Confidential

Chapter 2 Installing System

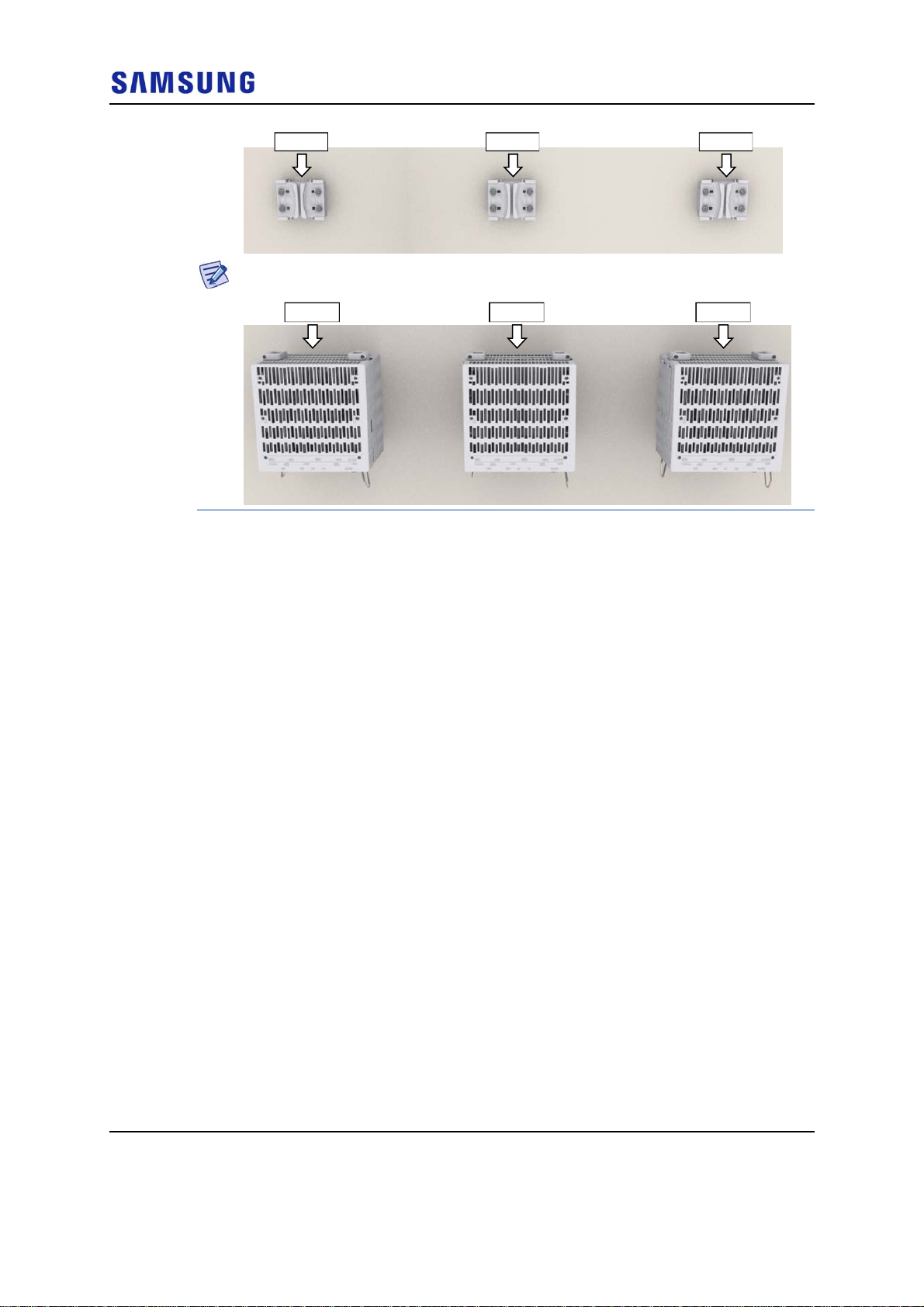

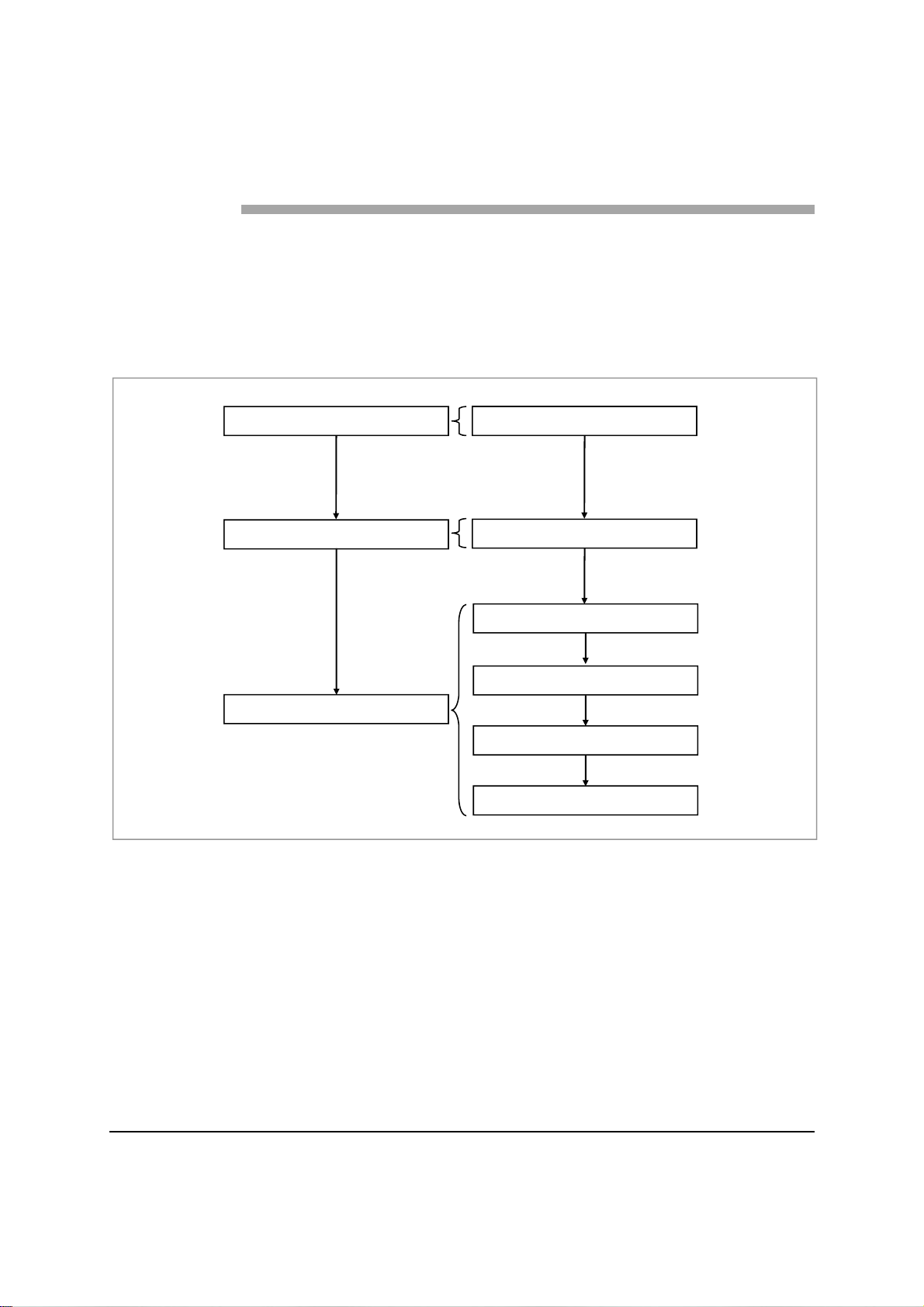

RRH-1RRH-0 RRH-2

Fix the RRH according to the order of [RRH-0 RRH-1 RRH-2].

RRH-1RRH-0 RRH-2

2

Hang the unit bracket hook of RRH-0 side on the mounting bracket_front

hook’s groove and fix it using fasteners.

RFV01U-D1A Installation Manual v2.0 46

Copyright © 2017, All Rights Reserved.

