Samsung SCX-5315F Series, SCX-5115 Service Manual

DIGITAL LASER MFP

SCX-5315F Series

SCX-5315F

SCX-5115

1. Precautions

2. Specifications

3. Disassembly

4. T roubleshooting

5. Exploded Views and Parts List

6. Block Diagram

7. Connection Diagram

DIGITAL LASER MFP

CONTENTS

SERVICE

MANUAL

Specification

Samsung Electronics

2-1

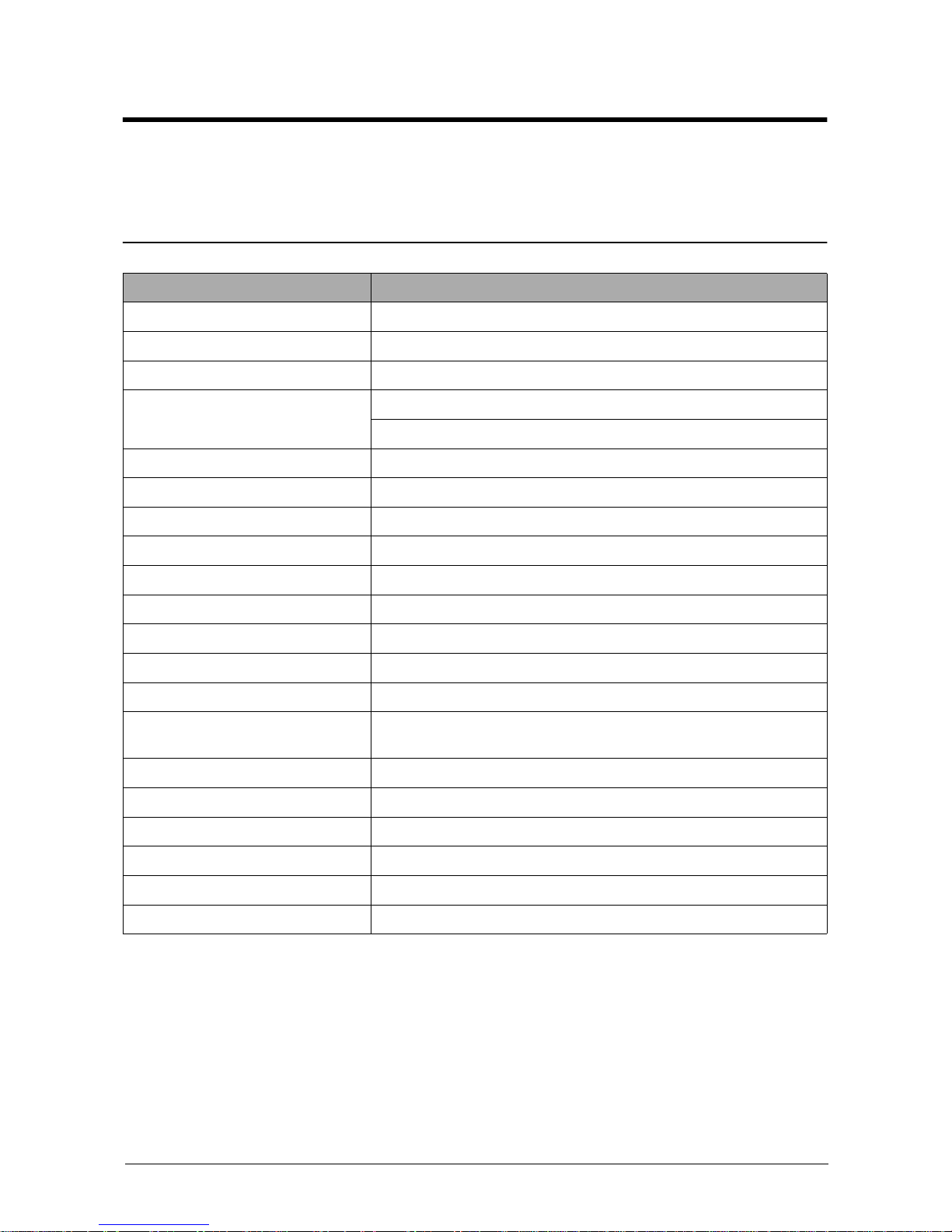

2. Specification

Specifications are correct at the time of printing. Product specifications are subject to change without notice.

See below for product specifications.

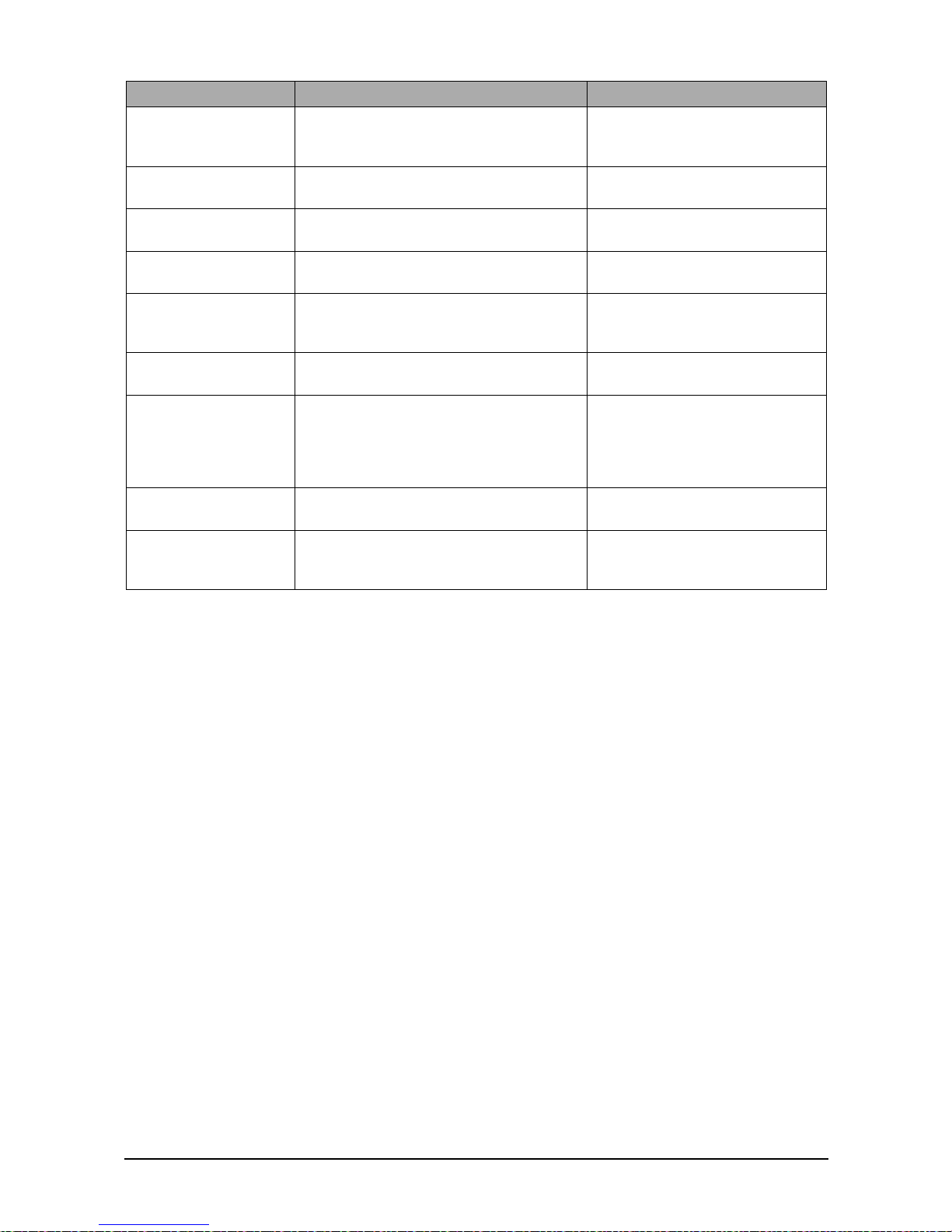

2-1 General Specifications

* Sound Pressure Level, ISO 7779

Item Description

Type of Unit Desktop

Operation System Win95/98/ME/ NT /2000/XP

Duplex Printing Yes(Default)

Interface IEEE1284(ECP)

USB(without HUB mode)

CPU 120 MHz(ARM946ES)

Emulation PCL6

Warming up Time 30 Sec (Stand-By), 25˚C

Absolute Storage Condition Temperature : -20°C ~ 40°C, Humidity : 10% RH ~ 95% RH

Operating Condition Temperature : 10˚C ~ 32˚C, Humidity : 20% RH ~ 80 % RH

Recommended Operating Condition Temperature : 16°C ~ 30°C, Humidity : 30% RH ~ 70% RH

Dimension(W X D X H) 560 X 433 X 459 mm

Weight About 22.5 Kg(with CRU)

* Acoustic Noise Less than 56/50 dB(Copy/Printing mode)

Power Rating AC 100VAC ~ 127VAC ± 15 %, 50/60Hz ± 3Hz

AC 220VAC ~ 240VAC ± 15 % , 50/60Hz ± 3Hz

Power Consumption Avg. 320Wh

Power Save Consumption Avg. 35Wh

Recommended System Requirement Pentium IV 1.2 Ghz, 128 MB RAM, 220MB(Hard Disk)

Minimum System Requirement Pentium II 400Mhz, 64 MB RAM, 120MB(Hard Disk)

LCD 16 characters X 2 lines

Memory 4 Mbyte for flash Memory , 16 Mbyte for SDRAM

Specification

Samsung Electronics2-2

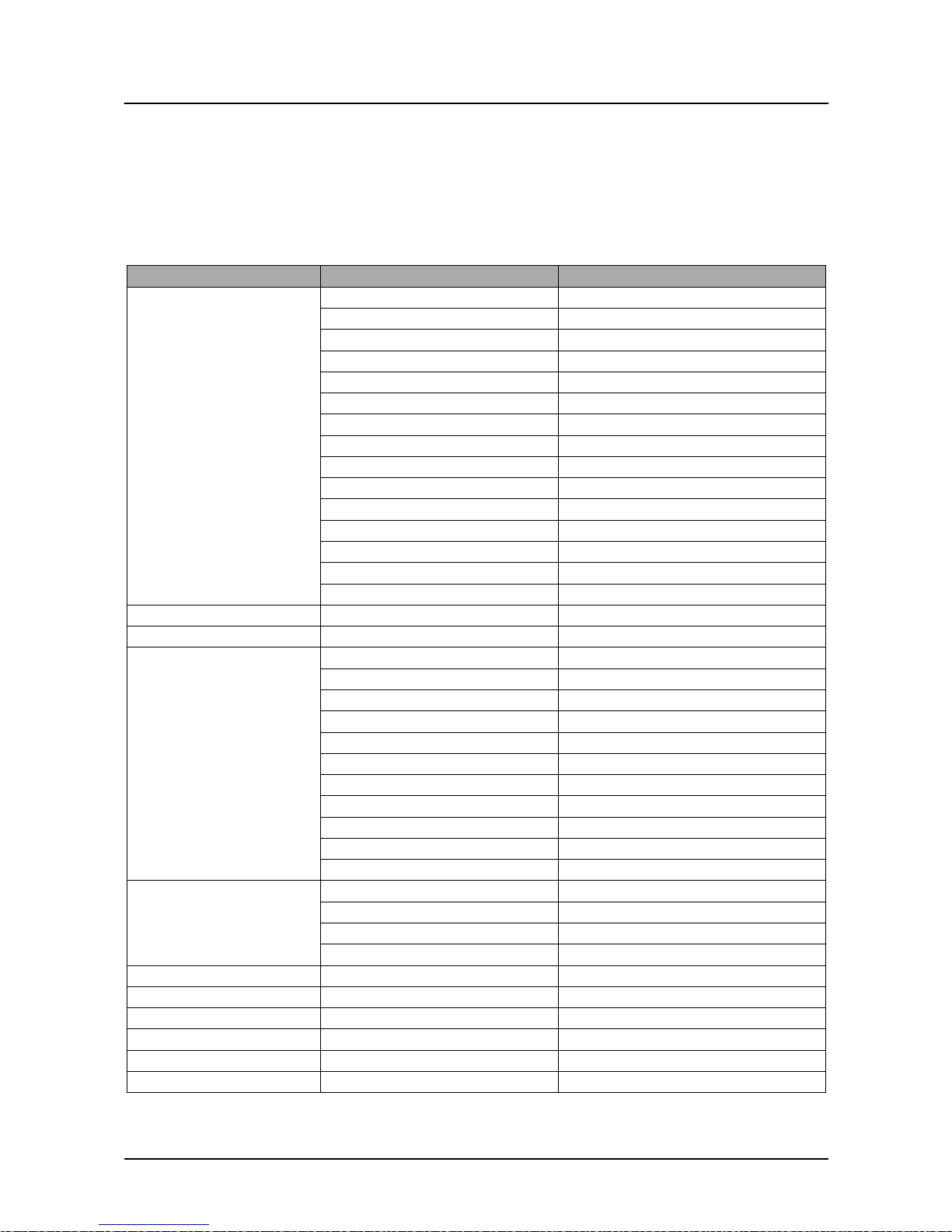

2-2 Printer Specifications

* Print speed will be affected by Operating System used, computing performance, application software,

connecting method, media type, media size and job complexity.

