DIGITAL VIDEO CAMCORDER

Chassis : Dragon (Delta III)

BASIC : SCD353

SCD353/XAA, XAO, XAC, XTC, XAX, RCL, XAP,

TWN, GEN, ZAM, SAM, AFS, XBG

SCD352/XAA, XAO, XAC, XTC, XAX, RCL, XAP,

TWN, GEN, ZAM, SAM, AFS, XBG

SCD351/XAA, XAO, XAC, XTC, XAX, RCL, XAP,

TWN, GEN, ZAM, SAM, AFS, XBG

SERVICE

; Shooting Design DVC Leader

; Use Built-in Flash Memory

; Multi Memory Card Slot

; Direct Print System : PictBridge ™

; Power Nite Pix

; High quality MPEG4

; Still image Interpolation

; Real Wide mode (16:9)

Manual

DIGITAL VIDEO CAMCORDER Merit & Character regarding Product

1. Precautions

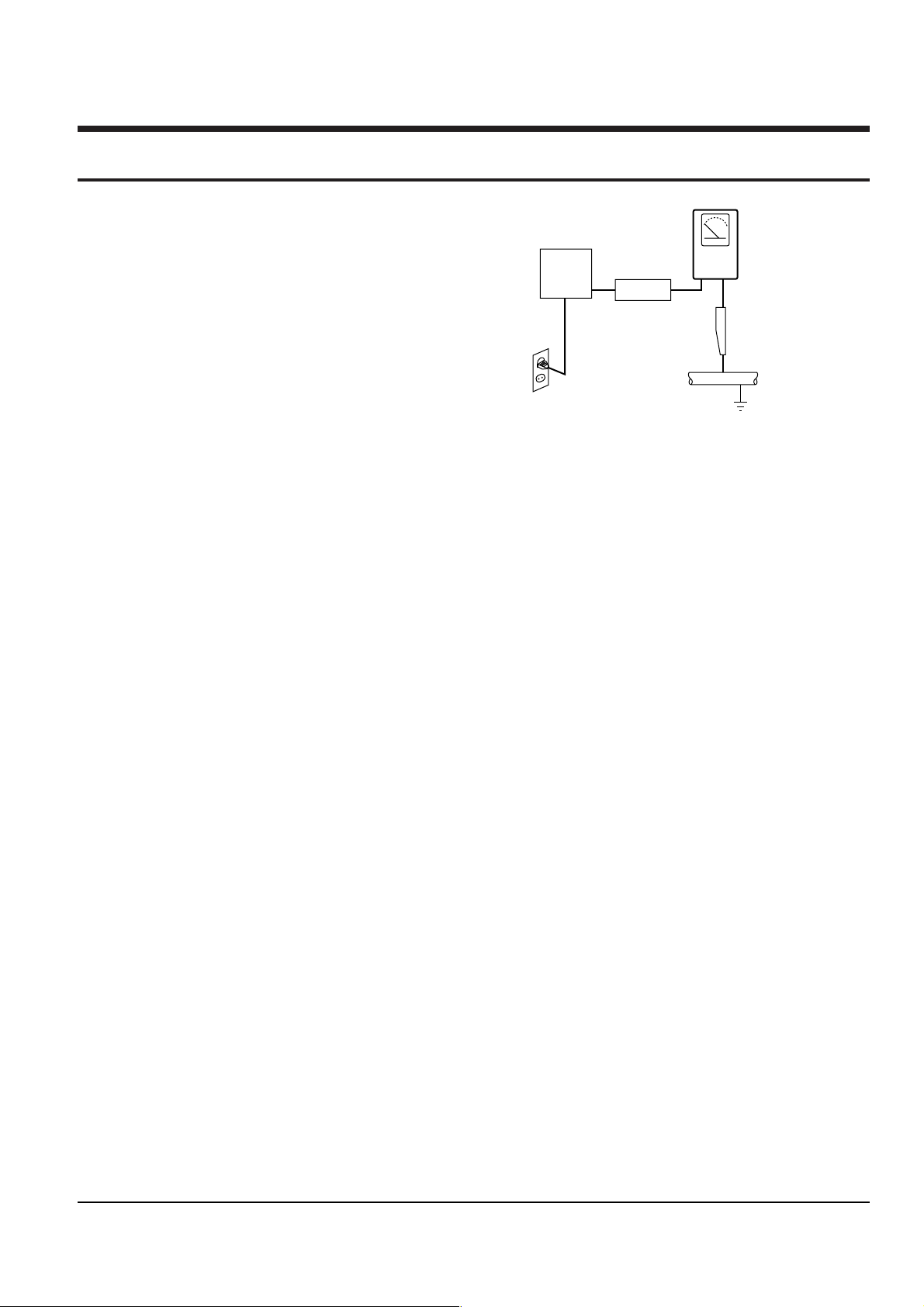

DEVICE

UNDER

TEST

(READING SHOULD

NOT BE ABOVE

0.5mA)

LEAKAGE

CURRENT

TESTER

EARTH

GROUND

TEST ALL

EXPOSED METER

SURFACES

ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

2-WIRE CORD

1. Be sure that all of the built-in protective devices are

replaced. Restore any missing protective shields.

2. When reinstalling the chassis and its assemblies, be

sure to restore all protective devices, including :

control knobs and compartment covers.

3. Make sure that there are no cabinet openings

through which people--particularly children

--might insert fingers and contact dangerous

voltages. Such openings include the spacing

between the picture tube and the cabinet mask,

excessively wide cabinet ventilation slots, and

improperly fitted back covers.

If the measured resistance is less than 1.0 megohm

or greater than 5.2 megohms, an abnormality exists

that must be corrected before the unit is returned

to the customer.

4. Leakage Current Hot Check (See Fig. 1-1) :

Warning : Do not use an isolation transformer

during this test. Use a leakage current tester or a

metering system that complies with American

National Standards Institute (ANSI C101.1,

Leakage Current for Appliances), and Underwriters

Laboratories (UL Publication UL1410, 59.7).

Fig. 1-1 AC Leakage Test

7. Antenna Cold Check :

With the unit’s AC plug disconnected from the

AC source, connect an electrical jumper across the

two AC prongs. Connect one lead of the ohmmeter

to an AC prong.

Connect the other lead to the coaxial connector.

8. High Voltage Limit :

High voltage must be measured each time

servicing is done on the B+, horizontal deflection

or high voltage circuits.

5. With the unit completely reassembled, plug the AC

line cord directly the power outlet. With the unit’s

AC switch first in the ON position and then OFF,

measure the current between a known earth

Heed the high voltage limits. These include the

X-ray protection Specifications Label, and the

Product Safety and X-ray Warning Note on the

service data schematic.

ground (metal water pipe, conduit, etc.) and all

exposed metal parts, including : antennas, handle

brackets, metal cabinets, screwheads and control

shafts. The current measured should not exceed

0.5 milliamp. Reverse the power-plug prongs in the

AC outlet and repeat the test.

9. Some semiconductor (“solid state”) devices are

easily damaged by static electricity.

Such components are called Electrostatically

Sensitive Devices (ESDs); examples include

integrated circuits and some field-effect transistors.

The following techniques will reduce the

6. X-ray Limits :

The picture tube is designed to prohibit X-ray

occurrence of component damage caused by static

electricity.

emissions. To ensure continued X-ray protection,

replace the picture tube only with one that is the

same type as the original.

10. Immediately before handling any semiconductor

components or assemblies, drain the electrostatic

charge from your body by touching a known

earth ground. Alternatively, wear a discharging

Samsung Electronics 1-1

Wrist-strap device. (Be sure to remove it prior to

applying power--this is an electric shock

precaution.)

Precautions

11. High voltage is maintained within specified limits

by close-tolerance, safety-related components and

adjustments. If the high voltage exceeds the

specified limits, check each of the special

components.

12. Design Alteration Warning :

Never alter or add to the mechanical or electrical

design of this unit. Example : Do not add

auxiliary audio or video connectors.

Such alterations might create a safety hazard.

Also, any design changes or additions will void

the manufacturer’s warranty.

13. Hot Chassis Warning :

Some TV receiver chassis are electrically

connected directly to one conductor of the AC

power cord. If an isolation transformer is not

used, these units may be safely serviced only if

the AC power plug is inserted so that the chassis

is connected to the ground side of the AC source.

To confirm that the AC power plug is inserted

correctly, do the following : Using an AC

voltmeter, measure the voltage between the

chassis and a known earth ground. If the reading

is greater than 1.0V, remove the AC power plug,

reverse its polarity and reinsert. Re-measure the

voltage between the chassis and ground.

14. Some TV chassis are designed to operate with 85

volts AC between chassis and ground, regardless

of the AC plug polarity. These units can be safely

serviced only if an isolation transformer inserted

between the receiver and the power source.

18. Picture Tube Implosion Warning :

The picture tube in this receiver employs

“integral implosion” protection. To ensure

continued implosion protection, make sure that

the replacement picture tube is the same as the

original.

19. Do not remove, install or handle the picture tube

without first putting on shatterproof goggles

equipped with side shields. Never handle the

picture tube by its neck. Some “in-line” picture

tubes are equipped with a permanently attached

deflection yoke; do not try to remove such

“permanently attached” yokes from the picture

tube.

20. Product Safety Notice :

Some electrical and mechanical parts have special

safety-related characteristics which might not be

obvious from visual inspection. These safety

features and the protection they give might be

lost if the replacement component differs from the

original--even if the replacement is rated for

higher voltage, wattage, etc.

Components that are critical for safety are

indicated in the circuit diagram by shading,

( or ).

Use replacement components that have the same

ratings, especially for flame resistance and

dielectric strength specifications. Areplacement

part that does not have the same safety

characteristics as the original might create shock,

fire or other hazards.

15. Never defeat any of the B+ voltage interlocks.

Do not apply AC power to the unit (or any of its

assemblies) unless all solid-state heat sinks are

correctly installed.

16. Always connect a test instrument’s ground lead to

the instrument chassis ground before connecting

the positive lead; always remove the instrument’s

ground lead last.

17. Observe the original lead dress, especially near

the following areas : Antenna wiring, sharp

edges, and especially the AC and high voltage

power supplies. Always inspect for pinched, outof-place, or frayed wiring. Do not change the

spacing between components and the printed

circuit board. Check the AC power cord for

damage. Make sure that leads and components

do not touch thermally hot parts.

1-2 Samsung Electronics

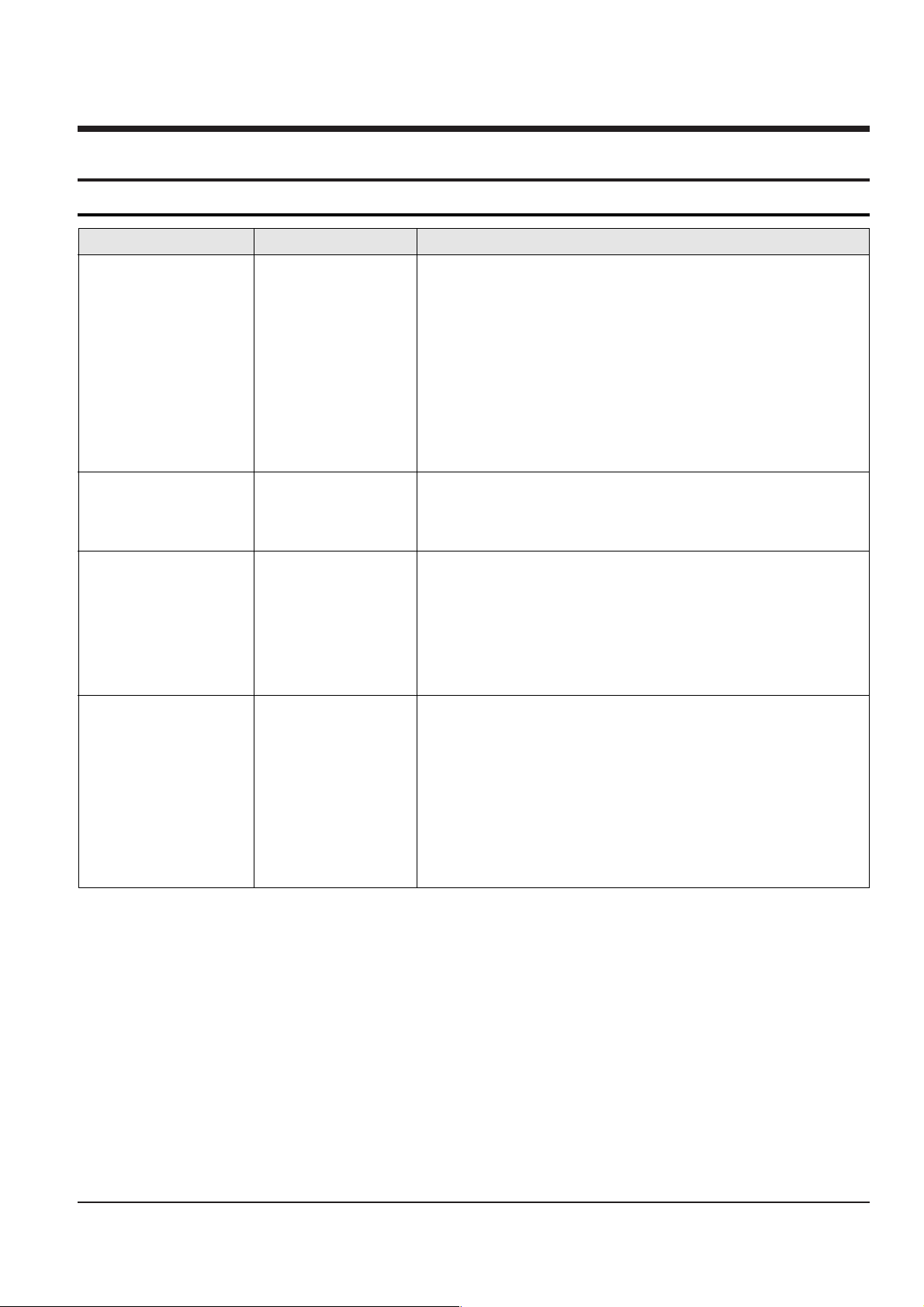

2. Product Specifications

2-1 Product Specification

Operation Description

System

LCD monitor/Viewfinder

Connectors

General

Video signal

Video recording system

Audio recording system

Usable cassette

Tape speed

Tape recording time

FF/REW time

Image device

Lens

Filter diameter

Size/dot number

LCD monitor Method

Viewfinder

Video output

S-video output

Audio output

DV input/output

USB output

External mic

Power source

Power source type

Power consumption

(Recording)

Operating temperature

Storage temperature

External dimension

Weight

Built-in MIC

NTSC

2 rotary heads, Helical scanning system

Rotary heads, PCM system

Digital video tape (6.35mm width): Mini DV cassette

SP: approx. 18.81mm/s LP: approx. 12.56mm/s

SP: 60 minutes (when using DVM 60), LP: 90 minutes (when using DVM 60)

Approx. 150 sec. (using DVM60 tape)

CCD / 680K (Still Image : 48K)

F1.4 20x(Optical), 900x(Digital) Electronic zoom lens

Ø30

2.5inchs 112k

TFT LCD

B/W LCD

1Vp-p (751 terminated)

Y: 1Vp-p, 751, C: 0. 286Vp-p, 751

-7.5dBs (6001 terminated)

4pin special in/out connector,

Mini-B type connector

Ø3.5 stereo

DC 8.4V, Lithium Ion Battery Pack 7.4V

Lithium Ion Battery Pack, Power supply (100V~240V) 50/60Hz

4.4W(LCD), 4.0W(Viewfinder)

0˚~40˚C (32˚F~104˚F)

-20˚C ~ 60˚C (-4˚F ~ 140˚F)

Length 90mm, Height 110mm, Width 60mm

400g (Except for Lithium Ion Battery Pack and tape)

Omni-directional stereo condenser microphone

Samsung Electronics

2-1

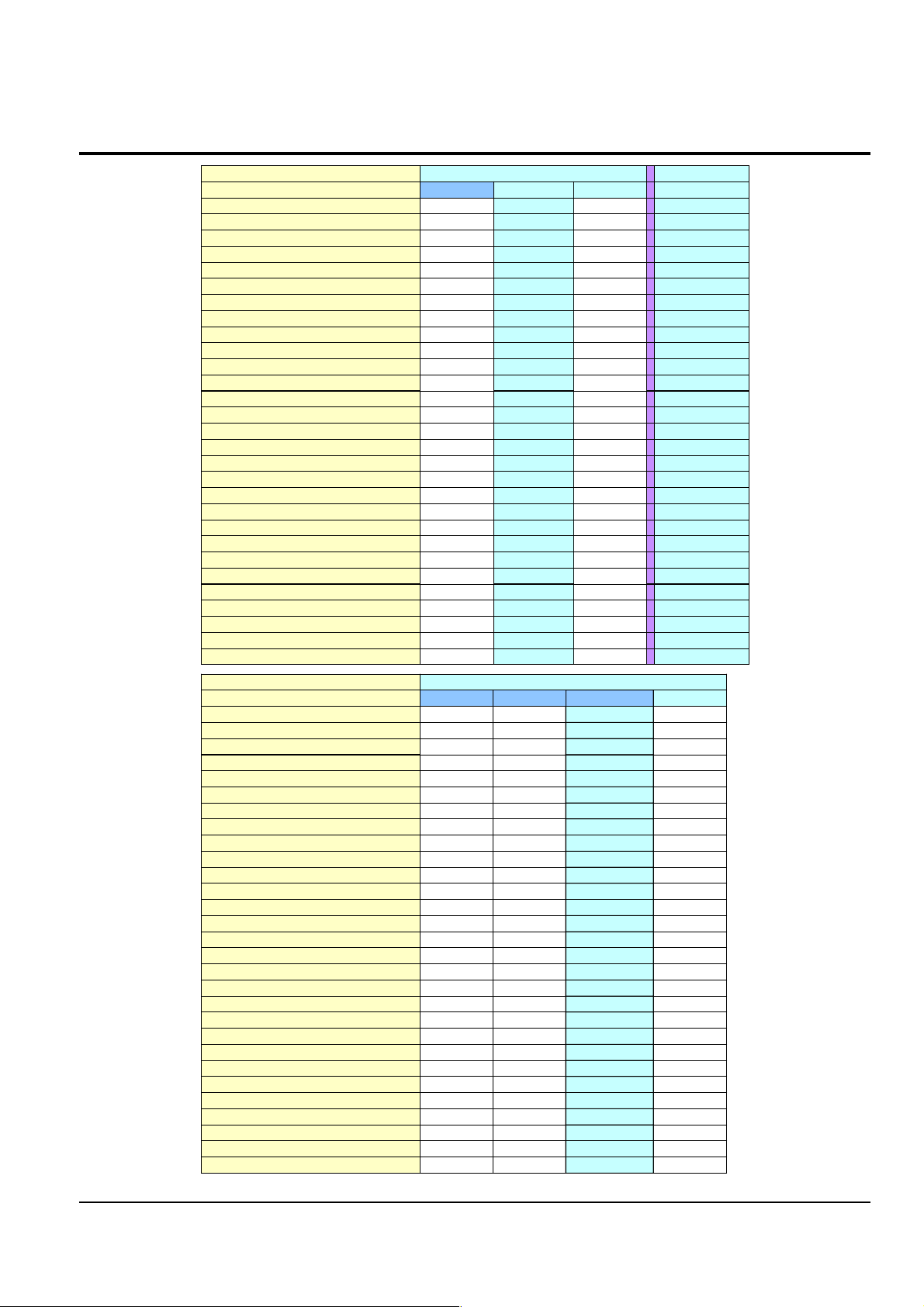

Product Specification

--

Acces sory Comment

-/--/ -

S-Cable / Scart Jack

Opt./Opt.Opt./Opt.

Carrying Case / Tape

T.B.DT.B.D

Battery Pack

O/XO / --/ -

Remocon / Acces sory Shoe

OO-

Analog In

O/O/OO/O/O

Multi Lang./ Batt. Check/Instant On

O/GUI/OO/GUI/OO/OSD/O

Beep Sound / Display / PB Zoom

O/O/O/-O/O/O/-

AV / S.Jack / Ext.Mic / H.phone

O/O/OO / O / O-/ -/ O

Light / Night Captur e / LSS

T.B.DT.B.D

JPEG Multi Display

T.B.DT.B.D

Continuous Shot / Im age Mix

M4/VG/30fM4/VG/30f

MPEG Clip Form at / size / F.Ratio

XGAXGA

JPEG Recording Si ze to Memory

----

Memory Card

16M32M--

Builtin Memory

Multi CardMulti CardM.S. Slot-

Memory Card Slot

MJ/QQ/15fMJ/QQ/15f

Web camera (For./size/F.rate)

M4/VG/30fM4/VG/30f

USB Stream. (For./size/F.Rate)

USB2.0USB2.0

USB

In/OutIn/Out

IEEE1394

DISDIS

Image Stabili zer

12/16b PCM12/16b PCM

Audio

BWColorBW

Viewfinder

2.5", 112K2.5", 112K

LCD

680K680K

CCD

20x / 900x20x / 900x

Zoom/Digita l Zoom

520 line520 line

Resolution

MiniDVMiniDV

Format

VM-F730D355SC-D353D351

Model cod e

NTSC (

Rsx

)NTSC(America)

Region

-

Acces sory Comment

Opt./Opt.

S-Cable / Scart Jack

Opt./Opt.

