Page 1

52

Check the exchange of fuse and

disconnection cause.

- Check the connections of main PCB.

- Check the connections between upper

hinge and CABI-door.

- Check the connections between door and

panel PCB.

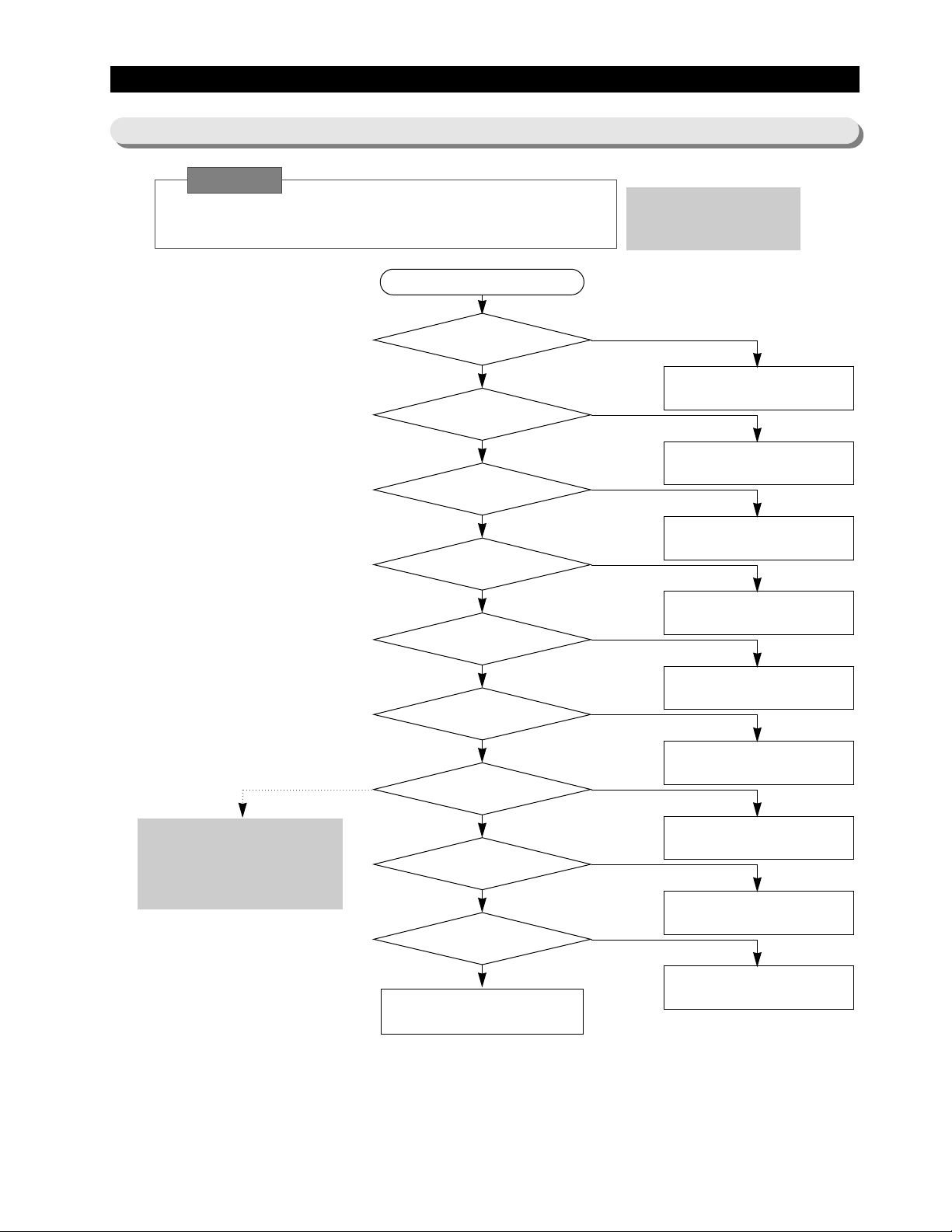

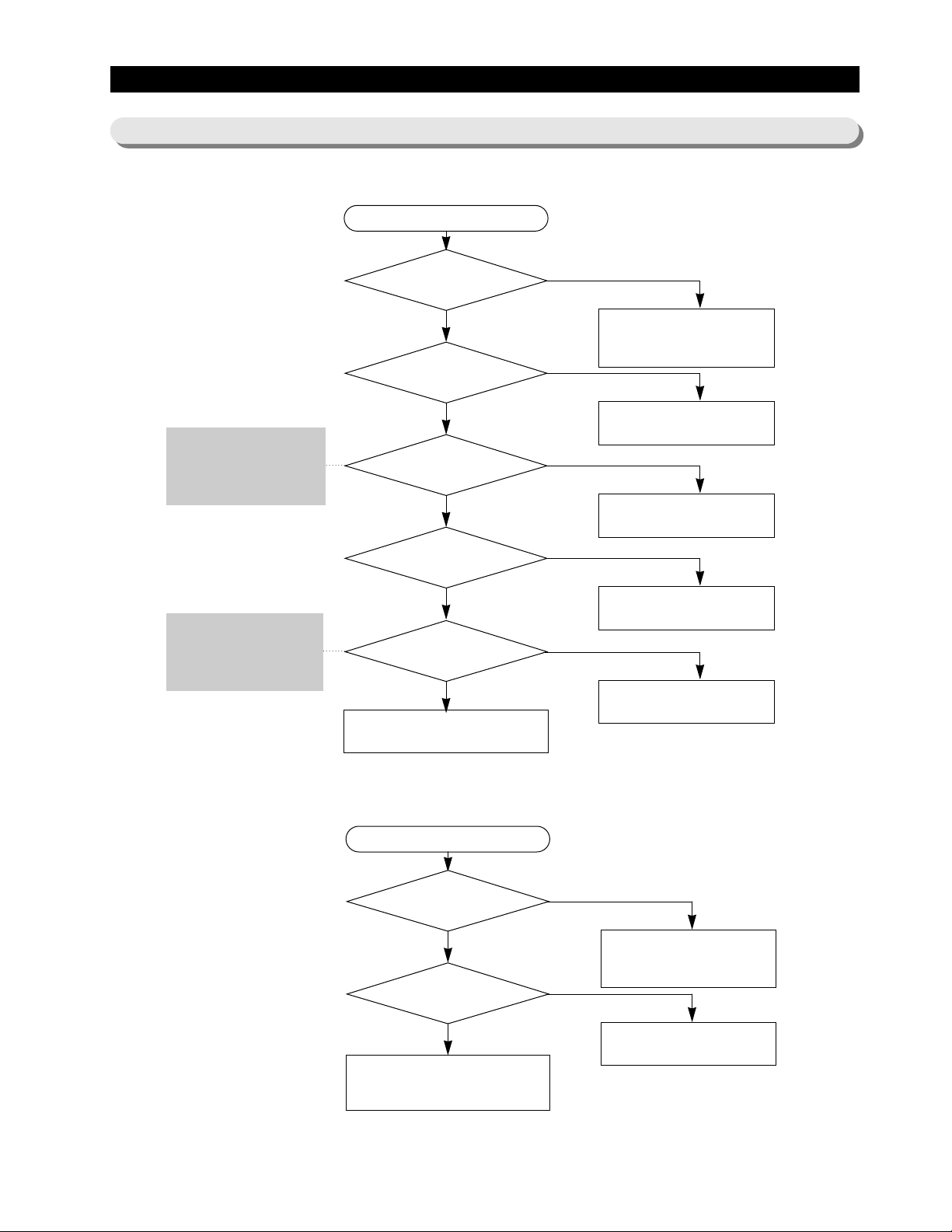

11. Diagnostics

11-1) If power is not ON

At the power of main PCB, the 1 15V power and a high-voltage over DC

170V occur. Please take care of yourself on repair and measurement.

Is 230V AC fuse down?

Is power 230V

both terminals of CN10?

Is fuse on main PCB down?

Is DC 320V impressed to both

terminals of BD1?

Top S/W 233Y

Is the voltage impressed DC 5.8V

between C and S ?

Is 12V impressed to both

terminals of C102?

Is the load such as relay normal?

Is normal the load, such as

relay?

Is there any PCB soldering, short or broken?

Normal

Start

To check the main PCB, please apply

descriptions of operation and

references in the manual.

YES

Check the assembly and connection of

electric wires.

NO

Exchange fuse

250V/ 2A?

YES

Check the PCB pattern and replace BD1.

NO

Replace PCB assembly.

NO

1) Replace D104 (D5S6M).

2) Replace PCB assembly.

NO

Replace REG1(KA7805)

NO

1) Check the assembly of electric wires and troubleshoot.

2) Replace the panel PCB.

NO

1) Replace the corresponding relay.

2) Check lead wire for contact.

NO

Caution!

