Page 1

USER’S MANUAL

SRP-770II

LABEL PRINTER

ٻ

KA04-00019E

Rev. 1.02

www.samsungminiprinters.comٻ

ٻ

ڌ

Page 2

Safety Precautions

ٻ

ٻ

ٻ

ٻ

ٻ

ٻ

ٻ

In using the present appliance, please keep the following safety

regulations in order to prevent any hazard or material damage.

WARNING

Violating following instructions can cause serious injury or death.

Do not plug several products in one

multi-outlet.

This can provoke over-heating and a fire.

If the plug is wet or dirty, dry or wipe it

before usage.

If the plug does not fit perfectly with the

outlet, do not plug in.

Be sure to use only standardized

multi-outlets.

PROHIBITED

Do not pull the cable to unplug.

This can damage the cable, which is the

origin of a fire or a breakdown of the printer.

PROHIBITED

Do not plug in or unplug with your hands

wet.

You can be electrocuted.

PROHIBITED

You must use only the supplied adapter.

It is dangerous to use other adapters.

Keep the plastic bag out of children’s reach.

If not, a child may put the bag on his head.

PROHIBITED

If you observe a strange smoke, odor or

noise from the printer, unplug it before

taking following measures.

Switch off the printer and unplug the set

from the mains.

After the disappearance of the smoke, call

your dealer to repair it.

ONLY SUPPLIED ADAPTER

WARNING

Violating following instructions can cause slight wound or damage the appliance.

Keep the desiccant out of children’s

reach.

If not, they may eat it.

PROHIBITED

Use only approved accessories and do

not try to disassemble, repair or remodel

it for yourself.

Call your dealer when you need these

services.

DISASSEMBLING

PROHIBITED

Do not let water or other foreign objects

in the printer.

If this happened, switch off and unplug the

printer before calling your dealer.

PRINER

Install the printer on the stable surface.

If the printer falls down, it can be broken

and you can hurt yourself.

PRINTER

PROHIBITED

Do not use the printer when it is out of

order. This can cause a fire or an

electrocution.

Switch off and unplug the printer before

calling your dealer.

TO UNPLUG

PRINTER

DEALER

Do not bend the cable by force or leave it

under any heavy object.

A damaged cable can cause a fire.

PROHIBITED

ٻ

TO UNPLUG

ڍٻ

PRINTER

PROHIBITED

ٻ

PRINTER

ڎ

Page 3

Table of Contents

(

)

(

)

