Page 1

Radio Access Network

RT4401-48A

Installation Manual

<Replace this text with a short document summary of no more two or three lines>

Document Version 3.0

February 2019

Document Number: 2600-00NETNGAA

Page 2

© 2019 SAMSUNG Electronics Co., Ltd.

This manual should be read and used as a guideline for properly installing and/or operating the

product. Owing to product variations across the range, any illustrations and photographs used in

this manual may not be a wholly accurate depiction of the actual products you are using.

This manual may be changed for system improvement, standardization and other technical

reasons without prior notice.

Samsung Networks documentation is available at http://www.samsungdocs.com

All Rights Reserved. No part of this document shall be photocopied, reproduced, stored in a

retrieval system, or transmitted, in any form or by any means whether, electronic, mechanical, or

otherwise without the prior written permission of SAMSUNG Electronics Co., Ltd.

No warranty of accuracy is given concerning the contents of the information contained in this

publication. To the extent permitted by law no liability (including liability to any person by reason of

negligence) will be accepted by SAMSUNG Electronics Co., Ltd., its subsidiaries or employees for

any direct or indirect loss or damage caused by omissions from or inaccuracies in this document.

SAMSUNG Electronics Co., Ltd. reserves the right to change details in this publication without notice.

SNMTC-v3-0312

Page 3

Contents

Preface x

Conventions in this Document ......................................................................................................... x

New and Changed Information ....................................................................................................... xi

Revision History ............................................................................................................................... xi

Organization of This Document ...................................................................................................... xi

Related Documentation .................................................................................................................. xi

Personal and Product Safety ........................................................................................................... xii

Equipment Markings ...................................................................................................................... xvi

Chapter 1 Before Installation 1

System View and External Interface ................................................................................................ 1

System View ................................................................................................................................. 1

System External Interface ............................................................................................................ 2

Specifications ................................................................................................................................... 5

Cautions for Installation ................................................................................................................... 7

Before Installing ........................................................................................................................... 7

While Installing ............................................................................................................................ 7

After Installing ............................................................................................................................. 8

Installation Tools .............................................................................................................................. 9

Chapter 2 Installing System 12

Installation Procedure .................................................................................................................... 12

System Arrangement ..................................................................................................................... 13

Using Tilting and Swiveling Bracket ........................................................................................... 13

Using Tilting Bracket .................................................................................................................. 16

Without Tilting Bracket .............................................................................................................. 17

Using Side by Side Bracket ......................................................................................................... 17

Transporting and Unpacking .......................................................................................................... 19

Bringing in Items ........................................................................................................................ 19

Unpacking .................................................................................................................................. 19

Fixing RRH ...................................................................................................................................... 20

Assembling Clip on Antenna ...................................................................................................... 20

Assembling AC-DC Power Unit ................................................................................................... 24

Using Tilting and Swiveling Bracket ........................................................................................... 26

Using Tilting Bracket .................................................................................................................. 46

Without the Tilting Bracket ....................................................................................................... 54

Using Side by Side Bracket ......................................................................................................... 62

Chapter 3 Connecting Cables 80

Cabling Procedure .......................................................................................................................... 80

Guidelines for Cable Connections .................................................................................................. 81

Cable Path Inspection ................................................................................................................ 81

Cable Cutting ............................................................................................................................. 82

Cable Installation ....................................................................................................................... 82

Cable Binding ............................................................................................................................. 83

Connector Attachment............................................................................................................... 83

Identification Tag Attachment ................................................................................................... 84

Cabling Diagram ............................................................................................................................. 85

RT4401-48A Installation Manual v3.0 iii

Copyright © 2019, All Rights Reserved.

Page 4

Contents

Grounding ...................................................................................................................................... 87

Connecting Ground Cable .......................................................................................................... 87

Power Cabling ................................................................................................................................ 92

Connecting Power Cable ............................................................................................................ 93

Interface Cable Connection .......................................................................................................... 104

Remove/Insert Optical Module ................................................................................................ 104

Connecting CPRI Cable ............................................................................................................. 106

Connecting UDA Cable ............................................................................................................. 110

Connecting RET Cable .............................................................................................................. 115

Connecting RF Cable (External RF Antenna connection) .......................................................... 118

Assembling Cable Cover ............................................................................................................... 124

Chapter 4 Inspect the Installation 126

Appendix A Acronyms 130

Appendix B Clean the Optical Connectors 131

Introduction ................................................................................................................................. 131

Measure the Optical Output and Connecting the Optical Connector ...................................... 131

Appendix C Standard Torque 133

RT4401-48A Installation Manual v3.0 iv

Copyright © 2019, All Rights Reserved.

Page 5

List of Figures

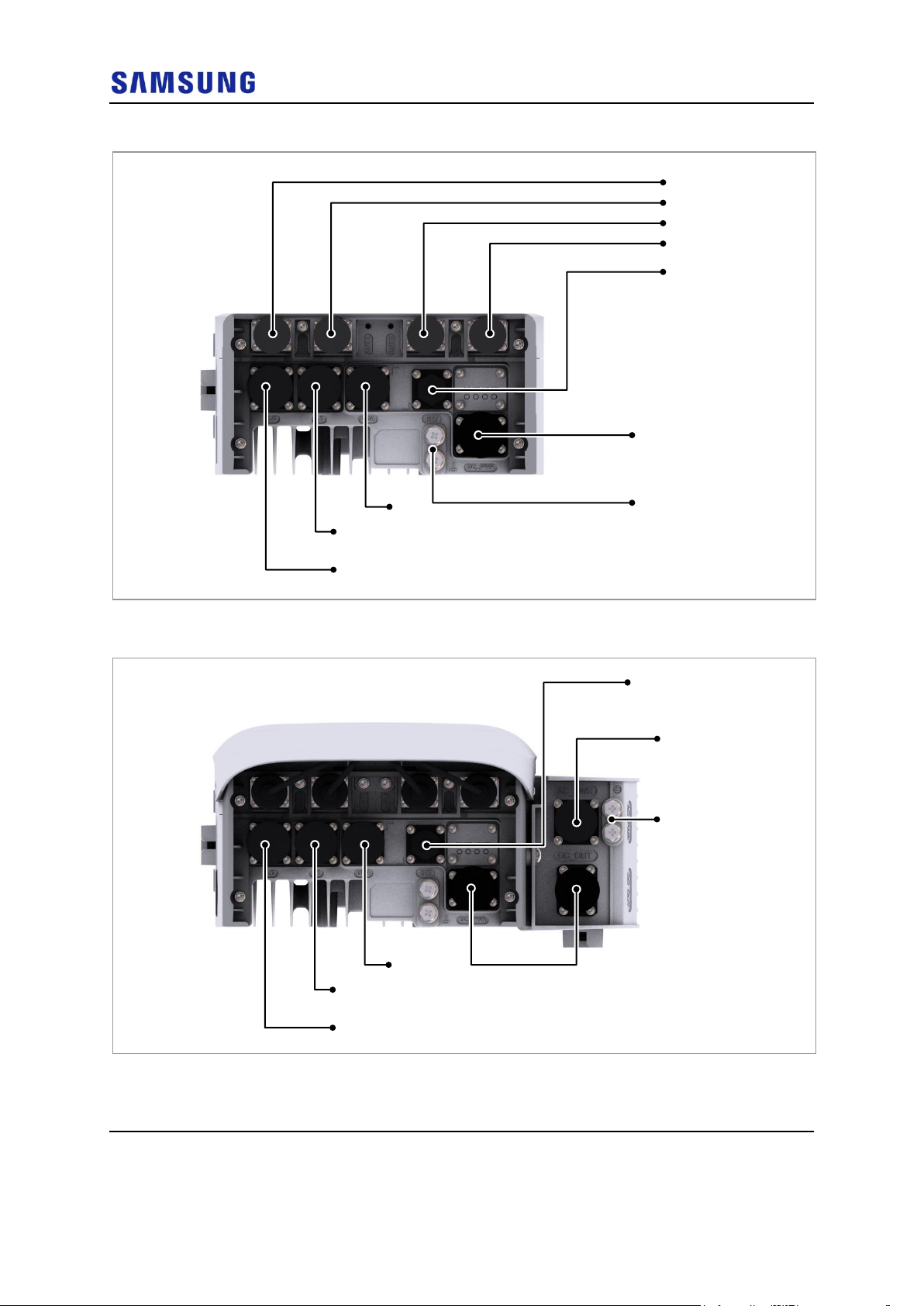

Figure 1. System View (RRH only) ................................................................................................................... 1

Figure 2. System View (with Clip-on: Antenna + AC-DC Power Unit).............................................................. 2

Figure 3. System External Interface (RRH only) .............................................................................................. 3

Figure 4. System External Interface (with Clip-on: Antenna + AC-DC Power Unit) ......................................... 3

Figure 5. Procedure to Install the RRH .......................................................................................................... 12

Figure 6. RRH Arrangement_1 Sector Pole Type Installation ........................................................................ 13

Figure 7. RRH Arrangement_1 Sector Wall Type Installation ....................................................................... 14

Figure 8. RRH Arrangement_1 Sector Tilting ................................................................................................ 14

Figure 9. RRH Arrangement_Swivelling ........................................................................................................ 15

Figure 10. RRH Arrangement_3 Sector Pole Type Installation ........................................................................ 16

Figure 11. RRH Arrangement_3 Sector Tilting ................................................................................................ 16

Figure 12. RRH Arrangement_3 Sector Pole Type Installation ........................................................................ 17

Figure 13. RRH Arrangement_3 Sector Pole Type Side by Side Installation ................................................... 18

Figure 14. RRH Arrangement_3 Sector Wall Type Side by Side Installation ................................................... 18

Figure 15. Assembling Clip on Antenna (1) ..................................................................................................... 20

Figure 16. Assembling Clip on Antenna (2) ..................................................................................................... 21

Figure 17. Assembling Clip on Antenna (3) ..................................................................................................... 22

Figure 18. Assembling Clip on Antenna (4) ..................................................................................................... 23

Figure 19. Assembling Clip on Antenna (5) ..................................................................................................... 24

Figure 20. Assembling AC-DC Power Unit (1) .................................................................................................. 25

Figure 21. Assembling AC-DC Power Unit (2) .................................................................................................. 26

Figure 22. Fixing Unit Bracket (1) .................................................................................................................... 27

Figure 23. Fixing Unit Bracket (2) .................................................................................................................... 27

Figure 24. Fixing Unit Bracket (3) .................................................................................................................... 28

Figure 25. Fixing Mounting Bracket on the Pole (1) ........................................................................................ 29

Figure 26. Fixing Mounting Bracket on the Pole (2) ........................................................................................ 29

Figure 27. Fixing Mounting Bracket on the Pole (3) ........................................................................................ 30

Figure 28. Fixing Mounting Bracket on the Pole (4) ........................................................................................ 30

