Page 1

SSA-S3010

SSA-S3011

SSA-S3020

SSA-S3021

SSA-S3040

SSA-S3041

Standalone Biometric

Access Controller

user manual

imagine the possibilities

Thank you for purchasing this Samsung product.

To receive more complete service,

please visit our website.

www.samsungsecurity.com

Page 2

safety information

CAUTION

RISK OF ELECTRIC SHOCK.

DO NOT OPEN

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK, DO NOT REMOVE COVER (OR BACK) NO USER SERVICEABLE

PARTS INSIDE. REFER SERVICING TO QUALIFIED SERVICE PERSONNEL.

This symbol indicates that dangerous voltage consisting a risk of electric shock is

present within this unit.

This exclamation point symbol is intended to alert the user to the presence of

important operating and maintenance (servicing) instructions in the literature

accompanying the appliance.

WARNING

To reduce the risk of fi re or electric shock, do not expose this appliance to rain or moisture.

•

WARNING

1.

Be sure to use only the standard adapter that is specifi ed in the specifi cation sheet.

Using any other adapter could cause fi re, electrical shock, or damage to the product.

2.

Incorrectly connecting the power supply or replacing battery may cause explosion, fi re, electric shock, or damage to

the product.

3.

Do not connect multiple controllers to a single adapter. Exceeding the capacity may cause abnormal heat generation or fi re.

4.

Securely plug the power cord into the power receptacle. Insecure connection may cause fi re.

5.

When installing the controller, fasten it securely and fi rmly. The fall of controller may cause personal injury.

6.

Do not place conductive objects (e.g. screwdrivers, coins, metal parts, etc.) or containers fi lled with water on top of the

controller. Doing so may cause personal injury due to fi re, electric shock, or falling objects.

7.

Do not install the unit in humid, dusty, or sooty locations. Doing so may cause fi re or electric shock.

8.

If any unusual smells or smoke come from the unit, stop using the product. In such case, immediately disconnect the

power source and contact the service center. Continued use in such a condition may cause fi re or electric shock.

9.

If this product fails to operate normally, contact the nearest service center. Never disassemble or modify this product in

any way. (SAMSUNG is not liable for problems caused by unauthorized modifi cations or attempted repair.)

10.

. When cleaning, do not spray water directly onto parts of the product. Doing so may cause fi re or electric shock.

CAUTION

1.

Do not drop objects on the product or apply strong blows to it. Keep away from a location subject to excessive

vibration or magnetic interference.

2.

Do not install in a location subject to high temperature (over 50°C), low temperature (below 0°C), or high humidity.

Doing so may cause fi re or electric shock.

3.

If you want to relocate the already installed product, be sure to turn off the power and then move or reinstall it.

4.

Remove the power plug from the outlet when there is a lighting storm. Neglecting to do so may cause fi re or damage

to the product.

5.

Keep out of direct sunlight and heat radiation sources. It may cause fi re.

6.

Install it in a place with good ventilation.

2_ safety information

Page 3

Avoid aiming the controller directly towards extremely bright objects such as sun.

7.

Apparatus shall not be exposed to dripping or splashing and no objects fi lled with liquids, such as vases, shall be

8.

placed on the apparatus.

The Mains plug is used as a disconnect device and shall stay readily operable at any time.

9.

FCC Statement

Caution : Any changes or modifi cations in construction of this device which are not expressly approved by the

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions:

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

- Consult the dealer or an experienced radio/TV technician for help.

party responsible for compliance could void the user’s authority to operate the equipment.

1)

This device may not cause harmful interference, and

2)

This device must accept any interference received, including interference that may cause undesired operation.

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, any cause harmful interference to radio communications. However,

there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the equipment off and on, the user

is encouraged to try to correct the interference by one or more of the following measures:

IMPORTANT SAFETY INSTRUCTIONS

Read these instructions.

1.

Keep these instructions.

2.

Heed all warnings.

3.

Follow all instructions.

4.

Do not use this apparatus near water.

5.

Clean only with dry cloth.

6.

Do not block any ventilation openings. Install in accordance with the manufacturer’s instructions.

7.

Do not install near any heat sources such as radiators, heat registers, or other apparatus (including amplifi ers) that

8.

produce heat.

Do not defeat the safety purpose of the polarized or grounding-type plug. A polarized plug has two blades with one

9.

wider than the other. A grounding type plug has two blades and a third grounding prong. The wide blade or the third

prong is provided for your safety. If the provided plug does not fi t into your outlet, consult an electrician for

replacement of the obsolete outlet.

Protect the power cord from being walked on or pinched particularly at plugs, convenience receptacles, and the

10.

point where they exit from the apparatus.

Only use attachments/accessories specifi ed by the manufacturer.

11.

Use only with cart, stand, tripod, bracket, or table specifi ed by the manufacturer, or sold with

12.

the apparatus.

Unplug this apparatus when a card is used. Use caution when moving the cart/ apparatus

13.

combination to avoid injury from tip-over.

Refer all servicing to qualifi ed service personnel. Servicing is required when the apparatus has been damaged in any

14.

way, such as powersupply cord or plug is damaged, liquid has been spilled or objects have fallen into the apparatus,

the apparatus has been exposed to rain or moisture, does not operate normally, or has been dropped.

SAFETY INFORMATION

English English _ 3

Page 4

contents

PRODUCT INTRODUCTION

7

INSTALLATION AND EXTERNAL

CONNECTION

14

INITIALIZATION

23

7 Features

9 What’s included

10 At a glance

12 Cable Color Scheme

13 Cable Selection

14 Installing the rear template

15 Connecting the termination resistor and

diode

15 Bypass Diode Connection

16 Earth-grounding the communication cables

17 I/O Connection

19 External Reader Connection

20 Communication Line Connection

23 Initializing the system

24 To access the master mode

24 Registering a master ID

26 Name Display

27 User Count Setup

27 Language Setup

28 Date/Time Setup

28 Communication Address Setup

29 Baud Rate Setup

29 Factory Defaults

4_ contents

READER MODE SETUP

30

30 Reader #1 Mode

30 READER #2 Mode

31 READER #1 Key Input

31 READER #2 Key Input

32 Dual Fingerprint Mode

33 Adaptive Mode

33 Identifi cation Mode

Page 5

USER MANAGEMENT

34

34 Registering ID in Quick mode

35 Registering the ID

37 To delete ID

38 Viewing the ID list

38 To check the number of registered IDs

39 To remove all registered IDs

39 To check the number of registered

fi ngerprints

40 To remove the master IDs

40 Duress Mode

41 Door Open Alarm Time Setup

41 Arm/Disarm

42 Two Men Operation Mode

42 To check the number of events

43 To remove all events

43 To remove the time schedule

CONTENTS

I/O TIME SETUP

44

ADVANCED SETUP

54

44 Exit Button Output

44 Door Contact Sensor Setup

45 Auxiliary Input #1 Setup

45 Auxiliary Input #2 Setup

46 Tamper Alarm Output Setup

46 Cut Off Output Setup

47 Duress Mode Output Setup

47 ARM/DISARM Output Setup

48 Door Open Timeout Setup

48 Output Setup for Level IDs Accessing

READER #1

50 READER #1 Error Output Setup

51 Output Setup for Level IDs Accessing

READER #2

52 READER #2 Error Output Setup

54 Time Unit Setup

54 Output Time Schedule+ID

55 AntiPassBack Mode

55 Time Schedule Setup

56 Holiday Setup

57 Holiday Code Setup

58 Reader Mode Time Schedule

59 Voice Message Time Schedule

59 Output Time Schedule Setup

60 Input Time Schedule Setup

60 Input Cut Off Check Setup

English English _ 5

Page 6

contents

ADDITIONAL FEATURES

61

OTHER INFORMATION

69

TROUBLESHOOTING

77

61 Event Memory Setup

61 ID Display

62 WIEGAND Output Setup

62 Voice Volume Setup

63 One Time Read

63 Version Check

64 Input Test

64 Output Test

65 LCD Test

65 Keypad Test

66 READER Test

66 Memory Test

67 Communication Test

67 Fingerprint Module Version Check

68 Input Type Setup

69 Menu Structure

75 Default Settings

77 TroubleShooting

6_ contents

PRODUCT SPECIFICATIONS

79

79 Product Specifi cations

Page 7

product introduction

FEATURES

State-of-the-art Access Controller

This product is a state-of-the-art access controller that is optimal for time and attendance management, and

provides 4 input ports and 2 2Form-C relay outputs along with 2 TTL output ports, RS-232/RS-485 and TCP/IP

ports to meet the high-level security system requirements and various customer needs.

With its simple manipulation and the highest security system, this product enables you to register up to 1000

persons’ fi ngerprints (2000 fi ngerprints for SSA-S302X and 4000 for SSA-S304X, depending on the model), and

save up to 20,000 IDs (10,000 for events) or up to 20,000 events (10,000 for IDs). All events can be transferred to

the host PC before being saved to the database, and output in formats of PDF, TIF or text fi le using the PC

applications for time and attendance management purposes.

This product consists of: a built-in fi ngerprint recognition module, a proximity card reader with 26 bit Wiegand(SSAS30X1: 34 bit Wiegand), and a 24-key keypad (10 numeric keys, 2 control keys and 12 function keys) for a wide

range of applications. With this, you can obtain access with any combination of your fi ngerprint, proximity card/PIN,

and password. This product is featured by the Exit button, Motion Detector, Door Contact sensor and 4 external

input ports connected to the exit alarm system preventing unauthorized access.

It also has 2 relay outputs that can control the door lock and alarm relay.

In the mean time, the graphics LCD panel supports multilingual display, enabling it operated around the world

beyond the language barrier. The dual tamper switch triggers an alert if the product is forcibly disassembled.

All system settings can be confi gured using the front keypad or through the Windows-based software. This product

works as a standalone system and is designed to operate via the network.

Standalone Operation

SSA-S30XX is connected to the external card reader, which is used to control one entrance. It determines to allow

access by reading data from the internal or external card reader, and controls the open/close of the door relay and

other output settings.

On an external signal (from a sensor or Exit button) reception, the device (relay) corresponding to the signal starts

operating.

This product has an independent control system, assuring a normal operation regardless of problems on other

systems and, not affecting them in a reversed situation.

Computer-based Management

All records of authorized or unauthorized accesses and any external signal will be saved in the internal memory. You can

download such data onto your computer according to the specifi ed communications protocol. With the downloaded

data, you can store, process, create a report based on your query (access and alert details, etc) on the connected

computer.

Keypad Registration

Even if SSA-S30XX is not connected to the host PC, you can use the built-in keypad and LCD module to register or

delete the card or confi gure necessary settings independently.

Time Scheduling

SSA-S30XX is featured by so-called time schedule, which allows you to instruct it to perform a specifi c operation for a

specifi c period of time. You can set a total of 10 time schedule codes, each of which can be assigned to each user.

Each time schedule code has a total of 8 different time zones including Monday through Sunday (7 time zones) plus

one holiday, each of which can be divided in up to 5 different time intervals, indicating you can program different time

codes.

You can also create time schedule codes to manage separate I/Os. If a time schedule code is assigned to an input

device, for instance, that device will stay active only for the time specifi ed. Each time schedule code is linked to the

holiday schedule, which is void only to the holiday time code of the time schedule. (refer to “Time Scheduling” on pages

55 to 56)

PRODUCT INTRODUCTION

English English _ 7

Page 8

product introduction

External I/O Pins

SSA-S30XX has 4 input pins and 4 output pins installed(2 relay and 2 TTL outputs) The input pins can receive signals

from the Exit button and the Door Contact sensor, while the two relays can be connected to the Door Lock and the

alarm device. You can specify the output time for these output pins. (Refer to “I/O Wiring” on pages 17 to 18)

Holiday Scheduling

In total, 10 holiday schedule codes are available for SSA-S30XX models, and each holiday schedule code can be

confi gured for up to 100 holidays except Sundays. Each holiday code can be linked to the time schedule code.

You can set all holidays to holiday schedule codes, and holiday schedule code is based on the holiday time zone for

the time scheduling. (Refer to “Holiday Scheduling” on page 56)

Forced Door Open Alarm

You can set the Forced Door Open Alarm to activate when the door is opened by force.

For its application, you must have installed the door contact sensor and properly set the door contact time and output

settings for the alarm device. The Forced Door Open Alarm lasts until the alarm event is terminated. (Refer to “Door

Contact Sensor” on page 44)

ANTIPASSBACK

A door has two card readers installed: one for the entrance, and the other for the exit, so anyone who enters should

recognize his/her card on the reader at the entrance time before he can exit normally. If a person does not go under

the card recognition process and just follows another person’s way inside the door, the person is not allowed to exit

when he/she recognizes the access card on exit card reader, and the antipassback error (APB error) occurs which

will be saved into the internal memory. And you can confi gure to output a signal through a specifi c pin when such an

error occurs. (Refer to “Antipassback Error Output Setup” at pages 50 and 53.)

Arm/Disarm

As long as the device is in Arm mode, the reader ports are all frozen so that no one can get access to the door and

any input from the corresponding external pin will not be processed. In this mode, SSA-S30XX transmits a specifi c

signal to the connected security devices so that they responds properly. (Refer to “Arm/Disarm” on page 41)

Door Open Timeout Alarm

The Door Open Timeout Alarm notifi es the administrator of the fact with an alarm if a door stays open after the normal

service time. The Door Open Timeout Alarm lasts until the door is closed.

