Samsung Electronics 7-1

7. Maintenance & Troubleshooting

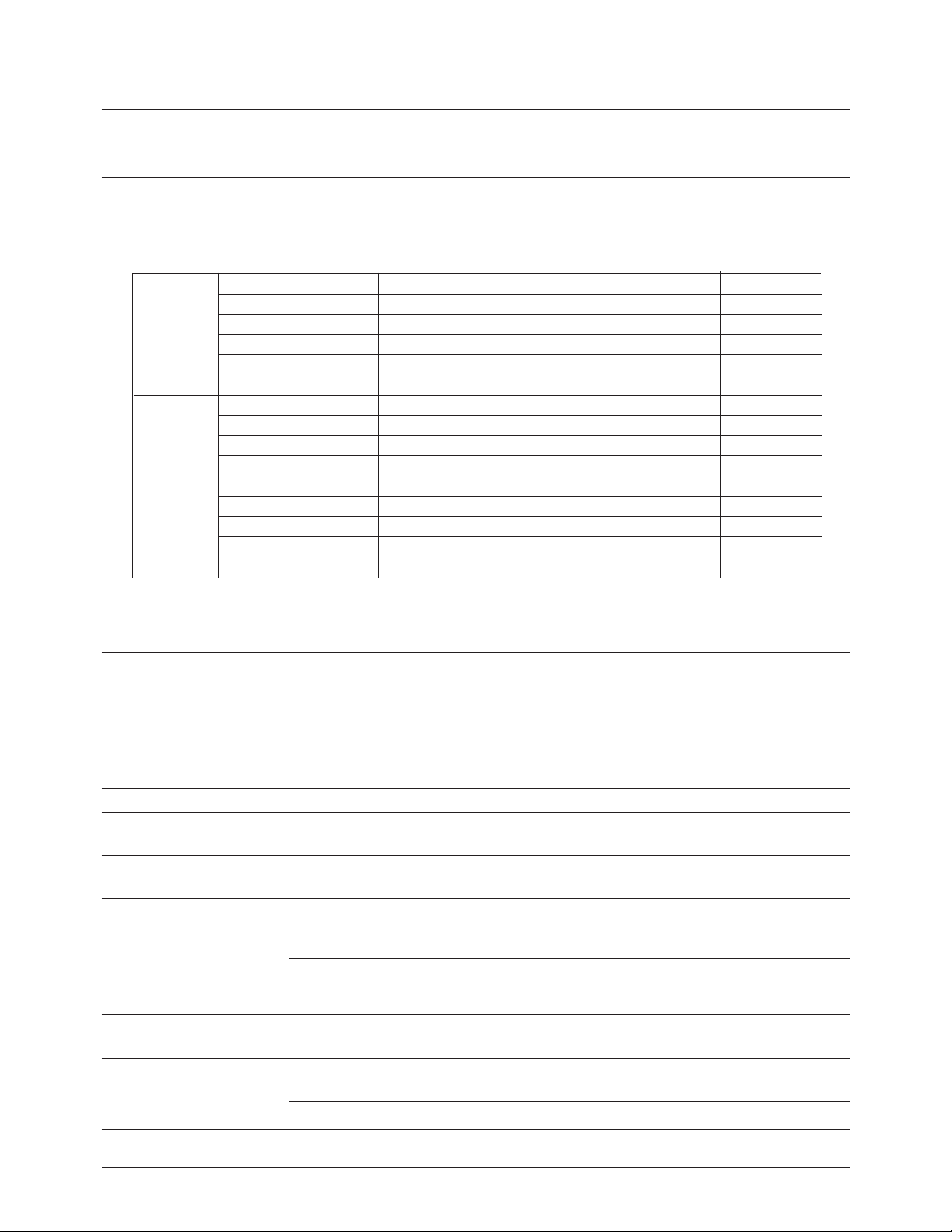

7-1 Preventative Maintenance

The cycle period outlined below is a general guideline for maintenance. The example list is for an average

usage of 50 transmitted and received documents per day. Environmental conditions and actual use will vary

these factors. The cycle period given below is for reference only.

7-2 Diagnostics

This section describes methods and procedures to isolate the cause of a malfunction in the machine. This

machine displays diagnostic information on the LCD. In addition, it can perform a series of tests that allow

the machine to observe individual machine functions.

