SAMSUNG RL33EBMS, RL33EAMS, RL33EBSW Service Manual

MANUALMANUAL

SERVICE SERVICE

MODEL:

RL33EBMS

Electric Refrigerator

C C

CONTENTS

PREVENTIVE ACTIONS 2

PRODUCT SPECIFICATIONS 3

ELECTRIC & COOLING PART SPEC. & CRITERION 4

FUNCTIONAL & OPERATIONAL INSTRUCTIONS 5

FUNCTIONS 10

CIRCUIT DETAILS 15

TROUBLE ANALYSIS & REPAIR SOLUTIONS 19

PART BREAKDOWN AND LIST 24

DISASSEMBLY & ASSEMBLY 33

CIRCUIT DISGRAM 39

1. PREVENTIVE ACTIONS

1-1 Safety Precautions

Only qualified technicians who have full command and knowledge of the

cooling system and safety inspection are allowed to deliver the maintenance

service as specified on the manual.

Please be sure to keep the work place ventilated and safe as this product

!

adopts the combustible and explosive R600a refrigerant.

Prior to repair, please pull the plug out of the socket from the wall to disconnect the

power to hold the human and wealth harmless.

Do not make any by-pass or circuit change attempt without manufacturer's prior

suggestion.

No prelonged cable or double terminal board is recommended.

For human safety, this procut must be properly earthed. But phone lines and gas

pipes are not recommended for earthing.

1-2 Preparations Before Maintenance

1-2-1.Direct plug in-and-out is recommended when replacing the relay that attaches to

the compactor lead terminal. When inserting and pulling the plug, relay wobbling

will more likely destroy the compactor terminals or relay.

1-2-2.Restart is not allowed within 5 minutes after power off. Immediate plug in-and-out

will disable the restart.

This represents the materials with regard to the A/C circuit and spare part safety.

!

This represents the materials included in the appliance maintenance.

1

1-3.Warning

1-3-1 Pay attention to the safety during maintenance as R600a refrigerant is

combustible and explosive.

1-3-2 Keep the work place well ventilated without fire source and combustible and

explosive objects arround during the maintenance of R600a refrigerator.

1-3-3 Make sure to lay the R600a clean during CYCLE maintenance (ensure the

system unblocked by inflating nitrogen under HV and LV state.)

1-3-4 Fire soldering is not allowed until the work place is ventilative without R600a

left in the CYCLE.

1-3-5 When no leakage and blocking are found by nitrogen inflation, shut the fire by

the soldering fulid pipe (valve core available at one end) at the process pipe.

1-3-6 Adding the fulid by vacuumizing the liquid pipe and screw on the nut.(no fire,

appliance, MP3, walkman and mobile phone are allowed during operation)

Note: LOCK RING is only used for pipe connection rather than pipe sealing after

adding fluid. If special tools are available for liquid releasing, lead the R600a

via pipes to the designated location.

