Ver.

2600-00ETB9GAA

2.0

310 Mobile WiMAX/TD-LTE RRH-2WB

Installation Manual

COPYRIGHT

This manual should be read and used as a guideline for properly installing and operating the product.

This manual may be changed for the system improvement, standardization and other technical reasons

without prior notice.

Updated manuals are available at:

https://systems.samsungwireless.com/

For questions on the manuals or their content, contact

NetSysTechWriter@sta.samsung.com

This manual is proprietary to SAMSUNG Electronics Co., Ltd. and is protected by copyright.

No information contained herein may be copied, translated, transcribed or duplicated for any

commercial purposes or disclosed to the third party in any form without the prior written

consent of SAMSUNG Electronics Co., Ltd.

TRADEMARKS

Product names mentioned i this manual may be trademarks and/or registered trademarks of

their respective companies.

©2012 SAMSUNG Electronics Co., Ltd. All rights reserved.

INTRODUCTION

Purpose

This manual describes how to install the RRH-2WB of TD-LTE Flexible system (SLSBD104) which is a multi-mode BS of Mobile WiMAX/TD-LTE, and how to connect cables.

Document Content and Organization

This document consists of 3 Chapters, 6 Annex and Abbreviation, which are summarized as

follows:

310 RRH-2WB (TD-LTE Fx) Installation Manual

CHAPTER 1. Before Installation

This chapter introduces the safety rules that must be understood for installing the RRH-2WB

and describes the block diagram of the RRH-2WB.

CHAPTER 2. Installing System

This chapter describes the procedures to install the RRH-2WB.

CHAPTER 3. Connecting Cables

This chapter describes the procedures to connect the cables to the RRH-2WB installed.

ANNEX A. Sector Antenna Installation

This annex describes cautions and installation procedure of the sector antenna.

ANNEX B. Installing Feeder Cable

This annex describes cautions and allowed radius of curvature when installing feeder line.

ANNEX C. Connector Assembly

This annex describes the procedure of assembling connector.

ANNEX D. Cleaning Optic Connector

This annex describes the procedure of cleaning the optic connector and cleaning tool.

© SAMSUNG Electronics Co., Ltd.

I

ANNEX E. Pressure Terminal Assembly

This annex describes the procedure of assembling the pressure terminal.

ANNEX F. Standard Torque

This annex describes the standard torque when assembling the fixing materials.

ABBREVIATION

Describes the acronyms used in this manual.

Conventions

The following types of paragraphs contain special information that must be carefully read and

thoroughly understood. Such information may or may not be enclosed in a rectangular box,

separating it from the main text, but is always preceded by an icon and/or a bold title.

310 RRH-2WB (TD-LTE Fx) Installation Manual

WARNING

Provides information or instructions that the reader should follow in order to avoid

personal injury or fatality.

CAUTION

Provides information or instructions that the reader should follow in order to avoid a

service failure or damage to the system.

CHECKPOINT

Provides the operator with checkpoints for stable system operation.

NOTE

Indicates additional information as a reference.

© SAMSUNG Electronics Co., Ltd.

II

VERSION

DATE OF ISSUE

REMARKS

2.0

06. 2012.

- ‘Humidity condition’ was changed. (1.2)

- ‘Table 3.5’~‘Table 3.7’ were changed.

- ‘Cable Connection of RET’ (3.5.2) was added.

- DU configuration was changed. (Figure 3.2, Table 3.7)

1.0

04. 2012.

First Version

Revision History

310 RRH-2WB (TD-LTE Fx) Installation Manual

© SAMSUNG Electronics Co., Ltd.

III

SAFETY CONCERNS

The purpose of the Safety Concerns section is to ensure the safety of users and prevent

property damage. Please read this document carefully for proper use.

Symbols

Caution

Indication of a general caution

310 RRH-2WB (TD-LTE Fx) Installation Manual

Restriction

Indication for prohibiting an action for a product

Instruction

Indication for commanding a specifically required action

© SAMSUNG Electronics Co., Ltd.

IV

WARNING

Warning

Power and Grounding

310 RRH-2WB (TD-LTE Fx) Installation Manual

Watches, Rings, and Other Metallic Accessories

Do not wear accessories such as watches and rings in order to prevent electrical

shock.

Power Switch Off

Make sure the power switch of power supplier is off when installing the system.

Installing the system with power switch on may cause system damage or fatal

human injury when cables are not correctly connected.

Warning for Connecting the Ground Cable

In cabling, the connection of cables without the connection to the ground cable may

cause the damage of the equipment or the injury of the worker.

Connect the ground cable first.

Installation

Warning for Laser Beam Running through Optical Cables

In the system, the laser beam emitting light runs through the optical cable.

The exposure of the laser beam on worker’s eye may cause serious injury so that it

should be handled with care.

Protection gloves and goggles

Make sure that worker wears protection gloves and goggles to prevent damages

from debris while drilling holes in a wall or ceiling.

© SAMSUNG Electronics Co., Ltd.

V

CAUTION

Caution

Power and Feeder line

310 RRH-2WB (TD-LTE Fx) Installation Manual

Cautions while Cleaning Power Supply

While cleaning the power supply device, take caution that the device does not come

in contact with alien bodies that may cause power failure.

