Page 1

OEM MANUAL

g

SFD-321B

3.5inch DUAL DENSITY

FDD

MICRO FLOPPY DISK DRIVE

SPECIFICATIONS

SEMA ELECTRONICS CO.,LTD

XiaLingBei HengKeng Management Area

Liaobu Town Dongguan City

Guan

dongProvince,China

SEMA ELECTRONICS CO.,LTD

Page 2

FLOPPY DISK DRIVE SPECIFICATION

CONTENTS

1. INTRODUCTION

1.1 Application

1.2 Disk Used

2. GENERAL SPECIFICATIONS

2.1 Performance

2.2 Environmental Conditions

2.3 Reliability

2.4 Power Supply

2.5 Physical Specifications

PAGE 1

MODEL

SFD-321B

3. INSTALLATION

4. ELECTRICAL INTERFACE

4.1 Signal Interface

4.2 Power Interface

4.3 Interface Connectors

5. SIGNAL CHARACTERISTICS

5.1 Signal Level

5.2 Recommended Interface Circuit

5.3 Input Sig n als

5.4 Output Signals

6. TIMING DIAGRAM

6.1 Seek Operation Timing

6.2 Read / Write Operation Timing

SEMA ELECTRONICS CO.,LTD

Page 3

FLOPPY DISK DRIVE SPECIFICATION

7. SAFETY STANDARDS

8. PACKAGING DESCRIPTION

8.1 Label Description

8.2 Packaging Method

8.3 Pallet Dimension and the Method

9. OPTION SELECTION

9.1 Trace Options

9.2 Other Options (Buyer Selection)

10. GENERAL COMMENT

PAGE 2

MODEL

SFD-321B

※

LIST of FIGURES

Figure 2-1. Physical Dimensions (With Bezel Type)

Figure 2-2. Physical Dimensions (Without Bezel Type)

Figure 3-1. Installation

Figure 4-1. Signal Interface Connector and Cable Side Connector

Figure 4-2. Power Interface Connector and Cable Side Connector

Figure 4-3. Rear View of FDD

Figure 8-1. Packaging Method

Figure 8-2. Pallet Dimension & Method

SEMA ELECTRONICS CO.,LTD

Page 4

PAGE 3

FLOPPY DISK DRIVE SPECIFICATION

MODEL

1. INTRODUCTION

1.1 Application

This manual shall be applied for SAMSUNG SFD-321B - double side, dual

density (option : 3 mode), 3.5 inch micro floppy disk drive

(hereinafter referred to as "FDD").

1.2 Disk Used

3.5 inch micro floppy disks (hereinafter referred to as "DISK"),

the use of which will be mutually agreed between the customers an d

SAMSUNG, shall be used.

