Page 1

VIDEO CASSETTE LINE RECORDER

SVR-18A

SVR-18B

SVR-18C

SERVICE

SVR-18B

SVR-18C

SVR-18A

ON STANDBY EJECT

REC SYSTEM

ON STANDBY STOP PLAY REC II P/S TRACKING

PLAY STOP

REW

F.F

ON STANDBY EJECT REC

ON STANDBY STOP PLAY REC II P/S

TRACKING

SYSTEM

REW PLAY STOP F.F

ON STANDBY EJECT

REC SYSTEM

ON STANDBY STOP PLAY REC II P/S TRACKING

PLAY STOP

REW

F.F

Manual

VIDEO CASSETTE LINE RECORDER CONTENTS

For mechanical disassembly and adjustment, refer to the “Mechanical Manual”

(DX7-A/AC, DX8-A/AC AC68-20392A).

1. Precautions

2. Reference Information

3. Product Specifications

4. Disassembly and Reassembly

5. Alignment and Adjustment

6. Exploded View and Parts List

7. Electrical Parts List

8. Block Diagrams

9. PCB Diagrams

10. Wiring Diagram

11. Schematic Diagrams

© Samsung Electronics Co., Ltd. APR. 1998 AC68-20404A

Page 2

Samsung Electronics 1-1

1. Precautions

1. Be sure that all of the built-in protective devices are

replaced. Restore any missing protective shields.

2. When reinstalling the chassis and its assemblies, be

sure to restore all pretective devices, including :

control knobs and compartment covers.

3. Make sure that there are no cabinet openings

through which people--particularly children

--might insert fingers and contact dangerous

voltages. Such openings include the spacing

between the picture tube and the cabinet mask,

excessively wide cabinet ventilation slots, and

improperly fitted back covers.

If the measured resistance is less than 1.0 megohm

or greater than 5.2 megohms, an abnormality exists

that must be corrected before the unit is returned

to the customer.

4. Leakage Current Hot Check (See Fig. 1) :

Warning : Do not use an isolation transformer

during this test. Use a leakage current tester or a

metering system that complies with American

National Standards Institute (ANSI C101.1,

Leakage Current for Appliances), and Underwriters

Laboratories (UL Publication UL1410, 59.7).

5. With the unit completely reassembled, plug the AC

line cord directly the power outlet. With the unitÕs

AC switch first in the ON position and then OFF,

measure the current between a known erath

ground (metal water pipe, conduit, etc.) and all

exposed metal parts, including : antennas, handle

brackets, metal cabinets, screwheads and control

shafts. The current measured should not exceed

0.5 milliamp. Reverse the power-plug prongs in the

AC outlet and repeat the test.

6. X-ray Limits :

The picture tube is designed to prohibit X-ray

emissions. To ensure continued X-ray protection,

replace the picture tube only with one that is the

same type as the original.

Fig. 1-1 AC Leakage Test

7. Antenna Cold Check :

With the unitÕs AC plug disconnected from the

AC source, connect an electrical jumper across the

two AC prongs. Connect one lead of the ohmmeter

to an AC prong.

Connect the other lead to the coaxial connector.

8. High Voltage Limit :

High voltage must be measured each time

servicing is done on the B+, horizontal deflection

or high voltage circuits.

Heed the high voltage limits. These include the

X-ray protection Specifications Label, and the

Product Safety and X-ray Warning Note on the

service data schematic.

9. Some semiconductor (Òsolid stateÓ) devices are

easily damaged by static electricity.

Such components are called Electrostatically

Sensitive Devices (ESDs); examples include

integrated circuits and some field-effect transistors.

The following techniques will reduce the

occurrence of component damage caused by static

electricity.

10. Immediately before handling sny semiconductor

components or assemblies, drain the electrostatic

charge from your body by touching a known

earth ground. Alternatively, wear a discharging

Wrist-strap device. (Be sure to remove it prior to

applying power--this is an electric shock

precaution.)

Device

Under

Test

(Reading should

not be above

0.5mA)

Leakage

Currant

Tester

Earth

Ground

Test all

exposed metal

surfaces

Also test with

plug reversed

(using AC adapter

plug as required)

2-Wire Cord

Page 3

Precautions

1-2 Samsung Electronics

11. High voltage is maintained within specified limits

by close-tolerance, safety-related components and

adjustments. If the high voltage exceeds the

specified limits, check each of the special

components.

12. Design Alteration Warning :

Never alter or add to the mechanical or electrical

design of this unit. Example : Do not add

auxiliary audio or video connectors. Such

alterations might create a safety hazard. Also, any

design changes or additions will void the

manufacturerÕs warranty.

13. Hot Chassis Warning :

Some TV receiver chassis are electrically

connected directly to one conductor of the AC

power cord. If an isolation transformer is not

used, these units may be safely serviced only if

the AC power plug is inserted so that the chassis

is connected to the ground side of the AC source.

To confirm that the AC power plug is inserted

correctly, do the following : Using an AC

voltmeter, measure the voltage between the

chassis and a known earth ground. If the reading

is greater than 1.0V, remove the AC power plug,

reverse its polarity and reinsert. Re-measure the

voltage between the chassis and ground.

14. Some TV chassis are designed to operate with 85

volts AC between chassis and ground, regardless

of the AC plug polarity. These units can be safely

serviced only if an isolation transformer inserted

between the receiver and the power source.

15. Never defeat any of the B+ voltage interlocks.

Do not apply AC power to the unit (or any of its

assemblies) unless all solid-state heat sinks are

correctly installed.

16. Always connect a test instrumentÕs ground lead to

the instrument chassis ground before connecting

the positive lead; always remove the instrumentÕs

ground lead last.

17. Observe the original lead dress, especially near

the following areas : Antenna wiring, sharp

edges, and especially the AC and high voltage

power supplies. Always inspect for pinched, outof-place, or frayed wiring. Do not change the

spacing between components and the printed

circuit board. Check the AC power cord for

damage. Make sure that leads and components

do not touch thermally hot parts.

18. Picture Tube Implosion Warning :

The picture tube in this receiver employs

Òintegral implosionÓ protection. To ensure

continued implosion protection, make sure that

the replacement picture tube is the same as the

original.

19. Do not remove, install or handle the picture tube

without first putting on shatterproof goggles

equipped with side shields. Never handle the

picture tube by its neck. Some Òin-lineÓ picture

tubes are equipped with a permanently attached

deflection yoke; do not try to remove such

Òpermanently attachedÓ yokes from the picture

tube.

20. Product Safety Notice :

Some electrical and mechanical parts have special

safety-related characteristics which might not be

obvious from visual inspection. These safety

features and the protection they give might be

lost if the replacement component differs from the

original--even if the replacement is rated for

higher voltage, wattage, etc.

Components that are critical for safety are

indicated in the circuit diagram by shading,

( or ).

Use replacement components that have the same

ratings, especially for flame resistance and

dielectric strength specifications. A replacement

part that does not have the same safety

characteristics as the original might create shock,

fire or other hazards.

Page 4

Samsung Electronics 2-1

2. Reference Information

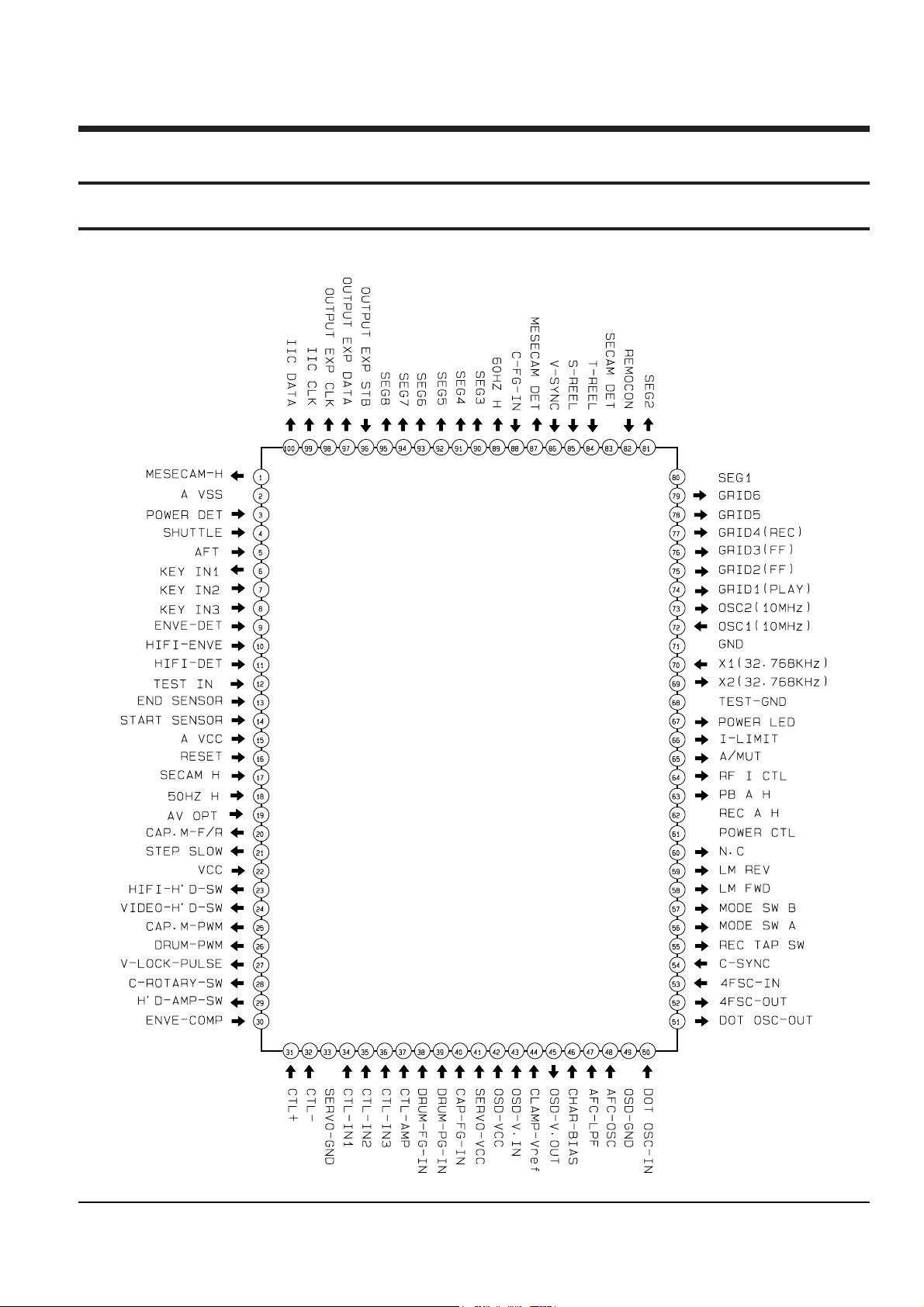

2-1 IC BLOCK

2-1-1 IC601 (HD6433977)

Page 5

Reference Information

2-2 Samsung Electronics

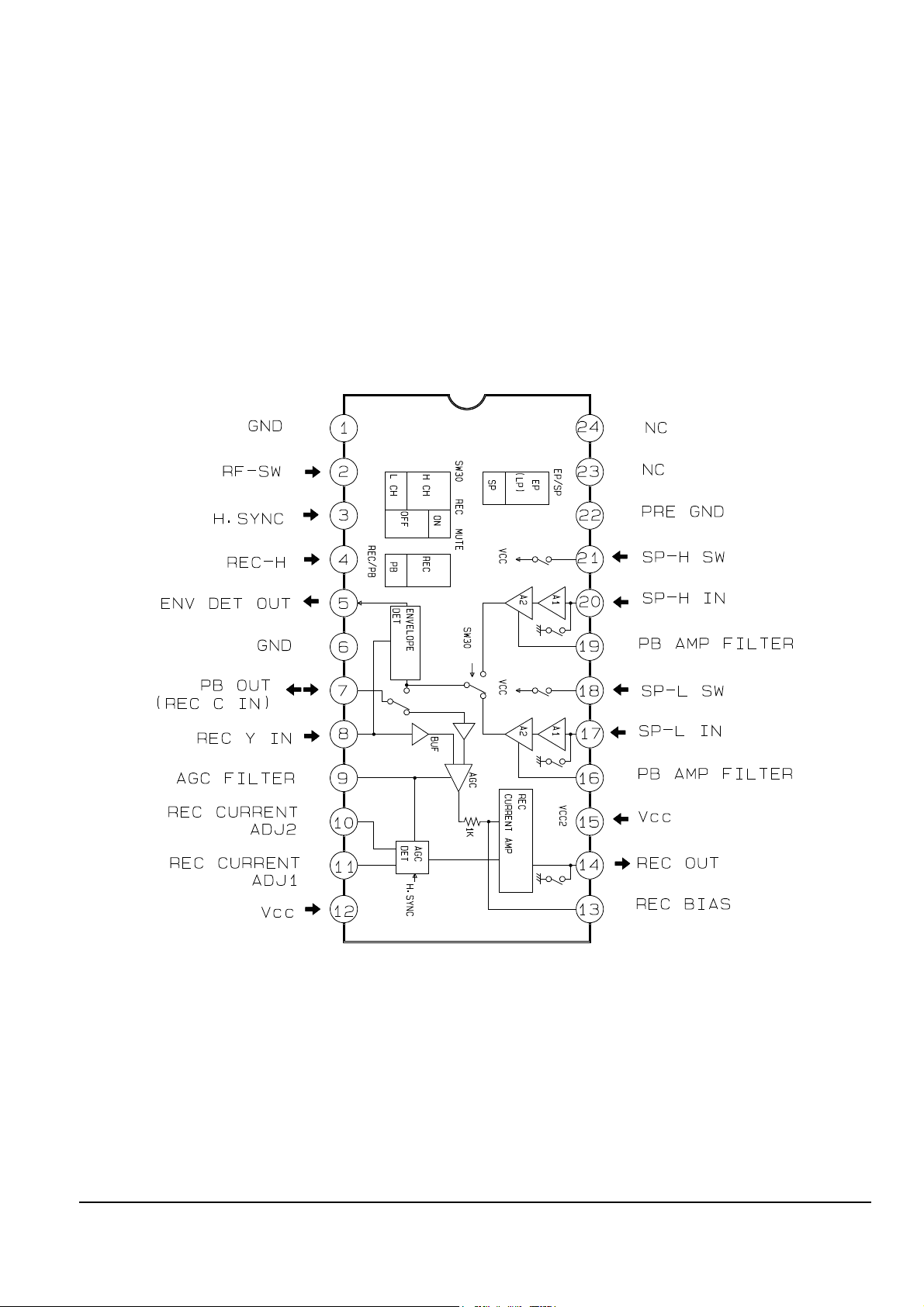

2-1-2 IC301 (LA7411)

Page 6

Reference Information

Samsung Electronics 2-3

2-1-3 IC302 (SS11501M/SS11511M)

Page 7

Reference Information

2-4 Samsung Electronics

2-1-3 IC303 (SS23378M/SS23377M)

Page 8

Samsung Electronics 3-1

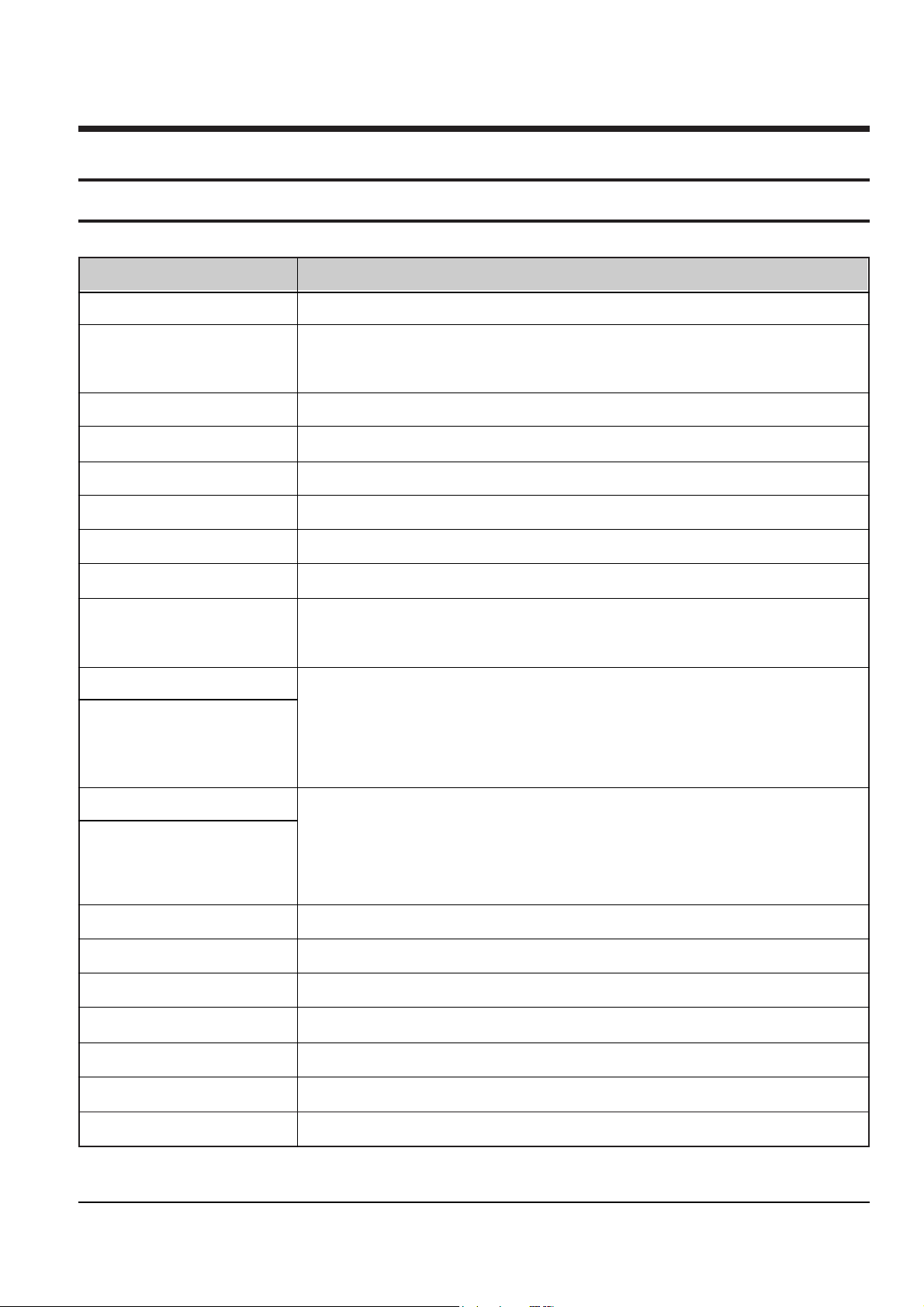

3. Product Specifications

3-1 Product Specifications

Operation Description

Format VHS PAL standard

Video recording system Video : 2 rotary heads, helical scanning system

Luminance : FM azimuth recording

Color : Down converted subcarrier phase shifted direct recording

Television system CCIR Standard G/K

Color system PAL, MESECAM, NT 3.58, NT 4.43, NT PB

Tape width 12.65 mm (1/2 inch)

Tape speed PAL : 23.39 mm/sec, NTSC : 33.35 mm/sec

Recording/playback time 4 hours with E-240 Tape

F.F/REW time About 150 ~ 200 sec with E-180

Heads Video : 2 rotary heads

Audio/Control : 1 stationary head

Erase : 1 full track erase head

VIDEO

Input 0.5 to 2.0 Vp-p : 75 ohm unbalanced

Output 1.0 Vp-p : 75 ohm unbalanced

Signal-to-noise ratio Better than 43 dB

Horizontal resolution More than 240 lines

Audio

Input Line : -8 dBm, 47 Kohm unbalanced

Output Line : -8 dBm, 1 Kohm unbalanced

Signal-to-noise ratio More than 42 dB min (IHF A filter)

Frequency response 100Hz - 8KHz

Output channel Channel 22 - 69 (preset ch36)

Power requirement AC 230V 50/60 Hz, DC12V

Power consumption Approx. 13 watts

Operation temperature 41°F-104°F (5°C-40°C)

Operation humidity 10%-75%

Weight (net) 3.5 Kg

Dimensions (W x H x D) 360 x 90.5 x 290 mm

Design and specifications are subject to change without notice.