Chapter 2 Installing System

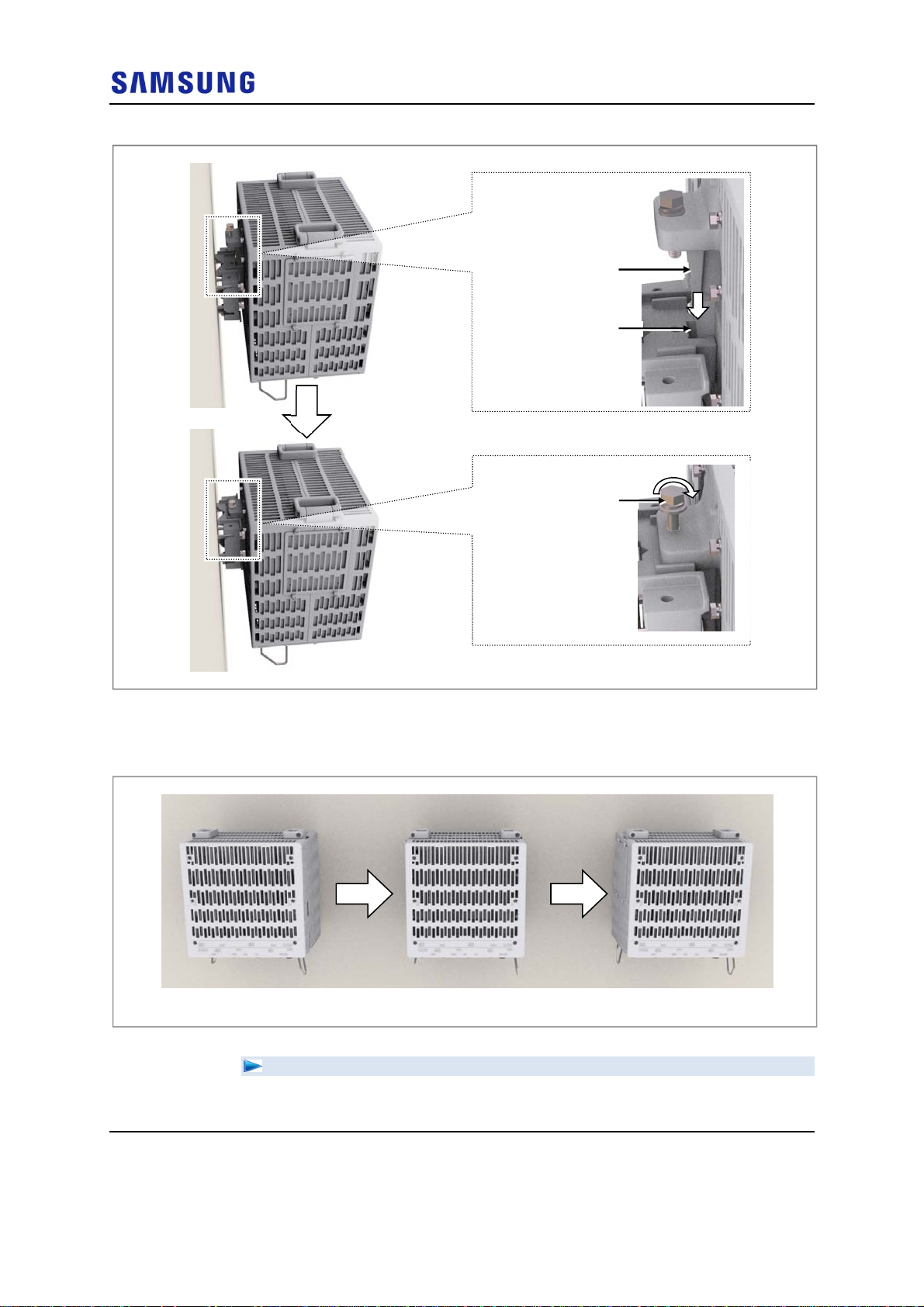

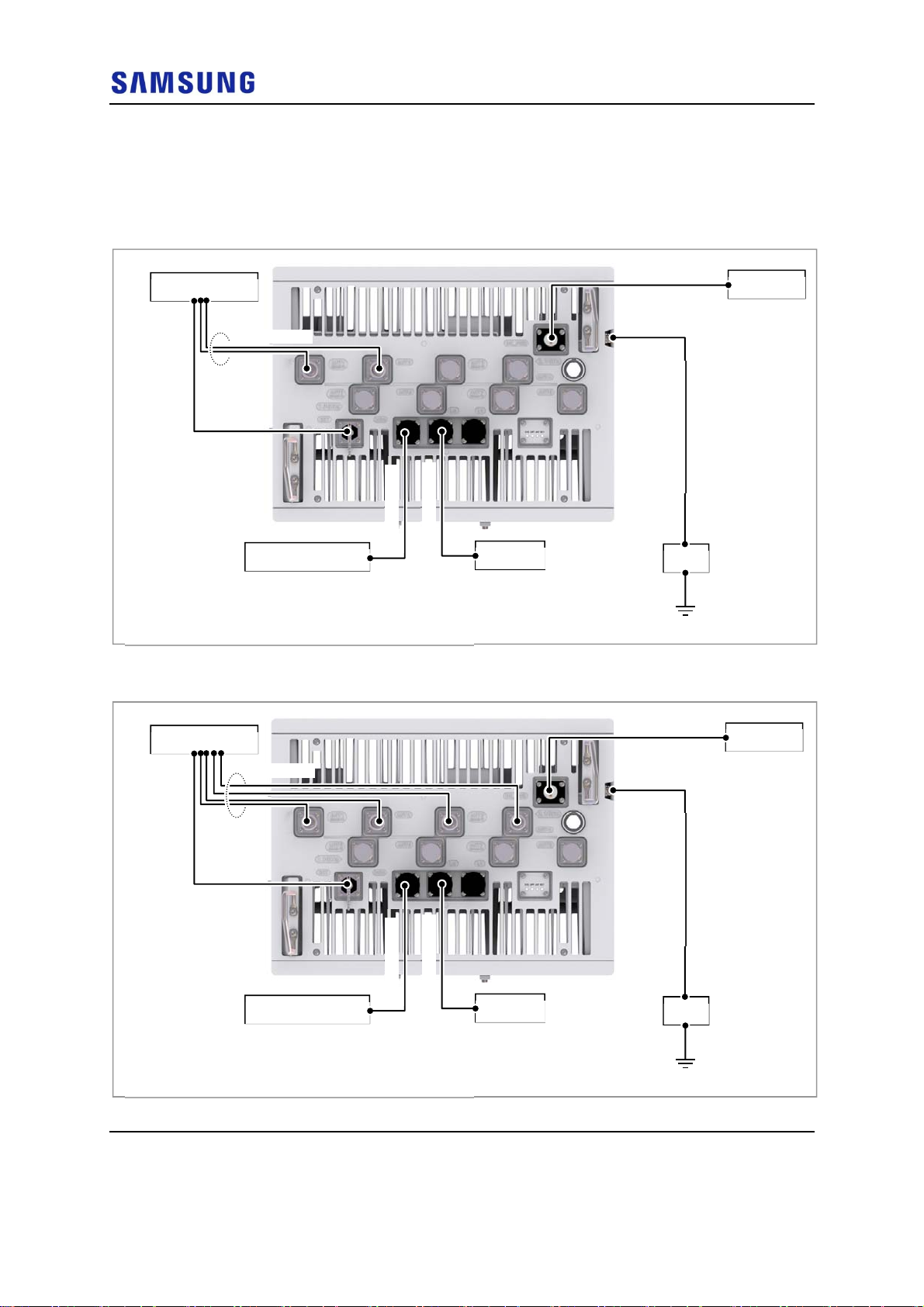

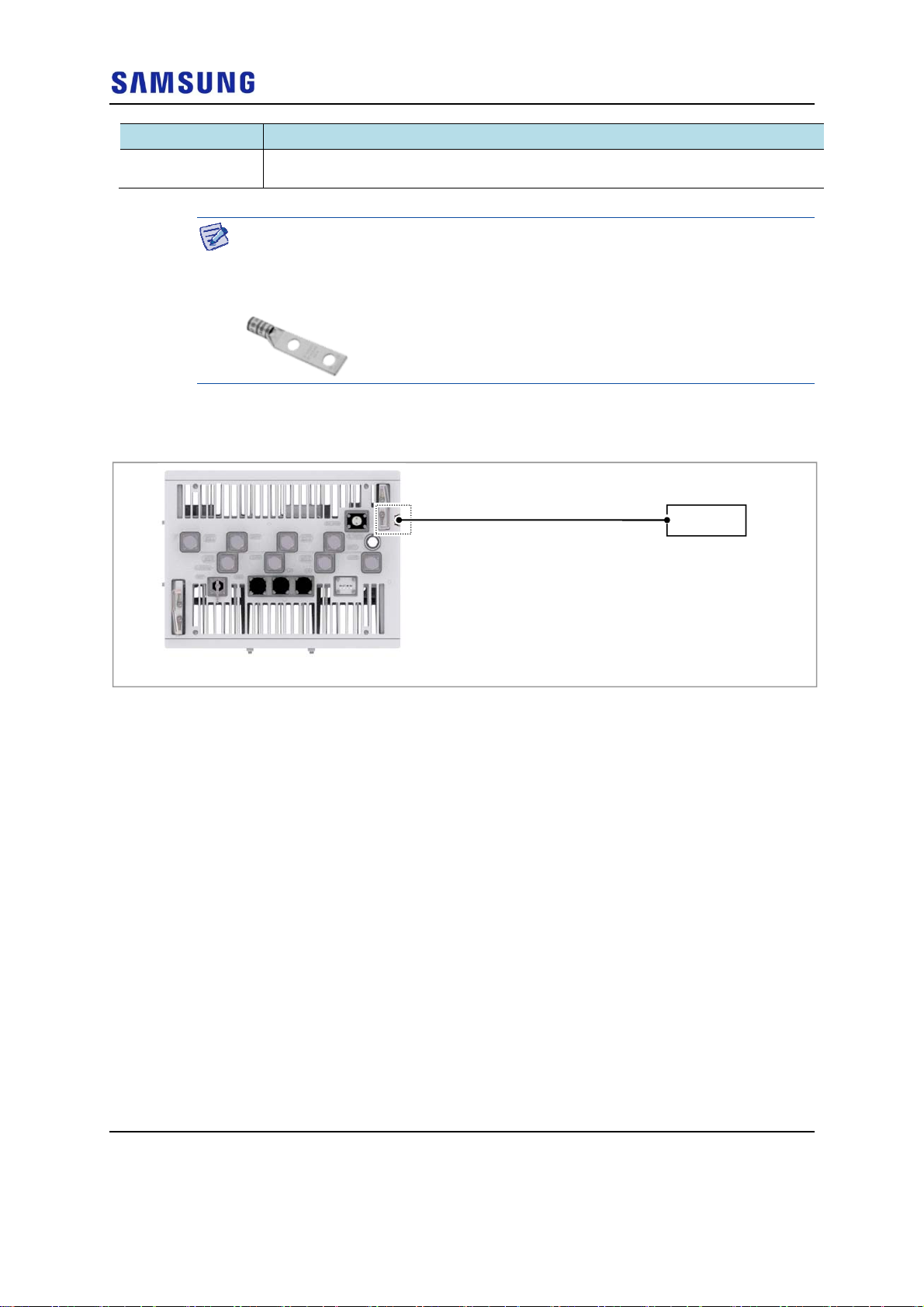

Figure 48. Fixing RRH_3 Sector Wall Type (Standard Installation 1)

Unit Bracket Hook

Confidential

Mounting Bracket_Front

M10 Hex. Bolt

(washer assembly)

3

Fix RRH-1 and RRH-2 in the same way as the RRH-0.

Figure 49. Fixing RRH_3 Sector Wall Type (Standard Installation 2)

Hook Groove

[RRH-0] [RRH-1]

[RRH-2]

To fix RRH_3 Sector Pole Type (Side Installation)

1

Make sure you have the following items:

RFV01U-D1A Installation Manual v2.0 47

Copyright © 2017, All Rights Reserved.