SFD-321B

SEMA ELECTRONICS CO.,LTD

Page 5

FLOPPY DISK DRIVE SPECIFICATION

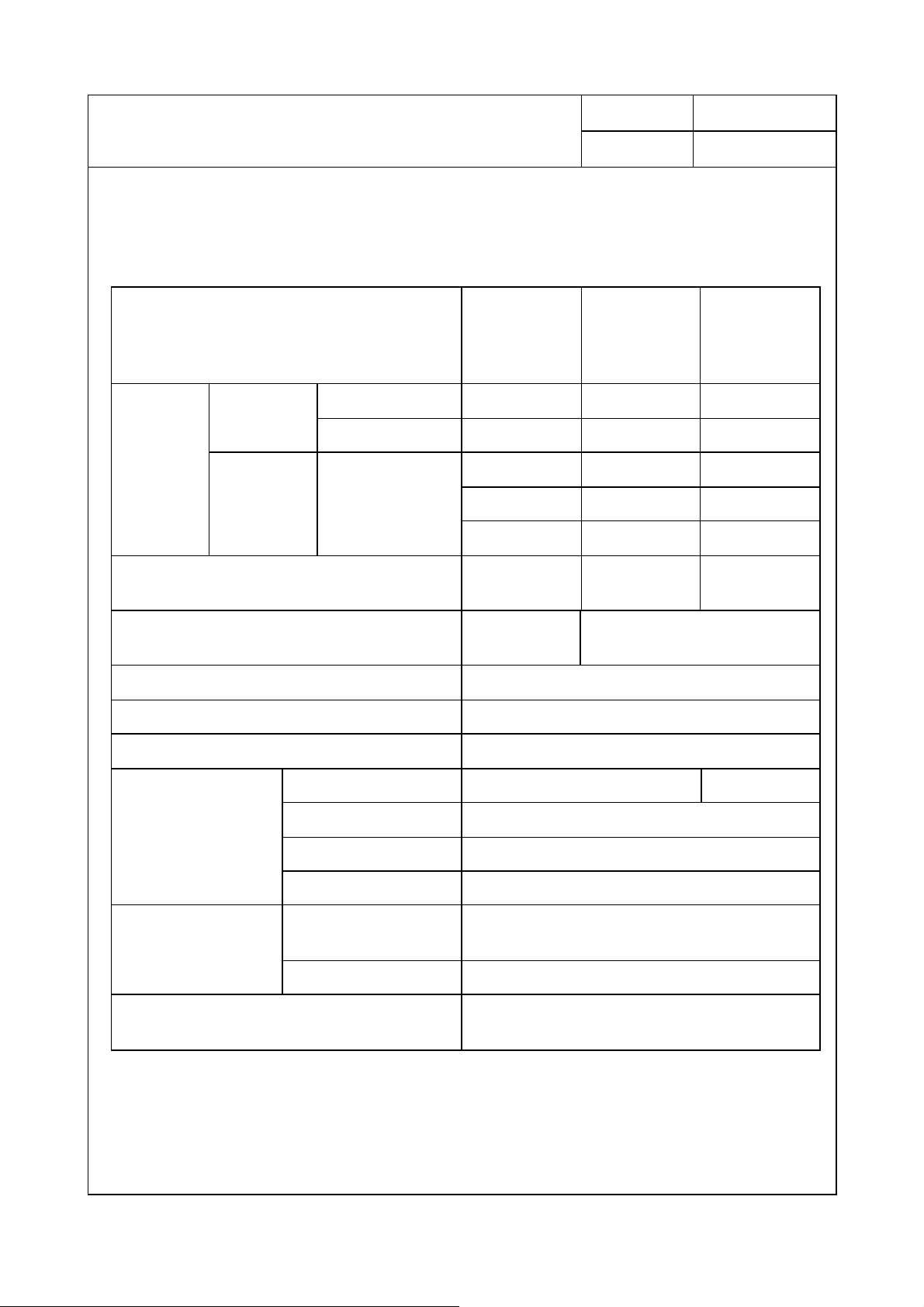

2. GENERAL SPECIFICATIONS

2.1 Performance

PAGE 4

MODEL

SFD-321B

LOW

ITEM

Per Disk 1000 2000 1600

Unformatted

Per Track 6.25 12.5 10.0

Capacity

(KBytes)

Formatted

Recording Density (BPI)

-Inner Most Track, side 1

Data Transfer Rate (KBits / sec)

Number of Heads 2

Number of Tr acks 160

Track Density (T PI) 135TPI (5.33 Tracks / m m)

Per Disk

(Sector / Track)

-MFM recording

DENSITY

STANDARD

1MB

655.4 (16) 1310.7 (32) 1065.0 (26)

737.3 (9) 1474.6 (18) 1228.8 (15)

819.2 (5) 1638.4 (10) 1310.7 (8)

8,717 17,434 14,528

250 500

HIGH

DENSITY

STANDARD

2MB

DENSITY

*OPT ION*

HIGH

1.6M B

Drive Motor

Specification

Access Time

Head 0 / Head 1 Offset

Rotational Speed 300 RPM 360 RPM

±

LSV

ISV

Start Time 500 m s Max.

Track to Track

Time

Head Settling Time 15 ms Max.

Head 1 is displaced 8 tracks toward the

drive spindle direction.

1.5 % Max.

±

1.5 % Max.

3ms

SEMA ELECTRONICS CO.,LTD

Page 6

FLOPPY DISK DRIVE SPECIFICATION

PAGE 5

MODEL

SFD-321B

ITEM

Media Operating

Force

LOW

DENSITY

STANDARD

1MB

Inserting 800 gr Max.

Ejecting 1300 gr Max.

HIGH

DENSITY

STANDARD

2MB

DENSITY

*OPT ION*

1.6M B

Media Ejec ting Distance 10 ~ 70 mm

AcousticNoiseat50cm

-at3msStepRate

50 dBA Max.

Read Bit Shift 1300 ns Max. 650 ns Max.

1. Measured with Brikon 723B on Track 79

with 0 ns precompensation on both heads.

Asymmetry 600 ns Max. 300 ns Ma x.

1. Measured with Brikon 723B on Track 00

with 0 ns precompensation on both heads.

HIGH

Both R/W heads must be radially aligned to all tracks

within±0.0200 mm when accessed from either

Radial Alignment

direction.

Measurement is to be made at normal voltage and

normal environmental condition

℃

and 50±5 % RH)

Max.

Azimuth Alignment

(23±2

±0°18′

0 ~ 13 00μs

Index to Data Burst

Measurement is to be made from the leading edge of

index pulse to the beginning of data burst on

Track 40.

