Page 1

Alignment and Adjustments

Samsung Electronics 1-1

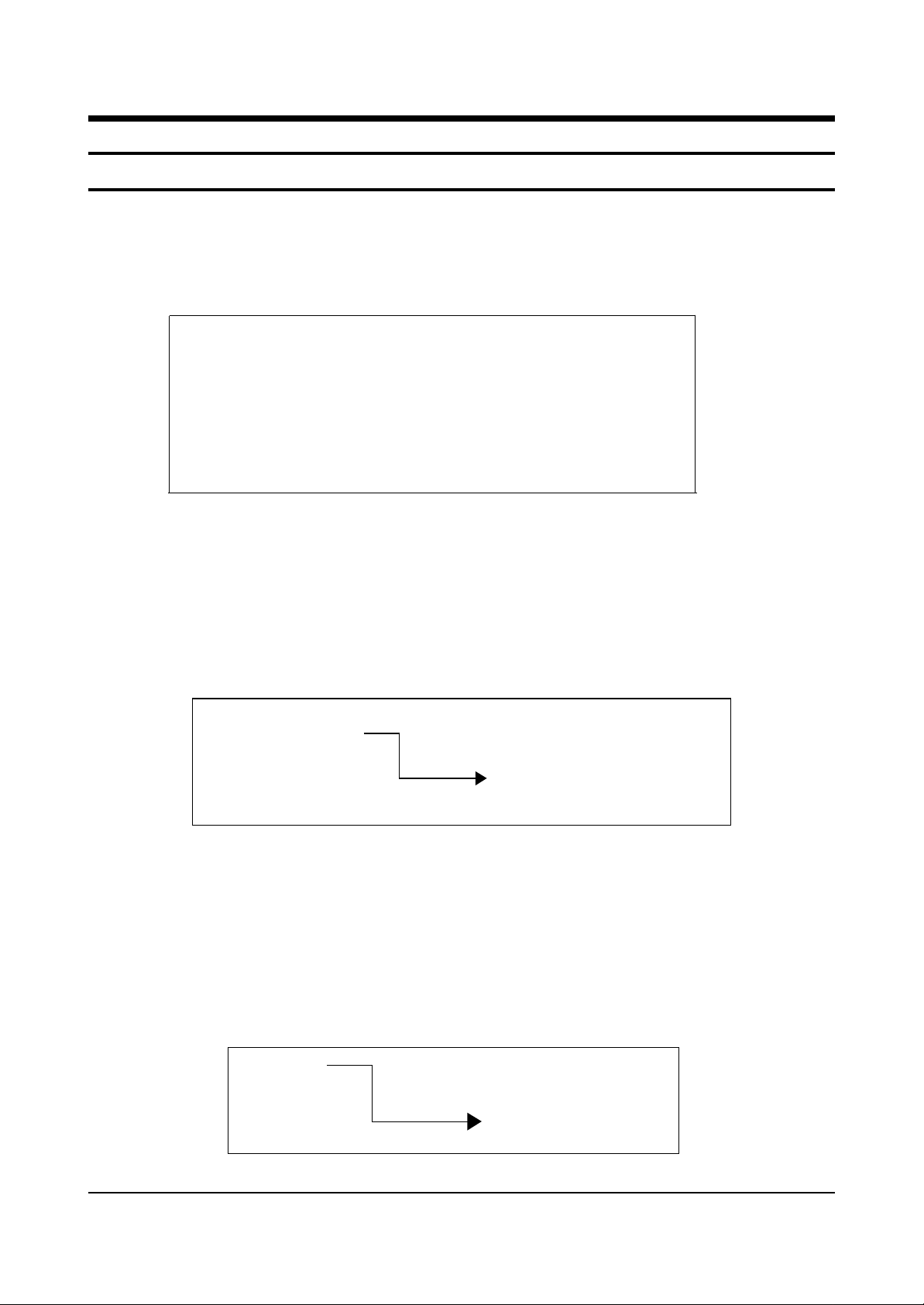

1. Alignment and Operation Checks

1-1 To enter the Factory mode and to select the item

1) Press the factory remote control keys in the following sequence : Display->Fcatory

2) Press the user remote control keys in the following sequence :

(In the standby mode) Display->Menu->Mute->Power

3) Move to target item with Up/Down cursor key or Channel Up/Down key.

4) Select target item with Left/Right cursor key or Volume Up/Down key.

1. ASI500 (Main) 8. DNIe

2. ASI500 (Sub) 9. L3E7050K (Epson)

3. VPC3230 (Main) 10. M62392E

4. VPC3230 (Sub) 11. DDP1010 (DLP)

5. FLI2200 12. Test Pattern

6. AD9888 13. Option Table

7. CXA2151Q 14. Reset

[Factory Main Menu]

