Page 1

Samsung Electronics 1-1

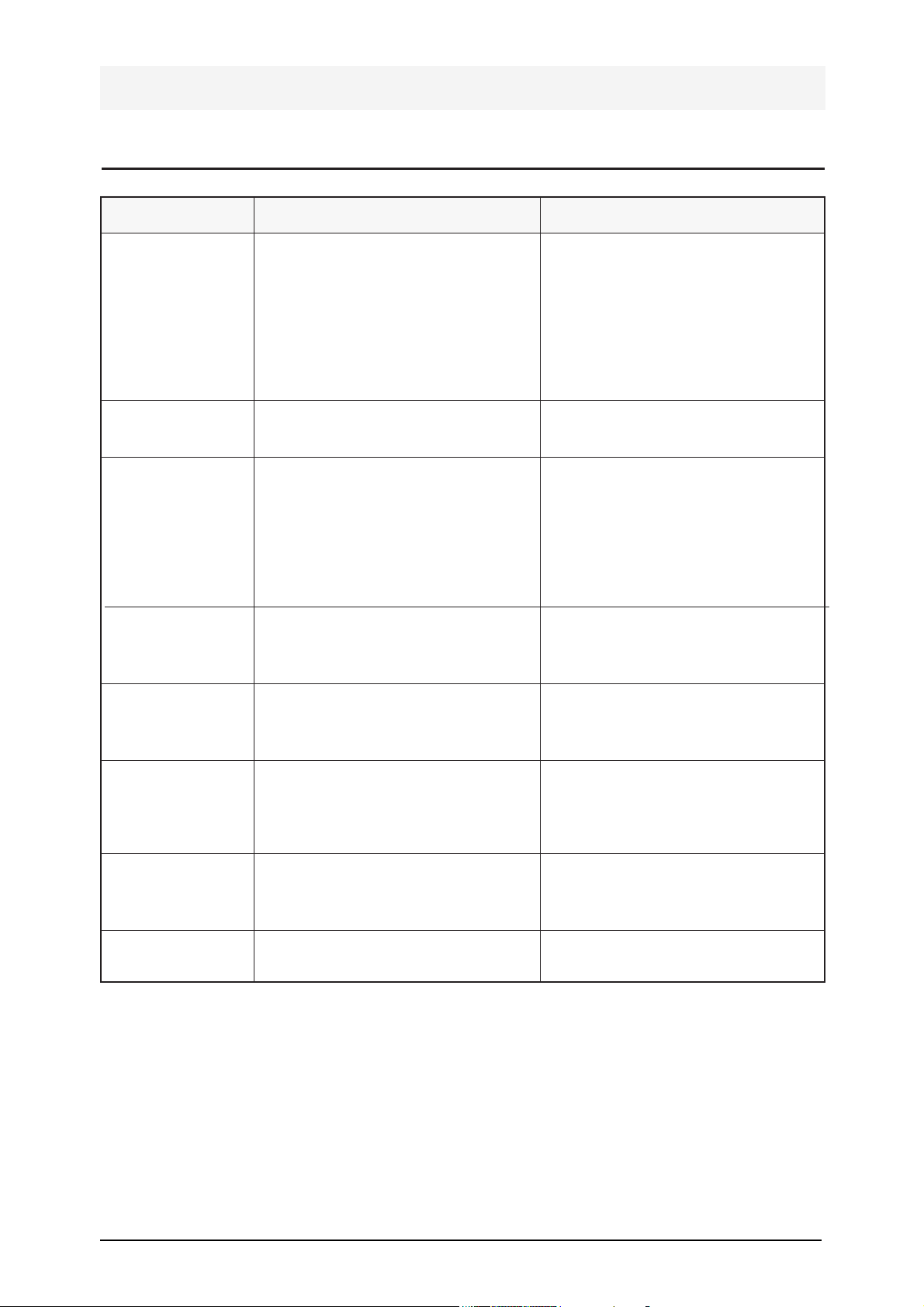

PROBLEM ITEMS TO BE CHECKED HOW TO SOLVE

6. REPAIR

6-1. SCANNER

Black data when

you scan or copy

Bright image

Dark image

Lamp blinks

Cannot turn on the

lamp

Overlapped or omitted image when you

scan or copy

Black in whole

when you scan or

copy

White lines when

you scan/copy.

