Samsung SMM-BMR004 User Manual

Ver.

2600-00F46VGAA

2.0

Smart MBS RRH-P4A

Installat ion Manual

Ver.

2600-00F46VGAA

2.0

COPYRIGHT

This manual is proprietary to SAMSUNG Electronics Co., Ltd. and is protected by copyright.

No information contained herein may be copied, translated, transcribed or duplicated for any commercial

purposes or disclosed to the third party in any form without the prior written consent of SAMSUNG Electronics

Co., Ltd.

TRADEMARKS

Product names mentioned in this manual may be trademarks and/or registered trademarks of their respective

companies.

This manual should be read and used as a guideline for properly installing and operating the product.

This manual may be changed for the system improvement, standardization and other technical reasons without prior

notice.

If you need updated manuals or have any questions concerning the contents of the manuals, contact our Document

Center at the following address or Web site:

Address: Document Center 3rd Floor Jeong-bo-tong-sin-dong. Dong-Suwon P.O. Box 105, 416, Maetan-3dong

Yeongtong-gu, Suwon-si, Gyeonggi-do, Korea 442-600

Homepage: http://www.samsungdocs.com

©2012 SAMSUNG Electronics Co., Ltd. All rights reserved.

Ver.

2600-00F46VGAA

2.0

INTRODUCTION

Purpose

This manual describes procedure and method for installing Smart MBS RRH-P4A.

Document Content and Organization

This manual consists of 2 Chapters, 6 Annex and Abbreviation as follows:

Smart MBS RRH-P4A Installation Manual

CHAPTER 1. Before Installation

This chapter introduces safety rules that must be understood for installing RRH-P4A and

describes the configuration of RRH-P4A.

CHAPTER 2. Installation of RRH-P4A

This chapter describes the procedure to install RRH-P4A.

ANNEX A. Sector Antenna Installation

This annex describes sector antenna configurations and its installation requirements.

ANNEX B. Feeder Line Work

This annex describes cautions and allowed radius of curvature when installing feeder line.

ANNEX C. Assembling connector

This annex describes the procedure of assembling connector.

ANNEX D. Cleaning Optic Connector

This annex describes the procedure of cleaning the optic connector and cleaning tool.

ANNEX E. Pressure Terminal Assembly

This annex describes the procedure of assembling the pressure terminal.

© SAMSUNG Electronics Co., Ltd.

I

Ver.

INTRODUCTION

2600-00F46VGAA

2.0

ANNEX F. Standard Torque

This annex describes the standard torque when assembling the fixing materials.

ABBREVIATION

Describes the acronyms used in this manual.

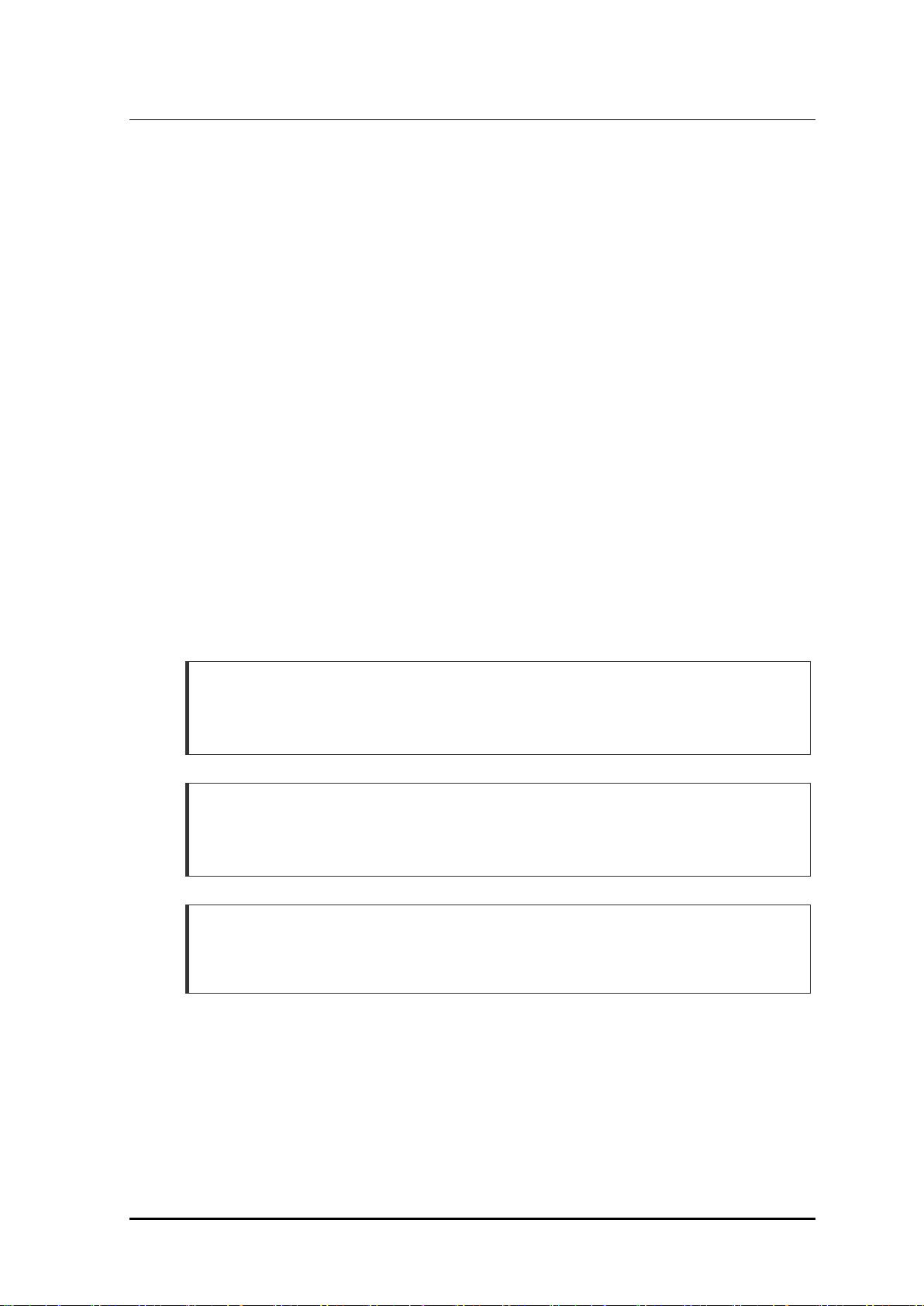

Conventions

The following types of paragraphs contain special information that must be carefully read

and thoroughly understood. Such information may or may not be enclosed in a rectangular

box, separating it from the main text, but is always preceded by an icon and/or a bold title.

WARNING

Provides information or instructions that the reader should follow in order to avoid

personal injury or fatality.

CAUTION

Provides information or instructions that the reader should follow in order to avoid

a service failure or damage to the system.

CHECKPOINT

Provides the operator with checkpoints for stable system operation.

NOTE

Indicates additional information as a reference.

II

© SAMSUNG Electronics Co., Ltd.

Ver.

Smart MBS RRH-P4A Installation Manual

2600-00F46VGAA

2.0

- 2.9 Installation Test

1.0

09. 2012.

