Page 1

Repair Manual

Repair Manual

1. Block Diagram

2. Connection Diagram

3. Circuit Description

4. Schematic Diagrams

CONTENTS

Digital Laser

MFP

SCX-5312F/SCX-5112

Page 2

Page 3

Samsung Electronics Digital Printing

CS Group

Copyright (c) 2001. 11

This manual is made and

described centering around

circuit diagram

and circuit description needed

in the repair center

in the form of appendix.

Page 4

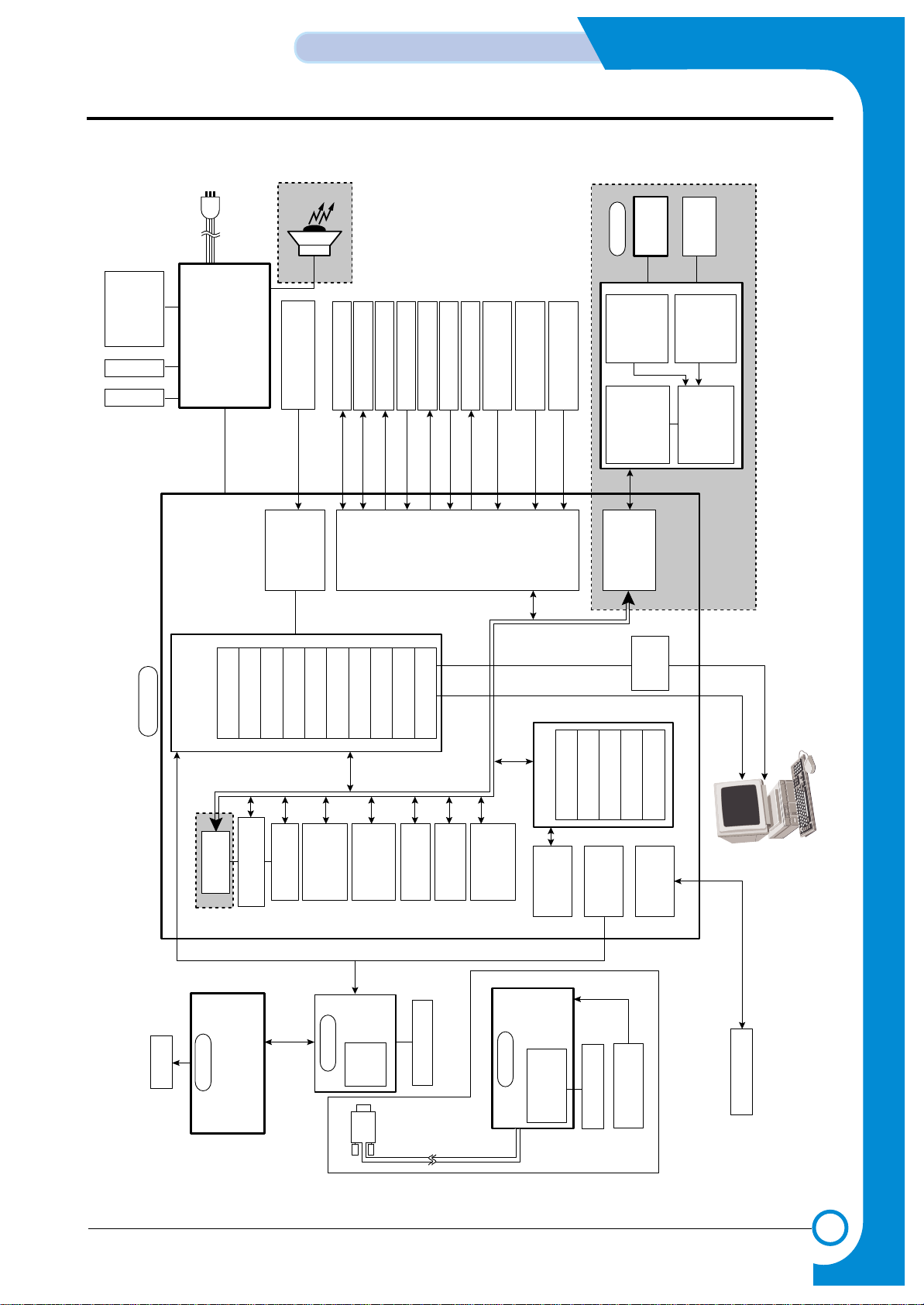

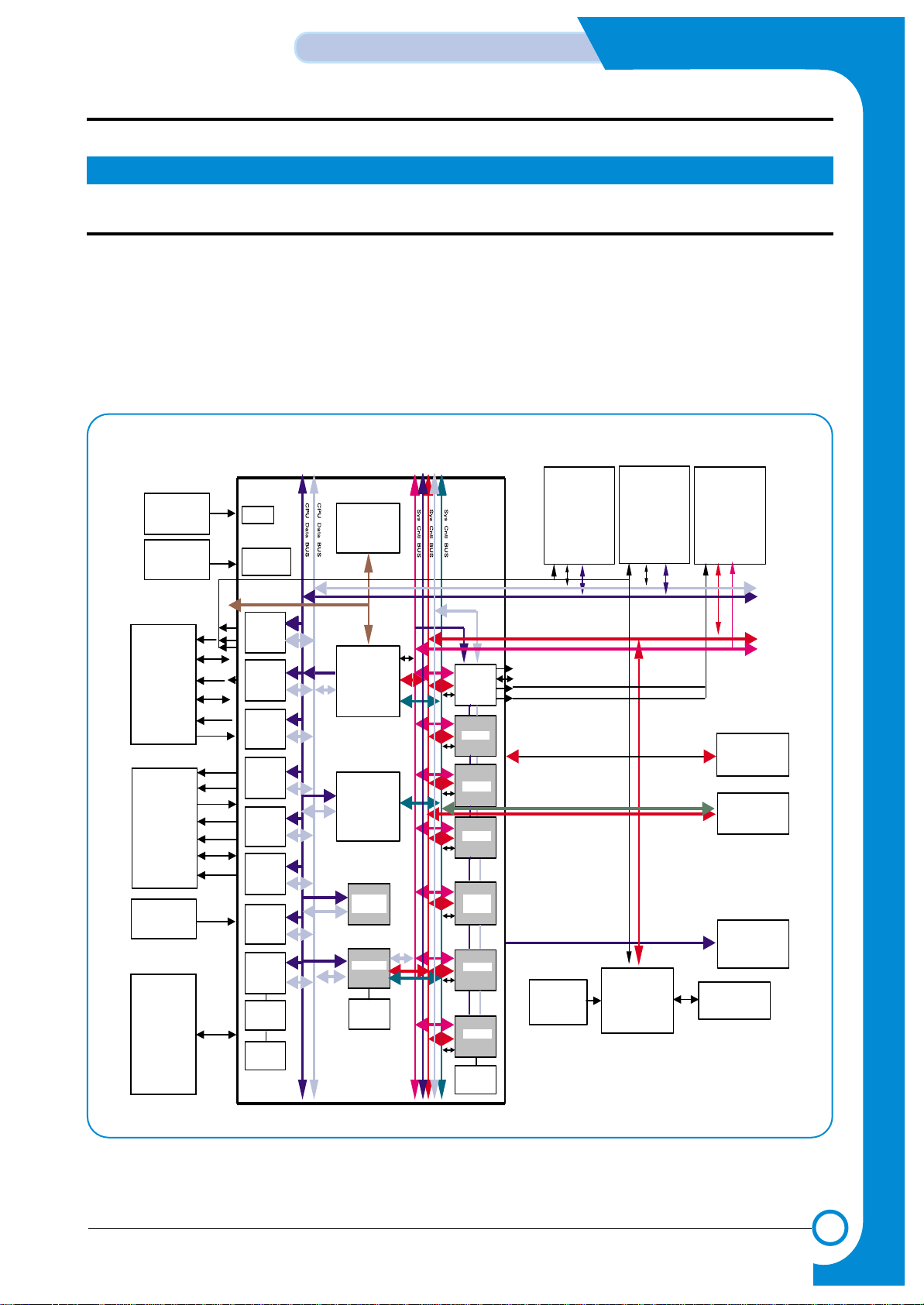

1

1-1

Samsung Electronics

BLOCK DIAGRAM

Repair Manual

1. Block Diagram

Only SCX-5312F

Only SCX-5312F

Only SCX-5312F

LCD

OPE

MICOM

- LCD Drive

- Key Scan

FLAT

D-SUB

CONN.

FLAT MOTOR

ADF

MOTOR

DRIVER

ADF MOTOR

PAPER SENSOR

POS, DET

3P X 2EA

ADF OPTION

CCD MODULE

22P

ARM7TDMI

UART * 2

MEMORY I/F

CACHE (8K)

DMA CNTR

PVC

GEU

I/O I/F

USB

IEEE1284

MOTOR

DRIVER

SW2918 / TEA3718

EXTERNAL

GPIO

74HC245

74HC273

11P

8P

2P

3P3P3P

4P4P2P

2P X 3EA

3P X 2EA

6P X 1EA

4P X 1EA

LSU

THE RMISTOR

FAN

DEV_ID

TONER_TX

TONER_RX

PTL

SOLENOID

PICK_UP, DUPLEX, MP

PAPER SENSOR

FEED+P.EMP, EXIT, MP,BIN-FULL

COVER OPEN S/W

+24V / +5V

LIU

LINE1

EXTERNAL

PHONE

TRANSFORMER

600 / / 600

TX : RX

MODEM &

EXT_PHONE

PAPER A TING

PART

EXTER NAL

PHONE

INTE RFACE

PART

LINE

INTERFACE

MODEM

33.6Kbps

14P

UNICON

USB CABLE

CENTRONICS

CABLE

Image Processor

12bit ADC

I/O PORT

Motor CNTR

DMA I/F

CIP3

FAST SRAM

(1Mbit)

MOTOR

DRIVER

CCD

I/F PART

15P D-SUB

24P

5P

RTC

Back-up Part

SRAM

(32KB)

FLASH ROM

(1MB) X 2EA

F/W

FLASH ROM

(1MB) X 2EA

PCL

DRAM

(8MB)

DRAM

(8MB)

FONT ROM

KM23C8105 H/L

PCL

SPGPe+

MAIN

24P

MOTOR 1

MOTOR 2

SMPS / HVPS

+5V/+24V/+12V/+24Vs/Fuser

T

H

V

M

H

V

DEV

SUPPLY

BLADE

Page 5

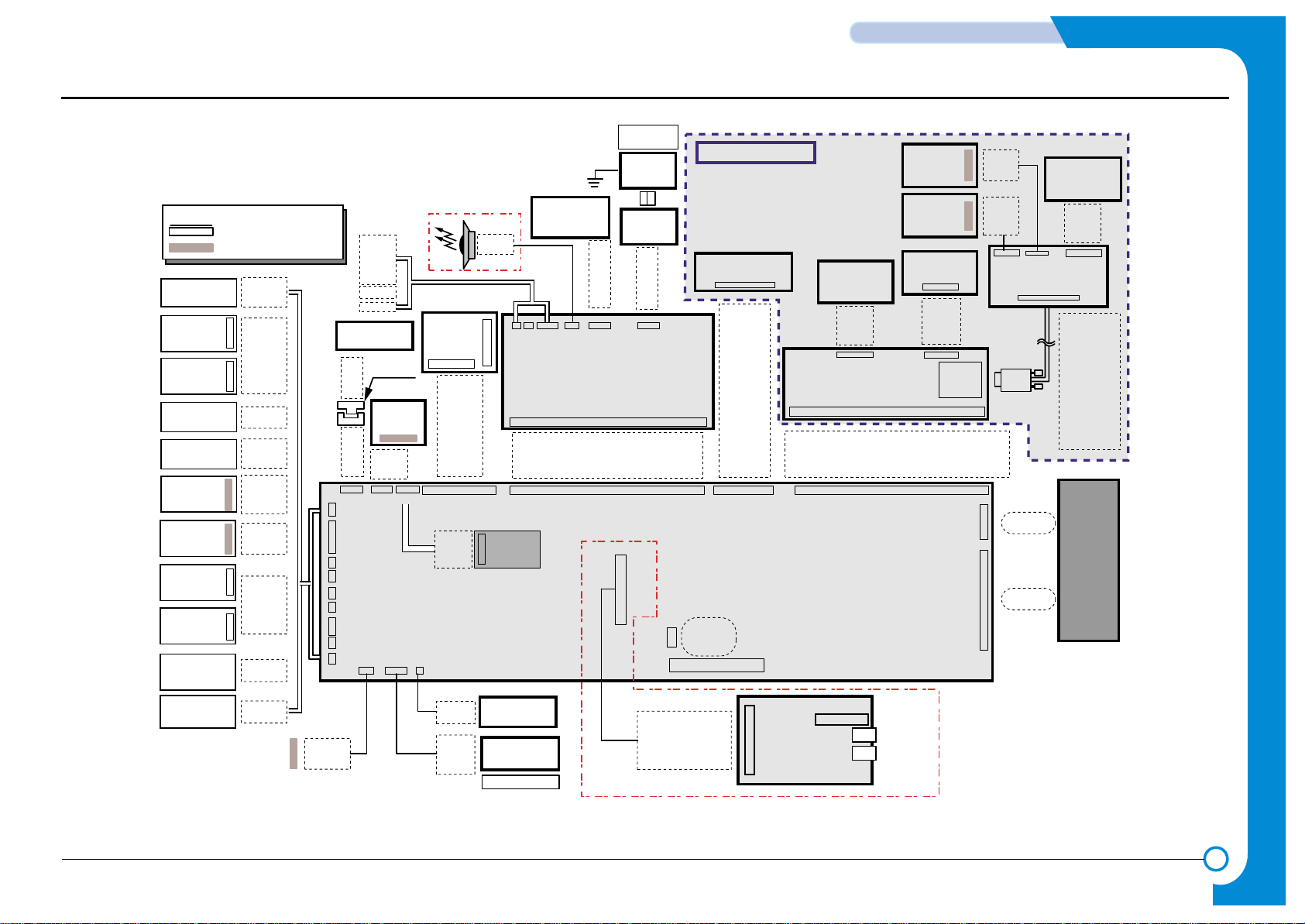

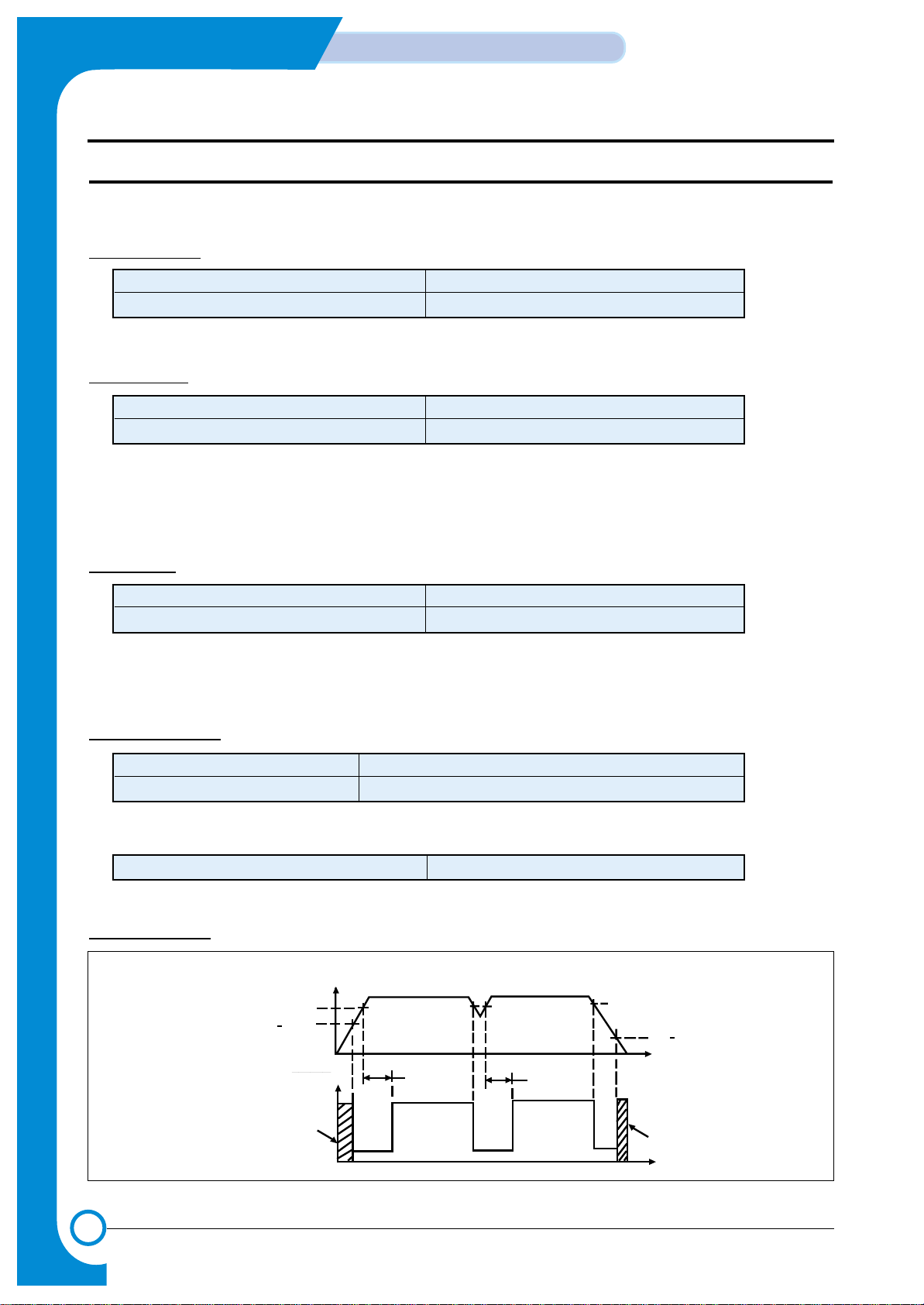

2

2-1

Samsung Electronics

CONNECTION DIAGRAM

Repair Manual

2. Connection Diagram

MAI N

FLAT

LS

U

CCD MO DUL E

THERMISTOR

D

UPLEX SOL.

DEV_I D

MP S OL.

LI U

SMPS / HVPS

1.GND_5 2. +5 V 3.

GND_5

4.+5V 5.GND_5

6. + 5V 7 .

GND_12

8.+12V 9.

GND_ 24

10.+24V 11.

GND_24

12. +24V 13.

GND_24

14. +24V 15.

THV_PWM

16 . +2 4V S 1 1 7 .

THV_EN

18. +24VS1

19.

THVREAD

20.

FUSER_ON

21.

MHV_PWM

22.SPK+ 23.

