Samsung SBB-SNOWJ3U, SBB-SNOWJMU, LH025IFH-DS, LH040IFH-DS, LH060IFH-DS Installation Manual

...

LED Display

Installation Manual

Ver. 2.9

LH025IFH*DS (P2.5)

LH040IFH*DS (P4.0)

Samsung Electronics

LH060IFH*DS (P6.0)

LH085IFHLDS (P8.5)

SBB-SNOWJ3U

SBB-SNOWJMU

Revision History

Version Date (Y/M/D) Description

2.0 2020/03/20 New Release

2.1 2020/06/19 Add SNOW1810U installation and Picture Setting

2.2 2020/08/07 Add Test Pattern function

2.3 2020/11/02 Modify dehumidification guide

2.4 2020/11/16 Add Network IP Setting by USB

2.5 2020/11/27 Update LSM guide

2.6 2020/12/01 Update Dehumidification Guide

2.7 2020/12/01 Update Picture Option

2.8 2020/12/14 Update Ventilation Guide

Samsung Electronics

2.9 2020/12/29 AC placement guide to prevent condensation

1

Table of Contents

1. Product Information and Precautions for Installation

2. Check Point about the Radiant Heat

3. Preparation for Product Installation

4. Frame Installation

5. LED Display Installation

6. S-BOX Connection

Samsung Electronics

7. Settings and How to Use

8. Issue and Solution

9. Cable Connection

10. Seam Adjustment

2

This contents must be noticed to customer.

Please print this page and hand it to user.

Dehumidification guidance – during installation

Samsung Electronics

When moist gets into LED package because of high humidity, ‘Line defect’ can

be caused by electrical short inside of LED Package.

For keeping the best quality of products during installation, please refer to the

below cautions.

- If the condition meets one of the below cases at least, dehumidification MUST be

processed. Do not play any contents on the screen before dehumidification finishes.

∙ Case when vacuum packaging is already unsealed before unpacking products.

∙ Case when environment condition is worse than Samsung working condition (0°C~40°C/10~80%RH).

∙ Case when it elapses longer than 7 days after unpacking them, even though the environment condition

satisfies Samsung working condition (0°C~40°C/10~80%RH).

∙ Case when production date on the label elapses more than 6 months, even though vacuum packaging is

sealed.

∙ Case when volatile chemicals such as oil paint, solvent are used in same place of installation.

(You can refer to Product Information and Precautions for Installation part in detail.)

- If the screen needs dehumidification on installation, MUST follow the directions of next page.

This contents must be noticed to customer.

Please print this page and hand it to user.

Dehumidification guidance – during installation

Samsung Electronics

How to install the screen in the case that dehumidification is necessary

※ Before finishing the directions explained in next pages, never play other contents or use them.

※ If the installation site has higher humidity, it is highly recommended to use dehumidifier.

(If A/C turned off after working hour, it may make humidity higher and cause line defects.)

※ Chilled air from A/C should never touch LED surface directly.

※ If thermo-hygrometer is equipped on the site while the screen is installed, it is useful to analyze

the cause of line defects.

1. Play a specific pattern of LSM program without any cabinets.

(This pattern should be used. If other pattern is used, it can cause line defects.)

① Select S-Box and Test Pattern

② Set darker gray pattern among various patterns.

2. Inspect cabinets with darker solid patterns(W/R/G/B) and turn off cabinets.

(It should take less than 30 seconds to show each solid patter and you can refer to

Screen check’ category in detail.)

‘Process of

This contents must be noticed to customer.

Please print this page and hand it to user.

Dehumidification guidance – during installation

How to install the screen in the case that dehumidification is necessary.

3. While installing cabinets, S-Box should play only this pattern.

• Check S-Box shows the pattern through monitor connected to S-Box service port.

• After installing each cabinet, check whether the pattern is shown in it.

• OCM cable connection can be checked through this.

• Before turning off S-Box, turn off the cabinets, first.

• After being sure S-Box plays this pattern, turn on the cabinets.

Samsung Electronics

4. After completing installation of cabinets, start 24hr dehumidification process.

5. After finishing 24hr dehumidification process, do edge correction and module calibration.

This information should be noticed to customer.

Please print this page and hand it to user.

Dehumidification guidance – during operation

Samsung Electronics

• Electrical short in package is possible to happen during products are working.

• For keeping quality of products during installation, please refer below cautions.

– If one of below case meet during operation, MUST do dehumidification process.

Case when environment condition is exceed operation condition.

Case when products are not working more than 1 month, even though environment condition is under

operation condition.

– When environment condition is exceed operation condition, products are out of warranty.

Please check environment condition.

– Even products are operating, if the installed place have extra construction such as interior

modification, MUST do dehumidification following installation condition.

– It is possible to happen dew condensation on surface of products, even though working on

operating condition. When happening dew condensation, MUST operate after cleaning the dew

condensation & dehumidification.

This information should be noticed to customer.

Please print this page and hand it to user.

Dew condensation due to overcooling

Samsung Electronics

Even though meet with Samsung recommended operation

condition, dew condensation is possible to happen when

surface of products is colder than environment temperature or

hot & humid air blow to cooled surface of products.

(cf : Principle of happening dew on surface of glass which have ice)

Case when dew condensation is happen on products, it is

possible to be the root of defect. In this case, it is possible to

be out of warranty.

This information should be noticed to customer.

Please print this page and hand it to user.

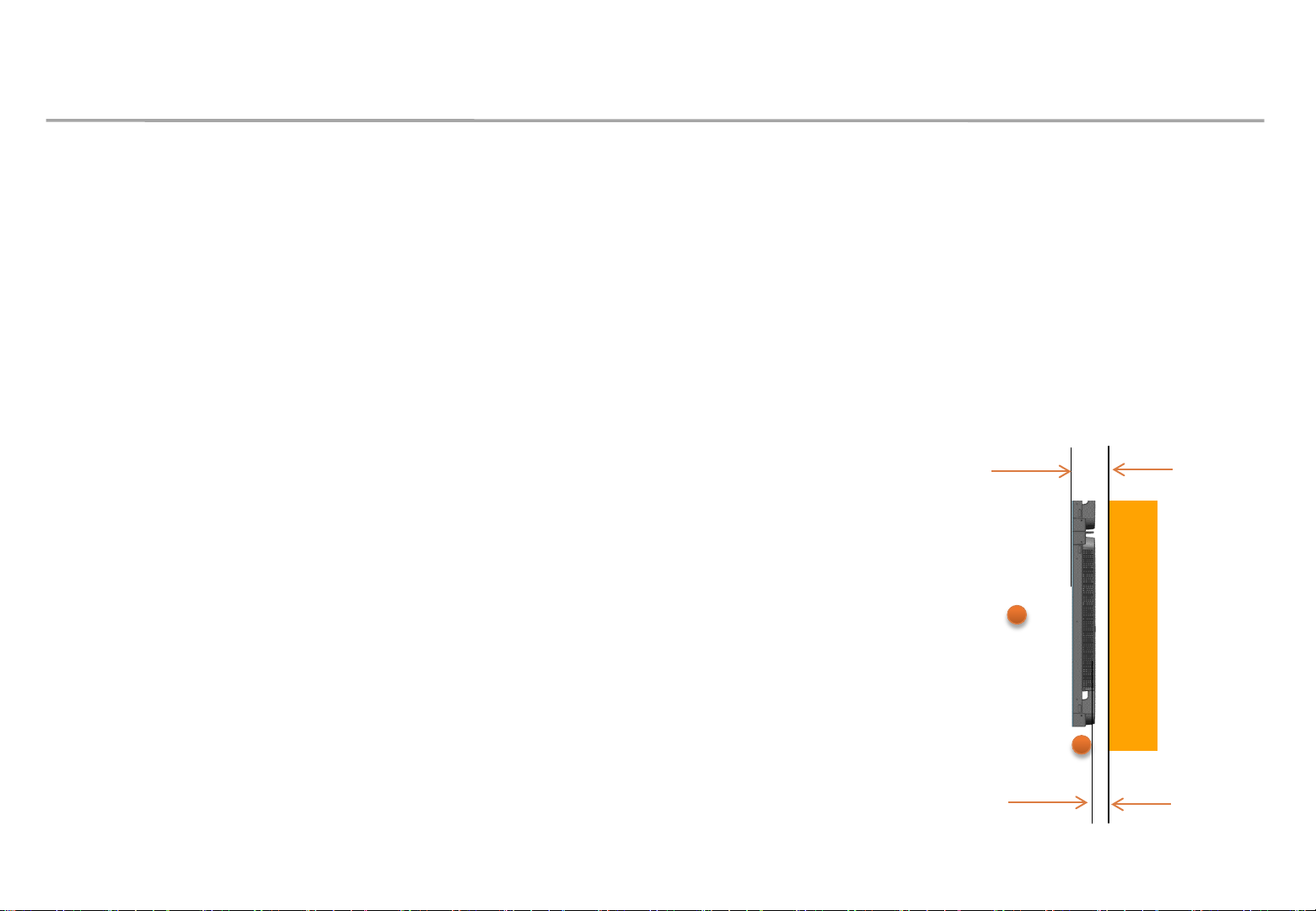

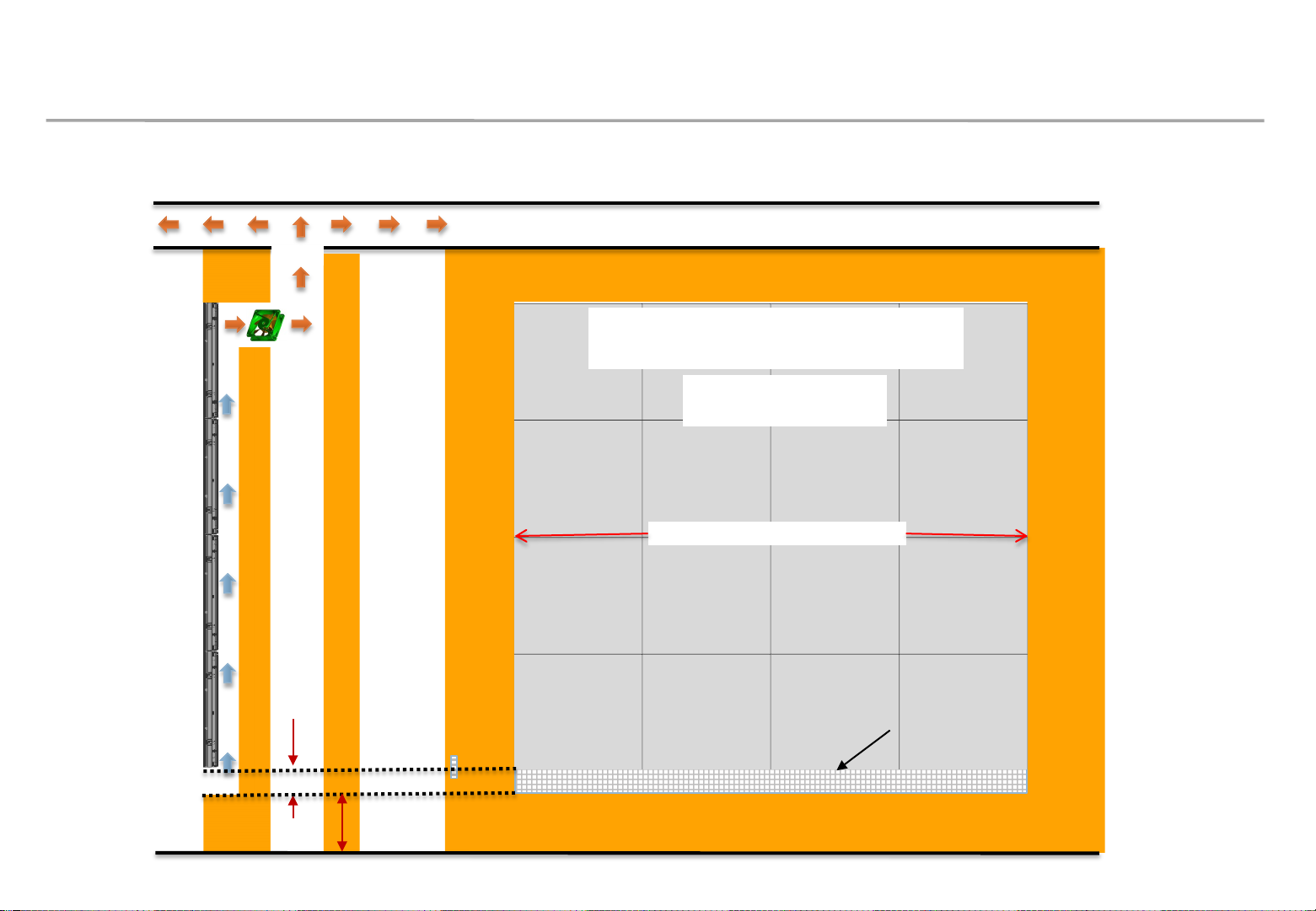

Prevent condensation due to A/C

Samsung Electronics

Make sure that the cold air does not blow directly on the screen.

– When the cold air from A/C (air conditioner) blows directly onto the screen surface,

condensation may occur depending on the ambient humidity and temperature of

screen surface.

– If the A/C and screen are close, install a wind deflector as shown in the figure

below to prevent condensation.

Install the wind deflector toward the screen.

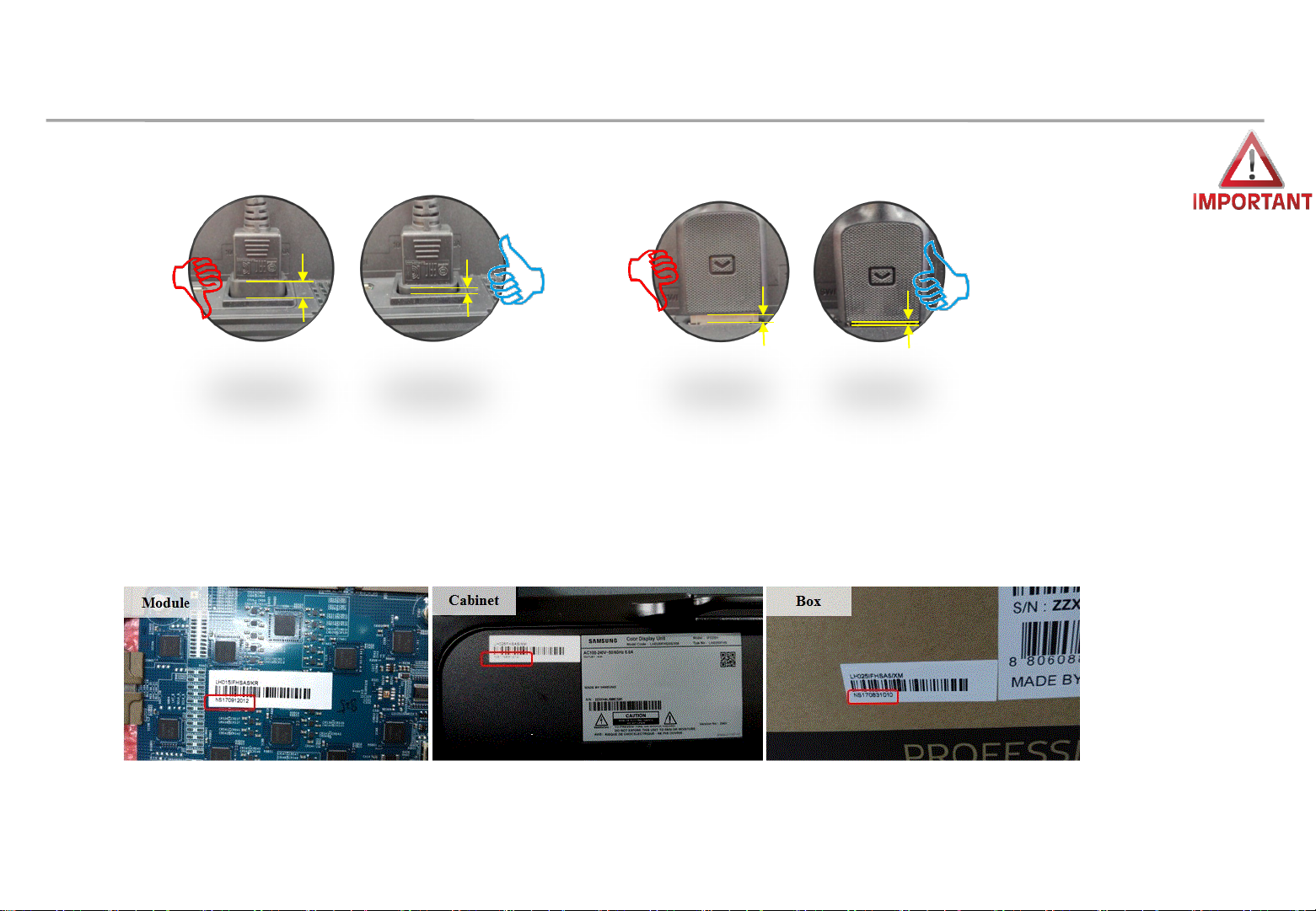

Guidance of latest firmware

When install products, please update latest firmware on online

- You can download latest firmware from SLM site.

∙ URL of SLM Page : https://www.secslm.com

∙ After login Help Download Center에서 Download

∙ Before you download firmware, you MUST check same firmware of model (marked red

letter in below) & upper number of version (marked blue in below).

Cabinet : Main - L-xxxMWWAC-nnnn.n xxx = Pan name, nnnn.n = version

FPGA - aabbd_ddddd aa = pixel pitch, bb = LED package type, d_ddddd= version

Example : IER P2.5 Cabinet : L-IERMWWAC-1003.1, FPGA : 25252-31046

Samsung Electronics

S-box : TB-KTM2SBMDWWC_100x.x

- You can update firmware through LSM.

∙ Please refer ‘7-1 PC control program’ for the way to update firmware.

9

1. Product Information and Precautions for Installation

• Power cable and OCM cable must be inserted tightly.

• Use *STP, *FTP Cable over CAT6, which length is about 15 ~ 100m for HDBT signal stability.

“Do not use CAT6 UTP”

Do not break or bind the cable into bundle.

• Do not mix the cabinets that have different project number each other.

Each cabinet has its own project number.

