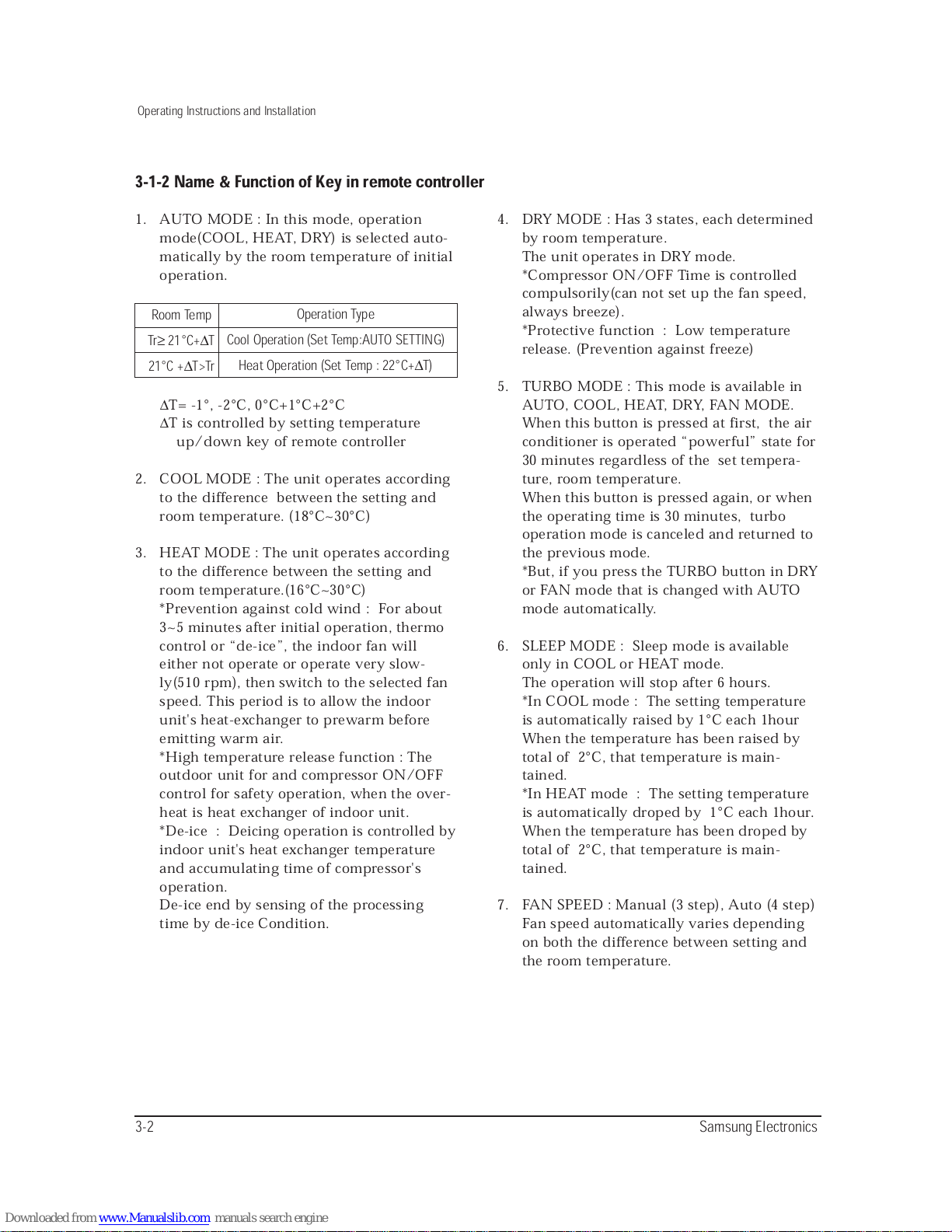

1. AUTO MODE : In this mode, operation

mode(COOL, HEAT, DRY) is selected auto-

matically by the room temperature of initial

operation.

∆

T= -1°, -2°C, 0°C+1°C+2°C

∆

T is controlled by setting temperature

up/down key of remote controller

2. COOL MODE : The unit operates according

to the difference between the setting and

room temperature. (18°C~30°C)

3. HEAT MODE : The unit operates according

to the difference between the setting and

room temperature.(16°C~30°C)

*Prevention against cold wind : For about

3~5 minutes after initial operation, thermo

control or “de-ice”, the indoor fan will

either not operate or operate very slow-

ly(510 rpm), then switch to the selected fan

speed. This period is to allow the indoor

unit's heat-exchanger to prewarm before

emitting warm air.

*High temperature release function : The

outdoor unit for and compressor ON/OFF

control for safety operation, when the over-

heat is heat exchanger of indoor unit.

*De-ice : Deicing operation is controlled by

indoor unit's heat exchanger temperature

and accumulating time of compressor's

operation.

De-ice end by sensing of the processing

time by de-ice Condition.

4. DRY MODE : Has 3 states, each determined

by room temperature.

The unit operates in DRY mode.

*Compressor ON/OFF Time is controlled

compulsorily(can not set up the fan speed,

always breeze).

*Protective function : Low temperature

release. (Prevention against freeze)

5. TURBO MODE : This mode is available in

AUTO, COOL, HEAT, DRY, FAN MODE.

When this button is pressed at first, the air

conditioner is operated “powerful” state for

30 minutes regardless of the set tempera-

ture, room temperature.

When this button is pressed again, or when

the operating time is 30 minutes, turbo

operation mode is canceled and returned to

the previous mode.

*But, if you press the TURBO button in DRY

or FAN mode that is changed with AUTO

mode automatically.

6. SLEEP MODE : Sleep mode is available

only in COOL or HEAT mode.

The operation will stop after 6 hours.

*In COOL mode : The setting temperature

is automatically raised by 1°C each 1hour

When the temperature has been raised by

total of 2°C, that temperature is main-

tained.

*In HEAT mode : The setting temperature

is automatically droped by 1°C each 1hour.

When the temperature has been droped by

total of 2°C, that temperature is main-

tained.

7. FAN SPEED : Manual (3 step), Auto (4 step)

Fan speed automatically varies depending

on both the difference between setting and

the room temperature.

Room Temp

Tr≥21°C+∆T

21°C +∆T>Tr

Operation Type

Cool Operation (Set Temp:AUTO SETTING)

Heat Operation (Set Temp : 22°C+∆T)

3-1-2 Name & Function of Key in remote controller

Samsung Electronics 3-3

Operating Instructions and Installation

8. COMPULSORY OPERATION :

For operating the air conditioner without

the remote controller.

*AUTO : The operating is the same func-

tion that AUTO MODE in the remote con-

troller.

9. SWING : BLADE-H is rotated vertically by

the stepping motor.

*Swing Set : Press the button under the

remote control is displayed on LCD the ,

and the blades move up and down, about 43°.

If the one more time press the button, bla-

tles location is stop.

10. Quick OFF TIMER: OFF timer (quick timer)

allows reservation or cancel the timer on

and timer off quickly

When OFF timer button is pressed at oper-

ating state, LCD displays the polling state

sequentially.

The LCD also displays the time remaining.

11. 24-Hour ON/OFF Real Setting Timer. : The

air conditioner is turned ON at a specified

time using .

OFF TIMER : The air Conditioner is turned

OFF at a specified time using .

*ON TIMER : Only timer LED lights on.

*OFF TIMER : Both timer and operation

LED lights on.

*3 minutes delay timer.