Carrying Case / Tape

T.B.D

Battery Pack

O/XX/XX/X

Remocon / Acces sory Shoe

-

Analog In

O/O/O

Multi Lang./ Batt. Check/Instant On

O/GUI/OO/OSD/OO/OSD/O

Beep Sound / Display / PB Zoom

O/O/O/-

AV / S.Jack / Ext.Mic / H.phone

O/O/O-/-/O-/-/O

Light / Night Captur e / LSS

T.B.DNoNo

JPEG Multi Display

T.B.DNoNo

Continuous Shot / Im age Mix

M4/VG/25fNoNo

MPEG Clip Form at / size / F.Ratio

XGANoNo

JPEG Recording Si ze to Memory

-

---

Memory Card

64M

---

Builtin Memory

Multi Card

M.S.NoNo

Memory Card Slot

MJ/QQ/12.5fNo

Web camera (For./size/F.rate)

M4/VG/25fNo

USB Stream. (For./size/F.Rate)

USB2.0No

USB

Out

IEEE1394

DIS

Image Stabili zer

12/16b PCM

Audio

Color

BW

Viewfinder

2.5", 112K

LCD

800K

CCD

20x / 900x

Zoom/Digita l Zoom

520 line

Resolution

MiniDV

Format

D355VP-D353D352D351

Model cod e

PAL (Europ e)

Region

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

OO

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

OO

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

2-2 Chassis Product Specification

2-2

Samsung Electronics

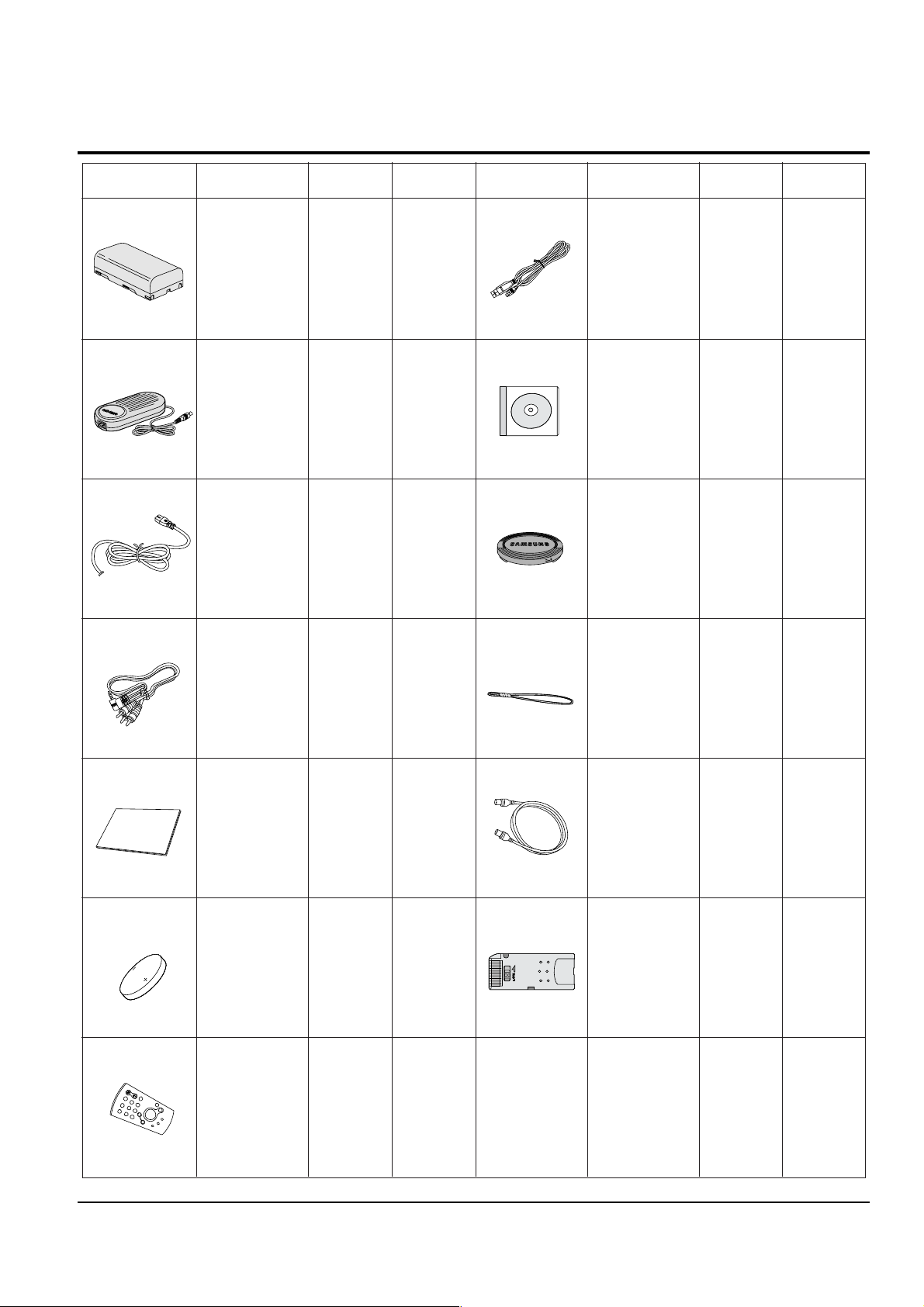

2-3 Accessories Supplied with Camcorder

(SCD354/

D355

only)

(SCD352/

D353/D354/

D355

only)

(SCD352/

D353/D354/

D355

only)

Basic

Accessories

Basic

Accessories

Basic

Accessories

Basic

Accessories

Basic

Accessories

Basic

Accessories

Basic

Accessories

Basic

Accessories

Basic

Accessories

Basic

Accessories

Basic

Accessories

Accessories

Accessories

Accessories Description Part No Remark Description Part No RemarkAccessories

1. Lithium Ion

Battery Pack

AD43-00136A

AD43-00146A

Optional

Optional

2. AC Power Adapter

(AA-E8 TYPE)

AD44-00090A

4. Audio/Video Cable

AD68-00839B

AD39-00001A

5. Instruction Book

6. Lithium Battery

(CR2025)

AD43-10130H

7. Remote Control

AD59-00085A

AD97-07354B

8. USB Cable

AD39-00073A

AD43-00128A

9.Software CD

10. Lens Cover

11.Lens Cover strap

AD72-00049A

13. Memory Stick

1109-001221

12. S-Video Cable

AC39-42001Z

3. AC

Cord

AD39-00076A

Product Specification

Samsung Electronics

2-3

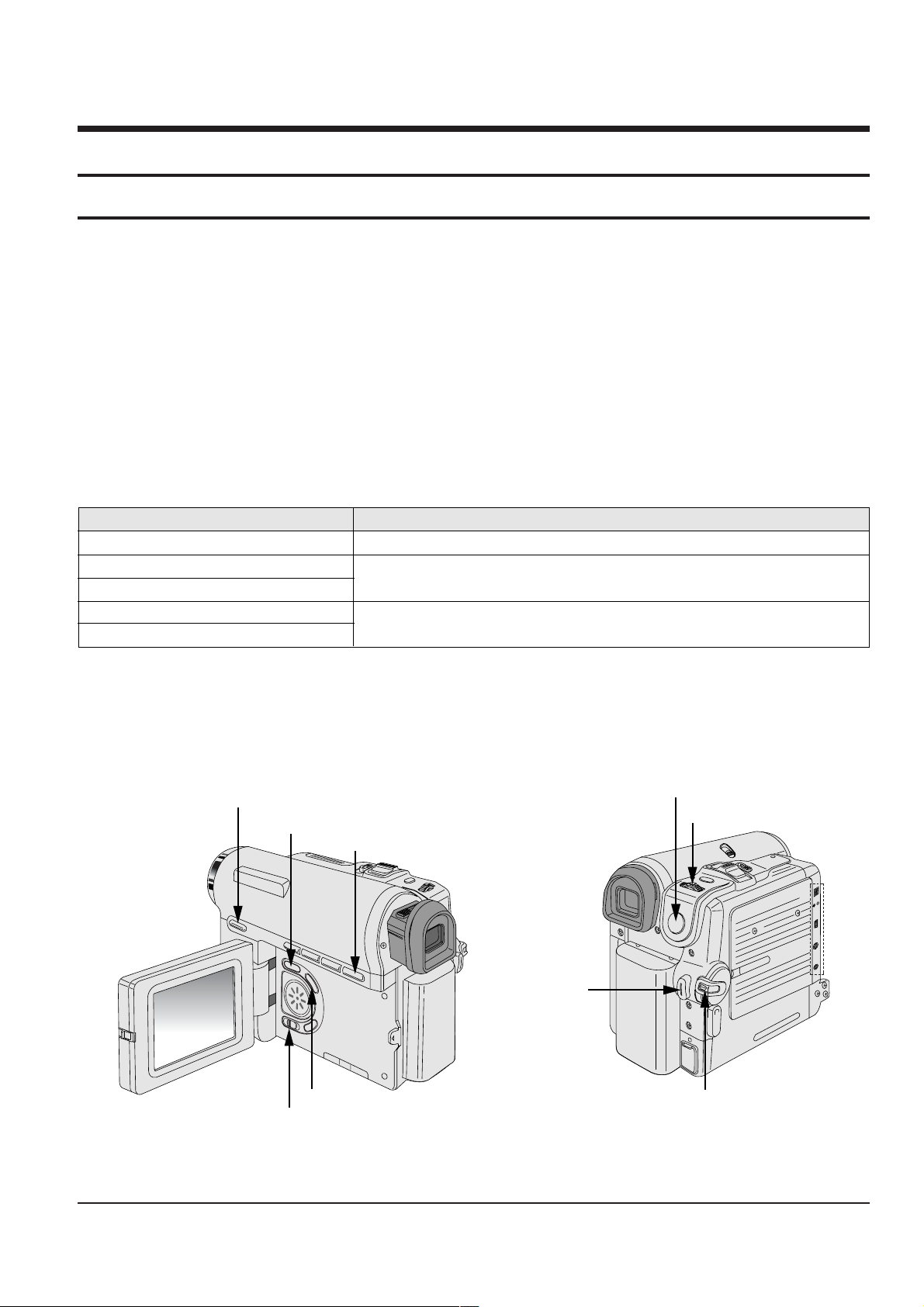

3. Alignment and Adjustment

MENU Button

EASY Q Button

Start/Stop Button

MENU Selector

DISPLAY Button

Mode switch

PB ZOOM

Power switch

STOP Button

DV

USB

AV

MIC

3-1 VCR Adjustment

3-1-1 Adjustment Preparation

1) Before you start

ΠUse the buttons on the CAMCORDER when adjusting VCR.

´ When changing the adjustment item, please press the “EASY-Q” and “DISPLAY” buttons on the

CAMCORDER.

ˇ The adjustment value can be changed by moving the “MENU Selector” Left or Right.

¨ Press the “MENU Selector” to store each adjustment into EEPROM.

ˆ The OSD shows “OK” after finishing each adjustment step.

Ø In order to exit the adjustment mode, disconnect the power source.

2) Function of each buttons on the Set Key

<Table 3-1>

Buttons Description

MENU Selector push (Confirm) Stores changed value in the adjustment and auto adjustment mode.

MENU Selector Right (Data Down)

MENU Selector Left (Data Up)

EASY-Q (Mode Up)

DISPLAY (Mode Down)

Changes data in the adjustment state.

Changes mode.

3) How to get into the VCR adjust mode

[STEP 1]

ΠConnect the Power source.

´ Set the Power Switch to “PLAYER” position and Mode Switch to “TAPE” position.

Fig. 3-1

Samsung Electronics

3-1

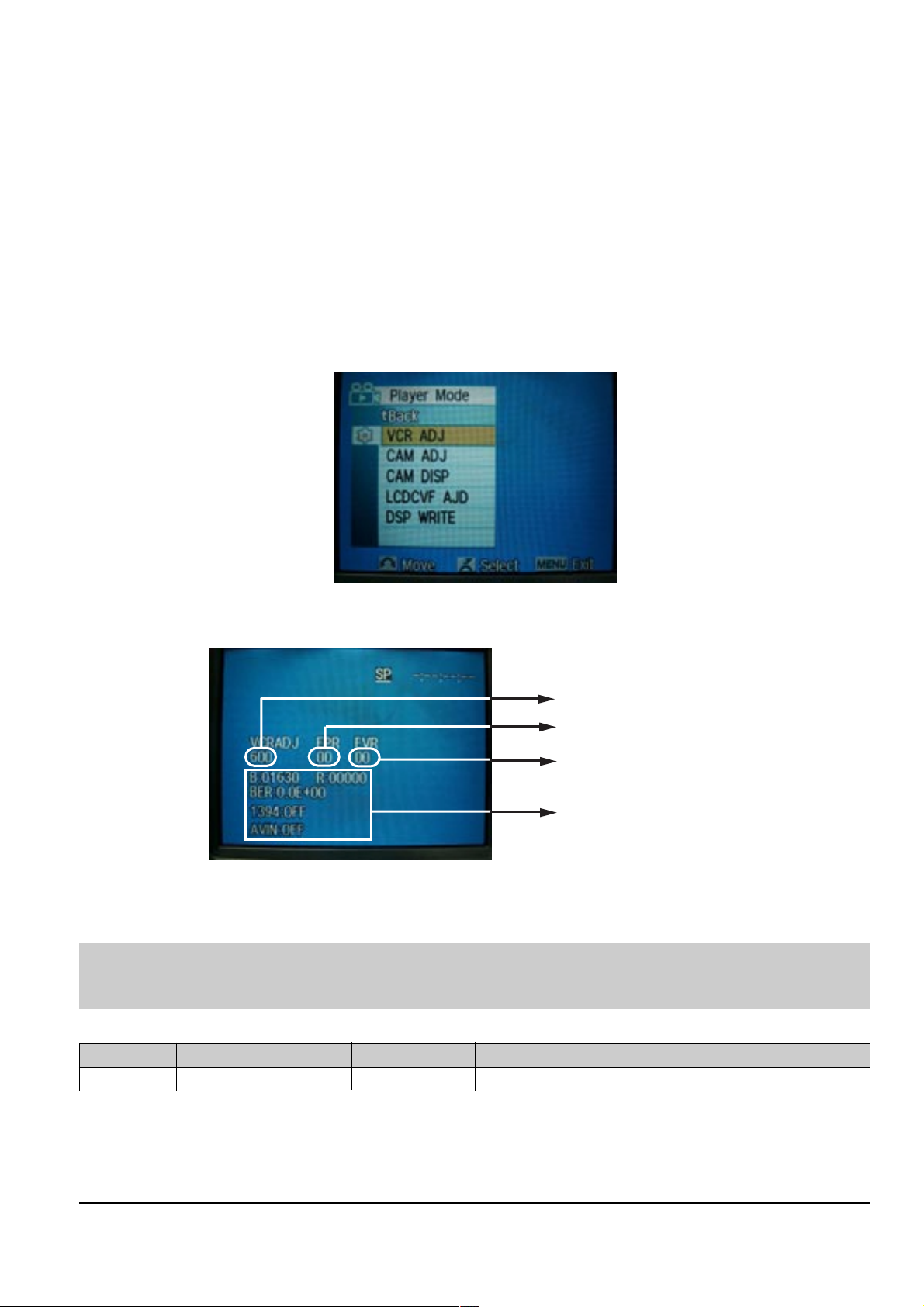

Alignment and Adjustments

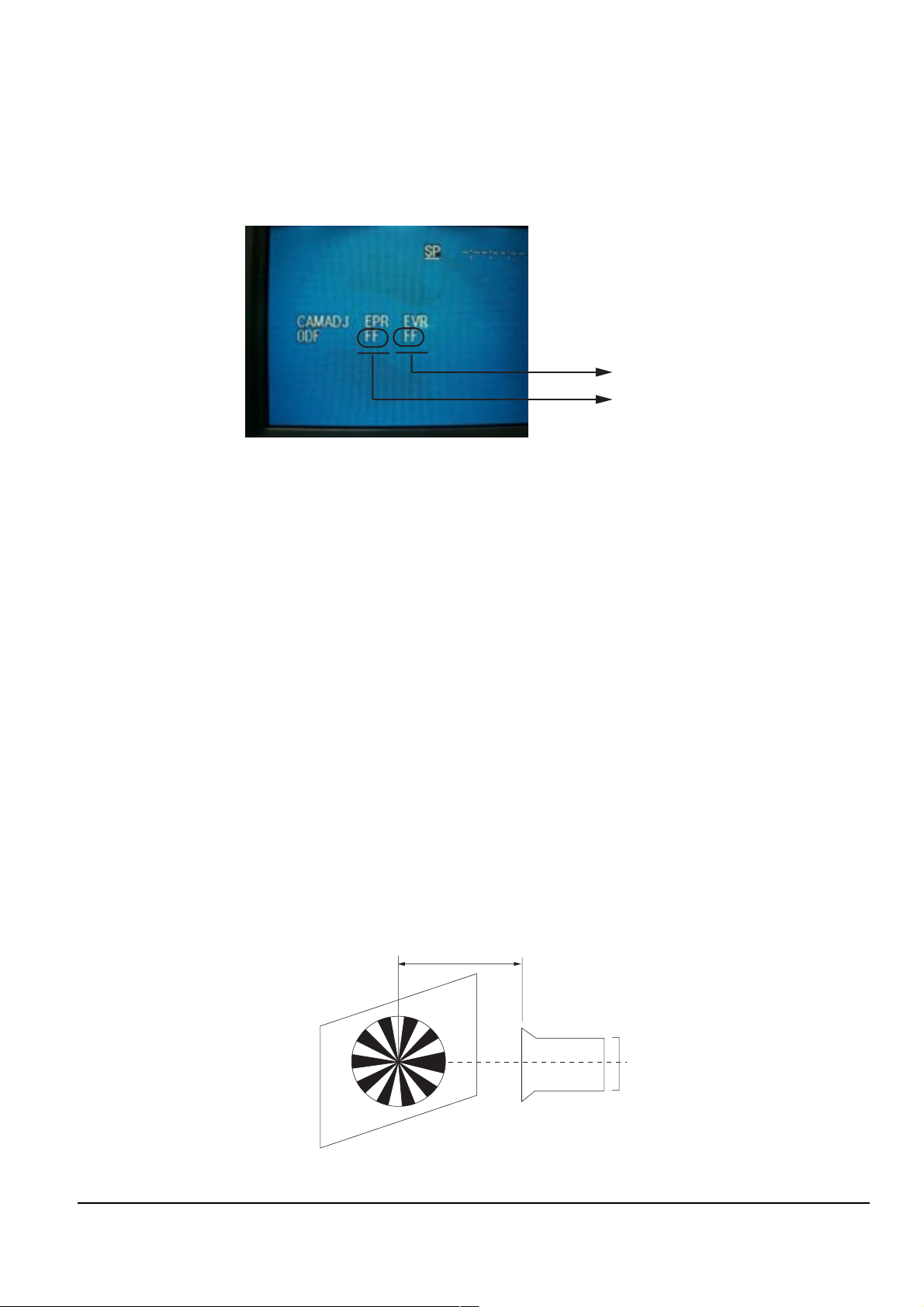

Indicates current adjustment item

Adjustment value

For Engineering Mode

Stored value

[STEP 2]

ΠPress and hold the "STOP" and "PB ZOOM" buttons on the video camera at the same time for more than

5 seconds.

´ When monitor OSD appears as shown Fig. 3-2, the adjustment mode has been activated successfully.

ˇ Move the “MENU Selector” to highlight VCR ADJ and push the “MENU Selector”.

¨ Monitor OSD shows Fig. 3-3.

Then VCR adjustment mode has been activated successfully.

[STEP 3]

In order to complete the adjustment the power must be reset.

This can be done by disconnecting and reconnecting the power source.

Fig. 3-2

Fig. 3-3

3-1-2 VCR Adjustment

Note : This is the only electronic adjustment for the VCR.

Other addresses have already been assigned data during the manufacturing process.

We don’t need any adjustment for those addresses.

<Table 3-2>

(Address)

Mode

61F SWP Position 8C Head Switching Position Adjust

Name Value Description

ΠGet into VCR ADJUST mode.

´ Move to the VCR ADJUST address “6IF”.

ˇ Play standard tape, and “Head Switching Position” will be adjusted automatically (within 5 Seconds).

3-2

Samsung Electronics

3-2 Camera Adjustment

Note : How to adjust the camera system.

1) EEPROM stores confirmed adjustment value of each adjustment step.

2) DSP (Digital Signal Process : ICM01-Main PCB) digitalizes the camera signal.

3) When changing IC505-Main PCB of EEPROM, readjust Main PCB.

While changing LCD PCB and CVF PCB- always readjust each part.

Since EEPROM stores confirmed adjustment value of each adjustment step, readjusting must be performed in order

to store the changed data.

4) Adjust the following items after changing LENS Ass’y.

ΠLens Zoom Track

´ Auto HALL

ˇ Auto IRIS

5) Adjust the following items after changing EEPROM and Camera Main PCB.

ΠLens Zoom Track

´ Zoom VR Center

ˇ Auto HALL

¨ Auto IRIS

ˆ Auto White Balance (indoor)

Ø Auto White Balance (outdoor)

Alignment and Adjustments

3-2-1 Adjustment Preparation

1) Before you start

ΠUse the buttons on the CAMCORDER when adjusting Camera.

´ When changing the adjustment item, please press the “EASY-Q” and “DISPLAY” buttons on the

CAMCORDER.

ˇ The adjustment value can be changed by moving the “MENU Selector” Left or Right.

