Page 1

4-1

Samsung Electronics

4. Troubleshooting

4-1 Preventative Maintenance

The cycle period outlined below is a general guideline for maintenance. The example list is for an average usage of 50 transmitted and received documents per day.

Environmental conditions and actual use will vary these factors. The cycle period given below is for reference only.

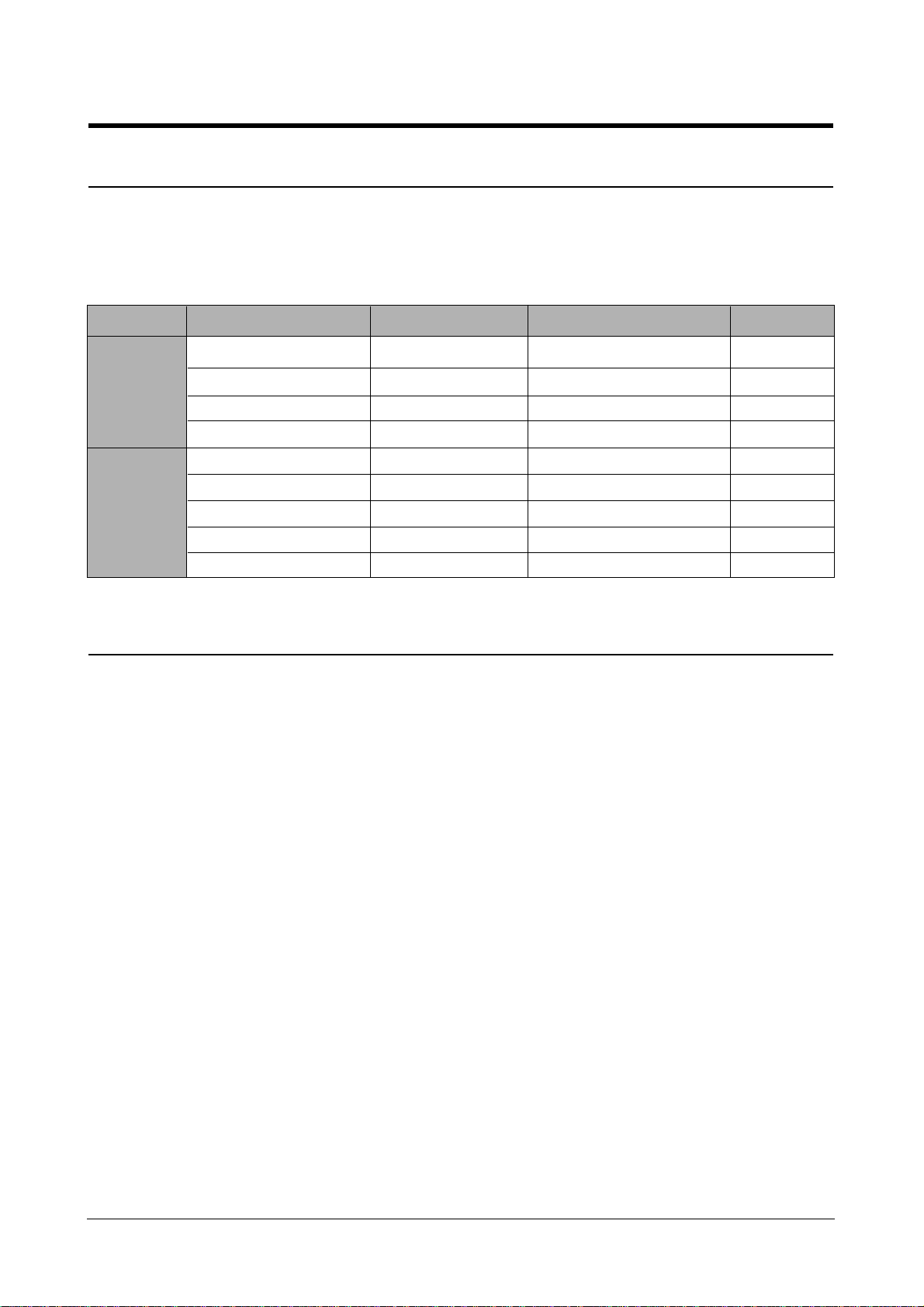

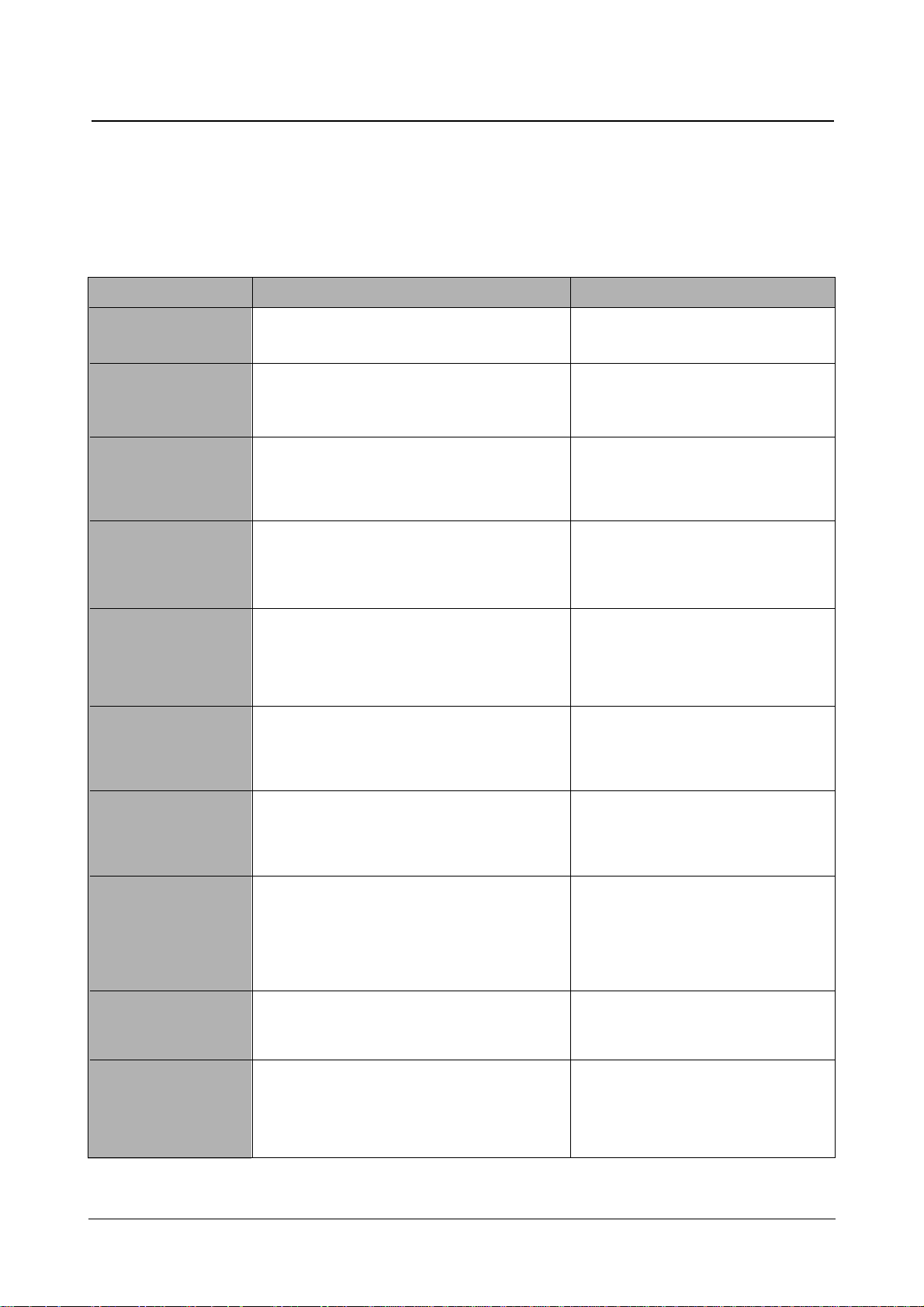

COMPONENT CLEANING CYCLE REPLACEMENT CYCLE SOLUTION

SCANNER

PRINTER

ADF Rubber

ADF Roller

White Roller

CIS

Cartridge

Pickup Roller

Feed Roller

Transfer Roller

Fuser

6 Months

1 Year

As Needed

As Needed

10,000 Pages

20,000 Pages

10,000 Pages

2,500 Pages

60,000 Pages

50,000 Pages

60,000 Pages

50,000 Pages

4-2 Tech Mode

In Tech mode, the technician can perform various tests to isolate the causes of a malfunction, and set the technical option features to customize the machine depending on the user’s operation environment.