2-3 Facsimile Specification(SCX-5315F Only)

Item Description

Printing Method Laser Scanning Unit + Electro Photography

*Speed Single Side : Up to 15 PPM

(Letter Size, 5% Character Pattern)

Duplex : Up to 7.5 IPM(Images/Min) (Letter Size, 5% Character Pattern)

Source of Light LSU(Laser Scanning Unit)

Duplex Printing Yes(Default)

Resolution(Horizontal X Vertical) Up to 1200 x 1200 DPI effective output

Feed Method Cassette Type , By Pass Tray,

ADF(Automatic Document Feeder)

Feed Direction FISO(Front-In Side-Out)

Paper Capacity(Input) Cassette : 550 Sheets

By Pass Tray : 100 Sheets(based on 75g/ß

≥ , 20lb)

Paper Capacity(Output) Face Down : 250 Sheets

Effective Print Width 203 ± 1mm (8 inch)

Item Description

Standard Recommendation ITU-T Group3(ITU : International Telecommunications Union)

Application Circuit PSTN or behind PABX

(PSTN : Public Switched Telephone Network.

PABX : Private Automatic Branch Exchange)

Data coding(Compression) MH/MR/MMR/JPEG(Transmission)

Modem speed 33600 /14400/12000/9600/7200/4800/2400 bps

Transmission Speed Approximately 3 sec(33,600 bps)

Effective Scanning Width 8.2 inches(208 mm)

Halftone 256 Levels

Paper Capacity(Input) ADF(Automatic Document Feeder) : 30Sheets(75g/ß

≥ )

FAX Mode Standard /Fine/Super Fine/Halftone

Memory 4MB

Specification

Samsung Electronics

2-3

2-4 Scanner Specification

* Speed will be affected by Operating System used, computing performance, application software, connecting

method, media type, media size and job complexity.

2-5 Copy Specification

NOTE :

(1) Speed claims based on the test chart : Letter size.

SDMP : Single Document Multiple Printout

MDSP : Multiple Document Single Printout

• Speed will be affected by Operating System used, computing performance, application software,

connecting method, media type, media size and job complexity.

Item Description

Type Flatbed(with ADF)

*Speed Mono : Up to 1.2 msec/line, Color : Up to 2.5 msec/line

Device Color CCD(Charge Coupled Device) Module

Interface IEEE1284(ECP Support)

USB(without HUB Mode)

Compatibility TWAIN Standard , WIA

Optical Resolution(H X V) Up to 600 x 600 DPI effective output

Interpolation Resolution Max. 4800 dpi

Halftone 256 Levels

Effective Scan width 8.2 inches(208 mm)

Item Description

Mode B/W

Quality Text/Photo/Mixed

Mono Copy Speed

(1)

Platen(SDMP) : Up to 12 cpm in A4 size, IDC 5% pattern

ADF (SDMP) : Up to 12 cpm in A4 size, IDC 5% pattern

ADF (MDSP) : Text/mixed : Approx. 7 cpm in A4 size, IDC 5% pattern

: Photo : Approx. 3 cpm in A4 size, IDC 5% pattern

Optical Resolution (H x V) Up to 600 x 600 DPI effective output

Multi Copy 99 pages

Maximum Original Size Legal

Maximum Page Size Legal

Paper Type Selection Plain , Legal , Cardstock , Transparency

Zoom Range Platen : 25 ~ 400%(1% Step)

ADF : 25~100 %(1% Step)

Specification

Samsung Electronics2-4

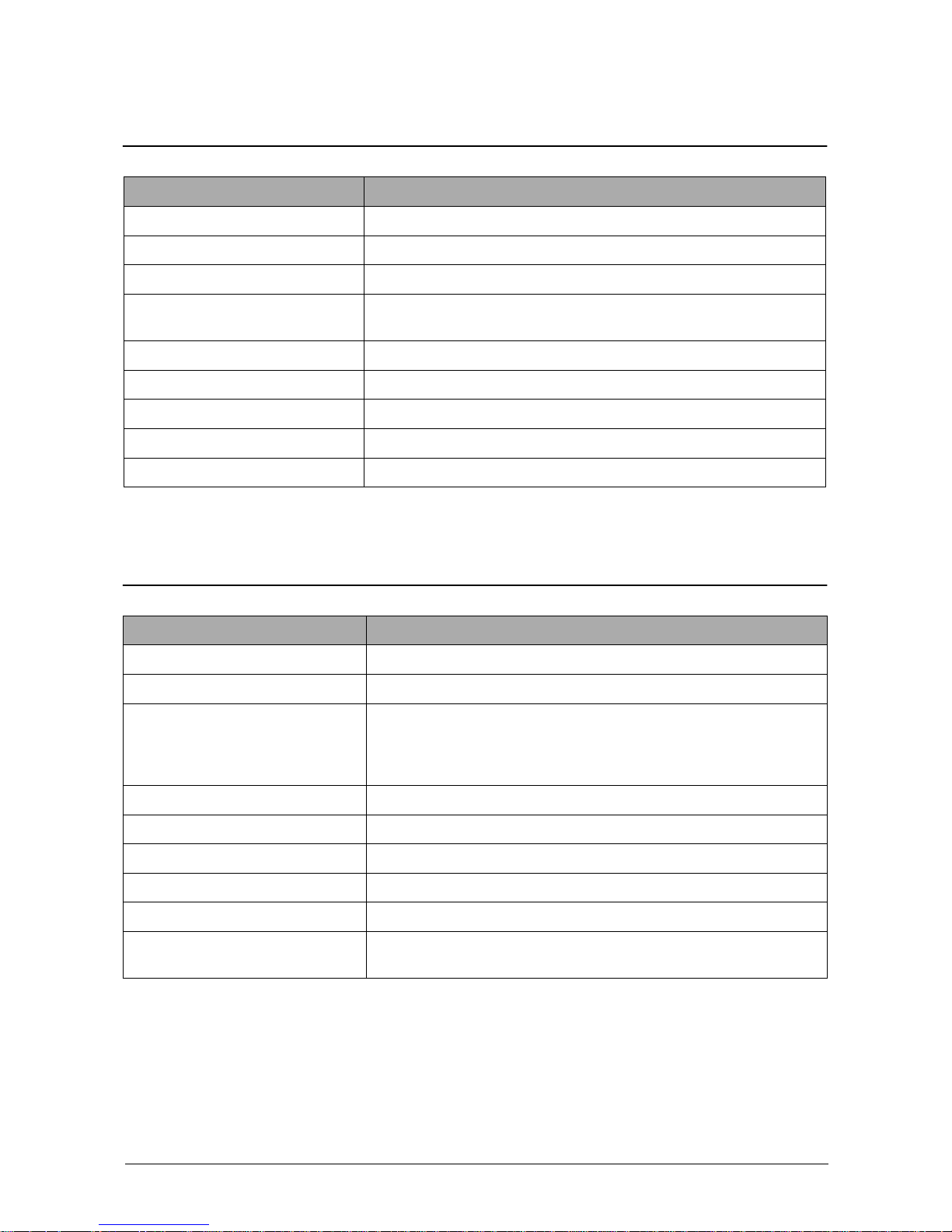

2-6 Telephone Specification(SCX-5315F Only)

2-7 Consumables

Item Description

Speed Dial 80EA

Tone/Pulse Tone only user modeTone/Pulse selectable in tech mode.

Item Description

Type Separate type

(Toner Cartridge / Drum Cartridge)

Life Toner Cartridge Up to 6,000 sheets

( 5% coverage pattern, simplex normal mode )

Drum Cartridge Up to 15,000 sheets

(simplex normal mode )

T I D I

This service manual is also provided on the web,

the ITSELF system Samsung Electronics Co., Ltd.

“http://itself.sec.samsung.co.kr”

© Samsung Electronics Co.,Ltd. JULY 2003

Printed in Korea.

VERSION NO. : 1.00 CODE : JC-0086A

This Service Manual is a property of Samsung Electronics

Co.,Ltd. Any unauthorized use of Manual can be punished

under applicable International and/or domestic law.

Disassembly and Reassembly

Samsung Electronics

3-1

3. Disassembly and Reassembly

3-1 General Precautions on Disassembly

When you disassemble and reassemble components, you must use extreme caution.

The close proximity of cables to moving parts makes proper routing a must. If components are removed, any

cables disturbed by the procedure must be restored as close as possible to their original positions. Before

removing any component from the machine, note the cable routing that will be affected.

Whenever servicing the machine, you must carry out the following :