Figure 29. Lifting RRH ...................................................................................................................................... 31

Figure 30. Fixing RRH on the Pole (1) .............................................................................................................. 32

Figure 31. Fixing RRH on the Pole (2) .............................................................................................................. 33

Figure 32. RRH Marking Dimensions ............................................................................................................... 35

Figure 33. Marking .......................................................................................................................................... 36

Figure 34. Drilling ............................................................................................................................................ 37

Figure 35. Fixing Mounting Bracket on the Wall (1) ....................................................................................... 38

Figure 36. Fixing Mounting Bracket on the Wall (2) ....................................................................................... 38

Figure 37. Fixing RRH on the Wall (1) .............................................................................................................. 39

Figure 38. Fixing RRH on the Wall (2) .............................................................................................................. 40

Figure 39. RRH Tilting Adjustment (1) ............................................................................................................. 41

Figure 40. RRH Tilting Adjustment (2) ............................................................................................................. 42

Figure 41. RRH Tilting Adjustment (3) ............................................................................................................. 43

Figure 42. RRH Swivelling Adjustment (1) ....................................................................................................... 44

Figure 43. RRH Swivelling Adjustment (2) ....................................................................................................... 45

Figure 44. RRH Swivelling Adjustment (3) ....................................................................................................... 46

Figure 45. Fixing Mounting Bracket on the Pole (1) ........................................................................................ 48

Figure 46. Fixing Mounting Bracket on the Pole (2) ........................................................................................ 49

Figure 47. Fixing Mounting Bracket on the Pole (3) ........................................................................................ 49

RT4401-48A Installation Manual v3.0 v

Copyright © 2019, All Rights Reserved.

Page 6

List of Figures

Figure 48. Fixing Mounting Bracket on the Pole (4) ........................................................................................ 50

Figure 49. Lifting RRH ...................................................................................................................................... 51

Figure 50. Fixing RRHs on the 3Sector Pole Type (1) ...................................................................................... 52

Figure 51. Fixing RRHs on the 3Sector Pole Type (2) ...................................................................................... 53

Figure 52. Fixing RRHs on the 3Sector Pole Type (3) ...................................................................................... 54

Figure 53. Fixing Unit Bracket (1) .................................................................................................................... 55

Figure 54. Fixing Unit Bracket (2) .................................................................................................................... 55

Figure 55. Fixing Mounting Bracket on the Pole (1) ........................................................................................ 57

Figure 56. Fixing Mounting Bracket on the Pole (2) ........................................................................................ 58

Figure 57. Fixing Mounting Bracket on the Pole (3) ........................................................................................ 58

Figure 58. Fixing Mounting Bracket on the Pole (4) ........................................................................................ 59

Figure 59. Fixing RRHs on the Pole (1) ............................................................................................................ 60

Figure 60. Fixing RRHs on the Pole (2) ............................................................................................................ 61

Figure 61. Fixing RRHs on the Pole (3) ............................................................................................................ 61

Figure 62. Fixing RRHs on the Pole (4) ............................................................................................................ 62

Figure 63. Fixing Unit Bracket_Side Installation (1) ........................................................................................ 63

Figure 64. Fixing Unit Bracket_Side Installation (2) ........................................................................................ 63

Figure 65. Assembling Mounting Bracket Assembly_Pole Type (1) ................................................................ 64

Figure 66. Assembling Mounting Bracket Assembly_Pole Type (2) ................................................................ 65

Figure 67. Assembling Mounting Bracket Assembly_Pole Type (3) ................................................................ 65

Figure 68. Fixing Side by Side Bracket Assembly_Pole Type (1) ...................................................................... 66

Figure 69. Fixing Side by Side Bracket Assembly_Pole Type (2) ...................................................................... 66

Figure 70. Fixing Side by Side Bracket Assembly_Pole Type (3) ...................................................................... 67

Figure 71. Fixing Side by Side Bracket Assembly_Pole Type (4) ...................................................................... 67

Figure 72. Levelling Side by Side Bracket Assembly_Pole Type ...................................................................... 68

Figure 73. Fixing RRH on the Pole Type Side by Side Installation (1) .............................................................. 70

Figure 74. Fixing RRH on the Pole Type Side by Side Installation (2) .............................................................. 70

Figure 75. RRH Marking Dimensions ............................................................................................................... 72

Figure 76. Marking .......................................................................................................................................... 72

Figure 77. Drilling ............................................................................................................................................ 73

Figure 78. Fixing Side by Side Bracket on the Wall (1) .................................................................................... 74

Figure 79. Fixing Side by Side Bracket on the Wall (2) .................................................................................... 75

Figure 80. Fixing Side by Side Bracket on the Wall (3) .................................................................................... 76

Figure 81. Fixing RRH on the Wall (1) .............................................................................................................. 78

Figure 82. Fixing RRH on the Wall (2) .............................................................................................................. 78

Figure 83. Procedure to Connect System Cable .............................................................................................. 80

Figure 84. Cable Connection Procedure.......................................................................................................... 81

Figure 85. RRH Cable Diagram (RRH only) ...................................................................................................... 85

Figure 86. RRH Cable Diagram (with Clip-on Antenna and AC-DC Power Unit) .............................................. 86

Figure 87. Connecting Ground Cable_only RRH (1) ........................................................................................ 89

Figure 88. Connecting Ground Cable_with AC-DC Power Unit (2) .................................................................. 89

Figure 89. Connecting Ground Cable_only RRH (3) ........................................................................................ 90

Figure 90. Connecting Ground Cable_with AC-DC Power Unit (4) .................................................................. 91

Figure 91. Power Equipment Elements_RRH only .......................................................................................... 92

Figure 92. Power Equipment Elements_with AC-DC Power Unit.................................................................... 92

Figure 93. Connecting DC Link Cable (1) ......................................................................................................... 94

Figure 94. Connecting DC Link Cable (2) ......................................................................................................... 94

Figure 95. Connecting DC Link Cable (3) ......................................................................................................... 95

Figure 96. Connecting AC/DC Power Unit AC Power Cable (1) ....................................................................... 97

Figure 97. Connecting AC/DC Power Unit AC Power Cable (2) ....................................................................... 98

Figure 98. Connecting AC/DC Power Unit AC Power Cable (3) ....................................................................... 98

Figure 99. Connecting DC Power Cable (1) ................................................................................................... 100

RT4401-48A Installation Manual v3.0 vi

Copyright © 2019, All Rights Reserved.

Page 7

List of Figures

Figure 100. Connecting DC Power Cable (2) ................................................................................................... 101

Figure 101. Connecting DC Power Cable (3) ................................................................................................... 102

Figure 102. Optical Module Removal (1) ........................................................................................................ 104

Figure 103. Optical Module Removal (2) ........................................................................................................ 104

Figure 104. Optical Module Removal (3) ........................................................................................................ 105

Figure 105. Optical Module Insert .................................................................................................................. 105

Figure 106. Connecting CPRI Cable (1) ............................................................................................................ 107

Figure 107. Connecting CPRI Cable (2) ............................................................................................................ 107

Figure 108. Connecting CPRI Cable (3) ............................................................................................................ 108

Figure 109. Connecting CPRI Cable (4) ............................................................................................................ 109

Figure 110. Connecting CPRI Cable (5) ............................................................................................................ 109

Figure 111. Connecting UDA Cable (1) ............................................................................................................ 111

Figure 112. Connecting UDA Cable (2) ............................................................................................................ 112

Figure 113. Connecting UDA Cable (3) ............................................................................................................ 113

Figure 114. Connecting UDA Cable (4) ............................................................................................................ 114

Figure 115. Connecting RET Cable (1) ............................................................................................................. 116

Figure 116. Connecting RET Cable (2) ............................................................................................................. 117

Figure 117. Connecting RET Cable (3) ............................................................................................................. 117

Figure 118. Connecting RET Cable (4) ............................................................................................................. 117

Figure 119. Connecting RF Cable (1) ............................................................................................................... 119

Figure 120. Connecting RF Cable (2) ............................................................................................................... 119

Figure 121. Connecting RF Cable (3) ............................................................................................................... 120

Figure 122. Connecting RF Cable (4) ............................................................................................................... 120

Figure 123. Connecting RF Cable (5) ............................................................................................................... 121

Figure 124. Connecting RF Cable (6) ............................................................................................................... 122

Figure 125. Connecting RF Cable (7) ............................................................................................................... 123

Figure 126. Assembling Cable Cover (1) .......................................................................................................... 124

Figure 127. Assembling Cable Cover (2) .......................................................................................................... 125

Figure 128. Installation Inspection Procedure ................................................................................................ 126

RT4401-48A Installation Manual v3.0 vii

Copyright © 2019, All Rights Reserved.

Page 8

List of Tables

Table 1. Specifications ................................................................................................................................... 5

Table 2. AC/DC Power Unit Specifications ..................................................................................................... 6

Table 3. Basic Installation Tools ..................................................................................................................... 9

Table 4. Parts and Tools for Assembling Clip on Antenna on RRH............................................................... 20

Table 5. Parts and Tools for Assembling AC-DC Power Unit on RRH ........................................................... 24

Table 6. Parts and Tools for Fixing Unit Bracket on RRH ............................................................................. 26

Table 7. Parts and Tools for Fixing Mounting Bracket on the Pole .............................................................. 28

Table 8. Parts and Tools for Fixing RRH on the Pole .................................................................................... 31

Table 9. Tools for Marking ........................................................................................................................... 34

Table 10. Parts and Tools for Drilling ............................................................................................................. 36

Table 11. Anchor Bolt Drill Bits and Hole Depth ............................................................................................ 36

Table 12. Parts and Tools for Fixing Mounting Bracket on the Wall .............................................................. 37

Table 13. Parts and Tools for Fixing RRH on the Wall .................................................................................... 39

Table 14. Tools for Tilting RRH ....................................................................................................................... 41

Table 15. Tools for Swiveling RRH .................................................................................................................. 44

Table 16. Parts and Tools for Fixing Unit Bracket on RRH ............................................................................. 47

Table 17. Parts and Tools for Fixing Mounting Bracket on the Pole .............................................................. 48

Table 18. Parts and Tools for Fixing RRH on the 3Sector Pole Type .............................................................. 51

Table 19. Parts and Tools for Fixing Unit Bracket on RRH ............................................................................. 54

Table 20. Parts and Tools for Fixing Mounting Bracket on the Pole .............................................................. 56

Table 21. Tools for Fixing RRHs on the Pole ................................................................................................... 59

Table 22. Parts and Tools for Fixing Unit Bracket on RRH ............................................................................. 62

Table 23. Parts and Tools for Fixing Side by Side Bracket on the Pole .......................................................... 64

Table 24. Parts and Tools for Fixing Side by Side Bracket Assembly_Pole Type ............................................ 65

Table 25. Parts and Tools for fixing RRH_Pole Type Side by Side Installation ............................................... 69