DEV_P W M

24. SPK-

1.nHSYNC

2.+5VS

3.GND_5

4.nLD_ON

5.nVDO

6.NC

7.LSU_CLK

8.nLREADY

9.PMOTOR

10. GND_24

11. +24VS1

123 45678 91011

123 456

7

8

9

1

0

1

1

1.

GND_24

2.+24V 3. +5V 4.GND_24 5.

ADF_PH A6.GND_57.ADF_I A( 1)

8.

ADF_I A( 0)9.ADF_I B(0 )

10 . A D F_ P HB11.

MODULE_DETECT

12. ADF _I B(1)

13.

ADF_P_POS14.ADF_P_DET

15.NC 16.

ADF_P_REGI

17.OPE_RXD

18.OPE_RST 19. OPE_TXD 20

.FLAT_COVER

21 . T M_A 2 2.

TM_NA

23. TM_B

24. TM_NB

123 45678 9101112131415161718192021222324

1 2 3 45 6 7 8 910 11121314 151617181920212223 24

2 1 4 36 5 8 7 109 12111413 161518172019222124 23

1,2. INV_POWER

3,4.GND_12

5.CCD_HOME

6,7. +12V

8.CCD_TG

9.GND_5

10.CCD_CLK1

11.GND_5

12.CCD_CLK2

13.GND_5

14.CCD_RS

15.GND_5

16.CCD_CP

17.GND_5

18.GND_12

19.

VOUT _

VOUT _

VOUT _

R

20. G

21. B

22. GND_12

PC

Parallel Port

36pin

USB Port

4pin

214 36587 1091211141316151817201922212423

FLAT

MOTOR

1.FLAT_A

2.FLAT_NA

3.FLAT_B

4.FLAT_NB

OPE

1.GND_5

2.+5V

3.OPE_TXD

4.OPE_RST

5.OPE_RXD

D-SUB

CONN.

15P D-SUB

ADF

1.+24V

2,3. GND_2 4

4.+5V

5.GND_5

6.ADF_PHA

7.ADF_IA( 0)

8.ADF_IA( 1)

9.ADF_PHB

10.ADF_IB(0)

11.ADF_IB(1)

12.

MODULE_DETECT

13. ADF_P

ADF_P

ADF_P

_DET

14. _POS

15. _REGI

16. NC

ADF

MOTO R

1.ADF_A

2.ADF_NA

3.ADF_B

4.ADF_NB

1.+5V

2.

SI GN AL

SI GN AL

3.GND_5

GND_5

1.+5V

2

3.

4,5. NC

SCANNER PART

DET EC T

SENSOR

SENSOR

POSI ON

EXIT

SENSOR

1.+5V

2.S IGNAL

3.GND_5

1

.

T

H

E

R

M

1

2

.

T

H

E

R

M

2

JOI N T T YP E

1

.

T

H

E

R

M

1

2

.

T

H

E

R

M

2

DC FAN

1.+24V

2.NC

3.Control

1.

MTR1

MTR1

MTR1

MTR1

MTR2

MTR2

MTR2

MTR2

_I B ( 0 )

2.

_I B ( 1 )

3.

_I A ( 0 )

4.

_I A ( 1 )

5.

_I A ( 0 )

6.

_I A ( 1 )

7.

_I B ( 0 )

8.

_I B ( 1 )

MOTOR_1

1

2

3

4

MOTOR_2

5

6

7

8

1.+24V

2.Control

1.DEV_I D1

2.NC

3.DEV_I D

RX

1.NC

2.S IGNAL

SIGNAL

SIGNAL

SIGNAL

3.GND_5

4.NC

TONER_

TONER_

TX

1.+5V

2.Control

3.NC

1.+5V

2.

3.GND_5

4.+5V

5.

6.GND_5

FEED

SENSOR

1

2

3

P. E M PT Y

SENSOR

4

5

6

PTL

1.+5V

2.Control

MP SOL .

1.+24V

2.Control

MP

SENSOR

1.+5V

2.

3.GND_5

1.+5V

2.+5VS

3.+24V

4.+24VS

MI CRO

SWITCH

1.+24V

2.Control

FOR LSU + 5VS CUT

REMARK

: Normal Connector

:BoardontyoeConnector

1.BLADE

2.NC

3. SU PPLY

4.NC

5.DEV

MHV

THV

1.SPK+

2.SPK

-

1

.

H

O

T

2

.

N

e

u

t

r

a

l

HEAT

LAM P( Fuser )

1

.

H

O

T

2

.

N

e

u

t

r

a

l

POWE R

SW I T CH

AC

IN-LET

110V for U SA

220V for EU

1.MODEM_RX 2. GND_12

3.MODEM_TXA1 4. MODEM_T X A2

5.+12V 6.REMOTE 7 . CML1

8.nHOOK29.nRING_DET

10.+5V 11.DP12.GND_5

13. RECALL 14. nE_DP

1. + 5V

2. HYPER_ TXD

3. HYPER_ RXD

4. GND_5

for System States viewer

Mod ul ar J A CK

Ext r na l L IN E

TEL LINE

CN14

CN11

CN2CN3CN8CN7CN5 CN29CN4

CN9

CN28

CN15

CN16

CN17

CN18

CN19

CN21

CN23

CN25 CN26 CN27

CN20

CN22

P1

CN14

CN2

CN4CN3 CN1

CN3

CN2

CN4

CN3

CN1

C0N3

C0N4 C0N2 C0N1

36pin

IEEE1284 Conn.

4pin

USB Con n.

(ONLY SCX-5312F)

(ONLY SCX-5312F)

1.+5V

2.S IGNAL

3

4. NC

.GND_5

BIN-FULL

SENSOR

1

2

3

Page 6

3

3-1

Samsung Electronics

CIRCUIT DESCRIPTION

Repair Manual

3. Circuit Description

3-1 Main PBA

3-1-1 SUMMARY

The main circuit that consists of CPU, MFP controller (built-in 32bit RISC processor core: ARM7TDMI) including various I/O

device drivers, system memory, scanner, printer, motor driver, PC I/F, and FAX transceiver controls the whole system. The

entire structure of the main circuit is as follows :

OSC

20 MHz

POWER

ON RESET

MODEM

CIP3

OSC.(Video)

45.3928 MHz

LIU

OSC.

48 MHz

USB

INTERFACE IC

(UNICON)

USB

RTC

PARALLEL

INTERFACE

OPE PANEL

INTERFACE

PROGRAM

ROM

1MB x 4EA

SRAM

256K

DATA RAM

(DRAM)

8MB x 2EA

PLL

Reset & WDT

Generation

ARM7TDMI

Cache 8KB

ROM/SRAM/

FLASH ROM

Control

(4 Bank)

I/O

Control

(5 Bank)

CPU BUS

Interface Block

GPIO

SYSTEM BUS

Interface Block

[Arbiter]

VIS

ADC

RAM : 512B

UART

(3 CH)

Interrupt

Control

(4 External)

Timer

(3 CH)

Tone

Generator

Engine

Comm. I/F

JBIG

LRAM:1296B

CXRAM:256B

RAM

512B+512B

HPVC

HCT

DMAC

(2 CH)

PPI

PVC

GEU

EDO/FPM

DRAM

Control

(4 Bank)

MA

MD

RAS

CAS

/CS,/RD,/WR

A/D BUS

IMCS

/MIR0,

/RD,/WR

D0~D7

A0~A4

RST_OUT

IOCS

/RST_OUT

/XDACK

/XDREQ

/SDIP CS

/RD,/WR

D0~D15

A0~A5

• Main B’D

<Block Diagram>

Page 7

3-2

CIRCUIT DESCRIPTION

Samsung Electronics

Repair Manual

3-2 Circuit Operation

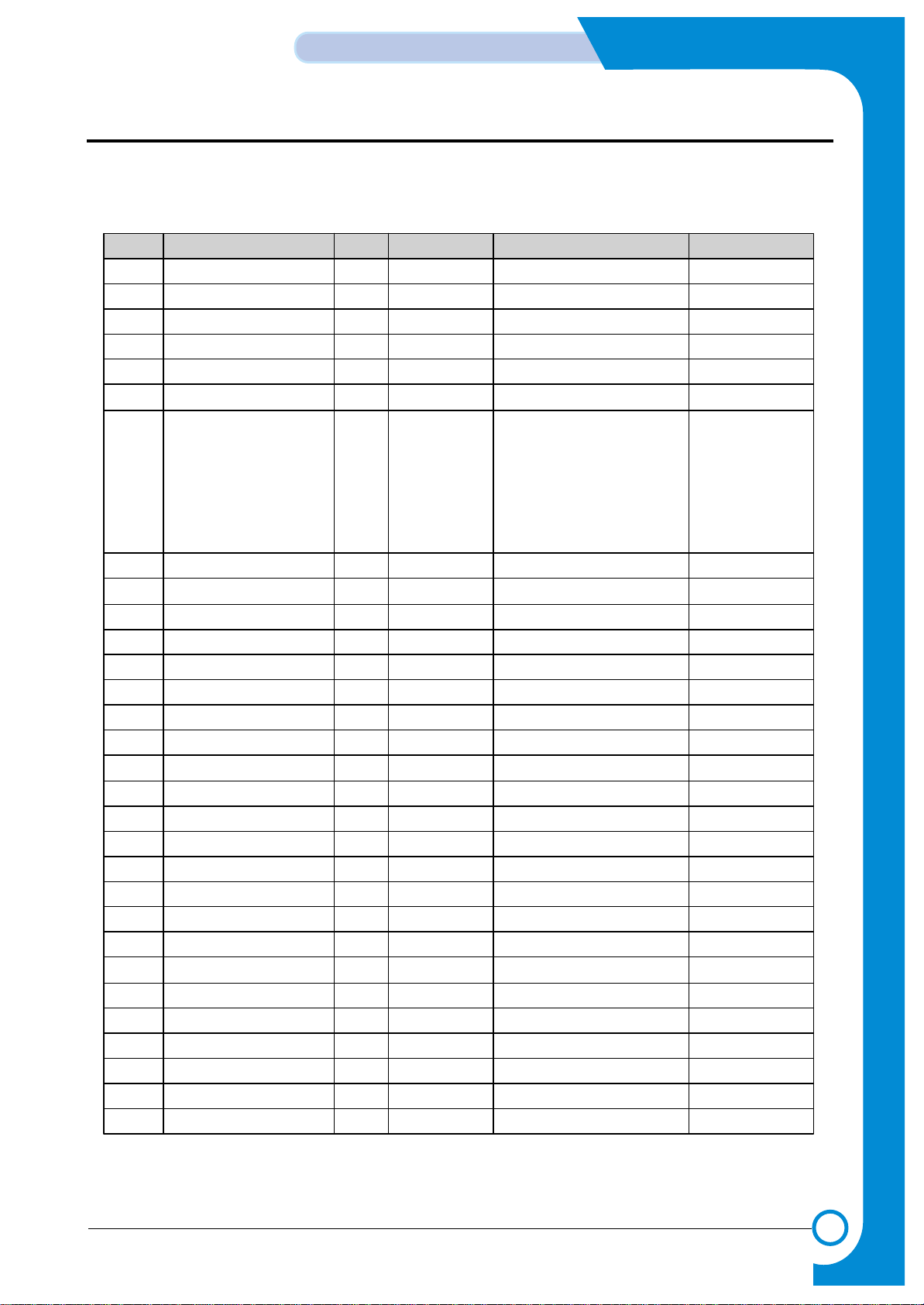

3-2-1 CLOCK

1) System Clock

• KS32C61200 RISC PROCESSOR: drives PLL internally and uses 60MHz.

2) Video Clock

• Fvd =((PAPER 1SCAN LINE sending time * SCAN effective late /1SCAN LINE DOT #)*4

=(600dpi*600dpi*58.208mm/s*216mm*4)/(25.4mm*25.4mm*76.1%)=28.697MHz

•PAPER 1SCAN LINE sending time=SCAN LINE interval/DOCUMENT SPEED (58.208mm/S)

•1SCAN LINE DOT #=MAZ SCAN distance(216mm)*DOT# per 1mm

3)USB Clock

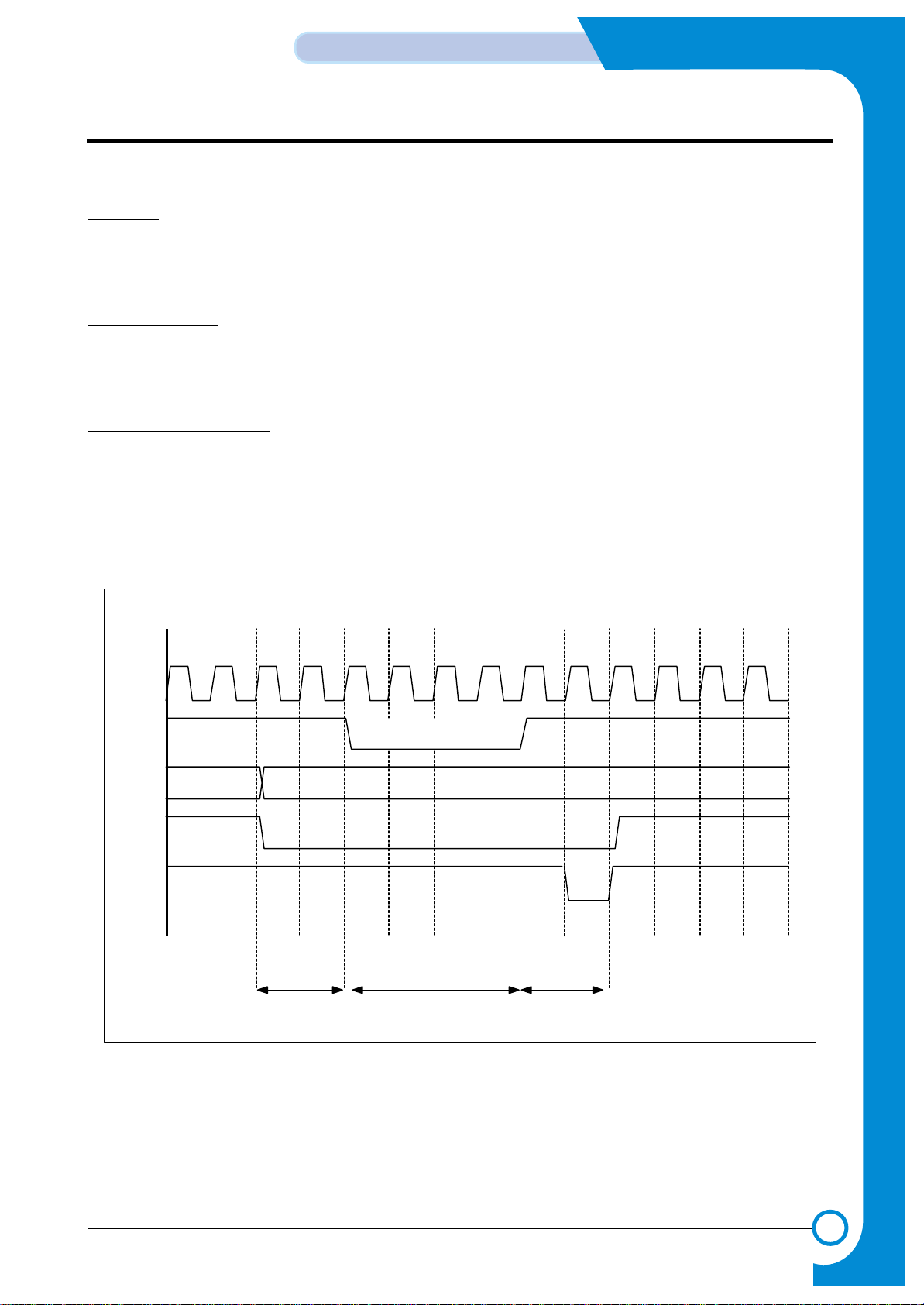

3-2-2 POWER ON/OFF RESET

1) Signal Operation

• POWER ON/OFF DETECT VCC RISING/FALLING 4.5°≠4.6V

• Td=(Ct*V sensing)/I charge (...Ct=33µF, Is=100µA)

2) TIMING CHART

Device Oscillator

Frequency 20MHz±%

Device Oscillator

Frequency 45.3928 MHz±%

Device Oscillator

Frequency 48MHz±%

Input Signal +5V Power Line (VCC)

