Samsung SF-750, SF-755P Service Manual

SERVICE

DIGITAL LASER MFP

SF-750

SF-755P

Manual

DIGITAL LASER MFP CONTENTS

1. Precautions

2. Reference Information

3. Specifications

4. Summary of product

5. Disassembly and Reassembly

6. Alignment and Adjustments

7. Troubleshooting

8. Exploded Views and Parts List

9. Block Diagram

10. Connection Diagram

1

1

1-1

Precautions

Service Manual

1. Precautions

In order to prevent accidents and to prevent damage to the equipment please read the precautions listed

below carefully before servicing the printer and follow them closely.

1.1 Safety W arning

(1) Only to be serviced by appropriately qualified service engineers.

High voltages and lasers inside this product are dangerous. This printer should only be serviced by a suitably

trained and qualified service engineer.

(2) Use only Samsung replacement parts

There are no user serviceable parts inside the printer. Do not make any unauthorized changes or

additions to the printer , these could cause the printer to malfunction and create electric shock or fire haz-ards.

(3) Laser Safety Statement

The Printer is certified in the U.S. to conform to the requirements of DHHS 21 CFR, chapter 1 Subchapter J for

Class 1(1) laser products, and elsewhere, it is certified as a Class I laser product

con-forming to the requirements of IEC 825. Class I laser products are not considered to be hazardous. The

laser system and printer are designed so there is never any human access to laser radiation above a Class I

level during normal operation, user maintenance, or prescribed service condition.

Warning >> Never operate or service the printer with the protective cover removed from Laser/Scanner assembly. The

reflected beam, although invisible, can damage your eyes. When using this product, these basic safety

pre-cautions should always be followed to reduce risk of fire, electric shock, and injury to persons.

CAUTION - INVISIBLE LASER RADIATION

WHEN THIS COVER OPEN.

DO NOT OPEN THIS COVER.

VORSICHT - UNSICHTBARE LASERSTRAHLUNG,

WENN ABDECKUNG GEFFNET.

NICHT DEM STRAHL AUSSETZEN.

ATTENTION - RAYONNEMENT LASER INVISIBLE EN CAS

D OUVERTURE. EXPOSITION DANGEREUSE

AU FAISCEAU.

ATTENZIONE - RADIAZIONE LASER INVISIBILE IN CASO DI

APERTURA. EVITARE L ESPOSIZIONE AL

FASCIO.

PRECAUCION - RADIACION LASER IVISIBLE CUANDO SE ABRE.

EVITAR EXPONERSE AL RAYO.

ADVARSEL. - USYNLIG LASERSTR LNING VED BNING, N R

SIKKERHEDSBRYDERE ER UDE AF FUNKTION.

UNDG UDSAETTELSE FOR STR LNING.

ADVARSEL. - USYNLIG LASERSTR LNING N R DEKSEL

PNES. STIRR IKKE INN I STR LEN.

UNNG EKSPONERING FOR STR LEN.

VARNING - OSYNLIG LASERSTR LNING N R DENNA DEL

R PPNAD OCH SP RREN R URKOPPLAD.

BETRAKTA EJ STR LEN. STR LEN R FARLIG.

VARO! - AVATTAESSA JA SUOJALUKITUS OHITETTAESSA

OLET ALTTIINA N KYM TT M LLE LASERS TEILYLLE L KATSO S TEESEEN.

1-2

Precautions

Service Manual

1.2 Caution for safety

1.2.1 Toxic material

This product contains toxic materials that could cause illness if ingested.

(1) If the LCD control panel is damaged it is possible for the liquid inside to leak. This liquid is toxic. Contact with the skin

should be avoided, wash any splashes from eyes or skin immediately and contact your doctor. If the liquid gets into

the mouth or is swallowed see a doctor immediately .

(2) Please keep toner cartridges away from children. The toner powder contained in the toner cartridge may be harmful

and if swallowed you should contact a doctor .

1.2.2 Electric Shock and Fire Safety Precautions

Failure to follow the following instructions could cause electric shock or potentially cause a fire.

(1) Use only the correct voltage, failure to do so could damage the printer and potentially cause a fire cause an

electric shock.

(2) Use only the power cable supplied with the printer. Use of an incorrectly specified cable could cause the cable

to overheat and potentially cause a fire.

(3) Do not overload the power socket, this could lead to overheating of the cables inside the wall and could lead to

a fire.

(4) Do not allow water or other liquids to spill into the printer, this can cause electric shock. Do not allow paper

clips, pins or other foreign objects to fall into the printer these could cause a short circuit leading to an electric

shock or fire hazard..

(5) Never touch the plugs on either end of the power cable with wet hands, this can cause electric shock. When

servicing the printer remove the power plug from the wall socket.

(6) Use caution when inserting or taking off the power plug. The power plug has to be inserted completely. If not,

a fire will be caused due to poor contact. When taking off the power plug, grip the plug and remove it.

(7) Take care of the power cable. Do not allow it to become twisted, bent sharply round corners or other wise

damaged. Do not place objects on top of the power cable. If the power cable is damaged it could overheat and

cause a fire or exposed cables could cause an electric shock. Replace a damaged power cable immediately,

do not reuse or repair the damaged cable. Some chemicals can attack the coating on the power cable,

weakening the cover or exposing cables causing fire and shock risks.

(8) Ensure that the power sockets and plugs are not cracked or broken in any way . Any such defects should be

repaired immediately. Take care not to cut or damage the power cable or plugs when moving the machine.

(9) Use caution during thunder or lightening storms. Samsung recommend that this machine be disconnected from

the power source when such weather conditions are expected. Do not touch the machine or the power cord if it

is still connected to the wall socket in these weather conditions.

(10) Avoid damp or dusty areas, install the printer in a clean well ventilated location. Do not position the machine

near a humidifier. Damp and dust build up inside the machine can lead to overheating and cause a fire.

(1 1) Do not position the printer in direct sunlight. This will cause the temperature inside the printer to rise possibly

leading to the printer failing to work properly and in extreme conditions could lead to a fire.

(12) Do not insert any metal objects into the machine through the ventilator fan or other part of the casing, it could

make contact with a high voltage conductor inside the machine and cause an electric shock.

1-3

Precautions

Service Manual

1.2.3 Handling Precautions

The following instructions are for your own personal safety, to avoid injury and so as not to damage the printer

(1) Ensure the printer is installed on a level surface, capable of supporting its weight. Failure to do so could cause

the printer to tip or fall.

(2) printer contains many rollers, gears and fans. Take great care to ensure that you do not catch your fingers, hair

or clothing in any of these rotating devices.

(3) Do not place any small metal objects, containers of water, chemicals or other liquids close to the printer which if

spilled could get into the machine and cause damage or a shock or fire hazard.

(4) Do not install the machine in areas with high dust or moisture levels, beside on open window or close to a

humidifier or heater. Damage could be cause to the printer in such areas.

(5) Do not place candles, burning cigarettes, etc on the printer , These could cause a fire.

1.2.4 Assembly / Disassembly Precautions

Replace parts carefully, always use Samsung parts. Take care to note the exact location of parts and also

cable routing before dismantling any part of the machine. Ensure all parts and cables are replaced correctly.

Please carry out the following procedures before dismantling the printer or replacing any parts.

(1) Check the contents of the machine memory and make a note of any user settings. These will be erased if the

mainboard or network card is replaced.

(2) Ensure that power is disconnected before servicing or replacing any electrical parts.

(3) Disconnect printer interface cables and power cables.

(4) Only use approved spare parts. Ensure that part number, product name, any voltage, current or temperature

rating are correct.

(5) When removing or re-fitting any parts do not use excessive force, especially when fitting screws into plastic.

(6) Take care not to drop any small parts into the machine.

(7) Handling of the Toner Cartridge

- The OPC Drum can be irreparably damaged if it exposed to light.

Take care not to expose the OPC Drum either to direct sunlight or to fluorescent or incandescent room

lighting. Exposure for as little as 5 mins can damage the surface’s photoconductive properties and will result

in print quality degradation. Take extra care when servicing the printer. Remove the OPC Drum and store it in

a black bag or other lightproof container. T ake care when working with the covers(especially the top cover)

open as light is admitted to the OPC area and can damage the OPC Drum.

- Take care not to scratch the green surface of OPC Drum Unit.

If the green surface of the Drum Cartridge is scratched or touched the print quality will be compromised.

1-4

Precautions

Service Manual

1.2.5 Disregarding this warning may cause bodily injury

(1) Be careful with the high temperature part.

The fuser unit works at a high temperature. Use caution when working on the printer . Wait for the fuser to cool

down before disassembly.

(2) Do not put finger or hair into the rotating parts.

Take care when using a printer. It contains many rotating parts. Ensure that fingers, hair, clothing etc. do not

become caught in the mechanism as this could cause injury.

(3) When you move the printer.

This printer weighs 14kg including toner cartridge and cassette. Use safe lifting and handling techniques. Use

the lifting handles located on each side of the machine. Back injury could be caused if you do not lift carefully.

(4) Ensure the printer is installed safely.

The printer weighs 14Kg, ensure the printer is installed on a level surface, capable of supporting its weight.

Failure to do so could cause the printer to tip or fall possibly causing personal injury or damaging the printer.

(5) Do not install the printer on a sloping or unstable surface. After installation, double check that the printer is

stable.

1-5

Precautions

Service Manual

1.3 ESD Precautions

Certain semiconductor devices can be easily damaged by static electricity . Such components are commonly called

“Electrostatically Sensitive (ES) Devices”, or ESDs. Examples of typical ESDs are: integrated circuits, some field

effect transistors, and semiconductor “chip” components.

The techniques outlined below should be followed to help reduce the incidence of component damage caused by

static electricity.

Caution >>Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

1. Immediately before handling a semiconductor component or semiconductor-equipped assembly, drain off any

electrostatic charge on your body by touching a known earth ground. Alternatively, employ a commercially available wrist strap device, which should be removed for your personal safety reasons prior to applying power to the

unit under test.

2. After removing an electrical assembly equipped with ESDs, place the assembly on a conductive surface, such as

aluminum or copper foil, or conductive foam, to prevent electrostatic charge buildup in the vicinity of the assembly .

3. Use only a grounded tip soldering iron to solder or desolder ESDs.

4. Use only an “anti-static” solder removal device. Some solder removal devices not classified as “anti-static” can

generate electrical charges sufficient to damage ESDs.

