Repair Manual

Repair Manual

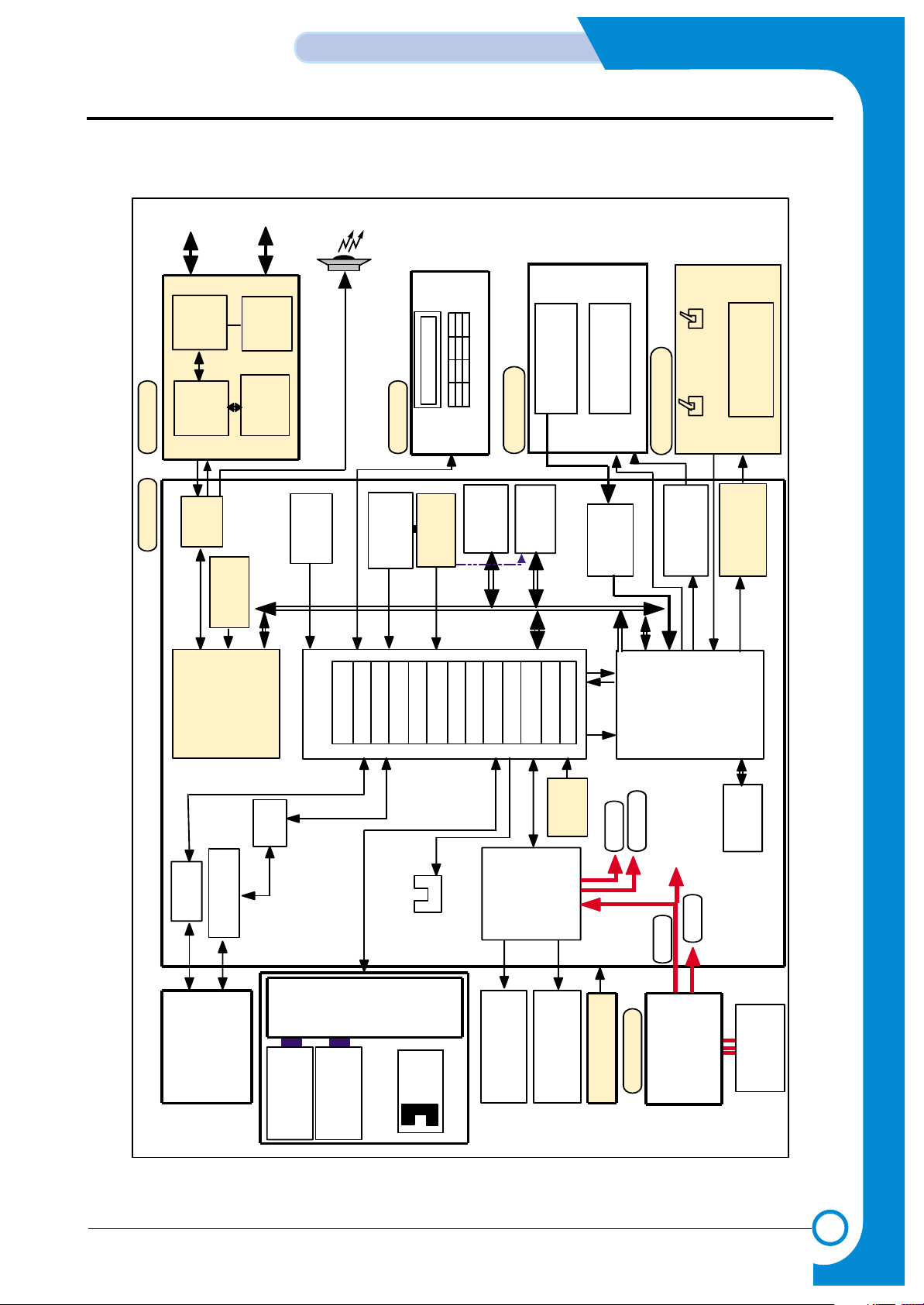

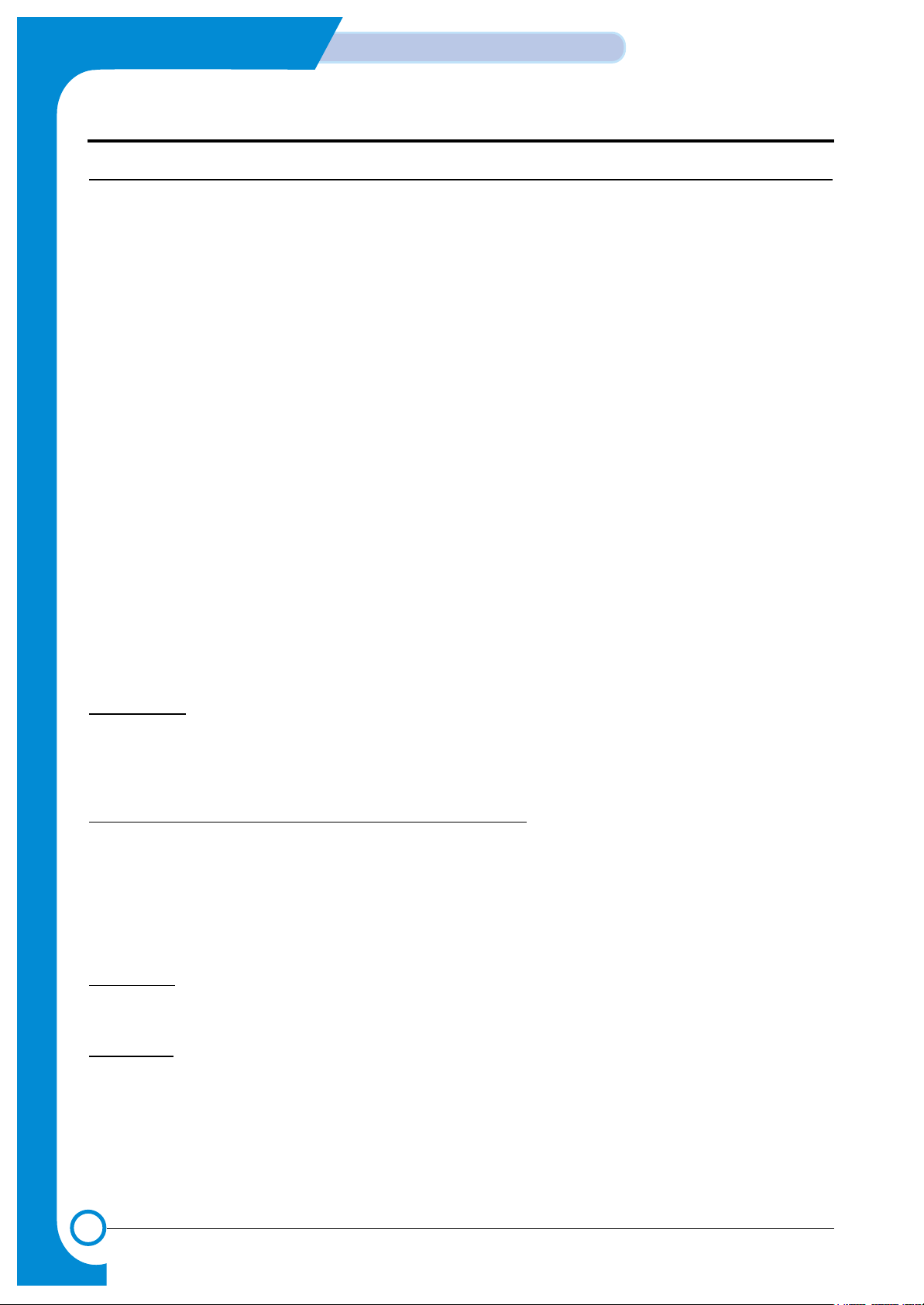

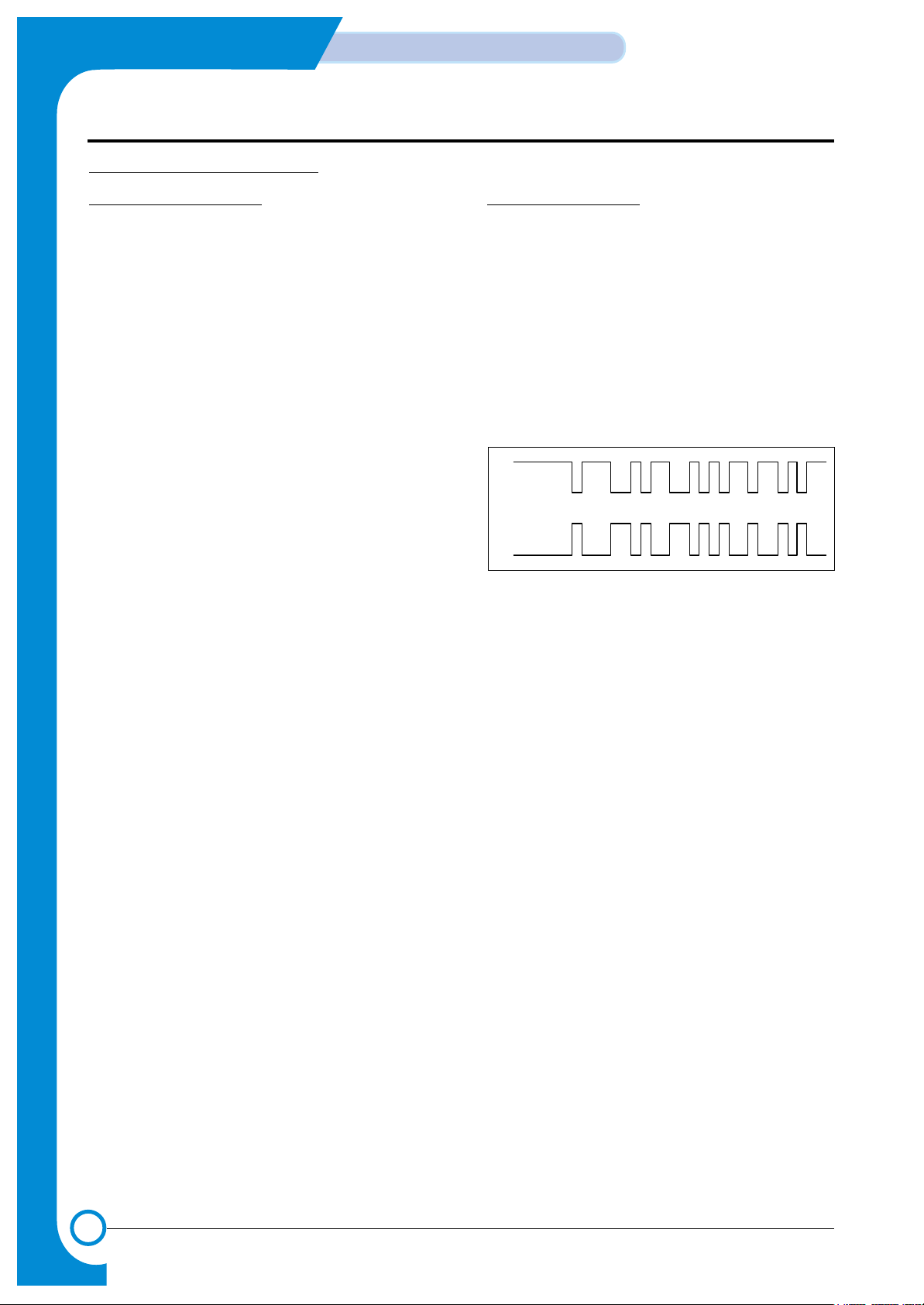

1. Block Diagram

2. Connection Diagram

3. Circuit Description

4. Schematic Diagrams

CONTENTS

INKJET PRINTER(MFP)

SCX-1150F

1

1-1

Samsung Electronics

BLOCK DIAGRAM

Repair Manual

1. Block Diag ram

AC

( 110~240

(64Mbit)

V)

SMPS

( 30V, 3. 3V)

Jupi t er3

UART 3

I/OPORT

INT. CNTR

USB

FLASH

Thunder bol

t

MOTOR

CCD Module

SCA NSTEPPER

SCAN MOTOR

(UNI-POLAR STEP)

COLOR

MON O

C A RTR I DG E

RESET

USB

PC

10MHz

48MH z

P1284 CONN

SCANNER

BU F FE

600/ / 600

Tx/ Rx

SPEAKER

SDRAM

AFE

BACK UP

(Super cap 1F)

ADF MODULE

ADF

RTC

Cl o c k

SDRA M

MODEM

Spi t f i r e

/REQ /ACK

ADC

DOC. POS SENSOR

DOC. DET SENSOR

OPE

POWER

+5V

+11.75V

+30V

+3.3V

LIUMAIN

PRINT HEAD(2PEN)

600DPI DOUBLE

HEIGHT

ENCORDER

SENSOR

LINE FEED

CARRIAGE

RETURN MOTOR

COVER OPEN SENSOR

PAPER

EXIT

SENSOR

IMAGE

PROCESSOR

OA-980

IEEE 1284

TIMERS

REAL TIME CLOCK

ARM7TDMI

MEM. SNTR

Head Control I/F

SCAN SNTR

DERASTERIZER

MODEM CLOCK

28.224MHz

MAIN CLOCK

ADF STEPPER

MOTOR DRIVER

KEY PANNEL

TELEPHONE

LINE

MODEM & EXT_PHONE

SEPERATING PART

EXTERNAL

LINE

RING

DETECTION

PA RT

EXTERNAL

PHONE

DETECTION

PA RT

TRANSFORMER

(64Mbit)

(8Mbit)

(33.6Kbps)

2

2-1

Samsung Electronics

CONNECTION DIAGRAM

Repair Manual

2. Connection Dia gr am

Refer to the Schematic diagram(See page 4-2)

3

3-1

Samsung Electronics

CIRCUIT DESCRIPTION

Repair Manual

3. Circuit Description

3-1. GENERAL DESCRIPTION

Main circuit consists of mainly consists of CPU and the controller part with various types of built-in I/O device driver(built-in

RISC Processor Core: ARM7TDMI), system memory part, OA980 controlling input of image received from media and con version, CF(COMP ACTstorage card) interface part. The following nomenclatures by section is the same as those listed in

the circuit diagram.