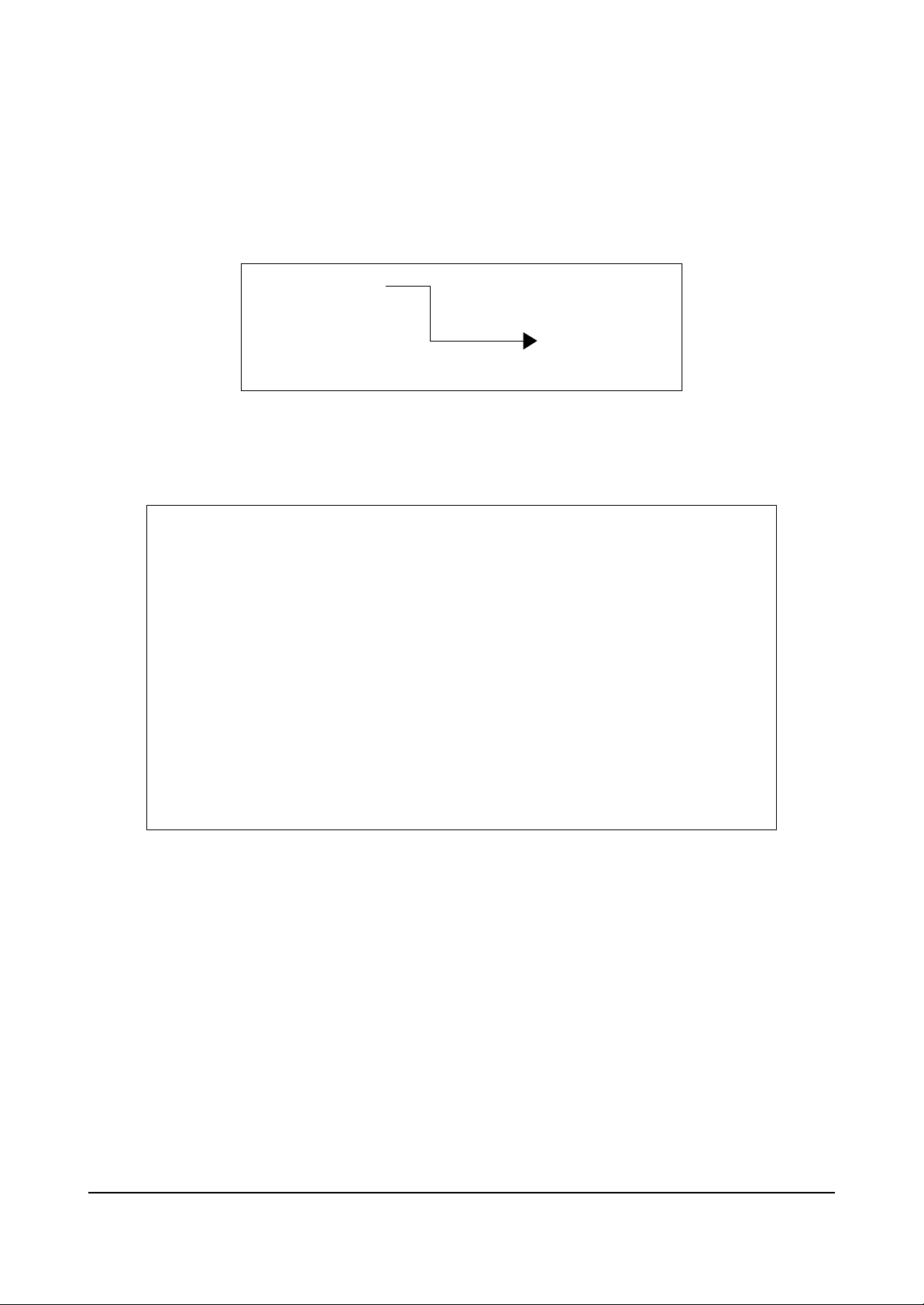

1-2 Image position Adjustment

1) Select L3E7050K in Factory Main Menu.

2) Horiziontal Adujustment : Use the sub item H Position (25) of L3E7050K.

The default value is 40.

3) Vertical Adjustment : Use the sub item V Position (26) of L3E7050K.

The default value is 17.

1) White Balance is individually adjustment per four for each different input modes; Video

(RF/VIDEO/Component SD), Component HD, PC and DVI.

2) Lowlight adjustment :

- Adjust it by changing Bright R/G/B Center value in DNIe item.

- Generally fix Bright G Center value, and change Bright R Center and Bright B center values.

- The Brightness of each color will get higher as the value increases.

- The default value of Video mode is 117, while it is 128 for Component HD, PC and DVI modes.

1-3 White Balance Adjustment

9. L3E7050K (Epson)

25. H position 40

26. V position 17

8. DNIe

27. Bright R Center

28. Bright G Center

29. Bright B Center

Page 2

Alignment and Adjustments

1-2 Samsung Electronics

3) Highlight adjustment

- Adjust it by changing R/G/B Contrast in L3E7050K item.

- Generally, fix G Contrast value, and change R Contrast and B Contrast values.

- The gain of each color will get higher as the value increases.

- Contrast 20 will be changed by step 20, and Contrast 01 will be changed by step 1.

- The default value of Video and Component HD mode is 512, while it is 500 for PC and DVI modes.

1-4. Test Patterns

The factory mode has various built-in test patterns.

1) Using method (Example: Step (18) test pattern)

- Move cursor to Step 8(18) test pattern 8 with up/down direction key or channel up/down key

of transmitter.

- Activate the test pattern with left/right direction key or volume up/down key of transmitter.

- Test pattern of white, blue, red, and green will be displayed in turn with press on left/right

direction key or volume up/down key.

- The display will be returned to the test pattern menu with press on up/down direction key or

channel up/down key at the test pattern display status.

