Page 1

Laser Facsimile

User’s Guide

Setup and Operation

SF-5800/SF-5800P

Page 2

P/N: JC68-00143A Rev.2.00

Internet Home Page :

http://samsungelectronics.com

ELECTRONICS

Page 3

Trademarks

¥ Windows is a trademark of Microsoft Corporation.

¥ IBM is a trademark of International Business Machines.

¥ Centronics is a trademark of Centronics Data Computer.

¥ Other names and trademarks mentioned in this manual are trademarks of their respective

holders.

Page 4

i

Contents

Set Up Your Machine _______________________________ 1.2

Unpacking _________________________________________ 1.2

Control Locations and Functions ______________________ 1.3

Front View ______________________________________ 1.3

Rear View _______________________________________ 1.4

Inside ___________________________________________ 1.4

Choosing a Location _________________________________ 1.5

Setting Up Your Machine _____________________________ 1.5

Document Tray ___________________________________ 1.5

Document Exit Tray _______________________________ 1.5

Handset and Handset Cradle ______________________ 1.6

Printer Exit Tray __________________________________ 1.7

Telephone Line ___________________________________ 1.8

Extension Phone __________________________________ 1.8

AC Power Cord __________________________________ 1.9

Printer Cable _____________________________________ 1.10

Installing the Image Cartridge ________________________ 1.11

Loading Paper ______________________________________ 1.13

Using the Automatic Paper Feeder __________________ 1.13

Using the Manual Feeder __________________________ 1.16

Paper Guidelines ____________________________________ 1.17

System Setup _______________________________________ 1.18

Ringer Volume ___________________________________ 1.18

Home Resolution and Home Contrast _______________ 1.18

Sound Control ___________________________________ 1.20

Remote Diagnosis Protection _______________________ 1.20

Select Language __________________________________ 1.21

Econo Mode Setting ______________________________ 1.21

Adjusting Speaker Volume ___________________________ 1.22

Setting the Date and Time ____________________________ 1.23

Setting the System ID (Your Number and Name) _____________ 1.24

Chapter 1 Getting Started

Page 5

ii

Using the Control Panel ______________________________ 2.2

Using the Number Keypad ___________________________ 2.4

Entering Alphanumeric Characters __________________ 2.4

Entering Numbers ________________________________ 2.6

Editing Numbers or Name _________________________ 2.6

Inserting Pause ___________________________________ 2.6

Sending a Fax ______________________________________ 2.7

Preparing Documents for Faxing or Copying ___________ 2.7

Setting Document Resolution and Contrast _____________ 2.8

Resolution _______________________________________ 2.8

Contrast _________________________________________ 2.8

Loading Document __________________________________ 2.9

Sending a Fax Automatically _________________________ 2.10

Canceling Transmission ____________________________ 2.10

Confirming Transmission __________________________ 2.10

Automatic Redial __________________________________ 2.11

Voice Request _______________________________________ 2.12

Sending a Voice Request ___________________________ 2.12

Answering a Voice Request _________________________ 2.12

Delayed Transmission _______________________________ 2.12

Memory Transmission (Broadcasting) ____________________ 2.14

Priority Transmission ________________________________ 2.15

Adding Documents To a Standby Operation ____________ 2.16

Canceling a Standby Operation _______________________ 2.16

Receiving a Fax _____________________________________ 2.17

Receiving a Fax _____________________________________ 2.17

Receiving Automatically in FAX Mode _________________ 2.18

Receiving Manually in TEL Mode _____________________ 2.18

1 Getting Started

2 Operation

3 Troubleshooting

Appendix

Chapter 2 Operation

Page 6

iii

Receiving Automatically in ANS/FAX Mode ___________ 2.19

If Your Machine is Out of Paper

When it Receives a Fax-Receiving into Memory _______ 2.20

Distinctive Ring Pattern Detection (DRPD) ___________ 2.20

Polling _____________________________________________ 2.21

What is Polling? __________________________________ 2.21

Being Polled By a Remote Machine __________________ 2.21

Adding Documents To the Job to be polled ___________ 2.22

Polling One or More Remote Machines ______________ 2.23

Making a Copy _____________________________________ 2.25

Making a Copy _____________________________________ 2.25

Automatic Dialing __________________________________ 2.27

One-Touch Dialing __________________________________ 2.27

Storing a Number for One-Touch Dialing ____________ 2.27

Sending a Fax Using a One-Touch Number __________ 2.28

Using Address Label ______________________________ 2.28

Speed Dialing _______________________________________ 2.29

Storing a Number for Speed Dialing ________________ 2.29

Sending a Fax Using a Speed Number _______________ 2.29

Group Dialing (for Multi-Address Transmission) ________ 2.30

Storing One-Touch or Speed Dial Numbers for

Group Dialing ___________________________________ 2.30

Storing a Group into a One-Touch Button ____________ 2.31

Sending a Fax Using Group Dialing

(Multi-Address Transmission) ______________________ 2.31

Searching for a Number in Memory ___________________ 2.32

Searching Sequentially through Memory ____________ 2.32

Searching for a Particular First Letter _______________ 2.32

Chapter 2 Operation (Continued)

Page 7

Other Functions ____________________________________ 2.33

Using Function Buttons ______________________________ 2.33

Redial ___________________________________________ 2.33

Tone ____________________________________________ 2.34

Flash(R) _________________________________________ 2.34

Chain Dialling ___________________________________ 2.35

Status ___________________________________________ 2.35

Printing Reports ____________________________________ 2.36

User Options _______________________________________ 2.38

Setting an Option _________________________________ 2.38

Selectable Options ________________________________ 2.38

Maintenance ________________________________________ 2.43

Cleaning Fuser ___________________________________ 2.43

Make Shading ____________________________________ 2.43

iv

Page 8

FCC Regulations РРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРР 4.2

Canadian Radio Interference Regulations РРРРРРРРРРРРРРР 4.2

EC Declaration of Conformity РРРРРРРРРРРРРРРРРРРРРРРР 4.3

Laser Safety Statement РРРРРРРРРРРРРРРРРРРРРРРРРРРРРРР 4.4

Safety Information РРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРР 4.5

Power Saver

РРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРР 4.6

Specifications РРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРР 4.7

Troubleshooting ____________________________________ 3.2

Clearing Jams _______________________________________ 3.2

Document Jams While Sending a Fax _______________ 3.2

Paper Jams While the Machine is Printing ____________ 3.3

Tips for Avoiding Paper Jams _______________________ 3.5

LCD Error Messages _________________________________ 3.6

Fixing Problems _____________________________________ 3.8

Fax Problems _____________________________________ 3.8

Maintenance _______________________________________ 3.10

Clearing Memory ___________________________________ 3.10

Cleaning the Document Scanner ______________________ 3.11

Managing Image Cartridge ___________________________ 3.13

Expected Cartridge Life ___________________________ 3.13

Replacing Image Cartridge ________________________ 3.13

Chapter 3 Troubleshooting

Appendix

v

Page 9

Important Safety Information

Always be careful when using the machine. To reduce the risk of fire, electrical shock,

and other injuries, keep these safety considerations in mind when installing, using,

and maintaining your machine:

¥ Stability. Place the machine on a secure, stable surface. The machine can cause serious

damage if it falls.

¥ Power Supply. Provide the correct power to the machine, as listed on its back. If you

arenÕt sure of the type of power thatÕs supplied to your home or office, call your electric

company.

¥ Grounding. If the plug has three prongs, it must be plugged into a grounded (three

hole) outlet. Grounded plugs and outlets are designed for your safetyÐdonÕt try to make

a three-prong plug fit into a two-prong outlet by modifying the plug or outlet in any

way. If you canÕt insert the plug into your wall outlet easily, the outlet should be

inspected by a qualified electrician.

¥ Overload. DonÕt plug too many electrical devices into a wall outlet or extension cord.

An overloaded outlet is a fire and electrical shock hazard.

¥ Cleaning. Before cleaning the machine, unplug it from both the power outlet and the

telephone jack. Clean exposed parts with a soft cloth slightly dampened with water.

DonÕt use aerosol cleaners.

¥ Thunderstorms. Unplug electrical appliances during thunderstorms. Avoid using any

telephone (except a cordless model) during a thunderstorm, since thereÕs a small chance

you could get an electrical shock from lightning.

¥ Gas Leaks. Never use any telephone close to a gas leak. If you think gas is leaking, call

the gas company immediately, but use a telephone far away from the leak area.

A small electrical spark in the telephone could cause a fire.

vi

Page 10

Getting Started

1

1.1

Page 11

1.2

Set Up Your Machine

Unpacking

Set Up Your

Machine

Machine

Toner cartridge

(Part Number :

SF-5800D5/SEE)

Document tray

CD-ROM

(SF-5800P Only)

UserÕs Guide

(Setup and Operation)

UserÕs Guide

(Application-

SF-5800P Only)

Printer exit tray

Document exit tray

01 02 03 04 05

06 07 08 09 10

11 12 13 14 15

16 17 18 19 20

Telephone/

Modem line cord

*

2

One-touch Label

AC power cord *

2

Handset *

1

*1 These parts may not be provided depending on country.

*2 The shape of power and telephone line cord plugs may differ, depending on your country.

Handset cradle *

1

Printer Cable

(SF-5800P Only)

Page 12

1.3

Set Up Your Machine

Control Locations and Functions

Take a moment to familiarize yourself with the main components and

understand their functions.

Front View

Paper Extension

Automatic Paper Feeder

Manual Paper Feeder

Document Guides

Paper Guides

Document Tray

Control Panel

Document

Exit Tray

Print Exit Tray

1 Getting Started

Note: Your machine may look slightly different than the illustration.

