samsung SF600 Service Manual

2. Specification

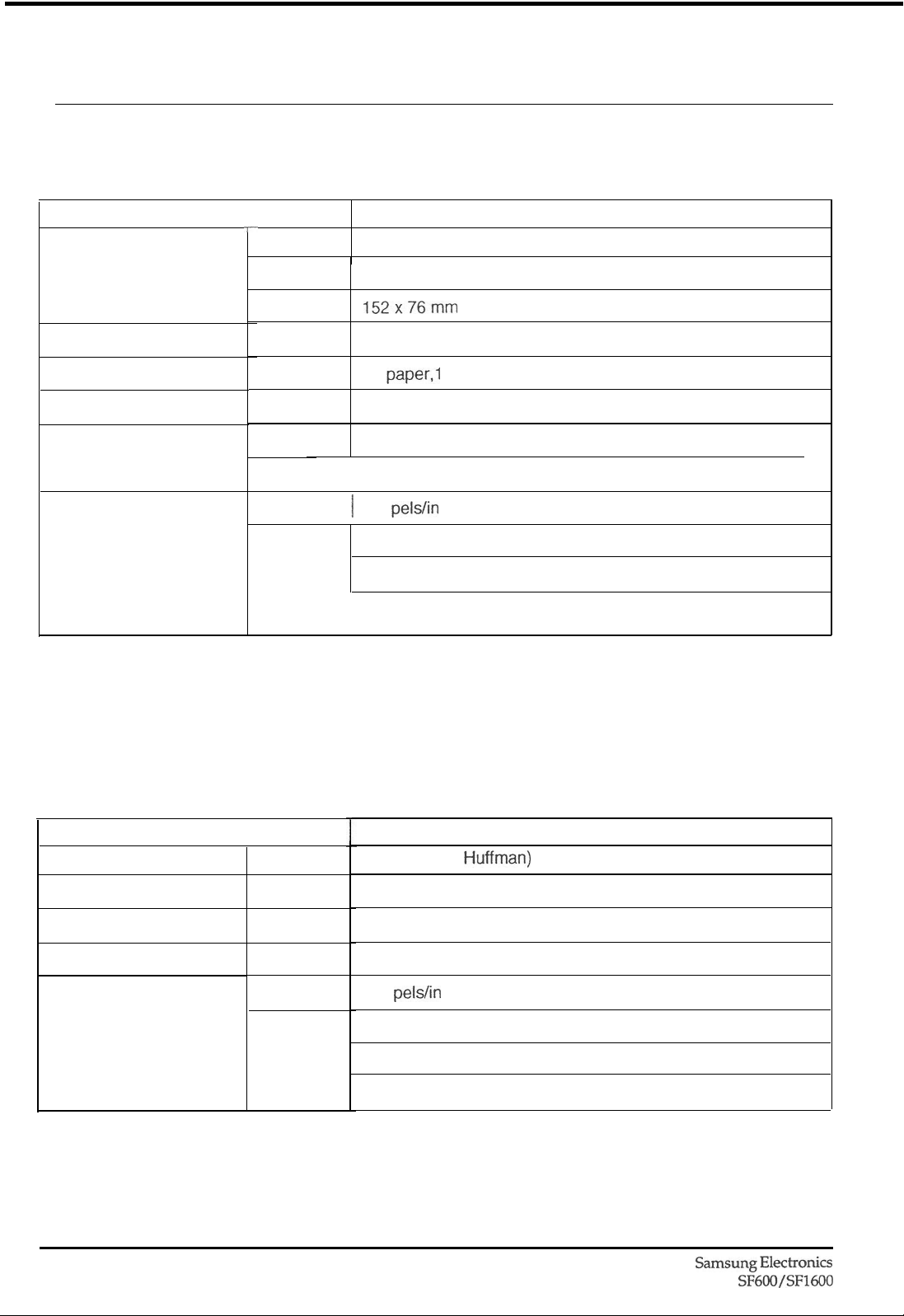

2-l Transmitter

Parameter

Document Size

Document Thickness

Scan Line Length

Effective Scanning Width

Scanning Method

Resolution

l--

Normal

Max. 216 x 1500 mm

Min.

Horizontal

Vertical

Horizontal 1 203

Vertical

Specification

210 x297 mm

l52x76mm

0.085 x 0.115 mm

A4

paper,1

210 mm

Flat-bed scanning using CIS

Intermittent scanning by stepping motor

Super Fine 98 lines/in (3.85 lines/mm)

Fine

Standard

728 scan elements along 216 line length

pels/in

(8 dots/mm)

196 lines/in (7.7 lines/mm)

392 lines/in (15.4 lines/mm)

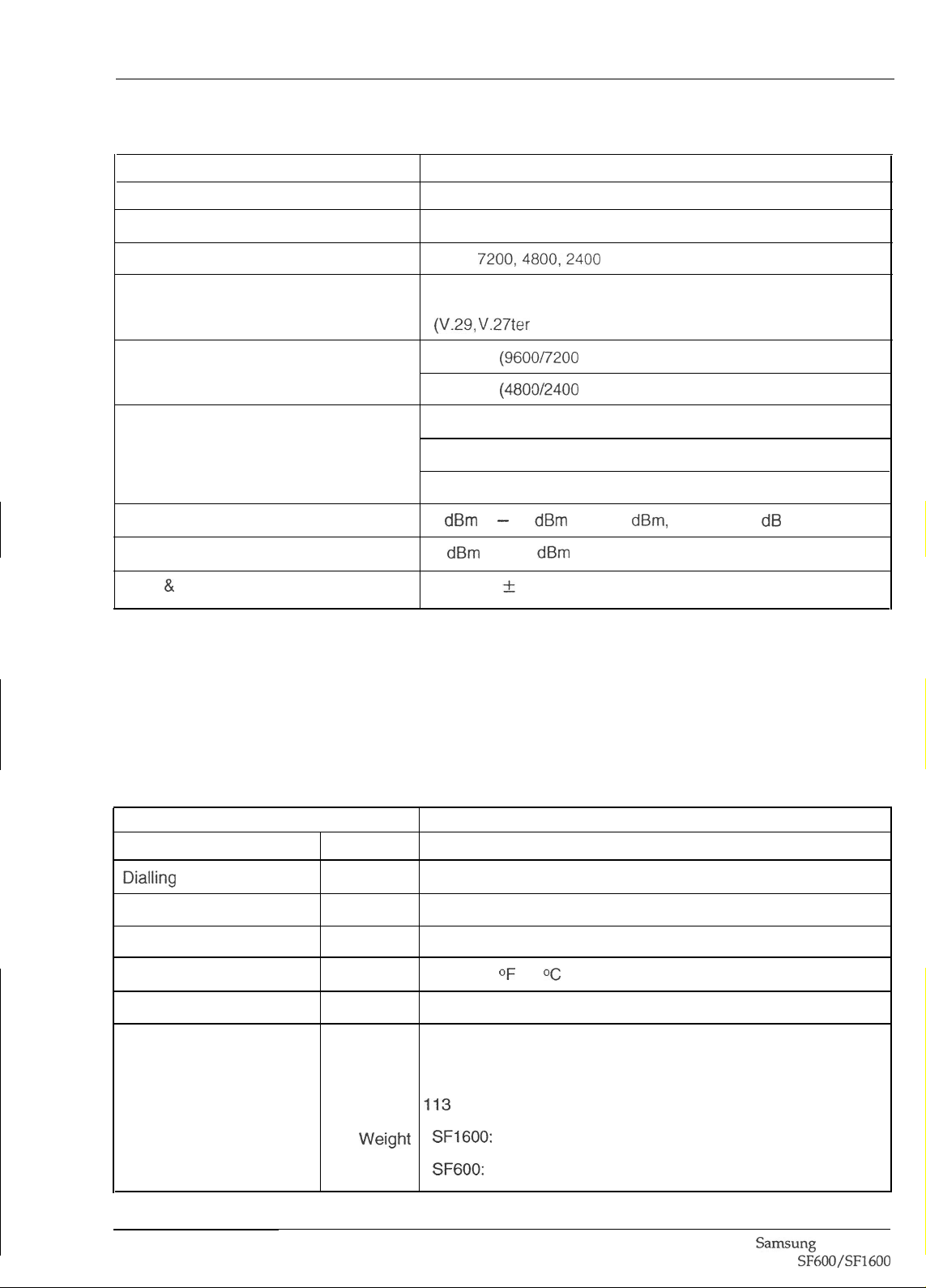

2-2 Receiver

r

Coding Scheme

Recording Paper Size

Effective Recording Width

Recording Method

Resolution

Parameter

Horizontal

Vertical

Specification

MH (Modified

216 mm x 30 m, core 12.7 mm diametre

216 mm

Thermal recording with solid state Thermal Printing Head

203

pels/in

Super Fine 98 lines/in (3.85 lines/mm)

Fine

Standard

Huffman)

(8 dots/mm)

196 lines/in (7.7 lines/mm)

392 lines/in (15.4 lines/mm)

2-1

Samsung

SF6OO/SFXOO

Ekctronics

Specifications

2-3 Line Control Block

Parameter

Communication Facility

Line Coupling

Transmission Speed

Modem

Carrier Frequency

Control Signal

Output Level

Input Sensitivity

Input & Output Impedance

Specification

Public Switched Telephone Network (PSTN)

Direct coupling

9600, 7200,4800,2400 bps

QAM, DPSK and FSK

(V-29, V.27ter

1700 Hz

1800 Hz

1100 Hz (CNG)

2100 Hz (CED)

300 bps (FSK)

0

dBm

to - 15 dBm +O.O/-3

0

dBm

to -43

600 ohm +- 30%

with fall back function and V.21)

