Samsung Spinpoint M9TU Product Manual

M9TU Product Manual

USB 3.0 - 2.5” Hard Disk Drive

September 05, 2013 Rev 1.0

PMM9T-USB3.0 100736109a

© 2013 Seagate Technology LLC. All rights reserved. Seagate and Seagate Technology are

registered trademarks of Seagate Technology LLC in the United States and/or other countries.

Momentus is either a trademark or registered trademark of Seagate Technology LLC or one of

its affiliated companies in the United States and/or other countries. All other trademarks or

registered trademarks are the property of their respective owners. When referring to drive

capacity, one gigabyte, or GB, equals one billion bytes and one terabyte, or TB, equals one

trillion bytes. Your computer’s operating system may use a different standard of

measurement and report a lower capacity. In addition, some of the listed capacity is used for

formatting and other functions, and thus will not be available for data storage. Actual data

rates may vary depending on operating environment and other factors. The export or reexport of hardware or software containing encryption may be regulated by the U.S.

Department of Commerce, Bureau of Industry and Security (for more information, visit

www.bis.doc.gov), and controlled for import and use outside of the U.S. Seagate reserves the

right to change, without notice, product offerings or specifications.

TABLE OF CONTENTS

CHAPTER 1 SCOPE ............................................................................................................................. 1

1.1 USER DEFINITION .............................................................................................................................. 1

1.2 M

ANUAL ORGANIZATION .................................................................................................................. 1

1.3 USB .................................................................................................................................................... 1

1.4 R

EFERENCE ........................................................................................................................................ 2

CHAPTER 2 DESCRIPTION ............................................................................................................. 3

2.1 INTRODUCTION .................................................................................................................................. 3

2.2 KEY FEATURES .................................................................................................................................. 3

2.3 S

TANDARDS AND REGULATIONS....................................................................................................... 4

2.4 H

ARDWARE REQUIREMENTS............................................................................................................. 4

CHAPTER 3 SPECIFICATIONS ....................................................................................................... 5

3.1 SPECIFICATION SUMMARY ................................................................................................................ 5

3.2 P

HYSICAL SPECIFICATIONS ............................................................................................................... 5

3.3 L

OGICAL CONFIGURATIONS.............................................................................................................. 5

3.4 PERFORMANCE SPECIFICATIONS ..................................................................................................... 6

3.5 P

OWER CONSUMPTION ..................................................................................................................... 7

3.6 E

NVIRONMENTAL SPECIFICATIONS ............................................................................................... 8

3.7 R

ELIABILITY SPECIFICATIONS ....................................................................................................... 9

CHAPTER 4 INSTALLATION......................................................................................................... 10

4.1 SPACE REQUIREMENTS................................................................................................................... 10

4.2 U

NPACKING INSTRUCTIONS............................................................................................................ 10

4.3 MOUNTING ...................................................................................................................................... 10

4.3.1 Orientation...................................................................................................................... 11

4.3.2 Ventilation ...................................................................................................................... 11

4.4 C

ABLE CONNECTORS....................................................................................................................... 12

4.4.1 USB Connectivity............................................................................................................ 12

4.5 D

RIVE INSTALLATION...................................................................................................................... 12

4.6 S

YSTEM STARTUP PROCEDURE ....................................................................................................... 13

CHAPTER 5 DISK DRIVE OPERATION........................................................................................ 14

5.1 HEAD / DISK ASSEMBLY (HDA) ...................................................................................................... 14

5.1.1 Base Casting Assembly ................................................................................................... 14

5.1.2 DC Spindle Motor Assembly ........................................................................................... 14

5.1.3 Disk Stack Assembly ....................................................................................................... 14

5.1.4 Head Stack Assembly ...................................................................................................... 14

5.1.5 Voice Coil Motor and Actuator Latch Assemblies ......................................................... 15

5.1.6 Air Filtration System....................................................................................................... 15

5.1.7 Load/Unload Mechanism................................................................................................ 16

5.2 D

RIVE ELECTRONICS ....................................................................................................................... 16

5.2.1 Digital Signal Process and Interface Controller ............................................................ 16

5.2.2 USB Interface Controller................................................................................................ 16

5.2.2.1 The Host Interface Control Block ................................................................................................. 16

5.2.2.2 The Buffer Control Block ............................................................................................................. 17

5.2.2.3 The Disk Control Block ................................................................................................................ 17

5.2.2.4 The Disk ECC Control Block........................................................................................................ 17

5.2.2.5 Power Management....................................................................................................................... 17

5.2.3 Read/Write IC ................................................................................................................. 18

5.2.3.1 Time Base Generator.......................................................................................................................... 18

5.2.3.2 Automatic Gain Control ..................................................................................................................... 18

5.2.3.3 Asymmetry Correction Circuitry (ASC) ............................................................................................ 18

5.2.3.4 Analog Anti-Aliasing Low Pass Filter ................................................................................................ 18

5.2.3.5 Analog to Digital Converter (ADC) and FIR ...................................................................................... 18

5.3 SERVO SYSTEM ................................................................................................................................ 20

5.4 R

EAD AND WRITE OPERATIONS ...................................................................................................... 20

5.4.1 The Read Channel........................................................................................................... 20

5.4.2 The Write Channel .......................................................................................................... 20

5.5 FIRMWARE FEATURES ..................................................................................................................... 21

5.5.1 Read Caching ................................................................................................................. 21

5.5.2 Write Caching ................................................................................................................. 22

5.5.3 Defect Management ........................................................................................................ 22

5.5.4 Automatic Defect Allocation ........................................................................................... 22

5.5.5 Multi Parities Error Correction ..................................................................................... 22

CHAPTER 6 USB INTERFACE AND USB COMMANDS ............................................................ 23

6.1 INTRODUCTION ................................................................................................................................ 23

6.2 PHYSICAL INTERFACE ..................................................................................................................... 23

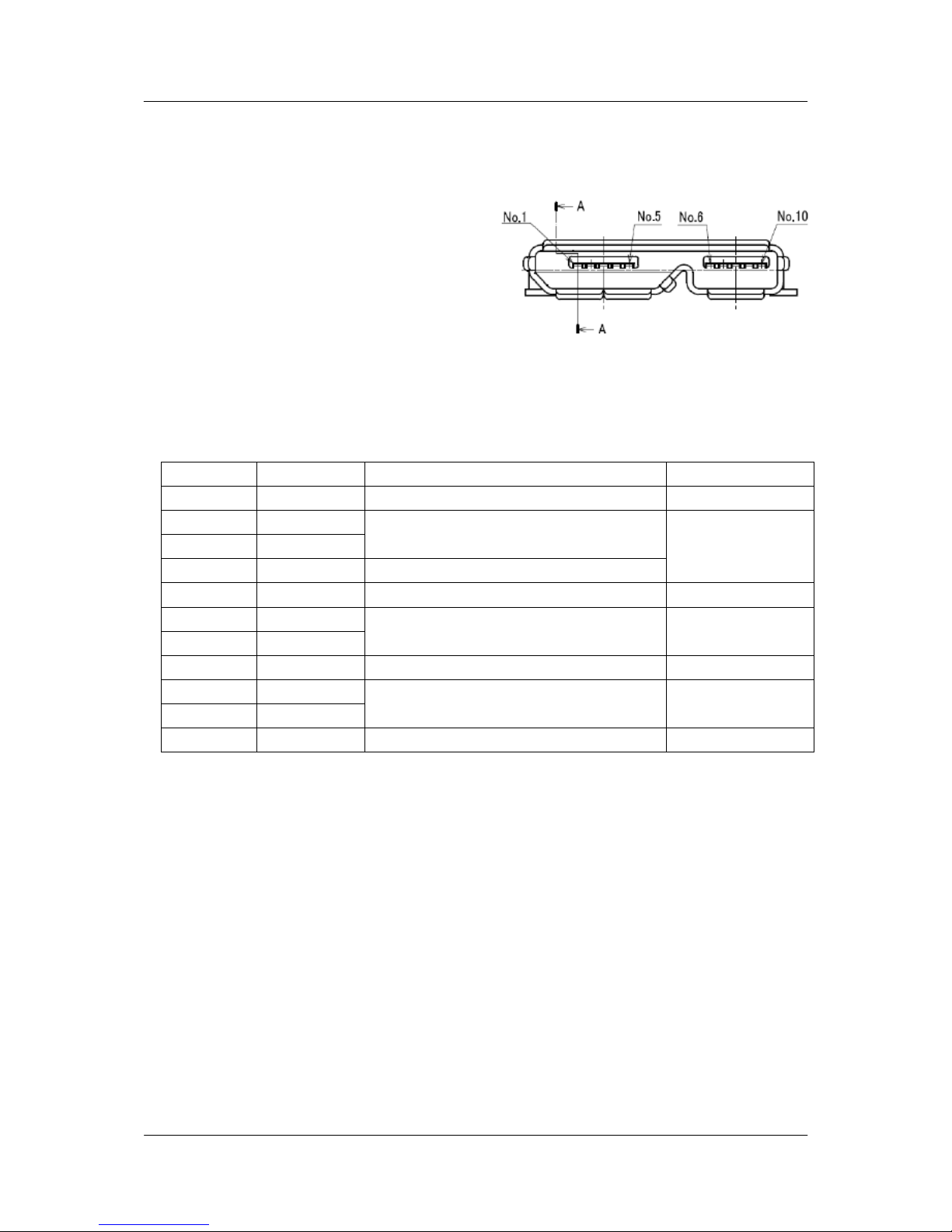

6.2.1 Mechanical Interface ...................................................................................................... 23

6.2.1.1 Mechanical Overview ................................................................................................................... 23

6.2.1.2 Connector ...................................................................................................................................... 24

6.2.1.2.1 USB Connector Termination Data.... ........................................ ....................................................................... 24

6.2.1.2.2 Series “A” and Series “B” Receptacles ........................................................................................................ 25

6.2.1.2.3 Series “A” and Series “B” Plugs ................................................................................................................... 26

6.2.1.3 Cable................................................................................................................................................. 27

6.2.1.4 Cable Assembly.................................................................................................................................. 27

6.2.1.4.1 Standard Detachable Cable Assemblies .................................................................................................... 27

6.2.1.4.2 High-/full-speed Captive Cable Assemblies............................................................................................... 30

6.2.1.4.3 Low-speed Captive Cable Assemblies ........................................................................................................ 31

6.2.1.4.4 Prohibited Cable Assemblies ...................................................................................................................... 31

6.2.2 Electrical Interface .......................................................................................................... 32

6.2.2.1 Electrical Overview ............................................................................................................................ 32

6.2.2.2 Signaling ............................................................................................................................................ 33

6.2.2.3 High-speed (480Mb/s) Driver Characteristics ................................................................................... 34

6.2.2.4 High-speed (480Mb/s) Signaling Rise and Fall Times ...................................................................... 35

6.2.2.5 High-speed (480Mb/ s) Receiver Characteristics ............................................................................... 35

6.2.2.6 High-speed (480Mb/s) Signaling Levels ........................................................................................... 36

6.2.3 Power Distribution ......................................................................................................... 37

6.2.3.1 Overview .............................................................................................................................................. 37

6.2.3.2 Bus-powered Hubs ............................................................................................................................... 37

6.2.3.3 Self-powered Hubs .............................................................................................................................. 38