Page 13

1.4

Set Up Your Machine

Printer Connector

Power Cord Connector

TEL LINE Jack

EXT. LINE Jack

Image Cartridge

Cover

Cover Release Buttons

(right and left)

Rear View

Inside

Page 14

1.5

Set Up Your Machine

1 Getting Started

Choosing a Location

To help guarantee trouble-free operation of your machine, place it on a

flat, stable surface near your workstation. Leave enough space to allow

for easy paper loading, paper out and opening the front cover.

Do not place your machine:

- In direct sunlight.

- Near heat sources or air conditioners.

- In dusty or dirty environments.

Setting Up Your Machine

Document Tray

Insert two tabs on the tray into the slots as shown. Fold out the

extender on the tray, if necessary.

Document Exit Tray

Insert the two tabs on the document exit tray into the slots on the

front of your machine. Fold out the extender, if necessary.

Extender

Insert one end first, then the other end by pulling this

leg inward to make the tray easy to insert.

Page 15

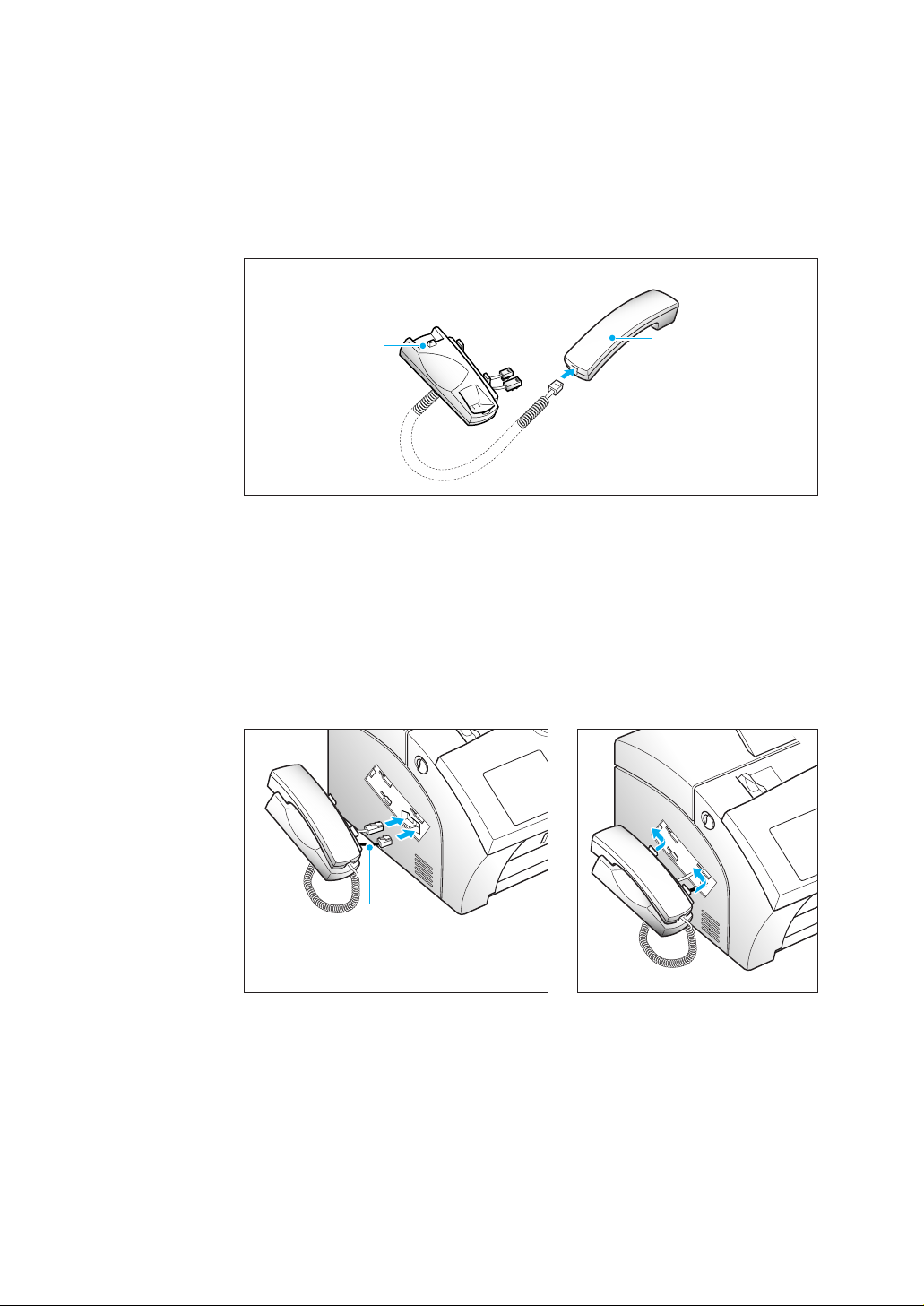

Handset and Handset Cradle

(only for the machine equipped with handset)

1. Plug one end of the coiled cord into the jack on the handset. Then

plug the other end into the modular jack on the bottom of the

handset cradle.

2. Plug the cradleÕs modular cords into the modular jacks on the left

side of your machine.

Attach the handset cradle to the main body. Insert the three tabs of

the cradle into the slots on the left side of the main body as shown,

and push it up.

Cradle

Handset

Black cord

Route the excess cord so that it could be

inserted into the cradle.

1.6

Set Up Your Machine

Page 16

Note: If you want to remove the handset, while pushing down the part A in

the bottom, slide the handset down, then take it out.

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

A

Printer Exit Tray

Holding the flexible side end, insert two tabs on the side ends into

the corresponding slots. Fold out the extender, if necessary.

Extender

1.7

Set Up Your Machine

1 Getting Started

Page 17

Extension Phone

If you want to use a regular phone or answering machine with your

machine, connect the phone into the EXT.LINE jack.

Plug the cord of your extension phone or answering machine into the

socket marked EXT.LINE on the back of the machine.

1.8

Set Up Your Machine

Telephone Line

Plug one end of the telephone line cord into the TEL LINE jack and

the other end into a standard phone wall jack.

EXT. LINE

TEL LINE

TEL LINE

EXT. LINE

Page 18

1.9

Set Up Your Machine

1 Getting Started

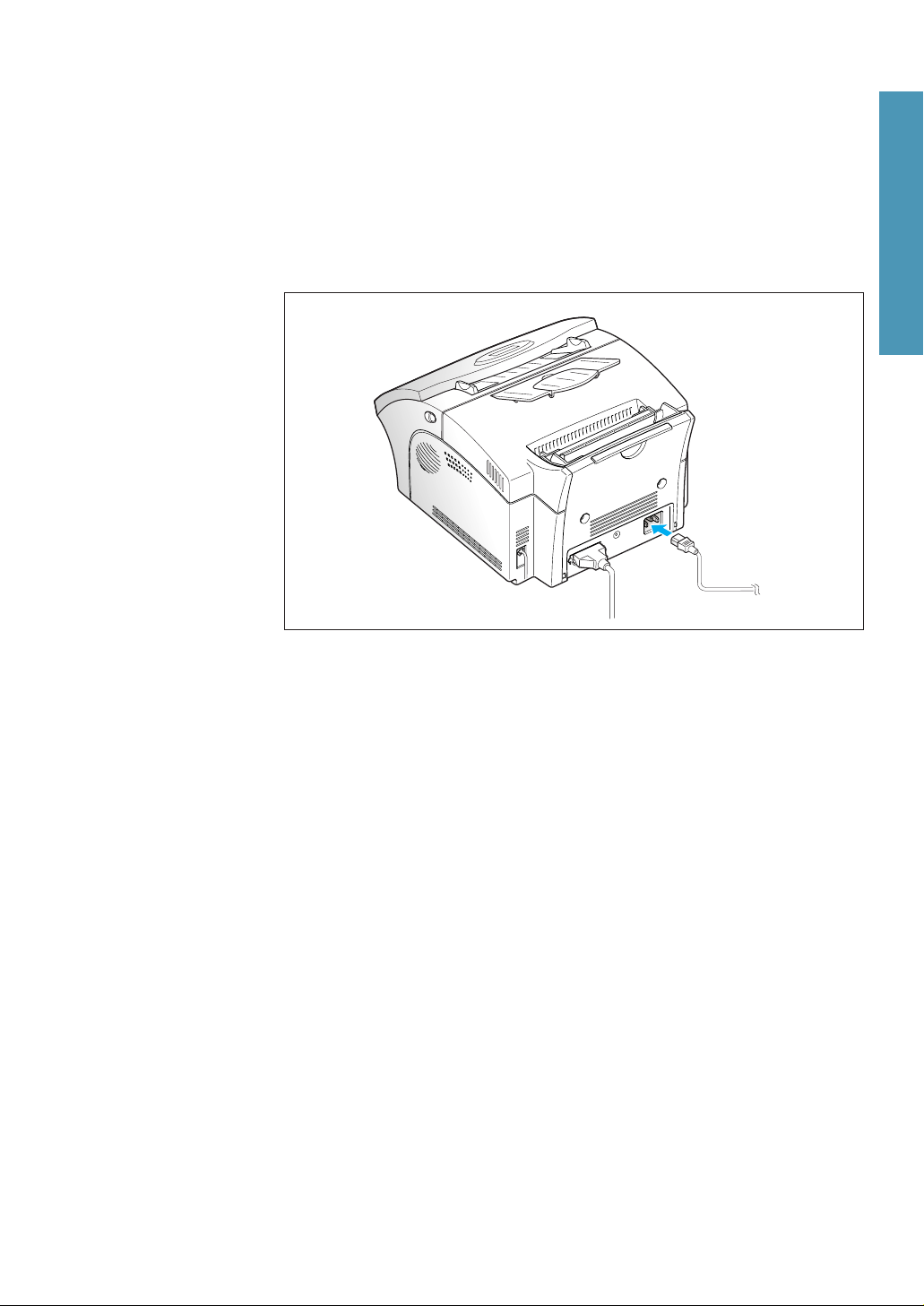

AC Power Cord

Plug one end of the cord into the back of the machine and the other

end into a standard AC power outlet.