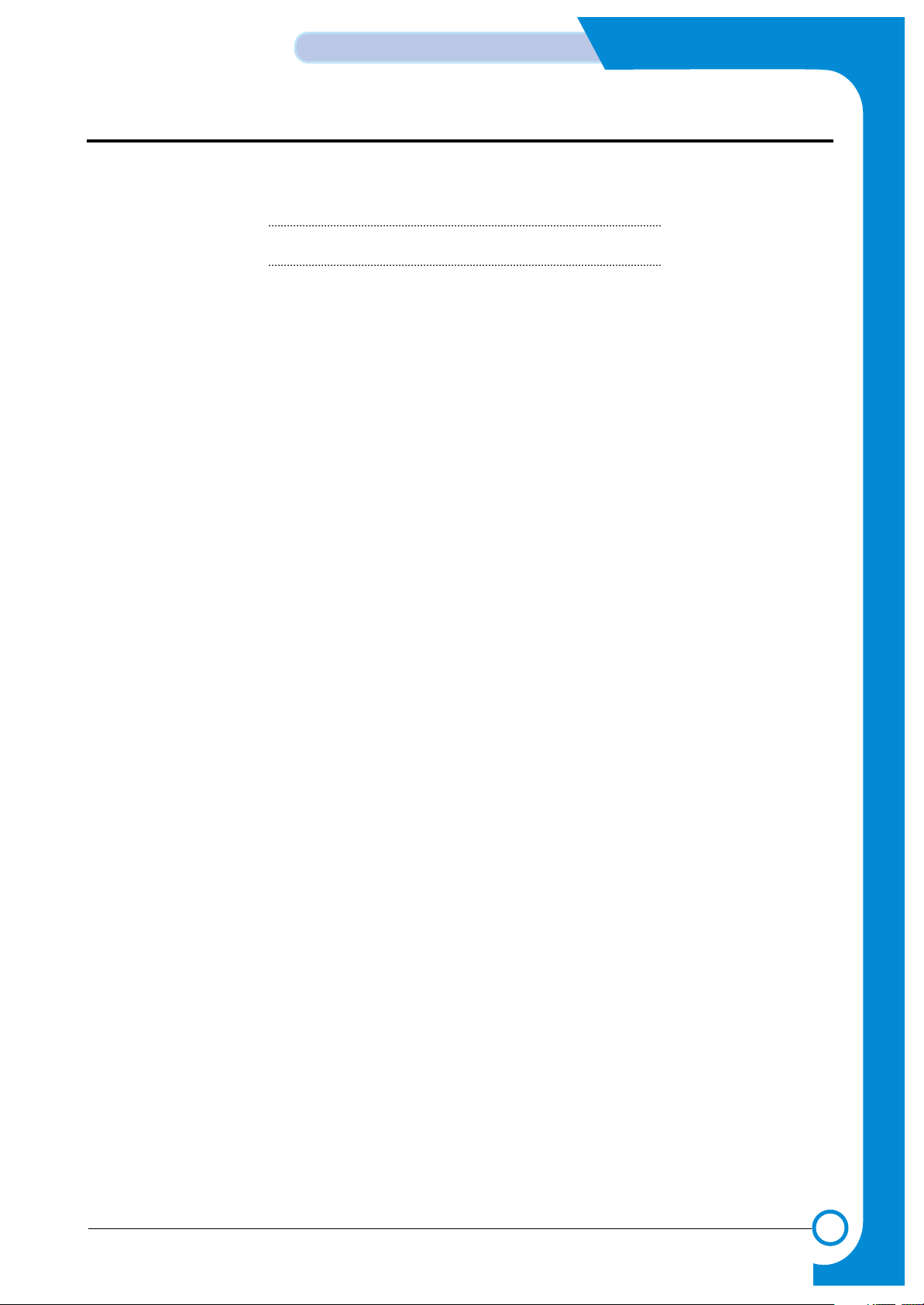

3-2. MEMORY MAP

The entire Addressing area provided by MAIN CONTROLLER(S3C46MOX(Jupiter3)) is 256MBytes from 0x00000000 to

0x10000000, and the Max. Address Range for each External Chip Select is 32M Byte or Half word from 0x000000 to

0x01FFFFFF and embodied with Big-Endian Bus interface. MEMORY area is divided into EXTERNAL ROM and RAM

areas(See (Figure 1)), and the areas actually used are 8M/8M BYTES SDRAM and 1M BYTES ROM(FLASH MEMORY).

0x0FFF_FFFF

GCS 7 Area

0x0E00_0000

0x0DFF_FFFF

GCS6 Area - DRAM(8MB)

0x0C00_0000

0x0BFF_FFFF

Reserved

0x0A00_0000

0x09FF_FFFF

GCS 4 Area - OA980 PO CS

0x0800_0 000

0x07FF_FFFF

GCS 3 Area - EXTENDED GPIO

0x0600_0 000

0x05FF_FFFF

GCS 2 Ar ea - MODEM

0x0400_0 000

0x03FF_FFFF

GCS 1 Area - OA980

0x0200_0 000

0x01FF_FFFF

Special Registers

0x01C0_0000

0x000F_FFFF

Program Area(1MB

used)

0x0000_0 000

USER MEMORY(3MB Start ~ )

0xC300000

PIXEL TO LINE BUFFER(30KB)

0xC2CBC20

Chunk Bu ffer(8KByte)

0xC2 C9C20

Re ad P rint B uffe r ( 32B yte)

0xC2 C9C00

Swath Buffer(300KByte)

0xC27EC00

Scan Buffer(810KB)

0xC1B4400

RGB Buffer(30KB)

0xC1ACC00

ECM Buffer(64KB)

0xC1 9C C00

RCP PC FAX Buffer(15KB)

0xC199000

JPEG DECODE BUFFER(64KB)

0xC099000

MDM Out Buffer(20KB)

0xC094000

MDM In Buffer(28KB)

0x C08D 000

JPEG INPUT Buffer(220KB)

0xC056000

System AREA(344K)

0xC000000

OASIS Rom Code : 256KB

(Sector 15 ~ Sector 18)

J3 ROM Code :704KB

(Sector 4 ~ Sector 14)

Backup Data(Sector 3:32KB)

Not Used(Sector 1,2: 16 KB)

Boot Rom Code(Sector 0 : 16KB)

Flash memory(1MB)

SDRAM(8MB)

<Figure 1. S3C46MOX(Jupiter3) MEMORY MAP>

◊ MAIN PBA

3-2

CIRCUIT DESCRIPTION

Samsung Electronics

Repair Manual

3-3.DETAILED DESCRIPTION

3-3-1 BLOCK DIAGRAM and MAIN CONTROLLER description

3-3-1-1 General description

MAIN CONTROLLER(S3C46MOX(Jupiter3),U15) consists of this system consists of CPU(ARM7TDMI RISC PROCESSOR), 8K BYTES CACHE, DATAand ADDRESS BUS, PLL deriding input frequency and CLOCK CONTROL part,

SERIAL COMMUNICATION part supporting UART, PRINT HEAD control part, PARALLELPORTINTERFACE part,

USB INTERFACE part, External DMApart for receiving data from external COLOR IMAGE PROCESSOR(OA980,U21), MEMORY and EXTERNAL BANK control part, SYNCHRONOUS SERIAL INTERFACE control part for interfacing Thunderbolt, and LF/CR Motor drive control and general purpose I/O control parts.(See Figure 2 )

3-3-2 S3C46MOX(Jupiter3) FUNCTION DESCRIPTION

3-3-2-1 SYSTEM CLOCK

There are two ways of Clock input method. One is the method to make Master Clock(MCLK) at the internal PLLby connecting X-tal and Capacitor to the outside, and another method is to use MCLK(When inputting 40MHz) directly, which

supplies maximum 40MHz Clock to the EXTCLK terminal(PIN65). The range of frequency being input in case of using

X-tal is limited to 4MHz~10MHz. This system uses SSCG(FS781) with a 10MHZ X-tal outside to make MCLK, and supplies Clock to the XIN terminal(PIN67) of ASIC by expanding Spectrum with bandwidth about 1.5% in comparison with

the basic frequency by using this IC. Inside the ASIC, the PLL makes 66MHz MCLK signal, which is the basic operation

frequency of the System. Also, this PLLmakes 48MHz, the operation frequency of USB Controller.

3-3-2-2 DATA and ADDRESS BUS CONTROL

1. /RD & /WR

/RD & /WR SIGNAL are synchronized with the inside MCLK(66MHZ) and becomes active to Low.

These signal are Strobe Signal used to Read or Write data when each Chip Select becomes active connected to

/RD,/WR PIN of RAM, ROM, OA-980.

2. CHIP SELECT (/ROMCS, /IP_CS,/MED_CS,/SCS0,/SCS1)

- /ROMCS : FLASH MEMORY(U7) CHIP SELECT (LOW ACTIVE)

- /IP_CS : OA-980(U21) CHIP SELECT

(LOW ACTIVE)

- /SCS1 : SDRAM(OPTION)(U12) CHIP SELECT (LOW ACTIVE)

In case each Chip Select is low, it may Read or Write data.

