SAMSUNG SH09ZP2 Service Manual

ROOM AIR CONDITIONER

INDOOR UNIT

SH07ZP2

SH07ZP2A

SH09ZP2

SH09ZP2A

SH12ZP4

SH12ZP4A

AQ07P2GE

AQ09P2GE

AQ12P4GE

AQT12P4GB

AQT12P4GE

SERVICE

OUTDOOR UNIT

SH07ZP2X

SH07ZP2AX

SH09ZP2X

SH09ZP2AX

SH12ZP4X

SH12ZP4AX

UQ07P2GE

UQ09P2GE

UQ12P4GE

UQT12P4GB

UQT12P4GE

Manual

CONTENTSAIR CONDITIONER

1. Product Specifications

2. Operating Instructions

3. Disassembly and Reassembly

4. Refrigerating Cycle Diagram

5. Set Up the Model Option

6. Troubleshooting

7. Exploded Views and Parts List

8. Block Diagram

9. PCB Diagram

10. Wiring Diagram

11. Schematic Diagram

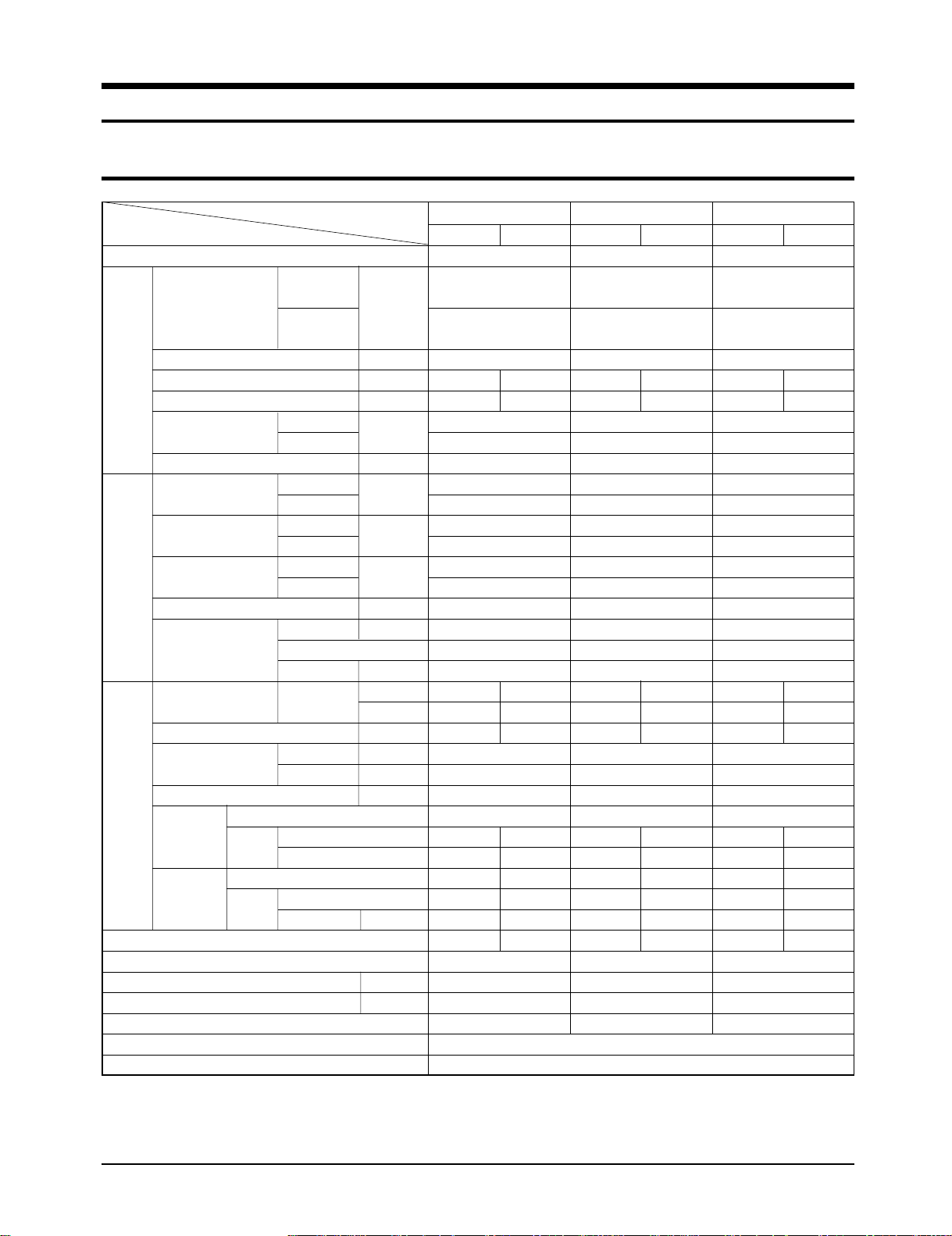

1. Product Specifications

1-1 Table

Item

Type

Capacity

( ) : RUSSIA, CIS

Performance

Dehumidifying

Air Volume m

Noise dB

Energy Efficiency Ratio

Power V-Hz

Power Consumption

Operating Current

Power Factor

Power

Starting Current A

Power Cord Number of Core Wire

Outer Dimension

Weight kg

Refrigerant Pipe

Drain Hose D x L(mm)

Size

Compressor Motor Type

Blower Motor Type

Heat Exchanger

Refrigerant Control Unit

Freezer Oil Capacity cc

Refrigerant to Change(R22) g

Protection Device(OLP)

Cooling Test Condition

Maximum Operation Condition

Type

Type

Cooling

Heating

Cooling

Heating

Cooling

Heating

Cooling

Heating

Cooling

Heating

Length m

Capacity A

W x H x D

Liquid mm x L(m)

GAS mm x L(m)

Rated Output

Rated Output W

Model

-

|/h

3

/min

W/W

W

A

%

mm

inch

SH07ZP2 SH09ZP2 SH12ZP4

Indoor unit Outdoor unit Indoor unit Outdoor unit Indoor unit Outdoor unit

Wall-mounted

2.20kW

(7,500 BTU/h)

2.30kW

(7,800 BTU/h)

0.9

6.5 24

36 50

3.24

3.65

1-220 / 240-50

680

630

3.0

2.8

98.6

97.8

21.0

-

-

250V-10 / 16A

795x258x179 660x495x235

31.3x10.2x7.0 26.0x19.5x9.3

7.5 22.5

ø6.35 x 5

ø9.52 x 5

ø18 x 2,000

Rotary

--

--

Cross-flow Propeller

steel steel

11 25

2ROW 10STEP 1ROW 18STEP

CAPILLARY TUBE

290

680

MRA99137-9201

INDOOR UNIT : DB27˚C WB19˚C OUTDOOR UNIT : DB35˚C WB24˚C

INDOOR UNIT : DB32˚C WB23˚C OUTDOOR UNIT : DB43˚C WB26˚C

Wall-mounted

2.60kW

(8,990 BTU/h)

2.90kW

(8,990 BTU/h)

1.4

7.0 24

40 51

2.89

3.41

1-220 / 240-50

900

850

4.0

3.8

97.8

97.3

21.0

-

-

250V-10 / 16A

795x258x179 660x495x235

31.3x10.2x7.0 26.0x19.5x9.3

7.5 26.5

ø6.35 x 5

ø9.52 x 5

ø18 x 2,000

Rotary

--

--

Cross-flow Propeller

steel steel

11 25

2ROW 10STEP 1ROW 18STEP

CAPILLARY TUBE

350

680

MRA98776

890x285x179 720x530x260

35.0x11.2x7.0 28.3x20.9x10.2

2ROW 12STEP 1ROW 20STEP

Wall-mounted

3.50kW

(11,990 BTU/h)

3.80kW

(11,990 BTU/h)

1.9

8.2 24

43 53

3.04

3.45

1-220 / 240-50

1,150

1,100

5.1

5.0

98.0

96.5

32.0

-

-

250V-10 / 16A

8.5 33.0

ø6.35 x 5

ø12.7 x 5

ø18 x 2,000

Rotary

--

--

Cross-flow Propeller

steel steel

15 25

CAPILLARY TUBE

410

800

Internal

1Samsung Electronics

Table(cont.)