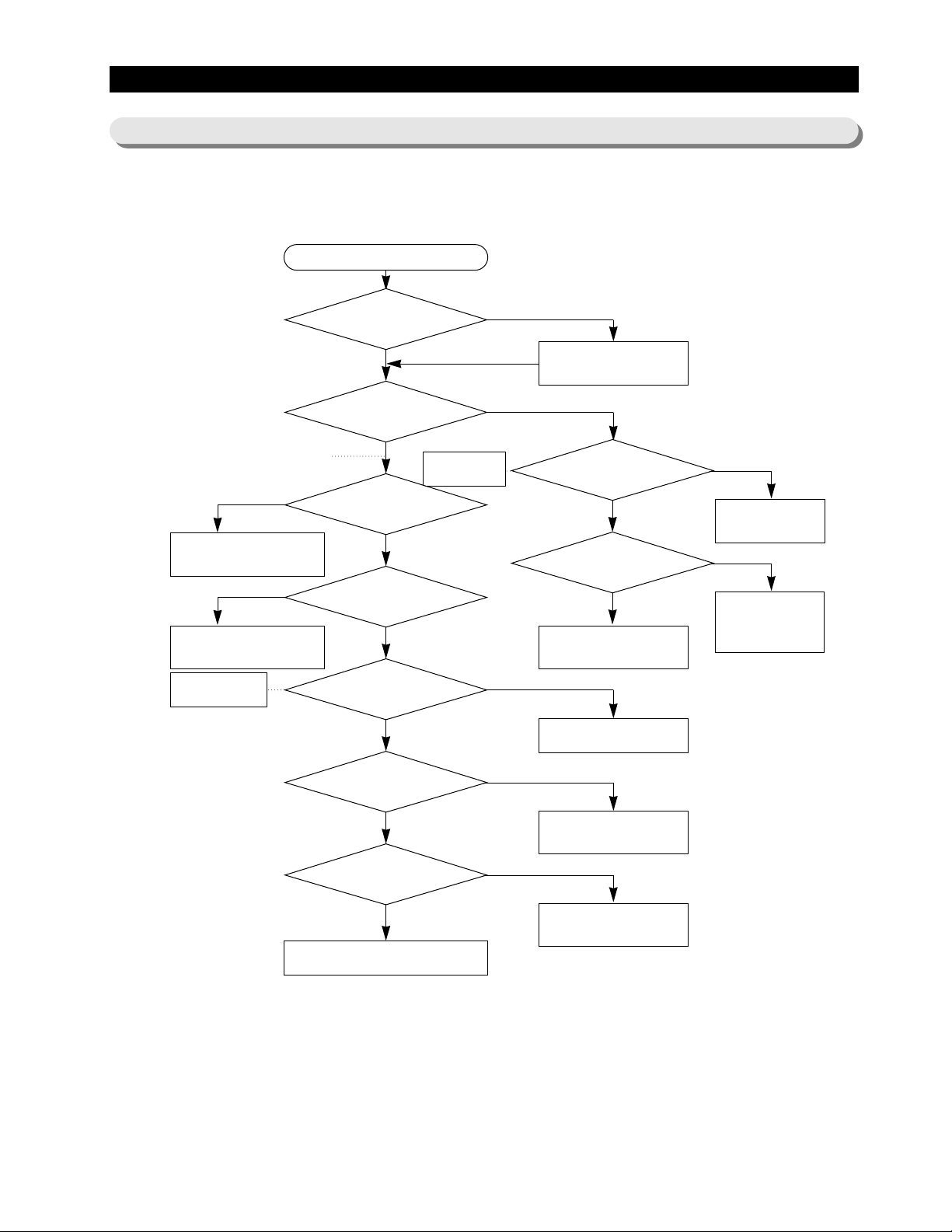

Page 2

53

Diagnostics

1 1-2) If the compressor and cooling fan motor don’t work normally

Apply Ref.4

Did 5 min pass after COMP. OFF?

Start

Check after a lapse of 5 min.

Did buzzer sound on forced operation?

(Check certainly after forced start.)

Exchange MICOM and PCB.

Exchange and repair IC03.

(ULN2803)

Does compressor work

with forced operation?

Is MICOM No.18 High?(5V)

Open and repair the

connection.

Troubleshoot the

sensor and Exchange

PCB.

Is the voltage of IC03 pin No. 14 between 0-1V?

Open and troubleshoot the

connection.

Is COMP relay normal?

Exchange or troubleshoot

COMP relay.

Apply Ref. 2

Is the contact of connector CN70 normal?

Insert connector completely?

Is COMP assembly normal?

Exchange and repair COMP.

assembly.

Normal

NO

YES

YES

NO

NO

NO

NO

YES

NO

YES

YES

YES

NO

YES

NO

YES

NO

YES

Is freezer sensor normal?

Is the temp. sense

of main PCB Normal?