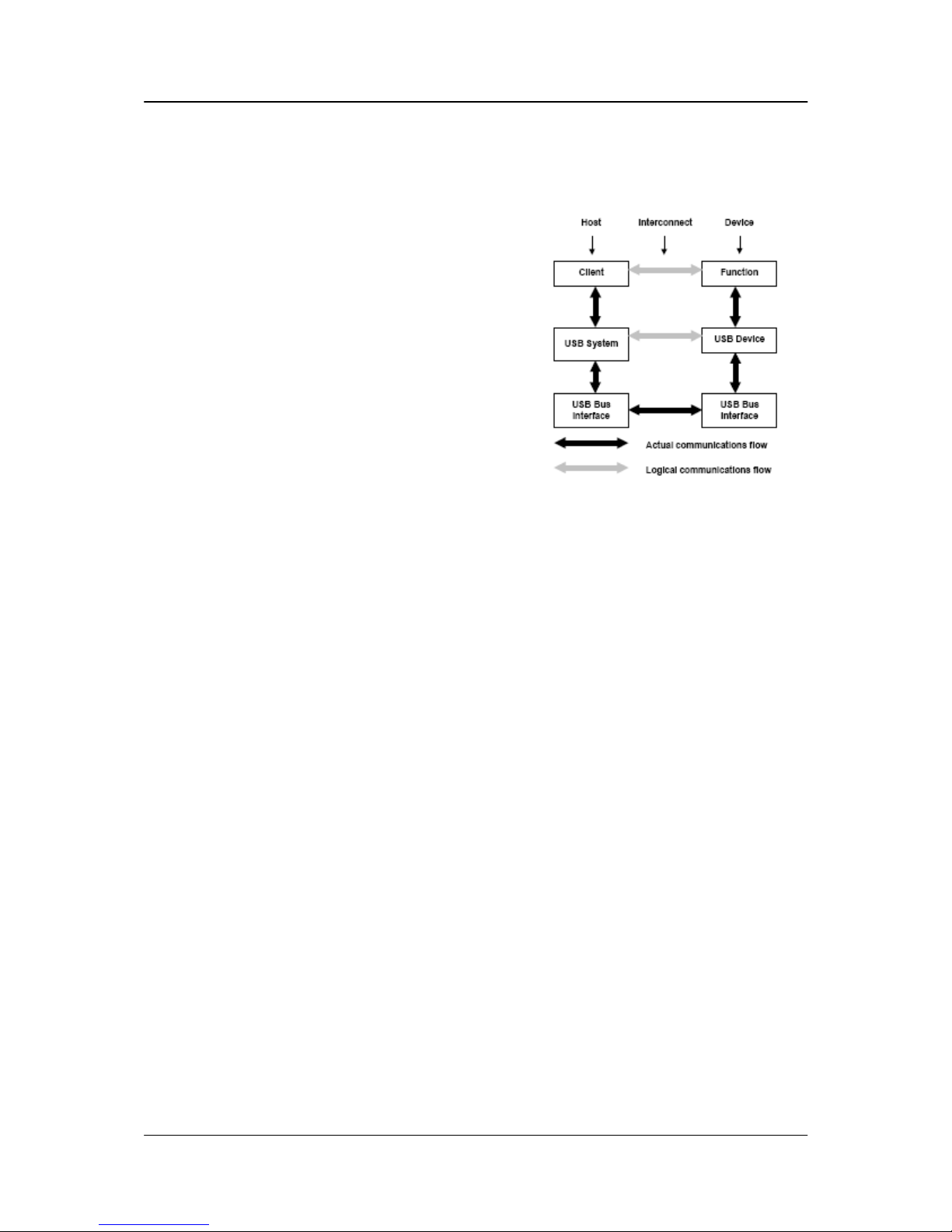

6.3 PROTOCOL LAYER ............................................................................................................................ 39

6.3.1 Protocol Layer Overview................................................................................................ 39

6.3.2 Common USB Packet Fields ........................................................................................... 40

6.3.2.1 SYNC Fields...................................................................................................................................... 40

6.3.2.2 Packet Identifier Fields...................................................................................................................... 40

6.3.2.3 Address Fields .................................................................................................................................. 41

6.3.2.4 Endpoint Fields.................................................................................................................................. 42

6.3.2.5 Frame Number Fi el ds ....................................................................................................................... 42

6.3.2.6 Data Fields ........................................................................................................................................ 42

6.3.2.7 Cyclic Redundancy Checks .............................................................................................................. 42

6.3.3 Packet Format ................................................................................................................. 43

6.3.3.1 Token Packet..................................................................................................................................... 43

6.3.3.2 Data Packet ....................................................................................................................................... 43

6.3.3.3 Handshake Packet ............................................................................................................................. 43

6.3.3.4 Start-of-Frame Packets................. ..................................................................................................... 44

6.3.4 Pipes ................................................................................................................................ 44

6.3.5 Transfer/Endpoint Types ................................................................................................. 45

6.3.5.1 Control Transaction........................................................................................................................... 46

6.3.5.2 Bulk Transaction................................................................................................................................ 48

6.3.6 USB Device Generic Framework .................................................................................... 50

6.3.6.1 USB Device Stat e ............................................................................................................................. 50

6.3.6.1.1 Attached .................................................................................................................................................. 51

6.3.6.1.2 Powered ................................................................................................................................................... 51

6.3.6.1.3 Default ..................................................................................................................................................... 52

6.3.6.1.4 Address ....................... .............................................................................................................................. 52

6.3.6.1.5 Configured ................................................................................................................................................ 52

6.3.6.1.6 Suspended ................................................................................................................................................ 52

6.3.6.1.7 Bus Enumeration ..................................................................................................................................... 52

6.3.6.2 Generic USB Device Operation...................................................................................................... 53

6.3.6.2.1 Dynamic Attachment and Removal ......................................................................................................... 53

6.3.6.2.2 Address Assignment ................................................................................................................................. 53

6.3.6.2.3 Configuration............................................................................................................................................ 54

6.3.6.2.4 Data Transfer ................... ........................................................................................................................ 54

6.3.6.2.5 Power Management .................................................................................................................................. 54

6.3.6.2.6 Request Processing ................................................................................................................................... 54

6.3.6.3 Standard USB Device Requests ..................................................................................................... 54

6.3.6.3.1 Standard USB Device Request Overview .............................................................................................. 56

6.3.6.3.2 Cl ea r Fea t u r e ( Request Code 1) ....... ..................................................................................................... 57

6.3.6.3.3 Get Configuration ( Request Code 8) ..................................................................................................... 58

6.3.6.3.4 Get Descriptor ( Request Code 6)........................................................................................................... 58

6.3.6.3.5 Get Interface ( Request Code 10) ........................................................................................................... 58

6.3.6.3.6 Get Status ( Request Code 0) .................................................................................................................. 59

6.3.6.3.7 Set Address ( Request Code 5) ................................................................................................................ 60

6.3.6.3.8 Set Configuration ( Request Code9) ....................................................................................................... 60

6.3.6.3.9 Set Descriptor ( Request Code 7)........................................................................................................... 62

6.3.6.3.10 Set Feature ( Request Code 3) ............................................................................................................... 62

6.3.6.3.11 Set Interface ( Request Code 11) ........................................................................................................... 63

6.3.6.3.12 Synch Frame ( Request Code 12) .......................................................................................................... 63

6.3.6.4 Standard USB Descriptor ............................................................................................................... 64

6.3.6.4.1 Standard USB Descriptor Overview .............................. ....................................................................... 64

6.3.6.4.2 D evi c e D es c r i pt o r ................................................................................................................................. 64

6.3.6.4.3 Device Qualifier Descriptor .................................................................................................................. 66

6.3.6.4.4 Configuration Descriptor ...................................................................................................................... 66

6.3.6.4.5 Other_Speed_Configuration_ Descriptor............................................................................................... 68

6.3.6.4.6 Interface Descriptor............................................................................................................................... 68

6.3.6.4.7 Endpoint Descriptor ....................... ....................................................................................................... 70

6.3.6.4.8 Stri ng Descriptor ................................................................................................................................... 72

6.4 BULK-ONLY TRANSPORT ................................................................................................................ 73

6.4.1 FUNCTIONAL CHARACTERISTICS .............................................................................................. 73

6.4.1.1 BULK-ONLY MASS STORAGE RESET (CLASS-SPECIFIC REQUEST).................................. 73

6.4.1.2 GET MAX LUN (CLASS-SPECIFIC REQUEST)........................................................................... 73

6.4.1.3 HOST/DEVICE PACKET TRANSFER ORDER............................................................................. 73

6.4.1.4 COMMAND QUEUING .................................................................................................. ................ 73

6.4.1.5 BI-DIRECTIONAL COMMAND PROTOCOL ............................................................................ 73

6.4.2 STANDARD DESCRIPTORS ........................................................................................................... 74

6.4.2.1 DEVICE DESCRIPTOR .................................................................................................................. 74

6.4.2.2 CONFIGURATIO N DESCRIPTOR (TABLE 6-22)........................................................................ 75

6.4.2.3 INTERFACE DESCRIPTOR ........................................................................................................... 75

6.4.2.4 ENDPOINT DESCRIPTOR .......................................................................................................... 76

6.4.3 PROTOCOL (COMMAND/DATA/STATUS) ................................................................................... 77

6.4.3.1 COMMAND BLOCK WRAPPER (CBW) ...................................................................................... 78

6.4.3.2 COMMAND STATUS WRAPPER (CSW) ..................................................................................... 79

6.4.3.3 DATA TRANSFER CONDITIONS ................................................................................................. 79

6.4.3.3.1 COMMAND TRANSPORT ...................................................... .............................................................. 79

6.4.3.3.2 DATA TRANSPORT......................................... ...................................................................................... 80

6.4.3.3.3 STATUS TRANSPORT .......................................................................................................................... 80

6.4.3.3.4 PHASE ERROR ...................................................................................................................................... 80

6.4.3.3.5 RESET RECOVERY………………………………………..................................................................... 80

6.4.4 HOST/DEVICE DATA TRANSFERS ............................................................................................... 80

6.4.4.1 OVERVIEW ..................................................................................................................................... 80

6.4.4.2 VALID AND MEANINGFUL CBW............................................................................................... 80

6.4.4.3 VALID AND MEANINGFUL CSW ............................................................................................... 81

6.4.4.4 DEVICE ERROR HANDLING ....................................................................................................... 81

6.4.4.5 HOST ERROR HANDLING ............................................................................................................ 81

6.4.4.6 ERROR CLASSES ........................................................................................................................... 81

6.4.4.6.1 CBW NOT VALID .................................................................................................................................. 81

6.4.4.6.2 INTERNAL DEVICE ERROR................................................................................................................. 81

6.4.4.6.3 HOST/DEVICE DISAGREEMENTS ..................................................................................................... 81

6.4.4.6.4 COMMAND FAILURE ........................................................................................................................... 81

6.5 UFI COMMAND SET ......................................................................................................................... 82

6.5.1 OVERVIEW ...................................................................................................................................... 82

6.5.1.1 HOST/UFI DEVICE CONCEPTUAL VIEW ............................................................................................... 82

6.5.1.2 UFI COMMAND SET OVERVIEW .................................................... ........................................................ 83

