Page 1

Circuit Diagram

Service Manual

11-1

1

1

1

1

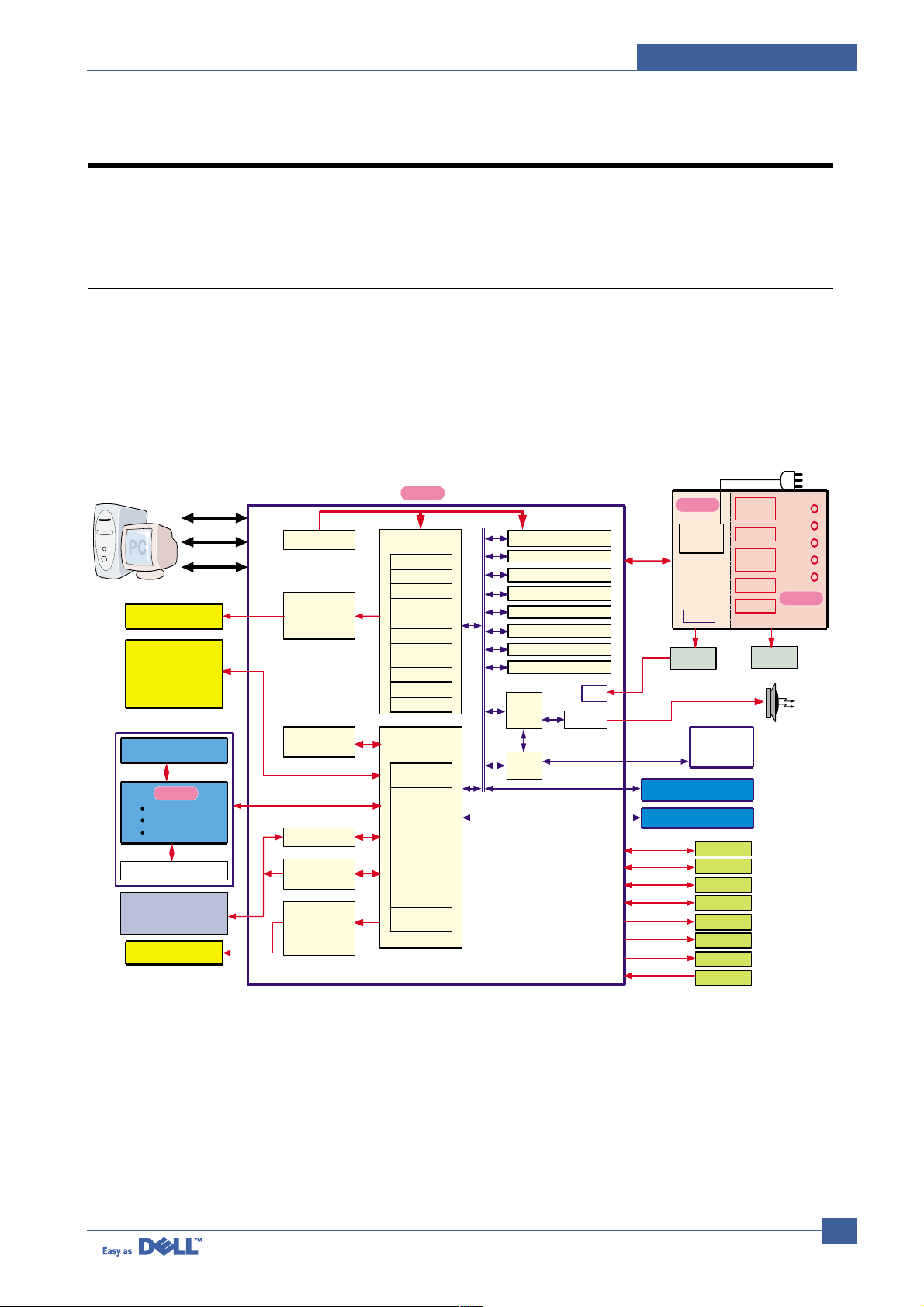

11. Circuit Description

11.1 System Configurations

SCX-4920N is roughly made up Main Control part, Operation Panel part, Scanner part, Line Interface part and

Power part. Each Part is separated Module which focus on common and standard design of different

kind products. main control part adopting Fax & LBP Printer exclusive Controller is composed of 2

CPU and 1 Board. Scanner part is composed of ADF and Platen and is connected with Main by

Harness . Line Interface part is designed to apply TBR21 standard(Domestic, Europe,etc..)

MHV

+5V/

+12V

+24V

+24VS

INLET &

POWER S/W

PAPER EMPTY

SENSOR

EXIT SENSOR

MP EMPTY

SENSOR

FEED SENSOR

COVER S/W

AC PWR

SUPPLY

DEV

THV

OPC GND

SPGPm

ARM946ES

CACHE(16K*2)

SDRAM Control

ROM Control

DMA Control

PVC

GEU/HCT/gCOD

EC

I/O I/F

Engine Control

IEEE1284/USB2.0

MAIN MOTOR

DRIVER

A3977S LR

Reset

THERM

26P

2P

MODEM

SFM336

33.6KBP

AUDIO Drv.

2P

600 DPI, COLOR CCD

MAIN MOTOR

FLATEN MOTOR

FAST SRA M

(128 KB yte)

CIP4

Image P rocesser

AFE I/F

I/O PORT

Motor Control

DMA Control

RTC

JBIG Codec

CIP 4 AFE

FLATEN

MOTOR

DRIVER

TEA3718 X 2EA

CCD DRIVING

PART

USB 2.0

IEEE1284

NETWORK

ADF UNIT

P-REGI, P-DET, P-POS

SENSOR

ADF MOTOR DRIVER

TEA3718 X 2EA

FLAT COVER SENSOR

LCD, 16*2 LINES

14P

3P

FUSER

2P

FAN

2P

NE TWORK INTERFAC E CA RD

SCF (Option)

BootROM

(1MBX2ea or 2MBX2ea)

MEMO RY DIMM

Smart DAA

CX20493

PS3 / PCL6 DIMM(SEC)

SRAM

(128KByte) or

Not Used

SDRAM(16MB or 32MB)

DRAM Backup logic

PCL6(2MB x 2ea)

PS3(2MB x 2 ea) : DELL

3P

LINE

EXT. PHONE

LSU

11P

PTL

DEV_FUSE

MAIN CLUTCH

2P

2P

3P

MP CLUTCH

4P

TONER RX

CARIDGE INFO.

.