(9600/7200

(4803/2400

dBm

bps)

bps)

dBm,

adjustable 1 dB steps

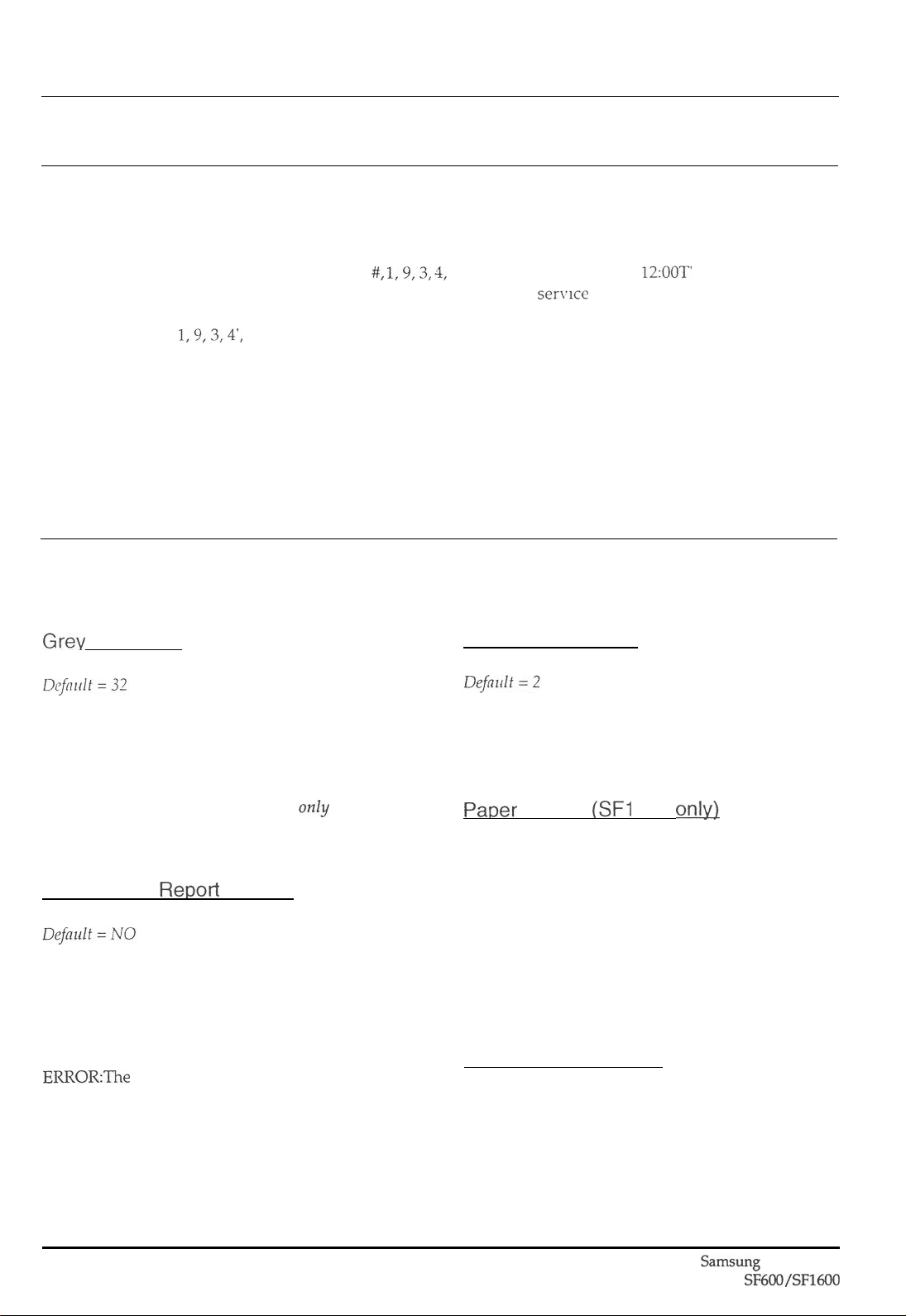

2-4 Others

Parameter

Dialling Signal

Diailing

Memory Capacity

Power Requirement

Temperature

Relative Humidity

Dimension

Method

Specification

DP/DTMF

Direct dialing, Memory dialing, Redialing

10 memory dial (power on)

230-240 VAC, 50-60 Hz

50 to 95

20 to 80 % RH (Non-Condensing)

Width 340 mm

Depth 235 mm

Height

Weight

113

mm

SF1600:

SF600:

7.96 lb (3.61 kg)

OF

(10

OC

to 35 “C)

8.69 lb (3.94 kg)

2-2

Samsung Electronics

SF6OO/SF1600

3. Operating Instructions

3-l Service Mode

In service mode (tech) mode, the technician can check the machine and perform various test to isolate the

cause of a malfunction.

To enter service mode, press MENU/POLL, #,

at the right end of the LCD to confirm that the machine has entered

mode, the machine still performs all normal operations. To return to normal user mode, press

‘MENU/POLL, #,

Options changed while in service mode do not remain changed, unless you first clear machine memory.

To communicate using via direct connection with another unit, press OHD/V.REQ followed by

START/COPY.

1,9,3,4’,

in sequence again, or turn the power switch off, then on again.

1,9,3, -1-,

in sequence, and ‘0101 95

service

(tech) mode. While in service

12:OOT’

will be displayed

3-2 Changing Options

3-2-l Selectable Options

Grey

scale level

Choose either 16 or 32 grey scale levels. The

selected level is also used in the photo sending

mode. If you select 32 levels, transmission time is

longer, however the result at the receiving end

will be superior. This mode works

remote machine is capable of super-fine mode.

oylZy

when the

Rinq Before Answer

Select the number of rings (1 to 7) the machine

allows before it answers a call in automatic

receiving mode.

PaDer

Default = YES

Cuttinq

(SF1

600 onlv)

Confirmation

Select whether a confirmation report prints each

time a user sends a fax.

YES: The machine prints out the report

automatically after each fax sent.

ERRORThe machine prints a report only when

there is an error.

NO: The machine does not print the report

automatically. User can print the list on demand.

3-1

ReD0t-t

Printout

Choose cutting or non-cutting mode.

YES: The paper will be cut automatically after

each document received or copied.

NO: The machine prints a tear line and does not

cut the paper.

Remote Receive Code

Default = 9

This code can be used only with a phone extension

connected to the FAX machine. The user can

initiate FAX receive mode by entering a remote

Samsung

Electronics

SF6OO/SF1600

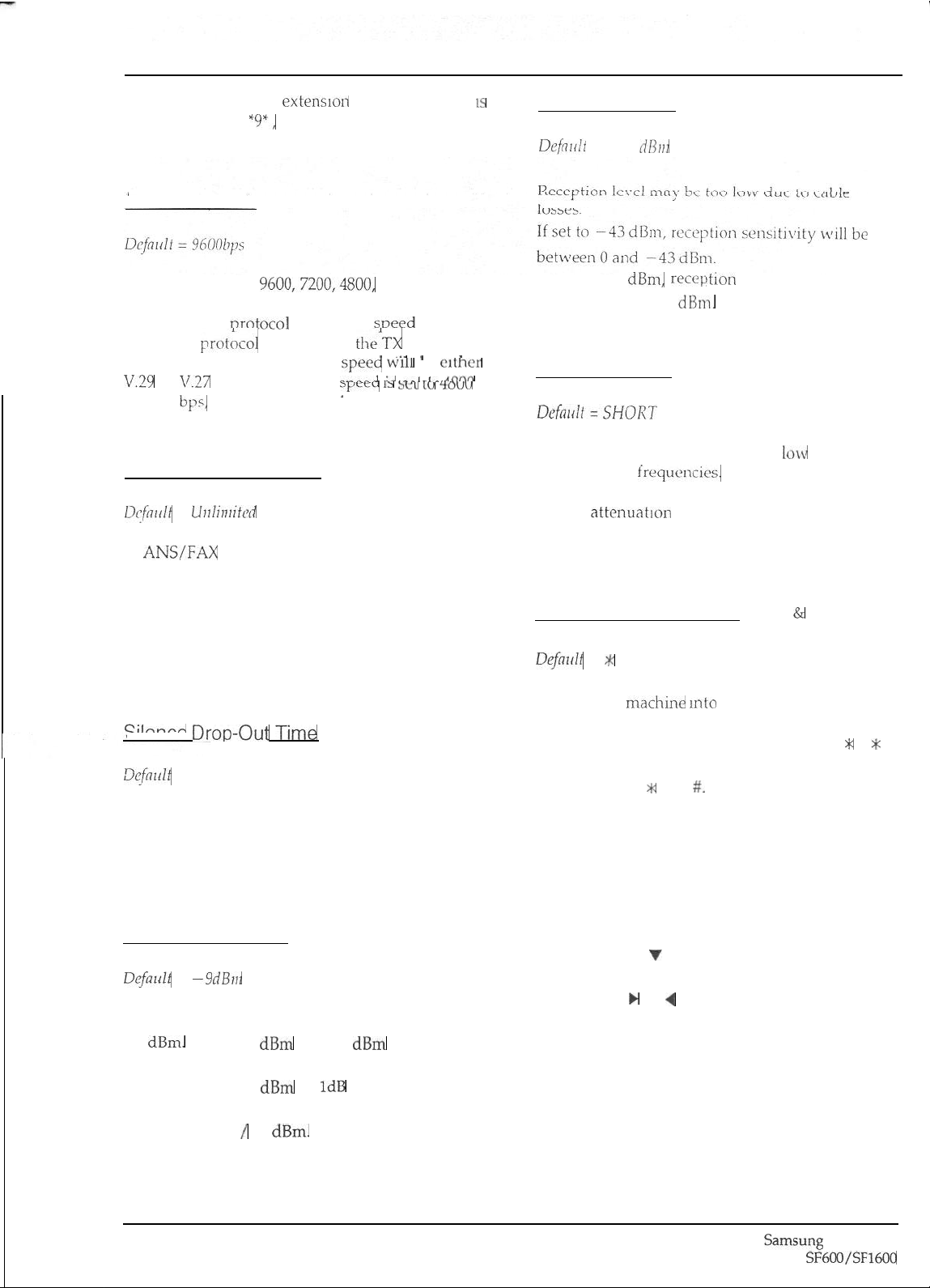

Operating Instructions

receiving code on the

factory preset to *9*, and the middle digit may be

changed to any digit between 0 and 9.

extension

phone. The code

Modem Speed

Select baud rate of 9600,7200,4800, or 2400 bps.