7-2-1 Error Messages

COMPONENT

ADF Rubber

ADF Roller/Feed Roller

Roll Pinch

White Roller

CIS

Cartridge

Cleaning Felt

Pickup Roller

Feed Roller

Transfer Roller

Fuser

Driver

DRV, DEV

Frame PAD

SCANNER

PRINTER

SOLUTION

See p.6-2

See p.6-5

See p.6-7

See p.6-2

See p.6-4

See p.3-13

See p.3-15

See p.6-31

See p.6-30

See p.6-26

See p.6-20

See p.6-15

See p.6-33

CLEANING CYCLE

6 Months

6 Months

6 Months

6 Months

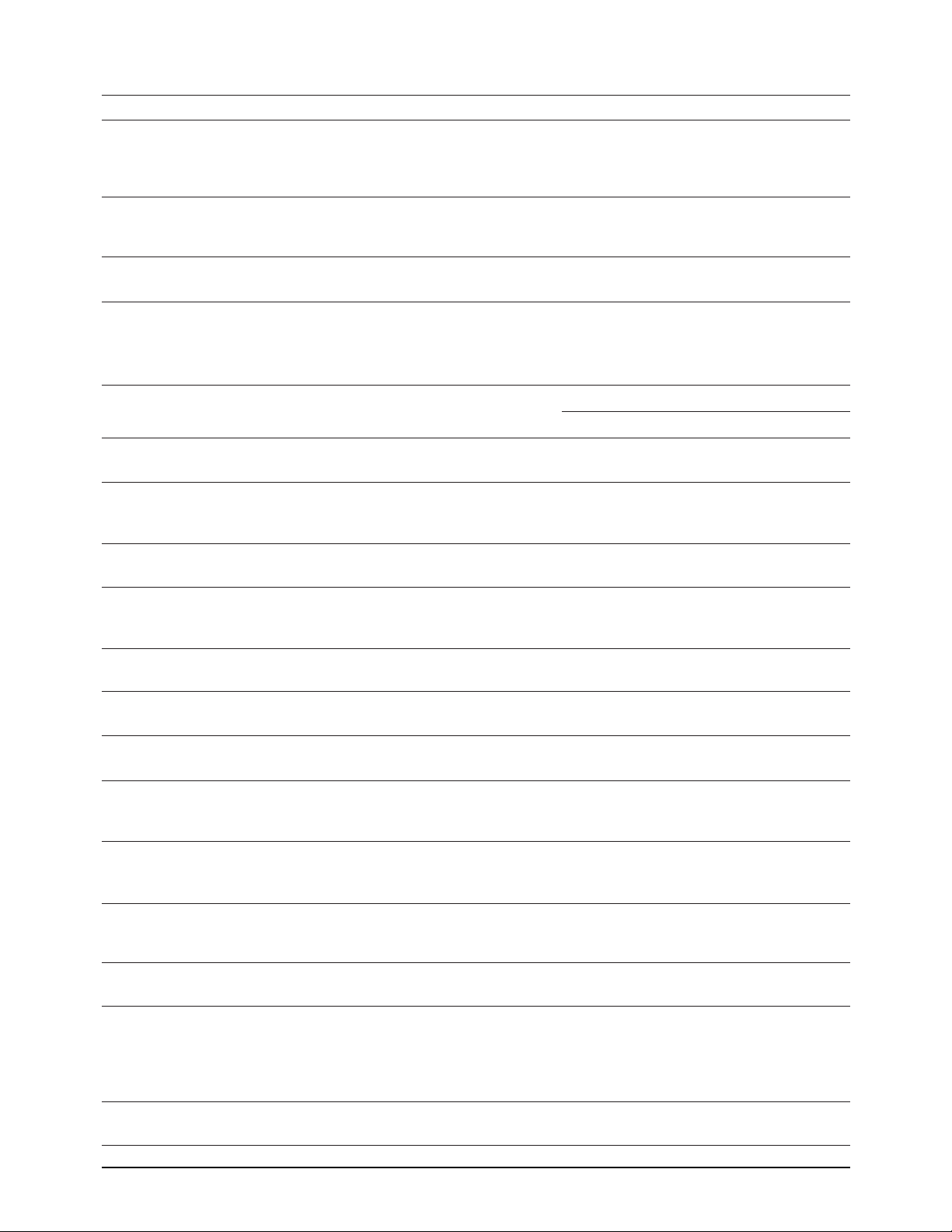

Error Message Description Solution

BUSY REDIAL? The machine is waiting the programmed You can press START to immediately redial,

interval to automatically redial. or STOP to cancel the redial operation.

COMM. ERROR A problem with the facsimile Try again.

communications has occurred.

INCOMPATIBLE Remote party did not have the requested Reconfirm your remote party's feature.

feature, such as a confidential

transmission or relay transmission.

It also occurs if the remote machine has

insufficient memory space to complete

the operation you are attempting

DOCUMENT JAM Loaded document has Jammed Clear the document Jam.

in the feeder

DOOR OPEN OR The top cover is not securely latched. Press down on the cover until you feel it

FUSER COVER OPEN latch securely.

The fuser cover is not securely latched. Replace the cover firmly until it clicks in place.

REPLACEMENT CYCLE

20,000 Pages

50,000 Pages

50,000 Pages

50,000 Pages

5,000 Pages

5,000 Pages

50,000 Pages

50,000 Pages

50,000 Pages

80,000 Pages

80,000 Pages

80,000 Pages

50,000 Pages

Maintenance & Troubleshooting

7-2 Samsung Electronics

Error Message Description Solution

GROUP NOT AVAILABLE You have tried to select a group location Try again, check location for group.

where only a single location number can

be used, such as when adding locations

for a multi-dial operation.

LINE ERROR Your unit cannot connect with the remote Try again. If failure persists, wait an hour

machine, or has lost contact because or so for the line to clear then try again.

of a problem on the phone line.

LOAD DOCUMENT You have attempted to set up a sending Load a document and try again.

operation with no document loaded.

MEMORY FULL The memory has become full. Either delete unnecessary documents, or

retransmit after more memory becomes

available, or split the transmission into

more than one operation.

NO ANSWER Try again.

Make sure the remote machine is OK.

TONER EMPTY or No toner cartridge in the fax machine. Install the toner cartridge in place

NO CARTRIDGE The machine stops. properly.

NO. NOT ASSIGNED The one-touch or speed dial location Dial the number manually with the

you tried to use has no number keypad, or assign the number.

assigned to it.

NO PAPER or The recording paper has run out. Load the recording paper in the paper

NO CASSETTE The printer system stops. cassette.

OVERHEAT The printer part has overheated. Your unit will automatically return to the standby

mode when it cools down to normal operating

temperature. If failure persists, call service.

PAPER JAM 0 Recording paper has jammed in paper Press STOP and clear the jam.

feeding area.

PAPER JAM 1 Recording paper has jammed inside Clear the jam.

the unit.

PAPER JAM 2 The jammed paper still remains inside Clear the jam.

the unit.

POLL CODE ERROR When setting up to poll another fax Enter the correct poll code.

machine, you have used an incorrect

poll code.

POLLING ERROR The remote fax machine you want to The remote operator should know in

poll is not ready to respond to your advance that you are polling and have their

poll. fax unit loaded with the original document.

POWER FAILURE A power failure has occurred. If there has been documents stored in

memory. Power failure report will be printed

automatically when the power is restored.

TONER EMPTY, RE- The toner is empty. The machine Replace with a new toner cartridge.

PLACE[CARTRIDGE] stops.

TONER LOW The toner is almost empty. After recording several sheets of letter

size recording paper, 'TONER EMPTY,

REPLACE[CARTRIDGE]' message appears

in the display, and the machine stops.

Replace with a new one.

WARM UP The machine is warming up and is off Wait until the machine is on-line.

PLEASE WAIT line.

The remote machine was not answered

after all the redial attempts.

Maintenance & Troubleshooting

Samsung Electronics 7-3

7-2-2 Test Mode

The test mode is used to test certain functions of

the machine. The available tests are:

¥ Pattern Test ¥ Memory Test

¥ Switch Test ¥ ROM Test

¥ CIS Test ¥ Make Shading

¥ Modem Test

To enter the Test Mode:

1. Get into the Tech mode by pressing MENU, #,

1, 9, 3, 4.

2. In Tech mode, press MENU, and one-touch 04

'SYSTEM SETUP'.

3. Scroll to the options by pressing ▼ or ▲

repeatedly until you find the one you want.

