Samsung RS267LBBP, RS263BBWP, RS265LBWP, RS263BBSH, RS267LBSH Service Manual

...

REFRIGERATOR

SIDE BY SIDE

BASIC : RS265BBWP, RS267LBBP

MODEL NAME : RS263BBWP RS265LBBP

RS263BBBB RS265LBWP

RS263BBSH RS267LBSH

RS264ABBP RS264ABRS

RS264ABSH RS264ABWP

RS267BBBB RS269LBRS

RS267BBSH RS267BBRS

MODEL CODE : RS263/264/265/267/269**/XAA

REFRIGERATOR PRODUCT FEATURE

●●

NEW DIGITAL DISPLAY(LED)

●●

TOWER LIGHTING

●●

CONTOUR DOOR/HIDDEN HINGE

●●

CLEAN LOOK DRAWER

●●

TWIN COOLING

●●

HUMAN TOUCH HANDLE

RS26**

For the latest information, Please access to our service web site (http://itself.sec.samsung.co.kr)

IMPORTANT SAFETY NOTICE

The service guide is for service men with adequate backgrounds of

electrical, electronic, and mechanical experience. Any attempt to repair

a major appliance may result in personal injury and property damage.

The manufacturer or dealer cannot be responsible for the interpretation

of this information.

SAMSUNG ELECTRONICS AMERICA, INC.

Technical Service Guide

Copyright ⓒ2006

All rights reserved. This service guide may not be reproduced in whole or in

part in any form without written permission from the SAMSUNG ELECTRONICS

Company.

WARNING

3

Contents

1. PRECAUTIONS (SAFETY WARNINGS) ······················· 4

2. PRODUCT SPECIFICATIONS

·····························

8

3. OPERATING INSTRUCTIONS & INSTALLATION

··················

20

4. ALIGNMENT AND ADJUSTMENTS

··························

28

5. DISASSEMBLY AND REASSEMBLY

·························

36

6. TROUBLESHOOTING

·································

49

7. EXPLODED VIEW & PARTS LIST

···························

62

8. BLOCK DIAGRAM

····································

79

9. WIRING DIAGRAM

···································

80

10. PCB DIAGRAM

·····································

82

11. CIRCUIT DIAGRAM ·································· 84

12. CIRCUIT DESCRIPTIONS

······························

85

13. SAFETY INSTRUCTIONS ON SERVICE

······················

94

14. REFERENCE INFORMATION

····························

100

4

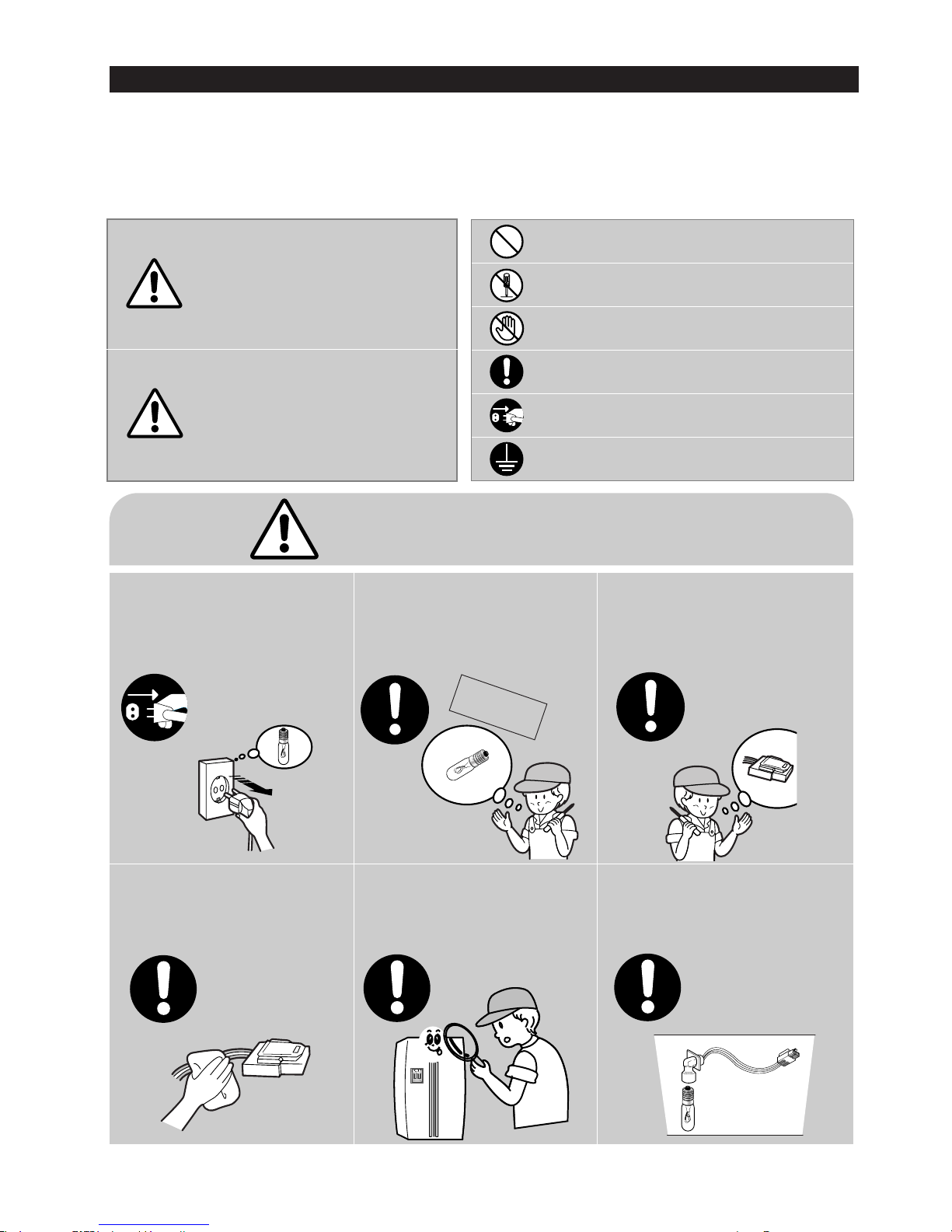

1. PRECAUTIONS(SAFETY WARNINGS)

●

Pull the power plug out before for the change or repair of electric parts.

→

Be careful the electric shock.

●

When exchanging the parts, use the correct parts.

→

Check the model name, rating voltage, rating current, running

temperature symbols.

●

When troubleshooting, connect firmly the types of harness.

→

Make not to be separated when some power is imposed.

●

Check the traces of water infiltration at the electric parts.

→

If there is a trace of water infiltration, exchange or tape the parts.

●

Check the assemble status of parts after troubleshooting.

→

It should be done indiscriminately as before the repair.

●

Check the use circumstance of refrigerator.

→

If the refrigerator is installed at the place that is damp or wet, or

status of installation is unstable, change the installation place.

●

Do earth in case of need.

→

Particularly, Be sure to earth when there is a risk of an electric

leakage by humidity or wetness.

●

Do not use multi plugs in a plug socket at the same time.

Check if the power cord and socket is damaged, pressed, squeezed,

or fired.

→

If the plug or plug socket is damaged, repair or exchange that

immediately.

●

Do not repair the refrigerator by user himself.

●

Do not store other materials except the foods.

→

Drugs or scientific materials : difficult to keep precise temperature.

→

The inflammables(alcohol, benzene, ether, LP gas, butane gas etc.):

have risk of explosion.

5

1. PRECAUTIONS(SAFETY WARNINGS)

Read all instructions before repairing the product and follow the instructions

in order to prevent danger or property damage.

CAUTION/WARNING SYMBOLS DISPLAYED

SYMBOLS

Indicates that a

danger of death

or serious injury

exists.

Indicates that a risk

of personal injury

or material damage

exists.

means “Prohibition”.

means “Do not disassemble”.

means “No contact”.

means ”The things to

be followed”.

means “Earth to prevent Electric

shock”.

means “Power cord should be

unplugged from the consent”

Pull the power plug out to

exchange the interior lamp

of the refrigerator.

●

It may cause electric shock.

Warning

Warning & Caution

Caution

Unplug

Use the rated components

on the replacement.

●

Check the correct model, rated

voltage, rated current, operating

temperature and so on.

On repair, make sure that the

wires such as harness are

bundled tightly.

●

Bundle tightly wires in order not to be

detached by the external force and then not

to be wetted.

Check if there is any trace

indicating the permeation

of water.

●

If there is that kind of trace, change

the related components or do the

necessary treatment

such as taping

using the

insulating tape.

After repair, check the

assembled state of components.

●

It must be in the same assembled state

when compared with the state before

disassembly.

On repair, remove completely dust

or other things of housing parts,

harness parts, and check parts.

●

Cleaning may prevent the possible fire by

tracking or short.

Rated

components

6

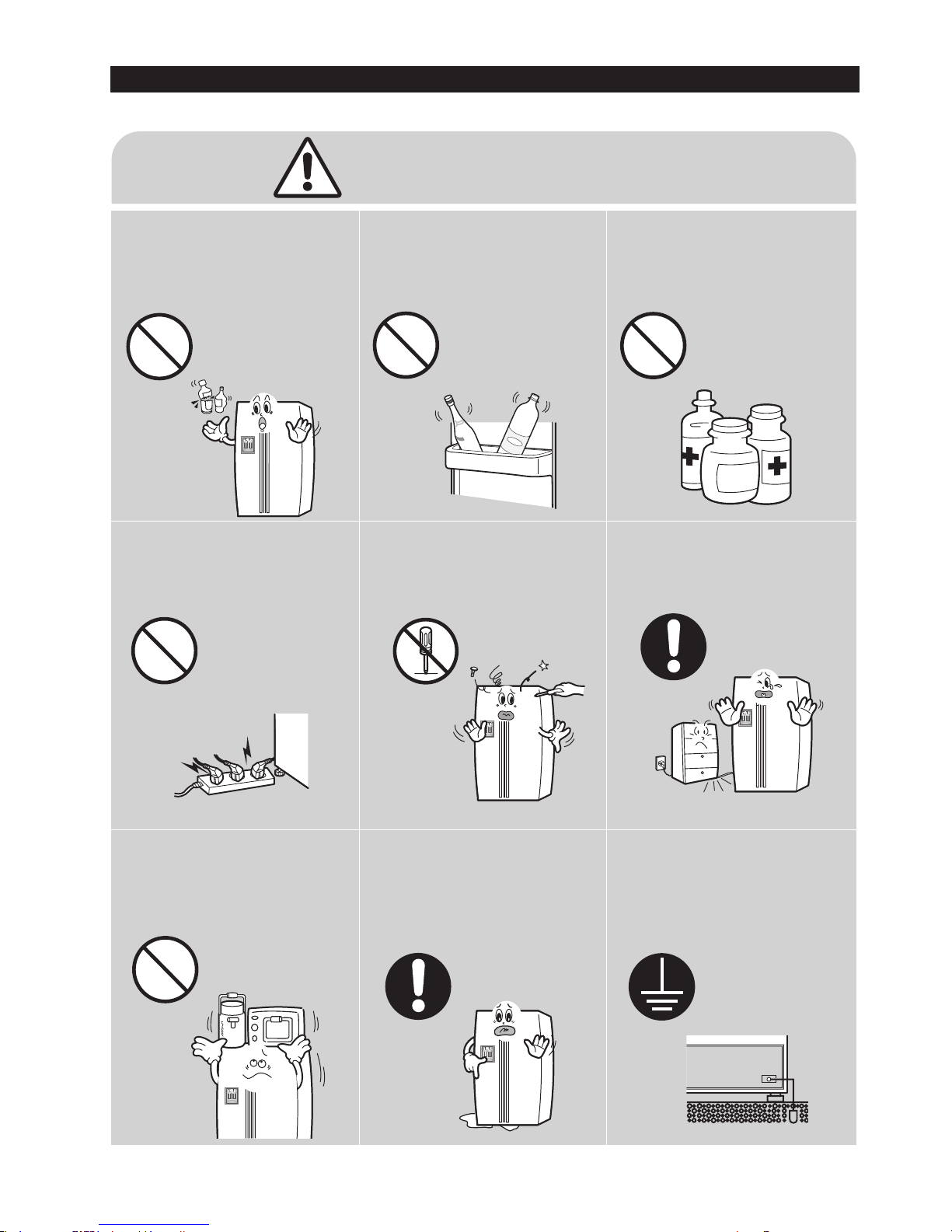

1. PRECAUTIONS(SAFETY WARNINGS)

❈

Please let users know following warnings & cautions in detail.

Do not allow users to put bottles or

kinds of glass in the freezer.

●

Freezing of the contents may inflict a wound.

Do not allow users to store narrow

and lengthy bottles or foods in a

small multi-purpose room.

●

It may hurt you when refrigerator door is

opened and closed resulting in falling stuff

down.

Do not allow users to store

pharmaceutical products, scientific

materials, etc., in the refrigerator.

●

The products which temperature control

should not be stored in the refrigerator.

Do not allow users to store

articles on the product.

●

Opening or closing the door may cause

things to fall down, with may inflict a

wound.

Prohibition

Prohibition

Prohibition

Prohibition

Warning & Caution

Do not allow users to

disassemble, repair or alter.

●

It may cause fire or abnormal

operation which leads to injury.

Do not

disassemble

Do not allow users to insert the

power plugs for many products

at the same time.

●

May cause abnormal generation of

heat or fire.

Prohibition

Do not allow users to bend the

power cord with excessive force

or do not have the power cord

pressed by heavy article.

●

May cause fire.

Do not allow users to install the

refrigerator in the wet place or

the place where water splashes.

●

Deterioration of insulation of electric

parts may cause electric shock or fire.

Make sure of the earth.

●

If earthing is not done, it will cause

breakdown and electric shock.