5. Do not use Freon-propelled chemicals. When sprayed, these can generate electrical charges sufficient to damage ESDs.

6. Do not remove a replacement ESD from its protective packaging until immediately before installing it. Most

replacement ESDs are packaged with all leads shorted together by conductive foam, aluminum foil, or a comparable conductive material.

7. Immediately before removing the protective shorting material from the leads of a replacement ESD, touch the protective material to the chassis or circuit assembly into which the device will be installed.

8. Maintain continuous electrical contact between the ESD and the assembly into which it will be installed, until completely plugged or soldered into the circuit.

9. Minimize bodily motions when handling unpackaged replacement ESDs. Normal motions, such as the brushing

together of clothing fabric and lifting one’s foot from a carpeted floor, can generate static electricity sufficient to

damage an ESD.

2-1

Samsung Electronics

Reference Information

Service Manual

2

2

2. Reference Information

This chapter contains the tools list, list of abbreviations used in this manual, and a guide to the

location space required when installing the printer. A definition of tests pages is also included.

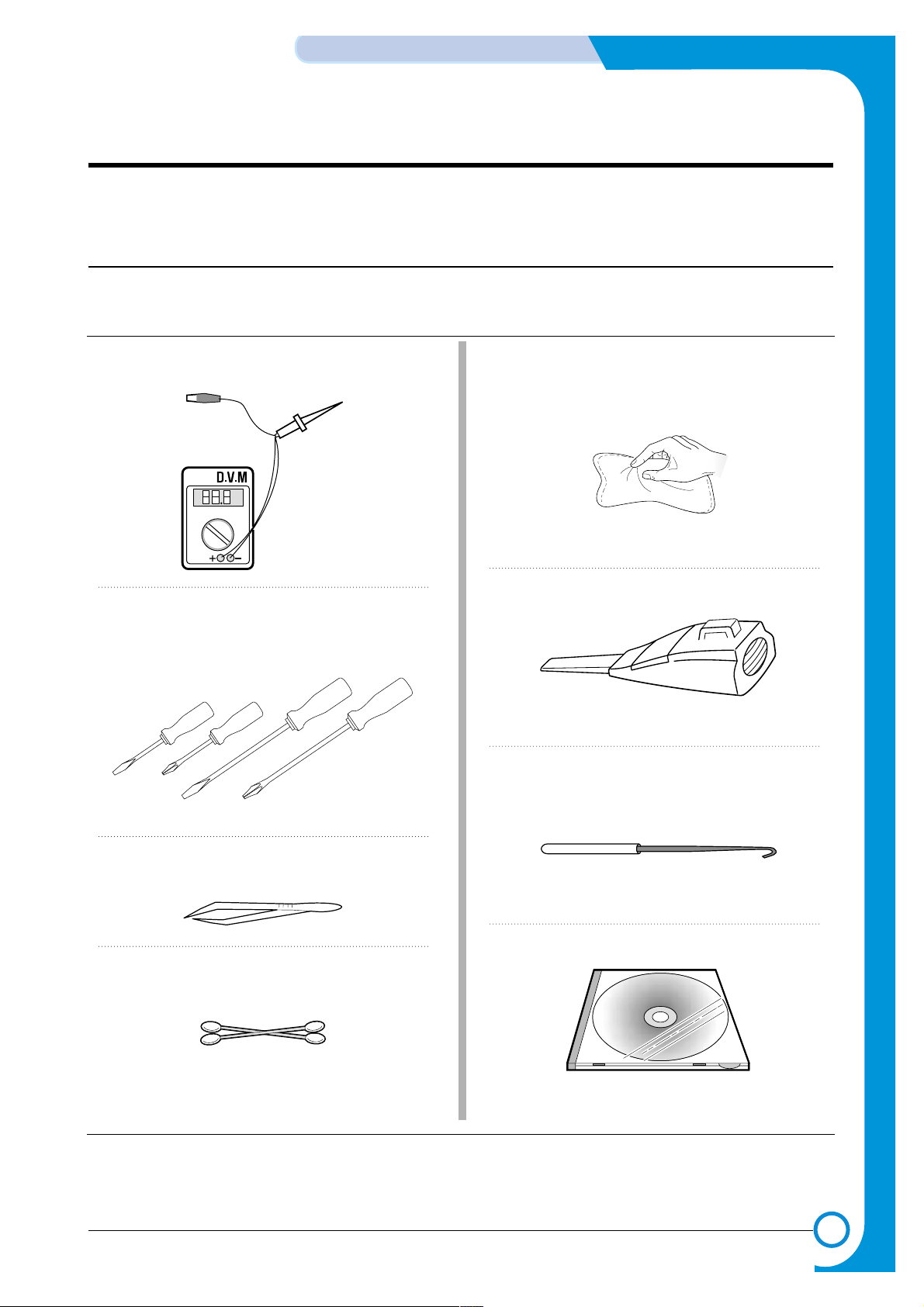

2.1 Tool for Troubleshooting

The following tools are recommended safe and easy troubleshooting as described in this service manual.

• DVM(Digital Volt Meter)

Standard : Indicates more than 3 digits.

• Driver

Standard : "-" type, "+" type (M3 long, M3 short, M2

long, M2 short).

• Tweezers

Standard : For general home use, small type.

• Cotton Swab

Standard : For general home use, for medical service.

• Cleaning Equipments

Standard : An IPA(Isopropyl Alcohol)dry wipe tissue or

a gentle neutral detergent and lint-free cloth.

• Vacuum Cleaner

• Spring Hook

Standard : For general use

• Software (Driver) installation CD ROM

2-2

Reference Information

Samsung Electronics

Service Manual

2.2 Acronyms and Abbreviations

The table in the below explains abbreviations used in this service manual.

The contents of this service manual are declared with abbreviations in many parts. Please refer to the

table.

ADC Analog-to-Digital-Conversion EPP Enhanced Parallel Port

AP Access Point F/W Firmware

AC Alternating Current FCF/FCT First Cassette Feeder/First Cassette Tray

ASIC Circuit

Application Specific Integrated FISO Front-In, Side-Out

ASSY Assembly FPOT First Print out Time

BIOS Basic Input Output System GDI Windows Graphic Device Interface

BLDC Motor

Brushless DC Motor GIF Graphic Interchange Format

CMOS Complementary Metal Oxide Semiconductor HBP Host Based Printing

CMYK Cyan, Magenta, Yellow, Black GND Ground

CN Connector HDD Hard Disk Drive

CON Connector HTML Hyper Text T ransfer Protocol

CPU Central Processing Unit HV High Voltage

CTD Sensor

Color T oner Density Sensor HVPS High V oltage Power Supply

dB Decibel I/F Interface

dBA A-Weighted decibel I/O Input and Output

dBm Decibel milliwatt lb Pound(s)

DC Direct Current IC Integrated Circuit

DCU Diagnostic Control Unit ICC International Color Consortium

DIMM Dual In-line Memory Module IDE Intelligent Drive Electronics or

Integrated Drive Electronics

DPI Dot Per Inch IEEE Institute of Electrical and

DRAM Dynamic Random Access Memory Electronics Engineers. Inc

DVM Digital Voltmeter IOT Image Output Terminal

(Color printer, Copier)

ECP Enhanced Capability Port IPA Isopropy Alcohol

ECU Engine Control Unit IPC Inter Process CommunicationEPP

Enhanced parallel Port

EEPROM Electronically Erasable IPM Images Per Minute

Programmable Read Only Memory

EMI Electro Magnetic Interference ITB Image Transfer Belt

EP Electro photographic RAM Random Access Memory

LAN local area network ROM Read Only Memory

LBP Laser Beam Printer SCF/SCT Second Cassette Feeder/Second

Cassette Tray

2-3

Samsung Electronics

Reference Information

Service Manual

LCD Liquid Crystal Display SMPS Switching Mode Power Supply

LED Light Emitting Diode SPGP Samsung Printer Graphic Processor

LSU Laser Scanning Unit SPL Samsung Printer Language

MB Megabyte Spool Simultaneous Peripheral Operation Online

MHz Megahertz SURF Surface Rapid Fusing

MPBF Mean Prints Between Failure SW Switch

MPF/MPT Multi Purpose Feeder/Multi Purpose Tray sync Synchronous or Synchronization