1. Check to verify that documents are not stored in memory.

2. Unplug the power cord.

3. Use a flat and clean surface.

4. Replace only with authorized components.

5. Take care when removing plastic component-do not force.

6. Make sure all components are in their proper position.

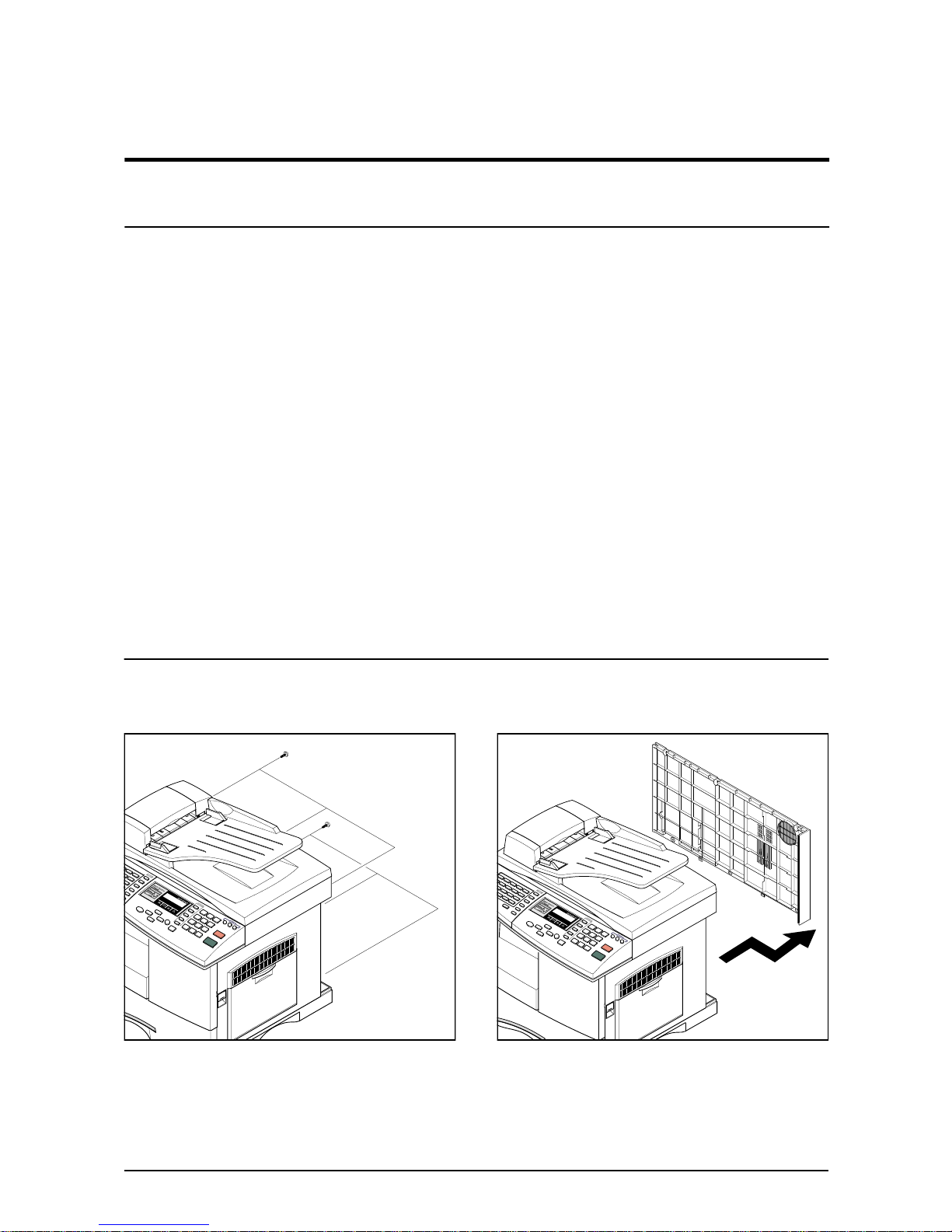

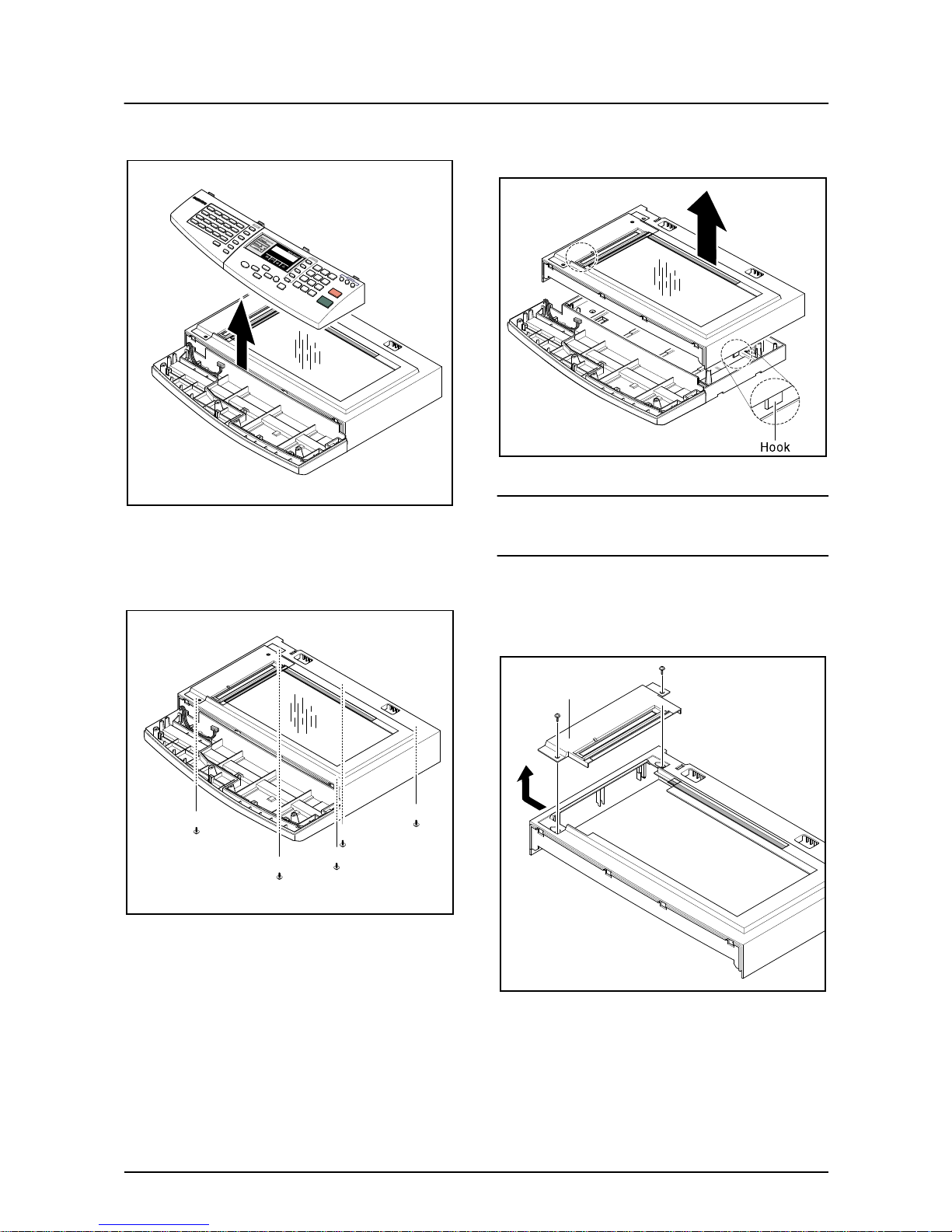

3-2 Rear Cover

1. Remo ve the six screws securing the Rear Cov er .

2. Separate the rear cover from the base frame

and Scanner Ass'y.

Disassembly and Reassembly

3-2

Samsung Electronics

3-3 Scanner Ass'y

1. Before you remove the Scanner Ass'y, you

should remove:

- Rear Cover (see page 3-1)

2. Take out the Shield Main Upper.Unplug the one

connector and CCD cable.

Notice :

T o a void damage to the CCD cab le connector ensure that

you pull the cable out carefully. Pull in line with the connector not at an angle.

3. Remove the three screws, as shown below.

4. Open the Side Cover assembly first to open the

Front cover. In the other words, close the front

cover first to assembly it.

5. Remove two screws.

Side Cover Ass’y

Front Cover

1

2

Disassembly and Reassembly

Samsung Electronics

3-3

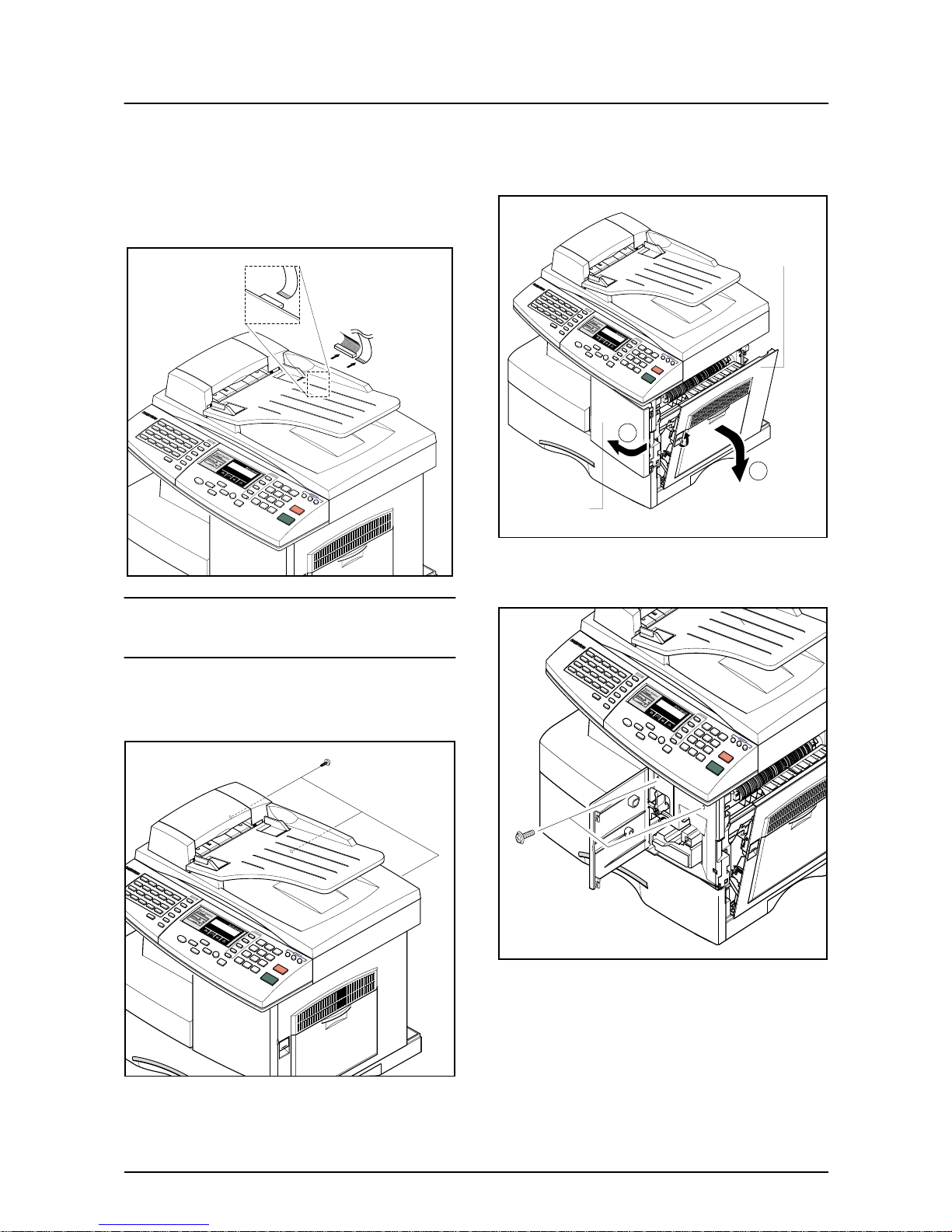

6. Pull up the Scanner Ass'y in the direction of

arrow.

7. Remove the connector from the Platen Ass'y.

8. Open the ADF Ass’y in the direction of arrow.

Pull the ADF Ass'y upward and remove it.

9. Remove the three screws securing the Platen

Ass'y.

Disassembly and Reassembly

3-4

Samsung Electronics

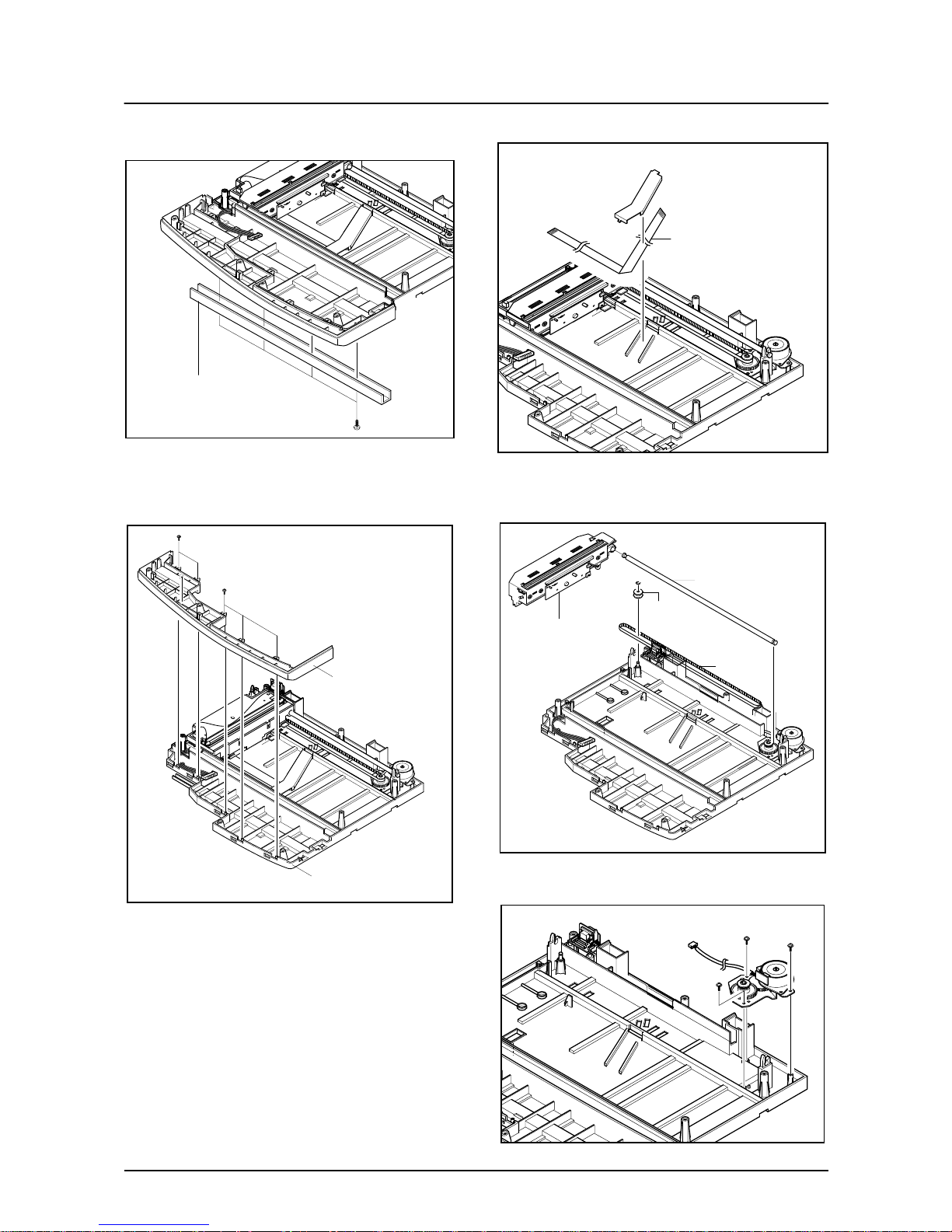

10. Pull the OPE Ass'y and unplug the one connector.

11. Remove the five screws securing the Platen Ass'y.

12. Unlatch the Scan Upper Ass'y securing the

glass and remove it.

Notice :

When dismantling the Scan Assy ensure your work area

is clean. Dirt or dust on the scan head can lead to a degradation in scanned image quality.

13. Remove the two scews and pull the Dummy

Upper Ass’y.