¨ Press the “MENU Selector” to store each adjustment into EEPROM.

ˆ The OSD shows “OK” after finishing each adjustment step.

Ø In order to exit the adjustment mode, disconnect the power source.

2) Function of each buttons on the Sst Key

<Table 3-3>

Buttons Description

MENU Selector push (Confirm) Stores changed value in the adjustment and auto adjustment mode.

MENU Selector Right (Data Down)

MENU Selector Left (Data Up)

EASY-Q (Mode Up)

DISPLAY (Mode Down)

Changes data in the adjustment state.

Changes mode.

Samsung Electronics

3-3

Alignment and Adjustments

MENU Button

EASY Q Button

Start/Stop Button

MENU Selector

DISPLAY Button

Mode switch

PB ZOOM

Power switch

STOP Button

DV

USB

AV

MIC

5) How to set up the camera adjustment mode

[STEP 1]

ΠConnect the Power source.

´ Set the Power Switch to “CAM” position and Mode Switch to “TAPE” position.

[STEP 2]

ΠPress and hold the "STOP" and "PB ZOOM" buttons on the video camera at the same time for more than

5 seconds.

´ When monitor OSD appears as shown Fig. 3-5, the adjustment mode has been activated successfully.

ˇ Move the “MENU Selector” to highlight CAM ADJ and push the “MENU Selector”.

¨ Monitor OSD shows Fig. 3-6.

Then Camera adjustment mode has been activated successfully.

[STEP 3]

In order to complete the adjustment the power must be reset.

This can be done by disconnecting and reconnecting the power source.

3-4

Fig. 3-4

Fig. 3-5

Samsung Electronics

Alignment and Adjustments

Adjusted values

Stored values

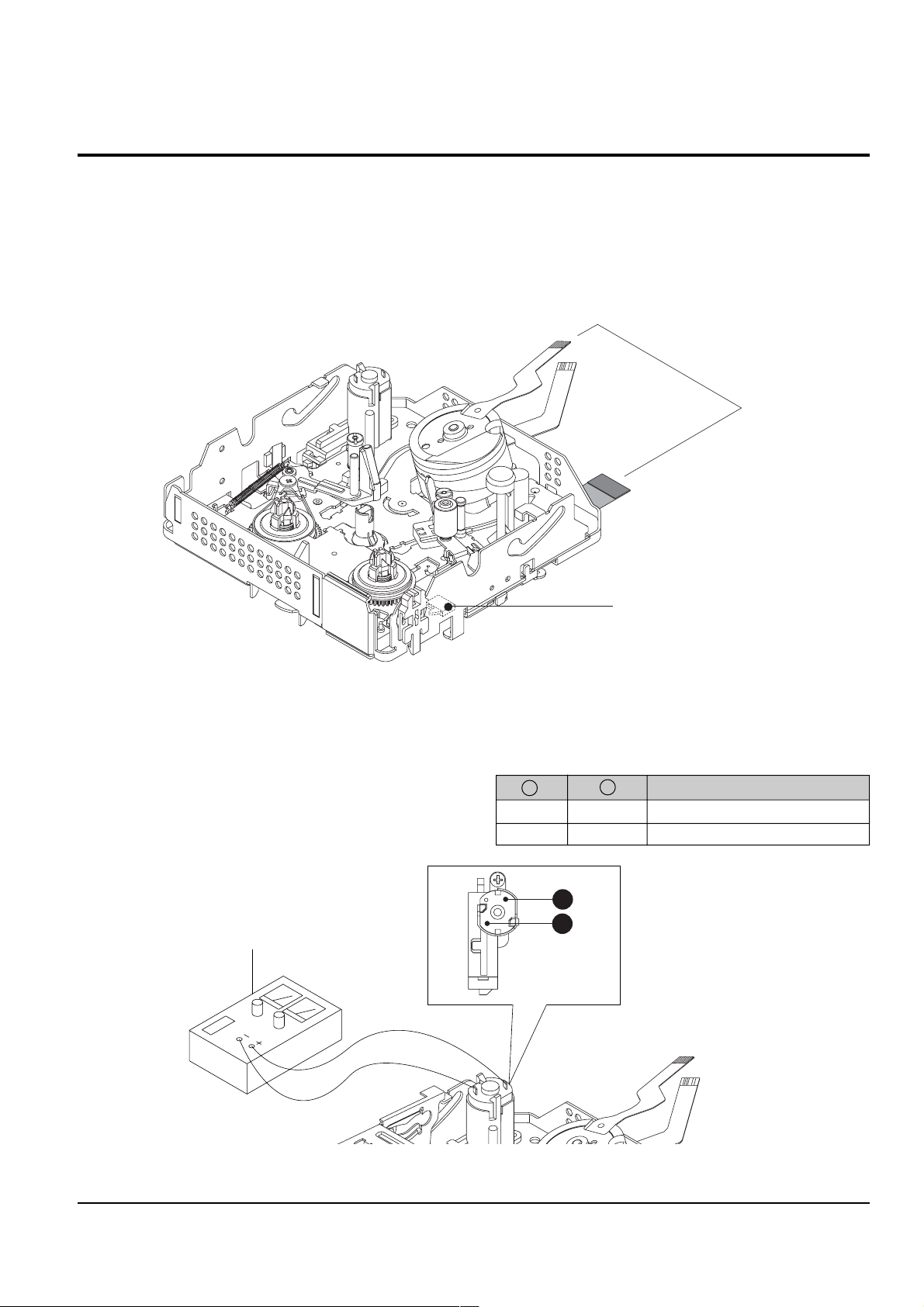

3M ± 1cm

(Be sure to maintain the distance)

CCDLENS

3-2-2 Camera Adjustment

Note : "XX XX" indicate the previous preset value and adjusted value.

Press the “MENU Selector” (Confirm) to store the adjusted value.

Fig. 3-6

1) EEPROM Data Initialize

Caution : These adjustments must be done when installing a new EPROM (IC105) or Main PCB.

Œ Press the “EASY-Q”(Mode Up)/”DISPLAY”(Mode Down) buttons until CAMADJ displays “0DF XX XX”.

´ Use the “MENU Selector” (Data Up/Down) until the display data for EVR is “A0”.

ˇ Press the “MENU Selector” (Confirm).

¨ The OSD shows “OK” after finishing the initalize.

2) Lens Zoom Track

Caution : For whole zoom range, it shall be in focus.

The location of a focus lens is moving depending on the location of Zoom Lens.

During adjusting, micom measures the focus location from a near distance to a long.

ΠCamera is set to E-E mode.

´ Focus chart photo.

ˇ Center the camera about 3m from a focus chart which, should be placed on a flat surfaced white or gray wall.

¨ Connect the video output terminal to a TV.

ˆ Press the “EASY-Q” (Mode Up)/”DISPLAY” (Mode Down) buttons until CAMADJ displays “0DE XX XX”.

Ø Press the “MENU Selector” to begin adjustment.

The camera must be kept still when adjusting the zoom and focus lens.

If you don’t have any chart, you can use the object which has a lot of vertical line.

The OSD shows “OK” after finishing the adjustment.

(The word “OK” is displayed for only a fraction of a second.)

Samsung Electronics

Fig. 3-7

3-5

Alignment and Adjustments

3) Zoom VR Center

ΠConnect a video output terminal to a TV.

´ Press the “EASY”(Mode Up)/”DISPLAY”(Mode Down) buttons so that OSD shows “0D6 XX XX”.

ˇ Press the “MENU Selector” (Confirm).

¨ Then Micom finds out Zoom VR center position.

Store Zoom VR center value in OB7.

4) Auto HALL

ΠConnect a video output terminal to a TV.

´ Press the “EASY-Q”(Mode Up)/”DISPLAY”(Mode Down) buttons so that OSD shows "0CD XX XX".

ˇ Press the “MENU Selector” (Confirm).

¨ Then micom finds out max. Hall value with an iris opened and min. Hall value with an iris closed.

Store max. and min. value of Hall in OAD and OAC respectively.

ˆ The OSD shows “OK” after finishing the adjustment.

(The word “OK” is displayed for only a fraction of a second.)

5) Auto IRIS Level

ΠConnect a video output terminal to a wave form monitor and a TV.

´ Press the “EASY-Q”(Mode Up)/”DISPLAY”(Mode Down) buttons so that OSD shows "0CE XX XX".

ˇ Press the “MENU Selector” (Confirm).

¨ Then micom finds out max. Hall value with an iris opened and min.

Hall value with an iris closed. Store max. and min. value of in 00BC, 00BD and 00BB respectively.

ˆ The OSD shows “OK” after finishing the adjustment.

(The word “OK” is displayed for only a fraction of a second.)

6) Auto White Balance (indoor)

Œ Camera mode & 3100˚ K gray scale chart.

´ Connect a video output terminal to a vectorscope and a TV.

ˇ Press the “EASY-Q”(Mode Up)/”DISPLAY”(Mode Down) buttons so that OSD shows "0D4 XX XX".

¨ Ensure that camera picks up image 40µs on 3100˚K gray scale chart precisely and the illumination is 1500~2000

Lux.

ˆ Press the “MENU Selector” (Confirm) to ensure that white spot on a vectorscope is moving in the middle of

screen.

Ø The OSD shows “OK” after finishing the adjustment.

(The word “OK” is displayed for only a fraction of a second.)

7) Auto White Balance (outdoor)

Œ Camera mode & 5100˚ K gray scale chart.

´ Connect a video output terminal to a vectorscope and a TV.

ˇ Press the “EASY-Q”(Mode Up)/”DISPLAY”(Mode Down) buttons so that OSD shows "0D5 XX XX".

¨ Ensure that camera picks up image 40 µs on 5100 gray scale chart (3100 gray scale chart + C16 filter) precisely

and the illumination is 1500~2000 Lux.

ˆ Press the “MENU Selector” (Confirm) to ensure that white spot on a vectorscope is moving in the middle of

screen.

Ø The OSD shows “OK” after finishing the adjustment.

(The word “OK” is displayed for only a fraction of a second.)

3-6

Samsung Electronics

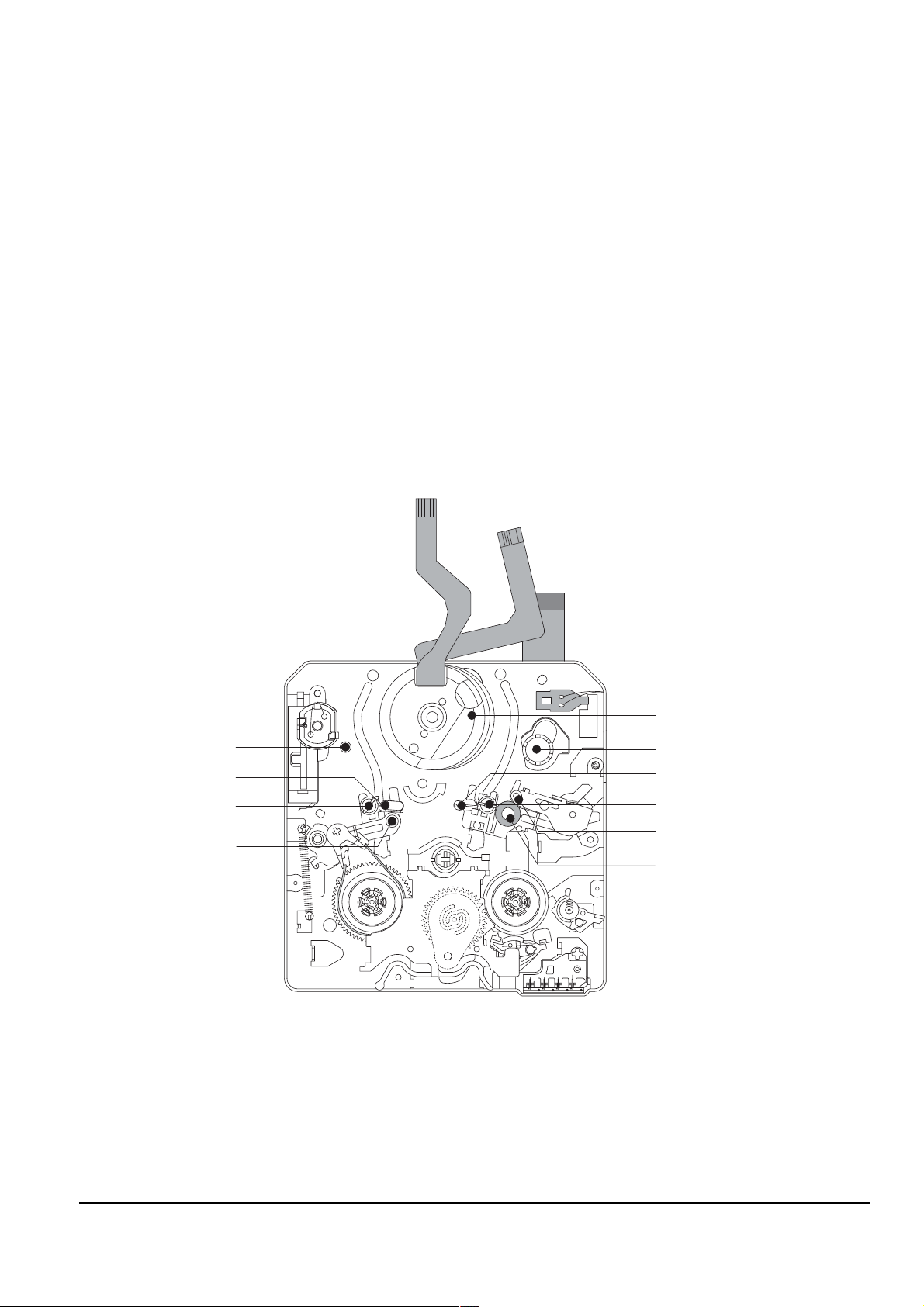

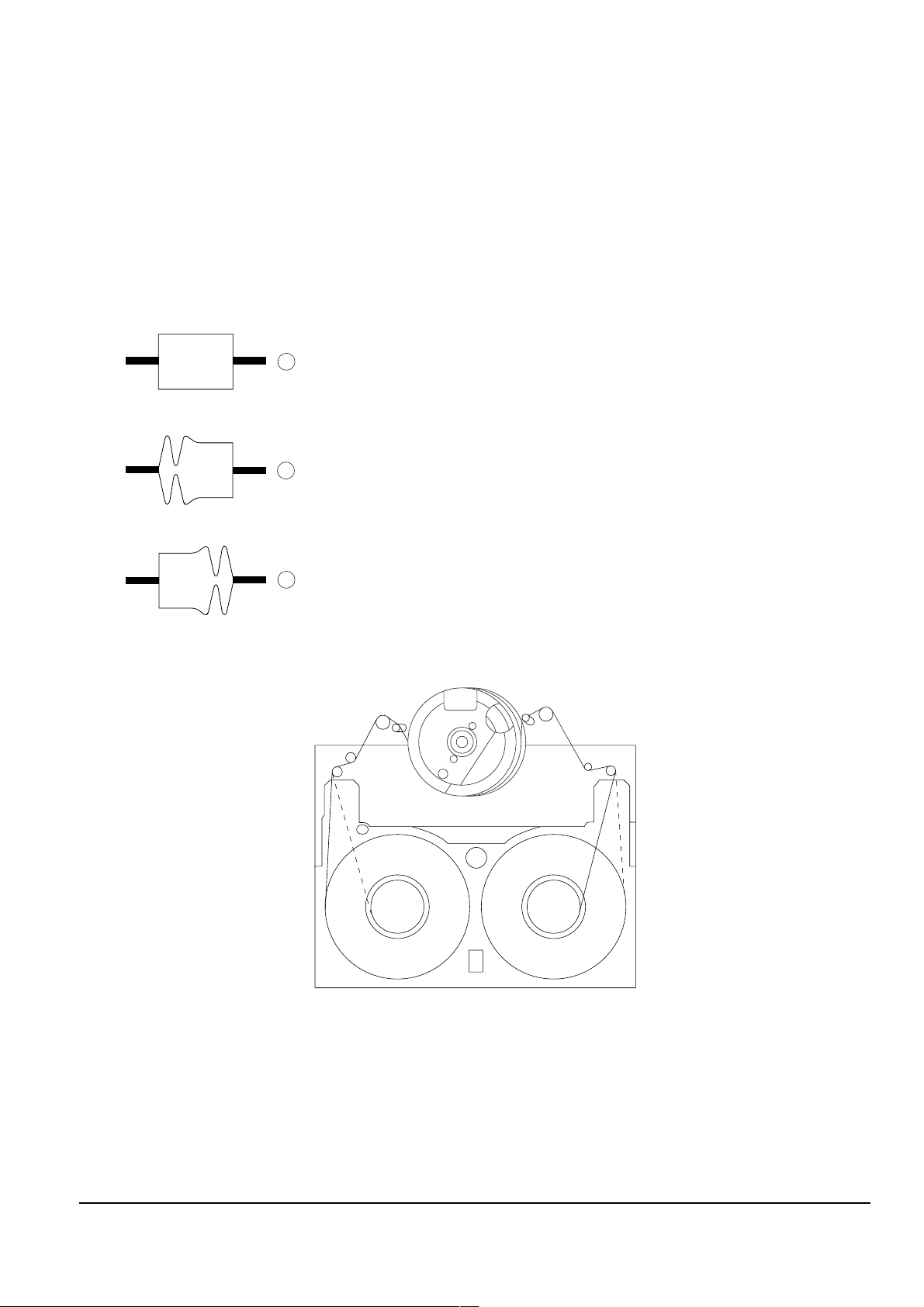

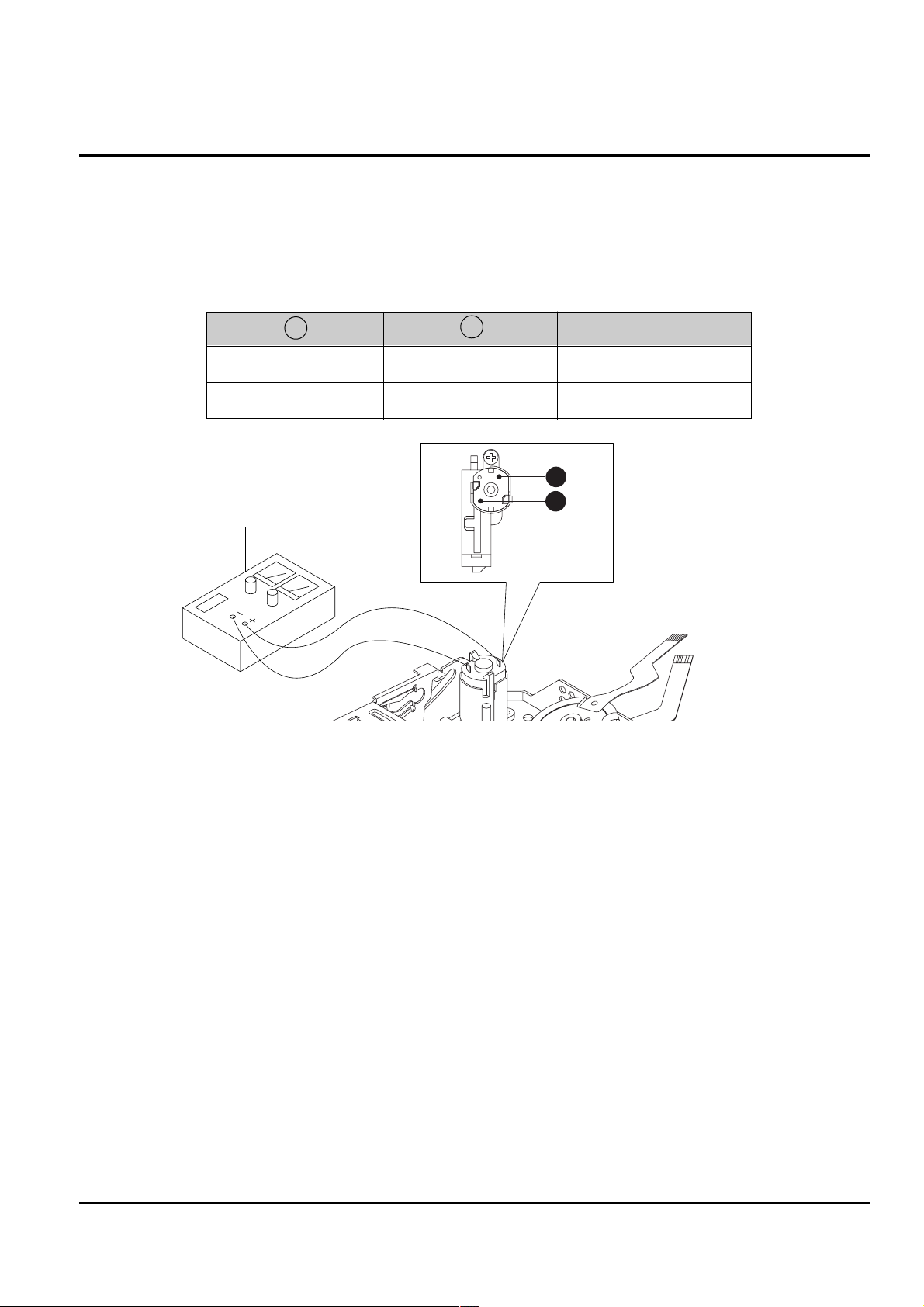

3-3 Deck Adjustment

Connceted the Recorder Circuit

SWITCH C-IN

DC POWER SUPPLY

A

B

Alignment and Adjustments

3-3-1 Operation Without Housing Assembly

1) Remove the Housing Ass’y from the Deck Ass’y.