Samsung Electronics

10

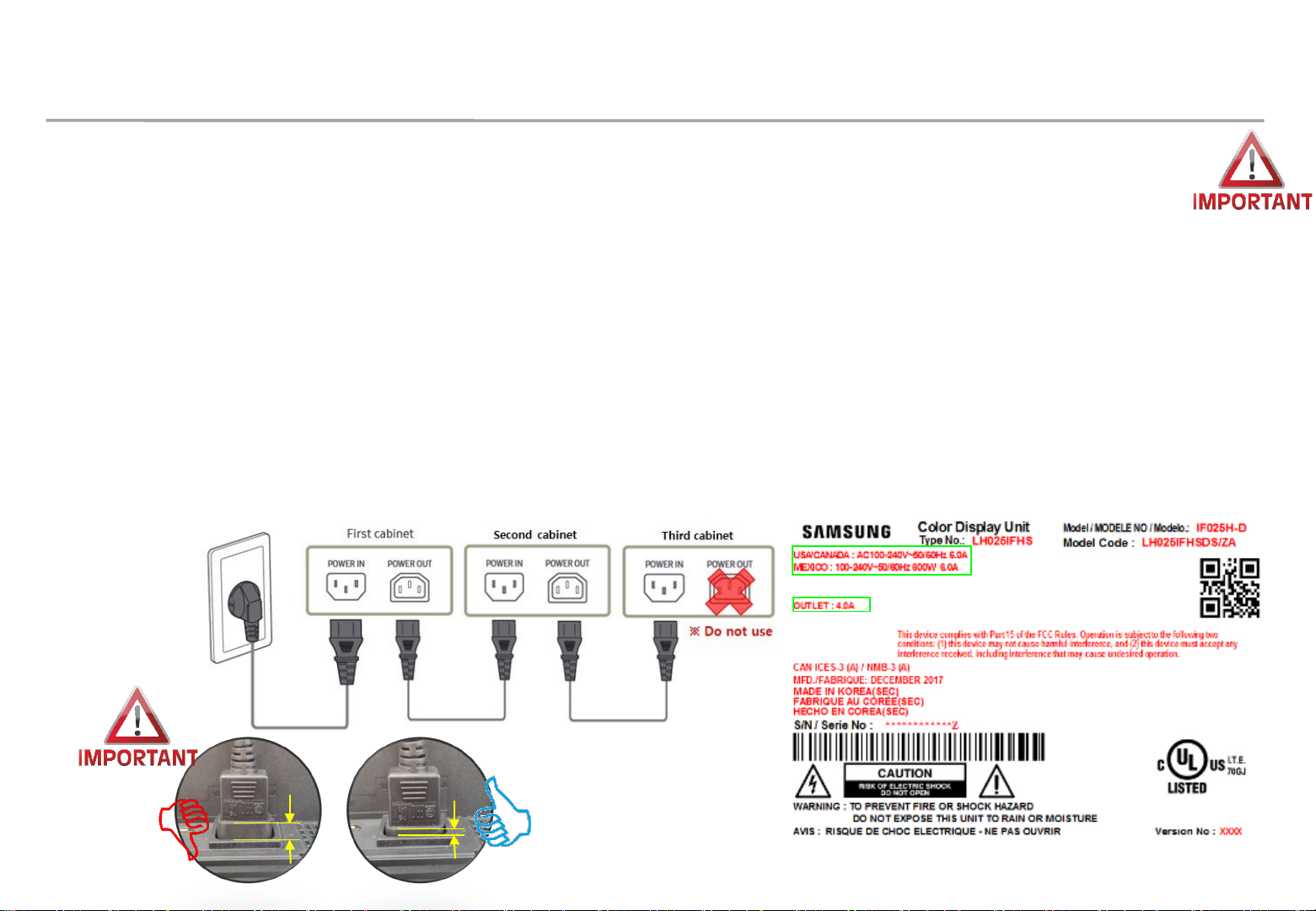

1. Product Information and Precautions for Installation

• If using 110V/220V, you can connect at most 3 IFH-D(IF040/IF060/IF025) devices.

• Exceeding the recommended maximum number of devices can cause the circuit breaker of the

product to trigger due to overload. SURELY CONNECT the devices less than the recommended

maximum number of devices.

※ No responsible for Samsung Electronics in case of exceeding the recommended maximum

number of devices connection.

• The label info which is attached behind product shows rated power of cabinet and rated current of

outlet.

Samsung Electronics

11

1. Product Information and Precautions for Installation

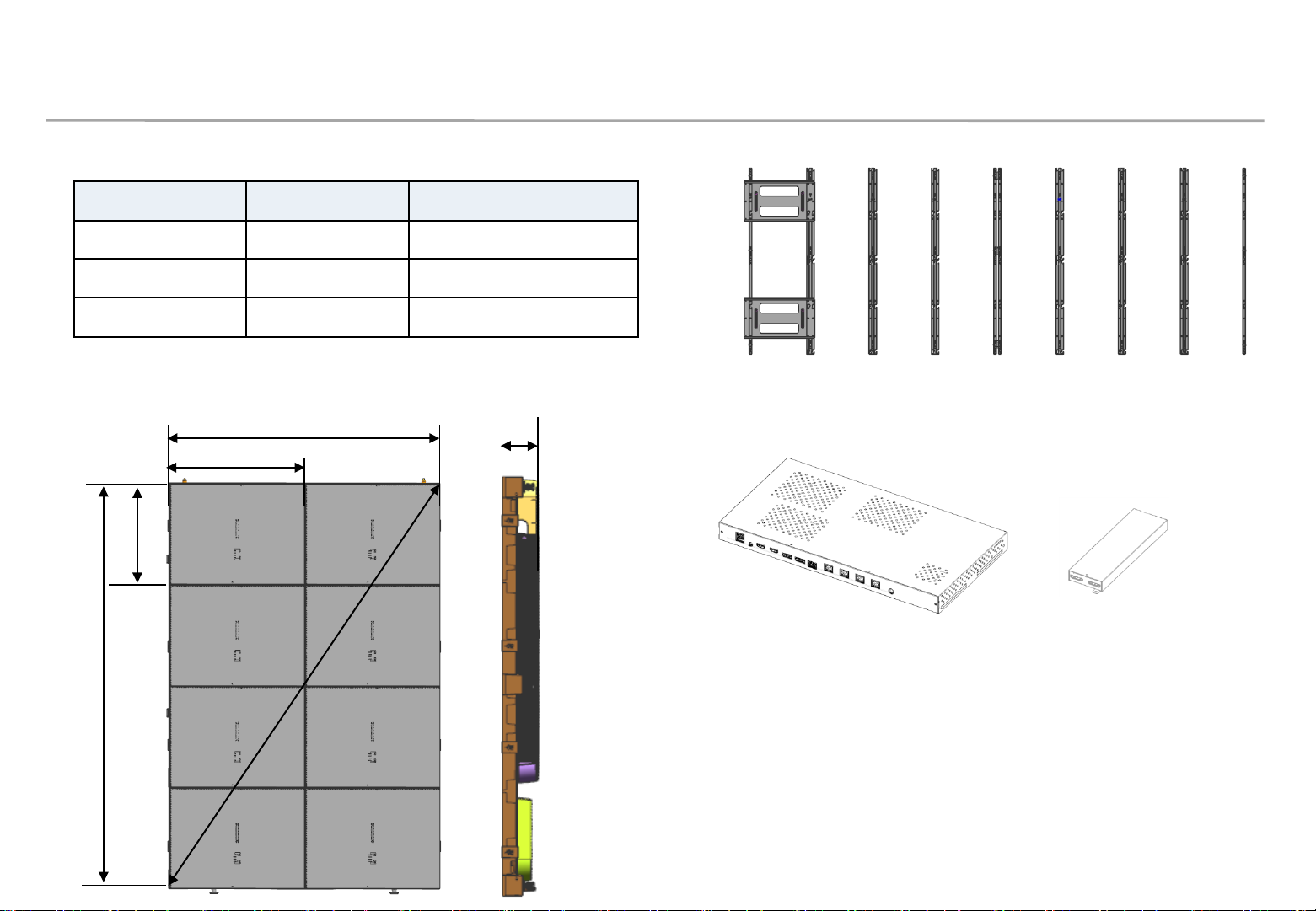

◇ Frame Kit Composition ( Refer to Page 29 )

Frame Kit Composition Size [mm]

Samsung Electronics

VG-LFH81SWD

VG-LFH82SWD

VG-LFH83SWD

8x1(8 Set)

8x2(16 Set)

8x3(24 Set)

3840 x 720 (1 row)

3840 x 1440 (2 rows)

3840 x 2160 (3 rows)

◇ Cabinet Product Information ( Fig2.)

479.9

239.9

179.9

34”

719.9

64.2

<8x2 Frame>

◇ SBB-SNOWJ3U (S-Box, I/G)

<S-Box> <I/G>

(Interface Gender)

※ Power system should be designed

according to Screen composition. 1 FHD

Screen should be in same power system.

(Refer to page 69 )

12

1. Product Information and Precautions for Installation

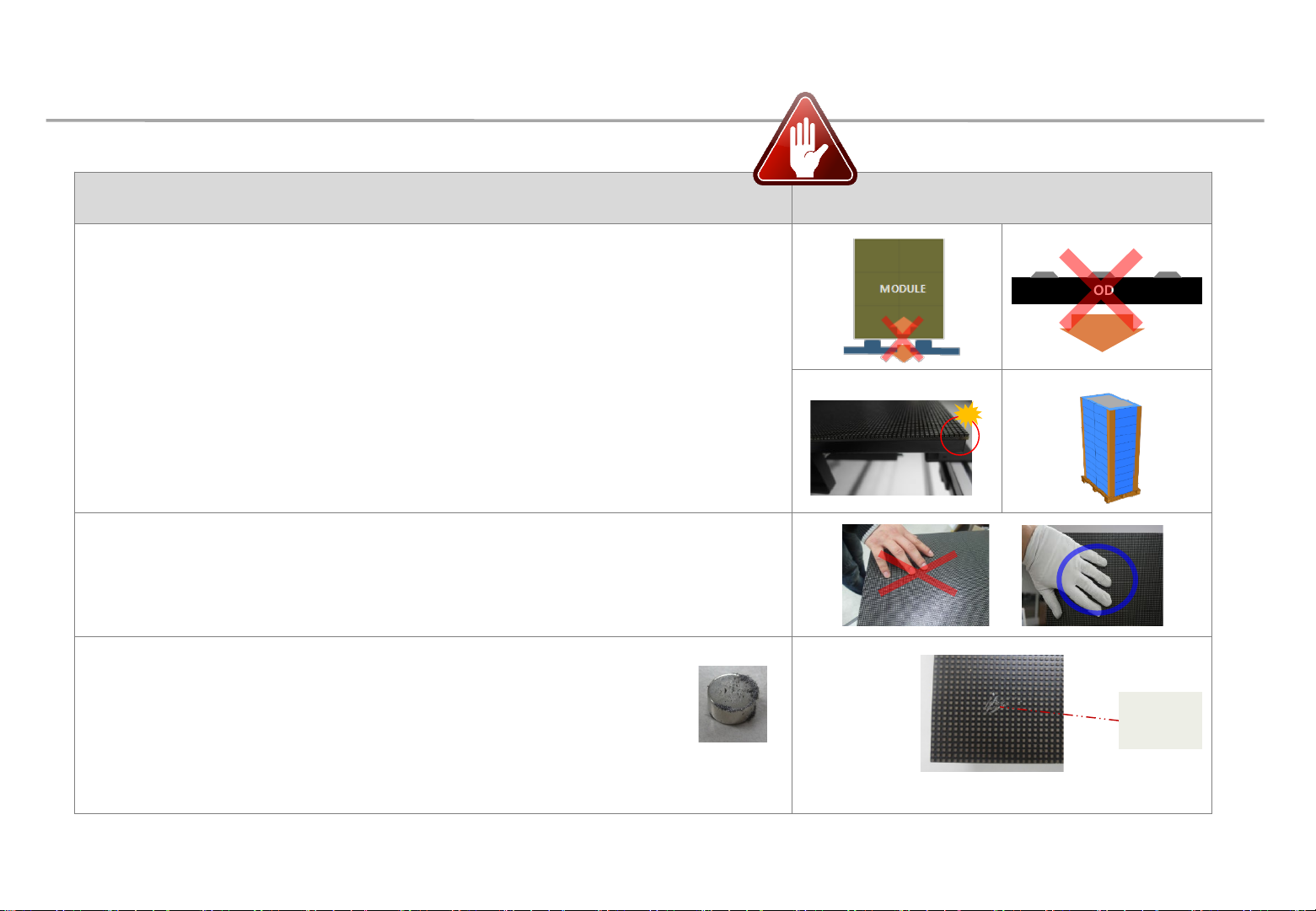

◇ Precautions for Installation (LED Physical damage)

Precautions Images

[ Beware of Outside Impact, Fall]

Samsung Electronics

① Beware not to cause any impact on the LED screen or drop the product on the floor

after the protection gets taken off for installation.

② Beware not to put the LED side headed downwards to the floor after the protection

gets taken off for installation.

③ Beware not to have the corner area of LED module be damaged due to the contact

with the outside.

④ Beware not to put more than 12 layers.

[Beware of LED Damage due to Static Electricity]

▶ Beware not to touch LED screen with bare hands without putting gloves on.

[Beware of LED Damage due to Metallic Substances]

▶ Beware not to have metallic substances pulled in to the surface

due to the magnetic force on the front side of the LED.

▶ If any metallic substances get drawn in on the surface, please disassemble the

MODULE

Front

① ②

③ ④

Metallic

substance

module and then remove the pollutants by using a magnet.

13

1. Product Information and Precautions for Installation

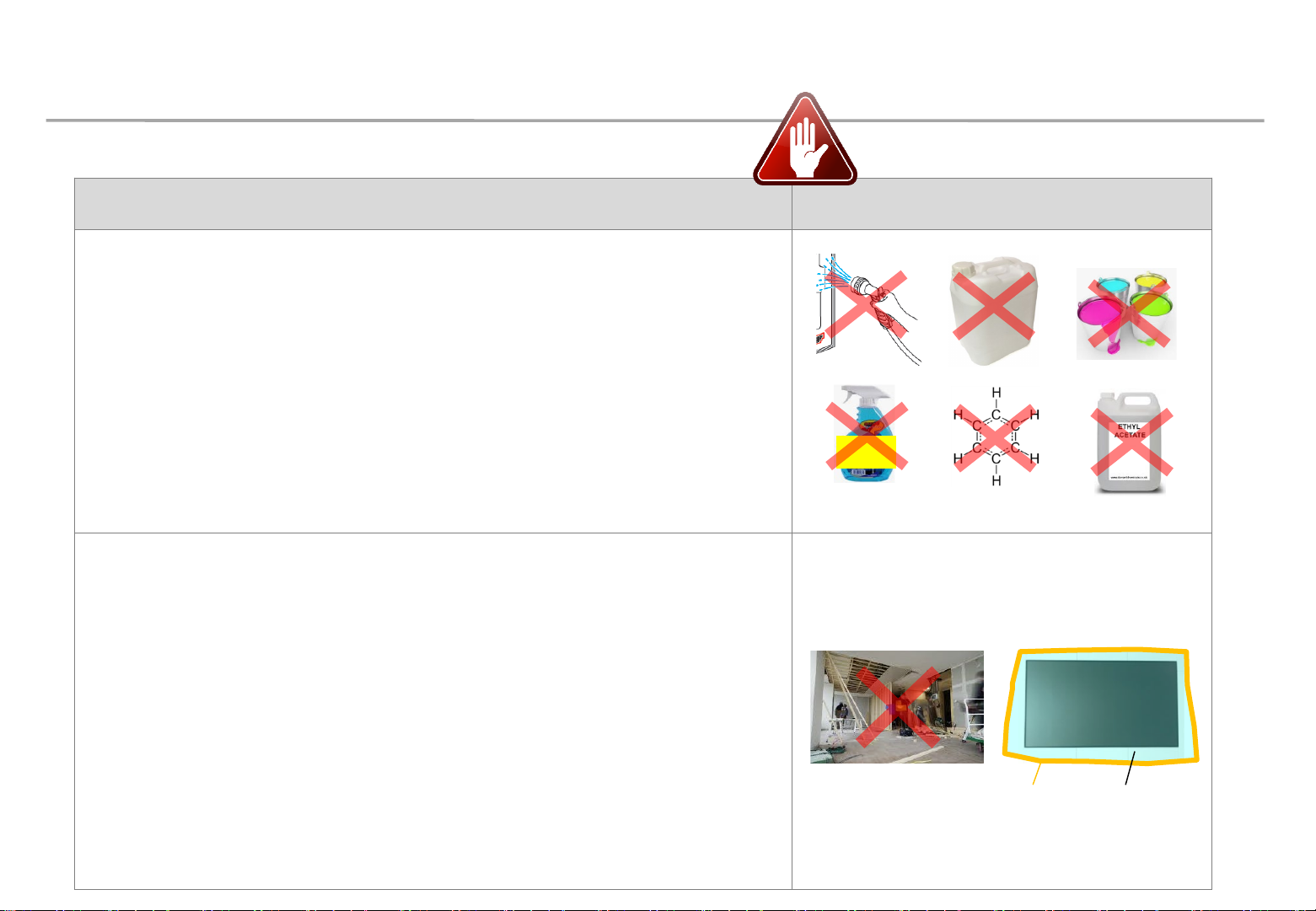

◇ Precautions for Installation (LED Chemical damage)

Precautions Images

[Beware of LED Damage due to chemicals]

▶ Beware not to contact the following materials with the product, and minimize

exposure of the product to their vapor

- Water (including sweat and saliva)

- Detergents (e.g. detergents for carpet cleaning)

- Paint, glass cleaner, mosquito repellent, fragrance

- Substances containing benzene, toluene, xylene, solvent, surfactant,

thinner, chlorine, etc.

▶ When the product is installed, the air conditioner should be operated enough to

minimize sweat flow, and avoid sweating the product.

▶ Minimize saliva by wearing a mask

[Precautions for construction and cleaning]

▶ When installing on the construction site, it should be installed after construction and

cleaning.

▶ If there is construction inevitably in the space where the product is installed, take

the following measures.

- To minimize the exposure of the product to dust and solvent vapors,

the whole product is covered with a vinyl shield,

and tape is used to attach the end of the vinyl shield to the wall.

- Operate video or 100 gray scale white for more than 2 hours every day.

- After the construction is finished, remove the vinyl shield after the dust and

solvent vapor have been sufficiently removed.

▶ When cleaning the floor with detergent or water, install a shield when there is a

possibility of reaching the product.

