Samsung PLK405WX-XAC, SLK407WX-XAC Service Manual

LCD PROJECTION TELEVISION

Chassis : L56A

Model : PLK405WX/XAC

SLK407WX/XAC

LCD PROJECTION TELEVISION CONTENTS

Precautions

Reference Information

Specifications

Disassembly and Reassembly

Alignment and Adjustments

Troubleshooting

Exploded View and Parts List

Electrical Parts List

Block Diagram

Wiring Diagram

Schematic Diagrams

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

ELECTRONICS

© Samsung Electronics Co., Ltd. SEP. 2000

Printed in Korea

3L56A-4020

1. Precautions

1-1 Safety Precautions

1. Be sure that all of the built-in protective

devices are replaced. Restore any missing

protective shields.

2. When reinstalling the chassis and its

assemblies, be sure to restore all protective

devices, including: nonmetallic control knobs

and compartment covers.

3. Make sure that there are no cabinet openings

through which people—particularly

children—might insert fingers and contact

dangerous voltages. Such openings include

the spacing between the picture tube and the

cabinet mask, excessively wide cabinet

ventilation slots, and improperly fitted back

covers.

If the measured resistance is less than 1.0

megohm or greater than 5.2 megohms, an

abnormality exists that must be corrected

before the unit is returned to the customer.

4. Leakage Current Hot Check (Figure 1-1):

Warning: Do not use an isolation

transformer during this test. Use a leakagecurrent tester or a metering system that

complies with American National Standards

Institute (ANIS C101.1, Leakage Current for

Appliances), and Underwriters Laboratories

(UL Publication UL1410, 59.7).

5. With the unit completely reassembled, plug

the AC line cord directly into the power

outlet. With the unit’s AC switch first in the

ON position and then OFF, measure the

current between a known earth ground (metal

water pipe, conduit, etc.) and all exposed

metal parts, including: antennas, handle

brackets, metal cabinets, screwheads and

control shafts. The current measured should

not exceed 0.5 milliamp. Reverse the powerplug prongs in the AC outlet and repeat the

test.

Fig. 1-1 AC Leakage Test

6. Antenna Cold Check:

With the unit’s AC plug disconnected from the

AC source, connect an electrical jumper across

the two AC prongs. Connect one lead of the

ohmmeter to an AC prong. Connect the other

lead to the coaxial connector.

7. X-ray Limits:

The picture tube is especially designed to prohibit X-ray emissions. To ensure continued

X-ray protection, replace the picture tube only

with one that is the same type as the original.

Carefully reinstall the picture tube shields and

mounting hardware; these also provide X-ray

protection.

8. High Voltage Limits:

High voltage must be measured each time servicing is done on the B+, horizontal deflection

or high voltage circuits. Correct operation of

the X-ray protection circuits must be

reconfirmed whenever they are serviced.

(X-ray protection circuits also may be called

“horizontal disable” or “hold-down”.)

Heed the high voltage limits. These include

the X–ray Protection Specifications Label, and

the Product Safety and X-ray Warning Note on

the service data schematic.

Precautions

Samsung Electronics 1-1

LEAKAGE

CURRENT

TESTER

DEVICE

UNDER

TEST

TEST ALL

EXPOSED METAL

SURFACES

2-WIRE CORD

ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

EARTH

GROUND

(READING SHOULD

NOT BE ABOVE

0.5mA)

Follow these safety, servicing and ESD precautions to prevent damage and protect against potential

hazards such as electrical shock and X-rays.

1-1 Safety Precautions (Continued)

9. High voltage is maintained within specified

limits by close-tolerance, safety-related

components and adjustments. If the high

voltage exceeds the specified limits, check

each of the special components.

10. Design Alteration Warning:

Never alter or add to the mechanical or

electrical design of this unit. Example: Do not

add auxiliary audio or video connectors. Such

alterations might create a safety hazard. Also,

any design changes or additions will void the

manufacturer’s warranty.

11. Hot Chassis Warning:

Some TV receiver chassis are electrically

connected directly to one conductor of the AC

power cord. If an isolation transformer is not

used, these units may be safely serviced only

if the AC power plug is inserted so that the

chassis is connected to the ground side of the

AC source.

To confirm that the AC power plug is inserted

correctly, do the following: Using an AC

voltmeter, measure the voltage between the

chassis and a known earth ground. If the

reading is greater than 1.0V, remove the AC

power plug, reverse its polarity and reinsert.

Re-measure the voltage between the chassis

and ground.

12. Some TV chassis are designed to operate with

85 volts AC between chassis and ground,

regardless of the AC plug polarity. These units

can be safely serviced only if an isolation

transformer inserted between the receiver and

the power source.

13. Some TV chassis have a secondary ground

system in addition to the main chassis ground.

This secondary ground system is not

isolated from the AC power line. The two

ground systems are electrically separated by

insulating material that must not be defeated

or altered.

14. Components, parts and wiring that appear to

have overheated or that are otherwise

damaged should be replaced with parts that

meet the original specifications. Always

determine the cause of damage or overheating, and correct any potential hazards.