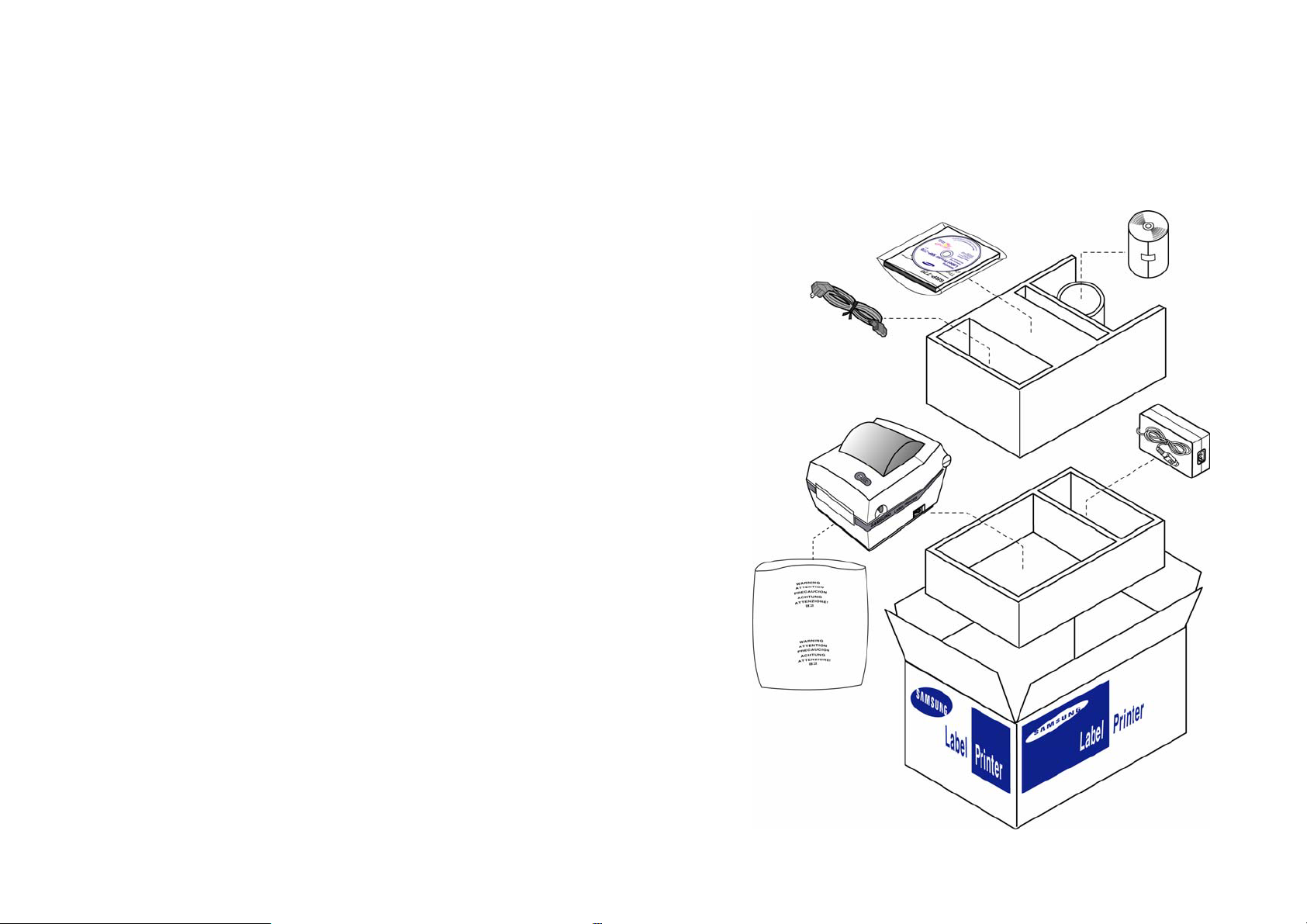

1. Unpacking & Repacking

Your printer box should include these items. If any items are damaged or missing,

please contact your dealer for assistance.

1. Unpacking & Repacking......................................................................... 5

2. Samsung Label Printer ................................................................... 6

3. Connecting the Power Supply......................................................7

4. Connecting the Interface Cable .................................................. 8

5. Installing or Replacing the Paper Roll...................................... 9

6. Setting the Dip Switches .............................................................10

7. The Self Test.....................................................................................11

8. LED Display .......................................................................................12

9. Pause / Restart ............................................................................... 12

ٻ

10. Gap sensor auto-calibration

.....................................................13

ٻ

11. The Peel-off

....................................................................................14

12. Using Fan Fold Paper ..................................................................15

Note : Please keep the packing materials(ྙ,ྚ,ྜ,ྞ) for future repacking to send

a printer for repairs.

ľ Operator’s Manual & CD

Ľ Power Cord

Ļ Printer (SRP-770)

Ŀ Label

(Paper)

ļ Cushion

TOP

Ĺ Power Supply

ĸ Cushion

Bottom

ٻ

13. Auto Cutter (Option)...................................................................16

ٻ

14. Cleaning Head

ٻ

15. Memory Switch Setting

16.

Install and Uninstall Windows Driver

ٻ

...............................................................................17

..............................................................18

...........................................20

ڏٻ

ĺ Pe-bag

ķ Printer Box

You can repack the printer package in above numeric order(ķ~Ŀ)