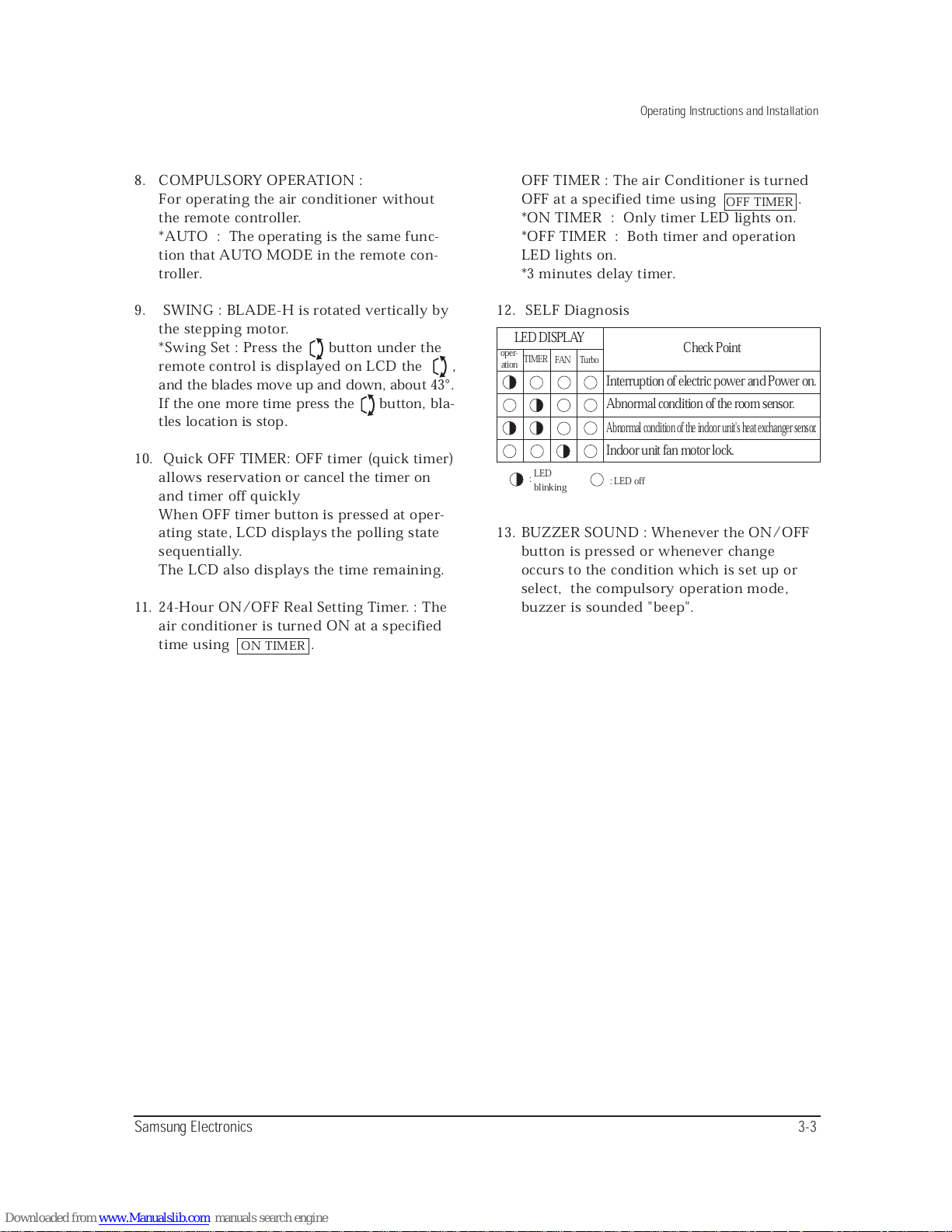

12. SELF Diagnosis

13. BUZZER SOUND : Whenever the ON/OFF

button is pressed or whenever change

occurs to the condition which is set up or

select, the compulsory operation mode,

buzzer is sounded "beep".

ON TIMER

OFF TIMER

Interruption of electric power and Power on.

Check Point

LED DISPLAY

oper-

ation

TIMER

FAN

LED

:

blinking

: LED off

Turbo

Abnormal condition of the room sensor.

Indoor unit fan motor lock.

Abnormal condition of the indoor unit's heat exchanger sensor.

3-4 Samsung Electronics

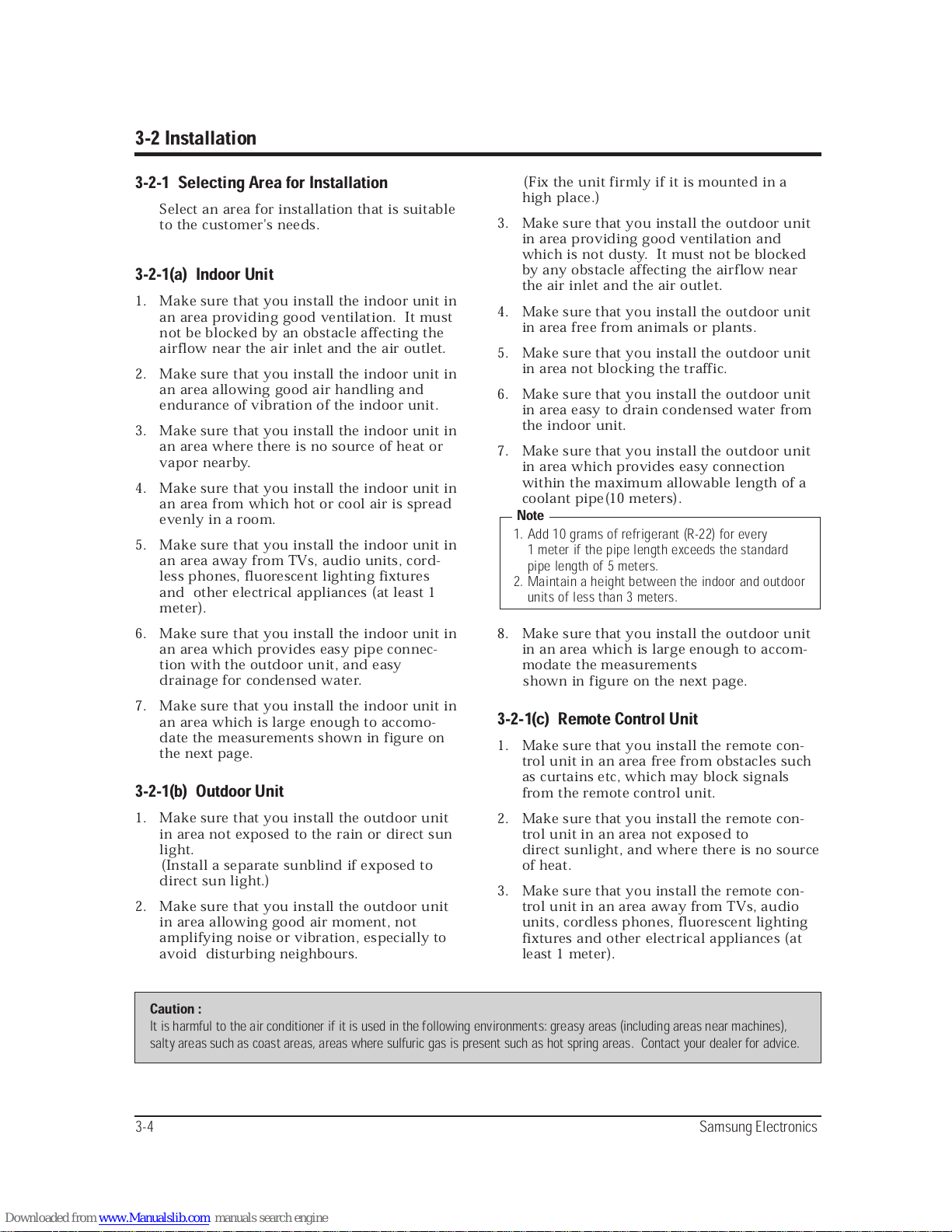

3-2 Installation

3-2-1 Selecting Area for Installation

Select an area for installation that is suitable

to the customer's needs.

3-2-1(a) Indoor Unit

1. Make sure that you install the indoor unit in

an area providing good ventilation. It must

not be blocked by an obstacle affecting the

airflow near the air inlet and the air outlet.

