Page 1

PROJECTION TV RECEIVER

Chassis : SPT51A (VERSION1)

Model: SPM5288PF

SPM5288PTR

SPM4388PF

SPM4388PTR

PROJECTION TV RECEIVER CONTENTS

Precautions

Reference Information

Specifications

Disassembly and Reassembly

Alignment and Adjustment

Troubleshooting

Exploded View and Parts List

Areas and Option Specification

Electric Parts List

Block Diagrams

Wiring Diagram

Schematic Diagrams

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12

Page 2

ELECTRONICS

©

Samsung Electronics Co., Ltd. SEP 1997

Printed in Korea

3SPT51A-8801

Page 3

1. Precautions

Follow these safety, servicing and ESD precautions to prevent damage and protect against potential

hazards such as electrical shock and X-rays.

1-1 Safety Precautions

1 . Be sure that all of the built-in protective

devices are replaced. Restore any missing

protective shields.

2 . When reinstalling the chassis and its

assemblies, be sure to restore all protective

devices, including: nonmetallic control

knobs and compartment covers.

3 . Make sure that there are no cabinet

openings through which people-particularly children--might insert fingers

and contact dangerous voltages. Such

openings include the spacing between the

picture tube and the cabinet mask,

excessively wide cabinet ventilation slots,

and improperly fitted back covers.

If the measured resistance is less than 1.0

megohm or greater than 5.2 megohms, an

abnormality exists that must be corrected

before the unit is returned to the customer.

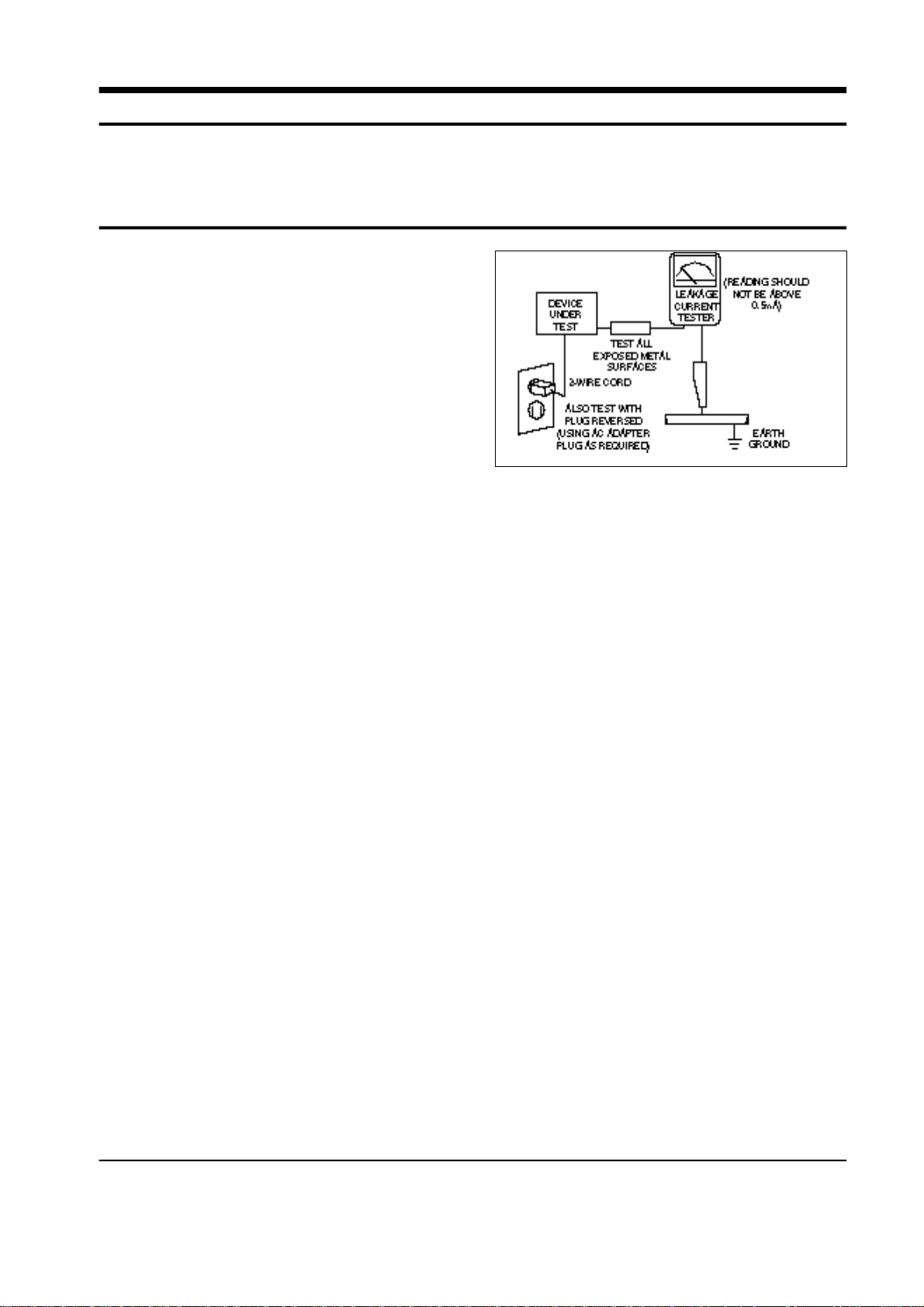

4 . Leakage Current Hot Check (Figure 1-1):

Warning: Do not use an isolation

transformer during this test. Use a leakagecurrent tester or a metering system that

complies with American National Standards

Institute (ANSI C101.1, Leakage Current for

A p p l i a n c e s ) , and Underwriters Laboratories

(UL Publication UL1410, 59.7).

6 . Antenna Cold Check:

With the unit's AC plug disconnected from

the AC source, connect an electrical jumper

across the two AC prongs. Connect one

lead of the ohmmeter to an AC prong.

Connect the other lead to the coaxial

connector.

7 . X-ray Limits:

The picture tube is especially designed to

prohibit X-ray emissions. To ensure

continued X-ray protection, replace the

picture tube only with one that is the same

type as the original. Carefully reinstall the

picture tube shields and mounting

hardware; these also provide X-ray

p r o t e c t i o n .

Fig. 1-1 AC Leakage Test

5 . With the unit completely reassembled, plug

the AC line cord directly into the power

outlet. With the unit's AC switch first in the

ON position and then OFF, measure the

current between a known earth ground

(metal water pipe, conduit, etc.) and all

exposed metal parts, including: antennas,

handle brackets, metal cabinets, screwheads

and control shafts. The current measured

should not exceed 0.5 milliamp. Reverse the

power-plug prongs in the AC outlet and

repeat the test.

8 . High Voltage Limits:

High voltage must be measured each time

servicing is done on the B+, horizontal

deflection or high voltage circuits. Correct

operation of the X-ray protection circuits

must be reconfirmed whenever they are

serviced. (X-ray protection circuits also may

be called "horizontal disable" or "holdd o w n " . )

Heed the high voltage limits. These include

the X–ray Protection Specifications Label, a n d

the Product Safety and X-ray Warning Note o n

the service data schematic.

1-1Samsung Electronics

Page 4

Precautions

1-1 Safety Precautions (Continued)

9 . High voltage is maintained within specified

limits by close-tolerance, safety-related

components and adjustments. If the high

voltage exceeds the specified limits, check

each of the special components.

1 0 . Design Alteration Warning:

Never alter or add to the mechanical or

electrical design of this unit. Example: Do

not add auxiliary audio or video

connectors. Such alterations might create

a safety hazard. Also, any design changes

or additions will void the manufacturer's

warranty.

1 1 . Hot Chassis Warning:

Some TV receiver chassis are electrically

connected directly to one conductor of the

AC power cord. If an isolation transformer

is not used, these units may be safely

serviced only if the AC power plug is

inserted so that the chassis is connected to

the ground side of the AC source.

To confirm that the AC power plug is

inserted correctly, do the following: Using

an AC voltmeter, measure the voltage

between the chassis and a known earth

ground. If the reading is greater than 1.0V,

remove the AC power plug, reverse its

polarity and reinsert. Re-measure the

voltage between the chassis and ground.

1 2 . Some TV chassis are designed to operate

with 85 volts AC between chassis and

ground, regardless of the AC plug polarity.

These units can be safely serviced o n l y i f

an isolation transformer inserted between

the receiver and the power source.

1 5 . Observe the original lead dress,

especially near the following areas:

Antenna wiring, sharp edges, and

especially the AC and high voltage power

supplies. Always inspect for pinched,

out-of-place, or frayed wiring. Do not

change the spacing between components

and the printed circuit board. Check the

AC power cord for damage. Make sure

that leads and components do not touch

thermally hot parts.

1 6 . Picture Tube Implosion Warning:

The picture tube in this receiver employs

"integral implosion" protection. To

ensure continued implosion protection,

make sure that the replacement picture

tube is the same as the original.

1 7 . Do not remove, install or handle the

picture tube without first putting on

shatterproof goggles equipped with side

shields. Never handle the picture tube by

its neck. Some "in-line" picture tubes are

equipped with a permanently attached

deflection yoke; do not try to remove

such "permanently attached" yokes from

the picture tube.

1 8 . Product Safety Notice:

Some electrical and mechanical parts

have special safety-related characteristics

which might not be obvious from visual

inspection. These safety features and the

protection they give might be lost if the

replacement component differs from the

original--even if the replacement is rated

for higher voltage, wattage, etc.

1 3 . Some TV chassis have a secondary

ground system in addition to the main

chassis ground. This secondary ground

system is not isolated from the AC power

line. The two ground systems are

electrically separated by insulating

material that must not be defeated or

a l t e r e d .

1 4 . Components, parts and wiring that

appear to have overheated or that are

otherwise damaged should be replaced

with parts that meet the original

specifications. Always determine the

cause of damage or overheating, and

correct any potential hazards.

1-2 Samsung Electronics

Components that are critical for safety are

indicated in the circuit diagram by

shading, ( ) or ( ).

Use replacement components that have

the same ratings, especially for flame

resistance and dielectric strength

specifications. A replacement part that

does not have the same safety

characteristics as the original might create

shock, fire or other hazards.

Page 5

Precautions

1-2 Servicing Pre c a u t i o n s

W A R N I N G1 : First read the "Safety Precautions" section of this manual. If some unforeseen circumstance creates a conflict

between the servicing and safety precautions, always follow the safety precautions.

W A R N I N G2: An electrolytic capacitor installed with the wrong polarity might explode.

1 . Servicing precautions are printed on the

cabinet. Follow them.

2 . Always unplug the unit's AC power cord

from the AC power source before

attempting to: (a) Remove or reinstall any

component or assembly, (b) Disconnect an

electrical plug or connector, (c) Connect a

test component in parallel with an

electrolytic capacitor.

3 . Some components are raised above the

printed circuit board for safety. An

insulation tube or tape is sometimes used.

The internal wiring is sometimes clamped to

prevent contact with thermally hot

components. Reinstall all such elements to

their original position.

4 . After servicing, always check that the

screws, components and wiring have been

correctly reinstalled. Make sure that the

portion around the serviced part has not

been damaged.

5 . Check the insulation between the blades of

the AC plug and accessible conductive parts

(examples: metal panels, input terminals

and earphone jacks).

6 . Insulation Checking Procedure: Disconnect

the power cord from the AC source and

turn the power switch ON. Connect an

insulation resistance meter (500V) to the

blades of the AC plug.

The insulation resistance between each

blade of the AC plug and accessible

conductive parts (see above) should be

greater than 1 megohm.

7 . Never defeat any of the B+ voltage

interlocks. Do not apply AC power to the

unit (or any of its assemblies) unless all

solid-state heat sinks are correctly installed.

8 . Always connect a test instrument's ground

lead to the instrument chassis ground

before connecting the positive lead; always

remove the instrument's ground lead last.

1-3 Precautions for Electrostatically Sensitive Devices (ESDs)

1 . Some semiconductor ("solid state") devices

are easily damaged by static electricity.

Such components are called Electrostatically

Sensitive Devices (ESDs); examples include

integrated circuits and some field-effect

transistors. The following techniques will

reduce the occurrence of component

damage caused by static electricity.

2 . Immediately before handling any

semiconductor components or assemblies,

drain the electrostatic charge from your

body by touching a known earth ground.

Alternatively, wear a discharging

wrist-strap device. (Be sure to remove it

prior to applying power--this is an electric

shock precaution.)

3 . After removing an ESD-equipped assembly,

place it on a conductive surface such as

aluminum foil to prevent accumulation of

electrostatic charge.

4 . Do not use freon-propelled chemicals.

These can generate electrical charges that

damage ESDs.

5 . Use only a grounded-tip soldering iron

when soldering or unsoldering ESDs.

6 . Use only an anti-static solder removal

device. Many solder removal devices are

not rated as "anti-static"; these can

accumulate sufficient electrical charge to

damage ESDs.

7 . Do not remove a replacement ESD from its

protective package until you are ready to

install it. Most replacement ESDs are

packaged with leads that are electrically

shorted together by conductive foam,

aluminum foil or other conductive

m a t e r i a l s .

8 . Immediately before removing the protective

material from the leads of a replacement

ESD, touch the protective material to the

chassis or circuit assembly into which the

device will be installed.

9 . Minimize body motions when handling

unpackaged replacement ESDs. Motions

such as brushing clothes together, or lifting

a foot from a carpeted floor can generate

enough static electricity to damage an ESD.

Samsung Electronics

1-3

Page 6

1-4 Samsung Electronics

Page 7

2. Reference Information

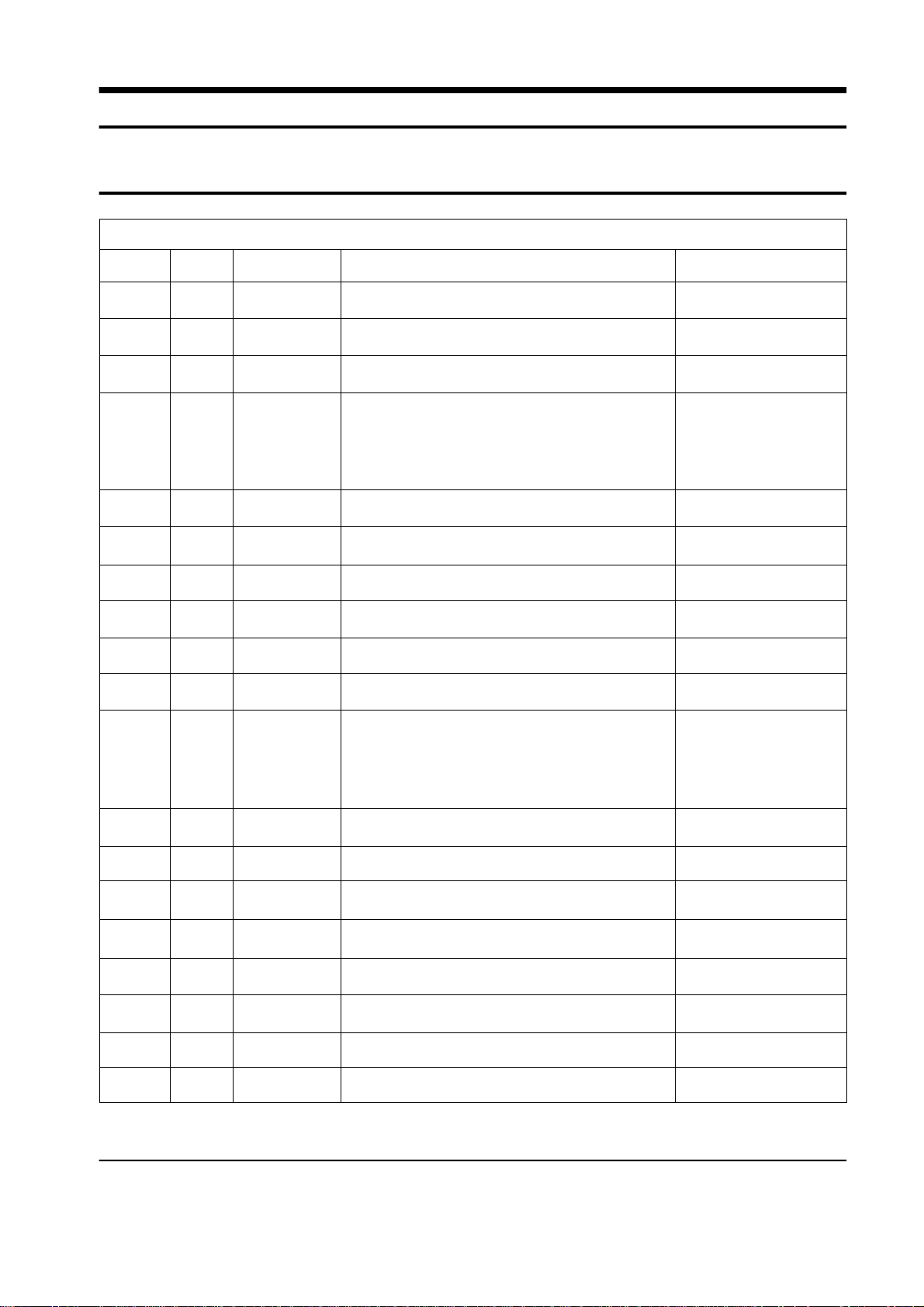

2-1 IC Summary

Table 2-1 IC Summary

Loc No.

IC111

IC201

IC202

IC203

IC204

IC205

IC206

IC207

IC208

IC301

No.

10

1

2

3

4

5

6

7

8

9

Specification

TDA9815

TDA4566

TDA9160A

TDA4780

TDA4665

TDA9170

MC14577BP

AN5342K

TEA5114A

TDA8350Q

Description

VIF-PLL/DUAL FM-PLL/AM DEMODULATOR

COLOUR TRANSIENT IMPROVEMENT

PAL/NTSC/SECAM DECODER AND SYNC PROCESSOR

RGB VIDEO PROCESSOR

BASEBAND DELAY LINE

YUV PICTURE IMPROVEMENT PROCESSOR

DUAL VIDEO AMPLIFIERS

VIDEO CONTOUR COLLECTION

RGB SWITCHING

VERTICAL DEFLECTION

Remarks

AUTOMATIC CUT-OFF

CONTROL AND COMMA

ADJUST

IC501

IC502

IC503

HC651

IC602

IC603

ICJ01

ICJ02

ICE01

ICE02

ICE03

11

12

13

14

15

16

17

18

19

TDA6101Q

STK4142•±

UPC1853

TDA9840

SAA7283

MC4558C

M65831P

NJM3403AD

UPC1406HA

VIDEO OUTPUT AMPLIFIER

AUDIO AMPLIFIER

MATRIX SURROUND IC

STEREO/DUAL SOUND PROCESSOR

NICAM DECODER

OP-AMPLIFIER

DIGITAL ECHO

QUAD OP-AMPLIFIER

DUAL ATTENUATOR

NICAM PART

NICAM PART

KARAOKE PART

KARAOKE PART

KARAOKE PART

2-1Samsung Electronics

Page 8

Reference Information

Table 2-1 IC Summary(Continued)

Loc No.

IC701

IC702

IC703

IC704

IC801

IC901

ICT01

ICT02

ICP101

ICP102

ICP103

ICP201

No.

20

21

22

23

24

25

26

27

28

29

Specification

TC4053BP

KA2192

STR-S6709

RM130

SAA5281

TEA5114A

TDA9160A

TDA9815

PAP101

SDA9187

Description

A/V SWITCHING IC

A/V SWITCHING IC

SMPS CONTROL

MICOM

TELETEXT

RGB SWITCHING

PAL/NTSC/SECAM DECODER AND SYNC PROCESSOR

VIF-PLL

IF PRE-AMP

PIP PROCESSOR

Remarks

A/V SWITCHING PART

A/V SWITCHING PART

POWER PART

TELETEXT PART

TELETEXT PART

PIP PART

PIP PART

PIP PART

PIP PART

ICP105

30

SDA9189

ICZ30

31

TEA5114A

ICZ31

ICZ202

32

74HC123P

HCZ03

HCZ04

33

STK391-020

HCZ05

Option: OSD Language

Loc No.

