Page 1

SRP-500

SRP-500

Page 2

EMC and Safety standards Applied

Product Name : SRP-500

The following standards are applied only to the printers that are so labeled.

Europe : CE marking, TUV/GS : EN60950 ; 1999

North America : EMI : FCC Class A

Safety standards : UL / C-UL : UL60950-3rd.

National : CB-scheme : IEC 60950 ; 1999

WARNING

The connection of a non-shielded printer interface cable to this printer

will invalidate the EMC standards of this device.

You are cautioned that changes or modifications not expressly approved

by the party responsible for compliance could void your authority to operate the

equipment.

CE Marking

The printer conforms to the following Directive and Norms

Directive 89/336/EEC EN 55022 Class A :1998

EN 55024 : 1998

(EN 61000-4-2 : 1995+A1 : 1998)

(EN 61000-4-3 : 1996)

(EN 61000-4-4 : 1995)

(EN 61000-4-5 : 1995)

(EN 61000-4-6 : 1996)

(EN 61000-4-11 : 1994)

EN 61000-3-2 : 1995+A1 : 1998+A2 : 1998)

EN 61000-3-3 : 1995

Directive 73/23/EEC Safety : EN 60950 ; 1999

All rights reserved. No part of this publication may reproduced,

stored in a retrieval, or transmitted in any form or by any means,

electronic, mechanical, photocopying, recording, or otherwise, without

the prior written permission of SAMSUNG ELECTRO-MECHANICS.

No patent liability is assumed with respect to the use of the

information contained herein. While every precaution has been taken

in the preparation of this book, SAMSUNG ELECTRO-MECHANICS

assumed no responsibility for errors or omissions. Neither is any

liability assumed for damages resulting from the use of the

information contained herein.

Neither SAMSUNG ELECTRO-MECHANICS nor its affiliates shall be liable

to the purchaser of this product or third parties for damages, losses, costs,

or expenses incurred by purchaser or third parties as a result of : accident,

misuse, or abuse of this product or unauthorized modifications, repairs,

or alterations to this product, or(excluding the U.S) failure to strictly comply

with SAMSUNG ELECTRO-MECHANICS’ s operating and maintenance

instructions.

SAMSUNG ELECTRO-MECHANICS shall not be liable against any damages

or problems arising from the use of any options or ant consumable products

other than those designated as Original Samsung products or Samsung

Approved products by SAMSUNG ELECTRO-MECHANICS.

Notice

The contents of this manual are subject to change without notice.

Copyright © 2002 SAMSUNG ELECTRO-MECHANICS. CO., LTD

Page 3

Table of contents

Introduction 1

Chapter 1. Setting up the printer

1-1. Unpacking 3

1-2. Choosing a place for the printer 4

1-3. Connecting the cables 5

1-4. Installing or replacing the paper roll 7

1-5. Installing new ink cartridge(s) 9

1-6. Using the control panel 11

1-7. Self test 13

Chapter 2. Troubleshooting

2-1 The printer does not start printing 14

2-2 The printer stops printing 15

2-3 You want to check the operation of the printer by itself 15

2-4 Printing is poor 16

2-5 You want to check a software program 17

Chapter 3. DIP switch

3-1 Setting the DIP switches 18

3-2 Changing the DIP switch setting 19

Chapter 4. Code table 20

Chapter 5. Control commands list

5-1. Commands 32

5-2. Character code tables 34

5-3. Command descriptions 35

Chapter 6. Reference information

6-1 Printing specification 64

6-2 Paper specification 64

6-3 Ink cartridge specification 64

6-4 Electrical characteristics 65

6-5 Reliability 65

6-6 Environmental conditions 65

6-7 Dimension & Weight 66

6-8 Optional features 66

Page 4

21

Introduction

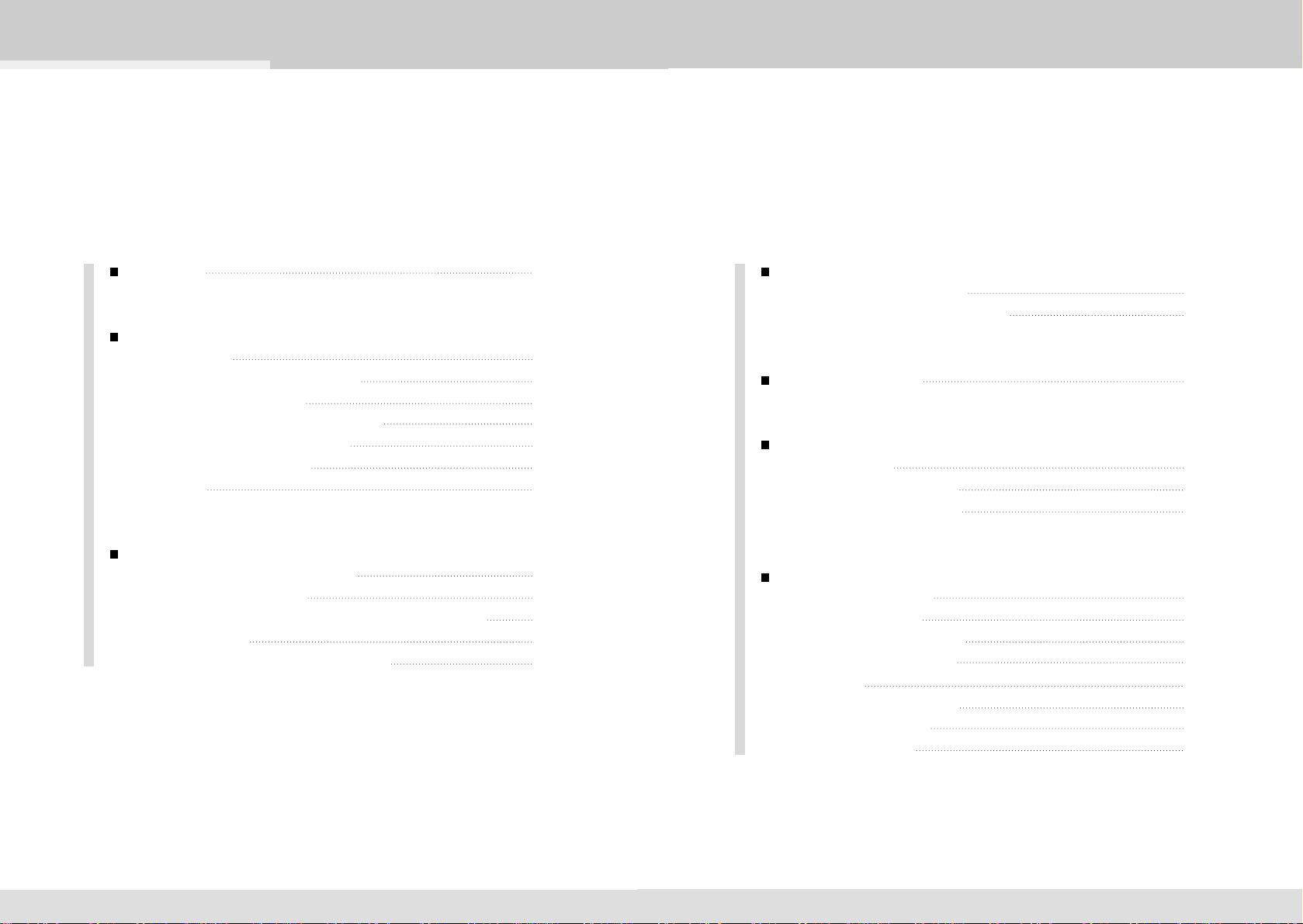

Front view

Rear view

Front cover Rear cover

Open button

Control pannel

Power switch

Drawer kick-out

connector

Interface

connector

Power

connector

The SRP-500 is high-quality inkjet POS printer that can print on roll paper.

This is compact, light-weight and highly reliable one-station printer

and has the following features.

Compact design and light-weight.

High-speed printing using logic-seeking.

Easy to use: clamshell mechanism.

High reliability and long life due to the use of stepping motors for both

carriage return and paper feeding.

Two color printing (red/black/blue/green) available.

Various formats are possible because the paper feeding pitch is selectable.

High general control utility based on the ESC/POS (TM) standard.

2 drawers can be driven due to the internal drawer interface.

Character font (12X12, 12X14) is selectable.

The auto cutter uses a circular method with a high-quality blade and a long

life (Approximately 500,000 cuts)

Paper near end sensor is standard.

Please be sure to read the instructions in this manual carefully before

using your new printer.