GLASS

CLEANER

CARPET

CLEANER

Samsung Electronics

Tape Vinyl shield

14

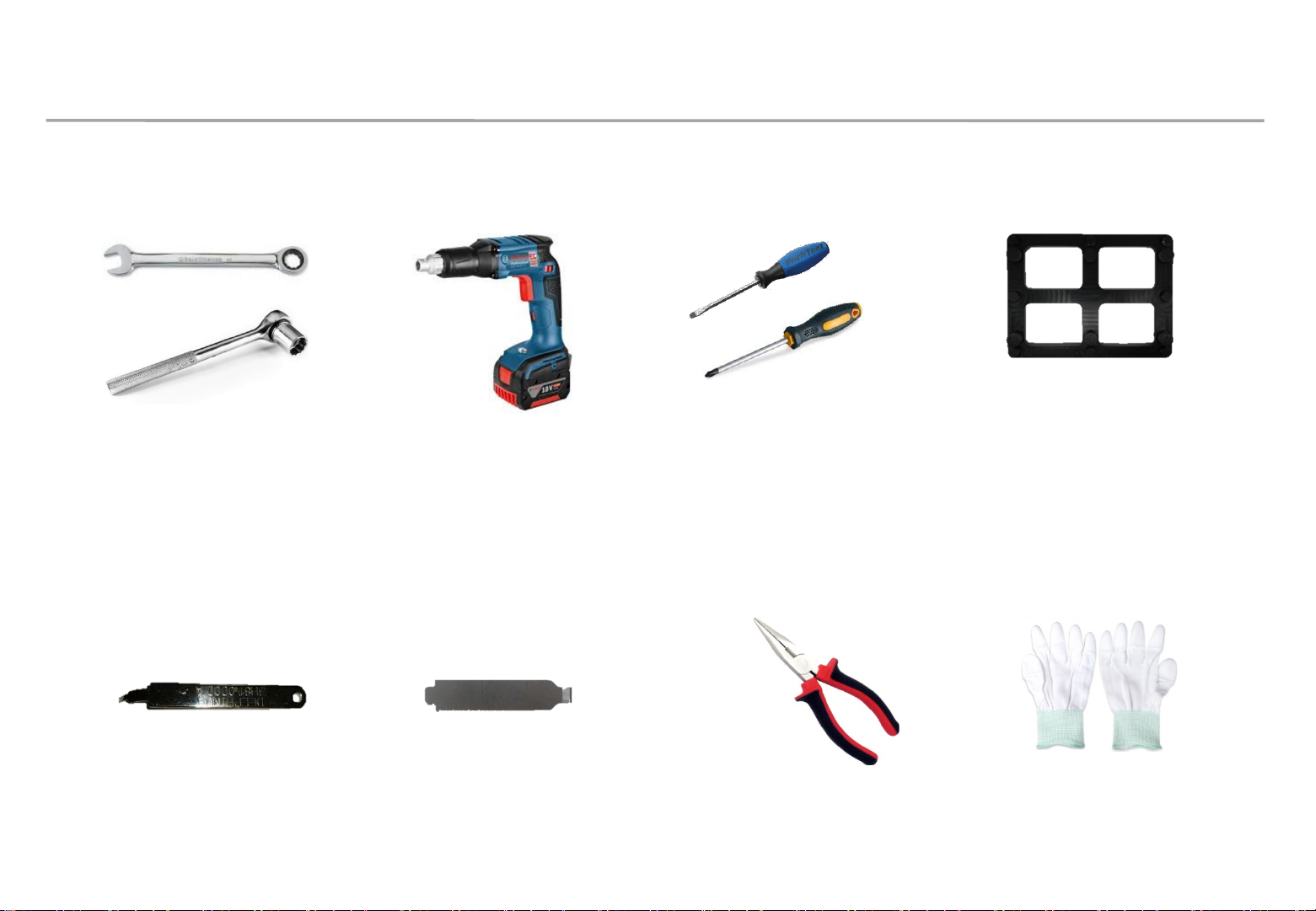

1. Product Information and Precautions for Installation

◇ Preparations for Installation

10.0mm Wrench

Electric Driver

(-) (+) Driver

Samsung Electronics

LED MODULE JIG

(model name: CY-LJFNAS)

Service JIG

(BH81-00001A)

Holder Magnet Tool

Plier

Antistatic

Glove

15

2. Check Point about the Radiant Heat

Samsung Electronics

◇ Radiate heat guide

INDOOR Installation Condition

- SAMSUNG WALL MOUNT Using Condition(ADA Satisfied)

∙ Product Front to Wall Gap : 90mm

∙ Product Rear to Wall Gap : 25mm

- When sunlight light up

∙ Need inquiry when sunlight shine through window or wall

- Air conditioner effect

∙ Avoid cold&hot air

※ Written under ‘Full white, (back light 7)’ standard

Written under ‘Video, (back light 10)’ standard

※ ADA (American’s with Disabilities Act)

90mm

Outdoor temp

check position

wall

- Outdoor temperature measure spot

∙ Center of Product & Air inlet

Outdoor temp

check position

25mm

16

2. Check Point about the Radiant Heat– without Fan

Minimum spacing for wall mounting installation

Min condition : 30mm (set ~ ceiling)

Recommended condition : more than 500mm

Air vent area

Air vent area

WALL

(more than 60%

of opening rate)

Samsung Electronics

Min condition: 30mm (set ~ floor)

Recommended condition : more than 500mm

Air vent area

(more than 60%

of opening rate)

17

2. Check Point about the Radiant Heat– without Fan

Minimum spacing for processed installation

Min condition : 0mm (set ~ ceiling)

Recommended condition : more than 500mm

Samsung Electronics

Essential cond. : more than 30mm of 100% opening rate

WALL

Essential cond. : more than 30mm of 100% opening rate

Min condition: 0mm (set ~ floor)

Recommended condition : more than 500mm

Air vent area

Air vent area

18

2. Check Point about the Radiant Heat

◇ Axial FAN(selection example)

Samsung Electronics

6

5 80 CFM

4 65 CFM

3

2

1

※ Example) Total CFM? (Outdoor temperature 30℃ , Cabinet (5x5) on condition.)

※ FAN flow rate is not a MAX, but a real flow rate.

No need for FAN

1 2 3 4 5 6 7 8 9 10 11 12

→ 80CFM x 5 = 400CFM

- Ebm papst : http://www.ebmpapst.com

∙ Model name : 614 J/2 HHP Size : 60*60*32

∙ Flow rate : MAX 48.3 CFM FAN : 3ea per column

∙ delta-fan : http://www.delta-fan.com

∙ Model Name : AFB0612HHE Size : 60*60*38

※ Fan Margin for the pressure drop / flow reduction

95 CFM

FHD

UHD

No need for FAN

Total 400 CFM

80CFM 80CFM 80CFM 80CFM80CFM

FAN

Outdoor

temperature

30℃

5 Cabinets

∙ Flow rate : MAX 54.5 CFM FAN : 3ea per column

※ Fan Margin for the pressure drop / flow reduction

5 Cabinets

19

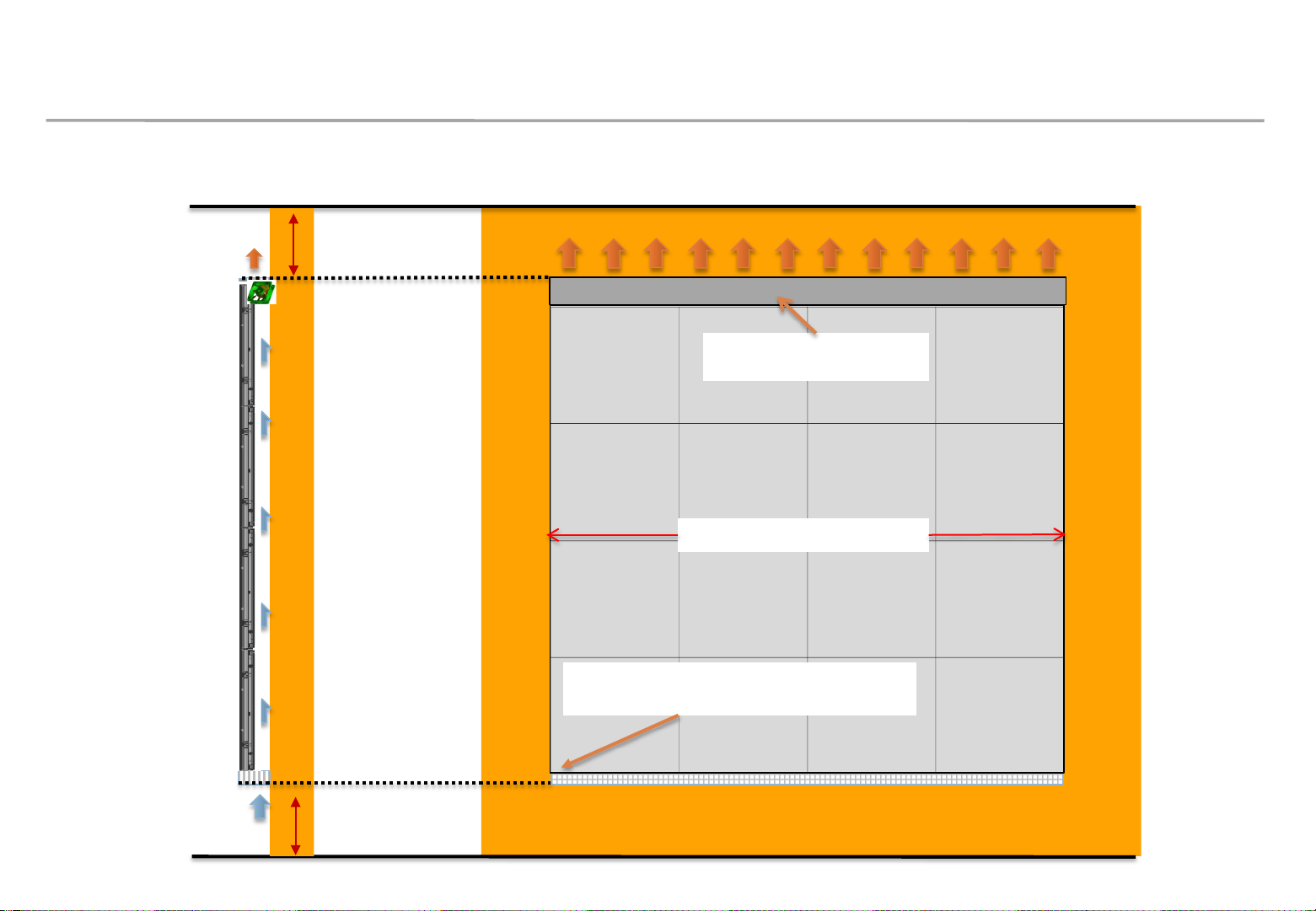

2. Check Point about the Radiant Heat

Samsung Electronics

◇ FAN Using condition

- Air Vent : install at bottom

- Top: Seal except fan hole

FAN

WALL

Seal right and left side

좌우측면 밀폐

FAN

Seal except fan hole

◇ Vent specification

Using over 70% open ratio vent

- Open ratio (%) =

B

d

. ℎ

Air vent area

(Bottom only)

c

A

20

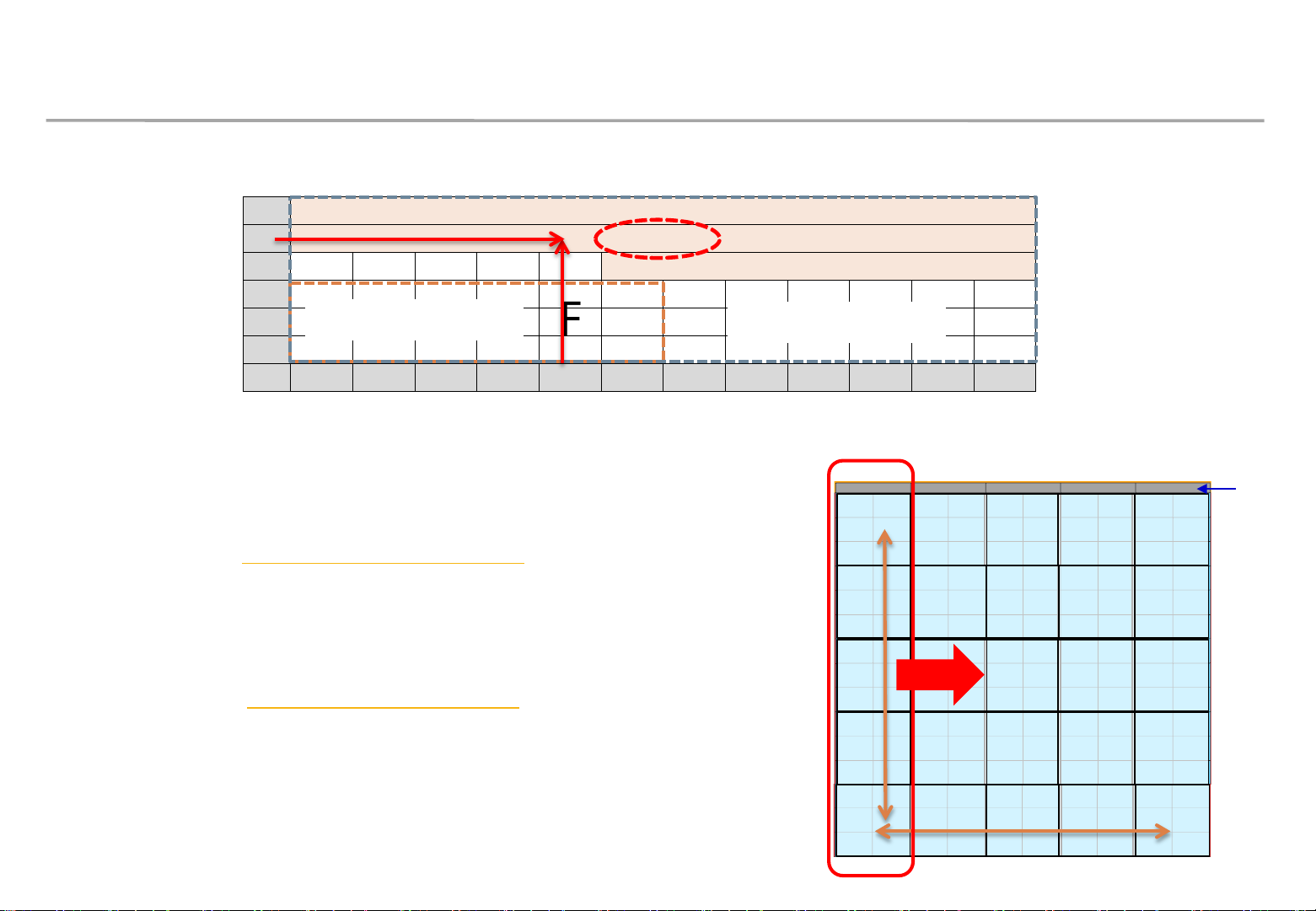

2. Check Point about the Radiant Heat– with Fan

Example of minimum spacing and FAN allocation for wall mounting installation

Min condition : 30mm (set ~ ceiling)

Recommended condition : more than 500mm

Other parts except for FAN

area should be sealed

left and right should be sealed

WALL

left and right sealing

Samsung Electronics

Air vent area should be mesh type with

an opening rate of more than 60%.

Min condition: 30mm (set ~ floor)

Recommended condition : more than 500mm

21

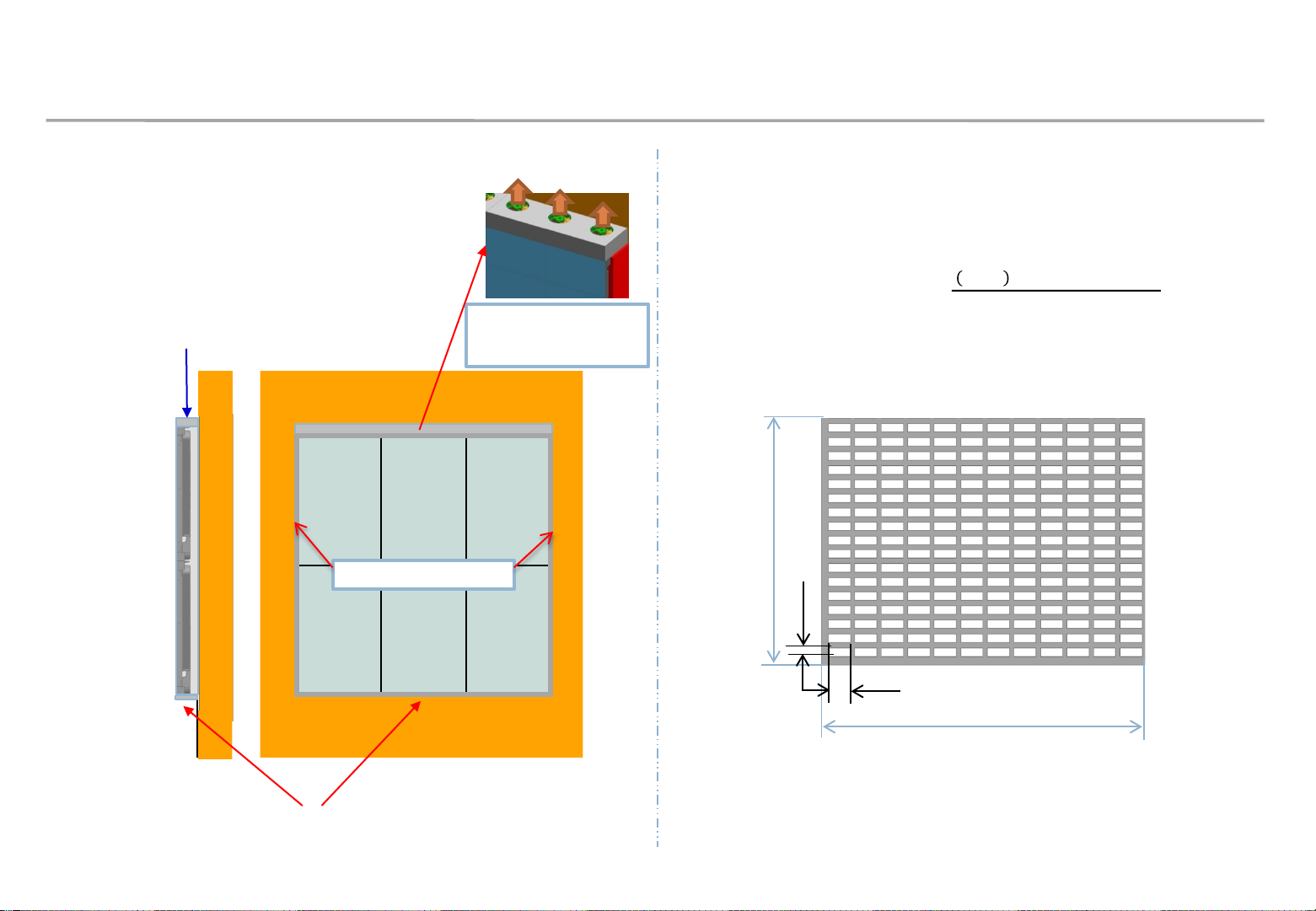

2. Check Point about the Radiant Heat– with Fan

Example of minimum spacing and fan allocation for recessed installation

Min condition: 0mm (set ~ ceiling)

Recommended condition : 500mm

Essential cond. : more than 30mm of 100% opening rate

Other parts except

for FAN area should

Samsung Electronics

be sealed

WALL

Essential cond. : more than 30mm of 100% opening rate

Min condition: 0mm (set ~ floor)

Recommended condition : 500mm

left and right should be sealed.