ٻ

ڐ

Page 4

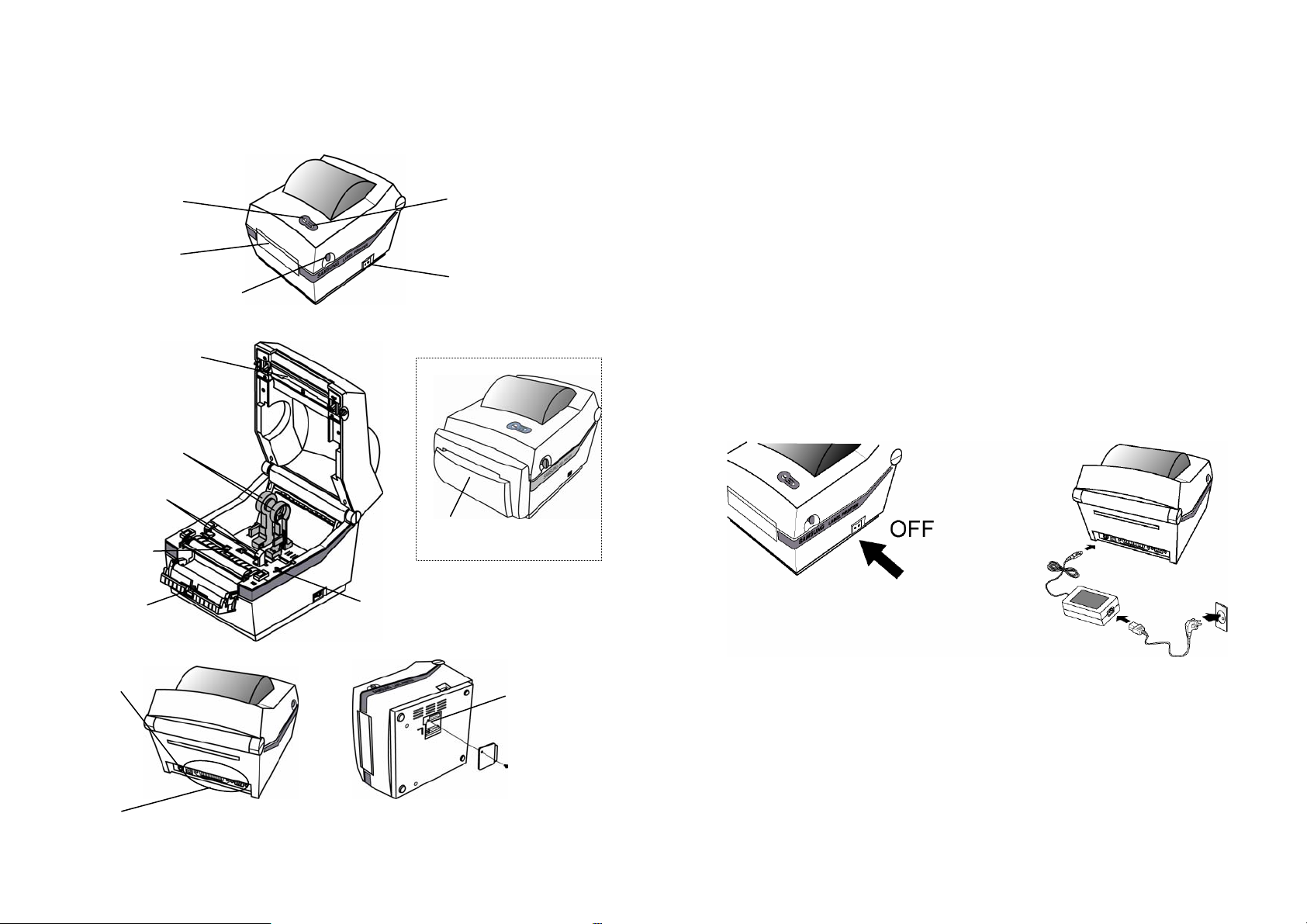

2. Samsung Label Printer

OvPG

Feed Button

Cover Peel-off

Cover Open/Close

Printer Head

Paper Holder

Paper Guide

Paper(gap) Sensor

Status Indicator

Power Switch

Auto Cutter

3. Connecting the Power Supply

CAUTIONS:

When connecting or disconnecting the power supply from the printer, make sure that

the power supply is not plugged into an electrical outlet. And the power supply’s

rated voltage and your outlet’s voltage do not match, contact your dealer for

assistance. Then do not plug in the power cord. Otherwise, you may damage the

power supply or the printer.

1. Make sure that the printer’s power switch is turned off, and the power supply’s power

cord is unplugged from the electrical outlet.

2. Check the label on the power supply to make sure that the voltage required by the

power supply matches that of your electrical outlet.

3. Plug in the power supply’s cable as shown below. Notice that the flat side of the

plug faces down.

