Samsung SCX 1100 Service Manual

SERVICE

SAMSUNG

INKJET PRINTER(MFP)

SCX-1100

Manual

INKJET PRINTER(MFP) CONTENTS

1. Precautions

2. Specifications

3. Disassembly and Reassembly

4. Troubleshooting

5. Exploded Views and Parts List

6. Block Diagram

7. Connection Diagram

ELECTRONICS

© Samsung Electronics Co.,Ltd. March

2001

Printed in Korea.

VERSION NO. : 1.02 CODE : JB-0023A

This service manual is also provided on the web,

the ITSELF system Samsung Electronics Co., Ltd.

“http://itself.sec.samsung.co.kr”

- This Service Manual is a property of Samsung Electronics Co.,Ltd.

Any unauthorized use of Manual can be punished under applicable

International and/or domestic law. -

This manual is stated and

provided for service description.

All rights reserved. Any parts of the

information in this manual are prohibited

from free duplication, use or translation

without prior written approval except in

cases allowed by the Copyright Act.

Specifications are subject to change without

prior notice.

Copyright (c) 2002. 3.

Samsung Electronics Digital Printing CS Group

1-1

Samsung Electronics

1. Precautions

Please read the following carefully to prevent any accidents and not to damage the unit during service.

1-1 Safety Precautions

1-2 Precautions on Disassembly and Reassembly

1. Safety Precautions

There are some electric or machinery parts with safety

related property. If the parts replaced are different from

the original, the safety may not function. Even if the part

could allow higher voltage than that of the part used, do

not replace it and use a regular product clarified in specifications.

2. Be careful not to leave a switch, a cover or a safety device

out when reinstalling or assembling the product after

repair.

3. Replacing Precautions

Do not change or add parts as you like. You cannot benefit from such a remodeled product at your will during the

term of guarantee.

4. You must replace overheated or damaged parts or cords

with regular products. Please solve the problem causing

any damage or overheating and troubles beforehand.

Especially mind the safety on the part with this

mark.

You must use regular parts described in specifications for the parts inflammable and where the current can be flown. Otherwise any hazard such as

an electric shock or a fire could occur .

Very careful precautions should be taken when replacing

parts. Before replacing, please check cables because you

cannot put the cables that you removed for replacing parts

into the proper place if you would not make sure of where

they were connected and in which condition.

Please do the following before disassembling

for a repair or replacement of parts.

1. Pull out paper cassette, printer cartridge installed.

Especially careful not to be scratched by the surface of

developer or not to expose them to light.

2. Turn the power switch off.

3. Take out the power plug, printer cable from the printer.

4. Use only the same type of part as original when replacing

parts.

5. Do not force to open or fasten plastic material components.

6. Be careful that small parts such as screws should not get

in the printer.

7. When disassembling, assembling, also observe small

components are located in place.

8. If you uncover and turn the machine over to replace some

parts, toner or paper particles may contaminate the LSU

window. Protect the LSU window with clean paper.

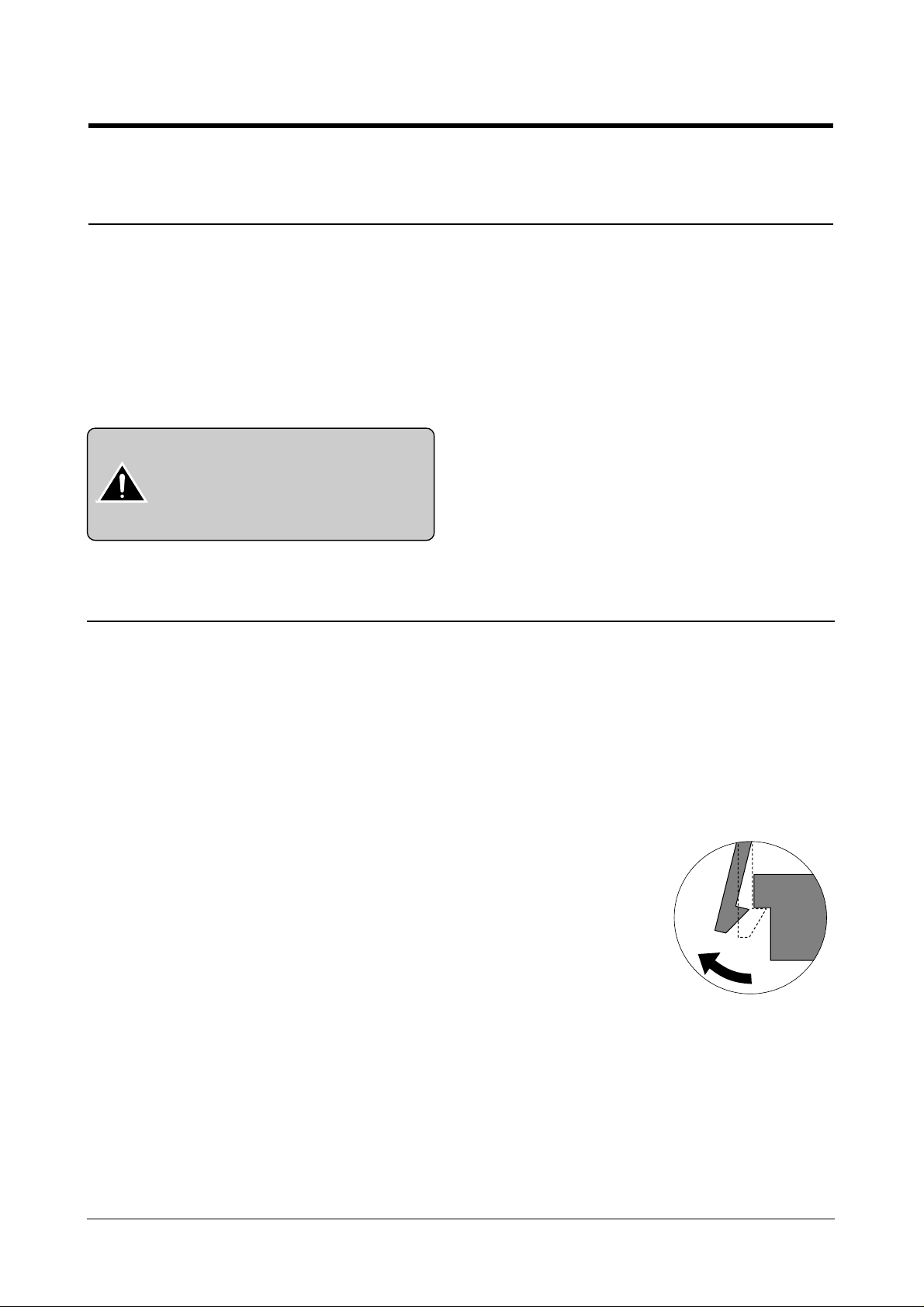

Releasing Plastic Latches

Many of parts are held in

place with plastic latches.

The latches break easily :

release them carefully.

To remove such parts, press

the hook end of the latch

away from the part to which

it is latched.

Certain semiconductor devices can be easily damaged by

static electricity. Such components are commonly called

“Electrostatically Sensitive (ES) Devices”, or ESDs.

Examples of typical ESDs are: integrated circuits, some field

effect transistors, and semiconductor “chip” components.

The techniques outlined below should be followed to help

reduce the incidence of component damage caused by static electricity.

1. Immediately before handling a semiconductor component or semiconductor-equipped assembly, drain off any

electrostatic charge on your body by touching a known

earth ground. Alternatively, employ a commercially available wrist strap device, which should be removed for your

personal safety reasons prior to applying power to the unit

under test.

2. After removing an electrical assembly equipped with

ESDs, place the assembly on a conductive surface, such

as aluminum or copper foil, or conductive foam, to prevent electrostatic charge buildup in the vicinity of the

assembly .

3. Use only a grounded tip soldering iron to solder or desolder ESDs.

4. Use only an “anti-static” solder removal device. Some solder removal devices not classified as “anti-static” can

generate electrical charges sufficient to damage ESDs.

5. Do not use Freon-propelled chemicals. When sprayed,

these can generate electrical charges sufficient to damage ESDs.

6. Do not remove a replacement ESD from its protective

packaging until immediately before installing it. Most

replacement ESDs are packaged with all leads shorted

together by conductive foam, aluminum foil, or a comparable conductive material.

7. Immediately before removing the protective shorting

material from the leads of a replacement ESD, touch the

protective material to the chassis or circuit assembly into

which the device will be installed.

8. Maintain continuous electrical contact between the ESD

and the assembly into which it will be installed, until completely plugged or soldered into the circuit.

9. Minimize bodily motions when handling unpackaged

replacement ESDs. Normal motions, such as the brushing together of clothing fabric and lifting one’s foot from a

carpeted floor, can generate static electricity sufficient to

damage an ESD.

1-3 ESD Precautions

Precautions

1-2

Samsung Electronics

CAUTION:

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

Precautions

1-3

Samsung Electronics

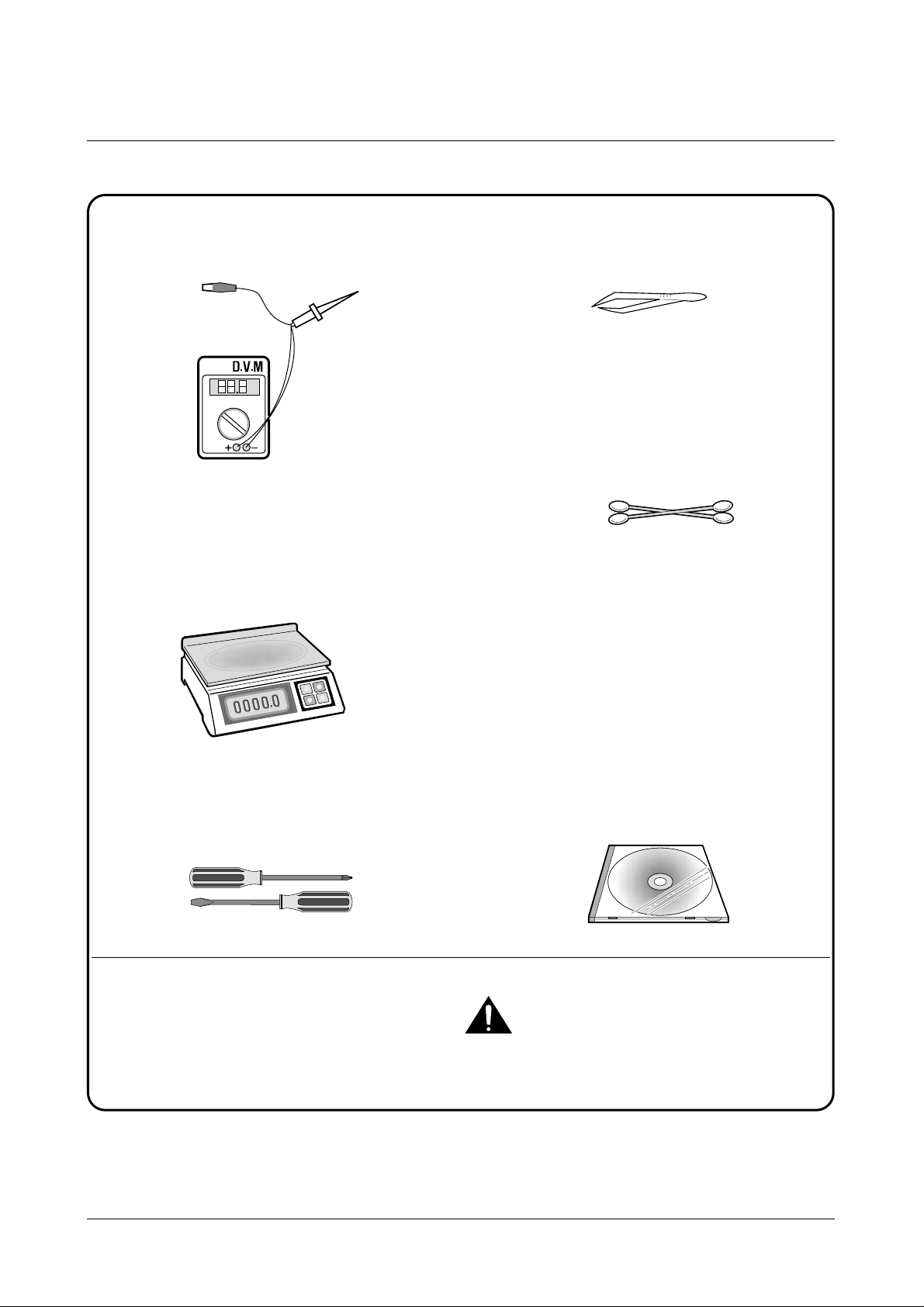

1-4 Tools for Troubleshooting

The following tools are recommended for safe and smooth troubleshooting described in this service manual.

DVM(Digital Volt Meter)

Standard: Indicates more than 3 digits.

Electronic Scale

Standard: Equipment to check the weight of consumables supplied by Samsung Electronics.

(The gram unit can be measured.)

Driver

Standard: "-" type, "+" type (M3 long, M3 short,

M2 long, M2 short).

Pinset

Standard: For general home use, small type.

Cotton Swab

Standard : For general home use, for medical ser-

vice.

Cleaning Equipments a IPA(Isopropyl

Alcohol)dry cloth or a soft stuff neutral

detergent.

