Samsung SF6500, SF6600 Service manual

FACSIMILE

SF6500/SF6600

CONTENTS

1. Precautions

2. Specification

3. Installation

4. Theory of Operation

5. Circuit Description

6. Disassembly and Reassembly

7. Maintenance & Troubleshooting

8. Electrical Parts List

9. PCB Diagrams

10. Block Diagram

11. Wiring Diagram

12. Schematic Diagrams

FACSIMILE

SERVICE

Manual

Samsung Electronics Co.,Ltd. June. 1998

Printed in Korea.

JC68-61013A

ELECTRONICS

Samsung Electronics 1-1

1. Precautions

Follow these safety, ESD, and servicing precautions to prevent personal injury and equipment damage.

1-1 Safety Precautions

1. Be sure that all built-in protective devices are in

place. Restore any missing protective shields.

2. Make sure there are no cabinet openings

through which people- particularly childrenmight insert fingers or objects and contact

dangerous voltages.

3. When re-installing chassis and assemblies, be

sure to restore all protective devices, including

control knobs and compartment covers.

4. Design Alteration Warning:

Never alter or add to the mechanical or electrical

design of this equipment, such as auxiliary

connectors, etc. Such alterations and

modifications will void the manufacturer's

warranty.

5. Components, parts, and wiring that appear to

have overheated or are otherwise damaged

should be replaced with parts which meet the

original specifications. Always determine the

cause of damage or overheating, and correct any

potential hazards.

6. Observe the original lead dress, especially near

sharp edges, AC, and high voltage power

supplies. Always inspect for pinched, out-ofplace, or frayed wiring. Do not change the

spacing between components and the printed

circuit board.

7. Product Safety Notice:

Some electrical and mechanical parts have

special safety-related characteristics which might

not be obvious from visual inspection. These

safety features and the protection they provide

could be lost if a replacement component differs

from the original. This holds true, even though

the replacement may be rated for higher voltage,

wattage, etc.

Components critical for safety are indicated in

the parts list with symbols . Use only

replacement components that have the same

ratings, especially for flame resistance and

dielectric specifications. A replacement part that

does not have the same safety characteristics as

the original may create shock, fire, or other

safety hazards.

Laser statement (Laserturvallisuus)

WARNING NEVER OPERATE AND SERVICE THE

FAX WITH PROTECTIVE COVER

REMOVED FROM LASER/SCANNER

ASSEMBLY. THE REFLECTED BEAM,

ALTHOUGH INVISIBLE, CAN DAMAGE

YOUR EYES.

Class 1 laser product

Product laser de la premi•re classe

Laser beam wavelength: 780nm

Longueur d'ondes de rayon laser: 780nm

Laser beam power: 0.18mW +/-0.009mW

Puissance de rayon laser: 0.18mW +/-0.009mW

Samsung Electronics

Precautions

1-2

1-2 ESD Precautions

Certain semiconductor devices can be easily

damaged by static electricity. Such components are

commonly called "Electrostatically Sensitive (ES)

Devices", or ESDs. Examples of typical ESDs are:

integrated circuits, some field effect transistors, and

semiconductor "chip" components.

The techniques outlined below should be followed

to help reduce the incidence of component damage

caused by static electricity.

CAUTION: Be sure no power is applied to the

chassis or circuit, and observe all other safety

precautions.

1. Immediately before handling a semiconductor

component or semiconductor-equipped

assembly, drain off any electrostatic charge on

your body by touching a known earth ground.

Alternatively, employ a commercially available

wrist strap device, which should be removed for

your personal safety reasons prior to applying power

to the unit under test.

2. After removing an electrical assembly equipped

with ESDs, place the assembly on a conductive

surface, such as aluminum or copper foil, or

conductive foam, to prevent electrostatic charge

buildup in the vicinity of the assembly.

3. Use only a grounded tip soldering iron to solder

or desolder ESDs.

4. Use only an "anti-static" solder removal device.

Some solder removal devices not classified as

"anti-static" can generate electrical charges

sufficient to damage ESDs.

5. Do not use Freon-propelled chemicals. When

sprayed, these can generate electrical charges

sufficient to damage ESDs.

6. Do not remove a replacement ESD from its

protective packaging until immediately before

installing it. Most replacement ESDs are

packaged with all leads shorted together by

conductive foam, aluminum foil, or a

comparable conductive material.

7. Immediately before removing the protective

shorting material from the leads of a

replacement ESD, touch the protective material

to the chassis or circuit assembly into which the

device will be installed.

8. Maintain continuous electrical contact between

the ESD and the assembly into which it will be

installed, until completely plugged or soldered

into the circuit.

9. Minimize bodily motions when handling

unpackaged replacement ESDs. Normal

motions, such as the brushing together of

clothing fabric and lifting one's foot from a

carpeted floor, can generate static electricity

sufficient to damage an ESD.

1. Exercise caution when replacing a Lithium

battery. There could be a danger of explosion

and subsequent operator injury and/or

equipment damage if incorrectly installed.

2. Be sure to replace the battery with the same or

equivalent type recommended by the

manufacturer.

3. Lithium batteries contain toxic substances and

should not be opened, crushed, or burned for

disposal.

1-3 Lithium Battery Precautions

Samsung Electronics 2-1

2. Specifications

2-1 Basic Features

Machine type : Desk Top

Applicable line : Public Switched Telephone Network (PSTN) or behind PABX

Compatibility : CCITT Group 3, ECM

Data coding : MH/MR/MMR

Modem speed : 33600/28800/14400/12000/9600/7200/4800/2400 bps

Transmission speed : Approx. 2.6 sec. (V.34 ECM : 33600 bps)

Effective scanning width : 8.3 inches (210 mm)

Effective printing width : 8.2 inches (208 mm)

Scanning method : Sheet-fed scanning using a Contact Image Sensor (CIS)

Memory : 4 MByte

Halftone : 64 levels

Printing speed : 6 PPM (Letter size)

Automatic document feeder : 30 pages

Phone : Built-in handset

One-touch dial : 20 locations

LCD : 16 characters X 2 lines

Dimension (H X W X D) : 9.8 X 14.3 X 17.5 inches (249 X 363 X 446 mm)

(trays and optional second cassette excluded)

Weight : Approx. 33.1 lb (15 kg) (fully equipped)

Approx. 22 lb (10 kg) (cartridge and recording paper excluded)

Power : 220V AC, 50/60 Hz

2-2 Technical Parameters

SCANNER

Scanning Method : Sheet-fed scanning by CIS and step feeding of the document by a

stepping motor

Resolution

Horizontal : 11.8 lines/mm (300 dpi)

Vertical : STANDARD : 3.85 lines/mm (98 Lpi)

FINE : 7.7 lines/mm (196 Lpi)

11.8 lines/mm (300 Lpi)

SUPER FINE : 15.4 lines/mm (392 Lpi)

Photo scale : 64 shades

Specification

2-2 Samsung Electronics

Scanning period : STANDARD : 5 ms/line

FINE : 2.5 ms/line

SUPER FINE : 2.5 ms/line

Document size

Width : 5.8 to 8.5 inches (148 to 216 mm)

Length :

Single page : 5 to 14 inches (128 to 356 mm)

Multi page : 5 to 11.7 inches (128 to 297 mm)

Manual assistance : infinite

Weight

single page : 12.5 Ib. ~ 32 Ib. (Thickness 0.07 ~ 0.15 mm)

Multi page : 12.5 Ib. ~ 24 Ib. (Thickness 0.07 ~ 0.15 mm)

Automatic document feeder (ADF) 30 sheets (Letter size/A4 size)

Class 1-5 : 10 sheets

Class 1-3 : 20 sheets

Thickness of document according to each class (Letter size/A4 size)

Scanning position

Top edge : 2 mm 2 mm (0.079 0.079 inch)

Bottom edge : 0 mm 2.5 mm (0 0.098 inch)

PRINTER

Recording method : Electrostatic image recording with LSU array

Printing speed : 6 pages (Letter size)/minute recording density

Horizontal : 11.8 lines/mm (300 dpi)

Vertical : 11.8 lines/mm (300 lpi)

Recording paper size : A4 : 8.3 × 11.7 inches (210 × 297 mm)

Letter : 8.5 × 11 inches (216 × 279 mm)

Legal : 8.5 ×14 inches (216 × 356 mm)

Weight : 16 ~ 24 Ibs (60 ~ 90 g/m2)

Thickness : 0.08 ~ 0.12 mm

Recording paper cassette

Basic cassette : 250 sheets (Letter size/A4 size)

Reference weight : 75 g/m2(20 Ibs)

CLASS THICKNESS WEIGHT (U.S. POUND)

1 0.075 mm 12.5 Ib

2 0.10 mm 20.0 Ib ADF: 30 sheets

3 0.12 mm 24.0 Ib ADF: 10 sheets

4 0.13 mm 28.0 Ib

5 0.15 mm 32.0 Ib

Specification

Samsung Electronics 2-3

Effective recording area

First sheet copying time : Less than 30 seconds

Warm up time : Less than 30 seconds (at ambient temperature of 25 oC/77oF)

Recording paper stack

Type : Face down stack

Capacity : 100 sheets

Reference weight : 75 g/m2(20 Ibs)

Printing density and uniformity

Density : Greater than 1.0 O.D (Optical Density)

Uniformity : Less than 0.3 O.D

MODEM

Modulation

Group 3/ECM : CCITT V.34

CCITT V.17

CCITT V.29 V.27ter

Binary signal : CCITT V.21 T.30

Tonal signal : CCITT T.30

SOUND

Key click : Frequency 1.6 kHz, Duration 30 msec.

Alarm : Frequency 1.6 kHz, Duration 2 msec.

Transmission completion : Normal 1 sec./Error 1 sec.

Operator call : 15 sec. (1.28 sec. On/1.28 sec. OFF)

4 mm 4 mm

3 mm

EFFECTIVE RECORDING AREA

Top

Bottom

3 mm

Specification

2-4

POWER SUPPLY

Input voltage : 220V AC, 50/60Hz

Power consumption

Standby : 13 watts

Copy : 170 W (typical)

580 W (max.)

High voltage power supply

Input : 24 Vdc, 1.0 A

Output : 4.0 kVdc at 100 Mohm (Transfer Voltage)

-1.10 kVdc at 40 Mohm (Charge Voltage)

-900 Vdc at 100 Mohm (Retransfer Voltage)

-400 Vdc at 40 Mohm (Bias Voltage)

2-3 Second Paper Cassette (Option)

GENERAL

Dimension (HWD :) 4.2 x 14.1 x 16.1 inches (107 x 360 x 410 mm)

Weight : approx. 11 lb (5 kg)

RECORDING PAPER SIZE

Size : Letter size : 8.5 x 11 inches (216 x 279 mm)

A4 size : 8.3 x 11.7 inches (210 x 297 mm)

Legal size : 8.5 x 14 inches (216 x 356 mm)

Weight : 16 ~ 24 lbs (60 ~ 90 g/m2)

Thickness : 0.08 ~ 0.12 mm

CASSETTE

Basic : 250 sheets (Letter/Legal/A4 size)