Output Signal KS32C61200 nRESET 29F800B nRESET

RESET TIME (Td) 1.48~1.52ms

and SENSEV

CC

Threahold Voltage

V

V

CC

CC

3.6V

V

CC

2V

Output

Undefined

RESET

d

t

d

t

Output

Undefined

Page 8

3-3

Samsung Electronics

CIRCUIT DESCRIPTION

Repair Manual

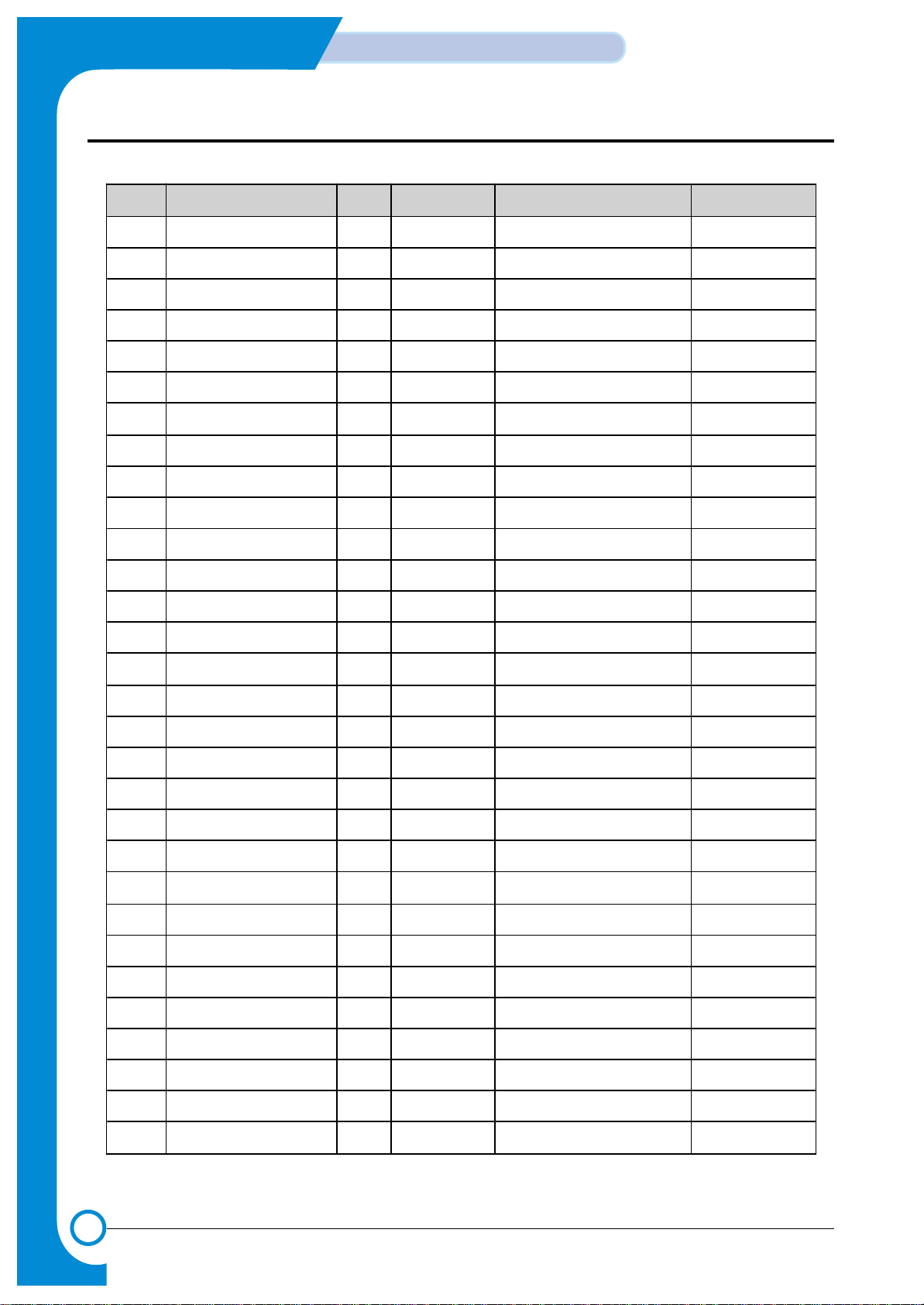

3-2-3 RISC MICROPROCESSOR

1) RISC MICROPROCESSOR PIN & INTERFACE

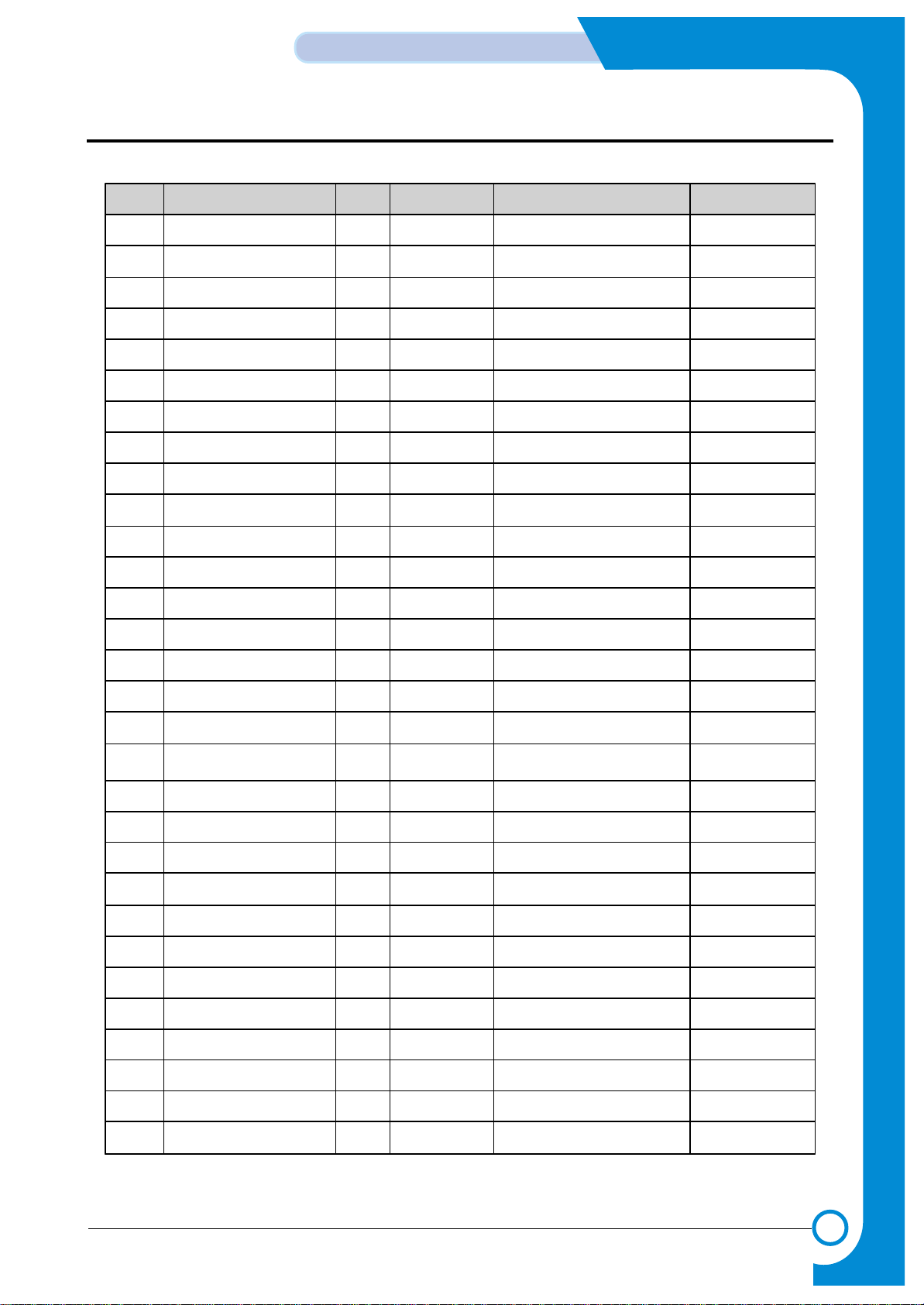

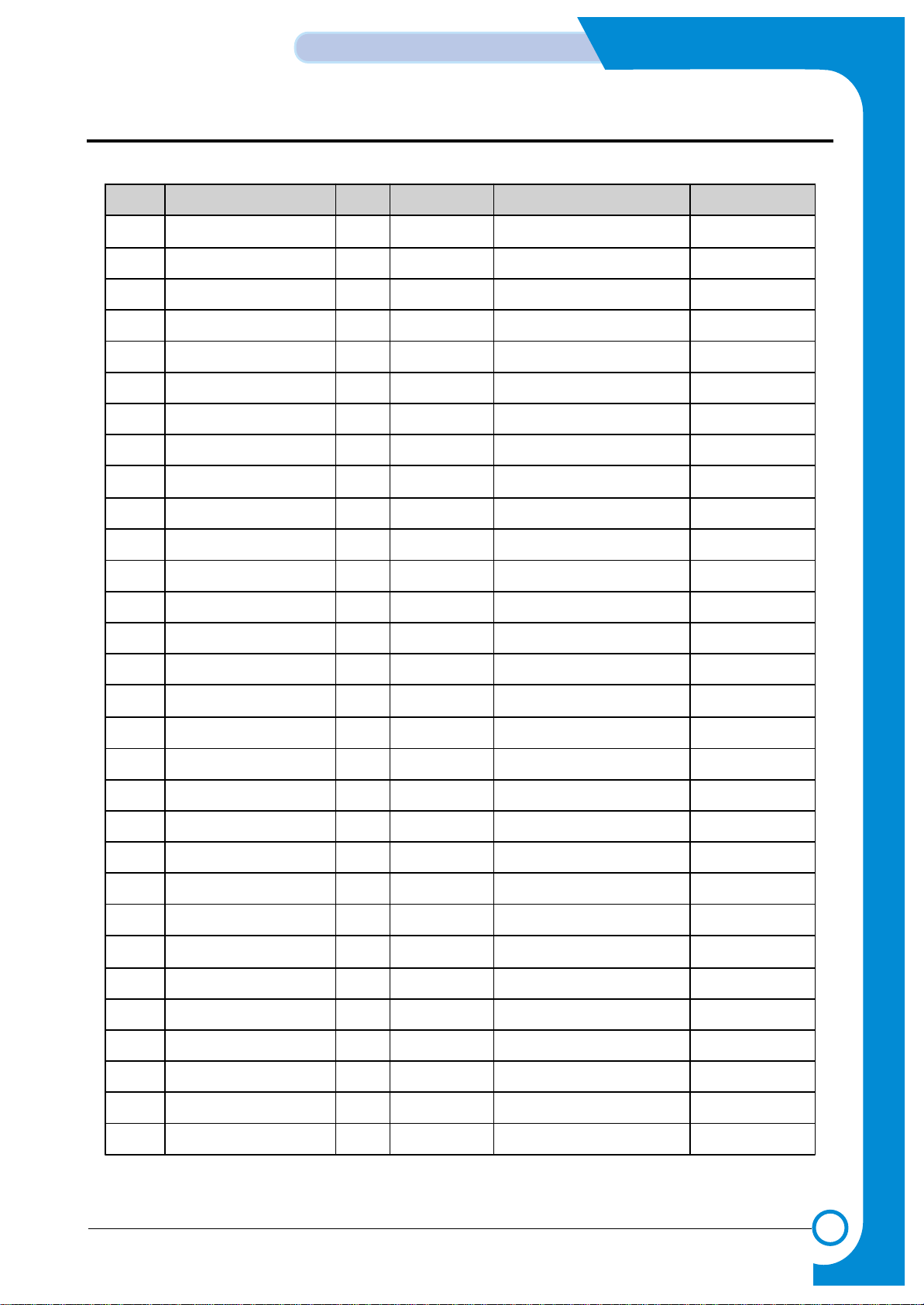

No Pin Name I/O Reset Value Description PAD

1 DATA0 I/O Input CPU Data Bus 0 PHBTT8, 8 mA

2 DATA1 I/O " CPU Data Bus 1 "

3 DATA2 I/O " CPU Data Bus 2 "

4 DATA3 I/O " CPU Data Bus 3 "

5 Vsso Vss - 5VGnd

6 DATA4 I/O Input CPU Data Bus 4 PHBTT8, 8 mA

7 Vddo Vdd - 5V

8 DATA5 I/O Input CPU Data Bus 5 PHBTT8, 8 mA

9 DATA6 I/O " CPU Data Bus 6 "

10 DATA7 I/O " CPU Data Bus 7 "

11 DATA8 I/O " CPU Data Bus 8 "

12 Vssi Vss - 3.3 V Gnd

13 DATA9 I/O Input CPU Data Bus 9 PHBTT8, 8 mA

14 Vddi Vdd 3.3 V

15 DATA10 I/O Input CPU Data Bus 10 PHBTT8, 8 mA

16 DATA11 I/O " CPU Data Bus 11 "

17 DATA12 I/O " CPU Data Bus 12 "

18 DATA13 I/O " CPU Data Bus 13 "

19 Vsso Vss - 5VGnd

20 DATA14 I/O Input CPU Data Bus 14 PHBTT8, 8 mA

21 DATA15 I/O " CPU Data Bus 15 "

22 DATA16 I/O " CPU Data Bus 16 "

23 DATA17 I/O " CPU Data Bus 17 "

24 Vsso Vss - 5VGnd

25 DATA18 I/O Input CPU Data Bus 18 PHBTT8, 8 mA

26 DATA19 I/O " CPU Data Bus 19 "

27 DATA20 I/O " CPU Data Bus 20 "

28 DATA21 I/O " CPU Data Bus 21 "

29 Vddi Vdd - 3.3 V

30 DATA22 I/O Input CPU Data Bus 22 PHBTT8, 8 mA

Page 9

3-4

CIRCUIT DESCRIPTION

Samsung Electronics

Repair Manual

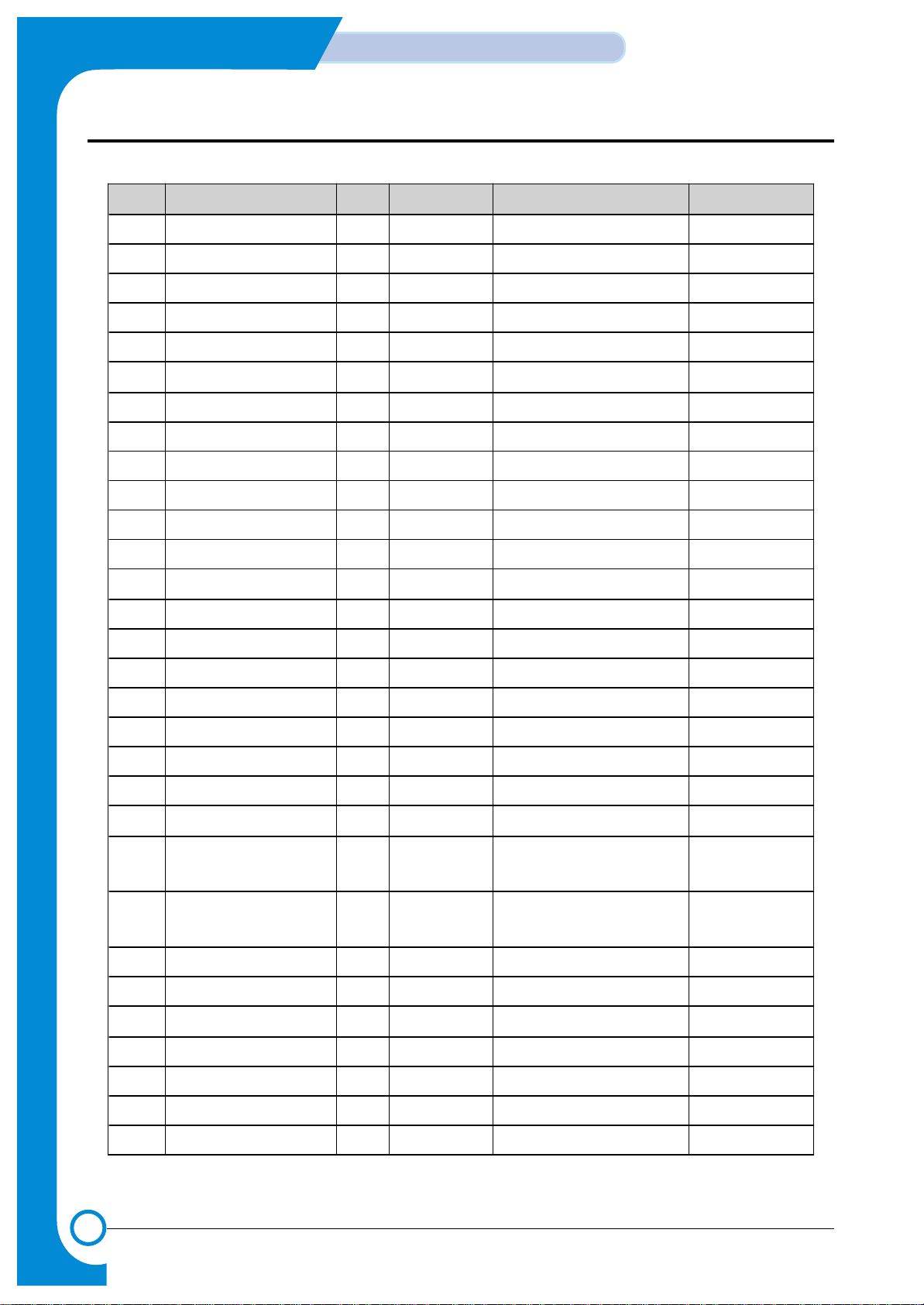

No Pin Name I/O Reset Value Description PAD

31 Vssi Vss - 3.3 V Gnd

32 DATA23 I/O Input CPU Data Bus 23 PHBTT8, 8 mA

33 DATA24 I/O " CPU Data Bus 23 "

34 Vddp Vdd - 5V

35 DATA25 I/O Input CPU Data Bus 23 PHBTT8, 8 mA

36 Vssp Vss - 5VGnd

37 DATA26 I/O Input CPU Data Bus 23 PHBTT8, 8 mA

38 DATA27 I/O " CPU Data Bus 23 "

39 Vddo Vdd - 5V

40 DATA28 I/O Input CPU Data Bus 23 PHBTT8, 8 mA

41 Vsso Vss - 5VGnd

42 DATA29 I/O Input CPU Data Bus 23 PHBTT8, 8 mA

43 DATA30 I/O " CPU Data Bus 23 "

44 DATA31 I/O " CPU Data Bus 23 "

45 Vssi Vss - 3.3 V Gnd

46 LFIA0 / OP4 O H Line Feed Motor Phase A PHOB4, 4mA

47 Vddi Vdd - 3.3 V

48 LFIA1 / OP5 O H Line Feed Motor Phase /A PHOB4, 4mA

49 LFIB0 / OP6 O " Line Feed Motor Phase B "

50 LFIB1 / OP7 O " Line Feed Motor Phase /B "

51 TnRST I TAP Controller Reset PHIT

52 TMS I TAP Controller Mode Sel PHIT

53 TDI I TAP Controller Data In "

54 TCK I TAP Controller Clock "

55 TDO O TAP Controller Data Out PHOB4

56 AVdd Vcca - Analog 3.3 V

57 AVin[0] I - Analog Input 0 PICA

58 AVin[1] I - Analog Input 1 "

59 AVss Vssa - Analog Gnd

60 AVssAVin[2] I - Analog Input 2 PICA

Page 10

3-5

Samsung Electronics

CIRCUIT DESCRIPTION

Repair Manual

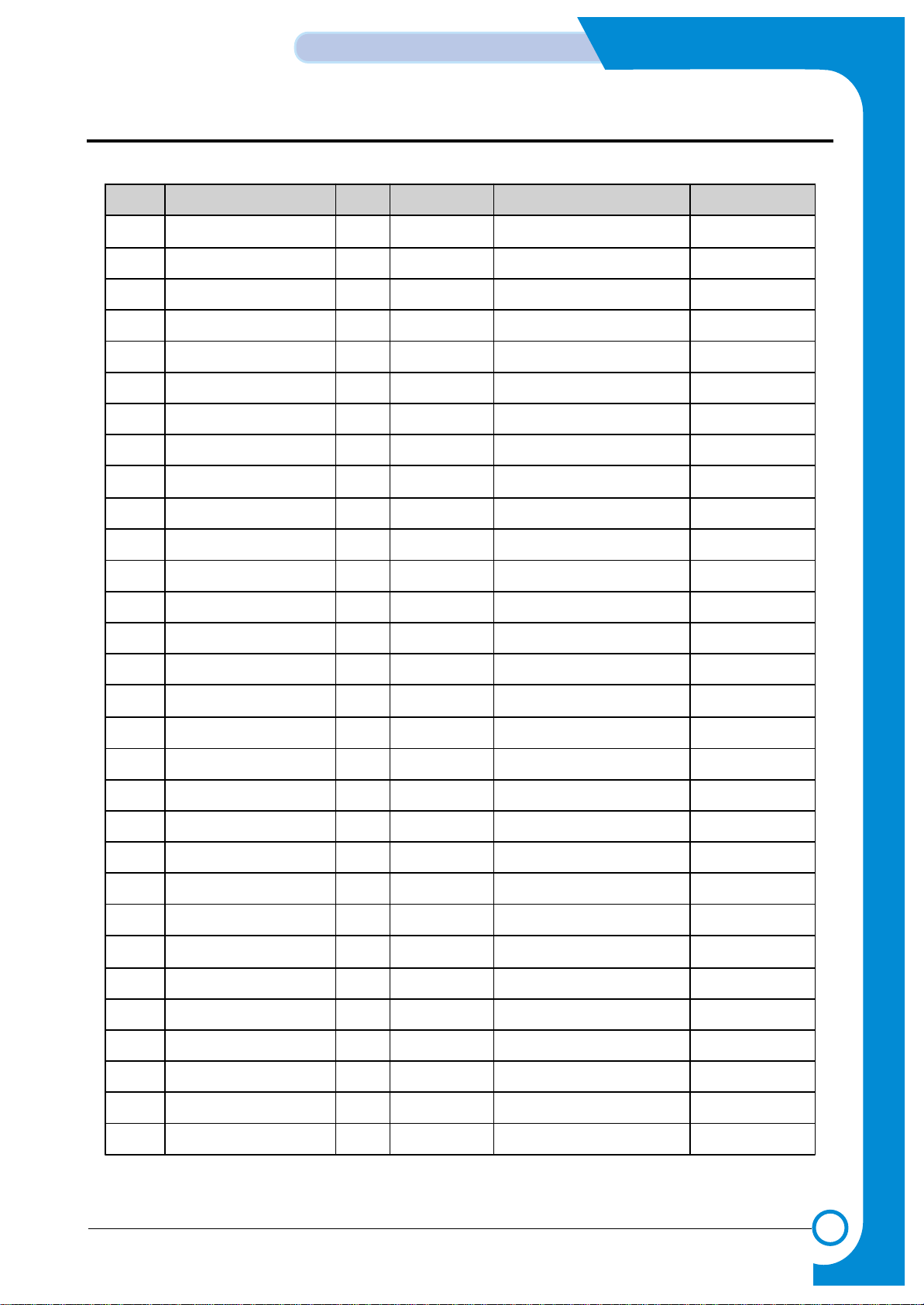

No Pin Name I/O Reset Value Description PAD

61 AVref I - Analog Positve Reference PICA

62 nIOCS0 O H IO Chipselect 0 PHOB4, 4 mA

63 nIO CS2/ToneOut O " IO Chipselect 2 / ToneOut "