Page 5

43

Setting up the printer

Chapter 1

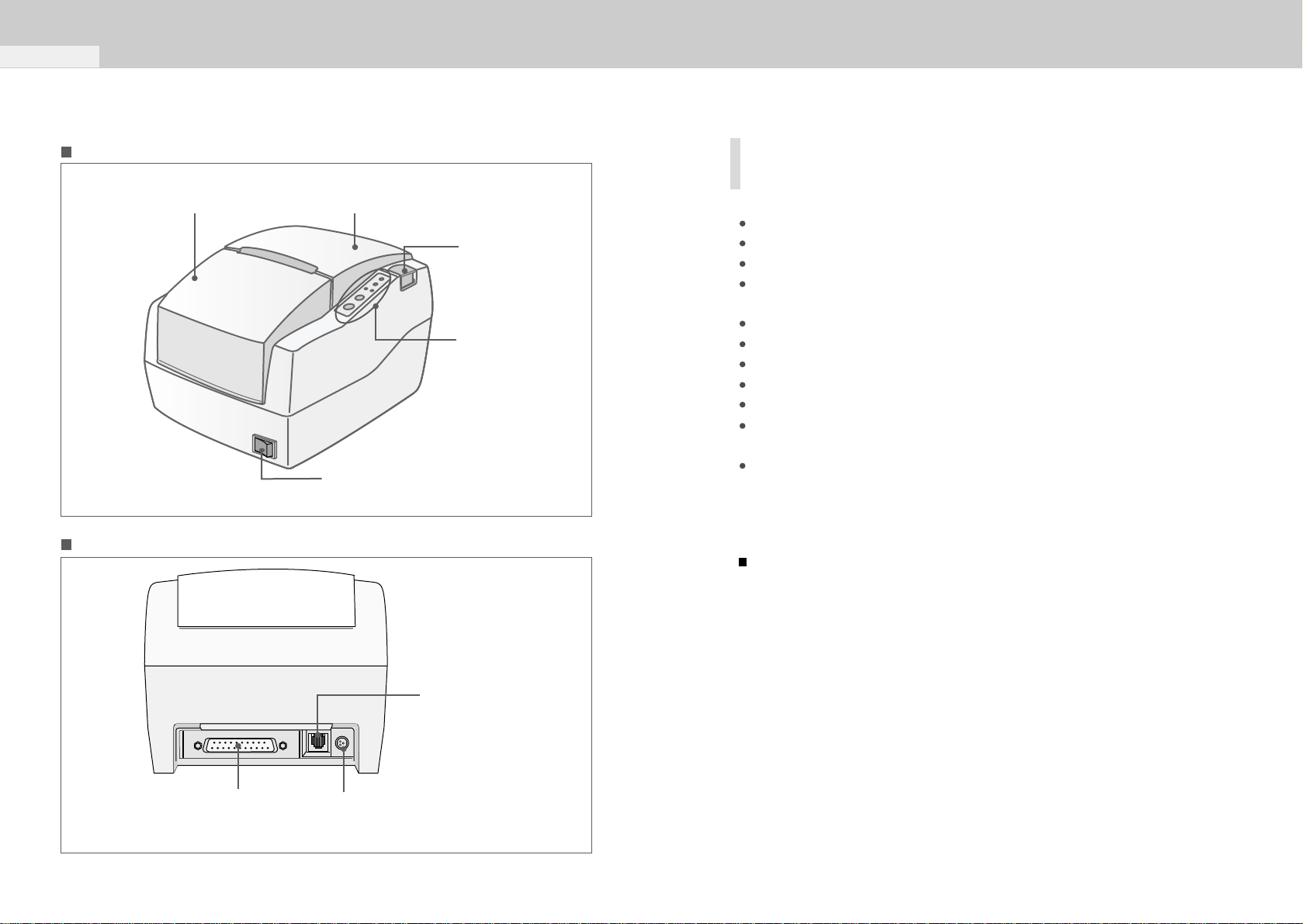

1-1. Unpacking 1-2. Choosing a place for the printer

SRP-500

AC adapter Power code Paper roll

Operator’s

manual

Ink cartridges Cable cover

Your printer box should include the item shown in the illustration below.

If any items are damaged or missing, please contact your dealer.

Avoid locations that are subject to direct sunlight or excessive heat.

Avoid using or storing the printer in place subject to excessive temperature

or moisture.

Do not use or store the printer in a dirty location.

When setting up the printer, choose a stable, horizontal location.

Intense vibration or shock may damage the printer.

Ensure the printer has enough space to be used easily.

Page 6

65

Setting up the printer

Chapter 1

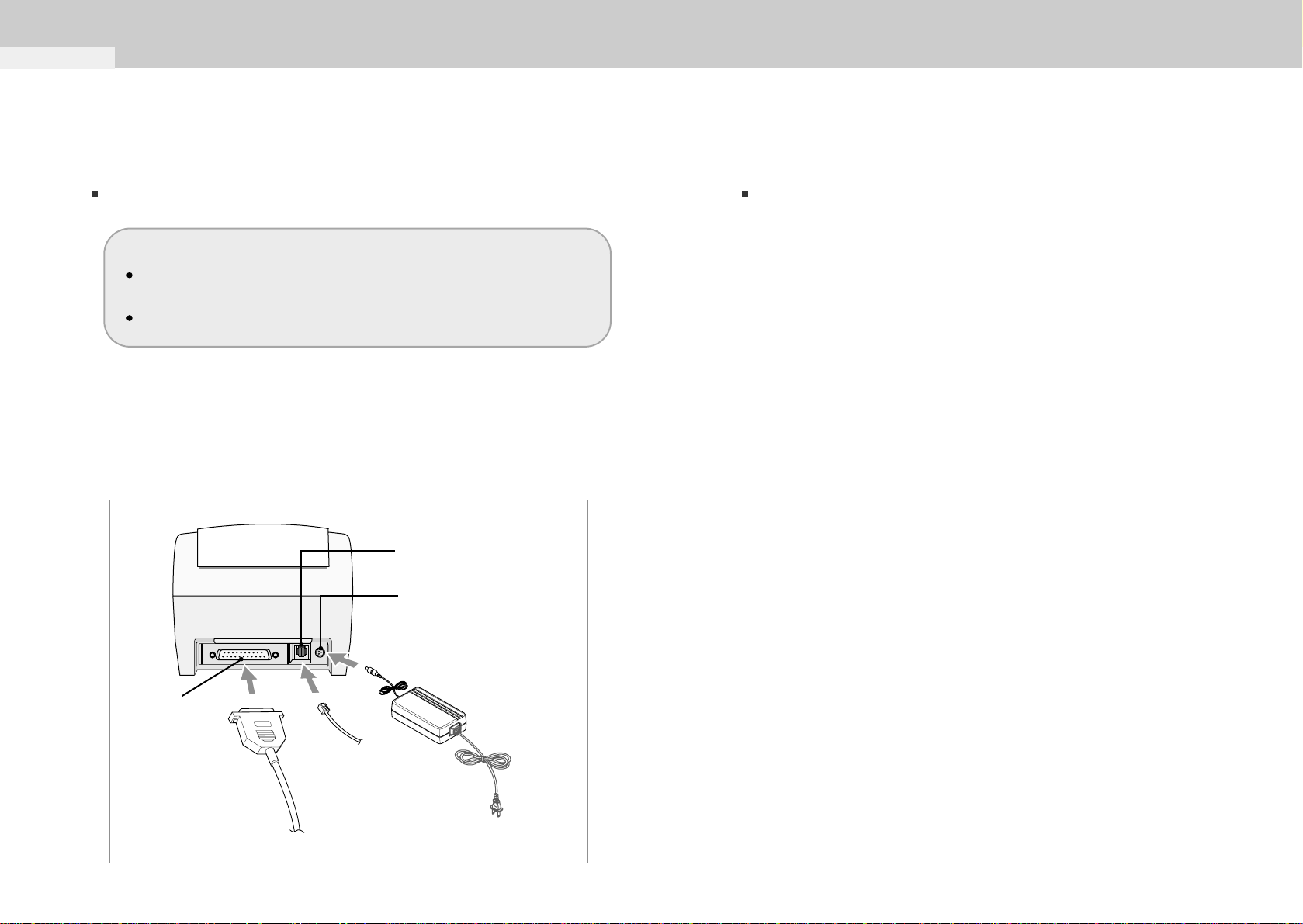

1-3. Connecting the cables

Plugging in AC adapter

Connect the AC adapter according to the following procedure.

1) Make sure the printer is turned off.

2) Plug the AC adapter cable into the printer’s power connector.

3) Plug the power cord into the outlet, and turn on the power.

Connect the printer to the host ECR (host computer) though an

interface cable matching the specification of the printer and the host

ECR (host computer).

Be sure to use a drawer that matches the printer’s specification.

Depending on the interface your system uses, either connect

the serial, parallel or USB communication cable to the appropriate

connector on the back of the printer.

Cable are provided by your dealer or system installer.

Before connecting the printer to the power supply, make sure that the voltage and power

specifications match the printer’s requirements.

Using an incorrect power supply can cause serious damage to the printer.

CAUTION

Connecting the interface cable

1) Turn off printer and the ECR (host computer) host.

2) Plug the interface cable into the interface connector on the printer

then fasten the screw on both sides of the connector.

3) Plug the drawer kick-out cable into the drawer Kick-out connector

on the printer. (When removing the drawer kick-out cable,

press in on the connector’s clip and pulling out.)

Connect the interface cable according to the following procedure.

Drawer kick-out

Connector

Power

connector

Interface

connector

Serial/Parallel/USB

Interface cable

Drawer kick-out

cable

Power cord

AC adapter

Page 7

87

Setting up the printer

Chapter 1

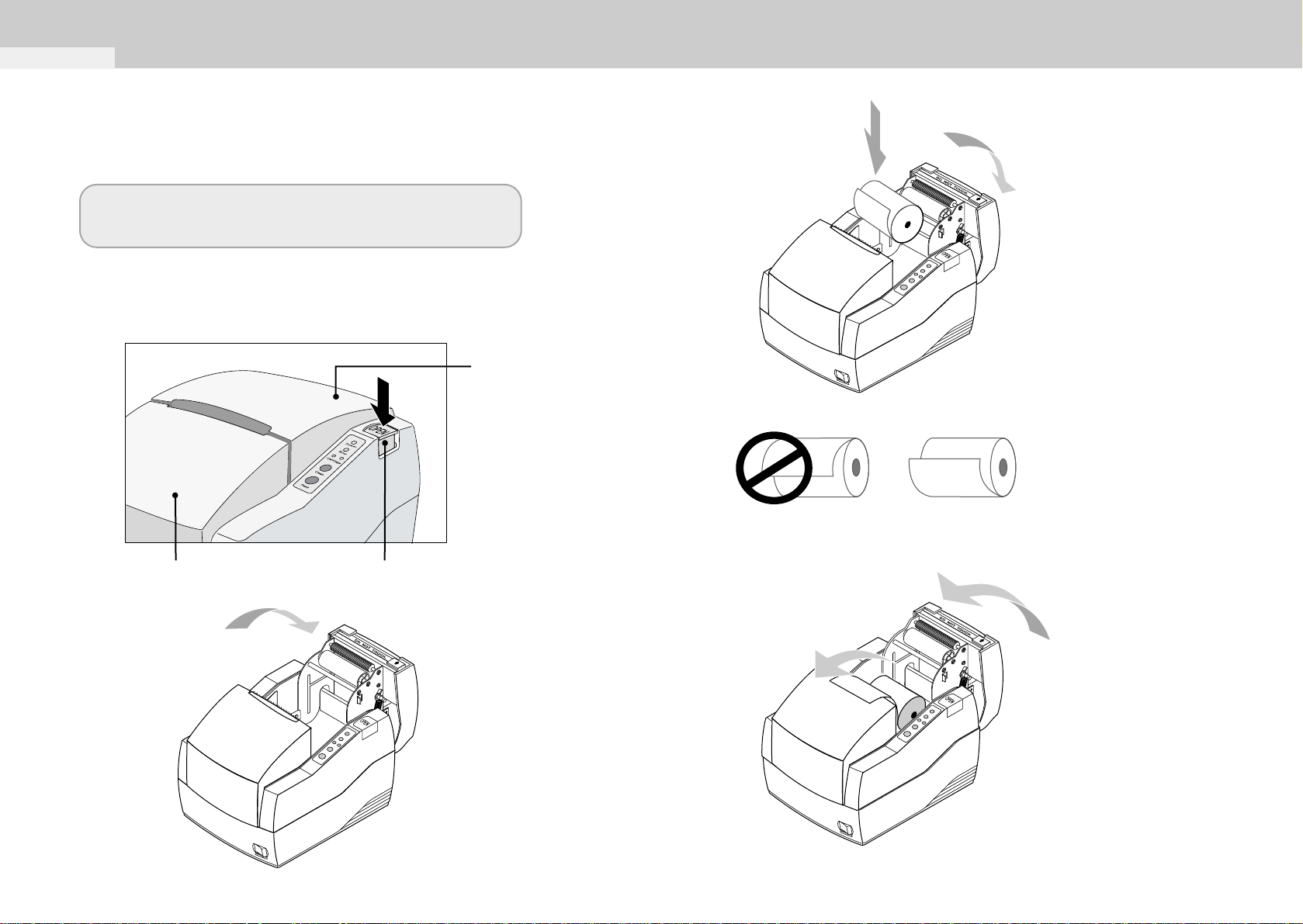

1-4. Installing or replacing paper roll

Notice the caution label and do not touch the auto cutter blade

when you open rear cover.

