samsung SCD351-XAA, SCD351- XAO, SCD351- XAC, SCD351- XTC, SCD351- XAX Service Manual

...

DIGITAL VIDEO CAMCORDER

Chassis : Dragon (Delta III)

BASIC : SCD353

SCD353/XAA, XAO, XAC, XTC, XAX, RCL, XAP,

TWN, GEN, ZAM, SAM, AFS, XBG

SCD352/XAA, XAO, XAC, XTC, XAX, RCL, XAP,

TWN, GEN, ZAM, SAM, AFS, XBG

SCD351/XAA, XAO, XAC, XTC, XAX, RCL, XAP,

TWN, GEN, ZAM, SAM, AFS, XBG

SERVICE

; Shooting Design DVC Leader

; Use Built-in Flash Memory

; Multi Memory Card Slot

; Direct Print System : PictBridge ™

; Power Nite Pix

; High quality MPEG4

; Still image Interpolation

; Real Wide mode (16:9)

Manual

DIGITAL VIDEO CAMCORDER Merit & Character regarding Product

1. Precautions

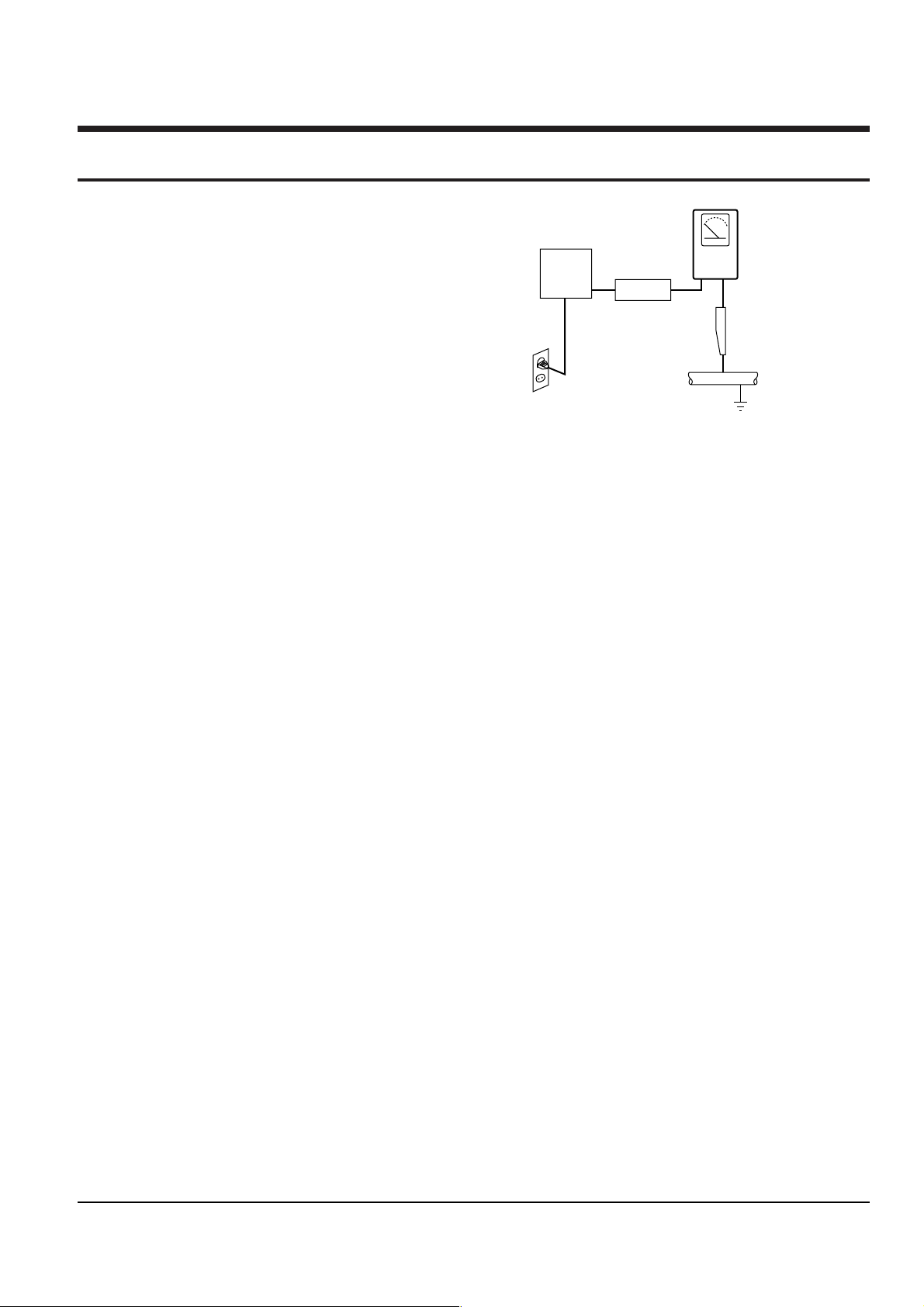

DEVICE

UNDER

TEST

(READING SHOULD

NOT BE ABOVE

0.5mA)

LEAKAGE

CURRENT

TESTER

EARTH

GROUND

TEST ALL

EXPOSED METER

SURFACES

ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

2-WIRE CORD

1. Be sure that all of the built-in protective devices are

replaced. Restore any missing protective shields.

2. When reinstalling the chassis and its assemblies, be

sure to restore all protective devices, including :

control knobs and compartment covers.

3. Make sure that there are no cabinet openings

through which people--particularly children

--might insert fingers and contact dangerous

voltages. Such openings include the spacing

between the picture tube and the cabinet mask,

excessively wide cabinet ventilation slots, and

improperly fitted back covers.

If the measured resistance is less than 1.0 megohm

or greater than 5.2 megohms, an abnormality exists

that must be corrected before the unit is returned

to the customer.

4. Leakage Current Hot Check (See Fig. 1-1) :

Warning : Do not use an isolation transformer

during this test. Use a leakage current tester or a

metering system that complies with American

National Standards Institute (ANSI C101.1,

Leakage Current for Appliances), and Underwriters

Laboratories (UL Publication UL1410, 59.7).

Fig. 1-1 AC Leakage Test

7. Antenna Cold Check :

With the unit’s AC plug disconnected from the

AC source, connect an electrical jumper across the

two AC prongs. Connect one lead of the ohmmeter

to an AC prong.

Connect the other lead to the coaxial connector.

8. High Voltage Limit :

High voltage must be measured each time

servicing is done on the B+, horizontal deflection

or high voltage circuits.

5. With the unit completely reassembled, plug the AC

line cord directly the power outlet. With the unit’s

AC switch first in the ON position and then OFF,

measure the current between a known earth

Heed the high voltage limits. These include the

X-ray protection Specifications Label, and the

Product Safety and X-ray Warning Note on the

service data schematic.

ground (metal water pipe, conduit, etc.) and all

exposed metal parts, including : antennas, handle

brackets, metal cabinets, screwheads and control

shafts. The current measured should not exceed

0.5 milliamp. Reverse the power-plug prongs in the

AC outlet and repeat the test.

9. Some semiconductor (“solid state”) devices are

easily damaged by static electricity.

Such components are called Electrostatically

Sensitive Devices (ESDs); examples include

integrated circuits and some field-effect transistors.

The following techniques will reduce the

6. X-ray Limits :

The picture tube is designed to prohibit X-ray

occurrence of component damage caused by static

electricity.

emissions. To ensure continued X-ray protection,

replace the picture tube only with one that is the

same type as the original.

10. Immediately before handling any semiconductor

components or assemblies, drain the electrostatic

charge from your body by touching a known

earth ground. Alternatively, wear a discharging

Samsung Electronics 1-1

Wrist-strap device. (Be sure to remove it prior to

applying power--this is an electric shock

precaution.)

Precautions

11. High voltage is maintained within specified limits

by close-tolerance, safety-related components and

adjustments. If the high voltage exceeds the

specified limits, check each of the special

components.

12. Design Alteration Warning :

Never alter or add to the mechanical or electrical

design of this unit. Example : Do not add

auxiliary audio or video connectors.

Such alterations might create a safety hazard.

Also, any design changes or additions will void

the manufacturer’s warranty.

13. Hot Chassis Warning :

Some TV receiver chassis are electrically

connected directly to one conductor of the AC

power cord. If an isolation transformer is not

used, these units may be safely serviced only if

the AC power plug is inserted so that the chassis

is connected to the ground side of the AC source.

To confirm that the AC power plug is inserted

correctly, do the following : Using an AC

voltmeter, measure the voltage between the

chassis and a known earth ground. If the reading

is greater than 1.0V, remove the AC power plug,

reverse its polarity and reinsert. Re-measure the

voltage between the chassis and ground.

14. Some TV chassis are designed to operate with 85

volts AC between chassis and ground, regardless

of the AC plug polarity. These units can be safely

serviced only if an isolation transformer inserted

between the receiver and the power source.

18. Picture Tube Implosion Warning :

The picture tube in this receiver employs

“integral implosion” protection. To ensure

continued implosion protection, make sure that

the replacement picture tube is the same as the

original.

19. Do not remove, install or handle the picture tube

without first putting on shatterproof goggles

equipped with side shields. Never handle the

picture tube by its neck. Some “in-line” picture

tubes are equipped with a permanently attached

deflection yoke; do not try to remove such

“permanently attached” yokes from the picture

tube.

20. Product Safety Notice :

Some electrical and mechanical parts have special

safety-related characteristics which might not be

obvious from visual inspection. These safety

features and the protection they give might be

lost if the replacement component differs from the

original--even if the replacement is rated for

higher voltage, wattage, etc.

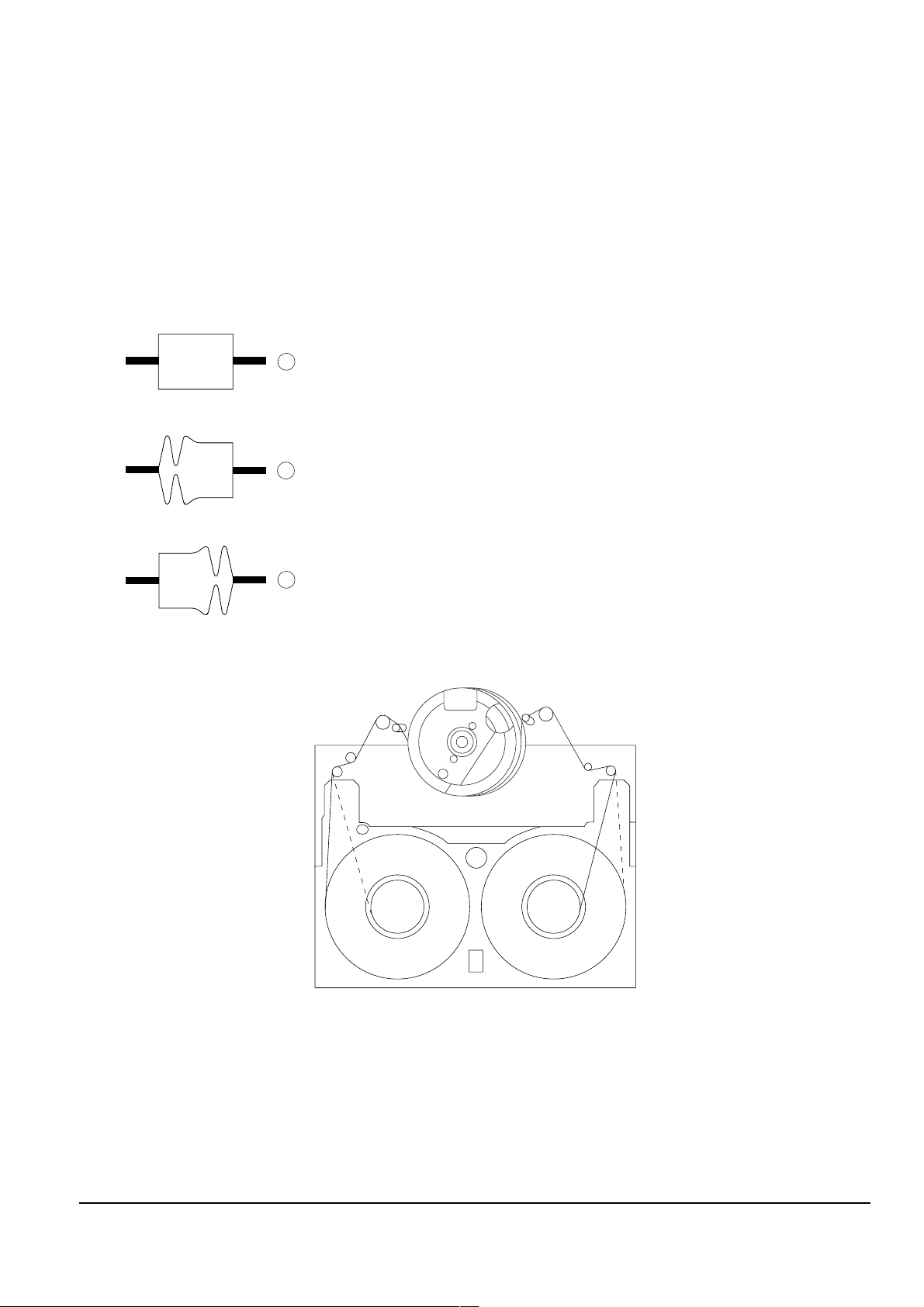

Components that are critical for safety are

indicated in the circuit diagram by shading,

( or ).

Use replacement components that have the same

ratings, especially for flame resistance and

dielectric strength specifications. Areplacement

part that does not have the same safety

characteristics as the original might create shock,

fire or other hazards.

15. Never defeat any of the B+ voltage interlocks.

Do not apply AC power to the unit (or any of its

assemblies) unless all solid-state heat sinks are

correctly installed.

16. Always connect a test instrument’s ground lead to

the instrument chassis ground before connecting

the positive lead; always remove the instrument’s

ground lead last.

17. Observe the original lead dress, especially near

the following areas : Antenna wiring, sharp

edges, and especially the AC and high voltage

power supplies. Always inspect for pinched, outof-place, or frayed wiring. Do not change the

spacing between components and the printed

circuit board. Check the AC power cord for

damage. Make sure that leads and components

do not touch thermally hot parts.