Overwrite Modulation -26 dB o r less a t Tra ck 00

* Read/Write Compensation : 125ns is recommended

SEMA ELECTRONICS CO.,LTD

Page 7

FLOPPY DISK DRIVE SPECIFICATION

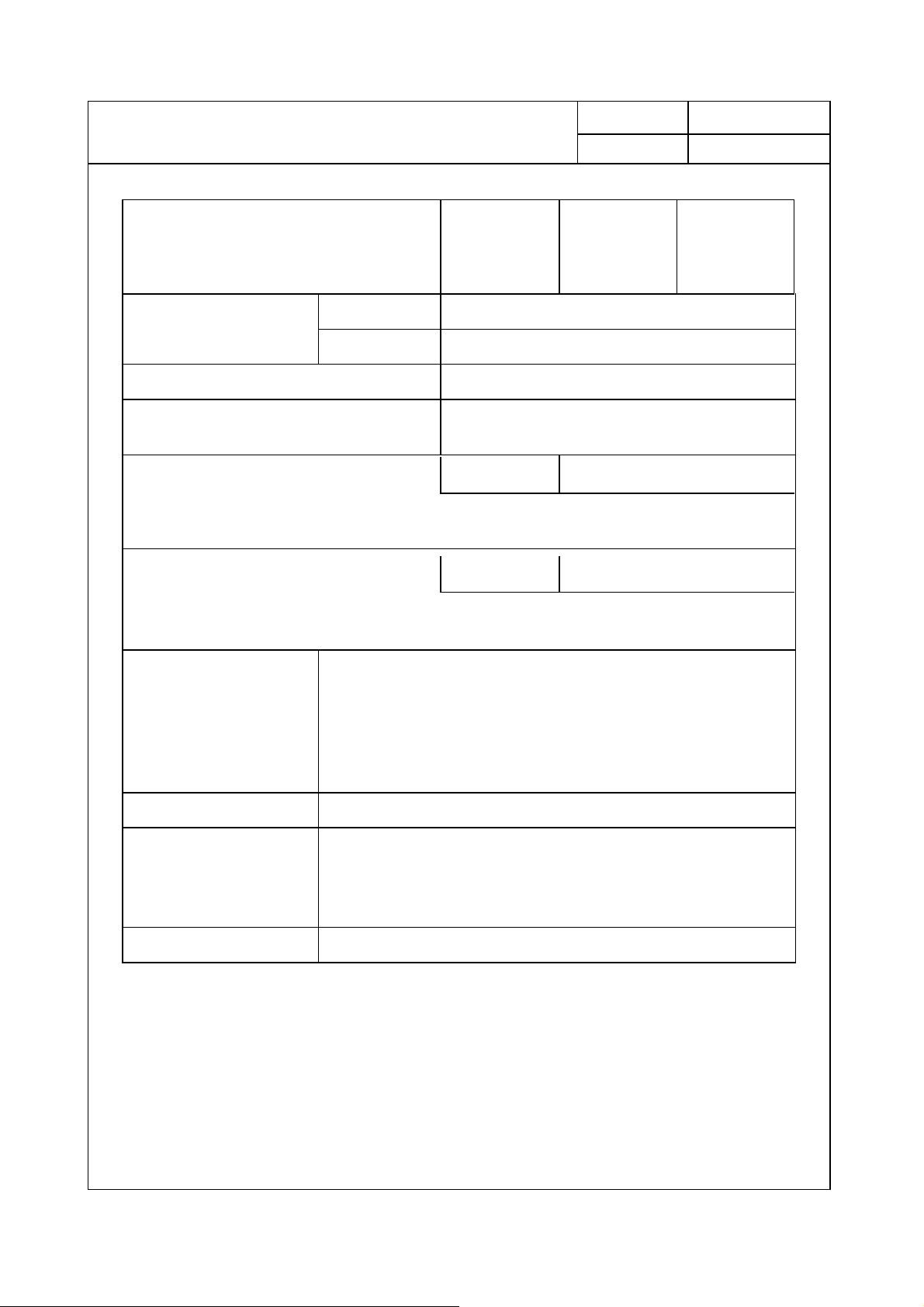

2.2 Environmental Conditions

ITEM SPECIFICATION

PAGE 6

MODEL

SFD-321B

Ambient

Temperature

Relative

Hum idity (%)

*No-condensation

Vibration

(30 min. swe ep

cycle)

*Exclude

resonant

frequency

Operating (℃) 0

Storage (℃) -40

Transportation (℃) -40

Temperature Gradient

℃

(

/Hr)

Operating : 29

Storage : 40

Transportation : 45

Operating

Transportation : 5 ~ 600 Hz

℃

Max. wet bulb temp. 20

℃

Max. wet bulb temp. 0

℃

5~100Hzfrequencyrange 1.5 G Max.

100~ 200 Hz frequency range 1.0 G Max.

200~ 600 Hz frequency range 0.5 G Max.

frequency range

Operating 20 Max.

Non-operating 30 Max.

Max.

wet bulb temp.

3GMax.

∼

50

∼

70

∼

70

∼

80

∼

90

∼

0

90

Shock (11 ms

half sine wave)

Operating 5GMax.

Transportation 100 G Max.

SEMA ELECTRONICS CO.,LTD

Page 8

FLOPPY DISK DRIVE SPECIFICATION

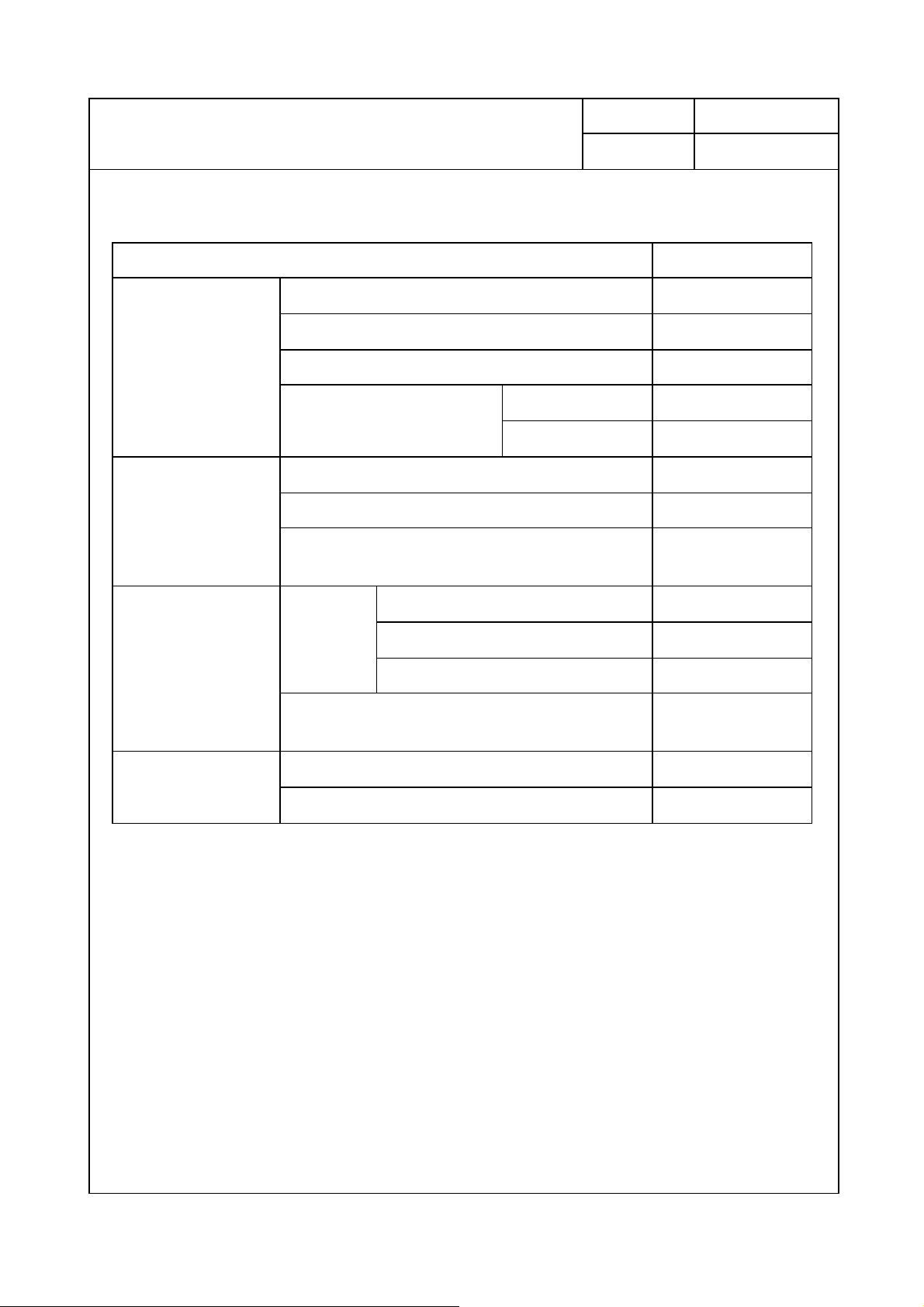

2.3 Reliability

ITEM SPECIFICATION

PAGE 7

MODEL

SFD-321B

M.T.B.F.(Mean time between failures)

M.T.T.R.(Meantimetorepair) 30 minutes Max.