CAUTION

1) To prevent data loss, make sure that the printer is not receiving data.

2) Open the rear cover by pressing the open button and push the arrow

mark back.

3) Remove the used

paper roll core if

there is one.

4) Insert the paper

roll as shown.

5) Be sure note the

correct direction

that the paper should

come off the roll.

6) Pull out small amount

of paper as shown.

Then close the cover

and tear off the extra

paper by pulling it

toward the front of the

printer.

Rear cover

Front cover Open button

Page 8

Setting up the printer

Chapter 1

109

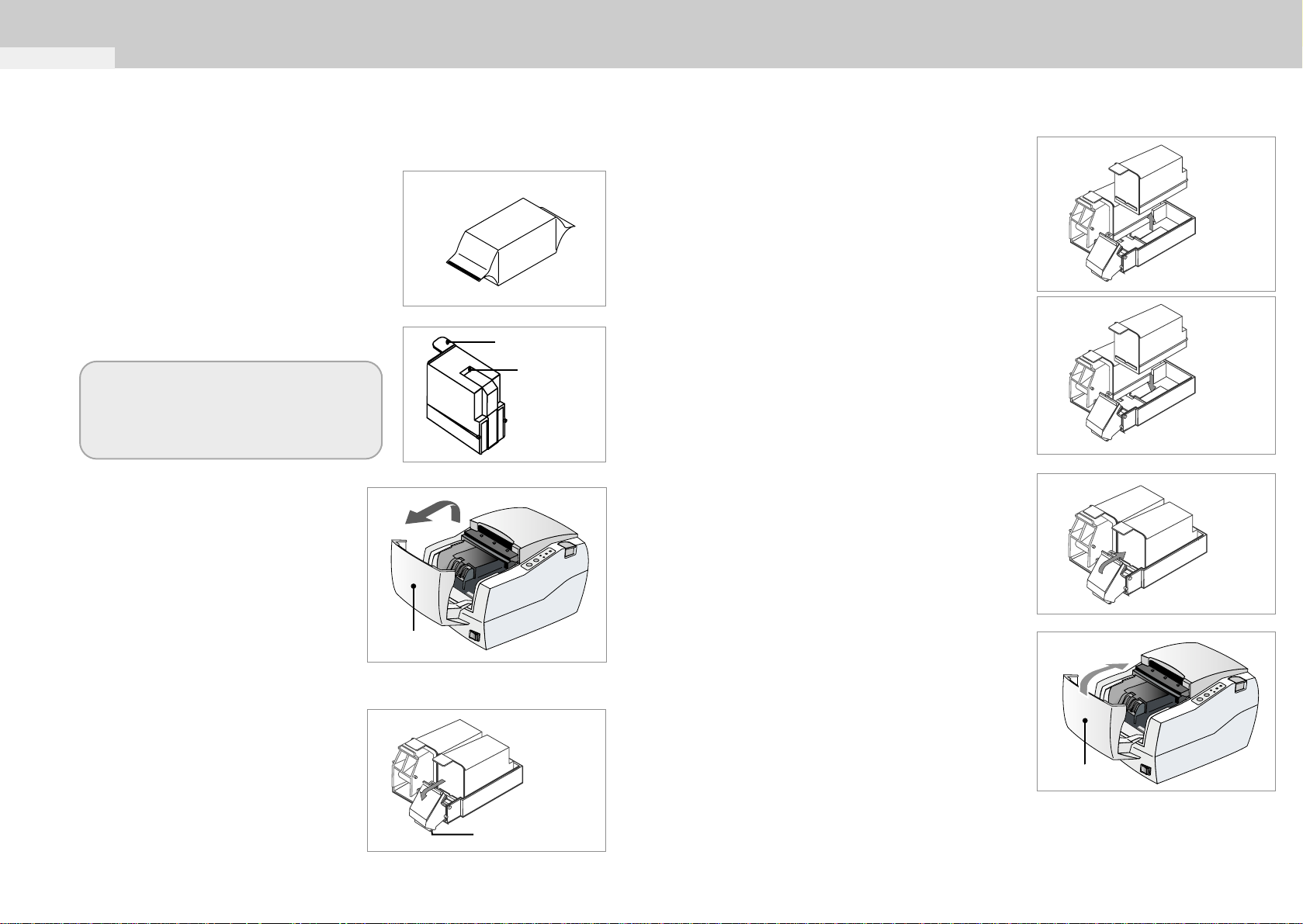

1-5. Installing new Ink cartridge(s)

1) Remove new ink cartridge from sealed pouch.

(Hold cartridge by round plastic avoid

contamination)

5) Take out old ink cartridge(s).

Place new cartridge(s) into carriage.

Hold plastic tab to ensure clean installation.

Black cartridge goes into the left carriage.

The color cartridge goes into right carriage.

(tab faces front of printer.)

6) Close cartridge holder.

7) Close from cover of printer.

Notice

The ink drop counter is automatically reset when the ink-cartridge is installed.

2) Remove Mylar from face of new cartridge.

3) Turn the printer on and

open the font cover of printer.

4) Pull down cartridge holder.

Do not touch ink cartridge’s metallic connector

surface with your fingers.

Doing so will contaminate the connector and

produce bad print quality.

CAUTION

Tab

Mylar tape

5a-remove

old cartridge

5a-remove

old cartridge

Front cover

Front cover

Cartridge holder

Page 9

Setting up the printer

Chapter 1

1211

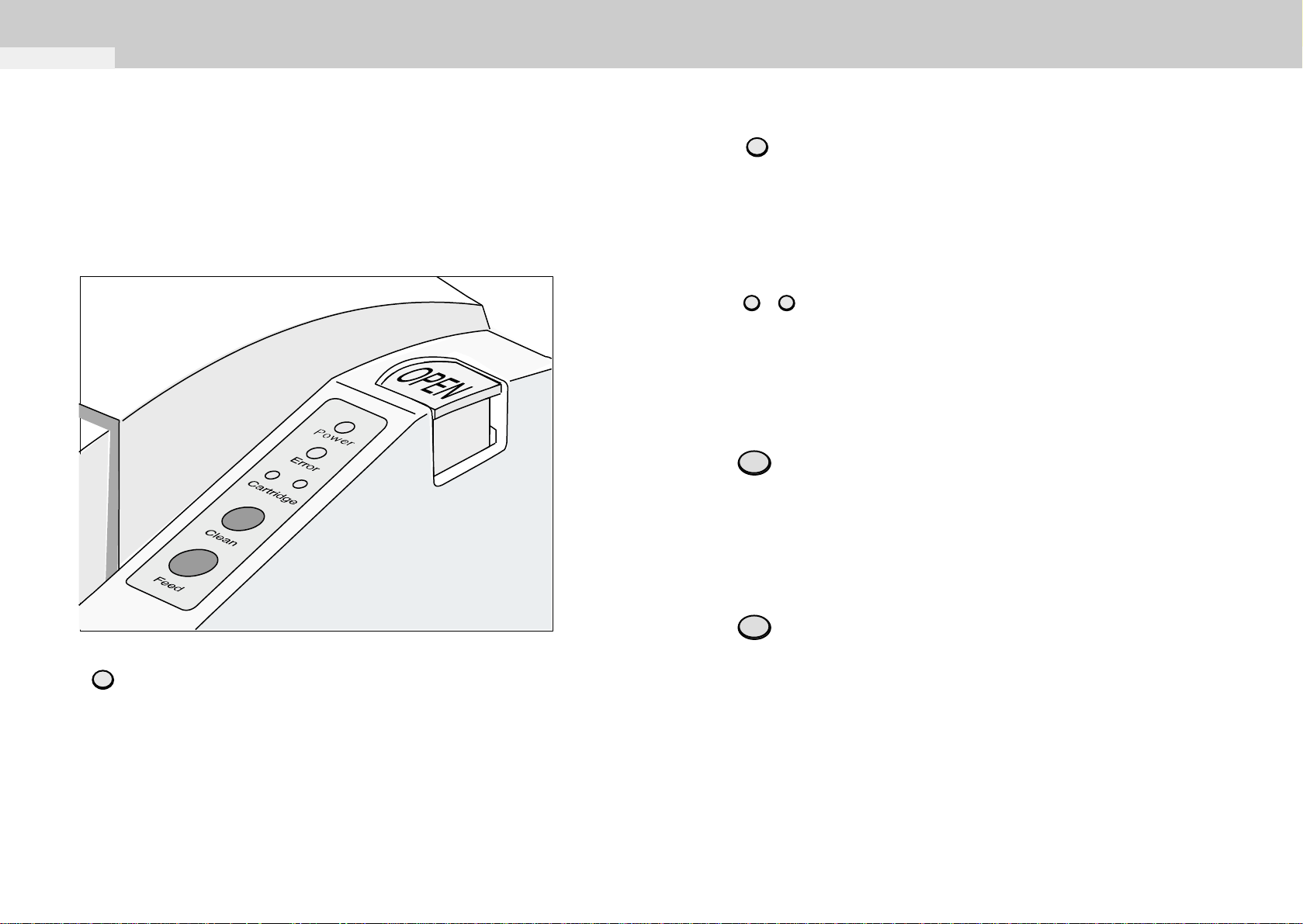

1-6. Using the control panel

Control panel

Power (LED)

Most of the functions of this printer are governed by software,

but you can monitor the printer’s status by looking at the lights on the control panel

and for some procedures you will use the buttons.

This indicator light is on when the power is turned on.

It blinks when the printer is in the self test printing stanby state.

Always wait until this indicator light stops blinking before you start using

the printer and before you turn it off.

Error (LED)

When this indicator light is on(but not blinking), it means that the printer is out of

paper or almost out of paper or the printer covers are open.

When this light is blinking, there is an error. If you see this light is blinking,

turn off the printer for a few seconds and then turn it back on.

If the light is still blinking, call your supervisor or a service person.