2) Connect the Mechanical Chassis to the recorder

circuit to supply voltage.

3) Set to Unload mode.

4) Press the S/W Push (Keep ON status)to start loading, and push the PLAY Key.

(Cover the Top/End sensor with black tape,

because they do not operate.)

Note : For the removal of the Housing Ass’y refer to

4-2-2 (page 4-7).

Fig. 3-8

3-3-2 Setting Mechanical Mode (Without Recorder Circuit)

1) Set the power-supply output to approx. 3V~5V.

2) Choose the polarity (depending on whether loading or unloading).

3) Supply the voltage to the Motor Loading, and set

to the desired mode.

<Table 3-4>

A B Movement of Chassis

+ - Unloading

- + Loading

Samsung Electronics

Fig. 3-9

3-7

Alignment and Adjustments

P5

P2

P4

P3

P1

P8

P6

P7

P9

PINCH ROLLER

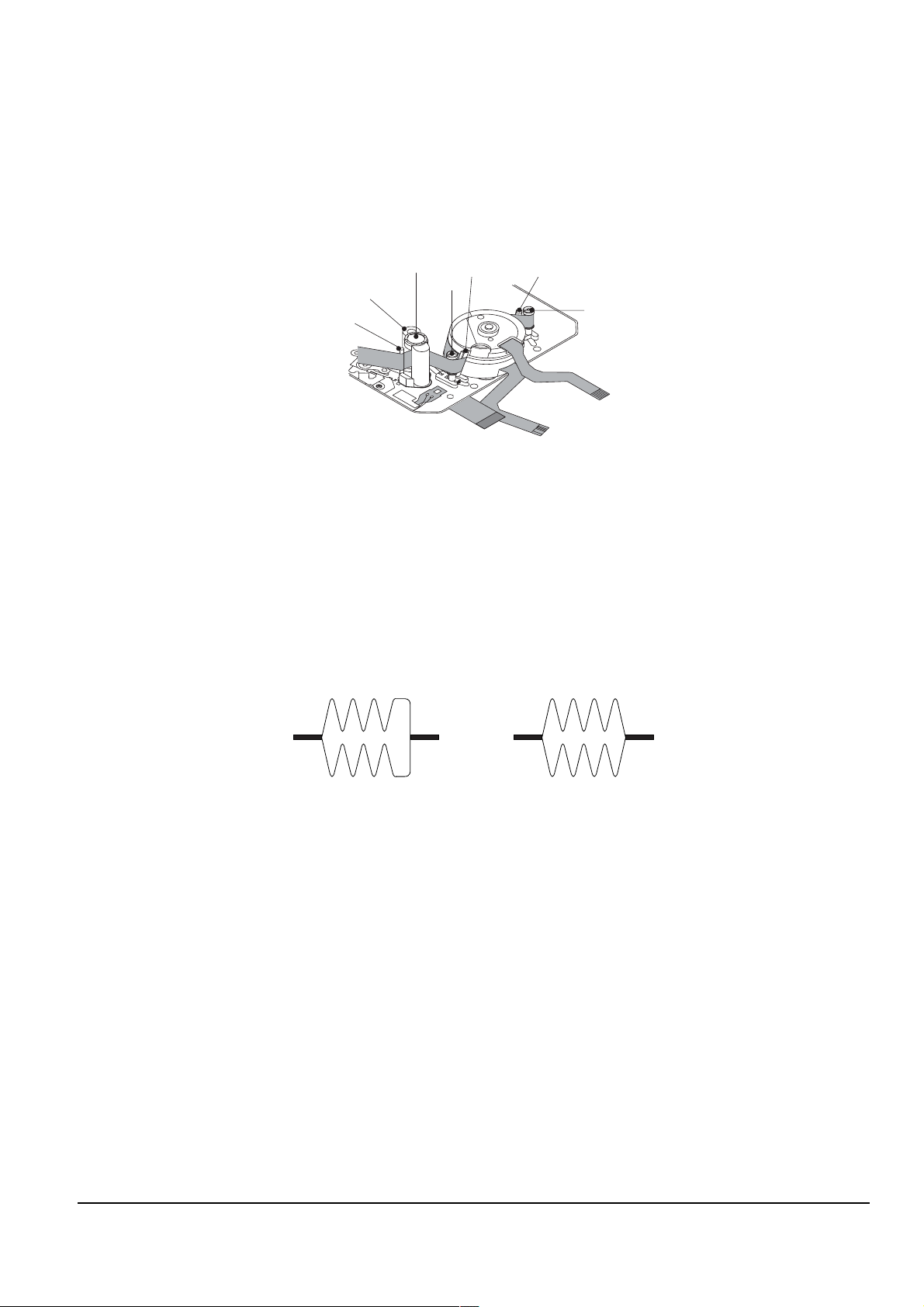

3-3-3 Maintenance

Carry out the following periodic maintenance checks in order to fully exercise all functions, operations and tape.

After repairing, service the set as follows:

1) Cleaning of Drum Assembly

ΠGently apply lens tissue soaked in ethyl alcohol to the Drum assembly.

Clean the Upper Drum assembly while rotating it slowly counterclockwise(by hand).

Note : Do not rotate the motor by power or rotate the Upper Drum assembly clockwise.

Also, the Head tip will be damaged if the lens tissue is moved in a perpendicular direction.

Be sure to follow these instructions when cleaning the Drum Ass’y

2) Cleaning of Tape Path

ΠIn EJECT mode, clean the tape path system(from Pole Tension P1 through Pole Review P9, Pinch Roller and

Capstan Shaft) and the Lower Drum. Using the lens tissue soaked in ethyl alcohol.

Note : Make sure that no oil or grease adheres to the lens tissue.

3-8

Fig. 3-10

Samsung Electronics

3) Periodic Maintenance and Check List

2mm

OIL

When overhauling, refer to the following table.

Alignment and Adjustments

<Table 3-5>

Maintenance checks

Hours of use (H)

500 1000 1500 2000 2500 3000 3500 4000 4500 5000

system

D

R

V

N

G

Perform-

Tape

path

I

I

ance

Cleaning of tape path O O O O O O O O O O

Cleaning and degaussing of drum ass’y

S

Y

S

T

E

M

Capstan Shaft 66666

Gear Capstan 66666

Gear Pully Shaft 66666

Belt Timing ŮŮŮŮŮ

Motor Loading ŮŮŮŮŮ

OOOOOOOOOO

Abnormal Noise ŮŮŮŮŮŮŮŮŮ

Back Tension ŮŮŮŮŮ

Confirmation

Brake System ŮŮŮŮŮ

PB, REV Torque Measurement

ŮŮŮŮŮ

O : Cleaning ¨ : Oil Ů : Confirmation

Ů When lubrication bearings, be sure to keep the oil

free of dust. (Oil contaminated with dust might

cause the bearings to wear out or seize.)

Ů A“drop”of oil is defined as the amount attached to

the tip of a Ø 2mm stick as shown in Fig. 3-11.

Remark

- Never let oil get on to the tape path

surface.

Samsung Electronics

Fig. 3-11

3-9

Alignment and Adjustments

1 0.5

ARM TENSION Œ

CAP ADJUST ´

"B"

"A"

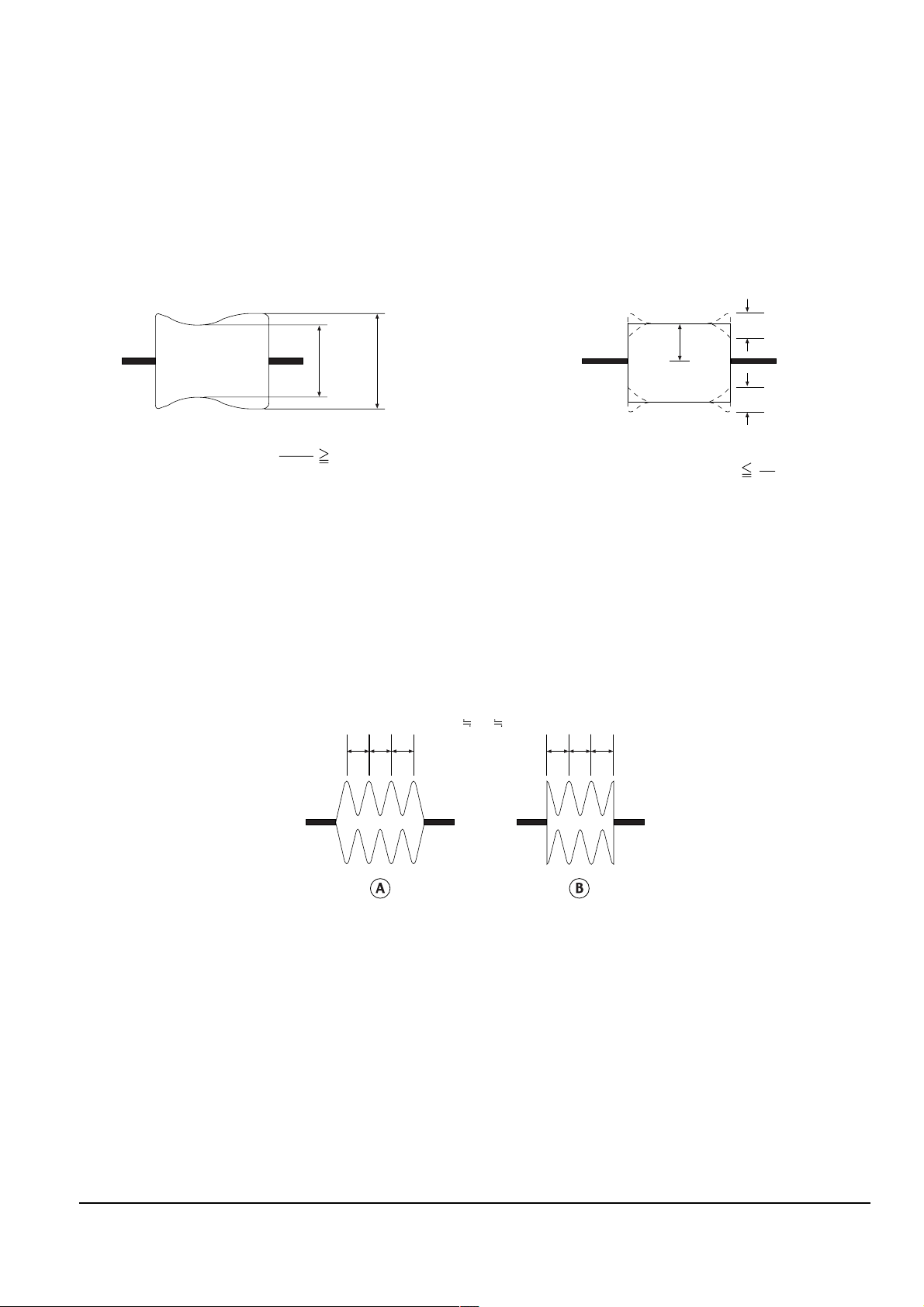

3-3-4 Mechanical Check and Adjustment

3-3-4(a) Tension Regulator Adjustment

1) Disassembly

Œ For the removal of the Housing Ass’y refer to 4-2-2 (page 4-7).

2) Adjustment

ΠSet to PLAY mode (without cassette tape).

´ Check that the distance between external surface of Holder Loading and extenal diamater of Arm Tension is

1±0.5mm. (Fig. 3-12)

ˇ If necessary, proceed to step 4.

¨ If the Arm Tension Œ is located inside (or right) the position specified, adjust the Cap Adjust Œ toward

arrow “A”. (If it is located outside (or left), adjust toward arrow “B”.)

Note : Check if the Arm Tension can be moved toward arrow “C” in PB mode.

3) Reassembly

Œ For the removal of the Housing Ass’y refer to 4-2-2 (page 4-7).

3-10

Fig. 3-12

Samsung Electronics

Alignment and Adjustments

REEL DISK S TABLE

RESTING SURFACE

REEL DISK T TABLE

RESTING SURFACE

CHASSIS MAIN

b

a

3-3-4(b) Back Tension Confirmation

1) Set up the cassette-torque tape.

2) Set to CAMERA mode, push the EDIT(+) KEY and check that the torque value of Reel S is 4±1g.cm.

3) If necessary, proceed to step 4.

4) If the Tension value is Low specified, moved to toward “a”.

If the Tension value is High specified, moved to toward “b”.

Reference : After changed, insert Cassette torque tape and confirm torque value.

Fig. 3-13

3-3-4(c) PB/REV Torque check

1) Set up the cassette torque tape.

2) Set to CAMERA mode, Push the EDIT(+) button and check that the torque value of Reel T is 9.5±3.5g.cm.

3) Push the EDIT(-) button and check that the torque value of Reel S is 15±4g.cm.

4) If necessary, replace the defective Reel Disk S, T Ass’y.

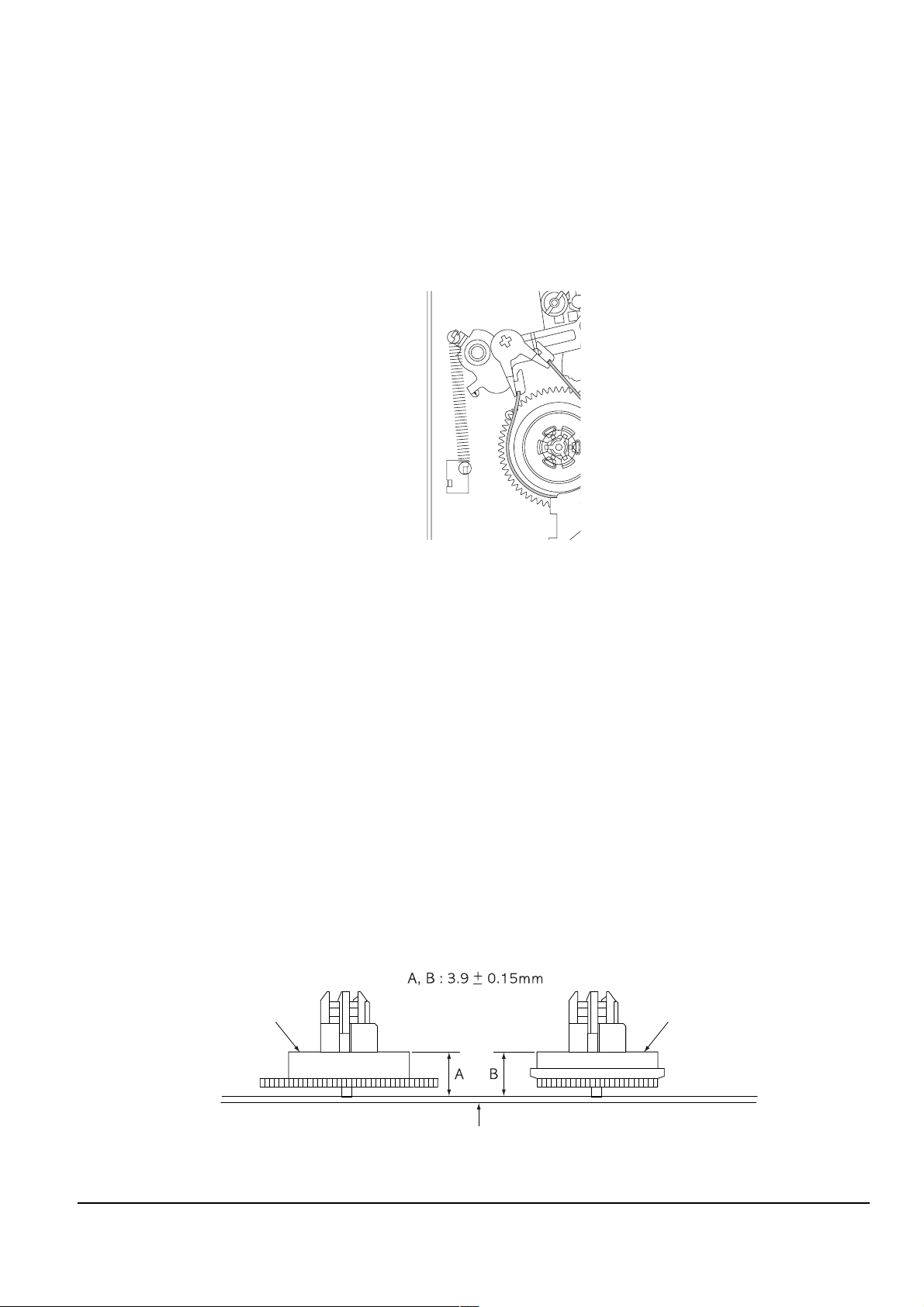

3-3-4(d) Reel Table Height Check

1) Removal

Œ For the removal of the Housing Ass’y refer to 4-2-2 (page 4-7).

´ For the removal of the Idler Ass’y refer to 4-2-3 (page 4-8).

2) Check

ΠUsing vernier calipers, check the following distances : From the upper surface of the Main Chassis to the

resting surfaces of Reel S, T table should each be 3.9±0.15mm.

3) Mounting

Œ For the removal of the Idler Ass’y refer to 4-2-3 (page 4-8).

´ For the removal of the Housing Ass’y refer to 4-2-2 (page 4-7).

Samsung Electronics

Fig. 3-14

3-11

Alignment and Adjustments

P1

P2

P3

P4

P5

P7

P6

P8

P9

A

B

C

INLET OUTLET

NORMAL

DEFECT AT INLET

DEFECT AT OUTLET

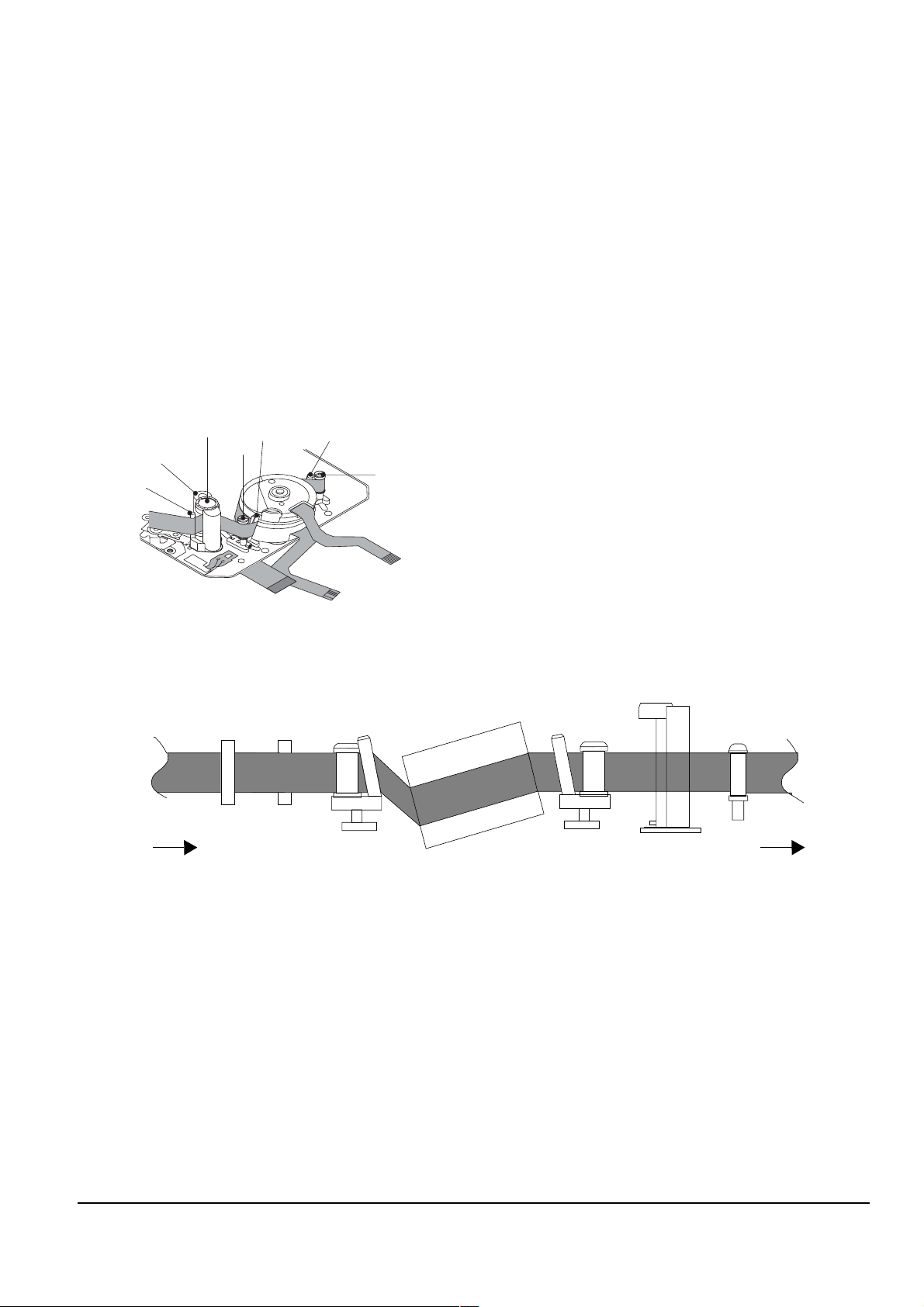

3-3-5 Tape Path Adjustment

3-3-5(a) Preparation for Adjustment

ΠClean the tape running surface (Poles, Drum, Capstan Shaft, Pinch Roller).

´ Observe the PB RF signal and Head Switching Pulse on an oscilloscope.