TONER TX

4P

3P

4P

AC 110V/220V

MICOM

LCD/LED Drive

Key Scan

OPE

MAIN

SMPS

HVPS

Page 2

Service Manual

Circuit Diagram

11-2

CPU Part

1) CPU : Use 32Bit RISC Processor, ARM946ES,which is exclusive controller to execute Printer & FAX Function

and to execute operation block by flash memory within system program, and to control whole system.

- Main function block

- Completely Integrated System for Embedded Applications,

- 32 Bit Risc Architecture, Efficient and Powerful ARM9 Core.

- LSU Interface Module for Interfacing PVC or HPVC with LSU

- 2 Channel General Purpose DMA Controller for High Speed I/O

- Dual Memory Bus Architecture

- Operation Frequency : AHB Bus: 60MHz, Internal System Bus: 120MHz

- Operation Voltage : 3.3V

- POWER ON RESET TIME :

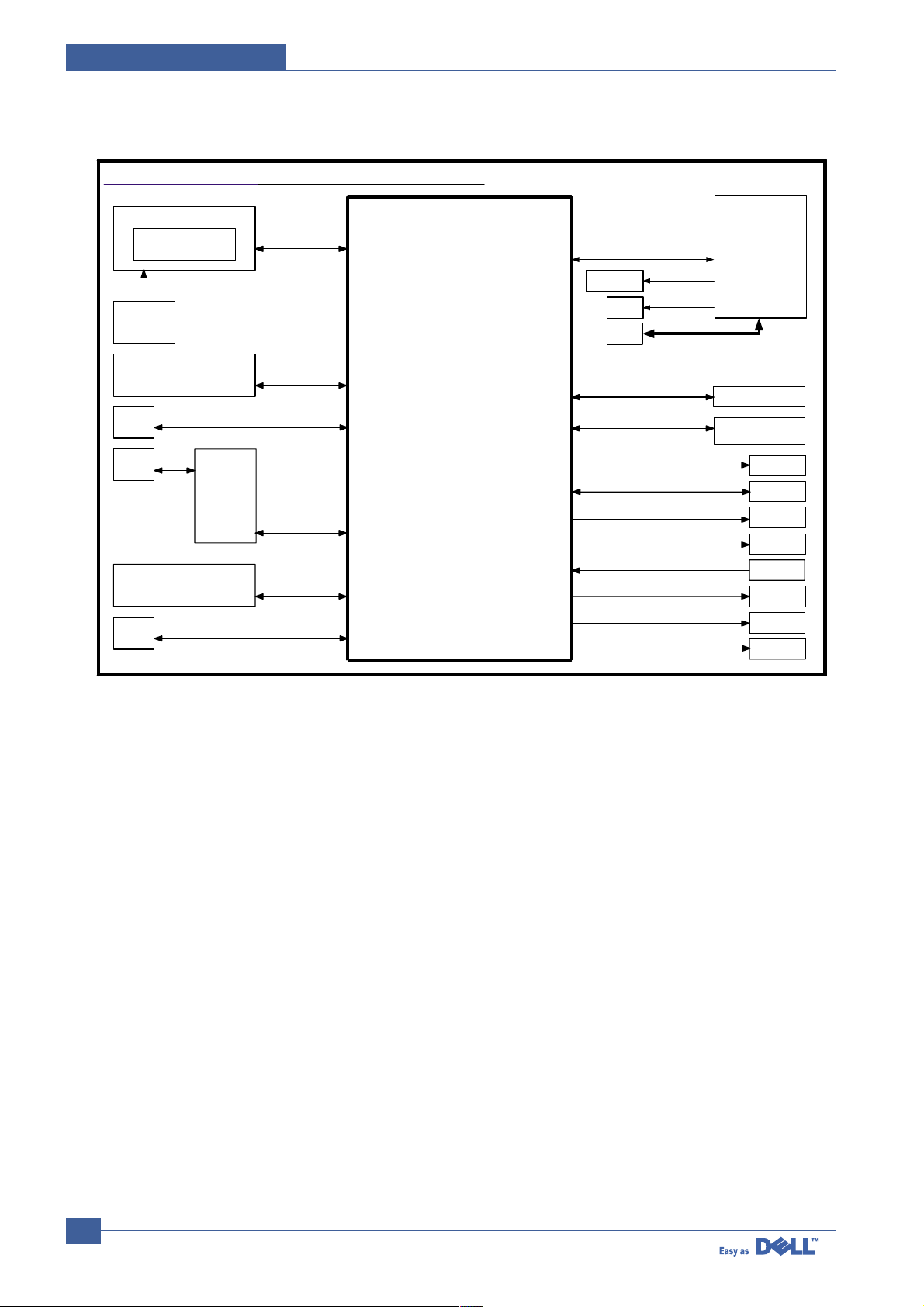

Laser MFP 1600n CONNECTION DIAGRAM

LCD MODUL E

16 X 2LINE

OPE B’d

1:DGND

2:+5V

3:OPE_TXD

4:OPE_RST

5:OPE_RXD

6 : nLED8

FLATE N

COVER

SENSOR

1:+5V

2:SIGNAL

3:GND

1,3,5,7,8 :DGND

2 : CCD_VOB

4 : CCD_VOR

6 : CCD_VOG

12,16,17,20 : DGND

9,10,11 : CCD_PI_TG

13 : CCD_PI_RS

14 : CCD_PI2

15 : CCD_PI1

16,17,20,24 : DGND

18 : CCD_PI_CP

19 : +5V

21 : CCD_HOME

22 : +24V

23 : INV_POWER

CCD MODULE

FLATEN

MOTOR

1:MA

2:MB

3:MA

4:MB

ADF

MOTOR

DRIVER

SENSOR

-P_POS

-P_PEG

-P_DET

ADF

MOTOR

1:MA

2:MB

3:MA

4:MB

1,4,11,15 : DGND

2:+24V

3:+5V

5:ADF_NA

6:ADF_PHB

7:ADF_PHA

8:ADF_B

9:ADF_NA

10 : ADF_NA

12 : nADF_P_DET

13 : nADF_DET

14 : nADF_P_REG

16 : nADF_P_POS

SCF Unit

1:+3.3V

2 : nS CF_STATUS

3:SCF_CMD

4:SCF_CLK

5:SCF_READY

6:+24V

7,8 : DGND

MAIN

MOTOR

1:MA

2:MB

3:MA

4:MB

1 : P_ EMPT Y

3,4 : +5V

7:+12V

13 : MP_EMPTY

15,22,23 : N.C

17 : N.C

19 : THV_EN

21 : MHV_PWM

25 : FUSER_ON

SMPS / HVPS

MAIN

CLUTCH

MP

CLUTCH

PTL

1:SIGNAL

2:N.C

3:+4VS

1:+24VS

2:SIGNAL

1:+5V

2:SIGNAL

TONER

RX

TONER

TX

CARTRIDGE

1:SIGNAL

2:N.C

3:+24VS

1:+24VS

2:SIGNAL

1:+3.3V

2:CART_DIN

SENSOR

-MPSENSOR

-P_EMPSEN.