- The display will be returned to the main menu of the factory mode with press on menu key at

the status of the test pattern display status.

2) Types of patterns

A) LCD patterns: These patterns are made from LCD driver board, which are ranged from

Single Color (06)to Dart 4%(14) pattern.

9. L3E7050K (Epson)

01 R Contrast 20

02 R Contrast 01

03 G Contrast 20

04 G Contrast 01

05 B Contrast 20

06 B Contrast 01

Test Pattern

01 Cross Bar 14 Dark 4%

02 Cross Hatch 15 Step 64

03 Checker 16 Step 32

04 Character 17 Step 16

05 Box 18 Step 8

06 Single Color 19 Color B ar

07 White 75% 20 Flic ker _100

08 White 50% 21 Flic ker _75

09 White 25% 22 Flic ker _50

10 White 10% 23 Flic ker _25

11 Dark 1% 24 P atter n Tone 3

12 Dark 1.5% 25 V _Fr equency_60Hz 0

13 Dark 3% 26 OSD Mix ed 0

[

‚† Test Pattern Menu]

Page 3

Alignment and Adjustments

Samsung Electronics 1-3

- Function of Pattern Tone(24): Only available on LCD patterns

* 1: Test pattern signal is displayed after adjusted with white balance and gamma correction.

* 2: Test pattern signal is displayed after adjusted with gamma correction.

* 3: Test pattern signal is displayed to LCD panel without adjustment. (Mainly used to

measure optical characteristics.)

- Normal display of LCD pattern indicates at least that the status of optical engine including the

LCD board is normal.

B) Scaler Patterns: These patterns are made from scaler IC on digital board which are ranged from

Cross Bar(01) to Box(05) and from Step 64(15) to Flicker_25(23) pattern.

- OSD Mixed: Only available on Scaler Patterns.

* 0: Test pattern will disappear when the display is returned to the menu at test pattern display status.

* 1: Test pattern will be a background picture when the display is returned to menu at test

pattern display status.

- Normal display of scaler patterns means at least the parts after scaler IC are normal.

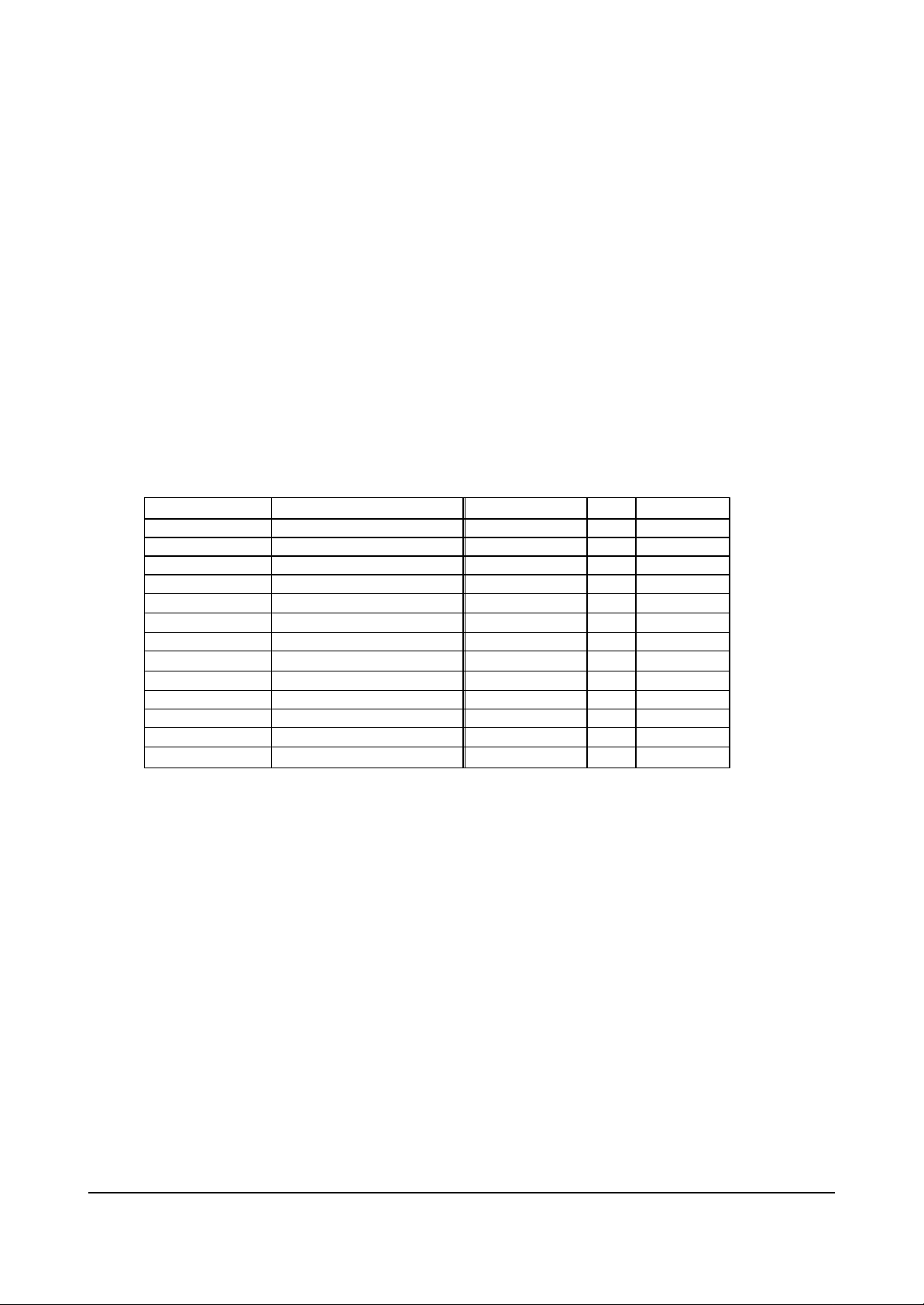

1-5 M62392E LCD driver control

1) LCD EEP &DIG EEP

- LCD board and digital board can simultaneously backup the data of gamma (uniformity) and

