Page 1

USER’S MANUAL

SRP-275

IMPACT PRINTER

All specifications are subjected to change without notice

www.samsungminiprinters.com

Page 2

Page 3

SRP-275

All rights reserved. No part of this publication may reproduced, stored in a retrieval, or transmitted in an y

form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior

written permission of SAMSUNG ELECTRO-MECHANICS.

No patent liability is assumed with respect to the use of the information contained herein. While every

precaution has been taken in the preparation of this book, SAMSUNG ELECTRO-MECHANICS assumed no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of

the information contained herein.

Neither SAMSUNG ELECTRO-MECHANICS nor its affiliates shall be liable to the purchaser of this product

or third parties for damages, losses, costs, or expenses incurred by purchaser or third parties as a result of :

accident, misuse, or abuse of this product or unauthorized modifications, repairs, or alterations to this

product, or (excluding the U.S.) failure to strictly comply with SAMSUNG ELECTRO-MECHANICS s

operating and maintenance instructions.

SAMSUNG ELECTRO-MECHANICS shall not be liable against any damages or problems arising from the

use of any options or ant consumable products other than those designated as Original Samsung products

or Samsung Approved products by SAMSUNG ELECTRO-MECHANICS.

------------------------------------------------------------------------------------------------------------------------------------------------

Notice

The contents of this manual are subject to change without notice.

Copyright© 2004 SAMSUNG ELECTRO-MECHANICS CO., LTD

------------------------------------------------------------------------------------------------------------------------------------------------

EMC and Safety standards Applied

Product Name : SRP-275

The following standards are applied only to the printers that are so labeled.

Europe :

North America : EMI : FCC Class A

Safety standards : UL / C-UL : UL60950-1

National : CB-scheme : IEC 60950-1: 2001

------------------------------------------------------------------------------------------------------------------------------------------------

WARNING

The connection of a non-shielded printer interface cable to this printer will invalidate the EMC standards of

this device. You are cautioned that changes or modifications not expressly approved by the party

responsible for compliance could void your authority to operate the equipment.

------------------------------------------------------------------------------------------------------------------------------------------------

CE Marking

The printer conforms to the following Directive and Norms

EMC Directive 89/336/EEC EN55022 Class A : 1998+A1 : 2000

Low Voltage Directive 73/23/EEC Safety : EN60950-1 : 2001

CE marking, TUV/GS : EN60950-1; 2001

EN55024 : 1998:+A1 : 2001

EN61000-3-2 : 2000

EN61000-3-3 : 1995+A1 : 2001

Page 4

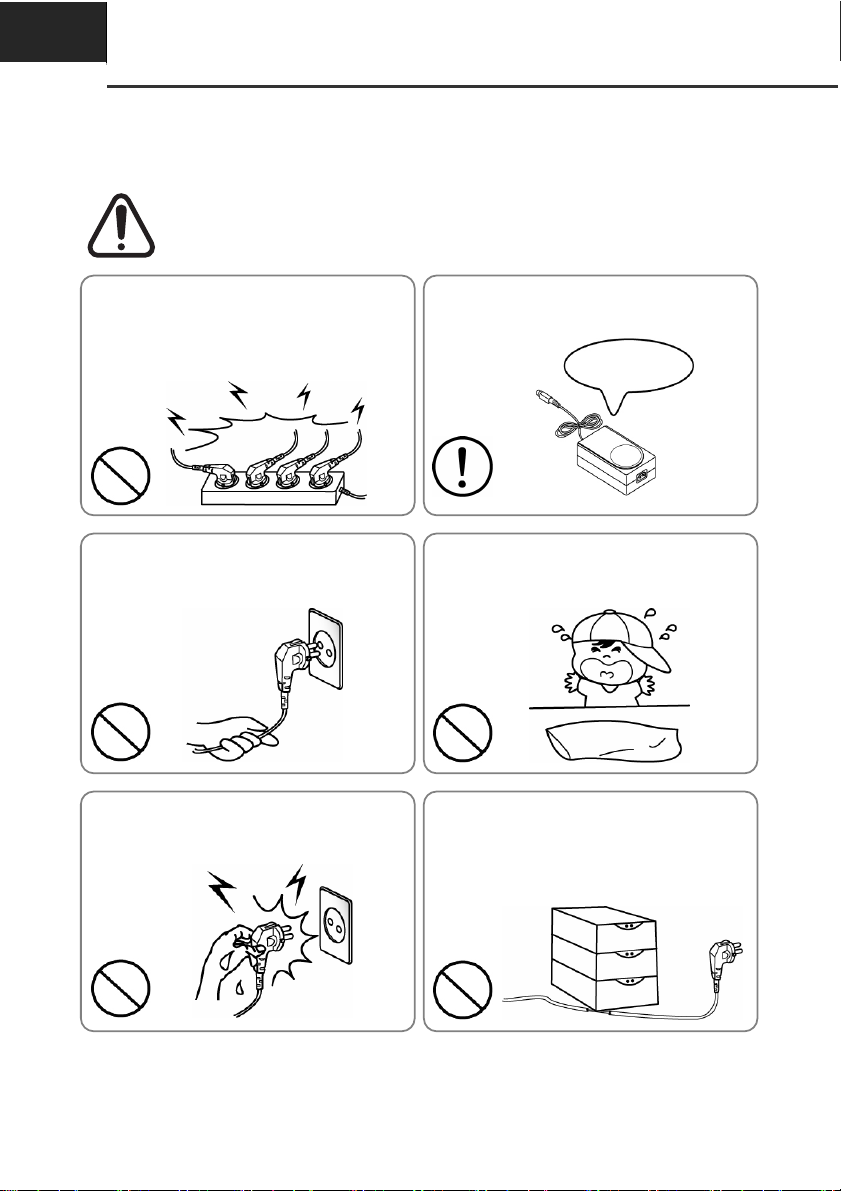

Safety precautions

▌In using the present appliance, please keep the following safety regulations in

order to prevent any hazard or material damage.

WARNING

Violating following instructions can cause serious injury or death.

Do not plug several products in one multi-outlet.

• This can provoke over-heating a nd a fire.

• If the plug is wet or dirty, dry or wipe it before usage.

• If the plug does not fit perfec tly with the outlet, do not plug in.

• Be sure to use only standardized multi-outle ts.

PROHIBIT

You must use only the supplied adapter.

• It is dangerous to use other adapters.

ONLY SUPPLIED ADAPTER

Do not pull the cable to unplug.

• This can damage the c able, which is the origin of a fire or a

breakdown of the printer.

PROHIBIT

Do not plug in or unplug with your hands wet.

• You can be electrocuted.

PROHIBIT

Keep the plastic bag out of children’s reach.

• If not, a child may put the bag on his head.

PROHIBIT

Do not bend the cable by force or leave it under any

heavy object.

• A damaged cable can cause a fire.

PROHIBIT

Page 5

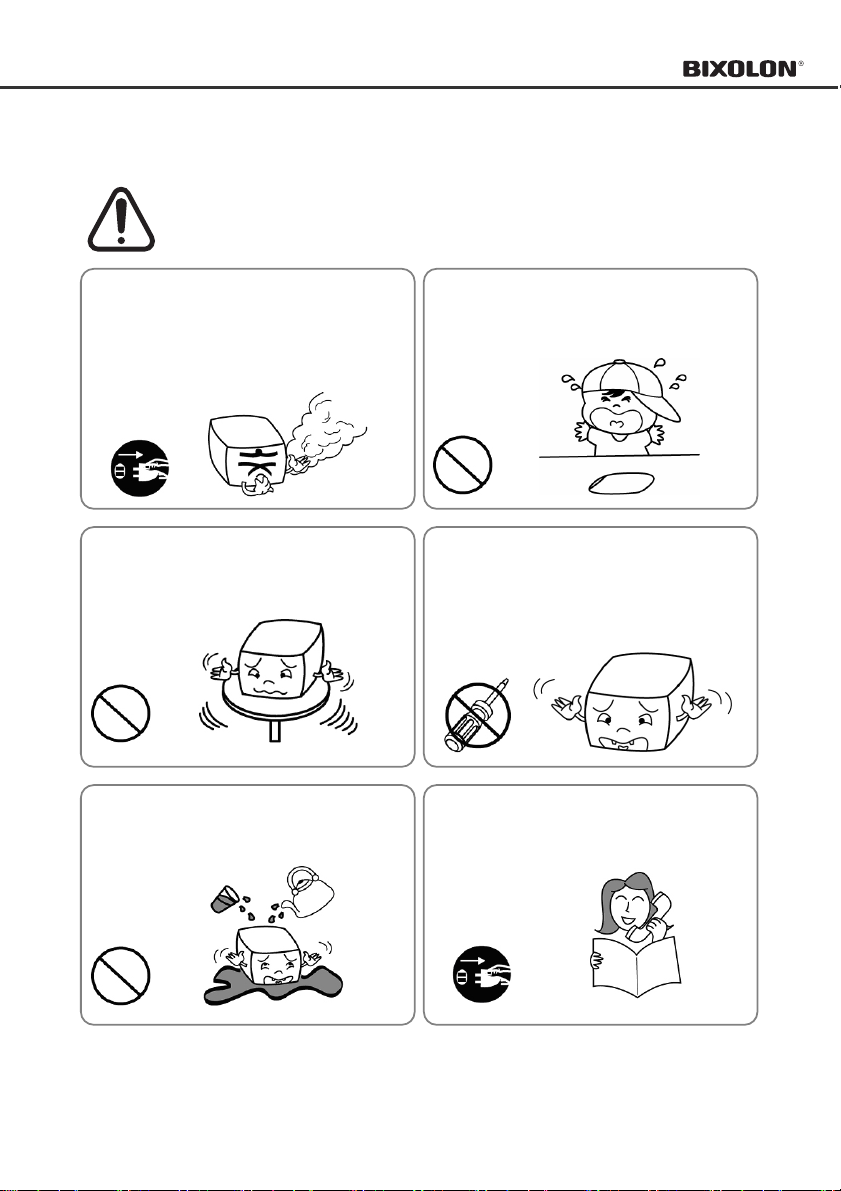

WARNING

Violating following instructions can cause serious injury or death.

If you observe a strange smoke, odor or noise from

the printer, unplug it before taking following

measures.

• Switch off the printer and unplug the set from the mains.

• After the disappear ance of the smoke, call your dea ler to

repair it.

Keep the desiccant out of children’s reach.

• If not, they may eat it.

TO UNPLUG

PRINTER

Install the printer on t he stable surface.

• If the prin ter falls down, it can be br oken and you can hurt

yourself.

PRINTER

PROHIBIT

Do not let water or other foreign objects in the

printer.

• If this happened, switch off and unplug the printer before

calling your dealer.

PROHIBIT

PRINTER

PROHIBIT

Use only approved acce ssories and do not try to

disassemble, repair or remodel it for yourself.

• Call your dealer when you need thes e services.

• Do not touch the blade of auto cutter.

DISASSEMBLING

PROHIBITED

Do not use the printer when it is out of order. This

can cause a fire or an electrocution.

• Switch off and unplug the printer before calling your dealer.

TO UNPLUG

PRINTER

PRINTER

DEALER

Page 6

Table of contents

Chapter 1 Setting up the printer

1.1 Unpacking ···················································································································· 1-1

1.2 Choosing a place for the printer ················································································· 1-1

1.3 Connecting the cables································································································· 1-2

1.3.1 Connecting the AC adaptor ············································································ 1-2

1.3.2 Connecting the interface cable and drawer kick-out cable···························· 1-2

1.4 Installing the ribbon cassette ······················································································ 1-3

1.5 Installing the paper roll ································································································ 1-4

1.6 Changing the paper width ··························································································· 1-5

1.7 Installing the wall mount (Option) ··············································································· 1-6

1.8 Using the operation panel ··························································································· 1-7

1.9 Self test························································································································ 1-8

Chapter 2 Troubleshooting

2.1 ERROR LED blinking pattern ····················································································· 2-1

2.2 The printer does not start printing··············································································· 2-2

2.3 The printer stops printing ···························································································· 2-3

2.4 You want to check the operation of the printer by itself ············································· 2-3

2.5 Printing is poor ············································································································ 2-4

2.6 You want to check a software program ······································································ 2-4

Chapter 3 Setting the switches

3.1 Setting the DIP Switch ································································································ 3-1

3.1.1 DIP Switch setting for Epson(ESC/POS) mode············································· 3-1

3.1.2 DIP Switch setting for Citizen(iDP 3550) mode ············································· 3-2

3.1.3 DIP Switch setting for Star(SP500) mode······················································ 3-3

3.1.4 Changing the DIP Switch setting···································································· 3-4

3.2 Setting the Memory Switches ····················································································· 3-5

3.2.1 Memory Switch setting for Epson(ESC/POS) mode ····································· 3-5

3.2.2 Memory Switch setting for Star mode ···························································· 3-9

Chapter 4 Control commands list

4.1 Command notation······································································································ 4-1

4.2 Explanation of term ····································································································· 4-1

4.3 Exception processing ·································································································· 4-2

4.4 Commands for SRP-275 series ·················································································· 4-3

4.4.1 Commands list for EPSON mode (TM-U220) ················································ 4-3

4.4.2 Command description for EPSON mode (TM-U220) ···································· 4-4

4.4.3 Commands list for STAR mode (SP500) ····················································· 4-28

4.4.4 Commands list for CITIZEN mode (iDP3550/3551) ···································· 4-30

Chapter 5 Reference information

5.1 Printing specification ··································································································· 5-1

5.2 Paper specifications ···································································································· 5-1

5.3 Ribbon cassette specification ····················································································· 5-1

5.4 Electrical characteristics ····························································································· 5-2

Page 7

5.5 Reliability ····················································································································· 5-2

5.6 Environment conditions······························································································· 5-2

5.7 Environment conditions······························································································· 5-3

5.8 Opntional features ······································································································· 5-3

Appendix A Code table

A.1 Page 0 (PC 437 : USA, Standard Europe(International Character Set : USA)) ·······A-1

A.2 Page 1 (Katakana) ······································································································A-2

A.3 Page 2 (PC850 : Multilingual)·····················································································A-3

A.4 Page 3 (PC860 : Portuguese) ····················································································A-4

A.5 Page 4 (PC863 : Canadian-French)···········································································A-5

A.6 Page 5 (PC865 : Nordic) ···························································································· A-6

A.7 Page 16 (WPC1252 : Latin1) ····················································································· A-7

A.8 Page 17 (PC866 : Russian) ························································································A-8

A.9 Page 18 (PC852 : Latin2) ···························································································A-9

A.10 Page 19 (PC858 : Euro) ·························································································A-10

A.11 Page 21 (PC862 : Israel) ························································································ A-11

A.12 Page 22 (PC864 : Arabic) ·······················································································A-12

A.13 Page 23 (Thai character code 42)··········································································A-13

A.14 Page 24 (WPC1253 : Greek) ················································································· A-14

A.15 Page 25 (WPC1254 : Turkish)················································································A-15

A.16 Page 26 (WPC1257 : Baltic) ··················································································A-16

A.17 Page 27 (Farsi) ······································································································· A-17

A.18 Page 28 (WPC1251 : Russian) ··············································································A-18

A.19 Page 29 (PC737 : Greek) ·······················································································A-19

A.20 Page 30 (PC775 : Baltic) ························································································A-20

A.21 Page 31 (Thai character code 16)··········································································A-21

A.22 Page 32 (OldCode : Israel)·····················································································A-22

A.23 Page 33 (WPC 1255 : Israel) ·················································································A-23

A.24 Page 34 (Thai character code 11)··········································································A-24

A.25 Page 35 (Thai character code 18)··········································································A-25

A.26 International character code table··········································································A-26

Appendix B Connectors

B.1 RS-232C Serial I/F ······································································································B-1

B.1.1 RS-232C Serial I/F cable connection ···························································B-1

B.1.2 RS-232C Serial I/F signal descriptions ························································B-1

B.2 IEEE 1284 Parallel I/F ······························································································ B-2

B.2.1

B.3 USB I/F ······················································································································B-3

IEEE 1284 Parallel I/F signal specification (Compatibility / Nibble / Byte mode)

B.3.1 USB I/F signal description ············································································B-3

B.4 Drawer kick-out ·········································································································B-3

B.4.1 Drawer kick-out connection ··········································································B-3

······B-2

Page 8

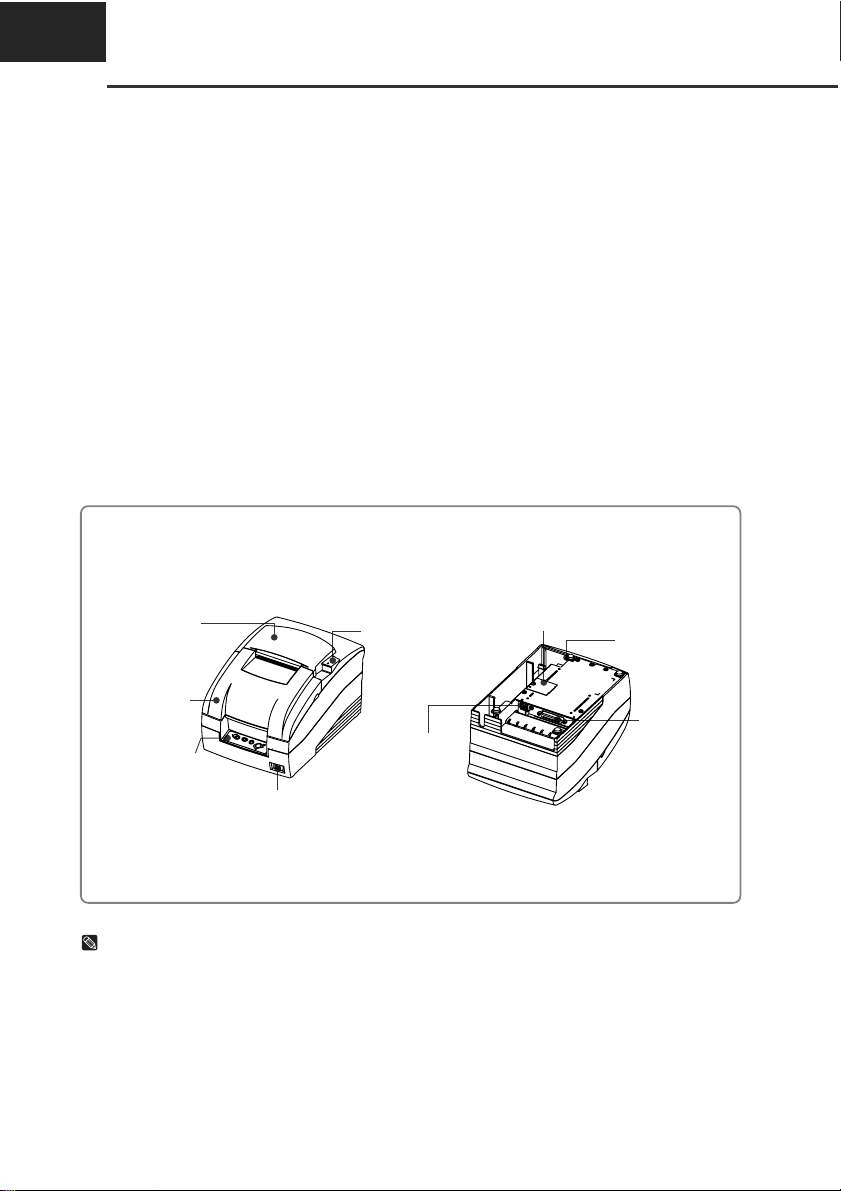

Introduction

▌The SRP-275 is a high-quality impact printer.