Dummy Upper Ass’y

Disassembly and Reassembly

Samsung Electronics

3-5

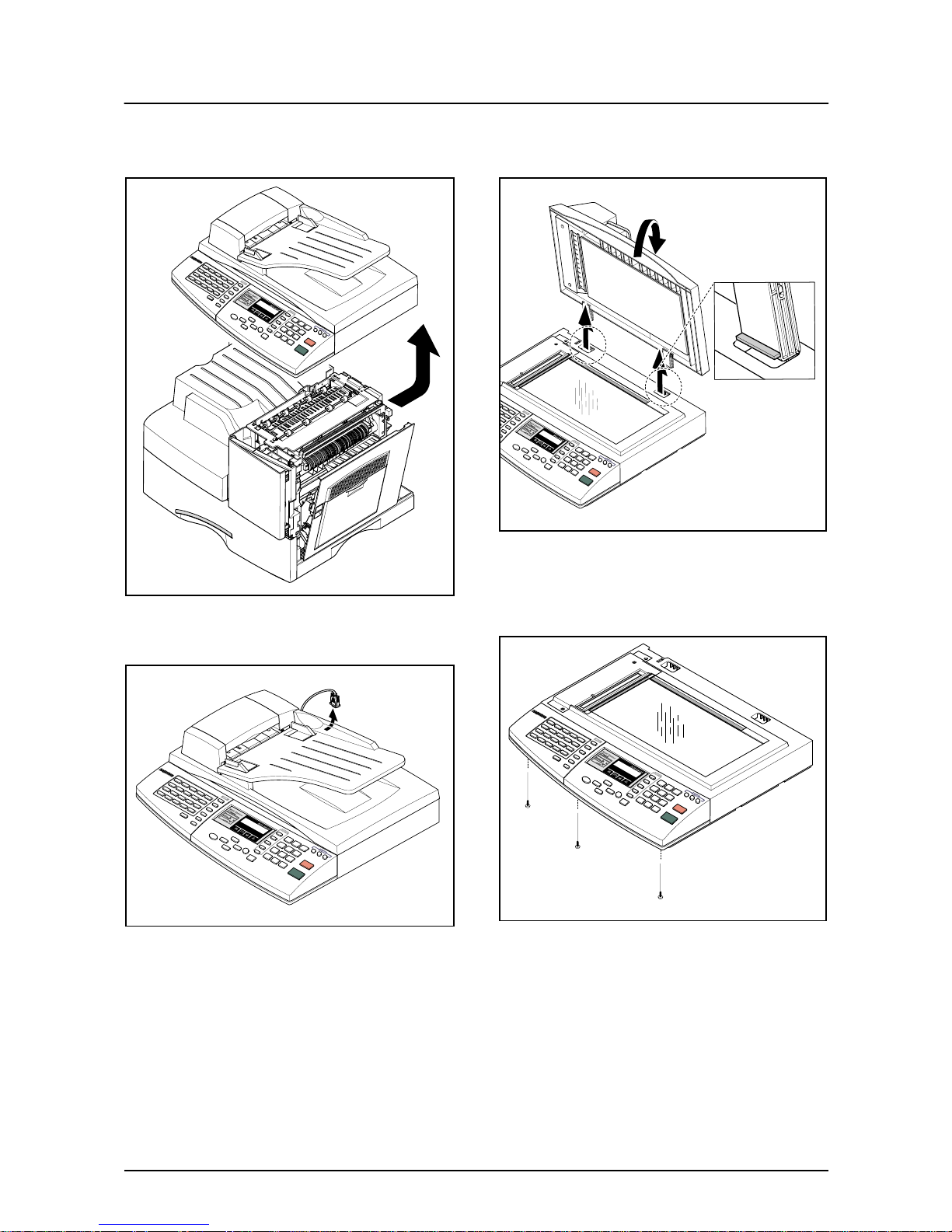

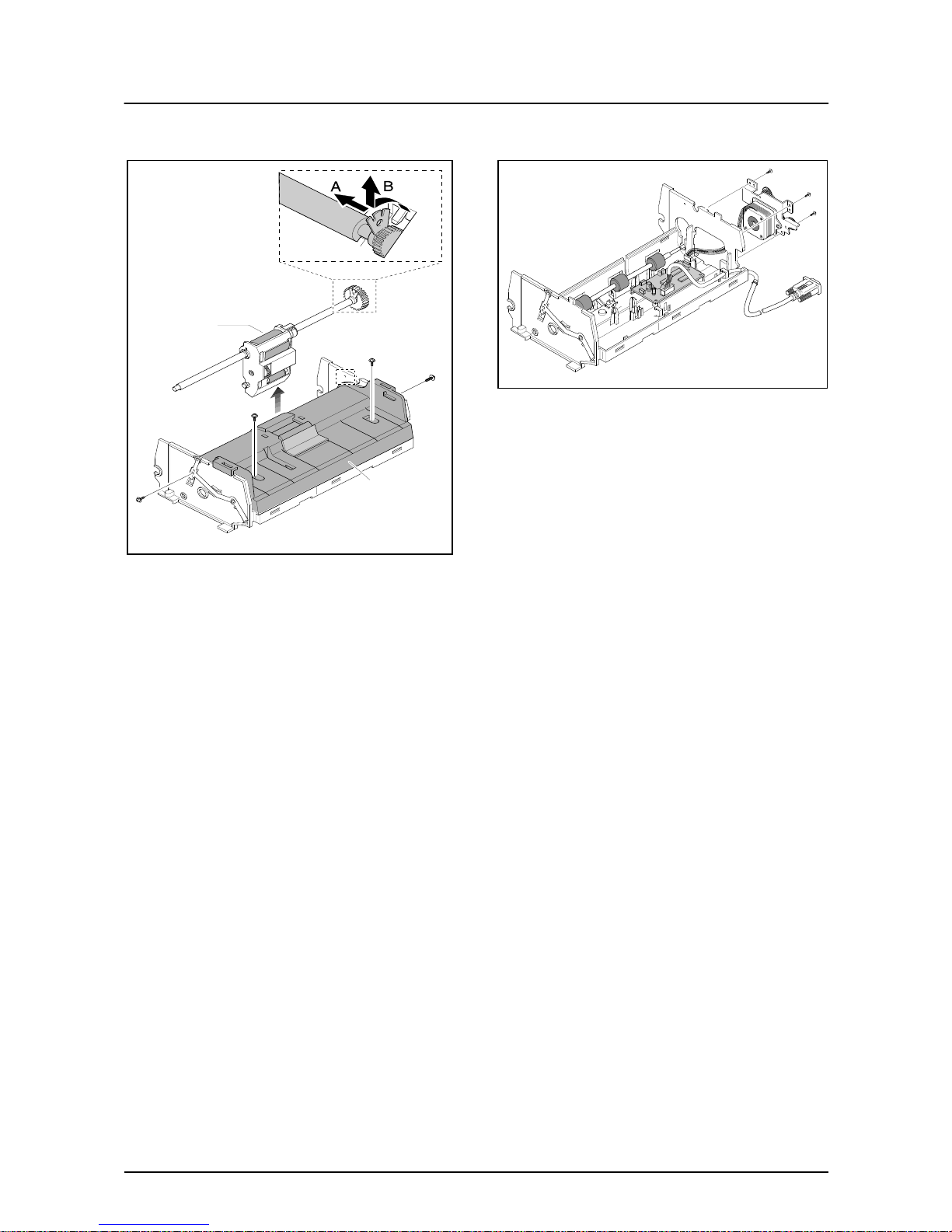

14. Remove the four screws and Channel Base

Frame.

15. Remove the five screws and Dummy ScanLower.

16. Remove the CCD cable.

17. Pull up the Shaft CCD and tak e out the Scanner

Module.

18. Remove three screws and take out the Motor

Bracket.

Channel Base Frame

Cover Scan Lower

Cover Dummy Lower

CCD Cable

Scanner Module

Shaft CCD

Belt

Pully

Disassembly and Reassembly

3-6

Samsung Electronics

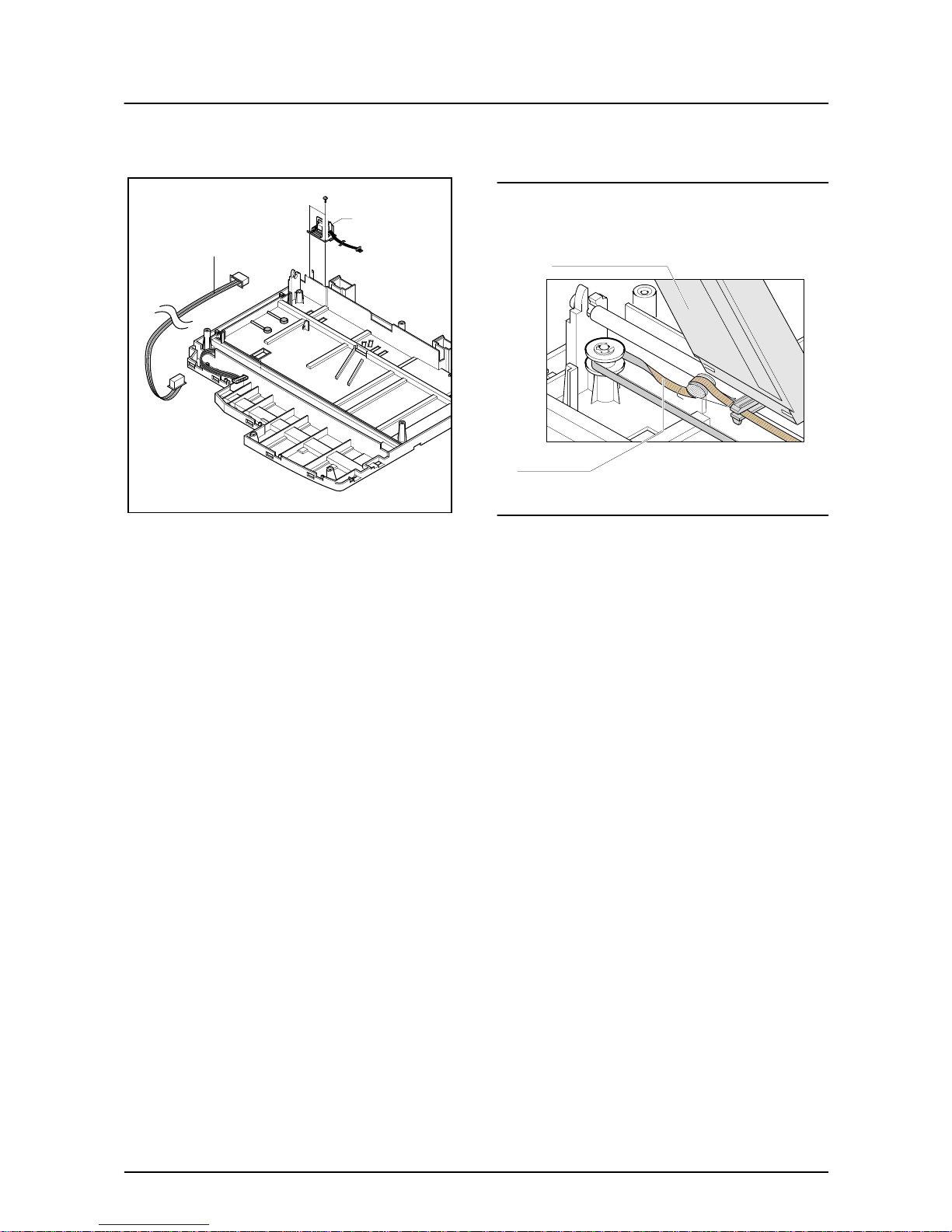

19. Remove the OPE Harness from the Platen

PBA. Remove two screws and take out the

Platen PBA.

Notice :

Take special care when reassembling the CCD Module

onto the Platen Ass'y. The CCD Module is located just to

the right side the Belt Tension Spring as shown below.

Platen PBA

OPE Harness

Scanner Module

Belt Tension Spring

Disassembly and Reassembly

Samsung Electronics

3-7

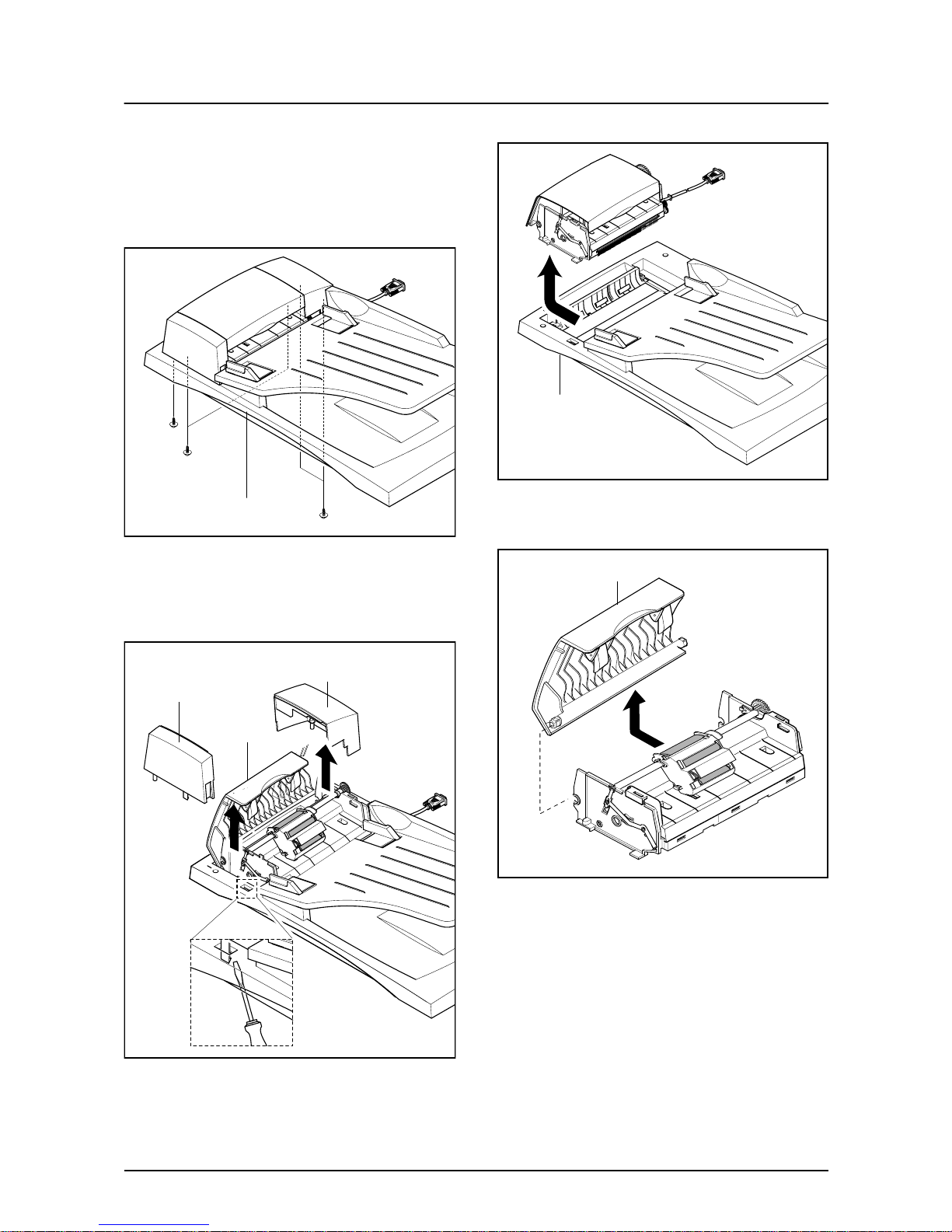

3-4 ADF Ass'y

1. Before you remove the ADF Ass'y, you should

remove:

- Rear Cover (see page 3-1)

- Scanner Ass'y (see page 3-2)

2. Remove the five screws from the Platen Cover.

3. Open the Co ver. Remov e Co ver Side R. Unlatch

the Side Cover L by pushing the catch hook ed to

the Platen Cover using a sharp tool and remove

Side Cover L.