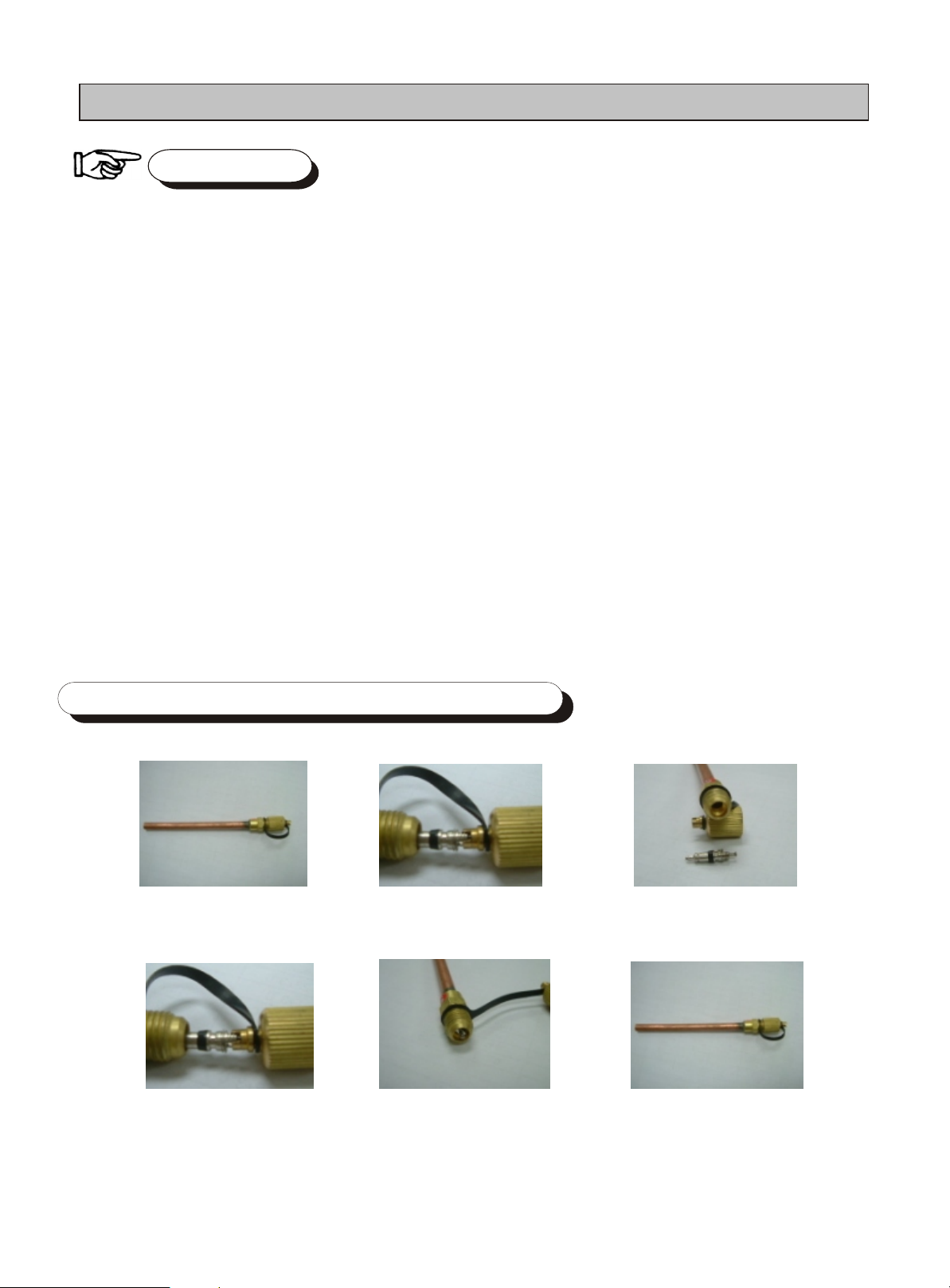

1-4 Special Tools During Maintenance

1)Liquid Adding Pipe

2)Turn off the valve core

3)Solder the pipe onto

the compactor

4) Turn on the valve

core tightly

5)Vacuumize and add liquid

2

6) Onload the pipe nut

1-5 Maintenance Method

1.Maintenance Environment

1-1 Pay attention to the safety during maintenance as R600a refrigerant is

combustible and explosive.

1-2 Keep the work place well ventilated without sparks and hot resource around

when repairing the refrigerator's cooling system. Soldering or heating are not

recommended. No smoke also.

1-3 Fire soldering is not allowed until the work place is ventilated without R600a

left in the CYCLE.

2.Refrigerant Remnants Discharging

Prior to reinjecting the refrigerant, conduct the trouble inspection. If the leaking

point is found, eject the remained R600a out.