Peel-off Sensor

Power Connector

Interface Connectors

[RS-232C, IEEE1284, USB]

ٻ

ڑٻ

Paper Adjuster

Dip Switch

ٻ

ڒ

Page 5

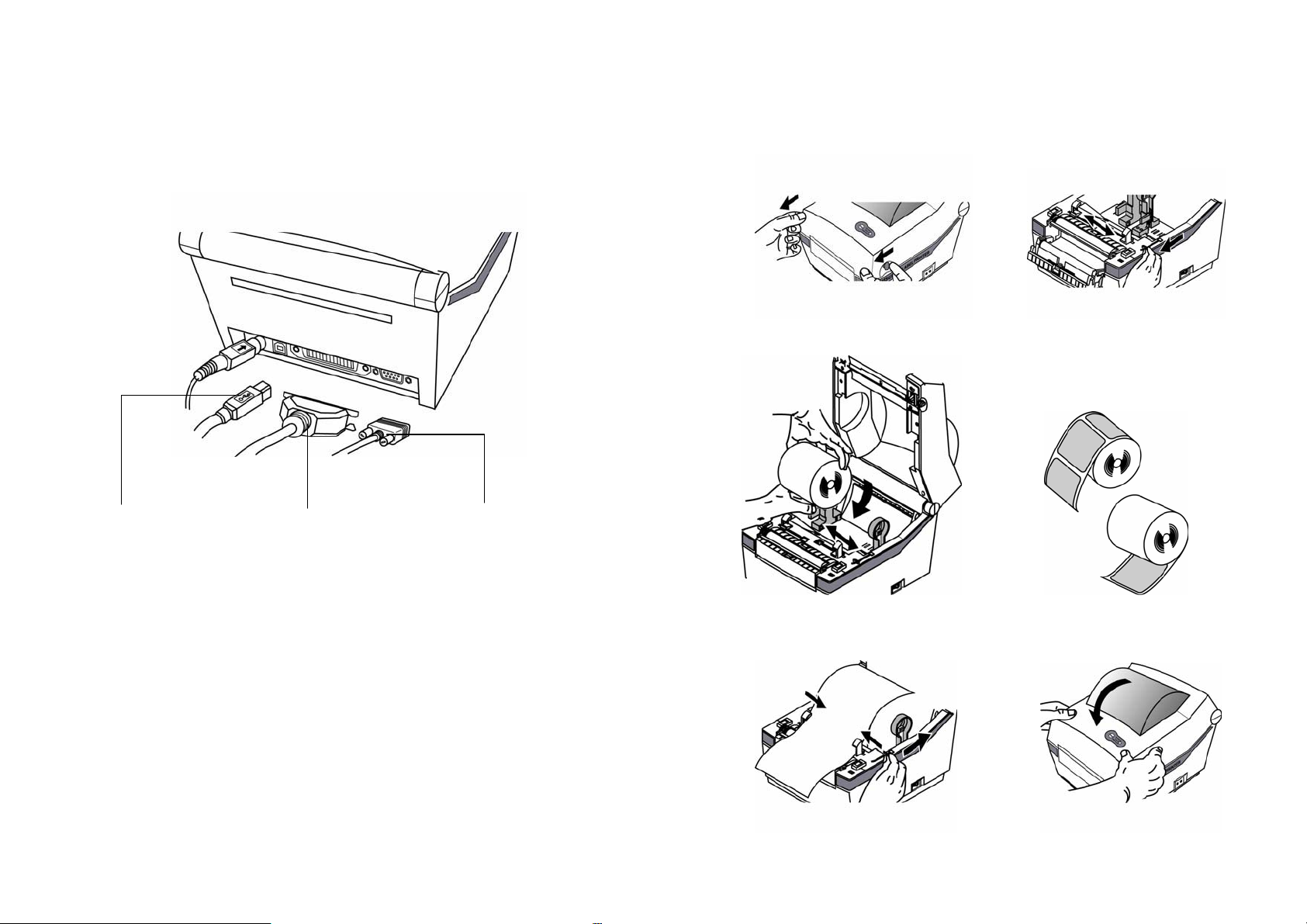

4. Connecting the Interface Cable

5.