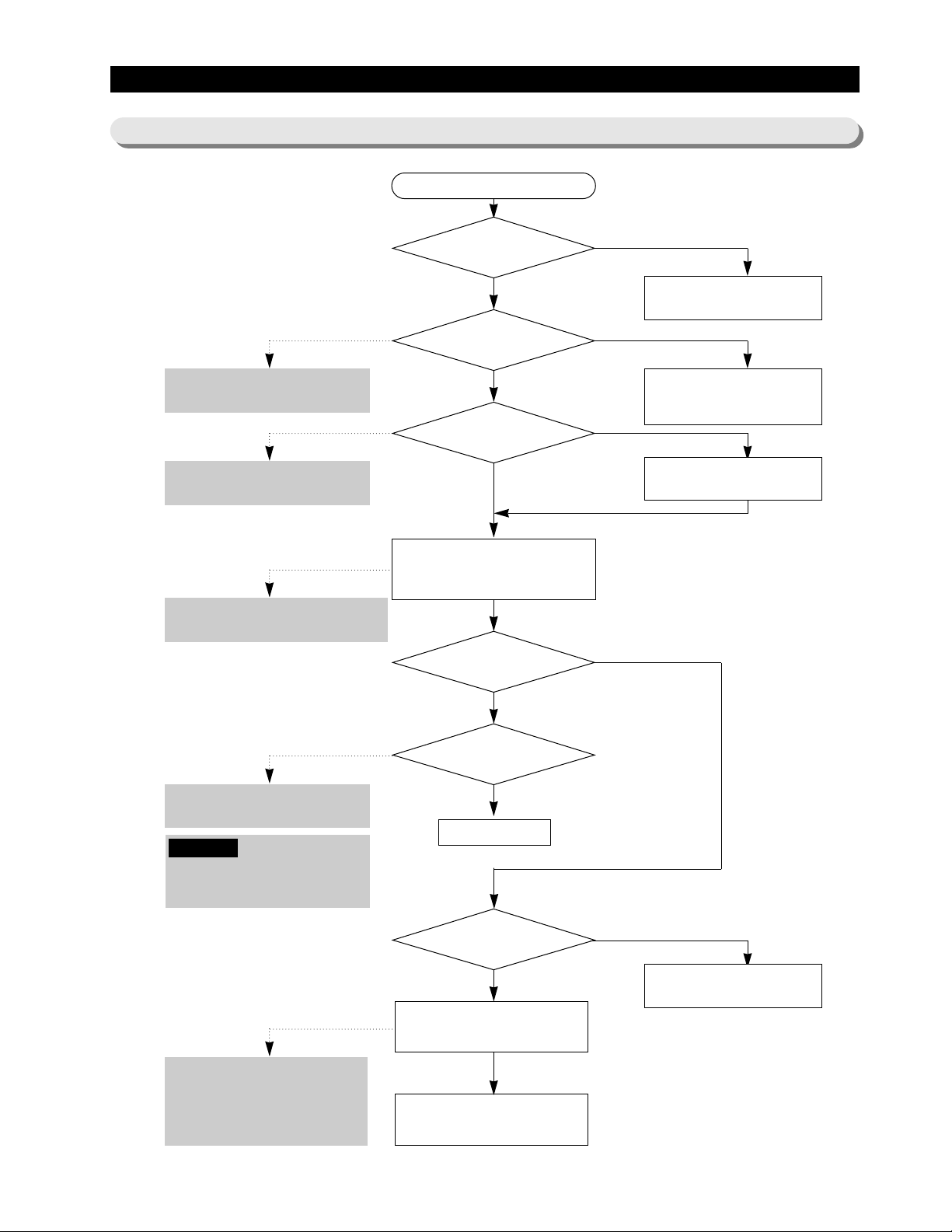

Page 3

54

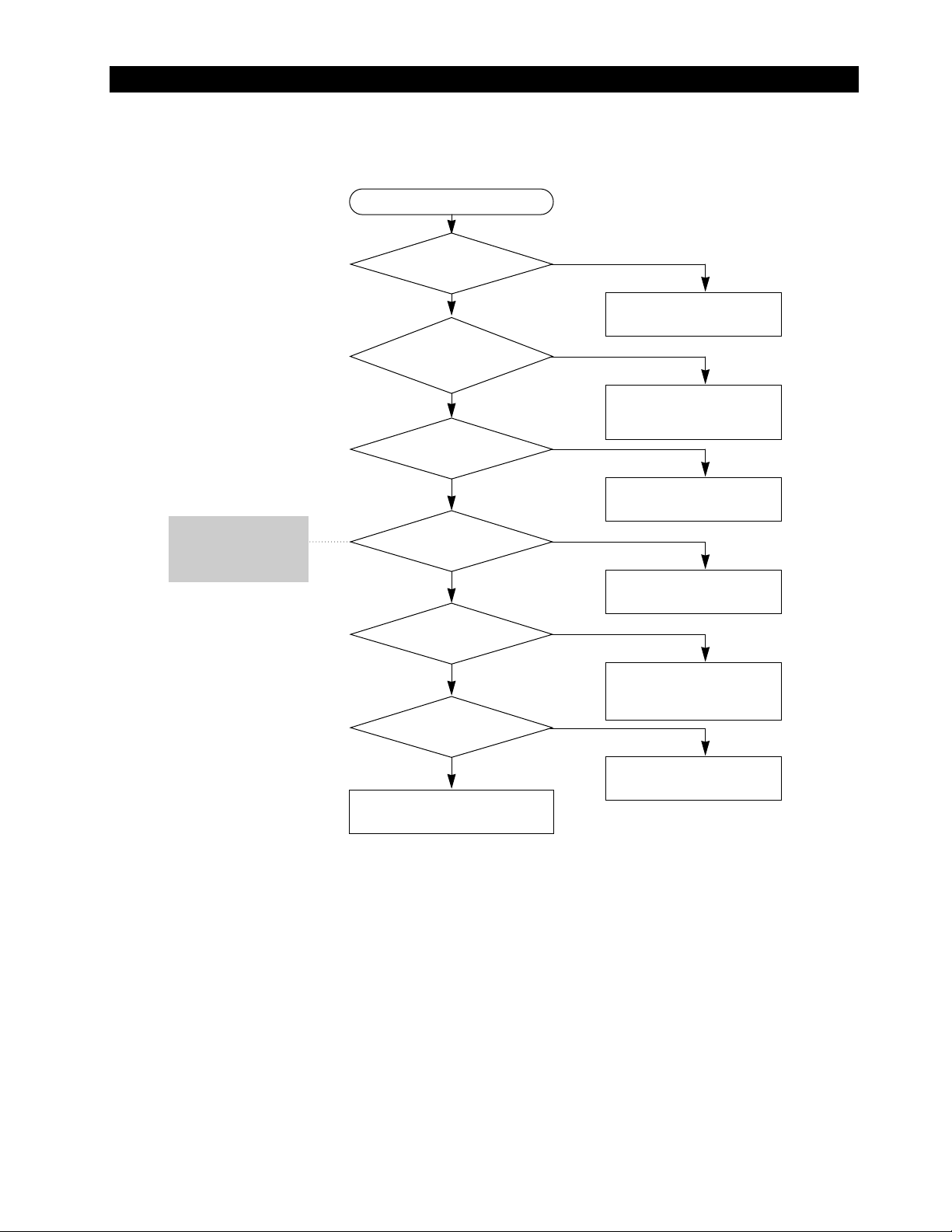

Diagnostics

11-3) If defrost function

Is F, R defrosting sensor by

self-diagnosis normal?

Start

Exchange and troubleshoot the

corresponding sensor.

See Ref. 3: ‘Check load’ in the manual.

Make decision on the basis of ref. 4 and

6 in the manual.

See test function in the manual.

Recheck the corresponding sensor for

an error if it fails in return.

See ‘Load Drive Circuit section’ and

Ref. 2: How to check failure of relay.

Is F, R Room defrosting heater normal?

Check temp. fuse,

breaking of heater wire, contact of

wire and so on.

Is temp. of the defrosting

sensor below 23℉?

Run forced operation for a

specified period.

Repair the connection terminal.

Perform forced defrosting for F and

R room at a time.

Normal

Check temp. fuse, breaking of heater wire,

contact of wire, and so on.

Exchange or troubleshoot the failure relay or

exchange PCB ass’y.

Is power applied to the

respective defrosting heaters?

Does the system

return to cooling operation after heating

for a specified period of time?

Recheck the connection

terminal in Main PCB

NO

NO

YES

YES

NO

YES

NO

NO

NO

YES

YES

YES

If temp. of F, R defrosting sensor by the

working of heater are over 10℃, 17℃

Reference

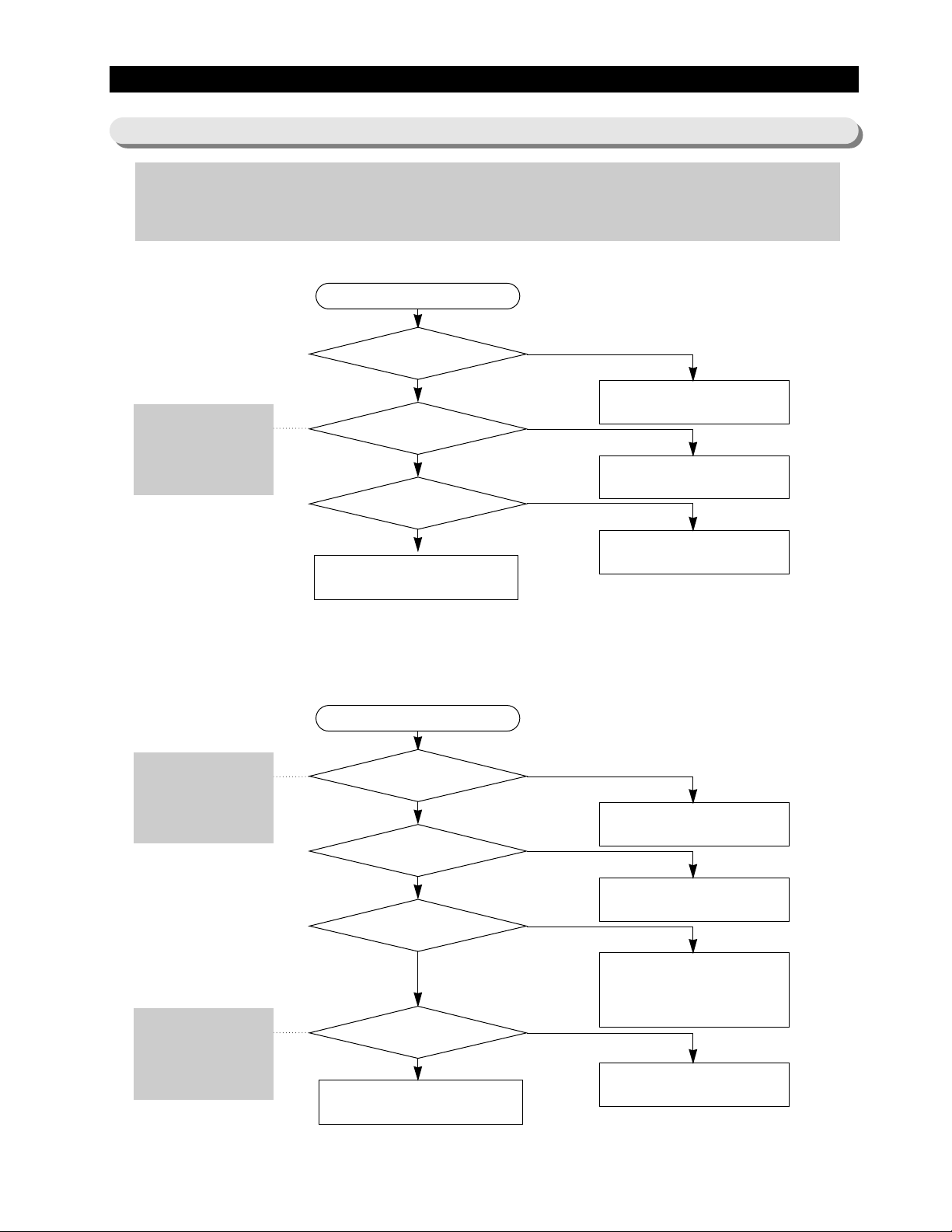

Page 4

55

Diagnostics

1 1-4) If there is a trouble with self-diagnosis

1) If the ambient sensor has trouble

No trouble with PCB and temperature sensor.

Recheck the contact failure of connector.

YES

YES

YES

2) If the temperature sensor of F and R room has trouble

See Ref. 4 (descriptions of

circuit operation, and how

to check temperature

sensor in the manual.)

- Error of sensor can be seen on the front display of refrigerator. If power is impressed to refrigerator first, an failure of sensor is found. The refrigerator

will stop working and display(blink) the region of trouble-occurred sensor repetitively.