Earth

7

2. PRODUCT SPECIFICATIONS

2-1) Introduction of main function ·····························8

2-2)

Specifications

·······································9

2-3)

Interior Views

······································ 10

2-4)

Model Specification &Comparison Chart

······················· 11

2-5)

Model Specification &Comparison Chart

······················· 12

2-6)

Dimensions of Refrigerator (Inches)

·························· 15

2-7)

Optional Material Specification

····························· 16

2-8)

Refrigerant Route in Refrigeration cycle

························· 17

2-9)

Cooling Air Circulation

·································· 18

8

2. PRODUCT SPECIFICATIONS

●●

A newly developed SAMSUNG side by side refrigerator in 2006 has the following

characteristics.

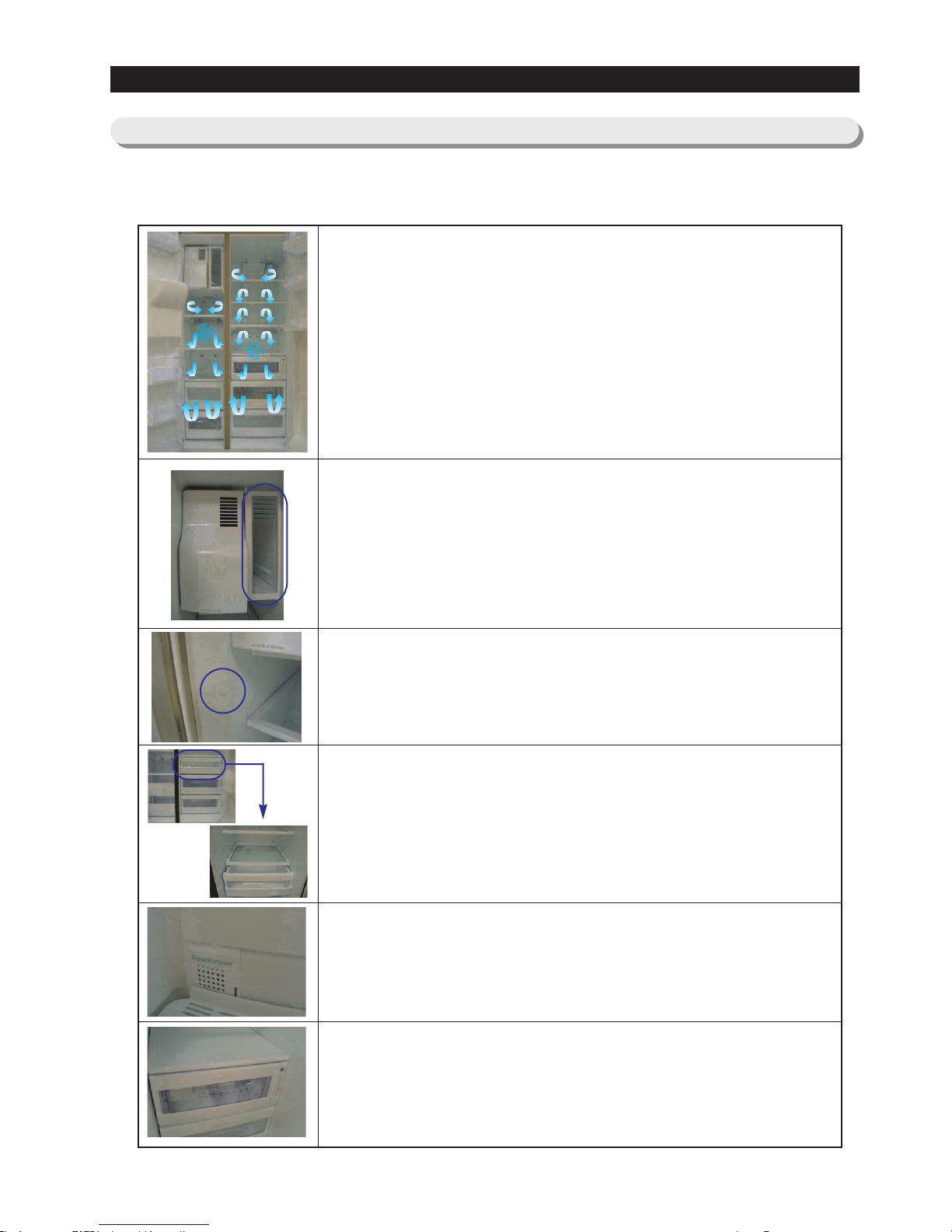

Twin Cooling System

●●

The refrigerator and the freezer have two evaporators. Given this

independent system, the freezer and the refrigerator are cooled

individually as required and are, therefore, more efficient. Food

odor from the refrigerator does not affect food in the freezer due

to separate air flow circulation.

Multi-Flow System

●●

Cool air circulates through multiple vents on every shelf level.

This provides even distribution of cooling inside cabinets to keep

your food fresh longer.

Xtra Space

TM

●●

Vertical room next to the ice maker in the freezer provides space

for pizza etc.

Door Alarm

●●

Beep sound reminds you the door is open.

Xtra Fresh

TM

●●

Optimized humidity control keeps vegetables & fruits fresh.

(RS263B/RS265L)

Deodorizer

●●

Reusable twin deodorizers keep the refrigerator air fresh and odor

free.

CoolSelect ZoneTMDrawer

(RS265B,RS267B,RS267L,RS269L)

●●

User can select Quick Cool, Thaw, for quickly chill items, thaw

items. Select Soft freeze, Chill or Cool to control the temperature

of the drawer.

2-1) Introduction of main function

9

2-2) Specifications

2. PRODUCT SPECIFICATIONS

Defrost Control From 24 to 32 hrs

Defrost Thermistor(502AT) 50℉(off)

Electrical Rating AC115V 60Hz 11.6 Amps

Maximum Current Leakage 0.25 mA

Maximum Ground Path Resistance 0.1 Ohm

Energy Consumption KWH/mo.

Ambient Temperature 70

℉ 90℉

Refrigerator,℉ 34∼46 34∼46

Freezer,℉ -14∼8 -14∼8

Run Time,% 40 60

Refrigerant Charge (R134a) 7.76 oz

Compressor(MK183C-L2U) 532.3 Btu/hr

Compressor oil Freol α-10

Capillary tube(Dia, Length)

0.033"",130

""

Dryer

Molecular Sieve XH-9

Clearance must be provided for air circulation

AT TOP 2

""

AT SIDES 0.1

""

AT REAR 2

""

RS265(Good), RS267(Better), RS269(Best)

Main PCB ASS’Y(Dispenser with CoolSlelect Zone

TM

)

DA41-00104Z

Main PCB ASS’Y

(

(Dispenser

)

DA41-00396A

Thermistor(Freezer) DA32-10109W

Thermistor(Freezer Evaporator) DA32-00006A

Thermistor(Refrigerator) DA32-10105U

Thermistor(Refrigerator Evaporator)

DA32-00006B

Thermistor(Ambient) DA32-10109V

Thermistor(CoolSelect ZoneTM)

DA32-10109X

Thermistor(Ice-Maker)

DA32-10108B

Relay DA35-10013Q

Overload Relay DA34-10003D

Run Capacitor (12㎌) 2501-001045

Fan-Motor(FRE) DA31-00020E

Fan-Motor(REF) DA31-00002S(RS2534)

Fan-Motor(REF) DA31-00020E(RS2556/2578)

Fan-Motor(Condenser) DA31-00020H

Thermal Fuse DA47-00095C

Senser-Flow DA32-10110B

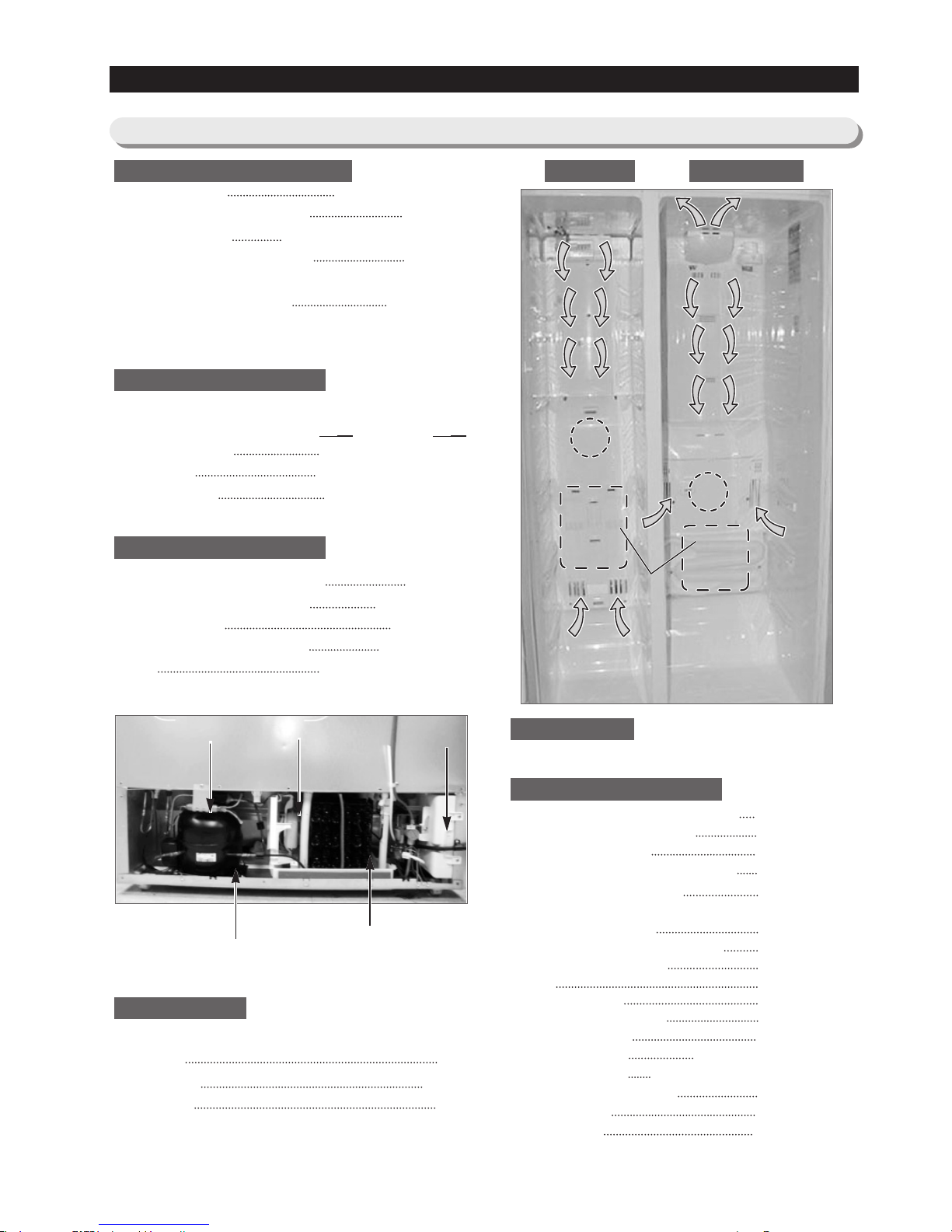

Fan

Fan

(Air inlet)

(Air inlet)

Heat exchanger

Compressor

C-FanDryer Electric box

Sub-condenser

ELECTRICAL SPECIFICATIONS Freezer Refrigerator

NO LOAD PERFORMANCE

REFRIGERATION SYSTEM

INSTALLATION

MODELS

REPLACEMENT PARTS

Fan

Fan

Fan

Heat exchanger

Heat exchangerHeat exchanger

(Air inlet)

(Air inlet)

Fan

(Air inlet)

(Air inlet)

10

2. PRODUCT SPECIFICATIONS

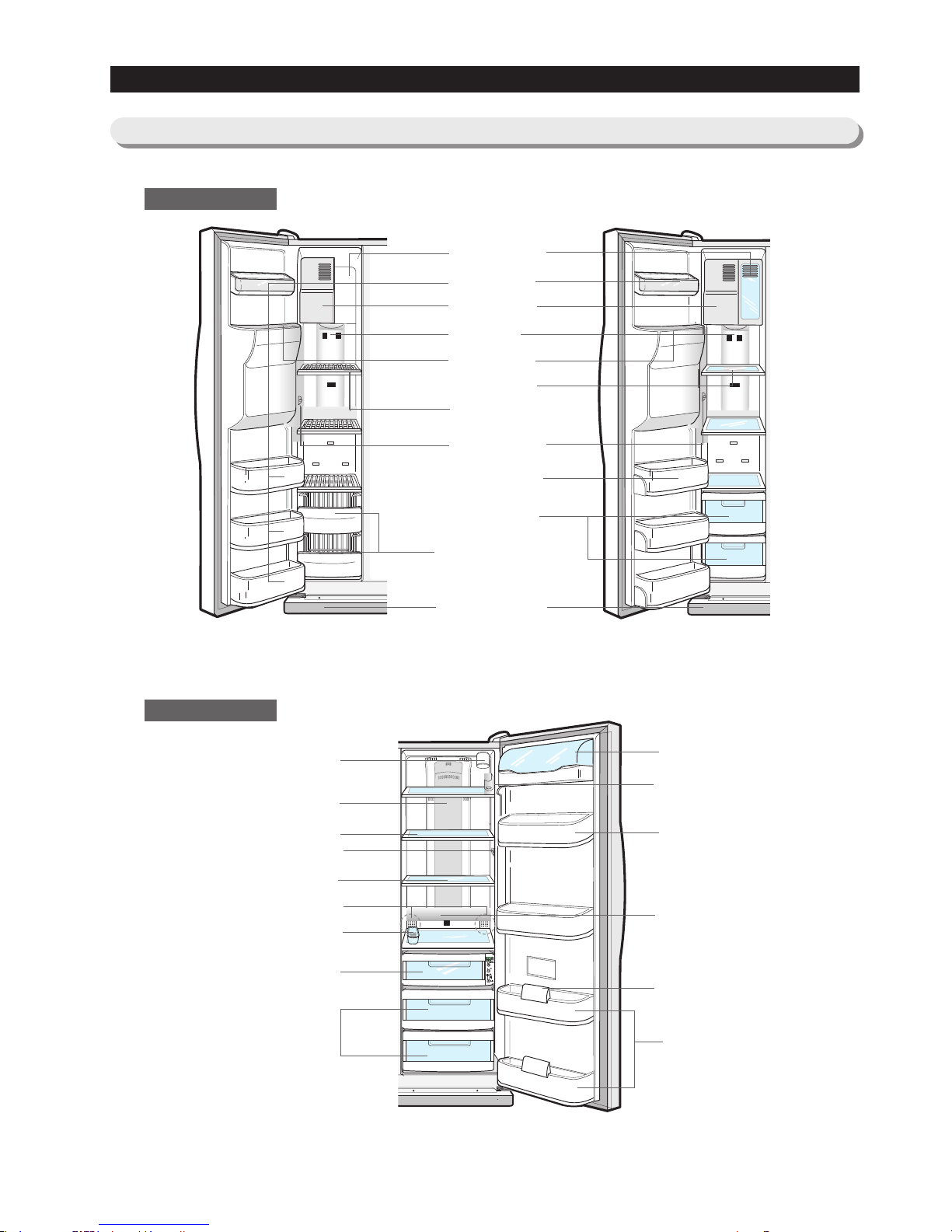

2-3)