Handling the Power Cable

- Handling the power cable incorrectly may damage the rack or cause an electric

shock through the cable. Ensure the power switch on the rectifier or the system is

turned off before handling the power cable.

- The fixing materials for power cable must be tightly secured to prevent electrical

accidents.

Power cable

In case of using AWG8 (6 mm2 × 2C) power cable, it is applicable up to 70 m (299.66

ft). When the distance is 70 m (299.66 ft), followings should be considered.

- Do not rapid ON/OFF (within one second): The voltage loss value caused by the

cable resistance loss is 3 V, and the RRH-2WB could be damaged by the

counter electromotive force caused by the cable inductance.

- The battery’s life could be shorten: The RRH-2WB could be off in spite the

battery remains. (When the battery capacity is designed within one hour)

- Do not use the power cables linked: Using the power cables linked each other,

the loss will be increased.

Precautions for Measuring Insulation Resistance

Since a high voltage is used for measuring insulation resistance, insulation

resistance should not be measured when the system is in operation. Make sure to

only measure the insulation resistance of the appointed part. Other components

such as the system’s internal components and the unit (system frame), components

of the communication cables, units, etc. should not be measured.

© SAMSUNG Electronics Co., Ltd.

Cable Work Sequence

When performing cable work for the system, proceed with the ground work before

any other work to prevent errors occurring due to static electricity and other reasons.

VI

310 RRH-2WB (TD-LTE Fx) Installation Manual

Connection of Feeder Cable Connector

Connecting the feeder cable connector is critical process, so the qualified workers

who finished the related education should perform.

Radius of Curvature of Feeder Line

When installing a feeder line, the radius of curvature of the sections where cables

bent should be larger than the allowed radius of curvature. If the radius of curvature

for the feeder line installation is less than the allowed radius of curvature, it may affect

the performance of the system.

Installation

Cautions while Cleaning the Rack

Make sure that worker does not damage installed cables while cleaning the rack.

System Installation and Access

Only authorized workers are allowed to install or access the system.

Do not Work by Yourself

Worker must not work alone in any key process.

Management of Unused Ports

Cover the unused ports (conduit, cable gland, etc.) with waterproof cap (sealing cap)

to prevent infiltration of foreign material such as dust, moisture, or bug.

Caution When Connecting the Optical Cable

When connecting the optical cable, be careful to keep the cutting section of the

connector core away from dust and foreign substances. If the cable is soiled with

foreign substances, do not blow on the cable to remove them. Make sure to remove

the dust or foreign substances in accordance with the cleaning instructions provided

by the connector manufacturer.

© SAMSUNG Electronics Co., Ltd.

VII

Finishing Heat Shrink Tube of a Sector Antenna

1) Insert an antenna protection plate to antenna port.

2) Place the heat shrink tube on the connection point and shrink the heat shrink tube

using a heat gun. Avoid aiming the heating gun toward the antenna’s body.

Installing the Antenna

When you install the antenna, the distant and angle between the antenna and

lightning rod must be within the protective angle (left/right side 45° each from the

central axis) to prevent the antenna from lightning damage.

California USA Only

This Perchlorate warning applies only to primary CR (Manganese Dioxide) Lithium

coin cells in the product sold or distributed ONLY in California USA

‘Perchlorate Material-special handling may apply, See

www.dtsc.ca.gov/hazardouswaste/perchlorate.’

310 RRH-2WB (TD-LTE Fx) Installation Manual

© SAMSUNG Electronics Co., Ltd.

VIII

310 RRH-2WB (TD-LTE Fx) Installation Manual

TABLE OF CONTENTS

INTRODUCTION I

Purpose ...................................................................................................................................................... I

Document Content and Organization ....................................................................................................... I

Conventions .............................................................................................................................................. II

Revision History ....................................................................................................................................... III

SAFETY CONCERNS IV

Symbols .................................................................................................................................................... IV

Warning ..................................................................................................................................................... V

Caution ..................................................................................................................................................... VI

California USA Only ............................................................................................................................... VIII

CHAPTER 1. Before Installation 1-1

1.1 System Configuration and Structure .................................................................................... 1-1

1.2 Specifications ......................................................................................................................... 1-4

1.3 Cautions for Installation ........................................................................................................ 1-6

1.4 Pre-survey .............................................................................................................................. 1-8

1.5 Installation Tools .................................................................................................................... 1-9

CHAPTER 2. Installing System 2-1

2.1 Installing the RRH-2WB ......................................................................................................... 2-1

2.2 Foundation Work .................................................................................................................... 2-2

2.2.1 System Arrangement ............................................................................................................... 2-2

2.2.2 Marking and Drilling ................................................................................................................. 2-3

2.3 Unpacking and Transporting................................................................................................. 2-4

2.3.1 Importing Items ........................................................................................................................ 2-4

2.3.2 Unpacking Items ...................................................................................................................... 2-4

2.4 Fixing the System .................................................................................................................. 2-5

2.4.1 Fixing the Wall Type RRH-2WB .............................................................................................. 2-5

2.4.2 Fixing the Pole Type RRH-2WB ............................................................................................. 2-8

2.4.3 Fixing the Tower type RRH-2WB .......................................................................................... 2-22

© SAMSUNG Electronics Co., Ltd.