64 nIOCS3/BufferSel O " IO Chipselect 2 / BufferSel "

65 Vssi Vss - 3.3 V Gnd

66 nSELECTIN I - Select Input PHIL, ST

67 nFAULT O H Fault for Error Condition PHOB8, 8 mA

68 nAUTOFD I - Auto Feed PHIL, ST

69 nINIT I - Initialization "

70 SELECT O L Parallel Port Select PHOB8, 8 mA

71 Vddp Vdd - 5V

72 PERROR O L Paper Error PHOB8, 8 mA

73 BUSY O " Parallel Port Busy PHOB8, 8 mA

74 nACK O H Parallel Port Acknowledge PHOB8, 8 mA

75 Vssp Vss - 5VGnd

76 PD0 I/O Input Parallel Port Data 0 PHBTT8, 8 mA

77 PD1 I/O " Parallel Port Dat a "

78 Vddi Vcca - 3.3 V f or Ring OSC

79 PD2 I/O Input Parallel Port Dat a PHBTT8, 8 mA

80 PD3 I/O " Parallel Port Dat a "

81 Vssi Vssa - 3.3 V Gnd for Ring OSC

82 PD4 I/O Input Parallel Port Dat a PHBTT8, 8 mA

83 PD5 I/O " Parallel Port Dat a "

84 Vddo Vdd - 5V

85 PD6 I/O Input Parallel Port Dat a PHBTT8, 8 mA

86 PD7 I/O " Parallel Port Dat a "

87 nSTROBE I - Data Strobe PHIL, ST

88 Vsso Vss - 5VGnd

89 RxD1 / CTin[2] I - Uart 1 Rx Data PHIL, ST

90 TxD1 O H Uart 1 Tx Data PHOB4, 4 mA

Page 11

3-6

CIRCUIT DESCRIPTION

Samsung Electronics

Repair Manual

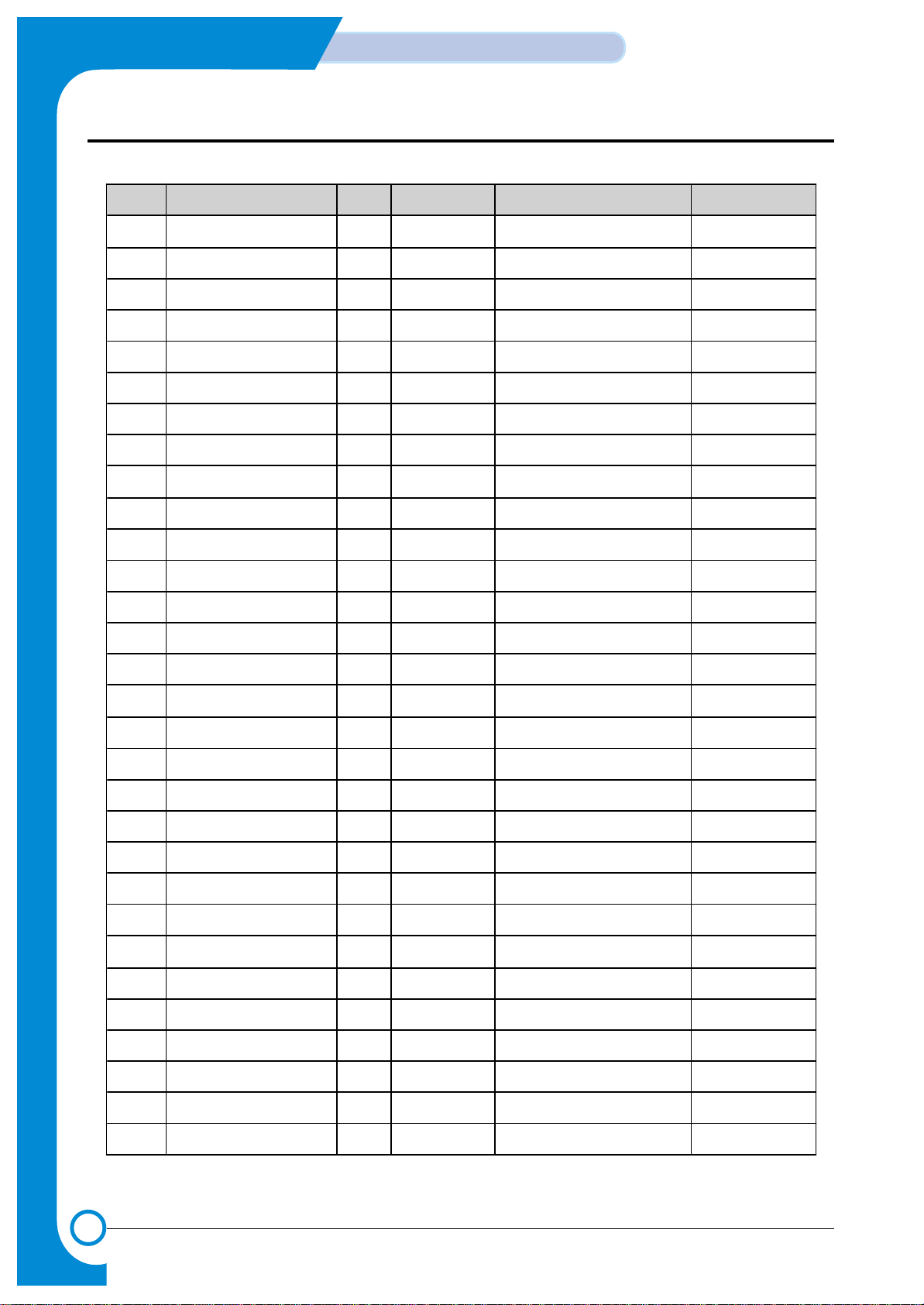

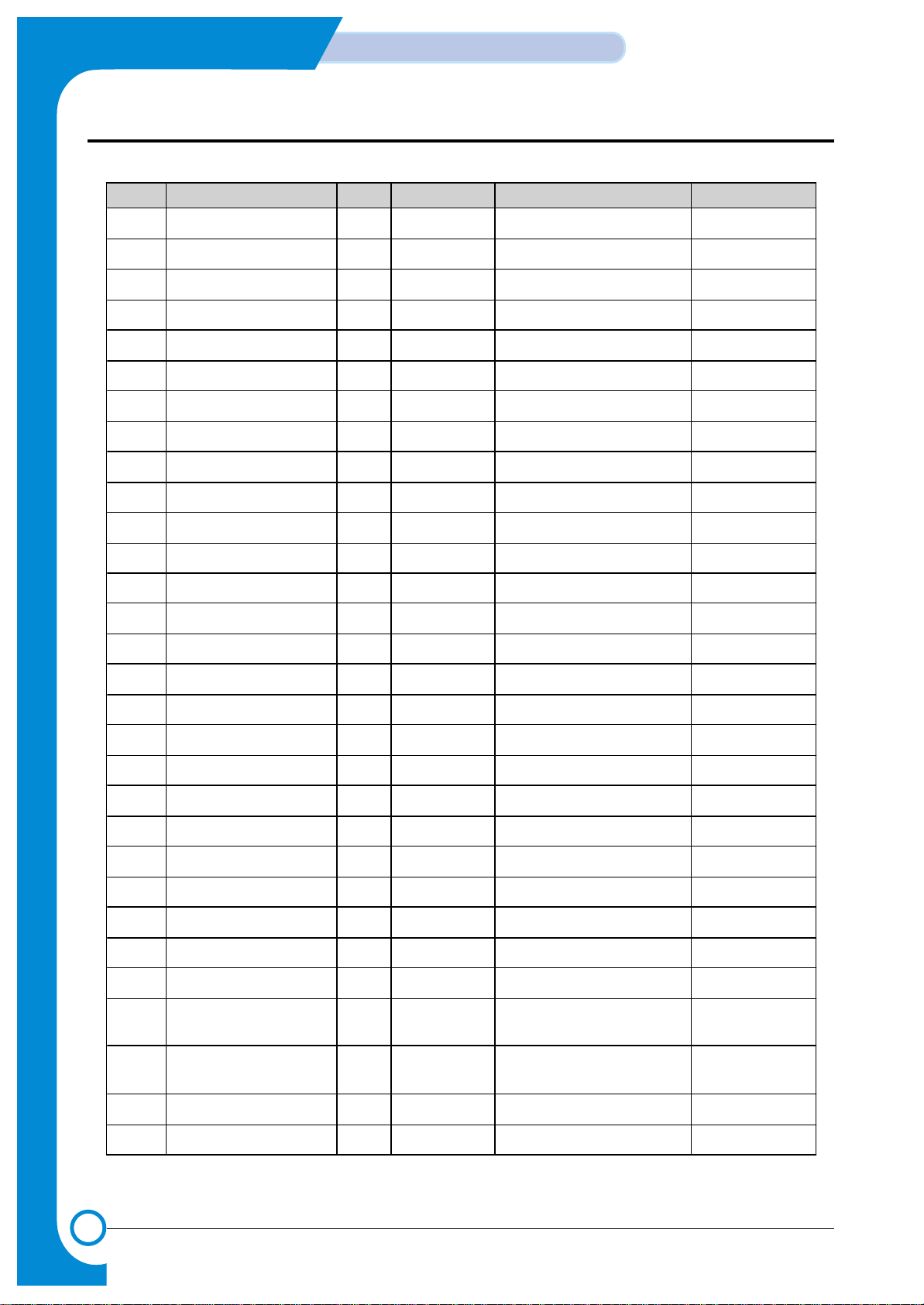

No Pin Name I/O Reset Value Description PAD

91 nDREQ1/RxD2/CTin[1] I - DMA Request1/Uart 2 RxD PHIL, ST

92 nDMACK1 / TxD2 O H DMA Ack1/Uart 2 TxD PHOB4, 4 mA

93 nIOCS1 / nIOCS5 O " IO CS1 / DMA IO1 CS "

94 Vddi Vdd - 3.3 V

95 nDREQ0 /IP1/CTin[0] I - DMA Request0 / Input Port PHIL, ST

96 nDMACK0 / OP1 O H DMA Ack1 / Out Port PHOB4, 4 mA

97 nIO CS4 / O P2 O " DMA IO0 CS / Out Port "

98 EIRQ0 I - External Interrupt 0 PHILU50, ST

99 EIRQ1 I - External Interrupt 1 "

100 EIRQ2 I - External Interrupt 2 "

101 nWait/EIRQ3 I - Wait Request / Ex. IRQ 3 "

102 Vssi Vss - 3.3 V Gnd

103 VCLK I - Video Clock Input PHIC

104 Vddi Vdd - 3.3 V

105 IP[7] / nFSYNC I - Input Port / Frame Sync PHIL, ST

106 nLSYNC I - Line Sync "

107 OP[8] / nPRINT O H OutPort/PrintStart PHOB4, 4 mA

108 Vssi Vss - 3.3 V Gnd

109 VDO O H Video Data Output PHO B16, 16mA

110 Vsso Vss - 5VGnd

111 CCLK / PWM[0] O H Com. Clock / PWM [0] PHOB4, 4 mA

112 nEPRDY / RxD0 I -

Engine Power Ready

/Uart0RxData

PHIL, ST

113 nCBSY / TxD0 O H

Command Busy

/Uart0TxData

PHOB4, 4 mA

114 nEMSG / PWM[1] I/O Input Eng. Message / PWM [1] PHBLT4,ST,4mA

115 nEBSY / nLsuReady I - Eng. Busy / LSU Ready PHIL, ST

116 nCMSG / PWM[ 2] O H Com. Busy / PWM [2] PHOB4, 4 mA

117 Vddo Vdd - 5V

118 nDRAMCAS0 O L DRAM Cas Strobe 0 PHOB8, 8 mA

119 nDRAMCAS1 O " DRAM Cas Strobe 1 "

120 nDRAMCAS2 O " DRAM Cas Strobe 2 "

Page 12

3-7

Samsung Electronics

CIRCUIT DESCRIPTION

Repair Manual

No Pin Name I/O Reset Value Description PAD

121 nDRAMCAS3 O L DRAM Cas Strobe 3 PHOB8, 8 mA

122 Vsso Vss - 5VGnd

123 nDRAMOE O H DRAM Data Out Enable "

124 nDRAMWE O H DRAM Data Write Enable "

125 Vssi Vss - 3.3 V Gnd

126 nDRAMRAS0 O L DRAM Ras Strobe 0 PHOB8, 8 mA

127 Vddi Vdd - 3.3 V

128 nDRAMRAS1 O L DRAM Ras Strobe 1 PHOB8, 8 mA

129 nDRAMRAS2 O " DRAM Ras Strobe 2 "

130 nDRAMRAS3 O " DRAM Ras Strobe 3 "

131 Vsso Vss - 5VGnd

132 DRAMD0 I/O Input DRAM Data Bus 0 PHBTT12, 12mA

133 Vddo Vdd - 5V

134 DRAMD1 I/O Input DRAM Data Bus 1 PHBTT12, 12mA

135 DRAMD2 I/O " DRAM Data Bus 2 "

136 DRAMD3 I/O " DRAM Data Bus 3 "

137 DRAMD4 I/O " DRAM Data Bus 4 "

138 Vsso Vss - 5VGnd

139 DRAMD5 I/O Input DRAM Data Bus 5 PHBTT12, 12mA

140 DRAMD6 I/O " DRAM Data Bus 6 "

141 DRAMD7 I/O " DRAM Data Bus 7 "

142 Vssi Vss - 3.3 V Gnd

143 DRAMD8 I/O Input DRAM Data Bus 8 PHBTT12, 12mA

144 Vddi Vdd - 3.3 V

145 DRAMD9 I/O Input DRAM Data Bus 9 PHBTT12, 12mA

146 DRAMD10 I/O " DRAM Data Bus 10 "

147 DRAMD11 I/O " DRAM Data Bus 11 "

148 Vssp Vss - 5VGnd

149 DRAMD12 I/O Input DRAM Data Bus 12 PHBTT12, 12mA

150 Vddp Vdd - 5V

Page 13

3-8

CIRCUIT DESCRIPTION

Samsung Electronics

Repair Manual

No Pin Name I/O Reset Value Description PAD

151 DRAMD13 I/O Input DRAM Data Bus 13 PHBTT12, 12mA

152 DRAMD14 I/O " DRAM Data Bus 14 "

153 DRAMD15 I/O " DRAM Data Bus 15 "

154 DRAMD16 I/O " DRAM Data Bus 16 "

155 Vsso Vss - 5VGnd

156 DRAMD17 I/O Input DRAM Data Bus 17 PHBTT12, 12mA

157 Vddo Vdd - 5V

158 DRAMD18 I/O Input DRAM Data Bus 18 PHBTT12, 12mA

159 DRAMD19 I/O " DRAM Data Bus 19 "

160 DRAMD20 I/O " DRAM Data Bus 20 "

161 DRAMD21 I/O " DRAM Data Bus 21 "

162 Vssi Vss - 3.3 V Gnd

163 DRAMD22 I/O Input DRAM Data Bus 22 PHBTT12, 12mA

164 Vddi Vdd - 3.3 V

165 DRAMD23 I/O Input DRAM Data Bus 23 PHBTT12, 12mA

166 DRAMD24 I/O " DRAM Data Bus 24 "

167 DRAMD25 I/O " DRAM Data Bus 25 "

168 DRAMD26 I/O " DRAM Data Bus 26 "

169 Vsso Vss - 5VGnd

170 DRAMD27 I/O Input DRAM Data Bus 27 PHBTT12, 12mA

171 Vddo Vdd - 5V

172 DRAMD28 I/O Input DRAM Data Bus 28 PHBTT12, 12mA

173 DRAMD29 I/O " DRAM Data Bus 29 "

174 DRAMD30 I/O " DRAM Data Bus 30 "

175 DRAMD31 I/O " DRAM Data Bus 31 "

176 Vsso Vss - 5VGnd

177 DRAMA0 O L DRAM Address Bus 0 PHOB8, 8 mA

178 DRAMA1 O " DRAM Address Bus 1 "

179 DRAMA2 O " DRAM Address Bus 2 "

180 DRAMA3 O " DRAM Address Bus 3 "

Page 14

3-9

Samsung Electronics

CIRCUIT DESCRIPTION

Repair Manual

No Pin Name I/O Reset Value Description PAD

181 DRAMA4 O L DRAM Address Bus 4 PHOB8, 8 mA

182 Vsso Vss - 5VGnd

183 DRAMA5 O " DRAM Address Bus 5 "

184 DRAMA6 O " DRAM Address Bus 6 "

185 DRAMA7 O " DRAM Address Bus 7 "

186 Vddo Vdd - 5V

187 DRAMA8 O L DRAM Address Bus 8 PHOB8, 8 mA

188 Vsso Vss - 5VGnd

189 DRAMA9 O L DRAM Address Bus 9 PHOB8, 8 mA

190 DRAMA10 O " DRAM Address Bus 10 "

191 DRAMA11 O " DRAM Address Bus 11 "

192 Vssi Vss - 3.3 V Gnd

193 nROMCS0 O H ROM Chip Select 0 PHOB4, 4 mA

194 Vddi Vdd - 3.3 V

195 nROMCS1 O H ROM Chip Select 1 PHOB4, 4 mA

196 nROMCS2 O " ROM Chip Select 2 "