Com ponent Life 5years

Disk Life 3×106passes per track or more

Disk Insertion 3×104times or more

Soft Read Error

(*1)

Error Rate

<Note>

Hard Read Error

(*2)

Seek Error

(*3)

20000 power on hours (POH)

(25% duty)

1per109bits read

1per1012bits read

1per106seeks

(*1) A soft (recoverable) e rror is defined as a successful a ttempt to read a track

of data within 3 retries after a read failure.

A read retry is defined as an attempt to read the entire track that a read

failure occurred on.

(*2) A hard (non-recoverable) error is defined as a failure to read a track of

data within 3 retries after a read failure.

(*3) A seek (access) error is defined as the inability o f the drive to seek to

a targeted track within 1 retry. An access retry is defined as one recalibration

with an attempt to seek to the targeted track.

SEMA ELECTRONICS CO.,LTD

Page 9

FLOPPY DISK DRIVE SPECIFICATION

2.4 Power Supply

ITEM SPECIFICATION

PAGE 8

MODEL

SFD-321B

Required Power D.C. 5 V

AllowableRippleVoltage 100 mV

Average Current Average Power

Operating Mode

Typ. Typ.

Stand - by 2mA 10mW

Power

Consumption

Rea d Ope ration 0.3 A 1.5 W

Write Operation 0.3 A 1.5 W

Seek Operation (3 ms) 0.7 A 3.5 W

Drive Motor Start 0.7 A 3.5 W

+5 V (*1)

Current (A)

0.3 A

±

10 %

(including spike noise)

p-p

0.7 A Typ.0.7 A Typ.

18 ms Max.

Seek

2mA

Stand-by

(*2)

500 m s Max.

Spindle motor ON Read /

Write

<Note>

(*1) Typical values are specified at 5.0 V

(*2) Stand-by : Under the condition that all input lines are inactive.

SEMA ELECTRONICS CO.,LTD

Page 10

PAGE 9

FLOPPY DISK DRIVE SPECIFICATION

MODEL

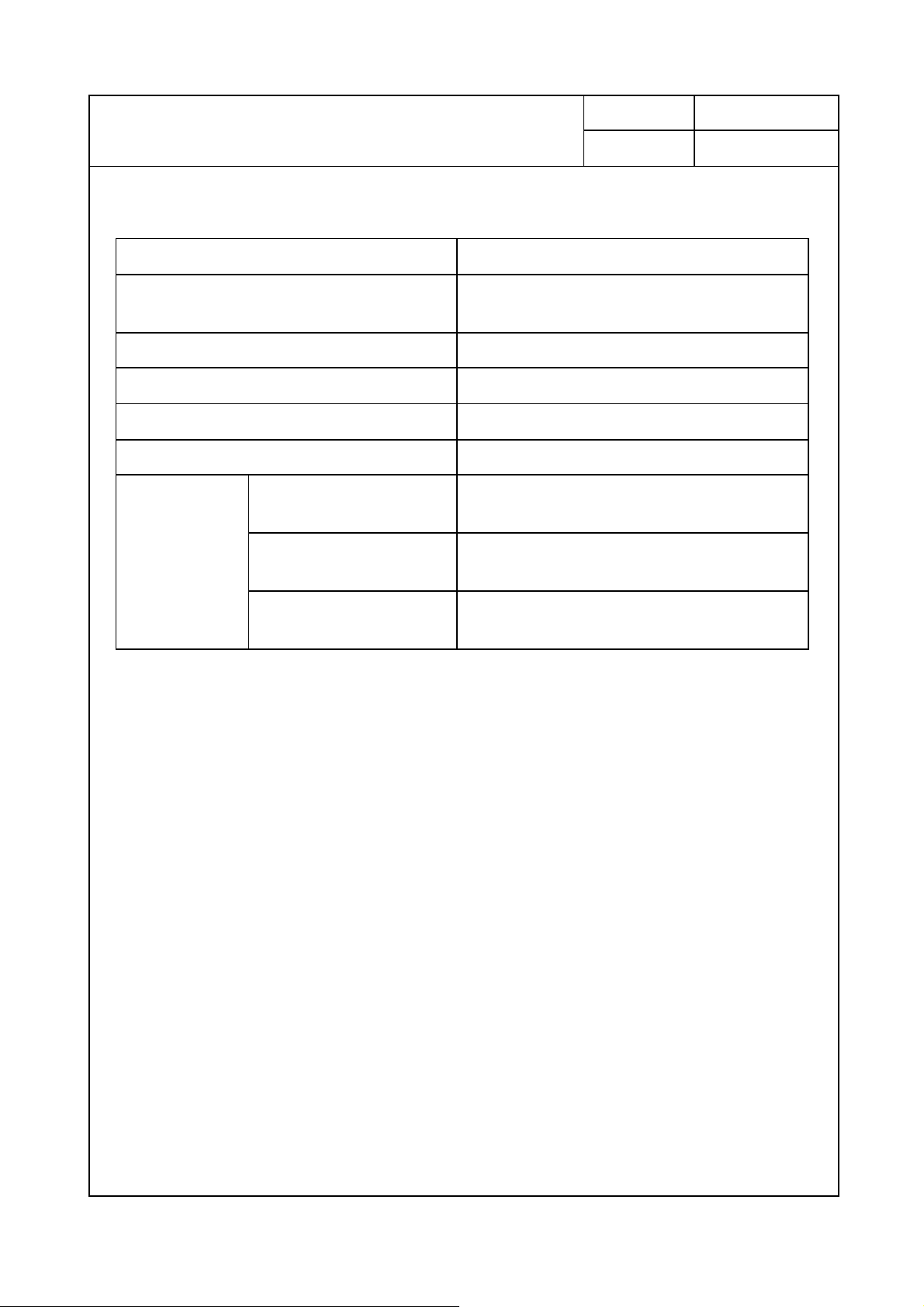

2.5 Physical Specifications

ITEM SPECIFICATION

Width (mm) 101.6

Mechanical

Dimen sion

Weight (gr) 460.0 typ.