1-2 Samsung Electronics

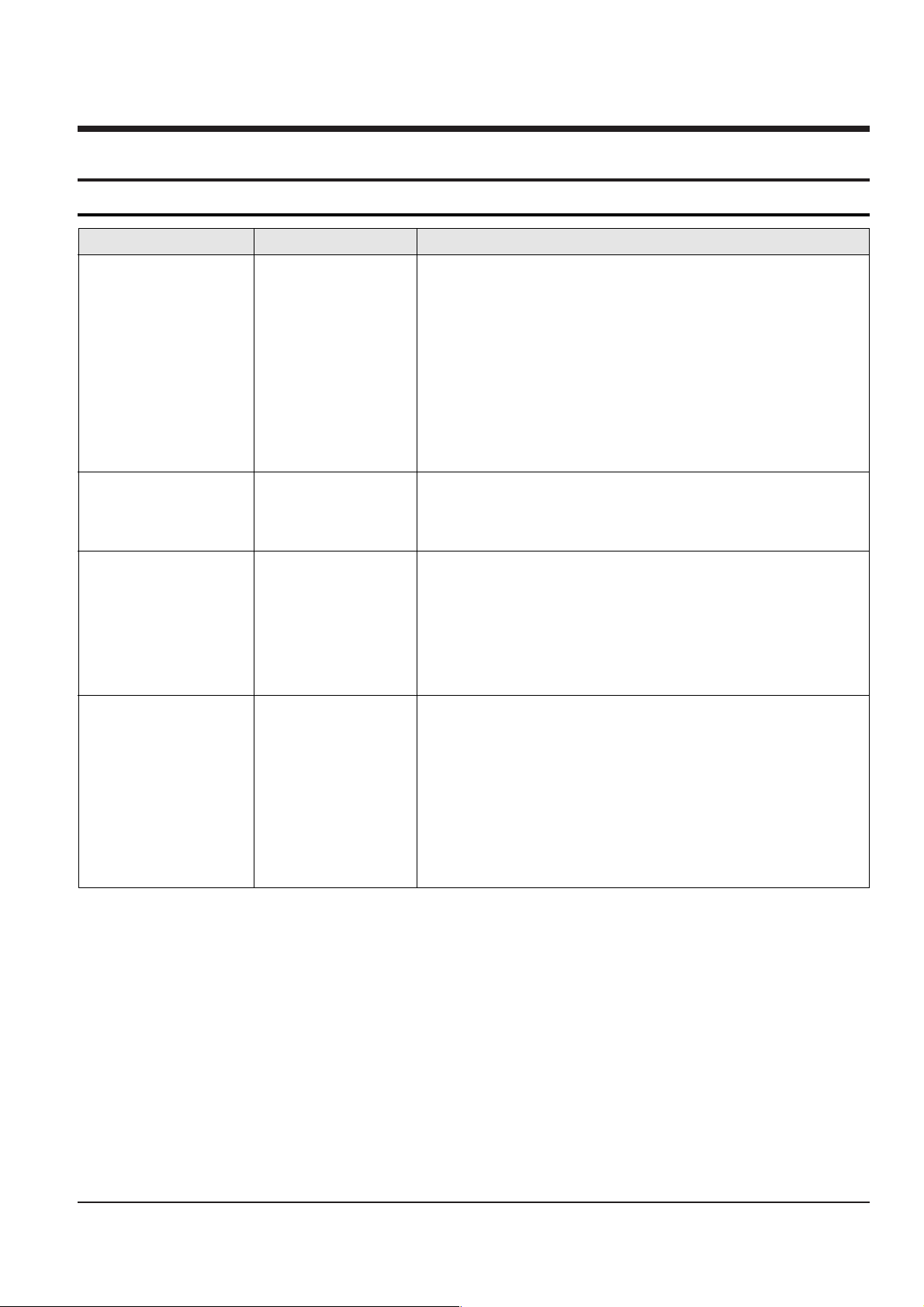

2. Product Specifications

2-1 Product Specification

Operation Description

System

LCD monitor/Viewfinder

Connectors

General

Video signal

Video recording system

Audio recording system

Usable cassette

Tape speed

Tape recording time

FF/REW time

Image device

Lens

Filter diameter

Size/dot number

LCD monitor Method

Viewfinder

Video output

S-video output

Audio output

DV input/output

USB output

External mic

Power source

Power source type

Power consumption

(Recording)

Operating temperature

Storage temperature

External dimension

Weight

Built-in MIC

NTSC

2 rotary heads, Helical scanning system

Rotary heads, PCM system

Digital video tape (6.35mm width): Mini DV cassette

SP: approx. 18.81mm/s LP: approx. 12.56mm/s

SP: 60 minutes (when using DVM 60), LP: 90 minutes (when using DVM 60)

Approx. 150 sec. (using DVM60 tape)

CCD / 680K (Still Image : 48K)

F1.4 20x(Optical), 900x(Digital) Electronic zoom lens

Ø30

2.5inchs 112k

TFT LCD

B/W LCD

1Vp-p (751 terminated)

Y: 1Vp-p, 751, C: 0. 286Vp-p, 751

-7.5dBs (6001 terminated)

4pin special in/out connector,

Mini-B type connector

Ø3.5 stereo

DC 8.4V, Lithium Ion Battery Pack 7.4V

Lithium Ion Battery Pack, Power supply (100V~240V) 50/60Hz

4.4W(LCD), 4.0W(Viewfinder)

0˚~40˚C (32˚F~104˚F)

-20˚C ~ 60˚C (-4˚F ~ 140˚F)

Length 90mm, Height 110mm, Width 60mm

400g (Except for Lithium Ion Battery Pack and tape)

Omni-directional stereo condenser microphone

Samsung Electronics

2-1

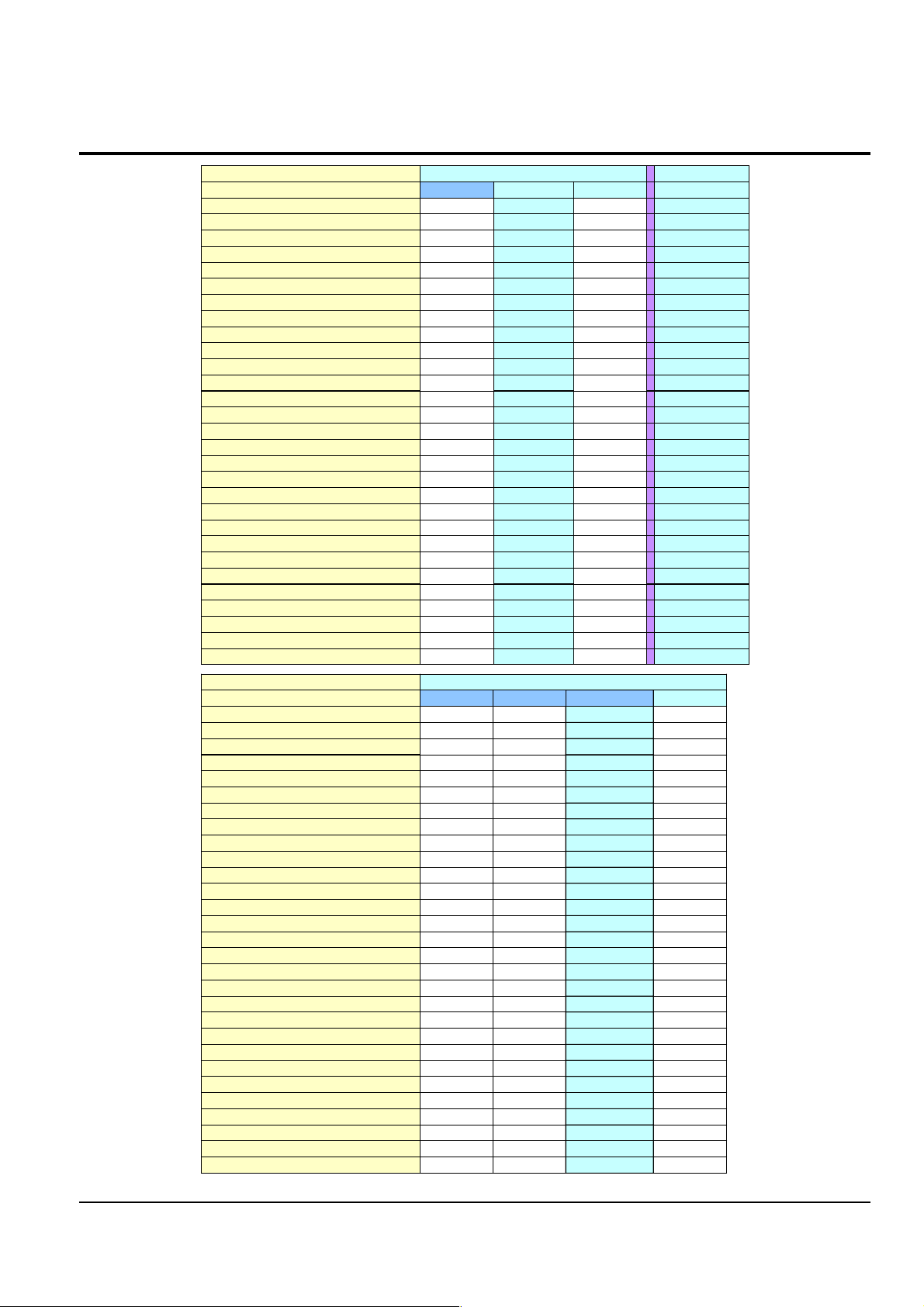

Product Specification

--

Acces sory Comment

-/--/ -

S-Cable / Scart Jack

Opt./Opt.Opt./Opt.

Carrying Case / Tape

T.B.DT.B.D

Battery Pack

O/XO / --/ -

Remocon / Acces sory Shoe

OO-

Analog In

O/O/OO/O/O

Multi Lang./ Batt. Check/Instant On

O/GUI/OO/GUI/OO/OSD/O

Beep Sound / Display / PB Zoom

O/O/O/-O/O/O/-

AV / S.Jack / Ext.Mic / H.phone

O/O/OO / O / O-/ -/ O

Light / Night Captur e / LSS

T.B.DT.B.D

JPEG Multi Display

T.B.DT.B.D

Continuous Shot / Im age Mix

M4/VG/30fM4/VG/30f

MPEG Clip Form at / size / F.Ratio

XGAXGA

JPEG Recording Si ze to Memory

----

Memory Card

16M32M--

Builtin Memory

Multi CardMulti CardM.S. Slot-

Memory Card Slot

MJ/QQ/15fMJ/QQ/15f

Web camera (For./size/F.rate)

M4/VG/30fM4/VG/30f

USB Stream. (For./size/F.Rate)

USB2.0USB2.0

USB

In/OutIn/Out

IEEE1394

DISDIS

Image Stabili zer

12/16b PCM12/16b PCM

Audio

BWColorBW

Viewfinder

2.5", 112K2.5", 112K

LCD

680K680K

CCD

20x / 900x20x / 900x

Zoom/Digita l Zoom

520 line520 line

Resolution

MiniDVMiniDV

Format

VM-F730D355SC-D353D351

Model cod e

NTSC (

Rsx

)NTSC(America)

Region

-

Acces sory Comment

Opt./Opt.

S-Cable / Scart Jack

Opt./Opt.

Carrying Case / Tape

T.B.D

Battery Pack

O/XX/XX/X

Remocon / Acces sory Shoe

-

Analog In

O/O/O

Multi Lang./ Batt. Check/Instant On

O/GUI/OO/OSD/OO/OSD/O

Beep Sound / Display / PB Zoom

O/O/O/-

AV / S.Jack / Ext.Mic / H.phone

O/O/O-/-/O-/-/O

Light / Night Captur e / LSS

T.B.DNoNo

JPEG Multi Display

T.B.DNoNo

Continuous Shot / Im age Mix

M4/VG/25fNoNo

MPEG Clip Form at / size / F.Ratio

XGANoNo

JPEG Recording Si ze to Memory

-

---

Memory Card

64M

---

Builtin Memory

Multi Card

M.S.NoNo

Memory Card Slot

MJ/QQ/12.5fNo

Web camera (For./size/F.rate)

M4/VG/25fNo

USB Stream. (For./size/F.Rate)

USB2.0No

USB

Out

IEEE1394

DIS

Image Stabili zer

12/16b PCM

Audio

Color

BW

Viewfinder

2.5", 112K

LCD

800K

CCD

20x / 900x

Zoom/Digita l Zoom

520 line

Resolution

MiniDV

Format

D355VP-D353D352D351

Model cod e

PAL (Europ e)

Region

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

OO

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

OO

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

2-2 Chassis Product Specification

2-2

Samsung Electronics

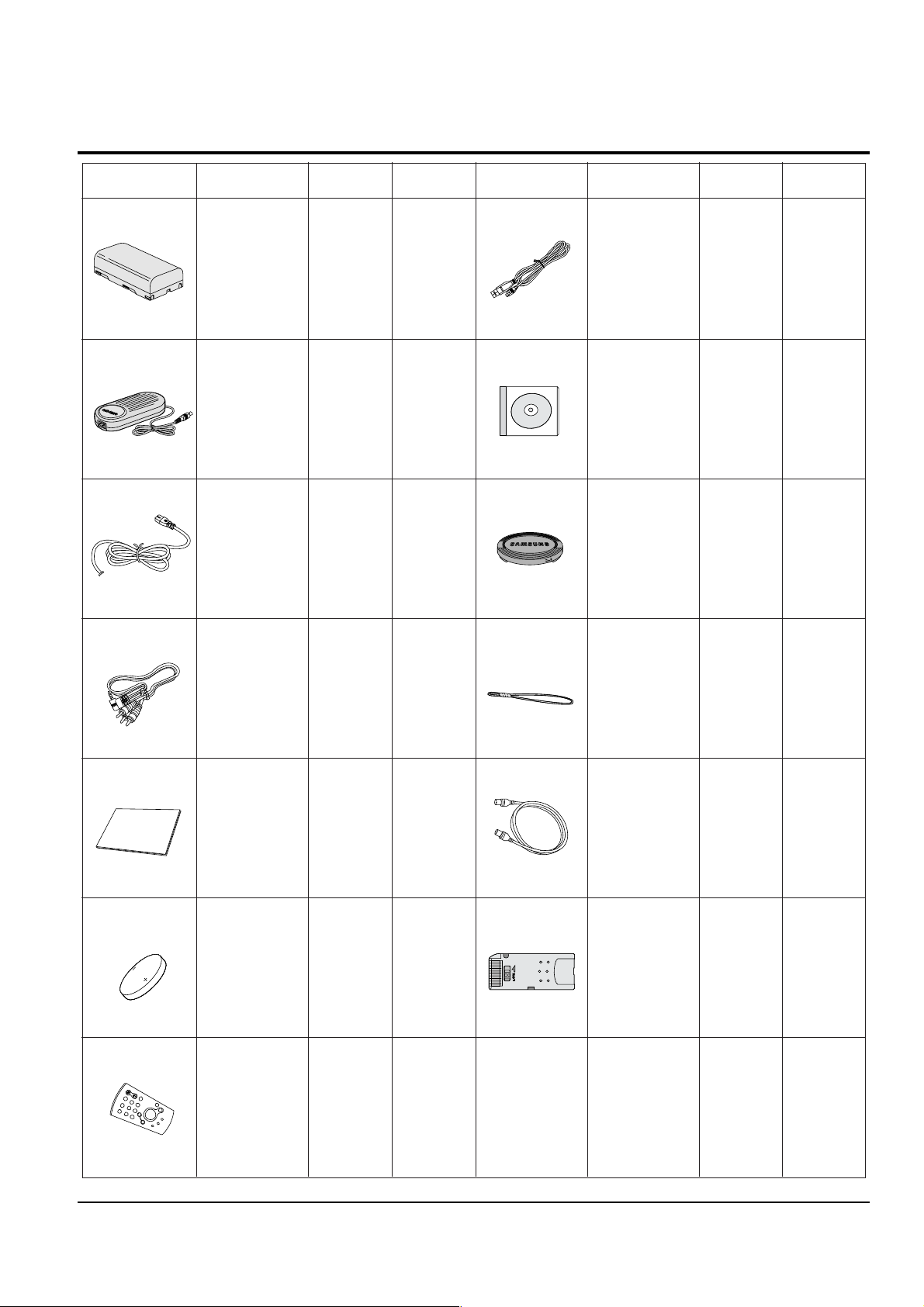

2-3 Accessories Supplied with Camcorder

(SCD354/

D355

only)

(SCD352/

D353/D354/

D355

only)

(SCD352/

D353/D354/

D355

only)