To access TECH mode

: Press SETUP, #, 1, 9, 3, 4 in sequence, and the LCD displays ‘TECH’in the standby mode screen. While in TECH mode,

the machine still performs all normal operations.

To return to the normal user mode

: Turn the power off, then back on.

The technical options you have set in TECH mode are not changed unless you clear the machine’s memory in TECH mode.

To communicate via direct connection with another fax machine, press OHD/V.REQ followed by Start/Enter.

• Caution :

When you finish operating in Tech Mode, you must turn the power Off/On.

Page 2

Troubleshooting

4-2

Samsung Electronics

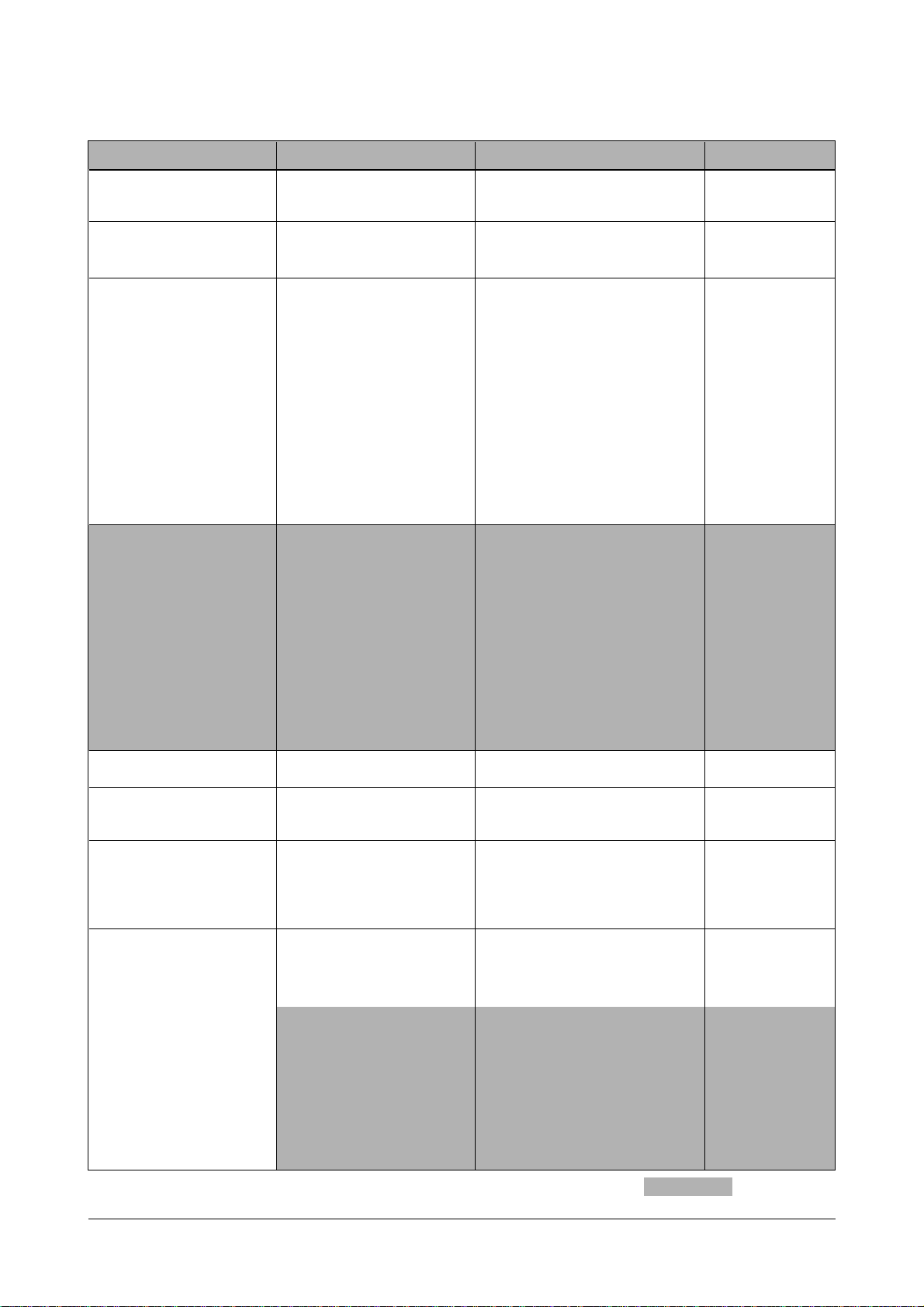

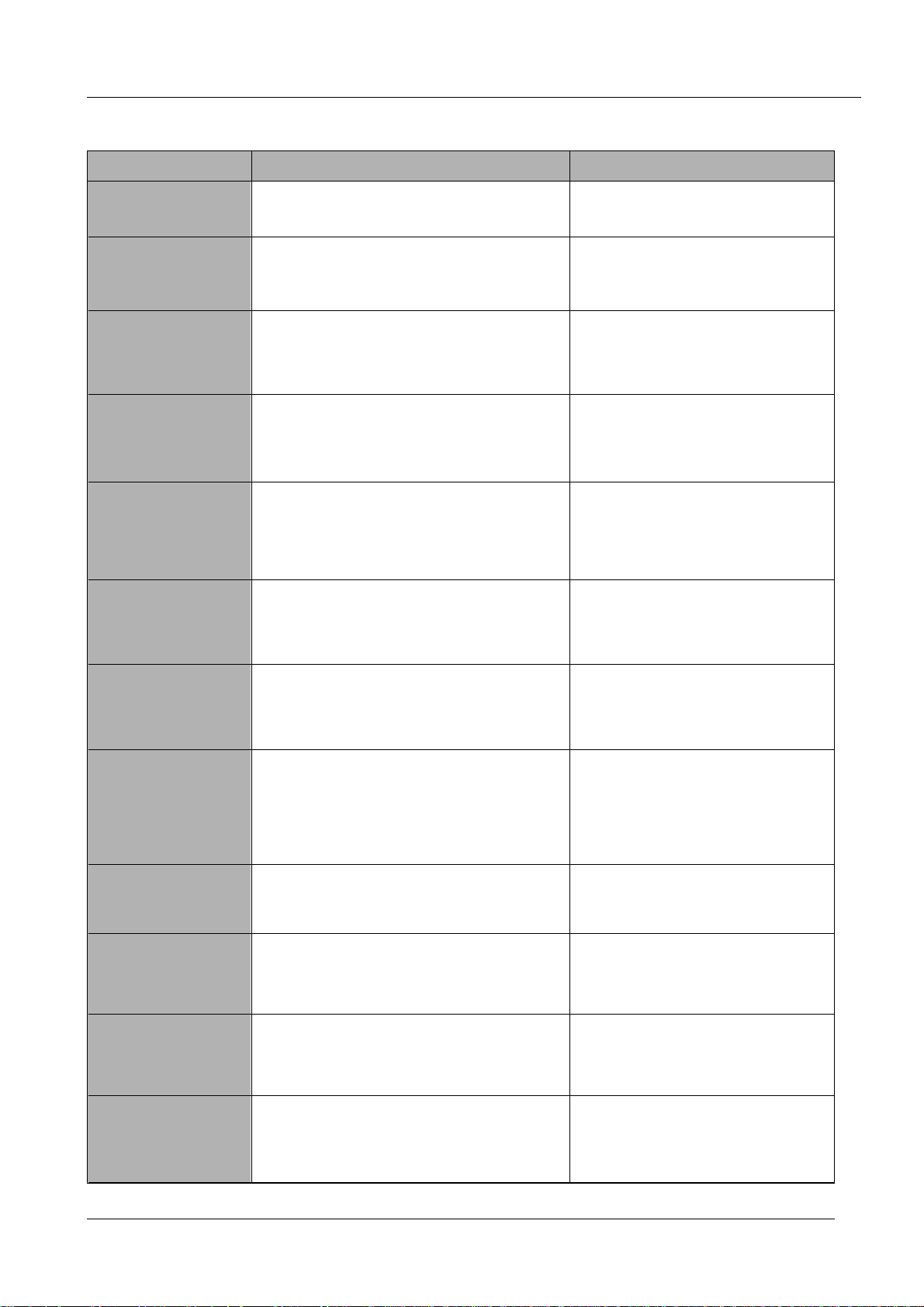

Function Item Content Default

FAX NUMBER/NAME FAX NUMBER

FAX NAME

TIME/DATE SETUP DATE FORMAT EUROPE/USA EUROPE

TIME/DA TE

SYSTEM SETUP LANGUAGE ENG/GER/FRE/ITA/SPA/POR/DUT ENGLISH

SENDING MEMORY ON/OFF ON

SEND FROM CONFIRM ON/OFF/ERROR ERROR

FAX PAPER SIZE LETTER/A4/LEGAL A4

AUTO REDUCTION ON/OFF ON

DISCARD SIZE 0~30mm 20MM

RINGS TO ANSWER 1~7 2

ST AMPRCV .NAME ON/OFF OFF

RCV.START CODE 0~9 * 9 *

ECM MODE ON/OFF ON

CALLER ID ON/OFF OFF

JUNK FAX BARRIER ON/OFF OFF

DRPD MODE ON/OFF OFF

TECH MODE MODEM SPEED 2.4/4.8/7.2/9.6/12.0/14.4/28.8/33.6 26.4 KBPS

DIALING MODE TONE/PULSE TONE

SEND FAX LEVEL 0~15 -12 DBM

RCV. FAX LEVEL 40~50 -43DBM

FLASH TIME(RECALL TIME) 80/280/600 80 MS

P AUSE TIME 1~9 4 SEC

REDIAL INTERVAL 1~15 3 MIN

REDIAL COUNT 0~5 2

DP MAKE/BREAK 40/60~33/67 33/67

SILENCE TIME UNLIMITED/12SEC UNLIMITED

ERROR RATE 5%/10% 10%

IGNORE TONER EMPTY ON/OFF OFF

GROUP DIAL SETUP GROUP NO[1-20]

VOLUM SETUP ALARM VOLUM ON/OFF ON

KEY VOLUM ON/OFF ON

MEMORY CLEAR FAX NUMBER/NAME

DIAL/SCHEDULE

JOURNAL

DEFAULT SETUP

MAINTENANCE CLEANING DRUM

ADJUST SHADING

REMOTE TEST OFF/ON

NOTIFY TONER LOW OFF/ON

ROM TEST ROM OK! (VERSION)

CIS TEST

DRAM TEST DRAM OK

SWITCH TEST

DTMF TEST

TONER COUNT

PRINTING INFO OFF/ON

PROGRAM DOWNLOAD

SCAN COUNT CLEAR COUNT CLEARING .

4-2-1 System Data List in TECH MODE

: Only Tech Mode

Page 3

Troubleshooting

4-3

Samsung Electronics

In TECH mode, press SETUP, then press or until

‘TECH MODE’ appears in the display. Press Start/Enter.

The following technical options are available.

Note : If necessary, print System Data List in TECH mode.

The list shows all current system data settings

including the TECH MODE options. To print the system data list, press Report/Help, then press

or until ‘SYSTEM DATA ’appears in the dis-

play, and press Start/Enter.

Modem Speed

• You can set the maximum modem speed.

• Communication is done with modem speed automatically

set at lower speed when communicating with the modem

with lower speed since communication is done on the standard of the side where modem speed is low for transmission/reception. It is better set 26.4KBPS as default setting.

DIALING MODE

• Select the dialing mode according to the user's line status.

• TONE: Electrical type of dial

• PULSE: Mechanical type of dial

SEND FAX LEVEL

• You can set the level of the transmission signal. Typically,

the Tx level should be under -12 dBm. The level within the

range of 1 to -15 dBm is acceptable.

• Caution: The Send Fax Level is set at the best condition

in the shipment from factory. Never change settings arbitrarily.

RCV FAX LEVEL

• You can set the level of the receiving signal.

•

The reception level may be too low due to the cable losses.

• If it is set to -43 dBm, the reception sensitivity will be

between 0 and -43 dBm. If it is set to -48 dBm, the reception sensitivity will be between 0 and -48 dBm.

• Caution: The Send Fax Level is set at the best condition

in the shipment from factory. Never change settings arbitrarily.

FLASH TIME

• Set the flash time to 80, 280, or 600 milliseconds.

PAUSE TIME