197 nROMCS3 O " ROM Chip Select 3 "

198 nROMRD O " ROMorIORead PHOB8, 8 mA

199 Vssp Vss - 5VGnd

200 nROMWR O H ROMorIOWrite PHOB8, 8 mA

201 Vddp Vdd - 5V

202 ADDR2 O L Address Bus 2 for ROM PHOB8, 8 mA

203 ADDR3 O " Address Bus 3 f or ROM "

204 ADDR4 O " Address Bus 4 f or ROM "

205 Vsso Vss - 5VGnd

206 ADDR5 O L Address Bus 5 for ROM PHOB8, 8 mA

207 ADDR6 O " Address Bus 6 f or ROM "

208 ADDR7 O " Address Bus 7 f or ROM "

209 Vssi Vss - 3.3 V Gnd

210 ADDR8 O L Address Bus 8 for ROM PHOB8, 8 mA

Page 15

3-10

CIRCUIT DESCRIPTION

Samsung Electronics

Repair Manual

No Pin Name I/O Reset Value Description PAD

211 ADDR9 O L Address Bus 9 for ROM PHOB8, 8 mA

212 Vddo Vdd - 5V

213 ADDR10 O L Address Bus 10 for RO M PHOB8, 8 mA

214 Vsso Vss - 5VGnd

215 ADDR11 O L Address Bus 11 for RO M PHOB8, 8 mA

216 ADDR12 O " Address Bus 12 for RO M "

217 ADDR13 O " Address Bus 13 for RO M "

218 ADDR14 O " Address Bus 14 for RO M "

219 Vsso Vss - 5VGnd

220 ADDR15/CTO ut[0] O L Address Bus 15 for RO M PHOB8, 8 mA

221 ADDR16/CTO ut[1] O " Address Bus 16 for ROM "

222 ADDR17/CTO ut[2] O " Address Bus 17 for ROM "

223 ADDR18/CTO ut[3] O " Address Bus 18 for ROM "

224 Vsso Vss - 5VGnd

225 ADDR19/CTO ut[4] O L Address Bus 19 for RO M PHOB8, 8 mA

226 ADDR20/CTO ut[5] O " Address Bus 20 for ROM "

227 ADDR21/CTO ut[6] O " Address Bus 21 for ROM "

228 ADDR22/CTO ut[7] O " Address Bus 22 for ROM "

229 Vddo Vdd - 5V

230 ADDR23/PTOut O L Address Bus 23 for RO M PHOB8, 8 mA

231 Vsso Vss - 5VGnd

232 TESTSE I - Scan Enable :Tied to Gnd PHILD50, ST

233 TM I - TestMode:TiedtoGnd "

234 Vddi Vcca - 3.3 V for PLL

235 MCLK I - Master Clock PHIC

236 Vssi Vssa - 3.3 V Gnd for PLL

237 FILTER O -

Charge Pump Out :

Capacitor is connected

POBA

238 CPUTEST I -

CPU Test Mode :

Tied to Gnd

PHILD50, ST

239 nRESET I - Reset Input PHIL, ST

240 nRSTOUT O L Reset Output PHOB8, 8 mA

Page 16

3-11

Samsung Electronics

CIRCUIT DESCRIPTION

Repair Manual

3-2-4 PROGRAM ROM (FLASH MEMORY) CONTROL

1) DEVICE

TYPE No...................................AM29F800B

CAPACITY................................4 MBYTE (512K * 16BITS * 4)

2) PROGRAMMING

BEFORE ASS’Y.......................EPROM PROGRAMMER or PROGRAMMING at the factory

AFTER ASS’Y..........................DOWNLOAD from PC

3) OPERA

TING PRINCIPLE

When the RCSO(ROM CHIP SELECT)signal is activated from the CPU after the POWER is ON, it activates RD SIGNAL

and reads the DATA(HIGH/LOW) stored in the FLASH MEMORY to control the overall system.

The FLASH MEMORY may also write. When turning the power on, press and hold the key(power switch) for 2 - 3 seconds,

then the LED will scroll and the PROGRAM DOWNLOAD MODE will be activated. In this mode, you can download the program through the parallel port.

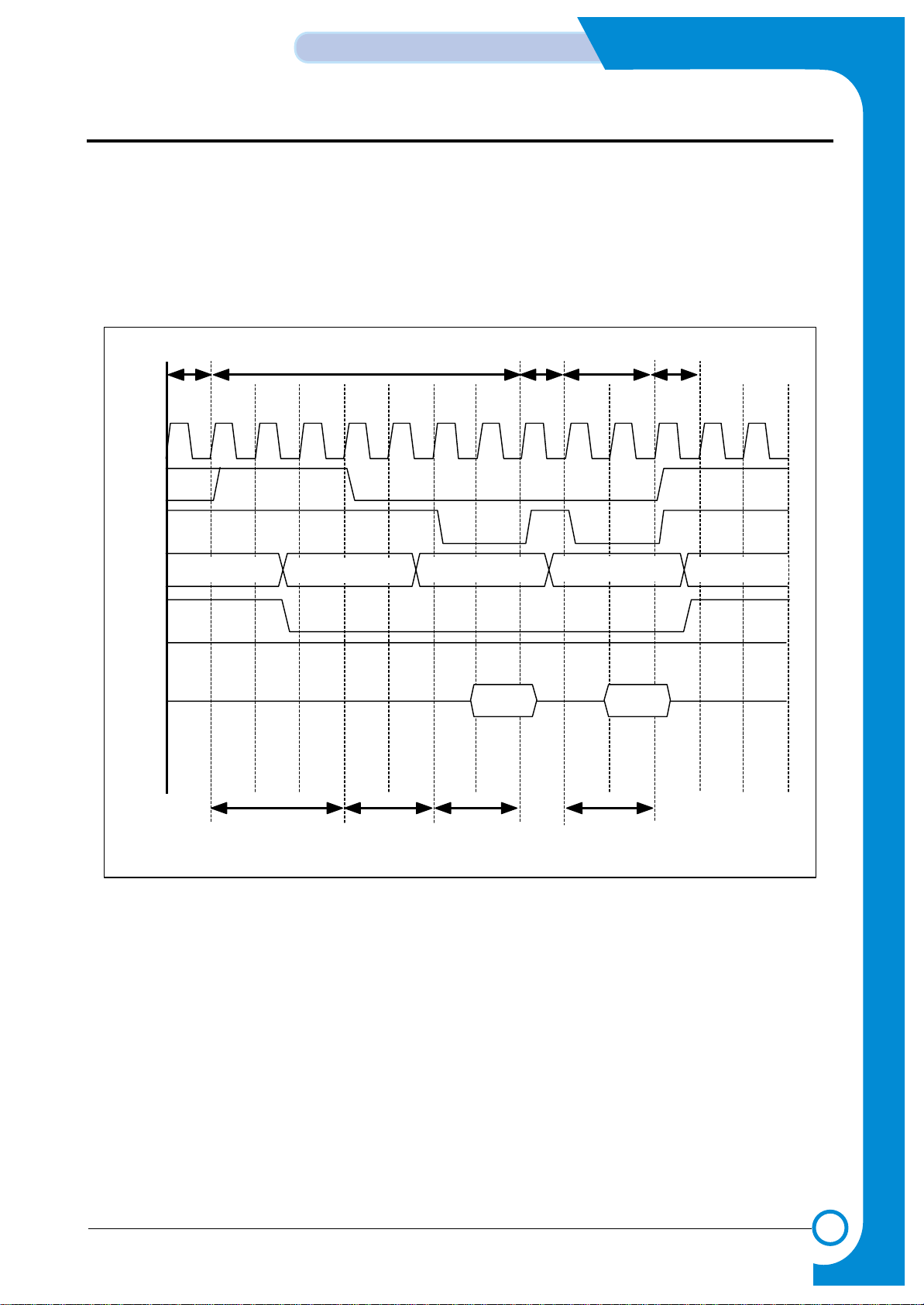

Tr TwTwTwTwTwTwTw TrTrTrTrTdTa

MCLK

nROMCS

A23-2

nTA

ACC+1

HOLD

SETUP

nWR

<Write Timing Diagram for Two Beat Burst Cycle>

Page 17

3-12

CIRCUIT DESCRIPTION

Samsung Electronics

Repair Manual

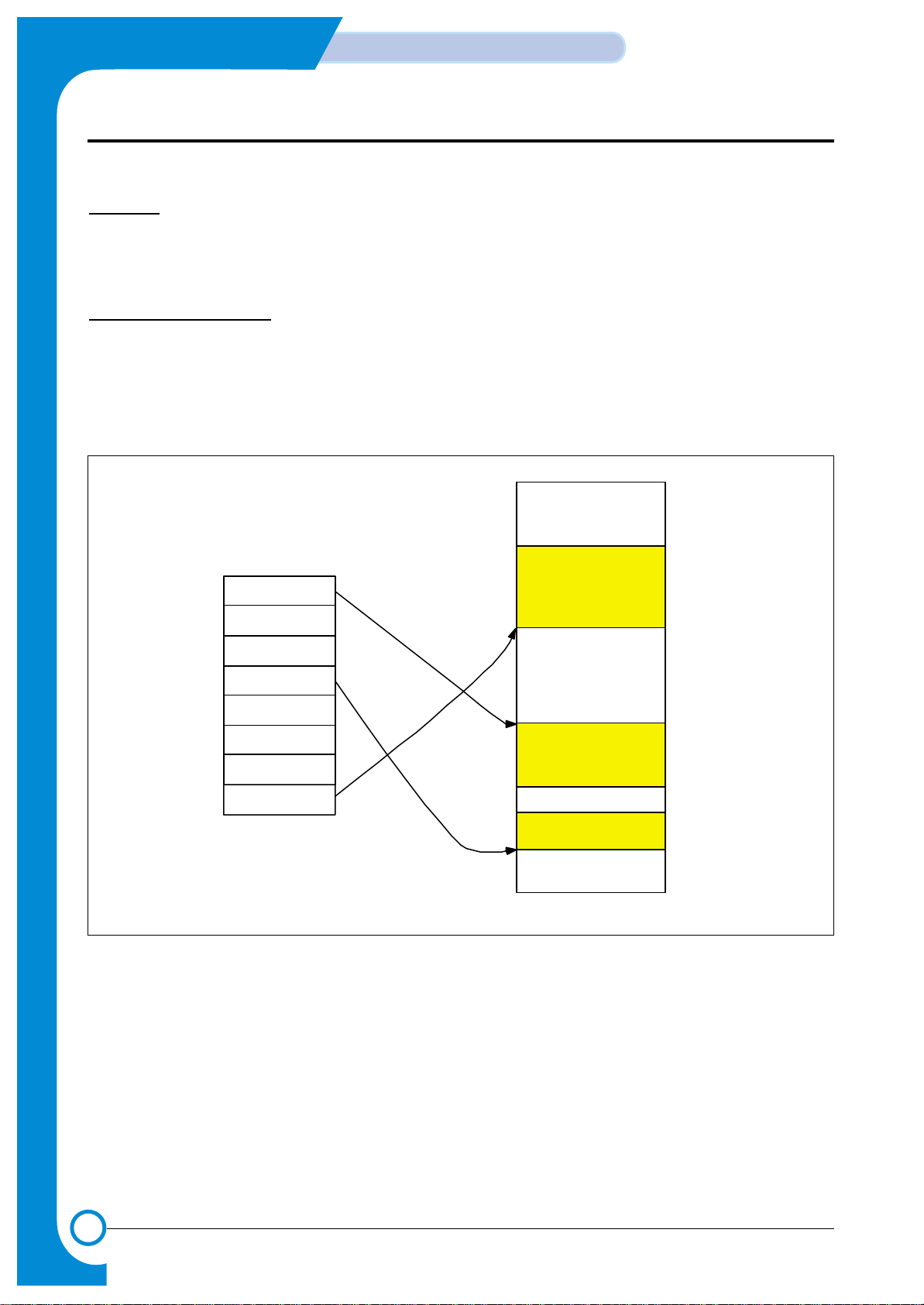

3-2-5 DRAM CONTROL

1) DEVICE

TYPE NO..................................K4E6411D EDO TYPE

CAPACITY................................4MBYTES (1M*16BITS*2)

2) OPERATING PRINCIPLE

DRAM can either read or write. The data can be stored in the DRAM only when the power is on. It stores data white the CPU

processes data. The address to read and write the data is specified by RAS SIGNALand CAS SIGNAL. DRAMWE*SIGNAL

is activated when writing data and DRAMOE*SIGNAL, when reading. You can expand up to 64MBYTE of DRAM in this system.

0x00

000

00

0xf f f ff f f

bank3 Next

bank3 Base

bank2 Next

bank2 Base

bank1 Next

bank1 Base

bank0 Next

bank0 Base

<DRAM Bank Configuration>

Page 18

3-13

Samsung Electronics

CIRCUIT DESCRIPTION

Repair Manual

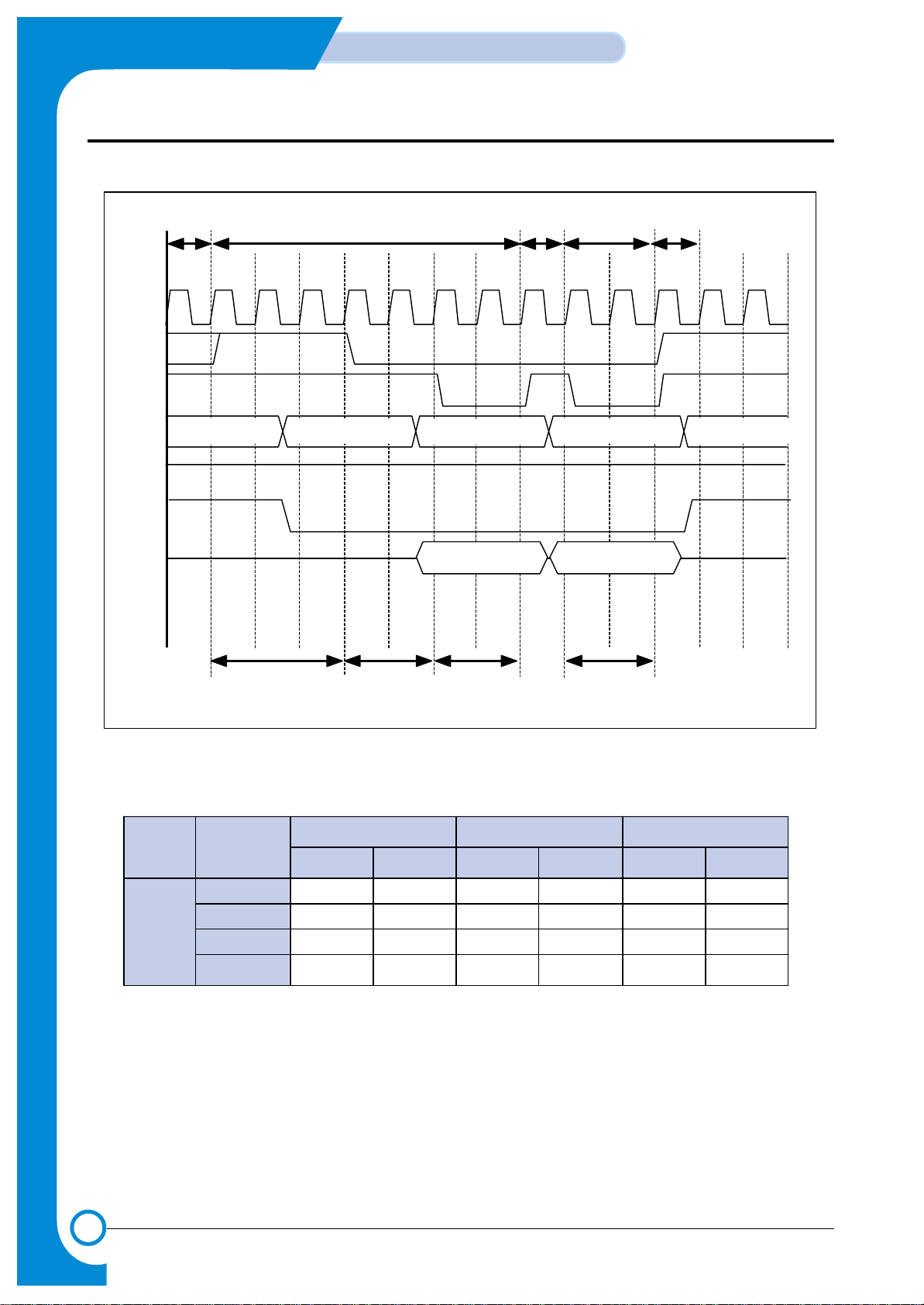

3-2-5-1 Fpm DRAM reading Timing

Fast Page Mode DRAM can access the page mode. It can read consecutive cells by accessing the page mode while accessing the burst. For FPM DRAM, the data are valid only when the nCAS is active.

While configuring the software, you must set the timing register of SFR considering the clock speed and the DRAM spec.

