SAMSUNG SG626ECSWQDOR Service Manual

REFRIGERATOR

Model : SR-L676EV

SR-L678EV

SR-L626EV

SR-L628EV

GREEN

REFRIGERATOR CONTENTS

1. Precautions

2. Product Specifications

3. Electrical Part Specifications & Standard

4. Circuit Diagram

5. Functions & Operating Instruction

6. Circuit Descriptions

7. Troubleshooting

8. Parts List

9. Disassembly & Assembly

SR-L676EV

SR-L678EV

SR-L626EV

SR-L628EV

10. PCB Circuit Diagram

11. PCB Parts List

12. Specifications of Main Components

ELECTRONICS

© Samsung Electronics Co., Ltd

August, 1998

Printed in Korea

Code No. DA68-60281C

1. Precautions

Warning : Please abide by the following

precautions in order to conduct the

maintenance procedures in a

safety fashion.

1-1. Caution when doing repairs

• Do work after extinguishing fire in the

surrounding area. When freon-gas makes

contact with the heater, hazardous gas will

leak out.

• Don’t use welding machines in confined

indoors.

• In the case of gas leakage, always open the

windows.

• When cutting the SUCTION, DISCHARGE

pipe of the compressor, always take

caution of the inner pressure of the

remaining gas.

1-2. Take out the power plug

• Always take out the power plug from the

outlet when doing repairs.

1-8. Check for disconnection

• After completing the assembly, always

measure the disconnection resistance level,

and turn on the power after checking it is

above 1MΩ.

1-9. Earth

• Check the status of earthing and repair the

incomplete ones.

1-10. Be careful of children

• There is always the possibility of danger

involved so make sure children can’t

come nearby when doing repairs.

Cleaning : After completing repairs, clean the

surrounding area and the

refrigerator and tell the consumer

about the repairs being made.

Refers to prohibition.

1-3. Be careful of electric shocks

• When inspecting the circuit, don’t touch

the battery charger and be careful of

electric shocks.

1-4. Use proper components

• Always use the component labeled in the

service component chart when replacing

components for repairs.

1-5. Use proper tools

• Always use proper tools for repairs. If

worn out tools are used, it would cause

defects in tuning and electrical contact,

leading to accidents.

1-6.

When doing repairs, inspect the

CORD

wire and make sure they are replaced.

or whether there is fire in the lead

POWER

1-7. Cutting of LEAD-WIRE

• For connecting the lead-wire that has been

cut off, use soldering or connector and

always disconnect the vinyl tapes.

Refers to prohibition of dismantling.

Refers to prohibition of contact.

Refers to guidelines which have to be

followed.

Refers to detaching the power plug

from the outlet.

Refers to earth connection for

preventing electric shocks.

Refers to possibility of death or

serious injury of a person.

Warning

Refers to possibility of injury of a

person or damage to property.

Caution

Samsung Electronics 1

Reference

Reference1

Reference2

NO

C

NC

Coil bisection

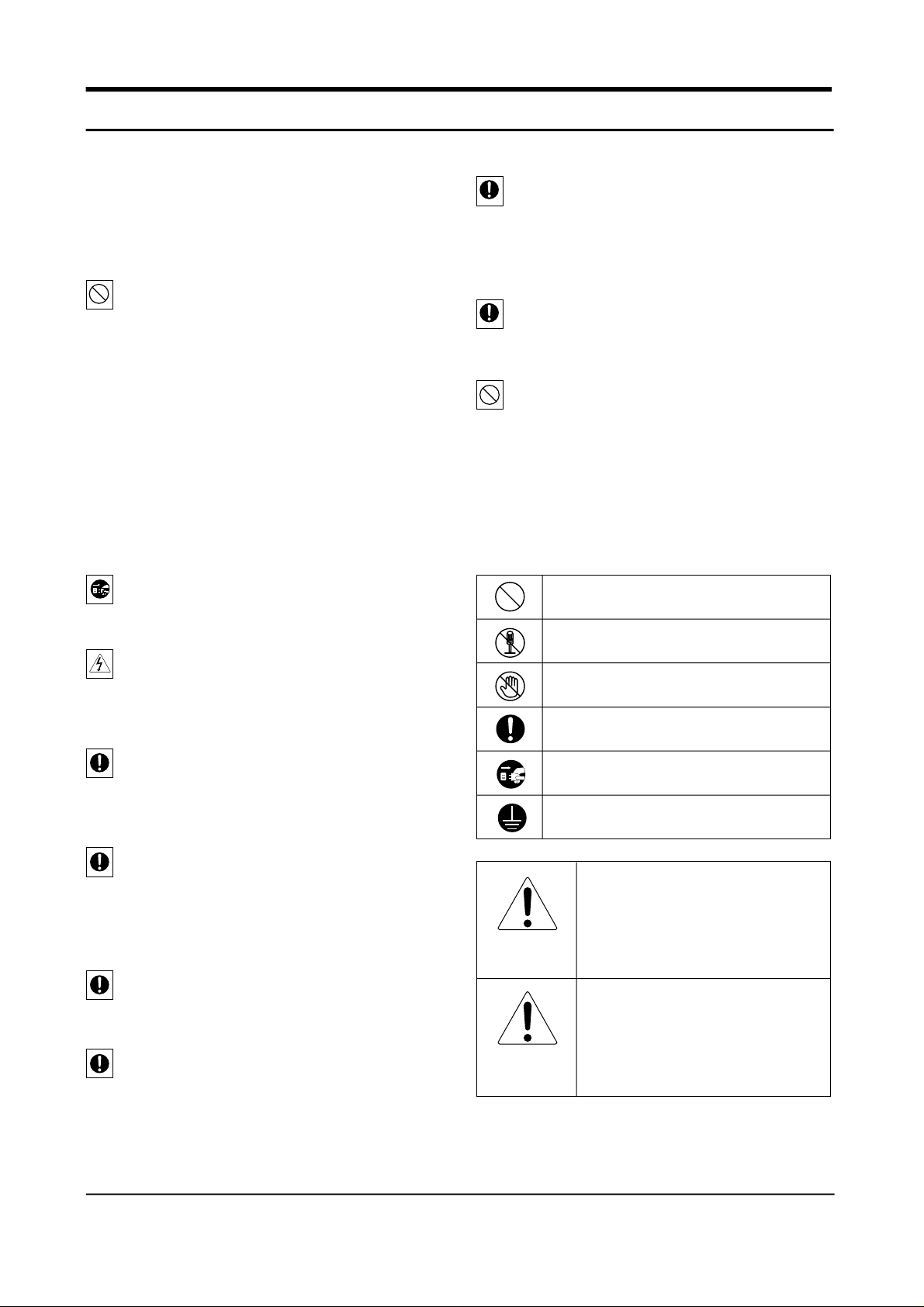

The connection of DOOR-CABI

BLK

1

2

BRN

3

MAIN

PCB

RED

4

ORG

5

YEL

6

PNK

7

BLU

8

PUR

9 9 9

GRY

10

WHT

11

S/BLU

CON7

Inspection of Relay

Coil bisection

Measure after

separation

(Relay Movement)

CON9

CON10

MAIN PCB

CON8

10

11

12

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

10

11

12

10

11

1

2

3

4

5

6

7

8

9

BLK

BRN

RED

ORG

YEL

PNK

BLU

PUR

GRY

WHT

S/BLU

PANEL

PCB

* First separate the housing connected to the

main PCB CON C8, 09, 10 and measure the

following items.

1. M e a s u re the coil bisection of the relay and

check whether it works.

2. Measure the apex bisection for open circuit.

Apex category The voltage of

coil bisection

DC 12V(Operation)

Apex 3

DC 05V(Standstill)

Apex 2

DC 12V(Operation)

DC 0V(Standstill)

Judging the apex

bisection

C:NO SHORT

C:NC OPEN

C:NO OPEN

C:NC SHORT

SHORT

OPEN

Note) C →Common, NO → Normal open, NC → Normal close

3. When it operates as above, it is normal and

when it does not operate, report the

corresponding relay.

36 Samsung Electronics

Reference3

Short

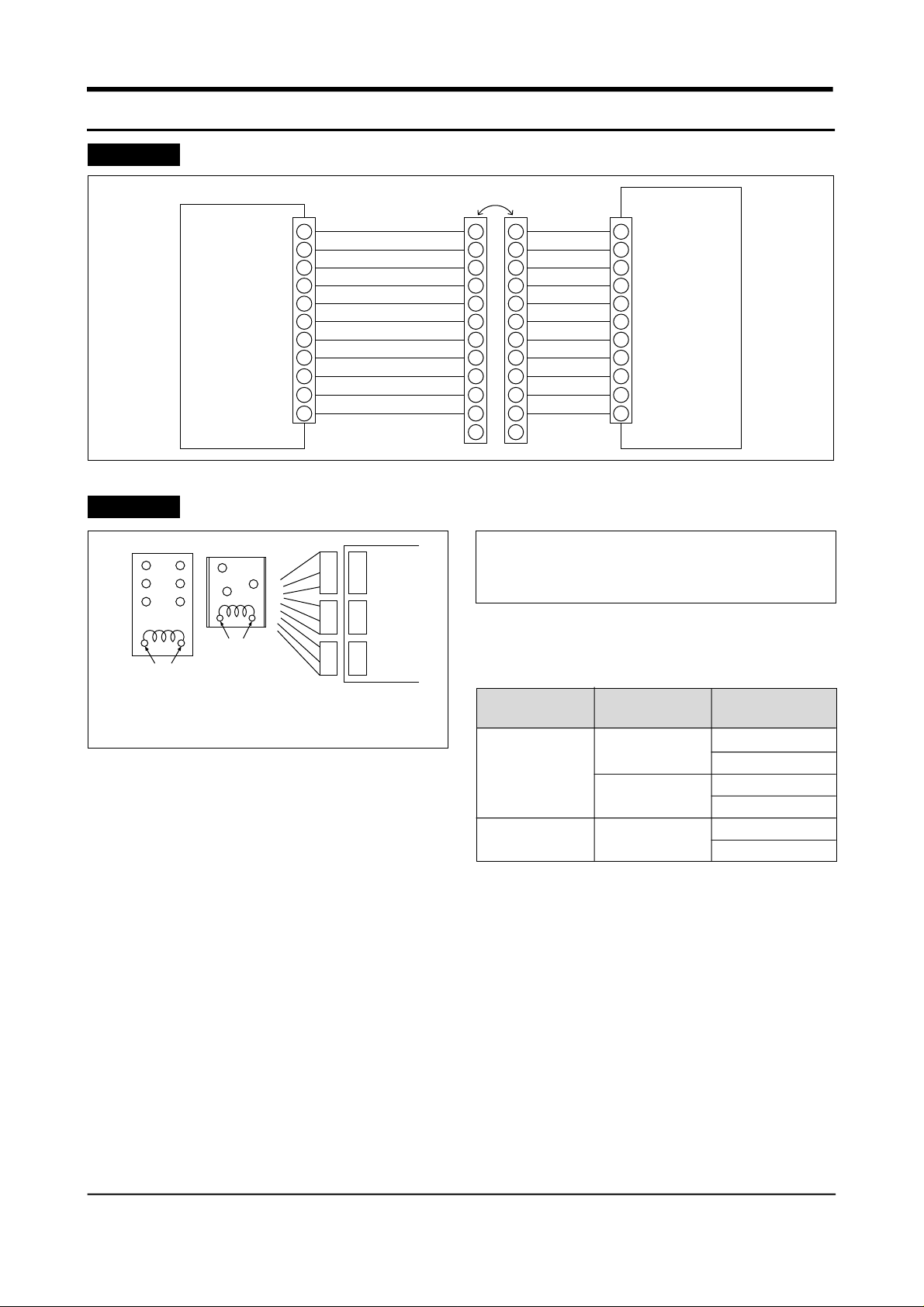

Check for malfunctioning of the subordinate

Measure after separation

* Cut off the power code, separate the housing

from the main PCB CON 08, 09, 10 and

measure the following.

