Page 1

1 / 26

PRODUCT SPECIFICATION

Lithium Ion Battery System for UPS – U6A4

(34.6kWh, 32.6kWh, 28.5kWh, 26.5kWh, 20.4kWh)

Page 2

2 / 26

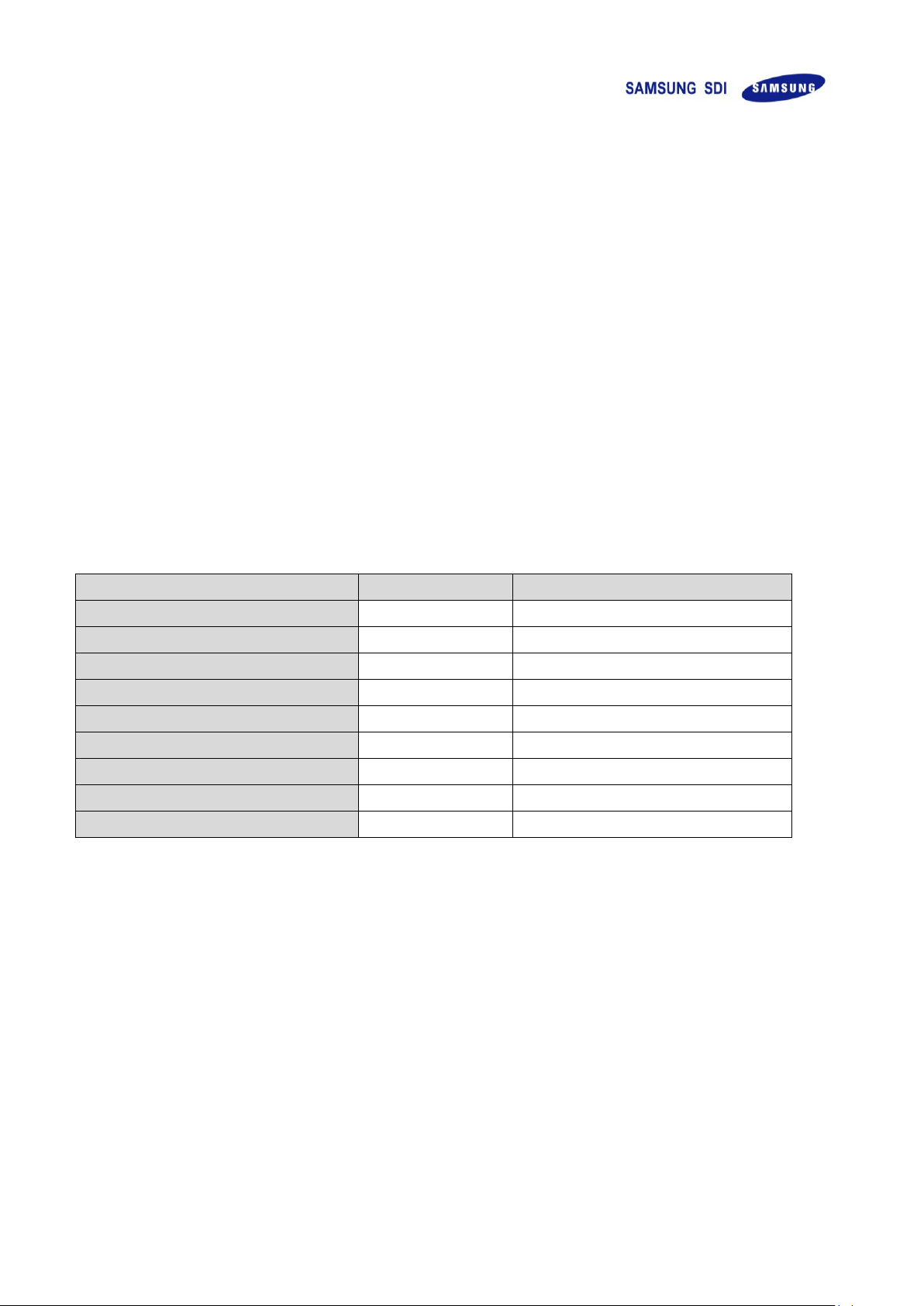

Revision History

Revision

Date

Description

Pages

Changed

0.0

2019.06.22

First draft

0.1

2019.09.24

SMU Auxiliary switch and SMPS Status auxiliary contact

electrical ratings added

(Table 10, Table 17)

