Samsung TSL3099 Service Manual

COLOR TELEVISION RECEIVER

Chassis : K54A(P)

Model : TSL3099WF/XAA

COLOR TELEVISION RECEIVER CONTENTS

Precautions

Reference Information

Specifications

Alignment and Adjustments

Troubleshooting

Exploded Views and Parts List

Electrical Parts List

Block Diagrams

Schematic Diagrams

1.

2.

3.

4.

5.

6.

7.

8.

9.

1. Precautions

1-1 Safety Precautions

1. Be sure that all of the built-in protective

devices are replaced. Restore any missing

protective shields.

2. When reinstalling the chassis and its

assemblies, be sure to restore all protective

devices, including: nonmetallic control knobs

and compartment covers.

3. Make sure that there are no cabinet openings

through which people—particularly

children—might insert fingers and contact

dangerous voltages. Such openings include

the spacing between the picture tube and the

cabinet mask, excessively wide cabinet

ventilation slots, and improperly fitted back

covers.

If the measured resistance is less than 1.0

megohm or greater than 5.2 megohms, an

abnormality exists that must be corrected

before the unit is returned to the customer.

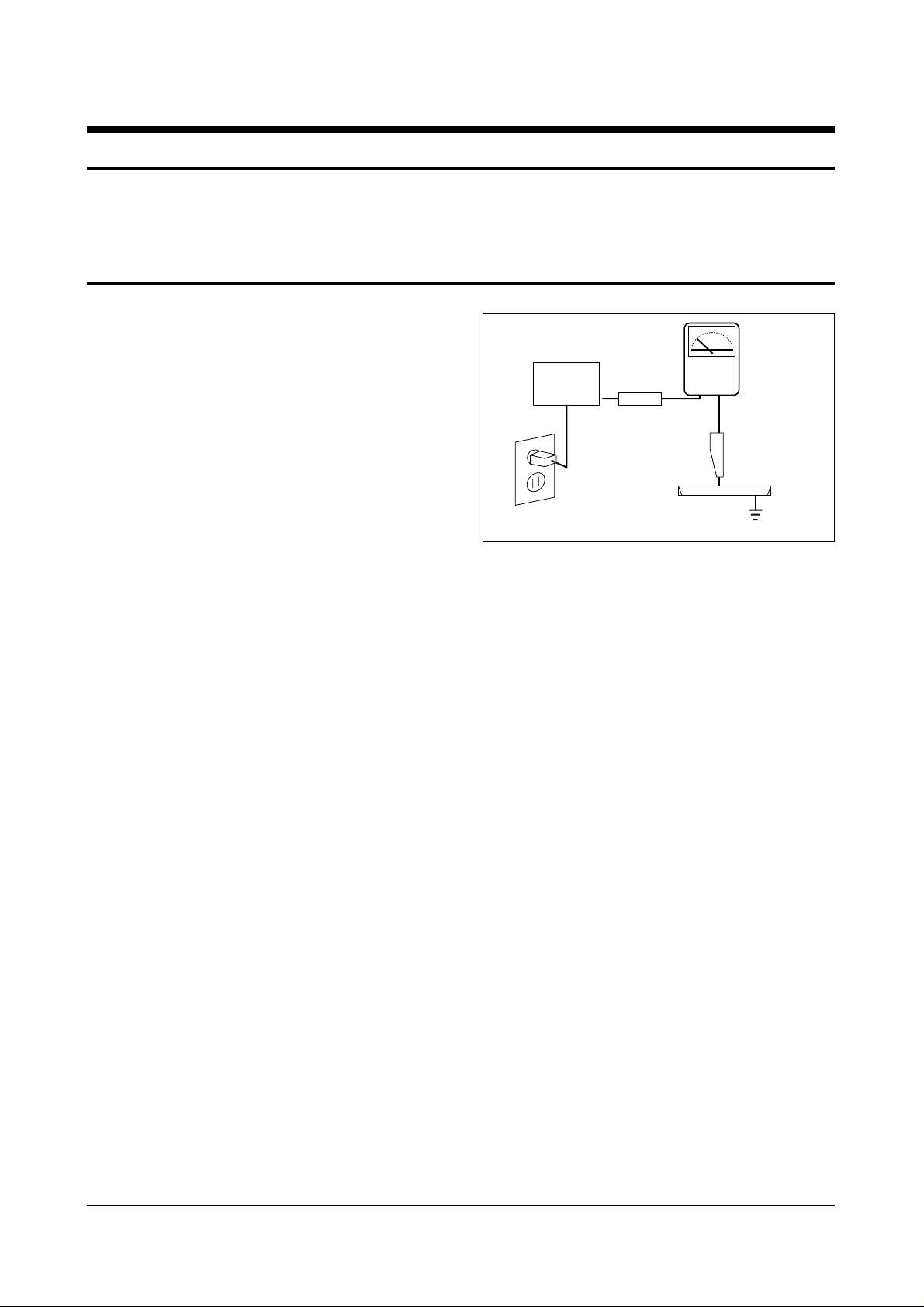

4. Leakage Current Hot Check (Figure 1-1):

Warning: Do not use an isolation

transformer during this test. Use a leakagecurrent tester or a metering system that

complies with American National Standards

Institute (ANIS C101.1, Leakage Current for

Appliances), and Underwriters Laboratories

(UL Publication UL1410, 59.7).

5. With the unit completely reassembled, plug

the AC line cord directly into the power

outlet. With the unit’s AC switch first in the

ON position and then OFF, measure the

current between a known earth ground (metal

water pipe, conduit, etc.) and all exposed

metal parts, including: antennas, handle

brackets, metal cabinets, screwheads and

control shafts. The current measured should

not exceed 0.5 milliamp. Reverse the powerplug prongs in the AC outlet and repeat the

test.

Fig. 1-1 AC Leakage Test

6. Antenna Cold Check:

With the unit’s AC plug disconnected from the

AC source, connect an electrical jumper across

the two AC prongs. Connect one lead of the

ohmmeter to an AC prong. Connect the other

lead to the coaxial connector.

7. X-ray Limits:

The picture tube is especially designed to

prohibit X-ray emissions. To ensure continued

X-ray protection, replace the picture tube only

with one that is the same type as the original.

Carefully reinstall the picture tube shields and

mounting hardware; these also provide X-ray

protection.

8. High Voltage Limits:

High voltage must be measured each time

servicing is done on the B+, horizontal

deflection or high voltage circuits.

Correct operation of the X-ray protection

circuits must be reconfirmed whenever they

are serviced.

(X-ray protection circuits also may be called

“horizontal disable” or “hold-down”.)

Heed the high voltage limits. These include

the X–ray Protection Specifications Label, and

the Product Safety and X-ray Warning Note on

the service data schematic.

Precautions

Samsung Electronics 1-1

LEAKAGE

CURRENT

TESTER

DEVICE

UNDER

TEST

TEST ALL

EXPOSED METAL

SURFACES

2-WIRE CORD

ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

EARTH

GROUND

(READING SHOULD

NOT BE ABOVE

0.5mA)

Follow these safety, servicing and ESD precautions to prevent damage and protect against potential

hazards such as electrical shock and X-rays.

1-1 Safety Precautions (Continued)

9. High voltage is maintained within specified

limits by close-tolerance, safety-related

components and adjustments. If the high

voltage exceeds the specified limits, check

each of the special components.

10. Design Alteration Warning:

Never alter or add to the mechanical or

electrical design of this unit. Example: Do not

add auxiliary audio or video connectors. Such

alterations might create a safety hazard. Also,

any design changes or additions will void the

manufacturer’s warranty.

11. Hot Chassis Warning:

Some TV receiver chassis are electrically

connected directly to one conductor of the AC

power cord. If an isolation transformer is not

used, these units may be safely serviced only

if the AC power plug is inserted so that the

chassis is connected to the ground side of the

AC source.

To confirm that the AC power plug is inserted

correctly, do the following: Using an AC

voltmeter, measure the voltage between the

chassis and a known earth ground. If the

reading is greater than 1.0V, remove the AC

power plug, reverse its polarity and reinsert.

Re-measure the voltage between the chassis

and ground.

12. Some TV chassis are designed to operate with

85 volts AC between chassis and ground,

regardless of the AC plug polarity. These units

can be safely serviced only if an isolation

transformer inserted between the receiver and

the power source.

13. Some TV chassis have a secondary ground

system in addition to the main chassis ground.

This secondary ground system is not

isolated from the AC power line. The two

ground systems are electrically separated by

insulating material that must not be defeated

or altered.

14. Components, parts and wiring that appear to

have overheated or that are otherwise

damaged should be replaced with parts that

meet the original specifications. Always

determine the cause of damage or

overheating, and correct any potential

hazards.

15. Observe the original lead dress, especially

near the following areas: Antenna wiring,

sharp edges, and especially the AC and high

voltage power supplies. Always inspect for

pinched, out-of-place, or frayed wiring. Do

not change the spacing between components

and the printed circuit board. Check the AC

power cord for damage. Make sure that leads

and components do not touch thermally hot

parts.

16. Picture Tube Implosion Warning:

The picture tube in this receiver employs

“integral implosion” protection. To ensure

continued implosion protection, make sure

that the replacement picture tube is the same

as the original.

17. Do not remove, install or handle the picture

tube without first putting on shatterproof

goggles equipped with side shields. Never

handle the picture tube by its neck. Some

“in-line” picture tubes are equipped with a

permanently attached deflection yoke; do not

try to remove such “permanently attached”

yokes from the picture tube.

18. Product Safety Notice:

Some electrical and mechanical parts have

special safety-related characteristics which

might not be obvious from visual inspection.

These safety features and the protection they

give might be lost if the replacement

component differs from the original—even if

the replacement is rated for higher voltage,

wattage, etc.

Components that are critical for safety are

indicated in the circuit diagram by shading,

( ) or ( ).

Use replacement components that have the

same ratings, especially for flame resistance

and dielectric strength specifications.

A replacement part that does not have the

same safety characteristics as the original

might create shock, fire or other hazards.