Interior Views

Door Bin

Xtra Space

TM

Ice Maker

Light

Ice Chute

Glass Shelf

Wire Shelf

Light Switch

Light Switch

Deodorizer

Plastic Drawers

Wire Drawers

Front Leg Cover

Tilt Pockets

RS263B/RS265L Model

Egg Container

Foldable Shelf

(RS265B/RS267B/RS267L/RS269L)

Light (upper)

Water Filter

Spill-proof glass Shelf

Dairy Compartment

Wine Shelf

Gallon Door Bin

Lights (lower)

Gallon Door Bins

Door Bin Top Lips

CoolSelect Zone

TM

Drawer for

RS265B/RS267B/RS267L/RS269L

(Chilled Bin for RS263B/RS265L)

Vegetable & Fruit Drawers

RS265B/RS267B/RS267L/RS269L Model

Freezer

Refrigerator

11

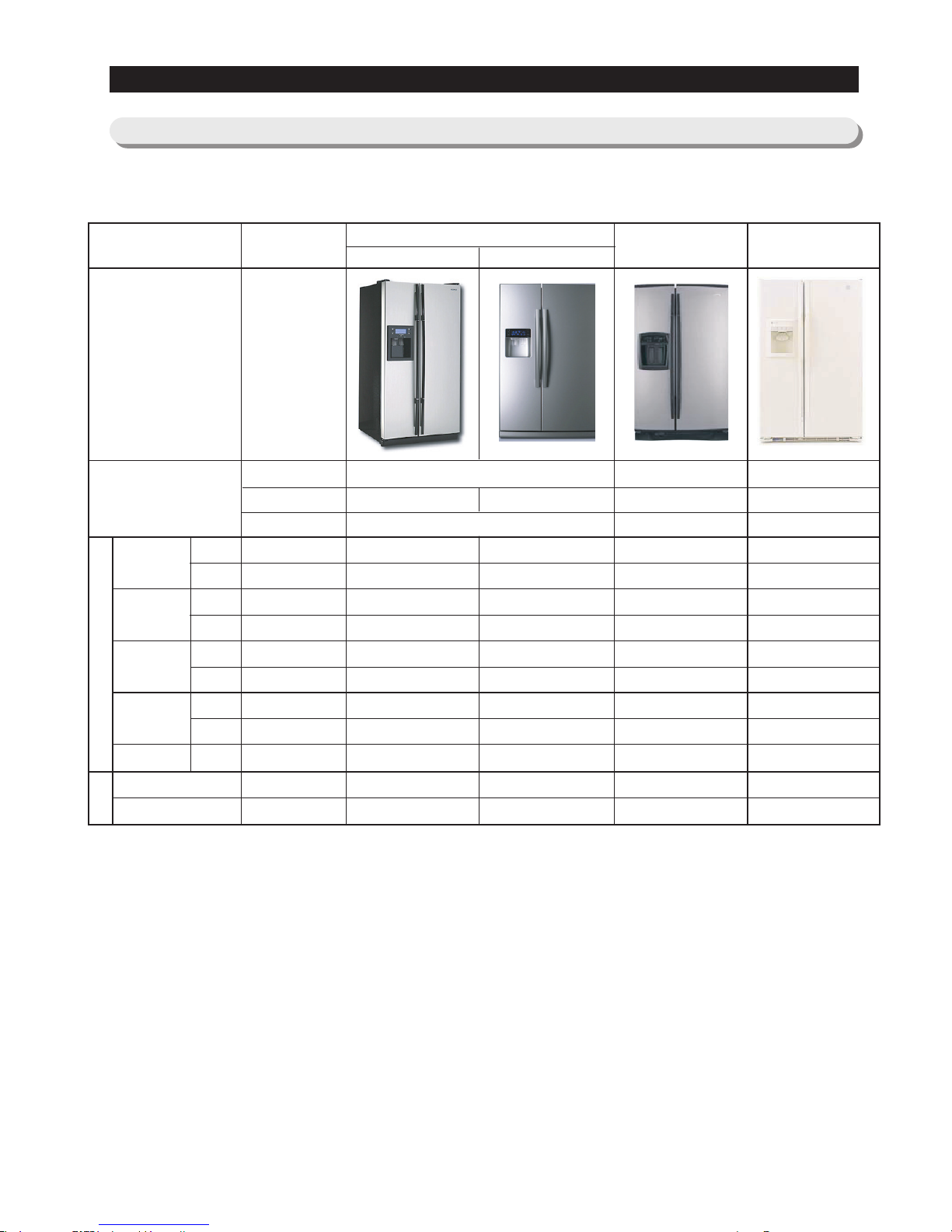

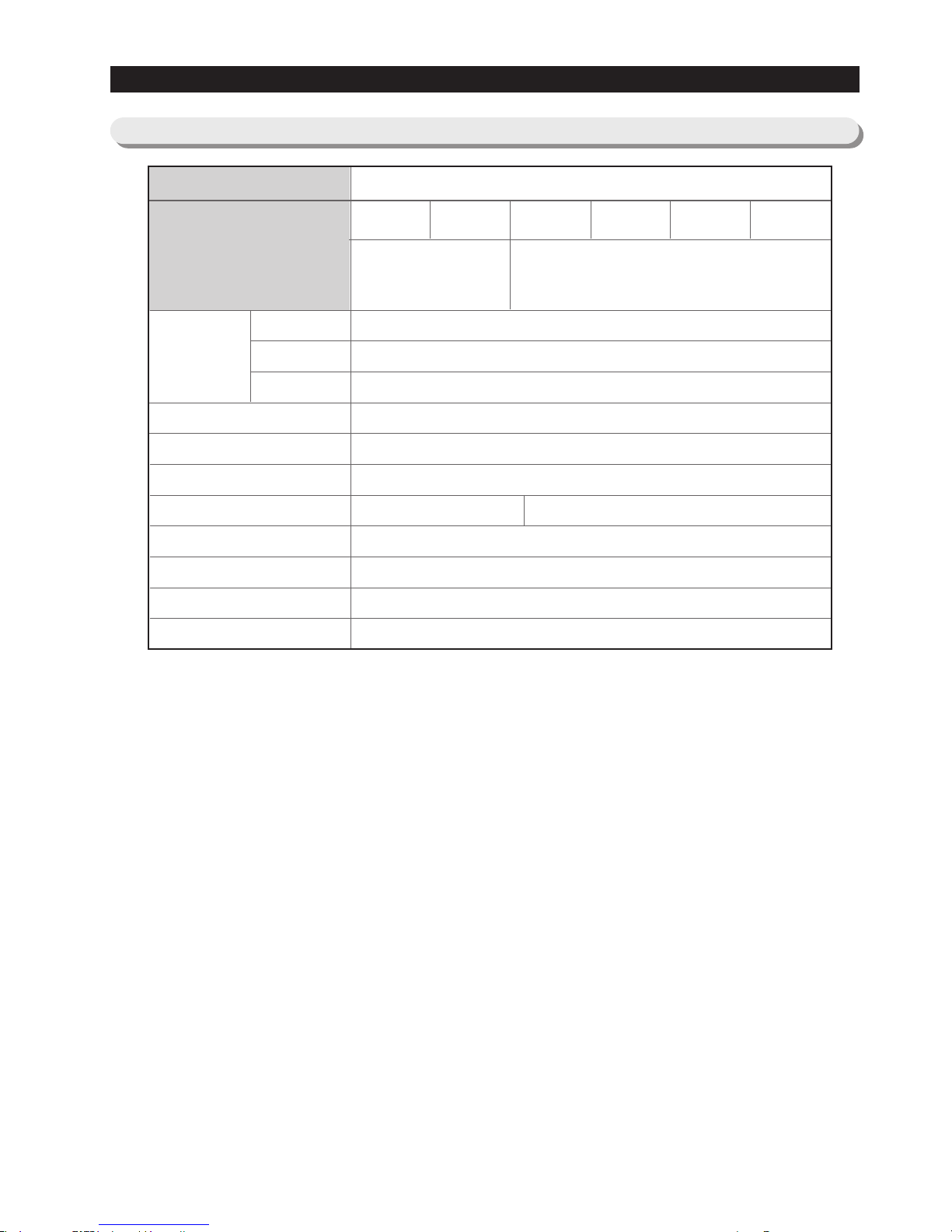

2-4) Model Specification &Comparison Chart

PRODUCT SPECIFICATIONS

Spec

WHIRLPOOL

GS6SHAXLS

GE

GSS25JFP

ITEM

Appearance

Product Zone

Performance

Noise

SAMSUNG

Twin Cooling

Flat Contour

Cool select Zone

167.2 159.3 111.6 199.0

108.5 104.2 386.4 202.0

-29.9 -30.0 -29.8 -27.2

0.1 -1.0 -4.6 -1.1

-24.0 -23.7 -24.7 -20.4

1.3 -0.3 3.4 1.1

1.3 0.9 1.7 1.0

1.5 1.2 2.1 3.3

53.2 55.5 48.8 55.3

44.4 43.3 45.0 46.7

41.3 41.1 40.0 45.0

Cooling Tech

Door Shape

Special Room

Mono Cooling Mono Cooling

Contour Contour

Convertible Bin Convertible Bin

A-TOP05 A-TOP06

200↓

150↓

-26↓

0±1.5

-18↓

5↓

2.0↓

2.0↓

65%↓

45dB↓

43dB↓

F-Room

Cooling

Speed(Min)

32℃

43℃

Temperature

Distribution

(Fridge)

Operation rate

R-Room

F-Room

R-Room

F-Room

R-Room

F-Room

R-Room

N-N

Sound power level

Sound pressure level

12

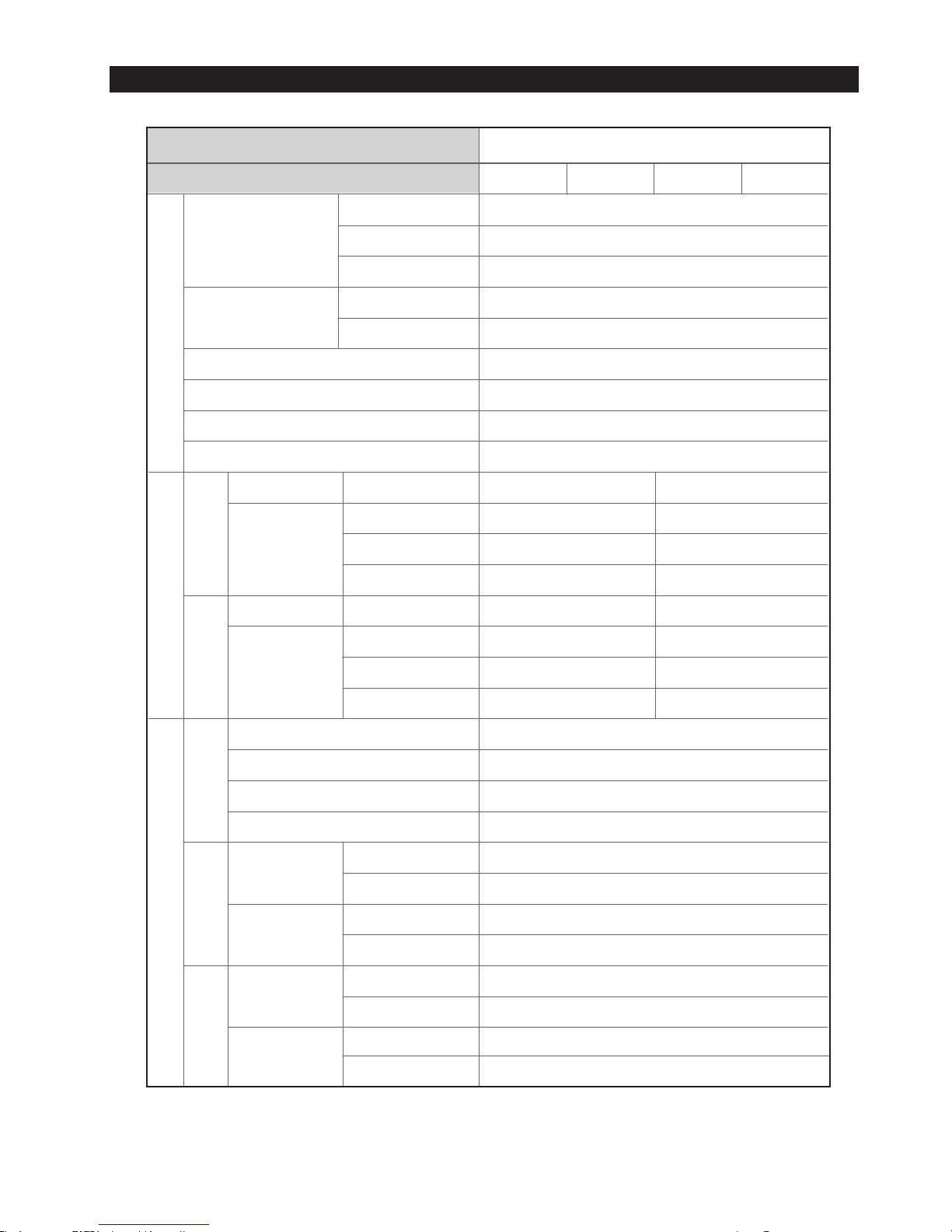

2-5) Model Specification &Specification Chart

PRODUCT SPECIFICATIONS

Indirect Cooling Method Refrigerator

R134a

7.76oz

309 Pounds

35.7inch x 36.5inch x 70inch

AC 115V/60Hz

Net Dimension(W×D×H)