IX

310 RRH-2WB (TD-LTE Fx) Installation Manual

2.5 System Leveling ................................................................................................................... 2-31

2.6 Insulation Test ...................................................................................................................... 2-33

CHAPTER 3. Connecting Cables 3-1

3.1 Work Flow for Cabling ........................................................................................................... 3-1

3.2 Cabling .................................................................................................................................... 3-5

3.3 Grounding ............................................................................................................................... 3-7

3.3.1 Grounding the System ............................................................................................................. 3-8

3.4 Power Construction ............................................................................................................. 3-10

3.4.1 Installing the Power Cable ..................................................................................................... 3-10

3.5 External Interface Construction .......................................................................................... 3-14

3.5.1 Cable Connection between the DU and the RRH-2WB ...................................................... 3-14

3.5.2 Cable Connection of RET ..................................................................................................... 3-20

3.5.3 Connection of Feeder Cable ................................................................................................. 3-22

3.6 Installation Test .................................................................................................................... 3-30

ANNEX A. Sector Antenna Installation A-1

A.1 Cautions when Installing a Sector Antenna .........................................................................A-1

A.2 Sector Antenna Layout ..........................................................................................................A-1

A.3 Sector Antenna Installation ...................................................................................................A-2

ANNEX B. Installing Feeder Cable B-1

B.1 Cautions When Installing Feeder Cable ...............................................................................B-1

B.2 Antenna Feeder Cable Ground .............................................................................................B-4

B.3 Tower Ground Construction .................................................................................................B-8

ANNEX C. Connector Assembly C-1

C.1 N type-male (1/2 in. feeder line) ............................................................................................C-1

C.2 Din type-male (1/2 in. Feeder Line) .......................................................................................C-6

C.3 Finishing the Connector Connection Part by Tape .............................................................C-8

C.4 How to Shrink the Heat Shrink Tube ....................................................................................C-9

C.4.1 When Assembling a Connector to the Feeder Line .............................................................. C-9

C.4.2 When Connecting a Connector to another Connector ........................................................C-11

C.5 Power Connector Assembly ................................................................................................C-15

© SAMSUNG Electronics Co., Ltd.

X

310 RRH-2WB (TD-LTE Fx) Installation Manual

ANNEX D. Cleaning Optic Connector D-1

D.1 Cleaning Optic Connector .....................................................................................................D-1

D.2 IBCTM Brand Cleaner ..............................................................................................................D-2

D.2.1 IBCTM Brand Type Cleaner (P/N 9393).................................................................................. D-2

D.2.2 IBCTM Brand Type Cleaner (P/N 12910) ............................................................................... D-5

ANNEX E. Pressure Terminal Assembly E-1

ANNEX F. Standard Torque F-1

ABBREVIATION I

L ~ V ............................................................................................................................................................ I

LIST OF FIGURES

Figure 1.1 RRH-2WB Configuration ....................................................................................... 1-1

Figure 1.2 RRH-2WB Configuration When the Solar Shield is Assembled ............................. 1-2

Figure 1.3 RRH-2WB External Interface ................................................................................ 1-3

Figure 2.1 Procedure to Install the RRH-2WB ........................................................................ 2-1

Figure 2.2 RRH-2WB Installation Space ................................................................................. 2-2

Figure 2.3 RRH-2WB Marking ................................................................................................ 2-3

Figure 2.4 Fixing the RRH-2WB_Wall Type (1) ...................................................................... 2-5

Figure 2.5 Fixing the RRH-2WB_Wall Type (2) ...................................................................... 2-6

Figure 2.6 Fixing the RRH-2WB_Wall Type (3) ...................................................................... 2-7

Figure 2.7 Example of Installing on Wall Mount Pole .............................................................. 2-8

Figure 2.8 Example of Installing on Mono Pole ...................................................................... 2-9

Figure 2.9 Example of Installing on Pole .............................................................................. 2-10

Figure 2.10 Example of Installing on Pole (Detail A, Detail B) .............................................. 2-11

Figure 2.11 Fixing 1 Sector Pole Type RRH-2WB (1) ........................................................... 2-12

Figure 2.12 Fixing 1 Sector Pole Type RRH-2WB (2) ........................................................... 2-13

Figure 2.13 Fixing 1 Sector Pole Type RRH-2WB (3) ........................................................... 2-14

Figure 2.14 Fixing 3 Sector Pole Type RRH-2WB (1) ........................................................... 2-15

Figure 2.15 Fixing 3 Sector Pole Type RRH-2WB (2) ........................................................... 2-16

Figure 2.16 Fixing 3 Sector Pole Type RRH-2WB (3) ........................................................... 2-17

Figure 2.17 Fixing 3 Sector Pole Type RRH-2WB (4) ........................................................... 2-18

© SAMSUNG Electronics Co., Ltd.