External View Refer to Fig. 2-1 and Fig. 2-2

Installation Holes Refe r to Fig. 2-1 and Fig. 2-2

Height (mm) 25.4

Dep th (mm ) 145.0 (without Front Bezel)

SFD-321B

SEMA ELECTRONICS CO.,LTD

Page 11

SEMA ELECTRONICS CO.,LTD

Page 12

SEMA ELECTRONICS CO.,LTD

Page 13

SEMA ELECTRONICS CO.,LTD

Page 14

FLOPPY DISK DRIVE SPECIFICATION

4. ELECTRICAL INTERFACE

4.1 Signal Interface

PAGE 13

MODEL

SFD-321B

HOST

CONTROLLER

SYSTEM

Density Select

In Use (Spare)

Drive Select 3 (Spare)

Index

Drive Select 0

Drive Select 1

Drive Select 2 (Spare)

Motor On

Direction Select

Step

Write Data

Write Gate

Track 00

Write Protect

Read Da ta

Side Select

Ready/Disk Change

2

4

6

8

10

12

14

16

SFD-321B(*1)

18

20

22

24

26

28

30

32

34

FDD

<Note>

(*1) All odd numbers : GND

4.2 Power Interface

HOST

CONTROLLER

POWER

SUPPLY

+5 V

+5 V Return (GND)

No Connection (GND)

No Connection

SEMA ELECTRONICS CO.,LTD

1

2

3

4

FDD

SFD-321B

Page 15

FLOPPY DISK DRIVE SPECIFICATION

4.3 Interface Connectors

4.3.1 Signal Interface Connector

Side Connector

FDD HIROSE P/N 5003-001-7347 or eq uivalent (*1)

HOST (Connector) 3M NO. 7934 or equivalent

HOST (Ca ble) 3M 3365/34 or equivalent (*2)

<Note>

(*1) 33 pins, 2.54 pitch (Pin #3,5,7,9,13,15,17,19,23,25,27,31 : cut off)

Wall Type

PAGE 14

MODEL

SFD-321B

(*2) Cable length : 1m (3.3 feet) Max.

24 ~ 34

13 ~ 33

PIN NO.3,5,7,9,13,15,17,19,23,25,27,31 : Cut off

PCB

Rear View

FRONT

Top View

< Signal Interface Connector (FDD) > < Cable Side Connector (HOST) >

Fig 4-1. Signal Interface Connector and Cable Side Connector

SEMA ELECTRONICS CO.,LTD

Page 16

FLOPPY DISK DRIVE SPECIFICATION

4.3.2 Power Interface Connector

Side Connector

FDD ELCO P/N 9251-004-000-809 or equivalent

HOST (Connector) AMP 171822-4 or equivalent

HOST (Ca ble) AWG #20-26

PAGE 15

MODEL

SFD-321B

PCB

4321

Rear View

Top View

< Power Interface Connector (FDD) > < Cable Side Connector (HOST) >

Fig 4-2. Power Interface Connector and Cable Side Connector

SEMA ELECTRONICS CO.,LTD

Page 17

FLOPPY DISK DRIVE SPECIFICATION

5. SIGNAL CHARACTERISTICS

5.1 Signal Level

Signal Log ic Input Level Output Level (*1)

Low (True) 0.9 V Max. 0.4 V Max.

High (False ) 2.2 V Min. 2.4 V Min.

<Note>

(*1) "LOW" level Max. sink current is 48 mA.

5.2 Recommended Interface Circuit

PAGE 16

MODEL

SFD-321B

HOST SIDE

7438 SERIES

CMOS OR

EQUIVALENT

74LS14

74HC14 OR

EQUIVALENT

Vdd

150

(1

(1

Ω∼

㏀

is recommended)

2.2

㏀

㏀

)

FDD SIDE

Vdd

CMOS

(SCHMITT TRIGGER INPUT)

INPUT

OUTPUT

OPEN DRAIN

FRAME GND

SEMA ELECTRONICS CO.,LTD

Page 18

FLOPPY DISK DRIVE SPECIFICATION

5.3 Input Signals

5.3.1 Density Select

This siganl is used to distinguish between 1.6MB and 2MB Mode.

The interface pin No.2 can be used as Density Select Input signal by

attaching 0

is inserted. The "HIGH" level designates 2MB Mode and the "LOW" level

designates 1.6MB Mode. FDD can tell whether the inserted media is high

or Low density by checking the signal coming from mechanical switch which

detects the density selecting hole on the media.

Ω

resistor onto "OPA" short plug when the High density media

Type Contents

PAGE 17

MODEL

SFD-321B

2Mode

(2.0 / 1.0MB)

(Non-connection of "OPA")

3Mode

(2.0 / 1.6 / 1.0MB)

(Connection of "OPA")

5.3.2 Drive Select 0 and 1

Two trace plugs on the PCB, DS0 and DS1 are provided to select which

Drive Select line will activate the interface signals for a unique drive in the

daisy chain connection up to two drive units. Drive Select, when activated

logical "LOW", enables all the I/O lines except Motor On line.

This signal also controls the lightening of In-Use LED.

Automatic Switching

2.0MB : If High density media is inserted.

1.0MB : If Low density media is inserted.

Automatic Switching with "Density Select"

2.0MB : If High density media is inserted

with "Density Select" is "HIGH".

1.6MB : If High density media is inserted

with "Density Select" is "LOW".