Installing or Replacing the Paper Roll

1. Open Cover 2. Open Guides

3. Install Roll

Universal Serial Bus

(USB)

ٻ

ٻ

Parallel Interfaceٻ

ٻ

ړٻ

Serial Interface

RS-232 default

setting is 19200 baud,

no parity, 8 data bits

and 1 stop bit

ٻ

4. Close Guides to the Width of the paper

ٻ

5. Close Cover

ڔ

Page 6

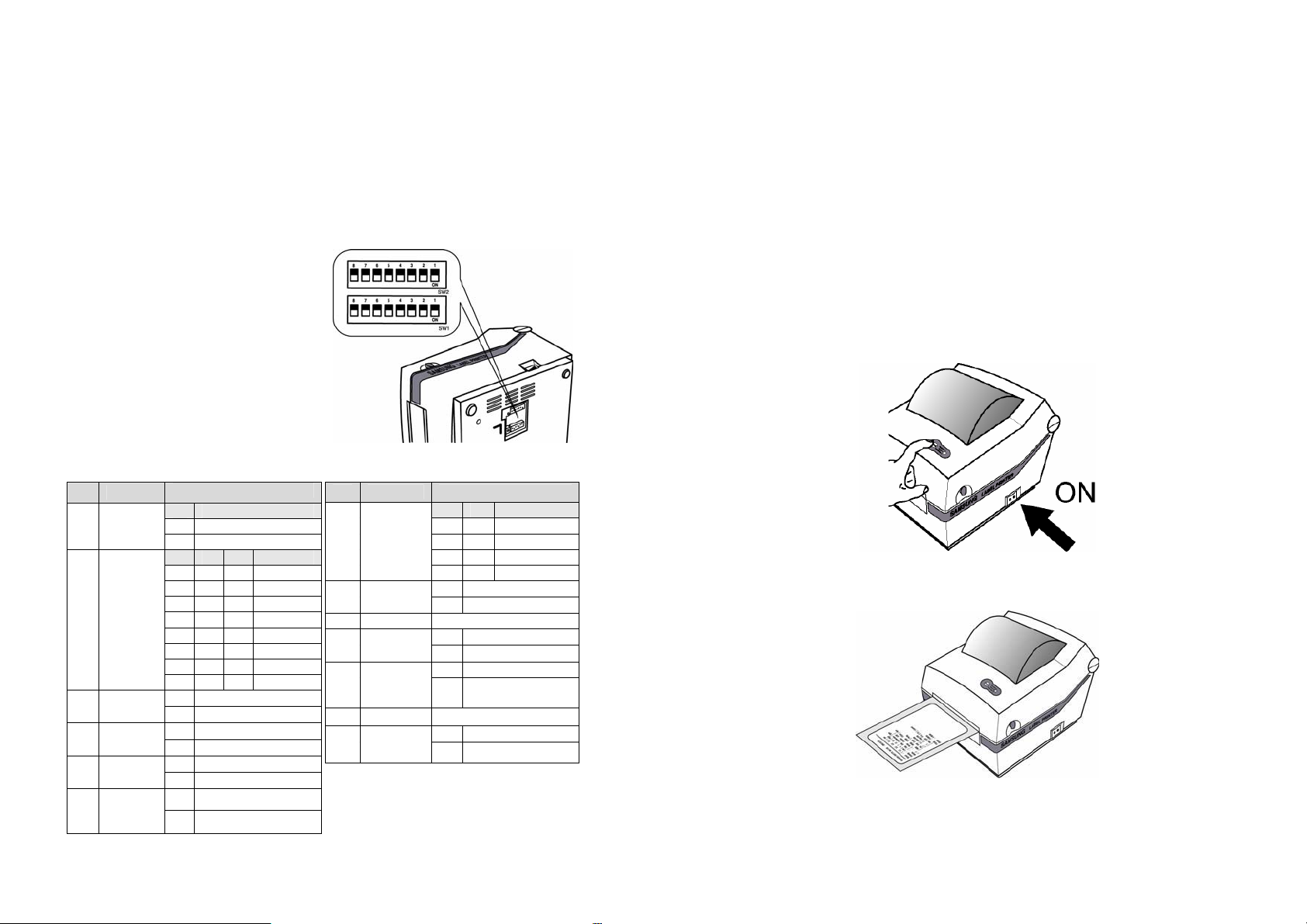

6. Setting The Dip Switches

7

. The Self Test

6-1. Setting the Dip Switches

The Dip Switches are located on the bottom of the printer. The Dip Switches are used to

set the Printer to perform various functions. Follow these steps when changing Dip

Switches setting :

1. Turn the printer power switch off.

2. Remove the screw on the bottom

of the printer and open the bracket.