22, 28

0.2

2019.11.14

Dimensions corrected

14

0.3

2019.12.05

Maximum operating altitude spec added

14

0.4

2020.08.11

Product model numbers updated

Updated Table 4: Battery System General Specification

(Changed “Storage Humidity” to “Humidity”)

8,19,21,24,29

14

0.41

2020.08.11

Edited for end customer

Removed “confidential” in the document header

Page 3

3 / 26

Table of Contents

Revision History ................................................................................................................................. 2

Table of Contents ............................................................................................................................... 3

Tables ................................................................................................................................................ 4

Figures ............................................................................................................................................... 5

Acronyms and Abbreviations .............................................................................................................. 6

1. Product Overview .......................................................................................................................... 7

1.1 Scope ............................................................................................................................................. 7

2. Product Description ........................................................................................................................ 8

3. Safety Information and Handling .................................................................................................... 9

3.1 Safety Symbols .............................................................................................................................. 9

3.2 General Safety Information ........................................................................................................ 10

3.2.1 Protective Equipment .................................................................................................................10

3.2.2 Organic Solvent Electrolyte ........................................................................................................10

3.2.3 Electrolyte Vent Product ............................................................................................................10

3.2.4 High Voltage Sources ..................................................................................................................11

3.2.5 Unloading and Unpacking ..........................................................................................................11

3.2.6 Storage ........................................................................................................................................11

3.3 General Handling Information .................................................................................................... 12

4. Specification and Characteristics ................................................................................................... 13

5. Block Diagram and Configuration .................................................................................................. 17

6. Detail Product Description ............................................................................................................ 18

6.1 Battery Module ........................................................................................................................... 18

6.2 SMU ............................................................................................................................................. 19

6.3 SMPS Assembly ........................................................................................................................... 20

6.4 Rack Frame .................................................................................................................................. 21

7. LED Indication .............................................................................................................................. 22

7.1 Battery Status Display ................................................................................................................. 22

8. Evaluation .................................................................................................................................... 23

9. Packaging and Shipment ............................................................................................................... 24

10. Service, Maintenance and Warranty ........................................................................................... 25

10.1 Service ....................................................................................................................................... 25

10.2 Maintenance ............................................................................................................................. 25

10.3 Warranty ................................................................................................................................... 25

Contact Information ......................................................................................................................... 26

Page 4

4 / 26

Tables

Table 1: Acronyms and Abbreviations ................................................................................................. 6

Table 2: Component Information ........................................................................................................ 7

Table 3: Safety Symbols ....................................................................................................................... 9

Table 4: Battery System General Specification .................................................................................. 13

Table 5: 136S Battery System Specification ....................................................................................... 14

Table 6: 128S Battery System Specification ....................................................................................... 14

Table 7: 112S Battery System General Specification ......................................................................... 15

Table 8: 104S Battery System General Specification ......................................................................... 15

Table 9: 80S Battery System General Specification ........................................................................... 16

Table 10: LED Indicator ...................................................................................................................... 22

Table 11: Indicated Codes .................................................................................................................. 22

Table 12: List of Standards and Regulations ...................................................................................... 23

Page 5

5 / 26

Figures

Figure 1: 34.6kWh Lithium Ion Energy Storage System ....................................................................... 8

Figure 2: Storage Guide ..................................................................................................................... 12

Figure 3: General System Block Diagram ........................................................................................... 17

Figure 4 : Battery Module Type A ...................................................................................................... 18

Figure 5 : Battery Module Type B ...................................................................................................... 18

Figure 6: SMU .................................................................................................................................... 19

Figure 7: SMPS Assembly ................................................................................................................... 20

Figure 8: Rack Frame ......................................................................................................................... 21

Page 6

6 / 26

Acronyms and Abbreviations

The following acronyms and abbreviations are used in this manual.