4. Press ENTER to initiate the test mode.

PATTERN TEST

There are 2 different pattern tests which can be run

to determine the condition of the LSU and the

printer components. When the LCD prompts you

to choose PATTERN 1, press ENTER. If you want

to choose PATTERN 2, press ▼ or STOP, and

press ENTER when the LCD displays 'PATTERN

2'. The test patterns include various black,

medium gray, and light gray scales. If the machine

is operating properly, each area appears even,

distinct, and with no inconsistencies in printing.

SWITCH TEST

This test checks the operation of the LCD display

and the LED indicators that interface the switches

on the operation panel.

CIS TEST

This test mode checks the condition of the Contact

Image Sensor. This is a true test of the white

reference level.

MODEM TEST

This test causes the machine to generate a

particular frequency to verify the operation of the

modem control circuits and the modem.

MEMORY TEST

This test is used for checking the Random Access

Memory (RAM) on the main PBA. If all memory is

working normally, the LCD shows TESTING OK!.

When this testing is carried out, any picture data

stored in memory is erased.

ROM TEST

This test mode will display and check the current

ROM level in your machine.

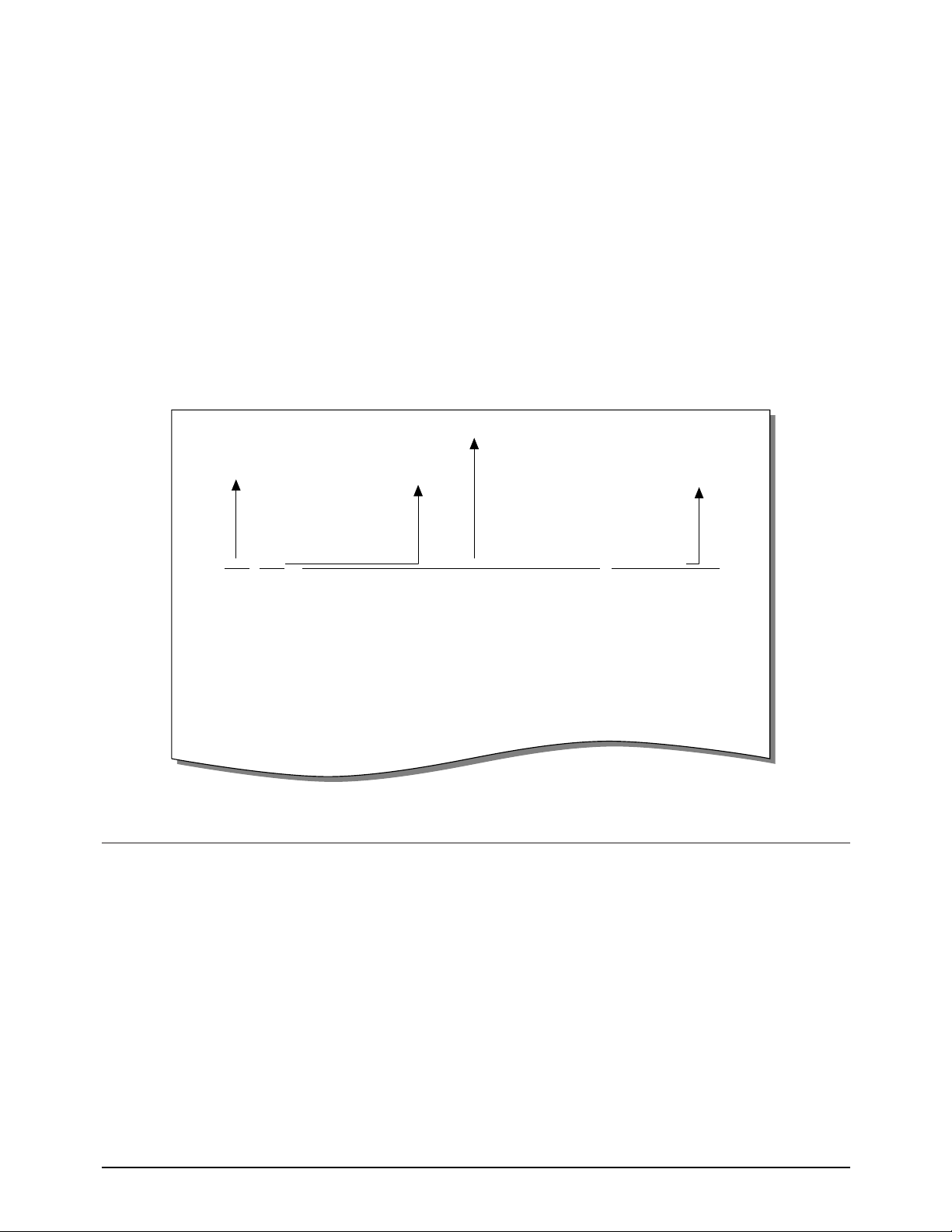

MAKE SHADING

This procedure is needed to set (make) a new

shading reference value. The reference value is

preset at factory. However, when the CIS or the

main board is replaced with new one, the

reference value must be set again.

Load the white, letter-sized paper into the feeder

and perform the test mode (MENU+ONE-TOUCH

04 'SYSTEM SETUP' in tech mode). When you

choose 'MAKE SHADING ?' option, the LCD displays

'REFERENCE [WHITE PAPER]', or 'REFERENCE

[WHITE ROLLER]'. [WHITE PAPER] message

indicates this procedure has been already

performed. The [WHITE ROLLER] message

indicates you must perform this procedure. Follow

the next steps as instructed through the LCD

window. After the shading value is newly set, the

shading value pattern is automatically printed.

Check for the waveform in the pattern. It is best

when the wave form is level. If there are many

points sharply broken, perform the Make shading

procedure several times until you get a level

waveform.