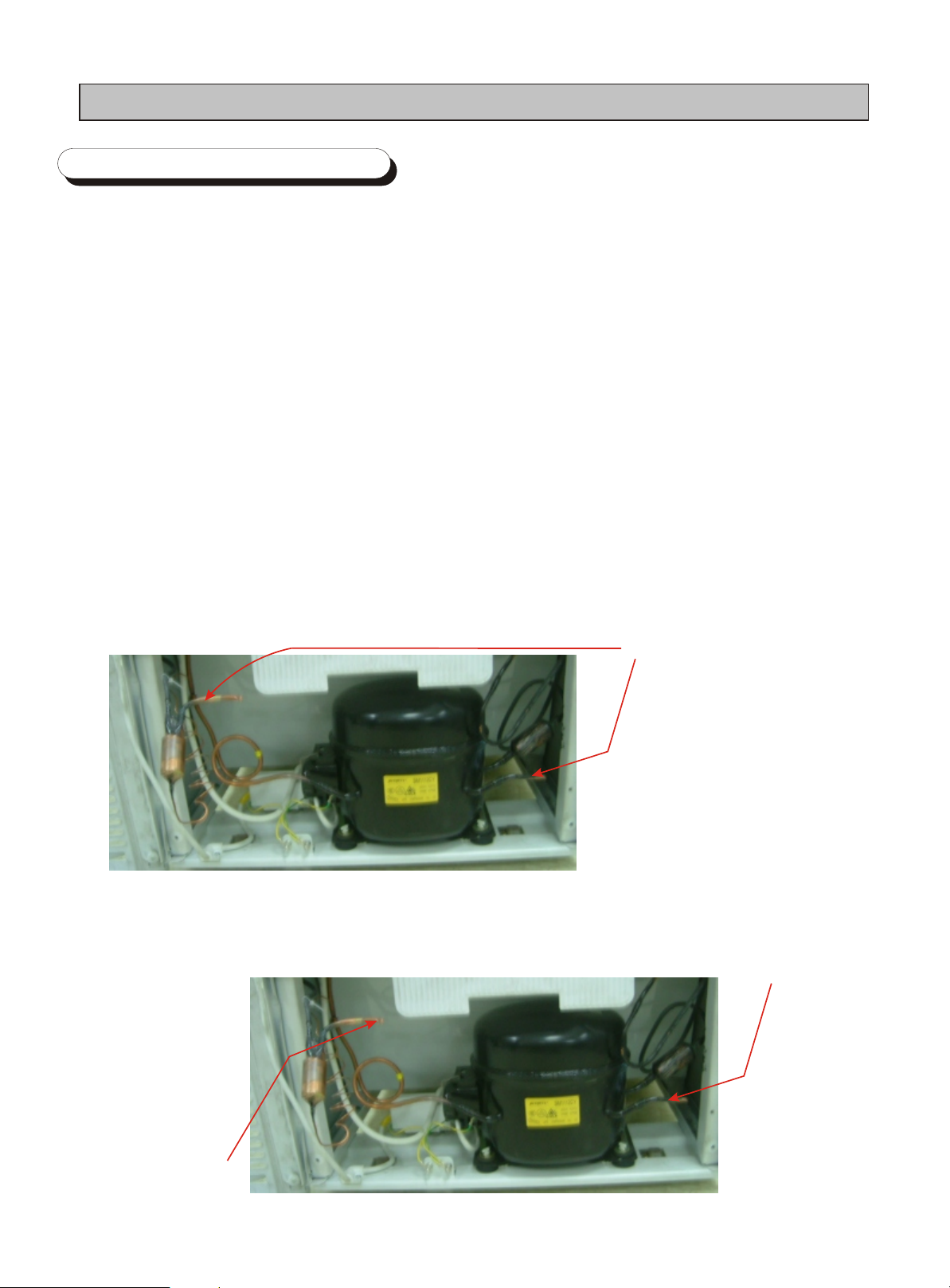

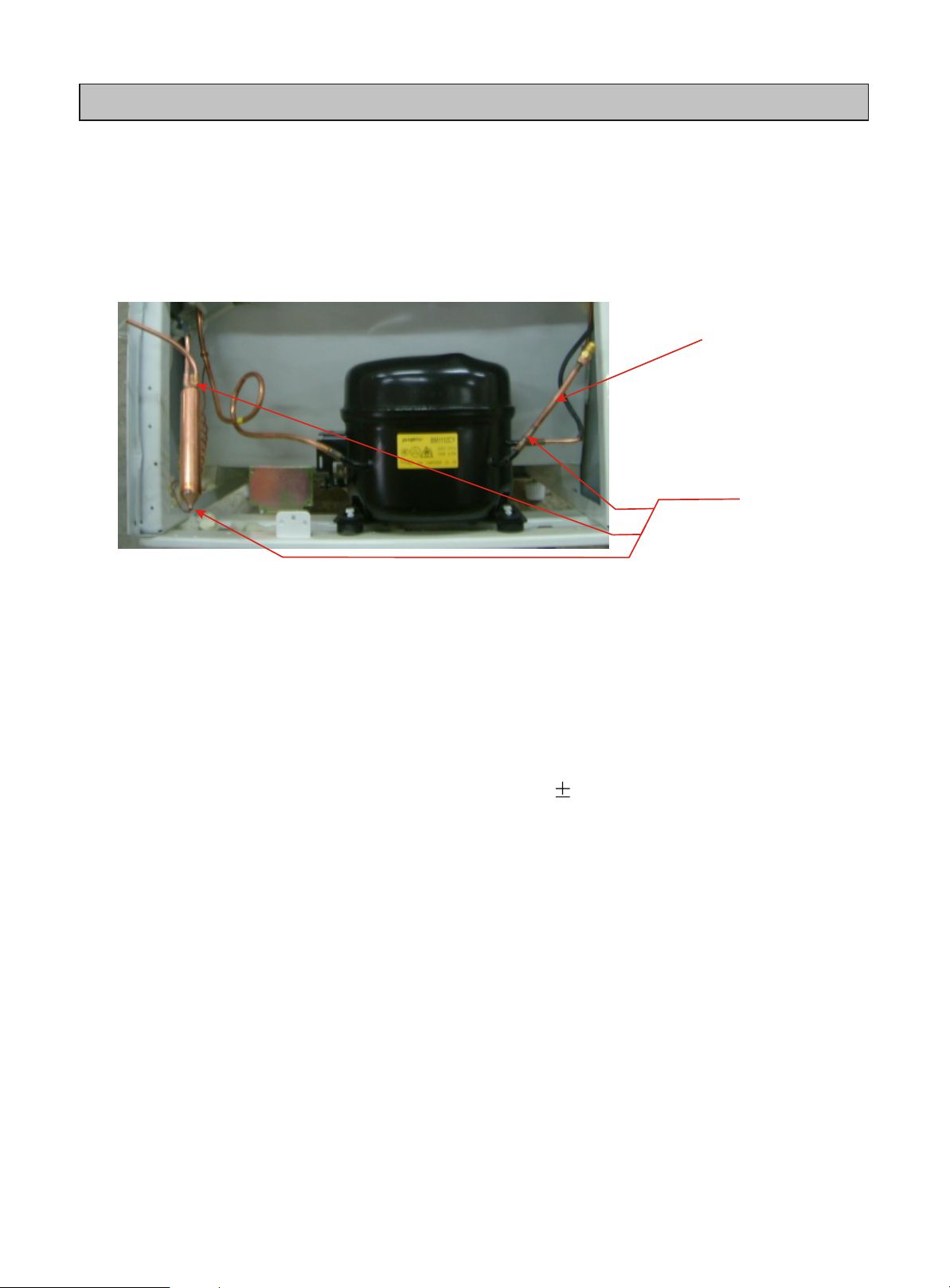

2-1 Open the compactor back cover, reel out the two process pipes and cut them

by a knife or pilers to discharge the remained R600a refrigerant.(See figure 1)

cutting position

2.2 Leave the refrigerant for a while (about 30 minutes) and connect to the dry

nitrogen to ensure R600a refrigerant is completely discharged and the system

are unblocked.

connect to the nitrogen

Gas out

3

3.Vacuumizing

3-1 After all the refrigerants are out, repair the leaking points and replace the driers

and process pipes. The compactor must be fitted with the special liquid process

pipes (see below figure)

Special liquid process pipe

fire soldering

3-2 Close the process pipe on the dry filter and connect the compactor's special

liquid process pipe to a vacuum pump for vacuumizing.

4.Reinjection of Refrigerant

4-1 When the pipe is entirely vacuumized, fill in the R600a refrigerant in the

quantity as shown on the brandplate, and weigh by the electric balance. The

injection quantity must be exact to the evel of 2g.

4-2 No fire is allowed around when adding liquid. No pocket mobile phone and

walkman are allowed during operation.

4-3 Turn on the pipe nut when finishing the liquid adding, and sort the pipes to

avoid the abnormal noise.