3. D0 ~ D15

- 16BIT DATA BUS

4. A0 ~ A24

- ADDRESS BUS (A23 ~ A24 RESERVED)

3-3

Samsung Electronics

CIRCUIT DESCRIPTION

Repair Manual

<Figure 2. Block Diagram of Main Part>

AC

( 110~240

(64Mbit)

V)

SMPS

( 30V, 3. 3V)

Jupi t er3

UART 3

I/OPORT

INT. CNTR

USB

FLASH

Thunder bol

t

MOTOR

CCD Module

SCA NSTEPPER

SCAN MOTOR

(UNI-POLAR STEP)

COLOR

MON O

CARTRI DGE

RESET

USB

PC

10M Hz

48MH z

P1284 CONN

SCANNER

BU F FE

600/ / 600

Tx/ Rx

SPE AKER

SDRAM

AFE

BACK U P

(Super cap 1F)

ADF MODULE

ADF

RTC

Cl o c k

SDRA M

MODEM

Spi t f i r e

/REQ /ACK

ADC

DOC. POS SENSOR

DOC. DET SENSOR

OPE

POWER

+5V

+11.75V

+30V

+3.3V

LIUMAIN

PRINT HEAD(2PEN)

600DPI DOUBLE

HEIGHT

ENCORDER

SENSOR

LINE FEED

CARRIAGE

RETURN MOTOR

COVER OPEN SENSOR

PAPER

EXIT

SENSOR

IMAGE

PROCESSOR

OA-980

IEEE 1284

TIMERS

REAL TIME CLOCK

ARM7TDMI

MEM. SNTR

Head Control I/F

SCAN SNTR

DERASTERIZER

MODEM CLOCK

28.224MHz

MAIN CLOCK

ADF STEPPER

MOTOR DRIVER

KEY PANNEL

TELEPHONE

LINE

MODEM & EXT_PHONE

SEPERATING PART

EXTERNAL

LINE

RING

DETECTION

PA RT

EXTERNAL

PHONE

DETECTION

PA RT

TRANSFORMER

(64Mbit)

(8Mbit)

(33.6Kbps)

3-4

CIRCUIT DESCRIPTION

Samsung Electronics

Repair Manual

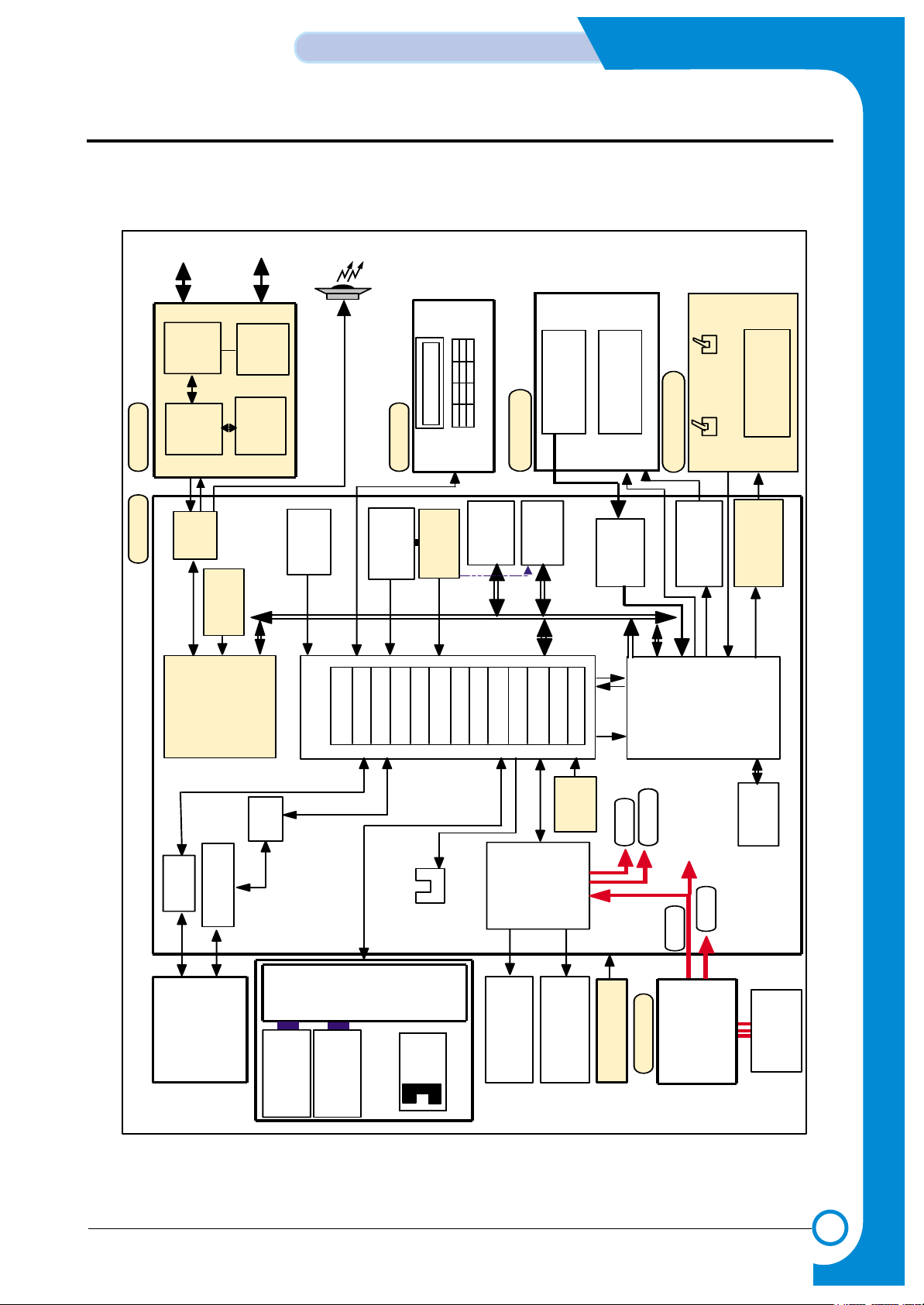

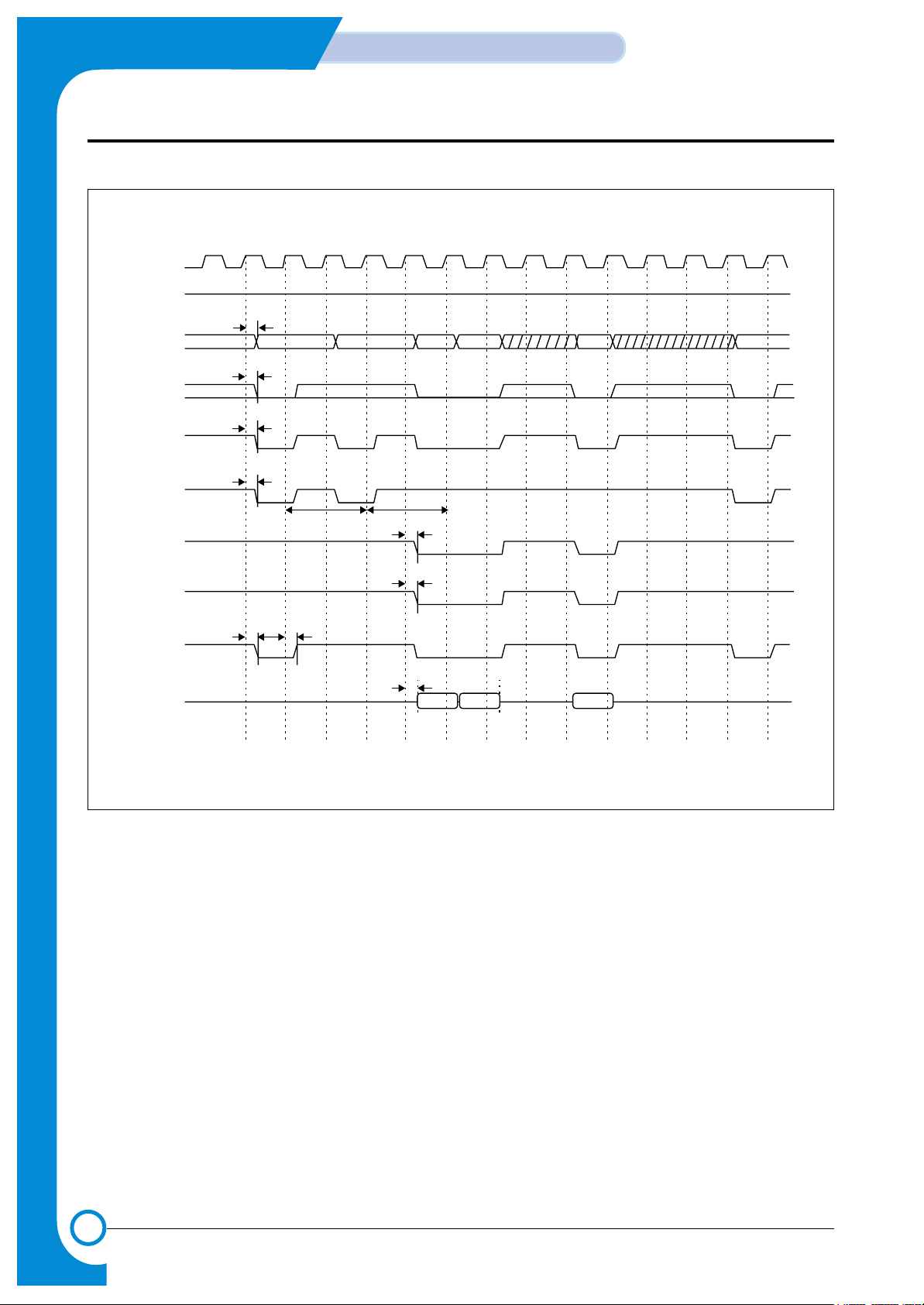

<Figure 3. Flash Memory Read Timing>

<Figure 4. Flash Memory Write Timing>

EXTCLK

nGCSx

nGCSx

ADDR

tRWD

tRAD

Tacs

tRCD

nWE

DATA

nBEx

Tacc

Toch

Tcah

Tocs

tRCD

tRWD

tRDD

tRAD

tRDH

’1’