Table 1: Acronyms and Abbreviations

Abbreviations

Full Name

BMS

Battery Management System

ESS

Energy Storage System

OCP

Over Current Protection

OTP

Over Temperature Protection

OVP

Over Voltage Protection

SMPS

Switching Mode Power Supply

SMU

String Management Unit

SOC

State Of Charge

SOH

State Of Health

UTP

Under Temperature Protection

UVP

Under Voltage Protection

UPS

Uninterruptible Power Supply

Page 7

7 / 26

1. Product Overview

Customer:

Model Number:

PHR3462-001A (136S), PHR3262-001A (128S), PHR2852-001A (112S), PHR2652-001A (104S),

PHR2042-001A (80S)

Product Name: Lithium Ion Battery System for UPS

Supplier: Samsung SDI Co., Ltd.

1.1 Scope

This document details the safety and handling information, characteristics, requirements, installation

instructions, operating guidelines, service, maintenance and warranty of Lithium Ion Battery System

manufactured by Samsung SDI Co., Ltd. It is intended to provide certified personnel and users with

information on safe handling, installation and usage of the specified product. Consult with Samsung SDI if

some usages not described are expected.

This product is comprised of the following components.

Table 2: Component Information

Component

Model No.

Note

67Ah Cell

CM0630R0002A

67Ah 8S1P Battery Module Type A

EM2031AE003A

67Ah 8S1P Battery Module Type B

EM2031AE004A

String Management Unit (SMU)

V049-0011AA

UL

SMPS Assembly 3 Phase Type A

V044-0006AA

3 Phase AC input, System BMS

SMPS Assembly 3 Phase Type B

SJ94-00238B

3 Phase AC input, no System BMS

SMPS Assembly 1 Phase Type A

V044-0004AA

1 Phase AC input, System BMS

SMPS Assembly 1 Phase Type B

V044-0005AA

1 Phase AC input, no System BMS

Rack Frame

V808-00068A

Black

Page 8

8 / 26

2. Product Description

The Battery system consists of four major components: 67Ah 8S1P Battery Module (“Battery Module”

hereinafter), String Management Unit (SMU) and SMPS Assembly. A single rack configuration of 34.6kWh

Battery System is comprised of one SMU and one SMPS Assembly and 17 Battery Modules.

Battery Module is the most basic component of the Battery System and it contains the energy storing battery

cells. There is a Module BMS inside each Battery Module. Module BMS checks the status of a Battery Module

by measuring its voltage and temperature. It also communicates with the SMU to send all measured voltage

and temperature data, and to receive commands to control cell balancing.

SMU collects all information about the battery system and controls the battery system by switching the main

power line and controls each Battery Module by cell balancing. SMU calculates the state-of-charge (SOC) and

state-of-health (SOH) of the battery system. Key components in the SMU are Rack BMS, MCCB, and shunt

resistor. Rack BMS is the main controller that takes all data from the Module BMS, measures the string

voltage and current, determines the state of the battery and controls the MCCB accordingly.

SMPS Assembly Type A is comprised of System BMS and switching mode power supply (SMPS). SMPS

Assembly Type A supplies power to the BMS and communicates with Uninterruptible Power Supply (UPS).

SMPS Assembly Type B is comprised of only SMPS which supplies power to the BMS.

Figure 1: 34.6kWh Lithium Ion Energy Storage System

Page 9

9 / 26

3. Safety Information and Handling

This Part details the safety information that personnel must fully understand and follow while transporting,

storing, installing, operating or servicing the Battery System. Before proceeding with unloading, unpacking,

handling, installation and operation, read the following details.