The machine turns on. If there is no cartridge installed, or no paper, the

display shows ÔDOOR OPEN OR NO TONERÕ or [NO PAPER].

If you want to turn it off, unplug the power cord.

Page 19

1.10

Set Up Your Machine

Printer Cable

(SF-5800P only)

Your Machine has a parallel interface port, which allows you to use it

with IBM PCs and compatible computers. You have to purchase a

Centronics parallel interface cable that supports bi-directional

communications (IEEE standard 1284). Ask your dealer for assistance if

you need help selecting the right cable.

To connect the printer to the computer, follow the steps below:

1. Make sure that both the machine and the computer are turned off.

2. Plug the cable into the connector on the back of the machine. Push

the metal clips down to fit inside the notches on the cable plug.

3. Connect the other end of the cable to the parallel interface port on

your computer. See your computer documentation if you need help.

Page 20

1.11

Set Up Your Machine

1 Getting Started

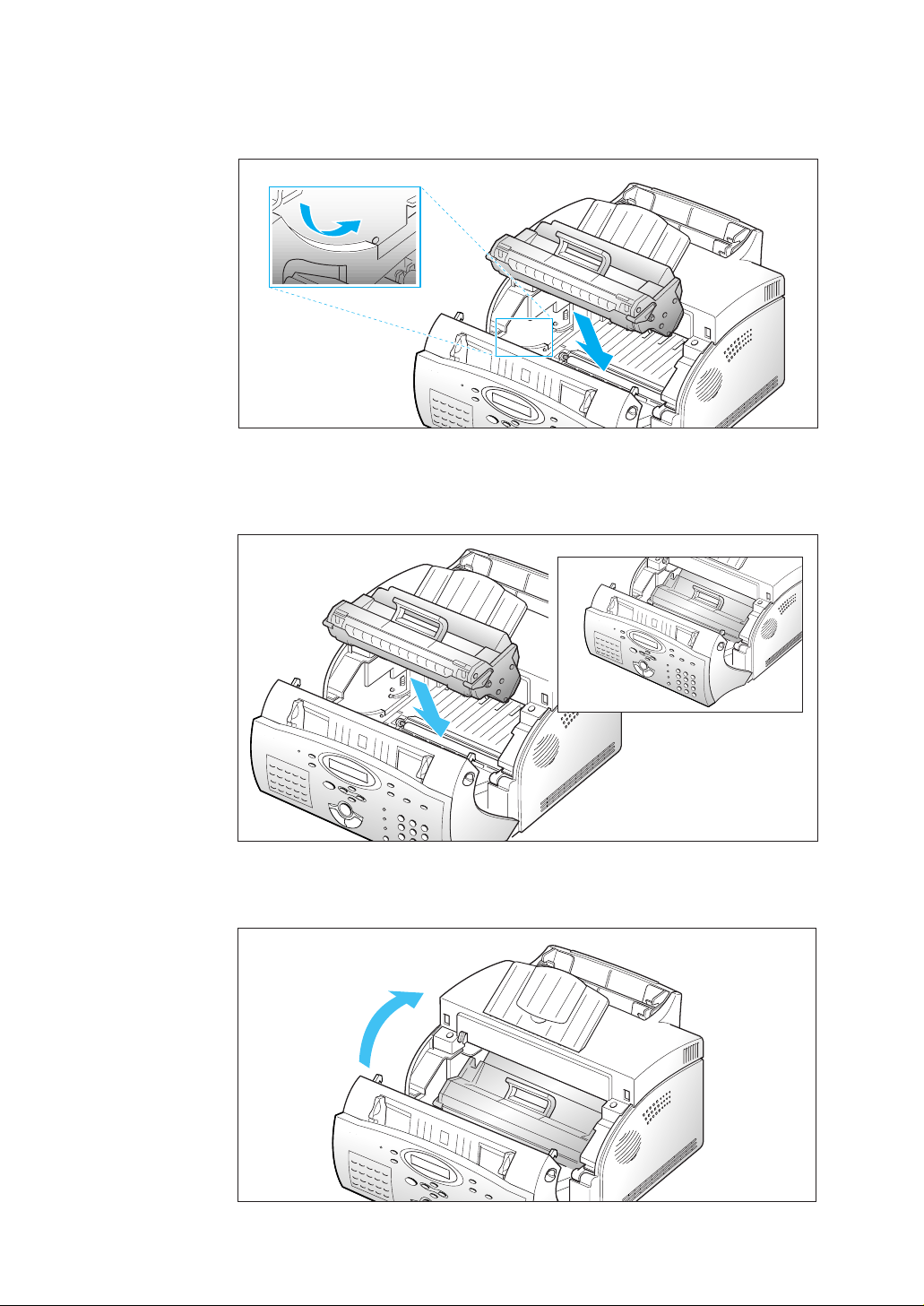

Installing the Image Cartridge

1. Pulling the cover release button toward you, open the cover.

2. Unpack the image cartridge, then carefully remove the sealing tape.

3. Shake the cartridge from side to side 5 or 6 times to distribute the

toner evenly inside the cartridge.

Page 21

1.12

Set Up Your Machine

4. Find the cartridge slots inside the printer, one on each side.

6. Close the cover. Make sure that the cover is securely closed.

5. Grasp the handle and slide the cartridge down between the

cartridge slots, until it drops into place.

Page 22

1.13

Set Up Your Machine

1 Getting Started

Extender

Automatic feeder

Manual feeder

Loading Paper

For best results, use high quality xerographic copier paper.

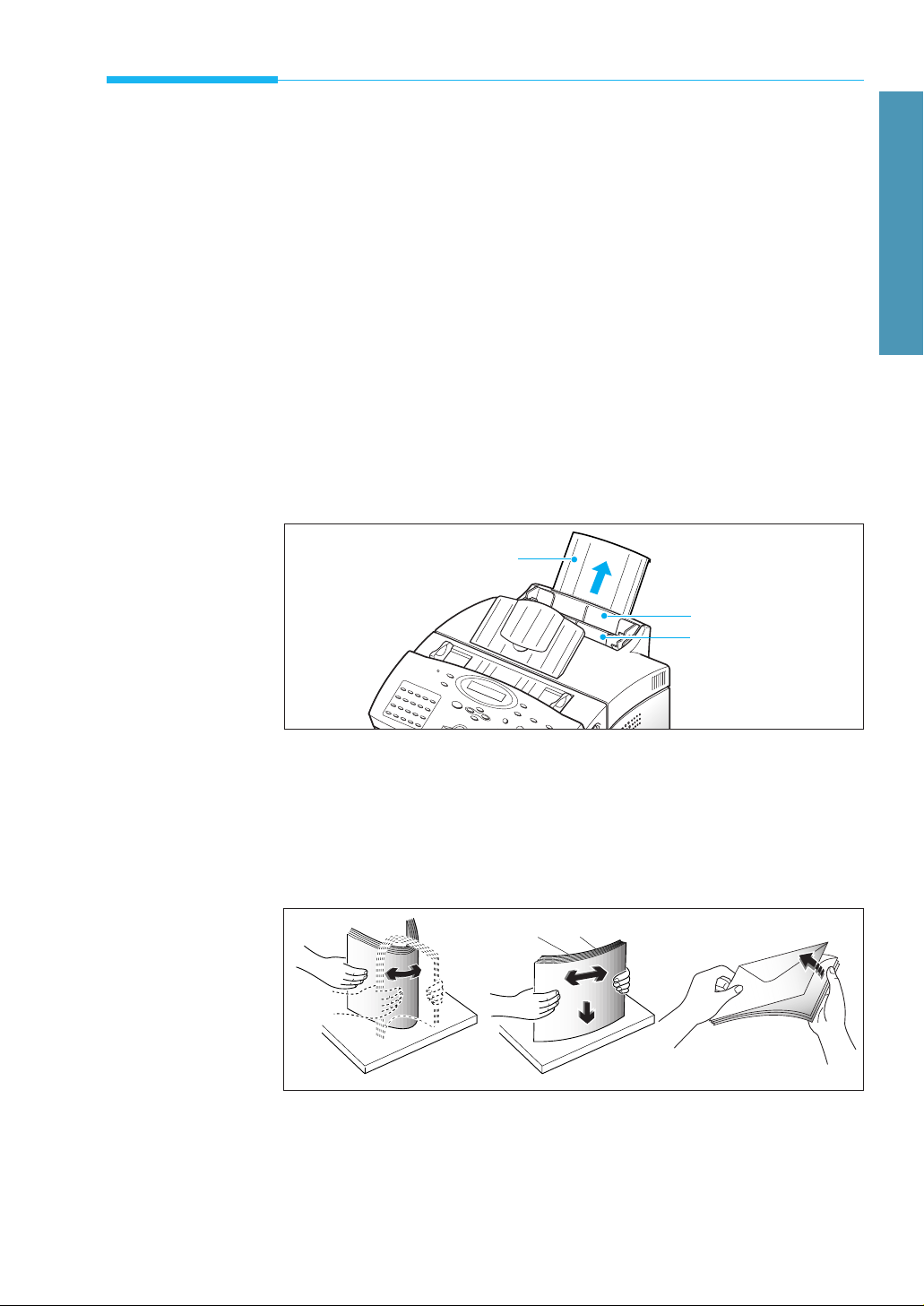

Using the Automatic Paper Feeder

You can stack paper, envelopes, card stocks, labels, or transparencies in

the automatic paper feeder to feed automatically. The automatic feeder

can hold a maximum of 150 sheets of plain paper, and 5 envelopes or

other print media. The maximum capacity may reduce, depending on

the thickness.

Note: If you experience feeding problems, try printing one at a time from the

manual feeder. See page 1.16.