Basic

Accessories

Basic

Accessories

Basic

Accessories

Basic

Accessories

Basic

Accessories

Basic

Accessories

Basic

Accessories

Basic

Accessories

Basic

Accessories

Basic

Accessories

Basic

Accessories

Accessories

Accessories

Accessories Description Part No Remark Description Part No RemarkAccessories

1. Lithium Ion

Battery Pack

AD43-00136A

AD43-00146A

Optional

Optional

2. AC Power Adapter

(AA-E8 TYPE)

AD44-00090A

4. Audio/Video Cable

AD68-00839B

AD39-00001A

5. Instruction Book

6. Lithium Battery

(CR2025)

AD43-10130H

7. Remote Control

AD59-00085A

AD97-07354B

8. USB Cable

AD39-00073A

AD43-00128A

9.Software CD

10. Lens Cover

11.Lens Cover strap

AD72-00049A

13. Memory Stick

1109-001221

12. S-Video Cable

AC39-42001Z

3. AC

Cord

AD39-00076A

Product Specification

Samsung Electronics

2-3

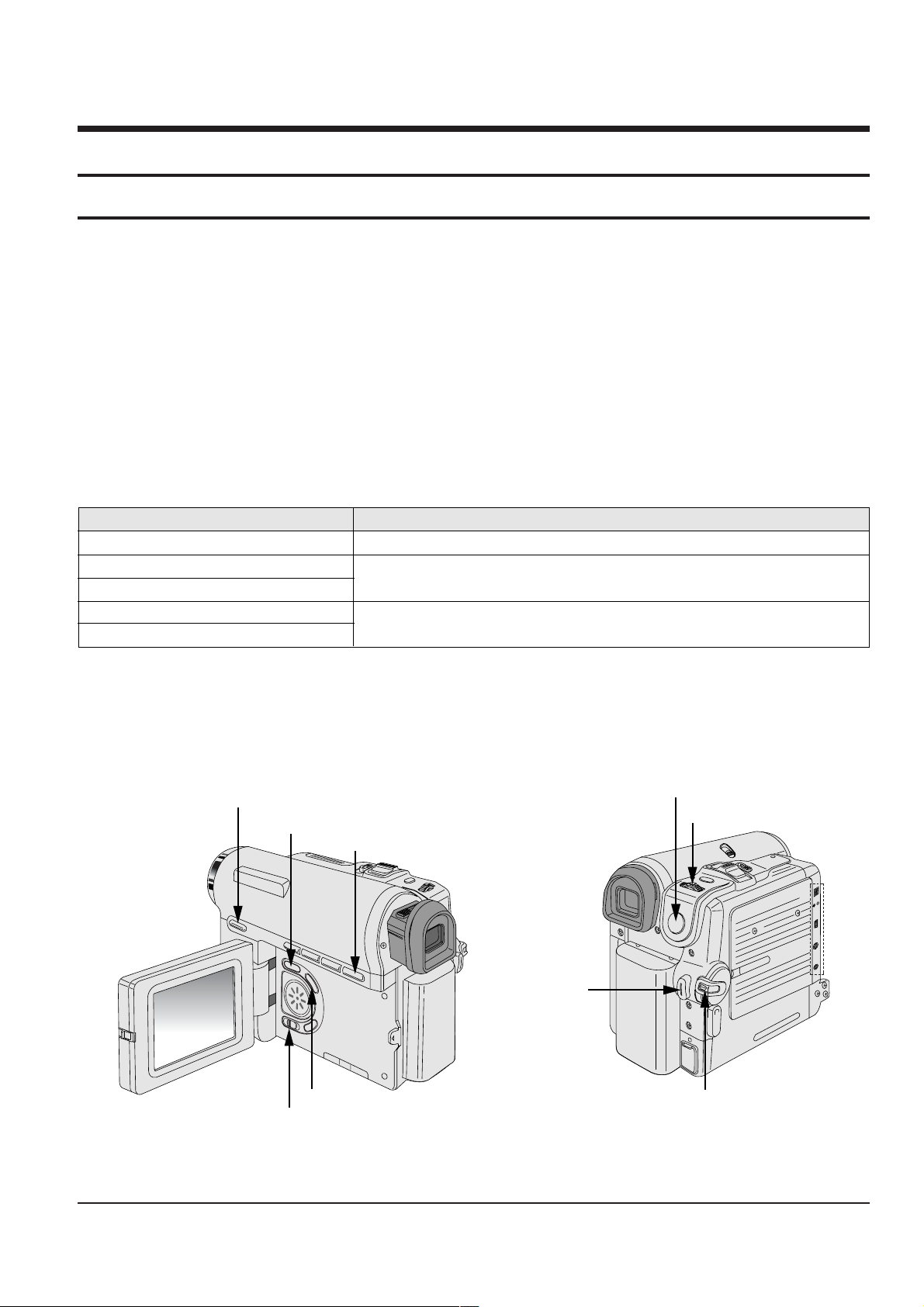

3. Alignment and Adjustment

MENU Button

EASY Q Button

Start/Stop Button

MENU Selector

DISPLAY Button

Mode switch

PB ZOOM

Power switch

STOP Button

DV

USB

AV

MIC

3-1 VCR Adjustment

3-1-1 Adjustment Preparation

1) Before you start

ΠUse the buttons on the CAMCORDER when adjusting VCR.

´ When changing the adjustment item, please press the “EASY-Q” and “DISPLAY” buttons on the

CAMCORDER.

ˇ The adjustment value can be changed by moving the “MENU Selector” Left or Right.

¨ Press the “MENU Selector” to store each adjustment into EEPROM.

ˆ The OSD shows “OK” after finishing each adjustment step.

Ø In order to exit the adjustment mode, disconnect the power source.

2) Function of each buttons on the Set Key

<Table 3-1>

Buttons Description

MENU Selector push (Confirm) Stores changed value in the adjustment and auto adjustment mode.

MENU Selector Right (Data Down)

MENU Selector Left (Data Up)

EASY-Q (Mode Up)

DISPLAY (Mode Down)

Changes data in the adjustment state.

Changes mode.

3) How to get into the VCR adjust mode

[STEP 1]

ΠConnect the Power source.

´ Set the Power Switch to “PLAYER” position and Mode Switch to “TAPE” position.

Fig. 3-1

Samsung Electronics

3-1

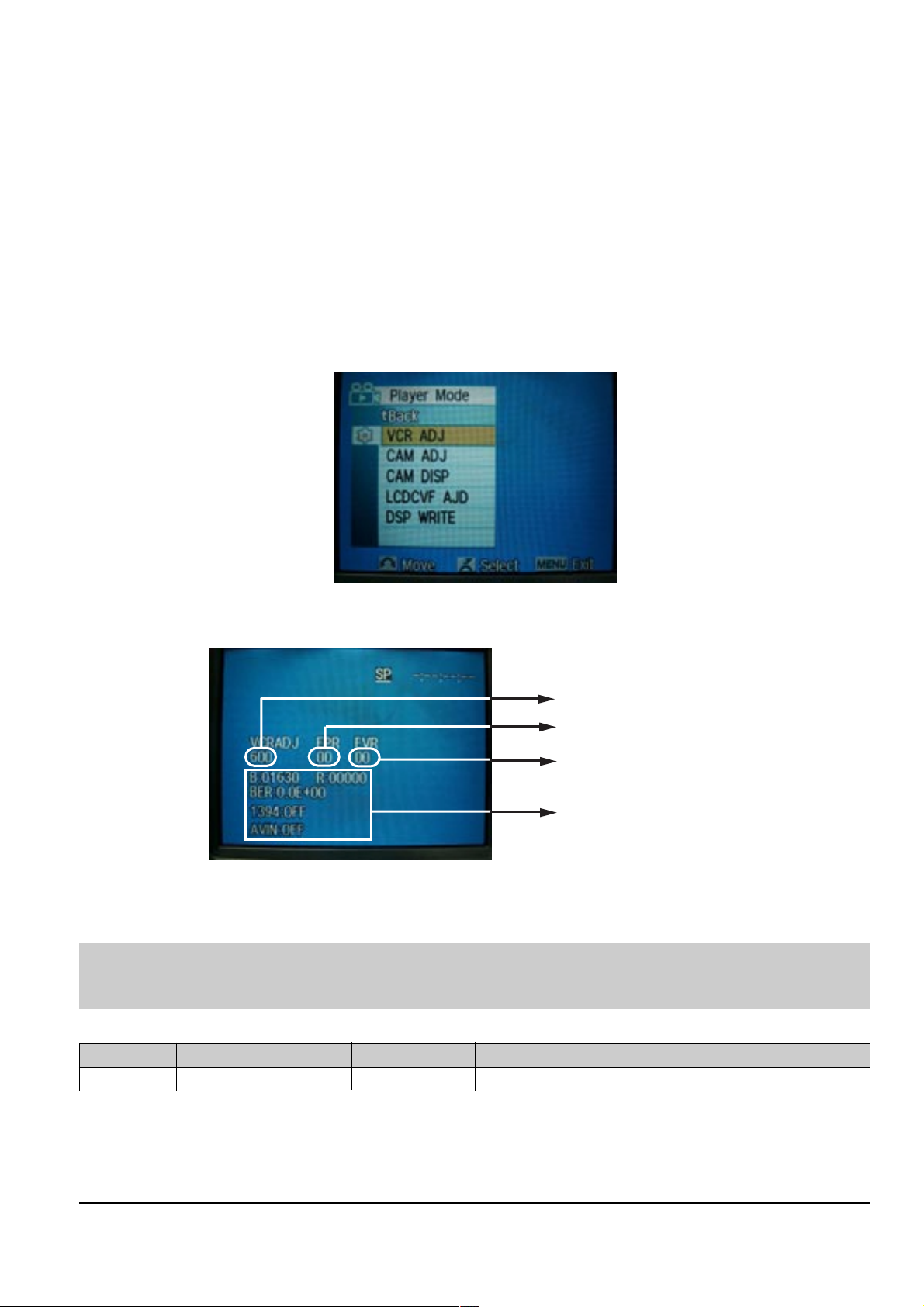

Alignment and Adjustments

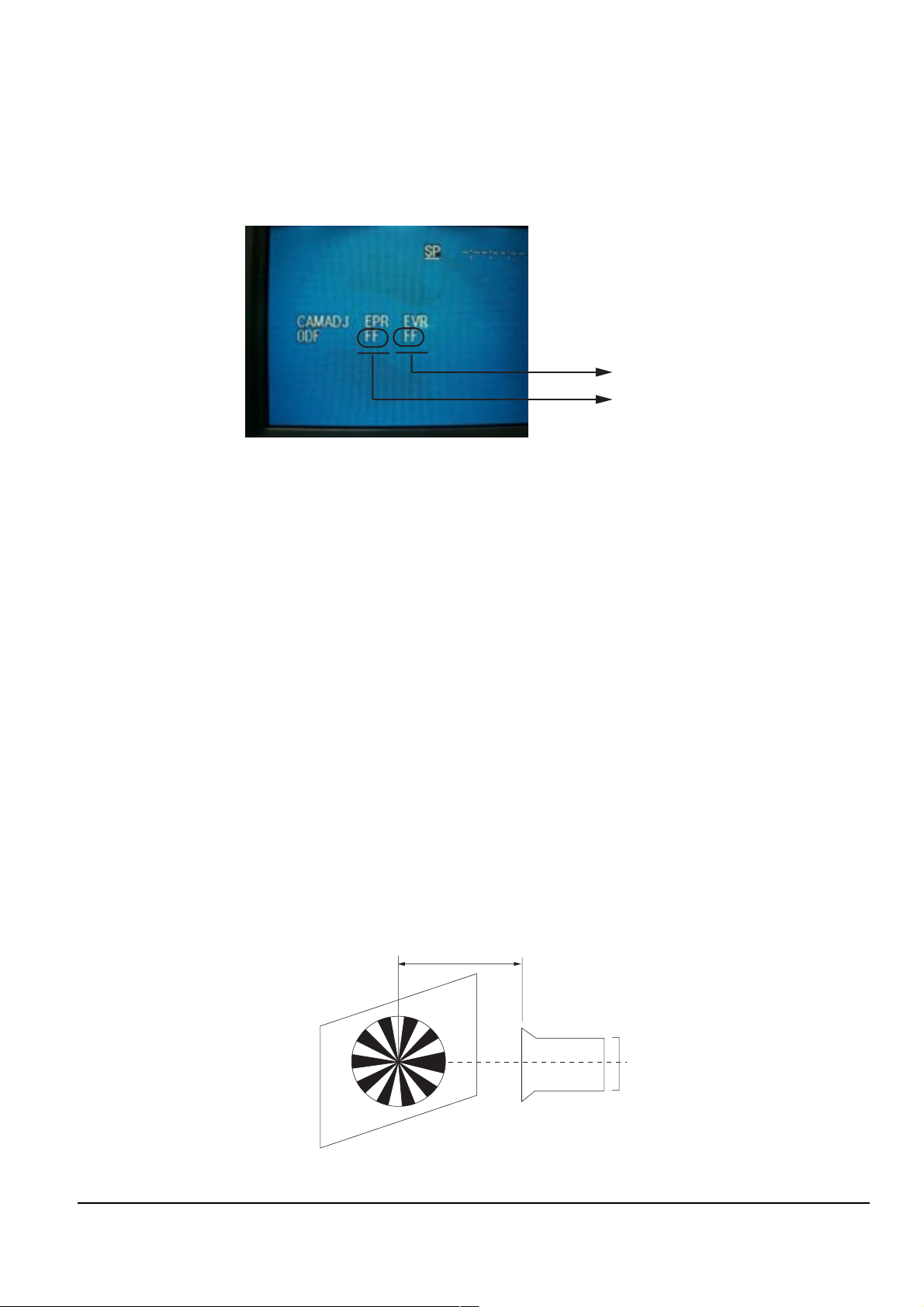

Indicates current adjustment item

Adjustment value

For Engineering Mode

Stored value

[STEP 2]

ΠPress and hold the "STOP" and "PB ZOOM" buttons on the video camera at the same time for more than

5 seconds.

´ When monitor OSD appears as shown Fig. 3-2, the adjustment mode has been activated successfully.

ˇ Move the “MENU Selector” to highlight VCR ADJ and push the “MENU Selector”.

¨ Monitor OSD shows Fig. 3-3.

Then VCR adjustment mode has been activated successfully.

[STEP 3]

In order to complete the adjustment the power must be reset.

This can be done by disconnecting and reconnecting the power source.

Fig. 3-2

Fig. 3-3

3-1-2 VCR Adjustment

Note : This is the only electronic adjustment for the VCR.

Other addresses have already been assigned data during the manufacturing process.

We don’t need any adjustment for those addresses.

<Table 3-2>

(Address)

Mode

61F SWP Position 8C Head Switching Position Adjust

Name Value Description

ΠGet into VCR ADJUST mode.

´ Move to the VCR ADJUST address “6IF”.

ˇ Play standard tape, and “Head Switching Position” will be adjusted automatically (within 5 Seconds).

3-2

Samsung Electronics

3-2 Camera Adjustment

Note : How to adjust the camera system.

1) EEPROM stores confirmed adjustment value of each adjustment step.

2) DSP (Digital Signal Process : ICM01-Main PCB) digitalizes the camera signal.

3) When changing IC505-Main PCB of EEPROM, readjust Main PCB.

While changing LCD PCB and CVF PCB- always readjust each part.