First Version

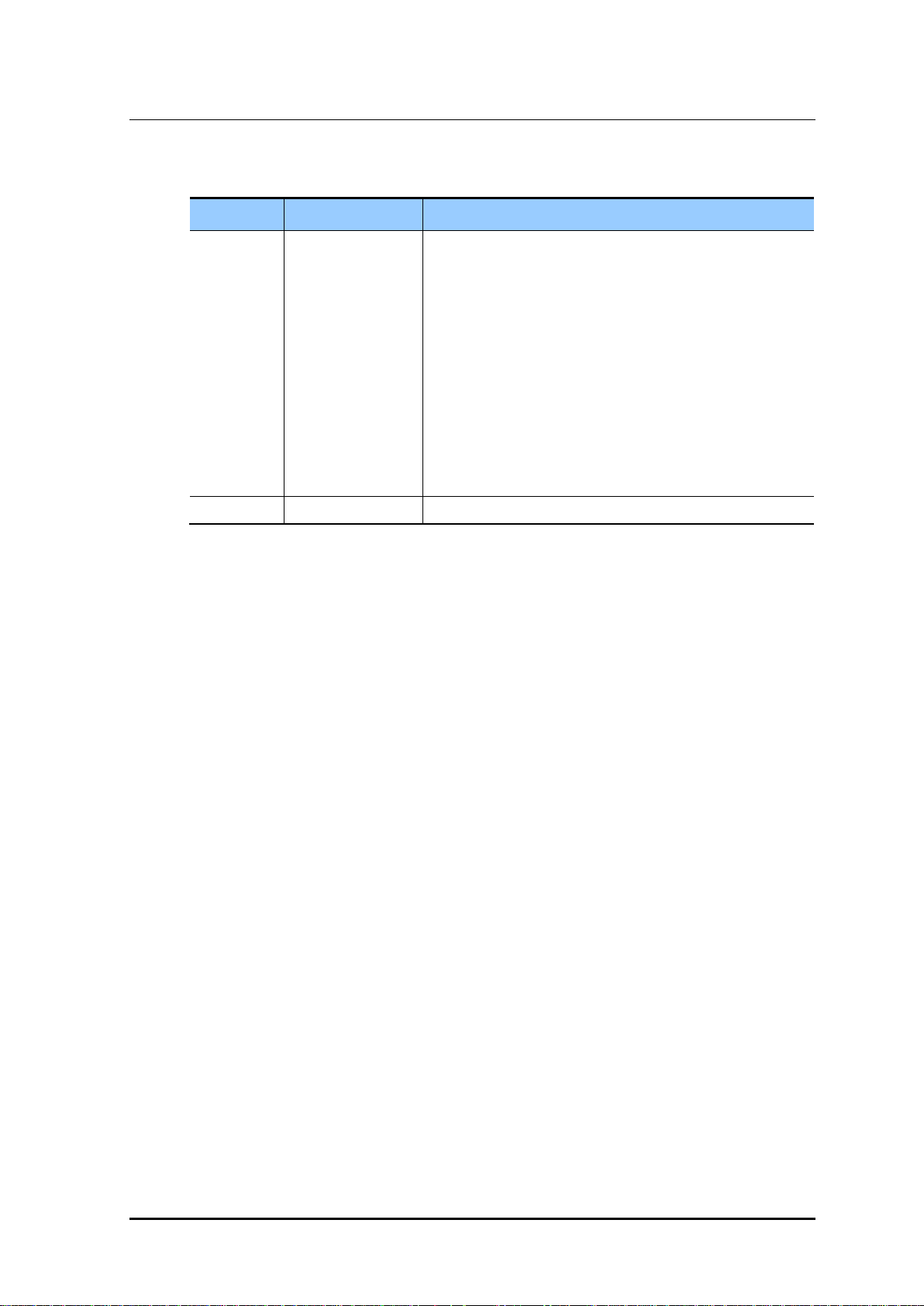

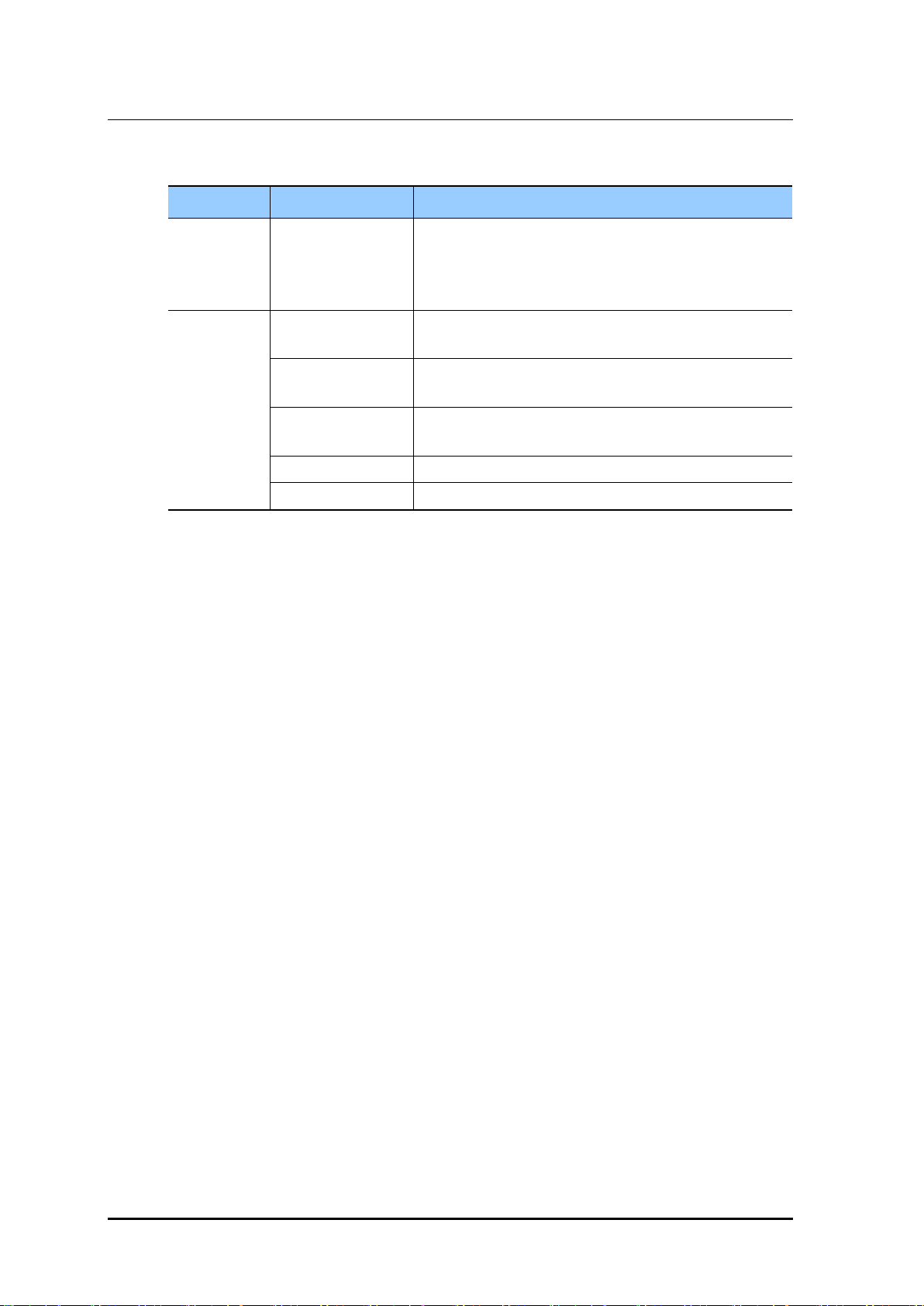

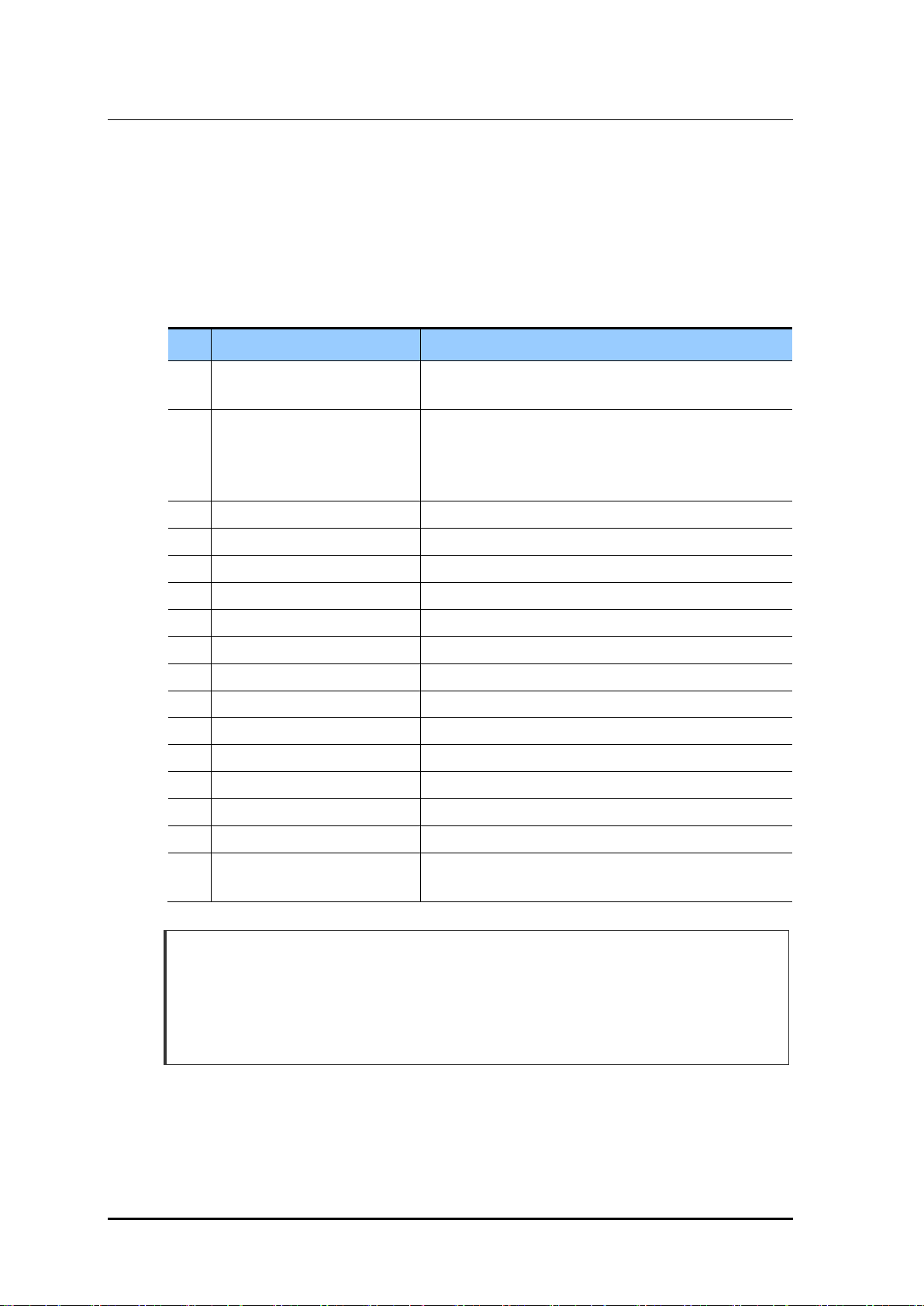

Revision Histor y

VERSION DATE OF ISSUE REMARKS

2.0 11. 2012. * Added

2.8.5 Hybrid Cable Shield Grounding Connection

* Modified

- Figure 1.3 Cabling Diagram

- Table 1.1 System Cabling

- Figure 2.15 Connecting RET cable

- Figure 2.16 RET Cable connector

- Table 2.3 RET Cable-Side Connector Pin Map

- 2.7.1 Grounding RRH-P4A

- 2.8.3 Connecting RRH-P4 Power Cable

- 2.8.4 Connecting RRH-P4 CPRI cable-Power Window

© SAMSUNG Electronics Co., Ltd.

III

Ver.

INTRODUCTION

2600-00F46VGAA

2.0

This page is intentionally left blank.

IV

© SAMSUNG Electronics Co., Ltd.

Ver.

2600-00F46VGAA

2.0

SAFETY CONCERNS

The purpose of the Safety Concerns section is to ensure the safety of users and prevent

property damage. Please read this document carefully for proper use.

Symbols

Caution

Indication of a general caution

Smart MBS RRH-P4A Installation Manual

Restriction

Indication for prohibiting an action for a product

Instruction

Indication for commanding a specifically required action

© SAMSUNG Electronics Co., Ltd.

V

Ver.