Item

Type

Capacity

( ) : RUSSIA, CIS

Perfor-

mance

Dehumidifying |/h

Air Volume m3/min

Noise dB

Energy Efficiency Ratio

Power V-Hz

Power Consumption

Operating Current

Power Factor

Power

Starting Current A

Power Cord Number of Core Wire

Outer Dimension

Weight kg

Refrigerant Pipe

Drain Hose D x L(mm)

Size

Compressor Motor Type

Blower Motor Type

Heat Exchanger

Refrigerant Control Unit

Freezer Oil Capacity cc

Refrigerant to Change(R22) g

Protection Device(OLP)

Cooling Test Condition

Maximum Operation Condition

Type

Type

Cooling

Heating

Cooling

Heating

Cooling

Heating

Cooling

Heating

Cooling

Heating

Length m

Capacity A

W x H x D

Liquid mm x L(m)

GAS mm x L(m)

Rated Output

Rated Output W

Model

-

W/W

W

A

%

mm

inch

SH07ZP2A SH09ZP2A SH12ZP4A

Indoor unit Outdoor unit Indoor unit Outdoor unit Indoor unit Outdoor unit

Wall-mounted

2.30kW

(7,500BTU/h)

2.40kW

(7,800BTU/h)

0.9

6.5 24

36 50

3.15

3.53

1-220/240-50

730

680

3.3

3.1

96.2

95.4

21.0

-

-

250V-10/16A

795x258x179 660x495x235

31.3x10.2x7.0 26.0 x 19.5x9.3

7.5 26.0

ø6.35 x 5

ø9.52 x 5

ø18 x 2,000

Rotary

--

--

Cross-Flow Propeller

steel steel

15 25

2ROW 10STEP 1ROW 18STEP

CAPILLARY TUBE

360

630

RAC12144-9622

INDOOR UNIT : DB27˚C WB19˚C OUTDOOR UNIT : DB35˚C WB24˚C

INDOOR UNIT : DB32˚C WB23˚C OUTDOOR UNIT : DB43˚C WB26˚C

Wall-mounted

2.65kW

(8,990BTU/h)

2.90kW

(8,990BTU/h)

1.4

7.0 24

39 51

2.82

3.30

1-220/240-50

940

880

4.3

4.0

95.0

95.7

21.0

-

-

250V-10/16A

795x258x179 660x 495x235

31.3x10.2x7.0 26.0x19.5x9.3

7.5 26.5

ø6.35 x 5

ø9.52 x 5

ø18 x 2,000

Rotary

--

--

Cross-Flow Propeller

steel steel

15 25

2ROW 10STEP 1ROW 18STEP

CAPILLARY TUBE

360

600

RAC12110-9622

890x285x179 720x530x260

35.0x11.2x7.0

Cross-Flow Propeller

2ROW 12STEP 1ROW 20STEP

Wall-mounted

3.50kW

(11,990BTU/h)

3.80kW

(11,990BTU/h)

1.9

8.2 24

43 53

3.04

3.45

1-220/240-50

1,150

1,100

5.1

5.0

98.0

95.7

32.0

-

-

250V-10/16A

28.3x20.9x10.2

8.5 33.0

ø6.35 x 5

ø12.7 x 5

ø18 x 2,000

Rotary

--

--

steel steel

15 25

CAPILLARY TUBE

600

800

RAC12074-9622

Samsung Electronics2

Item

Type

Capacity

Dehumidifying |/h

Air Volume m3/min

Perfor-

mance

Power

Noise dB

Energy Efficiency Ratio

Power V-Hz

Power Consumption

Operating Current

Power Factor

Starting Current A

Power Cord Number of Core Wire

Outer Dimension

Weight kg

Refrigerant Pipe

Drain Hose D x L(mm)

Type

Compressor Motor Type

Size

Type

Blower Motor Type

Heat Exchanger

Refrigerant Control Unit

Freezer Oil Capacity cc

Refrigerant to Change(R22) g

Protection Device(OLP)

Cooling Test Condition

Maximum Operation Condition

Cooling

Heating

Cooling

Heating

Cooling

Heating

Cooling

Heating

Cooling

Heating

Length m

Capacity A

W x H x D

Liquid mm x L(m)

GAS mm x L(m)

Rated Output

Rated Output W

BTU/W.h

Model

BTU/h

W

A

%

mm

inch

AQ07P2GE AQ09P2GE AQ12P4GE

Indoor unit Outdoor unit Indoor unit Outdoor unit Indoor unit Outdoor unit

Wall-mounted

7,500

7,800

0.9

6.5 24

36 50

10.3

11.5

1-220/240-50

730

680

3.3

3.1

96.2

95.4

21.0

-

-

250V-10/16A

795x258x179 660x495x235

31.3x10.2x7.0 26.0 x 19.5x9.3

7.5 26.0

ø6.35 x 5

ø9.52 x 5

ø18 x 2,000

Rotary

--

--

Cross-Flow Propeller

steel steel

15 25

2ROW 10STEP 1ROW 18STEP

CAPILLARY TUBE

360

630

RAC12144-9622

INDOOR UNIT : DB27˚C WB19˚C OUTDOOR UNIT : DB35˚C WB24˚C

INDOOR UNIT : DB32˚C WB23˚C OUTDOOR UNIT : DB43˚C WB26˚C

Wall-mounted

9,000

10,000

1.4

7.0 24

39 51

9.57

11.4

1-220/240-50

940

880

4.3

4.0

95.0

95.7

21.0

-

-

250V-10/16A

795x258x179 660x 495x235

31.3x10.2x7.0 26.0x19.5x9.3

7.5 26.5

ø6.35 x 5

ø9.52 x 5

ø18 x 2,000

Rotary

--

--

Cross-Flow Propeller

steel steel

15 25

2ROW 10STEP 1ROW 18STEP

CAPILLARY TUBE

360

600

RAC12110-9622

Wall-mounted

12,000

13,000

1.9

8.2 24

43 53

10.4

11.8

1-220/240-50

1,150

1,100

5.1

5.0

98.0

95.7

32.0

-

-

250V-10/16A

890x285x179 720x530x260

35.0x11.2x7.0

8.5 33.0

Cross-Flow Propeller

steel steel

2ROW 12STEP 1ROW 20STEP

CAPILLARY TUBE

28.3x20.9x10.2

ø6.35 x 5

ø12.7 x 5

ø18 x 2,000

Rotary

--

--

15 25

600

800

RAC12074-9622

3Samsung Electronics

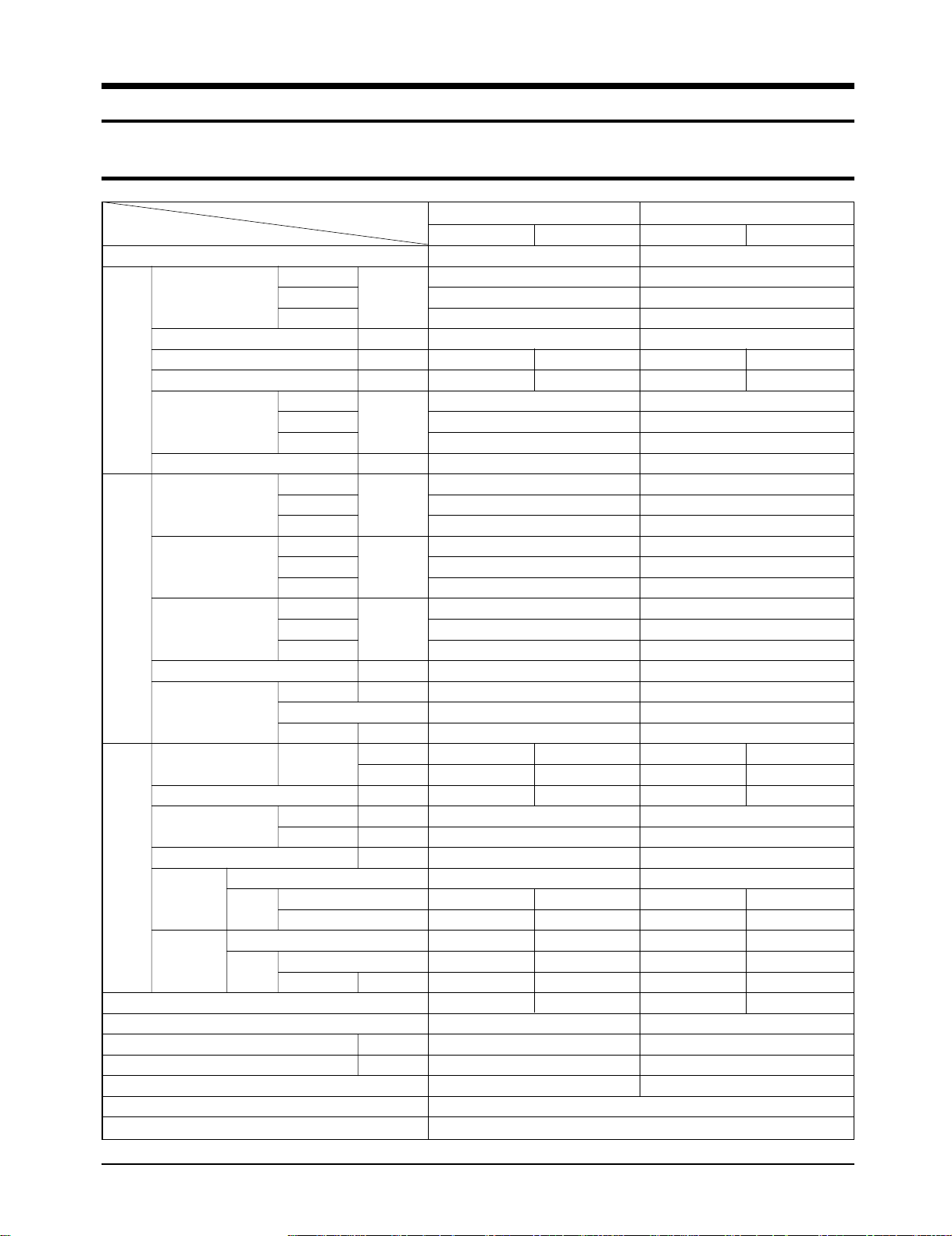

Table(cont.)