ˇ Play back the alignment tape.

¨ Check that the waveform of the RF signal is flat at both inlet and outlet(A in Fig. 3-15).

If not flat (B or C in Fig. 3-15), do adjustments 3-3-5(b) through 3-3-5(d).

Fig. 3-15

Fig. 3-16

3-12

Samsung Electronics

3-3-5(b) Tracking adjustment

P9

P8

P7

P6

P4

P3

MOTOR CAPSTAN

(DEFECTIVE) (CORRECT)

ΠPlay Back the alignment tape.

´ Turn P3 to flatten the waveform at the inlet.

ˇ Turn P7 to flatten the waveform at the outlet.

Alignment and Adjustments

Fig. 3-17

3-3-5(c) Take Up Path Adjustment

ΠPlay back the alignment tape, and confirm that the tape is not twisted between the Guide Roller T and

Capstan. (Fig. 3-17)

´ Set to REV mode and observe the outlet waveform of PB RF signal. (Fig. 3-18)

NOTE : If the outlet waveform is out-of-spec, replace the Arm Review or the Arm Pinch Ass’y,

and redo steps 1 and 2.

Fig. 3-18

Samsung Electronics

3-13

Alignment and Adjustments

Emin Emax

Emax

Emin

80(%)

A

A

C

C

C

1

8

abc a

abc

bc

3-3-5(d) Check After Adjustment

1) Tracking Check

ΠPlayback the alignment tape.

´ Confirm that the minimum amplitude value(E min.)is 80% of the maximum value(E max.) or larger.

(Fig. 3-19)

ˇ Confirm that no large fluctuation occur on the waveform. (Fig. 3-20)

Fig. 3-19

2) CUE and REV Check

ΠPlayback the alignment tape, and set to REV mode.

Confirm that the waveform peaks have a uniform Pitch. (Fig. 3-21 A)

If the track pitch is not uniform, do section 3-3-5(b) (Tracking adjustment).

´ Set to CUE mode.

Confirm that the waveform peaks still have a uniform pitch. (Fig. 3-21 B)

If the track pitch is not uniform, do section 3-3-5(b) (Tracking Adjustment).

Fig. 3-21

Fig. 3-20

3-14

Samsung Electronics

Alignment and Adjustments

P9

P8

P7

P6

P4

P3

MOTOR CAPSTAN

P1 P2 P3 P4 P6 P7 P9

FROM THE S REEL

TO THE T REEL

3) Rise Time Check

ΠPlayback the alignment tape.

´ Set to playback mode, and confirm that the waveform of PB RF signal rises flat within 3 seconds.

Also confirm that the tape is not twisted or curled around the Pinch Roller. (Fig. 3-23)

ˇ Run the tape in CUE/REV and FF/REW modes, then playback.

Confirm the waveform of PB RF signal rises flat within 3 seconds. Also confirm that the tape is not twisted or

curled around the Pinch Roller.

¨ Repeat steps 2. and 3.

4) Tape Path Check

ΠIn CUE and REV modes, check that the tape is not curled around the P3, P7 upper flange and P9

upper/Lower flanges.

Fig. 3-22

Fig. 3-23

Samsung Electronics

3-15

4. Disassembly and Reassembly

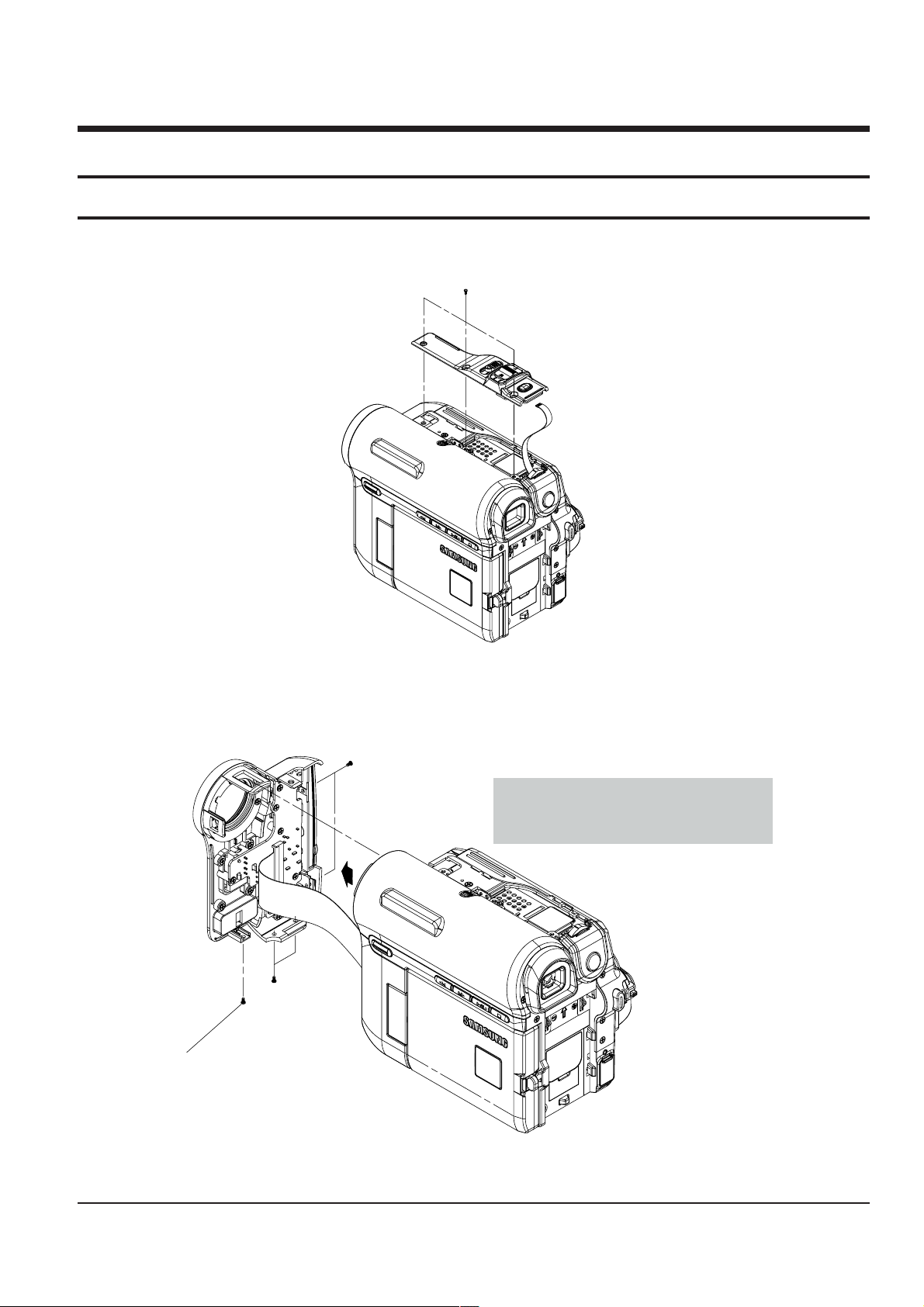

ΠREMOVE 3 SCREWS

(M 1.7 X 4 BLK)

ΠREMOVE 2 SCREWS

(M1.7 X 4 BLK)

´ REMOVE

2 SCREWS

(M1.7 X 4 BLK)

ˇ REMOVE 1 SCREW

(M1.7 X 5 WHT)

Caution : Please indicate that the connector

must be detached before separating

the Front Assembly

4-1 Cabinet and PCB

4-1-1 Ass’y Zoom Removal

4-1-2 Ass’y Front Removal

Fig. 4-1 Ass’y Zoom Removal

Samsung Electronics 4-1

Fig. 4-2 Ass’y Front Removal

Disassembly and Reassembly

ΠREMOVE 1 SCREW

(M1.7 X 4 BLK)

´ REMOVE 1 SCREW

(M1.7 X 5 WHT)

ΠREMOVE 3 SCREWS

(M1.7 X 4 BLK)

´ REMOVE 2 SCREWS

(M1.7 X 4 BLK)

ˇ REMOVE 1 SCREW

(M1.7 X 5 WHT)

Caution : Please indicate that the connectors

must be detached before separating

the Left Assembly

4-1-3 Ass’y Top Removal

4-1-4 Ass’y Left Removal

Fig. 4-3 Ass’y Top Removal

4-2

Fig. 4-4 Ass’y Left Removal

Samsung Electronics

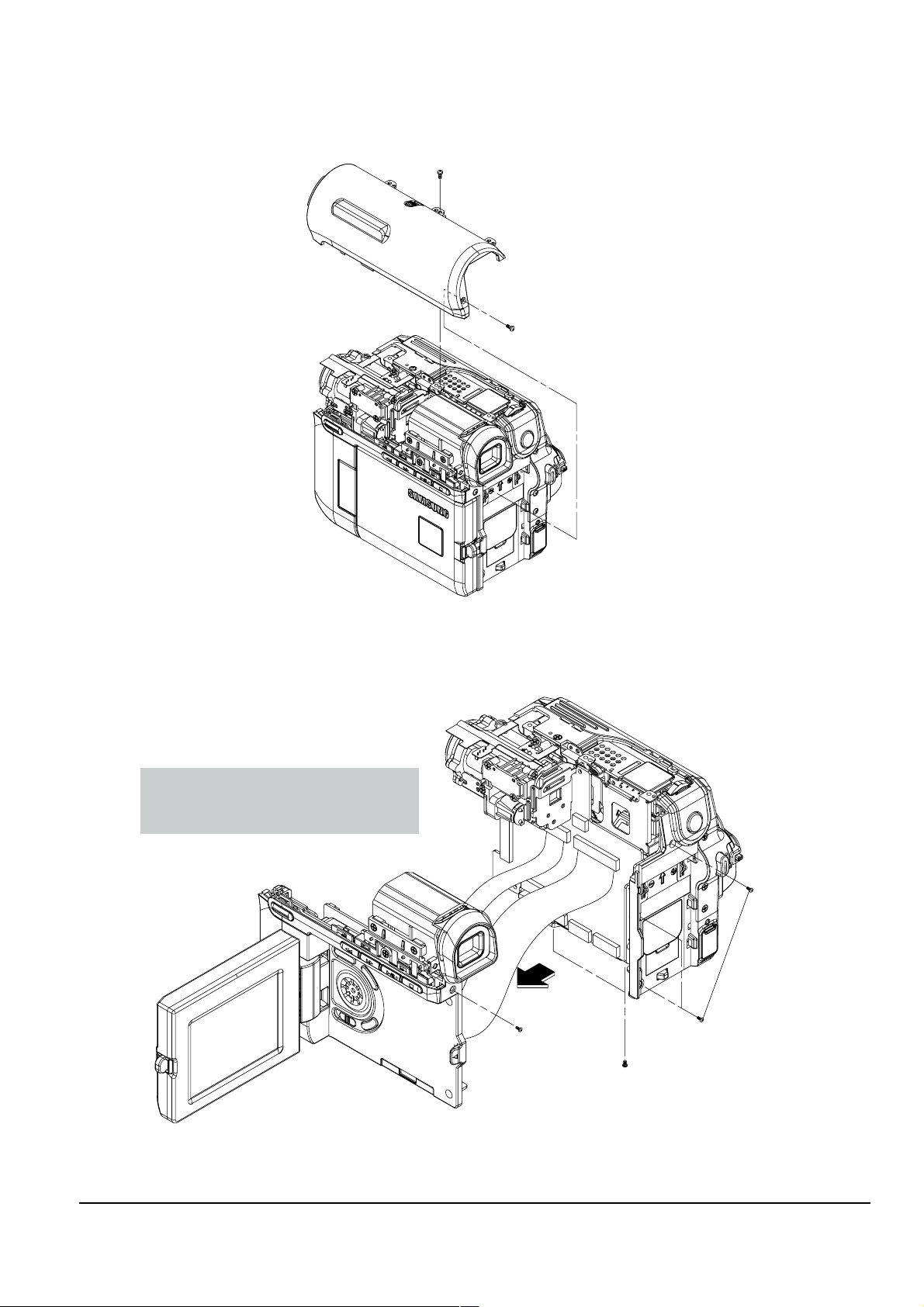

4-1-5 Ass’y LCD & EVF/CVF Removal

ΠREMOVE 3 SCREWS

(T1.7 X 4 BLK)

´ REMOVE 1 SCREW

(M1.7 X 5 WHT)

ˇ REMOVE 4 SCREWS

(T2 X 5 BLK)

¨ REMOVE 2 SCREWS

(M1.7 X 3 WHT)

Caution : Please indicate that there is a

connector on the View-Finder

that must be detached

Caution : Please indicate that this connector

must be detached before separating

the LCD Assembly

ΠREMOVE 4 SCREWS

(M1.7 X 4 BLK)

Caution : The Rear Assembly is connected to the

Main PCB. Pulling it to the left as

indicated in the illustraton can cause

the connector to break. This removal

instruction should indicate that the Rear

assembly should be pulled Forward first

in order to disconnect it from the Main PCB.

Then it can be pulled to the left

to separate it from the Main PCB

Disassembly and Reassembly

4-1-6 Ass’y Rear Removal

Fig. 4-5 Ass’y LCD & EVF/CVF Removal

Fig. 4-6 Ass’y Rear Removal

4-3Samsung Electronics

Disassembly and Reassembly

ΠREMOVE 2 SCREWS

(M1.4 X 3 BLK)

ΠREMOVE 2 SCREWS

(M1.7 X 4 BLK)

´ REMOVE 2 SCREWS

(T1.7 X 4 BLK)

4-1-7 Ass’y Cover Housing Removal

4-1-8 Ass’y Right Removal

Fig. 4-7 Ass’y Cover Housing Removal

4-4

Fig. 4-8 Ass’y Right Removal

Samsung Electronics

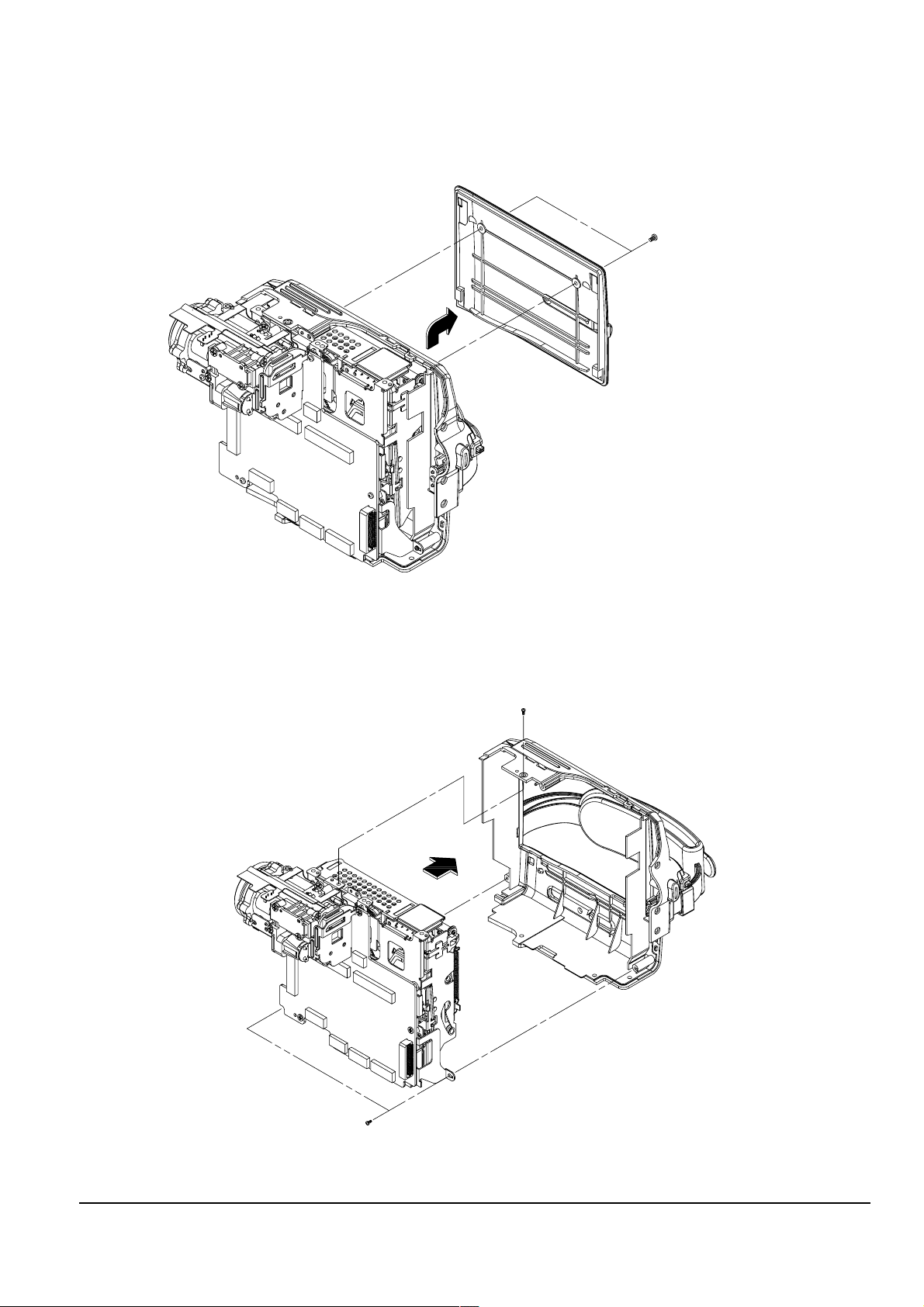

4-1-9 Ass’y Deck Removal

ΠREMOVE 3 SCREWS

(M1.7 X 2.5 BLK)

Caution : Please indicate that these connectors

must be detached before separating

the Deck Assembly from the MAIN PCB.

ΠREMOVE 3 SCREWS

(M1.7 X 2.5 BLK)

Caution : The Lens Assembly is connected to the Main PCB.

Pulling it to the left as indicated in the illustration

can cause the connector to break. This removal

instruction should indicate that the Lens assembly

should be pulled Forward first in order to disconnect

it from the Main PCB. Then it can be pulled to the

left to separate it from the Main PCB.

Disassembly and Reassembly

4-1-10 Ass’y Main PCB Removal

Fig. 4-9 Ass’y Deck Removal

Fig. 4-10 Ass’y Main PCB Removal

4-5Samsung Electronics

Disassembly and Reassembly

DC POWER SUPPLY

A

B

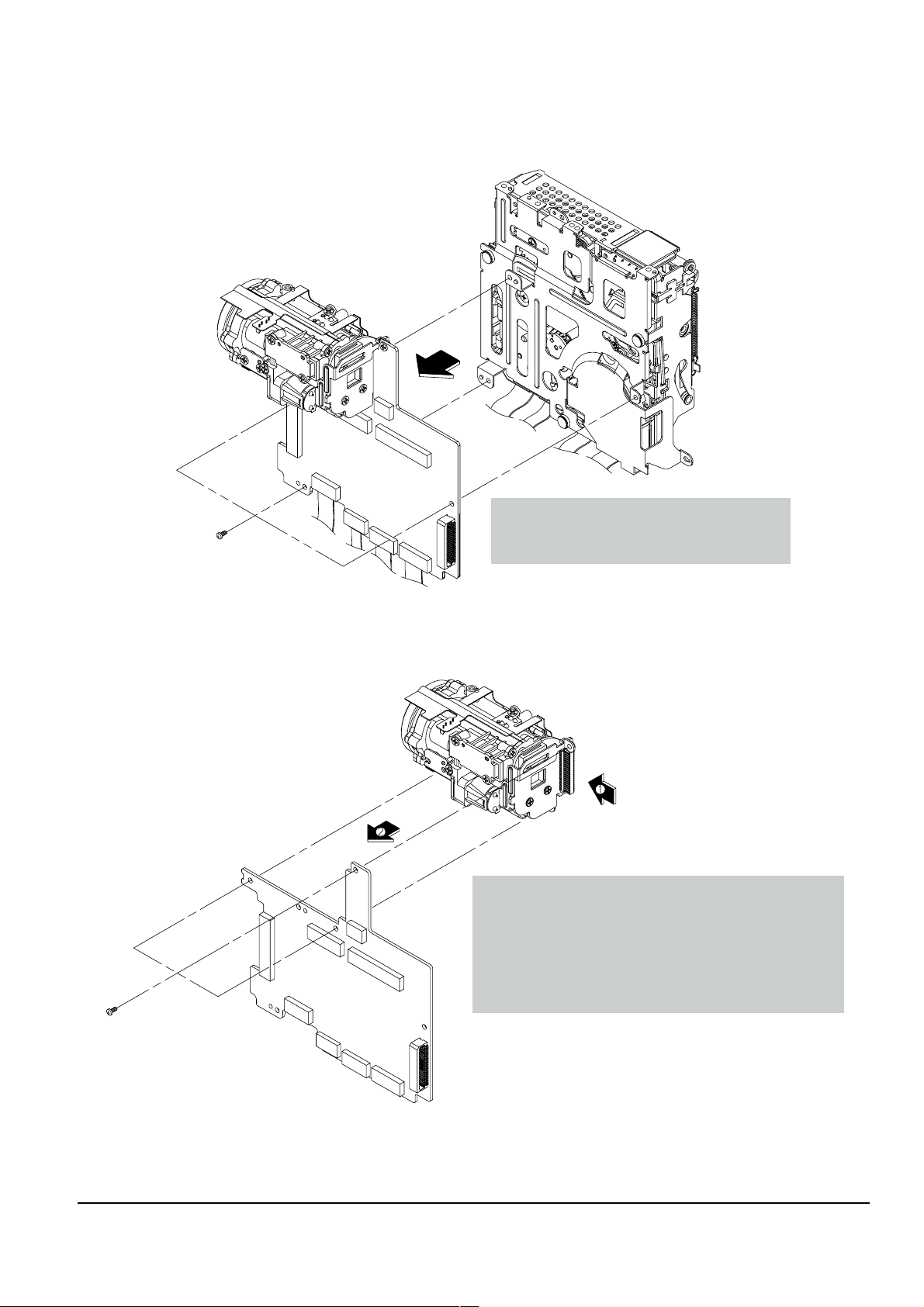

4-2 Deck

4-2-1 How to Load and Unload (Setting the Mechanical Modes)

1) Set the power-supply output to approximately 3V~5V, and connect it to the Motor Loading(= Loading Motor).