NIC Network Interface Card T1 ITB

NPC Network Printer Card T2 Transfer Roller

NVRAM Nonvolatile Random Access Memory TRC Toner Reproduction Curve

OPC Organic Photo Conductor PnP Universal Plug and Play

PBA Printed Board Assembly URL Uniform Resource Locator

TRC Toner Reproduction Curve USB Universal Serial Bus

PCL Printer Command Language , VCCI Voluntary Control Council for

Printer Control Language Interference Information

Technology Equipment

PCI Peripheral Component Interconnect by WECA Wireless Ethernet Compatibility

Intel 1992/6/22, is a local bus standard developed by Alliance

Intel and introduced in April, 1993 : A60, B60 Pins

PDF Portable Document Format Wi-Fi Wireless Fidelity

PDL Page Description Language

Ping Packet internet or Inter-Network Groper

PPD Postscript Printer Discription

PPM Page Per Minute

PS Post Script

PTL Pre-Transfer Lamp

PWM Pulse Width Moduration

Q'ty Quantity

2-4

Reference Information

Samsung Electronics

Service Manual

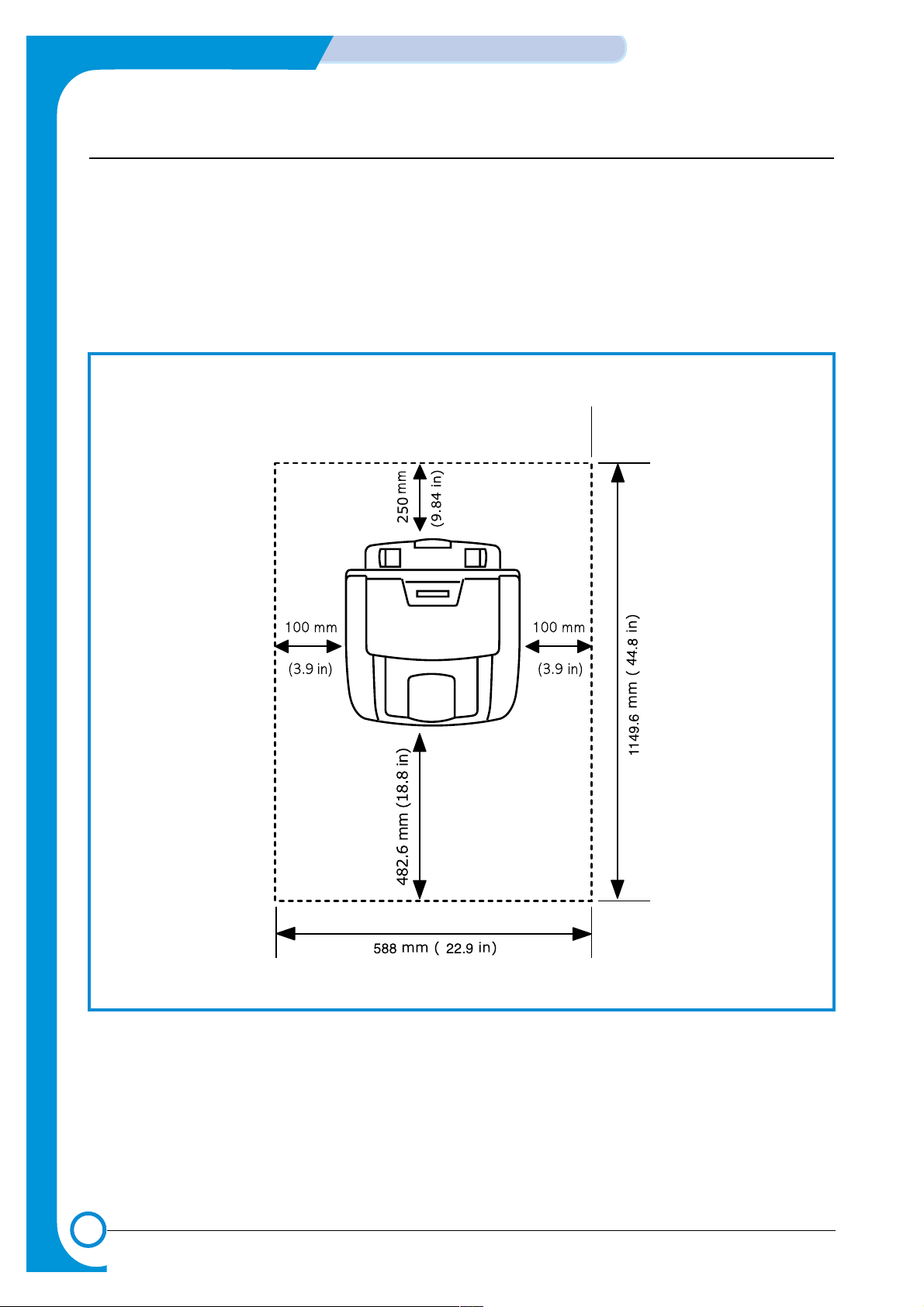

2.3 Select a location for the printer

• Leave enough room to open the printer trays, covers, and allow for proper ventilation. (see diagram

below)

• Provide the proper environment :

- A firm, level surface

- Away from the direct airflow of air conditioners, heaters, or ventilators

- Free of extreme fluctuations of temperature, sunlight, or humidity

- Clean, dry, and free of dust

2-5

Samsung Electronics

Reference Information

Service Manual

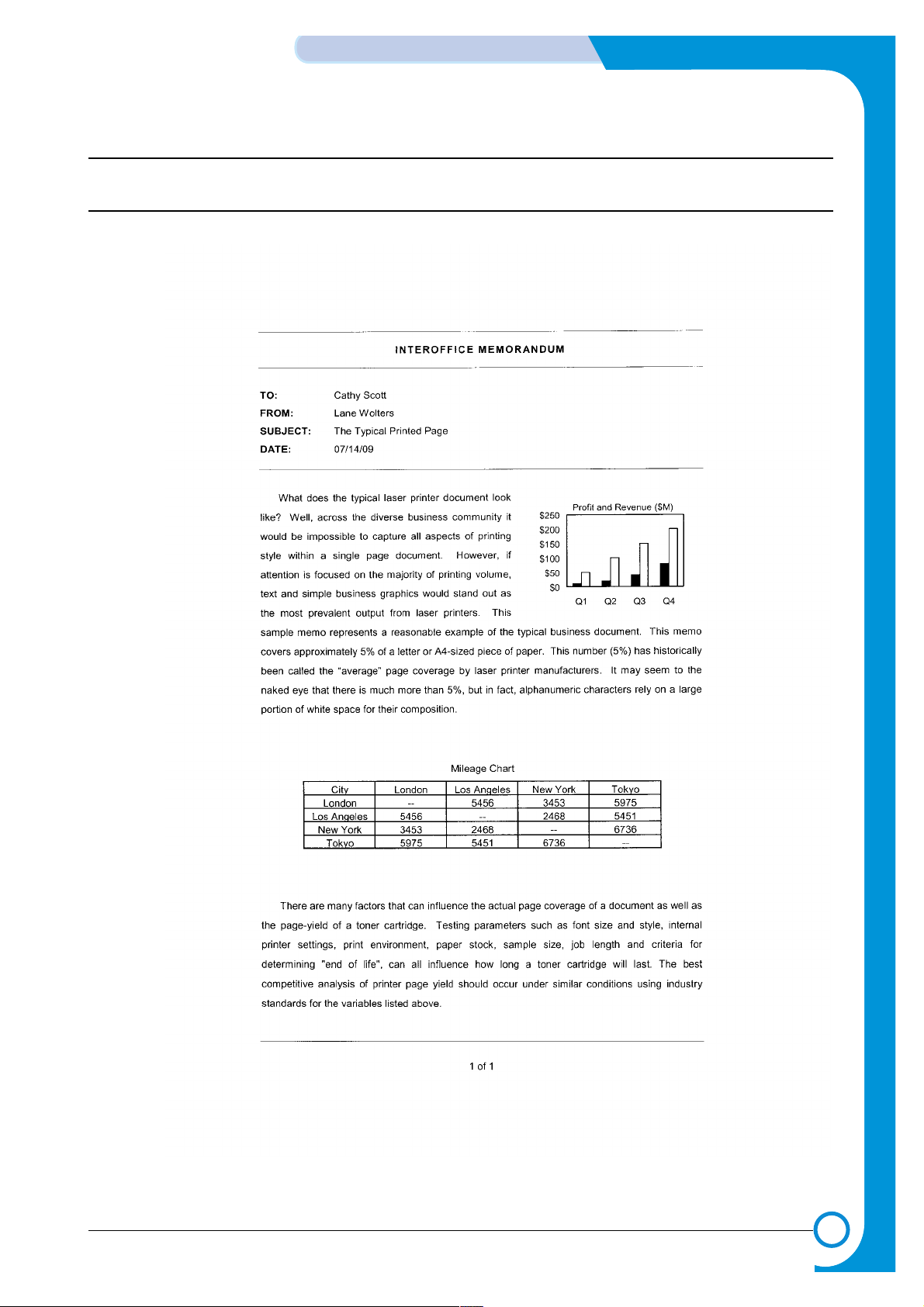

2.4 The Sample Pattern for the Test

The sample pattern shown in below is the standard pattern used in a factory.

The contents of the life span and the printing speed are measured with the pattern shown in below.

(The picture in the manual is 70% size of the actual A4 size.)

2.4.1 A4 5% Pattern

2-6

Reference Information

Samsung Electronics

Service Manual

2.4.2 A4 2% Pattern

2-7

Samsung Electronics

Reference Information

Service Manual

2.4.3 A4 IDC 5% Patten

2-8

Reference Information

Samsung Electronics

Service Manual

Specifications

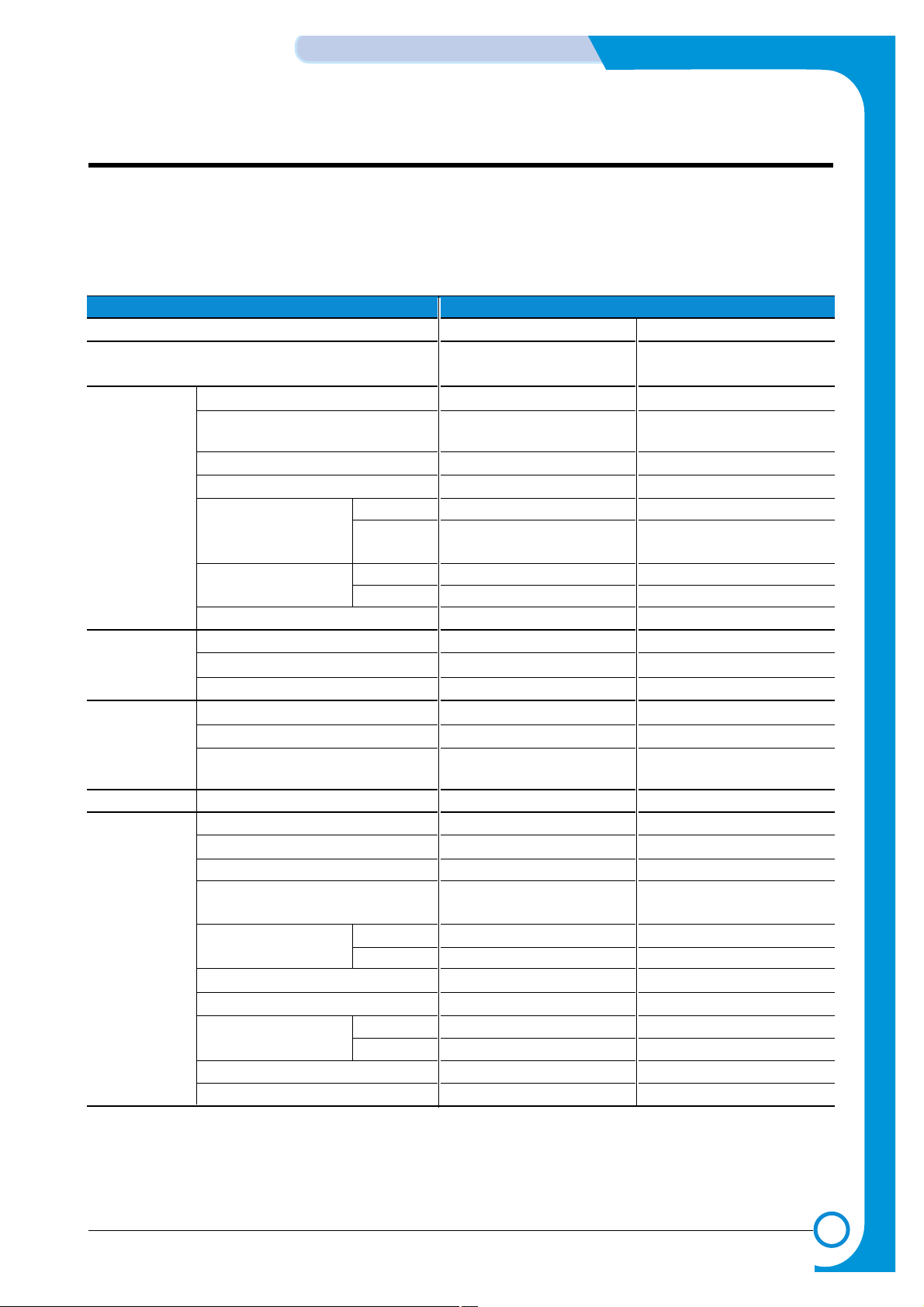

Items SF-750 Series

Model Name SF-755P SF-750

Functions Fax,Copier,Printer,Scanner Fax,Copier

General Size (W*D*H) w/o Hand Set 383.7 * 416.8 * 334.9(mm) 383.7 * 416.8 * 334.9(mm)