Confidential

Chapter 2 Installing System

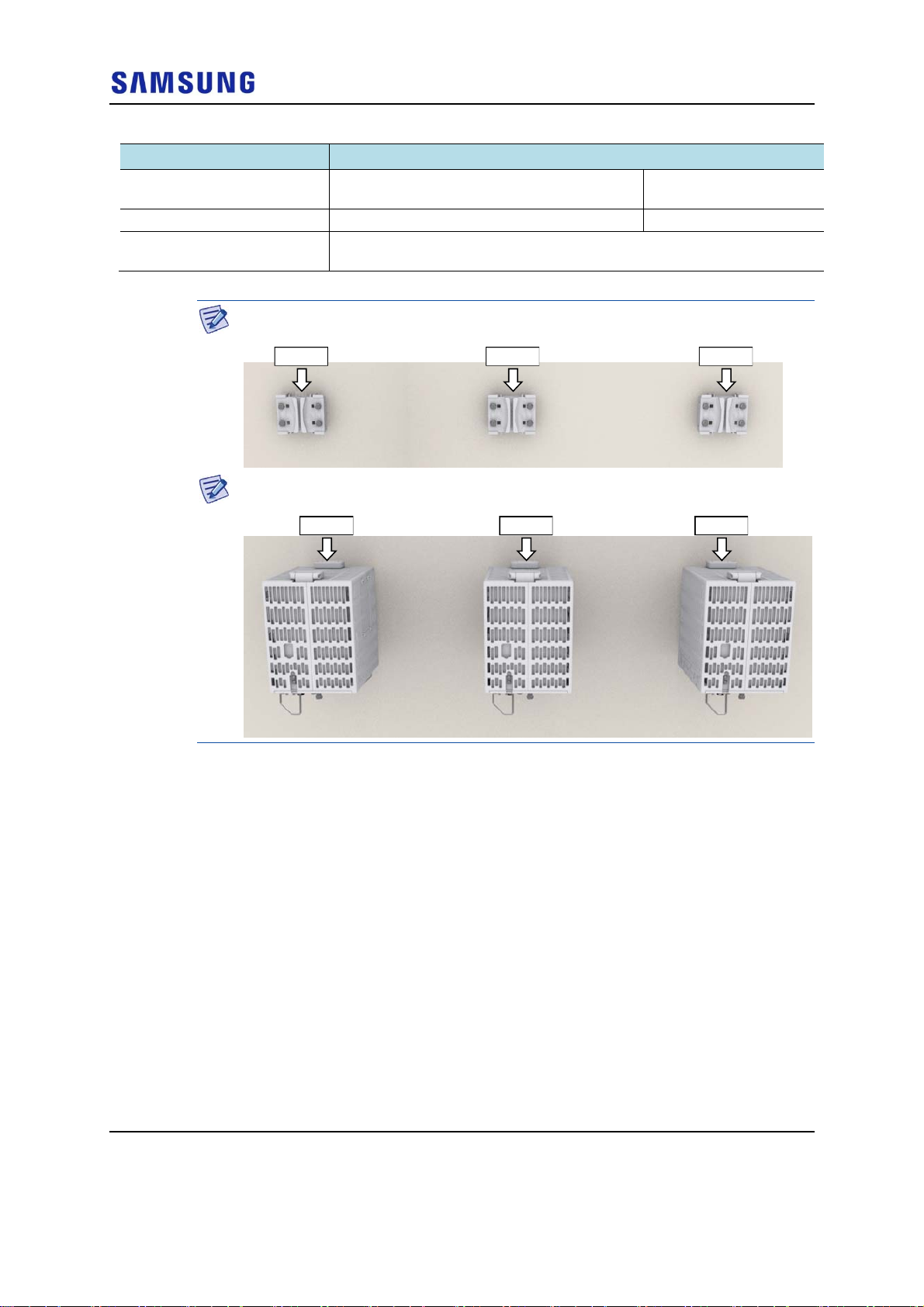

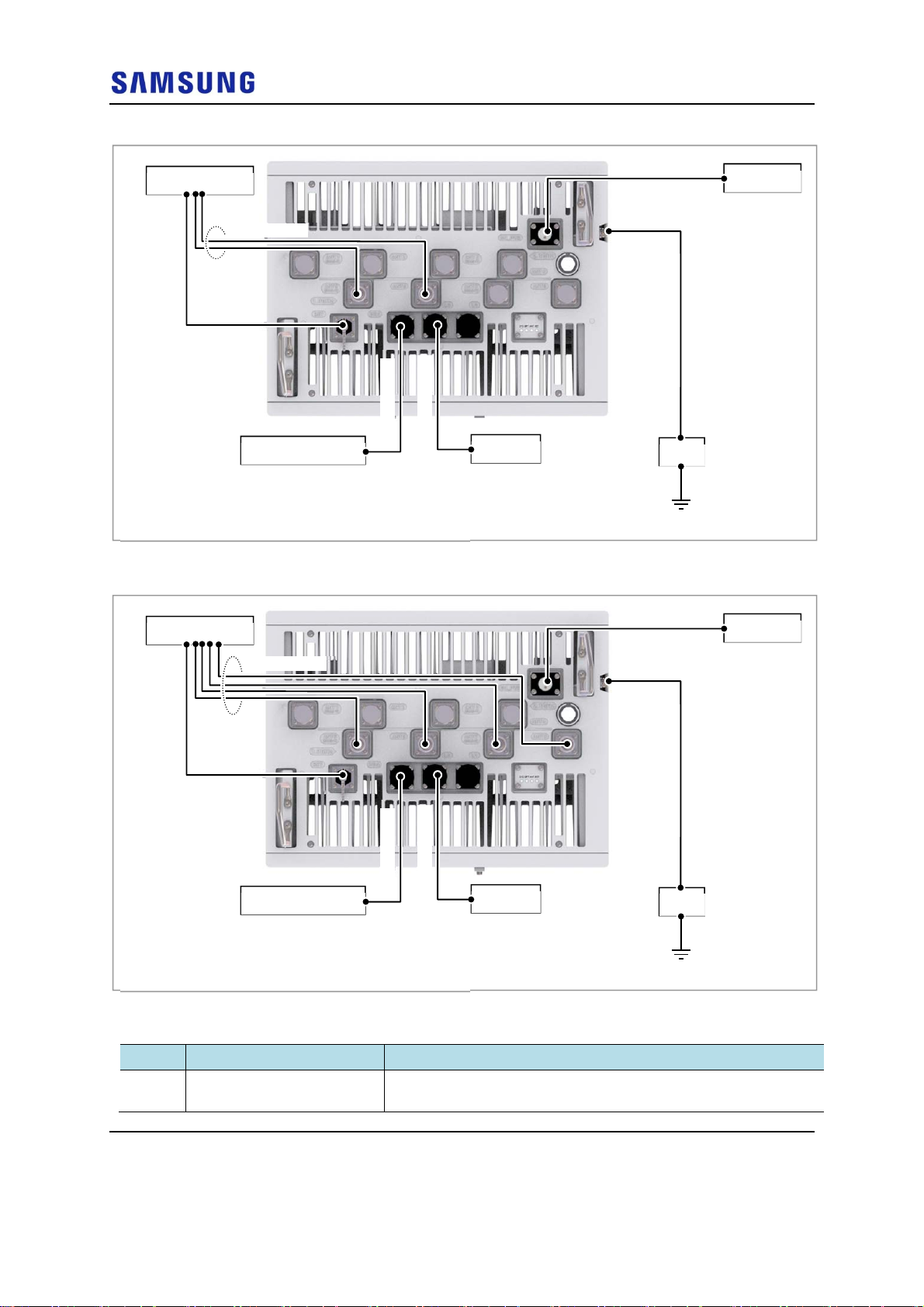

Table 18. Parts and Tools for fixing RRH_3 Sector Wall Type (Side Installation)

Category Description

Parts

Recommended Torque Value M10 Hex. Bolt 217 lbfin (250 kgf·cm)

Working Tools

M10 × 35L Hex. Bolt(washer assembly,

attached to the unit bracket)

Torque Wrench (100~400 lbf·in), Torque Wrench Spanner head (apply Hex.

Head: 17 mm), Spanner (17 mm)

1 EA/RRH

Check the location to install the RRH.

RRH-1RRH-0 RRH-2

Fix the RRH according to the order of [RRH-0 RRH-1 RRH-2].

RRH-1RRH-0 RRH-2

2

Hang the unit bracket hook of RRH-0 side on the mounting bracket_front

hook’s groove and fix it using fasteners.

RFV01U-D1A Installation Manual v2.0 48

Copyright © 2017, All Rights Reserved.