※ Vent and interior finishing work will proceed after screen installation

Air vent area

22

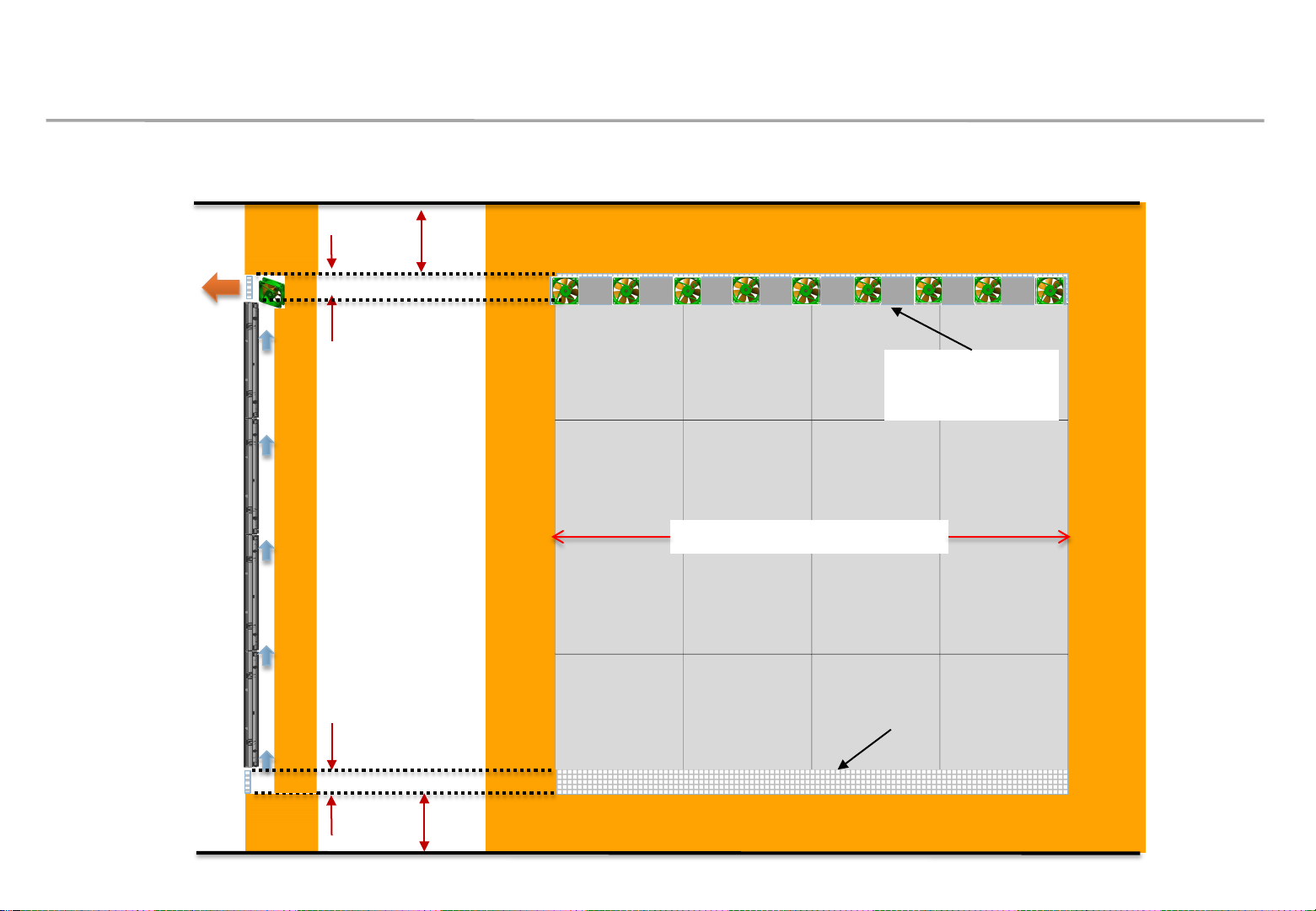

2. Check Point about the Radiant Heat– with Fan

Example of minimum spacing and placement during rear exhaust

Ambient temperature on the back of

the wall should be less than 30 ℃.

Other parts except for

FAN should be sealed.

WALL

left and right should be sealed.

Samsung Electronics

Essential cond. : more than 30mm of 100% opening rate.

Min condition: 0mm (set ~ floor)

Recommended condition : 500mm

Air vent area

23

2. Check Point about the Radiant Heat

◇ IFH-D P2.5 (~35℃ under)

8

7

6

5

4

FHD

3

Vertical

No need for

Samsung Electronics

※ SAMSUNG WALL MOUNT , Full white, back light 7, VENT 70%

UHD

No need for

FAN

2

1

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

FAN

Horizontal

24

2. Check Point about the Radiant Heat

◇ IFH-D P4.0 (~25℃ under)

12

Samsung Electronics

※ SAMSUNG WALL MOUNT , Full white, back light 7, VENT 70%

11

10

UHD

No need for

9

8

7

6

5

FHD

FAN

Vertical

4

3

2

1

1~6 7~14 15~16 17~22 23~29 30~32

No need for

FAN

Horizontal

25

2. Check Point about the Radiant Heat

◇ IFH-D P4.0 (25~30℃ under)

Samsung Electronics

※ SAMSUNG WALL MOUNT , Full white, back light 7, VENT 70%

12

11

10

9 170 CFM

8 150 CFM

7

6

5

FHD

230 CFM

210 CFM

UHD

190 CFM

Vertical

4

3

2

1

1~6 7~14 15~16 17~22 23~29 30~32

No need for

FAN

No need for

FAN

Horizontal

26

2. Check Point about the Radiant Heat

◇ IFH-D P6.0 (~25℃ under)

Samsung Electronics

※ SAMSUNG WALL MOUNT , Full white, back light 7, VENT 70%

18

17 215 CFM

16 200 CFM

15 190 CFM

14 175 CFM

13 165 CFM

12 150 CFM

11 140 CFM

10 125 CFM

9 115 CFM

8 100 CFM

7 90 CFM

Vertical

6

5

4

3

2

1

1~10 11~19 20~24 24~29 29~37 38~46 47~48

No need for

FAN

FHD

225 CFM

UHD

No need for

FAN

Horizontal

27

2. Check Point about the Radiant Heat

◇ IFH-D P6.0 (25~30℃ under)

Samsung Electronics

※ SAMSUNG WALL MOUNT , Full white, back light 7, VENT 70%

18

17 345 CFM

16 325 CFM

15 305 CFM

14 285 CFM

13 265 CFM

12 245 CFM

11 225 CFM

10 205 CFM

9 185 CFM

8 165 CFM

7 145 CFM

Vertical

6 125 CFM

5 105 CFM

4 85 CFM

3

2

1

1~7 8~16 17~24 24~34 35~43 44~48

No need for

FAN

FHD

365 CFM

UHD

Horizontal

28

2. Check Point about the Radiant Heat

◇ IFH-DL P8.5 (~25℃ under)

13 165 CFM

Samsung Electronics

※ SAMSUNG WALL MOUNT , Full white, back light 7, VENT 70%

12 150 CFM

11 140 CFM

10 125 CFM

9 115 CFM

8

7

6

Vertical

5

4

3

2

1

No need for

FAN

1~10 11~19 20~24 24~29 29~34

Horizontal

UHD

No need for

FAN

29

2. Check Point about the Radiant Heat

◇ IFH-DL P8.5 (25~30℃ under)

13 265 CFM

Samsung Electronics

※ SAMSUNG WALL MOUNT , Full white, back light 7, VENT 70%

12 245 CFM

11 225 CFM

10 205 CFM

9 185 CFM

8 165 CFM

7 145 CFM

6 125 CFM

Vertical

5

4

3

2

1

1~7 8~16 17~24 24~34

No need for

FAN

UHD

Horizontal

30

3. Preparation for Cabinet Installation

◇ Preparations Before Installation

Samsung Electronics

SLIDING SCREW

Top-Cushion

Box

Fig.1 Box Opening

IB & cable

BottomCushion

LED set

handle

Fig. 2 Handle

① Remove the Box tape at the upper area and then open up the box. (Fig.1)

suburb hole

Fig.3 Bolt Assembly

② Remove the Top–Cushion and hold the handle inside PE-Bag and pull out the set then remove PE bag.

(Fig.2)

③ Assemble four(4) Sliding Screw for installation at the hole located at the outermost part of the Corner. (Fig.3)

31

3. Preparation for Cabinet Installation

Switch Button

Screw

Samsung Electronics

Cushion Top

Fig.4 Check the Screen

Fig.5 Cover Corner

Removal

Fig.6 Cabinet Storage

⑤ Check whether there is any abnormality on the screen by connecting the power cable.(Fig.4)

※ Press the ‘Switch’ button for five(5) seconds after applying the electricity.

If the information screen comes out, press the Switch button to switch the screens on W/Pattern and check the screens.

⑥ Unfasten the screws (total of four[4]) on the Cover Corner area to separate those screws. (Fig.5)

⑦ Put the Cabinet on the Cushion Top so that the LED screen will head upwards. (Fig.6)

32

※ Do not turn on OR display white pattern more than 10 second .

3. Preparation for Cabinet Installation

◈ Reference : Process of Screen check

Power In

Switch Button

Power out

◇ Connect Power Cable to SET.

Use internal pattern to check

dead pixel or any damage with

NO VIDEO

⑦

Push ‘Switch Button’ and

hold it for more than

three seconds.

Push

Switch

Button

Push

Switch

Button

Push

Switch

Button

Push ‘Switch

Button’ and hold

it for more than

three seconds.

①

⑥

Dehumidifying

Push

Switch

Button

Push ‘Switch Button’ and hold it for

④

more than three seconds.

Push ‘Switch

Button’ and

hold it for more

than three

seconds.

⑤

Samsung Electronics

Push Switch

Button

②

Push

Switch

Button

Push

Switch

Button

③

Push

Switch

Button

Push Switch

Button

Push

Switch

Button

screen.

① After turning on power, while showing ‘NO VIDEO’, push ‘Switch Button’ and hold it for more than three seconds.

※[Caution] If you push ‘Switch Button’ and hold it more than 10 secs, factory reset will be done.

② While ‘Dehumidifying’ shows off, if pushing ‘Switch Button’, OSD is shown.

③ Then, OSD, gray, dark red, dark green and dark blue are shown sequentially, whenever ‘Switch Button’ is pushed.

④ In order to go to ‘NO VIDEO’, while OSD is showing, push ‘Switch Button’ and hold it for more than three seconds.

⑤ If brighter patterns are needed, hold ‘Switch Button’ for more than three seconds from gray, dark red dark green or dark blue patterns.

⑥ Then, full white, full red, full green and full blue are shown sequentially, whenever ‘Switch Button’ is pushed.

⑦ Pushing ‘Switch Button’ and holding it for more than three seconds makes it go to ‘NO VIDEO’.

33

3. Preparation for Cabinet Installation

Samsung Electronics

⑧ Attach the PET Sheet and assemble Cover PCB for the Cabinet that is located at the

exterior.

※ PET Sheet & Cover PCB should be at the boundary of whole screen. (Blue area at the exterior of Fig.1)

※ Attach PET Sheet as shown below.(Fig.3), The areas where there is no tape should guide the LED module.

※ Assemble the Cover PCB as shown below.(Fig.4)

No Tape

0~0.5mm

PET-Sheet

Fig.3

Fig.4

Fig.1 Attach point of

Sheet PET

Fig.1 Attach point of

Sheet PET

Fig.1 Sheet PET/ Cover PCB

34

4. Frame Installation

① Frame Kit Composition

Samsung Electronics

No. Item

ⓐ

ⓑ

ⓒ

ⓓ

ⓔ

ⓕ

ⓖ

ASSY BRACKET SIDE

ASSY BRACKET MIDDLE

ASSY BRACKET CENTER

ASSY BRACKET JIG

ASSY SLIDING SCREW

ASSY ANCHOR SCREW

MANUAL-INSTALL

VG-LFH81SWD

8x1 8x2 8x3

Units

2 2 2

6 6 6

2 2 2

1 2 2

48 96 144

20 30 40

1 1 1

VG-LFH82SWD VG-LFH83SWD

Units Units

a

b

b

b

c

b

b

b

a

d

f

g

e

M5,L65, Anchor screw

ⓗ

ⓘ Wrench 1 1 1

Size of the installation Screen

Service JIG

(mm)

1 1 1

720x3840 1440x3840 2160x3840

h

i

35

4. Frame Installation

Samsung Electronics

② Put the ⓐBracket Side the end of the left side and then fasten the screws to install.(Fig.2)

※ After fastening one(1) screw, use the device for vertical positioning to set up straight vertical alignment. Then fasten up the remaining

holes. (Refer to Page 25 for the Precautions for fixing the Screws)

Order of Fastening the Screws (No. 1 → No. 2 → No. 3 ). (Fig.1)

ⓐ Bracket Side is located at 12mm of the end line of the screen. (Fig.3)

a

b

d

b

b

Fig.2 (Location of Componets)

c

25mm 이상

Min. 25mm

b

b

b

a

Min.

12mm

a

Fig.1 (Order of Work)

Min. 12mm

Fig.3(Distance between

Screen and Bracket side)

36

4. Frame Installation

Samsung Electronics

③ Install ⓑBracket Middle.

※ First, check the Hole to fix the ⓒ JIG. [Fig.1]

※ Second, Mount the ⓒ JIG inside the Bracket Hole and fasten up four(4) Screws [Fig.2]

※ Third, fasten the ⓑ Bracket Middle using Screws. [Fig.3]

※ Warning. ⓐ,ⓑand ⓒ sides should be attached,

and the three(3) sides of Wall/Frame side/Jig side should be parallel.[Fig.4]

④ Install ⓑBracket Middle in the same way (from left to right)

※ Install Bracket Center at the center of Frame KIT.

a

Wrong Installation(X) Correct Installation(O)

Wall

ⓐ,ⓑ,ⓒ

ⓓ

Fig4. Maintain the Parallel Frame

b

b

b

c

b

b

b

a

Fig1. Check the Hole

Fig2. Fix the Jig (Screw)

d

Fig3. Fasten the Screw Fig.5 (Location of Components )

37

4. Frame Installation

Samsung Electronics

◇ When installing three or more ASSY BRACKETs, adjust their levels because they may be

distorted by walls or structures.

– After installing three or more ASSY BRACKETs, place another

ASSY BRACKET horizontally on them and measure if there is a

height difference among them. If a height difference is found,

adjust the Z-Bolt heights of ASSY BRACKETs to make them level

with each other.

– Adjusting the heights

1. To adjust the Z-Bolt height of the frame, first remove the washer.

2. After removing the washer, use a wrench (28 mm) to adjust the

Z-Bolt height.

38

4. Frame Installation

Samsung Electronics

⑤ After installing Bracket Center, install cabinets on the bottom line.. [Fig.6]

⑥ When the cabinet installation is finished, slide the LED modules toward the center and check the

flushes between the cabinets and the LED modules at both ends.

[Fig.7]

⑦ Make the left and right flushes equal, and then adjust the flushes according to the following criteria. [Fig.8]

• If the flush is more than 0.5 mm, move the Frame outward.

• If the flush is less than 0.0 mm, move the Frame inward.

• Adjust the flush each time you install a cabinet additionally. If the flush is 0.0 to 0.5 mm, you don’t

need to adjust.

⑧ When the flush adjustment is finished, install the next Bracket Middle. For the installation method,

refer to Step 2 and the following steps.

⑨ Finally, install Bracket Side.

Fig6. Install cabinets

Fig7. Check flushes

[Fig.9]

Fig8. Adjust flushes

Fig9. Installation of 6x3

39

4. Frame Installation

Samsung Electronics

◇ You can extend a Frame KIT product to any size.

- The VG-LFH82SWD and VG-LFH83SWD models can be extended in both horizontal and vertical directions, for example, to

construct 10 × 6, 10 × 5, or other layouts.

- The VG-LFH81SWD model can be extended only in the horizontal direction.

- When installing the ASSY BRACKET JIG to fix the connection part between ASSY BRACKETs, make sure that 2 people work

together because it is difficult to fix ASSY BRACKET JIG.

(Make sure that one person hold ASSY BRACKET JIG in the fixing position and the other one fasten its screws.)

- When extending the Frame KIT, it is required to install ASSY BRACKET CENTERs between ASSY BRACKET MIDDLEs.

(Recommended specification: one ASSY BRACKET CENTER per three or four ASSY BRACKET MIDDLEs)

Extended installation example

40

4. Frame Installation

◇ Precautions for Fastening the Screws

Samsung Electronics

41

5. LED Display Installation

Samsung Electronics

◇ Fix I/G Location

① Install I/G first on the back side of the Cabinet of each Type. (Fig.1)

※ Location to Install: Locate the I/G at the point 35~40mm below, which is the standard for carving at the right side of the frame,

and then fasten the screws.(Fig.2)

Fig1. Location to Fix the I/G and Order of Installing the Cabinet

I/G

Fig2. Location to Fix I/G

70~80mm

35~40mm

42

5. LED Display Installation

Samsung Electronics

② Adjust the Corners of the Cabinet to each of the cravings to be closer to the Frame.

※ Order of Cabinet Installation (28 Page Fig. 1)

※ Check whether all the six(6) bolts are put into the frame. (Fig.1)

③ Press the upper side of the Frame and assemble so that it slides towards downward diagonal direction

(Fig.2)

④ From the layers above the second floor, insert the Service Jig between each Cabinet,

Marked

Area

remove the Service Jig, slowly lower the Cabinet.

※ Beware not to have the Service Jig touch the LED Module.

※ Check whether the gap between each module widens,

whether the size of the pitch differs every time of installation.

Marked

Area

Marked

Area

Fig.1 Fig.2 Fig.3

(Fig.3)

Sliding Screw

43

5. LED Display Installation

⑤ If modules are too tight, it could be difficult to pick out.

During the installation process,

select some modules and make sure they are easily picked out and reassembled.

Samsung Electronics

44

5. LED Display Installation

Samsung Electronics

◇ Protection of I/G

To prevent unexpected removing IG box, the Protection Bracket should be attached on left / right

side of the display (Fig.1)

* In case of pocket installation, do not need to attach the protection.