SF6500 /OK

CHECK SUM=C0, V01

Maintenance & Troubleshooting

7-4 Samsung Electronics

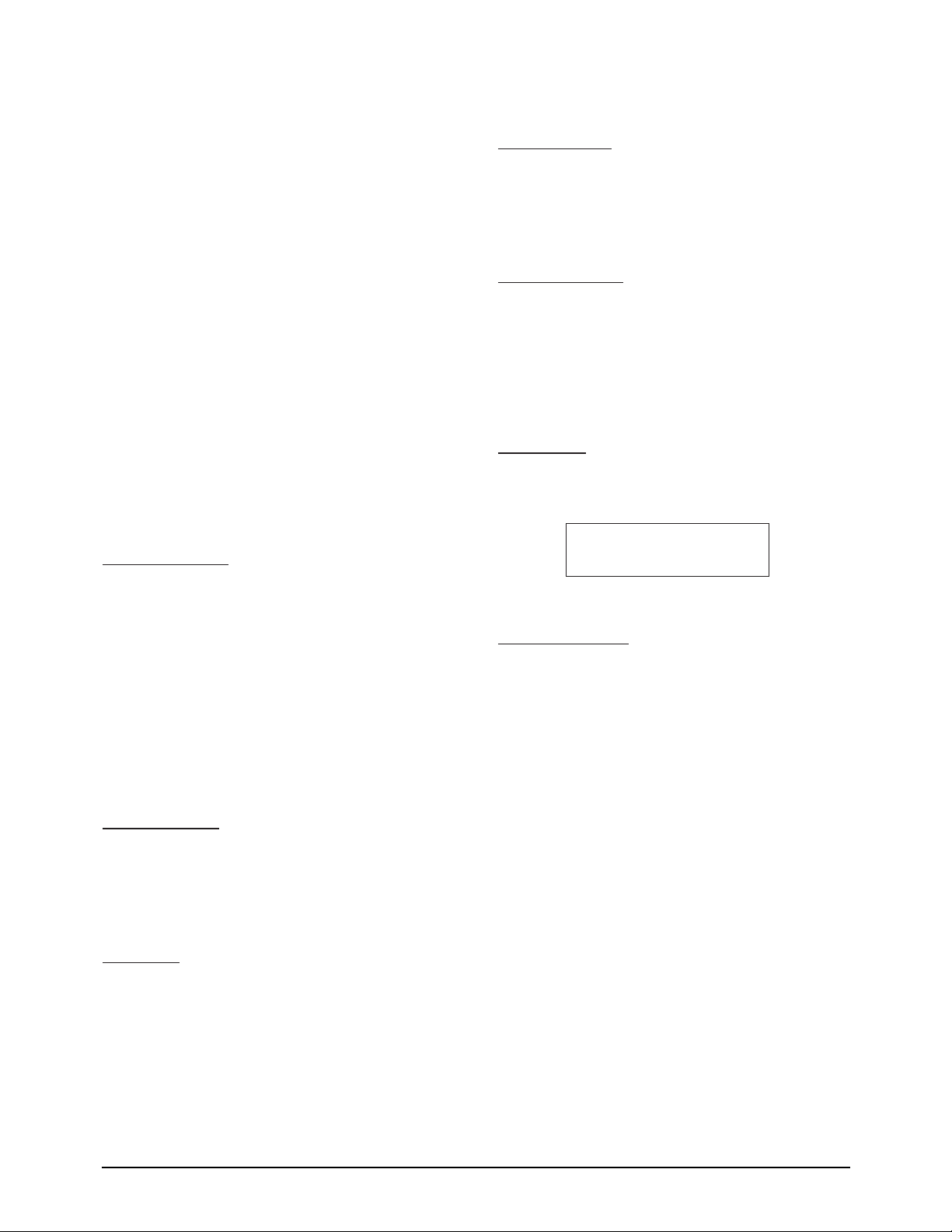

7-2-3 Maintenance List

A number of reports can be printed from the fax

machine within the test mode. The protocol list

and memory dump list all contain detailed

information which may be required when

contacting technical support.

To printout the protocol and memory dump lists:

1. Get into the Tech mode by pressing MENU, #,

1, 9, 3, 4.

2. In Tech mode, press MENU, and one-touch 16

'TX. CONFIRM'.

3. Press ▼ or ▲ repeatedly until you find the

Protocol Dump List. When you find

'PROTOCOL REPORT?', press ENTER.

Remote Diagnostics on the dex 825 is preformed

by a remote PC. The dex 825 has to be conditioned

o that remote PC can perform remote diagnostics.

1. Press MENU, One-touch 04 'SYSTEM SETUP'.

2. Press ▲ or ▼ until 'REMOTE DIAGNOSIS

PROTECTION ?' is displayed.

3. Press ENTER.

4. Press 1 for protection or press 2 to allow remote

diagnosis.

5. Press ENTER.

6. Press STOP to exit routine.

S NSF 61005020003380140200001302090018010000

S/R FCF FIF DATA ASCII

S CSI 2020202020202020202020202O20202020202020

S CSI 202020202020202020202022O202020220202020

R TSI 2020202020202020202020202O20202020202020

S DIS 00000000 01110111 00010111 00100010

S DIS 00000000 01110111 00010111 00100010

R DCS 00000000 01100001 00010101 00000000

R TSI 2020202020202020202020202O20202020202020

R DCS 00000000 01100001 00010101 00000000

S CFR

R MPS

S MCF

S DCN

S FTT

S NSF 61005020003380140200001302090018010000

PROTOCOL DUMP LIST AUG-20-94 06:35

Sending/Receiving

Name of signal

(Facsimile Control Field)