CON9

R-Defrost heater

SWINT MOTOR

R-C/FAN

RED

Note) The compressor is impossible to measure resistance by the

running and starting condenser.

Reference4

R-Lamp

F-Lamp

F-C/FAN

COMP.

Inspection of the sensor

R2 ROOM

R1 ROOM

F - ROOM

R / DEF - SONSOR

F / DEF - SONSOR

RED

8

7

5

3

1

CON10

9

7

5

4

3

2

1

CON3

1

2

3

4

5

6

Measure after separation

CON2

4

3

2

1

MAIN PCB

1

2

3

CON3

4

5

6

CON9

CON10

1. Measure resistance between the terminals and

check for malfunctioning of L/W.

Subordinate

R Defrost heater

F Defrost heater

Comp

Swing motor

R-Circulation fan

F-Circulation fan

R-Lamp

F-Lamp

M e a s u r e m e n t

t e r m i n a l

CON9 ⑨& CON10

CON8 ③& CON10

CON8 ⑤& CON10

CON8 ①& CON9

CON8 ①& CON9

CON8 ①& CON10

CON8 ①& CON9

CON8 ①& CON10

Evaluation of mea-

surement result

③

0Ω or ∞Ω(defect)

③

Impossible to measure 0Ω indicator

⑤

0Ω or ∞Ω(defect)

⑤

③

⑦

①

⑨

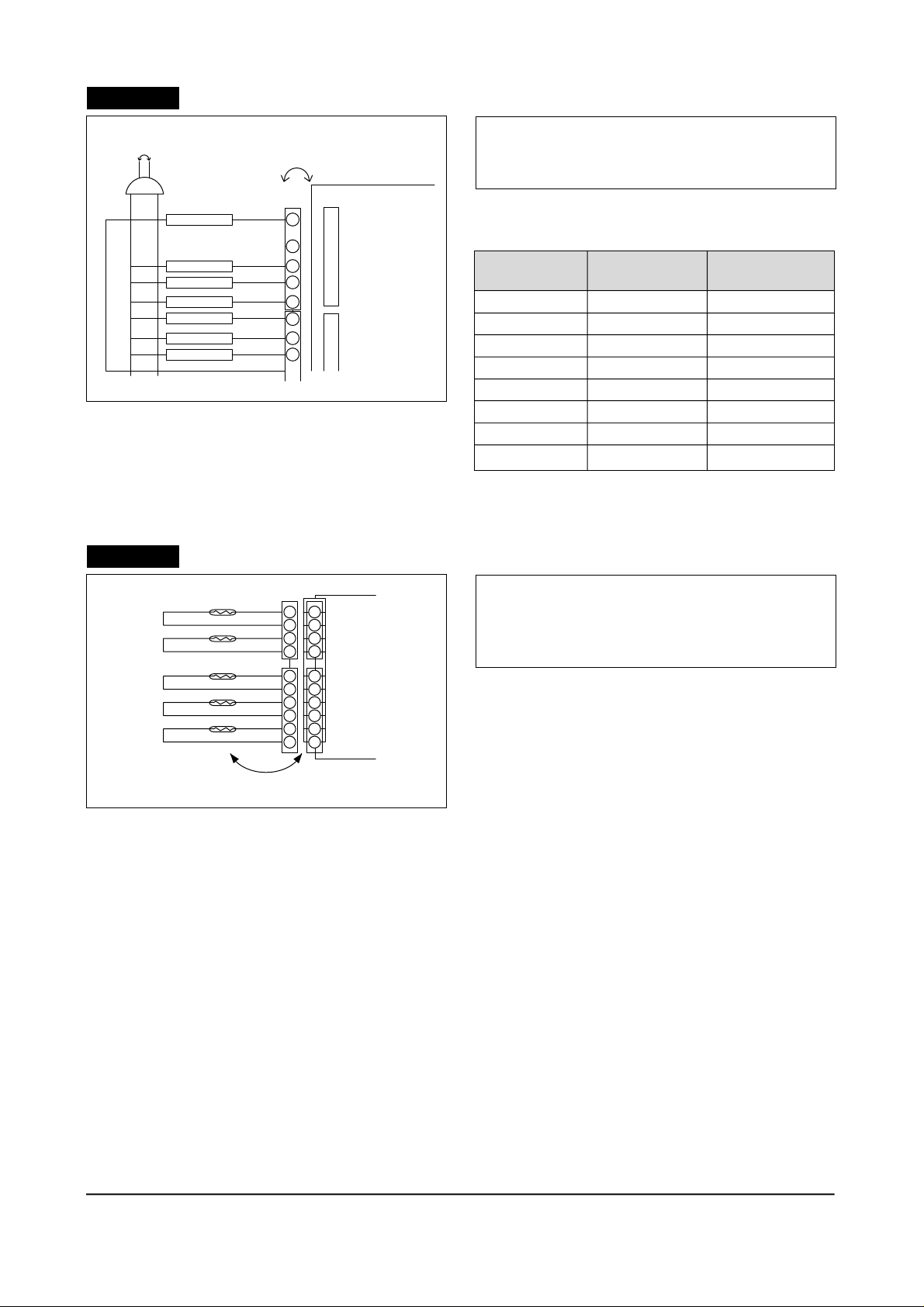

* Separate the housing connected to main PCB

CON2 and CON3.

* Resistance value lowers while temperature

rises, because it is a NTC type sensor.

1. R1 sensor measures resistance of CON2

between ①~②.

2. R2 sensor measures resistance of CON2

between ③~④.

3. Freezer sensor measures resistance of CON3

between ①~②.

4. R-defrost sensor measures resistance of CON3 between ③~④.

5. F-defrost sensor measures resistance CON3 between ⑤~⑥.

6. The measurement value above is calculated by comparing th e present temperature of the sensor and

the temperecture table in specification found in the manual.

Samsung Electronics 37

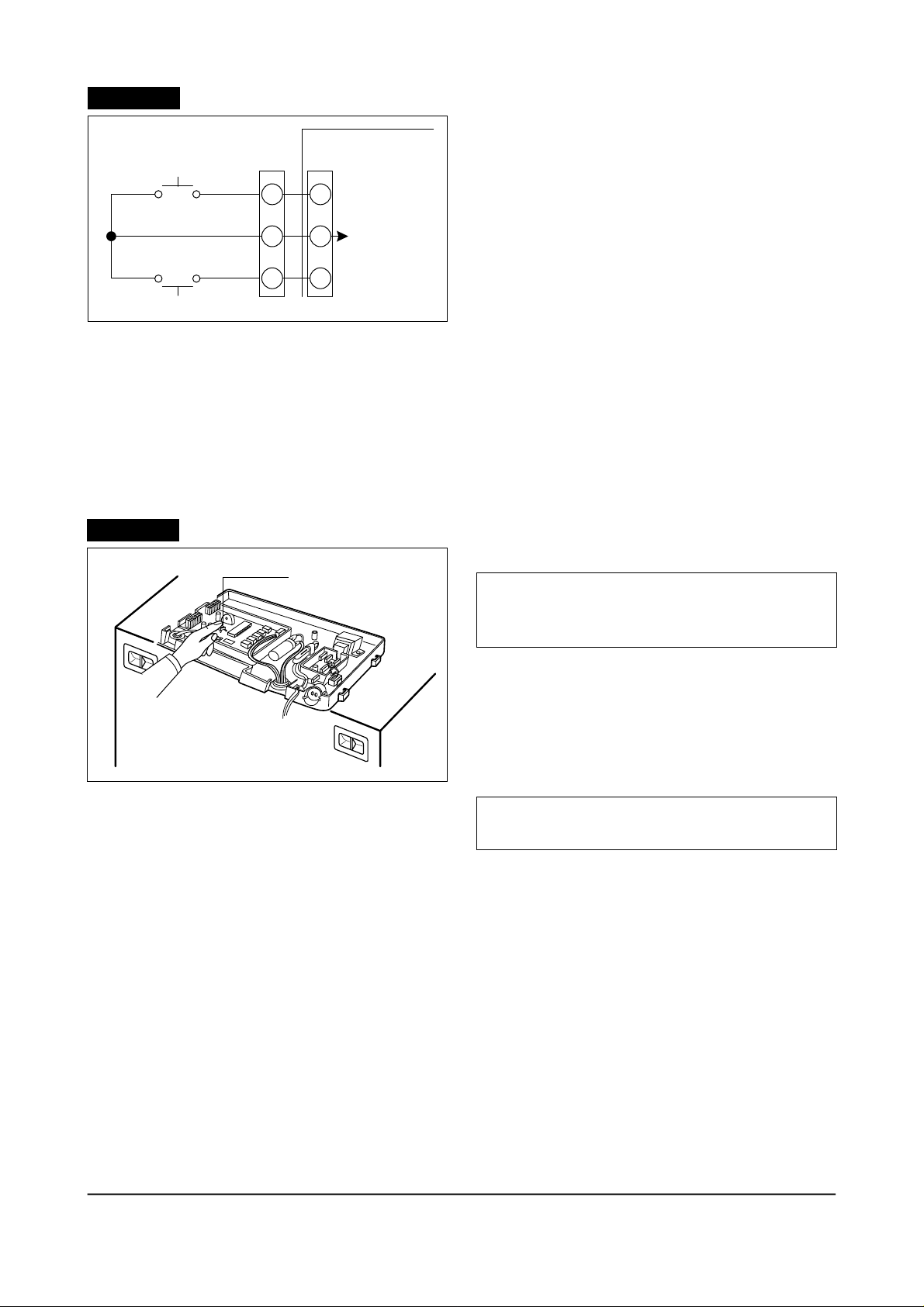

Reference5

Checking the Door S/W

(Refrigerator Bulb)

1. Open the door and check if the freezer bulb

F - Door S/W

1

1

22

CON6

MAIN

PCB

DC 12V

turns on.

2. Press the Door S/W and check if the freezer

bulb turns off.

3. Close the door of freezer and repeat 1 and 2 for

refrigerator.