- Even if sensor has failure during the operation, the refrigerator will not stop working but can run the normal cooling operation because of being operated

in the Emergency Operation mode. Therefore you’ re requested to use how to check self-diagnosis in the manual.

A bad contact or connector missing?

Was the Main

– PCB connector(CN31) inserted

correctly?

Is the ambient temperature

sensor normal?

Is the input of voltage to

MICOM pin No. 63 normal?

Start

NO

Exchange the temperature sensor.

NO

Check the iced solder and

short of main-PCB.

NO

YES

YES

YES

YES

See Ref.4 (descriptions of

circuit operation, and how

to check temperature

sensor in the manual.)

For sensor resistance per

temperature, make use of

the resistance values from

Ref. 4 and 5.

Exchange the temperature sensor.

Is the unit of

Fridge’s temperature

sensor normal?

Was the Main – PCB

connector(CN30) inserted

correctly?

Is the sequence of

insertion of connector(CN30) wire identical to

the circuit diagram?

Is the input voltage to

MICOM pin No. 59 normal?

Start

NO

Troubleshoot a bad contact or missing of

connector.

NO

Check if the iced solder of main PCB is

short.

NO

Modify the wrong configuration of connector

wire -in case of being not inserted or

incorrectly inserted - to be coincided with the

circuit diagram.

NO

No trouble with PCB and temperature sensor.

Recheck the connector for an error of contact.

Page 5

56

Freezer door MICOM No. 43,

Fridge door MICOM No. 44

– Regular voltage are 5V to Open :

0V to Close.

Separate the door S/W and

check if the measured value of

unit is changed from 0 to∞Ω

according to S/W ON/OFF.

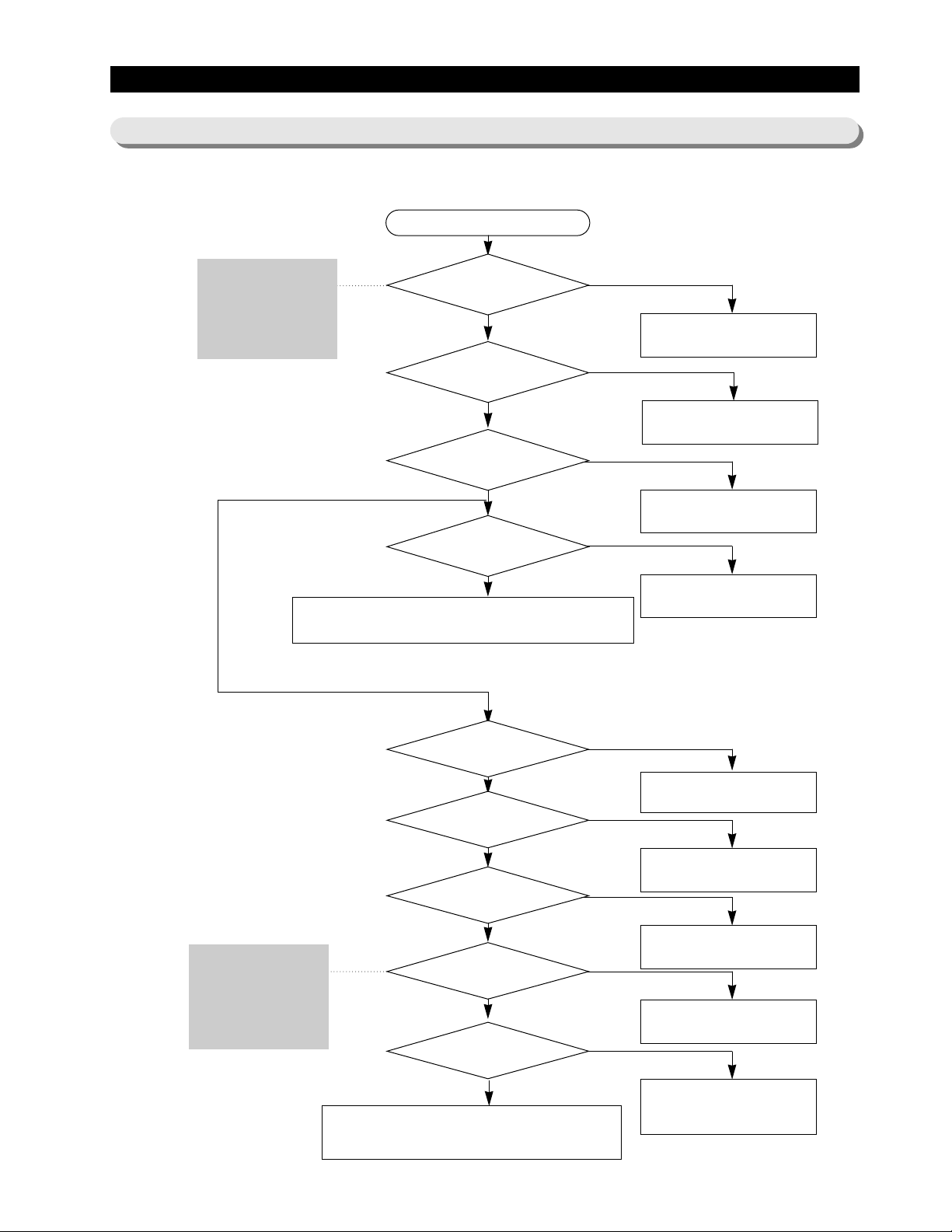

1) If “Ding-Dong” sounds continuously

Isn’t the door opened minutely?

Start

Remove causes after

comprehending the conditions of

interference by door gasket, food etc.

Isn’t water penetrated

into the door S/W?

Exchange the door S/W.

Is the input voltage of

main No. 43 and 44 changed at door-open,

door-close?

Troubleshoot the breaking of wire and

bad door S/W.

Main PCB and door S/W are normal.

Yes

NO

No

YES

NO

Connector not inserted. Troubleshoot

poor contact.

NO

Exchange the door S/W.

NO

YES

Is the state of inserted connector

(CN30)being normal?

YES

Is the door S/W self-unit normal?

YES

2) If “Beep” sounds continuously

Didn’t you

select forced operation and forced

defrosting?

Start

Release the forced operation and

forced defrosting functions, or turn ON

again after power OFF.

Do buzzer

still sound after power-on

again?

Main-PCB is normal

Check if there is any short parts due to

foreign matters and the test

jumper part in the main-PCB.

Selected

NO

YES

YES

Diagnostics

11-5) If alarm sound

Page 6

57

Diagnostics

3) Without sound of buzzer operation

Does it sound

‘Ding-Dong’if you press a button

on front panel?

Start

Main PCB is normal; buzzer normal.

Check the panel PCB with the

reference of ‘how to check panel

display’.

Buzzer is broken – replace it.

Does it make a sound of ‘door-open’ alarm

when you are opening the door of freezer or fridge

more than 2 min?

Is the bent or go-out of the buzzer

in the main PCB?

The main PCB and buzzer are normal

YES

YES

NO

NO

YES

NO

NO

Replace the main PCB.

(failure of MICOM)

Are signals coming

out of MICOM No. 21 in a 1-sec cycle

after the Forced operation?

Is signal of Q801

Base ouputted with 1 sec. intervals

in the condition above?

Did lead of a

component fall on the vibration plate

of buzzer?

NO

Check the state of pattern connection

between MICOM No.21 and Q801.

(Check Open/Short)

NO

Poor buzzer is broken down or

replace the buzzer.

YES

YES

YES

Refer the description of

Test function in the manual

for the Forced operation.

Page 7

58

Diagnostics

11-6) If the panel PCB is not working normally:

1) Where lighting of the panel PCB is disabled, or only some lamps are disabled.

2) Where the Panel PCB key isn’t selected:

- The basic check way : If you is troubleshooting in the basic check method, then

Is the connector

of upper hinge cover inserted

normally?

Start

Reinsert the connector. Troubleshoot

a poor contact.

Is the main PCB

connector(CN50) inserted

normally?

Reinsert the connector in the main

PCB.

Is the connector of

door panel PCB connector inserted

normally?

Reinsert the connector. Troubleshoot

a poor contact.

1. Check the door wire of freezer – the disconnection of wire, short between wires.

2. Check the CABI wire of freezer – the disconnection of wire, short between wires.

3. Check the panel lighting circuit section within the main PCB for short open.

1. Check the door wire of freezer – check the breaking of wire, short between wires.

2. Check the CABI wire of freezer – check the breaking of wire, short between wires.

3. Check for Short/Open of the Panel Lighting Circuit section in the main PCB.

NO

NO

YES

YES

NO

Panel PCB itself has trouble.

YES

YES

Is lighting operated

normally when the exchange of panel

PCB?

NO

NO

Recheck after the release of locking

function.

YES

Is the locking lamp lit on?

YES

Reassemble the PCB ass’y/Enforce

the cancellation of pressed keys.

NO

Aren’t a key or more buttons

pressed continuously?

YES

Reassemble the PCB ass’y/Enforce

the cancellation of pressed keys.

