Page 1

MODEL:

RL17MBSW

RL17MBMS

Service Manual

Rifrigerator

Contents

1. Precaution............................................1

2. Specification.........................................5

3. Specification and standard...................6

4. Structure...............................................7

5. Refrigerating circulation diagram..........8

6. Diagram circuit......................................9

7. Operation principle and inspection

method of main parts...........................10

8. Trouble shooting..................................13

9. How to change main parts...................14

10. Parts list.............................................15

Page 2

1. PRECAUTION

1-1. Security

Only the qualified technician who knows the refrigeration circulatory system technology and

rule of security examination, carry on maintenance operation according to the

handbooks.

1-1-1.

1-1-2.

1-1-3.

1-1-4.

Before maintenance, the power plug must be pulled out from socket,

make the refrigerator power cut to avoid human harm and property loss.

If no suggestions from manufactory, don't change the circuit joined and

other operation about circuits change.

Don't use lengthen power line or a pair of wiring boards.

A socket should be grounding and it is not permitted to connect the

grounding line to such places as water telephone line, gas pipeline.

1-2. Precaution

1-2-1.

When change the relay linking with the lead wire on compressor, must

pull out and insert directly. Don't shake the relay from side to side,

otherwise the lead wire on compressor or relay will be damaged.

1-2-2.

!

The refrigerator is restarted at least 5 minutes interval after power off.

If the plug will be inserted at once after the plug pulled off, the

refrigerator can't be started at once .

This is the data correlated with the security of alternating current

circuit and spare parts of refrigerator.

This is the data for maintaining refrigerator.

1

Page 3

1-3.Warning

1-3-1 Pay attention to the safety during maintenance as R600a refrigerant is

combustible and explosive.

1-3-2 Keep the work place well ventilated without fire source and combustible and

explosive objects arround during the maintenance of R600a refrigerator.

1-3-3 Make sure to lay the R600a clean during CYCLE maintenance (ensure the

system unblocked by inflating nitrogen under HV and LV state.)

1-3-4 Fire soldering is not allowed until the work place is ventilative without R600a

left in the CYCLE.

1-3-5 When no leakage and blocking are found by nitrogen inflation, shut the fire by

the soldering fulid pipe (valve core available at one end) at the process pipe.

1-3-6 Adding the fulid by vacuumizing the liquid pipe and screw on the nut.(no fire,

appliance, MP3, walkman and mobile phone are allowed during operation)

Note: LOCK RING is only used for pipe connection rather than pipe sealing after

adding fluid. If special tools are available for liquid releasing, lead the R600a

via pipes to the designated location.