Table 26. Tools for Marking ........................................................................................................................... 71

Table 27. Parts and Tools for Drilling ............................................................................................................. 73

Table 28. Bolt Drill Bits and Hole Depth ......................................................................................................... 73

Table 29. Parts and Tools for Fixing Side by Side Bracket on the Wall .......................................................... 74

Table 30. Parts and Tools for Fixing RRH on the Wall .................................................................................... 77

Table 31. Recommended Minimum Allowed Cable bend Radius .................................................................. 82

Table 32. RRH Connection Cable ................................................................................................................... 85

Table 33. RRH Connection Cable ................................................................................................................... 86

Table 34. Parts and Tools for Connecting Ground Cable ............................................................................... 87

Table 35. Parts and Tools for Connecting Power Cable ................................................................................. 93

Table 36. Parts and Tools for Connecting AC Power Cable ............................................................................ 96

Table 37. AC/DC Power Unit AC Power Cable Connector Pin Map ................................................................ 96

Table 38. Parts and Tools for Connecting DC Power Cable............................................................................ 99

Table 39. DC Power Cable/Connector Pin Map ........................................................................................... 100

Table 40. Parts and Tools for connecting CPRI Cable .................................................................................. 106

Table 41. Parts and Tools for Connecting UDA Cable .................................................................................. 110

Table 42. UDA Cable Pin Map ...................................................................................................................... 111

Table 43. Parts for connecting RET Cable .................................................................................................... 115

Table 44. RET Cable Pin Map ....................................................................................................................... 116

Table 45. RF Cable Minimum Radius of Curvature ...................................................................................... 118

Table 46. Parts and Tools for connecting RF cable ...................................................................................... 118

Table 47. Parts and Tools for Assembling Cable Cover ................................................................................ 124

RT4401-48A Installation Manual v3.0 viii

Copyright © 2019, All Rights Reserved.

Page 9

List of Tables

Table 48. Construction Situation Checklist .................................................................................................. 127

Table 49. Standard Torque Value for Fastening Bolts ................................................................................. 133

Table 50. Brass Bolts Torque Value.............................................................................................................. 133

Table 51. Connector Connection Torque Value ........................................................................................... 133

RT4401-48A Installation Manual v3.0 ix

Copyright © 2019, All Rights Reserved.

Page 10

Preface

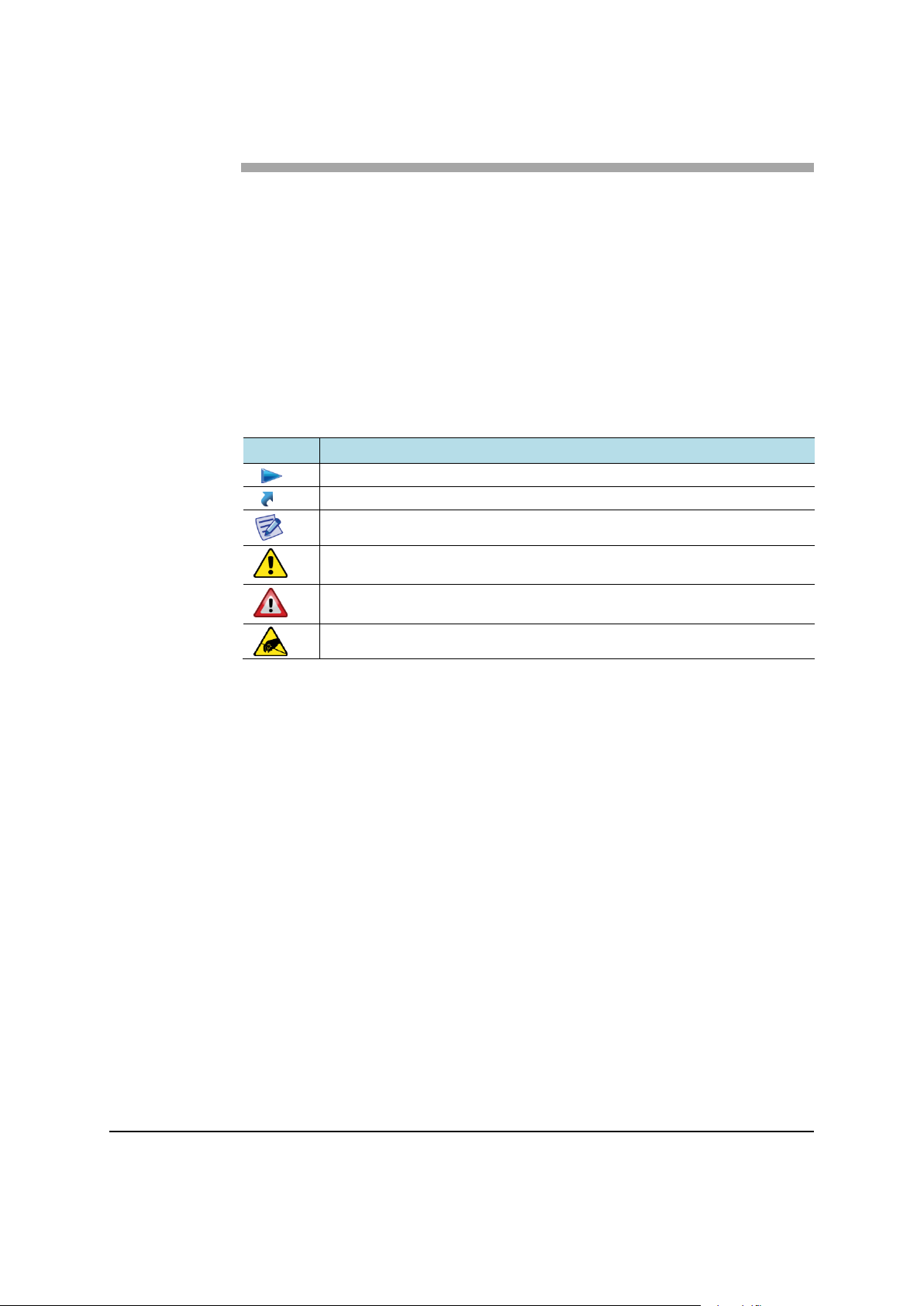

Symbol

Description

Indicates a task.

Indicates a shortcut or an alternative method.

Provides additional information.

Provides information or instructions that you should follow to avoid service

failure or damage to equipment.

Provides information or instructions that you should follow to avoid personal

injury or fatality.

Provides antistatic precautions that you should observe.

This manual describes how to install the RT4401-48A (CBRS RRH) including

how to connect cables. This manual includes the following RRH:

Conventions in this Document

Samsung Networks product documentation uses the following conventions.

Symbols

Menu Commands

menu | command

This indicates that you must select a command on a menu, where menu is the

name of the menu, and command is the name of the command on that menu.

File Names and Paths

These are indicated by a bold typeface. For example:

Copy filename.ext into the /home/folder1/folder2/bin/ folder.

User Input and Console Screen Output Text

The input and output text is presented in the Courier New font. For example,

context <designated epc-context-name>

The CLI command is presented in capital letters and Courier New, bold style.

For example, Type the RTRV-NE-STS command in the input field.

The YANG object is presented in the small letters and boldface. For example,

eutran-cell-conf-idle

RT4401-48A Installation Manual v3.0 x

Copyright © 2019, All Rights Reserved.