Operated by

separation

Isn’t the PCB system

still operated by seperating of the

mechanism?

NO

Panel PCB has trouble for itself.

YES

Is lighting

operated normally in the exchange

of panel-PCB?

YES

1. Replace the main PCB.

2. Check the short wires of CoolSelect

Zone

TM

panel.

NO

Is a periodic

wave form outputted from the main

PCB IC9?

See Ref. 1: ‘View of the

connection cabinet-door

for the wire assembly’ in

the manual.

Refer to the description of

circuit operation in the

manual 10-6) Key scan

and display Circuit

selection’s, and measure

the wave pattern.(page 40)

Page 8

59

Diagnostics

1 1-7) If fan doesn’t work:

The refrigerator has been applied with the BLDC fan motor. For RS2533, R room Fan is AC motor used. The BLDC

motor is driven by DC 8-12V.

Under the normal condition of COMP ON, it is operated together with F-FAN motor. With operation of the CoolSelect

ZoneTMfunction, the F-Fan motor may do not work. If the door is opened and closed once at a high ambient

temperature, the BLDC motor would be operated after a 1-minute or longer delay. Therefore, you’ re advised not to

take it for an error .

When the refrigerator is open, the freezer fan motor will also stop working simultaneously with the fan motor. (for the

purpose of performance improvement).

Reference

COMP OFF?

Start

Execute Forced

operation. (See page

34 in the manual)

Is the voltage DC 9-11V between

GND of the main-PCB section and

CN72 pin No. 6?

Fan works normally.

Is the voltage DC 0V between

CN30 No. 1 and No. 2

in the main-PCB?

Troubleshoot the

connections of door S/W.

In the first power application, the

freezer / fridge / compressor fans

work for 5 minutes regardless of the

condition.

Apply power around 5 minutes

after the power OFF. (Prevent

overload of compressor.)

Expected causes :

1. Check if the fan motor has failure itself.

2. Check if the wire connections have a trouble of contact.

3. Check the input of the fan motor rotation pulse in the operation motor

fan. (See the details of Fan Motor Drive Circuit section.)

YES

YES

NO

NO

NO

YES

Is the voltage DC10V between

GND of the main-PCB and pin No. 4

of CN72 ?

Is the voltage DC 0V between

CN30 No. 5 and No. 6 in the main-PCB

section?

NO

Is the voltage between GND

of the main-PCB and pin No. 4 of CN72

around DC 8-10V?

NO

YES

Does DC 9-11V alternate

with below DC 2V between GND of the main-PCB section

and CN72 pin No. 6?

Exchange or troubleshoot the

main PCB.

Measure with the door closed.

- door open: DC 5V

- door close : 0V

NO

YES

CN72 No. 3(F), 2(R),1(C) will be generated pulse signals when the motor rotates. These signals will be

inputted into MICOM. Unless signals are not inputted in the restart of motor, it will be ON 10 seconds after

the fan OFF. But if signals are not still entered, the above operation will restart four times more. Without

signals entered continuously, the motor will get restarted after 10 minutes. This function is effective where

the normal operation of motor would be restrained due to foreign matters such as ice.

Reference

Does DC 10V alternate

with below DC 2V between GND of the main-PCB section and

CN72 pin No. 5?

YES

Does DC 8-10V alternate

with below DC 2V between GND of the main-PCB

section and CN72 pin No. 4?

YES

For C-FAN

For C-FAN For R-RAN For F-FAN

For R-FAN For F-Fan

Page 9

60

Diagnostics

11-8) If CoolSelect Zone

TM

isn’t operated normally

1) If the lamp of CoolSelect Zone

TM

is not lit.

2) If the Panel PCB key isn’t selected:

- The basic method is applied to check – if you fail in troubleshooting after above the execution, then

Is the connector of

CoolSelect Zone

TM

inserted correctly

in the refrigerator?

Start

Reinsert the connector; troubleshoot

a bad contact.

Is the connector of main

PCB (CN51) inserted correctly?

Reinsert the connector in the main

PCB.

Is the connector of

CoolSelect ZoneTMpanel PCB

inserted ?

Reinsert the connector; troubleshoot

a bad contact.

1.Check the wires of CoolSelect Zone

TM

– check the disconnection of wire, short between wires.

2. Check the Lighting Circuit of CoolSelect Zone

TM

panel in the main PCB for Short/Open.

3. Check the main PCB of CoolSelect Zone

TM

assembly for Short; the wire assembly state between

the panel and main PCB.

1. Check the wires of CoolSelect Zone

TM

– check the disconnection of wire, short between wires.

2. Check Short/Open the Lighting Circuit section of CoolSelect Zone

TM

panel in the main PCB.

3. Check the short of main PCB in CoolSelect Zone

TM

. Check the wire assembly

NO

NO

YES

YES

NO

Panel PCB has trouble for itself.

YES

YES

Is lighting operated

normally in the exchange of CoolSelect Zone

TM

panel PCB?

If the Panel key isn’ t selected:

NO

YES

Reassemble the PCB ass’y/Enforce

the cancellation of pressed keys

NO

Aren’t a key or more pressed

continuously?

YES

Reassemble the PCB asswmbly and

Enforce the cancellation of pressed keys

NO

Isn’t the PCB system

still operated by separation?

NO

Panel PCB has trouble for itself.

YES

Is lighting operated

normally after the exchange of

panel-PCB?

YES

1. Replace the main PCB.

2. Check the wire shorts of CoolSelect

ZoneTMpanel.

NO

Is a periodical wave

form outputted from the main

PCB IC9?

Refer to 8-7) CoolSelect Zone

TM

,

Panel Circuit and measure the

wave form.

Page 10

61

Diagnostics

1 1-9) If the lamps of freezer / refrigerator does not light.

1. When you are exchanging the lamp of freezer, please exchange or troubleshoot it with the power OFF to

avoid an electric shock.

2. Please keep in mind you do not get burnt by the excessive heating of an incandescent light bulb.

Is the inside lamp filament cut?

Start

Exchange or troubleshoot the

inside lamp.

Does the F-door S/W

have a normal contact?

Exchange or troubleshoot the

door S/W

Check the connections of F and R-door S/W;

check and troubleshoot the inside lamp socket.

YES

NO

NO

YES

Caution!

Separate the door S/W and measure its

resistance with a measure. As the result,

every Open/Close of the door S/W should turn 0/

∞, respectively.

1) Where 0 alone comes out : Door S/W has Short

trouble.

2) Where ∞ alone comes out : Door S/W has

Open trouble.

How to check :

If the door is opened, then the contact of door S/W is opened and MICOM gets applied 5V to finally sense Open. If 5V has been sensed over two

minutes afterwards, then an Door-Open alarm will sound ‘Ding-Dong’ for 10 seconds in a one-minute cycle. For that reason, if the door S/W has failure, the

refrigerator can make a “Ding-Dong” sound per a one-minute cycle. Please note step for its service!

Reference

Page 11

62

Diagnostics

11-10) If the solenoid in the ice-chute cover doesn’t work :

Is the S/N(solenoid) for

0.3 sec operated after 5 seconds

from power ON?

Start

Is MICOM No. 27 on

PCB maintaining High for 0.3 sec at the first

power ON?

Press Ice lever and keep it open.

Is the cover closed of

S/N after about

7∼10 seconds?

With the ice S/W ON

and ICE S/W on, ice-movement motor in F room?

Does C-E(between C and E)

of TR Q701 turn ON for 0.3 sec?

MICOM control port is normal.

Exchange the main PCB assembly.

The S/N control PCB assembly and

wire system have no trouble.

All the control system of cover iceroute has no trouble.

Check the ICE S/W, and troubleshoot

the wire connection syste

m.

- Main PCB and the sensing section of

ice-S/W are normal.

- Check the operation of SSR71 and

Q701.

Check the stop lever and support

time-delay.

After replace TR Q701 and check SSR71 then

exchange the failed components or replace the

PCB assembly.

TR701 and SSR71 are normal

YES

YES

NO

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

1) Check if the solenoid is unconditionally operated for 0.3 sec, independent of the Open/Close condition of cover ice-route, after

a lapse of about 5 seconds from power ON. (Before installation, the cancellation of cover ice-route open is enabled.)

2) Check if the connector in upper hinge section is hook-up correctly.

Preliminary check

Subject to the ice

S/W ON, do CN31 No. 2 and MICOM No. 45

get impressed 0V?

Page 12

63

Is ice ejected?

What’s your selection

between crushed and cubed?

Is the cube ice ejected sufficiently?

Does ice in the ice tray exist ?

Do you see Ice Stop on the digital panel?

Is the Crushed Ice extracted

sufficiently?

Start

The close condition on operation

is subject to the freezer door.

1) Check the ice-ejector S/W.

2) Check the door S/W.

3) Check the ice moving motor.

4) Check the cut of wire in the Ice

moving Motor section.