-EXITSEN.

- FEED SEN

SWITCH

-DOOROPEN

2:P_FEED

5,6,8,9,10 : GND

11,12 : +24VS

14 : +24V

16 : THV_READ

18 : THV_PWM

20 : DEV_PWM

24 : FAN

26 : P_EXIT

1:LSUCLK

3:nPMOTOR

5:+24VS

7:+5V

LSU

2:nLREADY

4,8,9,11 : DGND

6:nHSYNS

10 : VDO

FAN

PWR

S/W

LIU

LINE / EXT. Phone

1:LINE1

2:LINE2

3:EXT.PHONE

MAIN B’d

SPK

1 : SPK+

2 : SPK-

THERMISTOR

1 : THERMISTER

2 : THERMISTER

FUSER

3 : CART_DOUT

4:DGND

Page 3

Circuit Diagram

Service Manual

11-3

2) Flash Memory : Record System Program, and download System Program by PC INTERFACE.

FAX for Journal List, and Memory for One Touch Dial, Speed Dial List.

- Size : 4M Byte

- Access Time : 70 nsec

3) SDRAM : is used as Swath Buffer in Printing, Scan Buffer in Scanning, ECM Buffer in FAX receiving, and

System Working Memory Area

- size 32MB : 32Mbyte(Basic).

TBD MB :System Working Memory Area and Scan Buffer

TBD MB :FAX Memory Receive Area

TBD MB :Printing System Working Memory Area

- Max Frequency : 133MHz

- store Fax Receive Memory Data by using Battery

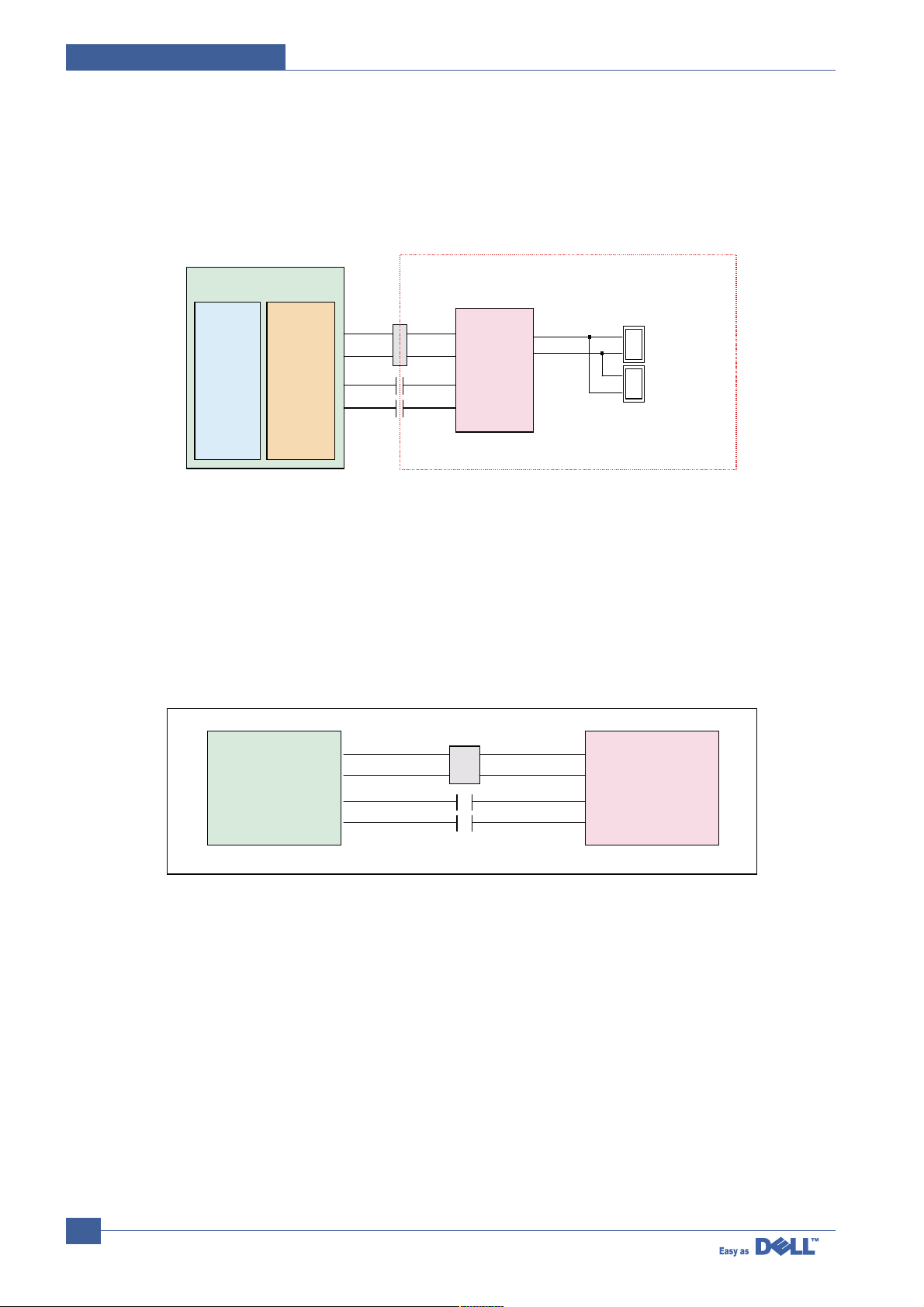

MAIN

CONTROLLER

(CPU, DMAC)