2. Make sure that you install the indoor unit in

an area allowing good air handling and

endurance of vibration of the indoor unit.

3. Make sure that you install the indoor unit in

an area where there is no source of heat or

vapor nearby.

4. Make sure that you install the indoor unit in

an area from which hot or cool air is spread

evenly in a room.

5. Make sure that you install the indoor unit in

an area away from TVs, audio units, cord-

less phones, fluorescent lighting fixtures

and other electrical appliances (at least 1

meter).

6. Make sure that you install the indoor unit in

an area which provides easy pipe connec-

tion with the outdoor unit, and easy

drainage for condensed water.

7. Make sure that you install the indoor unit in

an area which is large enough to accomo-

date the measurements shown in figure on

the next page.

3-2-1(b) Outdoor Unit

1. Make sure that you install the outdoor unit

in area not exposed to the rain or direct sun

light.

(Install a separate sunblind if exposed to

direct sun light.)

2. Make sure that you install the outdoor unit

in area allowing good air moment, not

amplifying noise or vibration, especially to

avoid disturbing neighbours.

(Fix the unit firmly if it is mounted in a

high place.)

3. Make sure that you install the outdoor unit

in area providing good ventilation and

which is not dusty. It must not be blocked

by any obstacle affecting the airflow near

the air inlet and the air outlet.

4. Make sure that you install the outdoor unit

in area free from animals or plants.

5. Make sure that you install the outdoor unit

in area not blocking the traffic.

6. Make sure that you install the outdoor unit

in area easy to drain condensed water from

the indoor unit.

7. Make sure that you install the outdoor unit

in area which provides easy connection

within the maximum allowable length of a

coolant pipe(10 meters).

8. Make sure that you install the outdoor unit

in an area which is large enough to accom-

modate the measurements

shown in figure on the next page.

3-2-1(c) Remote Control Unit

1. Make sure that you install the remote con-

trol unit in an area free from obstacles such

as curtains etc, which may block signals

from the remote control unit.

2. Make sure that you install the remote con-

trol unit in an area not exposed to

direct sunlight, and where there is no source

of heat.

3. Make sure that you install the remote con-

trol unit in an area away from TVs, audio

units, cordless phones, fluorescent lighting

fixtures and other electrical appliances (at

least 1 meter).

Caution :

It is harmful to the air conditioner if it is used in the following environments: greasy areas (including areas near machines),

salty areas such as coast areas, areas where sulfuric gas is present such as hot spring areas. Contact your dealer for advice.

1. Add 10 grams of refrigerant (R-22) for every

1 meter if the pipe length exceeds the standard

pipe length of 5 meters.

2. Maintain a height between the indoor and outdoor

units of less than 3 meters.

Note

3-5Samsung Electronics

Operating Instructions and Installation

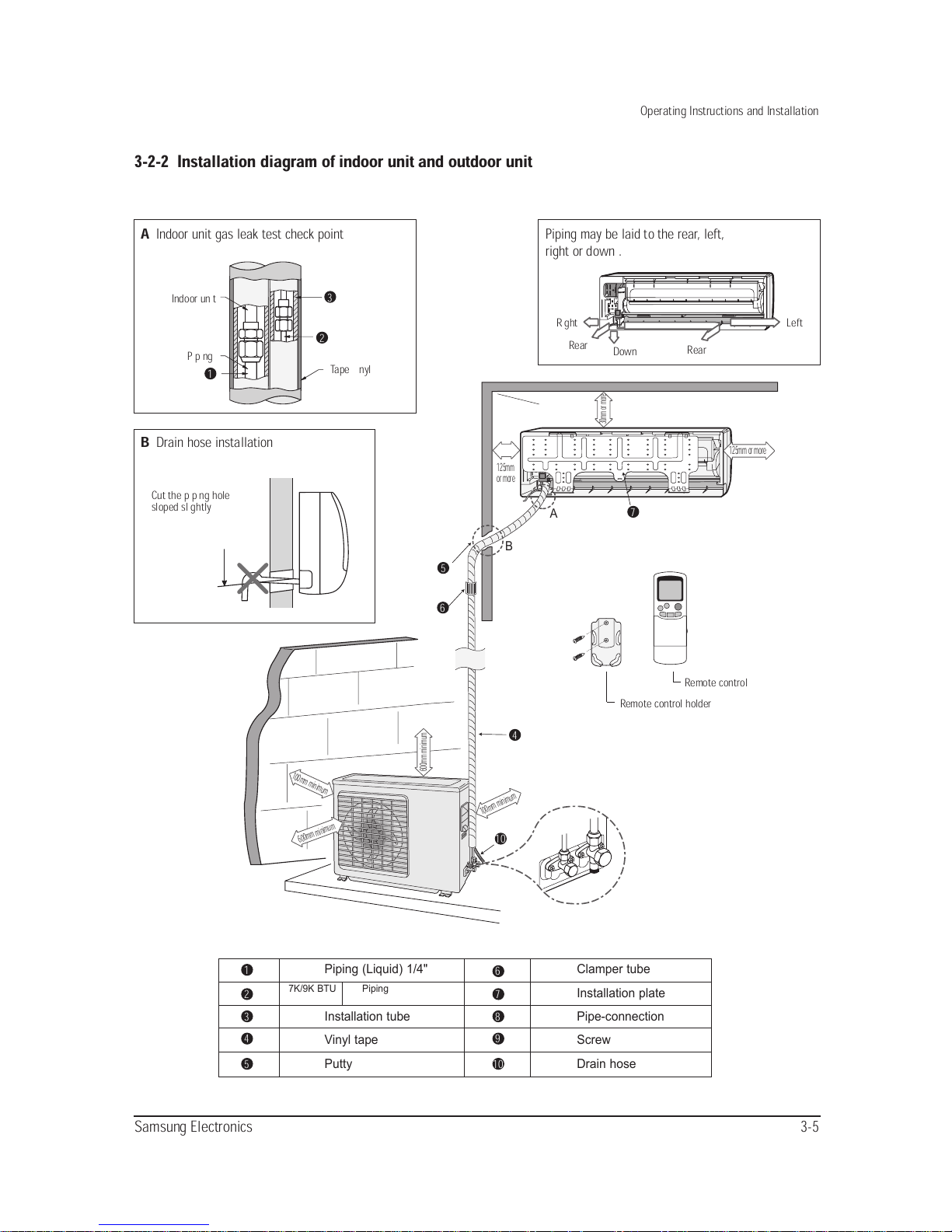

A

B

Cut the piping hole

sloped slightly

3-2-2 Installation diagram of indoor unit and outdoor unit

A

Indoor unit gas leak test check point

Tape vinyl

Piping

Indoor unit

B

Drain hose installation

Cut the piping hole

sloped slightly

Piping (Liquid) 1/4" Clamper tube

Installation plate

Installation tube Pipe-connection

Vinyl tape Screw

Putty Drain hose

Piping may be laid to the rear, left,

right or down .