(Refer to “Door Open Timeout Setup” on page 48)

Duress Alarm

This is used in a situation where you should open the door inevitably by a robber insisting to do so. Entering the twodigit duress alarm password with pressing the

opens the door, while this forcibly unarmed situation will be notifi ed to the PC application with an alarm event. (Refer

to “Duress Mode” on page 40)

Two Men Operation Mode

In this mode, SSA-S30XX permits a certain person (visitor) to enter or exit only when accompanied by a special user

(administrator). Both the visitor and the administrator should be authorized before they can get access. (Refer to

“Registering the ID card” on page 35)

4 Levels of Individual Door Opening Time Setting

You can use this function to set 4 different door opening time points. (Refer to “Output Setup for Level IDs Accessing

Reader” at pages 48 and 51.)

Name Display

SSA-S30XX can display the name of a person when the person is authorized to get access. (Refer to “Name Display”

on page 26)

ENT

button and recognizing the registered card (or card number)

8_ product introduction

Page 9

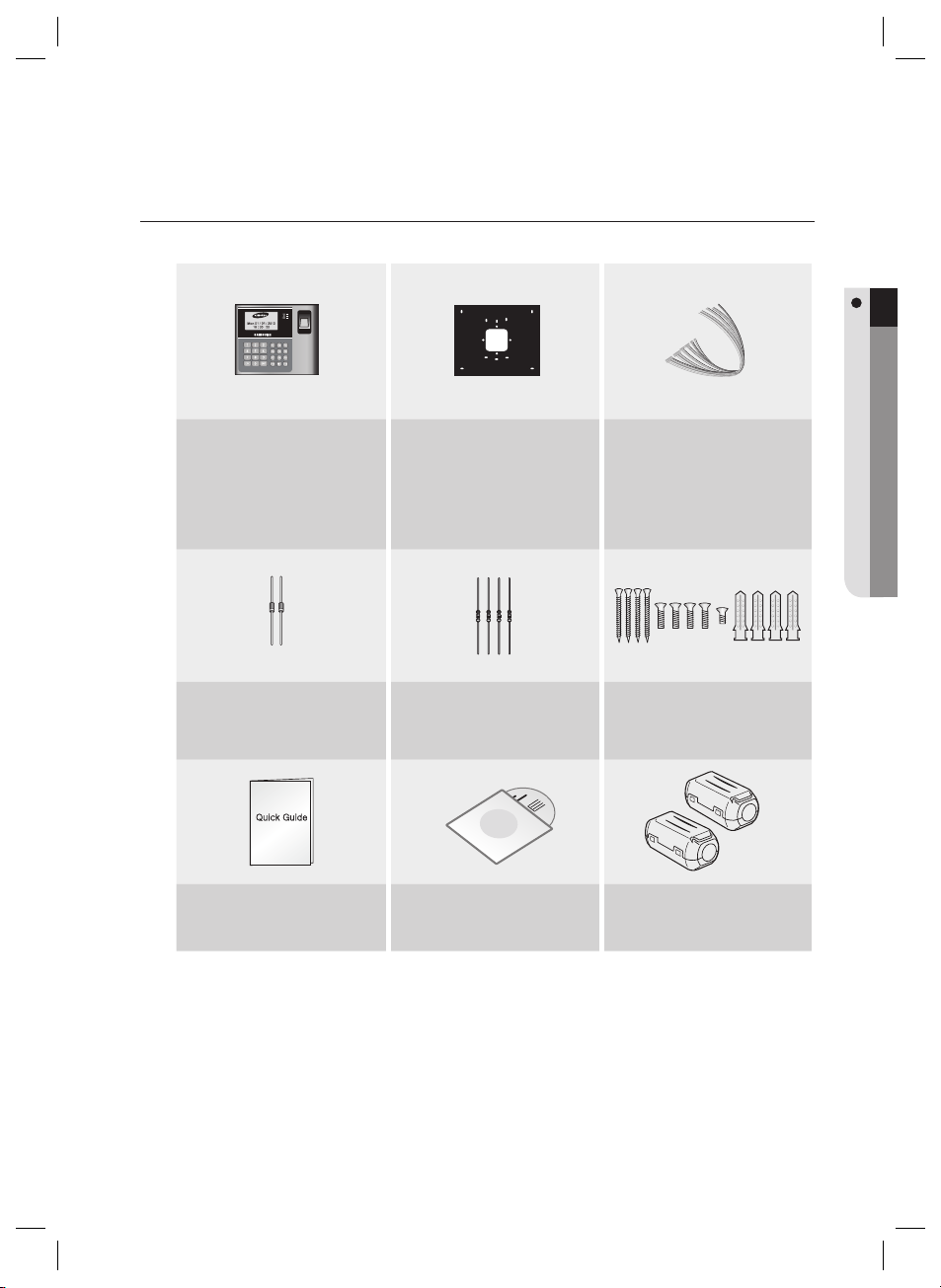

WHAT’S INCLUDED

Check if the following items are included in the product package.

Main Unit Wall Mount

PRODUCT INTRODUCTION

CABLE:

2PIN Connector (X 1)

3PIN Connector (X 1)

4PIN Connector (X 1)

5PIN Connector (X 1)

6PIN Connector (X 1)

8PIN Connector (X 1)

Diode (X 2)

(UF4004, 1N4001~4007)

xGn

Quick Guide CD Manual Ferrite Cores X 2

Resistor (X 4)

(2.2kΩ, 1/4W)

3.5 X 40mm screws (X 4)

3.5 X 12mm screws (X 4)

3 X 8mm screws (X 1)

6 X 30mm Plastic Anchor (X 4)

English English _ 9

Page 10

product introduction

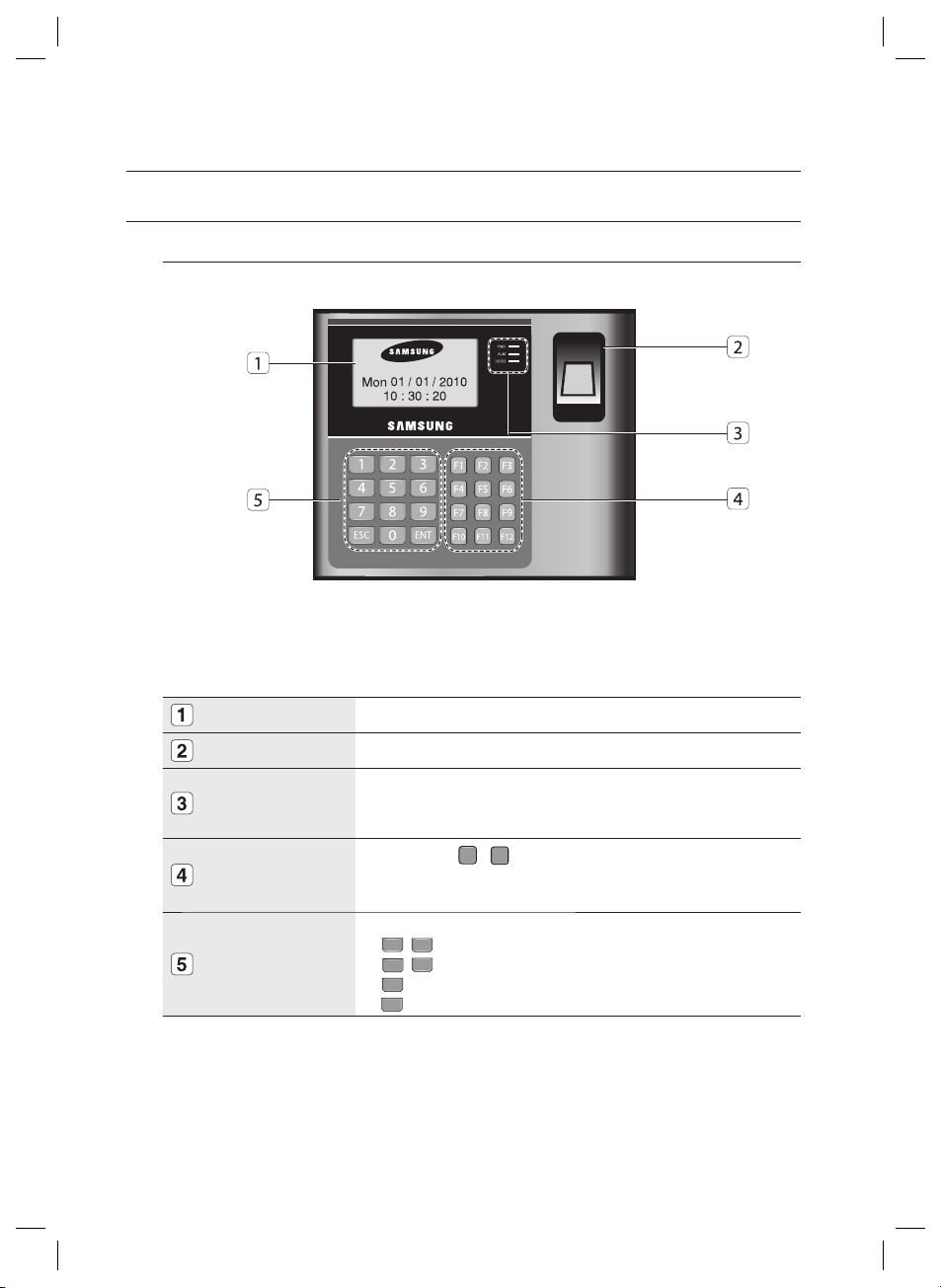

AT A GLANCE

Front Panel

LCD

Fingerprint Scanner

System Status LED

Menu Buttons

Input Keys

10_ product introduction

This module displays the operation status of the product.

Fingerprint scanner module.

The red indicator turns on when the product turns on.

The red indicator turns on when relay #1 becomes active.

The yellow indicator turns on when relay #2 becomes active.

F

1

12 menu buttons (

Press a menu button to enter the corresponding menu.

For the complete list of menus, refer to “Menu Structure”. (on pages 69 through 74)

Use these to enter numbers or navigate through the menu.

4

,6 : Left/right direction buttons

•

2

,8: Up/down direction buttons

•

ENT

: Select

•

ESC

: Cancel

•

F12

~

) are available for use.

Page 11

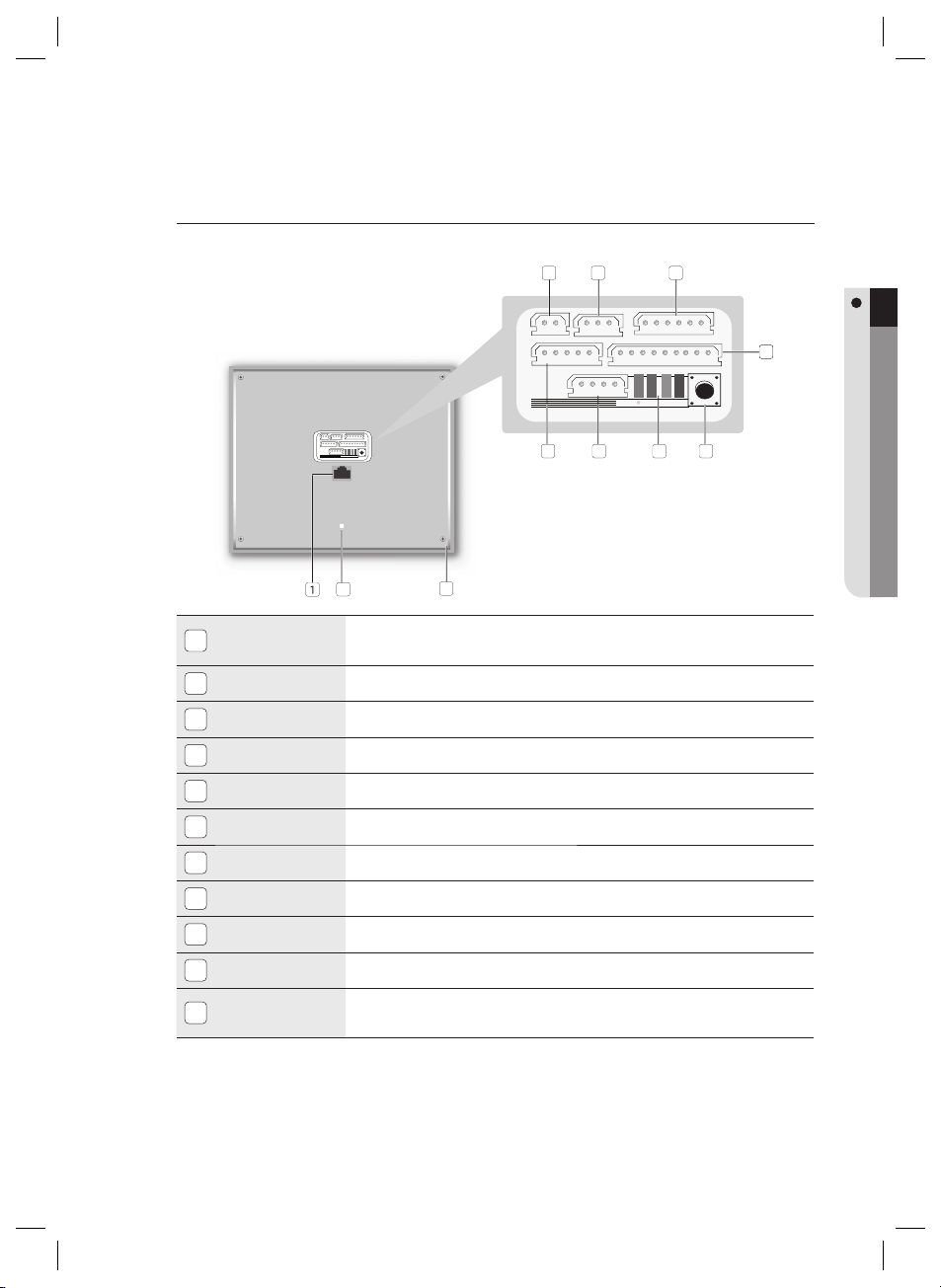

Rear Panel

Used in TCP/IP communications.