SRAM

SRAM

ANALOG

FRONT END

DATA

MEMORY

IMAGE SENSOR

CIP4

data bus address bus

control signals

control signals

data bus address bus

Page 4

Service Manual

Circuit Diagram

11-4

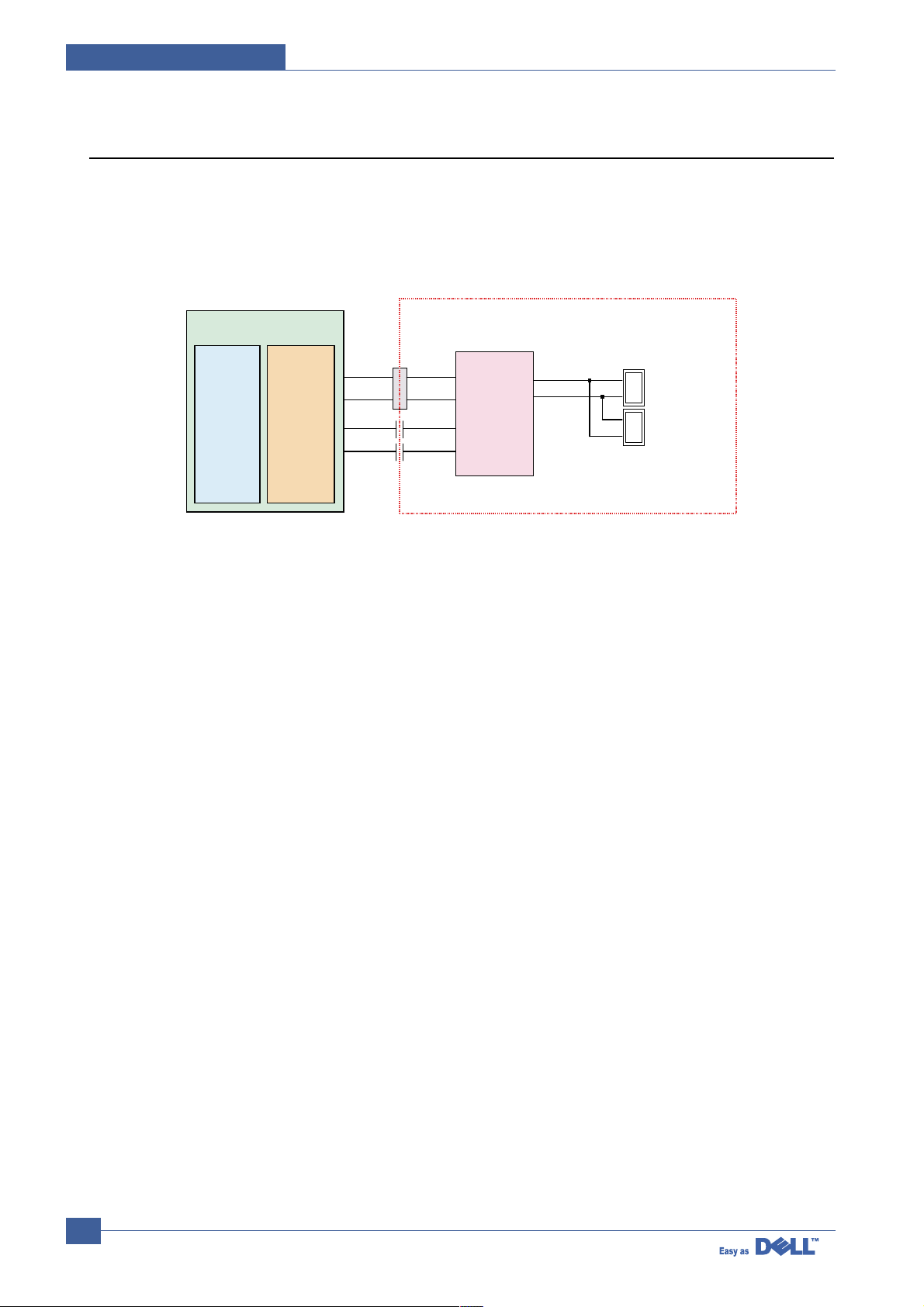

11.2 FAX Section

11.2.1 Modem Part

11.2.1.1 BLOCK DIAGRAM

DSP SSD

System

Side

Dervice

CX20493

LSD

Line

Side

Dervice

Transformer

Capacitor

Ext Line

Implemented by based on Conexant DAA (Data Access Arrangement) Solution , and is roughly composed of two

kinds Chip Solution

- CX82500(SFM336) : Existing Modem Chip which adds SSD (System Side Device) for interfacing between -

- LSD and DIB of FM336Plus Core

- CX20493(LSD) : LIU (Line Interface Unit) Chip which is controlled by SSD and satisfies each PSTN

requirements by modulating internal Configuration with connecting Tel Line.

Page 5

Circuit Diagram

Service Manual

11-5

11.2.1.2 Modem(SFM336) specification

• 2-wire half-duplex fax modem modes with send and receive data rates up to 14,400 bps

V.17, V.33, V.29, V.27 ter, and V.21 Channel 2

- Short train option in V.17 and V.27 ter

• PSTN session starting

- V.8 and V.8bis signaling

• HDLC support at all speeds

- Flag generation, 0-bit stuffing, ITU CRC-16 or CRC-32 calculation and generation

- Flag detection, 0-bit deletion, ITU CRC-16 or CRC-32 check sum error detection

- FSK flag pattern detection during high-speed receiving

• Tone modes and features

- Programmable single or dual tone generation

- DTMF receiver

- Tone detection with three programmable tone detectors

• Receive dynamic range:

- 0 dBm to –43 dBm for V.17, V.33, V.29, V.27 ter and V.21 Channel 2

• Programmable transmit level: -9 to –15 dBm

• Serial synchronous data

• Parallel synchronous data

• TTL and CMOS compatible DTE interface

- ITU-T V.24 (EIA/TIA-232-E) (data/control)

- Microprocessor bus (data/configuration/control)

Page 6

Service Manual

Circuit Diagram

11-6

1) Line Interface Signal of Tel Line and LSD is Analog Signal.

2) there is A/D, D/AConverter in LSD, so Analog Signal from Tel Line is transited in Digital through A/D Converter

in DAA and transfer to SSD by DIB Capacitor Digital Signal from SSD is converted to Analog by D/A Converter

in DAA and transfer to Tel Line

3) Transformer transfer Clock from SSD to LSD and Clock Frequency is 4.032MHz. LSD fullwave rectifies Clock to

use as inner Power supply and also use as Main Clock for DIB Protocol Sycn between LSD and SSD.

Transformer transfer Clock by separatin Primary and Secondary, and amplifies Clock Level to LSD by Coil

Turns Ratio 1:1.16.

11.2.1.3 Clock

- Clock is supplied by transformer from SSD to LSD, and There is PWROUT to adjust output impedance of

Clock Out Driver is inside SSD and CLKSHIGH Registor to adjust duty of HLPWR Registor and Clcok. Clock

from SSD to LSD has Differential structure of 180 phase difference for Noise Robustness DIB Data transfer

Data From SSD to LSD By Capacitor, and also transfer specific data from LSD to SSD. after transfering data

to SSD, RSP is transfered and LSD recognize RSP and change LSD to output Driver transfer Data to SSD.