Does the lamp operate normally while

shuttle module operates?

Check if white ref. panel is too dirty.

1. Is the lamp supplied with appropriate power when the scanner operates?

2. Does the output of module satisfy

specifications?

3. Does (-)Vref value satisfy specifications?

Check power of the lamp. (12V serial

connection)

Check the power of the lamp. (12V

serial connection)

Check scan connector on circuit board.

Check if screws of CR fixing part are

loose.

Check if LF connector is properly

connected.

Check the scanner of the main board.

Check scanner cable.

Check the scanner.

Check if there is foreign substances on

LABEL(P)-REFERENCE.

- Check module lamp.

- Check FPC of the main board & module.

(J1-1<=> CON2-1: LAMP ON)

- Check the path of the main board.

(U17[#10]->R185[1K]-Q8->R262->Q7> CON2[#1])

- Replace module.

- Replace the main board.

- Clean white ref. panel.

- Replace white ref. panel.

1. Check the lamp-on level of module

and the main board.(+11.75V/ + 5V)

(J1-1<=> CON2-1: LAMP ON)

2. Check video signal output of module

and main board.

3. Check (-) Vref value.

Replace FPC-SCAN connecting power

of the lamp.

Replace the scanner.

Check the power of the lamp.

Replace the scanner. Connect the

connector.

Screw down

Connect LF connector.

Replace the main board.

Replace FPC-SCAN.

Replace the scanner.

Wipe LABEL(P)-REFERENCE.

Page 2

1-2 Samsung Electronics

PROBLEM ITEMS TO BE CHECKED HOW TO SOLVE

6-2. SENSOR

Black data when

you scan/copy

CanÕt print/copy

with No Paper displayed

Does the carriage operate normally and

go to the initial place, when you turn it

on with the carriage placed in the

middle?

- Is No Paper cleared when you press

No Paper sensor on ASF?

- Does the level of CON7-#2 turn from

H to L when you press No Paper

sensor on ASF?

- Check connection between the sensor

board of the carriage and the main

and check if FPC cable is damaged.

- Check if FPC is connected properly

with CN1 of the sensor board.

- Check if the signal of the sensor is

delivered well to CN1-#2 of the sensor

board.

- Replace FPC cable.

- Replace the sensor board.

- Check connection with CON7 of the

main board.

- Replace No Paper sensor on ASF.