Item

Type

Cooling

Capacity Heating BTU/h

SASO

Dehumidifying |/h

Perfor-

mance

Air Volume m

Noise dB

Cooling

Energy Efficiency Ratio Heating BTU/W.h

SASO

Power V-Hz

Cooling

Power Consumption Heating W

SASO

Cooling

Operating Current Heating A

Power

Power Factor Heating %

Starting Current A

Power Cord Number of Core Wire

Outer Dimension

Weight kg

Refrigerant Pipe

Size

Drain Hose D x L(mm)

Type

Compressor Motor Type

Type

Blower Motor Type

Heat Exchanger

Refrigerant Control Unit

Freezer Oil Capacity cc

Refrigerant to Change(R22) g

Protection Device(OLP)

Cooling Test Condition

Maximum Operation Condition

SASO

Cooling

SASO

Length m

Capacity A

W x H x D

Liquid mm x L(m)

GAS mm x L(m)

Rated Output

Rated Output W

Model

3

/min

mm

inch

AQT12P4GB AQT12P4GE

Indoor unit Outdoor unit Indoor unit Outdoor unit

Wall-mounted

12,000

13,000

10,500

1.9

8.2 2.4

43 53

10.0

10.5

7.44

1-220-60

1,200

1,240

1,410

5.5

5.7

6.5

99.2

98.9

98.6

32.0

-

-

250V-10/16A

890x285x179 720x530x260

35.0x11.2x7.0 28.3x20.9x10.2

8.5 33.0

ø6.35 x 5

ø12.7 x 5

ø18 x 2,000

Rotary

--

--

Cross-Flow Propeller

steel steel

15 25

2ROW 12STEP 2ROW 24STEP

CAPILLARY TUBE

600

960

RBC12107-12500

INDOOR UNIT : DB27˚C WB19˚C OUTDOOR UNIT : DB35˚C WB24˚C

INDOOR UNIT : DB32˚C WB23˚C OUTDOOR UNIT : DB43˚C WB26˚C

890x285x179 720x530x260

35.0x11.2x7.0 28.3x20.9x10.2

Cross-Flow Propeller

2ROW 12STEP 2ROW 24STEP

Wall-mounted

12,000

13,000

-

1.9

8.2 2.4

43 53

10.0

11.0

-

1-220/240-50

1,200

1,180

-

5.3

5.2

-

98.4

98.7

-

32.0

-

-

250V-10/16A

8.5 33.0

ø6.35 x 5

ø12.7 x 5

ø18 x 2,000

Rotary

--

--

steel steel

15 25

CAPILLARY TUBE

410

940

RBC12050-12500

Samsung Electronics4

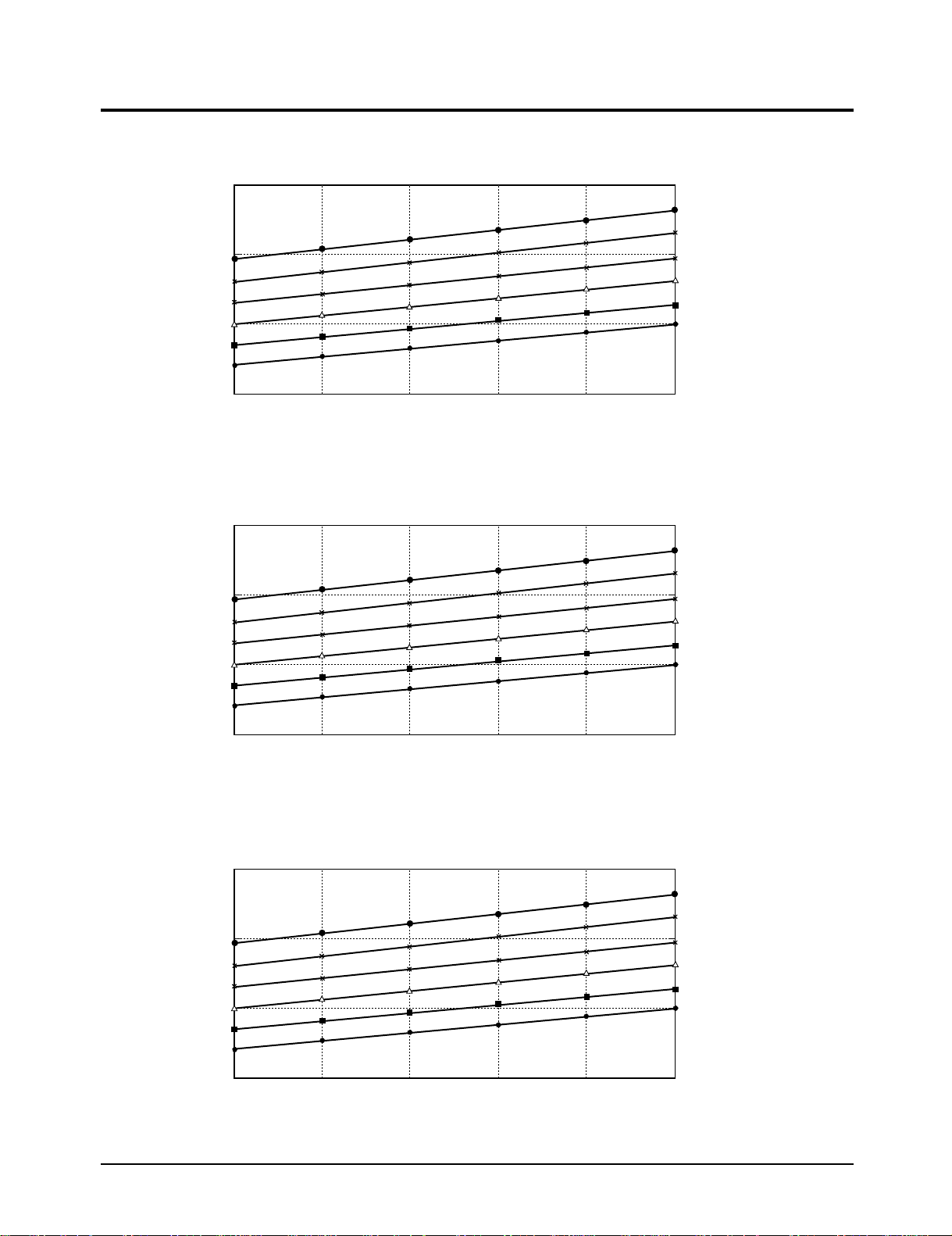

1-2 Pressure Graph

■ 7K BTU

7

G)

2

■ 9K BTU

2

6

5

Low pressure (kg/cm

4

20 25 30 35 40 45

6.5

G)

5.5

4.5

32.4/24.0

30.6/22.5

28.8/21.0

27.0/19.0

24.0/17.0

21.5/15.0

Indoor inlet air D.B. temp (˚C)

Outdoor inlet air D.B. temp (˚C)

32.4/24.0

30.6/22.5

28.8/21.0

27.0/19.0

24.0/17.0

21.5/15.0

■ 12K BTU

Low pressure (kg/cm

3.5

20 25 30 35 40 45

6.5

G)

2

5.5

4.5

Low pressure (kg/cm

3.5

20 25 30 35 40 45

Indoor inlet air D.B. temp (˚C)

Outdoor inlet air D.B. temp (˚C)

32.4/24.0

30.6/22.5

28.8/21.0

27.0/19.0

24.0/17.0

21.5/15.0

Indoor inlet air D.B. temp (˚C)

Outdoor inlet air D.B. temp (˚C)

5Samsung Electronics

2. Operating Instructions

Low Medium High

Automatic(rotated : )