1.0MB : If Low density media is inserted

"Density Select" is not available.

SEMA ELECTRONICS CO.,LTD

Page 19

FLOPPY DISK DRIVE SPECIFICATION

5.3.3 Motor On

Logical "LOW" level of this signal makes the spindle motor be turned on.

The motor reaches to the rated rotational speed within 500 ms after this

sign al change s to "L OW".

This input signal is ignored when no disk is installed.

5.3.4 Direction Select

This signal specifies the moving direction of the R/W head when the Step

input is activated.

Logical "LOW" level : the direction to the inner tracks of a disk.

"HIGH" level : the direction to the outer tracks of a disk.

PAGE 18

MODEL

SFD-321B

5.3.5 Step

This is a control signal to move the R/W head, and the head starts

moving attherisingedgeoftheStepsignal.

3msMin.

㎲

0.15

Min.

5.3.6 Write Data(MFM)

Each time this signal changes from "HIGH" level to "LOW" level,

the direction of the current flowing into the R/W head is reversed,

and the data bit is written on the disk.

Ta±0.5 % Tb±0.5 %

Tc±0.5 %

0.15 ~ 1.1

Tw

㎲

Density Mode

Density Transfer Rate

Ta (㎲)

(Typ.)

Tb (㎲)

(Typ.)

Tc (㎲)

(Typ.)

1.0MB 250 kbps 4 6 8

1.6MB 500 kbps 2 3 4

2.0MB 500 kbps 2 3 4

SEMA ELECTRONICS CO.,LTD

Page 20

FLOPPY DISK DRIVE SPECIFICATION

5.3.7 Write Gate

"LOW" level of this signal enables the write data to be written on the disk

provided that the drive is selected, disk used is not write protected and

se ek operation is completed.

When this signal changes to "HIGH" level, the read or seek op eration

becomes possible.

5.3.8 Side Select

This signal selects the side of Heads.

Logical "HIGH" level : the lower side (side 0) of Heads

"LOW " level : the upper side (side 1) of Heads

PAGE 19

MODEL

SFD-321B

WRITE GATE

SIDE SELECT

READ DATA

5.4 Output Signals

5.4.1 Index

This is a pulse signal output to indicate the start of the track, and it

outputs at every revolution of the disk.

This output signal is activated when only the drive is in Ready state.

1∼8ms

100㎲Min.

100㎲Min.

valid valid

valid

650

650

㎲

㎲

Min.

Min

100

valid

㎲

Min.

200±3ms

±

(166.7

2.5 ms)(*1)

<Note>

(*1) The value in parenthsis is for 360 rpm (1.6MB Mode) rotation speed.

SEMA ELECTRONICS CO.,LTD

Page 21

FLOPPY DISK DRIVE SPECIFICATION

5.4.2 Track 00

"LOW" level of this signal indicates the head is on Track 00 position

and stepping motor is at the specified position respectively.

5.4.3 Write Protect

When a write-protected disk is inserted, this signal becomes "LOW"

and the data on the disk is protected from mis-erasing and

the write operation is inhibited.

5.4.4 Read Data (MFM)

Read Data read out from the disk is transferred to the ho st system

in the same form as it was received on the Write Data line. Each flux

reversal sensed on the d isk produces the only transition from "HIGH"

level to "LOW" level. For the seperation of the clock bits from the data,

the leading edge of a change from "HIGH" to "LOW" level is used.

PAGE 20

MODEL

SFD-321B

±

Ta

0.5 %

Density Mode

Density Transfer Rate

Tb

±

0.5 %

Ta (㎲)

(Typ.)

±

Tc

Tb (㎲)

(Typ.)

0.5 %

400 ns±20 %

Tc (㎲)

(Typ.)

1.0MB 250 kbps 4 6 8

1.6MB 500 kbps 2 3 4

2.0MB 500 kbps 2 3 4

SEMA ELECTRONICS CO.,LTD

Page 22

FLOPPY DISK DRIVE SPECIFICATION

5.4.5 Disk Change / Ready

By selecting p roper trace plugs, this signal line (pin # 34) can be used for

Ready or Disk Change line.

-. Ready

This line becomes a ctive "LOW" when the drive is selected, a disk is

clampedandthespindlemotorisuptospeed.

(after counting at least two Index pulses)

Otherwise this line goes logical "HIGH" level.

-. Disk Change

This line is active "LOW" unless disk is clamped and a Step pulse is

received when the d rive is selected.