▌This one-station printer has the following features.

Compact design and light-weight.

•

• High-speed printing using logic-seeking (5.1LPS).

• Easy to use : Easy paper loading.

• High reliability and long life due to the use of stepping motors for head carriage return

and paper feeding.

• Two color printing (red/black) available.

• Various formats are possible because the paper feeding pitch is selectable.

• High general control utility based on the ESC/POS(TM) standard.

• The head can be driven due to the internal drawer interface.

• Character font (7ⅹ9, 9ⅹ9) is selectable.

• The auto cutter uses a circular method with a high-quality blade and a long life

(Approximately 1,000,000 cuts).

• Paper near end Switch is standard.

• A internal AC adaptor.

• Front view • Rear view

Rear cover

Open button

DIP Switch cover

Power connec t

Front cover

Inter face

connector

Control panel

Power switch

Drawer kick-out

connect

NOTES

Please be sure to read the instructions in this manual carefully before using your new printer.

Page 9

Page 10

Page 11

CHAPTER 1

Setting up the printer

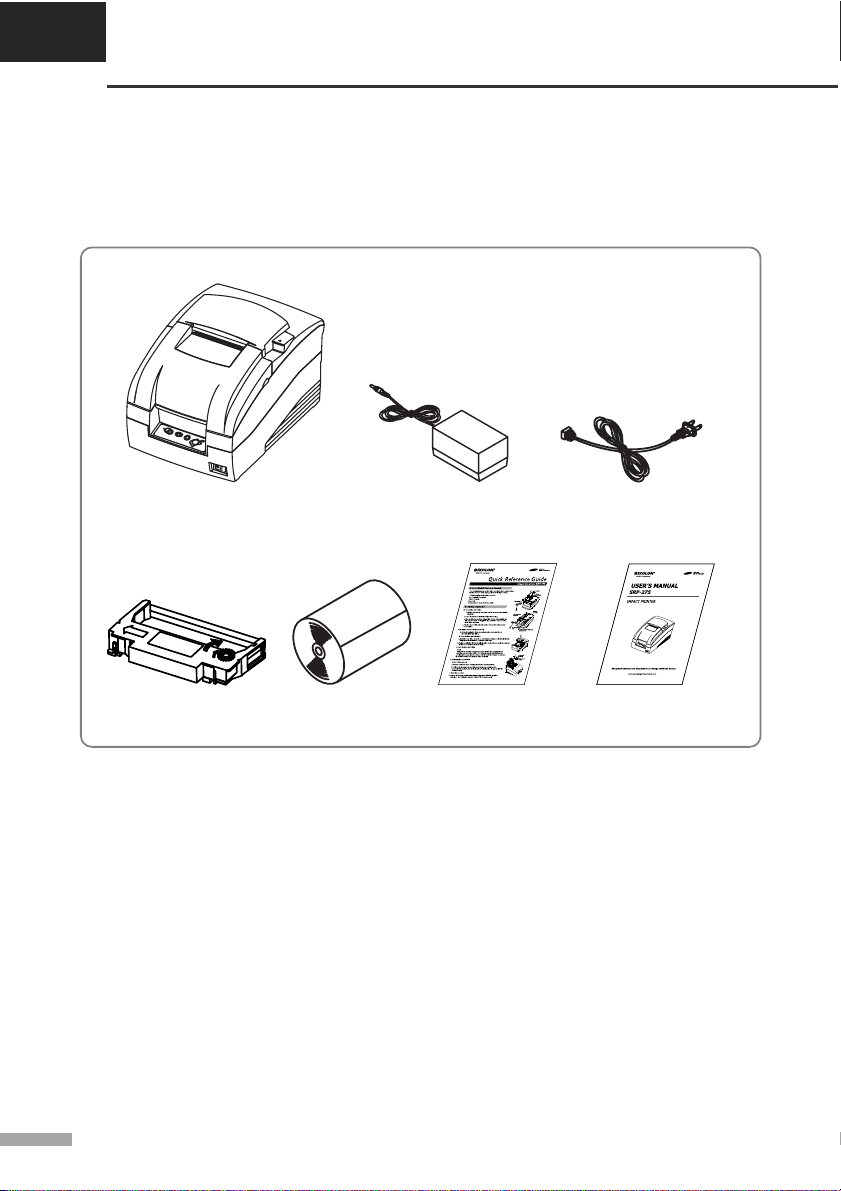

▌1.1 Unpacking

Your printer box should include the items shown in the illustration below.

If any items are damaged or missing, please contact your dealer.

SRP-275A, C AC adaptor Power cord

Ribbon cassette Paper roll Quick reference guide User’s manual

▌1.2 Choosing a place for the printer

• Avoid locations that are subject to direct sunlight or excessive heat.

• Avoid using or storing the printer in a place subject to excessive temperature or moisture.

• Do not use or store the printer in a dirty location.

• When setting up the printer, choose a stable, horizontal location.

• Intense vibration or shock may damage the printer.

• Ensure the printer has enough space to be used easily.

1-1

Page 12

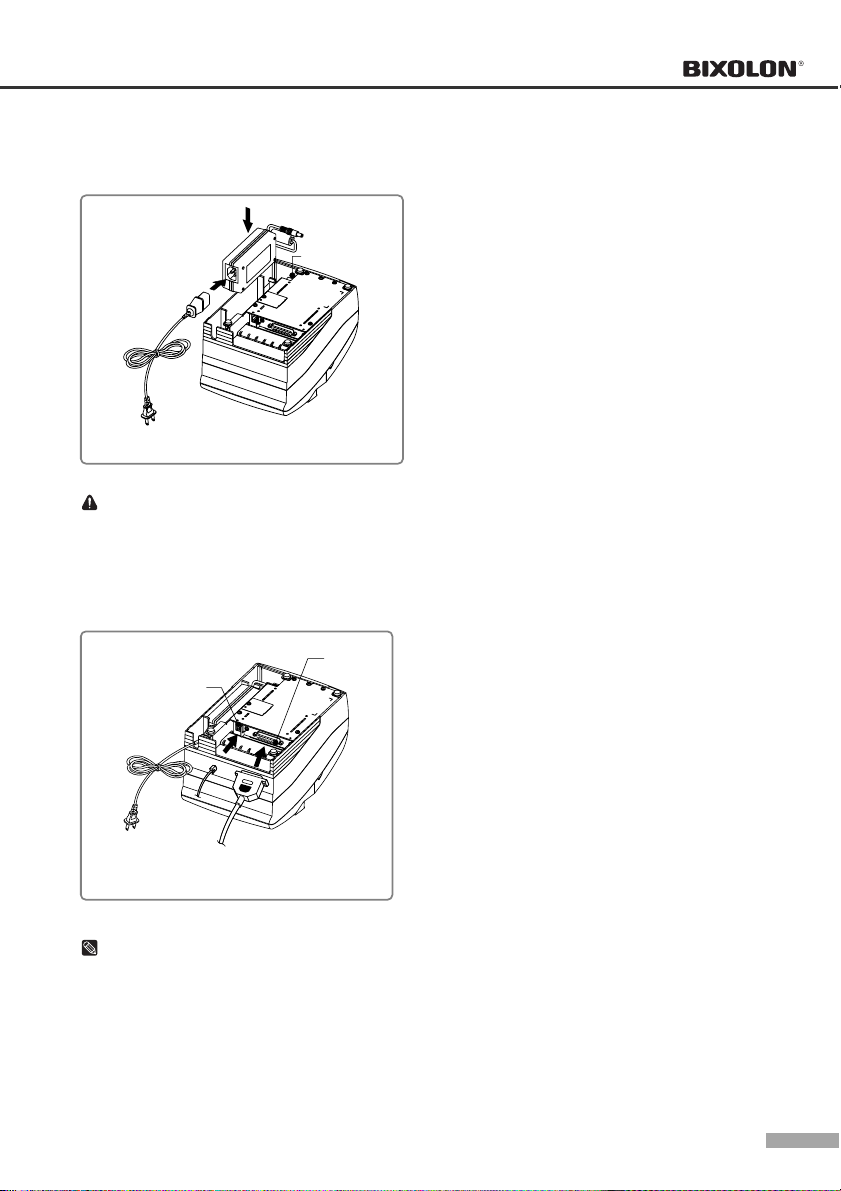

▌1.3 Connecting the cables

▌1.3.1 Connecting the AC adaptor

AC adaptor

Power connector

Power cord

CAUTION

Before connecting the printer to the power supply, make sure that the voltage and power specifications

match the printer’s requirements. Using an incorrect power supply can cause serious damage to the

printer.

▌1.3.2 Connecting the interface cable and drawer kick-out cable

• Connect the AC adapter according to the

following procedure.

1) Make sure the printer is turned off.

2) Before inserting the AC adaptor, connect the

power cord.

3) Insert the AC adaptor as shown.

4) Plug the AC adapter cable into the printer’s

power connector.

5) Plug the power cord into the outlet, and turn on

the power.

• Connect the cables according to the

following procedure.

Drawer kick-o ut connector

Interface

connector

1) Turn off printer and the host ECR (host

computer).

2) Plug the interface cable into the interface

connector on the printer then fasten the screw

Drawer kick-o ut

cable

Serial/ Parallel/ USB/ Ethernet

Interface cable

on both sides of the connector.

3) Plug the drawer kick-out cable into the drawer

kick-out connector on the printer.

(When removing the drawer kick-out cable,

press on the connector’s clip while pulling out.)

NOTES

Connect the printer to the host ECR (host computer) though an interface cable matching the specification

of the printer and the host ECR (host computer). Be sure to use a drawer that matches the printer ’s

specification.

Depending on the interface your s ystem uses , either connect the s erial, parallel, USB or Ethernet

communication cable to the appropriate connector on the back of the printer. Cables are pr ovided by

your dealer or system installer.

1-2

Page 13

CHAPTER 1

Setting up the printer

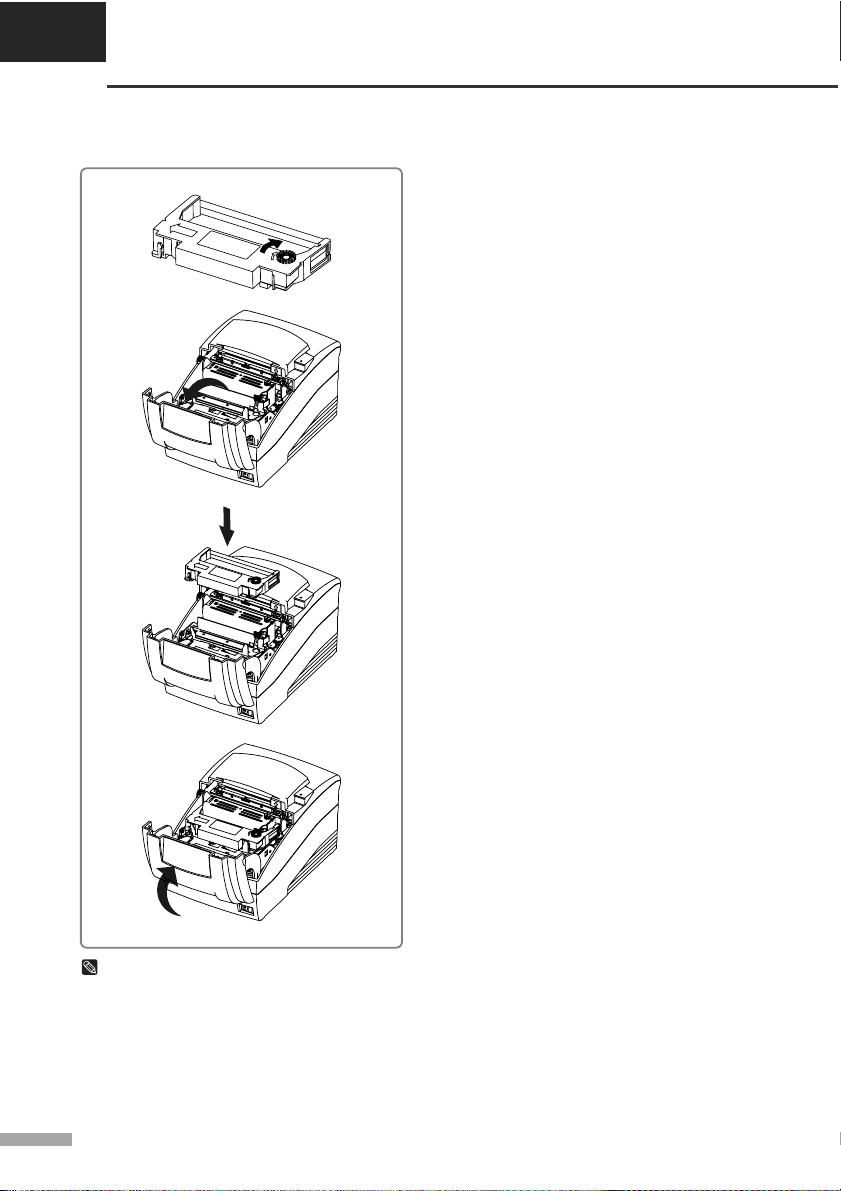

▌1.4 Installing the ribbon cassette

1) Before inserting the ribbon cassette, turn the

knob clockwise to prevent twisting the ribbon.

2) Open the front cover of printer.

3) Take out the old ribbon cassette if there is one.

4) Insert the new ribbon cassette as shown and

pay particular attention to the placement of the

ribbon behind the Printer Head.

5) During inserting the ribbon cassette, turn the

knob clockwise again to make sure the ribbon

moves freely in the cassette.

6) Close front cover of printer.

NOTES

Malfunctions and other problems may arise if other than specified ribbon cassettes are us ed in the printer.

The Warranty may be void if oth er than specified ribbon cassettes are used. Contact your dealer or place

of purchase for more information about proper ribbon cassettes.