Software(Driver) installation CD ROM

Mind your hands not to be touched when you

disassemble and reassemble PBAASS'Y, such as

the main board.

Note

1

2

3

4

5

6

7

Samsung Electronics

2-1

2. Specifications

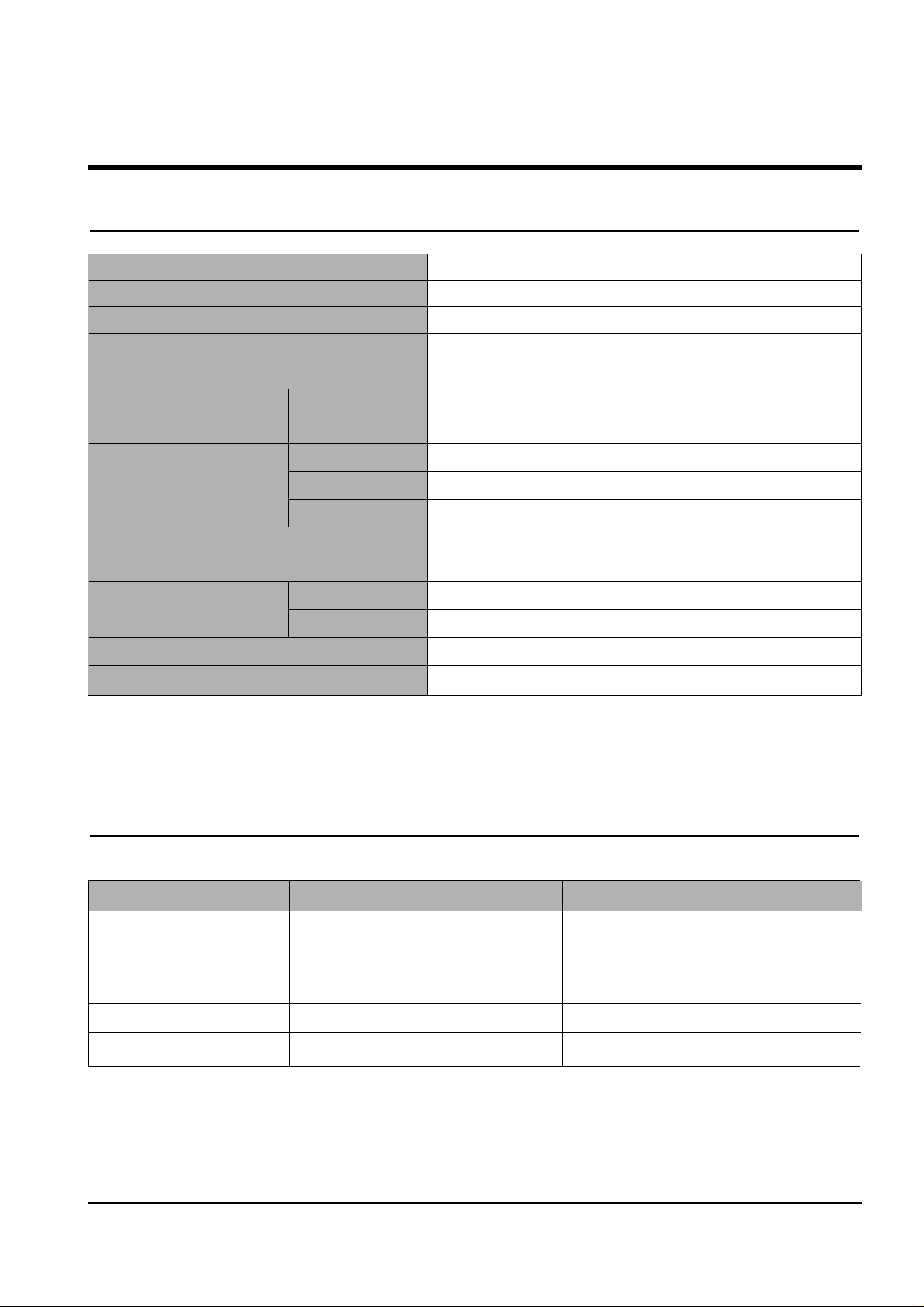

2-1 Printer Engine

2-2 Ink Cartridge

Babbage mono standard Birch color

Model No. M50 C60

Print Head 208 nozzles 192 nozzles

Ink type Pigment Dye

Ink Color Black (Babbage) Color (Birch)

Ink Yield about 1075 sheets (5% Pattern, A4) about 275 sheets (15% Pattern, A4)

Technology Color Thermal Inkjet

Engine Type 2-Pen (K and CMY)

Operating System Windows 95/98/2000/Me/XP

Interface USB (without HUB Mode), Centronics 1284

Emulation HBP(GDI)

Print Speed

(2)

Mono 14 ppm Draft / 10 ppm Normal

Color 7 ppm Draft / 2 ppm Normal

Print Resolution (H x V) Quick 300 x 600 dpi

Normal 600 x 600 dpi

High Quality 2400(H) x 1200(V) dpi (Addressable)

Maximum Paper Size A4, Letter, Legal, Banner

Effective Printing Width 8.0'' (203 ± 1mm)

Feeding Method Automatic 100 Sheets (Maximum stacking height : 9mm)

Manual Tray No

Output Tray Capacity Maximum 30 sheets

Maximum Cable Length USB Cable, Max 6ft

(3)

Note:

(2) Speed claims based on the test files: spdtstc.sam(mono), spdtstc2.sam(color)/Letter size

(3) Non-standard cable can cause misoperations.

Samsung Electronics

Specifications

2-2

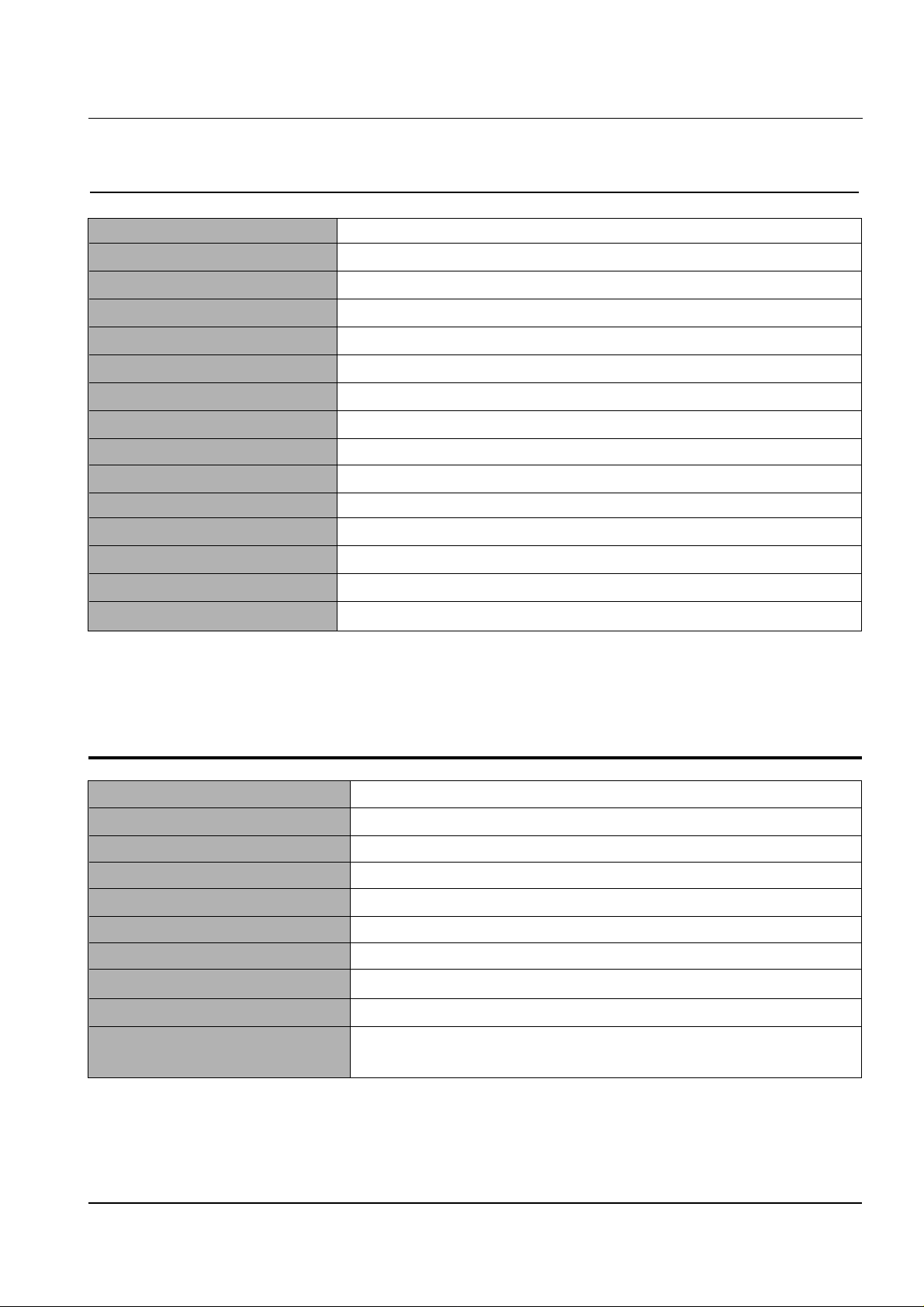

2-3 Copier

Scanner Type Flat-bed without ADF (Automatic Document Feeder)

Maximum Original Size A4/Letter

Maximum Paper Size A4/Letter/Legal

Maximum Scan Width 216 mm

Optical Resolution (HxV) 600 x 600 dpi

Copy Quality Draft, Normal, Best

Paper Type Selection Plain, Glossy, Transparency

Mono Copy Speed

(1)

Draft: 10cpm

Color Copy Speed

(1)

Draft: 5cpm

Effective Print-edge Margin Top: 3.4mm, Bottom: 19.05mm, Each Side: 6.5mm(LTR), 3.5mm(A4)

Multi copy 99 pages (Memory Multi copy)

Zoom Rate 25 % ~ 400 % (1 % Step)

Contrast Control 3 Steps

Ink Saver Mode Use Draft Mode (<20 % Savings)

Auto Sensing Check Paper Jam , Low Ink

Note:

(1) Speed claims based on the test chart : Printed spdtstc.sam(mono), Printed spdtstc2.sam(color)/Letter size

2-4 Scanner

Operation System Windows 98/Me/2000/XP

Interface USB (without HUB Mode) and Centronics 1284

Compatibility TWAIN Standard.

Device Platen Color CCD

Scan Width Max.: 8.5” (216 mm), Effective: 8.2” (210 mm)

Color Depth Internal 36 bit, External 24 bit

Optical Resolution (H x V) 600 x 1200 dpi

Interpolation Resolution Max. 4800 dpi

Pre-scan Mode Yes, 75 dpi

Scan Speed about 2'30 sec/A4 True Color

(Pentium II 300M, 64MB Memory, 300dpi)

Samsung Electronics

Specifications

2-3

2-5 Power Supply

Rated AC Input Voltage 110 ~ 240 VAC (Universal)

Rated Input Frequency 50 ~ 60 Hz

Minimum/Maximum AC Input 90 VAC/265 VAC

Maximum Input Current 0.5 A

DC Channels

(4)

(2 Channels) +3.3V +

5%, +30V +10%

External Power On/Off Key Power Down Key (It does not cut the primary power input off)

2-6 Dimension

Machine Size (W x D x H, mm) 477(W) X 415(D) X 252(H)

Machine Weight About 8.5 Kg (Machine itself)

Note:

(4) No load condition.

2-7 Environmental Condition

Absolute Storage Temperature

(5)

-20oC ~ 55oC

Absolute Storage Humidity

(5)

10% RH ~ 90% RH

Recommended Temperature 5oC ~ 40oC

Operating Condition Humidity 15% RH ~ 85% RH

Note:

(5) Packing Condition

3. Disassembly and Reassembly

3-1 General Precautions on Disassembly

When you disassemble and reassemble components, you

must use extreme caution.

The close proximity of cables to moving parts makes proper

routing a must. If components are removed or replaced, any

cables disturbed by the procedure must be replaced as close

as possible to their original positions.

Before removing any component from the machine, note the

cable routing that will be affected.