flicker adjustment, because they have the same capacity of EEPROM.

- LCD EEP: It indicates the status of EEPROM in the LCD board.

* Cremo: With the eguipment used during engine assembly at the factory, it indicates that the adjusted

gamma and flicker data is stored.

* Download: It indicates that the gamma and flicker data on the digital board is downloaded and

stored through D->L Trans(14) operation.

At replacement of the LCD board, 14 D->L Trans operation should be carried out.

* Default: It indicates that the default value of Gamma and flicker data is stored.

- DIG EEP: It indicates the status of the EEPROM of the digital board.

* Download: It indicates that the gamma and flicker data on the LCD board is downloaded and

stored through factory reset operation. At replacement of the digital board, the data in EEPROM of

the LCD board should be backed up to EEPROM of the new digital board by factory reset.

* Default: It indicates that the default value of gamma and flicker data is stored.

It Item Default Fuction em Default F uction

01 V middle 1 1

02 V refence 230 F ix ed 5 LCD All Initial - Don't use

03 NRSL 103 F ix ed 6 OSD Start P os 00 F ix ed

04 NRSH R ed 96 Fix ed 7 L C D EE P - Refer below

05 NRSH G reen 96 Fix ed 8 DIG EE P - Refer below

06 NRSH B lue 96 Fix ed

07 LCCO M Red 94 Red F lick er control

08 LCCO M Gr ee 94 Gr een Flicker conrol

09 L CCOM Blue 94 Blue Flicker co ntr o l

10 UpDown 01 Image Flip

11 LeftRight 01 Image Flip

12 Uniformity 00 Fix ed

13 Cremo Debug 00 Fix ed

85 F ix ed 4 D ->L Trans - Refer below

1

1

1

1

[

M62392E Menu]

Page 4

Alignment and Adjustments

1-4 Samsung Electronics

2)LCCOM (LCD COMMON VOLTAGE)

- LCCOM Red: It is used for the LCCOM adjustment of the Red panel.

It adjusts the flicker of the Red panel.

- LCCOM Green: It is used for the LCCOM adjustment of the Green panel.

It adjusts the flicker of the Green panel.

- LCCOM Blue: It is used for the LLCOM adjustment of the Blue panel.

It adjusts the flicker of the Blue panel.

1-6 Flicker agjustment

* Basically, the flicker is agjusted to an optimal status during the assembly of the optical engine. In

case additional adjustment is needed, please refer to the following; (ex. Blue panel)

1) Select Test Pattern item.

1) Set item OSD Mixed(26) to 1.

2) Select item Flicker_50(22) (Signal level 50%) pattern.

3) Selecting Blue color, and check the value of the flicker.

4) Press Menu key.

5) Select item M62392E(10).

6) Adjust flicker by selecting item LCCOM Blue(9).

7) Press again Menu key.