EXTCLK

ADDR

nGCSx

nWE

nGCSx

nBEx

DATA

tRAD

tRCD

Tacs

tRWD

Tocs

tRWBED

Tcos

tRDD

Tacc

tRAD

tRCD

Tcah

tRWD

Toch

tRWBED

Toch

tRDD

3-5

Samsung Electronics

CIRCUIT DESCRIPTION

Repair Manual

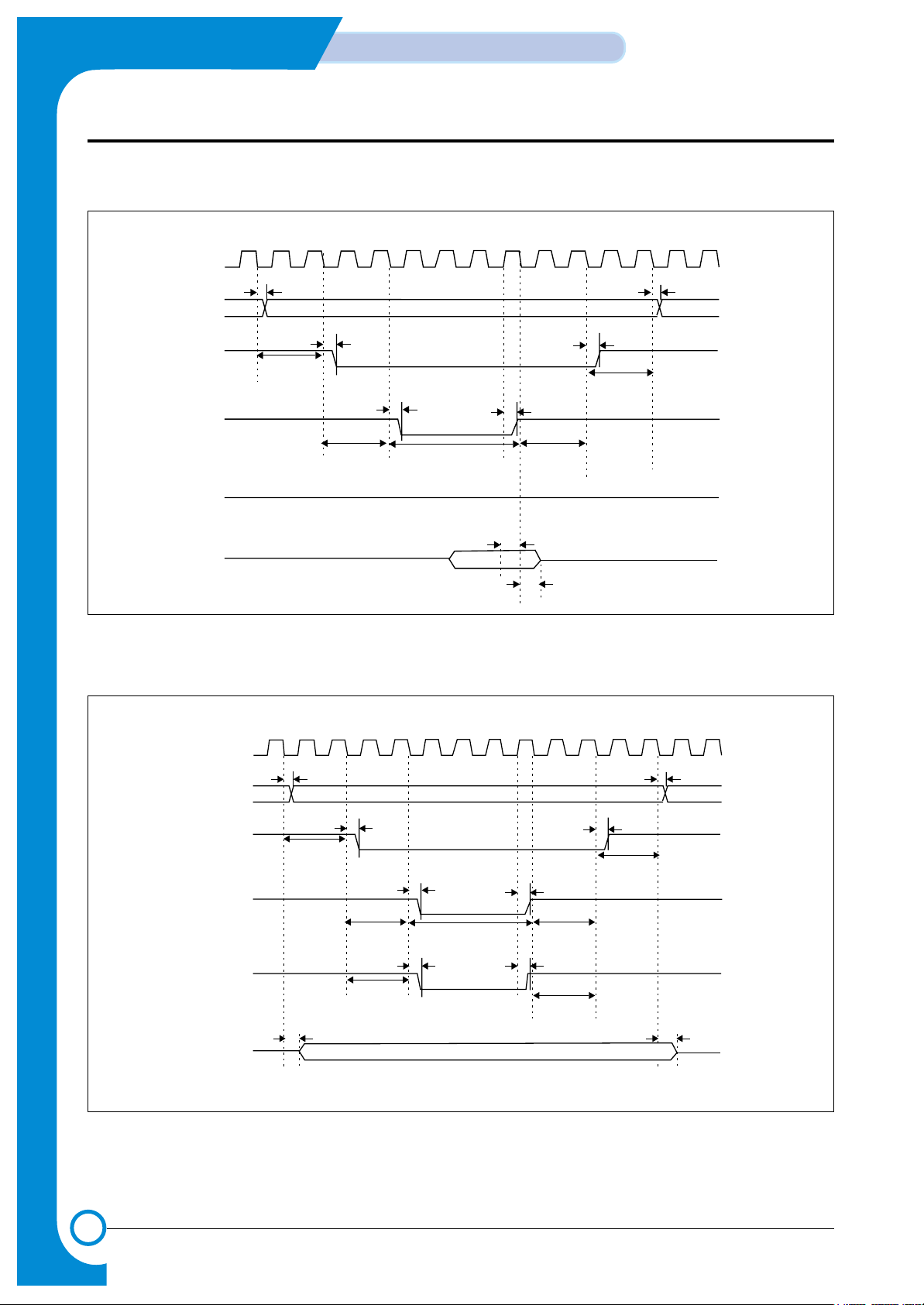

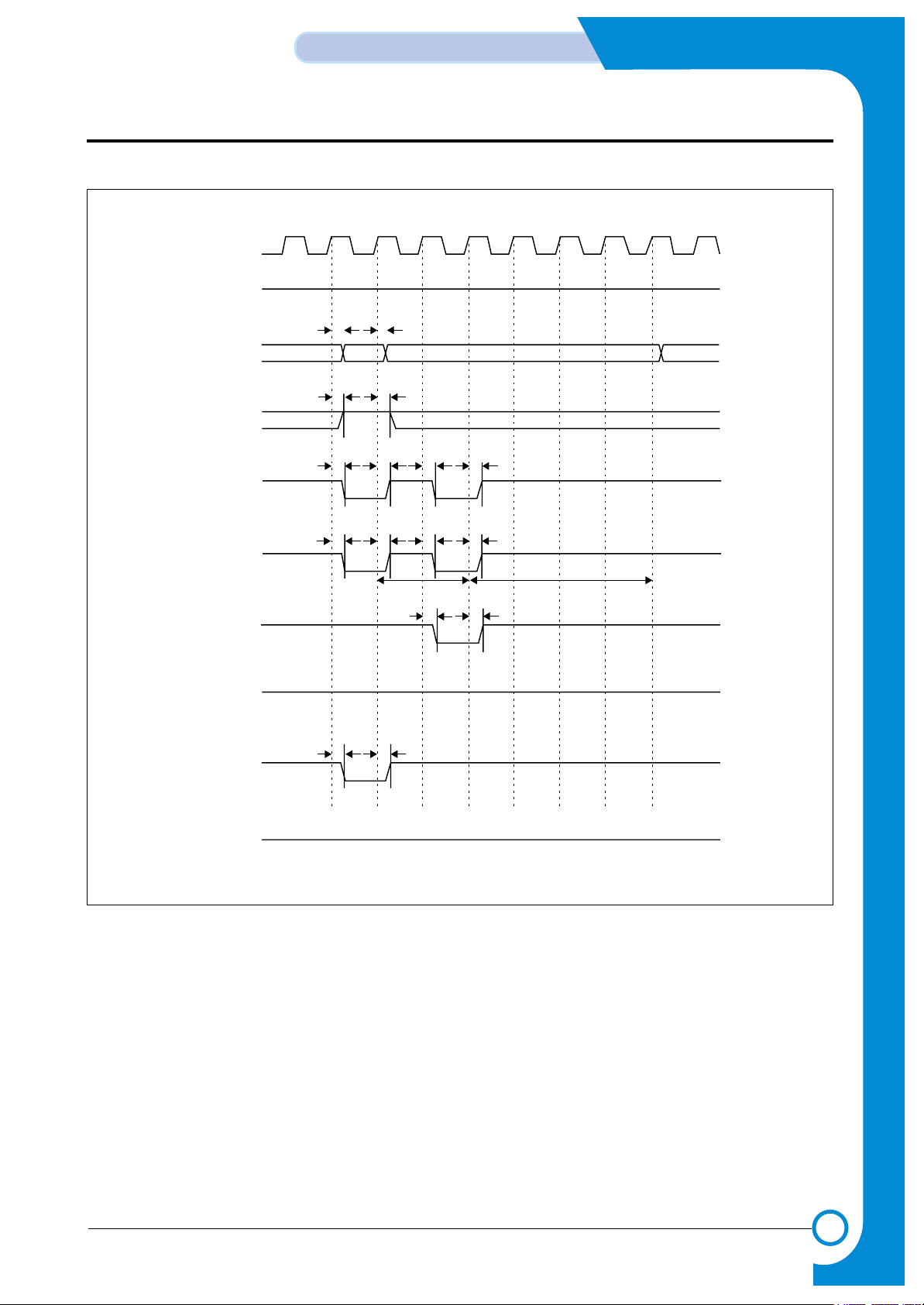

<Figure 5. SDRAM Read Timing>

SCLK

SCKE

ADDR/BA

AP/A10

nGCSx

nSRAS

nSCAS

nBEx

nWE

DATA

’1’

tSAD

tSAD

tSCSD

tSRD

Trp Trcd

tSCD

tSBED

Tcl

tSWD

tSDS

tSDH

3-6

CIRCUIT DESCRIPTION

Samsung Electronics

Repair Manual

<Figure 6. SDRAM Write Timing>

SCLK

’1’

SCKE

ADDR/BA

AP/A10

nGCSx

nSRAS

nSCAS

nBEx

nWE

DATA

tSAD

tSAD

tSCSD

tSRD

Trp

Trcd

tSWD

tSDD

tSDD

tSBED

tSCD

3-7

Samsung Electronics

CIRCUIT DESCRIPTION

Repair Manual

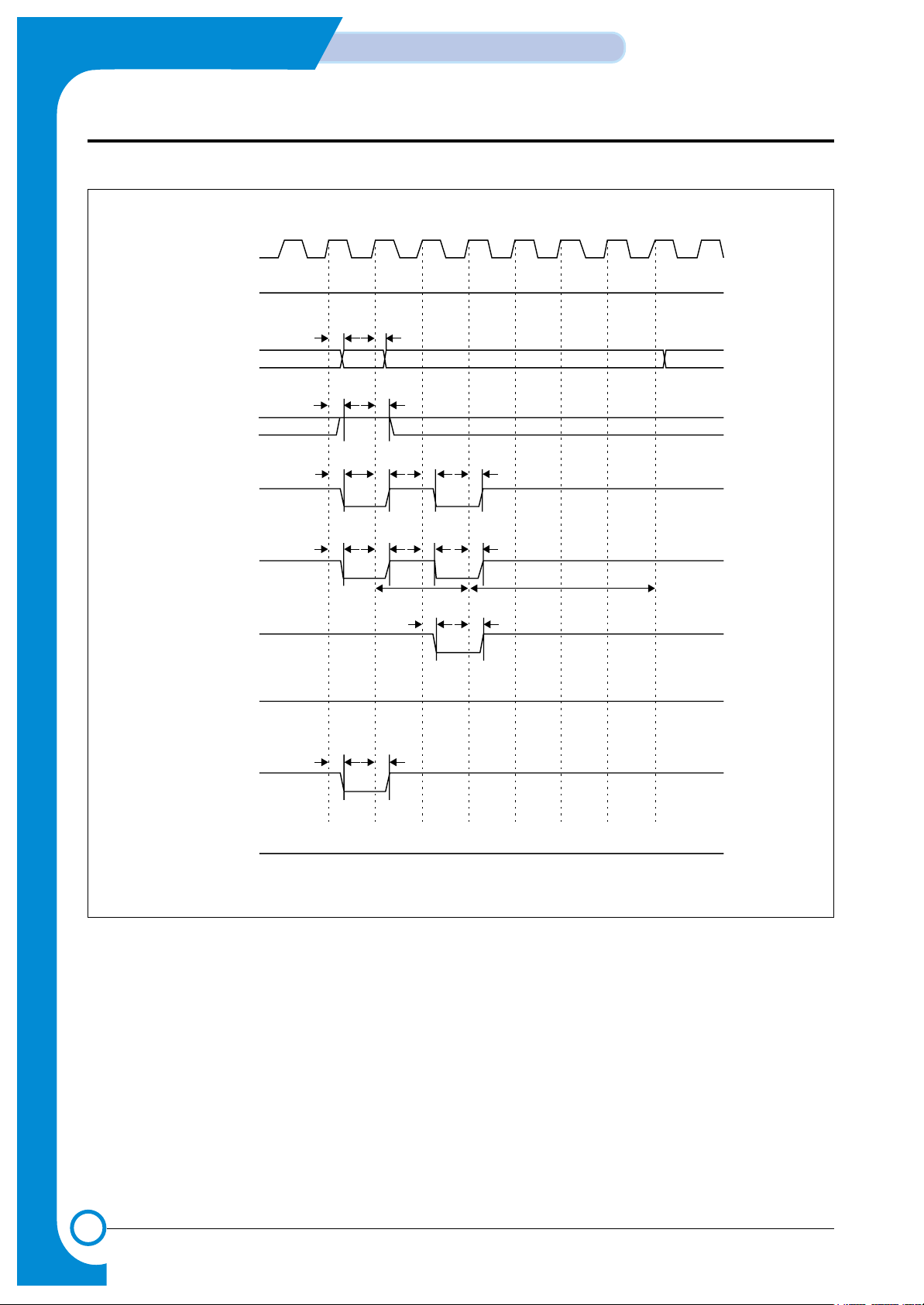

<Figure 7. SDRAM Write Timing>

SCLK

SCKE

ADDR/BA

AP/A10

nGCSx

nSRAS

nSCAS

nBEx

nWE

DATA

tSAD

’1’

’1’

’HZ’

tSAD

tSCSD

tSRD tSRD

tSCD

tSWD

tSCSD

tSAD

Trp Trc

3-8

CIRCUIT DESCRIPTION

Samsung Electronics

Repair Manual

<Figure 8. SDRAM auto Refresh Timing>

SCLK

SCKE

ADDR/BA

AP/A10

nGCSx

nSRAS

nSCAS

nBEx

nWE

DATA

tSAD

’1’

’1’

’HZ’

tSAD

tSCSD

tSRD tSRD

tSCD

tSWD

tSCSD

tSAD

Trp Trc

3-9

Samsung Electronics

CIRCUIT DESCRIPTION

Repair Manual

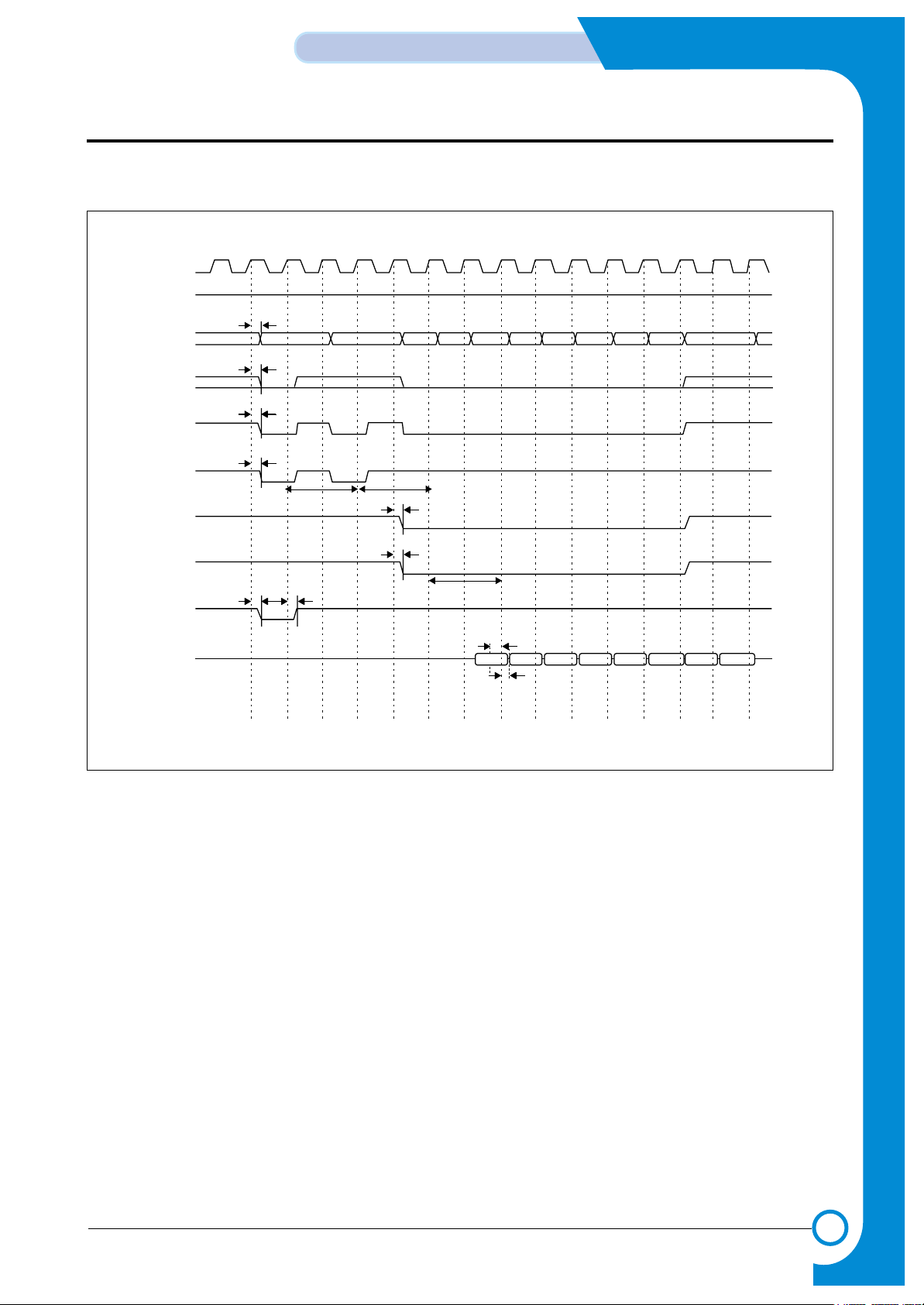

<Figure 9. SDRAM Self Refresh Timing>

SCLK

SCKE

ADDR/BA

AP/A10

nGCSx

nSRAS

nSCAS

nBEx

nWE

DATA

’HZ’

tSWD

’HZ’