6.5.2 INQUIRY COMMAND (12H) .......................................................................................................... 84

6.5.3 READ(10) COMMAND (28H) ......................................................................................................... 85

6.5.4 READ CAPACITY COMMAND (25H) ............................................................................................ 85

6.5.5 READ FORMAT CAPACITY COMMAND (23H)............................................................................ 86

6.5.5.1 CAPACITY LIST ......................................................................................................................................... 87

6.5.6 WRITE(10) COMMAND (2AH) ................................................................................................... 88

CHAPTER 7 MAINTENANCE........................................................................................................ 89

7.1 GENERAL INFORMATION ............................................................................................................... 89

7.2 M

AINTENANCE PRECAUTIONS ......................................................................................................... 89

7.3 S

ERVICE AND REPAIR ...................................................................................................................... 91

TABLE OF TABLES

Table 3-1 : Specifications......................................................................................................................................... 5

Table 3-2 : Physical Specifications .......................................................................................................................... 5

Table 3-3 : Logical Configurations ........................................................................................................................... 5

Table 3-4 : Performance Specifications ..................................................................................................................... 6

Table 3-5 : Power consumption ................................................................................................................................ 7

Table 3-6 : Environmental Specifications ................................................................................................................. 8

Table 3-7 : Reliability Specifications ........................................................................................................................ 9

Table 4-1 : USB Connector Pin Definitions .............................................................................................................. 12

Table 4-2 : Logical Drive Parameters ....................................................................................................................... 13

Table 6-1 : USB Connector Termination Data .......................................................................................................... 24

Table 6-2 : High-speed Signaling Levels .................................................................................................................. 36

Table 6-3 : PID Types ............................................................................................................................................... 41

Table 6-4 : Visible Device States .............................................................................................................................. 51

Table 6-5 : Format of Setup Data .............................................................................................................................. 55

Table 6-6 : Standard Device Request ........................................................................................................................ 56

Table 6-7 : Standard Request Codes ......................................................................................................................... 57

Table 6-8 : Descriptor Types..................................................................................................................................... 57

Table 6-9 : Standard Feature Sectors ........................................................................................................................ 57

Table 6-10 : Test Mode Selectors ............................................................................................................................. 63

Table 6-11 : Standard Device Descriptor .................................................................................................................. 65

Table 6-12 : Device Qualifier Descriptor .................................................................................................................. 66

Table 6-13 : Standard Configuration Descriptor ....................................................................................................... 67

Table 6-14 : Other Speed Configuration Descriptor ................................................................................................. 68

Table 6-15 : Standard Interface Descriptor ............................................................................................................... 69

Table 6-16 : Standard Endpoint Descriptor ............................................................................................................... 70

Table 6-17 : Allowed wMaxPacketSize Values for Different Numbers of Transaction per Microframe................. 72

Table 6-18 : String Descriptor Zero, Specifying Language Supported by the Device .............................................. 72

Table 6-19 : UNICODE String Descriptor ................................................................................................................ 72

Table 6-20 : Bulk Only Transport Device Descriptor ............................................................................................... 74

Table 6-21 : Example Serial Number Format ........................................................................................................... 74

Table 6-22 : Bulk Only Transport Configuration Descriptor .................................................................................... 75

Table 6-23 : Bulk Only Data Interface Descriptor .................................................................................................... 75

Table 6-24 : Bulk-In Endpoint Descriptor................................................................................................................. 76

Table 6-25 : Bulk-Out Endpoint Descriptor .............................................................................................................. 76

Table 6-26 : Command Block Wrapper .................................................................................................................... 78

Table 6-27 : Command Status Wrapper .................................................................................................................... 79

Table 6-28 : Command Block Status Values ............................................................................................................ 79

Table 6-29 : UFI Commands Set ............................................................................................................................. 83

Table 6-30 : INQUIRY Command ............................................................................................................................ 84

Table 6-31 : INQUIRY Data Format ........................................................................................................................ 84

Table 6-32 : READ(10) Command ........................................................................................................................... 85

Table 6-33 : READ CAPACITY Command ............................................................................................................. 85

Table 6-34 : READ CAPACITY Data ...................................................................................................................... 86

Table 6-35 : READ FORMAT CAPACITY Command............................................................................................ 86

Table 6-36 : Capacity List......................................................................................................................................... 87

Table 6-37 : Capacity List Header ............................................................................................................................ 87

Table 6-38 : Current/Maximum Capacity Descriptor................................................................................................ 87

Table 6-39 : Descriptor Code Definition................................................................................................................. 88

Table 6-40 : Formattable Capacity Descriptor ........................................................................................................ 88

Table 6-41 : WRITE(10) Command ....................................................................................................................... 88

TABLE OF FIGURES

Figure 3-1 : Measurement Position ........................................................................................................................... 9

Figure 4-1 : Mechanical Dimension .......................................................................................................................... 10

Figure 4-2 : Mounting-Screw Clearance ................................................................................................................... 11

Figure 4-3 : USB connector type.............................................................................................................................. 12

Figure 5-1 : Exploded Mechanical View ................................................................................................................. 15

Figure 5-2 : Read/Write 88C10010........................................................................................................................... 19

Figure 6-1 : Interlayer Communication Flow............................................................................................................ 23

Figure 6-2 : Keyed Connector Protocol .................................................................................................................... 24

Figure 6-3 : USB Series “A” Receptacle Interface.................................................................................................... 25

Figure 6-4 : USB Series “B” Receptacle Interface .................................................................................................... 25

Figure 6-5 : USB Series “B” Plug Interface .............................................................................................................. 26

Figure 6-6 : USB Series “B” Plug Interface .............................................................................................................. 26

Figure 6-7 : USB Standard Detachable Cable Assembly .......................................................................................... 27

Figure 6-8 : USB High-/full-speed Hardwired Cable Assembly ............................................................................... 30

Figure 6-9 : USB Low-speed Hardwired Cable Assembly........................................................................................ 31

Figure 6-10 : USB Cable Signal................................................................................................................................ 32

Figure 6-11 : Example High-speed Capable Transceiver Circuit .............................................................................. 33

Figure 6-12 : Compound Bus-powered Hub ............................................................................................................ 38

Figure 6-13 : Compound Self-powered Hub ............................................................................................................. 38

Figure 6-14 : PID Format .......................................................................................................................................... 40

Figure 6-15 : ADDR Field ........................................................................................................................................ 41

Figure 6-16 : Endpoint Field ..................................................................................................................................... 42

Figure 6-17 : Data Field Format................................................................................................................................ 42

Figure 6-18 : Token Format ...................................................................................................................................... 43

Figure 6-19 : Data Packet Format ........................................................................................................................... 43

Figure 6-20 : Handshake Format ............................................................................................................................. 43

Figure 6-21 : SOF Packet ........................................................................................................................................ 44

Figure 6-22 : Control Transaction Model ................................................................................................................ 46

Figure 6-23 : Setup Stage ........................................................................................................................................ 46

Figure 6-24 : Data Stage ........................................................................................................................................... 47

Figure 6-25 : Status In Stage ................................................................................................................................... 47

Figure 6-26 : Status Out Stage ................................................................................................................................ 47

Figure 6-27 : Bulk Transaction Model .................................................................................................................... 48

Figure 6-28 : Bulk Transaction Diagram ................................................................................................................. 49

Figure 6-29 : Enumeration ...................................................................................................................................... 50

Figure 6-30 : Enumeration ...................................................................................................................................... 51

Figure 6-31 : wIndex Format when Specifying an Endpoint ................................................................................... 55

Figure 6-32 : wIndex Format when Specifying an Interface .................................................................................... 56

Figure 6-33 : Information Returned by a GetStatus() Request to a Device ............................................................ 59

Figure 6-34 : Information Returned by a GetStatus() Request to an Interface ......................................................... 59

Figure 6-35 : Information Returned by a GetStatus() Request to an Endpoint ......................................................... 60

Figure 6-36 : Command/Data/Status Flow .............................................................................................................. 77

Figure 6-37 : Status Transport Flow ........................................................................................................................ 77

Figure 6-38 : Host/UFI Device Conceptual View ..................................................................................................... 82

Figure 7-1 : HDD handling guide-Please handle HDD by side surfaces!..................................................................... 90

Figure 7-2 : HDD handling guide-Do not Touch Cover and PCB ............................................................................ 90

Figure 7-3 : HDD handling guide-Do Not Stack! ..……………………...................................................... 90

Figure 7-4 : HDD handling guide-Prevent Shocks! ................................................................................. 91

SCOPE

Spinpoint M9TU-USB 3.0 Product Manual REV 1.0

1

CHAPTER 1 SCOPE

Welcome to the Spinpoint™ M9TU USB 3.0 series of Samsung™ hard disk drive. This series of drives

consists of the following models: ST2000LM005 and ST1500LM008. This chapter provides an overview of the

contents of this manual, including the intended user, manual organization, terminology and conventions. In

addition, it provides a list of references that might be helpful to the reader.

1.1 User Definition

The Spinpoint M9TU-USB 3.0 product manual is intended for the following readers:

• Original Equipment Manufacturers (OEMs)

• Distributors

1.2 Manual Organization

This manual provides information about installation, principles of operation, and interface command

implementation. It is organized into the following chapters:

•

Chapter 1 - SCOPE

•

Chapter 2 - DESCRIPTION

•

Chapter 3 - SPECIFICATIONS

•

Chapter 4 - INSTALLATION

•

Chapter 5 - DISK DRIVE OPERATION

•

Chapter 6 - USB INTERFACE AND USB COMMANDS

•

Chapter 7 - MAINTENANCE

In addition, this manual contains a glossary of terms to help you understand important information

1.3 USB

A USB system has an asymmetric design, consisting of a host, a multitude of downstream USB ports, and

multiple peripheral devices connected in a tiered-star topology. Additional USB hubs may be included in

the tiers, allowing branching into a tree structure, subject to a limit of 5 levels of tiers. USB host may have

multiple host controllers and each host controller may provide one or more USB ports. Up to 127 devices,

including the hub devices may be connected to a single host controller.

USB supports four data rates:

A Low Speed (1.1, 2.0) rate of 1.5Mbit/s (187.5kB/s) that is mostly used for Human Interface Devices

(HID) such as keyboards, mice, and joysticks.

A Full Speed (1.1, 2.0) rate of 12Mbit/s (1.5MB/s). Full Speed was the fastest rate before the USB 2.0

specification and many devices fall back to Full Speed. Full Speed devices divide the USB bandwidth

between them in a first-come first-served basis and it is not uncommon to run out of bandwidth with

several isochronous devices. All USB Hubs support Full Speed.

A Hi-Speed (2.0) rate of 480Mbit/s (60MB/s).