3.1 Safety Symbols

Table 3: Safety Symbols

DANGER

‘DANGER’ indicates a hazardous situation which will result in death

or serious injury if not avoided.

WARNING

‘WARNING’ indicates a hazardous situation which could result in

death or serious injury if not avoided.

CAUTION

‘CAUTION’ indicates a hazardous situation which could result in

minor or moderate injury if not avoided.

NOTICE

‘NOTICE’ indicates a hazardous situation which could result in

property damage if not avoided.

Energy Storage Device

To help avoid burns or electric shock :

- Service by qualified personnel only

- Disconnect main power before maintenance

- Turn off the Battery System before maintenance

Electric shock hazard

Do not remove cover or disassemble.

Explosive gas

Do not expose to flame, incinerate, puncture, or impact

Shield eyes

Wear safety goggles at ALL times. (Installation, maintenance, etc.)

Electrolyte hazard

Do not contact eyes, skin or clothing.

If it happens, Flush with water and seek medical aid immediately.

Do not dispose in trash

Transport legally. Follow manufacturer’s instructions for disposal.

Please recycle Lithium ion battery. Do not discard.

Page 10

10 / 26

Qualified technicians use this manual for service and replacement.

This symbol is attached to the position near the DC+, DC- and

communication port. If the user wants to access to the points near

this symbol, he has to be fully aware of the contents in this manual.

This symbol is near to the point for grounding.

Wire for grounding has to be connected to the point with this

symbol.

3.2 General Safety Information

The Battery System provides a safe source of electrical energy when operated as intended and as designed.

Potentially hazardous circumstances such as excessive heat or electrolyte mist may occur under improper

operating conditions, damage, misuse and/or abuse. The following safety precautions and the warning

messages described in this Part must be observed.

If any of the following precautions are not fully understood, or if you have any questions, contact Customer

Support for guidance. The Safety Part may not include all regulations for your locale; personnel working with

the Battery System must review applicable federal, state and local regulations as well as the industry

standards regarding this product.

3.2.1 Protective Equipment

When working with the Battery System, the following personal protective equipment must be worn:

- High voltage rated rubber gloves

- Safety goggles or other eye protection

3.2.2 Organic Solvent Electrolyte

Cell components of the Battery System contain organic solvent-based electrolyte. Breach of individual cells

may allow some electrolyte to be released from the cell. Direct contact with the liquid electrolyte can cause

skin irritation.

If contact with the liquid electrolyte occurs, follow the suggestions below to minimize the chance of injury:

- Flush eyes immediately with cold running water for at least 15 minutes.

- Rinse skin immediately with water for at least 15 minutes.

- Remove clothing if soiled.

- Seek immediate medical attention.

3.2.3 Electrolyte Vent Product

The Lithium-Ion chemistry used in the Battery System contains an organic solvent-based electrolyte. If the

Battery System is misused, damaged or abused, internal cell pressure may increase to excessive levels. Each

Page 11

11 / 26

cell within the Battery System is equipped with a non-resettable vent so that if internal cell pressure

increases, the cell’s vent will activate releasing the electrolyte vent products. When operated as intended and

designed, internal cell pressure remains stable and no electrolyte product venting occurs. Other structure

(rack, enclosure e.g.) must not interfere gas vent.

Organic solvent electrolyte vent products are flammable. To avoid serious injury from the release and ignition

of flammable products, the following guidelines must be observed:

- Operate the Battery System under conditions only as specified in this manual.

- Keep sparks, flames and smoking materials away from the Battery System.

- Do not incinerate, puncture or impact the Battery System.

- Do not solder or weld to the Battery System.

3.2.4 High Voltage Sources

DANGER: HIGH VOLTAGE – ELECTRIC SHOCK HAZARD. The Battery System contains high voltage

electric shock sources. Do NOT open any cover of Battery Module, SMU and SMPS Assembly.