Right

Rear

Down

30mm or more

600mm minimum

600mm minimum

100mm minimum

100mm minimum

125mm

or more

125mm or more

Rear

Left

3

2

5

7

6

4

10

1

2

3

4

5

6

7

8

9

10

1

Remote control

Remote control holder

7K/9K BTU Piping(Gas)3/8”

12K BTU Piping(Gas)1/2”

3-6 Samsung Electronics

Operating Instructions and Installation

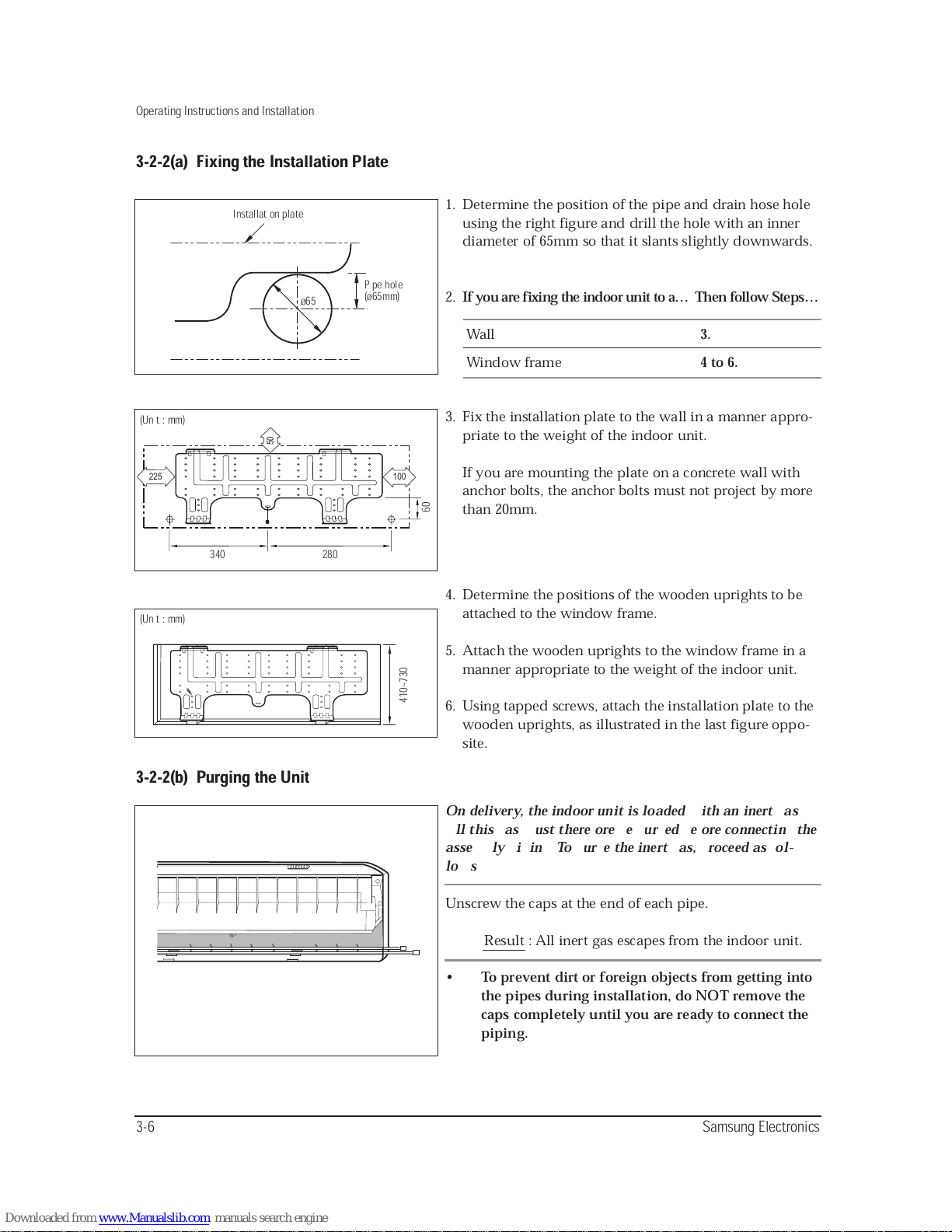

3-2-2(a) Fixing the Installation Plate

3-2-2(b) Purging the Unit

Installation plate

Pipe hole

(ø65mm)

ø65

50

225

100

340

(Unit : mm)

280

60

(Unit : mm)

410~730

1. Determine the position of the pipe and drain hose hole

using the right figure and drill the hole with an inner

diameter of 65mm so that it slants slightly downwards.

2.

If you are fixing the indoor unit to a… Then follow Steps…

Wall

3.

Window frame

4 to 6.

3. Fix the installation plate to the wall in a manner appro-

priate to the weight of the indoor unit.

If you are mounting the plate on a concrete wall with

anchor bolts, the anchor bolts must not project by more

than 20mm.

4. Determine the positions of the wooden uprights to be

attached to the window frame.

5. Attach the wooden uprights to the window frame in a

manner appropriate to the weight of the indoor unit.

6. Using tapped screws, attach the installation plate to the

wooden uprights, as illustrated in the last figure oppo-

site.

On delivery, the indoor unit is loaded with an inert gas.

All this gas must therefore be purged before connecting the

assembly piping. To purge the inert gas, proceed as fol-

lows.

Unscrew the caps at the end of each pipe.

Result : All inert gas escapes from the indoor unit.

• To prevent dirt or foreign objects from getting into

the pipes during installation, do NOT remove the

caps completely until you are ready to connect the

piping.

3-7

Samsung Electronics

Operating Instructions and Installation

To install the drain hose, proceed as follows.

1. If necessary, connect the 2-metre extension to the drain hose.

2. If you are using the extension, insulate the inside part of the extension drain hose with a shield.

3. Pass the drain hose under the refrigerant piping, taking care to keep the drain hose tight.

4. Pass the drain hose through the hole in the wall, making sure that it is sloping downwards, as

shown in the illustrations above.

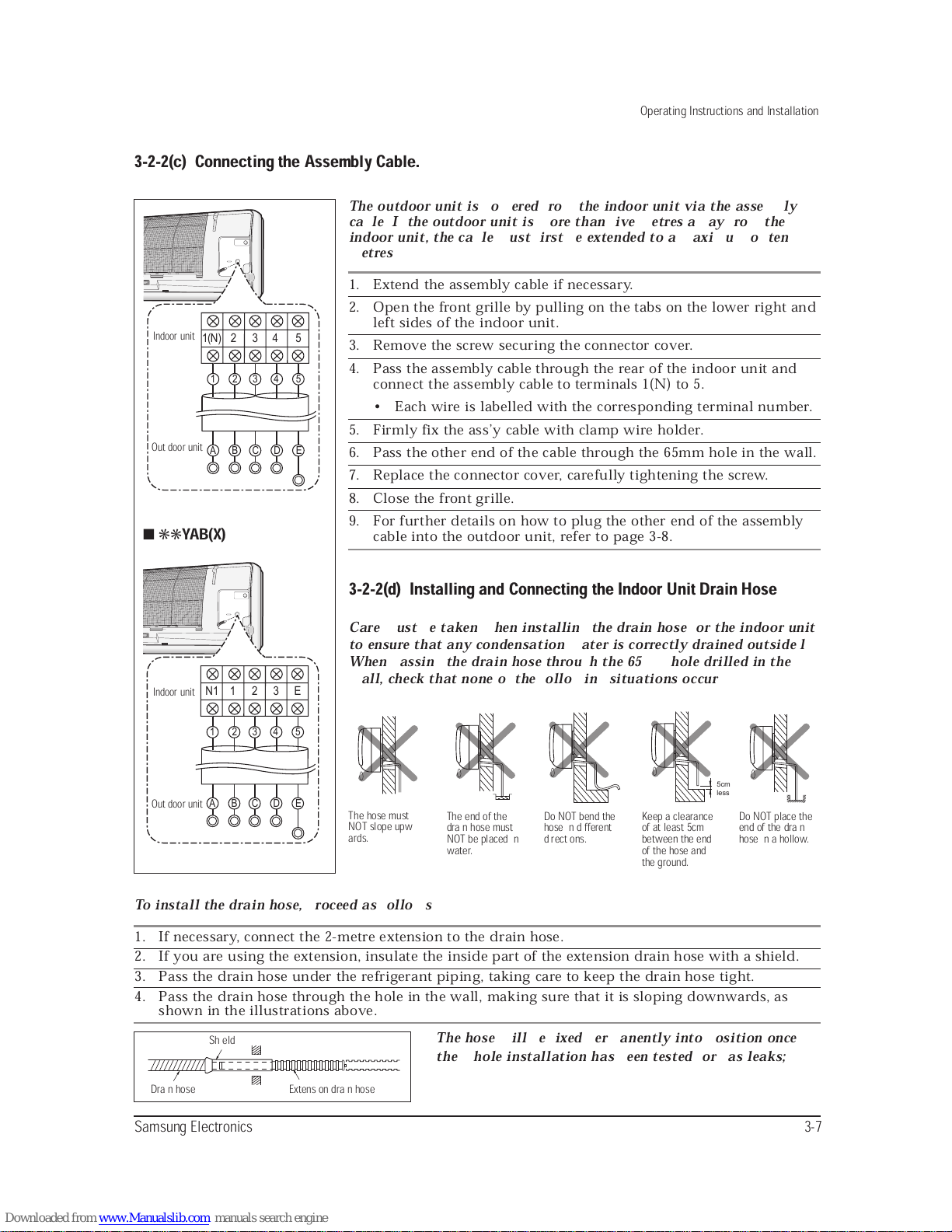

3-2-2(d) Installing and Connecting the Indoor Unit Drain Hose

Care must be taken when installing the drain hose for the indoor unit

to ensure that any condensation water is correctly drained outside.l

When passing the drain hose through the 65mm hole drilled in the

wall, check that none of the following situations occur.