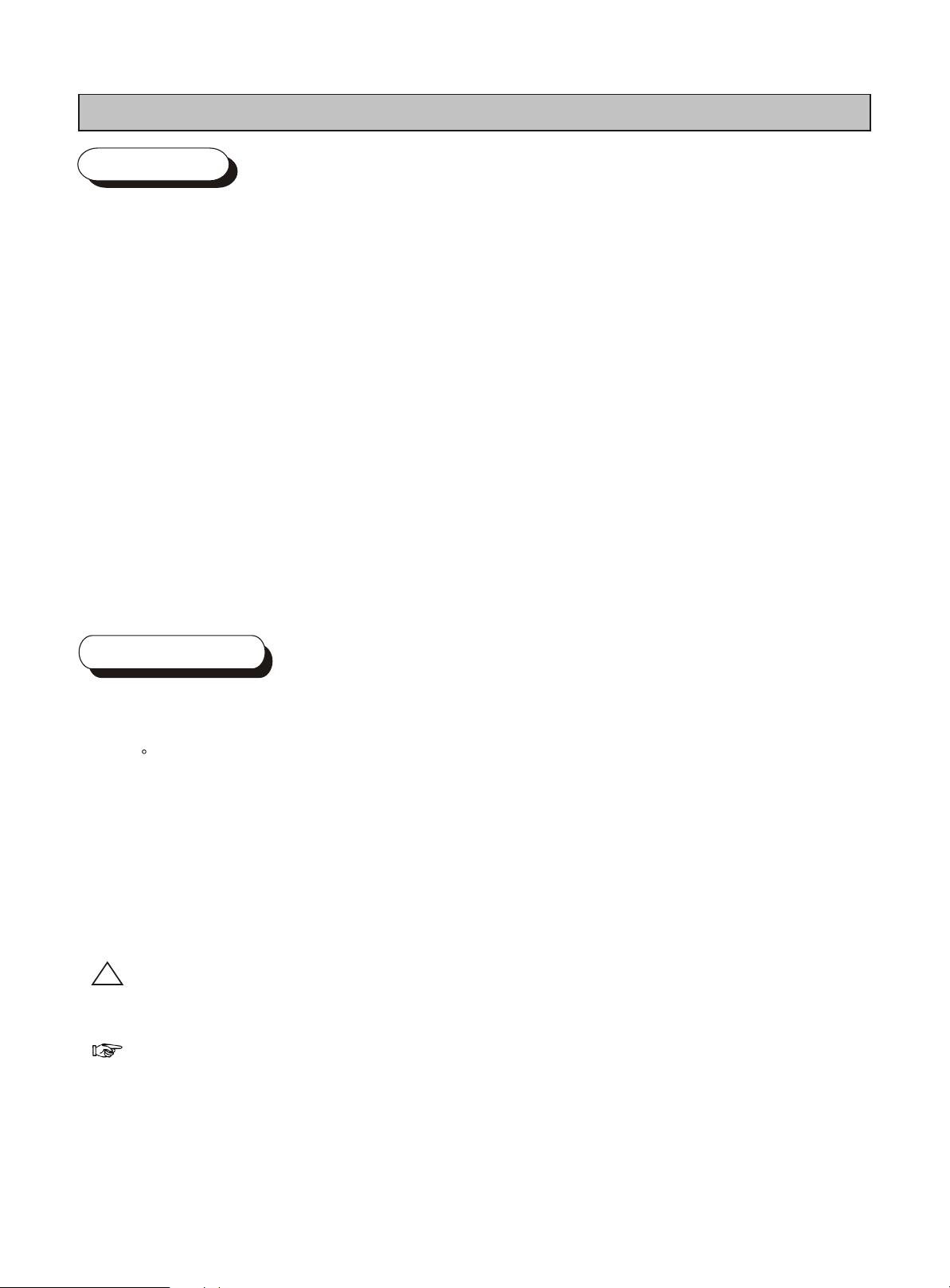

1-4.The special tool for maintaining

1)Liquid Adding Pipe

4) Turn on the valve

core tightly

2)Turn off the valve core

5)Vacuumize and add liquid

3)Solder the pipe onto

the compactor

6) Onload the pipe nut

2

Page 4

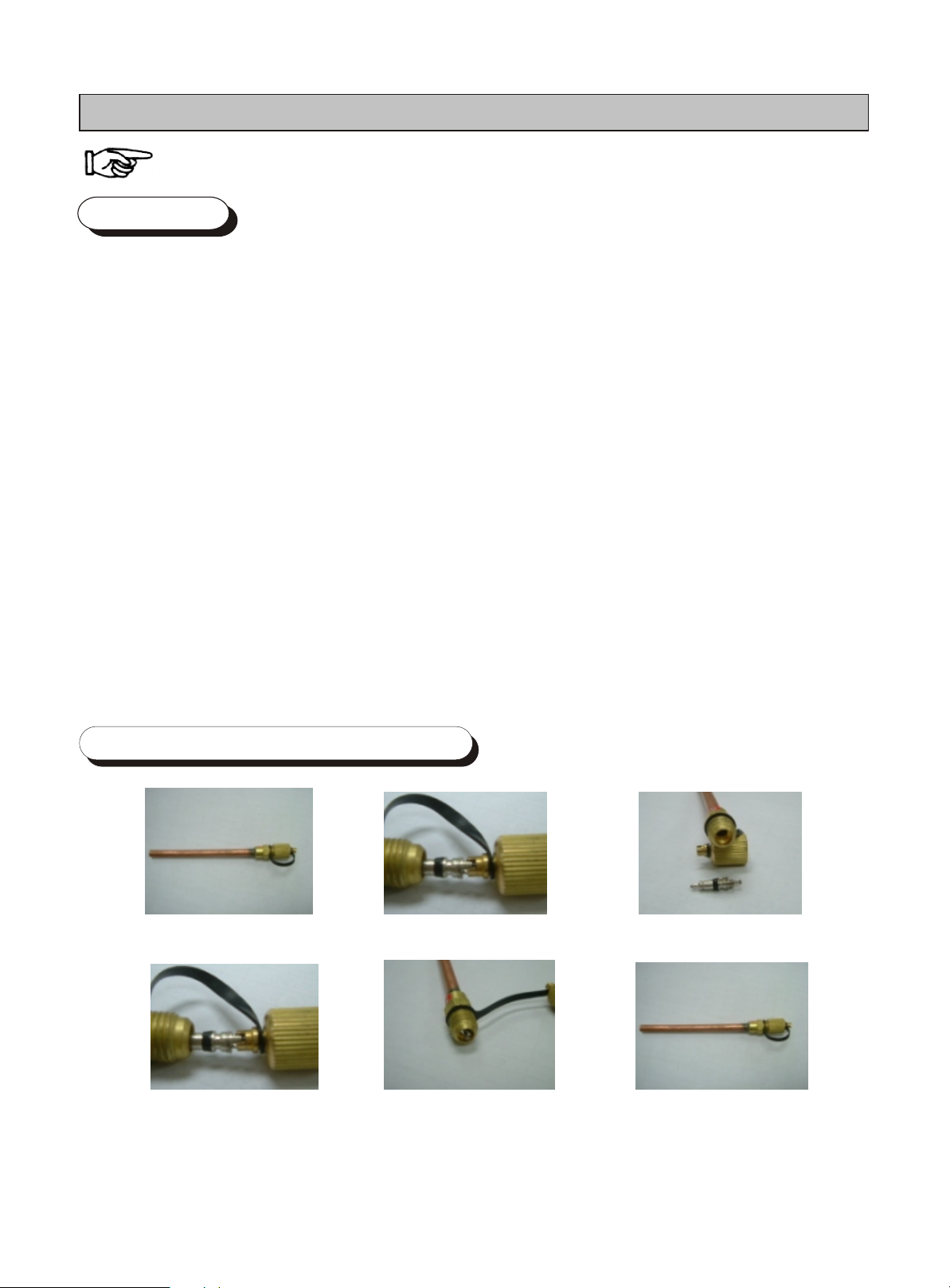

1-5.Maintaining Method

1 Maintaining condition

R600a is inflammable and explosive, must take care while maintaining

While maintaining the refrigerating system, there are no flame and

inflammable substance around, keep draughty.

Confirm there is no R600a in CYCLE and keep draughty around,

flaming weld is permitted.

Release the remaining refrigerant

Troubleshooting should be carried on before readding the refrigerant, the

remaining R600a should be discharged outdoor after examining leak.

open the afterward cover of the compressor, pull out two technical

pipes, cut off by vice or knife and discharge the remaining

R600a(figure1).

the spot of cutting

Enter dry nitrogen after setting for some time(about 30 minutes) to

guarantee R600a discharged completely and system unblocked.

enter dry nitrogen

the air is out

3

Page 5

Release vacuum

After discharging refrigerant completely, repair all leaks, change

desiccant and technical pipe, change special pipe for adding refrigerant

on compresso.

special pipe for

adding refrigerant

flame welding

Seal technical pipe in the dry filter, link special technical pipe for adding

refrigerant on the compressor with the vacuum pump and release the

vacuum.

The refrigerant is poured again

After releasing vacuum, the refrigerant R600a is poured into the

charging quantity according to the nameplate, then weigh by electronic

balance.

When filling R600a, the flame is forbidden, don't use mobile phone,

walkman while operating.

After finishing filling refrigerant, screw the pipe bonnet and refurnish the

pipe to prevent from arising the noise.