3

R - Door S/W

3

4. If there is a problem, check bulb and door S/W.

5. Check wire connection.

(Micom signal)

1. Check if CON6 ① and ③is 0V DC after closing the F·R doors.

2. Check if CON6 ①is 12V DC when opening F door.

2. Check if CON6 ③is 12V DC when opening R door.

3. If there is problem, check door S/W and wire connection.

Reference6

Forced starting & forced defrosting

TEST S/W

(Forced starting)

* This function is used to turn on the comp and

fan immediately regardless of the temperature

of freezer.

1. Press the button on the PCB after removing the

main PCB cover from the upper part of

refrigerator.

2.

Buzzer will sound to indicate the forced starting.

(Forced defrosting)

* This function is used to turn on the defrosting

regardless of defrost time.

1. Press the button twice during forced starting.

Then, defrosting is performed.

2. If the button is press 3 times during Rdefrosting, F-defrosting is also performed at

the same time.

3. If the button is pressed 4 times during R-f

defrosting, test mode is released.

38 Samsung Electronics

Reference7

Sensor Short : Micom 0V.

Sensor Open : Micom 5V.

Sensor resistance and voltage conversion table for temperature

(Sensor pressure voltage 10KΩ – Voltage converted by the F-reference)

* Voltage conversion table depends on H/W structure of MICOM port input voltage.

✽ Sensor partial pressure resistance 10KΩ

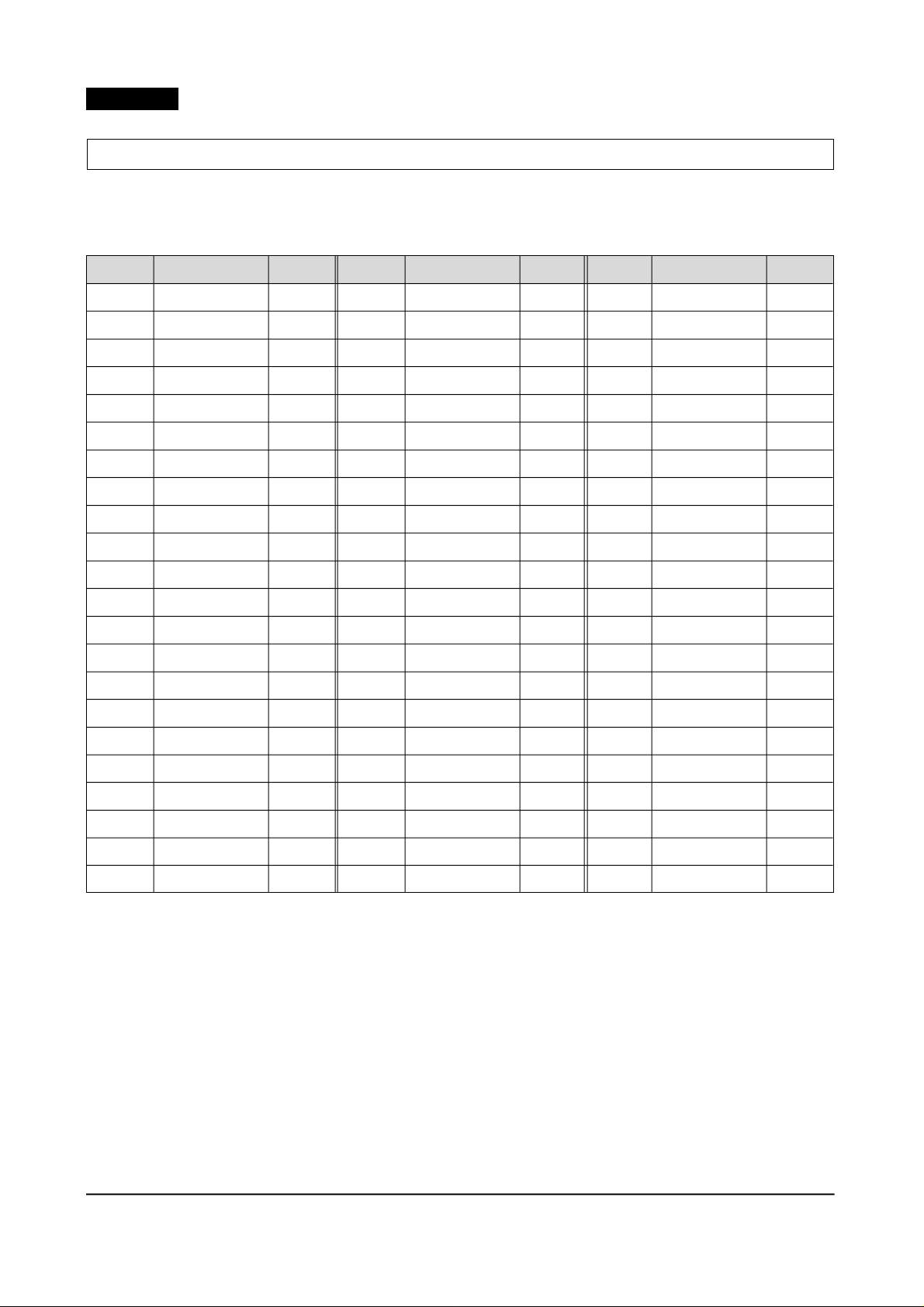

TEMP.

– 35

– 34

– 33

– 32

– 31

– 30

– 29

– 28

– 27

– 26

– 25

– 24

– 23

– 22

– 21

– 20

Resistance KΩ ± 1%

68.648

65.011

61.595

58.384

55.366

52.526

49.854

47.337

44.967

42.733

40.626

38.640

36.765

34.995

33.323

31.743

Voltage(V)

4.364

4.333

4.301

4.268

4.235

4.2

4.164

4.127

4.09

4.051

4.012

3.972

3.93

3.888

3.845

3.802

TEMP.

– 13

– 12

– 11

– 10

– 9

– 8

– 7

– 6

– 5

– 4

– 3

– 2

– 1

0

1

2

Resistance KΩ ± 1%

22.832

21.814

20.848

19.932

19.062

18.237

17.453

16.709

16.001

15.328

14.688

14.080

14.501

12.949

12.424

11.924

Voltage(V)

3.477

3.428

3.379

3.329

3.279

3.229

3.178

3.127

3.076

3.025

2.974

2.923

2.872

2.821

2.77

2.719

TEMP.

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Resistance KΩ ± 1%

9.016

8.673

8.345

8.032

7.732

7.446

7.172

6.910

6.659

6.420

6.190

5.970

5.759

5.557

5.363

5.178

Voltage(V)

2.37

2.322

2.274

2.227

2.18

2.134

2.088

2.043

1.998

1.954

1.911

1.869

1.786

1.786

1.745

1.705

– 19

– 18

– 17

– 16

– 15

– 14

30.250

28.838

27.502

26.237

25.040

23.906

3.757

3.712

3.666

3.62

3.573

3.525

3

4

5

6

7

8

11.447

10.993

10.559

10.146

9.752

9.375

2.668

2.618

2.567

2.518

2.468

2.419

25

26

27

28

29

30

5.000

4.829

4.665

4.508

4.357

4.212

1.666

1.628

1.59

1.553

1.517

1.481

Samsung Electronics 39

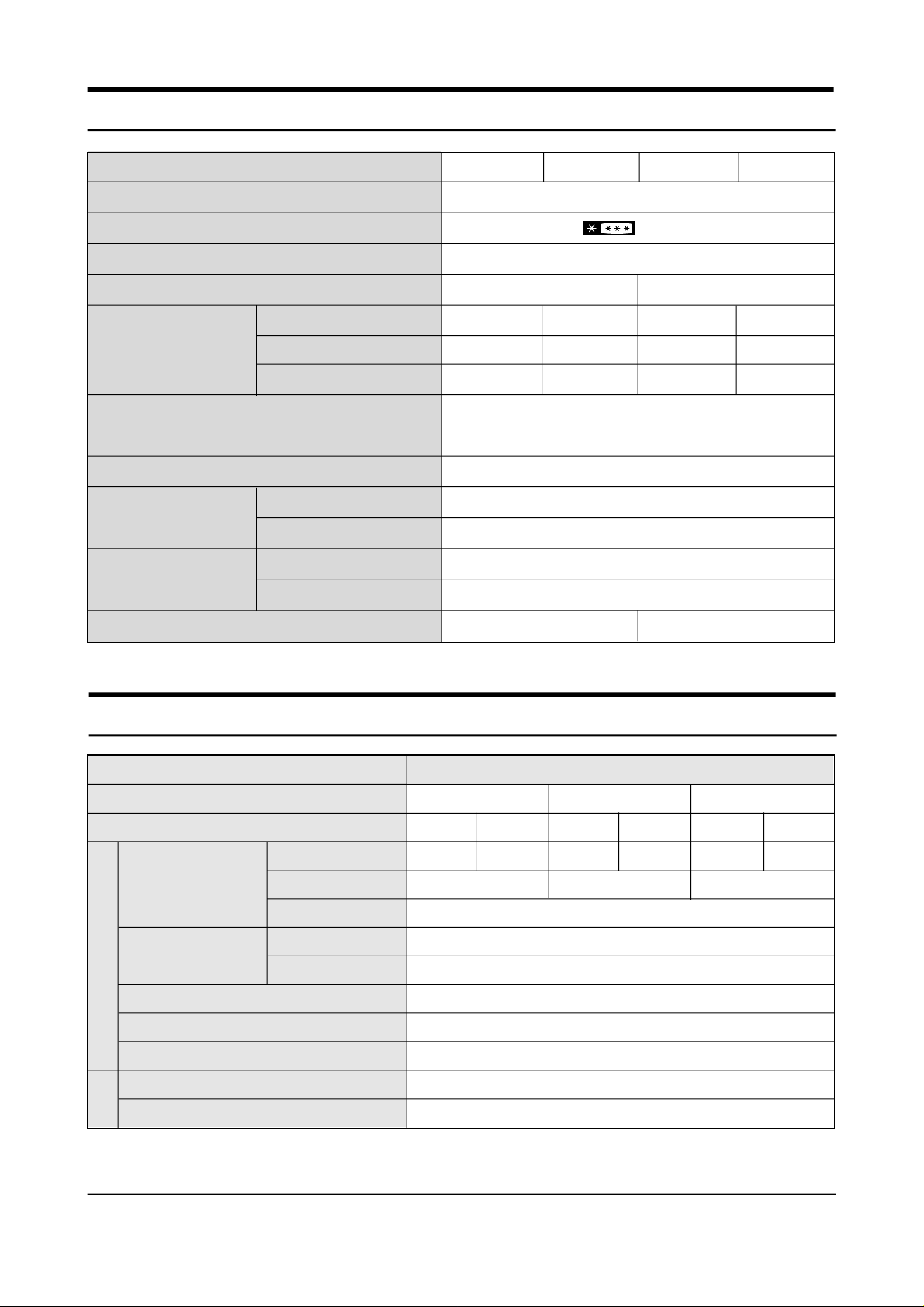

2. Product Specifications

Freezer performance

Temperature control

Net Capacity

l/(ft3)

Foam

Liner

Model

Type

Water dispenser

Net dimension

(WXDXH)

Refrigerant

Cabinet insulation

Door insulation

Freezer

Refrigerator

Total

Cabinet

Door

SR-L628EV SR-L678EV SR-L626EV SR-676EV

(LMF(Freezer/Refrigerator) 2 Door)