Reference weight : 75 g/m

2

REPLACEMENT CYCLE

Pickup roller : Cleaning: 1 year / Replacement : 3 ~ 5 years or 50,000 sheets

Feed roller : Cleaning: 1 year / Replacement : 3 ~ 5 years or 50,000 sheets

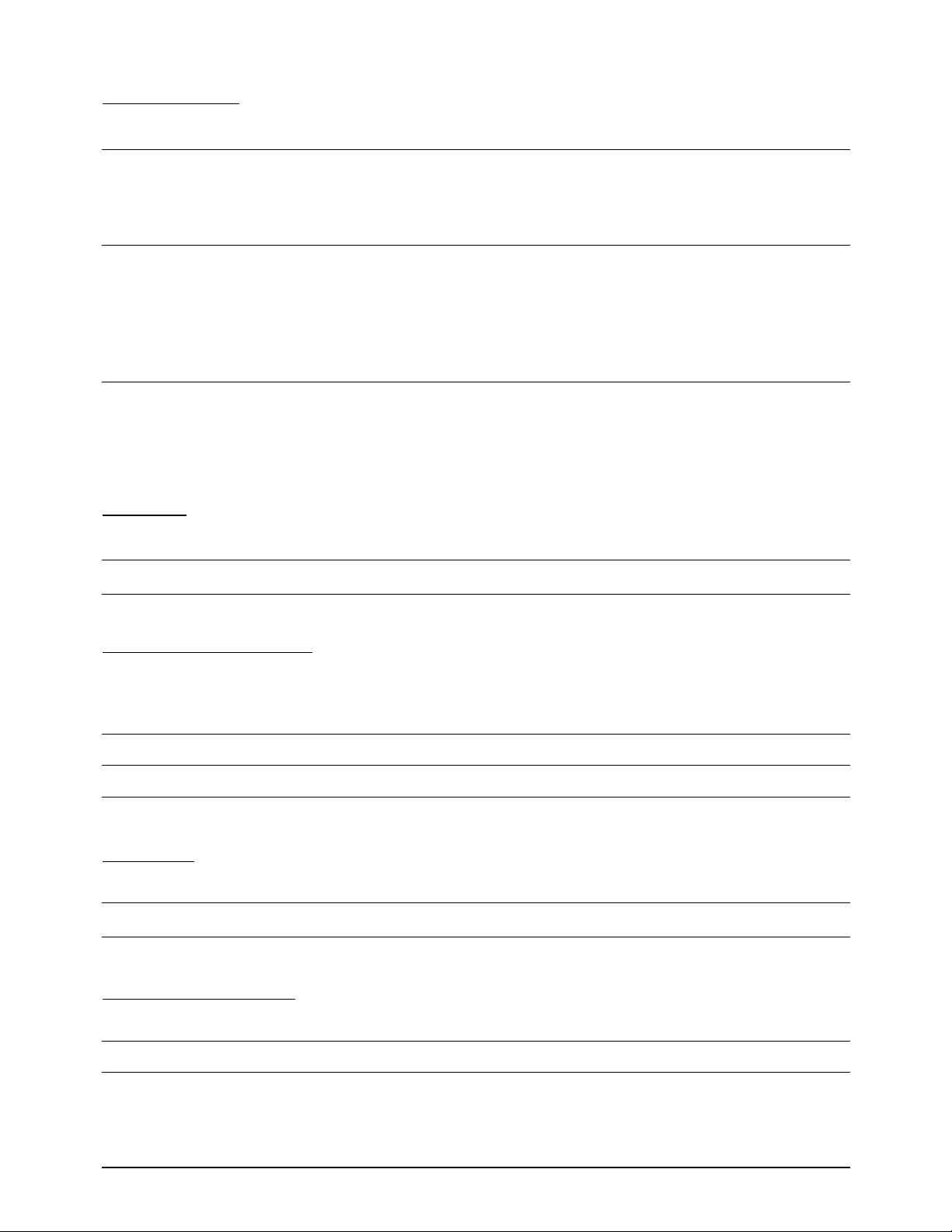

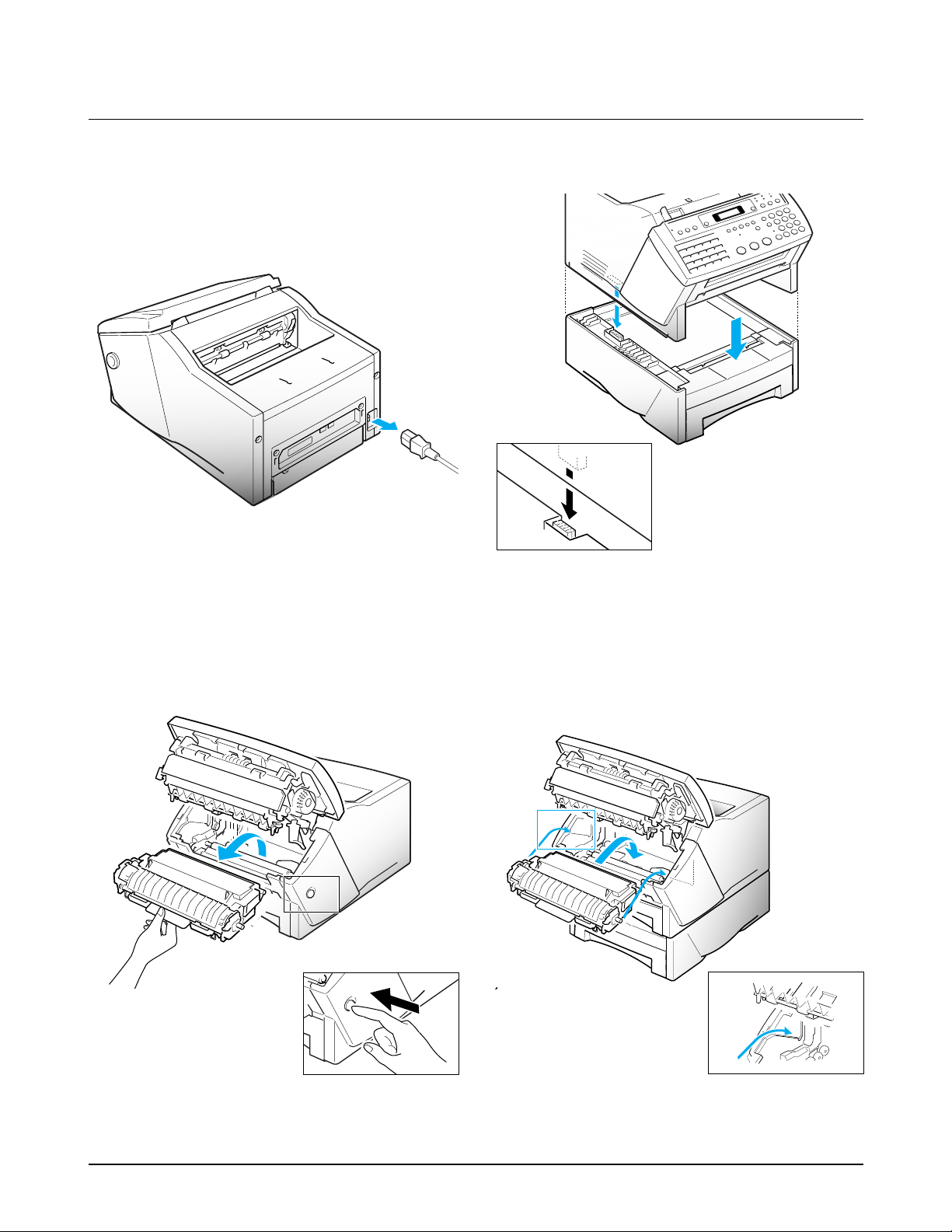

1. Insert two tabs on the document exit tray into the

slots on the front of your machine.

2. Fold out the extender, if necessary.

The extender can be folded out up to 3 steps.

This tray is also used to feed envelopes or recording

paper manually to print out PC job if your machine

is upgraded to use with PC.

Adjust the guides to match the width of the paper.

Document

exit tray

A4 B5

A5

A6

Ltr

3. Installation

3-1 Document Tray

1. Insert two tabs on the document tray into the

corresponding slot as shown.

2. Fold out the extender on the document tray, if

necessary.

Document

tray

Extender

Figure 3.5

Figure 3.3

Figure 3.4

Figure 3.1 Figure 3.2

3-2 Document Exit Tray (and Manual Feeder for upgraded model)

The document exit tray catches documents fed through the machine from the automatic document feeder.

Installation

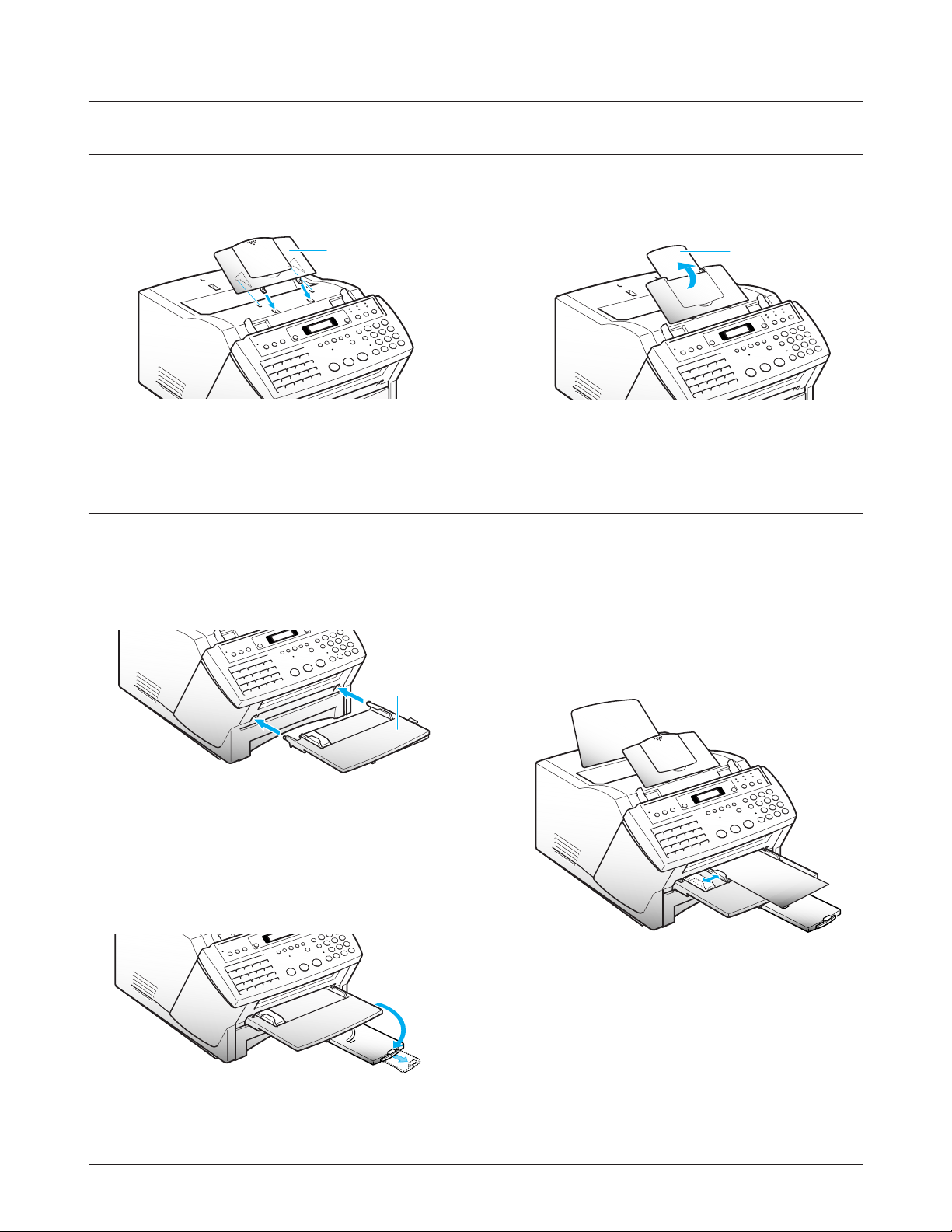

3-3 Printer Exit Tray

The printer exit tray supports printed output.

1. Insert two tabs on the printer exit tray into the

slots on the top of your machine.

Printer

exit tray

Figure 3.7

Figure 3.8

Figure 3.6

Wandsteckdose

N

F

N

3-4 Telephone Line

Plug one end of the telephone line cord into the

LINE jack and the other end into a standard phone

wall jack.

LINE

3-5 AC Power Cord

Plug one end of the cord into the back of the

machine and the other end into a standard,

grounded 3-prong AC power outlet.

The machine turns on. All lamps on the control

panel light up and the LCD window displays

'WARM UP PLEASE WAIT' then 'NO PAPER

or NO CASSETTE

.' Load the paper as described

on page 3-10.

If you want to power the machine off, unplug the

power cord.

Note : If documents are lost from memory due to a

power failure, the machine automatically prints a

report when power is supplied.