Facsimile Information Field

data described in hexdecmal code

FIF data described

in ASCII code

SAMPLE OF A PROTOCOL DUMP LIST

7-3 Remote Diagnostics and Control

Maintenance & Troubleshooting

7-5Samsung Electronics

Y

Y

YY

YYY

YY

YY

Y

N

N

NN

NNN

NN

N

N

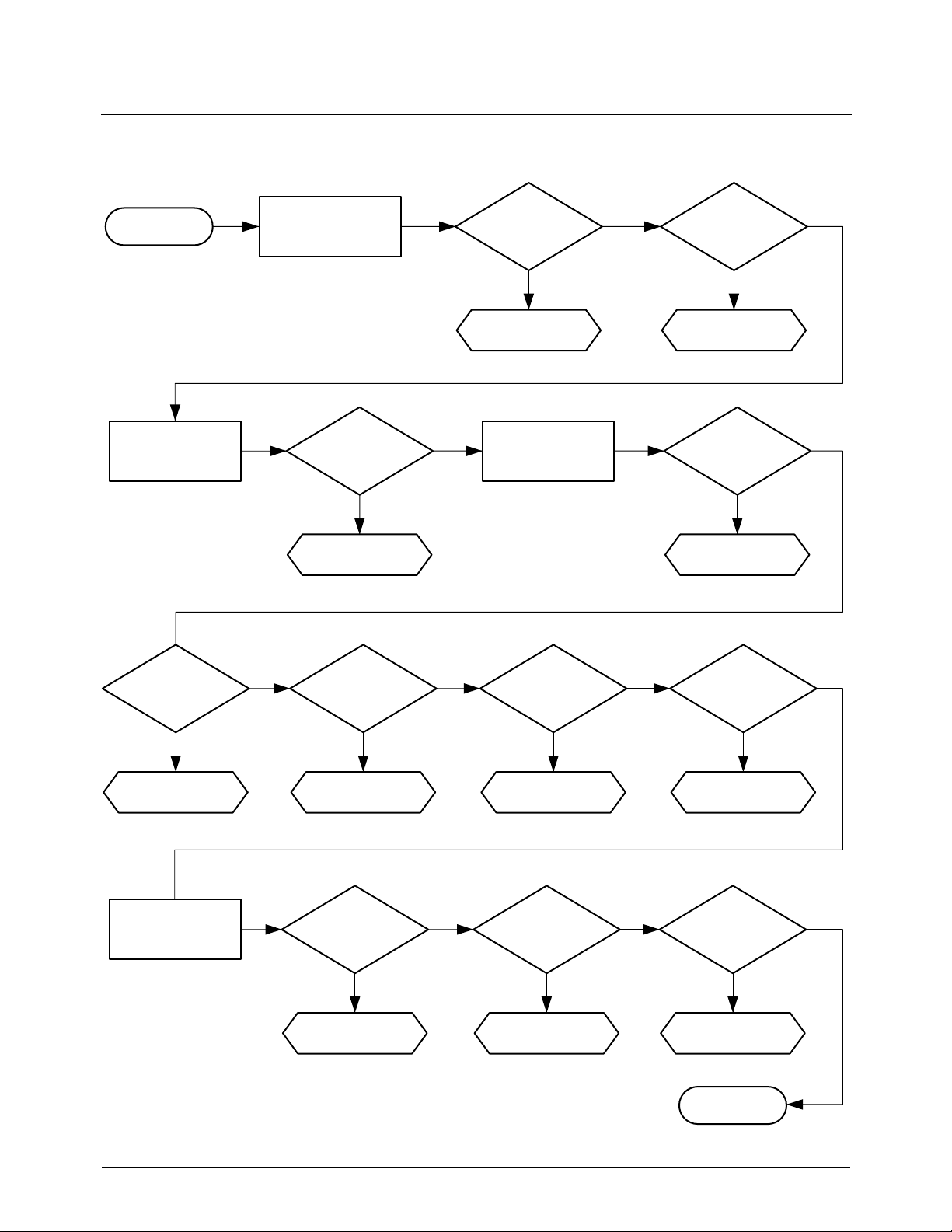

START

See chart 7-4-2

See chart 7-4-4

See chart 7-4-6

See chart 7-4-7

See chart 7-4-10 See chart 7-4-11

See chart 7-4-12

END

See chart 7-4-8 See chart 7-4-9

See chart 7-4-5

See chart 7-4-3

Plug the power cord

Load document

Copy OK?

Lift the handset

Do you hear

dial tone?

PC printing OK?

Sending OK?

Auto answer?

Manual operation?

RX OK?

Press COPY

button

CIS on?

Document fed?

LCD display

is on?

System

initialized?

7-4 Troubleshooting Flow chart

7-4-1 Overall

Maintenance & Troubleshooting

Samsung Electronics7-6

Y

N

Y

N

Y

YY Y

N

N

N

Y

Y

N

N

Y

Y

N

N

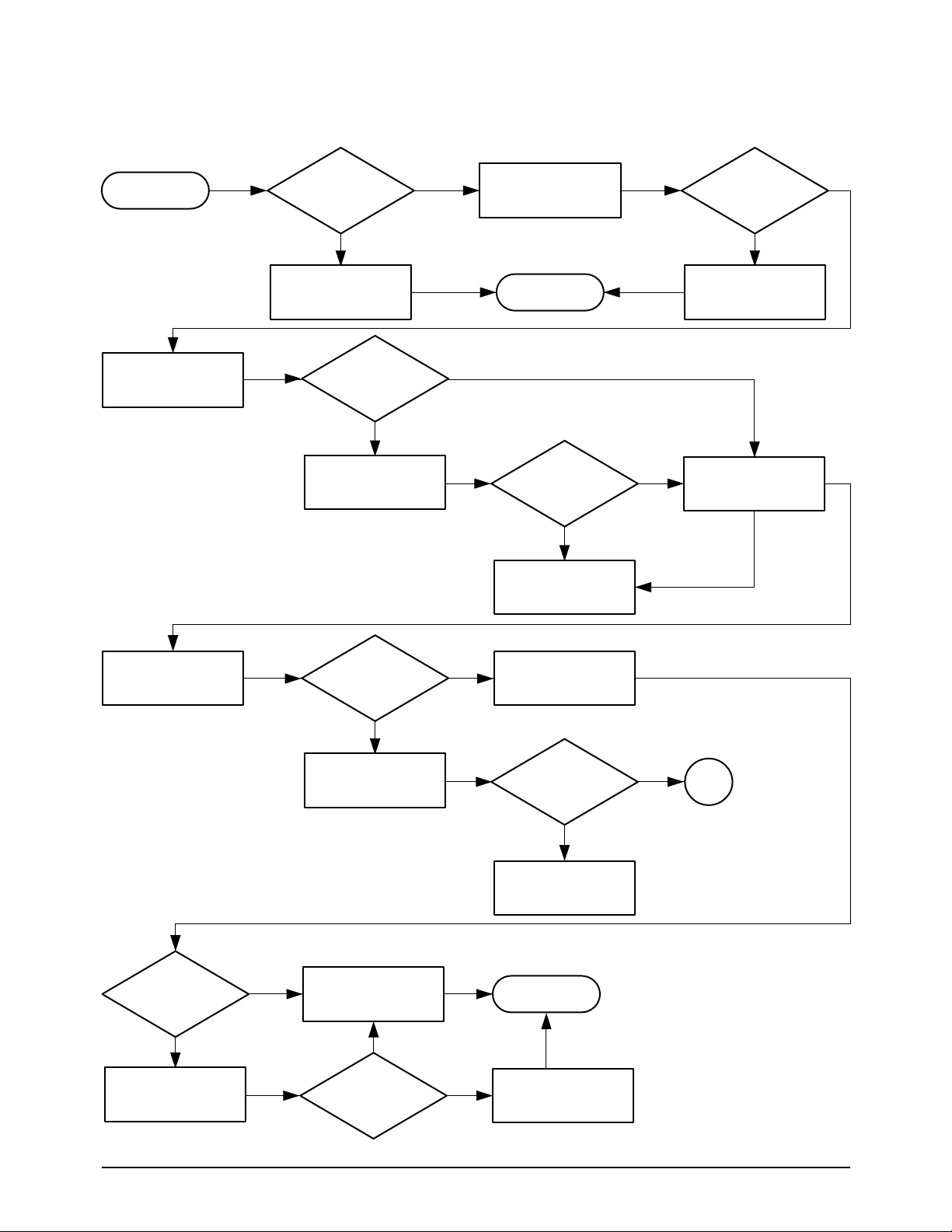

7-4-2 Malfunction of LCD Display

START

END

Power cord

connected?