1-3

Page 14

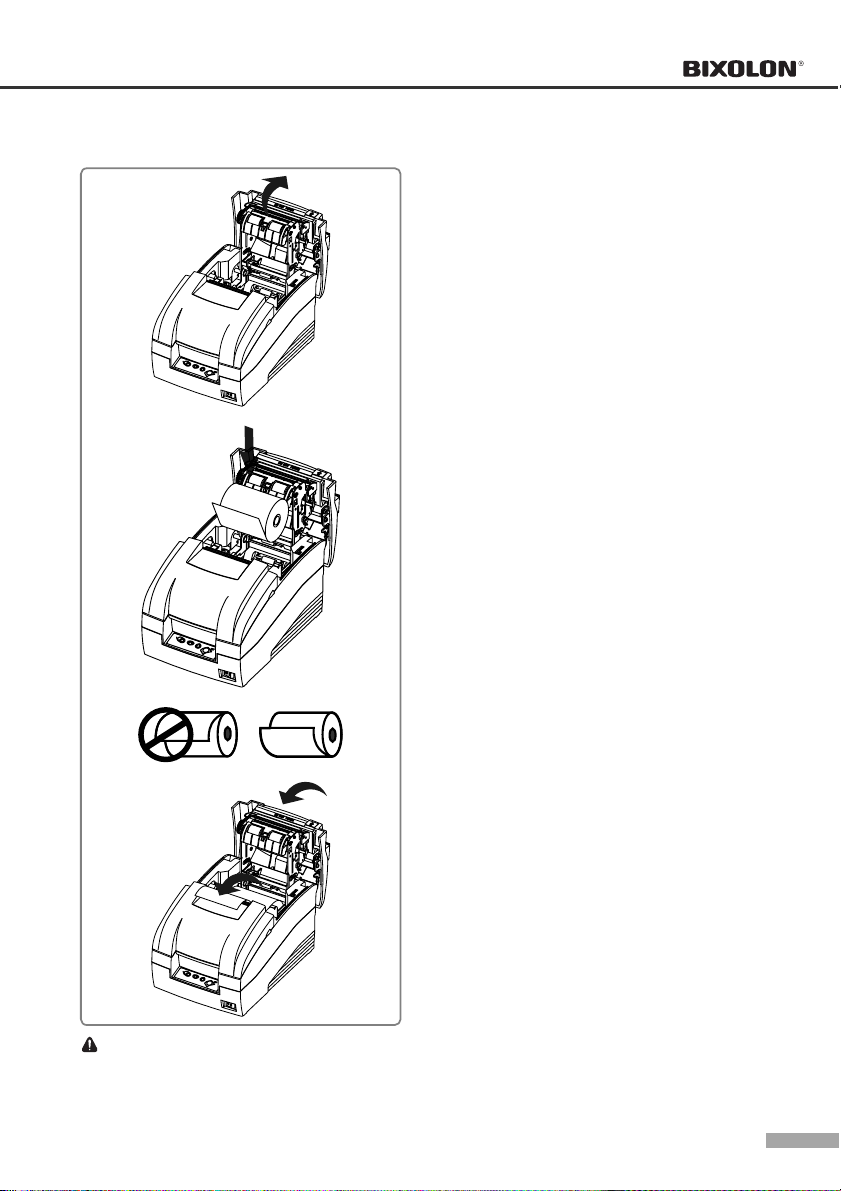

▌1.5 Installing the paper roll

1) To prevent data loss, make sure that the printer

is not receiving data.

2) Open the rear cover by pushing the open

button.

CAUTION

Do not touch the auto cutter blade when you open rear cover.

3) Remove the used paper roll core if there is one.

4) Insert the paper roll as shown.

5) Be sure to note the correct direction that the

paper should come off the paper roll.

6) Pull out small amount of paper as shown. Then

close the cover and tear off the extra paper by

pulling it toward the front of the printer.

1-4

Page 15

CHAPTER 1

Setting up the printer

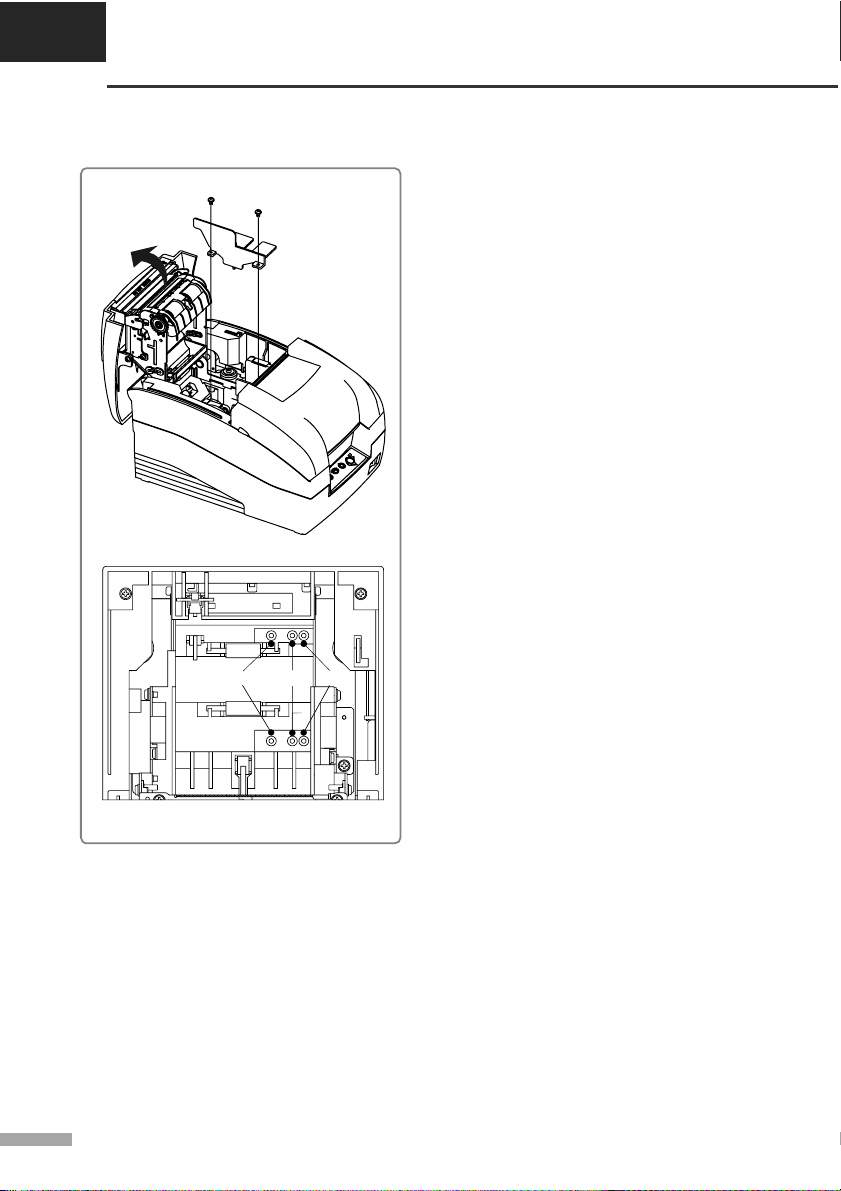

▌1.6 Changing the paper width

Screw(3x6 )(2pieces)

Frame paper control

69.5mm 76mm(default)

57.5mm

1) Open the rear cover.

2) Remove the frame paper control by loosing the

two screws(3×6).

3) Reattach the frame paper control in you want.

(Insert and tighten two screws(3×6) to reattach.)

4) Close the rear cover.

5) Change the Memory Switch setting for changing

paper roll width. (See the instructions "Setting

the Memory Switches"(3.1) in Chapter 3.)

1-5

Page 16

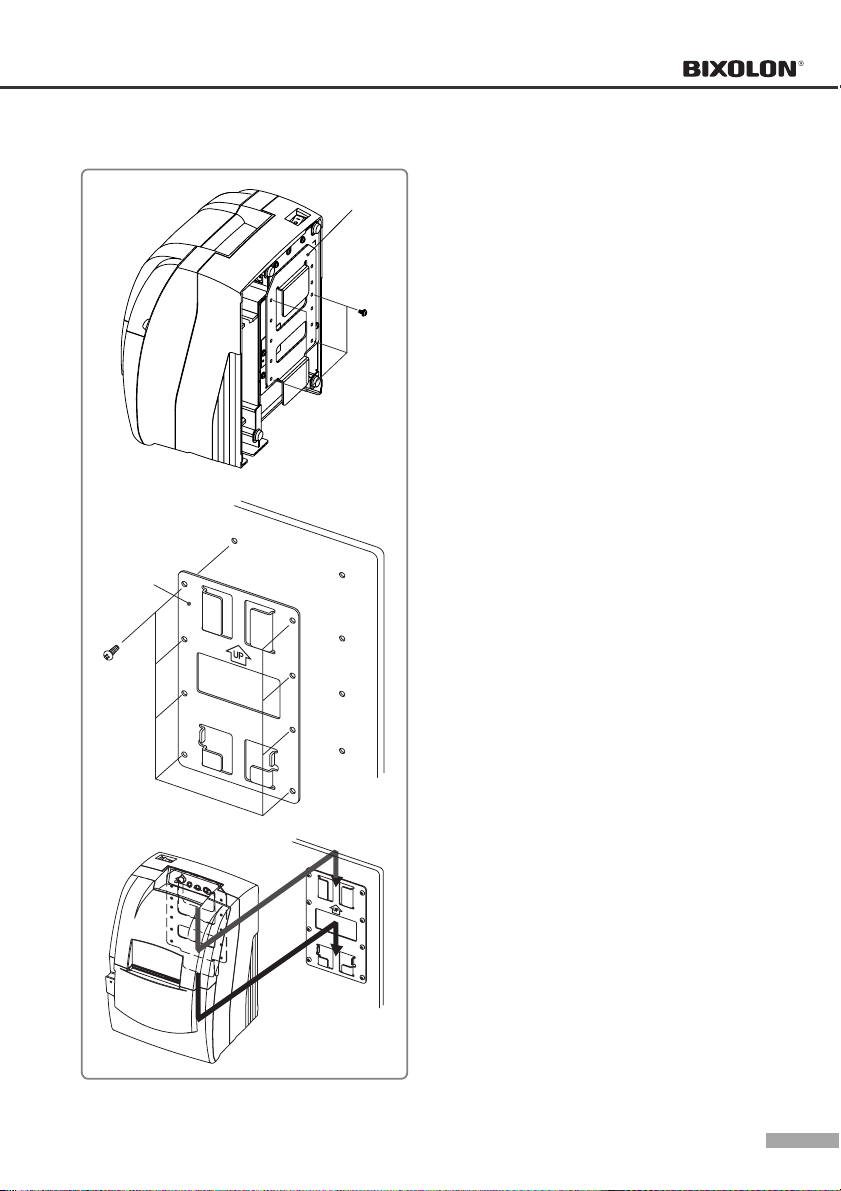

▌1.7 Installing the wall mount (Option)

Bracket mount

Screw(4x10)

(8pieces)

Bracket hanger

Screw(3x5)

(4pieces)

1) Turn the Set over and attach the Bracket

hanger to the Frame base then tighten four

screws.

2) Attach the Bracket mount to the wall firmly with

the eight screws. Be sure that the Bracket

attached properly to match the direction of

arrow as shown. And the Bracket mount should

be always fixed vertically.

3) Insert the Bracket hanger of Set to the Bracket

mount as shown.

1-6

Page 17

CHAPTER 1

Setting up the printer

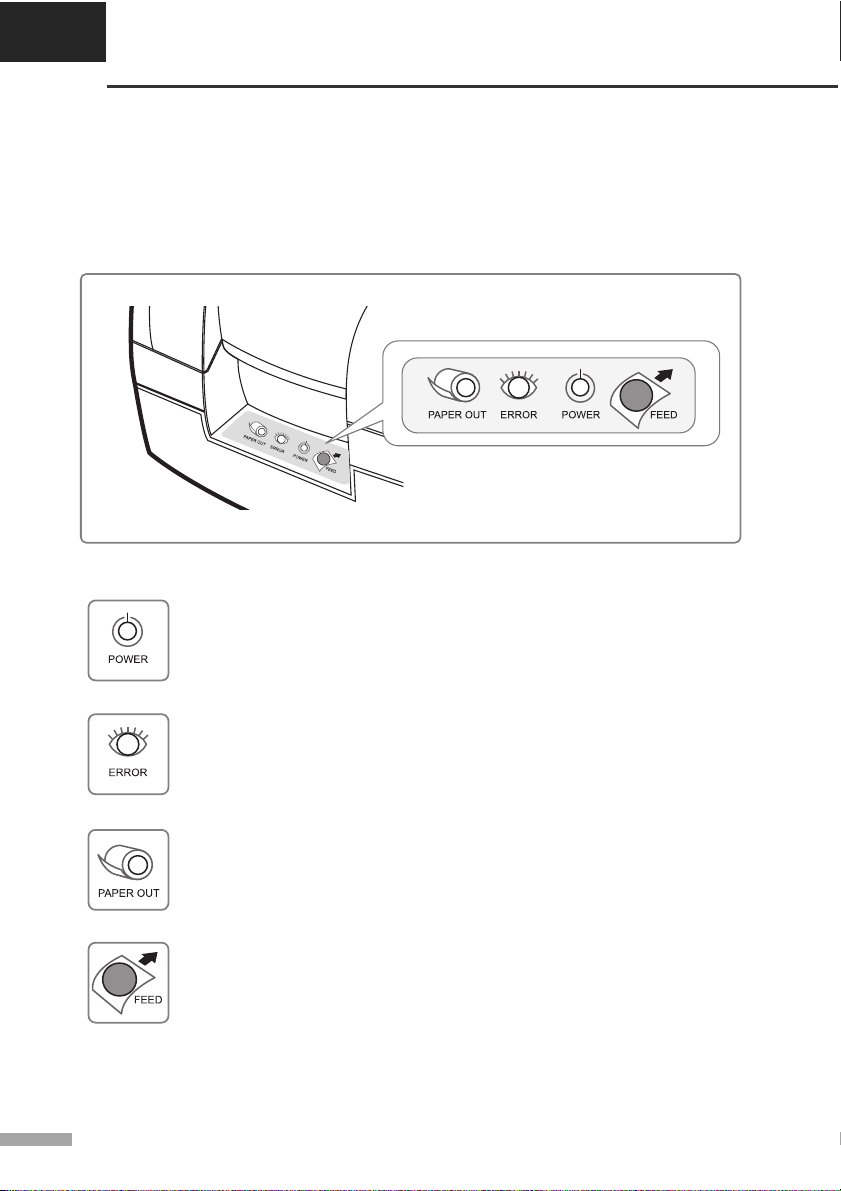

▌1.8 Using the operation panel

Most of the functions of this printer are governed by software, but you can monitor the printer s status by

looking at the lights on the control panel and for some procedures you will use the buttons.

• Control panel

- POWER LED (Green Color)

This indicator light is on when the power is turned on. It blinks when the printer is in the self

test printing standby state. Always wait until this indicator light stops blinking before you

start using the printer and before you turn it off.

- ERROR LED (Red Color)

When this indicator light is on (but not blinking), it means that the printer is out of paper or

almost out of paper or the printer covers are open. When this light blinking, there is an

error. (See "ERROR LED blinking pattern" (2.1) in Chapter 2.) If you see this light blinking,

turn off the printer for a few seconds and then turn it back on. If the light is still blinking, call

your supervisor or a service person.

- PAPER OUT LED (Red Color)

When this indicator light is on, it means that the paper near end. Replace the new paper

roll. When ERROR and PAPER OUT indicator lights are on it means paper end. Install the

paper roll.(See "Installing paper roll"(1.5)in Chapter 1.)

- FEED button

Use this button to feed paper or to start self test and for hexadecimal dump mode.

(See the instructions "Self test" (1.7) in this chapter for self test.)

(See the instructions "Hexadecimal dump" (2.6) in Chapter 2 for hexadecimal dump mode.)

1-7

Page 18

▌1.9 Self test

The self test let you know if your printer is operating properly. It checks the printing quality, ROM version,

DIP Switch settings, memory switch settings and statistic data.

The test is independent of any other equipment or software, so it is a good idea to run it when you first set

up the printer or if you have any trouble. If the self test works correctly, the problem is in the other equipment

or the software, not the printer.

• Running the self test

1) Make sure the printer is turned off and the printer cover is closed properly.

2) While holding down the FEED button, turn on the printer and continue to hold until the paper begins to

feed. The self test prints the printer DIP Switch settings and memory switch settings. And cuts the paper

and pauses. (The power light blinks.)

3) Press the FEED button to continue printing the statistic data.

4) Press the FEED button to continue printing the rolling ASCII pattern.

5) The self test mode terminates after printing the rolling ASCII pattern automatically.

1-8

Page 19

CHAPTER 2

Troubleshooting

This chapter gives solutions to some printer problems you may have.