3. Flip the Dip Switches using tweezers

or another narrow-ended tool.

Switches are off when up and on

when down in the Figure below.

4. The new setting takes effect

when you turn on the printer.

Note : Always change Dip Switch settings

only when the printer is turned off.

6-2. Functions of Dip Switches

6-2-1. Dip S/W 1 6-2-2. Dip S/W 2

No Functions

Speed

1

Selection

2

Density

3

Selection

4

Exhibition

5

Selection

Media

6

Selection

7 Auto Cutter

Near End

8

Sensor

Status

Details

1 Speed

Off 4.0 ips

On 5.0 ips

4 3 2 Density

Off Off Off 13

Off Off On 14

Off On Off 15

Off On On 16

On Off Off 17

On Off On 18

On On Off 19

On On On 20

Off Normal mode

On Demo mode

Off Label Paper

On

Thermal Continuous Paper

Off Without Auto Cuter

On With Auto Cutter

Off Enable

On Disable

No Functions Details

2 1 Baud Rate

1,2

Baud

Rate

Media

3

Detection

4 Reserved --

5 Emulation

Busy

6

Condition

7 Reserved --

Long label

8

Split printing

Off Off 9,600 bps

Off On 19,200 bps

On Off 57,600 bps

On On 115,200 bps

Off Detect Gap

On Detect Black-mark

Off SAMSUNG command

On Emulation

Off Receive Buffer Full

On

Off Disable

On Enable

*Offline

*Receive Buffer Full

ٻ

The self-test checks whether the printer has any problems. (You cannot perform this

procedure if using the printer’s label peel-off option) If the printer does not function

properly, contact your dealer. The self-test checks the following;

1. Make sure that paper roll has been installed properly.

2. Turn on the power while holding(2sec) down the FEED button. The self-test begins.

3. The self-test prints the current printer status, which provides the control ROM version

and the DIP switch setting.

ٻ

ڌڋٻ

ٻ

ڌڌ

Page 7

8. LED Display

10. Gap Sensor Auto-Calibration

LED display indicates the printer status.

1. Green LED on

- The printer waits for the data from Host (PC) in normal mode.

2. Orange LED on

- It means paper gap sensing error. It becomes on when the printer fails to detect the

paper or paper jam occurred. When fails to detect the paper correctly use

Auto-Calibration function.

3. Red LED on

- The printer has stopped by pressing FEED button. It restarts printing when pressed

again.

4. Green LED blinking

1) TPH (Thermal Printing Head) overheated or ;

2) The printers is waiting for the button input to run Auto-Calibration function.

5. Orange LED blinking

- No paper. Make sure the paper is loaded correctly.

6. Red LED blinking

1) The printer cover is open or ;

2) Auto cutter has error such as paper jam in case of auto cutter built-in model.

9. Pause / Restart

Gap sensor auto-calibration is used when the printer does not detect a gap on the label

paper correctly. Generally a printer is set to detect most of gap types but sometimes it fails

to detect and keep feeding the paper without a stop when special paper used. In such case,

use gap sensor auto-calibration function for a proper detection.

1. Make sure that paper roll has been installed properly.

2. Turn on the power while holding down FEED button with cover open.

Then the Green LED blinks.

O

n

3. Close the cover and guide message is printed automatically.

Then a printer waits for input with red LED on.

4. Press FEED button once to initialize gap sensor and set it back to the

factory setting. LED changes to Orange.

5. Press FEED button twice to run auto-calibration function.

LED changes first to Orange and second to Green.

It feeds 2-3 papers while auto-calibration executed.

Make sure to press a button one by one while checking LED changes.

6. Saved sensing value remains valid at power off unless otherwise above

gap sensor initialization is executed again.

Press FEED button to pause at the middle of labels printing.

1. Pause

- Press FEED once. Printer stops after on-going printing and Red LED becomes on.