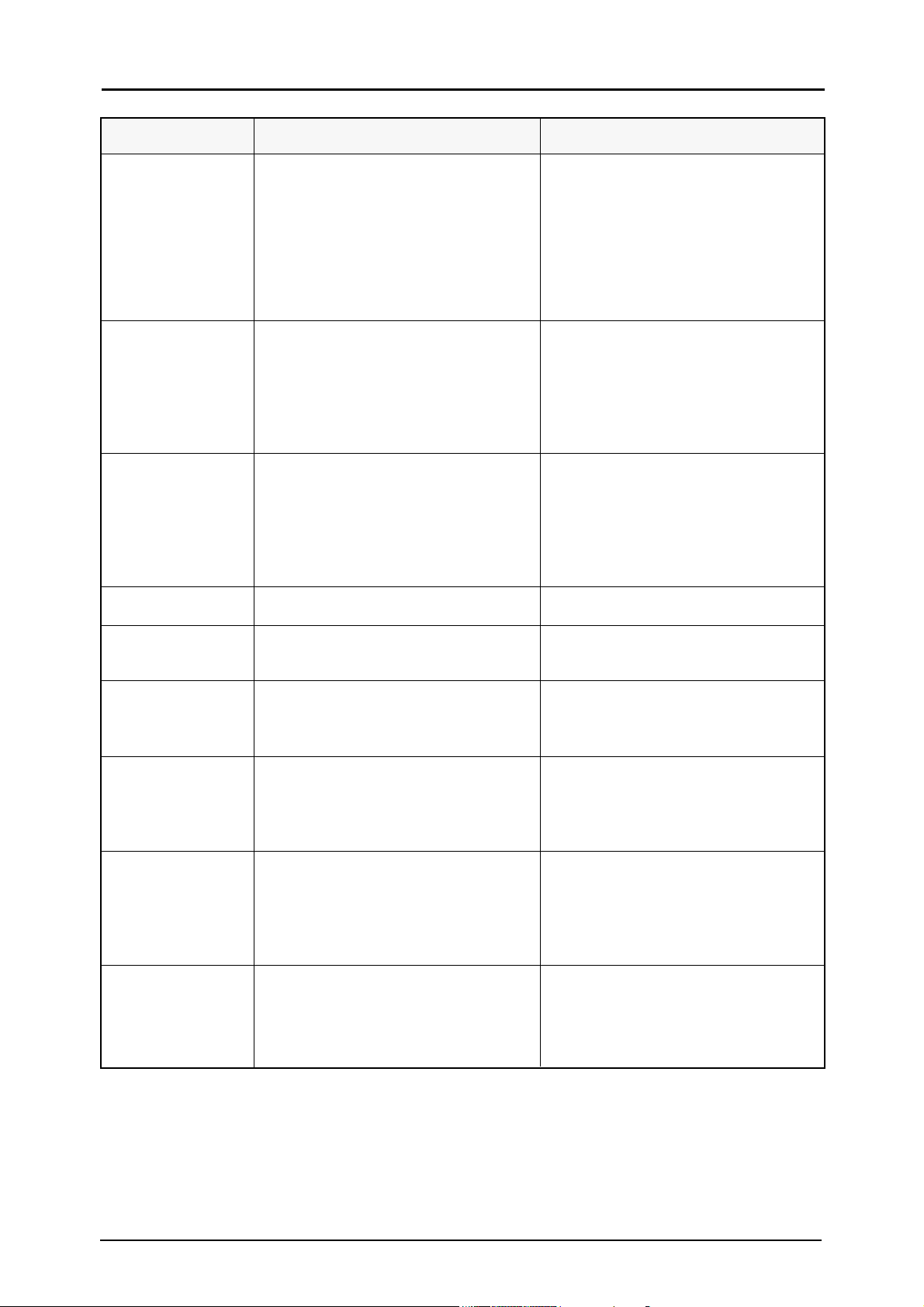

PROBLEM ITEMS TO BE CHECKED HOW TO SOLVE

6-3. PAPER FEED

Automatic sheet

feeder feeds paper

but paper is not supplied to the engine.

Automatic sheet

feeder cannot feed

paper.

CanÕt feed envelopes

Tilted Printing

- Check if actuator feed operates perfectly.

- Check if paper sensing optical sensor

is normal.

- Check if stopper clutch operates

perfectly.

- Check if too much paper has been

supplied.

- Check if pickup roller rubber of the

automatic sheet feeder is worn out.

- Check the location of the envelope

guide of automatic sheet feeder.

- Check if paper guide of the automatic

sheet feeder is adjusted to the size of

paper.

- Replace actuator feed, spring, or other

defective parts.

- Replace the paper sensing optical

sensor.

- Replace stopper clutch assembly.

- Supply appropriate amount of

paper(100 sheets of normal copying

paper).

- Replace pickup roller rubber.

- Open the envelope guide when you

feed envelopes.

- Adjust paper guide to the size of

paper.