Cartridge (LED)

The right indicator is for the right cartridge and the left indicator for the left

cartridge. If the printer is a single color printer, the left cartridge indicator will be

used. In the most cases, the left cartridge is back, and the right is a color.

This indicator light (LH/RH) blinks when the cartridge is almost out of ink and

stays on when the cartridge (s) is removed.

Clean (BUTTON)

Use this button to clean the printer head.

(See the instructions “Printing is poor” (2-4) in chapter 2 for Cleaning

The Printer Head.)

Feed (BUTTON)

Use this button to feed paper or to start self test and for hexadecimal dump

mode.

(See the instructions “Self Test” (1-7) in this chapter for self test.)

(See the instructions “Hexadecimal Dump” (2-5) in chapter 2 for hexadecimal

dump mode.)

Page 10

1413

1-7. Self test

The self test lets you know if your printer is operating properly.

It checks the control circuits, printer mechanisms, print quality,

ROM version, and DIP switch settings.

The test is independent of any other equipment or software,

so it is a good idea to run it when you first set up the printer or if you have

any trouble. If the self test works correctly, the problem is in the other

equipment or the software, not the printer.

2-1. The printer does not start printing.

Are any of the control panel lights on?

If no control panel lights are on, check the following:

This chapter gives solutions to some printer problems you may have.

Running the self test

1) Make sure the printer is turned off and the printer cover is closed

properly.

2) Turn on the printer, while holding down the Feed button, and then

continue to hold until the paper begins to feed.

3) Press the Feed button. The self test prints the printer settings

and then cuts the paper, and pauses. (The power light blinks.)

4) Press the Feed button to continue printing.

The printer prints rolling ASC II pattern, nozzle pattern,

receipt pattern, NV bit image.

5) The self test automatically enters the hexadecimal dump mode.

6) Power off to terminate self mode.

Setting up the printer

Chapter 1

Troubleshooting

Chapter 2

Make sure that the printer is turned on.

Make sure that the power supply cable is correctly plugged into the printer

and to the power outlet.

If any of the lights are on, please check the following:

If the Power light is blinking, the printer is not yet ready.

Wait until the light quits blinking and the printer should be to use.

If the Error light is on(but not blinking), the printer is off line.

Check to see that the covers are closed and check the paper state.

See Chapter 1 for instructions on installing or replacing the paper roll.

If the Error light is blinking, there is an error.

In this case, turn off the printer for a few seconds and then turn it back on.

If the light is still blinking, call your supervisor or service person.

If the Cartridge lights(LH/RH) is on, check the Cartridges in the printer.

See chapter 1 for instruction on installing new ink-Cartridges.

Page 11

2-2. The printer stops printing.

If the Error light is on (but not blinking), the printer is off line.

Check to see that the covers are closed and check the paper state.

See Chapter 1 for instructions on installing or replacing the paper roll.

If the Error light is blinking, there is an error. In this case, turn off the

printer for a few seconds and then turn it back on.

If the light is still blinking, call your supervisor or a service person.

Turn off the printer and check for a paper jam.

To clear paper jam, follow th steps below:

1) Turn the printer off and open the rear cover of the printer.

2) Remove the jammed paper and reload the paper roll as described in Chapter1.

3) Check the position of circular cutter in Auto Cutter Assembly.

If it is not located in Home Position(Right-Hand Side End),

Turn the printer on to locate it on Home position.

4) Close the rear cover.

Troubleshooting

Chapter 2

1615

2-4. Printing is poor

Obstructed ink nozzles in the print head and lower the print quality.

Try cleaning the print head as described below:

1) Make sure that the printer is turned on.

2) Press the Clean button.

The printer begins its self cleaning process, which takes less than 5 seconds.

The power light blinks during the cleaning process.

3) When the cleaning action is finished (Power light is ON), resume printing

or run a self test (as described in Chapter 1).

4) If the printing quality has not improved, repeat this process 2-3 more times.

If the printing quality has not still improved, replace the ink cartridge.

If, after the new ink cartridge has been installed, the printing quality has not still

improved, call your supervisor or a service person.

2-3. You want to check the operation of the printer by itself.

Self test

Try to run the self test to check that the printer works properly.

See the self test instructions in Chapter 1 to run the self test.

If the self test does not work, contact your supervisor or a service person.

If the self test works properly, check the following:

If the printer still does not print, contact your dealer or a qualified service person.

1) Check the connection at both ends of the interface cable between the printer

and the computer. Also make sure that this cable meets the specifications for

both the printer and the computer.

2) The data transmission settings may be different between the printer and

computer. Make sure that the printer’s DIP switch settings for data transmission

are the same as the computer’s. You can see the printer’s interface settings

on your self test printout.

Cleaning the print head

Page 12

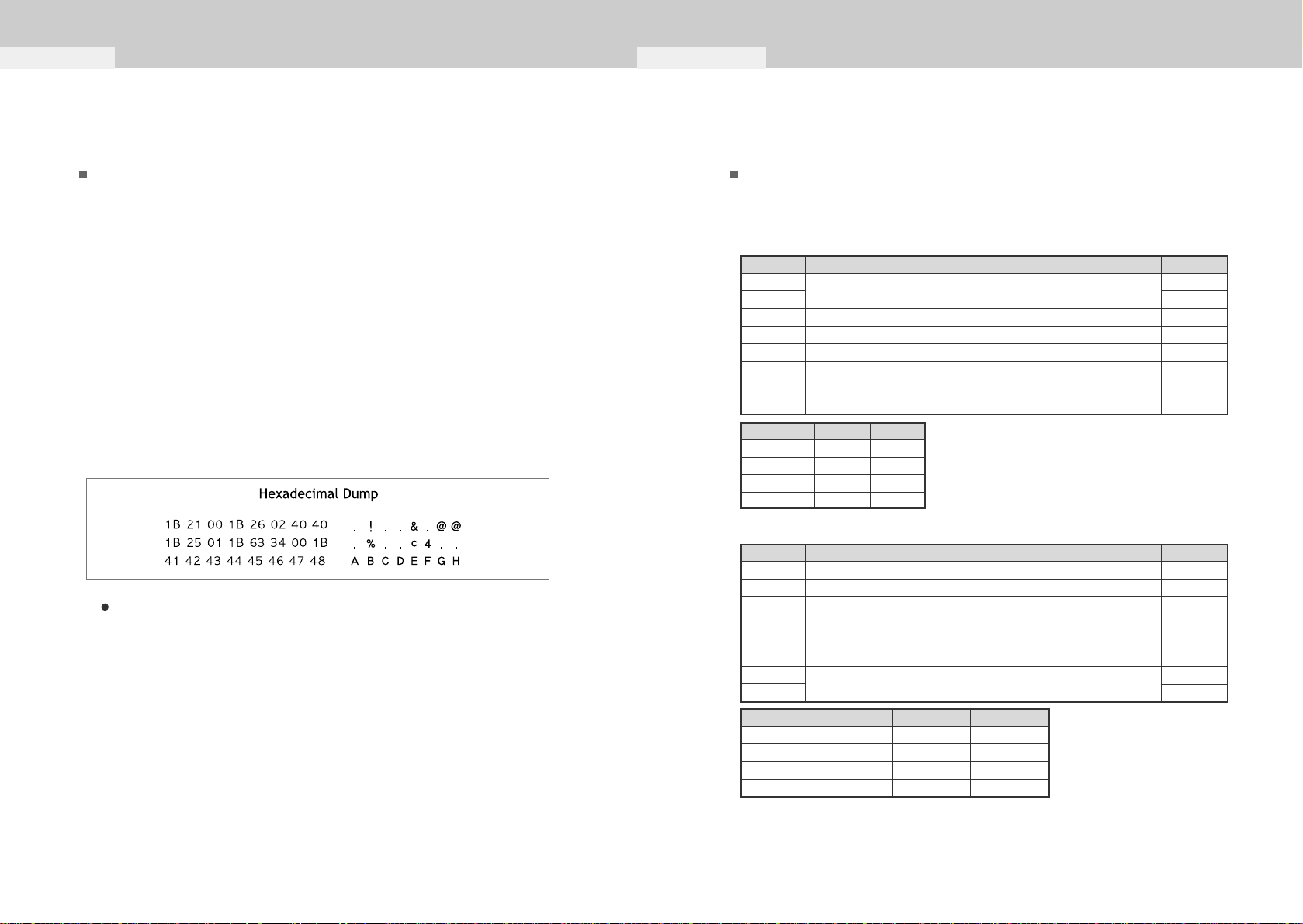

2-5. You want to check a software program.

Troubleshooting

Chapter 2

17

Hexadecimal Dump

This feature allows experienced users to see exactly what data is coming

to the printer. This can be useful in finding software problems. When you

turn on the hexadecimal dump function, the printer prints all commands

and other data in hexadecimal format along with a guide section to

help you find specific commands.

To use the hexadecimal dump feature, follow these steps:

1) After you make sure that the printer is off, open the front cover of the printer.

2) Hold down the Feed button while you turn on the printer.

3) Close the front cover.

4) Run any software program that sends data to the printer. The printer prints

“Hexadecimal Dump” and then all the codes it receives in a two – column

format. The first column contains the hexadecimal codes and the second

column gives the ASCII characters that correspond to the codes.

5) When the printing finishes, turn off the printer.

A period(.) is printed for each code that has no ASCII equivalent.

3-1. Setting the DIP switches

DIP switch functions

DIP - SW1

Your printer has two sets of DIP switches.

The functions of the switches are shown in the following table.

EPSON-KP(EPSON Kitchen Printer mode)

A alarm is generated by printer after auto-cutting

and in paper-end error. (It needs buzzer accessory.)

DIP switch settings

Although the factory settings are best for almost all users,

if you have special requirements, you can change the DIP switch.

Chapter 3

Switch

1-1

1-2

1-3

1-4

1-5

1-6

1-7

1-8

Function

Emulation Selection

Auto cutter

Cartridge

Density

Near end sensor

Low ink check

ON

Selection

one cartridge

Enable

Disable

Refer to the following table

Bold

Reserved

OFF

Disable

two cartridges

Normal

Disable

Enable

Defult

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

EPSON

STAR

CITIZEN

EPSON-KP

1-1

OFF

OFF

ON

ON

1-2

OFF

ON

OFF

ON

DIP - SW2

Switch

2-1

2-2

2-3

2-4

2-5

2-6

2-7

2-8

Function

Data receive error

Hand Shaking

Word length

Parity check

Parity selection

Baud rate selection

ON

Print “?”