Whenever servicing the machine, you must perform as follows:

1. Check to verify that documents are not stored in memory.

2. Unplug the power cord.

3. Use a flat and clean surface.

4. Replace only with authorized components.

5. Do not force to remove or planten plastic-material components.

6. Make sure all components are in their proper position.

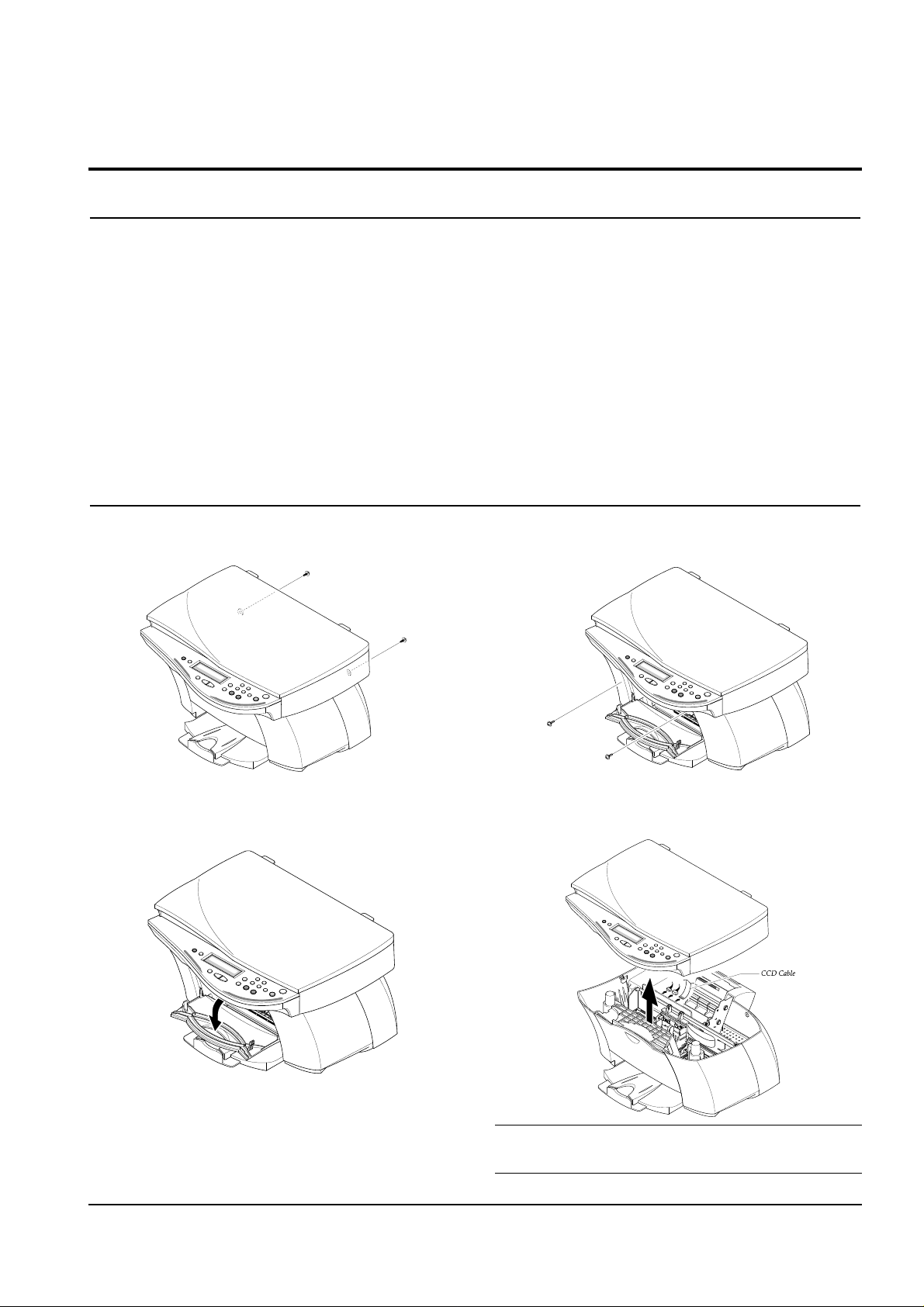

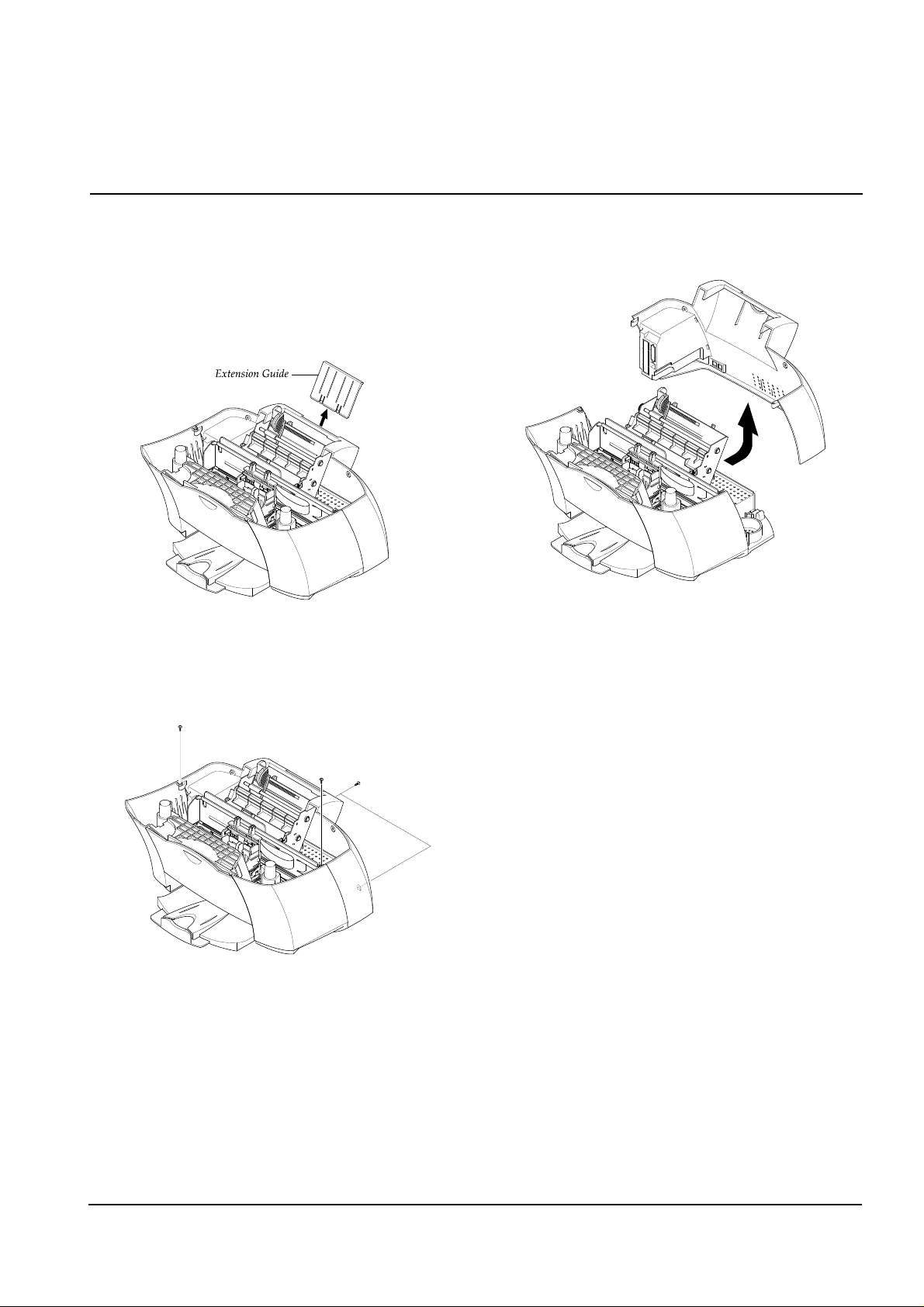

3-2 Scanner Ass'y

1. Remove two screws securing the rear cover.

2. Open the front door from the main cover.

3. Remove two screws securing the main cover.

4. Pull the scanner ass'y upward then, unplug the two

connectors and CCD cable.

Note :

You should connect or remove the CCD cable vertically to avoid the CCD cable pin damage.

3-1samsung Electronics

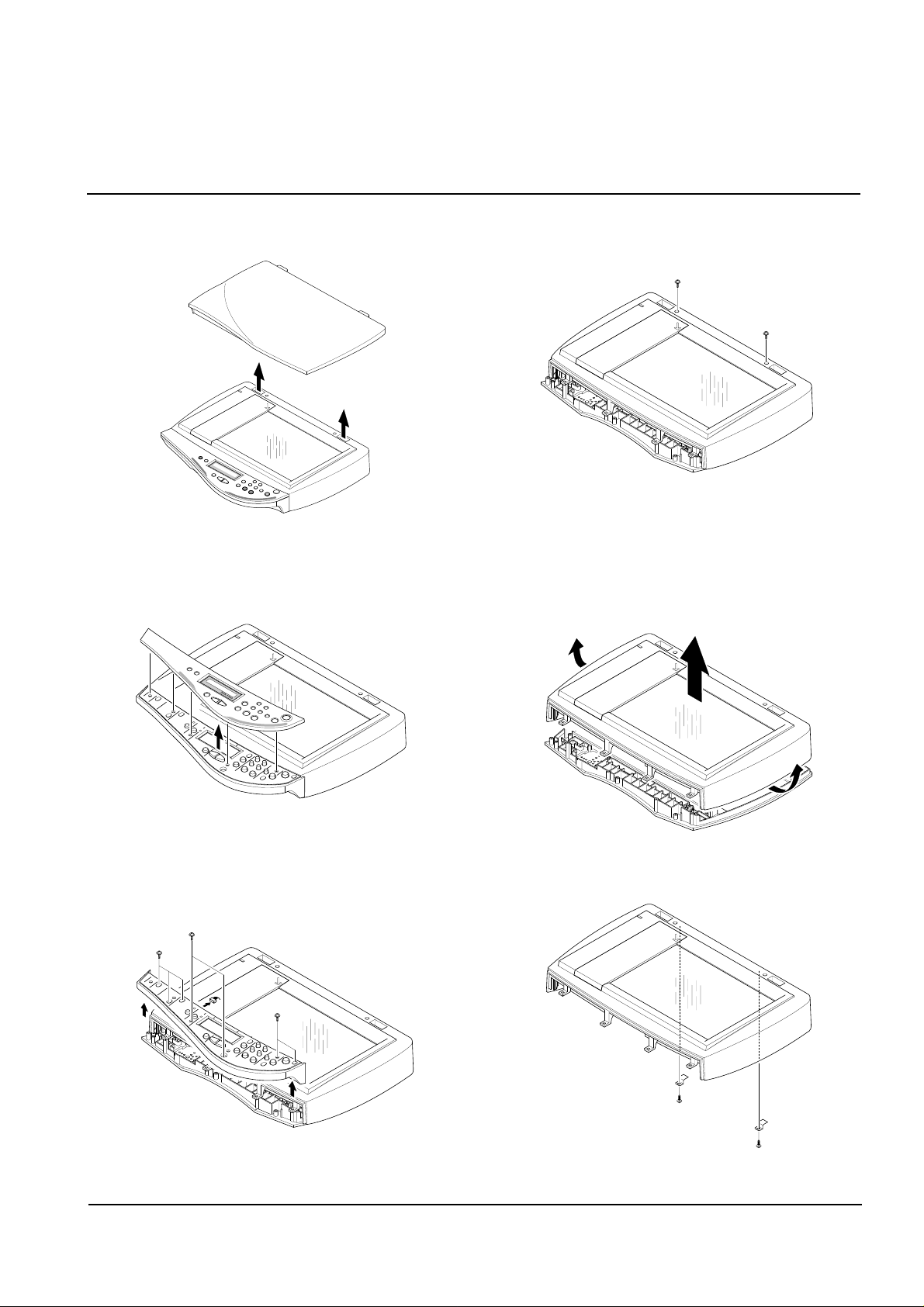

5. Pull the platen cover upward and remove it.

6. Pull the OPE cover upward and remove it.

7. Remove five screws securing the OPE upper and

unplug the one connector from the OPE panel.

8. Remove two screws securing the scan upper and

remove it.

9. Unlatch the scan lawer securing the scan upper and

remove it.

10. Remove the two screws securing the scan upper.

3-2 samsung Electronics

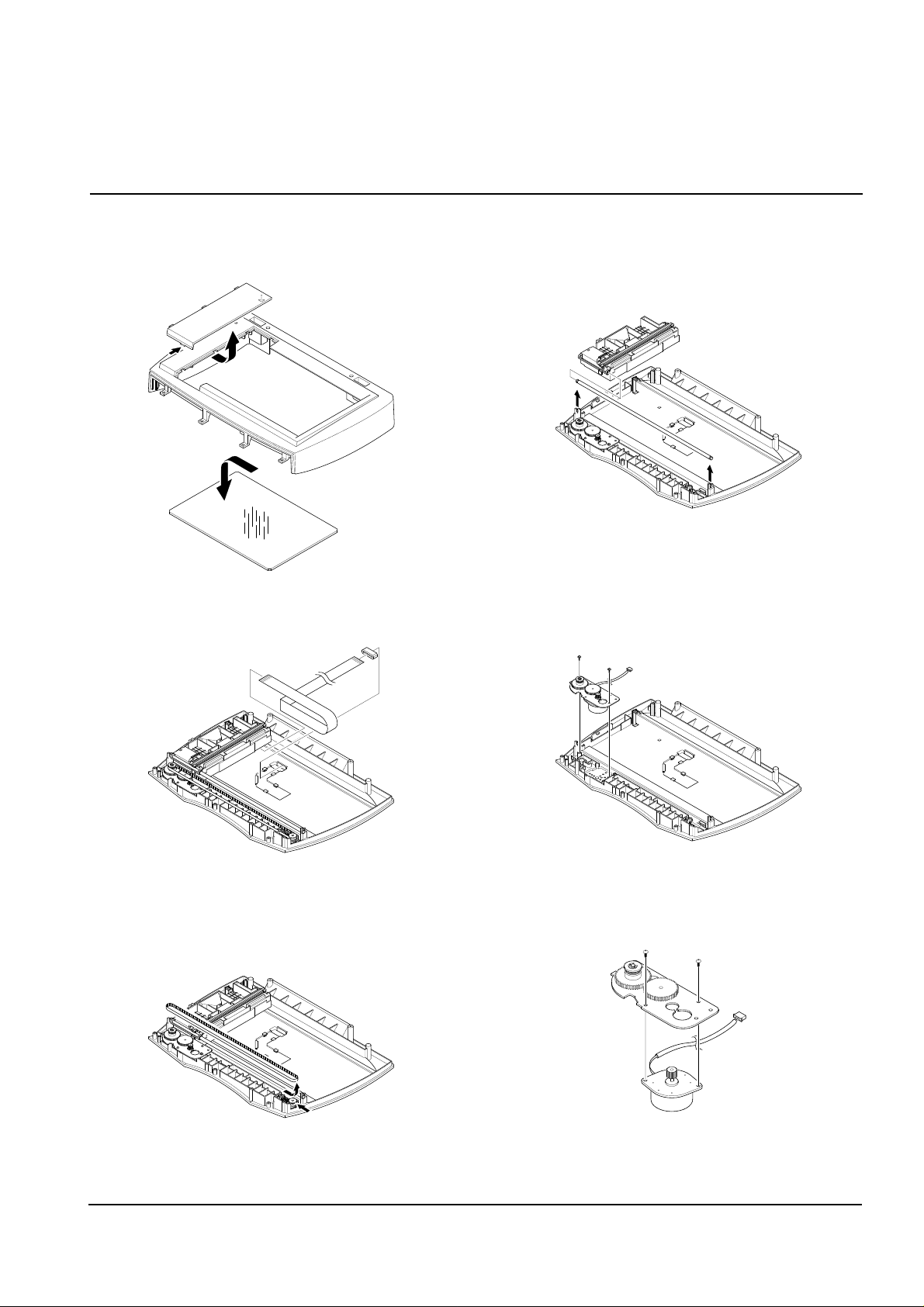

Disassembly and Reassembly

11. Unlatch the scan dummy and take out the glass

from the scan upper.