Page 3

Samsung Electronics 1-3

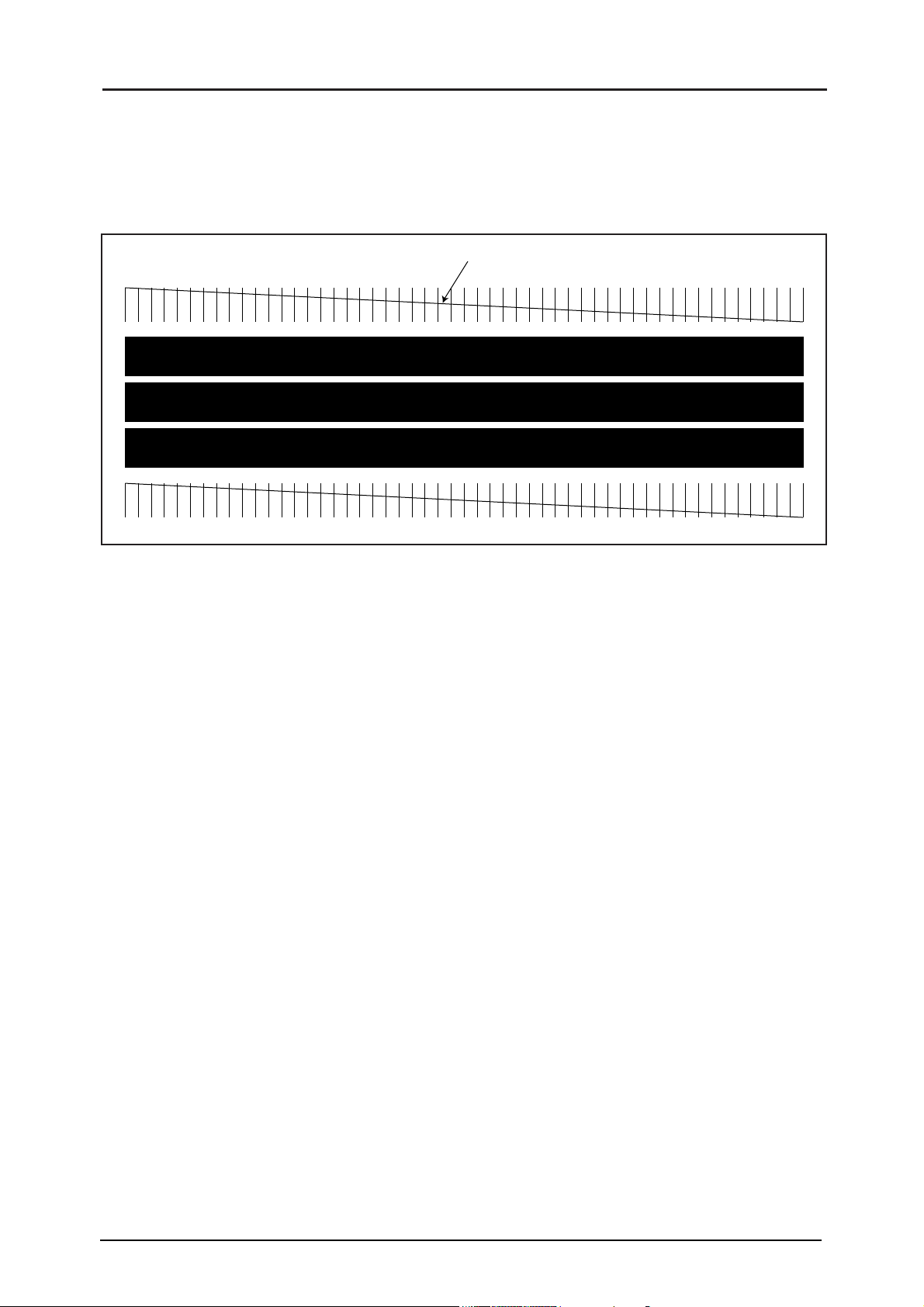

6-4-1 White lines on letters or graphics.

■ Cause

If nozzles in print head has a probkem, white lines are marked on the print.

ÔSelf-diagnostic printingÕ will let you know if nozzles have problems.

6-4. PRINTING QUALITY

If this line is broken, it confirms that

nozzles have problems.

■ Solution

1) Run Ôprint control panelÕ to Òclean cartridgeÓ and check if nozzles have been blocked.

2) Wipe with soft cloth the contact surfaces of ink cartridge and carriage, and check if nozzles have been

cleaned properly.

3) Separate ink cartridge from carriage and combine them. Repeat it about 5 to 6 times and check if connection is proper.

4) Replace ink cartridge and check whether thereÕs a problem with thehead.

5) Check if head cable is inserted well into the main circuit board and then check if nozzles have problems.

6) Check if head cable is broken or torn and then check if nozzles have problems.

7) Replace the main circuit board with a new one and check if nozzles have problems.

Page 4

1-4 Samsung Electronics

6-4-2 When perpendicular lines are printed crookedly

■ Cause : Perpendicular lines are printed crookedly if you do not Òalign perpendicular linesÓ on the

printer.

■ Solution

1) Run print control panel to Òalign perpendicular linesÓ, and

2) Select the best one of the above samples and enter the number.

3) This function to align perpendicular lines is available both for mono and color cartridges.