• Pause time mean delay time (unit: second) inserted

between dial number signal and the next number of signal

in the automatic dial (One touch, Speed dial, Redial) and

the manual dial.

• Caution: The Send Fax Level is set at the best condition

in the shipment from factory. Never change settings arbitrarily.

REDIAL INTERV AL

• If the remote machine is busy when the machine sends a

fax using automatic dialing, the machine automatically

redials the number. Select the time interval between automatic redial attempts. Enter the desired redial interval

using the number keypad: 1 - 15 minutes.

REDIAL COUNT

• You can set times that redial automatically attempts when

automatic transmission is done or when the remote

machine is busy or when the machine send a fax. If there

is no response after redialing by the times already set,

redial is no longer attempted. No redial is attempted if the

settings is 0. Enter the desired times from 1 through 5.

DP Make/Break

• Select the dial pulse make and break time: 40-60 or 33-67

• Caution: Send Fax Level is set at the best condition in the ship-

ment from factory. Never change settings arbitrarily.

SILENCE TIME

• In ANS/F AX mode, after a call is picked up by the answer ing machine, the machine monitors the line.

• If a period of silence is detected on the line at any time, the

call will be treated as a fax message and the machine

begins receiving.

• Silence detection time is selectable between limited (about

12 seconds) and unlimited time.

• When '2 sec' is selected, the machine switches to receiving mode as soon as it detects a period of silence. When

'unlimited'is selected, the machine waits until the answering operation is concluded even though a period of silence

is detected. After the answering operation is concluded,

the machine switches to receiving mode.

ERROR RATE

• When the error rate is about to be over the setting value,

the Baud rate automatically lowers up to 2400 bps to make

the error rate remain below the setting value.

• You can select the rate between 5% and 10%.

IGNORE TONER EMP

• You can set this function ON if desiring to drive the engine

continuously even though the life of toner is run out and it

becomes Toner Empty status.

4-2-2 Tech Mode Options

Page 4

Troubleshooting

4-4

Samsung Electronics

In TECH mode, press SETUP, then press or until

‘MAINTENANCE’ appears in the display. Press Start/Enter.

The following technical options are available

CLEAN DRUM

• Use this feature to get rid of the toner remained in the

development unit, so you can get a clean printout.Perform

this feature if stains or specks appear on the printing materials and print quality falls.

• Perform this feature several times until a clean printing

material appears.

ADJUST SHADING

• Use this feature to correct the white reference of the scanner if you experience bad copy images. When using this

feature, a white paper should be used to get clean copy

images.

• Use this adjustment feature to achieve best image (scan)

quality depending on the characteristics of the CIS (Contact

Image Sensor) parts.

1. Select [ADJUST SHADING] from the Service Mode.

2. Insert a clean white original [Letter Size] into the paper

loading part.

3. Original is scanned if pressing the Setting button.

4. If the original scan is completed, message is displayed

on the LCD window and CIS SHADING PROFILE is

output.

• If the output image is different from the normal screen, the

CIS is poor.

Caution:

1. Always perform the CIS TEST after downloading

Firmware. Otherwise, the system may not operate properly .

2. Always perform ADJUST SHADING after replacing the

CIS.

3. Always use a clean white paper in ADJUST SHADING

(Maximum paper width: Letter Size).

4. ADJUST SHADING may be performed even in the User

Mode but ADJUST SHADING profile is output only in the

TECH MODE.