Weight Without Toner Cartridge 11kg 11kg

With Toner Cartridge 14kg 14kg

LCD 16*2 Char 16*2 Char

Interface IEEE1284, USB 2.0 USB 2.0 : f/w Down Load

AMV(Average Month Volume)

Printing 1,000 1,000

Scan to Copy

1,000 1,000

or Scan to Fax

Duty cycle, Monthly Printing Up to 10,000 pages Up to 10,000 pages

ADF SCAN Up to 5,000 pages Up to 5,000 pages

Engine Life Up to 120,000 pages Up to 120,000 pages

Power Power Switch Y es Yes

Consumption Input Voltage

AC1 10V~127V , 220V ~ 240V AC1 10V~127V , 220V ~ 240V

Power Sleep Mode Energy Star Compliant Energy Star Compliant

**Noise Operating(ADF) Less than 52 dBA Less than 52 dBA

Standby Less than 39 dBA Less than 39 dBA

Printing Less than 50 dBA

Less than 50dBA

(Fax Rec., Memory Copy)

EMI Approval EMI Approval Class B Class B

PC Print Power Save Mode Y es (5/10/15/30/45min.off) Yes (5/10/15/30/45min.off)

Print Method Laser Laser

N/W I/f No No

*Speed (Eninge) Up to 16 PPM in A4 size,

Up to 17 PPM in Letter size -

Resolution Normal

Up to 600 x 600 DPI effective output

-

RET No Print Language GDI Toner Save Y es Yes(Text Mode)

Fpot Stand by Approx. 12 seconds -

Power Save Less than 42 seconds Printable Area 208 x 273 mm (Letter) Duplex Print

Manual (driver support provided)

-

3

3

3-1

Samsung Electronics

Service Manual

3. Specifications

Specfications are correct at the time of printing. Product specifications are subject to change without notice.

See below for product specifications.

* Speed will be affected by Operating System used, computing performance, application software, connect-

ing method, media type, media size and job complexity.

** Sound Pressure Level, ISO 7779

3-2

Specifications

Samsung Electronics

Service Manual

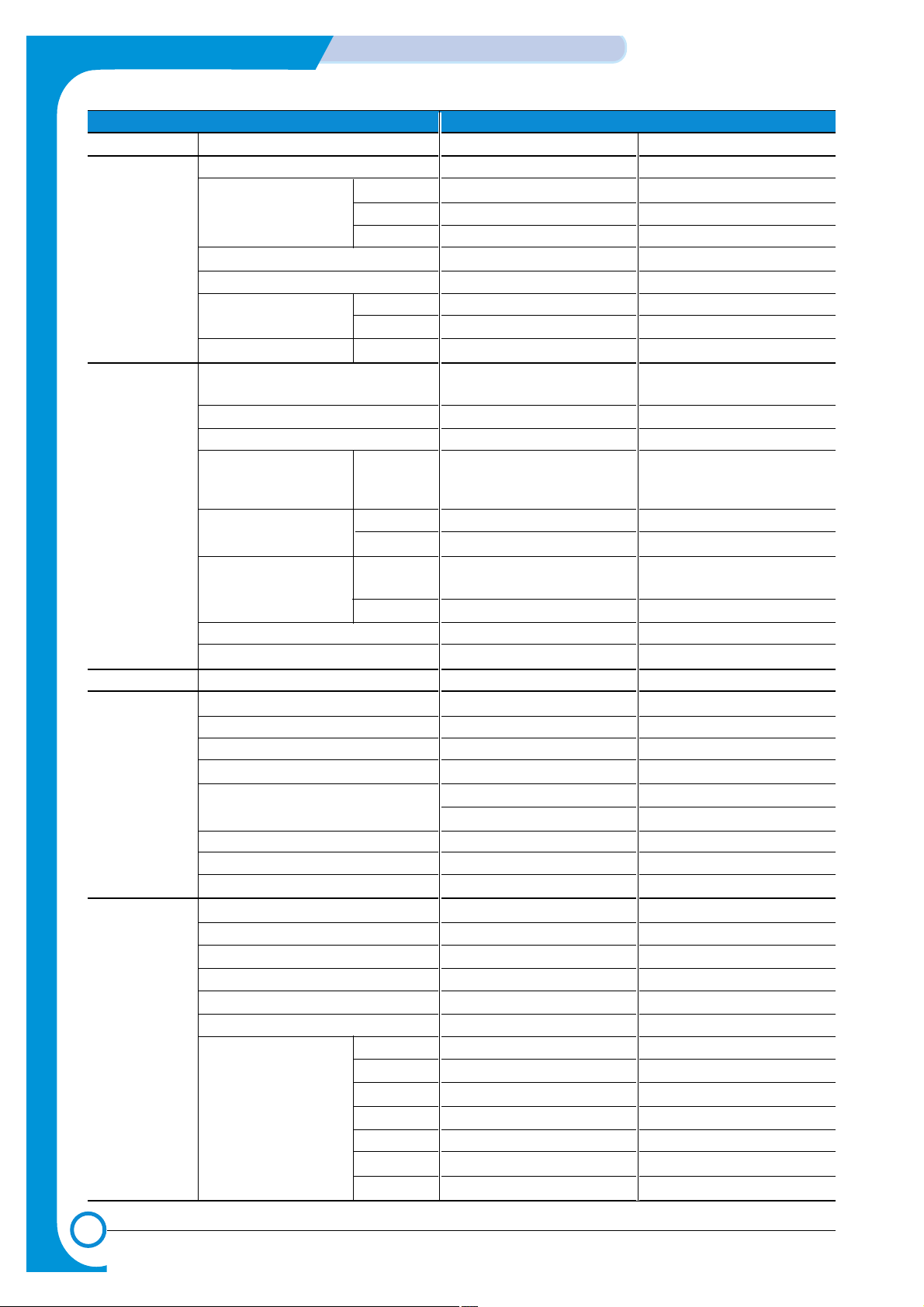

Items SF-750 Series

Model Name SF-755P SF-750

Scan Scan Method CIS, Color CIS, Color

* Scan Speed Gray Up to 72 sec (Second /scan) Color

Up to 20 sec 75 DPI (256 color)

-

Black&White Up to 25 sec -

Resolution(Optical)

Up to 1200 x 1200 DPI effective output

Halftone 256level Scan Width Max 216mm -

Effective 208mm -

Scan Length Max 400mm -

Copy * Speed Up to 16 PPM in A4 size, Up to 16 PPM in A4 size,

Up to 17 PPM in Letter size Up to 17 PPM in Letter size

Resolution 600x600dpi 600x600dpi

Halftone 256level 256level

Cop y Q u a l i t y S e l e c t i o n Text 5.5sec/Letter 5.5sec/Letter

or O r i g i n al Im a ge ty p e Photo 5.5sec/letter 5.5sec/letter

selection Mode

FCOT Power Save approx : 45sec approx : 45sec

Stand by approx : 15sec approx : 15sec

* Copy Speed SDMC Up to 16 PPM in A4 size, Up to 16 PPM in A4 size,

Up to 17 PPM in Letter size Up to 17 PPM in Letter size

MDMC 10cpm(Ltr) 10cpm(Ltr)

Zoom Range 50-200% 50-200%

Multi Copy 1~99 1~99

Telephone Handset No No

1-Touch Dial 40 Locations(20X2) 40 Locations(20X2)

Speed Dial 150 150

T AD No No

T AD I/F Yes Yes

Tone/Pulse Tone (DTMF) Tone (DTMF)

Pulse : setting in tech mode Pulse : setting in tech mode

Earth/Recall No No

SMS NO NO

External Phone Interface Y es Yes

Fax Compatibility ITU-T G3 ITU-T G3

Communication System PSTN/PABX PSTN/PABX

Modem Speed 33.6Kbps 33.6Kbps

TX Speed approx. 3 sec approx. 3 sec

Compression MH/MR/MMR/JBIG MH/MR/MMR/JBIG

ECM Yes Yes

Resolution Std

Up to 203 x 98 DPI effective output Up to 203 x 98 DPI effective output

Fine

Up to 203 x 196 DPI effective output Up to 203 x 196 DPI effective output

S.Fine

Up to 300 x 300 DPI effective output Up to 300 x 300 DPI effective output

Photo

Up to 200 x 200 DPI effective output Up to 200 x 200 DPI effective output

Std Up to 1.5 sec Up to 1.5 sec

Fine Up to 3 sec Up to 3 sec

S.Fine Up to 4.2 sec Up to 4.2 sec

3-3

Samsung Electronics

Specifications

Service Manual

Items SF-750 Series

Model Name SF-755P SF-750

Fax Halftone 256level 256level

(Continued) Memory Capacity

Total memory: 32MB( Fax: 5MB) Total memory: 32MB( Fax: 5MB)

Optional Memory

No No

Broadcasting Yes Y es

Delay TX Yes Y es

Memory RX Yes Y es

Functions Voice Request No No

TTI Yes Yes

RTI Yes Yes

Polling Rx Polling Rx Polling

Security Receive

Yes Yes

Flash No No

Auto Reduction Y es Yes

"F/W Upgrade Y es Yes

from Remote"

Memory B/U Y es(Max. 72Hours) Y es(Max. 72Hours)

Paper Handling

Casstte Type Cassette Cassette

Input Capacity 250 Sheets/20lb 250 Sheets/20lb

Optional Cassette

250 Sheets/20Ib 250 Sheets/20Ib

Output Capacity

Max. 150 Sheets/20lb Max. 150 Sheets/20lb

Output Control Face down Face down

Bypass 1sh 1sh

Media Size for For Fax and Copy: A4,Letter, For Fax and Copy: A4,Letter,

Main Tray Legal For PC Print : A4,Letter, Legal For P C Prin t : A4 , L e t t e r,

Legal. Folio, Executive, B5 Legal. Folio, Executive, B5"

Media Size for Envelope6 3/4, 7 3/4,#9, Envelope6 3/4, 7 3/4,#9,

Bypass #10,DL,C5,B5 #10,DL,C5,B5

Media Weight Auto : 16 ~ 28 Ib Auto : 16 ~ 28 Ib

Bypass: 16 ~ 43 Ib Bypass: 16 ~ 43 Ib

ADF Input Capacity Max. 50 Sheets Max. 50 Sheets

Media Weight 12.5lb ~ 28lb, 32lb(1 sheet) 12.5lb ~ 28lb, 32lb(1 sheet)

* Copy or Scan speed will be affected by Operating System used, computing performance, application software,

connecting method, media type, media size and job complexity.