1. Pull the extender on the automatic paper feeder all the way up.

2. Prepare the print material for loading.

¥ For paper and envelopes:

- Flex paper or fan envelopes back and forth. Do not fold or crease

the paper. Straighten the edges on a level surface.

Note: If envelopes jam while printing, try reducing the number of envelopes in

the automatic feeder.

Page 23

1.14

Set Up Your Machine

3. Load the print material in the automatic feeder. Do not load too

much print material. Do not mix types. See the following directions

to load each type of print material.

¥ Load paper or transparencies with the print side facing you.

¥ For transparencies:

- Hold the transparencies by the edges and avoid touching the

print side.

- Fan the stack of transparencies to prevent feeding failures. Be

careful not to scratch or leave fingerprints on the print sides.

Place the print side

facing you.

Page 24

1.15

Set Up Your Machine

1 Getting Started

¥ Load envelopes with the flap side facing away from you. The stamp

area is on the left side. The end of the envelope with the stamp area

enters the feeder last.

¥ Load letterhead paper with the design facing you. The top edge of

the sheet with the logo should enter the printer first.

Notes:

¥ Do not feed stamped envelopes. The stamp is shown for placement only.

¥ Never use envelopes with clasps, snaps, windows, coated linings, or self-stick

adhesives. These envelopes may severely damage the machine.

¥ Depending on the thickness of your envelopes, the multipurpose paper feeder

can hold up to 5 envelopes. If you experience envelope feeding problems, try

placing envelopes one at a time into the manual paper feeder.

4. Adjust the paper guides to the width of the print material. Slide

the guides until they lightly touch the stack of print material. Do not

bend the print material.

Paper guide

Note: If you print a job from PC, make sure that you select the correct paper

size and feed source in your application before printing.

LETTERHEAD

Page 25

1.16

Set Up Your Machine

Using the Manual Feeder

Use the front manual feeder in order to feed paper one sheet at a time

into your machine.

Note: When you print a file from PC, make sure that you select the manual

feeding source and the correct paper size from your software application

before starting your print job. (SF-5800P Only)

1. Place the paper in the manual feeder and adjust the paper guides

to the width of the print material.

Refer to the instructions to load each type of material on page 1.15.

2. Make sure that the paper is as far down as it will go.

3. Press Start to start manual feeding. If you have more than one page

to print, press Start for each page.

Manual paper feeder

Page 26

1.17

Set Up Your Machine

Paper Guidelines

When selecting or loading paper, envelopes, or other special media,

keep these guidelines in mind:

¥ Attempting to print on damp, curled, wrinkled, or torn paper can

cause paper jams and poor print quality.

¥ Use cut-sheet paper only. You cannot use multipart paper.

¥ Use only high quality, copier grade paper. Avoid paper with

embossed lettering, perforations, or texture that is too smooth or too

rough.

¥ Colored paper should be of the same high quality as white photocopy

paper. The pigments must withstand the printerÕs fusing temperature

of 392 oF (200 oC) for 0.1 second without deterioration. Do not use

paper with a colored coating that was added after the paper was

produced.

¥ Pre-printed forms must be printed with non-flammable, heat-resistant

inks that do not melt, vaporize, or release hazardous emissions when

subject to the printerÕs approximately 392 oF (200 oC) fusing

temperature for 0.1 second.

¥ Store paper in its ream wrapper until ready to use. Place cartons on

pallets or shelves, not on the floor. Do not place heavy objects on top

of the paper, whether it is packaged or unpackaged. Keep it away

from moisture, or other conditions that can cause it to wrinkle or curl.

¥ During storage, moisture-proof wrap (any plastic container or bag)

should be used to prevent dust and moisture from contaminating

your paper.

¥ Always use paper and other media that conform with those listed

under ÔSpecificationsÕ on page 4.7.

¥ When you choose envelopes, use only well-constructed envelopes

with sharp, and well creased folds.

- DO NOT use envelopes with clasps and snaps.

- DO NOT use envelopes with windows, coated linings, self-stick

adhesives, or other synthetic materials.

- DO NOT use damaged or poorly made envelopes.

1 Getting Started

Page 27

1.18

Set Up Your Machine

System Setup

Ringer Volume

You can adjust the volume of the ringer to the desired loudness.

1. Press Menu, then press System Setup on the one-touch keypad.

The display shows ÔRINGER VOLUME?.Õ

2. Press Enter, then use

¹

or to choose the desired loudness of the

ringer.

The selected ringer sounds and the display shows the loudness level

with > symbol. The more, the louder.

No > symbol turns the ringer off. The machine will work normally

even if the ringer is set to off.

3. Press Enter when the desired volume level is selected. The display

shows the next setup menu ÔDEFAULT SETTINGS?Õ For details on

menu, see below.

4. To return to Standby mode, press Stop.

Home Resolution and Home Contrast

The print resolution and contrast can be set to their most frequently

used modes. Whenever a document is sent or copied, the home

contrast and resolution mode will be activated unless otherwise

changed by using Resolution or Contrast button on the control

panel. See page 2.8 for details.

1. Press Menu, then press System Setup on the one-touch keypad.

The display shows ÔRINGER VOLUME?.Õ

2. Press ¹or until you find ÔDEFAULT SETTINGS?Õ.

RINGER VOLUME

[>>>>>>>> ]

Page 28

1.19

Set Up Your Machine

1 Getting Started

3. Press Enter. The display asks you to choose the home resolution

mode.

4. Press Ãor ¨repeatedly until you find the desired mode:

¥STANDARDÐuse with most documents.

¥FINEÐuse for documents with fine detail, such as small print.

¥SUPER FINEÐuse for documents that have extremely fine detail.

5. Press Enter when you find the mode. The display asks you to

choose the home contrast mode.

6. Press Ãor ¨repeatedly until you find the desired mode:

¥NORMALÐuse with documents of average or normal contrast.

¥DARKENÐuse with documents with low contrast or light images.

¥LIGHTENÐuse with documents with high contrast or dark images.

¥PHOTOÐfor obtaining maximum image quality with documents

that contain pictures or photographs with shades of gray.

7. Press Enter when you find the mode. The display shows the next

setup menu ÔSOUND CONTROL?.Õ For details on ÔSound ControlÕ

menu, see the following page.

8. To return to Standby mode, press Stop.

HOME RESOLUTION

[ STANDARD ]

HOME CONTRAST

[ NORMAL ]

Page 29

1.20

Set Up Your Machine

Sound Control

You can choose an alarm tone to sound when an error occurs (ALARM

SOUND) or any key is pressed (KEY SOUND).

1. Press Menu, then press System Setup on the one-touch keypad.

The display shows ÔRINGER VOLUME?.Õ

2. Press ¹or until you find ÔSOUND CONTROL?.Õ

3. Press Enter. The display prompts you to turn ON or OFF the alarm

sound.

4. Press 1 to turn the sound ON, or 2 to turn it OFF. You can also use

Ã

or

¨

button to choose ÔONÕ or ÔOFFÕ, then press Enter to confirm.

5. The display asks you to turn ON or OFF the key sound. Press 1 to

turn the sound ON, or 2 to turn it OFF.

6. The display shows the next setup menu. To return to Standby mode,

Press Stop.

Remote Diagnosis Protection

Remote diagnosis feature allows your machine to be checked out by

service company at a remote place through phone line.

If you do not want to use the remote diagnosis feature and want to

protect your machine from being open by an unauthorized person, you

can enable this remote diagnosis protection feature.

1. Press Menu, then press System Setup on the one-touch keypad.

The display shows ÔRINGER VOLUME?.Õ

2. Press ¹or until you find ÔREMOTE DIAGNOSIS

PROTECTION?Õ, then press Enter.

3. The display asks you to turn the feature ON or OFF. Press 1 to turn

it ON, or 2 to turn it OFF.

4. The display shows the next setup menu. To return to Standby mode,

Press Stop.

Page 30

1.21

Set Up Your Machine

1 Getting Started

Select Language

You can select the LCD display language between English, German, etc.

1. Press Menu, then press System Setup on the one-touch keypad.

The display shows ÔRINGER VOLUME?.Õ

2. Press ¹or until you find ÔSELECT LANGUAGE?Õ, then

press Enter.

3. Press ¹or to choose the desired display language, then

press Enter. You can also press the number of the language in the

display.

4. The display shows the next setup menu. To return to Standby mode,

Press Stop.

Econo Mode Setting

To get the most from your toner supply, set the Econo mode to On. If

set to On, you can preserve the toner supply. The print quality may be

reduced.

1. Press Menu, then press System Setup on the one-touch keypad.

The display shows ÔRINGER VOLUME?.Õ

2. Press ¹or until you find ÔECONO MODE SETTING?Õ, then

press Enter.

3. The display asks you to set the mode to ON or OFF. Press 1 to set

ON, or 2 to set OFF.

4. The display shows the next setup menu. To return to Standby mode,

Press Stop.

Page 31

Adjusting Speaker Volume

1. Press OHD to adjust the speaker volume. If you cannot hear dial

tone, check the phone line connection.

2. Press ¹or repeatedly until you find the desired loudness (0~7).

The display shows the current volume level.

3. After choosing the desired volume level, press OHD.

1.22

Set Up Your Machine

Page 32

1.23

Set Up Your Machine

1 Getting Started

Setting the Date and Time

The current date and time are shown in the display when the machine

is on and ready for use (Standby mode). The date and time are printed

on all faxes you send.

1. Press Menu, then press Date & Time on the one-touch keypad.

The display shows the currently set date and time.

05-03-1999

08:36 (PM)

e.g. 12 HOURS format

05-03-1999

20:36

e.g. 24 HOURS format

2. Enter the correct date and time using the number keypad.

DD (Day) = 01~31

MM (Month) = 01~12

YY (Year) = four digits (1990~2089)

HH (Hour) = 00~23 (24 HOURS format)

= 01~12 (12 HOURS format)

MM (Minute) = 00~59

AM (Ante Meridiem)

PM (Post Meridiem)

3. Press Enter when the date and time in the display is correct.

If you enter an invalid number, the machine beeps and doesnÕt

proceed to the next step. If this happens, just reenter the correct

number.