12. Remove the CCD cabl.

13. Push the belt holder and take out the belt, as

shown below.

14. Pull up the CCD shaft and take out the scanner

module.

1

5. Remove two screws and take out the motor bracket.

16. Remove two screws securing the scan motor and

remove it.

samsung Electronics 3-3

Disassembly and Reassembly

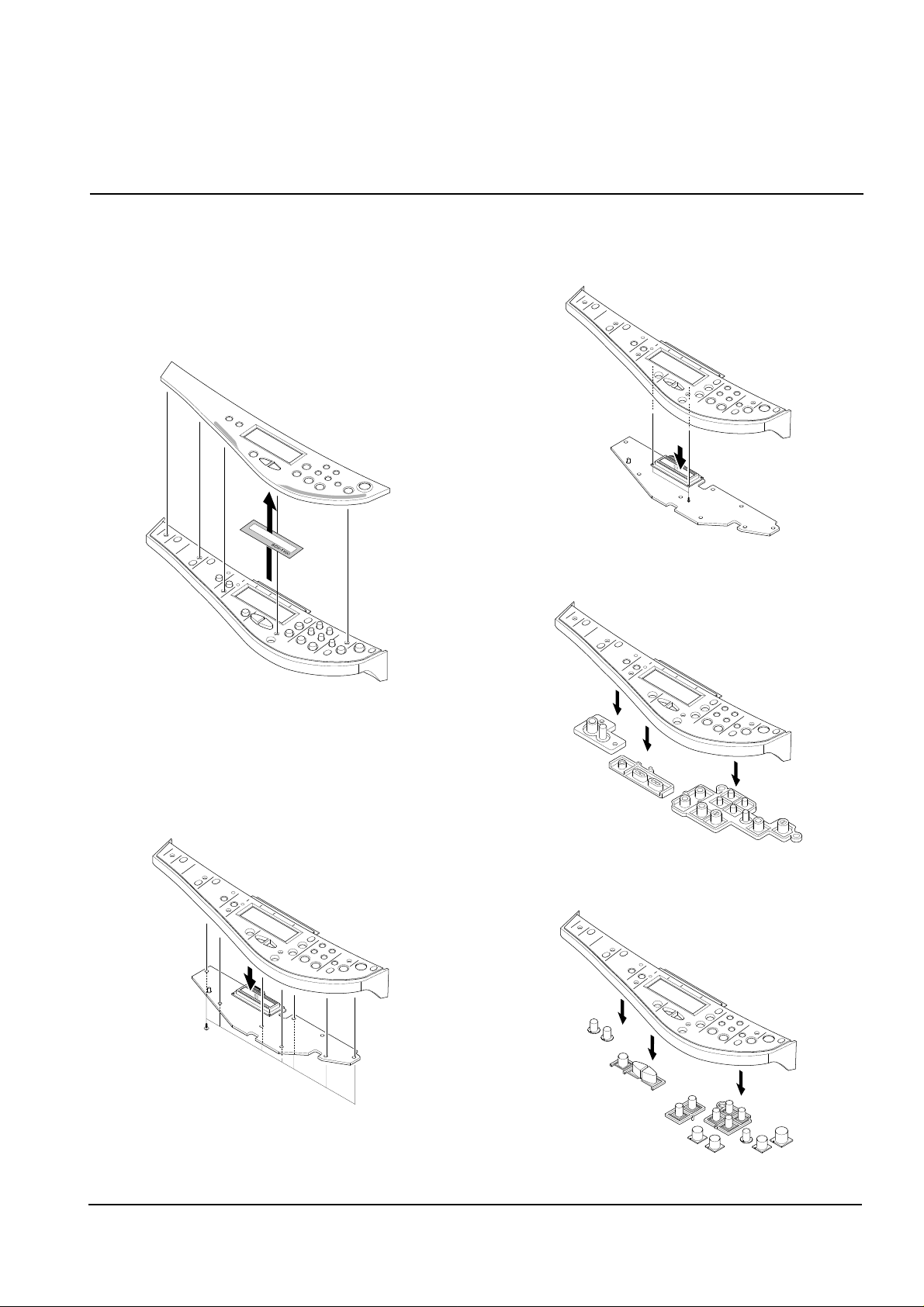

3-3 OPE Unit

1. Before you remove the ope unit, you should remove:

• Scanner Ass'y (see page 3-1)

2. Pull the OPE cover upward and remove it.

Take out the LCD window from the OPE cover.

3. Remove five screws securing the OPE upper to the

OPE PBA.

4. Remove two screws securing the OPE upper to the

LCD board.

5. Remove the contact rubber from the OPE upper.

6. Remove the Key pad from the OPE upper.

3-4 samsung Electronics

Disassembly and Reassembly

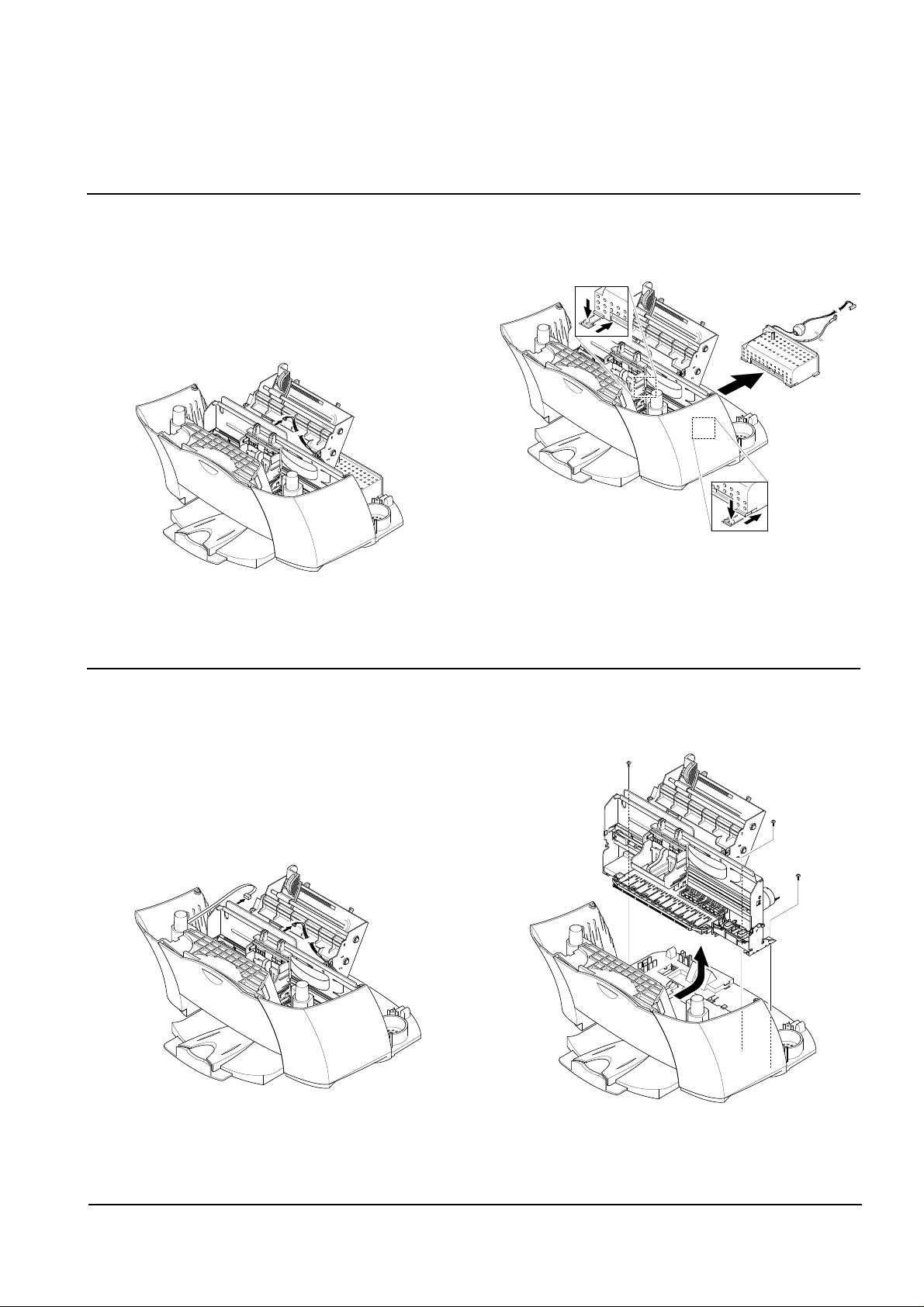

3-4 Rear Cover

1. Before you remove the rear cover, you should

remove:

• Scanner Ass'y (see page 3-1)

2. Pull the extension guide upward and remove it.

3. Remove four screws securing the rear cover.

4. Remove the rear cover, as shown below.

samsung Electronics 3-5

Disassembly and Reassembly

samsung Electronics

Disassembly and Reassembly

3-5 SMPS

1. Before you remove the SMPS, you should remove:

• Scanner Ass'y (see page 3-1)

• Rear Cover (see page 3-5)

2. Unplug the one connector from the main PBA.

3. Pushing down the hooks on both ends, pullout the

SMPS.

3-6

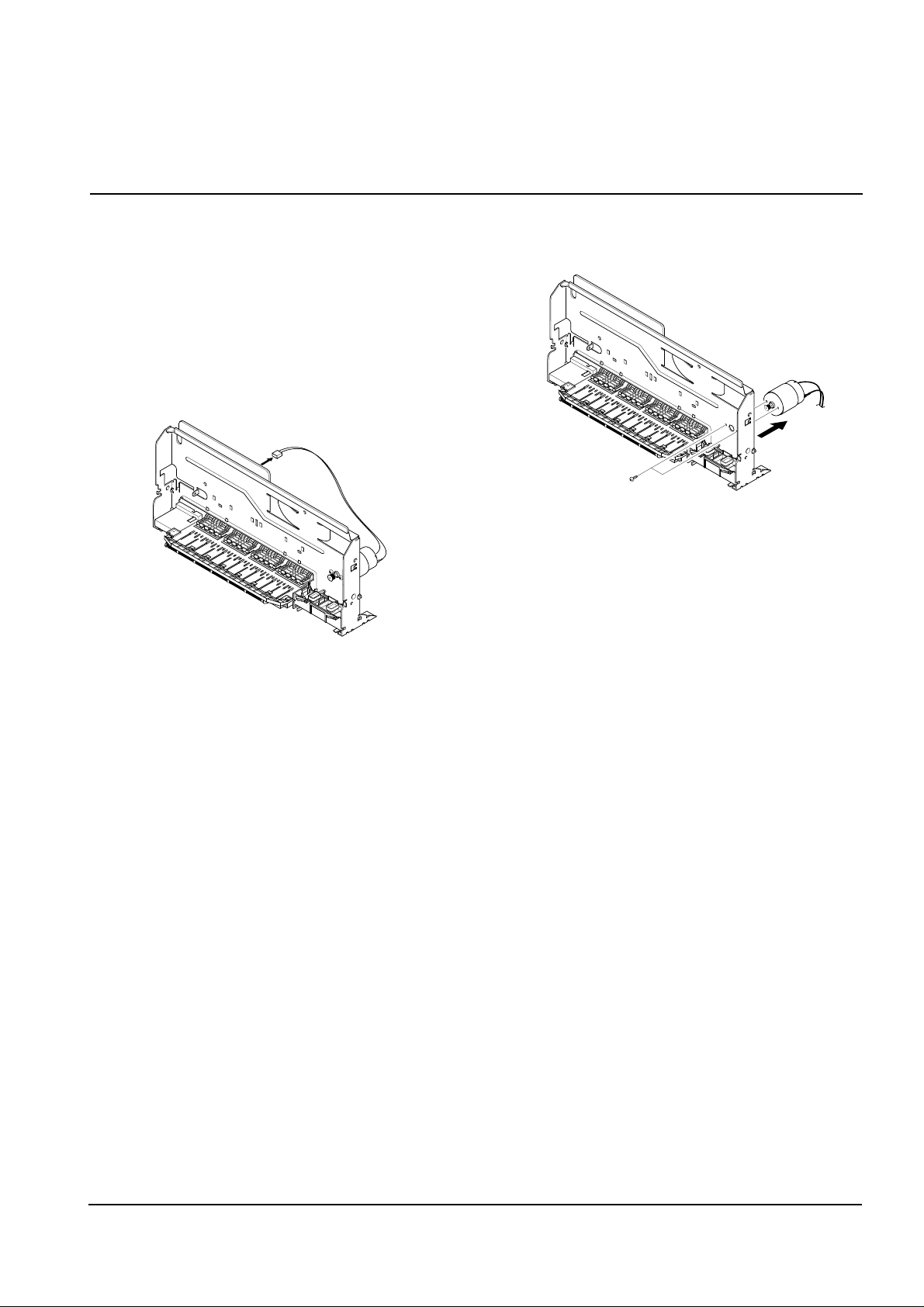

3-6 Engine Ass'y

1. Before you remove the engine ass'y you should

remove:

• Scanner Ass'y (see page 3-1)

• Rear Cover (see page 3-5)

2. Unplug the SMPS connector and cover open sensor

connector from the main PBA.