DIB Data form SSD to LSD by Capacitor has Differential structure of 180 phase difference between DIBP and

DIBN for Noise Robustness

Tel Line

CX20493

LSD

Line

Side

Device

CX82500(SFM336)

SSD

System

Side

Device

DSP

Capacitor

Transformer

Primary Parts

Ext Line

LSD

SSD

CLKP

CLKN

DIBP

DIBN

Page 7

Circuit Diagram

Service Manual

11-7

1) Application Network: 3 PSTN (RJ-11)

2) Communication Mode: Half-Duplex, ITU V.8, V.34, V.17, V.29, V.21, ECM

> Modem will auto train down only.

> .

3) Communication Standard: ITU-T Group 3

4) Max. Modem Speed: 33.6 Kbps

5) Encoding: MH, MR, MMR, JPEG

6) Transfer Rate: 3 seconds (standard resolution, MMR, 33.6kbps)

> Phase “C” by ITU-T No.1 Chart/Memory Transmission/ECM

7) Fax Modes: Standard (203 x 98 dpi)

> Fine (203 x 196 dpi)

> Super Fine (300 x 300 dpi)

8) Fax Contrast: Adjustable 3 levels (Light/Normal/Dark)

9) Fax Memory: 4MB (About 300 Sheets of CCITT No.1 Chart at standard resolution).

User selectable parameters will be stored in NVRAM.

10) TX/RX Journal : Available.

1 1) Tel/ID List: Available.

12) Confirmation Reports for Send: Upon successful transmission

> Upon failure

> Reduced image of first page (except OHD, and partial page for

complexity of the images)

> Customer On/Off selectable

13) Management Reports:

> System Data List

> Image TCR for Memory TX

14) TTI/RTI: TTI (Transmit Terminal Identification) printed at top of Fax Image.

> RTI(Receiver Terminal Identification) printed at bottom of Fax

Image the Transmitting devices fax number is substituted for

receving devices fax number is this footer..

15) Line Control Unit (LIU): > Input Sensitivity: Not programmable

> Output Level: 9 to 15 db (programmable)

> Cable Equalization: Not programmable

> Input/Output Impedance: per PTT requirements (programmable)

> DC Resistance: per PTT requirements (programmable)

> Insulation Resistance: Minimum 5M ohm

16) Header Transmission (Always On): Local Machine date and time

> Local Machine ID

> Local Machine Name

> Transmit page count (3 digits)

Page 8

Service Manual

Circuit Diagram

11-8

This is Connection Part between system and PSTN(Public Switched Telephone Network), and 1 st side circuit is

usually located. Main functions are Line Interface, Telephone Connection and Line Condition Monitoring.

1. Telephone Line Connection

• Modular Plug : RJ-11C

• LIU PBA Modular Type : 623 PCB4-4

• Line Code Length : 2m

• Line Code Color : Ivory

11.2.1.4 ON HOOK state Characteristic

1) DC Resistance

• DP Dial Mode (Direct Current 30mA) : 50 ~ 300ohm

• DTMF Dial Mode (Direct Current 20mA) : 50 ~ 540ohm

2) Ring Sensitivity

• Ring detection Voltage : 40Vrms % 150Vrms (condition :Current=25mA,Frequency=15Hz)

product Margin : 30Vrms % 150Vrms

• Ring detection Frequency : 15.3Hz % 68Hz (condition : Voltage=45Vrms,Current=25mA )

product Margin : 15Hz % 70Hz

• Ring detection Current : 20mA % 100mA (condition : Voltage=40Vrms,Frequency=20Hz)

product Margin : over 15mA

3) False Ring Sound

• Ring Frequency : 750Hz + 1020Hz

• Ring interrupt Cycle : On/Off depending on input Ring Signal Cycle.

Page 9

Circuit Diagram

Service Manual

11-9

11.3 Scanner Section

11.3.1 Scan Part

Pictorial signal input part : output signal of CCD passes through Bypass_Cap change to ADC at AFE_CIP4 , and

defined signal between AFE_CIP4 and CIP4 processes the Image signal. When AFE accept each pixel,

CDS(Correlated Double Sampling ) technique which samples arm-level twice is used on each pixel by using CIP4

signal.

1) Pictorial image processing part : read CCD Pixel data in terms of 600dpi Line and process LAT algorithm on

Text mode, Error Diffusion Algorithm on Mixed mode, and store Data at Scan Buffer on PC Scan mode without

algorithm. on every mode Shading Correction and Gamma Correction are executed ahead, then processing is

executed later

* Scan Image Control Specification

• Minimum Scan Line Time : 0.72ms

• Scan Resolution : Max. 600DPI

• Scan Width : 216mm

• main function

- Internal 12bit ADC

- White Shading Correction

- Gamma Correction

- CCD Interface

- 256 Gray Scale

2) CCD Operating Part : CCD Image sensor use +5V and Inverter uses +24V

- CCD Maximum Operating Frequency : 10MHz

- CCD Line time : 0.72ms

- White Data output Voltage : 0.7V & 0.5V (Mono Copy, 0.72ms/line)

- Maximum Inverter Current : 600 mA Max.( +24V)