Page 9

Product Specifications

3-2 Samsung Electronics

MEMO

Page 10

Samsung Electronics 4-1

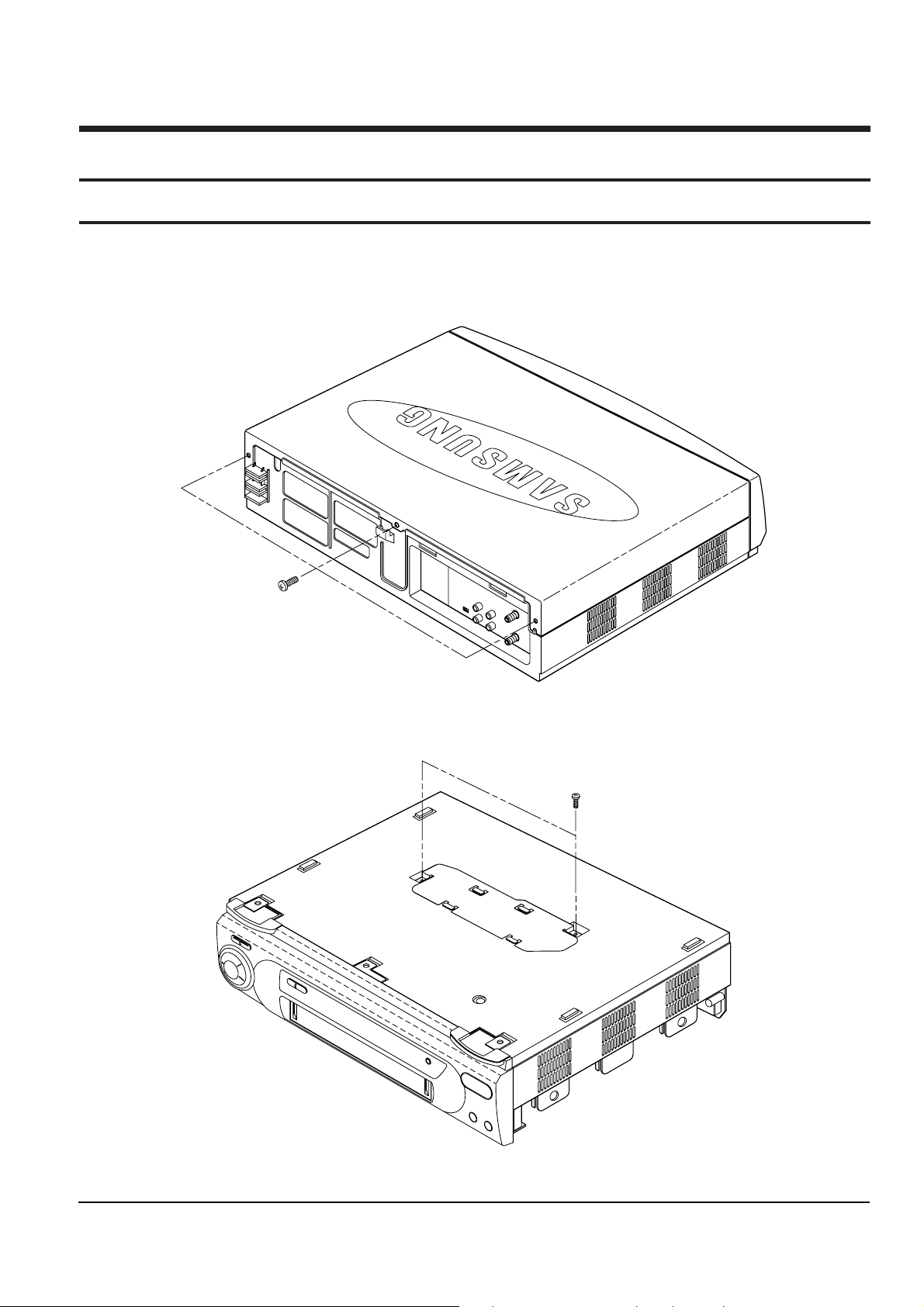

4. Disassembly and Reassembly

4-1 Cabinet Assembly

Note : Disassemble in the order shown.

Reassemble in reverse order.

4-1-1 Cabinet Top removal

ΠREMOVE 3 SCREWS

Fig. 4-1 Cabinet Top removal

4-1-2 Bottom cover removal

ΠREMOVE 2 SCREWS

Fig. 4-2 Bottom cover removal

Page 11

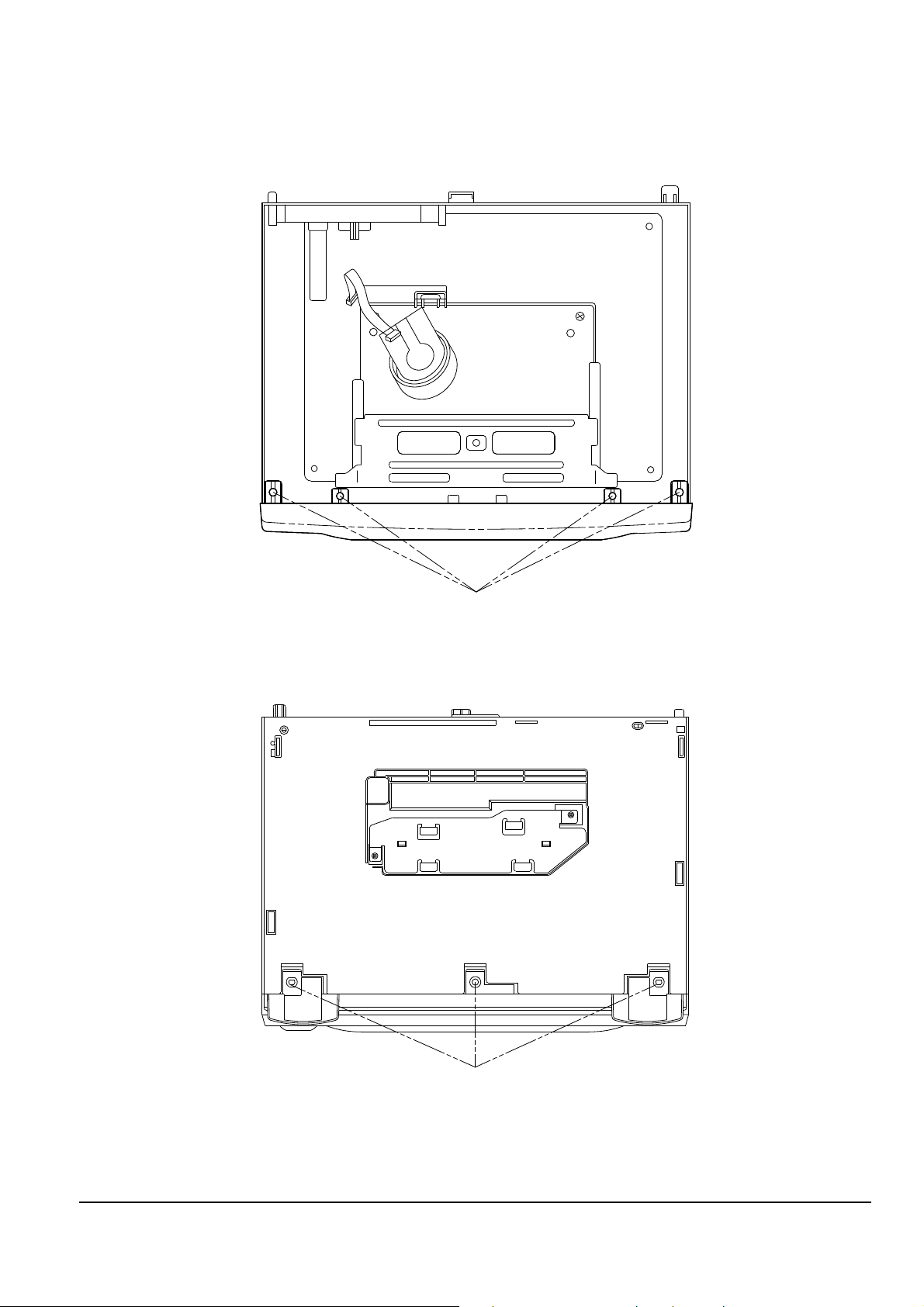

Disassembly and Reassembly

4-2 Samsung Electronics

4-1-3 Ass’y Front Panel removal

(Bottom view)

´ RELEASE 4 HOOKS

ˇ RELEASE 3 HOOKS

(Top view)

Fig. 4-3 Ass’y Front Panel removal

Page 12

Disassembly and Reassembly

Samsung Electronics 4-3

4-1-4 Ass’y Function-Timer removal

Note : Take extreme care not to damage the PCB when removing it.

ΠRELEASE 6 TABS

Fig. 4-4 Ass’y Function-Timer removal

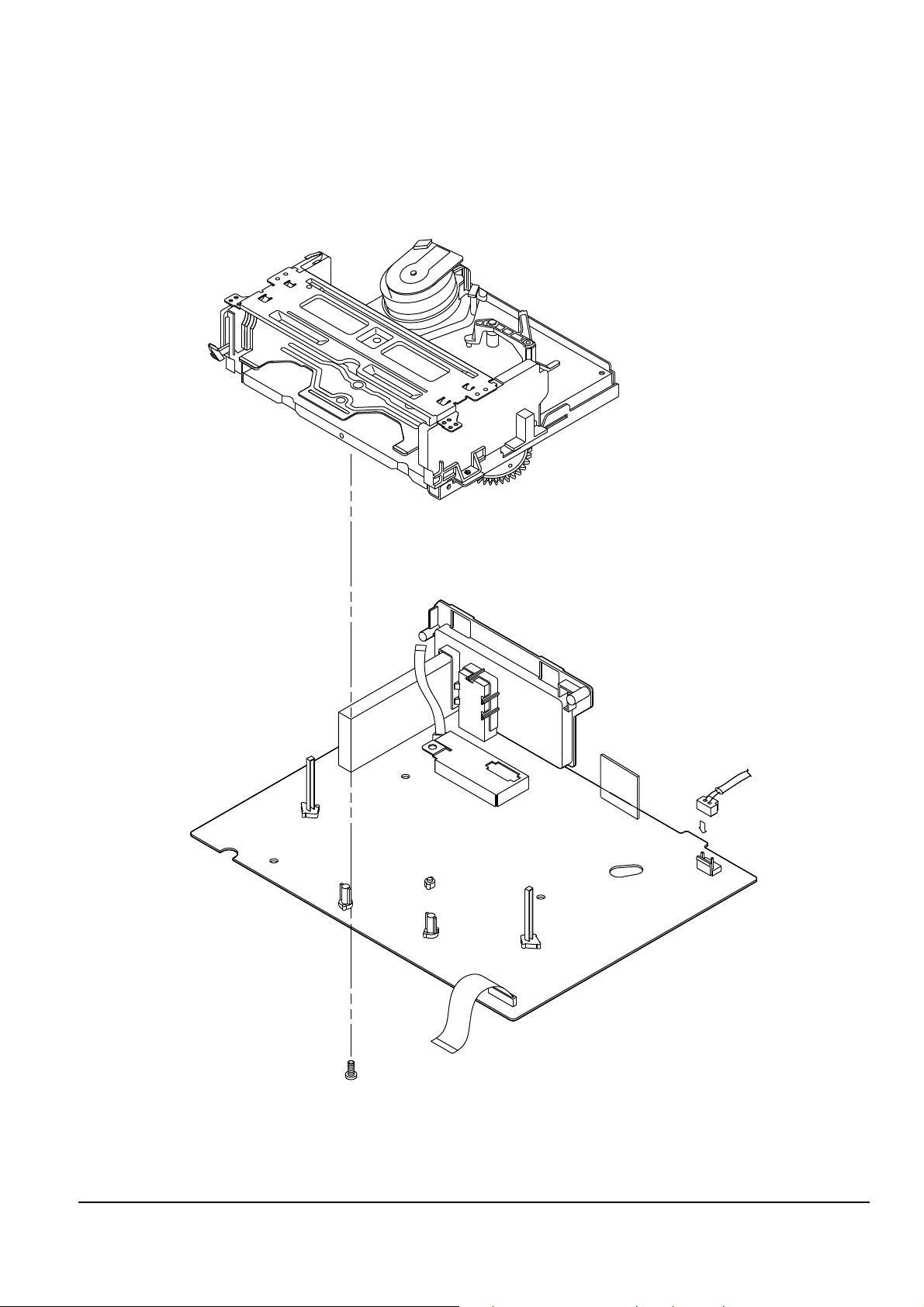

Page 13

Note : When removing chassis, take extreme care not to damage the main PCB front.

Disassembly and Reassembly

4-4 Samsung Electronics

4-1-5 Chassis removal

Fig. 4-5 Chassis removal

ΠREMOVE 2 SCREWS

´ REMOVE 2 SCREWS

Page 14

Disassembly and Reassembly

Samsung Electronics 4-5

Note : When reinstalling the deck on the main PCB, take extreme care not to damage the sensor.

4-1-6 Main board removal

Fig. 4-6 Main board removal

ΠREMOVE 1 SCREW

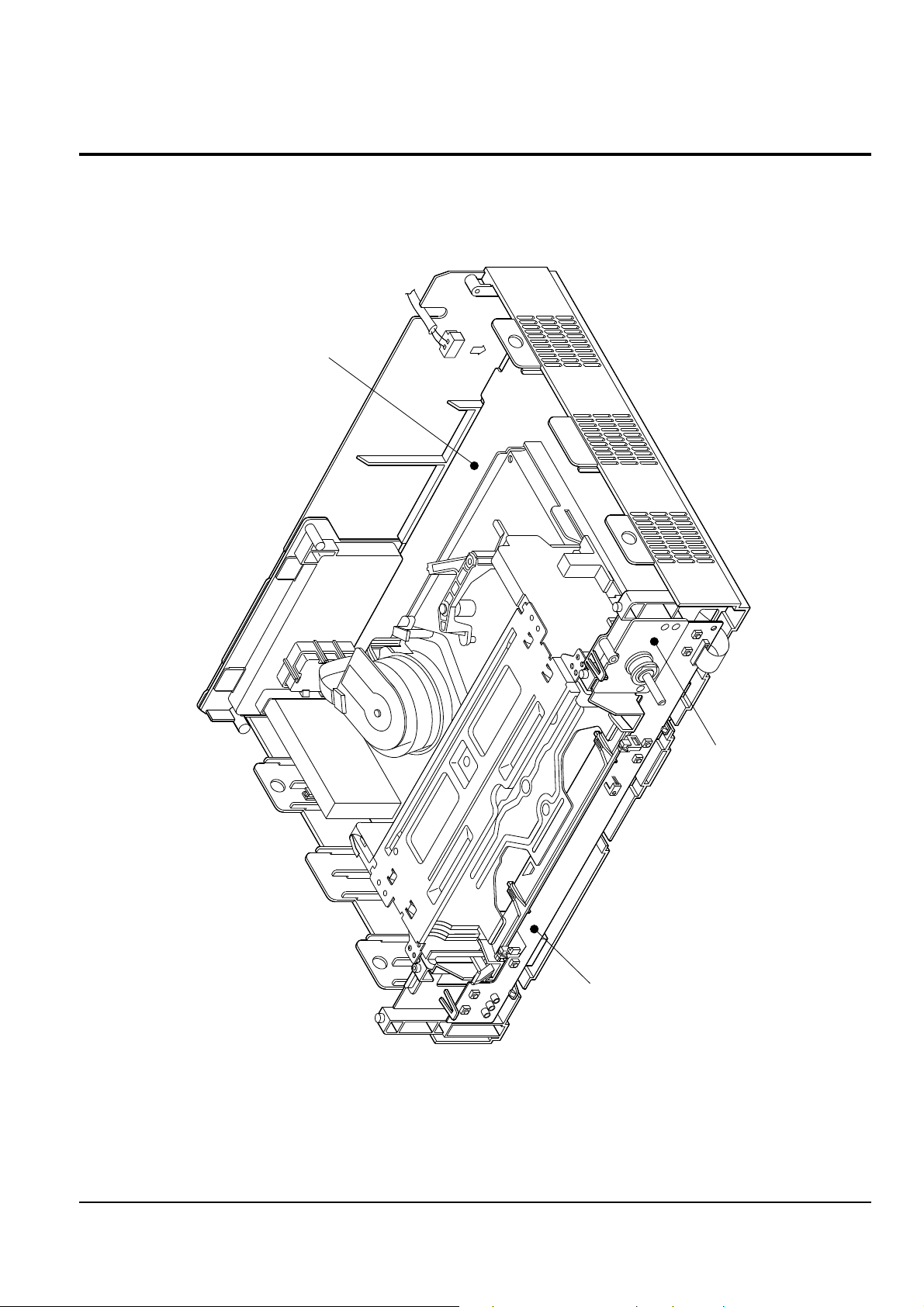

Page 15

Disassembly and Reassembly

4-6 Samsung Electronics

4-2 Circuit Board Locations

SHUTTLE BOARD

(OPTION)

MAIN BOARD

FUNCTION BOARD

Fig. 4-7 Circuit board locations

Page 16

Samsung Electronics 5-1

5. Alignment and Adjustment

Note : After replacing the assÕy full deck, the assÕy main, the cylinder assÕy and the micom(IC601), the remote

control assÕy can be used to adjust the ÒX-point (tracking center) adjustmentÓ and ÒHead S/W pointÓ

adjustment.