2) Choose the polarity depending on whether loading or unloading. (See Table 4-1)

3) Supply the voltage to the Motor Loading(= Loading Motor).

<Table 4-1>

AB

+

_

Fig. 4-11 Loading and Unloading

_

+ Loading

Movement of Chassis

Unloading

4-6

Samsung Electronics

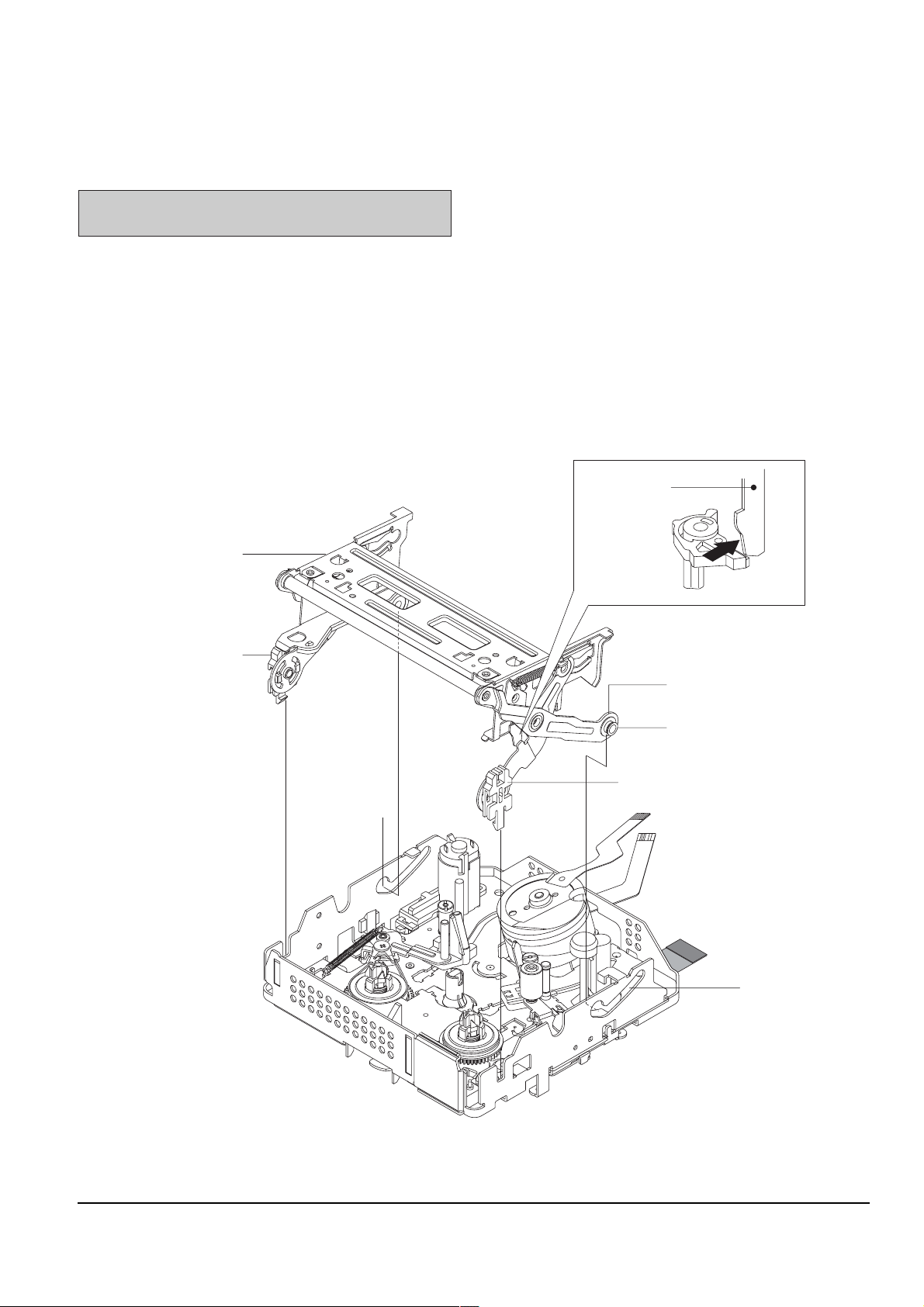

4-2-2 Housing Ass’y

3

HOUSING LOCK L ´

ˇ HOUSING LOCK R

ΠLEVER LOCK

¨ LEVER HOUSING

ˆ SHAPE OF PIN

Ø CAM PART

∏ CAM PART

HOUSING ASS'Y ”

<DETAIL A>

"A"

Disassembly and Reassembly

4-2-2(a) Disassembly

Note : Do disassembly and reassembly in the

unloading mode.

1) Push the Lever(see arrow “A”, Detail A) turn the

Lever Lock Œ and open the Housing Ass’y ”.

2) Separate the Hook of Housing Lock L ´ and

Housing Lock R ˇ and then lift it.

3) Separate the Shape of Pin L and R ˆ from Cam

Parts Ø, ∏ of Main Chassis and then lift the

Housing Ass’y ”.

4-2-2(b) Reassembly

1) Mount the Shape of Pin L and R ˆ to Cam Parts Ø,

∏ of Main Chassis.

2) Mount Housing Lock L ´, R ˇ to right and left ,

and then locked.

Fig. 4-12 Housing Ass’y

4-7Samsung Electronics

Disassembly and Reassembly

"A"

2

ΠCOVER REEL ASS'Y

´ IDLER ASS'Y

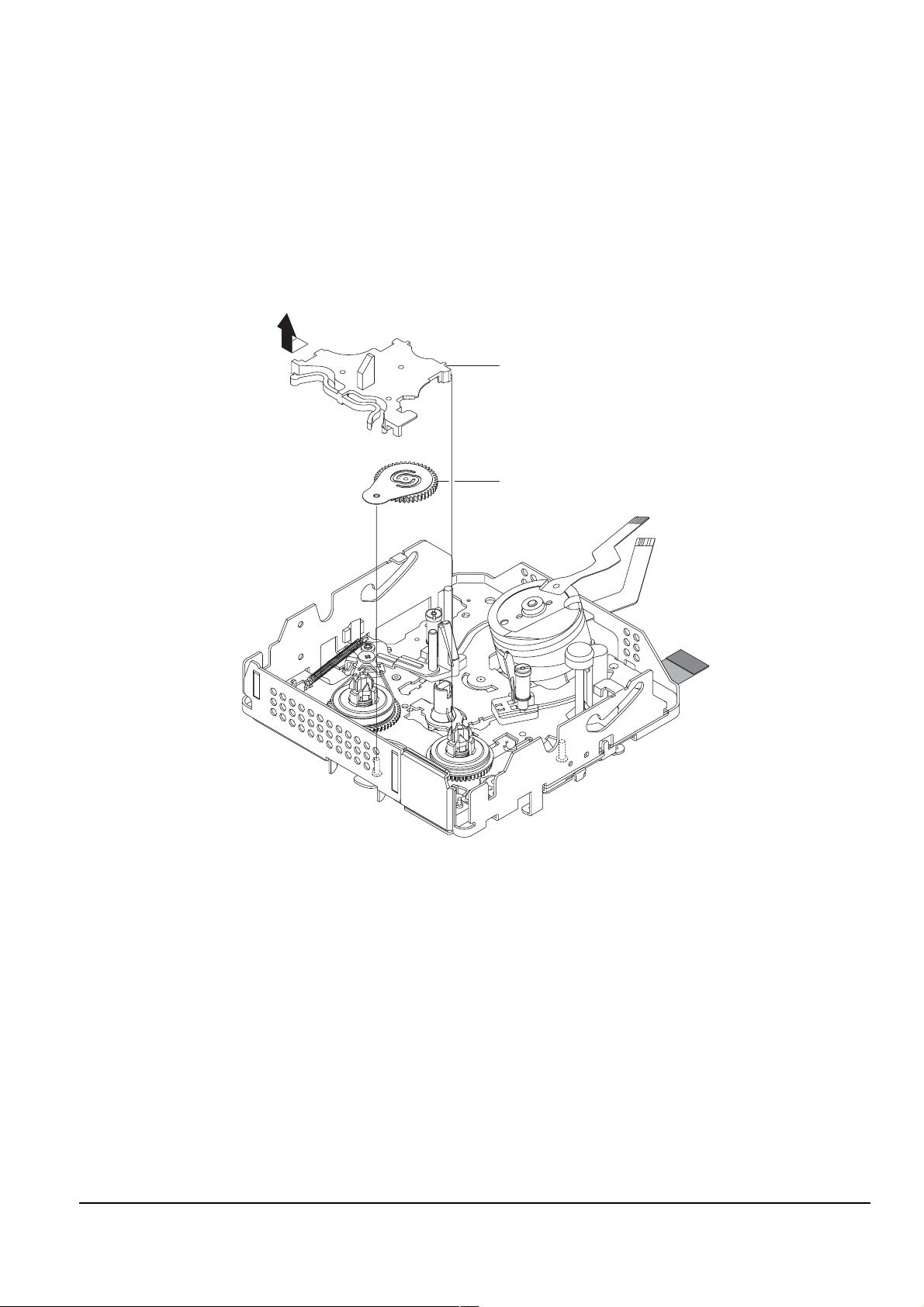

4-2-3 Cover Reel Ass’y, Idler Ass’y

4-2-3(a) Disassembly

1) Lift the Cover Reel Ass’y Œ (See arrow “A”).

2) Then lift the Idler Ass’y ´.

4-2-3(b) Reassembly

1) Fit the Idler Ass’y ´ into the Pin.

2) Mount the Cover Reel Ass’y Œ to the Main Chassis

is groove in the oposite direction of arrow “A”.

4-8

Fig. 4-13 Cover Reel Ass’y, Idler Ass’y

Samsung Electronics

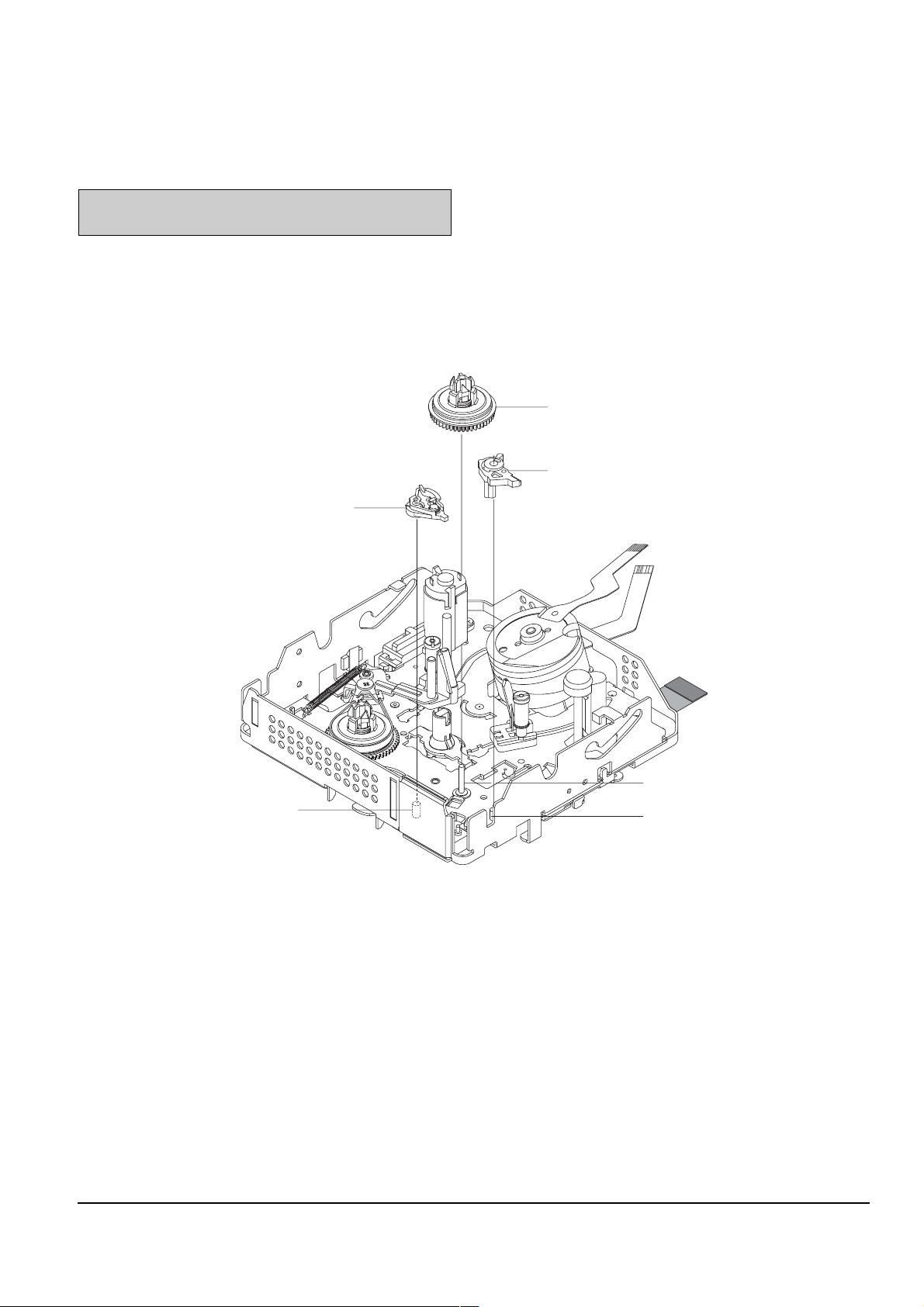

4-2-4 Reel Disk T, Brake T, Lever Eject

4

6

BRAKE T ´

ˇ LEVER EJECT

SHAPE OF PIN ˆ

Ø PIN

ΠREEL DISK T

¨ SHAPE OF PIN

Disassembly and Reassembly

4-2-4(a) Disassembly

Note 1 : When disassembling, take care not to deform

the part. Do not stain the post.

1) Lift up the Brake T ´.

2) Lift up the Reel Disk T Œ.

3) Separate the Lever Eject’s hook from the Main

Chassis, and then Lift up the Lever Eject ˇ.

4-2-4(b) Reassembly

1) Insert the Lever Eject ˇ into the shape of pin ¨,

and then lock the Lever Eject’s hook Eliminate

this step.

2) Mount the Reel Disk T Œ to the pin Ø.

3) Insert the Brake T ´ into the shape of pin ˆ.

Fig. 4-14 Reel Disk T, Brake T, Lever Eject

4-9Samsung Electronics

Disassembly and Reassembly

4

"A"

3

SPRING TENSION (=TENSION SPRING) Œ

ARM TENSION (=TENSION ARM) HOOK ∏

PIN Ø

MAIN CHASSIS HOOK ´

¨ ARM TENSION (=TENSION ARM) ASS'Y

ˆ REEL DISK S

ˇ WASHER SLIT

4-2-5 Arm Tension (=Tension Arm) Ass’y, Reel Disk S

4-2-5(a) Disassembly

Note 1 : When disassembling, take care not to deform

any part. Do not stain the post.

1) Separate the Spring Tension (=Tension Spring)Œ

form Hook of Main Chassis.

2) Remove the Washer Slit ˇ, and then lift up the Arm

Tension (=Tension Arm) ¨.

3) Lift up the Reel Disk S ˆ.

4-2-5(b) Reassembly

1) Mount the Reel Disk S ˆ.

2) Push the Arm Tension (=Tension Arm) Ass’y ¨

in the direction “A”, and then insert into the Pin Ø.

3) Insert the Washer Slit ˇ, and then attach the Spring

Tension (=Tension Spring) Πto Main Chassis Hook

´ and Arm Tension Hook ∏.

Note 1 : When reassembling or disassembling,

position of Spring Tension (=Tension

Spring) Πis same.

Note 2 : When inspecting the motion, Forward and

Reverse Tensions must be inspected.

Note 3 : When reassembling, confirm that the bending

of the Arm Tension (=Tension Arm) is

inserted into the Guide Cam.

Fig. 4-15 Arm Tension (=Tension Arm) Ass’y, Reel Disk S

4-10

Samsung Electronics

4-2-6 Drum

7

5

4

2

1

Ø HEAD TIP

DRUM ˇ

¨ 1 BENDING

∏ PUTTING PLACE OF DRUM

ˆ 1 HOLE

´ SPRING PLATE

Π3 SCREWS

Disassembly and Reassembly

4-2-6(a) Disassembly

Note 1 : Do not touch the Head tip Ø when removing

or reassembling the Drum ˇ.

Note 2 : Do not touch the path post when removing or

reassembling

1) Remove 3 Screws Œ, and then remove the Spring

Plate ´.

2) Lift up the Drum ˇ.

4-2-6(b) Reassembly

1) Mount and insert the Drum ˇ to the 1 Bending ¨

and 1 Hole ˆ.

2) Insert the Spring Plate ´, and then secure

3 Screws Œ.

Fig. 4-16 Drum

4-11Samsung Electronics

Disassembly and Reassembly

3

4

2

SOLDER POINTS

LOADING MOTOR ASS'Y ¨

ˇ 1 SCREW

ΠPINCH REVIEW ASS'Y

4-2-7 Loading Motor Ass’y, Pinch Review Ass’y

4-2-7(a) Disassembly

Note : When disassembling and reassembling, be

careful not to touch the Pinch Roller

and the review post.

1) In unload mode, rotate the Pinch Review Ass’y Œ

in a clockwise direction and left up the

Pinch Review Ass’y Œ.

2) De-solder the 2 points.

3) Remove the 1 screw ˇ and separate the 1 hook of

Loading Motor Ass’y ¨.

4) Lift up the Loading Motor Ass’y ¨.

4-2-7(b) Reassembly

1) Lock the one hook of Loading Motor Ass’y ¨ and

secure one screw ˇ.

2) Re-solder the 2 wires.

(+ into red wire , - into blue wire)

3) In disassembling position, insert the Pinch Review

Ass’y Œ and rotate the Pinch Review Ass’y Œ in

unload position.

4-12

Fig. 4-17 Loading Motor Ass’y, Pinch Review Ass’y

Samsung Electronics

4-2-8 Guide Roller S,T , Pole Base S,T , Gear Loading S,T Ass’y

6

2

3

GUIDE ROLLER S ˆ

ˇ POLE BASE T ASS'Y

POLE BASE S ASSY Œ

Ø GUIDE ROLLER T

GEAR LOADING S ASS'Y ´

∏ MAIN CHASSIS

¨ GEAR LOADING T ASS'Y

Disassembly and Reassembly

Note1 : When disassembling and reassembling, be

careful not to touch the Guide

Roller S ˆ and T Ø.

Note2 : When disassemblig and reassembling the

Guide Roller S ˆ and T Ø, be careful not to

deform the Gear Loading S ´ and T ¨ Ass’y.

4-2-8(a) Disassembly

1) Lift up the Pole Base S Œ(T ˇ) Ass’y form the link

of the Gear Loading S ´(T ¨) Ass’y.

2) Turn the S ˆ and T Ø Guide Rollers counter

clockwise to remove them.

3) Separate the hook of the Gear Loading S ´ and

lift down the Gear Loading S ´(T ¨) Ass’y.

4-2-8(b) Reassembly

1) Turn the S ˆ and T Ø Guide Rollers clockwise and

reassemble.

2) Replace the S ´ and T ¨ Gear Loading assemblies.

3) Fit the Pole Base S Œ(T ˇ) Ass’y in the link of the

Gear Loading S ´(T ¨) Ass’y.

Note 1 : When reassembling, confirm the assemble

point.

Note 2 : Disassembly and reassembly is done in the

Unload mode.

Note 3 : After assembling, make sure that loading and

unloading work correctly by applying 3V~5V

to the Loading Motor.

Fig. 4-18 Guide Roller S,T , Pole Base S,T , Gear Loading S,T Ass’y

4-13Samsung Electronics

Disassembly and Reassembly

Π1 SCREW

´ SLIDE MAIN

ˇ GEAR CAM MAIN

1 SCREW ¨

GEAR MODE SWITCH ˆ

GEAR CAM MAIN

ASSEMBLE POINT

(TWO ARROWS)

GEAR MODE SWITCH

4-2-9 Slide Main, Gear Cam Main, Gear Mode Switch

Note : Disassembly and reassembly must be done

with the Deck Assembly in the Unload mode.

4-2-9(a) Disassembly

1) Remove the 1 screw Œ and lift up the Slide Main ´.

2) Lift up the Gear Cam Main ˇ.

3) Remove the 1 screw ¨ and lift up the

Gear Mode Switch ˆ.

4-2-9(b) Reassembly

1) Mount the Gear Mode Switch ˆ and secure the

1 screw ¨.