Page 11

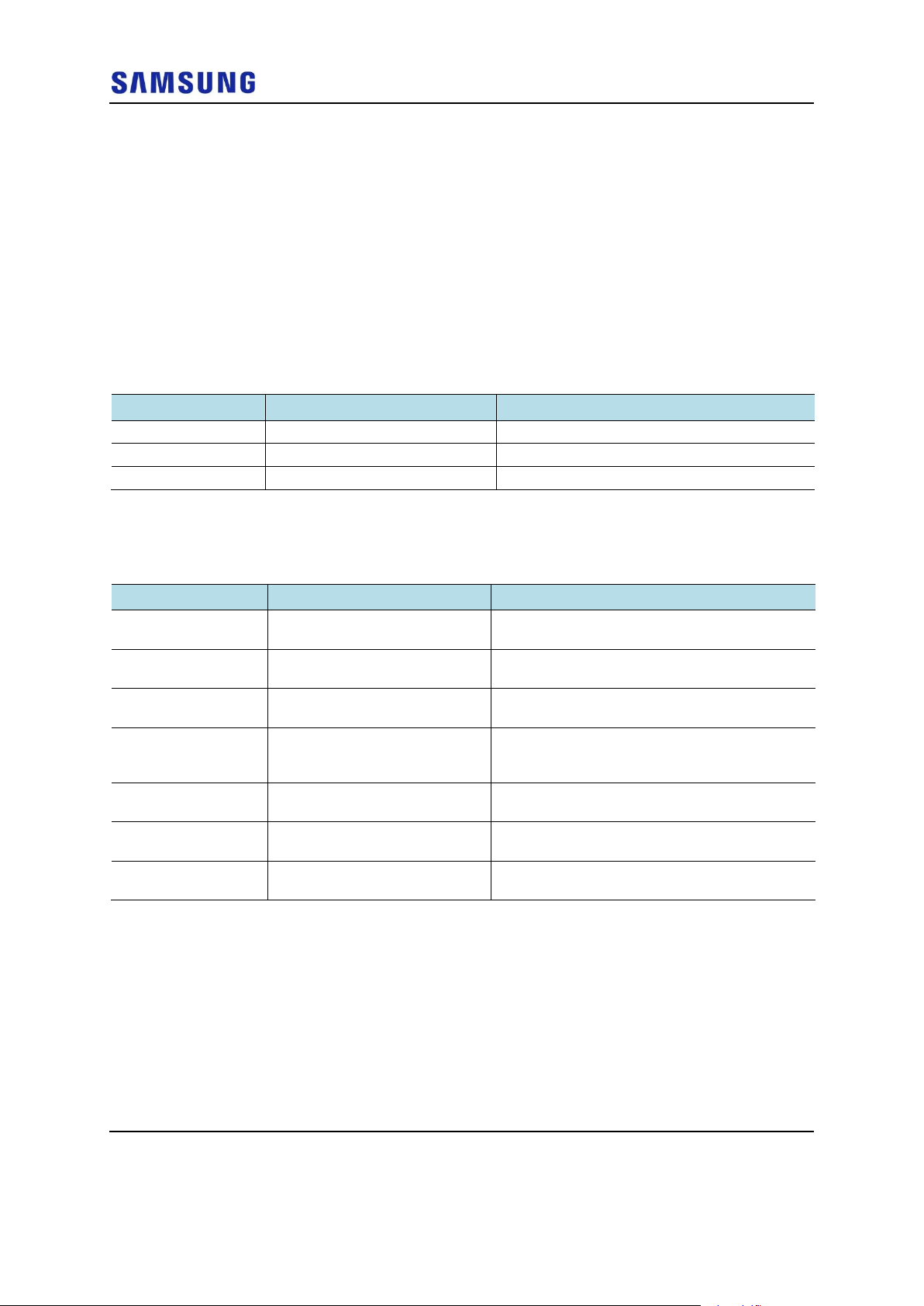

New and Changed Information

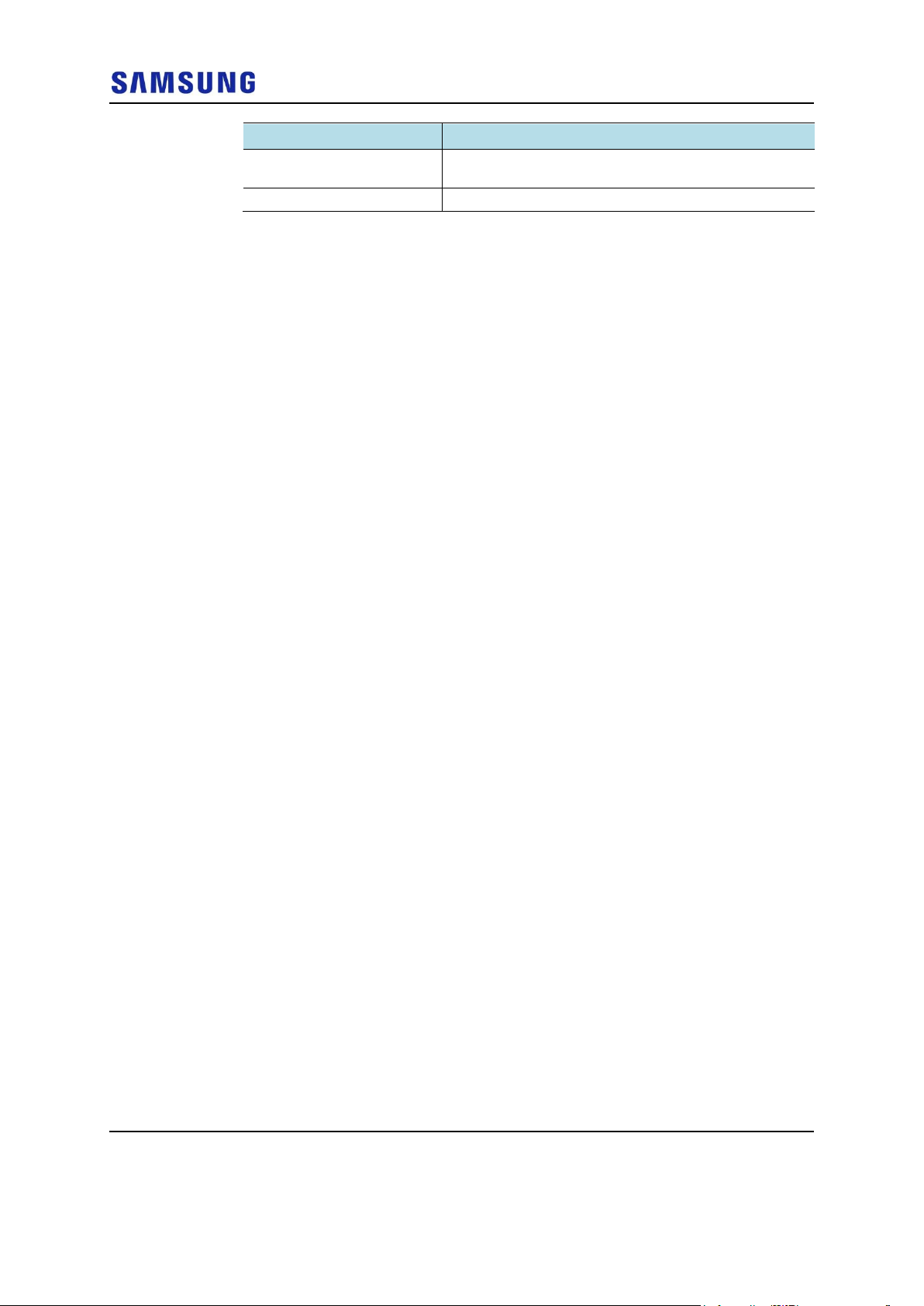

Document Version

Publication Date

Remarks

1.0

January 2019

First version

2.0

January 2019

-

3.0

February 2019

-

Section

Title

Description

Chapter 1

Before Installation

This chapter introduces RRH and describes items

should be understood before installation.

Chapter 2

Installing System

This chapter describes the procedures to install

the RRH.

Chapter 3

Connecting Cables

This chapter describes the procedures to connect

the cables to the RRH installed.

Chapter 4

Inspect the Installation

This chapter describes the procedures of

inspecting installation status after RRH

installation and cabling is completed.

Appendix A

Acronyms

This annex describes the acronyms used in this

manual.

Appendix B

Clean the Optical Connectors

This annex describes the procedure of cleaning

the optical connector and cleaning tool.

Appendix C

Standard Torque

This annex describes the standard torque when

fastening the bolt.

This section describes information that has been added/changed since the previous

publication of this manual.

The 'Installation' section and the 'Power Supply Connection' section of

Personal and Product Safety is updated.

Revision History

The following table lists all versions of this document.

Preface

Organization of This Document

Related Documentation

LTE eNB System Description

RT4401-48A Installation Manual v3.0 xi

Copyright © 2019, All Rights Reserved.

Page 12

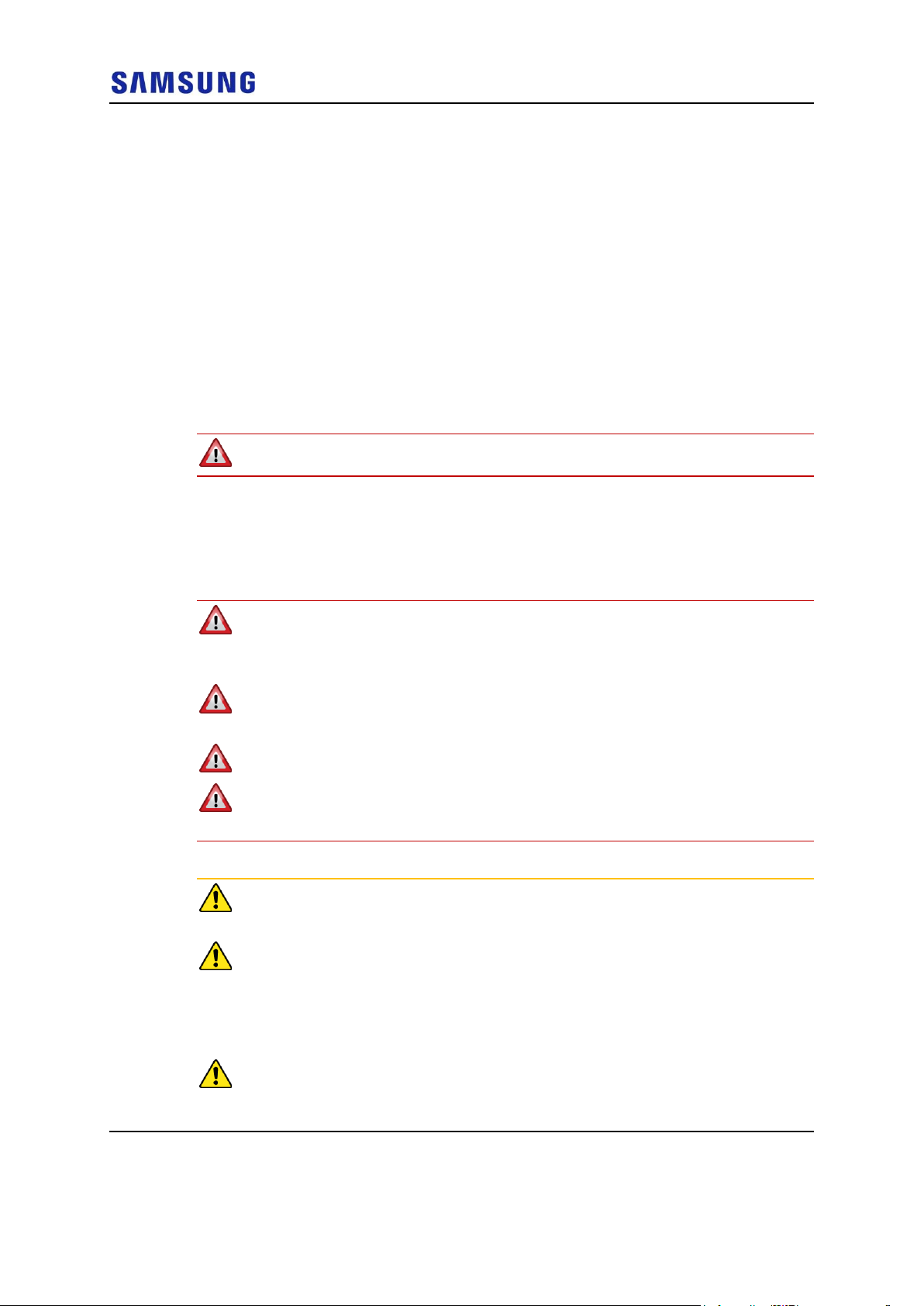

Personal and Product Safety

This product safety information includes European directives, which you must

follow. If these do not apply in your country, please follow similar directives that

do apply in your country.

Electrical

The product is designed to operate from a -48 V DC supply and is therefore

classified as Safe Extra Low Voltage (SELV) equipment.

All structural parts are grounded and all input and outputs have built-in isolation

from the network. All input and output ports that connect to external power

sources are designed to meet relevant national safety requirements.

The product contains hazardous energy levels as defined by UL 60950. Care must

be taken when maintaining this equipment as injury to personnel or damage to the

equipment could result from mistakes. Maintenance should only be carried out by

trained and competent engineers who are familiar with the relevant procedures and

instructions.

Preface

Lasers

The product is fitted with optical modules rated as Class 1 radiation-emitting

devices under EN 60825-1. During installation, operation, and maintenance, never

look into the end of an optical fiber directly or by reflection either with the naked

eye or through an optical instrument. Do not operate equipment with exposed fiber

connectors-cover these with fiber cables or blanking caps. Do not remove

equipment covers during operation unless requested to do so in the documentation.

Carry out normal safety precautions when trimming fibers during installation.

Manual Handling

Care should be taken when handling equipment. Give due consideration to the

weight of the equipment, the physical capability of the individuals handling the

equipment, and movements such as twisting, bending and stooping, which could

lead to skeletal and muscular injuries.

Installation

Installation must be carried out by trained and competent engineers only. All

relevant safety measures should be taken to ensure equipment is not connected to

live power and transmission sources during installation. Equipment must be

correctly installed to meet the relevant safety standards and approval conditions.