Precautions

1-2 Samsung Electronics

1-2 Servicing Precautions

1. Servicing precautions are printed on the

cabinet. Follow them.

2. Always unplug the unit’s AC power cord from

the AC power source before attempting to:

(a) Remove or reinstall any component or

assembly, (b) Disconnect an electrical plug or

connector, (c) Connect a test component in

parallel with an electrolytic capacitor.

3. Some components are raised above the printed

circuit board for safety. An insulation tube or

tape is sometimes used. The internal wiring is

sometimes clamped to prevent contact with

thermally hot components. Reinstall all such

elements to their original position.

4. After servicing, always check that the screws,

components and wiring have been correctly

reinstalled. Make sure that the portion around

the serviced part has not been damaged.

5. Check the insulation between the blades of the

AC plug and accessible conductive parts

(examples: metal panels, input terminals and

earphone jacks).

6. Insulation Checking Procedure: Disconnect the

power cord from the AC source and turn the

power switch ON. Connect an insulation

resistance meter (500V) to the blades of the AC

plug.

The insulation resistance between each blade

of the AC plug and accessible conductive parts

(see above) should be greater than 1 megohm.

7. Never defeat any of the B+ voltage interlocks.

Do not apply AC power to the unit (or any of

its assemblies) unless all solid-state heat sinks

are correctly installed.

8. Always connect a test instrument’s ground

lead to the instrument chassis ground before

connecting the positive lead; always remove

the instrument’s ground lead last.

Precautions

Samsung Electronics 1-3

Warning1: First read the “Safety Precautions” section of this manual. If some unforeseen circumstance creates a conflict between

the servicing and safety precautions, always follow the safety precautions.

Warning2: An electrolytic capacitor installed with the wrong polarity might explode.

1. Some semiconductor (“solid state”) devices

are easily damaged by static electricity. Such

components are called Electrostatically

Sensitive Devices (ESDs); examples include

integrated circuits and some field-effect

transistors. The following techniques will

reduce the occurrence of component damage

caused by static electricity.

2. Immediately before handling any semicon

ductor components or assemblies, drain the

electrostatic charge from your body by

touching a known earth ground. Alternatively,

wear a discharging wrist-strap device. (Be

sure to remove it prior to applying power—

this is an electric shock precaution.)

3. After removing an ESD-equipped assembly,

place it on a conductive surface such as

aluminum foil to prevent accumulation of

electrostatic charge.

4. Do not use freon-propelled chemicals. These

can generate electrical charges that damage

ESDs.

5. Use only a grounded-tip soldering iron when

soldering or unsoldering ESDs.

6. Use only an anti-static solder removal device.

Many solder removal devices are not rated as

“anti-static”; these can accumulate sufficient

electrical charge to damage ESDs.

7. Do not remove a replacement ESD from its

protective package until you are ready to

install it. Most replacement ESDs are

packaged with leads that are electrically

shorted together by conductive foam,

aluminum foil or other conductive materials.

8. Immediately before removing the protective

material from the leads of a replacement ESD,

touch the protective material to the chassis or

circuit assembly into which the device will be

installed.

9. Minimize body motions when handling

unpackaged replacement ESDs. Motions such

as brushing clothes together, or lifting a foot

from a carpeted floor can generate enough

static electricity to damage an ESD.

Precautions

1-4 Samsung Electronics

1-3 Precautions for Electrostatically Sensitive Devices (ESDs)

Reference Information

Samsung Electronics 2-1

2. Reference Information

2-1 Tables of Abbreviations and Acronyms

A

Ah

Å

dB

dBm

°C

°F

°K

F

G

GHz

g

H

Hz

h

ips

kWh

kg

kHz

kΩ

km

km/h

kV

kVA

kW

I

MHz

Ampere

Ampere-hour

Angstrom

Decibel

Decibel Referenced to One

Milliwatt

Degree Celsius

Degree Fahrenheit

degree Kelvin

Farad

Gauss

Gigahertz

Gram

Henry

Hertz

Hour

Inches Per Second

Kilowatt-hour

Kilogram

Kilohertz

Kilohm

Kilometer

Kilometer Per Hour

Kilovolt

Kilovolt-ampere

Kilowatt

Liter

Megahertz

MV

MW

MΩ

m

µA

µF

µH

µm

µs

µW

mA

mg

mH

mI

mm

ms

mV

nF

Ω

pF

Ib

rpm

rps

s

V

VA

W

Wh

Megavolt

Megawatt

Megohm

Meter

Microampere

Microfarad

Microhenry

Micrometer

Microsecond

Microwatt

Milliampere

Milligram

Millihenry

Milliliter

Millimeter

Millisecond

Millivolt

Nanofarad

Ohm

Picofarad

Pound

Revolutions Per Minute

Revolutions Per Second

Second (Time)

Volt

Volt-ampere

Watt

Watt-hour

Table 2-1 Abbreviations

Reference Information

2-2 Samsung Electronics

Table 2-2 Table of Acronyms

ABL

AC

ACC

AF

AFC

AFT

AGC

AM

ANSI

APC

APC

A/V

AVC

BAL

BPF

B-Y

CATV

CB

CCD

CCTV

Ch

CRT

CW

DC

DVM

EIA

ESD

ESD

FBP

FBT

FF

FM

FS

GND

G-Y

H

HF

HI-FI

IC

IC

IF

Automatic Brightness Limiter

Alternating Current

Automatic Chroma Control

Audio Frequency

Automatic Frequency Control

Automatic Fine Tuning

Automatic Gain Control

Amplitude Modulation

American National Standards Institute

Automatic Phase Control

Automatic Picture Control

Audio-Video

Automatic Volume Control

Balance

Bandpass Filter

Blue-Y

Community Antenna Television (Cable TV)

Citizens Band

Charge Coupled Device

Closed Circuit Television

Channel

Cathode Ray Tube

Continuous Wave

Direct Current

Digital Volt Meter

Electronics Industries Association

Electrostatic Discharge

Electrostatically Sensitive Device

Feedback Pulse

Flyback Transformer

Flip-Flop

Frequency Modulation

Fail Safe

Ground

Green-Y

High

High-Frequency

High Fidelity

Inductance-Capacitance

Integrated Circuit

Intermediate Frequency

I/O

L

L

LED

LF

MOSFET

MTS

NAB

NEC

NTSC

OSD

PCB

PLL

PWM

QIF

R

RC

RF

R-Y

SAP

SAW

SIF

SMPS

S/N

SW

TP

TTL

TV

UHF

UL

UV

VCD

VCO

VCXO

VHF

VIF

VR

VTR

VTVM

TR

Input/output

Left

Low

Light Emitting Diode

Low Frequency

Metal-Oxide-Semiconductor-Field-Effect-Tr

Multi-channel Television Sound

National Association of Broadcasters

National Electric Code

National Television Systems Committee

On Screen Display

Printed Circuit Board

Phase-Locked Loop

Pulse Width Modulation

Quadrature Intermediate Frequency

Right

Resistor & Capacitor

Radio Frequency

Red-Y

Second Audio Program

Surface Acoustic Wave(Filter)