Cancel Ice Stop, select

the Cubed/Crushed ice.

Normal operation

1) Check the water hose for folding or

fastening.

2) Check the ice-water-way and

solenoid value

3) Check the wires of ice-maker.

NO

Crushed ice

Cubed ice extracted

Normal operation

YES

NO

Does MICOM No. 25 turn 5V if

pressing Ice S/W?

Failure of Main PCB and exchange it.

YES

NO

Does the voltage

of IC3 No. 18 turn 0V even in the ice

S/W OFF?

Failure of Main PCB(IC3) and

exchange it.

YES

NO

Does the contact

shelf of RY77 relay turn 0Ω even in the

power OFF?

Failure of Main PCB – exchange.

(The contact terminal of RY77

relay short failure.)

YES

NO

Failure of Main PCB. –Exchange it.

NO

Failure of Main PCB(IC3) –

exchange it.

Main PCB is normal.

- - - Necessary to check other sections.

1) Check the wire between terminals of the AUGER motor

and main PCB.

2) Failure of cube solenoid itself, or bad contact of the

connector.

Main PCB is normal.

- - - Check other sections.

1) Check the wire between the

AUGER motor and main

PCB.

Measure both contact

terminals of RY77 after the

separation of CN70, CN71

connectors.

Measure both terminals of RY77

contact after the separation of CN70,

CN71 connectors.

NO

Exchange of Main PCB(RY77

relay).

NO

Cubed ice

NO

Does MICOM No. 25 turn

5V if pressing Ice S/W?

Does IC3 No. 18 turn 0V if

pressing Ice S/W?

Does the

contact shelf of RY77 relay turn 0Ωif

pressing ICE S/W?

YES

YES

YES

NO

NO

YES

YES

YES

Diagnostics

1 1-11) If Crushed Ice/Cubed Ice doesn’t work properly:

Page 13

64

Check with power applied.

The Door S/W is a two-contact switch. One

detects Door Open/Close with DC 5V at the

PCB and the other one turns on/off the room

light.

(R-Room Light)

1 . Check if the light comes on by opening the R-Door. If it lights up, check if the light goes off by pressing down

the Door S/W with the door open.

If there is any problem, check the R-Door S/W.

(R-Door Open Sensing Part of MAIN PCB)

1 . Place the positive(+) terminal on CN30 No.⑤ and the negative(-) on No.⑩.And,check the voltage.

2. When the voltage is DC 5V with the door open, it is normal.

3. When the voltage is DC 0V with the door closed, it is normal. If there is any problem, check the Door S/W and

the wire connections.

(F-Room Light)

1 . Check if the light comes on by opening the F-Door. If it lights up, check if the light goes off by pressing down

the Door S/W with the door open.

If there is any problem, check the F-Door S/W.

(F-Door Open Sensing Part of MAIN PCB)

1 . Place the positive(+) terminal on CN30 No.① and the negative(-) on No.⑨. And,checkthe voltage.

2. When the voltage is DC 5V with the door open, it is normal.

3. When the voltage is DC 0V with the door closed, it is normal. If there is any problem, check the Door S/W and

the wire connections.

Disconnect the connector from the Main PCB,

than measure the resistance of the following

sensors.

1. Check the resistance the Freezer sensor cn30 between the no. 2 and 3.

2. Check the resistance the Fridge Room sensor cn30 between the no. 6 and 7.

3. Check the resistance the F Defrosting sensor cn30 between the no. 2 and 4.

4. Check the resistance the R Defrosting sensor cn30 between the no. 6 and 8.

5. Check the resistance between the no. ① and ④ the ambient Air sensor cn31.

6. Check the resistance between the no. ③ and ④of the Ice-Maker sensor cn90.

7. Check the resistance between the no. ⑬ and ⑭ of the CoolSelect Zone

TM

sensor cn51.

8. Decide the sensor by comparing above resistances to the temperature of

each sensor with the conversion table of sensor resistance and voltage from

the reference temperature of Ref. 6 on this manual.

※When the resistance is ∞Ωor 0Ω,check the connection of electric wire and

sensorconnector.

Appendix ⅠⅠ(Reference for circuit diagnostics)

Ref. 1) Check sensors

Ref. 2) Check Door S/W

Main PCB

F-DOOR S/W

(If Door Close : 1<->2 OPEN)

4

R-DOOR S/W

(If Door Close : 1<->2 OPEN)

4

213

HOME BAR S/W

213

F-SENSOR

F-DEF-SENSOR

R-SENSOR

R-DEF-SENSOR

Ass'y

1

2

3

4

5

6

7

8

9

10

11

Measuring Terminals

(1<->9)

Measuring Terminals

(5<->10)

Page 14

Appendix ⅠⅠ(Reference for circuit diagnostics)

Ref. 3) Table of temperature sensor according to resistance and voltage conversion.

Temp.(℉)

-43.6

-41.8

-40.0

-38.2

-36.4

-34.6

-32.8

-31

-29.2

-27.4

-25.6

-23.8

-22.0

-20.2

-18.4

16.6

-14.8

-13.0

-11.2

-9.4

-7.6

-5.8

-4.0

-2.2

-0.4

1.4

3.2

5.0

6.8

8.6

10.4

Resistance(㏀)

98.870

93.700

88.850

84.150

79.800

75.670

71.800

68.150

64.710

61.480

58.430

55.550

52.840

50.230

47.770

45.450

43.260

41.190

39.240

37.390

35.650

33.990

32.430

30.920

29.500

28.140

26.870

25.650

24.510

23.420

22.390

Voltage(V)

4.541

4.518

4.494

4.469

4.443

4.416

4.389

4.360

4.331

4.301

4.269

4.237

4.204

4.170

4.134

4.098

4.061

4.023

3.985

3.945

3.905

3.863

3.822

3.778

3.734

3.689

3.644

3.597

3.551

3.504

3.456

The input voltage to the MICOM PORT could be different by a hardware. This is a table based on the

voltage using the 10kohm-F.

MICOM PORT voltage when the sensor is open: about DC 5V(Vcc LEVEL)

MICOM PORT voltage when the sensor is shorted: about DC 0V(Ground LEVEL)

Temp.(℉)

12.2

14.0

15.8

17.6

19.4

21.2

23.0

24.8

26.6

28.4

30.2

32.0

33.8

35.6

37.4

39.2

41.0

42.8

44.6

46.4

48.2

50.0

51.8

53.6

55.4

57.2

59.0

60.8

62.6

64.4

66.2

Resistance(㏀)

21.410

20.480

19.580

18.730

17.920

17.160

16.430

15.740

15.080

14.450

13.860

13.290

12.740

12.220

11.720

11.250

10.800

10.370

9.959

9.569

9.195

8.839

8.494

8.166

7.852

7.552

7.266

6.992

6.731

6.481

6.242

Voltage(V)

3.408

3.360

3.310

3.260

3.209

3.159

3.108

3.057

3.006

2.955

2.904

2.853

2.801

2.750

2.698

2.647

2.596

2.545

2.495

2.445

2.395

2.346

2.296

2.248

2.199

2.151

2.104

2.057

2.012

1.966

1.922

Temp.(℉)

68.0

69.8

71.6

73.4

75.2

77.0

78.8

80.6

82.4

84.2

86.0

87.8

89.6

91.4

93.2

95.0

96.8

98.6

100.4

102.2

104.0

105.8

107.6

109.4

111.2

113.0

114.8

116.6

118.4

120.2

Resistance(㏀)

6.013

5.792

5.581

5.379

5.185

5.000

4.821

4.650

4.487

4.329

4.179

4.033

3.894

3.760

3.631

3.508

3.390

3.276

3.167

3.062

2.962

2.864

2.770

2.680

2.593

2.510

2.429

2.352

2.278

2.206

Voltage(V)

1.878

1.834

1.791

1.749

1.707

1.667

1.626

1.587

1.549

1.511

1.474

1.437

1.401

1.366

1.332

1.298

1.266

1.234

1.203

1.172

1.143

1.113

1.085

1.057

1.030

1.003

0.977

0.952

0.928

0.904

Page 15

66

1

2

3

5

6

7

10

11

12

14

15

17

NO CODE-NO PART NAME SPECIFCATION

Q’TY

※ The last no. of the code number such as DA41-xxxxx? for the Main PCB-ASS’Y could be changed by

MICOM and option.

Appendix ⅠⅠ(Reference for circuit diagnostics)

Ref. 4) Service part lists of each circuit board.