4

Page 6

2. Specification

Model

Type

Power

Frozen food storage compartment

Volume L()

Fresh food storage compartment

Total

W(mm)

Dimensions

D (mm)

H (mm)

refrigerant and charging

quantity of refrigerant

temperature control

Foaming

cabinet heatproof thickness

door heatproof thickness

Interior casing door casing/

RL17MBSW RL17MBMS

drawer style and two-door refrigerator-freezer

AC 220/50Hz

54

106

169

451

542

1545

R600a 35g

mechanical controller

Polyurethane foaming

HIPS

egg bin-1

Accessory

Door

Frozen food storage compartment

Fresh food storage compartmen

Cabinet

Lamp

1( )Fresh food storage compartment

Trolley

rectify foot

2 ( )cabinet forehead

bottle rack-3

ice-making case-1

Drawer-3

evaporator part-1

Shelf-4

Crisper-1

2 ( )cabinet rear

5

Page 7

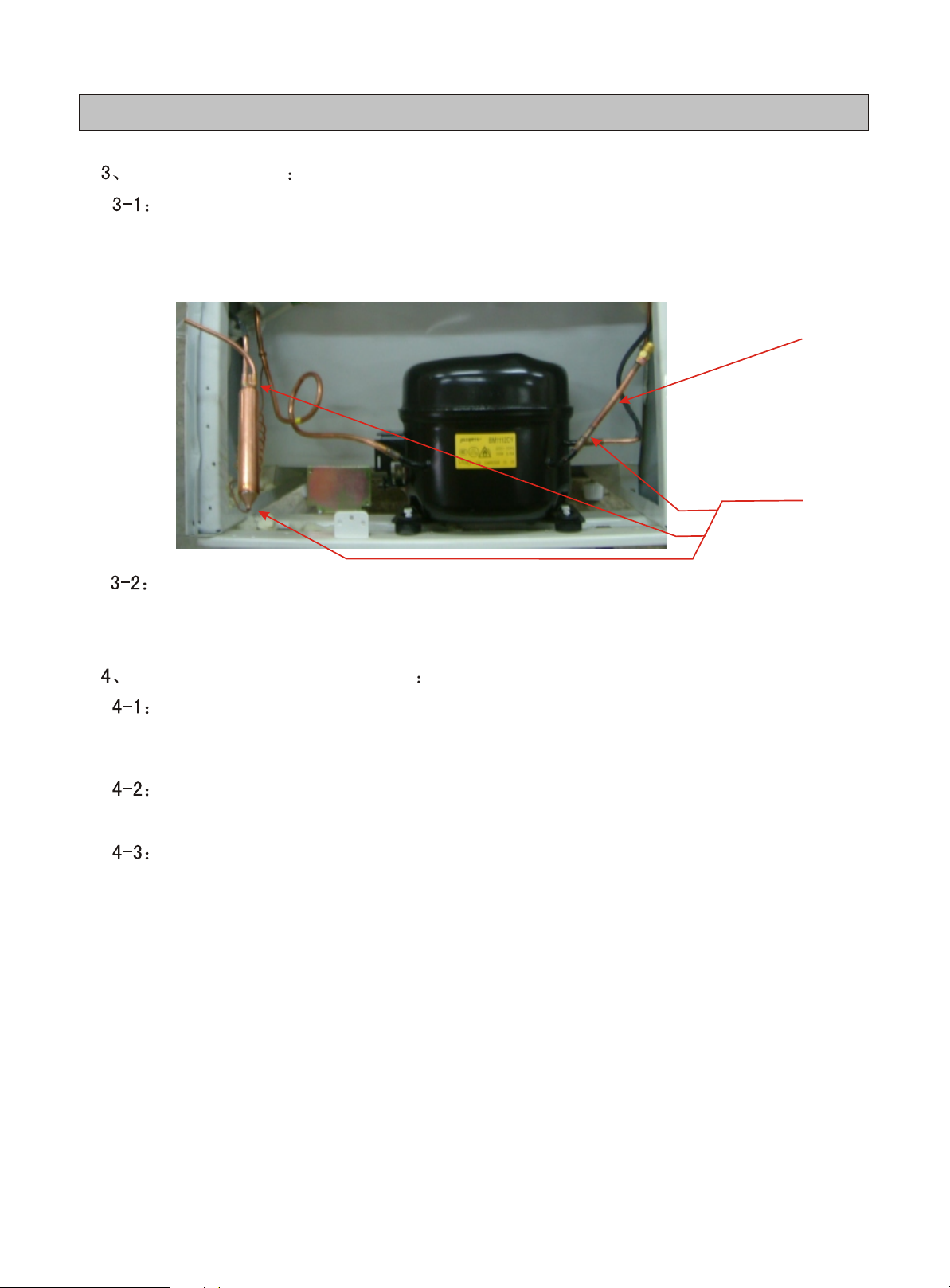

3Specification and standard

Compressor

refrigerating cycle

temperature controller

heat compensatory line

Lamp

door switch

earth screw

Item

Model No

Power

Model No

starting type

lubrication type

Evaporator

Condenser

drier filter

Capillary

Standard

.