15. Observe the original lead dress, especially

near the following areas: Antenna wiring,

sharp edges, and especially the AC and high

voltage power supplies. Always inspect for

pinched, out-of-place, or frayed wiring. Do

not change the spacing between components

and the printed circuit board. Check the AC

power cord for damage. Make sure that leads

and components do not touch thermally hot

parts.

16. Picture Tube Implosion Warning:

The picture tube in this receiver employs

“integral implosion” protection. To ensure

continued implosion protection, make sure

that the replacement picture tube is the same

as the original.

17. Do not remove, install or handle the picture

tube without first putting on shatterproof

goggles equipped with side shields. Never

handle the picture tube by its neck. Some

“in-line” picture tubes are equipped with a

permanently attached deflection yoke; do not

try to remove such “permanently attached”

yokes from the picture tube.

18. Product Safety Notice:

Some electrical and mechanical parts have

special safety-related characteristics which

might not be obvious from visual inspection.

These safety features and the protection they

give might be lost if the replacement component differs from the original—even if the

replacement is rated for higher voltage,

wattage, etc.

Components that are critical for safety are

indicated in the circuit diagram by shading,

( ) or ( ).

Use replacement components that have the

same ratings, especially for flame resistance

and dielectric strength specifications.

A replacement part that does not have the

same safety characteristics as the original

might create shock, fire or other hazards.

Precautions

1-2 Samsung Electronics

1-2 Servicing Precautions

1. Servicing precautions are printed on the

cabinet. Follow them.

2. Always unplug the unit’s AC power cord from

the AC power source before attempting to: (a)

Remove or reinstall any component or

assembly, (b) Disconnect an electrical plug or

connector, (c) Connect a test component in

parallel with an electrolytic capacitor.

3. Some components are raised above the printed

circuit board for safety. An insulation tube or

tape is sometimes used. The internal wiring is

sometimes clamped to prevent contact with

thermally hot components. Reinstall all such

elements to their original position.

4. After servicing, always check that the screws,

components and wiring have been correctly

reinstalled. Make sure that the portion around

the serviced part has not been damaged.

5. Check the insulation between the blades of the

AC plug and accessible conductive parts

(examples: metal panels, input terminals and

earphone jacks).

6. Insulation Checking Procedure: Disconnect the

power cord from the AC source and turn the

power switch ON. Connect an insulation

resistance meter (500V) to the blades of the AC

plug.

The insulation resistance between each blade

of the AC plug and accessible conductive parts

(see above) should be greater than 1 megohm.

7. Never defeat any of the B+ voltage interlocks.

Do not apply AC power to the unit (or any of

its assemblies) unless all solid-state heat sinks

are correctly installed.

8. Always connect a test instrument’s ground

lead to the instrument chassis ground before

connecting the positive lead; always remove

the instrument’s ground lead last.

9. When some parts inside the optical engine

(except lamp) are damaged, replace the whole

optical engine.

Precautions

Samsung Electronics 1-3

Warning 1 : First read the “Safety Precautions” section of this manual. If some unforeseen circumstance creates a

conflict between the servicing and safety precautions, always follow the safety precautions.

Warning 2 : An electrolytic capacitor installed with the wrong polarity might explode.

1. Some semiconductor (“solid state”) devices

are easily damaged by static electricity. Such

components are called Electrostatically

Sensitive Devices (ESDs); examples include

integrated circuits and some field-effect

transistors. The following techniques will

reduce the occurrence of component damage

caused by static electricity.

2. Immediately before handling any semicon

ductor components or assemblies, drain the

electrostatic charge from your body by

touching a known earth ground. Alternatively,

wear a discharging wrist-strap device. (Be

sure to remove it prior to applying power—

this is an electric shock precaution.)

3. After removing an ESD-equipped assembly,

place it on a conductive surface such as

aluminum foil to prevent accumulation of

electrostatic charge.

4. Do not use freon-propelled chemicals. These

can generate electrical charges that damage

ESDs.

5. Use only a grounded-tip soldering iron when

soldering or unsoldering ESDs.

6. Use only an anti-static solder removal device.

Many solder removal devices are not rated as

“anti-static”; these can accumulate sufficient

electrical charge to damage ESDs.

7. Do not remove a replacement ESD from its

protective package until you are ready to

install it. Most replacement ESDs are

packaged with leads that are electrically

shorted together by conductive foam,

aluminum foil or other conductive materials.

8. Immediately before removing the protective

material from the leads of a replacement ESD,

touch the protective material to the chassis or

circuit assembly into which the device will be

installed.

9. Minimize body motions when handling

unpackaged replacement ESDs. Motions such

as brushing clothes together, or lifting a foot

from a carpeted floor can generate enough

static electricity to damage an ESD.