SAFETY CONCERNS

2600-00F46VGAA

2.0

WARNING

Warning

Power and Grounding

Watches, Rings, and Other Metallic Accessories

Do not wear accessories such as watches and rings in order to prevent electrical

Connecting Ground Cable

In cabling, the connection of cables without the connection to the ground cable

shock.

may cause the damage of the equipment or the bodily injury of the worker.

Connect the ground cable first.

Caution When Opening and Closing Power Window Cover

Make sure to turn off the breaker connected to the RRH-P4A power before

opening or closing the power window cover of the RRH-P4A.

If you open or close the power window cover when the breaker is turned on, it

may cause damage to the system, or cause an electric short circuit resulting in

severe injury.

Installation General

Caution for Laser Beam of Optical Module and Cable

The optical module and cable used in the system emit bright laser beams.

Always handle them with care as there is risk of serious injury if the eyes are

exposed to the laser beam of the optical cable.

Wearing protection gloves and goggles

Make sure to wear protection gloves and goggles to prevent damages from debris

while drilling holes in a wall or ceiling.

VI

© SAMSUNG Electronics Co., Ltd.

Ver.

Smart MBS RRH-P4A Installation Manual

2600-00F46VGAA

2.0

CAUTION

Caution

Power and Feeder line

Caution for cleaning the Power Supply

While cleaning the power supply device, take caution that the device does not

come in contact with alien bodies that may cause power failure.

Caution for installing the power cable

To maintain cable gland’s rain protection performance, 11.81 in. (300 mm) or

more interval should be kept straight. According to the radius of curvature of the

cable specification should be considered.

Caution for cutting the power cable

Cut power cable after installing power cable to RRH-P4A power terminal taking

into account the radius of curvature according to the cable specifications.

When cutting the cable first, the length difference of cable end can be occurred by

cable curvature and the power terminal may cause contact fault.

Caution When Connecting Optical Cables

Before connecting an optical cable, make sure that there is no dust or foreign

substance on the cross-section of the connector core. If there is any dust or

foreign substance, do not remove it by blowing with your mouth. Remove the dust

or foreign substance by referring to the method of cleaning optic connector.

Caution on Rain-proof Gasket Damage When Installing Window Cover

Be careful so as not to let the rain-proof gasket get damaged (broken or

incorrectly positioned). Check whether the rain-proof gasket is damaged before

closing the power window cover and the optic window cover.

IF the rain-proof gasket is damaged, replace the system (RRH-

P4A) with a new one.

© SAMSUNG Electronics Co., Ltd.

VII

Ver.

SAFETY CONCERNS

2600-00F46VGAA

2.0

Radius of Curvature of Feeder Line

When installing a feeder line, the radius of curvature of the sections where cables

Connection of Feeder Cable Connector

Connecting the feeder cable connector is critical process, so the qualified workers

Caution When Connecting RET Cable

Make sure to turn off the breaker connected to the RRH-P4A power of the DU

If you connect or disconnect the RET cable while the breaker is turned on, it may

bent should be larger than the allowed radius of curvature. If the radius of curvature

for the feeder line installation is less than the allowed radius of curvature, it may

affect the performance of the system.

who finished the related education should perform.

cabinet before connecting the RET cable between the antenna RET port and the

RRH-P4A RET port.

cause an electric short circuit resulting in damage to the RET function.

Installation General

Caution when losing External Power Cable Support Bracket

External Power Cable Support Bracket and two cable tie (stainless steel) for fixing

cable are enclosed in RRH-P4A package. Be careful not to lose when unpacking

package.

Managing unused port

Finish unused port of UADU by dust-cap, not making the alien substance flowed.

Finishing Cable Insertion Hole

Finishing work is required on cable insertion holes (Cable gland, Conduit and

etc.) to prevent entering of any foreign substance, external air and moisture.

- Unused cable insertion hole: Finish cable insertion hole using fishing materials

such as dust cap, rubber packing and etc.

- Cable-installed insertion hole: After installing cable, finish insertion hole using

tape, compressed sponge, rubber packing, silicon, etc. to prevent empty space.

VIII

© SAMSUNG Electronics Co., Ltd.

Ver.

Smart MBS RRH-P4A Installation Manual

2600-00F46VGAA

2.0

Caution when assembling the cable gland

Ensure that all parts of the cable gland are assembled in the correct sequence.

Incorrect assembly may result in influx of external air or moisture into the system

and may cause corrosion, system malfunction and/or critical failure of the cooling

system.

Caution when installing the cable in the cable gland

Only one cable of permitted specification (radius) should be installed in the cable

gland.

- Installing a cable of smaller radius than the permitted specification may result in

influx of external air or moisture into the system and may cause corrosion or

system malfunction.

- Installing a cable thicker than the permitted specification or installing two or

more cables in the gland may damage the gland.

Caution when loosen and tighten the Cable Gland Nut

In case of assembling the cable gland and cabling, do not loosen and tighten by

turning the cable gland body or other parts. turning the cable gland body may

cause corrosion and system failure by entering of any external air and moisture.

Checking assembly state of the unused cable gland

All components of the unused cable gland must be secured in the original factory

configuration. If the cable gland nut is fitted without the rain protection filler or the

protection cover in place, reassemble them as illustrated in ‘Figure 2.7’.

Do not work by yourself

Do not work by yourself in any key process.

Caution for cleaning the Rack

Make sure that worker does not damage installed cables while cleaning the rack.

Cautions When Connecting the CRPI Cable

Failure to observe the CPRI cable connection specified in Table 2.5 may impair

the communication between the CDMA and LTE FDD terminal.

© SAMSUNG Electronics Co., Ltd.

IX

Ver.

SAFETY CONCERNS

2600-00F46VGAA

2.0

RRH-P4A optic cable connection standard

Cable connection standard between UADU CPRI port and RRH-P4A optic port is

Connect the optic cable (Refer to the connection standard of ‘table 2.6’ and ‘table

Caution when Installing the RF antenna

To protect from lightning, the RF antenna must be installed within the shielding

- The protection angle of the lightning rod should be 45 degrees.

different according to the count (One or two) of CDMA UADU (Installed in DU

cabinet).

2.7’). Because false connection can cause the fault of call connection, be

cautious.

angle as shown below, considering the downward distance and the angle from

the tower lightning rod or the antenna pole lightning rod.

Finishing Heat Shrink Tube of a Sector Antenna

1) Insert an antenna protection plate.

2) Place the heat shrink tube on the connection point and shrink the heat shrink

tube using a heat gun.

3) Avoid aiming the heating gun toward the antenna’s body.

California USA Only

This Perchlorate warning applies only to primary CR (Manganese Dioxide)

Lithium coin cells in the product sold or distributed ONLY in California USA

‘Perchlorate Material-special handling may apply, See

www.dtsc.ca.gov/hazardouswaste/perchlorate.’

X

© SAMSUNG Electronics Co., Ltd.

Ver.

Smart MBS RRH-P4A Installation Manual

2600-00F46VGAA

2.0

TABLE OF CONTENTS

INTRODUCTION I

Purpose ...................................................................................................................................................... I

Document Content and Organization ....................................................................................................... I

Conventions ............................................................................................................................................... II

Revision History ....................................................................................................................................... III

SAFETY CONCERNS V

Symbols ..................................................................................................................................................... V

Warning ..................................................................................................................................................... VI

Caution ..................................................................................................................................................... VII

California USA Only .................................................................................................................................. X

CHAPTER 1. Before Installation 1-1

1.1 System Configuration ............................................................................................................ 1-1

1.2 Specifications......................................................................................................................... 1-3

1.3 Cabling .................................................................................................................................... 1-5

1.4 Installation Precaution .......................................................................................................... 1-7

1.5 Installation Tool .................................................................................................................... 1-12

CHAPTER 2. Installation of RRH-P4A 2-1

2.1 Installation Procedure ........................................................................................................... 2-1

2.2 Foundation Work ................................................................................................................... 2-2

2.2.1 Equipment Arrangement .......................................................................................................... 2-2

2.3 Unpacking and Transporting ................................................................................................ 2-3

2.3.1 Importing Items......................................................................................................................... 2-3

2.3.2 Unpacking Items ...................................................................................................................... 2-4

2.4 Cable Gland Assembly and Cable Installation .................................................................... 2-5

2.4.1 Cable Gland Parts .................................................................................................................... 2-6

2.4.2 Cable Gland Assembly and Cabling Procedure ..................................................................... 2-7

© SAMSUNG Electronics Co., Ltd.

XI

Ver.

TABLE OF CONTENTS

2600-00F46VGAA

2.0

2.4.3 Checking and Assembling Unused Cable Gland ................................................................ 2-10

2.5 Fixing the System ................................................................................................................. 2-11

2.5.1 Fixing Wall Mount ................................................................................................................. 2-11

2.5.2 Fixing 1 Sector Pole .............................................................................................................. 2-14

2.6 Connecting cable between RRH and Antenna ................................................................... 2-17

2.6.1 Connecting Feeder Line ....................................................................................................... 2-17

2.6.2 Connecting RET cable .......................................................................................................... 2-22

2.7 Connecting ground cable ................................................................................................... 2-25

2.7.1 Grounding RRH-P4A ............................................................................................................ 2-25

2.8 Connecting Hybrid cable ..................................................................................................... 2-28

2.8.1 Installing Hybrid cable ........................................................................................................... 2-28

2.8.2 Connecting DU Cabinet side cable ...................................................................................... 2-33

2.8.3 Connecting RRH-P4A Power Cable .................................................................................... 2-39

2.8.4 Connecting RRH-P4A CPRI cable ....................................................................................... 2-57

2.8.5 Hybrid Cable Shield Grounding Connection ....................................................................... 2-63

2.8.6 Remaining Hybrid cable ........................................................................................................ 2-65

2.9 Installation Test .................................................................................................................... 2-68

ANNEX A. Sector Antenna Installation A-1

A.1 Cautions when Installing a Sector Antenna ........................................................................ A-1

A.2 Sector Antenna Layout ......................................................................................................... A-1

A.3 Sector Antenna Installation .................................................................................................. A-2

ANNEX B. Feeder Line Work B-1

B.1 When installing the feeder, the cautions ............................................................................. B-1

B.2 Antenna Feeder Cable Ground ............................................................................................. B-4

B.3 Tower Ground Construction ................................................................................................. B-8

ANNEX C. Assembling connector C-1

C.1 RJ-45 (Shield type) ................................................................................................................ C-1

C.2 RJ-45 (Normal type) ............................................................................................................... C-3

C.3 N type-male (LMR-400) .......................................................................................................... C-4

C.4 TNC-male (LMR-400) ............................................................................................................. C-6

C.5 N type-male (1/2 in. feeder line) ............................................................................................ C-8

C.6 Din type-male (1/2 in. Feeder Line) .................................................................................... C-12

XII

© SAMSUNG Electronics Co., Ltd.