4

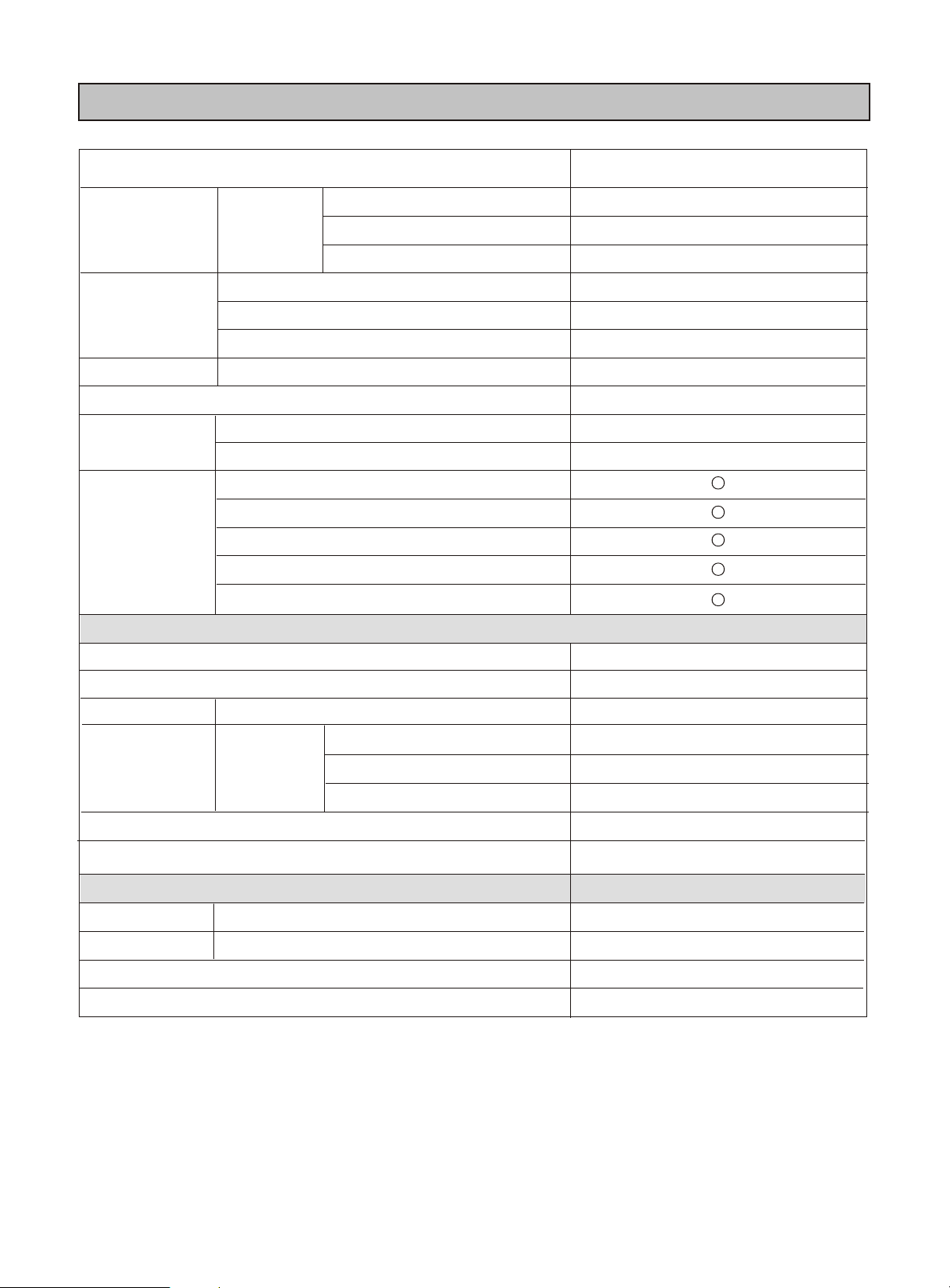

2. PRODUCT SPECIFICATION

Model

Volume (ISO)

Size

N.W. (Kg)

Cooling mode

Control &

display

Functions

Refrigerating compartment

N.V. (L)

Width (mm)

Deepth(mm)

Height(mm)

Total volume

Freeze compartment

Refrigerating compartment

Temp control type

Temp display type

Fast refrigeration

Fast freeze

Standard run

Refrigerating off

Door opening alarm

Rl33EBMS

290

90

200

595

646

1768

76

Compartment cooling

Electronic

Digital

Shelf

Fruit& vege. Tray/partition

Spotlight

Bottle guard

Bottle guard partition

Egg tray

Freeze compartment

Drawer

Ice box

Vesicant

Refrigerant

Lamp

dairy guard

Three-piece set

Revolving ice box

Milk guard

Big bottle guard

Egg guard

toughened glass shelf

1EA/1EA

1EA

2EA

1EA

1EA

1EA

1EA

3EA

1EA

Cyclopentane

R600a(60g)