IC901

Specification

RM130ECP

RM130ERP

RM130EAP

RM130EUP

RM130ETP

PIP PROCESSOR

OSD/CONVERGENCE SWITCHING

DYNAMIC FOCUS

CONVERGENCE AMP

Table 2-2

Description

SSOM-130ECP

SSOM-130ERP

SSOM-130EAP

SSOM-130EUP

SSOM-130ATP

Remarks

ENG/CHINA

ENG/RUS/HUN/POL

ENG/ARABIC

ENG/UGO/CHE/RUM

ENG/TAI/MAL/IND

PIP PART

CONVERGENCE PART

CONVERGENCE PART

2-2 Samsung Electronics

Page 9

3. Specifications

MODEL

TUNING

SYSTEM COLOUR

SOUND

NICAM

ANTENNA IMPEDANCE

SCREEN SIZE

POWER CONSUMPTION

REQUIREMENTS

FREQUENCY

PROGRAMME CHANNEL

SOUND OUTPUT

4388 5288

Frequency Synthesizer

PAL, SECAM, NTSC3.58, NTSC4.43

B/G, D/K, I,M

B/G,I

75 ohm unbalanced coaxial

109 cm 132 cm

275 watts 275 watts

Main voltage : 220V/230V/240V

Cover range : 100 - 260V

50/60Hz

100 channels

25 watts/ch. x 2

DIMENSIONS SET

(W x D x H) TRANSMITTER

WEIGHT SET

TRANSMITTER

Specifications are subject to change.

950 x 476 x 1247 (mm) 1168 x 589 x 1384 (mm)

64 x 234 x 20(mm)

63 Kg 73 Kg

140g (Including Batteries)

3-1Samsung Electronics

Page 10

3-2 Samsung Electronics

Page 11

Disassembly and Reassembly

Samsung Electronics 4-1

4. Disassembly and Reassembly

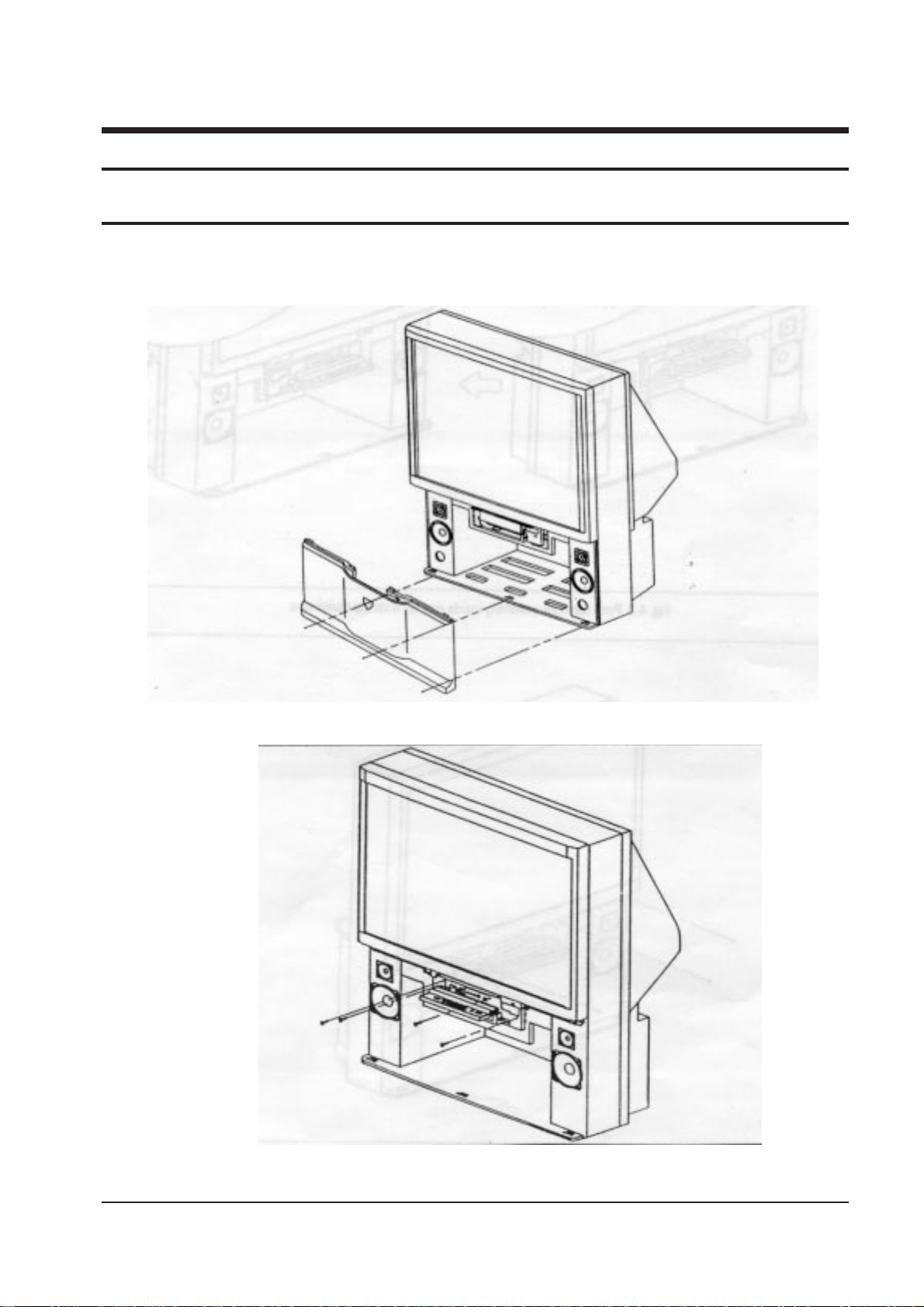

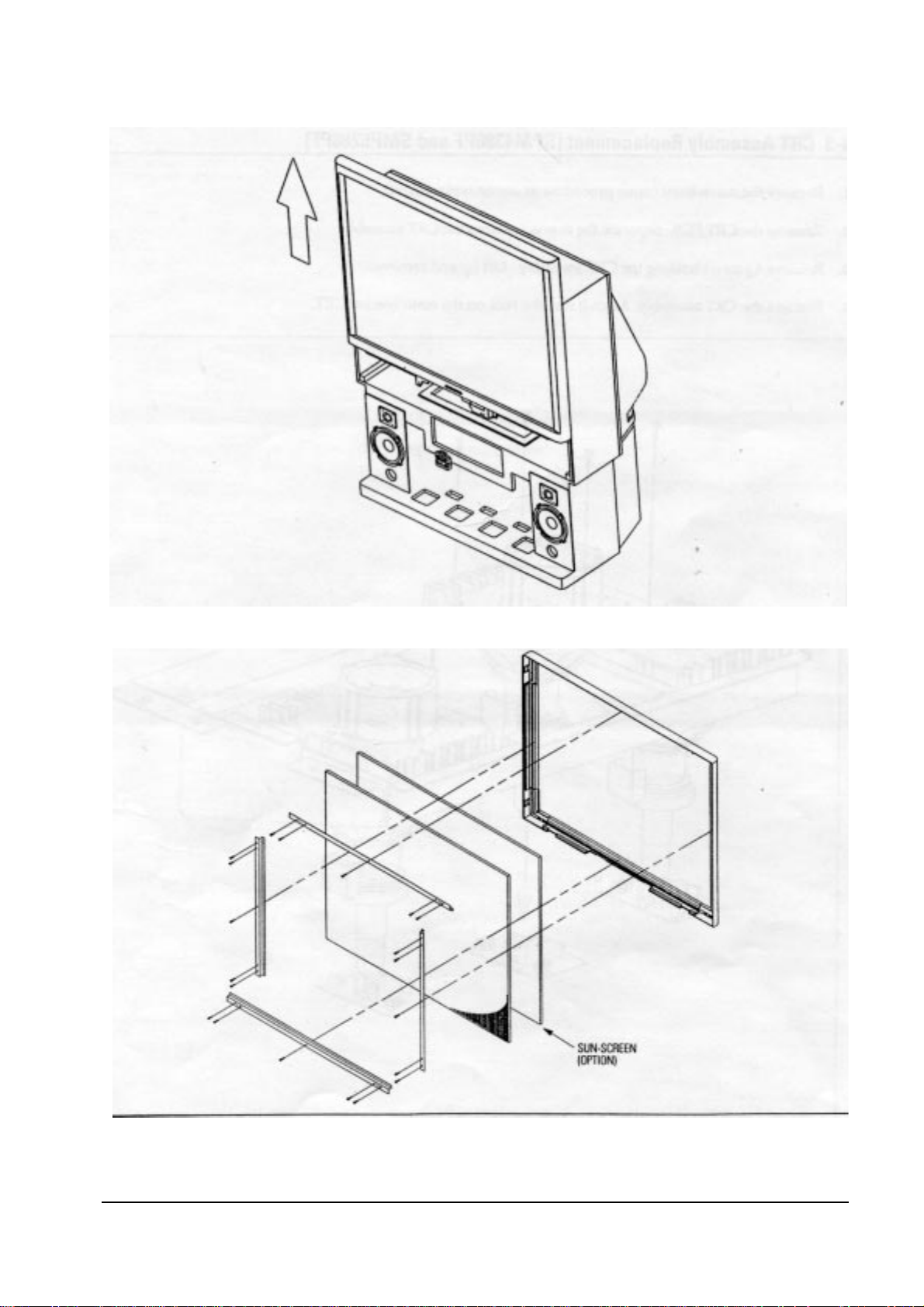

4-1 Screen Replacement for SPM-4388PF

1. Figures 4-1 through 4-6 show the disassembly steps.

2. To reassemble, repeat the sequence in reverse order.

Fig. 4-1 Remove 3 screws located on the bottom of the cover grill. Pull the grill forward to remove if from the mainframe.

Fig. 4-2 Remove 4 screws holding the door assembly.

Page 12

Disassembly and Reassembly

4-2 Samsung Electronics

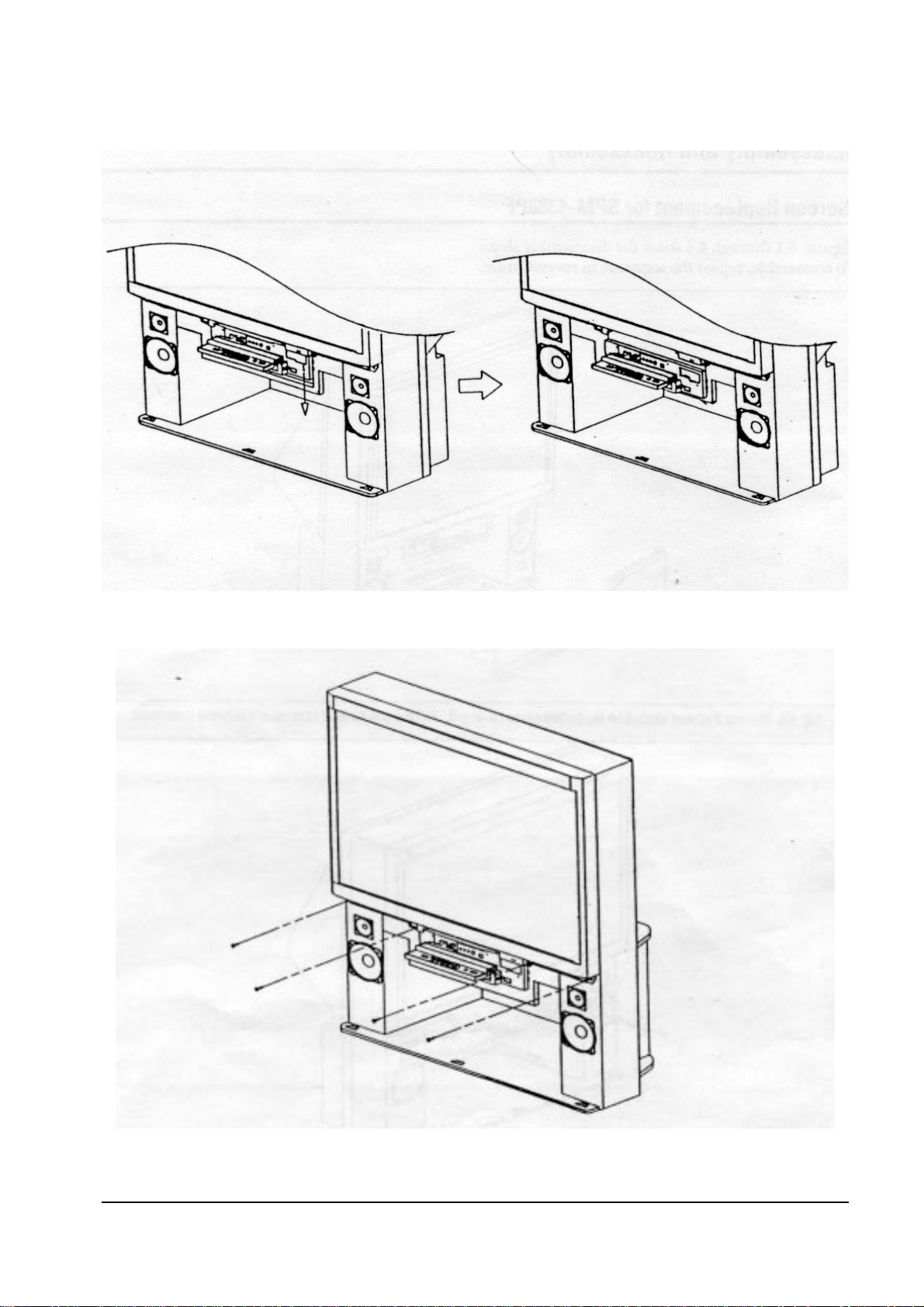

Fig. 4-3 Push the door assembly inside and lay it on the mainframe.

Fig. 4-4 Remove the 4 screws located below the mask-front.

Page 13

Disassembly and Reassembly

Samsung Electronics 4-3

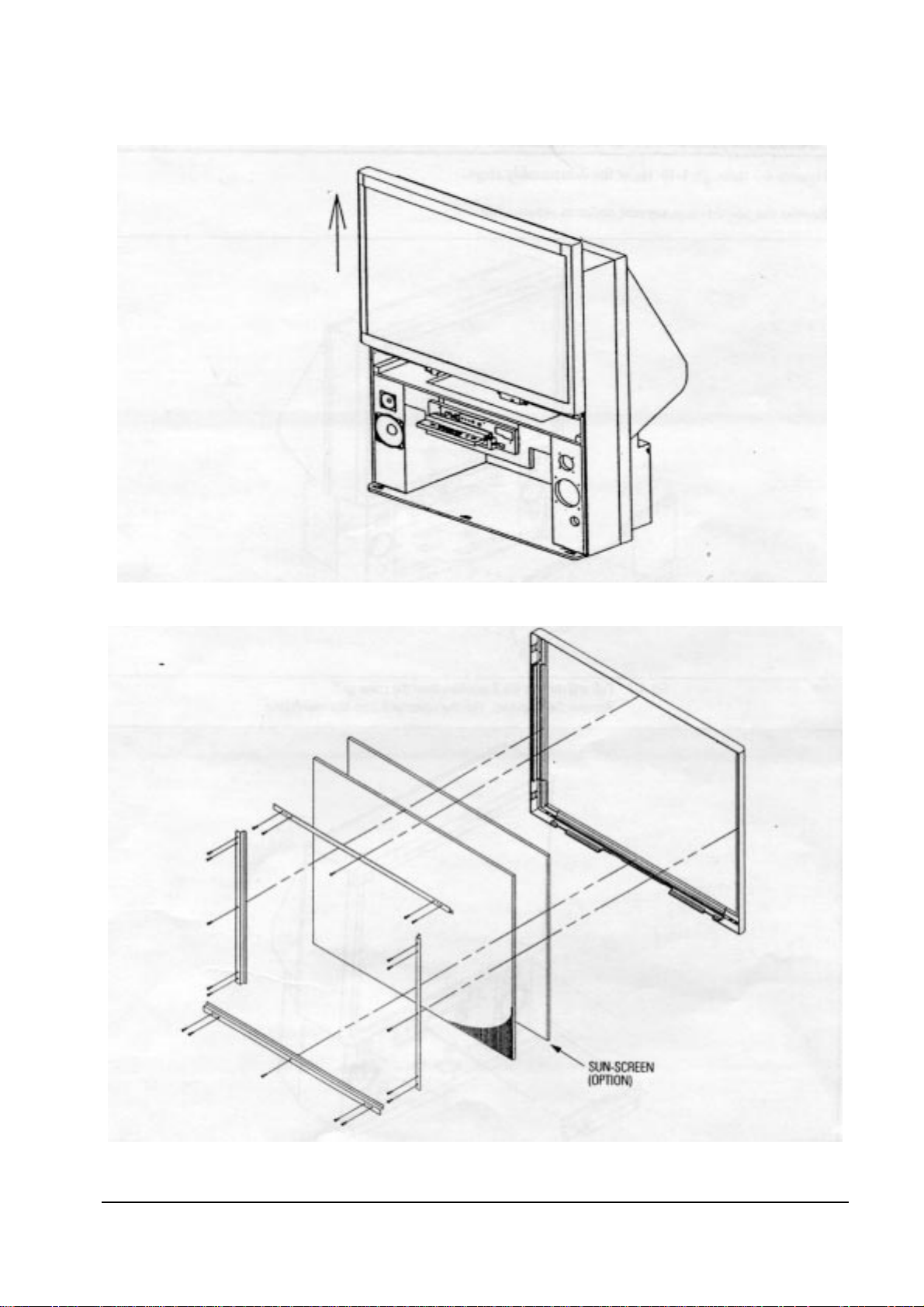

Fig. 4-5 Lift and remove the mask-front.

Fig. 4-6 Remove the bracket and replace the screen.

Page 14

Disassembly and Reassembly

4-4 Samsung Electronics

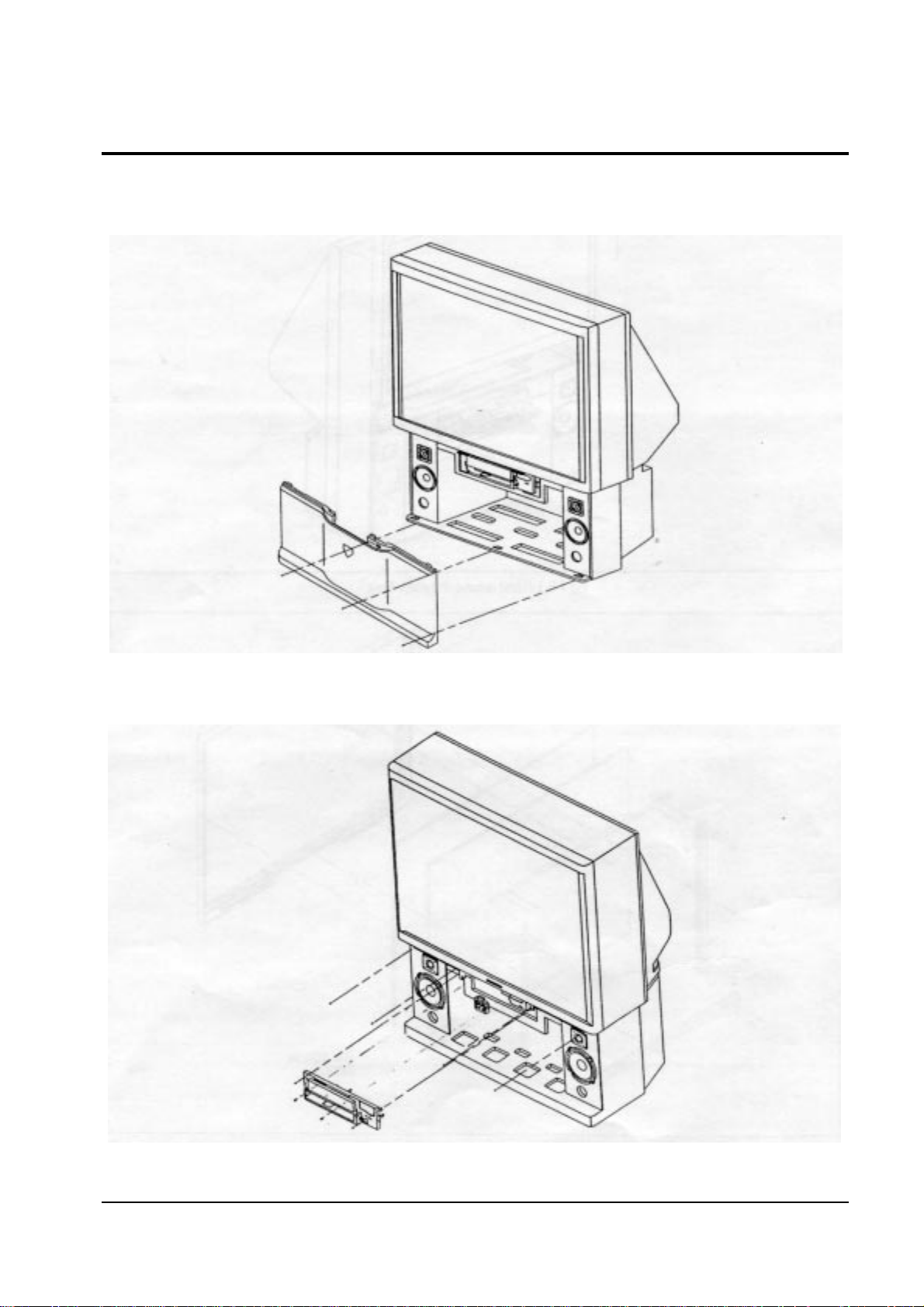

Fig. 4-7 Pull and remove the 2 woofers from the cover grill.