AC 220/50Hz

.

SPEC

SPEC

SPEC

BM1112CY

PTC

mineral oil

Tubule

Built-in

molecule filter

Bore 0.65*2800

WDF-31

220V 6W

220V 10W

FN4-0.5/BX

Cu M4*16

RL17MBMSRL17MBSW

electrical appliance system

6

Page 8

4.Structure

Dimension

AA

GG

FF

EE BB C C DD

Model

RL17MB**

Code

¦È¦È

JJ

JGFEDCBA

946.5

7

Unit mm

13854215153080310655451

Page 9

5.Refrigerating circulation diagram

left condenser pipe

Right left condenser pipe

Assistant evaporator part

Molecule drier filter

Silence

Capillary

Asistant evaporator part

Compressor

8

Page 10

6.Diagram circuit

ѹËõ»úѹËõ»úѹËõ»úѹËõ»ú

S

C

3

1

MMMM

M

1~1~1~1~

2

tttt

9

Page 11

7. Operation principle and inspection method of main parts

7-1.Compressor

Operation principle

Compressor motor is assembled with the

compressor directly and sealed in the steel

shell. The motor has two groups of

windings: One is starting winding, another

is operating winding. Two groups of

windings are joined inside and formed a

sharing joint.

A lead is drawn outside from every winding

group. Then three leads are jointed

together in the sealed junction and extend

to the compressor shell.

Three lead junctions form a triangular,

distinguished from left to right indoors

separately: Start junction, share junction

and operate junction.

Inspection method

1 Check the resistance of every

winding group of compressor

. Pull down power wire

. Remove relay from compressor

. Measure resistance of every winding group

A.The Max resistance between start junction

and operate junction is composed of start

winding group and operate winding group.

B.The Min. Resistance is one be

tween operate junction and share junction.

The Mid resistance is one between

C.

start junction and share junction.

B+C=A

2) Put Ohmmeter to the Max measurement

and measure resistance of each junction .

If the short circuit is found, the compressor

is out of order.

7-2.Overload protector

Operation principle

Overload protector protects the

compressor through temperature sensor and

electric current

Overload protector is consist of a group of

closed junction and two metal parts.

Overload protector is installed on

compressor external, connected with the

shell of compressor and linked with the

winding group.

If the compressor isn't work, the overload

electric current will make two metal parts heat

to bend quickly, lead the junction to cut off.

Inspection Method

1 Continue to use the ohmmeter to measure

If the overload protector is off, cooled

to room temperature and measure

continually

Although the working of overload

protector can be observed

continually, it is difficult to confirm

parts working well or not according to

If any question, please change same parts.

Temporal measure should change

regular replacement relay in advance.

10

Page 12

Operation principle

Meanwhile, if the compressor motor is

overheat, the effects of electric current and

temperature will lead two metal parts cut off.

If the troubleshooting isn't settled, the

compressor will be worked or stopped with

two metal parts operation cyclically under the

overload condition.

7-3. Relay

This solid relay is different from mechanical relay, which has no coil and movable

junction.

This relay is consist of a little solid wafer. The solid wafer is low resistance (5~33 )

in room temperature, which is installed between two poles.

Inspection Method

When the voltage is existed in the circuit of compressor, the electric current will

pass operate winding group, relay and start winding group. Firstly, low resistance of

relay can make the enough electric current start compressor by start winding group,

then the relay resistance is increased and electric current is decreased, only tiny

electric current flows relay, which make the relay keep high resistance.

This relay is called PTC relay, the resistance will be increased with the temperature

raise.

Can use the Ohmmeter to check this solid relay. Under the room temperature

condition, the relay resistance should be 10% regular range of refrigerator electric

diagram request.

11

Page 13

7-4 Temperature Controller

Compressor operation is controlled by temperature controller, the temperature

controller is mainly consist of capillary, corrugated pipe, a group of closed junction and

a mechanical link.