5-1 Reference

5-1-1 The type of remote control ass’y

1. Remote control assÕy (AC93-10039Y/69099-633-252)

is specified as a service jig in the service manual of

X-5/X-6(DX5-R/DX5-RC/DX6-R/DX6-RC) chassis.

(See Fig. 5-1)

2. Normal remote control assÕy for X-7/X-8

(DX7-R/DX7-RC/DX8-R/DX8-RC) chassis.

(See Fig. 5-2)

5-1-2 How to identify between normal

remote control ass’y and multi

remote control ass’y for X-7/X-8

chassis (See Fig. 5-2)

1. The color of some buttons related to TV function are

gold.

2. Audio button is added instead of the test button

hidden behind of inlay.

3. The positions of some buttons are different.

EJECT

2

456

789

0

CLK/COUNT

REW

F.F

STOP

CLR/RST DISPLAY

Q-PRO

MENU

S

H

I

F

T

S

H

U

T

T

L

E

DAILY WEEKLY

REC

P/S

PRESET BAND

SEARCH MEMORY

OUTPUT

INDEX SLOW INPUT

INPUT BUTTON

SP/LP BUTTON

SP LP A.DUB VPS

FINE CH

TRK

(TRACKING, FINE)

BUTTON

POWER BUTTON

POWER

PLAY BUTTON

PLAY

TEST BUTTON IS

HIDDEN BEHIND

OF INLAY.

3

HEAD S/W ADJ.

("INPUT" OR "TEST"

AND "3" BUTTON)

1

TRACKING

CENTER ADJ.

("INPUT" OR "TEST"

AND "1" BUTTON)

633-252

REMOTE CONTROL

ASS'Y PART NO.

Fig. 5-1 Remote Control Ass’y Jig for X-5/X-6 Chassis

(AC93-10039Y/69099-633-252)

EJECT

2

456

789

0

CLK/COUNT

REW

F.F

STOP

AUDIO

DISPLAY

REC

P/S

INDEX A.TRK

INPUT BUTTON

FINE PROG

TRK

(TRACKING, FINE)

BUTTON

POWER BUTTON

POWER

PLAY BUTTON

PLAY

TEST BUTTON IS

HIDDEN BEHIND

OF INLAY.

3

HEAD S/W ADJ.

("INPUT" OR "TEST"

AND "3" BUTTON)

1

TRACKING

CENTER ADJ.

("INPUT" OR "TEST"

AND "1" BUTTON)

SYSTEM

CLR/RST

S

H

U

T

T

L

E

SPEED BUTTON

SPEED AFT

INPUT

TV/VCR

PICTURE

A.DUB

2

456

789

0

CLK/COUNT

REW

F.F

STOP

DISP./

REC

P/S

INDEX

VCR

POWER

PLAY

3

1

VCR

CLR/RST

S

H

U

T

T

L

E

SPEED

TV/VCR

PICTURE

A.DUB

NORMAL REMOTE CONTROL ASS'Y

(CAN ADJUST)

MULTI REMOTE CONTROL ASS'Y

(CAN NOT ADJUST)

-/--

FINE

AUDIO

ADD BUTTON(AUDIO)

GOLD COLOR

TV

GOLD COLOR

TV

POWER

INPUT

GOLD COLOR

VOLUME PROG

GOLD COLOR

MENU

Q-PRO

SLOW

SOFTEN OK SHARPEN

MENU

Q-PRO

SLOW

SOFTEN OK SHARPEN

Fig. 5-2 Remote Control Ass’y for X-7/X-8 Chassis

Page 17

Alignment and Adjustment

5-2 Samsung Electronics

5-2 Mechanical Adjustment

Note : Refer to the Mechanical Manual ÒDX7-A/DX7-AC/DX8-A/DX8-AC (AC68-20392A)Ó for the adjustment

and confirmation of assÕy full deck.

5-2-1 The number and position of test point

GND

CTL

H'D SW

ENV.

A-OUT

V-OUT

W308

TP601

TP602

TP301

TP302

TP303

Fig. 5-3 The position of test point (Main PCB-Component side)

Test point : TP601 (CTL Pulse)

TP602 (H’D S/W -Trigger)

TP301 (Envelope)

TP302 (Audio out)

CTL PULSE

ENVELOPE

AUDIO OUT

H’D S/W -TRIGGER

Page 18

Alignment and Adjustment

Samsung Electronics 5-3

5-2-2 X-Point(Tracking center) adjustment

(See the 2-2-1 (d) AC HEAD

POSITION(X-POINT) ADJUSTMENT

on page 2-3 of the mechanical

manual)

5-2-2 (a) IF THE REMOTE CONTROL ASS’Y IS

NOT AVAILABLE

1. Playback the colorbar alignment tape.

2. Connect CH-1 scope probe to ÒTP601Ó and CH-2

scope probe to ÒTP602Ó. And then, trigger head

switching pulse.

3. Set tracking preset to 2.7msec, using the ÒFINE

(Tracking)Ó button / of the other

remote control assÕy except the remote control

assÕy jig for X-5/X-6 chassis and the normal remote

control assÕy for X-7/X-8 chassis.

4. Insert the adjusting driver (+) into X-position

adjusting gear. Adjust the driver in either direction

for maximum envelope waveform.

Note :

Since the adjusting gear unit may be damaged, do

not adjust by force when adjusting the X-point using the

adjusting driver (+). After turn the X-point adjusting screw

(D) counterclockwise a little, perform the adjustment.

After adjustment is completed, tighten the screw.

5-2-2 (b) IF THE REMOTE CONTROL ASS’Y

(AC93-10039Y/69099-633-252) IS

AVAILABLE

Note : How to use the ÒTESTÓ button.

1. Disattach the inlay of remote control assÕy.

(See Fig. 5-1 and Fig. 5-2)

2. Press the ÒTESTÓ button with the pincers and the

precise driver as shown in Fig. 5-1 and 5-2)

1. When using the ÒINPUTÓ button of remote

control assÕy;

1) Simultaneously press the ÒINPUTÓ button and Ò1Ó

button in PB mode.

This will adjust the tracking center automatically.

2) Set the tracking preset using the ÒFINE (Tracking)

button of remote control.

3) After adjustment is completed, press the

ÒPOWERÓ button to release.

2. When using the ÒTESTÓ button of remote

control assÕy ;

1) Simultaneously press the ÒTESTÓ button and Ò5Ó

button in PB mode.

This will adjust the tracking center automatically.

2) Set the tracking preset using the ÒFINE (Tracking)

button of remote control.

3) After adjustment is completed, press the

ÒPOWERÓ button to release.

<Setting of scope>

- Volt/div. : CH-1 = 0.1V - Time/div. : 5msec

CH-2 = 0.2V

Fig. 5-4 Tracking preset adjustment

Fig. 5-5 Tracking preset adjustment

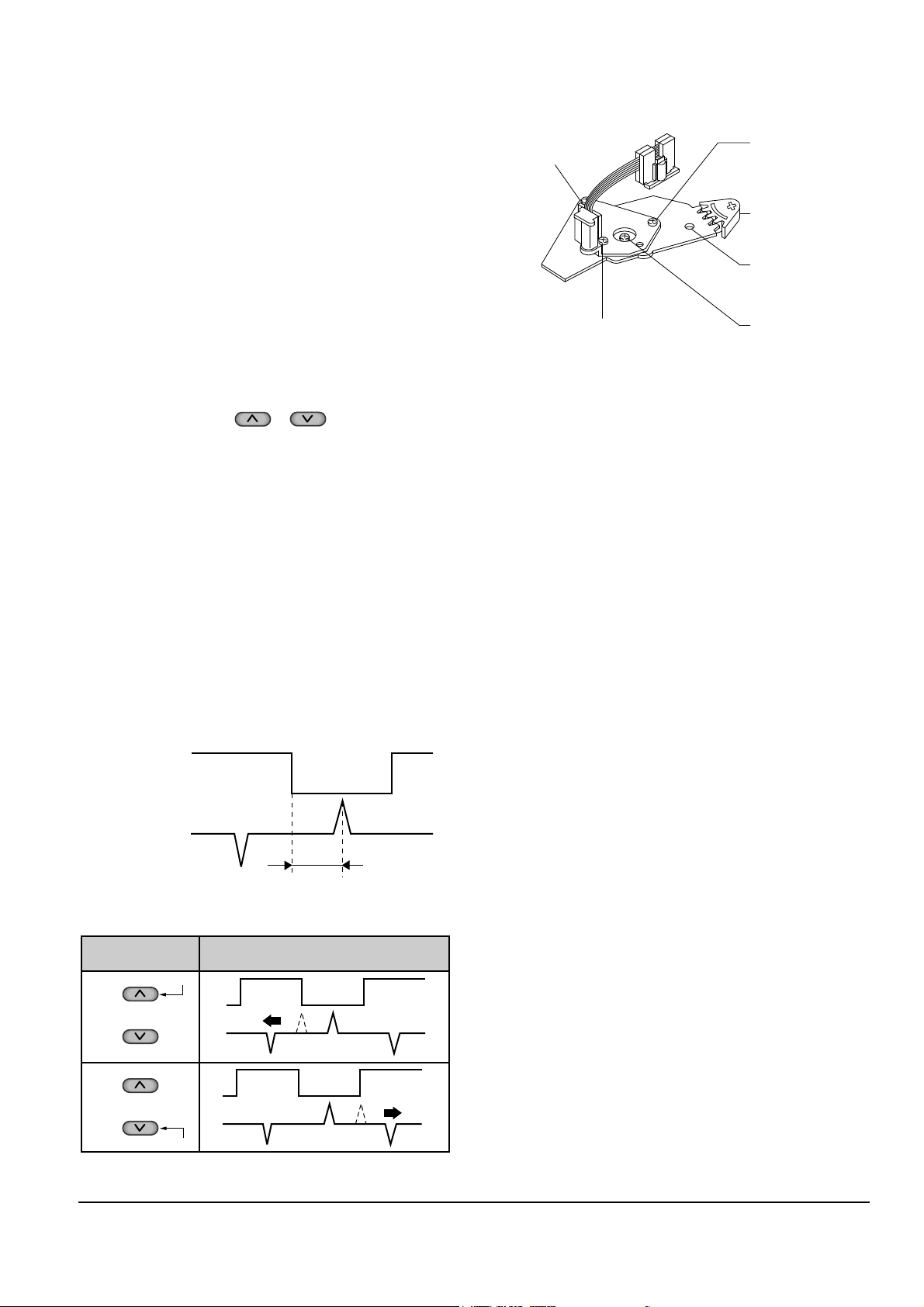

SCREW(C)

TILT ADJUST

X-POSITION

ADJUST GEAR

HOLE

SCREW(A)

HEIGHT ADJUST

SCREW(B)

AZIMUTH ADJUST

SCREW(D)

X-POINT LOCKING

Fig. 5-6 Location of A/C Head adjustment screw

2.7msec

CH-2 Probe

TP602

H'D S/W Pulse

CH-1 Probe

TP601

CTL Pulse

REMOTE

BUTTONS

CONTROL PULSE REMOVE

FINE

FINE

PUSH

PUSH

Page 19

Alignment and Adjustment

5-4 Samsung Electronics

5-2-2 (b) IF THE NORMAL REMOTE CONTROL

ASS’Y OF X-7/X-8(DX7-R/DX7-RC/

DX8-R/DX8-RC) CHASSIS IS

AVAILABLE

Note 1 : Two kinds of remote control assÕy are used

for X-7/X-8(DX7-R/DX7-RC/DX8-R/

DX8-RC) chassis.

1. One is a normal remote control assÕy, the other is a

multi remote control assÕy

2. All adjustments are adjusted by normal remote

control assÕy only.

3. For the identification of normal remote control

assÕy and multi remote control assÕy, See page 5-1.

Note 2 : How to use the ÒTESTÓ button.

1. Disattach the inlay of remote control assÕy.

(See Fig. 5-1 and Fig. 5-2)

2. Press the ÒTESTÓ button with the pincers and the

precise driver as shown in Fig. 5-1 and 5-2)

1. When using the ÒINPUTÓ button of remote

control assÕy;

1) Simultaneously press the ÒINPUTÓ button and Ò1Ó

button in PB mode.

This will adjust the tracking center automatically.

2) Set the tracking preset using the ÒFINE (Tracking)

button of remote control.

3) After adjustment is completed, press the

ÒPOWERÓ button to release.

2. When using the ÒTESTÓ button of remote

control assÕy ;

1) Simultaneously press the ÒTESTÓ button and Ò5Ó

button in PB mode.

This will adjust the tracking center automatically.

2) Set the tracking preset using the ÒFINE (Tracking)

button of remote control.

3) After adjustment is completed, press the

ÒPOWERÓ button to release.

Page 20

Alignment and Adjustment

Samsung Electronics 5-5

5-3 Electrical Adjustment

5-3-1 Head S/W Adjustment

Note : Only remote control assÕy can adjust.

5-3-1 (a) IF REMOTE CONTROL ASS’Y

(AC93-10039Y/69099-633-252) IS

AVAILABLE

1. When using the ÒINPUTÓ button of remote control

assÕy ;

1) Insert an SP tape into the housing assÕy.

2) Press the ÒPLAYÓ button.

3) Press the ÒINPUTÓ button and Ò3Ó button simultaneously.

4) This will adjust the head S/W point adjustment

automatically.

5) After the adjustment is completed, press

ÒPOWERÓ button to release.

2. When using the ÒTESTÓ button of remote control

assÕy ;

1) Insert an SP tape into the housing assÕy.

2) Press the ÒPLAYÓ button.

3) Press the ÒTESTÓ button and ÒSP/LPÓ button

simultaneously.

4) This will adjust the head S/W point adjustment

automatically.

5) After adjustment is completed, press the

ÒPOWERÓ button to release.

5-3-1 (b) IF NORMAL REMOTE CONTROL

ASS’Y FOR X-7/X-8(DX7-R/DX7-RC/

DX8-R/DX8-RC) CHASSIS IS

AVAILABLE

1. When using the ÒINPUTÓ button of remote control

assÕy ;

1) Insert an SP tape into the housing assÕy.

2) Press the ÒPLAYÓ button.

3) Press the ÒINPUTÓ button and Ò3Ó button

simultaneously.

4) This will adjust the head S/W point adjustment

automatically.

5) After the adjustment is completed, press

ÒPOWERÓ button to release.

2. When using the ÒTESTÓ button of remote control

assÕy ;

1) Insert an SP tape into the housing assÕy.

2) Press the ÒPLAYÓ button.

3) Press the ÒTESTÓ button and ÒSPEEDÓ button

simultaneously.

4) This will adjust the head S/W point adjustment

automatically.

5) After adjustment is completed, press the

ÒPOWERÓ button to release.