Remove the 9 screws. Pull the cover grill from the mainframe.

Fig. 4-8 Remove 4 screws holding the door assembly.

1. Figures 4-7 through 4-10 show the disassembly steps.

2. Repeat the sequence in reverse order to reassemble.

4-1 Screen Replacement for SPM-4388PF

Page 15

Disassembly and Reassembly

Samsung Electronics 4-5

Fig. 4-9 Lift and remove the mask front.

Fig. 4-10 Remove the bracket and replace the screen.

Page 16

Disassembly and Reassembly

4-6 Samsung Electronics

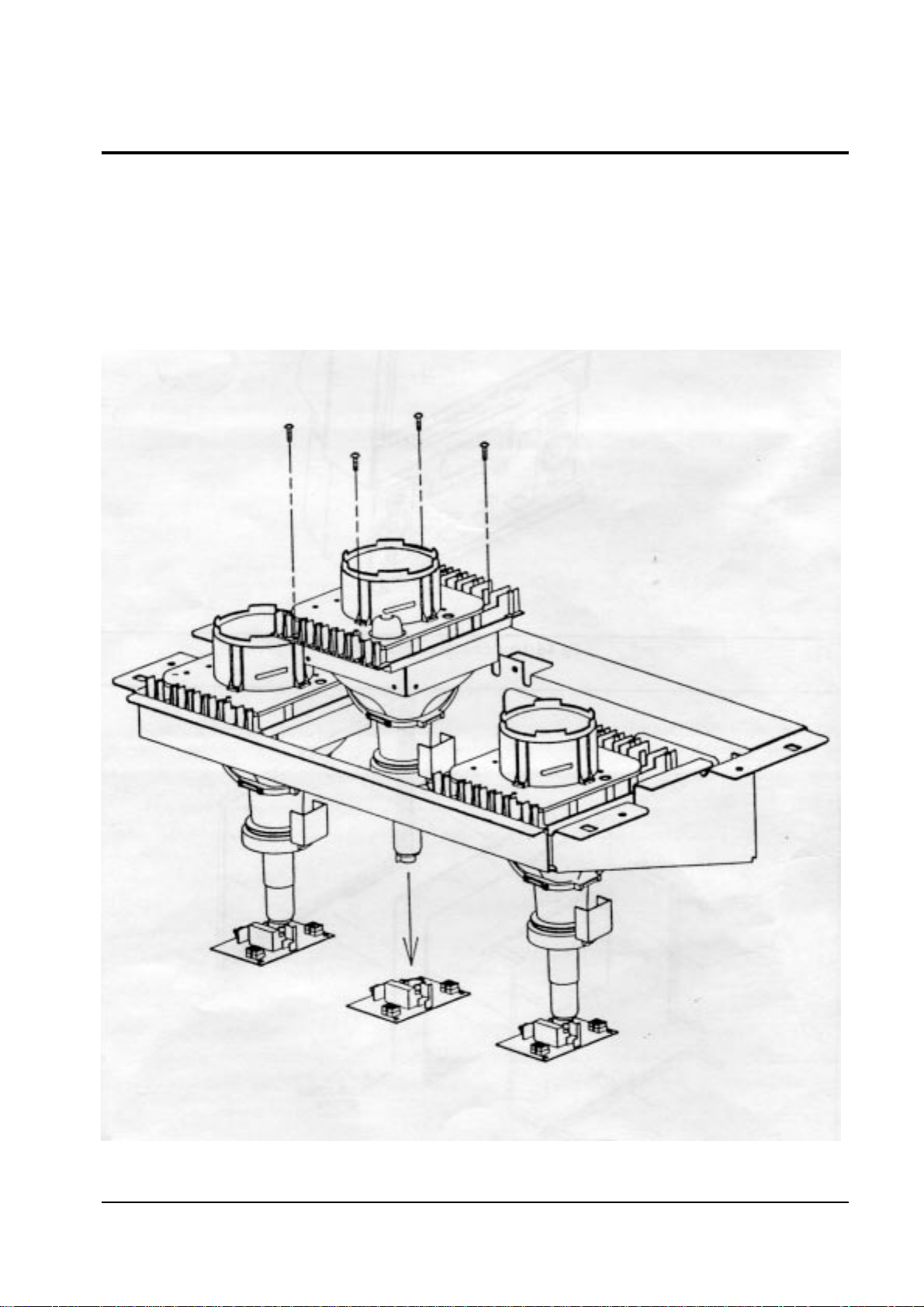

4-3 CRT Assembly Replacement (SPM4388PF and SMP5288PF)

1. Remove the mask-front (same procedure as screen replacement).

2. Remove the CRT PCB. Separate the connector from the CRT assembly.

3. Remove 4 screws holding the CRT assembly. Lift up and remove.

4. Position the CRT assembly. Align it into the hole on the main bracket CRT.

Fig. 4-11 Replacement of CRT Assembly

Page 17

5. Alignment and Adjustments

5-1 RF AGC Adjustment

1. Tune to the strongest local station.

2. Turn the AGC control fully clockwise (VR111,

on the IF board).

3. Adjust the AGC control until noise (snow)

disappears from the screen.

5-2 Screen Adjustment

1. Turn to the Active channel.

2. Adjust the VR (VR501, VR531, VR561) screen

for a normal picture is (no blooming or flyback

line).

3. Adjust the FOCUS control for well defined

scanning lines in the center area of the screen.

5-3 Horizontal Dynamic Focus

Adjustment

5-4 FBT B+Voltage Adjustment

PREPARATION

1. Note: The B+voltage adjustment (FBT) is

done during the chassis check at the factory.

Perform this adjustment after Sub-Brightness

and Convergence.

2. Warm up the TV for at least for 10 minutes.

3. Input 100% white pattern.

4. Select the “STANDARD“ video mode.

ADJUSTMENT

1. Connect the leads of a multimeter to GT405

(B+) and GT406(G).

2. Set VR401 (on deflection board) to either

126.9V (for NTSC), or 125.6V (for PAL).

PREPARATION

1. Input a crosshatch pattern.

2. Cover the Red and Blue Lenses.

3. Enter “STANDARD“ video mode.

4. Adjust the Green Lens for best focus.

ADJUSTMENT

Adjust VRZ01 (located on the convergence board).

Balance the left and right sides of the dynamic

focus lines.

Fig. 5-1 Balance the left and right sides

5-1Samsung Electronics

Page 18

Alignment and Adjustments

5-5 Lens Focus and Static Focus

Adjustment

5-5-1 Static Focus (Electric Focus)

PREPARATION

1. Select the “STANDARD“ video mode.

2. Input a crosshatch pattern.

3. Cover the lenses that are not being adjusted.

4. Connect a convergence jig and read data.

5. Adjust the lens for best focus.

ADJUSTMENT

Vary the focus pack VR (Red, Blue) on the front

cabinet. Adjust the TV for best possible focus

around the center of the crosshatch pattern,

without losing overall screen balance.

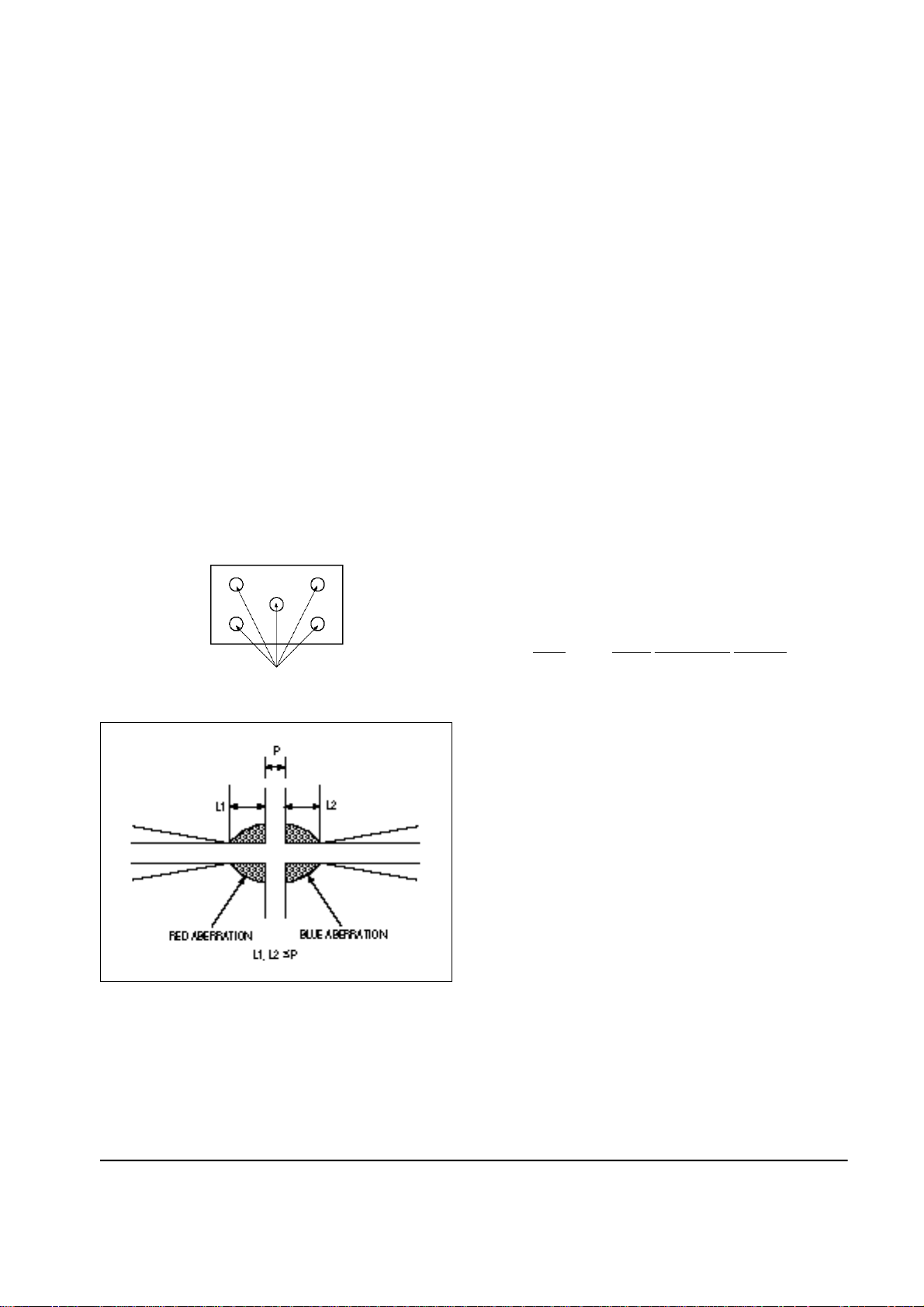

5-5-2 Lens Focus

PREPARATION

1. Do this adjustment after the static focus

adjustment .

2. Select the “ STANDARD“ video mode.

(Contrast: 64, Brightness: 32)

3. Input a cross hatch pattern.

ADJUSTMENT

1. Loosen the lens screws.

2. Cover the two lenses that are not being

adjusted.

3. Adjust the lens, observing the color aberration

vertically and horizontally within 3 blocks of

the center of the crosshatch pattern.

4. When the lens is turned clockwise, the color

aberration will change as follows:

Fig. 5-2 Crosshatch Pattern. Examine these points together

Fig. 5-3 Color Aberration

Lens Color Aberration Change

R Orange —- Crimson

G Blue —- Red

B Purple —- Green

5. Green lens adjustment:

Set the lens at the point where Blue just

changes to Red. If the color aberration is

irregular throughout the picture screen,

adjust the lens to show Red within a 3-block

grid around the horizontal center-line.

Observe the the color aberration near the

intersection points of the horizontal and

vertical lines (approximately 1 - 3 mm area).

If the aberration is irregular, adjust the lens as

shown in the diagram below. (Accurate

alignment of Green is important for overall

color quality.)

6. Set the Red lens at the point where Orange

becomes Crimson.

7. Set the Blue lens at the point where Purple

becomes Green.

5-2 Samsung Electronics

Page 19

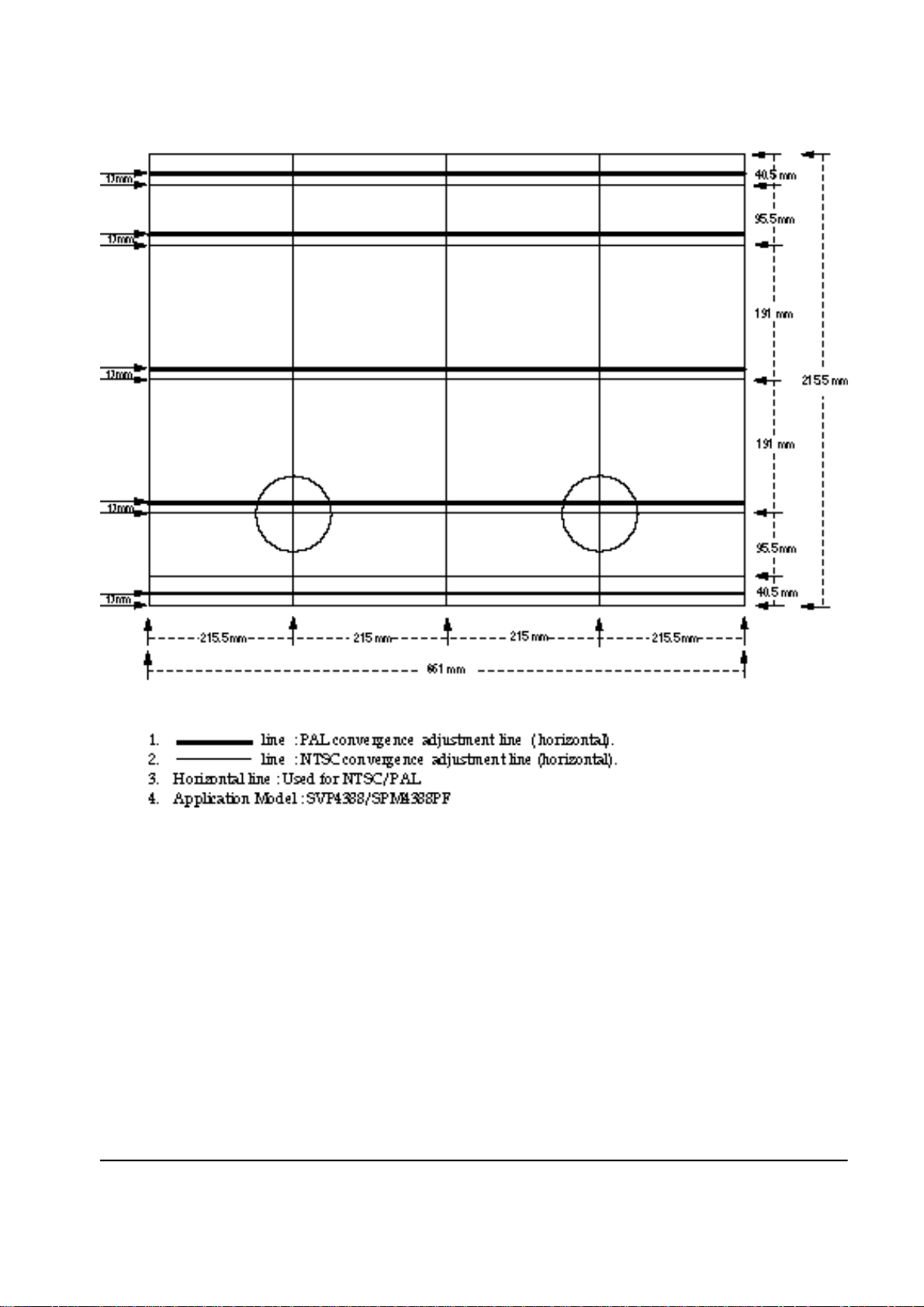

5-6 Convergence Adjustment

5-6-1 Convergence Adjustment

Alignment and Adjustments

1. Input a PAL pattern.

2. Warm up the set for 30 minutes before

adjustment.

3. Display the test pattern (Crosshatch) by

pressing the remote-control keys in this

sequence : Conv.°Ê Mute °Ê 1°Ê 8°Ê 2.

4. When the convergence data is severely tilted

(or if readjustments are necessary because the

convergence module was replaced), select the

"Mute" and "Yellow (TTX)" keys in turn so that

the basic data of module micom applies to the

convergence adjustments.

When making only one convergence

adjustment, only one parameter needs to be

adjusted. (The basic data does not change.)

5. After selecting R-Mute and B-Mute, display

only a green color pattern. Center the pattern

by adjusting CY.

6. After selecting G-Mute and B-Mute, adjust the

Red CY to center the picture.

7. Center the Blue Pattern as above.

11. Adjust Blue as above.

12. After the adjustments are completed, press

"Recall" to save the data.

13. Change from PAL mode to NTSC when

making NTSC adjustments.

14. After setting the NTSC line (on Screen Jig),

readjust as 7~10.

15. After the NTSC pattern adjustments are

completed, press the " RECALL" key to save

the NTSC data.

16. After the Convergence Adjustments are

completed, press the Escape key.

Note

1. If the convergence data is lost during

adjustment, use the"Saturation" (TV/Video)

key to reset the data to the initial values of the

ROM.

2. Make minor adjustments with the User

Convergence key.

A "+" pattern appears when "Conv." is pressed.

8. After the picture is centered, begin the

convergence adjustments.

First, display the green pattern:

The "Menu" key moves the cursor vertically

and horizontally.

Use the Channel and Volume keys

( Up/Down) to adjust convergence.

9. Use the "Surround" key for minor adjustments.

10. After the Green Adjustment is completed,

press the R-Mute key (confirm Green to Red).

Samsung Electronics

3. Use the "R/B" and "Ch/Vol" keys to correct

convergence. After the adjustments are

completed, press "Escape".