The gas pressure in the capillary and corrugated pipe is controlled by

temperature sensor pipe, the temperature raise will cause the corrugated pipe

to push the link and close the junction.

When the temperature is dropped, the corrugated pipe will be shrinked to

push the link and open the junction.

Connect the probe of Ohmmeter with the temperature controller and turn ON

and OFF to check the junction .

12

Page 14

8.Trouble shooting

Another faults, please read “Instruction Manual”

No refrigerating Inspection of refrigerating system( Figure 1)

Normal

No good

Inspection of

compressor

operation

unnormal operation inspection of electrical appliance circuit Figure2

no turning inspection of electrical appliance circuit Figure3

refrigerati

ng

8-1. Troubleshooting Of Refrigerating System

Temperature

controller

unsealed door seal strips

frosted evaporator

Low(high) setting

o f temperature

Unnormal(change)

temperature controller

Inspection Method

After operating for 20 mins. A drop of

water is dropped on the evaporator to

check frosted or not.

Check leak, released vacuum and fill refrigerant

Settlement

8-2. Compressor operation but unnormal . Inspection diagram of electric circuit

Inspection item Reason Settlement

starting power low power

PTC relay damage change relay

Electric conduction test of compressor motor wire is broken Change the compressor

Parts of other electric appliance are normal

The motor and compressor

are damaged

Change the compressor

rising power

8-3.Check electric circuit when the compressor doesn't operate

inspection item Reason Settlement

Power wire, plug the line was broken, or taken off. Repair or change power wire , plug

Electric conduction test of

temperature controller junction

PTC relay damage change relay

Overload protector

Electric conduction test of

compressor motor

The junction is useless,

temperature sensor pipe is

leaked

the junction is useless,

wire is broken inside

Group of compressor motor

13

change temperature controller

Change overload protector

Change the compressor

Page 15

9 How to change main parts

9-1. Change Temperature Controller

1 Pull down the screw fasten light box in temperature controller,

2 Pull down the screw fasten temperature sensor in temperature controller,

3 Pull down connecting line,

4 pull down screw in the shelf of temperature controller.

5 Put out temperature controller.

9-2. Change The Relay

1 pull down fixing button, pull down the relay cover

2 Put down the relay,

9-3. Change Compressor And Drier Filter

Using a knife like welding torch type to cut off the pipe connecting with the

compressor, pull down the connecting line and fasten screw. Then, change compressor.

Notice: when changing compressor, don't let the pipe in flat, otherwise the pipe will be

obstructed .

While linking compressor, the inserted depth should be 6-8mm. While changing filter,

the capillary should be cut off 30mm then insert to the filter, the depth is 13¡À2mm.

After finishing welding, release the vacuum and fill the refrigerant again, the charging

quantity accords with the request on the nameplate and seal the pipe finally.

9-4. Change The Freezing Evaporator

Take out drawer in freezing compartment, pull down the freezing evaporator and put

out the welding joint. Cut off the technical pipe linking with compressor, release

refrigerant , cut off the enter and exit hole of freezing evaporator by welding gun . Pull

out the fasten button of the freezing evaporator, put out the freezing evaporator

,change the new one. After changing, release the vacuum, the charging quantity

accords with the request on the nameplate and seal the pipe.