Sound Intermediate Frequency

Switching Mode Power Supply

Signal/Noise

Switch

Test Point

Transistor Transistor Logic

Television

Ultra High Frequency

Underwriters Laboratories

Ultraviolet

Variable-Capacitance Diode

Voltage Controlled Oscillator

Voltage Controlled Crystal Oscillator

Very High Frequency

Video Intermediate Frequency

Variable Resistor

Video Tape Recorder

Vacuum Tube Voltmeter

Transistor

Reference Information

Samsung Electronics 2-3

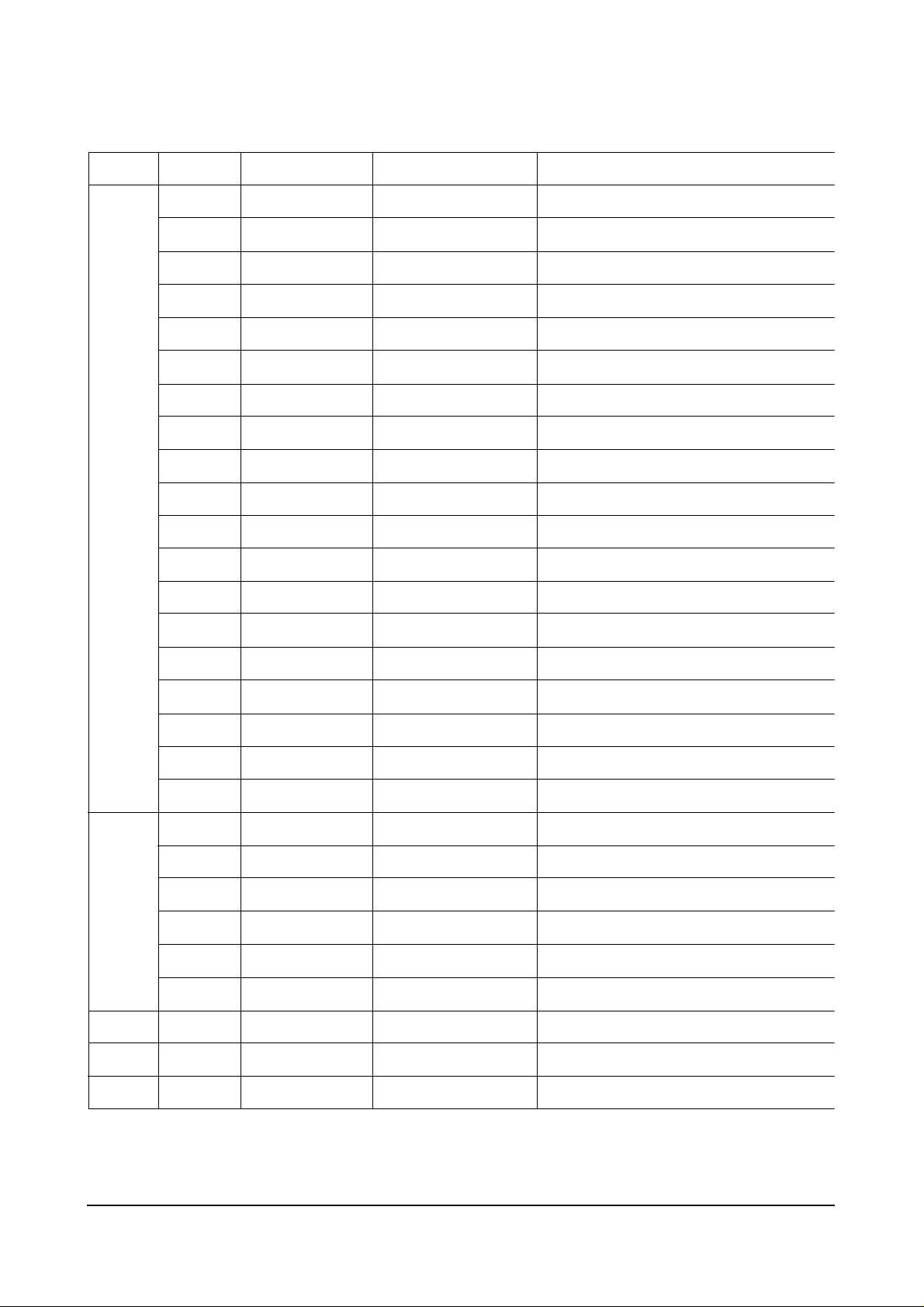

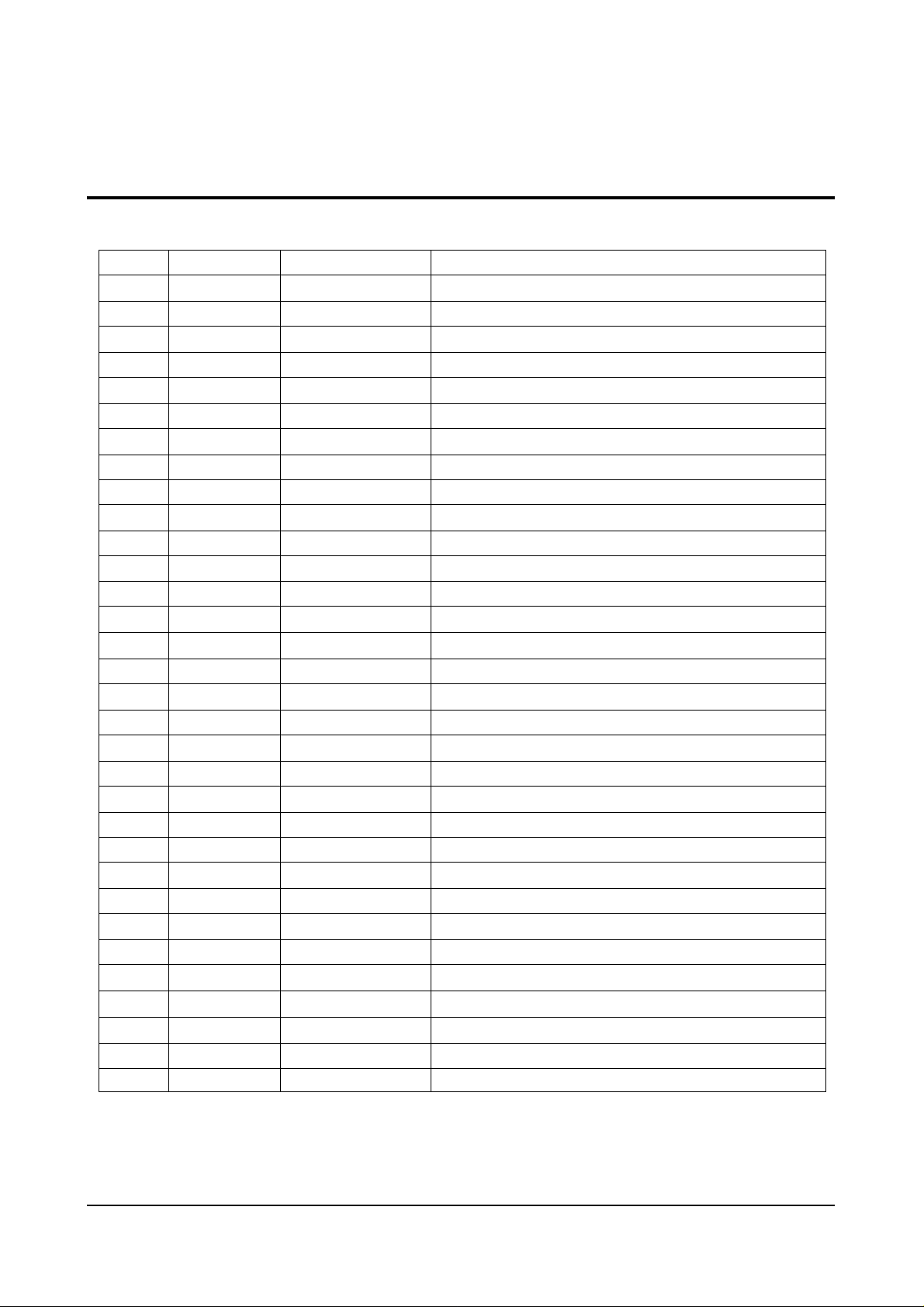

2-2 IC Line Up

Part-Number

IC Name

MSP3440G-A4

TCLN318PA09A(S)

TCPN3081PC09A(S)

TNY253P

FMQG5GS

FMQG5GS

SE140N DIP

MAIN

Block Des-Loc Part-Number

MAIN

IC601

IC701

IC702

IC703

TU01

TUP01

IC905

ICG01

ICH01

IC602

IC603

IC804

IC805

ICH01

1204-001575

1001-001073

1001-001113

1002-001193

AA40-00020A

AA40-00032A

1103-001171

0801-000314

1204-001454

1201-000407

1201-001385

1203-000203

1203-000203

1201-000191

TCLN318PA09A(S)

TCPN3081PC09A(S)

IC Name

MSP3440G-A4

TEA6415C

TEA6422

PCF8591P

24L161

74HCT86

TDA7449L

TDA7050

TDA7269A

SI3050

SI3050

4558

Description

IC-SOUND PROCESSOR

IC-VIDEO SWITCH

IC-AUDIO SWITCH

IC-A/D & D/A CONVERTER

TUNER-F/S

TUNER-F/S

IC-EEPROM

IC-CMOS LOGIC

IC-VOLUME CONTROL

IC-POWER AMP

IC-POWER AMP

IC-POSI.ADJUST REG.

IC-POSI.ADJUST REG.

IC-OP AMP

POWER

IC802

IC803

IC801

IC301

D801S

IC801S

IC803S

Q403

Q404

QH407

QH408

QH406

QH405

QH401

DH400

1203-000293

1203-000298

1203-000165

1204-000517

0402-001399

1203-002091

AA13-00024A

0505-000156

0505-001116

0502-001187

0502-001104

0502-001100

0505-001202

0402-001176

0402-001176

KA7808

KA7809

78R12

LA7845

GSDIB660

STR-F6658B

TNY253P

IRF620

BUZ73A

2SC5612

2SD921

2SD4125

IRF640

FMQG5GS

FMQG5GS

IC-POSI.FIXED REG.

IC-POSI.FIXED REG.

IC-POSI.ADJUST REG.

IC-VERTIVAL DEF.

IC-HYBRID

IC-HYBRID

IC-HYBRID

FET-SILICON

FET-SILICON

TR-POWER

TR-POWER

TR-POWER

FET-HYBRID

TR-DIODE

TR-DIODE

Q801

1004-000101

SE140N DIP

IC-HYBRID

2-4 Samsung Electronics

Reference Information

F-BOX

DOLBY

Block Des-Loc Part-Number IC Name Description

F-BOX

IC01

IC02

IC05

IC06

IC07

IC08

IC03

IC04

PIC01

PIC02

PIC04

PIC05

IC902

IC903

1204-001598

AA13-00095A

1002-001045

1204-001372

1204-001550

AA13-00084A

1105-001035

1105-001035

1204-001598

1109-001144

1203-001419

1203-001419

1203-001140

1203-001274

VPC3230D-A0

SDP01

SDA9280

SDA9361

CXA2101AQ

M4LV-32/32-12VC48

416S1120

416S1120

VPC3230D-A0

81V04160

4931

4931

7039

7545

IC-VIDEO PROCESS

IC-ASIC

IC-D/A CONVERTER

IC-HOR./VER.PROCESS

IC-VIDEO PROCESS

IC-ASIC

IC-DRAM

IC-DRAM

IC-VIDEO PROCESS

IC-FIFO

IC-VOLTAGE REGULATOR

IC-VOLTAGE REGULATOR

IC-VOL.DETECTOR

IC-VOL.DETECTOR

CRT

DOLBY

MICOM

3D-COMB

IC11

IC12

IC13

IC14

IC04

IC501

IC502

IC503

QF10

QF09

IC504

IC601

IC901

IC01

1203-001419

1203-001140

1203-001359

1202-000001

1203-001419

1201-001588

1201-001588

1201-001588

0502-000153

0502-000131

1201-000010

1204-001198

AA09-00101A

1204-001556

4931

7039

1086

KA7533

4931

TDA6120Q

TDA6120Q

TDA6120Q

2SC2344-D

2SA1011A-D

2030

DPL3519A

Z9037116PSC-OTP

UPD64082GF

IC-VOLTAGE REGULATOR

IC-VOL.DETECTOR

IC-POSI.FIXED REG.

IC-VOLTAGE COMP.