3-4

Specifications

Samsung Electronics

Service Manual

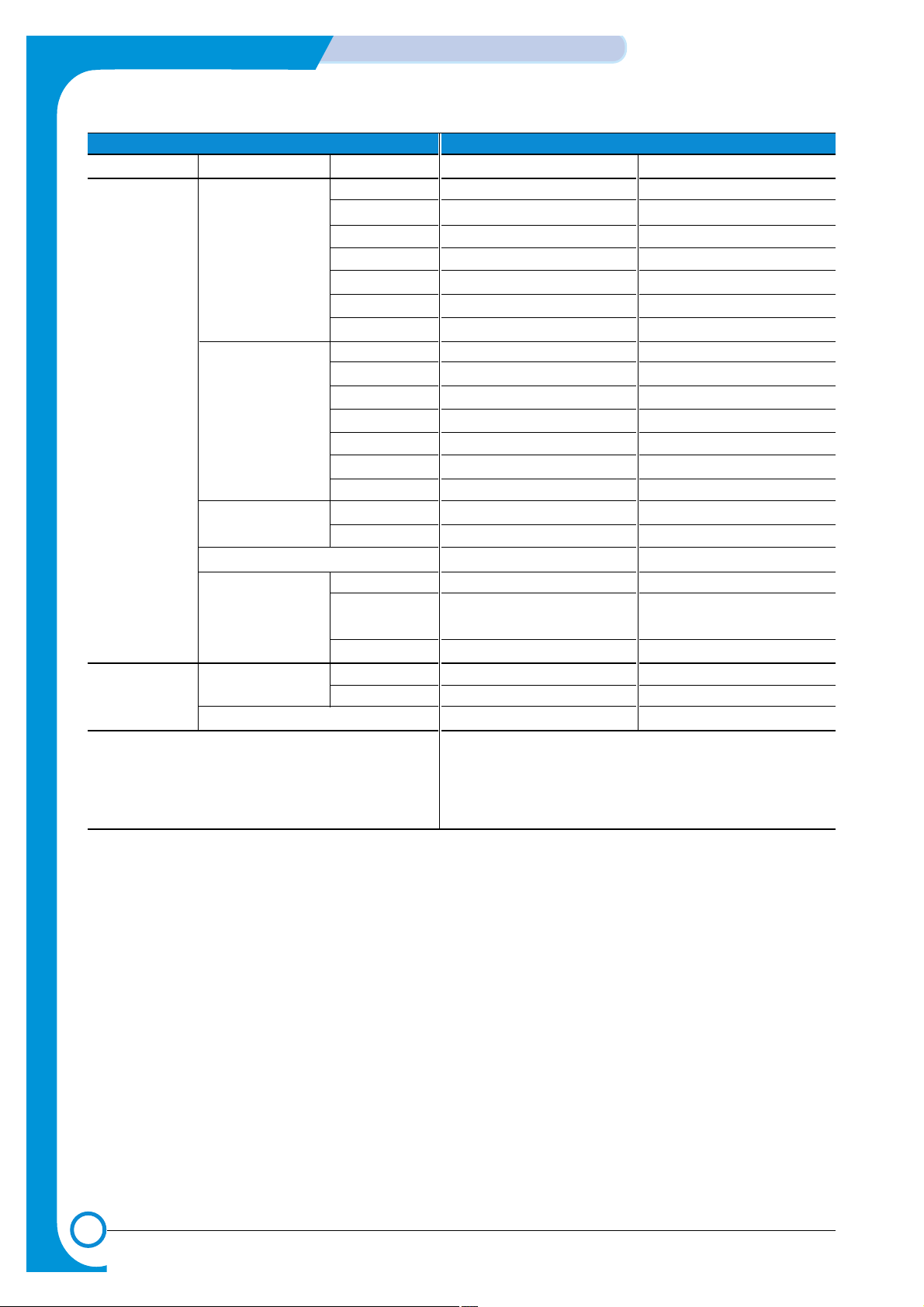

Items SF-750 Series

Model Name SF-755P SF-750

Software Compatibility DOS No No

Win 3.x No No

Win 95 Yes No

Win 98&WinME Yes No

Win NT 4.0 Yes No

Win 2000 Y es No

Win XP Yes No

Driver GDI Printer SPL No

TWAIN Yes No

FaxRCP Y es No

Mac Printer Y es No

Linux Printer Yes No

Linux Scanner Yes No

PC-FAX No No

M/S Certification WHQL Y es (WinXP Printer driver only) -

WIA No No

Bundle S/W SmarThru 3 Media CD-ROM Yes -

Manual Standalone Fax: Book Standalone Fax: Book

MFP: CD

Diskette No No

Consumables Life Initial Up to 3,000 Pages Up to 3,000 Pages

Running Up to 3,000 Pages Up to 3,000 Pages

Toner Sensor (Software) Yes(Dot Counter) Yes(Dot Counter)

Periodic Replacing Parts ADF Rubber Pad : Up to 20,000 Pages

Paper Feeding Roller : Up to 60,000 Pages

Transfer Roller :Up to 60,000 Pages

Fuser Unit : Up to 60,000 Pages

4

4

4-1

Samsung Electronics

SUMMARY OF PRODUCT

Service Manual

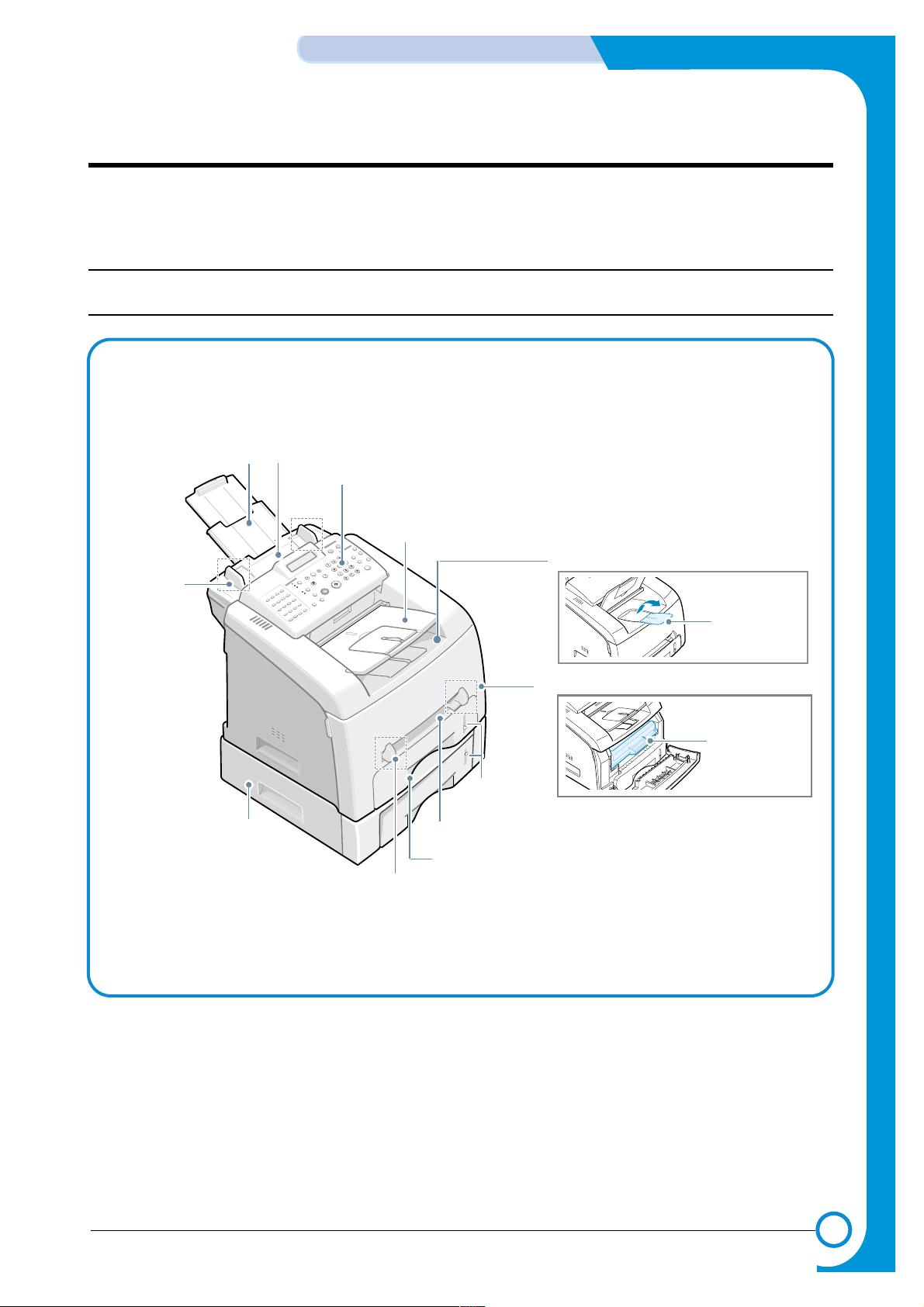

4. Summary of Product

This chapter describes the functions and operating principal of the main component.