Each power feed to the unit requires a separate fused feed from the provided

power supply. The cable between the power distribution point and the installed

equipment must have a minimum cross-sectional area of 2.5 mm2.

RT4401-48A Installation Manual v3.0 xii

Copyright © 2019, All Rights Reserved.

Page 13

The CBRS RU product is installed on the Network Telecommunication Facilities.

Maintenance

Maintenance must only be carried out by a suitably trained and competent

technician. All safety instructions must be carefully observed at all times.

Equipment covers should not be removed while live power and transmission is

connected unless in a controlled environment by trained technicians.

Fire

The product is powered from a -48 V DC. To protect against fire, the equipment is

fused.

Environment

The product must be operated in an environment with the specified relative

humidity and ambient temperature ranges.

Keep all liquids away from the equipment as accidental spillage can cause severe

damage.

Preface

Anti-Static Precautions

The circuit boards and other modules in the product are sensitive to and easily

damaged by static electricity. If any card or sub-assembly is removed from the unit,

the following anti-static precautions must be observed at all times:

Service personnel must wear anti-static wrist straps.

Circuit boards and sub-assemblies must be placed on ground conductive mats

or in conductive bags.

All tools must be discharged to ground before use.

The anti-static wrist strap and cord must be checked at regular intervals for

their suitability for use.

Grounding

To comply with UL 60950, the equipment must be connected to a safety

grounding point through a permanent link. Grounding points are located on the

product for this purpose. Always connect the ground cable before fitting other

cables. The product must remain grounded continuously unless all connections to

the power supply and data network are all removed.

If equipment is grounded through a cabinet or rack, make sure it is done so

properly.

RT4401-48A Installation Manual v3.0 xiii

Copyright © 2019, All Rights Reserved.

Page 14

Power Supply Connection

Power connections and installation of associated wiring must be carried out by a

suitably qualified technician.

Only devices that comply with all relevant national safety requirements should be

connected to the unit's power supply inlets. Other usage will invalidate any

approval given to this equipment.

Connection of this equipment to devices that are not marked with all relevant

national safety requirements may produce hazardous conditions on the network.

When the power supply is obtained by a rectifier/safety isolation transformer, the

supply must meet the requirements of UL 60950 providing double/reinforced

insulation between hazardous voltages and SELV/TNV circuits. Any battery must

be separated from hazardous voltages by reinforced insulation.

The RTN of the CBRS RU is not connected to Grounding.

Indirect Connection

Before indirectly connecting any equipment to another device through a shared

power supply, ALWAYS seek advice from a competent engineer.

Preface

Devices that are not marked according to the relevant national safety standards

may produce hazardous conditions on the network.

Product Disposal

To reduce the environmental impact of products, Samsung has joined WEEE

compliance activities.

The WEEE symbol on the product indicates that the product is covered by the

European Directive 2002/96/CE for the disposal of Waste Electrical and Electronic

Equipment (WEEE). This means that the product should be disposed of separately

from the municipal waste stream through designated collection facilities appointed

by the government or the local authorities. This will help prevent potential

negative consequences for the environment and human health. Please check the

terms and conditions of the purchase contract for information about correct

disposal.

California USA Only

This Perchlorate warning applies only to primary CR (Manganese Dioxide)

Lithium coin cells in the product sold or distributed ONLY in California USA

‘Perchlorate Material-special handling may apply, See

www.dtsc.ca.gov/hazardouswaste/perchlorate.’

FCC Statement

This equipment has been tested and found to comply with the limits for a Class A

RT4401-48A Installation Manual v3.0 xiv

Copyright © 2019, All Rights Reserved.

Page 15

Preface

digital device, pursuant to part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at

his own expense.

Any changes or modifications not expressly approved by the party responsible for

compliance could void the user's authority to operate this equipment.

RT4401-48A Installation Manual v3.0 xv

Copyright © 2019, All Rights Reserved.

Page 16

Equipment Markings

This marking on the product, accessories or literature indicates that the

product and its electronic accessories (for example. charger, headset, and

USB cable) should not be disposed of with other household waste at the

end of their working life. To prevent possible harm to the environment or

human health from uncontrolled waste disposal, please separate these

items from other types of waste and recycle them responsibly to promote

the sustainable reuse of material resources.

Household users should contact either the retailer where they purchased

this product, or their local government office, for details of where and how

they can take these items for environmentally safe recycling.

Business users should contact their supplier and check the terms and

conditions of the purchase contract. This product and its electronic

accessories should not be mixed with other commercial wastes for disposal.

Protective earth

RRH AC/DC power unit should be grounded.

Preface

RT4401-48A Installation Manual v3.0 xvi

Copyright © 2019, All Rights Reserved.

Page 17

Chapter 1 Before

[Bottom View]

[Front View]

[Top View]

[Left View]

[Right View]

[Rear View]

13.9 (353.5)

8.6 (217.4)

Unit: in. (mm)

4.2

(105.5)

Installation

System View and External Interface

This section provides the physical structure of the RRH system and its interfaces.

System View

The figure below depicts the physical structure of the system.

Figure 1. System View (RRH only)

RT4401-48A Installation Manual v3.0 1

Copyright © 2019, All Rights Reserved.

Page 18

Figure 2. System View (with Clip-on: Antenna + AC-DC Power Unit)

[Bottom View]

[Front View]

[Top View]

[Left View]

[Right View]

[Rear View]

16.2 (410.5)

11.4 (289.4)

Unit: in. (mm)

5.5

(138.5)

Chapter 1 Before Installation

System External Interface

The figure below depicts the external interface structure of the RRH system.

RT4401-48A Installation Manual v3.0 2

Copyright © 2019, All Rights Reserved.

Page 19

Figure 3. System External Interface (RRH only)

DC_PWR

Ground Terminal

UDA

L0

L1

RET

AC_PWR

ANT 4

ANT 3

ANT 2

ANT 1

DC_PWR

Ground Terminal

UDA

L0

L1

RET

Chapter 1 Before Installation

Figure 4. System External Interface (with Clip-on: Antenna + AC-DC Power Unit)

RT4401-48A Installation Manual v3.0 3

Copyright © 2019, All Rights Reserved.

Page 20

Chapter 1 Before Installation

When interoperating the AC-DC power unit, the ground cable must be connected

to the ground terminal of the AC-DC power unit.

RT4401-48A Installation Manual v3.0 4

Copyright © 2019, All Rights Reserved.

Page 21

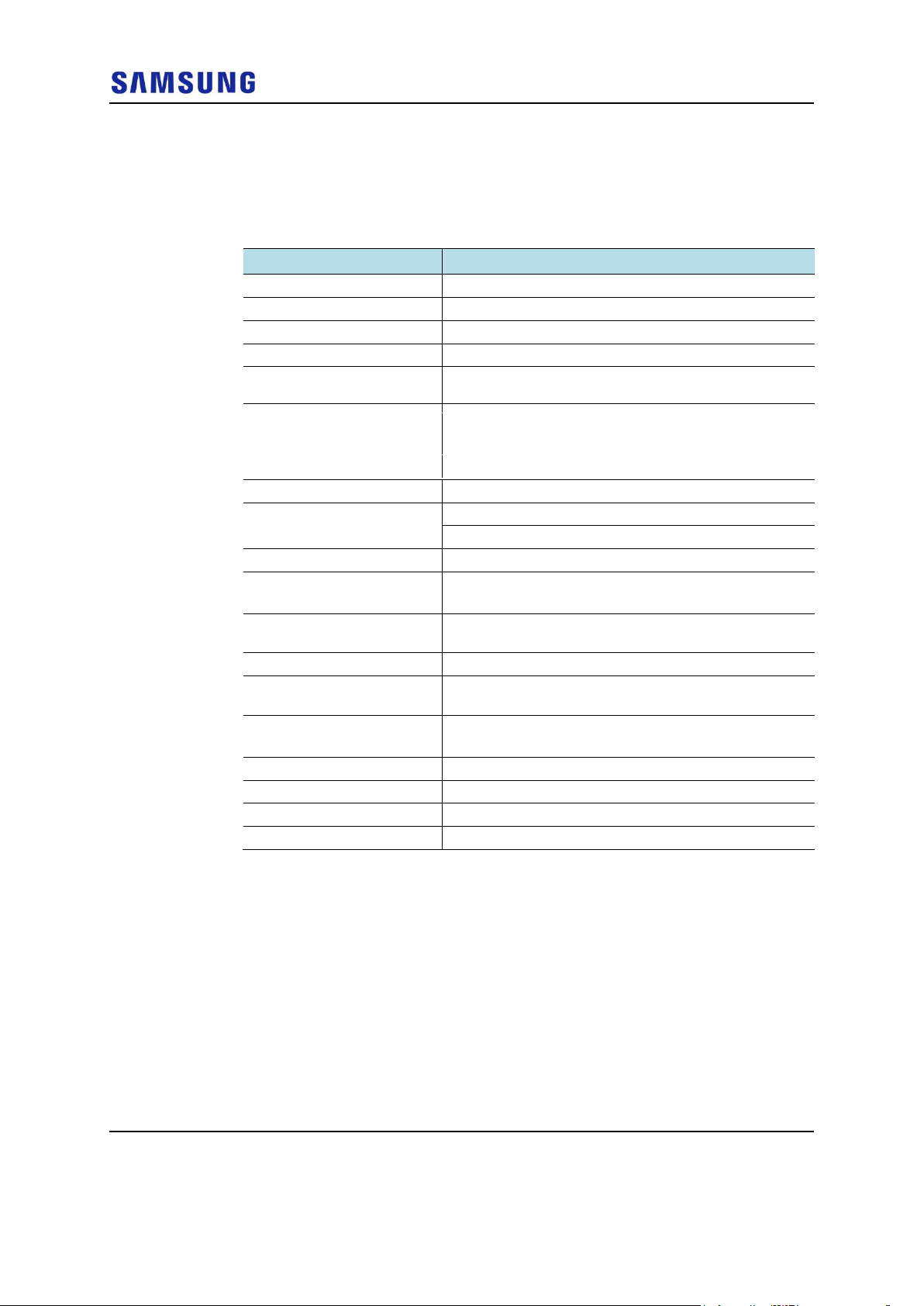

Specifications

Item

RT4401-48A

Air Technology

LTE

Band

Band 48 (3.5 GHz)

Operating Frequency (MHz)

3550 to 3700

The table below outlines the main specifications of the RRH.