4 5 6

PRODUCT INTRODUCTION

7

67

RJ45 Connector

1

Tamper Switch

2

Fixing Hole

3

2-pin Connector

4

3-pin Connector

5

6-pin Connector

6

8-pin Connector

7

Initialize switch

8

LED

9

4-pin Connector

10

5-pin Connector

11

10

11

2

Used in TCP/IP communications.

Tamper switch.

Hole for a fi xing screw.

Can be connected to the power cable.

Preliminary connector for extension.

Can be connected to the I/O cable.

Can be connected to the relay wiring cable.

System Initialize switch.

Communication status indicator.

Preliminary connector for extension.

Can be connected to the RS-232 and RS-485 communication cables.

3

89

English English _ 11

Page 12

product introduction

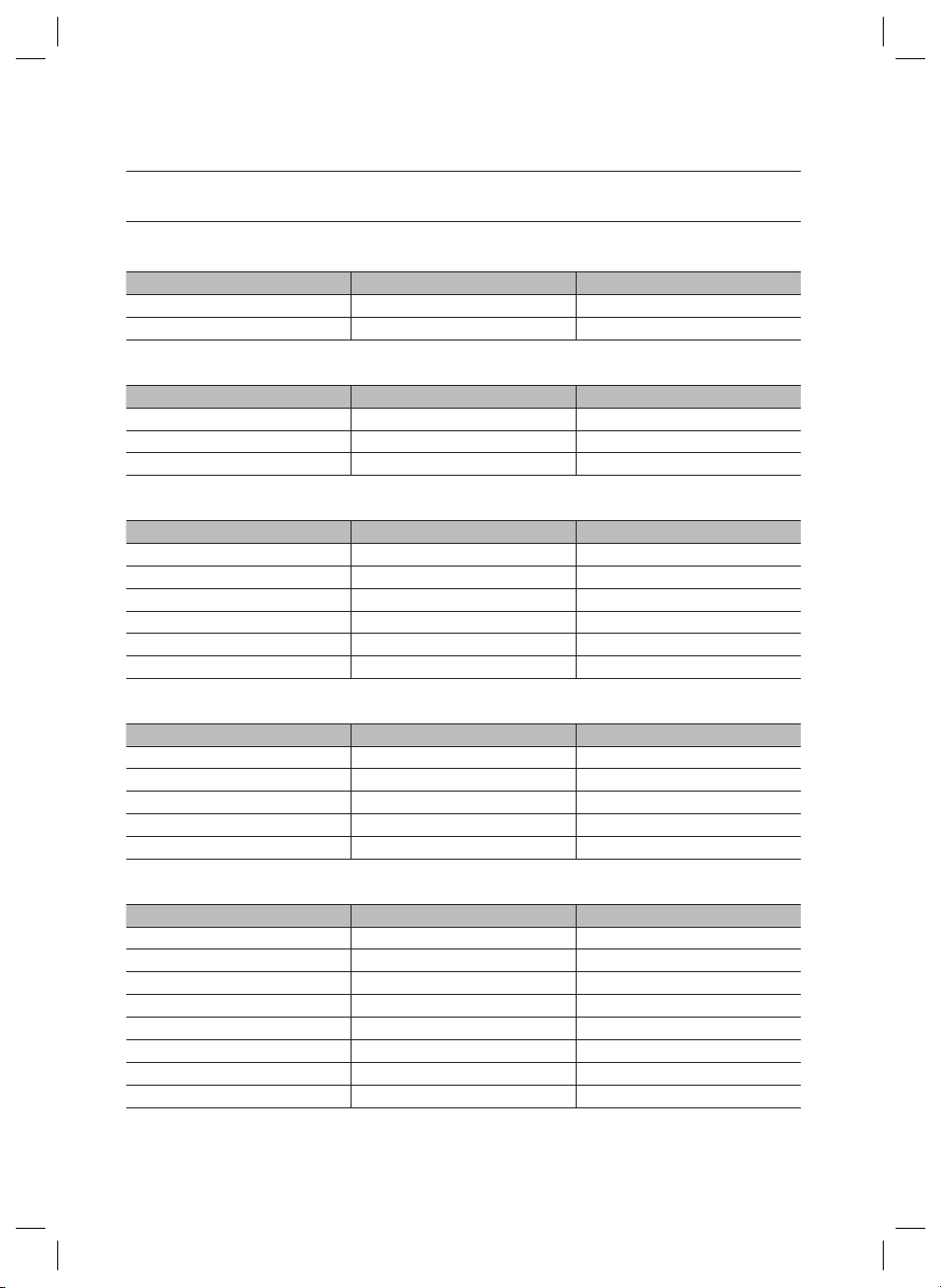

CABLE COLOR SCHEME

2-PIN Connector

❖

I/O Pins Signal Cable Color

Power (+12V) DC +12V Red

Earth-grounding GND (-) Black

3-PIN Connector

❖

I/O Pins Signal Cable Color

RESERVED 1 Pink with White Stripes

RESERVED 2 Sky Blue with White Stripes

RESERVED 3 Black

6-PIN Connector

❖

I/O Pins Signal Cable Color

TTL Output #1 TTL#1, WIK_D_OUT0 Orange with White Stripes

TTL Output #2 TTL#2, WIK_D_OUT1 Brown with White Stripes

Auxiliary Input #1 AUX_IN#1 Green

Auxiliary Input #2 AUX_IN#2 Green with White Stripes

Wiegand Data Input 0 WIK_D_IN0 Pink

Wiegand Data Input 1 WIK_D_IN1 Sky Blue

5-PIN Connector

❖

I/O Pins Signal Cable Color

RS-485-RTX(+) RS-485-A(+) Yellow

RS-485-RTX(-) RS-485-B(-) Gray

RS-232-TX TXD Black with White Stripes

RS-232-RX RXD Red with White Stripes

RS-232-GND GND Black

8-PIN Connector

❖

I/O Pins Signal Cable Color

Door RELAY(NC) NC(1) Blue with White Stripes

Door RELAY(COM) COM(1) Gray with Red Stripes

Door RELAY(NO) NO(1) White with Red Stripes

Alarm RELAY(NC) NC(2) Purple with White Stripes

Alarm RELAY(COM) COM(2) White

Alarm RELAY(NO) NO(2) Purple

Exit Button EXIT Orange

Door Contact Sensor CONTACT Yellow with Red Stripes

12_ product introduction

Page 13

Cable Type

Belden #9409, 18 AWG, 2 Conductor, Unshielded

4-PIN Connector

❖

I/O Pins Signal Cable Color

RESERVED 1 Orange with Red Stripes

RESERVED 2 Orange with Black Stripes

RESERVED 3 Blue

RESERVED 4 Brown

TCP/IP RJ45 Connector

❖

CABLE SELECTION

PRODUCT INTRODUCTION

Description

Product Power (DC12V)

1

This product

Reader (power and data)

External reader

2

product

Door Contact Sensor

Exit Button

3

Sensor Input

Input This product

RS-232 Cable

4

Converter Host P.C.

RS-485 Cable

This product This product

5

This product Converter

This

Cable Type

Belden #9409, 18 AWG, 2 Conductor, Unshielded

Belden #9512, 22 AWG, 4 Conductor, Shielded

Belden #9514, 22 AWG, 8 Conductor, Shielded

Belden #9512, 22 AWG, 4 Conductor, Shielded

Belden #9514, 22 AWG, 8 Conductor, Shielded

Belden #9829, 24 AWG, 2-twisted pair, Shielded

Belden #9829, 24 AWG, 2-twisted pair, Shielded

English English _ 13

Page 14

installation and external connection

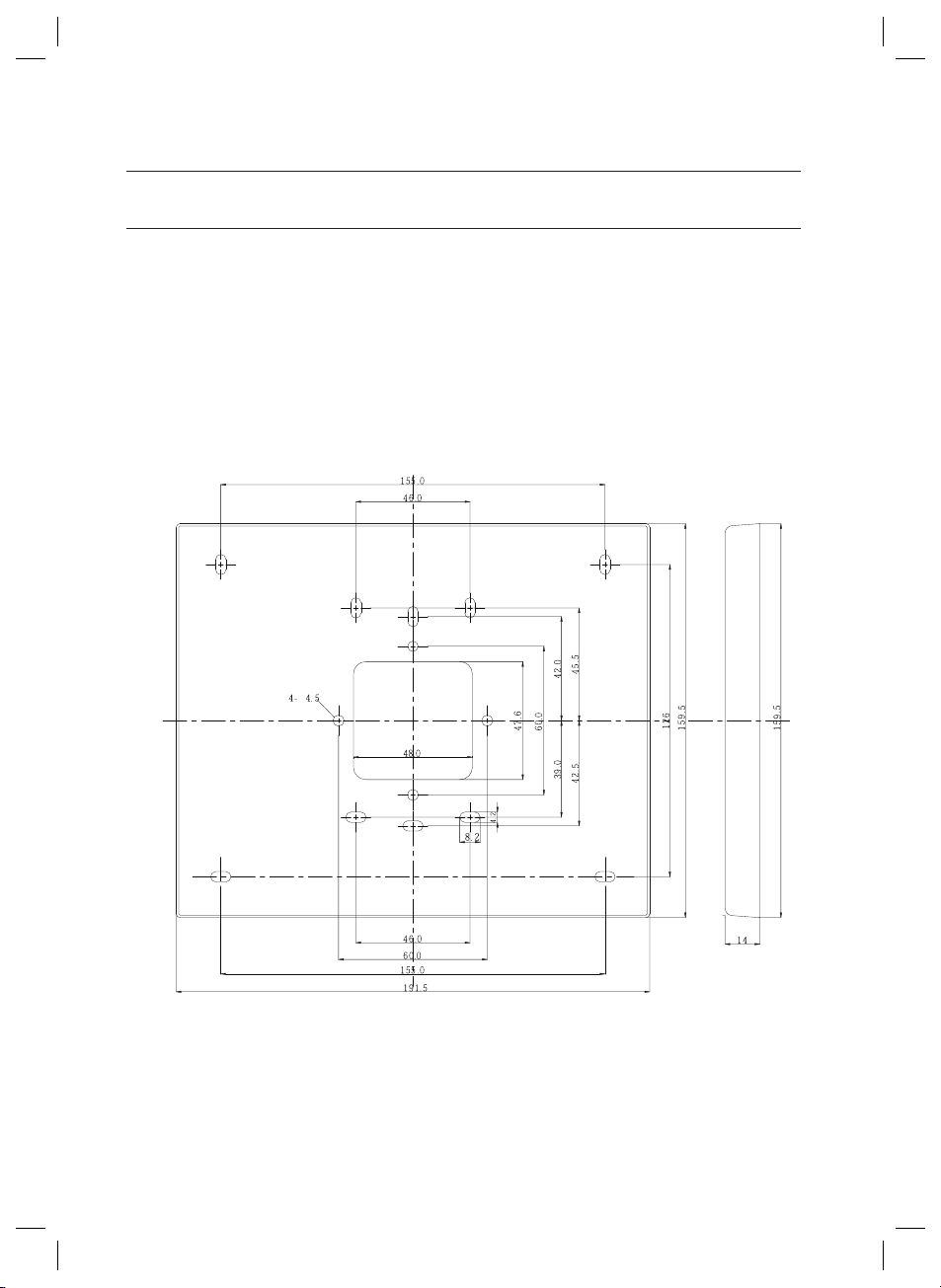

INSTALLING THE WALL MOUNT

Follow the instructions below to install the wall mount.

1.

Place the wall mount on the installation point and mark the 4 holes for the screws. Drill at least 4 of 6-32 holes.

2.

Drill a 1/2” hole on the center of the wall mount.

3.

Use 4 screws to fi x the wall mount to an appropriate point.

4.

Arrange the cables through the center hole.

5.

Connect the cable and use one screw on the bottom of the wall mount to fi x it to the product.

Do not install the product on a metal wall. Otherwise, this will cause malfunction due to radio frequency interference

J

against the wall.