Page 21

Alignment and Adjustment

5-6 Samsung Electronics

MEMO

Page 22

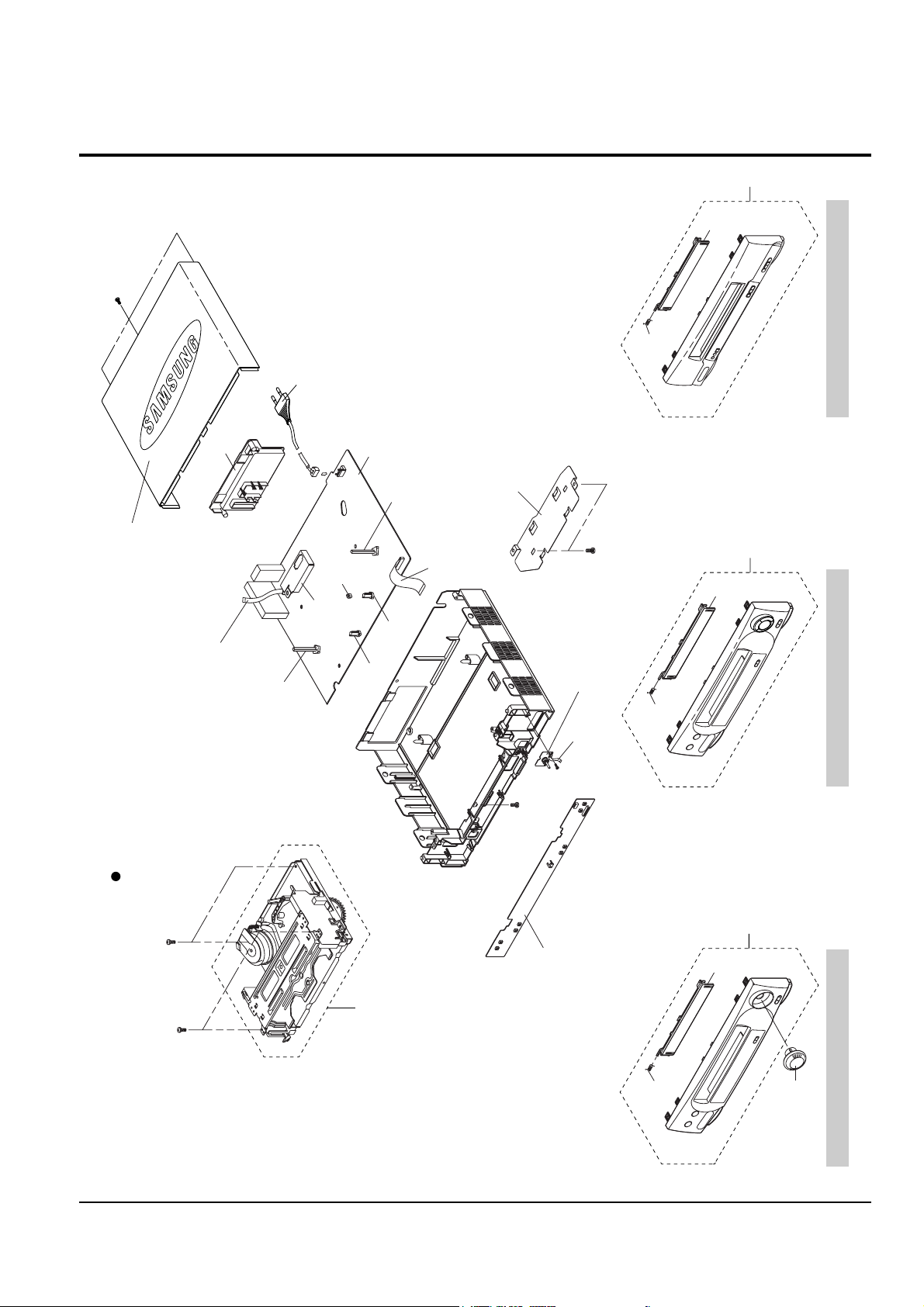

Samsung Electronics 6-1

6. Exploded View and Parts List

6-1 Cabinet Assembly - - - - - - - - - - - - - - - - - - - - - - - - - - -

6-2 Mechanical Parts (Top Side) - - - - - - - - - - - - - - - - - - - -

6-3 Mechanical Parts (Bottom Side) - - - - - - - - - - - - - - - - -

6-4 Housing Assembly - - - - - - - - - - - - - - - - - - - - - - - - - - -

Page

6-2

6-4

6-6

6-8

Page 23

Exploded View and Parts List

6-2 Samsung Electronics

6-1 Cabinet Assembly

S.N.A ; Service Not Available

157

157

CN77A

153

157

FULL DECK (S.N.A)

108

MAIN PCB (S.N.A)

S602A

S601A

SC301

661

LD601A

PT602A

PT601A

CN606A

CN601A

155

FUNCTION PCB

(S.N.A)

21

22

51

1

21

22

1

SVR-18A

SVR-18B SVR-18C

157

109

SHUTTLE PCB

(S.N.A)

21

22

1

TOP CABINET (S.N.A)

Page 24

Exploded View and Parts List

Samsung Electronics 6-3

Loc. No Part No Description and Specification Remark

1

AC98-11240B

ASSY-PANEL FRONT SVR-18A

AC98-11249D ASSY-PANEL FRONT SVR-18B

AC98-11249F ASSY-PANEL FRONT SVR-18C

21

AC64-50928R

DOOR-CASSETTE SVR-18A

AC64-50928X DOOR-CASSETTE SVR-18B

AC64-50928Y DOOR-CASSETTE SVR-18C

22 AC61-62003A SPRING;-,SUS304,(GE/RCA),-,-,-,51

AC98-12073D

ASSY KNOB-SHUTTLE;SV-B10G,-

108

AC61-11004B

ASSY-CONNECTOR BOARD

109 AC63-30514A COVER-BOTTOM;SV-A120U,SECC,-,T0.5,-,153 AC60-12126A SCREW-BH;-,BH,-,4*12,FE,FZY,-,-,155 AC60-12134A SCREW-TAP BH;-,BH,-,2-4X16,-,FE

157 AC60-10063A SCREW-TAPTITE;BH,+,-,M3,L12,ZPC3,SWRCH18

661

AC39-10019A

POWER-CORD

CN601A 3809-001090 CABLE-FLAT;30V,80C,100mm,22P,1.0mm,UL289

CN606A 3809-001048 CABLE-FLAT;30V,80C,110mm,6P,1.25mm,UL289

CN77A 3809-001094 CABLE-FLAT;30V,80C,40mm,5P,1.25mm,UL2896

LD601A AC61-22345A HOLDER-LED;POM,-,-,-,-,PT601A AC61-22344A HOLDER-PHOTO;POM,-,-,-,-,PT602A AC61-22344A HOLDER-PHOTO;POM,-,-,-,-,S601A AC61-22321A HOLDER-TR;POM,-,-,-,-,S602A AC61-22321A HOLDER-TR;POM,-,-,-,-,SC301 AC98-12023J ASSY-S/C P/AMP TOP

Page 25

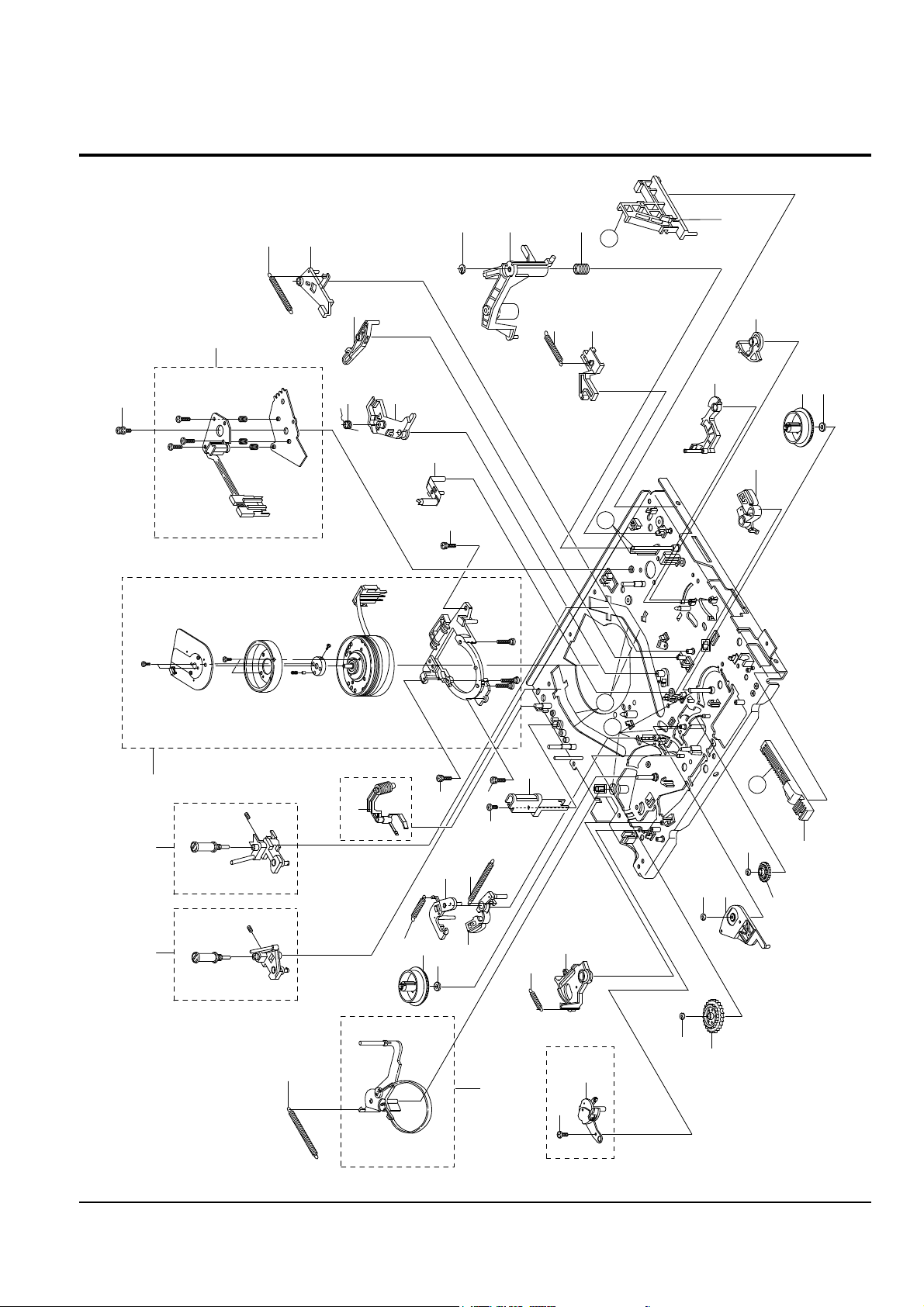

Exploded View and Parts List

6-4 Samsung Electronics

6-2 Mechanical Parts (Top Side)

T216

T201

T207

T300

901

920

901

T203

T209

T240

900

T239

T210

956

956

956

T208

T227

T233

957

T234

T228

T230

T229

T231

901

T233

T204

T238

T232

T225

T226

952

G

T236

T211

T223

T217

T219

952

T218

T220 T221

T222

G

G

O

G

919

T224

T212

<DX7-AC/DX8-AC ONLY>

<DX7-AC/DX8-AC

ONLY>

T202

Page 26

Exploded View and Parts List

Samsung Electronics 6-5

Loc. No Part No Description and Specification Remark

900 AC60-12091A SCREW-MACHINE;FP,BH,-,M3,L4,SWRCH10A,YEL ROB (OPTIONAL)

901 AC60-10012A SCREW-MACHINE;BH,+,M3,L8,-,FE,-,-,919 AC60-10004A SCREW-MACHINE;BH,+,M3,L8,ZPC,SWRCH18A,-,

920 AC60-10007A SCREW-TAPPING;BH,+,M2.6,L12,-,SWRCH18A,952 AC60-30018A WASHER-PLAIN;PLAIN,M3.2,D6,T0.5,POLYSLID

956 AC60-30007A WASHER-SLIT;PLAIN,ID2.5,OD7,T0.5,SPC1,-,

957 AC60-30008A WASHER-SLIT;-,ID3.5,OD9,T0.5,SPC1,-,T201 AC66-10023A REEL-DISK L ASSY;POM,-,PACKAGE,X-5,T202 AC66-10022A REEL-DISK R (ASSY);POM,-,PACKAGE,X-5,T203 AC66-30474A BRAKE-SUB L;-,PBT,-,-,-,X-5/IS

T204 AC66-30148A BRAKE SUB R;-,-,-,-,X5,T207 AC66-30475A BRAKE-MAIN L ASS’Y;-,POM+PELT,-,-,-,X-5/

T208 AC66-30476A BRAKE-MAIN R ASS’Y;-,POM+PELT,-,-,-,X-5/

T209 AC61-60112A SPRING- BRAKE MAIN;ES,SUS304WPB,PI0.35,I

T210 AC66-20073A GEAR RELAY S-ASSY;-,-,-,-,-,X5,T211 AC66-20037A GEAR- RELAY T;PEBAX7033,X-5,Z39,GEAR-SPU

T212 AC66-30073A ARM-TENSION ASSY;-,DX5-R,-,-,-,T216 AC61-60119A SPRING TENSION;ES,SWPB,PI0.4,D3,L33(OD3.

T217 AC66-30470A LEVER-REC S/W;-,PBT #3300,T4.0,L32,-,(XT218 AC61-62017A SPRING-SUB BRAKE L;ES,SUS304,PI0.23,D3.5

T219 AC33-10003P HEAD- MAGNET F/E;MH131S,-,-,-,L51.05XW7.

T220 AC66-82050A SLIDER-G/R ASSY(S);-,-,-,-,X-5

T221 AC66-82054A SLIDER-G/R ASSY(T);-,-,-,-,X-5

T222 AC33-10002E HEAD-CLEANER;-,-,-,X-5 (OPTIONAL)

T223 AC66-20065A RACK-HOUSING;L74.29,POM M90-44,BLK,M1,3.

T224 AC33-10216K HEAD-ACE ALL ASSY;-,-,-,-,X-7A

T225 AC66-80005A SLIDER-PINCH;POM(M90-44),T10.5,L54.35,NA

T226 AC66-30014A LEVER-REVIEW;ZYTEL(70G-43L),T5,-,PCD25.6

T227 AC66-30099A ARM-REVIEW ASSY;-,-,-,-,DX5-R,T228 AC66-30013A LEVER- CAM;PBT 6300T,-,L45,W9,X-5,T229 AC66-30003A LEVER-PINCH COMP;PBT 3300,T7.5,L45.25,-,

T230 AC61-60116A SPRING- PINCH COMP;TS,SWPB,PI1.0,D6,L38(

T231 AC67-32001A PRISM-LED;PMMA,D5,IF-850,-,-,T232 AC66-82049A SLIDER-PUSH;LUPOX 2150,T2,-,NTR,T233 AC61-62016A SPRING-SLIDE PUSH;ES,SUS304WPB,PI0.55,D3

T234 AC59-90402A UNIT-PINCH ROLLER;X-7A,RESIN BEARING

T236 AC66-10010A IDLER-ASSY;PACKAGE,-,X-5,T238 AC61-60132A SPRING ARM PINCH;CS,SUS304WPB,PI0.4,D7.1

T239 AC66-30132A LEVER JOG-ASS’Y;-,-,-,X-5 (OPTIONAL)

T240 AC61-60505A SPRING-REC S/W;-,ES,SUS304 WPB,PI0.29,PI

T300 AC96-10475D ASSY-CYLINDER;CX8A-S2P

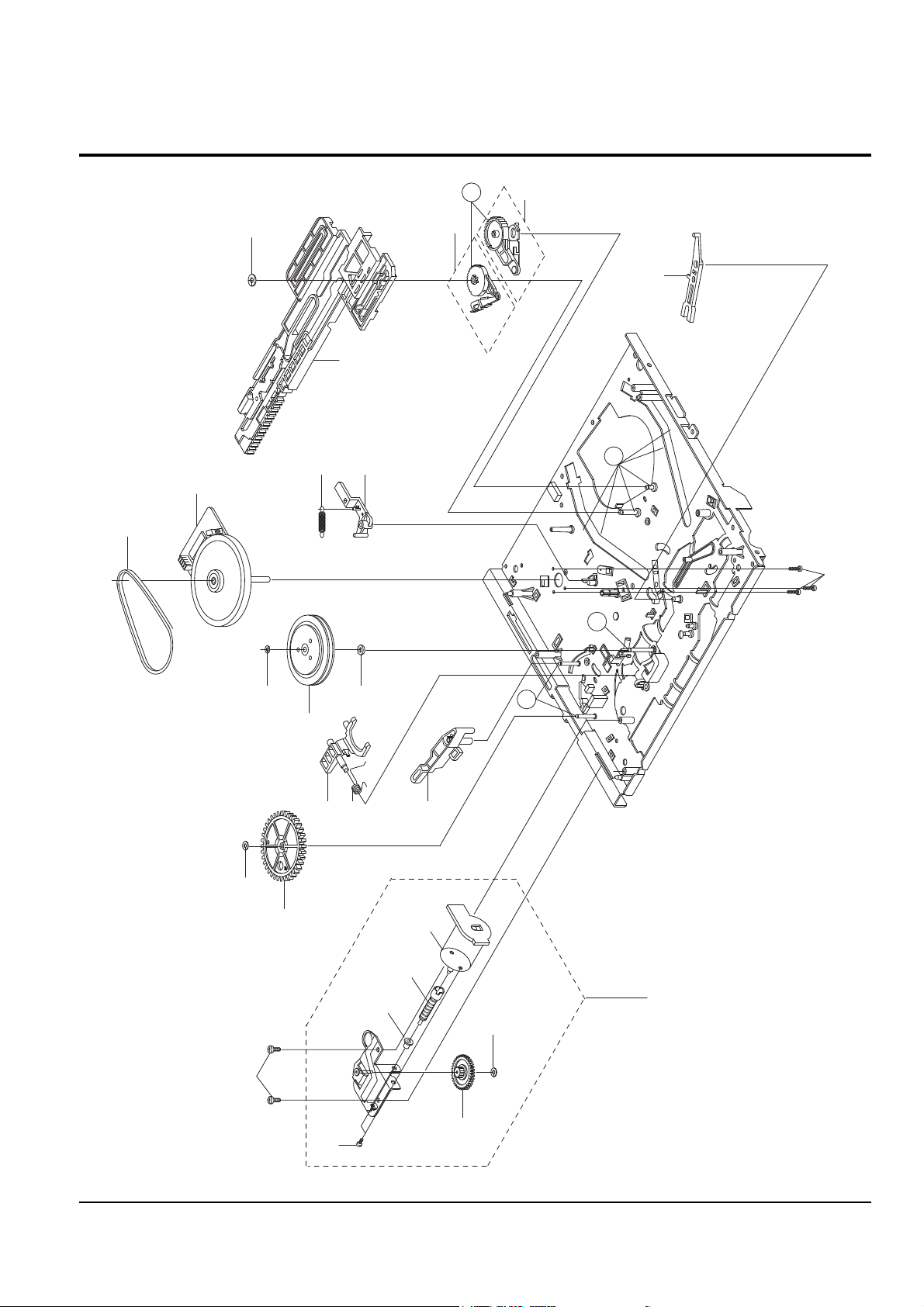

Page 27

Exploded View and Parts List

6-6 Samsung Electronics

6-3 Mechanical Parts (Bottom Side)

B257

G

G

O

B256

B254

951

951

952

918

B258

B261

B255

B260

B267

B266

B265

956

902

922

B259

B262

B253

B263

B268

B251

958

B252

G

B264

Page 28

Exploded View and Parts List

Samsung Electronics 6-7

Loc. No Part No Description and Specification Remark

902 AC60-10051A SCREW-TAPPING;BH,-,-,M3,L8,FZY

918 AC60-10041A SCREW-TAPPING;BH,+,-,M2.6XL7.5,ZPC3

922 AC60-10504A SCREW-MACHINE;-,PH,+,-,M3,L3,FE,FZY,YEL

951 AC60-30025A WASHER-SLIT;-,ID2.5,OD5.0,T0.5,POLY SLID

952 AC60-30018A WASHER-PLAIN;PLAIN,M3.2,D6,T0.5,POLYSLID

956 AC60-30007A WASHER-SLIT;PLAIN,ID2.5,OD7,T0.5,SPC1,-,

958 AC60-30028A WASHER-SLIT;-,D2.5,D9.0,T0.5,NUMIRROR,-,

B251 AC66-82043A SLIDER-MAIN;TOPEX 4010S,-,-,-,B252 AC66-20019A GEAR-LOADING L ASSY;-,-,-,PACKAGE,-,X-5,

B253 AC66-20069A GEAR-LOADING R ASSY;-,-,-,-,-,X5,B254 AC61-60115A SPRING-BRAKE CAPSTAN;ES,SUS304WPB,PI0.4,

B255 AC66-20004A GEAR-MASTER;POM (M90-44),M 1,Z 60,SP,-,X

B256 AC31-12006A MOTOR-D/D CAPSTAN;DMVCMC07A,-,B257 AC66-62008A BELT-CAPSTAN;-,DLB-601,T2,8,L134.9,BLK,X

B258 AC66-20066A GEAR-CLUTCH ASSY;X-5,-,-,-,-,-,B259 AC66-32185A LEVER-SLIDER PINCH;PBT,T4,NAT,-,-,B260 AC66-20016A GEAR- WORM WHEEL;POM SW-01,M0.55/M1,Z57/

B261 AC66-30011A LEVER- SHIFT;PBT2002K,T10.9,L35,-,-,B262 AC66-30012A LEVER- IDELR CHANGE;PBT330,T33,L50,-,W6.