A SuperSpeed (3.0) rate of 5Gbit/s (625MB/s)

SCOPE

Spinpoint M9TU-USB 3.0 Product Manual REV 1.0

2

1.4 Reference

For additional information about the USB interface, refer to:

• USB 0.7: Released in November 1994

• USB 0.8: Released in December 1994

• USB 0.9: Released in April 1995

• USB 0.99: Released in August 1995

• USB 1.0 Release candidate: Released in November 1995

• USB 1.0 (1.5Mbit/s, Low-Speed and 12Mbit/s, Full-Speed): Released in January 1996

• USB 1.1: Released in September 1998

• USB 2.0 (480Mbit/s, Hi-Speed): Released in April 2000

• USB 3.0 (5Gbit/s, SuperSpeed): Released in November 2008

For introduction about USB interface please refer to:

• Universal Serial Bus (USB*) Overview (URL: http://www.intel.com/technology/usb/index.htm)

• USB Implementers Forum, Inc (URL:

http://www.usb.org)

• USB 3.0 Specification (URL:

http://www.usb.org/developers/docs/)

Spinpoint M9TU-USB 3.0 Product Manual REV 1.0

3

DESCRIPTION

CHAPTER 2 DESCRIPTION

This chapter summarizes general functions and key features of the Spinpoint M9TU-USB 3.0 hard disk drive,

as well as the standards and regulations they meet.

2.1 Introduction

The Samsung Spinpoint M9TU-USB 3 .0 2.5 inch hard disk drive is high capacity, high performance random

access storage device, which uses non-removable 2.5-inch disks as storage media. Each disk incorporates thin film

metallic media technology for enhanced performance and reliability. And for each disk surface there is a

corresponding movable head actuator assembly to randomly access the data tracks and write or read the user data.

The Spinpoint M9TU-USB 3.0 hard disk drive includes the USB controller embedded in the disk drive PCB

electronics. The drive’s electrical interface is compatible with all mandatory, optional and vendor-specific

commands within the USB specification.

Drive size conforms to the industry standard 2.5-inch form factor and mini USB interface.

The Spinpoint M9TU-USB 3 .0 hard disk drive incorporates TuMR head and Noise Predictive PRML (Partial

Response Maximum Likelihood) signal processing technologies. These advanced technologies allow for areal

density of about 950 Gigabits per square inch and storage capacity of maximum 667 Gigabytes per disk.

The heads, disk(s), and actuator housing are environmentally sealed within an aluminum-alloy base and

cover. As the disks spin, air circulates within this base and cover, commonly referred to as the head and disk

assembly (HDA), through a non-replaceable absolute filter ensuring a contamination free environment for the

heads and disks throughout the life of the drive.

2.2 Key Features

Key features of the Spinpoint M9TU-USB 3.0 hard disk drive includes:

• Formatted capacities are 1.5TB and 2TB

• 9.5 ± 0.2 mm height form factor

• 5400 RPM Class

• 12 ms average seek time

• High accuracy rotary voice coil actuator with embedded sector servo

• Universal Serial Bus (USB) Interface (Supports USB 3.0 speed)

• Supports LBA Addressing modes

• Supports all logical geometries as programmed by the host

• 32MB buffer memory for read and write cache.

• Transparent media defect mapping

• High performance in-line defective sector skipping

• Auto-reassignment

• Automatic error correction and retries

• On-the-fly (OTF) error correction

• Noise predictive PRML read channel

• TA detection and correction

• TuMR/PMR head

• SMART III support

• 1MB = 1,000,000 Bytes, 1GB = 1,000,000,000 Bytes

Accessible capacity may vary as some OS uses binary numbering system for reported capacity

Spinpoint M9TU-USB 3.0 Product Manual REV 1.0

4

DESCRIPTION

2.3 Standards and Regulations

The Samsung Spinpoint M9TU / Seagate

®

Momentus® hard disk drive depends upon its host equipment to

provide power and appropriate environmental conditions to achieve optimum performance and compliance with

applicable industry and governmental regulations. Special attention has been given in the areas of safety,

power distribution, shielding, audible noise control, and temperature regulation.

The Spinpoint M9TU-USB 3.0 hard disk drive satisfies the following standards and regulations:

• Underwriters Laboratory (UL): Standard 1950.

Information technology equipment including business equipment.

• Canadian Standards Association (CSA): Standard C22.2 No.3000-201.

Information technology equipment including business equipment.

• Technisher Überwachungs Verein (TUV): Standard EN 60 950.

Information technology equipment including business equipment.

2.4 Hardware Requirements

The Spinpoint M9TU-USB 3.0 hard disk drive is designed for use with host computers and controllers

that are USB compatible. It is connected to a PC either by:

• Using an adapter board with USB interface, or

• Plugging a cable from the drive directly into a PC motherboard with an USB interface.

Spinpoint M9TU-USB 3.0 Product Manual REV 1.0

5

SPECIFICATIONS

CHAPTER 3 SPECIFICATIONS

This chapter gives a detail description of the physical, electrical and environmental characteristics of

the Spinpoint M9TU-USB 3.0 hard disk drive.

3.1 Specification Summary

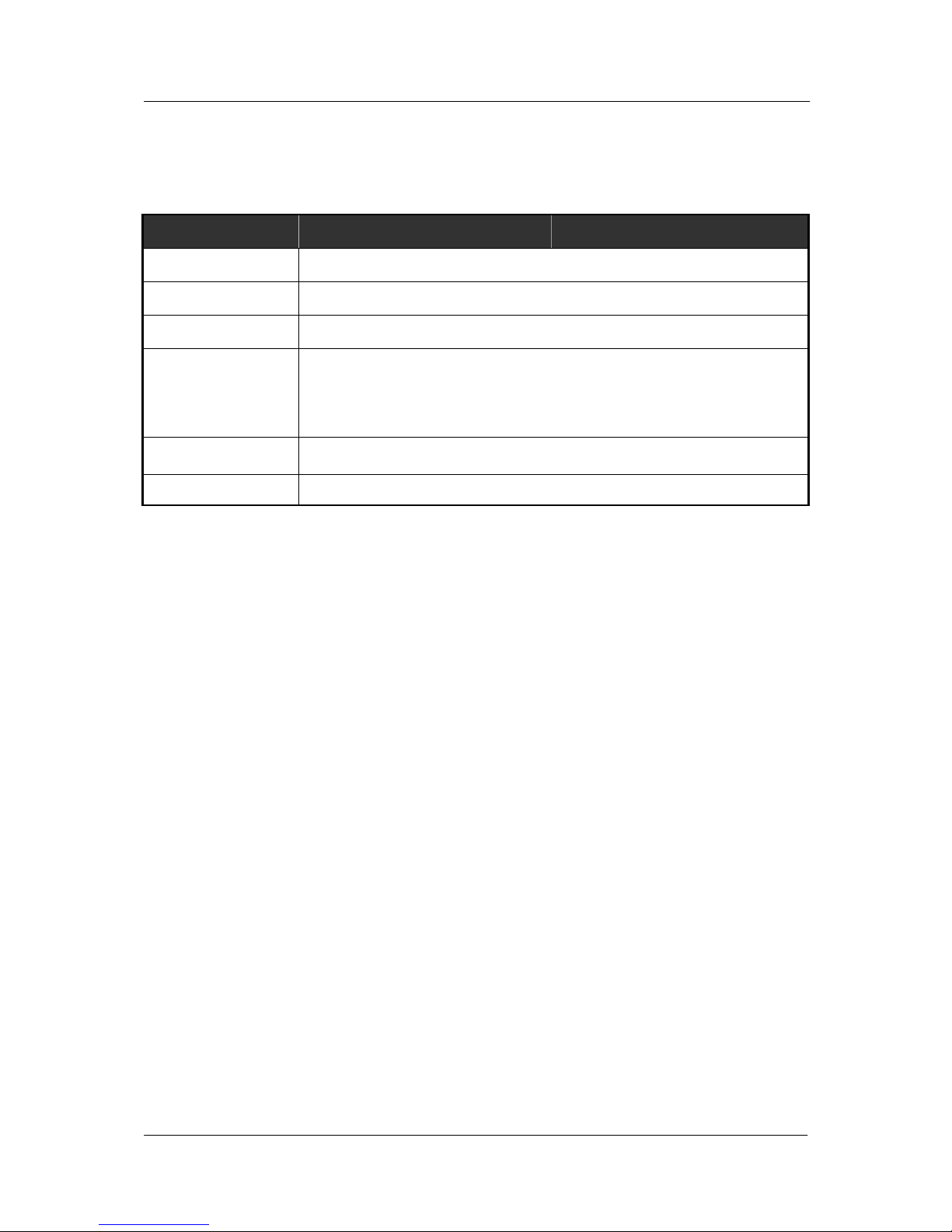

Table 3-1: Specifications

DESCRIPTION

ST1500LM008 ST2000LM005

Number of R/W heads

6

6

Maximum BPI

2731K

Flexible data TPI

480K

Encoding method

LDPC (low density parity check) encoding

Interface

USB interface (Supports USB 3.0 speed)

Actuator type

Rotary Voice Coil

Servo type

Embedded Sector Servo

Spindle Speed (RPM)

5400 RPM Class

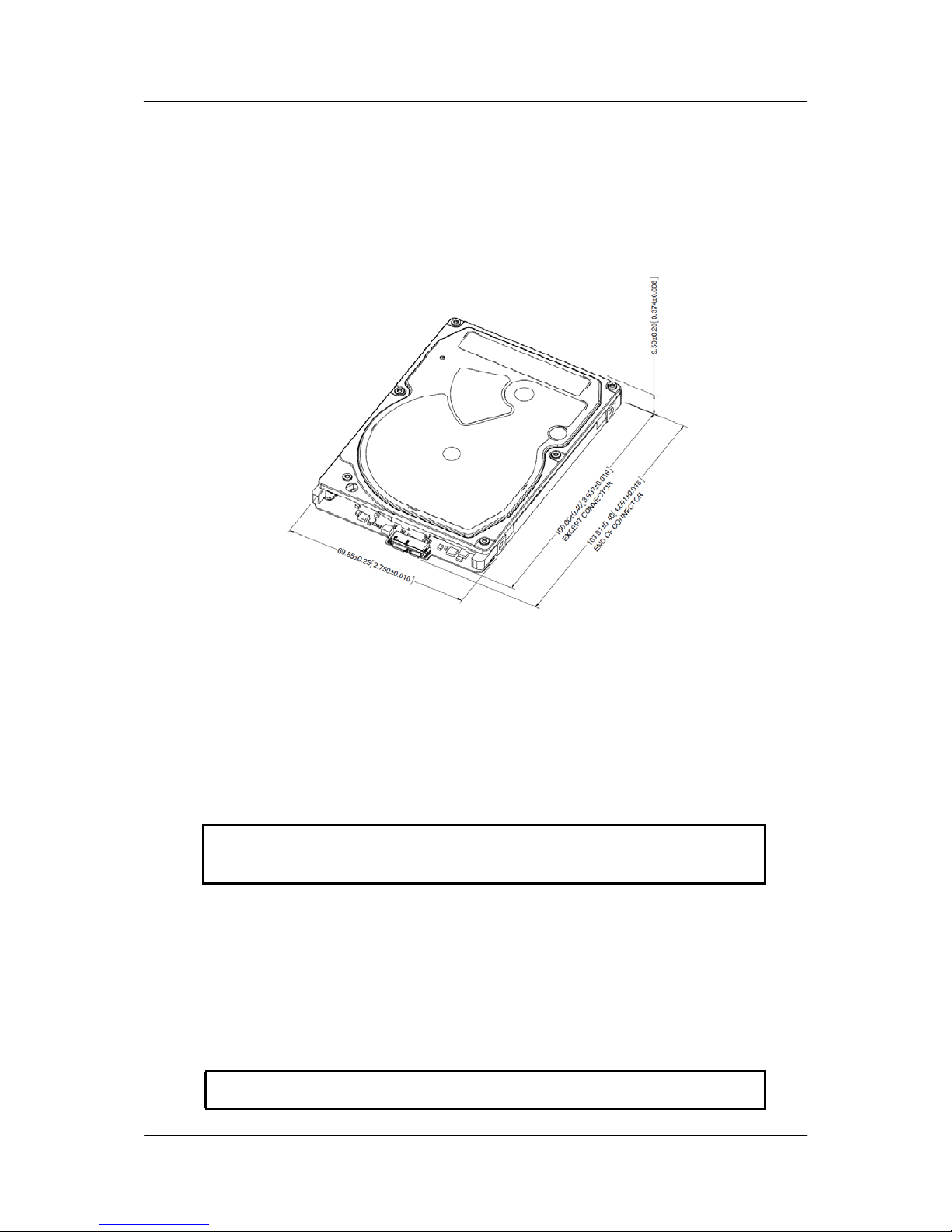

3.2 Physical Specifications

Table 3-2: Physical Specifications

DESCRIPTION ST1500LM008 ST2000LM005

Length (mm)

Width (mm)

Height (mm)

Weight (g, max)

103.9

69.85

9.5

130

3.3 Logical Configurations

Table 3-3: Logical Configurations

DESCRIPTION ST1500LM008 ST2000LM005

Total Number

of logical sectors

Capacity

2,930,277,168 3,907,029,168

1.5TB 2TB

* 1MB = 1,000,000 Bytes, 1GB = 1,000,000,000 Bytes

* Accessible capacity may vary as some OS uses binary numbering system for reported capacity.