5-3

Page 20

Alignment and Adjustments

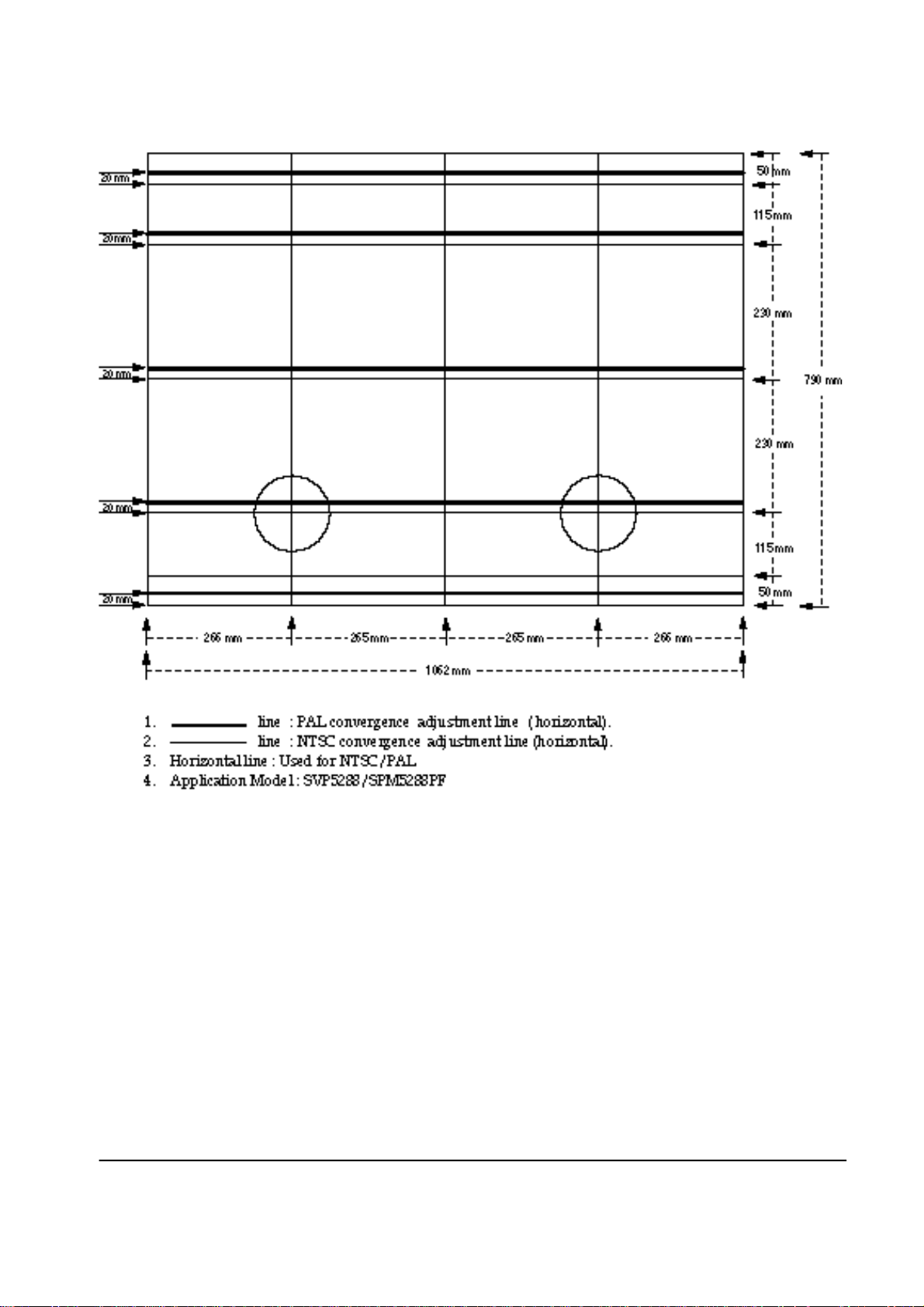

5-6-2 Screen Jig

Fig. 5-5 43 inch JIG Screen

5-4 Samsung Electronics

Page 21

Alignment and Adjustments

Samsung Electronics

Fig. 5-5 52 inch JIG Screen

5-5

Page 22

Alignment and Adjustments

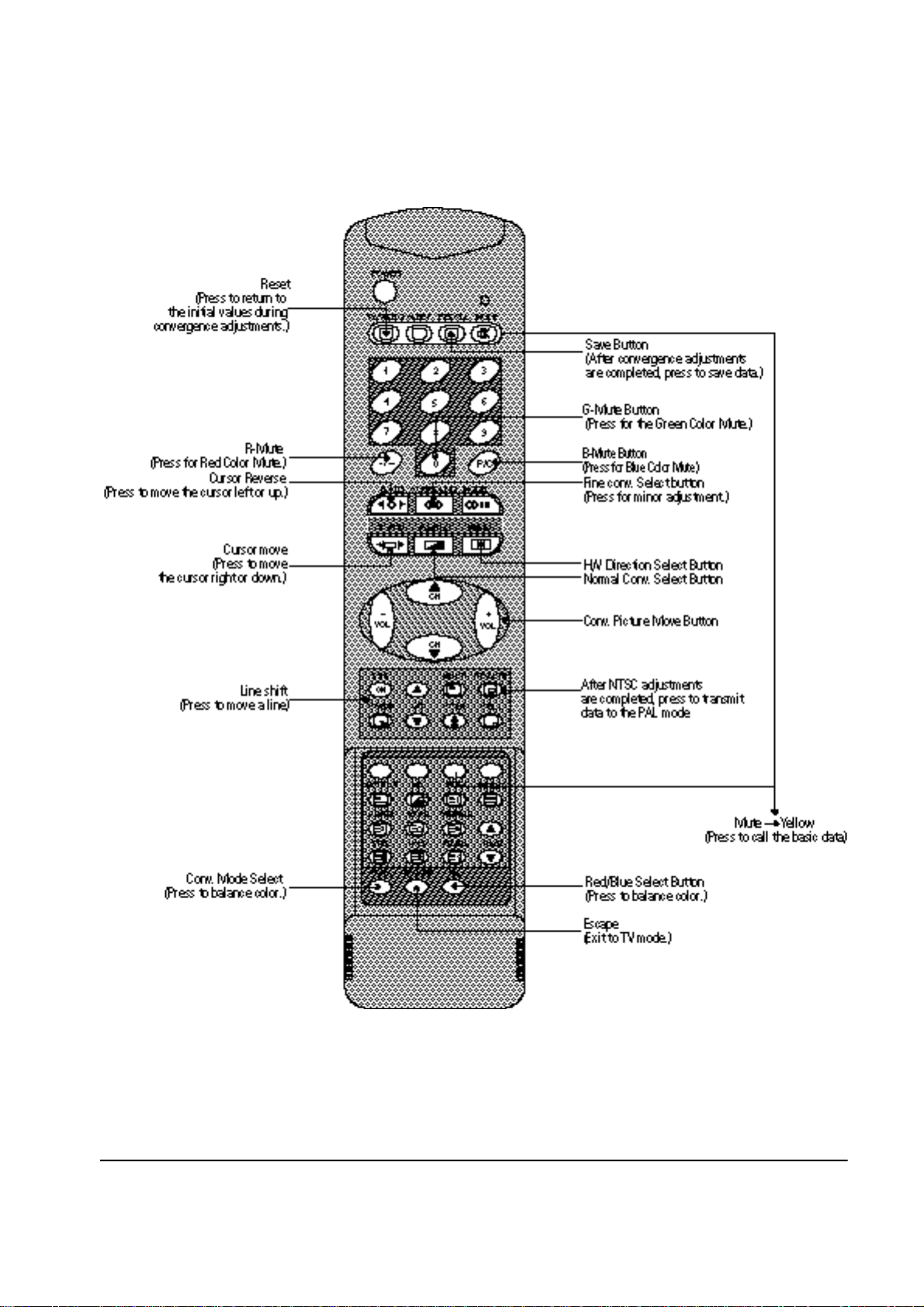

5-6-3 Remote Control for Servicing

5-6 Samsung Electronics

Page 23

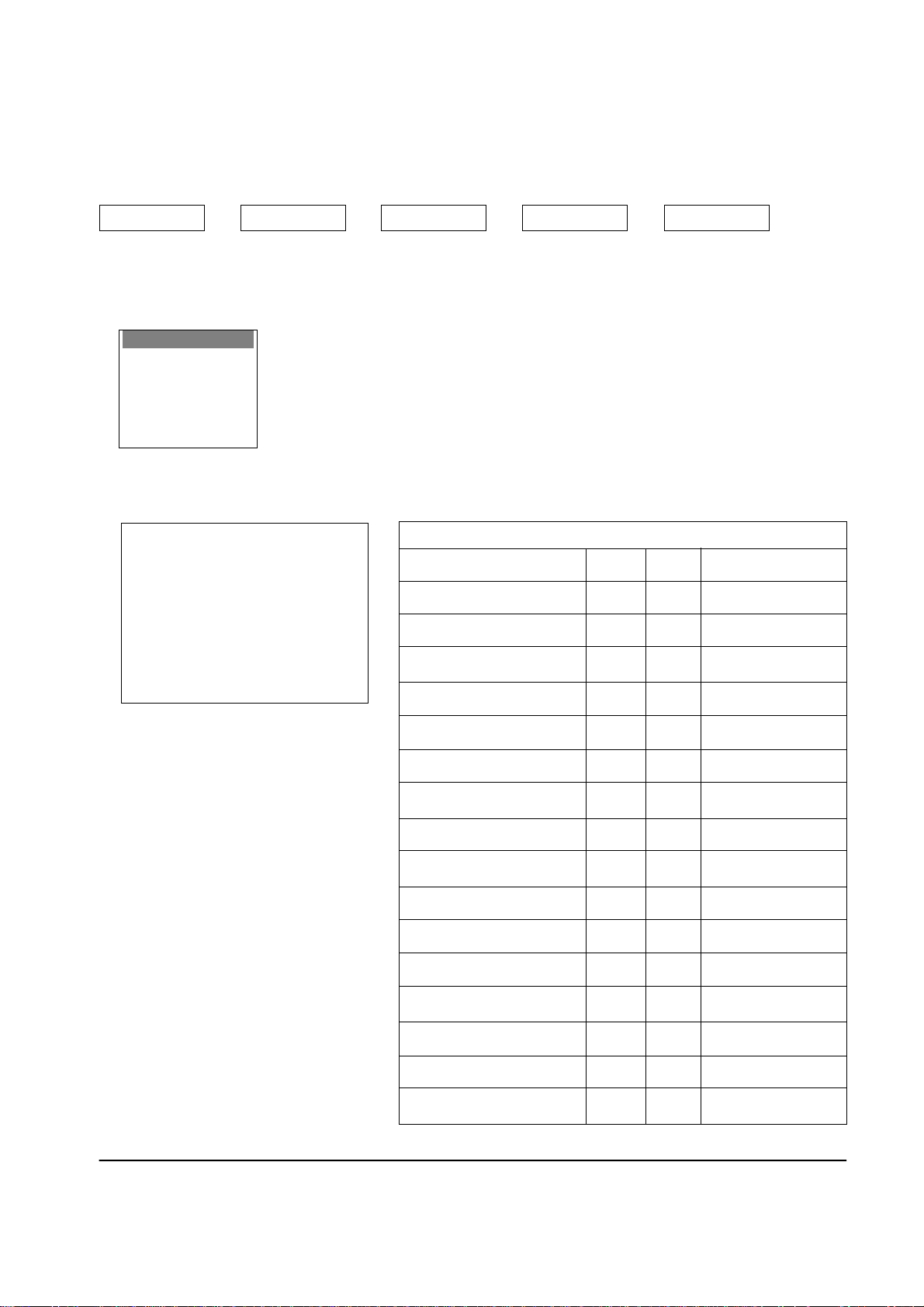

5-7 Manual Alignment (Factory Mode)

1. Enter the Factory Mode. Press the remote-control keys in this sequence:

Alignment and Adjustments

PICTURE OFF

2. Use the CHANNEL and VOLUME keys (Up/Down) to move the cursor. Select

an alignment parameter:

SERVICE MODE

ADJUSTMENT

TEST PATTERN

OPTION BYTES

RESET

BONUS

3. Adjustment must be done for both 50Hz and 60Hz field rates:

SBT 08 GG 49

SCR 10 BG 32

SCT 13 PW 32

STT 08 GAM 00

RRC 26 ALS 07

GRC 42 ASS 32

BRC 32 PCT 04

RG 28 PTT 32

¢°

Adjustment I

SLEEP

¢°

P.STD

Function

SUB-BRIGHT

SUB-COLOR

SUB-CONTRAST

SUB-TINT

RED REFERENCE

¢°

MUTE

¢°

Table 5-1

OSD

SBT

SCR

SCT

STT

RRC

Range

00~13

00~13

00~13

00~13

00~63

PICTURE ON

Note

Low-light adjustment

Samsung Electronics

GREEN REFERENCE

BLUE REFERENCE

RED GAIN

GREEN GAIN

BLUE GAIN

PEAK WHITE

GAMMA

AUDIO LEVEL SETTING

AUDIO SEPARATION SETTING

PIP CONTRAST

PIP TINT

GRC

BRC

RG

GG

BG

PW

GAM

ALS

ASS

PCT

PTT

00~63

00~63

00~63

00~63

00~63

00~63

00~63

00~15

00~63

00~15

00~63

"

"

High-light adjustment

"

"

5-7

Page 24

Alignment and Adjustments

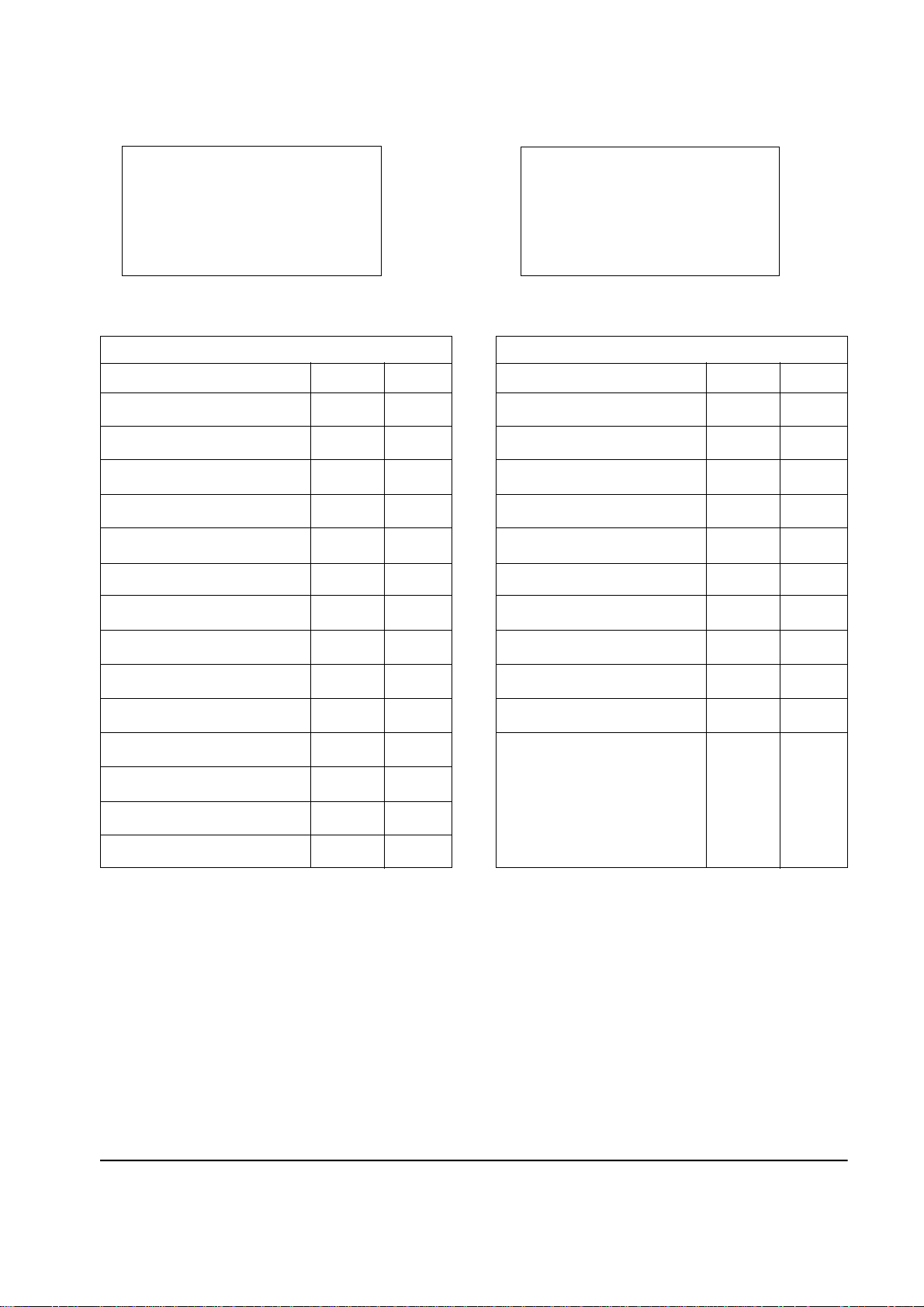

4. Access Adjustment II by pressing the CHANNEL keys (Up/Down) while the cursor is positioned

on "SBT" or "PTT" (see Adjustment I):

PHS 42 PVA 15

PEW 27 PSC 30

PEP 23 PVS 10

PEC 02 HSP 13

PET 47 PVP 10

PSC 40 PHP 72

Adjustment II - 50Hz Picture

Table 5-2

Function

PAL HORIZONTAL SHIFT

NTSC HORIZONTAL SHIFT

PAL E-W WIDTH

NTSC E-W WIDTH

PAL E-W PARABOLA

NTSC E-W PARABOLA

OSD

PHS

NHS

PEW

NEW

PEP

NEP

Range

00~63

00~63

00~63

00~63

00~63

00~63

NHS 32 NVA 32

NEW 27 NSC 13

NEP 30 NVS 55

NEC 02 HSN 11

NET 28 NVP 04

NSL 16 NHP 73

Adjustment II - 60Hz Picture

Table 5-2 (Continued)

Function

PAL VERTICAL SHIFT

NTSC VERTICAL SHIFT

PIP PAL HORIZONTAL SHIFT

PIP NTSC HORIZONTAL SHIFT

PIP PAL VERTICAL POSITION

PIP NTSC VERTICAL POSITION

OSD

PVS

NVS

HSP

HSN

PVP

PVN

Range

00~63

00~63

05~20

00~20

00~33

00~33

PAL E-W TRAPEZIUM

NTSC E-W TRAPEZIUM

PAL VERTICAL SLOPE

NTSC VERTICAL SLOPE

PAL VERTICAL AMPLITUDE

NTSC VERTICAL AMPLITUDE

PAL S CORRECTION

NTSC S CORRECTION

PET

NET

PSL

NSL

PVA

NVA

PSC

NSC

00~63

00~63

00~63

00~63

00~63

00~63

00~63

00~63

PIP PAL HORIZONTAL

POSITION

PIP NTSC HORIZONTAL

POSITION

PHP

PHN

00~83

00~83

5-8 Samsung Electronics

Page 25

Alignment and Adjustments

5. After the Factory Mode Adjustments are completed, return to the first menu and set up "Test Pattern,"

"Option" and "Bonus." Use the CHANNEL and VOLUME keys to position the cursor and make a

selection:

7-Color Bar

Cross hatch

Red

Green

Blue

Test Pattern I

OE 80

BON 01

WD 08

01 40

02 32

03 10

AMS 00

SVR 00

Bonus (see data, below)

Kara-OK On

TTX On

Tuner CCIR

List

OSD Language Select

Option Bytes

Table 5-3

Content

TDA4780 BLACK STRETCH

TDA9170 BLACK OFFSET COMPENSATION ENABLE

TDA9170 WINDOW SELECT

USER VARIABLE GAMMA (TDA9170)

ADAPTIVE GAMMA (TDA9170)

NON LINEARITY AMPLITUDE (TDA9170)

AMPLITUDE SELECTION (TDA9170)

FULL SCREEN BLACK LEVEL (TDA9170)