The display shows the date and time you have set, then returns to

Standby mode.

Page 33

1.24

Set Up Your Machine

Setting the System ID (Your Number and Name)

The System ID will be printed at the top of each page sent from your

machine.

1. Press Menu, then press System ID on the one-touch keypad.

The display asks you to enter the telephone number.

If there is a number previously registered, the number appears.

2. Enter the telephone number (up to 20 digits) which your machine is

connected to. You can include + and - symbol by pressing and #

respectively.

If you make a mistake, press Ãor ¨to move the cursor under the

wrong digit, then enter the correct number to change or press Delete

to delete the number.

3. Press Enter when the number in the display is correct. The display

asks you to enter your ID name.

4. Enter your ID name (up to 20 characters).

You can enter alphanumeric characters using the number keypad,

and include special symbols by pressing 0 repeatedly.

For details on how to use the number keypad to enter alphanumeric

characters, see page 2.4.

If you want to enter the same letter or number in succession (e.g. SS,

AA, 777), enter one digit, then move the cursor by pressing ¨, and

enter the next digit.

If you want to insert a space in the name, you can also use ¨button

to move the cursor to skip the position.

5. Press Enter when the name in the display is correct.

Note: If there is a number and name previously registered, the number and

name previously registered, the number and name appears in the upper

line and ÔED:1 DEL:2 NXT:3Õ in the bottom line.

Press 1to edit the existing number. Press 2to delete the number. The

machine deletes the number and continues next step. Press 3to keep the

number and continue.

Page 34

Operation

2

2.1

Page 35

2.2

01

System Data System ID Date & Time System Setup Memory Clear

02 03 04 05

06 07 08 09 10

Delay TX Memory TX Priority TX Polling

11 12 13 14 15

Add/Cancel Group Dial Maintenance Journal Help List

16 17 18 19 20

TX Confirm Schedule Job Phone Book System List

Print Priority

On/Off Line

Volume

Stop

Multifunction LASER Facsi

Menu

Copy

On/Off Line and Lamp

Turn your machine On-line or Off-line.

The lamp lights while the machine is

on-line, indicating the machine is ready

for printing a PC file.

Print Priority

Use to give print priority to PC file

while the machine prints

a received fax.

Power Save

The power saving menu item lets you

reduce power usage when the printer is

idle.

Reset

Restores user-selectable options to the

default value.

One-Touch Dial and

Special Function Buttons

Use to call most frequently used

numbers with one button. Also, use

these buttons with Menu button to set

up special functions or print lists.

LCD Display

The display shows the current status of

your machine and guides you through

various tasks using a menu system for

each of operation.

¹

and

Use to display the next or last menu item.

Also, use to adjust audible volume.

Menu

Use to choose special functions.

Ã

and

¨

Use to move cursor left or right

through the display.

Stop

Use to stop an operation at any time.

Copy

Use to copy a document.

Start/Enter

Use to start a job. Also use to activate the

selection shown in the display.

Using the Control Panel

SF-5800P

SF-5800

Page 36

2.3

ABC

Rcv.Mode Resolution Contrast

Search/Delete

DEF

JKL MNO

TUV WXYZ

Speed/Status

GHI

Redial/Pause

mile

Flash

Start/

Enter

OHD/V.Req.

PQRS

213

546

879

0

Search/Delete

Use to search for numbers in memory.

Or use to delete digits in the edit mode.

Rcv.Mode

(Receive Mode)

Use to choose the receive mode you

want to use. See page 2.17. The selected

mode is displayed.

Resolution

Use to choose the resolution of

transmitted documents.

Contrast

Use to choose the contrast of copied or

transmitted documents.

Speed/Status

Use to dial calls and send fax documents by entering a 2-digit number.

Also use to switch the LCD while performing dual jobs.

Redial/Pause

Use to redial the last phone number called. You can also use it to add a pause

when storing a number in memory.

Flash(R)

Use to perform a switch-hook operation such as call waiting.

OHD (On-Hook Dial) / V.Req (Voice Request)

Use to dial numbers without picking up the handset. Also use it

to make a voice call after sending or receiving a fax.

Number Keypad

Use to dial numbers manually or to

enter letters.

2 Operation

Page 37

2.4

Using the Number Keypad

As you perform various tasks, you will need to enter names and

numbers. For example, when you set up your machine you enter your

name (or your companyÕs name) and telephone number. When you use

the one-touch dial or speed dial, you also enter the telephone numbers

and names.

When the display asks you to enter a name, the LCD display reads:

You can then use the procedures described below to enter up to 20

letters and special characters, numerals, or spaces.

Entering Alphanumeric Characters

You can include special characters (space, plus sign, etc.) in the name by

using 0 key. See `KEYPAD CHARACTER ASSIGNMENTSÕ on page 2.5.

1. Locate the button labeled with the letter you want Ð then press the

button repeatedly until the correct letter appears in the display.

For example, to enter an O, press 6 (labeled MNO). Each time you

press 6 the display shows a different letterÐfirst M, then N, and O,

and finally 6.

The letter appears in the display.

ID)_

ID)O

ABC DEF

JKL MNO

TUV WXYZ

Speed/Status

GHI

Redial/Pause

Flash

OHD/V.Req.

PQRS

213

546

879

0

Page 38

2.5

2. When the letter you want appears in the display, press another

number key labeled with the next letter you want.

If the next letter is printed on the same number button, move the

cursor by pressing ¨, then press the button.

The blinking cursor moves right and the next letter appears in the

display.

3. Select additional letters in the same way. When youÕre finished

entering letters, press Enter.

KEYPAD CHARACTER ASSIGNMENTS

ID)OP

Key

1

2

3

4

5

6

7

8

9

0

1

A ➝ B ➝ C ➝ 2

D ➝ E ➝ F ➝ 3

G ➝ H ➝ I ➝ 4

J ➝ K ➝ L ➝ 5

M ➝ N ➝ O ➝ 6

P ➝ Q ➝ R ➝ S ➝ 7

T ➝ U ➝ V ➝ 8

W ➝ X ➝ Y ➝ Z ➝ 9

Space ➝

, ➝ . ➝ / ➝ + ➝➝& ➝ 0

Assigned numbers, letters, or characters

2 Operation

Page 39

2.6

Entering Numbers

You can enter the number of the remote fax machine manually by using

the number keypad. The number you pressed appears in the display.

When the display asks you to enter a number, you can also use a onetouch dial button (including Group dial) and 2-digit speed dial number.

Your machine lets you send the same document to more than one

location. When you enter a fax number, if the display reads ÔANOTHER

FAX NUMBER?Õ you are allowed to enter another fax number. To enter

ANOTHER FAX NUMBER, you can enter the number manually, or use

one-touch or 2-digit speed dial number. Note that you can not use

Group dial button for ANOTHER FAX NUMBER.

Editing Numbers or Name

If you make a mistake while entering a number or name, move the

cursor under the wrong digit by using Ãor ¨. Then press the correct

number to change, or press Delete to delete the number.

Inserting Pause

With some private telephone systems, you must dial an access code (9,

for example) and listen for a second dial tone before dialing an outside

number. In such cases, you must insert a pause in the number. Insert a

pause in a number when you are setting up a one-touch or speed dial

number, or when you dial a number without lifting the handset.

To insert a pause, press Pause while entering the number.

When you dial a number, the dialing process pauses for about 3~4

seconds at the point where you pressed Pause.

If you require a longer pause time, press Pause twice.

TEL)95551212_

Page 40

2.7

Sending a Fax

Sending a Fax

Preparing Documents for Faxing or Copying

You can use the machine to fax, or copy documents that are printed on

standard letter, legal, or A4 size paper. Follow these guidelines to

prepare your documents.

¥ Do not attempt to feed the following types of documents into the

machine. Instead, make copies and insert the copies into the

document tray.

- wrinkled or creased paper

- curled or rolled paper

- torn paper

- carbon-paper or carbon-backed paper

- coated paper

- onion skin or thin paper

¥ Remove all staples, paper clips, and the like before feeding the

document.

¥ Make sure any glue, ink, or correction fluid on the paper is

completely dry before feeding the document.

¥ Do not feed documents with pages that are different sizes or of

different thicknesses.

2 Operation

Page 41

2.8

Sending a Fax

Setting Document Resolution and Contrast

We recommend sending documents printed using a typewriter, felt tip

pen, black ink, or laserwriter. The paper should be white or very light,

and of normal weight-not cardboard. Blue lines on a ruled pad donÕt

fax well.

When you send normal documents, you need not adjust the resolution

and the contrast.

If you send documents with unusual contrast characteristics, including

photographs, you can adjust the resolution and contrast to send a highquality transmission of the documents.

Resolution

Press Resolution button to increase sharpness and clarity. By pressing

Resolution button repeatedly after loading a document, you can

choose between STANDARD, FINE, or SUPER FINE mode.

STANDARD works well for documents with normal sized characters.

FINE is good for documents containing small characters or thin lines, or

print from a dot-matrix printer.

SUPER FINE works well for documents containing extremely fine

detail. SUPER FINE works only if the remote machine also has the

SUPER FINE feature.

Contrast

Press Contrast button to compensate for the brightness or darkness

of your faxed document. By pressing Contrast button repeatedly after

loading a document, you can choose between NORMAL, DARKEN,

LIGHTEN, or PHOTO.

NORMAL works well for normal documents.

DARKEN works with light print or faint pencil markings.

LIGHTEN works with dark print.

PHOTO is used when faxing photographs or other documents

containing color or shades of gray. Although your machine wonÕt

transmit color, it will print and send up to 64 shades of gray.