Installation

Figure 3.11

Figure 3.13

Figure 3.10

Figure 3.9

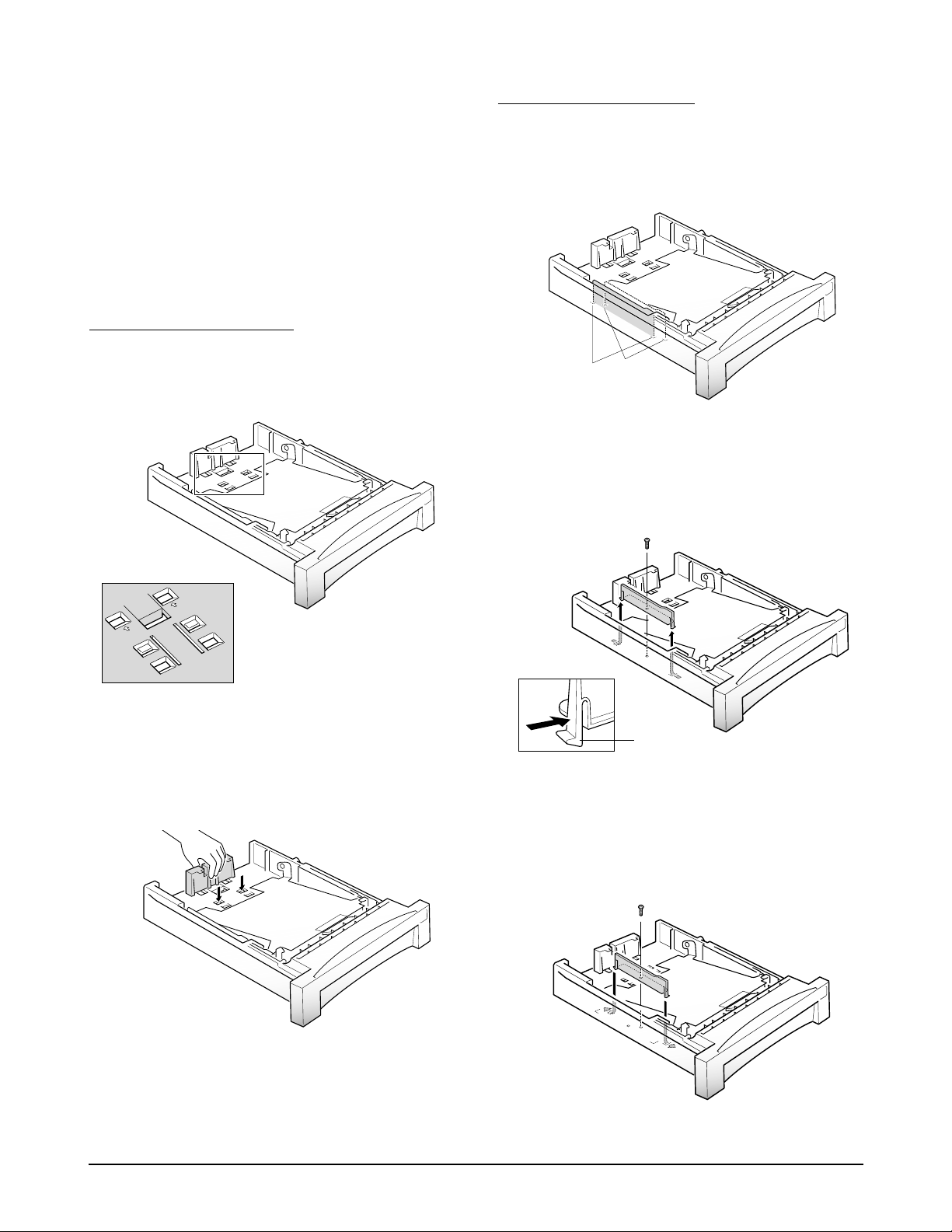

3-6 Second Paper Cassette (Option)

1. Unpack the second paper cassette box. It contains

the second cassette, second cassette frame, and

installation manual.

2. Unplug the power cord, and remove all trays

from the fax machine.

4. Carefully place the fax machine on top of the

second cassette unit, keeping the machine level.

Make sure the connector

is properly inserted.

3. Press the cover release button to open the cover,

and remove the toner cartridge. Then close the

cover.

5. Press the cover release button to open the cover

and install the toner cartridge.

Install all trays, and plug the power cord.

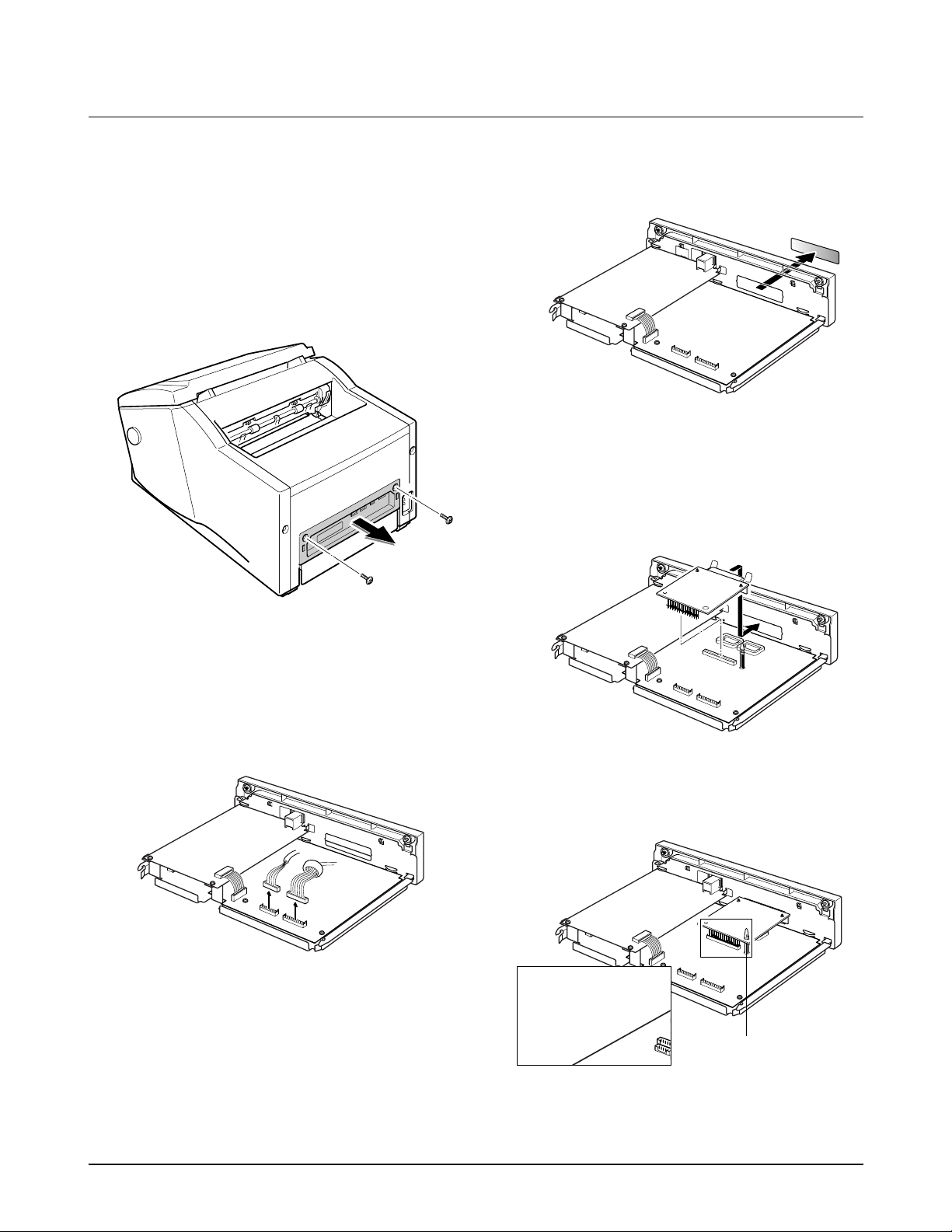

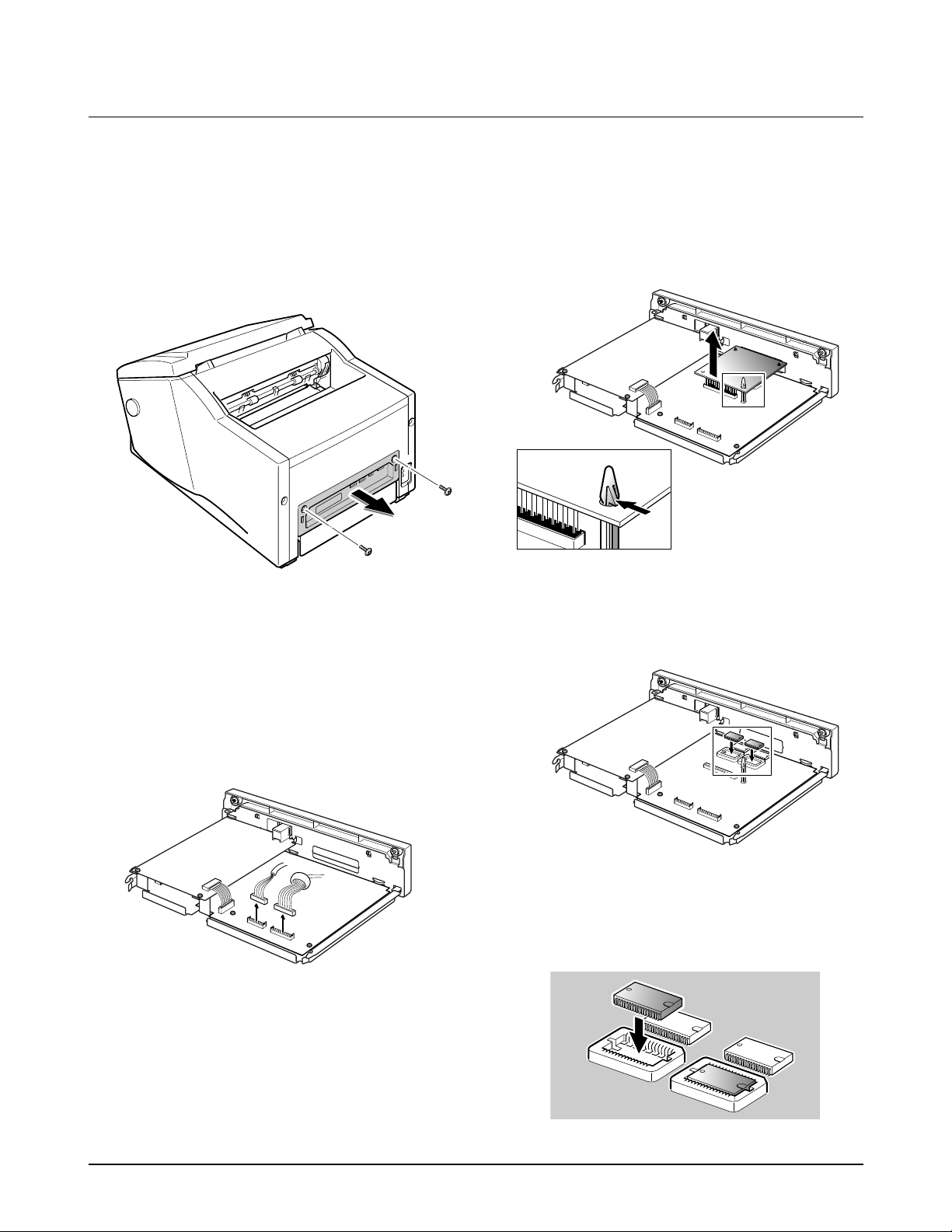

1. Unpack the MFP box. It contains the MFP board,

Printer cable, screws, Installation Software

diskettes, and Installation manual.

2. Unplug the power cord.

3. Remove the two screws and take out the board

cover.

4. Unplug all the connectors from the board.

5. Remove the printer connector cover.

6. Insert the printer connector of the MFP board into

its place, then push down the MFP board so that

the P1 connector on the MFP board is properly

installed into the P3 connector on the main board.

Make sure the PCB supporter is also properly

inserted.

Installation

Figure 3.14

Figure 3.15

Figure 3.16

Figure 3.17

3-7 MFP Board (Option)

This board is required to upgrade this machine to use with PC for PC printing, scanning, and faxing.

Insert the P1 connector

fully until it stops.

PCB supporter

Figure 3.18

Installation

Figure 3.19

7. Fasten the two screws to secure the printer

connector to the main frame.

8. Plug all the connectors from the two boards into

their places, replace the board cover, and fasten

the two screws.