REMOTE TEST

• The Remote Test feature can be enabled in order to allow

a remote location to call up and run a diagnostic test on

your machine. You may be instructed by a service representative to enable this feature.

NOTIFY TONER LOW

• With this feature enabled, when the toner becomes low, the

toner low information will be sent to ta specified contact

point, for example, the service company. After you access

this menu, select ON, and when the LCD prompts, enter

the name and the number of the contact point, the customer's fax number, the model name, and the serial number.

ROM TEST

• Use this feature to test the machine'S ROM. The result and

the software version appear in the LCD display.

CIS TEST

• This test checks the operation of the Contact Image Sensor

(CIS). Each time the number changes by one increment,

the average ADC value of CIS prints out.

DRAM TEST

• Use this feature to test the machine's DRAM. The result

appears in the LCD display.

SWITCH TEST

Use this feature to test all keys on the operation control

panel. The result is displayed on the LCD window each time

you press a key.

MODEM TEST

• Use this feature to hear various transmission signals to the

telephone line from the modem and to check the modem.

• If no transmission signal sound is heard, it means that the

modem part of the main board is poor.

DTMF TEST

• DTMF (Dual Tone Multi Frequency) signal. When you

press any key on the number keypad including • and #, you

will hear the corresponding key tone.

TONER COUNT

•This feature shows the current state of the toner cartridge.

•TONER CNT: The total number of the dots used to print up

to current time.

•CRU STATE: The page number which the toner cartridge

can print.

• Caution : After replacing Main board to new one, you

should update the information to the new board.

4-2-3 Maintenance Options

Page 5

Troubleshooting

4-5

Samsung Electronics

PRINTING INFO

• This feature allows the machine to automatically print various information, like toner count, transfer voltage, fusing

temperature and so on, at the bottom of each printed page.

• PAGE T ONER CNT: prints the number of dots used to print

the page.

• TOTAL TONER CNT: prints the total number of the dots

used to print up to current time.

• THV ON DUTY: prints ADC value of transfer voltage.

• THERMISTER: prints ADC value of fusing temperature.

• P: prints the page number.

PROGRAM DOWNLOAD

• Use this feature to download a new upgraded ROM file

from a PC that is connected to the machine with a parallel

cable (IEEE 1284).

SCAN COUNT CLEAR

• If performing this feature, the value of scanning original until

now is initialized (0). (Total scan count value on the system

data list becomes 0.)

Adjust Shading Sample Pattern

Page 6

Troubleshooting

4-6

Samsung Electronics

In TECH mode, press Report/Help, then select the desired

list or report by using or key, then press Start/Enter.

The following options are available

HELP

• It shows a brief description on the machine's basic functions and commands.Use it as a quick reference guide

SENT JOURNAL

• This journal shows a specific information concerning transmission activities, the time and dates of up to 40 of the

most recent transmissions.

RECEIVED JOURNAL

• This journal shows a specific information concerning

reception activities, the time and dates of up to 40 of the

most recent receptions.

PHONEBOOK

• It lists all telephone numbers that have been stored in the

machine.

SENDING CONFIRM

• It shows the result of the last send operation.

SCHEDULE INFORM

• This list shows a specific information on the documents

currently stored for delayed transmission. It provides the

operation number, starting time, type of operation, etc.

SYSTEM DATA

• This list provides a list of the user system data settings and

tech mode settings.

PROTOCOL LIST

• This list shows the sequence of the CCITT group 3 T.30

protocol during the most recent sending or receiving operation. Use this list to check for send and receive errors. If

a communication error occurs while the machine is in

TECH mode, the protocol list will print automatically.

PATTERN PRINT

• Using this pattern printout, you can check if the printer

mechanism is functioning properly. Examine the pattern

and look for a break in the diagonal line. If the diagonal

lines are not broken, the printer mechanism is functioning

properly .

SHADING PRIN

• With this print, you can check the scanning elements of the

CIS (Contact Image Sensor).

The Engine test mode is used to check the operation of the

components related to the printer engine.

The following test are available.

To access the Engine Test Mode:

1. Press Setup, #, 1, 9, 3, 1 in sequence.

2. When ‘ENGINE TEST?’ appears, press Start/Enter.

3. Scroll the options by pressing or repeatedly find

the one you want.

4. Press Start/Enter to start the test.

5. Press Stop to exit the Engine test mode.

• Caution :

When you finish operating in Engine Test Mode, you must turn

the power Off/On.

Engine Test Mode Options :

1. MAIN MOTOR TEST

2 PTL TEST

3. FAN TEST

4. FUSER TEST

( FUSER ON : 145˚C , FUSER OFF : 145˚C )

5. LSU MOTOR TEST

6. LD(LASER DIODE) TEST

7. HSYNC TEST (NG/OK)

8. LSU OPERATION TEST (NG/OK)

9.

SENSOR TEST ( FEED , EXIT , PAPER EMPTY , COVER OPEN)

10. SOLENOID TEST

11. MHV TEST( -1550 V )

12. DEV TEST ( - 430 V )

13. THV(+) TEST ( +1300 V )

14. THV(-) TEST

15. THV TRIGGER TEST

16. ALL FUNCTION TEST :

This function is for a manufacturing press . You can test

all function(1~15)

• When you push the “Start” button, the Main Motor runs.

• If you push the “Start” button again , the current test

stops, and the next test starts.