(4-STAR)

Electronic control

Yes

171(6.04) 192(6.78)

345(12.18) 376(13.28)

516(18.22) 568(20.06)

820X715X1790 (mm) (SR-L626(8)EV)

820X765X1790 (mm) (SR-L676(8)EV)

HFC-134a(160gr)

CYCLO-PENTANE

CYCLO-PENTANE

171(6.04) 192(6.78)

351(12.39) 382(13.49)

522(18.43) 574(20.27)

A.B.S

A.B.S

No

Net weight

114Kg 113Kg

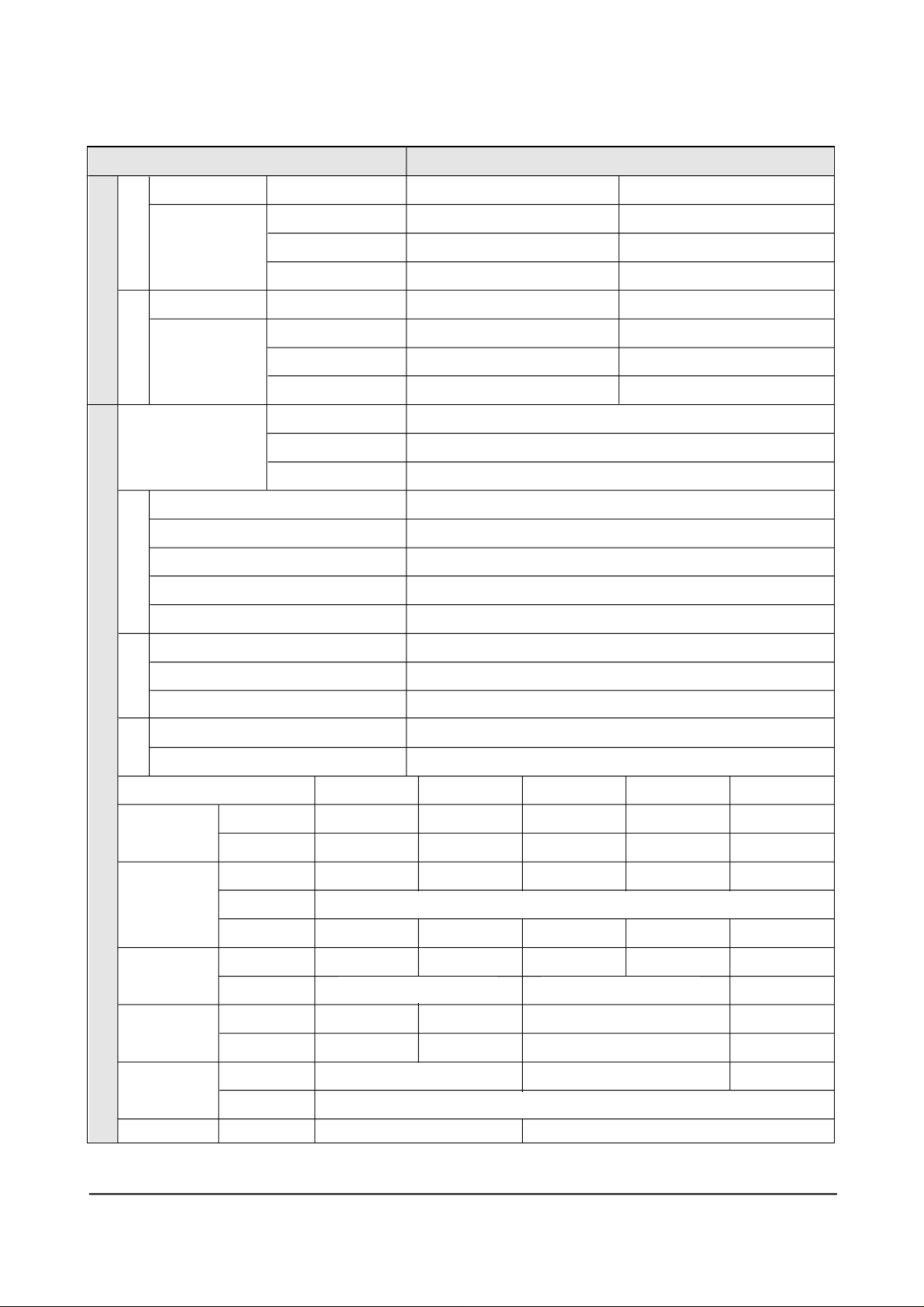

3. Electrical part specifications & standard

ITEM

Model

Input Source

Compressor

Evaporator

Condenser

Refrigeration Cycle

Dryer

Capillary tube

Model

Starting type

Oil charge

Freezer

Refrigerator

SR-L626/628EV SR-L626(8/676(8)EV SR-L676/678EV

220V 240V

SK182H-L2U SK182Q-L2U

RSCR

Forced & Natural Convection Type

115V 127V

SK182E-L2W SK182P-L2

Freon α-15(ESTER)

Molecular Sieve XH-9

ID0.85XL2500 3.79kg/cm

STANDARD

220V 240V

W

SK190H-L2U SK190Q-L2U

CSR RSCR

Split Fin Type

Split Fin Type

2

Earth screw

Door switch

2 Samsung Electronics

BSBN(Brass screw)

250V/0.5A

ITEM STANDARD

FreezerRefrigerator

F-Sensor

Temperature

R-Sensor

Defrosting

Sensor

Type

Type

Defrost cycle

Freezer-Sensor

Refrigerator-Sensor

FRE EVAP-Sensor

REF EVAP-Sensor

Room TEMP-Sensor

Mode

High

Mid

Low

Mode

High

Mid

Low

Rest time

First cycle

ON(˚C)

–20˚C

–16.5˚C

–14˚C

ON(˚C)

–0.5˚C

3.5˚C

6.5˚C

OFF(˚C)

–22˚C

–18.5˚C

–16˚C

OFF(˚C)

–1.5˚C

2.5˚C

5.5˚C

Freezer:6 – 16hr/Refrigerator:12 – 32hr

10min±2min

4hr±10min

502AT

502AT

502AT

502AT

502AT

Heater

Fuse

Electrical parts

VOLTAGE 115V 127V

C O N D E N S E R

O V E R - L O A D

P R O T E C T O R

S TA RT I N G R E L A Y

M O T O R - FA N

L A M P

M O T O R - G E A R E D

FRE Defrost-Heater

REF Defrost-Heater

Lamp-Heater

FRE Defrost-Fuse

REF Defrost-Fuse

STARTING

RUNNING

MODEL

1 2 5 VA C / 1 2 5

2 5 0 VA C / 1 2

4 T M 4 4 5 S H B Y Y- 5 3

ON TEMP .

OFF TEMP .

MODEL

P T H A S - T 1 0 0 M 2 0 0 B

RESIST ANCE

FRE. REF .

C I R C U I T- M O T O R

I S 3 2 0 8 T M D A - 4

I S 3 2 0 8 - S C F 6 A

FRE.

REF.

REF.

200W (115V, 127V, 220V, 240V)

130W (115V, 127V, 220V, 240V)

2W (115V, 127V, 220V, 240V)

250V 10A 72 ± 4˚C

250V 10A 72 ± 4˚C

2 2 0 V

1 2 5 VA C / 1 2 5

µ F

2 5 0 VA C / 1 2

µ F

4 T M 4 4 4 N H B Y Y- 5 3

µ F

µ F

3 5 0 VA C / 5

4 T M 3 0 8 P H B Y Y- 5 3

( 6 2 6 / 6 2 8 E V )

2 2 0 V

µ F

3 5 0 VA C / 5

4 T M 3 1 4 R H B Y Y- 5 3

( 6 7 6 / 6 7 8 E V )