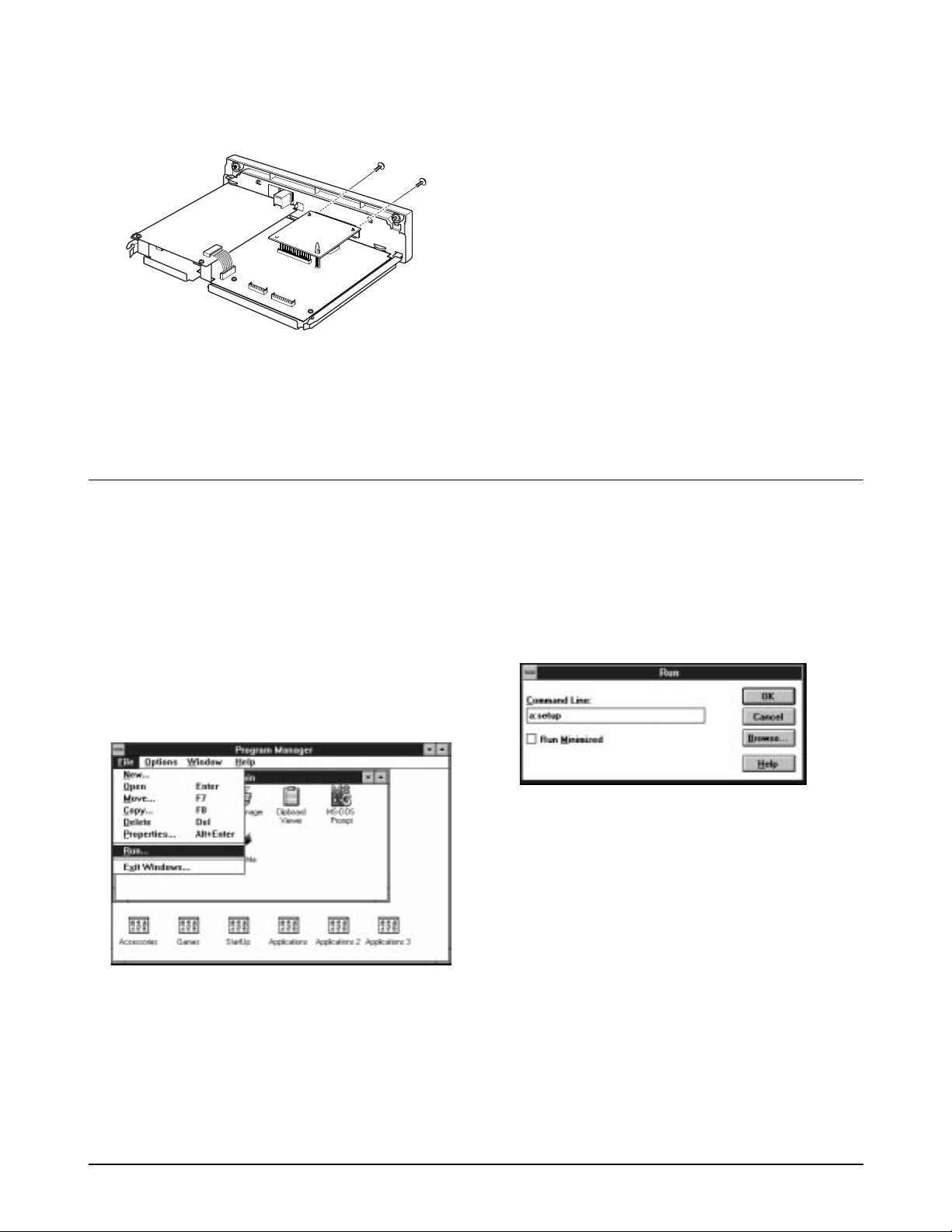

3-7 Installing the Printer Software

If you have installed the MFP board to this machine, now you need to install this printer software.

3-7-1 With Windows 3.1

1. Start Windows.

2. Insert the setup diskette into drive A (or B)

3. In Windows Program Manager, click on 'File',

then choose 'Run'.

4. In the command box, type 'a:\setup (or b:\setup)',

then click 'OK'.

5. Follow the instructions on the installation

screens.

6. Restart Windows.

Note : For the latest information on installing and

using the printer with Windows applications,

consult the Read Me and Online Help files in the

SF6000 Series MFP program group window.

Installation

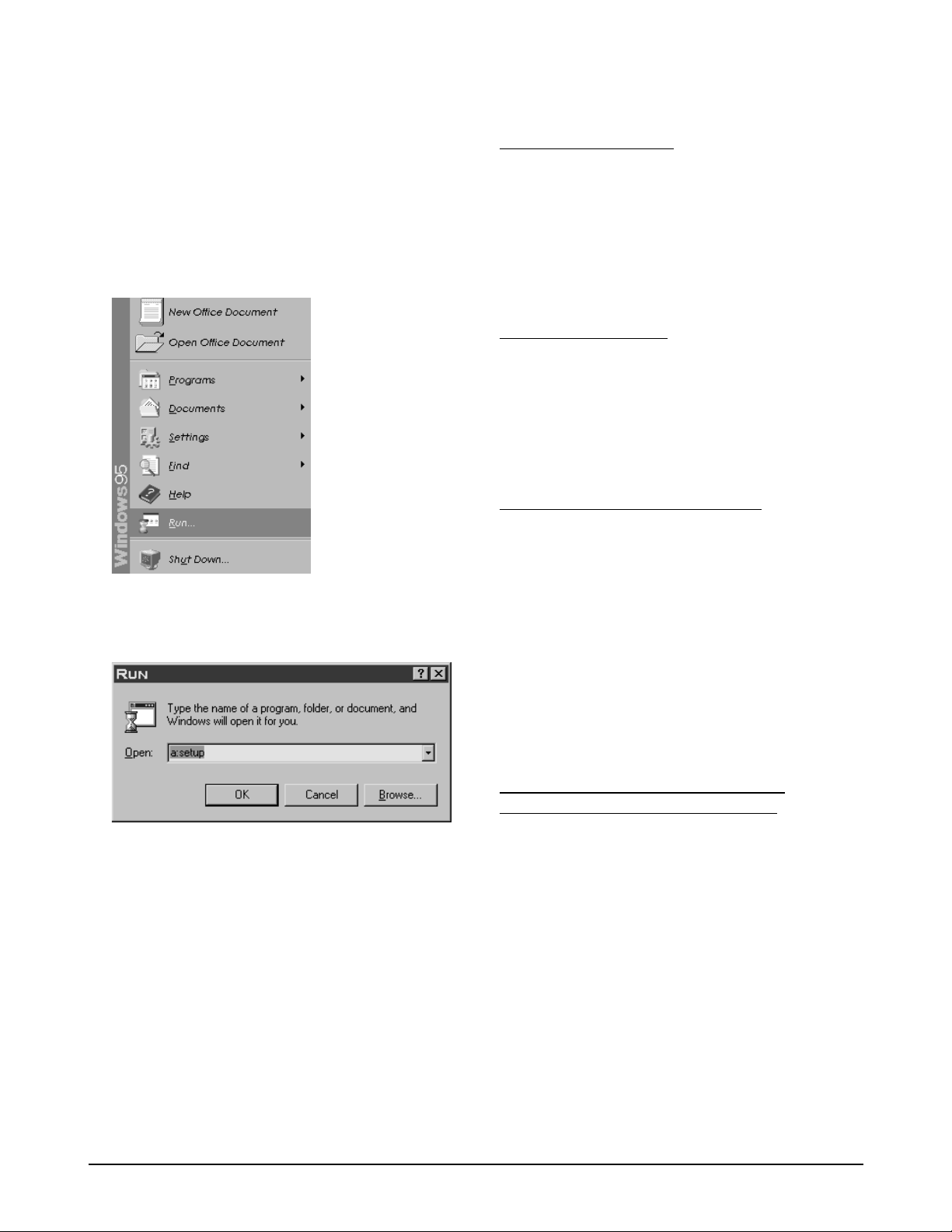

3-7-2 With Windows 95

To install the printer software with Windows 95 :

1. Start Windows.

2. Insert the setup diskette into drive A (or B).

3. Click 'Start' on the desktop, and then choose

'Run'.

4. In the Run dialog box, type 'a:\setup (or b:\setup)',

then click 'OK'.

5. Follow the SF6000 Series MFP Setup instructions.

'SETUP' will install the SF6000 Series software.

Note : Remove the floppy diskette from drive A (or

B) before Windows is restarted.

6. Restart Windows 95.

3-7-3 Running Printer Software

HARDWARE/SYSTEM

Before using the Application Print commands, check

that you have installed your printing device and

software, and turned on the printer. Application

does not show the Print menu if its options do not

apply that is, if you have no scanner or the installed

printer is not GDI-compliant.

BEFORE YOU PRINT

Make sure the SF6000 Series MFP is listed as your

default printer in the Windows Control Panel.

Print as you normally would -for example, by

choosing 'Print' from your applications 'File' menu.

CHANGING PRINTER SETTINGS

1. You can use paper sizes that are : letter - 8.5 X 11

inches, legal - 8.5 X 14 inches, and A4 - 8.2 X 11.7

inches. When you load the paper, adjust the

paper cassette for the paper size you chosen, and

make sure the proper size is set on these printer

software.

2. You can choose the print orientation from

Landscape and Portrait.

3. Resolution is fixed only 300 X 300 dpi.

CHOOSING PRINT OPTIONS FROM

WINDOWS-BASED APPLICATIONS

The following steps are general instructions. Your

Windows-based application may require a slight

variation from procedure. For example, in step 3,

your application may have a 'Printer' button in the

'Printer Setup' dialog box instead of an 'Options'

button.

1. Open the application's 'File' menu.

2. Choose 'Print (or Printer) Setup.'

3. In the 'Print Setup' dialog box, choose 'Options' to

open the 'SF6000 Series' dialog box.

Installation

4. Use the tabs to browse through the available

options.

After choosing print options, you are ready to

print.

CHOOSING PRINT OPTIONS FROM

WINDOWS CONTROL PANEL

1. In the Windows 'Main group' windows, doubleclick the 'Control Panel' icon.

2. From the 'Control Panel', double-click the

'Printers' icon to open the 'Printers' dialog box.

3. From the list of installed printers, select the

'SF6000 Series MFP.'

4. Click the 'Setup' button to open the 'SF6000 Series

MFP' dialog box.

After choosing options, you are ready to print.

3-7-4 Using SF6000 Series MFP

Manager

The MFP manager configures and monitors the

operations of the SF6000 Series MFP. It is a

Windows program that silently runs in the

background all the time. You can open the MFP

Manager display by clicking on it's icon in the

Control Panel menu. You can also terminate the

MFP Manager at any time, if that is necessary. When

you exit the MFP Manager it will offer you two

options. One option is to terminate the SF6000 Series

MFP, and the other option is to keep the MFP

manager running in the background. If you decide

to terminate the MFP manager than all current and

future SF6000 Series MFP usage will be terminated

until you restart the MFP manager or restart

Windows. You can also restart the MFP manager

from the Control Panel menu at any time.

CONFIGURE

Your SF6000 Series MFP can print, scan, and fax. It

appears to your Windows computer as three

separate peripherals: a Printer, Scanner, and a Fax

Modem. These three peripherals appear to be three

separate ports on the cable that attaches the SF6000

Series MFP to your computer. These three SF6000

Series MFP ports are configured automatically

during installation. The cable is also configured

automatically to attach to your computer's LPT1

during installation. However, you can change the

Cable, Print or Fax configuration by pressing the

Configure button.

Cable Port: This is the computer port to which you

connect the SF6000 Series MFP cable. It is configured

automatically to LPT1 during installation. LPT1 is

also configured automatically to use IRQ (7) and

DMA (channel 3) in Windows 3.x. You can connect

the SF6000 Series MFP cable to another LPT port on

your computer. You can also change the IRQ and

DMA assignments for the LPT port in Windows 3.x.

Please consult your computer hardware

documentation for the appropriate IRQ and DMA

assignments. You must restart Windows after you

make changes to the Cable Port LPT, IRQ, or DMA

configuration. The new assignments will become

effective when Windows restarts.

Print Port: This port is pre-configured to LPT3 in

Windows 3.x or LPT4 in Windows 95. You print

Windows documents on the SF6000 Series MFP by

connecting the SF6000 Series MFP printer driver to

this Print Port. You only need to change the

configuration of the Print Port if the LPT3 or LPT4

assignments are in conflict with your PC hardware

or software. You can select another configuration of

the Print Port between LPT2 and LPT9. When you

change the Print Port configuration you will also

need to open the Windows Printer Control and

reconnect the SF6000 Series MFP printer driver of

the new LPT assignment. You must restart

Windows after you make changes to the Print Port

configuration. The new assignment will become

effective when Windows restarts.