The lower the baud rate, the larger the acceptable

error rate. T30 motocol has a fixed

bps in the

set to 9600 or 7200 bps, the RX

V.29

or 2400

or

pro&co1

V.27

bps,

the RX speed will

mode. When the’TX speed is

ter. When the TX

sDeed

’ ‘“’ ’

speecl will

^_^^J *^

bpt-eu I> ser

^

be V.27 ter.

--. I-

of 300

.

’

be eitner

Ant-In

w

YWIJ

Silence Detection Time

D+lrlf

= UlllilllitCn

In RNS/FAX mode, after a call is picked up by the

answering machine, the fax machine monitors the

line. If a period of silence is detected on the line at

any time, the call will be treated as a fax message

and the fax machine begins receiving. Silence

detection time is selectable between limited (about

12 seconds) or unlimited time.

IS

Reception Level

Defoz1!t

= -33

If set to -48

between 0 and -48

1113172

dBm, recep

dBm.

ftion

sensitivity will be

Cable Eaualiser

Copper telephone wire attenuates

less than high frequenclcs. The longer a cable is,

the more pronounced the effect. To compensate

for this

machine to match the cable length currently used.

Select short or long.

attenuation

you may need to set the

lo\\?

frequencies

Remote Receive Code (first& & last digit)

Defndf

=

x

Cilnnnr, “vop-out

Time

3gfod: = 2 seconds

If any signal (tone, voice, fax tone, etc.) is detected

during the silence drop-out time, prior

accumulated silence time will be ignored, and

silence detection time is restarted.

Transmission Level

Defizrlt = -9dBm

FCC requires that transmission level be less than

-9

dBm.

From -9 dBm to -15 dBm is

acceptable. You can set the transmission level to

between 0 and -15 dBm in

control panel keypad.

Accuracy is + 0 / -3 dBm.

1dB

steps using the

To place the machme

phone extension, the fax machine must detect the

receive code, which comes factory preset to * 9 * .

YOU can change the first and last characters to any

digit including * and #. But they must be

different from the middle digit.

mto

receive mode via a

3-2-2 Changing Options

Press MENU/POLL, 2, START/COPY in

sequence. Press v or A to select the desired

option item. When the desired option item

appears, use ) or 4 to change the status of a

selected function.

3-2 Samsung Electronics

SF6OO/SF1600

Operating Instructions

3-3 Test Mode

Test mode is used to test machine functions. To enter test mode, press MENU/POLL, 9, START/COPY

buttons in sequence.

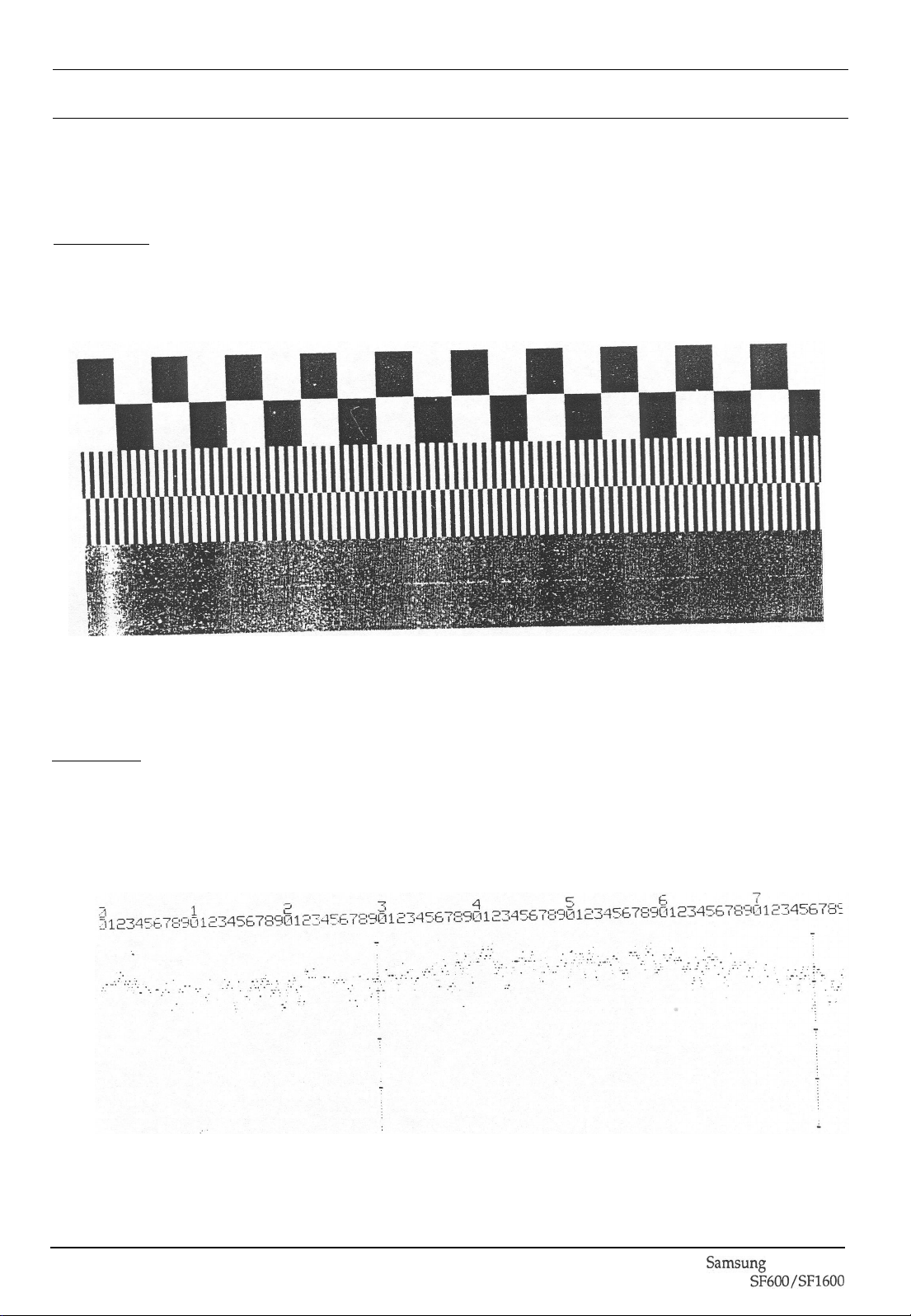

TPH TEST

You can print a TPH test pattern and check the

heating element of TPH with this test pattern.

Figure 3-1 is a sample test pattern.

Figure 3-1: TPH Test Pattern

CIS TEST

You can check the scanning elements of the CIS

(Contact Image Sensor) and print a shading

waveform graphically with dots. The graph

waveform will resemble figure 3-2, below.

3-3

Figure 3-2: CIS Shading Waveform

Samsung

SF6OO/SF1600

Electronics

Operatin;;

Instruction5

MODEM TEST

The modem

the telephone line. You can check the following:

*

FSK test

-

tones: 1100

-

G3

traming: 9600,7200,4800,2400

DTMF TEST

The machine tests its DTMF (Dual Tone Multi

Frequency). When you press any key on the

keypad, including * and #, you will hear the

corresponding key tone.

tvill

send various transmit signals

HL,

1650 Hz, lS50 Hz, 2100 Hz

bps

(~~600 only)

3-4 Report Printout

on

LINE PATH TEST

Tests the telephone line loop

(~~600 only)

ROM TEST

Tests

machtne

result and the software version appear in the LCD

in the

follorirng

CHKSUM=

ROM (Read

format:

FE; VOl,

OK

01-11~

Memory). The

MEMORY CLEAR

Erases contents of RAM. When memory is cleared,

the machine returns to default settings.

A number of useful reports can be printed in service mode. One of these lists is the protocol list, which

contains detailed information which may be required when contacting technical support. To print this list,

press MENU/POLL, 3, START/COPY in sequence.

When a report name appears in the display, scroll through the list of reports by pressing v or A. When a

desired report is selected, press START/COPY.

CONFIRMATION REPORT

Shows the last transmission result.

TX/RX JOURNAL

Shows information about faxes sent and received.

TELEPHONE NUMBER LIST

Lists all numbers stored in the machine’s

touch and speed dialling memory.

SYSTEM DATA

LET

one-

PROTOCOL LIST

This list is available in the service mode only, and

shows the sequence of the

protocol during the most recent TX or

operation. You can check for send and receive

errors with this list.

If a communication error occurs while the

machine is in service mode, the protocol list will

print automatically.

CCITI

group 3 T.30

Rx

HELP LIST

This

report illustrates the machine’s basic

functions and commands. Use as a quick reference

guide.

Shows all options that were set in user mode and

service mode.

3-4

Samsung

SFhOO/SF1600

Electronics

3-5 LCD Display

3-5-l During communication

In user mode, the LCD shows the remote

machme’s

(send or receive), and page number.

In service mode, the display shows the

communication type, abbreviations for the CCITT

Group 3 T.30 protocol as they occur, the protocol

type

kbps, and line time.

TTI number, communication type,

(GL?),

coding type (MH/MR), baud rate in

3-5-2 If a communication problem

occurs:

In user mode, the display shows one of the

following reasons:

SEND ERROR, or RECEIVE ERROR.

In service mode, the

messages available in user mode, as well as

additional error messages not available in user

mode.

Error messages shown in service mode only are as

follows:

PRE-MESSAGE ERROR: problem occurred during

phase B of session

MESSAGE ERROR: problem occurred during

phase C of session

POST-MESSAGE ERROR: problem occurred

during phase D of session

LINE ERROR: machine cannot connect or has lost

connection with the remote machine

PAPER JAM, CUTTER JAM,

displai

shows all error

Additional messages, not shown above, will

appear in the TX/RX journal printed in service

mode.