Page 10

Service Manual

Circuit Diagram

11-10

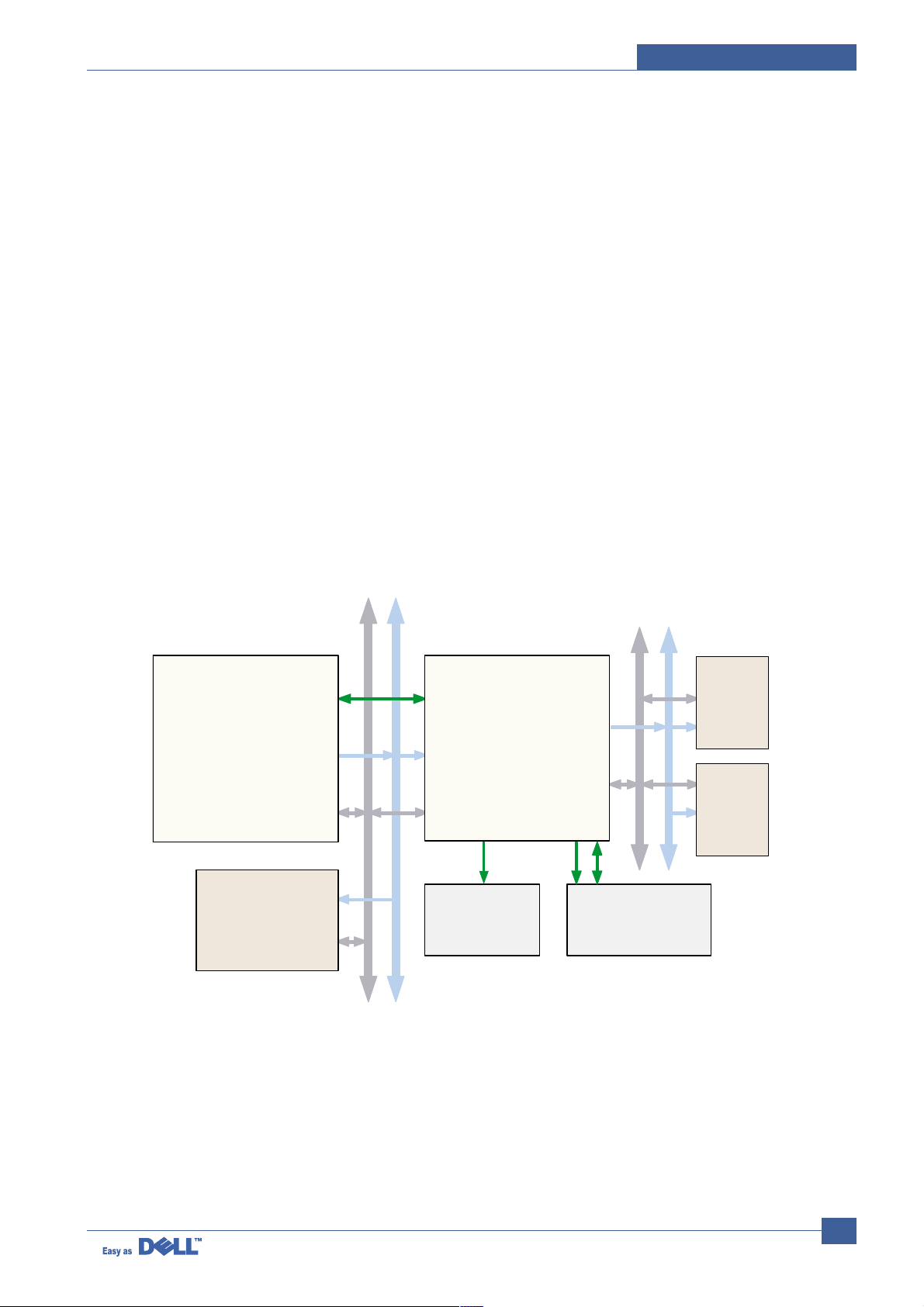

11.3.2 IP Block Diagram

Crystal

20MHz

CIP4

Oscillation Pad

40MHz

80MHz

SRAM Data

SRAM Address

A/D Converted DataSensor Signal

DMA Request

CPU Address

CPU Data

DMA Acknowledge

Table2

Table1

Table3

Table4

Line

Bufter

CPU

IRQ Ctrl

I/O

Register

Tex DMA

Interface

Sensor

Interface

Image

Engancement

Enlargement/

Reduction

Motor

Control

Vpeak

Control

Gamma

Control

Shading

Acquistion/

Correction

Analog

Front End

Image Sensor

Internal Core

Internal SRAM

External Circuit

Table1: Gamma T able

Table2: IEM T able

Table3: Binary T able

Table4: Motor T able

Extermal

RAM

Control

Binarization

MAIN

MHIMRIMMR

CODEC

Page 11

Circuit Diagram

Service Manual

1) Scanning Device: Color CCD (Charge Coupled Device) Module

2) Supported Operating Systems: Windows 98/2000/NT4.0/ME/XP, MAC (English only, no status

monitor, web download only)

3) Compatibility: TWAIN Standard

4) Maximum Scan Width: 216mm (8.5 inches)

5) Effective Scan Width: 208mm (8.2 inches)

6) Optical Resolution: 600x1200 dpi

7) Interpolated Resolution: Maximum 4800 dpi

8) Preview Scan: 75 dpi

ADF Linearity : 20 sec. (Letter, 300dpi, USB)

Gray Scale : 64 sec. (Letter, 300dpi, USB)

Color : 64 sec. (Letter, 300dpi, USB)

9) Scan Modes/Speeds:

10) ADF Capacity: 50 sheets (20 lb)

11) Image Compression: None

12) PC Interface: > USB (without HUB mode)

Requires 6 ft. USB Cable (not supplied by SEC)

(USB & Parallel are not >

simultaneously supported)

13) Minimum PC Specification: Pentium-II 233MHz, 64MB RAM, 120MB free disk space

14) Registration Position for Original: > Platen: Rear-Left Corner(when facing front/operator panel).

> ADF: Center

15) Number of Copes: 2 digits (99 maximum for LCD display and reports)

11.3.3 Ope Pannel Section

(1)Configuration

operation Panel uses Main Control and separated Ope Chip Micom and work as inner program, systemic

operation is serial system which exchange Date with SIO Port of Main Control. Ope Panel is approximately

composed of Micom part, Matrix part and LCD.

(2) Micom controller

Micom has ROM, RAM, I/O Port built-in and displays and lights LCD by CPU command of Main Control Part

and report Key recognition Data to Main Control Board.

(USB 1.1, 300dpi, Letter

Size, Pentimum 4 1.xGHz,

128MB RAM)

ADF Linearity : 20sec.(Letter, 300dpi, USB)

Gray Scale : 64 sec. (Letter, 300dpi, USB)

Color : 64 sec. (Letter, 300dpi, USB)

Platen Linearity : 18 sec. (Letter, 300dpi, USB)

Gray Scale : 62 sec. (Letter, 300dpi, USB)

Color : 62 sec. (Letter, 300dpi, USB)

11-11

Page 12

Service Manual

Circuit Diagram

11-12

11.4 Printer Section

Printer is consisted of the Engine parts and F/W, and said engine parts is consisted of the mechanical parts

comprising Frame, Feeding, Developing, Driving, Transferring, Fusing, Cabinet and H/W comprising the main

control board, power board, operation panel, PC Interface.

The main controller is consisted of Asic(SPGPm) parts, Memory parts, Engine interface parts and it functions as

Bus Control, I/O Handing, drivers & PC Interface by CPU.

Memory Access supports 16bit Operation, and Program Memory 2MB and Working Memory as well.

The Engine Board and the Controller Board are in one united board, and it is consisted of CPU part and print part

in functional aspect. The CPU is functioned as the bus control, I/O handling, drivers, and PC interface. The main

board sends the Current Image, Video data to the LSU and manages the conduct of Electrophotography for

printing. It is consisted of the circuits of the motor (paper feed, pass) driving, clutch driving, pre-transfer lamp

driving, current driving, and fan driving. The signals from the paper feed jam sensor and paper empty sensor are

directly inputted to the main board.