4. Pull the ADF Ass'y upward and remove it.

5. Tack out he Open Cover.

Platen Cover Ass’y

Side Cover L

Cover Open

Side Cover R

Platen Cover Ass’y

Open Cover

Disassembly and Reassembly

3-8

Samsung Electronics

6. Take out the Pick-up Ass’y.

Remove the four screws and the ADF Upper.

7. Remove three screws and take out the ADF

Motor ass'y.

Pick-up Ass’y

ADF Upper

Disassembly and Reassembly

Samsung Electronics

3-9

3-5 OPE Ass'y

1. Before you remove the OPE Ass'y, you should

remove:

- Rear Cover (see page 3-1)

- Scanner Ass'y (see page 3-2)

2. Remove ten screws securing the OPE PBA and

the LCD Module from the OPE Cover.

3. Remove the contact rubbers from the unit.

4. Remove the key pad from the unit.

Caution

The above information is for the SCX-5315F model.

For the SCX-5115 model, the OPE Ass’y is slightly different, prats maked “a” are not fitted.

Disassembly and Reassembly

3-10

Samsung Electronics

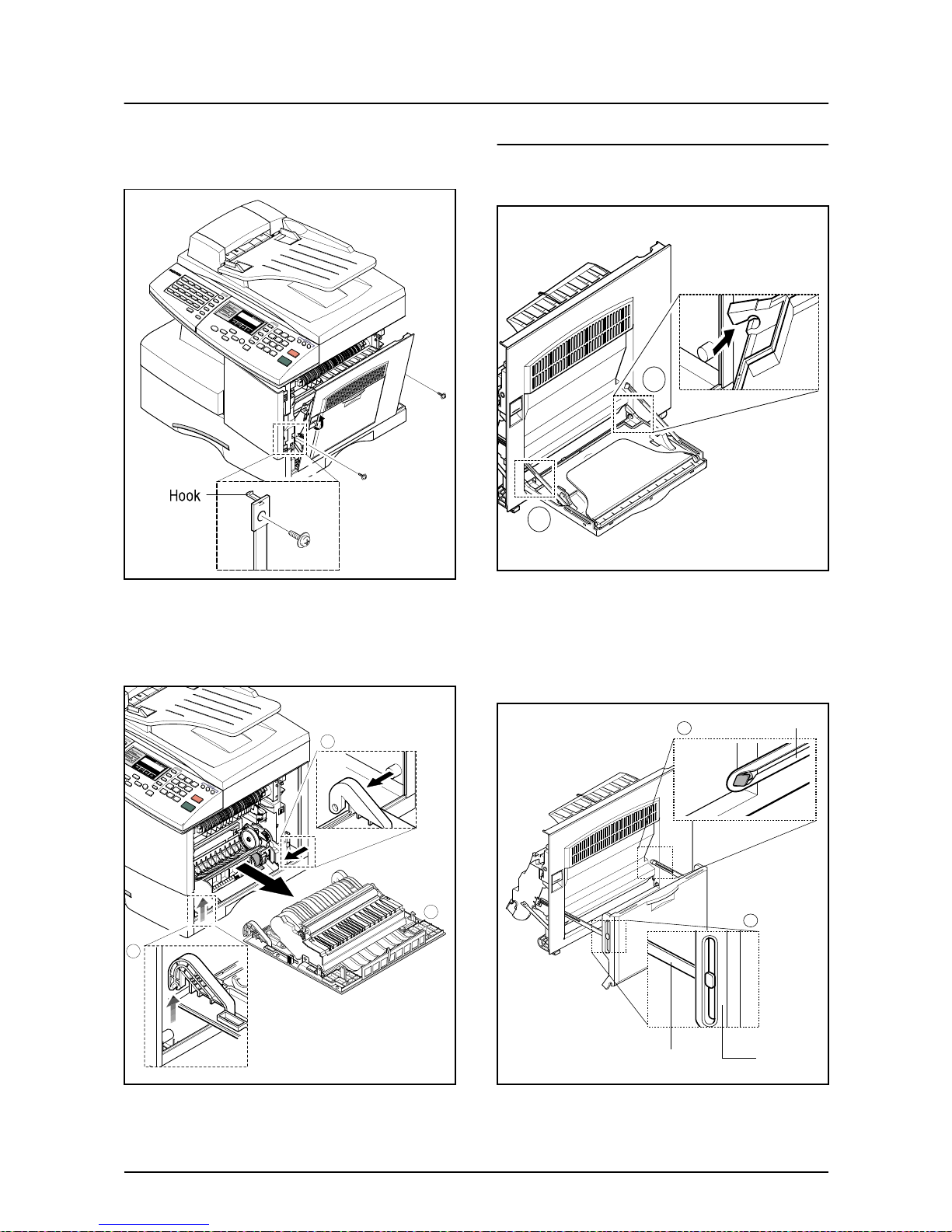

3-6 Side Cover Ass'y

1. Remove the two screws to release the Stopper(Main Frame side) securing the Side Cover

to the Main Frame.

2. Completely open the Side Cover door. The left

hand hinge (1) should be lifted to free it. Then

push the whole door assembly to the left to free

the right hand hinge (2).

* MP-Tray

1. To dismantle the MP tray release the lower

hinges (1).

2. As shown in (1) below align the door supports in

a horizontal position. This will allow the TrayCase to be removed from the Tray Links. To

remove the Tray-Links adjust the position of the

Tray Link to a 45?angle to align the slot in the

Tray Link

Tray-Case

MP Tray

1

2

1

1

1

2

3

Disassembly and Reassembly

Samsung Electronics

3-11

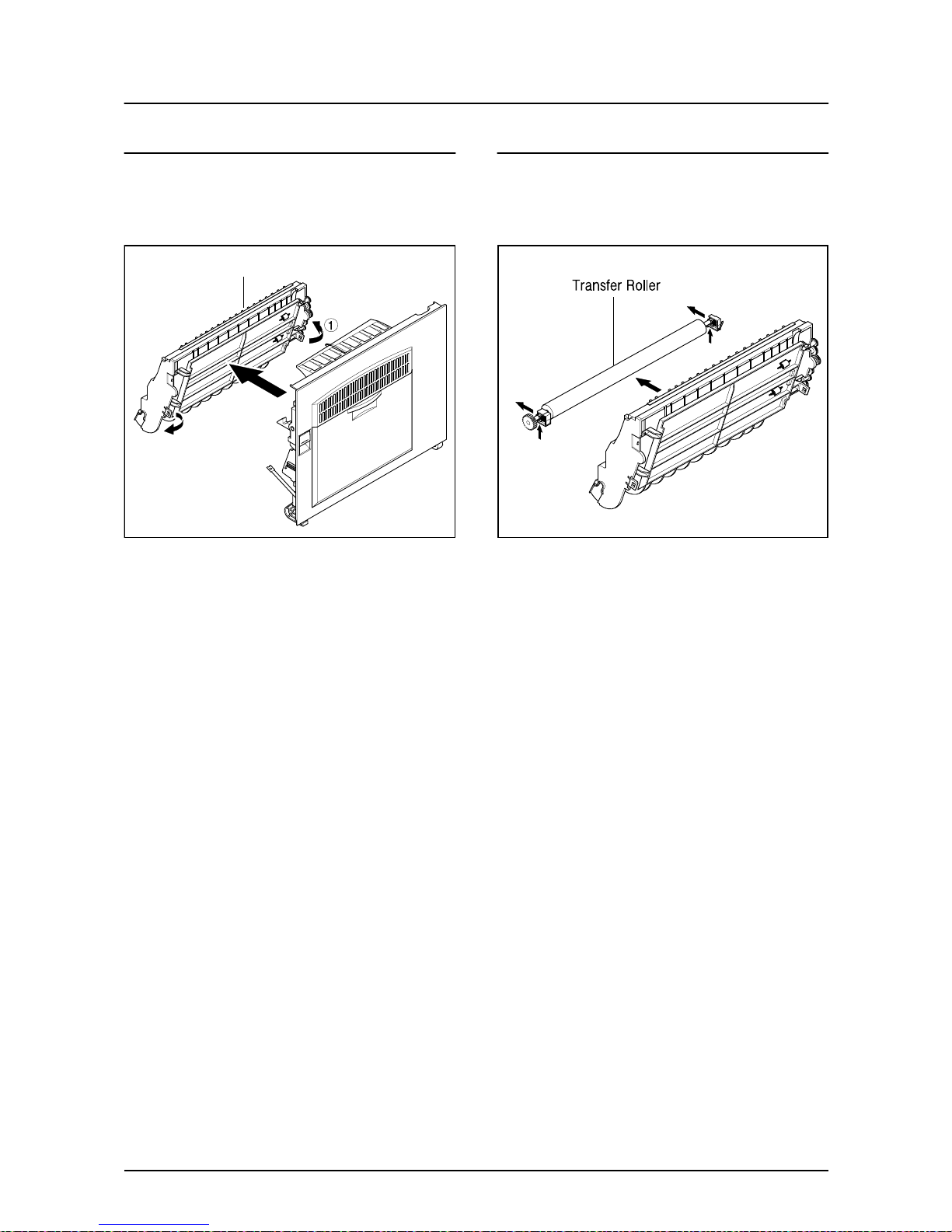

* Duplex Ass’y

1. To remove the Duplex Ass'y from the Side Door

Ass' locate the plastic clips, 2 on each side, and

release them.