OSD

OE

BON

WD

01

02

03

AMS

SVR

Samsung Electronics

5-9

Page 26

5-10 Samsung Electronics

Page 27

Troubleshooting

Samsung Electronics 6-1

6. Troubleshooting

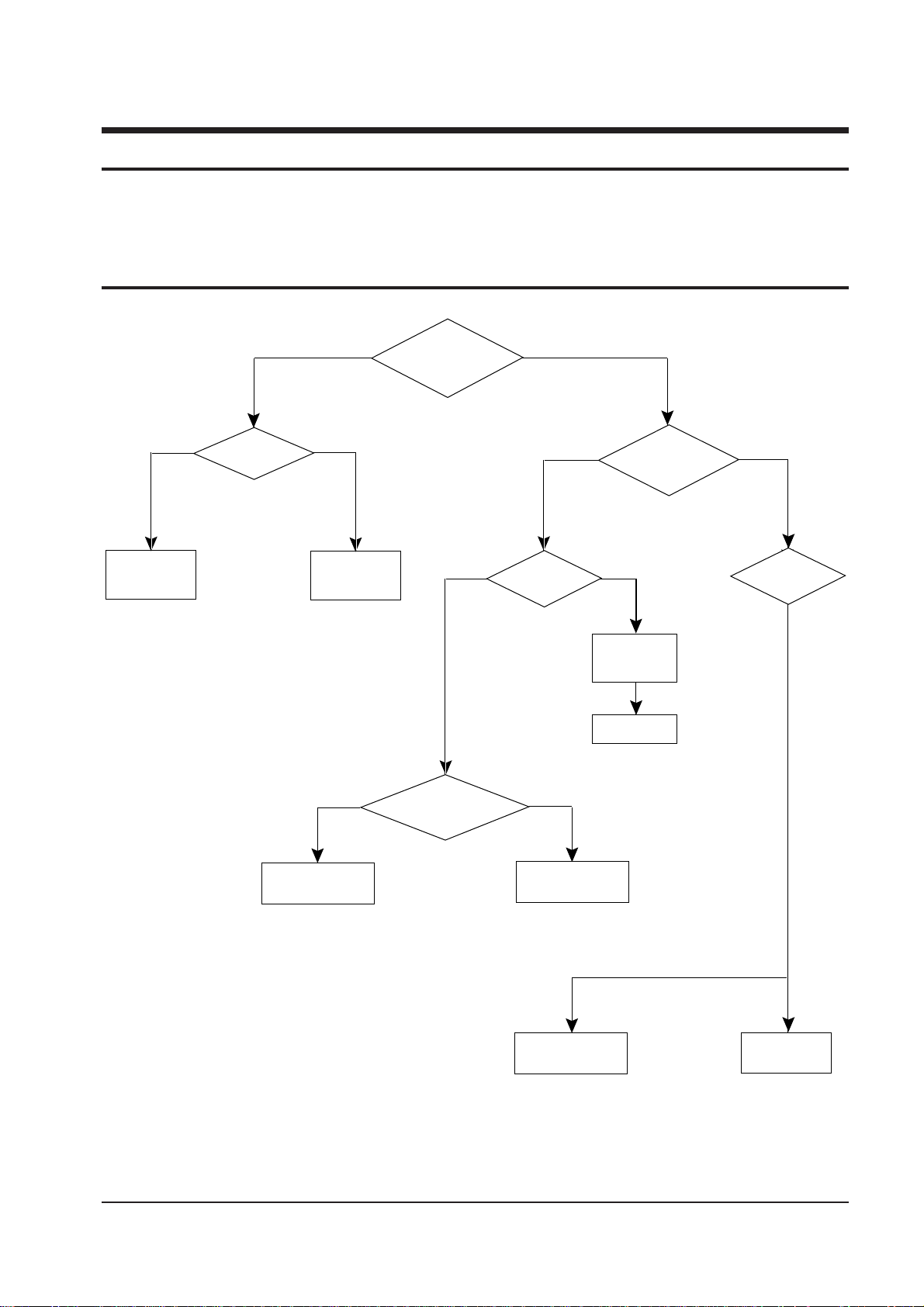

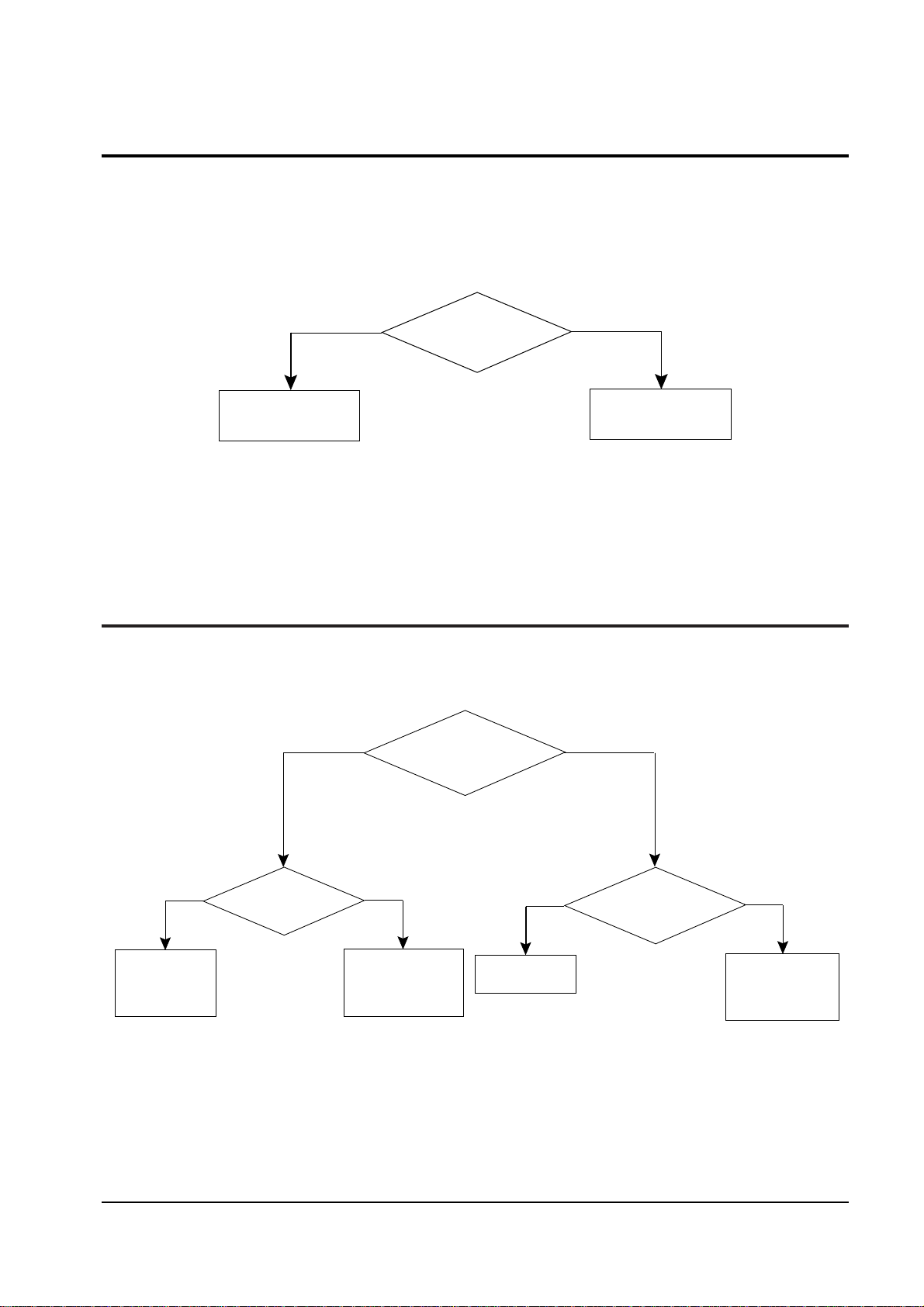

6-1 No Power

Normal

Check CN801 Pin 2

(STB B ).

Check C801

Check F851.

Check the voltage

on CN801 Pin 1

Check the base voltage

on Q852

Check/Replace

Q851 and Q852.

Check/Replace

Q854.

Check/Replace

D808 & R801

Normal

Normal 0V

Normal 12V

Abnormal 0V

Abnormal

Abnormal 0.6V

0V

3V

Check/Replace

Q401 and Q402

Replace F854

Check IC901

(VCC)

Normal

Check IC901

Peripheral Circuits

Replace IC901

Abnormal

Abnormal

Check/Replace

HC801

+

Page 28

Troubleshooting

6-2 Samsung Electronics

6-2 No Picture

Abnormal

Normal

Check Pin 8 of IC501,

IC502, IC503

Check TDA4780

(IC203) Pin 1, Pin 13

Low-High

Check TDA9160 (IC202)

Y-output (Pin 1)

Check/Replace

m-com (IC901

Replace

TDA9160 (IC202)

Normal

Check TDA4780

Y-input (Pin 8)

Abnormal

Check/Replace

IC203

Abnormal

Normal

Page 29

Troubleshooting

Samsung Electronics 6-3

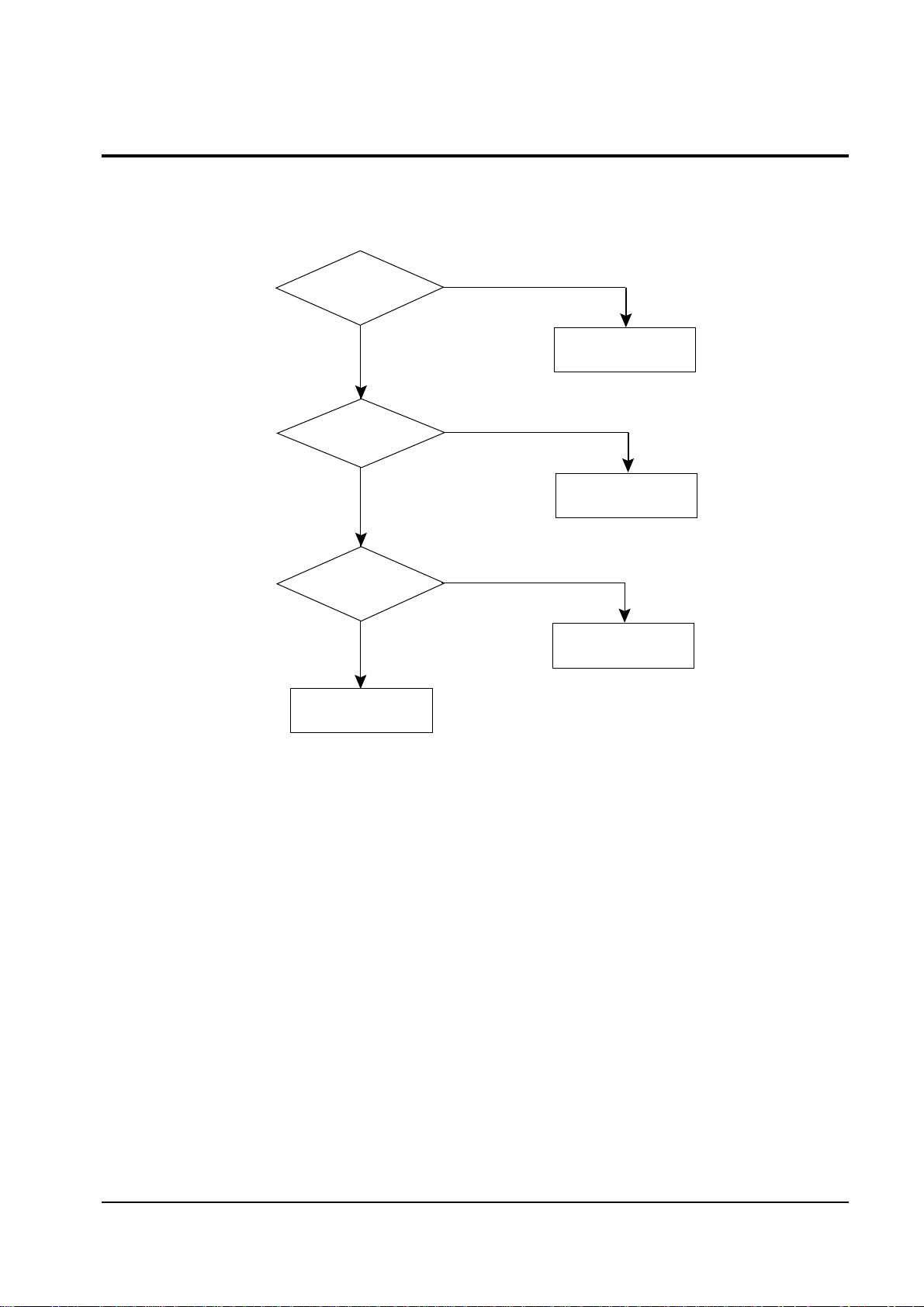

6-3 No Sound

Abnormal

Check the Pin 5

of the CN601(mute)

Check pins 9 and 11

of HC651

Abnormal (0V)

Check D859,D860,

F852, F853 on the SMPS

Check/Replace RL651

and m-com (IC901

Abnormal

Check pins 3 and 5 of

the Audio module

Normal ( 28V)

+_

Normal

Normal

Check pins 24 and 22

of the Audio mdl

Abnormal Normal

Check pins 16 and 18

of the audio mdl

Check/Replace

upc1853 (IC602)

Check/Replace KA2192,

TC4053BP on the A/V switch

Abnormal

Check/Replace

TDA9840

Check/Replace

IC601

Normal

Page 30

Troubleshooting

6-4 Samsung Electronics

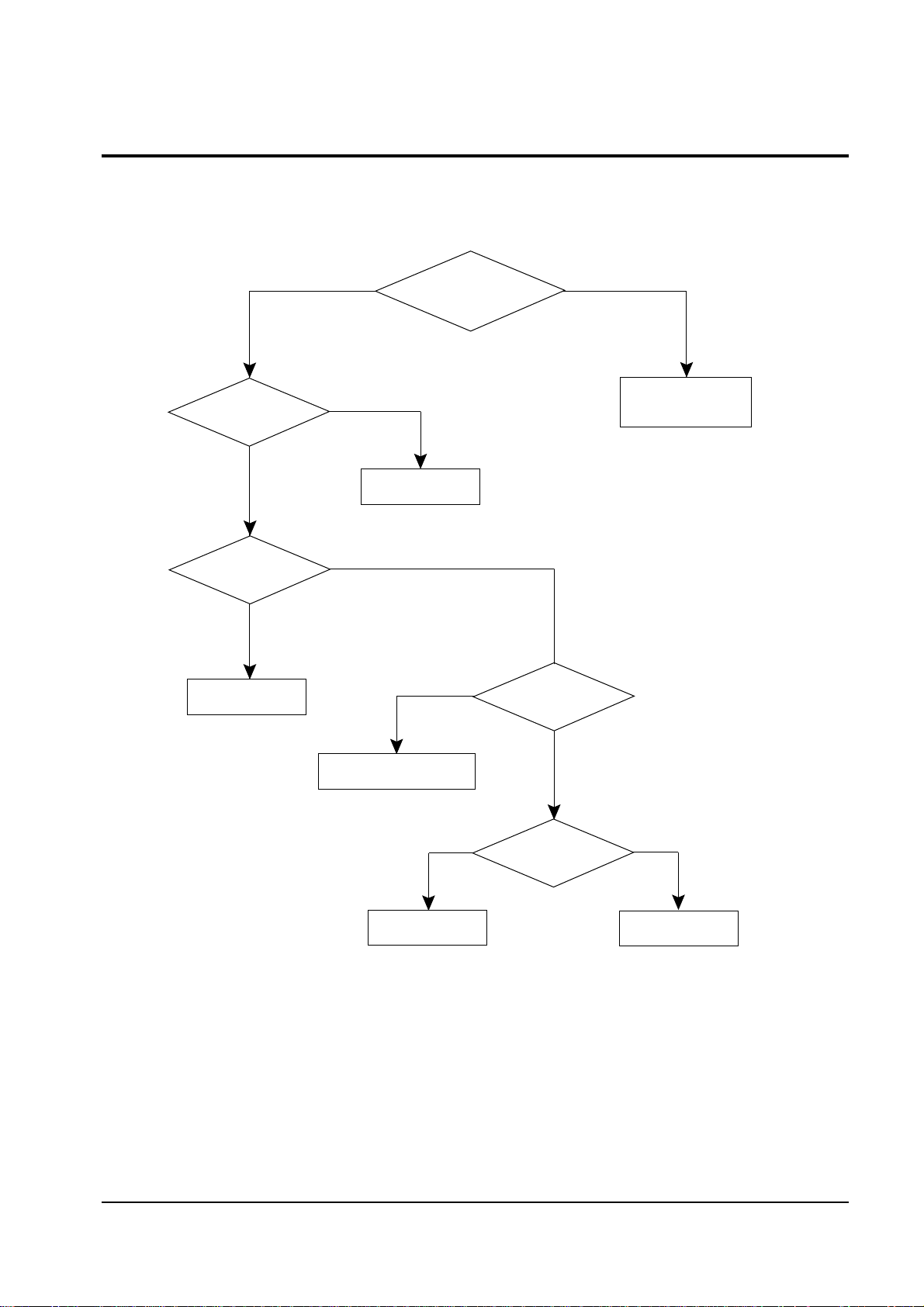

6-4 Horizontal Line

Abnormal

Normal

Check IC202 and its

peripherial circuits

Check IC301 and its

peripheral circuits

Check the Waveform of

IC202 Pin 15,16

6-5 Convergence Misaligned

Abnormal

Normal

Check

the waveform of each

terminal in Convergence Module

CN203

After checking the 26V

load line, check/replace

the Fuse F854, F855 on

the SMPS board

Check the Differential

Amplifier of each

Convergence terminal

Abnormal

Normal

Check the Waveform of

each terminal in Convergence

Module CN202

Replace the

Convergence Module.

Check the Circuits

Connected to each

terminal of Convergence

Module CN202

Check the voltage on

CN803 pins 4,6

Normal

Abnormal

+

_

Page 31

7. Exploded View & Parts List

7-1 SPM-4388PF/51AX

Exploded View & Parts List

Samsung Electronics 7-1

Page 32

Exploded View & Parts List

7-2 Samsung Electronics

Page 33

Exploded View & Parts List

Samsung Electronics 7-3

Page 34

Exploded View & Parts List

7-4 Samsung Electronics

7-2 SPM-5288PF/51AX

Page 35

Exploded View & Parts List

Samsung Electronics 7-5

Page 36

Exploded View & Parts List

7-6 Samsung Electronics

Page 37

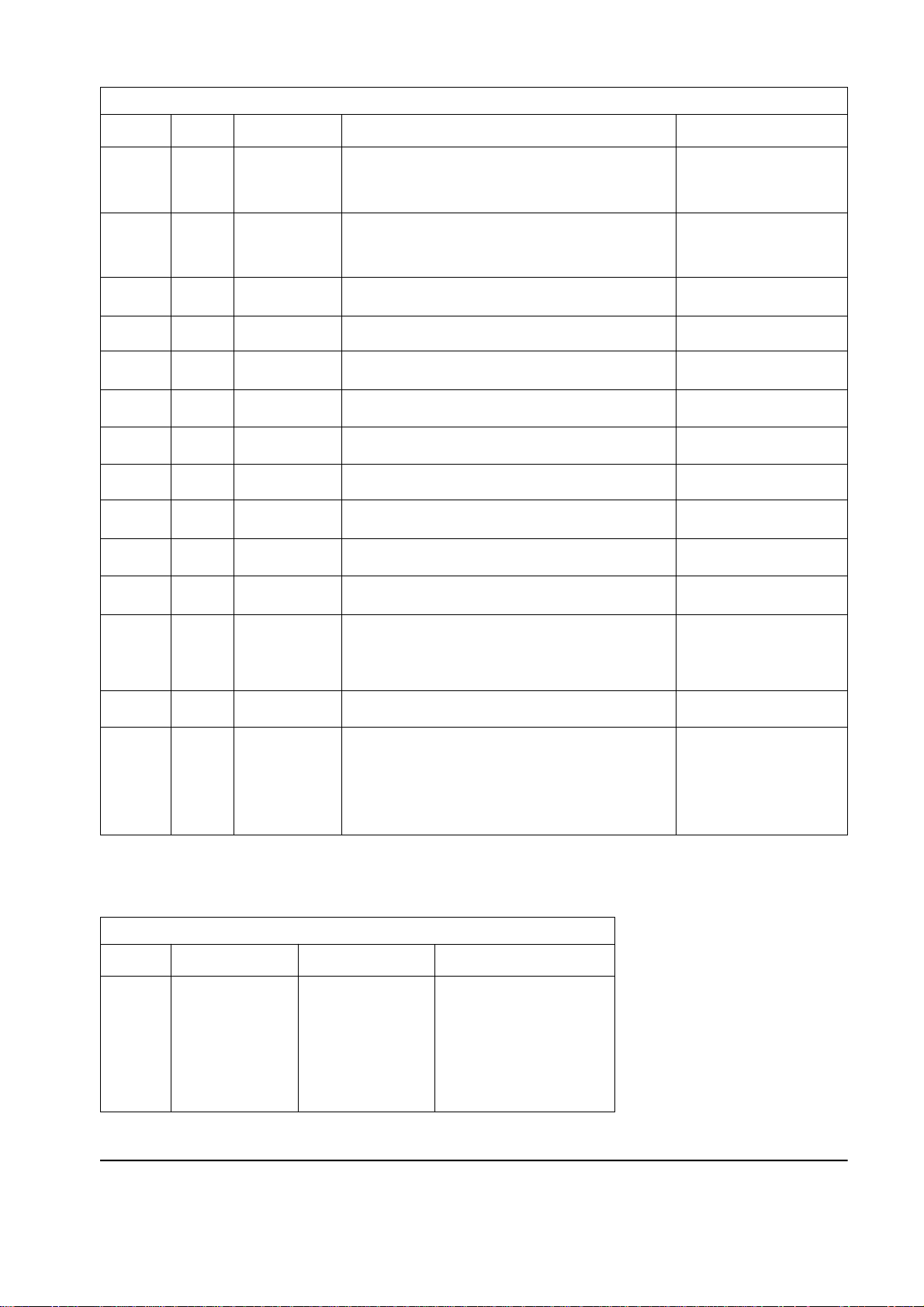

Areas and Option Specification

Samsung Electronics 8-1

8. Areas and Option Specification

8-1 Local Specification & BOM option

AA68-10761A

CHI

AA68-10759A

ENG

AA68-10766A

IND

AA68-10759A

ENG

AA68-10759A

ENG

AA68-10759A

ENG

AA68-10759A

ENG

AA68-10759A

ENG

AA68-10759A

ENG

AA68-10759A

ENG

AA68-10760A

ARAB

AA68-10759A

ENG

AA68-10760A

ARAB

RM130ECP

(ENG/CHI)