Precautions

1-4 Samsung Electronics

1-3 Precautions for Electrostatically Sensitive Devices (ESDs)

Reference Information

Samsung Electronics 2-1

2. Reference Information

2-1 Tables of Abbreviations and Acronyms

A

Ah

Å

dB

dBm

°C

°F

°K

F

G

GHz

g

H

Hz

h

ips

kWh

kg

kHz

kΩ

km

km/h

kV

kVA

kW

I

MHz

Ampere

Ampere-hour

Angstrom

Decibel

Decibel Referenced to One

Milliwatt

Degree Celsius

Degree Fahrenheit

degree Kelvin

Farad

Gauss

Gigahertz

Gram

Henry

Hertz

Hour

Inches Per Second

Kilowatt-hour

Kilogram

Kilohertz

Kilohm

Kilometer

Kilometer Per Hour

Kilovolt

Kilovolt-ampere

Kilowatt

Liter

Megahertz

MV

MW

MΩ

m

µA

µF

µH

µm

µs

µW

mA

mg

mH

mI

mm

ms

mV

nF

Ω

pF

Ib

rpm

rps

s

V

VA

W

Wh

Megavolt

Megawatt

Megohm

Meter

Microampere

Microfarad

Microhenry

Micrometer

Microsecond

Microwatt

Milliampere

Milligram

Millihenry

Milliliter

Millimeter

Millisecond

Millivolt

Nanofarad

Ohm

Picofarad

Pound

Revolutions Per Minute

Revolutions Per Second

Second (Time)

Volt

Volt-ampere

Watt

Watt-hour

Table 2-1 Abbreviations

Reference Information

2-2 Samsung Electronics

Table 2-2 Abbreviations

ABL

AC

ACC

AF

AFC

AFT

AGC

AM

ANSI

APC

APC

A/V

AVC

BAL

BPF

B-Y

CATV

CB

CCD

CCTV

Ch

CRT

CW

DC

DVM

EIA

ESD

ESD

FBP

FBT

FF

FM

FS

GND

G-Y

H

HF

HI-FI

IC

IC

IF

Automatic Brightness Limiter

Alternating Current

Automatic Chroma Control

Audio Frequency

Automatic Frequency Control

Automatic Fine Tuning

Automatic Gain Control

Amplitude Modulation

American National Standards Institute

Automatic Phase Control

Automatic Picture Control

Audio-Video

Automatic Volume Control

Balance

Bandpass Filter

Blue-Y

Community Antenna Television (Cable TV)

Citizens Band

Charge Coupled Device

Closed Circuit Television

Channel

Cathode Ray Tube

Continuous Wave

Direct Current

Digital Volt Meter

Electronics Industries Association

Electrostatic Discharge

Electrostatically Sensitive Device

Feedback Pulse

Flyback Transformer

Flip-Flop

Frequency Modulation

Fail Safe

Ground

Green-Y

High

High-Frequency

High Fidelity

Inductance-Capacitance

Integrated Circuit

Intermediate Frequency

I/O

L

L

LED

LF

MOSFET

MTS

NAB

NEC

NTSC

OSD

PCB

PLL

PWM

QIF

R

RC

RF

R-Y

SAP

SAW

SIF

SMPS

S/N

SW

TP

TTL

TV

UHF

UL

UV

VCD

VCO

VCXO

VHF

VIF

VR

VTR

VTVM

TR

Input/output

Left

Low

Light Emitting Diode

Low Frequency

Metal-Oxide-Semiconductor-Field-Effect-Tr

Multi-channel Television Sound

National Association of Broadcasters

National Electric Code

National Television Systems Committee

On Screen Display

Printed Circuit Board

Phase-Locked Loop

Pulse Width Modulation

Quadrature Intermediate Frequency

Right

Resistor & Capacitor

Radio Frequency

Red-Y

Second Audio Program

Surface Acoustic Wave(Filter)

Sound Intermediate Frequency

Switching Mode Power Supply

Signal/Noise

Switch

Test Point

Transistor Transistor Logic

Television

Ultra High Frequency

Underwriters Laboratories

Ultraviolet

Variable-Capacitance Diode

Voltage Controlled Oscillator

Voltage Controlled Crystal Oscillator

Very High Frequency

Video Intermediate Frequency

Variable Resistor

Video Tape Recorder

Vacuum Tube Voltmeter

Transistor

H001 AA40-10005R TUNER, TECC1070PG30A(S) SEMCO

H002 AA40-10005U TUNER, TCPN9082PC27A(S) SEMCO

IC601 AA96-50367A ASSY-H/S SOUND AMP TDA7265 PHILIPS

MAIN IC902 1103-000128 24C02, EEPROM ATMEC

IC905 0904-001121 PCF8574P, I/O EXPANDER PHILIPS

REL601 3501-000332 Relay-Power OMRON

X901 2801-0003120 CRYSTAL, 8.388Mhz KONY

IF IC101 1204-001435 IC-IF SYSTEM, LA7565B, DIP SANYO

MTS

H009 AA59-40003Q MODULE-MTS (MZ-202)