Ver.

Smart MBS RRH-P4A Installation Manual

2600-00F46VGAA

2.0

C.7 Finishing connector conne c tion with the t ape .................................................................. C-14

C.8 How to Shrink the Heat Shrink Tube .................................................................................. C-15

C.8.1 When assembling a connector to the feeder line ................................................................ C-15

C.8.2 When connecting a connector to another connector .......................................................... C-17

ANNEX D. Cleaning Optic Connector D-1

D.1 Cleaning Optic Connector ..................................................................................................... D-1

D.2 IBCTM Brand Cleaner .............................................................................................................. D-2

D.2.1 IBCTM brand type cleaner (P/N 9393) .................................................................................... D-2

ANNEX E. Pressure Terminal Assembly E-1

E.1 Preparations ........................................................................................................................... E-1

E.2 Pressure Reference Table ..................................................................................................... E-2

E.3 Assembling Pressure Terminal............................................................................................. E-5

ANNEX F. Standard Torque F-1

ABBREVIATION I

C ~ T .......................................................................................................................................................... I

U ......................................................................................................................................................... II

LIST OF FIGURES

Figure 1.1 RRH-P4A Configuration ........................................................................................ 1-1

Figure 1.2 External Interfaces of RRH-P4A ............................................................................ 1-2

Figure 1.3 Cabling Diagram.................................................................................................... 1-5

Figure 2.1 System Installation & Cable Connection Procedure .............................................. 2-1

Figure 2.2 RRH-P4A Installation Space (1 sector pole type) .................................................. 2-2

Figure 2.3 Cable Gland Parts ................................................................................................. 2-6

Figure 2.4 Cable Gland Assembly and Cable Installation Procedure (1) ................................ 2-7

Figure 2.5 Cable Gland Assembly and Cable Installation Procedure (2) ................................ 2-8

Figure 2.6 Cable Gland Assembly and Cable Installation Procedure (3) ................................ 2-9

Figure 2.7 Checking and Assembling Unused Cable Gland ................................................. 2-10

Figure 2.8 Fixing Wall Mount (1) ........................................................................................... 2-11

© SAMSUNG Electronics Co., Ltd.

XIII

Ver.

TABLE OF CONTENTS

2600-00F46VGAA

2.0

Figure 2.9 Fixing Wall Mount (2) ........................................................................................... 2-12

Figure 2.10 Fixing 1 sector pole (1) ...................................................................................... 2-14

Figure 2.11 Fixing 1 sector pole (2) ....................................................................................... 2-15

Figure 2.12 RRH-P4A Feeder Line Connection Diagram ...................................................... 2-17

Figure 2.13 Connecting RRH-P4A Feeder Line (1) ............................................................... 2-18

Figure 2.14 Connecting RRH-P4A Feeder Line (2) ............................................................... 2-19

Figure 2.15 Connecting RET cable ....................................................................................... 2-22

Figure 2.16 RET Cable Connector ........................................................................................ 2-23

Figure 2.17 Connecting RRH-P4A Ground cable .................................................................. 2-26

Figure 2.18 Installing Hybrid cable (1) .................................................................................. 2-28

Figure 2.19 Installing Hybrid cable (2) .................................................................................. 2-29

Figure 2.20 Installing Hybrid cable (3) .................................................................................. 2-30

Figure 2.21 Installing Hybrid cable (4) .................................................................................. 2-31

Figure 2.22 Peeling off the Hybrid Cable Sheath .................................................................. 2-34

Figure 2.23 Connecting Hybrid cable (1) .............................................................................. 2-35

Figure 2.24 Connecting Hybrid cable (2) .............................................................................. 2-36

Figure 2.25 Connecting Hybrid cable (3) .............................................................................. 2-37

Figure 2.26 Connecting Hybrid cable (4) .............................................................................. 2-37

Figure 2.27 Connecting RRH-P4A power cable (AWG8) (1) ................................................. 2-39

Figure 2.28 Connecting RRH-P4A power cable (AWG8) (2) ................................................. 2-40

Figure 2.29 Connecting RRH-P4A power cable (AWG8) (3) ................................................. 2-41

Figure 2.30 Connecting RRH-P4A power cable (AWG8) (3) ................................................. 2-42

Figure 2.31 Connecting RRH-P4A power cable (AWG8) (4) ................................................. 2-43

Figure 2.32 Connecting RRH-P4A power cable (AWG8) (5) ................................................. 2-44

Figure 2.33 Connecting RRH-P4A power cable (AWG8) (6) ................................................. 2-45

Figure 2.34 Connecting RRH-P4A power cable (AWG10) (1) ............................................... 2-48

Figure 2.35 Connecting RRH-P4A power cable (AWG10) (2) ............................................... 2-49

Figure 2.36 Connecting RRH-P4A power cable (AWG10) (3) ............................................... 2-50

Figure 2.37 Connecting RRH-P4A power cable (AWG10) (3) ............................................... 2-51

Figure 2.38 Connecting RRH-P4A power cable (AWG10) (4) ............................................... 2-52

Figure 2.39 Connecting RRH-P4A power cable (AWG10) (5) ............................................... 2-53

Figure 2.40 Connecting RRH-P4A power cable (AWG10) (6) ............................................... 2-54

Figure 2.41 Connecting RRH-P4A CPRI cable (1) ................................................................ 2-57

Figure 2.42 Connecting RRH-P4A CPRI cable (2) ................................................................ 2-59

Figure 2.43 Hybrid Cable Shield Grounding Connection_DU Cabinet .................................. 2-63

Figure 2.44 Hybrid Cable Shield Grounding Connection_Tower Ground Bar........................ 2-64

Figure 2.45 Remaining Hybrid cable (1) ............................................................................... 2-65

Figure 2.46 Remaining Hybrid cable (2) ............................................................................... 2-66

Figure 2.47 Remaining Hybrid cable (3) ............................................................................... 2-67

XIV

© SAMSUNG Electronics Co., Ltd.

Ver.

Smart MBS RRH-P4A Installation Manual

2600-00F46VGAA

2.0

Figure 2.48 RRH-P4A Power Section Test ........................................................................... 2-69

Figure A.1 Sector Antenna ..................................................................................................... A-2

Figure B.1 Feeder Cable Grounding (1) ................................................................................. B-4

Figure B.2 Feeder Cable Grounding (2) ................................................................................. B-5

Figure B.3 Feeder Cable Grounding (3) ................................................................................. B-6

Figure B.4 Feeder Cable Grounding (4) ................................................................................. B-7

Figure B.5 Connecting the Tower Ground Cable .................................................................... B-8

Figure C.1 Assembling the RJ-45 Connector (Shield Type) (1) .............................................. C-1

Figure C.2 Assembling the RJ-45 Connector (Shield Type) (2) .............................................. C-2

Figure C.3 Assembling the RJ-45 connector (Normal type) ................................................... C-3

Figure C.4 Assembling the N type-male connector (LMR-400) (1) ......................................... C-4

Figure C.5 Assembling the N type-male connector (LMR-400) (2) ......................................... C-5

Figure C.6 Assembling the TNC-male connector (1) .............................................................. C-6

Figure C.7 Assembling the TNC-male connector (2) .............................................................. C-7

Figure C.8 Assembling the N type-male Connector (1/2 in. Feeder Line) (1) ......................... C-8

Figure C.9 Assembling the N type-male Connector (1/2 in. Feeder Line) (2) ......................... C-9

Figure C.10 Assembling the N type-male Connector (1/2 in. Feeder Line) (3) ..................... C-10

Figure C.11 Assembling the N type-male Connector (1/2 in. Feeder Line) (4) ..................... C-11

Figure C.12 Assembling the Din type-male Connector (1/2 in. Feeder Line) (1) .................. C-12

Figure C.13 Assembling the Din type-male Connector (1/2 in. Feeder Line) (2) .................. C-13

Figure C.14 Finishing connector connection with the tape ................................................... C-14

Figure C.15 Shrinking the Heat Shrink Tube-Feeder line (1) ................................................ C-15

Figure C.16 Shrinking the Heat Shrink Tube-Feeder line (2) ................................................ C-16

Figure C.17 Shrinking the Heat Shrink Tube-Connector (1) ................................................. C-17

Figure C.18 Shrinking the Heat Shrink Tube-Connector (2) ................................................. C-18

Figure C.19 Shrinking the Heat Shrink Tube-Connector (3) ................................................. C-19

Figure D.1 Optic Connector Cleaner (IBC

TM

Brand Type Cleaner: P/N 9393) ........................ D-2

Figure D.2 Optic Module Cleaning (LC type Jack) ................................................................. D-3

Figure D.3 Optic Cable Connector Cleaning (LC type plug) ................................................... D-4

Figure D.4 Measuring the Optical Output and Connecting the Optic Connector .................... D-5

Figure E.1 Preparations.......................................................................................................... E-1

Figure E.2 Pressure Reference Drawing (Handheld Compressor) ......................................... E-2

Figure E.3 Pressure Reference Drawing (Hydraulic Press) ................................................... E-3

Figure E.4 Stripping Cable Sheath (1) .................................................................................... E-5

© SAMSUNG Electronics Co., Ltd.

XV

Ver.