Scan Port: This port is pre-configured to COM9 in

Windows 3.x and Windows 95. Your SF6000 Series

MFP Scanner software is automatically configured

to connect to COM9. This assignment is fixed.

Installation

Fax Port: This port is pre-configured to COM3 in

Windows 3.x and Windows 95. You can use the

SF6000 Series MFP as a fax modem by connecting

your Windows fax application to COM3. You only

need to change the configuration of the Fax Port if

the COM3 assignment is in conflict with your PC

hardware or software. You can select another

configuration of the Fax Port between COM3 and

COM8. When you change the Fax Port configuration

you will also need to reconnect your Windows fax

application to the new COM assignment. You must

restart Windows after you make changes to the Fax

Port configuration. The new assignment will become

effective when Windows restarts.

MONITOR

The MFP manager displays the status of SF6000

Series MFP ports when you press the Monitor

button. Active jobs are indicated by the word

'Active' in the Cable, Print, Scan, or Fax port. A

blinking dot also appears next to active port.

EXIT

The Exit button allows you to close the MFP

manager display or terminate the MFP manager.

The MFP manager will display a dialog box when

you press Exit. The dialog box has a Cancel and OK

buttons that mean the following:

Cancel button: This is the default button that you

would normally press to close the MFP manager

display and keep the MFP manager running in the

background. The MFP manager must be running in

the background when you want to use your SF6000

Series MFP.

OK button: This is the button you would press to

terminate the MFP manager. You do not want to

terminate the MFP manager under normal

circumstances. This button is provided for the case

when Windows requests that you terminate all

running programs. The MFP manager is a Windows

program that silently runs in the background all the

time.

If you decide to press the OK button then all

current and future SF6000 Series MFP usage will

be terminated until you restart the MFP manager,

or restart Windows.

You can restart the MFP manager from the Control

Panel menu at any time. Double click on the SF6000

Series MFP icon in Control Panel, press the Exit

button then press the Cancel button. The MFP

manager will silently run in the background and

you can use SF6000 Series MFP again.

UNINSTALL

The Uninstall button allows you to delete the SF6000

Series MFP software from your PC. When you press

the Uninstall button, the SF6000 Series MFP

manager will ask you to confirm that you want all

SF6000 Series MFP software files removed.

If you press the OK button then all of the SF6000

Series MFP files are removed from your PC.

Windows must be restarted when all of the SF6000

Series MFP software files are removed.

Installation

3-8 Memory (Option)

This machine is preset with two 2 Mbyte DRAMs at factory and can be upgraded up to 8 Mbytes by installing

optional two 2 Mbyte DRAMs into the machine. There are two DRAM sockets on the main board of the

machine. If you install one 2 Mbyte DRAM, you can use any socket. You must use KM48C2100 DRAM.

1. Unplug the power cord.

2. Remove the two screws and pull out the board

cover.

3. Unplug all the connectors from the boards, and

take out the board cover.

4. If an optional MFP board have been installed,

remove the MFP board. See 'MFP Board' on page

6-34.

5. Insert one or two KM48C2100 DRAM IC(s) into

the appropriate socket(s) on the main board.

Note : You must observe the correct direction when

you insert the IC. See the direction of the IC

currently inserted.

Figure 3.21

Figure 3.22

Figure 3.20

Figure 3.23

Installation

Figure 3.25

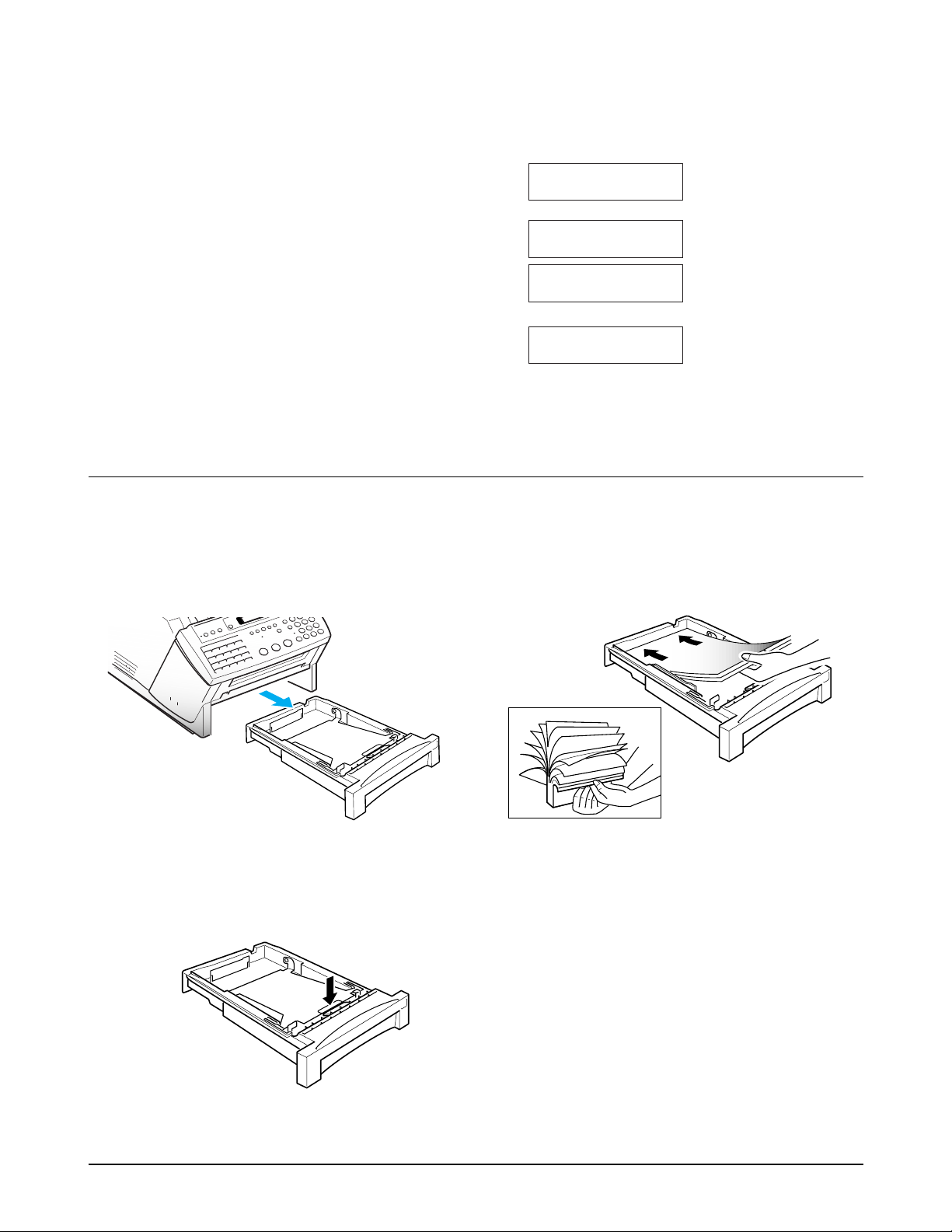

3-9 Loading Paper

The LCD displays 'NO PAPER or NO CASSETTE' when no paper is loaded. You can load approximately

250 sheets of paper.

1. Remove the paper cassette if previously installed,

by pulling it out of the cassette port.

2. To load the paper into the cassette, press down

the metal plate in the cassette.

3. Fan the paper and insert the paper with the print

side facing up.

Note : If you fail to fan the paper, it may cause

multi-paper feeding and jams.

Figure 3.26

6. Plug all the connectors into their places, install

the MFP board if required, reinstall the board

cover, and fasten the screws.

7. Plug the power cord to power the machine on.

8. Get into the Tech mode by Pressing MENU, #, 1,

9, 3, 4.

9. In Tech mode, Press MENU, and one touch 04

ÔSYSTEM SETUP.Õ

10. Press ▼ or ▲ repeatedly until you find 'DRAM

TEST'.

11. Press ENTER. The LCD briefly displays

'TESTING

...

' then shows the result of the

DRAM test as follows:

: Optional two DRAMs

are installed properly.

: Optional one DRAM is

installed properly.

: Optional DRAM is not

installed or not

properly.

Check if the connection

is made properly.

[NO DRAM] OR

[DRAM FAIL]

4M DRAM [OK]

2MDRAM [EVEN-OK]

2MDRAM [ODD-OK]

Figure 3.24

Installation

Figure 3.27

Figure 3.28

4. Gently press the upper corners of the paper down

under the cassette tabs.

5. Insert the cassette into the port on the front of the

machine until it stops.

Adjusting Paper Guide

The following paper sizes can be used in your

machine:

◆ Letter : 8.5 X 11.0 inches (216 X 279 mm)

◆ A4 : 8.3 X 11.7 inches (210 X 297 mm)

To use Letter size paper, change the position of the

paper guide before loading paper.

1. Remove one screw fastened the paper guide and

take out the guide while pushing the low end

inward.

2. Insert the guide into the slots as shown in the

figure and fasten the screw.

Note : If you want to change the recording paper

size, you must set your machine to use the selected

paper. See 'User Options' on page 3-16. Your

machine is preset to use A4-sized paper.

Figure 3.29

Figure 3.31

Figure 3.30

Installation

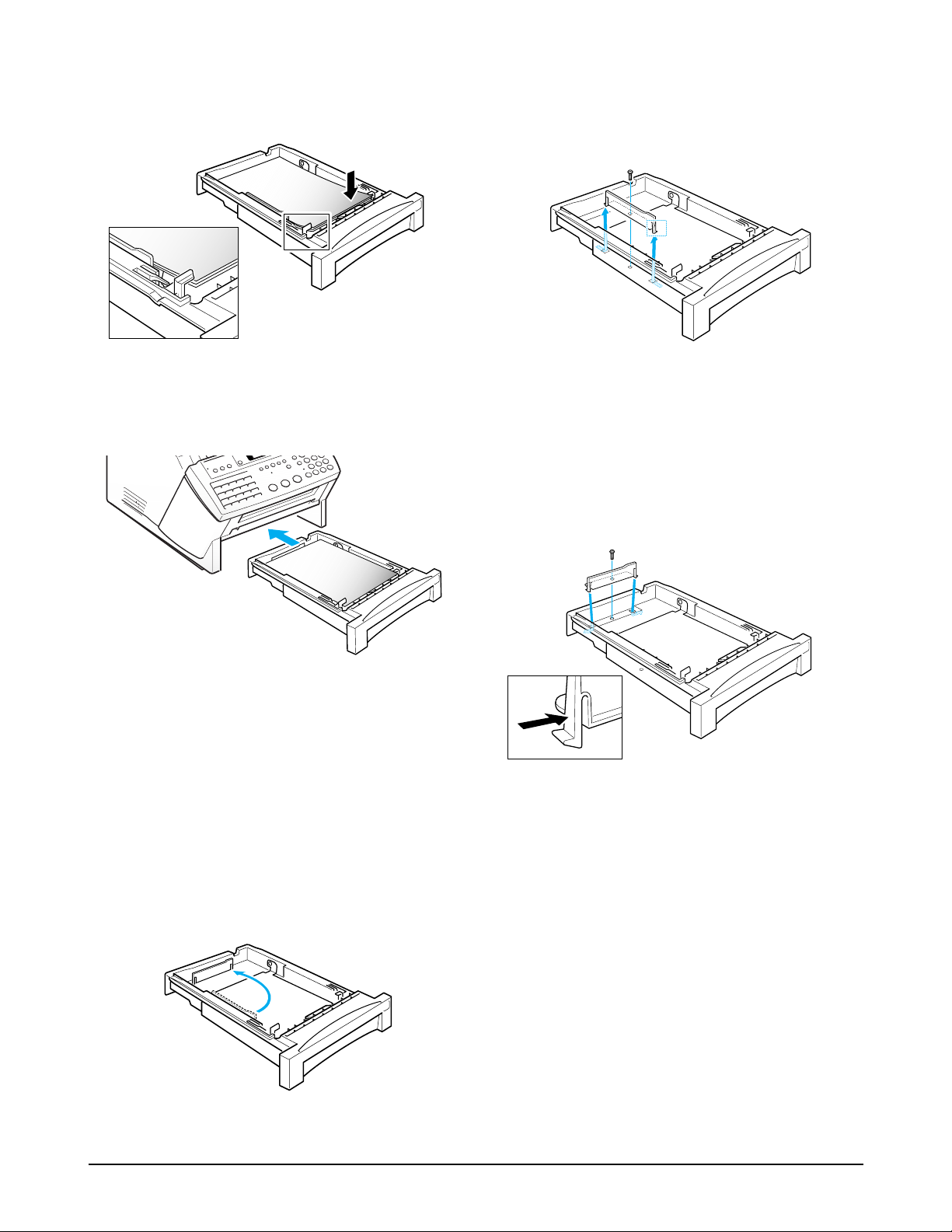

Second Lower Cassette (Option)

An optional second cassette can hold three differentsize paper; letter, legal, and A4. The paper cassette is

preset to load the letter-sized paper. If necessary,

adjust the cassette to the desired paper size. You can

use two guides to adjust the cassette. Place the

guides at the appropriate position for the paper size

you want to use.