Spinpoint M9TU-USB 3.0 Product Manual REV 1.0

6

SPECIFICATIONS

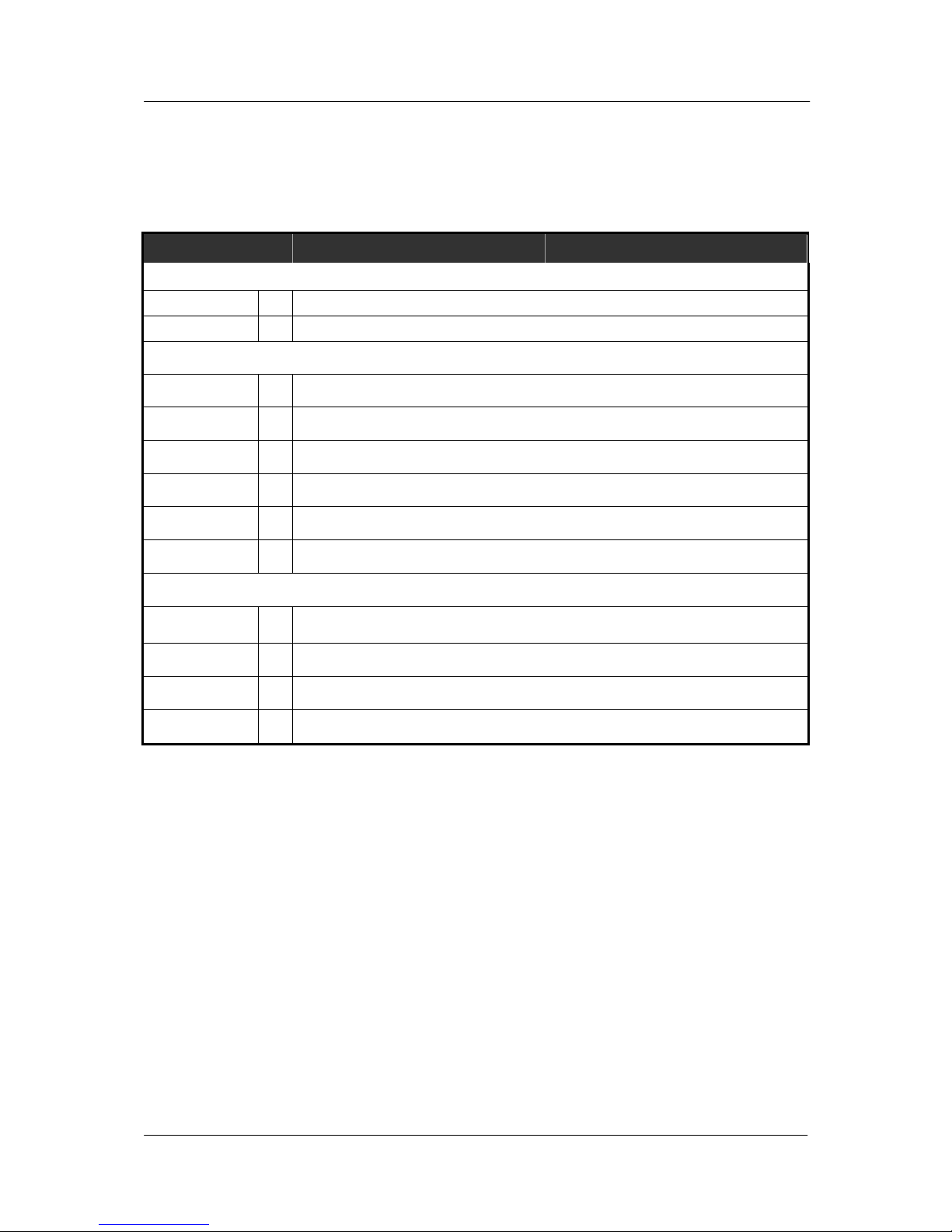

3.4 Performance Specifications

Table 3-4: Performance Specifications

DESCRIPTION ST1500LM008 ST2000LM005

Average Seek Time

12msec

Average Latency

5.6 ms

Spin up Time

6 sec

Data Transfer Rate (Max)

buffer to/from media

host to/from buffer

169 MB/s

625 MB/s

Rotational Speed

5,400 RPM Class

Buffer size

32MB

NOTES: ∗ Seek time is defined as the time from the receipt of a read, write or seek

command until the actuator has repositioned and settled on the desired track

with the drive operating at nominal DC input voltages and nominal operating

temperature.

∗ Average seek time is determined by averaging the time to complete 1,000

seeks of random length.

∗ Average latency is the time required for the drive to rotate 1/2 of a revolution

and on average is incurred after a seek completion prior to reading or writing

user data.

∗ Spin up time is the time elapsed between the supply voltages reaching operating

range and the drive being ready to accept all commands.

∗ Actual rotational speed can be different a little.

Spinpoint M9TU-USB 3.0 Product Manual REV 1.0

7

SPECIFICATIONS

3.5 Power consumption

Table 3-5: Power consumption

DESCRIPTION

ST1500LM008 ST2000LM005

Rated

Voltage V +5

Current A 0.85

Power Consumption

Spin-Up (Max) mA

750.00

Idle

Watt

1.8

Seq W/R (File) Watt

3.2

Random Seek Watt

3.0

Stand by

Watt

1.4

Sleep

Watt

1.4

Power Requirements

Tolerance For + 5V

%

+/- 5

Ripple, 0-30MHz

mV

p-p

100

Supply Rise Time

msec

7-100

Supply Fall Time

Sec

<5

Spinpoint M9TU-USB 3.0 Product Manual REV 1.0

8

SPECIFICATIONS

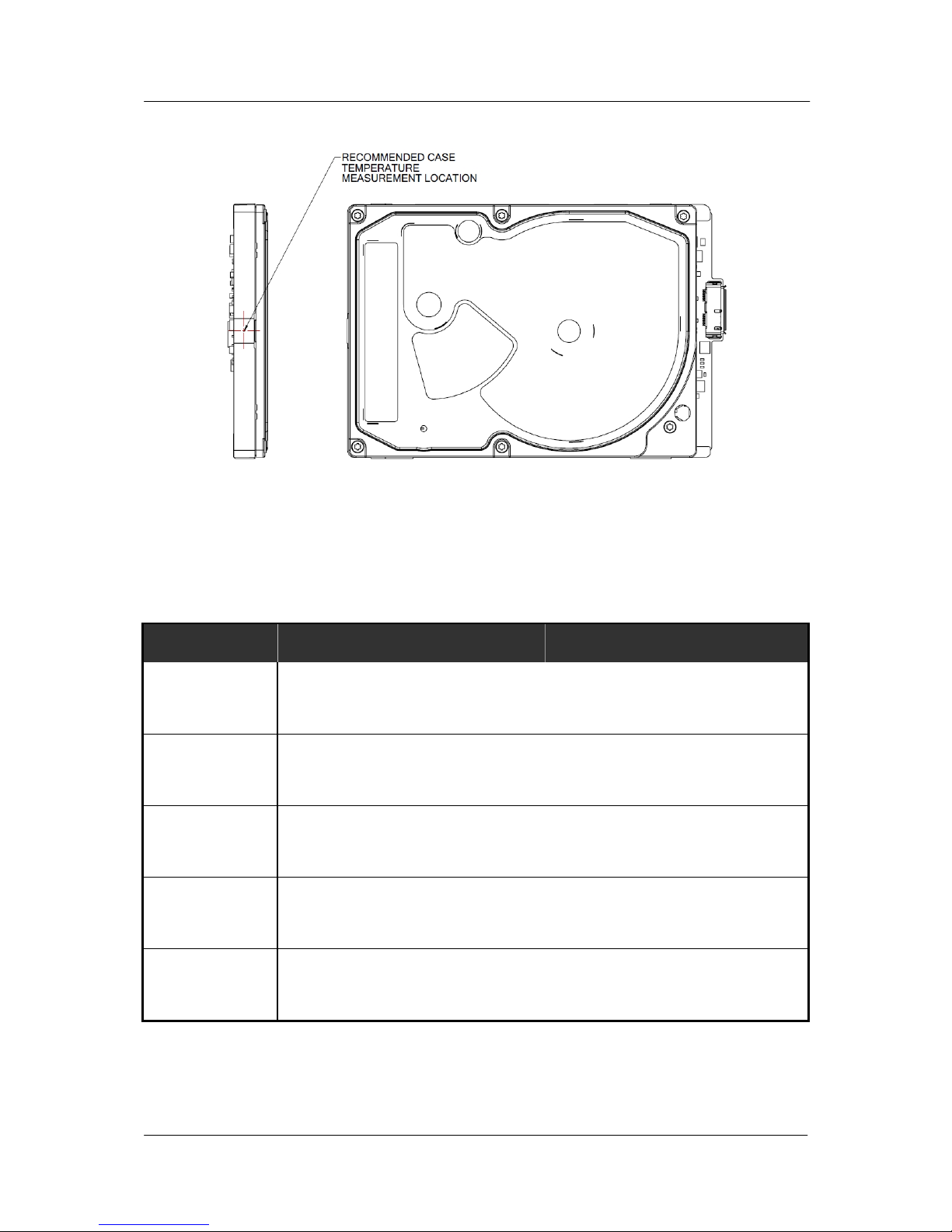

3.6 Environmental Specifications

Table 3-6: Environmental Specifications

DESCRIPTION

ST1500LM008 ST2000LM005

Ambient Temperature

Operating

Non-operating

Max. gradient

(Temperature/Humidity)

(Drive temperature measured on position of figure 3-1 should be max 65C

in range of 0°C -60°C, specified operation temperature.)