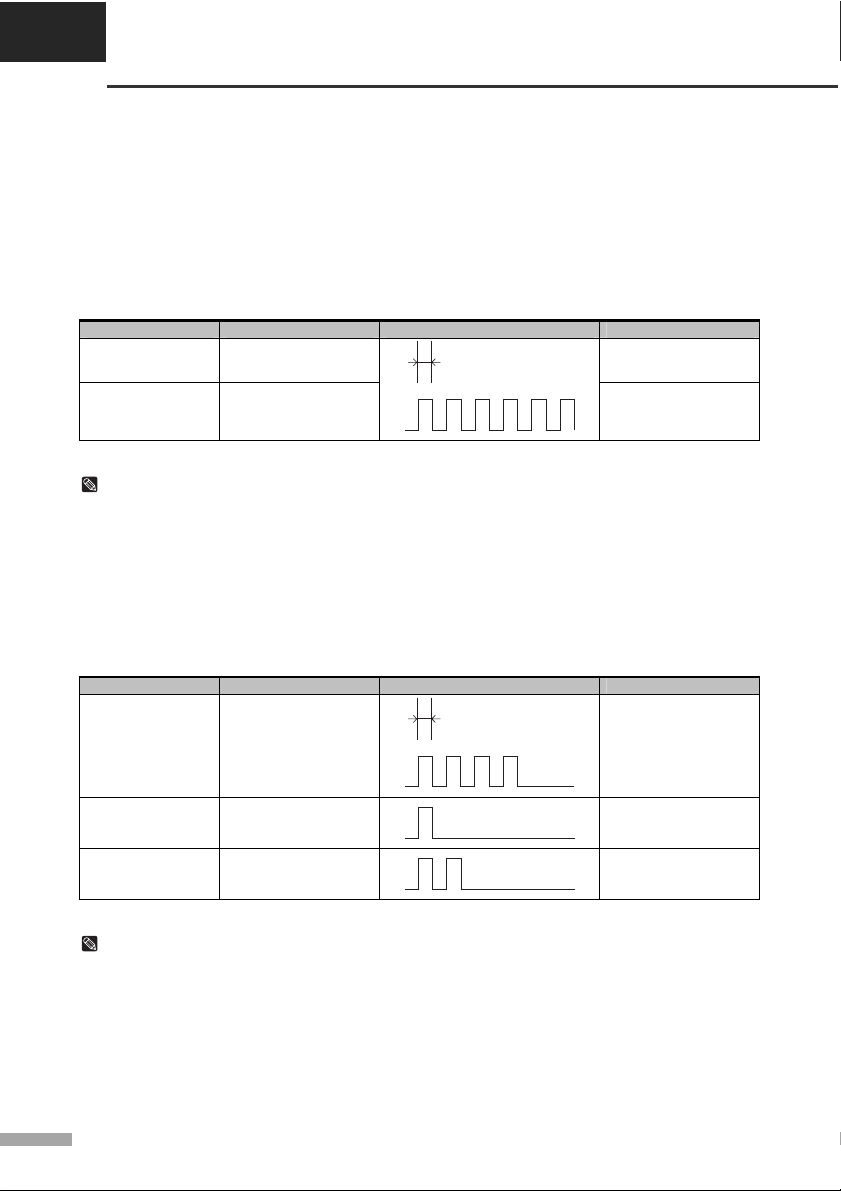

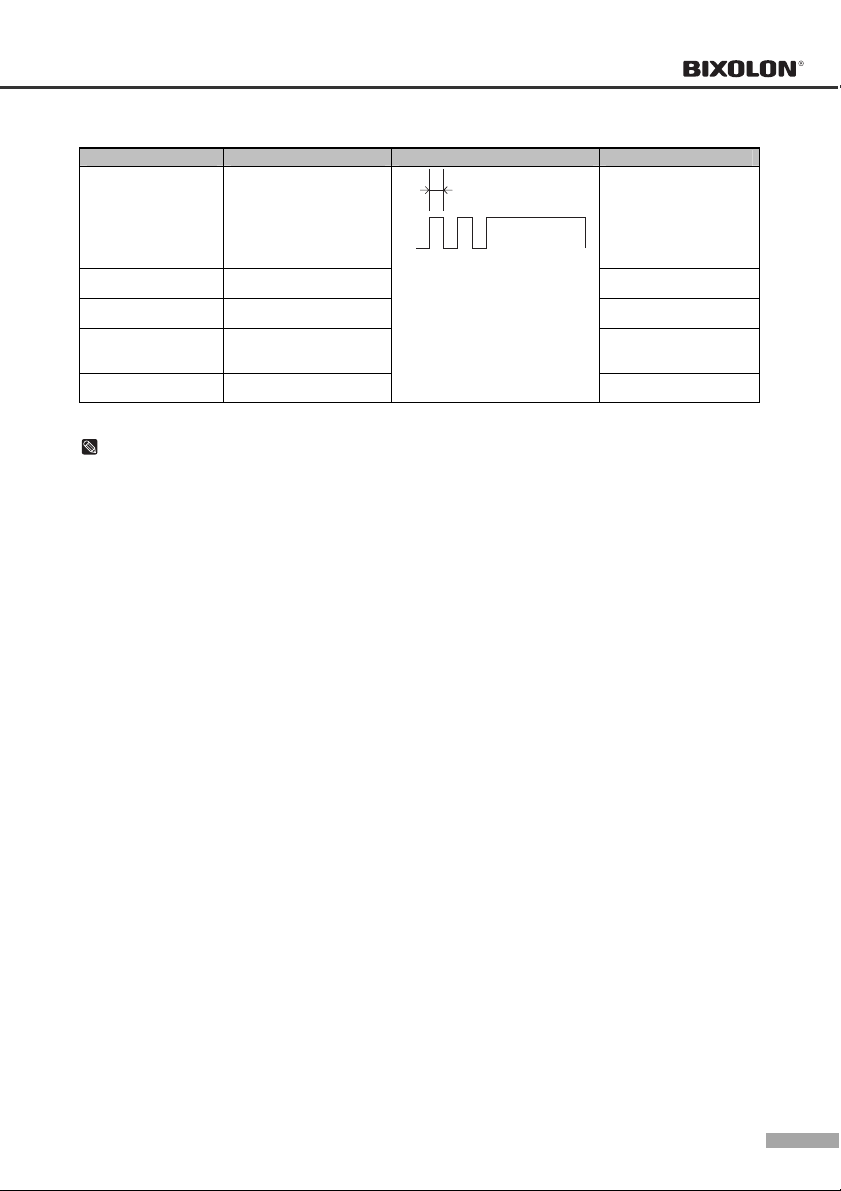

▌2.1 ERROR LED blinking pattern

The printer stops all printer operations for the selected paper section, goes off line, and the ERROR LED

blinks when an error is detected.

• Errors that automatically recover

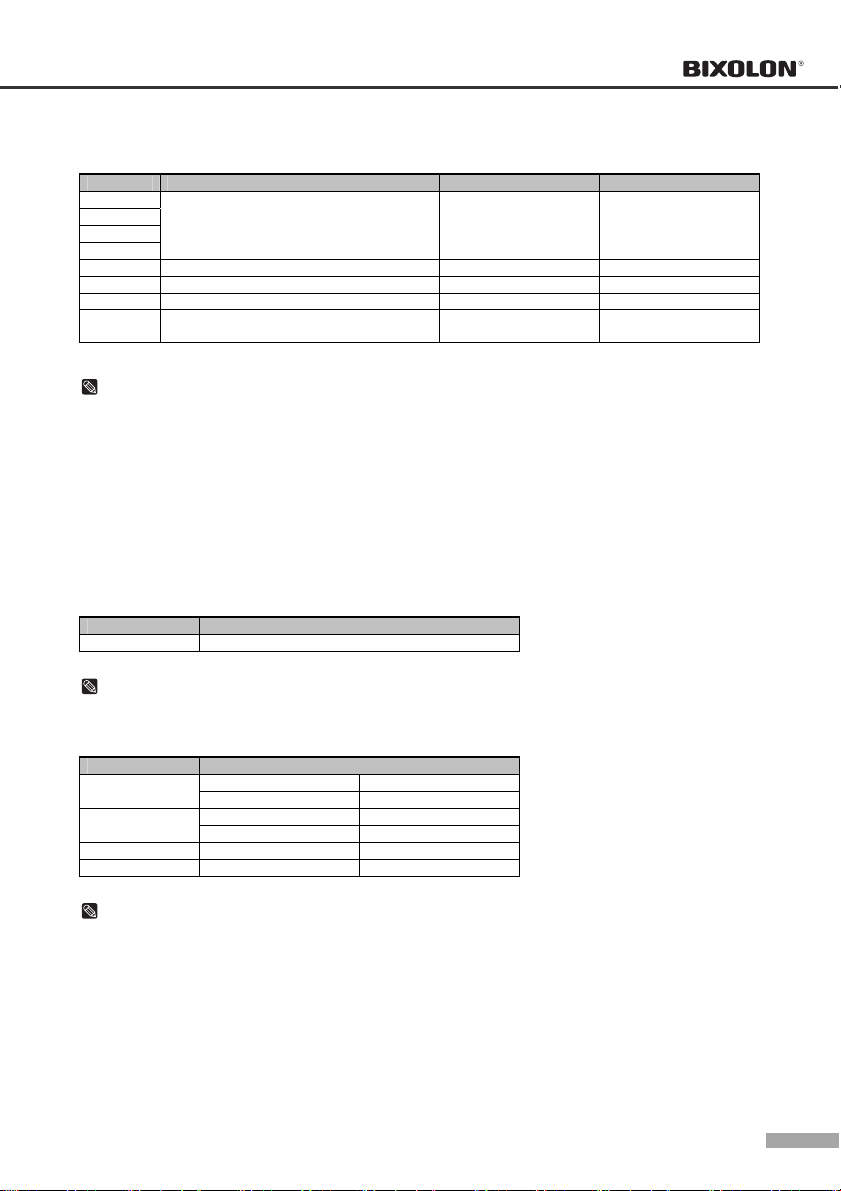

Error Description ERROR LED blinking pattern Recovery

Rear cover open error

(When recoverab le

Error is selected)(*1)

Print head

temperature er ror(*2)

The rear cover is opened

when printing

The temperature of the

print head is extrem ely

high.

200ms

NOTES

(*1) These conditions are selected by MSW8-5, 8-8. When MSW8-5 (mapping of the cover open status)

is off, the error hasn’t occurre d but there is a “paper end error” instead. If MSW8-8 is off, this error

is handled as an automatically recoverable error.

(*2) Print head temperature error is not abnormal.

• Recoverable errors

When a recoverable error occurs, after the cause of the error is removed, the printer can recover from the

error by receiving an error recovery command without turning off the power.

Error Description ERROR LED blinking pattern Recovery

Recovers automatically

when the rear cover is

closed.

Recovers automatically

when the print head

cools.

Rear cover open error

(*1)

Auto cutter error

(Type C only)

Home position

detection error (This

is “Mechanical err or”)

The rear cover is opene d

when printing.

The auto cutter does not

work correctly.

The home position

cannot be detected due

to a paper jam.

200ms

Recovers automatically

when the rear cover is

closed.

Recovers by error

recovery command.

Recovers by error

recovery command.

NOTES

(*1) These conditions are selected by MSW8-5, 8-8. When MSW8-5 (mapping of the cover open status)

is off, the error hasn’t occurre d but there is a “paper end error” instead. If MSW8-8 is off, this error

is handled as an automatically recoverable error.

2-1

Page 20

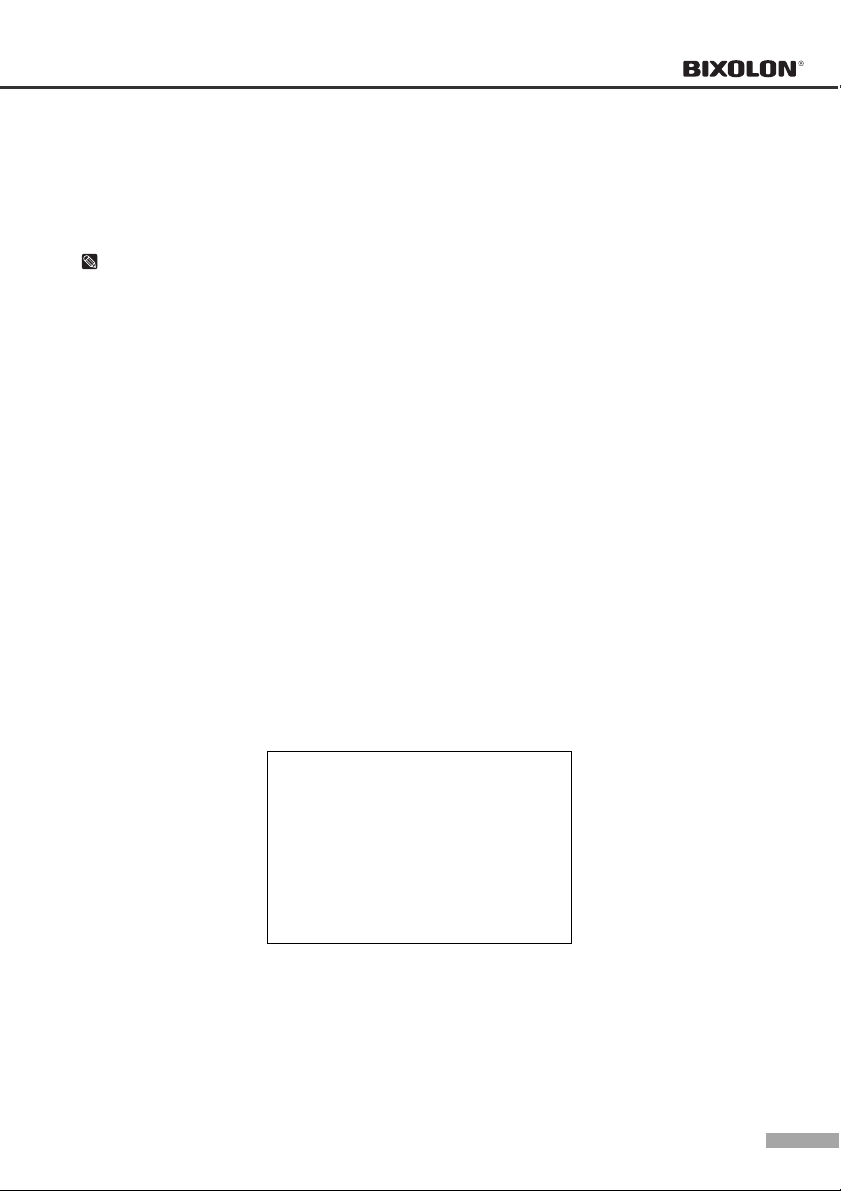

• Errors that are impossible to recover

Error Description ERROR LED blinking pattern Recovery

R/W error in memory

or gate array

High voltage error

Low voltage error

CPU execution error

Print head temperature

detection circuit error.

After R/W checking, the

printer does not work

correctly.

Writing to, reading out, or

erasing the NV memory for

image scanning results

does not work correctly.

The power supply voltage

is extremely high.

The power supply voltage

is extremely low.

The CPU executes an

incorrect address or I/F

board is not connected.

There is an abnormality is

the print head temperature.

200ms

Recovers automatically

when the rear cover is

closed.

Impossible to recover.

Impossible to recover.

Impossible to recover.

Impossible to recover.

NOTES

If you see this light blinking, turn off the printer for a few seconds and then turn it back on.

If the light is still blinking, call your supervisor or a service person.

▌2.2 The printer does not start printing

• Are any of the operation panel lights on, If no operation panel lights are on, check the following:

- Make sure that the printer is turned on.

- Make sure that the power supply cable is correctly plugged into the printer and to the power outlet.

• If any of the lights are on, please check the following:

- If the POWER LED is blinking, the printer is not ready yet.

Wait until the light quits blinking and the printer is ready to use.

- If the ERROR LED is on (but not blinking), the printer is off line. Check to see that the covers are closed

and check the paper state. See "Installing paper roll" (1.5) in Chapter 1 for instructions on installing or

replacing the paper roll.

- If the ERROR LED is blinking, there is an error. In this case, turn off the printer for a few seconds and

then turn it back on. If the light is still blinking, call your supervisor or service person.

- If the PAPER OUT LED is on, check the paper roll in the printer. See "Installing paper roll" (1.5) in

Chapter 1 for instruction on installing the paper roll.

2-2

Page 21

CHAPTER 2

Troubleshooting

▌2.3 The printer stops printing

• If the ERROR LED is on (but not blinking), the printer is off line. Check to see that the covers are closed

and check the paper state. See "Installing paper roll"(1.5) in Chapter 1 for instructions on installing or

replacing the paper roll.

• If the ERROR LED is blinking, there is an error. In this case, turn off the printer for a few seconds and then

turn it back on. If the LED is still blinking, call your supervisor or a service person.

• Turn off the printer and check for a paper jam. To clear paper jam, follow the steps below:

1) Turn off the printer and open the rear cover of the printer.

2) Remove the jammed paper and reload the paper roll as described in Chapter 1.

3) Close the rear cover.

4) Turn on the printer.

▌2.4 You want to check the operation of the printer by itself

• Self test

Try to run the self test to check that the printer works properly. See the self test instructions in Chapter 1

to run the self test. If the self test does not work, contact your supervisor or a service person.

If the self test works properly, check the following:

1) Check the connection at both ends of the interface cable between the printer and the computer. Also

make sure that this cable meets the specifications for both the printer and the computer.

2) The data transmission settings may be different between the printer and computer. Make sure that the

printer’s DIP Switch settings for data transmission are the same as the computer’s. You can see the

printer’s interface settings on your self test printout.

NOTES

If the printer still does not print, contact your dealer or a qu alified service person.

2-3

Page 22

▌2.5 Printing is poor

Check the state of ribbon cassette. If the ribbon cassette life ends, replace the ribbon cassette as

described in Chapter 1.

NOTES

If the printer is still poor, contact your dealer or a qualified service person.

▌2.6 You want to check a software program

• Hexadecimal dump

This feature allows experienced users to see exactly what data is coming to the printer.

This can be useful in finding software problems. When you turn on the hexadecimal dump function, the

printer prints all commands and other data in hexadecimal format along with a guide section to help you

find specific commands.

• To use the hexadecimal dump feature, follow these steps:

1) After you make sure that the printer is off, open the rear cover of the printer.

2) Hold down the FEED button while you turn on the printer.

3) Close the rear cover.

4) Run any software program that sends data to the printer. The printer prints "Hexadecimal dump" and

then all the codes are received in a two column format. The first column contains the hexadecimal

codes and the second column gives the ASCII characters that correspond to the codes.