Exposure to high voltage can cause serious electrical burns, shock or death. To avoid high voltage

electrical shock, follow the guidelines below:

- Do not work with high voltages unless you are qualified personnel.

- Personnel must fully understand the safety precautions associated with working on high voltage circuits.

- Personnel must fully understand the risk of working with batteries, and be prepared and equipped to

take the necessary safety precautions.

- Necessary equipment, including but not limited to insulated tools, high voltage rated rubber gloves,

rubber aprons, safety goggles, and face protection must be used.

- Ensure that the system is powered off and disconnected from outside circuits before servicing the unit.

3.2.5 Unloading and Unpacking

Carefully remove the plastic cover from the pallet. The packages are situated on a pallet on which it can be

transported via forklift from location to location.

A damaged box or rattles during transport may indicate rough handling. Make a descriptive notation on the

delivery receipt before signing. If damage is found, request an inspection by the carrier and file a damage

claim. Pay particular attention to a damaged crate or staining from electrolyte or other fluids. Delay in

notifying carrier may result in the loss of reimbursement for damages.

3.2.6 Storage

Follow the guidelines below when storing the Battery Modules.

- The battery module box should be upright as in Fig. 1 below. Do not stack or place upside down when

storing the battery module box.

Page 12

12 / 26

Figure 2: Storage Guide

- Do not stack more than five Battery Module boxes.

- Storage temperature must be in the range of 0 to 40°C.

- Storage humidity is recommended to be less than 60% RH under noncondensing.

- Capacity degradation will occur depending on storage time.

To minimize capacity degradation, storage temperature of less than 10°C and 3.630V per cell is

recommended.

3.3 General Handling Information

Follow the guidelines below when handling the Battery System.

- Do not short circuit the positive (+) and negative (-) terminals with metallic object intentionally.

- Do not remove insulation cap on the terminals. If insulation cap is removed, avoid contacting between

the metals and the battery terminals. Do not damage the screw thread.

- Do not use seriously scarred or deformed battery. Dispose them immediately according to proper

regulations.

- Do not damage sheath of cable and connectors.

Page 13

13 / 26

4. Specification and Characteristics

Table 4: Battery System General Specification

No.

Item

Specification

Remarks

1

Dimension

[mm, (inch)]

SMU

583 x 359.6 x 235.6,

(22.95 x 14.16 x 9.28)

Battery Module

403.5 x 214 x163,

(15.89 x 8.43 x 6.42)

Type A and Type B

SMPS Assembly 3 phase

397.4 x 355.6 x 85.5,

(15.64 x 14 x 3.37)

Type A and Type B

SMPS Assembly 1 phase

397.4 x 355.6 x 85.5,

(15.64 x 14 x 3.37)

Type A and Type B

Rack Frame

650 x 530 x 2055

(25.59 x 20.87 x 80.91)

2

Weight

[kg,(lb)]

SMU

About 18, (40)

Battery Module

About 16.5, (36)

Type A and Type B

SMPS Assembly

About 5, (11)

Type A and Type B

Rack Frame

About 163.4, (360)

136S Battery System

About 510, (1124)

128S Battery System

About 493, (1087)

112S Battery System

About 459, (1012)

104S Battery System

About 442, (974)

80S Battery System

About 391, (862)

3

Minimum Capacity

67Ah

1/3C (22A) charge and

discharge @25oC

4

Recommended Operation Temperature

23±5°C

5

Maximum Operating Altitude

2,000m above sea level

6

Storage Temperature

0 ~ 40°C

7

Storage Humidity

Less than 90 % RH

Noncondensing

8

Recommended Storage Humidity

Less than 60 % RH

Noncondensing

9

Storage Period1

Less than 6 months

10

Communication (Internal)

Differential UART,

2 Mbps

SMU – Battery Module

11

Communication (External)1

RS485

UPS – SMPS Assembly

Communication (External)2

TCP/IP

UPS – SMPS Assembly

Communication (External)3

Dry contact

UPS – SMPS Assembly

1

The Capacity degradation will occur depending on storage time.

