Samsung SCX-5315F Service Manual

DIGITAL LASER MFP

SCX-5315F Series

SCX-5315F

SCX-5115

SERVICE

DIGITAL LASER MFP

MANUAL

CONTENTS

1. Precautions

2. Specifications

3. Disassembly

4. T roubleshooting

5. Exploded Views and Parts List

6. Block Diagram

7. Connection Diagram

Precautions

1. Precautions

Follow these safety, ESD, and servicing precautions to prevent personal injury and equipment damage.

1-1 Safety Precautions

1. Be sure that all built-in protective devices are in

place. Replace any missing protective shields.

2. Make sure there are no cabinet openings

through which people-particularly children- might

insert fingers or objects and contact dangerous

voltages.

3. When re-installing chassis and assemblies be

sure to replace all protective devices including

control knobs and compartment covers.

4. Design Alteration Warning:Never alter or add to

the mechanical or electrical design of this equipment, such as auxiliary connectors, etc. Such

alterations and modifications will void the manufacturer’s warranty.

5. Components, parts, and wiring that appear to

have overheated or are otherwise damaged

should be replaced with parts which meet the

original specifications. Always determine the

cause of damage or overheating, and correct any

potential hazards.

6. Observe the original lead routing, especially near

sharp edges, AC, and high voltage power supplies. Always inspect for pinched, out-of-place,

or frayed wiring. Do not change the spacing

between components and the printed circuit

board.

7. Product Safety Notice:Some electrical and

mechanical parts have special safety-related

characteristics which might not be obvious from

visual inspection. These safety features and the

protection they provide could be lost if a replacement component differs from the original. This

holds true, even though the replacement may be

rated for higher voltage, wattage, etc.

8. Components critical for safety are indicated in

the parts list with symbols .

Use only replacement components that have the

same ratings, especially for flame resistance and

dielectric specifications. A replacement part that

does not have the same safety characteristics as

the original may create shock, fire, or other

safety hazards.

1-2 Precautions on Disassembly and Reassembly

Take great care when replacing parts. Before removing a part take careful note of its orientation and any

wiring routing. Ensure that all parts removed are correctly replaced in their original positions and all wiring is routed as it was originally manufactured.

Changing wiring routes can cause electrical interference or degradation in set performance.

Please do the following before disassembling for a

repair or replacement of parts.

1. Remove the paper cassette and toner cartridge.

Take great care to ensure that the developer

drum surface is not scratched or damaged by

exposure to light.

2. Turn the power switch off.

3. Take out the power plug and disconnect the printer

cable from the printer.

4. Use only the same type of part as originally fitted

when replacing parts.

5. Take care when dismantling plastic components

and covers. Ensure covers are not damaged. Do

not force plastic components apart they may

break.

6. Be careful that small parts such as screws do not

get lost inside the printer.

7. When disassembling take note of the placement of

small parts. Ensure all small parts are properly

reassembled.

8. If is is necessary to turn the printer upside down

protect the LSU window with clean paper so that

no loose toner particles contaminate the glass.

Releasing Plastic Latches

Many of parts are held in

place with plastic latches.

The latches break easily :

release them carefully.

To remove such parts,

press the hook end of the

latch away from the part to

which it is latched.

Samsung Electronics

1-1

Precautions

1-3 ESD Precautions

1. Certain semiconductor devices can be easily

damaged by static electricity. Such components

are commonly called “Electrostatically Sensitive

(ES) Devices”, or ESDs. Examples of typical

ESDs are: integrated circuits, some field effect

transistors, and semiconductor “chip” components.

The techniques outlined below should be followed to help reduce the incidence of component

damage caused by static electricity.

CAUTION : Be sure no po wer is applied to the chassis

or circuit, and observe all other safety precautions.

2. Immediately before handling a semiconductor

component or semiconductor-equipped assembly, drain off any electrostatic charge on your

body by touching a known earth ground. Alternatively, employ a commercially available wrist

strap device, which should be removed for your

personal safety reasons prior to applying power

to the unit under test.

3. After removing an electrical assembly equipped

with ESDs, place the assembly on a conductive

surface, such as aluminum or copper foil, or conductive foam, to prevent electrostatic charge

buildup in the vicinity of the assembly.

4. Use only a grounded tip soldering iron to solder

or desolder ESDs.

Use only an “anti-static” solder removal device.

Some solder removal devices not classified as

“anti-static” can generate electrical charges sufficient to damage ESDs.

5. Do not use Freon-propelled chemicals. When

sprayed, these can generate electrical charges

sufficient to damage ESDs.

6. Do not remove a replacement ESD from its protective packaging until immediately bef ore installing it. Most replacement ESDs are packaged

with all leads shorted together by conductive

foam, aluminum f oil, or a comparable conductive

material.

7. Immediately before removing the protective

shorting material from the leads of a replacement ESD, touch the protective material to the

chassis or circuit assembly into which the device

will be installed.

8. Maintain continuous electrical contact between

the ESD and the assembly into which it will be

installed, until completely plugged or soldered

into the circuit.

9. Minimize bodily motions when handling unpackaged replacement ESDs. Normal motions, such

as the brushing together of clothing fabric and

lifting one’s f oot from a carpeted floor , can generate static electricity sufficient to damage an ESD.

1-4 Super Capacitor or Lithium Battery Precautions

1. Exercise caution when replacing a super capacitor or Lithium battery. There could be a danger of

explosion and subsequent operator injury and/or

equipment damage if incorrectly installed.

2. Be sure to replace the battery with the same or

equivalent type recommended by the manufacturer.

3. Super capacitor or Lithium batteries contain toxic

substances and should not be opened, crushed,

or burned for disposal.

4. Dispose of used batteries according to the manufacturer’s instructions.

Samsung Electronics1-2

Precautions

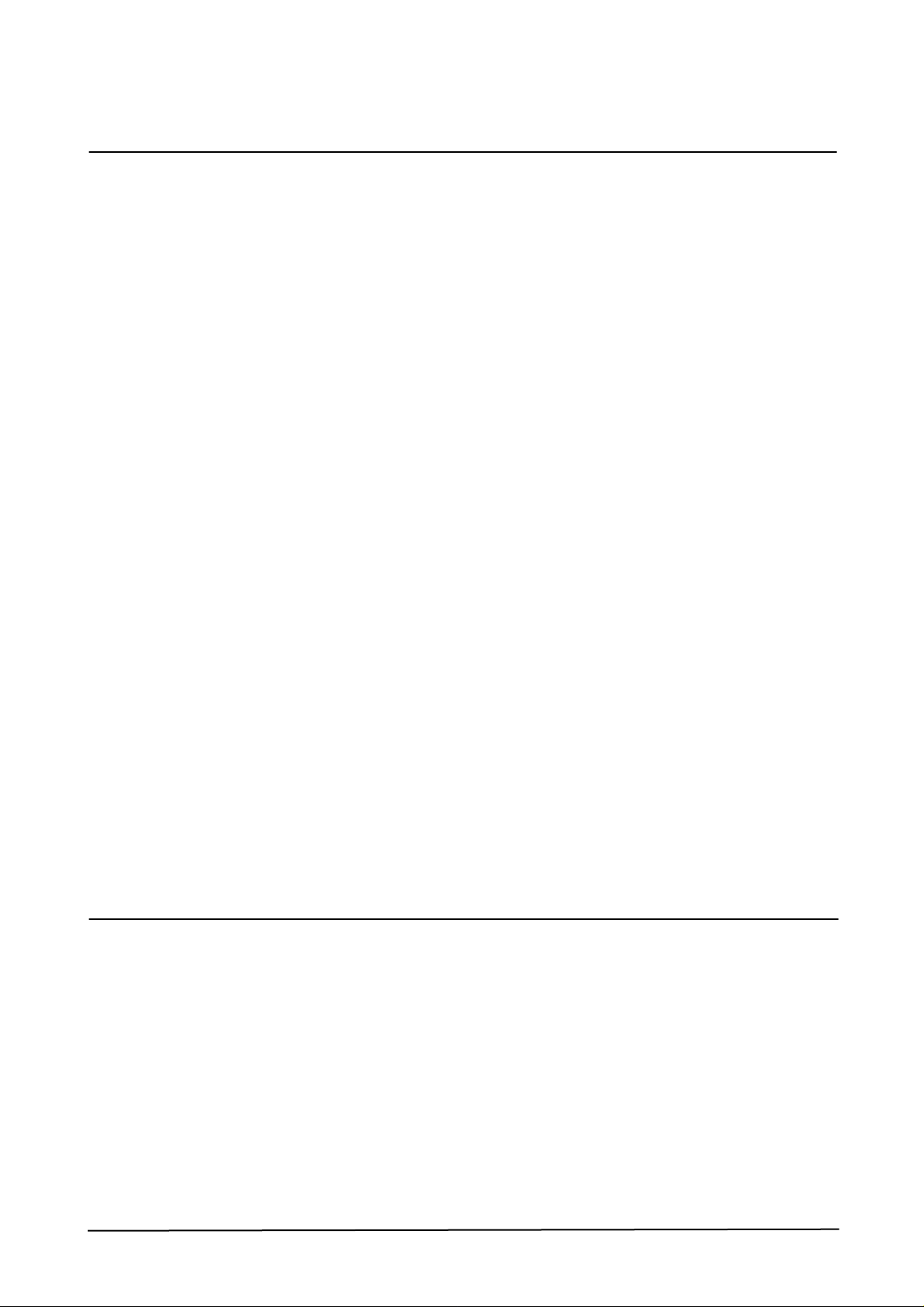

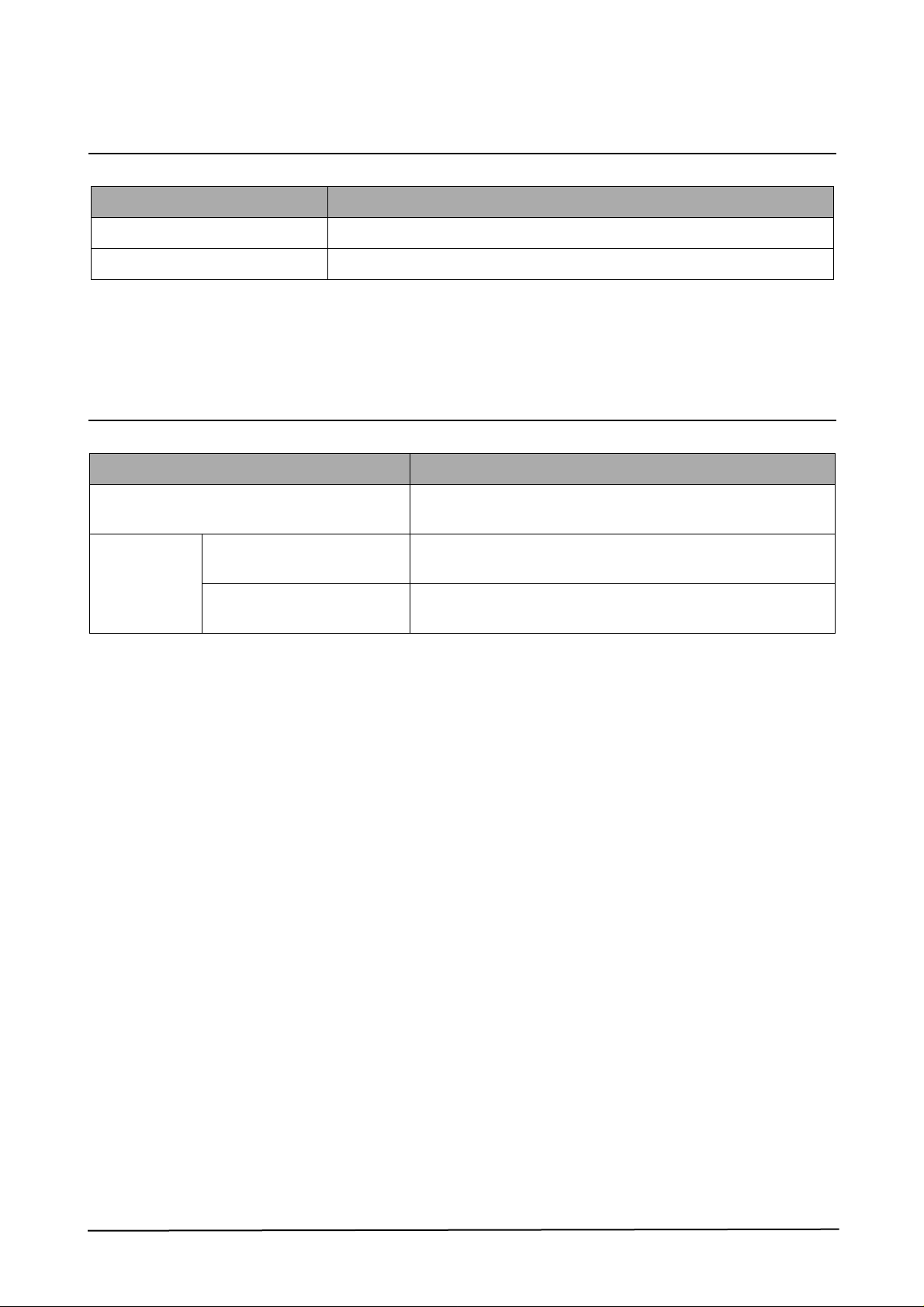

1-5 Tools for Troubleshooting

The following tools are recommended for safe and smooth troubleshooting described in this service manual.

1

DVM(Digital Volt Meter)

Standard : Indicates more than 3 digits.

3

Driver

Standard : "-" type, "+" type (M3 long, M3 short, M2

long, M2 short).

4

T weezers

Standard : For general home use, small type.

2

Electronic Scales

Standard : Equipment to check the weight of consum-

ables(toner cartridge) supplied by Samsung

Electronics. (The scales should measure in

grams.)

5

Cotton Swab

Standard : For general home use, for medical service.

6

Cleaning Equipments

Standard : An IPA(Isopropyl Alcohol)dry wipe tissue or

a gentle neutral detergent and lint-free

cloth.

7

Software (Driver) installation CD ROM

Samsung Electronics

1-3

Specification

2. Specification

Specifications are correct at the time of printing. Product specifications are subject to change without notice.

See below for product specifications.