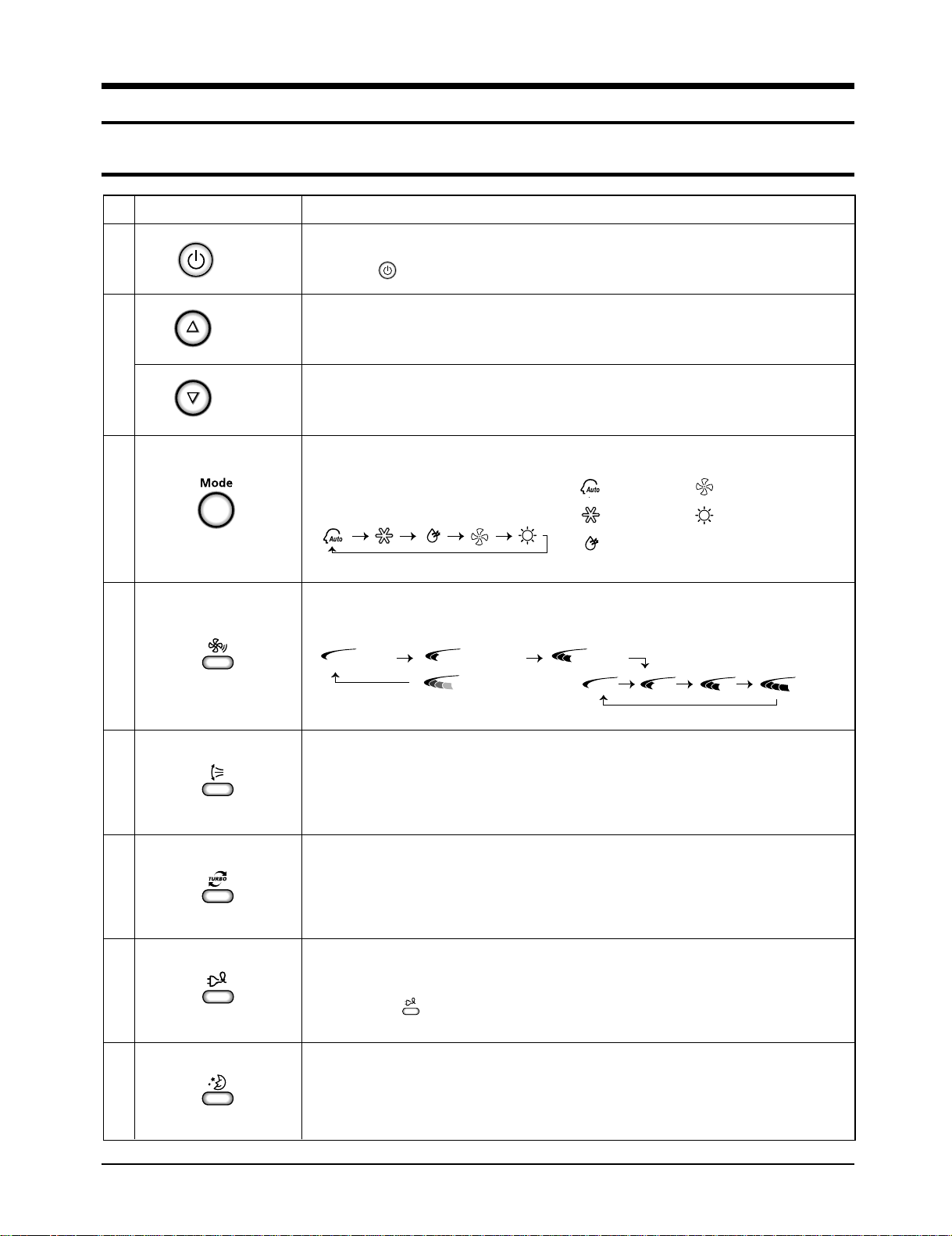

2-1 The Feature of Key in remote control

NAMED OF KEYNo

1

2

3

4

(On/Off)

(UP)

(DOWN)

On/Off button.

Press the button to stop or run the air conditioner.

Temperature adjustment button(UP).

To increase the temperature by the pressing the temperature button.

Temperature adjustment button(DOWN).

To decrease the temperature by the pressing the temperature button.

Mode selection button.

Each time you press this button

Mode is changed in the following order

Fan speed adjustment button.

Each time you press this button, FAN SPEED is changed in the following order.

FUNCTION OF KEY

: Auto Mode : Fan Only

: Cool Mode : Heat Mode

: Dry Mode

5

6

7

8

Swing button.

It adjusts the airflow to upward and downward.

Turbo button.

The air conditioner cools or heats the room as quickly as possible.

After 30minutes, the air conditioner is reset automatically to the previous mode.

Energy saving button.

If you wish to save energy when using your air conditioner, select the Energy saving

mode with the button.

Sleep button.

The sleep timer can be used when you are cooling or heating your room to switch the

air conditioner off automatically after a period of 6 hours.

Samsung Electronics6

Operating Instructions

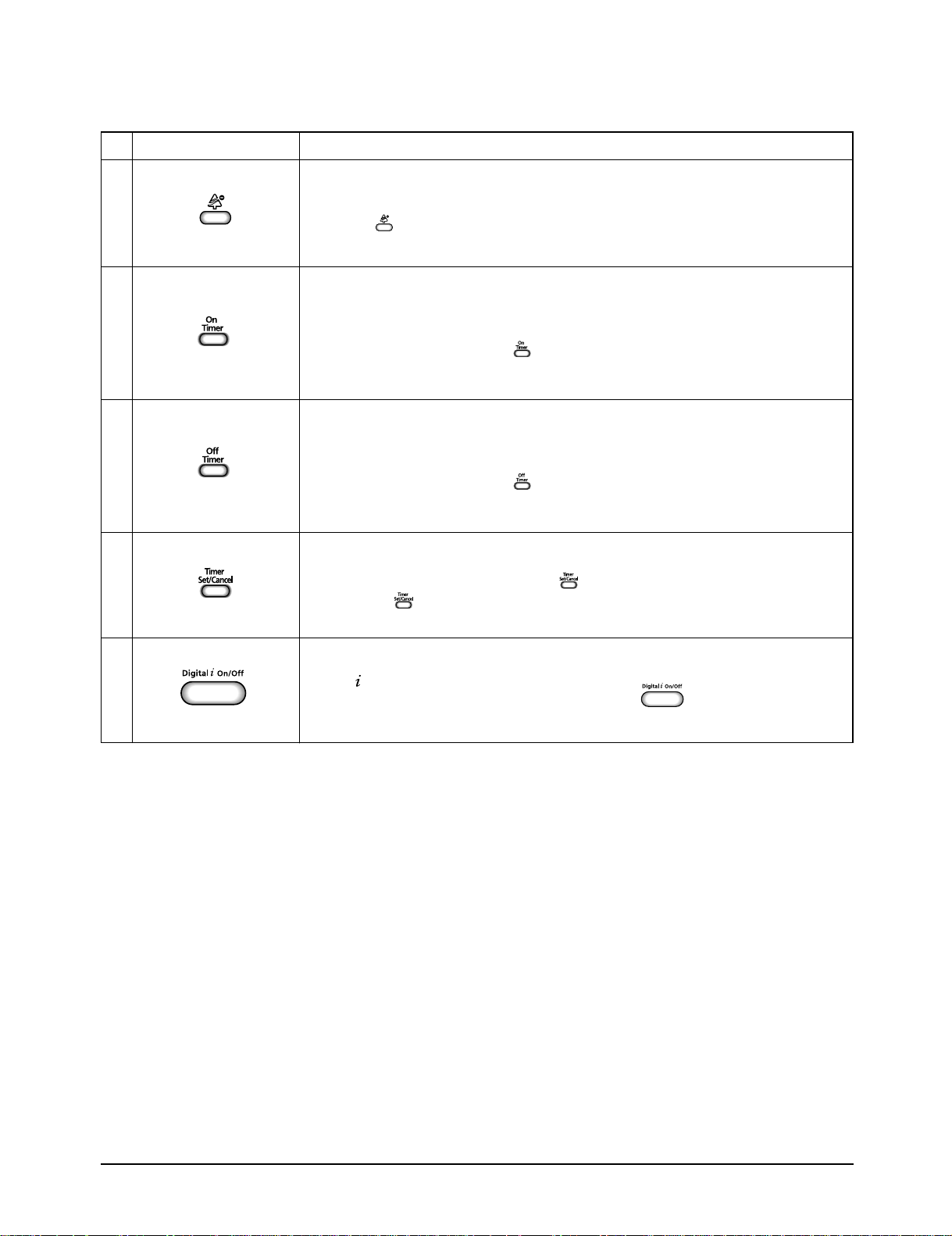

10

11

12

NAMED OF KEYNo

9

Anion button.

Press the button to generate ion from the air conditioner.

On Timer button.

The On Timer enables you to switch on the air conditioner automatically after

a given period of time that is from 30 minutes to 24 hours.

To set the operating time, press the button one or more times until the required

time display.

Off Timer button.

The Off Timer enables you to switch off the air conditioner automatically after

a given period of time that is from 30 minutes to 24 hours.

To set the operating time, press the button one or more times until the required

time display.

Timer Set/Cancel button.

After setting On Timer or Off Timer, press the button to set it completely.

And press the button again to cancel On Timer or Off Timer set.

FUNCTION OF KEY

13

Digital On/Off button.

If you want to turn off the display during operation press the button.