Since EEPROM stores confirmed adjustment value of each adjustment step, readjusting must be performed in order

to store the changed data.

4) Adjust the following items after changing LENS Ass’y.

ΠLens Zoom Track

´ Auto HALL

ˇ Auto IRIS

5) Adjust the following items after changing EEPROM and Camera Main PCB.

ΠLens Zoom Track

´ Zoom VR Center

ˇ Auto HALL

¨ Auto IRIS

ˆ Auto White Balance (indoor)

Ø Auto White Balance (outdoor)

Alignment and Adjustments

3-2-1 Adjustment Preparation

1) Before you start

ΠUse the buttons on the CAMCORDER when adjusting Camera.

´ When changing the adjustment item, please press the “EASY-Q” and “DISPLAY” buttons on the

CAMCORDER.

ˇ The adjustment value can be changed by moving the “MENU Selector” Left or Right.

¨ Press the “MENU Selector” to store each adjustment into EEPROM.

ˆ The OSD shows “OK” after finishing each adjustment step.

Ø In order to exit the adjustment mode, disconnect the power source.

2) Function of each buttons on the Sst Key

<Table 3-3>

Buttons Description

MENU Selector push (Confirm) Stores changed value in the adjustment and auto adjustment mode.

MENU Selector Right (Data Down)

MENU Selector Left (Data Up)

EASY-Q (Mode Up)

DISPLAY (Mode Down)

Changes data in the adjustment state.

Changes mode.

Samsung Electronics

3-3

Alignment and Adjustments

MENU Button

EASY Q Button

Start/Stop Button

MENU Selector

DISPLAY Button

Mode switch

PB ZOOM

Power switch

STOP Button

DV

USB

AV

MIC

5) How to set up the camera adjustment mode

[STEP 1]

ΠConnect the Power source.

´ Set the Power Switch to “CAM” position and Mode Switch to “TAPE” position.

[STEP 2]

ΠPress and hold the "STOP" and "PB ZOOM" buttons on the video camera at the same time for more than

5 seconds.

´ When monitor OSD appears as shown Fig. 3-5, the adjustment mode has been activated successfully.

ˇ Move the “MENU Selector” to highlight CAM ADJ and push the “MENU Selector”.

¨ Monitor OSD shows Fig. 3-6.

Then Camera adjustment mode has been activated successfully.

[STEP 3]

In order to complete the adjustment the power must be reset.

This can be done by disconnecting and reconnecting the power source.

3-4

Fig. 3-4

Fig. 3-5

Samsung Electronics

Alignment and Adjustments

Adjusted values

Stored values

3M ± 1cm

(Be sure to maintain the distance)

CCDLENS

3-2-2 Camera Adjustment

Note : "XX XX" indicate the previous preset value and adjusted value.

Press the “MENU Selector” (Confirm) to store the adjusted value.

Fig. 3-6

1) EEPROM Data Initialize

Caution : These adjustments must be done when installing a new EPROM (IC105) or Main PCB.

Œ Press the “EASY-Q”(Mode Up)/”DISPLAY”(Mode Down) buttons until CAMADJ displays “0DF XX XX”.

´ Use the “MENU Selector” (Data Up/Down) until the display data for EVR is “A0”.

ˇ Press the “MENU Selector” (Confirm).

¨ The OSD shows “OK” after finishing the initalize.

2) Lens Zoom Track

Caution : For whole zoom range, it shall be in focus.

The location of a focus lens is moving depending on the location of Zoom Lens.

During adjusting, micom measures the focus location from a near distance to a long.

ΠCamera is set to E-E mode.

´ Focus chart photo.

ˇ Center the camera about 3m from a focus chart which, should be placed on a flat surfaced white or gray wall.

¨ Connect the video output terminal to a TV.

ˆ Press the “EASY-Q” (Mode Up)/”DISPLAY” (Mode Down) buttons until CAMADJ displays “0DE XX XX”.

Ø Press the “MENU Selector” to begin adjustment.

The camera must be kept still when adjusting the zoom and focus lens.

If you don’t have any chart, you can use the object which has a lot of vertical line.

The OSD shows “OK” after finishing the adjustment.

(The word “OK” is displayed for only a fraction of a second.)

Samsung Electronics

Fig. 3-7

3-5

Alignment and Adjustments

3) Zoom VR Center

ΠConnect a video output terminal to a TV.

´ Press the “EASY”(Mode Up)/”DISPLAY”(Mode Down) buttons so that OSD shows “0D6 XX XX”.

ˇ Press the “MENU Selector” (Confirm).

¨ Then Micom finds out Zoom VR center position.

Store Zoom VR center value in OB7.

4) Auto HALL

ΠConnect a video output terminal to a TV.

´ Press the “EASY-Q”(Mode Up)/”DISPLAY”(Mode Down) buttons so that OSD shows "0CD XX XX".

ˇ Press the “MENU Selector” (Confirm).

¨ Then micom finds out max. Hall value with an iris opened and min. Hall value with an iris closed.

Store max. and min. value of Hall in OAD and OAC respectively.

ˆ The OSD shows “OK” after finishing the adjustment.

(The word “OK” is displayed for only a fraction of a second.)

5) Auto IRIS Level

ΠConnect a video output terminal to a wave form monitor and a TV.

´ Press the “EASY-Q”(Mode Up)/”DISPLAY”(Mode Down) buttons so that OSD shows "0CE XX XX".

ˇ Press the “MENU Selector” (Confirm).

¨ Then micom finds out max. Hall value with an iris opened and min.

Hall value with an iris closed. Store max. and min. value of in 00BC, 00BD and 00BB respectively.

ˆ The OSD shows “OK” after finishing the adjustment.

(The word “OK” is displayed for only a fraction of a second.)

6) Auto White Balance (indoor)

Œ Camera mode & 3100˚ K gray scale chart.

´ Connect a video output terminal to a vectorscope and a TV.

ˇ Press the “EASY-Q”(Mode Up)/”DISPLAY”(Mode Down) buttons so that OSD shows "0D4 XX XX".

¨ Ensure that camera picks up image 40µs on 3100˚K gray scale chart precisely and the illumination is 1500~2000

Lux.

ˆ Press the “MENU Selector” (Confirm) to ensure that white spot on a vectorscope is moving in the middle of

screen.

Ø The OSD shows “OK” after finishing the adjustment.

(The word “OK” is displayed for only a fraction of a second.)

7) Auto White Balance (outdoor)

Œ Camera mode & 5100˚ K gray scale chart.

´ Connect a video output terminal to a vectorscope and a TV.

ˇ Press the “EASY-Q”(Mode Up)/”DISPLAY”(Mode Down) buttons so that OSD shows "0D5 XX XX".

¨ Ensure that camera picks up image 40 µs on 5100 gray scale chart (3100 gray scale chart + C16 filter) precisely

and the illumination is 1500~2000 Lux.

ˆ Press the “MENU Selector” (Confirm) to ensure that white spot on a vectorscope is moving in the middle of

screen.

Ø The OSD shows “OK” after finishing the adjustment.

(The word “OK” is displayed for only a fraction of a second.)