4-2-4 Printout Report

4-2-5 Engine Test Mode

Page 7

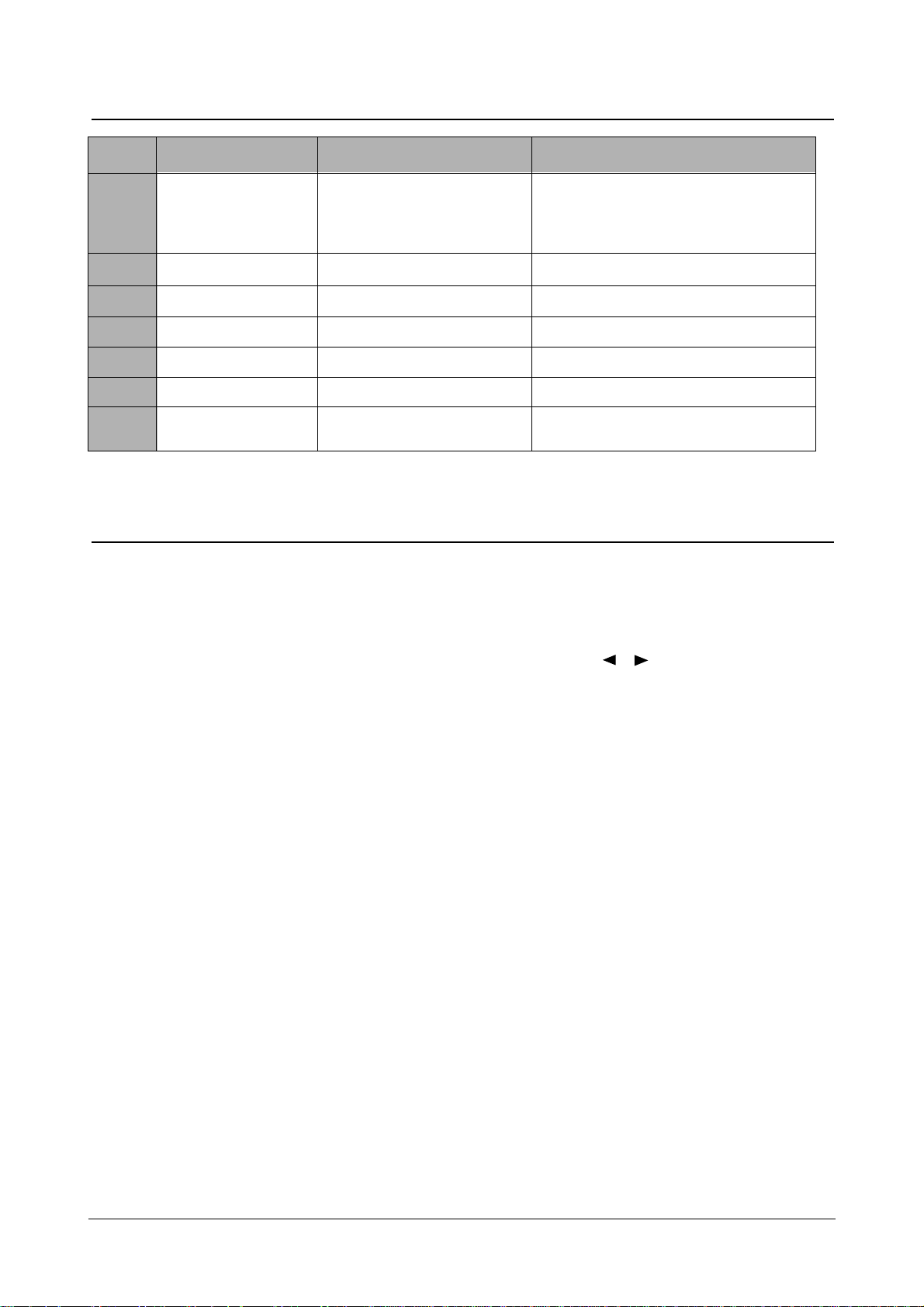

S NSF 61005820003380140200001302090018010000

S/R FCF FIF DATA ASCII

S CSI 2020202020202020202020202O20202020202020

S CSI 202020202020202020202022O202020220202020

R TSI 2020202020202020202020202O20202020202020

S DIS 00000000 01110111 00010111 00100010

S DIS 00000000 01110111 00010111 00100010

R DCS 00000000 01100001 00010101 00000000

R TSI 2020202020202020202020202O20202020202020

R DCS 00000000 01100001 00010101 00000000

S CFR

R MPS

S MCF

S DCN

S FTT

S NSF 61005020003380140200001302090018010000

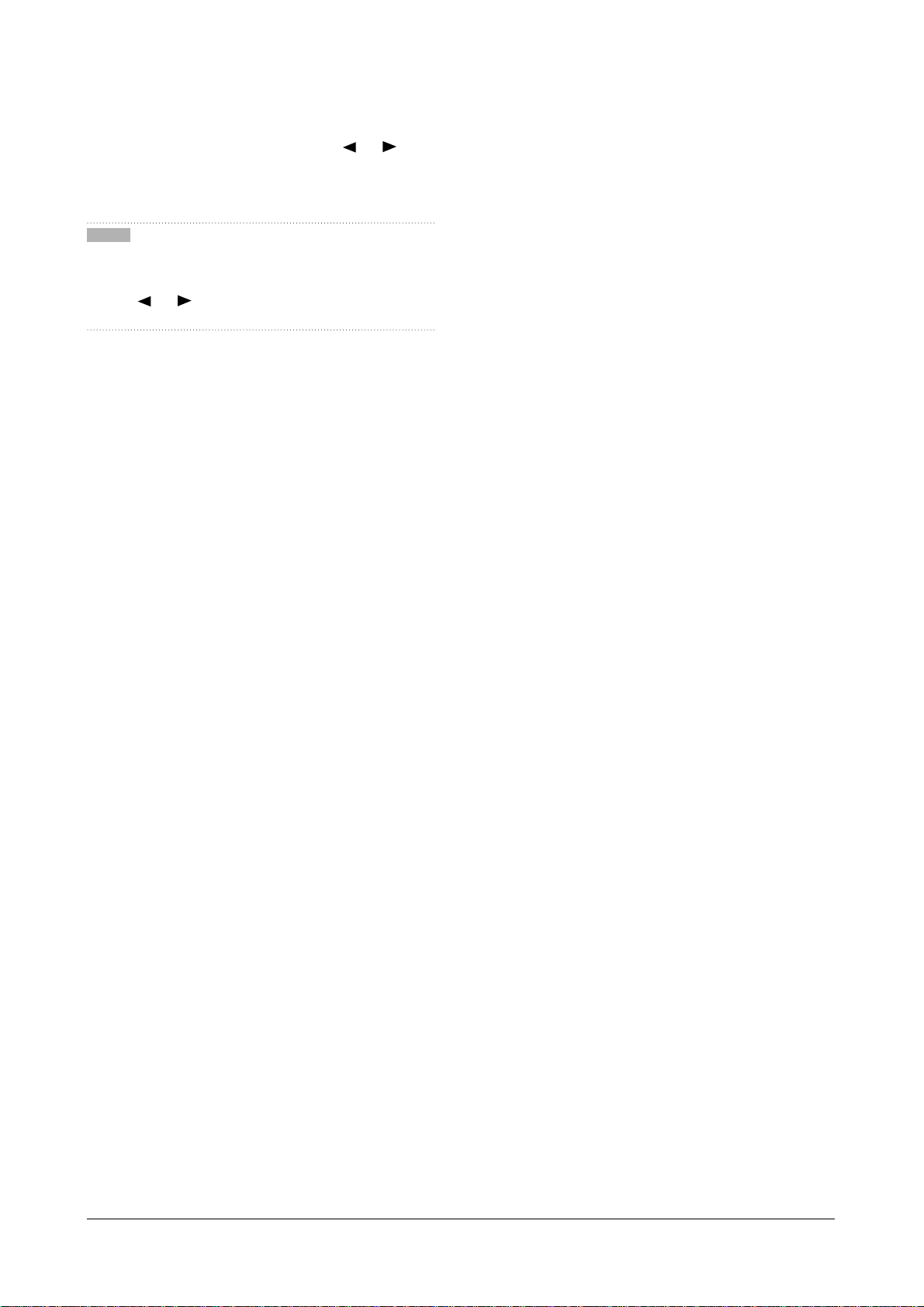

PROTOCOL DUMP LIST OCT-20-1999 06:35

Sending/Receiving

Name of signal

(Facsimile Control Field)

Facsimile Information Field

data described in hexdecmal code

FIF data described

in ASCII code

Troubleshooting

4-7

Samsung Electronics

< SAMPLE OF APROTOCOL DUMP LIST >

A number of reports can be printed from the fax machine

within the test mode. The protocol list all contain detailed

information which may be required when contacting technical support.

To printout the protocol list :

1. Get into the Tech mode by pressing Setup, #, 1, 9, 3, 4.

2. In Tech mode, press Report/Help.

3. Press or repeatedly until you find the Protocol

List. When you find ‘PROTOCOL LIST’, press ENTER.

SAMPLE OF APROTOCOLDUMP LIST

4-2-6 Maintenance List

Page 8

Troubleshooting

4-8

Samsung Electronics

4-3 Diagnostics

This section describes methods and procedures to isolate the cause of a malfunction in the machine. This machine displays diagnostic information on the LCD. In addition, it can perform a series of tests that allow the machine to observe individual machine

functions.

4-3-1 Error Messages

DOCUMENT JAM

DOOR OPEN

LINE ERROR

LOAD DOCUMENT

LSU ERROR

The loaded document has jammed in the feeder. Clear the document jam.

The top cover is not securely latched. Press down on the cover until it clicks in

place.

Your unit cannot connect with the remote

machine, or has lost contact because of a problem on the phone line.

Try again. If failure persists, wait an hour

or so for the line to clear, then try again.

Or, turn the ECM mode on.

You have attempted to set up a sending operation with no document loaded.

Load a document and try again.

There occurs a problem in the LSU

(Laser Scanning Unit).

Unplug the power code and plug it back

in. If the problem still persists, please call

for service.

FUSER ERROR

There occurs a problem in the fuser unit.

Unplug the power code and plug it back

in. If the problem still persists, please call

for service.

MEMORY FULL

The memory is full. Either delete unnecessary documents, or

retransmit after more memory becomes

available, or split the transmission into

more than one operation.

JAM/NO CARTRIDGE

Recording paper has jammed inside the unit, or

the toner cartridge is not installed.

Clear the jam, or install the cartridge

NO ANSWER

The remote machine has not answered after all

the redial attempts.

Try again. Make sure the remote machine

is operational.

NO. NOTASSIGNED

The one-touch or speed dial location you tried

to use has no number assigned to it.

Dial the number manually with the keypad, or assign a number.