14_

installation and external connection

Page 15

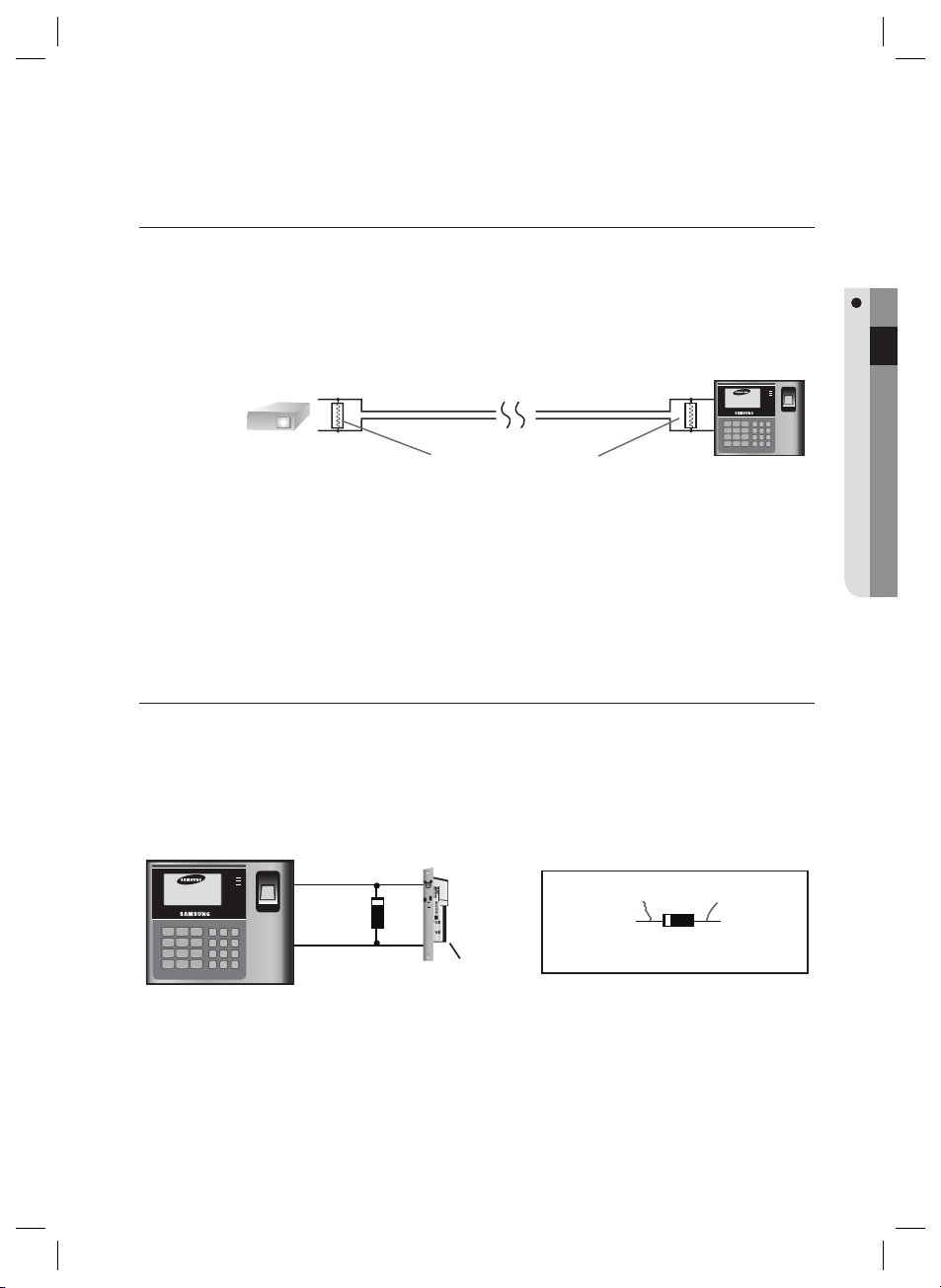

CONNECTING THE TERMINATION RESISTOR AND DIODE

A resistor is inserted for line’s impedance matching to prevent distortion and reduction in RS-422 or RS-485 long distance

data communications, which is referred to as termination resistor.

Note that termination resistors of lower than 90 are not allowed, neither more than one termination resistor is accepted

for the communications system.

183

"-.

RS485/RS232

Converter

"

#

120Ω

RS-485 RS-485

Termination Resistors

120Ω

A

B

Mon 01 / 01 / 2010

10 : 30 : 20

1 32

54

7 98

ESC0ENT

%003

F1 F2 F3

F4 F5 F6

6

F7 F8 F9

F10 F11 F12

BYPASS DIODE CONNECTION

If you connected an inductor (door locks or alarm device) to the output relay, there should occur a surge voltage while the

inductor was turning on and off. If you do not connect a bypass diode to the relay, the surge voltage will cause damage to

the electric circuit of the controller. To reduce this surge, it is recommended to connect a bypass diode between the

devices.

INSTALLATION AND EXTERNAL CONNECTION

Mon 01 / 01 / 2010

10 : 30 : 20

1 32

7 98

ESC0ENT

183

"-.

%003

F1 F2 F3

F4 F5 F6

654

F7 F8 F9

F10 F11 F12

DC12V

GND(-)

Cathode Anode

1N4004~1N4007 or equiv.

Lock/Alarm

English English _ 15

Page 16

installation and external connection

EARTH-GROUNDING THE COMMUNICATION CABLES

We recommend you to use a proper grounding system for the communication cables.

The best grounding method is to earth-ground the shield wire of the communication cable. However, earth-grounding the

communication cable isn’t that easy, apart from the cost increase.

There are three grounding points available for installation:

1. Earth Ground

2. Chassis Ground

3. Power Ground

The most important thing about the earth-grounding is not connecting both ends of the shield wire to the same grounding

system; Connecting both to the same end will cause a current fl ow through the shield wire due to the voltage level

difference between the both ends of the shield wire, and this current fl ow will introduce some noise and interference to

communications.

We recommend you connect ONLY one end of the shield wire of the communication cable to the grounding system. If you

can locate an earth grounding point nearby, connect one end of the shield wire to that point.

If you could hardly locate an earth grounding point nearby, connect one end of the shield wire to the chassis ground point.

If you could locate neither of an earth or chassis grounding point nearby, connect one end of the shield wire to the power

ground point (GND). Note that if the chassis is not properly earthed and fl oated from the ground level, then grounding

communication cable to the chassis will produce the worst communication. If this is the case, use the power grounding

point rather than the chassis grounding.

RS-485/RS-232

RS-232

HOST PC

Earth Ground

or Chasis Ground

or Power Ground

GND GND GND GND

16_

installation and external connection

Converter

Communication

Wires

Connect

RS-485 RS-485 RS-485

Mon 01 / 01 / 2010

10 : 30 : 20

1 32

54

7 98

ESC0ENT

183

"-.

%003

F1 F2 F3

F4 F5 F6

6

F7 F8 F9

F10 F11 F12

Mon 01 / 01 / 2010

10 : 30 : 20

1 32

54

7 98

ESC0ENT

183

"-.

%003

F1 F2 F3

F4 F5 F6

6

F7 F8 F9

F10 F11 F12

ShieldWire

Mon 01 / 01 / 2010

10 : 30 : 20

1 32

F1 F2 F3

F4 F5 F6

54

6

F7 F8 F9

7 98

ESC0ENT

F10 F11 F12

Open

183

"-.

%003

Mon 01 / 01 / 2010

10 : 30 : 20

1 32

54

7 98

ESC0ENT

183

"-.

%003

F1 F2 F3

F4 F5 F6

6

F7 F8 F9

F10 F11 F12

Page 17

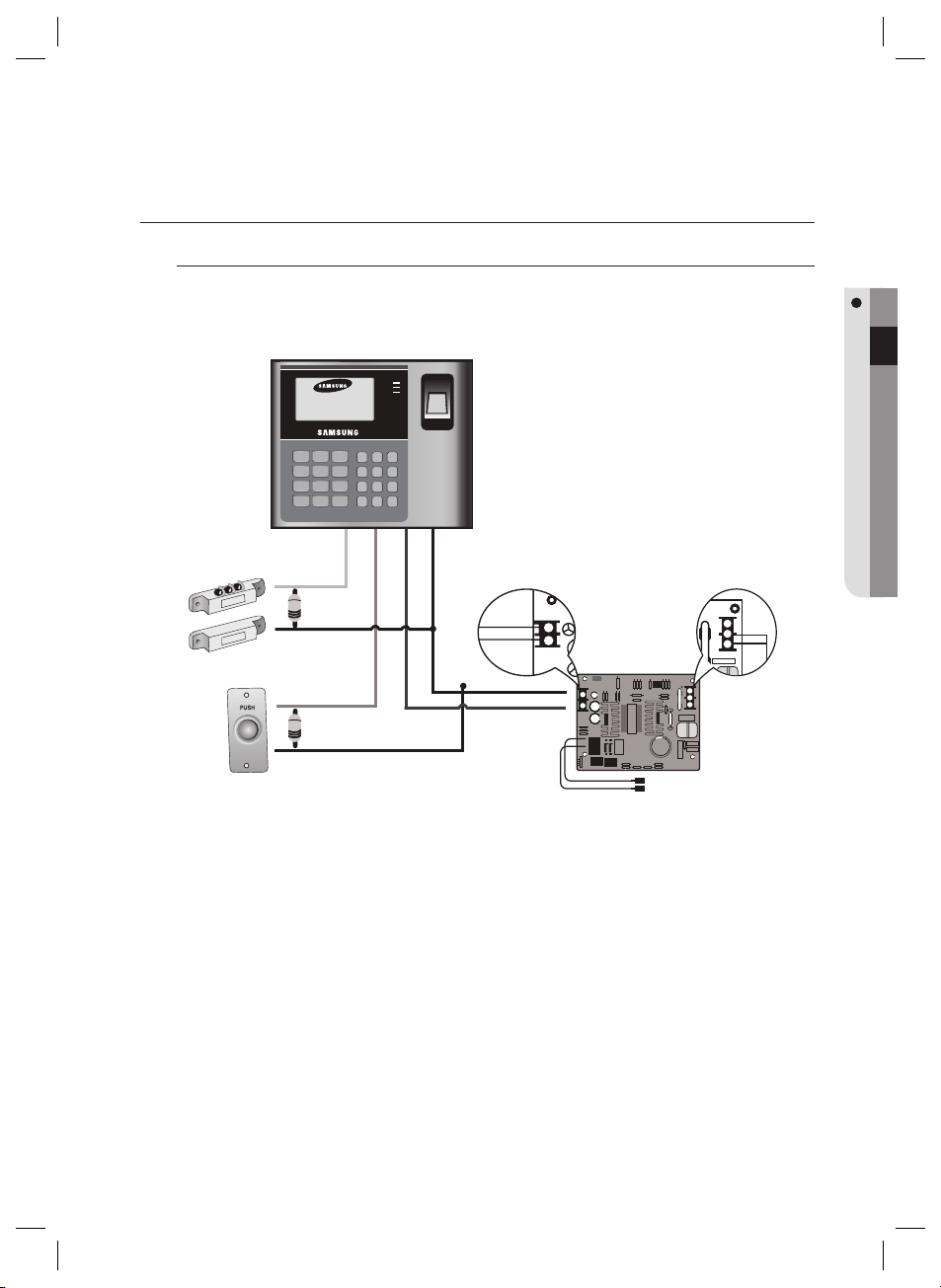

I/O CONNECTION

Input Connection

ESC0ENT

Door Contact Sensor

Mon 01 / 01 / 2010

10 : 30 : 20

1 32

654

7 98

F1 F2 F3

F4 F5 F6

F7 F8 F9

F10 F11 F12

INSTALLATION AND EXTERNAL CONNECTION

183

"-.

%003

Door Contact Sensor: Yellow with the red stripe, GND

Exit Button: Orange line, GND

Connect 2.2K to check for cut-off detection

Black -

Red +

GND

DC+12v

FG

L

N

Exit Button

Power

Supply

Connect the DC 12V(+) line of the power supply unit to the red line.

1.

Connect the GND(-) line of the power supply unit to the black line.

2.

- Exit Button Connection

Connect one end of the Exit button to the orange line.

1.

Connect the other end of the Exit button to GND

2.

- Door Contact Sensor Connection

1.

Connect one end of the door contact sensor to the yellow with red stripes.

Connect the other end of the door contact sensor to GND.

2.

-

Auxiliary Input Device Connection (auxiliary input #1 – green, auxiliary input #2 – green with white stripes)

1.

Connect one end of the auxiliary input device to auxiliary input #1 or auxiliary input #2.

2.

Connect the other end of the auxiliary input device to GND.

100V-220V

English English _ 17

Page 18

installation and external connection

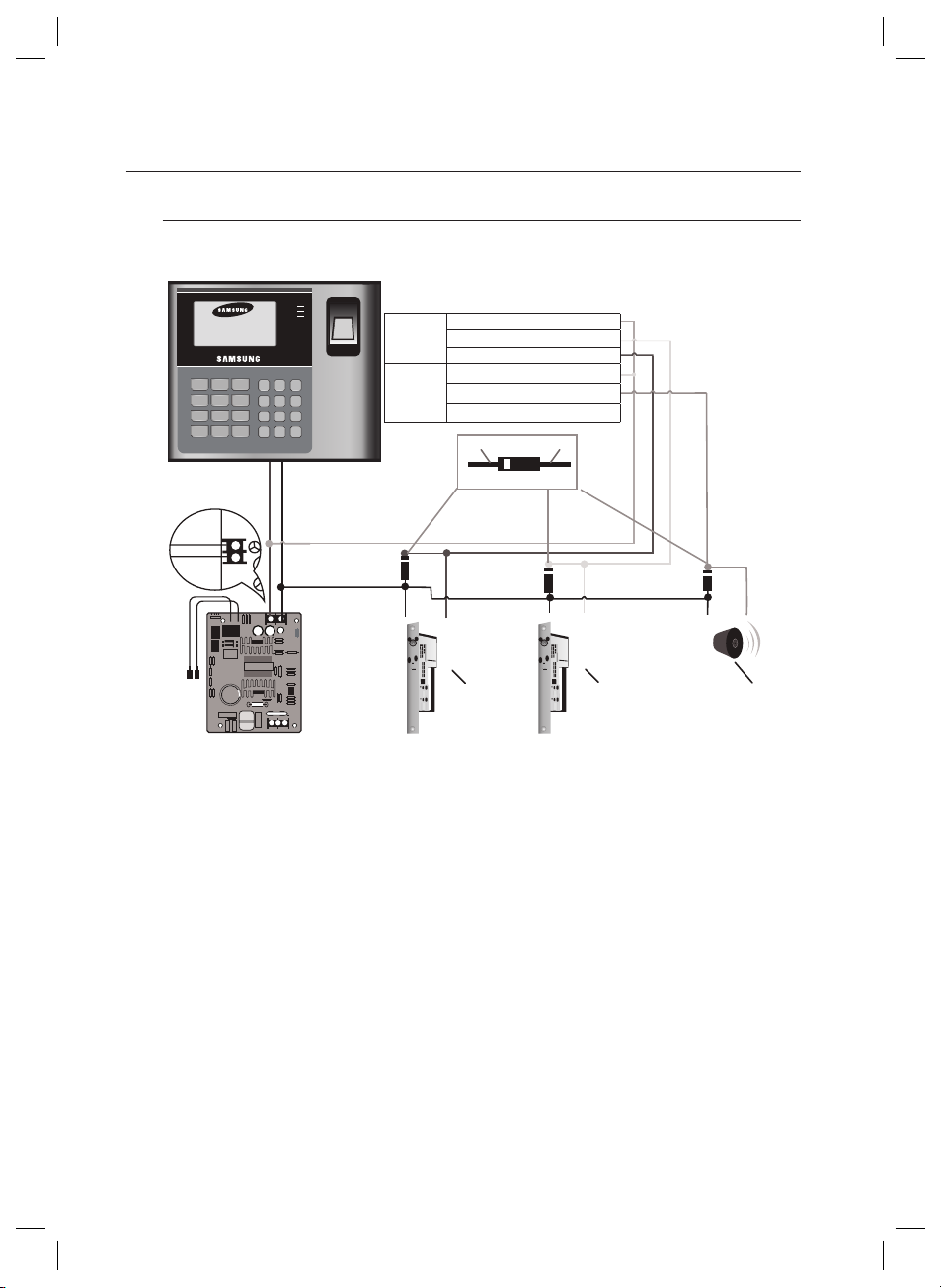

Output Connection

Connect the 8-pin connector (relay connector) of this product as follows:

183

"-.