6-4-3 When ink spreads on transparent film

■ Cause : You selected a wrong medium on the driver or you did not use transparent film designated for

inkjet.

■ Solution

1) Use only transparent film designated for inkjet when you print on transparent film by an inkjet

printer.

2) Run ÒWindows driverÓ and select Òtransparent filmÓ as the kind of paper if you print on Windows.

12 3 45

6-5. Setting a PC BIOS to invoke ECP Mode

SMARTJET use ECP mode of Nibble mode when SMARTJET are transferring scanned data to a PC through

a centronics cable. Depending upon a parallel port connection (P1284) mode, scan speed of our unit can vary

in great deal, and sometimes unexpected problems like SIO chip detection problem might come up due to a

mode difference between a host PC and our unit.

When a PC is booting, a PC BIOS initializes the SIO chip of PC in parallel port and sets the mode of parallel

port. But when parallel port is set in a nibble mode, a SIO chip in some certain PCs prohibit PC software(the

twain driver) from changing the mode of parallel port. In order to enhance the speed of parallel port and to

solve some parallel port connection problems it is strongly recommended that the service man who has

encounterde these problems must set the parallel port connection(P1284) mode to a ECP mode in a PC BIOS.

Page 5

Samsung Electronics 1-5

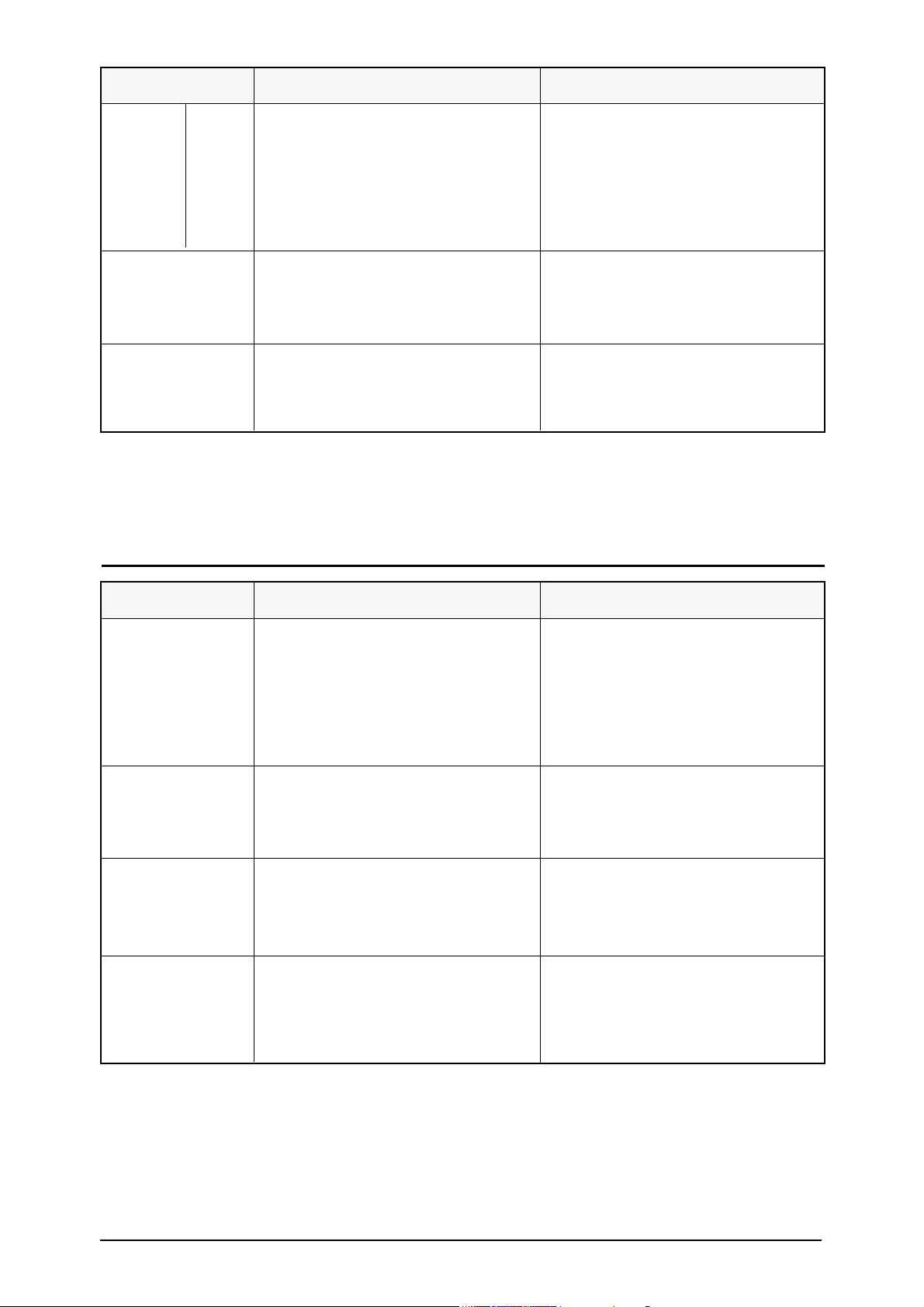

PROBLEM ITEMS TO BE CHECKED HOW TO SOLVE

6-6. Defective Operation

ÒReadyÓ LED wonÕt

light up.

LF motor does not

operate.

CR motor does not

operate.

Paper Jam

Document Jam

No Paper

No Document

No Cartridge

Ink low

1. No Power?

2. VCC(+5V) ³ +4.5V?

3. U15-130(/POR) is HIGH? (+4.5V or

over)

4. U15-153(/RST_OUT) is HIGH? (+4V

or over)

1. Check control signal of U15-141 - 145.

2. Check driving output and input signal of U27 and U28.

1. Check control signal of U15-31 - 36.

2. Check driving output and input signal of U25 and U26.

Check sheet feeder and ejector.

Check manual document feeder.

1. No paper?

2. U17-24 is HIGH? (+4V or over)

1. No document?

2. U15-125 is HIGH? (+4V or over)

1. Check if ink cartridge is mounted.