(A period(.) is printed for each code that has no ASCII equivalent.)

5) When the printing finishes, turn off the printer.

Hexadecimal Dump

To terminate hexadecimal dump

Press FEED button three times

1B 21 00 1B 26 02 40 40 . ! . . & . @ @

1B 25 01 1B 63 34 00 1B . % . . c 4 . .

41 42 43 44 45 46 47 48 A B C D E F G H

<Online Hex Dump Completed>

2-4

Page 23

CHAPTER 3

Setting the switches

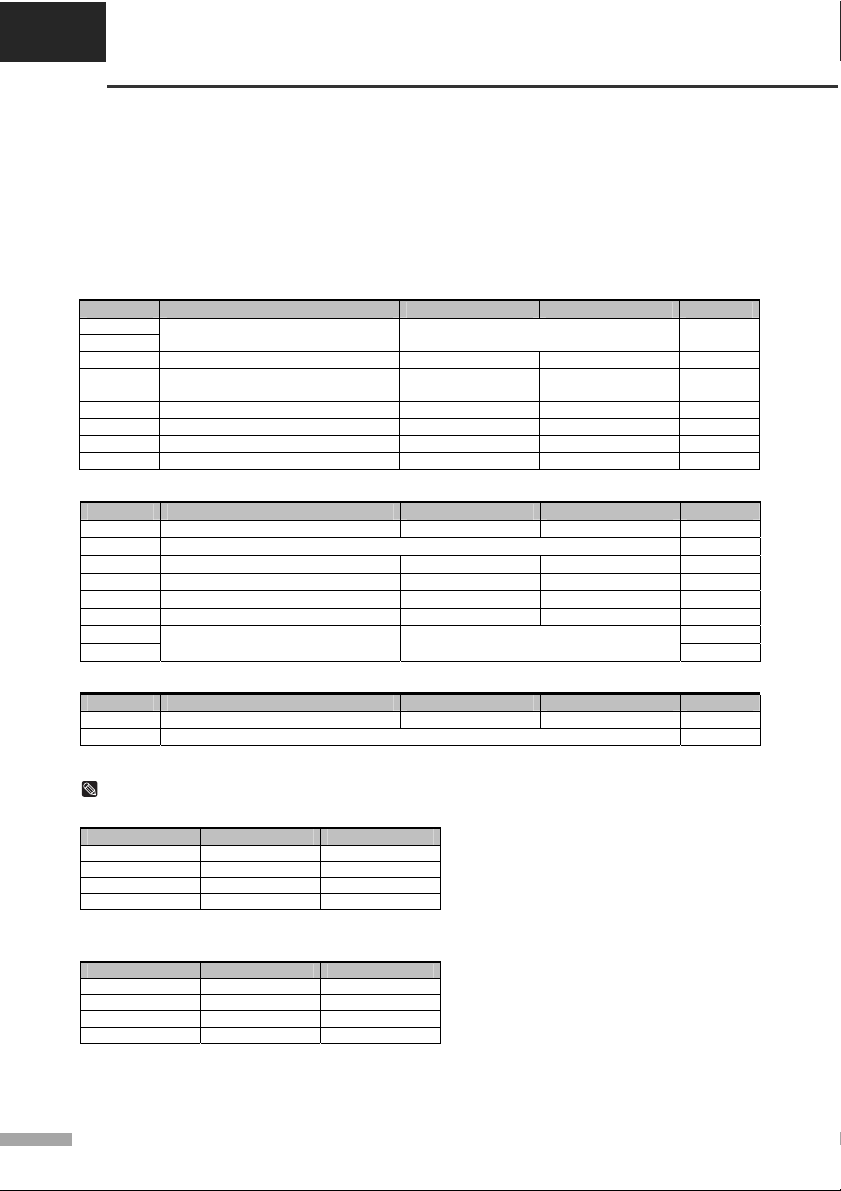

▌3.1 Setting the DIP Switch

Although the factory settings are best for almost all users, if you have special requirements, you can change

the DIP Switch. Your printer has two sets of DIP Switches. The functions of the switches are shown in the

following table.

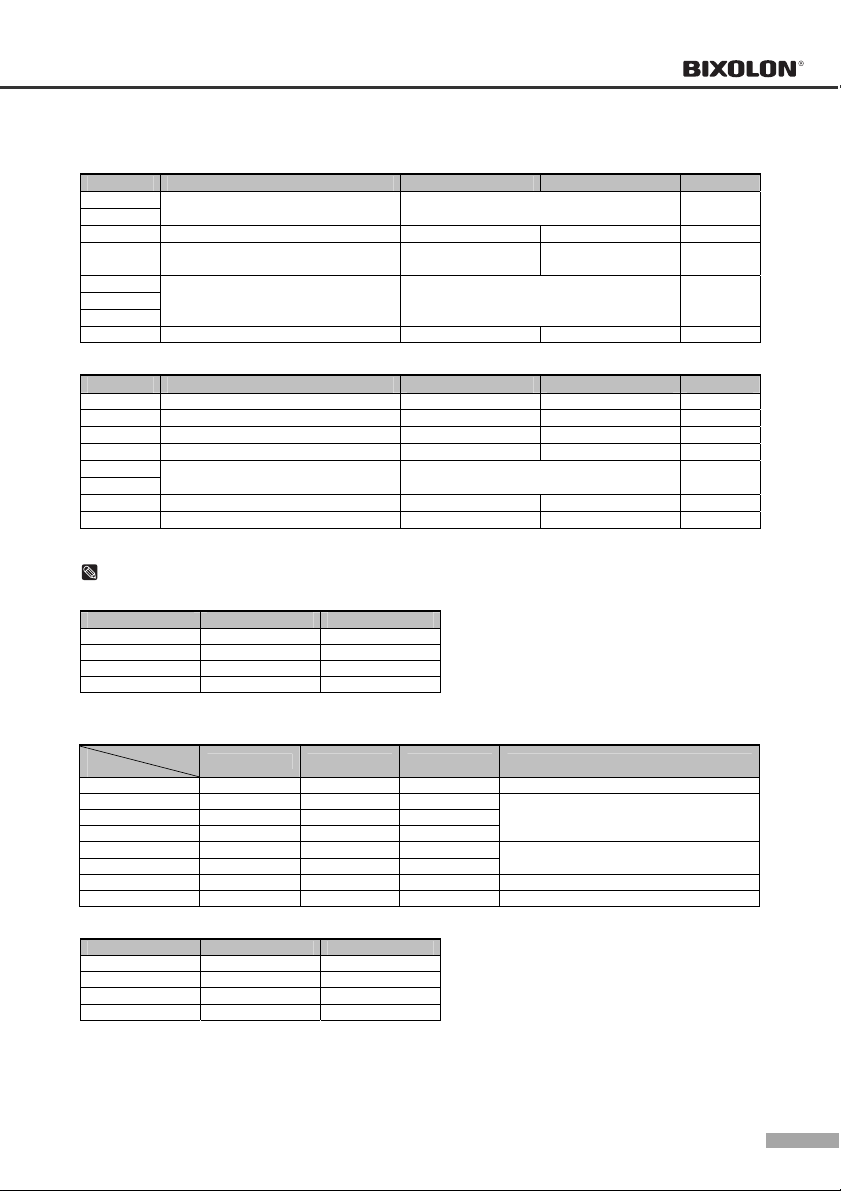

▌3.1.1 DIP Switch setting for Epson(ESC/POS) mode

• DIP Switch 1

Switch Function ON OFF Default

1-1

Emulation Selection (*1) Refer to the following table OFF

1-2

1-3 Auto cutter Enable Disable OFF

1-4 BUSY condition Receive buffer full

1-5 Serial interface selection Memory Switch DIP Switch OFF

1-6 Print NV bit image #1 after cutting Enable Disable OFF

1-7 Near end switch Enable Disable OFF

1-8 Print column 42/35 40/33 OFF

• DIP Switch 2 (RS232C serial interface model)

Switch Function ON OFF Default

2-1 Data receive error Ignore Print “?” OFF

2-2 Reserved OFF

2-3 Hand shaking XON/XOFF DTR/DSR OFF

2-4 Word length 7 bits 8 bits OFF

2-5 Parity check Enable Disable OFF

2-6 Parity selection EVEN ODD OFF

2-7 OFF

Baud rate selection (*2) Refer to the following table

2-8

• DIP Switch 2 (Parallel interface model)

Switch Function ON OFF Default

2-1 Auto Line Feed Enable Disable OFF

2-2~8 Undefined OFF

NOTES

(*1) Emulation Selection (DSW 1-1 and 1-2)

Emulation 1-1 1-2

EPSON OFF OFF

STAR OFF ON

CITIZEN ON OFF

EPSON-KP ON ON

- EPSON-KP(EPSON Kitchen Printer mode) : A alarm is generated by printe r after auto cutting and in paper end error.

(*2) Baud rate selection (Transmission speed)

Transmission 2-7 2-8

2400 baud ON ON

4800 baud OFF ON

9600 baud OFF OFF

19200 baud ON OFF

Receive buffer full

or Offline

OFF

OFF

3-1

Page 24

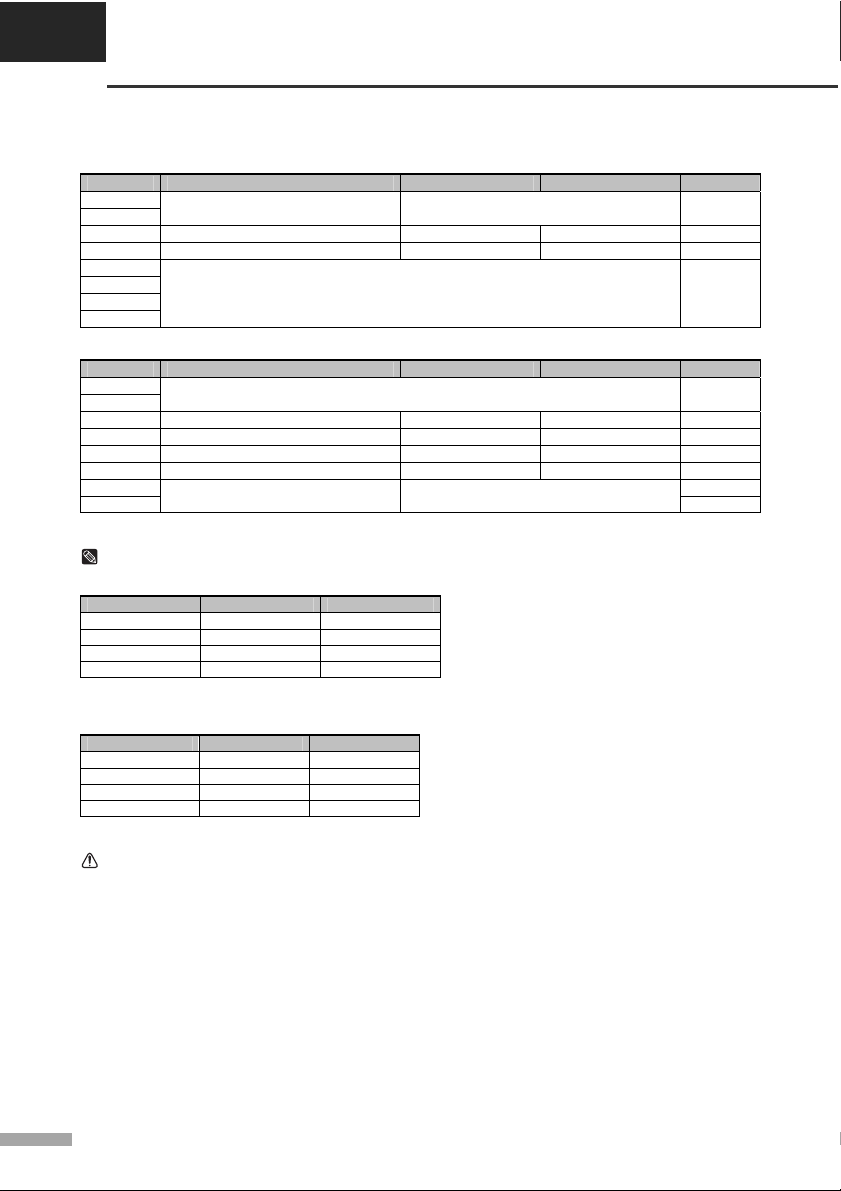

▌3.1.2 DIP Switch setting for Citizen(iDP 3550) mode

• DIP Switch 1

Switch Function ON OFF Default

1-1

Emulation Selection (*1) Refer to the following table OFF

1-2

1-3 Auto cutter Enable Disable OFF

1-4 CBM command

1-5

International characters (*2) Refer to the following table ON

1-6

1-7

1-8 CR mode CR CR+LF OFF

• DIP Switch 2 (RS232C serial interface model)

Switch Function ON OFF Default

2-1 Word length 8 bits 7 bits ON

2-2 Parity check Disable Enable ON

2-3 Parity selection ODD EVEN ON

2-4 Hand shaking DTR/DSR XON/XOFF ON

2-5

Baud rate selection (*3) Refer to the following table OFF

2-6

2-7 Near end switch Enable Disable OFF

2-8 Mechanism type Graphic Character OFF

NOTES

(*1) Emulation Selection (DSW 1-1 and 1-2)

Emulation 1-1 1-2

EPSON OFF OFF

STAR OFF ON

CITIZEN ON OFF

EPSON-KP ON ON

- EPSON-KP(EPSON Kitchen Print er mode) : A alarm is generated by printer after auto cutting and in paper end error.

(*2) International Character Selection

No.

Country

U.S.A. ON ON ON Page 0 (PC437 : U.S.A.)

France OFF ON ON

Germany ON OFF ON

U.K. OFF OFF ON

Denmark ON ON OFF

Sweden OFF ON OFF

Italy ON OFF OFF Page 2 (PC850 : Multilingual)

Windows Code OFF OFF OFF Windows Code

(*3) Baud rate selection (Transmission speed)

Transmission 2-5 2-6

2400 baud ON ON

4800 baud OFF ON

9600 baud OFF OFF

19200 baud ON OFF

DSW 1-5 DSW 1-6 DSW 1-7 Code page

CBM2 mode

(iDP3530 system)

CBM1 mode

(iDP3540 system)

Page 2 (PC850 : Multilingual)

Page 5 (PC865 : Nordic)

OFF

3-2

Page 25

CHAPTER 3

Setting the switches

▌3.1.3 DIP Switch setting for Star(SP500) mode

• DIP Switch 1

Switch Function ON OFF Default

1-1

Emulation Selection (*1) Refer to the following table OFF

1-2

1-3 Auto cutter Enable Disable OFF

1-4 Black/Red Printing Enable Disable OFF

1-5

1-6

1-7

1-8

• DIP Switch 2 (RS232C serial interface model)

Switch Function ON OFF Default

2-1

2-2

2-3 Hand shaking XON/XOFF DTR/DSR OFF

2-4 Word length 7 bits 8 bits OFF

2-5 Parity check Enable Disable OFF

2-6 Parity selection EVEN ODD OFF

2-7 OFF

Baud rate selection (*2) Refer to the following table

2-8

NOTES

(*1) Emulation Selection (DSW 1-1 and 1-2)

Emulation 1-1 1-2

EPSON OFF OFF

STAR OFF ON

CITIZEN ON OFF

EPSON-KP ON ON

- EPSON-KP(EPSON Kitchen Print er mode) : A alarm is generated by printer after auto cutting and in paper end error.

(*2) Baud rate selection (Transmission speed)

Transmission 2-7 2-8

2400 baud ON ON

4800 baud OFF ON

9600 baud OFF OFF

19200 baud ON OFF

NOTICE

Change in DIP Switch settings are recognized only when the printer power is turned on or when the

printer is reset by using the int erface. I f the DI P Switch setting is changed after the printer power is

turned on, the change does not take effect until the printer is turned on again or is reset.