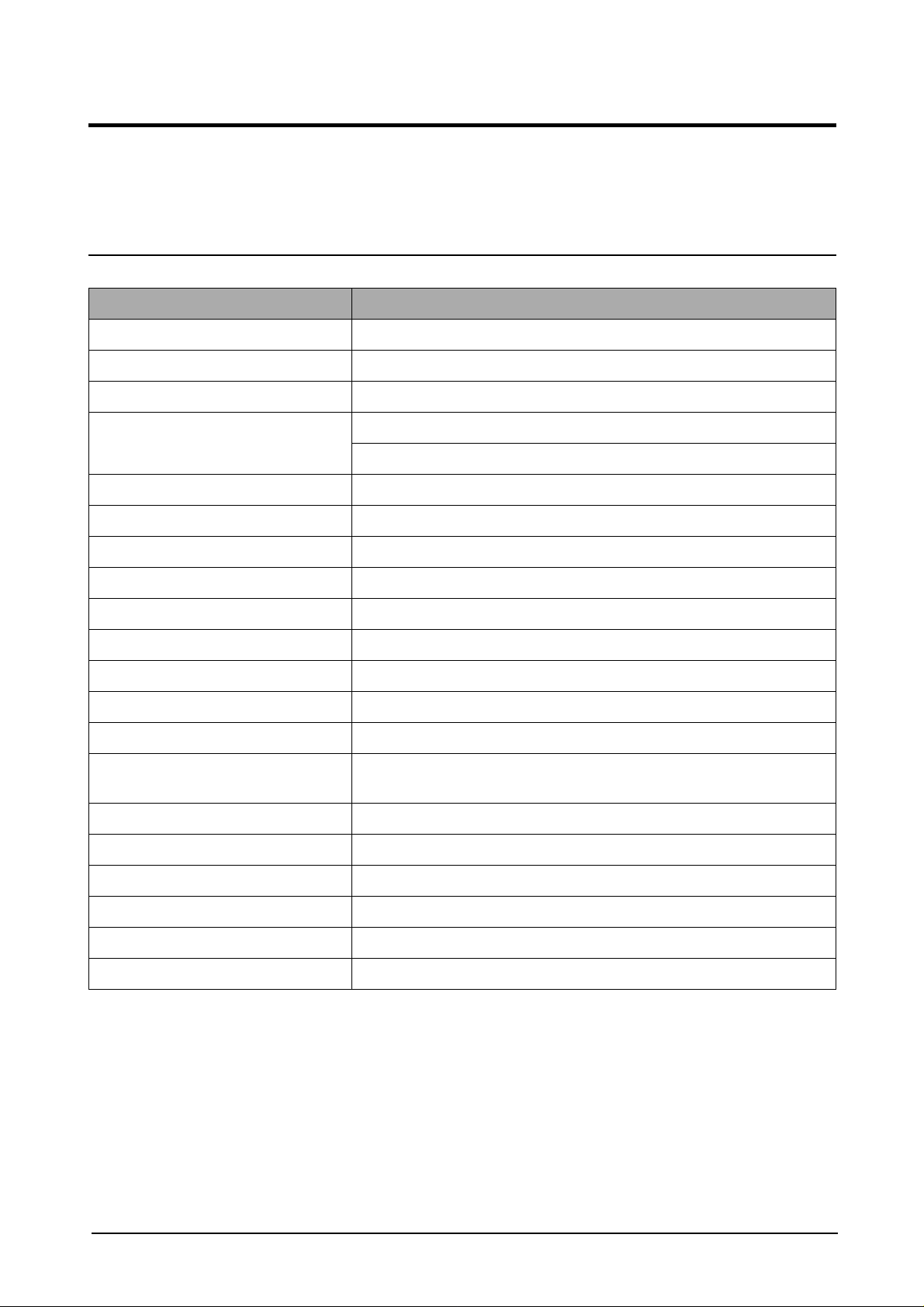

2-1 General Specifications

Item Description

Type of Unit Desktop

Operation System Win95/98/ME/ NT /2000/XP

Duplex Printing Yes(Default)

Interface IEEE1284(ECP)

USB(without HUB mode)

CPU 120 MHz(ARM946ES)

Emulation PCL6

Warming up Time 41 Sec (Stand-By), 25˚C

Absolute Storage Condition Temperature : -20°C ~ 40°C, Humidity : 10% RH ~ 95% RH

Operating Condition Temperature : 10˚C ~ 32˚C, Humidity : 20% RH ~ 80 % RH

Recommended Operating Condition Temperature : 16°C ~ 30°C, Humidity : 30% RH ~ 70% RH

Dimension(W X D X H) 560 X 433 X 459 mm

Weight About 22.5 Kg(with CRU)

Acoustic Noise Less than 56/50 dB(Copy/Printing mode)

Power Rating AC 100VAC ~ 127VAC, 50/60Hz ± 3Hz

AC 220VAC ~ 240VAC , 50/60Hz ± 3Hz

Power Consumption Avg. 350Wh (110V), 320Wh (220V)

Power Save Consumption Avg. 30Wh

Recommended System Requirement Pentium IV 1.2 Ghz, 128 MB RAM, 220MB(Hard Disk)

Minimum System Requirement Pentium II 400Mhz, 64 MB RAM, 120MB(Hard Disk)

LCD 16 characters X 2 lines

Memory 4 Mbyte for flash Memory , 16 Mbyte for SDRAM

Samsung Electronics

2-1

Specification

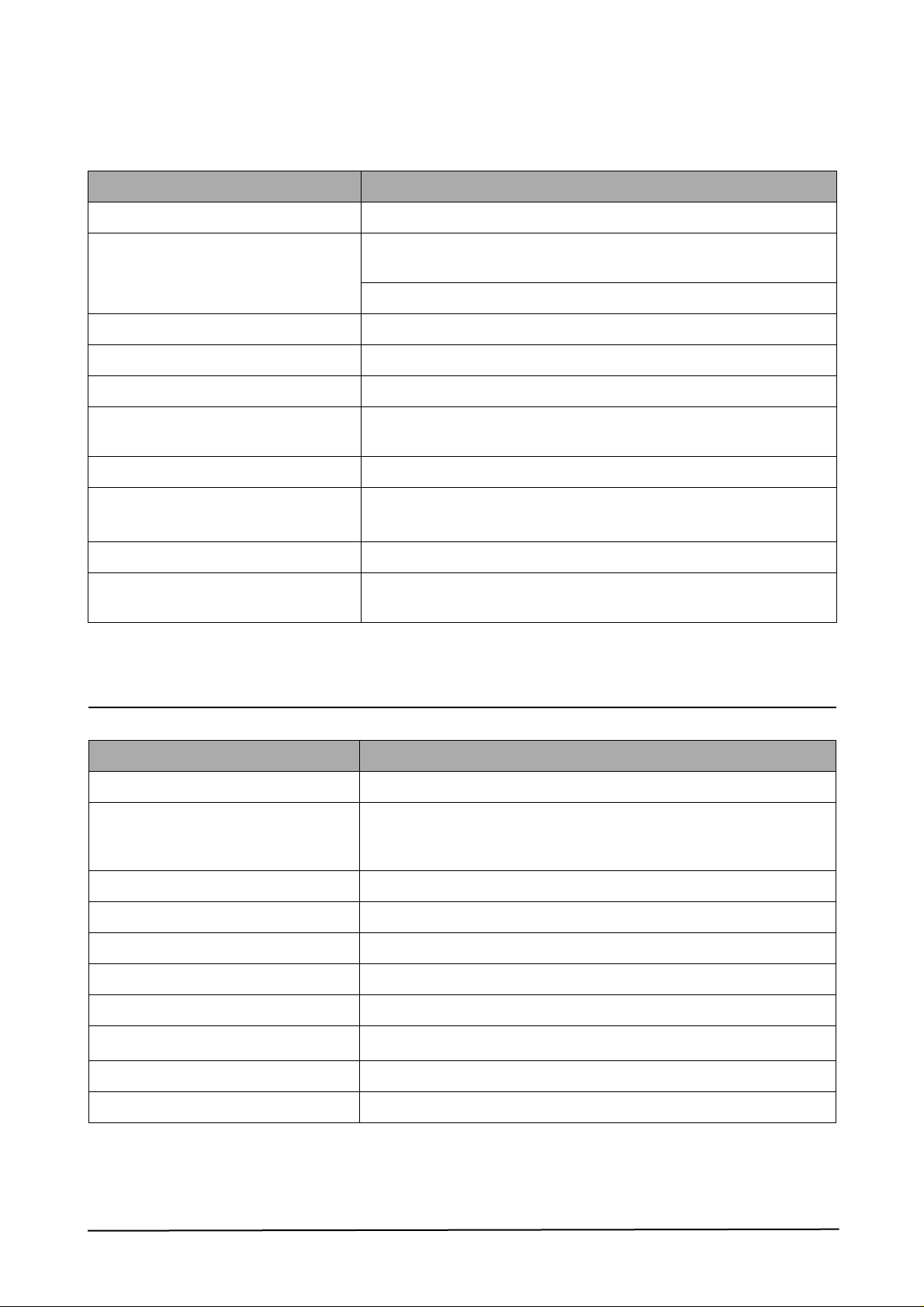

2-2 Printer Specifications

Item Description

Printing Method Laser Scanning Unit + Electro Photography

Speed Single Side : 15 PPM

(A4 Size, 5% Character Pattern), Letter : 16 PPM

Duplex : 9 IPM(Images/Min) (A4 Size, 5% Character Pattern)

Source of Light LSU(Laser Scanning Unit)

Duplex Printing Yes(Default)

Resolution(Horizontal X Vertical) True 600 X600 DPI , 1200 DPI Class

Feed Method Cassette Type , By Pass Tray,

ADF(Automatic Document Feeder)

Feed Direction FISO(Front-In Side-Out)

Paper Capacity(Input) Cassette : 550 Sheets

By Pass Tray : 100 Sheets(based on 75g/m

Paper Capacity(Output) Face Down : 250 Sheets

Effective Print Width 208mm for Letter/Legal

202mm for All

2

≥ , 20lb)

2-3 Facsimile Specification(SCX-5315F Only)

Item Description

Standard Recommendation ITU-T Group3(ITU : International Telecommunications Union)

Application Circuit PSTN or behind PABX

(PSTN : Public Switched Telephone Network.

PABX : Private Automatic Branch Exchange)

Data coding(Compression) MH/MR/MMR/JPEG(Transmission)

Modem speed 33600/28800/21600/19200/14400/12000/9600/7200/4800/2400 bps

Transmission Speed Approximately 3 sec(33,600 bps)

Effective Scanning Width 8.2 inches(208 mm)

Halftone 256 Levels

Paper Capacity(Input)

FAX Mode Standard /Fine/Super Fine/Halftone

Memory 4MB

ADF(Automatic Document Feeder) : 30Sheets(75g/m

2

≥ )

Samsung Electronics2-2

2-4 Scanner Specification

Item Description

Type Flatbed(with ADF)

Speed Mono : 1.25 msec/line, Color : 2.5 msec/line

Device Color CCD(Charge Coupled Device) Module

Interface IEEE1284(ECP Support)

USB(without HUB Mode)

Compatibility TWAIN Standard , WIA

Optical Resolution(H X V) 600 X 600 dpi

Interpolation Resolution Max. 4800 dpi

Halftone 256 Levels

Specification

Effective Scan width 8.2 inches(208 mm)

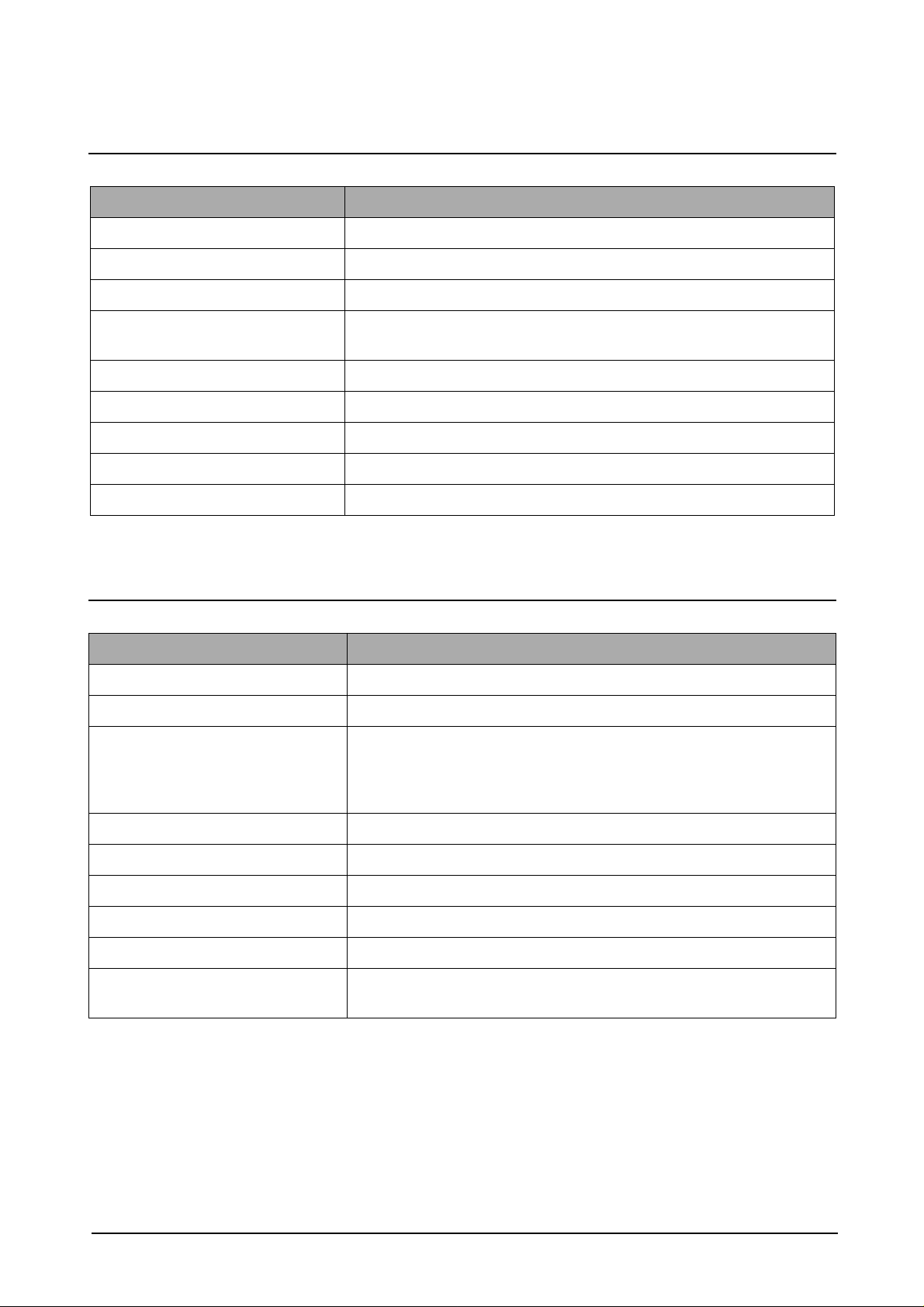

2-5 Copy Specification

Item Description

Mode B/W

Quality Text/Photo/Mixed

Mono Copy Speed

Optical Resolution (H x V) 600 X 600 dpi

Multi Copy 999 pages

Maximum Original Size Legal

Maximum Page Size Legal

(1)

Platen(SDMP) : 15 cpm

ADF (SDMP) : 15 cpm

ADF (MDSP) : Text/mixed : Approx. 8 cpm

: Photo : Approx. 3 cpm

Paper Type Selection Plain , Legal , Cardstock , Transparency

Zoom Range Platen : 25 ~ 400%(1% Step)

ADF : 25~100 %(1% Step)

NOTE :

(1) Speed claims based on the test chart : A4 size.

SDMP : Single Document Multiple Printout

MDSP : Multiple Document Single Printout

Samsung Electronics

2-3

Specification

2-6 Telephone Specification(SCX-5315F Only)

Item Description

Speed Dial 80EA

Tone/Pulse Tone only user modeTone/Pulse selectable in tech mode.

2-7 Consumables

Item Description

Type Separate type

(Toner Cartridge / Drum Cartridge)

Life Toner Cartridge 6,000 sheets

( 5% coverage pattern, simplex normal mode )

Drum Cartridge 15,000 sheets

(simplex normal mode )

Samsung Electronics2-4

Disassembly and Reassembly

3. Disassembly and Reassembly

3-1 General Precautions on Disassembly

When you disassemble and reassemble components, you must use extreme caution.

The close proximity of cables to moving parts makes proper routing a must. If components are removed, any

cables disturbed by the procedure must be restored as close as possible to their original positions. Before

removing any component from the machine, note the cable routing that will be affected.