Chapter 2 Installing System

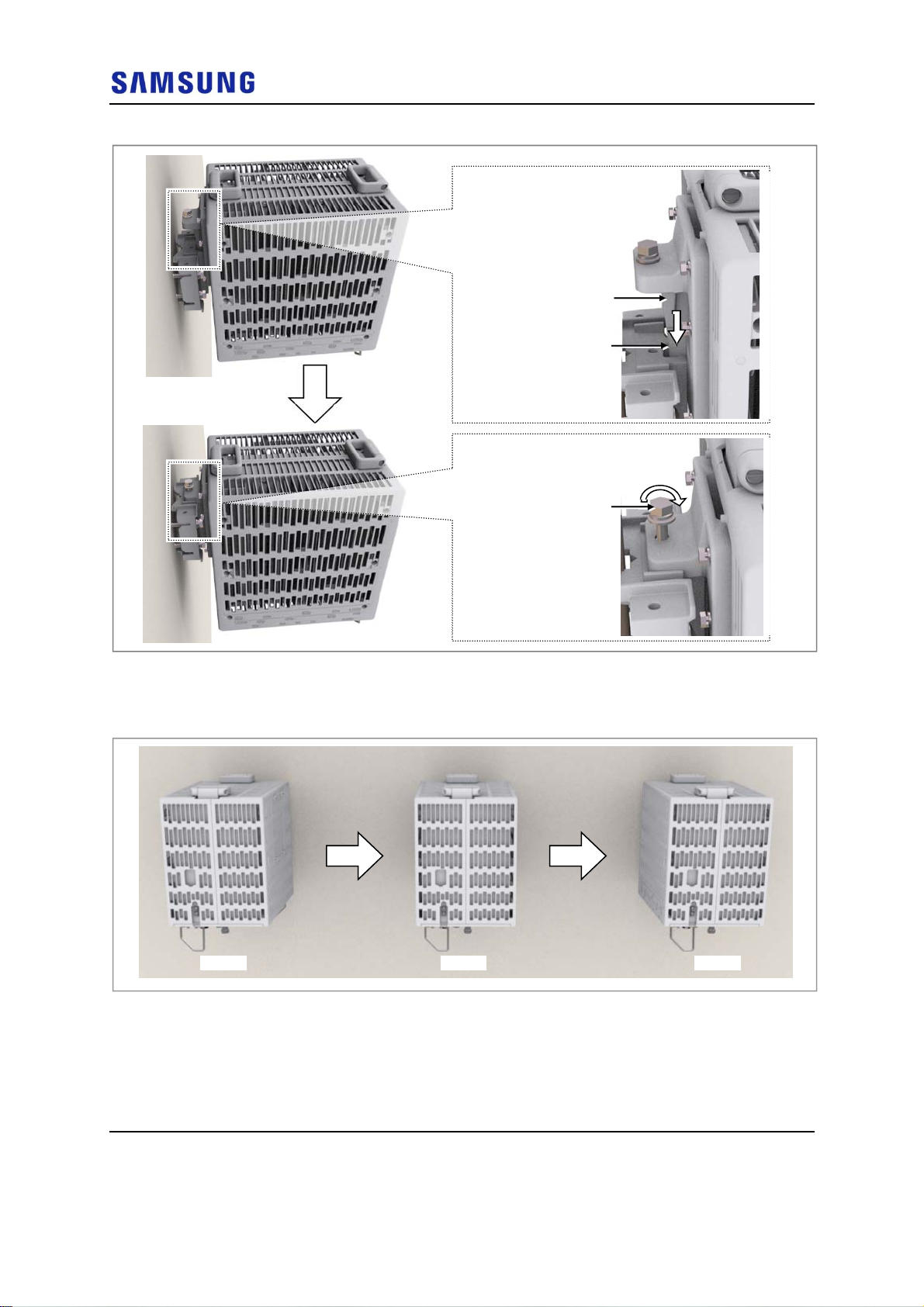

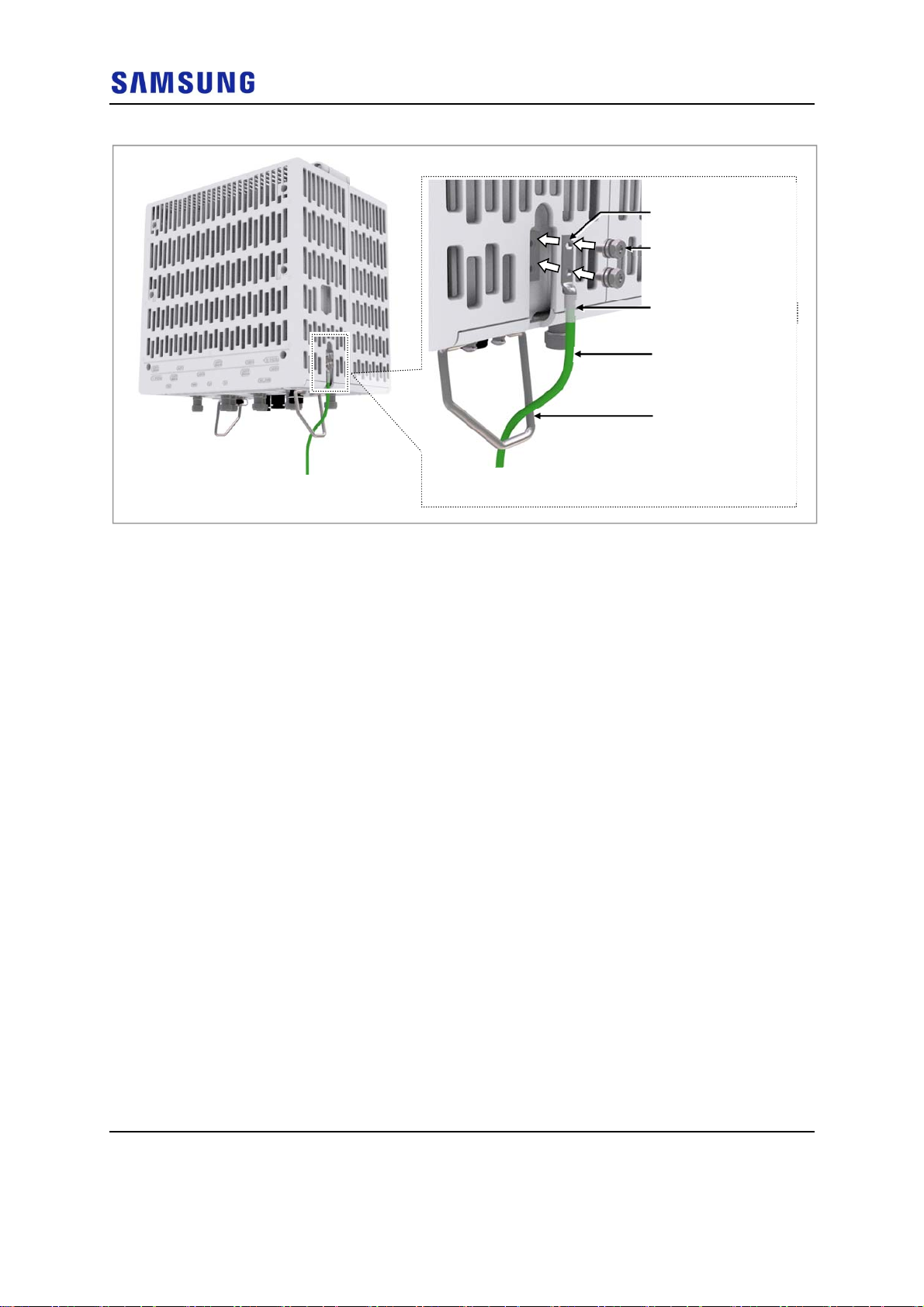

Figure 50. Fixing RRH_3 Sector Wall Type (Side Installation 1)

Unit Bracket Hook

Confidential

Mounting Bracket_Front

(washer assembly)

3

Fix RRH-1 and RRH-2 in the same way as the RRH-0.

Figure 51. Fixing RRH_3 Sector Wall Type (Side Installation 2)

Hook Groove

M10 Hex. Bolt

[RRH-0] [RRH-1]

[RRH-2]

RFV01U-D1A Installation Manual v2.0 49

Copyright © 2017, All Rights Reserved.