3-6

Samsung Electronics

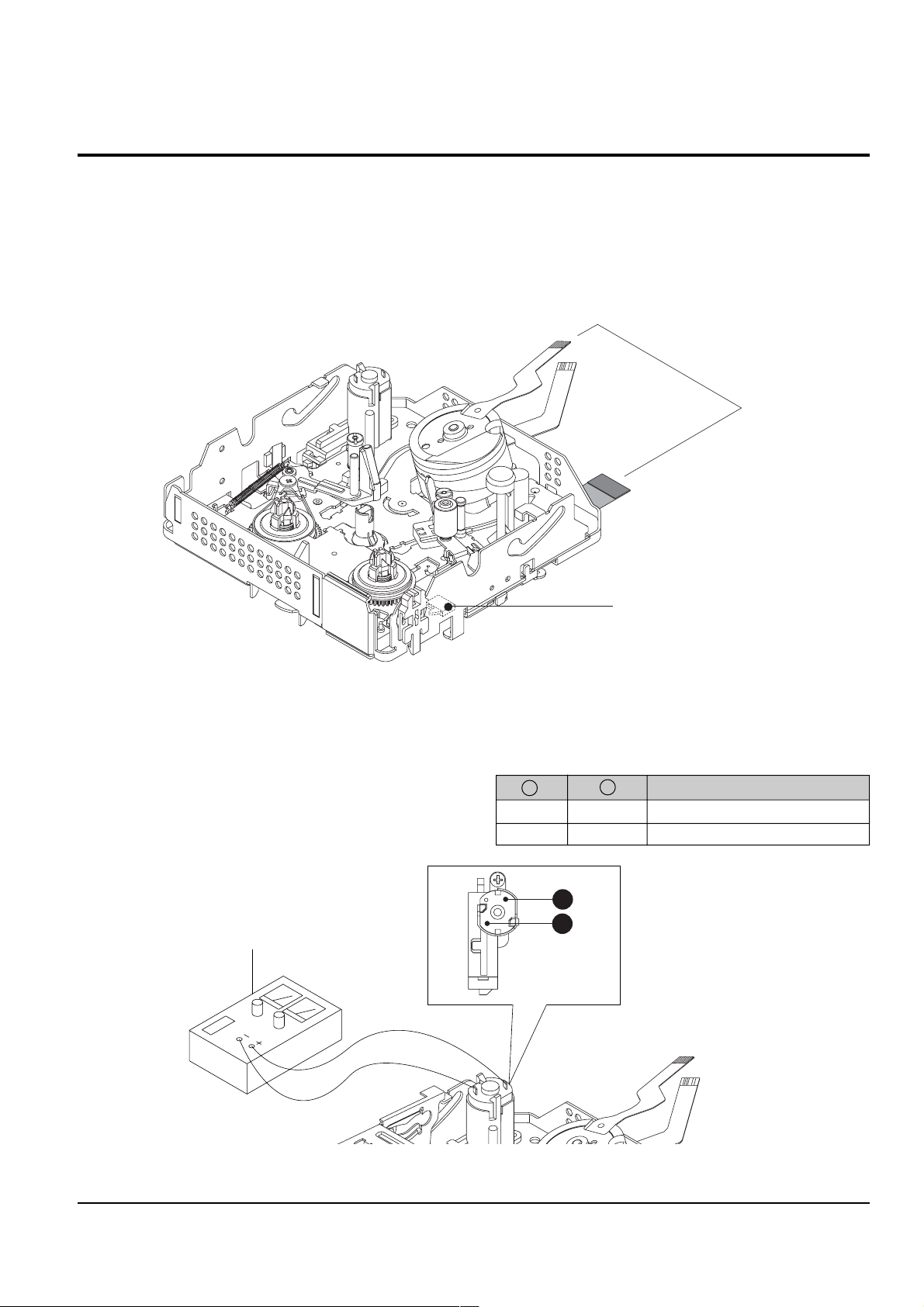

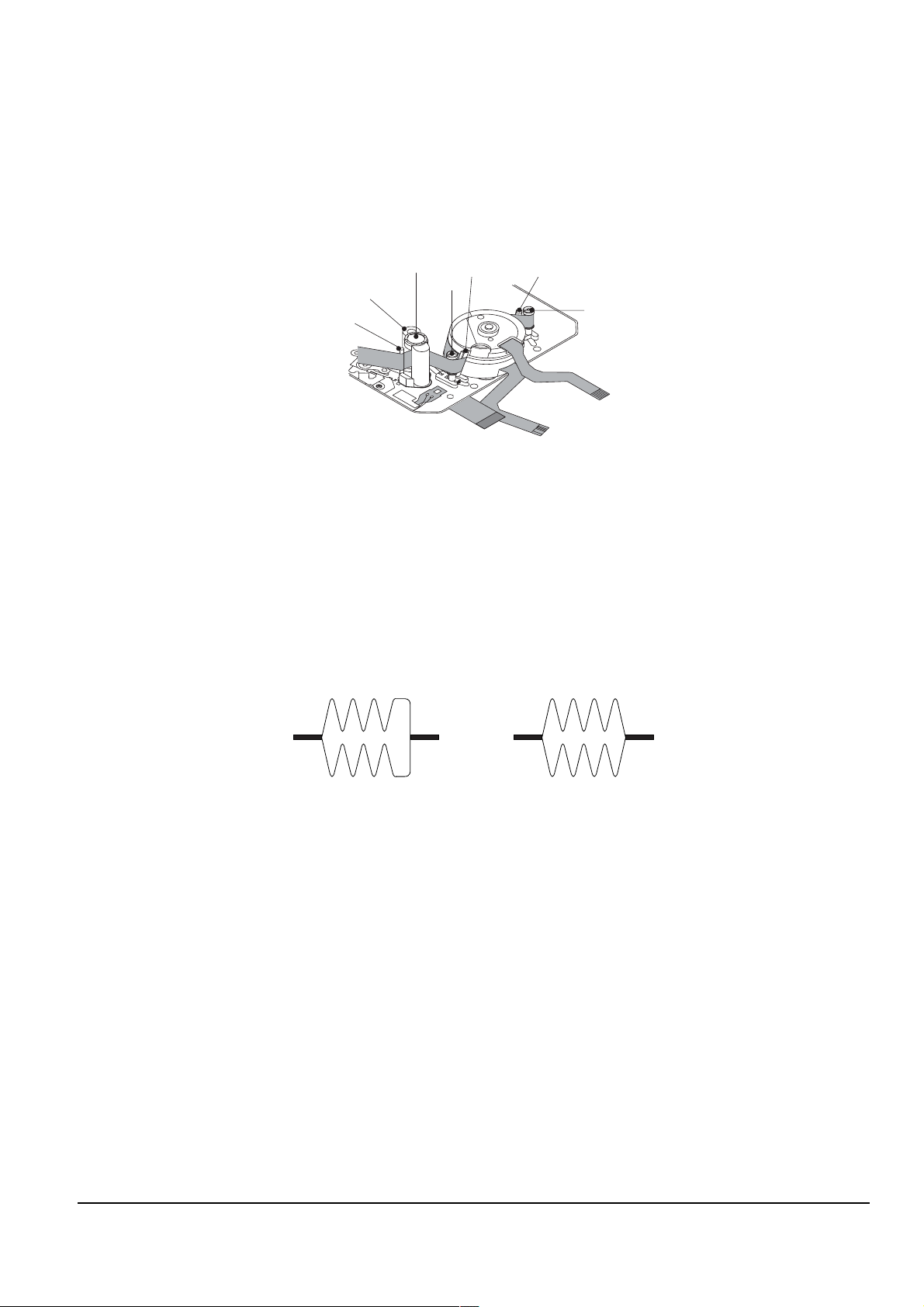

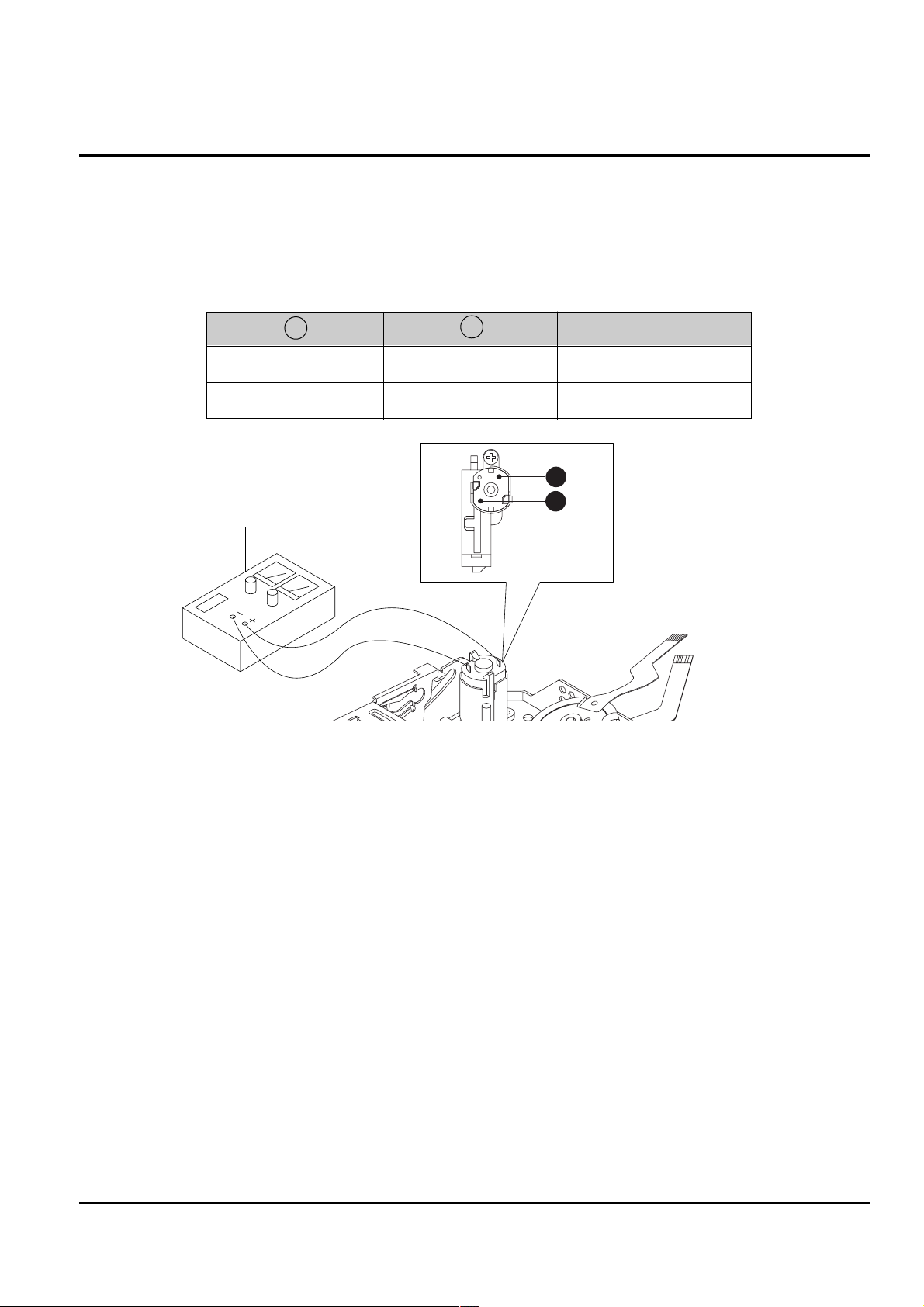

3-3 Deck Adjustment

Connceted the Recorder Circuit

SWITCH C-IN

DC POWER SUPPLY

A

B

Alignment and Adjustments

3-3-1 Operation Without Housing Assembly

1) Remove the Housing Ass’y from the Deck Ass’y.

2) Connect the Mechanical Chassis to the recorder

circuit to supply voltage.

3) Set to Unload mode.

4) Press the S/W Push (Keep ON status)to start loading, and push the PLAY Key.

(Cover the Top/End sensor with black tape,

because they do not operate.)

Note : For the removal of the Housing Ass’y refer to

4-2-2 (page 4-7).

Fig. 3-8

3-3-2 Setting Mechanical Mode (Without Recorder Circuit)

1) Set the power-supply output to approx. 3V~5V.

2) Choose the polarity (depending on whether loading or unloading).

3) Supply the voltage to the Motor Loading, and set

to the desired mode.

<Table 3-4>

A B Movement of Chassis

+ - Unloading

- + Loading

Samsung Electronics

Fig. 3-9

3-7

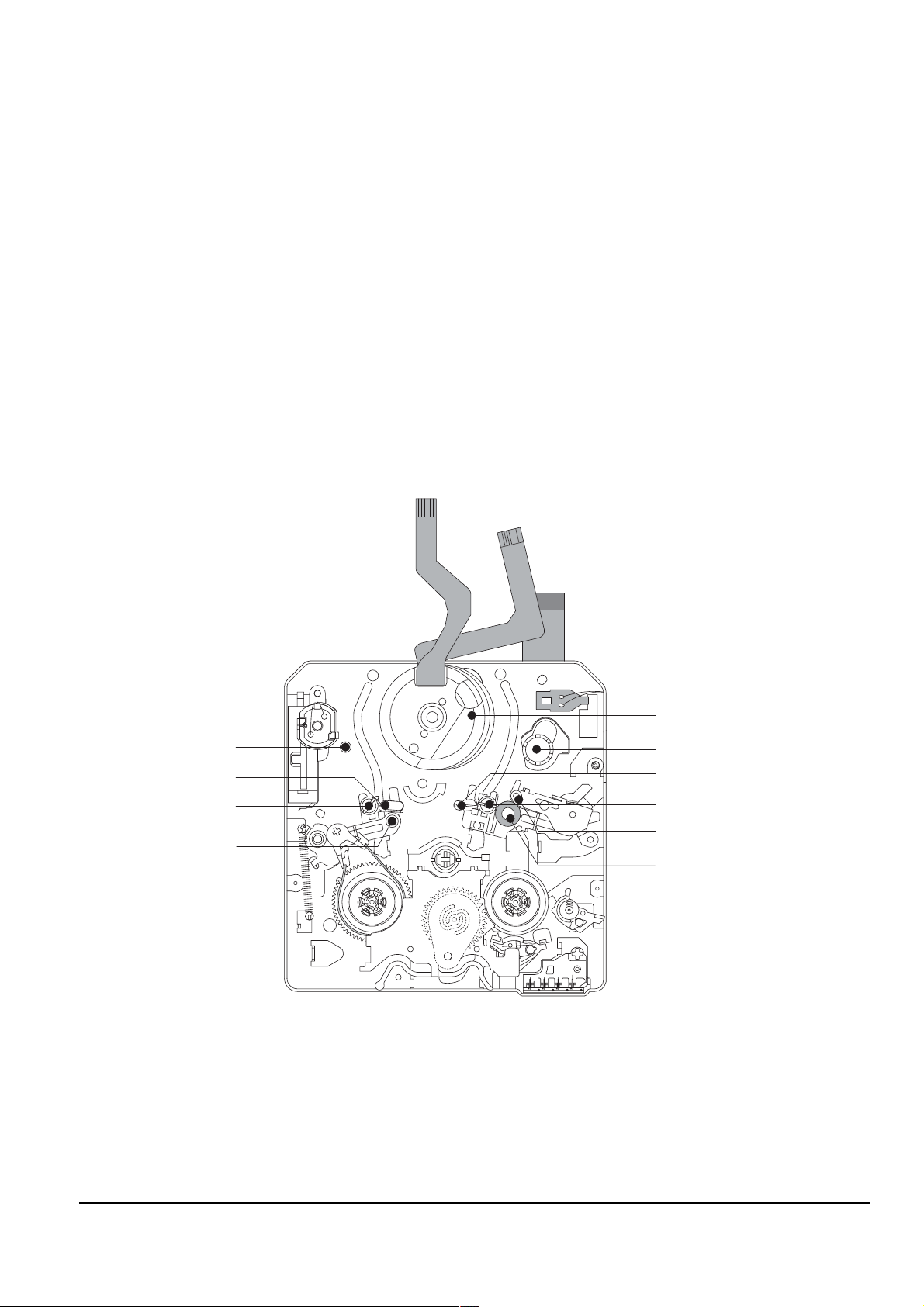

Alignment and Adjustments

P5

P2

P4

P3

P1

P8

P6

P7

P9

PINCH ROLLER

3-3-3 Maintenance

Carry out the following periodic maintenance checks in order to fully exercise all functions, operations and tape.

After repairing, service the set as follows:

1) Cleaning of Drum Assembly

ΠGently apply lens tissue soaked in ethyl alcohol to the Drum assembly.

Clean the Upper Drum assembly while rotating it slowly counterclockwise(by hand).

Note : Do not rotate the motor by power or rotate the Upper Drum assembly clockwise.

Also, the Head tip will be damaged if the lens tissue is moved in a perpendicular direction.

Be sure to follow these instructions when cleaning the Drum Ass’y

2) Cleaning of Tape Path

ΠIn EJECT mode, clean the tape path system(from Pole Tension P1 through Pole Review P9, Pinch Roller and

Capstan Shaft) and the Lower Drum. Using the lens tissue soaked in ethyl alcohol.

Note : Make sure that no oil or grease adheres to the lens tissue.

3-8

Fig. 3-10

Samsung Electronics

3) Periodic Maintenance and Check List

2mm

OIL

When overhauling, refer to the following table.

Alignment and Adjustments

<Table 3-5>

Maintenance checks

Hours of use (H)

500 1000 1500 2000 2500 3000 3500 4000 4500 5000

system

D

R

V

N

G

Perform-

Tape

path

I

I

ance

Cleaning of tape path O O O O O O O O O O

Cleaning and degaussing of drum ass’y

S

Y

S

T

E

M

Capstan Shaft 66666

Gear Capstan 66666

Gear Pully Shaft 66666

Belt Timing ŮŮŮŮŮ

Motor Loading ŮŮŮŮŮ

OOOOOOOOOO

Abnormal Noise ŮŮŮŮŮŮŮŮŮ

Back Tension ŮŮŮŮŮ

Confirmation

Brake System ŮŮŮŮŮ

PB, REV Torque Measurement

ŮŮŮŮŮ

O : Cleaning ¨ : Oil Ů : Confirmation

Ů When lubrication bearings, be sure to keep the oil

free of dust. (Oil contaminated with dust might

cause the bearings to wear out or seize.)

Ů A“drop”of oil is defined as the amount attached to

the tip of a Ø 2mm stick as shown in Fig. 3-11.

Remark

- Never let oil get on to the tape path

surface.

Samsung Electronics

Fig. 3-11

3-9

Alignment and Adjustments

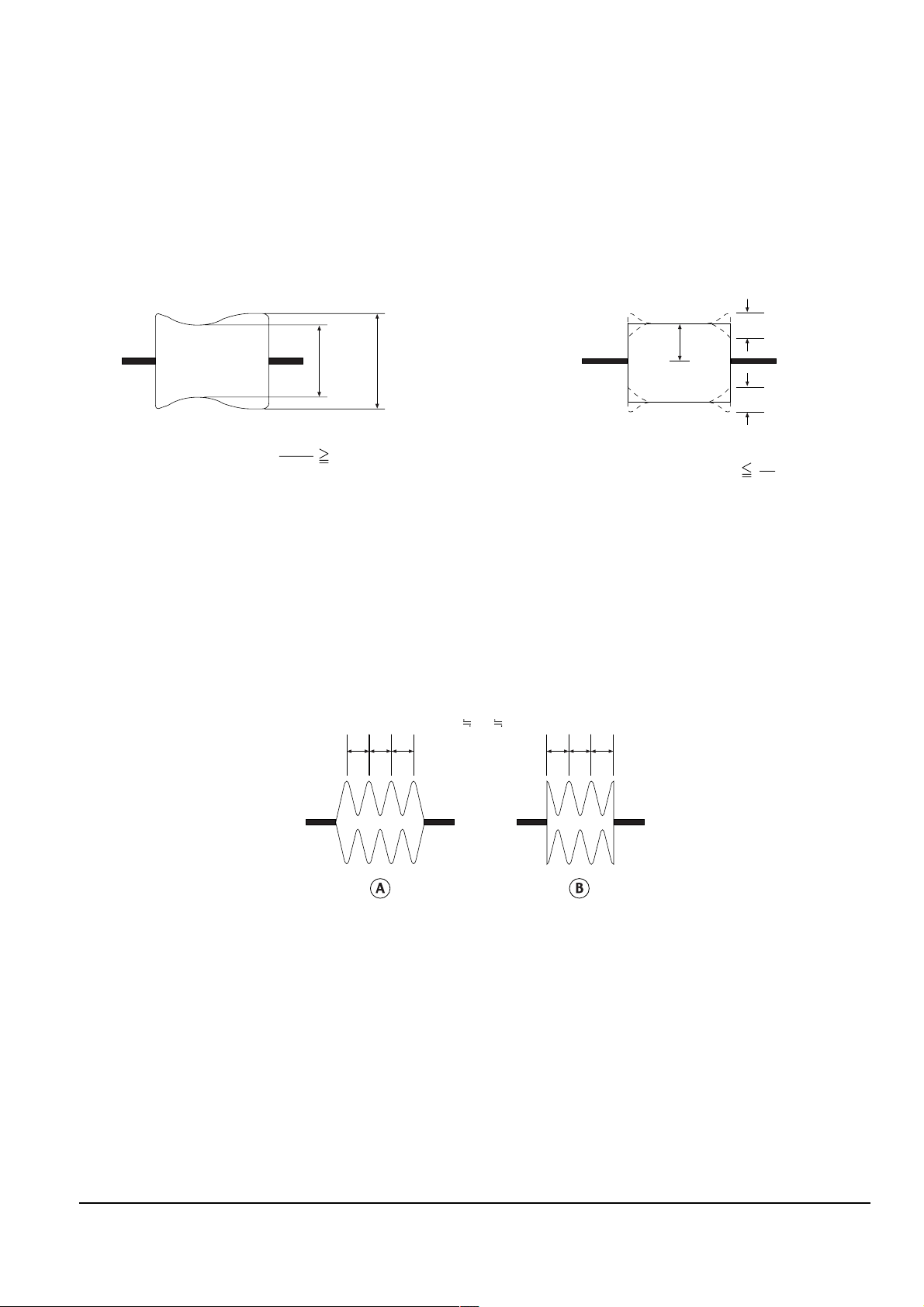

1 0.5

ARM TENSION Œ

CAP ADJUST ´

"B"

"A"

3-3-4 Mechanical Check and Adjustment

3-3-4(a) Tension Regulator Adjustment

1) Disassembly

Œ For the removal of the Housing Ass’y refer to 4-2-2 (page 4-7).

2) Adjustment

ΠSet to PLAY mode (without cassette tape).

´ Check that the distance between external surface of Holder Loading and extenal diamater of Arm Tension is

1±0.5mm. (Fig. 3-12)

ˇ If necessary, proceed to step 4.

¨ If the Arm Tension Œ is located inside (or right) the position specified, adjust the Cap Adjust Œ toward

arrow “A”. (If it is located outside (or left), adjust toward arrow “B”.)

Note : Check if the Arm Tension can be moved toward arrow “C” in PB mode.

3) Reassembly

Œ For the removal of the Housing Ass’y refer to 4-2-2 (page 4-7).

3-10

Fig. 3-12

Samsung Electronics

Alignment and Adjustments

REEL DISK S TABLE

RESTING SURFACE

REEL DISK T TABLE

RESTING SURFACE

CHASSIS MAIN

b

a

3-3-4(b) Back Tension Confirmation

1) Set up the cassette-torque tape.

2) Set to CAMERA mode, push the EDIT(+) KEY and check that the torque value of Reel S is 4±1g.cm.

