Page 1

1-1

Samsung Electronics

1. Precautions

Please read the following carefully to prevent any accidents and not to damage the unit during service.

1-1 Safety Precautions

1-2 Precautions on Disassembly and Reassembly

1. Safety Precautions

There are some electric or machinery parts with safety

related property. If the parts replaced are different from

the original, the safety may not function. Even if the part

could allow higher voltage than that of the part used, do

not replace it and use a regular product clarified in specifications.

2. Be careful not to leave a switch, a cover or a safety device

out when reinstalling or assembling the product after

repair.

3. Replacing Precautions

Do not change or add parts as you like. You cannot benefit from such a remodeled product at your will during the

term of guarantee.

4. You must replace overheated or damaged parts or cords

with regular products. Please solve the problem causing

any damage or overheating and troubles beforehand.

Especially mind the safety on the part with this

mark.

You must use regular parts described in specifications for the parts inflammable and where the current can be flown. Otherwise any hazard such as

an electric shock or a fire could occur.

LASER STATEMENT (LASERTURVALLISUUS)

WARNING : NEVER OPERATE AND SERVICE THE PRINTER

WITH THE PROTECTIVE COVER REMOVED

FROM LASER/SCANNER ASSEMBLY. THE

REFLECTIVE BEAM, ALTHOUGH INVISIBLE, CAN

DAMAGE YOUR EYES.

Class 1 laser product

Luokan 1 laserlaite

Klass 1 laser apparat

Allonpituus 770-795nm

Teho 0.3mW±0.03mW

CAUTION

VORSICHT

ATTENTION

ATTENZIONE

PRECAUCION

CAUTION : Avoid exposure to invisible laser radiation when the

development unit is not installed.

INVISIBLE LASER RADIATION WHEN

THIS COVER OPEN. DO NOT OPEN

THIS COVER.

UNSICHTBARE LASERSTRAHLUNG,

WENN ABDECKUNG GEOFFNET.

NIGHT DEM STRAHLAUSSETZEN.

REYONNEMENT LASER INVISIBLE EN CAS

D’OUVERTURE. EXPOSITION DANGERUSE AU

FAISCEAU.

RADIAZIONE LASER INVISIBLE IN CASO DI

APERTURA. EVITARE L’ESPOSIZONE LA FASCIO.

REDIACION LASER INVISIBLE CUANDO SE

ABRE. EVITAR EXPONERSE AL RAYO.

Very careful precautions should be taken when replacing

parts. Before replacing, please check cables because you

cannot put the cables that you removed for replacing parts

into the proper place if you would not make sure of where

they were connected and in which condition.

Please do the following before disassembling

for a repair or replacement of parts.

1. Pull out paper cassette, printer cartridge installed.

Especially careful not to be scratched by the surface of

developer or not to expose them to light.

2. Turn the power switch off.

3. Take out the power plug, printer cable from the printer.

4. Use only the same type of part as original when replacing

parts.

5. Do not force to open or fasten plastic material components.

6. Be careful that small parts such as screws should not get

in the printer.

7. When disassembling, assembling, also observe small

components are located in place.

8. If you uncover and turn the machine over to replace some

parts, toner or paper particles may contaminate the LSU

window. Protect the LSU window with clean paper.

Releasing Plastic Latches

Many of parts are held in

place with plastic latches.

The latches break easily :

release them carefully.

To remove such parts, press

the hook end of the latch

away from the part to which

it is latched.

Page 2

Certain semiconductor devices can be easily damaged by

static electricity. Such components are commonly called

“Electrostatically Sensitive (ES) Devices”, or ESDs.

Examples of typical ESDs are: integrated circuits, some field

effect transistors, and semiconductor “chip” components.

The techniques outlined below should be followed to help

reduce the incidence of component damage caused by static electricity.

1. Immediately before handling a semiconductor component or semiconductor-equipped assembly, drain off any

electrostatic charge on your body by touching a known

earth ground. Alternatively, employ a commercially available wrist strap device, which should be removed for your

personal safety reasons prior to applying power to the unit

under test.

2. After removing an electrical assembly equipped with

ESDs, place the assembly on a conductive surface, such

as aluminum or copper foil, or conductive foam, to prevent electrostatic charge buildup in the vicinity of the

assembly .

3. Use only a grounded tip soldering iron to solder or desolder ESDs.

4. Use only an “anti-static” solder removal device. Some solder removal devices not classified as “anti-static” can

generate electrical charges sufficient to damage ESDs.

5. Do not use Freon-propelled chemicals. When sprayed,

these can generate electrical charges sufficient to damage ESDs.

6. Do not remove a replacement ESD from its protective

packaging until immediately before installing it. Most

replacement ESDs are packaged with all leads shorted

together by conductive foam, aluminum foil, or a comparable conductive material.

7. Immediately before removing the protective shorting

material from the leads of a replacement ESD, touch the

protective material to the chassis or circuit assembly into

which the device will be installed.

8. Maintain continuous electrical contact between the ESD

and the assembly into which it will be installed, until completely plugged or soldered into the circuit.