2. Check contacted part of the head.

3. Check head checking circuit and driver.: Check U15-8,9,10,128,154,156,

U17-23 control signals and head data.

Check the amount of ink.

1. Check power(SMPS).

1) Cord connection

2) Check each power channel.

(+5V, +11.75V, +30V)

2. Check power.

3. Check the circuit around U16.

4. Check data bus of U15. Exchange the

main PBA.

1. Replace the main PBA if control signal is not generated though the other

functions of the system are normal.

2. Replace U27 and U28 if driving output is defective though input signal is

normal.

1. Replace the main PBA if control signal is not generated though the other

functions of the system are normal.

2. Replace U25 and U26 if driving output is defective though input signal is

normal.

Get rid of jammed paper.

Remove jammed documents and insert

it again.

1. Feed paper.

2. If high, replace the paper empty

sensor. If low, replace the main PBA.

1. Insert documents.

2. If high, check SEN1 and the surrounding circuit. If low, replace the

main PBA.

1. Mount ink cartridge.

2. Clean it.

3. Replace the main PBA.

Replace ink cartridge.

After replacing it, press Ôink replacementÕ key for over 3sec to inform the

system of new ink.

Page 6

1-6 Samsung Electronics

PROBLEM ITEMS TO BE CHECKED HOW TO SOLVE

CanÕt copy

CanÕt PRINT

1. Refer to Ôproblems of scanner.Õ

2. Poor quality of printed image : Print

test pattern and check if nozzles have

fallen out.

3. CanÕt print.: Check U17-34, 36 signals.(LOW ACTIVE)

1. Check centronics cable connection.

2. Is ÔStandbyÕ LED of the system on?

3. Check how print driver has been

installed.

4. Check I/F part of parallel port.

1) Check the initial state of print con-

trol signal of CON8.: No.1, 10 ~14,

31, 32, 36

2) Check input and output signal of

U14.

3) Check input and output signals of

U15-43~51 and U15-53~61.

5. Refer to 2 and 3 of 6-4 ÔPRINGTING

QUALITYÕ.

1. Check CON3(main PBA), main LIU

harness, and P1(LIU PBA).

2. 1) Is external telephone hooked off?

2) Output of U2-4(LIU PBA) is LOW?

3. Check HOOK-OFF. (Line connection):

U17-8(/CML1) is HIGH?