’1’

’1’

’1’

’1’

’1’

’1’

’1’

tCKED

tSAD

tSAD

tSCSD

tSRD tSRD

tSCD

tSCSD

tSAD

tCKED

Trc

Trp

3-10

CIRCUIT DESCRIPTION

Samsung Electronics

Repair Manual

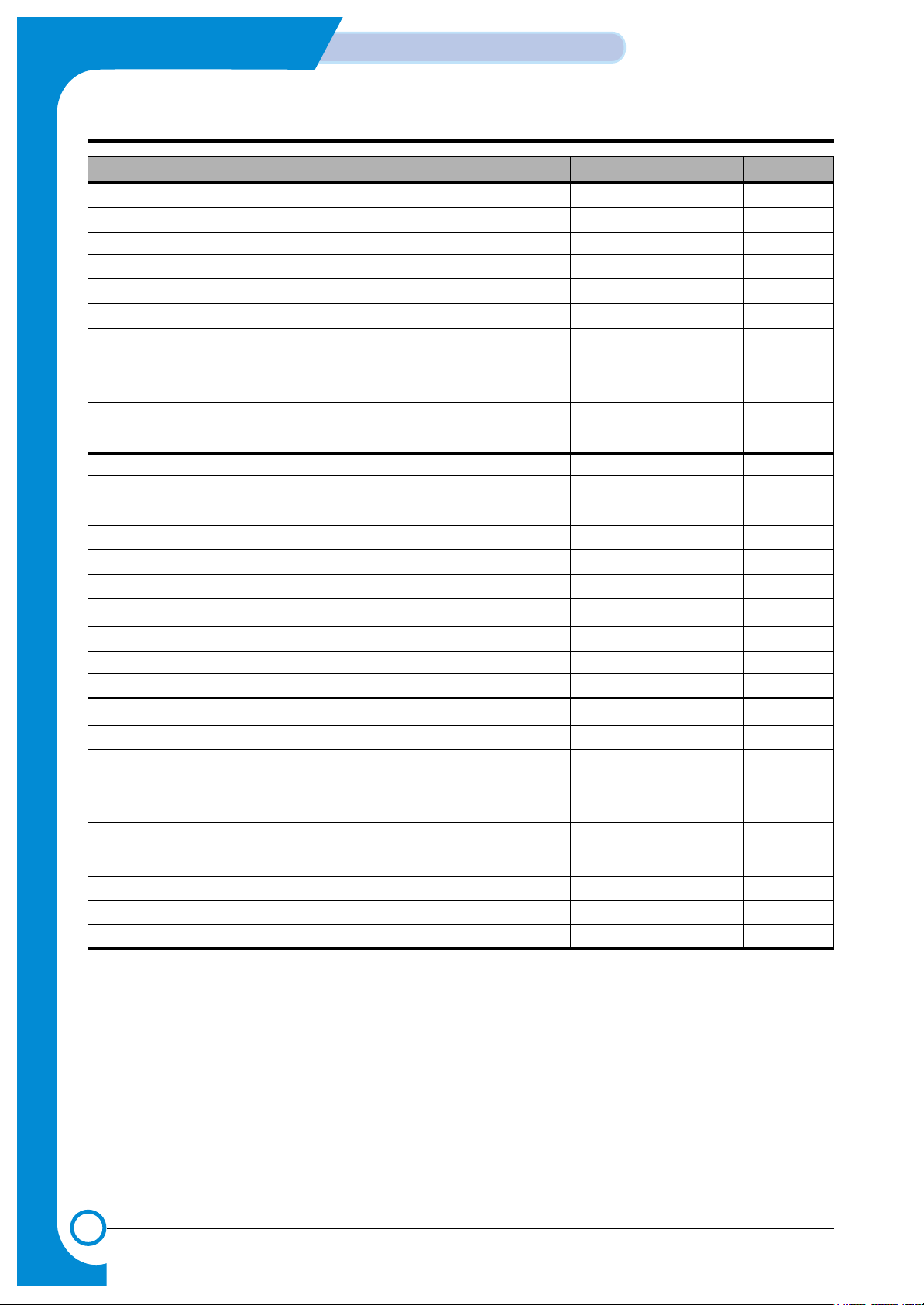

Parameter Symbol Min T yp. Max Unit

ROM/SRAM Address Delay

t

RAD - 12 - ns

ROM/SRAM Chip select Delay

t

RCD - 11 - ns

ROM/SRAM Output enable Delay

t

ROD - 1 1 - ns

ROM/SRAM read Data Setup time

t

RDS - 1 - ns

ROM/SRAM read Data Hold time

t

RDH - 5 - ns

ROM/SRAM Byte Enable Dalay

t

RBED - 13 - ns

ROM/SRAM Write Byte Enable Delay

t

RWBED - 14 - ns

ROM/SRAM output Data Delay

t

RDD - 14 - ns

ROM/SRAM external Wait Setup time

t

WS - 1 - ns

ROM/SRAM external Wait Hold time

t

WH - 5 - ns

ROM/SRAM Write enable Delay

t

RWD - 14 - ns

DRAM Address Delay

t

DAD - 12 - ns

DRAM Row active Delay

t

DRD - 11 - ns

DRAM Read Column active Delay

t

DRCD - 1 1 - ns

DRAM Output enable Delay

t

DOD - 12 - ns

DRAM read Data Setup time

t

DDS - 1 - ns

DRAM read Data Hold time

t

DDH - 5 - ns

DRAM Write Cas active Delay

t

DWCD - 14 - ns

DRAM Cbr Cas active Delay

t

DCCD - 12 - ns

DRAM Write enable Delay

t

DWD - 13 - ns

DRAM output Data Delay

t

DDD - 14 - ns

SDRAM Address Delay

t

SAD - 4 - ns

SDRAM Chip Select Delay

t

SCSD - 4 - ns

SDRAM Row active Delay

t

SRD - 4 - ns

SDRAM Column active Delay

t

SCD - 4 - ns

SDRAM Byte Enable Delay

t

SBED - 5 - ns

SDRAM Write enable Delay

t

SWD - 5 - ns

SDRAM read Data Setup time

t

SDS - 4 - ns

SDRAM read Data Hold time

t

SDH - 0 - ns

SDRAM output Data Delay

t

SDD - 8 - ns

SDRAM Clock Enable Delay

t

CKED - 5 - ns

< ROM/SRAM Bus Timing Constants >

(V

DDP

: 3.3V, V

DDI

: 2.5V, Ta =25˚C, PLCAP=70pf, Max/Min=typ. ±30%)

3-11

Samsung Electronics

CIRCUIT DESCRIPTION

Repair Manual

3-3-2-3 EXTERNAL DMA part

The function of this part is to bring data from external

DEVICE(OASIS:U21) by using GENERAL DMA. If DMA

REQUEST(/IP_REQ) is sent from external DEVICE to

S3C46MOX(JUPITER3:U15), DMA ACKNOWLEDGE

SIGNAL(/IP_ACK) is activated and the GENERAL DMA is

driven, so READ STROBE(/RD) in the external DEVICE to

bring data from the external DEVICE requiring CHANNEL.

To transfer this DA TA to the DESTINATION MEMORY, the

ADDRESS of the DESTINATION MEMORY, CHIP

SELECT and WRITE STROBE(/WR) are generated to

store.

That is, if the EXTERNAL DMA is required by the external

DEVICE, S3C46MOX(Jupiter3:U15) responds to drive the

inside DMA CONTROLLER and then allocate GENERAL

DMA to external CHANNEL so that the data may be transferred to MEMORY TO MEMORY or external DEVICE TO

MEMORY.

• For more details, see the circuit description, see the circuit

description part of IMAGE PROCESSOR (5.3).

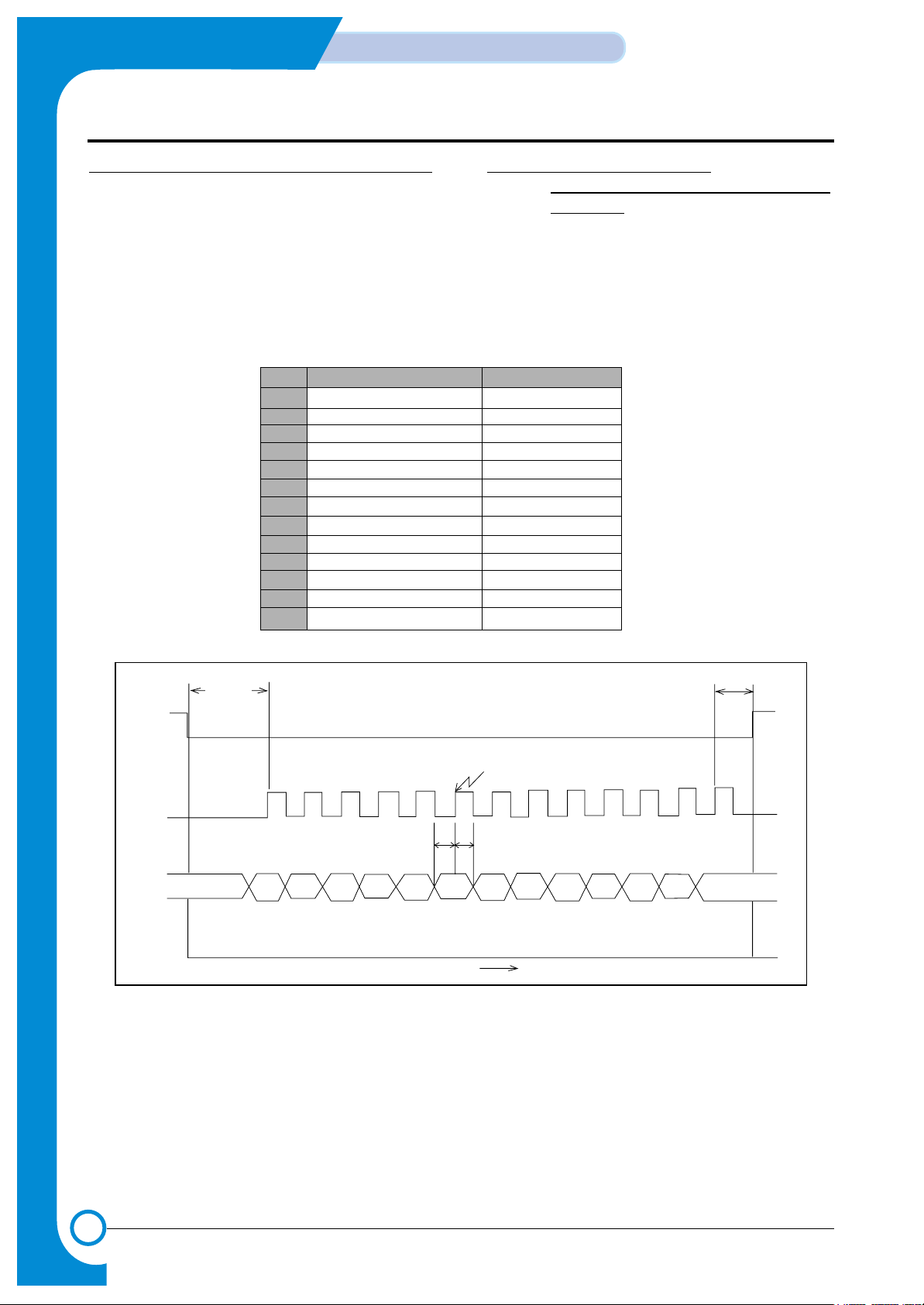

3-3-2-4 DRAM control part

Since S3C46MOX(Jupiter3) has the DRAM CONTROLLER build-in, it may be used by connecting DRAM

with external memory.