14

Page 16

10.Parts list

10-1. Parts Of Door

1

5

6

8

9

10

13

2

7

3

4

11

14

15

12

15

Page 17

NO CODE NO PART NAME Q'ty SPEC REMARK

1 DA63-01950C GASKET DOOR-REF 1 160G,SOFT-PVC,-,-,2 DA91-01833J ASSY DOOR FOAM REF 1 WHT,NLO RL17MBSW

DA91-01833K ASSY DOOR FOAM REF 1 SILVER, RL17MBMS

3 DA61-01790C STOPPER DOOR 2 POM,-,-,-, RL17MBSW

DA61-01790D STOPPER DOOR 2 POM,-,-,-,T-S RL17MBMS

4 6002-001111 SCREW-TAPPING 1 TH,+,SJ2823-87,M3.5,L

5 DA97-01751A ASSY SHELF REF 3 139G,PP+GLASS

6 DA63-01942A GUARD EGG 1 GPPS,-,-,-,-,EGG

7 DA63-01945A TRAY EGG 2 GPPS,-,-,-,-,-,8 DA63-01944A GUARD EGG 1 GPPS,-,-,-,-,BOX

9 DA63-01943A GUARD BOTTLE 1 GPPS,-,-,-,-,-

10 DA63-01949A TRAY-VEG 1 GPPS,-,-,-,-,-,11 DA63-01951A GASKET DOOR-FRE 1 139G,SOFT-PVC,-,-,12 DA91-01832G ASSY DOOR FOAM FRE 1 WHT,NLO RL17MBSW

DA91-01832H ASSY DOOR FOAM FRE 1 SILVER, RL17MBMS

13 DA63-02153A TRAY ICE 1 LDPE,-,-,-,-,-,H

14 DA63-01946A TRAY FRE-UPP 2 GPPS,-,-,-,-,-,15 DA63-01948A TRAY FRE-LOW 1 GPPS,-,-,-,-,-,-

10-2. List

16

Page 18

10-3. Parts of Cabinent

8

9

24

4

3

2

1

6

5

7

15

14

13

16

18

19

10

11

12

22

21

20

17

23

17

Page 19

NO CODE NO PART NAME Q'ty SPEC REMARK

1 DA61-01754B CASE THERMO 1 ABS,-,-,-,-,EN

2 DA47-00153A SOCKET 1YUYAO,E14H,HUARI,-,250V,2A,-

3 DA47-00148A LAMP-INCANDESET 1 ,-,-,-,-,-,10

4 DA47-00149B THERMOSTAT 1 RL17MB,WDF31C-L,250V,6A,

5 DA63-01952A COVER LAMP 1 PP,-,-,-,-,-,-,-

6 DA34-00034B SWITCH- SEASION 1 YUYAO,-,ANTI-BLAST,-

7 DA34-00035B SWITCH DOOR 1 FN12-0.5EA,YUYAO,ANTI-B

8 DA63-02154A TRAY DRAIN-WATER 1 HIPS,-,-

9 DA63-01954C COVER COMP 1 PP,-,-,-,-,-,-,- RL17MBSW

DA63-01954D COVER COMP 1 PP,-,-,-,-,-,T- RL17MBMS

10 DA61-01593A HINGE-MID 1 139G,SCP1,-,-,-,-,-,-

11 DA61-01760A STOPPER-R-UPP 2 139/160GY,HIPS,-,-,-, RIGHT

DA61-01759A STOPPER-L-UPP 2 139/160GY,HIPS,-,-,-, LEFT

12 DA61-01761A STOPPER-R-LOW 1 139/160GY,HIPS,-,-,-, RIGHT

DA61-01763A STOPPER-L-LOW 1 139/160GY,HIPS,-,-,-, LEFT

13 DA59-00307A COMPRESSOR 1 220V

14 DA35-00054A RELAY-O/L 1 -,JIXIN JIAXIBEILA

15 DA35-00055A RELAY PTC 1 -,JIAXIN JIAXIBEILA

16 DA62-00690A DRYER 1 CU,-,-,-,-,TAIZHOU KAIDA

17 DA61-01757A BASE-COMP 1 SGCC,1.2,-,-,YE

18 DA66-00280A ROLLER 2 NYLON 1010,-,-,-,-

19 DA61-01755A LEG-ADJUST 2 HARD PVC,-,-,-

20 DA63-01953C COVER-BOTT,FRONT 1 ,ABS,-,-,-,-, RL17MBSW

DA63-01953D COVER-BOTT,FRONT 1 ABS,-,-,- RL17MBMS

21 DA59-00313A EVAP 1 WIRE-PIPE,DW ST,-,-,-

22 DA61-01594A HINGE-LOW 1 SCP1,-,-,-,-,-,-

23 DA39-00284B CBF-POWER CORD 1 RL17MB,UCP2,YUYAO,-,

24 DA64-01138A TOP TABLE 1 ABS,YEL,-,-,-,- RL17MBSW

DA64-01138D TOP TABLE 1 ABS,T-SILVER,-,- RL17MBMS

10-4. List

18

Page 20

Loading...

Loading...