3-5

Samsung

SF6OO/SF1600

Electronics

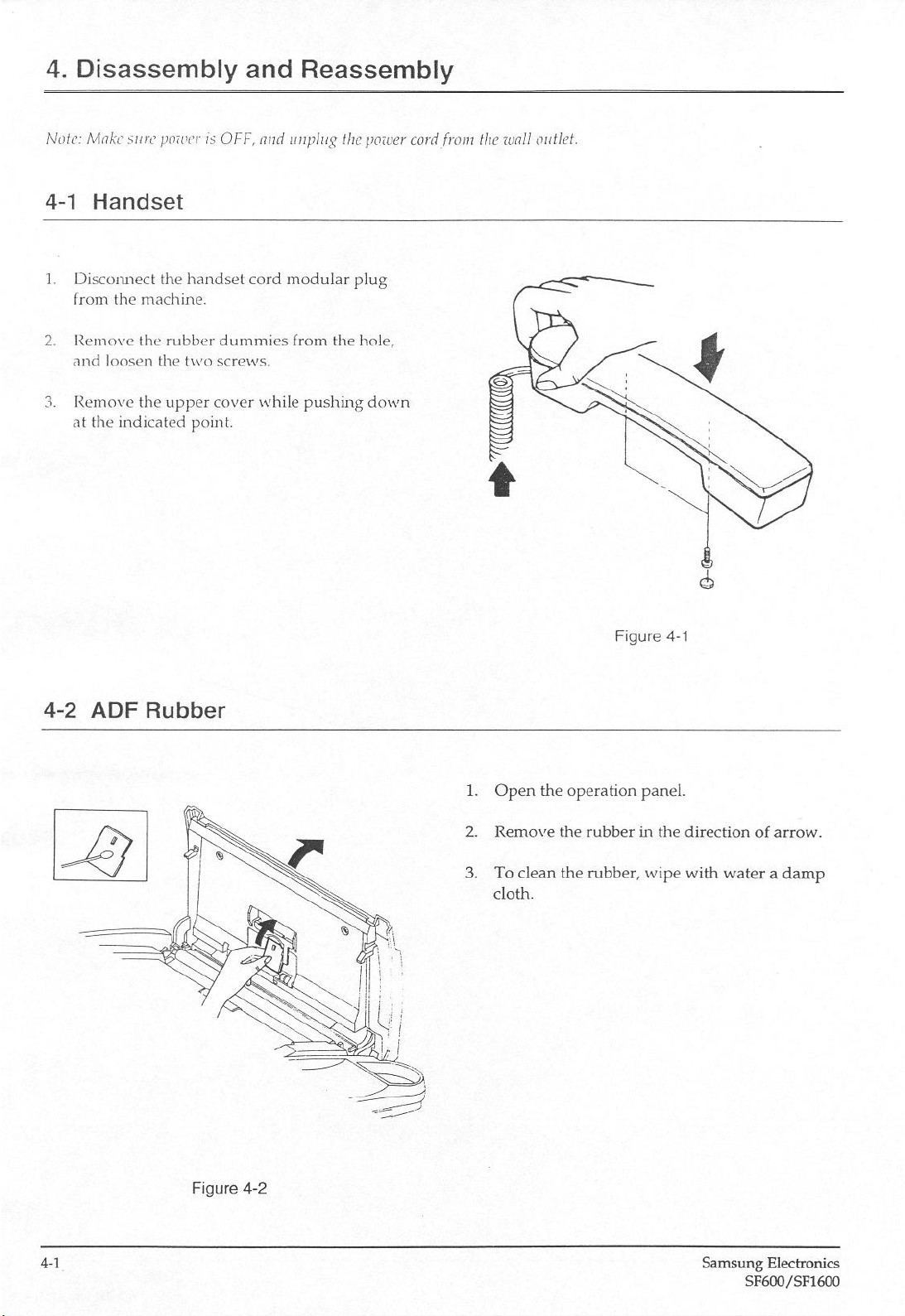

Disassembly and

Reassembl!

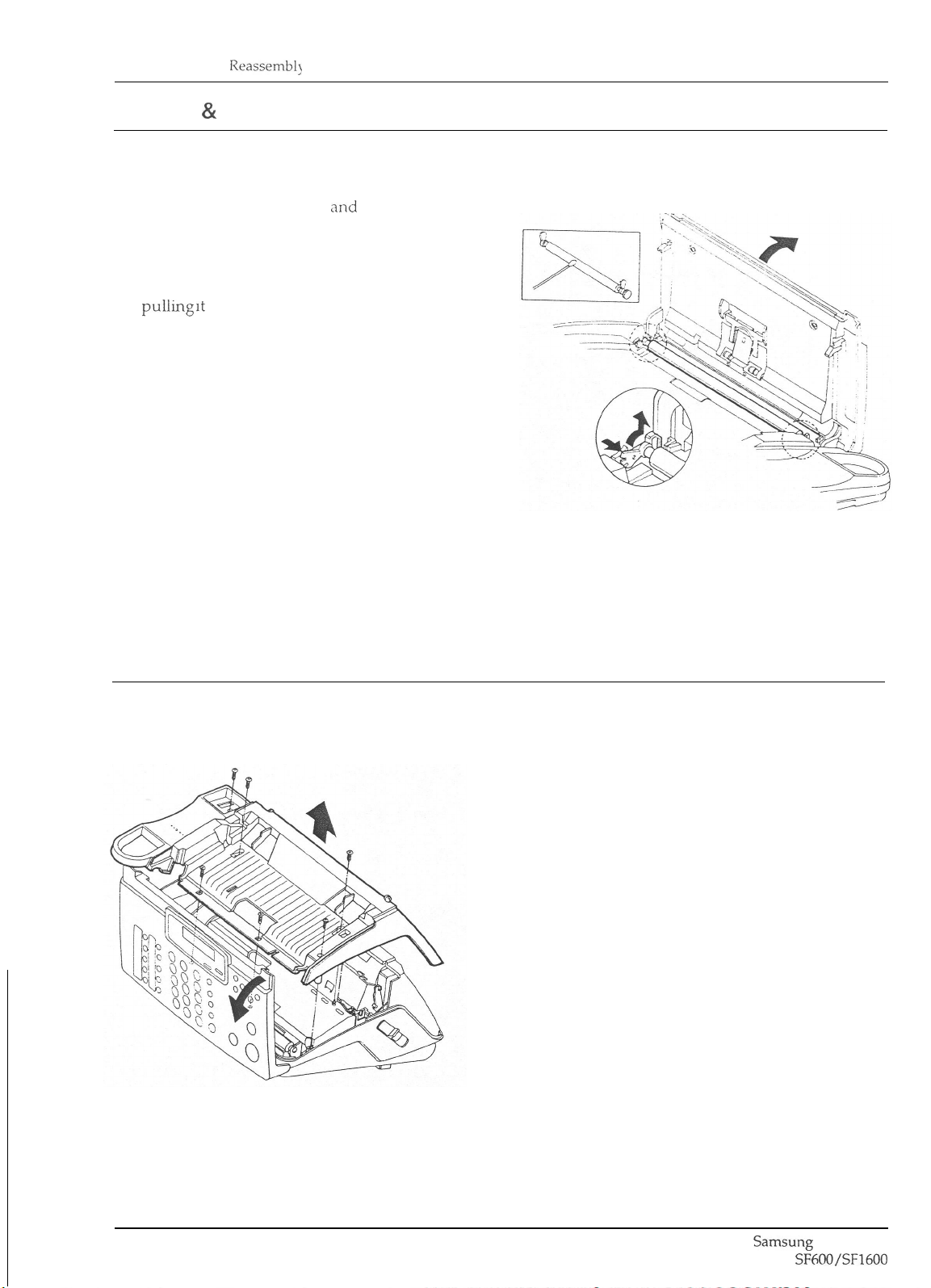

4-3 CIS & Roller

1.

Open the operation panel,

white roller against the CIS glass.

2. Turn the shaft-bushing located at each end of

the roller in the direction of arrow, while

pullmg rt

3.

Lift this assembly. Be careful not to lose the

bushings from the roller ends.

4.

To clean the CIS and roller, wipe with water a

damp cloth.

slightly inward.