Fuse OK ?

+5 V ?

+5 V ?

OK ?

Normal?

A

END

Fuse remain

good ?

Check AC voltage 220 VAC?

Notify customer

Connect as

required

1. Unplug machine

2. Check fuse

1. Replace fuse

2. Plug in machine

Check power

supply voltage

Measure voltage on

the scan b'd (CN7-1)

Measure on the

OPE b'd (CN1-1)

Replace harness

Check harness

Replace OPE b'd

and LCD module

Check harness

Replace harness

Replace power

supply

7-7Samsung Electronics

Maintenance & Troubleshooting

Y

N

Y

Y

N

N

N

Y

+5 V ?

A

Unplug CN6 in

the scan board

Replace OPE b'd

and LCD module

Replace the main b'd

Replace the main b'd

Check CPU-RSTO

(pin 67 of U18) in

the main board

Check system clock

(pin 50 of U18) in

the main board

Start

END

Logic 'H' ?

Replace the OPE

board

Check Vcc (+5 V)

from P1-16 to P1-18

Vcc ≥ 4.5V ?

19.6608 MHz ?

Replace power

supply

Replace the main

board

7-4-3 System Not Initialized

Maintenance & Troubleshooting

Samsung Electronics7-8

Y

Y

Y

Y

Y

Y

Y

Y

N

N

N

N

N

N

N

N

Start

END

'DOCUMENT

READY' displayed ?

Key in ?

Document fed ?

Normal?

Logic 'H'?

Document fed?

+24 V?

Check the OPE

MICOM

Check LCD display

when document

is loading

Replace the

OPE board

Replace mother

b'd

Check

motor pulse (P1-9,

10, 11, 12) in the

main board

5V

0V

Check +24V motor

enable

(P2-27) in

the main board

Replace the

main b'd

Replace the

motor ass'y

Replace the

scan b'd

Check +24V from

P19, 20 of CN7 in

the scan b'd

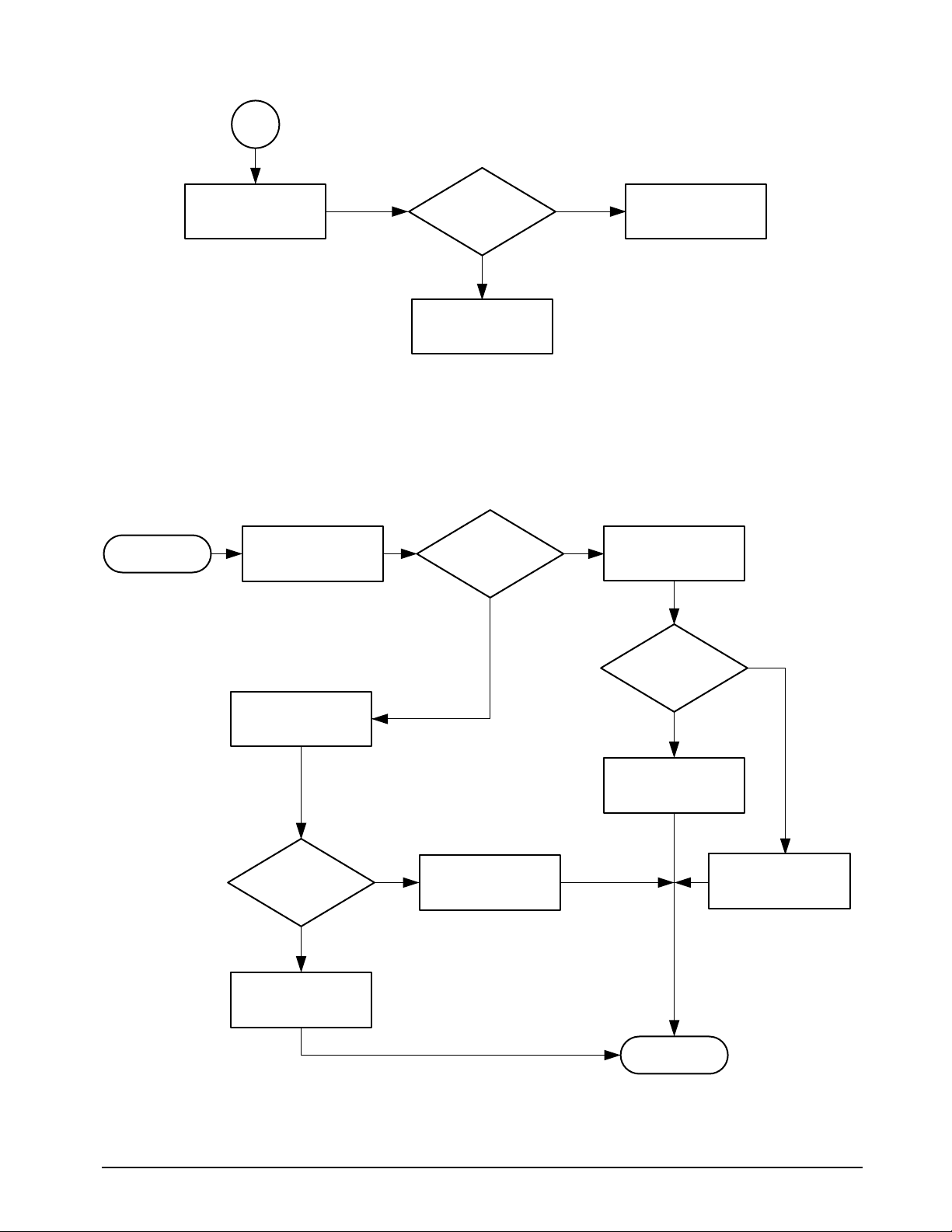

7-4-4 Malfunction on Document Feeding

7-9Samsung Electronics

Maintenance & Troubleshooting

Y

N

N

N

N

Y

Y

Y

7-4-5 CIS LED Not Lit

START

See chart 7-4-4

Load document in

feeder

Works properly?

Normal?

+5 V ?

CIS LED lights

Check +5V, +12V

(P1-16, 17, 18, P1-1

in the main b'd)

Replace the power

supply

Replace CIS

Replace the main b'd

Check PIN27 of

U25

END

Press the COPY

button

Document fed?