B263 AC61-60111A SPRING-LEVER SHIFT;TS,SWPB,PI0.7,D5.5,L1

B264 AC59-90001A UNIT-LOADING ASSY;X-5,-,B265 AC31-12015A MOTOR-LOADING ASSY;POM+RF370C X-5

B266 AC66-20039A GEAR- WORM LO;PBT 2002K,-,-,-,D4.5,3,B267 AC61-20224A HOLDER SHAFT;POM M90-44,T1.25,NTR,PI5XH5

B268 AC66-30149A BRAKE CAPSTAN;-,-,-,-,X5,-

Page 29

Exploded View and Parts List

6-8 Samsung Electronics

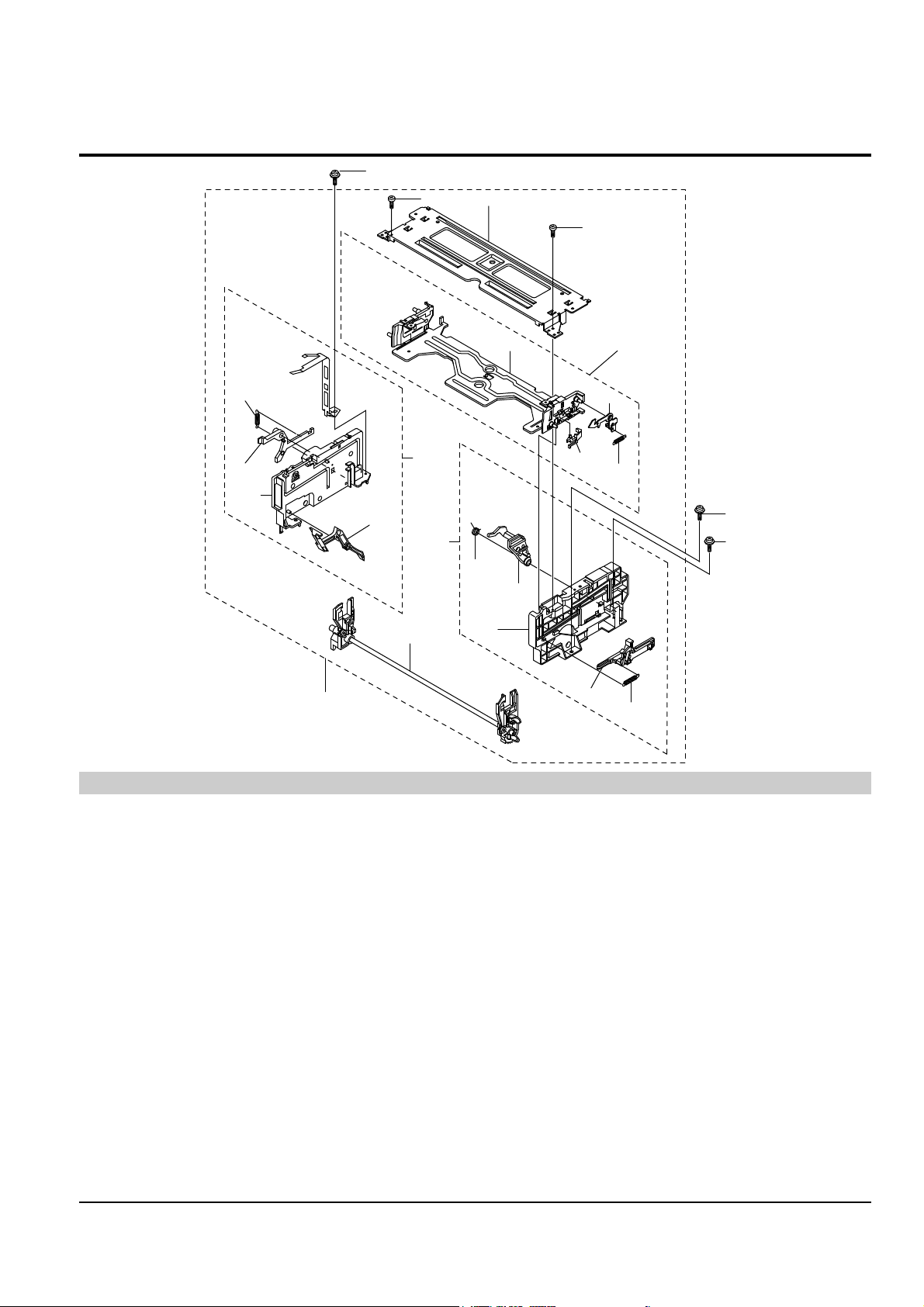

6-4 Housing Assembly

Loc. No Part No Description and Specification Remark

914

902

H510

H550

H500

H520

H522

H524

H526

902

H521

H533

H532

H531

H535

H530

H540

H545

H544

H541

H543

H542

914

914

902 AC60-10051A SCREW-TAPPING;BH,-,-,M3,L8,FZY

914 AC60-10067A SCREW-TAPTITE;PWH,+,-,M3,L8,MFZN2-C,SWCH

H500 AC61-82014D HOUSING-ASSY;-,X7FL26280B,230X130X60,-,X

H510 AC61-10006A CHASSIS- UPPER;SECC 20/20,-,T1.0,BLK,-,X

H520 AC61-20932B HOLDER-CASSETTE ASSY;-,X5FL06080A,-,-,-,

H521 AC61-20922B HOLDER-CASSETTE;-,SECC T1.2,-,NAT,-,X-7(

H522 AC66-30018A LEVER-LOCK R;SECC 20/20,T1.2,L44,W32,-,H524 AC61-60121A SPRING-LEVER LOCK;ES,SUS304 WPB,PI0.2,D2

H526 AC66-30019A LEVER-KEY CASSETTE;LUCEL N109-LD,T2.5,L2

H530 AC61-11033A CHASSIS-SIDE L ASSY;-,-,-,-,-,X5FL0505A,

H531 AC61-10004A CHASSIS- SIDE L;ABS HF-380,-,T10,BLK,-,X

H532 AC66-30004A LEVER- LIGHT SHUTTER;LUCEL N109-LD,T2.5,

H533 AC61-60142A SPRING- LIGHT;ES,SUS304WPB,PI0.2,L11.4(O

H535 AC66-30017A LEVER- DOOR;LUCELN109-LD,T3.5,L74.3,W21.

H540 AC61-11032A CHASSIS-SIDE R ASSY;-,-,-,-,-,X5FL0505A,

H541 AC61-10003A CHASSIS- SIDE R;ABS HF-380,-,T10,BLK,-,X

H542 AC66-80008A SLIDER DAMPER;LUCEL N109-LD,T4,L87,-,-,H543 AC61-60120A SPRING-SLIDER;ES,SUS 304WPB,PI0.4,D3.8,L

H544 AC66-30016A LEVER- LID OPENER;LUCEL N109-LD,T4.0,L34

H545 AC61-60123A SPRING-LID OPENER;TS,SWPB,PI0.55,D8.9,L1

H550 AC61-50654A SHAFT-ARM ASSY;-,SUM24L,-,-,-,-,X-5

Page 30

SMPS/POWER PARTS (230 VOLTAGE)

C1D41 2401-000306 C-AL;100uF,20%,25V,GP,6.3x11mm,2.5m

C1D42 2202-000780 C-CERAMIC,MLC-AXIAL;100nF,+80-20%,50V,Y5

C1P04 2401-001912 C-AL;1uF,20%,50V,GP,5x11mm,2mm,BK

C1S01 2305-001021 C-FILM,MPEF;100nF,20%,275V,TP,17.5x7x13.

C1S02 2201-000808 C-CERAMIC,DISC;2.2nF,10%,400V,Y5P,12x7.5

C1S03 2201-000934 C-CERAMIC,DISC;3.3nF,20%,400V,Y5P,18x8,1

C1S05 2305-001021 C-FILM,MPEF;100nF,20%,275V,TP,17.5x7x13.

C1S11 2401-003302 C-AL;47uF,20%,400V,GP,TP,18X31.5,7.

C1S12 2201-000934 C-CERAMIC,DISC;3.3nF,20%,400V,Y5P,18x8,1

C1S13 2201-000915 C-CERAMIC,DISC;100pF,10%,1KV,Y5P,TP,6x5,

C1S15 2401-000905 C-AL;22UF,20%,16V,BP,-,6X11,2.5MM

C1S16 2301-000361 C-FILM,PEF;1.2NF,10%,50V,TP,-,5MM

C1S17 2301-000445 C-FILM,PEF;4.7nF,5%,50V,5.5x7x3mm,5mm,TP

C1S18 2301-000224 C-FILM,PEF;22nF,5%,50V,TP,7.4x3.9x13mm

C1S19 2401-001912 C-AL;1uF,20%,50V,GP,5x11mm,2mm,BK

C1S20 2301-000224 C-FILM,PEF;22nF,5%,50V,TP,7.4x3.9x13mm

C1S21 2401-000970 C-AL;22uF,20%,50V,WT,TP,5x11,2mm

C1S30 2401-000385 C-AL;10UF,20%,100V,GP,-,6.3X11,2.5M

C1S32 2401-001998 C-AL;1000uF,20%,25V,GP,TP,10x20,5mm

C1S33 2401-000306 C-AL;100uF,20%,25V,GP,6.3x11mm,2.5m

C1S34 2401-000118 C-AL;1000uF,20%,10V,GP,TP,10x12.5,5

C1S35 2401-000306 C-AL;100uF,20%,25V,GP,6.3x11mm,2.5m

C1S38 2301-000129 C-FILM,PEF;100nF,5%,50V,10X9X4.3X5,5mm,T

CN1S01 3711-000178 CONNECTOR-HEADER;1WALL,2P,1R,3.96mm,STRA

D1D41 0402-000132 DIODE-RECTIFIER ;1N4004,400V,1A,DO-41

D1D42 0402-000132 DIODE-RECTIFIER ;1N4004,400V,1A,DO-41

D1D43 0402-000132 DIODE-RECTIFIER ;1N4004,400V,1A,DO-41

D1D44 0402-000132 DIODE-RECTIFIER ;1N4004,400V,1A,DO-41

D1P05 0401-000101 DIODE-SWITCHING;1N4148,100V,200mA,500mW,

D1P06 0402-000132 DIODE-RECTIFIER ;1N4004,400V,1A,DO-41

D1S01 0402-001009 DIODE-RECTIFIER;1SR139,600V,1A,MSR

D1S02 0402-001009 DIODE-RECTIFIER;1SR139,600V,1A,MSR

D1S03 0402-001009 DIODE-RECTIFIER;1SR139,600V,1A,MSR

D1S04 0402-001009 DIODE-RECTIFIER;1SR139,600V,1A,MSR

D1S11 0402-000378 DIODE-RECTIFIER;EG01C,1000V,500mA,DO-41

D1S12 0401-000101 DIODE-SWITCHING;1N4148,100V,200mA,500mW,

D1S13 0402-001013 DIODE-RECTIFIER;1SR153-400,400V,800mA,DO

D1S30 0402-001013 DIODE-RECTIFIER;1SR153-400,400V,800mA,DO

D1S32 0402-001069 DIODE-RECTIFIER;RL10Z,200V,2A,DO,TP

D1S33 0402-001069 DIODE-RECTIFIER;RL10Z,200V,2A,DO,TP

F1S01 A3065-0157 FUSE;FST 250V 1.6A 20MM SEMKO S505 C

IC1P02 AC14-12001E IC;KA7809,-,IC1S13 0604-011028 PHOTO-COUPLER;PS2561-1 ST DIP

IC1S31 AC14-12006D IC;KA431Z,TO-92,TAPING

L1S02 A1151-0042 COIL-LINE FILTER;BSF-2120Z 25MH 3.2OHM

L1S03 AC27-92001M INDUCTOR;70UH-M RT BFS3565R2F,-,-,-,L1S12 AC27-92001M INDUCTOR;70UH-M RT BFS3565R2F,-,-,-,L1S30 AC27-12001N COIL-CHOKE;10UH-15%,RA,K-30,Q80,150KHZ,L1S31 AC27-12001N COIL-CHOKE;10UH-15%,RA,K-30,Q80,150KHZ,-

PT1S11 AC26-20120C TRANS-SWITCHING;-,100/230V,UL/CSA,EE28*2

Q1P02 0501-000616 TR-SMALL SIGNAL;KSC2328A-Y,NPN,1W,TO-92L

Q1P04 0504-000118 TR-DIGITAL;KSR1003,NPN,300mW,22K-22K,TOQ1P05 0501-000616 TR-SMALL SIGNAL;KSC2328A-Y,NPN,1W,TO-92L

Q1P06 0501-000610 TR-SMALL SIGNAL;KSA928A-Y,PNP,1W,TO-92L,

Q1S11 0502-001050 TR-POWER;2SC4517A,NPN,30W,TO-220,ST,10Q1S12 0501-000442 TR-SMALL SIGNAL;KTC3203-Y,NPN,400MW

R1P01 2004-001096 R-METAL;560ohm,5%,1/4W,AA,TP,2.4X6.4mm

R1P05 2004-000571 R-METAL;220ohm,5%,1/4W,AA,TP,2.4x6.4mm

R1P08 2001-000449 R-CARBON;2.2Kohm,5%,1/8W,AA,TP,1.8x3.2m

R1P09 2001-000221 R-CARBON;1.2Kohm,5%,1/8W,AA,TP,1.8x3.2m

R1P10 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R1P11 2004-001096 R-METAL;560ohm,5%,1/4W,AA,TP,2.4X6.4mm

R1S11 2006-000262 R-CEMENT;2.7ohm,10%,2W,CB,ST,7.5x11x20.

R1S12 2001-000305 R-CARBON;110Kohm,5%,1/8W,AA,TP,1.8x3.2m

R1S13 2001-000305 R-CARBON;110Kohm,5%,1/8W,AA,TP,1.8x3.2m

R1S14 2001-000305 R-CARBON;110Kohm,5%,1/8W,AA,TP,1.8x3.2m

R1S15 2001-000305 R-CARBON;110Kohm,5%,1/8W,AA,TP,1.8x3.2m

R1S17 2006-000273 R-CEMENT;27Kohm,5%,2W,CA,BK,6.4x27x6.4m

R1S18 2003-000264 R-METAL OXIDE;300ohm,5%,1W,AD,TP,4.3x12m

R1S19 2001-000003 R-CARBON ;330 OHM,5%,1/8W,AA,T

R1S20 2001-000003 R-CARBON ;330 OHM,5%,1/8W,AA,T

R1S21 2003-000273 R-METAL OXIDE;33Kohm,5%,2W,AA,TP,6x16mm

R1S30 2001-000515 R-CARBON;220ohm,5%,1/8W,AA,TP,1.8x3.2mm

R1S31 2001-000221 R-CARBON;1.2Kohm,5%,1/8W,AA,TP,1.8x3.2m

R1S32 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R1S33 2004-000869 R-METAL;3Kohm,1%,1/8W,AA,TP,1.8x3.2mm

R1S34 2004-000459 R-METAL;2.2Kohm,1%,1/8W,AA,TP,1.

R1S40 2003-000119 R-METAL OXIDE;0.68ohm,5%,2W,AE,TP,6x16mm

VA1S01 1405-001026 VARISTOR;470V,600A,9x7mm,TP

ZD1P05 0403-000557 DIODE-ZENER;MTZ5.1C,5.1V,5.09-5.37V,500m

ZD1S11 0403-000539 DIODE-ZENER;MTZ18C,18V,17.42-18.33V,500m

ZD1S12 0403-000294 DIODE-ZENER;MTZ4.7B,4.55-4.80V,500mW,DOZD1S30 0403-000571 DIODE-ZENER;UZP43B,43V,40-46V,1W,DO-41,T

SYSTEM CONTROL/SERVO PARTS

C601 2202-000807 C-CERAMIC,MLC-AXIAL;22NF,+80-20%,25V,Y5V

C602 2202-000797 C-CERAMIC,MLC-AXIAL;10NF,30%,16V,Y5P,TP,

C603 2202-000850 C-CERAMIC,MLC-AXIAL;2.2NF,30%,16V,Y5R,TP

C604 2202-000781 C-CERAMIC,MLC-AXIAL:100pF,10%,50V,Y5P,TP

C605 2401-000918 C-AL;22uF,20%,16V,GP,-,6.3x7,5

C606 2202-000797 C-CERAMIC,MLC-AXIAL;10NF,30%,16V,Y5P,TP,

C607 2202-000781 C-CERAMIC,MLC-AXIAL:100pF,10%,50V,Y5P,TP

C608 2202-000807 C-CERAMIC,MLC-AXIAL;22NF,+80-20%,25V,Y5V

C609 2202-000781 C-CERAMIC,MLC-AXIAL:100pF,10%,50V,Y5P,TP

C610 2202-000791 C-CERAMIC,MLC-AXIAL;150PF,10%,50V,Y5P,TP

C6107 2202-000162 C-CERAMIC,MLC-AXIAL;15pF,5%,50V,SL,TP,3.

C611 2401-001952 C-AL;4.7UF,20%,50V,-,TP,6.3X7,5

C6114 2202-000145 C-CERAMIC,MLC-AXIAL;120PF,10%,50V,Y5P,3.