* Keep free space on Top and Bottom for ventilation

Recommended specification for Protection Bracket

① Material: Aluminum or steel, thickness 1.0mm~2.0mm, black coating.

② Dimension: Width 49mm, Length 719.0mm / 1439.0mm / 2159.0mm (same with Frame, Fig.2)

③ Screw hole position: interval 200mm, first screw has distance 130mm to bottom line (Fig.3)

49mm

④ Screw: M4*0.7mm , length 6mm.

Protection

Protection

Fig.1 Protection

VG-LFH81 VG-LFH82 VG-LFH83

Width (mm) 49.0 49.0 49.0

Length (mm) 719.0 1439.0 2159.0

Fig.2 Protection dimension

M4

screw

hole

Fig.3 Screw location

34mm (screw position)

Interval 200mm

130mm

(VG-LFH81SWD 90mm)

45

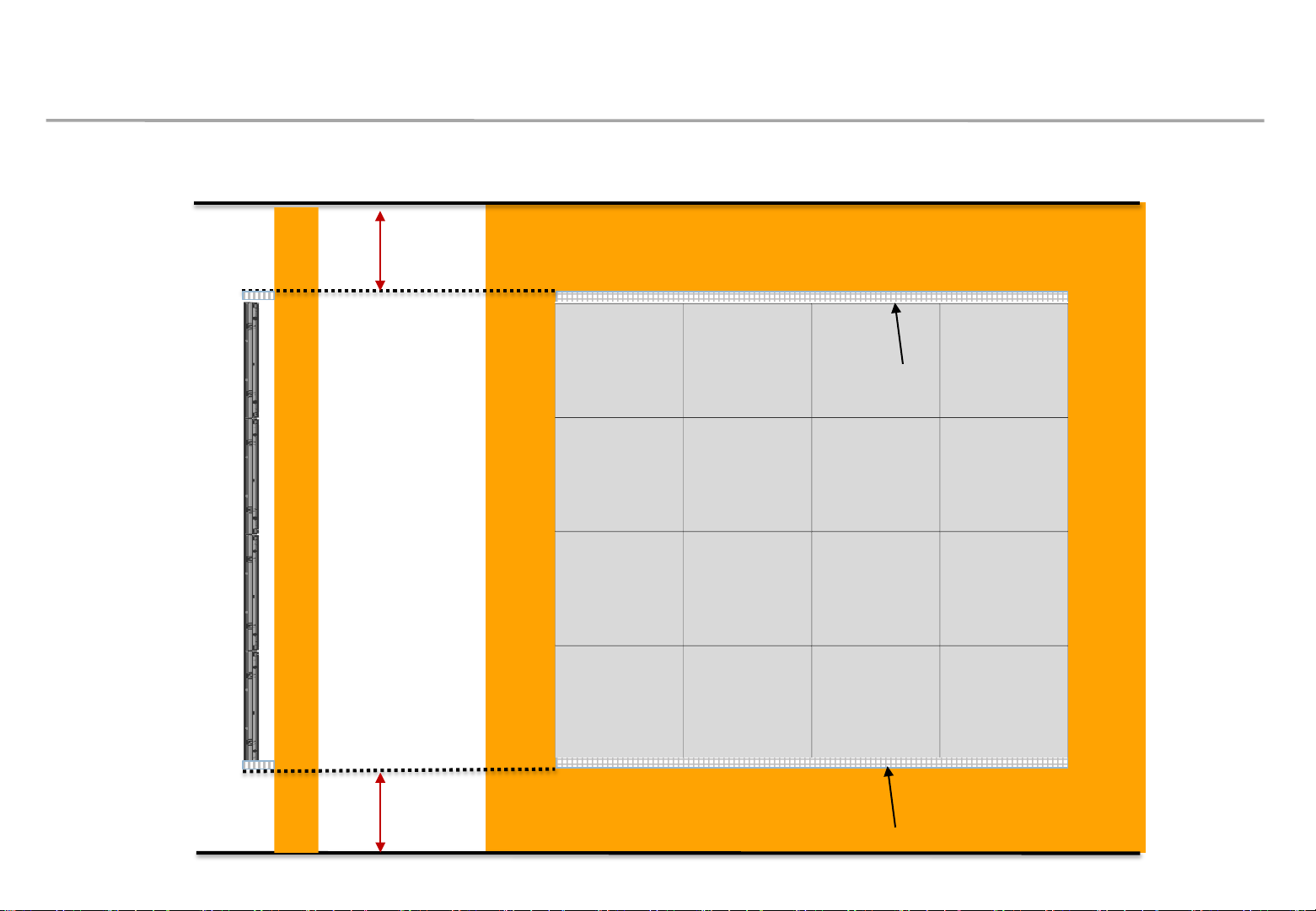

5. LED Display Installation

Samsung Electronics

◇ Installation Guide of recessed screen

When installing recessed screen, minimal work space is needed from the edge of the

screen.

– In order to finish seam adjustment, fixation parts should be installed on the screen edge. If the parts

are not installed, seam between modules could be made.

– The parts can be fixed on the screen by tools and space for tools are needed on the edge. Though

it may be dependent on your tools, more than 50mm is required in general.

[Fixation parts]

More than 50mm

- The Wall : Holder PCB, Cover PCB

- IFH/IFJ/IER/IFR : Cover PCB

Left work space

Screen

Cabinet

Front View

Top View

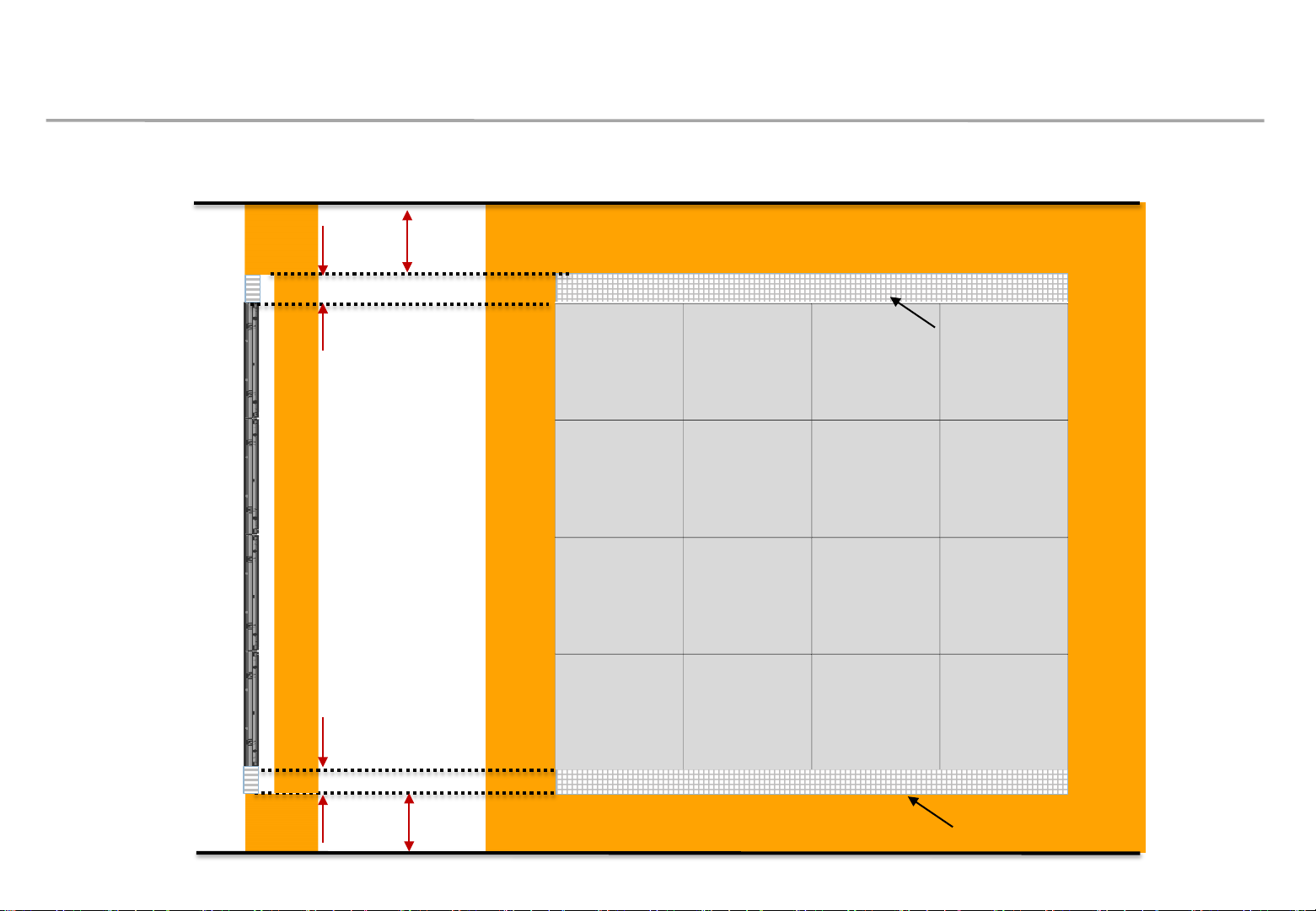

5. LED Display Installation

◇ Installation Guide of recessed screen

Work space should be finished with detachable material for service.

– Work space more than 1mm should be secured for safety of the screen.

Be cautious of safety of the screen while detaching and attaching finishing material.

– Top and bottom materials should have enough ventilation hole.

If there is enough heat dissipation space behind the screen, it can be omitted.

– Finishing materials is recommended to have same pattern and material as the wall.

– If metal parts of the screen is shown from the side of it, finish it with black tape.

Detachable

Samsung Electronics

Screen

Front View

Top View

More than 1mm

※ Because wall is not flat perfectly, difference from wall

finishing material and the screen could be made.

In order to prevent it, each part should be designed,

manufactured and constructed.

SBB-SNOWJAU / SBB-SNOWJMU

6. S-BOX Installation and Connection

Samsung Electronics

• S-BOX Installation Precautions

① Product recommend installing this product in a standard 19-inch server rack.

※ When connecting two or more times for the purpose of using multi-link HDR, install it on the ground shielded

rack and use it. (SBB-SNOWJMU model)

② Install ventilation opening, do not install the vent by turning it sideways or upside down

③ When installing the product, do not block the air vent on the top to prevent the product from overheating

④ When installing multiple Sbox, Install at least 1U (44.45mm) or more apart from the ventilation openings on the top

of the product

⑤ When installing on a wall, keep all distances between the wall and the top, bottom, left, right sides of the product at

least 10 mm, and also keep the distance between the wall and the ports on the back of the product at least 50 mm

for cable connection.

⑥ Make sure that the ambient temperature inside the rack mount does not exceed 35°.

⑦ Take care not to allow liquid foreign objects to enter the ventilation

openings on the top of the product

48

6. S-BOX Installation and Connection(Only SBB-SNOWJMU model)

• How to install when use Multi Link HDR function

Product recommend installing this product in a standard 19-inch server rack,

please refer 36 page about basic installation guide.

① Please open rubber plug of Multi Link HDR port.

Multi Link HDR Port

② Connect the connector of the cable of Multi Link HDR to

the Multi Link HDR port of each S-BOX.

(Refer 38 page about Cable)

(※ Note : Connect the connector’s structure to face up)

③ Menu – Picture – LED HDR – Multi Link HDR Settings –

ON

④ Set the quantity of S-BOX connected each other. (2/3/4)

⑤ Set S-BOX ID

(※ Note: It is necessary to set the ID not to overlap

between connected S-BOX)

Multi Link HDR Port

Samsung Electronics

UP

SIDE

49

6. S-BOX Installation and Connection(Only SBB-SNOWJMU model)

• Multi Link HDR Cable

Use the appropriate cable according to the quantity of S-BOX connected.

Multi Link HDR Port

Multi Link HDR Port

Samsung Electronics

50

6. S-BOX Installation and Connection(Only SBB-SNOWJMU model)

• FPGA Update Guide when using Multi Link HDR Cable

※ Note : Before update, disconnect the Multi Link HDR Cable from S-BOX.

Samsung Electronics

Factory update method

① Save a SW program called ‘TB-XCKUSBMWWS.bin’ in USB root.

② Connect the USB to S-BOX.

③ Enter Factory mode.

(Remote control ‘mute +1+8+2+Power ON’ in power off state)

④ Select “SVC → UPGRADE” menu.

⑤ Move the cursor to “FPGA UPGRADE” menu.

⑥ Press ‘Enter’ in the remote control.

⑦ Press ‘▶’ button in remote control to start the upgrade.

LSM update method

① Select ‘S-BOX Settings – Software Update’ in LSM menu.

② Select ‘Broswer’ and move to the folder with the FPGA update file

(TB-XCKUSBMWWF.bin + Info.txt)

※ Version in ‘Info.txt’ file should be higher than currently installed

version

③ Select ‘TB-XCKUSBMWWF.bin’ file.

④ Select ‘Update’ button to start the upgrade.

Multi Link HDR Port

※ Note : In case of the sites that are difficult to remove the Multi Link HDR cable, all connected S-BOX

should be AC power off/on after LSM update done. (Must turn off AC power after the update

of all S-BOX are completed)

Check the version of FPGA after update.

51

6. S-BOX Connection

Samsung Electronics

① Input the video signal to the S-BOX. (Input terminal : HDMI, DP)

② Check the signal input from SOURCE STATUS.(RED : HDMI1 , GREEN : HDMI2, Blue : DISPLAY PORT)

③ Connect from the HDBT OUT port of S-BOX to HDBT IN port of Interface Gender using LAN cable.

④ Connect from DATA OUT port of Interface Gender to DATA IN port of the first cabinet using OCM Cable.

⑤ When HDMI UHD Color is set to On, up to the 3840 x 2160 @ 60 Hz resolution is supported

by S-BOX. When HDMI UHD Color is set to Off, up to 1920 x 1080 @ 60 Hz resolution is supported.

※ Menu – Picture – Advanced Settings – HDMI UHD Color : ON

(Default: OFF, S-BOX will be reboot when it is changed.)

⑥ One SNOW-1703U supports only one type

of LED pitch cabinets. Do not connect different types

of LED pitch cabinets.

⑦ SNOW-1703U displays the screen starting

from the upper left cabinet. To view the screen,

connect the HDBT cable to the HDBT OUT 1 port on S-BOX.

• For HDBT signal stability, use the cable above CAT6

STP or FTP level. ( Length 15m~100m )

- Do not use “comb” or “pinstripe” cable.

52

6. S-BOX Installation and Connection

Samsung Electronics

⑧ Instruction for handling HDBase-T cable

Do not use “comb” or “pinstripe” cable

Use HDBase-T cables with 15 meter long at minimum

and 100 meter long at maximum.

Use only HDBase-T Alliance recommended Cables as described below.

HDBase-T Alliance Site :

Do not over bend HDBase-T cables for cable integrity.

Do not tie HDBase-T cables tightly in bundling

https://hdbaset.org/hdbaset-recommended-cables/

★ Orderly Rolled (Recommend) ★ Random Rolled

(Not Recommend)

Do not bundle HDBase-T cables with any AC power cable.

53

6. S-BOX Installation and Connection

⑧ Instruction for handling HDBase-T cable

EMI sources: Keep the cable away from electromagnetic interference environments such as high-voltage

electrical cables, electric motors (such as elevators or refrigerators), fluorescent, light-fixtures and so on

Minimum distance between HDBase-T and AC power cables

: Keep the cable at a distance of at least 12” (=30.48cm) from AC power cables

HDBase-T cables can be bundled with up to 4 cables from single S-BOX.

Do not use RJ45 coupler.

Samsung Electronics

54

6. S-BOX Installation and Connection

⑨ Instruction for trimming HDBase-T cable on site.

STP RJ45 shielded Plug. RJ45 Connector should be CAT6 or CAT7 shielded RJ45 and load bar.

Load bar

Insert conductors into the plastic loader : Using the standard wiring scheme shown here (T-568B), insert

the conductors into the plastic loader piece of the R-J45 connector. The plastic loader is necessary because

the thickness of CAT 6 cable does not allow it to sit flat in an RJ-45 connector like in normal CAT 5.

Samsung Electronics

Load bar and Drain wire

Wires aligned with Load bar

55

6. S-BOX Installation and Connection

⑩ Instruction for trimming HDBase-T cable on site.

Slide the plastic loader down the cable : Slide the plastic loader down the cable as close to the base as

possible.

Cut all conductors Using the wire cutters, cut all conductors leaving approximately 0.5” remaining.

Case 1) Cable with drain wire : See next page Case 2) Cable without drain wire: Use copper foil to touch

on the connector shell as below

Samsung Electronics

Touch on the Al foil or Braid

Copper foil

Connector shell

56

6. S-BOX Installation and Connection

⑩ Instruction for trimming HDBase-T cable on site.

Flip the drain wire up onto the RJ-45 connector Flip the drain wire up onto the RJ-45 connector. Clamp the

strain relief down on the purple jacket of the BC-HDKat6a cable using the pair of pliers.

Solder the drain wire to the metal casing of the RJ-45 connector : Solder the drain wire to the metal

casing of the RJ-45 connector and cut off the excess using the wire cutters. Verify the continuity of the

conductors and the shield using a cable tester.

Recommendation) Drain wire soldering + Copper foil

Samsung Electronics

57

6. S-BOX Connection (Redundancy)

Samsung Electronics

① If Redundant Spec should be used,

Connect from DATA IN port of Interface Gender to DATA OUT port of the last cabinet by using OCM Cable.

• For HDBT signal stability, use the cable above CAT6

SFTP level. ( Length 15m~100m )

- Do not use “comb” or “pinstripe” cable.

58

6. S-BOX Connection (Panel Setting)

① S-Box Initial Image Setting

• First S-Box Default Image Setting is optimized to LH015IFHSAS

• Image Setting will be automatically changed when LED Display is connected

• For optimized image setting, Please connect S-box to LSM

• LED Display should be connected to HDBT1 port

• Image setting will be set according to Master Cabinet connected to HDBT1 port

* If you don’t connect Sbox to LSM, Image can be unnatural.

Samsung Electronics

Control PC

(LSM)

Ethernet

S-box

HDBT

Interface Gender

Vx1+Ethernet

Cabinet 1

(Master)

Vx1

……………

<connect screen>

Cabinet N

59

6. S-BOX Connection (Grouping)

S-Box Grouping is a function used to configure a single screen using multi S-Box.

If you configure one screen with a single S-Box, do not use this function !!

When S-Box Grouping is set up, the quality improvement function(LED HDR) does not work.

Samsung Electronics

60

6. S-BOX Connection (Grouping)

② S-Box Grouping Activate

Remote controller [HOME -> Video wall -> On]

Samsung Electronics

[CAUTION]

1) Before changing S-Box Grouping in LSM, Input source resolution should change to S-Box

recommended resolution

2) If input source is not supported resolution, screen noise could occur.