Duplex Ass’y

* Transfer Roller Ass’y

1. Take out the Transfer Roller, as shown below.

Disassembly and Reassembly

3-12

Samsung Electronics

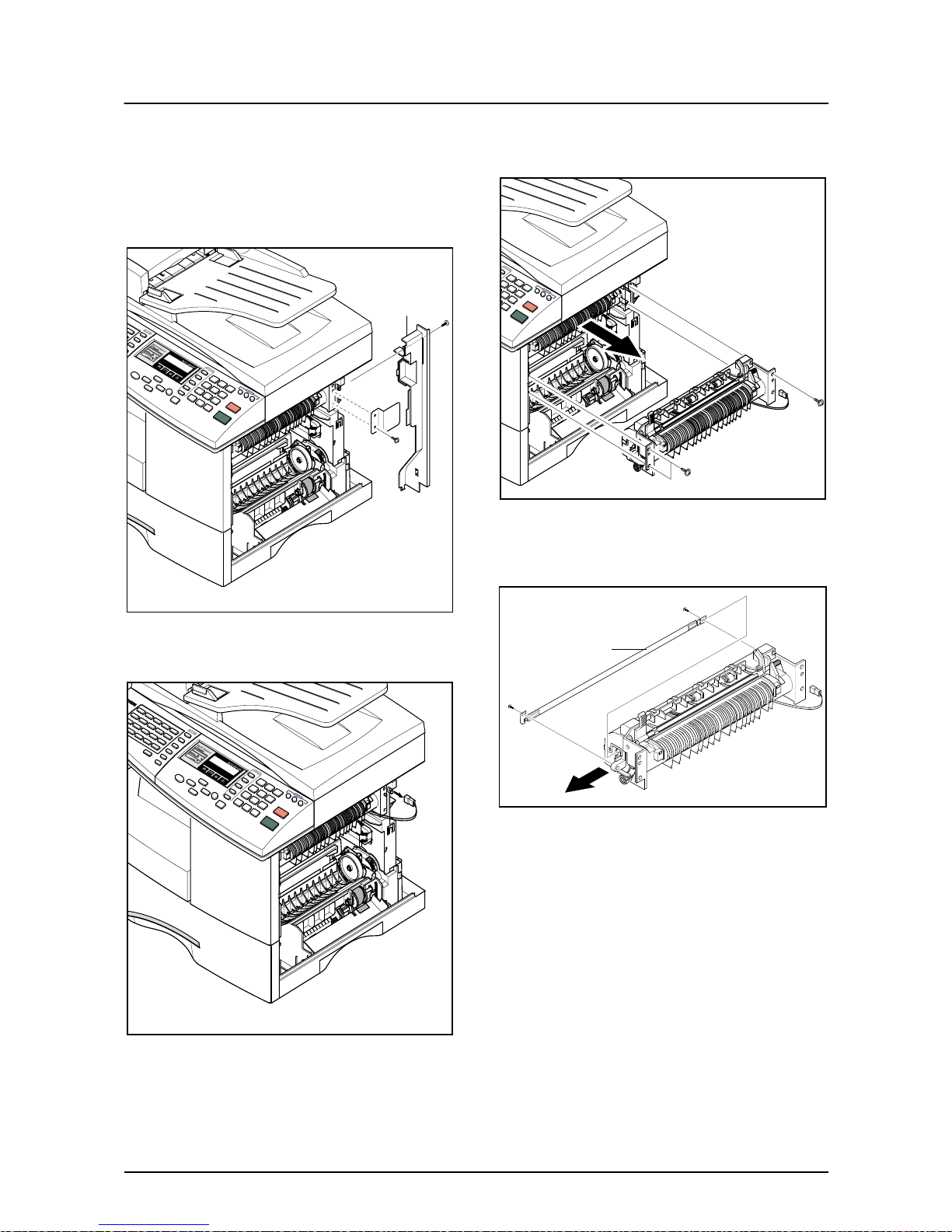

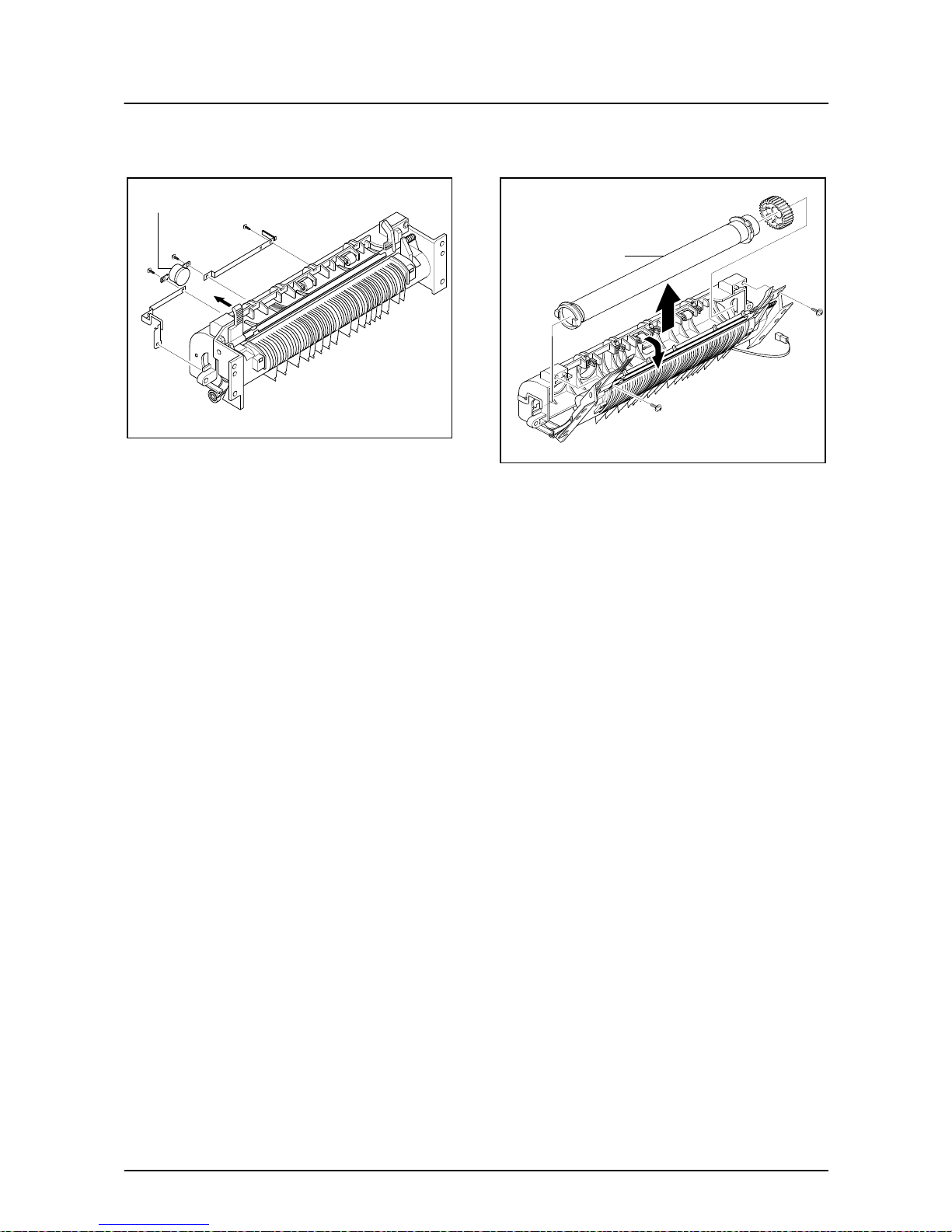

3-7 Fuser Ass'y

1. Before you remove the Fuser Ass'y, you should

ensure power is off and remove :

- Rear Cover Ass'y (see page 3-1)

- Side Cover Ass'y (see page 3-9)

2. Remove the two screws and take out the Connector Cover and the Cover Bracket.

3. Unplug the one connector.

4. Remo v e the three scre ws and tak e out the Fuser

Ass'y.

5. Remove the four screws and take out the Thermostat.

Cover Bracket

Halogen Lamp

Disassembly and Reassembly

Samsung Electronics

3-13

6. Remove the two screws and take out the Halogen Lamp.

7. Remove 2 screws and hinge open the Lower

Fuser Ass'y, remove the Heat Roller Ass'y from

the Upper Fuser Ass'y.

Thermostat

Heat Roller

Disassembly and Reassembly

3-14

Samsung Electronics

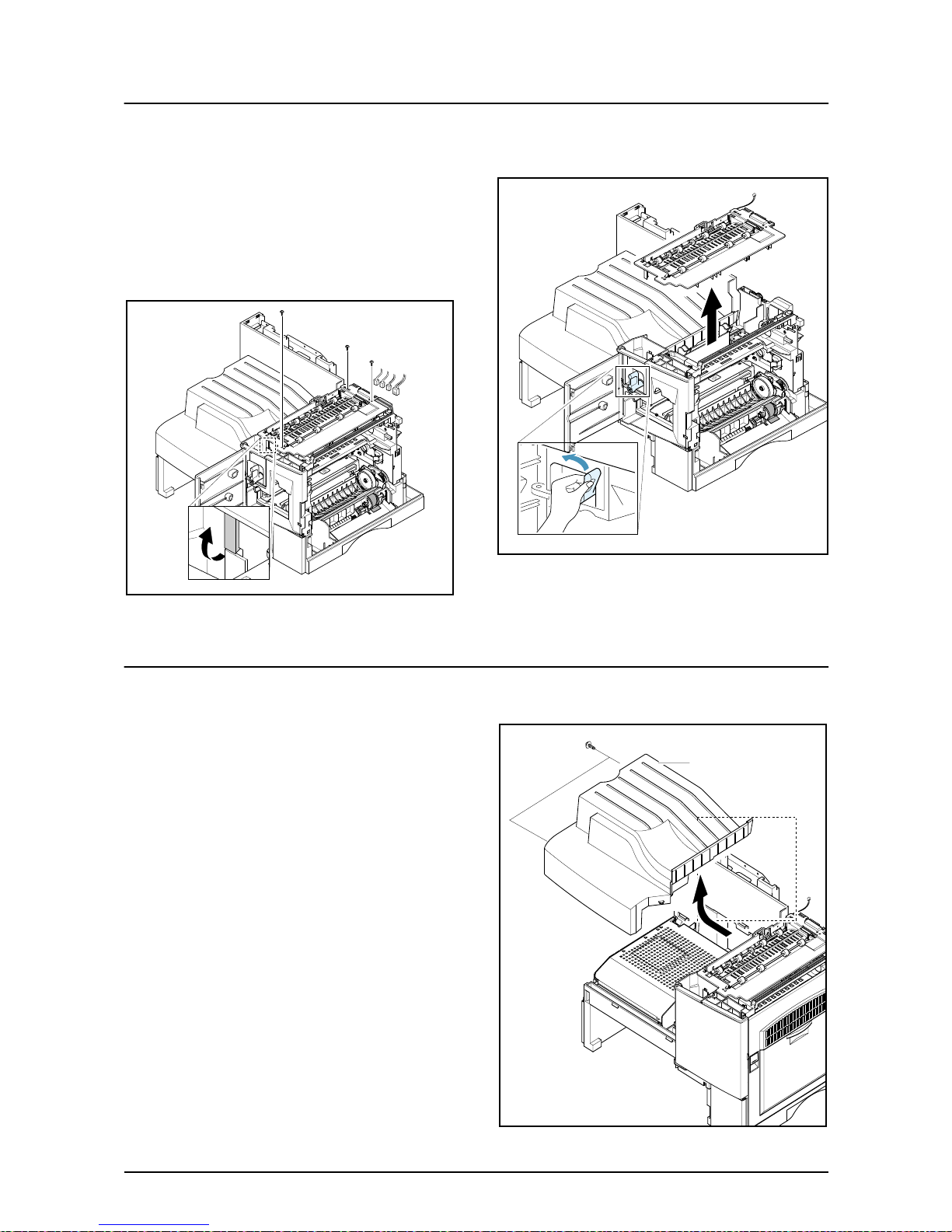

3-8 Exit Ass'y

1. Before you remove Exit Ass'y, you should

remove:

- Rear Cover (see page 3-1)

- Scanner Ass'y (see page 3-2)

2. Remo ve four screws, and then untie the harness

from the Exit Upper. Unplug f our connectors and

unlatch the Dummy Base Frame, as shown

below.

3. Mo ve the Exit Roller Release Le v er to the upright

position as shown in the diagram below and lift

the exit ass'y to remove it.

3-9 Cover Paper Exit Ass'y

1. Before you remove the Cover Paper Exit Ass'y,

you should remove:

- Rear Cover (see page 3-1)

- Scanner Ass'y (see page3-2)

2. Remo ve two screws and Cover Paper Exit Ass'y,

as shown below.

Cover Paper Exit Ass’y

Disassembly and Reassembly

Samsung Electronics

3-15

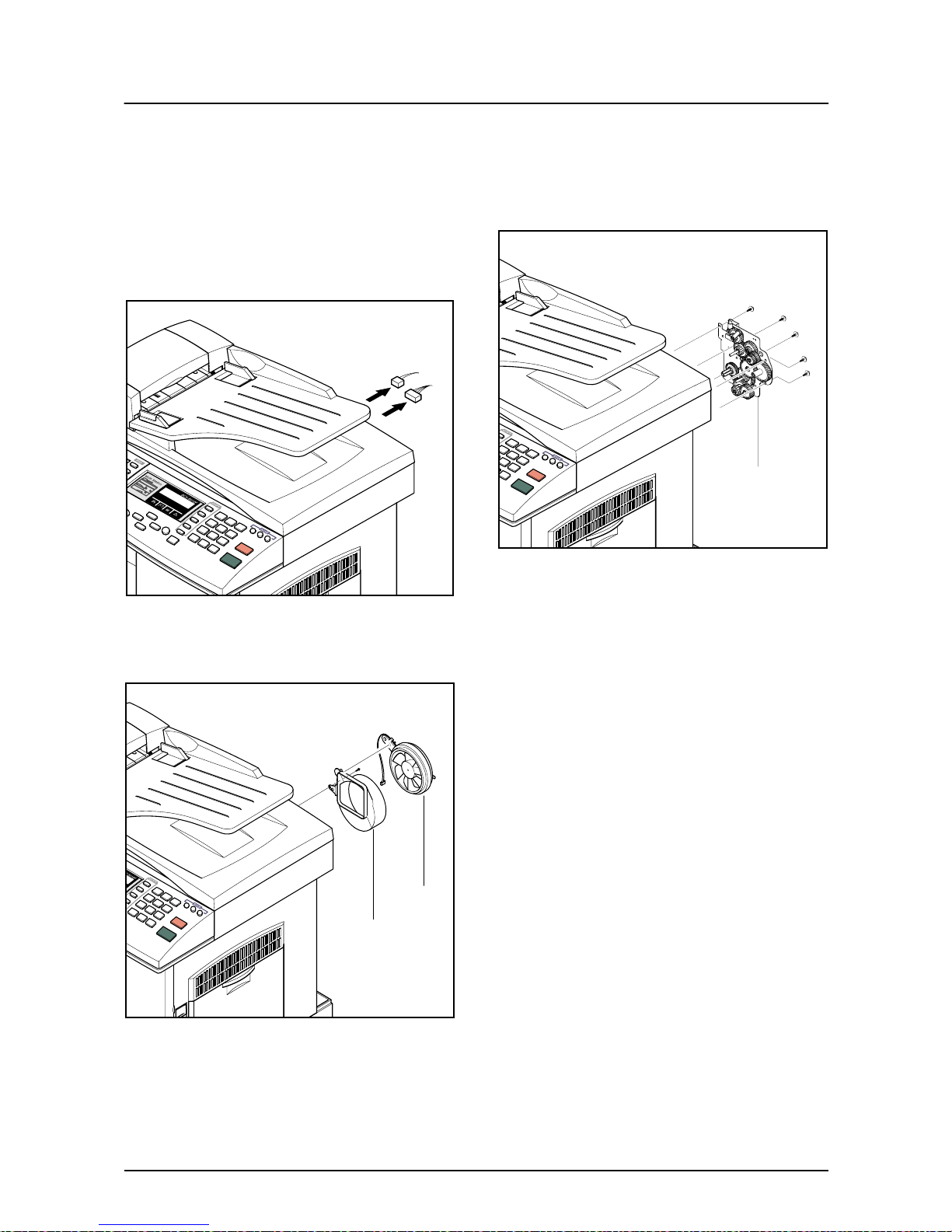

3-10 Drive Ass'y

1. Before you remove the Drive Ass'y, you should

remove:

- Rear Cover (see page 3-1)

- Shield Main Upper (see page 3-2)

2. Unplug the two connectors.

(Main Motor:9pin, Duplex Solenoid : 2pin)

3. Remo ve the one screw and take out the Fan and

Dust Fan.

4. Remove the five screws and take out the Drive

Ass'y.

Fan

Dust Fan

Drive Ass’y

Troubleshooting

Samsung Electronics 4-1

4. Maintenance & Troubleshooting

This chapter covers product maintenance, problem diagnosis and troubleshooting. It includes instructions for

diagnosing and resolving print quality problems.

This service manual covers both the SCX5315F and SCX5115 models. SCX5115 has printer, copier and

scanner functions. The SCX5315F has all of the features of the SCX5115 and in addition has Fax capabilities.