XI

310 RRH-2WB (TD-LTE Fx) Installation Manual

Figure 2.18 Fixing 3 Sector Pole Type RRH-2WB (5) ........................................................... 2-19

Figure 2.19 Fixing 3 Sector Pole Type RRH-2WB (6) ........................................................... 2-20

Figure 2.20 Bolt Specifications for 3 Sector Pole Type RRH-2WB-Examples....................... 2-21

Figure 2.21 Example of Installing on the Tower .................................................................... 2-22

Figure 2.22 Fixing Tower Type RRH-2WB (1) ....................................................................... 2-23

Figure 2.23 Fixing Tower Type RRH-2WB (2) ....................................................................... 2-24

Figure 2.24 Fixing Tower Type RRH-2WB (3) ....................................................................... 2-25

Figure 2.25 Fixing Tower Type RRH-2WB (4) ....................................................................... 2-26

Figure 2.26 Fixing Tower Type RRH-2WB (5) ....................................................................... 2-27

Figure 2.27 Fixing Tower Type RRH-2WB (6) ....................................................................... 2-28

Figure 2.28 Fixing Tower Type RRH-2WB (7) ....................................................................... 2-29

Figure 2.29 Fixing Tower Type RRH-2WB (8) ....................................................................... 2-30

Figure 2.30 Leveling Test before Fixing Anchor Bolts ........................................................... 2-31

Figure 2.31 Leveling Test before Fixing System ................................................................... 2-32

Figure 2.32 Schematic Diagram for Insulation Test .............................................................. 2-33

Figure 3.1 Work Flow for Cabling ........................................................................................... 3-1

Figure 3.2 Cabling Diagram .................................................................................................... 3-5

Figure 3.3 Connection of the RRH-2WB Ground Cable ......................................................... 3-8

Figure 3.4 Power Equipment Diagram .................................................................................. 3-10

Figure 3.5 Installing the RRH-2WB Power Cable (1) ............................................................ 3-11

Figure 3.6 Installing the RRH-2WB Power Cable (2) ............................................................ 3-12

Figure 3.7 Power Cable Connector ...................................................................................... 3-13

Figure 3.8 Cable connection between the DU and the RRH-2WB (Optical connection) ....... 3-15

Figure 3.9 Optic Cable Connector between DU and RRH-2WB_RRH-2WB side ................. 3-16

Figure 3.10 Cable Connection of RET .................................................................................. 3-20

Figure 3.11 RET Cable Connector ........................................................................................ 3-21

Figure 3.12 Feeder Line Connection Diagram ...................................................................... 3-22

Figure 3.13 Connection of Feeder Cable (Detail A) .............................................................. 3-23

Figure 3.14 Connection of Feeder Cable (Detail B) .............................................................. 3-24

Figure 3.15 Heat Shrink Tube Specification .......................................................................... 3-26

Figure A.1 Sector Antenna ...................................................................................................... A-2

Figure B.1 Feeder Cable Grounding (1) ................................................................................. B-4

Figure B.2 Feeder Cable Grounding (2) ................................................................................. B-5

Figure B.3 Feeder Cable Grounding (3) ................................................................................. B-6

Figure B.4 Feeder Cable Grounding (4) ................................................................................. B-7

Figure B.5 Connecting the Tower Ground Cable .................................................................... B-9

© SAMSUNG Electronics Co., Ltd.

XII

310 RRH-2WB (TD-LTE Fx) Installation Manual

Figure C.1 Assembling the N type-male (1/2 in. Feeder Line) Connector (1) .........................C-2

Figure C.2 Assembling the N type-male (1/2 in. Feeder Line) Connector (2) .........................C-3

Figure C.3 Assembling the N type-male (1/2 in. Feeder Line) Connector (3) .........................C-4

Figure C.4 Assembling the N type-male (1/2 in. Feeder Line) Connector (4) .........................C-5

Figure C.5 Assembling the Din type-male (1/2 in. Feeder Line) Connector (1) ......................C-6

Figure C.6 Assembling the Din type-male (1/2 in. Feeder Line) Connector (2) ......................C-7

Figure C.7 Finishing the Connector Connection Part by Tape ................................................C-8

Figure C.8 Shrinking the Heat Shrink Tube_Feeder Line (1) ..................................................C-9

Figure C.9 Shrinking the Heat Shrink Tube_Feeder Line (2) ................................................C-10

Figure C.10 Shrinking the Heat Shrink Tube_Connection between Connectors (1) ............. C-11

Figure C.11 Shrinking the Heat Shrink Tube_Connection between Connectors (2) .............C-12

Figure C.12 Shrinking the Heat Shrink Tube_Connection between Connectors (3) .............C-13

Figure C.13 Power Connector Assembly (1).........................................................................C-15

Figure C.14 Power Connector Assembly (2).........................................................................C-16

Figure D.1 Optic Connector Cleaner (IBCTM Brand Type Cleaner: P/N 9393) ........................D-2

Figure D.2 Optic Module Cleaning (LC Type Jack) .................................................................D-3

Figure D.3 Optic Cable Connector Cleaning (LC Type Plug) ..................................................D-4

Figure D.4 Optic Connector Cleaner (IBCTM Brand Type Cleaner: P/N 12910) ......................D-5