Rated Frequency and Frequency

Motor Rated Consumption Power

Electric Heater Rated Consumption Power

Kind of Refrigerator

Refrigerant

Refrigerant Input Amount

Product Weight

Item

Specification

NNeett

CCaappaacciittyy

TToottaall

RReeffrriiggeerraattoorr

FFrreeeezzeerr

Models

26.1 cu.ft

10.0 cu.ft

16.1 cu.ft

414W 415W

160W

Dispenser

Dispenser with

Coolselect Zone™

RS263BB RS265LB RS265BB RS267LB RS267BB RS269LB

Items

13

PRODUCT SPECIFICATIONS

THERMISTOR

(R-SENSOR)

502AT

Models

Condenser

Dryer

Capillary tube(Dia

×

Length)

Refrigerant

FREOL α-10

SPLIT FIN TYPE

SPLIT FIN TYPE

Forced and natural convection type

Molecular sieve XH-9

0.033 ”×130 ”

R134a

ON(℉) OFF(℉)

-11℉ -17℉

-1℉ -7℉

11℉ 5℉

ON(℉) OFF(℉)

36℉ 32℉

40℉ 36℉

46℉ 42℉

4 hr ± 10 min

12~24hr(vary according to the conditions used)

6~12hr(vary according to the conditions used)

10 ± 2 min

THERMISTOR (502AT)

5.0㏀ at 50℉

THERMISTOR (502AT)

5.0㏀ at 50℉

AC 125V 10A

Off:140 ℉/On:104℉

AC 250V 10A

170.6 ℉(+0 ℉/-10 ℉)

Components for Freezer

Room Temperature Sensor Components

Freezer

Model

Temperature Selection

-14℉

-4℉

8℉

THERMISTOR

(F-SENSOR)

502AT

Model

Temperature Selection

34℉

38℉

44℉

Refrigerator

Defrost Cycle

Defrost SensorThermal-Fuse

F Defrost-

Sensor

F Bimetal-

thermo

R Thermal

Fuse

R Defrost-

Sensor

First Defrost Cycle (Concurrent defrost of F and R)

Defrost Cycle(FRE)

Defrost Cycle(REF)

Pause time

Model

SPEC

Model

SPEC

Rated

Operating temperature

Rated

Operating temperature

Defrost Related Components

Compressor

Model

Starting type

Oil Charge

Evaporator

Freezer

Refrigerator

MK183C-L2U

R.S.C.R

RS263 RS265 RS267 RS269

Specification

14

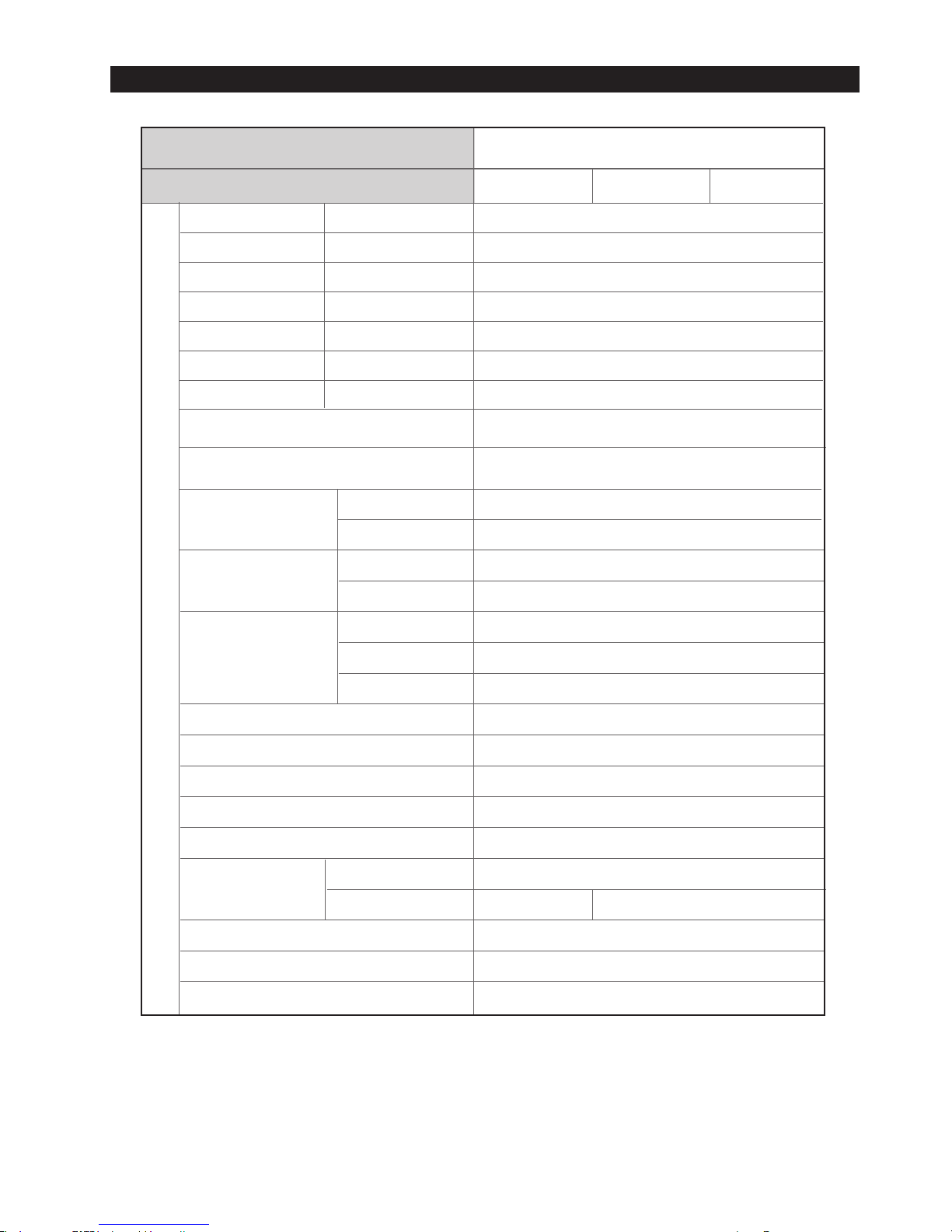

PRODUCT SPECIFICATIONS

Electric Components

AC 115V,215W

AC 115V,140W

AC 115V,45W

Single Body with Defrost Heater(REF)

AC 125V 10A Off:-76 ℉/On:104 ℉

AC 250V 10A 170.6 ℉(+0 ℉/-10 ℉)

Specification

Items

Model

Conducting at F Defrosting

Conducting at R Defrosting

Conducting at F Defrosting

Conducting at R Defrosting

Interlock with F-FAN

-

-

Defrost Heater(FRE)

Defrost Heater(REF)

Drain Heater(FRE)

Drain Heater(REF)

DISPENSER Heater

WATER PIPE Heater

WATER TANK- Heater

Condenser for

COMP

(Package type)

Running

Starting

Model

Operation

Model

Temp. ON

Temp. OFF

Starting-Relay

Over load Relay

MOTOR-BLDC(FRE)

MOTOR-BLDC(REF)

MOTOR-BLDC (Circuit)

Lamp(FRE)

Door Switch

Power cord

Earth Screw

Bimetal-thermo for preventing

Overheating of Freezer Defrost-Heater

12μF,250

V

-

J531Q32E4R7M180-2

4.7Ω±20%

4TM265RFBZZ53

257 ℉±10

℉

156.2℉±18

℉

AC 115V/60Hz

DC12V/DREP3030 LA

DC12V/DREP3020 LA

DC12V/DRCP3030 LA

AC115V/40W(1EA)

AC120V/40W(3EA)

AC 250V 0.5A×2

AC125V 15A

BSBN (BRASS SCREW)

Thermal Fuse for preventing

Overheating of Refrigerator Defrost-Heater

Rated Voltage

AC 115V,5W

AC 115V,5W

AC 115V,4W

RS263BB

RS265LB

RS265BB

RS267LB

RS267BB

RS269LB

Lamp(REF)

UPPER

LOWER

AC130V/30W(1EA)-

15

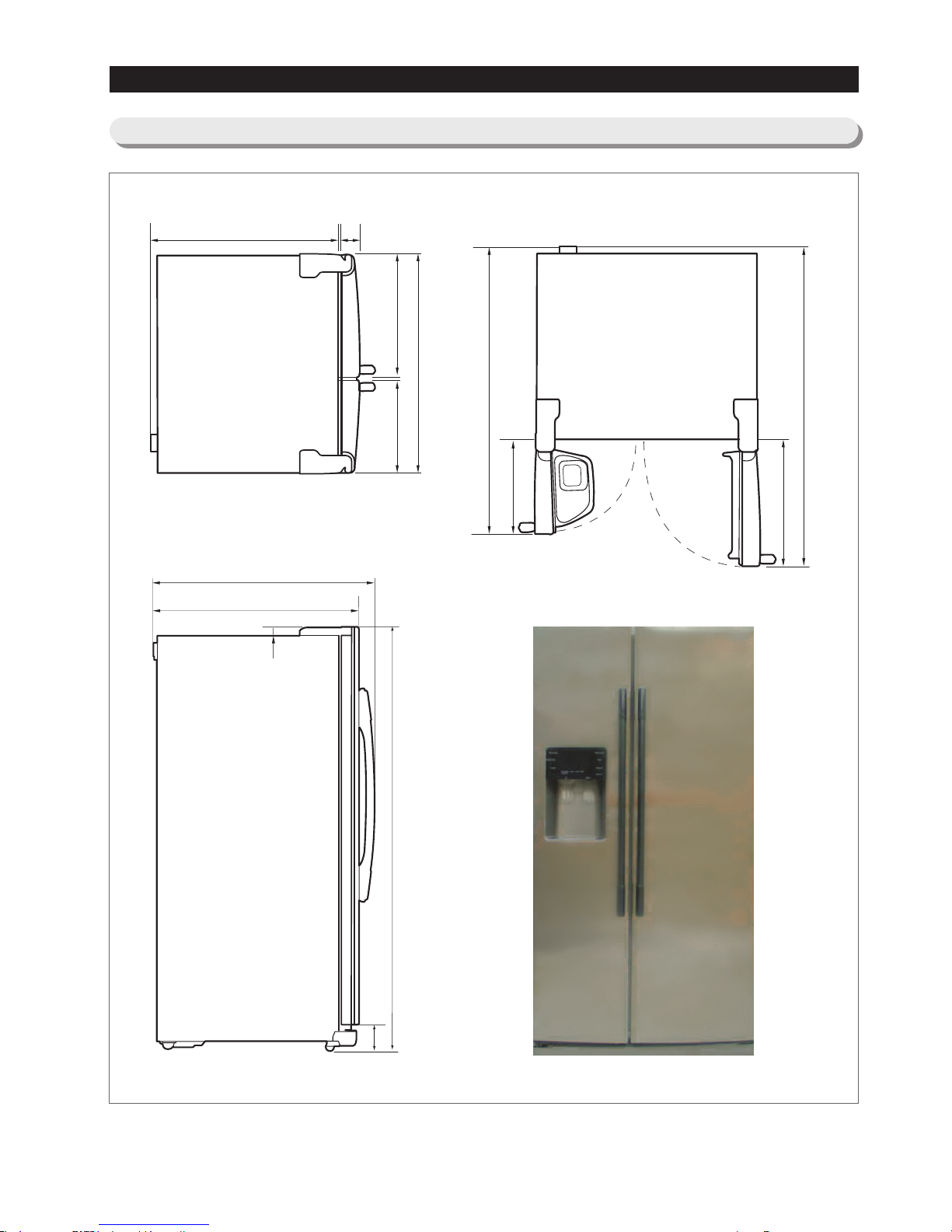

2. PRODUCT SPECIFICATIONS

35.9

46.8

16.3

21.2

51.7

20.3

30.5

36.5

34

3

15.3

1.2

4.3

70

2-6)Dimensions of Refrigerator (Inches)

16

2. PRODUCT SPECIFICATIONS

2-7) Optional Material Specification

Photographe Part Name

FILTER

WATER-ASSY

DA29-00003B

ASSY-PACKING

SUB

DA99-00240A

LAMP INCANDENT

4713-001206

LAMP INCANDENT

4713-001197

Part Code

17

Compressor → Sub-condenser → Side Cluster Pipe(FRE) → Side Cluster Pipe(REF) → Hot Pipe

→ Dryer → Capillary Tube → Refrigerator Evaporator → Freezer Evaporator→ Suction Pipe → Compressor