8) Select test pattern item, and return item OSD Mixed(26) to 0

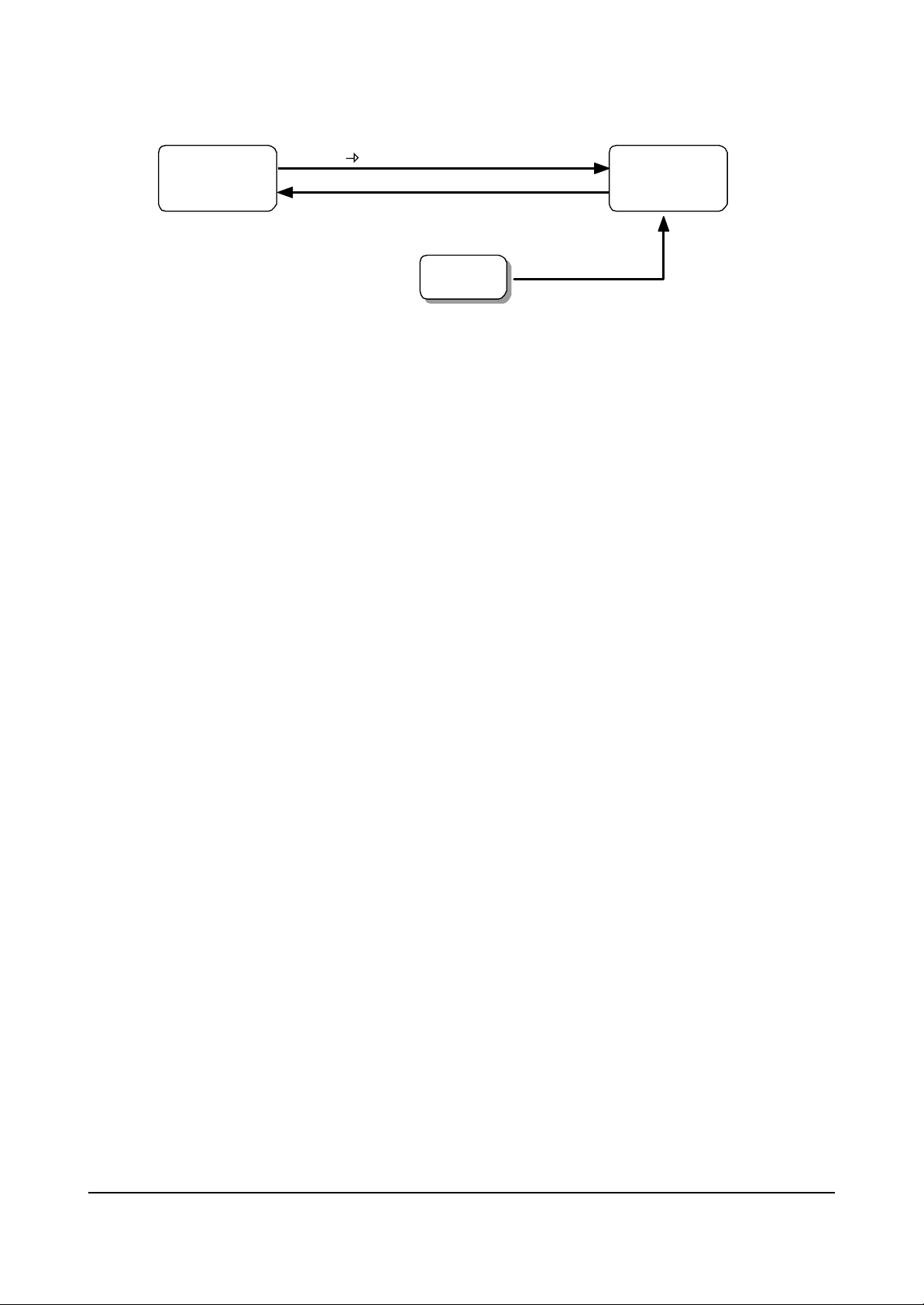

14 D L Trans (L CD E E P : download)

Digital Board LCD Board

F actory reset ( DIG E E P : download)

Factory

Adjustment

(LCD EEP : Cremo)

[‚† EEPROM Status Diagram]