IC101 1204-001204 IC-DECODER,TDA9850,DIP,32P PHILIPS

3D-COMB IC01 1204-001556 C-SEPARATION, UPD64082GF NEC

IC02 1105-001172 IC-DRAM, 416C1204 SAMSUNG

IC04 1203-001419 IC-VOLTAGE REGULATOR, 4931 SGS

FD00,01,03 2909-001051 FILTER-LC, 6Mhz TOKO

FD02 2909-001052 FILTER-LC, 3.58Mhz TOKO

XTAL01 2801-000199 CRYSTAL-UNIT, 20Mhz

PIP & ICT00 1203-001419 IC-VOLTAGE REGULATOR, 4931

CAPTION ICT01 1204-001668 IC-PICTURE PROCESS, SDA9488X SIEMENS

ICT02 1001-001083 IC-VIDEO SWITCH, NJM2248D JRC

ICT03 1001-001083 IC-VIDEO SWITCH, NJM2248D JRC

ICT04 1204-001388 IC-DECODER, Z86129 Zilog

ICT05 1204-001610 IC-DECODER, Z86130 Zilog

XT00 2801-003432 CRYSTAL-UNIT, 20.25Mhz

Reference Information

Samsung Electronics 2-3

2-2 IC Line Up

Table 2 - 3 IC Line - Up

Assy

Component RemarksDescriptionLoc.No.

Reference Information

2-4 Samsung Electronics

ICP101 1204-001362 IC-VIDEO PROCESS, VPC3215C ITT

ICP103 1205-001172 IC-INTERFACE, CIP3250A ITT

ICP301 1204-001623 IC-VERTICAL PROCESSOR, SDA9400 SIEMENS

ICP302 1203-001419 IC-VOLTAGE REGULATOR, 4931

PROSCAN ICP401 1002-001045 IC-D/A CONVERTER, SDA9280 SIEMENS

ICP501 1204-001550 IC-VIDEO PROCESS, CXA2101AQ SONY

ICP601 1204-001372 IC-HOR./VER.PROCESSOR, SDA9361 SIEMENS

ICP901 1202-000001 IC-VOLTAGE COMP., 7533

XP101 2801-003432 CRYSTAL-UNIT, 20.25Mhz

XP601 2801-003811 CRYSTAL-UNIT, 24.576Mhz

ICL104,9 0801-000901 74HC04D PHILIPS

ICL106,7,8 1201-001083 CXA1211M SONY

LCD-CTRL ICL201,2,3 1002-000134 TDA8444 PHILIPS

ICL204 1003-001094 CXA1853Q SONY

ICL205 1003-001093 CXA2504N SONY

ICL301 1003-001095 CXD2443Q SONY

POWER

IC801 AA96-50366C ASSY-H/S, STR83145 SANKEN

IC802 AA98-50366B ASSY-H/S, STR-6709 SANKEN

Table 2 - 3 IC Line - Up (Continued)

Assy

Component RemarksDescriptionLoc.No.

Specifications

Samsung Electronics 3-1

3. Specifications

MODEL

TUNING

SYSTEM COLOUR

SOUND

ANTENNA IMPEDANCE

SCREEN SIZE

CONSUMPTION

POWER REQUIREMENTS

FREQUENCY

TUNING RANGE

SOUND OUTPUT

DIMENSIONS SET

PLH403W / PLK405W / SLK407W

Frequency Synthesizer

NTSC 3.58

Stereo System

75 ohm Unbalanced Coaxial

101.6 cm

170 Watts

Input : 120V

60 Hz

VHF CH : 2 ~13

UHF CH : 14 ~ 69

CATV CH : 1, 14 ~ 125

13 Watts/CH x 2

1012 x 349 x 736mm

(W x D x H) TRANSMITTER

WEIGHT SET

TRANSMITTER

Specifications are subject to change.

60 x 18 x 227mm

27 Kg

152g (Including Batteries)

3-2 Samsung Electronics

MEMO

Disassembly and Reassembly

Samsung Electronics 4-1

4. Disassembly and Reassembly

4-1 Back Cover Removal

1. After removing the 16 screws, pull the bottom part of the cabinet backwards.

2. Loosen the 4 screws and remove

the supporter.

4. Loosen the 2 screws. Remove the optical

meter.

3. After loosening the 4 screws, remove the lens

cover and fan duct.

5. Loosen the 2 screws. Remove the stabilizer.

Disassembly and Reassembly

4-2 Samsung Electronics

6. After loosening the 2 screws, remove the

chassis holder and power mounting.

7. After removing the 6 screws, pull the top

cabinet backwards.

Disassembly and Reassembly

Samsung Electronics 4-3

4-2 Lamp Replacement

1. Loosen the screw.

3. Using a hexagonal wrench, loosen the two

screws that secure the lamp.

2. Remove the cover.

4. Pull out the lamp.

5. PROCEDURE

After completing the lamp replacement, enter

the Service Mode

(use a remote control).

(1) Select the 84 (lamp life) with using the

volume DOWN key (See the figure below).

(2) Press the Mute key to reset the lamp life

(“0000”).

(3) Press the ADD key to exit.

LAMP

84 lamp life 0000

Disassembly and Reassembly

4-4 Samsung Electronics

4-2-1 Lamp (bulb only) Replacement

1. Loosen the two screws.

3. After loosening the two brackets, remove the

lamp-holder and wires.

2. Remove the lamp-bracket from the lamp

assembly.

4. After loosening one screw and one nut,

remove the bulb.