5

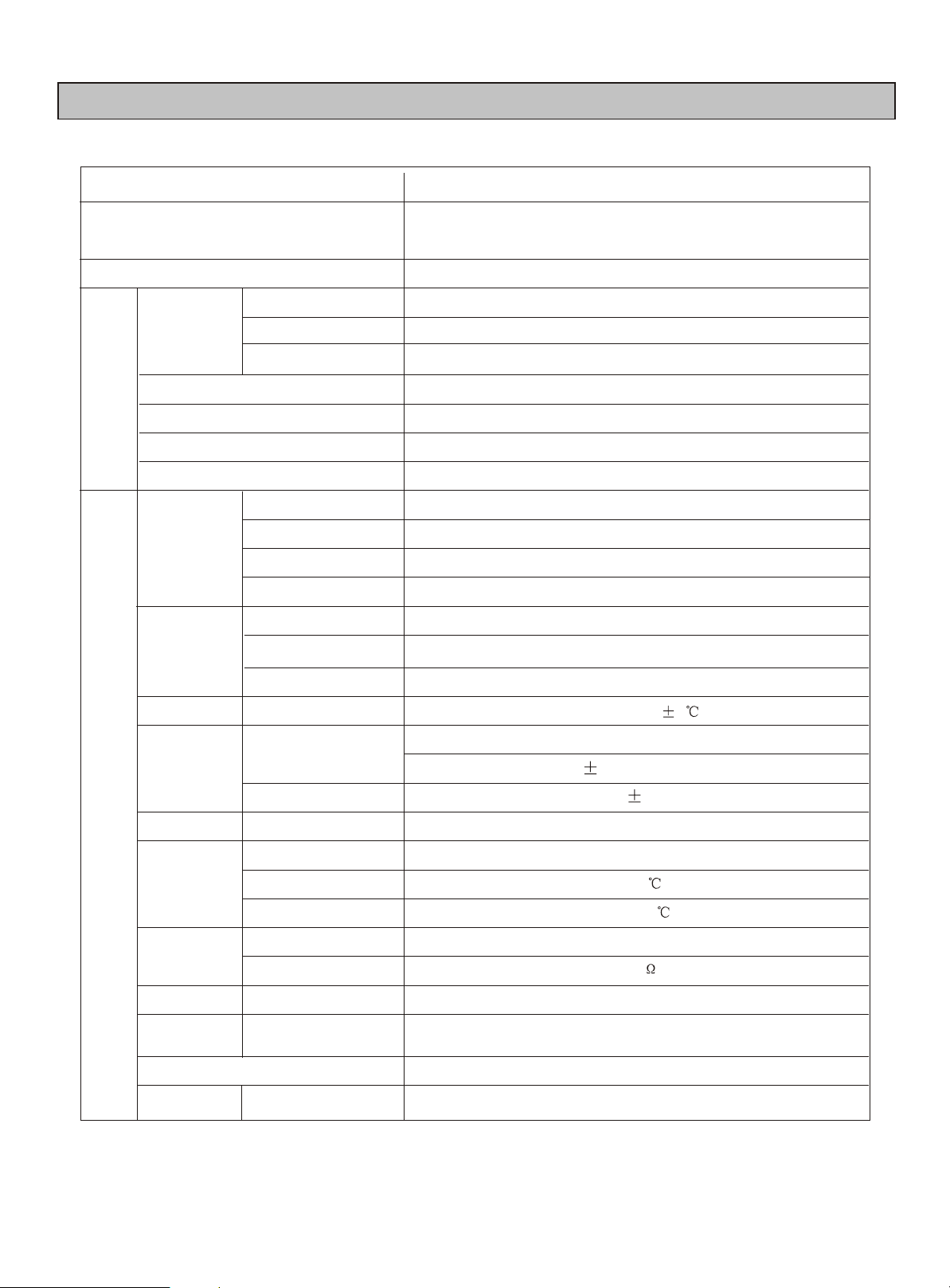

3. SPEC. AND CRITERION OF ELECTRIC & COOLING PARTS

Compressor

Cooling cycle

Sensor

Item

Model

Power

Start mode

Evaporator

Condenser

Drying filter

Capillary

Refrigerating

Environmental temp

Model

Oil type

Freeze

Defrost

Defrost

SPEC

Rl33EBMS

230V/50Hz

JIA XIPERA ZBS1115CY

RSCR

HC-10

Finned

Natural convection

Molecular sieve XH-9

ID 0.72L2800mm

502AT

502AT

502AT

502AT

280W/220V

Heater

Fuse

Defrost

Capacitor

Electric spare parts

Overload

protector

PTC relay

Lamp

Gear motor

Fan motor

Air heater

Return-air heater

Defrost

Defrost time

Hold time

Run capacitor

Model

ON temp

OFF temp

Model

Resistance

Refrigerating compartment

Freeze

compartment

Door light switch

Freeze compartment

7W/220V

15W/220V

250V/10A,72 4

3-19 hours (vary with environmental temp.)

4hours 10min (first cycle)

7min 2 min

400VAC/4.5uF

B52-120/B

55~70

115~125

QP2-12/B

9~17

240V/15W

220~240VAC,50/60Hz

MN71MNBA6(M2LA49Z)