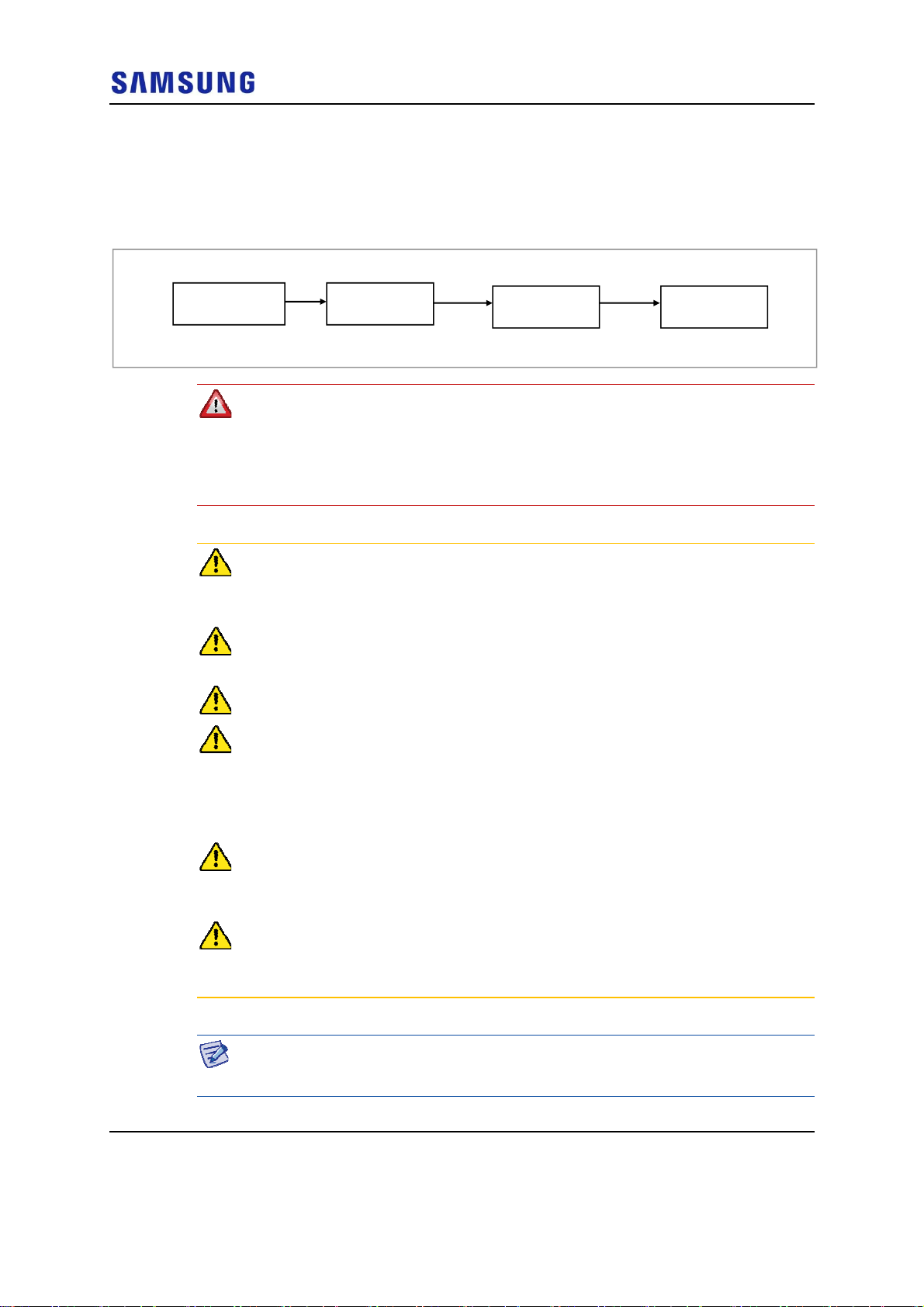

Chapter 3 Connecting

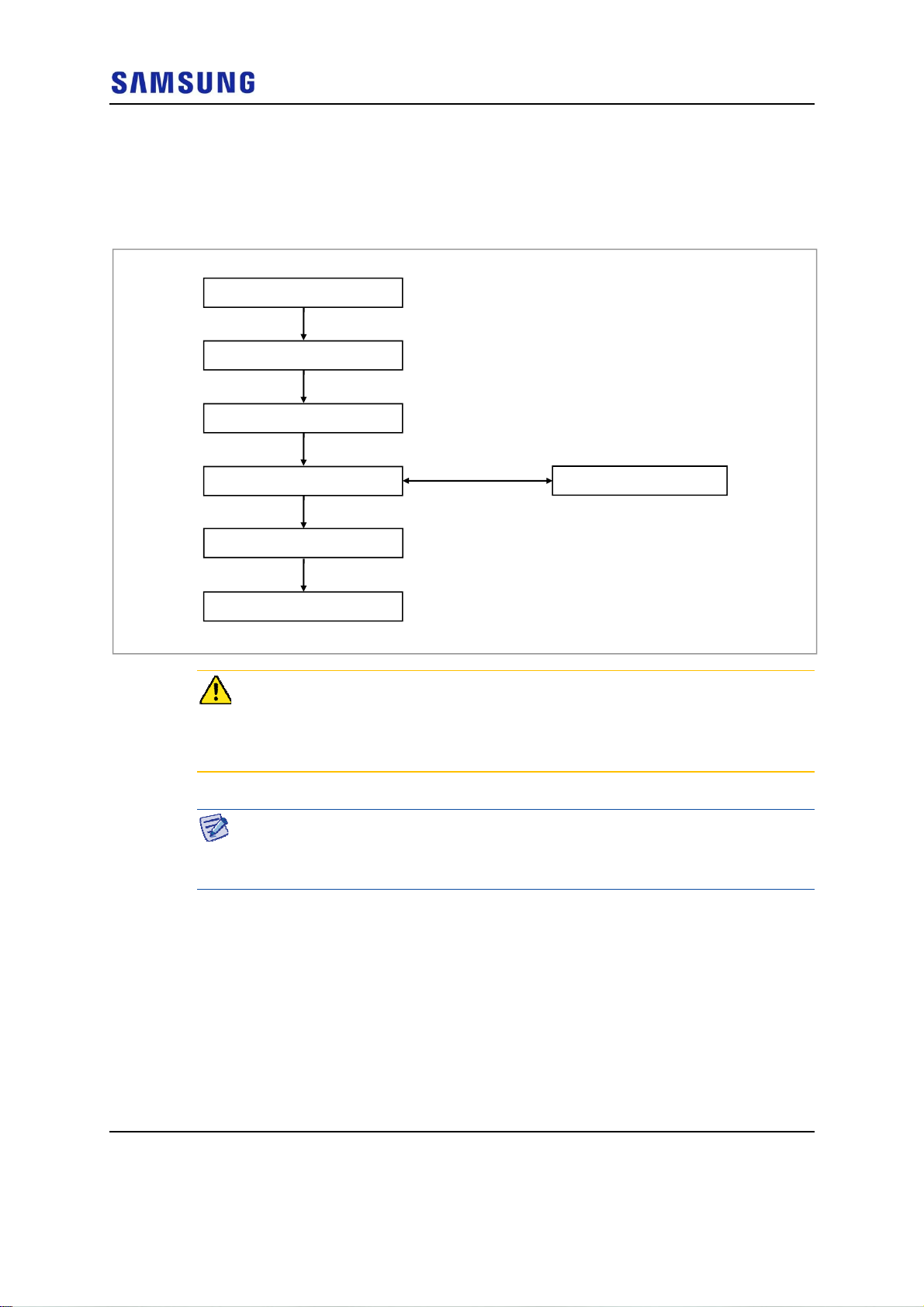

Cabling Procedure

The procedure to connect system cables is as follows:

Figure 52. Procedure to Connect System Cable

Confidential

Cables

Grounding

Power Cabling

External Interface Connection

Ground Cable Connection

Power Cable Connection

CPRI Cable Connection

UDA Cable Connection

RET Cable Connection

RF Cable Connection

RFV01U-D1A Installation Manual v2.0 50

Copyright © 2017, All Rights Reserved.

Chapter 3 Connecting Cables

Guidelines for Cable Connections

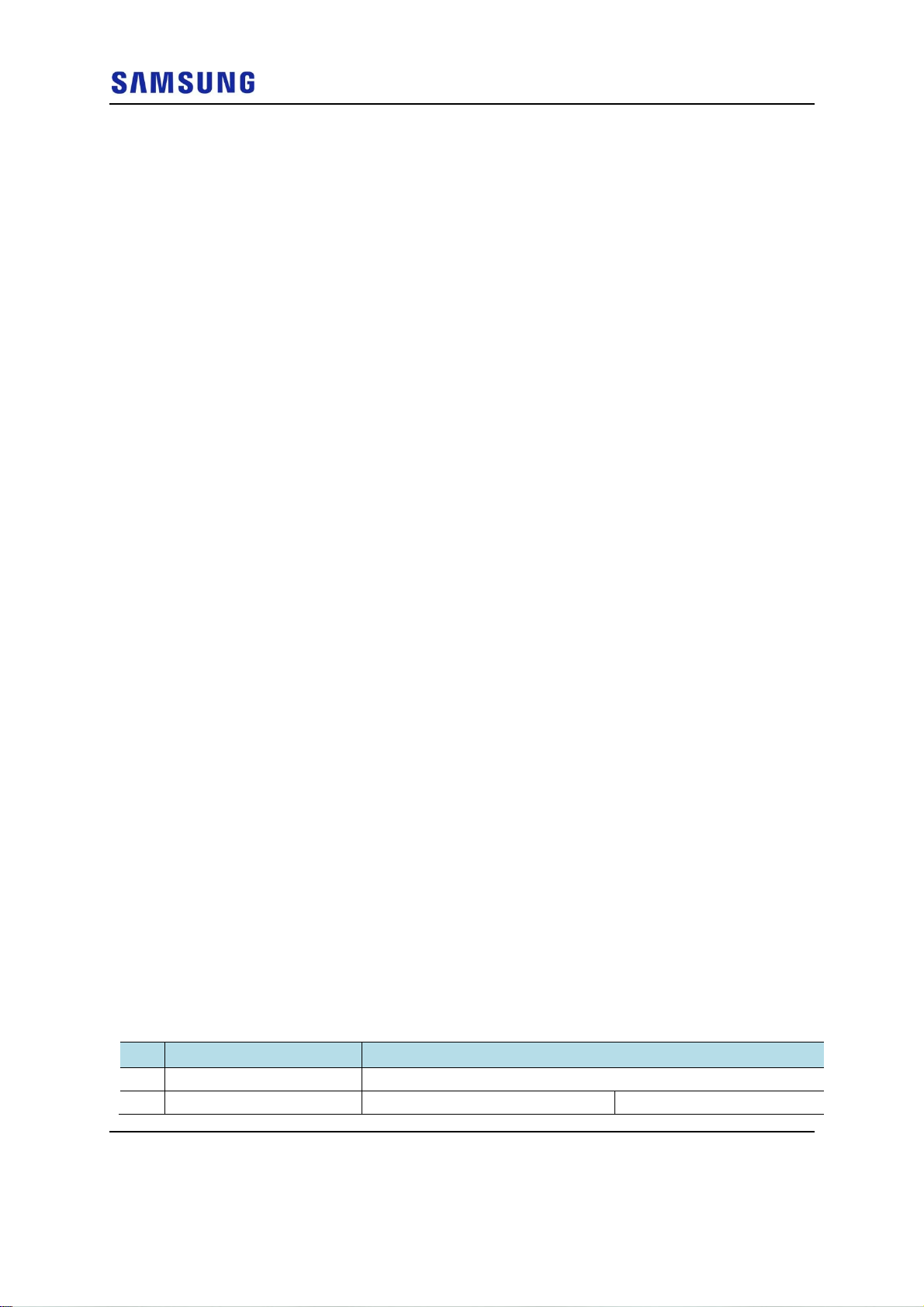

The procedure for cable connections is as follows:

Figure 53. Cable Connection Procedure

Cable Path Inspection

Cable Cutting

Cable Installation

When assembling the

Connector Attachment

connector at the site

Connector Assembly

Confidential

Cable Binding

Identification Tag Attachment

When cutting the cable after installation, make sure that the connector is

disconnected. Installation of the cable with the connector connected to the system

may cause contact failure or damage to the connector assembled to the system and

the cable due to cable tension or the operator’s mistakes.

The sequence of cable cutting and installation of the cable workflow can be

changed depending on the field situation such as ‘cutting after installing’ or

‘installing after cutting’.

Cable Path Inspection

When installing a cable that connects between the rectifier, Main Ground Bar

(MGB), and backhaul device, and so on within the system, the cable path, length

and the cable installation method, and so on must be inspected.

Follow these guidelines when inspecting the cabling path.

A minimum cable length must be selected provided that it does not affect the

cable installation and maintenance.

RFV01U-D1A Installation Manual v2.0 51

Copyright © 2017, All Rights Reserved.

The cable must be placed in a location where it will not be damaged by

In areas where the cable may be damaged by external factors, ensure that

Cable Cutting

Measure the exact distance, carefully checking the route, and cut the cable using a

cutting tool.

Follow these guidelines when cutting the cable.

Cut the cable to the length determined in the Cable Path Inspection step.

Use a dedicated cable cutting tool.

Cut the cable at right angles.

Be careful to keep the cable away from any moisture, iron, lead, dust, or other

Confidential

Chapter 3 Connecting Cables

external factors (power line, flooding, footpaths, and so on).

measures are taken to prevent damage to the cable (cable tray, ducts, flexible

pipe, and so on).

foreign material when cutting.

Remove any foreign material attached to the cable using solvent and a brush.

Cable Installation

Cable installation involves running the cable along the cabling path to the target

connector of the system or an auxiliary device after cable path inspection and cable

cutting have been completed.