Whenever servicing the machine, you must carry out the following :

1. Check to verify that documents are not stored in memory.

2. Unplug the power cord.

3. Use a flat and clean surface.

4. Replace only with authorized components.

5. Take care when removing plastic component-do not force.

6. Make sure all components are in their proper position.

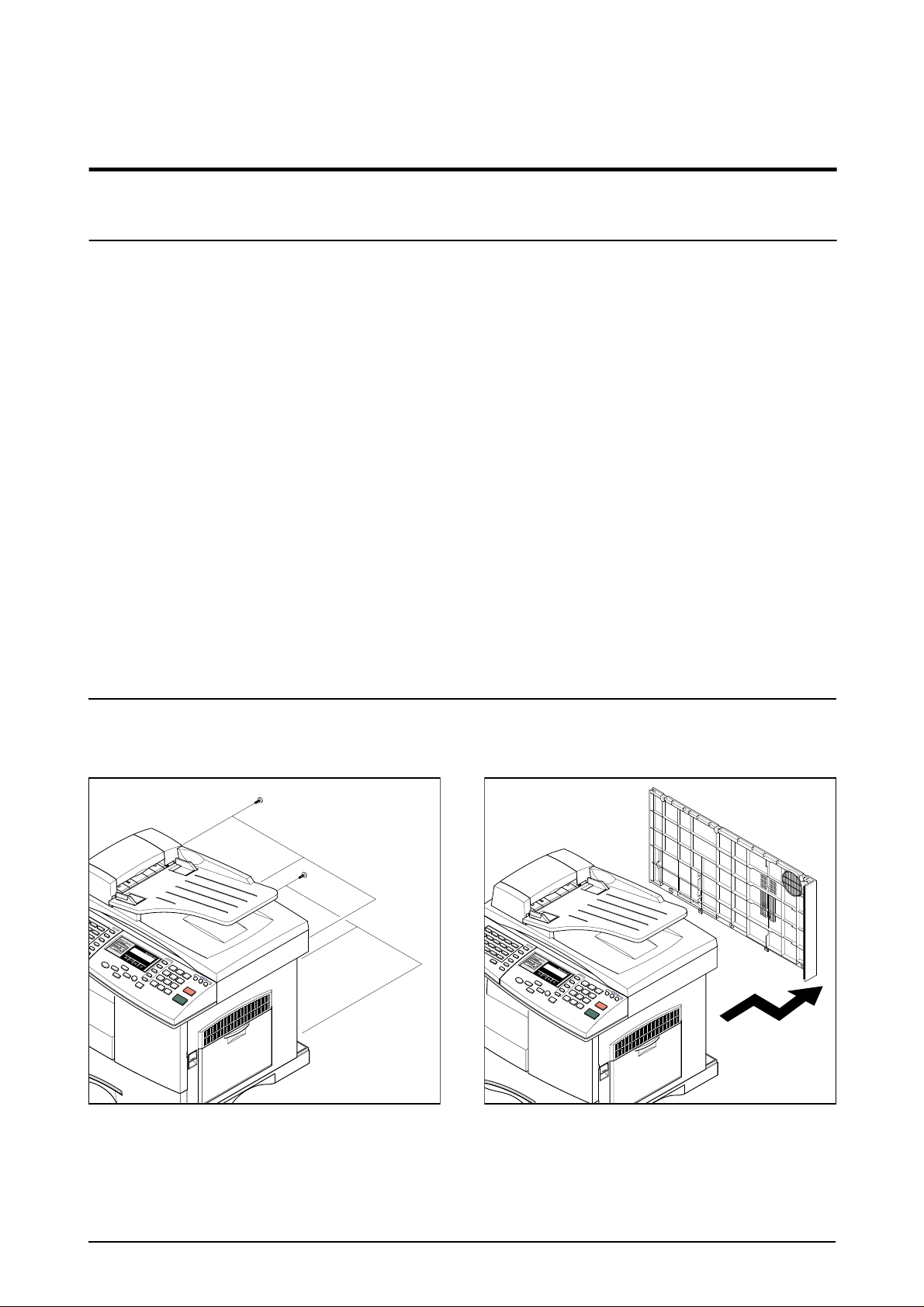

3-2 Rear Cover

1. Remo ve the six screws securing the Rear Cov er .

2. Separate the rear cover from the base frame

and Scanner Ass'y.

Samsung Electronics

3-1

Disassembly and Reassembly

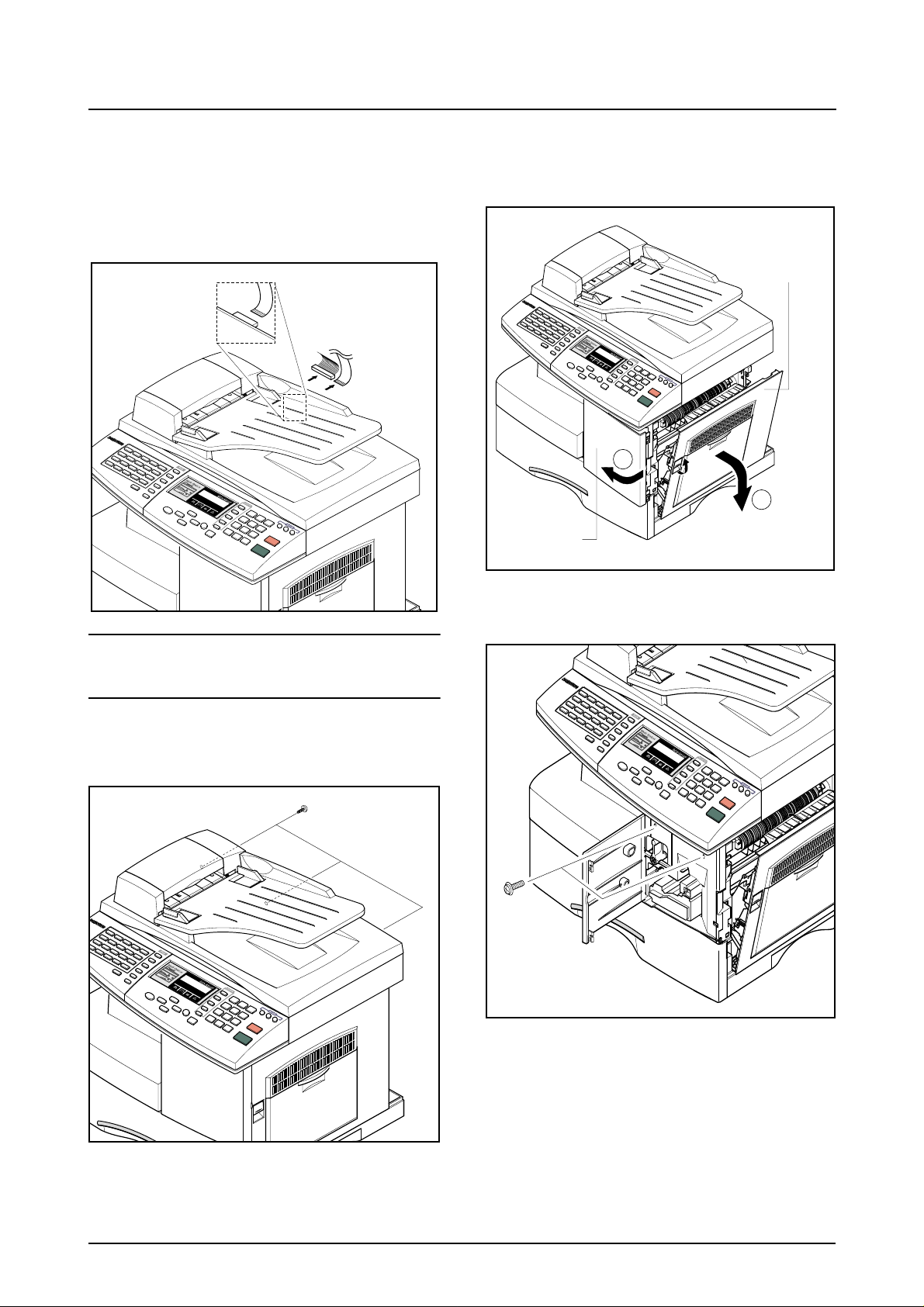

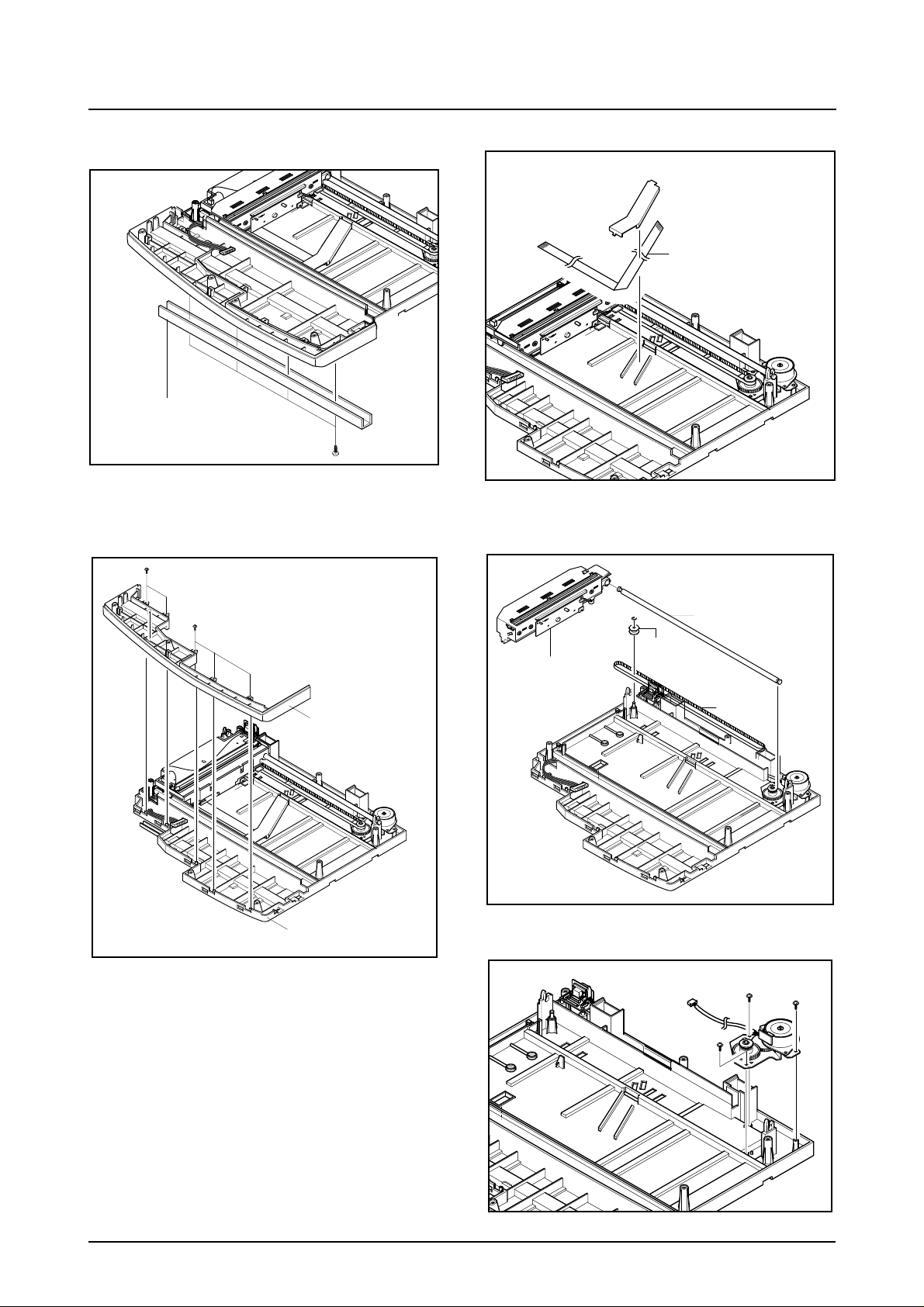

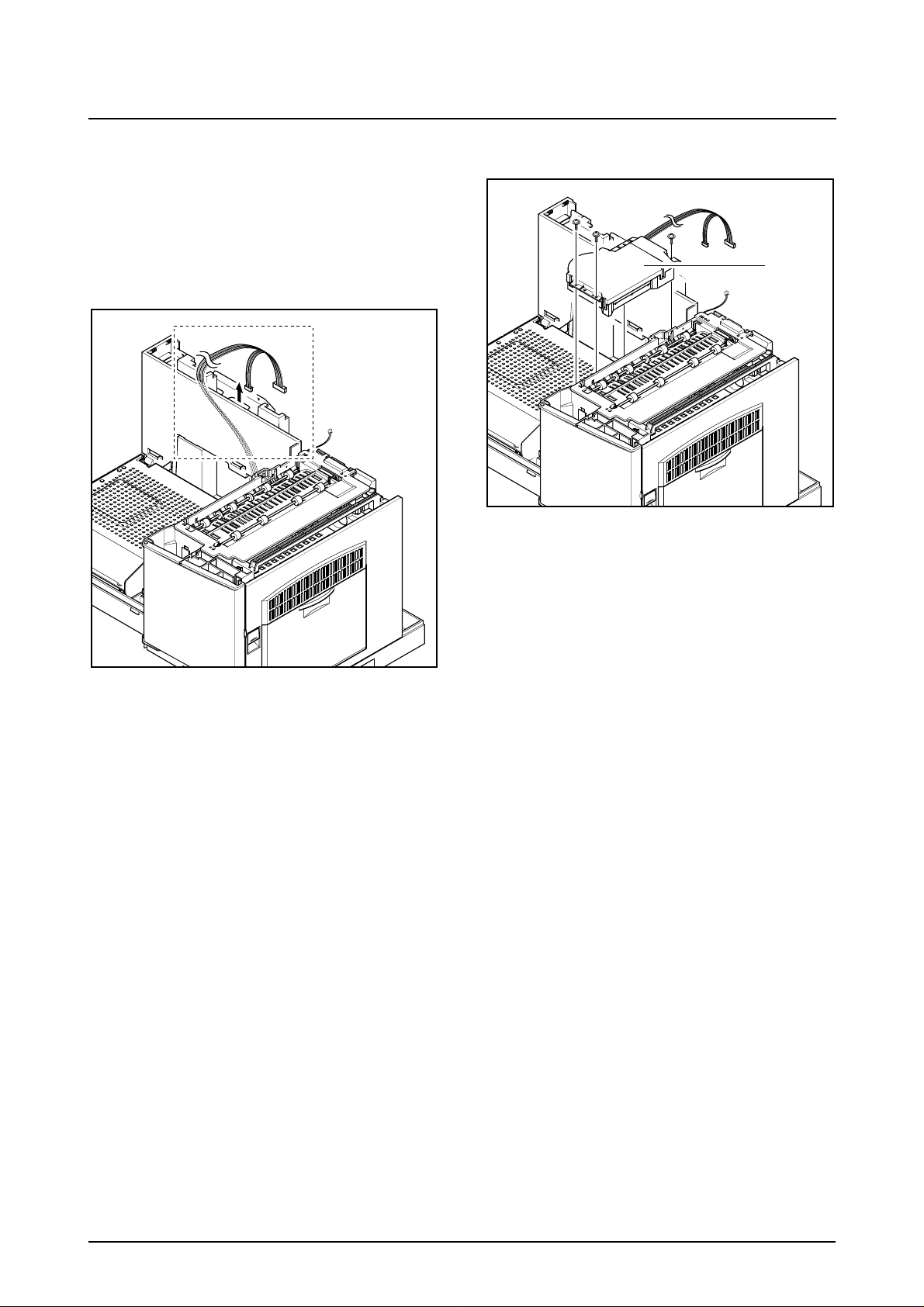

3-3 Scanner Ass'y

1. Before you remove the Scanner Ass'y, you

should remove:

- Rear Cover (see page 3-1)

2. Take out the Shield Main Upper.Unplug the one

connector and CCD cable.

4. Open the Side Cover assembly first to open the

Front cover. In the other words, close the front

cover first to assembly it.

Side Cover Ass’y

2

1

Front Cover

Notice :

To avoid damage to the CCD cable connector ensure that

you pull the cable out carefully. Pull in line with the connector not at an angle.