Figure D.5 Optic Port Cleaning (ODC, PT/LC Jack) ...............................................................D-6

Figure D.6 Optic Cable Connector Cleaning (ODC Type Plug) ..............................................D-7

Figure D.7 Optic Cable Connector Cleaning (PT/LC Type Plug) ............................................D-8

Figure D.8 Measuring the Optical Output and Connecting the Optic Connector.....................D-9

Figure E.1 Pressure Terminal Assembly (1) ............................................................................ E-1

Figure E.2 Pressure Terminal Assembly (2) ............................................................................ E-2

LIST OF TABLES

Table 1.1 Basic Installation Tools ............................................................................................ 1-9

Table 2.1 Recommended Distances for System ..................................................................... 2-2

Table 2.2 Anchor Bolt Drill Bits and Hole Depth ...................................................................... 2-3

Table 3.1 Recommended Minimum Allowed Cable Bend Radius ........................................... 3-3

Table 3.2 RRH-2WB Connecting Cable .................................................................................. 3-6

Table 3.3 Amphenol CJE-AL06M25U15-2S Power Connector Pin Map ............................... 3-13

Table 3.4 Cable Spec for Mobile WiMAX Only Operation Mode ........................................... 3-17

© SAMSUNG Electronics Co., Ltd.

XIII

310 RRH-2WB (TD-LTE Fx) Installation Manual

Table 3.5 Optic Connector Pin Map between RRH-2WB and

DU for Mobile WiMAX Only Operation Mode ........................................................ 3-17

Table 3.6 Cable Spec for WIMAX + TD-LTE Dual Mode ....................................................... 3-18

Table 3.7 Optic Connector Pin Map between RRH-2WB and

DU for WIMAX + TD-LTE Dual Mode .................................................................... 3-18

Table 3.8 RET Cable-side Connector Pin Map ..................................................................... 3-21

Table 3.9 RF Cable Identification Tag ................................................................................... 3-29

Table 3.10 Construction Situation Checklist ......................................................................... 3-30

Table B.1 Curvature Radius of Feeder Cable for Outdoor ...................................................... B-1

Table B.2 Curvature Radius of Feeder Cable for Indoor (Based on LS Feeder Line) ............. B-2

Table B.3 Curvature Radius of LMR-400 (Based on Times Microwave System) .................... B-2

Table B.4 Connector Connection Torque Value ...................................................................... B-3

Table B.5 TGB Installation Example ....................................................................................... B-7

Table E.1 Compressor Specification by Cable Thickness ....................................................... E-2

Table F.1 Standard Torque Value for Tightening Bolts ............................................................. F-1

© SAMSUNG Electronics Co., Ltd.