1) Printing Method: Laser-based Electrophotography

2) Supported Operating Systems: Windows 98/2000/NT4.0/ME/XP/ MAC (English only, no status

monitor, web download only)

3) Emulation: SPL(GDI) , PCL6, PS3,PCL5e

4) Maximum Paper Size: Legal

5) Effective Printing Width: > Letter/Legal: 208mm

> A4: 202mm

6) Resolution: > Addressable 1200 x1200 dpi

(selectable from Print Driver) > 600x600 dpi (True; no RET)

7) Speed: 22ppm (Letter)

8) Input Paper Capacity: > Tray: 250 sheets (20 lb)

> Bypass: Single sheet

9) Output Paper Capacity: 150 sheets (20 lb; sequenced 1 to N, face down)

10) Feed Direction: Front In, Front Out (FIFO)

11) PC Interface: > USB 2.0(without HUB mode)

Requires 6 ft. USB Cable (not supplied by SEC)

12) Toner Cartridge: > Toner Low Sensor: None

> Toner Low Indicator: Message displayed on LCD

> Cartridge Missing Indicator: Message displayed on LCD

13) Paper Sensing: > Tray: “Add Paper” message displayed on LCD

> Bypass: “Add Paper” message displayed on LCD

Page 13

Circuit Diagram

Service Manual

11-13

11.4.1 ASIC

• ARM946ES

- 32-bit RISC embedded processor core

- 16KB instruction cache and 16KB data cache

- No Tightly Coupled Memory

- Memory Protection Unit & CP15 control program

• Dual bus architecture for bus traffic distribution

- AMBAHigh performance Bus (AHB)

- System Bus with SDRAM

• Printer Video Controller for LBP engines

• Graphic Execution Unit for banding support of Printer Languages

• Printer Video Controller for LBP engines

- PVC : Printer Video Controller without RETAlgorithm

- HPVC : Printer Video Controller with RET algorithm

(Line Memory & Lookup Table Memory : 512 x 8 , 4096 x 16)

• Engine Controller

- Motor Control Unit

- Motor Speed Lookup Table Memory (128 x 16 x 2)

- Pulse Width Modulation Unit

- 4 Channels are supported

- ADC Interface Unit

- 3 ADC Channels are available

- ADC Core (ADC8MUX8) maximum clock frequency : 3 MHz

• USB 2.0 Interface

• Package : 272 pins PBGA

• Power : 1.8V(Core), 3.3V(IO) power operation

Page 14

Service Manual

Circuit Diagram

11-14

11.4.2 Speed : 166MHz core(ARM946ES) operation, 60MHz bus operation

ADDR/

DATA

MUX

ROM

CONTROLLER

EXTERNAL

DMA CONTROLLER

(4CH)

ARM946E-S CORE

16KB ICACHE

16KB DCACHE

USB2.0

ARBITER

DECODER

MAC

SYSMAC

SFR Bus

AHB Bus

System Bus

SYSTEM BUS

ARBITER

SYSTEM PLL

(120MHz)

CLOCK & RESET

GENERAT OR

SDRAM

CONTROLLER

(5CH)

GRAPHIC

EXECUTION

UNIT

ROTATOR/

SCALER/

HALFTONER

1024x8, 256x8x4

EPI

MISC

CONTROLLER

PARALLEL PORT

INTERFACE

HCT

ENGINE

CONTROLLER

UART(3CH)

gCODEC

TIME CONTROL

UNIT

INTERRUPT

CTRL (5CH)

ENGINE

Comm. I/F

ADC (3CH)

MOTOR

CONTROLLER

128x16x2

PULSE WIDTH

MODULATOR

HPVC

512x8

4096x16

PVC

LSU I/F

SFR BUS

INTERFACE

IO

CONTROLLER

SYSTEM

BUS

INTERFACE

Page 15

Circuit Diagram

Service Manual

11-15

11.5 Copier Section

1) Copy Mode: Black and White

2) Scanner Type: CCD with Flatbed/Platen and ADF

3) Maximum Size of Original: > Platen: 216 x 297 mm

> ADF: Legal (216 x 356 mm)

(max. width = 218 mm,

max length = 400 mm)

4) Optical Resolution: 600 x 600 dpi

5) Copy Quality - H x V: > Text : 600 x 300 dpi (default)

(User selectable via Content button) > Mixed : 600 x 300 dpi

> Photo : 600 x 600 dpi

6) Supported Media Types: Plain, Label, Cardstock, Transparency

7) Copy Speed: > Platen, SDMP: 22cpm (Letter)

(SDMP = Single Document, > ADF, SDMP: 22cpm (Letter)

Multiple Printout, > ADF, MDSP: 7cpm (Letter, Text or Mixed)

4cpm (Letter, Photo)

MDSP = Multiple Document,

Single Printout)

8) Reduce/Enlarge: Platen: 25% - 400% (1% increments)

> ADF: 25% - 100% (1% increments)

9) Non-printable Area: 4 mm (Top, Bottom, and each Side)

10) Copy Count: 1 to 99

(Page count displayed on LCD

during copy operation)

11) Copy Modes: Text, Mixed, Photo

12) Fixed R/E Setting: 1 00%, Auto-fit, 2(4)-Up

13) Darkness Control: 3 levels

14) First Copy Output Time (FCOT): > Platen: 10 sec. (600 x 300 dpi)

> ADF: 15 sec. (600 x 300 dpi)

15) Duplex Copy > TBD

Page 16

Service Manual

Circuit Diagram

11-16

11.6 Telephone Section

1) Speed Dial: 200 Locations (46 digits maximum per location)

2) On-hook Dial (manual fax): Yes

3) Last Number Redial: Yes

4) Automatic Redial: Y es

5) Pause: Yes (using Redial key)

6) Ringer Volume: Off, Low, Medium, High

7) Tone/Pulse: Selectable (Tech Mode Only no Telecom certification for Pulse mode)

11.7 SMPS & HVPS Section

The SMPS supplies DC Power to the System.

It takes 110V/220V and outputs the +5V, +24V to supply the power to the main board and ADF board. The HVPS

board creates the high voltage of THV/MHV/Supply/Dev and supplies it to the developer part for making best

condition to display the image. The HVPS part takes the 24V and outputs the high voltage for THV/MHV/BIAS,

and the outputted high voltage is supplied to the toner, OPC cartridge, and transfer roller.