3. Remove the three screws, as shown below.

5. Remove two screws.

3-2

Samsung Electronics

Disassembly and Reassembly

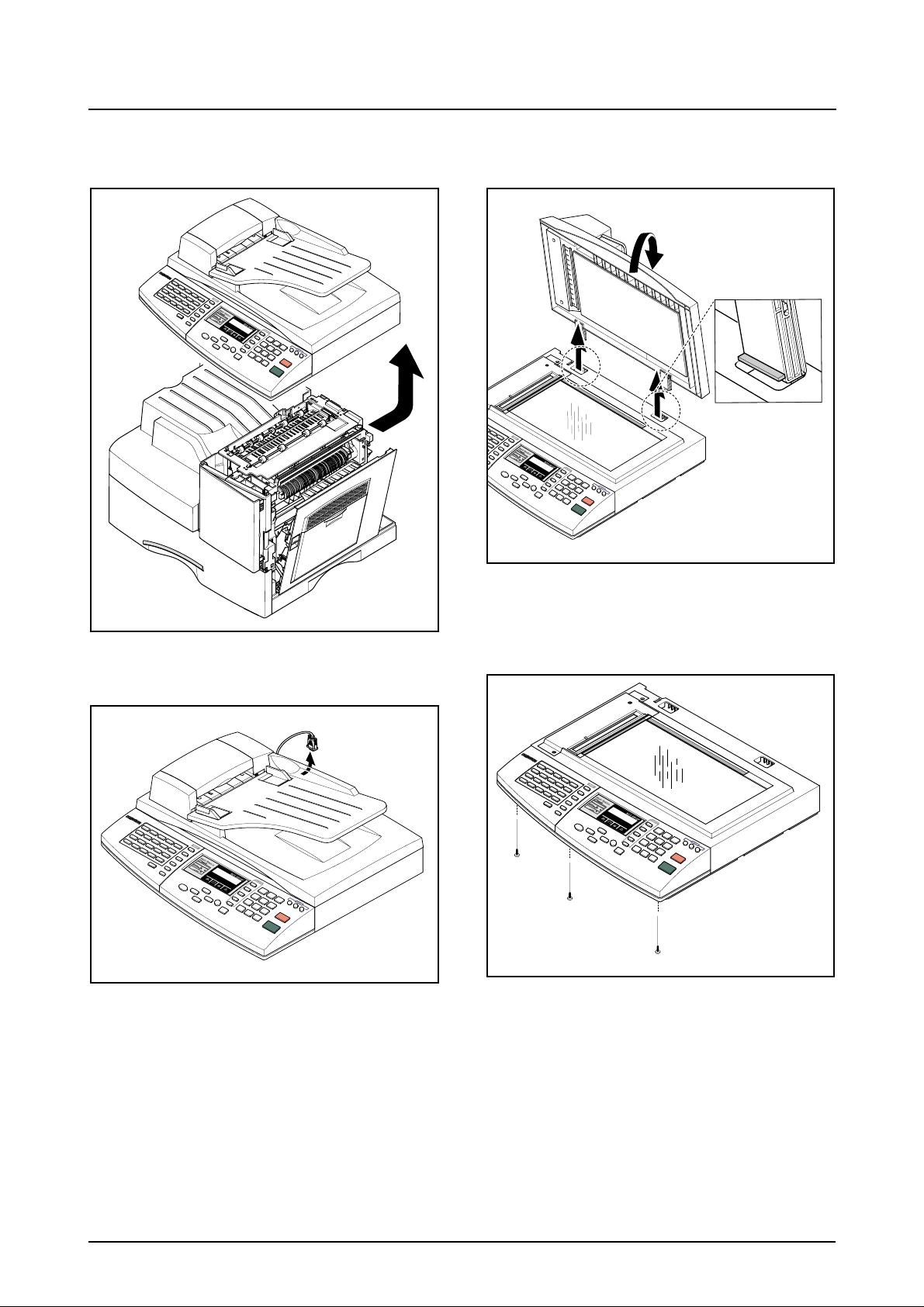

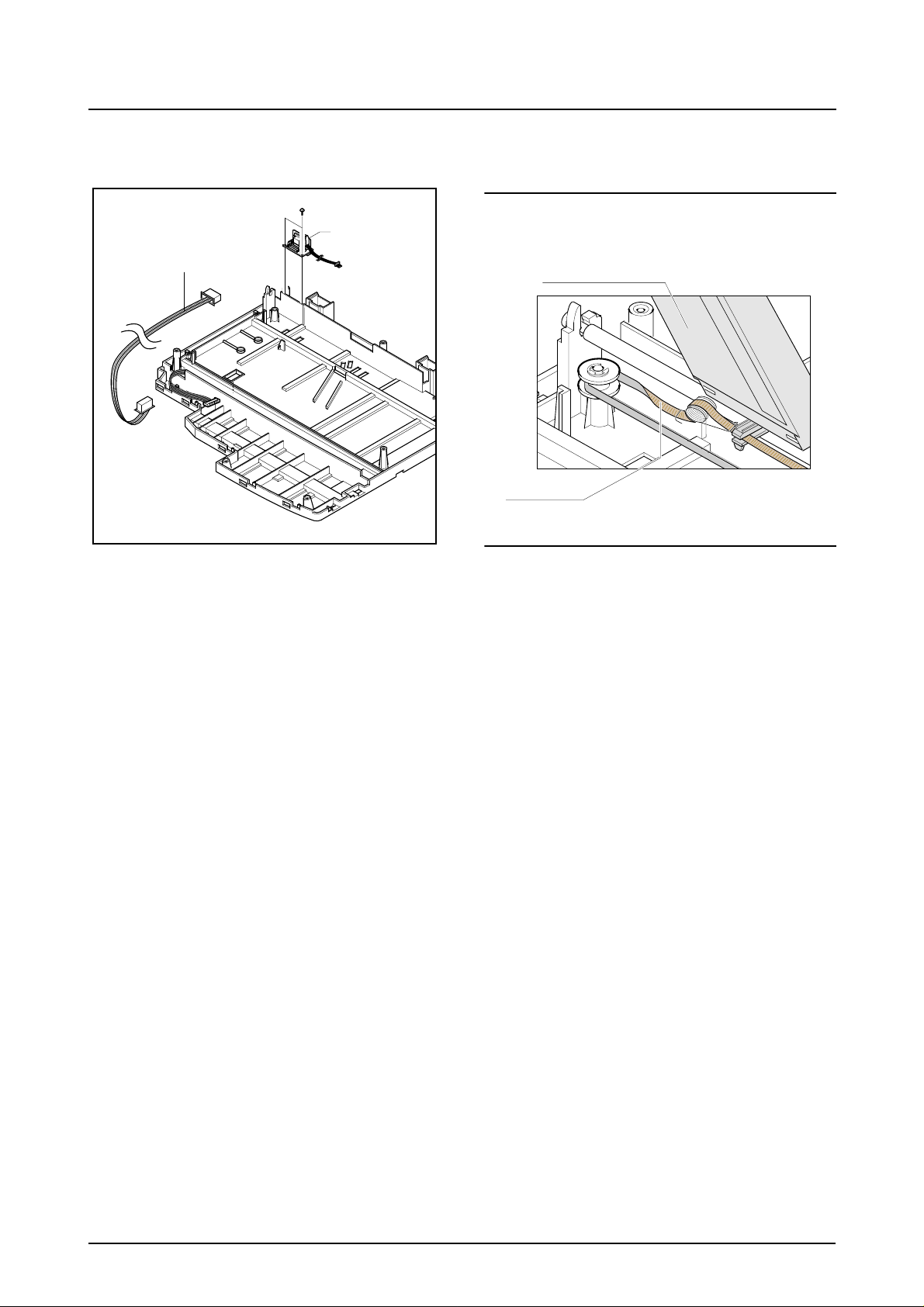

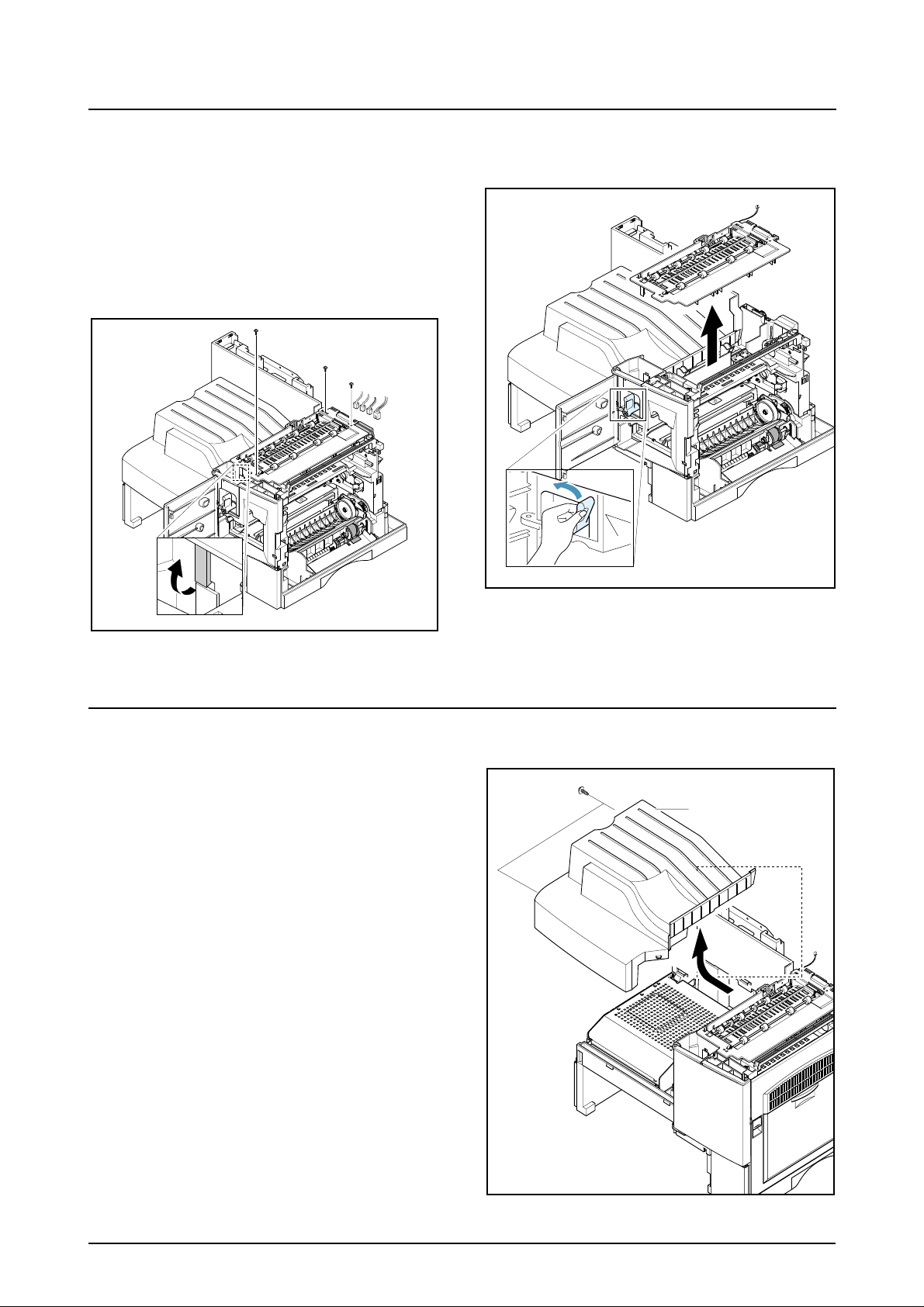

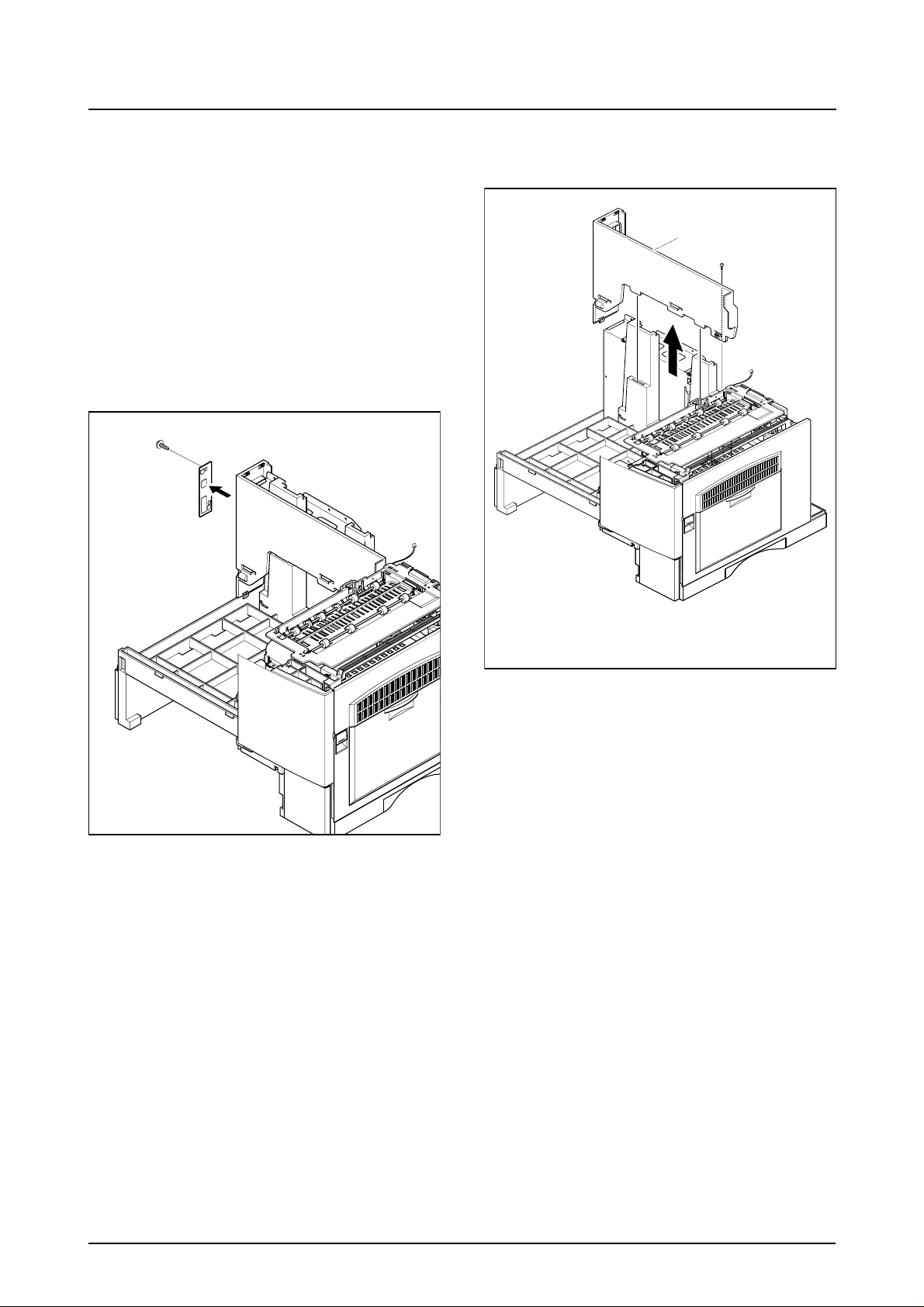

6. Pull up the Scanner Ass'y in the direction of

arrow.

8. Open the ADF Ass’y in the direction of arrow.

Pull the ADF Ass'y upward and remove it.

7. Remove the connector from the Platen Ass'y.

9. Remove the three screws securing the Platen

Ass'y.