µ F

3 5 0 VA C / 5

4 T M 2 3 2 S H B Y Y- 5 3

6 9 0˚ C

1 3 5˚C

1 0W ± 2 0 %

1 2 0˚ C

P T H A S - T 1 0 0 M 2 0 0 B

I S 3 2 0 8 T M D A - 8

I S 3 2 0 8 - S C O 6 A

1 2 5˚ C

P T H A S - T 2 2 0 M 3 5 0 D

2 2W ± 2 0 % 3 3W ± 2 0 %

I S 3 2 0 8 T M D A - 2 A

I S 3 2 0 8 - S C F 7 A

1 3 0˚ C

P T H A S - T 2 2 0 M 3 5 0 D

1 3 5˚ C

P T H A S - T 3 3 0 M 3 8 5 D

I S 3 2 0 8 T M D A - 6

I S 3 2 0 8 - S C L 5 A

1 1 0 V ~ 1 3 0 V / 1 5 W 2 2 0 V / 1 5 W 2 4 0 V / 1 5 W

OSRAM DEULX S/E IIW

M 2 B C 1 8 A R 0 2 M 2 L C 1 8 A R 0 2

2 4 0 V

µ F

Samsung Electronics 3

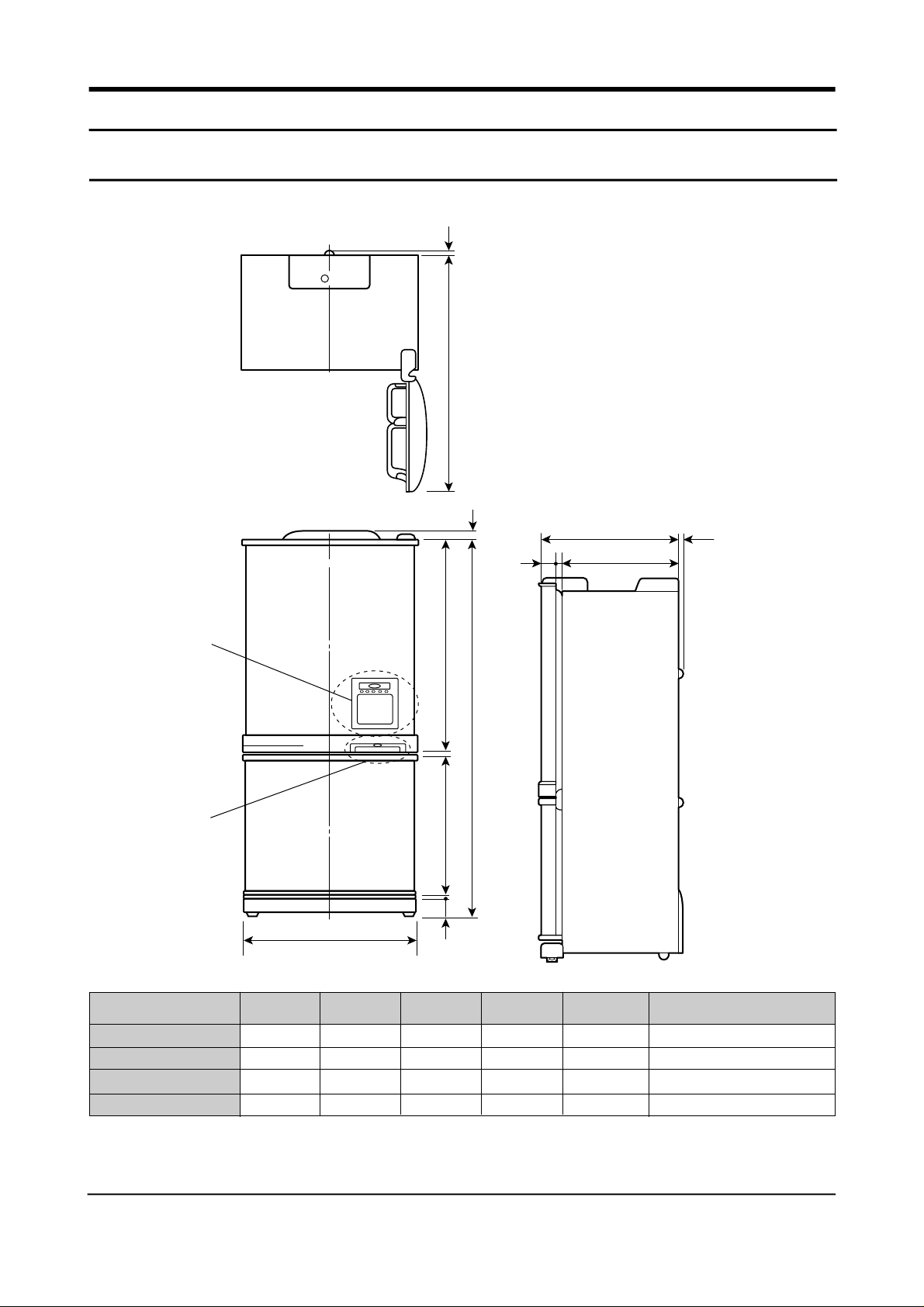

5. Function & Operating Instruction

• 5-1 Product Dimension

10

C

"X"

"Y"

820

B

673.5

10

64

11

D

E

40

77

A

8

10

MODEL

SRG-L678EV

SRG-L676EV

SR-L628EV

SR-L626EV

6 Samsung Electronics

A

1750.0

1750.0

1750.0

1750.0

B

994.5

994.5

994.5

994.5

C

1509.7

1509.7

1459.7

1459.7

D

755

755

715

715

E

667

667

627

627

Remarks

"X"

"Y"

"X"

"Y"

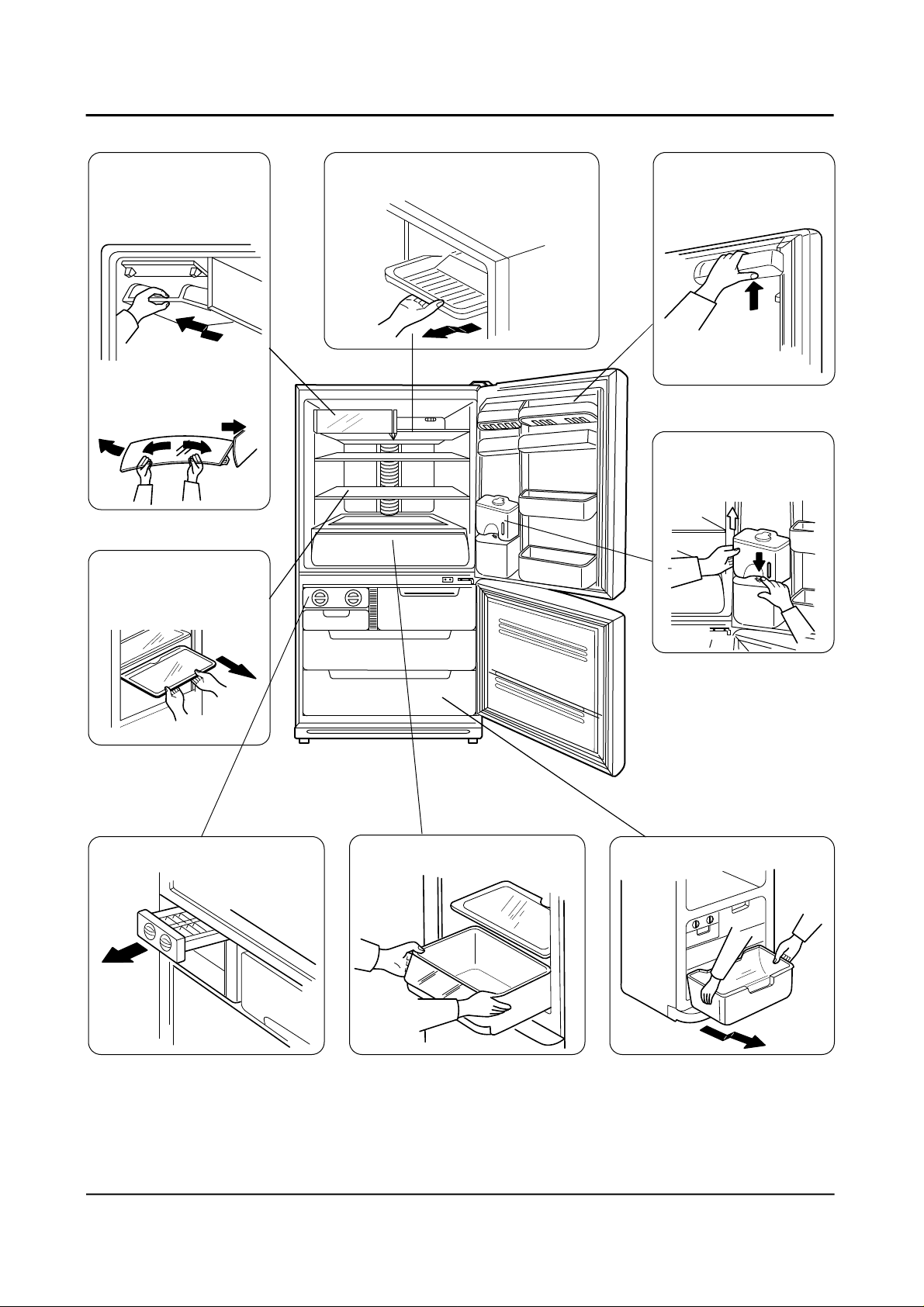

5-2 Part Name & Disassembly

• Chilled Compartment

disassembly

1. Pull it out by following

the arrow.

2. Bend the cover and

take it out.

②

①

• Tray disassembly

Pull it out by following

the arrow.

• Top tray disassembly

Pull it forward.

•

•

•

•

•

Take out food stuffs and

pull it out by following

the arrow.

•

Take out the water

bottle with the bottom

latch pressed.