3. Remove the three screws securing the engine ass'y

and remove it.

samsung Electronics

Disassembly and Reassembly

3-7 ASF Feeder

1. Before you remove the asf feeder, you should

remove:

• Scanner Ass'y (see page 3-1)

• Rear Cover (see page 3-5)

• SMPS (see page 3-6)

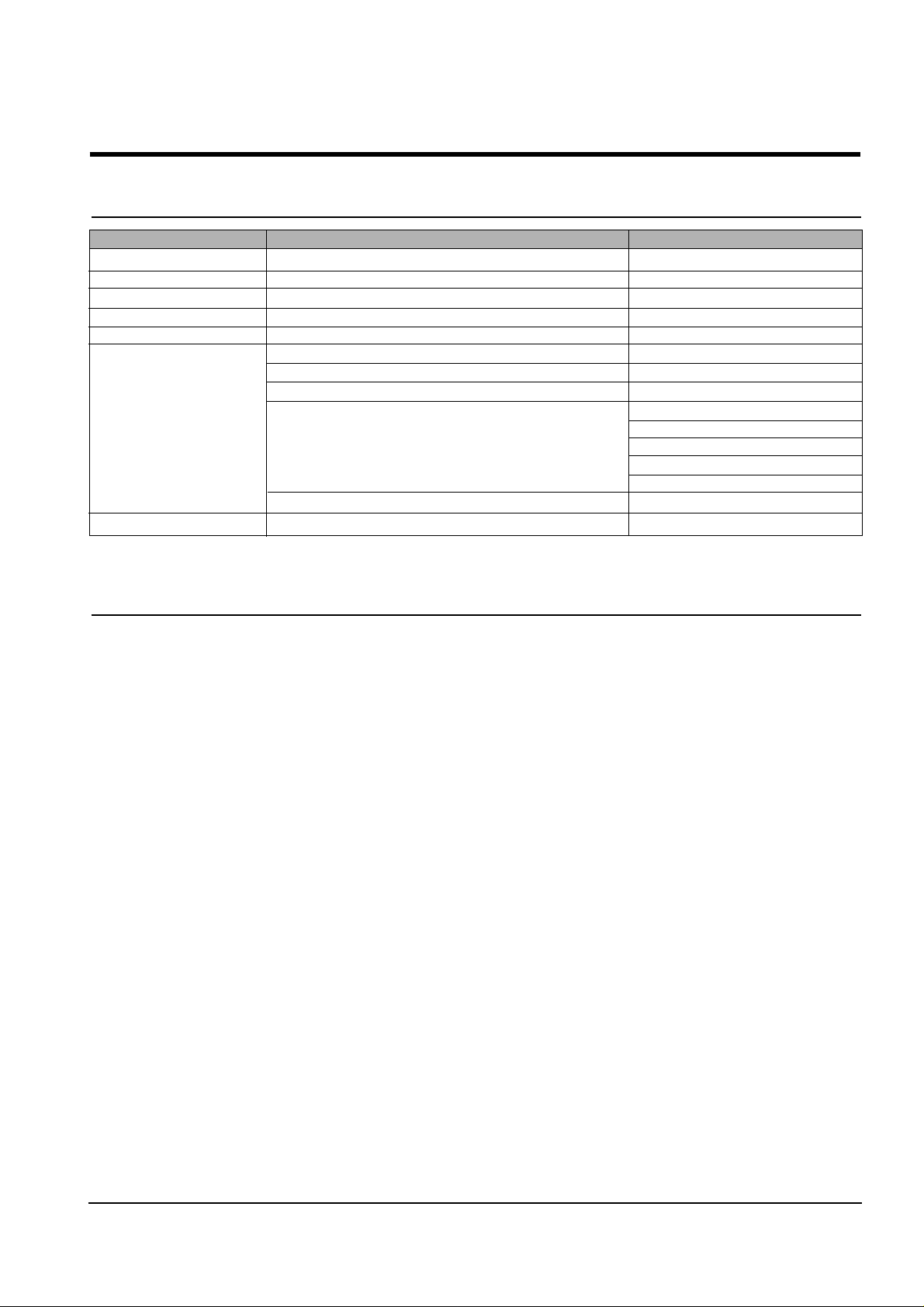

2. Make sure the harness is released from the hooks,

as shown below.

3. Remove three screws securing the ASF feeder to the

main cover.

Take out the ASF feeder.

3-7

3-8 Cartridge Ass'y

1. Before you remove the cartridge ass'y you should

remove:

• Scanner Ass'y (see page 3-1)

• Rear Cover (see page 3-5)

• Engine Ass'y (see page 3-6)

• ASF Feeder (see page 3-7)

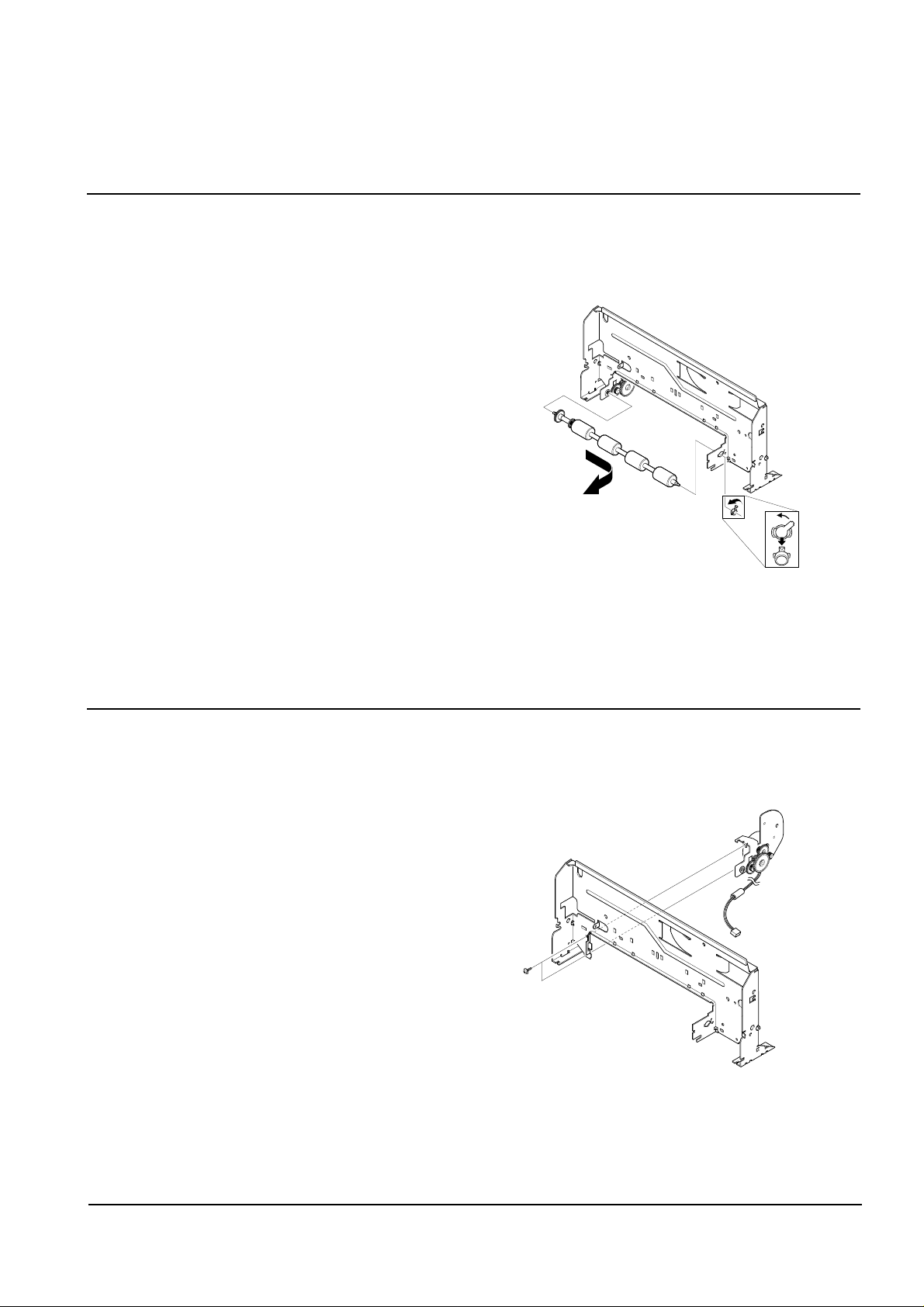

2. Rotate to remove both springs securing the carrier

shaft. Then take out the carrier shaft.

3. Remove the C-cab.

4. Take out the emcoder strip, as shown below.

5. Push the holder pulley to the right and take out the

belt.

6. Take out the cartridge carrier from the main frame.

3-8 samsung Electronics

Disassembly and Reassembly

3-9 Carrier Motor

1. Before you remove the carrier motor, you should

remove:

• Scanner Ass'y (see page 3-1)

• Rear Cover (see page 3-5)

• Engine Ass'y (see page 3-6)

• ASF Feeder (see page 3-7)

• Cartridge Ass'y (see page 3-8)

2. Unplug the one connector from the main PBA.

3. Remove two screws securing the carrier motor and

take out the motor from the main frame.

samsung Electronics 3-9

Disassembly and Reassembly

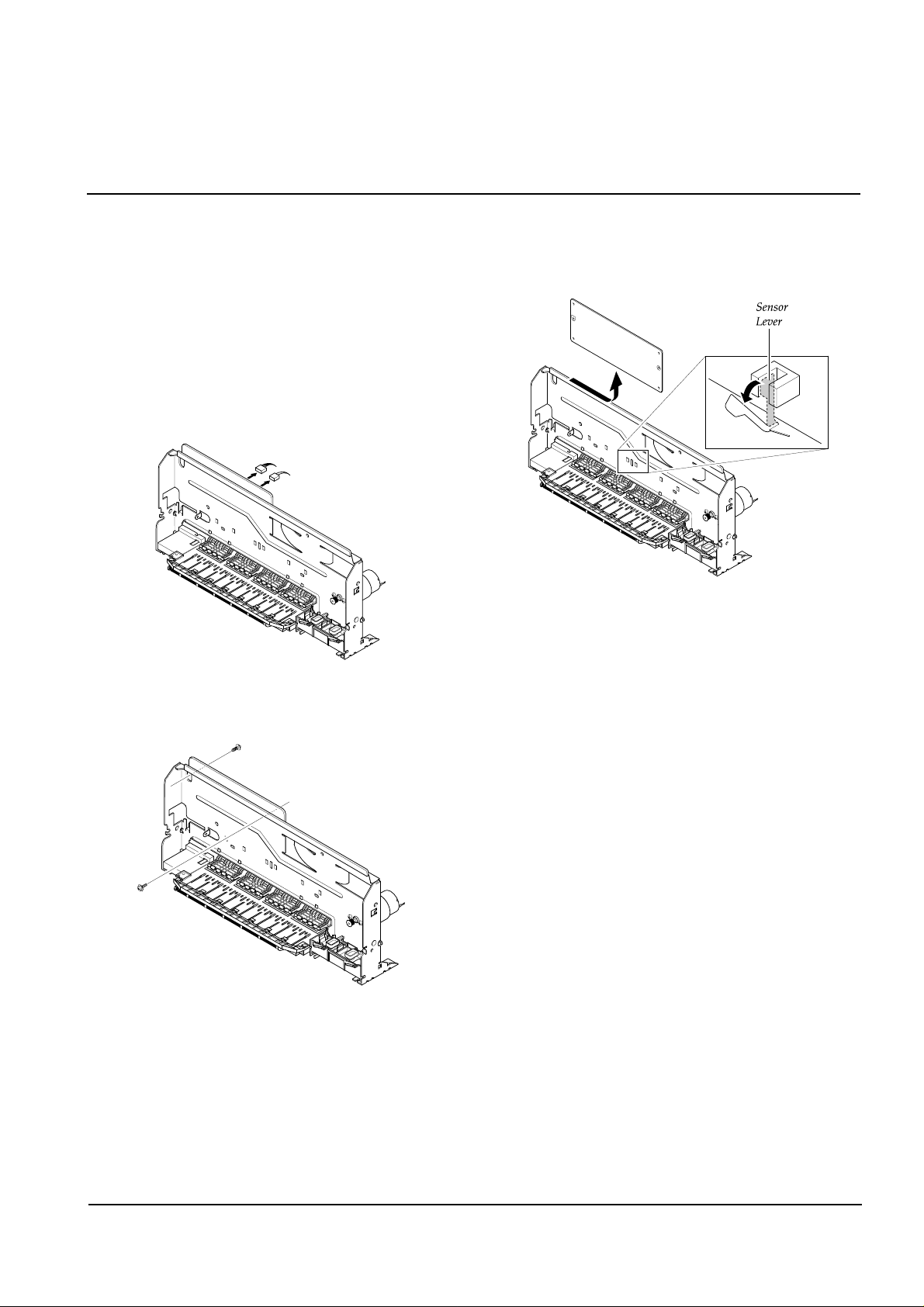

3-10 Main PBA

1. Before you remove the main PBA, you should

remove:

• Scanner Ass'y (see page 3-1)

• Rear Cover (see page 3-5)

• Engine Ass'y (see page 3-6)

• ASF Feeder (see page 3-7)

• Cartridge Ass'y (see page 3-8)

2. Unplug all connectors from the main PBA.

3. Remove the two screws securing the main PBA.

4. Pull the sensor lever backward and take out the main

PBA, as shown below.