Maintenance & Troubleshooting

Samsung Electronics7-10

Y

Y

N

N

N

N

N

N

Y

Y

Y

Y

Y

N

7-4-6 Malfunction on Copy

START

See chart7-4-4

See chart 7-4-5

1

1

Load document in

feeder

Replace CIS

Replace the main b'd

Replace the

scan b'd

Check harness

Replace the

power supply

Replace the

harness

Measure

LED +12V on

scan b'd (CN 3-9)

+12 V?

Good?

Copy produced?

Press the COPY

button

Document fed?

CIS LED on?

Copy works

properly?

Normal?

Check

CIS clock (P2-16)

in the main board

5V

0V

7-11Samsung Electronics

Maintenance & Troubleshooting

Y

Y

Y

Y

N

N

N

N

1

Run the printer test

Run the CIS test

Replace the CIS

Replace the main b'd

END

Good copy quality?

Normal?

Good copy quality?

Good printer

quality?

Maintenance & Troubleshooting

Samsung Electronics7-12

Y

Y

Y

N

N

N

7-4-7 Malfunction in Auto Answer

START

END

Call the machine

from another phone

Check ring signal

on P4-8 in main b'd

Check ring signal on

U1-25, 28 in LIU b'd

Replace the LIU b'd

Replace the main b'd

Auto answer?

Normal?

5V

?

0V

7-13Samsung Electronics

Maintenance & Troubleshooting

Y

Y

N

N

N

Y

7-4-8 Malfunction in Manual Receiving

START

END

Press OHD and

press START

Check signal in

P4-12 in main b'd

Replace the main b'd

Replace the LIU b'd

Replace the flat

cable

Check control

signal(P1-13, 14) in

the LIU b'd

Goes on line?

Logic 'L'?

Logic 'L'?

Maintenance & Troubleshooting

Samsung Electronics7-14

Y

Y

Y

Y

N

N

N

N

7-4-9 Malfunction in Automatic Receiving

START

See chart 7-4-7

END

END

Call the machine

from another phone

Check the

telephone line

Check Tx/Rx signal

in P1-4, P1-7 in the

LIU b'd

Replace the main b'd

Auto answer?

Normal?

Normal?

Notify to customer

Replace the LIU b'd

Receive data?

7-15Samsung Electronics

Maintenance & Troubleshooting

Y

Y

Y

N

N

N

7-4-10 Malfunction in Transmission

START

See chart 7-4-4

END

Load document in

feeder

Call the receiving

machine

Press the START

button

Replace the LIU b'd

Replace the main b'd

Document fed?

The document

sends out?

Sending works

properly?

Maintenance & Troubleshooting

Samsung Electronics7-16

Y

Y

N

N

Y

N

N

N

Y

Y

Y

N

7-4-11 Malfunction in PC Printing

START

END

Print text file in windows version editor

Run MFP825 control program

Run 'Print test page'

Setup MFP825 Printer driver.

Check application S/W.

Replace centronics cable.

Install MFP board correctly.

Replace MFP board.

Replace Main b'd

Check bi-directional centronics cable

Make sure the MFP board is

installed properly.

Printer self test

Works properly?

Works properly?

Works properly?

OK?

OK?

OK?

7-17Samsung Electronics

Maintenance & Troubleshooting

Does the toner

adhere to magnetic roller

of developer unit ?

Are the sealing

tapes on the toner cartridge

removed ?

N

N

Y

Y

N

Remove the

sealing tapes.

N

Y

N

Y

Y

A

B

START

Is there any

image printed ?

Does the cartridge

work normally ?

Does the trouble

occur even with another

cartridge ?

Check the HVPS and replace

the HVPS necessary

Replace the cartridge.

7-4-12 No Paper of the Image (All white printed)

Maintenance & Troubleshooting

Samsung Electronics7-18

N

Y

N

Y

N

Y

A

B

Is the transfer roller O.K ?

Does the trouble occur even with

another LSU unit ?

Does the trouble occur even

with another toner cartridge ?

Check the developer driver unit and

then replace it if necessary. See page 6-27.

Replace the toner cartridge.

Check the LSU unit and

then replace it if necessary.

Replace the transfer roller.

Replace the HVPS or connect the

harness properly.

Nomal voltage in HVPS ?

Its wiring harness O.K ?

Maintenance & Troubleshooting

7-19Samsung Electronics

N

N

Y

Y

N

Y

N

Y

START

Does the trouble occur even with

another cartridge ?

Nomal voltage in HVPS ?

Its wiring harness O.K ?

Is the development bias connector

of cartridge O.K ?

Check LSU unit and then

replace it if necessary.

Replace the HVPS or connect

the wiring harness properly.

Replace the HVPS or connect

the wiring harness properly.

Replace the transfer unit. See page 6-26.

Replace the cartridge. See page 3-14.

Is the transfer unit O.K ?

7-4-13 Pale/Weak Image Quality

7-4-14 High Background Density (Toner in the background areas)

N

START

Does the trouble occur even with

another cartridge ?

Check HVPS and replace it if necessary.

Replace the cartridge.

Maintenance & Troubleshooting

Samsung Electronics7-20

7-4-15 Uneven Density

N

Y

N

Y

START

Is the transfer unit O.K ?

Check the LSU unit and then

replace it if necessary.

Check the transfer roller or replace

the transfer unit.

Replace the cartridge.

Does the trouble occur even with

another cartridge ?

7-4-16 All Black Printed

N

N

Y

Y

N

Y

START

Is the drum installed properly ?

Is charge wring harness in HVPS O.K ?

Check the LSU unit and then replace

it if necessary.

Connect the harness properly or

replace it.

N

Y

Does the trouble occur even with

anther HVPS ?

Replace the HVPS.

Replace the cartridge.

Replace drum properly.

Does the trouble occur even with

another cartridge ?

Maintenance & Troubleshooting

7-21Samsung Electronics

7-4-17 Black Vertical Line

N

Y

N

Y

Occured during

receiving.

Check the LSU unit and then replace

it if necessary.

Replace the cartridge.

Trouble on the remote fax machine.

Does the trouble occur even

with another cartridge ?

N

Y

Replace the fuser unit.

Is the heat roller of the

fuser unit damaged ?

Pattern test O.K ?

N

Y

N

Y

Occured during

copying.

Check the LSU unit and then replace

it if necessary.

Replace the cartridge.

Check CIS or white roller and

then replace it if necessary.

Does the trouble occur even

with another cartridge ?