Page 5

Alignment and Adjustments

Samsung Electronics 1-5

1-7 Option Tables

Ite m

01 Europe Asia Dependent on Area

Language Group

L an g uag e

02 - - Dependent on Nation

Jac k T y pe

03 Scar t RCA Sc art/RC A

AT M/Ar ea

04 ATM Area ATM/Area

CW/CS

05 CW CS

LNA

06 On On

TOP TTX

07 On On

TTX Group

08 - - Dependent on Area

TTX Contrast

09 3 3

High Deviation

10 Off Off

Carrier Mute

11 On On

Picture Aspect

12 Last Memory Last Memory Last/Wide

Scar t WS S

13 Normal Normal Normal/Wide/Panorama

C lo ck D is play

14 12Hrs 12Hrs 12Hrs/24Hrs

AV Input

15 TV TV T V/L ast memory

Plug & Play

16 On On

P ix e l Num be r

17 01 01

Pixel T ime

18 01 01

Melo d y V o lum e

19 05 05 Power on/off Melody volume

PAL OSD/DNIe Shift

20

NT OSD Shift

21 0 0 Fixed

Auto P ower

22 On On

Lamp Time

23 - -

Lamp Time Clear

24

Pixel Shift

25 Off Off

DN Ie D emo

26 On On

Ar ab ic/Per sian

27 - - OSD language selection

61 In ch

28 - - See 5- 8. 61" Option

D efa ult ( E u r o pe ) Default (Asia) ETC

0/0

or 0/-1 or 0/-1

0/0

Fixed

Page 6

Alignment and Adjustments

1-6 Samsung Electronics

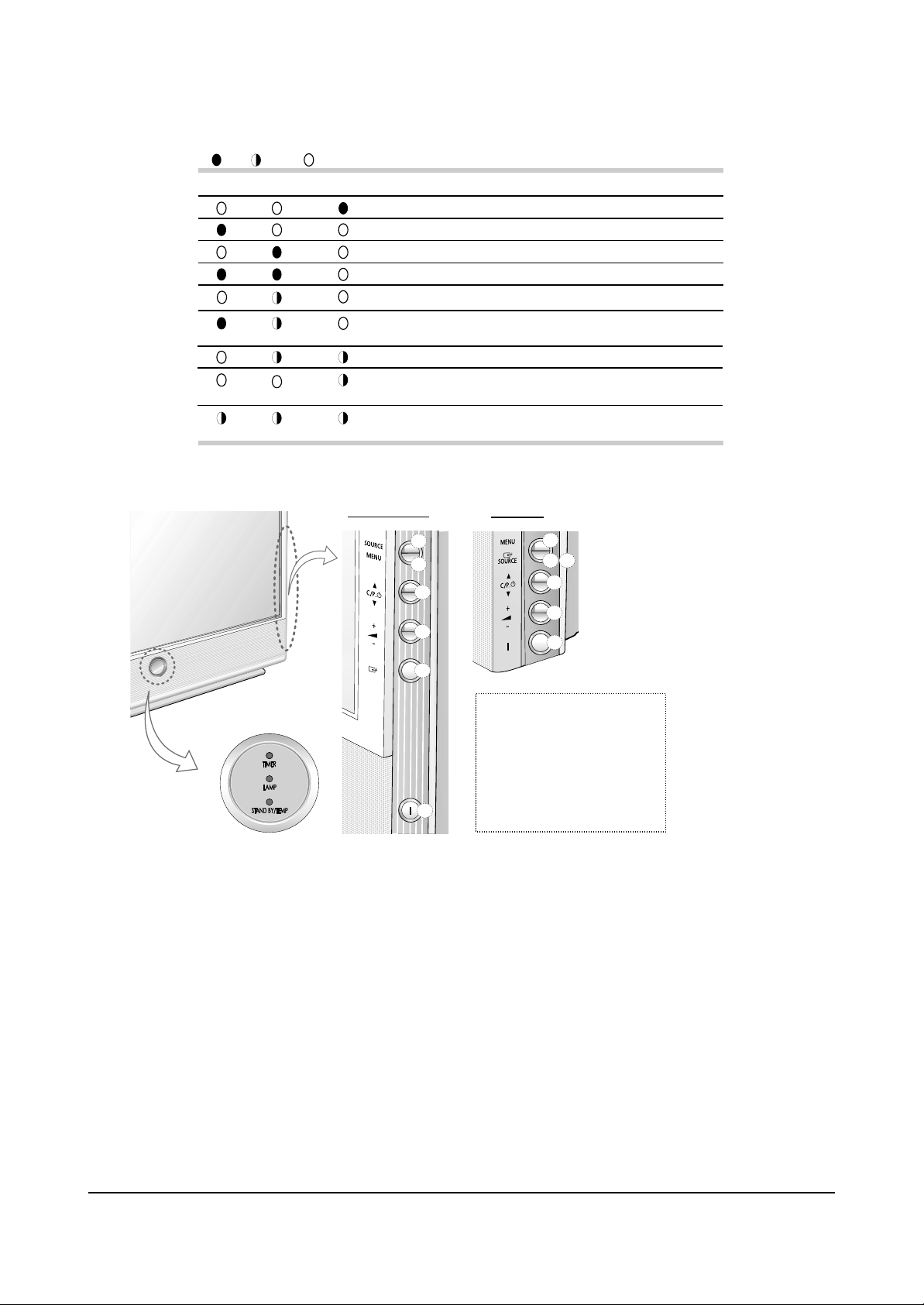

1-8 LED Operation

1-9 61” Option

* The 61" model has no additional Enter button, and the Source button provides an Enter

function as well. That is, the Source button is for Entering with at status with the OSD menu,

while it is also for the Source Selection at status without OSD menu.

1-10 Lamp Time Clear

* Existing lamp time should be cleared after replacing lamp.

1) Select Option Table.

2) Run item lamp time clear(24) on the 2nd page of option table.

1-11 Display spots

1) Appearance: Some areas, lines, or points with black, cyan, yellow, magenta, etc, that is not white color

are found in the white (10~100%) picture among repose pictures, and in some cases, red, green, blue color

of area is appeared at black picture.

(

:On,

TIMER LAMP STAND BY/TEMP Indication

:Blinking, : off

)

SP43L2/50L2HX

Standby mode.

A timer pilot light when Timer Auto On or is selected.

Normal operation

Normal operation(When Timer Auto On or off is selected.)

Lamp is warming up. The normal picture comes on after 25 seconds.

The normal picture comes on after 25 seconds.(when Timer Auto On or

off is seleted.

Air vent cover in the rear of the TV is not properly installed.

Inside temperature of the TV is over normal. Clean the air vent cover in

the rear of the TV. Turn the TV back on after 1hour.

The lamp does not work, please contact an authorized service center for

assistance.

SP61L2HX

a

b

c

d

b

a

e

c

d

f

e

LED Indicators

f

(a) Input Source Selection

(b) Menu Display

(c) Channel Selection

(d) Volume Adjustment

(e) Confirm your choice

(Store or Enter)