Mon 01 / 01 / 2010

1 32

7 98

ESC0ENT

Black -

Red +

10 : 30 : 20

654

GND

DC+12V

F1 F2 F3

F4 F5 F6

F7 F8 F9

F10 F11 F12

%003

DOOR

RELAY

ALARM

RELAY

⾄⾉⾅ ⾄⾉⾅ ⾄⾉⾅⾄⾅ ⾄⾅ ⾄⾅

COM (gray with red stripes)

NO (white with red stripes)

NC (blue with white stripes)

COM (white)

NO (purple)

NC (purple with white stripes)

Cathode Anode

1N4004-1N4007 or equivalent

POWER FAIL

SAFE

POWER FAIL

SECURE

Power Supply

- POWER FAIL SAFE: Door is opened when the power is disconnected

Connect the relay COM line (gray with red stripes for locking the door) to DC +12V.

1.

Connect the relay NC line (blue with white stripes for locking the door) to the plus(+) line of the door lock.

2.

Connect the minus (-) line of the door lock to GND (-).

3.

- POWER FAIL SECURE: Door is closed when the power is disconnected

Connect the relay COM line (gray with red stripes for locking the door) to DC +12V.

1.

Connect the relay NO line (white with red stripes for locking the door) to the plus (+) line of the door lock

2.

Connect the minus (-) line of the door lock to GND (-).

3.

- Alarm Connection (Alarm Relay)

Connect the relay COM (white for the alarm device) to DC +12V.

1.

Connect the relay NO line (purple for the alarm device) to the plus (+) line of the alarm device.

2.

Connect the minus (-) line of the alarm device to GND (-).

3.

18_

installation and external connection

Alarm

Device

Page 19

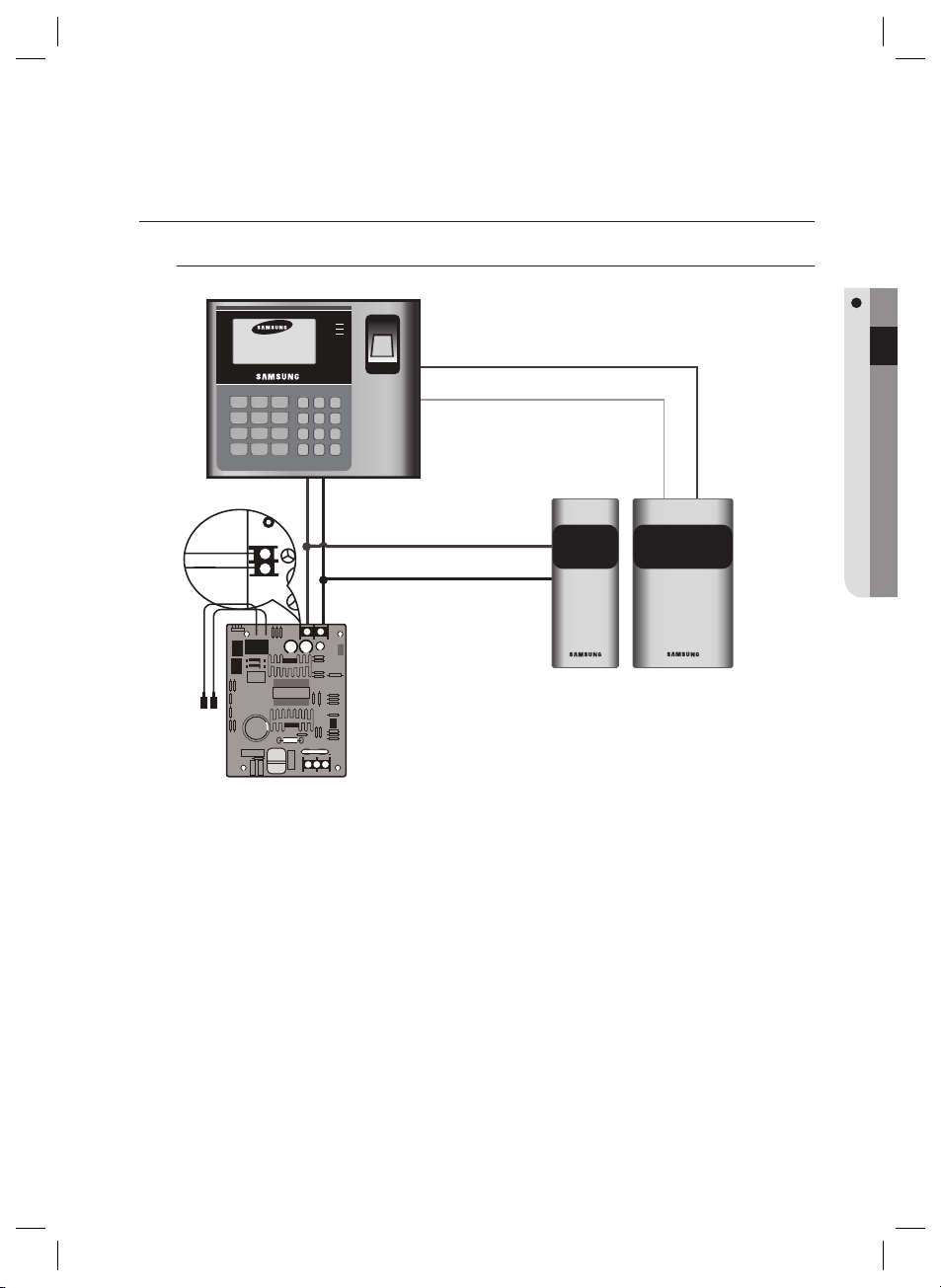

EXTERNAL READER CONNECTION

External Reader Connection

183

"-.

654

F1 F2 F3

F4 F5 F6

F7 F8 F9

F10 F11 F12

%003

Wiegand DATA0 (Pink)

Wiegand DATA1 (sky blue)

⾄⾇⾅

⾄⾉⾅

Power

Supply

Black -

Red +

Mon 01 / 01 / 2010

10 : 30 : 20

1 32

7 98

ESC0ENT

GND

DC+12V

- Proximity Reader Connection

Connect the DC 12V(+) line of the power supply unit to the plus (+) line of the reader.

1.

Connect the GND(-) line of the power supply unit to the minus(-) line of the reader

2.

Connect the Wiegand data input line 0 of the proximity reader to the pink line

3.

Connect the Wiegand data input line 1 of the proximity reader to the sky blue line

4.

For a list of compliant readers (external readers), see the followings:

•

SSA-S30X0

- Standard 26bit Wiegand format proximity reader

- Standard 26bit Wiegand + 8bit Burst format proximity/keypad reader

SSA-S30X1

- Standard 34bit Wiegand format proximity reader

- Standard 34bit Wiegand + 8bit Burst format proximity/keypad reader

INSTALLATION AND EXTERNAL CONNECTION

English English _ 19

Page 20

installation and external connection

COMMUNICATION LINE CONNECTION

RS-232 Communication Port Connection

A 9-pin connector (serial communication connector, female) is needed to connect the product to the host PC via

RS-232 communication. Please follow the steps below:

HOST PC

Mon 01 / 01 / 2010

10 : 30 : 20

1 32

7 98

ESC0ENT

654

F1 F2 F3

F4 F5 F6

F7 F8 F9

F10 F11 F12

183

"-.

%003

RS-232

2

3

5

Black with white stripes

Red with white stripes

Black

9pin Female Connector

1.

Connect RS-232 TX (Black with white stripes) to the pin #2 (RXD) of the 9-pin female connector.

2.

Connect RS-232 RX (Red with white stripes) to the pin #3 (TX) of the 9-pin female connector.

3.

Connect the GND (black) line of the product to pin #5 of the 9-pin female connector.

4.

Plug in the 9-pin female connector to serial port (COM port) of the host PC.

5.

Install and launch the application (SAMS).

20_

installation and external connection

Page 21

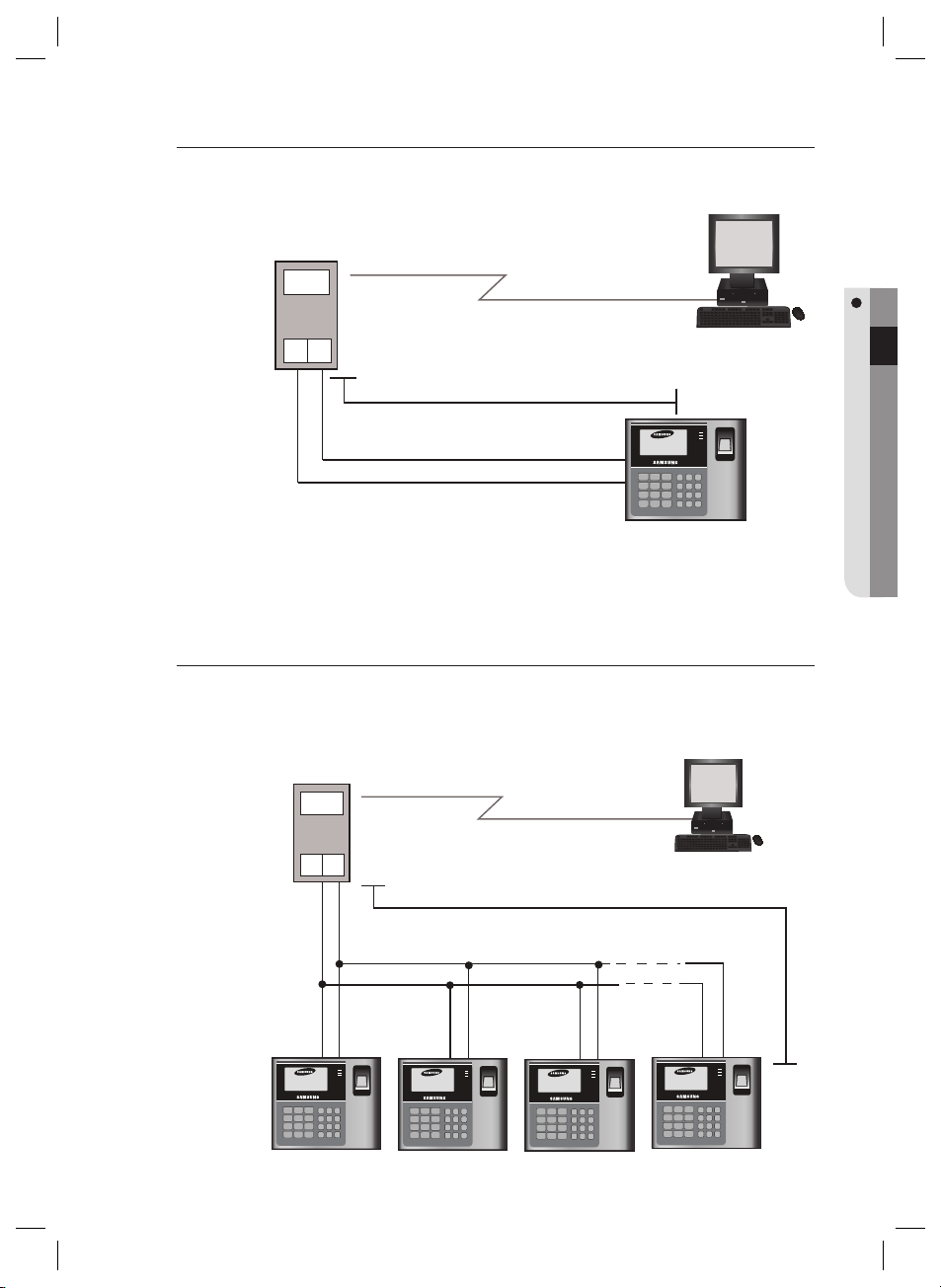

RS-485 Communication Port Connection (Standalone)

A RS-485/RS-232 converter is needed to make RS485 communications between the product and the host PC.

Please follow the steps below:

RS-485/RS-232

Converter

A B

RS-232

RS-485

HOST PC

Max. 1200m

183

"-.

%003

Gray

Yellow

1.

Connect the yellow RS-485 RTX (+) line to RS-485 A port of the converter.

2.