Reserved OFF

Reserved OFF

OFF

3-3

Page 26

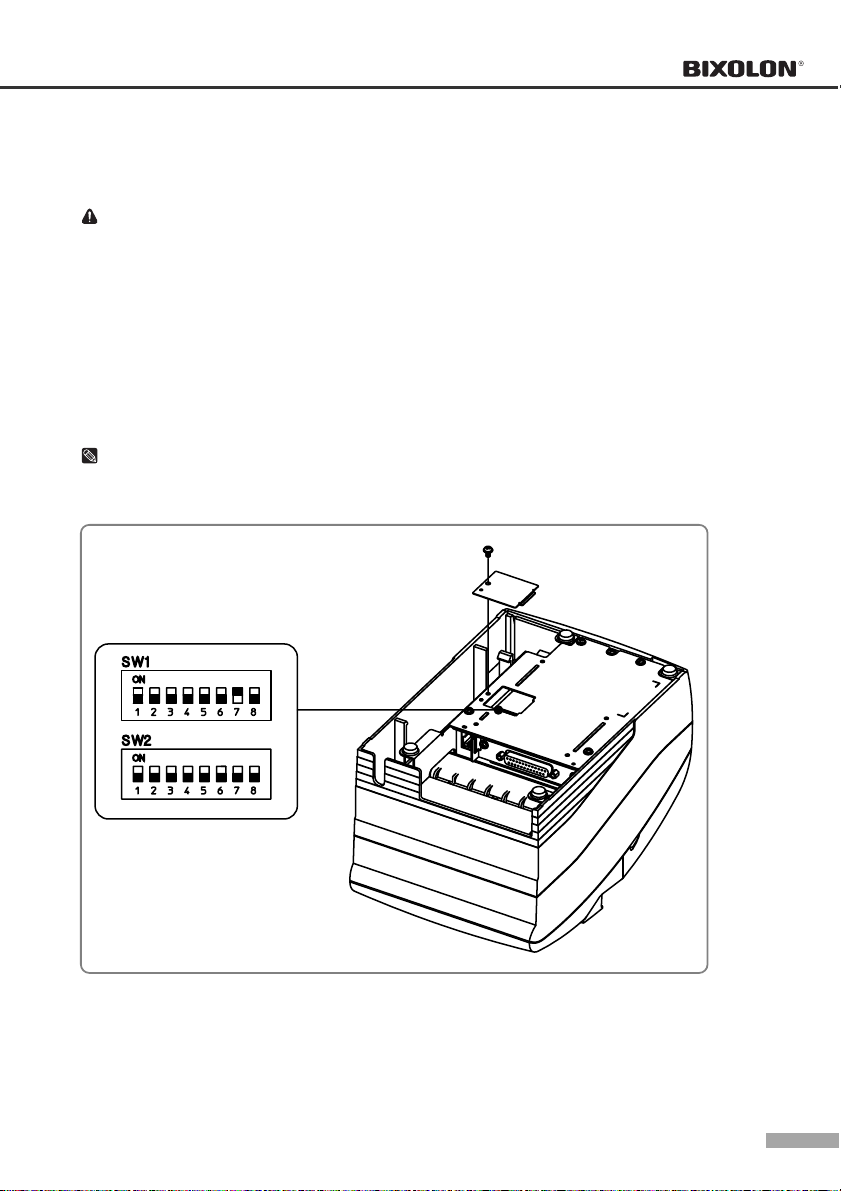

▌3.1.4 Changing the DIP Switch setting

If you need to change settings, follow the steps below to make your changes.

CAUTION

Turn off the printer before removing the DIP Switch cover to prevent an electric short, which can damage

the printer.

1) Make sure the printer is turned off.

2) Remove the screw from the DIP Switch cover.

Then take off the DIP Switch cover, which is shown in the illustration below.

3) Set the switches using a pointed tool, such as tweezers or a small.

4) Replace the DIP Switch cover. Then secure it with the screw.

NOTES

The new settings take effect when you turn on the printer.

3-4

Page 27

CHAPTER 3

Setting the switches

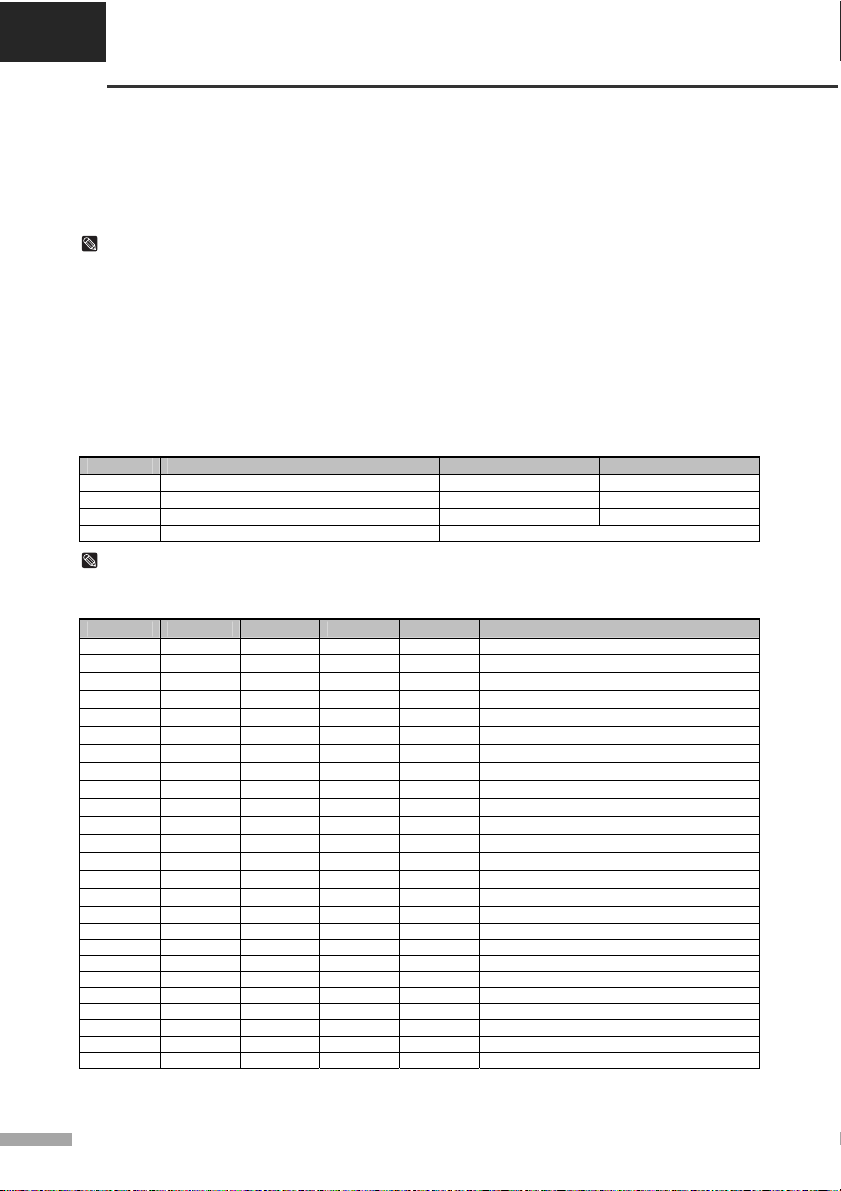

▌3.2 Setting the Memory Switches

▌3.2.1 Memory Switch setting for Epson(ESC/POS) mode

This printer has “Memory Switch” set which is software switches. Memory Switch set has “MSW 2”, “MSW 8”,

“Customize value”, “Serial communication condition”. “Memory Switch setting utility” can change the Memory

Switch set to ON or OFF as shown in the table below (default: all OFF):

NOTES

The Memory Switch is available to be changed by three methods:

- Memory Switch setting utility

- Memory Switch setup mode (there are limitations on what can be changed)

- Control from ESC/POS command

- Some Memory Switch settings can be changed by the “Memory Switch setting mode”. See “Procedure of

Memory Switch setting”.

Settings of the Memory Switch are stored in the NV memory; therefore, even if the printer is turned off, the

settings are maintained. When you replace a SRP-270 with a SRP-275, you should adjust the MSW 8-5 to

OFF.

• Memory Switch 2

Switch Function On Off

1 Reserved - Fixed to Off

2 Reserved - Fixed to Off

3 Reserved for Chinese selection - Fixed to Off

4~8 Code page selection (*1) Refer to the following table

NOTES

Desired code page can be selected using Memory Switch 2-4~8 by setting as following.

(*1) Code page selection

MSW 2-8 MSW 2-7 MSW 2-6 MSW 2-5 MSW 2-4 Character Table

0 0 0 0 0 Page 0 (PC437 : U.S.A.)

0 0 0 0 1 Page 1 (Katakana)

0 0 0 1 0 Page 2 (PC850 : Multilingual)

0 0 0 1 1 Page 3 (PC860 : Portuguese)

0 0 1 0 0 Page 4 (PC863 : Canadian-French)

0 0 1 0 1 Page 5 (PC865 : Nordic)

0 0 1 1 0 Page 16 (WPC1252 : Latin1)

0 0 1 1 1 Page 17 (PC866 : Russian)

0 1 0 0 0 Page 18 (PC852 : Latin2)

0 1 0 0 1 Page 19 (PC858 : Euro)

0 1 0 1 0 Page 21 (PC862 : Israel)

0 1 0 1 1 Page 22 (PC864 : Arabic)

0 1 1 0 0 Page 23 (Thai character code 42)

0 1 1 0 1 Page 24 (WPC1253 : Greek)

0 1 1 1 0 Page 25 (WPC1254 : Turkish)

0 1 1 1 1 Page 26 (WPC1257 : Baltic)

1 0 0 0 0 Page 27 (Farsi) (*2)

1 0 0 0 1 Page 28 (WPC1251 : Russian) (*2)

1 0 0 1 0 Page 29 (PC737 : Greek) (*2)

1 0 0 1 1 Page 30 (PC775 : Baltic) (*2)

1 0 1 0 0 Page 31 (Thai character code 16)

1 0 1 0 1 Page 32 (OldCode : Israel)

1 0 1 1 0 Page 33 (WPC1255 : Israel)

1 0 1 1 1 Page 34 (Thai character code 11)

1 1 0 0 0 Page 35 (Thai character code 18)

(*2) Only Font B available.

3-5

Page 28

• Memory Switch 8

Switch Function On Off

1

2

Reserved - Fixed to Off

3

4

5 Selection of the cover open status Cover open Paper end

6 Reserved - Fixed to Off

7 Receive buffer full release Remaining 522 bytes Remaining 640 bytes

8 Printer (Cover open during operation)

Errors that can

possibly recover

Errors that

automatically recover

NOTES

MSW 8-5:

When Off is selected, a bit of the “paper end sensor” in each status that is transmitted from the printer is

changed every time the rear cover is open or closed. When On is selected, a bit of the “rear cover open /

close" in each status that is transmitted from the printer is changed every time the rear cover is open or

closed. When you replace a SRP-270 with a SRP-275, you should adjust the MSW 8-5 to Off.

MSW 8-8:

When Off is selected, a bit of the “automatic recoverable error” in each status that is transmitted from

the printer is changed every time the rear cover is open. Whe n On is selected, a bit of the “mechanical

error” in each status that is transmitted from the printer is changed every time the rear cover is open.

The setting of MSW 8-5 and 8-8 can be set by “Memory Switch setup mode”.

• Customize value

Function Selectable value

Paper roll width 57.5 mm / 69.5 mm / 76 mm (default value)

NOTES

These setting can be set by “Memory Switch setup mode.”

• Serial communication

Function Selectable value

baud rate

Parity

2400 bps 4800 bps

9600 bps 19200 bps

None Odd

Even Handshake DSR/DTR XON/XOFF

Data length 7 bit 8 bit

NOTES

There are two methods, DIP Switch and Memory Switch, to adjust the serial communication conditions.

DIP Switch 1-5 selects which is effective, DIP Switch or Memory Switch.

To enable the “Serial communication“ setting, you have to adjust the “Serial interface selection“ function

of DIP Swi tch 1-5 to “Memory Switch”.

These settings can be set by “Memory Switch setup mode”.

3-6

Page 29

CHAPTER 3

Setting the switches

• Memory Switch Setup Mode

The following items are specified in the Memory Switch setup mode:

Basic Serial communication condition (Serial communication)

- Transmission speed

- Parity

- Handshaking

- Data length

Receive buffer full release condition (MSW 8-7)

Paper roll width (Customize value)

Cover open status (MSW 8-5)

NOTES

All new settings will be lost if the power supply is turned off in the Memory Switch setup mode. Be sure to

follow the proper procedure, and turn the power off at the correct time.

Use the following procedure to start the Memory Switch setup mode.

1) Open the rear cover.

2) Turn the power on while pressing the paper FEED button.

3) Press the FEED button twice while POWER, ERROR, and PAPER OUT LEDs are lit.

4) Close the cover. The printer prints the enabled settings of the Memory Switches and instructions.

5) Follow the instructions to process the switch setup.

NOTES

In the Memory Switch setup, the power LED m ay be flas hing.

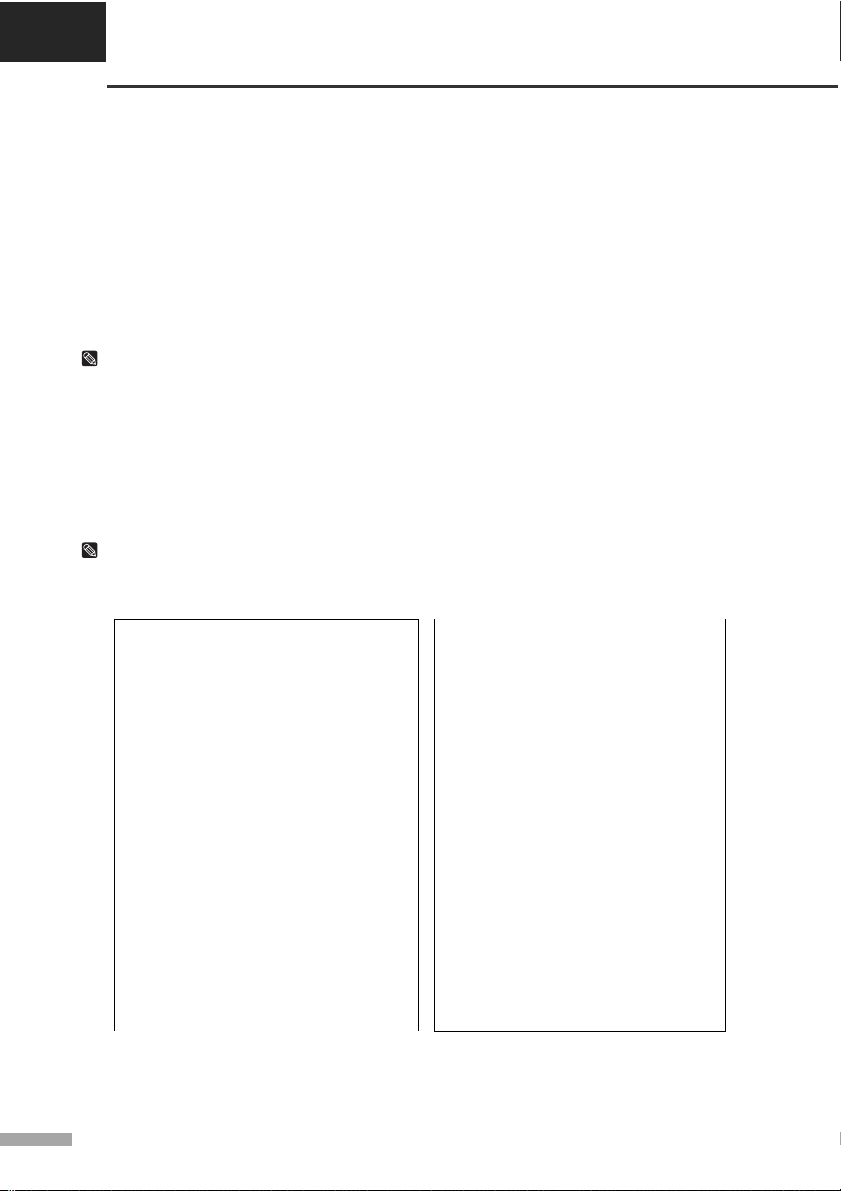

• Example of Memory Switch setup sheet

Memory S/W Setup

You can ch oose desired item using

YES or NO as following

YES: Keep pressing FEE D button

Until printing st arts

NO : Press & release i t swiftly

Serial interface setting

Do you wan t to change

Serial interface co ndition?

Buffer ful l release co ndition

Current co ndition: 640 bytes left

Do you wan t to change

Buffer full release condition?

Paper width

Current paper width: 76.0 mm

Do you want to change

paper width?

Cover open status

Current status: Paper out

Do you want to change

cover open status?

3-7

Page 30

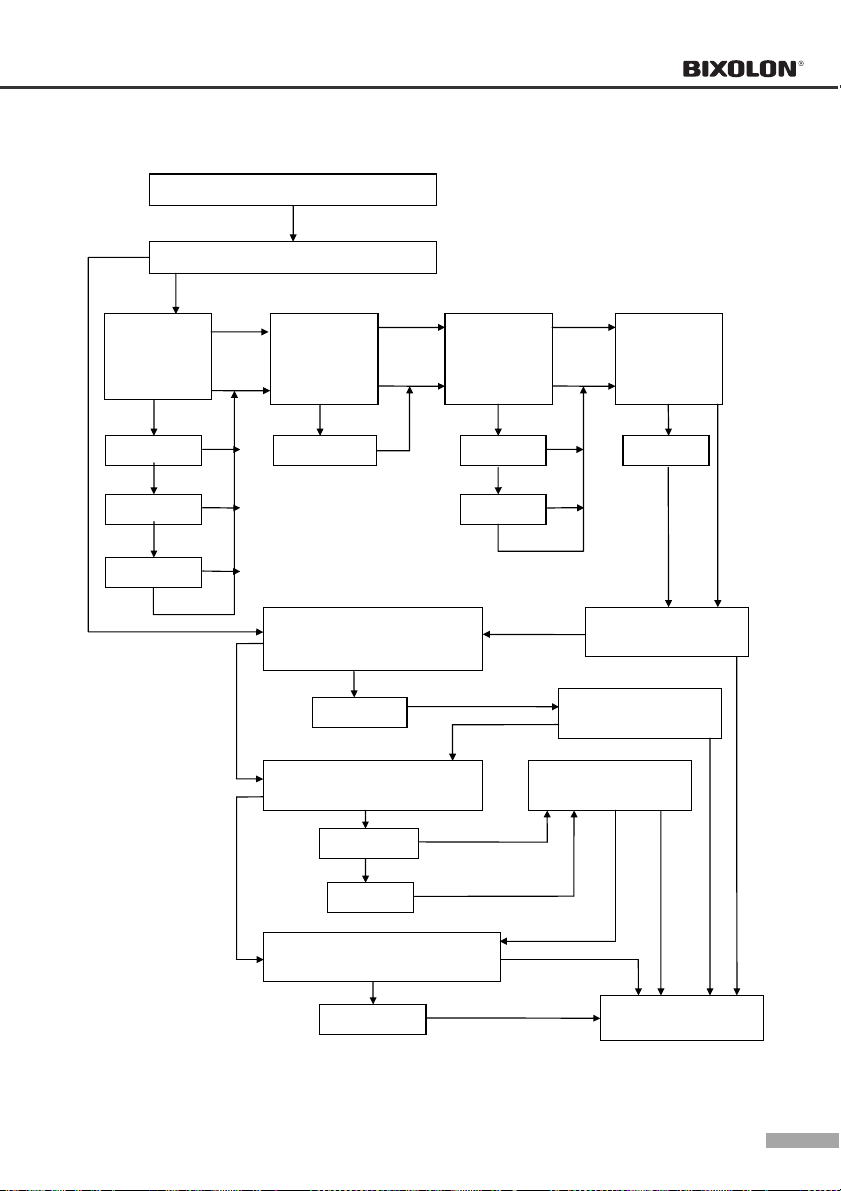

• Procedure of Memory Switch setting

Entering Memory Switch Setting Mode

① Resetting Basic Serial Interface?