C6119 2401-001572 C-AL;47UF,20%,50V,GP,-,6.3X11,2.5MM

C612 2401-001511 C-AL;47UF,20%,16V,GP,-,6X7,5

C6120 2202-000797 C-CERAMIC,MLC-AXIAL;10NF,30%,16V,Y5P,TP,

C6126 2401-000419 C-AL;10UF,20%,16V,GP,-,4X7,5

C613 2202-000780 C-CERAMIC,MLC-AXIAL;100nF,+80-20%,50V,Y5

C614 2401-001325 C-AL;470nF,20%,50V,GP,TP,3x5,5

C615 2202-000781 C-CERAMIC,MLC-AXIAL:100pF,10%,50V,Y5P,TP

C616 2202-000797 C-CERAMIC,MLC-AXIAL;10NF,30%,16V,Y5P,TP,

C617 2202-000216 C-CERAMIC,MLC-AXIAL;27pF,5%,50V,SL,TP,3.

C6170 2202-000780 C-CERAMIC,MLC-AXIAL;100nF,+80-20%,50V,Y5

C618 2202-000216 C-CERAMIC,MLC-AXIAL;27pF,5%,50V,SL,TP,3.

Loc.No

Part No Desc & Spec Remark

Loc.No

Part No Desc & Spec Remark

Samsung Electronics

7-1

7. Electrical Parts List

Page 31

C619 2202-000205 C-CERAMIC,MLC-AXIAL;22pF,5%,50V,SL,TP,1.

C620 2202-000205 C-CERAMIC,MLC-AXIAL;22pF,5%,50V,SL,TP,1.

C621 2202-000162 C-CERAMIC,MLC-AXIAL;15pF,5%,50V,SL,TP,3.

C622 2202-000162 C-CERAMIC,MLC-AXIAL;15pF,5%,50V,SL,TP,3.

C623 2202-000162 C-CERAMIC,MLC-AXIAL;15pF,5%,50V,SL,TP,3.

C624 2202-000162 C-CERAMIC,MLC-AXIAL;15pF,5%,50V,SL,TP,3.

C625 2201-000928 C-CERAMIC,DISC;2.7NF,20%,16V,Y5R,TP,3.5X

C626 2401-001511 C-AL;47UF,20%,16V,GP,-,6X7,5

C627 2202-000797 C-CERAMIC,MLC-AXIAL;10NF,30%,16V,Y5P,TP,

C628 2401-001978 C-AL;47UF,20%,25V,GP,TP,6.3X5,5

C630 2202-000780 C-CERAMIC,MLC-AXIAL;100nF,+80-20%,50V,Y5

C631 2202-000797 C-CERAMIC,MLC-AXIAL;10NF,30%,16V,Y5P,TP,

C632 2202-000797 C-CERAMIC,MLC-AXIAL;10NF,30%,16V,Y5P,TP,

C634 2401-000419 C-AL;10UF,20%,16V,GP,-,4X7,5

C635 2401-000199 C-AL;1000UF,20%,6.3V,GP,TP,10X12.5,

C636 2202-000780 C-CERAMIC,MLC-AXIAL;100nF,+80-20%,50V,Y5

C637 2202-000780 C-CERAMIC,MLC-AXIAL;100nF,+80-20%,50V,Y5

C639 2202-000791 C-CERAMIC,MLC-AXIAL;150PF,10%,50V,Y5P,TP

C640 2202-000807 C-CERAMIC,MLC-AXIAL;22NF,+80-20%,25V,Y5V

C641 2202-000807 C-CERAMIC,MLC-AXIAL;22NF,+80-20%,25V,Y5V

C642 2202-000796 C-CERAMIC,MLC-AXIAL;UP050 B102KB INF,10%

C643 2401-001915 C-AL;1uF,20%,50V,GP,TP,3x5,1mm

C645 2401-001904 C-AL;10UF,20%,16V,-,TP,4X7MM,5

C646 2202-000780 C-CERAMIC,MLC-AXIAL;100nF,+80-20%,50V,Y5

C647 2202-000780 C-CERAMIC,MLC-AXIAL;100nF,+80-20%,50V,Y5

C648 2202-000780 C-CERAMIC,MLC-AXIAL;100nF,+80-20%,50V,Y5

C649 2401-000918 C-AL;22uF,20%,16V,GP,-,6.3x7,5

C650 2401-001978 C-AL;47UF,20%,25V,GP,TP,6.3X5,5

C651 2202-000797 C-CERAMIC,MLC-AXIAL;10NF,30%,16V,Y5P,TP,

C653 2401-001511 C-AL;47UF,20%,16V,GP,-,6X7,5

C654 2202-000780 C-CERAMIC,MLC-AXIAL;100nF,+80-20%,50V,Y5

C655 2202-000780 C-CERAMIC,MLC-AXIAL;100nF,+80-20%,50V,Y5

C656 2401-001978 C-AL;47UF,20%,25V,GP,TP,6.3X5,5

C657 2401-001978 C-AL;47UF,20%,25V,GP,TP,6.3X5,5

C658 2202-000797 C-CERAMIC,MLC-AXIAL;10NF,30%,16V,Y5P,TP,

C659 2202-000780 C-CERAMIC,MLC-AXIAL;100nF,+80-20%,50V,Y5

C665 2202-000780 C-CERAMIC,MLC-AXIAL;100nF,+80-20%,50V,Y5

C666 2202-000806 C-CERAMIC,MLC-AXIAL;220PF,10%,50V,Y5P,TP

C667 2202-000806 C-CERAMIC,MLC-AXIAL;220PF,10%,50V,Y5P,TP

C668 2202-000797 C-CERAMIC,MLC-AXIAL;10NF,30%,16V,Y5P,TP,

C670 2202-000780 C-CERAMIC,MLC-AXIAL;100nF,+80-20%,50V,Y5

C672 2202-000807 C-CERAMIC,MLC-AXIAL;22NF,+80-20%,25V,Y5V

C673 2202-000797 C-CERAMIC,MLC-AXIAL;10NF,30%,16V,Y5P,TP,

C674 2202-000780 C-CERAMIC,MLC-AXIAL;100nF,+80-20%,50V,Y5

C675 2202-000780 C-CERAMIC,MLC-AXIAL;100nF,+80-20%,50V,Y5

C676 2202-000780 C-CERAMIC,MLC-AXIAL;100nF,+80-20%,50V,Y5

C690 2401-001572 C-AL;47UF,20%,50V,GP,-,6.3X11,2.5MM

C691 2202-000797 C-CERAMIC,MLC-AXIAL;10NF,30%,16V,Y5P,TP,

C699 2202-000797 C-CERAMIC,MLC-AXIAL;10NF,30%,16V,Y5P,TP,

CN601 3708-001251 CONNECTOR-FPC/FC/PIC;22P,1mm,STRAIGHT-F,

CN602 3711-002445 CONNECTOR-HEADER;BOX,2P,2R,1.5MM,STRAIGH

CN606 3708-001165 CONNECTOR-FPC/FC/PIC;6P,1.25mm,STRAIGHT,

CN607 3711-003749 CONNECTOR-HEADER;BOX,8P,2R,2mm,STRAIGHT,

D602 0401-000101 DIODE-SWITCHING;1N4148,100V,200mA,500mW,

D604 0402-000132 DIODE-RECTIFIER ;1N4004,400V,1A,DO-41

D605 0401-000101 DIODE-SWITCHING;1N4148,100V,200mA,500mW,

D606 0401-000101 DIODE-SWITCHING;1N4148,100V,200mA,500mW,

D607 0402-000132 DIODE-RECTIFIER ;1N4004,400V,1A,DO-41

D609 0401-000101 DIODE-SWITCHING;1N4148,100V,200mA,500mW,

D6102 0401-000101 DIODE-SWITCHING;1N4148,100V,200mA,500mW,

D6104 0401-000101 DIODE-SWITCHING;1N4148,100V,200mA,500mW,

D6105 0401-000101 DIODE-SWITCHING;1N4148,100V,200mA,500mW,

D619 0402-000132 DIODE-RECTIFIER ;1N4004,400V,1A,DO-41

D620 0402-000132 DIODE-RECTIFIER ;1N4004,400V,1A,DO-41

D690 0402-000132 DIODE-RECTIFIER ;1N4004,400V,1A,DO-41

IC601 AC09-10457E IC-MCU;HD6433976RA83F,100PIN,QFP,SVB1

IC602 1003-001090 IC-MOTOR DRIVER;LB1643,SIP,10P,-,SINGLE,

IC603 1201-000230 IC-OP AMP;6324,DIP,14P,-,QUAD,15/100mV,P

IC604 AC14-12006C IC;KA7533,DIP,IC605 AC11-12001H IC-EEPROM;24LC02B/P,DIP,-

IC606 AC14-12001G IC;KA78L05,T,L601 AC27-92001B COIL-PEAKING AXIAL;BAL04ST101K,-,-,-,L602 AC27-92001B COIL-PEAKING AXIAL;BAL04ST101K,-,-,-,L603 AC27-92001B COIL-PEAKING AXIAL;BAL04ST101K,-,-,-,L604 2701-000131 INDUCTOR-AXIAL;15UH,5%,2.4X3.4MM

L6101 AC27-92001B COIL-PEAKING AXIAL;BAL04ST101K,-,-,-,L6103 2701-000117 INDUCTOR-AXIAL;10uH,5%,2.4x3.4mm

LD601 0601-000495 LED-IR;ROUND,3mm,150mW,6V,950nm,BK

PT601 0604-000188 PHOTO-INTERRUPTER;TR,-,-,DIP-4,TR

PT602 0604-000188 PHOTO-INTERRUPTER;TR,-,-,DIP-4,TR

Q604 0501-000398 TR-SMALL SIGNAL;KSC945,NPN,250mW,TO-92,T

Q605 0501-000398 TR-SMALL SIGNAL;KSC945,NPN,250mW,TO-92,T

Q609 0501-000303 TR-SMALL SIGNAL;KSA733,PNP,250mW,TO-92,T

Q610 0504-000144 TR-DIGITAL;KSR2002,PNP,300mW,10K-10Kohm,

Q6102 0501-000398 TR-SMALL SIGNAL;KSC945,NPN,250mW,TO-92,T

Q6106 0501-000398 TR-SMALL SIGNAL;KSC945,NPN,250mW,TO-92,T

Q6108 0501-000303 TR-SMALL SIGNAL;KSA733,PNP,250mW,TO-92,T

Q611 0504-000203 TR-DIGITAL;KSR1004,NPN,300mW,47K-47K,TOR601 2001-000010 R-CARBON;68KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R603 2001-000864 R-CARBON;56Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R604 2001-000554 R-CARBON;270OHM,5%,1/8W,AA,TP,1.8X3.2MM

R605 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R607 2001-000508 R-CARBON ;220K OHM,5%,1/8W,AA,

R608 2001-000508 R-CARBON ;220K OHM,5%,1/8W,AA,

R609 2001-001031 R-CARBON;91KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R610 2001-000290 R-CARBON;10Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R6101 2001-000331 R-CARBON;12Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R6102 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R6103 2001-000290 R-CARBON;10Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R6104 2001-000290 R-CARBON;10Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R6105 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R6106 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R611 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R6113 2001-000008 R-CARBON;15Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R6115 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R6119 2001-000864 R-CARBON;56Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R612 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R6120 2001-000435 R-CARBON;1Mohm,5%,1/8W,AA,TP,1.8x3.2mm

R6121 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R6122 2001-000290 R-CARBON;10Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R6123 2001-000786 R-CARBON;47Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R6124 2001-000633 R-CARBON;30Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R6125 2001-000633 R-CARBON;30Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R6128 2001-000534 R-CARBON;240ohm,5%,1/8W,AA,TP,1.8x3.2mm

R6129 2001-000281 R-CARBON;100ohm,5%,1/8W,AA,TP,1.8x3.2mm

R613 2001-000786 R-CARBON;47Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R6131 2001-000281 R-CARBON;100ohm,5%,1/8W,AA,TP,1.8x3.2mm

R6134 2001-000864 R-CARBON;56Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R614 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R615 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

Loc.No

Part No Desc and Spec Remark

Loc.No

Part No Desc and Spec Remark

7-2

Samsung Electronics

Electrical Parts List

Page 32

R6150 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R6151 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R6152 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R6153 2001-000947 R-CARBON;7.5KOHM,5%,1/8W,AA,TP,1.8X3.2M

R6154 2001-000290 R-CARBON;10Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R6155 2001-000290 R-CARBON;10Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R6156 2001-000347 R-CARBON;13Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R6157 2001-000347 R-CARBON;13Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R6159 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R616 2001-000864 R-CARBON;56Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R6160 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R6161 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R6162 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R6163 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R6164 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R6165 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R617 2001-000290 R-CARBON;10Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R6170 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R618 2001-000290 R-CARBON;10Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R619 2001-000554 R-CARBON;270OHM,5%,1/8W,AA,TP,1.8X3.2MM

R620 2001-000832 R-CARBON;510ohm,5%,1/8W,AA,TP,1.8x3.2mm

R621 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R622 2001-000012 R-CARBON;680Kohm,5%,1/8W,AA,TP,1.8x3.2m

R624 2001-000773 R-CARBON;470Kohm,5%,1/8W,AA,TP,1.8x3.2m

R625 2001-000802 R-CARBON;5.6KOHM,5%,1/8W,AA,TP,1.8X3.2M

R626 2001-000281 R-CARBON;100ohm,5%,1/8W,AA,TP,1.8x3.2mm

R627 2001-000290 R-CARBON;10Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R628 2001-000290 R-CARBON;10Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R629 2001-000258 R-CARBON;1.8Kohm,5%,1/8W,AA,TP,1.8x3.2m

R630 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R631 2001-000435 R-CARBON;1Mohm,5%,1/8W,AA,TP,1.8x3.2mm

R634 2001-000273 R-CARBON;100Kohm,5%,1/8W,AA,TP,1.8x3.2m

R635 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R636 2001-000281 R-CARBON;100ohm,5%,1/8W,AA,TP,1.8x3.2mm

R637 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R638 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R639 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R641 2001-000435 R-CARBON;1Mohm,5%,1/8W,AA,TP,1.8x3.2mm

R643 2001-000290 R-CARBON;10Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R644 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R645 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R648 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R649 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R651 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R656 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R659 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R660 2001-000281 R-CARBON;100ohm,5%,1/8W,AA,TP,1.8x3.2mm

R663 2001-000679 R-CARBON;36KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R664 2001-000411 R-CARBON;18Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R665 2001-000734 R-CARBON;4.7Kohm,5%,1/8W,AA,TP,1.8x3.2m

R666 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R669 2001-000864 R-CARBON;56Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R671 2001-000802 R-CARBON;5.6KOHM,5%,1/8W,AA,TP,1.8X3.2M

R675 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R676 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R679 2001-000508 R-CARBON ;220K OHM,5%,1/8W,AA,

R680 2001-000832 R-CARBON;510ohm,5%,1/8W,AA,TP,1.8x3.2mm

R681 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R682 2001-000508 R-CARBON ;220K OHM,5%,1/8W,AA,

R683 2001-000832 R-CARBON;510ohm,5%,1/8W,AA,TP,1.8x3.2mm

R685 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R686 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R687 2001-000290 R-CARBON;10Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R688 2001-000554 R-CARBON;270OHM,5%,1/8W,AA,TP,1.8X3.2MM

R691 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R692 2001-000347 R-CARBON;13Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R693 2001-000539 R-CARBON;24Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R694 2001-000221 R-CARBON;1.2Kohm,5%,1/8W,AA,TP,1.8x3.2m

R695 2001-000850 R-CARBON;560Kohm,5%,1/8W,AA,TP,1.8x3.2m

R696 2001-000539 R-CARBON;24Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R697 2003-000259 R-METAL OXIDE;3.9OHM,5%,2W,AE,TP,6X16MM

R698 2001-000786 R-CARBON;47Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R699 2001-000786 R-CARBON;47Kohm,5%,1/8W,AA,TP,1.8x3.2mm

RS601 3409-000176 SWITCH-DETECTOR;30Vdc,100mA,SPST,-,S601 0603-000112 PHOTO-TR;NPN,35V,6V,50mA,75mW,-

S602 0603-000112 PHOTO-TR;NPN,35V,6V,50mA,75mW,SW601 AC34-22001E SWITCH-PROGRAM;MXS00281MLB0,-,-,-,-,-,-,

XT601 2801-003293 CRYSTAL-UNIT;10MHZ,50PPM,28-AAA,16PF,50O

XT602 2801-003318 CRYSTAL-UNIT;32.768KHz,20ppm,28-AAP,12.5

XT6102 2801-003311 CRYSTAL-UNIT;17.734475MHz,50ppm,28-AAA,1

AUDIO/VIDEO PARTS

C301 2202-000243 C-CERAMIC,MLC-AXIAL;33PF,5%,50V,SL,3.5X1

C302 2202-000243 C-CERAMIC,MLC-AXIAL;33PF,5%,50V,SL,3.5X1

C305 2202-000797 C-CERAMIC,MLC-AXIAL;10NF,30%,16V,Y5P,TP,

C309 2202-000797 C-CERAMIC,MLC-AXIAL;10NF,30%,16V,Y5P,TP,

C310 2301-000392 C-FILM,PEF;15nF,5%,50V,6.5x8.5x3.2mm,5mm

C3101 2401-000419 C-AL;10UF,20%,16V,GP,-,4X7,5

C314 2401-001975 C-AL;47UF,20%,16V,GP,TP,5X11MM,5

C315 2202-000780 C-CERAMIC,MLC-AXIAL;100nF,+80-20%,50V,Y5

C316 2202-000797 C-CERAMIC,MLC-AXIAL;10NF,30%,16V,Y5P,TP,

C317 2401-001912 C-AL;1uF,20%,50V,GP,5x11mm,2mm,BK

C320 2202-000797 C-CERAMIC,MLC-AXIAL;10NF,30%,16V,Y5P,TP,

C321 2202-000797 C-CERAMIC,MLC-AXIAL;10NF,30%,16V,Y5P,TP,

C322 2202-000797 C-CERAMIC,MLC-AXIAL;10NF,30%,16V,Y5P,TP,

C324 2301-000283 C-FILM,PEF;47nF,5%,100V,TP,7.3X7X3.2X5,5

C325 2202-000797 C-CERAMIC,MLC-AXIAL;10NF,30%,16V,Y5P,TP,

C326 2202-000797 C-CERAMIC,MLC-AXIAL;10NF,30%,16V,Y5P,TP,

C327 2202-000797 C-CERAMIC,MLC-AXIAL;10NF,30%,16V,Y5P,TP,

C328 2202-000216 C-CERAMIC,MLC-AXIAL;27pF,5%,50V,SL,TP,3.