Table 1. Specifications

RF Chain 4TX/4RX

Input Power -48 V DC (-38 to -57 V DC, 1 SKU), with clip-on AC-DC

Dimension (W × D × H) (mm)

Cooling Natural convection

Unwanted Emission 3GPP 36.104 Category A

Spectrum Analyzer TX/RX Support

Antenna Type Integrated (Clip-on) antenna (Option),

Operating Humidity 5 to 100 [%] (RH), condensing, not to exceed 30 g/m3

Altitude -60 to 1,800 m

Earthquake Telcordia Earthquake Risk Zone4 (Telcordia GR-63-

Vibration in Use

Transportation Vibration

Noise Fanless (natural convection cooling)

Wind Resistance Telcordia GR-487-CORE, Section 3.34

EMC FCC Title 47, CFR Part 96

Safety UL 60950-1 2nd ED

Chapter 1 Before Installation

converter (Option)

8.55 in. (217.4) × 4.15 in. (105.5) × 13.91 in. (353.5)

* RRH only

11.39 in. (289.4) × 5.45 in. (138.5) × 16.16 in. (410.5)

* with Clip-on antenna, AC-DC power unit

[B48]: FCC 47 CFR 96.41 e)

External antenna (Option)

absolute humidity

CORE)

Office Vibration

Transportation Vibration

RT4401-48A Installation Manual v3.0 5

Copyright © 2019, All Rights Reserved.

Page 22

Chapter 1 Before Installation

Item

RT4401-48A

UL 62368-1

UL 60950-22

RF

FCC Title 47, CFR Part 96

The table below outlines the AC/DC power unit specifications of the RRH system.

RT4401-48A Installation Manual v3.0 6

Copyright © 2019, All Rights Reserved.

Page 23

Cautions for Installation

Observe the safety instructions described in this section when installing the system.

Installation should be done in accordance with the applicable local electric codes.

Before Installing

Before starting the installation, ensure the following:

Post warning signs in areas where high-voltage cables are installed.

Post “off limit” signs in areas where accidents are most expected.

Use guardrails or fences to block open areas such as ditches, open roof areas,

and scaffolds.

Install the system in the restricted access area.

While Installing

Chapter 1 Before Installation

During installation, ensure the following:

The system power must be cut off before installing.

Ensure that the power switch of the power supply is off when installing the system.

Installing the system with power on may cause system damage or fatal human

injury when connecting or disconnecting cables.

Ensure that workers wear protection gloves and goggles to prevent injury from

debris while drilling holes in a wall or ceiling.

Do not wear accessories such as watches and rings to prevent electrical shock.

When using the AC / DC converter, connect the DC power cable first before

connecting the AC power.

Cover unused ports with a cap. This prevents foreign substances from entering into

the unused ports.

To prevent foreign substances, outdoor air, and moisture from entering the cable

inlet (including cable gland and conduit), finish the inlet as follows:

- Unused inlet: Use the hole finishing materials including cap and rubber packing.

- Cable-installed inlet: After cable installation, block any space in the inlet with

tape, compressed sponge, rubber packing, and silicone.

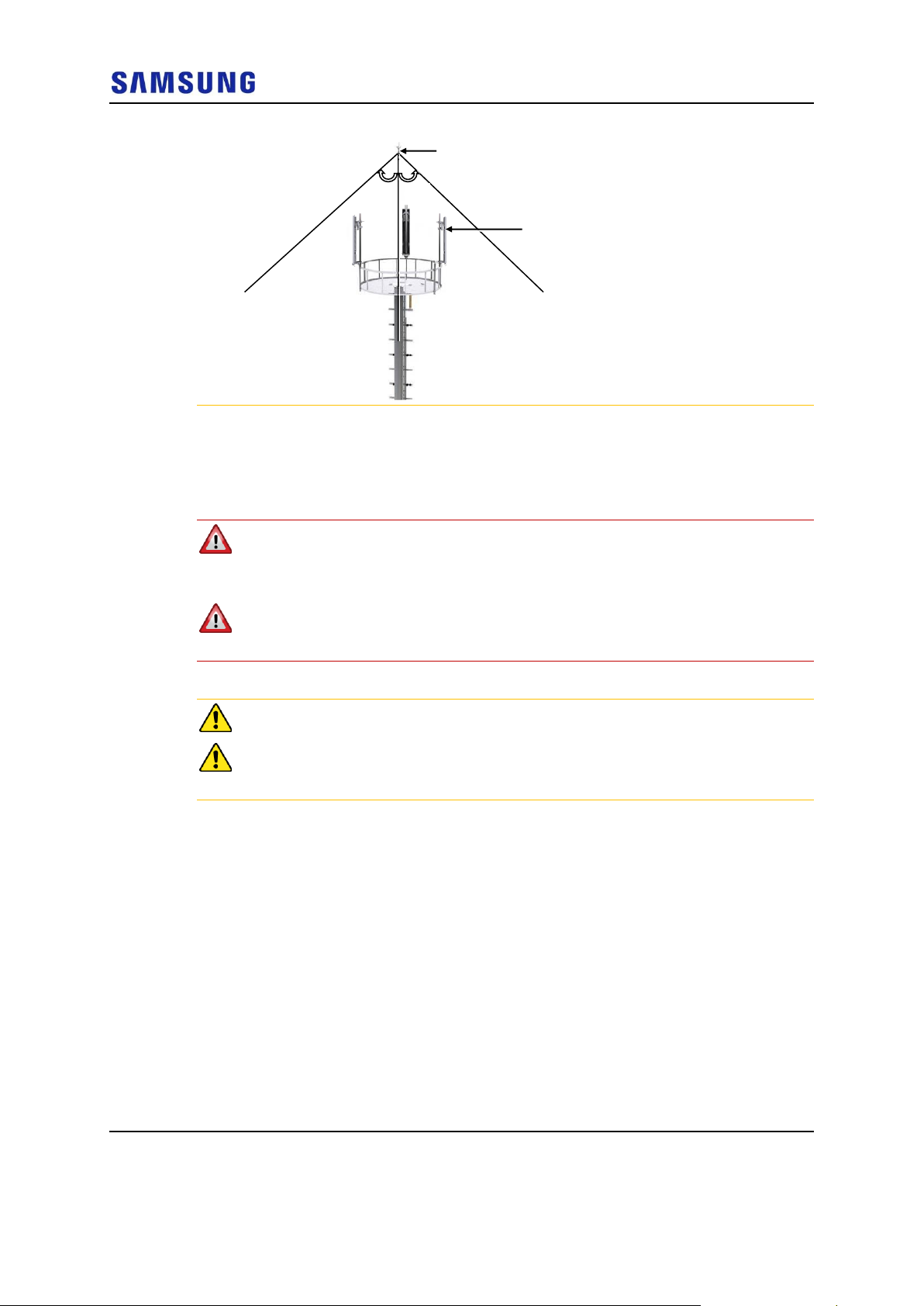

When operator installs the RRH, the RRH must be within the protective angle

(left/right side 45° each from the central axis) to prevent the RRH from lightning

RT4401-48A Installation Manual v3.0 7

Copyright © 2019, All Rights Reserved.

Page 24

damage.

Lightning Rod

45°

45°

RRH

After Installing

After installation, remove any debris produced during the work and clean up the

installation site.

Chapter 1 Before Installation

In the system, the laser beam light runs through the optical cable. The workers

must handle the optical cables with care as the laser beam can seriously damage

the eyes.

When using the AC / DC converter, if servicing of the RRU is required, disconnect

the AC power first.

Ensure that the workers do not damage installed cables while cleaning the system.

While cleaning the power supply device, take precaution that the device does not

come in contact with foreign objects that may cause power failure.

RT4401-48A Installation Manual v3.0 8

Copyright © 2019, All Rights Reserved.

Page 25

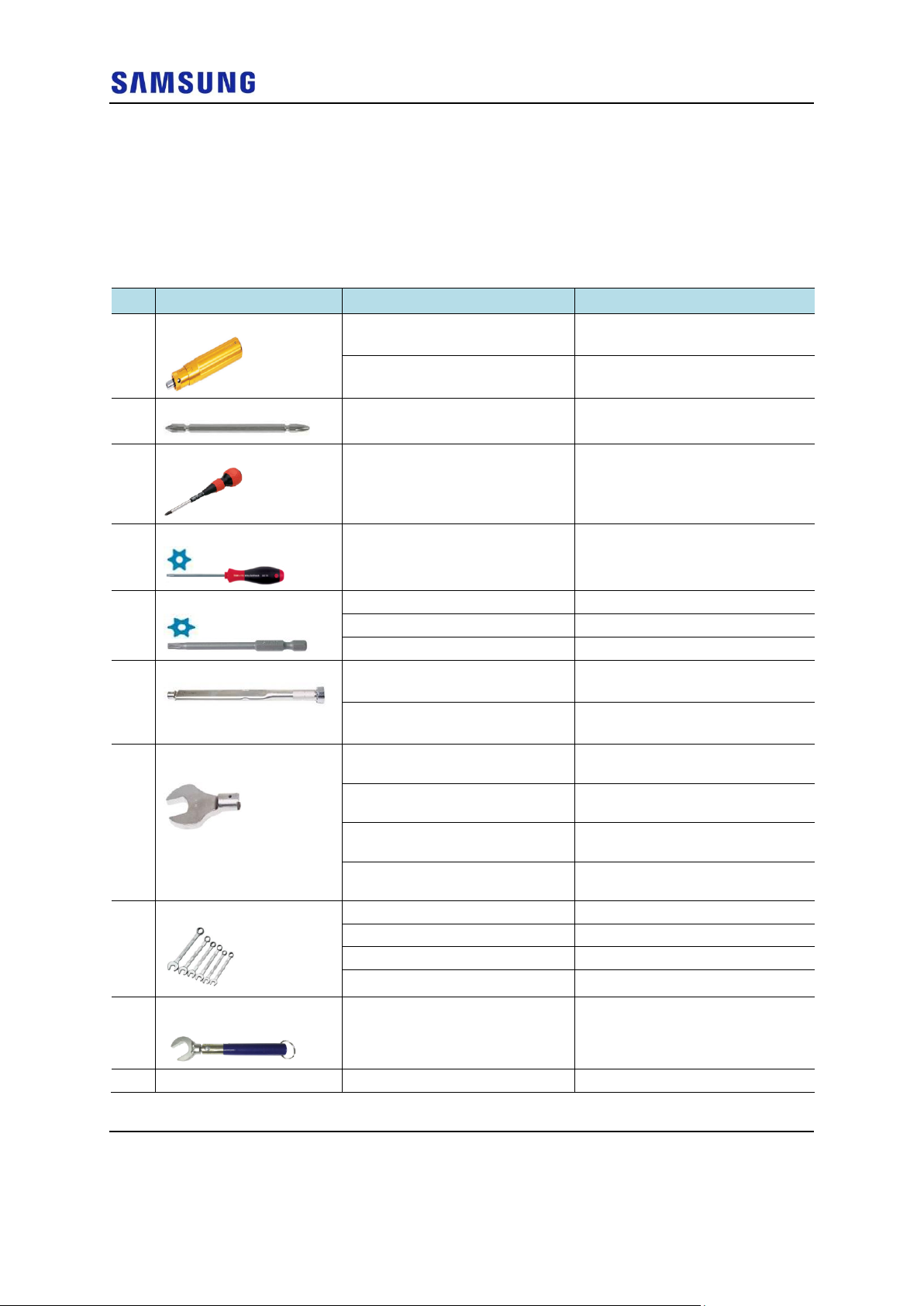

Installation Tools

No.