HC-050K4 2.5A 250VAC

240V 6.5W

6

4. FUNCTIONAL & OPERATIONAL INSTRUCTIONS

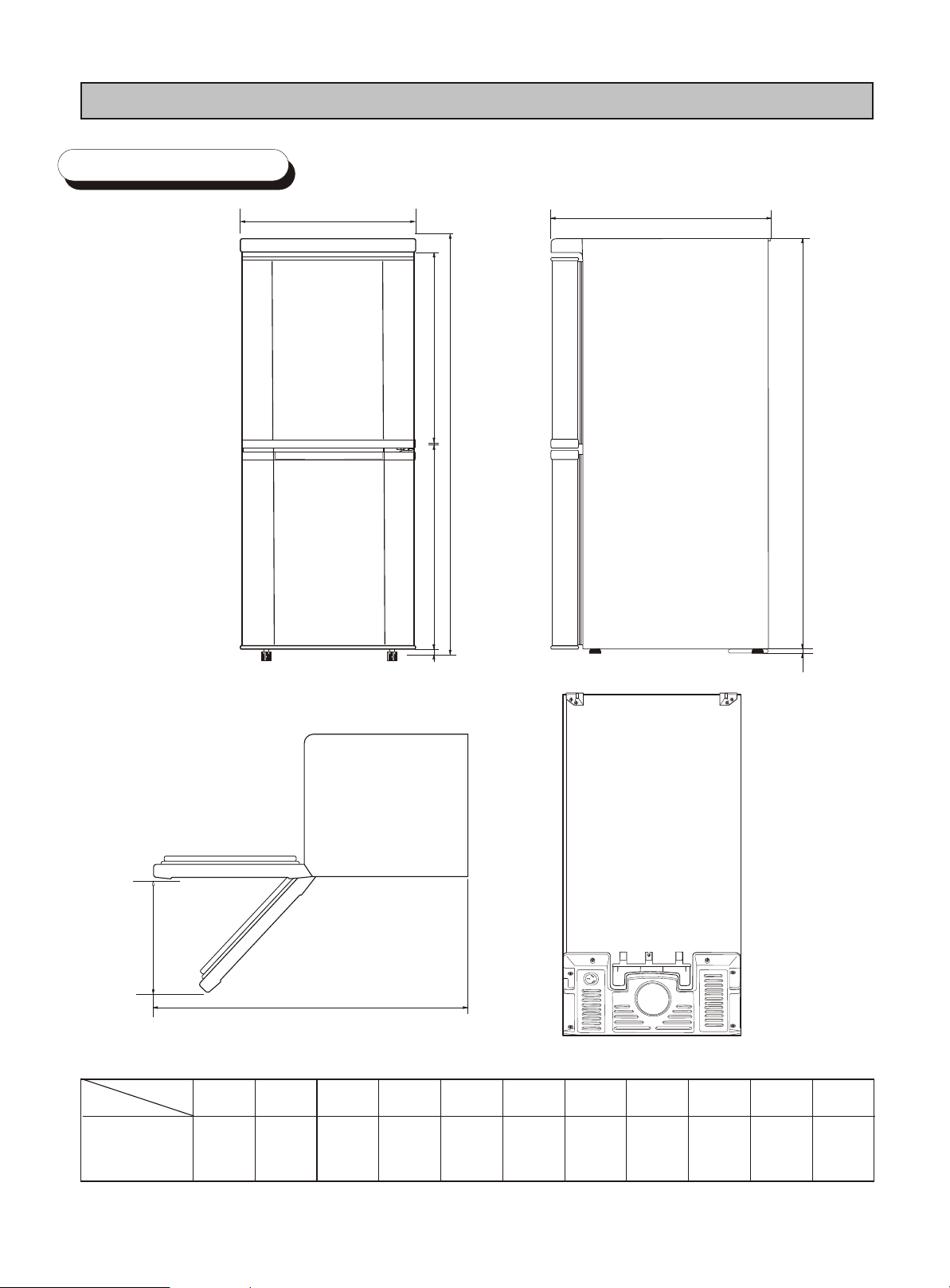

4-1 Product size

A

G

D

CB

F

H

I

E

Model

RL33****

J

Code

K

Unit:mm

A B C D E F G H I J K

595 764.5 9 900 42.5 1768 646 1725 43 38.2 1161

7

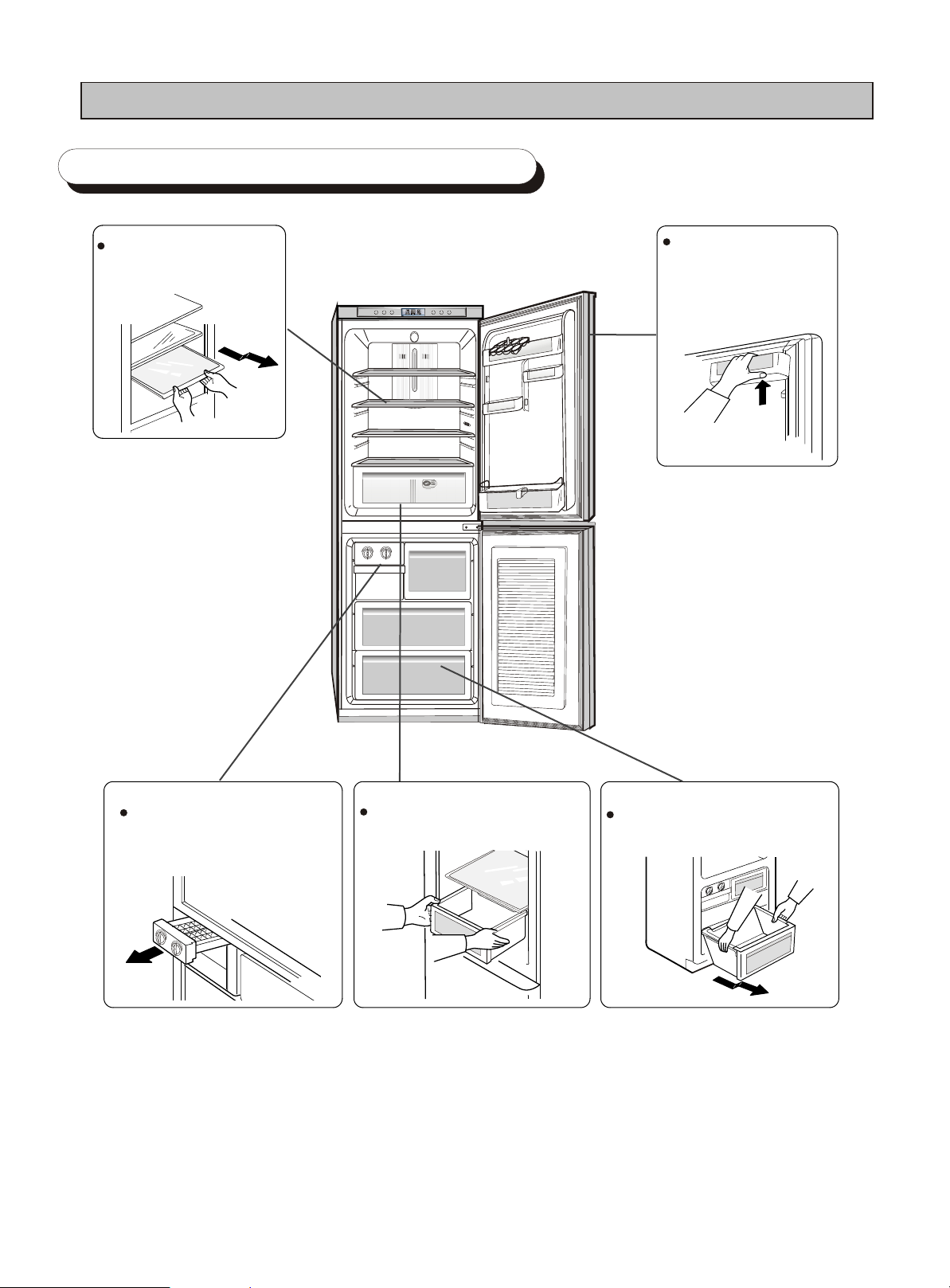

4-2 Part Discription & Disassembly

Pull out the shelf in the

arrow direction to

disassembly it.