USING THE REAR GUIDE

1. There are three adjustable positions for the rear

guide, which are marked with the corresponding

paper size.

2. To move the rear guide, push down the tabs of

the guide, and pull the guide inwards or

outwards so that the tabs are placed at the

desired position.

USING THE SIDE GUIDE

1. There are two adjustable positions for the side

guide. If you are using A4 size paper, place the

guide at the front position. Otherwise, place the

guide at the back.

2. To move the side guide, remove the screw

securing the guide and take out the guide while

you push the legs of the guide inwards.

3. Insert the guide into the desired position and

fasten the screw.

LGL

LGL

A4

A4

LTR

LTR

LTR

Letter, legal

A4

Leg

Figure 3.32

Figure 3.33

Figure 3.34

Figure 3.35

Figure 3.36

Installation

3-10 Installing or Replacing Toner Cartridge

When the toner supply is low, a 'TONER LOW' message will be displayed. Remove the toner cartridge and shake

it several times. Several can still be printed before the toner supply runs out completely and the toner cartridge

unit must be replaced.

When the toner supply is depleted, 'TONER EMPTY, REPLACE [CARTRIDGE]' appears in the display.

Supplies are available by contacting your local dex Business Systems representative.

Notes :

¥ When you replace the toner cartridge, you must replace the cleaning felt. If not, the print quality may be

degraded.

¥ When you move the fax machine, do not move it with the toner cartridge installed in the machine. First

remove the toner cartridge then carry the machine.

TONER CARTRIDGE

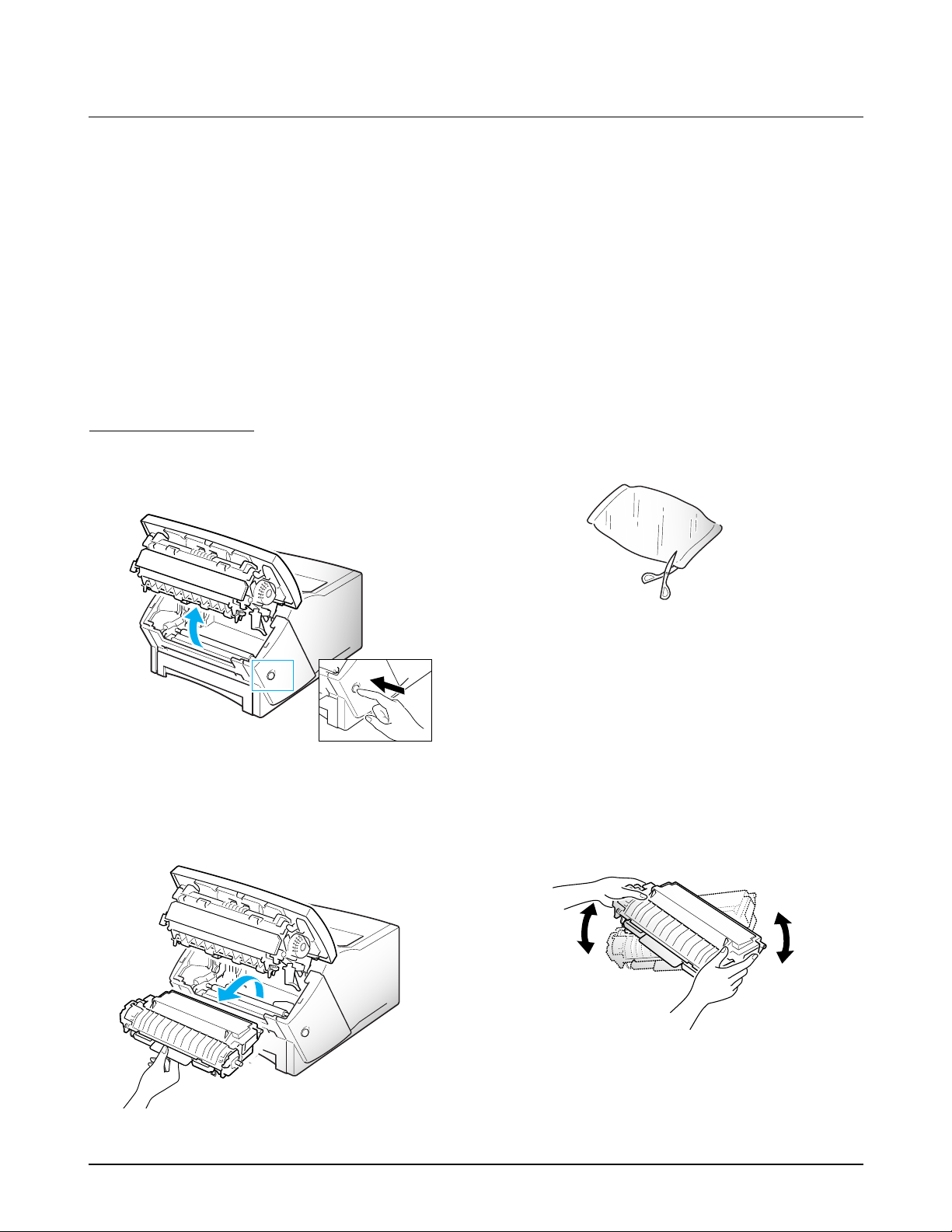

1. Press the cover release button, and fully open the

operation unit assembly.

2. Hold the toner cartridge by the green tab and

remove the used unit, if necessary.

3. Unpack the toner cartridge.

4. Hold the toner unit as shown below and gently

shake it one side up, the other side down, and

vice versa several times to distribute the toner

evenly inside the unit.

Note : If the toner inside the unit is shifted to one

side, it may cause degraded print quality.

Figure 3.37

Figure 3.39

Figure 3.40

Figure 3.38

Installation

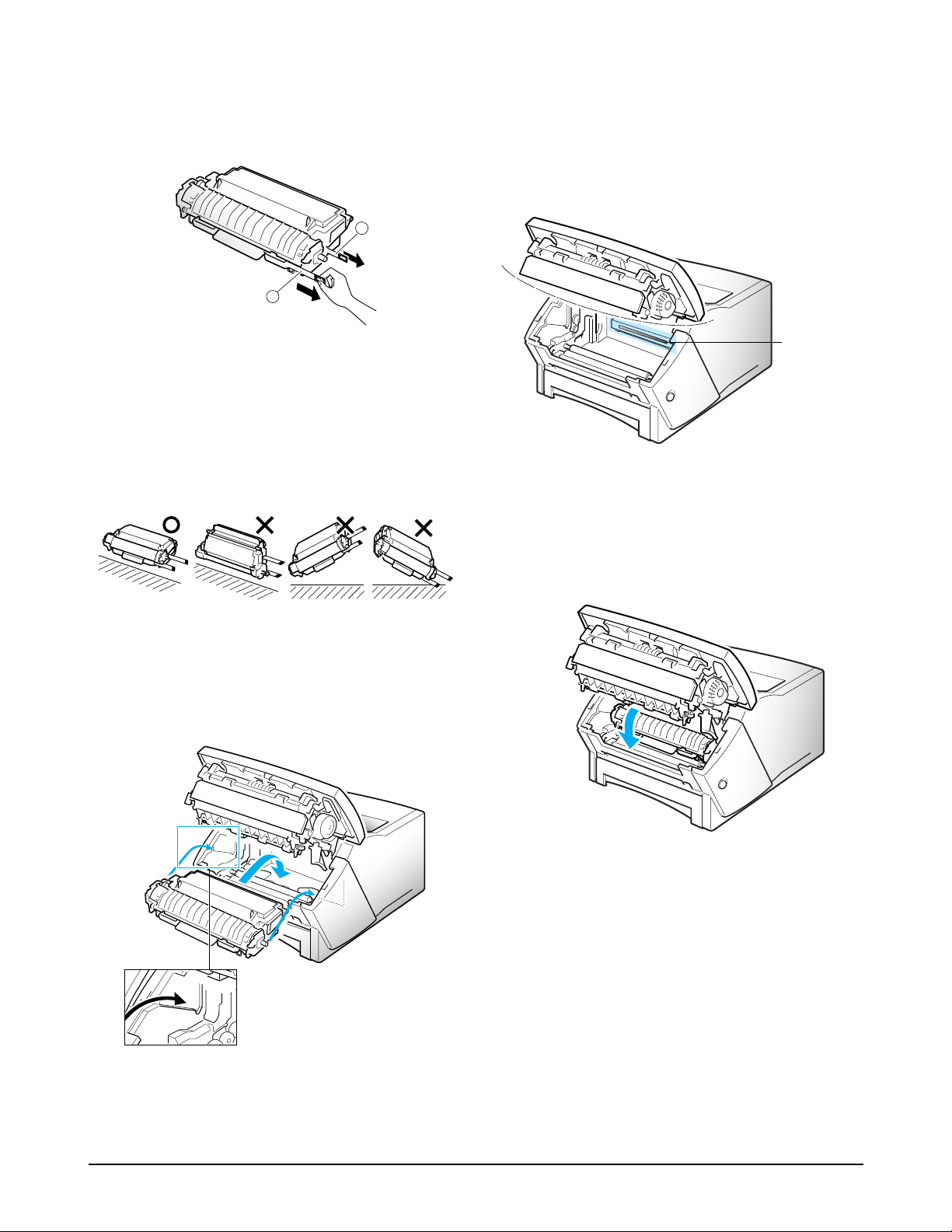

5. Remove the sealing tapes ➀ first, ➁ next, by

pulling them straight out completely. Be careful

not to tear them off.

Warning : When you remove the sealing tapes,

you must hold the toner cartridge horizontally

and pull the tape evenly. Never tip the cartridge

or turn the handle side down. This may cause

degraded print quality.

6. Holding the toner cartridge unit in hand, fit the

tabs on either side of the cartridge the either side

of the compartment as shown, and slide it down

firmly into your fax machine until it clicks in

place.

Warning : Your machine is designed to stop the

machine operation and cut off the laser beam that

can damage your eye if the cover is opened.

However, for safety's sake, do not look at the LSU

window in front where the laser beam might

come out when you open the cover.

7. After installing the toner cartridge, close the

operation unit assembly.