4.1 Printer Components

4.1.1 Front View

Control Panel

Front Cover

Paper Tray(Tray1)

Front Output Tray

(Face down)

Document Input

Support

Automatic

Document Feeder

Toner Cartridge

Paper

Extension

Manual Feeder

Manual Feeder

Guides

Document

Guides

Document

Output Tray

Optional Paper

Tray(Tray2)

Paper Level

Indicator

4-2

SUMMARY OF PRODUCT

Samsung Electronics

Service Manual

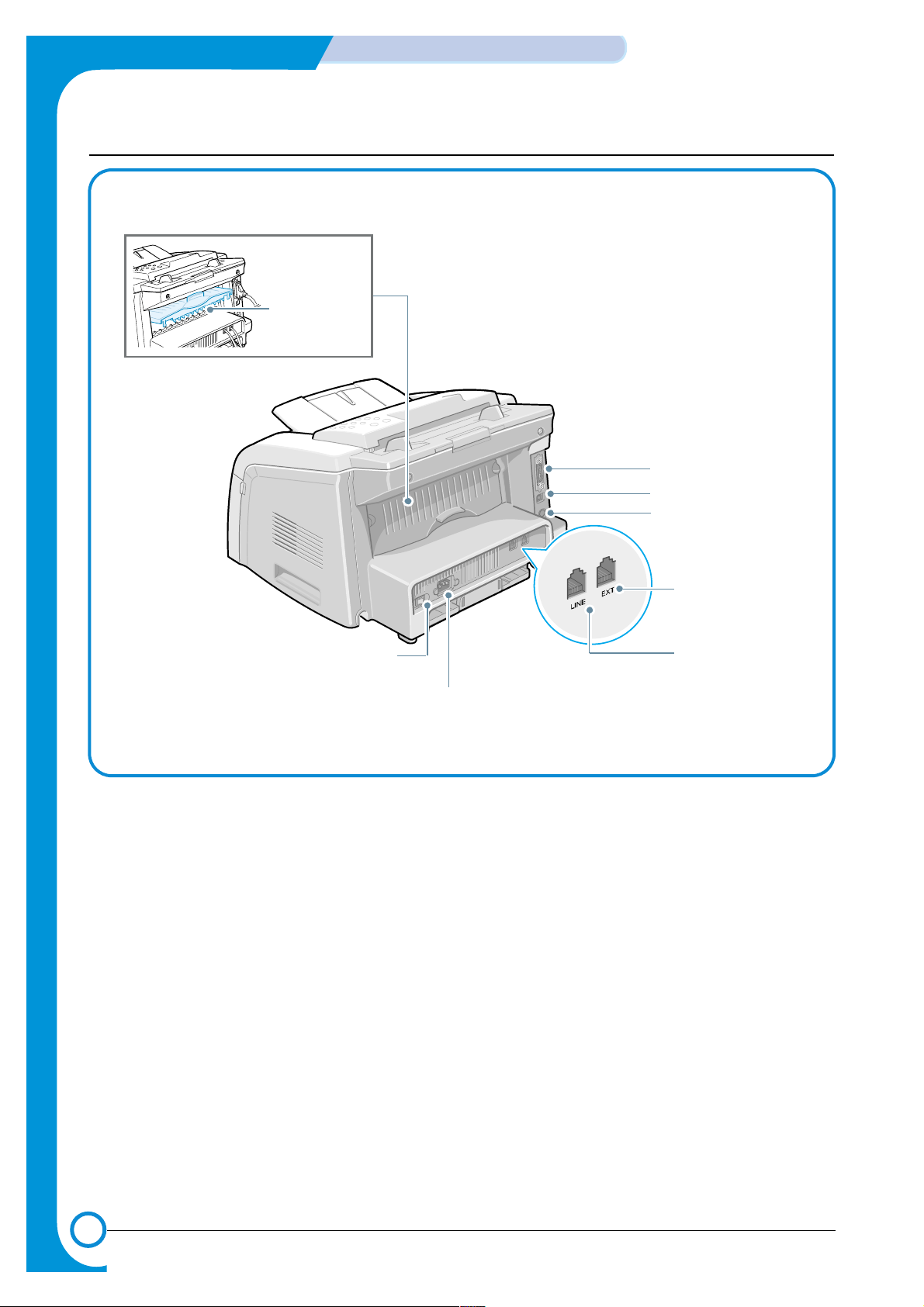

4.1.2 Rear View

Line Jack EXT.Jack

Power Switch

USB Connector

AC Power Cord

Connector

EXT Jack

*

Line Jack

*

If your country has a different

telephone connection system,

this socket may be blocked.

Rear Output

Slot (Face up)

Tray 2 Cable

Connector

Parallel Connector

4-3

Samsung Electronics

SUMMARY OF PRODUCT

Service Manual

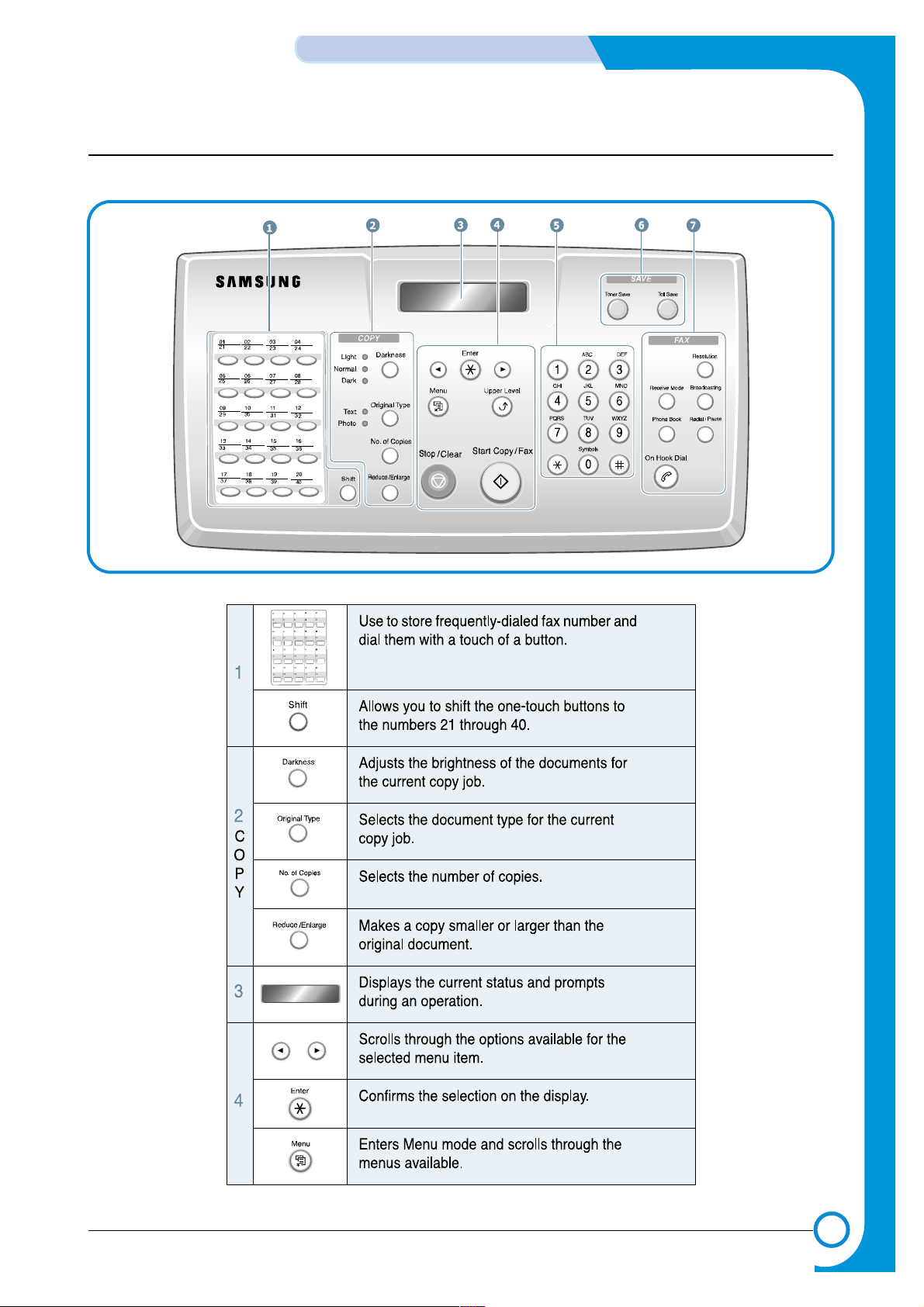

4.1.3 Control Panel

< SF-750/755P >

4-4

SUMMARY OF PRODUCT

Samsung Electronics

Service Manual

4-5

Samsung Electronics

SUMMARY OF PRODUCT

Service Manual

4.2 Overview of System

SF-750/SF-755P can be divided into the following main constituent parts: Main Controller, Operator’s Panel, PC

Interface, Scanner, Line Interface and Power Supply. The Main Controller uses the SPGPm processor. The

Operator’s panel; (OPE) has its own MICOM which communicates serially with a UART built into the SPGPm

processor. The Scanner uses the CIP4e processor to control the CIS. The Line Interface is an FM336 integrated

with the Main Board which communicates with the LIU at speeds up to 33.6Kbps.

The Power Supply has both the SMPS and HVPS integrated on one PBA. Because of the structure and layout of

the set many of the sensors are also located on the SMPS/HVPS board. Signals from these sensors are passed

to the main board for processing.

4.2.1 Main Control Part.

The Main Controller of the SF-750/755P consists of two ASICs (CPU, Image Processor), Scanner, Fax Modem

and Print sections. Bus Control, I/O Handling, Engine motor drivers and the PC Interface function is controlled by

the CPU (SPGPm).

The Image Processor (CIP4e) controls the ADF motor, CIS scanner and is responsible for image manipulation and

compression.

4.2.2 Line Interface Part

This part connects the set with the PSTN. The main functions of this section are Line Interface, Line Monitoring,

and connection to an external phone or TAD using the built in EXT connector..

4.2.3 Print Engine.

The Print Engine consists of the following sections: Frame, Paper Feed, Image Transfer , Imaging Unit, T oner

Cartridge, Fuser, High Voltage Supply and Scanner. The set uses an Electro Photographic process using the LSU

to develop a latent image on the OPC drum. The T oner process is a single part diamagnetic process. Copy and

Transfer processes use a CIS Module.

4.2.4 Scan Part

The scanner is designed around a 600dpi CIS module. The CIS scanning width is maximum 216mm, effective

width is 208mm..

4.2.5 Summary of Main Unit

- Main Board

This is an integral unit having the Engine and Video control on a single PBA. It controls the Electrophotographic

Process to take the image from the PC Interface and generate the Video Data for the LSU. It also manages the

transfer of that image onto paper and the fusing of the image. The main PBA unit consists of the following circuits:

Motor (Paper Feed and Exit) Driver, the Clutch driver , Pre-transfer Lamp Driver, the Fuser Driver and the Fan

Driver. The signals from the Paper Feed Sensor, the Paper Empty Sensor , MP sensor and Exit Sensor are input to

the Main Board from the SMPS/HVPS PBA.