C329 2202-000797 C-CERAMIC,MLC-AXIAL;10NF,30%,16V,Y5P,TP,

C330 2202-000797 C-CERAMIC,MLC-AXIAL;10NF,30%,16V,Y5P,TP,

C331 2401-000918 C-AL;22uF,20%,16V,GP,-,6.3x7,5

C332 2202-000279 C-CERAMIC,MLC-AXIAL;47PF,5%,50V,SL,3.5X1

C333 2202-000814 C-CERAMIC,MLC-AXIAL;390pF,10%,50V,Y5P,3.

C335 2202-000162 C-CERAMIC,MLC-AXIAL;15pF,5%,50V,SL,TP,3.

C336 2201-000376 C-CERAMIC,DISC;220pF,5%,50V,SL,TP,4x4,5

C340 2401-001965 C-AL;470NF,20%,50V,-,BK,4X7MM,1.5MM

C341 2401-001917 C-AL;1UF,20%,50V,-,TP,5X7MM,5

C342 2202-000780 C-CERAMIC,MLC-AXIAL;100nF,+80-20%,50V,Y5

C343 2401-001975 C-AL;47UF,20%,16V,GP,TP,5X11MM,5

C344 2401-000419 C-AL;10UF,20%,16V,GP,-,4X7,5

C345 2202-000780 C-CERAMIC,MLC-AXIAL;100nF,+80-20%,50V,Y5

C346 2401-001975 C-AL;47UF,20%,16V,GP,TP,5X11MM,5

C347 2401-000419 C-AL;10UF,20%,16V,GP,-,4X7,5

C348 2401-001912 C-AL;1uF,20%,50V,GP,5x11mm,2mm,BK

C349 2401-001912 C-AL;1uF,20%,50V,GP,5x11mm,2mm,BK

C350 2202-000797 C-CERAMIC,MLC-AXIAL;10NF,30%,16V,Y5P,TP,

C351 2202-000780 C-CERAMIC,MLC-AXIAL;100nF,+80-20%,50V,Y5

C352 2401-001975 C-AL;47UF,20%,16V,GP,TP,5X11MM,5

C353 2202-000797 C-CERAMIC,MLC-AXIAL;10NF,30%,16V,Y5P,TP,

Loc.No

Part No Desc and Spec Remark

Loc.No

Part No Desc and Spec Remark

Electrical Parts List

Samsung Electronics

7-3

Page 33

C355 2202-000797 C-CERAMIC,MLC-AXIAL;10NF,30%,16V,Y5P,TP,

C356 2202-000797 C-CERAMIC,MLC-AXIAL;10NF,30%,16V,Y5P,TP,

C357 2202-000780 C-CERAMIC,MLC-AXIAL;100nF,+80-20%,50V,Y5

C358 2401-001912 C-AL;1uF,20%,50V,GP,5x11mm,2mm,BK

C359 2202-000797 C-CERAMIC,MLC-AXIAL;10NF,30%,16V,Y5P,TP,

C360 2202-000797 C-CERAMIC,MLC-AXIAL;10NF,30%,16V,Y5P,TP,

C361 2401-001975 C-AL;47UF,20%,16V,GP,TP,5X11MM,5

C362 2401-001912 C-AL;1uF,20%,50V,GP,5x11mm,2mm,BK

C363 2202-000807 C-CERAMIC,MLC-AXIAL;22NF,+80-20%,25V,Y5V

C364 2401-001912 C-AL;1uF,20%,50V,GP,5x11mm,2mm,BK

C366 2202-000797 C-CERAMIC,MLC-AXIAL;10NF,30%,16V,Y5P,TP,

C367 2202-000780 C-CERAMIC,MLC-AXIAL;100nF,+80-20%,50V,Y5

C368 2202-000854 C-CERAMIC,MLC-AXIAL;47NF,30%,50V,Y5R,TP,

C369 2401-001912 C-AL;1uF,20%,50V,GP,5x11mm,2mm,BK

C370 2301-000283 C-FILM,PEF;47nF,5%,100V,TP,7.3X7X3.2X5,5

C371 2202-000797 C-CERAMIC,MLC-AXIAL;10NF,30%,16V,Y5P,TP,

C373 2301-000439 C-FILM,PEF;3NF,5%,50V,TP,5.5X7X3MM,5MM

C374 2202-000781 C-CERAMIC,MLC-AXIAL:100pF,10%,50V,Y5P,TP

C375 2401-001511 C-AL;47UF,20%,16V,GP,-,6X7,5

C376 2202-000797 C-CERAMIC,MLC-AXIAL;10NF,30%,16V,Y5P,TP,

C377 2202-000797 C-CERAMIC,MLC-AXIAL;10NF,30%,16V,Y5P,TP,

C380 2401-001905 C-AL;10UF,20%,16V,BP,BK,6X11MM,2.5M

C390 2202-000797 C-CERAMIC,MLC-AXIAL;10NF,30%,16V,Y5P,TP,

C391 2202-000797 C-CERAMIC,MLC-AXIAL;10NF,30%,16V,Y5P,TP,

C3A01 2401-001893 C-AL;100uF,20%,16V,GP,TP,6.3x7mm,5

C3A02 2301-000283 C-FILM,PEF;47nF,5%,100V,TP,7.3X7X3.2X5,5

C3A03 2401-001511 C-AL;47UF,20%,16V,GP,-,6X7,5

C3A04 2301-000299 C-FILM,PEF;6.8nF,5%,100V,TP,5.8x12.5mm,5

C3A05 2301-000445 C-FILM,PEF;4.7nF,5%,50V,5.5x7x3mm,5mm,TP

C3A06 2301-000408 C-FILM,PEF;2.7nF,5%,50V,5.5x7x3mm,5mm,TP

C3A07 2301-000400 C-FILM,PEF;1NF,10%,50V,TP,5X7X2.8MM,5MM

C3A08 2401-001917 C-AL;1UF,20%,50V,-,TP,5X7MM,5

C3A09 2401-003122 C-AL;4.7UF,20%,50V,LL,TP,4X7,1.5

C3A10 2401-001904 C-AL;10UF,20%,16V,-,TP,4X7MM,5

C3A11 2401-001904 C-AL;10UF,20%,16V,-,TP,4X7MM,5

C3A12 2301-000381 C-FILM,PEF;10nF,5%,50V,TP,6.5x5.5x3mm,5m

C3A15 2401-001912 C-AL;1uF,20%,50V,GP,5x11mm,2mm,BK

C3A16 2401-001917 C-AL;1UF,20%,50V,-,TP,5X7MM,5

C3A17 2301-000299 C-FILM,PEF;6.8nF,5%,100V,TP,5.8x12.5mm,5

C3A18 2301-000299 C-FILM,PEF;6.8nF,5%,100V,TP,5.8x12.5mm,5

C3A19 2301-000314 C-FILM,PEF;8.2nF,5%,50V,TP,6.5x3.0x5.5mm

C3A21 2401-000918 C-AL;22uF,20%,16V,GP,-,6.3x7,5

C3A22 2301-000217 C-FILM,PEF;220nF,5%,50V,8.0X9.5X4.5X5,5m

C3A23 2401-001169 C-AL;33UF,20%,16V,GP,-,6.3X7,2.5MM

C3A24 2301-000217 C-FILM,PEF;220nF,5%,50V,8.0X9.5X4.5X5,5m

C3A25 2202-000780 C-CERAMIC,MLC-AXIAL;100nF,+80-20%,50V,Y5

C3A26 2401-001511 C-AL;47UF,20%,16V,GP,-,6X7,5

C3A27 2401-003122 C-AL;4.7UF,20%,50V,LL,TP,4X7,1.5

C3A28 2202-000780 C-CERAMIC,MLC-AXIAL;100nF,+80-20%,50V,Y5

C3A29 2301-000381 C-FILM,PEF;10nF,5%,50V,TP,6.5x5.5x3mm,5m

C3A30 2301-000392 C-FILM,PEF;15nF,5%,50V,6.5x8.5x3.2mm,5mm

CN301 3708-000395 CONNECTOR-FPC/FC/PIC;8P,1.25MM,STRAIGHT,

CN3A01 3708-001053 CONNECTOR-FPC/FC/PIC;7P,1.25MM,STRAIGHT,

CN3A02 3711-000371 CONNECTOR-HEADER;-,2P,1R,2MM,STRAIGHT,D307 0401-000101 DIODE-SWITCHING;1N4148,100V,200mA,500mW,

FL3A01 AC27-80100A COIL-OSC;126QN-K5272YHC=K,-,AM

IC301 AC14-12014L IC-LINEAR;LA7411,DIP,PRE-AMP

IC302 1204-001056 IC-SIGNAL PROCESSOR;SS11501M,QFP,80P,-,PMULTI

IC302 1204-001057 IC-SIGNAL PROCESSOR;SS11511M,QFP,80P,-,PPALONLY

IC303 1209-001023 IC-DELAY LINE;SS23377M,SOP,14P,225MIL,PL PALONLY

IC303 1209-001024 IC-DELAY LINE;SS23378M,SOP,14P,225MIL,PL MULTI

L301 AC27-92001B COIL-PEAKING AXIAL;BAL04ST101K,-,-,-,L303 2701-000206 INDUCTOR-AXIAL;56UH,5%,2.4X3.4MM

L304 2701-000206 INDUCTOR-AXIAL;56UH,5%,2.4X3.4MM

L308 AC27-92001B COIL-PEAKING AXIAL;BAL04ST101K,-,-,-,-

L3A02 AC27-92001B COIL-PEAKING AXIAL;BAL04ST101K,-,-,-,L3A03 2702-000120 INDUCTOR-RADIAL;15mH,5%,6.2x7.4mm

L3A04 AC27-92001B COIL-PEAKING AXIAL;BAL04ST101K,-,-,-,Q302 0501-000303 TR-SMALL SIGNAL;KSA733,PNP,250mW,TO-92,T

Q303 0501-000303 TR-SMALL SIGNAL;KSA733,PNP,250mW,TO-92,T

Q304 0501-000398 TR-SMALL SIGNAL;KSC945,NPN,250mW,TO-92,T

Q308 0504-000203 TR-DIGITAL;KSR1004,NPN,300mW,47K-47K,TOQ309 0501-000398 TR-SMALL SIGNAL;KSC945,NPN,250mW,TO-92,T

Q310 0501-000303 TR-SMALL SIGNAL;KSA733,PNP,250mW,TO-92,T

Q312 0501-000398 TR-SMALL SIGNAL;KSC945,NPN,250mW,TO-92,T

Q324 0501-000398 TR-SMALL SIGNAL;KSC945,NPN,250mW,TO-92,T

Q3A01 0501-000231 TR-SMALL SIGNAL;2SD1468SQ,NPN,300MW,TO-9

Q3A02 0501-000231 TR-SMALL SIGNAL;2SD1468SQ,NPN,300MW,TO-9

Q3A03 0501-000010 TR-SMALL SIGNAL;KSC1008,NPN,80V,60V,700m

Q3A04 0501-000303 TR-SMALL SIGNAL;KSA733,PNP,250mW,TO-92,T

Q3A05 0501-000398 TR-SMALL SIGNAL;KSC945,NPN,250mW,TO-92,T

Q3A06 0504-000203 TR-DIGITAL;KSR1004,NPN,300mW,47K-47K,TOR302 2001-000302 R-CARBON;10ohm,5%,1/8W,AA,TP,1.8x3.2mm

R303 2001-000522 R-CARBON;22Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R305 2001-000241 R-CARBON;1.5Kohm,5%,1/8W,AA,TP,1.8x3.2m

R306 2001-000864 R-CARBON;56Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R307 2001-000273 R-CARBON;100Kohm,5%,1/8W,AA,TP,1.8x3.2m

R309 2001-000577 R-CARBON ;2KOHM,5%,1/8W,AA,TP,

R310 2001-000613 R-CARBON ;3.9K OHM,5%,1/8,AA,T

R311 2001-000221 R-CARBON;1.2Kohm,5%,1/8W,AA,TP,1.8x3.2m

R312 2001-000577 R-CARBON ;2KOHM,5%,1/8W,AA,TP,

R314 2001-000554 R-CARBON;270OHM,5%,1/8W,AA,TP,1.8X3.2MM

R315 2001-000613 R-CARBON ;3.9K OHM,5%,1/8,AA,T

R316 2001-000977 R-CARBON;8.2Kohm,5%,1/8W,AA,TP,1.8x3.2m

R317 2001-000660 R-CARBON;33Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R318 2001-000660 R-CARBON;33Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R319 2001-000005 R-CARBON;390ohm,5%,1/8W,AA,TP,1.8x3.2mm

R320 2001-000221 R-CARBON;1.2Kohm,5%,1/8W,AA,TP,1.8x3.2m

R321 2001-000005 R-CARBON;390ohm,5%,1/8W,AA,TP,1.8x3.2mm

R322 2001-000241 R-CARBON;1.5Kohm,5%,1/8W,AA,TP,1.8x3.2m

R323 2001-000734 R-CARBON;4.7Kohm,5%,1/8W,AA,TP,1.8x3.2m

R324 2001-000241 R-CARBON;1.5Kohm,5%,1/8W,AA,TP,1.8x3.2m

R328 2001-000221 R-CARBON;1.2Kohm,5%,1/8W,AA,TP,1.8x3.2m

R329 2001-000449 R-CARBON;2.2Kohm,5%,1/8W,AA,TP,1.8x3.2m

R331 2001-000449 R-CARBON;2.2Kohm,5%,1/8W,AA,TP,1.8x3.2m

R332 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R333 2001-000977 R-CARBON;8.2Kohm,5%,1/8W,AA,TP,1.8x3.2m

R337 2001-000472 R-CARBON;2.7Kohm,5%,1/8W,AA,TP,1.8x3.2m

R338 2001-000734 R-CARBON;4.7Kohm,5%,1/8W,AA,TP,1.8x3.2m

R339 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R340 2001-000449 R-CARBON;2.2Kohm,5%,1/8W,AA,TP,1.8x3.2m

R341 2001-000472 R-CARBON;2.7Kohm,5%,1/8W,AA,TP,1.8x3.2m

R350 2001-000258 R-CARBON;1.8Kohm,5%,1/8W,AA,TP,1.8x3.2m

R383 2001-000802 R-CARBON;5.6KOHM,5%,1/8W,AA,TP,1.8X3.2M

R384 2001-000786 R-CARBON;47Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R385 2001-000241 R-CARBON;1.5Kohm,5%,1/8W,AA,TP,1.8x3.2m

R399 2001-000003 R-CARBON ;330 OHM,5%,1/8W,AA,T

R3A02 2001-000405 R-CARBON ;180 OHM,5%,1/8W,AA,T

R3A03 2001-000780 R-CARBON;470ohm,5%,1/8W,AA,TP,1.8x3.2mm

R3A04 2001-000258 R-CARBON;1.8Kohm,5%,1/8W,AA,TP,1.8x3.2m

Loc.No

Part No Desc and Spec Remark

Loc.No

Part No Desc and Spec Remark

7-4

Samsung Electronics

Electrical Parts List

Page 34

R3A05 2001-000449 R-CARBON;2.2Kohm,5%,1/8W,AA,TP,1.8x3.2m

R3A06 2001-000449 R-CARBON;2.2Kohm,5%,1/8W,AA,TP,1.8x3.2m

R3A07 2001-000458 R-CARBON;2.2ohm,5%,1/8W,AA,TP,1.8x3.2mm

R3A08 2001-000290 R-CARBON;10Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R3A09 2001-000522 R-CARBON;22Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R3A10 2001-000241 R-CARBON;1.5Kohm,5%,1/8W,AA,TP,1.8x3.2m

R3A11 2001-000660 R-CARBON;33Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R3A12 2001-000362 R-CARBON;150ohm,5%,1/8W,AA,TP,1.8x3.2mm

R3A13 2001-000645 R-CARBON;330Kohm,5%,1/8W,AA,TP,1.8x3.2m

R3A14 2001-000734 R-CARBON;4.7Kohm,5%,1/8W,AA,TP,1.8x3.2m

R3A15 2001-000331 R-CARBON;12Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R3A17 2001-000802 R-CARBON;5.6KOHM,5%,1/8W,AA,TP,1.8X3.2M

R3A19 2001-000221 R-CARBON;1.2Kohm,5%,1/8W,AA,TP,1.8x3.2m

R3A20 2001-000786 R-CARBON;47Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R3A22 2001-000786 R-CARBON;47Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R3A24 2001-000454 R-CARBON;2.2Mohm,5%,1/8W,AA,TP,1.8x3.2m

R3A25 2001-000890 R-CARBON;6.8Kohm,5%,1/8W,AA,TP,1.8x3.2m

R3A26 2001-000947 R-CARBON;7.5KOHM,5%,1/8W,AA,TP,1.8X3.2M

R3A27 2001-000734 R-CARBON;4.7Kohm,5%,1/8W,AA,TP,1.8x3.2m

R3A28 2001-000290 R-CARBON;10Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R3A29 2001-000006 R-CARBON;2.4Kohm,5%,1/8W,AA,TP,1.8x3.2m