Name

Specification

Purpose of use

1

Torque Driver

Apply a torque range

: 20 to 90 lbf·in

Fastening M6 SEMS

Apply a torque range

: 6 to 22 lbf·in

Fastening M3, M4 Torx screw

2

Screw Driver Bit

'+', No. 3

Fastening M6 SEMS

3

Screw Driver

'+', No. 3

Loosening M6 SEMS

4

Torx Screw Driver

(T10H/T2H/T25H)

Loosening Torx screw

5

Torx Driver Bit

T10H

Fastening Torx screw (T10H)

T20H

Fastening Torx screw (T20H)

T25H

Fastening Torx screw (T25H)

6

Torque Wrench

Apply a torque range

: 10 to 50 lbf·in

Tightening M6 Hexagonal. bolt

Apply a torque range

: 100 to 400 lbf·in

Tightening M10, M12 hexagonal.

bolt

7

Torque Wrench Spanner

Head

Apply hexagonal.bolt head: 10 mm

(for 10 to 50 lbf·in)

Tightening M6 hexagonal.bolt

Apply hexagonal. bolt head: 13

mm (for 100 to 400 lbf·in)

Tightening M8 hexagonal.bolt

Apply hexagonal.bolt head: 17 mm

(for 100 to 400 lbf·in)

Tightening M10 hexagonal.nut

Apply hexagonal.bolt head: 19 mm

(for 100 to 400 lbf·in)

Tightening M12 hexagonal.nut

8

Spanner

10 mm

Tightening M6 hexagonal. bolt

13 mm

Tightening M8 hexagonal. bolt

17 mm

Tightening M10 hexagonal. bolt

19 mm

Tightening M12 hexagonal. bolt

9

Mini DIN Male Torque

Wrench

TQ-78-F8

Tightening 4.3-10 and mini din

connector

10

Tape Measure

16 ft./150 ft.

Measuring length

The basic tools required for installation are listed in the table below. The

additional tools required for each site need to be identified and arranged during a

site survey before starting the installation.

Table 3. Basic Installation Tools

Chapter 1 Before Installation

RT4401-48A Installation Manual v3.0 9

Copyright © 2019, All Rights Reserved.

Page 26

Chapter 1 Before Installation

No.

Name

Specification

Purpose of use

11

Level

Normal

Levelling horizontality and verticality

12

Power Extension Cable

100 ft.

Basic tool

13

Hammer Drill

Normal

Wall type drilling

14

Optical Connector Cleaner

For LC Connector

Cleaning optical connector

15

Concrete Drill Bit

14 mm

Setting M10 anchor

16

Anchor Punch (Set)

M10

Setting M10 anchor

17

Hammer

Normal

Fixing anchor

18

Vacuum Cleaner

Normal

Removing dust during the drilling

work

19

Cable Cutter

0.24-1.26 in. (6-32 mm)

Cutting cable

20

Crimping Tool

14 AWG-4 AWG (1.5 to 16 mm2)

Crimping pressure terminal

21

Cable Stripper

Apply cable thickness: 1.5 to 6.2

in. (4 to 16 mm)

Removing cable sheath

22

Nipper

Basic Tool

Cutting cable

23

Flush cutter

Basic Tool

For cutting cable tie

24

Industrial Scissor

Basic Tool

Cutting

RT4401-48A Installation Manual v3.0 10

Copyright © 2019, All Rights Reserved.

Page 27

Chapter 1 Before Installation

No.

Name

Specification

Purpose of use

25

Knife

Basic Tool

Cutting

26

Heating Gun

50°C to 300°C

Shrinking the feeder cable tube

27

Multi tester

Digital Pocket Tester

Checking voltage and current to

detect cable disconnection

28

Angle Meter

Normal

Checking RRH tilting

29

Fiber Optical Test Set

Wave length:

1270 nm, 1310 nm, 1550 nm

(single-mode)

850 nm, 1310 nm (multi-mode)

Checking optical level

30

RF Alignment Tool

-

Checking azimuth and tilting

The required installation tools may vary depending on the site conditions.

In addition to the basic tools, protractor, ladder, safety equipment, and cleaning

tools must also be arranged, considering the site conditions.

RT4401-48A Installation Manual v3.0 11

Copyright © 2019, All Rights Reserved.

Page 28

Chapter 2 Installing System

Foundation Work

Unpacking and Transporting

Fixing System

Unpacking Items

Bringing in Items

Fixing Unit Bracket

Fixing Mounting Bracket

Fixing RRH

This chapter describes the installation procedures of the RRH.

Installation Procedure

The figure below depicts the overall procedures for installing the RRH:

Figure 5. Procedure to Install the RRH

Ensure that the power switch of the power supply is OFF when installing the

system. Installing the system with the power switch ON may cause system damage

or fatal human injury when connecting or disconnecting the cables.

To prevent the risk of electrical shock, do not wear accessories such as watches

and rings.

RT4401-48A Installation Manual v3.0 12

Copyright © 2019, All Rights Reserved.

Page 29

System Arrangement

Unit: in. (mm)

[Top View]

[Front View]

≥ 12 (300)

≥ 8 (200)

≥ 32 (800)

11.1 (283)

≥ 12 (300)

≥ 8 (200)

Pole

(Ф 4.5 in./114.3 mm)

※ Example for 100 A pole

Category

Recommended Distances

Remarks

Front

≥ 32 in. (800 mm)

-

Sides

≥ 8 in. (200 mm)

Standard Installation

Top

≥ 12 in. (300 mm)

-

Bottom

≥ 12 in. (300 mm)

Over the air, without cover

≥ 16 in. (400 mm)

Over the ground, without cover

A minimum distance must be secured around the RRH, in each direction for

installation and maintenance.

The recommended clearance for installing the RRH is as follows.

Using Tilting and Swiveling Bracket

The figures below depict the recommended distances for each direction of the

RRH using the tilting and swiveling bracket for the wall and the pole type

installations.

Chapter 2 Installing System

Figure 6. RRH Arrangement_1 Sector Pole Type Installation

RT4401-48A Installation Manual v3.0 13

Copyright © 2019, All Rights Reserved.

Page 30

Figure 7. RRH Arrangement_1 Sector Wall Type Installation

Unit: in. (mm)

[Down Tilting 15°]

[Up Tilting 15°]

12 (304)

11.6 (294)

[Pole Type]

14.1 (358)

13.7 (348)

[Pole Type]

[Wall Type]

[Wall Type]

Unit: in. (mm)

[Top View]

[Front View]

≥ 8 (200)

11.5 (293)

≥ 8 (200)

≥ 12 (300)

≥ 12 (300)

≥ 32 (800)

Figure 8. RRH Arrangement_1 Sector Tilting

Chapter 2 Installing System

RT4401-48A Installation Manual v3.0 14

Copyright © 2019, All Rights Reserved.

Page 31

The dimensions of the RRH change according to the tilt angle, and the maximum

Unit: in. (mm)

[Left Swivelling 30°]

[Right Swivelling 30°]

12.1 (307)

12.5 (317)

[Pole Type]

11.4 (290)

11.8 (300)

[Wall Type]

[Wall Type]

[Pole Type]

dimensions are described in the figure above (RRH Arrangement_Down, Up

Tilting 15°).

Figure 9. RRH Arrangement_Swivelling

Chapter 2 Installing System

RT4401-48A Installation Manual v3.0 15

Copyright © 2019, All Rights Reserved.

The dimensions of the front of the RRH change according to the tilt angle, and the

maximum dimensions are described in the figure above. (RRH Arrangement_Left,

Right Swivelling 30°).

Page 32

Using Tilting Bracket

Unit: in. (mm)

[Down Tilting 15°]

[Up Tilting 15°]

27.7 (704)

30.9 (786)

※ Example for 200 A pole

※ Example for 200 A pole

[Top View]

[Top View]

Unit: in. (mm)

[Front View]

≥ 12 (300)

≥ 12 (300)

15.6 (695)

[Top View]

≥ 32 (800)

≥ 32 (800)

≥ 32 (800)

Pole

(Ф 8.7 in./220 mm)

※ Example for 200 A pole

The figures below depict the recommended distances for each direction of the

RRH using the tilting bracket for the pole type installation.

Figure 10. RRH Arrangement_3 Sector Pole Type Installation

Chapter 2 Installing System

Figure 11. RRH Arrangement_3 Sector Tilting

RT4401-48A Installation Manual v3.0 16

Copyright © 2019, All Rights Reserved.

Page 33

The dimensions of the RRH change according to the tilt angle, and the maximum

Unit: in. (mm)

[Front View]

≥ 12 (300)

≥ 12 (300)

23.0 (584)

[Top View]

≥ 32 (800)

≥ 32 (800)

≥ 32 (800)

Pole

(Ф 8.7 in./220 mm)

※ Example for 200 A pole

dimensions are described in the figure above (RRH Arrangement_Down, Up

Tilting 15°).

Without Tilting Bracket

The figures below depict the recommended distances for each direction of the

RRH without using the tilting bracket.

Figure 12. RRH Arrangement_3 Sector Pole Type Installation

Chapter 2 Installing System

Using Side by Side Bracket

RT4401-48A Installation Manual v3.0 17

Copyright © 2019, All Rights Reserved.

The figures below depict the recommended distances for each direction of the

RRH using the side by side bracket for the pole type installation.

Page 34

Figure 13. RRH Arrangement_3 Sector Pole Type Side by Side Installation

Unit: in. (mm)

[Front View]

≥ 12 (300)

≥ 12 (300)

15.75 (400)

[Top View]

≥ 32 (800)

≥ 32 (800)

≥ 32 (800)

Pole Size (Diameter)

Length of Stud Bolt

50 A to 100 A

8.7 in. (220 mm)

Unit: in. (mm)

[Front View]

≥ 12 (300)

≥ 12 (300)

15.75 (400)

[Top View]

≥ 32 (800)

≥ 32 (800)

Pole

(Ф 4.5 in./114.3 mm)

≥ 32 (800)

Chapter 2 Installing System

When fixing a mounting bracket, the length of stud bolts are 8.7 in. (220 mm) for

the pole diameter of 50 to100 A.

Figure 14. RRH Arrangement_3 Sector Wall Type Side by Side Installation

RT4401-48A Installation Manual v3.0 18

Copyright © 2019, All Rights Reserved.

Page 35

Transporting and Unpacking

This section describes how to transport the items to the installation place and

provides the procedure to unpack cabinets and other components.

Bringing in Items

Ensure the following at each stage of transportation of the items:

Before moving a system, check storage place for the system and remove

obstacles in advance.