and

you will find a

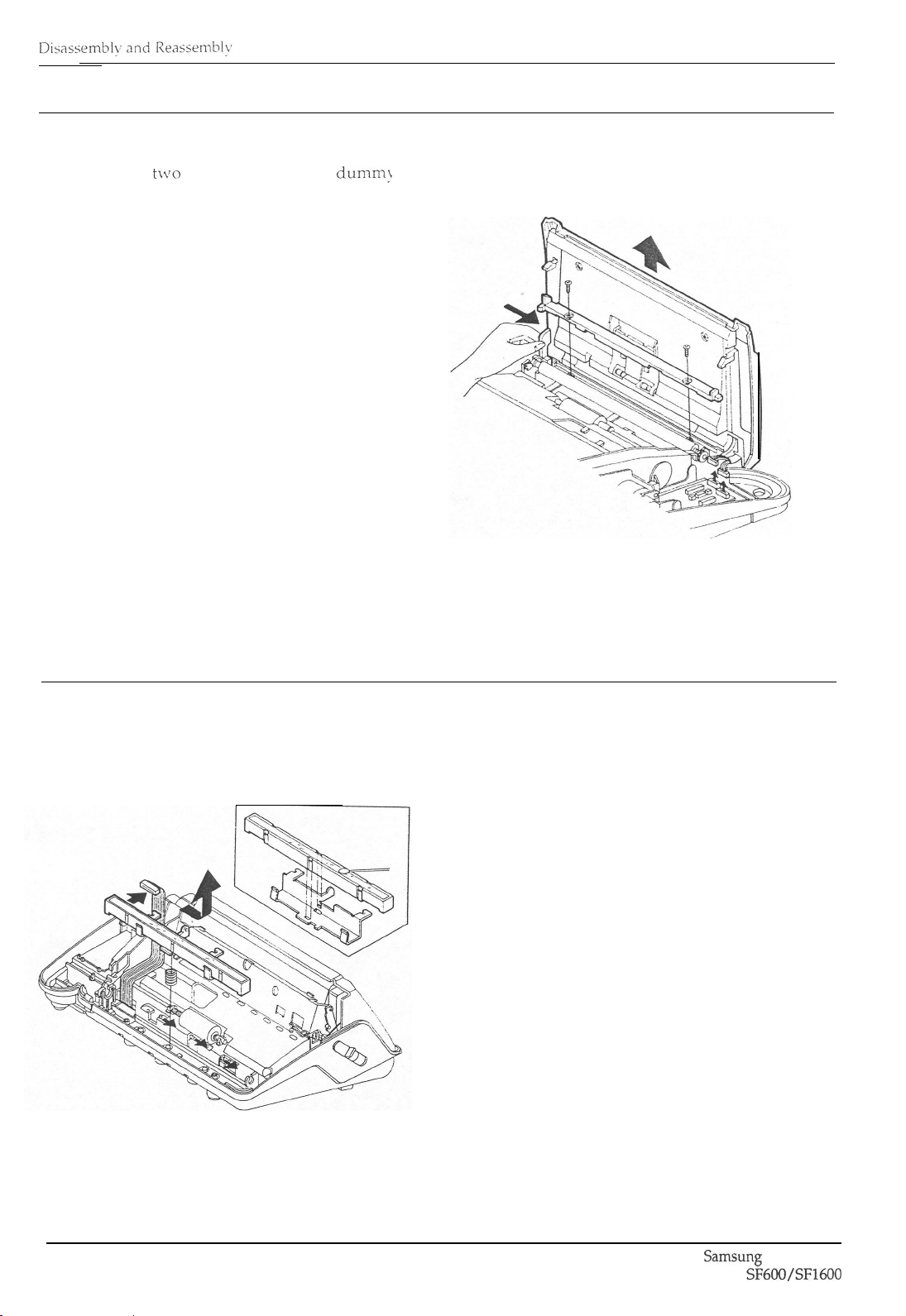

4-4 Top Cover

Figure 4-3

Open the operation panel.

1.

Loosen the six screws fastening the top cover.

2.

Lift the top cover carefully.

3.

4-2

Figure 4-4

Samsung Electronics

SF6OO/SFl600

4-5 Separation of Operation Panel Assembly

1.

Loosen the

and CIS.

2.

Carefully lift the harness.

3.

Remove the frame hinge by pulling it in the

direction of arrow.

4.

Lift the operation panel assembly.

txvo

screws fastening the dumm)

4-6 Base

4-6-l CIS Assembly

Figure 4-5

1.

Lift the CIS assembly by pulling it slightly to

the right.

2. Unplug the connector.

3.

Remove the CIS from the CIS holder.

Note: During reassembly, be sure the hole located

in the center of the CIS clicks into the holder.

4-3

Figure 4-6

Samsung

SF6OO/SF1600

Electronics

Disassembly and Reassembly

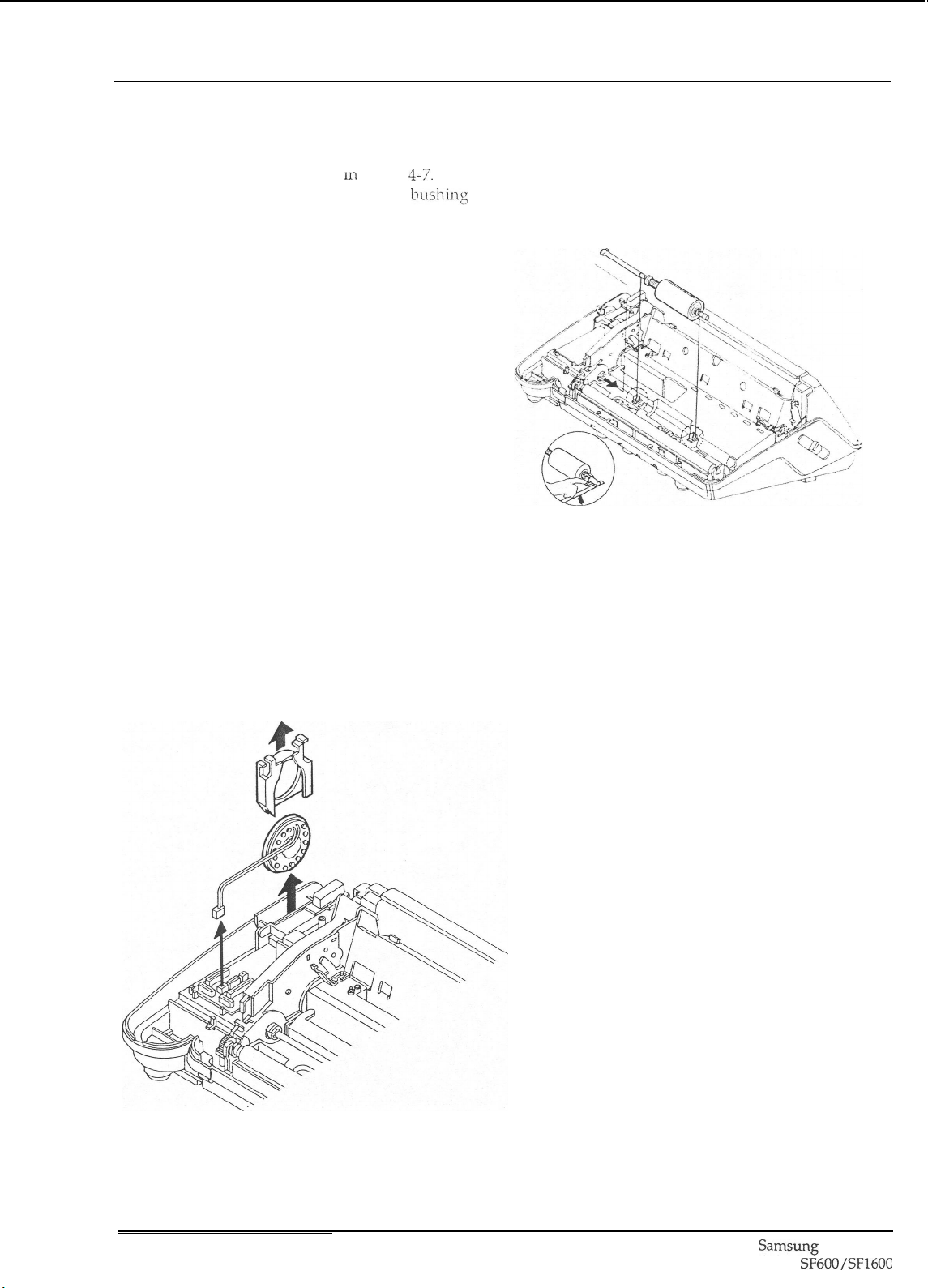

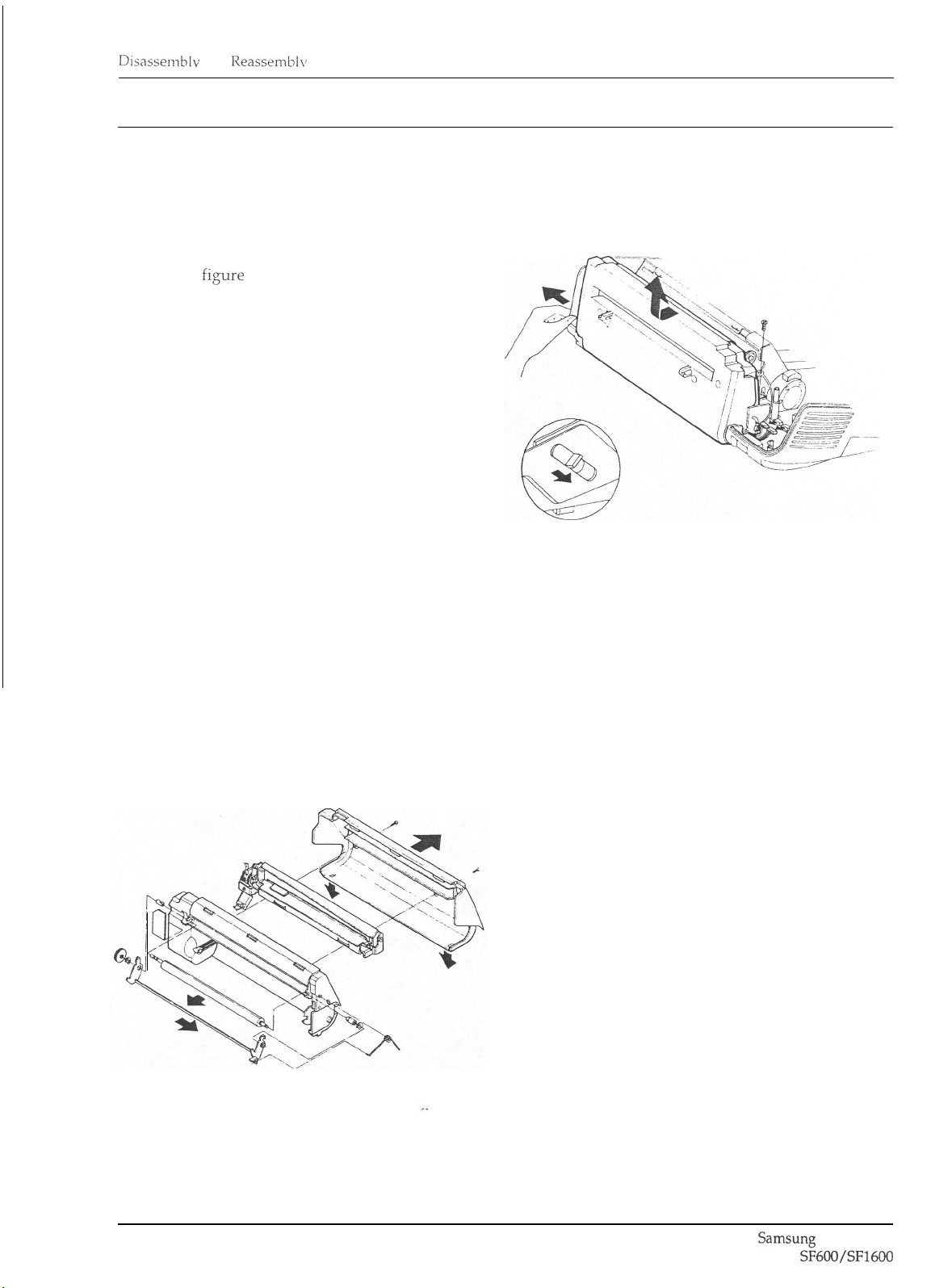

4-6-2 Automatic Document Feeder Roller Assembly

1.