IC-VOLTAGE REGULATOR

IC-VIDEO AMP

IC-VIDEO AMP

IC-VIDEO AMP

TR-POWER

TR-POWER

IC-OP AMP

IC-DSP

IC-MCU

IC-SEPARATOR

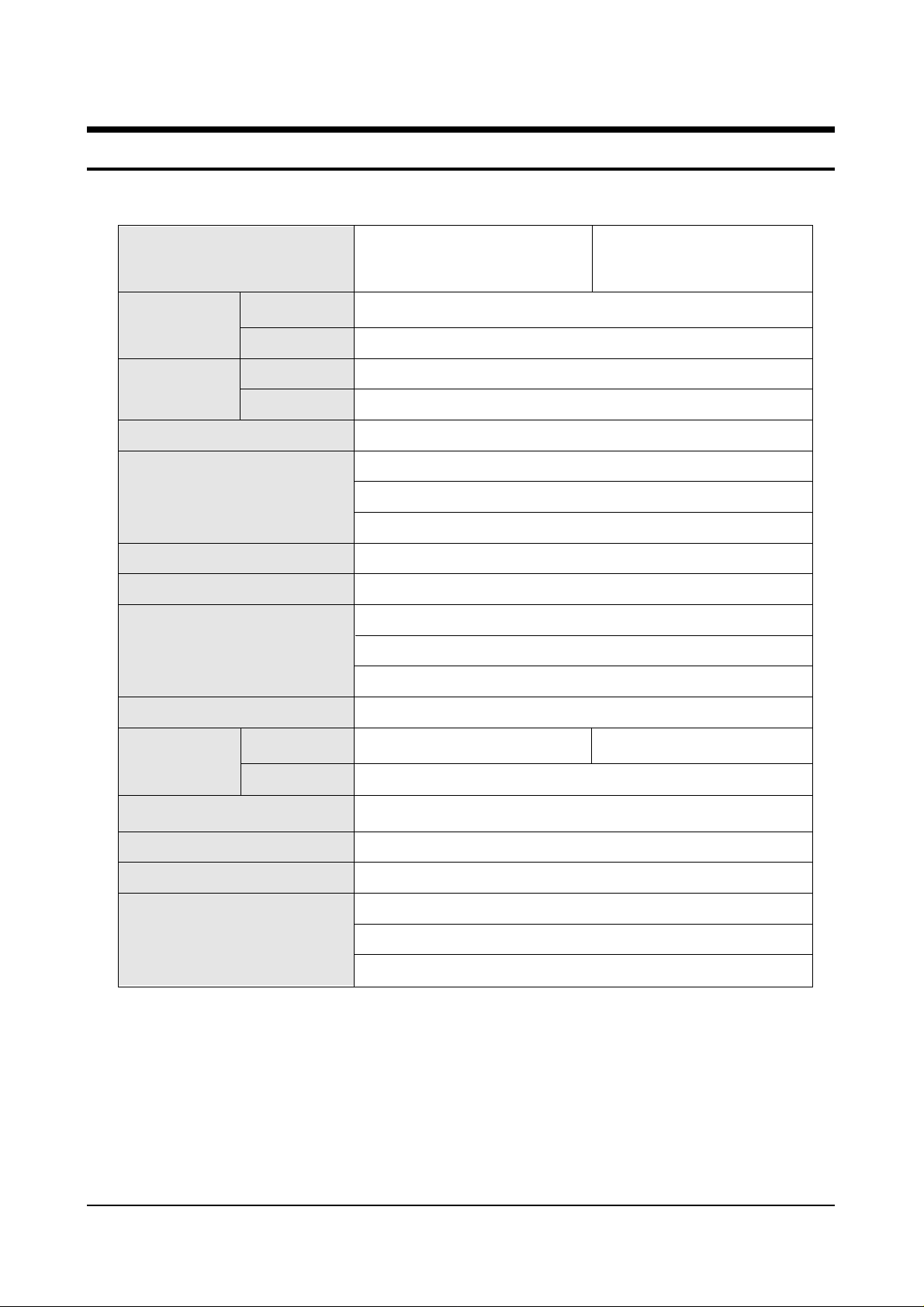

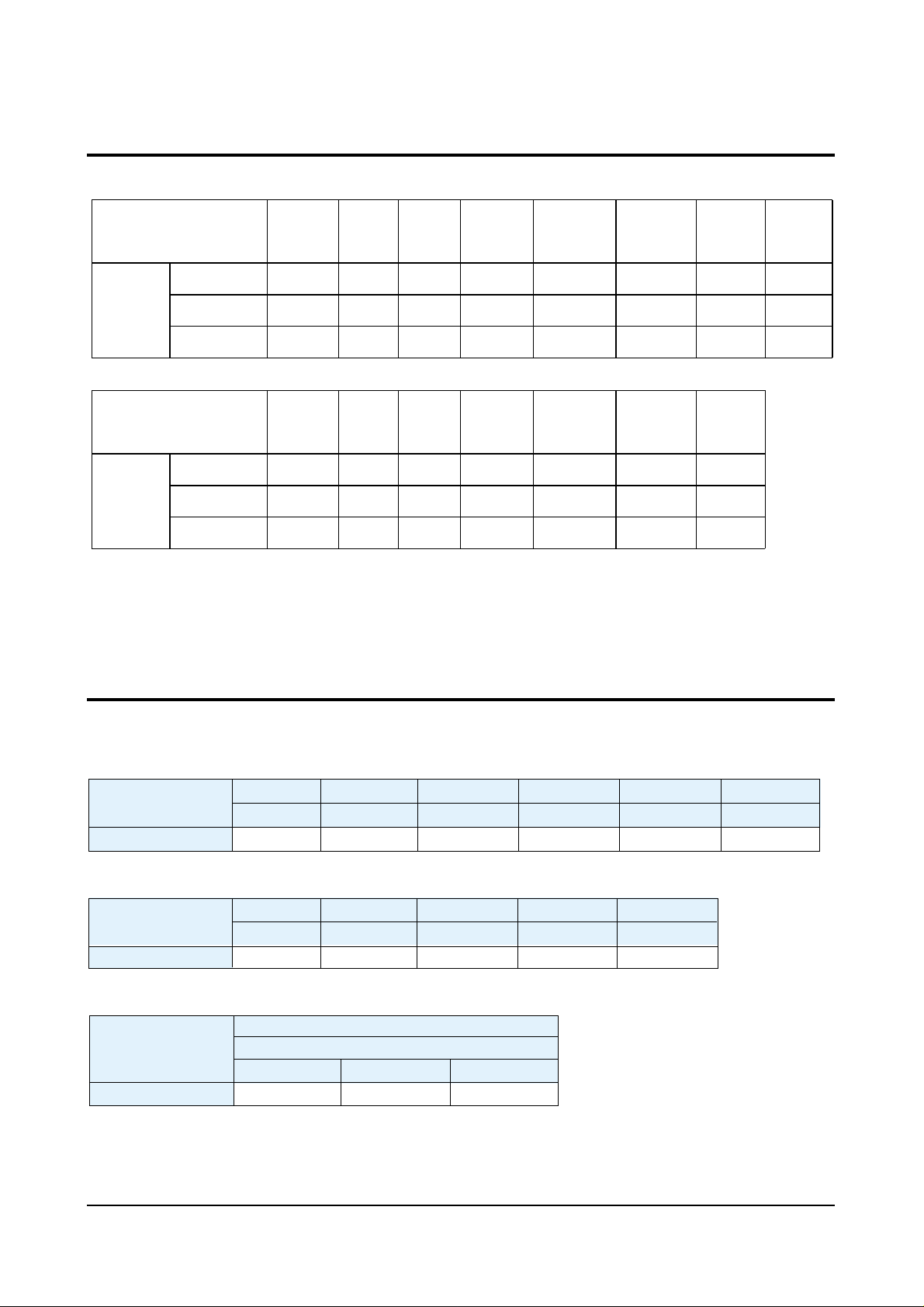

Specifications

Samsung Electronics 3-1

3. Specifications

Specifications are subject to change.

Model

Dimensions

(mm)

Weight

Set

Transmitter

Tuning Ranges

Television System

Intermediate Frequency

Set

Transmitter

TSL3099WF

65 Kg

153 g (including batteries)

Hi Contrast Instant Reception Type

VHF (CH 2 ~ 13)

UHF (CH 14 ~ 69)

CATV (CH 1, 14 ~ 125)

NTSC-M

VHF, UHF: 75 ohm unbalanced type

Video: 45.75 MHz

Sound: 41.25 MHz

Chrominance Subcarrier: 42.17 MHz

Reverse Automatic Gain Control (Reverse AGC)

910 (W) x 455 (D) x 578 (H)

54 (W) x 31.5 (D) x 220 (H)

CT-29A7PD9X, CT-34A7PD9X

Set

Transmitter

Picture Tube

Antenna Input

Automatic Gain Control

Power Supply

AC 120 V, 60 Hz

AC 100-240, 50/60Hz

DC 1.5V (AAA Size) x 2

220 W

Insulation Switch

7.5 W x 2, WOOFER: 22WX1

Transmitter Adjustment: Infrared Rays Type

UHF/VHF electronic tuner fine tuning: Electronic Type

Electronic Function Adjustment

Power Consumption

Rectification

Sound Output

Adjustment System

3-2 Samsung Electronics

MEMO

Alignment and Adjustments

Samsung Electronics 4-1

4. Alignment and Adjustments

4-1 Adjustments

Usually, a color TV needs only slight touch-up adjustment upon installation. Check the basic

characteristics such as vertical size, horizontal size, and focus. Observe the picture and check for

good black and white details. There must be no objectionable color shading: If color shading is

present, demagnetize the receiver. If color shading persists, re-do purity and convergence adjustments.

Note :

1. This ‘4. Alignment and Adjustments’ applies to K54A chassis applications.

2. AC Power Supply: 220 V only

3. This service manual has been written on the basis of domestic remote-control model adopting K54A

chassis. Depending on sales location and product specifications, some of specifications herein may

be changed.