The manual contents are primarily written for the SCX5315F, where there are differences between the two

models this is highlighted.

4-1 Preventative Maintenance

The cycle period outlined below is a general guideline for maintenance.

The example list is for an average usage of 50 transmitted and received documents per day.

Environmental conditions and actual use will vary these factors.

The cycle period given below is for reference only.

COMPONENT REPLACEMENT CYCLE

ADF Rubber 20,000 Pages

ADF Roller 50,000 Pages

Pick-up Roller 75,000 Pages

Transfer Roller 75,000 Pages

Fuser 75,000 Pages

Toner Cartridge 6,000 Pages

Drum Cartridge 15,000 Pages

Troubleshooting

4-2

Samsung Electronics

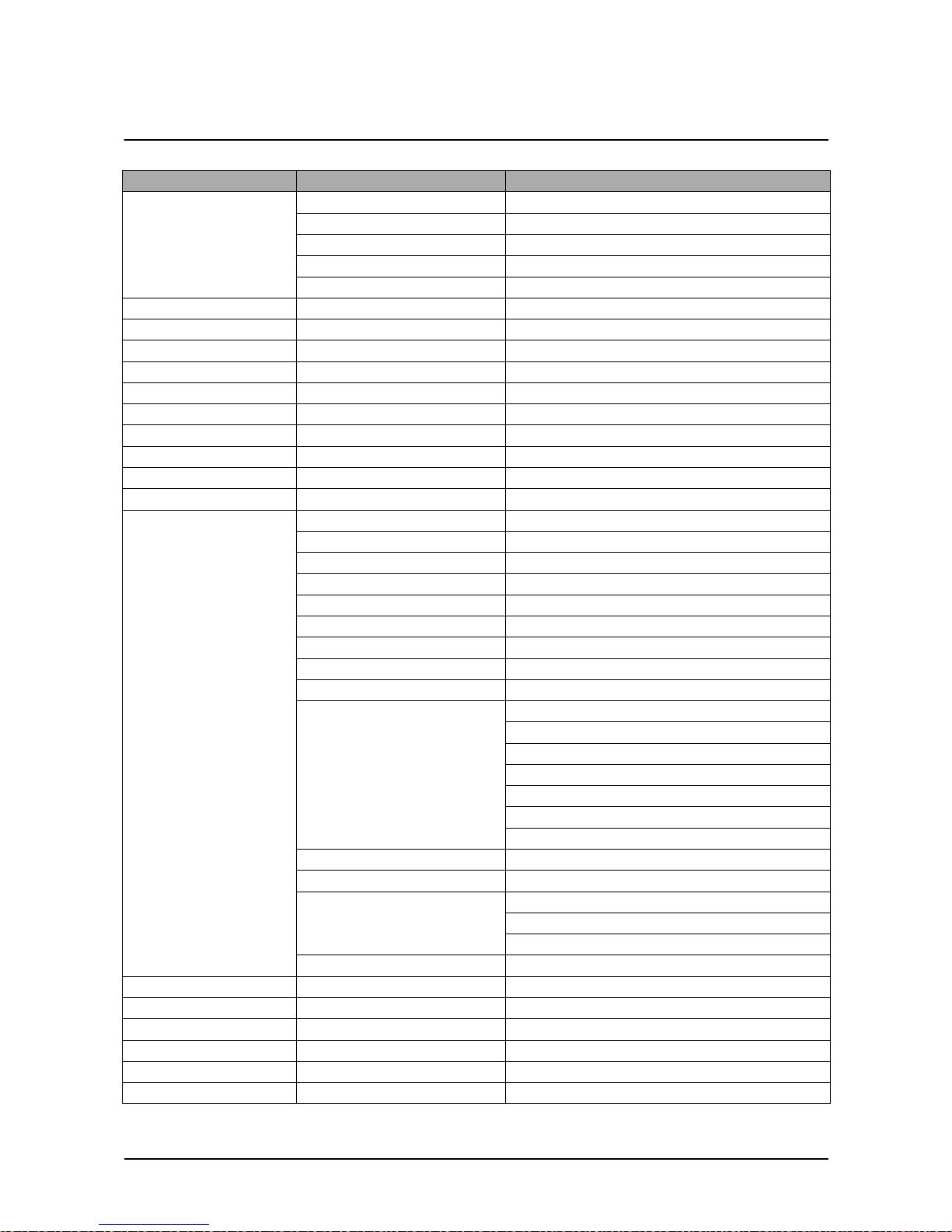

4-2 Error Messages

Error Message Description Solution

RETRY REDIAL? The machine is waiting for the programmed inter-

val to automatically redial.

You can press START to immediately

redial, or STOP to cancel the redial

operation.

COMM. ERROR A problem with FAX communications has

occurred.

Try again.

DOCUMENT JAM Loaded document has Jammed in the scanner

document feeder

Clear the document Jam.

DOOR OPEN The side cover is not securely latched The side door and front door must be

closed in the correct order. Open both

doors. Close the front door first then

close the side door.

GROUP NOT AVAILABLE You have tried to select a group location where

only a single location number can be used, such

as when adding locations for a multi-dial operation.

Try again, check location for group.

LINE ERROR Your unit cannot connect with the remote

machine, or has lost contact because of a problem on the phone line.

Usually caused by a telephone line

problem. Try again. If failure persists,

wait an hour or so for the line to clear

then try again

LOAD DOCUMENT You have attempted to set up a sending opera-

tion with no document loaded.

Load a document and try again.

MEMORY FULL The memory has become full. Either delete unnecessary documents, or

retransmit after more memory becomes

available, or split the transmission into

more than one operation.

NO ANSWER The remote machine was not answered after all

the redial attempts.

Try again.

Make sure the remote machine is OK.

NO. NOT ASSIGNED The speed dial location you tried to use has no

number assigned to it.

Dial the number manually with the keypad, or assign the number.

NO PAPER

[ADD PAPER]

There is no paper in the paper cassette. Printing

stops until paper is loaded.

Re-load the paper cassette.

OVERHEAT The printer part has overheated. Your unit will automatically return to the

standby mode when it cools down to normal operating temperature. If failure persists, call service.

PAPER JAM 0

OPEN/CLOSE DOOR

Recording paper has jammed in paper feeding

area.

Recording paper is jammed in pick-up unit

Press STOP and clear the jam.

PAPER JAM 1/2

OPEN/CLOSE DOOR

Recording paper has jammed inside the unit.

Recording paper has jammed in paper exit unit.

Clear the jam.

TONER LOW Toner cartridge is almost empty, or toner particles

in the cartridge are unevenly distributed in the cartridge

Remove the toner cartridge and gently

rock it from side to side.

Try again. If problem persists replace the

cartridge.

TONER EMPTY Toner cartridge is now empty Replace the Toner Cartridge.

Troubleshooting

Samsung Electronics 4-3

DRUM WARNING A warning that the OPC drum has almost reached

the end of its life (14,000 Sides)

You have 1000 pages of print life left in

the OPC Drum. Continue to use, order

a new OPC drum.

REPLACE DRUM OPC drum is now life-expired

(15,000 sides)

Replace the OPC Drum Cartridge.

NO CARTRIDGE When the machine detects that the toner cartridge

has not been installed.

Install the Cartridge.

BYPASS JAM Paper feed problem from the BYPASS (Manual

feed) Tray.

Open the side Cover and clear the jam.

DUPLEX JAM Paper feed problem in the duplex return path Release Output Feed lever and check

output area clear. Also open side door

and check duplex unit is clear.

LINE BUSY The remote FAX didn’t answer Try again.

OPEN HEAT EROR No power to the Fuser lamp Check thermostat, thermistor, fuser lamp

and fuser connector and associated wiring. Also check the ‘Fuser On’ signal

from main PWA to Power Supply. Check

cable from Main PWA to Power Supply

Heating Error During operation, Temperature does not go up Check thermister contact point &

Heating Lamp.

Scanner Locked Scanner head does not move. Check transit lock, check scanner cables

are connected, check scanner home

sensor, scanner motor or drive belt.

Error Message Description Solution

Troubleshooting

4-4

Samsung Electronics

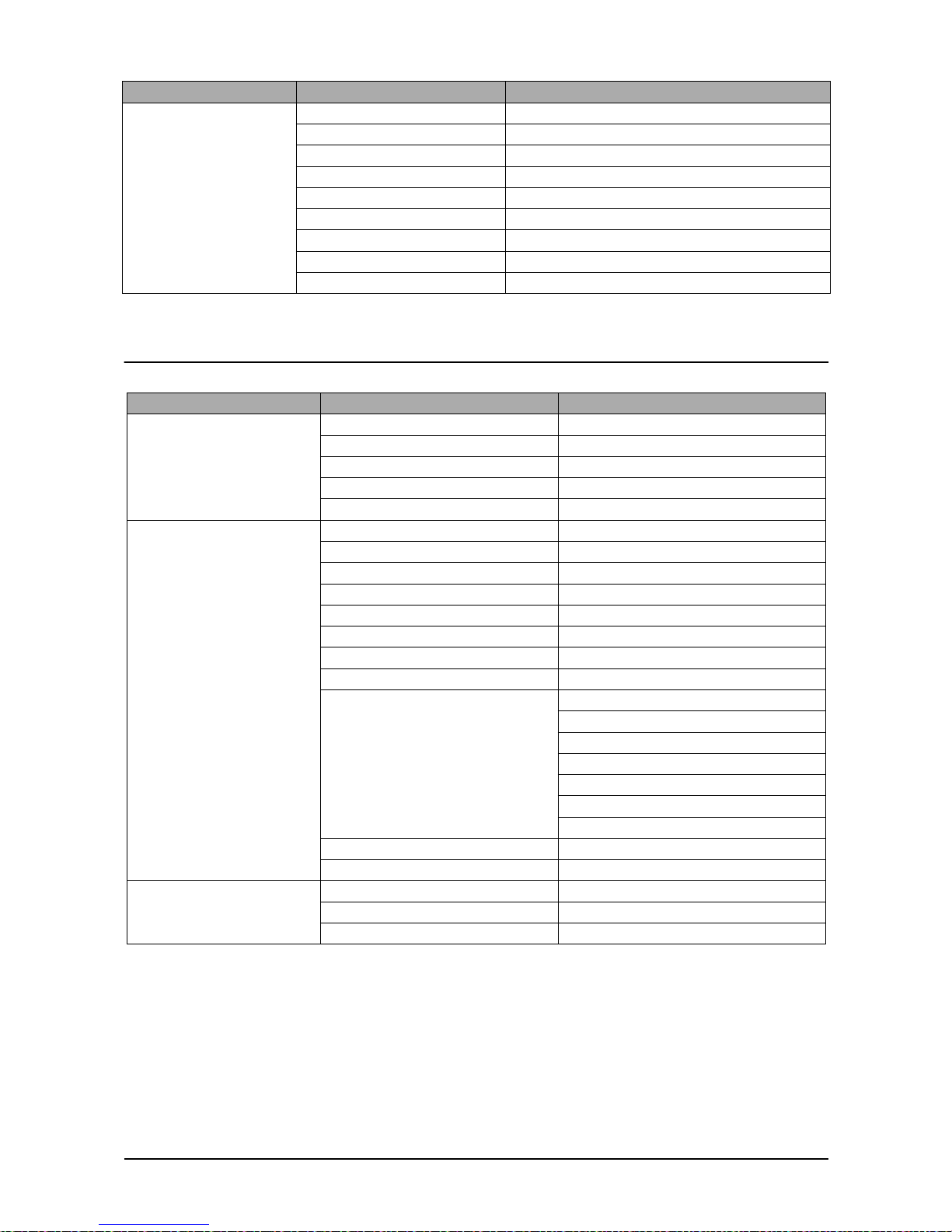

4-3 User Mode

The table below shows the settings and functions available in the User Mode. These are described in the user

Guide. The table is given here to indicate possible settings that the user may have changed.

4-3-1 SCX-5315F

✳❑n❄❏❊on✳❑n❄❏❊on

✳❑n❄❏❊on✳❑n❄❏❊on

✶❏❆m✶❏❆m

✶❏❆m✶❏❆m

✰on❏❆n❏✰on❏❆n❏

✰on❏❆n❏✰on❏❆n❏

SYSTEM DATA CASSETTE PAPER LETTER / A4 / LEGAL

BYPASS PAPER LETTER / A4 / LEGAL

MESSAGE CONF. ON / OFF / ERROR

AUTO JOURNAL ON / OFF

RECEIVE CODE 0-9

POWER SAVE ON / OFF

ECM MODE ON / OFF

RX REDUCTION ON / OFF

DISCARD SIZE 0-30mm

REDIAL INTERVAL 1-15

REDIALS 1-13

ANSWER ON RING 1-7

SEND FROM MEMORY ON / OFF

LOCAL ID ON / OFF

CLOCK MODE 12 / 24 HOUR

SYSTEM ID FAX / ID

DATE & TIME

SYSTEM SETUP PREFIX DIAL NO.