0 ∼ 60°C

-40 ∼ 70°C

20°C/20%/hr

Relative Humidity

(non condensing)

Operation

Non-operation

Maximum wet bulb

temperature

Operating

Non-operating

5~90 %

5~95 %

30° C

40° C

Altitude

(relative to sea level)

Operating

Non-operating

-304.8 ∼ 3,048 m

-304.8 ∼ 12,192 m

Vibration

Operating :

(10-500 Hz, Random)

Non-operating :

(10-500 Hz, Random)

1.5 Grms

5.85 Grms

mtLinear Shock

(1/2 sine pulse)

Operating 2.0 ms

Non-operating 1.0 ms

Rotational Shock

Operating 2.0 ms

Non-operating 2.0 ms

300G

800G

3K rad/sec

2

30K rad/sec

2

Acoustic Noise

(Typical Sound Power)

Idle

Seek

2.5 Bels

2.7 Bels

Spinpoint M9TU-USB 3.0 Product Manual REV 1.0

9

SPECIFICATIONS

Figure 3-1 :

Measurement Position.

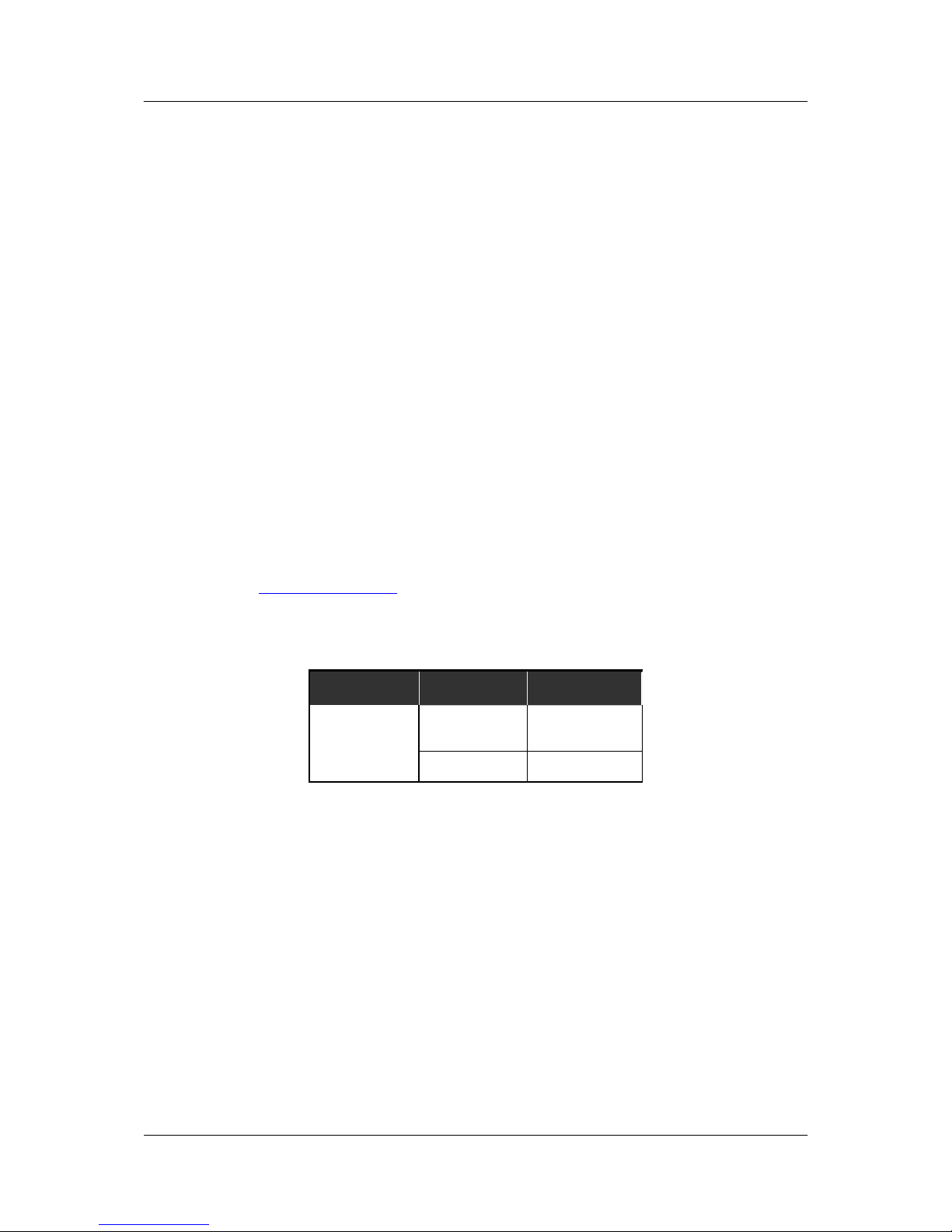

3.7 Reliability Specifications

Table 3-7: Reliability Specifications

DESCRIPTION

ST1500LM008 ST2000LM005

Recoverable

Read Error

<10 in 10

11

bits

Non-Recoverable

Read Error

<1 sector in 10

14

bits

MTBF (POH)

550,000 hours

MTTR (Typical)

5 minutes

Load/Unload Cycles

Ambient

600,000

Spinpoint M9TU-USB 3.0 Product Manual REV 1.0

10

INSTALLATION

CHAPTER 4 INSTALLATION

This chapter describes how to unpack, mount, configure and connect a Spinpoint M9TU-USB 3.0

hard disk drive. It also describes how to install the drive in systems.

4.1 Space Requirements

Figure 4-1 shows the external dimensions of the drive.

Figure 4-1: Mechanical Dimension

4.2 Unpacking Instructions

(1) Open the shipping container of the Spinpoint M9TU-USB 3.0 hard disk drive.

(2) Lift the packing assembly that contains the drive out of the shipping container.

(3) Remove the drive from the packing assembly. When you are ready to install the drive, remove it from

the ESD (Electro Static Discharge) protection bag. Take precautions to protect the drive from ESD

damage after removing it from the bag.

CAUTION: During shipment and handling, the anti-static ESD protection bag prevents

electronic component damage due to electrostatic discharge. To avoid accidental damage to

the drive, do not use a sharp instrument to open the ESD protection bag.

(4) Save the packing material for possible future use.

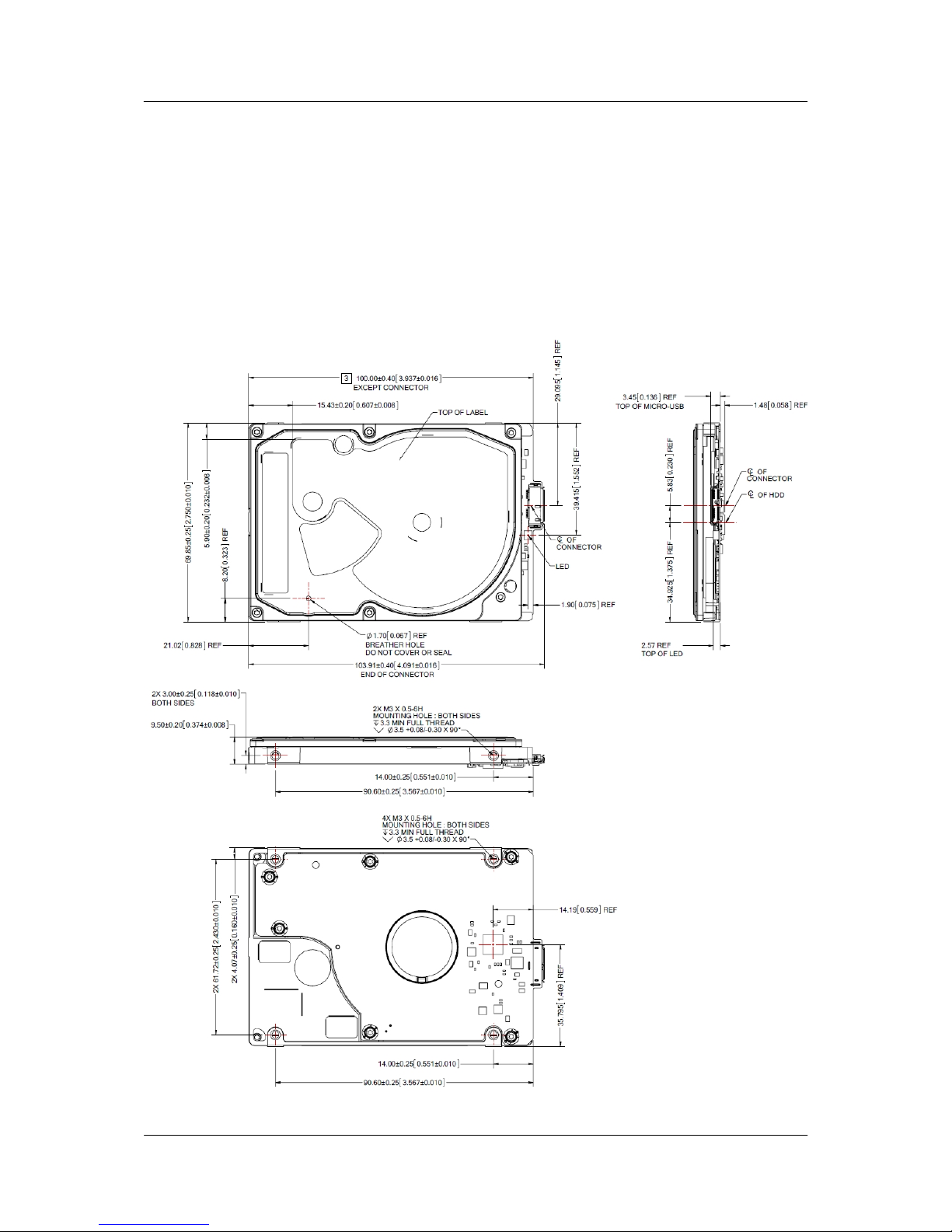

4.3 Mounting

Refer to your system manual for complete mounting details.

(1) Be sure that the system power is off.

(2) For mounting, use four M3 screws.

CAUTION: Torque applied to the screws is recommended to be 3.5 [kg* cm] ±0.5

(3.0 [inch *pounds] ±0.5)

Spinpoint M9TU-USB 3.0 Product Manual REV 1.0

11

INSTALLATION

4.3.1 Orientation

Figure 4-2 shows the physical dimensions and mounting holes located on each side of the drive. The

mounting holes on Spinpoint M9TU-USB 3.0 hard disk drive allow the drive to be mounted in any direction.

4.3.2 Ventilation

The Spinpoint M9TU-USB 3.0 hard disk drive is designed to operate without the need of a cooling fan

provided the ambient air temperature does not exceed 60ºC. Any user-designed cabinet must provide

adequate air circulation to prevent exceeding the maximum temperature.

Figure4-2: Mounting Dimensions

Spinpoint M9TU-USB 3.0 Product Manual REV 1.0

12

INSTALLATION

4.4 Cable Connectors

4.4.1 USB Connectivity

The USB interface is connected within a point to point

configuration with the USB host port. There is no master

or slave relationship within the devices. Spinpoint

M9TU-USB 3.0 does not require extra power.

USB3.0 Micro B type applied to Spinpoint M9TU-USB

3.0. Figure 4.3 illustrates USB3.0 Micro B type

connector.

Figure 4-3 USB connector type

Table 4-1 lists the signals connection on the USB interface.