When carrying the system:

o Fasten the system firmly to the transport vehicle or carrier to prevent

damage to the system from a vibration or shock.

o Use an elevator to prevent accidents. However, if the system must be

carried by people, ensure there are enough people to carry the system.

The system must not be shocked physically.

The system should be protected from dust, moisture, and static electricity.

Chapter 2 Installing System

Unpacking

To unpack the items, ensure the following:

The items must be packed until they reach the installation place.

The items are classified in accordance with each job specification and stored at

a place that does not interfere with working.

Unpacked systems must be installed immediately. If immediate installation of

the systems is not planned, the systems must be stored in the installation place

temporarily.

Unpack only external packing, leaving the internal packing in unpacked status.

Unpack the inner packaging after each system is placed on its installation

location.

Dispose by-products (packaging waste) in accordance with waste management

rules. Do not recycle the by-products.

RT4401-48A Installation Manual v3.0 19

Copyright © 2019, All Rights Reserved.

Page 36

Fixing RRH

Category

Description

Parts

Clip on Antenna

1 EA

Fasteners

M4 × L10 Torx Screw

4 EA

Recommended Torque Value

M4 Torx Screw

13 lbfin

4.3-10 (Plus) Male Connector

44 lbfin

Working Tools

Torque Wrench (10 to 50 lbf·in)

Torque Driver (6 to 22 lbf·in)

Screw Driver Bit (T20H)

Torque Wrench Spanner Head (apply Hex. head: 22 mm)

Clip on Antenna

1

2

This section describes the procedures to fix the RRH with different methods.

Assembling Clip on Antenna

This section describes the procedure to fix the clip on antenna on the RRH.

Assembling Clip on Antenna

To fix the clip on antenna, do the following:

Prerequisites

Before proceeding with assembling the clip on antenna, make sure that you have

the items mentioned in the table below.

Table 4. Parts and Tools for Assembling Clip on Antenna on RRH

Chapter 2 Installing System

1 Check the position for mounting the clip on antenna on the front of the RRH

and place it in that position.

Figure 15. Assembling Clip on Antenna (1)

RT4401-48A Installation Manual v3.0 20

Copyright © 2019, All Rights Reserved.

Page 37

2 Fix the clip on antenna using the fasteners.

Port Seal

Screw

thread

Screw

thread

M4 Torx Screw

2

M4 Torx Screw

4 1 3

Figure 16. Assembling Clip on Antenna (2)

Chapter 2 Installing System

3 Insert port seal into RRH ANT 1, 2, 3, 4 port.

When inserting the port seal to RRH ANT port, take care of the direction.

- The screw thread of port seal should be downwards.

RT4401-48A Installation Manual v3.0 21

Copyright © 2019, All Rights Reserved.

Page 38

Figure 17. Assembling Clip on Antenna (3)

1

2

ANT Port

Port Seal

Chapter 2 Installing System

4 Connect the RF connector of clip on antenna to the RRH ANT 1, 2, 3, 4 port.

RT4401-48A Installation Manual v3.0 22

Copyright © 2019, All Rights Reserved.

Page 39

Figure 18. Assembling Clip on Antenna (4)

RF Port

Tag Color

ANT1

RED

ANT2

Orange

ANT3

Yellow

ANT4

Aqua blue

ANT1

ANT2

ANT3

ANT4

1

2

ANT Port

4.3-10 (Plus) Male Connector

Chapter 2 Installing System

When connecting the RF cable, check the color of the tags on the side of RF cable.

5 Push weatherproof boots up to the port seal.

RT4401-48A Installation Manual v3.0 23

Copyright © 2019, All Rights Reserved.

Page 40

Figure 19. Assembling Clip on Antenna (5)

Category

Description

Parts

AC-DC Power Unit

1 EA

Fasteners

M5 × L16 Torx Screw

2 EA

Recommended Torque Value

M5 Torx Screw

25 lbfin

Working Tools

Torque Driver (20 to 90 lbf·in)

Screw Driver Bit (T25H)

1

2

Port Seal

Weatherproof Boots

Chapter 2 Installing System

Assembling AC-DC Power Unit

This section describes the procedure to fix the AC-DC power unit on the RRH.

Assembling Clip on Antenna

To fix the AC-DC power unit, do the following:

Prerequisites

Before proceeding with assembling the AC-DC power unit make sure that you

have the items mentioned in the table below.

Table 5. Parts and Tools for Assembling AC-DC Power Unit on RRH

1 Place an AC-DC power unit to the right side of the RRH.

RT4401-48A Installation Manual v3.0 24

Copyright © 2019, All Rights Reserved.

Page 41

Figure 20. Assembling AC-DC Power Unit (1)

AC-DC Power Unit

1

2

Hook

Chapter 2 Installing System

2 Fix the AC-DC power unit using the fasteners.

RT4401-48A Installation Manual v3.0 25

Copyright © 2019, All Rights Reserved.

Page 42

Figure 21. Assembling AC-DC Power Unit (2)

Category

Description

Parts

Unit Bracket

1 EA/RRH

Fasteners

M6 × L20 hexagonal bolt (Washer

assembly)

4 EA/RRH

M8 × L30 hexagonal bolt (Washer

assembly)

1 EA/RRH

Recommended Torque Value

M6 hexagonal bolt

43 lbfin

Working Tools

Torque Wrench (10 to 50 lbfin)

Torque Wrench Spanner Head (apply hexagonal head: 10 mm)

Spanner (apply hexagonal head: 13 mm)

M5 Torx Screw

2

4

M5 Torx Screw

1

3

Chapter 2 Installing System

Using Tilting and Swiveling Bracket

This section describes the procedure to fix the unit bracket using the tilting and

swiveling bracket.

Fixing Unit Bracket

To fix the unit bracket, do the following:

Prerequisites

Before proceeding with fixing the unit bracket, make sure that you have the items

mentioned in the table below:

Table 6. Parts and Tools for Fixing Unit Bracket on RRH

RT4401-48A Installation Manual v3.0 26

Copyright © 2019, All Rights Reserved.

Page 43

1 Inset the M8 hexagonal bolt to the unit bracket temporarily.

Unit Bracket

Fixing Point

1

2

Unit Bracket

1

2

Unit Bracket

M8 Hex. Bolt

(Washer Assembly)

≒ 0.4 in. (10 mm)

* Keep the distance between the M8

Hex. Bolt and unit bracket by 0.4 in.

(10 mm)

Figure 22. Fixing Unit Bracket (1)

Chapter 2 Installing System

2 Check the position for mounting the unit bracket on the back of the RRH and

place it in that position.

Figure 23. Fixing Unit Bracket (2)

3 Fix the unit bracket using the fasteners.

RT4401-48A Installation Manual v3.0 27

Copyright © 2019, All Rights Reserved.

Page 44

Figure 24. Fixing Unit Bracket (3)

Category

Description

Parts

Mounting Bracket

1 EA

Fasteners

Steel Band

2 EA

Recommended Torque Value

Steel Band Fixing Screw

110 lbfin

Working Tools

Torque Driver (20 to 90 lbfin)

Screw Driver Bit ('+', No. 3)

Antenna Alignment Tool

Unit Bracket

M6 Hex. Bolt

(Washer Assembly)

1

2

Chapter 2 Installing System

Fixing Pole Type_1 Sector

This section describes the procedures for fixing the system on the pole.

The standard of the pole on which the mounting bracket can be attached using

steel bands is 50 A to 125 A. When installing on a pole of 125 A or more, the steel

band should be replaced.

Assembling Mounting Bracket

To assemble the mounting bracket for 1-sector, do the following:

Prerequisites

Before proceeding with assembling the mounting bracket for 1-sector, make sure

that you have the items mentioned in the table below:

Table 7. Parts and Tools for Fixing Mounting Bracket on the Pole

RT4401-48A Installation Manual v3.0 28

Copyright © 2019, All Rights Reserved.

1 Pass the steel band through the fixing hole of the mounting bracket.

Page 45

Figure 25. Fixing Mounting Bracket on the Pole (1)

1

2

Pole

1

2

Steel Band

Mounting Bracket

Chapter 2 Installing System

2 Place the mounting bracket to the pole.

Figure 26. Fixing Mounting Bracket on the Pole (2)

3 Fix the mounting bracket to the pole using the steel band.

RT4401-48A Installation Manual v3.0 29

Copyright © 2019, All Rights Reserved.

Page 46

Figure 27. Fixing Mounting Bracket on the Pole (3)

If it is level, the bubble of the

spirit level is positioned at the

center of both lines.

1 2 3

4

Chapter 2 Installing System

4 Check the level of mounting bracket on the pole and adjust the level.

Figure 28. Fixing Mounting Bracket on the Pole (4)

When fixing the mounting bracket on the pole, ensure to check the level of bracket.

After finishing the installation, adjust the level minutely.

RT4401-48A Installation Manual v3.0 30

Copyright © 2019, All Rights Reserved.

Page 47

When poor leveling happens, adjust the position of fasteners used to fix the

Category

Description

Fasteners

M8 × L30 hexagonal bolt (Washer assembly)

1 EA

Recommended Torque Value

M8 hexagonal. bolt

110 lbfin

Working Tools

Torque Wrench (100 to 400 lbfin)

Torque Wrench Spanner Head (apply hexagon head: 13 mm)

RF Alignment Tool

RRH

Mounting Bracket

Cherry Picker

Operator

mounting bracket.

After fixing the steel band, push the remainder of band inside the mounting

bracket.

Lifting RRH

To lift the RRH, do the following:

Lift the RRH with a cherry picker.

Figure 29. Lifting RRH

Chapter 2 Installing System

Fixing RRH on the Pole

To fix the RRH on the pole, do the following:

Prerequisites

Before proceeding with fixing the RRH on the pole, make sure that you have the

items mentioned in the table below.

Table 8. Parts and Tools for Fixing RRH on the Pole

1 Place the unit bracket on the fixing groove of the mounting bracket.

RT4401-48A Installation Manual v3.0 31

Copyright © 2019, All Rights Reserved.

Page 48

Figure 30. Fixing RRH on the Pole (1)

Fixing Groove

Unit Bracket

1

2

M6 Hex. Bolt

Chapter 2 Installing System

2 Fix the RRH using the fasteners.

RT4401-48A Installation Manual v3.0 32

Copyright © 2019, All Rights Reserved.

Page 49

Figure 31. Fixing RRH on the Pole (2)

[Angle pointer position for unit bracket with

0° tilt when installing the RRH]

Tilting angle scale of the unit bracket

M8 Hex. Bolt

(Washer Assembly)

1

2

Chapter 2 Installing System

When installing the RRH, the tilting angle pointer of the unit bracket should point

to 0°.

3 Check the tilt and the azimuth using the RF alignment tool, and adjust when

there is an issue.

For detailed instructions of how to use the RF alignment tool, refer to the user