K54A contains a dynamic focus circuit. When CRT PCB, FBT or CRT is replaced, be sure to adjust

in the following sequence:

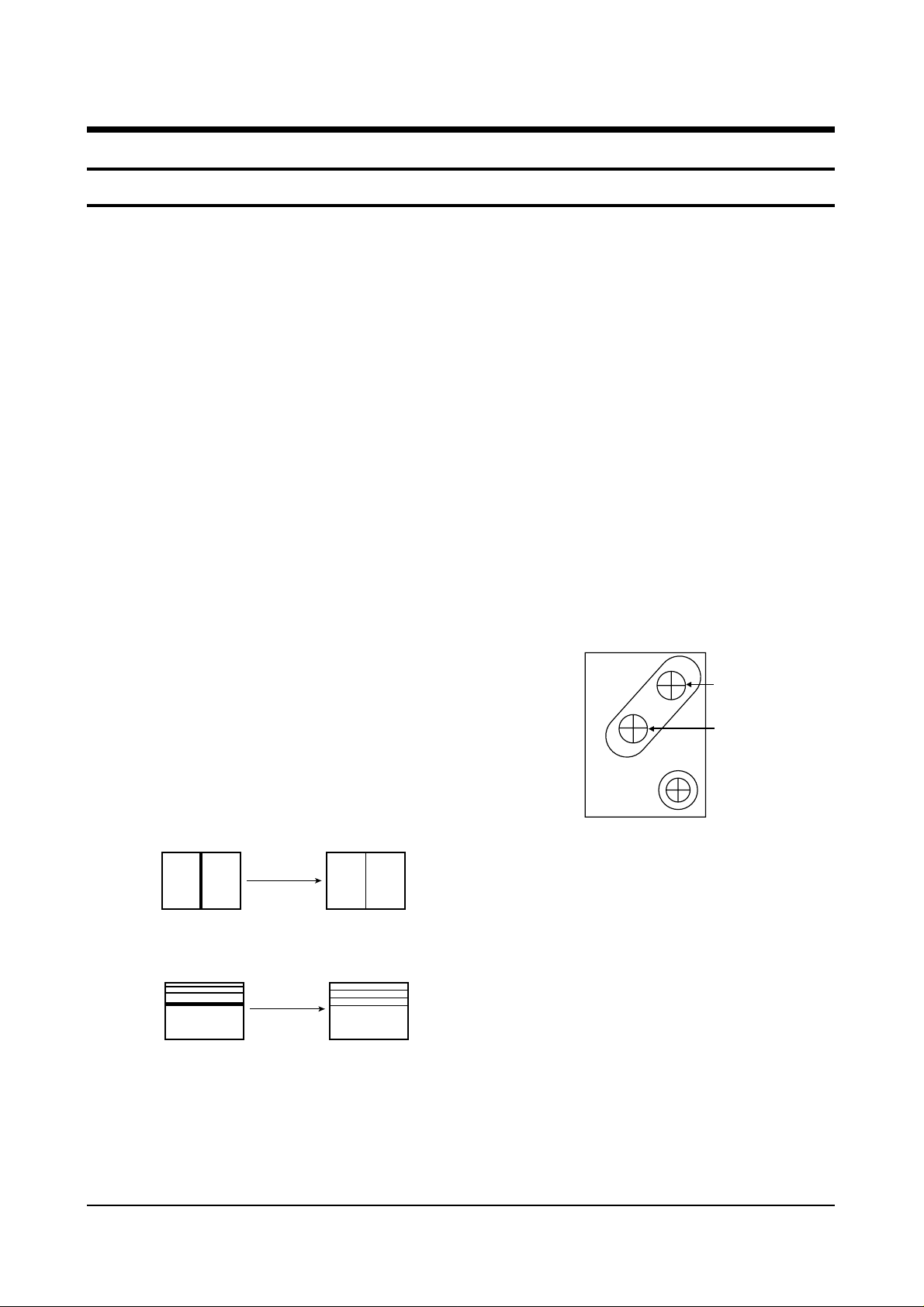

4-1-1 General Alignment Instructions

4-1-2 Focus Adjustment

Dynamic Focus Adjustment

1. Input a crosshatch pattern.

2. Select “Standard” from the menu,

3. Turn the Static Focus VR clockwise to set it to its maximum.

4. Turn the Dynamic Focus VR counterclockwise to set it to its

maximum.

5. Turn the Static Focus VR counterclockwise slowly for the clearest

center vertical line.

<FBT FOCUS PACK>

6. Turn the Dynamic Focus VR clockwise slowly for the clearest third line.

7. Check for the FOCUS of entire screen. If necessary, re-do adjustments 3~6.

V

STATIC FOCUS VR

H

DYNAMIC FOCUS VR

NO USE

After Adjustment

1

2

3

Alignment and Adjustments

4-2 Samsung Electronics

4-1-3 Screen Voltage Adjustment

1. Enter the Video/Component Mode. Just connect a jack and do not supply a video signal.

2. Use a DC multi-meter to identify RK, GK, BK. And then adjust FBT Screen VR so that the highest

voltage becomes 175 Vp-p.

4-1-4 White Balance Adjustment

1. Select “Standard” from the menu.

2. Input an 100% White pattern.

3. In standby, press the remote-control keys in the following sequence: Mute 1 8 2

Power on the TV set.

4. Warm up the TV set at least for 30 minutes.

5. Input a 10-step stair signal.

6. Use the Volume +/- buttons on the remote-control to select RDR, GDR, BDR, CON.

7. Adjust Low-Light while viewing the darker side of screen.

8. Use the Volume +/- buttons on the remote-control to select RCT, GCT, BCT, SBT.

9. Adjust High-Light while viewing the brighter side of screen.

10. If not proper, re-adjust White Balance.

11. Press the Memory button to exit.

4-1-5 Sub-Brightness Adjustment

1. In standby, press the remote-control keys in the following sequence: Mute 1 8 2

Power on the TV set.

2. Use the Channel Up/Down buttons to receive the sub bright adjustment signal.

3. Use the Volume +/- buttons to select SBT.

4. Press the Menu or Mute button on the remote control to adjust so that the seventh step on

the right of screen cannot be seen.

5. Press the Memory button to exit.

Alignment and Adjustments

Samsung Electronics 4-3

This circuit uses in pulse width modulation method to check high voltage difference and then adjust

energy of storage trans. in order to compensation and stabilize high voltage.

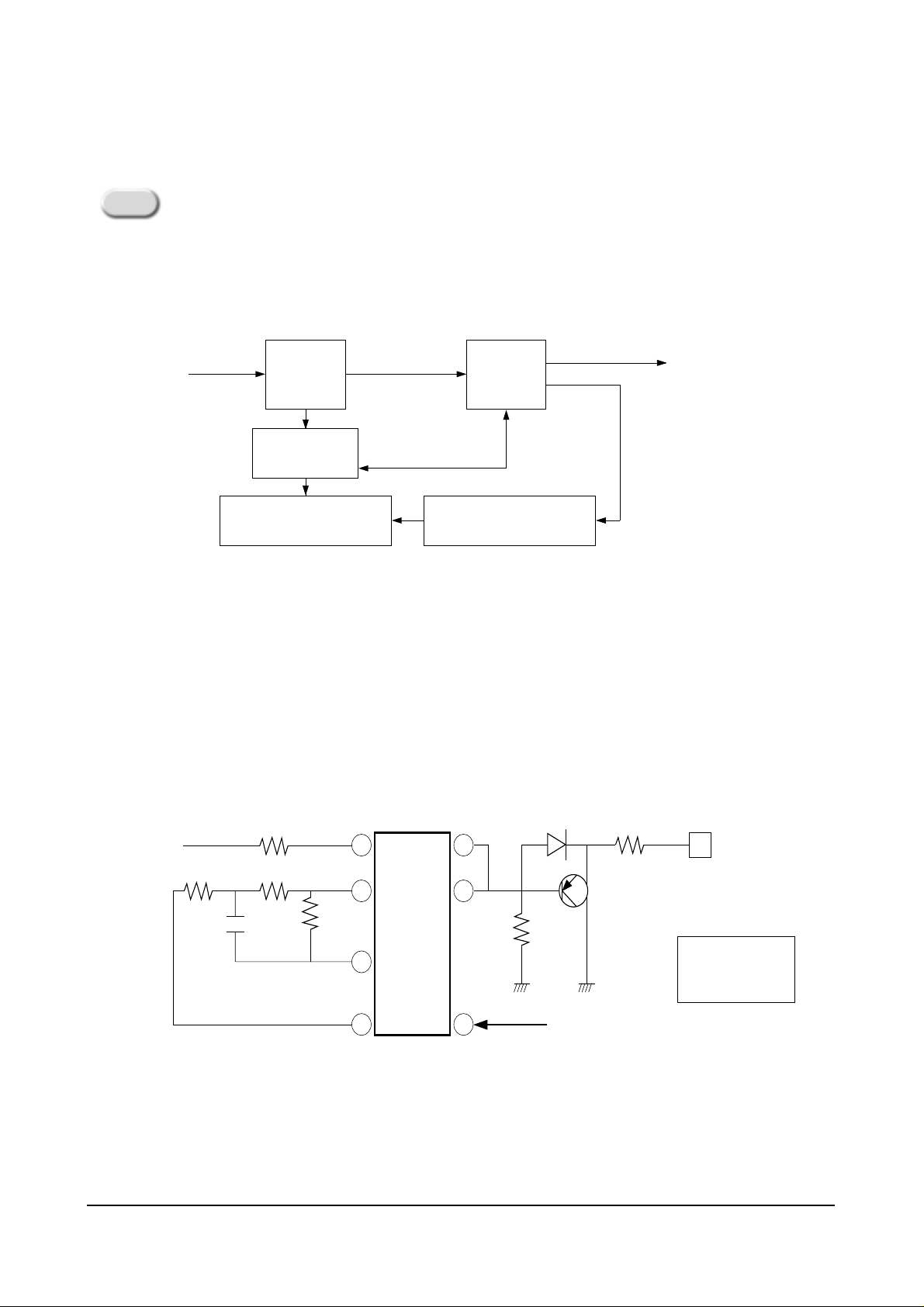

1)Block Diagram

Note1.