Disassembly and Reassembly

Samsung Electronics 4-5

4-3 Air Filter Check

2. Remove the cover.

3. After removing the holder and filter from the

cover, clean the filter.

1. Loosen the screw.

FILTER

Disassembly and Reassembly

4-6 Samsung Electronics

4-4 Liquid Crystal Panel Replacement

1. After removing the 16 screws, pull the cabinet

backwards.

3. After loosening the 4 screws, remove the lens

cover and fan duct.

5. Remove the GUIDE from the FPC-Connector.

2. Loosen the 3 screws. Remove the supporter.

4. Loosen the 2 screws. Remove the optical

meter.

6. Remove FPC cable from the FPC-Connector.

Disassembly and Reassembly

Samsung Electronics 4-7

7. Loosen the 4 screws and remove

the PCB-LCD.

9. Lift the LCD in the direction of arrow.

8. Using a hexagonal wrench, loosen the two

screws.

Disassembly and Reassembly

4-8 Samsung Electronics

4-5 Speaker Removal

1. Loosen the 4 screws and remove the speaker holders.

Alignment and Adjustments

Samsung Electronics 5-1

5. Alignment and Adjustments

5-1 Lens and Mirror Cleaning

1. Mix the alcohol and ethyl in appropriate proportions.

2. Use a clean cotton cloth or a cleaning paper.

3. Clean the top of the lens by turning it as shown. The pattern starts at the

center and proceeds outward, as shown below:

4. Use minimal pressure when rubbing the mirror. Otherwise, the surface

will be damaged.

5-2 Focus Adjustment for projection Lens

1. Loosen the 4 screws that secure the optical

assembly.

2. After setting the optical assembly on the front

cabinet, secure the unit temporarily using the two

screws.

3. After applying the liquid crystal panel signal,

input a lion head pattern from a pattern

generator.

4. Move the focus adjustment screws right and left

until the liquid crystal picture element

is clearly displayed on the screen.

5. Reposition the optical assembly, and fasten all 4

screws.

6. Check the focus adjustment.

7. Repeat adjustments 1~5, if necessary.

FIG. 5-1

FOCUS SECURING SCREW

FOCUS

ADJUSTMENT

SCREW

FOCUS SECURING SCREW

Alignment and Adjustments

5-2 Samsung Electronics

After installing the new liquid crystal panel, make sure that the liquid crystal

screen center is aligned with the screen center. If they are not aligned, make

the following adjustments:

1. Using a hexagonal wrench, loosen the two screws that secure the liquid crystal

panel.

Note: Loosen the screws just until the panel can move easily.

2. Using two fingers, lift the liquid crystal upward. (The screen moves

downward.)

3. When moving the liquid crystal panel towards the left, the screen moves right

(and vice versa).

5. Repeat adjustments 2~4 until the screen center is aligned vertically and

horizontally.

6. Using a hexagonal wrench, refasten the two screws.

5-3 Liquid Crystal Screen Center Adjustment

FIG. 5-2

HEXAGONAL SCREW

(FOR SECURING LIQUID CRYSTAL PANEL)

Alignment and Adjustments

Samsung Electronics 5-3

5-4 Side Panel Controls

5-4-1 Rear Panel Jacks

SLK407WX/XAA

PLK405WX/XAA, PLH403W3X/XAA, PLH403W3SX/XAA

LED LIGHT

SIDE PANEL CONTROLS

(THE OPERATION PANEL OPENS

OUTWARD WHEN PRESSED)

MUTE

TV/VIDEO

MENU

CHANNEL

VOLUME

I

L3

N

P

U

R3

T

4

V3

S-VHS

2 IN

TIMER/LAMP/TEMP

Channel Select Button

1. Press for the channel selection.

2. Press for the content adjustment.

Volume Button

1. Press for the volume UP/DOWN.

2. Press for content adjustment.

Sound Input Terminal (left)

Sound Input Terminal (Right)

Video Input Terminal

S-Video Input Terminal

AV INPUT

2

1

75

75

V

I

D

E

O

V1

L

|

A

U

L1

D

I

O

|

R

R1

AV INPUT

2

1

V

I

D

E

O

V1

L

|

A

U

L1

D

I

O

|

R

R1

VHF/UHF

EXTERNAL-SPEAKER(8‰/13W)

RL

VHF/UHF

EXTERNAL-SPEAKER(8‰/13W)

RL

DTV

COMPONENT

Y

DVD

INPUT

MONITOR

OUT

3

V2

L2

R2

DVD

INPUT

V2

L2

R2

V

Y

Pb

Pr

3

Y

Pb

Pr

MONITOR

OUT

S-VHS

1 IN

L

R

V

L

R

S-VHS

1 IN

HEADPHONE

HEADPHONE

L

Pb

AUDIO

R

Pr

0 main bright 63 34 Adjusts for DC level of R,G,B signal before doing the gamma

adjustment. The greater the value, the darker it gets

1 R main bright 63 36 Adjusts for DC level of R signal before doing the gamma adjustment.

The greater the value, the darker it gets

2 B main bright 63 36 Adjusts for DC level of B signal before doing the gamma adjustment.

The greater the value, the darker it gets

3 gamma gain1 63 42 Adjusts the gain of black side on the gamma curve (R,G,B)