XIV

310 RRH-2WB (TD-LTE Fx) Installation Manual

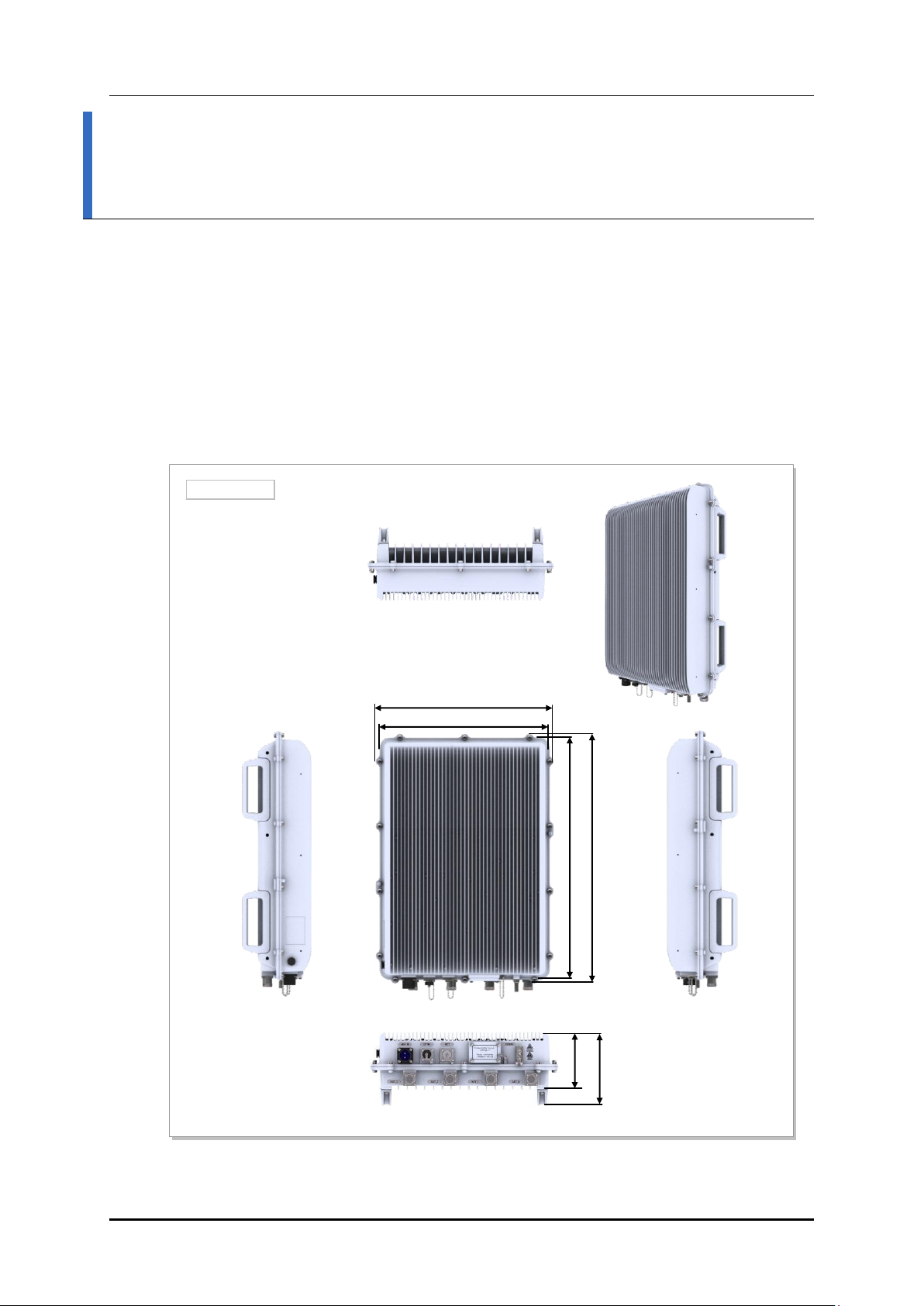

[Bottom View]

[Front View]

[Right View]

[Top View]

[Left View]

143.5 (5.65)

354 (13.94)

370 (14.57)

504 (19.84)

520 (20.47)

112 (4.41)

Unit: mm (in.)

CHAPTER 1. Before Installation

1.1 System Configuration and Structure

RRH-2WB Configuration

The configuration of RRH-2WB is as follows:

© SAMSUNG Electronics Co., Ltd.

Figure 1.1 RRH-2WB Configuration

1-1

310 RRH-2WB (TD-LTE Fx) Installation Manual

[Bottom View]

[Front View]

[Right View]

[Top View]

[Left View]

169 (6.65)

386.5 (15.22)

576 (22.68)

Unit: mm (in.)

When the solar shield is assembled, the RRH-2WB should be configured as follows:

Figure 1.2 RRH-2WB Configuration When the Solar Shield is Assembled

© SAMSUNG Electronics Co., Ltd.

1-2

310 RRH-2WB (TD-LTE Fx) Installation Manual

[Bottom View]

ATN_3

ATN_0

ATN_1

ATN_2

-48 V IN

Optic

RET

Frame Ground

Debug

RRH-2WB External Interface

The external interface of RRH-2WB is as follows:

Figure 1.3 RRH-2WB External Interface

© SAMSUNG Electronics Co., Ltd.

1-3

Category

System Capacity

Channel Bandwidth

- Mobile WiMAX: 10 MHz

- TD-LTE: 20 MHz

RF Band

2,496~2,690 MHz

Maximum Number of Carriers

- 10 MHz Mobile WiMAX 1 carrier/path

- 20 MHz TD-LTE 1 carrier/path

Interface between DU and RRH-2WB

CPRI, Optic (4 Core)

In band Spectral Mask

FCC 43 + 10 logP

Tx/Rx Performance

- Mobile WiMAX: RCT

- TD-LTE: 3 GPP TS 36.104

Output

Antenna Port-based

- 5 W/Carrier/Path @ WiMAX 10 MHz

- 10 W/Carrier/Path @ TD-LTE 20 MHz

Category

Standard

System Input Voltage

-48 VDC (Voltage Variation Range: -40~-56 VDC)

System Input Current (Max.)

6.25 A @ -48 V

Category

Standard

Size

mm

354 (W) × 112 (D) × 504 (H)

in.

13.94 (W) × 4.41 (D) × 19.84 (H)

Weight

kg

20.4 or less

lb

45 or less

1.2 Specifications

RF Specification

The RF specification of the RRH-2WB is as follows:

310 RRH-2WB (TD-LTE Fx) Installation Manual

Input Power

The table below lists the power standard for the RRH-2WB.

System Input Voltage

If the operator wants AC power for the system input voltage, it can be supplied using

an additional external rectifier.

Unit Size and Weight

The table below lists the size and weight of the RRH-2WB.

© SAMSUNG Electronics Co., Ltd.

1-4

310 RRH-2WB (TD-LTE Fx) Installation Manual

Category

Range

Temperature Conditiona)

-40~+50°C (-104~122°F)

Humidity Conditiona)

5~100%, condensing, not to exceed 30g/m3 absolute humidity

Altitude

-60~1,800 m (197~6,000 ft)

Vibration

GR-487-CORE Sec.3.39

- Transportation shock

- Transportation vibration

- Installation shock

- Environmentally induced vibration

- Earthquake resistance

Noise (sound pressure level)

Under 65 dBA in height of 1.0 m (3 ft) and distance of 1.5 m (5 ft).