NO

YES

YES

YES

YES

NO

NO

NO

Handsha ke

Current

setting:

YES

DSR/DTR

NO

XON/XOFF

② Resetting Buffer full release

condition?

Current setting: 640 bytes

YES

③ Resetting Paper width?

Current setting: 76 mm

Baud rate

Current

setting:

9600 bps

NO

19200bps

NO

4800bps

NO

2400bps

NO

522 bytes

69.5 mm

57mm

NO NO

Parity

Current

YES

YES

NO

setting:

Non

YES

NO

NO

NO

YES

YES

Even

Odd

NO

NO

Finishing Memory

S/W Set ting Mode?

YES

YES

Data bit

Current

YES

setting:

8 bits

NO

7 bits

Finishing Memory

S/W Setting Mode?

Finishing Memory

S/W Set ting Mode?

YES

NO

YES

YES

YES

YES

④ Resetting Cover open status?

Current se tti ng: P ape r out

YES

Cover open

YES

NO

Memory S/W Setting

Completed

3-8

Page 31

CHAPTER 3

Setting the switches

▌3.2.2 Memory Switch setting for Star mode

• Settings

Memory Switches are from MSW 0 to MSW 8. They are stored in non-volatile memory (flash memory). To

change the settings, send the following commands from the host.

[Name] Set Memory Switch

[Code] ASCII ESC GS # m N n1 n2 n3 n4 LF NUL

Hexadecimal 1B 1D 23 m N n1 n2 n3 n4 0A 00

Decimal 27 29 35 m N n1 n2 n3 n4 10 0

[Defined Region] m = "W", "T", ",", "+", "-", "@"

"0" ≤ N,n1,n2,n3,n4 ≤ "9",

"A" ≤ N,n1,n2,n3,n4 ≤ "F"

[Function] Sends command to write after defining Memory Switch using the definition command

specified by the following classes to set the Memory Switch. The printer is automatically

reset after writing the setting defined by that command to the non-volatile memory.

Do not turn off the power to the printer while sending commands to the non volatile

memory. Doing so will destroy the Memory Switch setting. It is also possible for all Memory

Switch settings to become offset to their initial, default settings.

Consider the life of the non-volatile memory and avoid over-use of this command.

Function Class m N n1 n2 n3 n4

Data Definition (Data Specification) Definition "," N n1 n2 n3 n4

Data definition (set specified bit) Definition "+" N n1 n2 n3 n4

Data definition (clear specified bit) Definition "-" N n1 n2 n3 n4

Data Definition (clear all data) Definition "@" Fixed at "0" Fixed at "0000"

Definition data write and reset Write "W" Fixed at "0" Fixed at "0000"

Definition data write and reset and test print Write "T" Fixed at "0" Fixed at "0000"

(Ex) Memory Switch 1-8 = 0; Memory Switch 2-7 = 1: Memory Switch 2-A =1 for a test print:

PRINT #1, CHR$(&H1B);CHR$(&H1D);CHR$(&H23);CHR$(&H2D);CHR$(&H31); ' <ESC><GS> # - 1

PRINT #1, CHR$(&H30);CHR$(&H31);CHR$(&H30);CHR$( &H30);CHR$(&H0A);CHR$(0); ' 0100 <LF><NUL>

PRINT #1, CHR$(&H1B);CHR$(&H1D);CHR$(&H23);CHR$(&H2B);CHR$(&H32); ' <ESC><GS> # + 2

PRINT #1, CHR$(&H30);CHR$(&H34);CHR$(&H38);CHR$(&H30);CHR$(&H0A);CHR$(0); ' 0480 <LF><NUL>

PRINT #1, CHR$(&H1B);CHR$(&H1D);CHR$(&H23);CHR$(&H54);CHR$(&H30); ' <ESC><GS> # T 0

PRINT #1, CHR$(&H30);CHR$(&H30);CHR$(&H30);CHR$(&H30);CHR$(&H0A);CHR$(&H0); ' 0000 <LF><NUL>

3-9

Page 32

• Default S ettings

The default settings for Memory Switch 0 to Memory Switch 8 are shown below.

Settings vary for single byte character countries (standard specifications (SBCS)) and for double-byte

character countries (Chinese character specifications (DBCS)).

- Standard Specifications (SBCS)

Memory Switch Number Ex-factory Settings (n1, n2, n3, n4)

MSW 0 "0000"

MSW 1 "0000"

MSW 2 "0000"

MSW 3 "0000"

MSW 4 "0000"

MSW 5 "0000"

MSW 6 "0000"

MSW 7 "0000"

MSW 8 "0000"

- Chinese character specifications (DBCS) (For China)

Memory Switch Number Ex-factory Settings (n1, n2, n3, n4)

MSW 0 "0010"

MSW 1 "0000"

MSW 2 "0000"

MSW 3 "0000"

MSW 4 "0000"

MSW 5 "0000"

MSW 6 "0000"

MSW 7 "0000"

MSW 8 "0000"

3-10

Page 33

CHAPTER 3

Setting the switches

• Function

- Memory Switch 0

Bit Function 0 1

F~C Reserved

B~A

(*1) Country Specifications

Country MSW 0-4 = 0 MSW 0-4 = 1

Overseas Standard Specifications Chinese Ch aracters

(*2) <FF> Command Function Selection

MSW 0-3 MSW 0-2 <FF> Command Function <FF> Com mand Function

Auto cutter model Tear Bar Model (SRP-275A type)

(*3) Red and Black (inverted black and white) Commands

MSW 0-B MSW 0-A <ESC> 4 / <ESC> 5 Command Functions

This setting functions to specify adornments when the subsequent red (white/black inversion) print

command is set. It is a substitute function for the conventional red/black (white/black inversion) printing.

<ESC> “4”: Red (white/black inversion) printing

<ESC> “5”: Red (white/black inversion) printing cancelled.

When using <ESC> 5 to cancel adornmen ts, it returns to the previously set adornments. (Adornments

such as underli ne, upper line, d ouble-tall expanded and enhancing are cancelled if there is no command

to set them (for example the <ESC> “-” 1 specification for underlines).)

This setting is enabled only for ANK characters and block characters. It is disabled for IBM block

characters and Chinese characters composed of 12 dot vertical characters (IBM block characters and

Chinese characters do not have adornment with this command).

- Precautions for selecting Option 1.

1) Prints white/black inverted characters using 7 × 9 fonts regardless of the current font size setting.

2) Inserts a one dot string of black printing to the head of the white/black invert ed character s.

3) Printing data created on a conventional red/black printer, using 1 and 2 above, there are cases in

which the printing position will shift to the right and a line of printable characters reduced.

(For example, to write 42 digits of red print data using conventional a 7 × 9 font, there is a line feed at

the 35th digit, and the remaining 7 digits are printed on the next line.)

4) Download defined characters defined with 7 × 9 fonts are printed regardless of the current font setting

(7×9/9×9).

5) MSW 3-6 must not be set to 1 (ANK character count = many). (This will cause a while line to appear

between characters.)

- Precautions for selecting Option 2 and Option 3.

1) Do not apply an upper line or an underline to characters when rotating 90 or 270 degrees.

Red and Black

(inverted black and white) Commands (*3)

Refer to the following table

9~5 Reserved

4 Country Specifications (*1)

SBCS

(Single Byte countries)

DBCS

(Double Byte countries)

3~2 <FF> Command (*2) Refer to the following table

1~0 Reserved

NOTES

0 0 Executes a form feed. Executes a form feed.

0 1

1 0 Executes a form feed. Executes a form feed.

1 1

0 0 White/black inverted printing (1 Pass)

0 1 <Option 1> White/black inversion (7 × 9 font print) + enhancing (2 passes)

1 0 <Option 2> Upper line + Underline + enhancing (2 passes)

1 1 <Option 3> Upper line + Underline + double tall expanded + enhancing (4 passes)

After paper fed to cutting position

executes partial cut (*3)

After paper fed to cutting position

executes partial cut (*3)

Paper fed to the tear-bar position

Paper fed to the tear-bar position

3-11

Page 34

)

- Memory Switch 1

Bit Function 0 1

F Reserved

E~5

4 Zero style Normal Slash zero

3~0 International Characters(*1

Refer to the following table

NOTES

(*1) International Characters Default Value Settings

MSW1-3 MSW1-2 MSW1-1 MSW1-0 International Characters

0 0 0 0 U.S.A

0 0 0 1 France

0 0 1 0 Germany

0 0 1 1 U.K.

0 1 0 0 Denmark1

0 1 0 1 Sweden

0 1 1 0 Italy

0 1 1 1 Spain1

1 0 0 0 Japan

1 0 0 1 Norway

1 0 1 0 Denmark2

- Memory Switch 2

Bit Function 0 1

F Reserved

E How to recover to print ready after inserting paper Press FEED. Auto-recovery

D~C Reserved

B Printing region width (*1) Refer to the following table

A Paper width selection (*1) Refer to the following table

9~4

Contextual auto-cut function (*2)

3

Disabled Enabled

2

Near end switch function (*3)

1~0

Refer to the following table

NOTES

(*1) Print Region Width (MSW 2-B)/Paper Width (MSW 2-A) Selection

MSW 2-B MSW 2-A Printing Region Width Paper Width

0 0 400 half dots 76mm

0 1 300 half dots 57.5mm

1 0 385 half dots 76mm

1 1 297 half dots 57.5mm

(*2) Contextual Auto-cut Function

This function auto-cuts paper when a paper feed command that feeds continuously over 7/6 inch.

Hosts that cannot send an escape sequence, such as <ESC> “d” 0 can cut paper if a 1/6 inch line feed

code <LF> is sent seven times.

(*3) Near end switch Function

When an near end switch is mounted, settings should abide by those shown in the table below.

MSW 2-1 MSW 2-0 Near end switch Function

0 0 Disabled

0 1 Disabled

1 0

1 1

Reflects the near end switch state to the status.

Printing does not stop for near end, and the printer does not go offline.

Reflects the near end switch state to the status.

Printing does stop for near end, and the printer goes offline.

3-12

Page 35

CHAPTER 3

Setting the switches

- Memory Switch 3

Bit Function 0 1

F~D

C~8 Character Table (*2) Refer to the following table

7~2

1~0 <CR> Command Functions (*1) Refer to the following table

NOTES

(*1) <CR> Command Functions

MSW3-1 MSW3-0 <CR> Functions

0 0 Ignored

0 1 Ignored

1 0 Prints and performs a line feed (same as <LF>.)

1 1 Prints (No line feed)

(*2) Character Table Settings

These settings are enabled only on standard specification printers .

MSW3-C MSW3-B MSW3-A MSW3-9 MSW3-8 Character Table

0 0 0 0 0 Page 0 (PC437 : U.S.A.)

0 0 0 0 1 Page 1 (Katakana)

0 0 0 1 0 Page 2 (PC850 : Multilingual)

0 0 0 1 1 Page 3 (PC860 : Portuguese)

0 0 1 0 0 Page 4 (PC863 : Canadian-French)

0 0 1 0 1 Page 5 (PC865 : Nordic)

0 0 1 1 0 Page 16 (WPC1252 : Latin1)

0 0 1 1 1 Page 17 (PC866 : Russian)

0 1 0 0 0 Page 18 (PC852 : Latin2)

0 1 0 0 1 Page 19 (PC858 : Euro)

0 1 0 1 0 Page 21 (PC862 : Israel)

0 1 0 1 1 Page 22 (PC864 : Arabic)

0 1 1 0 0 Page 23 (Thai character code 42)

0 1 1 0 1 Page 24 (WPC1253 : Greek)

0 1 1 1 0 Page 25 (WPC1254 : Turkish)

0 1 1 1 1 Page 26 (WPC1257 : Baltic)

1 0 0 0 0 Page 27 (Farsi) (*3)

1 0 0 0 1 Page 28 (WPC1251 : Russian) (*3)

1 0 0 1 0 Page 29 (PC737 : Greek) (*3)

0 0 0 1 1 Page 30 (PC775 : Baltic) (*3)

1 0 1 0 0 Page 31 (Thai character code 16)

1 0 1 0 1 Page 32 (OldCode : Israel)

1 0 1 1 0 Page 33 (WPC1255 : Israel)

1 0 1 1 1 Page 34 (Thai character code 11)

1 1 0 0 0 Page 35 (Thai character code 18)

(*3) Only Font B available.

3-13

Page 36

- Memory Switch 4

Bit Function 0 1

F~9

8 Automatic Status Function Disabled Enabled

7~4

3 ESC RS a n command function Only Setting

2~1

0 Data reception error (serial) Prints “?” Ignored

- Memory Switch 5

Bit Function 0 1

F~0 Reserved

- Memory Switch 6

Bit Function 0 1

F~A

9 BUSY Condition

8~0

- Memory Switch 7

Bit Function 0 1

F~0 Reserved

Reception Buffer or

Offline

Auto-status sent only

once

Reception Buffer Full

3-14

Page 37

CHAPTER 4

Control commands list

▌4.1 Command notation

XXXX

[Name] The name of the command.

[Format] The code sequence.

[Range] Gives the allowable ranges for the arguments.

[Description] Describes the command’s function.

[Notes] Provides important information on setting and using the printer command, if necessar y.

Item(s) marked with * indicates "important notice".

[Default] Gives the default values (if any) for the command arguments.

[Reference] Lists related commands.

ASCII indicates the ASCII equivalents.

Hex indicates the hexadecimal equivalents.

Decimal indicates the decimal equivalents.

[ ] k indicates the contents of the [ ] should be repeated k times.

▌4.2 Explanation of term

Item Description

The reception buffer is a buffer that stores, as is, the data received from the host (the

Reception buffer

Print buffer The print buffer is a buffer that stores the image data to be printed.

Print buffer full

Start of line

Printable area The maximum range within which printing is possible under the printer specifications.

Inch A unit of length. One inch is 25.4mm.

MSB Most Significant Bit

LSB Least Significant Bit

reception data). The reception data is stored in the reception buffer temporarily, and is then

processed sequentially.

This is the state where the print buffer is full. If new print data is input while the print buffer is

full, the data in the print buffer is printed out and a line feed is executed. This is the same

operation as the LF operation.

The start of line state satisfies the following condition:

There is no print data (including spaces and portions of data skipped due to HT) currently in

the print buffer.

4-1

Page 38

▌4.3 Exception processing

• Undefined codes

This term refers to the codes ranging from 00H to 1FH in the character code table. If a code in this range

that is not defined as a command is input, that code (one byte) is read in and discarded, and subsequent

data is processed as normal data.

Example : 30H, 31H, 03H, 32H, 0AH, 33H

If the above data string is input, the printer reads in and discards "03H" as an undefined code.

Note that 0AH is defined as a command (LF). As a result, the data string that is actually processed is: 30H,

31H, 32H, 0AH, 33H

• Undefined commands

If the data following ESC (1BH) or GS (1DH) is not defined as a command, then the two bytes (ESC/GS and

the code that follows) are read in and discarded.

Example : 30H, 1BH, 22H, 31H, 32H

If the above data string is input, the printer discards the data 1BH and 22H as undefined commands.

As a result, the data string that is actually processed is: 30H, 31H, 32H

• Settings outside the defined range

If a value outside of the defined range is input for a command that takes parameters, that command is

ignored and the previous value for that setting remains unchanged. In the case of a command that takes

multiple parameters, command processing is halted the moment that a value outside of the defined range is

input and subsequent values are processed as normal data.

Example : 1BH, 52H, 15H

If the above data string is input, 1BH and 52H are defined as a command (ESC R), but the parameter 15H is

outside of the defined range. As a result, the printer reads in and discards the data string 1BH, 52H, 15H.

Accordingly, the previously set international character set is not changed.