4-6

SUMMARY OF PRODUCT

Samsung Electronics

Service Manual

- SMPS Board & HVPS Board

These are integrated into a singe PBA. The Power Supply uses the 110VAC/220VAC supply voltage to generate

the DC Voltages used by the system. The SMPS has 3 output channels (+5V, +12V , +24V, +24VS) and supplies

the Main Board and the OPE Board.

The HVPS creates the high voltages (THV/MHV/Supply/Dev) used for the electrophotographic process. The high

voltage is created from the 24VS line from the SMPS. High Voltage output is supplied to the Toner , the OPC

Cartridge and the T ransfer Roller .

- OPE Board

The Operation Panel is driven by its own internal program using the OPE MICOM chip separate from the Main

Board processor. Data is transferred using the UART Port in the Main Controller serially. This unit

consists of the MICOM, the Key Pad Matrix and the LCD.

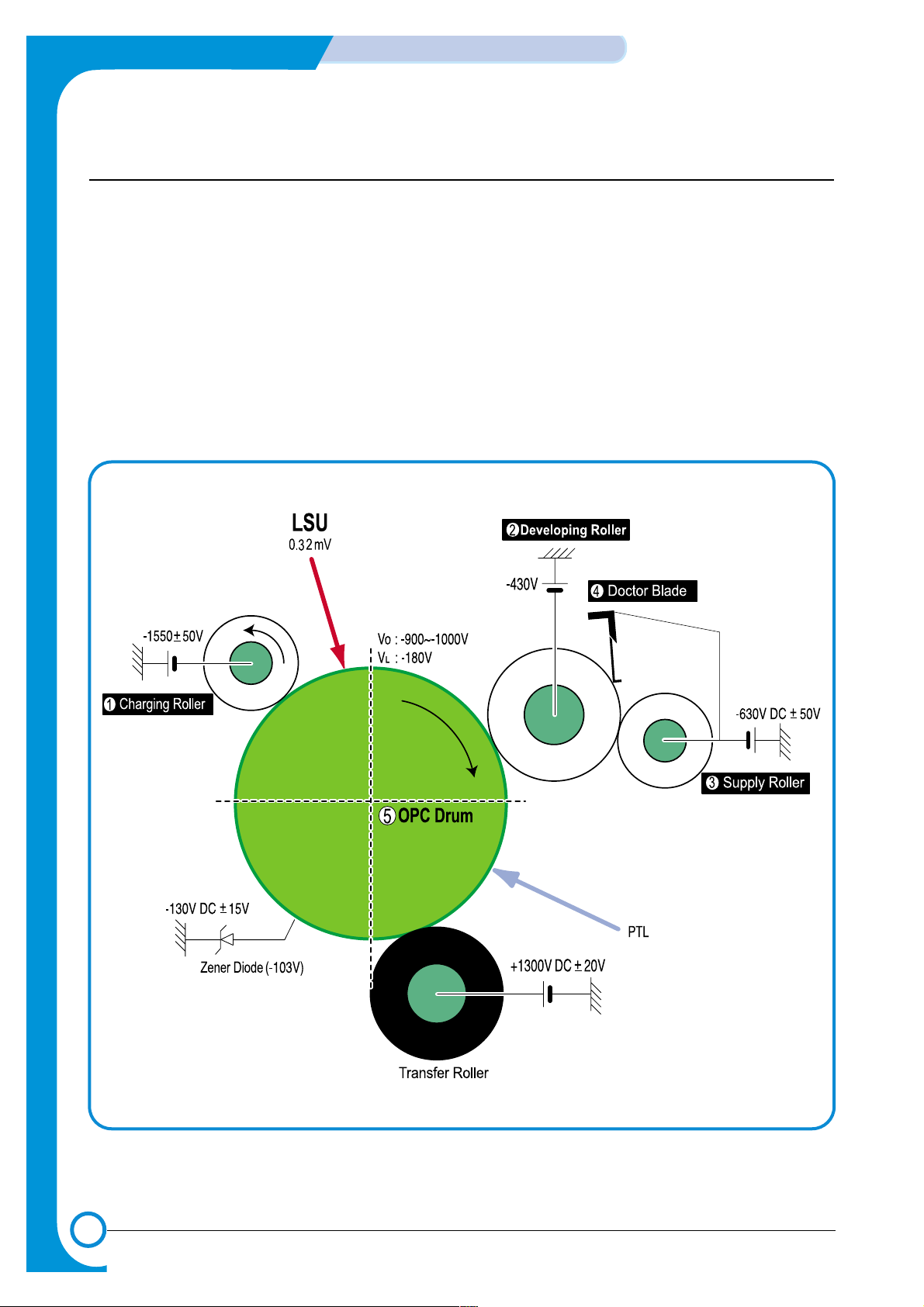

- Toner Cartridge

The Toner Cartridge consists of integrated Exposure and Developer units. The Exposure Unit consists of the OPC

Drum and the Charge Roller, and the Developer Unit consists of the toner particles and its tank, the Supply Roller

and the Developer Roller .

- LSU (Laser Scanner Unit)

This is the core of the laser printer. It converts the video data received from the computer into an electrostatic

latent image on the surface of the OPC drum. This is achieved by controlling the laser beam and exposing the surface of the OPC drum to the laser light. A rotating polygon mirror reflects the laser light onto the OPC and each

side of the mirror is one scan line. The OPC drum turns as the paper feeds to scan the image down the page.

The /HSYNC signal is created when the laser beam from LSU reaches the end of the polygon mirror and this signal is sent to the controller. The controller detects the /HSYNC signal to adjust the vertical line of the image on

paper. In other words after the /HSYNC signal is detected the image data is sent to the LSU to adjust the left margin on the paper .

- Toner T ransfer

Toner is transferred from the OPC drum onto the paper using a PTL (Pre-transfer Lamp) and a transfer roller. The

PTL shines light onto the OPC, this reduces the electrical charge on the surface of the OPC

surface and improves the efficiency of the transfer .

The transfer roller transfers toner from the OPC drum to the paper.

Life span: Print over 100,000 sheets (at 15~30ºC)

- Fuser

This consists of a heat lamp, heat roller, pressure roller, thermistor and thermostat. By use of heat and pressure

toner is caused to melt and adhere to the paper surface in order to complete the printing process.

4-7

Samsung Electronics

SUMMARY OF PRODUCT

Service Manual

4.3 System Layout

4.3.1 Feeding section

There is a universal cassette which automatically loads paper and the manual feed which supplies paper

single sheet at a time. The cassette has a friction pad which separates paper to ensure single sheet

feeding, and it has a sensor, which checks when the paper tray is empty.

- Feeding Method: Universal Cassette Type

- Feeding Standard: Center Loading

- Feeding Capacity: Cassette-250 sheets (75g/m2, 20lb paper standard)

Manual 1 sheet (Paper, OHP, Envelop, etc.)

- Paper detecting sensor: Photo sensor

- Paper size sensor: None

4.3.2 Transfer Ass’y

This consists of the PTL (pre-transfer lamp) and the Transfer Roller. The PTL shines a light onto the OPC

drum. This lowers the charge on the drum’s surface and improves transfer efficiency.

The transfer roller transfers toner from the OPC drum surface to the paper.

- Life expectancy: Over 60,000 sheets (at 15~30°C)

4.3.3 Driver Ass’y

- Gear driven power unit. The motor supplies power to the paper feed unit, the fuser unit, and the toner

cartridge.

4.3.4 Fixing Part(Fuser)

- The fuser consists of the Heat Lamp, Heat Roller, Pressure Roller, Thermistor, and Thermostat. It fixes

toner to the paper using pressure and heat to complete the printing job.

4.3.4.1 Temperature-Intercepting Device (Thermostat)

The thermostat is a temperature sensing device, which cuts off the power to the heat lamp to prevent

overheating fire when the heat lamp or heat roller overheats.

4.3.4.2 Temperature Detecting Sensor (Thermistor)

The Thermistor detects the surface temperature of the heat roller, this information is sent to the main

processor which uses this information to regulate the temperature of the heat roller.

4.3.4.3 Heat Roller

The surface of the Heat Roller is heated by the Heat Lamp. As the paper passes between the Heat and

Pressure rollers the toner is melted and fixed permanently to the paper. The surface of the roller is coated

with Teflon. This ensures that toner does not adhere to the roller surface.

4.3.4.4 Pressure roller

The Pressure Roller mounted under the heat roller, it is made of a silicon resin, and the surface of the roller

is coated with Teflon. This ensures that toner does not adhere to the roller surface.

4-8

SUMMARY OF PRODUCT

Samsung Electronics

Service Manual

4.3.4.5 Safety Features

• To prevent overheating

- 1st protection device: Hardware cuts off when overheated

- 2nd protection device: Software cuts off when overheated

- 3rd protection device: Thermostat cuts off mains power to the lamp.

• Safety device

- Fuser power is cut off when the front cover is opened

- LSU power is cut off when the front cover is opened

- The temperature of the fuser cover's surface is maintained at less than 80ºC to protect the user and a

caution label is attached where the customer can see it easily when the rear cover is opened.