3-2-2(c) Connecting the Assembly Cable.

1(N) 2 3 4 5

1 5432

A B C D E

The outdoor unit is powered from the indoor unit via the assembly

cable. If the outdoor unit is more than five metres away from the

indoor unit, the cable must first be extended to a maximum of ten

metres.

1. Extend the assembly cable if necessary.

2. Open the front grille by pulling on the tabs on the lower right and

left sides of the indoor unit.

3. Remove the screw securing the connector cover.

4. Pass the assembly cable through the rear of the indoor unit and

connect the assembly cable to terminals 1(N) to 5.

• Each wire is labelled with the corresponding terminal number.

5. Firmly fix the ass’y cable with clamp wire holder.

6. Pass the other end of the cable through the 65mm hole in the wall.

7. Replace the connector cover, carefully tightening the screw.

8. Close the front grille.

9. For further details on how to plug the other end of the assembly

cable into the outdoor unit, refer to page 3-8.

The hose will be fixed permanently into position once

the whole installation has been tested for gas leaks;

Keep a clearance

of at least 5cm

between the end

of the hose and

the ground.

Do NOT bend the

hose in different

directions.

The end of the

drain hose must

NOT be placed in

water.

The hose must

NOT slope upw

ards.

Do NOT place the

end of the drain

hose in a hollow.

Shield

Drain hose Extension drain hose

Indoor unit

Out door unit

5cm

less

N1 1 2 3 E

1 5432

A B C D E

■ ✳✳

YAB(X)

Indoor unit

Out door unit

3-8 Samsung Electronics

Operating Instructions and Installation

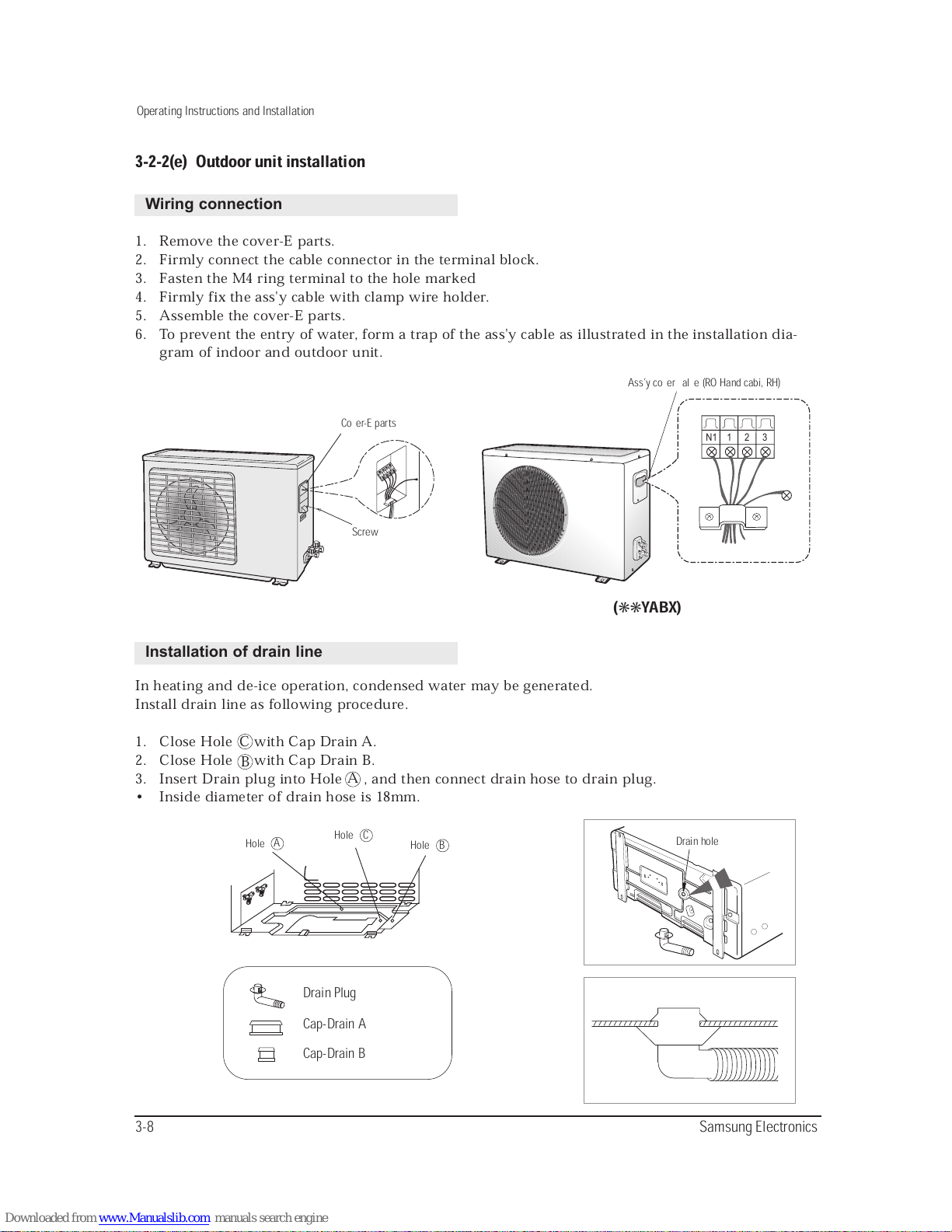

3-2-2(e) Outdoor unit installation

1. Remove the cover-E parts.

2. Firmly connect the cable connector in the terminal block.

3. Fasten the M4 ring terminal to the hole marked

4. Firmly fix the ass'y cable with clamp wire holder.

5. Assemble the cover-E parts.

6. To prevent the entry of water, form a trap of the ass'y cable as illustrated in the installation dia-

gram of indoor and outdoor unit.

In heating and de-ice operation, condensed water may be generated.

Install drain line as following procedure.

1. Close Hole with Cap Drain A.

2. Close Hole with Cap Drain B.

3. Insert Drain plug into Hole , and then connect drain hose to drain plug.

• Inside diameter of drain hose is 18mm.