7Samsung Electronics

Operating Instructions

2-1-1 Name & Function of Key in remote control

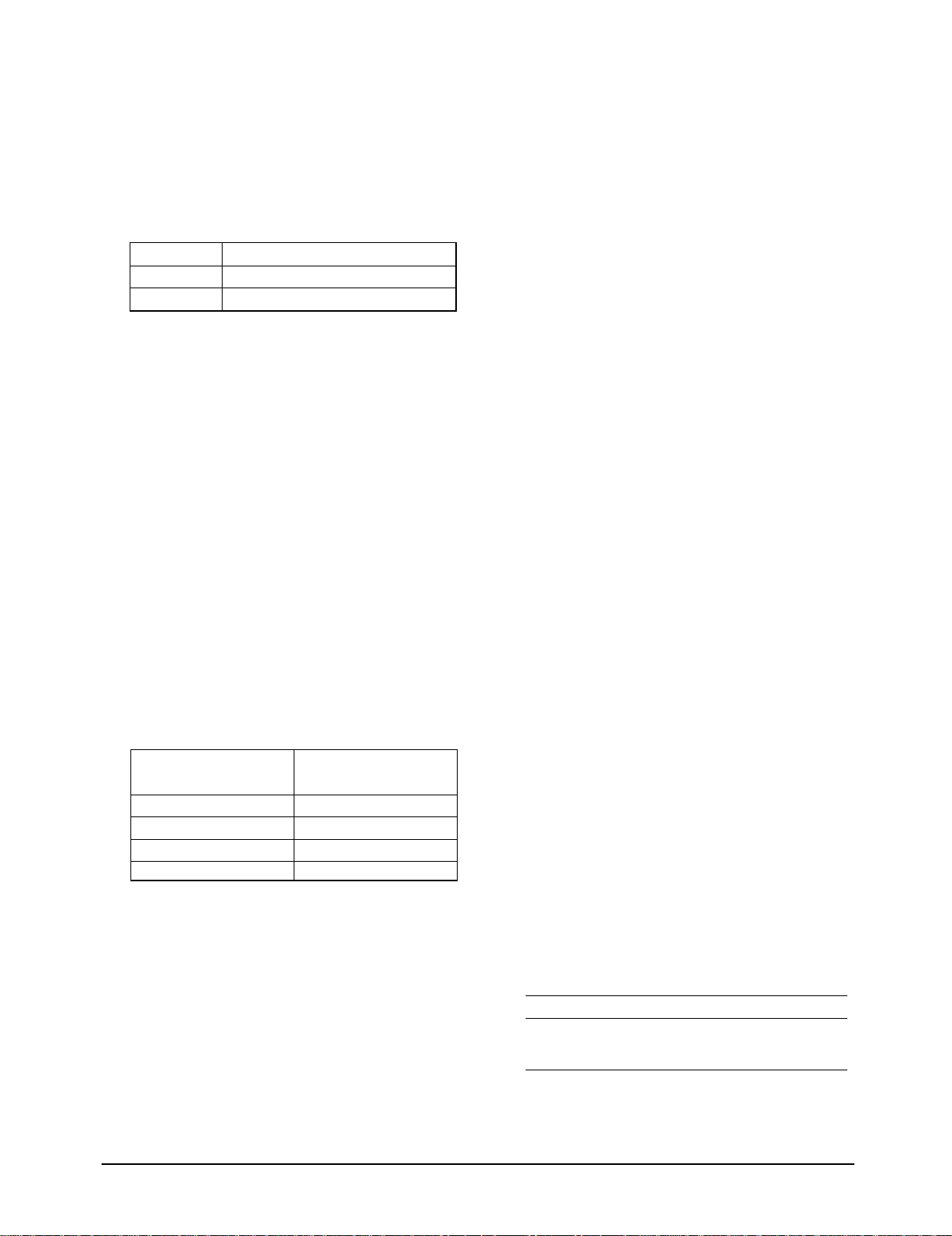

1. AUTO MODE : In this mode, operation mode(COOL,

HEAT) is selected automatically by the room temperature

of initial operation.

Room Temp

Tr≥ 21°C+∆T

21°C +∆T>Tr

Cool Operation (Set Temp:24˚C+∆T)

Heat Operation (Set Temp:22˚C+∆T)

Operation Type

∆T= -1°C, -2°C, 0°C, +1°C, +2°C

∆T is controlled by setting temperature up/down key of

remote control

2. COOL MODE : The unit operates according to the

difference between the setting and room temperature.

(18°C~30°C)

3. HEAT MODE : The unit operates according to the

difference between the setting and room temperature.

(16°C~30°C)

*Prevention against cold wind : In order to prevent the

cool air from flowing out at the heat mode, the indoor fan

does not operate or operates very slowly in the

following cases. At this time, the indoor heat exchanger

will be preheating.

- For 3~5 minutes after the initial operation

- For deicing operation

- The operation of an indoor fan in accordance with

the temperature of an indoor heat exchanger

The temperature of

indoor heat exchanger

below 28˚C

28˚C~below 34˚C

34˚C~below 40˚C

above 40˚C

Indoor fan speed

off

LL Speed

L Speed

Setting Speed

*High temperature release function : It is a function to

detect an outdoor overload by the sensor of an indoor

heat exchanger and to turn the outdoor fan or the

compressor ON/OFF for safety.

*Deice : Deicing operation is controlled by indoor unit's

heat exchanger temperature and accumulating time of

compressor's operation.

Deice ends by sensing of the processing time by deice

condition.

4. DRY MODE : Has 3 states, each determined by room

temperature.

The unit operates in DRY mode.

*Compressor ON/OFF Time is controlled compulsorily

(can not set up the fan speed, always breeze).

*Protective function : Low temperature release.

(Prevention against freeze)

5. TURBO MODE : This mode is available in AUTO, COOL,

HEAT, DRY, FAN MODE.

When this button is pressed at first, the air conditioner is

operated “powerful” state for 30 minutes regardless of the

set temperature, room temperature.

When this button is pressed again, or when the operating

time is 30 minutes, turbo operation mode is canceled and

returned to the previous mode.

*But, if you press the TURBO button in DRY or FAN

mode that is changed with AUTO mode automatically.

6. SLEEP MODE : Sleep mode is available only in COOL or

HEAT mode.

The operation will stop after 6 hours.

*In COOL mode : The setting temperature is automatical-

ly raised by 1°C each 1hour When the temperature

has been raised by total of 2°C, that temperature is

maintained.

*In HEAT mode : The setting temperature is automatically

dropped by 1°C each 1hour.

When the temperature has been dropped by total of 2°C,

that temperature is maintained.

7. FAN SPEED : Manual (3 step), Auto (4 step)

Fan speed automatically varies depending on both the

difference between setting and the room temperature.

8. COMPULSORY OPERATION :

For operating the air conditioner without the remote

control.

*The air conditioner starts up in the most suitable mode

for the room temperature:

Room Temperature

Less than 21˚C

21˚C or above

Operating Mode

Heat

Cool

Temperature Setting

22˚C approx.

24˚C approx.

Samsung Electronics8

Operating Instructions

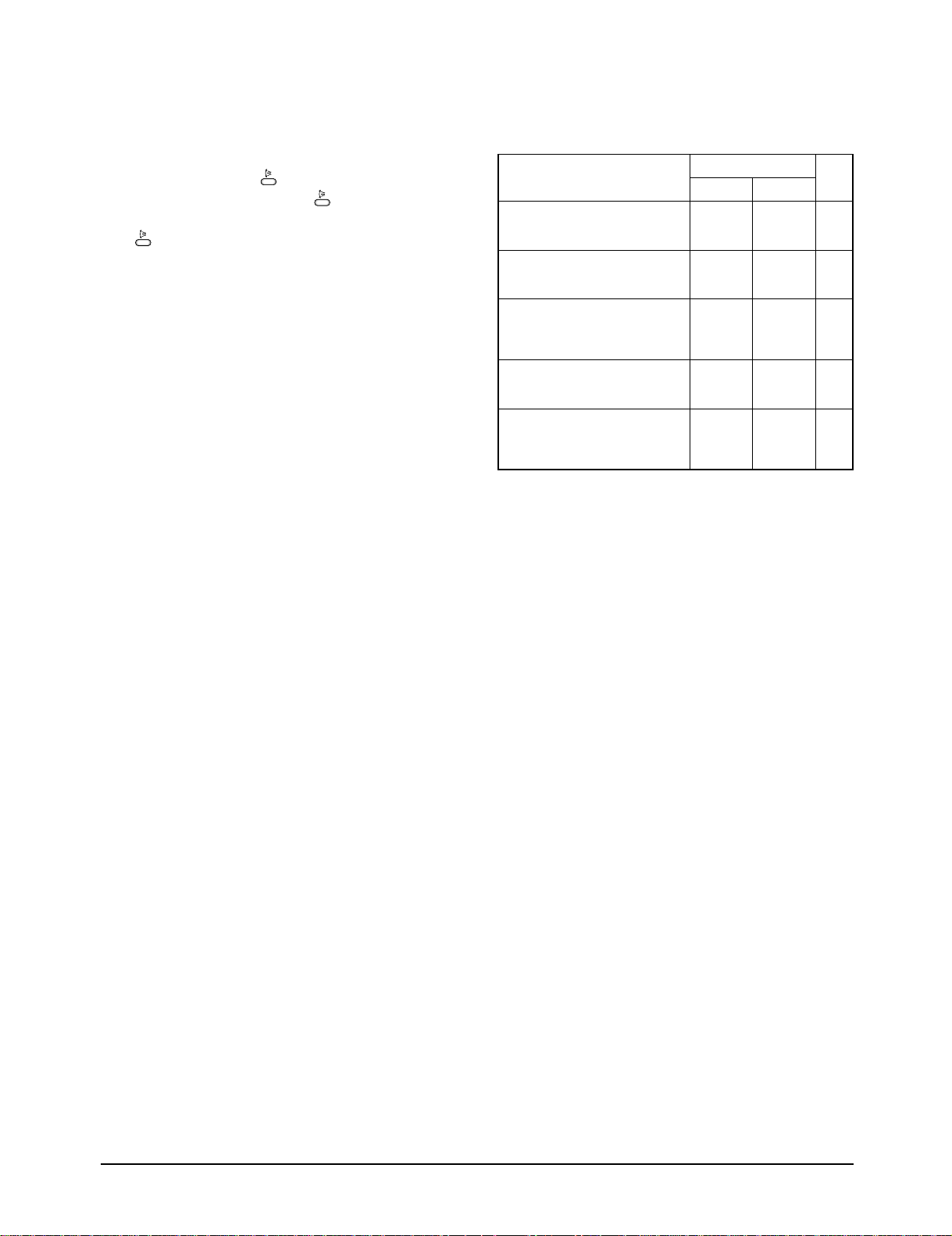

9. SWING : BLADE-H is rotated vertically by the stepping

motor.

*Swing Set : Press the button under the remote

control is displayed on LCD the and the blades

move up and down. If the one more time press the

button, blades location is stop.