Refrigerator Evaporator

Capillary Tube

ACCUMULATOR

Freezer Evaporator

SUCTION PIPE

Dryer

Muffler

SUB-CONDENSER

Hot Pipe

Hot Pipe

Compressor

SIDE CLUSTER PIPE

2. PRODUCT SPECIFICATIONS

2-8) Refrigerant Route in Refrigeration cycle

18

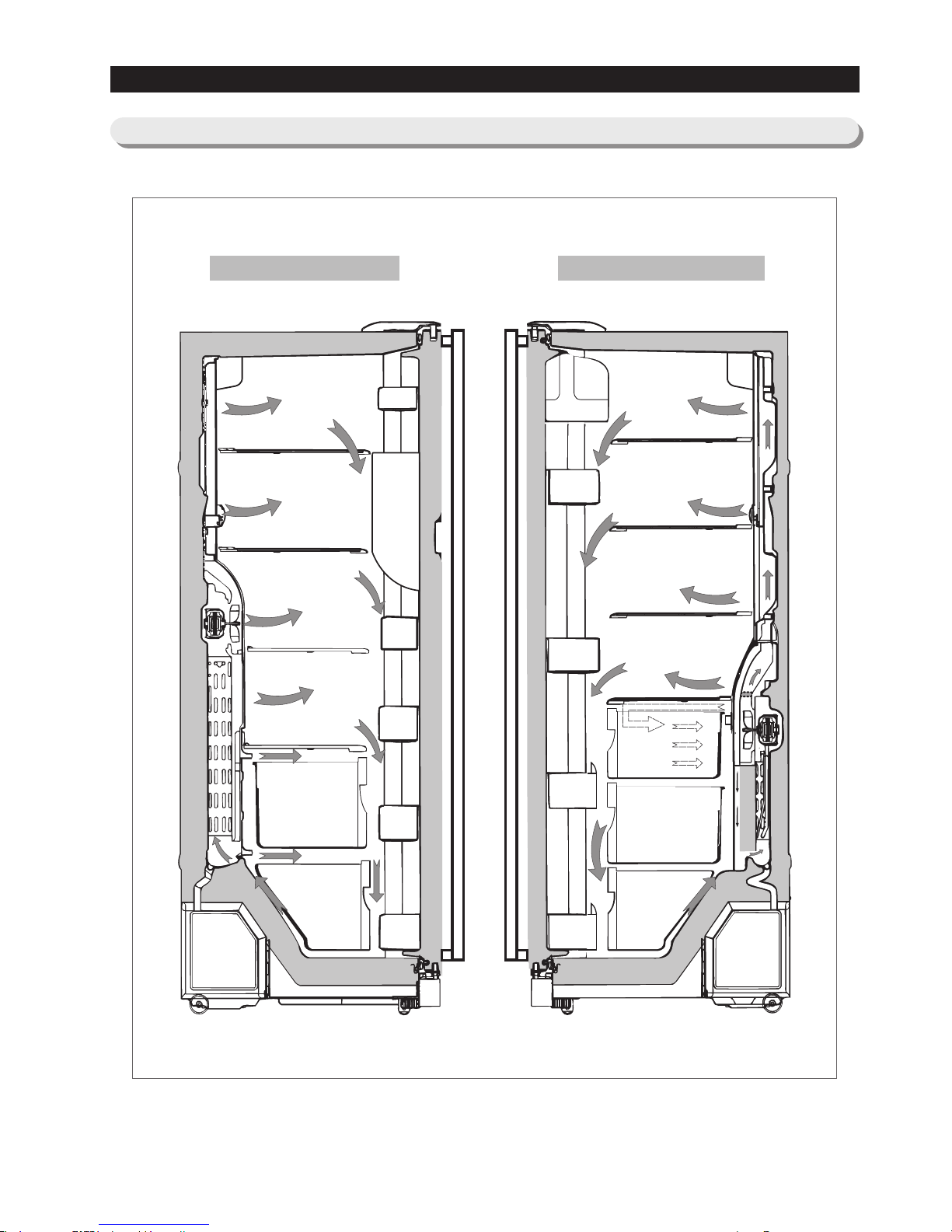

Refrigerator

2. PRODUCT SPECIFICATIONS

2-9) Cooling Air Circulation

Freezer

19

3. OPERATING INSTRUCTIONS & INSTALLATION

3-1) Digital Panel ······································20

3-2) Temperature Control Function

····························20

3-3) Power Freeze and Power Cool Functions

······················21

3-4) Child Lock Function

··································21

3-5) Ice & Water Dispenser Function

···························22

3-6) C-Fan Motor Delay Function of the Machine Compartment

···········22

3-7) CoolSelect ZoneTM Function (RS267LA,RS269LA)

···············22

3-8) Water Filter Indicator Function

····························23

3-9) Ice-Maker Function

··································23

3-10) Defrost Function

···································25

3-11) Installation

·······································26

20

3. OPERATING INSTRUCTIONS & INSTALLATION

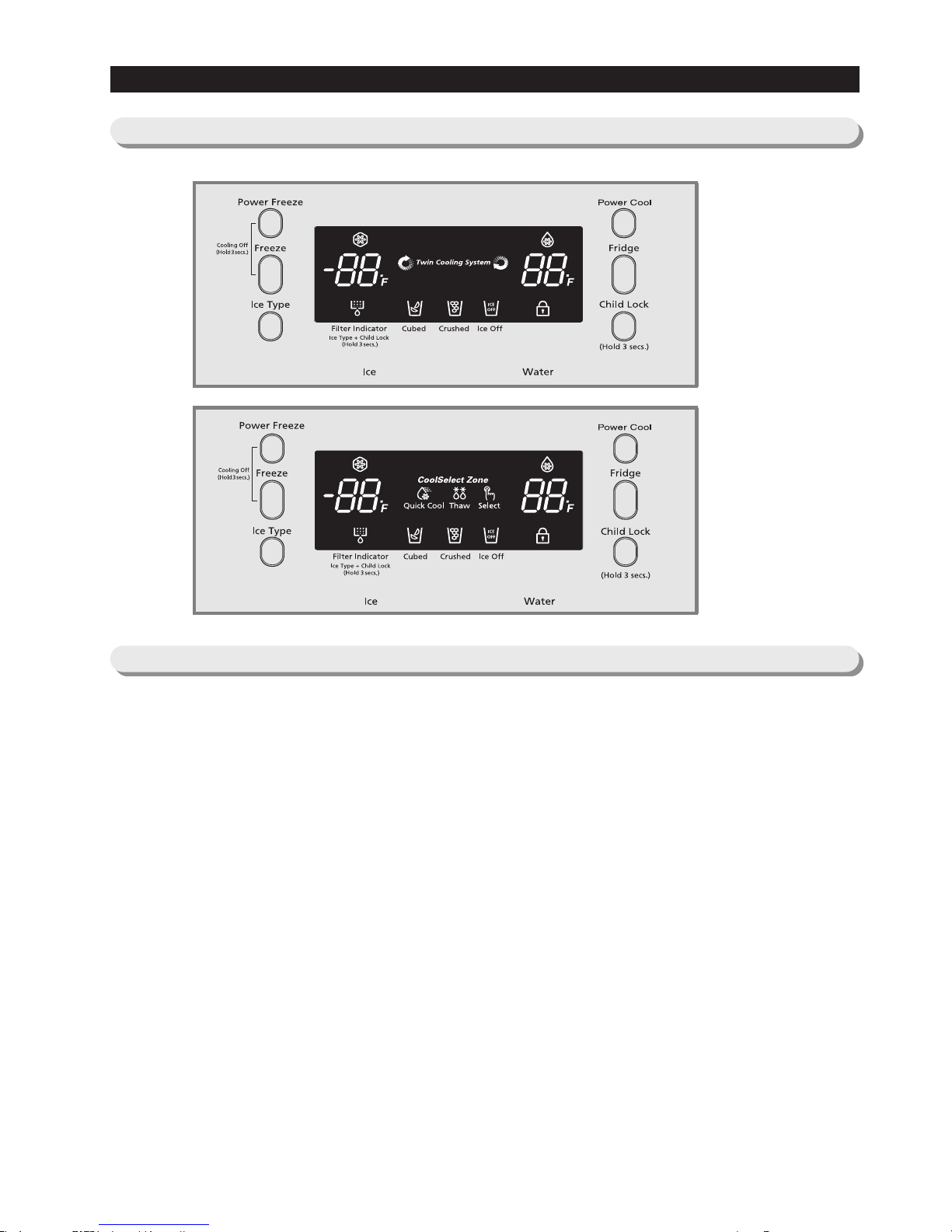

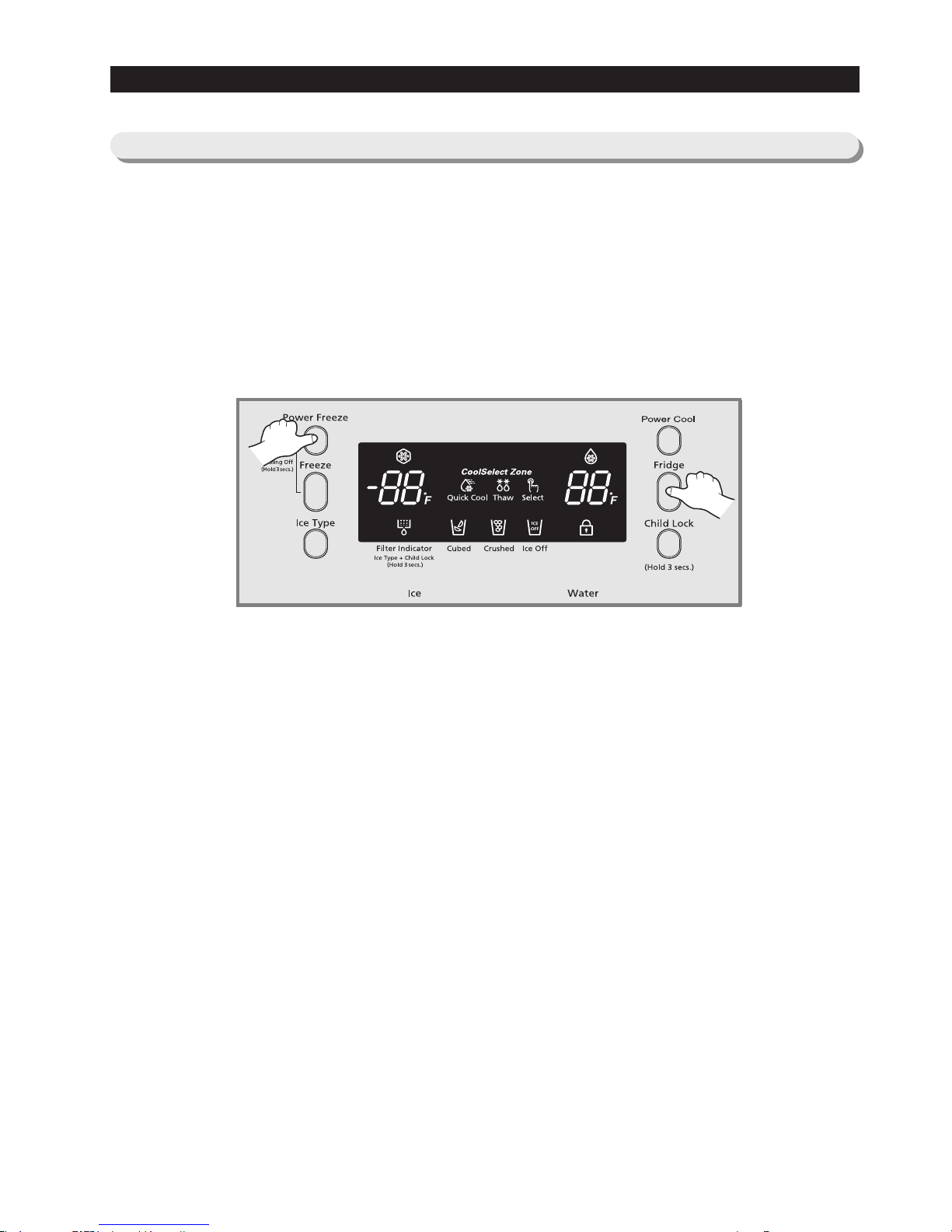

3-1) Digital Panel

When the system power is initally engaged, the default set temperature are -4℉ for the freezer and 38℉ for the set

refrigerator, respectively. The numbers shown on the digital display panel stand for the actual compartments

temperatures. When the compartment temperatures go down, so do the numbers on the display panel, and finally they

reach the set temperatures. Once the system is stabilized, the display temperatures are the set temperature.

1) Freezer Temperature Control.

To select a set temperature, press the Freezer Temp. button. The display shows the set temperature from -14℉ to

8 ℉ in sequence.

2) Quick Ice Freezer Temperature Control

Interior Temperature of the freezer will be controlled with -14 degrees Fahrenheit until the ice bucket is filled up with

ice cubes. When the ice bucket is filled up with ice cubes, the freezer will run with original set temperature. Also,

whenever the ice bucket is released from being filled with ice cube, the freezer will repeat

to be controlled with -14 degrees Fahrenheit. But if you select "Ice Off, the freezer always will be controlled with

original set temperature.

3) Refrigerator Temperature Control.

To select a set temperature, press the Fridge Temp. button. The display shown the set temperature from 34℉ to

46℉ in sequence.

note) Because of the temperature sensor sensivity, the refrigerator can be under and/or over cooled when

the air flow is blocked by stored foods. (Temperature range of the sensor : 15℉∼80℉)

In the event of a power failure, if the freezer temperature is maintained lower than 41℉, the last

selected set temperature and functions memorized in EEPROM will be restored when the power is on.

for RS263BB

RS265LB

for RS265BB

RS267BB

RS267LB

RS269LB

3-2) Temperature Control Function

21

3. OPERATING INSTRUCTIONS & INSTALLATION

3-3) Power Freeze and Power Cool Functions

3-4) Child Lock Function

● Select the Power Freeze or Power Cool buttons separately.

● These buttons are toggled ON and OFF and the indicators as well.

● Although you select Power Freeze or Power Cool, the set temperatures in the freezer and refrigerator are not

changed.

● The set temperatures for the compartments can be changed while these functions are in use.

1) Power Freeze function

1-1) When you press the Power Freeze button, the LED indicator lights right away, but there is 10 seconds lag time to

an actual

operation. When this button is pressed again, the Power Freeze function stops and the indicator is off

immediately .

1-2) If you select Power Freeze, both the compressor and the freezer fan run for 2.5 hours continuously.

1-3) During Power Freeze, the freezer retains the current settings.

1-4) When Power Freeze expires, the indicator goes off and the freezer set temperature will be restored.

2) Power Cool function

2-1) Power Cool operation and the indicator work exactly same as the Power Freeze function.

2-2)When Power Cool is selected, COMP and Refrigerator Fan operate continuously until the refrigerator reaches

25℉. This function will be terminated after 2

½ hr running.