TABLE OF CONTENTS

2600-00F46VGAA

2.0

Figure E.5 Stripping Cable Sheath (2) ................................................................................... E-6

Figure E.6 Fixing Pressure Terminal_Handheld Compressor (1) ........................................... E-8

Figure E.7 Fixing Pressure Terminal_Handheld Compressor (2) ........................................... E-9

Figure E.8 Fixing Pressure Terminal_Hydraulic Press (1) ..................................................... E-11

Figure E.9 Fixing Pressure Terminal_Hydraulic Press (2) .................................................... E-12

Figure E.10 Assembling Heat Shrink Tube .......................................................................... E-14

LIST OF TABLES

Table 1.1 RRH-P4A Cabling .................................................................................................... 1-6

Table 1.2 Allowed Mnimum Cable Bend Radius ..................................................................... 1-9

Table 1.3 Basic Installation Tools .......................................................................................... 1-12

Table 2.1 Recommended Distances for System Arrangement ................................................ 2-2

Table 2.2 GPS Identification Tag of Feeder line .................................................................... 2-21

Table 2.3 RET Cable-side Connector Pin Map ...................................................................... 2-23

Table 2.4 Hybrid Cable Color Map ........................................................................................ 2-36

Table 2.5 CPRI Cable connection configuration .................................................................... 2-60

Table 2.6 CPRI cable connection standard-When CDMA DU Shelf is one............................ 2-60

Table 2.7 CPRI cable connection standard-When CDMA DU Shelf is two ............................ 2-61

Table 2.8 Construction Status Checklist ................................................................................ 2-70

Table B.1 Curvature Radius of Feeder Cable for Outdoor...................................................... B-1

Table B.2 Curvature Radius of Feeder Cable for Indoor ........................................................ B-2

Table B.3 Curvature Radius of LMR-400 (Based on Times Microwave system) .................... B-2

Table B.4 Connector Connection Torque Value ...................................................................... B-3

Table B.5 TGB Installation Example ....................................................................................... B-7

Table E.1 Pressure Reference Table for Pressure Terminal ................................................... E-2

Table E.2 Compressor Specifications per Cable Thickness ................................................... E-4

Table F.1 Standard Torque Value for Fastening Bolts ............................................................. F-1

Table F.2 Brass Bolts Torque .................................................................................................. F-1

XVI

© SAMSUNG Electronics Co., Ltd.

Ver.

Smart MBS RRH-P4A Installation Manual

2600-00F46VGAA

2.0

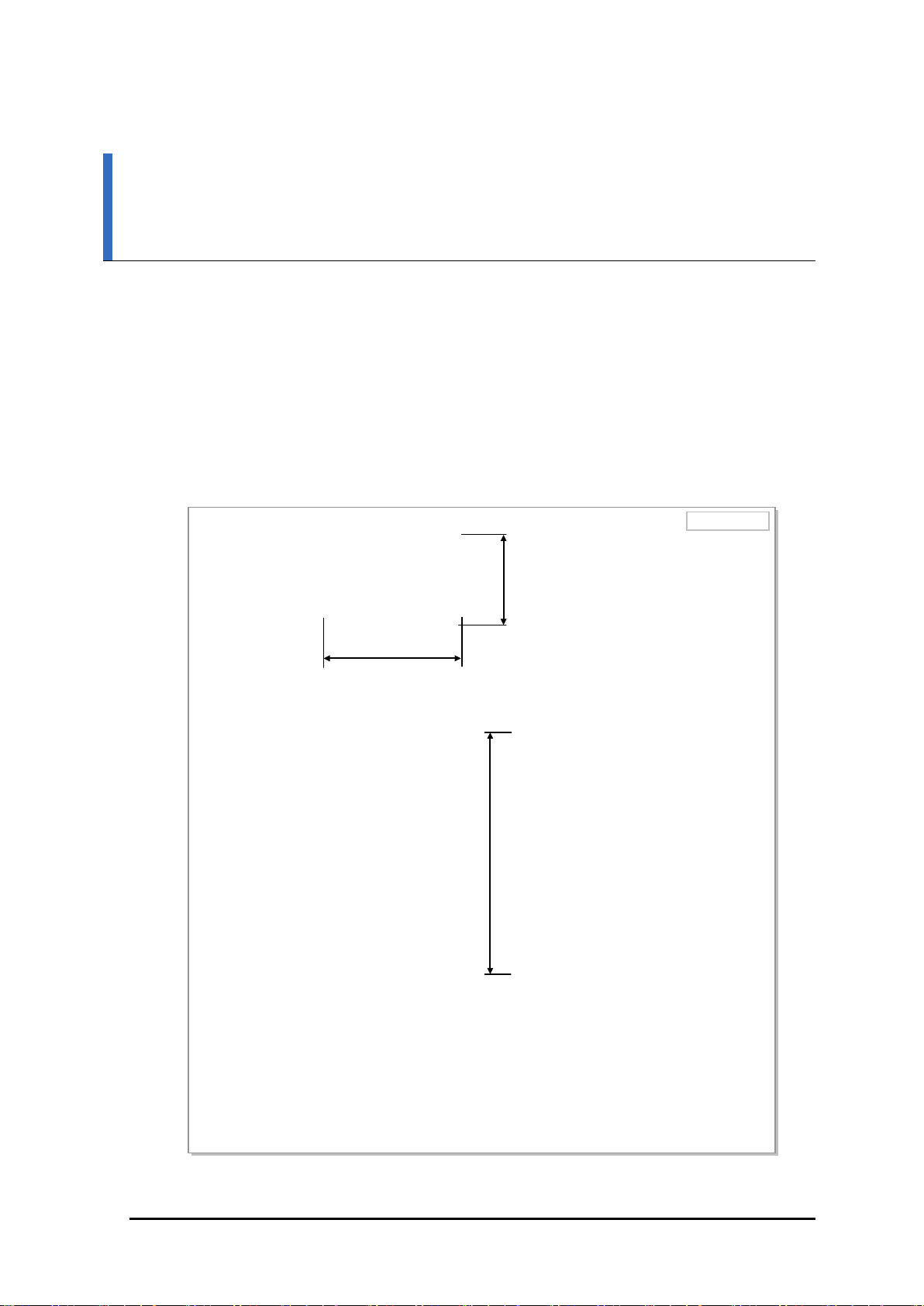

[Top View]

[Front View]

[Bottom View]

[Right View]

[Left View]

[Rear View]

23.81 (605)

8.96 (227.5)

13.78 (350)

Unit: in. (mm)

CHAPTER 1. Before Installation

1.1 System Configuration

RRH-P4A Configuration

The following shows the configuration of RRH-P4A.

© SAMSUNG Electronics Co., Ltd.

Figure 1.1 RRH-P4A Configuration

1-1

Ver.

CHAPTER 1. Before Installation

2600-00F46VGAA

2.0

ANT 3

OPTIC

ANT 2

ANT 1

ANT 0

External Interfaces of RRH-P4A

The following shows the external interfaces of RRH-P4A.

RET Ground

POWER

[-48 V]

[Bottom View]

Figure 1.2 External Interfaces of RRH-P4A

1-2

© SAMSUNG Electronics Co., Ltd.

Ver.

Smart MBS RRH-P4A Installation Manual

2600-00F46VGAA

2.0

Air specification

CDMA/LTE FDD

- UL: 1,850~1,915 MHz

- LTE FDD: 5 MHz/10 MHz

- LTE FDD: Max. 4 Carrier @ 5 MHz

- LTE: 2T4R/4T4R

DU~RRH-P4A Interface

2.5 Gbps, CPRI 4.0 (Optic)

Input voltage

-48 V DC: -40~-56 V DC

Current consumption

20.3 A

350 × 227.5 × 605 (mm)

Weight

59.52 lb (27 kg) or less

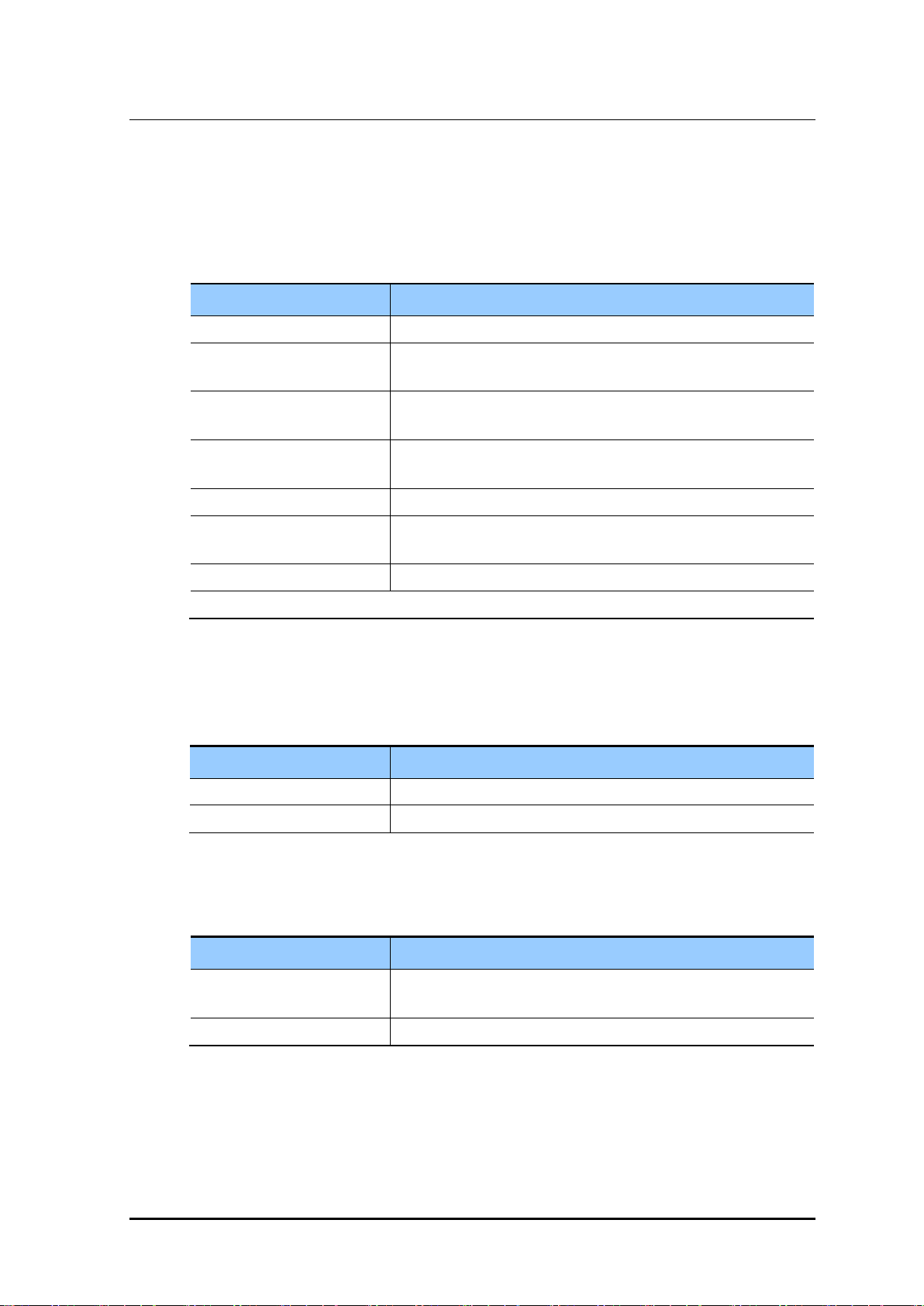

1.2 Specifications

Capacity

The following table shows the specifications for RRH-P4A.