- To minimize capacity degradation, storage temperature of less than 10°C and 3.630V per cell is recommended.

Page 14

14 / 26

Table 5: 136S Battery System Specification

No.

Item

Specification

Remarks

1

Number of Module

17

8 Type A

9 Type B

2

Nominal Capacity

34.6kWh

1/3C @25oC

3

Nominal Voltage1

516.8V DC

3.8V/cell

4

Maximum Voltage1

571.2V DC

4.2V/cell

5

Discharging Method

Constant Power

End of Discharge Voltage1

408V DC

3.0V/cell

Recommended End of Discharge Voltage1

435.2V DC

3.2V/cell

Standard Discharging Current1

22.3A

1/3C @25oC

Maximum Continuous Discharge Power1

183.6kW

Peak 450A @ EODV

6

Charging Method

CC-CV, Floating

Floating Charging Voltage1

571.2V DC

4.2V/cell

Standard Charging Current1

22.3A

1/3C

Maximum Peak Charging Current1

250A

2 second pulse

Maximum Continuous Charging Current1

67A

1C

1

Specified voltage and current must be satisfied in all load and charging conditions.

Notice: After a full discharge at maximum continuous discharge power, cool the battery for at least

12 hours before another discharge in order to avoid over-temperature protection. Immediate

recharging is allowed with standard charging current. For optimal performance, wait until the

battery temperature returns to at least ±3°C within the room temperature.

Table 6: 128S Battery System Specification

No.

Item

Specification

Remarks

1

Number of Module

16

8 Type A

8 Type B

2

Nominal Capacity

32.6kWh

1/3C@R.T

3

Nominal Voltage1

486.4V DC

3.8V/cell

4

Maximum Voltage1

537.6V DC

4.2V/cell

5

Discharging Method

Constant Power

End of Discharge Voltage1

384V DC

3.0V/cell

Recommended End of Discharge Voltage1

409.6V DC

3.2V/cell

Standard Discharging Current1

22.3A

1/3C@R.T

Maximum Continuous Discharge Power1

173kW

Peak 450A @ EODV

6

Charging Method

CC-CV, Floating

Floating Charging Voltage1

537.6V DC

4.2V/cell

Standard Charging Current1

22.3A

1/3C

Maximum Peak Charging Current1

250A

2 second pulse

Maximum Continuous Charging Current1

67A

1C

1

Specified voltage and current must be satisfied in all load and charging conditions.

Notice: After a full discharge at maximum continuous discharge power, cool the battery for at

least 12 hours before another discharge in order to avoid over-temperature protection.

Immediate recharging is allowed with standard charging current. For optimal performance, wait

until the battery temperature returns to at least ±3°C within the room temperature.

Page 15

15 / 26

Table 7: 112S Battery System General Specification

No.

Item

Specification

Remarks

1

Number of Module

14

6 Type A

8 Type B

2

Nominal Capacity

28.5kWh

1/3C@R.T

3

Nominal Voltage1

425.6V DC

3.8V/cell

4

Maximum Voltage1

470.4V DC

4.2V/cell

5

Discharging Method

Constant Power

End of Discharge Voltage1

336V DC

3.0V/cell

Recommended End of Discharge Voltage1

358.4V DC

3.2V/cell

Standard Discharging Current1

22.3A

1/3C@R.T

Maximum Continuous Discharge Power1

151kW

Peak 450A @ EODV

6

Charging Method

CC-CV, Floating

Floating Charging Voltage1

470.4V DC

4.2V/cell

Standard Charging Current1

22.3A

1/3C

Maximum Peak Charging Current1

250A

2 second pulse

Maximum Continuous Charging Current1

67A

1C

1

Specified voltage and current must be satisfied in all load and charging conditions.

Notice: After a full discharge at maximum continuous discharge power, cool the battery for at

least 12 hours before another discharge in order to avoid over-temperature protection.