PAGE 21

MODEL

SFD-321B

DRIVE SE LECT

DIS K IN

STEP

DIS K

CHANGE

inserted

ejected

0.5㎲Max

0.5

㎲

Max

SEMA ELECTRONICS CO.,LTD

Page 23

FLOPPY DISK DRIVE SPECIFICATION

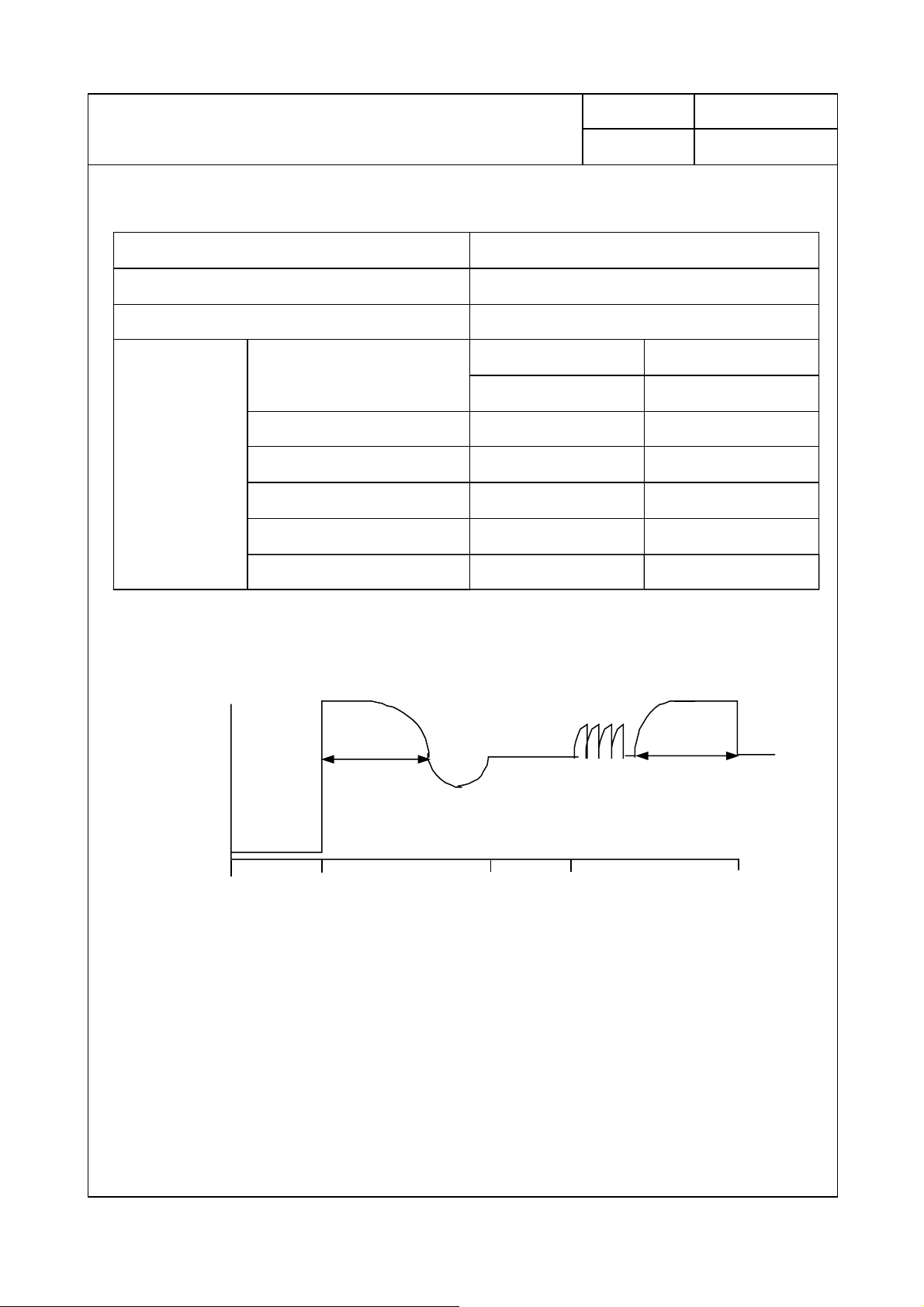

6. TIMING DIAGRAM

6.1 Seek Operation Timing

DRIVE SELECT

PAGE 22

MODEL

SFD-321B

DIRECTION

SELECT

500㎱Min.

STEP

3㎳Min.

TRACK 00

1

6.2 Read / Write Operation Timing

MOTOR ON

600㎳Max.

DRIVE S ELECT

READY

REVERSE

㎲

Min.

18㎳Min. (*1)

2.8㎳Max.

FORWARD

㎲

1

Min.

10㎲Max.

650㎲Min.

650㎲Min.

㎲

1

Min.

0.3㎳Max.

STEP

DENS ITY

SELECT

READ DAT A

WRITE GATE

WRITE DAT A

18 ms Min.

0Min.

18 m s Min.

0Min.

100㎲Min. (*3)

100㎲Min (*3)

8㎲Max.

(*2)

(*2)

8㎲Max.

<Note>

(*1) Turn Around Time is 18 ms Min. when Direction is changed.

(*2) 750㎲Min. ( including 100

(*3) When spindle motor speed is changed (300 rpm

㎲

Side Se lec t timing )

↔

360 rpm )

this value is 500 m s Min.

(*2)

100㎲Min. (*3)

SEMA ELECTRONICS CO.,LTD

Page 24

FLOPPY DISK DRIVE SPECIFICATION

7. SAFETY STANDARDS

This drive is appro ve d by the followin g s ;

.CE

.CSA

.UL

.TUV

.MIC

. BSMI

.FCC

PAGE 23

MODEL

SFD-321B

SAMSUNG ELECTRO-MECHANICS CO.,LTD.

SEMA ELECTRONICS CO.,LTD

Page 25

FLOPPY DISK DRIVE SPECIFICATION

8. PACKAGING DESCRIPTION

8.1 Label Description

8.1.1 Serial Number Label Marking

BAR CODE

FBT6 S1ARB00001

①

Product name : "F"

②

Model name : "B"

③

Revision name (Major)

④

Revision name (Minor)

⑤

Production division : "S"

⑥

Production site

→

FDD

→

SFD-321B

→

FBT6 S1ALB00001

①②③④ ⑤⑥⑦⑧⑨⑩

SEMA ELECTRONICS CO.,LTD

PAGE 24

MODEL

SFD-321B

Marking

Production site

⑦

Production line : "A"

⑧

Year of manufacturing

Year 2001 2002 2003 2004 2005 2006 2007

Marking M N P Q R S T

⑨

Month of manufacturing

Month Marking Month Marking Month Marking Month Marking

1 1 4 4 7 7 10 A

2 2 5 5 8 8 11 B

3 3 6 6 9 9 12 C

⑩

Consecutive nu mber

8.1.2 Label Description

1 2

China factory

(SEMA China)

→

A-Line, "B" ~ "Z"

FBT6 S1R1100001

Outside supplier

(OEM)

Bar co de

①

REV. T6

②

①

Serial number

②

Revision

③

Buy er na me

④

Production site

⑤

CE m a rking

③

SFD-321B /

⑥

⑦

⑧

⑨

⑩

⑪

****

DC5V 0 .7V

CSA ma rking

UL ma rking

TUV mark ing

MIC marking (for only domestic)