3) If necessary, proceed to step 4.

4) If the Tension value is Low specified, moved to toward “a”.

If the Tension value is High specified, moved to toward “b”.

Reference : After changed, insert Cassette torque tape and confirm torque value.

Fig. 3-13

3-3-4(c) PB/REV Torque check

1) Set up the cassette torque tape.

2) Set to CAMERA mode, Push the EDIT(+) button and check that the torque value of Reel T is 9.5±3.5g.cm.

3) Push the EDIT(-) button and check that the torque value of Reel S is 15±4g.cm.

4) If necessary, replace the defective Reel Disk S, T Ass’y.

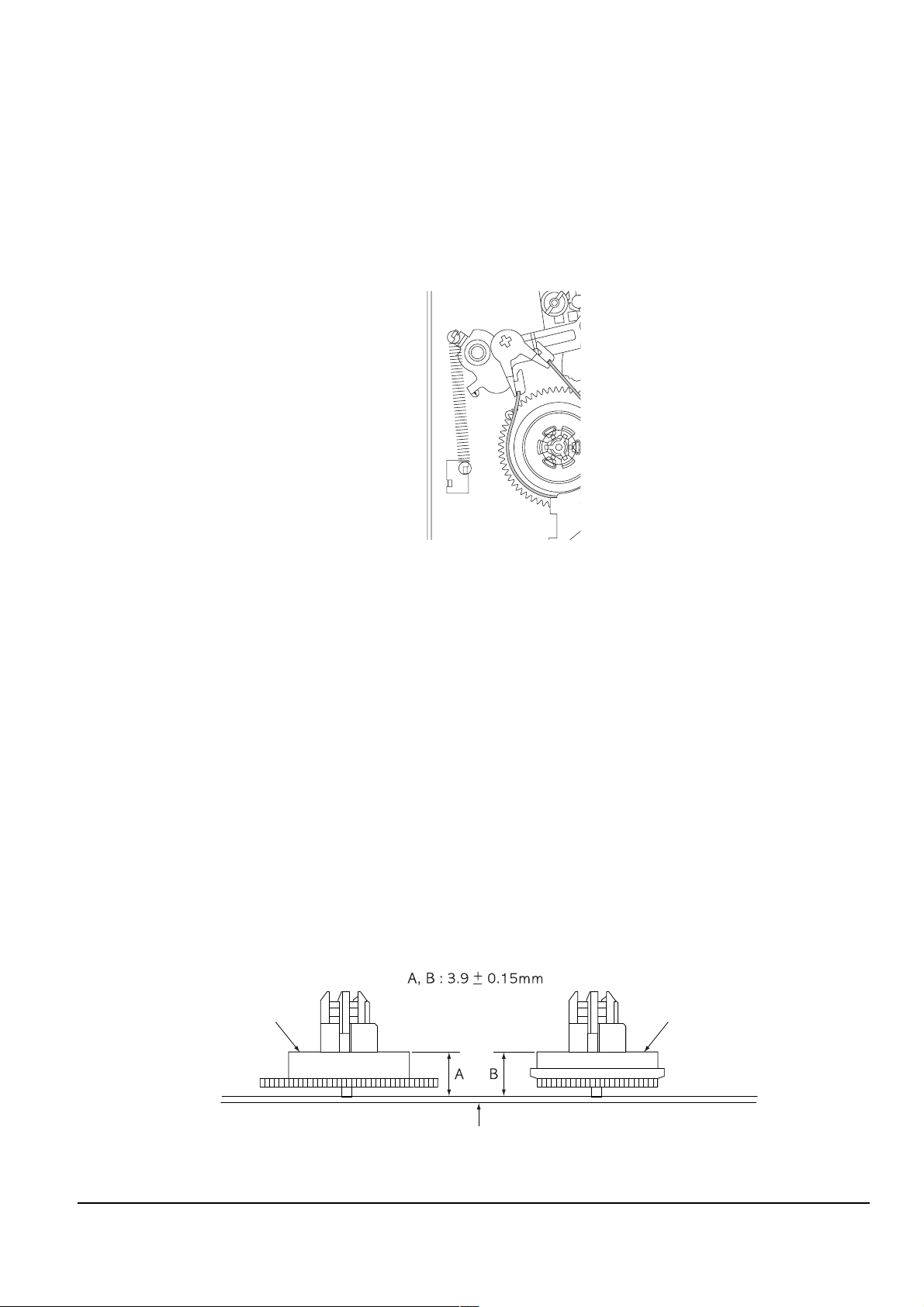

3-3-4(d) Reel Table Height Check

1) Removal

Œ For the removal of the Housing Ass’y refer to 4-2-2 (page 4-7).

´ For the removal of the Idler Ass’y refer to 4-2-3 (page 4-8).

2) Check

ΠUsing vernier calipers, check the following distances : From the upper surface of the Main Chassis to the

resting surfaces of Reel S, T table should each be 3.9±0.15mm.

3) Mounting

Œ For the removal of the Idler Ass’y refer to 4-2-3 (page 4-8).

´ For the removal of the Housing Ass’y refer to 4-2-2 (page 4-7).

Samsung Electronics

Fig. 3-14

3-11

Alignment and Adjustments

P1

P2

P3

P4

P5

P7

P6

P8

P9

A

B

C

INLET OUTLET

NORMAL

DEFECT AT INLET

DEFECT AT OUTLET

3-3-5 Tape Path Adjustment

3-3-5(a) Preparation for Adjustment

ΠClean the tape running surface (Poles, Drum, Capstan Shaft, Pinch Roller).

´ Observe the PB RF signal and Head Switching Pulse on an oscilloscope.

ˇ Play back the alignment tape.

¨ Check that the waveform of the RF signal is flat at both inlet and outlet(A in Fig. 3-15).

If not flat (B or C in Fig. 3-15), do adjustments 3-3-5(b) through 3-3-5(d).

Fig. 3-15

Fig. 3-16

3-12

Samsung Electronics

3-3-5(b) Tracking adjustment

P9

P8

P7

P6

P4

P3

MOTOR CAPSTAN

(DEFECTIVE) (CORRECT)

ΠPlay Back the alignment tape.

´ Turn P3 to flatten the waveform at the inlet.

ˇ Turn P7 to flatten the waveform at the outlet.

Alignment and Adjustments

Fig. 3-17

3-3-5(c) Take Up Path Adjustment

ΠPlay back the alignment tape, and confirm that the tape is not twisted between the Guide Roller T and

Capstan. (Fig. 3-17)

´ Set to REV mode and observe the outlet waveform of PB RF signal. (Fig. 3-18)

NOTE : If the outlet waveform is out-of-spec, replace the Arm Review or the Arm Pinch Ass’y,

and redo steps 1 and 2.

Fig. 3-18

Samsung Electronics

3-13

Alignment and Adjustments

Emin Emax

Emax

Emin

80(%)

A

A

C

C

C

1

8

abc a

abc

bc

3-3-5(d) Check After Adjustment

1) Tracking Check

ΠPlayback the alignment tape.

´ Confirm that the minimum amplitude value(E min.)is 80% of the maximum value(E max.) or larger.

(Fig. 3-19)

ˇ Confirm that no large fluctuation occur on the waveform. (Fig. 3-20)

Fig. 3-19

2) CUE and REV Check

ΠPlayback the alignment tape, and set to REV mode.

Confirm that the waveform peaks have a uniform Pitch. (Fig. 3-21 A)

If the track pitch is not uniform, do section 3-3-5(b) (Tracking adjustment).

´ Set to CUE mode.

Confirm that the waveform peaks still have a uniform pitch. (Fig. 3-21 B)

If the track pitch is not uniform, do section 3-3-5(b) (Tracking Adjustment).

Fig. 3-21

Fig. 3-20

3-14

Samsung Electronics

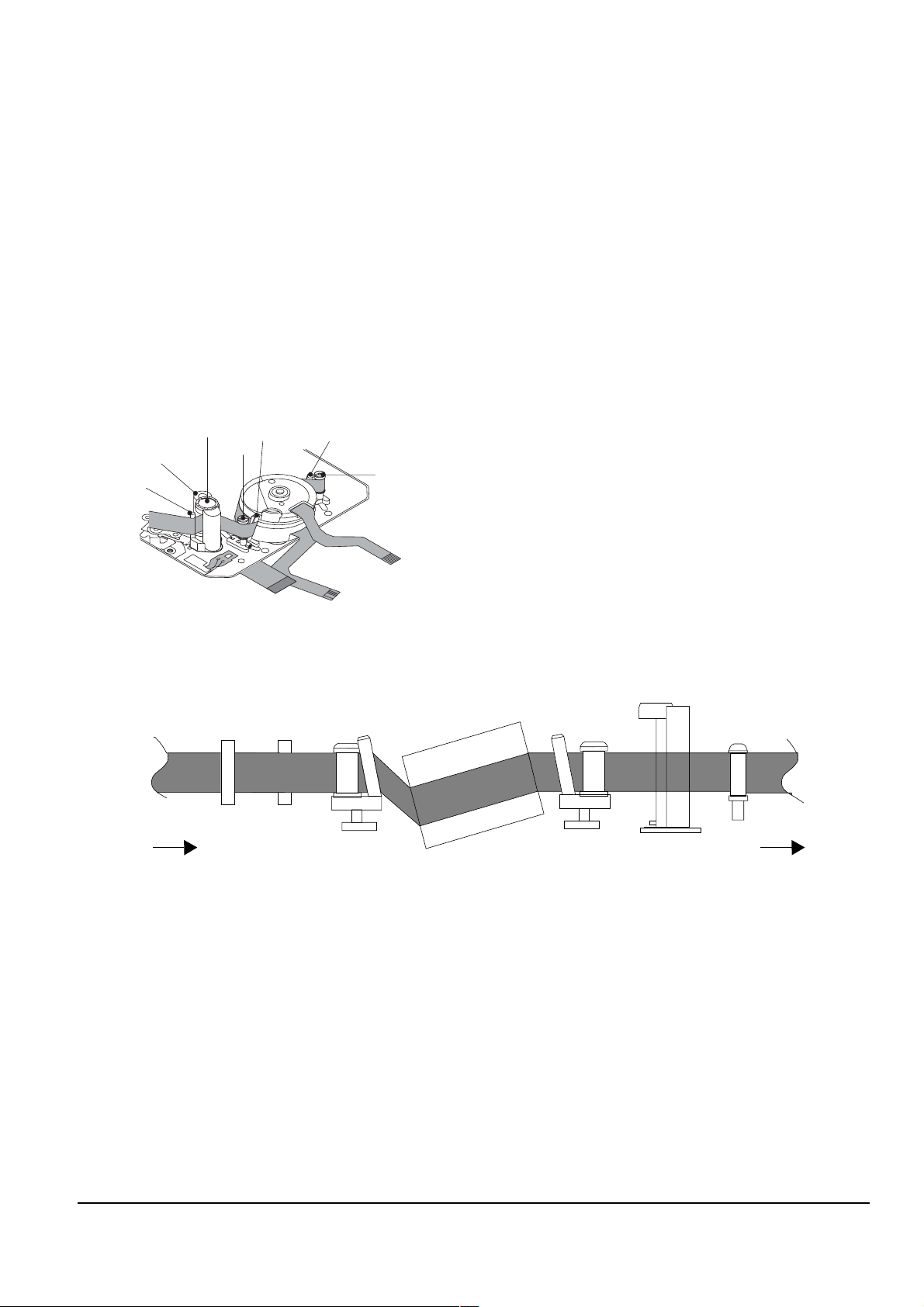

Alignment and Adjustments

P9

P8

P7

P6

P4

P3

MOTOR CAPSTAN

P1 P2 P3 P4 P6 P7 P9

FROM THE S REEL

TO THE T REEL

3) Rise Time Check

ΠPlayback the alignment tape.

´ Set to playback mode, and confirm that the waveform of PB RF signal rises flat within 3 seconds.

Also confirm that the tape is not twisted or curled around the Pinch Roller. (Fig. 3-23)

ˇ Run the tape in CUE/REV and FF/REW modes, then playback.

Confirm the waveform of PB RF signal rises flat within 3 seconds. Also confirm that the tape is not twisted or

curled around the Pinch Roller.

¨ Repeat steps 2. and 3.

4) Tape Path Check

ΠIn CUE and REV modes, check that the tape is not curled around the P3, P7 upper flange and P9

upper/Lower flanges.

Fig. 3-22

Fig. 3-23

Samsung Electronics

3-15

4. Disassembly and Reassembly

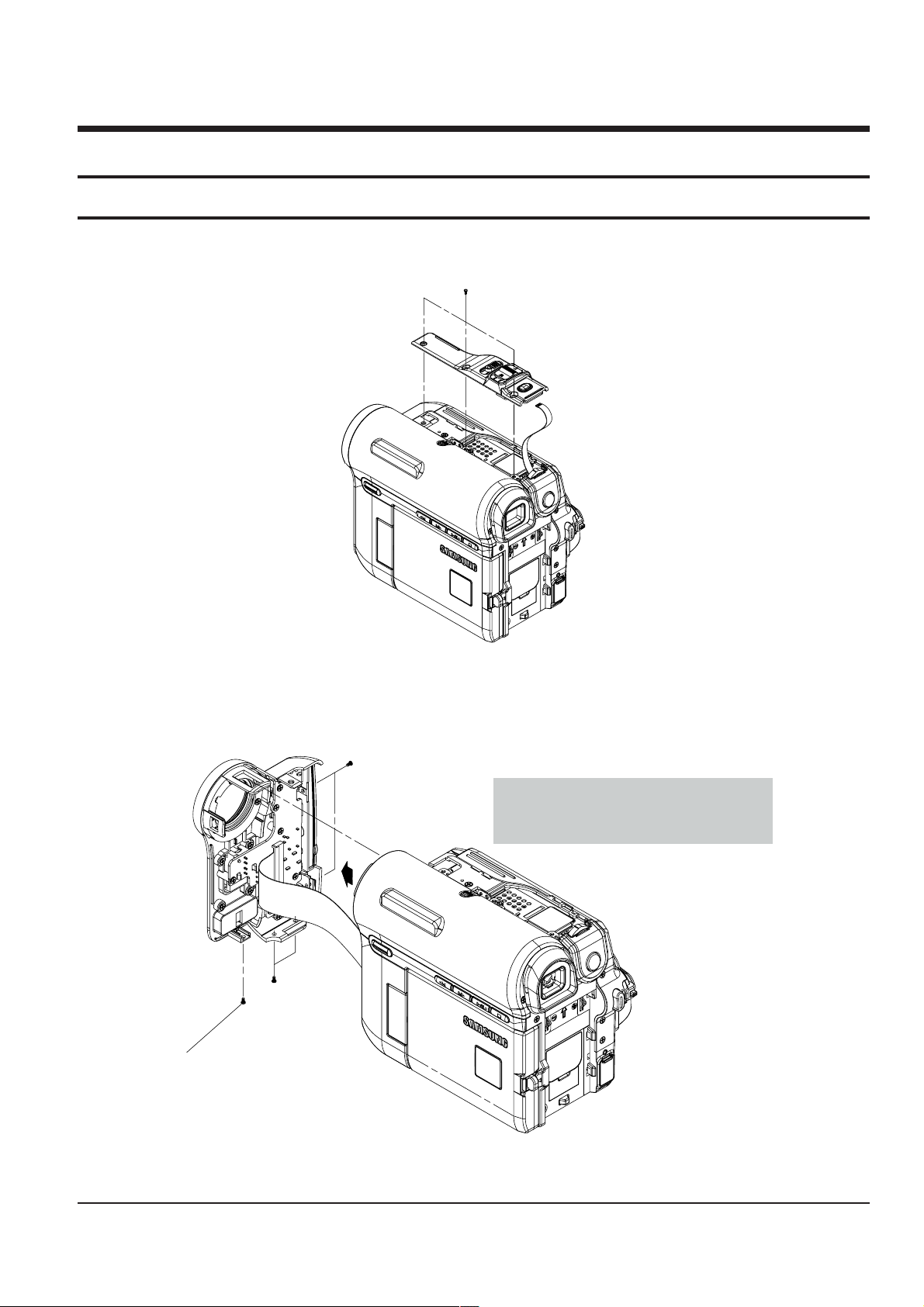

ΠREMOVE 3 SCREWS

(M 1.7 X 4 BLK)