4 R gamma gain1 63 36 Adjusts the gain of black side on the gamma curve for R

5 B gamma gain1 63 36 Adjusts the gain of black side on the gamma curve for B

6 gamma ctrl1 63 40 Adjusts the change point of the black side on the gamma curved line

of R,G,B signal. The greater the value, the more the point moves

towards black

7 R gamma ctrl1 63 36 Adjusts the change point of the black side on the gamma curve for R.

The greater the value, the more the point moves towards black

8 B gamma ctrl1 63 36 Adjusts the change point of the black side on the gamma curve for B.

The greater the value, the more the point moves towards black

9 gamma gain2 63 16 Adjusts the gain of white side on the gamma curve (R,G,B)

10 reserved 63 36 reserved for R gamma gain2 (not used)

11 B gamma gain2 63 36 Adjusts the gain of white side on the gamma curve B

12 gamma ctrl2 63 34 Adjusts the change point of the white side on the gamma curved line

of R,G,B signal. The smaller the value, the more the point moves

towards white

13 reserved 63 36 reserved for R gamma ctrl2 (not used)

14 reserved 63 36 reserver for B gamma ctrl2 (not used)

15 sub contrast 63 40 Adjusts the gain of R,G,B voltage (applied to LCD)

16 R sub contrast 63 37 Adjusts the gain of R voltage (applied to LCD)

17 B sub contrast 63 42 Adjusts the gain of B voltage (applied to LCD)

18 sub bright 63 30 Adjustment for the brightness of R,G,B after doing the gamma

adjustment. No change on the gamma curve. The greater the value,

the darker it gets

19 R sub bright 63 34 Adjustment for the brightness of R after doing the gamma

adjustment. The greater the value, the darker it gets

20 B sub bright 63 37 Adjustment for the brightness of B after doing the gamma

adjustment. The greater the value, the darker it gets

Alignment and Adjustments

5-4 Samsung Electronics

5-5 Service Mode Adjustments

5-5-1 LCD Interface IC (CXA1853) Adjustment

No. Item Range Initial value Description

Values to be adjusted for each set

26 lcd H pos 255 128 Determines the start location of horizontal indication by picture

element (Pixel)

27 lcd V pos 15 7 Determines the start location of vertical indication (within 1H)

28 sh position 15 7 Determines the phase of the sample/hold pulse

29 PC H pos 255 128 Determines the start location of horizontal indication by picture element

(Pixel). Used for PC RGB mode

30 PC V pos 15 7 Determines the start location of vertical indication (within 1H). Used for

PC RGB mode

31 PC sh position 15 7 Determines the phase of the sample/hold pulse. Used for PC RGB mode

Alignment and Adjustments

Samsung Electronics 5-5

21 signal center 63 14 Adjusts the DC level of video signals (applied to LCD). Set the signal

center to 7V

22 common control 63 30 Adjusts the common voltage (applied to LCD)

23 white limit 63 32 Adjusts the limiter voltage of white peak of R,G,B signal (applied to

LCD). The greater the value, the lower the limiter voltage becomes

24 SID ctrl 63 29 Adjusts the improvement pulse for uniformity of LCD

25 reserved 63 36 reserved

No. Item Range Initial value Description

5-5-1 LCD Interface IC (CXA1853) Adjustment (Continued)

No. Item Range Initial value Description

5-5-2 LCD Controller (CXD2443) Adjustment

32 PC H Blank phase 63 14 Determines the phase of the H blank. Used for PC RGB mode

33 PC H Sync phase 255 0 Determines the phase of the H sync. Used for PC RGB mode

No. Item Range Initial value Description

5-5-3 Progressive Module (SDA9361) Adjustment

Alignment and Adjustments

5-6 Samsung Electronics

5-5-5 Progressive Module (SDA9280) Adjustment

5-5-6 MTS Module (TDA9850) Adjustment

5-5-4 Progressive Module (CIP3250) Adjustment

34 DVD U gain 63 41 Adjusts the gain of DVD Component U

35 DVD V gain 63 41 Adjusts the gain of DVD Component V

36 DVD Y gain 63 41 Adjusts the gain of DVD Component Y

37 DVD Y bright 255 0 Adjusts the brightness of DVD Component

38 PIP U gain 63 31 Adjusts the gain of PIP U

39 PIP V gain 63 31 Adjusts the gain of PIP V

40 PIP Y gain 63 31 Adjusts the gain of PIP Y

41 PIP Y bright 255 0 Adjusts the brightness of PIP

No. Item Range Initial value Description

42 DCTIC 255 10 Digital Color Transient Improvement

43 LFC 255 10 Luminance Feature Control

44 LPC lowpass 255 72 Luminance Peaking Control Lowpass

45 LPC highpass 255 68 Luminance Peaking Control Highpass

No. Item Range Initial value Description

46 ST 15 7 Default

47 SP 15 7 Default

48 L 15 9 Default

49 AL1 31 20 Default

50 AL2 31 10 Default

51 AL3 7 0 Default

52 ADJ 1 0 Default

No. Item Range Initial value Description

Alignment and Adjustments

Samsung Electronics 5-7

5-5-7 Progressive Module (CXA2101) Adjustment

58 sub bright 63 55 0:-13 IRE, 31:CENTER, 63:+13 IRE

59 CR offset1 15 7 Fixed value (7:0mV)

60 CB offset1 15 7 Fixed value (7:0mV)

61 sub con 15 7 Contrast gain control

(0:-1.9dB, 7:0dB, 15:+1.7dB)