(f) Power On/Off

Page 7

Alignment and Adjustments

Samsung Electronics 1-7

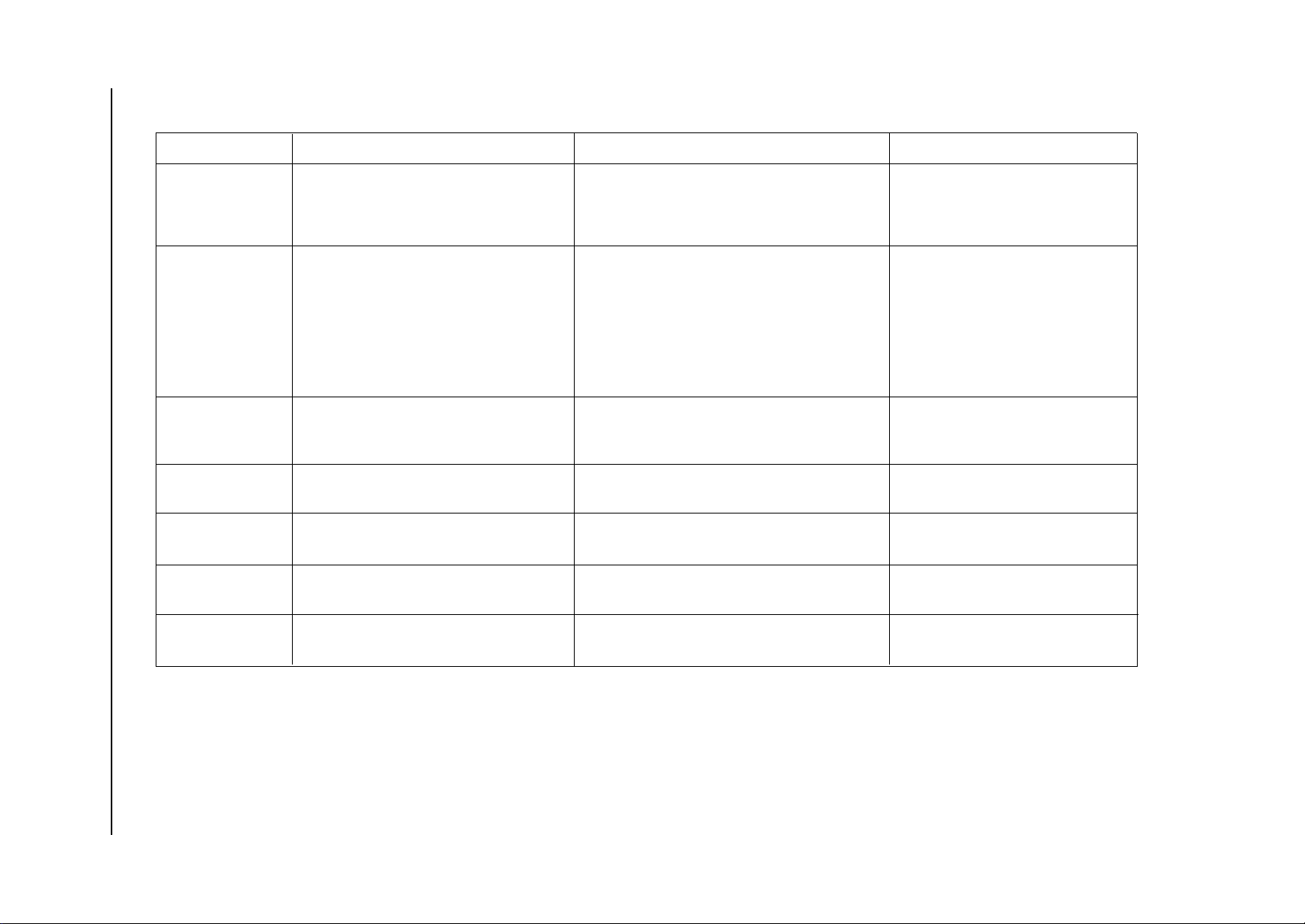

2) Types

Screen dust

Engine dust

Mirror or Screen

contamination

Bad Mirror Shape

Bad Uniformity

Contamination of

transmitting Lens

Bad transmitting Lens

Appearance

Cause

Countermeasure

1 to 3mm diameter of surrounding boundary is

seen clear at white picture, and is more of a

polygon than circle. (It’s the same with the

shape of dust)

It is found well from white 40 to 80% as cyan,

yellow, or magenta color etc, and has the 8 to

20mm circle of shape with unclear boundary.

Water drop shape is displayed on a white

picture, and its surrounding boundary is a little

cloudy.

Various shapes are displayed with a cloudy

surrounding boundary in a white picture.

The white picture is very big and black is the

main color found compared to other colors.

A big light pink spot is found in the white

picture.

A wave shape is found in the white picture.

It is caused by contamination due to fingerprint

on the surface of the transmitting lens, etc.

It is caused by a scratch on the surface of the

transmitting lens.

Replace engine.

Clean transmitting lens.

Dust located in the engine lighting system is

blocking the lighting.

Replace engine.

It is displayed on screen in case mirror or

screen inside is contaminated.

Clean Mirror or Screen.

It is caused by dust stuck to the screen inside the

set, caused by static electricity.

A minute dust on the polarizer or panel part of the

engine sticks to one channel among red, green, blue,

and is displayed with its size 60 times increased. The

diameter of dust stuck to a panel part is displayed a

smaller while it is bigger on polarizer.

Dust stuck to a panel is found red, green, blue color,

etc at the same location of black picture.

Reflection image is displayed on the screen due to

light distorted by a pin hole or bad shape on the

reflection side of the mirror.

Replace mirror.

1.Remove dust by discharging high

pressure of air to the filter of the engine.

2.Remove dust with air pump for lens

cleaning after removing cover-lens.

3.Replace engine.

Remove the dust on the screen.

Page 8

Alignment and Adjustments

1-8 Samsung Electronics

1-12 ASSEMBLY

ASSY COVER P-FAN Separation :

Remove the 3 screws securing the COVER-DUCT, TOP.

ASSY COVER P-FAN Separation :

Pull out the screws while holding and pressing on the HOOK of the HOLDER-FILTER.

1-12-1 ASSY COVER P-FAN

Page 9

Alignment and Adjustments

Samsung Electronics 1-9

ASSY COVER P-FAN Separation :

Pull out the HANDLE-FILTER in the direction shown in the figure.