5Mhz

MCLK

DRAMD

nWE

nOE

DRAMA

nCAS

nRAS

Tr p Trc

Tcas

Tcas

data 1data 0

row address

column address

column address

addr

wait waitdata

data

<FPM Read Timing Diagram>

Page 19

3-14

CIRCUIT DESCRIPTION

Samsung Electronics

Repair Manual

3-2-5-2 fpm DRAM write timing

5Mhz

MCLK

DRAMD

nWE

nOE

DRAMA

nCAS

nRAS

Trp Trc Tc as Tcas

data 1

data 0

row address

column address

column address

addr

wait waitdata

data

clock

type

Trp Trc Tcas

cycle

#

register cycle

#

register cycle

#

register

58Mhz

40 ns FPM 2 0x1 2 0x1 1 0x0

50 ns FPM 2 0x1 2 0x1 1 0x0

60 ns FPM 3 0x2 2 0x1 2 0x1

70 ns FPM 3 0x2 2 0x1 2 0x1

<FPM Write Timing Diagram>

<SFR Values Example for FPM>

Page 20

3-15

Samsung Electronics

CIRCUIT DESCRIPTION

Repair Manual

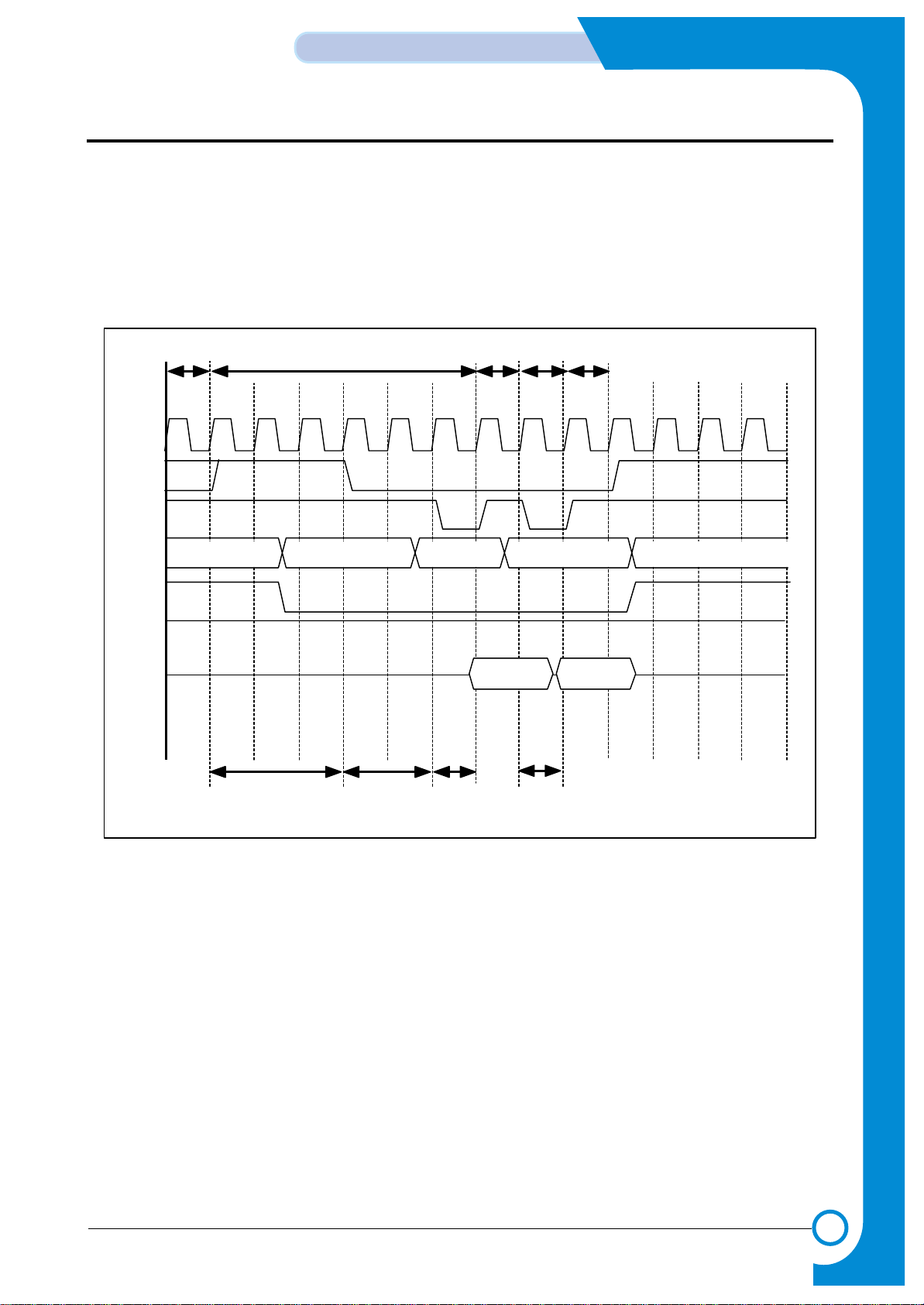

3-2-5-3 EDO DRAM read timing

Basically the Extended Data Out DRAM is similar to Fast Page Mode DRAM. For FPM, the data are valid only when the

nCAS is active while reading the internal data, however, it has a latch that the data will be

continuously outputted even after the nCAS is inactivated.

While configuring the software, you must set the timing register of SFR considering the clock speed and the DRAM spec.

5Mhz

MCLK

DRAMD

nWE

nOE

DRAMA

nCAS

nRAS

data 1

data0

row address

column

Trp

Trc Tc as

Tcas

addr

wait

wait

data

data

column

<EDO Read Timing Diagram>

Page 21

3-16

CIRCUIT DESCRIPTION

Samsung Electronics

Repair Manual

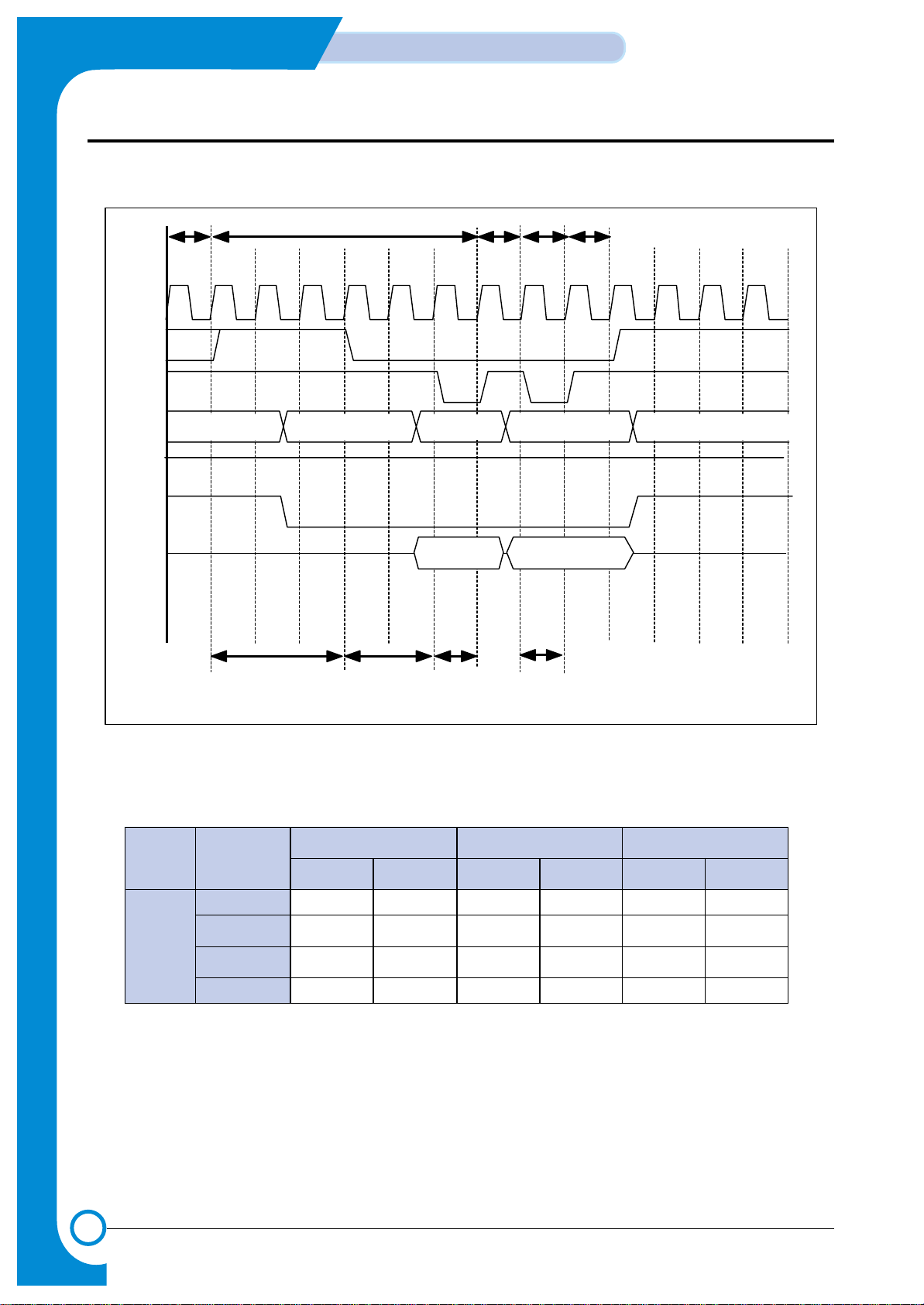

3-2-5-4 edo DRAM write timing

5Mhz

MCLK

DRAMD

nWE

nOE

DRAMA

nCAS

nRAS

data 1data 0

row address

column

Trp

Trc

Tcas

Tcas

addr

wait

wait

data

data

clock

type

Trp Trc Tcas

cycl e

#

register cycle

#

register cy cle

#

register

58Mhz

40 ns EDO 2 0x1 2 0x1 1 0x0

50 ns EDO 2 0x1 2 0x1 1 0x0

60 ns EDO 3 0x2 2 0x1 1 0x0

70 ns EDO 3 0x2 2 0x1 2 0x1

column

<FPM Write Timing Diagram>

<SFR Values Example for FPM>

Page 22

3-17

Samsung Electronics

CIRCUIT DESCRIPTION

Repair Manual

3-2-6 FS781 (FREQUENCY ATTENUATOR)

This system used FS781 for the main clock for EMI SUPPRESSION.

It spreads the source clock in a consistent bandwidth to disperse the energy gathered in order to attenuate the energy.

The capacitor value of the loop filter(PIN 4) is set depending on the source clock used or the spread bandwidth. Refer to

FS781 Spec. for detail.

3-2-7 USB (UNIVERSAL SERIAL BUS)

NS’s USBN9602 is used as the interface IC and 48MHz clock is used.

When the data is received through the USB port, EIRQ1 SIGNAL is activated to send interrupt to CPU, then it directly sends

the data to DRAM by IOCS4*&DRAMA(11) SIGNAL through DRAMD (24;31).

3-2-8 SRAM; 32KB SRAM

It stores a variety of option data.

3-2-9 FAX TRANSCEIVER (Only SCX-5312F)

3-2-9-1. GENERAL

This circuit processes transmission signals of modem and between LIU and modem.

3-2-9-2. MODEM (u44)

FM336 is a single ship fax modem. It has functions of DTMF detection and DTMF signal production as well as functions of

modem. TX A1, 2 is transmission output port and RX IN is received data input port. / POR signal controlled by MFPcontroller

(U36:KS32C61200) can initialize modem (nMODEM_RST) without turning off the system.

D0-D7 are 8-bit data buses. RS0-RS4 signals to select the register in modem chips. /RS and /WR signals control READ and

WRITE respectively. /IRQ is a signal for modem interrupt.

Transmission speed of FM336 is supported up to 33.6k. The modem is connected to LINE through transformer directly.

< FAX TRANSCEIVER >

Page 23

3-18

CIRCUIT DESCRIPTION

Samsung Electronics

Repair Manual

3-3 Scanner

3-3-1 SUMMARY

This flat-bed type device to read manuscripts has 600dpi CCD as an image sensor. There is one optical sensor for detecting

CCD home position and Scan-end position. The home position is detected by a optical sensor which is attached to the CCD

Module. The Scan-end position is calculated by number of motor step.

CCD

: Charge Coupled Device improves productivity and allows a compact design.

This machine uses a color CCD.

• Minimum Scan Line Time for One Color : 5mS

• Light Source Power : +12V

• Maximum Pixel frequency : 6 MHz

• Effective Sensor Element : 5340 X 3

• Clamp Level : 0.7~0.8V

• Bright Output : MIN 0.8V

IRQ

[AFE]

12-bit

A/ D c onverter

Shading

Correctio n

Enlargement

/ Reduction

SRA M

8192x8

(2line)

Image

Processing

Module

DMA

Int e rfac e

CIP3

Register

CPU I/F

Module

Vp ea k

Cont ro l

Motor

Con tro l

AIN

AD C_REF T

ADC_REFB

PI_TG

PI 1

R_L ED,

G_LED,

B _LE D

Gamma

Correction

SRAM_A[ 15:0]

SRAM_D[15:0]

SRA M_ nRD

SRA M_ nWR

A [ 5 : 0] D [ 15 : 0]nCS nRD n WR nXD REQ n XDAC K

TX_A, B

nTX_A, B

TX_EN1, EN2

Sensor

Int e rfac e

Shading

Acqu isitio n

SRA M

1024x8

(R/G/B)

SRAM

4096x16

(2 line)

SRA M

256x8

PI 2

EXT SRAM

Interrupt

Cont ro l

Vertical

Decimation

SRA M

1024x8

<Block Diagram>

Page 24

3-19

Samsung Electronics

CIRCUIT DESCRIPTION

Repair Manual

3-3-2 KEY FEATURES

Overview

(1) 0.5µm C-MOS process(TLM), 208-PIN QFP, STD85 library

(2) Frequency : 50 MHz

(3) On-Chip oscillator

(4) Method : Raster scanning method

(5) Image Sauce : 300/400/600dpi CIS & CCD

(6) Scanning Mode

• color gray image : each 8 bits / RGB

• mono gray image : 8 bits / pixel

• binary image : 1 bit / pixel (for text/photo/mixed mode)

(7) Maximum scanning width : A3, 600dpi (8K effective pixels)

(8) Ideal MSLT (A4, 600/300dpi)

• color gray image : 3x5Kx80nsec = 1.2msec (7/28 CPM)

• mono gray image : 1x5Kx80nsec = 0.4msec (21/84 CPM)

• binary image : 1x5Kx80nsec = 0.4msec (21/84 CPM)

(9) A/D conversion depth : 12bits

Pixel processing structure

• Minimum pixel processing time : 4 system clocks

• High speed pipelined processing method

(Shading correction, Gamma correction, Enlargement/Reducement, and Binarization)

Shading Correction

(1) White shading correction support for each R/G/B

(2) White shading data memory : 3x8Kx12bits = 288Kbits 384Kbits (external)

(3) Black shading data memory : 3x8Kx12bits = 288Kbits 384Kbits (external)

Gamma Correction

(1) Independent Gamma table for each RGB component

(2) Gamma table data memory : 3x1Kx8bits = 24Kbits (internal)

Binarization (mono)

(1) 256 Gray’s halftone representation for Photo document : 3x5 EDF(Error DifFusion) method proposed by Stuck.

(2) LAT(Local Adaptive Thresholding) for Text document :

• use of 5x5 LOCAL WINDOW (TIP ALGORITHM)

• ABC(Automatic Background Control) :Tmin Automatic change

(3) Mixed mode processing for text/photo mixed document

(4) EDF data memory : 2x4Kx16bits = 128Kbits (internal)

(5) LAT data memory : 4x4Kx16bits = 256Kbits (external)

Scaling of input image

(1) Scaling factor

• Horizontal direction : 25 ~ 800% by 1% unit

• Vertical direction : 25 ~ 100% by 1% unit

(2) Scaling data memory : 2x8Kx8bits = 128Kbits (internal)

Page 25

3-20

CIRCUIT DESCRIPTION

Samsung Electronics

Repair Manual

Intelligent scan motor controller

(1) Automatic acceleration/deceleration/uniform velocity

(2) Data memory : 256x16bits = 4Kbits (internal)

Auto-Run

Automatic CLK_LINE (line processing start control) and •’TG (line scan start control) signal generation|

(1) Available resynchronization of øTG signal

(2) programmable øTG’s period & CLK_LINE’s occurrence number

Processed data output format in DTM(Data Transfer Module)

(1) DMA mode : Burst/On-demand mode

(2) CDIP I/F : LINE_SYNC, PIXEL_SYSNC, PIXEL_DATA[7:0]

• 36 General Purpose Input/Output : 8(GPO), 28(GPIO)

• Black/White reversion, and Image Mirroring support

CPU

(Jupiter)

DMA Controller

(Jupiter)

DAT A- BUS

Scanner

D OCU MENT IMAG E

Analog Signal

T

R

D

M

A

_

R

E

Q

Image

Processor

T

R

D

M

A

_

A

C

K

Scan/Motor

Driver

PI_TG

ADC_CLK

LINE_PERIOD

CLK_PIX

CLK_LINE

Tx_A, Tx_B,

nTx_A, nTx_B

DATA MEMORY

1M bit

SRAM

ADDR BUS

DATA BUS

AFE

CD S2_CLK

AFE Control

Signal

PI1 , PI2

12b it ADC

12bit (R/ G/ B)

IW IN

CIP3

DAT A- BUS

ADD R- BUS ADDR- BUS

<External interface with CIP3>

Page 26

3-21

Samsung Electronics

CIRCUIT DESCRIPTION

Repair Manual

IRQ

[AFE]

12-bit

A/ D converter

Shading

Correction

Enlarge ment

/ Reduction

SRA M

8192x8

(2line)

Image

Processing

Module

DMA

Interfac e

CIP3

Register

CPU I/F

Module

Vp e a k

Contro l

Motor

Con tro l

AIN

AD C_ REF T

ADC_REFB

PI_TG

PI 1

R_L ED ,

G_LED,

B _LE D

Gamma

Correction

SRAM_A[ 15:0]

SRAM_D[ 15: 0]

SRA M_nRD

SRA M_nWR

A [ 5: 0] D [ 15 : 0]nCS nRD nWR nXDREQ nXDAC K

TX_A, B

nTX_A, B

TX_EN1, EN2

Sensor

Interfac e

Shading

Acqu isitio n

SRA M

1024x8

(R/G/B)

SRAM

4096x16

(2 line)

SRA M

256x8

PI 2

EXT SRAM

Interrupt

Contro l

Vertical

Decimation

SRA M

1024x8

<Block diagram of CIP3>

Page 27

3-22

CIRCUIT DESCRIPTION

Samsung Electronics

Repair Manual

3-4 HOST INTERFACE:

Referred to IEEE 1284 standard.