3-10 samsung Electronics

Disassembly and Reassembly

samsung Electronics

Disassembly and Reassembly

3-11

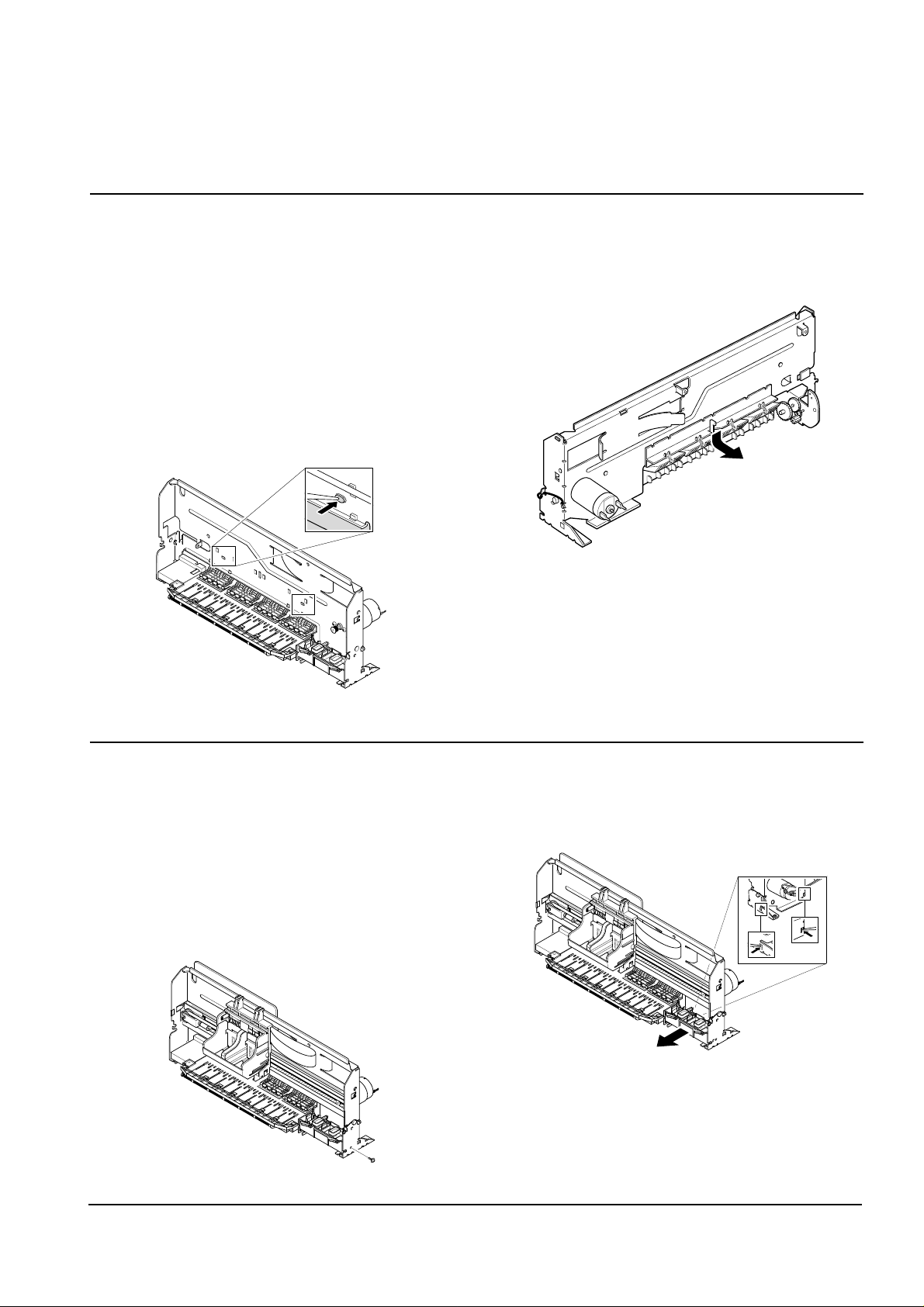

3-11 Holder Roller

1. Before you remove the holder roller, you should

remove:

• Scanner Ass'y (see page 3-1)

• Rear Cover (see page 3-5)

• Engine Ass'y (see page 3-6)

• ASF Feeder (see page 3-7)

• Cartridge Ass'y (see page 3-8)

• Main PBA (see page 3-10)

2. Unlatch the holder by pushing the parts hooked to

the main frame using a sharp tool.

3. Pull the holder downward and take it out from the

main frame.

3-12 Home Ass'y

1. Before you remove the home ass'y you should

remove:

• Scanner Ass'y (see page 3-1)

• Rear Cover (see page 3-5)

• Engine Ass'y (see page 3-6)

• ASF Feeder (see page 3-7)

2. Remove one screw securing the home ass'y.

3. Unlatch the home ass'y by pushing the parts hooked

to the main frame using a sharp tool. Take out the

home ass'y from the main frame.

samsung Electronics

Disassembly and Reassembly

3-12

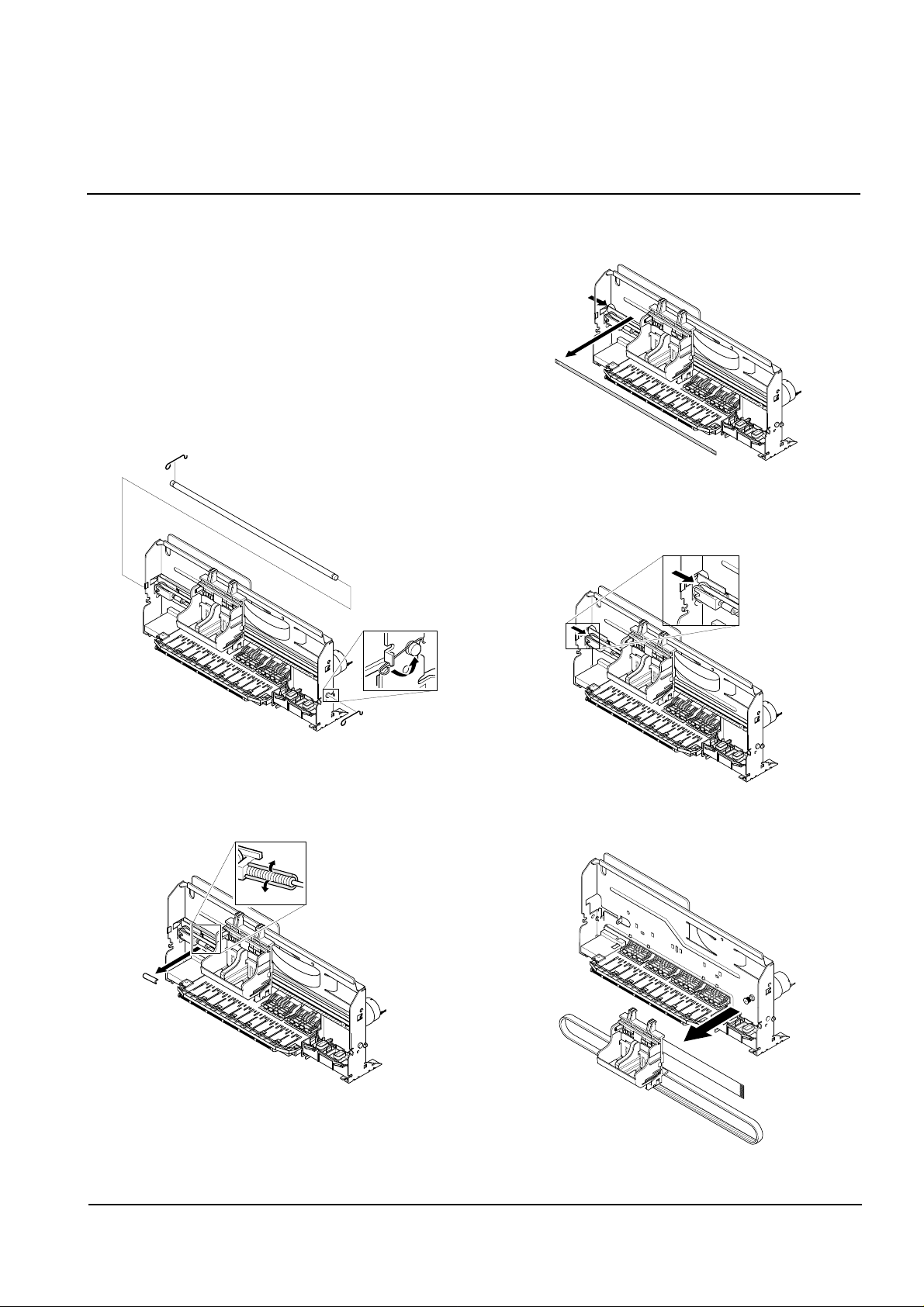

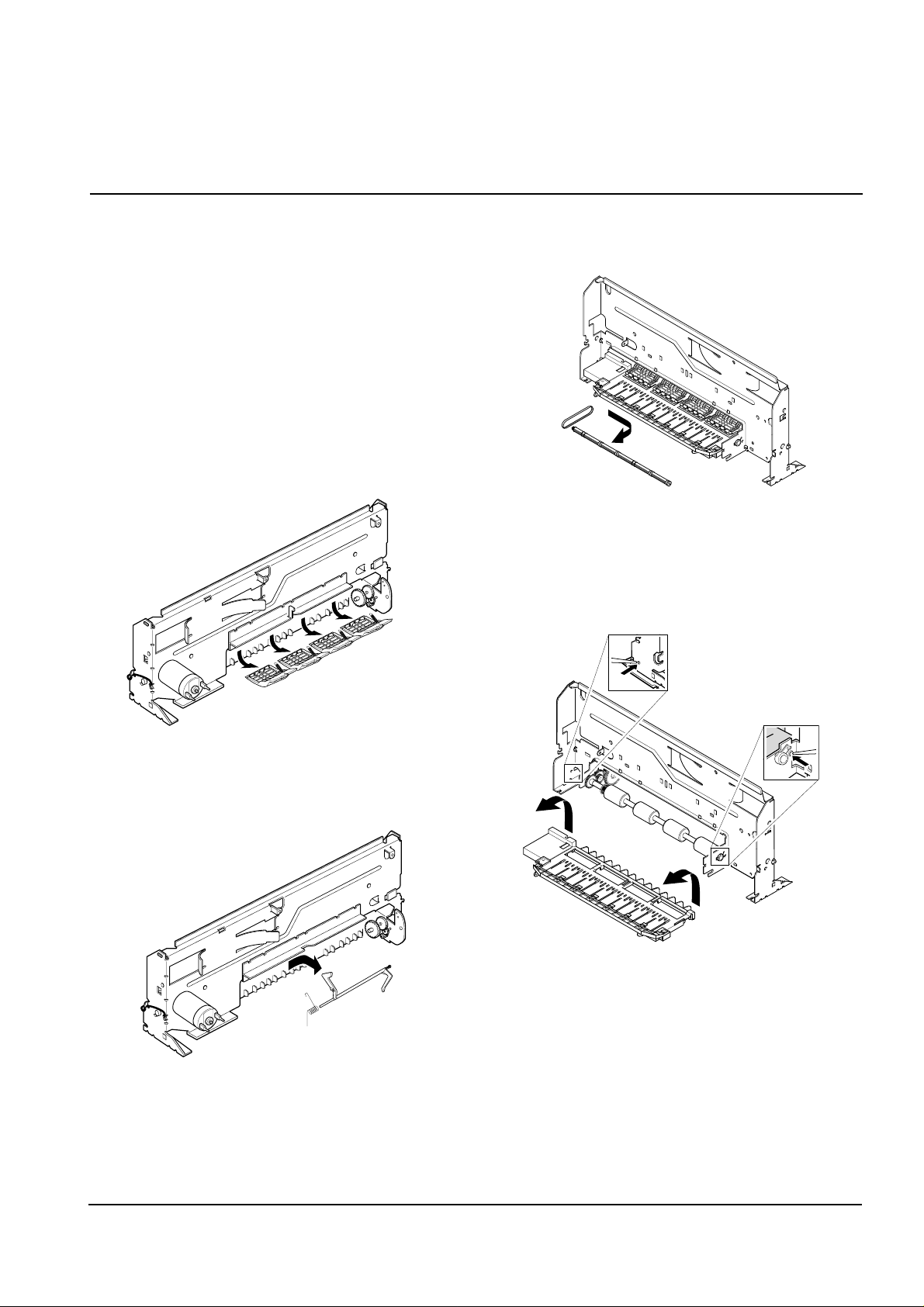

3-13 Base Frame

1. Before you remove the base frame, you should

remove:

• Scanner Ass'y (see page 3-1)

• Rear Cover (see page 3-5)

• Engine Ass'y (see page 3-6)

• ASF Feeder (see page 3-7)

• Cartridge Ass'y (see page 3-8)

• Main PBA (see page 3-10)

• Hold Roller (see page 3-11)

• Home Ass'y (see page 3-11)

2. Remove the four springs and take out the four roller

frictions, as shown below.