Item Specifications

Operating Frequency - DL: 1,930~1,995 MHz

Channel Bandwidth - CDMA: 1.25 MHz

Capacity - CDMA: Max. 8 Carrier

RF Power per Sector a) 40 W × 4Tx (Total 160 W)

Multiple Antenna - CDMA: 1T2R/2T2R/1T4R/2T4R

a) Output power at the RU antenna port. (Not external filter antenna port)

Input Power

The following table shows the power specifications for RRH-P4A. RRH-P4A complies

with UL60950 safety standard for electrical equipment.

Item Specifications

Unit Size and Weight

The following table shows the size and weight of RRH-P4A.

Item Specifications

Size (W × D × H) 13.78 × 8.96 × 23.81 (in.)

© SAMSUNG Electronics Co., Ltd.

1-3

Ver.

CHAPTER 1. Before Installation

2600-00F46VGAA

2.0

Temperaturea)

-40~131°F (-40~55°C) without solar load

The moisture content must not exceed 0.024 kg per 1 kg of air.

Altitude

0~6,000 ft (0~1,800 m)

Transportation Vibration

Noise (sound pressure level)

Max. 65 dBA at distance of 5 ft (1.5 m) and height of 3 ft (1.0 m)

(EMC)

US Federal Regulation

FCC Title47 Part27

from the front panel of the RRH-P4A.

Ambient Conditions

This section describes the operating temperature, humidity level and other ambient

conditions and related standard of RRH-P4A.

The following table shows the ambient conditions and related standard of RRH-P4A.

Item Range

Humiditya) 10~95 %

Vibration GR-63-CORE Sec.4.4

Earthquake

Office Vibration

Electromagnetic compatibility

a) Temperature and humidity are measured at 59 in. (1.5 m) above the floor and at 15.8 in. (400 mm) away

FCC Title47 Part 15 Class B

1-4

© SAMSUNG Electronics Co., Ltd.

Ver.

Smart MBS RRH-P4A Installation Manual

2600-00F46VGAA

2.0

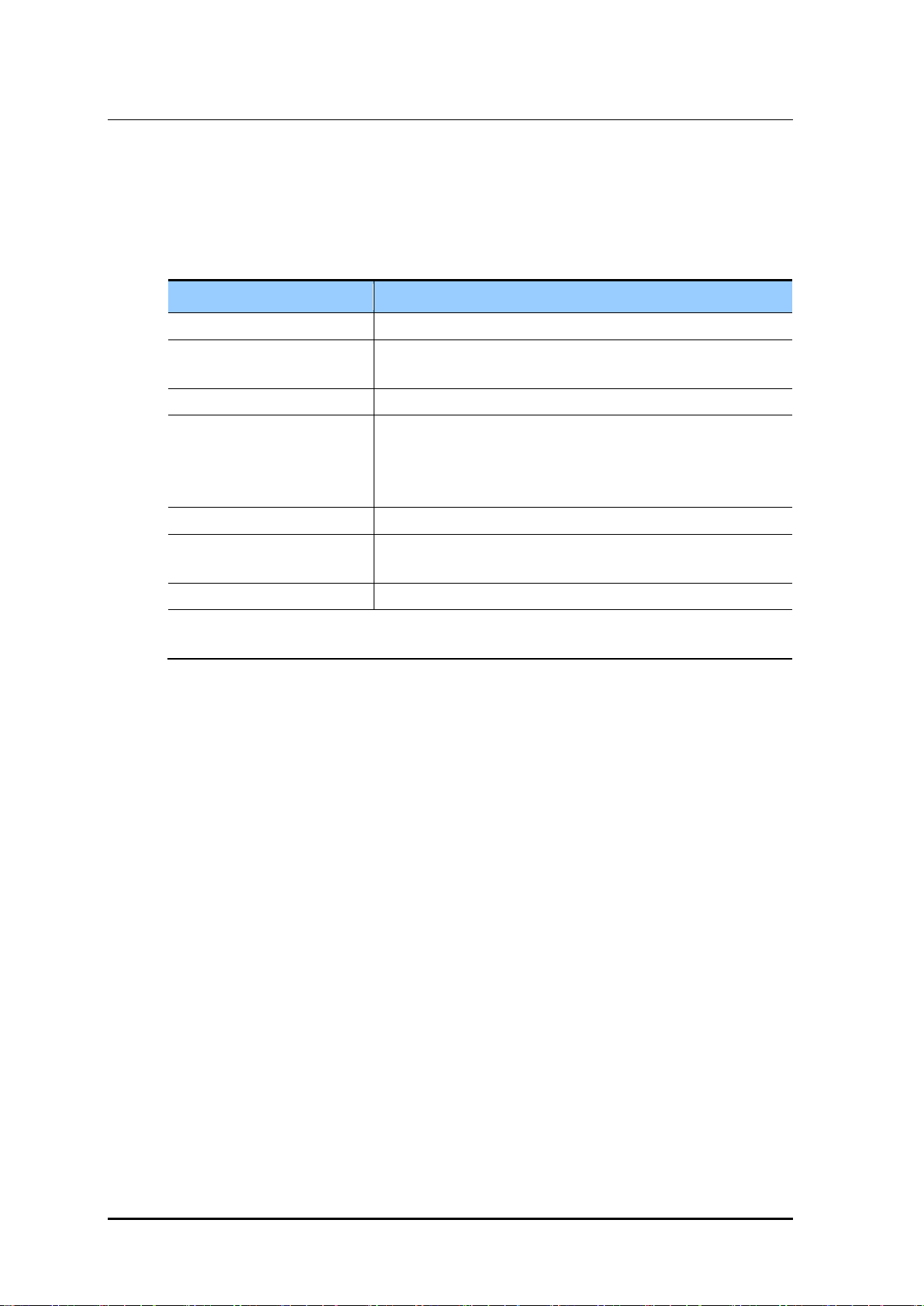

[RF Antenna]

1) TGB Ground Cable

[TGB]

(Ground Kit/7/8 in. Feeder Line or more)

※ TGB and Ground Kit are used in case of the 7/8 in. feeder line or more.

[UADU]

3) Power Cable

6) RF Cable

2) RRH-P4A Ground Cable

1.3 Cabling

The following shows the cables connected to RRH-P4A.

[Rectifier]

4) CPRI Cable

5) RET Cable

© SAMSUNG Electronics Co., Ltd.

Figure 1.3 Cabling Diagram

Feeder Line Ground Cable

1-5

Ver.

CHAPTER 1. Before Installation

2600-00F46VGAA

2.0

standard of service provider)

: AWG 8, GV 6 mm2 × 1C

: AWG 10 , 4 mm2 × 2C (or AWG8, 6 mm2 × 2C)

: Optic Cable (Single Mode)

RET

5) RET Cable Ass’y (Shield Cable)

Antenna

6) RF Cable (1/2 in. or 7/8 in. Feeder Line)

From To Cable

Table 1.1 RRH-P4A Cabling

Underground

Ground

TGB

(Tower Ground Bar)

1) TGB Ground Cable

: AWG 2, GV 25 mm2 × 1C

(However, This can be different, defending on the

RRH-P4A MGB 2) RRH-P4A Ground Cable

Rectifier 3) Power Cable

UADU 4) CPRI Cable

1-6

© SAMSUNG Electronics Co., Ltd.

Ver.

Smart MBS RRH-P4A Installation Manual

2600-00F46VGAA

2.0

1.4 In stallation Precaution

The following precaution must be observed to prevent accidents during RRH-P4A

installation.

Before Installation

Install a high voltage warning sign near the area where high voltage cable is located.

Install a restricted entry warning sign near the potential accident area.

Cover exposed areas such as junctions, ceilings, footholds etc. with safety rails or

fence off the area.

Study use of the fire alarm and the location of the fire extinguisher and how to use it.

Check the location of the nearest emergency exit.

During Installation

Cut all equipment power before installation.

Always wear protection gloves and goggles when drilling holes into the wall or ceiling.

To prevent electric shocks from metallic objects, remove all accessories such as

watches or rings.

Wearing protection gloves and goggles

Make sure to wear protection gloves and goggles to prevent damages from debris

while drilling holes in a wall or ceiling.

Watches, Rings, and Other Metallic Accessories

Do not wear accessories such as watches and rings in order to prevent electrical

shock.

Do not work by yourself

Do not work by yourself in any key process.

© SAMSUNG Electronics Co., Ltd.

1-7

Ver.

CHAPTER 1. Before Installation

2600-00F46VGAA

2.0

Cable Path Inspection

When installing a cable that connects between the rectifier, Main Ground Bar (MGB), and

backhaul device, etc. within the system, the cable path length and the cable installation

method, etc. must be inspected.