Follow these guidelines when installing a cable:

Be careful not to damage the cable.

If the cable is damaged, cut out the damaged section before installing, or

replace the cable.

Run the cable so that it is not tangled. In particular, when installing a cable

from a horizontal section to a vertical section, be careful not to reverse the

upper and lower lines of the cable.

Always use the maximum curvature radius possible, and make sure that the

minimum curvature radius specification is complied with.

If the cable needs to be protected, use for example, a PVC channel, spiral

sleeve, flexible pipe, cable rack, and so on.

Install the DC power cable and data transmission cable away from the AC

power cable to prevent electromagnetic induction.

Table 19. Recommended Minimum Allowed Cable bend Radius

No Type Allowed Cable Bend Radius

1 Ground/Power Cable 8 times of the cable external diameter

2 Optical Cable (indoor) Unloaded Condition (Installed)

RFV01U-D1A Installation Manual v2.0 52

Copyright © 2017, All Rights Reserved.

Loaded Condition (During

Confidential

Chapter 3 Connecting Cables

No Type Allowed Cable Bend Radius

: 20 times of cable external diameter Installation)

: 40 times of cable external

diameter

3 Optical Cable (Outdoor) Unloaded Condition (Installed)

: 10 times of cable external diameter

4 UTP/FTP/S-FTP Cable 4 times of the cable external diameter

5 1/2 in. Feeder Line (Flexible) 4.92 in. (125 mm)

※ If the allowed cable bend radius is specified by the manufacturer, comply with the bend radius specified.

Loaded Condition

(During Installation)

: 20 times of cable external

diameter

Cable Binding

Cable binding involves fixing and arranging an installed cable using binding

thread, cable ties, binding wire, and ram clamps, and so on.

Follow these guidelines when binding a cable.

Be careful not to damage the cable during binding.

Use appropriate cable binding tools according to the target location (indoor or

outdoor, and so on) and the type of the cable (power supply cable, optical

cable, feeder line, and so on).

Do not let the cutting section of a cable tie and binding line, and so on be

exposed to the outside. This may cause damage to cables or personal injury.

Make sure that the cutting sections of cable ties and binding lines, and so on

are not exposed to the outside.

Cut off the remainder of the cable thread by leaving about 50 mm of extra

length to prevent the knot from easily getting untied.

If there is a danger that contact failure may occur in a connector connection

due to tension, bind the cable at the closest location to the connector.

Connector Attachment

Connector attachment involves assembling a connector to an installed cable or to a

device on the site.

Follow these guidelines when attaching a connector.

Make sure operator is fully aware of the connector assembly method before

assembling a connector. Assemble the connector in accordance with its pin

map.

Each connector has a hook to prevent its core positions from being changed.

Check the corresponding grooves before connecting a connector to another

connector.

Use a heat shrink tube at a connector connection for cables that are installed

outdoor, such as feeder lines, to prevent water leakage and corrosion from

RFV01U-D1A Installation Manual v2.0 53

Copyright © 2017, All Rights Reserved.

Chapter 3 Connecting Cables

occurring at the part exposed to the outside.

Connect each cable of the connector assembly in a straight line.

Be careful when connecting a cable so that contact failure does not occur at a

connector connection due to tension.

Identification Tag Attachment

Identification tag attachment involves attaching a marker cable tie, nameplate, and

label, and so on to the both ends of a cable (connections to a connector) to identify

its use and cabling path.

Follow these guidelines when attaching an identification tag.

When installing a cable outdoor, use relief engraving and coated labels, and so

on to prevent the markings from being erased.

Since the form and attachment method for identification tags are different for

each provider, consult with the provider before attaching them.

Confidential

When connecting the cables, always connect the ground cable first. If worker

contacts the equipment, connect a cable or perform maintenance without

connecting the ground cable, the system can be damaged or a worker may be

injured due to static electricity and short circuit.

When performing cable work for the system, proceed with the ground work before

any other work to prevent errors occurring due to static electricity and other

reasons.

After completing cable installation, unused port should be capped.

When installing, take care not to overlap or tangle the cables; also, consider future

expansion. Install the DC power cable and data transmission cable away from the

AC power cable to prevent electromagnetic induction.

Make sure the work is done by personnel properly trained for the cabling job.

RFV01U-D1A Installation Manual v2.0 54

Copyright © 2017, All Rights Reserved.

Chapter 3 Connecting Cables

Cabling Diagram

The cabling diagram of the RRH is as follows:

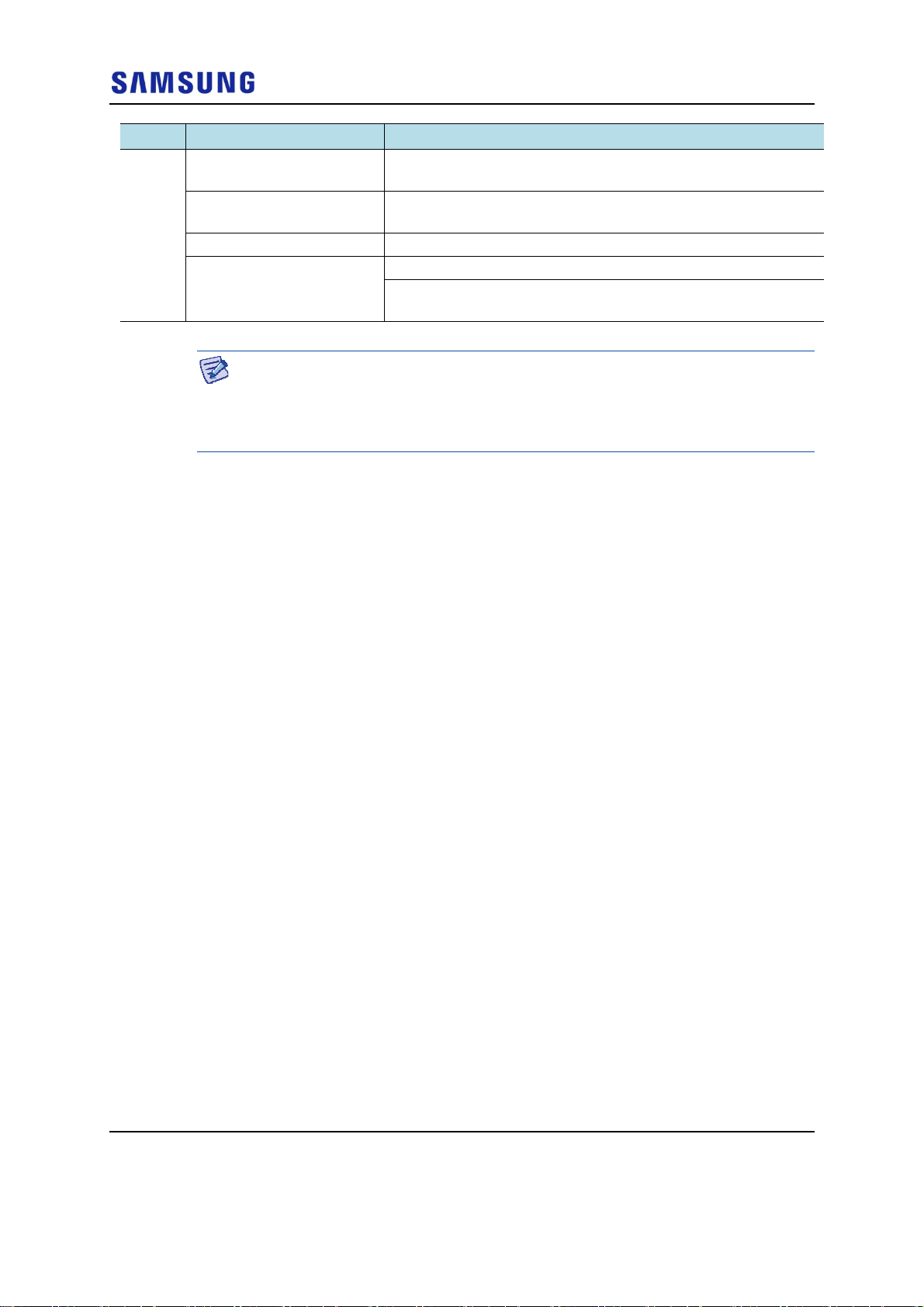

Figure 54. Cable Diagram_2.1 GHz RF Connection: 2T2R

Confidential

RF Antenna

6) RF Cable

5) RET Cable

4) UDA Cable

3) CPRI Cable

External Device

[Bottom View]

* When using the TMA, the RET cables are not connected.