Off video wall function and change input source frequency to 50~60Hz

※ LSM released 17.6 offer S-Box Grouping, Check LSM Version

61

6. S-BOX Connection (Grouping)

③ PC Frequency Change Method

Right button → Select Image Resolution → Advanced Option

Monitor Tap → Screen Frequency 60Hz

Samsung Electronics

62

6. S-BOX Connection (Grouping)

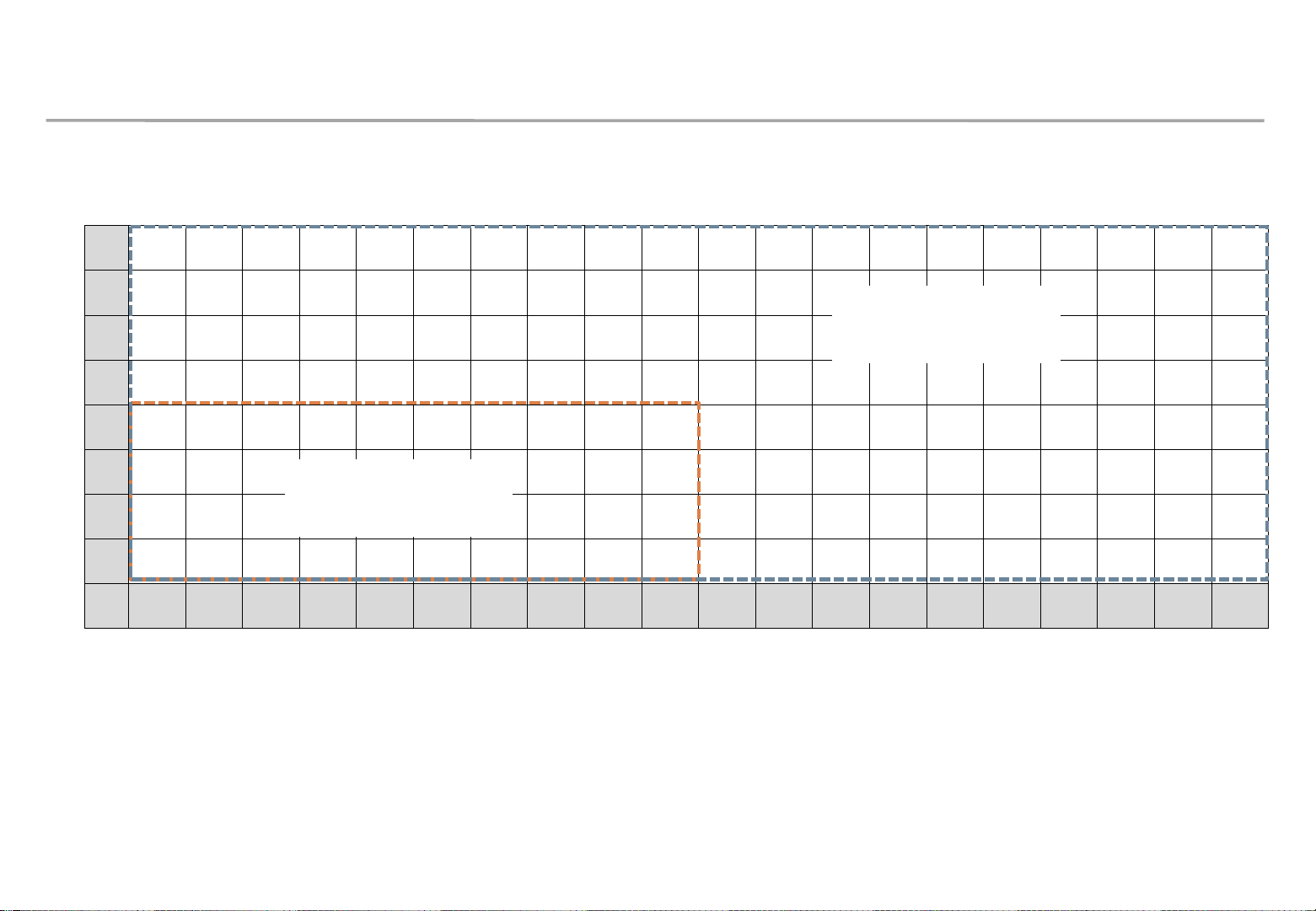

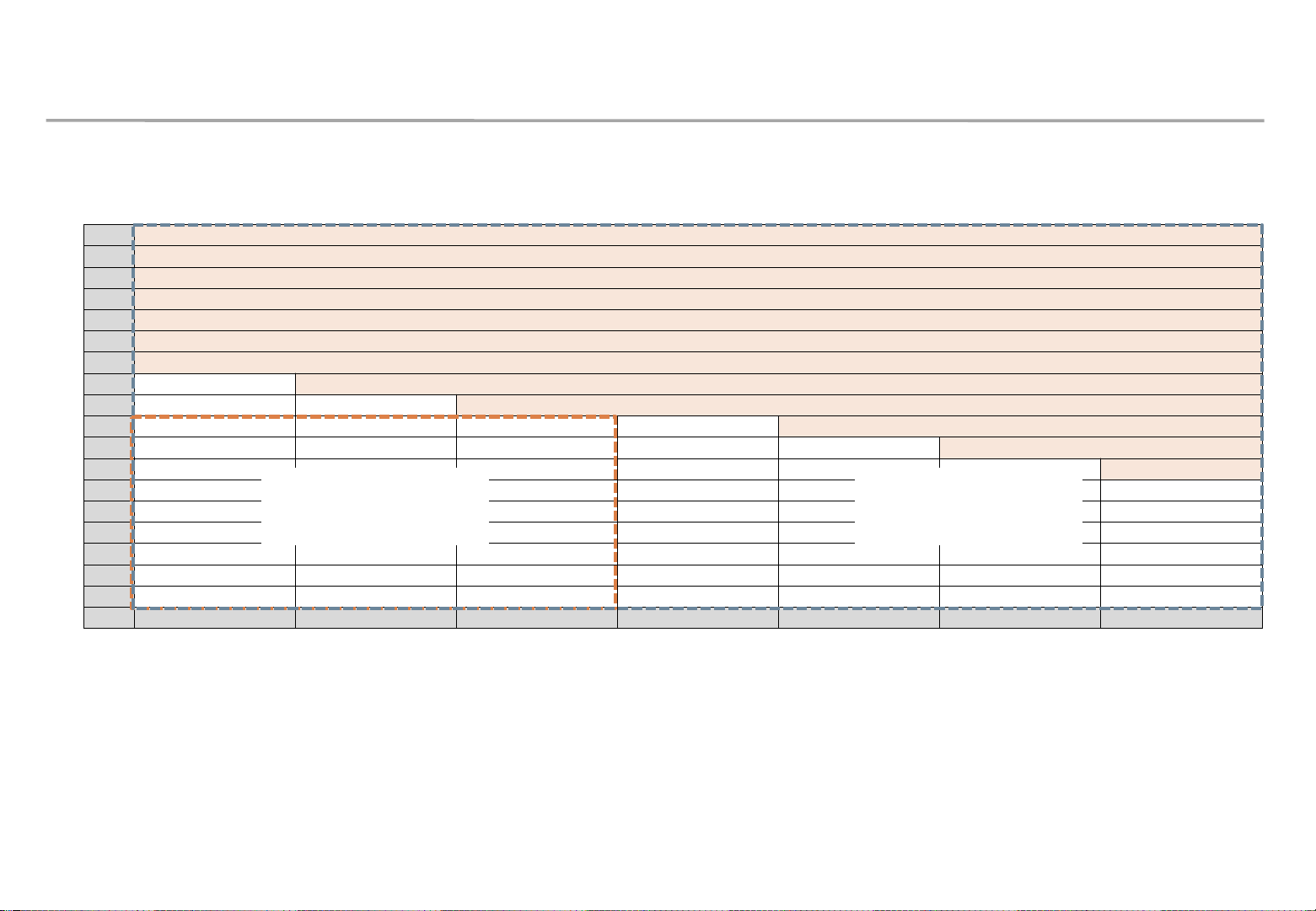

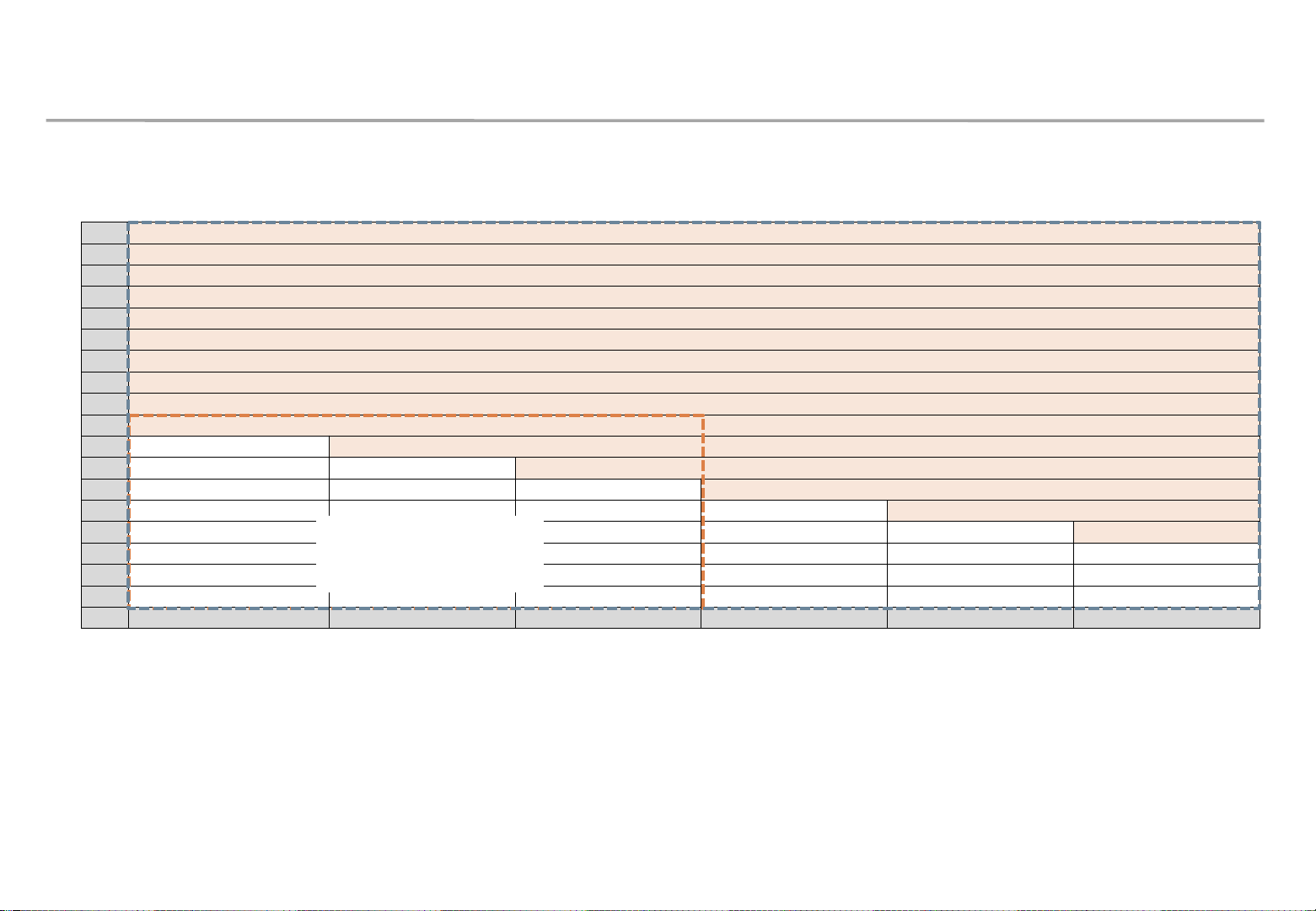

④ S-box Grouping support resolution

Samsung Electronics

63

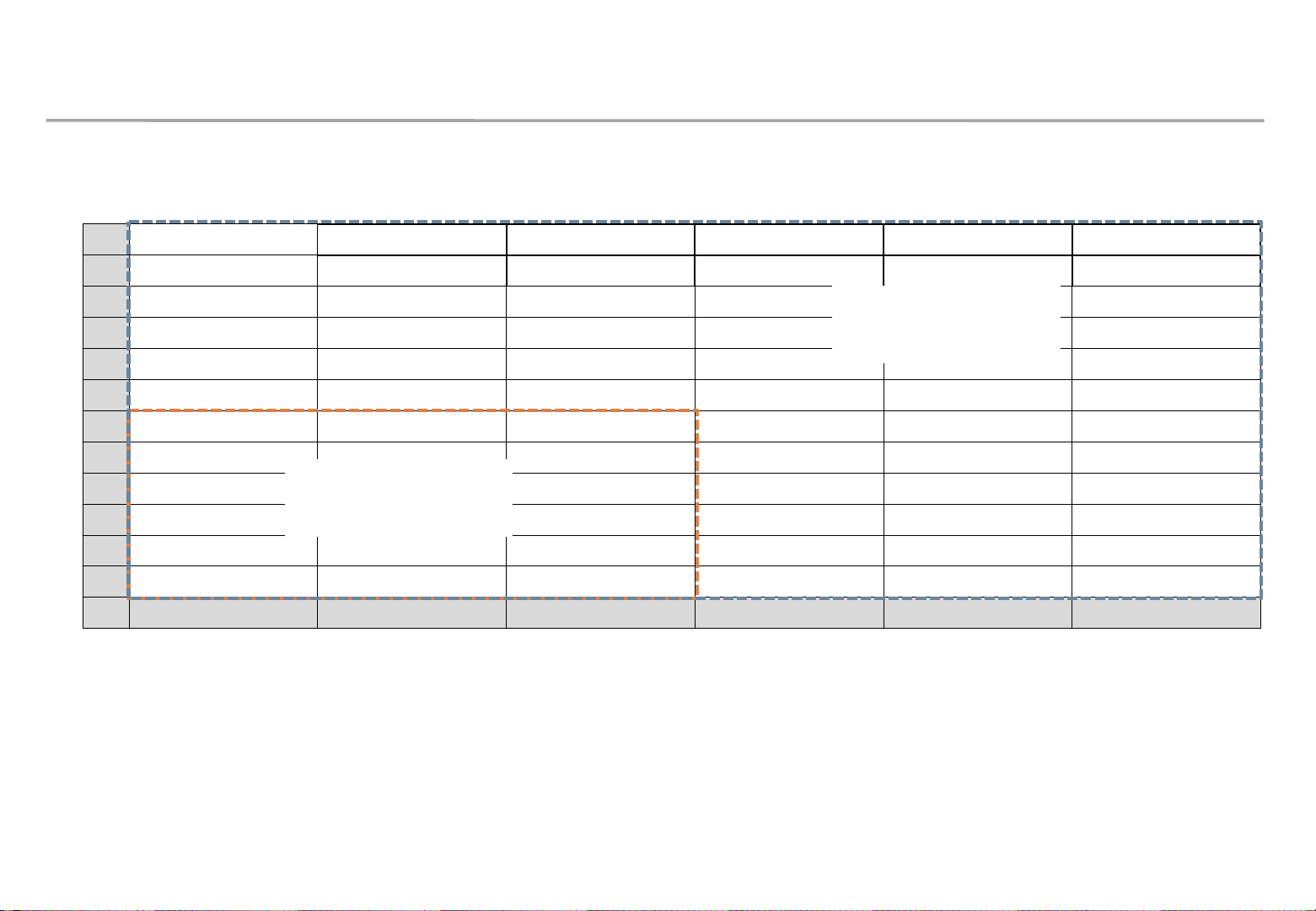

6. S-BOX Connection (Grouping)

④ S-box Grouping support resolution

Samsung Electronics

64

6. S-BOX Connection (Grouping)

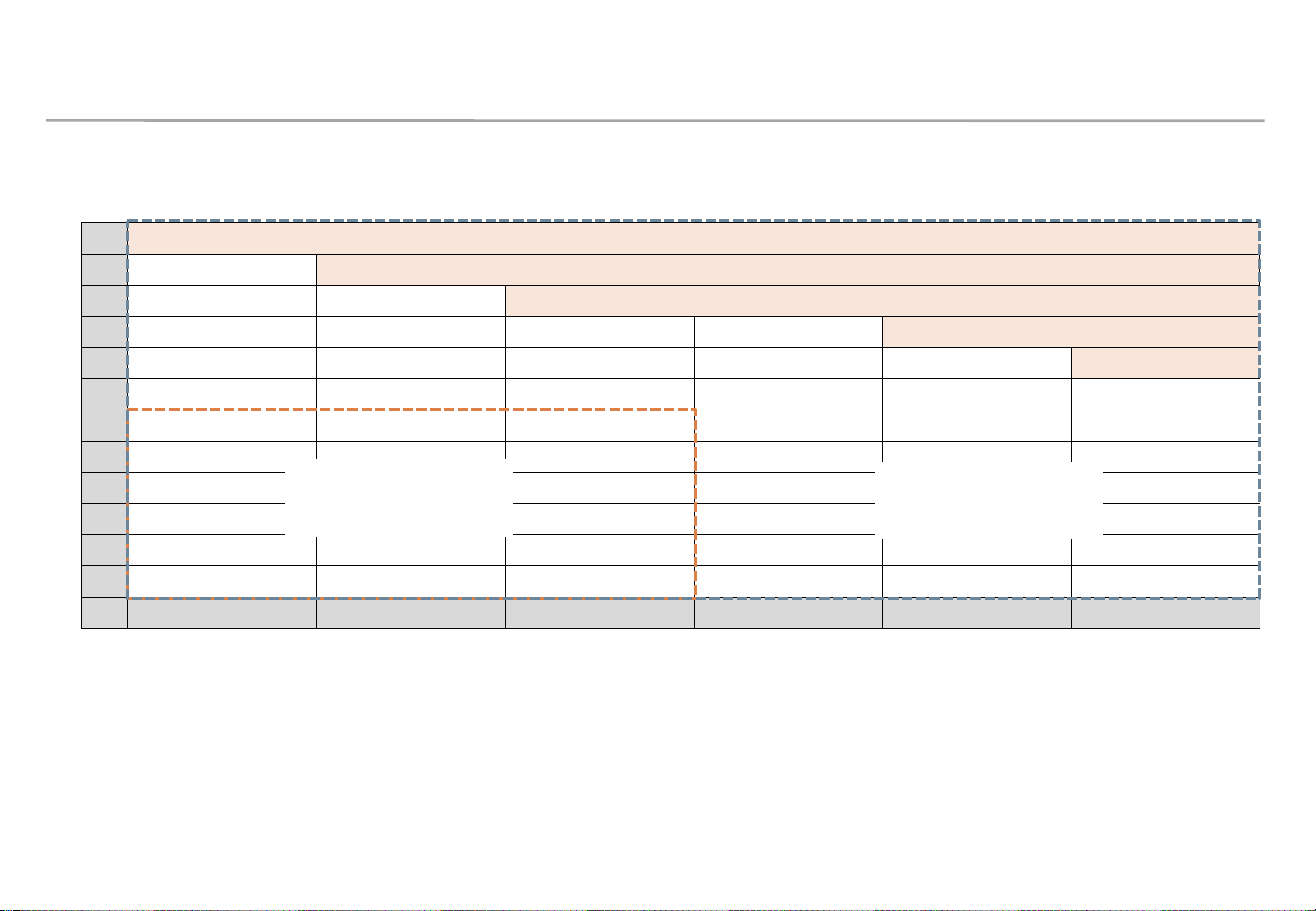

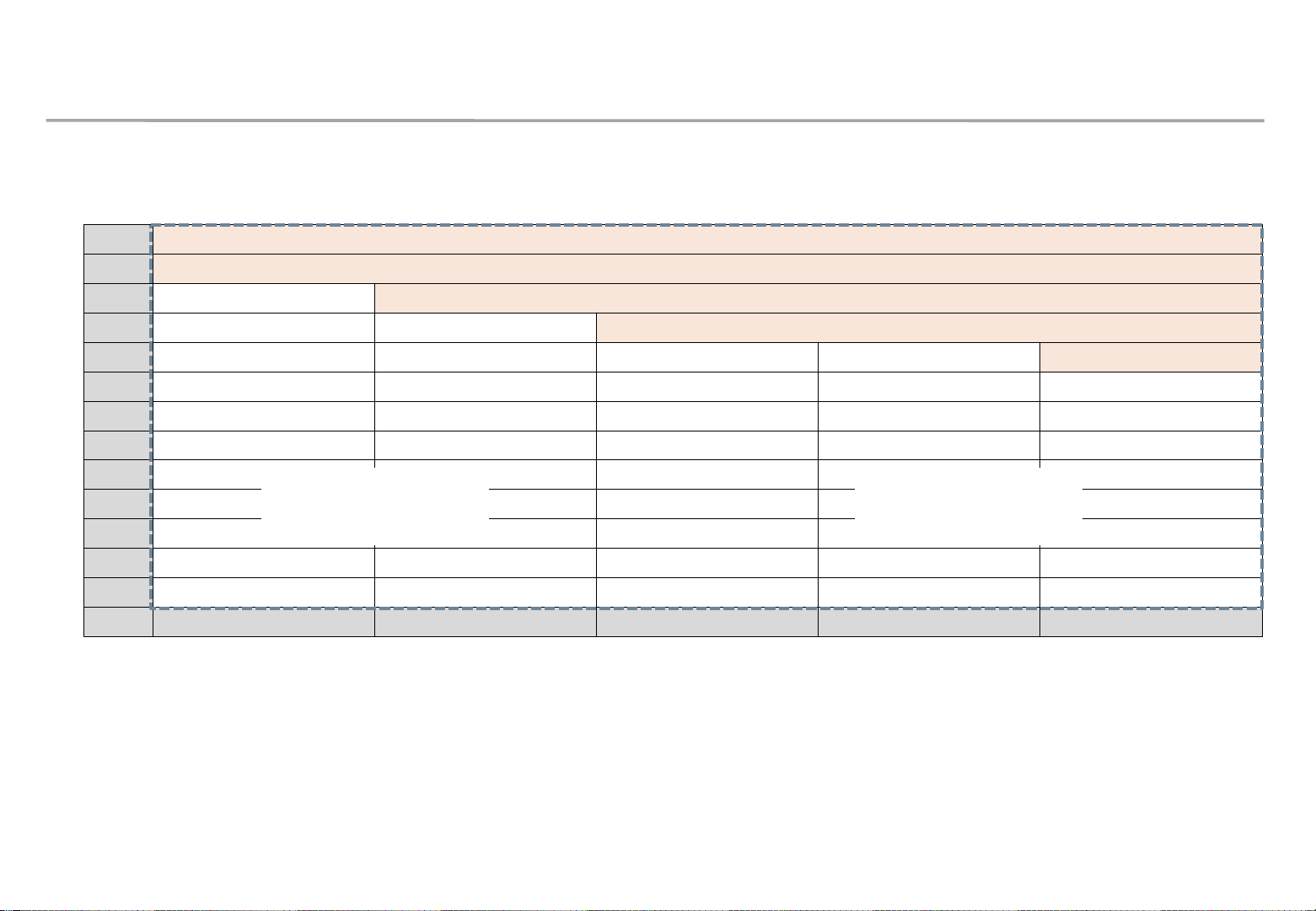

⑤ Picture menu setting

Both “Dynamic Contrast” and “Black Tone” should be off when using S-Box Grouping, since it may causes a

color difference between S-Box.

Menu → Picture → Advanced Settings,

- Dynamic Contrast : default “Medium” → Off

- Black Tone : default “Darker” → Off

Samsung Electronics

SBB-SNOWJAU / SBB-SNOWJMU

Eco Image Enhancer

*

6. S-BOX Connection (Grouping)

Samsung Electronics

⑤ Picture menu setting

When using S-Box grouping, you must set Picture mode to Calibration. Calibration mode deactivates Contrast

Enhancer, Black Tone, Auto Motion plus function so that there is no screen difference between S-Box.

In addition, change the option in other picture modes as follows table.

Picture Setting Option

Picture Mode Calibration

Advanced Settings Picture Enhancer Off

LED Picture Size Output Resolution UHD

Inverse Tone Mapping Off

Picture Mode

Dynamic Peaking Off*

LED HDR

Off

If Multi link HDR is used, the Dynamic Peaking must turn “On”.

Color Mapping Off

Picture Option Color Tone Off

6. S-BOX Connection (Service Port)

Service Port is used for check full screen, when product fail

As follows, only using compatibility monitor

■ Service port monitor: LH**PMF, LH**PHF, LU28E590DS , LU24E590DS

[CAUTION!] SERVICE PORT can be used service

Service monitor flicker is unrelated to LED Screen

※ If you use LH**PMF, LH**PHF , Change “UHD Color” On

Samsung Electronics

67

7. Settings and How to Use

Samsung Electronics

7-1 Control Program for PCs

LSM(LED Signage Manager)

• LSM Download : Samsung Display Solutions (https://displaysolutions.samsung.com)

Samsung Display Solutions > SOLUTIONS > SOFTWARE SOLUTIONS > LED Signage Solution > LED Signage Manager

※ Partner login is necessary for program download

68

7. Settings and How to Use

7-1 Control Program for PCs

Network IP Setting by USB Configuration File

Samsung Electronics

(※ S-Box(JAU and JMU only) supports since v1050.0)

This is how to set the network information of S-Box with USB

configuration file instead of network IP setting tool.

1. Saves the network information to be configured in the file 'tizen

_netconf.toml'.

2. Copy the file 'tizen_netconf.toml' to USB memory.

3. When you plug the USB memory into the USB port on the S-Box,

it is automatically set.

4. If the IP settings are successful, the LSM and S-Box are normally

connected and the execution result can be viewed through the

'tizen_netconf_result.log' file that is automatically generated in

the USB memory.

tizen_netconf.toml

[network]

device_name = "SNOWBOX“

ip_v4 = "192.168.100.10“

gateway = "192.168.100.1“

subnet = "255.255.255.0“

dns = "192.168.100.11“

[magicinfo]

ip_v4 = "127.0.0.1“

port = 7001

ssl = false

[pc_connection]

mode = "LAN" #LAN : RJ-45, Serial : RS232C

#this is a comment

[★ Notice!] If you plug the USB memory where the file 'tizen_netconf.toml'

is stored into the S-Box, the IP is automatically set. Please rename or delete

the setting file after the configuration is completed.

69

7. Settings and How to Use

7-1 Control Program for PCs

Network IP Setting Tool

Samsung Electronics

Execute : [Start] – Program – Samsung – LED Signage Manager – Network

Configuration

1. Connect PC and Sbox with RS232C Cable, select connected

SerialPort(COM*). And click “open” button.

2. Default ID of SBox is 1.

3. Enter IP, SubnetMask, Gateway, DNS of S-box, and click “Apply”

button.

4. Check the result of connection and status of MDC Protocol.

5. When IP address is normally setup, “Change Type to RJ45” button is

appear. If LSM and SBox is connected successfully, click “Change Type

to RJ45”. Then, PC connection with s-box is changed to RJ45 from

RS232.

[★ Cautions!] Recommend to use static IP address for the S-Box.

If DHCP is used, IP address is changed automatically and LSM can be

disconnected.

The 192.168.10.x band is used for internal communication of the LED Cabinet.

Please use IP another IP band (except 192.168.10.x band)

Do not assign the temporary IP, assign the S-Box IP (1 EA) through IT

manager.

1

2

3

4

70

7. Settings and How to Use

7-1 Control Program for PCs

LSM(LED Signage Manager)

• Software that adjusts the LED Cabinet Layout in Remote

Samsung Electronics

1. PC and S-box should be connected through Ethernet connection.

2. S-box is connected to Interface Gender using HDB-T Lan Cable

3. Interface Gender is connected to the first LED Cabinet using OCM cable.

4. LED cabinets are connected in daisy chain method using OCM cable.

S-box

HDBT

Vx1+Ethernet

Cabinet 1

Cabinet 4

Ethernet

Control PC

Interface Gender

Vx1

Cabinet 2

Vx1

Vx1

Cabinet 3

71

7. Settings and How to Use

7-1 Control Program for PCs

LSM(LED Signage Manager)

• Start– Login Page

1. If the LSM gets operated for the first time, the