Wiring connection

Installation of drain line

A B C D

N1 1 2 3

Cover-E parts

Screw

Hole

C

B

A

A

Hole

C

Hole

B

Drain Plug

Cap-Drain A

Cap-Drain B

Ass’y cover valve (RO Hand cabi, RH)

Drain hole

(✳✳YABX)

Samsung Electronics 3-9

Operating Instructions and Installation

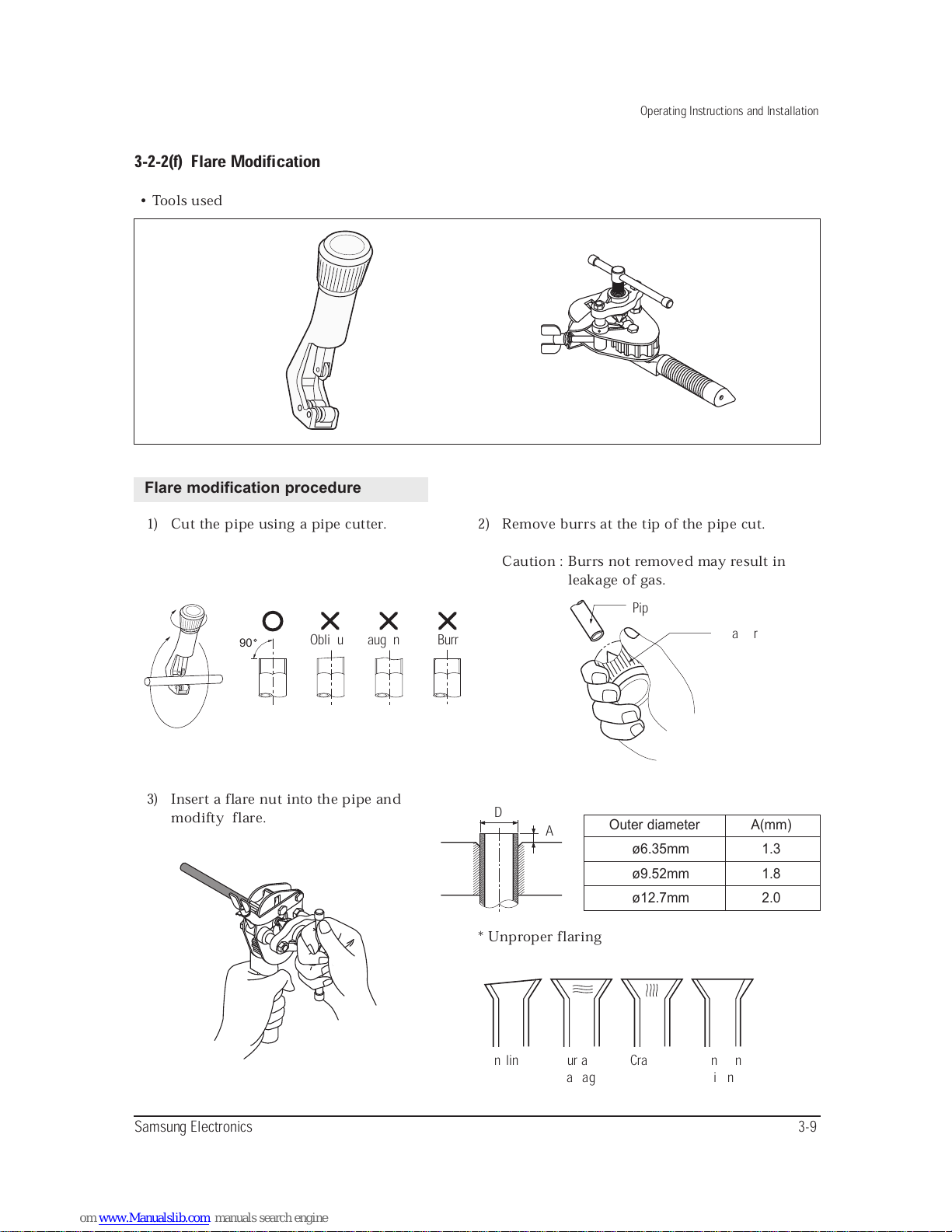

3-2-2(f) Flare Modification

Flare modification procedure

1) Cut the pipe using a pipe cutter.

• Tools used

2) Remove burrs at the tip of the pipe cut.

Caution : Burrs not removed may result in

leakage of gas.

3) Insert a flare nut into the pipe and

modifty flare.

* Unproper flaring

Outer diameter A(mm)

ø6.35mm 1.3

ø9.52mm 1.8

ø12.7mm 2.0

90

D

A

Oblique Raughness Burr

Pipe

Reamer

Inclined Surface

damaged

Cracked Uneven

thickness

D

A

3-10 Samsung Electronics

Operating Instructions and Installation

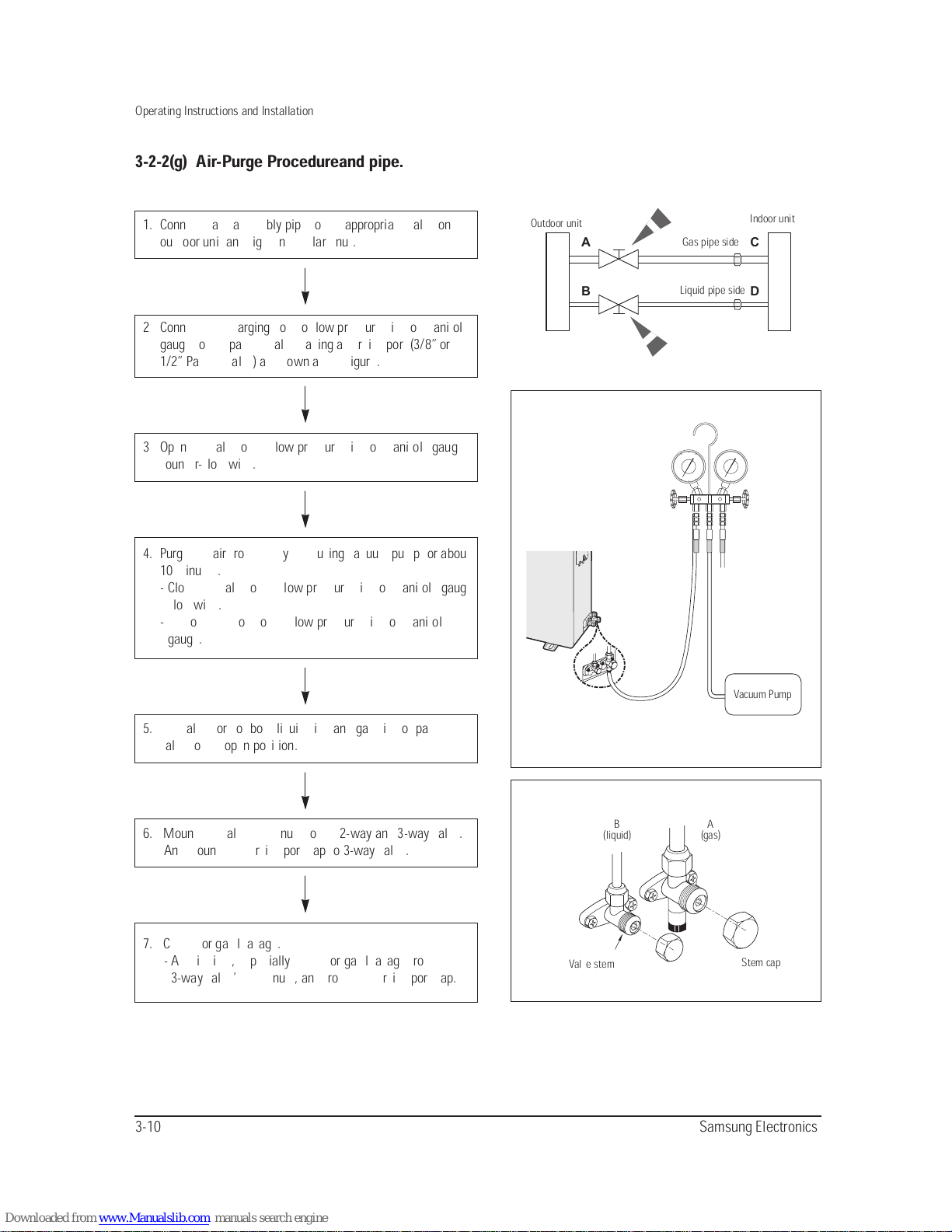

3-2-2(g) Air-Purge Procedureand pipe.