11.7.1 HVPS (High Voltage Power Supply)

• Transfer High Voltage (THV+)

> Input Voltage : 24 V DC & 15%

> Output Voltage : MAX +5.0KV & 5 %,(Duty Variable, no loading )

- 1.2KV & 15% (when cleaning,200 ( )

> Output Voltage Trigger : 6.5 )

> Input contrast of the Voltage stability degree :under & 5 % (fluctuating input 21.6V % 26.4V)

Loading contrast : & 5 % or less

> Output Voltage Rising Time : 100 ms Max

> Output Voltage Falling Time : 100 ms Max

> Fluctuating transfer voltage with environmental various : +650 V(Duty 10%) ~ 5 KV (Duty 90%)

> Environment Recognition Control Method : The THV-PWM ACTIVE is transfer active signal. It detects the

resistance by recognizing the voltage value, F/B, while permits the environmental recognition voltage.

> Output Voltage Control Method : Transfer Output Voltage is outputted and controlled by changing Duty of

THVPWM Signal. 10% Duty : +650V, 90% Duty : +5KV & 5%

Page 17

Circuit Diagram

Service Manual

11-17

• Charge Voltage (MHV)

> Input Voltage : 24 V DC & 15%

> Output Voltage : -1.3KV ~ -1.8KV DC +/- 50V

> Output Voltage Rising Time : 50 ms Max

> Output Voltage Falling Time : 50 ms Max

> Output Loading range : 30 M * ~ 1000 M *

> Output Control Signal(MHV-PWM) : CPU is HV output when PWM is Low

• Cleaning Voltage (THV-)

> The (+) Transfer Voltage is not outputted because the THV PWM is controlled with high.

> The (-) Transfer Voltage is outputted because the THV-Enable Signal is controlled with low

> The output fluctuation range is big because there is no Feedback control.

• Developing Voltage (DEV)

> Input Voltage : 24 V DC & 15%

> Output Voltage: -200V ~ -600V DC & 20 V

> Output Voltage Fluctuation range: PWM Control

> Input contrast of the output stability degree : & 5 % or less

Loading contrast : & 5 % or less

> Output Voltage Rising Time : 50 ms Max

> Output Voltage Falling Time : 50 ms Max

> Output Loading range : 10M * ~ 1000 M *

> Output Control Signal (BIAS-PWM) : the CPU output is HV output when PWM is low.

•S upply

> Output Voltage : -400 V ~ -800V DC & 50 V(ZENER using, DEV )

> Input contrast of the output stability degree : under & 5 %

Loading contrast : & 5 % or less

> Output Voltage Rising Time : 50 ms Max

> Output Voltage Falling Time : 50 ms Max

> Output Loading range : 10 M * ~ 1000 M *

> Output Control Signal (BIAS-PWM) : the CPU is HV output when PWM is low.

Page 18

Service Manual

Circuit Diagram

11-18

11.7.2 SMPS (Switching Mode Power Supply)

It is the power source of entire system. It is assembled by an independent module, so it is possible to use for

common use. It is mounted at the bottom of the set.

It is consisted of the SMPS part, which supplies the DC power for driving the system, and the AC heater control

part, which supplies the power to fuser. SMPS has two output channels. Which are +5V and +24V.

• AC Input

> Input Rated Voltage : AC 220V ~ 240V AC 120V / AC 220V(EXP version)

> Input Voltage fluctuating range : AC 198V ~ 264V AC 90V ~ 135V / AC 198V ~ 264V

> Rated Frequency : 50/60 Hz

> Frequency Fluctuating range : 47 ~ 63 Hz

> Input Current : Under 5.0Arms / 2.5Arms (But, the status when lamp is off or rated voltage is

inputted/outputted )

• Rated Output Power

NO ITEM CH2 CH3 Remark

1 CHANNEL NAME +5V +24.0V

2 CONNECTOR PIN CON 3 CON 3

5V PIN: 8 24V PIN:11,12,13

GND PIN: 7 GND PIN:9,10

3 Rated Output +5V & 5% +24V & 10%

(4.75 % 5.25V) (21.6 % 26.4V)

4 Max. Output voltage 0.14 A 2.0 A

5 Peak Loading voltage 0.14 A 2.5 A 1ms

6 RIPPLE NOISE 100mVp-p Under 500mVp-p

Voltage

7 Maximum output 0.35W 48W

8 Peak output 0.7W 60W 1ms

9 Protection for loading -

shortage and

overflowing current

Page 19

Circuit Diagram

Service Manual

11-19

• Consumption Power

• Length of Power Cord : 1830 & 50mm

• Power Switch : Use

• Feature

> Insulating Resistance : 50 ( or more (at DC 500V)

> Insulating revisiting pressure : Must be no problem within 1 min. (at 1500Vac,10mA)

> Leaking Current : under 3.5mA

> Running Current : under 40A PEAK (AT 25 + , COLD START)

under 60A PEAK (In other conditions)

> Rising Time : within 2Sec

> Falling Time : over 20ms

> Surge : Ring Wave 6KV-500A (Normal, Common)

• Environment Condition

> Operating temperature range : 0 +% 40 +

> Maintaining temperature range : -25 +% 85 +

> Preserving Humidity Condition : 30% % 90% RH

> Operating atmospheric pressure range : 1atm

• EMI Requirement : CISPR ,FCC, CE, MIC, C-Tick.

• Safety Requrement :IEC950 UL1950, CSA950, C-UL,NOM,TUV,Semko,Nemko,iK,CB, CCC(CCIB),GOST,

EPA, Power Save

NO ITEM CH2 (+5V) CH3 (+24V) Remark

1 Stand-By 0.07A 0.4 A AVG:55 Wh

2 PRINTING 0.14A 2.0 A AVG 350 Wh

3 Sleep-Mode 0.01A 0.4A AVG : 20 Wh

Page 20

Service Manual

Circuit Diagram

11-20

11.7.3 Fuser Ac Power Control

Fuser(HEAT LAMP) gets heat from AC power. The AV power controls the switch with the Triac, a semiconductor

switch. The ‘ON/OFF control’is operated when the gate of the Triac is turned on/off by Phototriac (insulting part).

In other words, the AC control part is passive circuit, so it turns the heater on/off with taking signal from engine

control part.

When the ‘HEATER ON’ signal is turned on at engine, the LED of PC1 (Photo Triac) takes the voltage and

flashes. From the flashing light, the Triac part (light receiving part) takes the voltage, and the voltage is supplied to

the gate of Triac and flows into the Triac. As a result, the AC current flows in the heat lamp, and heat is occurred.

On the other hand, when the signal is off, the PC1 is off, the voltage is cut off at the gate of Triac, the Triac

becomes off, and then the heat lamp is turned off.

• Triac (THY1) feature :12A, 600V SWITCHING

• Phototriac Coupler (PC3)

> Turn On If Current : 15mA% 50mA(Design: 16mA)

> High Repetive Peak Off State Voltage : Min 600V

Loading...

Loading...