3. Take out the actuator feed from the main frame, as

shown below.

4. Remove the exit roller from the main frame and take

out the exit belt.

5. Unlatch the base frame ass'y by pushing the parts

hooked to the main frame using a sharp tool, as

shown below.

samsung Electronics

Disassembly and Reassembly

3-13

3-14 Feed Roller

1. Before you remove the feed roller, you should

remove:

• Scanner Ass'y (see page 3-1)

• Rear Cover (see page 3-5)

• Engine Ass'y (see page 3-6)

• ASF Feeder (see page 3-7)

• Cartridge Ass'y (see page 3-8)

• Main PBA (see page 3-10)

• Hold Roller (see page 3-11)

• Home Ass'y (see page 3-11)

• Base Frame (see page 3-12)

2. Turn the bearing feed counterclockwise and take out

the base frame and feed roller from the main frame.

3-15 Line Feed Bracket Ass'y

1. Before you remove the LF bracket ass'y, you should

remove:

• Scanner Ass'y (see page 3-1)

• Rear Cover (see page 3-5)

• Engine Ass'y (see page 3-6)

• ASF Feeder (see page 3-7)

• Cartridge Ass'y (see page 3-8)

• Main PBA (see page 3-10)

• Hold Roller (see page 3-11)

• Home Ass'y (see page 3-11)

• Base Frame (see page 3-12)

• Feed Roller (see page 3-13)

2. Remove two screws and take out the LF bracket

ass'y from the main frame.

4-1

Samsung Electronics

4. Troubleshooting

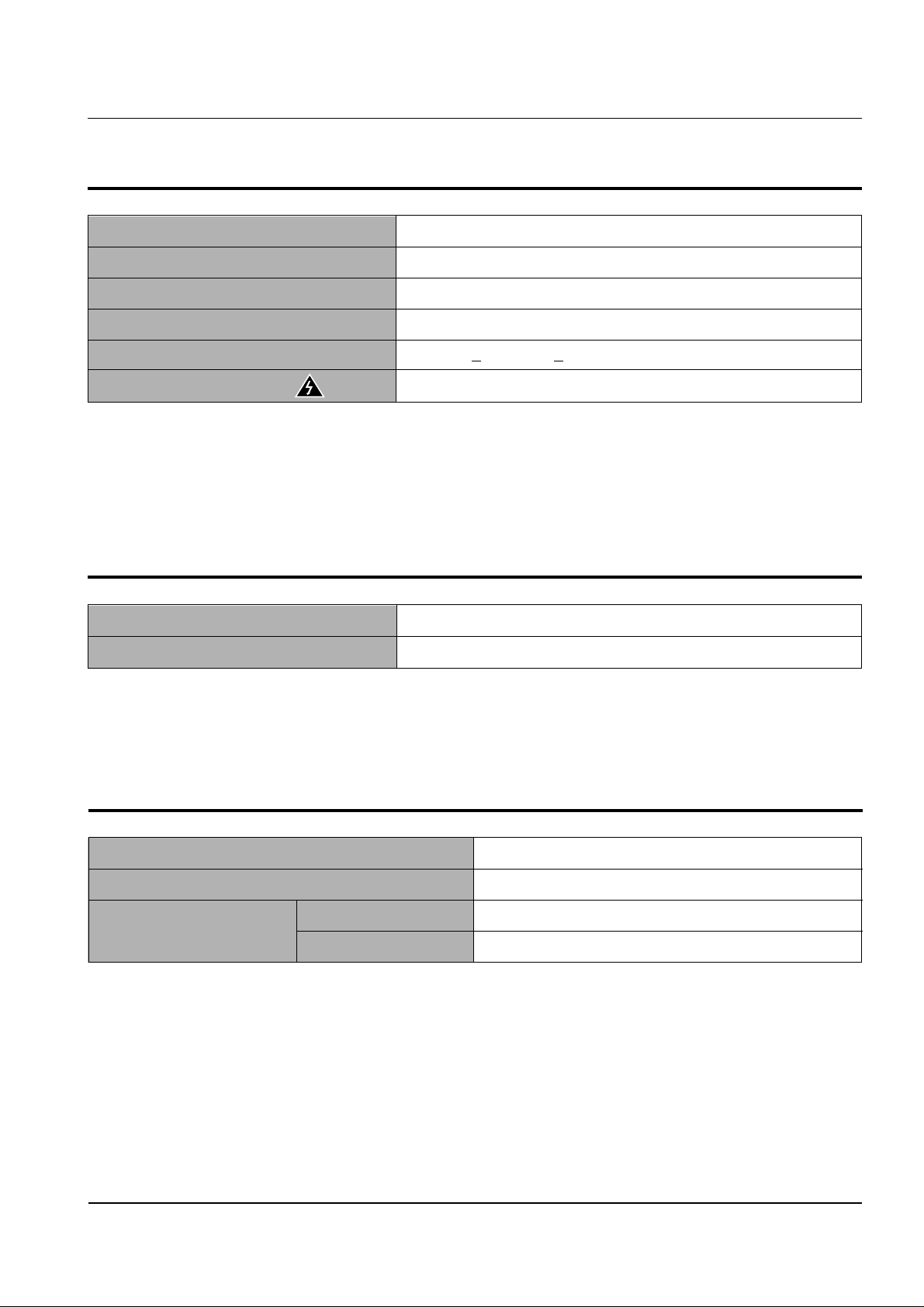

4-1 Setting-up System in User Mode

FUNCTION ITEM DEFAULT

LANGUAGE ENG/GER/FRE/ITA/SPA/POR/DUT ENGLISH

POWER SAVE MODE 1/4/8/12 HOUR 1

PAPER SIZE LETTER/A4/LEGAL A4

P APER TYPE PLAIN/INKJET/PHOTO/TRANSPARENCY PLAIN PAPER

MAINTENANCE CLEAN CARTRIDGE

ALIGN CARTRIDGE

VIEW INK LEVEL "COLOR : _/8 , BLOCK : _/8"

HELP LIST

DEFAULT SETUP CONTRAST

QUALITY

COPY P AGE

ZONE RATE

RESOLUTION

ADJUST SHADING

KEY SOUND ON/OFF ON

4-2 Setting-up System in Service Mode

• How to enter service mode

In service (tech) mode, the technician can check the machine and perform various tests to isolate the cause of a malfunction.

To enter the service mode, press ENTER, LEFT, RIGHT, LEFT, SETUP in sequence, and the LCD displays ‘ T ’, the machine

has entered service (Tech) mode.

To return to normal user mode, press ENTER, LEFT, RIGHT, LEFT, SETUP in sequence again, or turn the power off, then

on by unplugging and plugging the power cord.

Because the explanation of the User Mode items is already mentioned at the User guide in detail, It will not be described at

Service manual.

4-2

Troubleshooting

Samsung Electronics

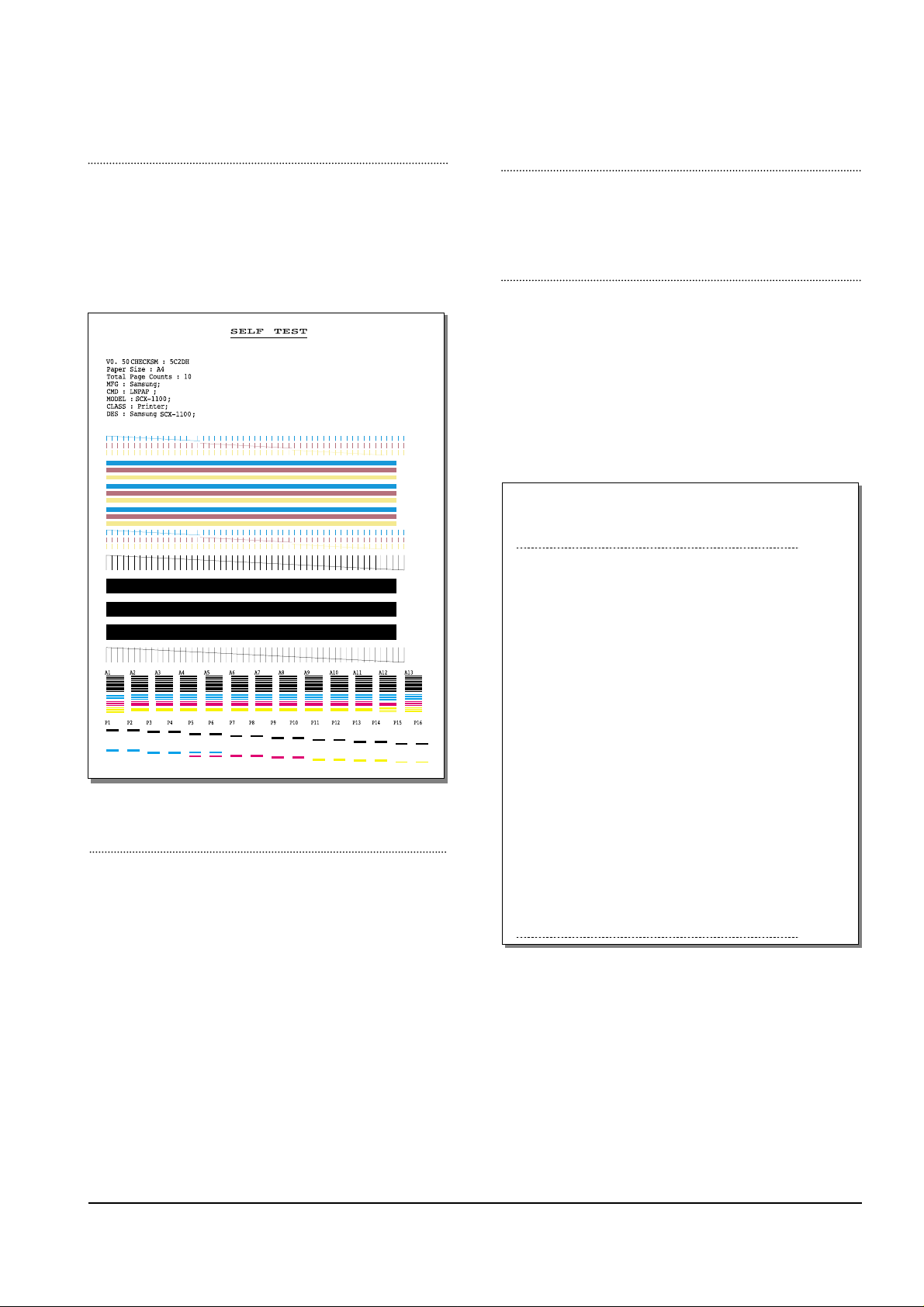

FACT OR Y SELFTEST

Using this pattern printout, you can check if the printer

mechanism is functioning properly. Examine the pattern

and look for a break in the diagonal line. If the diagonal

lines are not broken, the printer mechanism is functioning

properly .

ROM TEST

Use this feature to test the machine'S ROM. The result and the

software version appear in the LCD display .

PRINT NVRAM TEST

1. Press the SETUP button until “PRINT NVRAM DUMP”

is displayed in LCD.

2. Press the START button when the NVRAM Test opera-

tion menu displayed. And then the machine prints the

list for NVRAM testing.

The Remote Test feature can be enabled in order to allow

a remote location to call up and run a diagnostic test on

your machine. You may be instructed by a service representative to enable this feature.

NVRAM DUMP LIST

LIST Left Head Detect : 1c

Right Head Detect : 7

Left Head Type : 1c

Right Head Type : 7

< Device Identification >

MFG:Samsung;

CMD:LNPAP;

MODEL:SCX-1100;

CLASS :Printer;

DES:Samsung SCX-1100;

< Dot Count Variables >

Black Dot Count : 2436256

Color Cyan Dot Count : 1368128

Color Magenta Dot Count : 1368128

Color Yellow Dot Count : 1368128

Photo Black Dot Count : 0

Photo Cyan Dot Count : 0

Photo Magenta DotCount : 0

Total Black Dot Count : 2436256

Total Color Cyan Dot Count : 1368128

Total Color Magenta Dot Count : 1368128

Total Color Yellow Dot Count : 1368128

Total Photo Cyan Dot Count : 0

Total Photo Magenta Dot Count : 0

Total Photo Black Dot Count : 0

< Page Count Variables >

Total Page Count : 2

< Cartridge Types >

Left Cartridge Type : Color Standard Capacity

Right Cartridge Type : Black High Capacity

< Alignment Variables >

Horizontal Align Value : 15

Vertical Align Value : 8

Quick Black Bidi Align Value : 15

Quick Color Bidi Align Value : 15

Normal Black Bidi Align Value : 15

Normal Color Bidi Align Value : 15

Photo Horizontal Align Value : 15

Photo Vertical Align Value : 8

Photo Normal Black Bidi Align Value : 15

Photo Normal Color Bidi Align Value : 15

PROGRAM DOWNLOAD

Use this feature to download a new upgraded ROM file from

a PC which is connected to the machine with a parallel cable

(IEEE 1284).