HIGH VOLTAGE REGULATOR CIRCUIT(DIGITAL TV)

2) Circuit description

This circuit detect high voltage difference from FBT, will be compared with reference voltage of HVIC02.

The varied voltage will be changed pulse width modulation by PWM Generator HVIC02. This pulse will

vary energy of storage trans(TD402S) according to high voltage difference the varied energy is added to

basic high voltage pulse of FBT. As a result, this circuit will be stable high voltage.

2-1) Working description in case of high voltage Up & Down

In case high voltage goes up(or down) due to change of beam current, the voltage of high voltage

detection prove will be goes up(or down) according to Divider resistance value(which are inside of

FBT(T4440) and outside resistance), and this increased voltage will be supplied to PWM PULSE

IC(HVIC02) pin #1.

This IC(HVIC02) provide complete pulse width modulation system in a single monolithic intergrated

circuit.

The voltage which is inputed to HVIC02 pin #1 will be compared with reference voltage(HVIC02 pin #14,

5V), and then its difference voltage will be amplified.

Its value will be convert PWM in HVIC02, and then PWM pulse will be output from HVIC02 pin #9, #10.

Transistor HVQ01 is used as Buffer for impedance matching.

+

B INPUT

TRANS(TD402S)

PWM OUT FET(QH405)

(HVQ06 IC CURRENT CONTROL)

HV OUT

TRANSISTOR

(QH406)

STORAGE

F.B.T

(T444S)

PWM GENERATOR & CHECK

HIGH VOLTAGE DIFFERENCE(HVIC02)

HIGH VOLTAGE

OUTPUT

HIGH VOLTAGE

CHECK

HIGH VOLTAGE

DETECTOR

HVR19

HVR20

HVR20

HVIC02 HVDZ01 HVR36

1

2

9

10

PWM PULSE

OUT PUT

TS13

HVQ01

HVR10

HVR14

3

ASSY-H/V

MODULE

REFERENCE VOLTAGE

14

4

F/S CHECK

Alignment and Adjustments

4-4 Samsung Electronics

The PWM duty which is outputed from HVQ01 is variable according to Beam current of high woltage. In

case high voltage goes up(or down) due to change of Beam Current, PWM duty will be decreased9or

increased). This pules which is inputed to QH406 Gate(FBT) will be turn on between source and will be

charge energy in primary of storage trans(TD402S) and then will be charge ener gy in primary of storage trans

during trace perido. This energy is variable according to pluse duty, and will be inducted to secondary of

TD402S. The inducted energy will be added to basic high voltage generation pulse in FBT(T444S). As a

result, high voltage will be regulated by this method.

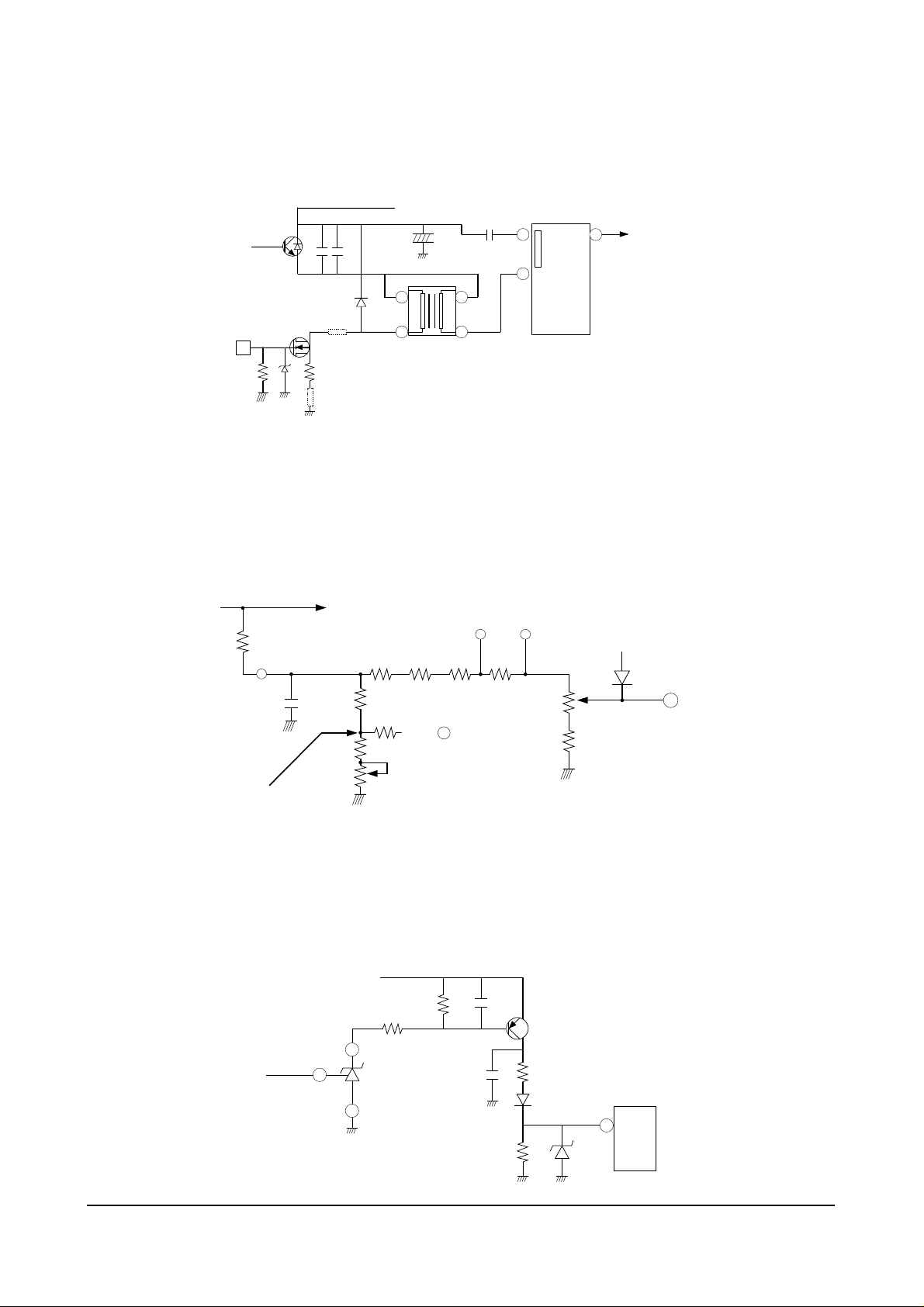

3)F/S circuit description

In case high voltage goes up, consequently detected voltage will be goes up and this voltage will be divided

regularly through R432, R433, R434, RR400S R and R441.

1

6

9

5

11

2

+

B INPUT

FBT

T444S

CR411S

C472

QH405

CR410S CR409S

D410

TS13

R486

L481

R449

DZ400

L403

TD402S

HIGH VOLTAGE

OUTPUT

QH406

GD

S

H-DRIVE

This divided voltage will be inputed to HVIC03 pin #R, and then in this case voltage goes up more than 2.95v,

Between pin #K and pin #A of HVIC03 will be turn on and will be decreased Base voltage of HVQ02, and

then E-C of HVQ02 will be turn on and will be detected high level voltage by R482.

Its value will be inputed HVIC02 PIN #4(X-ray detect), and high voltage oscillation will be OFF in order to

protect X-ray. In this case, high voltage will be On if power is re-ON.

HVC03

HVR01

+

12V

K

A

A

R

F/S DETECTOR

HVIC03(L431)

X-ray

HVIC02

HVQ02

HVR08

HVD01

TS14

HVDZ02

HVR25

HVC02

HVR13

T44S

R1

C480

11

ANODE

R432 R433 R434 R437

X-ray Test pin

r

X

D411

HVIC03

R

TL431

F/S

R430

HVR20

HVIC02 1 PIN

TL494CN

RR400S

R441

HV-REG.

RR401S

HIGH VOLTAGE

CHECK VOLTAGE

Alignment and Adjustments

Samsung Electronics 4-5

4-2 SZM 410A(ZILOG90371) Micom

4-2-1 Pin Layout

P16/SCLK

NC

NC

NC

NC

1

2

3

4

5

6

7

8

9

10

11

12

IRIN

P0C

P0B

P0A

P09

P0D

P07/CYNC

P06/CNTR

P03/1HSYNC

P01/12CSC

P02/12CSD

POWER

IR-IN

VGA-ID

1080i S/W

5VB-CHECK

1H-SYNC

SCL-2

SDA-2

Z

9

0

3

7

1

1

P15/B(1)

P14/B(0)

P13/G(1)

P18/G(0)

P08/R(1)

P10/R(0)

PWM6

PWM5

PWM4

PWM3

PWM2

PWM1

52

NC

51

NC

50

NC

49

HOLD

48

NC

47

NC

46

LED2(TIMER)

45

LED1(STAND BY)

44

D-COIL

43

MUTE(AMP)

42

TILT

41

S-RESET

CVBS

LOOP FILTER

ANALOG GND

S-AFT

KEY1

M-AFT

KEY2

BUS STOP

ANALOG GND

ANALOG VCC

HALF TONE

OSD-B

OSD-G

OSD-R

13

14

15

16

17

18

19

20

21

22

23

24

25

26

CV1/ADC0

LPF

AGNDF

ADC5

P04/ADC4

P04/ADC3

P04/ADC2

P04/ADC1

AGND

AVCC

P0F/SOVL

V3(B)

V2(G)

V1(R)

6

P

S

C

|

O

T

P

GND

VCC

GND

XTAL2

XTAL1

RESET

12CMC1

12CMD1

POE

P11/12CMC2

P12/12CMD2

V-SYNC

H-SYNC

OVL

40

39

38

37

36

35

34

33

32

31

30

29

28

27

XTAL GND

VCC

GND

XTAL2

XTAL1

RESET

NC

NC

WP

SCL-1

SDA-1

V-SYNC(2V)

H-SYNC(2H)

BLANK(F/B)