The Control mode of DRAM CONTROLLER provided by

S3C46MOX(Jupiter3) is available for EARLY WRITE,

NORMAL READ, PAGE MODE, and BYTE/HALF WORD

ACCESS, and is supported even by EDO DRAM,and

SDRAM as well as, Fast page DRAM.

This system uses SDRAM, and the signal used for

READ/WRITE uses /RD,/WR signal used for SYSTEM

BUS CONTROL. It is supported with auto REFRESH and

also by the Self-refresh mode for DRAM

BACK UP. It con-

sists of 2 Banks connected to co

mmon /SCS[1:0], /SCAS,

/SRAS, /SCLK, /SCKE, /DQM[1:0], each of them may use

up to 2M ~ 32M HALF WORD.

In this system, 2 MB is applied as system memory. The

area of DRAM is specified in the DRAM MEMORY MAP of

Fig. 1, while the related TIMING DIAGRAM in Fig. 5, 6, 7,

8, 9.

3-3-2-5 RTC (REAL TIME CLOCK) part

RTC Circuit is logic for maintaining information of the current time, and it is operated in both conditions, Primary

Power and Battery Back-up. Additional RTC IC is not used

because RTC is built-in at MFP Controller.

RTC Logic at inner part of ASIC accepts Crystal

(32.768KHz:X3), which is inputted from outside, as a Clock

Source, and it divides the Clock by every minute for mak-

ing hour, minute, second, year, month, and day. While the

power is on and the Crystal is being oscillation, the RTC

Logic independently counts the time without control by

Software and marks the value of hour, minute, second,

year, month, and day at the appropriated Register.

Software confirms the value of the Register and displays it

at LCD.

3-3-2-6 P ARALLEL PORT INTERFACE division

S3C46MOX(Jupiter3) has the Parallel Port Interface part

enabling Parallel Interface with PC.

This part is connected to PC through Centronics Connector

in this system, which consists of /ERROR, PE, BUSY,

/ACK, SLCT, /INIT, /SLCTIN, /AUTOFD, /STB and 245DIR

as the part generating the main control signal used to drive

PARALLEL COMMUNICATION. Data transmission

method between this part and PC supports the method

specified in P1284 Parallel Port Standard

(http://www.fapo.com/ieee1284.html) of IEEE.

That is, the Compatibility mode, the fundamental transmission method of print data, supports the Nibble Mode(4bits

data) supporting the Data Uploading to PC, Byte

Mode(8bits data), and ECP(Enhanced Capabilities Port : 8

bits data transmission & receiving) supporting two-way

high speed transmission to PC. The Compatibility mode

and ECP mode may be simply explained as follows.

The Compatibility mode is generally called Centronics

mode and is the protocol used for transmitting data by most

of PC. The ECP mode provides two-way high speed communication as the protocol suggested for improved communication with peripheral equipments such as printer and

scanner.

The ECP mode provides two types of cycles in two-way

transmission. They are data and command cycles.

Command cycle again has Run-length count and Channel

addressing types.

First, RLE (Run Length Encoding) type, having 64-fold

compressibility , is available for the real time data compression, and is used usefully for printer and scanner, which

have to transmit large capacity of raster image having a

series of same data. Next, Channel Addressing is proposed for addressing single structure of multi-device.

For example, although the printer channel is processing

the printer image when the fax/printer/scanner have one

structure like this system, they may use parallel port for

another use. This system does not apply to the parallel port

Interface.