2) After assemble and fit the Gear Cam Main ˇ,

Gear Mode Switch ˆ to assemble point.

3) Mount the Slide Main ´ and secure 1 screw Œ.

Note : When reassembling, confirm that pin of Slide

Main ´ is inserted into the cam of

Gear Cam Main ˇ.

Fig. 4-19 Slide Main, Gear Cam Main, Gear Mode Switch

4-14

Samsung Electronics

4-2-10 Cover Capstan, Capstan Motor Ass’y

2

3

4

1 SCREW Œ

´ COVER CAPSTAN

ˇ 2 SCREWS

¨ CAPSTAN MOTOR ASS'Y

Disassembly and Reassembly

Note : Be careful not to damage the gears during the

disassembly and reassembly process.

4-2-10(a) Disassembly

1) Remove the 1 Screw Œ.

2) Separe 2 hooks of Cover Capstan ´ and then lift up

the Cover Capstan ´.

3) Remove the 2 Screws ˇ, and then lift up the

Capstan Motor Ass’y ¨.

4-2-10(b) Reassembly

1) Mount the Capstan Motor Ass’y ¨ and secure the

2 Screws ˇ.

2) Lock the 2 hooks of Cover Capstan ´ and

1 Screw Œ.

Fig. 4-20 Cover Capstan, Capstan Motor Ass’y

4-15Samsung Electronics

Disassembly and Reassembly

2

3

4

LEVER REVIEW Œ

GEAR PULLEY ˆ

´ WASHER SLIT

ˇ GEAR CAPSTAN

¨ PULLEY BELT TIMING (=TIMING BELT)

4-2-11 Belt Timing (Timing Belt), Gear Capstan, Gear Pulley, Lever Review

4-2-11(a) Disassembly

1) Lift up the Lever Review Œ.

2) Remove the Washer Slit ´ and lift up the

Gear Capstan ˇ.

3) Separate the Pulley Belt Timing (=Timing Belt) ¨

and lift down the Gear Pulley ˆ.

4-2-11(b) Reassembly

1) Mount the Gear Pulley ˆ and hang the Belt

Timing (=Timing Belt) ¨ on the Gear Pulley ˆ.

2) Hang the Pulley Belt Timing ¨ on the lower gear

of the Gear Capstan ˇ, and then mount the Gear

Capstan ˇ.

3) Insert the Washer Slit ´.

4) Mount the Lever Review Œ.

Fig. 4-21 Belt Timing (=Timing Belt), Gear Capstan, Gear Pulley, Lever Review

4-16

Samsung Electronics

5. Exploded View and Parts List

Page

5-1 Ass’y Chassis - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-2

5-2 Ass’y Left (SCD353) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-4

5-3 Ass’y Left (SCD352/SCD351)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-6

5-4 Ass’y LCD- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-8

5-5 Ass’y Front (SCD353/SCD351)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-10

5-6 Ass’y Front (SCD352) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-12

5-7 Ass’y Rear - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-14

5-8 Ass’y EVF - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-15

5-9 Ass’y Zoom- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-16

5-10 Ass’y Case Right - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-17

5-11 Mechanical Parts (Main Chassis) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-18

5-12 Mechanical Parts (Sub Chassis) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-20

Notice

You can search for the updated part code through ITSELF web site.

URL; http://itself.sec.samsung.co.kr

Samsung Electronics 5-1

Exploded View and Parts List

W125

W126

C201

C607 P053

P002

W126

W125

P051

W225

P001

C050

M001

(M1.7 X L4 BLK)

(M1.7 X L4 BLK)

(M1.7 X L2.5 BLK)

(M1.7 X L2.5 BLK)

(M1.4 X L4.7 (2.5) YEL)

5-1 Ass’y Chassis

5-2 Samsung Electronics

Exploded View and Parts List

Loc. No Parts No. Description ; Specification Remark

C050 AD97-09608A ASSY-CHASSIS DECK;ASSY,DRAGON-PJ,C201 AD61-01994A BRACKET-LENS;DRAGON-PJ,SUS304 1/2H,T0.5,

C607 0605-001099 CCD;COLOR,DIP,14P,8.2x8.36x3.5mm,6

M001 AD97-09507A ASSY-DECK;ASSY,DD-10,P001 AD97-09528A ASSY-MAIN BOARD;DRAGON-PJ,SC-D353,MAIN B SCD353 Only

AD97-09528C ASSY-MAIN BOARD;DRAGON-PJ,SC-D352,MAIN B SCD352 Only

AD97-09528E ASSY-MAIN;DRAGON-PJ,SC-D351,MAIN BOARD(N SCD351 Only

P002 AD97-09533A ASSY-CCD BOARD;-,DELTA3,CCD BOARD,C

P051 AD97-08324A ASSY-LENS-ZOOM;PC,SHML,20X

P053 AD60-00053A SPACER-CCD;ALPHA_PJ,SILICON,-,-,-,BLK,0.

W125 6001-001385 SCREW-MACHINE;CH,+,M1.7,L2.5,ZPC(BLK),SW

W126 6003-001300 SCREW-TAPTITE;CH,+,B,M1.7,L4,ZPC(BLK),SW

W225 6009-001410 SCREW-SPECIAL;CH,+,-,M1.4,L4.7(2.5),ZPC(

5-3Samsung Electronics

Exploded View and Parts List

W112

P003

W112

P054

C007

C002

C208

W117

C003

C008

P004

C626

W112

C001

C623

C622

C323

C208

W112

W112

C621

C005

C640

C635

5-2 Ass’y Left (SCD353)

5-4 Samsung Electronics

Exploded View and Parts List

Loc. No Parts No. Description ; Specification Remark

C001 AD63-00709A COVER-LEFT;DRAGON-PJ,ABS,T14,W30,L58,-,C002 AD61-01977B CASE-LEFT;SC-D353,ABS 94HB,T25,W79,L99,S

C003 AD61-01694A HOLDER-TRIPOD;THETA3-PJ,PC,T1.0,W30,L14,

C005 AD63-00706B COVER-DOOR;DRAGON-PJ,PC,T1,W10,L29,-,-,?

C007 AD61-01988A HOLDER-SELECT;DRAGON-PJ,POM,T7,W8,L11,NA

C008 AD64-01322A KNOB-SELECT;DRAGON-PJ,ABS,T4,W5,L8,-,SIL

C208 AD61-12033A BRACKET-NUT;SV-D10,SECC,-,-,-,-,T0.8

C323 AD61-02069A HOLDER-DOOR MS;DRAGON-PJ,ABS,T7,W12,L32,

C621 AD61-01990A BRACKET-DOOR;DRAGON-PJ,SUS304 1/2H,T0.8,

C622 AD64-01314A BUTTON-FUNCTION A;DRAGON-PJ,ABS,W11xH10x

C623 AD64-01315A BUTTON-FUNCTION B;DRAGON-PJ,ABS,W45xH14x

C626 AD63-00716A COVER-DUMMY FUNCTION;DRAGON-PJ,ABS,T9,W1

C635 AD66-00350A SHAFT-DOOR;DRAGON-PJ,SUS,L35,0.8,-,-,C640 AD61-02005A SPRING ETC-DOOR;DRAGON-PJ,SUS,0.2,1,1.4,

P003 AD97-09524C ASSY-LEFT BOARD;DRAGON-PJ,M/S, EVF,LEFT

P004 AD97-09526A ASSY-FUNCTION BOARD;DRAGON-PJ,VP-D353,FU

P054 AD97-08377A ASSY-SPEAKER;DELTA2-PJ,SC-D103,SPEAKER

W112 6003-001453 SCREW-TAPTITE;BH,+,B,M1.7,L4,ZPC(BLK)

W117 6003-001490 SCREW-TAPTITE;PH,+,B,M1.7,L4,NI PLT,SWCH

5-5Samsung Electronics

Exploded View and Parts List

W112

P003

W112

P054

C002

C208

W117

C003

P004

C626

W112

C001

C623

C622

C208

W112

5-3 Ass’y Left (SCD352/SCD351)

5-6 Samsung Electronics

Exploded View and Parts List

Loc. No Parts No. Description ; Specification Remark

C001 AD63-00709A COVER-LEFT;DRAGON-PJ,ABS,T14,W30,L58,-,C002 AD61-01977E CASE-LEFT;SC-D352,ABS 94HB,T25,W79,L99,S SCD352 Only

AD61-01977C CASE-LEFT;SC-D351,ABS 94HB,T25,W79,L99,S SCD351 Only

C003 AD61-01694A HOLDER-TRIPOD;THETA3-PJ,PC,T1.0,W30,L14,

C208 AD61-12033A BRACKET-NUT;SV-D10,SECC,-,-,-,-,T0.8

C622 AD64-01314A BUTTON-FUNCTION A;DRAGON-PJ,ABS,W11xH10x

C623 AD64-01315A BUTTON-FUNCTION B;DRAGON-PJ,ABS,W45xH14x

C626 AD63-00716A COVER-DUMMY FUNCTION;DRAGON-PJ,ABS,T9,W1

P003 AD97-09524B ASSY-LEFT BOARD;DRAGON-PJ,NO Slot, EVF,L SCD352/351 Only

P004 AD97-09526A ASSY-FUNCTION BOARD;DRAGON-PJ,VP-D353,FU

P054 AD97-08377A ASSY-SPEAKER;DELTA2-PJ,SC-D103,SPEAKER

W112 6003-001453 SCREW-TAPTITE;BH,+,B,M1.7,L4,ZPC(BLK)

W117 6003-001490 SCREW-TAPTITE;PH,+,B,M1.7,L4,NI PLT,SWCH

5-7Samsung Electronics

Exploded View and Parts List

L010

L006

L009

L007

L008

W118

L011

W112

L004

C349

L053

L013

L001

W116

L015

L017

L016

L014

W117

W120

C208

W118

5-4 Ass’y LCD

5-8 Samsung Electronics

Exploded View and Parts List

Loc. No Parts No. Description ; Specification Remark

C208 AD61-12033A BRACKET-NUT;SV-D10,SECC,-,-,-,-,T0.8

C349 AD97-09664A ASSY-LED BL;-,DELTA3-PJ,LED BACK LIGHT

L001 AD97-09605C ASSY-LCD;ASSY,SC-D353,- SCD353 Only

AD97-09605B ASSY-LCD;ASSY,SC-D352,DRAGON-PJ SCD352 Only

AD97-09605A ASSY-LCD;ASSY,SC-D351,- SCD351 Only

L004 AD97-09599A ASSY-LCD BOARD;DRAGON-PJ,DIGITAL,LCD BOA

L006 AD61-01974C CASE-LCD TOP;SC-D353,ABS 94HB,T7,W50,L70 SCD353 Only

AD61-01974B CASE-LCD TOP;SC-D352,ABS 94HB,T7,W50,L70 SCD352 Only

AD61-01974A CASE-LCD TOP;DRAGON-PJ,ABS 94HB,T7,W50,L SCD351 Only

L007 AD64-01329A LOCKER-LCD;DRAGON-PJ,POM,NATU,-,-,T3.5,W

L008 AD63-00745A COVER-LOCK LCD;DRAGON-PJ,ABS,T2,W5,L8,-,

L009 AD61-01299A SPRING ETC-LOCK LCD;THETA-PJ,SWPB,-,-,-,

L010 AD64-01332B INLAY-MS;DRAGON-PJ,PC,T0.6,W15,L15,SIL, SCD353 Only

AD64-01332C INLAY-DV;DRAGON-PJ,PC,T0.6,W15,L15,SIL, SCD352/351 Only

L011 AD64-00808A BADGE-SAMSUNG;ALPHA_PJ,AL,T0.7,-,-,-,SIL

L013 AD61-01975A CASE-LCD BOTTOM;DRAGON-PJ,ABS 94HB,T4,W5

L014 AD63-00562A COVER-HINGE TOP 2.5;DELTA2-PJ,ABS 94V0,

L015 AD63-00563A COVER-HINGE BOTTOM 2.5;DELTA2-PJ,ABS 94

L016 AD97-08469A ASSY-HINGE;-,DELTA2-PJ,HINGE

L017 AD97-06489A ASSY-LCD FPC;.,DELTA-PJ,LCD FPC

L053 AD07-00049A LCD-PANNEL;A024CN02 V0,DELTA3-PJ,480*234

W112 6003-001453 SCREW-TAPTITE;BH,+,B,M1.7,L4,ZPC(BLK)

W116 6001-001527 SCREW-MACHINE;CH(0.3),+,M1.7,L2.0,NI PLT

W117 6003-001490 SCREW-TAPTITE;PH,+,B,M1.7,L4,NI PLT,SWCH

W118 6003-001291 SCREW-TAPTITE;CH,+,B,M1.4,L3.0,ZPC(BLK),

W118 6003-001291 SCREW-TAPTITE;CH,+,B,M1.4,L3.0,ZPC(BLK),

W120 6001-001716 SCREW-MACHINE;BH,+,M2,L4,NI PLT

5-9Samsung Electronics

Exploded View and Parts List

C210

C471

C625

C062

C031

P058

C013

W127

C037

C597

C627

W112

W127

W112

W112

C208

C034

W112

P006

5-5 Ass’y Front (SCD353/SCD351)

5-10 Samsung Electronics

Exploded View and Parts List

Loc. No Parts No. Description ; Specification Remark

C013 AD63-00713A COVER-JACK;DRAGON-PJ,ABS+URETHAN,T3,W8,L

C031 AD63-00568A SHEET-MIC;DELTA2-PJ,0Œ¡˜6˜,T0.2,W12.2,L2

C034 AD61-01976A CASE-FRONT;DRAGON-PJ,ABS 94HB,T13,W20,L8

C037 AD61-01984A HOLDER-HOOD;DRAGON-PJ,PC,T10,W34,L34,BLK

C062 AD63-00707A COVER-FRONT;DRAGON-PJ,ABS,T5,W23,L55,-,C208 AD61-12033A BRACKET-NUT;SV-D10,SECC,-,-,-,-,T0.8

C210 AD61-01993A BRACKET-GRIP FRONT;DRAGON-PJ,SUS304 1/2H

C471 AD63-00705A COVER-S JACK;DRAGON-PJ,URETHAN,T3,W14,L1

C597 AD63-00711A COVER-TOP;DRAGON-PJ,ABS,T34,W38,L102,-,C625 AD63-00714A COVER-DUMMY FRONT;DRAGON-PJ,ABS 94HB,T23 SCD353 Only

AD63-00714B COVER-DUMMY FRONT;DRAGON-PJ,ABS 94HB,T23 SCD351 Only

C627 AD63-00719A COVER-DUMMY TOP;DRAGON-PJ,PC,T11,W11,L8,

P006 AD97-09525F ASSY-JACK BOARD;DRAGON-PJ,USB,JACK BOARD SCD353 Only

AD97-09525B ASSY-JACK BOARD;DRAGON-PJ,ALL(X),JACK BO SCD351 Only

P058 AD97-08597A ASSY-UNIT MIC;-,THETA2-PJ,UNIT MIC

W112 6003-001453 SCREW-TAPTITE;BH,+,B,M1.7,L4,ZPC(BLK)

W127 6003-001292 SCREW-TAPTITE;CH(0.3),+,B,M1.7,L3,ZPC(BL

5-11Samsung Electronics

Exploded View and Parts List

C210

C471

C625

C062

C031

P058

C013

W127

C037

C597

C053

C054

C658

W127

C627

W112

W127

W112

W112

C208

C034

W112

P006

5-6 Ass’y Front (SCD352)

5-12 Samsung Electronics

Exploded View and Parts List

Loc. No Parts No. Description ; Specification Remark

C013 AD63-00713A COVER-JACK;DRAGON-PJ,ABS+URETHAN,T3,W8,L

C031 AD63-00568A SHEET-MIC;DELTA2-PJ,0Œ¡˜6˜,T0.2,W12.2,L2

C034 AD61-01976A CASE-FRONT;DRAGON-PJ,ABS 94HB,T13,W20,L8

C037 AD61-01984A HOLDER-HOOD;DRAGON-PJ,PC,T10,W34,L34,BLK

C053 AD64-01319A KNOB-NIGHT SHOT;DRAGON-PJ,ABS 94HB,T6,W1

C054 AD61-01985A HOLDER-NIGHT SHOT;DRAGON-PJ,ABS,T12,W15,

C062 AD63-00707A COVER-FRONT;DRAGON-PJ,ABS,T5,W23,L55,-,C208 AD61-12033A BRACKET-NUT;SV-D10,SECC,-,-,-,-,T0.8

C210 AD61-01993A BRACKET-GRIP FRONT;DRAGON-PJ,SUS304 1/2H

C471 AD63-00705A COVER-S JACK;DRAGON-PJ,URETHAN,T3,W14,L1

C597 AD63-00710A COVER-TOP;DRAGON-PJ,ABS,T34,W38,L102,-,C625 AD63-00714A COVER-DUMMY FRONT;DRAGON-PJ,ABS 94HB,T23

C627 AD63-00719A COVER-DUMMY TOP;DRAGON-PJ,PC,T11,W11,L8,

C658 AD61-01995A BRACKET-NIGHT SHOT;DRAGON-PJ,SUS304 1/2H

P006 AD97-09525E ASSY-JACK BOARD;DRAGON-PJ,USB, LED, NITE

P058 AD97-08597A ASSY-UNIT MIC;-,THETA2-PJ,UNIT MIC

W112 6003-001453 SCREW-TAPTITE;BH,+,B,M1.7,L4,ZPC(BLK)

W127 6003-001292 SCREW-TAPTITE;CH(0.3),+,B,M1.7,L3,ZPC(BL

W127 6003-001292 SCREW-TAPTITE;CH(0.3),+,B,M1.7,L3,ZPC(BL

5-13Samsung Electronics

Exploded View and Parts List

W112

P009

C354

C306

C045

C044

C208

C041

C015

C042

C334

C208

5-7 Ass’y Rear

Loc. No Parts No. Description ; Specification Remark

C015 AD63-00527D COVER-LI BATTERY;OMEGA2-PJ(2M),ABS94+URE

C042 AD63-00584B COVER-JIG;OMEGA2-PJ(2M),ABS 94HB,T2,W20,

C044 AD64-01156B KNOB-BATTERY EJECT;DRAGON-PJ,ABS 94HB,T5

C045 AD61-01980A HOLDER-BATT EJECT;DRAGON-PJ,ABS,T3.2,W9,

C208 AD61-12033A BRACKET-NUT;SV-D10,SECC,-,-,-,-,T0.8

C306 AD61-01625B SPRING ETC-BATTERY EJECT;THETA2-PJ,SUS30

C334 AD63-00704A COVER-DC JACK;DRAGON-PJ,URETHAN,T7,W8.2,

C354 AD97-09612A ASSY-REAR;ASSY,DRAGON-PJ,P009 AD97-09529A ASSY-REAR BOARD;DRAGON-PJ,SC-D353,REAR B

W112 6003-001453 SCREW-TAPTITE;BH,+,B,M1.7,L4,ZPC(BLK)

5-14 Samsung Electronics

5-8 Ass’y EVF

L055

C208

C208

C208

L054

C630

L060

L056

L062

W206

W206

L061

L063

C208

L065

Exploded View and Parts List

Loc. No Parts No. Description ; Specification Remark

C208 AD61-12033A BRACKET-NUT;SV-D10,SECC,-,-,-,-,T0.8

C630 AD61-01983A HOLDER-FRAMELESS;DRAGON-PJ,ABS,T8.7,W15.

L054 AD97-09687A ASSY-UNIT-EVF(NTSC);-,DRAGON-PJ,UNIT-EVF

L055 AD61-01972A CASE-EVF MAIN;DRAGON-PJ,PC/ABS,T32,W32,L

L056 AD61-01973A CASE-EVF SLIDE;DRAGON-PJ,ABS 94V0,T21.7,

L060 AD64-01165B KNOB-EVF;DRAGON-PJ,POM,T4.5,W3.6,L5,-,G

L061 AD61-01609A HOLDER-LENS EVF;DELTA2-PJ,ABS 94 HB,T7.8

L062 AD67-00250A LENS-EVF 18X-G1;SHML-PJ,PMMA,WHITE,15,6,

L063 AD73-00145A RUBBER-EYE CUP;DRAGON-PJ,URETHANE,W10.8x

L065 AD61-01982A HOLDER-EYE CUP;DRAGON-PJ,ABS,T7.1,W18.5,

W206 6001-001373 SCREW-MACHINE;PH,T0.5,+,M1.7,L3.0,BLK,SW

5-15Samsung Electronics

Exploded View and Parts List

W112

P008

L072

5-9 Ass’y Zoom

Loc. No Parts No. Description ; Specification Remark

L072 AD97-09683A ASSY-CASE ZOOM;ASSY,DRAGON-PJ,EXPORT

P008 AD97-09527A ASSY-TOP BOARD;DRAGON-PJ,SC-D353,TOP BOA

W112 6003-001453 SCREW-TAPTITE;BH,+,B,M1.7,L4,ZPC(BLK)

5-16 Samsung Electronics

5-10 Ass’y Case Right

W112

C212

W112

C059

C019

C303

C351

C309

C208

C010

C014

C020

C636

C018

Exploded View and Parts List

Loc. No Parts No. Description ; Specification Remark

C010 AD61-01978A CASE-RIGHT;DRAGON-PJ,ABS 94HB,T36,W85,L1

C014 AD59-00139A UNIT-BELT GRIP;DRAGON-PJ,-,LEATHER,-,-,C018 AD64-01321A KNOB-POWER;DRAGON-PJ,ABS,T7.4,W16,L18.1,

C019 AD61-01996A PLATE-POWER;DRAGON-PJ,SUS 305 1/2H,T0.5,

C020 AD64-01325A LOCKER-POWER;DRAGON-PJ,POM,GREEN,-,-,T3.