Electromagnetic Wave (EMI)

FCC Title 47 Part 15 Class B

EN 301 489 Section 7.1 EMC emission

GR-1089-CORE(Issue4) Sec. 3.2 Emission Criteria

RF Regulation

FCC Title 47 Part 27

a) The standards of temperature/humidity conditions are based on the value on the position where is 400 mm

(1.3 ft) away from the front of the DU and in the height of 1.5 m (5 ft) on the bottom.

Category

Description

Total Tx Output Power

30 W

- Mobile WiMAX: 5 + 5 W

- TD-LTE: 10 + 10 W

Tx Constellation error

- Mobile WiMAX: RCT

- TD-LTE: 3 GPP TS 36.104

RX Sensitivity

- Mobile WiMAX: RCT

- TD-LTE: 3 GPP TS 36.104

Environmental Condition

The table below lists the environmental conditions and related standards such as operational

temperature and humidity.

RF Specification

The table below lists the RF characteristics of the RRH-2WB.

© SAMSUNG Electronics Co., Ltd.

1-5

1.3 Cautions for Installation

Observe the following safety instructions when installing the RRH-2WB:

Before Installing

Post warning signs in areas where high-voltage cables are installed.

Post ‘off limit’ signs in areas where accidents are most expected.

With guardrails or fences, block open areas such as connecting parts, roof, and scaffold.

While Installing

The power must be cut off before installing.

Be careful that boards mounted on the system and the cables among the boards are

damaged or scratched when the system is transported or installed.

Power Switch Off

Make sure the power switch of power supplier is off when installing the system.

Installing the system with power switch on may cause system damage or fatal

human injury when cables are not correctly connected.

310 RRH-2WB (TD-LTE Fx) Installation Manual

Protection gloves and goggles

Make sure that worker wears protection gloves and goggles to prevent damages

from debris while drilling holes in a wall or ceiling.

Watches, Rings, and Other Metallic Accessories

Do not wear accessories such as watches and rings in order to prevent electrical

shock.

Do not Work by Yourself

Worker must not work alone in any key process.

System Installation and Access

Only authorized workers are allowed to install or access the system.

© SAMSUNG Electronics Co., Ltd.

1-6

310 RRH-2WB (TD-LTE Fx) Installation Manual

Fixing Materials for outdoor

Stud bolts, Hex. nuts, spring washers, and plane washers that are used to fix the

pole should be made of stainless materials (STS 304). If not, the joint parts may

oxidize or gather rust.

After Installing

Cover the cable holes drilled on the floor with a solid cover.

Remove any debris produced during the work and clean up the installation site.

Warning for Laser Beam Running through Optical Cables

In the system, the laser beam emitting light runs through the optical cable.

The exposure of the laser beam on worker’s eye may cause serious injury so that it

should be handled with care.

Cautions while Cleaning the Rack

Make sure that worker does not damage installed cables while cleaning the rack.

Cautions while Cleaning Power Supply

While cleaning the power supply device, take caution that the device does not come

in contact with alien bodies that may cause power failure.

Management of Unused Ports

Cover the unused ports (conduit, cable gland, etc.) with waterproof cap (sealing cap)

to prevent infiltration of foreign material such as dust, moisture, or bug.

© SAMSUNG Electronics Co., Ltd.

1-7

1.4 Pre-survey

Before starting the construction, the constructor and the departments concerned with the

construction inspect the following items with a pre-survey checklist for the smooth progress

of the construction. If any insufficiencies or problems are found, make the plan upon

deliberation with the departments.

Installation/construction personnel and the service provider carry out the site survey for the

system installation focusing on the following items:

Examination about the conformance and the economical efficiency of the place that the

system is transported or installed.

Status of external interfaces

Power capacity and wiring status

Possibility of system extension

Review if the place has the enough space to operate and maintain.

310 RRH-2WB (TD-LTE Fx) Installation Manual

© SAMSUNG Electronics Co., Ltd.

1-8

No.

Name

Specification

1

Torque driver set

- No.0~+ No.3 (M2.6~M6 ‘+’ Driver)

- 1.0~60 kgf.cm (0.07~4.34 lbf·ft)

2

Torque wrench set

- M6~M12

- 10~30 kgf.cm (0.72~2.17 lbf·ft), 100~500 kgf.cm

(7.23~36.15 lbf·ft), Replaceable head

3

Nut driver set

6~10 mm (0.24~0.39 in.)

4

Hacksaw Frame/Blade

Normal/HIS

5

Level/Plumb bobs

Normal/500 g (1.10 lb)

6

Heating gun

50~300°C (122~572°F)

7

Solder

30~130 W

8

Power extension cable

30 m

9

Tape measure

5 m/50 m (196.85 in./1.97 in.)

10

Cable cutter

325 mm (12.80 in.)

11

Silicon gun/Silicon

Normal/Gray & Colorless

12

Spanner

19 mm, 24 mm, 36 mm (0.75 in. 0.94 in. 1.42 in.)

1.5 Installation Tools

The basic tools for installation are listed in the table below. The additional tools required for

each site need to identified and prepared during a site survey before starting installation.