Figure 3.41

Figure 3.43

Figure 3.44

LSU Window

Figure 3.42

1

2

Installation

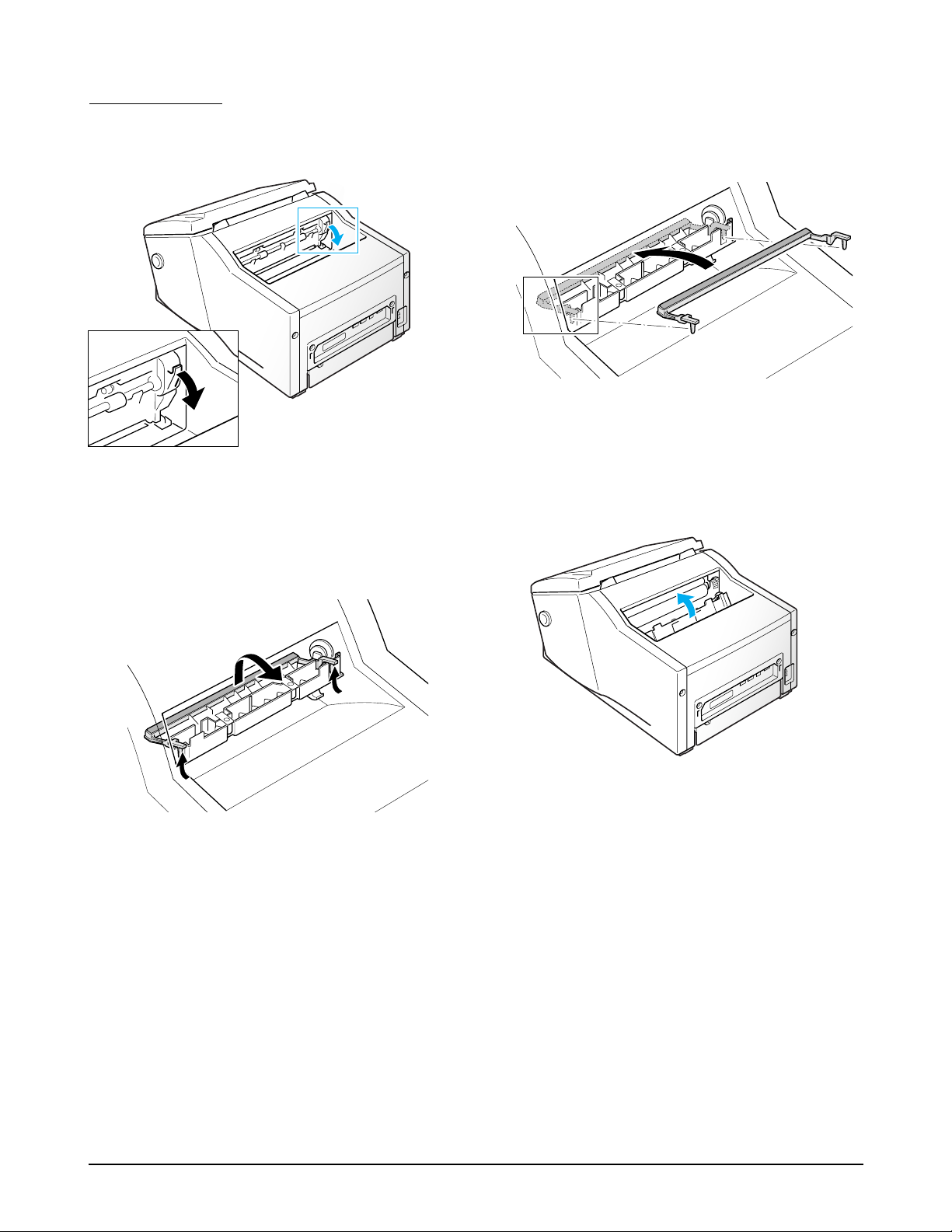

3. Insert new cleaning with the white felt faced out

as show.

CLEANING FELT

1. Open the fuser cover by pulling the release lever.

2. Remove the cleaning felt used.

4. Close the fuser cover.

Note : You must install a new cleaning felt when

you install a new toner cartridge. If not, the print

quality may be degraded.

Figure 3.45

Figure 3.46

Figure 3.47

Figure 3.48

Installation

3-11 Memory Clear

3-11-1 Memory Clear in User Mode

In the user mode, you can selectively clear

information stored in this machine's memory. The

list of data you can clear is as follows:

1:SYSTEM ID : your terminal ID number and name

are erased from the machine's memory.

2:SYSTEM DATA : restores user-selectable options

to the default value.

3:DIAL & DELAYED : clears the One-Touch, Speed

Dial, or Group Dial numbers stored in memory.

In addition, all the delayed time operations you

have reserved are also canceled.

4:TX-RX JOURNAL : clears all records of

transmissions & receptions.

1. If the machine is in the tech mode, return to the

user mode by pressing MENU, #, 1, 9, 3, 4 in

sequence.

2. Press MENU, and the one-touch key 5

'MEMORY CLEAR'.

The LCD displays the type of memory you can

choose.

3. Scroll to the options by pressing or ¹ until you

find the one you want to clear. When the cursor

blinks under the memory you want to clear, press

ENTER.

Otherwise, you can enter the number of the

memory.

4. The LCD prompts you to confirm your selection.

Press ENTER. If you press STOP, the machine

returns to Standby Mode.

3-11-2 Memory Clear in Tech Mode

Memory clear, contained in the tech mode, is used

for clearing all the user's data in memory and setting

to default status.

1. If not in the tech mode, Press MENU, #, 1, 9, 3, 4

in sequence to initiate the tech mode.

2. Press MENU, and the one-touch key 5

'MEMORY CLEAR'.

The LCD displays 'MEMORY ALL CLEAR'.

3. Press 1 to clear all memory.

If you want to cancel, press 2. The machine

returns to Standby Mode.

3-12-1 System Data Settings in User-mode

The fax machine has various user-selectable

functions. These functions are usually selected

during the initial setup of the machine, and there

should be little need to change them there after.

Note : Before you begin, print out the system data

list to see the current settings. To print the system

data list, press MENU, and one-touch 19 'SYSTEM

DATA.'

1. Press MENU, then one-touch 01 'SYSTEM DATA.'

The LCD displays user-selectable options.

2. Scroll to the options by pressing ▼ or ▲ repeatedly.

3. When the option you want appears in the display,

enter the number for the desired status. You can

use à or ¨ button and press ENTER to select the

desired status.

3-12-2 User-Selectable Options

These instructions assume you've followed the steps

under 'System Data Settings in User-mode' and the

machine is asking if you want to change one of the

options listed here.

3-12 System Data Set-up

There are system data settings that are set by the user in the user-mode, and system data settings set by the

technician in the tech mode.

Installation

Paper Size-Select the paper size you will use for

the recording paper.

Press 1 for letter (LTR) or, 2 for A4 size paper.

If your machine is equipped with an optional lower

cassette, select the paper size for the lower cassette.

Press 1 for letter (LTR), 2 for A4, or 3 for legal (LGL)

size paper.

Message Confirmation Report-A confirmation

report shows whether the transmission was

successful or not, how many pages were sent, etc.

Press 1 to print out journal automatically each time

you send a fax.

Press 2 to print only when an error occurs and the

transmission was not successful.

Auto Print Journal-A journal report shows specific

information concerning transmission and reception

activities, the time and dates up to 50 of the most

recent transmission and reception.

Press 1 to print journal automatically after every 50

transmission and receptions.

Press 2 to print journal manually.

Remote Receive Start Code-The remote receive

code allows you to initiate fax receive from an

extension phone. If you pick up the extension phone

and hear fax tones, enter the remote receive code

and the fax will start receiving. The password is

preset to 9 at factory.

Enter the desired code 0 to 9 on the number keypad.

Power Save Mode-The power save mode allows

you to shut off the machine's printer heater

automatically after a document is printed, to

conserve electricity and reduce your utility bills. The

fax machine automatically turns on the printer again

when it receives a document or is instructed to make

a copy. In this mode, it takes the machine a little

longer to print out fax messages or copies since it

must first re-heat the printer.

Press 1 to turn this feature on. If you want to set the

time duration that the machine activates the power

save mode, enter the time in 24-hour format.

Press 2 to turn this feature off.

Dial Mode-Select the type of dial system your fax

machine is connected to.

Press 1 if the fax machine is connected to a tone

(Touch Tone) dial line.

Press 2 if the fax machine is connected to a pulse

(Rotary) dial line.

Security Communication-This mode allows your

fax machine to send and receive documents to and

from a predetermined location where the fax

machine has the security code that matches your

security code.

Press 1 to turn on the Security Communication

mode.

Press 2 to turn off the Security Communication

mode.

Error Correction Mode-This mode compensates for

poor line quality and ensures accurate, error-free

transmission with any other ECM-equipped

facsimile machine. If the line quality is poor,

transmission time may be increased when ECM is

enabled.

Press 1 to turn on the error correction mode.

Press 2 to turn off the error correction mode.

Automatic Reduction in Receiving-When

receiving a document as long as or longer than the

paper installed in your machine, the machine can

reduce the data in the document to fit on your

recording paper size. The machine will reduce the

data in vertical. If you have an optional lower

cassette, your machine will automatically select the

cassette in which the desired-size paper is loaded.

Turn on this feature if you want to reduce an

incoming page that may otherwise need to be

divided into two pages with only a few centimeters

on the second page. If the fax machine cannot reduce

the data to fit into one page with the feature enabled,

the data is divided and printed in actual size on two

or more sheets if needed.

Press 1 to turn this feature on.

Press 2 to turn this feature off. The overflowed data

will be printed out on a second page.

Installation

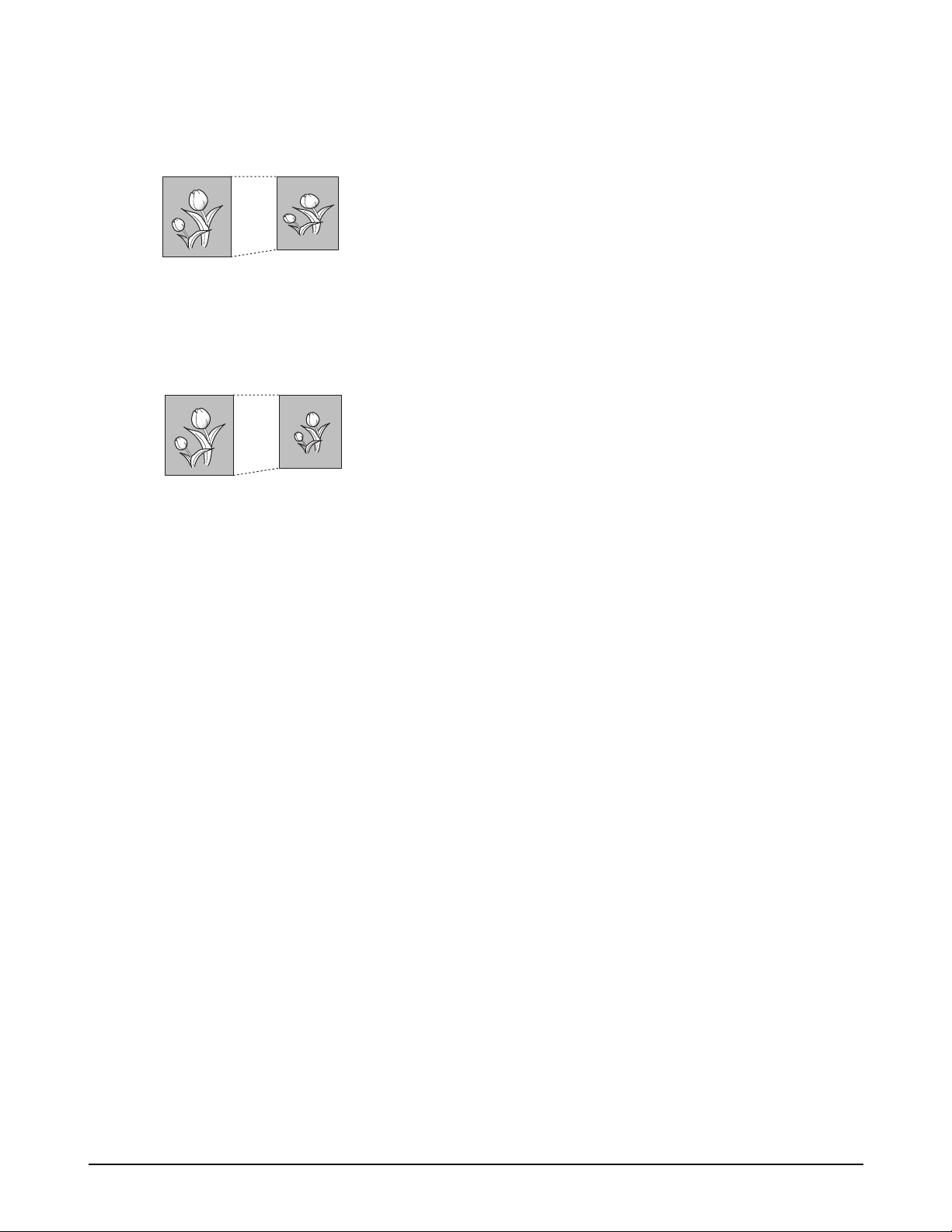

Horizontal Reduction-When you turn on the

automatic reduction feature and an incoming page

contains overflowed data, the machine reduce the

data only in vertical as shown below.

If you want to reduce both in vertical and horizontal

at the same rate in order to maintain height to width

relationships, use the horizontal reduction option. If

you turn on this feature, the machine reduces the

data as shown below.

Press 1 to turn this feature on.

Press 2 to turn this feature off.

Automatic Discard Size-When receiving a

document as long as or longer than a standard letter

size paper installed in your fax machine, you can set

the fax machine to discard any excess image at the

bottom of the page to fit the recording paper size.