A

B

C

D

Outdoor unit

Indoor unit

Gas pipe side

Liquid pipe side

Vacuum Pump

B

(liquid)

Valve stem

Stem cap

A

(gas)

3 Open the valve of the low pressure side of manifold gauge

counter-clockwise.

6. Mount the valve stem nuts to the 2-way and 3-way valve.

And mount the service port cap to 3-way valve.

4. Purge the air from the system using vacuum pump for about

10 minutes.

- Close the valve of the low pressure side of manifold gauge

clockwise.

- Remove the hose of the low pressure side of manifold

gauge.

7. Check for gas leakage.

- At this time, especially check for gas leakage from the

3-way valve’s stem nuts, and from the service port cap.

5. Set valve cork of both liquid side and gas side of packed

valve to the open position.

1. Connect each assembly pipe to the appropriate valve on the

outdoor unit and tighten the flare nut.

2 Connect the charging hose of low pressure side of manifold

gauge to the packed valve having a service port (3/8” or

1/2” Packed valve) as shown at the figure.

Samsung Electronics 3-11

Operating Instructions and Installation

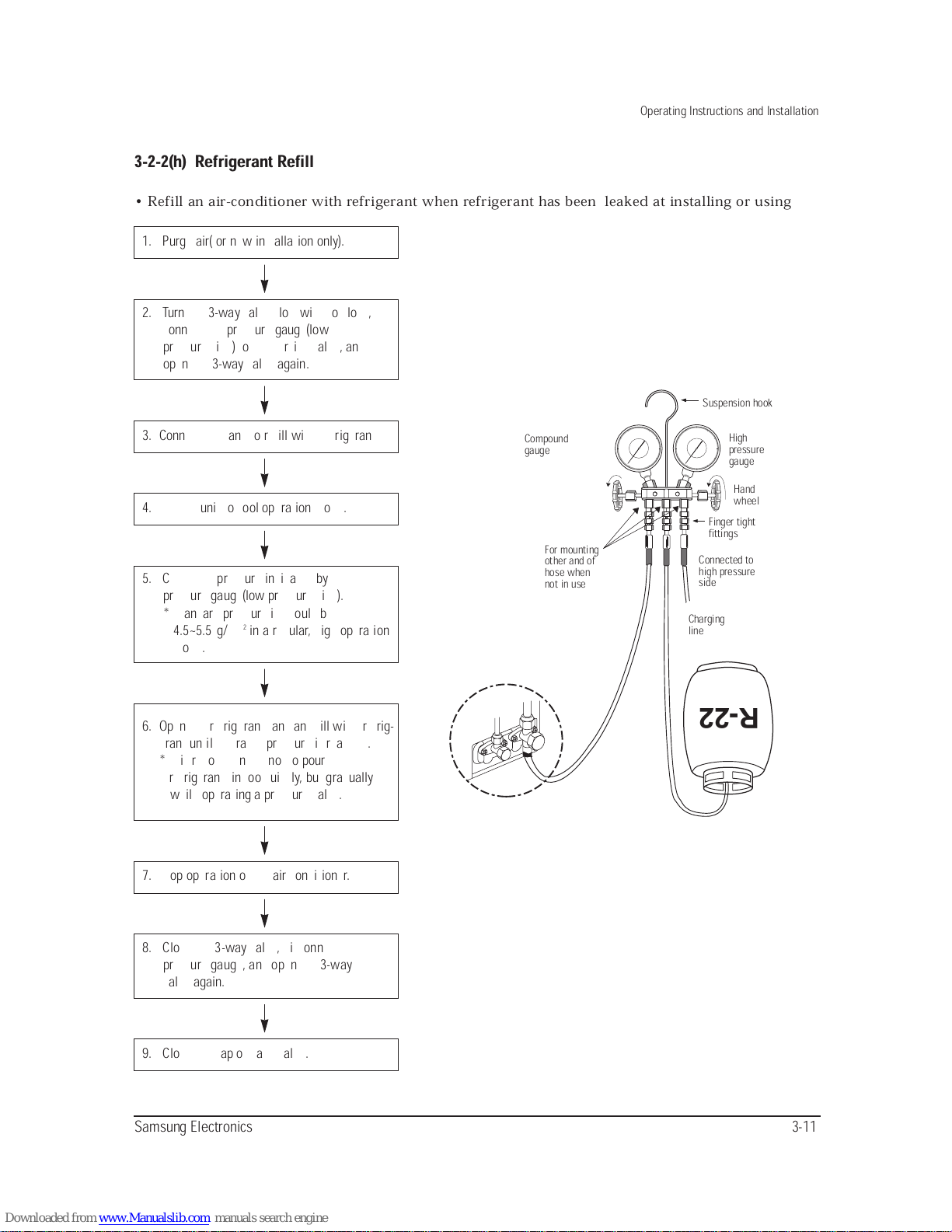

3-2-2(h) Refrigerant Refill

• Refill an air-conditioner with refrigerant when refrigerant has been leaked at installing or using

1. Purge air(for new installation only).

3. Connect the tank to refill with Refrigerant

4. Set the unit to cool operation mode.

7. Stop operation of the air conditioner.

9. Close the cap of each valve.

2. Turn the 3-way valve clockwise to close,

connect the pressure gauge(low

pressure side) to the service valve, and

open the 3-way valve again.

5. Check the pressure indicated by the

pressure gauge(low pressure side).

* Standard pressure is should be

4.5~5.5kg/cm

2

in a reqular, high operation

mode.

6. Open the refrigerant tank and fill with refrig-

erant until the rated pressure is reached.

* It is recommended not to pour the

refrigerant in too quickly, but gradually

while operating a pressure valve.

8. Close the 3-way valve, disconnect the

pressure gauge, and open the 3-way

valve again.