2. Restart

- Press FEED once again. It restarts printing in a queue.

ٻ

ڌڍٻ

ٻ

ڌڎ

Page 8

11. The Peel-off

12. Using Fan Fold Paper

This function is used to separate label from liner automatically.

CAUTIONS:

1) Peeler is for Label Paper only.

2) When the peeler switch is on, label is not printed before when

the previous printed label is taken off from the peeler.

3) When the peeler function is not used set peeler switch off.

With this switch on printer may not work correctly.

1. Open the peel-off cover and turn on peeler switch.

(Check if Peeler LED is on.)

2. Remove the paper and 3. Adjust the paper guides and close the cover.

insert the paper through slot.

Insert paper through both the rear slot and guides.

Adjust holders and guides to the width of the paper.

Open the Dust Cover

and Insert paper

Adjust holders papers and paper Fixed Adjust Guides

ٻ

Dust Coverٻ

remove

4. Turn off and on the printer.

ٻ

ڌڏٻ

Paper Fixed

ٻ

ڌڐ

Page 9

13. Auto Cutter (Option)

䧎

14. Cleaning Head

Auto cutter should be used for continuous paper only. ( i.e. roll paper)

1. Open the Dip switch cover, and make the switch 1 number 7 “On”.

(Refer to printer mode setting at Chapter 6.)

2. Put a paper roll into the printer and close the cover.

CAUTIONS: (Partial cut)

Once the printer cut the paper, remove the receipt in order for next printing.

Otherwise the receipt could be back into the printer and the cutter would

cut it again.

Paper dust on the heating elements may lower the printer quality. In this case, clean the

print head as follows :

CAUTIONS:

1) Turn Off the printer power before cleaning.

2) Note that the thermal head becomes very hot during normal operation,

creating the danger of burn injury. Be sure to wait for about 2~3 minutes

after turning printer power off before beginning the cleaning.

1. Open the printer cover.

2. Clean the thermal element (the area which is marked a thin black line) of the thermal

head with a cotton swab moistened with a alcohol solvent (ethanol, methanol, or IPA).

3. After confirming that the alcohol solvent has been dried up completely, close the

cover-open.

Note 1) Never touch the thermal element with your hand,

then the thermal element can be damaged.

2) Don’t scratch the printer head.

Clean it up when you replace every roll of paper to prevent the quality

deterioration.

ٻ

ڌڑٻ

ٻ

ڌڒ

Page 10

15. Memory Switch Setting

1. Models : SRP-770II, SRP-780

2. Features

It helps users through the setting of code pages, serial setting, paper size and print

density as necessary.

3. How to use

ཛ Press Get Status button and it displays the current setting.

ٻ

ڌړٻ

ཛྷ Press Set Status button after changing the setting as you need.

Then it saves as default.

ٻ

ڌڔ

Page 11

16.

Install and Uninstall Windows Driver

13.1 Download install-program from Website

(1) Execute web-browser.(Ex: Internet Explorer)

(2) Type http://www.bixolon.com

(3) Connect website.

(4) In “Quick menu”, click download button.

(5) Download “SRP-770II_V3.X.X.exe” in SRP-770II section.

13.2 Install Windows Driver

13.2.1 Serial Parallel interface

(1) Double click “SRP-770II_V3.X.X.exe” file.

(2) Click “Next” Button.

(3) Click “Install” Button.

(4) Select operating system type.

ٻ

ڍڋٻ

ٻ

ڍڌ

Page 12

(5) Select interface (port) type.

(6) Please click “Continue Anyway”.

13.2.2 USB interface

A. Windows 95/98/ME

(1) Double click “SRP-770II_V3.X.X.exe” file.

(2) Click “Next” Button.

* If you can see this dialog, don’t worry comment of dialog. Printer and

driver works well. Please click “Continue Anyway” button.

(7) Please reboot computer.

ٻ

ڍڍٻ

ٻ

ڍڎ

Page 13

(3) Click “Install” Button.

(5) Select “USB” interface (port) type.

(6) Please turn-off printer and turn-on printer.

(4) Select operating system type.

ٻ

ڍڏٻ

(7) When “Add new hardware wizard” for install “USB print support” driver pops up,

click “Next” button.

ٻ

ڍڐ

Page 14

(8) Please click “Next” button three times.