3-4-1. HOST INTERFACE

PARALLEL PORT INTERFACE PART KS32C61200 has the Parallel Port Interface Part that enables Parallel Interface with

PC. This part is connected to PC through Centronics connector. It generates major control signals that are used to actuate

parallel communication. It is comprised of/ERROR, PE, BUSY, /ACK, SLCT, /INIT, /SLCTIN, /AUTOFD and /STB. This part

and the PC data transmission method support the method specified in IEEE P1283 Parallel Port Standard

(http://www.fapo.com/ieee1284.html). In other words, it supports both compatibility mode (basic print data transmitting

method), the nibble mode (4bit data; supports data uploading to PC) and ECP (enhanced capabilities port: 8bits data - high

speed two-way data transmission with PC). Compatibility mode is generally referred to as the Centronics mode and this is

the protocol used by most PC to transmit data to the printer. ECP mode is an improved protocol for the communication

between PC and peripherals such as printer and scanner, and it provides high speed two-way data communication. ECP

mode provides two cycles in the two-way data transmission; data cycle and command cycle. The command cycle has two

formats; Run-Length Count and Channel Addressing. RLE (Run-Length Count) has high compression rate (64x) and it

allows real-time data compression that it is useful for the printer and scanner that need to transmit large raster image that has

a series of same data. Channel Addressing was designed to address multiple devices with single structure. For example,

like this system, when the fax/printer/scanner have one structure, the parallel port can be used for other purposes while the

printer image is being processed.This system uses RLE for high speed data transmission. PC control signals and data

send/receive tasks such as PC data printing, high speed uploading of scanned data to PC, upload/download of the fax data

to send or receive and monitoring the system control signal and overall system from PC are all processed through this part.

PPD(7: 0)

nSTROBE

BUSY

nAC

K

DATA

<Compatibility Hardware Handshaking Timing>

Page 28

3-23

Samsung Electronics

CIRCUIT DESCRIPTION

Repair Manual

PPD(7: 0)

nAUTOFD

nSTROBE

BUSY

BY TE0

BY TE1

COMM

AND

BY TE

DATA BYTE

12345 6

<ECP Hardware Handshaking Timing (forward) >

<ECP Hardware Handshaking Timing (forward)

1. The host places data on the data lines and indicates a data cycle by setting nAUTOFD

2. Host asserts nSTROBE low to indicate valid data

3. Peripheral acknowledges host by setting BUSY high

4. Host sets nSTROBE high. This is the edge that should be used to clock the data into the Peripheral

5. Peripheral sets BUSY low to indicate that it is ready for the next byte

6. The cycle repeats, but this time it is a command cycle because nAUTOFD is low

1. The host request a reverse channel transfer by setting nINIT low

2. The peripheral signals that it is OK to proceed by setting PE low

3. The peripheral places data on the data lines and indicates a data cycle by setting BUSY high

4. Peripheral asserts nACK low to indicate valid data

5. Host acknow ledges by setting nAUTOFD high

6. Peripheral sets nACK high. This is the edge that should be used to clock the data into the host

7. Host sets nAUTOFD low to indicate that it is ready for the next byte

8. The cycle repeats, but this time it is a command cycle because BUSY is low

12 3 4 56

78

nACK

nAUTOFD

PPD

nINIT

(7: 0)

BUSY

PE

BYTE0

DAT A BYTE

BYTE1

COMM AND BYTE

Page 29

3-24

CIRCUIT DESCRIPTION

Samsung Electronics

Repair Manual

3-4-2 USB INTERFACE

CS

RD VVR

A0/ALE

D[7:0]/AD[7:0]

INTR

MODE[1:0]

Microcontroller Interface

Endpoint/Contol FIFOs

Control

Status

RX

TX

RESET

Vcc

GND

XIN

XOUT

CLKOUT

48 MHz

Oscillator

Clock

Generator

SIE

Media Access Controller[MAC]

Physical Layer interface[PHY]

Trans ceiver

VReg

Clock

Recovery

USB Event

Detect

V3.3

AGND

D+

D-

Upstream Port

3-4-2-1 Features

• Full-Speed USB Node Device

• USB transceiver

• 3.3V signal voltage regulator

• 48 MHz oscillator circuit

• Programmable clock generator

• Serial Interface Engine consisting of Physical Layer In-terface (PHY) and Media

• Access Controller (MAC), USB Specification 1.0 compliant

• Control/Status Register File

• USB Function Controller with seven FIFO-based End-points :

• One bidirectional Control Endpoint 0 (8bytes) : Three Transmit Endpoints (2*32 and 1*64 bytes)

• Three Receive Endpoints (2*32 and 1*64 bytes)

• 8-bit parallel interface with two selectable modes : non-multiplexed

• multiplexed (Intel compatible)

• DMAsupport for parallel interface

• MICROWIRE/PLUS Interface

• 28-pin SO package

Page 30

3-25

Samsung Electronics

CIRCUIT DESCRIPTION

Repair Manual

CS

A0

VVR

RD

D[7:0]

DAT A_IN

DAT A_OUT

ADDR

DAT A_IN

DAT A_OUT

ADDRESS

0x00

0x3F

REGISTERFILE

<Non-Multiplexed Mode Interface Block Diagram>

<Non-Multiplexed Mode Basic Timing Diagram>

cs

A0

RD

VVR

D[7:0]

input

vvrte Address

out

Read Data

out

Burst Read Data

Page 31

3-26

CIRCUIT DESCRIPTION

Samsung Electronics

Repair Manual

3-5 Engine Controller

3-5-1. FUSER CONTROL / THERMISTOR CIRCUIT

This circuit controls the heat lamp temperature to fix the transferred toner on the paper. It is comprised of the thermistor that

has the negative resistance against the temperature and LM393 (voltage comparator) and transistor for switching.

The thermistor has the resistance value reverse proportional to the heat lamp surface temperature. The voltage value is read

by #60 pin(A VIN2) of CPU refering to the parallel combined resistance with the resistor(R43) connected parallel to it and the

voltage distribution of R29. The voltage read activates (inactivates) ‘fuser’ signal to high (or low) referring to the set temperature and when the ‘fuseron’ signal turns down(high) to low(high) by Q3 switching, the S21ME4 inside SMPS (PC3) turns

on(off) and this eventually turns two-way thyristor(THY501) on(off) to allow(shut) AC voltage to the heat lamp.

LM393 is a H/W designed to protect the system when the software heat lamp control does not run normal. When the thermistor temperature goes up to 210°C, #1 pin’s level (LM393) will turn low to turn the ‘fuseron’signal to high. (forcefully shuts

off Q3)In other words LM393 shuts off the heat lamp forcefully.

3-5-2. PAPER SENSING CIRCUIT

1) Cover Open Sensing

Cover Open Sensor is located on the right rear side of the printer. In case the right cover is open, it shuts +5V (LSU laser

unit) and +24V( polygon motor of fixer LSU and HVPS) that are supplied to each unit. It detects the cover opening through

CPU. In this case, the red LED of the OP Panel LED will turn on.

2) Paper Empty Sensing

The paper empty sensor (photo interrupter), located inside bottom of the bin cassette detects paper with the actuator con-

nected to it and informs the CPU of whether there is paper. When there is no paper in the cassette, the red LED of the OP

panel LED will turn on to tell the user to fill the cassette with papers.

3) Paper Feeding When the paper is fed into the set and passes through the actuator of the feed sensor unit, transistor inside

the photo interrupter will turn on, ‘nFEED’ signal will turn low and inform CPU that the paper is currently fed into the system. CPU detects this signal and sprays video data after certain time (related to paper adjustment). If the paper does not

hit the feed sensor within certain time, CPU detects this and informs as “Paper Jam0” (red LED on the OP panel will turn

on).

4) Paper Exit Sensing

The system detects the paper going out of the set with the exit sensor assembled to the actuator attached to the frame. If

CPU does not turn back high a while after the paper hits the exit sensor, CPU detects this and inform as “Paper Jam2” (red

LEDs on the OP panel will turn on).

3-5-3. LSU CIRCUIT

1) Polygon Motor Unit (actuated by +24V)

The polygon motor inside LSU rotates by the ‘PMOTOR’signal. When it reaches the motor constant velocity section through

the initial transient (transient response) section, it sends the ‘nLREADY’ signal to the CPU. The ‘clock’ pin is the pin that

receives clock of the required frequency when LSU uses external CLK as the motor rotational frequency. Currently the external clock circuit is located in the HVPS and 1686Hz = 6.9083MHz (crystal frequency)÷4096(74HC4060N IC), is used as

the rotational frequency of the polygon motor.

2) Laser Unit (actuated by +5V)

After laser is turned on by ‘nLD_ON’ signal, it is reflected by 6 mirrors (polygon mirror) attached to the polygon motor and

performs scan in horizontal way.When the laser beam hits the corner of the polygon mirror, it generates ‘nHSYNC’ signal

(pulse) and the CPU forms the left margin of the image using this signal (horizontal synchronous signal).

Page 32

3-27

Samsung Electronics

CIRCUIT DESCRIPTION

Repair Manual

3-5-4. FAN/SOLENOID ACTUATION CIRCUIT

The fan actuation circuit its power using NPN TR. When it receives ‘FAN’ signal from the CPU. The TR will turn on to make

the voltage supplied to the fan to 24V in order to actuate the fan.

The solenoid is actuated in the same way. When it receives control signal from the CPU, the solenoid for paper feeding is

actuated by switching circuit.

D29(1N4003) diode is applied to the both ends of the output terminal to protect Q22(KSC1008-Y) from noise pulse induced

while the solenoid is de-energized.

3-5-5. PTL ACTUATION CIRCUIT

PTL actuation circuit switches its power using NPN TR.

3-5-6. MOTOR ACTUATION CIRCUIT

Motor actuation circuit is determined while selecting the initial driver IC (provided by the vendor). This system uses

TEA3718(U57, U58), A2918(U59)’s motor driver IC. However, the sensing resistance (R273, R274, R292, R293) and refer-

ence resistance (R284, R289, R294, R295) can vary depending on the motor actuation current value.

It receives motor enable signal (2 phase) from CPU and generates bipolar pulse (constant-current) and sends its output to

stepping motor input.

3-5-7. HIGH VOLTAGE POWER SUPPLY

3-5-7-1. Summary

It is the high voltage power supply that has DC+24V/DC+5V (used for the image forming device in OA digital picture developing method) as the rated inputs. It supplies electrifying voltage (MHV), supply voltage (SUPPLY), developing voltage (DEV),

blade voltage(BLADE) and transferring voltage (THV).

Each high voltage supply shows the voltage required in each digital picture process.

3-5-7-2. Digital Picture Process

Digital picture developing method is widely used by copy machine, laser beam printer and fax paper.

The process is comprised of electrification, exposure, develop, transfer and fixing.

First, in the electrification process, retain constant charge at approx. -900V for the electric potential on the OPC surface by

electrifying OPC drum at approx. -1.4KV through the electrification roller.

The electrified surface of OPC is exposed responding to the video data by the LSU that received print command due to rotation. The unexposed non-video section will retain the original electric potential of -900V, but the electric potential of the image

area exposed by LSU will be approx. -180V that it will form the electrostatic latent image. The surface of the photo-conductive drum where the electrostatic latent image is formed reaches the developer as the drum rotates. Then the electrostatic

latent image formed on the OPC drum is developed by the toner supplied to the developing roller by supplying roller and it is

transformed into visible image. It is the process to change the afterimage on the OPC drum surface formed by LSU into visible image by the toner particles.

While the supply roller energized with -450V by HVPS and the developer roller energized with -300V rotate in the same

Page 33

3-28

CIRCUIT DESCRIPTION

Samsung Electronics

Repair Manual

HEAT ROLLER

PRESSURE ROLLER

MHV

LSU

DEV

BLADE

SUPPLY

THV

SUPPLY ROLLER

DEVELOPER ROLLER

DIRECTION OF PAPER

ELECTRIFICATION

ROLLER

TRANSFER ROLLER

direction, it keeps the toner particles between two rollers supplied to OPC drum in negative state by the friction between two

rollers.

The toner supplied to the developer roller is biased to bias electric potential by the developer roller and transferred to the

developing area. After (-) toner is attached to the developer roller, it will move to the exposed high electric potential surface (180V) rather than to the unexposed low electric potential surface (-900V) of the developer roller and OPC drum. Eventually

the toner will not settle in the low electric potential surface to form the visible image.

Later, the OPC drum continues to rotate and reaches to transfer location in order to accomplish the transfer process.

This process transfers the (-)toner on the transfer roller to the printing paper by the transfer roller. The (-)toner attached to the

OPC drum will be energized to hundreds to thousands of the (+)transfer voltage by HVPS. The (+)electrostatic force of the

transfer roller generated has higher adhesiveness than the (-)toner OPC drum and thus it moves to the surface of the paper

passing through the transfer roller. The toner transferred to the paper with weak electrostatic force is fixed to the paper by the

pressure and heat of the fixer composed of pressure roller and heat roller. The toner attached to the paper is melted by applying the heat (approx. 180°C) from the heat roller and the pressure (approx. 4kg) from the pressure roller. After the fixing

process, the paper is sent out of the set to finish the printing process.

3-5-7-3. Organization of the Device

HVPS is comprised of electrification output unit, bias output unit and transfer output unit.

1) Input Unit

2) Electrification Output (Enable) Unit: MHV (Main High Voltage)

3) Bias Output (Enable) Unit: DEV (Development Voltage)/Supply(Supply Voltage)/BLADE(Blade Voltage)

4) Transfer ‘+’ Output (Enable) Unit: THV(+)(Transfer High Voltage(+))

5) Transfer ‘-’ Output (Enable) Unit: THV(-)(Transfer High Voltage(-))

6) Switching Unit

7) Feedback Unit

8) Regulation Unit

9) Output Unit

Page 34

3-29

Samsung Electronics

CIRCUIT DESCRIPTION

Repair Manual

SWITCHING

CONTROL UNIT

TRANS

MHV-PWM

MHV

REGULATION

CIRCUIT

OUTPUT

CIRCUIT

THVPWM

<Electrification Unit Block-Diagram>

<Transfer Output Unit Block Diagram>

<MHV Output unit Block Diagram>

<BIAS Output Unit Block Diagram>

THVEA

THVREAD

MHV-PWM

PWM

CONTROL UNIT

SWITCHING

CONTROL UNIT

THV

ENVIRONMENT

RECOGNITION

CIRCUIT

PWM

CONTROL UNIT

SWITCHING

CONTROL UNIT

FEEDBACK

TRANS

FEED BACK

TRANS

REGULATION

CIRCUIT

SWITCHING

CONTROL UNIT

TRANS

REGULATION

CIRCUIT

REGULATION

CIRCUIT

THV

MHV

OPC

BIAS-PWM

PWM

CONTROL UNIT

FEEDBACK

SWITCHING

CONTROL UNIT

FEEDBACK

TRANS

REGULATION

CIRCUIT

BLADE

SUPPLY

DEV

Page 35

3-30

CIRCUIT DESCRIPTION

Samsung Electronics

Repair Manual

3-5-7-4 MHV (Electrification Output Enable)

Electrification Output Enable is the electrification output control signal 'PWM-LOW ACTIVE'.

When MHV-PWM LOW signal is received, Q401 turns on and the steady voltage will be accepted to the non-inverting terminal of OP-AMP 324. As the voltage higher than the inverting reference voltage of OP-AMP, which is set to R405 and

R406, OP-AMP output turns high. This output sends IB to the TRANS auxiliary wire through current-restricting resistance Q402 via R408 and C403 and Q402 turns on. When the current is accepted to Q402, Ic increases to the current proportional to time through the T401 primary coil, and when it reaches the Hfe limit of Q402, it will not retain the "on" state, but

will turn to "off". As Q402 turns 'off', TRANS N1 will have counter-electromotive force, discharge energy to the secondary unit, sends current to the load and outputs MHV voltage through the high voltage output enable, which is comprised of Regulation– circuit.

3-5-7-5 BIAS (supply/dev/blade output unit)

BIAS (Electrification Output Enable)Electrification Output Enable is the electrification output control signal ‘PWM-LOW

ACTIVE’.When BIAS-PWM LOW signal is received, Q501 turns on and the steady voltage will be accepted to the non-inverting terminal of OP-AMP 324. As the voltage higher than the inverting reference voltage of OP-AMP, which is set to R506

and R507, OP-AMP output turns high. This output sends IB to the TRANS auxiliary wire through current-restricting

resistance Q502 via R509 and C504 and Q502 turns on. When the current is accepted to Q502, Ic increases to the current proportional to time through the T201 primary coil, and when it reaches the Hfe limit of Q502, it will not retain the “on”

state, but will turn to “off”. As Q502 turns ‘off’, TRANS N1 will have counter-electromotive force, discharge energy

to the secondary unit, sends current to the load and outputs DEV voltage through the high voltage output enable, which

is comprised of Regulation-circuit.

MHV-PWM

U103 7407

R412 2.2K

18V

Q401 A708

R403 130K

R402

82K

R411 2K

R404

27K

C407

104

R406

2.2K

R405 220K

24VS

+

_

R408

47K

R409

390

KA324

C403

333

Q402

D526

24VS

T401

C404

3K/471

D402

4KV

C406

3K/471

R416

15M

R413

12M

ZD401

150V

OPC

R417

15M

MHV OUTPUT

BIAS-PWM

CON03-#24

5V

R520

26K

2

U103-A

7407

R501

100

R519

2.2K

R502

2K

Q501

A708-Y

R503

100KF

R504

56.6KF

C501

104

C502

222

R506

86.6KF

24VS

T201

KAB-007

1

R511

1W 3

5

2

4

C503

R508

104

47K

5

_

7

U1

+

6

U101-B

KA324

R507

12KF

R509

47K

R510

430

C504

333

Q502

D526-Y

7

6

C505

2KV 680

D502

4KV

C506

3KV 471

ZD501

100V

R512

MGR1/2W 12MF

R514

MGR1/2W 50K

R515

MGR1/2W 50K

ZD501

100V

R516

MGR1/2W 50K

BLADE

SUPPLY

DEV

Page 36

3-31

Samsung Electronics

CIRCUIT DESCRIPTION

Repair Manual

3-5-7-6. THV(THV(+)/THV(-) Output Unit)

Transfer(+) output unit is the transfer output control signal 'PWM-LOW ACTIVE'.

When THV-PWM LOW signal is received, Q203 turns on and the steady voltage will be accepted to the non-inverting terminal of OP-AMP 324. As the voltage is higher than the inverting reference voltage of OP-AMP, OP-AMP output turns high.

The 24V power adjusts the electric potential to ZD201 and ZD202, sends IB to TRANS auxiliary wire through currentrestricting resistance R215 via R212 and C204, and eventually Q204 will turn on. When the current is accepted to Q402,

Ic increases to the current proportional to time through the T201 primary coil, and when it reaches the Hfe limit of Q204, it will

not retain the "on" state, but will turn to "off". As Q402 turns 'off', TRANS N1 will have counter-electromotive force, discharge energy to the secondary coil, sends current to the load and outputs THV voltage through the high voltage output

enable, which is comprised of Regulation– circuit. The output voltage is determined by the DUTY width. Q203 switches

with PWM DUTY cycle to fluctuate the output by fluctuating the OP-AMP non-inverting end VREF electric potential, and

the

maximum is output at 0% and the minimum, at 100%.Transfer(-) output unit is THV-EA 'L' enable.