Error Message Description Solution

Page 9

Troubleshooting

4-9

Samsung Electronics

NO PAPER

OVER HEAT

POLLING ERROR

POWER FAILURE

RECEIVE ERROR

The recording paper has run out. Load the recording paper.

The printer part in your unit has overheated. Please wait until it cools down.

If you cannot solve the problem, please

call for service.

The remote fax machine you want to poll is not

ready to respond to your poll.

Or When setting up to poll another fax machine,

you have used an incorrect poll code.

The remote operator should know in

advance that you are polling and have

their fax unit loaded with the original document. Enter the correct poll code.

A power failure has occurred. If documents have been stored in the

memory, a ‘Power Failure Report’ will be

printed automatically when the power is

restored.

A fax has not been received successfully. A problem with the facsmile communica-

tions has occurred. Ask the sender to try

again.

PAPER JAM 0

Recording paper has jammed in the paper feeding area.

Clear the jam.

RETRY REDIAL ?

The machine is waiting for a specified time interval to redial a previously busy station.

You can press Start to immediately redial, or Stop to cancel the redial operation.

PAPER JAM 2

Jammed paper still remains inside the unit.

Clear the jam, or install the cartridge

SEND ERROR

Your fax has not gone through successfully. A problem with the facsmile communica-

tions has occurred. Try again.

TONER EMPTY

TONER LOW

WARMING UP

The toner cartridge has run out. The machine

stops.

The toner is almost empty.

The printer is warming up and is off-line.

Replace with a new toner cartridge.

Take out the toner cartridge and gently

shake it. Using this way, you can temporarily re-establish the print quality.

Wait until the printer is on-line.

Error Message Description Solution

Page 10

Troubleshooting

4-10

Samsung Electronics

When you replace the main board to new one, the information on the toner state is cleared. Therefore, you should

update the information to the new board by entering the

exact value of total toner count and specifying the toner cartridge installed currently is shipped with the machine or new.

If not, ‘TONER LOW/EMPTY’ message may not appear

when the toner is run out.

1. In Tech mode, print ‘SYSTEM DATA LIST’. The list

includes the total toner count and CRU state information.

• TOTAL TONER COUNT: The total number of the dots

used to print up to current time.

• CRU STATE: The page number which the toner cartridge can print. (The yield of a new toner cartridge is

approximately 2,500 pages and that of the cartridge

supplied with the machine is approximately 1.000

pages.)

2. Replace Main board.

3. In Tech mode,

3-1) Press Setup, and find ‘MAINTENANCE’ by pressing

repeatedly or , then press Start/Enter.

3-2) When ‘TONER COUNT’ is displayed in LCD, press

Start/Enter, and enter the value of the total toner

count in the system data list.

3-3) When you are prompted to enter CRU STATE, press

Start/Enter.

3-4) When you see ‘[1.1000 2.2300]’ in LCD, select the

value of the CRU state in the system data list.

4. In T ech mode, print ‘SYSTEM DAT ALIST’and make sure

that the toner information is updated.

4-4 Print Quality

4-5 Note for replacing Main board

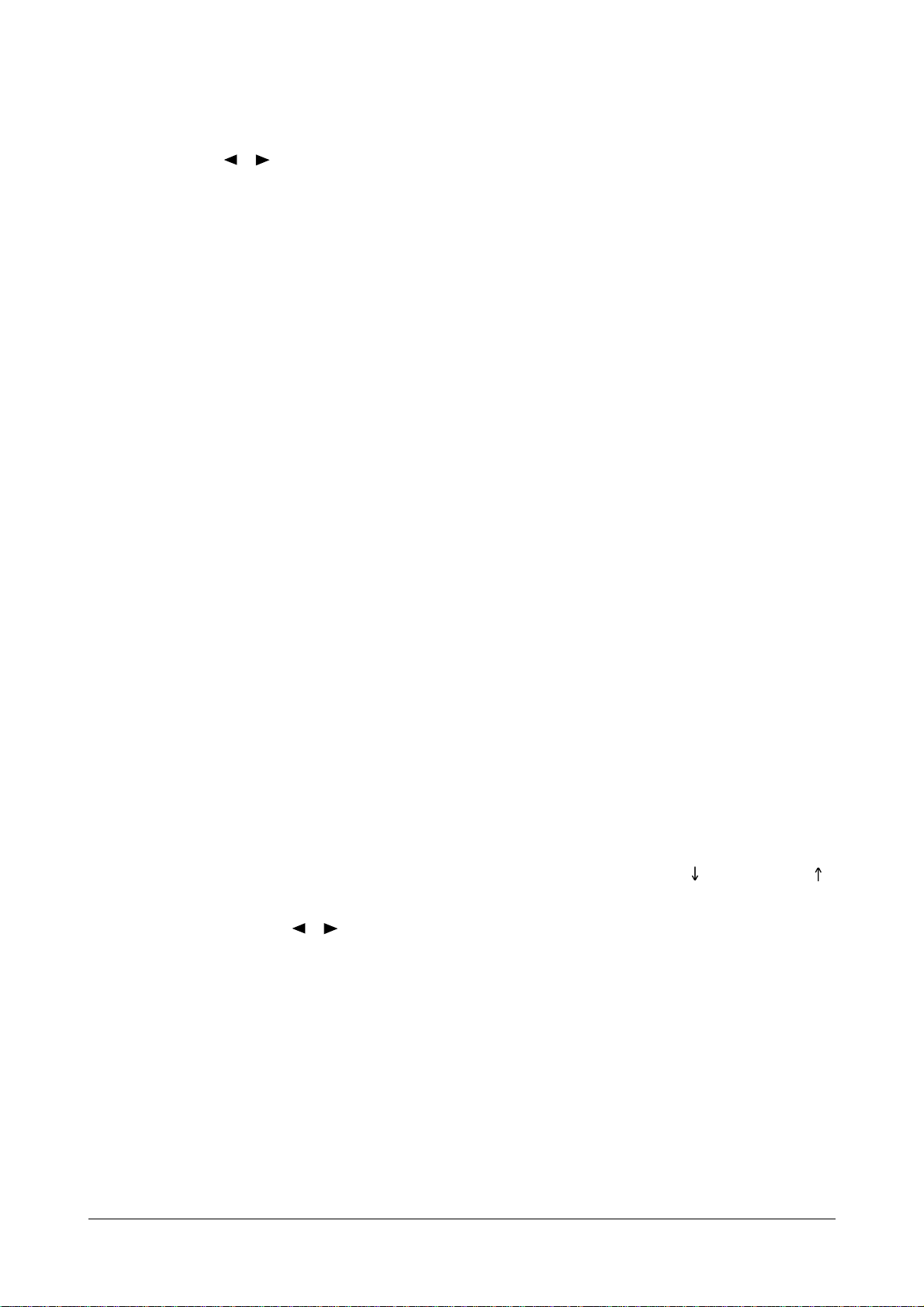

No Roller Abnormal image period Kind of abnormal image

1 OPC Drum 75.4mm •White spot on black image

•Black spot

2 Charge Roller 37.7mm Black spot

3 Supply Roller 26.8mm Horizontal density band

4 Develope Roller 31.6mm Horizontal density band

5 Transfer Roller 47.1mm Black side contamination/transfer fault

6 Heat Roller 50.1mm Black spot, White spot

7 Pressure Roller 50.2mm Black side contamination

Page 11

Troubleshooting

4-11

Samsung Electronics

Vertical black line and band

YES

NO

YES

OK after

replacing the LSU?

Remove part on the paper

path causing the trouble

NO

OK after replacing

developer?

Any obstacles on

the developer blocking

the laser beam.

OK after

removing the

obstacles?

Any obstacles ON

mirror lens of LSU and

laser path?

Remove the obstacles.

Replace the LSU

Replace the developer

END

YES

YES

YES

NO

NO

NO

4-6 Troubleshooting Flow Chart

Page 12

Troubleshooting

4-12

Samsung Electronics

Check connection to

computer or replace

controller

Take out the cartridge

and prepare the tester

for electronic connection

Repair or replace the GND

terminal

Check the path between

video controller, engine board

and HVPS. Repair or replace

the defective component

or board

The mirror in LSU might be

misplaced so the light path to the

OPC deviates ->Repair or replace

LSU or remove any deffective

matters in the machine

Self test

pattern prints?