Follow these guidelines when inspecting the cabling path.

A minimum cable length must be selected provided that it does not affect the cable

installation and maintenance.

The cable must be placed in a location where it will not be damaged by external

factors. (Power line, flooding, footpaths, etc.)

In areas where the cable can be damaged by external factors, ensure that measures are

taken to prevent damages to the cable. (Cable tray, ducts, flexible pipe, etc.)

Cable Cutting

Measure the exact distance, carefully checking the route, and cut the cable using a cutting tool.

Follow these guidelines when cutting the cable.

Cut the cable to the length determined in the Cable Path Inspection step.

Use a dedicated cable cutting tool.

Cut the cable at right angles.

Be careful to keep the cable away from any moisture, iron, lead, dust or other foreign

material when cutting. Remove any foreign material attached to the cable using

solvent and a brush.

Cable Installation

Cable installation involves running the cable along the cabling path to the target connector

of the system or an auxiliary device after cable path inspection and cable cutting have been

completed.

Follow these guidelines when installing a cable.

Be careful not to damage the cable.

If the cable is damaged, cut out the damaged section before installing.

Run the cable so that it is not tangled. In particular, when installing a cable from a

horizontal section to a vertical section, be careful not to reverse the upper and lower

lines of the cable.

Always use the maximum curvature radius possible, and make sure that the minimum

curvature radius specification is complied with.

If the cable needs to be protected, use a PVC channel, spiral sleeve, flexible pipe, and

cable rack, etc.

1-8

© SAMSUNG Electronics Co., Ltd.

Ver.

Smart MBS RRH-P4A Installation Manual

2600-00F46VGAA

2.0

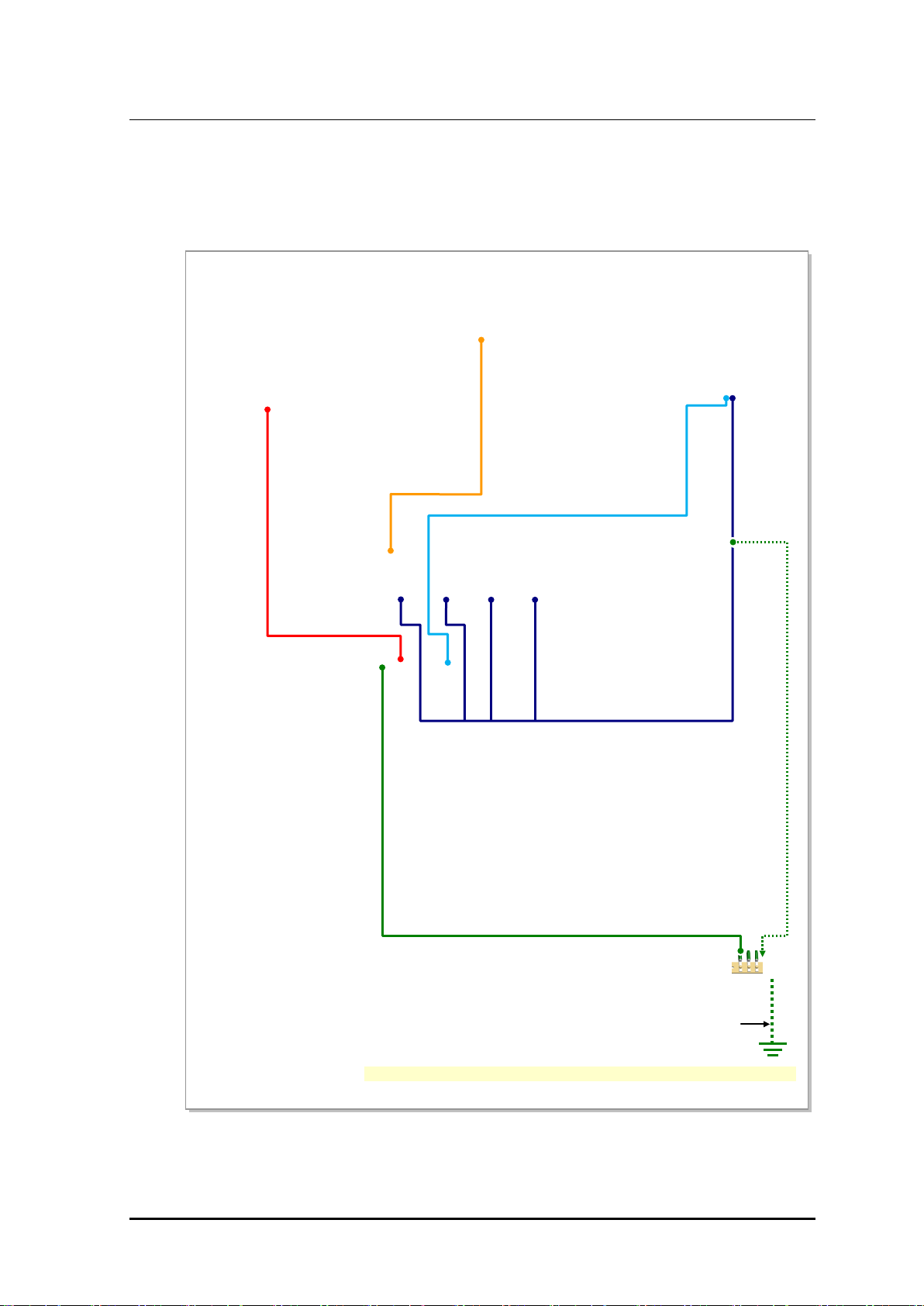

Bend Radius

diameter

cable

diameter

diameter

4 Pair

4

1/2 in. Feeder Line (Indoor)

1.26 in. (32 mm)

RFS, LS

5

1/2 in. Feeder Line (Outdoor)

4.92 in. (125 mm)

RFS, LS

6

7/8 in. Feeder Line (Outdoor)

9.84 in. (250 mm)

RFS, LS

7

1 1/4 in. Feeder Line (Outdoor)

14.96 in. (380 mm)

RFS, LS

8

1 5/8 in. Feeder Line (Outdoor)

19.69 in. (500 mm)

RFS, LS

1 in. (25.4 mm)

Installation

4 in. (101.6 mm)

Repeated

10

RG-316D

0.59 in. (15 mm)

-

external diameter: 0.98 in. (25 mm)

11.81 in. (300 mm)

-

external diameter: 1.06 in. (27 mm)

13.0 in. (330 mm)

-

external diameter: 1.26 in. (32 mm)

17.71 in. (450 mm)

-

* If the allowed cable bend radius is specified by the manufacturer, comply with the bend radius specified.

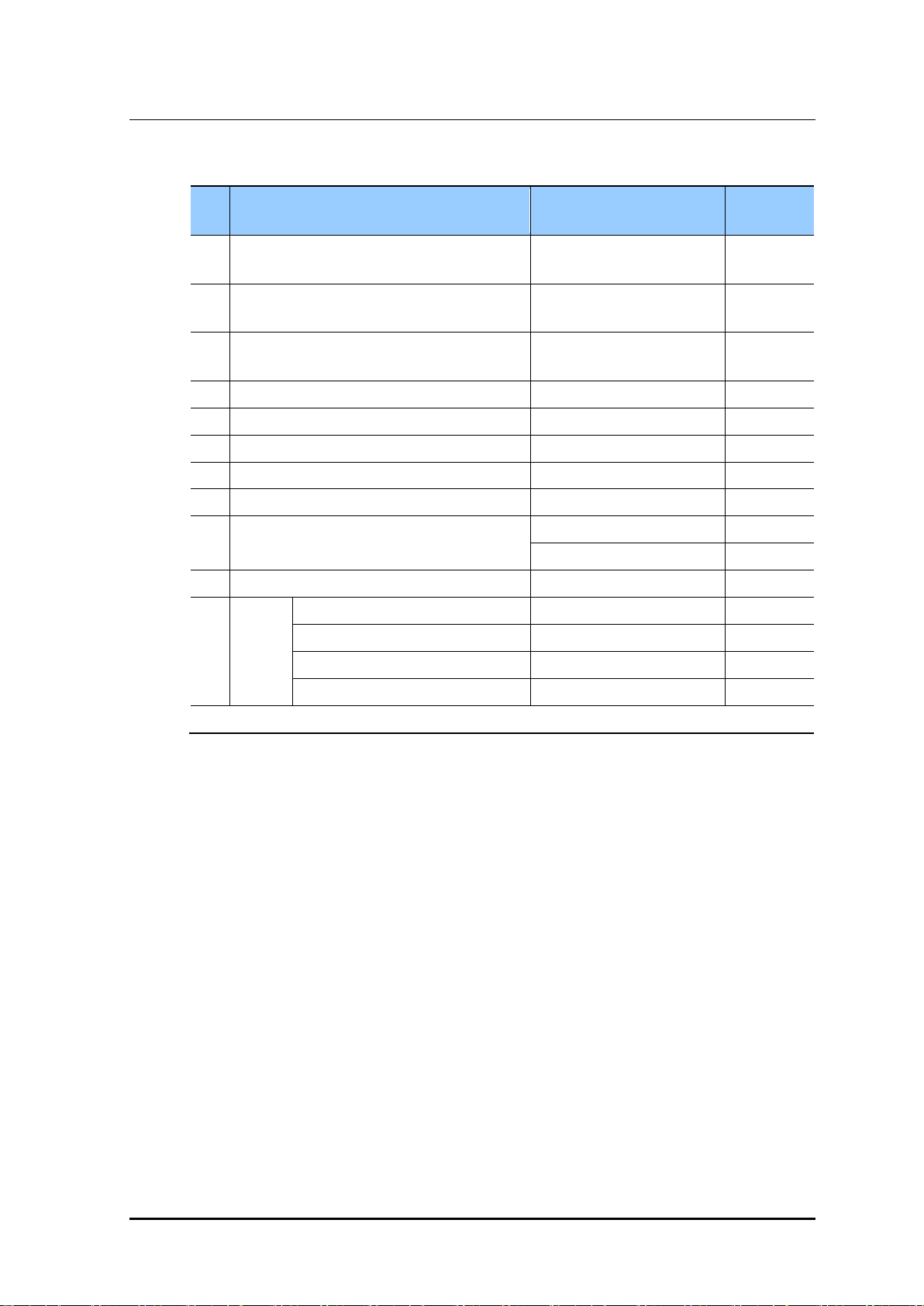

Table 1.2 Allowed Mnimum Cable Bend Radius

No Type

1 GV/CV/FR-8 8 times of the cable external

2 Optic Cable 20 times of the cable external

3 UTP/FTP/S-FTP Cable 4 times of the cable external

9 LMR-400

11 Hybrid

Cable

Allowed Minimum Cable

Remarks

0.6/1 KV

-

PVC/LSZH,

external diameter: 1.18 in. (30 mm) 15.35 in. (390 mm) -

Cable Binding

Cable binding involves fixing and arranging an installed cable using binding strings, cable

ties, binding lines, and ram clamps, etc.