Samsung Electronics

3-3

Disassembly and Reassembly

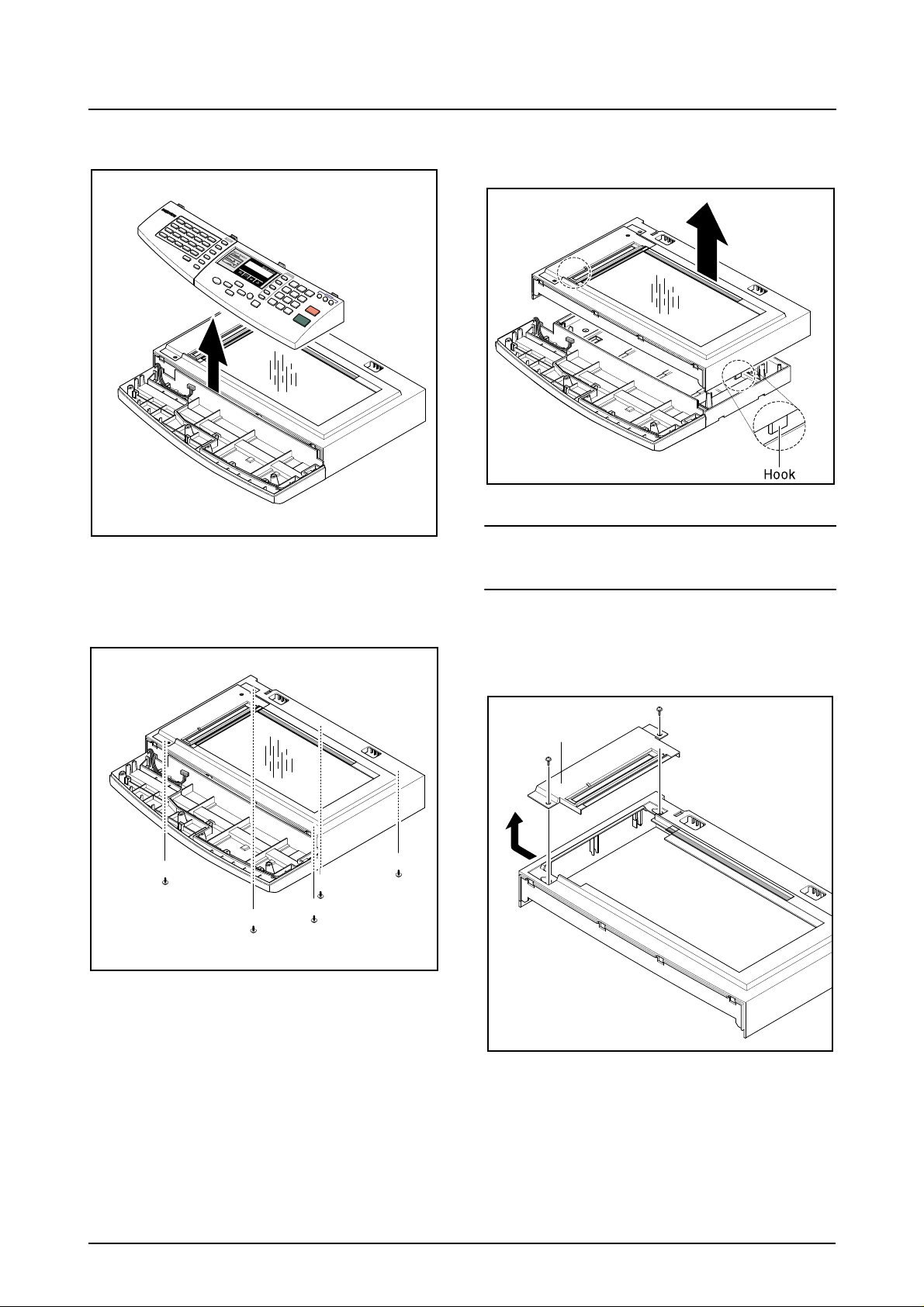

10. Pull the OPE Ass'y and unplug the one connector.

12. Unlatch the Scan Upper Ass'y securing the

glass and remove it.

Notice :

When dismantling the Scan Assy ensure your work area

is clean. Dirt or dust on the scan head can lead to a degradation in scanned image quality.

11. Remove the five screws securing the Platen Ass'y.

13. Remove the two scews and pull the Dummy

Upper Ass’y.

Dummy Upper Ass’y

3-4

Samsung Electronics

Disassembly and Reassembly

14. Remove the four screws and Channel Base

Frame.

Channel Base Frame

15. Remove the five screws and Dummy ScanLower.

16. Remove the CCD cable.

CCD Cable

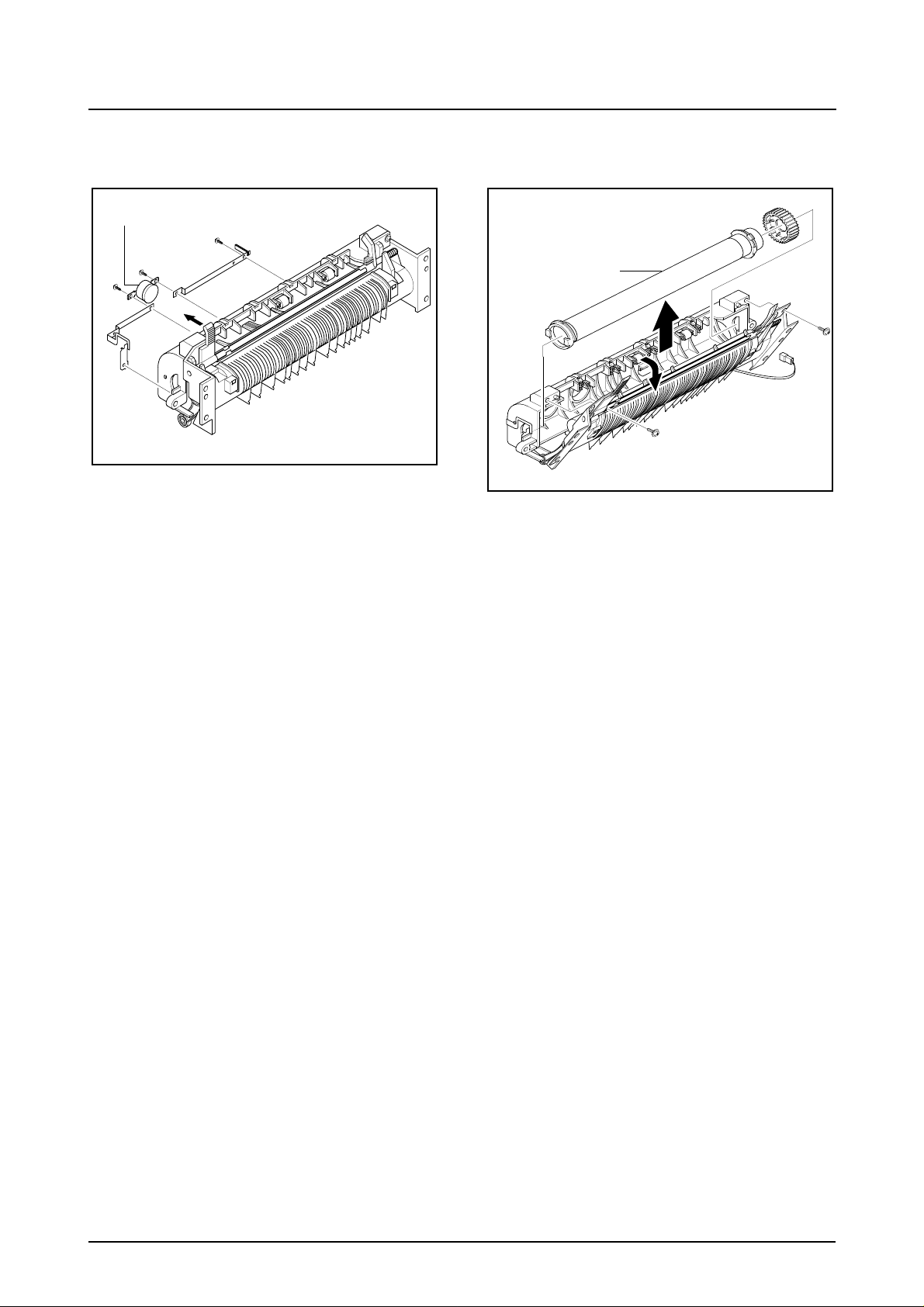

17. Pull up the Shaft CCD and tak e out the Scanner

Module.

Cover Dummy Lower

Cover Scan Lower

Shaft CCD

Pully

Scanner Module

Belt

18. Remove three screws and take out the Motor

Bracket.

Samsung Electronics

3-5

Disassembly and Reassembly

19. Remove the OPE Harness from the Platen

PBA. Remove two screws and take out the

Platen PBA.

Platen PBA

OPE Harness

Notice :

Take special care when reassembling the CCD Module

onto the Platen Ass'y. The CCD Module is located just to

the right side the Belt Tension Spring as shown below.

Scanner Module

Belt Tension Spring

3-6

Samsung Electronics

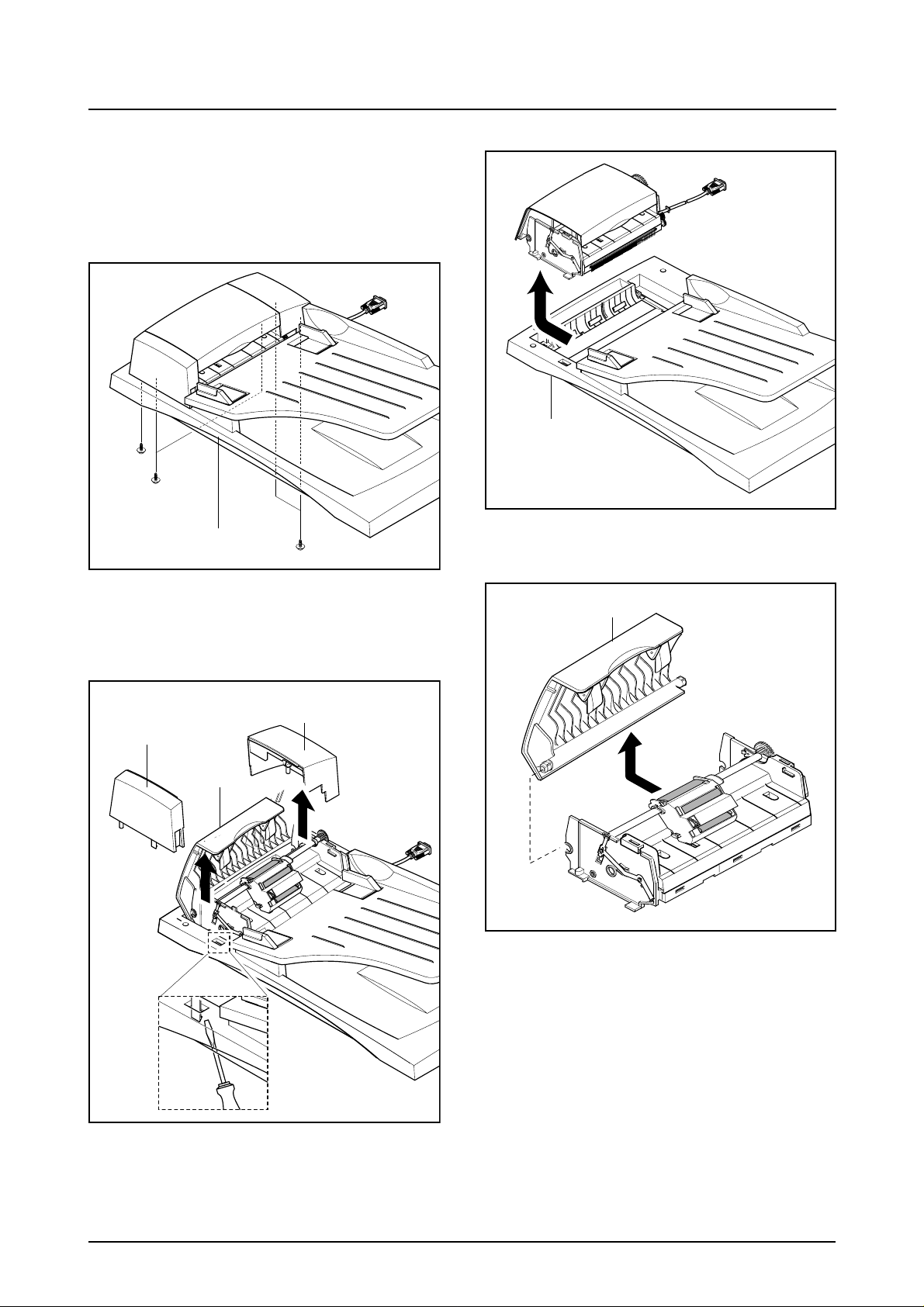

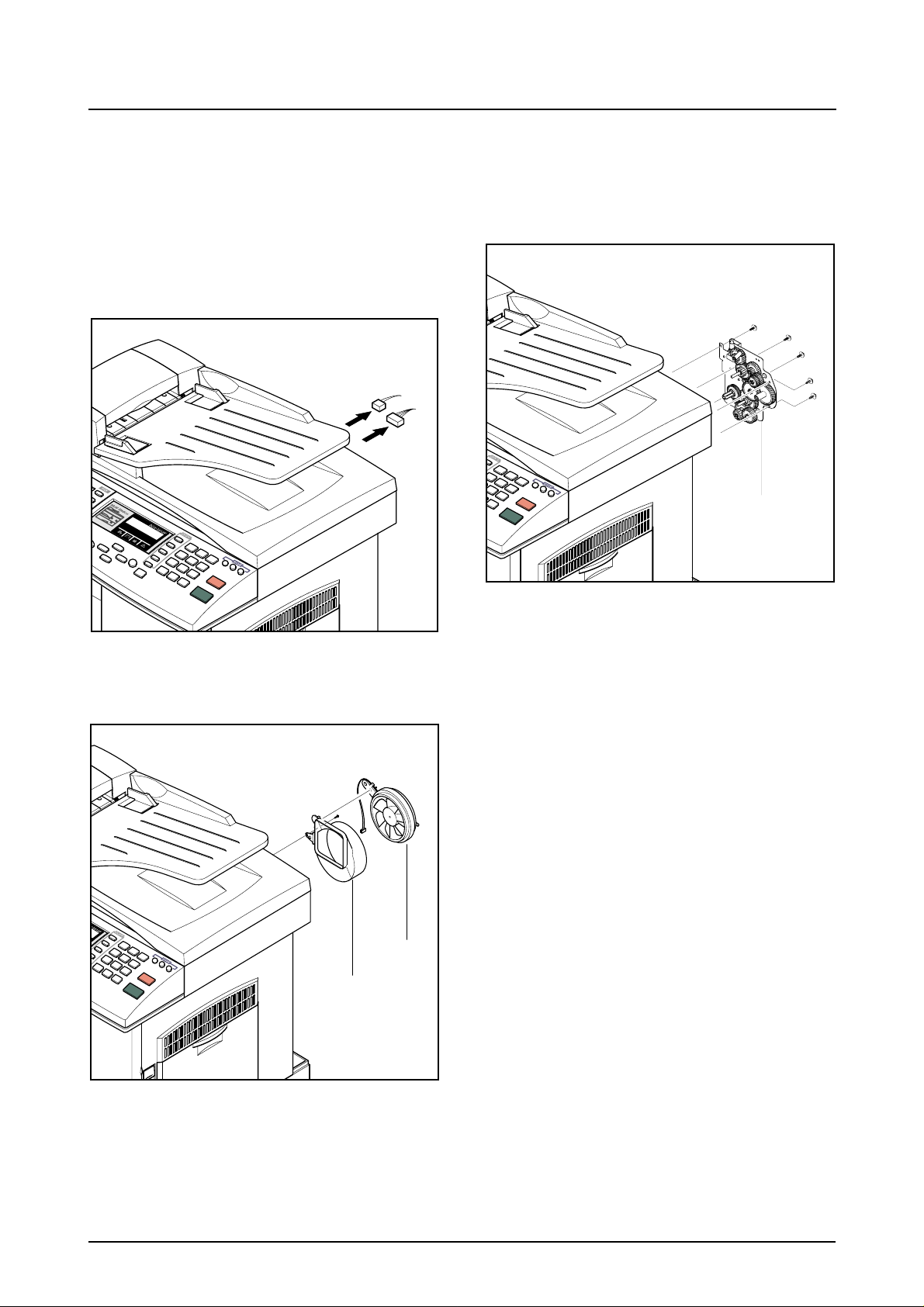

3-4 ADF Ass'y

Disassembly and Reassembly

1. Before you remove the ADF Ass'y, you should

remove:

- Rear Cover (see page 3-1)

- Scanner Ass'y (see page 3-2)

2. Remove the five screws from the Platen Cover.

Platen Cover Ass’y

4. Pull the ADF Ass'y upward and remove it.

Platen Cover Ass’y

5. Tack out he Open Cover.

3. Open the Co ver. Remove Cover Side R. Unlatch

the Side Cover L by pushing the catch hook ed to

the Platen Cover using a sharp tool and remove

Side Cover L.