RM130ETP

(ENG/TAI/M

AL/IND)

RM130ECP

ENG/CHI)

RM130ETP

(ENG/TAI/

MAL/IND)

RM130ETP

(ENG/TAI/

MAL/IND)

RM130ETP

(ENG/TAI/

MAL/IND)

RM130ETP

(ENG/TAI/

MAL/IND)

RM130ETP

ENG

RM130EAP

ENG/ARAB

RM130EAP

ENG/ARAB

SACI

SISIR

SSIR

SASO

Non-

forced

Stan-

dard

Safety S t a n d a r d

PB1209

PB1206

PB1267

PB1208

PB1207

PB1243

PB1244

PB1241

PB1246

PB1265

PB1042

PB1266

PB1042

Others

OCT, 96

OCT, 96

OCT, 96

NOV,96

NOV,96

NOV,96

SEP, 96

SEP, 96

Introduction

GAUSS:300mg

LATING:100~260V

50/60Hz, MIC

PLUG-CONV

GAUSS:-200mG

RATING:100~260V

50/60Hz

GAUSS:-150mG

LATING:230V

50Hz

GAUSS:100mG

LATING:100~260V

50/60Hz W/C, CP2

GAUSS:-100mG

LATING:230V50Hz

Same

Specification as

Singapore

GAUSS:100mG

LATING:100~260V

50/60Hz

W/C, EP2-NO

GAUSS:100mG

LATING:100~260V

50/60Hz W/C

GAUSS:100mG

LATING:100~260V

50/60Hz

GAUSS:200mG

LATING:100~260V

(WARRANTY

CARD)

50/60Hz

GAUSS:200mG

LATING:100~260V

50/60Hz

Special

Specification

AA95-10002H

L802~4:10mH

L848~9:10mH

AA95-10008P

L802~4:2mH

L848~9:10mH

(2902-001001)

AA95-10002H

L802~4:10mH

L848~9:10mH

AA95-10008P

L802~4:2mH

L848~9:2mH

(2902-001001)

AA95-10002H

L802~4:10mH

L848~9:10mH

AA95-10008P

L802~4:2mH

L848~9:2mH

(2902-001001)

AA95-10008P

L802~4:2mH

L848~9:2mH

(2902~001001)

AA95-10008P

L802~4:2mH

L848~9:2mH

(2902-001001)

AA95-10002H

L802~4:10mH

L848~9:10mH

AA95-10008P

L802~4:2mH

L848~9:2mH

(2902-001001)

AA96-20074A

CP2

AA96-20074A

CP2

AA96-20074A

CP2

AA96-20074A

CP2

AA96-20074A

CP2

AA96-20052C

AA96-20074A

CP2

AA96-20054C

AA96-20074A

AA96-20074A

AA95-90003U

ENG

FLOP

AA95-90003U

ENG

FLOF

AA95-90003U

ENG

FLOF

AA9590003U

ENG

FLOF

AA95-90003U

ENG

FLOF

AA95-90003U

ENG

FLOP

AA95-90003U

ENG

FLOF

AA95-90003U

FLOP

AA95-90003U

ENG

FLOF

AA95-90003U

ENG

FLOF

AA95-90012B

AA95-90003V

AA95-90003V

AA95-90003V

AA95-90003V

AA95-90003V

AA95-90003V

AA95-90003V

AA95-90003V

AA95-90003V

APPLIED

(AA95-

90001V)

NOT

APPLIED

NOT

APPLIED

NOT

APPLIED

NOT

APPLIED

NOT

APPLIED

NOT

APPLIED

NOT

APPLIED

NOT

APPLIED

NOT

APPLIED

SEHK

SME

S'PORE

MUR

SMARINA

TSE

SAVINA

SIEL

ZAMA

SGE

SPM5288PF/HKX

SPM5288PF/SMEX

SPM4388PF/SAPX

SPM5288PF/SAPX

SPM5288PF/MURX

SPM5288PF/MARX

SPM5288PF/TSEX

SPM5288PF/SVIX

SPM5288PF/SIX

SPM4388PF/ZAX

SPM5288PF/ZAX

SPM4388PF/SGEX

SPM5288PF/SGEX

CHINA

INDONESIA

SINGAPORE

MYANMAR

MALAYSIA

THAILAND

VIETNAM

INDIA

SAUDI-A

U.A.E

S

O

U

T

H

E

A

S

T

A

S

I

A

M

I

D

D

L

E

Local Specification & Bom Option

Area

Country

TTX I/B MICOMMIC

IF

Power

ASSY

Power

Code ASSY

Buyer Model Name

Page 38

Areas and Option Specification

8-2 Samsung Electronics

8-1 Local Specification & BOM option (Continued)

AA68-10761A

CHI

AA68-10759A

ENG

AA68-10766A

IND

AA68-10759A

ENG

AA68-10759A

ENG

AA68-10759A

ENG

AA68-10759A

ENG

AA68-10759A

ENG

AA68-10759A

ENG

AA68-10759A

ENG

AA68-10760A

ARAB

AA68-10759A

ENG

AA68-10760A

ARAB

RM130ECP

(ENG/CHI)

RM130ETP

(ENG/TAI/M

AL/IND)

RM130ECP

ENG/CHI)

RM130ETP

(ENG/TAI/

MAL/IND)

RM130ETP

(ENG/TAI/

MAL/IND)

RM130ETP

(ENG/TAI/

MAL/IND)

RM130ETP

(ENG/TAI/

MAL/IND)

RM130ETP

ENG

RM130EAP

ENG/ARAB

RM130EAP

ENG/ARAB

SACI

SISIR

SSIR

SASO

Non-

forced

Stan-

dard

Safety -

S t a n d a r d

PB1209

PB1206

PB1267

PB1208

PB1207

PB1243

PB1244

PB1241

PB1246

PB1265

PB1042

PB1266

PB1042

Others

OCT, 96

OCT, 96

OCT, 96

NOV,96

NOV,96

NOV,96

SEP, 96

SEP, 96

Introduction

GAUSS:300mg

LATING:100~260V

50/60Hz, MIC

PLUG-CONV

GAUSS:-200mG

RATING:100~260V

50/60Hz

GAUSS:-150mG

LATING:230V

50Hz

GAUSS:100mG

LATING:100~260V

50/60Hz W/C, CP2

GAUSS:-100mG

LATING:230V50Hz

Same

Specification as

Singapore

GAUSS:100mG

LATING:100~260V

50/60Hz

W/C, EP2-NO

GAUSS:100mG

LATING:100~260V

50/60Hz W/C

GAUSS:100mG

LATING:100~260V

50/60Hz

GAUSS:200mG

LATING:100~260V

(WARRANTY

CARD)

50/60Hz

GAUSS:200mG

LATING:100~260V

50/60Hz

Special

Specification

AA95-10002H

L802~4:10mH

L848~9:10mH

AA95-10008P

L802~4:2mH

L848~9:10mH

(2902-001001)

AA95-10002H

L802~4:10mH

L848~9:10mH

AA95-10008P

L802~4:2mH

L848~9:2mH

(2902-001001)

AA95-10002H

L802~4:10mH

L848~9:10mH

AA95-10008P

L802~4:2mH

L848~9:2mH

(2902-001001)

AA95-10008P

L802~4:2mH

L848~9:2mH

(2902~001001)

AA95-10008P

L802~4:2mH

L848~9:2mH

(2902-001001)

AA95-10002H

L802~4:10mH

L848~9:10mH

AA95-10008P

L802~4:2mH

L848~9:2mH

(2902-001001)

AA96-20074A

CP2

AA96-20074A

CP2

AA96-20074A

CP2

AA96-20074A

CP2

AA96-20074A

CP2

AA96-20052C

AA96-20074A

CP2

AA96-20054C

AA96-20074A

AA96-20074A

AA95-90003U

ENG

FLOP

AA95-90003U

ENG

FLOF

AA95-90003U

ENG

FLOF

AA9590003U

ENG

FLOF

AA95-90003U

ENG

FLOF

AA95-90003U

ENG

FLOP

AA95-90003U

ENG

FLOF

AA95-90003U

FLOP

AA95-90003U

ENG

FLOF

AA95-90003U

ENG

FLOF

AA95-90012B

AA95-90003V

AA95-90003V

AA95-90003V

AA95-90003V

AA95-90003V

AA95-90003V

AA95-90003V

AA95-90003V

AA95-90003V

APPLIED

(AA95-

90001V)

NOT

APPLIED

NOT

APPLIED

NOT

APPLIED

NOT

APPLIED

NOT

APPLIED

NOT

APPLIED

NOT

APPLIED

NOT

APPLIED

NOT

APPLIED

SEHK

SME

S'PORE

MUR

SMARINA

TSE

SAVINA

SIEL

ZAMA

SGE

SPM5288PF/HKX

SPM5288PF/SMEX

SPM4388PF/SAPX

SPM5288PF/SAPX

SPM5288PF/MURX

SPM5288PF/MARX

SPM5288PF/TSEX

SPM5288PF/SVIX

SPM5288PF/SIX

SPM4388PF/ZAX

SPM5288PF/ZAX

SPM4388PF/SGEX

SPM5288PF/SGEX

CHINA

INDONESIA

SINGAPORE

MYANMAR

MALAYSIA

THAILAND

VIETNAM

INDIA

SAUDI-A

U.A.E

S

O

U

T

H

E

A

S

T

A

S

I

A

M

I

D

D

L

E

Local Specification & Bom Option

Area

Country

TTX I/B MICOMMIC

IF

Power

ASSY

Power

Code ASSY

Buyer Model Name

Page 39

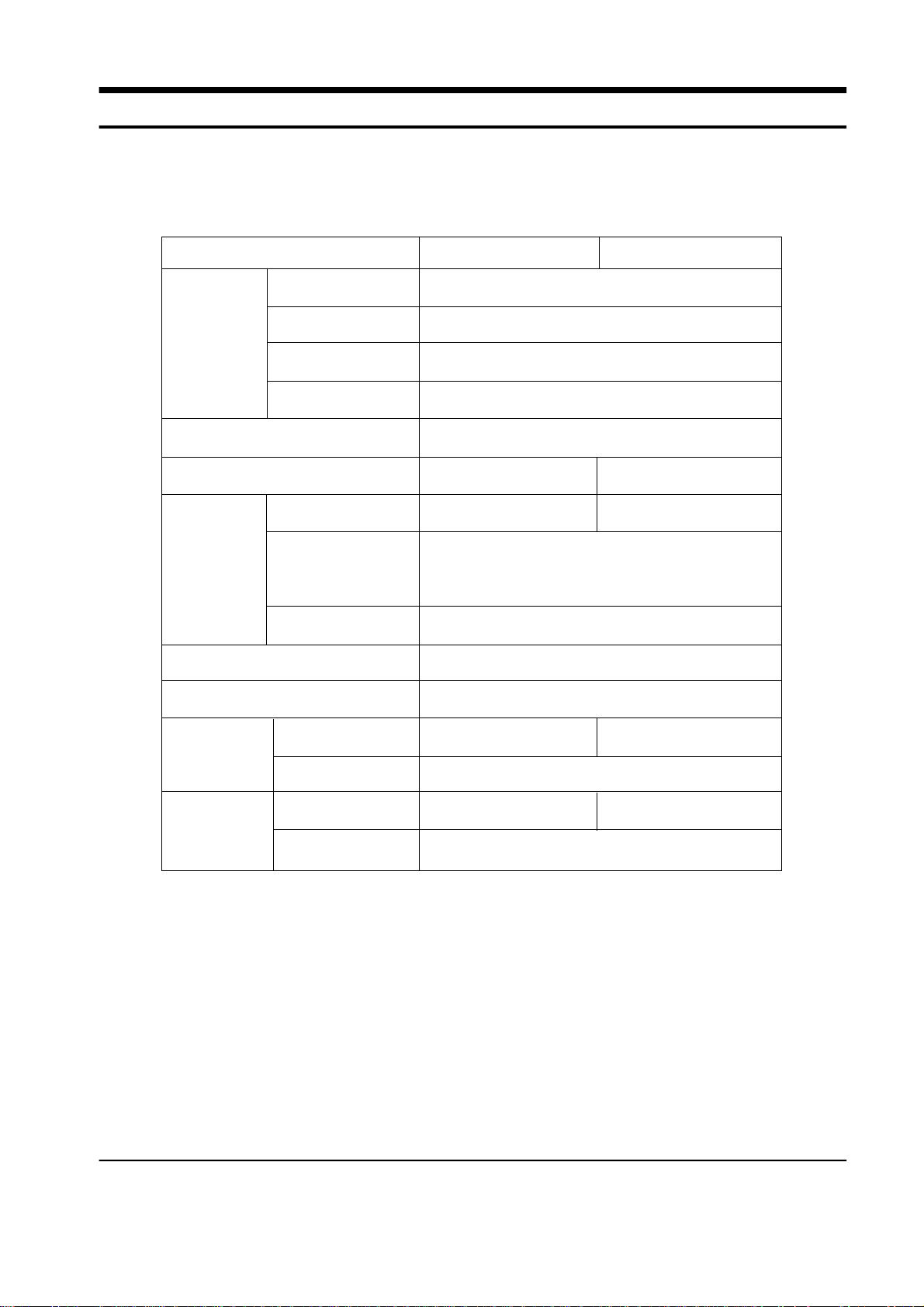

Areas and Option Specification

Samsung Electronics 8-3

8-1 Local Specification & BOM option (Continued)

AA68-10759A

ENG

AA68-10759A

ENG

AA68-10759A

ENG

AA68-10759A

ENG

AA68-10761A

CHI

RM130EAP

ENG/

ARAB

RM130ECP

ENG/CHI

RM130EAP

ENG

RM130EAP

ENG/

ARAB

RM130ECP

(ENG/CHI)

NONE

SACI

Safety S t a n d a r d

PB1374

PB1415

PB1415

PB1417

PB1435

PB1434

PB1436

Others

MAR,96

OCT, 96

Introduction

GAUSS:500mg

LATING:100~260V

50/60Hz

GAUSS:-500mG

RATING:240V

50/60Hz, AP2

GAUSS:-500mG

LATING:220V

60Hz

GAUSS:100mG

LATING:100~260V

50/60Hz

GAUSS:300mG

LATING:100~220V

50/60Hz, MIC

PLUG-CONV.

Special

Specification

AA95-10008P

L802~4:2mH

L848~9:2mH

AA95-10008P

L802~4:10mH

L848~9:10mH

AA95-10002H

L802~4:10mH

L848~9:10mH

AA95-10008H

L802~4:2mH

L848~9:2mH

AA95-10002H

L802~4:10mH

L848~9:10mH

AA96-20074A

AA96-20055C

AA96-20074A

AA96-20074A

AA96-20074A

CP2

AA95-90003U

FLOP

AA95-90003U

LIST

AA95-90003U

FLOF

AA95-90003U

FLOF

AA95-90003U

ENG

FLOP

AA95-90003V

AA95-90003V

AA95-90003V

AA95-90003V

AA95-90012B

NOT

APPLIED

NOT

APPLIED

NOT

APPLIED

NOT

APPLIED

APPLIED

(AA95-

90001V)

AFKO

SEAU

SAM

ELECTRA

SEHK

SPM5288PF/AMEX

SPM4388PF/SEUX

SPM5288PF/SEUX

SPM5288PF/TAHX

SPM4388PF/ELHX

SPM5288PF/ELHX

SPM4388PF/HKX

GHANA

AUSTRALIA

TAHITI

BANGLADESH

CHINA

A F R I C A

S

O

U

T

H

E

A

S

T

A

S

I

A

Local Specification & Bom Option

Area

Country

TTX I/B MICOMMIC

IF

Power

ASSY

Power

Code ASSY

Buyer Model Name

* Dissimilar Potion Specification (among assays)

1. Audio: AA95-40004L NICAM(for all SPT51A models)

AA95-40004Q No NICAM

2. IF :AA95-90003V All (excepting Czecho, China)

AA95-90004E Czecho (SFE 6.25MC Ceramic Filter used)

AA95-90012B China

3. PIP : AA95-90003W for 2 tuner

AA95-90004R for 1 tuner

4. TTX : AA95-90003U English-TTX countries

AA95-90003Y eastern Europe

5. MICOM

RM130EAP (English/Arabian)

RM130ECP (English/Chinese)

RM130ERP (English/Russian)

RM130ETP (English/Thai/Malay/Indonesian)

RM130EUP (English/Yugo/Czecho/Rumania/Croatia)

Page 40

ASSY-PCB,MAIN

* AA94-10088LASSY-PCB,MAIN(OPT);SPM4388PF/SGEX,SPT51A

BRKT AA61-10360ABRACKET-MODULE;-,-,CUS-1 1/2H,T0.5,-,SCT

C1001 2401-001840 C-AL;100uF,20%,16V,GP,TP,6.3x11,5

C1002 2306-000122 C-FILM,MPPF;100nF,5%,50V,TP,7.3x4.0x5.0m

C1003 2401-000962 C-AL;22uF,20%,50V,GP,TP,5x11,5

C1004 2306-000122 C-FILM,MPPF;100nF,5%,50V,TP,7.3x4.0x5.0m

C1005 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C1006 2401-001840 C-AL;100uF,20%,16V,GP,TP,6.3x11,5

C1007 2401-000027 C-AL;4.7uF,20%,50V,GP,TP,5x11,5

C1008 2201-000982 C-CERAMIC,DISC;10nF,+80-20%,50V,Y5V,TP,6

C1009 2401-001840 C-AL;100uF,20%,16V,GP,TP,6.3x11,5

C1015 2401-001840 C-AL;100uF,20%,16V,GP,TP,6.3x11,5

C1016 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C200 2201-000144 C-CERAMIC,DISC;100pF,5%,50V,CH,TP,8x3,5

C201 2401-001840 C-AL;100uF,20%,16V,GP,TP,6.3x11,5

C202 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C203 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C204 2309-000138 C-FILM,PE-PPF;100nF,5%,50V,TP,20x16x8.5,

C205 2201-000483 C-CERAMIC,DISC;33pF,5%,50V,CH,TP,5x3,5

C206 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C207 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C208 2301-000232 C-FILM,PEF;3.3nF,5%,50V,TP,8.1x4.5x13mm,

C209 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C210 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C2101 2305-000289 C-FILM,MPEF;220nF,5%,63V,TP,-,5mm

C2102 2305-000289 C-FILM,MPEF;220nF,5%,63V,TP,-,5mm

C2103 2305-000289 C-FILM,MPEF;220nF,5%,63V,TP,-,5mm

C2104 2305-000289 C-FILM,MPEF;220nF,5%,63V,TP,-,5mm

C2105 2305-000289 C-FILM,MPEF;220nF,5%,63V,TP,-,5mm

C2106 2305-000289 C-FILM,MPEF;220nF,5%,63V,TP,-,5mm

C2107 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C2108 2401-001840 C-AL;100uF,20%,16V,GP,TP,6.3x11,5

C2109 2201-000611 C-CERAMIC,DISC;56pF,5%,50V,CH,TP,6.5x3,5

C211 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C2110 2201-000234 C-CERAMIC,DISC;150pF,5%,50V,CH,TP,9.5x3,

C2111 2201-000504 C-CERAMIC,DISC;39pF,5%,50V,SL,TP,-,5

C2112 2401-000027 C-AL;4.7uF,20%,50V,GP,TP,5x11,5

C212 2305-000355 C-FILM,MPEF;330nF,5%,63V,TP,-,5mm

C213 2301-000232 C-FILM,PEF;3.3nF,5%,50V,TP,8.1x4.5x13mm,

C214 2301-000016 C-FILM,PEF;22nF,5%,100V,TP,7.2x4.5x9.0mm

C215 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C216 2201-000144 C-CERAMIC,DISC;100pF,5%,50V,CH,TP,8x3,5

C217 2201-000471 C-CERAMIC,DISC;330pF,10%,50V,Y5P,TP,5x3,

C218 2201-000375 C-CERAMIC,DISC;220pF,5%,50V,RH,TP,9.5x3.

C219 2305-000354 C-FILM,MPEF;330NF,5%,50V,TP,7.3X4.8X5.5M

C220 2201-000375 C-CERAMIC,DISC;220pF,5%,50V,RH,TP,9.5x3.