Connect the gray RS-485 RTX (-) line to RS-485 B port of the converter.

3.

Plug in the 9-pin connector (RS-232) of the converter into serial port (COM port) of the host PC.

4.

Install and launch the application (SAMS).

Mon 01 / 01 / 2010

10 : 30 : 20

1 32

54

7 98

ESC0ENT

F1 F2 F3

F4 F5 F6

6

F7 F8 F9

F10 F11 F12

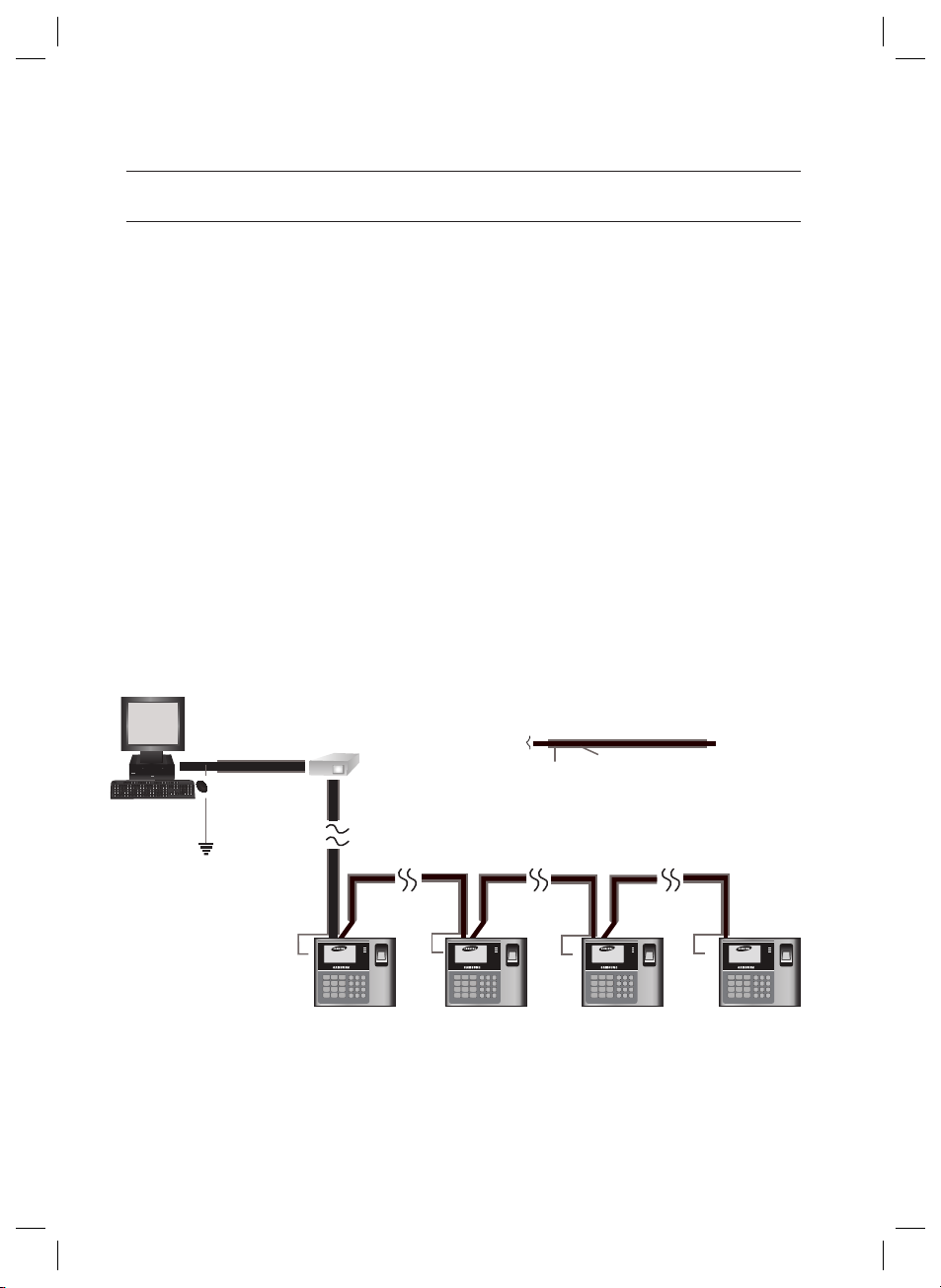

RS-485 Communication Port Connection (Multiple Units)

A RS-485/RS-232 converter is needed to make RS-485 communications across a multiple of the products

and the host PC.

Please follow the steps below:

A B

RS-232

RS-485

Max. 1200m

HOST PC

RS-485/RS-232

Converter

INSTALLATION AND EXTERNAL CONNECTION

Mon 01 / 01 / 2010

10 : 30 : 20

1 32

54

7 98

ESC0ENT

Gray

Yellow

183

"-.

%003

F1 F2 F3

F4 F5 F6

6

F7 F8 F9

F10 F11 F12

Mon 01 / 01 / 2010

10 : 30 : 20

1 32

54

7 98

ESC0ENT

183

"-.

%003

F1 F2 F3

F4 F5 F6

6

F7 F8 F9

F10 F11 F12

Mon 01 / 01 / 2010

10 : 30 : 20

1 32

54

7 98

ESC0ENT

183

"-.

%003

F1 F2 F3

F4 F5 F6

6

F7 F8 F9

F10 F11 F12

Mon 01 / 01 / 2010

10 : 30 : 20

1 32

54

7 98

ESC0ENT

183

"-.

%003

F1 F2 F3

F4 F5 F6

6

F7 F8 F9

F10 F11 F12

English English _ 21

Page 22

installation and external connection

- Connect all RS-485 ports of the product in parallel.

Connect the yellow RS-485 RTX (+) line of one unit to the yellow RS-485 RTX (+) line of another unit.

1.

Connect the gray RS-485 RTX (-) line of one unit to the gray RS-485 RTX (-) line of another unit.

2.

Set a unique communication address (COMM ADDR) for each unit.

3.

- Connect one RS-485 port of the product to the RS-485/RS-232 converter

1.

Connect the yellow RS-485 RTX (+) line to the RS-485 A port of the converter.

2.

Connect the gray RS-485 RTX (-) line to the RS-485 B port of the converter.

3.

Plug the 9-pin connector (RS-232) of the converter into serial port (

Install and launch the application (SAMS).

4.

RS-485 connection supports multi-drop communications up to 32 units.

M

TCP/IP Communication Port Connection

To implement TCP/IP communications for the host PC, follow the steps below:

TCP/IP

COM port)

HUB

of the host PC.

PC

183

"-.

%003

Mon 01 / 01 / 2010

10 : 30 : 20

1 32

F1 F2 F3

F4 F5 F6

54

6

F7 F8 F9

7 98

ESC0ENT

F10 F11 F12

Connect the RJ45 jack of the unit to the RJ45 plug, the LAN cable of the network system.

1.

Set a unique communication address (COMM ADDR) for each unit.

2.

Install and launch the application (SAMS).

3.

22_

installation and external connection

TCP/IP

Mon 01 / 01 / 2010

10 : 30 : 20

1 32

54

7 98

ESC0ENT

6

F1 F2 F3

F4 F5 F6

F7 F8 F9

F10 F11 F12

183

"-.

%003

Mon 01 / 01 / 2010

10 : 30 : 20

1 32

54

7 98

ESC0ENT

183

"-.

%003

F1 F2 F3

F4 F5 F6

6

F7 F8 F9

F10 F11 F12

Page 23

initialization

INITIALIZING THE SYSTEM

Initializing the system using the Initialize switch

Initialize the system using the Initialize switch on the rear of the product.

Check the power terminal on the rear of the product and disconnect the power

1.

cable.

While holding the Initialize switch, connect the power cable again.

2.

While holding the Initialize switch, wait until the “Initialize OK?” message

3.

appears on the screen.

It takes about 8 seconds to proceed.

Do not press the Initialize switch while the initialization message appears.

•

INITIALIZATION

INITIALIZE OK?

1:YES 0:NO

WAIT…

Press the button

4.

“WAIT…” message on the screen.

•

To cancel Initializing the system, press

5.

When the Initializing is done, you will move to the standby screen.

Note that the initialization process will restore all previous settings to the factory default.

J

1

to proceed with the initialization process with the

0

.

Sat 01 / 06 / 2010

10 : 30 : 20

System Initialization in Master Mode

You can Initialize the system through authentication of the master card. For entering the master mode, see page 24.

F

Press the

1.

Use the buttons

2.

press

3.

The initialization screen appears.

4.

Press the button

“WAIT…” message on the screen.

•

5.

When the Initializing is done, you will move to the standby screen.

J

8

SETUP MENU button.

4

ENT

To cancel Initializing the system, press

Note that the initialization process will restore all previous settings to the factory

default.

and 6 to move to the SYSTEM INIT. item and

.

1

to proceed with the initialization process with the

0

.

1. SYSTEM INIT.

1. SYSTEM INIT.

1:YES, 0:NO

WAIT…

English English _ 23

Page 24

initialization

TO ACCESS THE MASTER MODE

Apply the power to the product.

1.

2.

When the booting is done, press 0 8 consecutive times (00000000) and

ENT

press

M

REGISTERING A MASTER ID

To register a master card

Press the

1.

Use the buttons

2.

press

.

•

The master number of the initialization is “00000000” (“0000000000” for

SSA-S30X1).

If you have already registered the master ID, use the ID to get access.

When the system is initialized, the master number will be reset to “00000000”

If you have registered the master ID, you can not get access using “00000000”.

The master number for SSA-S30X1 is “0000000000 (10 digits)”.

F

7

SETUP MENU button.

4

ENT

and 6 to move to the MASTER ID REG item and

.

WELCOME!!

* * * * * * * *

Mon 01 /01 2010

10 :30 : 20

4. MASTER ID REG

3.

Select a master ID index to register and press

4.

To select a card, press

5.

Place the master card to register on the product.

6.

Enter the password for the master card and press

Press

0

to exit registering the master ID.

7.

1

.

24_ initialization

ENT

.

4. MASTER ID REG

MASTER #01

EMPTY

ENT

.

4. MASTER ID REG

1:CARD, 2:PIN

4. MASTER ID REG

SCANNING…

ID:12312345

ENTER PASSWORD

ID:12312345

P/W:5678

ENTER F/P FLAG

0:NOT USE 1: USE

Page 25

To register a master card along with your fi ngerprint

Follow the steps 1 through 6 above in “To register a master card”.

1

Press

7.

8.

Place your fi nger on the fi ngerprint scanner.

9.

Release your fi nger, then put your fi nger onto the fi ngerprint scanner

to register your fi ngerprint.

again when the light turns on.

10.

When done, the master ID and your fi ngerprint template will be registered.

The default master ID is “00000000”, and no fi ngerprint recognition is used.

M

If at least one master ID is registered, the default master ID, “00000000”, is no

longer available.

You can register up to a total of 10 master IDs (01 ~10).

To erase a master ID, enter “00000000” for the applicable master ID.

The master number for SSA-S30X1 is ““0000000000 (10 digits)”.

To register a master card PIN

F

Press the

1.

7

SETUP MENU button.

TO REGISTER F/P

1/2

PUT YOUR FINGER

2/2

LIFT AND

PUT YOUR FINGER

INITIALIZATION

Use the buttons

2.

3.

4.

5.

ENT

press

Select a master ID index to register and press

To select a PIN, press

Enter the PIN for the master card to register and press

•

PIN Range

4

and 6 to move to the MASTER ID REG item and

.

ENT

2

.

-SSA-S30x0 : Numeric letters in 8 digits

Ranges from 00000001 to 99999999

-SSA-S30x1 : Numeric letters in 10 digits

Ranges from 0000000001 to 4294967295

Press

0

to exit registering the PIN.

6.

4. MASTER ID REG

.

00/00

4. MASTER ID REG

ENT

.

MASTER #1

EMPTY

4. MASTER ID REG

1:CARD, 2:PIN

4. MASTER ID REG

ENTER PIN

PIN:_

PIN: 12312345

ENTER F/P FLAG

0:NOT USE 1: USE

English English _ 25

Page 26

initialization

To register a master card PIN along with your fi ngerprint

Follow the steps 1 through 5 above in “To register a master card PIN”

1

Press

6.

Place your fi nger on the fi ngerprint scanner.

7.

Release your fi nger, then put your fi nger onto the fi ngerprint scanner

8.

again when the light turns on.

When done, the master card PIN and your fi ngerprint template will be

9.

registered.

NAME DISPLAY

With “Name Display”, you can set to display the name of a user who enters.

The user name can be downloaded by using the provided application software only, and accepts only alphabetic

letters up to 8 characters. By using the unit, you can register a new user but cannot enter the user’s name. In case of

such a user’s accessing, no name will be displayed.

to register your fi ngerprint.

TO REGISTER F/P

1/2

PUT YOUR FINGER

2/2

LIFT AND

PUT YOUR FINGER

1.

Press the

2.

Use the buttons

press

3.

Use the buttons

•

USE : Name Display is enabled.

NOT USE : Name Display is disabled.

4.

When done, press

If you set Name Display to “USE”, the maximum number of IDs will be limited to 10000.

M

Make sure no ID should have ever be registered before using this function.

26_ initialization

F

3

SETUP MENU button.

4

ENT

and 6 to move to the NAME DISPLAY item and

.

4

and 6 to select USE or NOT USE, and press

ENT

to save your settings.

6. NAME DISPLAY

ENT

NOT USE

.

6. NAME DISPLAY

J NOT USE

Page 27

USER COUNT SETUP

You can select the maximum number of registered users to 10,000 or 20,000.