62 sub col 15 7 Color gain control

(0:-2.1dB, 7:0dB, 15:+1.8dB)

63 sub hue 15 5 Hue center control

(0:-8O red, 8:CENTER, 15:+8O green)

64 CTI level 3 0 Color difference signal edge enhancement setting

(0:OFF, 1:Low, 2:Medium, 3:High)

65 RY/R 15 2 R-Y axis +(R-Y) component setting

66 RY/B 15 6 R-Y axis -(B-Y) component setting

67 GY/R 15 9 G-Y axis -(R-Y) component setting

68 GY/B 15 12 G-Y axis -(B-Y) component setting

69 OSD gain 15 15 OSD gain contrl (0:-5dB, 15:0dB)

70 gamma 15 0 Control of gamma correction amount (0:OFF, 15:MAX)

71 sub shp 3 2 Sharpness center control (0:0dB, 3:+4dB)

72 shp f0 3 2 Sharpness f0 setting

73 PRE OVER 3 3 Preshoot to overshoot ratio setting

74 LTI level 3 1 Luminance signal edge enhancement setting

(0:OFF, 1:Low, 2:Medium, 3:High)

75 D PIC 3 3 Dynamic picture (black expansion) control

(0:OFF, 1:Low, 2:Medium, 3:High)

76 LIMIT level 3 0 Limiter to cope with excessively high inputs

(0:OFF, 1:111 IRE, 2:119 IRE, 3:127 IRE)

77 DC tran 3 2 Y system DC transmission ratio setting

No. Item Range Initial value Description

Alignment and Adjustments

5-8 Samsung Electronics

5-5-8 Option

78 MPX option 1 1 MPX mode setting

1:Maintains the setting for MPX mode

0:Switch the MPX mode to Mono(using the Channel Up/Down keys)

79 Image inversion 1 0 Image inversion setting (0:OFF, 1:ON)

80 AUTO power 1 0 Auto Power On setting (0:OFF, 1;ON)

81 timer on video 1 0 Timer On Video setting (0:OFF, 1:ON)

82 DTV RGB source 1 0 DTV RGB source setting (0:YPbPr, 1:RGBHV)

83 V-CHIP OPTION 1 1 V-Chip setting (0:Non-Vchip, 1:Vchip)

84 total time 00000 Records total elapsed time (from the point where power is first applied)

Reset not possible

85 lamp life 00000 Records total elapsed time (see above)

Reset (using the Mute key)