Alignment and Adjustments

4-6 Samsung Electronics

PIN NO

PIN NAME

POWER CONTROL OUTPUT

REMOCON INPUT

MAIN AFT INPUT

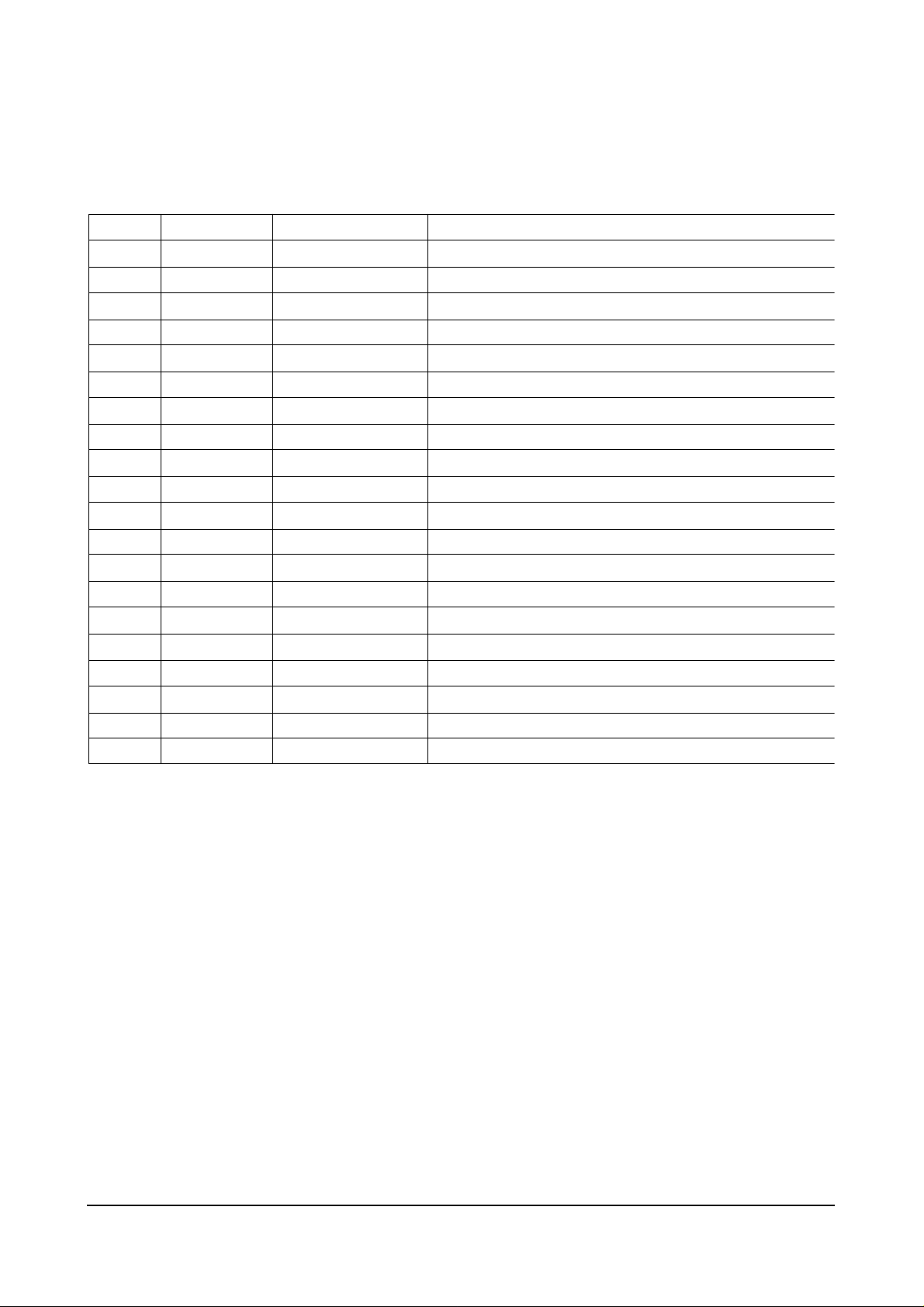

4-2-2 Port Assignment

PIN NO

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

PIN NAME

P16/SCLK POWER

IRIN IR INPUT

P0C VGA ID

P0B

P0A

P09

P0D

P07/CYNC

P06/CNTR 5VB CHECK

P03/1HSYNC 1HSYNC H/V SYNC FOR CCD

P01/I2CSC SCL2 E2PROM/PIP only,

P02/I2CSD SDA2 E2PROM/PIP only,

CVI/ADC0 CVBS IN CCD COMPOSITE INPUT

LPF LOOP FILTER

AGNDF GND

ADC5 S-AFT

P04/ADC4 KEY1 VOL UP/DOWN,CH UP/DOWN, KEY SCAN INPUT PORT 1

P04/ADC3 MAIN AFT

P04/ADC2 KEY2 POWER,MENU.TV/VIDEO, KEY SCAN INPUT PORT 2

P04/ADC1 BUS STOP

AGND GND

AVCC VCC

P0F/SOVL HALF TONE

V3(B) OSD B

V2(G) OSD G

V1(R) OSD R

OVL BLANK

HSYNC HSYNC

VSYNC VSYNC

P12/I2CMD2 SDA1

P11/I2CMC2 SCL1

P0E WP E2PROM WRITE PROTECT

D4 PIN

POWER CONTROL OUTPUT

REMOCON INPUT

PC SIGNAL DETECTOR, X-RAY DETECTOR

N.C

N.C

N.C

1080i S/W 1080i B+ UP S/W

N.C

5V-B+ CHECK

LOOP FILTER

ANALOG GND

PIP AFT INPUT

MAIN AFT INPUT

I2C BUS STOP

ANALOG GND

ANALOG VCC

HALF TONE

BLUE SIGNAL OF OSD

GREEN SIGNAL OF OSD

RED SIGNAL OF OSD

BLANKING SIGNAL OF OSD

HORIZONTAL SYNC INPUT FOR OSD

VERTICAL SYNC INPUT FOR OSD

I2C BUS DATA 1

I2C BUS CLK 1

DESCRIPTION

I2C BUS CLK2

I2C BUS DATA 2

Alignment and Adjustments

Samsung Electronics 4-7

GND

PWM6

RESET INPUT

SOUND AMP MUTE

PIN NO

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

PIN NAME D4 PIN

I2CMD1 N.C

I2CMC1 N.C

RESET RESET

RESET INPUT

XTAL1 XTAL1

XTAL2 XTAL2

GND GND

VCC VCC

GND

VCC

GND GND GND

PWM1 S-RESET

PWM2 TILT

PWM3 MUTE

PWM4 D-COIL

SOUND RESET

TILT CONTROL

SOUND AMP MUTE

DEGAUSSING COIL CONTROL OUTPUT

PWM5 LED1 STAND BY LED

PWM6

LED2

TIMER LED

P10/R(0) N.C

P08/R(1) N.C

P18/G(0) HOLD

P13/G(1) N.C

P14/B(0)

N.C

P15/B(1) N.C

DESCRIPTION

-

-

-

-

-

-

-

-

-

-

Alignment and Adjustments

4-8 Samsung Electronics

K54A chassis needs I2C for service mode adjustments. Since the outgone TV set has been

adjusted optimum, I2C Adjustment doesn’t need excluding when CRT, FBT, EEPROM (IC902)

is replaced.

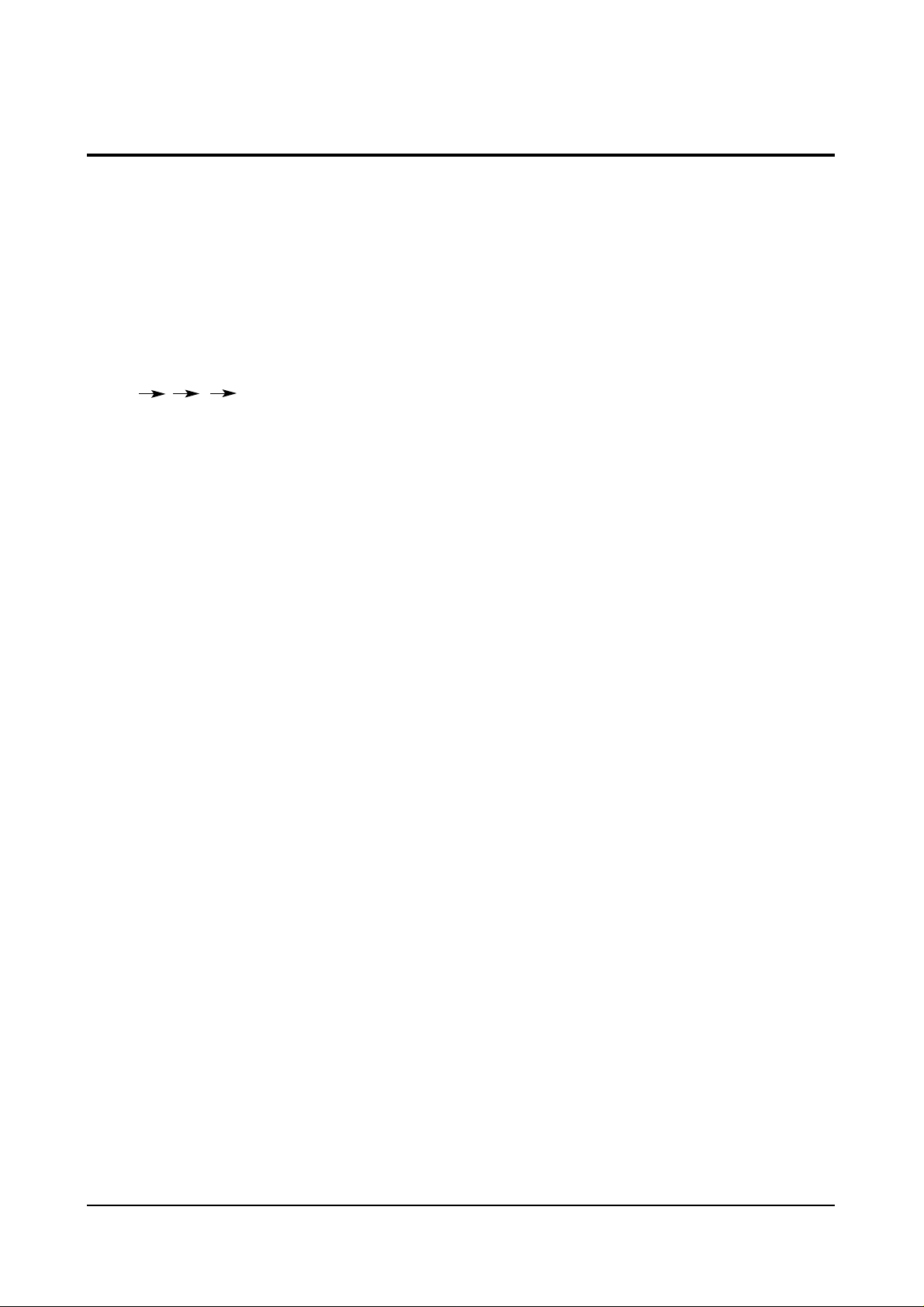

4-3-1 Entering the Service Mode

In standby, press the remote-control keys in the following sequence:

MUTE 1 8 2 POWER When the Service Mode is entered, use the Channel

UP/DOWN buttons on the remote control to move to the item to adjust.