DTR/DSR

7bit

Enable

EVEN

Reserved

Refer to the following table

OFF

lgnore

XON/XOFF

8bit

Disable

ODD

Defult

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

Transmission

2400 baud

4800 baud

9600 baud

19200 baud

2-8

ON

ON

OFF

OFF

2-7

ON

OFF

OFF

ON

Notice

Changes in DIP switch settings are recognized only when the printer power is

turned on or when the printer is reset by using the interface. If the DIP switch

setting is changed after the printer power is turned on, the change does not take

effect until the printer is turned on again or is reset.

18

Page 13

20

DIP switch settings

Chapter 3

19

3-2. Changing the DIP switch setting

The following page show the character code tables.

To fine the character corresponding to a hexadecimal number, count

across the top of the table for the left digit and count down the left

column of the table right digit. For example, 4A=J

Page 0 (PC437 : USA, Standard Europe)

(International Character Set : USA)

Turn off the printer before removing the DIP switch cover to prevent an electric short,

which can damage the printer.

CAUTION

1) Make sure the printer is turned off.

2) Remove the screw from the DIP switch cover.

Then take off the DIP switch cover, which is shown in the illustration below.

3) Set the switches using a pointed tool, such as tweezers or a small

screwdriver.

4) Replace the DIP switch cover. Then secure it with the screw.

* The new settings take effect when you turn on the printer.

If you need to change settings, follow the steps below to make your changes.

DIP switch cover

Code table

Chapter 4

Page 14

2221

Code table

Chapter 4

Page 2 (PC850 : Multilingual) Page 3 (PC860 : Portuguese)

Page 15

2423

Code table

Chapter 4

Page 4 (PC 863 : Canadian - French) Page 5 (PC 865 : Nordic)

Page 16

2625

Code table

Chapter 4

page 17 (PC 866 : Russian)page 16 (CP1252 : WinLatin1)

Page 17

2827

Code table

Chapter 4

page 18 (CP 852 : DosLatin2)

Page 19 (PC 858 : Euro)

Page 18

3029

Code table

Chapter 4

Page 21 (MS-DOS 862 : Israel) Page 22 (MS-DOS 864 : Arabic)

Page 19

31

Code table

Chapter 4

Page 23 (MS-DOS 874 :Thai)

Control commands list

Chapter 5

5-1. Commands

5.1.1 Commands list for SRP-500 Series. (EPSON TM-U200 Mode)

n

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

Command

CR

HT

LF

DLE EOT

DLE ENQ

ESC SP

ESC %

ESC &

ESC *

ESC !

ESC ESC =

ESC 2

ESC 3

ESC <

ESC ?

ESC @

ESC D

ESC E

ESC G

ESC J

ESC R

ESC U

ESC a

ESC c 3

ESC c 4

ESC c 5

ESC d

ESC m

ESC p

ESC r

ESC t

ESC {

GS I

GS V

GS a

GS r

Description

Print and carriage return

Horizontal tab

Print and linefeed

Transmit real-time status

Real-time request to printer

Set right-side character spacing

Select/Cancel user defined characters

Define user-defined characters

Select bit-image mode

Select print mode

Turn underline mode on/off

Select peripheral device status

Select default line spacing 1/6 lpi

Set line spacing

Return home

Cancel user defined characters

Initialize printer

Set horizontal positions

Turn emphasized mode on/off

Turn double-strike mode on/off

Print and feed paper <n> vertical units

Select an international character set

Turn unidirectional printing mode on/off

Select justification

Select paper sensor to output paper end signal Select

paper sensor to stop printing

Enable/disable panel button

Print and feed <n> line

Execute partial cut

Generate pulse

Select color

Select character code table

Turn upside-down printing mode on/off

Transmit printer ID

Select cut mode and cut paper

Enable/disable Automatic Status Back (ASB)

Transmit status

Hexadecimal

0D

09

0A

10 04

10 05

1B 20

1B 25

1B 26

1B 2A

1B 21

1B 2D

1B 3D

1B 32

1B 33

1B 3C

1B 3F

1B 40

1B 44

1B 45

1B 47

1B 4A

1B 52

1B 55

1B 61

1B 63 33

1B 63 34

1B 63 35

1B 64

1B 6D

1B 70

1B 72

1B 74

1B 7B

1D 49

1D 56

1D 61

1D 72

32

Page 20

3433

Control commands list

Chapter 5

5.1.2 Commands list for SRP-500 Series. (STAR Mode)

n

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

Command

BEL

FF

CR

SO

SI

DC2

DC4

CAN

EM

SUB

ESC BEL

ESC ESC 4

ESC 5

ESC @

ESC C

ESC E

ESC F

ESC M

ESC R

ESC U

ESC W 1

ESC W <1>

ESC W 0

ESC W <0>

ESC _ 1

ESC _ <1>

ESC _ 0

ESC _ <0>

ESC a

ESC d 0

ESC d 1

ESC e 1

ESC e <1>

ESC e 0

ESC e <0>

ESC f 1

ESC f <1>

ESC f 0

ESC f <0>

FS

Description

Deferred drive command “A” for peripheral unit 1

Page feed (Form feed)

Print and linefeed (same as LF)

Select expanded character mode

Select upside-down

Cancel upside-down character

Cancel expanded character mode(Default setting)

Cancel print data in buffer

Immediate drive command for peripheral unit2

Immediate drive command for peripheral unit 2

Adjust drive pulse width for peripheral unit (Default setting)

Set or Cancel underline mode

Red color print selection

Red color print deselection

Initialize printer

Set page length at n lines

Emphasized print mode

Emphasized print mode deselection (Default setting)

Select 9 x 7(Half dots) character size

Select international character set

Set or cancel uni-direction mode

Select expanded character mode

Cancel expanded character mode (Default setting)

Select over-line mode

Cancel over-line mode

Feed paper n lines

Partial cut

Partial cut

Set the control panel switch invalid

Set the control panel switch valid

Set the ON LINE switch invalid

Set the ON LINE switch valid

Immediate drive command “B” for peripheral unit 1

Hexadecimal

07

0C

0D

0E

0F

12

14

18

19

1A

1B 07

1B 2D

1B 34

1B 35

1B 40

1B 43

1B 45

1B 46

1B 4D

1B 52

1B 55

1B 57 31

1B 57 01

1B 57 30

1B 57 00

1B 5F 31

1B 5F 01

1B 5F 30

1B 5F 01

1B 61

1B 64 30

1B 64 31

1B 65 31

1B 65 01

1B 65 30

1B 65 00

1B 66 31

1B 66 01

1B 66 30

1B 66 00

1C

5.1.3 Commands list for SRP-500 Series. (CITIZEN Mode)

n

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

Command

BEL

LF

FF n

SO

SI

DC1

DC2

DC3

CAN

SUB

ESC BEL

ESC ESC 1

ESC 2

ESC C

ESC P <0>

ESC P <1>

FS

CR

ESC * n1 n2

ESC f <1>

Description

First drawer drive command1

Paper feed command

“n”-lines paper feed command

Enlarged character command

Normal character command

Initial set command

Inverted character command

Red color print command

Clear command

Second drawer drive command

Drive pulse setting command for the first drawer

Underline command

1/9 inch paper feed preset command

2/9 inch paper feed preset command

Paper length set command

Paper partial cut command

Paper partial cut command

First drawer quick drive command

Printing

Specifying the bit image mode

Form feed

Hexadecimal

07

0A

0C n

0E

0F

11

12

13

18

1A

1B 07

1B 2D

1B 31

1B 32

1B 43

1B 50 00

1B 50 01

1C

ØD

1B 2A n1 n2

1B 66 Ø1

5-2. Character Code Tables

n

0

2

3

4

5

16

17

18

19

21

22

23

Page

PC437

PC850

PC860

PC863

PC865

PC1252

PC866

PC852

PC858

PC862

PC864

PC874

Page 21

3635

Control commands list

Chapter 5

5-3. Command descriptions

HT

[Name] Horizontal tab

[Format] ASCII HT

Hex 09

Decimal 10

[Description] Moves the print position to the next horizontal tab position.

[Notes]

This command is ignored unless the next horizontal tab position

has been set.

Horizontal tab positions are set with ESC D.

The default tab positions are at intervals of 8 characters

(columns 9, 17, 25..) for the font B (12 x 12).

[Reference] ESC D

LF

[Name] Print and line feed

[Format] ASCII LF

Hex 0A

Decimal 10

[Description] Prints the data in the print buffer and feeds one line based on the

current line spacing.

[Note] This command sets the print position to the beginning of the line.

[Reference] ESC 2, ESC 3

CR

[Name] Print and carriage return

[Format] ASCII CR

Hex 0D

Decimal 13

[Description] This command prints the data in the print buffer and does not feed the paper.

[Note] Sets the print starting position to the beginning of the line

[Reference] LF

DLE EOT n

[Name] Real-time status transmission

[Format] ASCII DLE EOT n

Hex 10 04 n

Decimal 16 4 n

[Range] 1 ≤ n ≤ 4

[Description] Transmits the selected printer status specified by n in real time,

according to the following parameters:

n = 1: Transmit printer status

n = 2: Transmit off-line status

n = 3: Transmit error status

n = 4: Transmit paper roll sensor status

[Notes]

This command should not be used within the data sequence of

another command that consists of 2 or more bytes. For example,

If you attempt to transmit ESC 3 n to the printer, but DTR (DSR

for the host computer) goes to MARK before n is transmitted

and then DLE EOT 3 interrupts before n is received, the code

<10>H for DLE EOT 3 is processed as the code for ESC 3

<10>H.

Page 22

3837

Control commands list

Chapter 5

Bit

0

1

2

3

4

5

6

7

n = 1 : Printer status

Off/On

Off

On

Off

On

Off

On

On

Off

Off

Off

Hex

00

02

00

04

00

08

10

00

00

00

Decimal

0

2

0

4

0

8

16

0

0

0

Function

Not used. Fixed to Off.

Not used. Fixed to On.

Drawer kick-out signal is LOW (connector pin 3)

Drawer kick-out signal is HIGH (connector pin 3)

On-line.

Off-line.

Not used. Fixed to On.

Not used. Fixed to Off.

Not used. Fixed to Off.

Not used. Fixed to Off.

Bit

0

1

2

3

4

5

6

7

n = 2 : Off-line status

Bit 5 : On (printing stops due to paper-end) when printing stops due to paper-end

detected by the paper-end sensor or the paper near-end enabled by using the ESC c 4.

Off/On

Off

On

Off

Off

On

On

Off

On

Off

On

Off

Hex

00

02

00

00

08

10

00

20

00

40

00

Decimal

0

2

0

0

8

16

0

32

0

64

0

Function

Not used. Fixed to Off.

Not used. Fixed to On.