Table 4-1 USB Connector Pin

Definitions

Pin Number Signal Name Description Mating Sequence

1 VBUS Power Second

2 D-

USB 2.0 differential pair

Last

3 D+

4 ID OTG identification

5 GND Ground for power return Second

6 MicB_SSTX-

SuperSpeed transmitter differential pair

Last

7 MicB_SSTX+

8 GND_DRAIN Ground for SuperSpeed signal return Second

9 MicB_SSRX-

SuperSpeed receiver differential pair

Last

10 MicB_SSRX+

Shell Shield Connector metal shell First

4.5 Drive Installation

The Spinpoint M9TU-USB 3.0 hard disk drive can be installed in an USB-compatible system:

• To install the drive with a motherboard that contains USB port, connect the drive to the USB port using a

USB plugs (Micro B type).

• If the drive connects to the USB Hub or Keyboard USB port, make the drive bad detection or bad

operation (because of low bus power).

• If some OS in PC System or Host cannot detection the drive, the system need USB driver installation.

Spinpoint M9TU-USB 3.0 Product Manual REV 1.0

13

INSTALLATION

4.6 System Startup Procedure

Once the Spinpoint M9TU-USB 3.0 hard disk drive and along with the adapter board (if

required) have been installed in your system, the drive can now be partitioned and formatted

for operation. To set up the drive correctly, follow these instructions:

1. Power on the system.

2. Typically the system will detect a configuration change automatically. If so, then jump to step 5.

3. Connected Drive Detection normally as removable disk but cannot access drive folder, please create

partition & format first.

4. Perform the following steps that applies to your system: (example for XP)

I. Select Control Panel - Computer Management - Disk Manager in OS Utility.

II. Click the right mouse button of Selected USB device disk, and select New Partition.

III. Step 1. Click Next Button.

IV. Step 2. Select Partition Type and Click Next Button.

V. Step3. Select Partition Size and Click Next Button

VI. Step 4. Assign Drive Letter and Click Next Button.

VII. Step 5. Select File System, quick format option and Click Next Button.

VIII. Step 6. Click Finish Button

5. If the system recognizes the drive but experiences problem on properly handling the full capacity of the

drive, run Disk Manager utility program provided by Seagate and follow the instructions. The Disk

Manager utility program is available from Seagate on a floppy diskette, or downloadable from the Seagate

website at

http://www.seagate.com. If, after all these steps are successfully completed, your system will not

boot up, then contact technical support.

Table 4-2: Logical Drive Parameters

DESCRIPTION

ST1500LM008 ST2000LM005

Total Number of

logical sectors

Capacity

2,930,277,168 3,907,029,168

1.5TB 2TB

NOTES:

• The total numbers of sectors is calculated by (Cylinders x Heads x Sectors) of the selected drive

type.

• 1MB = 1,000,000 Bytes, 1GB = 1,000,000,000 Bytes

Accessible capacity may vary as some OS uses binary numbering system for reported capacity.

• Windows 95 or 98 that use FAT16 file system will limit the drive’s logical partition at 2.1GB

per logical drive. Windows95 OSR2 or later allow for the FAT32 file system which provides

access to greater than 2GB of logical capacity.

• A low-level format is not required, as this was done at the factory before shipment.

Spinpoint M9TU-USB 3.0 Product Manual REV 1.0

14

INSTALLATION

CHAPTER 5 DISK DRIVE OPERATION

This chapter describes the operation of the Spinpoint M9TU-USB 3.0 hard disk drive functional subsystems.

It is intended as a guide to the operation of the drive, rather than a detailed theory of operation.

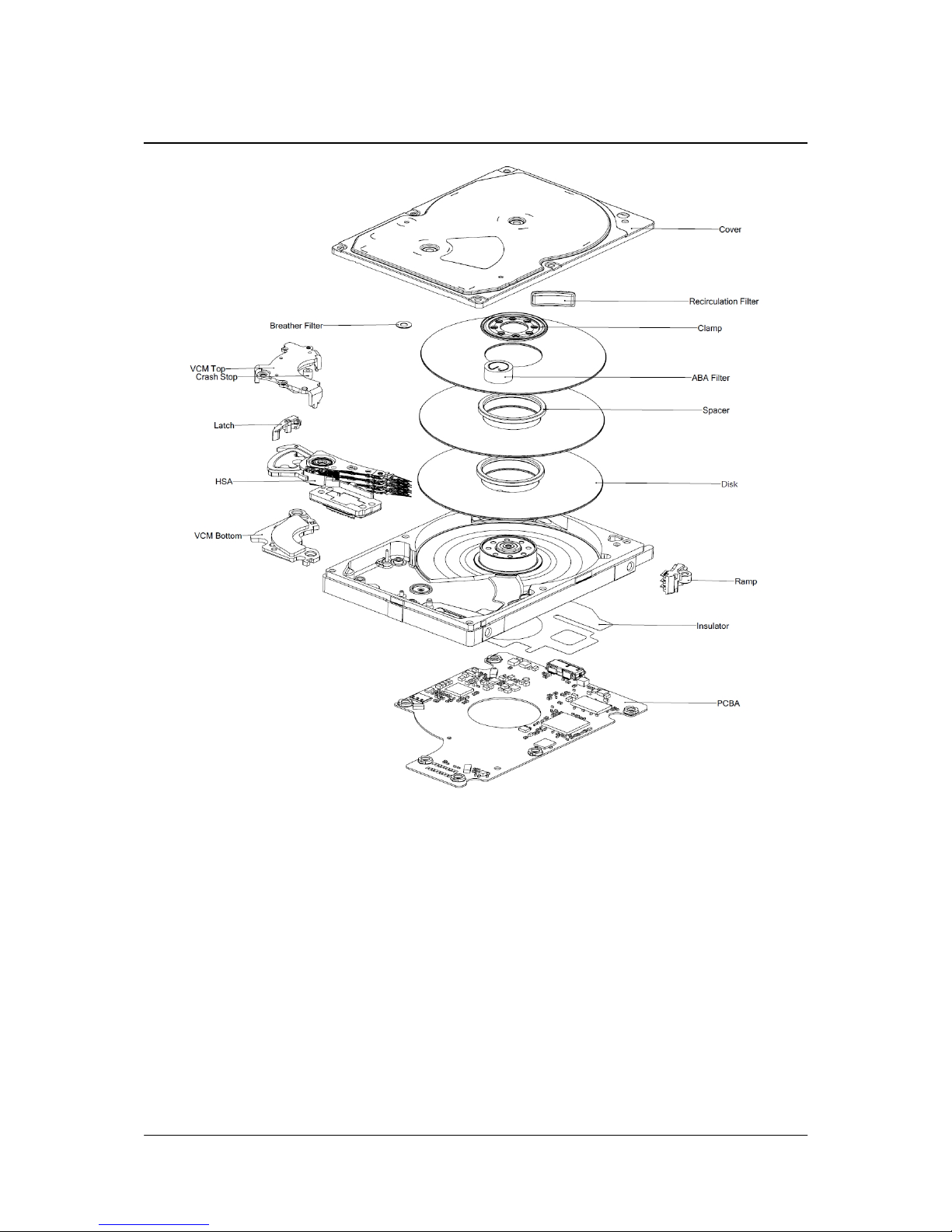

5.1 Head / Disk Assembly (HDA)

The Spinpoint M9TU-USB 3.0 hard disk drive consists of a mechanical sub-assembly and a printed circuit

board assembly (PCBA), as shown in Figure 5-1. This section describes the mechanism of the drive.

The head / disk assembly (HDA) contains the mechanical sub-assemblies of the drive, which are sealed

between the aluminum-alloy base and cover. The HDA consists of the base casting assembly (which

includes the DC spindle motor assembly), the disk stack assembly, the head

stack assembly, and the rotary

voice coil motor assembly (which includes the actuator latch assembly). The HDA is assembled in a clean

room. These subassemblies cannot be adjusted or field repaired.

CAUTION: To avoid contamination in the HDA, never remove or adjust its cover

and seals. Disassembling the HDA voids your warranty.

The Spinpoint M9TU-USB 3.0 hard disk drive models and capacities are distinguished by the number of

heads and disks. The ST750LM023 have three (3) disks and six (6) read/write heads. The ST1000LM025 has

two (2) disks and four (4) read/write heads.

5.1.1 Base Casting Assembly

A one piece, aluminum-alloy base casting provides a mounting surface for the drive mechanism and PCBA.

The base casting also serves as the flange for the DC spindle motor assembly. A gasket provides a seal

between the base and cover that enclose the drive mechanism.

5.1.2 DC Spindle Motor Assembly

The DC spindle motor assembly consists of the brush-less three-phase motor, spindle bearing (FDB)

assembly, disk mounting hub, and a labyrinth seal. The entire spindle motor assembly is completely

enclosed in the HDA and integrated to the base casting. The labyrinth seal prevents bearing lubricant from

coming out into the HDA.

5.1.3 Disk Stack Assembly

The disk stack assembly in the Spinpoint M9TU-USB 3.0 hard disk drive consists of 3 disks and disk spacers

secured on the hub of the spindle motor assembly by a disk clamp. The glass disks have a sputtered thin-film

magnetic co at

ing.

5.1.4 Head Stack Assembly

The head stack assembly consists of an E-block/coil sub-assembly, read/write heads, a flexible circuit, and

bearings. The E-block/coil sub-assembly is assembled with an E-block and bonded coil. Read/write heads

are mounted to spring-stainless steel flexures that are then swage mounted onto the E-block arms.

The flexible circuit connects the read/write heads with the PCBA via a connector through the base casting.

The flexible circuit contains a read/write Preamplifier IC.

Spinpoint M9TU-USB 3.0 Product Manual REV 1.0

15

INSTALLATION

Figure 5-1: Exploded Mechanical View

5.1.5 Voice Coil Motor and Actuator Latch Assemblies

The rotary voice coil motor consists of upper and lower permanent magnets and magnetic yokes fixed to the

base casting and a rotary bonded coil on the head stack assembly. Each magnet consists of two alternating

poles and is attached to the magnet yoke. Pawl latch and rubber crash stops mounted on a magnetic yoke

physically p revent the head(s) from moving beyond the designed inner boundary into the spindle or off the

disk surface.

Current from the power amplifier induces a magnetic field in the voice coil. Fluctuations in the field around

the permanent magnets move the voice coil s

o that heads can be positioned in the requested cylinder.

5.1.6 Air Filtration System

Heads fly very close to the disk surfaces. Therefore, it is very important that air circulating within the drive be

maintained free of particles. Seagate HDAs are assembled in a purified air environment to ensure cleanliness

and then sealed with a gasket. To retain this clean air environment, the Spinpoint M9TU-USB 3.0 hard disk

drive is equipped with a re-circulating filter, which is located in the path of the airflow close to the rotating

disk and is designed to trap any particles that may develop inside HDA.

DISK DRIVE OPERATION

Spinpoint M9TU-USB 3.0 Product Manual REV 1.0

16

5.1.7 Load/Unload Mechanism

Portable computer is exposed to heavy handling environment comparing with desk top computer. Load/Unload

mechanism provides to protect data loss caused by head hitting to disk due to the abnormal shock and vibration in

the transportation and handling.

When power is shut down, head will move to parking position on the ramp.