4.3.5 Scanner

• Scan Image Controller

1.Minimum Scan Line Time : 1.25ms

2.Scan Resolution : Color : Max. 600DPI

3.Scan Width : 208mm

4.Function

- White Shading Correction

- Gamma Correction

- CIS Interface

- 256 Gray Scale

• CIS Driver Circuit

- CIS Max Frequency : 2.5MHz

- CIS Line Time : 1.25ms/Line(at Fax Mode)

- White Data Output Voltage : Max 1.2V

• Tx Driver Circuit

- Tx Motor Speed : Max 2200pps

- Motor Driver : TEA3718

- Used Volt : 24V DC

4-9

Samsung Electronics

SUMMARY OF PRODUCT

Service Manual

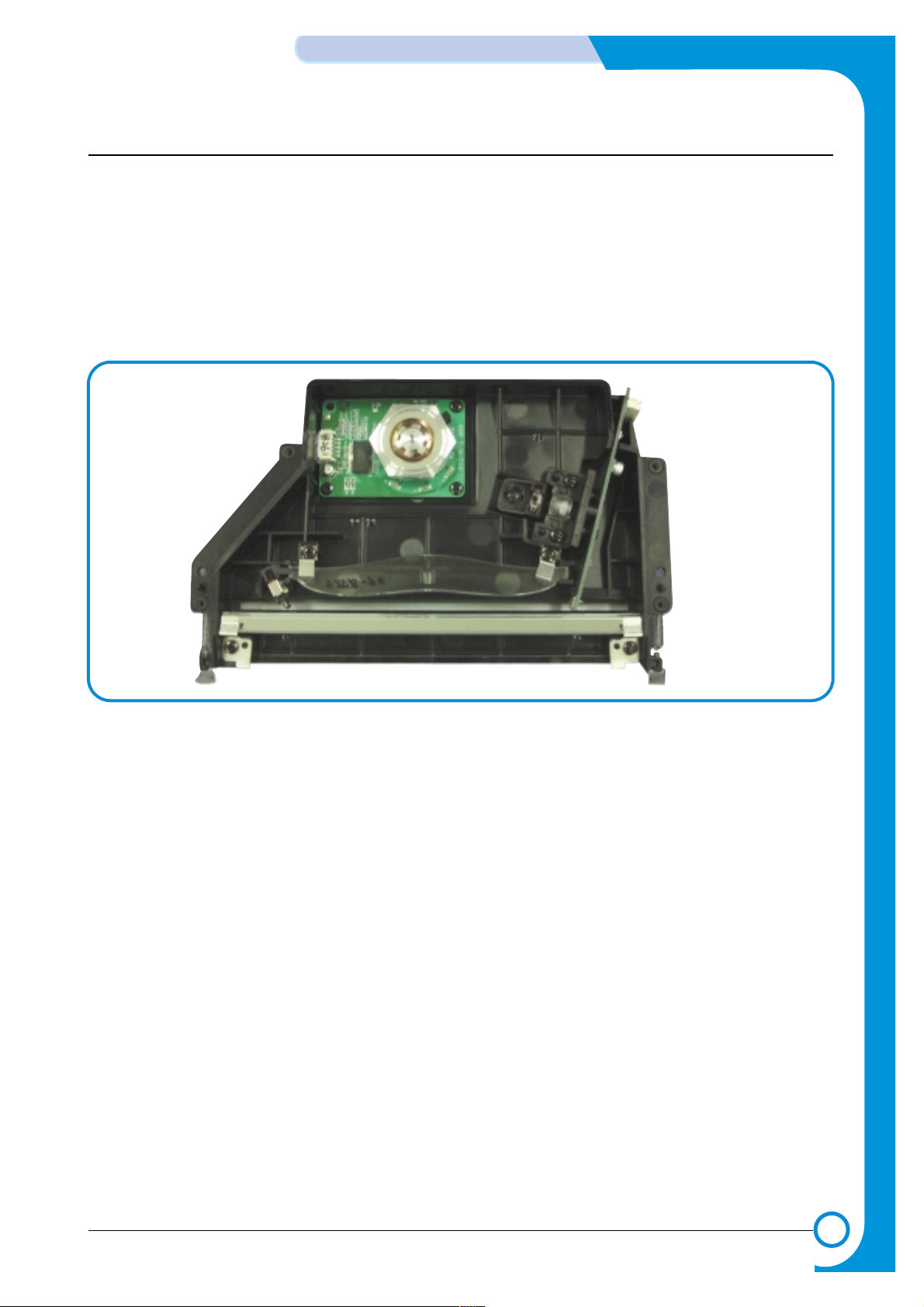

4.3.6 LSU (Laser Scanner Unit)

This is the core of the laser printer. It converts the video data received from the computer into an electrostatic

latent image on the surface of the OPC drum. This is achieved by controlling the laser beam and exposing the

surface of the OPC drum to the laser light. A rotating polygon mirror reflects the laser light onto the OPC and each

side of the mirror is one scan line. The OPC drum turns as the paper feeds to scan the image down the page.

The /HSYNC signal is created when the laser beam from LSU reaches the end of the polygon mirror and this

signal is sent to the controller. The controller detects the /HSYNC signal to adjust the vertical line of the image on

paper. In other words after the /HSYNC signal is detected the image data is sent to the LSU to adjust the left margin

on the paper.

4-10

SUMMARY OF PRODUCT

Samsung Electronics

Service Manual

4.3.7 Toner Cartridge

The toner cartridge is an integral unit containing the OPC unit and toner unit. The OPC unit consists of the

OPC drum and charging roller, and the toner cartridge unit consists of the toner, supply roller, developing

roller, and blade (Doctor blade)

- Developing Method: Non magnetic 1 element contacting method

- Toner: Non magnetic 1 element shatter type toner

- The life span of toner: 3,000 sheets (IDC Pattern/A4 standard)

- Toner remaining amount detecting sensor: Yes

- OPC Cleaning: Electrostatic process

- Management of waste toner: Collect the toner using a Cleaning Blade

- OPC Drum protecting Shutter: Yes

- Classifying device for toner cartridge: ID is classified by interruption of the frame channel

4-11

Samsung Electronics

SUMMARY OF PRODUCT

Service Manual

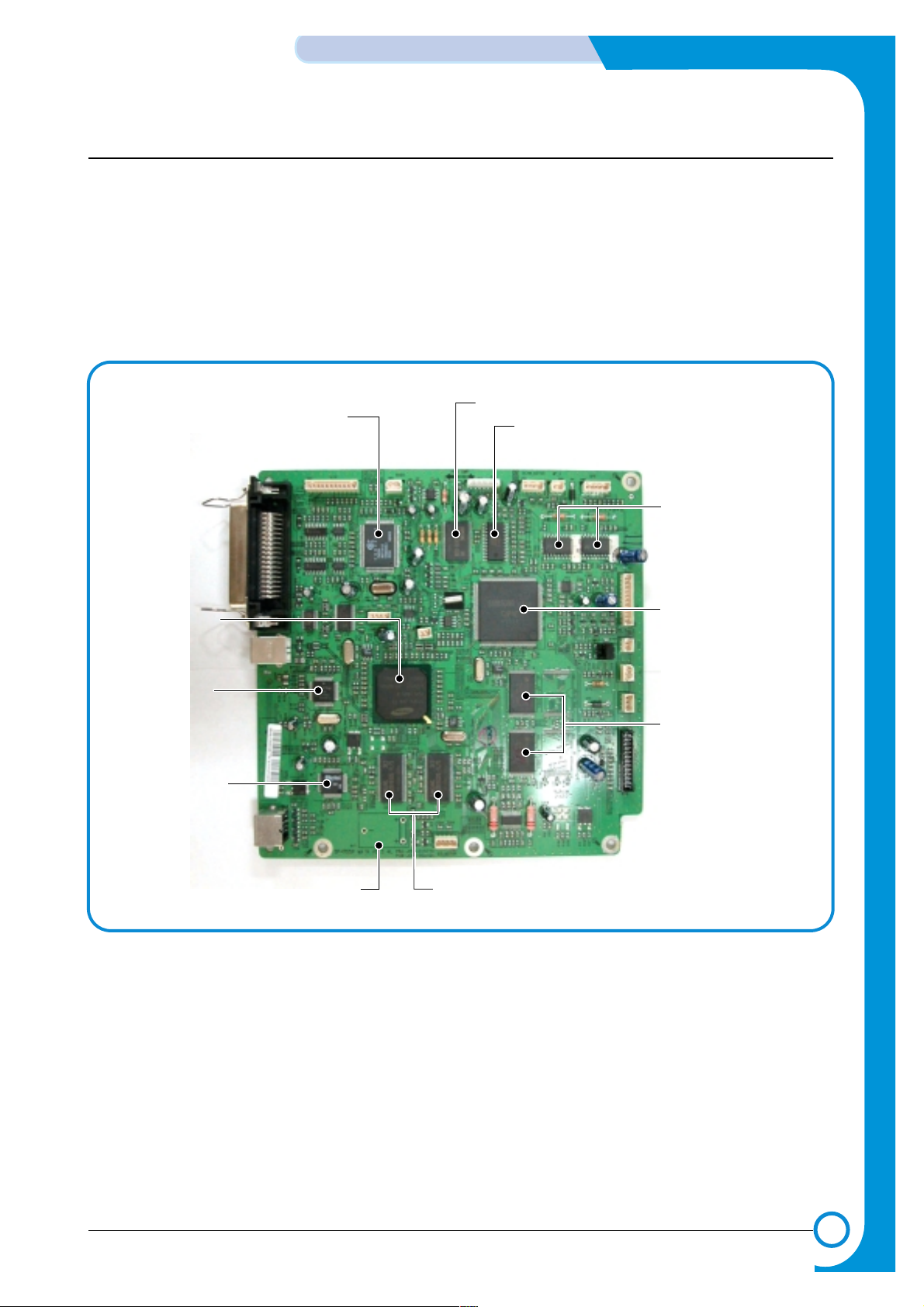

4.4 Main PBA(SPL Model)

The Engine Board and Controller Board have been integrated into a single PBA. This consists of the CPU,

printer scanner and line control functions. The CPU functions as the bus controller, I/O handler, motor driver

and PC inter-face. The main board sends the Current Image Video data to the LSU and manages the

Electrophotographic printing process. Circuits on the PBA drive include the main motor (paper feed,

cartridge, fuser), clutch driver, pre-transfer lamp driver, heat-lamp driver, CIS driver, scan motor driver,

modem and fan driver.

The signals from the paper feed jam sensor and paper empty sensor are inputted to the main board from

the power supply PBA..

MODEM

(FM336R6719-12)

SRAM(K6R1016VID)

A/D CONVERTER

(AFE-CIP4)

MOTOR DRIVER

(TEA3718SFP)

IMAGE PROCESSOR

(CIP4E)

BATTERY(3.6V)

FPGA ASIC

(EX64-FTQ64)

GRAPHIC

PROCESSOR ASIC

(SPGPM)

USB

(NET2270)

DRAM(K4S281632D)

FLASH MEMORY

(29LV800)

4-12

SUMMARY OF PRODUCT

Samsung Electronics

Service Manual

4.4.1 ASIC (SPG Pm)

The SPG Pm (32Bit RISC Processor), is the main processor in overall charge of the set’s operation. It is

controlled by the system program held in flash memory.

•Main function block

• 272 Pin PBGA Package

• 120MHz Core, 60MHz Bus Operation

• 326bit RISC Processor, ARM946ES Core

• USB 2.0 Interface

• Power Operation : 1.8V(Core), 3.3V(IO)

4.4.2 Flash Memory

This stores the system program. Firmware upgrade is achieved by downloading from the new image using the PC

Interface.

• Capacity : 2.0 M Byte

• Access T ime : 70 nsec

4.4.3 SDRAM

This is used as a buffer, system working memory area, etc. while printing and scanning. This memory is also used to

store faxes waiting to be sent or waiting to be printed.

• Operating Freguency : 60 MHz

Loading...

Loading...