Table 1.1 Basic Installation Tools

310 RRH-2WB (TD-LTE Fx) Installation Manual

Precautions when Using the Installation Tools

The required installation tools may vary depending on the conditions at the site.

In addition to the basic tools, a protractor, compass, GPS receiver, ladder, safety

equipment, cleaning tools etc. should also be prepared in consideration of the site

conditions.

© SAMSUNG Electronics Co., Ltd.

1-9

310 RRH-2WB (TD-LTE Fx) Installation Manual

Unpacking and Transporting

Fixing System

Grounding

Power Construction

External Interface Construction

CHAPTER 2.

Installing System

CHAPTER 3.

Connecting Cables

Foundation Work

Installation Test

Insulation Test

System Leveling

CHAPTER 2. Installing System

2.1 Installing the RRH-2WB

The procedure to install the RRH-2WB is listed in the flow chart below.

© SAMSUNG Electronics Co., Ltd.

Figure 2.1 Procedure to Install the RRH-2WB

2-1

Category

Recommended Distances

Front/Rear

800 mm (31.50 in.) or more

Side

200 mm (7.87 in.) or more

Top/Bottom (In case of Pole Type)

1,000 mm (39.37 in.) or more

Pole[76.3~114.3 (3~4.5)]

[Pole Type-3 RRH]

630.5 (24.82)

720.5 (28.37)

Pole[76.3~114.3 (3~4.5)]

[Pole Type-1 RRH]

390 (15.35)

140 (5.51)

200 (7.87)

390 (15.35)

[Tower Type]

200 (7.87)

Tower

Unit: mm (in.)

2.2 Foundation Work

2.2.1 System Arrangement

A certain distance must be secured around the RRH-2WB in each direction for installation

and maintenance.

Table 2.1 Recommended Distances for System

310 RRH-2WB (TD-LTE Fx) Installation Manual

© SAMSUNG Electronics Co., Ltd.

Figure 2.2 RRH-2WB Installation Space

System Installation Spaces

The space specifications in the Figure above apply when the pole diameter is 101.6

mm (4 in.). The dimensions may vary depending on the diameter of the pole.

2-2

Mounting Method

Anchor Bolt

Drill Bits

Hole Depth

Wall mount

M6

10 mm (0.39 in.)

33 mm (1.3 in.)

Anchor Bolt Hole

[Rear View]

168 (6.61)

370 (14.57)

576 (22.68)

520 (20.47)

330 (12.99)

390 (15.35)

Unit: mm (in.)

2.2.2 Marking and Drilling

System marking helps install the system in a precise location by marking the locations of the

system, anchor bolts, and cable racks on the floors, walls, and ceilings. When marking is

completed, drill holes for anchor bolts.

1) On the location of the system installation, mark the positions of the equipment and

anchor bolts as shown in the Figure below.

2) Drill holes to insert the anchor bolts and cover the holes with acetate tape before

installing the system.

Table 2.2 Anchor Bolt Drill Bits and Hole Depth

310 RRH-2WB (TD-LTE Fx) Installation Manual

© SAMSUNG Electronics Co., Ltd.

Figure 2.3 RRH-2WB Marking

2-3

310 RRH-2WB (TD-LTE Fx) Installation Manual

2.3 Unpacking and Transporting

This paragraph describes the work to unpack cabinets and other components and transport

them to the place to be installed. The cabinet is externally packed and cabinet and other

components are individually packed.

The external packing should be unpacked in the outside. If necessary, the packing can be

unpacked after transported into the area near installation place.

Transport the cabinet to the installation place. Beware of the damage of walls, pillars, and

bottom of the passage when transporting the cabinet.

Transport other components with packing and sort by types.

2.3.1 Importing Items

Bring in items, taking care of the followings:

Regarding equipment weight and size, check the path to bring the equipment.

Lay Iron and veneer boards on stairs or doorsills to make the transportation easy.

When bring in equipment, beware of damage or impairment of main entrance, walls,

pillars, and floors of the station. Prepare protection materials and fix them with a highstrength adhesive.

Carry boards in packing status, and unpack them when installing or mounting.

Vibration Level for Transportation

When carrying the system, fasten the system firmly not to exceed the proper vibration level

from 1 to 500 Hz.

When carrying system, use a lift to prevent accidents. However, if the system should be

carried by people, enough people are required to carry the system.

Before moving the system, check the storage place for the system and remove obstacles in

advance. While moving system, boards and other devices should not be shocked physically

and damaged caused by dust, moisture, and static electricity.

When installing the items imported, system must be installed in a location whose access is not

easy from outside.

2.3.2 Unpacking Items

The procedure to unpack items is as follows:

1) The packing items should be packed until they reach the installation place.

2) The items are classified in accordance with each job specification and stored on a place

that does not interfere with working.

3) Unpacked systems should be installed immediately. If not installed immediately, the

systems should be stored in the installation place temporarily.

4) Unpack only external packing, leaving the internal packing in unpacked status.

5) Unpack the inner packaging after each system is placed on its installation location.

6) Do not recycle packaging waste. Dispose of it in consultation with the provider.

© SAMSUNG Electronics Co., Ltd.

2-4

Loading...

Loading...