3) When you select Power Freeze and Power Cool together

Each function works at the same time. The COMP and Freezer Fan run continuously and the Refrigerator Fan runs

until 25℉in the refrigerator.

4) Initial Power-On

4-1

) When the freezer and the refrigerator temperatures are higher than 14℉ and 50℉, respectively, if Power

Freeze is selected, then the Refrigerator

Fan

will be off. If Power Cool is selected, then the Freezer

Fan

will be off.

4-2) When both functions are selected, there is no benefit of fast cooling for each compartment.

● When the child lock button is pressed for 3 seconds, the child lock indicator is on with an audible tone.

-When it is locked, no function commands except the Ice type button.

-This function will prevent accidental setting that may be caused by children or pets.

-To unlock the setting functions, press this button for 3 seconds again.

22

3. OPERATING INSTRUCTIONS & INSTALLATION

3-5) Ice & Water Dispenser Function

3-6) C-Fan Motor Delay Function of the Machine Compartment

3-7) CoolSelect ZoneTMFunction

(RS267LA,RS269LA)

● Among several ice-maker functions, the ice extraction function is performed by mechanical system. Only the relay

control for a cubed-ice dispensing and the SSR control for the ice chute door are performed electronically.

1) Select Cubed/Crushed/Ice-off function

1-1) The Ice Type button selects Cubed/Crushed/Ice-off options in sequence.

1-2) A default setting is Cubed option.

1-3) If Cubed ice is selected, the Crushed ice bypass solenoid and the geared motor will allow Cubed ice to by pass

the ice Crusher.

1-4) If Ice-off is selected, the ice maker will stop working. This option will be terminated when Cubed and Crushed

options are selected.

1-5) The ice chute door must remain open for 5 seconds after dispensing ceases. After this 5 seconds delay, SSR will

be controlled to shut the ice chute door.

2) Water Dispenser function

2-1) To dispense water, depress the water dispenser lever located in the dispenser recess.

2-2) When the lever is depressed, the water solenoid valve located in the machine compartment is open to flow water.

2-3) There is no electronic control function for this option.

● According to the ambient temperature, the condenser fan located in the machine compartment is operated with

different modes.

● To select this function, open the refrigerator door and press the button on the control panel of CoolSelect Zone

TM

drawer.

● When the CoolSelect Zone

TM

function is selected, the damper inside fan ductwork is open. So the refrigerator cooling

is performed first, then the damper is closed to control the CoolSelect Zone

TM

temperature.

Note) When the Ice-off indicator is on, only Cubed ice will be dispensed from the ice bucket.

Caution) Do not force to close the ice chute door. Try to dispense some more ice again to work it automatically.

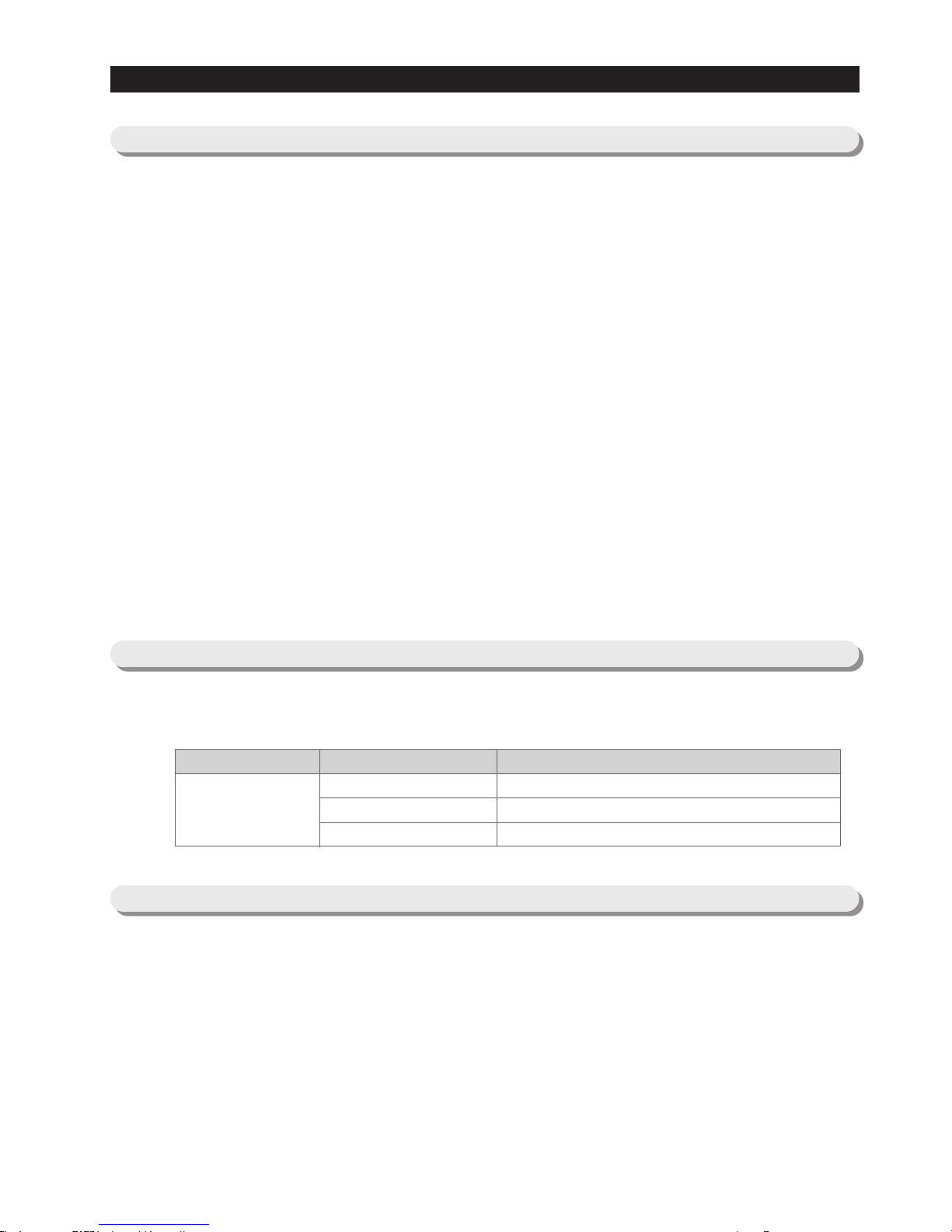

Ranges of ambient temp.

Above 66℉

61℉ ~ 65℉

Below 60℉

Condenser-Fan is ON as soon as the compressor is on.

Condenser-Fan is ON with 5 minutes delay from the compressor on.

Condenser-Fan is OFF regardless of the compressor operation.

Condenser Fan

Delay function

Operation

23

GUIDE-ICE(Lever to check ice full)

KNOB-TOUCH

1) Select function

1-1) Using Select button, Cool, Chill(30℉), and Soft Freeze(23℉) options can be selected in sequence. Cool option

maintains a set temperature of the refrigerator.

2) Quick Cool function

2-1) If the Quick Cool is selected, LEDs will flash 60 and Min. The count will be decreased in every minute.

2-2) To cancel this function, press Quick Cool button again or Thaw button or Select button. Otherwise, it will be

terminated 60 minutes later automatically.

2-3) After this function ends, this drawer will come back to Cool option.

2-4) A defrost cycle will be postponed until Quick Cool option is finished.

3) Thaw function

3-1)When the thaw button is pressed, LEDs will flash 4, 6, 10, and 12 in sequence and Hr.

3-2) The count will be decreased in every hour.

3-3) A cancellation of this function is the same as Quick Cool function.

3-4) After this function ends, this drawer will be maintained with 30℉.

3-5) While the compressor is on, this drawer retains a certain temperature and while the compressor is off, the defrost

heater is activated and Refrigerator Fan is on with a closed position of the damper.

1) Filter Indicator

1-1)This indicator initially lights in green. The light color will be changed to orange after 5 month operation then to red

at the 6th month. The EEPROM in the control board counts a period of time regardless of a power failure.

1-2)To reset the counter and the light color, press Ice Type button and Child lock button for 3 seconds simultaneously.

1-3)If these two buttons are pressed simultaneously for 5 seconds, this function will cease.

1-4)To restore this function, press these buttons again for 3 seconds.

● The Ice-maker is referred to the device with an automatic ice production, storage in the ice bucket and dispensing

through the ice chute.