ASSY COVER P-FAN Separation :

Lift up the COVER-DUCT TOP with your hand in order to pull out the FAN.

Page 10

Alignment and Adjustments

1-10 Samsung Electronics

ASSY COVER P-FAN Separation :

Pull out the FAN and let go of the COVER-DUCT TOP .

Page 11

Alignment and Adjustments

Samsung Electronics 1-11

LAMP CONNECTOR Separation :

6003-000335 SCREW-TAPTITE :RH,+2S,M3,L8,ZPC(YEL)SWRCH18A 4EA

Remove the 4 screws in order to pull out the LAMP_BALLAST CONNECTOR

LAMP CONNECTOR Separation :

Pull out the connector connected to the LAMP-BALLAST and the LAMP (Left Figure), and lift it up to

separate the two parts.(Right Figure)

1-12-2 LAMP_BALLAST

Page 12

LAMP CONNECTOR Separation :

Remove the 4 screws securing the LAMP-BALLAST.

Remove the ON/OFF CABLE inserted in the LAMP-BALLAST.

LAMP CONNECTOR Separation :

Remove the LAMP-BALLAST, and replace it.

Page 13

Alignment and Adjustments

Samsung Electronics 1-13

COVER-LENS Separation :

Remove the marked screws.

1-12-3 ASSY PCB S-LCD DRIVER

COVER-LENS Separation :

BP63-00039A COVER-LENS : HIPS VO BLACK

Pull out the COVER-LENS in upward direction as shown in the figure.

Page 14

Alignment and Adjustments

1-14 Samsung Electronics

ASSY MISC P-SHIELD-CASE,TOP Separation :

6003-000335 SCREW-TAPTITE :RH,+2S,M3,L8,ZPC(YEL)SWRCH18A

Remove the 4 marked screws.

ASSY MISC P-SHIELD-CASE,TOP Separation :

ABP96-00186A SSY MISC P-SHIELD-CASE,TOP

Hold both sides of the ASSY MISC P-SHIELD-CASE TOP and pull it out in the direction of the arrow to

separate it.

Page 15

Alignment and Adjustments

Samsung Electronics 1-15

LCD-PANEL Separation :

Separate the 3 marked parts of PANEL R,G,B.

Refer to the figure for details.

LCD PANEL Separation :

Separate each PANEL HOLDER

Refer to the figure for details.

LCD PANEL Separation :

Push both sides of each PANEL HOLDER in

direction of the arrow in the figure to separate it.

Page 16

Alignment and Adjustments

1-16 Samsung Electronics

LCD PANEL Separation :

A figure showing three separated panels

ASSY PCB S-LCD DRIVER Separation :

6003-000365 SCREW TAPTITE : BH S M3 L8 ZPC(YEL) SWRCH18A 4EA

Remove the 4 marked screws.

Page 17

Alignment and Adjustments

Samsung Electronics 1-17

ASSY PCB S-LCD DRIVER Separation :

Hold both sides of the ASSY MISC P-SHIELD-CASE BOT and pull it out upward in the direction of arrow

to separate it.

ASSY PCB S-LCD DRIVER Separation :

6003-000335 SCREW-TAPTITE :RH,+2S,M3,L8,ZPC(YEL)SWRCH18A 4EA

Remove the 4 marked screws.

Page 18

Alignment and Adjustments

1-18 Samsung Electronics

ASSY PCB S-LCD DRIVER Separation :

BP94-00474A ASSY PCB S-LCD DRIVER 1EA

Pull out the ASSY PCB S-LCD DRIVER.

1-12-4 FAN(FAN-BALLAST)

FAN-BALLAST Separation :

Remove the 2 screws securing the HOLDER-BALLAST.

Page 19

Alignment and Adjustments

Samsung Electronics 1-19

FAN-BALLAST Separation :

Pull out the ASSY BALLAST as shown in the figure.

FAN-BALLAST Separation :

Remove the 2 HOLDER screws securing the FAN.

Page 20

Alignment and Adjustments

1-20 Samsung Electronics

FAN-BALLAST Separation :

Remove the 2 screws securing the FAN.

FAN-LAMP Separation :

Remove the 2 screws

FAN-BALLAST Separation :

Pull out the FAN as shown in the figure and

replace it with a new one.

1-12-5 FAN(FAN-LAMP)

FAN-LAMP Separation :

Turn the HANDLE-LAMP by 90¢™

Page 21

Alignment and Adjustments

Samsung Electronics 1-21

FAN-LAMP Separation :

Pull out the ASSY-LAMP in the direction shown

in the figure while holding the HANDLE-LAMP.

FAN-LAMP Separation :

Remove the screws securing the FAN, and

replace the fan with a new one.

ASSY PCB S-INTERFACE Assembly :

Assemble the 4 screws.

1-12-6 ASSY PCB S-INTERFACE

Page 22

Alignment and Adjustments

1-22 Samsung Electronics

ASSY

MISC -TH ERMOST AT

ASSY

MISC -DE TECTOR S/W

FAN

(FAN-B ALL AST)

LAMP -BA LLAST

(TOS HIB A)

ASSY COVER

P-FAN

LAMP -BA LLAST

(PHI LIP S)

FAN

(

FAN - LA MP)

Loading...

Loading...