10. SETTING THE ON/OFF TIMER. :

*ON TIMER : The On Timer enables you to switch on the

air conditioner automatically after a given period of time.

You can set the period of time from 30 minutes to 24

hours.

*OFF TIMER : The Off Timer enables you to switch off

the air conditioner automatically after a given period of

time. You can set the period of time from 30 minutes to

24 hours.

1 1. GENERATING ANION :

The air conditioner can generate anion with an ionizer in

the indoor unit.

12. SELF DIAGNOSIS

Error Mode

Indoor unit room temperature sensor

error (open or short)

Indoor unit heat exchanger

temperature sensor error(open or short)

Indoor FAN MOTOR error :

Keep the RPM value 450 below for

15 seconds

EEPROM error

Error in option

In case of No option set-up

In case of option data error

DISPLAY 7-SEGMENT

Operation Off Operation On

OFF E1

OFF E2

OFF E3

OFF E6

All lamp

blinking

All lamp

blinking

Remark

13. BUZZER SOUND : Whenever the On/Off button is

pressed or whenever change occurs to the condition

which is set up or select, the compulsory operation mode,

buzzer is sounded "beep".

9Samsung Electronics

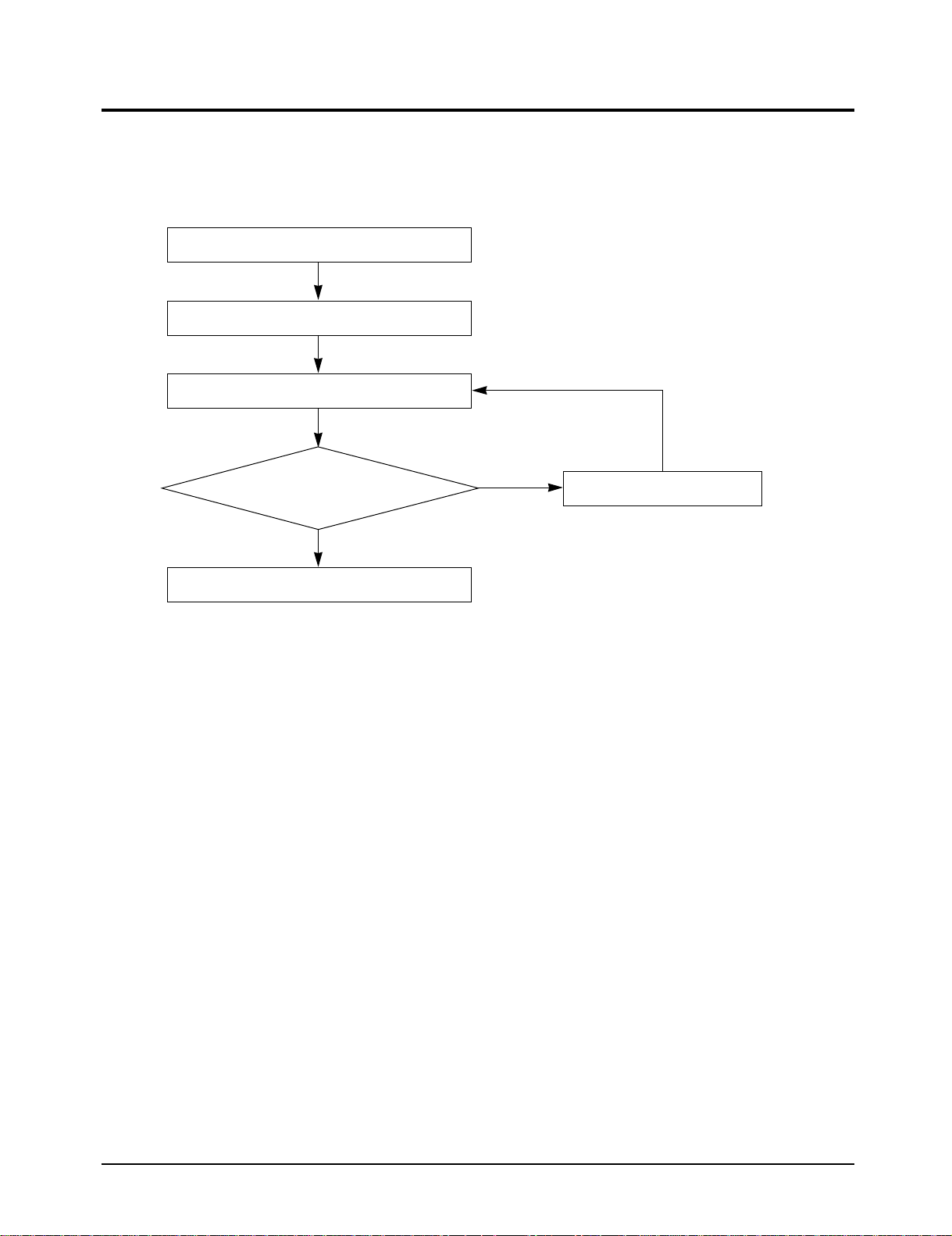

2-2 Replace PCB Model option

2-2-1 Replace PCB model option

Remove power cord

Replace the PCB module

Check the connection and plug in

Does all display lamp blink?

Yes

Refer to set up the Model option(17~19page)

No

Replace another PCB

Samsung Electronics10

3. Disassembly and Reassembly

Stop operation of the air conditioner and remove the power cord before repairing the unit.

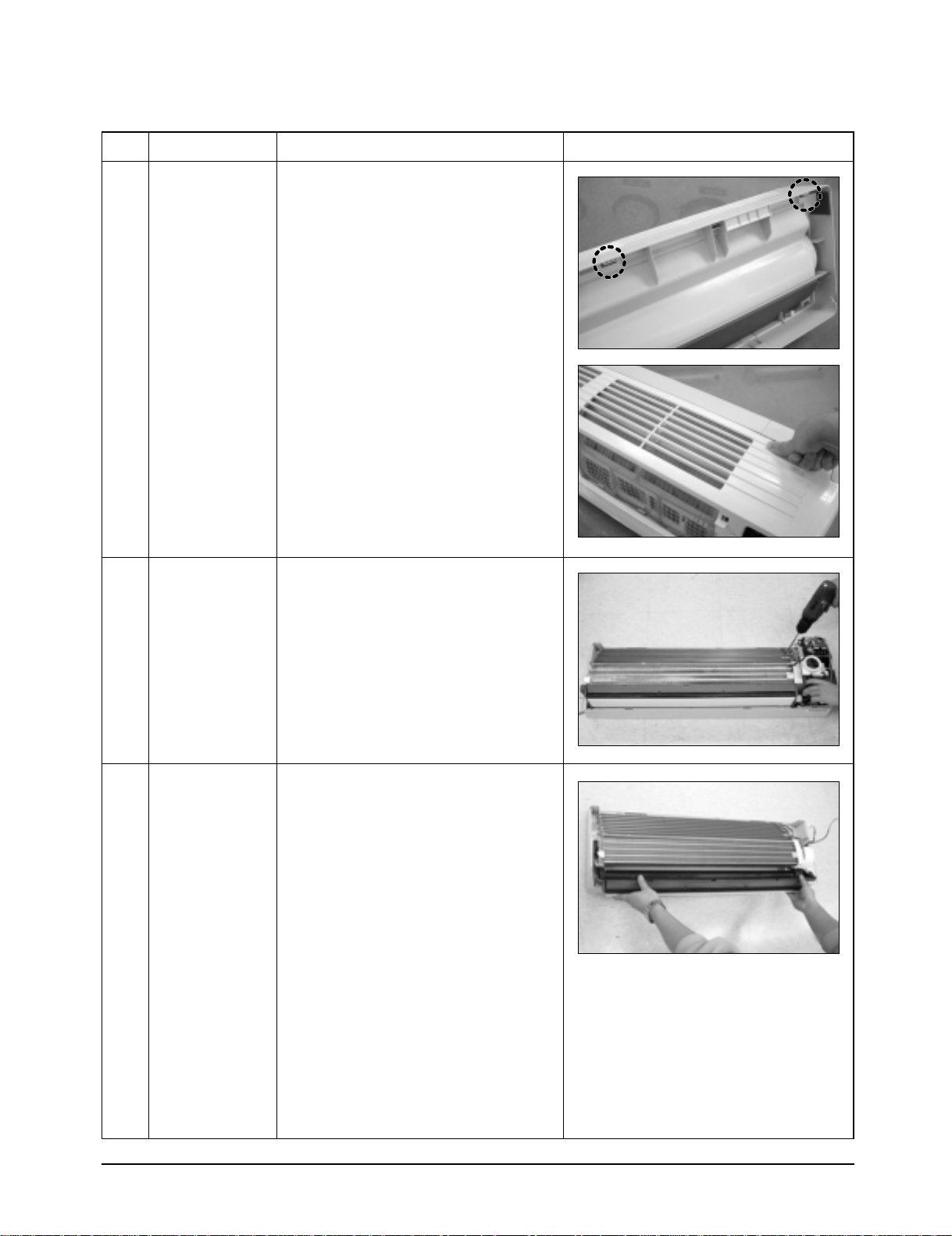

3-1 Indoor Unit

No Parts Procedure Remark

1 Front Panel

1) Stop the air conditioner operation and block

the main power.

2) Separate tape of Front Panel upper.