(9) When “USB print support” driver is installed, your system automatically restart

after 10 seconds.

(10) After the system restart, please turn-on printer.

B. Windows NT/2000

(1) Double click “SRP-770II_V3.X.X.exe” file.

(2) Click “Next” Button.

(3) Click “Install” Button.

(4) Select operating system type.

ٻ

ڍڑٻ

ٻ

ڍڒ

Page 15

(5) Select “USB” interface (port) type.

(6) Please turn-off printer and turn-on printer.

C. Windows XP/2003 Server

(1) Double click “SRP-770II_V3.X.X.exe” file.

(2) Click “Next” Button.

(3) Click “Install” Button.

* If you can see this dialog, don’t worry comment in dialog.

Printer and driver work well. Please click “Yes” button.

ٻ

ڍړٻ

ٻ

ڍڔ

Page 16

(4) Select operating system type.

(5) Select “USB” interface (port) type.

(6) Please turn-off printer and turn-on printer.

(7) If “Add new hardware wizard” for install “SAMSUNG SRP-770II” driver pops up,

click “Next” button.

* If you can see this dialog, don’t worry comment in dialog.

Printer and driver work well. Please click “Continue Anyway” button.

ٻ

ڎڋٻ

ٻ

ڎڌ

Page 17

(8) Please click “Next” button until you can see “Finish” button.

*If you can see this dialog, don’t worry comment in dialog.

Printer and driver work well. Please click “Continue Anyway” button.

(9) Please click “Finish” button.

13.3 Uninstall Windows Driver

(1) Click on the Start button, and then click on Settings > Control Panel.

(2) Double click “Add/Remove Programs” icon.

(3) Select “BIXOLON SAMSUNG SRP-770II POS Windows Driver 3.X.X”.

(4) Click “Change/Remove” button.

(5) Select printer to remove.

(6) Click “Uninstall” Button.

(7) Please reboot computer.

ٻ

ڎڍٻ

ٻ

ڎڎ

Page 18

13.4 Printer Settings

7) Customer Paper Size

a) Add Customized Form: Create new customized form. Customer must type

“Form Name”, “Width” and “Length”. Width and Length in customized form

1) Measurement: Select measurement of “Top Margin”. (Inch or millimeters)

2) Top Margin: top margin value of paper

3) Density: Select density of printing quality. (0 ~ 20)

4) Media Type: Select paper media type. (“Black Mark” is under development)

5) Orientation: Set printing direction.

6) Speed: Set printing speed. (2.5 ~ 3.0)

ٻ

ڎڏٻ

ٻ

must be the number in the range from Minimum to Maximum size.

b) Delete Customized Form: You can delete customized form but default form

may not be deleted.

c) Exit Program: Exit utility program.

ڎڐ

Page 19

ૺ

Specification

ૻ

Printing method Thermal line printing

Dot density 203 dpi (8 dot/mm)

Printing width 25.4 ~ 101.6 mm

Paper width 38.1 ~ 104 mm

Printing speed 127 mm/sec

Receive Buffer Size 32K Byte

Note : Printing speed can be different, depending on the data transmission speed

and combination of control commands.

Input voltage 100~240V AC

Supply voltage

Environmental

conditions

LIFE Mechanism Head

MCBF Mechanism 20,000,000 lines

Frequency 50/60 Hz

Output voltage DC 24V

Temperature

Humidity

5 ~ 45 (Operating)

-25 ~ 70 (Storage)

30 ~ 80 % RH (Operating)

10 ~ 90 % RH (Storage)

; Except for paper

10,000,000 lines

5×10

7

pulse (50km)

This marking shown on the product or its literature, indicates that is should not

be disposed with other household wastes at the end of its working life, To

prevent possible harm to the environment or human health from uncontrolled

responsibly to promote the sustainable reuse of material resources. Household users should

contact either the retailer where they purchased this product, or their local government

office, for details of where and how they can take this item for environmentally safe

recycling. Business users should contact their supplier and check the terms and conditions

of the purchase contract. This product should not be mixed with other commercial wastes

for disposal.

ٻ

waste disposal, please separate this from other types of wastes and recycle it

All specifications are subjected to change without notice

ڎڑٻ

.

Loading...

Loading...