Reset is done during the set shipment

Reset must be done after lamp replacement

No. Item Range Initial value Description

Alignment and Adjustments

Samsung Electronics 5-9

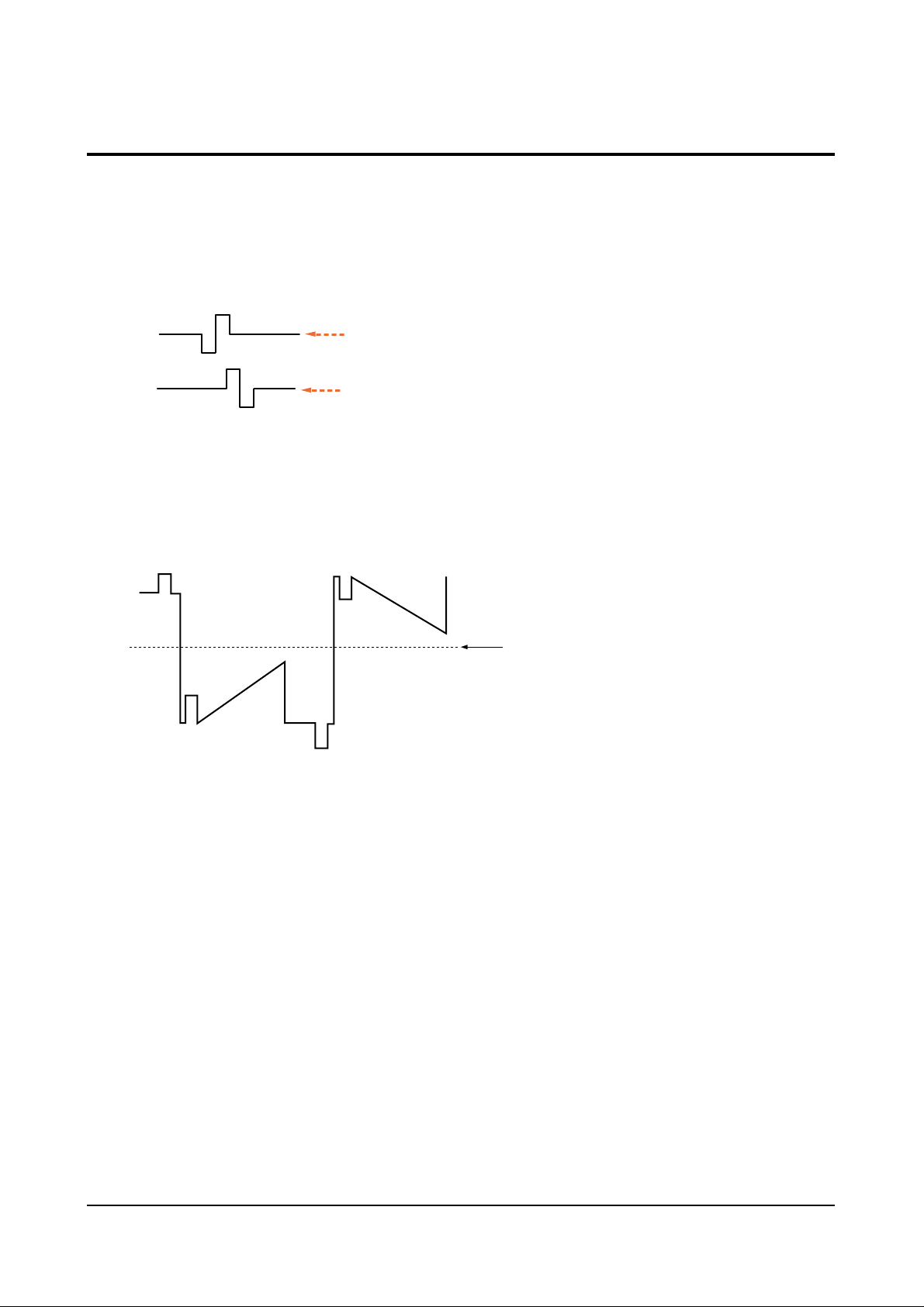

5-6-1 LCD Control Board PLL Adjustment (CNL06)

1. Input a color bar signal.

2. Connect RPD,FPD to an oscilloscope, and check the waveforms (1V/div, 20 µs /div).

5-6-2 Signal Center Adjustment

1. Input a 5-STEP or 7-STEP signal (COLOR OFF).

2. Connect TPL304 (G1) to an oscilloscope, and check the waveforms (2V/div,10µs /div).

5-6-3 Common Voltage Adjustment

1. Connect CNL08 (COMMON) to an oscilloscope (1V/div, 10 µsec/div).

2. Set the common control (#18) to DC 6.8V.

5-6-4 Center Convergence Adjustment

1. Input a lion head pattern from a pattern generator.

2. Adjust the LCD Horizontal/Vertical POS (#24, #25).

5-6-5 SH Position Adjustment

1. Input a lion head pattern from a pattern generator.

2. Adjust the SH position (#26) to balance the position of the sample/hold pulse.

5-6 Circuit Adjustments

RPD

FPD

Adjust so that the DC level

of RPD becomes 2.5V

Adjust so that the DC level of

FPD becomes 2.5V

Adjust the signal center (#19) so that the DC level of the signal center becomes 7V.

center

Alignment and Adjustments

5-10 Samsung Electronics

5-6-6 (C) ADJUSTMENTS

1. Preadjustment

- Input a 10-Step Gray-Scale Pattern.

- Enter the Factory Mode by pressing the TV/VIDEO on the remote control.

2. Sub-bright Adjustment : Adjust so that the value of luminance of the probe

➁

meets the reference coordinate table.

3. Middle White Adjustment : Adjust the factory value of r sub bright, b sub bright

so that the value of the probe

➁ meets the reference coordinate table.

4. High White Adjustment : Adjust the factory value of r sub contrast, b sub contrast

so that the probe

➂ meets the reference coordinate table.

5. Low White Adjustment : Adjust the factory value of

γ ctrl1 so that the value

of luminance of the probe

① meets the reference coordinate table.

6. Low White Adjustment : Adjust the factory value of r

γ ctrl1, b γ ctrl1 so that the

value of the probe

① meets the reference coordinate table.

7. Check that the measurement value of the probe

①,➁,➂ meets the reference coordinate

table (see above). Otherwise, re-do the white balance adjustments.

5-6-6 White Balance Adjustment

5-6-6 (A) REFERENCE COORDINATE TABLE

5-6-6 (B) POSITION OF MEASUREMENT PROBE

Special Notes:

- When the value of the Middle White does not meet the Reference Coordinate Table,

adjust after selecting the factory value of r,b main bright.

- Adjust the CA100 Probe after calibrating it.

- Use a Shibasoku Pattern Generator (10-Step Pattern Generator).

100mm

1

2 3 4 5 6 7 8 9 10

1Probe

2Probe

3Probe

10-sept signal input

W/B Spec

CA-100

Diffusion F ilter Used

yxY

H/L 270 261

7.0

M/L 273 250

L/L 275

260

±

±

±

0.5

0.5

1.5

0.20 0.03

Loading...

Loading...