Side Cover R

Side Cover L

Cover Open

Open Cover

Samsung Electronics

3-7

Disassembly and Reassembly

6. Take out the Pick-up Ass’y.

Remove the four screws and the ADF Upper.

Pick-up Ass’y

ADF Upper

7. Remove three screws and take out the ADF

Motor ass'y.

3-8

Samsung Electronics

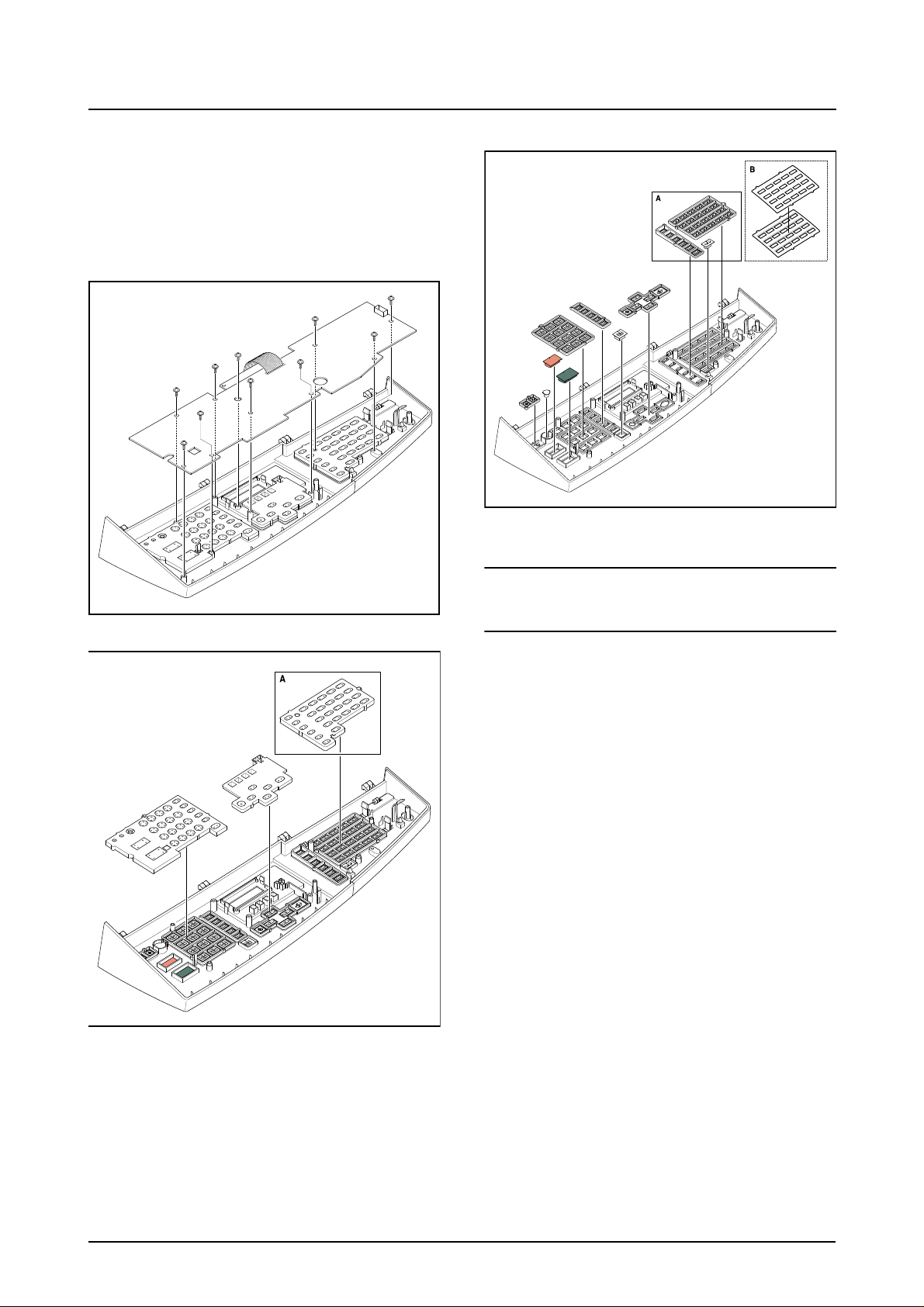

3-5 OPE Ass'y

Disassembly and Reassembly

1. Before you remove the OPE Ass'y, you should

remove:

- Rear Cover (see page 3-1)

- Scanner Ass'y (see page 3-2)

2. Remove ten screws securing the OPE PBA and

the LCD Module from the OPE Cover.

3. Remove the contact rubbers from the unit.

4. Remove the key pad from the unit.

Caution

The above information is for the SCX-5315F model.

For the SCX-5115 model, the OPE Ass’y is slightly different, prats maked “a” are not fitted.

Samsung Electronics

3-9

Disassembly and Reassembly

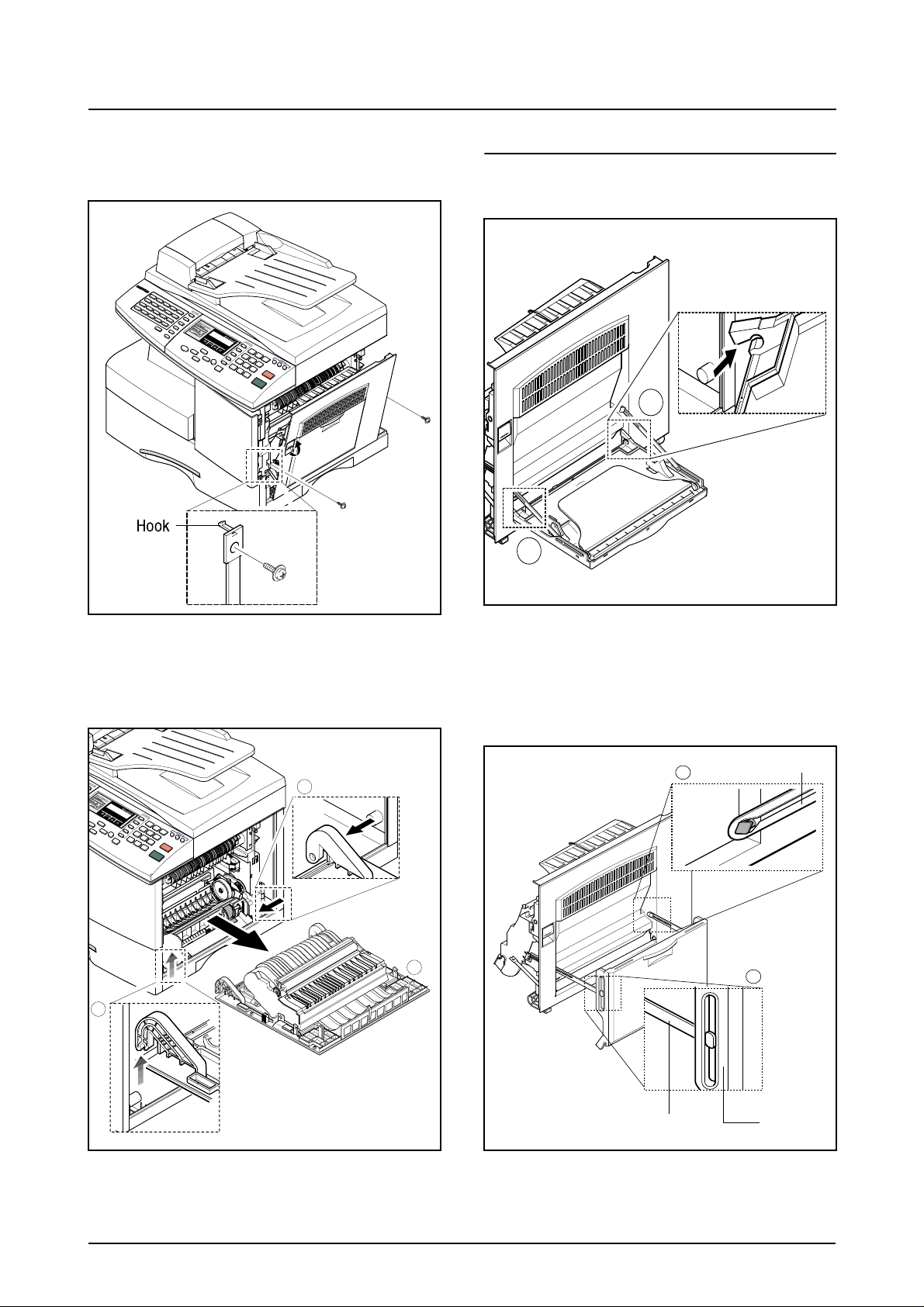

3-6 Side Cover Ass'y

1. Remove the two screws to release the Stopper(Main Frame side) securing the Side Cover

to the Main Frame.

* MP-Tray

1. To dismantle the MP tray release the lower

hinges (1).

1

1

2. Completely open the Side Cover door. The left

hand hinge (1) should be lifted to free it. Then

push the whole door assembly to the left to free

the right hand hinge (2).

2

3

1

2. As shown in (1) below align the door supports in

a horizontal position. This will allow the TrayCase to be removed from the Tray Links. To

remove the Tray-Links adjust the position of the

Tray Link to a 45?angle to align the slot in the

2

MP Tray

1

3-10

Tray Link

Tray-Case

Samsung Electronics

Disassembly and Reassembly

* Duplex Ass’y

1. To remove the Duplex Ass'y from the Side Door

Ass' locate the plastic clips, 2 on each side, and

release them.

Duplex Ass’y

* Transfer Roller Ass’y

1. Take out the Transfer Roller, as shown below.

Samsung Electronics

3-11

Disassembly and Reassembly

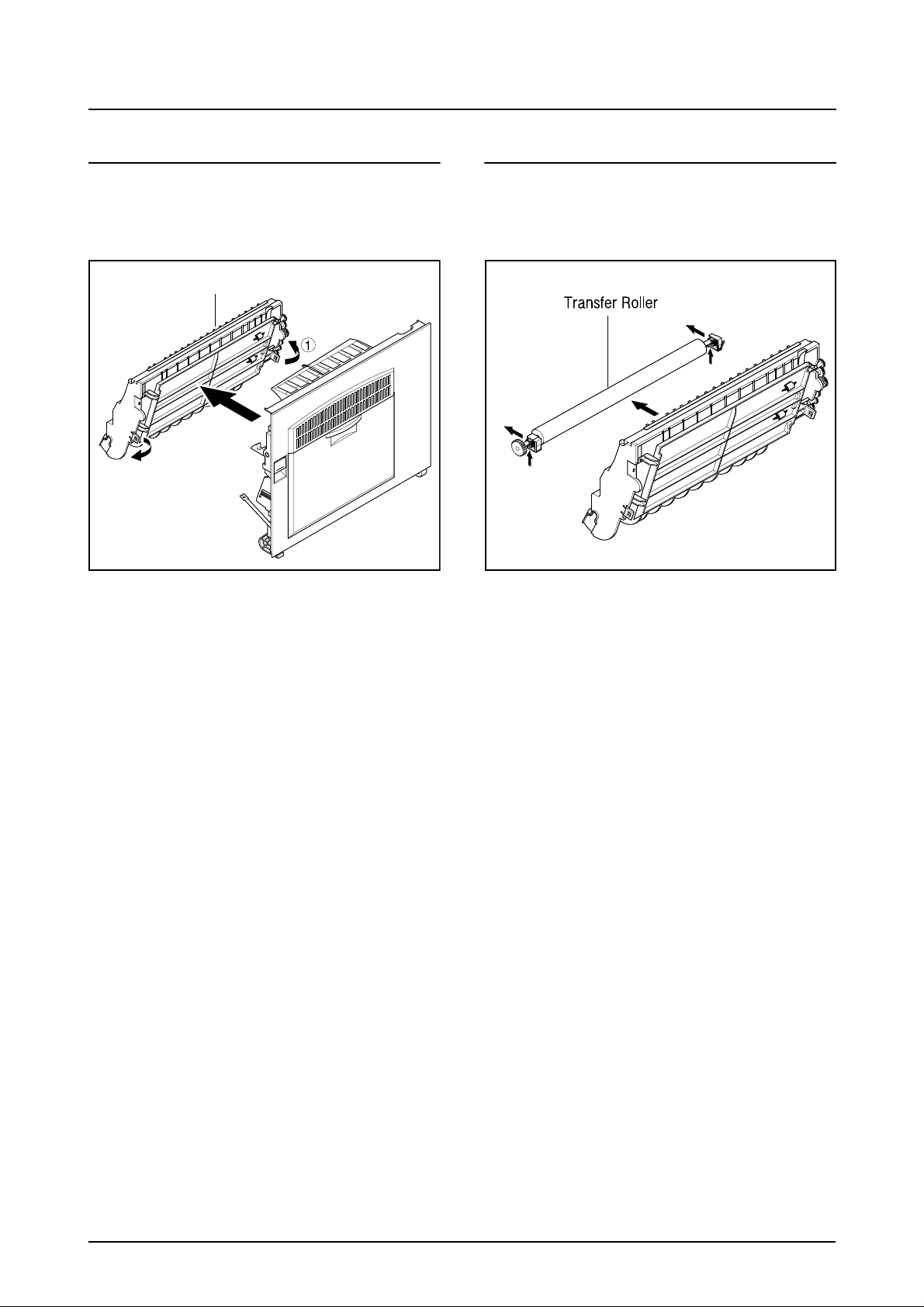

3-7 Fuser Ass'y

1. Before you remove the Fuser Ass'y, you should

ensure power is off and remove :

- Rear Cover Ass'y (see page 3-1)

- Side Cover Ass'y (see page 3-9)

2. Remove the two screws and take out the Connector Cover and the Cover Bracket.

Cover Bracket

4. Remo v e the three scre ws and tak e out the Fuser

Ass'y.

5. Remove the four screws and take out the Thermostat.

3. Unplug the one connector.

Halogen Lamp

3-12

Samsung Electronics

Disassembly and Reassembly

6. Remove the two screws and take out the Halogen Lamp.

Thermostat

7. Remove 2 screws and hinge open the Lower

Fuser Ass'y, remove the Heat Roller Ass'y from

the Upper Fuser Ass'y.

Heat Roller

Samsung Electronics

3-13

Disassembly and Reassembly

3-8 Exit Ass'y

1. Before you remove Exit Ass'y, you should

remove:

- Rear Cover (see page 3-1)

- Scanner Ass'y (see page 3-2)

2. Remove four scre ws, and then untie the harness

from the Exit Upper. Unplug four connectors and

unlatch the Dummy Base Frame, as shown

below.

3. Mo ve the Exit Roller Release Le v er to the upright

position as shown in the diagram below and lift

the exit ass'y to remove it.