Hold the bushing as shown

Remove the roller assembly from the

with screwdriver.

2.

Lift roller assembly, while pulling in the

direction of arrow.

III

figure

4-7.

bushing

4-6-3 Removing Speaker

Figure 4-7

Lift the speaker assembly and remove the

1.

rubber.

2. Unplug the connector.

4-4

Figure 4-8

Samsung Electronics

SF6OO/SF1600

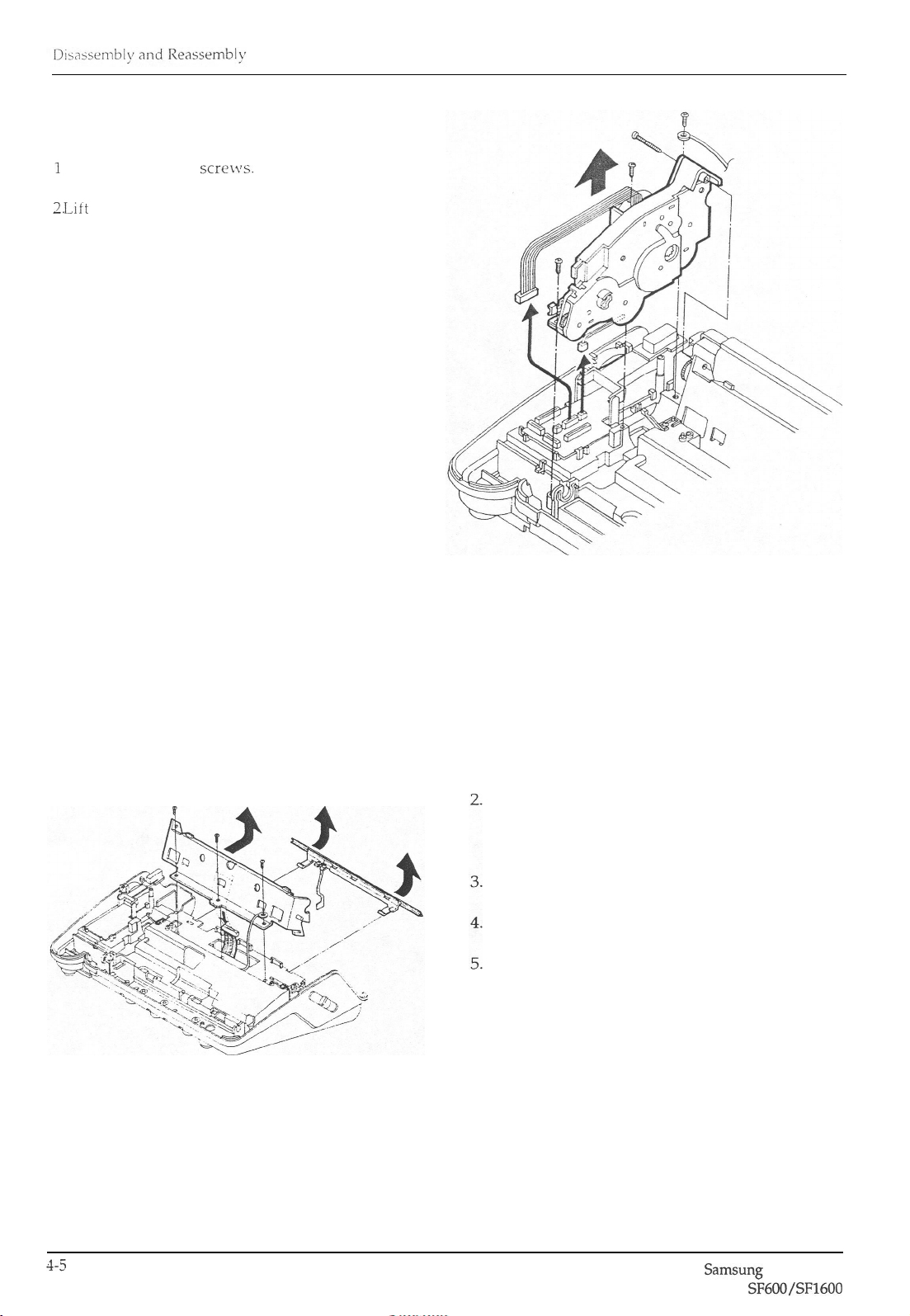

4-6-4 Motor Bracket Assembly

1

Loosen the four

3 Loft

the assembly.

-.

3. Unplug the connectors.

screlvs.

4-6-5 Thermal Printed Head Assembly

Figure 4-9

Loosen the three screws fastening the chassis

1.

board.

Remove the anti-curl plate assembly by

pulling in the direction of arrow while pulling

down the snap fastened on the base.

Loosen the screws fastening TPH bracket.

Unplug the connector.

Lift the assembly in the direction of arrow.

4-5

Figure 4-l 0

Samsung

SF6OO/SF1600

Electronics

Disassemblv

and

Reassemblv

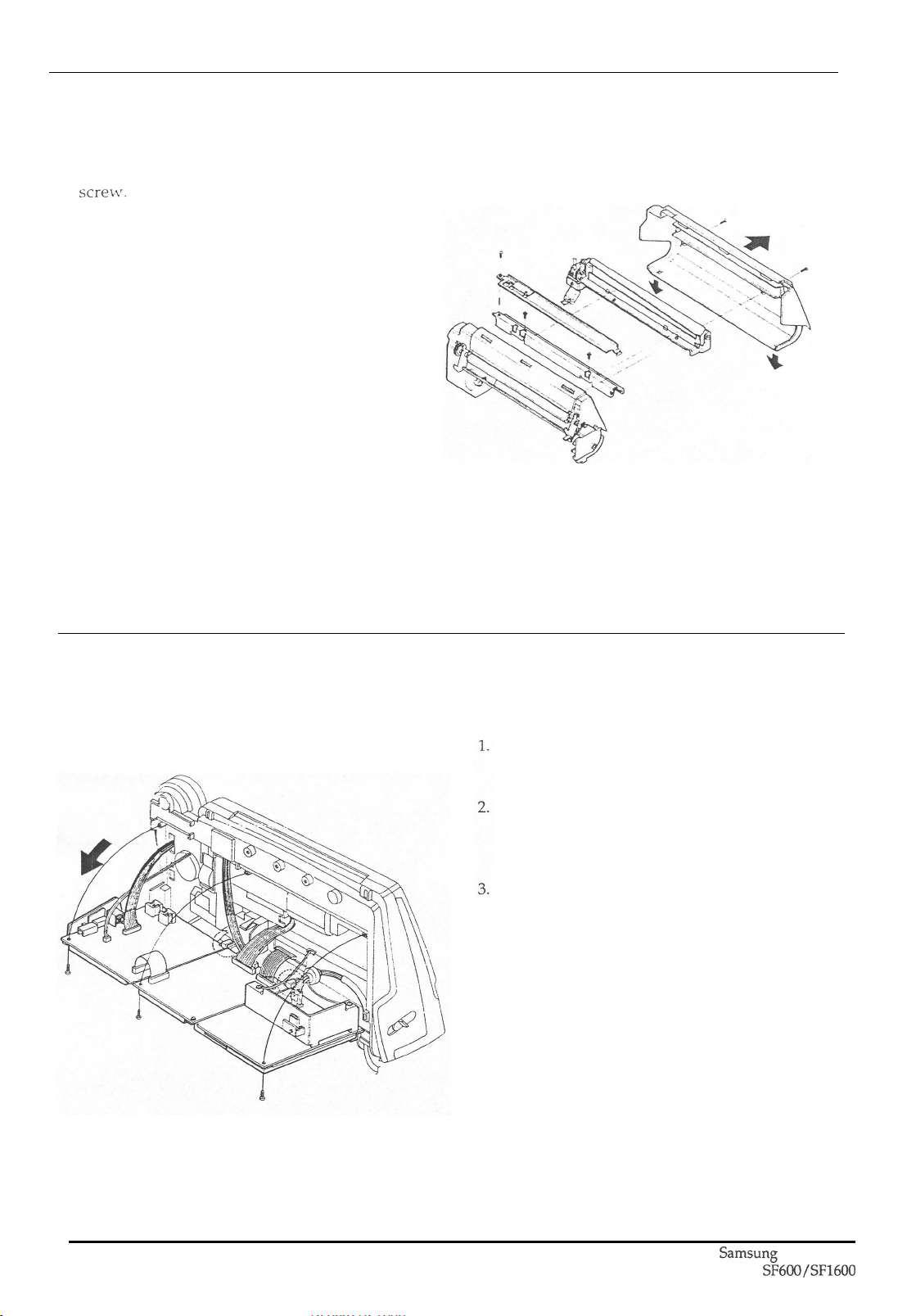

4-7 RX Unit

4-7-l RX Unit

1.

Open the RX cover by pushing the locking

knob in the direction of arrow, as shown in the

inset in

2.

Unplug the connector and GND wire

3.

Remove the RX unit by pulling it in the

direction of arrow (SF1600 only).

fipre

4-10.

4-7-2 Platen Roller

Figure 4-l 1

Loosen the two screws and remove rocker,

1.

then remove the RX cover.

Remove spring, frame sheet, and E-ring.

2.

Loosen the gear and bushing in the direction

3.

of arrow.

4. Remove the roller.

4-6

Figure 4-l 2

Samsung

SF600/SF1600

Electronics

Disassembly and Reassembly

4-7-3 Automatic Paper Cutter (SF1600 only)

Remove the paper guide by loosening one

1.

screM’.

Remove the paper cutter from the bracket by

2.

loosening two screws.