•

•

• Ice compartment • Vegetable compartment

• Freezing compartment

Samsung Electronics 7

9. Disassembly & Assembly

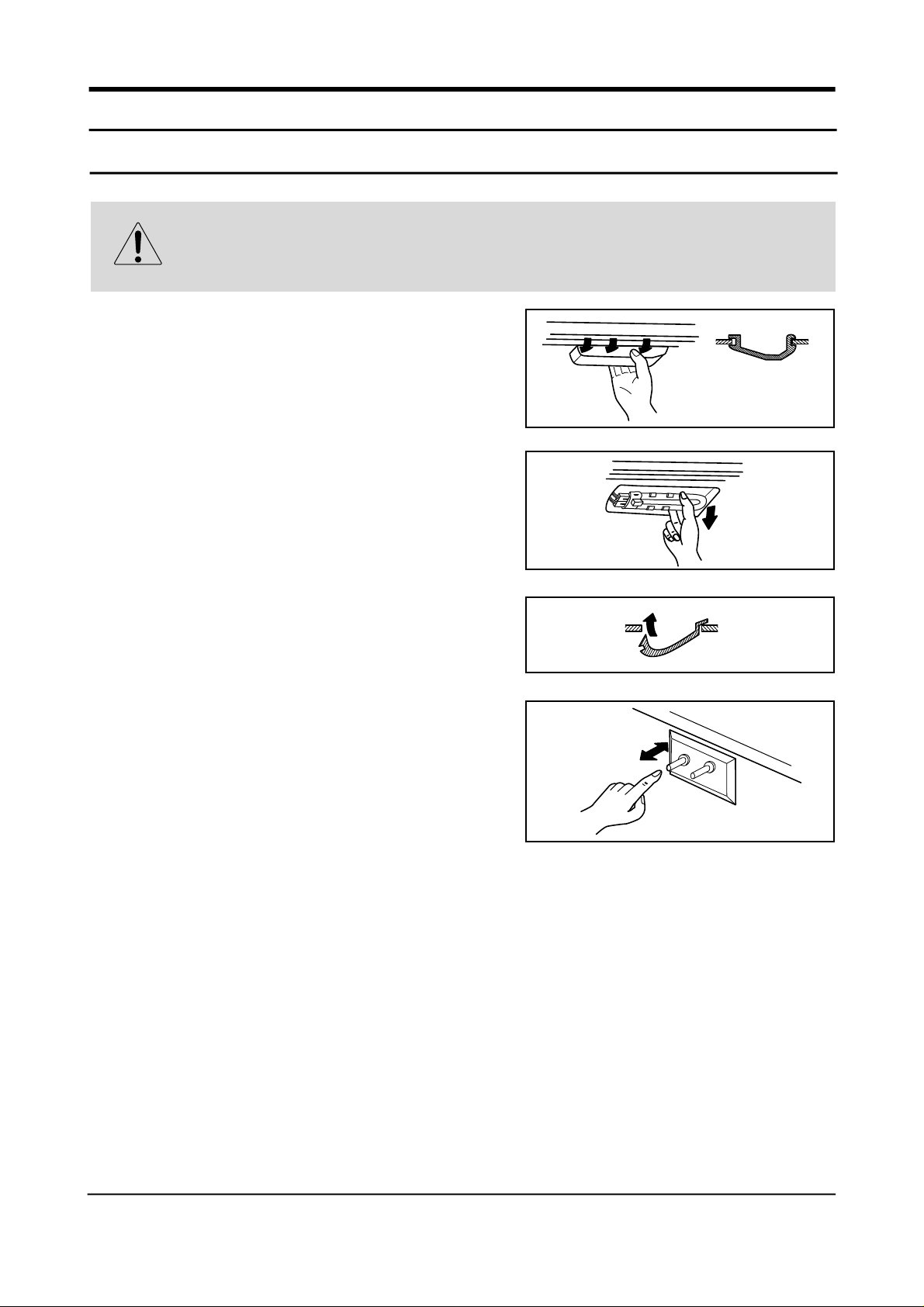

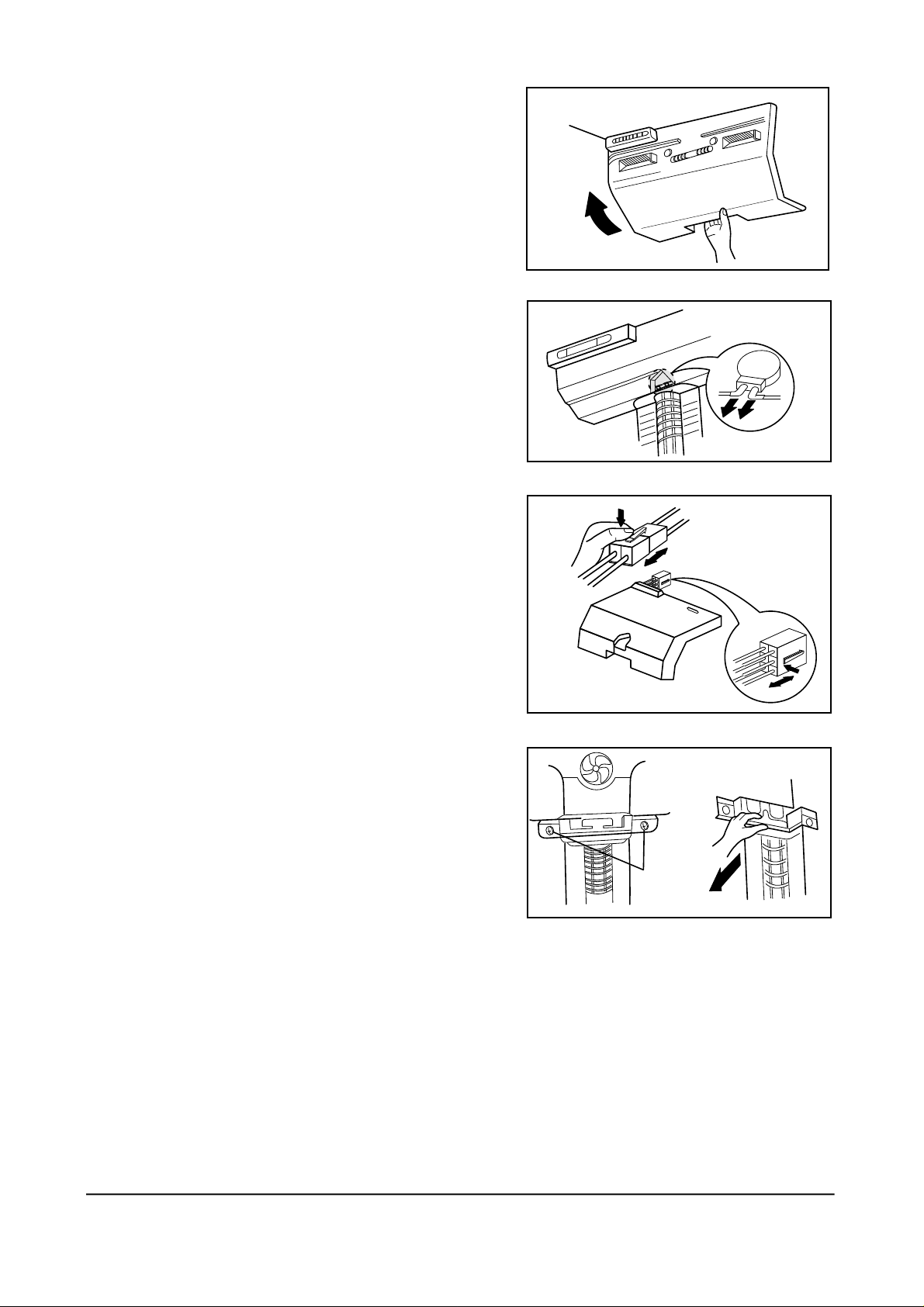

1. Replacement of refrigerator lamp

Warning

Always take out the power plug when replacing the refrigerator lamp. There is the danger of

electric shock.

1. Remove the cover with the back latch pressed.

2. Pull out the lamp.

3. After replacing the lamp, assemble the front latch of

cover and then connect the back latch.

4. Plug in and check if power is cut off or not by pressing

the R-door switch.

52 Samsung Electronics

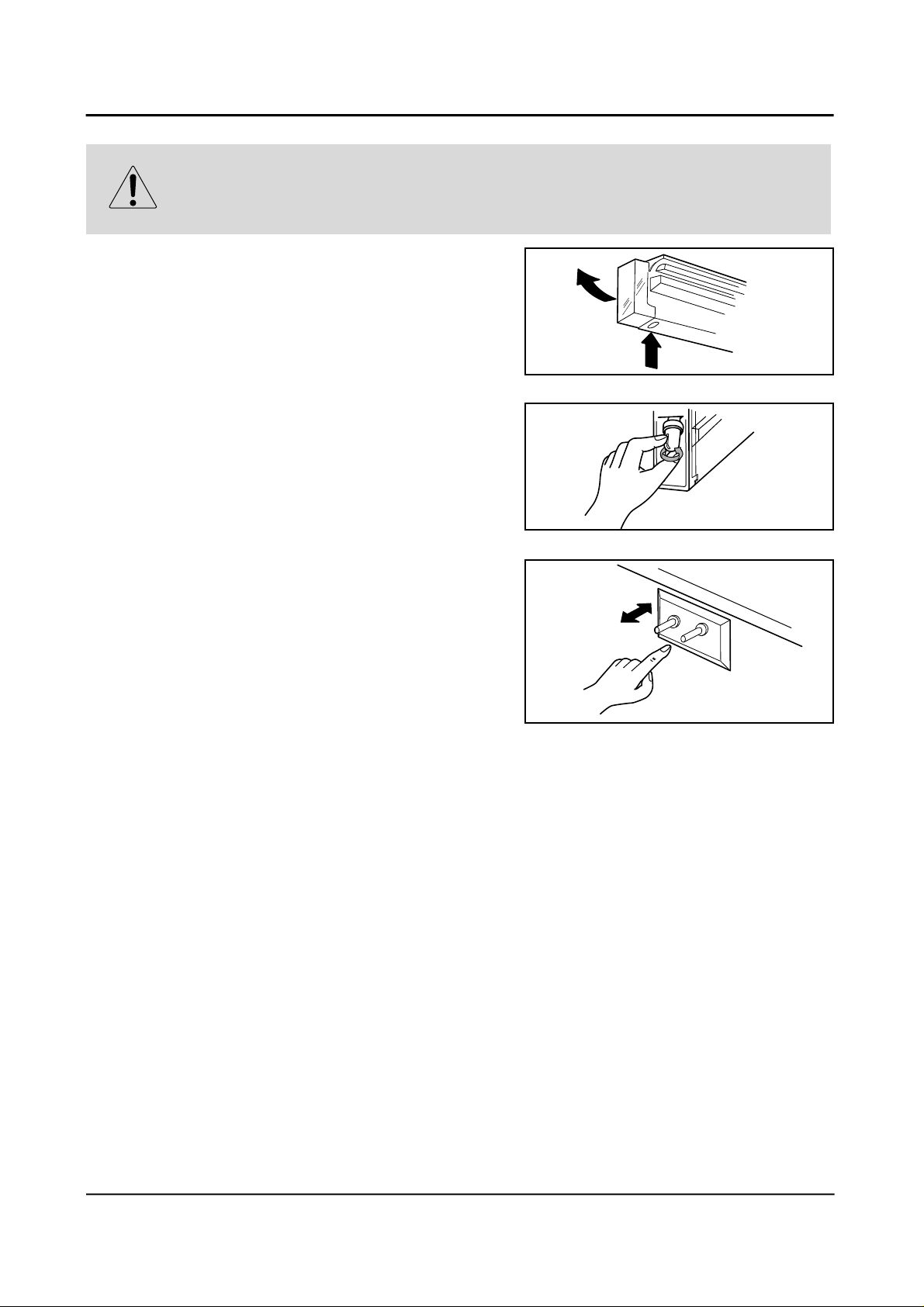

2. Replacement of freezer lamp

Warning

Always take out the power plug when replacing the refrigerator lamp. There is the danger of

electric shock.

1. Remove the cover by pressing the bottom latch.

2. Replace the lamp by turning it counter-clock wise.

3. Reassemble the cover in the reverse order of

disassembly and plug in and the check if power is cut

off by pressing the door switch.