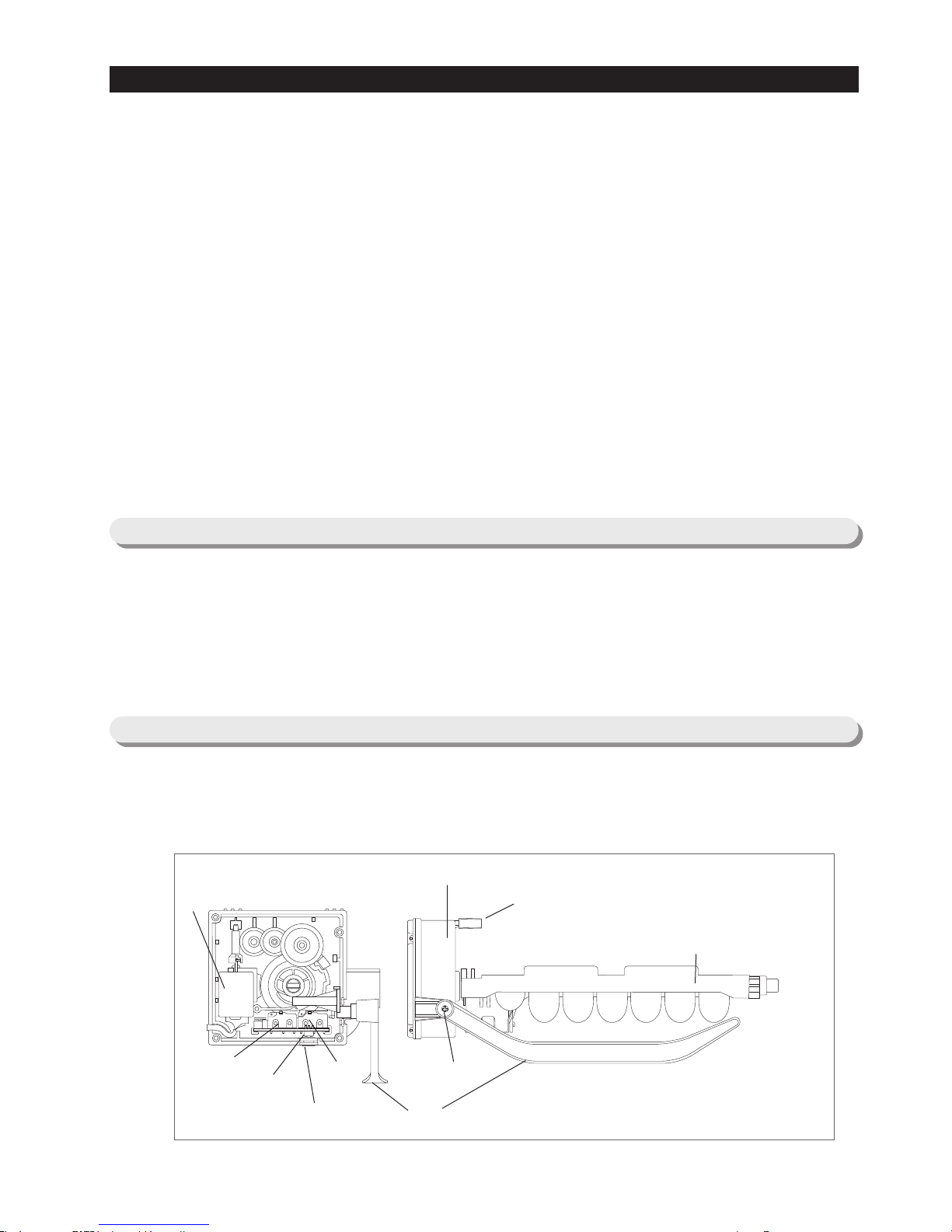

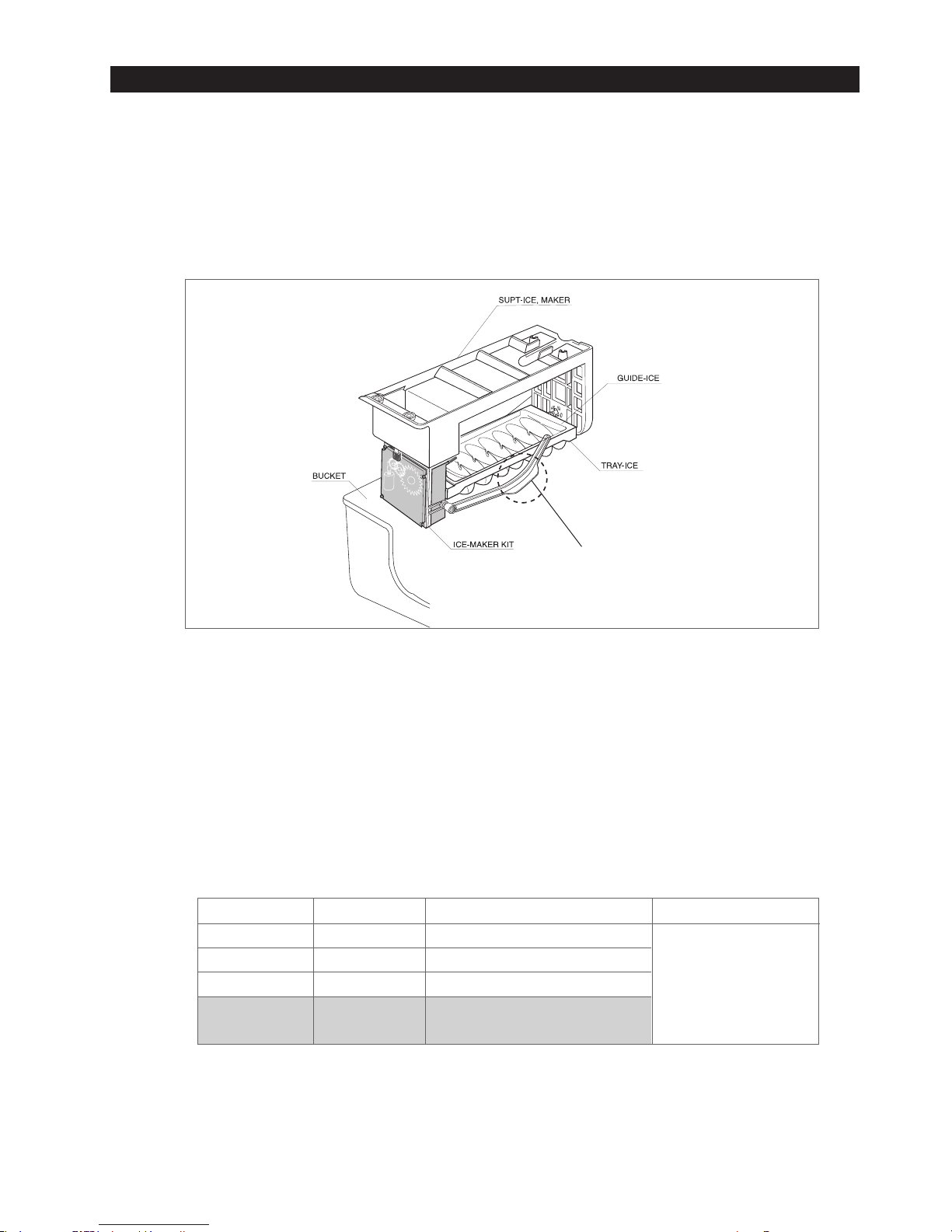

1) Ice-maker parts

TRAY-ICE

SCREW

SUPT-RUBBER

ICE-WAKER, KIT

EJECT-MOTOR

TEST-SWITCH

LEVELING-SWITCH

ICE Full-

SWITCH

3. OPERATING INSTRUCTIONS & INSTALLATION

3-8) Water Filter Indicator Function

3-9) Ice-Maker Function

24

3. OPERATING INSTRUCTIONS & INSTALLATION

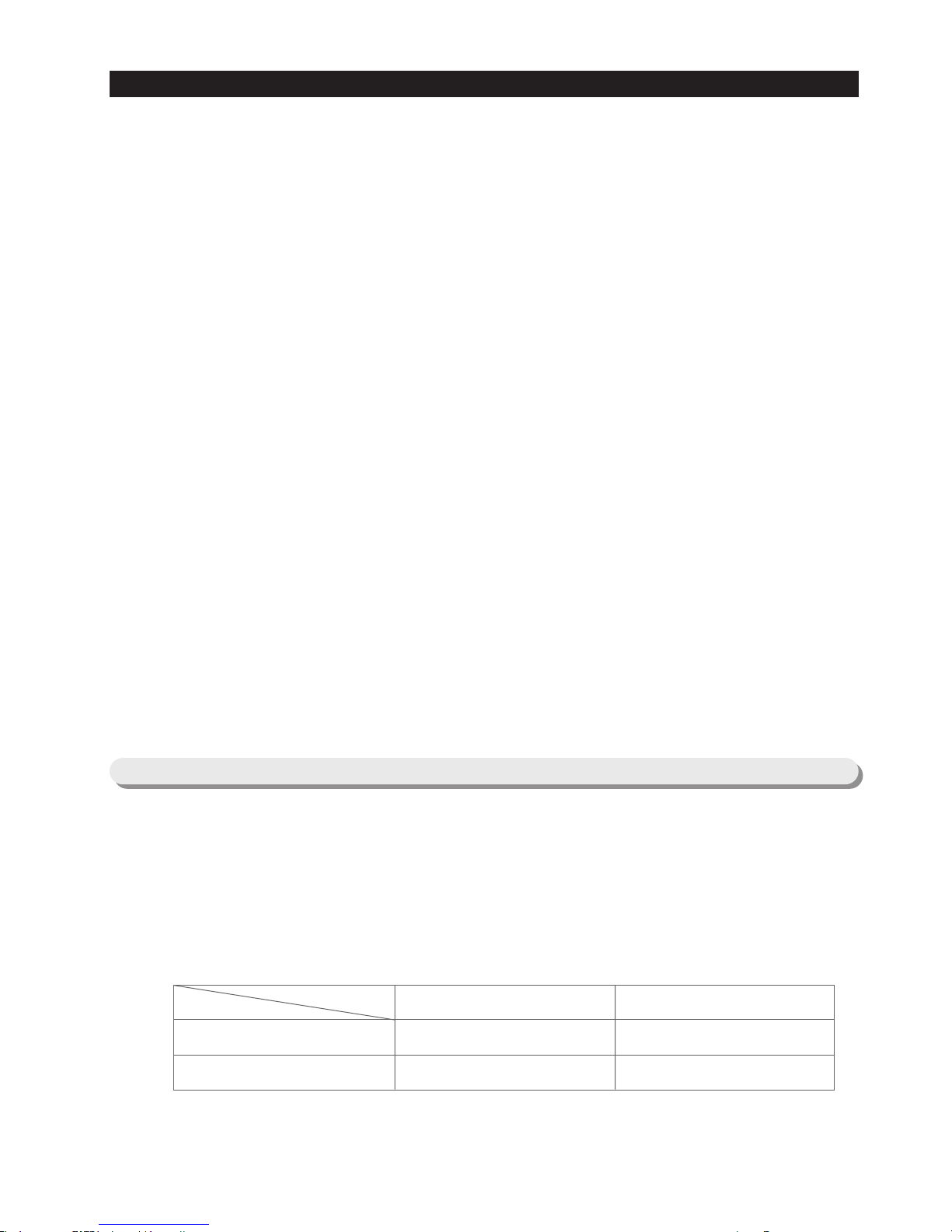

<Reference table>

Leveling S/W

ON(“LOW”)

ON(“LOW”)

OFF(“HIGH”)

OFF(“HIGH”)

Ice full S/W

ON(“LOW”)

OFF(“HIGH”)

ON(“LOW”)

OFF(“HIGH”)

Remark

·MICOM Port

PIN #51: Leveling

PIN #51: Ice full

·Port level

OFF : 4.5V ↑

ON : 0.5V ↓

Judgement

Not ready

Not ready

Not ready(Ice bucket with full of ice )

Ready

2) Preparation of Ice-maker

2-1) Connect the water line to the water supply valve of refrigerator to supply water. (See how to connect a water

supply line in the owner’s manual.)

2-2) Push the bucket back fully so that the guide-ice of ice maker should not touch the back of bucket. (If the back of

bucket is touched the guide-ice of ice maker, the ice maker will not make ice any more because of a ice full signal.)

2-3) It takes 6 hours to harvest a first ice, and throw away 2-3 times of these ice to make sure the supplied water clean.

1) Initial Operation function

1-1) Whenever the power is on, the control board checks the ice tray leveling with the leveling switch within 2 seconds.

1-2) If the leveling switch is not off position, the geared motor will turn to the initial position to make the ice tray leveled.

1-3) When the ice tray is leveled, it will remain this position for 2 hours (1 cycle time for ice production).

1-4) After 2 hours, the sensor located under the ice tray will measure the tray temperature. If the temperature is

maintained lower than 1℉ for 5 minutes, and the ice full switch is off position, the ice tray twisting process will

begin.

Push the bucket back fully so that the

lever should not be pushed up.

25

3. OPERATING INSTRUCTIONS & INSTALLATION

2) Water Supply function

2-1) When the ice tray is levelled again after ejecting ice, the water solenoid value will be controlled to supply water by

time check basis. (See the “Time to supply water” Table)

3) Ice production

3-1) After 60 minutes pass from the water supply, the control board will check the temperature.

3-2) If the sensor reads the temperature lower than 1℉ for more than 5 minutes, than the ice production process is

completed.

4) Test function

● In order to operate a test function, press the knob (Test Switch) for 1.5 second.

● This function can be used to check a proper working, to clean the ice tray, and to adjust the water level in the ice tray.

4-1) This function only works when the ice tray is leveled and the ice full signal is cleared.

4-2) When the water line is connected, each process such as a water supply, ejection, and leveling, can be investigated

by this button.

5) Ice off function

5-1) When the Ice off option is selected by Ice Type button, the ice making process will cease.

5-2) When the ice making process ceases, the final state will be the ice tray with supplied water.

5-3) When Cubed or Crushed option is selected again, the control board will check an accumulated time period. After

making it 60 minutes and when the ice tray temperature is acceptable, ice ejection process will begin.

6) Functions when the freezer door is open

● When the freeze door is open, all ice maker related processes will cease in order to minimize noise and to prevent ice

from dispensing.

6-1) The ice tray stops moving regardless of the position.

6-2) The water supply process remains working as usual.

6-3) If the ice tray is in the middle of ice ejecting process, close the freezer for 30 seconds and check if the tray is

leveled. If it is not leveled, it must be out of order.

1) A defrost is determined based on the accumulated compressor on-time.

2) When the power is engaged for the first time, the defrost cycle for the freezer and the refrigerator will begin after 4

hours of the accumulated compressor on-time.

3) A defrost interval depends on the ambient temperature, the number of door openings, and the door open time.

4) A minimum interval is 6 hours and a maximum is 8 hours for the refrigerator, and 12 hours and 16 hours for the

freezer, respectively.

5) The defrost heater on-time is determined by the defrost sensors as follow :

3-10) Defrost Function

Freezer

Below 50

℉

Refrigerator

63

℉

Heater ON

Heater OFF

-

50

℉

●●

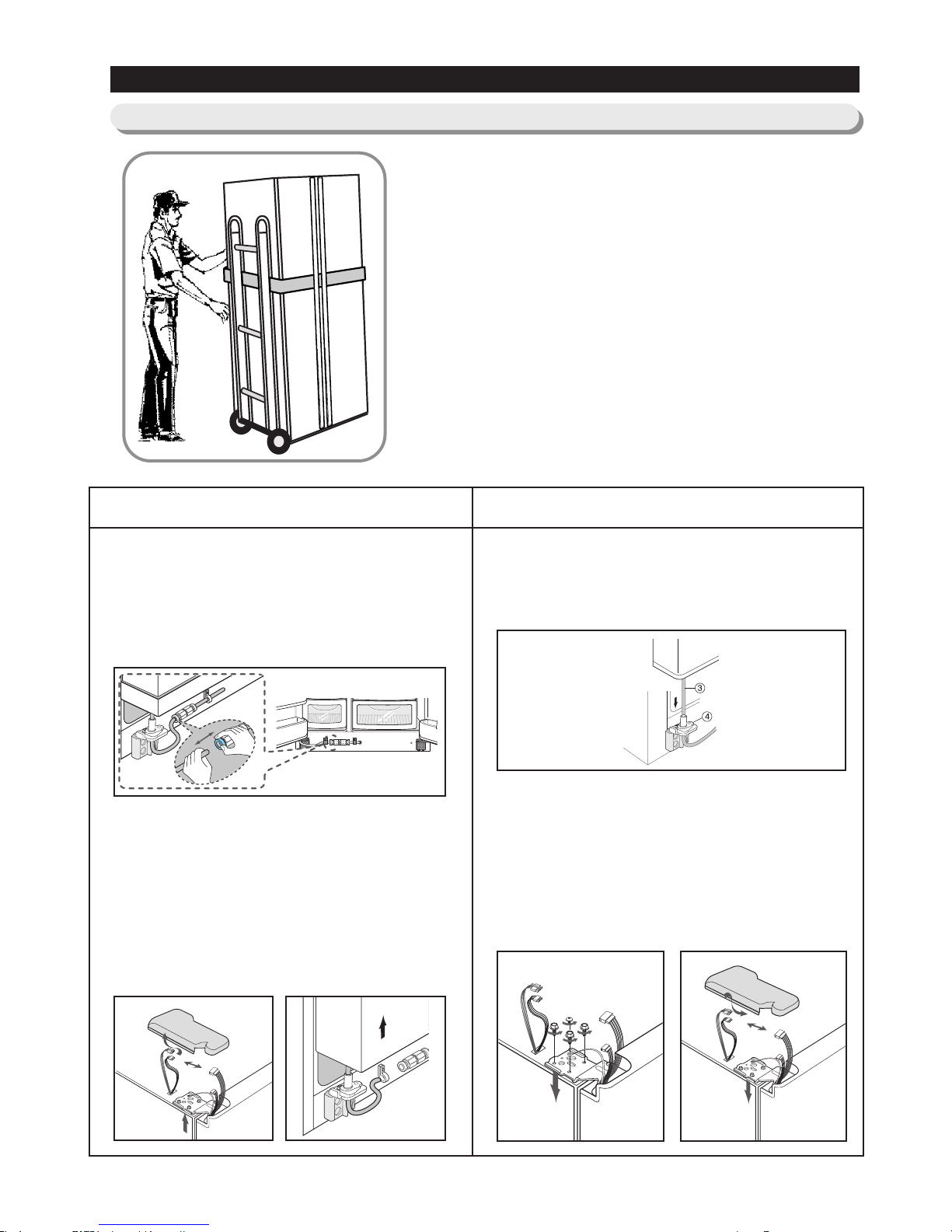

Removing Doors

Open the freezer and refrigerator doors, and

then take off the front leg cover assembly by

turning the three screws counter-clockwise.

Remove the screw from clamp, disconnect the

water tube by pressing the coupler, and pulling

the water tube away.

With the door closed, remove the upper hinge cover

using a screwdriver, and then disconnect the wires.

Remove hinge screws and ground screw counterclockwise, and take off the upper hinge. Take care

removing the door to ensure that it does not fall on you.

Remove the door from the lower hinge by carefully lifting

the door so as not to damage the water tube. Remove

the lower hinge from the lower hinge bracket by lifting

the lower hinge.

●●

Attaching Doors

Insert the lower hinge in the bracket lower

hinge. Attach the freezer door by inserting the

hose in the lower side of the door into the hole

in the lower hinge and pulling the hose down.