Not used. Fixed to Off.

Paper is not being fed by using the paper feed button.

Paper is being fed by the paper feed button.

Not used.

Fixed to On.

No paper-end stop.

Printing stops due to paper end.

No error. Error occurs.

Not used. Fixed to Off.

Bit

0

1

2

3

4

5

6

7

n = 3 : Error status

Off/On

Off

On

Off

On

Off

On

On

Off

On

Off

On

Off

Hex

00

02

00

04

00

08

10

00

20

00

40

00

Decimal

0

2

0

4

0

8

16

0

32

0

64

0

Function

Not used. Fixed to Off.

Not used. Fixed to On.

No mechanical error.

Mechanical error occurred.

No auto-cutter error.

Auto-cutter error occurs.

Not used. Fixed to On.

No unrecoverable error.

Unrecoverable error occurs.

Automatic recover error.

No automatic recover error.

Not used. Fixed to Off.

Bit

0

1

2, 3

4

5, 6

7

n = 4 : Continuous paper sensor status

Bit 2 : If these errors occur due to paper jams or the like, it is possible to recover by

correcting the cause of the error and executing DLE ENQ 2. If an error due to a

circuit failure (e.g. wire break) occurs, it is impossible to recover.

Off/On

Off

On

Off

On

On

Off

On

Off

Hex

00

02

00

0C

10

00

60

00

Decimal

0

2

0

12

16

0

96

0

Function

Not used. Fixed to Off.

Not used. Fixed to On.

Paper near-end sensor. Paper adequate.

Paper near-end is detected by the paper near-end sensor.

Not used. Fixed to On.

Paper end sensor. Paper adequate.

Paper end is detected by the paper end sensor.

Not used. Fixed to Off.

Page 23

4039

Control commands list

Chapter 5

DLE ENQ n

[Name] Real-time request to printer

[Format] ASCII DLE ENQ n

Hex 10 05 n

Decimal 16 5 n

[Range] n = 0, n = 2

[Description] The printer responds to a request from the host specified by n.

n = 0: Recovers to on-line state.

n = 2: Recovers from an error after clearing the receive and print buffers.

[Notes]

This command should not be used within the data sequence of

another command that consists of two or more bytes. For example,

If you attempt to transmit ESC 3 n to the printer, but DTR (DSR for the

host computer) goes to MARK before n is transmitted, and DLE ENQ 2

interrupts before n is received, the code <10>H for DLE ENQ 2 is

processed as the code for ESC 3 <10>H.

This command n = 2 is valid only when a mechanical error or an

auto-cutter error has occurred.

DLE ENQ 2 enables the printer to recover from an error after clearing

the data in the receive buffer and the print buffer.

The printer retains the settings (by ESC !, ESC 3, etc.) in effect when

the error occurred. The printer can be initialized completely by using

this command and ESC @. This command is enabled only for errors

that have the possibility of recovery

ESC SP n

[Name] Set right-side character spacing

[Format] ASCII ESC SP n

Hex 1B 20 n

Decimal 27 32 n

[Range] 0 ≤ n ≤ 255

[Description] Sets the character spacing for the right side of the character to

[ n x 0.122 mm {1/208 inches}] .

[Notes] The right-side character spacing for double-width mode is

twice the normal value.

[Default] n = 0

ESC ! n

[Name] Select print mode(s)

[Format] ASCII ESC ! n

Hex 1B 21 n

Decimal 27 33 n

[Range] 0 ≤ n ≤ 255

[Description] Selects print mode(s) using n as follows:

[Notes]

When both double-height and double-width modes are selected,

quadruple size characters are printed.

Underlining is added to the entire width of each character,

including the space to the right of a character, but is not added to

portions of lines that were skipped by means of an HT.

[Default] n = 1

[Reference] ESC E, ESC –

Bit

0

1

2

3

4

5

6

7

Off/On

Off

On

-

Off

On

Off

On

Off

On

Off

On

Hex

00

01

-

00

08

00

10

00

20

00

80

Decimal

0

1

-

0

8

0

16

0

32

0

128

Function

Character font A (12 x 14) selected.

Character font B (12 x 12) selected.

Undefined.

Undefined.

Emphasized mode not selected.

Emphasized mode selected.

Double-height mode not selected.

Double-height mode selected.

Double-width mode not selected.

Double-width mode selected.

Undefined.

Underline mode not selected.

Underline mode selected.

Page 24

4241

Control commands list

Chapter 5

ESC % n

[Name] Select/cancel user-defined character set

[Format] ASCII ESC % n

Hex 1B 25 n

Decimal 27 37 n

[Range] 0 ≤ n ≤ 255

[Description] Selects or cancels the user-defined character set.

When the Least Significant Bit (LSB) is 0, the user-defined character

set is canceled and the internal character set is enabled.

When the LSB is 1, the user-defined character set is selected.

[Notes]

When the downloaded character set has been released,

the internal character set is specified automatically.

[Default] n = 0

[Reference] ESC &, ESC ?

ESC & y c1 c2 [x1 d1...d(y x x1)]...[ xk d1... d(y x xk)]

[Name] Define user-defined characters

[Format] ASCII ESC & y c1 c2 [x1 d1...d(y x x1)]...[ xk d1... d(y x xk)]

Hex 1B 26 y c1 c2 [x1 d1...d(y x x1)]...[ xk d1... d(y x xk)]

Decimal 27 38 y c1 c2 [x1 d1...d(y x x1)]...[ xk d1... d(y x xk)]

[Range] y = 2

32 ≤ c1 ≤ c2 ≤ 255

0 ≤ x ≤ 14 (Font A)

0 ≤ x ≤ 12 (Font B)

0 ≤ d1 ... d(y x x) ≤ 255

[Description] Defines user-defined characters.

y specifies the number of bytes in the vertical direction.

c1 specifies the beginning character code for the definition, and c2

specifies the final code. When only one character is desired, use c1 = c2.

x specifies the number of dots in the horizontal direction.

[Notes]

Consecutive character codes for multiple characters can be defined in

one definition. When specifying only one character, specify c1 = c2.

"d" is definition data that indicates the pattern for " x" dots in the horizontal

direction starting from the left edge. If " x" does not satisfy the number of

dots in the character configuration pattern, the remaining dots on the right

are spaces.

The number of bytes required to download a character definition for one

character is " y" x " x".

In the definition data, a "1" represents a dot that is to be printed, and a "0"

represents a dot that is not to be printed.

Independent downloaded character definitions are possible for each font.

The font is selected by the "ESC !" command.

The defined downloaded characters are cleared in the following

circumstances:

1) When "ESC @" is executed

2) When deleted by "ESC ?"

3) When the printer is reset or turned off

[Default] The internal character set

[Reference] ESC %, ESC ?

Page 25

4443

ESC * m nL nH d1...dk

[Name] Select bit-image mode

[Format] ASCII ESC * m nL nH d1...dk

Hex 1B 2A m nL nH d1...dk

Decimal 27 42 m nL nH d1...dk

[Range] m = 0, 1

0 ≤ nL ≤ 255

0 ≤ nH ≤ 3

0 ≤ d ≤ 255

[Description] Selects a bit-image mode using m for the number of dots specified

by nL and nH

Divide the number of dots to be printed by 256. The interger answer is

nH and the remainder is nL. Therefore, the number of dots in the

horizontal direction is calculated by nL + 256 x nH.

If the bit-image data input exceeds the number of dots to be printed on

a line, the excess data is ignored.

d indicates the bit-image data. Set a corresponding bit to 1 to print a dot

or to 0 to not print a dot.

The bit-image modes selectable by m are as follows.

[Notes]

If the values of m and nH are out of the specified range, the following

data is processed as normal data.

After printing a bit image, the printer returns to normal data processing

mode.

The relationship between the image data and the dots to be printed is

as follows.

Control commands list

Chapter 5

m

0

1

No. of Vertical Dots

8

8

Dot Density

Single Density

Double Density

Adjacent

Dot

Permitted

Permitted

Maximum number of

dots

252

504

ESC - n

[Name] Turn underline mode on/off

[Format] ASCII ESC - n

Hex 1B 2D n

Decimal 27 45 n

[Range] n = 0, 1, 48, 49

[Description] Turns underline mode on or off,

When n = 0 or 48, underline mode is turned off.

When n = 1 or 49, underline mode is turned on.

[Notes]

Underlines can be printed for all characters,

but not for the space set by HT.

This command and ESC ! turn underline mode on or off in the same way.

If n is out of the specified range, this command is ignored.

[Default] n = 0

[Reference] ESC !

ESC 2

[Name] Select default line spacing

[Format] ASCII ESC 2

Hex 1B 32

Decimal 27 50

[Description] Selects default (1/6-inch) line spacing.

[Reference] ESC 3

Page 26

4645

ESC 3 n

[Name] Set line spacing

[Format] ASCII ESC 3 n

Hex 1B 33 n

Decimal 27 51 n

[Range] 0 ≤ d ≤ 255

[Description] Sets the line spacing to [ n x (1/192)] inches.

[Default] n = 32 (1/6 inch)

[Reference] ESC 2

ESC <

[Name] Return home

[Format] ASCII ESC <

Hex 1B 3C

Decimal 27 60

[Description] Moves the print head to the standby position.

[Notes]

The leftmost end is detected by the home position sensor.

Since the home position is detected when this command is executed,

the printing position may shift after this command is executed.

ESC = n

[Name] Select device

[Format] ASCII ESC = n

Hex 1B 3D n

Decimal 27 61 n

[Range] n = 1

[Description] Selects device to which host computer sends data.

n = 1 ; enable

n = 2 ; disable

[Default] n = 1

Control commands list

Chapter 5

ESC ? n

[Name] Cancel user-defined characters

[Format] ASCII ESC ? n

Hex 1B 3F n

Decimal 27 63 n

[Range] 32 ≤ n ≤ 255

[Description] Cancels user-defined characters.

[Notes]

This command cancels the pattern defined for the character code

specified by n. After the user-defined characters is cancelled, the

corresponding pattern for the internal character is printed.

This command deletes the defined pattern for the specified code in

the character font selected by the "ESC !" command.

If a user-defined character has not been defined for the specified

character code, the printer ignores this command.

[Reference] ESC &, ESC %

ESC @

[Name] Initialize printer

[Format] ASCII ESC @

Hex 1B 40

Decimal 27 64

[Description] Clears the data in the print buffer and resets the printer mode to the mode

that was in effect when the power was turned on.

[Notes]

The DIP switch settings are not checked again.

The data in the receive buffer is not cleared.