3) Slide the lower Front Grille down, then

disassemble it by pulling it forwards.

4) Open the upper Front Grille by pulling right

and left sides of the Grille.

5) Take the left and right Filter out.

6) Loosen one of the right screw and detach

the Terminal Cover.

7) Detach the thermistor from the Front Grille.

8) Loosen 5 fixing screws of Front Grille.

9) Pull the lower left and right of discharge

softly for the outside cover to be pulled out.

11Samsung Electronics

Disassembly and Reassembly

No Parts Procedure Remark

10) At first, press the left and center hook of

the back side of the Panel Grille with the

thumb to remove the hook. And press the

right of the upper side of the Panel Grille

with the fingers. And then disassemble the

Panel Grille.

2

3

Electrical Parts

(Main PCB)

Tray Drain

1) Take all the connector of PCB upper side

out.(Including Power Cord)

2) Detach the outdoor unit connection wire

from the Terminal Block.

3) If pulling the main PCB up, it will be taken

out.

1) Pull Tray Drain out from the Back Body.

Samsung Electronics12

Disassembly and Reassembly

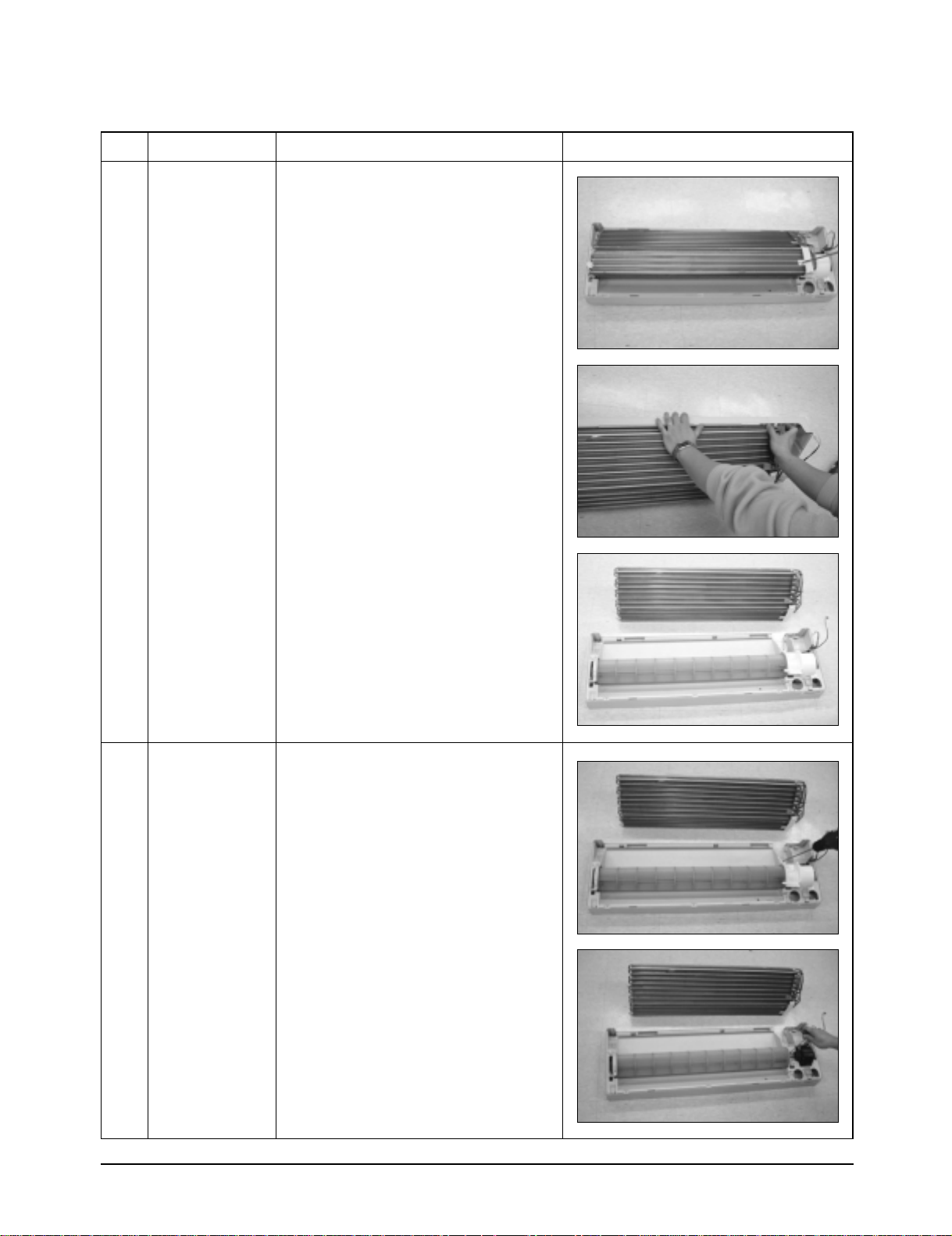

No Parts Procedure Remark

4

Heat Exchanger

1) Loosen 2 fixing earth screws of right side.

2) Detach the Connection Pipe.

3) Detach the Holder Pipe at the rear side.

4) Loosen 3 fixing screws of right and left

side.

5) Detach the Heat Exchanger from the

indoor unit.

5

Fan Motor

&

Cross Fan

1) Loosen 2 fixing screws and separate the

Motor Holder.

2) Loosen 1 fixing screw of Fan Motor.

(with a M3 wrench)

3) Detach the Fan Motor from the Fan.

4) Detach the Fan from the left Holder

Bearing.