Samsung Electronics 53

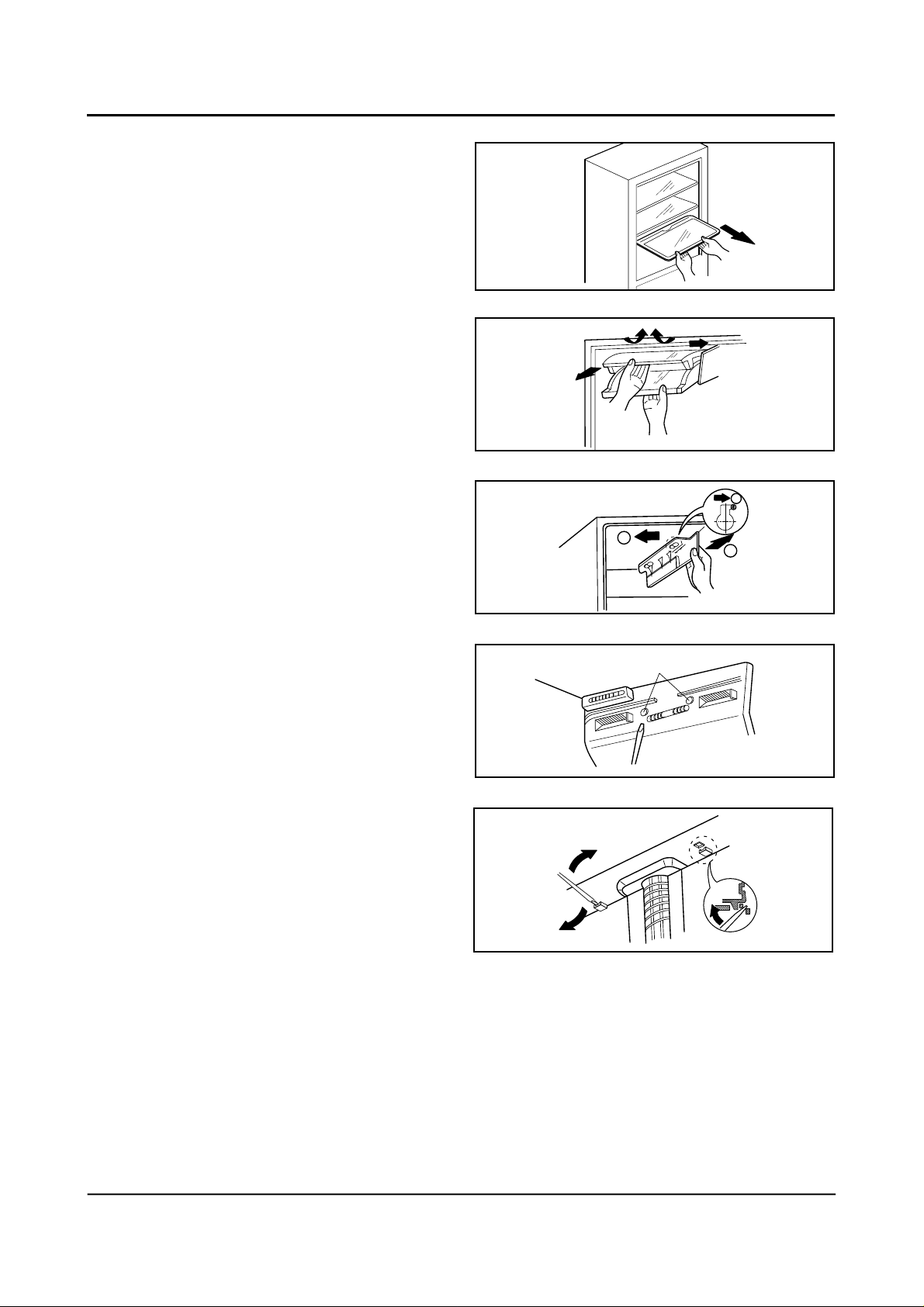

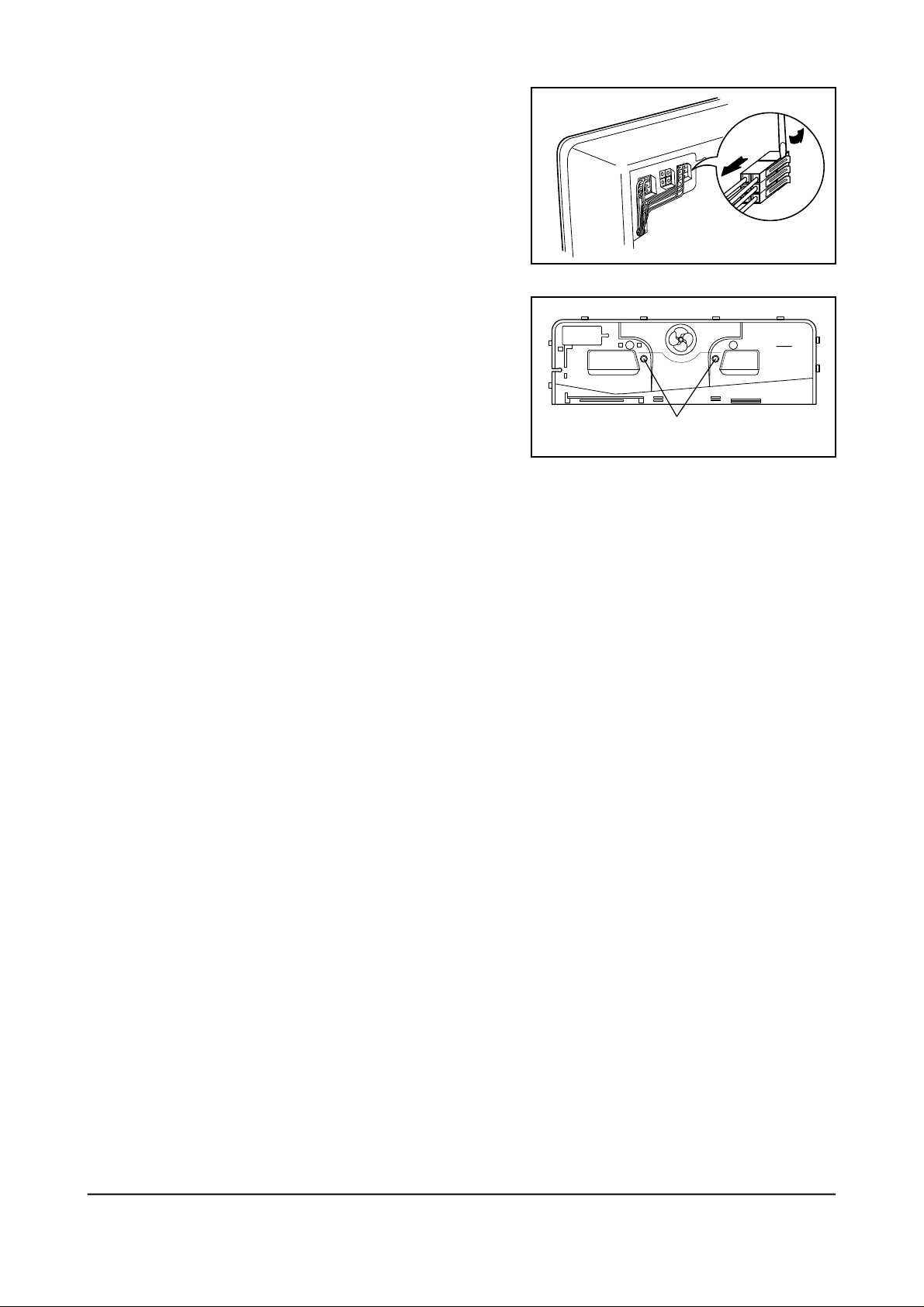

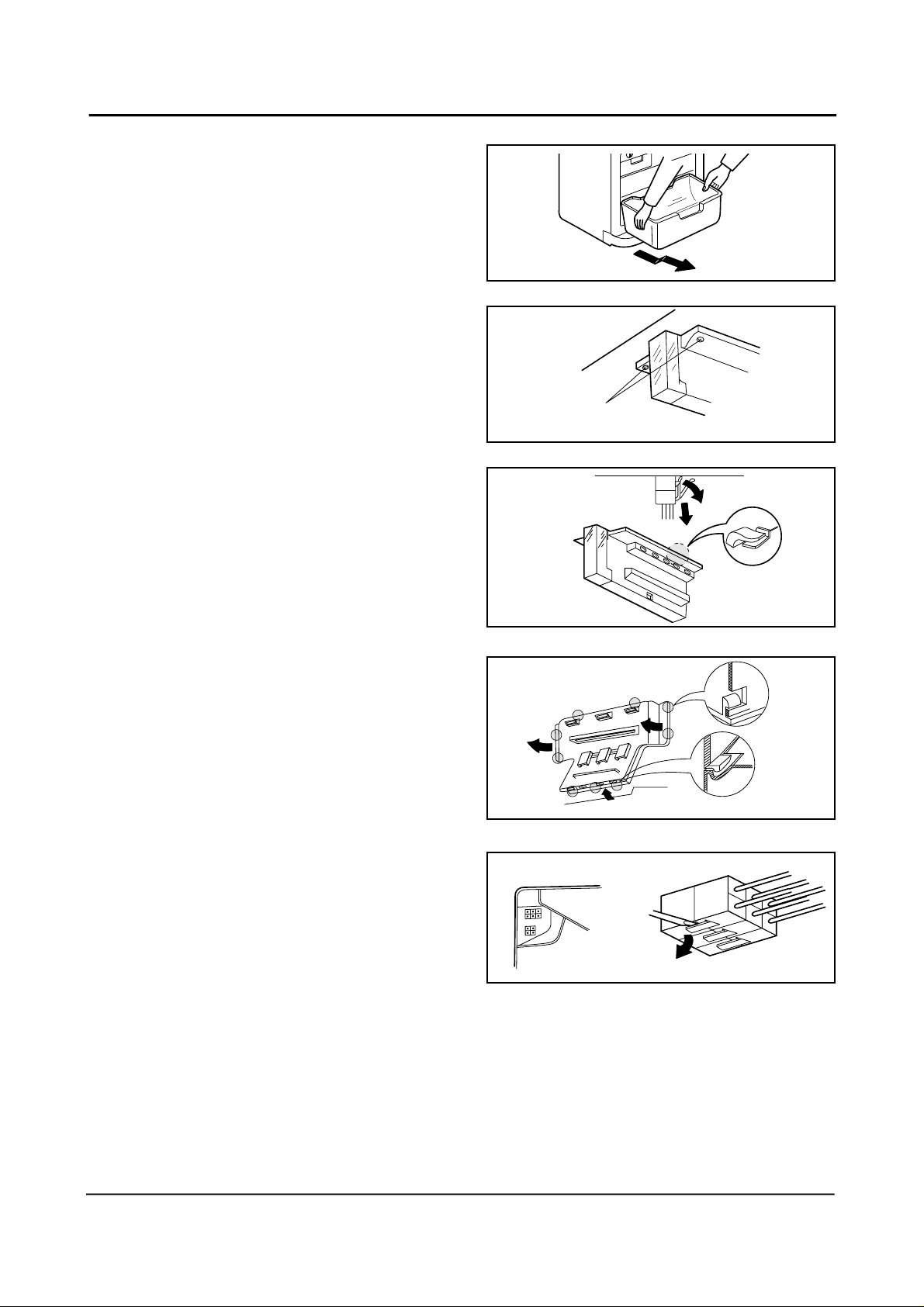

3. Disassembly of the cooling cycle in the refrigeration room

1. Take out food stuffs and trays from

refrigeration room.

2. Bend the cover of chilled compartment and

remove the left axis.

3. Move the holder of chilled compartment to the

arrow ¨and pull it out.

4. Remove 2 cap screws with (–) driver or similar

tools.

5. Remove 2 latches from the bottom of the cover

in the front of evaporator.

1

1

2

2 screws

54 Samsung Electronics

6. Remove the evaporator cover by pulling out the

bottom of the evaporator cover.

7. Remove the housing of wires from the center of the

cooling cycle unit and remove the terminal from the

geared motor.

8. Pull forward the insulating material of the cooling

cycle unit and remove the wire terminal and insulating

material.

9. Remove 2 screws securing refrigerator duct and pull it

out by following the arrow.

Remove 2 screws

Samsung Electronics 55

10. Remove the wire terminal from the left top of

refrigeration room

11. Remove 2 screws securing the back cover of cooling

cycle unit and remove the left and right latches with

(–) driver.