Page 27

4847

ESC D n1... nk NUL

[Name] Set horizontal tab positions

[Format] ASCII ESC D n1...nk NUL

Hex 1B 44 n1...nk 00

Decimal 27 68 n1...nk 0

[Range] 1 ≤ d ≤ 255

0 ≤ k ≤ 32

[Description] Sets horizontal tab positions.

n specifies the column number (counted from the beginning of the line)

for setting a horizontal tab position.

k indicates the total number of horizontal tab positions to be set.

[Notes]

The tab position is set at [character width x n] from the beginning

of the line. The character width includes the right-side space of the

character, and is twice the normal value when double-width is specified.

This command deletes horizontal tab positions that have already

been set.

When "n = 8" has been set for the horizontal tab position,

the printing position moves to the ninth digit when HT is executed.

Up to 32 tab positions can be set. Data exceeding 32 tab positions

is processed as normal data. Input <n>k in ascending order and place

a NUL code <00>H at the end when <n>k is less than or equal to the

preceding value <n>k-1, tab setting is finished and the following data

is processed as normal data.

ESC D NUL cancels all horizontal tab positions.

The previously specified horizontal tab positions do not change,

even if the character width changes.

[Default] The default tab positions are at intervals of 8 characters

(columns 9, 17, 25, ...) for the font B (12 x 14).

[Reference] HT

Control commands list

Chapter 5

ESC E n

[Name] Turn emphasized mode on/off

[Format] ASCII ESC E n

Hex 1B 45 n

Decimal 27 69 n

[Range] 32 ≤ n ≤ 255

[Description] Turns emphasized mode on or off.

When the LSB of n is 0, emphasized mode is turned off.

When the LSB of n is 1, emphasized mode is turned on.

[Notes] * Printing is slower in emphasized mode.

Only the lowest bit of n is enabled.

The printer does not emphasize bit-images.

This command and ESC ! turn on and off emphasized mode in the

same way. The last proceeded command becomes effective.

Printer output is the same in double-strike (ESC G) and in emphasized.

[Default] n = 0

[Reference] ESC !, ESC G

Page 28

5049

ESC G n

[Name] Turn double-strike mode on/off

[Format] ASCII ESC G n

Hex 1B 47 n

Decimal 27 71 n

[Range] 0 ≤ n ≤ 255

[Description] Turns double-strike mode on or off.

When the LSB of n is 0, double-strike mode is turned off.

When the LSB of n is 1, double-strike mode is turned on.

[Notes] * Printing is slower in double-strike mode.

Only the lowest bit of n is enabled.

The printer does not double-strike for bit-images.

Printer output is the same in double-strike and in emphasized (ESC E).

[Default] n = 0

[Reference] ESC E

ESC J n

[Name] Print and feed paper

[Format] ASCII ESC J n

Hex 1B 4A n

Decimal 27 74 n

[Description] Prints the data in the print buffer and feeds the paper

[ n x 0.122mm {1/192 inches}] .

[Notes]

After printing is completed, this command sets the print starting position

to the beginning of the line.

This command has no effect on the line feed amount set by the "ESC 2"

command or the "ESC 3" command.

Control commands list

Chapter 5

ESC R n

[Name] Select an international character set

[Format] ASCII ESC R n

Hex 1B 52 n

Decimal 27 82 n

[Range] 0 ≤ n ≤ 10

[Description] Selects an international character set n from the following table:

[Default] n = 0

ESC U n

[Name] Turn unidirectional printing mode on/off

[Format] ASCII ESC U n

Hex 1B 55 n

Decimal 27 85 n

[Range] 0 ≤ n ≤ 255

[Description] Turns unidirectional printing mode on or off

When the LSB of n is 1, turn on unidirectional printing mode.

[Notes]

Only the lowest bit of n is enabled.

To avoid horizontal printing misalignment, unidirectional printing

mode should be used.

[Default] n = 0

n

0

1

2

3

4

5

6

7

8

9

10

Character set

U.S.A

France

Germany

U.K.

Denmark I

Sweden

Italy

Spain I

--Norway

Denmark II

Page 29

5251

ESC a n

[Name] Select justification

[Format] ASCII ESC a n

Hex 1B 61 n

Decimal 27 97 n

[Range] 0 ≤ n ≤ 2, 48 ≤ n ≤ 50

[Description] Aligns all the data in one line to the specified position.

n selects the type of justification as follows:

[Notes]

The command is enabled only when input at the beginning of the line.

A portion of data skipped by means of HT is also target data for the

justification function.

[Default] n = 0

[Example]

Control commands list

Chapter 5

n

0, 48

1, 49

2, 50

Justification

Left justification

Centering

Right justification

Left justification

ABC

ABCD

ABCDE

Right justification

ABCC

ABCDC

ABCDEC

Centering

ABC

ABCD

ABCDE

ESC c 3 n

[Name] Select paper detector(s)to output paper end signals

[Format] ASCII ESC c 3 n

Hex 1B 63 33 n

Decimal 27 99 51 n

[Range] 0 ≤ n ≤ 255

[Description] Selects paper detector(s) to output paper end signals, using n as follows:

[Notes]

It is possible to select multiple detectors to output signals.

Then, if any of the detectors detects a paper end, the paper

end signal is output.

Detectors are switched when executing this command.

Because of this, the paper-out signal switching may delay depending

on the receive buffer state.

[Default] n = 15

Bit

0

1

2

3

4

5

6

7

Off/On

Off

On

Off

On

Off

On

Off

On

-

-

-

-

Hex

00

01

00

02

00

04

00

08

-

-

-

-

Decimal

0

1

0

2

0

4

0

8

-

-

-

-

Function

Paper roll near end sensor disabled.

Paper roll near end sensor enabled.

Paper roll near end sensor disabled.

Paper roll near end sensor enabled.

Paper roll end detector disabled.

Paper roll end detector enabled.

Paper roll end detector disabled.

Paper roll end detector enable.

Undefined

Undefined

Undefined

Undefined

Page 30

5453

Control commands list

Chapter 5

ESC c 4 n

[Name] Select paper sensor(s)to stop printing

[Format] ASCll ESC c 4 n

Hex 18 63 34 n

Decimal 27 99 52 n

[Range] 0 ≤ n ≤ 255

[Description] Selects the paper sensor(s) used to stop printing when a paper-end

is detected, using n as follows :

[Notes]

The printer goes off-line after printing stops.

The paper roll near-end sensor is an option, therefore,

if the paper roll near-end sensor is enabled by this command when the

sensor is not equipped, it does not stop printing.

The paper roll near-end sensor is enabled when either bit 0 or 1 is 1.

The paper roll end sensor is a sensor which is always used to

make an effective to stop printing.

[Default] n = 0

Bit

0

1

2

3

4

5

6

7

Off/On

Off

On

Off

On

-

-

-

-

-

-

Hex

00

01

00

02

-

-

-

-

-

-

Decimal

0

1

0

2

-

-

-

-

-

-

Function

Paper roll near end sensor disabled.

Paper roll near end sensor enabled.

Paper roll near end sensor disabled.

Paper roll near end sensor enabled.

Undefined

Undefined

Undefined

Undefined

Undefined

Undefined

ESC c 5 n

[Name] Enable/disable panel buttons

[Format] ASCII ESC c 5 n

Hex 1B 63 35 n

Decimal 27 99 53 n

[Range] 0 ≤ n ≤ 255

[Description] Enables or disables the panel buttons.

When the LSB of n is 0, the panel buttons are enabled.

When the LSB of n is 1, the panel buttons are disabled.

[Notes]

Only the least significant bit of "n" is valid.

When the panel buttons are disabled, no buttons on the panel are usable.

If "disabled" is set, the paper feed switch no longer functions.

[Default] n = 0

ESC d n

[Name] Print and feed n lines

[Format] ASCII ESC d n

Hex 1B 64 n

Decimal 27 100 n

[Range] 0 ≤ n ≤ 255

[Description] Prints the data in the print buffer and feeds n lines.

[Notes]

This command sets the print starting position to the beginning of the line.

The amount of paper fed per line is based on the value set using the line

spacing command (ESC 2 or ESC 3)

[Reference]

Page 31

5655

Control commands list

Chapter 5

ESC m

[Name] Execute partial cut

[Format] ASCII ESC m

Hex 1B 6D

Decimal 27 109

[Description] Execute partial cut with one point uncut

ESC p m t1 t2

[Name] Generate pulse

[Format] ASCII ESC p m t1 t2

Hex 1B 70 m t1 t2

Decimal 27 112 m t1 t2

[Range] m = 0, 1, 48, 49

0 ≤ t1 ≤ 255

0 ≤ t2 ≤ 255

[Description] Outputs the pulse specified by t1 and t2 to connector pin m as follows:

[Notes]

The pulse ON time is [ t1 x 2] ms and the OFF time is [ t2 x 2] ms.

When t2 < t1, the printer processes t1 x 2 ms.

[Reference]

m

0

1

Connector Pin

Drawer kick-out connector pin 2

Drawer kick-out connector pin 5

ESC r n

[Name] Select print color

[Format] ASCII ESC r n

Hex 1B 72 n

Decimal 27 114 n

[Range] n = 0, 1, 48, 49

[Description] Selects the print color.

[Notes]

Valid only when input at the beginning of a line.

[Default] n = 0

n

0, 48

1,49

Selected color

Black

Red

ESC t n

[Name] Select character code table

[Format] ASCII ESC t n

Hex 1B 74 n

Decimal 27 116 n

[Range] n = 0, 2, 3, 4, 5, 16, 17, 18, 19, 21, 22, 23

[Description] Selects a page n from the character code table.

[Default] n = 0

[Reference]

n

0

2

3

4

5

16

17

18

19

21

22

23

Page

PC437

PC850

PC860

PC863

PC865

PC1252

PC866

PC852

PC858

PC862

PC864

PC874

Page 32

5857

Control commands list

Chapter 5

ESC { n

[Name] Turns on/off upside-down printing mode

[Format] ASCII ESC { n

Hex 1B 7B n

Decimal 27 123 n

[Range] 0 ≤ n ≤ 255

[Description] Turns upside-down printing mode on or off.

When the LSB of n is 0, upside-down printing mode is turned off.

When the LSB of n is 1, upside-down printing mode is turned on.

[Notes]

Only the lowest bit of n is effective.

This command is enabled only when input at the beginning of a line.

In upside-down printing mode, the printer rotates the line to be

printed by 180° and then prints it.

[Default] n = 0

[Example]

Upside-down printing mode is furned off

Paper feed direction

ABCDEF

n012345

Upside-down printing mode is furned on

n012345

ABCDEF

GS I n

[Name] Transmit printer ID

[Format] ASCII GS I n

Hex 1D 49 n

Decimal 29 73 n

[Range] 1 ≤ n ≤ 3

[Function] Transmits the printer ID specified by n as follows:

n = 2, Type ID

[Notes]

The printer ID is transmitted when the data in the receive buffer is

developed. Therefore, there may be a time lag between receiving

this command and transmitting the status, depending on the

receive buffer status.