ΠREMOVE 2 SCREWS

(M1.7 X 4 BLK)

´ REMOVE

2 SCREWS

(M1.7 X 4 BLK)

ˇ REMOVE 1 SCREW

(M1.7 X 5 WHT)

Caution : Please indicate that the connector

must be detached before separating

the Front Assembly

4-1 Cabinet and PCB

4-1-1 Ass’y Zoom Removal

4-1-2 Ass’y Front Removal

Fig. 4-1 Ass’y Zoom Removal

Samsung Electronics 4-1

Fig. 4-2 Ass’y Front Removal

Disassembly and Reassembly

ΠREMOVE 1 SCREW

(M1.7 X 4 BLK)

´ REMOVE 1 SCREW

(M1.7 X 5 WHT)

ΠREMOVE 3 SCREWS

(M1.7 X 4 BLK)

´ REMOVE 2 SCREWS

(M1.7 X 4 BLK)

ˇ REMOVE 1 SCREW

(M1.7 X 5 WHT)

Caution : Please indicate that the connectors

must be detached before separating

the Left Assembly

4-1-3 Ass’y Top Removal

4-1-4 Ass’y Left Removal

Fig. 4-3 Ass’y Top Removal

4-2

Fig. 4-4 Ass’y Left Removal

Samsung Electronics

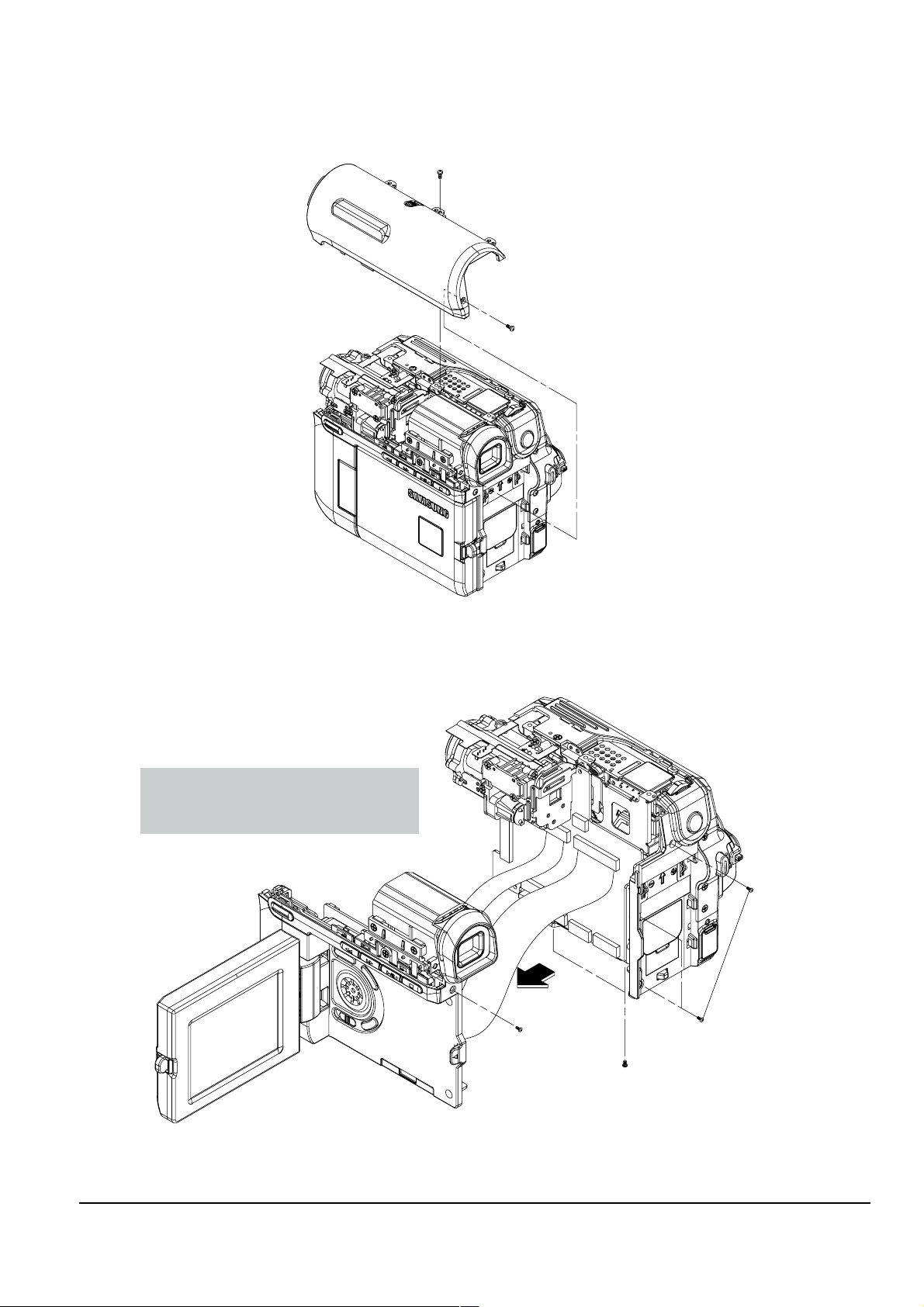

4-1-5 Ass’y LCD & EVF/CVF Removal

ΠREMOVE 3 SCREWS

(T1.7 X 4 BLK)

´ REMOVE 1 SCREW

(M1.7 X 5 WHT)

ˇ REMOVE 4 SCREWS

(T2 X 5 BLK)

¨ REMOVE 2 SCREWS

(M1.7 X 3 WHT)

Caution : Please indicate that there is a

connector on the View-Finder

that must be detached

Caution : Please indicate that this connector

must be detached before separating

the LCD Assembly

ΠREMOVE 4 SCREWS

(M1.7 X 4 BLK)

Caution : The Rear Assembly is connected to the

Main PCB. Pulling it to the left as

indicated in the illustraton can cause

the connector to break. This removal

instruction should indicate that the Rear

assembly should be pulled Forward first

in order to disconnect it from the Main PCB.

Then it can be pulled to the left

to separate it from the Main PCB

Disassembly and Reassembly

4-1-6 Ass’y Rear Removal

Fig. 4-5 Ass’y LCD & EVF/CVF Removal

Fig. 4-6 Ass’y Rear Removal

4-3Samsung Electronics

Disassembly and Reassembly

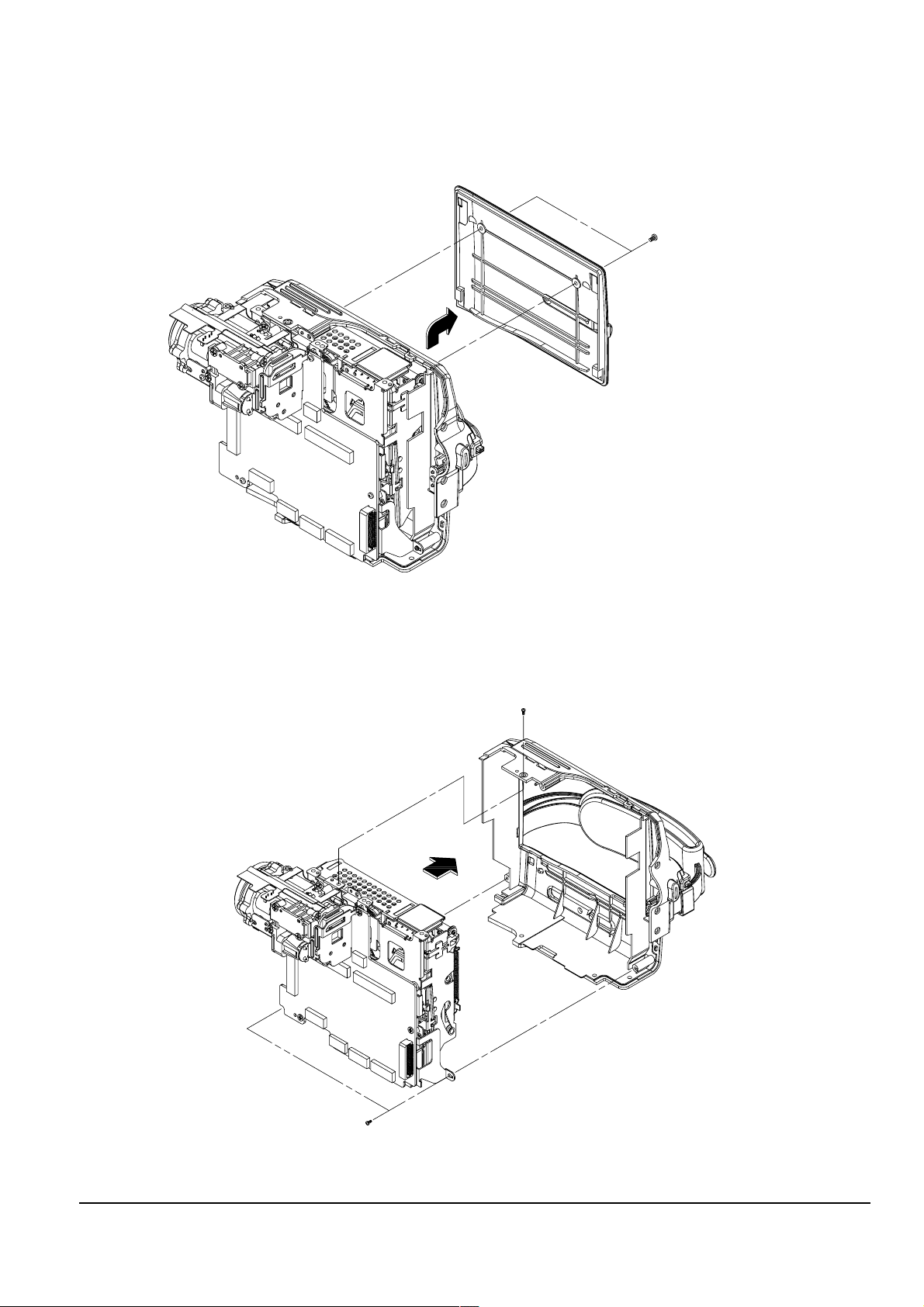

ΠREMOVE 2 SCREWS

(M1.4 X 3 BLK)

ΠREMOVE 2 SCREWS

(M1.7 X 4 BLK)

´ REMOVE 2 SCREWS

(T1.7 X 4 BLK)

4-1-7 Ass’y Cover Housing Removal

4-1-8 Ass’y Right Removal

Fig. 4-7 Ass’y Cover Housing Removal

4-4

Fig. 4-8 Ass’y Right Removal

Samsung Electronics

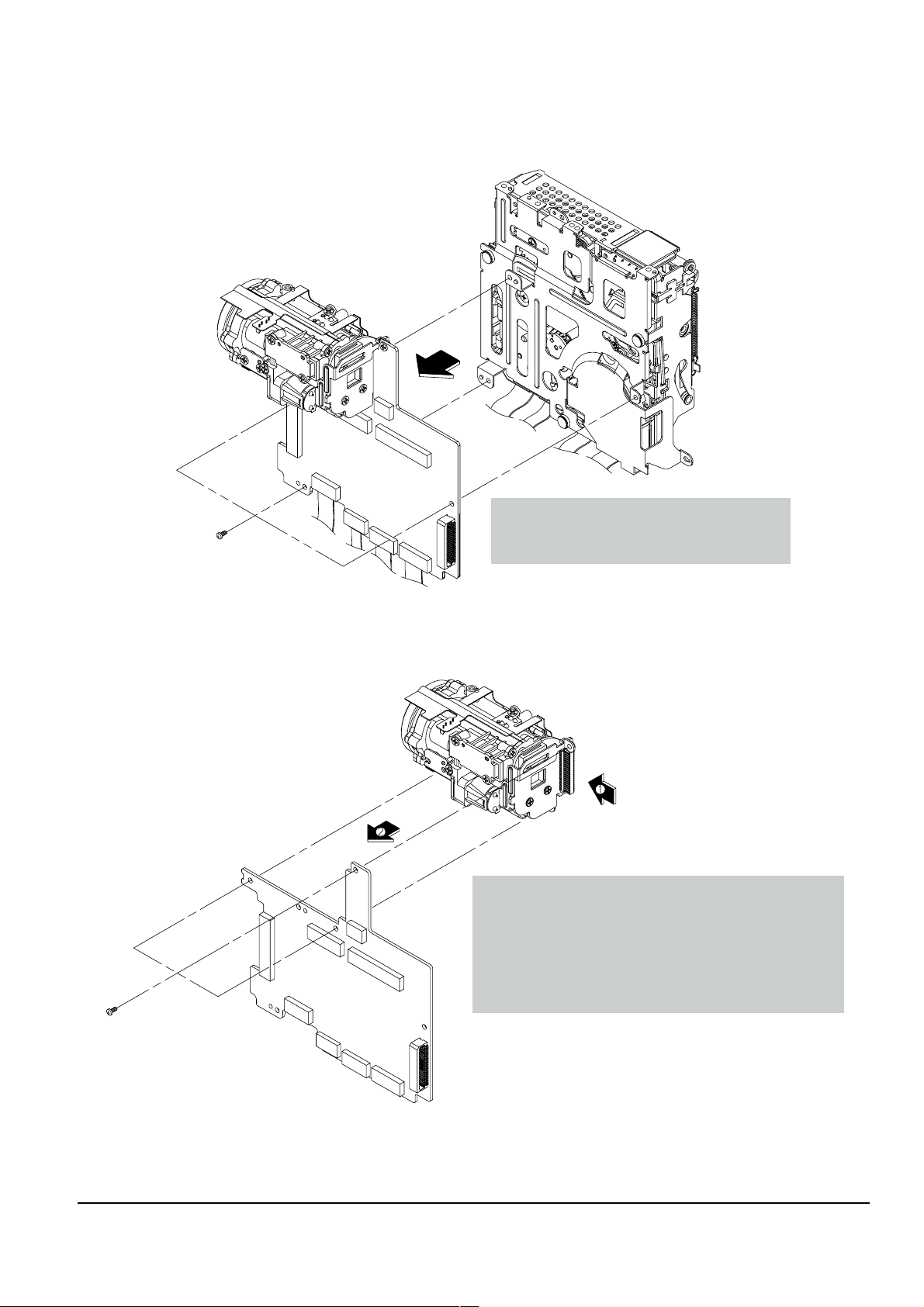

4-1-9 Ass’y Deck Removal

ΠREMOVE 3 SCREWS

(M1.7 X 2.5 BLK)

Caution : Please indicate that these connectors

must be detached before separating

the Deck Assembly from the MAIN PCB.