Figure 4-l 3

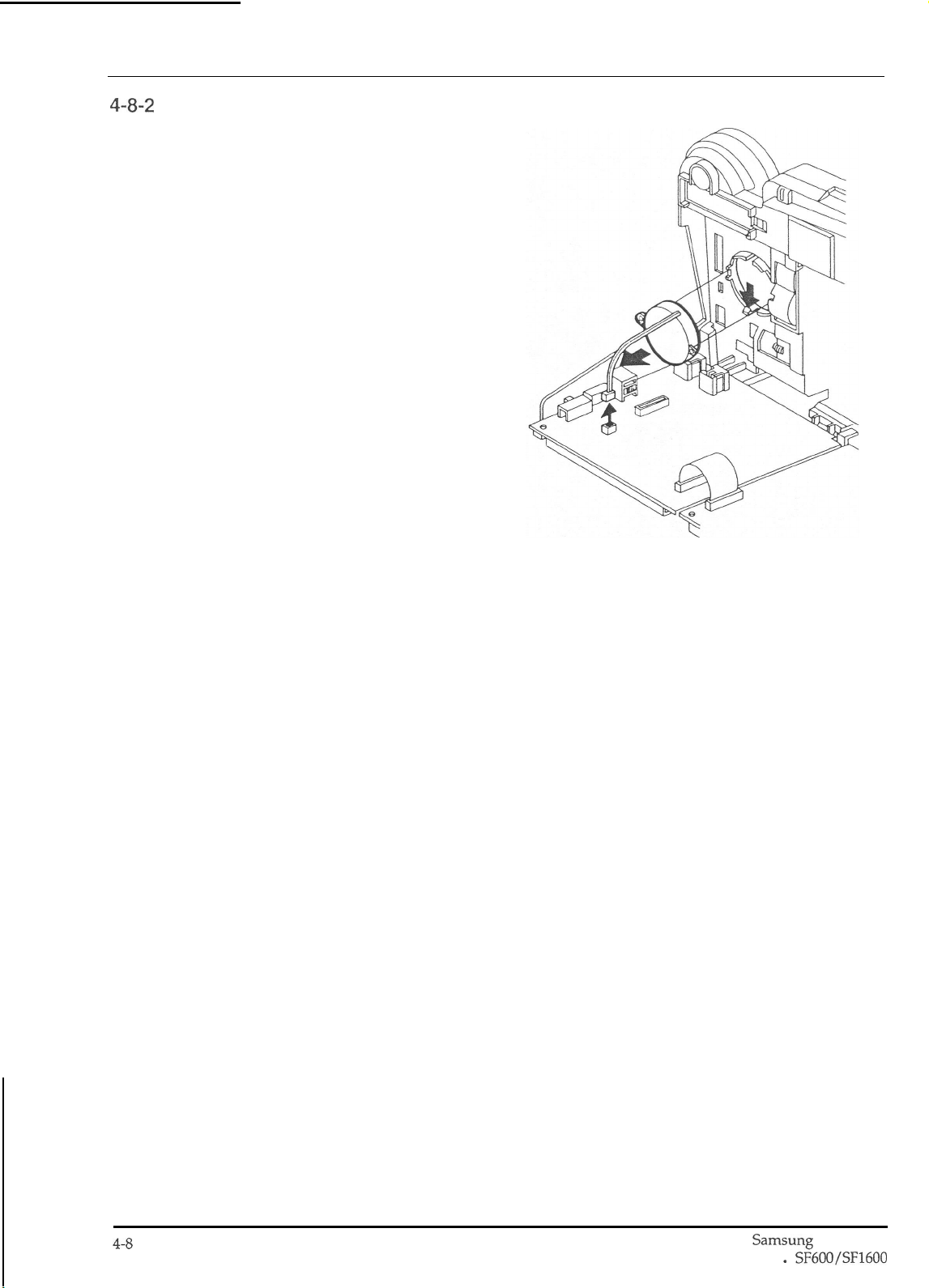

4-8 Chassis Board

4-8-l Main, LIU, and Power Boards

Loosen the three screws fastening the chassis

board.

Loosen all screws fastening the remaining

boards and unplug all connectors from the

boards.

Lift the boards.

Note: Be careful that CIS and main connector

harness does not touch the no-paper sensor.

4-7

Figure 4-14

Samsung

SF6OO/SF1600

Electronics

Disassembly and Reassembly

4-8-2

Removing Buzzer

1. Unplug the connector.

2.

Remove the buzzer by bending the locker.

Figure 4-l 5

4-8

Samsung Electronics

.

SF6OO/SF1600

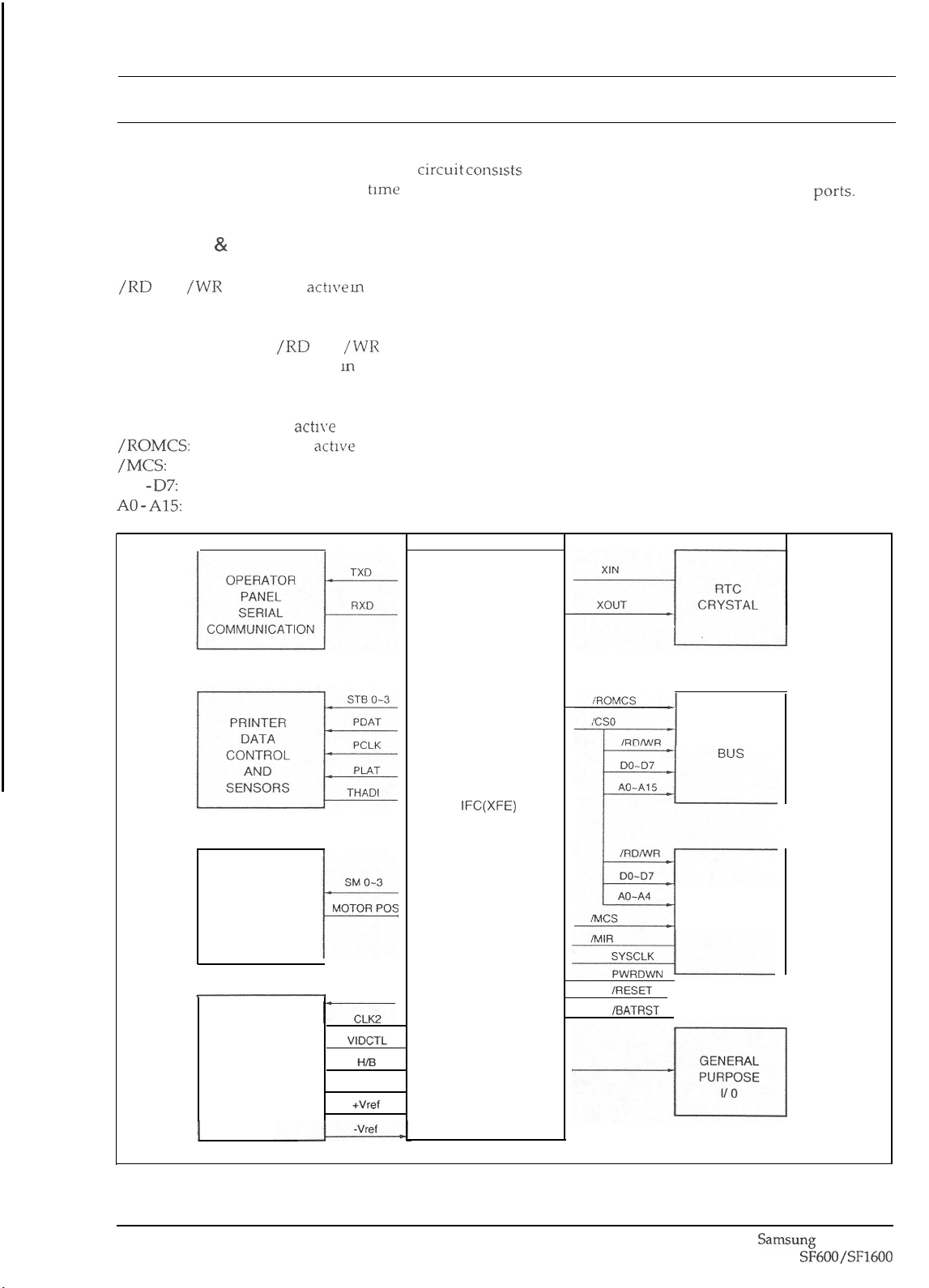

5. Circuit Description

5-1 General

The main circuit board consists of memory, MODEM, TX- and RX-related circuitry, and the Integrated

Facsimile Controller (IFC), which includes the CPU and I/O device drivers and controls the system.