Note: You can set the default resolution and contrast. The default mode

will be effective when a document is sent or copied unless you

change the setting for individual operation. Once the current

operation is completed, the setting will revert to their preset defaults

for the next operation. For details on how to set the default

resolution and contrast, see page 1.18.

Page 42

2.9

Sending a Fax

2 Operation

Loading Document

1. Turn the page face down.

2. Adjust the document guides to match the width of the document.

3. Slide the sheet down into the document tray until itÕs gripped by

the machine.

The automatic document feeder seizes and pulls in the page. The

display shows ÔDOCUMENT READYÕ and the remaining memory

capacity alternatively.

You can insert up to 30 sheets (75 g/m2 Paper) at a time. If you insert

more than one sheet, make sure the bottom sheet enters first. Stagger

the leading edge of the sheets slightly, and insert the sheets with a

slight push to ensure smooth feeding.

To add pages while the fax is sending, insert them into the loading

slot on top of the already loaded sheets.

4. If necessary, use the Resolution button to change the resolution and

the Contrast button to change the contrast (see page 2.8).

document guide

Page 43

2.10

Sending a Fax

Sending a Fax Automatically

1. After loading a document, enter the number of the remote fax

machine using the number keypad.

You can store one-touch or speed dial numbers so that you can dial

your most frequently used numbers with one touch of a button or 2digit speed dial number. For information on storing and using

numbers in memory, see page 2.27.

If you make a mistake while entering a number, move the cursor

under the wrong digit by using Ãor ¨, and correct the number or

press Delete to delete the number.

2. Press Start when the number appears correctly in the display. The

machine dials the number and begins to transmit.

Canceling Transmission

Press Stop any time during transmission. The machine continues to

send the fax and the display shows a message warning you that the

machine is in use. Press Stop again.

Confirming Transmission

When the last page of your document has been sent successfully, the

machine beeps and returns to Standby mode.

If something went wrong during your fax transmission, an error

message appears in the display. For a listing of error messages and their

meanings, see page 3.6.

If you receive an error message, press Stop to clear the message and try

to send the document again.

You can set your machine to print out a confirmation report

automatically each time sending is completed. For more information,

see `User OptionsÕ on page 2.38.

Page 44

2.11

Sending a Fax

2 Operation

Automatic Redial

When you send a fax, if the number you have dialed is busy or there is no

answer, the machine hangs up, waits for the specified retry term and

redials the number. If after the specified number of retry attempts (retry

count), the machine fails to connect, the machine returns to Standby

mode.

While the machine is redialing, the display shows ÔRETRY REDIAL?.Õ If

you want to redial the number immediately, press Start. To stop

redialing, press Stop.

You can select the number of retries and the retry term between each

redial attempt.

Page 45

2.12

Sending a Fax

Voice Request

If youÕre sending or receiving a document and need to speak to the

other person during the same phone call, use Voice Request to alert the

person at the remote site. You can also respond to a Voice Request made

by the person at the remote end.

Sending a Voice Request

1. Press V.Req while a document is being sent or received. Voice

Request signal is stored and then sent to the remote fax machine after

the document has been sent or received.

2. When the phone rings, pick up the handset and answer it.

You can cancel a Voice Request by pressing V.Req again while you

are sending or receiving a document.

Answering a Voice Request

When the phone rings after sending or receiving a fax, pick up the

handset and answer it.

If you donÕt answer the Voice Request, the machine prints out the

number that made the Voice Request, and the time and date the request

was made.

Note: If your machine is not equipped with handset, youÕll pick up the

handset of the extension phone connected to EXT.LINE jack. In the

case, pick up the handset, then press

Stop

.

Delayed Transmission

You can set your machine to send a fax at a later time when you will

not be present. A maximum of 30 transmission jobs can be reserved in

your machine.

1. Load the document face down. If necessary, adjust Resolution, or

Contrast. For details, see page 2.8.

2. Press Menu, then press Delay TX on the one-touch keypad.

3. Enter the number of the remote machine, then press Enter.

To enter the number, you can also press a one-touch button including

Group dial button. Otherwise, press Speed/Status, enter a 2-digit

speed dial number, then press Enter. The stored number (and name)

appears in the display. Press Enter to confirm the number.

Page 46

2.13

Sending a Fax

2 Operation

4. The display asks you to enter another fax number to send the

document to another location.

Note: The machine displays the ÔANOTHER FAX NUMBER?Õ message

repeatedly, each time you enter a fax number using manual dialing, OneTouch, 2-digit Speed Dialing, or Group Dialing. If you already used a

group number at step 3, you cannot use another group number any more.

You can use only one group number at this transmission job.

If you have used this multi-address transmission feature in other

operation(s) currently registered in memory, the machine does not display

ÔANOTHER FAX NUMBER?Õ.

5. If you want to send to more than one location, press Enter and enter

another fax number using the number keypad, one-touch dial, or 2digit speed dial number. Note that you cannot use Group dial number

for another fax number.

The number appears in the display. Press Enter to confirm the number.

Or

To send to one location or when you complete the last fax number

setting, press Stop.

6. The display asks you to enter a name. If you want to assign a name to

the transmission, enter the name. If not, skip over this step.

For details on how to enter letters using the number keypad, see page 2.4.

7. Press Enter. The display shows the current time on the upper line and

asks you to enter the time in the bottom line when the fax is to be sent.

8. Enter the time by using the number keypad, then press Enter.

Enter the time in 24-hour format or 12-hour format. For example, enter

2230 for 10:30 P.M. If you set a time earlier than the current time, the

document will be sent at that time on the following day.

9. The machine returns to Standby mode and the display shows a

reminder that a Delayed Transmission is set.

Note: If you want to cancel the Delayed Transmission, see ÔCanceling a Standby

OperationÕ on page 2.16.

ANOTHER

FAX NUMBER ?

CURRENT [12:30]

START [12:30]

Page 47

2.14

Sending a Fax

Memory Transmission (Broadcasting)

With Memory Transmission, documents are automatically stored in

memory and sent to a remote station. Use this feature to send your

documents to multiple locations. After sending, the documents are

automatically erased from memory.

1. Load the document face down. If necessary, adjust Resolution, or

Contrast. For details, see page 2.8.

2. Press Menu, then press Memory TX on the one-touch keypad.

3. Enter the number of the remote machine, then press Enter.

To enter the number, you can also press a one-touch button including

group dial button. Otherwise, press Speed/Status, enter a 2-digit

speed dial number, then press Enter. The stored number (and name)

appears in the display. Press Enter to confirm the number.

4. The display asks you to enter another fax number to send the

document to another location.

Note: The machine displays the ÔANOTHER FAX NUMBER?Õ message

repeatedly, each time you enter a fax number using manual dialing,

One-Touch, 2-digit Speed Dialing, or Group Dialing. If you already

used a group number at step 3, you cannot use another group number

any more. You can use only one group number at this transmission job.

If you have used this multi-address transmission feature in other

operation(s) currently registered in memory, the machine does not

display ÔANOTHER FAX NUMBER?Õ.

5. If you want to send to more than one location, press Enter and

enter another fax number using the number keypad, one-touch

dial, or 2-digit speed dial number. Note that you cannot use Group

dial number for another fax number.

The number appears in the display. Press Enter to confirm the

number.

Or

To send to one location or when you complete the last fax number

setting, press Stop.

6. The document will be scanned into memory before transmission. The

display shows the memory capacity and the number of pages, then

the machine begins sending the document.

ANOTHER

FAX NUMBER ?

Page 48

2.15

Sending a Fax

2 Operation

Priority Transmission

When priority transmission is enabled, a high priority document can be

transmitted ahead of reserved operations. The document is scanned

into memory, then transmitted when the current operation concludes. In

addition, a priority transmission will interrupt a broadcast operation

between stations (i.e., when transmission to station A ends, before

transmission to station B begins) or between redial attempts.

1. Load the document face down. If necessary, adjust Resolution, or

Contrast. For details, see page 2.8.

2. Press Menu, then press Priority TX on the one-touch keypad.

3. Enter the number of the remote machine, then press Enter.

To enter the number you can also press a one-touch button.

Otherwise, press Speed/Status, enter a 2-digit speed dial number,

then press Enter. The stored number (and name) appears in the

display. Press Enter to confirm the number. Note that you can not use

Group dial number.

4. The display asks you to enter a name. If you want to assign a name

to the transmission, enter the name. If not, skip over this step.

For details on how to enter letters using the number keypad,

see page 2.4.

5. Press Enter. The display shows the number being dialed, then the

machine begins sending the document.

Page 49

2.16

Sending a Fax

3. Press Enter to confirm ÔADDÕ. The display shows operation

currently reserved in memory.

4. Press or ¹repeatedly until you find operation you want to add

documents, then press Enter.

The machine automatically stores the documents in memory, and

displays the number of total pages and added pages, then returns to

Standby mode.

22:00 DELAY TX

SAMSUNG

Canceling a Standby Operation

1. Press Menu, then press Add/Cancel on the one-touch keypad. The

display asks you to select ÔADDÕ or ÔCANCELÕ.

2. Press 2 to choose ÔCANCELÕ. The display shows operation currently

reserved in memory.

3. Press or ¹repeatedly until you find the operation you want to

cancel, then press Enter when you find the operation.

Adding Documents To a Standby Operation

You can add documents to the delayed transmission previously

reserved in your machineÕs memory.

1. Load the document face down. If necessary, adjust Resolution, or

Contrast. For details, see page 2.8.

2. Press Menu, then press Add/Cancel on the one-touch keypad.

The display asks you to select ÔADDÕ or ÔCANCELÕ.

OPERATION

1.ADD 2.CANCEL

(e.g. Delay transmission is

scheduled to be sent at

10:00 PM.)