latch

Remove 2 screws

56 Samsung Electronics

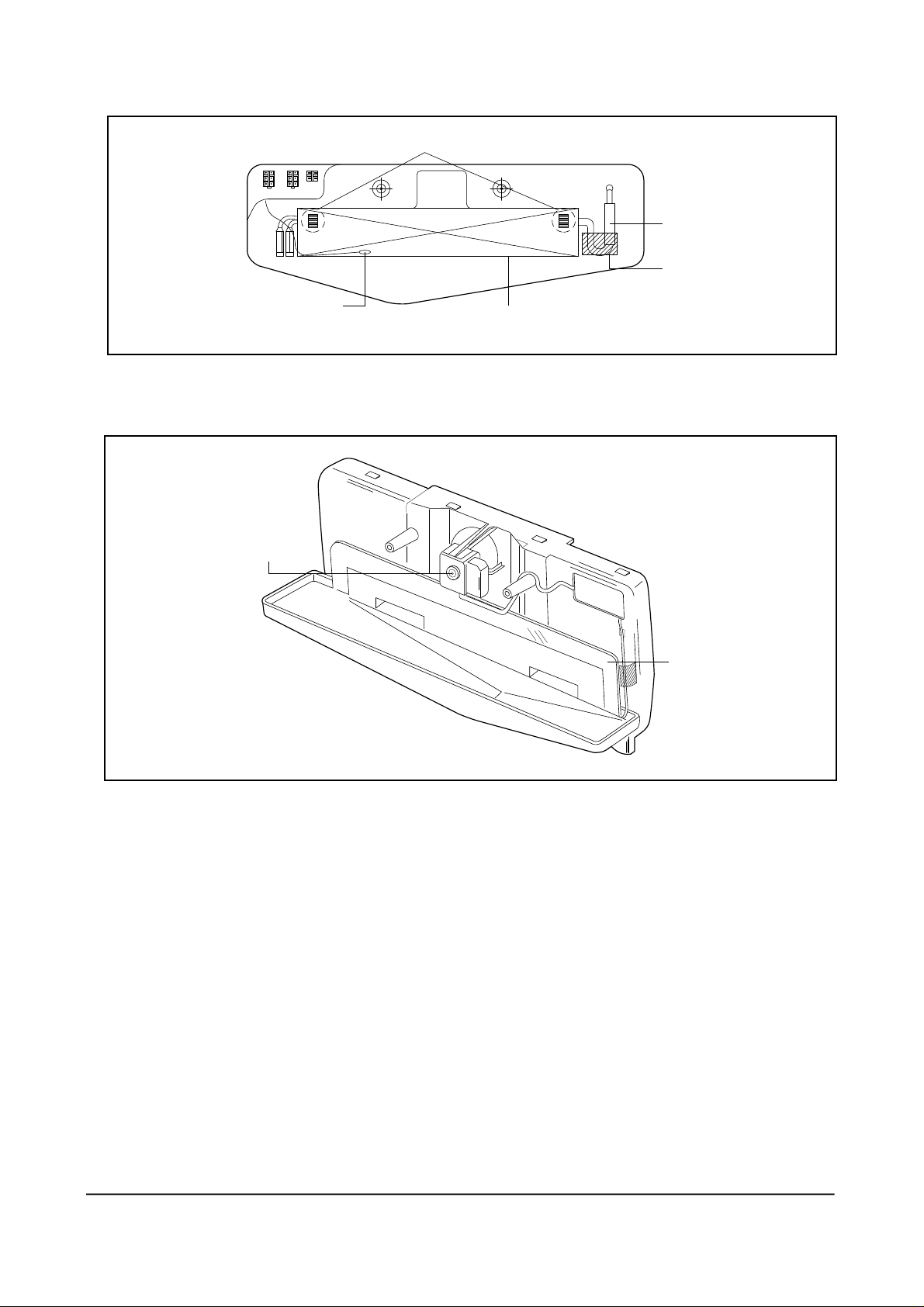

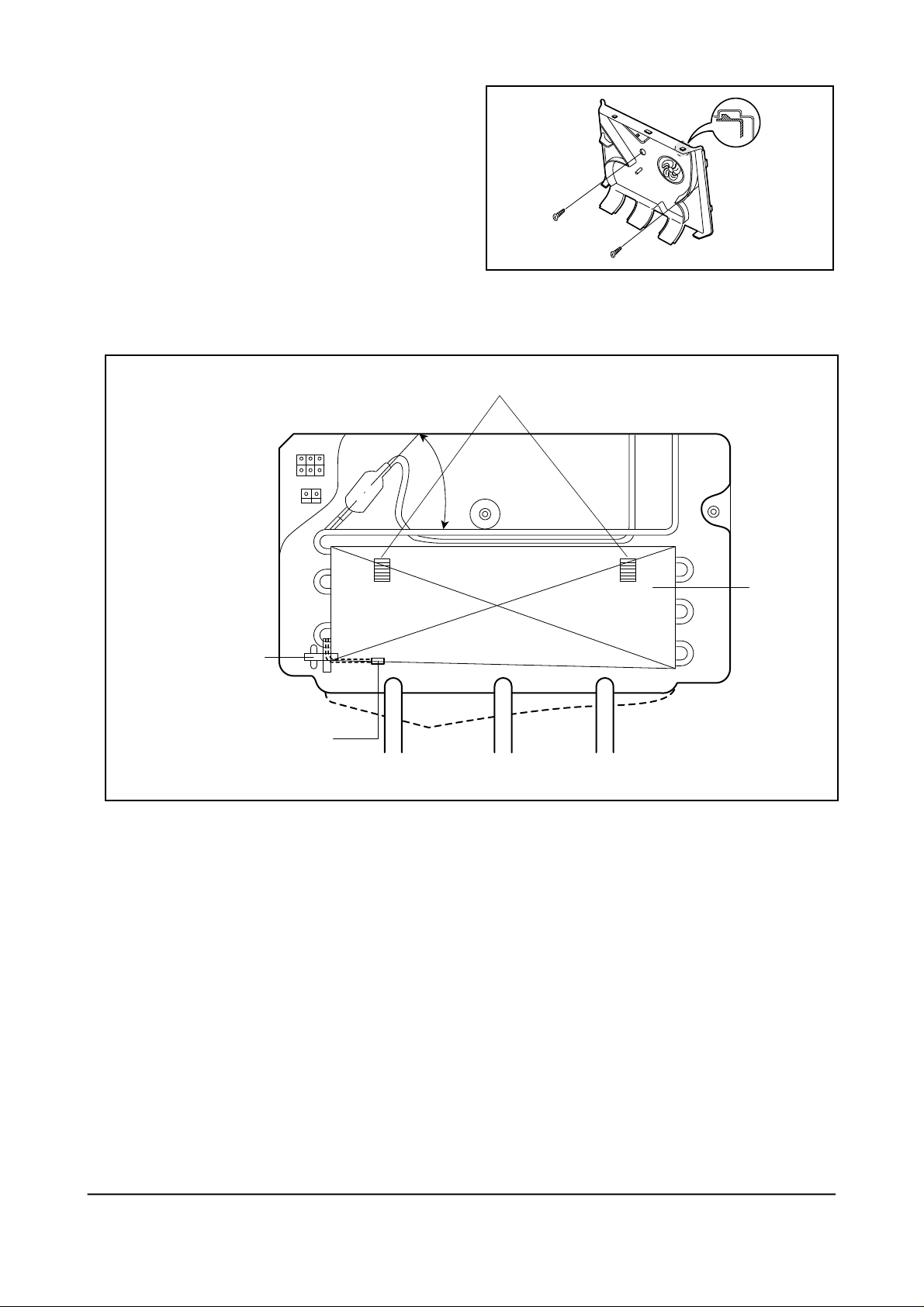

■ Cooling cycle unit assembly in the refrigeration room

2 holders securing evaporator

Temp. sensor

EVAP

■ Cooling cycle unit cover assembly in the refrigeration room

Absorber

sound(Noise protector)

TAPE-AL

(Groove for preventing

small ice when

defrosting)

Noise protector

Frost spreading

protection

Samsung Electronics 57

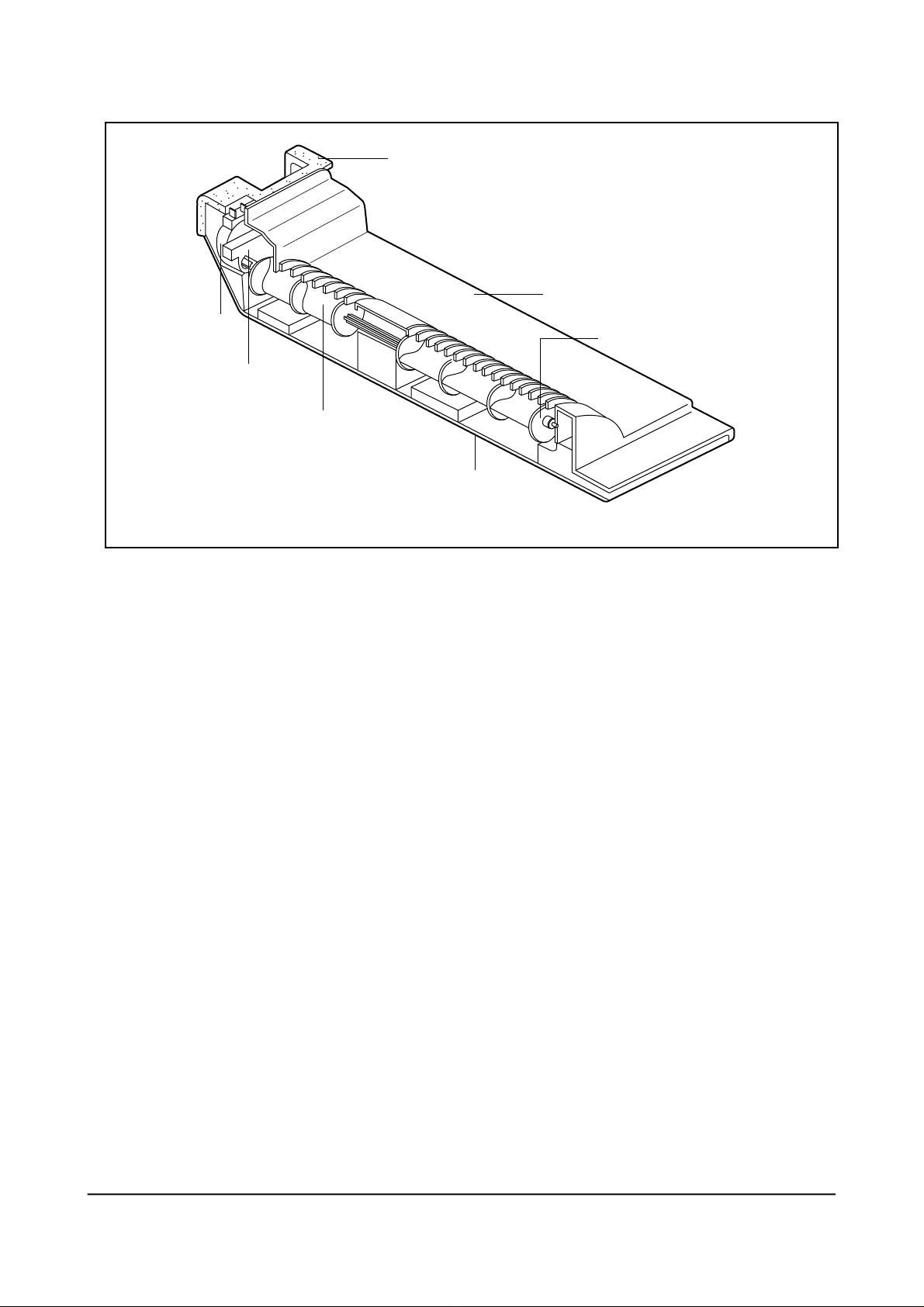

■ Rotating duct assembly in the refrigeration room

Seal-air

Cover-duct, REF

Motor-Geared

Reed S/W

Washer(Prevention noise)

Blade-air

Seal-duct, RE

(Prevention Temp.

distribution)

58 Samsung Electronics

4. Disassembly of the cooling cycle unit in the freezer

1. Take out the case from the freezer.

2. Remove 2 screws from the holder of the cooling

cycle unit.

3. Pull out the holder of the cooling cycle unit and

disconnect wire terminals.

2 screws

①

②

4. Remove the latch of the cooling cycle unit cover

from the bottom.

5. Remove each terminal from the top of the

left wire assembly.

③

①

②

Samsung Electronics 59

6. Remove 2 screws from the back cover of the

cooling cycle unit and remove the latch with (–)

driver.

■ Assembly of the cooling cycle unit in the freezer

EVAP holder

Maintains 45˚

(Coolant & noise

reduction)

Temp. Fuse

Temp. Sensor

EVAP

60 Samsung Electronics

Loading...

Loading...