When THV-EA is 'L', Q302 turns on and the VCE electric potential of Q302 will be formed and sends IB to TRANS auxiliary wire through R31 1, C305 and VR302 via current-restricting resistance R314, and eventually Q303 will turn on. When

the current is accepted to Q303, Q303's Ic increases to the current proportional to time through the T301 primary coil, and

when it reaches the Hfe limit of Q303, it will not retain the "on" state, but will turn to "off". As Q303 turns 'off', TRANS

N1 will have counter-electromotive force, discharge energy to the secondary coil, send current to load and output THV(-)

voltage through the high voltage output enable, which is comprised of Regulation– circuit.

#7 TEV-PWM

5V

U2

12

3

R201

10K

U2

R205

1.8K

R206

100

Q203

A708Y

R208

30K

18V

R209

100KF

VR201

50K

R207

2K

C201

103

C202

121

R210

845KF

D202

1N4148

R211

1MF

5

6

7

+

_

U1

11

KA324

24VS

+

C101

35V47

UF

D201

1N4148

24VS

R213

2.2K

R212

680K

C203

472

D203

1N4148

ZD201

5.65V

ZD202

705V

R214

2.2K

C204

333Z

Q204

D526

T201

KAB-007

C206

6KV470pF

C205

2KV68pF

D204

6KV

D206

6KV

C209

6KV

C208

6KV

D205

6KV

D207

6KV

R215

390

C207

3KV470pF

R216

SBR306

R218

MGR1/2W100KF

R217

SBR207

#17

#19

#5

#24

5V

TEV-EA

TEV-READ

5V

D301

1N4148

5

6

7

U2

7407

D-GND

24VS

C4

103

8

9

10

U1

+

_

KA324

R301

470K

C301

222

R302

33K

R303

100KF

C302

102

D302

1N4148

C303

103

R304

389KF

R305

10KF

VR301

5K

R306

26.1KF

C304

500V103Z

18V

R309

202K

R307

33K

Q301

A708Y

18V

R310

2.2K

R308

33K

Q302

A708Y

R312

1W56

R313

1W56

Q303

D526

R311

100KF

C305

333Z

VR302

2K

R314

1.7K

KAB-006

T301

1

5

2

4

6

7

1

5

2

4

7

6

C307

3KW470pF

D304

4KV

C306

2KV68pF

D303

4KV

C308

3KV470pF

R315

SBR306

Page 37

3-32

CIRCUIT DESCRIPTION

Samsung Electronics

Repair Manual

3-5-7-7. Environment Recognition

THV voltage recognizes changes in transfer roller environment and allows the voltage suitable for the environment in order

to realize optimum image output. The analog input is converted to digital output by the comparator that recognizes the

environmental changes of the transfer roller. It is to allow the right transfer voltage to perform appropriate environmental

response considering the environment and the type of paper depending on this digital output by the programs that can

be input to the engine controller ROM.

This environment recognition setting is organized as follows: First, set the THV(+) standard voltage.

Allow 200MΩ load to transfer output, enable output and set the standard voltage 800V using VR201.

Then set 56 (CPU's recognition index value) as the standard using VR302.

This standard value with CPU makes sure that the current feedback is 4µAwhen output voltage is 800V and load is 200MΩ.

If the load shows different resistance value when 800V is output, the current feedback will also be different and thus the

index value will also be different. according to the index value read by CPU, the transfer voltage output will differ according

to the preset transfer table.

The changes in transfer output required by each load is controlled by PWM-DUTY.

Page 38

3-33

Samsung Electronics

CIRCUIT DESCRIPTION

Repair Manual

3-6 OPE PBA

3-6-1 SUMMARY

OPE Board is separated functionally from the main board and operated by the micom(Z8601) in the board. OPE and the main

use UART (universal asynchronous receiver/transmitter) channel to exchange information. OPE reset can be controlled by

the main. OPE micom controls key-scanning and LCD and LED display . If there occurs an event in OPE (such as key touch),

it sends specific codes to the main to respond to the situation and the main analyzes these codes and operates the system.

For example, it the main is to display messages in OPE, the main transmits data through UART line to OPE according to the

designated format and OPE displays this on LCD, LED. OPE’s sensing is also transmitted to the main through UART line

and then the main drives necessary operation.

OPE PBA consists of U1(MICOM, Z8601),LCD, key matrix, LED indicators. Refer to OPE Schematic Diagram and Wiring

Diagram sections of this manual.

• Signals from the key matrix are delivered to U1 input pin group (D1~D6)

• U1 pin 48 (TX DATA) is the UARTcode sent to MAIN PBA.

• Display from the controller is received at U1 pin 5(RX DATA).

• LCD drive signals are sent from U1 P2-x pin group, P3-4~P3-6 pins.

• Machine status LED drive signals are sent from U1 LED0~LED7.

Connector

MICOM

Z8601

UART2

Reset

11

7

X

Y

8

RESONATOR

7.37 MHz

LCD

16 X 2 Line

Key Matrix

LEDs

<OPE BLOCK DIAGRAM>

Page 39

3-34

CIRCUIT DESCRIPTION

Samsung Electronics

Repair Manual

3-7 LIU PBA

3-7-1. SUMMARY

LIU WIRE CONNECTS Main B’D’s MODEM AND LINE PARTS, AND IMPEDANCE MATCHING (AC, DC), RING DETEC-

TION PART and LINE SEIZURE (DIALER).

3-7-2. DC MATCHING PART

Normal movement range of LIU is 12mA ~ 9mA.

Adapting CTR21 standard, the regulation limits to 60mA CURRENT flow through the terminal.

Therefore, select (*:for EU PIT) Option to connect necessary items then the current through LIU will not exceed 60mA.

• CTR21 Standard(Europe) : 12mA~60mA • OTHER Standard (U.S.) : 12mA~90mA

DC has a character to pass through the LINE. And with Q1 (VN2410) GATE section’s LINE INPUT corrent and Q1 Source

connection to R20, can be decided as follows :

• -VDCR = VL1 + ILINE X R20

(VDCR : Tip-Ring CD Voltage, ILINE : Current flow)VL1:Line Input Voltage, VL1=VBD1+VCE(Q2)+VDS(Q1)

3-7-3. AC MATCHING PART

Basic LIU’s AC IMPEDANCE is 600 and uses R47. 48. C36 to possibly control combined IMPEDANCE.

• U.S. Usage : A terminal IMPEDANCE Æ 600W(±30%)

• CTR21 : A Terminal IMPEDANCE Æ 270+750W//150nF

3-7-4. DIALER PART

*MF DIAL

DTMF Dialing is controlled by MODEM and should be selected by appropriate LEVELand On-off Time output based on each

countries’ own National specification.

• Tolerance : ±1.5%

High Group : 1209, 1336, 1477, 1633Hz

Low Group : 697, 770, 852, 941 Hz

*DP DIAL

Controls from MAIN through / DP-Terminal.

for U.S.Usage, set time to DF signal of 40:60 M/B. DP signal is made of U6 (pcb817). The DC current which flows thru Q2

Base is regulated by On/Off switch and turns to DP dial signal with a COUPLER.

• CTR 21 does not have telephone capability but has the number 3 and 4 Line Connection. No DP condition but possibility

to get approval only on DTMF Dial based terminal.

U.S. Usage CTR21

High Freq Level -9.0+2.0/-2.5 -7.0 +1.0/-2.0

Low Freq Level -9.0+1.0/-2.0 -11.0+2.5/-2.0

Page 40

3-35

Samsung Electronics

CIRCUIT DESCRIPTION

Repair Manual

3-7-5. RING DETECTION PART

RING SIGNALS from the LINE section (TIP, RING)are further passed through C5, R3, ZD1, and ZD2 and ends up at U9, (PC

814). U9 then detects above RING SIGNALand passes the output to MAIN B’D. The wilre diagram’s C5 is RINGER CAPACITOR and it normally uses 1UF/250V.

A R3 limits AC current and controls upper and lower REN meter.

3-8 SMPS (Switching Mode Power Supply) Unit.

3-8-1 SMPS SPECIFICATIONS

The SMPS (Switching Mode Power Supply) Unit used here is a PWM (Pulse Width Modulation) type power supply unit that

supplies DC+5V to controller and control panel, and DC+5V , DC+24V and DC+12V to the engine. It also supplies AC power

to fixer heat lamp.

No. Output Channel Ch.1 Ch.2 Ch.3

1 Channel Name +5.1V +24.0V +12.0V

2 Rated Output Voltage +5.1V +24.0V +12.0V

3 Rate Output Current 2A 2.5A 1.0A

4 Maximum Load Current 3A Continued 3.5AContinued 1.0A Continued

and Load Pattern

5 Load Change Range 0.5~2.0A 0.3~2.5A 0.2~1.0A

6 Rate output voltage +5.1V±5% +24.0V±10% +12V±5%

(For rated I/O) (+4.84~+5.35V) (+21.60~+26.40V) (+11.40~+12.60V)

7 1) Total Output Voltage Including All Including All Including All

Deviation +5.1V±5% +24.0V±10% +12V±5%

(Input, Load, Temp., Aging) (+4.84~+5.35V) (+21.60~+26.40V) (+11.40~+12.60V)

2) Dynamic Input Change Including Set Error Including Set Error Including Set Error

3) Dynamic Load Change

8 Refer to ripple & noise 27) 150mVp-p or less 500mVp-p or less 150mVp-p or less

9 Refer to load short and Must not ignite or Output voltage must Must not ignite or

overload protection 23) generate smoke shutdown withing generate smoke

Refer to load short and when output shorted the range of when output shorted

overload protection 23) for 5 sec. 3.5A~6.5A for 5 sec.

Page 41

3-36

CIRCUIT DESCRIPTION

Samsung Electronics

Repair Manual

3-8-2 AC INPUT STAGE

AC Input power path is consist of the Fase (F501) for AC current limit, the Varistor (TNR501) for by-passing high Voltage

Surge, the discharge resistor(R508), the AC Impalse Noise Filtering Circuit (C501, LF501, C503), the Common Mode

Grounding Circuit (C504, C505), the 2’nd noise filter (LF502), and the thermistor (TH501).

Wher power is turned on, TH 501 limits Inlush-Current by it’s high resistanle, and When it’s temperature rise, it’s resistance

become about Zero ohm.

3-8-3 SMC(SWITCHED MODE CONTROL)

The AC input voltage is rectified and filtered by BD552 and C507 to create the DC high voltage applied to the primary winding of T501. TR01 pin #1 is driven by the SMPS device U502. U502. auto-starts and chops the DC voltage. The U502 is PWM

SMPS IC and has internally a SMC(switched mode control) IC and a MOSFET output stage. The SMC IC has a Auto-restart

without a Power Supply for the IC and a Thermal Shutdown function and so on. C509, R512, C510, D505 clamp leadingedge voltage spikes caused by transformer leakage inductance.

The power secondary winding(pim #11-12)is rectified and filtered by D507, C552, L551, and C554 to create the 5V output

voltage. The bias winding(pin #4-5)is rectified and filltered by D506 and C511 to create U502 bias voltage. The secondary

output 5V is regulated through the path of the voltage divide by R553, R556-U503 switching PC252-the bias voltage of U502U503 PWM duty cycle-T501 secondary voltage. C508 filters internal pin, determines the auto-restart frequency, and together with R506, compensates the control loop. U552 of the secondary stage -12Vis the Low Power-loss Regulator with built-in

overcurrent protection function

3-8-4. FIXED TEMPERATURE CONTROL

3-8-4-1. Fixed Lamp Control Circui

AC Neutral

AC Power Live

C502

R502

R503

R505

L501

Logic Unit

Fuser On

SMPS Unit

DC Power

U501

4

2

1

6

THY501

CON502

Zero crossing circuit

<Fixed Lamp Control Circuit>

Page 42

3-37

Samsung Electronics

CIRCUIT DESCRIPTION

Repair Manual

3-8-4-2. The Concept of Fixed Lamp Control

For fixed lamp control, the logic unit "fuser on" control signal and SMPS unit DC power must be supplied. This circuit

turns on only when "fuser on" sends the signal and the DC power is supplied.

The following explains how the fixed lamp control circuit works.

logic unit "fuser on" sends trigger current to triac driver U501 LED, then the infrared ray is detected by U501 photo detector.

Next, U501 triac is conducted.

The conducted current sends trigger input to triac THY501 gate. At this point, THY501 is conducted and AC power is supplied to fixed lamp. Lamp is turned on and temperature rises.

As this fixed lamp control circuit uses the AC voltage ("+" and "-" are repeated) as the power supply, it used two-way triac

(THY501), which has advantage over one-way SCR considering the price, size and reliability.

Triac's gate can be triggered by either forward or reverse signal. Once triac is turned on, it will not be controlled by gate signal, but will be continuously on until the current between major terminals decreases below the holding current. In other

words, you cannot turn it off with reverse signal unlike SCR. This property is called current-voltage threshold rise

rate (commutation: dv/dt). In AC power control

application, triac has to turn off conduction in each zero crossing or switch it twice in each cycle. This switching operation is

called commutation. It is possible to turn off the triac at the end of half cycle by eliminating the gate signal when the load current (IL) is gained at the level equal to or lower than holding current. When triac commutes off-line, the direction of the

voltage of the both ends of triac will be reversed and increase up to the maximum value of line voltage (VAC). At this point,

the width of rise rate will be determined by dv/dt and overshoot voltage, by the circuit. When triac commutes off-line, the voltage of both ends of triac will have the same voltage as the line voltage.

VAC

IL

G

V

T

Inductive IL

<Inductive Circuit>

Page 43

4-1

Samsung Electronics

SCHEMATIC DIAGRAMS

Repair Manual

4

Samsung Electronics

SCHEMATIC DIAGRAMS

Repair Manual

4. Schematic Diagr ams

4-1 Main Circuit Diagram (1/14)

Page 44

4-2

SCHEMATIC DIAGRAMS

Samsung Electronics

Repair Manual

Main Circuit Diagram (2/14)

Page 45

4-3

Samsung Electronics

SCHEMATIC DIAGRAMS

Repair Manual

Main Circuit Diagram (3/14)

Page 46

4-4

SCHEMATIC DIAGRAMS

Samsung Electronics

Repair Manual

Main Circuit Diagram (4/14)

Page 47

4-5

Samsung Electronics

SCHEMATIC DIAGRAMS

Repair Manual

Main Circuit Diagram (5/14)

Page 48

4-6

SCHEMATIC DIAGRAMS

Samsung Electronics

Repair Manual

Main Circuit Diagram (6/14)

Page 49

4-7

Samsung Electronics

SCHEMATIC DIAGRAMS

Repair Manual

Main Circuit Diagram (7/14)

Page 50

4-8

SCHEMATIC DIAGRAMS

Samsung Electronics

Repair Manual

Main Circuit Diagram (8/14)

Page 51

4-9

Samsung Electronics

SCHEMATIC DIAGRAMS

Repair Manual

Main Circuit Diagram (9/14)

Page 52

4-10

SCHEMATIC DIAGRAMS

Samsung Electronics

Repair Manual

Main Circuit Diagram (10/14)

Page 53

4-11

Samsung Electronics

SCHEMATIC DIAGRAMS

Repair Manual

Main Circuit Diagram (11/14)

Page 54

4-12

SCHEMATIC DIAGRAMS

Samsung Electronics

Repair Manual

Main Circuit Diagram (12/14)

Page 55

4-13

Samsung Electronics

SCHEMATIC DIAGRAMS

Repair Manual

Main Circuit Diagram (13/14)

Page 56

4-14

SCHEMATIC DIAGRAMS

Samsung Electronics

Repair Manual

Main Circuit Diagram (14/14)

Page 57

4-15

Samsung Electronics

SCHEMATIC DIAGRAMS

Repair Manual

4-2 LIU Circuit Diagram

(BRW)

2.74K, 1%

600

*

180K, 1/4W

(YEL)

120K

(ORG)

(BLU)

*

,1W

*

/250V

ARS1-3 : OPTION

*

1K, 2W

*

/16V

*

*

*

*

*

*

/16V

*

*: for EU PTT

*

*

*

/250V

600:600

(GRN)

*

1K,1%

*

15nF/400V

*

(BLK)

10, 1%,0.25W

*

(RED)

0.22UF/16V

0.25W

Page 58

4-16

SCHEMATIC DIAGRAMS

Samsung Electronics

Repair Manual

4-3 OPE Circuit Diagram

Page 59

4-17

Samsung Electronics

SCHEMATIC DIAGRAMS

Repair Manual

4-4 HVPS Circuit Diagram(1/2)

R519

2.2K

R503

100KF

18V

C103

104

BLADE

24VS

R418

MGR1/2W 100KF

R506

86.6KF

5V

BIAS-PWM

U102

C502

222

DEV

C402

104

Q401

A708-Y

OPC

OUT

R406

16.2KF

R405

150KF

R407

85KF

D404

1N4148

R516

MGR1/2W 50K

C504

333

MHV

R416

MGR1/2W 30MF

C102

104

C406

3KV 471

GND

C404

3KV 471

R413

MGR1/2W 12MF

C405

2KV 680

+

-

U101-B

KA324

5

6

7

5V

IN

D403

4KV

R517

MGR1/2W 15MF

C505

2KV 680

+

-

U101-A

KA324

3

2

1

R512

MGR1/2W 12MF

D402

4KV

R402

56KF

18V

C503

104

C506

3KV 471

R403

62KF

C403

333

R412

2.2K

18V

DEV

50K

+

C104

35V 47uF

R505

27K

R410

1W 3

R419

5.6K

MHV-PWM

3 4

U103-A

D401

1N4148

Q402

D526-Y

C407

104

R501

100

R504

86.6KF

R509

47K

D502

4KV

C401

222

R409

430

R502

2K

R520

5.6K

CON03-#24

24VS

R510

430

R408

47K

Q501

A708-Y

ZD401

1W 150V

24VS

R404

33K

U103-B

T501

T1167

1

4

2

5

7

6

ZD502

150V

C501

104

R508

47K

7407

R515

MGR1/2W 50K

R401

100

SUPPLY

R411

2K

R514

MGR1/2W 50K

D501

1N4148

7407

T401

KAB-006

1

4

2

5

7

6

CON03-#22

R511

1W 3

ZD501

100V

1 2

MHV

50K

Q502

D526-Y

R507

12KF

KA7818

Page 60

4-18

SCHEMATIC DIAGRAMS

Samsung Electronics

Repair Manual

HVPS Circuit Diagram(2/2)

R305

9.53KF

5V

+

-

U101-D

KA324

12

13

14

4

11

7407

THV(-)

5K

R304

200KF

U103-C

9 8

14

7

C301

222

ZD201

5.6V

7407

D206

6KV

D303

4KV

R309