13Samsung Electronics

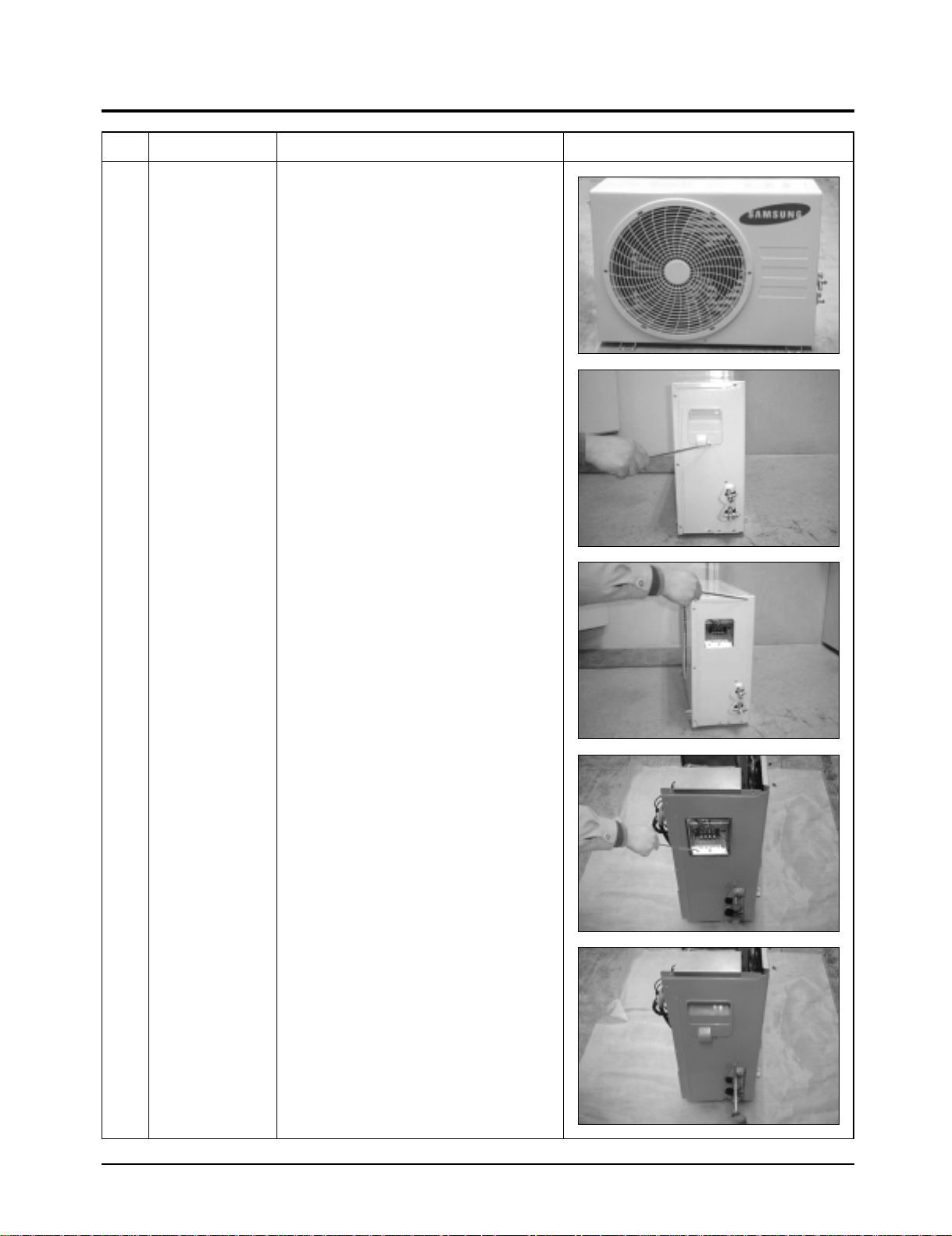

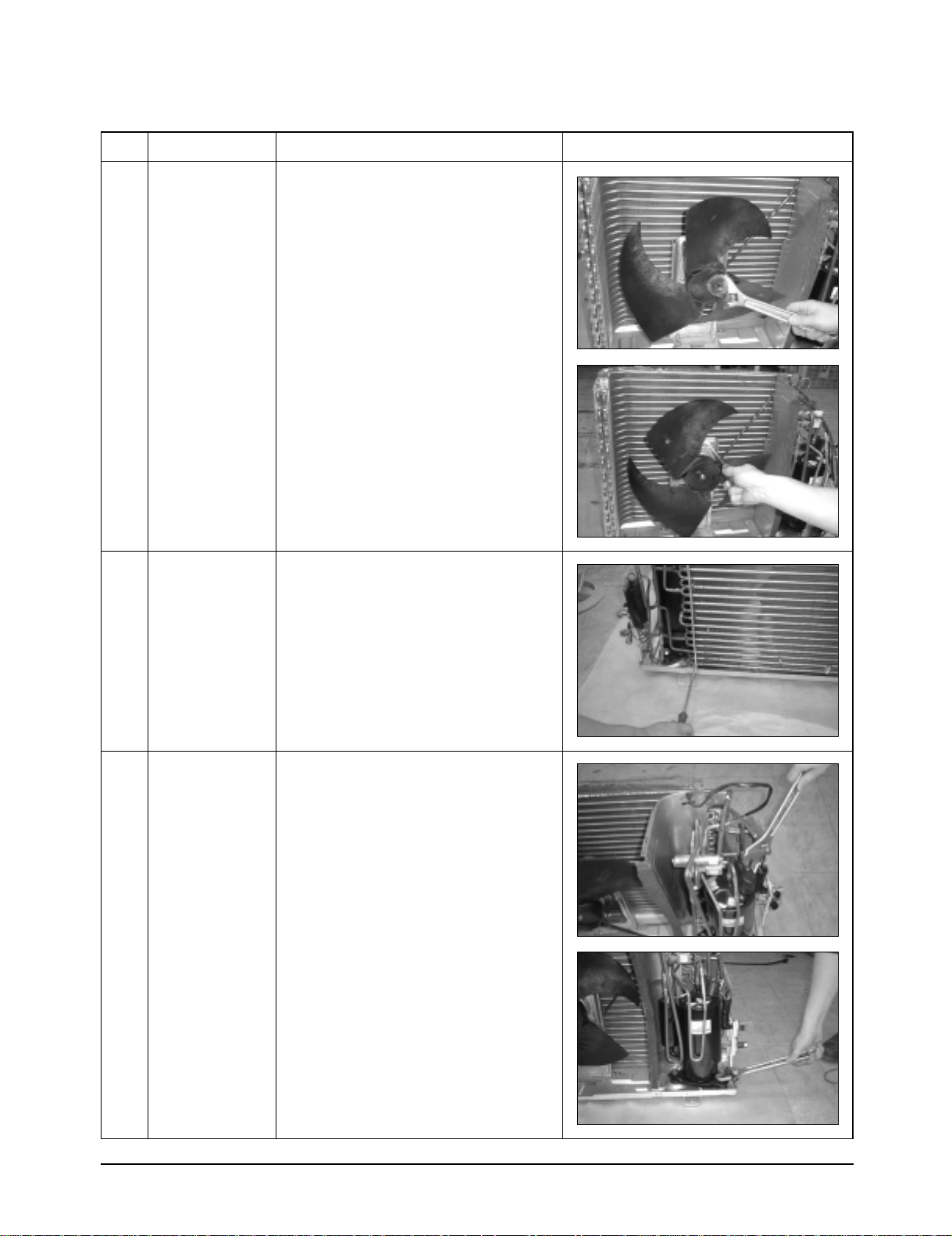

3-2 Outdoor Unit

No Parts Procedure Remark

1 Common Work

1) Loosen 1 fixing screw and detach the

Cover Terminal.

2) Loosen 1 fixing screw and detach the

Cover Control.

3) Detach the connection wire from the

Terminal Block.

4) Loosen 13 fixing screws and detach the

Cabinet-Front.

5) Loosen 1 fixing screw of Ass'y E-part.

6) Loosen 4 fixing screws and detach the

Cabinet-Side.

Samsung Electronics14

Disassembly and Reassembly

No Parts Procedure Remark

2

3

Fan

&

Motor

Heat Exchanger

1) Detach the Nut Flange (Turn to the clock-

wise).

2) Detach the Fan.

3) Loosen 4 fixing screws to detach the

Motor.

4) Loosen 5 fixing screws and detach the

Motor Bracket from the Base.

1) Loosen 2 fixing screws of left and right

side.

2) Disassemble the inlet and outlet pipe by

welding.

3) Detach the Heat Exchanger.

4

Compressor

1) Open the Terminal Cover of Compressor

and unscrew the Connection Terminal.

2) Disassemble the inlet and outlet pipe of

Compressor by welding.

3) Loosen 3 bolts of the lower part.

4) Detach the Compressor.

15Samsung Electronics

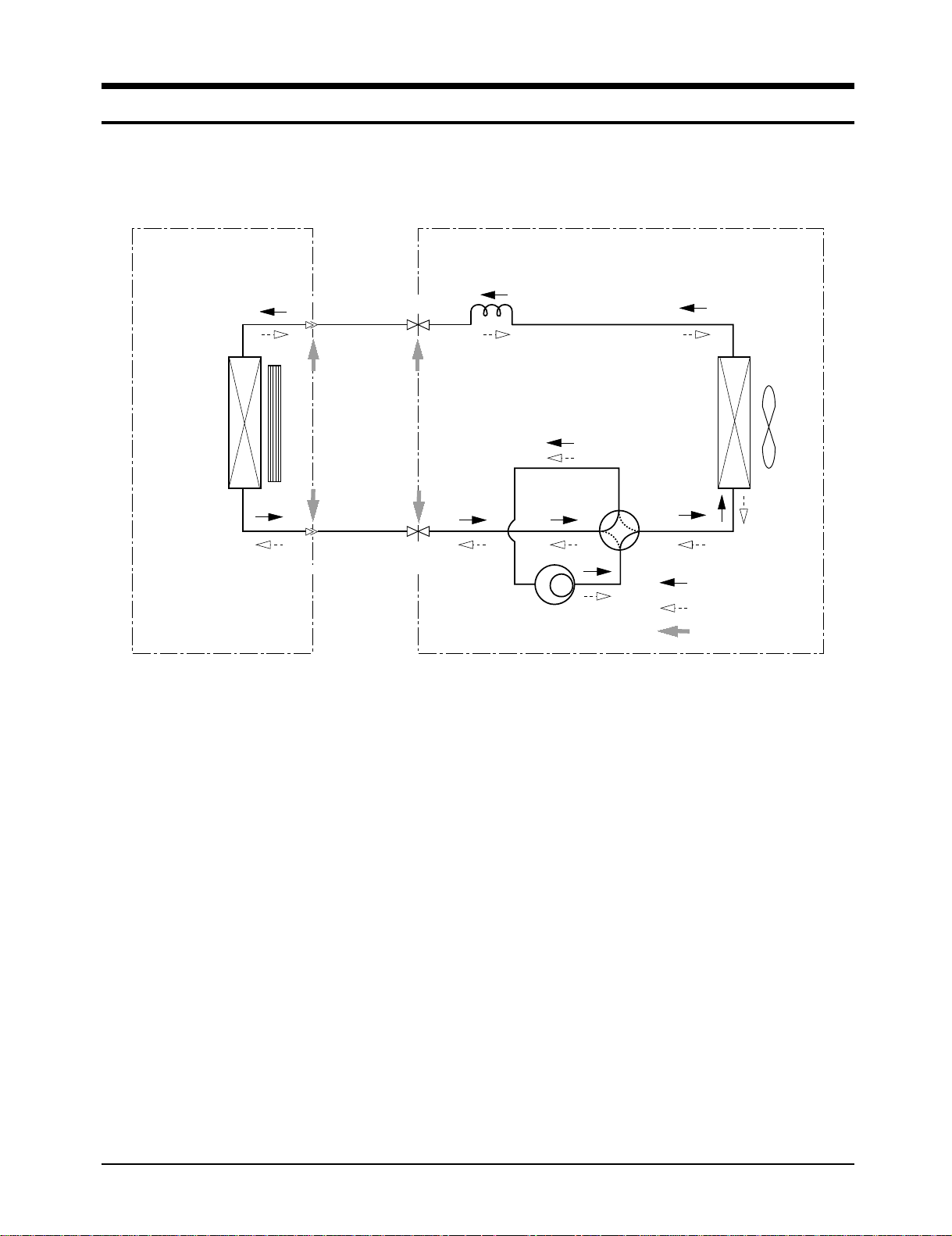

4. Refrigerating Cycle Diagram

Indoor Unit

Heat

Exchanger

(Evaporator)

Outdoor Unit

Capillary tube

T

1

Liquid side

Cross fan

T

2

Gas side

2-Way valve

3-Way valve

Compressor

Heat

Exchanger

(Condenser)

Propeller fan

4-Way valve

Cooling

Heating

Gas leak check point

Samsung Electronics16

Loading...

Loading...