ΠREMOVE 3 SCREWS

(M1.7 X 2.5 BLK)

Caution : The Lens Assembly is connected to the Main PCB.

Pulling it to the left as indicated in the illustration

can cause the connector to break. This removal

instruction should indicate that the Lens assembly

should be pulled Forward first in order to disconnect

it from the Main PCB. Then it can be pulled to the

left to separate it from the Main PCB.

Disassembly and Reassembly

4-1-10 Ass’y Main PCB Removal

Fig. 4-9 Ass’y Deck Removal

Fig. 4-10 Ass’y Main PCB Removal

4-5Samsung Electronics

Disassembly and Reassembly

DC POWER SUPPLY

A

B

4-2 Deck

4-2-1 How to Load and Unload (Setting the Mechanical Modes)

1) Set the power-supply output to approximately 3V~5V, and connect it to the Motor Loading(= Loading Motor).

2) Choose the polarity depending on whether loading or unloading. (See Table 4-1)

3) Supply the voltage to the Motor Loading(= Loading Motor).

<Table 4-1>

AB

+

_

Fig. 4-11 Loading and Unloading

_

+ Loading

Movement of Chassis

Unloading

4-6

Samsung Electronics

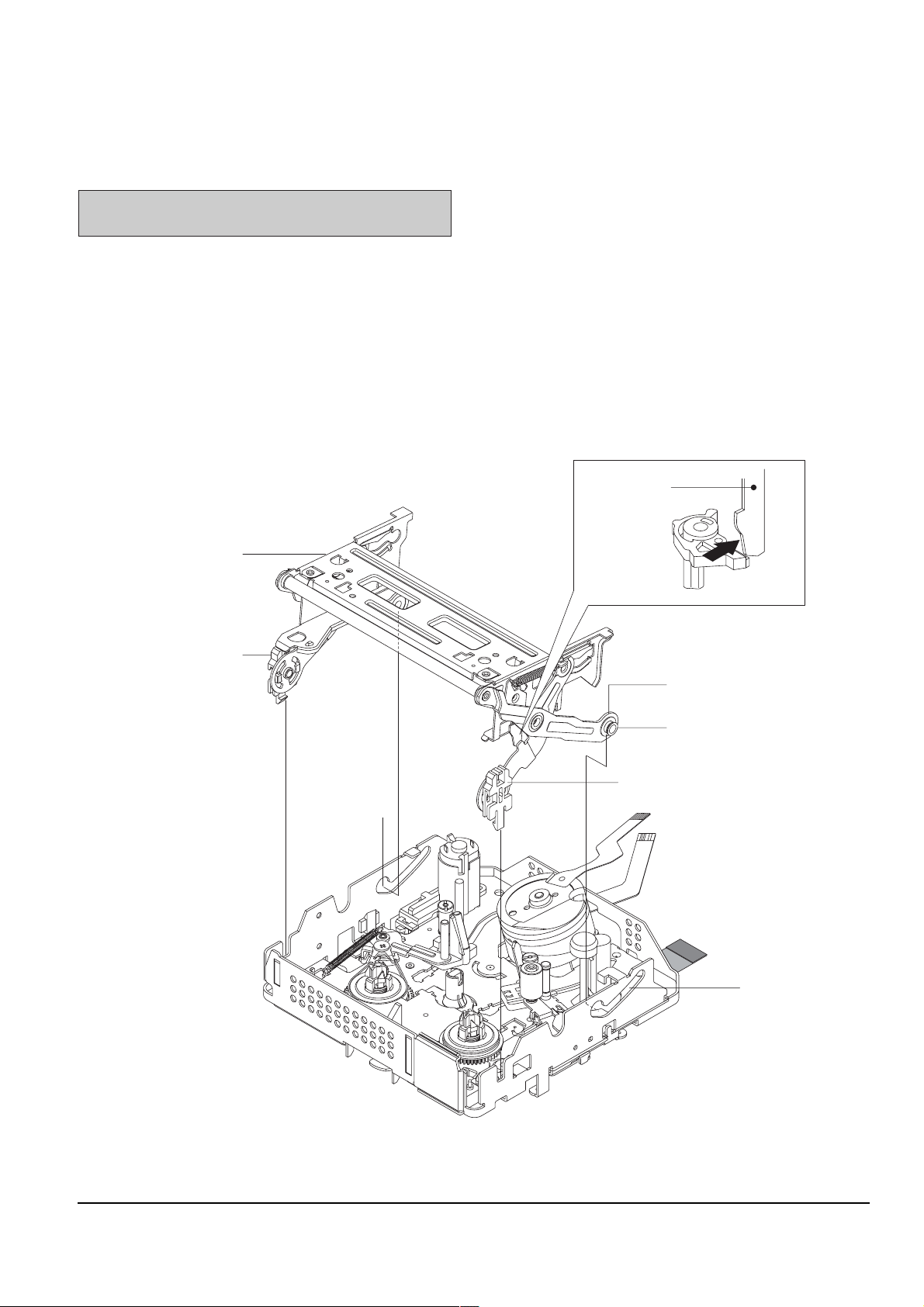

4-2-2 Housing Ass’y

3

HOUSING LOCK L ´

ˇ HOUSING LOCK R

ΠLEVER LOCK

¨ LEVER HOUSING

ˆ SHAPE OF PIN

Ø CAM PART

∏ CAM PART

HOUSING ASS'Y ”

<DETAIL A>

"A"

Disassembly and Reassembly

4-2-2(a) Disassembly

Note : Do disassembly and reassembly in the

unloading mode.

1) Push the Lever(see arrow “A”, Detail A) turn the

Lever Lock Œ and open the Housing Ass’y ”.

2) Separate the Hook of Housing Lock L ´ and

Housing Lock R ˇ and then lift it.

3) Separate the Shape of Pin L and R ˆ from Cam

Parts Ø, ∏ of Main Chassis and then lift the

Housing Ass’y ”.

4-2-2(b) Reassembly

1) Mount the Shape of Pin L and R ˆ to Cam Parts Ø,

∏ of Main Chassis.

2) Mount Housing Lock L ´, R ˇ to right and left ,

and then locked.

Fig. 4-12 Housing Ass’y

4-7Samsung Electronics

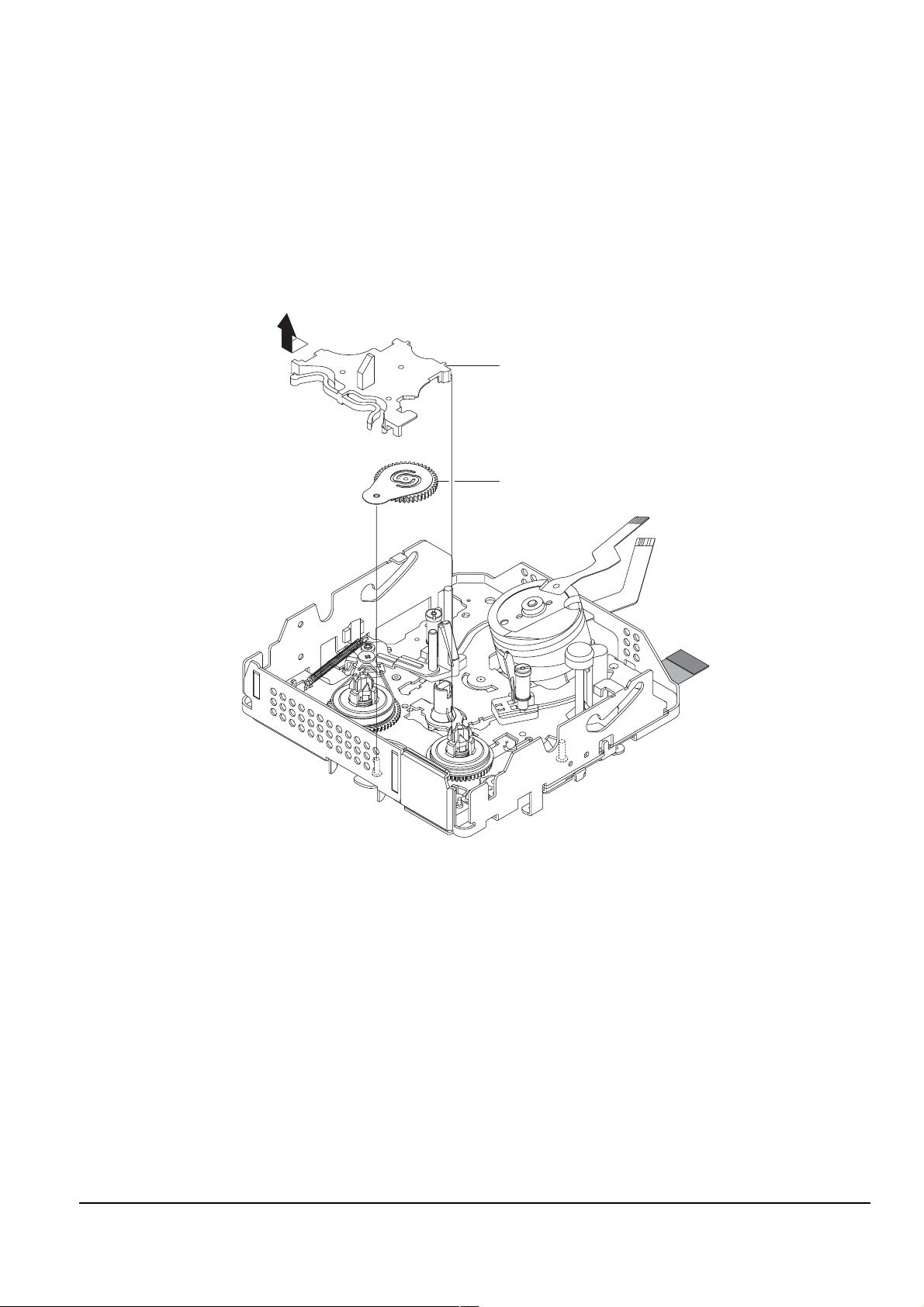

Disassembly and Reassembly

"A"

2

ΠCOVER REEL ASS'Y

´ IDLER ASS'Y

4-2-3 Cover Reel Ass’y, Idler Ass’y

4-2-3(a) Disassembly

1) Lift the Cover Reel Ass’y Œ (See arrow “A”).

2) Then lift the Idler Ass’y ´.

4-2-3(b) Reassembly

1) Fit the Idler Ass’y ´ into the Pin.

2) Mount the Cover Reel Ass’y Œ to the Main Chassis

is groove in the oposite direction of arrow “A”.

4-8

Fig. 4-13 Cover Reel Ass’y, Idler Ass’y

Samsung Electronics

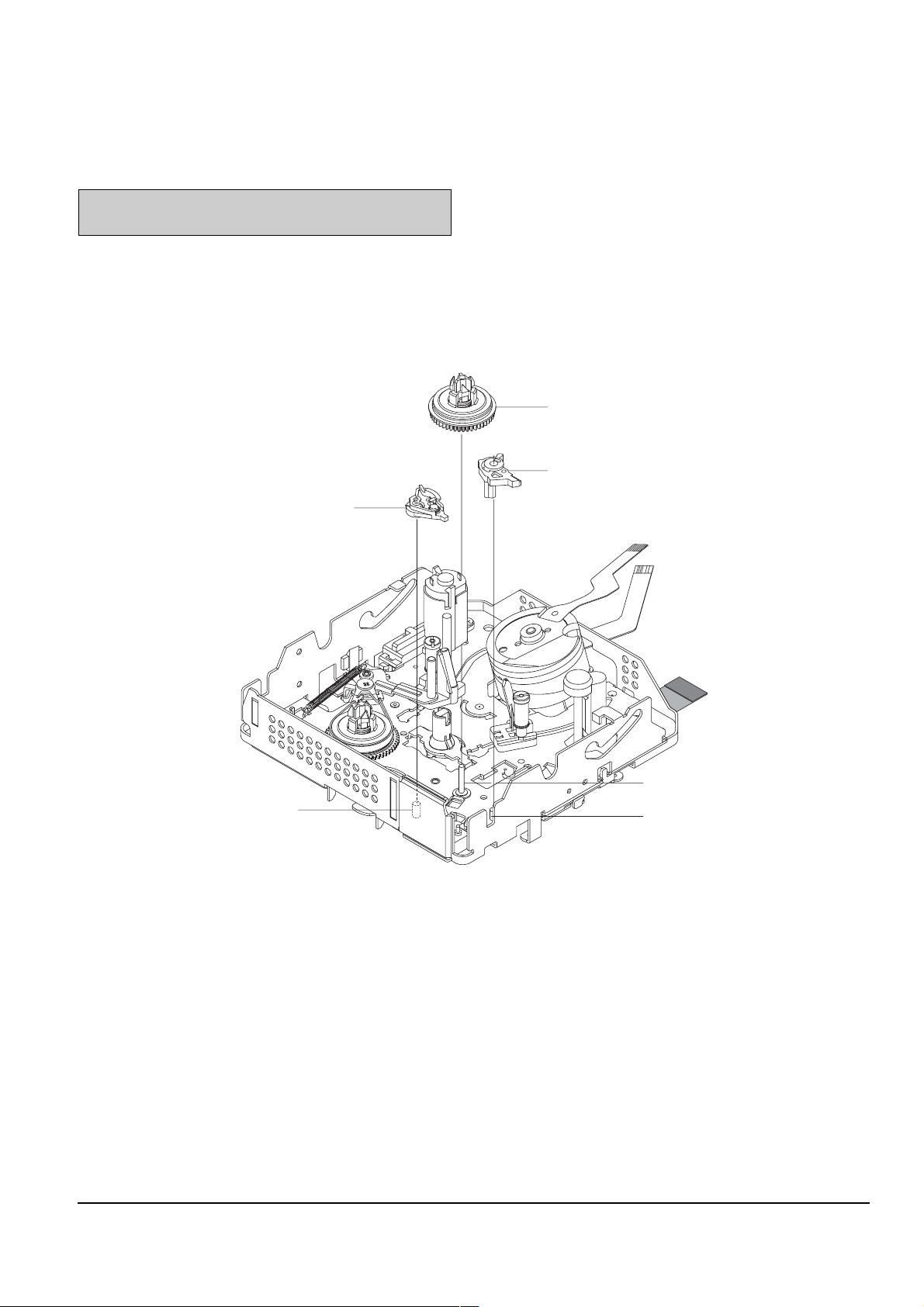

4-2-4 Reel Disk T, Brake T, Lever Eject

4

6

BRAKE T ´

ˇ LEVER EJECT

SHAPE OF PIN ˆ

Ø PIN

ΠREEL DISK T

¨ SHAPE OF PIN

Disassembly and Reassembly

4-2-4(a) Disassembly

Note 1 : When disassembling, take care not to deform

the part. Do not stain the post.

1) Lift up the Brake T ´.

2) Lift up the Reel Disk T Œ.

3) Separate the Lever Eject’s hook from the Main

Chassis, and then Lift up the Lever Eject ˇ.

4-2-4(b) Reassembly

1) Insert the Lever Eject ˇ into the shape of pin ¨,

and then lock the Lever Eject’s hook Eliminate

this step.

2) Mount the Reel Disk T Œ to the pin Ø.

3) Insert the Brake T ´ into the shape of pin ˆ.

Fig. 4-14 Reel Disk T, Brake T, Lever Eject

4-9Samsung Electronics

Loading...

Loading...