4

8

9

13

16

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

0

DA41-00195A

DA41-00195B

DA41-00185A

DA41-00103T

DA41-00103U

DA41-00173A

DA32-00006B

DA32-00006A

DA32-10109V

DA32-10109W

DA32-10109X

DA27-00002A

DA41-00185B

DA41-00173B

DA41-00108A

DA32-00105U

3301-000016

MAIN PCB ASS’Y

MAIN PCB ASS’Y

MAIN PCB ASS’Y

MAIN PCB ASS’Y

MAIN PCB ASS’Y

MAIN PCB ASS’Y

R-DEFROST Sensor

F-DEFROST Sensor

Ambient Temp.Sensor

F-Temp.Sensor

CoolSelectZone

TM

PCB ASS’Y

NOISE FILTER

MAIN PCB ASS’Y

PANEL PCB ASS’Y

CoolSelectZone

TM

PCB ASS’Y

R-Temp.Sensor

F-Temp.Sensor

FERRIETE CORE

(LOCK TYPE)

①Basic ②Basic with H/B

①Basic with CoolSelectZone

TM

①Dispenser ②Dispenser with H/B

①Basic ②Basic with H/B

①Basic with CoolSelectZone

TM

①Dispenser ②Dispenser with H/B

PX-41C

PX-41C

PX-41C

PX-41C (Use Only Dispenser Models)

PX-41C

USE ALL MODEL

①

Dispenser with CoolSelectZone

TM

②

Dispenser with H/B & CoolSelectZone

TM

①

Dispenser with CoolSelectZone

TM

②

Dispenser with H/B & CoolSelectZone

TM

①

Basic with CoolSelectZone

TM

②Dispenser with CoolSelectZone

TM

③Dispenser with H/B & CoolSelectZone

TM

PX-41C

PX-41C (Use Only Basic Models)

-

Page 16

67

Page 17

68

CIRCUIT DIAGRAM

For Basic Models

BLK

BRN

RED

ORG

YEL

PNK

BLU

PRP

GRY

WHT

S/BLU

W/BLK

W/RED

W/BLU

WHT

WHT

BLK

BRN

RED

ORG

YEL

PNK

BLU

PRP

GRY

WHT

S/BLU

W/BLK

W/RED

W/BLU

12

13

14

13

12

13

14

RED

RED

RED

RED

W/BLK

GRN/YEL

GRN/YELGRN/YEL

RED

RED

BLK

BLK

BLK

YEL

RED

R-ROOM LAMP

F-ROOM LAMP

W/BLK

W/BLK

BLK

BLK

BLK

C

M

S

PTC RELAY

RUNNING CAPACITOR

COMPRESSOR

F-FAN MOTOR

(BLDC)

R-FAN MOTOR

(BLDC)

COOLING-FAN

MOTOR (BLDC)

AMBIENT SENSOR

OVERLOAD

PROTECTOR

1

2

3

4

7

6

5

4

3

2

1

1

2

3

4

5

6

7

8

PANEL PCB

MAIN PCB

14-PIN

F-ROOM DOOR S/W

F-ROOM SENSOR

R-ROOM SENSOR

DEFROST SENSOR,F

DEFROST SENSOR,R

1

2

4

3

1

2

4

3

CN50(WHT)

CN70(WHT)

CN71(WHT)

CN72(WHT)

CN31(WHT)

CN10(WHT)

CN30(WHT)

RED

RED

DEFROST HEATER,F

DEFROST HEATER,R

DRAIN HEATER

F-DRAIN HEATER

THERMO FUSE,F

THERMO FUSE,R

BLK

RED

GND

Vcc

Vcc

Vcc

FG

FG

FG

NL

S/BLU

PNK

R-ROOM DOOR-S/W

NOISE

FILTER

RED-RED

BLU-BLUE

ORG-ORANGE

P/BLU-PINK/BLUE

BRN-BROWN

PNK-PINK

GRY-GRAY

W/BLU-WHITE/BLUE

WHT-WHITE

YEL-YELLOW

BLK-BLACK

PRP-PURPLE

W/BLK-WHITE/BLACK

S/BLU-SKY/BLUE

E-EARTH

W/RED-WHITE/RED

Reference

Page 18

69

CIRCUIT DIAGRAM

For Dispenser Models

BLK

BRN

RED

ORG

YEL

PNK

BLU

PRP

GRY

WHT

S/BLU

W/BLK

W/RED

W/BLU

WHT

ORG

ORG

WHT

BLK

BRN

RED

ORG

YEL

PNK

BLU

PRP

GRY

WHT

S/BLU

W/BLK

W/RED

W/BLU

RED

BLK

WHT

WHT

GRY

BLU

PRP

S/BLU

12

13

14

13

12

13

14

RED

RED

RED

RED

RED

W/BLK

GRN/YEL

GRN/YEL

RED

RED

RED

BLK

BLK

BLK

BLK

YEL

RED

R-ROOM LAMP

F-ROOM LAMP

W/BLK

W/BLK

RED

RED

RED

RED

GRY

BLK

BLK

BLK

BLK

BLK

BLK

FILTER

C

M

S

PTC RELAY

RUNNING CAPACITOR

COMPRESSOR

DISPENSER HEATER

ICE CUBE SOLENOID

F-FAN MOTOR

(BLDC)

R-FAN MOTOR

(BLDC)

COOLING-FAN

MOTOR (BLDC)

AMBIENT SENSOR

ICE S/W

OVERLOAD

PROTECTOR

10

9

7

6

4

3

2

1

1

2

3

4

5

6

1

2

3

4

7

7

6

5

4

3

2

1

8

1

12

13

2

3

4

5

6

7

8

EJECT MOTOR

ICE SENSOR

TEST S/W

HORIZONTAL S/W

ICE CHECK S/W

PANEL PCB

MAIN PCB

14-PIN

F-ROOM DOOR S/W

F-ROOM SENSOR

R-ROOM SENSOR

DEFROST SENSOR,F

DEFROST SENSOR,R

1

2

4

3

1

2

4

3

CN50(WHT)

CN70(WHT)

CN71(WHT)

CN72(WHT)

CN31(WHT)

CN10(WHT)

CN90(RED)

CN30(WHT)

FILTER

RED

RED

ICE ROUTE SOLENOID

ICE MAKER-SOLENOID VALVE

AUGER MOTOR

DEFROST HEATER,F

DEFROST HEATER,R

DRAIN HEATER

ICE MAKER PIPE HEATER

F-DRAIN HEATER

THERMO FUSE,F

THERMO FUSE,R

BLK

RED

GND

Vcc

Vcc

Vcc

FG

FG

FG

2

3

WATER-SOLENOID VALVE

WATER S/W

5

6

NOISE

FILTER

NL

S/BLU

PNK

R-ROOM DOOR-S/W

1

4

GRN/YEL

RED-RED

BLU-BLUE

ORG-ORANGE

P/BLU-PINK/BLUE

BRN-BROWN

PNK-PINK

GRY-GRAY

W/BLU-WHITE/BLUE

WHT-WHITE

YEL-YELLOW

BLK-BLACK

PRP-PURPLE

W/BLK-WHITE/BLACK

S/BLU-SKY/BLUE

E-EARTH

W/RED-WHITE/RED

Reference

Page 19

70

CIRCUIT DIAGRAM

For Dispenser & CoolSelect Zone

TM

Models

BLK

BRN

RED

ORG

YEL

PNK

BLU

PRP

GRY

WHT

S/BLU

W/BLK

W/RED

W/BLU

BLK

BLK

WHT

BLU

YEL

RED

WHT

ORG

ORG

WHT

BLK

BRN

RED

ORG

YEL

PNK

BLU

PRP

GRY

WHT

S/BLU

W/BLK

W/RED

W/BLU

BLK

BRN

RED

ORG

YEL

PNK

BLU

PRP

GRY

WHT

S/BLU

W/BLK

W/RED

W/BLU

BLK

BRN

RED

ORG

YEL

PNK

BLU

PRP

GRY

WHT

S/BLU

W/BLK

W/RED

W/BLU

RED

BLK

WHT

WHT

GRY

BLU

PRP

S/BLU

12

13

14

13

12

13

14

12

13

14

RED

RED

RED

RED

RED

W/BLK

GRN/YEL

GRN/YEL

RED

RED

RED

BLK

BLK

BLK

BLK

YEL

RED

R-ROOM LAMP

F-ROOM LAMP

W/BLK

W/BLK

RED

RED

RED

RED

GRY

BLK

BLK

BLK

BLK

BLK

BLK

FILTER

C

M

S

PTC RELAY

RUNNING CAPACITOR

COMPRESSOR

DISPENSER HEATER

ICE CUBE SOLENOID

F-FAN MOTOR

(BLDC)

R-FAN MOTOR

(BLDC)

COOLSELECT ZONE

DAMPER ASS'Y

COOLING-FAN

MOTOR (BLDC)

DAMPER HEATER

AMBIENT SENSOR

ICE S/W

OVERLOAD

PROTECTOR

12

13

10

9

7

6

4

3

2

1

1

2

3

4

5

6

1

2

3

4

1

2

3

4

5

6

3

4

1

6

2

5

7

7

6

5

4

3

2

1

8

1

12

13

2

3

4

5

6

7

8

14

15 16

WHT

WHT

COOLSELECT ZONE

SENSER

EJECT MOTOR

ICE SENSOR

TEST S/W

HORIZONTAL S/W

ICE CHECK S/W

COOLSELECT

ZONE PCB

PANEL PCB

MAIN PCB

14-PIN

(16-PIN)