C221 2201-000144 C-CERAMIC,DISC;100pF,5%,50V,CH,TP,8x3,5

C222 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C223 2401-001840 C-AL;100uF,20%,16V,GP,TP,6.3x11,5

C224 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C225 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C226 2401-000027 C-AL;4.7uF,20%,50V,GP,TP,5x11,5

C227 2401-000027 C-AL;4.7uF,20%,50V,GP,TP,5x11,5

C228 2306-000122 C-FILM,MPPF;100nF,5%,50V,TP,7.3x4.0x5.0m

C229 2401-001840 C-AL;100uF,20%,16V,GP,TP,6.3x11,5

C230 2305-000289 C-FILM,MPEF;220nF,5%,63V,TP,-,5mm

C231 2305-000289 C-FILM,MPEF;220nF,5%,63V,TP,-,5mm

C232 2305-000289 C-FILM,MPEF;220nF,5%,63V,TP,-,5mm

C233 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C234 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C235 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C236 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C237 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C238 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C239 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C240 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C241 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C242 2305-000354 C-FILM,MPEF;330NF,5%,50V,TP,7.3X4.8X5.5M

C243 2401-000603 C-AL;1uF,20%,50V,GP,TP,5x11,5

C244 2401-001668 C-AL;68uF,20%,16V,GP,TP,5x11,5

C245 2301-000342 C-FILM,PEF;2.2nF,5%,50V,TP,7.4x3.9x13mm,

C246* 2201-000273 C-CERAMIC,DISC;18pF,5%,50V,CH,TP,5x3mm,5

C247* 2401-000603 C-AL;1uF,20%,50V,GP,TP,5x11,5

C248 2401-000922 C-AL;22uF,20%,16V,GP,TP,5x5,5

C249 2305-000355 C-FILM,MPEF;330nF,5%,63V,TP,-,5mm

C250 2301-000148 C-FILM,PEF;10nF,5%,100V,TP,7x3.2x7mm,5mm

C251 2301-000148 C-FILM,PEF;10nF,5%,100V,TP,7x3.2x7mm,5mm

C252 2301-000148 C-FILM,PEF;10nF,5%,100V,TP,7x3.2x7mm,5mm

C253 2301-000148 C-FILM,PEF;10nF,5%,100V,TP,7x3.2x7mm,5mm

C254 2401-002144 C-AL;47uF,20%,16V,GP,TP,5x11,5

C255 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C256 2301-000148 C-FILM,PEF;10nF,5%,100V,TP,7x3.2x7mm,5mm

C257 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C258 2301-000383 C-FILM,PEF;10nF,5%,50V,TP,6x7x3.2mm,5mm

C259 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C260 2301-000383 C-FILM,PEF;10nF,5%,50V,TP,6x7x3.2mm,5mm

C261 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C262 2301-000383 C-FILM,PEF;10nF,5%,50V,TP,6x7x3.2mm,5mm

C265 2401-000922 C-AL;22uF,20%,16V,GP,TP,5x5,5

C266 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C268 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C269 2401-000947 C-AL;22uF,20%,35V,GP,TP,5x11,5

C270 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C271 2306-000122 C-FILM,MPPF;100nF,5%,50V,TP,7.3x4.0x5.0m

C274 2401-002144 C-AL;47uF,20%,16V,GP,TP,5x11,5

C275 2301-000383 C-FILM,PEF;10nF,5%,50V,TP,6x7x3.2mm,5mm

C277 2306-000122 C-FILM,MPPF;100nF,5%,50V,TP,7.3x4.0x5.0m

C278 2401-002144 C-AL;47uF,20%,16V,GP,TP,5x11,5

C279 2306-000122 C-FILM,MPPF;100nF,5%,50V,TP,7.3x4.0x5.0m

C280 2306-000122 C-FILM,MPPF;100nF,5%,50V,TP,7.3x4.0x5.0m

C281 2401-000947 C-AL;22uF,20%,35V,GP,TP,5x11,5

C282 2301-000383 C-FILM,PEF;10nF,5%,50V,TP,6x7x3.2mm,5mm

C283 2201-000375 C-CERAMIC,DISC;220pF,5%,50V,RH,TP,9.5x3.

C284 2301-000383 C-FILM,PEF;10nF,5%,50V,TP,6x7x3.2mm,5mm

C285 2301-000261 C-FILM,PEF;4.7nF,5%,100V,TP,10.5x12.5x6.

C286 2301-000383 C-FILM,PEF;10nF,5%,50V,TP,6x7x3.2mm,5mm

C287 2401-001333 C-AL;470nF,20%,50V,GP,TP,5x11,5

C288 2301-000383 C-FILM,PEF;10nF,5%,50V,TP,6x7x3.2mm,5mm

C289 2201-000375 C-CERAMIC,DISC;220pF,5%,50V,RH,TP,9.5x3.

C290 2301-000383 C-FILM,PEF;10nF,5%,50V,TP,6x7x3.2mm,5mm

C291 2301-000383 C-FILM,PEF;10nF,5%,50V,TP,6x7x3.2mm,5mm

C292 2201-000961 C-CERAMIC,DISC;10pF,0.5pF,50V,RH,TP,5x3m

C293 2201-000961 C-CERAMIC,DISC;10pF,0.5pF,50V,RH,TP,5x3m

C294 2401-000027 C-AL;4.7uF,20%,50V,GP,TP,5x11,5

C295 2301-000383 C-FILM,PEF;10nF,5%,50V,TP,6x7x3.2mm,5mm

C296 2201-000193 C-CERAMIC,DISC;10pF,0.3pF,50V,CH,TP,5x3,

C297 2306-000122 C-FILM,MPPF;100nF,5%,50V,TP,7.3x4.0x5.0m

C298 2401-002289 C-AL;470uF,20%,35V,WT,TP,10x20,5

C299 2201-000144 C-CERAMIC,DISC;100pF,5%,50V,CH,TP,8x3,5

C601 2401-002144 C-AL;47uF,20%,16V,GP,TP,5x11,5

C602 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C603 2401-001840 C-AL;100uF,20%,16V,GP,TP,6.3x11,5

C605 2401-000471 C-AL;10uF,20%,50V,BP,TP,5x11,5mm

C606 2401-001840 C-AL;100uF,20%,16V,GP,TP,6.3x11,5

C8001 2401-000302 C-AL;100uF,20%,25V,GP,TP,6.3x11,5

C8002 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C8003 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C8004 2401-001840 C-AL;100uF,20%,16V,GP,TP,6.3x11,5

C8005 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C8006 2401-000832 C-AL;220uF,20%,25V,GP,TP,8x11.5,5

Samsung Electronics 9-1

Electric Parts List

Loc. No. Code No. Description ; Specification Remark Loc. No. Code No. Description ; Specification Remark

9. Electric Parts List

9-1. SPM4388PF

Page 41

C8008 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C8009 2401-000832 C-AL;220uF,20%,25V,GP,TP,8x11.5,5

C8010 2401-002594 C-AL;220uF,20%,16V,GP,TP,8x11.5,5

C8012 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C8013 2401-001397 C-AL;470uF,20%,25V,GP,TP,10x16,5

C8014 2401-001840 C-AL;100uF,20%,16V,GP,TP,6.3x11,5

C8015 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C901 2401-001397 C-AL;470uF,20%,25V,GP,TP,10x16,5

C902 2401-000480 C-AL;10uF,20%,50V,GP,TP,5x11,5

C903 2201-000374 C-CERAMIC,DISC;220pF,5%,50V,CH,TP,12.5x3

C904 2401-002594 C-AL;220uF,20%,16V,GP,TP,8x11.5,5

C909 2201-000292 C-CERAMIC,DISC;1nF,10%,50V,Y5P,TP,5x3,5

C910 2201-000281 C-CERAMIC,DISC;1nF,79.8,50V,Y5V,TP,4x3.5

C911 2201-000247 C-CERAMIC,DISC;15pF,5%,50V,CH,TP,5x3,5

C912 2201-000247 C-CERAMIC,DISC;15pF,5%,50V,CH,TP,5x3,5

C913 2201-000423 C-CERAMIC,DISC;27pF,5%,50V,NPO,TP,5x3,2.

C914 2201-000423 C-CERAMIC,DISC;27pF,5%,50V,NPO,TP,5x3,2.

C917 2201-000611 C-CERAMIC,DISC;56pF,5%,50V,CH,TP,6.5x3,5

C918 2401-002594 C-AL;220uF,20%,16V,GP,TP,8x11.5,5

C919 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C920 2401-001840 C-AL;100uF,20%,16V,GP,TP,6.3x11,5

C921 2201-000982 C-CERAMIC,DISC;10nF,+80-20%,50V,Y5V,TP,6

C922 2401-000480 C-AL;10uF,20%,50V,GP,TP,5x11,5

C923 2201-000146 C-CERAMIC,DISC;100pF,5%,50V,SL,TP,5x3,5

C924 2401-000480 C-AL;10uF,20%,50V,GP,TP,5x11,5

C925 2401-000480 C-AL;10uF,20%,50V,GP,TP,5x11,5

C926 2301-000289 C-FILM,PEF;5.6nF,5%,50V,TP,7x6x3,5

CC01 2401-001840 C-AL;100uF,20%,16V,GP,TP,6.3x11,5

CC02 2401-002462 C-AL;33uF,20%,16V,GP,TP,5x11,5

CC03 2401-002462 C-AL;33uF,20%,16V,GP,TP,5x11,5

CC04 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

CC05 2401-000027 C-AL;4.7uF,20%,50V,GP,TP,5x11,5

CC06 2401-001840 C-AL;100uF,20%,16V,GP,TP,6.3x11,5

CC07 2306-000122 C-FILM,MPPF;100nF,5%,50V,TP,7.3x4.0x5.0m

CC10 2401-000027 C-AL;4.7uF,20%,50V,GP,TP,5x11,5

CC11 2401-000027 C-AL;4.7uF,20%,50V,GP,TP,5x11,5

CC12 2401-000480 C-AL;10uF,20%,50V,GP,TP,5x11,5

CF01 AA29-10002AFILTER-COMB;-,UGL-357KNT,NTSC,ST

CN201 3711-002646 CONNECTOR-HEADER;BOX,7P,1R,2.5mm,STRAIGH

CN202 3711-003641 CONNECTOR-HEADER;BOX,12P,1R,2.5mm,STRAIG

CN601 3711-002645 CONNECTOR-HEADER;BOX,6P,1R,2.5MM,STRAIGH

CN601 AA39-20038DLEAD-CONNECTOR,ASSY;-,67096-006,S,6P,300

CN701 3710-001155 CONNECTOR-SOCKET;20P,2R,2.54MM,STRAIGHT,

CN702 3710-001155 CONNECTOR-SOCKET;20P,2R,2.54MM,STRAIGHT,

CN801 3711-000628 CONNECTOR-HEADER;-,11P,1R,2.5mm,STRAIGHT

CN801 AA39-20160E LEAD CONNECTOR-ASSY;-,67096-011,S,11P,14

CN901 3711-002641 CONNECTOR-HEADER;BOX,10P,1R,2.54mm,STRAI

CN903 3711-002644 CONNECTOR-HEADER;BOX,5P,1R,2.5mm,STRAIGH

CN904 3711-002648 CONNECTOR-HEADER;BOX,9P,1R,2.5mm,STRAIGH

CN905 3711-002642 CONNECTOR-HEADER;BOX,3P,1R,2.5MM,STRAIGH

CN906 3711-002642 CONNECTOR-HEADER;BOX,3P,1R,2.5MM,STRAIGH

CNH02 AA39-20113ALEAD-CONNECTOR,ASSY;-,YFH806-06,-,6(2)P,

CNQ01 3711-002644 CONNECTOR-HEADER;BOX,5P,1R,2.5mm,STRAIGH

CNV01 3711-002642 CONNECTOR-HEADER;BOX,3P,1R,2.5MM,STRAIGH

CNV01 AA39-20016DLEAD-CONNECTOR,ASSY;-,67096-003,S,3P,500

CNX01 AA39-20010ELEAD-CONNECTOR,ASSY;-,YFH800-01,S,1P,800

CNZ01 3711-002648 CONNECTOR-HEADER;BOX,9P,1R,2.5mm,STRAIGH

CNZ01 AA39-20082CLEAD-CONNECTOR,ASSY;-,67096-009,S,9P,400

CP101 2401-000962 C-AL;22uF,20%,50V,GP,TP,5x11,5

CP1010 2401-001840 C-AL;100uF,20%,16V,GP,TP,6.3x11,5

CP102 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

CP103 2401-001840 C-AL;100uF,20%,16V,GP,TP,6.3x11,5

CP104 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

CP105 2401-002235 C-AL;10uF,20%,16V,GP,TP,5x11mm,5mm

CP106 2401-001840 C-AL;100uF,20%,16V,GP,TP,6.3x11,5

CP107 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

CP108 2401-001840 C-AL;100uF,20%,16V,GP,TP,6.3x11,5

CP109 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

CW901 2503-000158 C-NETWORK;330PFX4,20%,50V,MCCB1H331MX4YT

CW902 2503-000159 C-NETWORK;330PFX5,20%,50V,MCCB1H331MX5YT

CW903 2503-000161 C-NETWORK;330PFX8,20%,50V,MCCB1H331MX8YT

CW904 2503-000158 C-NETWORK;330PFX4,20%,50V,MCCB1H331MX4YT

CZ301 2305-000411 C-FILM,MPEF;470nF,5%,50V,TP,7.3x4.8x5.5m

CZ302 2305-000411 C-FILM,MPEF;470nF,5%,50V,TP,7.3x4.8x5.5m

CZ303 2305-000411 C-FILM,MPEF;470nF,5%,50V,TP,7.3x4.8x5.5m

CZ304 2305-000289 C-FILM,MPEF;220nF,5%,63V,TP,-,5mm

CZ305 2305-000289 C-FILM,MPEF;220nF,5%,63V,TP,-,5mm

CZ306 2305-000289 C-FILM,MPEF;220nF,5%,63V,TP,-,5mm

CZ307 2305-000289 C-FILM,MPEF;220nF,5%,63V,TP,-,5mm

CZ308 2305-000354 C-FILM,MPEF;330NF,5%,50V,TP,7.3X4.8X5.5M

CZ310 2201-000281 C-CERAMIC,DISC;1nF,79.8,50V,Y5V,TP,4x3.5

CZ311 2306-000122 C-FILM,MPPF;100nF,5%,50V,TP,7.3x4.0x5.0m

CZ312 2401-000302 C-AL;100uF,20%,25V,GP,TP,6.3x11,5

CZ313 2306-000122 C-FILM,MPPF;100nF,5%,50V,TP,7.3x4.0x5.0m

CZ314 2401-000302 C-AL;100uF,20%,25V,GP,TP,6.3x11,5

CZ315 2305-000149 C-FILM,MPEF;100nF,5%,100V,TP,12x12.5x6.5

CZ316 2401-000404 C-AL;10uF,20%,16V,BP,TP,5x11,5

D202 0401-000005 DIODE-SWITCHING;1N4148,75V,300mA,DO-35,T

D203 0401-000005 DIODE-SWITCHING;1N4148,75V,300mA,DO-35,T

D204 0401-000005 DIODE-SWITCHING;1N4148,75V,300mA,DO-35,T

D205 0401-000005 DIODE-SWITCHING;1N4148,75V,300mA,DO-35,T

D211 0401-000005 DIODE-SWITCHING;1N4148,75V,300mA,DO-35,T

D212 0401-000005 DIODE-SWITCHING;1N4148,75V,300mA,DO-35,T

D601 0401-000005 DIODE-SWITCHING;1N4148,75V,300mA,DO-35,T

D905 0401-000005 DIODE-SWITCHING;1N4148,75V,300mA,DO-35,T

D906 0401-000005 DIODE-SWITCHING;1N4148,75V,300mA,DO-35,T

D907 0401-000005 DIODE-SWITCHING;1N4148,75V,300mA,DO-35,T

D908 0401-000005 DIODE-SWITCHING;1N4148,75V,300mA,DO-35,T

D909 0401-000005 DIODE-SWITCHING;1N4148,75V,300mA,DO-35,T

D910 0401-000005 DIODE-SWITCHING;1N4148,75V,300mA,DO-35,T

D911 0401-000005 DIODE-SWITCHING;1N4148,75V,300mA,DO-35,T

D912 0401-000005 DIODE-SWITCHING;1N4148,75V,300mA,DO-35,T

D914 0401-000005 DIODE-SWITCHING;1N4148,75V,300mA,DO-35,T

D915 0401-000005 DIODE-SWITCHING;1N4148,75V,300mA,DO-35,T

DL201 4711-000205 DELAY LINE;0.140uS,-,-,TR

DZ201 0403-000563 DIODE-ZENER;MTZ9.1B,9.1V,8.57-9.01V,500m

DZ203 0403-000355 DIODE-ZENER;UZ5.1BSB,5.1V,4.97-5.18V,500

DZ204 0403-000300 DIODE-ZENER;MTZ8.2B,8.2V,7.78-8.19V,500m

DZ206 0403-000563 DIODE-ZENER;MTZ9.1B,9.1V,8.57-9.01V,500m

DZ207 0403-000289 DIODE-ZENER;MTZ10C,10V,9.7-10.2V,500mW,D

DZ208 0403-000654 DIODE-ZENER;MTZ12B,12V,11.44-12.03V,500m

DZ209 0403-000654 DIODE-ZENER;MTZ12B,12V,11.44-12.03V,500m

DZ210 0403-000654 DIODE-ZENER;MTZ12B,12V,11.44-12.03V,500m

DZ901 0403-000296 DIODE-ZENER;MTZ5.6B,5.6V,5.45-5.73V,500m

DZ902 0403-000297 DIODE-ZENER;MTZ6.2B,6.2V,5.96-6.27V,500m

DZC01 0403-000563 DIODE-ZENER;MTZ9.1B,9.1V,8.57-9.01V,500m

IC201 1204-000636 IC-PICTURE PROCESS;TDA4566,DIP,18P,300MI

IC202 1204-000530 IC-PAL/NTSC DECODER;TDA9160A,DIP,32P,400

IC203 1204-000464 IC-VIDEO PROCESS;TDA4780,DIP,28P,-,PLAST

IC204 1209-000214 IC-DELAY LINE;TDA4665,DIP,16P,300MIL,PLA

IC205 1204-000444 IC-PICTURE PROCESS;TDA9170,DIP,32P,-,PLA

IC206 1201-000501 IC-VIDEO AMP;14577,DIP,8P,300MIL,CMOS,-5

IC207 1204-000471 IC-PICTURE PROCESS;AN5342K,DIP,30P,400MI

IC208 1001-000223 IC-VIDEO SWITCH;TEA5114A,-,DIP,16P,334MI

IC8001 1203-000006 IC-POSI.FIXED REG.;7808,TO-220,3P,-,PLAS H/SINK

IC8002 1203-000274 IC-POSI.FIXED REG.;7805,TO-220,3P,-,PLAS H/SINK

IC8003 1203-000165 IC-POSI.ADJUST REG.;78R12,TO-220,3P H/SINK

IC8004 1203-000298 IC-POSI.FIXED REG.;7809,TO-220,3P,-,PLAS H/SINK

IC901 AA13-30002HIC-MCU;-,CXP853P40S-1,8bit,SDIP,-,64P

IC902 1103-000118 IC-EEPROM;2408,1Kx8BIT,DIP,8P,300MIL,10m

IC903 1202-000001 IC-VOLTAGE COMP.;7533,TO-92,3P,-,SINGLE,

ICC01 0801-000961 IC-CMOS LOGIC;4053B,MUTIPLEXER,DIP,16P,3

ICZ30 1001-000223 IC-VIDEO SWITCH;TEA5114A,-,DIP,16P,334MI

ICZ31 1001-000223 IC-VIDEO SWITCH;TEA5114A,-,DIP,16P,334MI

IF-C AA39-30007BIF-CABLE;-,T,150mm,1365#26

L1001 2701-000142 INDUCTOR-AXIAL;1uH,10%,2.5x3.4mm

L1002 2701-000142 INDUCTOR-AXIAL;1uH,10%,2.5x3.4mm

L1003 2701-000142 INDUCTOR-AXIAL;1uH,10%,2.5x3.4mm

L1004 2701-000114 INDUCTOR-AXIAL;10uH,10%,2.5x3.4mm

L1005 3301-000287 CORE-FERRITE BEAD;AA,3.5x1x6mm,1500,2400

L101 2701-000115 INDUCTOR-AXIAL;10uH,10%,2.8x7mm

L201 3301-000287 CORE-FERRITE BEAD;AA,3.5x1x6mm,1500,2400

L202 2701-000115 INDUCTOR-AXIAL;10uH,10%,2.8x7mm

L203 2701-000115 INDUCTOR-AXIAL;10uH,10%,2.8x7mm

L204 2701-000162 INDUCTOR-AXIAL;27uH,10%,2.5x3.4mm

L205 2701-000223 INDUCTOR-AXIAL;82UH,10%,2.5X3.4MM

L206 2701-000114 INDUCTOR-AXIAL;10uH,10%,2.5x3.4mm

L207 2701-000162 INDUCTOR-AXIAL;27uH,10%,2.5x3.4mm

L209 2701-000207 INDUCTOR-AXIAL;56uH,5%,2.5x3.4mm

L602 2701-000142 INDUCTOR-AXIAL;1uH,10%,2.5x3.4mm

L603 2701-000142 INDUCTOR-AXIAL;1uH,10%,2.5x3.4mm

L604 2701-000115 INDUCTOR-AXIAL;10uH,10%,2.8x7mm

L902 2701-000114 INDUCTOR-AXIAL;10uH,10%,2.5x3.4mm

L903 AA27-10003GCOIL-CHOKE;-,30uH,K,50,22.3mA,TP,EL0606R

Electric Parts List

9-2 Samsung Electronics

Loc. No. Code No. Description ; Specification Remark Loc. No. Code No. Description ; Specification Remark