R3A30 2001-000613 R-CARBON ;3.9K OHM,5%,1/8,AA,T

R3A31 2001-000613 R-CARBON ;3.9K OHM,5%,1/8,AA,T

R3A32 2001-000904 C-CARBON ;620OHM,5%,1/8,AA.TP,

XT301 2801-003610 CRYSTAL-UNIT;3.579545MHz,8ppm,28-AAA,S,1

XT302 2801-001397 CRYSTAL-UNIT;4.433619MHZ,HC-49/U-S 15PPM

I/O PARTS

C401 2202-000797 C-CERAMIC,MLC-AXIAL;10NF,30%,16V,Y5P,TP,

C402 2401-001975 C-AL;47UF,20%,16V,GP,TP,5X11MM,5

C403 2202-000797 C-CERAMIC,MLC-AXIAL;10NF,30%,16V,Y5P,TP,

C404 2202-000780 C-CERAMIC,MLC-AXIAL;100nF,+80-20%,50V,Y5

C405 2401-001975 C-AL;47UF,20%,16V,GP,TP,5X11MM,5

C415 2401-001572 C-AL;47UF,20%,50V,GP,-,6.3X11,2.5MM

C450 2202-000797 C-CERAMIC,MLC-AXIAL;10NF,30%,16V,Y5P,TP,

C451 2401-001975 C-AL;47UF,20%,16V,GP,TP,5X11MM,5

C801 2202-000780 C-CERAMIC,MLC-AXIAL;100nF,+80-20%,50V,Y5

C802 2401-001975 C-AL;47UF,20%,16V,GP,TP,5X11MM,5

C803 2401-001975 C-AL;47UF,20%,16V,GP,TP,5X11MM,5

C804 2201-000823 C-CERAMIC,DISC;270PF,5%,50V,SL,TP,5X3,5

C805 2201-000872 C-CERAMIC,DISC;82PF,5%,50V,CH,TP,13X4,5

C807 2201-000872 C-CERAMIC,DISC;82PF,5%,50V,CH,TP,13X4,5

C809 2401-002197 C-AL;4.7UF,20%,25V,GP,TP,4X7,5MM

JC801 AC37-20001H JACK-RCA;DPAM-,4P,MONO,PI3.3

JC802 AC37-20001M JACK-DC;DUAE-9519,4P/2C,DC,DLK

L401 AC27-92001B COIL-PEAKING AXIAL;BAL04ST101K,-,-,-,L403 AC27-92001B COIL-PEAKING AXIAL;BAL04ST101K,-,-,-,L801 2701-000181 INDUCTOR-AXIAL;33UH,5%,2.4X3.4MM

Q801 0501-000303 TR-SMALL SIGNAL;KSA733,PNP,250mW,TO-92,T

Q802 0501-000398 TR-SMALL SIGNAL;KSC945,NPN,250mW,TO-92,T

R401 2001-000281 R-CARBON;100ohm,5%,1/8W,AA,TP,1.8x3.2mm

R402 2001-000281 R-CARBON;100ohm,5%,1/8W,AA,TP,1.8x3.2mm

R801 2001-001026 R-CARBON;910ohm,5%,1/8W,AA,TP,1.8x3.2mm

R802 2001-000780 R-CARBON;470ohm,5%,1/8W,AA,TP,1.8x3.2mm

R803 2001-000780 R-CARBON;470ohm,5%,1/8W,AA,TP,1.8x3.2mm

R804 2001-000969 R-CARBON;75ohm,5%,1/8W,AA,TP,1.8x3.2mm

R805 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R806 2001-000969 R-CARBON;75ohm,5%,1/8W,AA,TP,1.8x3.2mm

R808 2001-000508 R-CARBON ;220K OHM,5%,1/8W,AA,

R810 2001-000007 R-CARBON;3Kohm,5%,1/8W,AA,TP,1.8x3.2mm

SW801 3408-000127 SWITCH-SLIDE;12V,100MA,-,U401 AC40-20100G RF-MODULATOR;RMUP74055VA,PALMULTI

ZD401 0403-000390 DIODE-ZENER;UZP33B,33V,31.4-34.6V,1W,DO-

FUNCTION PARTS

C701 2401-001893 C-AL;100uF,20%,16V,GP,TP,6.3x7mm,5

C702 2202-000797 C-CERAMIC,MLC-AXIAL;10NF,30%,16V,Y5P,TP,

C703 2202-000796 C-CERAMIC,MLC-AXIAL;UP050 B102KB INF,10%

CN701 3708-001251 CONNECTOR-FPC/FC/PIC;22P,1mm,STRAIGHT-F,

CN703 3708-001163 CONNECTOR-FPC/FC/PIC;5P,1.25mm,STRAIGHT,

D714 0401-000101 DIODE-SWITCHING;1N4148,100V,200mA,500mW,

D719 0401-000101 DIODE-SWITCHING;1N4148,100V,200mA,500mW,

D728 0401-000101 DIODE-SWITCHING;1N4148,100V,200mA,500mW,

D730 0401-000101 DIODE-SWITCHING;1N4148,100V,200mA,500mW,

D740 0401-000101 DIODE-SWITCHING;1N4148,100V,200mA,500mW,

D741 0401-000101 DIODE-SWITCHING;1N4148,100V,200mA,500mW,

D742 0401-000101 DIODE-SWITCHING;1N4148,100V,200mA,500mW,

D743 0401-000101 DIODE-SWITCHING;1N4148,100V,200mA,500mW,

D744 0401-000101 DIODE-SWITCHING;1N4148,100V,200mA,500mW,

D745 0401-000101 DIODE-SWITCHING;1N4148,100V,200mA,500mW,

L701 AC27-92001B COIL-PEAKING AXIAL;BAL04ST101K,-,-,-,LD701 0601-000497 LED;ROUND,GRN,3mm,565nm

LD702 0601-000497 LED;ROUND,GRN,3mm,565nm

LD703 0601-001201 LED;ROUND,RED,3mm,635nm

LD704 0601-000497 LED;ROUND,GRN,3mm,565nm

LD705 0601-000497 LED;ROUND,GRN,3mm,565nm

Q709 0501-000290 TR-SMALL SIGNAL;KSA643-Y,PNP,500MW,TO-92

Q710 0501-000290 TR-SMALL SIGNAL;KSA643-Y,PNP,500MW,TO-92

Q711 0501-000290 TR-SMALL SIGNAL;KSA643-Y,PNP,500MW,TO-92

Q712 0501-000290 TR-SMALL SIGNAL;KSA643-Y,PNP,500MW,TO-92

R717 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R718 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R719 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R720 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R729 2001-000290 R-CARBON;10Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R731 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R732 2001-000429 R-CARBON;1Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R733 2001-000660 R-CARBON;33Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R734 2001-000660 R-CARBON;33Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R735 2001-000660 R-CARBON;33Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R737 2001-000660 R-CARBON;33Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R739 2001-000660 R-CARBON;33Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R740 2001-000924 R-CARBON;680ohm,5%,1/8W,AA,TP,1.8x3.2mm

R741 2001-000362 R-CARBON;150ohm,5%,1/8W,AA,TP,1.8x3.2mm

R742 2001-000362 R-CARBON;150ohm,5%,1/8W,AA,TP,1.8x3.2mm

R743 2001-000362 R-CARBON;150ohm,5%,1/8W,AA,TP,1.8x3.2mm

R744 2001-000362 R-CARBON;150ohm,5%,1/8W,AA,TP,1.8x3.2mm

R745 2001-000362 R-CARBON;150ohm,5%,1/8W,AA,TP,1.8x3.2mm

RM701 AC59-60060A MODULE-REMOCON;GP1U281R/SHARP 38KHZ

SW701 3404-000165 SWITCH-TACT;12V,50mA,160gf+-50gf,6x6mm,S

SW702 3404-000165 SWITCH-TACT;12V,50mA,160gf+-50gf,6x6mm,S

SW703 3404-000165 SWITCH-TACT;12V,50mA,160gf+-50gf,6x6mm,S

SW704 3404-000165 SWITCH-TACT;12V,50mA,160gf+-50gf,6x6mm,S

SW705 3404-000165 SWITCH-TACT;12V,50mA,160gf+-50gf,6x6mm,S

SW706 3404-000165 SWITCH-TACT;12V,50mA,160gf+-50gf,6x6mm,S

SW707 3404-000165 SWITCH-TACT;12V,50mA,160gf+-50gf,6x6mm,S

SW709 3404-000165 SWITCH-TACT;12V,50mA,160gf+-50gf,6x6mm,S

Loc.No

Part No Desc and Spec Remark

Loc.No

Part No Desc and Spec Remark

Electrical Parts List

Samsung Electronics

7-5

Page 35

- ASSY-SHUTTLE-OTION

CN707 3708-001163 CONNECTOR-FPC/FC/PIC;5P,1.25mm,STRAIGHT,

SH701 2101-000101 VR-ROTARY;100Kohm,20%,1/10W,SIDE

AC59-10415A REMOCON-ASSY

AD64-50823A DOOR-BATTERY REMOCON;-,ABS94,HB,T1.5,L76

Loc.No

Part No Desc and Spec Remark

Loc.No

Part No Desc and Spec Remark

7-6

Samsung Electronics

Electrical Parts List

Page 36

Samsung Electronics 8-1

8. Block Diagrams

Page

8-2

8-3

8-4

8-1 Overall Block Diagram - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

8-2 System Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

8-3 Video - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Page 37

Block Diagrams

8-2 Samsung Electronics

8-1 Overall Block Diagram

FUNCTION

Page 38

Block Diagrams

Samsung Electronics 8-3

8-2 System Control

Page 39

Block Diagrams

8-4 Samsung Electronics

8-3 Video

Page 40

Samsung Electronics 9-1

9. PCB Diagrams

Page

9-2

9-4

9-4

9-1 Main - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

9-2 Function (SVR-18A/SVR-18B) - - - - - - - - - - - - - - - - - - - - - -

9-3 Function (SVR-18C) - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Page 41

PCB Diagrams

9-2 Samsung Electronics

9-1 Main

Page 42

PCB Diagrams

Samsung Electronics 9-3

Page 43

PCB Diagrams

9-4 Samsung Electronics

9-3 Function (SVR-18C)

9-2 Function (SVR-18A/SVR-18B)

Page 44

Samsung Electronics 10-1

10. Wiring Diagram

OPTION

Page 45

Samsung Electronics 11-1

11. Schematic Diagrams

Page

11-2

11-3

11-4

11-5

11-6

11-7

11-8

3 Block Identification of Main PCB - - - - - - - - - - - - - - - - - - - - - - - - - -

11-1 S.M.P.S/Power - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

11-2 System Control/Servo - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

11-3 Audio/Video - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

11-4 I/O - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

11-5 Function - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

11-6 Remote-Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Page 46

Schematic Diagrams

11-2 Samsung Electronics

For schematic Diagram

- Resistors are in ohms, 1/8W unless otherwise noted.

Note

Special note :

Most semiconductor devices are electrostatically sensitive and therefore require the special handling techniques

described under the “electrostatically sensitive (ES) devices” section of this service manual.

Note :

Do not use the part number shown on this drawing for ordering. The correct part number is shown in the parts

list (may be slightly different or amended since this drawing was prepared).

Important safety notices :

Components identified with the mark have the special characteristics for safety. When replacing any of these

components. Use only the same type.

3 Block Identification of Main PCB

(Conductor Side)(Component Side)

Page 47

Schematic Diagrams

Samsung Electronics 11-3

11-1 S.M.P.S/POWER

Page 48

Schematic Diagrams

11-4 Samsung Electronics

11-2 System Control/Servo

Page 49

Schematic Diagrams

Samsung Electronics 11-5

11-3 Audio/Video

Page 50

Schematic Diagrams

11-6 Samsung Electronics

VCR OPTION

11-4 I/O

Page 51

Schematic Diagrams

Samsung Electronics 11-7

11-5 Function

Page 52

Schematic Diagrams

11-8 Samsung Electronics

11-6 Remote-Control

Page 53

DX7-A/DX7-AC

DX8-A/DX8-AC

1. Disassembly and Reassembly

2. Alignment and Adjustment

VHS DECK CONTENTS

MECHANICAL

Manual

3 File with the SERVICE MANUAL.

© Samsung Electronics Co., Ltd. NOV. 1997 AC68-20392A

Page 54

Samsung Electronics 1-1

1-1 Deck Parts Locations

1-1-1 Deck (Top View)

1

2

3 4

5

8

9

10

11

12

13

14

15

1617

18

19

76

Fig. 1-1 Deck Top Parts Location (DX7-A/DX8-A DECK ONLY)

1. ARM TENSION FULL ASS’Y

2. BRAKE MAIN “L” ASS’Y

3. GUIDE ROLLER ASS’Y “T”

4. FULL ERASE HEAD

5. GUIDE ROLLER ASS’Y “S”

6. CYLINDER ASS’Y

7. LEVER PINCH COMP ASS’Y

8. LEVER PINCH CAM

9. FULL ACE HEAD AAS’Y

10. UNIT PINCH ROLLER ASS’Y

11. LEVER REVIEW

12. BRAKE SUB “R” ASS’Y

13. REEL DISK “R” ASS’Y

14. GEAR RELAY “T” ASS’Y

15. IDLER ASS’Y

16. GEAR RELAY “S” ASS’Y

17. REEL DISK “L” ASS’Y

18. LEVER JOG ASS’Y

(DX8-A/AC ONLY)

19. LEVER REC SWITCH

1. Disassembly and Reassembly

Page 55

Disassembly and Reassembly

1-2 Samsung Electronics

1-1-2 Deck (Top View)

1

2

3

465

7

8

9

10

11

12

13

14

151617

18

19

20

Fig. 1-2 Deck Top Parts Location (DX7-AC/DX8-AC DECK ONLY)

1. ARM TENSION FULL ASS’Y

2. BRAKE MAIN “L” ASS’Y

3. GUIDE ROLLER ASS’Y “T”

4. FULL ERASE HEAD

5. HEAD CLEANER ASS’Y

(DX7-AC/DX8-AC ONLY)

6. GUIDE ROLLER ASS’Y “S”

7. CYLINDER ASS’Y

8. LEVER PINCH COMP ASS’Y

9. LEVER PINCH CAM

10. FULL ACE HEAD AAS’Y

11. UNIT PINCH ROLLER ASS’Y

12. LEVER REVIEW

13. BRAKE SUB “R” ASS’Y

14. REEL DISK “R” ASS’Y

15. GEAR RELAY “T” ASS’Y

16. IDLER ASS’Y

17. GEAR RELAY “S” ASS’Y

18. REEL DISK “L” ASS’Y

19. LEVER JOG ASS’Y

(DX8-A/AC ONLY)

20. LEVER REC SWITCH

Page 56

Disassembly and Reassembly

Samsung Electronics 1-3

1-1-3 Deck (Bottom View)

1

2

3

4

6

5

7

8

9

10

11

13

12

Fig. 1-3 Deck Bottom Parts Location

1. LEVER SLIDE PINCH

2. BELT CAPSTAN

3. MOTOR D.D CAPSTAN

4. BRAKE CAPSTAN ASS’Y

5. GEAR LOADING “R” ASS’Y

6. MOTOR CYLINDER

7. GEAR LOADING “L” ASS’Y

8. SLIDE MAIN

9. LEVER REC SWITCH

10. LEVER IDLER CHANGE

11. CLUTCH ASS’Y

12. UNIT LOADING

13. GEAR MASTER

Page 57

Disassembly and Reassembly

1-4 Samsung Electronics

1-1-4 Housing

1

2 3

4

6

5

Fig. 1-4 Housing Parts Location

1. CHASSIS SIDE “L” ASS’Y

2. UPPER CHASSIS

3. CHASSIS SIDE “R” ASS’Y

4. SHAFT ARM ASS’Y

5. HOLDER CASSETTE ASS’Y

6. LEVER DOOR

Page 58

Disassembly and Reassembly

Samsung Electronics 1-5

1-2 Housing Assembly

1-2-1 Removal from Main Base

1. Remove 3 Screws !.

2. Lift the Housing AssÕy in the direction of arrow ÒBÓ, while pushing the tab @ in the direction of arrow ÒAÓ.

(Refer to detail drawing)

3 SCREWS

1

MAIN BASE

TAB

"A"

2

Fig. 1-5 Housing Ass’y Removal from Main Base

Page 59

Disassembly and Reassembly

1-6 Samsung Electronics

1-2-2 Diassembly

2 SCREWS

UPPER CHASSIS

CHASSIS SIDE "R"

HOLDER

CASSETTE ASS'Y

SHAFT ARM ASS'Y

CHASSIS SIDE "L"

Fig. 1-6 Housing Ass’y Removal

Page 60

Disassembly and Reassembly

Samsung Electronics 1-7

1-2-3 Upper Chassis Removal

1. Remove 2 Screws !.

2. Lift the Upper Chassis @ in the direction of arrow ÒAÓ.

2 SCREWS

UPPER CHASSIS

2

"A"

1

Fig. 1-7 Upper Chassis Removal

Page 61

Disassembly and Reassembly

1-8 Samsung Electronics

1-2-4 Holder Cassette Ass’y and Chassis Side L/R Removal

1. Lift the Cassette Holder ! in the direction of arrow ÒAÓ (Refer to Fig. A).

2. Remove the Side Chassis ÒLÓ @ and ÒRÓ # from Arm Shaft AssÕy $ in the direction of arrow ÒBÓ, ÒCÓ

(Refer to Fig. B).

HOLDER CASSETTE ASS'Y

"A"

1

2

4

SHAFT ARM ASS'Y

CHASSIS SIDE "L"

3

CHASSIS SIDE "R"

SLIDE DAMPER

"B"

<Fig. A>

<Fig. B>

<DETAIL>

(REASSEMBLY OF CHASSIS

SIDE "R" & SHAFT ARM "R")

(SIDE VIEW)

"C"

"D"

SHAFT ARM "R"

Fig. 1-8 Holder Cassette Ass’y and Chassis Side L/R

Page 62

Disassembly and Reassembly

Samsung Electronics 1-9

1-2-5 Chassis Side “R” Parts Locations

CHASSIS SIDE "R"

(SIDE VIEW "A")

SLIDE DAMPER

LEVER-LID OPENDER

"A"

SPRING-SLIDE DAMPER

SPRING-LID OPENDER

Fig. 1-9 Chassis Side “R” Parts Locations

Note : If you operate the deck when the Cassette AssÕy Holder is removed, the Arm Shaft ÒRÓ and the Damper

Slide are not returned to their original positions. If this happens by accident, push the Damper Slide of

Side Chassis ÒRÓ in the direction of arrow ÒDÓ, and return the Damper Slide in the reverse direction of

arrow ÒDÓ when the Arm Shaft AssÕy is in eject mode.

Page 63

Disassembly and Reassembly

1-10 Samsung Electronics

1-2-6 Slide Damper Removal

1. Remove the Slide Damper Spring !.

2. Push the Stopper # of the Side Chassis ÒRÓ $. Move the Damper Slide @ in the direction of arrow.

3. Align the Damper Slide @ with the chassis side tab (as shown detail drawing).

CHASSIS SIDE "R"

CHASSIS SIDE "R" TAB

SLIDE DAMPER

4

STOPPER

3

SLIDE DAMPER

2

SPRING- SLIDE DAMPER

1