SECURE RECEIVE

RINGER VOLUME LOW / HIGH (10 STEPS)

ALARM SOUND ON / OFF

KEY SOUND ON / OFF

SPEAKER CONTROL COM / ON /OFF

SELECT LANGUAGE ENG/GER/FRE/ITA/SPA/POR/DUT

USB MODE FAST / SLOW

FAX DUPLEX OFF / LONG EDGE / SHORT EDGE

IMAGE QUALITY NORMAL / TEXT / IMAGE

SCAN SLEEP MODE HOME SET

MEMORY CLEAR SYSTEM ID

SYSTEM DATA

PHONE BOOK / MEMORY

TX-RX JOURNAL

DELA Y TX

MEMORY TX

PRIORITY TX

POLLING

ADD/CANCEL ADD / CANCEL

GROUP DIAL

Troubleshooting

Samsung Electronics 4-5

4-3-2 SCX-5115

4-4 T ech Mode

4-4-1 How to Enter Service Mode

In service mode (tech) mode, the technician can check the machine and perform various tests to isolate the

cause of a malfunction.

To enter the Tech mode, press MENU, #, 1, 9, 3, 4 in sequence, and the LCD briefly displays ‘T’ or ‘TECH’,

the machine has entered service (tech) mode.

While in Tech mode, the machine still performs all normal operations.

To return to normal user mode, press MENU, #, 1, 9, 3, 4 in sequence again, or turn the power off, then on

by unplugging and plugging the power cord.

Options changed while in service mode remain in effect until they are changed again or until you clear the

machine’s memory.

MAINTENANCE CLEAN DRUM

NEW DRUM

NOTIFY TONER LOW ON / OFF

TX CONFIRM

SCHEDULE JOB

PHONE BOOK

SYSTEM LIST

TX JOURNAL

RX JOURNAL

HELP LIST HELP LIST

✳❑n❄❏❊on✳❑n❄❏❊on

✳❑n❄❏❊on✳❑n❄❏❊on

✶❏❆m✶❏❆m

✶❏❆m✶❏❆m

✰on❏❆n❏✰on❏❆n❏

✰on❏❆n❏✰on❏❆n❏

SYSTEM DATA CASSETTE PAPER LETTER / A4 / LEGAL

BYPASS PAPER LETTER / A4 / LEGAL

POWER SAVE ON / OFF

SELECT LANGUAGE ENG/GER/FRE/ITA/SPA/POR/DUT

USB MODE FAST / SLOW

HELP LIST HELP LIST PRINTOUT

MAINTENANCE CLEAN DRUM

NEW DRUM

REPORTS SYSTEM DATA

HELP LIST HELP LIST

✳❑n❄❏❊on✳❑n❄❏❊on

✳❑n❄❏❊on✳❑n❄❏❊on

✶❏❆m✶❏❆m

✶❏❆m✶❏❆m

✰on❏❆n❏✰on❏❆n❏

✰on❏❆n❏✰on❏❆n❏

Troubleshooting

4-6

Samsung Electronics

4-4-2 Setting-up System in Tech Mode

4-4-2-1 SCX-5315F(SETUP : #, 1, 9, 3, 4)

✳❑n❄❏❊on✳❑n❄❏❊on

✳❑n❄❏❊on✳❑n❄❏❊on

✶❏❆m✶❏❆m

✶❏❆m✶❏❆m

✰on❏❆n❏✰on❏❆n❏

✰on❏❆n❏✰on❏❆n❏

SYSTEM DATA DIAL MODE TONE / PULSE

MODEM SPEED

ERROR RATE 5% /10%

SET TX LEVEL 09-15

SILENCE TIME 12 / NU / OFF

SYSTEM ID The same as User Mode

DATE & TIME The same as User Mode

SYSTEM SETUP The same as User Mode

MEMORY CLEAR CLEAR ALL MEMORY

DELAY TX The same as User Mode

MEMORY TX The same as User Mode

PRIORITY TX The same as User Mode

POLLING The same as User Mode

ADD/CANCEL The same as User Mode

GROUP DIAL The same as User Mode

MAINTENANCE CLEAN DRUM

NEW DRUM

NOTIFY TONER LOW ON / OFF

SWITCH TEST

MODEM TEST

SRAM TEST

DRAM TEST

ROM TEST FLASH / ENGINE

PATTERN TEST PATTERN1-7, QAPATTERN1-4, ALL"1-7 , ALL"

CLEAR COUNT PASSWORD

(1934)

CRU PRINTS COUNT

FLT SCAN COUNT

ADF SCAN COUNT

USED DRUM COUNT

USED TONER COUNT

TOTAL PAGE COUNT

ANSWER ON CNG 1-4

ADJUST SHADING

FLASH UPGRADE LOCAL

REMOTE : USER PROGRAM ,

EMULATION ,BOOT PROGRAM

PROGRAM DIAL

TX CONFIRM The same as User Mode

SCHEDULE JOB The same as User Mode

PHONE BOOK The same as User Mode

SYSTEM LIST USER MODE

TX JOURNAL The same as User Mode

RX JOURNAL The same as User Mode

Troubleshooting

Samsung Electronics 4-7

4-4-2-2 SCX-5115(SETUP : #, 1, 9, 3, 4)

REPORTS MSG. CONFIRM

SCHEDULE JOB

PHONE BOOK

SYSTEM DATA

TRANSMISSION

RECEPTION

HELP LIST

PROTOCOL

ERROR CODE

✳❑n❄❏❊on✳❑n❄❏❊on

✳❑n❄❏❊on✳❑n❄❏❊on

✶❏❆m✶❏❆m

✶❏❆m✶❏❆m

✰on❏❆n❏✰on❏❆n❏

✰on❏❆n❏✰on❏❆n❏

SYSTEM DATA CASSETTE PAPER LETTER / A4 / LEGAL

BYPASS PAPER LETTER / A4 / LEGAL

POWER SAVE ON / OFF

SELECT LANGUAGE ENG/GER/FRE/ITA/SPA/POR/DUT

USB MODE FAST / SLOW

MAINTENANCE CLEAN DRUM

MODEM TEST

NEW DRUM

SWITCH TEST

SRAM TEST

DRAM TEST

ROM TEST FLASH / ENGINE

PATTERN TEST PATTERN1-7, QAPATTERN1-4 , ALL

CLEAR COUNT PASSWORD

CRU PRINTS COUNT

FLT SCAN COUNT

ADF SCAN COUNT

USED DRUM COUNT

USED TONER COUNT

TOTAL PAGE COUNT

ADJUST SHADING

FLASH UPGRADE

REPORTS SYSTEM DATA

HELP LIST HELP LIST

ERROR CODE

✳❑n❄❏❊on✳❑n❄❏❊on

✳❑n❄❏❊on✳❑n❄❏❊on

✶❏❆m✶❏❆m

✶❏❆m✶❏❆m

✰on❏❆n❏✰on❏❆n❏

✰on❏❆n❏✰on❏❆n❏

Troubleshooting

4-8

Samsung Electronics

4-4-3 SYSTEM DATA

DIALING MODE

Select the dialing mode according to the user's line status.

TONE: Electrical type of dial

PULSE: Mechanical type of dial

SILENCE TIME

In ANS/FAX mode, after a call is picked up by the answering machine, the machine monitors the line. If a

period of silence is detected on the line at any time, the call will be treated as a fax message and the machine

begins receiving.

Silence detection time is selectable between limited (about 12 seconds) and unlimited time.

When '12 sec' is selected, the machine switches to receiving mode as soon as it detects a period of silence.

When 'unlimited'is selected, the machine waits until the answering operation is concluded even though a

period of silence is detected. After the answering operation is concluded, the machine switches to receiving

mode.

SEND FAX LEVEL

You can set the level of the transmission signal. Typically, the Tx level should be under -12 dBm.

Caution: The Send Fax Level is set at the best condition in the shipment from factory. Never change

settings arbitrarily.

ERROR RATE

Tou can set the Error Rate between 5% and 10%. During operation the set monitors the rror rate.

When the rror rate approaches the preset value the machine automatically steps down the baude to 2400bps

to ensure that the selected error rate is not exceeded.

MODEM SPEED

You can set the maximum modem speed. It is better left set 33.6Kbps (the default setting ).

During call setup the baud rate is automatically adjusted to suite the slowest device. Only adjust this where

the local line conditions are extremely poor.

4-4-4 MEMORY CLEAR

CLEAR ALL MEMORY

This function resets the system to its original factory settings. All settings entered in User Mode and Tech

Mode are reset. This includes any User Phone Book entries, jobs stored in memory or received documents

that have not been printed. If possible use the Control Panel software to download customer settings and

phone book settings before carrying out a full reset.

When diagnosing or testing a faulty unit this function is often useful. Be aware that all error reports are also

cleared.

< Method >

1. Select the [MEMORY CLEAR] in TECH MODE.

2. Push the ENTER button.

3. Select your country.

4. Push the ENTER button and all memory will be cleared.

NOTICE : Always perform a memory clear after replacing the main board or updating the firmware. Oth-

erwise, the system may not operate properly.

Troubleshooting

Samsung Electronics 4-9

4-4-5 MAINTENANCE

CLEAN DRUM

Use this feature to remove toner particles remaining in the OPC drum unit.

Use this feature when print quality falls or when marks or specks appear on the printout.

You should perform this feature several times until a clean printout appears.

The machine automatically pulls in a sheet of paper and prints out. Excess toner particles on the OPC drum

surface are fixed to the paper.

FLASH UPGRADE

This function is used to update the system Firmware. There are 2 methods Local and Remote.

More information can be found in the firmware upgrade section.

ADJUST SHADING

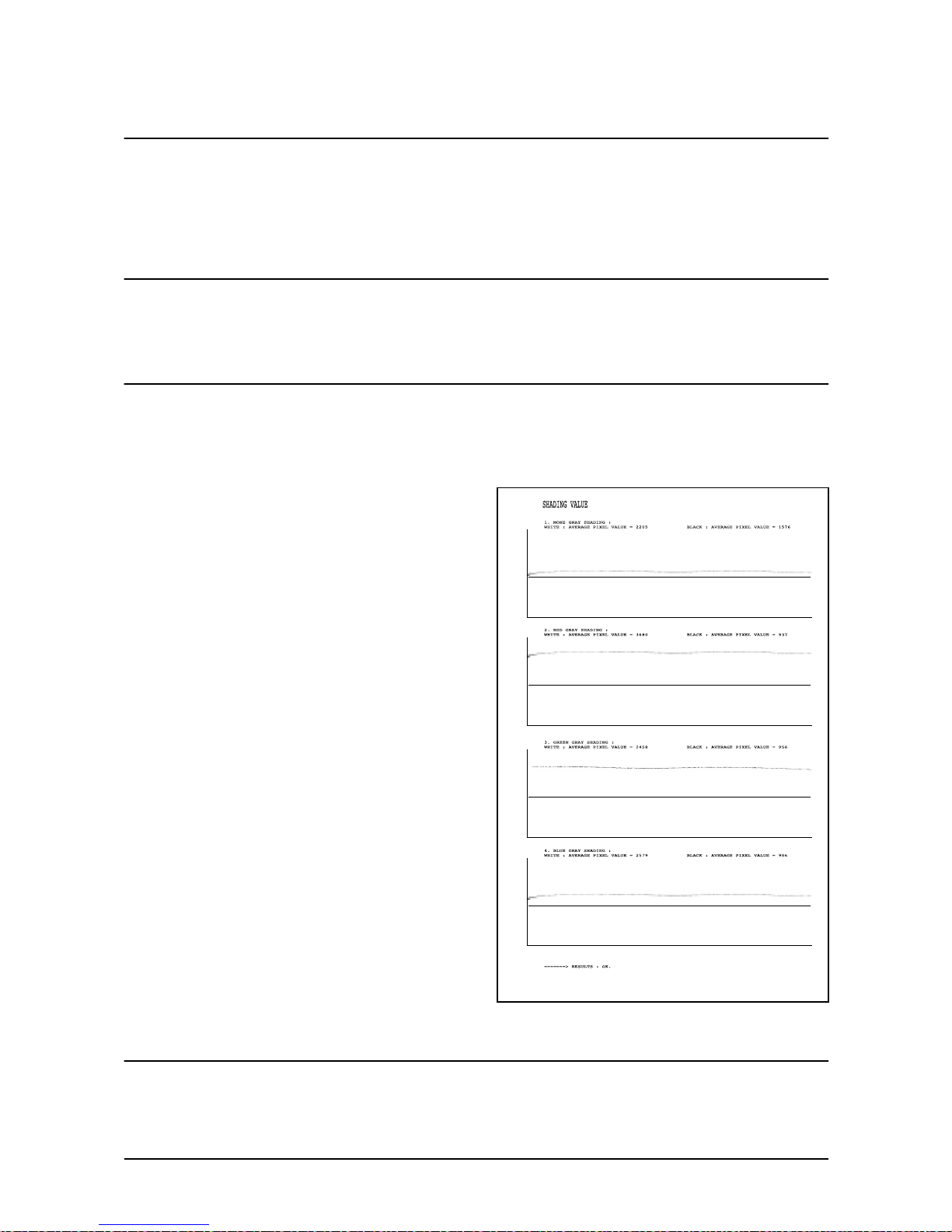

This option is used to test and check the functionality of the CCD (Charge Coupled Device). Use this when

poor quality scanning or copying is reported.

< Method >

1. Select the [ADJUST SHADING] in TECH MODE.

2. Push the SET UP button. The unit scans

a “white image” using the ‘white bar’

3. After the scan, CCD SHADING PROFILE similar to that

shown will be printed out.

4. If the printed image is different to the image, if the lines

are significantly lower or higher, or if there are high or low

spots in the chart then the CCD is defective.

NOTICE : When you test the CCD, make

sure that the cover is closed.”

ANSWER ON CNG

The function is to control the CNG T ONE recognition times f or entering receiving mode from the A UTO MODE

or ANS/FAX MODE.

Loading...

Loading...