page to set the password will appear.

2. To set the password, users have to input the

same password two times and then click the

“Start” button.

3. If the user does not want to use a password,

then please select “Don’t use password” option.

Samsung Electronics

Then, password input would no longer be

required whenever the LSM gets operated.

72

7. Settings and How to Use

7-1 Control Program for PCs

LSM(LED Signage Manager)

• New Connection

1. To add connection information, you can either use

Search function or input the IP address by yourself. If

you click on the Search button, the IP addresses

available on S-BOX in the same network will appear. If

you know the IP address of the S-BOX, then you can

input the address by yourself.

2. If you click Add button, the relevant connection

1 1

1

Samsung Electronics

1

2

information will be added on Setup and Connect.

3. Users can select the Model Type of S-Box. There are

three(3) Model Types (Without Cabinet IP / With

Cabinet IP(FHD) / With Cabinet IP(UHD)).

2

73

7. Settings and How to Use

7-1 Control Program for PCs

LSM(LED Signage Manager)

• New Connection-Connect

1. When you are using the previous version of S-BOX, select

“Without Cabinet IP” option.

2. If you are using UHD S-BOX, select “With Cabinet IP

(UHD)” option. You should designate the IP Address of

the LED Cabinet by each port. Set the number of units

Samsung Electronics

[★ Cautions!] Recommend to use static IP address for the LED devices.

If DHCP is used, IP address is changed automatically and LSM can be

disconnected.

The 192.168.10.x band is used for internal communication of the LED Cabinet.

Please use IP another IP band (except 192.168.10.x band)

Do not assign the temporary IPs, assign the LED IPs (4 EA) through IT

manager.

connected, and then click “Connect”.

3. If you are using FHD S-BOX, select “With Cabinet

IP(FHD)”. Set the IP Address and the number of units

connected in LED Cabinet, and then click “Connect”.

※ If you have already set the IP on the Cabinet, check “Connect with

existing settings” option.

※ For the case of UHD, if you are going to use only some of the

four(4) ports, input the IP Address only for that particular Group

relevant with your use.

※ Should be different than S-Box / Should be different for each groups

※ Should be same as S-Box

74

7. Settings and How to Use

Samsung Electronics

7-1 Control Program for PCs

[★ Cautions!]

LSM(LED Signage Manager)

• Main Window-Home Window

1. Home Screen : Information of the connected device, input source, cabinet composition, and error device are shown.

The network port 1515, 48484, 48485 and 58585 are used for internal

communication between S-BOX and LED Cabinet.

It should be include the firewall or network exception if customer used secured

network.

75

7. Settings and How to Use

7-1 Control Program for PCs

LSM(LED Signage Manager)

• Main Window-Home Window

1. Input source: Input source, resolution, connection time of

S-BOX are shown.

2. Cabinet Layout : Layout, number of units, number of

Samsung Electronics

connections and number of disconnections in all LED

cabinets are shown.

3. Faulty device: ID of the LED cabinet in error status and the

content of the error are shown.

76

7. Settings and How to Use

7-1 Control Program for PCs

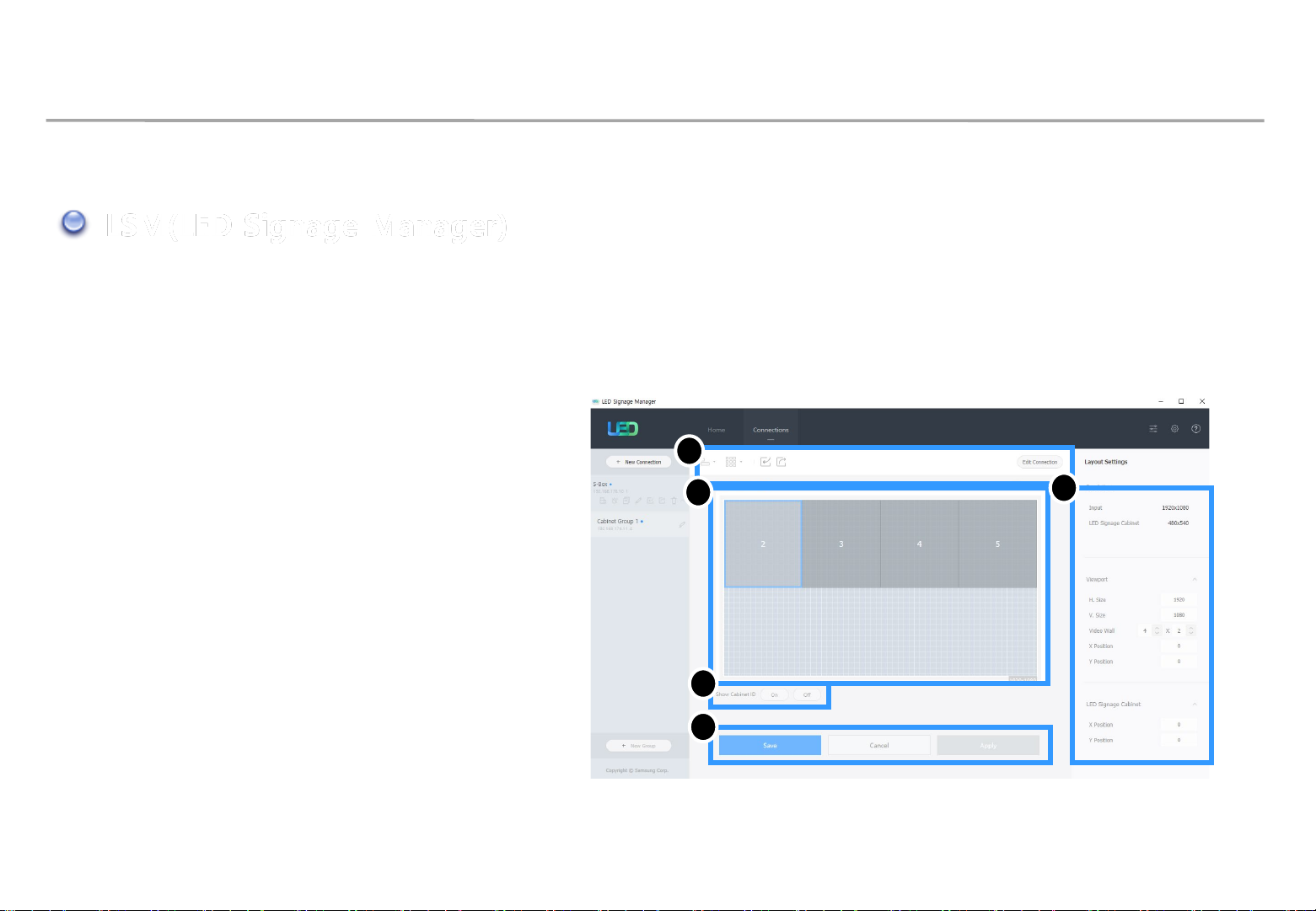

LSM(LED Signage Manager)

• Main Window-Edit Connection Layout Window

1. Connection layout: The location and the layout

of each LED cabinet are adjusted in the output

source area of the S-BOX.

2. Feature View: Edit button to modify the

connection information and LED cabinet

automatic alignment function, etc. are provided.

3. Device Information/Setting View:

The LED cabinet information is shown for in

three different categories below:

2

1

Samsung Electronics

3

(i) Resolution: Resolution information of the

input source

(ii) View Port: Width/Length size, Video wall

matrix, x/y coordinate settings

(iii) LED Signage Cabinet: x, y location of LED

cabinet

4. Show ID: IDs of each will be shown in all

connected LED cabinets when this option is

selected.

5. Save/Apply and Cancel

4

5

77

7. Settings and How to Use

7-1 Control Program for PCs

LSM(LED Signage Manager)

• Main Window-Connection Window

1. Device connection list view:

Check S-BOX composition, modify and

delete S-BOX connection, show by each

LED Cabinet Group

2. Connection layout (View Port):

Check the location and layout of each

LED cabinet

1

3

Samsung Electronics

6

4

2

3. Category View:

Home / Connections tab and settings

4. Device Information/Setting View:

Change S-BOX settings (screen settings,

etc.)

5. Sub Information View: Displays:

Monitoring log, S-BOX and LED cabinet

information

6. Link of LED Configurator, Preference,

Help files

5

78

7. Settings and How to Use

7-1 Control Program for PCs

LSM(LED Signage Manager)

• Main Window-Connection Window - Device Information/Setting View

1. Basic :

. Power On/Off, Change input source, Screen

Mute / Freeze

2. Picture

. Change Picture Mode, Brightness / Contrast

/ Sharpness, Color, Tint(G/R), Color Temp(K),

Gamma, White Balance adjustment

3. Picture Options

. Color Tone, HDMI Black Level, Film Mode,

etc.

Samsung Electronics

4. Advanced Settings

. Adjust Black Tone, Flesh Tone, Color Space,

etc.

5. System

. Auto Power On/Off, Standby Control

Clock, Timer, System Restart Interval

Software Update function

79

7. Settings and How to Use

7-1 Control Program for PCs

LSM(LED Signage Manager)

• System - System Restart Interval (Cont’d.)