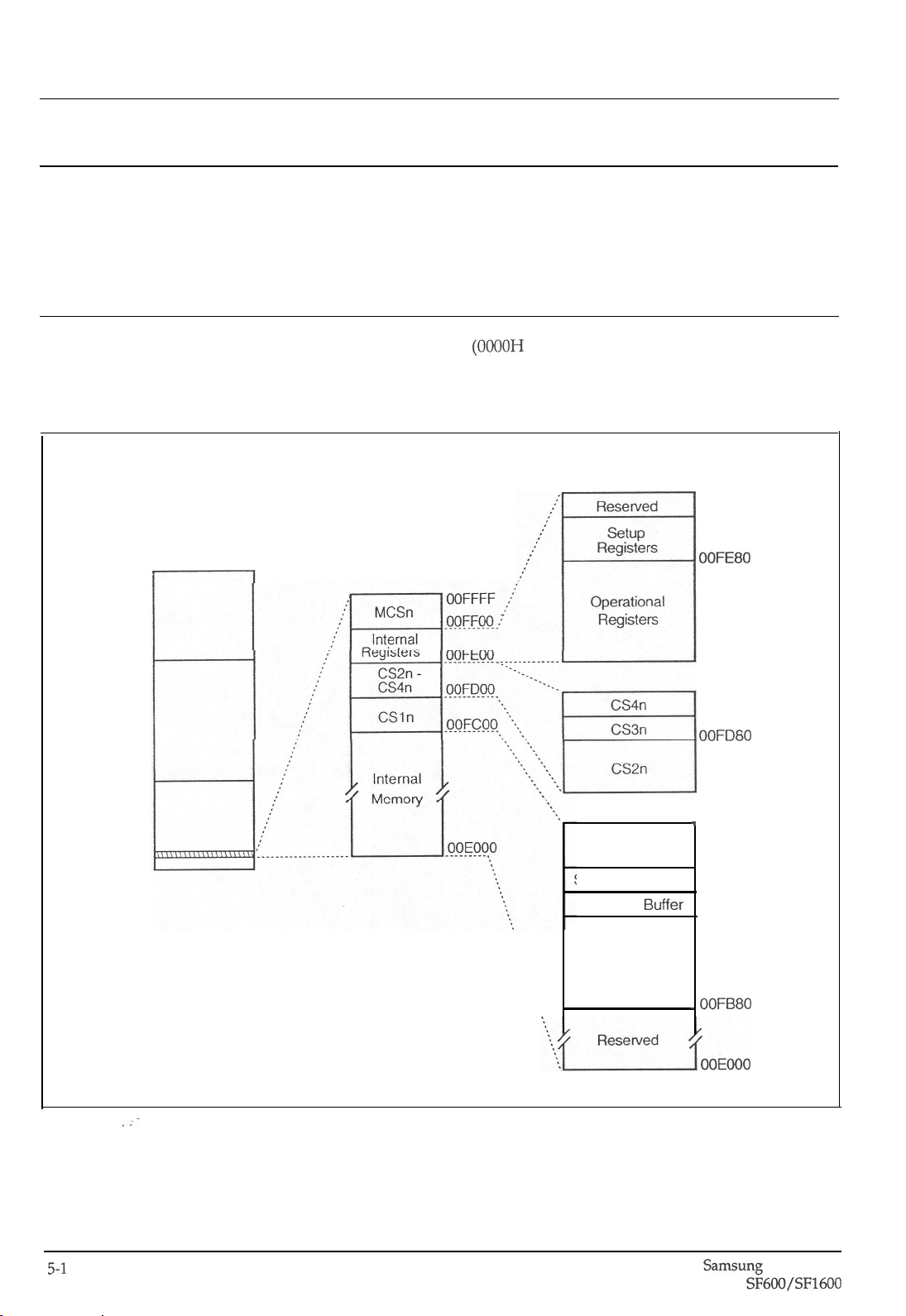

5-2 Memory Map

The external memory of the CPU is divided into 32kB RAM

(OOOOH

(FFOOOOH through FFFFFFH).

CPU

(Logical)

FFFFFF

FOOOOO

OFFFFF

Address Space

through SOOOH) and 64kB ROM

OOFEFF

OOFEEO

OOFE80

OOFEOO

OOFDFF

OOFDCO

OOFD60

OOFDOO

5-l

000000

Figure 5-1: XFE-B Memory Map

d

OOFBFF

Reserved

Shading Inversion OOFBDO

DBCMC Buffer OOFBCO

Dither Table

OOFBEO

_

OOFB80

Samsung

SF6OO/SFlf500

Electronics

Circuit Description

5-3 IFC

The Integrated Facsimile Controller (IFC)

control panel communication, real

trme

crrcuit consrsts

of system reset circuitry, Data and Address Bus,

clock (RTC), image sensor, motor driver control, and I/O ports.

5-3-l Data & Address Bus Control 5-3-2 System Clock

/RD

and

/WR

signals are

with the PH2 clock in a high state, and an internal

wait state occurs in the TSTCLK (6 MHz). These

signals are sent to the

RAM, ROM, and the MODEM m order to read or

write data when a chip select line is active.

/CSO\: RAM chip select

/ROMCS:

/MCS:

DO -

A0 - A15:

ROM chip select

MODEM chip select actrve (low)

D7:

8 bit data buses

address buses

/RD

actr\se

actrve m

and

/WR

(low)

actrve

the low state,

ports of

(low)

The 6 MHz internal clock frequency is derived by

dividing the MODEM 12 MHz system clock by

two.

MOTOR

DRIVER

(MOTOR)

p

SCANNER

CONTROL

AND

PROCESSING

IFC(XFE)

a

START

VIDCTL

H/B

Vin

+Vref

/RESET

IBATRST

Figure 5-2: XFE-B Hardware Interface Signals

EXTERNAL

MODEM

5-2

Samsung

SF6OO/SF1600

Electronics

Circuit Description

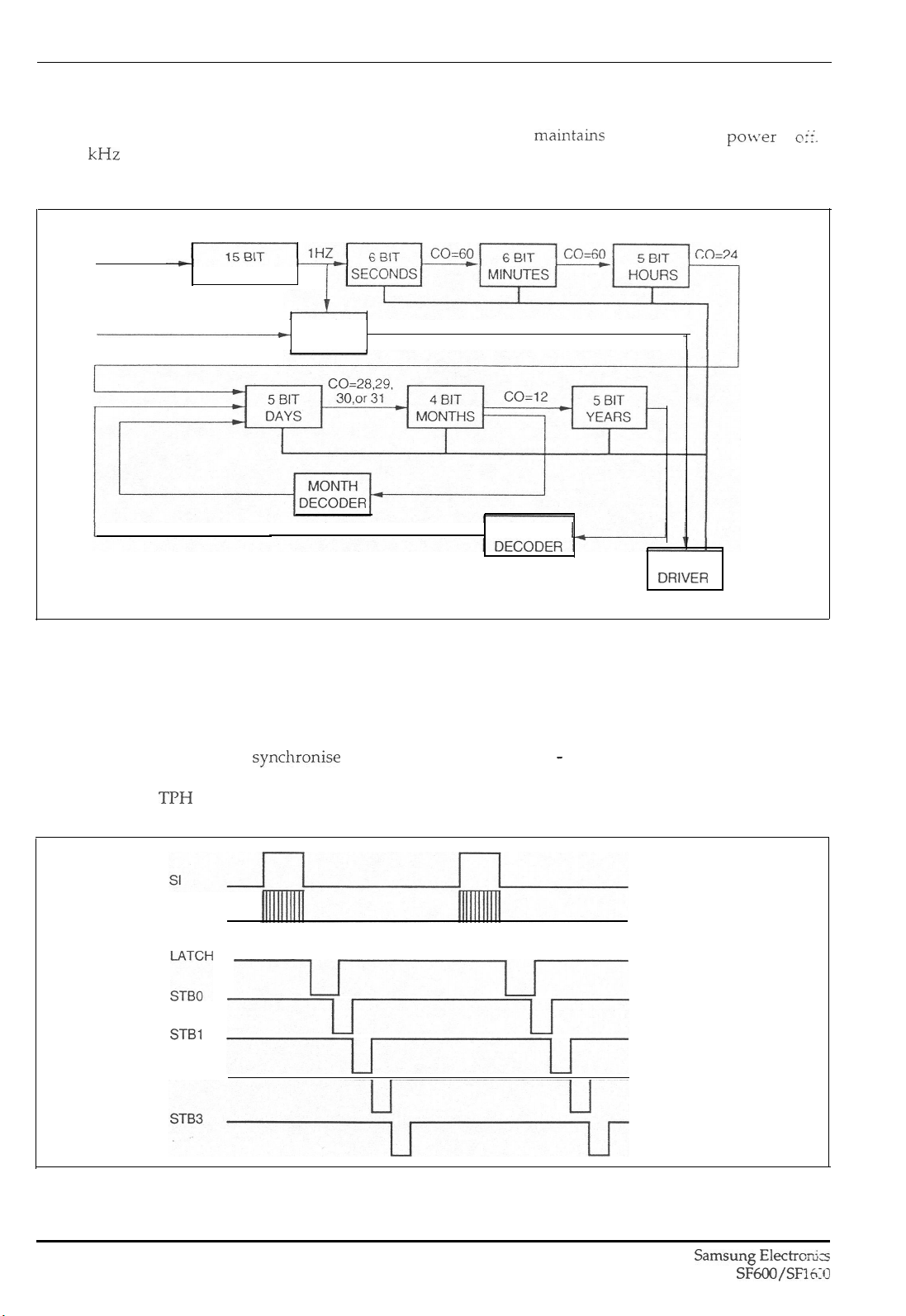

5-3-3 Real Time Clock (RTC)

This circuit receives clock pulses from an external

32.768

kHz

crystal, which it divides into hours,

minutes, seconds, year, month, and day.

32.768 KHz

PRESCALER

BUSY FLAG CLEAR

_

BUSY

DETECT

LEAP YEAR

A battery

XFE can up-track 32 years, beginning with 1997.

BUSY FLAG

mamtains

operation when polver is

3 STATE

DRWER

off.

Figure 5-3: RTC Block Diagram

5-3-4 Print Control

The PCLK and PDAT signals synchronise serial

print data to the TPH. PLAT latches TPH serial

print data to the TPH from a shift register through

CLOCK

Z”

x

STBl

STB2

1

u

PDAT. STBO - ST63 enable TPH printing in four

sequential intervals.

5-3

Figure 5-4: Printer Timing

Samsung

SF6OO/SF16:0

Electrcti~

Circuit Description

5-3-5 TPH A/D Converter

The

TADC

is composed of a 6 bit DAC,

comparator, filter, and 9 bit up/down counter.

The 6

MSBs

of the 9 bit counter generate a

reference signal to the comparator. TPH

temperature is sensed by comparing DAC output

voltage to the comparator with the thermistor

input voltage (THDI), which originates as an

output signal from the TPH. It then supplies the

proper strobe pulse to the TPH. The thermistor

input voltage (THDI) operates within a range of

to 4v.

1

THDI

:---. FilterClock

Figure 5-5: TPH A/D Converter

Vcc

1

Compararor

Rl

1

Counter Clock

DAC

_

6-hit

6 MS&

-.

3

al

m

z

a

+

THDI

Thermal Head

Thermistor

Rt

(T)

Approximate values of Rl and R2 can be calculated

from the following formulas:

R2=[1SRt (Tl)

R1=0.25

where:

Tl -

min temperature

T2 - max temperature

x Rt (T2)]/IRt

x

[I32

x Rt

(Tl)-16Rt (T2)]

(Tl)]JR2+Rt (Tl)]

Figure 5-6: THDIRPH Wiring Diagram

54

Samsung

SF6OO/SF1600

Electronics

Loading...

Loading...