BSMI ma rk in g

Label manufacturer identification

SEMA ELECTRONICS CO.,LTD

MA DE IN CHINA

⑩⑨⑧⑦⑥⑤

④

⑪

Page 26

SEMA ELECTRONICS CO.,LTD

Page 27

SEMA ELECTRONICS CO.,LTD

Page 28

PAGE 27

FLOPPY DISK DRIVE SPECIFICATION

MODEL

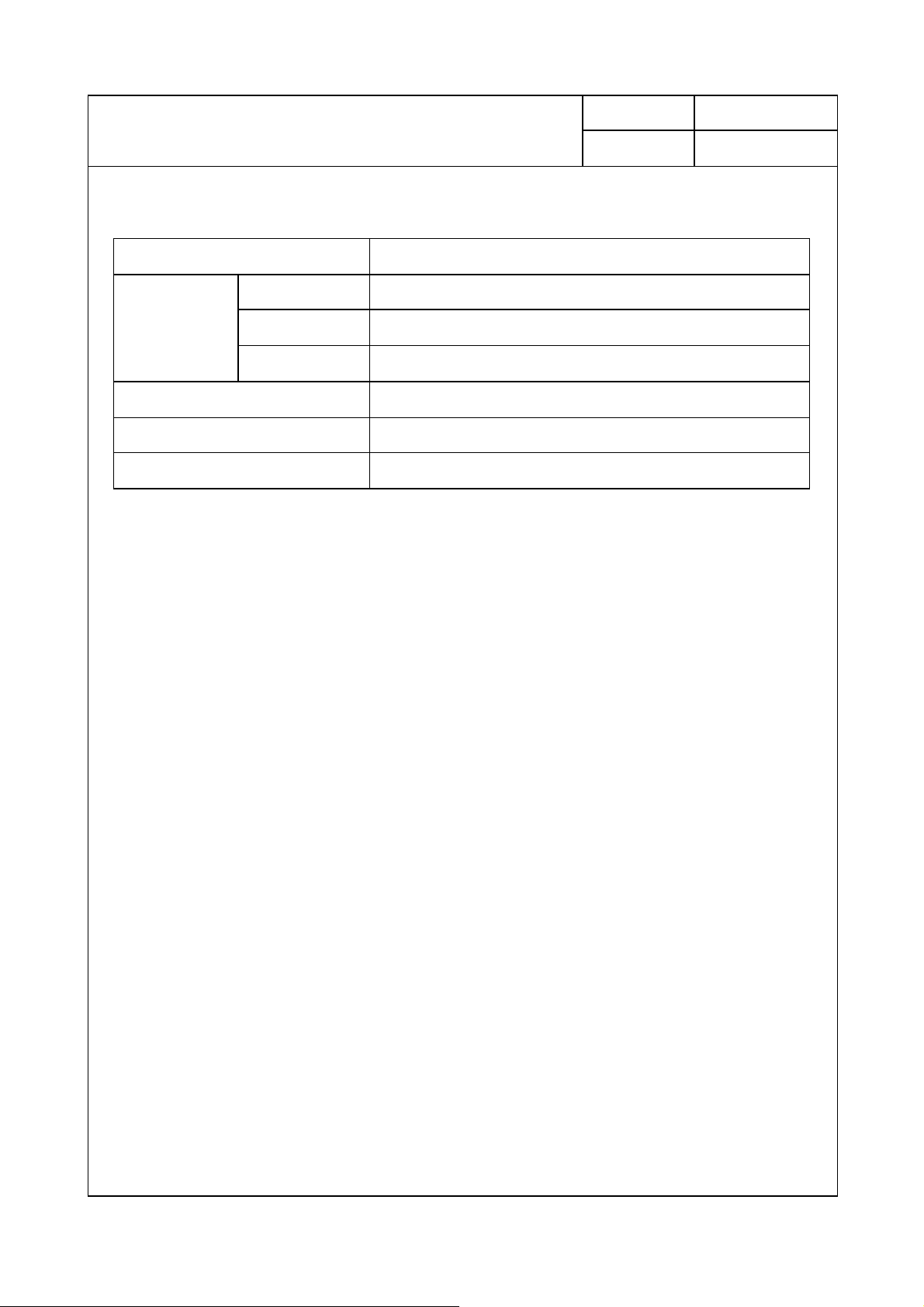

9. OPTION SELECTION

FDD can be modified for different functions than the standard specification.

These modifications should be implemented by the factory according to the

request of the customers.

9.1 Trace Options

By putting a chip-resistor onto a p roper trace, FDD ca n be used for the

following different functions.

Trace Name Description

SFD-321B

DS0

DS1

DC

RDY

OPA

OPB (*1)

<Note>

(*1) Both "OPA" and "OPB" op en : 2 Mode (1MB / 2MB)

"OPB" is connecte d and "OPA" is open : 2 Mo de (1MB / 1.6MB)

"OPA" is connecte d and "OPB" is open : 3 Mo de (1MB / 1.6MB / 2MB)

Activate Drive Select 0 line

Activate Drive Select 1 line

Activate Disk Change Signal

Activate Ready Signal

For 3 Mode usage

For 1.6MB usage

SEMA ELECTRONICS CO.,LTD

Page 29

PAGE 28

FLOPPY DISK DRIVE SPECIFICATION

MODEL

9.2 Other Options (Buyer Selection)

The colors of In-Use LED, Front-Panel, the value of the termination resistors

and the shape of button can be modified by customers' request.

9.2.1 Mode

SFD-321B

□

□

9.2.2 The Selection of Bezel Type

□

□

9.2.3 The Color of Bezel, Button

□

□

□

Color Number (Fill in this blank)

9.2.4 The Selection of LED Color

2Mode(1MB/2MB)

3 Mode (1MB / 1.6MB / 2MB)

With Bezel

Without Bezel

Black

Ivory

Gray

□

□

□

Green

Red

Amber

SEMA ELECTRONICS CO.,LTD

Page 30

FLOPPY DISK DRIVE SPECIFICATION

11. GENERAL COMMENT

PAGE 29

MODEL

SFD-321B

SEMA ELECTRONICS CO.,LTD

Page 31

SEMA ELECTRONICS CO.,LTD

Loading...

Loading...