5.2 Drive Electronics

The Spinpoint M9TU-USB 3.0 hard disk drive attains its intelligence and performance through the

specialized electronic components mounted on the PCBA. The components are mounted on one side of the

PCBA.

The Preamplifier IC is the only electrical component that is not on the PCBA. It is mounted on the flexible

circuit inside the HDA. Locating the Preamplifier IC as close as possible to the read/write heads via surface

mount technology improves the signal to noise ratio.

5.2.1 Digital Signal Process and Interface Controller

The DSP core controller has a dual ARM CPU that incorporates a true 16-bit digital signal processor (DSP),

a bus controller unit (BCU), an interrupt controller unit (ICU), a general purpose timer (GPT), and SRAM

5.2.2 USB Interface Controller

The USB interface disk controller works in conjunction with the DSP core to perform the USB interface

control, buffer data flow management, disk format/read/write control, and error correction functions of an

embedded disk drive controller. The DSP communicates with the disk controller module by reading from

and writing to its various internal registers.

To the DSP core, the registers of the disk controller appear as unique memory or I/O locations that are

randomly accessed and operated upon. By reading from and writing to the registers, the DSP core initiates

operations and examines the status of the different functional blocks. Once an operation is started, successful

completion or an error condition may cause the disk controller to interrupt the DSP core, which then

examines the status registers of the disk controller and determines an appropriate course of action. The local

DSP core may also poll the device to ascertain successful completion or error conditions.

5.2.2.1 The Host Interface Control Block

The HBI module responds to the command issued from the host and controls the data transfer between the

buffer memory module and the host.

The HBI module supports the following main features:

• Power Saving

• 8/16 bit host interface

• A deep FIFO (32 x 32 bit) used as the temporary buffer for the data transfer

• 512 byte

• Microprocessor Interrupts

• 6 endpoints ( EP0-EP2 IN/OUT)

• Mass Storage class bulk-only transport with flow control

• Support Control transport

• Support Suspend/resume mode

DISK DRIVE OPERATION

Spinpoint M9TU-USB 3.0 Product Manual REV 1.0

17

5.2.2.2 The Buffer Control Block

The Buffer Control block manages the flow of data into and out of the buffer. Significant automation

allows buffer activity to take place automatically during read/write operations between the host and the disk.

This automation works together with automation within the Host Interface Control and Disk Control blocks to

provide more bandwidth for the local microprocessor to perform non-data flow functions.

The buffer control circuitry keeps track of buffer full and empty conditions and automatically works with the

Disk Control block to stop transfers to or from the disk when necessary. In addition, transfers to or from the

host are automatically stopped or started based on buffer full or empty status.

Additional functionality is provided in the Buffer Control block through the following features:

• Increased automation to support minimal latency read operations with minimal latency.

• Capability to support the execution of multiple consecutive Auto-Write commands without loss of data

due to overwriting of data.

• Auto write pointer.

• A disk sector counter that can monitor the transfers between the disk and buffer.

• Read/Write cache support.

5.2.2.3 The Disk Control Block

The Disk Control block manages the flow of data between the disk and the buffer. Many flexible features and

elements of automation have been incorporated to complement the automation contributed by the Host and Buffer

blocks.

The Disk Control block consists of the programmable sequencer (Disk Sequencer), CDR/data split logic, disk

FIFO, fault tolerant sync detect logic, and other support logic.

The programmable sequencer contains a 32-by-4 byte programmable SRAM and associated control logic, which

is programmed by the user to automatically control all single track format, read, and write operations. From within

the sequencer micro program, the Disk Control block can automatically deal with such real time functions as

defect skipping, servo burst data splitting, branching on critical buffer status and data compare operations. Once

the Disk Sequencer is started, it executes each word in logical order. At the completion of the current instruction

word, it either continues to the next instruction, continues to execute some other instruction based upon an internal

or external condition having been met, or it stops.

During instruction execution or while stopped, registers can be accessed by the DSP to obtain status

information reflecting the Disk Sequencer operations taking place.

5.2.2.4 The Disk ECC Control Block

The Disk Control Block supports a programmable LDPC code. Error detection and correction is handled in

the Disk Control block. Automatic on-the-fly hardware correction will take place. Correction is guaranteed to

complete before the parity bits of the sector following the sector where the error occurred utilizing standard

ATA size sectors.

5.2.2.5 Power Management

Power managemen t features are incorp orated into each block of the Spinpoint M9TU-USB 3.0. This allows

the designer to tailor the amount of power management to the specified design. Other power management

features include:

• Independent power management control for each block.

• DSP block powered down and up when needed.

• Disk Sequencer and associated disk logic powered up when the Disk Sequencer is started.

• Weak pull-up structure on input pins to prevent undesirable power consumption due to floating CMOS

inputs.

Spinpoint M9TU-USB 3.0 Product Manual REV 1.0

18

DISK DRIVE OPERATION

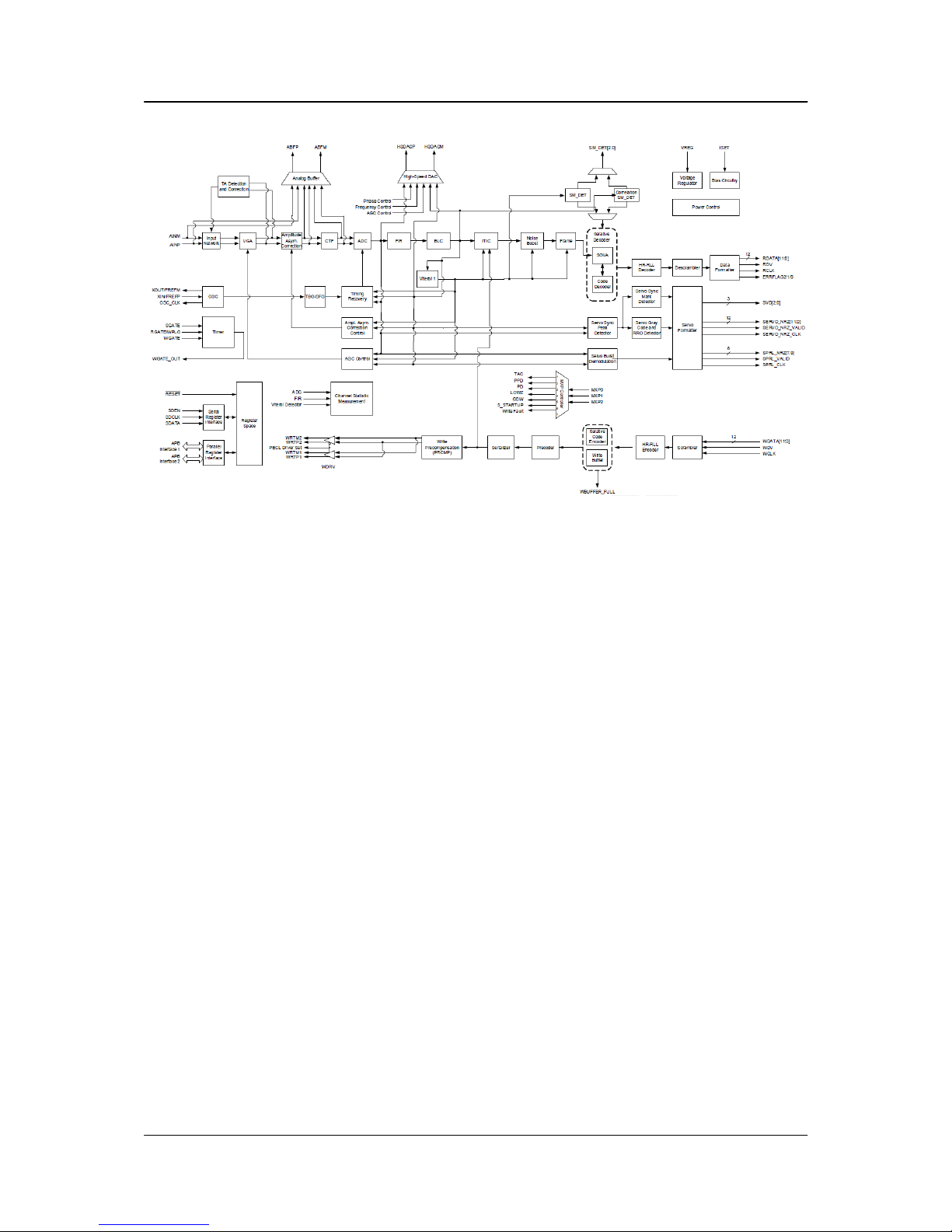

5.2.3 Read/Write IC

The Read/Write IC, shown in Figure 5-2 provides read/write-processing functions for the drive. The

Read/Write IC receives the Read GATE and Write GATE signals, write data, and servo AGC and gates from

the Interface Controller. The Read/Write IC sends decoded read data and the read reference clock. It

receives write data from the Interface Controller.

The 88C10010 which is embedded in 88i1022 is a sampled-data digital PRML channel designed to work

with a disk controller and a read/write preamplifier to provide the signal processing elements required to build

a state of the art high density, high speed disk d rive. The 88C10010 implements a noise predictive, PRML

Viterbi read channel (supporting) zone-bit recording,

The read/write channel functions include a time base generator, AGC circuitry, asymmetry correction

circuitry (ASC), analog anti-aliasing low-pass filter, analog to digital converter (ADC), digital FIR filter,

timing recovery circuits, Viterbi detector, sync mark detection, 30/32 rate block code ENDEC, serializer and

de-serializer, and write pre-compensation circuits. Servo functions include servo data detection and PES

demodulation. Additionally the 88C10010 contains specialized circuitry to perform various parametric

measurements on the processed read signal. This allows for implementation of self-tuning and optimization

capability in every drive

built using the 88C10010.

A 12-bit NRZ interface is provided to support high speed data transfers and from the controller.

Programming of the 88C10010 is performed through a serial interface. The serial interface is also used to

read various channel parameters that are computed on the fly.

5.2.3.1 Time Base Generator

The time base generator provides the write frequency and serves as a reference clock to the synchronizer during

non-read mode.

5.2.3.2 Automatic Gain Control

The AGC accepts a differential signal from the pre-amp, and provide constant output amplitude to the analog

filter. It’s capable of accepting signal ranges from 50 mV to 400 mVppd.

5.2.3.3 Asymmetry Correction Circuitry (ASC)

The ASC circuit is designed to correct for amplitude asymmetry introduced by MR heads . The compensation

range of this circuit is +/-30%. This circuit allows optimal bias current to be used independent of the

asymmetry effect.

5.2.3.4 Analog Anti-Aliasing Low Pass Filter

The 5

th

order equal-ripple analog filter provides filtering of the analog signal from AGC before it’s being

converted to digital signal with the ADC. Its main function is to avoid aliasing for the ADC circuit.

5.2.3.5 Analog to Digital Converter (ADC) and FIR

The output of the analog filter is quantified using a 6 bit FLASH ADC. The digitized data is then equalized by

the FIR to the NPV target response for Viterbi detection. The FIR filter consists of 10 independent

programmable taps

Spinpoint M9TU-USB 3.0 Product Manual REV 1.0

19

DISK DRIVE OPERATION

Figure 5-2: Read/Write 88C10010

Spinpoint M9TU-USB 3.0 Product Manual REV 1.0

20

DISK DRIVE OPERATION