10:00 PM DELAY TX

SAMSUNG

24-hour format

12-hour format

Page 50

2.17

Receiving a Fax

2 Operation

Receiving a Fax

Your multi-function machine has four reception modes:

¥ In FAX mode, the machine answers an incoming call and immediately

goes into receive mode, waiting for a fax to be sent.

¥ In ANS/FAX mode, the answering machine answers an incoming call,

and the caller can leave a message on the answering machine. If the

fax machine senses a fax tone on the line, the call automatically

switches over to the fax machine. To use the ANS/FAX mode, you

have to attach an answering machine to the EXT socket on your fax

machine (see page 1.8).

¥ In TEL mode, automatic fax reception is turned off. You can receive a

fax only by manually picking up the handset and pressing Start.

The current reception mode is displayed in the bottom line of the

display window when the machine is in Standby mode.

Note: While you print a PC file with this machine, an incoming fax will be

received and stored in memory. If you have a lot of pages to print, we

recommend stopping PC printing to prevent memory from becoming full.

(SF-5800P only)

Receiving a Fax

10-MAR-1999 100%

10:30 FAX

Receiving mode

MAR-10-1999 100%

10:30 FAX

or

Receiving mode

Page 51

2.18

Receiving a Fax

Receiving Automatically in FAX Mode

1. Press Rcv.Mode until the display shows ÔFAX.Õ

2. When you get a call, the machine answers the call on the default

ring and receives a fax automatically. You can change the number of

rings.

To adjust ringer volume, press Menu, System Setup on the one-touch

keypad, Enter to access the ringer volume mode, then use

¹

or to

choose the desired loudness.

Receiving Manually in TEL Mode

If you have the machine with handset or if you have a regular phone

connected to the EXT.LINE jack on the bottom of the machine, you can

answer calls using the handset, and start the machine to receive a fax.

1. Press Rcv.Mode until the display shows ÔTEL.Õ

2. When the telephone rings, pick up the handset and answer it.

3. If you hear a fax tone, or if the person on the other end asks you to

receive a document, press Start on the on the machine.

Or, press the buttons Ô 9 Õ (star-nine-star) on the extension

telephone.

Ô 9 Ô is the remote receive start code preset at the factory. The

first and the last asterisks are fixed, but you can change the middle

character to whatever you choose. For more information, see page

2.39.

4. Replace the handset. The machine begins receiving and returns to

Page 52

2.19

Receiving a Fax

Notes:

¥If you have set your machine to ANS/FAX mode and your answering machine

is switched off, or no answering machine is connected to the machine, the

machine will automatically go into fax receive mode after several rings.

¥If your answering machine has a Ôuser-selectable ring counterÕ, set the

machine to answer incoming calls within 4 ring.

¥If you are in TEL mode (manual reception) when the answering machine is

connected to your machine, you must switch off the answering machine, or

the outgoing message from the answering machine will interrupt your phone

conversation.

Receiving Automatically in ANS/FAX Mode

To use this mode, you must attach an answering machine to the

EXT.LINE jack on the back of your machine (see page 1.9).

1. Press Rcv.Mode until the display shows ÔANS/FAX.Õ

2. When you get a call, the answering machine answers it. If the caller

leaves a message, the answering machine stores the message normally.

If your machine hears a fax tone on the line, the fax receive mode is

activated.

2 Operation

Page 53

2.20

Receiving a Fax

If Your Machine is Out of Paper When it Receives a Fax Receiving into Memory

If your machine is set to receive a fax automatically and the recording

paper has run out, a paper jam has occurred, or you are making a copy

or printing a list, the incoming documents are automatically stored in

the fax machineÕs memory. After receiving documents, the machine

displays ÔMEMORY RECEIVEDÕ and the cause, ÔNO PAPERÕ, for

example.

You must clear the problem by loading new paper or clearing the jam.

Then your machine will automatically print the fax stored in memory.

If you clear the problem while the machine is receiving documents into

memory, it will print the stored document immediately after you clear

the problem.

Distinctive Ring Pattern Detection (DRPD) -

(Option)

ÒDistinctive RingÓ is a telephone company service which enables a user

to use a single telephone line to answer several different telephone

numbers. The particular number someone uses to call you on is

identified by a distinctive ringing pattern consisting of various

combinations of long and short ringing sounds. This feature is often

used by answering services who answer telephones for many different

clients and need to know which number someone is calling in on to

properly answer the phone.

Using the Distinctive Ring Pattern Detection feature (DRPD), this

machine can ÒlearnÓ the ring pattern you designate to be answered by

the fax machine. Unless you change it, this ringing pattern will continue

to be recognized and answered as a fax call, and all other ringing

patterns will be forwarded to the telephone or answering machine

plugged into the EXT.LINE jack. You can easily suspend or change

Distinctive Ring Pattern Detection at any time.

With the DRPD feature active, ÔDRPDÕ appears in the display and the

previously set reception mode is ignored. If you turn DRPD off, the

machine returns to any previously set reception mode.

Page 54

Polling

What is Polling?

Polling is used when one fax machine requests another to send a

document. This is useful when the person with the original document to

be sent is not in the office. The person who wants to receive the document

calls the machine holding the original and requests that the document be

sent. In other words, it ÒpollsÓ the machine holding the original.

Being Polled By a Remote Machine

You can program your fax machine to send documents in your absence

when polled by a remote fax machine. It is possible to use a Poll code to

prevent unauthorized polling of your fax machine. When you secure

your machine in this manner, only those who know the Poll code can

poll your machine.

1. Load the document face down. If necessary, use Resolution, or

Contrast. For details, see page 2.8.

2. Press Menu, then press Polling on the one-touch keypad. The display

prompts that you can choose the two polling options; TX POLL and

DELAY RX POLL.

3. Press Enter to confirm Ô1.TX POLL.Õ The display asks you to enter a

4-digit poll code. The poll code is preset to 0000 at the factory, which

represents no Poll code.

4. If you want to use a Poll code, enter the 4-digit code (except for

0000), then press Enter.

Or

If you do not want to secure the transmission with a Poll code, press

Enter when the display shows 0000 for TX-POLL CODE, or press 0000.

5. The display asks you to store the document in the machineÕs bulletin

memory.

If you store the document in the bulletin board memory, more than one

remote station can poll that document from your machine. If not, the file

will be automatically erased after being polled by a remote machine.

To store the document in the bulletin board memory, press Enter.

Or

If you do not want to store in the memory, press Stop.

2.21

Receiving a Fax

2 Operation

TX-POLL CODE

[0000]

Page 55

2.22

Receiving a Fax

6. The machine stores the document in memory. The display counts the

number of pages being stored in memory and the memory capacity

remaining.

The machine returns to Standby mode and the display shows a

reminder that a Polling Transmission is set. The machine

automatically switches to FAX mode (automatic receiving) when set to

be polled.

Adding Documents To the Job to be polled

If you want to add documents to the original documents waiting in

memory to be polled, load the additional documents face down into the

feeder and then follow the procedure below.

1. Press Menu, then press Polling, on the one-touch keypad. The LCD

displays the polling options.

2. Press 1 to select Ô1.TX POLLÕ. The display asks you to enter the Poll

code.

The last used Poll code is displayed. Poll code Ô0000Õ represents no

code.

3. Enter the 4-digit Poll code you have previously set, then press Enter.

The display asks you to select ÔADDÕ or ÔCANCEL.Õ

4. To add documents to the previously stored documents, press 1.

The machine stores the document in memory and returns to Standby

mode.

If you want to cancel the adding job and return to Standby mode,

press 2. The display asks you to confirm it. Press 1.

TX-POLL CODE

[0000]

TX POLL

1.ADD 2.CANCEL

Page 56

2.23

Receiving a Fax

2 Operation

Polling One or More Remote Machines

You can set your machine up to automatically receive documents from

one or more unattended remote fax machines now, or at a later time.

This feature permits unattended polling in the evening hours when

telephone rates are lower.

Note: The remote machine must be ready for polling.

1. Press Menu, then press Polling on the one-touch keypad. The

display shows the polling options.

2. Press 2 to select ÔDELAY RX POLL.Õ The display asks you to enter

the number of the remote fax machine.

3. Enter the number of the remote fax machine, then press Enter.

You can press a one-touch button including Group dial button.

Otherwise, press Speed/Status, enter a 2-digit speed dial number,

then press Enter. The stored number (and name) appears in the

display. You can use only one Group number at the polling job. Press

Enter when the number appears correctly in the display.

4. The display asks you to enter another fax number to receive

documents from another location.

To poll more than one location, press Enter and repeat steps 3-4.

Or

To poll one location or when you enter all locations, press Stop.

Note: The ANOTHER FAX NUMBER? prompt does not appear if any

broadcasting currently set up in your fax machine has not executed.

One operation can be set to call up to 10 other fax numbers in a

single operation.

5. The display asks you to enter a name for the job. To assign a name to

the polling job, enter the name. If not, skip over this step.

Page 57

2.24

Receiving a Fax

6. Press Enter when the name appears correctly or without entering a

name. The display asks you to enter a 4-digit code. Poll code Ô0000Õ

represents no code.

If the remote machine is secured with a Poll code, you must enter

the correct code, and press Enter.

Or

If the remote machine is not secured with a Poll code, press Enter

to accept [0000] which represents no code, or press 0000.

7. The display asks you to enter the time when your machine calls the

remote machine. Enter the time in 24-hour format or 12-hour format.

For example, enter 2030 for 08:30 P.M. If you set a time earlier than

the current time, your machine call the number at that time on the

following day.

Or

To call the remote machine immediately, skip over this step.

8. Press Enter when the time appears correctly in the display or

without entering the time. If you have entered a specific start time,

the machine will dial, and receive a document from the remote

machine at the time.

If not, the machine dials the remote machine immediately.