3-12

CIRCUIT DESCRIPTION

Samsung Electronics

Repair Manual

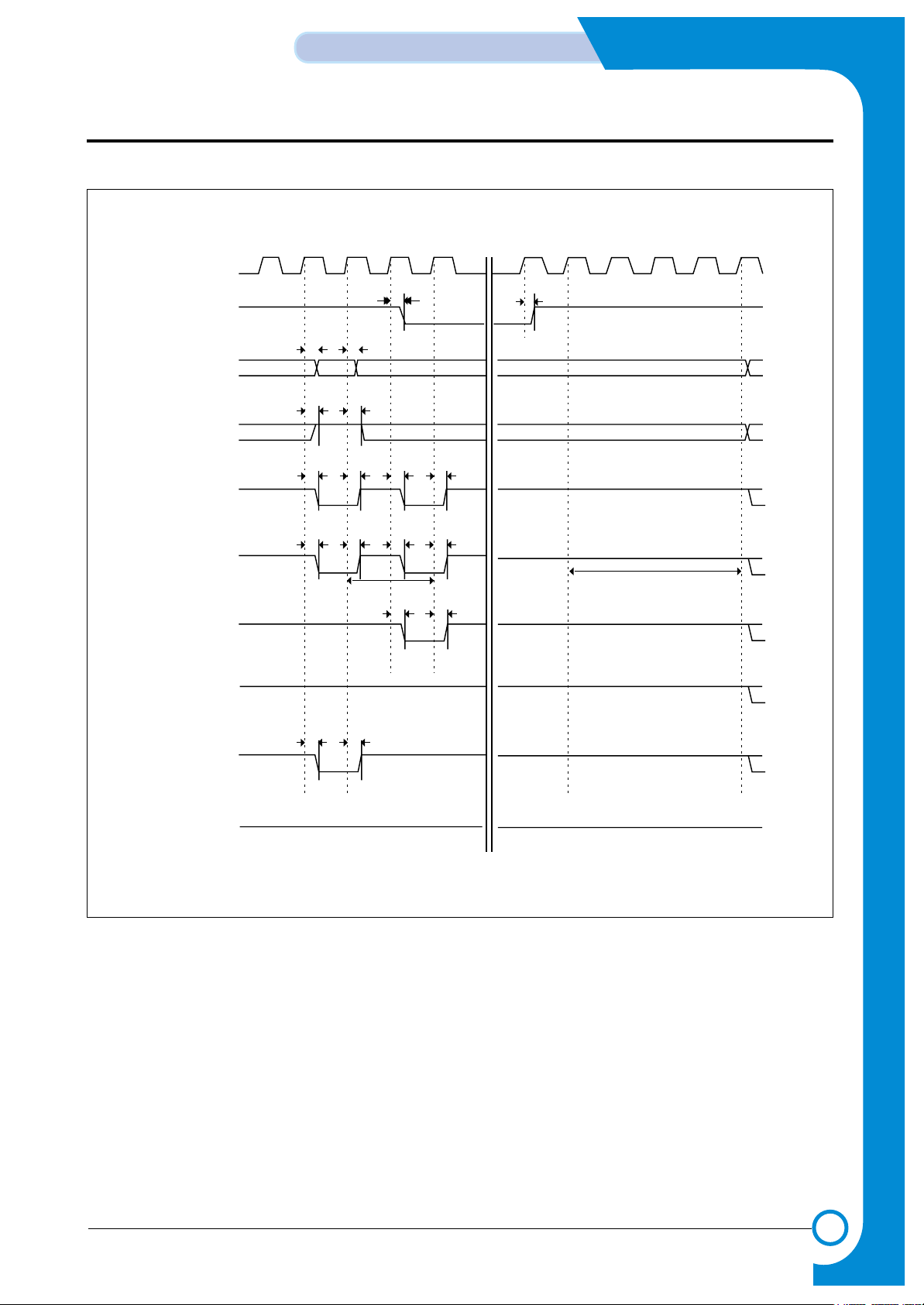

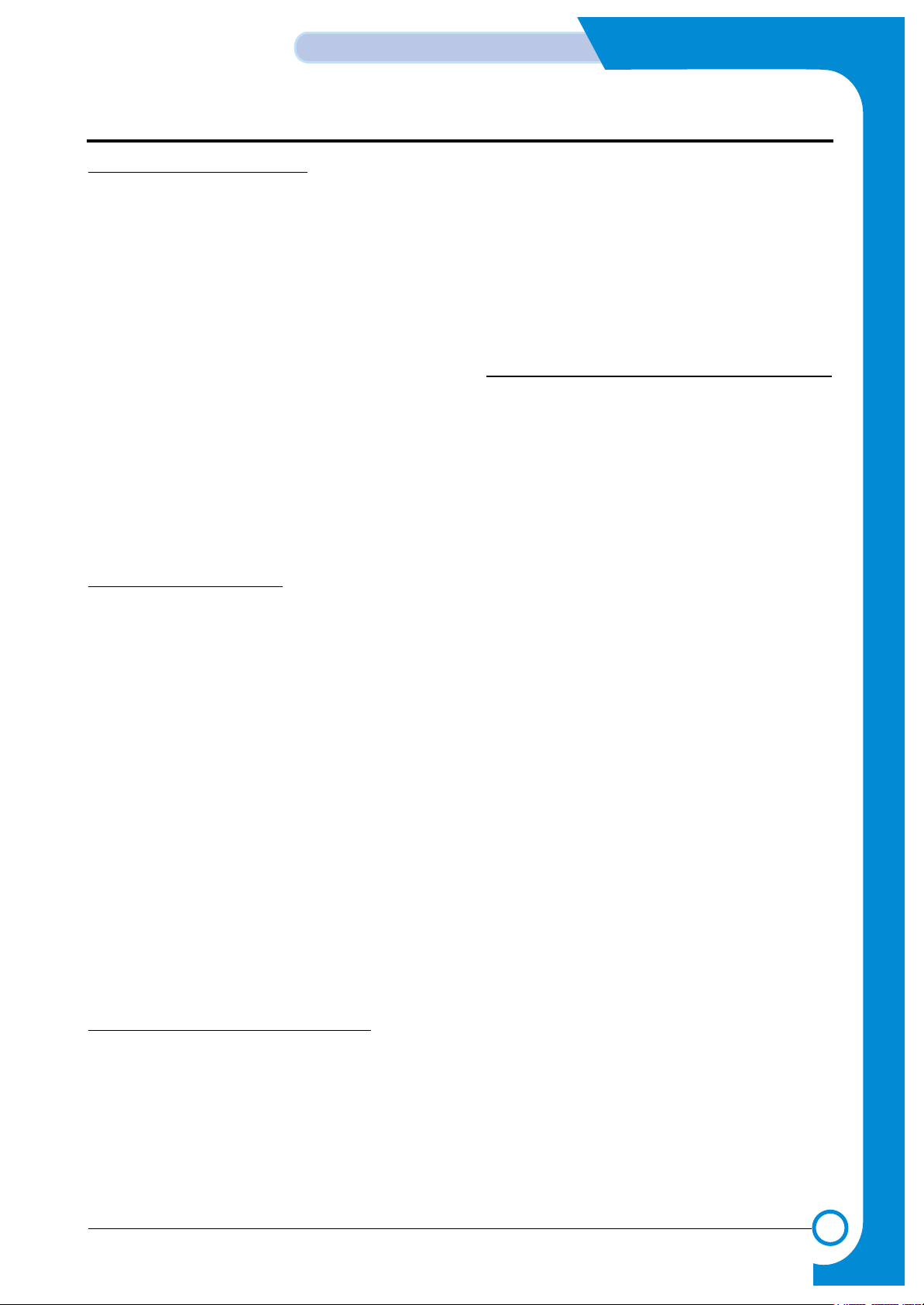

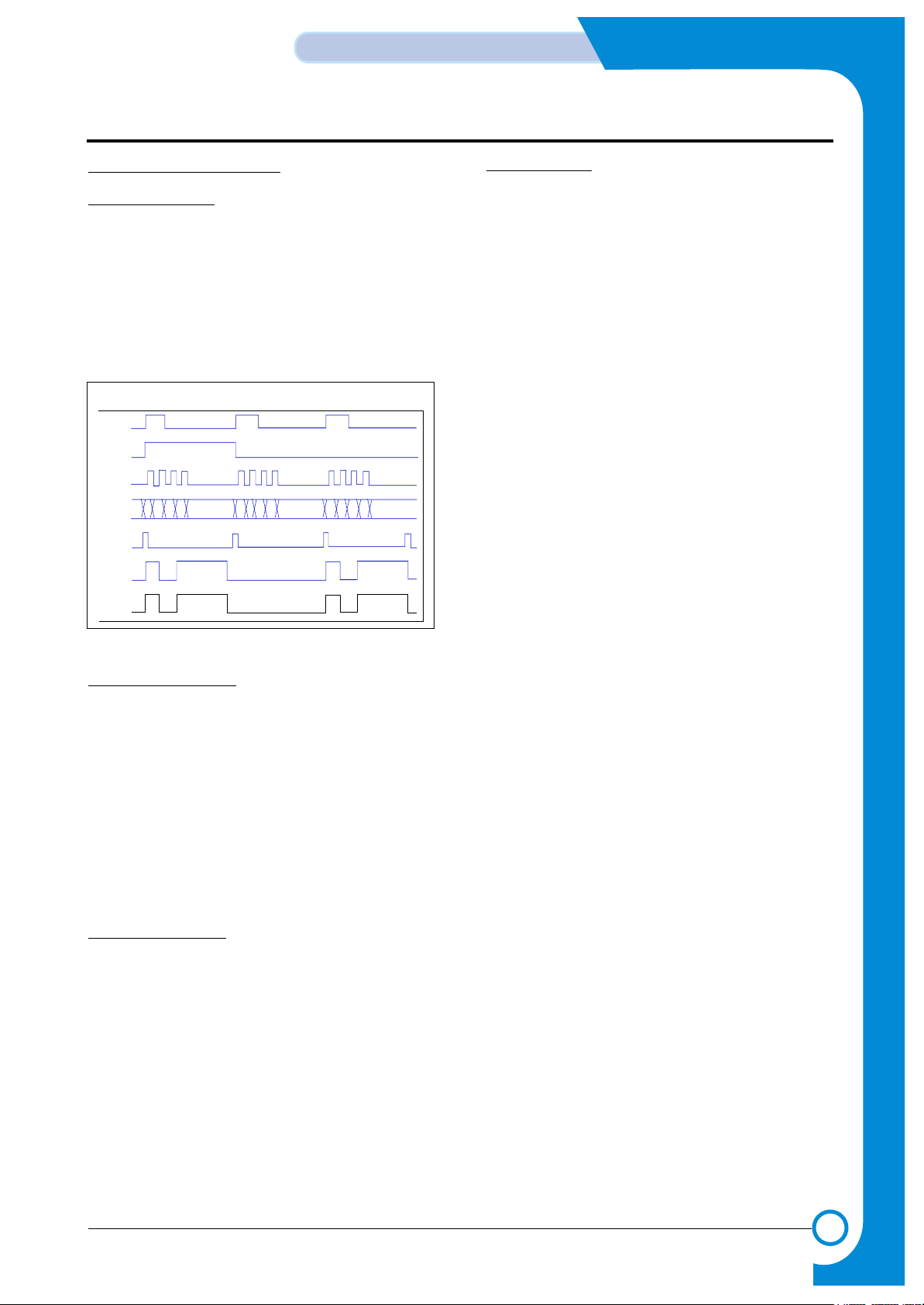

<Figure 10. Compatibility Hardware Handshaking Timing>

1. Write the data to the data register.

2. Program reads the status register to check that the printer is not BUSY.

3. If not BUSY, then Write to the Control Register to assert the STROBE line.

4. Write to the Control register to de-assert the STROBE line.

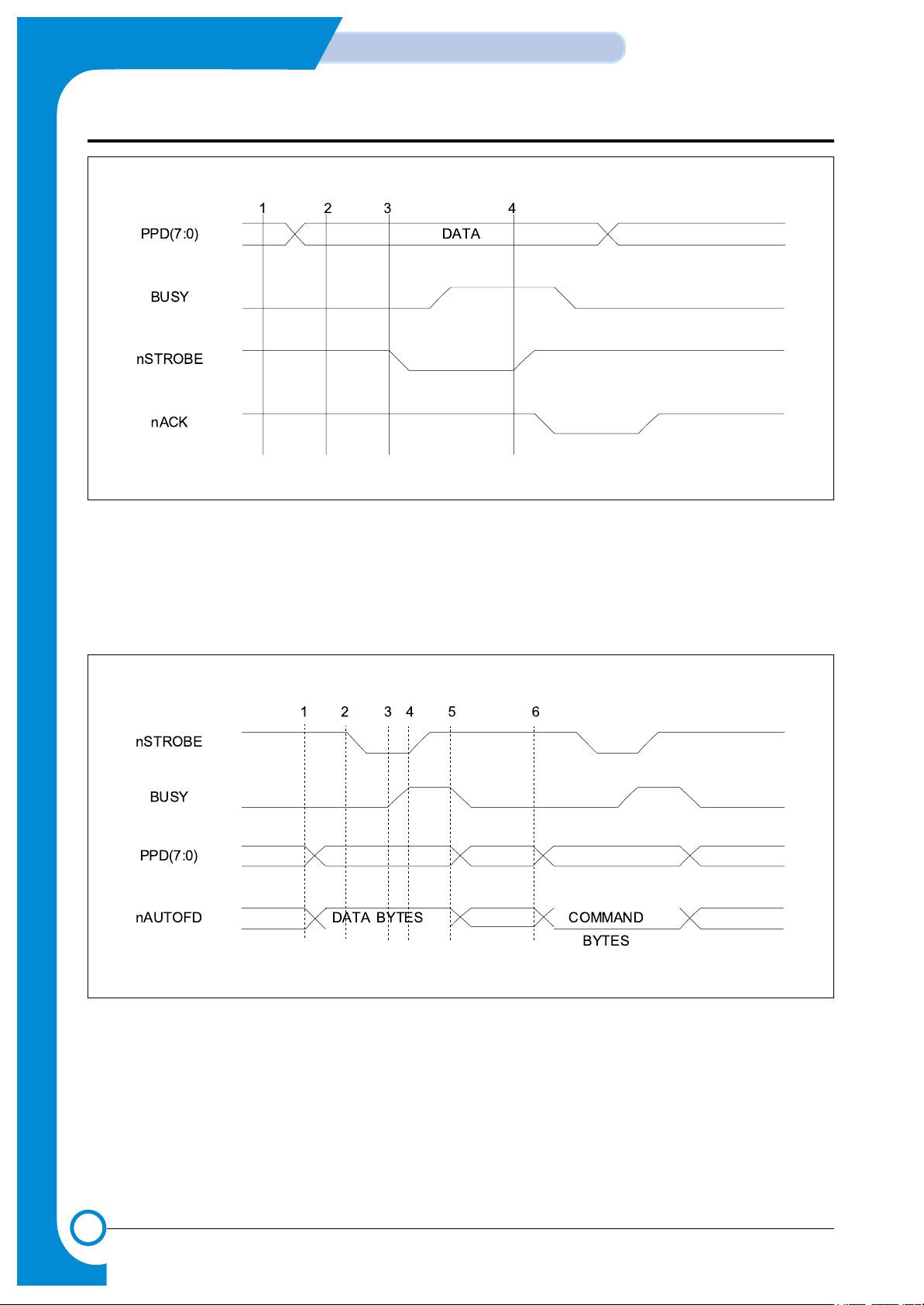

<Figure 10-1. ECP Hardware Handshaking Timing (forward)>

1. The host places data on the data lines and indicates a data cycle by setting nAUTOFD.

2. Host asserts nSTROBE low to indicate valid data.

3. Peripheral acknowledges host by setting BUSY high.

4. Host sets nSTROBE high. This is the edge that should be used to clock the data into the Peripheral.

5. Peripheral sets BUSY low to indicate that it is ready for the next BYTES.

6. The cycle repeats, but this time it is a command cycle because nAUTOFD is low.

BYTE 0 BYTE 1

3-13

Samsung Electronics

CIRCUIT DESCRIPTION

Repair Manual

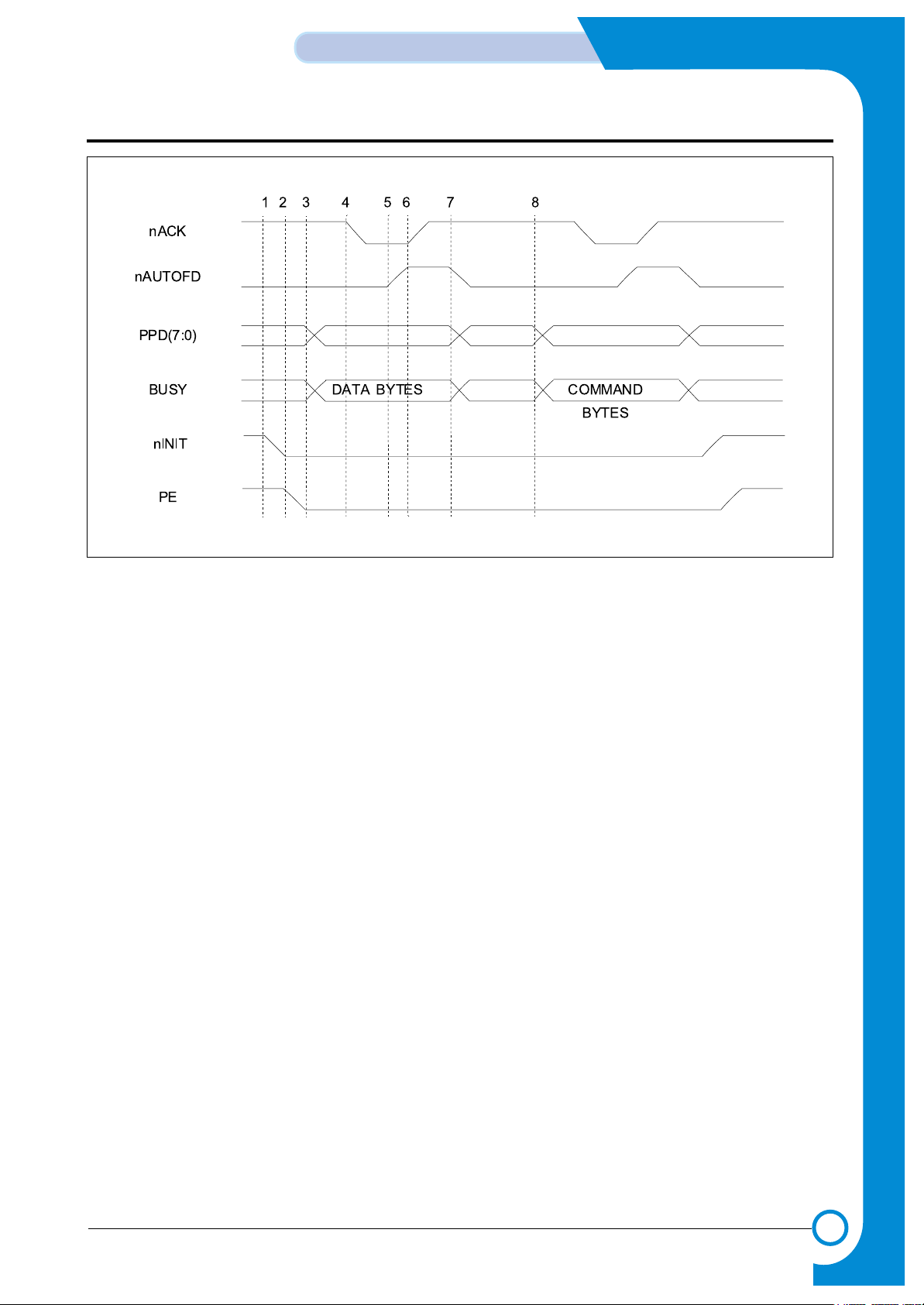

<Figure 10-2. ECP Hardware Handshaking Timing (reverse)>

1. The host request a reverse channel transfer by setting nINIT low.

2. The peripheral signals that it is OK to proceed by setting PE low.

3. The peripheral places data on the data lines and indicates a data cycle by setting BUSY high.

4. Peripheral asserts nACK low to indicate valid data.

5. Host acknowledges by setting nAUTOFD high.

6. Peripheral sets nACK high. This is the edge that should be used to clock the data into the host.

7. Host sets nAUTOFD low to indicate that it is ready for the next BYTES.

8. The cycle repeats, but this time it is a command cycle because BUSY is low.

BYTE 0 BYTE 1

3-14

CIRCUIT DESCRIPTION

Samsung Electronics

Repair Manual

3-3-2-7 USB INTERFACE PART

1. USB function description

As the mode of implementing low cost express PC

Interface, USB was applied. At USB, PC plays the role of

route hub simultaneously by existing in the highest level as

the host. That is, the device supporting each USB is connected centering on PC.

The device is available for Interface for the maximum of

127. USB cable is composed of total of a set of twisted pair

and 2 power lines. Cables have two types.