Take out the foods

and pull it out in the

arrow direction

C C

Ice box

Fruit& vege. Tray/salad box

8

Freeze compartment drawer

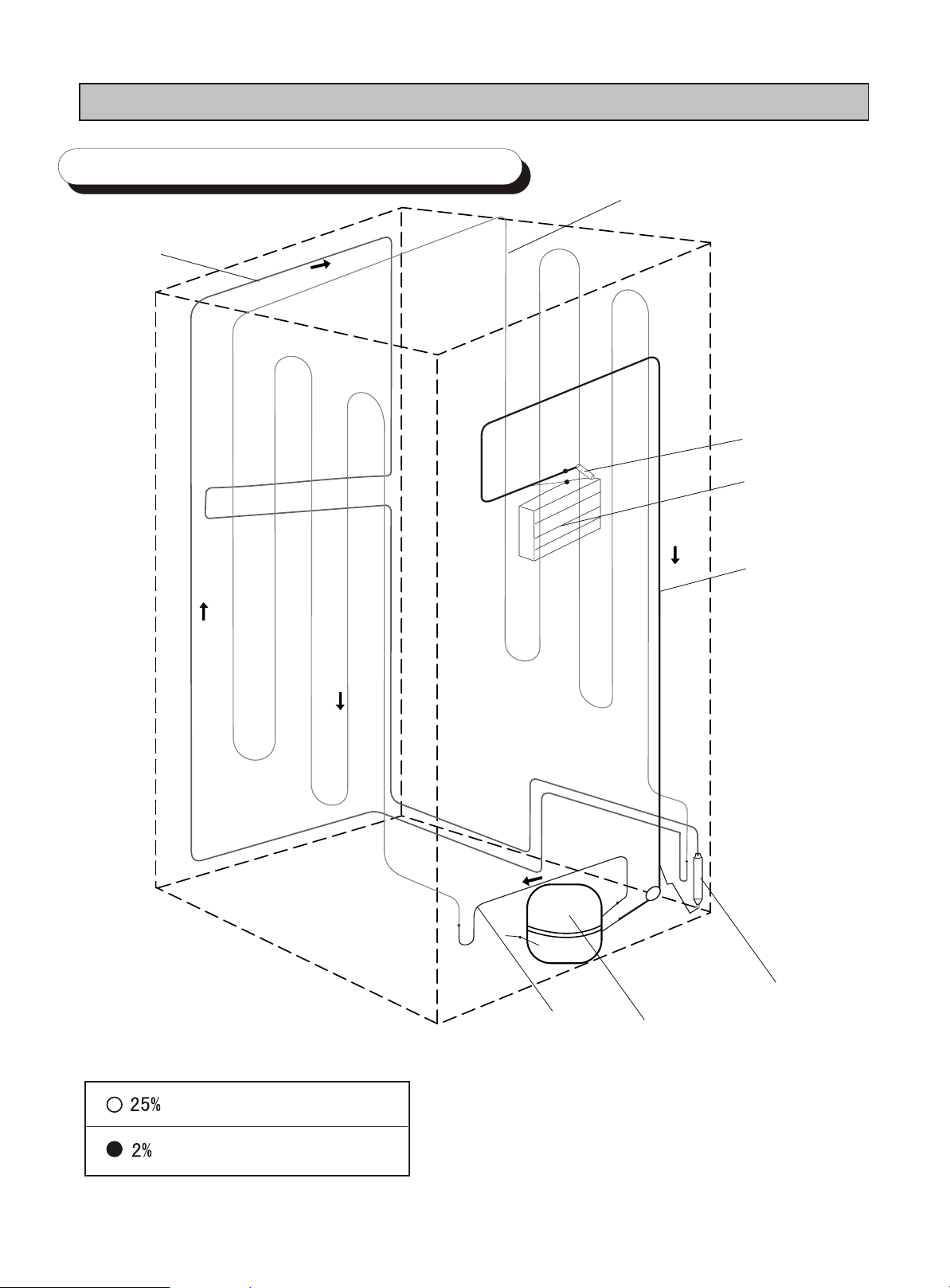

4-3Cooling System Cycle Diagram

dew proof pipe

condensing pipe

liquid barrel

Evaporator

loop pipe

silver welding rod soldering

silver welding rod soldering

discharge pipe

9

dry filter

Compressor

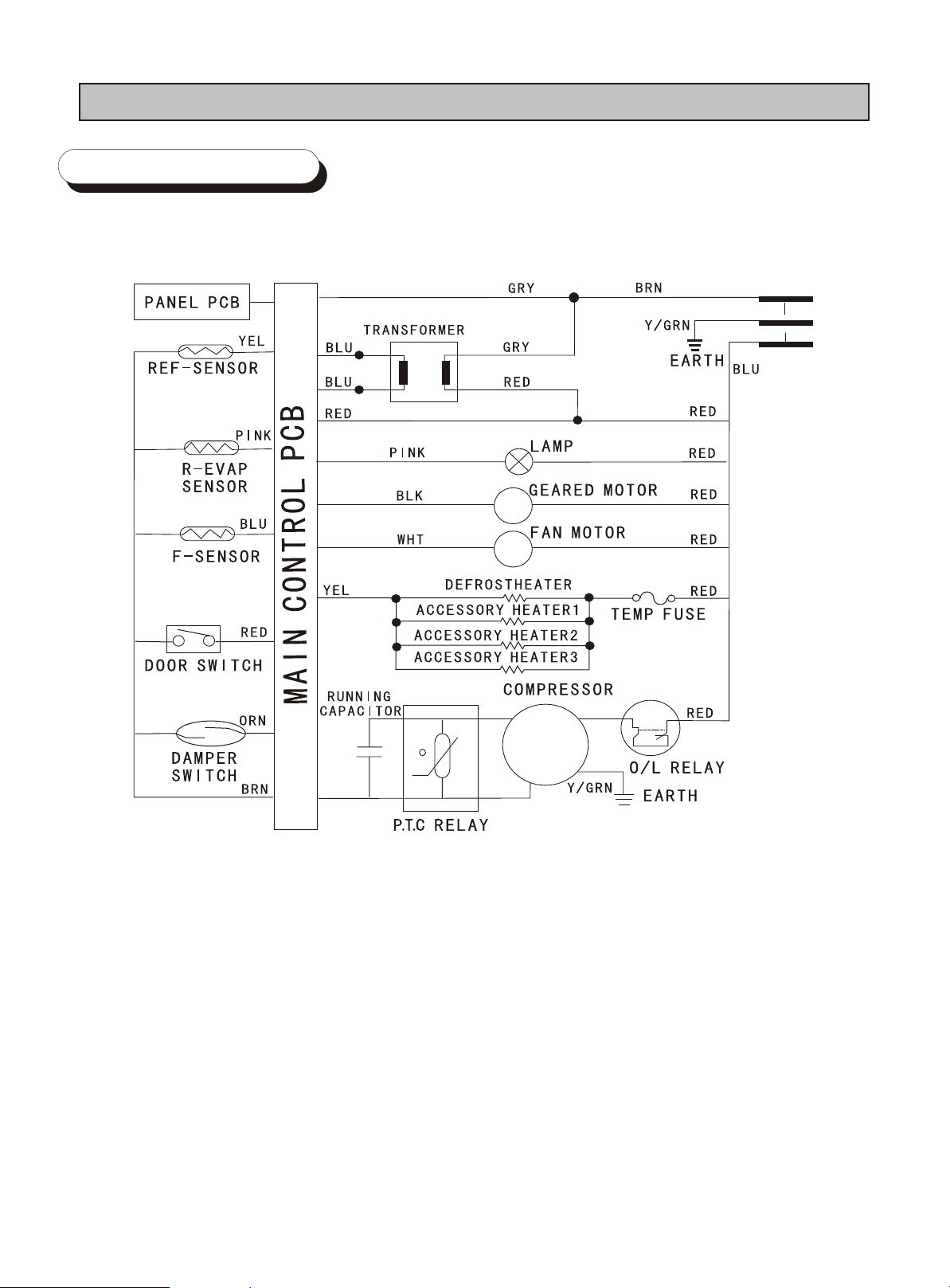

4-4Circuit Diagram

ζȴ«¸ÐÆ÷

°×É«

»ÒÉ«

·Ûºì

ÌìÀ¶

·Ûºì

ÌìÀ¶

·Ûºì

ÌìÀ¶

t

S

M

M

M

ѹËõ»ú

ѹËõ»ú

ѹËõ»ú

M

1~

C

ºìÉ«

3

ºìÉ«

1

2

10

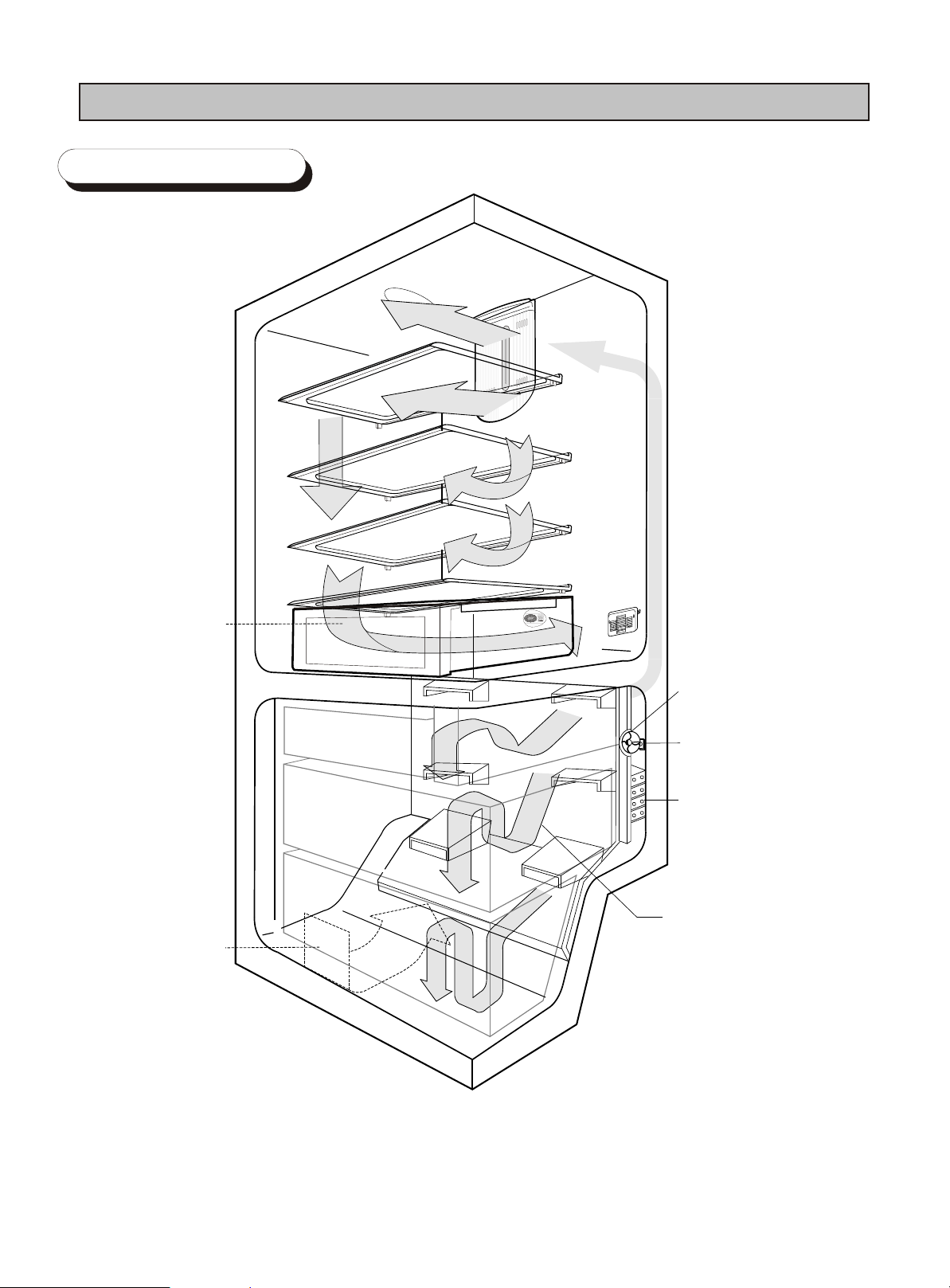

4-5 Cold Air Cycle

loop air

loop air

fan leaf

fan motor

Evaporator

air out

11

5. FUNCTIONS

5-1 Display

Part

Initializing

General run

Defrost

(forecooling+

heating+

time-delay)

Fast refrigeration

Fast freeze

Forced Startup

Forced Defrost

Refrigeraing

Freeze

Refrigeraing

Freeze

Functions

Display the actual temparature. It will display the default temperature

when the refrigerating temperature falls into the setting range (+5,-3)

and when the freeze temperature falls into the setting range (+3,-3).

When the actual temperature is within the setting range (+5,-3), it will

display the default temperature. If the actual temperature exceeds the

setting vaule of +3, it will display the setting with flashes. if the actural

temperature is less than the setting value of -3, it will display the actual

temperature

When the actual temperature is within the setting range (+3,-3), it will

display the default temperature. If the actual temperature exceeds the

setting vaule of +3, it will display the setting with flashes. If the actual

temparature reaches the setting value of -4, it will display the actual

temperature -1. if the actural temperature is less than the setting value

of -5, it will display the actual temperature -2.

During the defrost forecooling, when the actual temperature is within

the setting range (+5,-3), lock the current display till the first stop due

to compactor defrosting;

During the defrost heating, lock the current display till the first stop due

to compactor defrosting;

During the defrost forecooling, when the actual temperature is within

the setting range (+3,-3), lock the current display till the first stop due

to compactor defrosting;

During the defrost heating, lock the current display till the first stop due

to compactor defrosting;

If the actual temperature is less than the setting of -3, it will display the

actual temperature;

Display FF (Forced Startup)

Display Fd (Forced Defrost)

5-2 Constant Temperature Control

A.Freeze Temperature Control

1) You may control the freeze temperature by setting the freeze temerature from -15 to -23

at 1 interval.

2) Whenever you press the temperature control key, the temperature will display in the following

sequence: -18 ,-19 ,-20 ,-21 ,-22 ,-23 ,-15 ,-16 ,-17 ,-18 .

3) The freeze temperature is initialized as -18 .

12

Loading...

Loading...