3-9 Cover Paper Exit Ass'y

1. Before you remove the Cover Paper Exit Ass'y,

you should remove:

- Rear Cover (see page 3-1)

- Scanner Ass'y (see page3-2)

2. Remove two screws and Cover Paper Exit Ass'y,

as shown below.

Cover Paper Exit Ass’y

3-14

Samsung Electronics

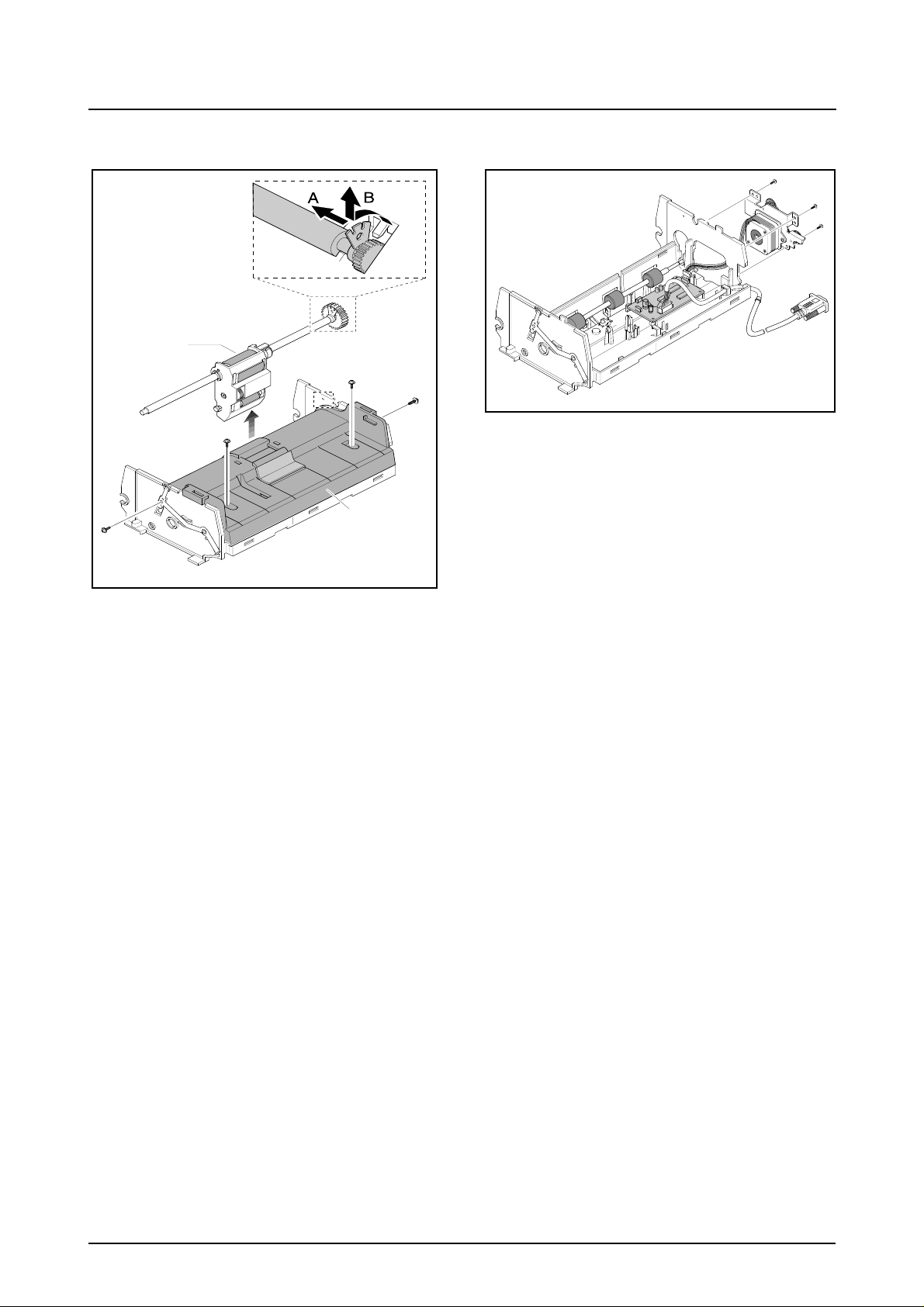

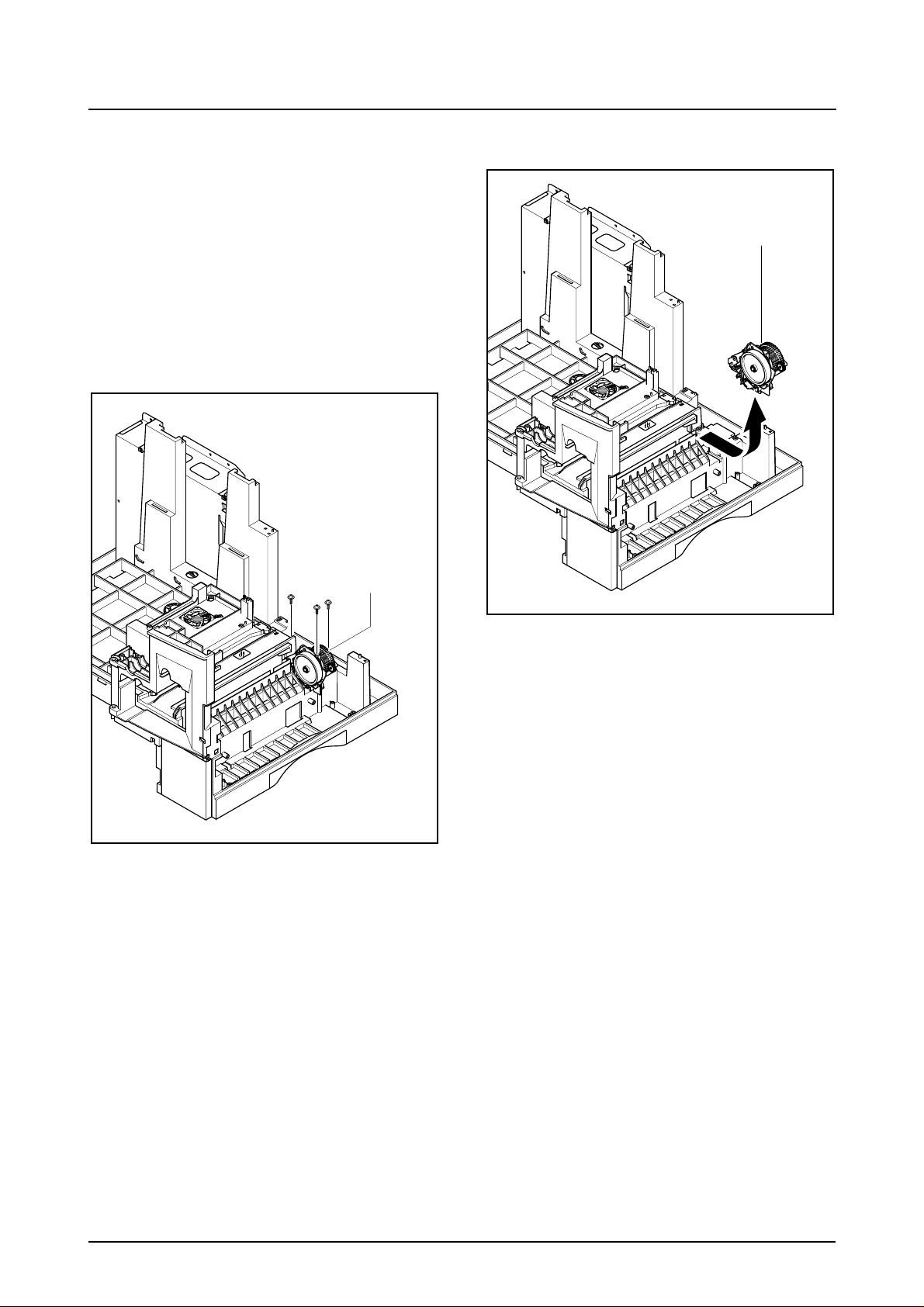

3-10 Drive Ass'y

1. Before you remove the Drive Ass'y, you should

remove:

- Rear Cover (see page 3-1)

- Shield Main Upper (see page 3-2)

2. Unplug the two connectors.

(Main Motor:9pin, Duplex Solenoid : 2pin)

4. Remove the five screws and take out the Drive

Ass'y.

Disassembly and Reassembly

3. Remo ve the one screw and take out the Fan and

Dust Fan.

Fan

Drive Ass’y

Samsung Electronics

Dust Fan

3-15

Disassembly and Reassembly

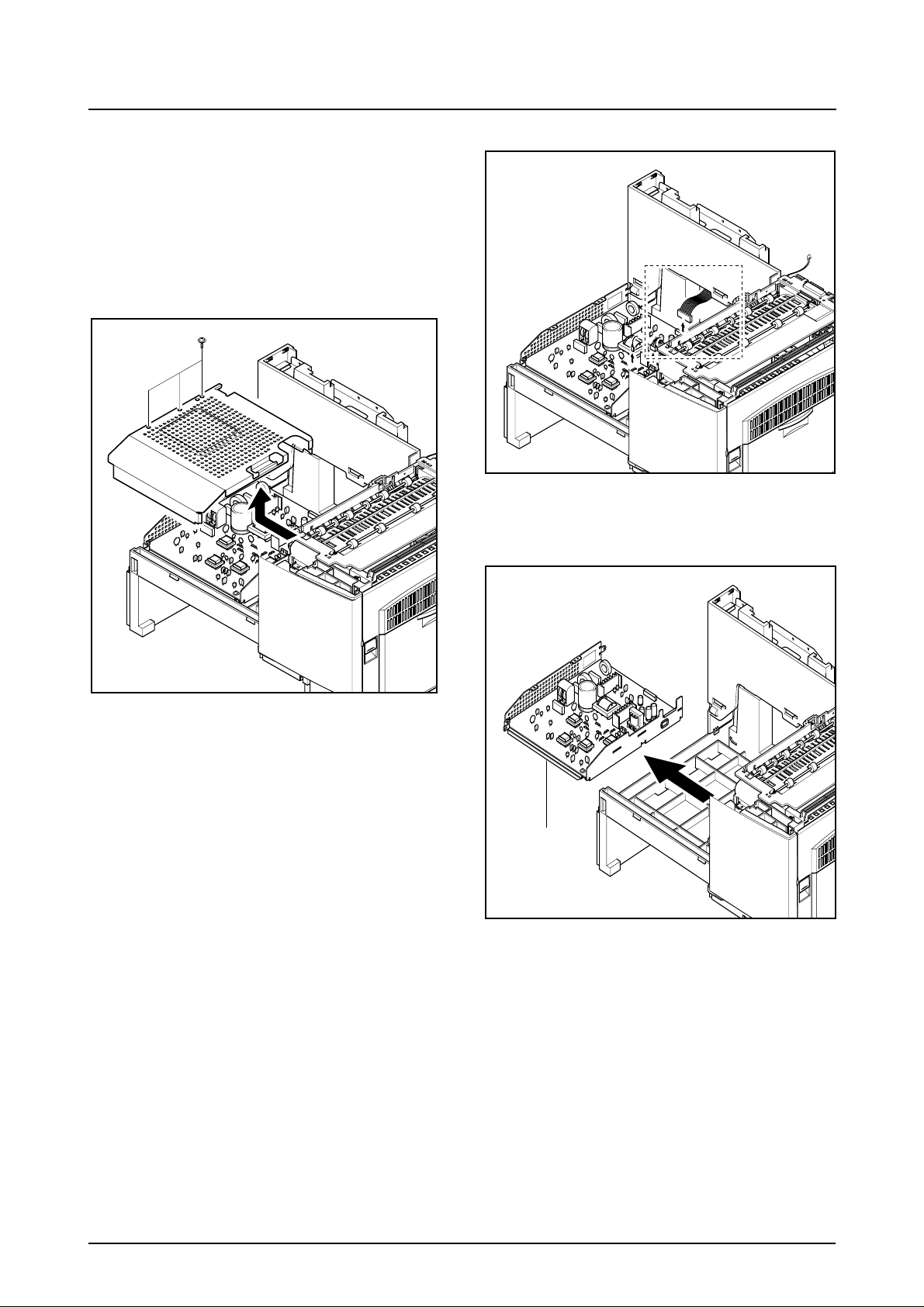

3-11 SMPS

1. Before you remove the LSU, you should remove:

- Rear Cover (see page 3-1)

- Scanner Ass'y (see page 3-2)

- Cover Paper Exit Ass’y(see page 3-12)

2. Remove three screws and take out the Shield

SMPS Upper.

3. Unplug the all connectors.

4. Remove the SMPS, as shown below.

3-16

SMPS

Samsung Electronics

3-12 LSU (Laser Scaning Unit)

Disassembly and Reassembly

1. Before you remove the LSU, you should remove:

- Rear Cover (see page 3-1)

- Scanner Ass'y (see page 3-2)

- Cover Paper Exit Ass’y (see page 3-12)

2. Unplug the two connectors.

3. Remo ve the three screws and tak e out the LSU.

LSU

Samsung Electronics

3-17

Disassembly and Reassembly

3-13 Cover Exit Rear

1. Before you remove the Cover Exit Rear, you

should remove:

- Rear Cover (see page 3-1)

- Scanner Ass'y (see page 3-2)

- Exit Ass'y (see page 3-12)

- Cover Paper Exit Ass’y(see page 3-12)

- SMPS (see page 3-14)

2. Remove the one screw and take out the Panel

Connect MPF.

3. Remove the one screw and Cover Exit Rear, as

shown below.