4-3-2 Adjustments Adjust

Detailed Items: Use the Channel UP/DOWN buttons.

Data Adjustment: Use the Volume +/- buttons.

Channel Switching: Enter the Channel No.

4-3-3 Special Notes

1. When IC902 (EEPROM) is replaced, warm up the TV for 4~5 seconds after plugging in.

2. After IC902 (EEPROM) is replaced, enter the Service Mode and standard data for all items.

3. Make the following adjustments: Geometric, White Balance, Sub-contrast, PIP contrast,

Sub-brightness

4-3 Service Mode Adjustments

Alignment and Adjustments

Samsung Electronics 4-9

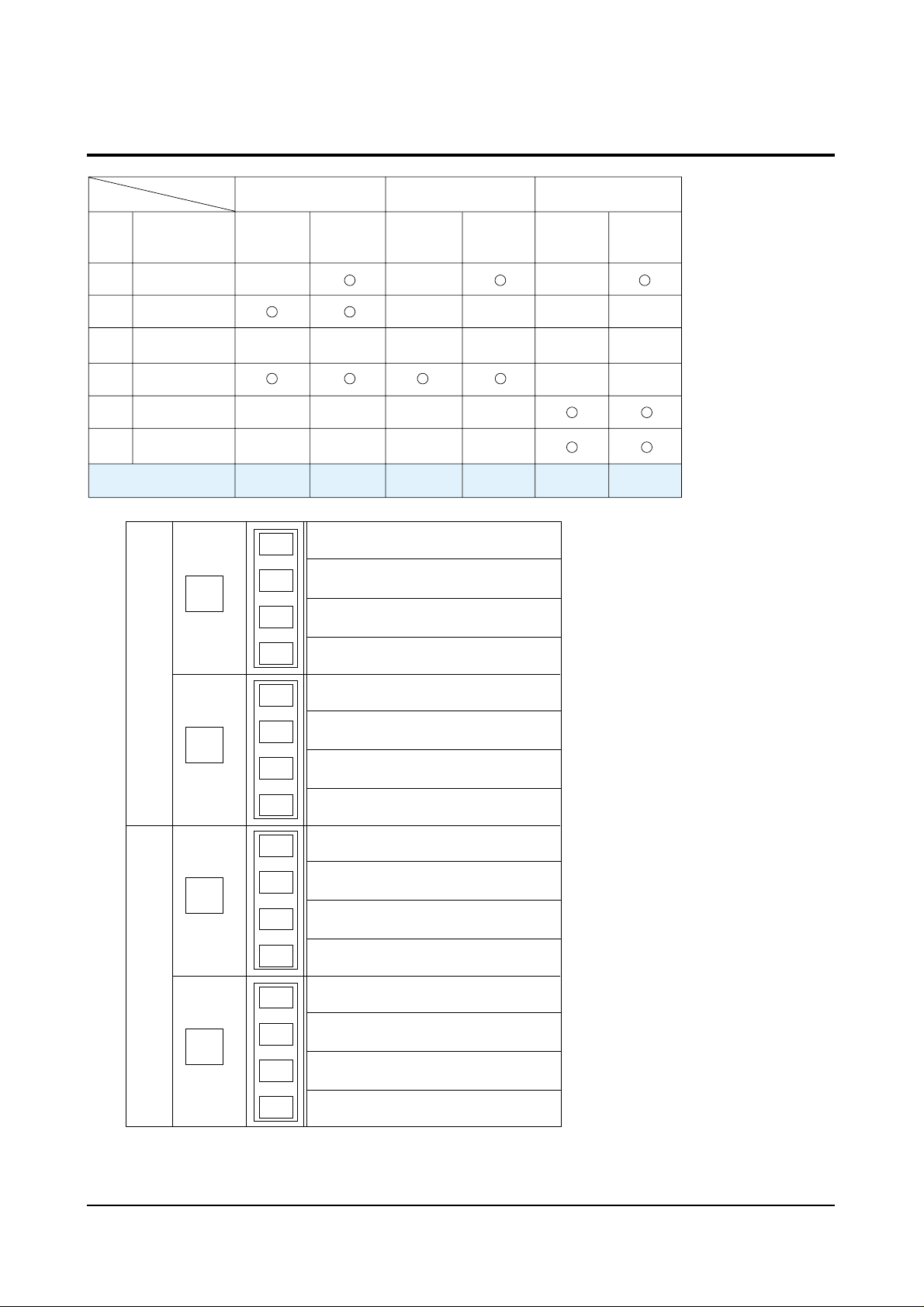

4-4 Option Byte

(HEX)

(HEX)

(HEX)

(HEX)

USA

CANADA NT Latin America

BYTE

B0

B1

B2

B3

B4

B5

OPTION BYTE

FUNCTION

WIDE

V-CHIP

AFN

NO PC

NO ACS

NO X-RAY

NORMAL WIDE NORMAL WIDE NORMAL WIDE

XX

XX

XX

0A 0B 08 09 30 31

0123

0

0123

OPTION BYTE 0OPTION BYTE 1

0

X

XXXX

XXXX

XX

XX

XXXX

0 : 4:3 (NORMAL)

1 : WIDE (16:9)

0 : V-CHIP OFF

1 : V-CHIP ON

0 : AIR/STD/HRC/IRC

1 : AIR/STD/HRC/AFN

0 : PC ON

1 : PC OFF

0 : ACS ON

1 : ACS OFF

0 : X-RAY ON

1 : X-RAY OFF

DON'T CARE

DON'T CARE

0123

0

0123

0

DON'T CARE

DON'T CARE

DON'T CARE

DON'T CARE

DON'T CARE

DON'T CARE

DON'T CARE

DON'T CARE

Alignment and Adjustments

Samsung Electronics%!PS-Adobe-2.0 EPSF

4-5 Picture

B-CUT OFF

GAMMA

VML

VM-LEVEL

32" WIDE

4-6 Picture

32"

WIDE

32"

WIDE

DESCRIPTION

RF Mode 160

480P Mode 190

1080i Mode 180

DESCRIPTION

RF Mode

480P Mode

1080i Mode

VS

V-SHIFT

UPC LOC HEH HS VAN VBO HSP

UP-CORR LO-CORR H-EHT H-SHIFT V-ANGLE V-BOW H-SYC-PH

180 150 0 (FIXED) 105 127 (FIXED)

180 130 0 (FIXED) 35 133 (FIXED)

200 150 0 (FIXED) 50 142 (FIXED)

VA

V-SIZE

130

140

130

VL

V-LINE

105 (FIXED)

105 (FIXED)

105 (FIXED)

VSC

V-S CORR

125 (FIXED)

125 (FIXED)

125 (FIXED)

VE

V-V EHT

0 (FIXED)

0 (FIXED)

0 (FIXED)

127 (FIXED)

127 (FIXED)

HA PPH PAM

H-SIZE PIN PHS PIN AMP

175 70 100

180 90 100

215 90 120

127 (FIXED)

127 (FIXED)

127 (FIXED)

138 (FIXED)

DESCRIPTION

32" WIDE

DESCRIPTION

32" WIDE

DESCRIPTION

32" WIDE

RDR GDR BDR RCT GCT BCT

R-DRIVE G-DRIVE B-DRIVE R-CUT OFF G-CUT OFF B-CUT OFF

32 22 (FIXED) 32 32 22 (FIXED) 32

SBT CON COL HUE GAM

SUB-BRT UB-CON UB-COL SUB-HUE GAMMA

25 6 12 (FIXED) 9 (FIXED) 10 (FIXED)

VML

VM-LEVEL

RF : 38 480 : 48 1080 : 58

235 (FIXED) 139 (FIXED) 139 (FIXED)

Alignment and Adjustments

Samsung Electronics 4-11

MEMORY DESCRIPTION

No. Item

Description

0 V Shift Vertical Shift

1 V Size Adjusts the vertical image size

2 V Linearity Adjusts the vertical linearity

3 V S Correction

Vertical S-Correction

4 V EHT Adjusts the vertical variance (depending on the high pressure)

5 H Size

Adjusts the horizontal size

6 Pin Phase

Adjusts the left/right symmetry of pincushion

7 Pin AMP

Adjusts Pincushion

8 Upper Corner

Adjusts the upper corner

9 Lower Corner

Adjusts the lower corner

10 H EHT Adjusts the horizontal variance (depending on the high pressure)

11 H Shift Horizontal Shift

12 V Angle Adjusts so that the vertical line becomes rectangular

13 V Bow Adjusts so that the vertical lines are symmetrical

14 H Sync Phase Adjusts the horizontal sync phase

4-7 White Balance

W/B

H/L L/L

32"

x:275, y:265, y:50 x:275, y:265, y:2.5

Loading...

Loading...