9. Minimize bodily motions when handling unpackaged

replacement ESDs. Normal motions, such as the brushing together of clothing fabric and lifting one’s foot from a

carpeted floor, can generate static electricity sufficient to

damage an ESD.

1-3 ESD Precautions

Precautions

1-2

Samsung Electronics

CAUTION:

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

Page 3

Precautions

1-3

Samsung Electronics

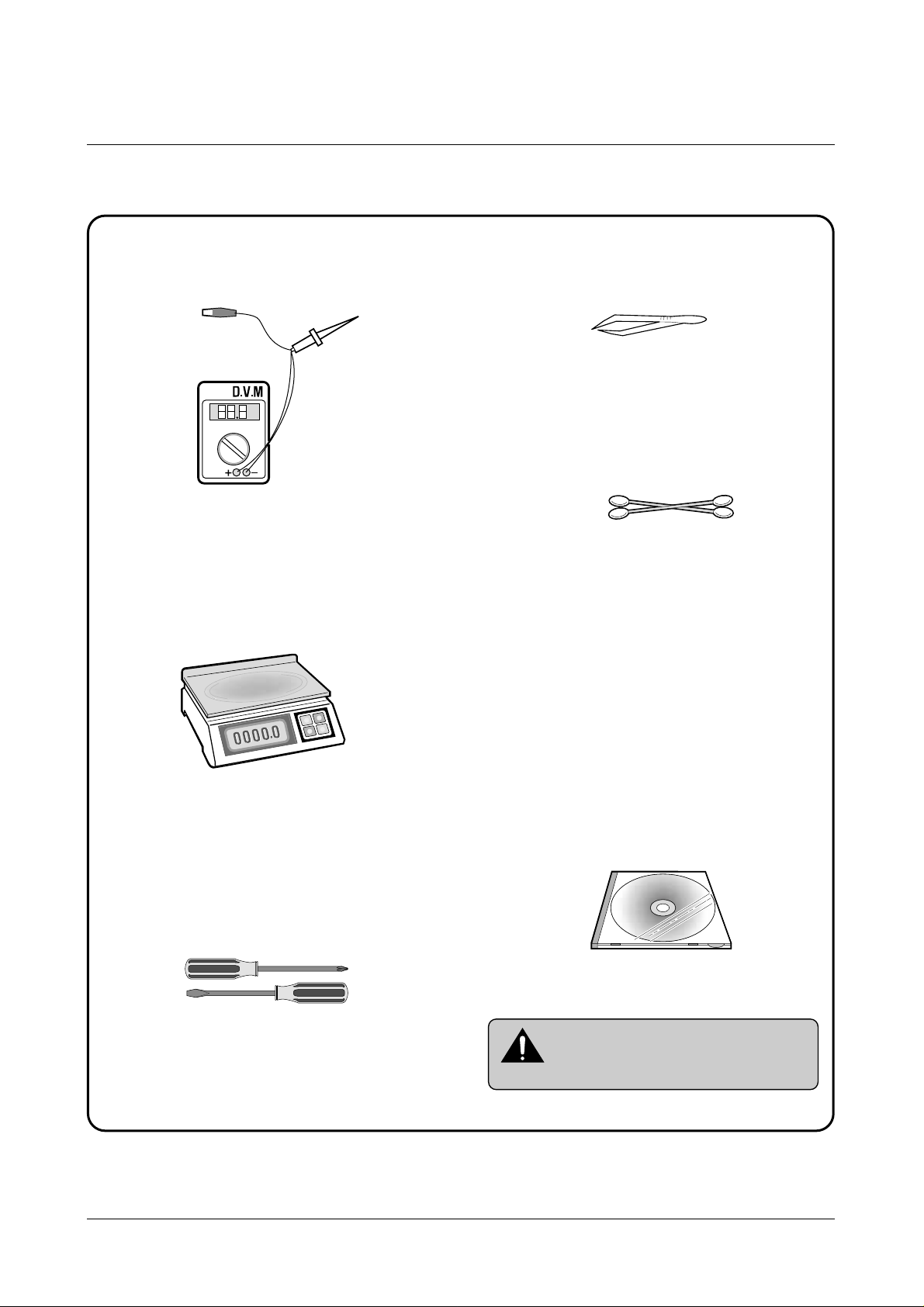

1-4 Tools for Troubleshooting

The following tools are recommended for safe and smooth troubleshooting described in this service manual.

DVM(Digital Volt Meter)

Standard: Indicates more than 3 digits.

Electronic Scale

Standard: Equipment to check the weight of consumables(toner cartridge) . (The gram unit can

be measured.)

Driver

Standard: "-" type, "+" type (M3 long, M3 short,

M2 long, M2 short)

Pinset

Standard: For general home use, small type.

Cotton Swab

Standard: For general home use, for medical ser-

vice.

Cleaning Equipments a IPA(Isopropyl

Alcohol)dry cloth or a soft stuff neutral

detergent.

Software(Driver) installation CD ROM

Mind your hands not to be touched when

you disassemble and reassemble PBAASS'Y,

such as the main board, SMPS, HVPS.

Note

1

2

3

4

5

6

7

Loading...

Loading...