Follow these guidelines when binding a cable.

Be careful not to damage the cable during binding.

Use appropriate cable binding tools according to the target location (indoor or outdoor,

etc.) and the use of the cable (power supply cable, optical cable, feeder line, etc.).

Do not let the cutting section of a cable tie and binding line, etc. be exposed to the

outside. This may cause damage to cables or personal injury. Make sure that the

cutting sections of cables are not exposed to the outside.

Trim the binding string so that you have about 1.97 in. (5 cm) of string left from the

knot. And insert the remaining string into the knot and make sure the knot does not

loosen.

If there is a potential danger of contact failure in a connector connection due to tension,

install the cable in the shortest distance.

© SAMSUNG Electronics Co., Ltd.

1-9

Ver.

CHAPTER 1. Before Installation

2600-00F46VGAA

2.0

Connector Attachment

Connector attachment involves assembling a connector to an installed cable or to a device

on the site.

Follow these guidelines when attaching a connector.

Make sure you are fully aware of the connector assembly method before assembling a

connector. Assemble the connector in accordance with its pin map.

Each connector has a hook to prevent its core positions from being changed.

Use a heat shrink tube at a connector connection for cables that are installed outdoor,

such as feeder lines, to prevent water leakage and corrosion from occurring at the part

exposed to the outside.

Connect each cable of the connector assembly in a straight line.

Be careful when connecting a cable not to trigger contact failure at a connector

connection due to tension.

Identification Tag Attachment

Identification tag attachment involves attaching a marker cable tie, nameplate, and label, etc. to

the both ends of a cable (connections to a connector) to identify its use and cabling path.

Marker Cable Tie

On the marker cable tie, a label can be attached.

The appearance and specification may differ depending

on the type and manufacturer

Follow these guidelines when attaching an identification tag.

When installing a cable outdoor, use relief engraving and coated labels, etc. to prevent

markings from being erased.

Since the form and attachment method for identification tags are different for each

provider, consult with the provider before attaching them.

Connecting Ground Cable

In cabling, the connection of cables without the connection to the ground cable

may cause the damage of the equipment or the bodily injury of the worker.

Connect the ground cable first.

1-10

© SAMSUNG Electronics Co., Ltd.

Ver.

Smart MBS RRH-P4A Installation Manual

2600-00F46VGAA

2.0

Cable Installation Checklist

When installing, take care not to overlap or tangle the cables; also, consider

future expansion. Install the DC power cable and data transmission cable away

from the AC power cable to prevent electromagnetic induction.

Cable Works

The cable works require knowledge for the cabling works such as cable

installation/binding.

After Installation

Cover the cable hole on the floor with a solid cover.

Remove all installation residues; clean the area.

Caution for Laser Beam of Optical Module and Cable

The optical module and cable used in the system emit bright laser beams.

Always handle them with care as there is risk of serious injury if the eyes are

exposed to the laser beam of the optical cable.

Caution for cleaning the Rack

Make sure that worker does not damage installed cables while cleaning the rack.

Caution for cleaning the Power Supply

While cleaning the power supply device, take caution that the device does not

come in contact with alien bodies that may cause power failure.

Damage Prevention

For handling devices sensitive to static electricity, be aware of the followings to avoid

damages of various board elements.

The board should be kept away from materials prone to static electricity such as plastic,

acrylic plates, paper, Styrofoam etc.

The board should be kept in a static electricity prevention storage box.

© SAMSUNG Electronics Co., Ltd.

1-11

Ver.

CHAPTER 1. Before Installation

2600-00F46VGAA

2.0

0.07~4.34 lbf·ft (1.0~60 kgf.cm)

Replaceable head

3

Torx Driver

T20 4 Nut driver set

0.24~0.39 in. (6~10 mm)

5

Hacksaw Frame/Blade

Normal/HIS

6

Level/Plumb bobs

Normal/1.10 lb (500 g)

Heating gun

122~572°F (50~300°C)

8

Solder

30~130 W

9

Power extension cable

98.42 ft (30 m)

10

Tape measure

16.4 ft (5 m)/164 ft (50 m)

11

Cable cutter

12.8 in. (325 mm)

12

Silicon gun/Silicon

Normal/Gray & Colorless

13

Spanner

0.75 in., 0.94 in., 1.42 in. (19 mm, 24 mm, 36 mm)

14

Hexagonal wrench bolt

-

15

Hoisting wire

82 ft (25 m)

Steel Cable Ties

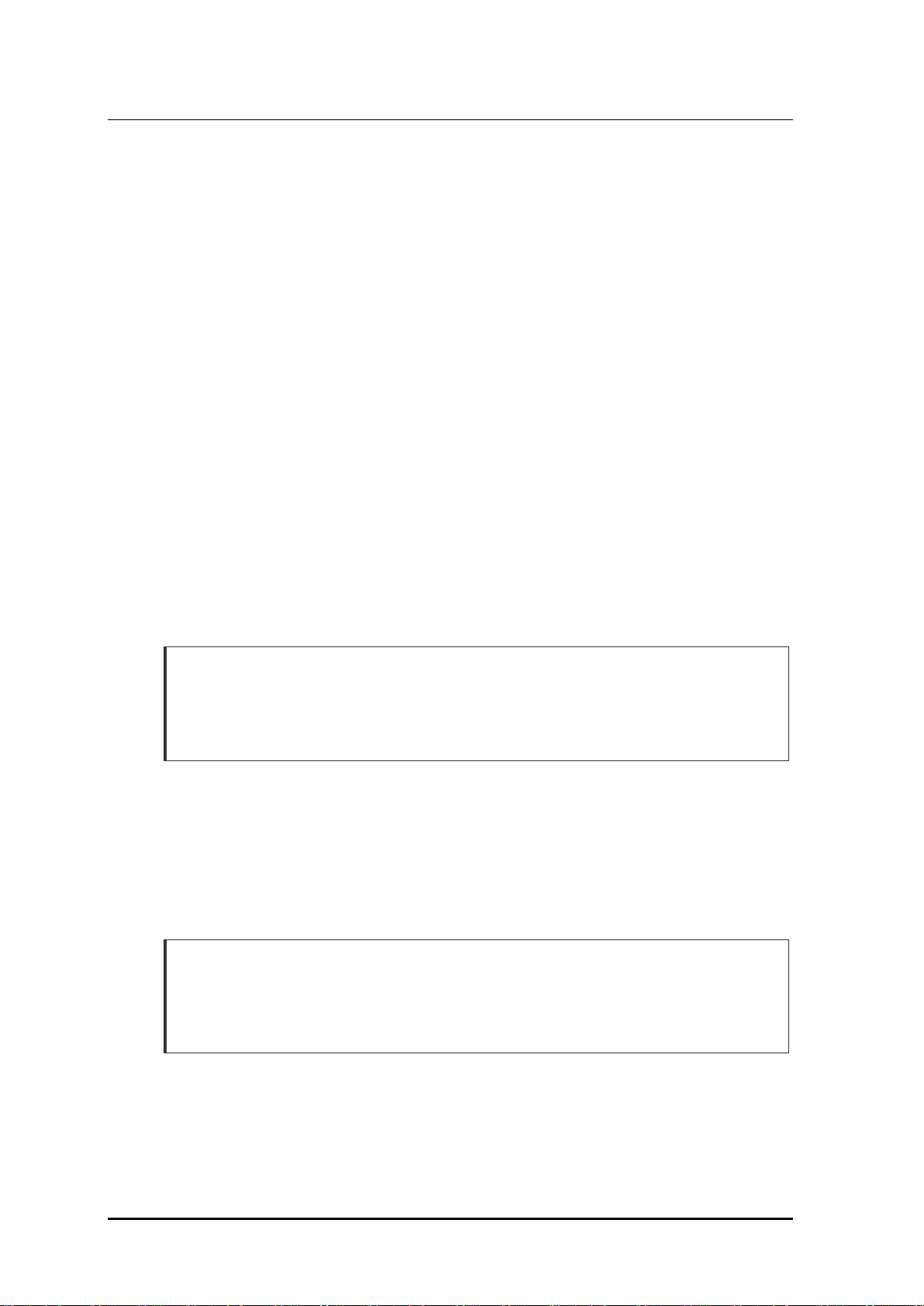

1.5 Installation Tool

The basic tools for installation are listed in the table below. The additional tools required

for each site need to be identified and prepared during a site survey before starting

installation.

Table 1.3 Basic Installation Tools

No. Name Specification

1 Torque driver set No.0~ + No.3 (M2.6~M6 ‘+’ Driver)

2 Torque wrench set M6~M12

0.72~2.17 lbf·ft (10~30 kgf.cm),

7.23~36.15 lbf·ft (100~500 kgf.cm)

7

16 Installation Tools for Stainless

DAS-250, ties up to 0.31 in. (7.9 mm) width straps.

Precautions for use of Installation Tools

The required installation tools may vary depending on the conditions at the site.

In addition to the basic tools, a protractor, compass, GPS receiver, ladder, safety

equipment, cleaning tools etc. should also be prepared in consideration of the site

conditions.

1-12

© SAMSUNG Electronics Co., Ltd.

Loading...

Loading...