[Reference]

n

1,49

2,50

3,51

Printer ID

Printer model ID

Type ID

ROM version ID

Specification

SRP-500 series See table

below

ROM version

ID (hexadecimal)

0D

Bit

0

1

2

3

4

5

6

7

Off/On

Off

On

Off

On

-

-

Off

-

-

Off

Hex

00

01

00

02

-

-

00

-

-

00

Decimal

0

1

0

2

-

-

0

-

-

0

Function

Two-byte character code not supported.

Two-byte character code supported.

Auto cutter not equipped.

Auto cutter equipped.

Undefined.

Undefined.

Not used. Fixed to Off.

Undefined.

Undefined.

Not used. Fixed to Off.

Page 33

6059

Control commands list

Chapter 5

GS a n

[Name] Enable/Disable Automatic Status Back

[Format] ASCII GS a n

Hex 1D 61 n

Decimal 29 97 n

[Range] 0 ≤ n ≤ 255

[Description] Enables or disables ASB and specifies the status items to include,

using n as follows:

1 GS V m

2 GS V m n

[Name] Feeds paper for cutting position.

[Format] 1 ASCll GS V m

Hex 1D 56 m

Decimal 29 86 m

2 ASCll GS V m n

Hex 1D 56 m n

Decimal 29 86 m n

[Range] 1 m = 1, 49 2 m = 66, 0 ≤ n ≤ 255

[Description] Feeds paper for cutting position as follows;

[Notes]

This command is effective only at the beginning of a line.

When n = 0, the printer feeds the paper to the cutting position.

When n , 0,the printer feeds the paper to

(cutting position +[ n x 0.122 mm {1/192 inches}]).

Bit

1, 49

66

Print mode

Partial cut (one portion left uncut)

Feeds paper for ( cutting position + [n x 0.122 mm {1/192 inches}]), and partial cut.

Bit

0

1

2

3

4

5

6

7

Off/On

Off

On

Off

On

Off

On

Off

On

-

-

-

-

Hex

00

01

00

02

00

04

00

08

-

-

-

-

Decimal

0

1

0

2

0

4

0

8

-

-

-

-

Status for ASB

Drawer kick-out connector pin 3 status disabled.

Drawer kick-out connector pin 3 status enabled.

On-line/off-line disabled.

On-line/off-line enabled

Error status disabled.

Error status enabled.

Paper roll sensor status disabled.

Paper roll sensor status enabled.

Undefined.

Undefined.

Undefined.

Undefined.

[Notes]

Even if only one of the statuses is enabled, the status is sent when

this command is executed. Subsequently, whenever the state of a

valid status changes, that status is sent. In this case, because the

current state is shown for each status, there is a possibility of a

state change for a status for which ASB is not enabled.

If all statuses are disabled, the Automatic Status Back (ASB)

function is disabled.

When transmitting a status, the printer transmits only four bytes.

Four bytes of status data must be consecutive, except for XOFF code.

This command is executed when the data in the receive buffer is

developed. Therefore, there may be a time lag between receiving

this command and transmitting the status, depending on the

receive buffer status.

When the printer is disabled by ESC = (Select peripheral device),

this command is disabled but ASB is not disabled.

The status to be transmitted are as follows:

Page 34

6261

Control commands list

Chapter 5

First byte (printer information)

Bit

0

1

2

3

4

5

6

7

Off/On

Off

Off

Off

On

Off

On

On

Off

Off

On

Off

Hex

00

00

00

04

00

08

10

00

00

40

00

Decimal

0

0

0

4

0

8

16

0

0

64

0

Function

Not used. Fixed to Off.

Not used. Fixed to Off.

Drawer kick-out connector pin 3 is LOW.

Drawer kick-out connector pin 3 is HIGH.

On-line.

Off-line.

Not used. Fixed to On.

Not used. Fixed to Off.

Paper is not being fed by the paper feed button.

Paper is being fed by the paper feed button.

Not used. Fixed to Off.

Second byte (printer information)

Bit

0

1

2

3

4

5

6

7

Off/On

Off

Off

Off

On

Off

On

Off

Off

On

Off

Off

Hex

00

00

00

04

00

08

00

00

20

00

00

Decimal

0

0

0

4

0

8

0

0

32

0

0

Function

Not used. Fixed to Off.

Not used. Fixed to Off.

No mechanical error.

Mechanical error.

No auto cutter error.

Auto cutter error occurred.

Not used. Fixed to Off.

No unrecoverable error.

Unrecoverable error.

Not used. Fixed to Off.

Not used. Fixed to Off.

Third byte (paper sensor information)

Bit

0, 1

2, 3

4

5

6

7

Off/On

Off

On

Off

On

Off

Off

Off

Off

Hex

00

03

00

0C

00

00

00

00

Decimal

0

3

0

12

0

0

0

0

Function

Paper near-end sensor: paper adequate. Paper

near-end sensor: paper near end.

Paper end sensor: paper present. Paper end sensor:

no paper present.

Not used. Fixed to Off.

Not used. Fixed to Off.

Not used. Fixed to Off.

Not used. Fixed to Off.

Fourth byte (paper sensor information)

Bit

0

1

2

3

4

5

6

7

Off/On

On

On

On

On

Off

Off

Off

Off

Hex

01

02

04

08

00

00

00

00

Decimal

1

2

4

8

0

0

0

0

Function

Not used. Fixed to On.

Not used. Fixed to On.

Not used. Fixed to On.

Not used. Fixed to On.

Not used. Fixed to Off.

Not used. Fixed to Off.

Not used. Fixed to Off.

Not used. Fixed to Off.

[Default] n = 0

[Reference]

Page 35

6463

Control commands list

Chapter 5

GS r n

[Name] Transmit status

[Format] ASCII GS r n

Hex 1D 72 n

Decimal 29 114 n

[Range] 1 ≤ n ≤ 2, 49 ≤ n ≤ 50

[Description] Transmits the status specified by n as, follows:

Paper sensor status (n = 1, 49)

[Notes]

This command is executed when the data in the receive buffer is

developed. Therefore, there may be a time lag between receiving this

command and transmitting the status, depending on the receive buffer status.

The status types to be transmitted are shown below:

[Reference]

Bit

0, 1

2, 3

4

5

6

7

Off/On

Off

On

Off

On

Off

Off

Off

Off

Hex

00

03

00

0C

00

00

00

00

Decimal

0

3

0

12

0

0

0

0

Status for ASB

Paper near-end sensor: paper present. Paper nearend sensor: paper near end.

Paper end sensor. Paper present. Paper end sensor:

no paper present.

Not used. Fixed to Off.

Not used. Fixed to Off.

Not used. Fixed to Off.

Not used. Fixed to Off.

Drawer kick-out connector status (n = 2,50)

Bit

0

1

2

3

4

6

7

Off/On

Off

On

Off

Off

Off

Off

Off

Off

Hex

00

01

00

00

00

00

00

00

Decimal

0

1

0

0

0

0

0

0

Status for ASB

Drawer kick-out connector pin 3 is LOW. Drawer

kick-out connector pin 3 is HIGH.

Not used. Fixed to Off.

Not used. Fixed to Off.

Not used. Fixed to Off.

Not used. Fixed to Off.

Not used. Fixed to Off.

Not used. Fixed to Off.

n

0, 48

1,49

Function

Transmits paper sensor status

Transmits drawer kick-out connector status

Reference information

Chapter 6

6-3. Ink cartridge specification

Model

Firing frequency

Operating Voltage

Resistance

Operating Temperature

Date of expiration

HP 6602X

3.0KHz – low density printing(Text)

1.5KHz – high density printing(Graphic)

19.9 ± 0.5V

60 Ω

10~40 ˚C

Two years after production

(at normal temperature)

6-2. Paper specification

Paper roll

Type

Size

Thickness

Maximum outside diameter

Paper core inside diameter

Normal paper

Width : 76 ± 0.5(mm)

0.06 to 0.09(mm)

ø 83mm

ø 10 to 12.5(mm)

Notice

Follow the laws or regulations of your country or community for disposing of used

ink cartridges.

6-1. Printing specification

Printing method

Printing direction

Resolution

Characters per line

Printing speed

printing Width

Line Interval

Character sets

Character font

Serial ink jet matrix method

Bidirectional(logic seeking) with friction feed

104 x 96(dpi): Text

208 x 96(dpi): Graphic

Max 42(characters)

6.5 LPS (Lines Per Second)

at 40 columns

63.5mm

4.233mm (1/6”)

Alphanumeric characters: 95

International characters: 32

Extended graphics: 128 x 12 pages

12 x 12 / 12 x 14

Page 36

Reference information

Chapter 6

6665

6-6. Environmental condition

Operating

Storage

Shipping

Relative Humidity

10 ˚ to 40 ˚C

-10 ˚ to 60 ˚C

-40 ˚ to 70 ˚C

Operating : 10 to 90% RH (non-condensing)

Storage : 10 to 90% RH (non-condensing)

Shipping : 5 to 90% RH (non-condensing)

6-5. Reliability

Life

Firing frequency

MTBF

Mechanism : 15,000,000 lines

Auto cutter : 500,000 cuts

(End of Life is defined as the point at

which the printer reaches the beginning

of the Wear out Period.)

30,000 hours

(Failure is defined as Random Failure occurring at

the time of the Random Failure Period.)

Notice

Maximum 1A for drawer kick-out driving

The printer will run its best when stored and operated in an environment

that meets the following temperature and humidity conditions:

* Exposure to high or low temperatures for periods of greater than

48 hours will lead to significantly reduced cartridge life.

6-4. Electrical characteristics

Supply voltage

Current

consumption

(at 24V,except for drawer

kick –out driving)

Operating

Standby

24V DC ± 5%

Mean : Approximately 0.5A

Peak : Approximately 1.5A

Mean : Approximately 0.3A

6-7. Dimensions & Weight

Dimension

W

D

H

6-8 . Optional features

The optional features either replace a standard feature or enhance the

operation of the printer. All optional features are installed at the factory and

must be selected when the printer is ordered.

Two color printing (Black / Red / Green / Blue)

Interface (serial / parallel / USB)

Cabinet color (Ivory / Dark gray)

Weight

Approx. Wt : 2.7kg

Shipping. Wt : 3.5Kg

Dimensions(mm)

W

172

D

226

H

152

Page 37

Memo

Loading...

Loading...