N

Y

Replace the fuser unit.

Is the heat roller of the

fuser unit damaged ?

Pattern test O.K ?

Maintenance & Troubleshooting

Samsung Electronics7-22

7-4-19 White Vertical Line

N

Y

START

Is there enough toner in the

developer unit ?

Check the LSU unit and then replace

it if necessary.

Y

N

Is the heat roller of the fuser unit

damaged ?

Replace fuser unit.

Replace the cartridge.

7-4-18 Black Horizontal Line

N

N

Y

Y

N

Y

START

Is the heat roller of the fuser unit

damaged ?

Check the LSU unit and then replace

it if necessary.

Replace the fuser unit.

Replace the fuser felt.

Replace the cartridge.

Does the trouble occur even with

another fuser felt ?

Does the trouble occur even with

another cartridge ?

Maintenance & Troubleshooting

7-23Samsung Electronics

7-4-20 All Black Printed

N

Y

N

Y

Occured during

receiving.

Check the LSU unit and then replace

it if necessary.

Replace the cartridge.

Trouble on the remote fax machine.

Does the trouble occur even

with another cartridge ?

Y

N

Replace the HVPS or connect

the harness properly.

Nomal voltage in HVPS ?

Its wiring harness O.K ?

Pattern test O.K ?

N

Y

N

Y

Occured during

copying.

Check the LSU unit and then replace

it if necessary.

Check CIS and then replace

it if necessary.

Does the trouble occur even

with another cartridge ?

Y

N

Pattern test O.K ?

Nomal voltage in HVPS ?

Its wiring harness O.K ?

Replace the cartridge.

Replace the HVPS or connect

the harness properly.

Maintenance & Troubleshooting

Samsung Electronics7-24

7-4-21 Avoid the Image

Y

N

START

Nomal voltage in HVPS ?

Its wiring harness O.K ?

Check the transfer roller and

then replace it if necessary.

Replace the HVPS or

connect the harness properly.

Maintenance & Troubleshooting

7-25Samsung Electronics

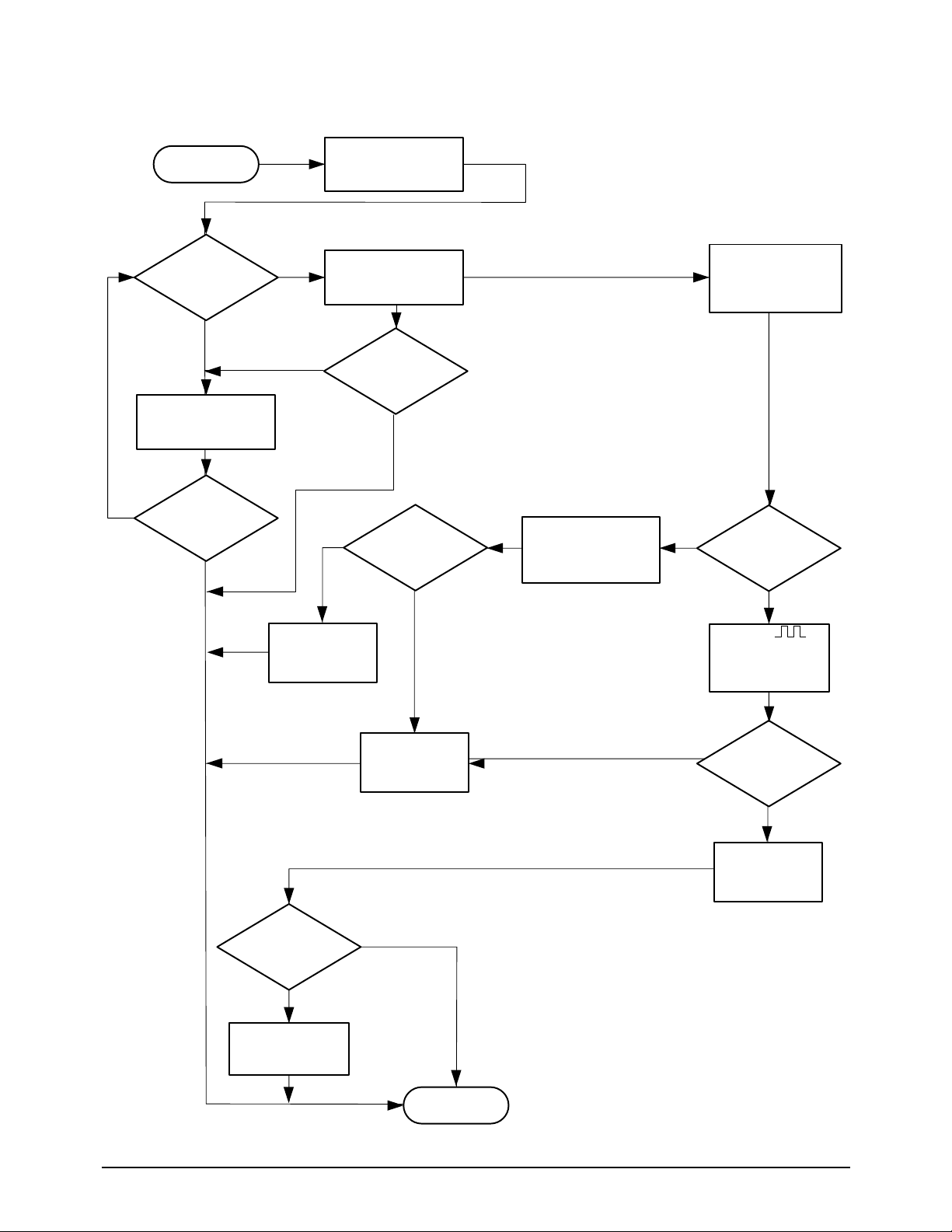

Y

Y

N

N

N

N

N

Y

Y

Y

START

Motor

driving ?

+5V ?

Logic 'L' ?

Check

motor pulse (CN2-1.2.3.4)

in the 2'nd cassette b'd

Normal ?

Replace 2'nd

cassette b'd

Replace motor ass'y

END

Replace main b'd

0V ?

Check SCFCLUTCH on the 2'nd

cassette b'd (CN2-6)

Measure voltage on

the 2'nd cassette b'd

(CN1-1)

Replace 2'nd

cassette b'd

Check harness and

replace harness

Check SCF-START

on the 2'nd cassette

b'd (CN1-3)

Replace solenoid

24V

0V

7-4-22 Second Paper Cassette (Option)

MALFUNCTION ON PAPER FEEDING

Loading...

Loading...