Cover Exit Rear

3-18

Samsung Electronics

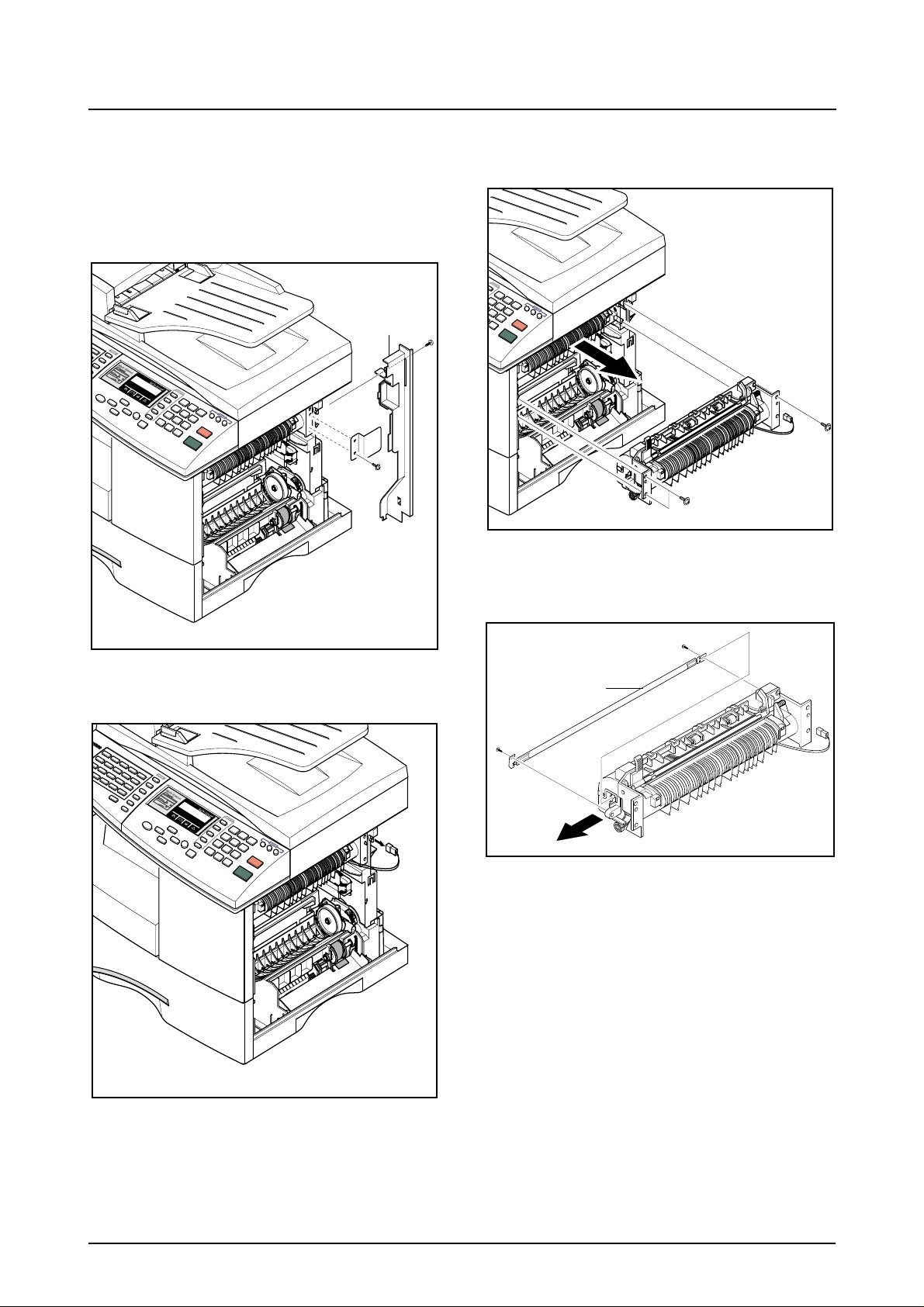

3-14 Main Frame Ass'y

Disassembly and Reassembly

1. Bef ore you remove the LSU, you should remove:

- Rear Cover (see page 3-1)

- Scanner Ass'y (see page 3-2)

- Side Cover Ass'y (see page 3-9)

- Fuser (see page 3-11)

- Exit Ass'y (see page 3-12)

- Cover Paper Exit Ass’y(see page 3-12)

- SMPS (see page 3-14)

- LSU (see page 3-15)

2. Remove the OPC Ground Screw (see diagram).

Take care when re-assembling as if the thread is

stripped the OPC ground may become intermittent causing print faults. Then remove the rest of

the five screws to dissassemble the Dummy

Base Frame , the Cov er Front and the Exit Roller

release cam.

OPC Ground Screw

Dummy Base Frame

Cam Jam Remove

4. Unplug the all connectors.

5. Remove the seven screws and take out the

Main Frame Ass'y.

Front Cover

3. Remove the Deve Lock Lever, and then remove

the one screw and the Cover Motor Bracket.

Cover Motor Bracket

Main Frame Ass’y

Lock Deve

Samsung Electronics

3-19

Disassembly and Reassembly

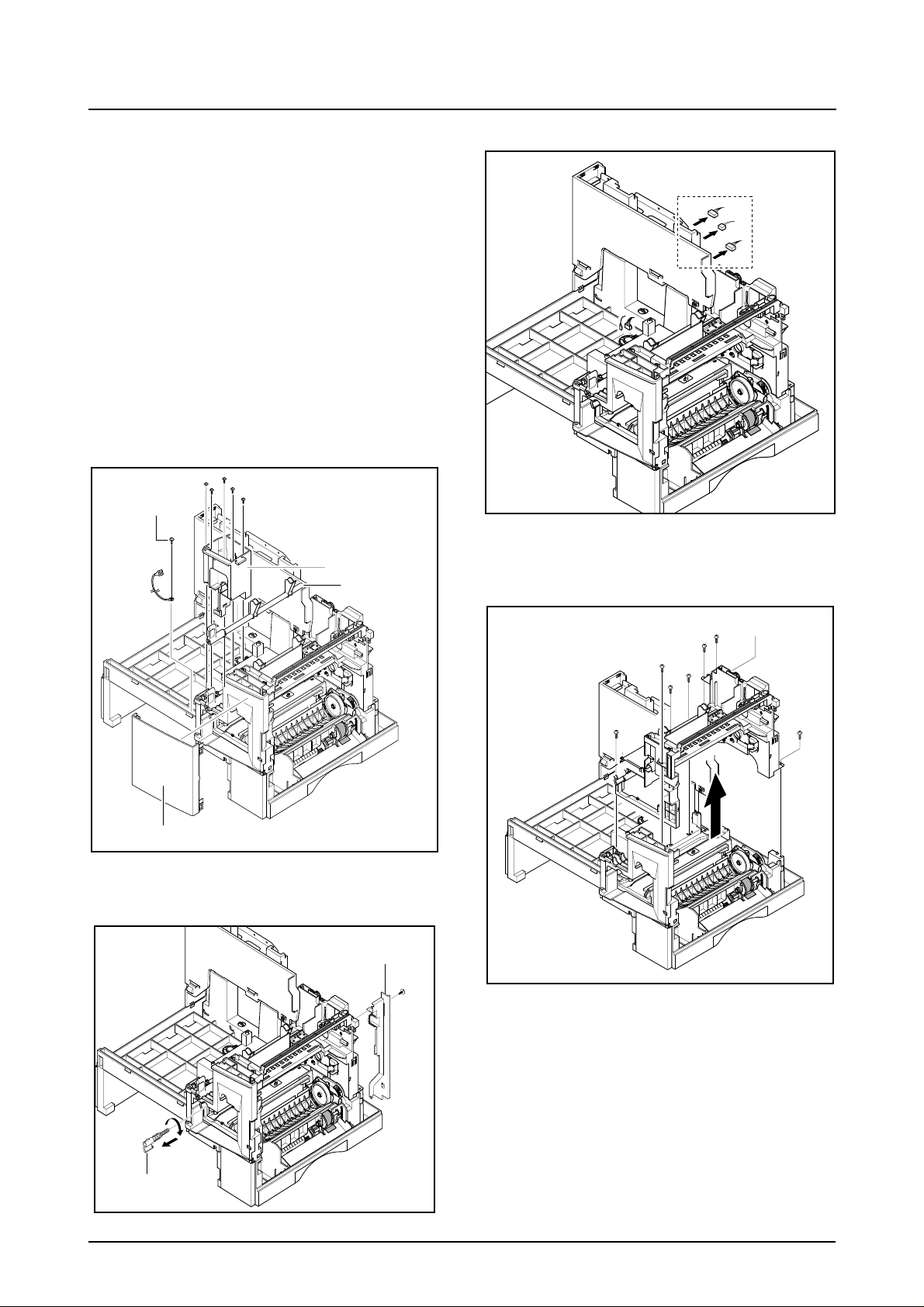

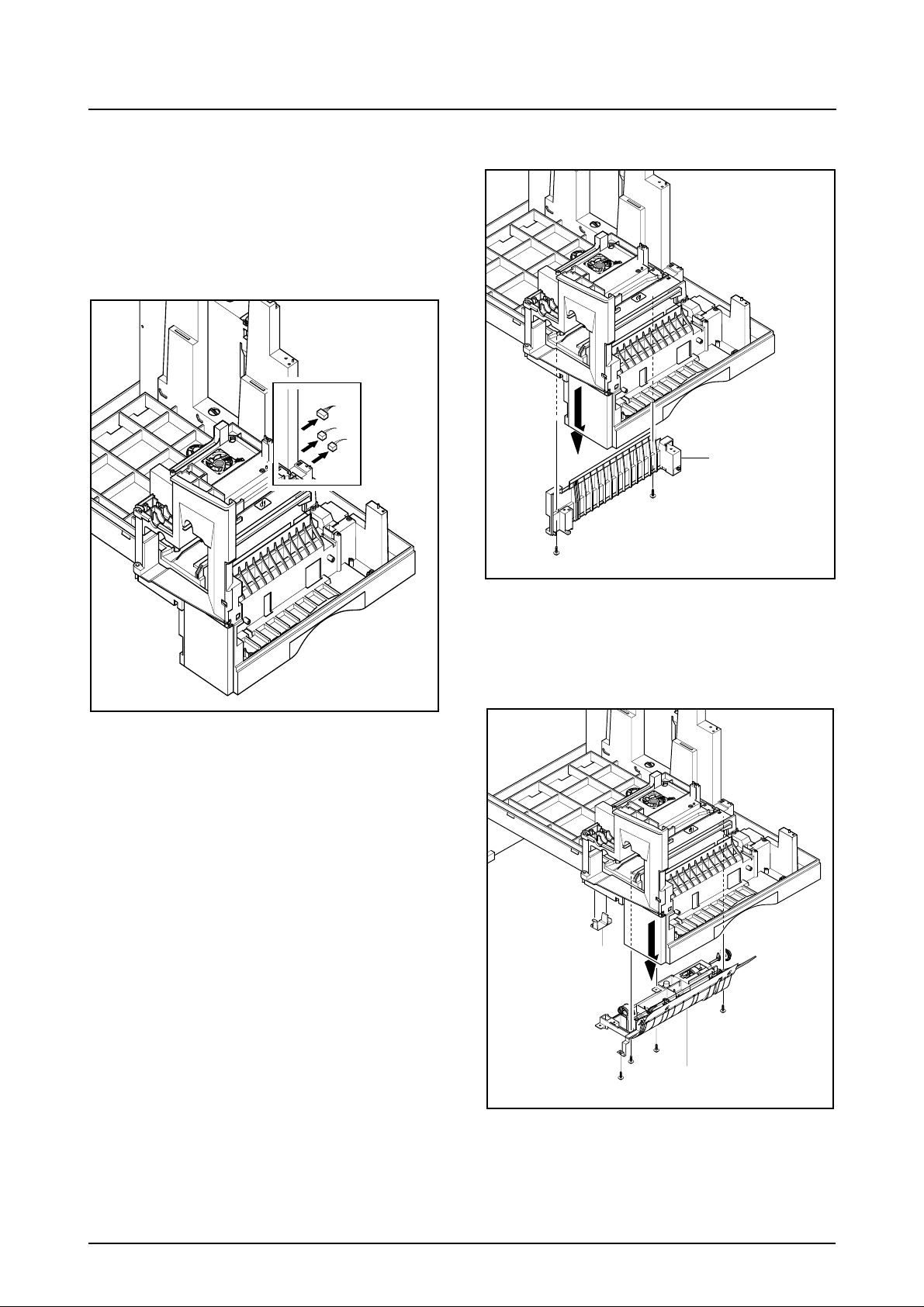

3-15 MP Ass'y

1. Before you remove the MP Ass’y, you should

remove:

- Rear Cover (see page 3-1)

- Shield Main Upper (see page 3-2)

- Side Cover Ass'y (see page 3-9)

2. Unplug the two connectors.

4. Remove the three screws.

3. Remove the one screw and take out the Dummy

Cover.

Dummy Cover

5. Release the SMPS fit. Pull the MP Ass'y upward

and remove it.

MP Ass’y

3-20

Samsung Electronics

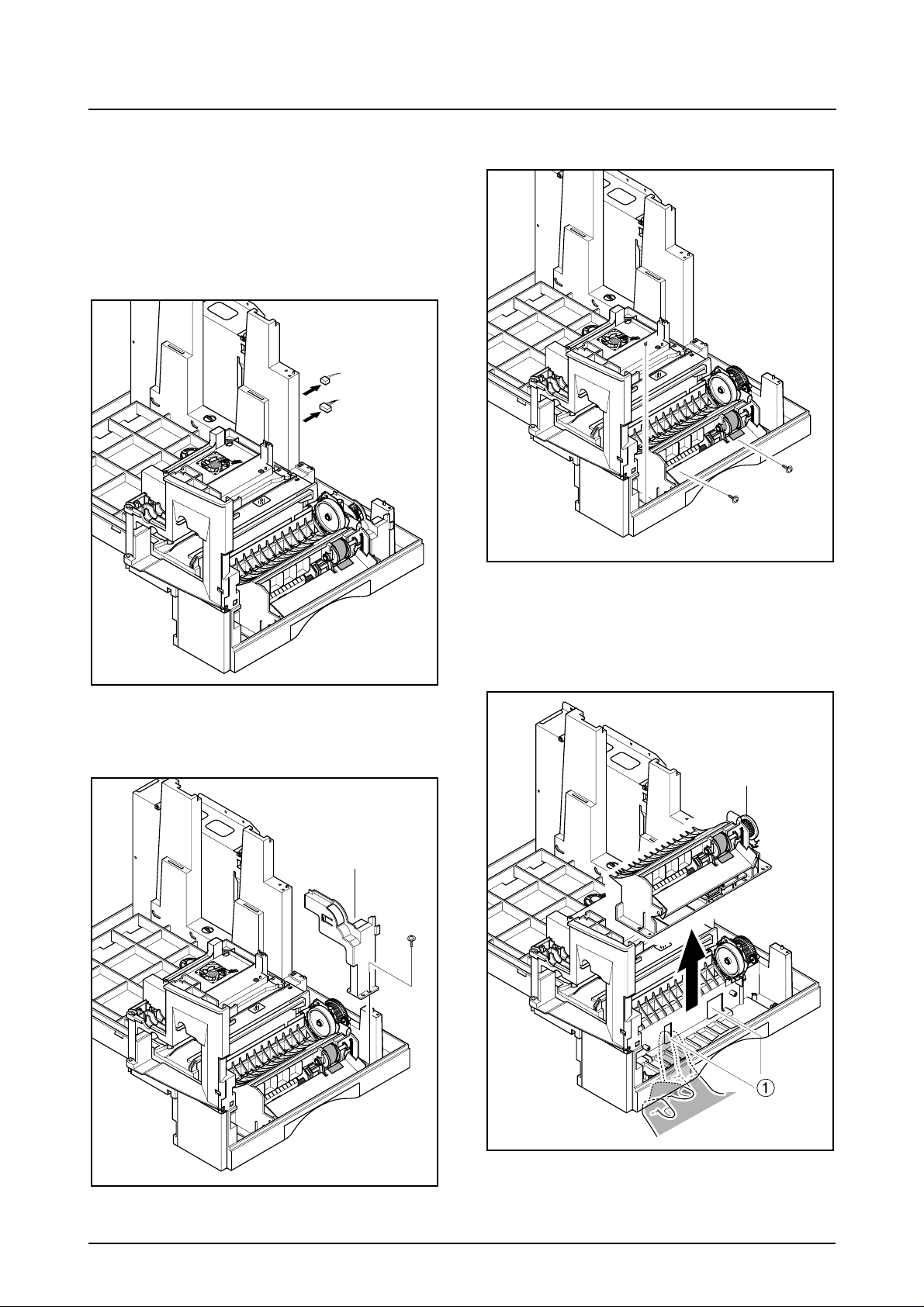

3-16 Feed Ass'y

Disassembly and Reassembly

1. Before you remove the Feed Ass’y, you should

remove:

- Rear Cover (see page 3-1)

- Scanner Ass'y (see page 3-2)

- Side Cover Ass'y (see page 3-9)

- Exit Ass'y (see page 3-12)

- Cover Paper Exit Ass’y(see page 3-12)

- LSU (see page 3-15)

- Main Frame Ass’y (see page 3-17)

2. Remove the three screws.

Feed Ass’y

3. Pull the Feed Ass'y upward and remove it.

Feed Ass’y

Samsung Electronics

3-21

Disassembly and Reassembly

3-17 Pick Up Ass'y

1. Bef ore y ou remov e the Pic k Up Ass’y, you should

remove:

- Rear Cover (see page 3-1)

- Shield Main Upper (see page 3-2)

- Drive Ass'y (see page 3-13)

2. Unplug the three connectors.

3. Remove the two screws and take out the Cassette Rail.

Cassette Rail

4. Remo ve the f our screws and tak e out the Pick Up

Ass'y, as shown below.

Guide Paper Out

Pick-up Ass’y

3-22

Samsung Electronics

Loading...

Loading...