Immediate recharging is allowed with standard charging current. For optimal performance, wait

until the battery temperature returns to at least ±3°C within the room temperature.

Table 8: 104S Battery System General Specification

No.

Item

Specification

Remarks

1

Number of Module

13

6 Type A

7 Type B

2

Nominal Capacity

26.5kWh

1/3C@R.T

3

Nominal Voltage1

395.2V DC

3.8V/cell

4

Maximum Voltage1

436.8V DC

4.2V/cell

5

Discharging Method

Constant Power

End of Discharge Voltage1

312V DC

3.0V/cell

Recommended End of Discharge Voltage1

332.8V DC

3.2V/cell

Standard Discharging Current1

22.3A

1/3C@R.T

Maximum Continuous Discharge Power1

140kW

Peak 450A @ EODV

6

Charging Method

CC-CV, Floating

Floating Charging Voltage1

436.8V DC

4.2V/cell

Standard Charging Current1

22.3A

1/3C

Maximum Peak Charging Current1

250A

2 second pulse

Maximum Continuous Charging Current1

67A

1C

1

Specified voltage and current must be satisfied in all load and charging conditions.

Notice: After a full discharge at maximum continuous discharge power, cool the battery for at

least 12 hours before another discharge in order to avoid over-temperature protection.

Immediate recharging is allowed with standard charging current. For optimal performance, wait

until the battery temperature returns to at least ±3°C within the room temperature.

Page 16

16 / 26

Table 9: 80S Battery System General Specification

No.

Item

Specification

Remarks

1

Number of Module

10

4 Type A

6 Type B

2

Nominal Capacity

20.4kWh

1/3C@R.T

3

Nominal Voltage1

304V DC

3.8V/cell

4

Maximum Voltage1

336V DC

4.2V/cell

5

Discharging Method

Constant Power

End of Discharge Voltage1

240V DC

3.0V/cell

Recommended End of Discharge Voltage1

256V DC

3.2V/cell

Standard Discharging Current1

22.3A

1/3C@R.T

Maximum Continuous Discharge Power1

108kW

Peak 450A @ EODV

6

Charging Method

CC-CV, Floating

Floating Charging Voltage1

336V DC

4.2V/cell

Standard Charging Current1

22.3A

1/3C

Maximum Peak Charging Current1

250A

2 second pulse

Maximum Continuous Charging Current1

67A

1C

1

Specified voltage and current must be satisfied in all load and charging conditions.

Notice: After a full discharge at maximum continuous discharge power, cool the battery for at

least 12 hours before another discharge in order to avoid over-temperature protection.

Immediate recharging is allowed with standard charging current. For optimal performance, wait

until the battery temperature returns to at least ±3°C within the room temperature.

Page 17

17 / 26

5. Block Diagram and Configuration

A single rack system consists of 1 SMU, 1 SMPS Assembly and Battery Modules ranging from 10 modules

(20.4kWh) to 17 modules (34.6kWh).

Refer to Figure 3: General System Block Diagram.

Figure 3: General System Block Diagram

Page 18

18 / 26

6. Detail Product Description

6.1 Battery Module

Type A: EM2031AE003A

Type B: EM2031AE004A

There are two types of 8S1P Battery Module depending on the position of terminal’s polarity.

Type A’s plus(+) terminal is on the right side. Type B is on the left.

Nominal capacity: 67 Ah

Nominal voltage: 30.40 V

Battery Module Type A (Isometric)

Battery Module Type A

(Front. Front cover removed)

Figure 4 : Battery Module Type A

Battery Module Type B (Isometric)

Battery Module Type B

(Front. Front cover removed)

Figure 5 : Battery Module Type B

Page 19

19 / 26

6.2 SMU

UL: V049-0011AA

The SMU consists of protection devices and a rack BMS. The key component of protection devices are as

follows

Fuse: 500A rating

MCCB UL/CE: 600A rating

Figure 6: SMU

Page 20

20 / 26

6.3 SMPS Assembly

3 Phase Type A (with System BMS): V044-0006AA

3 Phase Type B (without System BMS): SJ94-00238B

1 Phase Type A (with System BMS): V044-0004AA

1 Phase Type B (without System BMS): V044-0005AA

SMPS Assembly houses the System BMS and SMPS, which provides power to the System BMS and SMU. Two

options are available for the SMPS depending on the AC input range and cabling: 3 phase and 1 phase. The

System BMS assembly provides data to the external systems (i.e. building management system, UPS, etc.)

while controlling and monitoring all connected Rack BMS.