Insert the upper hinge shaft into the hole. After

leveling between the upper hinge hole and the

hole of the cabinet. Reattach hinge screws and

ground screw in the clockwise direction.

Connect the wires. (Put the front part of the

upper hinge cover on the front part of the

upper hinge and reattach from the front part

of the upper hinge cover first. )

26

3. OPERATING INSTRUCTIONS & INSTALLATION

3-11) Installation

1) To protect refrigerator in movement

Use padded hand truck as shown. If entrance width is

less than 39〃, remove doors prior to installation and

reattach doors according to procedure below.

2) Remove all protective tape and pad in refrigerators.

Connect water lines and power cord. Adjust the

clearance between the doors.

3) Set the temperature control to the temperature and

wait for an hour.

The refrigerator should get slightly chilled and the motor

runs smoothly.

4) Once the refrigerator temperature is sufficiently low

You can store food in the refrigerator. After starting the

refrigerator, it takes a few hours to reach the appropriate

temperature.

27

4. ALIGNMENT AND ADJUSTMENTS

4-1)

Forced Operation Function (Pull-down / Refrigerator Defrost / Refrigerator . Freezer-Defrost / Cancellation)

·28

4-2) Sound function

·····································29

4-3) Cooling Off Function

·································29

4-4) Self-Diagnostics Function

·······························29

4-5) Load Operation Check Function

···························31

4-6) Restoration Function for Power Outage

·······················31

4-7) Set Point Shift Function

································31

4-8) Table of Set Point Shift Function

··························32

28

4. ALIGNMENT AND ADJUSTMENTS

4-1)

Forced Operation Function (Pull-down / Refrigerator Defrost / Refrigerator . Freezer-Defrost / Cancellation)

● This function enables a pull-down mode, a defrost mode for the refrigerator only, a defrost mode for the freezer and the

refrigerator at the same time, and a cancellation of this function.

● Press Power Freeze and Fridge Temp. buttons for 8 seconds simultaneously to get in the ready mode for a forced

operation.

● The display panel will return to normal after 20 seconds in the ready mode.

● At the ready mode, press any button(except Ice Type and Child Lock) once to start a pull-down operation, twice for a

defrost cycle for the refrigerator, three times for a defrost cycle for the freezer and the refrigerator, and finally four times

for cancellation of this function.

● Another way to cancel this function is to simply plug out and in the power cord.

1) Pull-down

1-1) At the ready mode, press any button once then the buzzer will beep (ON for 1/2 second and OFF for 1/2 second)

until this mode is cancelled.

1-2) At this pull-down mode, the compressor will start immediately (No 5 minute delay) and if the system is in the

defrost cycle, it will be cancelled right away.

note) If this pull-down mode begins right after the compressor was off, the compressor may not start to run due to an

overload condition.

1-3) At this mode, the compressor and freezer fan will operate continuously for 24 hours and the refrigerator fan will be

on and off according to the set temperature(34℉)

1-4) After 24 hour operation, the system will be cycled at -14℉ for the freezer and 34℉ for the refrigerator.

1-5) In order to cancel this mode at any time, select the next mode on the ready mode or power off the system.

2) Refrigerator Defrost / Refrigerator . Freezer-Defrost operation

2-1) At the pull-down mode, press any button again on the ready mode to begin the defrost cycle for the refrigerator.

2-2) The beep sound continues for 3 second at the beginning, then ON for 3/4 seconds and OFF for 1/4 second until

this mode cease.

2-3) After this operation, the system will come back to normal operation.

2-4) At this mode, press any button again on the ready mode to operate the defrost cycles for both compartments.

2-5) The beep sound continues for 3 seconds at that time, then ON for 1/4 second and OFF for 3/4 seconds until the

defrost operation cease.

3) Cancellation

3-1) At the R,F-Defrost mode, press ant button again on the ready mode to return to a normal operation.

3-2) Simply unplug the power cord, then plug it again to return to a normal operation.

Press both button for 8seconds at the same time

29

4. ALIGNMENT AND ADJUSTMENTS

4-2) Sound function

1) Sound function

1-1) To make sure a command input, whenever a button is pressed, a “ding-dong” sounds.

1-2) When two or more buttons are pressed simultaneously or if a wrong button is pressed, there is no sound.

2) Door Open Alarm

2-1) When the doors remain open for 2 minutes, there are 10 times beeps.

2-2) If the doors continue to remain open more than 2 minutes, the additional 10 beeps interval will change to 1 minute.

2-3) The beeps will cease immediately when the doors are closed.

● This function is for a display purpose on the floor of show room or store.

1) Mode ON/OFF

1-1) For the Cooling Off mode, press Power Freeze and Freezer Temp, buttons simultaneously for 3 seconds until a

“ding-dong” sounds.

1-2) Press the same time buttons again for 3 seconds to cancel this mode put with a “ding-dong” sound.

2) Operation

2-1) Most of the system function except the compressor operation are working properly.

2-2) There is no defrost cycle in this mode.

2-3) “OF” is displayed on F, R Display.

2-4) Cooling Off mode is not cleared even if power is reset.

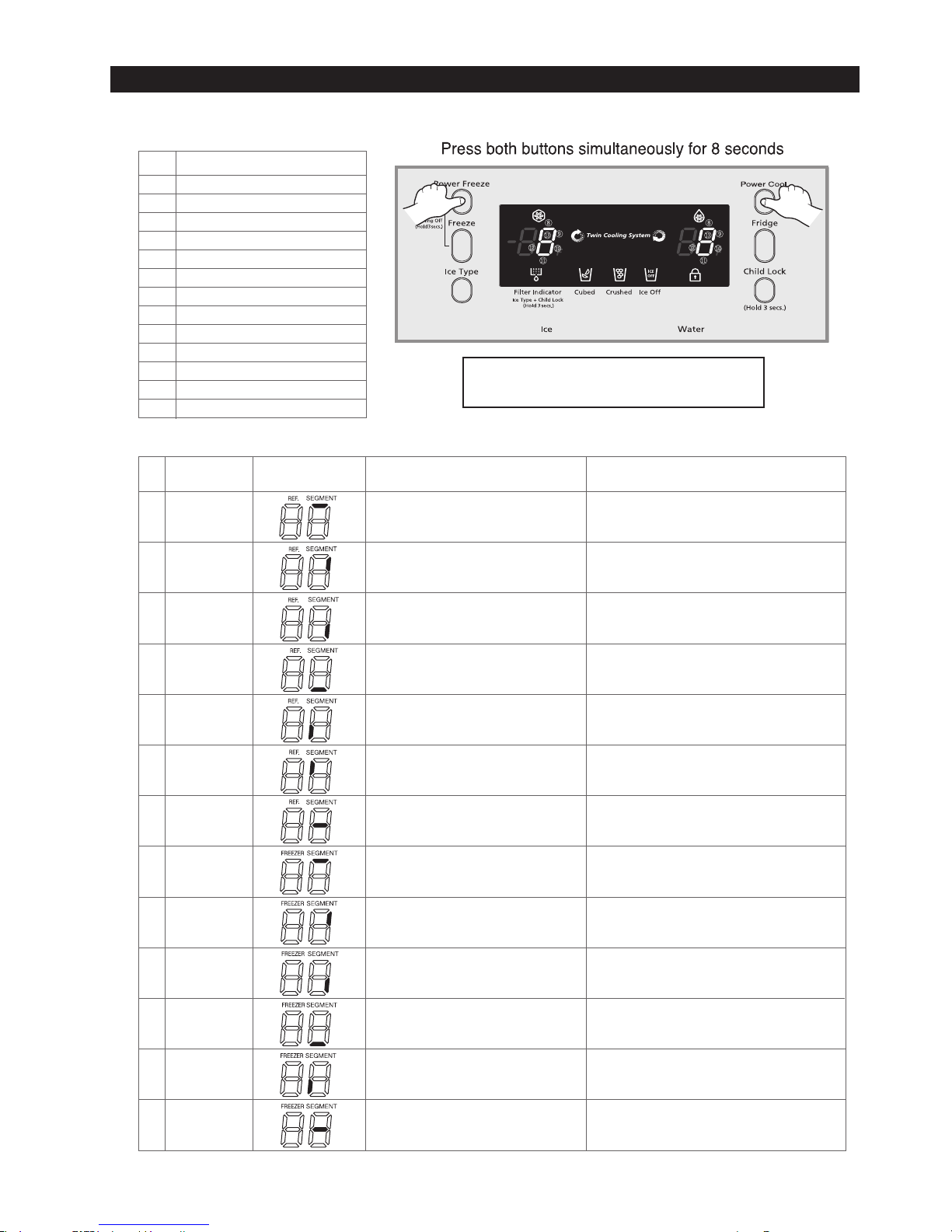

1) Self-Diagnostics in the initial Power ON

1-1)The control board performs a self diagnostics test within 1 second and check out the temperature sensors abilities.

1-2) If a sensor failure occurs, a corresponding LED segment will blink with a beep.

1-3) When a LED segment blinks, only the cancellation function (Press Power Freeze and Power Cool buttons

simultaneously for 8 seconds) is acceptable.

1-4) After a replacement of bad sensor or a cancellation of this function, this self diagnostics will end.

2) Self-Diagnostics in the normal operation

2-1) To select this function, press Power Freeze and Power Cool buttons simultaneously for 8 seconds with an audible

tone.

2-2) In the self diagnostic mode, only corresponding LED segments will be illuminated (see the check list on the next

page)

2-3) After a 30 second illumination of error signal, the system will return to the normal operation.

4-3) Cooling Off Function

4-4) Self-Diagnostics Function

30

4. ALIGNMENT AND ADJUSTMENTS

Self-diagnostics check list

If any LEDs blink, the corresponding sensors and

components must be checked for an error.

NO Error

ICE MAKER SENSOR

REFRIGERATOR SENSOR

REFRIGERATOR DEFROST SENSOR

REFRIGERATOR FAN ERROR

ICE MAKER function error

CoolSelect Zone

TM

SENSOR

REFRIGERATOR DEFROST ERROR

EXIT-SENSOR

FREEZER SENSOR

FREEZER DEFROST ERROR

FREEZER FAN ERROR

CONDENSER FAN ERROR

FREEZER DEFROST ERROR

①

②

③

④

⑤

⑥

⑦

⑧

⑨

⑩

⑪

⑫

⑬

Air sensor connector missing; contact failure,

electric wire cut, short-circuit; open air sensor

itself failure; and so on

CoolSelect

ZoneTMsensor

REFRIGERATOR

DEFROST ERROR

Ambient Air

SENSOR

The voltage should be within the range of 4.5V~1.0V

between MAIN PCB CN51 # 13 and # 14.

Read the resistance between the brown and the orange wire

terminals(the reading varies according to the basic Power Consumption.

0 Ohm→Heater Short,∞Ohm→Wire Cut or Blown Bimetal Thermo

The voltage should be within the range of 4.5V~1.0V

between MAIN PCB CN31 # 1 and # 4.

Freezer sensor connector missing; contact

failed, electric wire cut, short-circuit;Freezer

Room sensor itself failure.

FREEZER

SENSOR

The voltage should be within the range of 4.5V~1.0V

between MAIN PCB CN30 # 2 and # 3.

Freezer evaporator defrosting sensor connector

missing; contact failed, electric wire cut, shortcircuit; sensor itself failure; and so on

FREEZER

DEFROST SENSOR

The voltage should be within the range of 4.5V~1.0V

between MAIN PCB CN30 # 2 and # 4.

Freezer

Fan motor operation failure; feedback

signal line contact failure, motor’s electric wire

missing; and so on.

FREEZER FAN

ERROR

The voltage should be 7V~12V between MAIN PCB CN72 #

6(YELLOW) and # 7(GRAY).

Condenser Fan motor operation failure; feedback

signal line contact failure, motor’s electric wire

missing; and so on.

In the freezer room, if frost removal mode is

finished due to limited time of 70 minutes. Error is

displayed

CONDENSER FAN

ERROR

(COMP-FAN)

The voltage should be 7V~12V between MAIN PCB CN72 #

4(S/BLUE) and # 7(GRAY).

Read the resistance between the white and the orange wire

terminals(the reading varies according to the basic Power Consumption.

0 Ohm

→

Heater Short,∞Ohm→Wire Cut or Blown Thermo Fuse

FREEZER

DEFROST ERROR

NO Error items LED

Display

Details

How to Self-Diagnose

01

02

03

04

05

06

07

08

09

10

11

12

13

ICE MAKER

SENSOR

Ice Maker sensor connector missing; contact

failure, electric wire cut, short-circuit; Ice Maker

sensor failure; and so on

The voltage should be within the range of 4. 5V~1.0V

between MAIN PCB CN90 # 3 and # 4.

REFRIGERATOR

SENSOR

Refrigerator sensor connector missing; contact

failure, electric wire cut, short- circuit; Refrigerator

sensor itself failure; and so on

Refrigerator

Fan motor operation failure;

feedback signal line contact failed, electric wire

cut, short- circuit; and so on

The voltage should be within the range of 4.5V~1.0V

between MAIN PCB CN30 # 6 and # 7.

The voltage should be within the range of 4.5V~1.0V between MAIN PCB

CN30 # 6 and # 8.Indicate Error when the temperature sensed by

Refrigerator defrosting sensor is higher than

150℉or lower than –58℉

.

REFRIGERATOR

DEFROST SENSOR

Refrigerator evaporator internal defrosting sensor

connector missing; contact failure, electric wire cut,

short-circuit; sensor itself failure; and so on

The voltage should be 7V~12V between MAIN PCB CN72 #

5(ORANGE) and #7(GRAY).

Pusht het est b ut t ononanI / MAss' yandI tshoul d work.

REFRIGERATOR

FAN ERROR

ICE MAKER function

ERROR

Ice-ejector and level failed three times or more

Error items of self-diagnostics

CoolSelect ZoneTMsensor connector missing; contact

failed, electric wire cut, short-circuit; CoolSelect Zone

TM

sensor itself failed; and so on.

In the refrigerator room, if frost removal mode is

finished due to limited time of 80 minutes. Error

is displayed.

Loading...

Loading...