4. Check the signals of U15-122, 123.

5. Check transmission path: Check output of U21-44(main PBA) and input of

U3-3(LIU PBA).

6. Check reception path: Check output

of U3-40(LIU PBA) and input of

U21-45(main PBA).

1. Refer to Ôproblems of scanner.Õ

2. 1) Check contact between ink cartridge and the head.: Clean it.

2) Check print control signals of U151~10, U15-158 - 160, U15-12~19,

and U15-21~28. Check input and

output signals of U19,20,23, and

24. Replace the main PBA.

3. Replace the main PBA.

1. Connect it correctly.

2. Press ÔstandbyÕ key to keep the standby mode.

3. Install the print driver again and

reboot the system.

4. Replace the main PBA.

5. Refer to 2 and 3 of 6-4 ÔPRINGTING

QUALITYÕ.

1. Replace defective parts.

2. 1) Hook on external telephone

correctly.

2) If low, replace LIU PBA.

3. If low, replace main PBA. If it is

not hooked off though it is normal,

replace LIU PBA.

4. If the signals of U15-122(LIU_TXD)

are abnormal, replace main PBA. If

the signals of U15-123(LIU_RXD) are

abnormal, replace LIU PBA.

5. If it is abnormal, replace main PBA.

6. If the output of U3-40(LIU PBA) is

not confirmed, replace LIU PBA. If

the output of U3-40(LIU PBA) is confirmed but the input of U21-45(main

PBA) is not confirmed, check the

circuit around U6(main PBA).

Defective

Transmission

/ Reception

In case

PC

controls

Page 7

Samsung Electronics 1-7

PROBLEM ITEMS TO BE CHECKED HOW TO SOLVE

Automatic

Reception Failure

MF dial is possible

but not DP dial.

1. Check CON3(main PBA), main LIU

harness, and P1(LIU PBA).

2. Output of U2-4(LIU PBA) is HIGH?

(+4V or over)

3. Refer to 3,4,5 and 6 of ÔDefective

Transmission/ReceptionÕ in ÔIn case

PC controlsÕ.

1. Can you check ring? Check ring pattern of U17-18(main PBA).

2. Refer to ÔDefective Transmission/

ReceptionÕ.

1. Check the part around R2 and Q6 of

LIU PBA.

2. Check connection of R43 of LIU PBA.

1. Replace defective parts.

2. If high, check the surrounding circuit

and replace LIU PBA.

3. Refer to 3,4,5 and 6 of ÔDefective

Transmission/ReceptionÕ in ÔIn case

PC controlsÕ.

1. If not, replace LIU PBA.

2. Refer to ÔDefective Transmission/

ReceptionÕ.

1. Replace LIU PBA.

2. Replace LIU PBA.

PROBLEM ITEMS TO BE CHECKED HOW TO SOLVE

6-7. Other Problems

ÔInk LowÕ continues

to be displayed or

warning voice

sounds though ink

has been

replaced.

Printed color is

extremely different

from the color on

the screen of PC.

PC cannot check the

status of the printer.

Windows goes in

error and the computer gets down

after a diskette is

installed.

- Check if you reset ÔInk Low CounterÕ

when you replaced ink.

- Check by self diagnostic printing if

specific color ink is used up.

- Check if device driver has not been

installed or incorrectly installed.

- Check Ôvirtual memoryÕ of control

panel in the basic program group.

- Reset Ink Low Counter by pressing

Ôink replacementÕ button for more than

3 seconds when you replace ink using

the button.

- Reset Ink Low Counter by pressing

Ônew cartridge replacementÕ button

when you replace ink using PC.

- Replace color ink cartridge.

- Add Device=C: \ Myjet \ Mjtsr.exe to

Config.sys file and reboot the computer.

- Optimize PC memory by running

ÒMemmakerÓ.

- Press the 386 expansion icon of control

panel to change Ôvirtual memoryÕ from

temporary to permanent.

In case

you use

external

tele-

phones

Note) 1) Refer to 5. ÔCIRCUITÕ for the details about the signals mentioned above.

2) Unplug power cord and insert it again to cancel all operations (all operations being performed,

error, etc.) and initialize the system.

Loading...

Loading...