No image?

Self testing

is possible via

Tech Mode?

Is the OPC

terminal of machine

is well-connected

to Frame?

Does the

video data line to

LSU transit to High/Low

when printing?

Re-test after replacing the

conector or Main board

A on

next page

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

No Image

Page 13

Troubleshooting

4-13

Samsung Electronics

Transfer roller might be out of its location

-> Locate the roller into its place

This could occurrs when he power of LSU is low or

the density is low due to the obstacles on the window

-> Replace LSU or clean the window

A

Trnasfer

voltage OK? (on the

transfer roller

shaft)

Is the

connection of

OPC GND and Frame Ground

correct? (less than

10 ‰)

Are the

connection terminal

and connection

correct?

Repair or replace terminal

Replace HVPS or repair defective component

Is the connection

terminal OK?

Check the connection of

frame Ground and OPC GND

Replace HVPS or repair defective component

Repair or replace terminal

Developing

(-350V) and supplying

(-550V) voltage

are OK?

Does the

counter indicate over

the toner’s guarranty

life

Replace the toner cartridge

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

Page 14

Troubleshooting

4-14

Samsung Electronics

Replace the developer

NO

YES

YES

END

YESYES

NO

NO

NO

YES

YES

NO

Replace the HVPS

Ok after setting to the

normal mode?

YES

NO

Remove the obstacles

NO

YES

Clean transfer roller

and gear holder

YES

NO

Replace the LSU

Replace the developer

Is it not over

the guaranty life of dot

counter?

Is the toner save

mode or the light mode

is selected?

Is the high voltage

normal? (charging,

developing,

transfer)

Any obstacles on the

gab between high voltage

terminal and

developer?

Transfer roller

works OK?

OK after replacing

LSU?

HVPS works OK?

Light image

Page 15

Troubleshooting

4-15

Samsung Electronics

All black in

printing area?

Is transfer

voltage supplied

(-1.55 KV)?

Is the

Hsync/ signal received

in LSU?

Transfer part’s contact

is bad -> Repair or

replace toner cartridge

Does the

video data line to LSU

transit to High/Low when

printing?

Replace LSU

Check the path among video

controller, engine board,

HVPS, LSU for the shortage

or open -> Repair or replace

the boards

Repair or replace HVPS

Replace LSU

NO

NO

NO

NO

YES

YES

YES

YES

All Black

Page 16

Troubleshooting

4-16

Samsung Electronics

White line

missing definitely?

Dirt of dust stuck onto the window of internal

lens of LSU

-> Clean it or replace LSU

Preventive obstacles through the path between

OPC of developer and LSU prevent the path

-> Remove the obstacles

Check if the

printout is still has the

same problem even right after

passed through the

transfer roller

Toner material might be stuck to blade in the developer

inside and it prevents toner supply

-> Replace the toner cartridge

Check both if the toner cartridge’s counter is over its

guaranty and amount of the toner material

-> Replace the toner cartridge

The ribs in fuser or toner on the roller may invoke

the image problem

-> Replace the fuser cover or the defective part

The image is originally black or the black part is

far close to the top

-> Use the pattern which has the image below bigger

than 10mm from the top

NO

NO

END

NO

YES

Does the problem

persist?

YES

YES

Vertical White Line (Band)

Page 17

Troubleshooting

4-17

Samsung Electronics

Dark selected

via RCP?

Change to

Normal and test

Works cor

with -350V of Bias

voltage?

Works

correctly after

replaced LSU?

Repair or replace the defective

component

The power of LSU is set

high or internal problem

-> Replace LSU or adjust

voluem

Same at Normal?

END

NO

NO

NO

Toner over supply due to the

adjustment fault of metering

blade in developer

-> Replace developer

NO

YES

YES

YES

YES

Dark Image

Page 18

Troubleshooting

4-18

Samsung Electronics

Recommended

paper used?

Is pressure of

transfer roller too high?

Does the operation of

TR work properly?

Transfer,

charge and developing

voltage are OK?

Operating/

storage atmosphere is

too high temperature

/humidity?

Solve the problem under

the recommended condition

(10-32 degree Centigrade)

Dirt or

dust around the

charge roller?

Clean the charge roller

or replace step-up device

/terminal after check

Work OK?

Internal blade or suppying

part of the developer is

defective

-> Replace the toner cartridge

Check Terminals or contacts and ’Guide-Deve Spring’

are misplaced

-> Repair or replace transfer roller etc.

Print 20 to 30 pages using

the recommended paper

Same problem

occurs?

- Adjust voltage or replace HVPS

- Repair or replace after checking the

terminals’ contacts

Replace transfer

roller’s holder

END

Replace the

toner cartridge

NO

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

YES

Background

Page 19

Troubleshooting

4-19

Samsung Electronics

Is it regular

interval of 75.4mm?

Irregularity of NIP

between rollers in

developer

-> Replace developer

Clean heat roller

or replace it

Clean transfer roller’s holder and

TR drive gearor replace TR holder ass’y

Clean TR drive

and OPC gear

END

A specific part of the transfer roller has

ruined or its resistance value is changed

-> Replace transfer roller

Transfer roller cannot force regularly due

to the gears eccentricity of transfer roller

-> Replace the defective component

Adjust the Bias

voltage or replace HVPS

There may be a problem in toner

layer control in toner cartridge

-> Replace the developer

Use the machine with

recommended paper and

at condition

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

NO

YES

YES

YES

YES

Check HVPS

contacts and

HVPS’s self-output

-> If failed, repair/

replace HVPS

- Repair or replace HVPS

- Check and Repair or

replace the terminal

contacts

NO

NO

Is it regular

interval of 31.6mm?

Is it regular

interval of 47mm?

(as transfer roller

interval)

Is it regular interval of

50.4 mm?

Does

the operation

of TR work properly?

Transfer

voltage is set to

standard?

Does the same

problem persist?

Developing

/suppying voltage

normal? (-350V/

-550V)

Bias voltage

is OK? (-350V)

Operating/storage

temperature is too low or

not recommended

paper used?

Ghost

Page 20

Troubleshooting

4-20

Samsung Electronics

The problem occured

since the obstacles

stuck to charge roller

-> Replace toner cartridge

When taking

out the cartridge,

toner leaks?

Toner leaks and toner

material dropped onto

the paper -> Replace the

developer

Bad image

removes by

scratching?

Check toner is stuck onto

the P/R or H/R in fuser

-> Clean it or replace

The problem

randomly occured

due to the toner

fallen -> Clean the

machine

Remove obstacles

stuck on OPC

drum’s surface

Perform the OPC

cleaning using

the control panel

buttons.

END

NO

YES

NO

NO

YES

NO

YES

Does the same

problesm

persist?

Is it regular

interval of 37.7mm?

Is it regular

interval of 75.4 mm?

NO

YES

YES

Black Spot

Page 21

Troubleshooting

4-21

Samsung Electronics

NO

Black band?

The black

band has regular

interval?

Black band

is far about 10mm from

white band?

Problem of internal

contacts in OPC

-> Replace developer

The OPC is damaged under the

direct sunlight for around 5

minutes -> If the same problem

persists in 10 hours, replace

the developer

This occurs when no

Hsync/ at LSU

-> Replace LSU

75.4 mm interval?

Heat roller is ruined

-> Replace the roller

The OPC is damaged due to

the irregular transfer voltage

of HVPS

-> Repair/replace HVPS

-> If the same problem persists,

replace the developer

Does it appear

at every 56.1mm at

specific place?

Problems of terminal contact,

transfer voltage supplying,

and transfer roller’s due to the

charge roller is ruined (37.7mm)

-> Repair/replace HVPS,

developer

NO

NO NO

NO

YES

YES

YES

YES

Horizontal Band

Page 22

Troubleshooting

4-22

Samsung Electronics

Transfer roller

is clear ?

Clean the transfer roller

NO

YES

Paper path is

clear ?

Clean the paper path

Clean the pressure roller

NO

YES

Toner Contaminations on Back of Paper

Page 23

Troubleshooting

4-23

Samsung Electronics

Is it not over

the guaranty life of dot

counter?