4-2

Page 39

CHAPTER 4

Control commands list

▌4.4 Commands for SRP-275 series

▌4.4.1 Commands list for EPSON mode (TM-U220)

No. Command Description Hex

1 HT Horizontal tab 09

2 LF Print and line feed 0A

3 CR Print and carriage return 0D

4 DLE EOT Real-time status transmission 10 04

5 DLE ENQ Real-time request to printer 10 05

6 DLE DC4(fn = 1) Generate pulse at real-time 10 14

7 ESC SP Set rig ht-side character spacing 1B 20

8 ESC ! Select pr int mode(s) 1B 21

9 ESC % Select/cancel user-defined character set 1B 25

10 ESC & Define user-defined characters 1B 26

11 ESC * Select bit-image mode 1B 2A

12 ESC – Turn underline mode on/off 1B 2D

13 ESC 2 Select default line spacing 1B 32

14 ESC 3 Set line spacing 1B 33

15 ESC < Return home 1B 3C

16 ESC = Select peripheral device 1B 3D

17 ESC ? Cancel user-defined characters 1B 3F

18 ESC @ Initialize printer 1B 40

19 ESC D Set horizontal tab positions 1B 44

20 ESC E Turn emphasized mode on/off 1B 45

21 ESC G Turn double-strike mode on/off 1B 47

22 ESC J Print and feed paper 1B 4A

23 ESC K Print and reverse feed 1B 4B

24 ESC M Select character font 1B 4D

25 ESC R Select an international character set 1B 52

26 ESC U Turn unidirectional printing mode on/off 1B 55

27 ESC a Select justification 1B 61

28 ESC c 3 Select paper sensor(s) to output paper end signals 1B 63 33

29 ESC c 4 Select paper sensor(s) to stop printing 1B 63 34

30 ESC c 5 Enable/disable panel buttons 1B 63 35

31 ESC d Print and feed n lines 1B 64

32 ESC e Print and reverse feed n lines 1B 65

33 ESC g Start macro record (For logo) 1B 67 00

34 ESC g<n> Execute macro (For logo) 1B 67 <n>

35 ESC i Partial c ut (one point left uncut) 1B 69

36 ESC m Partial cut (one point left uncut) 1B 6D

37 ESC p Generate pulse 1B 70

38 ESC r Select print color 1B 72

39 ESC t Select character code table 1B 74

40 ESC u Transmit peripheral device status 1B 75

41 ESC v Transmit paper sensor status 1B 76

42 ESC { Turn upside-down printing mode on/off 1B 7B

43 FS p Print NV bit image 1C 70

44 FS q Define NV bit image 1C 71

45 GS ( A Execute test print 1D 28 41

46 GS ( C Edit NV user memory 1D 28 43

47 GS ( D Enable/disable real-time command 1D 28 44

48 GS ( E User setup commands 1D 28 45

49 GS I Transmit printer ID 1D 49

50 GS V Select cut mode and cut paper 1D 56

51 GS a Enable/disable Automatic Status Back (ASB) 1D 61

52 GS r Transmit status 1D 72

4-3

Page 40

▌4.4.2 Command description for EPSON mode (TM-U220)

HT

[Name] Horizont al tab

[Format] ASCII HT

Hex 09

Decimal 9

[Range] None

[Default] Non e

[Description] Moves the printing position to the next horizontal tab.

LF

[Name] Print and line feed

[Format] ASCII LF

Hex 0A

Decimal 10

[Range] None

[Default] Non e

[Description] Prints the data in the print buffer and feeds one line.

CR

[Name] Print and carriage return

[Format] ASCII CR

Hex 0D

Decimal 13

[Range] None

[Default] Non e

[Description]

When auto line feed is enabled(DSW 2-1)

(Only available with Parallel Interface)

Executes printing and one line feed as LF

When auto line feed is disabled

Prints data in print buff er and does not

feed the paper

4-4

Page 41

CHAPTER 4

Control commands list

DLE EOT

[Name] Real-time status transmission

[Format] ASCII DLE EOT n

Hex 10 04 n

Decimal 16 4 n

[Range] 1 ≤ n ≤ 4

[Description] Transmits 1 byte of status data speci fied in real time, u sing n as follows:

[Notes] • Printer status (n = 1) is as follows:

n Function

1 Transmit printer st atus

2 Transmit offline status

3 Transmit error status

4 Transmit paper sensor status

Bit Binary Hex Decimal Status

0 0 00 0. Not used. Fixed to Off

1 1 02 2 Not used. Fixed to On

0 00 0 Drawer kick-out connector pin 3 is LOW

2

1 04 4 Drawer kick-out connector pin 3 is HIGH

0 00 0 Online

3

1 08 8 Offline

4 1 10 16 Not used. Fixed to On

5 0 00 0 Not used. Fixed to Off

6 0 00 0 Not used. Fixed to Off

7 0 00 0 Not used. Fixed to Off

• Offline status (n = 2) is as follows:

Bit Binary Hex Decimal Status

0 0 00 0. Not used. Fixed to Off

1 1 02 2 Not used. Fixed to On

0 00 0 Cover is closed

2

1 04 4 Cover is open

0 00 0 Paper is not bein g fed by the paper feed button

3

1 08 8 Paper is being fe d by the paper feed button

4 1 10 16 Not used. Fixed to On

0 00 0 No paper end stop

5

1 20 32 Printing stops due to a paper end

0 00 0 No error

6

1 04 4 Error occurred

7 0 00 0 Not used. Fixed to Off

• Error status (n = 3) is as follows:

Bit Binary Hex Decimal Sta tus

0 0 00 0 Not used. Fixed to Off

1 1 02 2 Not used. Fixed to On

0 00 0 No mechanical error

2

1 04 4 Mechanical error occurred

0 00 0 No auto cutter error

3

1 08 8 Auto cutter error o ccurred

4 1 10 16 Not used. Fixed to On

0 00 0 No unrecoverable error

5

1 20 32 Unrecoverable error occurred

0 00 0 No auto-recoverable error

6

1 04 4 Auto-recoverable erro r occurred

7 0 00 0 Not used. Fixed to Off

• Paper sensor statu s (n = 4) is as follows:

Bit Binary Hex Decimal Sta tus

0 0 00 0 Not used. Fixed to Off

1 1 02 2 Not used. Fixed to On

00 00 0 Paper near end sensor: paper adequate

2,3

11 0C 12 Paper near end sensor: paper near end

4 1 10 16 Not used. Fixed to On

00 00 0 Paper end sensor: paper pre sent

5,6

11 60 96 Paper end sensor: paper not present

7 0 00 0 Not used. Fixed to Off

4-5

Page 42

DLE ENQ

[Name] Real-time request to printer

[Format] ASCII DLE ENQ n

[Range] n = 2

[Default] Non e

[Description] Recovers from an error after clearing the receive and print buffers.

Hex 10 05 n

Decimal 16 5 n

DLE DC4 (fn = 1)

[Name] Generate pulse at real-time

[Format] ASCII DLE DC4 n m t

[Range] n = 1

[Description] Outputs the pulse specified by t to connector pin m as follows in real time:

Hex 10 14 n m t

Decimal 16 20 n m t

m = 0, 1

1 ≤ t ≤ 8

m Connector pin

0 Drawer kick-out connector pin 2

1 Drawer kick-out connector pin 5

The pulse ON time is [t x100 ms] and the OFF time is [t x100 ms]

ESC SP

[Name] Set right-side character spacing

[Format] ASCII ESC SP n

[Range] 0 ≤ n ≤ 255

[Default] n = 0

[Description] Sets the righ t-side character spacing t o nⅹ(horizontal or vertical motion unit).

Hex 1B 20 n

Decimal 27 32 n

ESC !

[Name] Select print mode(s)

[Format] ASCII ESC ! n

[Range] 0 ≤ n ≤ 255

[Default] n = 1

[Description] Selects or cancel s print modes collectively (emphasized, double-he ight, double-width , underline)

Hex 1B 21 n

Decimal 27 33 n

using n as follows:

Bit On/Off Hex Decimal Function

0

1,2 - - - Unde fined

3

4

5

6 Off - - Undefined

7

Off 00 Character font A(9x9)selected

On 01 Character font B(7x9) selected

Off 00 0 E mphasized mode not selected

On 08 8 Emphasized mode selected

Off 00 0 Dou ble-height mode not selected

On 10 16 Double-height mode selected

Off 00 0 Double-width mode not selected

On 20 32 Double-width mode selected

Off 00 0 Underline mode not selected

On 80 128 Underline mode selected

4-6

Page 43

CHAPTER 4

Control commands list

ESC %

[Name] Select/cancel user-defined character set

[Format] ASCII ESC % n

[Range] 0 ≤ n ≤ 255

[Default] n = 0

[Description] Selects or cancels the use r-defined character set.

ESC &

[Name] Define user-defined characters

[Format] ASCII ESC & y c1 c2 [x1 d1 ... d(y

[Range] y = 2

[Default] Non e

[Description] Def ines user-defined characters from character code check c1 to c2.

[Notes] • The relationship between the definition data and printing result is as follows.

Hex 1B 25 n

Decimal 27 37 n

- When the LSB of n is 0, the user-defined character set is canceled.

- When the LSB of n is 1, the user-defined character set is selected.

Hex 1B 26 y c1 c2 [x1 d1 ... d(y

Decimal 27 38 y c1 c2 [x1 d1 ... d(y

32 ≤ c1 ≤ c2 ≤ 126

0 ≤ x ≤ 12 (Font A (9 x 9))

0 ≤ x ≤ 10 (Font B (7 x 9 ))

0 ≤ d ≤ 255

k = c2 – c1 + 1

- y specifies the number of bytes in the vertical direction.

- x specifies the number of dots in the horizontal direction.

- d is the dot data for the user-defined characters.

Example: Downloaded character definition consists of 9x7 dots.

d1 d3 d5 d7 d9 d11 d13

d2 d4 d6 d8 d10 d12 d14

ⅹ

x1)]... [xk d1 ... d(yⅹxk)]

ⅹ

x1)]... [xk d1 ... d(yⅹxk)]

ⅹ

x1)]... [xk d1 ... d(yⅹxk)]

MSB

LSB

MSB

LSB

4-7

Page 44

ESC *

[Name] Select bit-image mode

[Format] ASCII ESC * m n

[Range] m = 0 , 1

[Default] Non e

[Description] Selects a bit-image mode using m for the number of dots specified by (n

[Notes] • The relationship between the bit image data and the print result is as follows.

Hex 1B 2A m n

Decimal 27 42 m n

L ≤ 255

0 ≤ n

H ≤ 3

0 ≤ n

0 ≤ d ≤ 255

L + nH x 255

k = n

m Mode

0 8-dot single-density 8 Single-density nL + nH x 256

1 8-dot double-density 8 Double-den sity nL + nH x 256

d1 d2

• The modes selectable by m are as follows:

m Mode

8-dot

0

single-densi ty

8-dot

1

double-density

Number of bits

for vertical data

8 dot mode (m = 0,1)

Vertical

dot

density

72 dpi 80 dpi Permitted 192/ 180/ 148 200/ 180/ 150

72 dpi 160 dpi Proh ibited 385/ 360/ 297 400/ 360/ 300

ㆍㆍㆍ

Dot

density

L nH d1 ... dk

L nH d1 ... dk

L nH d1 ... dk

dk

Set

adjacent

dots

L + nH x 256) as follows:

Dot dens ity

in horizontal

MSB

LSB

Horizontal

Maximum number of dots

DSW1-8: ON DSW 1-8: OFF

Paper Width:

76/ 69.5/ 57.5

Amount of data (k)

(mm)

ESC -

[Name] Turn underline mode on/off

[Format] ASCII ESC – n

[Range] n = 0, 1, 48, 49

[Default] n = 0

[Description] Turns underline mode on or off using n as follows:

Hex 1B 2D n

Decimal 27 45 n

n Function

0, 48 Turns off underline mode

1, 49 Turns on underline mode (1-dot thick)

2, 50 Turns on underline mode (1-dot thick)

Paper Width:

76/ 69.5/ 57.5

(mm)

4-8

Page 45

CHAPTER 4

Control commands list

ESC 2

[Name] Select default line spacing

[Format] ASCII ESC 2

[Range] None

[Default] Non e

[Description] Sets the line spacing to the “default line spacing.”

ESC 3

[Name] Set line spacing

[Format] ASCII ESC 3 n

[Range] 0 ≤ n ≤ 255

[Default] Amount of line spacing which corresponds to “default line spacing.”

[Description] Sets the line spacing to n x (vertical or horizontal motion unit).

ESC <

[Name] Return home

[Format] ASCII ESC <

[Range] None

[Default] Non e

[Description] Moves the print head to the standby positi on.

ESC =

[Name] Select peripheral device

[Format] ASCII ESC = n

[Range] 0 ≤ n ≤ 255

[Default] n = 1

[Description] Selects t he device to which th e host computer se nds data, using n as follows:

ESC ?

[Name] Cancel user-defined characters

[Format] ASCII ESC ? n

[Range] 32 ≤ n ≤ 126

[Default] Non e

[Description] Cancels the user-defined characters defined for the character code n.

Hex 1B 32

Decimal 27 50

Hex 1B 33 n

Decimal 27 51 n

(See ESC 2 for the default line spacing.)

Hex 1B 3C

Decimal 27 60

Hex 1B 3D n

Decimal 27 61 n

n Functi on

1 Enables the printer

2 Disables the printer

3 Enables the printer

Hex 1B 3F n

Decimal 27 63 n

4-9

Page 46

ESC @

[Name] Initiali ze prin ter

[Format] ASCII ESC @

Hex 1B 40

Decimal 27 64

[Range] None

[Default] Non e

[Description] The data in the print buffer is cleared, and the printer mode(s) is reset to the mode that was in

effect when the power was turned on.

- Any macro definition s are not cleared.

- Contents of user NV memory are not cleared.

- NV bit image is not cleared.

ESC D

[Name] Set horizontal tab positions

[Format] ASCII ESC D n1 ... nk NULS

Hex 1B 44 n1 ... nk 00

Decimal 27 68 n1 ... nk 0

[Range] 0 ≤ n ≤ 255

0 ≤ k ≤ 32

[Default] n = 8, 16, 24, 32, ...

(Every eight characte rs for the default font set by ESC ! or ESC M)

[Description] Sets a horizontal tab to n columns from the beginn ing of the line.

- k indicates the number of horizontal tab positions to be set.

ESC E

[Name] Turn emphasized mode on/off

[Format] ASCII ESC E n

Hex 1B 45 n

Decimal 27 69 n

[Range] 0 ≤ n ≤ 255

[Default] n = 0

[Description] Turns emphasized mode on or off.

- When the LSB of n is 0, emphasized mode is turned off.

- When the LSB of n is 1, emphasized mode is turned on.

ESC G

[Name] Turn double-st rike mode on/off

[Format] ASCII ESC G n

Hex 1B 47 n

Decimal 27 71 n

[Range] 0 ≤ n ≤ 255

[Default] n = 0

[Description] Turns double-strike mode o n or off.

- When the LSB of n is 0, double-strike mode is turned off.

- When the LSB of n is 1, double-strike mode is turned on.

4-10

Page 47

CHAPTER 4

Control commands list

ESC J

[Name] Print and feed paper

[Format] ASCII ESC J n

[Range] 0 ≤ n ≤ 255

[Default] Non e

[Description] Prints th e data in the print buffer and feeds the paper n x (vertical or horizontal motion unit).

ESC K

[Name] Print and reverse feed

[Format] ASCII ESC K n

[Range] 0 ≤ n ≤ 24

[Default] Non e

[Description] Prints the data in the print buffer and feeds the paper n x (vertical motion unit) in the reverse

ESC M

[Name] Select character font

[Format] ASCII ESC M n

[Range] n = 0, 1, 48, 49

[Default] n = 1

[Description] Selects a character font, using n as follows:

ESC R

[Name] Select an international character set

[Format] ASCII ESC R n

[Range] 0 ≤ n ≤ 10

[Default] n = 0

[Description] Selects an internation al character set n as follows:

Hex 1B 4A n

Decimal 27 74 n

Hex 1B 4B n

Decimal 27 75 n

direction.

Hex 1B 4D n

Decimal 27 77 n

n Font

0, 48 Font A (9x9)

1, 49 Font B (7x9)

Hex 1B 52 n

Decimal 27 82 n

n Country

0 U.S.A.

1 France

2 Germany

3 U.K.

4 Denmark I

5 Sweden

6 Italy

7 Spain I

8 Japan

9 Norway

10 Denmark II

4-11

Page 48

ESC U

[Name] Turn unidirectional printing mode on/off

[Format] ASCII ESC U n

[Range] 0 ≤ n ≤ 255

[Default] n = 0

[Description] Turns unidirectional printing mode on or off.

Hex 1B 55 n

Decimal 27 85 n

- When the LSB of n is 0, unidirectional printing mode is turned off.

- When the LSB of n is 1, unidirectional printing mode is turned on.

ESC a

[Name] Select justification

[Format] ASCII ESC a n

[Range] 0 ≤ n ≤ 2, 48 ≤ n ≤ 50

[Default] n = 0

[Description] Aligns all the data in one line to a specified position, using n as follows:

Hex 1B 61 n

Decimal 27 97 n