USE

14-PIN

F-ROOM DOOR S/W

F-ROOM SENSOR

R-ROOM SENSOR

DEFROST SENSOR,F

DEFROST SENSOR,R

1

2

4

3

1

2

4

3

CN50(WHT)

CN70(WHT)

CN71(WHT)

CN72(WHT)

CN31(WHT)

CN73(WHT)

CN10(WHT)

CN51(RED)

CN90(RED)

CN30(WHT)

FILTER

RED

RED

ICE ROUTE SOLENOID

ICE MAKER-SOLENOID VALVE

AUGER MOTOR

DEFROST HEATER,F

DEFROST HEATER,R

DRAIN HEATER

ICE MAKER PIPE HEATER

F-DRAIN HEATER

THERMO FUSE,F

THERMO FUSE,R

BLK

RED

GND

Vcc

Vcc

Vcc

FG

FG

FG

2

3

WATER-SOLENOID VALVE

WATER S/W

5

6

A

B

A

B

NOISE

FILTER

NL

S/BLU

PNK

R-ROOM DOOR-S/W

1

4

GRN/YEL

RED-RED

BLU-BLUE

ORG-ORANGE

P/BLU-PINK/BLUE

BRN-BROWN

PNK-PINK

GRY-GRAY

W/BLU-WHITE/BLUE

WHT-WHITE

YEL-YELLOW

BLK-BLACK

PRP-PURPLE

W/BLK-WHITE/BLACK

S/BLU-SKY/BLUE

E-EARTH

W/RED-WHITE/RED

Reference

Page 20

71

CIRCUIT DIAGRAM

For Dispenser & Home Bar Models

BLK

BRN

RED

ORG

YEL

PNK

BLU

PRP

GRY

WHT

S/BLU

W/BLK

W/RED

W/BLU

WHT

ORG

ORG

WHT

BLK

BRN

RED

ORG

YEL

PNK

BLU

PRP

GRY

WHT

S/BLU

W/BLK

W/RED

W/BLU

RED

BLK

WHT

WHT

GRY

BLU

PRP

S/BLU

12

13

14

13

12

13

14

RED

RED

RED

RED

RED

W/BLK

GRN/YEL

GRN/YEL

RED

RED

RED

BLK

BLK

BLK

BLK

YEL

RED

R-ROOM LAMP

F-ROOM LAMP

W/BLK

W/BLK

RED

RED

RED

RED

GRY

BLK

BLK

BLK

BLK

BLK

BLK

FILTER

C

M

S

PTC RELAY

RUNNING CAPACITOR

COMPRESSOR

DISPENSER HEATER

HOME-BAR HEATER

ICE CUBE SOLENOID

F-FAN MOTOR

(BLDC)

R-FAN MOTOR

(BLDC)

COOLING-FAN

MOTOR (BLDC)

AMBIENT SENSOR

ICE S/W

OVERLOAD

PROTECTOR

10

9

7

6

4

3

2

1

1

2

3

4

5

6

1

2

3

4

7

7

6

5

4

3

2

1

8

1

2

12

13

3

4

5

6

7

8

EJECT MOTOR

ICE SENSOR

TEST S/W

HORIZONTAL S/W

ICE CHECK S/W

PANEL PCB

MAIN PCB

14-PIN

F-ROOM DOOR S/W

F-ROOM SENSOR

R-ROOM SENSOR

HOME-BAR

S/W

DEFROST SENSOR,F

DEFROST SENSOR,R

1

2

4

3

1

2

4

3

CN50(WHT)

CN70(WHT)

CN71(WHT)

CN72(WHT)

CN31(WHT)

CN10(WHT)

CN90(RED)

CN30(WHT)

FILTER

RED

RED

ICE ROUTE SOLENOID

ICE MAKER-SOLENOID VALVE

AUGER MOTOR

DEFROST HEATER,F

DEFROST HEATER,R

DRAIN HEATER

ICE MAKER PIPE HEATER

F-DRAIN HEATER

THERMO FUSE,F

THERMO FUSE,R

BLK

RED

GND

Vcc

Vcc

Vcc

FG

FG

FG

2

3

WATER-SOLENOID VALVE

WATER S/W

5

6

NOISE

FILTER

NL

S/BLU

PNK

R-ROOM DOOR-S/W

1

4

WHT

GRN/YEL

RED-RED

BLU-BLUE

ORG-ORANGE

P/BLU-PINK/BLUE

BRN-BROWN

PNK-PINK

GRY-GRAY

W/BLU-WHITE/BLUE

WHT-WHITE

YEL-YELLOW

BLK-BLACK

PRP-PURPLE

W/BLK-WHITE/BLACK

S/BLU-SKY/BLUE

E-EARTH

W/RED-WHITE/RED

Reference

Page 21

72

CIRCUIT DIAGRAM

For Dispenser & Home Bar & CoolSelect Zone

TM

Models

BLK

BRN

RED

ORG

YEL

PNK

BLU

PRP

GRY

WHT

S/BLU

W/BLK

W/RED

W/BLU

BLK

BLK

WHT

BLU

YEL

RED

WHT

ORG

ORG

WHT

BLK

BRN

RED

ORG

YEL

PNK

BLU

PRP

GRY

WHT

S/BLU

W/BLK

W/RED

W/BLU

BLK

BRN

RED

ORG

YEL

PNK

BLU

PRP

GRY

WHT

S/BLU

W/BLK

W/RED

W/BLU

BLK

BRN

RED

ORG

YEL

PNK

BLU

PRP

GRY

WHT

S/BLU

W/BLK

W/RED

W/BLU

RED

BLK

WHT

WHT

GRY

BLU

PRP

S/BLU

12

13

14

13

12

13

14

12

13

14

RED

RED

RED

RED

RED

W/BLK

GRN/YEL

GRN/YEL

RED

RED

RED

BLK

BLK

BLK

BLK

YEL

RED

R-ROOM LAMP

F-ROOM LAMP

W/BLK

W/BLK

RED

RED

RED

RED

GRY

BLK

BLK

BLK

BLK

BLK

BLK

FILTER

C

M

S

PTC RELAY

RUNNING CAPACITOR

COMPRESSOR

DISPENSER HEATER

HOME-BAR HEATER

ICE CUBE SOLENOID

F-FAN MOTOR

(BLDC)

R-FAN MOTOR

(BLDC)

COOLSELECT ZONE

DAMPER ASS'Y

COOLING-FAN

MOTOR (BLDC)

DAMPER HEATER

AMBIENT SENSOR

ICE S/W

OVERLOAD

PROTECTOR

12

13

10

9

7

6

4

3

2

1

1

2

3

4

5

6

1

2

3

4

1

2

3

4

5

6

3

4

1

6

2

5

7

7

6

5

4

3

2

1

8

1

2

12

13

3

4

5

6

7

8

14

15 16

WHT

WHT

COOLSELECT ZONE

SENSER

EJECT MOTOR

ICE SENSOR

TEST S/W

HORIZONTAL S/W

ICE CHECK S/W

COOLSELECT

ZONE PCB

PANEL PCB

MAIN PCB

14-PIN

(16-PIN)

USE

14-PIN

F-ROOM DOOR S/W

F-ROOM SENSOR

R-ROOM SENSOR

WHT

HOME-BAR

S/W

DEFROST SENSOR,F

DEFROST SENSOR,R

1

2

4

3

1

2

4

3

CN50(WHT)

CN70(WHT)

CN71(WHT)

CN72(WHT)

CN31(WHT)

CN73(WHT)

CN10(WHT)

CN51(RED)

CN90(RED)

CN30(WHT)

FILTER

RED

RED

ICE ROUTE SOLENOID

ICE MAKER-SOLENOID VALVE

AUGER MOTOR

DEFROST HEATER,F

DEFROST HEATER,R

DRAIN HEATER

ICE MAKER PIPE HEATER

F-DRAIN HEATER

THERMO FUSE,F

THERMO FUSE,R

BLK

RED

GND

Vcc

Vcc

Vcc

FG

FG

FG

2

3

WATER-SOLENOID VALVE

WATER S/W

5

6

A

B

A

B

NOISE

FILTER

NL

S/BLU

PNK

R-ROOM DOOR-S/W

1

4

GRN/YEL

RED-RED

BLU-BLUE

ORG-ORANGE

P/BLU-PINK/BLUE

BRN-BROWN

PNK-PINK

GRY-GRAY

W/BLU-WHITE/BLUE

WHT-WHITE

YEL-YELLOW

BLK-BLACK

PRP-PURPLE

W/BLK-WHITE/BLACK

S/BLU-SKY/BLUE

E-EARTH

W/RED-WHITE/RED

Reference

Loading...

Loading...