R-22

Suspension hook

High

pressure

gauge

Hand

wheel

Finger tight

fittings

Connected to

high pressure

side

Charging

line

For mounting

other and of

hose when

not in use

Compound

gauge

3-12 Samsung Electronics

Operating Instructions and Installation

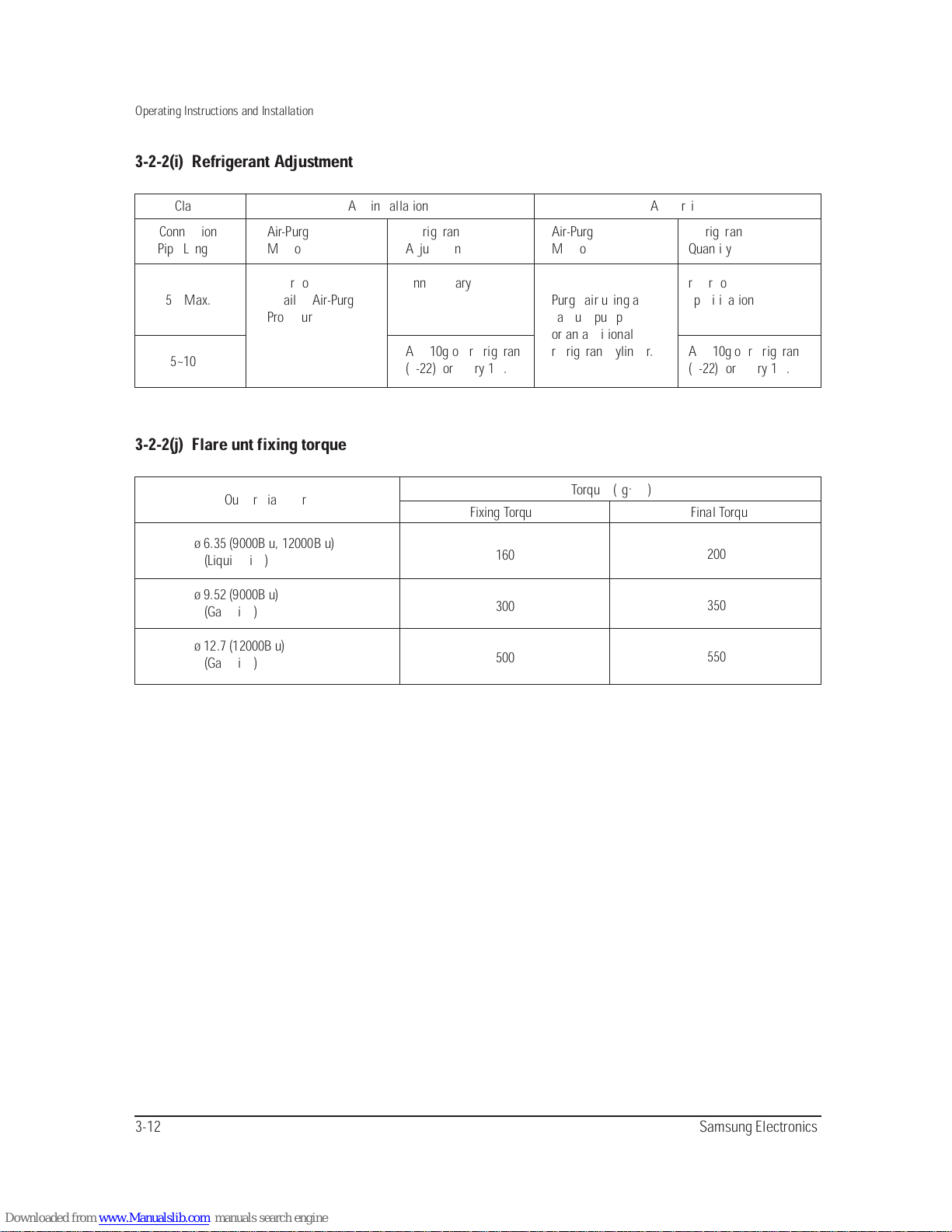

3-2-2(i) Refrigerant Adjustment

3-2-2(j) Flare unt fixing torque

Class At installation At service

Outter diameter

ø 6.35 (9000Btu, 12000Btu)

(Liquid Side)

ø 9.52 (9000Btu)

(Gas Side)

ø 12.7 (12000Btu)

(Gas Side)

160

300

500

200

350

550

Fixing Torque Final Torque

Torque (kg.cm)

Connection

Pipe Length

5m Max.

5~10m

Air-Purge

Method

Refer to the

detailed Air-Purge

Procedure

Refrigerant

Adjustment

Unnecessary

Add 10g of refrigerant

(R-22) for every 1m.

Air-Purge

Method

Purge air using a

vaccum pump

or an additional

refrigerant cylinder.

Refrigerant

Quantity

refer to

specification sheet

Add 10g of refrigerant

(R-22) for every 1m.

Samsung Electronics 3-13

Operating Instructions and Installation

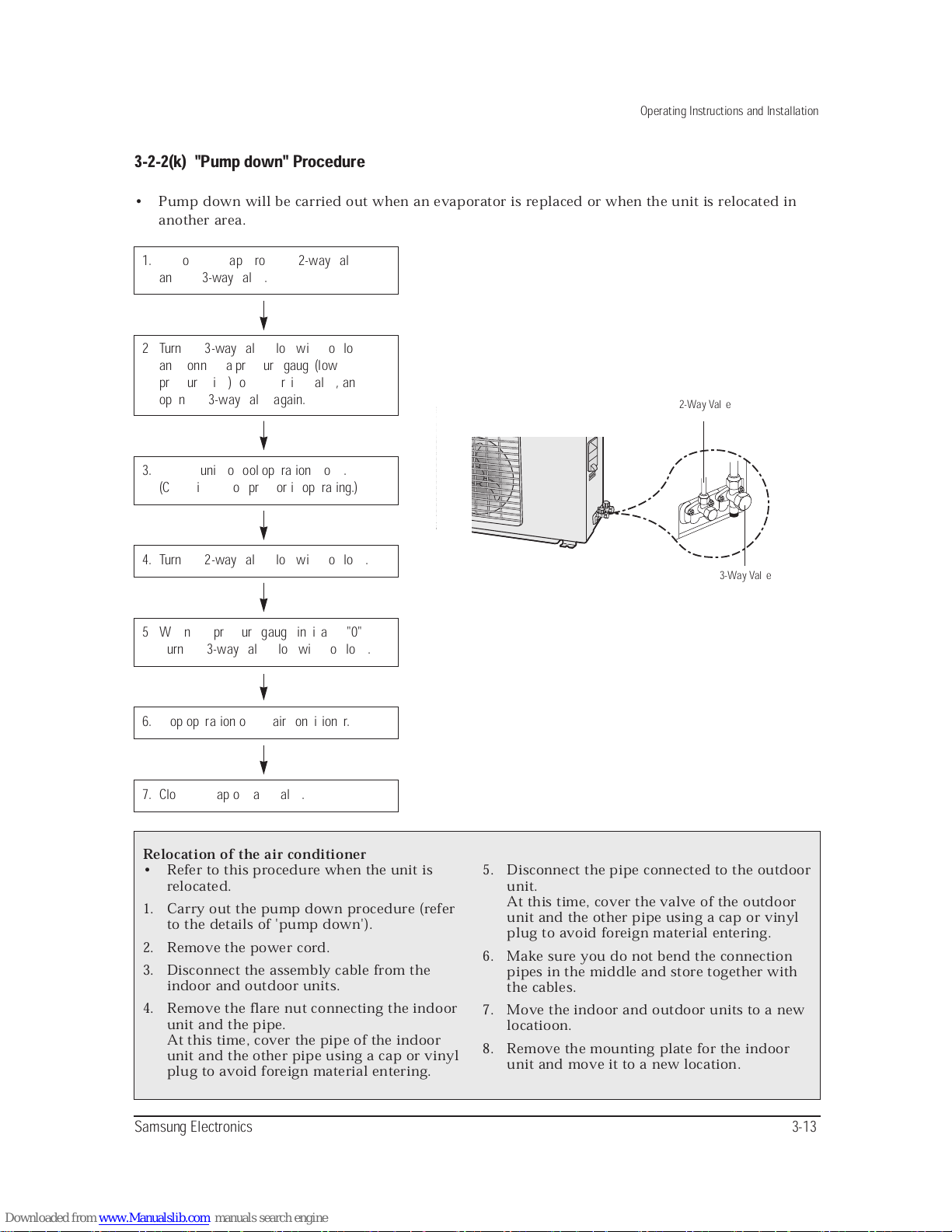

3-2-2(k) "Pump down" Procedure

• Pump down will be carried out when an evaporator is replaced or when the unit is relocated in

another area.

1. Remove the caps from the 2-way valve

and the 3-way valve.

3. Set the unit to cool operation mode.

(Check if the compressor is operating.)

5 When the pressure gauge indicates "0"

turn the 3-way valve clockwise to close.

4. Turn the 2-way valve clockwise to close.

6. Stop operation of the air conditioner.

7. Close the cap of each valve.

2 Turn the 3-way valve clockwise to close

and connect a pressure gauge(low

pressure side) to the service valve, and

open the 3-way valve again.

Relocation of the air conditioner

• Refer to this procedure when the unit is

relocated.

1. Carry out the pump down procedure (refer

to the details of 'pump down').

2. Remove the power cord.

3. Disconnect the assembly cable from the

indoor and outdoor units.

4. Remove the flare nut connecting the indoor

unit and the pipe.

At this time, cover the pipe of the indoor

unit and the other pipe using a cap or vinyl

plug to avoid foreign material entering.

5. Disconnect the pipe connected to the outdoor

unit.

At this time, cover the valve of the outdoor

unit and the other pipe using a cap or vinyl

plug to avoid foreign material entering.

6. Make sure you do not bend the connection

pipes in the middle and store together with

the cables.

7. Move the indoor and outdoor units to a new

locatioon.

8. Remove the mounting plate for the indoor

unit and move it to a new location.

2-Way Valve

3-Way Valve

Loading...

Loading...