Samsung RL-33EBMS PREVENTIVE ACTIONS

1. PREVENTIVE ACTIONS

1-1 Safety Precautions

Only qualified technicians who have full command and knowledge of the

cooling system and safety inspection are allowed to deliver the maintenance

service as specified on the manual.

Please be sure to keep the work place ventilated and safe as this product

!

adopts the combustible and explosive R600a refrigerant.

Prior to repair, please pull the plug out of the socket from the wall to disconnect the

power to hold the human and wealth harmless.

Do not make any by-pass or circuit change attempt without manufacturer's prior

suggestion.

No prelonged cable or double terminal board is recommended.

For human safety, this procut must be properly earthed. But phone lines and gas

pipes are not recommended for earthing.

1-2 Preparations Before Maintenance

1-2-1.Direct plug in-and-out is recommended when replacing the relay that attaches to

the compactor lead terminal. When inserting and pulling the plug, relay wobbling

will more likely destroy the compactor terminals or relay.

1-2-2.Restart is not allowed within 5 minutes after power off. Immediate plug in-and-out

will disable the restart.

This represents the materials with regard to the A/C circuit and spare part safety.

!

This represents the materials included in the appliance maintenance.

1

1-3.Warning

1-3-1 Pay attention to the safety during maintenance as R600a refrigerant is

combustible and explosive.

1-3-2 Keep the work place well ventilated without fire source and combustible and

explosive objects arround during the maintenance of R600a refrigerator.

1-3-3 Make sure to lay the R600a clean during CYCLE maintenance (ensure the

system unblocked by inflating nitrogen under HV and LV state.)

1-3-4 Fire soldering is not allowed until the work place is ventilative without R600a

left in the CYCLE.

1-3-5 When no leakage and blocking are found by nitrogen inflation, shut the fire by

the soldering fulid pipe (valve core available at one end) at the process pipe.

1-3-6 Adding the fulid by vacuumizing the liquid pipe and screw on the nut.(no fire,

appliance, MP3, walkman and mobile phone are allowed during operation)

Note: LOCK RING is only used for pipe connection rather than pipe sealing after

adding fluid. If special tools are available for liquid releasing, lead the R600a

via pipes to the designated location.

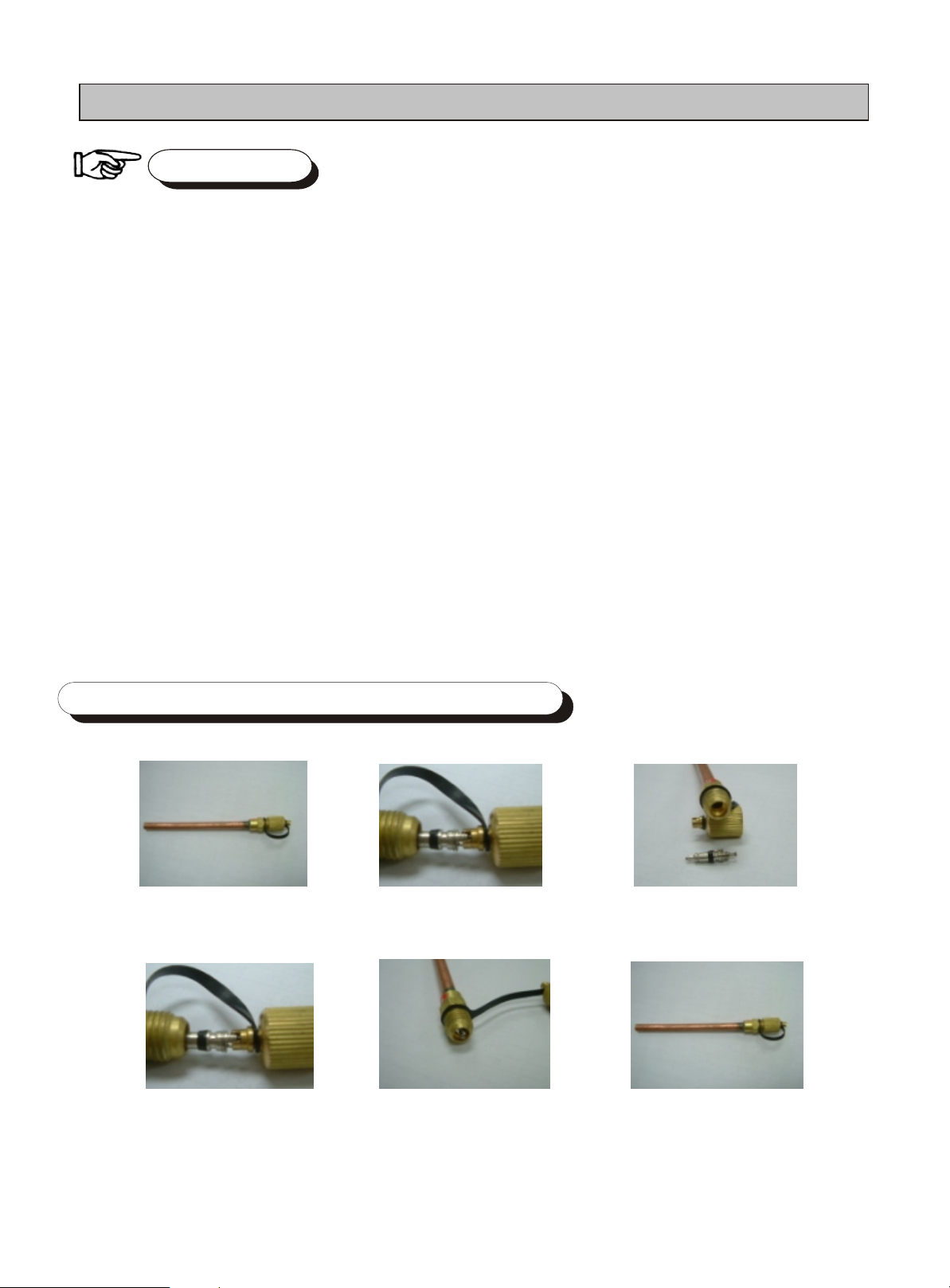

1-4 Special Tools During Maintenance

1)Liquid Adding Pipe

2)Turn off the valve core

3)Solder the pipe onto

the compactor

4) Turn on the valve

core tightly

5)Vacuumize and add liquid

2

6) Onload the pipe nut

Loading...

Loading...