There are two types of SMPS Assembly: Type A is with System BMS and Type B is without System BMS.

SMPS Assembly with 3 Phase AC Input

SMPS Assembly with 1 Phase AC Input

Type A (with System BMS)

Type B (without System BMS)

Figure 7: SMPS Assembly

Page 21

21 / 26

6.4 Rack Frame

Black: V808-00068A

The Rack Frame is used to mount the modules, SMU and SMPS Assembly and provides ground connections

for SMU and SMPS Assembly.

(Grounding cable/bus bar for the rack frame is necessary for the SMU and SMPS assembly as they are

grounded to the rack frame when installed.)

Figure 8: Rack Frame

Page 22

22 / 26

7. LED Indication

LED indicator in front of the SMU shows the status of the battery.

7.1 Battery Status Display The LED shows several battery conditions.

Table 10: LED Indicator

Items

POWER(Green)

FAULT(Red)

ALARM(Yellow)

CURRENT(Green)

Location

Status

On : MCCB Off

Off : Power Off

Blink : MCCB On

On : N/A

Off : Power Off

Blink : Major

Protection

On : N/A

Off : Power Off

Blink : Minor

Protection

On : Discharge

Off : Idle

Blink : Charge

Table 11: Indicated Codes

LED Status

Battery Status

Remarks

POWER steady

Normal status

MCCB Off

POWER blinking

Normal status

MCCB On

POWER blinking

CURRENT steady

Normal Status

Discharge

POWER blinking

CURRENT blinking

Normal Status

Charge

POWER steady

FAULT blinking

Major Protection

MCCB tripped

POWER blinking

ALARM blinking

Minor Protection

MCCB on

Page 23

23 / 26

8. Evaluation

This part lists all regulation and safety tests conducted by Samsung SDI or a third-party organization. Refer to

additional report for more information on test specification.

Table 12: List of Standards and Regulations

No.

Regulation

Tested Product

Result

1

UL1642

Cell

OK 2 UN38.3

Cell, 8S1P Module

OK 3 UL1973, UL991, UL1998

8S1P Module, System

OK 4 CE (IEC 62477-1, EN 61000), IEC 62619

8S1P Module, System

OK

※ Other evaluations are based on customer requirements or Samsung SDI’s standards.

Page 24

24 / 26

9. Packaging and Shipment

The Battery System is packaged in groups of each component. Refer to additional specification document on

packaging and shipment details.

Page 25

25 / 26

10. Service, Maintenance and Warranty

10.1 Service

There are no user serviceable parts in the Battery Module, SMU and SMPS Assembly. Written authorization

from Samsung SDI is required to open the Battery Module, SMU and SMPS assembly or perform any

maintenance thereon. For service inquiries and questions please contact Samsung SDI.

10.2 Maintenance

The Battery System is designed to be free of maintenance when the recommended operating parameters are

followed.

10.3 Warranty

Do not disassemble the Battery Modules, SMU and SMPS Assembly as doing so presents a safety hazard

and will void the warranty. Contact Samsung SDI for more information. Refer to the purchase agreement for

warranty details.

Page 26

26 / 26

Contact Information

Corporate Headquarters

Samsung SDI, Co. Ltd.

150-20, Gongse-ro, Giheung-gu, Yongin-si, Gyeonggi-do

Republic of Korea

Telephone: 82-31-8006-3336

Homepage: www.samsungsdi.com

Loading...

Loading...