If you set the maximum user count to 20,000, the maximum number of events will be changed to 10,000.

F

Press the

1.

Use the buttons

2.

press

Use the buttons

3.

•

M

3

SETUP MENU button.

4

ENT

10,000 : The max user count will be set to 10,000.

20,000 : The max user count will be set to 20,000.

Before setting the user count, you must initialize the system.

and 6 to move to the MAX USER SETUP item and

.

4

and 6 to select a max user count.

5. MAX USER SETUP

10000

5. MAX USER SETUP

J 10000

LANGUAGE SETUP

F

Press the

1.

1

SETUP MENU button.

INITIALIZATION

Use the buttons

2.

ENT

.

Use the buttons

3.

•

ENGLISH

ITALIANO

FRANÇAIS

(Optional language : Español, Deutsch)

The default language is ENGLISH.

M

By optional, Spanish, German are supported.

4

and 6 to move to the LANGUAGE item and press

4

and 6 to select a max user count.

1. LANGUAGE

ENGLISH

1. LANGUAGE

JENGLISH

English English _ 27

Page 28

initialization

DATE/TIME SETUP

F

1.

Press the

1

SETUP MENU button.

2.

Use the buttons

ENT

press

3.

Enter the values of year, month, day, hour, minute, second, and day of the

week in sequence.

•

YYYY : Year (4 digits)

MM : Month (2 digits)

DD : Day (2 digits)

hh : Hour (2 digits)

mm : Minute (2 digits)

ss : Second (2 digits)

w : Day of the week (1 digit)

1- Sunday, 2-Monday, 3-Tuesday, 4-Wednesday, 5-Thursday, 6-Friday,

7-Saturday

4.

When done, press

Enter each value for Date/Time to fi t the respective digits.

M

4

and 6 to move to the SET DATE/TIME item and

.

ENT

to save your settings.

COMMUNICATION ADDRESS SETUP

F

Press the

1.

Use the buttons

2.

press

3.

Enter the 3-digit communication address number.

•

4.

When done, press

1

SETUP MENU button.

4

ENT

Ex) if you set the COMM ADDR to 12, press 012 for that.

and 6 to move to the COMM ADDR SET item and

.

ENT

to save your settings.

2. SET DATE/TIME

YYYYMMDDhhmmssw

_______________

2. SET DATE/TIME

201001011030202

Mon 01 / 01 / 2010

10:30 20

7. COMM ADDR SET

000

7. COMM ADDR SET

_00

The default address is set to “000”.

M

Select a number between 000 and 255 for the address.

Each product in the same loop should have a unique communication address.

28_ initialization

7. COMM ADDR SET

012

Page 29

BAUD RATE SETUP

This product supports 9600, 19200, 38400, and 57600 bps, and it is set to 57600 bps by default.

An improper speed setting can cause a communication error so ensure that you specify the same speed in the same

network.

F

ENT

.

9600

1

SETUP MENU button.

4

and 6 to move to the BAUD RATE item and press

4

and 6 to select a serial communication speed.

Press the

1.

Use the buttons

2.

3.

Use the buttons

•

19200

38400

57600

When done, press

4.

If you encounter a problem with the communication, check the followings fi rst.

M

ENT

to save your settings.

- Check the communication addresses for this product and the host PC

(software).

- Check the baud rate settings of each of the host PC and this product.

- Check the communication port and cable.

- Check the host PC for the port settings.

FACTORY DEFAULTS

All menu settings will return to the factory default. (The memory is not deleted.)

F

Press the

1.

8

SETUP MENU button.

INITIALIZATION

8. BAUD RATE

57600

8. BAUD RATE

J19200

8. BAUD RATE

19200

Use the buttons

2.

ENT

.

3.

Press the button

•

To cancel initialization, press the button

4

and 6 to move to the DEFAULT SET item and press

1

to restore the menu settings to the default.

6. DEFAULT SET

0

.

6. DEFAULT SET

1:YES, 0:NO

English English _ 29

Page 30

reader mode setup

READER #1 MODE

READER#1 is the default reader that is built in this product.

F

Press the

1.

1

SETUP MENU button.

Use the buttons

2.

3.

ENT

press

Use the buttons

4

and 6 to move to the READER#1 MODE item and

.

4

and 6 to select a reader mode.

3 modes are available for your choice.

•

ID ONLY : In this mode, you can get access only with the proximity card

or ID number.

ID +F/P(P/W) : In this mode, you can get access through the fingerprint

authentication after entering the proximity card or ID

number.

If you have not registered your fingerprint, you can get

access with the password authentication.

ID+P/W+F/P : In this mode, you can get access through the two-pass

authentication of the password and your fingerprint after

using the proximity card or entering the ID number.

When done, press

4.

READER #2 MODE

ENT

to save your settings.

READER#2 is an external reader for exit.

F

Press the

1.

Use the buttons

2.

press

3.

Use the buttons

1

SETUP MENU button.

4

ENT

and 6 to move to the READER#2 MODE item and

.

4

and 6 to select a reader mode.

2 modes are available for your choice.

ID ONLY : In this mode, you can get access only with the proximity card

•

or ID number.

ID+P/W : In this mode, you can get access through the password

authentication after using the proximity card or entering the ID

number.

When done, press

4.

ENT

to save your settings.

3. READER#1 MODE

ID ONLY

3. READER#1 MODE

JID+F/P(P/W)

3. READER#1 MODE

ID+F/P(P/W)

4. READER#2 MODE

ID ONLY

4. READER#2 MODE

JID+P/W

4. READER#2 MODE

ID+P/W

30_ reader mode setup

Page 31

READER #1 KEY INPUT

This enables you to use the keypad (numeric keypad) of READER #1 to enter the ID.

If you want to use the registered ID (card number or PIN) to get access, set this mode to USE.

F

Press the

1.

Use the buttons

2.

press

3.

Use the buttons

•

4.

When done, press

1

SETUP MENU button.

4

ENT

USE :

and 6 to move to the RD#1 KEY INPUT item and

.

4

and 6 to select the use of the keypad of READER#1.

If set, you can get access using the keypad input.

NOT USE : If set, you can not get access using the keypad input.

ENT

to save your settings.

5. RD#1 KEY INPUT

NOT USE

5. RD#1 KEY INPUT

J USE

5. RD#1 KEY INPUT

USE

READER MODE SETUP

READER #2 KEY INPUT

This enables you to use the keypad of READER #2 (numeric keypad of the external device) to enter the ID.

If you want to use the registered ID (card number or PIN) to get access, set this mode to USE.

F

Press the

1.

2.

Use the buttons

press

3.

Use the buttons

•

4.

When done, press

1

SETUP MENU button.

4

ENT

USE :

and 6 to move to the RD#2 KEY INPUT item and

.

4

and 6 to select the use of the keypad of READER#2.

If set, you can get access using the keypad input.

NOT USE : If set, you can not get access using the keypad input.

ENT

to save your settings.

6. RD#2 KEY INPUT

NOT USE

6. RD#2 KEY INPUT

J USE

6. RD#2 KEY INPUT

USE

English English _ 31

Page 32

reader mode setup

DUAL FINGERPRINT MODE

In Dual Fingerprint mode, you can register two fi ngerprints for one user ID.

If one of your fi ngers is damaged with Dual Fingerprint mode set to USE, you can use the other fi nger registered for the

authentication.

1.

2.

3.

4.

M

F10

Press the

Use the buttons

press

Use the buttons

•

USE : If set, you can use the Dual Fingerprint mode.

When done, press

SETUP MENU button.

4

ENT

NOT USE :

For registering fi ngerprints, see the following table.

DUAL FINGER Template/Fingerprint Count

and 6 to move to the DUAL F/P MODE item and

.

4

and 6 to select the use of Dual Fingerprint mode.

If set, Dual Fingerprint mode is disabled.

ENT

to save your settings.

NOT USE

USE

2 fi ngerprint templates for one fi nger

1 fi ngerprint template for each of 2 different fi ngers

1. DUAL F/P MODE

NOT USE

1. DUAL F/P MODE

JNOT USE

1. DUAL F/P MODE

USE

Success

Ratio

High Identifi cation mode

Low Verifi cation mode

Recommended

Authentication Mode

Make sure not to mix Dual Finger enable/disable confi gurations for multiple units.

J

Otherwise, it may degrade the recognition performance or cause data communication errors.

If you switch the Dual Finger setup from disabled to enabled, all systems should have the consistent setups and

registered fi ngerprints must be registered again. Switching to disabled requires the same.

Before registering fi ngerprints and transfer data, make sure to setup all systems to have consistent setting at the

beginning.

32_ reader mode setup

Page 33

ADAPTIVE MODE

In Adaptive mode, the fi ngerprint image will be automatically compensated in an attempt to increase the successful

recognition rate of fi ngerprint authentication.

F10

Press the

1.

Use the buttons

2.

press

3.

Use the buttons

•

USE : If set, you can use the Adaptive mode

4.

When done, press

M

SETUP MENU button.

4

ENT

NOT USE :

and 6 to move to the ADAPTIVE MODE item and

.

4

and 6 to select the use of Adaptive mode.

If set, Adaptive mode is disabled

ENT

to save your settings.

In Adaptive mode, it may take longer to recognize the fi ngerprint.

Registering and recognizing fi ngerprints in ADAPTIVE MODE, the red LED of the

2. ADAPTIVE MODE

NOT USE

2. ADAPTIVE MODE

JNOT USE

2. ADAPTIVE MODE

optical sensor blinks multiple times while capturing the fi ngerprint.

USE

READER MODE SETUP

IDENTIFICATION MODE

You can select the use of 1:N Identifi cation mode. In this mode, the product analyzes the input fi ngerprint against all of

registered fi ngerprint data without demanding the input of the card or ID number, then it decides to authorize or

unauthorized the access.

F10

Press the

1.

Use the buttons

2.

press

3.

Use the buttons

•

USE : If set, you can use the Identifi cation mode

4.

When done, press

SETUP MENU button.

ENT

NOT USE :

4

.

4

If set, Identification mode is disabled

and 6 to move to the IDENTIFICATION item and

and 6 to select the use of Identifi cation mode.

ENT

to save your settings.

3. IDENTIFICATION

NOT USE

3. IDENTIFICATION

JNOT USE

3. IDENTIFICATION

USE

English English _ 33

Page 34

user management

REGISTERING ID IN QUICK MODE

To register ID

F12

Press the

1.

Use the buttons

2.

press

3.

Use one of the following two ways to enter an ID:

•

Place the card on the main unit to display the card ID on the screen.

•

Use the keypad to enter the number and press

4.

Enter the password and select whether to use the fi ngerprint and press

•

Set FINGER to 0.

5.

ID registration is completed.

•

Registering in Quick mode will set TA and TB to 00, and RD, MA, MB, LV to 0.

(Refer to page 35.)

To register ID along with fi ngerprint

Repeat steps 1 through 3 in “To register ID” above.

SETUP MENU button.

4

ENT

and 6 to move to the REGISTRATION item and

.

(QUICK MODE)

1. REGISTRATION

ENT

.

ENT

1. REGISTRATION

ID:_

ENTER PIN

.

PUT ID CARD

1. REGISTRATION

ID:12345678

PASS WORD:_

FINGER :0-N, 1-Y

ID REGISTERED!

Enter the password and select whether to use the fi ngerprint and press

4.

•

Set FINGER to 1.

5.

Place your fi nger on the fi ngerprint scanner.

6.

Release your fi nger, then put your fi nger onto the fi ngerprint scanner again

when the light turns on.

7.

Your ID and fi ngerprint are registered.

34_ user management

ENT

.

TO REGISTER F/P

PUT YOUR FINGER

LIFT AND

PUT YOUR FINGER

FP QUALITY

Q_#1[4] Q_#2[4]

ID REGISTERED!

1/2

2/2

Page 35

REGISTERING THE ID

To register the ID card

F

Press the

1.

Use the buttons

2.

press

3.

Press the button

•

7

SETUP MENU button.

4

ENT

and 6 to move to the REGISTRATION item and

.

1

to select CARD.

For card registration, select the card to register the ID.

For PIN registration, select PIN and use the keypad to register the ID.

4.

Put the card onto the main unit to display the card ID on the screen.

5.

Set each of PW/TA/TB/C/RD/MA/MB/LV/FP.

•

For more information about each item, refer to “ID Registration Items” below.

•

Set FP to 0.

6.

ID registration is completed.

ID Registration Item (PW /TA/TB/C/RD/MA/MB/LV/FP)

❖

Item Description

PW

4-digit password used in ID+PW

TA

Time schedule code for READER#1 (Internal reader)

TB

Time schedule code for READER#2 (external reader)

Permission code for the user ID

NO Description

0

1

C

2

3

4

Reader assignment to the card user

NO Description

RD

MA

0

1

2

3

READER#1 operation mode for the registered user

NO Description

0

1

2

3

Normal card

2-person authentication (administrator)

2-person authentication (visitor)

Set ARM/DISARM

Missing card

READER#1, READER#2 assigned

READER#1 assigned

READER#2 assigned

READER#1, READER#2 assigned

System Operation Mode

ID mode

ID+F/P(P/W)

ID+F/P+P/W

1. REGISTRATION

1. REGISTRATION

1:CARD 2:PIN

1. REGISTRATION

SCANNING…

1. REGISTRATION

ID:1230001

PW_ TA TB C

RD MA MB LV FP

ID REGISTERED!

Item Description

READER#2 operation mode for the registered user

NO Description

MB

LV

FP

0

1

2

Output operation level for the registered user

NO Description

0

1

2

3

4

Use/disuse of fi ngerprint

NO Description

0

1

System Operation Mode

ID mode

ID+P/W

Output Level 1 on access authentication

Output Level 1 on access authentication

Output Level 2 on access authentication

Output Level 3 on access authentication

Output Level 4 on access authentication

Fingerprint not used.