- For product stability, S-Box reboot every week.

- Default setting : 4:00am ~ 5:00am, Monday

- To change rebooting time, Use System Restart Interval of LSM

Samsung Electronics

※ Check LSM time correct, or S-Box will reboot succrently

80

7. Settings and How to Use

7-1 Control Program for PCs

LSM(LED Signage Manager)

• System - System Restart Interval

- If reboot function is unnecessary, go to factory menu and off the weekly boot

: Factory – Control – LFD Option – Weekly Reboot : ON → OFF

Samsung Electronics

81

7. Settings and How to Use

7-1 Control Program for PCs

LSM(LED Signage Manager)

• Main Window-Connection Window - Device Information/Setting View

6. Cabinet Settings (※ Each menu can be supported for some specific models)

. LOD (LED Open Detection) : Check the number of LED Off

(Screen can be blinking when Recheck)

. Pixel RGB Data Reload : Load the Pixel Calibration data to the screen

. Pixel RGB Data Request : Download the calibration data via Cal Reader.

. OnScreen Display : On or Off for “No Video” OSD display on cabinet.

. LED Brightness : Adjust the screen brightness (0 ~ 10)

Samsung Electronics

. Refresh Rate : Adjust refresh rate (Normal or High)

(Some models support only High)

. Software update : Update the cabinet software (Main sw, FPGA, Calibration data)

82

7. Settings and How to Use

7-1 Control Program for PCs

LSM(LED Signage Manager)

• Main Window-Connection Window - Device Information/Setting View

7. Cabinet Calibration

. Perform RGB CC calibration for each module/

Cabinet.

. Calibrate the boundary surface of each module.

. Multiple Selection : Check next page.

. Turn on/off CC. Turn on/off Edge Correction.

Samsung Electronics

. Gradation Calibration : For expert user only.

. Download module calibration data through Batch

Upload/Import/Export.

83

7. Settings and How to Use

7-1 Control Program for PCs

LSM(LED Signage Manager)

• Main Window-Connection Window - Device Information/Setting View

. Cabinet Calibration

└ Multiple Selection

: Calibrate the boundary surface of selected multiple modules. Change offset then brightness is adjusted for edge.

Use Apply button for applying.

Samsung Electronics

84

7. Settings and How to Use

7-1 Control Program for PCs

LSM(LED Signage Manager)

• Main Window-Connection Window - Sub Information View

1. Monitor Window:

Checking MDC communication log and

connected device information available,

able to be extracted via file

2. LED Signage Cabinet:

IC information and Power information of

LED cabinet

Samsung Electronics

3. LED Signage Box:

IP address, MAC address, ID range of LED

cabinet, number of LED cabinet

(all/connected/not connected), serial

number, version information

85

7. Settings and How to Use

7-1 Control Program for PCs

LSM(LED Signage Manager)

• Main Window-Preference

1. Options

number of times the command retried

interval of checking error status

alarm temperature warnings

2. Support

program language

Log data management

notify device error through Mail

Password settings option

Samsung Electronics

3. About Software

the current version of LSM and update

function

86

7. Settings and How to Use

7-1 Control Program for PCs

LSM(LED Signage Manager)

• Software Update

1. Prepare the update SW File

Samsung Electronics

Info.txt

L-IERMWWAC-1001.0

2. Click on the "Software Update" button in "Cabinet Settings" on the LSM menu.

※ For AM3352, update files for LSM and USB are different.

※ A separate tool is required to update the FPGA SW to USB.

L-IERMWWAC-1001.0

FPGAFW-2525218466

FPGAFW.bin

Info.txt

87

7. Settings and How to Use

7-1 Control Program for PCs

LSM(LED Signage Manager)

3. Click the Browse button to select the SW file to update.

Samsung Electronics

Info.txt

L-IERMWWAC-1001.0

※ Never update the "info.txt" file. Causes system failure.

4. Press the Update button to update the cabinet.

FPGAFW.bin

Info.txt

88

7. Settings and How to Use

7-1 Control Program for PCs

LSM(LED Signage Manager)

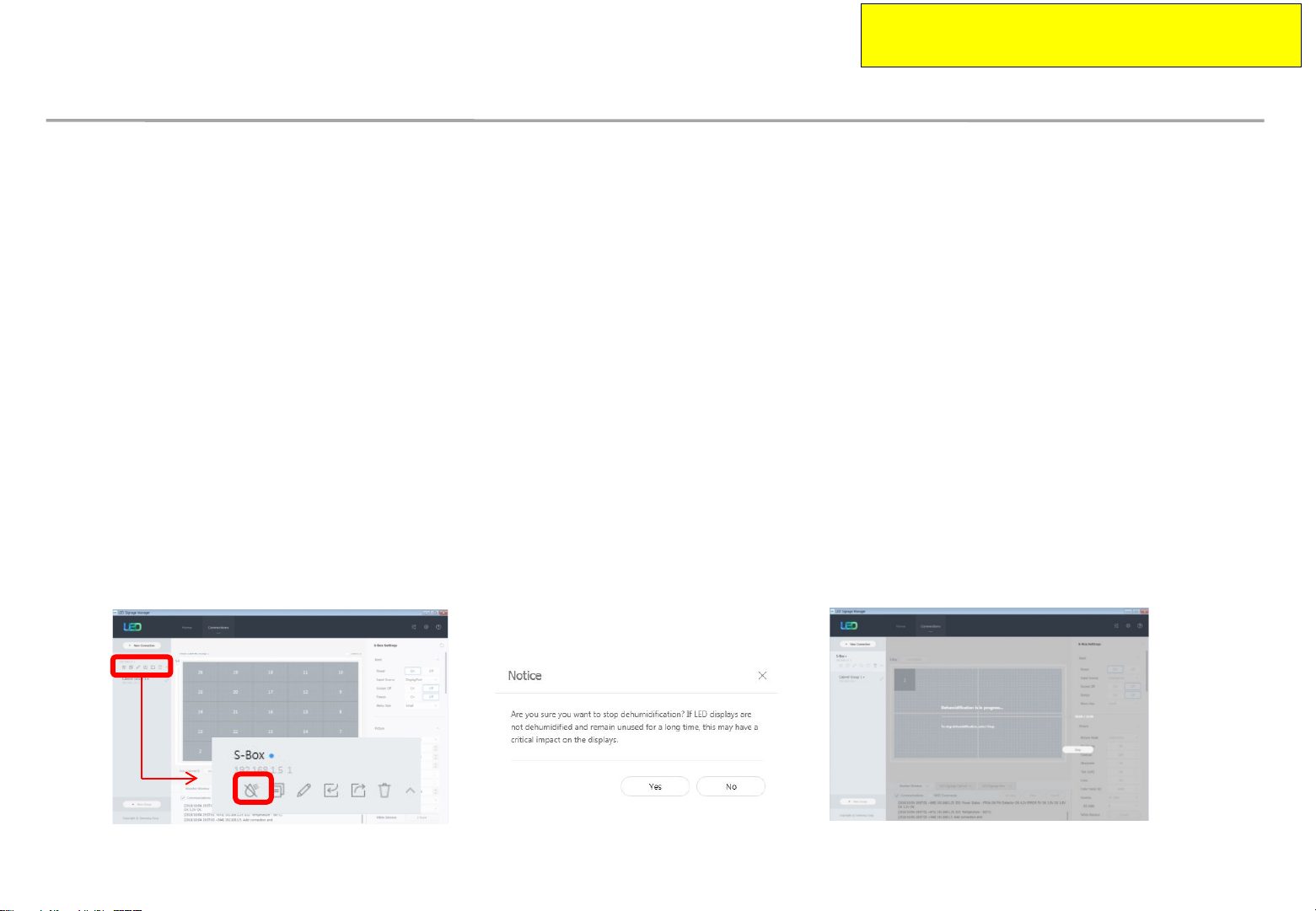

• Dehumidification Mode using LSM

1. The dehumidification mode icon is provided

under the S-Box menu.

2. To turn on dehumidification mode, click the icon.

(Proceed : 24 hours)

Samsung Electronics

3. It is possible to view how long the

dehumidification has been on.

4. To turn off the mode, click the “Stop” button.

89

7. Settings and How to Use

7-1 Control Program for PCs

LSM(LED Signage Manager)

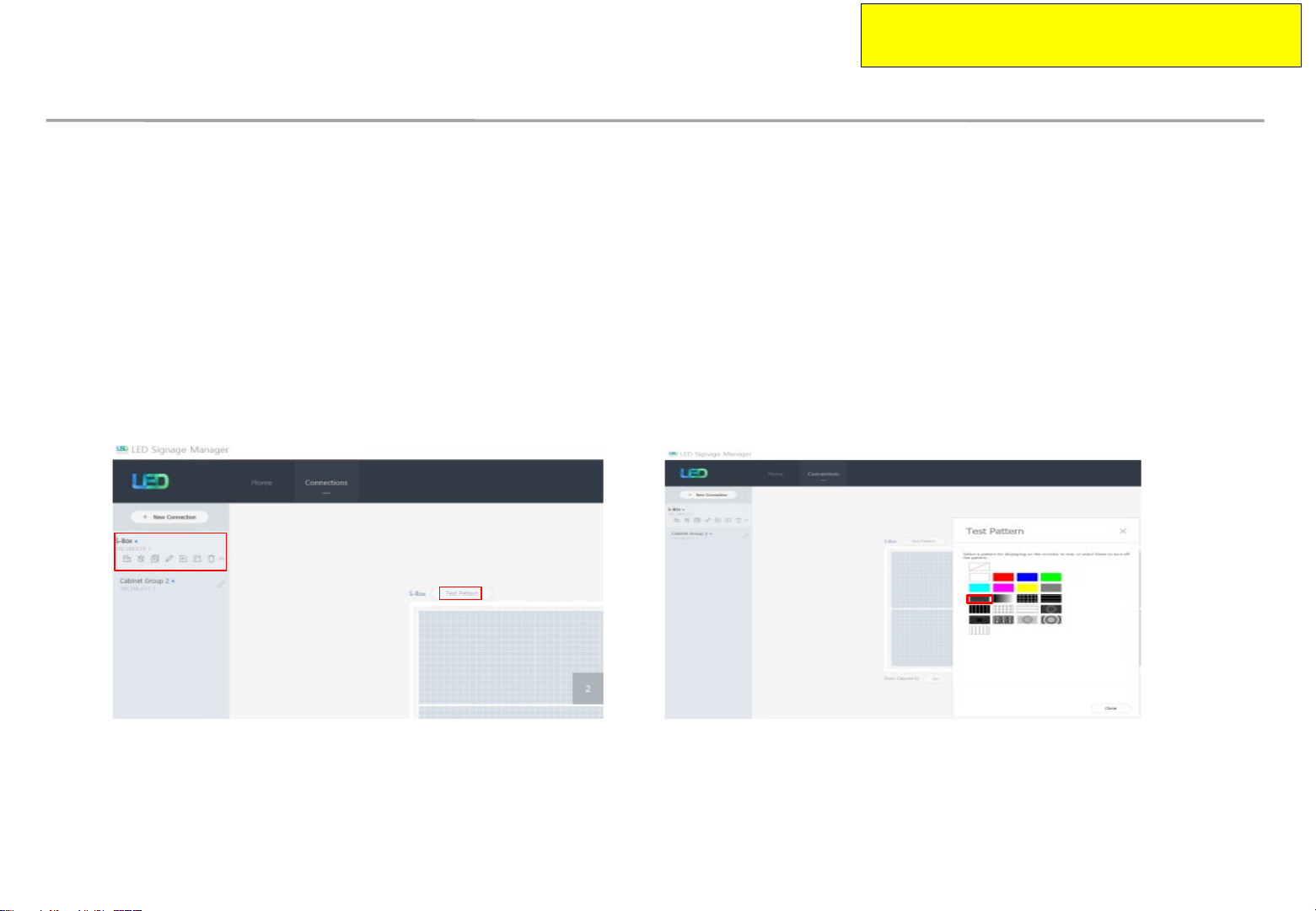

• test pattern using LSM

1. S-Box Test Pattern

- Utilize when installing cabinets (only for test)

*

When the test pattern is turned on / off or the pattern

is changed, background screen may be visible for a

while by overlay layer switching.

Samsung Electronics

90

8. Issue and Solution

Samsung Electronics

◇ Problem Case 1

Rule 1: The 1stCabinet from I/G board must be ID #2 for the LSM Setup

Rule 2: The 1stCabinet from I/G board must be set as Master. The 2ndMaster cabinet is not allowed for the LSM connection.

Situation: After changing Main board or Cabinet, If the original Master cabinet is move the other place,

LSM configuration will be fail because of violation of rule 1.

during the LSM setup it cause a network fail because the 1stcabinet is not ID #2.

HDB-T(LVDS)

OCM(Vx1)

Redundancy

OCM(Vx1)

Master

18 17 14 13 10 9

19 16 15 12 11 8

ID:2 3 4 5 6 7

Re- install

9 11 13 4 18 8

19 10 2 14 16 17

12 3 15 5 6 7

1stCabinet’s ID: 12

Violation of Rule #1

9 11 13 4 18 8

19 10 2 14 16 17

12 3 15 5 6 7

LSM Connection Fail because 1

cabinet is not ID 2

Solution: Do Factory Reset the 1stCabinet

st

91

Master

Master

8. Issue and Solution

Samsung Electronics

◇ Problem Case 1

Rule 1: The 1stCabinet from I/G board must be ID #2 for the LSM Setup

Rule 2: The 1stCabinet from I/G board must be set as Master. The 2ndMaster cabinet is not allowed for the LSM connection.

Situation: After changing Main board or Cabinet, If the original Master cabinet is move to slave cabinet area.

Although the 1stcabinet is set as a Master after doing factory reset, LSM configuration will be still fail

because of violation of rule 2. LSM setup can be start, but can’t be complete because of the 2ndMaster cabinet.

14 13 10 9

12 11 8

2 3 4 5 6 7

HDB-T(LVDS)

OCM(Vx1)

Redundancy

OCM(Vx1)

18 17 14 13 10 9

19 16 15 12 11 8

ID:2 3 4 5 6 7

9 11 13 4 18 8

19 10 2 14 16 17

Re- install

3 15 5 6 7

ID:

2

The factory reset of 1stcabinet is done

From ID 2 to ID13, the LSM connection will

be OK.

but 14

th

cabinet will be connection fail.

Over 14

might be not correct. Because of

nd

2

Solution: Do Factory Reset the 2

th

cabinet the picture

Master cabinet

nd

Master Cabinet

92

8. Issue and Solution

◇ How to do Factory Reset

After checking cable connection order, the cabinet which is not display the proper picture position will be

Wrong positioned Master cabinet. In this case, Do factory reset to change to slave cabinet .

Refer the below guide to do factory reset in front side and backside.

Samsung Electronics

The 1stcabinet is not ID number 2. Because all cabinets

connection are failed.

The 14thcabinet which is displaying the not proper picture

position might be wrong positioned Master cabinet.

Hook

Factory Reset in back side

Press button

over 10 Seconds.

Remove module in

the front

Hook

Set LSM again.

18 17 14 13 10 9

19 16 15 12 11 8

ID:2 3 4 5 6 7

Factory Reset in front side

Remove Cover

Do Factory Reset

Handle

Press hook unlock cover

93

9. Cable/Power Connection

Samsung Electronics

9-1 Cable Connection

• If using 110V/220V, you can connect at most 3 IFH-D(IF040/IF060/IF025) devices.

• Exceeding the recommended maximum number of devices can cause the circuit breaker of the

product to trigger due to overload. SURELY CONNECT the devices less than the recommended

maximum number of devices.

※ No responsible for Samsung Electronics in case of exceeding the recommended maximum

number of devices connection.

• The label info which is attached behind product shows rated power of cabinet and rated current of

outlet.

94

9. Cable/Power Connection

9-2. The caution for Cabinet installation and Cable connection(Full Front)

1) The set installation order Must be Left -> Right direction. Because The structure of Wall

mount hole for cabinet installation is downward diagonal direction.

→ The set installation order and The cable connection order are different.

2) After installing cabinets one line is complete, make sure the connection is OK

by connecting OCM/Power cable. Then, Install next line.

( Do not turn on the screen more than 10 seconds)

Samsung Electronics

3) In case of connecting OCM cable upward, Connect OCM cable to Lower set first.

4)

The two output of Interface gender should be connected to First cabinet and Last cabinet each

→ Interface Gender should be installed at Left-Center side of LED wall (refer to page13)

(Within 2~4M compared to first and last cabinet for connecting OCM cable)

95

9. Cable/Power Connection

Samsung Electronics

9-3 The direction for Cabinet installation

1) Installation of First row cabinet starts at the bottom of Left-end.

2) After installing cabinets one line is complete, make sure the connection is OK

by connecting OCM/Power cable. Then, Install next line.

3) From Second row, it starts from bottom to top.

1) 1strow :

Install set form Left-end

Check Gap between module

inside cabinet

2) Connect

Power/Signal Cables

3) 2ndrow :

Bottom to top

Check Gap between cabinets and

whether installed in a straight direction.

4) Same way

96

9. Cable/Power Connection

9-4. Cable Connection : Data flow standard

◎ Connect OCM cable Forward direction

Samsung Electronics

Reverse

Forward

P4.0 (1200X1080)

Reverse

Forward

P2.5 (1920X1440)

P6.0 (800X600)

97

9. Cable/Power Connection

9-5. Apply COVER CAP to POWER IN CABLE of the top cabinets.

Samsung Electronics

COVER-CAP

POWER-IN CABLE

COVER-CAP

8*3 (예시)

98

10. Seam Adjustment

Samsung Electronics

◇ Check and Adjust Seam

① Check whether there is any Black Line between the cabinets in White Screen. (Fig.1)

② Check whether gap, differences occur between each module. (Fig.2)

※ Gap: appears as a black line in every direction.

※ Difference: A bright white line occurs in one direction whereas a black line occurs in the opposite direction.

③ If gap occurs, use module with hand from the outermost corner.

④ If differences occur, disassemble low LED module, and spin the Holder-Magnet using tools to

adjust the height.

※ If the Tool spins 0.5 rotation first, and then spins 36 degrees later, the module height will be moved by 0.1mm. (Fig.3)

Black line occurs in white screen

GAP

LED module 1

CABINET

LED module 2

Tool

Moves 1mm

for each

rotation

Holder Magnet

Tool

(upside down)

Difference

LED module 1

LED module 2

CABINET

Fig.1 Black line Fig.2 Gap/Difference

between Modules

Fig.3 How to adjust Difference

Holder

Magnet

Moves 1mm

for each

rotation

99

Loading...

Loading...