If the received page is outside the margin you set, it

will be printed on two sheets of paper at the actual

size.

If the data is within the margin, and the Rx

Reduction feature is turned on, it will be reduced to

fit in the appropriate size paper (Discard does not

take place). If the Rx Reduction feature is turned

OFF or fails, the data within the margin will be

discarded.

Enter the desired discard size using the number

keypad, and press ENTER.

Automatic Redial Term-Your fax machine can

automatically redial a remote fax machine if it was

busy or does not answer the first call.

Enter the number of minutes (from 1 to 7) using the

number keypad.

Automatic Redial Try-Enter the number of

attempts (from 0 to 7) to redial the number before

giving up.

If you enter 0, the machine will not redial.

Ring Before Answer-You can select the number of

times your machine rings before answering an

incoming call. If you are using your machine as both

a telephone and a fax machine, we suggest you set

the ring count to at least 4 to give you time to

answer.

Enter a number from 1 through 7 on the number

keypad.

Smoothing-The smoothing feature enhances the

appearance of incoming faxes by making the lines

smooth and takes no additional time. This function

does not apply to outgoing faxes, or to lists or

reports you print. It is recommended to turn this

feature on for text data, turn it off for picture image.

Press 1 to turn the feature on.

Press 2 to turn the feature off.

Continuous Polling Report-Every time continuous

polling ends, a multi-communication report will be

printed to show the result for each registered station.

Press 1 to print the report automatically each time

continuous polling ends.

Press 2 to turn the feature off. The report will not be

printed.

Forced Memory Transmission-If you are annoyed

that you have to wait until documents in the feeder

are sent out when you try to send or reserve another

fax, turn this feature on. This feature enables all

transmission documents are automatically scanned

into memory before transmission. Memory might be

full.

Press 1 to turn this feature on.

Press 2 to turn this feature off. The LCD display

prompts you to choose either to scan the documents

into memory or not before dialing the number when

you try to send or reserve a fax.

Original Received data

Original Received data

Installation

Receive Terminal Identification-This feature

allows the machine to automatically print the

receive terminal ID (if registered), page number,

reduction rate, and the date and time of the

reception at the bottom of each page of a received

document.

Press 1 to turn this feature on.

Press 2 to turn this feature off.

Print Priority Term-This option is available only

when you install an optional MFP board into your

machine. When you want to print a PC document

while the machine prints a received fax on the

recording paper, you can interrupt the printing and

print the PC document. Press the PRINT PRIORITY

button to enable the feature. The LCD displays PP

on the lower line, right corner. The interrupted fax

data will be stored in memory. To disable, press the

PRINT PRIORITY button again. PP on the LCD

disappears.

You can set your machine to turn the feature off

automatically if there is no further data printed

within 30 minutes or 8 hours after PC printing.

Press 1 to select 8 hours. The machine turns off

automatically 8 hours after PC printing is

completed.

Press 2 to select 30 minutes. The machine turns off

automatically 30 minutes after PC printing is

completed.

3-14-3 Confiming System Data Settings

Confirm the system data settings by printing out a

system data list.

1. If not in the tech mode, press MENU, #, 1, 9, 3, 4 in

sequence to initiate the tech mode.

2. Press MENU.

3. Press one of the one-touch PRINT keys 16-20. The

LCD displays the lists you can print out.

4. Press or ¹ until you find 'SYSTEM DATA

LIST'.

5. Press ENTER. The machine prints the system

data list.

The system data list printed in the tech mode

contains the system data set in the tech mode as

well as in the user mode. The model number and

software version will be printed at the bottom of

the system data list.

Installation

3-14-4 System Data Settings in T ech-mode

Various technical features of fax machine are

provided with optional parameters. Set the features

to the user's need according to the following

procedure.

1. If not in the tech mode, press MENU, #, 1, 9, 3, 4

in sequence to initiate the tech mode.

2. Press MENU, one-touch 1 'SYSTEM DATA.'

The LCD displays 'TECH MODE SYSTEM DATA?'.

3. To set the system data available in tech mode,

press ENTER.

If you want to set the system data available in the

user mode, press STOP. The LCD displays 'USER

MODE SYSTEM DATA?'. Press ENTER to set the

system data available in the user mode.

4. The LCD displays the options you can choose. In

tech mode, the LCD displays the technicianselectable options as well as all the user-selectable

options.

5. Scroll to the options by pressing or ¹

repeatedly.

6. When the option you want appears in the display,

enter the number for the desired status. You can

use à or ¨ button and press ENTER to select the

desired status.

You can exit from setup mode at any time by

pressing STOP. When you press STOP, the

machine stores the options you've already changed

and returns to Standby mode.

FEATURE

Modem Speed 33600/28800/

14400/12000

9600/7200

4800/2400 bps

The maximum Tx speed can be limited to 33600, 28800, 14400, 9600, 7200, 4800 or

2400 bits per second. When the Tx speed is set to 33600 or 28800, the Rx speed can

be V.34. When the Tx speed is set to 14400, the Rx speed can be either V.33 or V.17

speed. When the Tx speed is set to 9600 or 7200, the Rx speed can be either V.29 or

V.27ter speed. When the Tx speed is set to 4800 or 2400, the Rx speed can be any

V.27ter speed.

Error Rate 6%, 12% If the error rate exceeds the chosen rate, fall back occurs which will lower the

baud rate automatically down to as low as 2400 baud until the error rate is less

than the chosen rate.

Tx Level -4 ~ -15 dBm You can set the level of transmission signal. Typically, Tx level should be under

-12 dBm. The level within the range of -4 dBm to -15 dBm is acceptable. Enter the

desired value using the dial keypad.

Super Fine Scan

to Memory

off/200/300 dpi

This feature allows the machine to scan documents in super fine resolution (200 X

400 dpi, 300 X 300 dpi). The other machine can receive super fine image. If the

remote machine is not capable of receiving super fine data, your machine fails to

send documents and displays 'INCOMPABLE ERROR'.

PARAMETER FUNCTION

Ring On Check

Time

Ring Off Check

Time

The machine must receive a ring signal with a specified active time from a

telephone exchange in automatic reception mode. The detection time that the

machine considers valid is adjustable via this option. If the active time of the ring

signal is less than the set value of the Ring On Check Time,the machine will not

consider it a ring signal.

The machine must receive a ring signal with a specified inactive time,as well as an

active time. If the inactive time of the ring signal is longer than the value of the

Ring Off Check Time,the machine will not consider it a valid ring signal.

Installation

3-14 LCD Display

3-14-1 During Communication

In user mode, the LCD shows the remote machine's

TTI number, TX or RX communication type,

(modem speed), and page number.

In service mode, the display shows the

communication type, abbreviations for the CCITT

Group 3 T.30 protocol as they occur, the protocol

type (G3), baud rate in kbps, and line time.

3-14-2 If a Communication Problem Occurs:

In user mode, the display shows one of the

following:

PAPER JAM, COMM.ERROR, LINE ERROR.

In service mode, the display shows all error

messages available in user mode, as plus additional

error messages available only in Service Mode.

Error messages shown in service mode only are as

follows:

PRE-MESSAGE ERROR : problem occurred during

phase B of session.

POST-MESSAGE ERROR : problem occurred during

phase D of session.

MESSAGE ERROR : problem occurred during phase

C of session.

LINE ERROR : machine cannot connect or has lost

connection with the remote machine.

Additional messages, not shown above, will appear

in the TX/RX journal printed in service mode.

Samsung Electronics 6-1

6. Disassembly and Reassembly

6-1 General Precautions on Disassembly

When you disassemble and reassemble components, you must use extreme caution. The close proximity of

cables to moving parts makes proper routing a must. If components are removed or replaced, any cables

disturbed by the procedure must be restored as close as possible to their original positions. Before removing any

component from the machine, note the cable routing that will be affected.

Whenever servicing the machine, you must perform as follows:

1. Check to verify that no documents are stored in memory. You can check it by printing the Delayed Dial List.

Press MENU, one-touch 17 'DELAYED DIAL', ENTER sequentially.

2. Remove the paper cassette, trays, and toner cartridge.

3. Unplug the power cord.

4. Use a flat and clean surface.

5. Replace with only an authorized component.

6. Do not force to open or fasten a plastic-material component.

7. Be careful no obstacles are included when you reassemble components.

8. When you assemble components, be careful small-sized components are located in place.

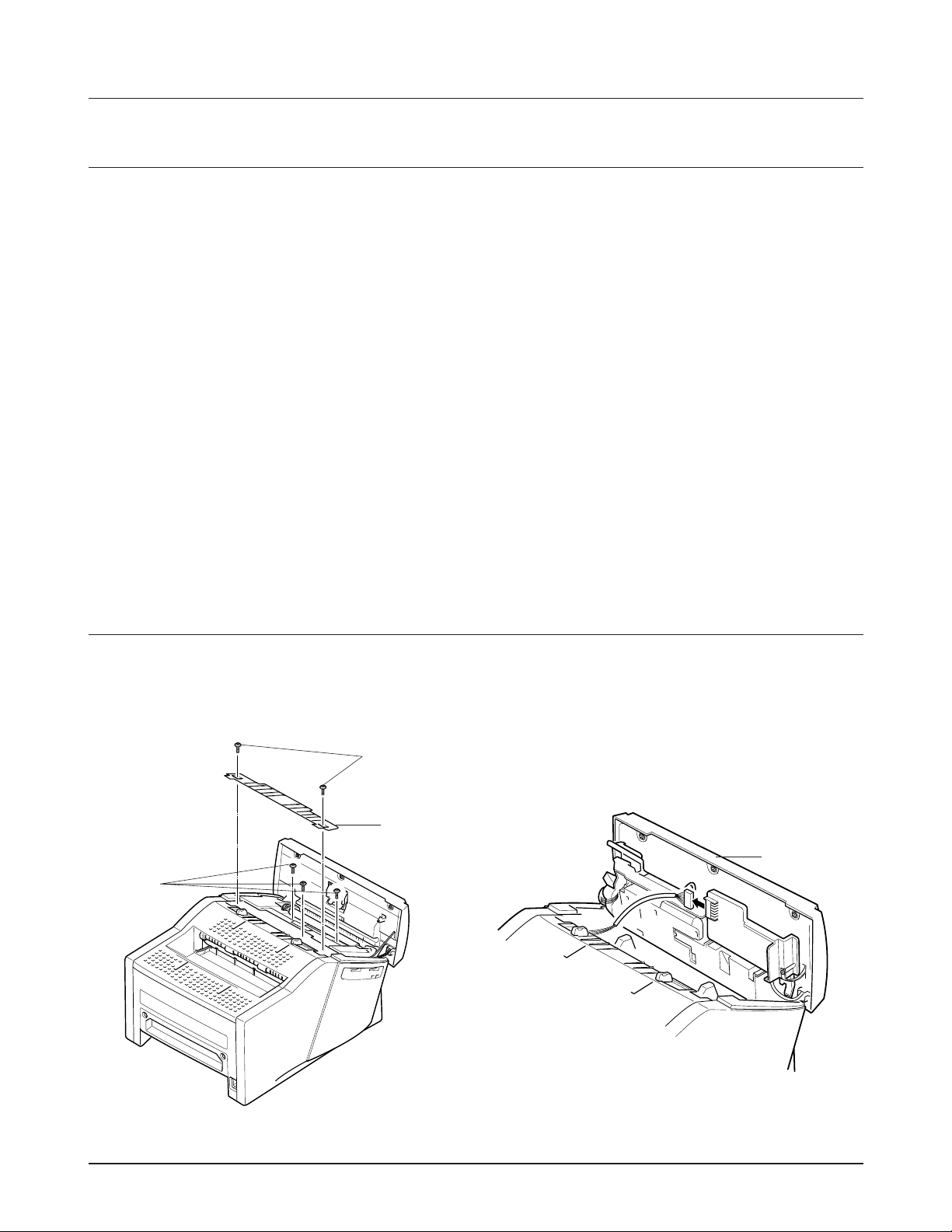

6-2 Scan Unit

1. Open the control panel by hand, remove the two

screws A. Remove the TX piece. Then remove

three screws B.

2. Close the Control panel, and take out the Scan

unit. Unplug the connector from the Scan PBA.

Figure 6.1 Figure 6.2

TX piece

Scan Unit

B

A

Loading...

Loading...