Replace the toner cartridge

NO

YES

YES

YES

Is toner cartridge

installed correctly?

Install the toner cartridge correctly

NO

Transfer roller

works properly?

Clean the TR holder, the TR gear,

OPC roller gear and the transfer roller

NO

- Clean the contact point of transfer roller

- Check the output of high voltage terminal

and adjust or replace if required

Partial Blank Image (not Periodic)

Page 24

Troubleshooting

4-24

Samsung Electronics

Is it not over

the guaranty life of dot

counter?

Replace the toner cartridge

NO

YES

YES

NO

NO

Is toner

cartridge installed

correctly?

Install the toner cartridge

correctly

NO

Is it regular

interval of 47.1mm?

Transfer roller

works properly?

OK after

replacing the transfer

roller?

Is it regular

interval of 75.4mm, 31.6mm

or 37.7mm?

Replace the fuser

(50.2mm, 45.2mm or exit roller

- Clean the contact point of

transfer roller.

- Check the output of high

voltage terminal and adjust or

replace if required.

Replace the toner cartidge

END

YES

YES

NO

YES

NO

YES

Clean the TR holder, the TR

gear OPC roller gear and the

transfer roller

Partial Blank Image (Periodic)

Page 25

Troubleshooting

4-25

Samsung Electronics

It is over the guaranty

life of toner cartridge

(Check the counter

and replace it)

Defective agitator in

the toner supplying part

of developer

->Replace the developer

Check if the ’guide deve

spring’ works OK and

repair/repalce

Check high voltage

output and repair/

replace terminals, HVPS

Irregualrity of toner

suppy from developer

-> Repalce developer

Light distortion due to

the mirror ruined or

LSU’s diffused reflection

-> Replace LSU

NO

NO

YES

YES

YES

YES

NO NO

OK after

taking out and

rocking the toner

cartridge?

When gray

pattern printing,

irregular density

persists?

transfer/

charge/developing

voltage drops while

printing?

Bad images

aroung the no image

area?

Irregular Density

Page 26

Troubleshooting

4-26

Samsung Electronics

Is it regular

interval of 75.4mm?

Obstacles stuck on OPC’s

surface

-> Clean the OPC and

machine or replace

developer

When putting in/out the

developer, scratch is made

-> Replace the developer

Transfer

voltage is normal?

D/R in developing unit has

the defect

-> Replace the developer

Too high voltage supplied

due to the setting error of

transfer voltage

-> Adjust/replace HVPS

NO

NO

YES

YES

White Spot

Page 27

Troubleshooting

4-27

Samsung Electronics

When multi-page OHP printng,

less than 10 films are

guranteed.

Use the recommended film

When OHP

printing, does the fan

temporarily stops

and revolves?

Use the recommended film

Other parts are touching the

fan and prevents it from

revolution

-> Check and repair

NO

NO NO

YES

Set to OHP mode

NO

YES

YES YES

Is the OPC

mode selected using

the software

application?

Recommended

OHP film used?

Inserted over

than 10 films into

the MPF?

Trembling at the End When OHP Printing

Page 28

Troubleshooting

4-28

Samsung Electronics

After printing

completed, any error

related fuser?

Both ends

of thermostat

open?

Replace thermostat

and re-test

Replace the contol

component on engine

board

Check any contact

problem in thermistor

and repair

The machine

placed under the

severe low tempera

ture for a long

time?

Place the machine

at normal

temperature and

re-test

While printing,

the voltage of pin 208

of U5 (CPU) on Main

board is 2.0V

~2.3V?

Thermistor’s

contact is OK?

Open the top

cover. When black

printing, is the fuser NIP

width is 1.2~

3.0mm?

The paper used is too

thick or contains too

much cotton in it

-> Re-test with the

recommended paper

Check if the hardness of

P/R, and spring force is OK?

(spring’s force: 2.5 Kg)

Re-assemble

thermistor

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

Poor Fusing Grade

Page 29

Troubleshooting

4-29

Samsung Electronics

Plug in the

power cord?

The power

voltage supplying is

the same as

rating?

The fan

revolves when

powered on?

LEDs blink

once when

powered on?

The On-Line

key is being pressed

or shortage on

the panel

board?

Repair/replace the

board

Check the voltage first and plug

the power cord

Supply the power as the rating

Connections

on board are OK?

Re-connect firmly

and re-test

The connection

error between

controller board

and panel board

or malfunction

of boards.

-> Replace the

boards

Fuse of SMPS

if open?

Shortage

between 5V and

GND, or between

24V and

GND?

Replace the fuse

Toner cartridge

is in the set?

Detect failure due to the

board which detects top

cover open or switch error

-> Replace the board or switch

Put in the

cartridge

Remove the shortage

or replace the board

NO

NO

NO

NO

NO

NO

NO NO

NO

YES

YES

YES

YES

YES

YES

YES

YES

YES

No Power (LCD NO display LED Off)

Page 30

Troubleshooting

4-30

Samsung Electronics

Less than 10W?

AC is being supplied?

The voltage

of pin #208 of U5

(CPU) on the Main board

is about 2.3V when

printing?

END

Thermostat is open due to the heat etc.

-> Replace the thermostat

Check the PCI and fusing

control part and CN502

on the SMPS

-> Replace the component

or replace the SMPS

Measure the resistance

at the both ends of AC

Line with covers open

Remove the covers

Re-assemble the top

cover and close it

Thermistor, connecting point or engine

board defect -> Repair/replace the

component/board

NO

NO

NO

YES

YES

YES

Fuser Error

Page 31

Troubleshooting

4-31

Samsung Electronics

Sounds the

solenoid on when starts

print?

Does the

paper move?

Does the

paper move more than

100mm?

The Engine board defected

-> Replace boards

The solenoid defected

-> Replace it

The pick-up unit is

assembled wrong

-> Re-assemble or replace

the unit

Feeder

sensor and paper

width detect sensor

are assembled

reverse?

Switch them

The Sensor board

defected

-> Repair/replace

Too many

papers in the

feeder?

Paper guides

fit the paper width?

Paper end curled?

Does the

extender pulled out?

<Recommendation>

Use the MPF for the thick

paper such as envelope

and cardstock

Reduce the amount

and re-test

Take out the paper

and re-insert

Use the recommended

and quality paper

Pull out the

extender

NO

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

YES YES

Paper Jam (Mis-feeding)

Page 32

Troubleshooting

4-32

Samsung Electronics

Paper

stopped before

the OPC?

Check the LSU and

if it has the defect

replace it

Paper

stopped before

the fuser?

Severe skew

when feeding?

Adjust the paper guides to fit the

paper width

The force of springs pressing the

developer is weak

-> Check guide-DEVE

The paper

came out through

between fuser and

developer?

Too thin

or sensitive paper to

static electricity?

Use the recommended

paper

Check guide transfer

is grounded Check

the shutter prevents

feeding

Check the input path

to the fuser (such as

mis-assembly)

The

actuator of

paper exit sensor

works OK?

Check the actuator exists and its

operation and around the engine board

-> Replace

Is the paper

rolled around the

presseure

roller?

Remove the fuser, remove

the paper and replace the

pressure roller, if necessary

Feeds

multiple pages?

Remove any factors

Check the roller

and ribs of fuser

are in place, and

remove burrs, if

any

-> Remove the

factors of jam

NO NO NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

YES

YES

Paper Jam (Jam1)

Page 33

Troubleshooting

4-33

Samsung Electronics

Try again to connector

or

Replace connector

END

NO

Check

CBF Harness28P

(MAIN B’D to ENGINE

B’D)

YES

Check

MAIN B’D CN9-6,

HSYNC Signal

( )

Replace LSU

NO

YES

Check

MAIN B’D CN9-3,

P_MOTOR Signal

( )

Replace MAIN B’D

NO

YES

Check

MAIN B’D CN9-4,

LREDADY Signal

( )

Replace LSU

NO

YES

Check

MAIN B’D CN9-9,

LDON Signal

( )

Replace MAIN B’D

NO

YES

LSU Error

Loading...

Loading...