Page 42

L904 2701-000115 INDUCTOR-AXIAL;10uH,10%,2.8x7mm

L906 2701-000114 INDUCTOR-AXIAL;10uH,10%,2.5x3.4mm

LP101 2701-000142 INDUCTOR-AXIAL;1uH,10%,2.5x3.4mm

LP102 2701-000115 INDUCTOR-AXIAL;10uH,10%,2.8x7mm

LP103 2701-000142 INDUCTOR-AXIAL;1uH,10%,2.5x3.4mm

LP104 2701-000142 INDUCTOR-AXIAL;1uH,10%,2.5x3.4mm

LP105 2701-000142 INDUCTOR-AXIAL;1uH,10%,2.5x3.4mm

LP106 2701-000142 INDUCTOR-AXIAL;1uH,10%,2.5x3.4mm

LP108 2701-000115 INDUCTOR-AXIAL;10uH,10%,2.8x7mm

LZ301 2701-000114 INDUCTOR-AXIAL;10uH,10%,2.5x3.4mm

LZ302 2701-000114 INDUCTOR-AXIAL;10uH,10%,2.5x3.4mm

LZ303 2701-000111 INDUCTOR-AXIAL;100uH,10%,2.5x3.4mm

LZ304 2701-000111 INDUCTOR-AXIAL;100uH,10%,2.5x3.4mm

LZ305 2701-000111 INDUCTOR-AXIAL;100uH,10%,2.5x3.4mm

M101 AA59-40003F MODULE-LNA;-,LNA1410AF(S),PAL,EU,TR TYPE

MODULE AA59-40003PMODULE-FOCUS,PACK;-,F300,NTSC,43,64x62,

Q1001 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,T

Q201 0501-000283 TR-SMALL SIGNAL;KSA539,PNP,400mW,TO-92,T

Q202 0501-000283 TR-SMALL SIGNAL;KSA539,PNP,400mW,TO-92,T

Q203 0501-000283 TR-SMALL SIGNAL;KSA539,PNP,400mW,TO-92,T

Q204 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,T

Q205 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,T

Q206 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,T

Q207 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,T

Q208 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,T

Q209 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,T

Q210 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,T

Q211 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,T

Q212 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,T

Q213 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,T

Q601 0501-000283 TR-SMALL SIGNAL;KSA539,PNP,400mW,TO-92,T

Q602 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,T

Q901 0501-000369 TR-SMALL SIGNAL;KSC2331-Y,NPN,1W,TO-92L,

Q903 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,T

Q904 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,T

Q905 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,T

Q906 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,T

Q907 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,T

Q908 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,T

Q909 0501-000283 TR-SMALL SIGNAL;KSA539,PNP,400mW,TO-92,T

Q910 0501-000283 TR-SMALL SIGNAL;KSA539,PNP,400mW,TO-92,T

QC01 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,T

QC02 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,T

QC03 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,T

QC04 0501-000283 TR-SMALL SIGNAL;KSA539,PNP,400mW,TO-92,T

QC05 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,T

QC06 0501-000283 TR-SMALL SIGNAL;KSA539,PNP,400mW,TO-92,T

QZ301 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,T

R1002 2001-000734 R-CARBON;4.7Kohm,5%,1/8W,AA,TP,1.8x3.2m

R1003 2001-000734 R-CARBON;4.7Kohm,5%,1/8W,AA,TP,1.8x3.2m

R1004 2001-000812 R-CARBON;5.6Kohm,5%,1/8W,AA,TP,1.8x3.2m

R1005 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,R1006 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,R1007 2001-000857 R-CARBON;560ohm,5%,1/8W,AA,TP,1.8x3.2mm

R201 2001-000008 R-CARBON;15Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R202 2001-001015 R-CARBON;9.1Kohm,5%,1/8W,AA,TP,1.8x3.2m

R203 2001-000281 R-CARBON;100ohm,5%,1/8W,AA,TP,1.8x3.2mm

R204 2001-000281 R-CARBON;100ohm,5%,1/8W,AA,TP,1.8x3.2mm

R205 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,R206 2001-000273 R-CARBON;100KOHM,5%,1/8W,AA,TP,R208 2001-000864 R-CARBON;56Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R210 2001-000563 R-CARBON;27Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R2100 2001-000633 R-CARBON;30Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R2101 2001-000832 R-CARBON;510ohm,5%,1/8W,AA,TP,1.8x3.2mm

R2103 2001-000812 R-CARBON;5.6Kohm,5%,1/8W,AA,TP,1.8x3.2m

R2106 2001-000008 R-CARBON;15Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R2107 2001-000837 R-CARBON;51Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R2108 2001-000568 R-CARBON;27ohm,5%,1/8W,AA,TP,1.8x3.2mm

R2109 2001-000832 R-CARBON;510ohm,5%,1/8W,AA,TP,1.8x3.2mm

R211 2004-001914 R-METAL;39Kohm,2%,1/8W,AA,TP,1.8x3.5mm

R2110 2001-000568 R-CARBON;27ohm,5%,1/8W,AA,TP,1.8x3.2mm

R2111 2001-000832 R-CARBON;510ohm,5%,1/8W,AA,TP,1.8x3.2mm

R2112 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,R2113 2001-000786 R-CARBON;47Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R2114 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,R2115 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,R2116 2001-000281 R-CARBON;100ohm,5%,1/8W,AA,TP,1.8x3.2mm

R2118 2001-000515 R-CARBON;220ohm,5%,1/8W,AA,TP,1.8x3.2mm

R2119 2001-000515 R-CARBON;220ohm,5%,1/8W,AA,TP,1.8x3.2mm

R212 2001-000977 R-CARBON;8.2Kohm,5%,1/8W,AA,TP,1.8x3.2m

R2120 2001-000515 R-CARBON;220ohm,5%,1/8W,AA,TP,1.8x3.2mm

R2121 2001-000405 R-CARBON;180ohm,5%,1/8W,AA,TP,1.8x3.2mm

R2122 2001-000995 R-CARBON;820ohm,5%,1/8W,AA,TP,1.8x3.2mm

R2123 2001-000995 R-CARBON;820ohm,5%,1/8W,AA,TP,1.8x3.2mm

R2124 2001-000995 R-CARBON;820ohm,5%,1/8W,AA,TP,1.8x3.2mm

R2126 2001-000490 R-CARBON;200ohm,5%,1/8W,AA,TP,1.8x3.2mm

R2127 2001-000405 R-CARBON;180ohm,5%,1/8W,AA,TP,1.8x3.2mm

R2128 2001-000490 R-CARBON;200ohm,5%,1/8W,AA,TP,1.8x3.2mm

R2129 2001-000405 R-CARBON;180ohm,5%,1/8W,AA,TP,1.8x3.2mm

R213 2001-000008 R-CARBON;15Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R2130 2001-000490 R-CARBON;200ohm,5%,1/8W,AA,TP,1.8x3.2mm

R2131 2001-000405 R-CARBON;180ohm,5%,1/8W,AA,TP,1.8x3.2mm

R2133 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,R2134 2001-000786 R-CARBON;47Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R2135 2001-000786 R-CARBON;47Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R214 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,R215 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,R217 2001-000786 R-CARBON;47Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R218 2001-000780 R-CARBON;470ohm,5%,1/8W,AA,TP,1.8x3.2mm

R219 2001-001000 R-CARBON;82Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R220 2001-000281 R-CARBON;100ohm,5%,1/8W,AA,TP,1.8x3.2mm

R2201 2001-000515 R-CARBON;220ohm,5%,1/8W,AA,TP,1.8x3.2mm

R2202 2001-000780 R-CARBON;470ohm,5%,1/8W,AA,TP,1.8x3.2mm

R221 2001-000281 R-CARBON;100ohm,5%,1/8W,AA,TP,1.8x3.2mm

R222 2001-000281 R-CARBON;100ohm,5%,1/8W,AA,TP,1.8x3.2mm

R223 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,R224 2001-000281 R-CARBON;100ohm,5%,1/8W,AA,TP,1.8x3.2mm

R225 2001-000281 R-CARBON;100ohm,5%,1/8W,AA,TP,1.8x3.2mm

R226 2001-000281 R-CARBON;100ohm,5%,1/8W,AA,TP,1.8x3.2mm

R227 2008-000300 R-FUSIBLE;560ohm,5%,1/2W,AA,TP,4.7x11mm

R228 2001-000281 R-CARBON;100ohm,5%,1/8W,AA,TP,1.8x3.2mm

R229 2001-000281 R-CARBON;100ohm,5%,1/8W,AA,TP,1.8x3.2mm

R230 2001-000281 R-CARBON;100ohm,5%,1/8W,AA,TP,1.8x3.2mm

R231 2001-000281 R-CARBON;100ohm,5%,1/8W,AA,TP,1.8x3.2mm

R232 2001-000281 R-CARBON;100ohm,5%,1/8W,AA,TP,1.8x3.2mm

R233 2001-000645 R-CARBON;330Kohm,5%,1/8W,AA,TP,1.8x3.2m

R234 2001-000281 R-CARBON;100ohm,5%,1/8W,AA,TP,1.8x3.2mm

R235* 2001-001000 R-CARBON;82Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R236 2001-000857 R-CARBON;560ohm,5%,1/8W,AA,TP,1.8x3.2mm

R237 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,R238 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,R239 2001-000780 R-CARBON;470ohm,5%,1/8W,AA,TP,1.8x3.2mm

R240 2001-000890 R-CARBON;6.8Kohm,5%,1/8W,AA,TP,1.8x3.2m

R241 2001-000812 R-CARBON;5.6Kohm,5%,1/8W,AA,TP,1.8x3.2m

R242 2001-000281 R-CARBON;100ohm,5%,1/8W,AA,TP,1.8x3.2mm

R243 2001-000281 R-CARBON;100ohm,5%,1/8W,AA,TP,1.8x3.2mm

R244 2001-000515 R-CARBON;220ohm,5%,1/8W,AA,TP,1.8x3.2mm

R245 2001-000515 R-CARBON;220ohm,5%,1/8W,AA,TP,1.8x3.2mm

R248 2001-000522 R-CARBON;22Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R249 2001-000780 R-CARBON;470ohm,5%,1/8W,AA,TP,1.8x3.2mm

R250 2001-000734 R-CARBON;4.7Kohm,5%,1/8W,AA,TP,1.8x3.2m

R251 2001-000832 R-CARBON;510ohm,5%,1/8W,AA,TP,1.8x3.2mm

R252 2001-000472 R-CARBON;2.7Kohm,5%,1/8W,AA,TP,1.8x3.2m

R253 2001-000857 R-CARBON;560ohm,5%,1/8W,AA,TP,1.8x3.2mm

R254 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,R255 2001-000633 R-CARBON;30Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R256 2001-000522 R-CARBON;22Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R257 2001-000008 R-CARBON;15Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R258 2001-000977 R-CARBON;8.2Kohm,5%,1/8W,AA,TP,1.8x3.2m

R259 2001-000800 R-CARBON;5.1Kohm,5%,1/8W,AA,TP,1.8x3.2m

R260 2001-000723 R-CARBON;4.3Kohm,5%,1/8W,AA,TP,1.8x3.2m

R261 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,R262 2001-000522 R-CARBON;22Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R263 2001-000258 R-CARBON;1.8KOHM,5%,1/8W,AA,TP,R264 2001-000252 R-CARBON;1.6KOHM,5%,1/8W,AA,TP,R265 2001-000302 R-CARBON;10ohm,5%,1/8W,AA,TP,1.8x3.2mm

R266 2001-000633 R-CARBON;30Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R267 2001-000008 R-CARBON;15Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R268 2001-000857 R-CARBON;560ohm,5%,1/8W,AA,TP,1.8x3.2mm

R269 2001-000660 R-CARBON;33Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R270 2001-000702 R-CARBON;39Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R271 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,R272 2001-000605 R-CARBON;3.6Kohm,5%,1/8W,AA,TP,1.8x3.2m

R273 2001-000613 R-CARBON;3.9Kohm,5%,1/8W,AA,TP,1.8x3.2m

Electric Parts List

Samsung Electronics 9-3

Loc. No. Code No. Description ; Specification Remark Loc. No. Code No. Description ; Specification Remark

Page 43

R274 2001-000734 R-CARBON;4.7Kohm,5%,1/8W,AA,TP,1.8x3.2m

R275 2001-000786 R-CARBON;47Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R276 2001-001000 R-CARBON;82Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R277 2004-001089 R-METAL;560Kohm,5%,1/8W,AA,TP,1.8x3.2m

R278 2001-000890 R-CARBON;6.8Kohm,5%,1/8W,AA,TP,1.8x3.2m

R279 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,R281 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,R282 2001-000347 R-CARBON;13Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R284 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,R285 2001-000924 R-CARBON;680ohm,5%,1/8W,AA,TP,1.8x3.2mm

R286 2001-000591 R-CARBON;3.3Kohm,5%,1/8W,AA,TP,1.8x3.2m

R287 2001-000857 R-CARBON;560ohm,5%,1/8W,AA,TP,1.8x3.2mm

R288 2001-000281 R-CARBON;100ohm,5%,1/8W,AA,TP,1.8x3.2mm

R289 2001-000554 R-CARBON;270ohm,5%,1/8W,AA,TP,1.8x3.2mm

R290 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,R291 2001-000302 R-CARBON;10ohm,5%,1/8W,AA,TP,1.8x3.2mm

R292 2001-000362 R-CARBON;150ohm,5%,1/8W,AA,TP,1.8x3.2mm

R293 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,R294 2008-000272 R-FUSIBLE;33ohm,5%,1/2W,AA,TP,2.5x6.5mm

R295 2001-000281 R-CARBON;100ohm,5%,1/8W,AA,TP,1.8x3.2mm

R297 2001-001015 R-CARBON;9.1Kohm,5%,1/8W,AA,TP,1.8x3.2m

R298 2001-000812 R-CARBON;5.6Kohm,5%,1/8W,AA,TP,1.8x3.2m

R299 2001-000007 R-CARBON;3Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R601 2001-000281 R-CARBON;100ohm,5%,1/8W,AA,TP,1.8x3.2mm

R602 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,R616 2001-000281 R-CARBON;100ohm,5%,1/8W,AA,TP,1.8x3.2mm

R8001 2001-000066 R-CARBON(S);10Kohm,5%,1/2W,AA,TP,2.4x6.4

R8003 2003-000590 R-METAL OXIDE(S);22ohm,5%,2W,AA,TP,4x12m

R8004 2003-000744 R-METAL OXIDE(S);56ohm,5%,2W,AA,TP,4x12m

R901 2001-000117 R-CARBON(S);68ohm,5%,1/2W,AA,TP,2.4x6.4m

R902 2001-000221 R-CARBON;1.2KOHM,5%,1/8W,AA,TP,R903 2001-000449 R-CARBON;2.2Kohm,5%,1/8W,AA,TP,1.8x3.2m

R904 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,R905 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,R906 2001-001093 R-CARBON(S);2.2Kohm,5%,1/2W,AA,TP,2.4x6.

R907 2001-001093 R-CARBON(S);2.2Kohm,5%,1/2W,AA,TP,2.4x6.

R908 2001-001093 R-CARBON(S);2.2Kohm,5%,1/2W,AA,TP,2.4x6.

R909 2001-001093 R-CARBON(S);2.2Kohm,5%,1/2W,AA,TP,2.4x6.

R910 2001-000786 R-CARBON;47Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R911 2001-000786 R-CARBON;47Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R912 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,R913 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,R914 2001-000362 R-CARBON;150ohm,5%,1/8W,AA,TP,1.8x3.2mm

R915 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,R916 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,R917 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,R918 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,R919 2001-000786 R-CARBON;47Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R920 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,R921 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,R922 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,R924 2001-000734 R-CARBON;4.7Kohm,5%,1/8W,AA,TP,1.8x3.2m

R925 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,R926 2001-000786 R-CARBON;47Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R927 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,R928 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,R929 2001-000786 R-CARBON;47Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R930 2001-000786 R-CARBON;47Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R931 2001-000786 R-CARBON;47Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R932 2001-000786 R-CARBON;47Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R933 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,R934 2001-000241 R-CARBON;1.5Kohm,5%,1/8W,AA,TP,1.8x3.2m

R935 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,R936 2001-000947 R-CARBON;7.5Kohm,5%,1/8W,AA,TP,1.8x3.2m

R937 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,R938 2001-000734 R-CARBON;4.7Kohm,5%,1/8W,AA,TP,1.8x3.2m

R939 2001-000281 R-CARBON;100ohm,5%,1/8W,AA,TP,1.8x3.2mm

R940 2001-000281 R-CARBON;100ohm,5%,1/8W,AA,TP,1.8x3.2mm

R941 2001-000281 R-CARBON;100ohm,5%,1/8W,AA,TP,1.8x3.2mm

R942 2001-000281 R-CARBON;100ohm,5%,1/8W,AA,TP,1.8x3.2mm

R943 2001-000734 R-CARBON;4.7Kohm,5%,1/8W,AA,TP,1.8x3.2m

R944 2001-000449 R-CARBON;2.2Kohm,5%,1/8W,AA,TP,1.8x3.2m

R945 2001-000734 R-CARBON;4.7Kohm,5%,1/8W,AA,TP,1.8x3.2m

R946 2001-000449 R-CARBON;2.2Kohm,5%,1/8W,AA,TP,1.8x3.2m

R947 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,R948 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,R949 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,-

R950 2001-000281 R-CARBON;100ohm,5%,1/8W,AA,TP,1.8x3.2mm

R951 2001-000281 R-CARBON;100ohm,5%,1/8W,AA,TP,1.8x3.2mm

R952 2001-000281 R-CARBON;100ohm,5%,1/8W,AA,TP,1.8x3.2mm

R953 2001-000281 R-CARBON;100ohm,5%,1/8W,AA,TP,1.8x3.2mm

R954 2001-000331 R-CARBON;12KOHM,5%,1/8W,AA,TP,R955 2001-000786 R-CARBON;47Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R956 2001-000812 R-CARBON;5.6Kohm,5%,1/8W,AA,TP,1.8x3.2m

R958 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,R959 2001-000786 R-CARBON;47Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R960 2001-000660 R-CARBON;33Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R961 2001-000554 R-CARBON;270ohm,5%,1/8W,AA,TP,1.8x3.2mm

R962 2001-000837 R-CARBON;51Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R963 2001-000837 R-CARBON;51Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R964 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,R965 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,R966 2001-000591 R-CARBON;3.3Kohm,5%,1/8W,AA,TP,1.8x3.2m

R967 2001-000009 R-CARBON;20KOHM,5%,1/8W,AA,TP,R968 2001-000325 R-CARBON;120ohm,5%,1/8W,AA,TP,1.8x3.2mm

R969 2001-000995 R-CARBON;820ohm,5%,1/8W,AA,TP,1.8x3.2mm

R970 2001-000995 R-CARBON;820ohm,5%,1/8W,AA,TP,1.8x3.2mm

R971 2001-000995 R-CARBON;820ohm,5%,1/8W,AA,TP,1.8x3.2mm