< Download >

1. Connect printer to PC with a parallel cable(IEEE 1284.)

2. Select the PROGRAM DOWNLOAD function at the TECH

MODE.

3. Input COPY/B FILENAME PRN at the MS-DOS and push

the ENTER key .

(filename : the latest ROM file name when the downloading)

4. After the download is completed, the system will be automatically initialized.

4-3

Troubleshooting

Samsung Electronics

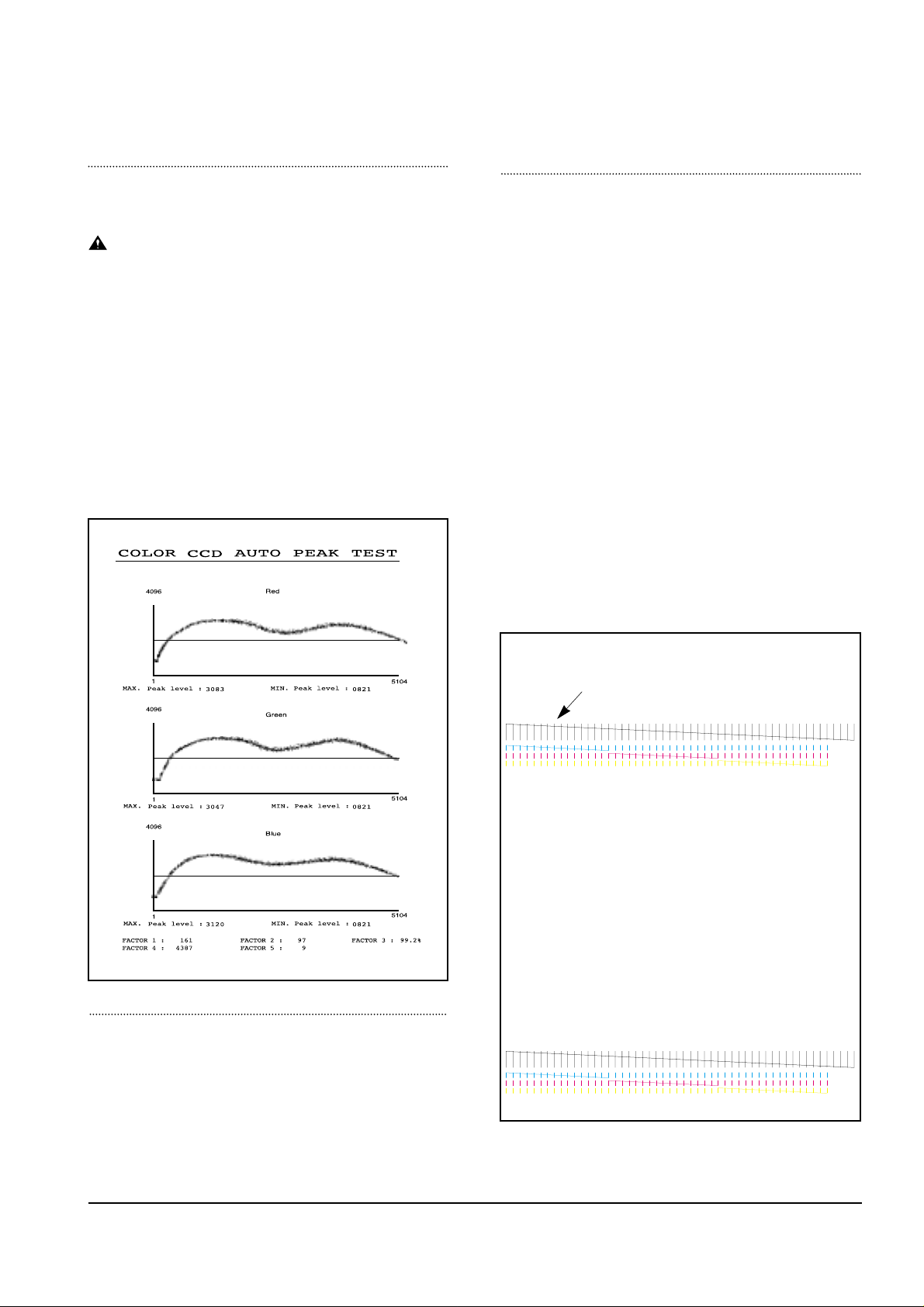

PRINT CCD PATTERN

It is used to adjust the light of CCD. It is already set at

CCD Test to get optimum quality.

NOTICE

When you test CCD, make sure that the cover is

closed.

1. Press the SETUP button until “Print CCD Pattern” is

displayed in LCD.

2. Press the START button when the CCD Test operation

menu displayed.

3. After scanner calibrating, wave form will be automatically printed out.

All the wave forms should be similar each other. CCD

problems may occur, if:

• More than one of the wave forms are straight lines.

• All wave forms are positioned under the center line.

WHITE LINES ON LETTERS OR GRAPHICS

• Cause

If nozzles in print head has a problem, white lines are

marked on the print.

‘CARTRIDGE MAINTENANCE’ will let you know if nozzles have fallen problems.

• Solution

1

) Run ‘print control panel’ to “clean print nozzles” and check if

nozzles have been blocked.

2) Wipe

with soft cloth the contact surfaces of ink cartridge and car-

riage, and check if nozzles have been cleaned properly.

3) Separate ink cartridge from carriage and combine them.

Repeat it about 5 to 6 times and check if connection is proper.

4) Replace ink cartridge and check whether there’s a problem

with the head.

5) Check if head cable is inserted well into the main circuit board

and then check if nozzles have problems.

6) Check if head cable is broken or torn and then check if nozzles

have problems.

7) Replace the main circuit board with a new one and

check if nozzles have problems.

MEMORYALL CLEAR

Initiating this function will put the system into the factory

shipping state. The procedure is as follows :

1. Unplug power

2. Press and hold " SETUP" button

3. Plug power in

4. Continue holding " SETUP" button until CLEARING

MEMORY message appears on LCD

5. Unplug power

If this line is broken, it confirms that nozzles

have problems.

4-4

Troubleshooting

Samsung Electronics

4-3. Troubleshooting

4-3-1 Defective PC Scan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4-5)

4-3-2 Defective Image quality of PC Scan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4-5)

4-3-3 Defective Operation (LCD WINDOW ) Display . . . . . . . . . . . . . . . . . . . . . . .page(4-6)

4-3-4 No Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4-6)

4-3-5 Defective LCD Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4-7)

4-3-6 Defective Operation of Key Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4-7)

4-3-7 Paper Jam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4-8)

4-3-8 Defective Paper Feed (1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4-8)

4-3-9 Defective Paper Feed (2) -Display of NO PAPER . . . . . . . . . . . . . . . . . . . . . . . . .page(4-9)

4-3-10 Multi-Feeding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4-9)

4-3-11 Defective Sensing-ink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4-10)

4-3-12 Defective Sensing-paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4-10)

4-3-13 Defective Motor Drive (LF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4-11)

4-3-14 Defective Motor Drive (CR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4-11)

4-3-15 Defective Motor Drive (Scan) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4-12)

4-3-16 Blank Page Print Out (When Copying) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4-12)

4-3-17 Vertical Black Line (When Copying) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4-13)

4-3-18 Contaminated Stains on Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4-13)

4-3-19 Bad printed Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4-14)

4-3-20 Vertical Lines are printed crookedly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4-14)

4-3-21 Bad Color (Intensity) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4-15)

4-3-22 The Printer is Not Working (1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4-15)

4-3-23 The Printer is Not Working (2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4-16)

4-3-24 Abnormal Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4-17)

4-3-25 Spool Error and Release of Spool Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4-18)

• The solutions of troubleshooting in this 'Service Manual' explain the expected causes and

how to check according to each problem and describe how to replace the defected parts (unit

of ASS'Y) if necessary.

• The contents of this 'Service Manual' describe general ones only among many kinds of problems and causes while using the Product.

• The contents of this 'Service Manual' describe mainly technical explanations of the Product

H/W and parts on the assumption that there is no problem in S/W.

4-5

Troubleshooting

Samsung Electronics

4-3-1 Defective PC Scan

4-3-2 Defective Image Quality of PC Scan

• Description

• Location 1.UBS Cable of the Printer or Centronics Cable 2.Driver 3.Main B’d

The PC Scan is not functioning at all.

Check and Cause Solution

1. Check the Cable (USB or Parallel)

2. Check if the driver is installed properly.

1. If the PC and the cable are not connected properly,

reconnect it.

2. After confirming that it is proper by performing a PC

printing test related to driver setup, if it is not so, reinstall

it. (Refer to User's Manual.)

• Description

• Location 1. CCD ASS'Y 2.Main B’d

The image PC scanned is not clear or bad.

Check and Cause Solution

1. Check the waveform form by performing a CCD test

in TECH mode. (Refer to 4-1-3)

2. Check if the resolution is set too low in PC Scan

options. (Refer to User's Manual.)

1. If the CCD waveform form is abnormal, try to replace

CCD ASS'Y.

2. If the resolution is set to low, let the user be acquainted

with the using method well.

4-6

Troubleshooting

Samsung Electronics

4-3-3 Defective Operation (LCD WINDOW ) Display

4-3-4 No Power

• Description

• Location 1.OPE ASS'Y 2.Connection between the Main B'D and OPE ASS'Y 3.Main B'D.

Strange characters are displayed on the OPE Panel and buttons are not operated.

Check and Cause Solution

1. Clear the memory.

2. Check if OPE HARNESS is connected to the Main

Board correctly.

1. Try again after clearing the memory.

2. After confirming that OPE HARNESS is connected to

the Main Board correctly, if it is so, then replace the

OPE ASS'Yand Main Board in sequence.

• Description

• Location

1.Power code 2.Connection between the Main B'D and Power HARNESS

3.Power ASS'Y 4.Main B'D. 5.OPE Ass’y

While the power S/W is turned on, it does not work at all.

Check and Cause Solution

1. Check if the connection of power code is normal.

2. Check if DC +3.3V and +30V is supplied to POWER

ASS'Y from MAIN B'd.

3. Check if POWER DOWN KEY in OPE ASS'Y is

working regularly.

1. Try to replace the power code.

2. If all the connections are correct, try to replace the

power ASS'Yand the Main B/D in sequence.

( +3.3V and +30V is supplied to POWER ASS'Y from

MAIN B'd)

3. Replace OPE ASS'Y

4-7

Troubleshooting

Samsung Electronics

4-3-5 Defective LCD Operation

4-3-6 Defective Operation of Key Button

• Description The LCD screen is not turned on or has a strange display.

Check and Cause Solution

1. Clear the memory. (Refer to page 4-1).

2. Confirm to catch a click sound, while a key on the

OPE panel is pressed on.

3. Check the status of Harness between LCD and OPE

Panel, replace in order of Main B'd/LE Motor.

1. The key is wrong itself or wrongly assembled.

2. Even after the key or harness has been replaced, it is

still wrong, try to replace the OPE ASS'Y and the Main

B'D in sequence.

• Description

• Location 1. OPE ASS'Y 2. Main Board

The button of the OPE Panel is not operated..

Check and Cause Solution

1. Confirm to catch a click sound while the key is

pressed on.

2. Check if a specific key is pressed by another equipment.

1. If you cannot catch a click sound, the key is wrong itself

or wrongly assembled.

2. Even after the key has been replaced, it is still wrong,

try to replace the OPE ASS'Yand the Main B'D in

sequence.

• Location 1.LCD 2.OPE Ass’y 3.Main B’d

4-8

Troubleshooting

Samsung Electronics

4-3-7 Paper Jam

4-3-8 Defective Paper Feed (1)

• Description

• Location ASF ASS'Y

The paper is jammed inside the set and not exited from.

Check and Cause Solution

1. Check if the paper is crumpled or preprinted.

2. Check if too many sheets of recording paper are put

into ASF (Automatic Sheet Feeder).

(Standard : up to 100 sheets).

3. Check if the remaining papers are stuck in the frame

base.

1. If the papers jammed or pieces of the paper are stuck

inside the set, remove them and then try it again.

2. If the problem still exists, try to replace ASF ASS'Y.

• Description

• Location ASF ASS'Y

A recording paper is tilted while feeding.

Check and Cause Solution

1. Check if the paper guide of ASF (Automatic Sheet

Feeder) is set up properly with the width of recording

paper.

2. Check if too many sheets of recording paper are put

into ASF (Automatic Sheet Feeder).

(Standard: up to 100 sheets).

3. Check if the recording paper is crumpled or preprinted.

1. After all have been checked, the problem still exists, try

to replace the ASF ASS'Y.

Loading...

Loading...