C059 AD61-01986A HOLDER-POWER;DRAGON-PJ,ABS,T7.3,W14.5,L1

C208 AD61-12033A BRACKET-NUT;SV-D10,SECC,-,-,-,-,T0.8

C212 AD61-01307A BRACKET-GRIP BACK;THETA-PJ,SUS,T0.8,-,-,

C303 AD61-01169A SPRING ETC-PLATE RECORD;DELTA-PJ,SUS ,-,

C309 AD64-01317A BUTTON-REC;DRAGON-PJ,ABS+PC,W6.2xL16.5xH

C351 AD97-09609A ASSY-COVER HOUSING;ASSY,DRAGON-PJ,C636 AD61-02006A SPRING ETC-POWER;DRAGON-PJ,SUS,0.16,1,1.

W112 6003-001453 SCREW-TAPTITE;BH,+,B,M1.7,L4,ZPC(BLK)

5-17Samsung Electronics

Exploded View and Parts List

W105

M011

C353

M036

M021

M203

M037

M048

M019

M209

M021

M047

C628

M035

M026

M032

C636

M022

M015

M034

M010

M033

5-11 Mechanical Parts (Main Chassis)

5-18 Samsung Electronics

Exploded View and Parts List

Loc. No Parts No. Description ; Specification Remark

C353 AD97-09363A ASSY-HOUSING;ASSY,DD-10,C628 AD63-00650A COVER-REEL;DD-10,DURACON M90-44,-,-,-,-,

C638 AD61-01925A STUD-GUIDE DRUM;DD-10,SWCH16A,-,OD1.4,L4

M010 AD97-09504A ASSY-MAIN CHASSIS;ASSY,DD-10,M011 AD97-09506A ASSY-LOADING MOTOR;ASSY,DD-10,M015 AD66-00322A LEVER-EJECT;DD-10,POM(DURACON MS-02),-,M019 AD97-09582A ASSY-DRUM;ASSY,DD-10,FP2 layer,TOE

M019 AD97-09689A ASSY-DRUM;ASSY,DD-10,Coil Motor,TOE

M021 AD61-01923A GUIDE-ROLLER;DD-10,HE73M,D3.2,-,-,-,M022 AD61-01864A PLATE-SPRING BASE;DD-10,SUS303,T0.15,-,M026 AD66-00316A GEAR-PULLEY;DD-10,DURACON (M90-44),-,-,M032 AD97-09367A ASSY-BRAKE T;ASSY,DD-10,M033 AD97-09364A ASSY-REEL DISK S;ASSY,DD-10,M034 AD97-09365A ASSY-REEL DISK T;ASSY,DD-10,M035 AD97-09366A ASSY-IDLER;ASSY,DD-10,M036 AD97-09362A ASSY-ARM TENSION;ASSY,DD-10,M037 AD61-01904A SPRING ETC-TENSION;-,SUS304 WPB,0.16,-,M047 AD97-09360A ASSY-POLE BASE T;ASSY,DD-10,M048 AD97-09359A ASSY-POLE BASE S;ASSY,DD-10,M203 6031-001430 WASHER-PLAIN;POLYSLIDER,-,ID0.8,D2.5,T0.

M209 AD97-09361A ASSY-PINCH REVIEW;ASSY,DD-10,W105 6001-001590 SCREW-MACHINE;PH,+,M1.4,L2.2,ZPC(BLK),SW

5-19Samsung Electronics

Exploded View and Parts List

W101

C624

W104

M017

M206

M207

M205

M024

M023

C634

M014

C639

M013

C637

M208

5-12 Mechanical Parts (Sub Chassis)

5-20 Samsung Electronics

Exploded View and Parts List

Loc. No Parts No. Description ; Specification Remark

C624 AD63-00672A COVER-CAPSTAN;DD-10,POM(DURACON M90-44),

C634 AD66-00318A LEVER-REVIEW;DD-10,SECC,T0.5,-,-,-,-,C637 AD61-01916A STUD-GEAR-MODE-SWITCH;DD-10,SWRCH18A,T2.

C639 AD61-01917A STUD-SLIDE MAIN;DD-10,SWRCH18A,T2.6,-,L5

M013 AD66-00312A GEAR-CAM MAIN;DD-10,POM(TR-20),-,-,-,-,M014 AD66-00327A SLIDER-MAIN;DD-10,SECC,T0.5,-,-,-,M017 AD97-09242A ASSY-CAPSTAN MOTOR;ASSY,DD-10,ƒ⁄.;1310

M023 AD66-00330A PULLEY-BELT TIMING;DD-10,POLYURETHAN Z,M024 AD66-00313A GEAR-CAPSTAN;DD-10,DYAMID(L1742K),-,-,-,

M205 6031-001432 WASHER-PLAIN;POLYSLIDE,M2.5,ID1.6,OD2.5,

M206 AD97-09357A ASSY-ARM LOADING S;ASSY,DD-10,M207 AD97-09358A ASSY-ARM LOADING T;ASSY,DD-10,M208 AD97-09374A ASSY-GEAR MODE SWITCH;ASSY,DD-10,W101 6001-001575 SCREW-MACHINE;PH,+,M1.4,L3.5,ZPC(WHT),SW

W104 6001-001715 SCREW-MACHINE;BH,+,M1.4,L2.2,ZPC(BLK)

5-21Samsung Electronics

6. Electrical Parts List

Loc.No Part No Description ; Specification Remark Loc.No Part No Description ; Specification Remark

P001 AD97-09528A ASSY-MAIN BOARD;DRAGON-PJ,SC-D353,MAIN B SCD353 Only

AD97-09528C ASSY-MAIN BOARD;DRAGON-PJ,SC-D352,MAIN B SCD352 Only

AD97-09528E ASSY-MAIN;DRAGON-PJ,SC-D351,MAIN BOARD(N SCD351 Only

B301 2901-001022 CORE-FERRITE BEAD;60ohm,1.6x0.8x0.8mm,20

B302 2901-001022 CORE-FERRITE BEAD;60ohm,1.6x0.8x0.8mm,20

B303 2901-001022 CORE-FERRITE BEAD;60ohm,1.6x0.8x0.8mm,20

BM01 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608

BM02 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608

BM03 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608

BM04 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608

BM05 2703-002174 INDUCTOR-SMD;10uH,10%,2520

BM06 2703-002174 INDUCTOR-SMD;10uH,10%,2520

BM07 2007-000029 R-CHIP;0ohm,5%,1/8W,TP,2012

BM08 2703-002174 INDUCTOR-SMD;10uH,10%,2520

BM09 2703-002174 INDUCTOR-SMD;10uH,10%,2520

BM10 2703-002174 INDUCTOR-SMD;10uH,10%,2520

BM73 2703-001883 INDUCTOR-SMD;22uH,10%,2520

C111 2203-005344 C-CER,CHIP;22nF,10%,25V,X7R,TP,1005,C112 2203-005344 C-CER,CHIP;22nF,10%,25V,X7R,TP,1005,C113 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C114 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C115 2404-001020 C-TA,CHIP;10uF,20%,10V,GP,TP,3216

C116 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C117 2404-001020 C-TA,CHIP;10uF,20%,10V,GP,TP,3216

C118 2203-002487 C-CER,CHIP;4.7nF,10%,25V,X7R,1005

C120 2203-000254 C-CER,CHIP;10nF,10%,16V,X7R,1005

C121 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C122 2203-000254 C-CER,CHIP;10nF,10%,16V,X7R,1005

C123 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C124 2404-001020 C-TA,CHIP;10uF,20%,10V,GP,TP,3216

C200 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C201 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C202 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C203 2203-001126 C-CER,CHIP;0.68nF,10%,50V,X7R,1608

C204 2404-001020 C-TA,CHIP;10uF,20%,10V,GP,TP,3216

C205 2404-001020 C-TA,CHIP;10uF,20%,10V,GP,TP,3216

C206 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C207 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C208 2404-001020 C-TA,CHIP;10uF,20%,10V,GP,TP,3216

C209 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C210 2404-001020 C-TA,CHIP;10uF,20%,10V,GP,TP,3216

C211 2203-005627 C-CER,CHIP;470NF,10%,10V,X5R,TP,1608

C212 2203-005923 C-CER,CHIP;1000NF,20%,6.3V,X5R,TP,1608

C213 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C214 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C215 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C216 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C217 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C218 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C219 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C220 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C221 2203-000254 C-CER,CHIP;10nF,10%,16V,X7R,1005

C222 2203-006006 C-CER,CHIP;0.005NF,°æ0.25PF,50V,C0G,TP,1

C223 2203-006006 C-CER,CHIP;0.005NF,°æ0.25PF,50V,C0G,TP,1

C224 2203-006006 C-CER,CHIP;0.005NF,°æ0.25PF,50V,C0G,TP,1

C225 2203-006006 C-CER,CHIP;0.005NF,°æ0.25PF,50V,C0G,TP,1

C226 2203-000585 C-CER,CHIP;0.22NF,10%,50V,X7R,TP,1005

C227 2404-000151 C-TA,CHIP;1uF,20%,16V,-,TP,3216

C228 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C229 2404-001020 C-TA,CHIP;10uF,20%,10V,GP,TP,3216

C230 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C231 2203-005065 C-CER,CHIP;1000nF,+80-20%,10V,Y5V,-,1608

C232 2203-000438 C-CER,CHIP;1nF,10%,50V,X7R,1005

C233 2203-005061 C-CER,CHIP;100nF,+80-20%,16V,Y5V,-,1005

C234 2203-000438 C-CER,CHIP;1nF,10%,50V,X7R,1005

C235 2203-005061 C-CER,CHIP;100nF,+80-20%,16V,Y5V,-,1005

C236 2404-000151 C-TA,CHIP;1uF,20%,16V,-,TP,3216

C237 2203-005061 C-CER,CHIP;100nF,+80-20%,16V,Y5V,-,1005

C238 2203-000438 C-CER,CHIP;1nF,10%,50V,X7R,1005

C239 2203-005061 C-CER,CHIP;100nF,+80-20%,16V,Y5V,-,1005

C240 2203-005061 C-CER,CHIP;100nF,+80-20%,16V,Y5V,-,1005

C241 2203-005061 C-CER,CHIP;100nF,+80-20%,16V,Y5V,-,1005

C242 2203-005061 C-CER,CHIP;100nF,+80-20%,16V,Y5V,-,1005

C243 2203-000438 C-CER,CHIP;1nF,10%,50V,X7R,1005

C244 2404-001020 C-TA,CHIP;10uF,20%,10V,GP,TP,3216

C245 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C246 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C247 2404-001020 C-TA,CHIP;10uF,20%,10V,GP,TP,3216

C300 2404-001251 C-TA,CHIP;22UF,20%,7V,-,TP,3216

C301 2404-001254 C-TA,CHIP;220uF,20%,2.5V,-,TP,3.5(L)X2.8

C302 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C303 2404-001020 C-TA,CHIP;10uF,20%,10V,GP,TP,3216

C304 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C305 2203-000254 C-CER,CHIP;10nF,10%,16V,X7R,1005

C306 2404-001251 C-TA,CHIP;22UF,20%,7V,-,TP,3216

C307 2203-000254 C-CER,CHIP;10nF,10%,16V,X7R,1005

C308 2203-000254 C-CER,CHIP;10nF,10%,16V,X7R,1005

C309 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C310 2404-000167 C-TA,CHIP;2.2uF,20%,16V,-,TP,3216

C311 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C312 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C316 2203-002487 C-CER,CHIP;4.7nF,10%,25V,X7R,1005

C317 2203-005993 C-CER,CHIP;68NF,10%,16V,X7R,TP,1005

C318 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C319 2203-002793 C-CER,CHIP;1000nF,+80-20%,25V,Y5V,2012

C320 2203-000254 C-CER,CHIP;10nF,10%,16V,X7R,1005

C321 2404-001020 C-TA,CHIP;10uF,20%,10V,GP,TP,3216

C322 2404-001254 C-TA,CHIP;220uF,20%,2.5V,-,TP,3.5(L)X2.8

C323 2404-001251 C-TA,CHIP;22UF,20%,7V,-,TP,3216

C324 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C325 2404-001020 C-TA,CHIP;10uF,20%,10V,GP,TP,3216

C326 2203-000330 C-CER,CHIP;0.012NF,5%,50V,C0G,TP,1005

C327 2203-000330 C-CER,CHIP;0.012NF,5%,50V,C0G,TP,1005

C328 2203-000330 C-CER,CHIP;0.012NF,5%,50V,C0G,TP,1005

C329 2203-000330 C-CER,CHIP;0.012NF,5%,50V,C0G,TP,1005

C330 2203-000330 C-CER,CHIP;0.012NF,5%,50V,C0G,TP,1005

C331 2203-000330 C-CER,CHIP;0.012NF,5%,50V,C0G,TP,1005

C333 2203-000330 C-CER,CHIP;0.012NF,5%,50V,C0G,TP,1005

C334 2203-000330 C-CER,CHIP;0.012NF,5%,50V,C0G,TP,1005

C335 2203-000330 C-CER,CHIP;0.012NF,5%,50V,C0G,TP,1005

C336 2203-000330 C-CER,CHIP;0.012NF,5%,50V,C0G,TP,1005

C337 2203-000330 C-CER,CHIP;0.012NF,5%,50V,C0G,TP,1005

C401 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C402 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C403 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C406 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C407 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C408 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C409 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C411 2404-001020 C-TA,CHIP;10uF,20%,10V,GP,TP,3216

C412 2404-001269 C-TA,CHIP;10uF,20%,20V,-,TP,3528

C413 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

Samsung Electronics

This Document can not be used without Samsung’s authorization

6-1

Electrical Parts List

C416 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C417 2203-005061 C-CER,CHIP;100nF,+80-20%,16V,Y5V,-,1005

C418 2203-002487 C-CER,CHIP;4.7nF,10%,25V,X7R,1005

C419 2203-005481 C-CER,CHIP;47nF,10%,10V,X7R,TP,1005,C420 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C421 2203-005923 C-CER,CHIP;1000NF,20%,6.3V,X5R,TP,1608

C422 2203-000234 C-CER,CHIP;0.1NF,5%,50V,C0G,TP,1005

C423 2203-000234 C-CER,CHIP;0.1NF,5%,50V,C0G,TP,1005

C424 2203-000234 C-CER,CHIP;0.1NF,5%,50V,C0G,TP,1005

C425 2203-006047 C-CER,CHIP;33NF,10%,16V,X7R,TP,1005

C426 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C427 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C428 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C429 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C430 2203-000489 C-CER,CHIP;2.2nF,10%,50V,X7R,1005

C431 2203-000489 C-CER,CHIP;2.2nF,10%,50V,X7R,1005

C432 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C505 2203-000254 C-CER,CHIP;10nF,10%,16V,X7R,1005

C506 2203-000714 C-CER,CHIP;3.3nF,10%,50V,X7R,TP,1005,C507 2203-006006 C-CER,CHIP;0.005NF,°æ0.25PF,50V,C0G,TP,1

C508 2203-000278 C-CER,CHIP;0.01nF,0.5pF,50V,C0G,1005

C509 2203-000254 C-CER,CHIP;10nF,10%,16V,X7R,1005

C510 2404-001020 C-TA,CHIP;10uF,20%,10V,GP,TP,3216

C512 2203-005061 C-CER,CHIP;100nF,+80-20%,16V,Y5V,-,1005

C513 2203-000254 C-CER,CHIP;10nF,10%,16V,X7R,1005

C514 2203-000254 C-CER,CHIP;10nF,10%,16V,X7R,1005

C515 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C516 2203-005061 C-CER,CHIP;100nF,+80-20%,16V,Y5V,-,1005

C517 2203-005061 C-CER,CHIP;100nF,+80-20%,16V,Y5V,-,1005

C518 2203-002717 C-CER,CHIP;10nF,+80-20%,50V,Y5V,TP,1005

C519 2203-002982 C-CER,CHIP;6.8nF,10%,50V,X7R,TP,1005

C520 2203-000254 C-CER,CHIP;10nF,10%,16V,X7R,1005

C521 2203-002982 C-CER,CHIP;6.8nF,10%,50V,X7R,TP,1005

C523 2404-001246 C-TA,CHIP;10uF,20%,6.3V,WT,TP,2012

C526 2203-000254 C-CER,CHIP;10nF,10%,16V,X7R,1005

C527 2203-000254 C-CER,CHIP;10nF,10%,16V,X7R,1005

C528 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C529 2404-001020 C-TA,CHIP;10uF,20%,10V,GP,TP,3216

C530 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C601 2404-001020 C-TA,CHIP;10uF,20%,10V,GP,TP,3216

C602 2404-001020 C-TA,CHIP;10uF,20%,10V,GP,TP,3216

C603 2404-001020 C-TA,CHIP;10uF,20%,10V,GP,TP,3216

C604 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C605 2404-001020 C-TA,CHIP;10uF,20%,10V,GP,TP,3216

C606 2404-001039 C-TA,CHIP;47uF,20%,6.3V,GP,TP,3528,C607 2404-001039 C-TA,CHIP;47uF,20%,6.3V,GP,TP,3528,C608 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C609 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C611 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C612 2404-001039 C-TA,CHIP;47uF,20%,6.3V,GP,TP,3528,C613 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C614 2404-001020 C-TA,CHIP;10uF,20%,10V,GP,TP,3216

C615 2404-000151 C-TA,CHIP;1uF,20%,16V,-,TP,3216

C616 2203-005686 C-CER,CHIP;2200nF,20%,10V,X5R,TP,2012

C617 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C618 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C621 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C622 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C623 2203-005686 C-CER,CHIP;2200nF,20%,10V,X5R,TP,2012

C624 2404-000151 C-TA,CHIP;1uF,20%,16V,-,TP,3216

C625 2404-001020 C-TA,CHIP;10uF,20%,10V,GP,TP,3216

C626 2404-000232 C-TA,CHIP;4.7uF,20%,10V,-,TP,3216

C627 2203-005887 C-CER,CHIP;680NF,+80-20%,10V,Y5V,TP,1608

C628 2404-001020 C-TA,CHIP;10uF,20%,10V,GP,TP,3216

C629 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C630 2203-005686 C-CER,CHIP;2200nF,20%,10V,X5R,TP,2012

Loc.No Part No Description ; Specification RemarkLoc.No Part No Description ; Specification Remark

C631 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C632 2404-001020 C-TA,CHIP;10uF,20%,10V,GP,TP,3216

C633 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C634 2404-001020 C-TA,CHIP;10uF,20%,10V,GP,TP,3216

C635 2203-002487 C-CER,CHIP;4.7nF,10%,25V,X7R,1005

C636 2203-002487 C-CER,CHIP;4.7nF,10%,25V,X7R,1005

C701 2404-001269 C-TA,CHIP;10uF,20%,20V,-,TP,3528

C703 2404-000212 C-TA,CHIP;3.3uF,20%,25V,-,TP,3528

C704 2203-005686 C-CER,CHIP;2200nF,20%,10V,X5R,TP,2012

C705 2203-005344 C-CER,CHIP;22nF,10%,25V,X7R,TP,1005,C706 2203-005344 C-CER,CHIP;22nF,10%,25V,X7R,TP,1005,C707 2203-005344 C-CER,CHIP;22nF,10%,25V,X7R,TP,1005,C708 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,TP,1608

C709 2203-000438 C-CER,CHIP;1nF,10%,50V,X7R,1005

C710 2203-006048 C-CER,CHIP;100NF,10%,10V,X7R,TP,1005

C711 2203-000585 C-CER,CHIP;0.22NF,10%,50V,X7R,TP,1005

C712 2203-000438 C-CER,CHIP;1nF,10%,50V,X7R,1005

C713 2203-000438 C-CER,CHIP;1nF,10%,50V,X7R,1005

C714 2203-005344 C-CER,CHIP;22nF,10%,25V,X7R,TP,1005,C715 2203-005344 C-CER,CHIP;22nF,10%,25V,X7R,TP,1005,C716 2203-005344 C-CER,CHIP;22nF,10%,25V,X7R,TP,1005,C717 2203-005344 C-CER,CHIP;22nF,10%,25V,X7R,TP,1005,C718 2203-005344 C-CER,CHIP;22nF,10%,25V,X7R,TP,1005,C719 2203-006320 C-CER,CHIP;2200nF,10%,16V,X7R,TP,2012

C720 2203-005686 C-CER,CHIP;2200nF,20%,10V,X5R,TP,2012

C721 2404-000284 C-TA,CHIP;10uF,20%,16V,-,TP,3528

C723 2203-006320 C-CER,CHIP;2200nF,10%,16V,X7R,TP,2012

C724 2203-005686 C-CER,CHIP;2200nF,20%,10V,X5R,TP,2012

C725 2404-000284 C-TA,CHIP;10uF,20%,16V,-,TP,3528

C727 2203-006320 C-CER,CHIP;2200nF,10%,16V,X7R,TP,2012

C728 2203-002793 C-CER,CHIP;1000nF,+80-20%,25V,Y5V,2012

C729 2203-002793 C-CER,CHIP;1000nF,+80-20%,25V,Y5V,2012

C730 2203-002793 C-CER,CHIP;1000nF,+80-20%,25V,Y5V,2012