Page 58

2.25

Receiving a Fax

2 Operation

Making a Copy

Making a Copy

The resolution is automatically set to S.FINE while the copy feature is in

use, however, the contrast can be changed to produce the best copy

quality for the particular document containing faint markings, dark

image, photographs, or other halftone images.

When you make a copy, your machine provides several option features

you can choose as follows:

-Multiple copies : 1 to 99 copies of the document can be made.

-Copy rate : You can reduce or expand the image size by 1% increments

from 50% to 200%.

-Collation : When COPY COLLATE menu is set to ON, the machine

sorts the print job. For example, if you copy a three-page job to print 2

copies, the machine prints page1, page2, page3, page1, page2, page3.

To make a direct single copy without setting any option:

1. Load a document with the print side facing down. If necessary,

adjust Contrast button to change the contrast. For details on the

Contrast, see page 2.8.

2. Press Copy twice or press Copy then Enter. The machine starts

copying.

Page 59

To set copy options:

1. Load a document with the print side facing down. If necessary, adjust

Contrast button to change the contrast. For details on the Contrast, see

page 2.8.

2. Press Copy. The display asks you to enter the number of copies (1 to 99).

3. If you need two or more copies, enter the desired number using the

dial keypad, then press . You can also press without setting the

number of copies. The display shows the next option; copy rate menu.

4. If you want to reduce or expand the image size, press 2, enter the

number of the desired copy rate, then press

. Go to step 7.

If not, press 1.

5. The display asks you to choose how to collate. There are two ways to

collate multiple copies; OFF and ON.

The ÔOFFÕ is the stacking method. This will make ÔnÕ copies of page

one, ÔnÕ copies of page two, and so on. These will all be stacked on top

of each other. The second method ÔONÕ is the sorting method. This will

make 1 copy of page 1, 2, 3, 4, in order, then makes a second copy of 1,

2, 3, 4 until a total of ÔnÕ copies has been made.

Press 1 or 2 to choose the desired collation method. You can also

press without setting the collation. The LCD display scrolls back

and shows the first option; number of copies.

6. Press Copy to begin the copy operation.

Note: When you set the copy options, pressing Copy anytime begins the copy

operation immediately without displaying the remaining options.

2.26

Making a Copy

ENTER RATE

[50-200] <100>

[COPY COLLATE]

1:ON 2:OFF

OFF

COPY

[01-99] <01>

REDUCE/ENLARGE

1:AUTO 2:MANUAL

1

ON

1

1

2

2

2

3

2

1

3

2

1

Page 60

2.27

Automatic Dialing

2 Operation

One-Touch Dialing

One-Touch dialing lets you use any one of the 20 One-touch buttons

located on the left of the machineÕs control panel to automatically dial a

number.

Storing a Number for One-Touch Dialing

1. Press and hold the one-touch button (01 through 20) for 2 seconds

that you want to assign. The display shows `Txx:Õ, where `xxÕ

represents the selected one-touch button.

2. Enter the number up to 46 digits you want to store by using the

number keypad, then press Enter.

To insert a pause between numbers, press Redial/Pause;

a Ô-Õ(hyphen) symbol appears in the display.

If you make a mistake while entering a number, use Ãor ¨to move

the cursor under the wrong digit, then enter the correct digit, or press

Delete.

Automatic

Dialing

Page 61

2.28

Automatic Dialing

3. The display asks you to enter a name. Enter the desired name (up to

20 digits). For information on how to enter names, see page 2.4.

Or

If you donÕt want to assign a name, skip this step.

If you assign a name to the number, the name appears in the display

when you press the one-touch button.

4. Press Enter when the name appears correctly or without entering a

name.

5. To set another one-touch number, press the desired one-touch

button and repeat steps 2 through 5.

Or

To return to Standby mode, press Stop.

Sending a Fax Using a One-Touch Number

1. Load a document you want to send a fax.

2. Press the one-touch button (01 through 20) to which you stored a

number. The number will be automatically dialed, then the document

begins to transmit when the remote fax machine answers the phone.

Using Address Label

A One-touch label sheet is included with your machine. As you store

numbers in one-touch dial buttons, make a note of the numbers on the

label to remind you which number is stored in each position.

1. Remove the clear cover and

label using an instrument

with a pointed end, as

shown at right.

2. Write information on the

label and replace the label

and cover.

You may want to use pencil

in case you wish to change

these numbers later.

Page 62

2.29

Automatic Dialing

2 Operation

Speed Dialing

You can store up to 80 numbers in 2-digit Speed Dial locations (01-80).

Storing a Number for Speed Dialing

1. Press and hold Speed/Status for 2 seconds.

2. Enter a 2-digit location number to which you want to store a

number, then press Enter.

If a number is already stored in the location you chose, the display

shows the number in the upper line and `ED:1 DEL:2 NXT:3Õ in the

bottom line. Press 1 to edit that number, 2 to delete that number, or 3

to keep that number and choose another location.

3. Enter the number you want to store, then press Enter.

4. To assign a name to the number, enter the desired name. For

information on how to enter names, see page 2.4.

Or

If you donÕt want to assign a name, skip this step.

5. Press Enter when the name appears correctly or without entering a

name.

6. To store more telephone numbers, repeat steps 2 through 5.

Or

To return to Standby mode, press Stop.

Sending a Fax Using a Speed Number

1. Load a document you want to send a fax.

2. Press Speed/Status, then enter a 2-digit speed dial location

number.

3. Press Start to dial the number. The number will be automatically

dialed, then the document begins to be transmitted when the remote

fax machine answers the phone.

Page 63

2.30

Automatic Dialing

Group Dialing (for Multi-Address Transmission)

Numerous one-touch and speed dial numbers can be registered as a

Group. By using the Group number, you can send a document to

multiple parties in a single operation. Your machine will dial the remote

numbers in stored sequence. If the number is busy, your machine will

dial the next stored number and after dialing all of the stored numbers,

will automatically redial any number previously busy. Before you can

use this feature, you must coordinate and store the Group numbers

desired.

Storing One-Touch or Speed Dial Numbers for Group

Dialing

1. Press Menu, then press Group Dial on the one-touch keypad.

2. Enter a 2-digit location number you want to use for group dial,

then press Enter.

The display asks you to press a one-touch button or enter a speed

dial number you wish to include in the group.

ENTER ONE-TOUCH

/ SPEED DIAL> ##

3. Press a one-touch button to which the fax number you wish to

include in the group is stored.

Or

Enter a 2-digit speed dial location to which the fax number you

wish to include in the group is stored.

4. Press Enter. Repeat steps 3 and 4 to enter more destination numbers

into the selected group.

5. Press Stop when you have entered all the desired destinations. The

display asks you to enter a name.

6. To assign a name to the Group, enter the desired name.

Or

If you donÕt want to assign a name, skip this procedure.

7. Press Enter. If you want to store another group dial number, repeat

steps 2 through 7.

Or

To return to Standby mode, press Stop.

Page 64

2.31

Automatic Dialing

2 Operation

Storing a Group into a One-Touch Button

You can use a Group number as One-touch dialing. Before you can use

this feature, you must first register the Group number (see ÔStoring a

Number for One-Touch DialingÕ on page 2.27), and then store the

registered Group number into an empty One-touch button.

1. Press and hold the One-touch button that you want to assign (01

through 20) for 2 seconds.

2. Enter the 2-digit Group number, then press Enter. The group

number is stored in the selected one-touch button, and the display

asks you to enter one-touch button for another group dial if you

wish.

3. If you want to store another One-touch Group Dial numbers, repeat

steps 1-3. If you want to return to Standby mode, press Stop.

Sending a Fax Using Group Dialing

(Multi-Address Transmission)

You can use Group Dialing for Memory Transmission, or Delayed

Transmission.

Follow the procedure of the desired operation (Memory Transmission p. 2.14, Delayed Transmission - p. 2.12). When you come to a step in

which the display requests you to enter the remote fax number, press

the one-touch button to which you stored the group number. You can

use only one group number at one operation. Then continue the

procedure to complete the desired operation.

Your machine automatically scans the document loaded in the

document tray into memory, and the machine will dial each of the

numbers included in the Group.

Page 65

2.32

Automatic Dialing

Searching for a Number in Memory

There are two ways to search for a number in memory. You can either

scan from A to Z sequentially, or you can search using the first letter of

the name associated with the number.

Searching Sequentially through Memory

1. Press Search, then press

to move downward through the

memory until you find the number you want. To move upward,

press ¹.

Pressing allows you to search downward through the entire

memory in alphabetical order (from A to Z), and ¹allows you to

search upward in reverse alphabetical order (from Z to A).

Each time you press or ¹, the display shows the next number

stored in memory.

While searching through the machineÕs memory, youÕll see that each

entry is preceded by one of three letters: ÔTÕ for one-touch dial, ÔSÕ for

speed, or ÔGÕ for group dial number. These letters tell you how the

number is stored.

2. When the number you want appears in the display, press Start to

dial.

If a document is loaded, the document begins to be transmitted when

the remote fax machine answers the phone.

Searching for a Particular First Letter

1. Press Search, then press the button labeled with the letter you

want to search for. A name beginning with the letter appears in the

display.

For example, if you want to find the name ÔMOBILE,Õ press the Ô6Õ

button, which is labeled with ÔMNO.Õ

2. Press to display the next name in the list, or ¹to display the

previous name.

3. When the name and number you want appear, press Start to dial.

Page 66

Using Function Buttons

Redial

TO REDIAL THE NUMBER LAST CALLED

Press Redial. If a document is loaded in the document tray, the machine

automatically begins to send.

TO SEARCH THROUGH REDIAL MEMORY

1. Press and hold Redial for 2 seconds. The Redial memory in your

machine retains the last 10 numbers called. If you have dialed the

same number multiple times, the machine does not count the

duplicates.

2. Press or ¹to search through memory until you find the number

you want.

3. When the number you want appears in the display, press Start to