Fingerprint used.

English English _ 35

USER MANAGEMENT

Page 36

user management

To register the ID card along with your fi ngerprint

Follow the steps 1 through 4 in “To register the ID card” above

Set each of PW/TA/TB/C/RD/MA/MB/LV/FP.

5.

For more information about each item, refer to “ID Registration Items” on

•

page 35.

Set FP to 1.

•

ENT

Press

•

Place your fi nger on the fi ngerprint scanner.

6.

Release your fi nger, then put your fi nger onto the fi ngerprint scanner

7.

again when the light turns on.

Your ID and fi ngerprint will be registered.

8.

To register the PIN number

1.

Press the

.

F

7

SETUP MENU button.

TO REGISTER F/P

1/2

PUT YOUR FINGER

2/2

LIFT AND

PUT YOUR FINGER

FP QUALITY

Q_#1[4] Q_#2[4]

ID REGISTERED!

2.

Use the buttons

ENT

press

3.

Press the button

•

For card registration, select the CARD to register the ID.

For PIN registration, select PIN and use the keypad to register the ID.

4.

Use the keypad to enter the ID and press

5.

Set each of PW/TA/TB/C/RD/MA/MB/LV/FP.

•

For more information about each item, refer to “ID Registration Items” on

page 35.

•

Set FP to 0.

6.

ID registration is completed.

You can use the keypad to enter the ID in the following digits depending on the

M

model.

- PIN Range

SSA-S30x0 : Numeric letters in 4 ~ 8 digits

Ranges from 00000001 to 99999999

SSA-S30x1 : Numeric letters in 4 ~ 8 or 10 digits

36_ user management

4

and 6 to move to the REGISTRATION item and

.

2

to select PIN.

Ranges from 0001 to 99999999, 0000000001 to 4294967295

1. REGISTRATION

1. REGISTRATION

ENT

.

1:CARD 2:PIN

1. REGISTRATION

ID:

1. REGISTRATION

ID:1230001

PW_ TA TB C

RD MA MB LV FP

ID REGISTERED!

Page 37

To register the PIN number along with your fi ngerprint

Follow steps 1 through 4 in “To register the PIN number” above.

Set each of PW/TA/TB/C/RD/MA/MB/LV/FP.

5.

For more information about each item, refer to “ID Registration Items” on

•

page 35.

Set FP to 1.

•

ENT

Press

•

Place your fi nger on the fi ngerprint scanner.

6.

Release your fi nger, then put your fi nger onto the fi ngerprint scanner

7.

.

again when the light turns on.

Your ID and fi ngerprint will be registered.

8.

TO REGISTER F/P

PUT YOUR FINGER

LIFT AND

PUT YOUR FINGER

FP QUALITY

Q_#1[4] Q_#2[4]

ID REGISTERED!

TO DELETE ID

A registered ID can be deleted by entering the ID using the card or keypad in ID DELETE mode.

The number of the ID to delete will be displayed on the screen.

F

Press the

1.

7

SETUP MENU button.

1/2

USER MANAGEMENT

2/2

2.

Use the buttons

ENT

.

3.

Enter the ID to delete, and press

•

If you enter the card, you don’t need to press

4.

When the ID is deleted, you will see a message of “ID DELETED!!!” on the

screen.

4

and 6 to move to the ID DELETE item and press

ENT

.

ENT

.

2.ID DELETE

2.ID DELETE

ENTER PIN

J_

ID DELETED!!!

If the entered ID is not registered with the product, you will see a message of “UNREGISTERED ID” on the screen.

M

If an ID that is out of the acceptable range is entered , “INVALID NUMBER” message appears.

The ID DELETE menu in QUICK MODE under [F12] is the same as ID DELETE under [F7].

English English _ 37

Page 38

user management

VIEWING THE ID LIST

You can check the list of IDs registered with the product.

F

Press the

1.

7

SETUP MENU button.

Use the buttons

2.

3.

The list of registered IDs appears on the screen.

•

The list of registered IDs appears on the screen.

ID INDEX : Number of registered items

ID : ID number

C : ID permission code

PW : password

TA : Time schedule of READER #1

TB : Time schedule of READER #2

RD : Readers accessible

MA : Operation mode of READER #1

MB : Operation mode of READER #2

LV : Output level

FP: Use/disuse of fi ngerprint(0:disuse, 1:Use)

Use the buttons

4.

The “EMPTY” message will appear if there is no user ID registered.

M

The “FIRST ID” message indicates that the ID displayed on the screen is the fi rst one.

The “LAST ID” message indicates that the ID displayed on the screen is the last one.

4

and 6 to move to the ID LIST item and press

4

and 6 to check other registered IDs.

TO CHECK THE NUMBER OF REGISTERED IDs

You can check the total number of registered IDs.

ENT

.

3.ID LIST

ID INDEX:00001

ID:12300001 C:0

PW0000 TA00 TB00

RD0 MA0 MB0 LV1 FP1

F

Press the

1.

2.

Use the buttons 4 and 6 to move to the REG. ID COUNT item and

press

3.

The number of registered IDs will be shown on the screen.

M

7

SETUP MENU button.

ENT

.

The number of registered IDs will be displayed in 5 digits.

38_ user management

5. REG. ID COUNT

00123

Page 39

TO REMOVE ALL REGISTERED IDs

You can remove all of the registered user IDs.

F

Press the

1.

2.

Use the buttons 4 and 6 to move to the ALL ID CLEAR item and

press

3.

Press the button 1 to delete all registered IDs.

•

J

8

SETUP MENU button.

ENT

.

0

To cancel the work, press the button

Please upload the ID data to the host PC before deletion, just for backup purposes.

.

USER MANAGEMENT

3. ALL ID CLEAR

3. ALL ID CLEAR

1:YES, 0:NO

TO CHECK THE NUMBER OF REGISTERED FINGERPRINTS

You can check the total number of registered fi ngerprints.

F10

Press the

1.

2.

Use the buttons 4 and 6 to move to the FP REG. COUNT item and

press

The number of registered / total recordable fi ngerprints will be shown.

3.

SETUP MENU button.

ENT

.

4. FP REG. COUNT

4. FP REG. COUNT

0021 / 1000

English English _ 39

Page 40

user management

TO REMOVE THE MASTER IDs

If you want to remove all master IDs (card IDs), use this menu.

F

Press the

1.

2.

Use the buttons 4 and 6 to move to the MASTER ID CLR item and

press

3.

Press the button 1 to delete all registered master IDs.

•

J

DURESS MODE

You can set Duress Mode for READER#1. Duress mode is a special feature that outputs a special alarm signal when a

it is forced to open the restricted area, whose default is NOT USE. When selecting USE, you are prompted to enter the

two-digit numbers for the Duress mode password, whose default is ‘00’.

If it is set to USE, enter the two-digit Duress password and press

alarm signal is transmitted to the host PC.

Press the

1.

8

SETUP MENU button.

ENT

.

0

To cancel the work, press the button

Before removing all master IDs, ensure that the master IDs are no longer in use.

F

2

SETUP MENU button.

.

ENT

; this will open the door normally, but the Duress

4. MASTER ID CLR

4.MASTER ID CLR

1:YES, 0:NO

Use the buttons

2.

3.

4.

5.

M

ENT

press

Use the buttons

•

NOT USE

USE : If set to USE, proceed with the followings:

The DURESS password is shown.

ENT

Press

Enter the two-digit password and press

The Duress Mode password should be different from the Arm/Disarm code.

You can specify the output time for each signal out for Duress Alarm.

47 for “Duress Mode Output Setup”.)

4

.

4

: Duress Mode is disabled.

.

40_ user management

and 6 to move to the DURESS MODE item and

and 6 to select USE.

ENT

.

(See Page

6.DURESS MODE

J NOT USE

6.DURESS MODE

J USE

DURESS PASSWORD

00

ENTER DURESS P/W

█

Page 41

DOOR OPEN ALARM TIME SETUP

In this menu, you can set the delay time until the product triggers the door open alarm if the door stays open after the Door

Relay time. To use this function, the Door Contact sensor should have been installed on the entrance door. (see page 17)

The default is ‘03’.

F

Press the

1.

2.

Use the buttons 4 and 6 to move to the OPEN ALR TIME item and

press

3.

Use the keypad to enter the time in two digits and press

•

2

SETUP MENU button.

ENT

.

ENT

.

00 : The alarm will sound shortly if the door stays open after the Door Relay

Time.

01~ 98 : The alarm will sound shortly if the door stays open after both of

Door Relay time and Door Delay alarm. (01~98 seconds)

99 : The Door Open alarm will not sound.

To use this function, the Door Contact sensor should have been installed on the entrance door.

M

8.OPEN ALR TIME

03

8.OPEN ALR TIME

10

USER MANAGEMENT

ARM/DISARM

With the ARM/DISARM code active, you can set the ARM mode by entering the ARM code and presenting the card

(assigned Code 3 in registration) of a person who has the ARM/DISARM permissions. In this mode, all connected readers

will not take the card input any further. To release the ARM mode, enter the DISARM code and present the ARM/DISARM

card.

F

Press the

1.

2.

Use the buttons 4 and 6 to move to the ARM/DISARM SET item

and press

You are prompted to enter the ARM code.

3.

Use the keypad to enter the ARM code in two digits and press

You are prompted to enter the DISARM code.

4.

3

SETUP MENU button.

ENT

.

ENT

Use the keypad to enter the DISARM code in two digits and press

The Arm/Disarm code should be different from the Duress Mode password.

M

You can specify the output time for each signal out when ARM function is enabled.

(See Page 47 for “ARM/DISARM Output Setup”.)

2.ARM/DISARM SET

00/00

.

ARM CODE

ENT

.

00

DISARM CODE

00

English English _ 41

Page 42

user management

TWO MEN OPERATION MODE

With TWO MEN MODE active, the door will be opened if both administrator card and visitor card are entered in a row

within 10 seconds.

F

1.

Press the

2.

Use the buttons 4 and 6 to move to the TWO MEN MODE item and

press

3.

Use the buttons

•

M

TO CHECK THE NUMBER OF EVENTS

You can check the total number of events stored in the memory. When an event is stored in the memory, the count will

increase accordingly.

The total number of events is 20,000.

Once a specifi c event is uploaded successfully to the host PC, it will be removed from the internal memory.

3

SETUP MENU button.

ENT

.

4

and 6 to select USE or NOT USE, and press

USE

: TWO MEN MODE is enabled.

NOT USE : TWO MEN MODE is disabled.

To enable this function, the preferred administrator card should be assigned code 1, while the visitor card be

assigned code 2. (See Page 35 for “Registering the ID ”.)

3.TWO MEN MODE

J NOT USE

ENT

.

3.TWO MEN MODE

J USE

F

Press the

1.

2.

Use the buttons 4 and 6 to move to the EVENT COUNT item.

3.

The number of events stored in the memory will be shown.

M

7

SETUP MENU button.

To remove the event, refer to “To delete all events”. (see page 43)

The number of registered IDs will be displayed in 5 digits.

When the memory is full, please refer to “Event Memory Setup”. (see page 61)

42_ user management

6.EVENT COUNT

00014

Page 43

TO REMOVE ALL EVENTS

If the event memory is full or you want to change the number of IDs, you can use this menu to clear the event memory.

F

Press the

1.

2.

Use the buttons 4 and 6 to move to the EVENT CLEAR item and

press

3.

Press the button 1 to remove all events.

•

8

SETUP MENU button.

ENT

.

To cancel the work, press the button 0.

2.EVENT CLEAR

1:YES, 0:NO

DELETE ALL EVENT

WAIT…

To reserve the events, upload them to the host PC before deletion.

J

TO REMOVE THE TIME SCHEDULE

All time schedules (01~10), all holiday schedules (01~10), holiday codes, and time schedules for reader#1 and reader#2

modes can be deleted. With the

0

button to cancel the work.

ENT

button pressed, press the 1 button to remove all time schedules or press the

USER MANAGEMENT

F

Press the

1.

2.

Use the buttons 4 and 6 to move to the T/S CLEAR item and

press

3.

Press the button 1 to remove all time schedules.

•

•

J

8

SETUP MENU button.

ENT

.

0

To cancel the work, press the button

.

You will see the message as shown at the right.

Before removing all time schedules, ensure that they are no longer in use.

5.T/S CLEAR

1:YES, 0:NO

DELETE TS

WAIT…

English English _ 43

Page 44

I/O time setup

EXIT BUTTON OUTPUT

F

Press the

1.

Use the buttons 4 and 6 to move to the EXIT BUTTON item and

2.

press

3.

You can make input when the prompt blinks.

•

M

DOOR CONTACT SENSOR SETUP

You can specify the signal output if a door is forcibly opened without through the normal authentication process. (The Door

Contact sensor should have been installed.)

5

SETUP MENU button.

ENT

.

Use the keypad to enter the time for each output operation and press

DR : Door relay output

AR : Alarm relay output

T1 : TTL #1 output

T2 : TTL #2 output

BZ : Buzzer output

The output time differs, depending on the time unit.

If the time unit is 0.1 (second), you can specify the value between 0.0 and 9.8 second; if set to 1 (second), you can

specify between 0 and 98 seconds.

For the time unit, refer to the ‘Time Unit Setup’ under the advanced setup. (see page 54)

If you enter 99 for the value, the product stays in output mode until you change the setting regardless of the time

unit.

1.EXIT BUTTON

DR AR T1 T2 BZ

03 00 00 00 00

ENT

.