One is used for express transmission of 12Mbps and may

be extended as long as 5m. The part for implementing USB

function is included in S3C46MOX(Jupiter3).

For Interface of USB, pull-up of 15KΩ is interfaced to the

data line of high level instruments, and, among data lines

of lower level instruments, pull-up resistance of 1.5KΩ is

interfaced to any one.

At this time, D+ line is pulled up for Full Speed device, and,

for Low Speed device, D-line is pulled up. For upper level

instruments(Host, HUB) speed of device is classified interfaced to low level by detecting any one among D+ and D-.

If both lines are in the level of GND at the same time, device

is judged that low device is not interfaced. In the transmission mode of USB, there are

(1) Control transmission,

(2) Interrupt transmission,

(3) Bulk transmission, isochronous transmission

.

Control transmission is for Host to find out configuration

information from USB device. This is conducted when

device is interfaced. Interrupt transmission is used when

small quantity of data is sent periodically. Interval value

may be known from device in the case of initial setting. Bulk

transmission is valid in case of trying to transmit data in

large quantities or in case of transmitting them accurately.

Isochronous transmission should be assured of bandwidth,

and is used when transmitting large quantities of information. Data in voice is used where delay is not allowed but

small error is allowed. At USB coding mode and bit stepping are being conducted. First, in case original data is 1,

bit shall not change, and only when original data is 001, it

shall be inverted. Only while data is 1, 1 and 0 shall be

repeated. Also, in case 1, original data, is continued in 6 bit,

0 shall be inserted, Also, in the 1st phase of packet, data in

the synchronized pattern shall be sent. About more

detailed information regarding USB, see

http//:www.usb.org.

2. operation description

This system, when Host and USB cables are connected,

and when +5V is detected in power detector inside chip

and Vbus(U15-98), 3.3V comes out through Pull-uP terminal. This is also connected to D+ in pattern of hardware and

supports Full-speed. Utilizing Configuration Endpoint,

EPO, in USB controller, Plug & Play function is operated.

Exchange of information between PCs is accomplished

through D+(U15-95) and D-(U15-96) terminals. This terminal decides transmission speed depending on connection

of regulator output in USB controller, and decides size of

signal following USB and SPFC. Signal of general D+ and

D- terminals are same as Figure 10-3.

D+

D-

< Figure 10-3. USB Signal Line DIAGRAM >

3-15

Samsung Electronics

CIRCUIT DESCRIPTION

Repair Manual

3-3-2-8 HEAD control part

1. Entire description

As part to drive INKJET HEAD, it is composed of ACLK,

AGATE, LDCS, LATCHCTL, PCLK, PDATA[3:0], PLOAD,

PENABLE signals for controlling Spitfire of CR B’D generating signal, which is driving Nozzle of Head, and

PH_ID[1:0] and OK2Print signals receiving from Spitfire.

Here,HEAD being used here is DOUBLE HEIGHT PRINT

HEAD, and MONO is configured with 208 NOZZLE, and

COLOR is with 192 NOZZLE.

<Figure 11 HEAD Control Part Timing Diagram>

2. A-LINE driving circuit

13 Address Lines are input into 13 Address Counters in

sequence at Rising edge of ACLK signal, which is input

serially into Spitfire. Output of this Counter was connected

to each A-line driver, and this driver output becomes A-line

signal. The sequence of signal input into Address Counter

is decided by ADIR, and if it is ADIR=0, it is input in

sequence of A13A1, and if it is ADIR=1, in sequence of A1

=> A13. AGATE signal is used to reset Address Counter. If

it becomes AGATE=1, A-Line output becomes Low state.

The cycle of ACLK is 1.5ß¡ in minimum, and Sink current of

each Driver is 60mA.

3. P-LINE drive circuit

P-Line values are clocked to 4-bit Serial to Parallel Shift

Register Clock in Spitfire ASIC, and ASIC shall clock-in Pline NO. of fitting value at Rising Edge of PCLK. These values are latched to Holding register at Rising Edge of

PLOAD. PLOAD Pulse Duration is 50n, and P-line value of

Holding Register is done AND with PENABLE signal in

order to generate appropriate Fire Pulse. PLCK is available

for handling as much as 4MHz. Drive Current of P-line is

400mA. Data of P1°≠P4 is shifted to PDATAO, that of P5P8 shifted to PDATA1, that of P9-P12 shifted to PDATA2,

and that of P13-P16 shifted to PDATA3.

4. Control Signal

• The signal loaded on PDATAO - PDATA2 at Rising edge

of LATCHCTL(Latch Control Nibble) is used as function

as follows in Spitfire.

- PDATA0 == ADIR —> Low : ACLK is operated in Count

Down, High : ACLK is operated in Count

Up.

- PDATA1 == When Fault Test —> High, check whether

P-Line of Head became short with GND.

- PDATA2 == When Print Head ID Check —> high,

make sure that Check mode is set, and,

after that, by using the PDATA0~PDATA2

LIne, make A1-A3 signal for sending, and

Head ID shall come out with PH_IDn output. At this time ID could be displayed only

if each Substrate heater is turned on.

• The signal loaded into PDATAO-PDATA3 at Rising

edge of LDCS(LoadHtrcs) signal is used in the following functions in Spitfire.

- PDATA0 == BLKHTR—> High : Turn on Substrate

Heater of Mono Head.

- PDATA1 == COLHTR—> High : Turn on Substrate

Heater of Color Head.

- PDATA2 == nHSM—> Low : Enable Select Signal of

Mono Head.

- PDATA3 == nHSC—> Low : Enable Select Signal of

Color Head.

When Substrate Heater is turned on, Over-current Check

circuit is operated, automatically , and,if the current is above

750mA, the printer stops operation after OK2PRT

becomes low.

The Timing diagam below shows signal timin for the P-line block

ACLK

An

PCLK

PDATA

PLOAD

PENABLE

Pn

3-16

CIRCUIT DESCRIPTION

Samsung Electronics

Repair Manual

3

-3-2-9 SYNCHRONOUS SERIAL INTERFACE part

As the part interfacing with THUNDERBOLT ASIC, it consists of /TBCS,TBCLK,TBDO. In sending SERIAL DATA

of 13 BIT to Thunderbolt ASIC, meaning of each bit is as

follows. BIT 1 is the bit to do On/Off VPH(+11.82V), BIT

[2:7] is the bit for driving MOTOR 1, BIT [8:13] is the bit to

drive MOTOR 2. MOTORs are available for being used as

STEPPER MOTOR and DC MOTOR respectively.

3-3-2-10 MOTOR control part

(DIR, PWM, LFPHA,LFPHB, LFIA[0:1],

LFIB[0:1])

S3C46MOX(Jupiter3) is arranged to support one Step

motor and one DC motor. This system does not use the

Motor control part provided by S3C46MOX(Jupiter3).

< Figure 12 SYNCHRONOUS SERIAL INTERFACE TIMING DIAGRAM >

/TBCS

TBCLK

TBDO

Tcs-sclk

Tcs-sclk

bit 1 bit 2 bit 3 bit 4 bit 5 bit 6 bit 7 bit 8 bit 9 bit 10 bit 11 bit 12 bit 13

SDI stays at

last value

MSBLSB

Data Latcked on the rising edge of SCLK

time

Tdhd

Tdsu

STEPPER MOTOR DC MOTOR

BIT 1 VPH_ENABLE VPH_ENABLE

BIT 2 MOTOR1_CURR_I1_PHASEB Not used in this mode.

BIT 3 MOTOR1_CURR_I0_PHASEB Not used in this mode.

BIT 4 MOTOR1_DIR_PH_B Not used in this mode.

BIT 5 MOTOR1_CURR_I1_PHASEA Not used in this mode.

BIT 6 MOTOR1_CURR_I0_PHASEA Not used in this mode.

BIT 7 MOTOR1_DIR_PH_A MOTOR1_DIRECTION

BIT 8 MOTOR2_CURR_I1_PHASEB Not used in this mode.

BIT 9 MOTOR2_CURR_I0_PHASEB Not used in this mode.

BIT 10 MOTOR2_DIR_PH_B Not used in this mode.

BIT 11 MOTOR2_CURR_I1_PHASEA Not used in this mode.

BIT 12 MOTOR2_CURR_I0_PHASEA Not used in this mode.

BIT 13 MOTOR2_DIR_PH_A MOTOR2_DIRECTION

3-17

Samsung Electronics

CIRCUIT DESCRIPTION

Repair Manual

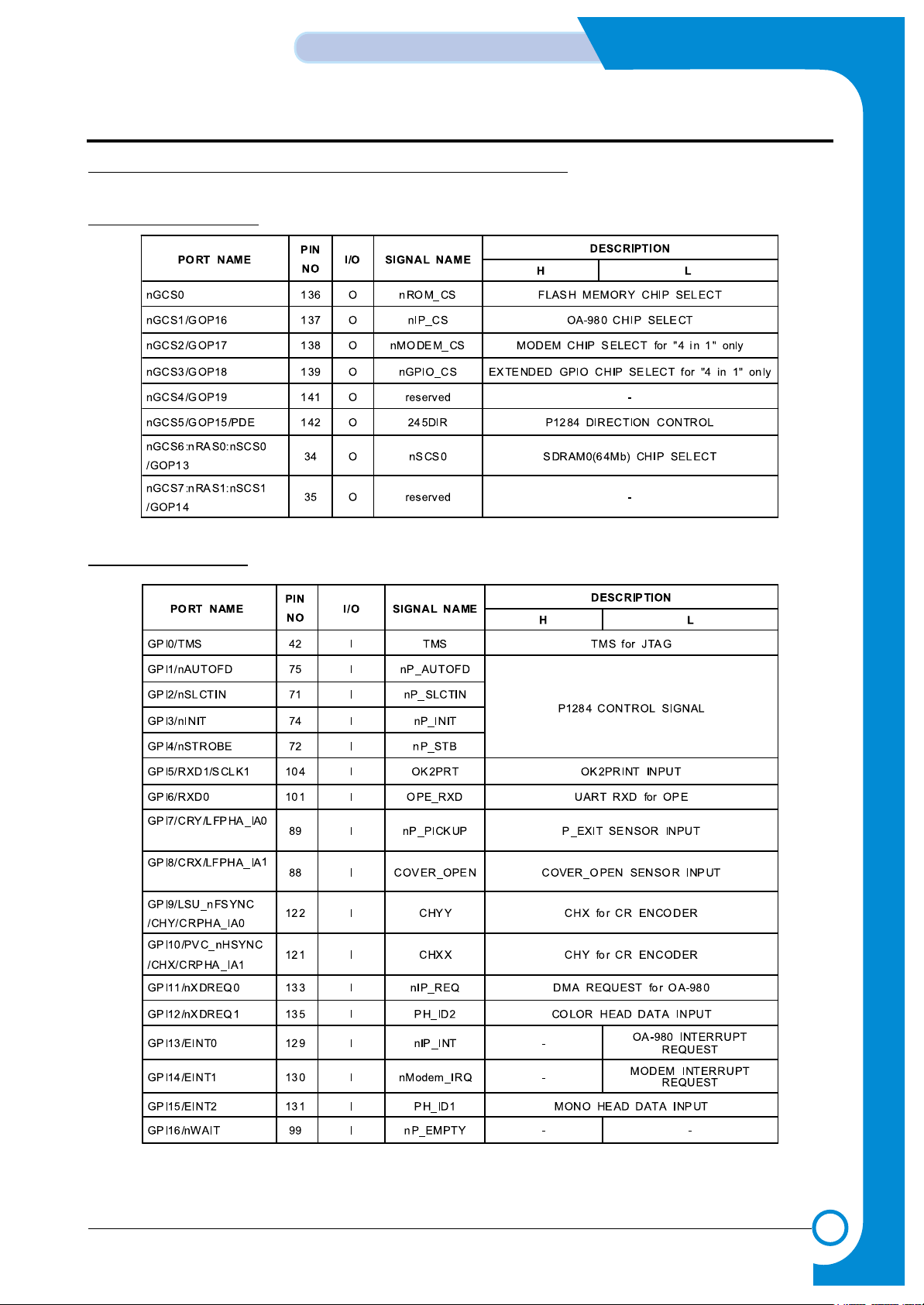

3-3-2-11 GENERAL PURPOSE I/O PORT of S3C46MOX(Jupiter3)

1. J3 Assigned GCS Ports

2. J3 Assigned GPI Ports

Loading...

Loading...