CDU

Figure 55. Cable Diagram_2.1 GHz RF Connection: 2T4R, 4T4R

2) Power Cable

Rectifier

1) Ground Cable

MGB

RF Antenna

6) RF Cable

5) RET Cable

4) UDA Cable

3) CPRI Cable

External Device

[Bottom View]

* When using the TMA, the RET cables are not connected.

CDU

2) Power Cable

1) Ground Cable

MGB

Rectifier

RFV01U-D1A Installation Manual v2.0 55

Copyright © 2017, All Rights Reserved.

Chapter 3 Connecting Cables

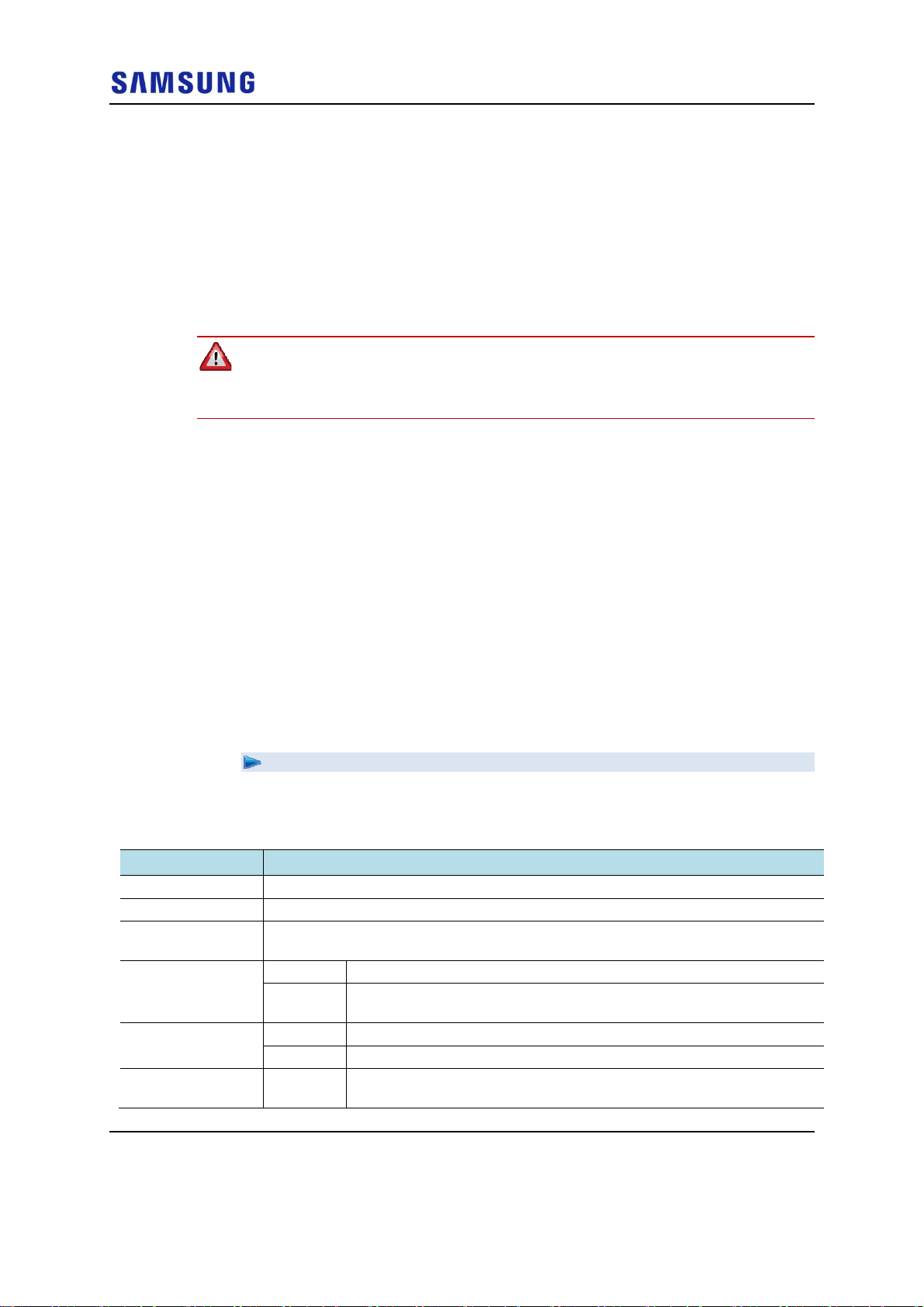

Figure 56. Cable Diagram_1.9 GHz RF Connection: 2T2R

Confidential

RF Antenna

6) RF Cable

5) RET Cable

4) UDA Cable

3) CPRI Cable

External Device

[Bottom View]

* When using the TMA, the RET cables are not connected.

CDU

Figure 57. Cable Diagram_1.9 GHz RF Connection: 2T4R, 4T4R

2) Power Cable

Rectifier

1) Ground Cable

MGB

RF Antenna

6) RF Cable

5) RET Cable

4) UDA Cable

3) CPRI Cable

External Device

[Bottom View]

* When using the TMA, the RET cables are not connected.

Table 20. RRH Connection Cable

From To Cable

MGB RRH 1 Ground Cable

: AWG 8 × 1C

CDU

2) Power Cable

Rectifier

1) Ground Cable

MGB

RFV01U-D1A Installation Manual v2.0 56

Copyright © 2017, All Rights Reserved.

Chapter 3 Connecting Cables

From To Cable

RRH Rectifier 2 Power Cable

: AWG 8 × 2C

CDU 3 CPRI Cable

: Single Mode (Outdoor Type)

External Device 4 UDA Cable Assembly

RF Antenna 5 RET Cable Assembly

6 RF Cable

: 1/2 in. Feeder Line

The inlet hole finishing method of external equipment must be progressed after

consultation with operation company in case of the cable connected to external

equipment. (Optical distribution box, etc)

- The Cable: Power Cable, CPRI Cable, UDA Cable

Confidential

RFV01U-D1A Installation Manual v2.0 57

Copyright © 2017, All Rights Reserved.

Chapter 3 Connecting Cables

Grounding

Grounding is the process of operating an electronic system (for example. power

supplying system, communication system, and control system) stably from a

lightning, transient-current, transient-voltage and electric noise and of preventing

injury from electric shock.

Ground equipment minimizes the electrical potential of the electronic device to

that of the ground, which is zero electrical potential, so that it can prevent the

device from occurring electrification.

Connect the ground cable first. In cabling, the connection of cables without the

connection to the ground cable may cause damage of the equipment or bodily

injury to personnel.

The purposes of the ground construction are as follows:

To prevent human life and the system from over-current, over-voltage, and

Confidential

lightning

To provide a discharge path for surge voltage generated by lightning and

power switch

To protect the system from static electricity

To eliminate or minimize the high-frequency potential in the system housing

To provide a conductor for the balance and stability of high-frequency current

To stabilize the potential of the circuit against the ground

Connecting Ground Cable

To connect Ground Cable

1 Make sure you have the following items:

Table 21. Parts and Tools for connecting Ground Cable

Category Description

Installation Section MGB~RRH Ground Terminal

Cable AWG 8 × 1C

Heat Shrink Tube

(Spec/Color/Length)

Pressure Terminal MGB Checking MGB specifications per site and preparing connecting parts

Fastener MGB Checking MGB specifications per site and preparing connecting parts

Recommended

Torque Value

Ф 0.47 in. (12 mm)/Clear/1.96 in. (50 mm)

RRH

RRH M6 × 12L SEMS (Hex. +)/2 EA

M6 SEMS 43 lbf·in (50 kgf·cm)

AWG 8, 2 Hole, Hole diameter:1/4 in. (6.4 mm), Hole spacing: 0.63 in. (16

mm)

RFV01U-D1A Installation Manual v2.0 58

Copyright © 2017, All Rights Reserved.

Chapter 3 Connecting Cables

Category Description

Working Tools

Cable Cutter, Wire Stripper, Crimping tool, Heating Gun, Nipper, Screw Driver (‘+’, No.

3), Torque Driver (20~90 lbf·in.), Screw Driver Bit (‘+’, No. 3 )

For the pressure terminal or the cable, the UL Listed products or equivalent should

be used.

Ex) Manufacturer-Panduit

RRH: AWG8 Pressure Terminal (LCD8-14A-L)

2 Install a ground cable from the MGB to the RRH ground terminal.

Figure 58. Connecting Ground Cable (1)

Confidential

Ground Cable

[Bottom View]

MGB

3 Assemble a pressure terminal and a heat shrink tube at the end of the RRH

ground cable.

4 Align the pressure terminal to the mounting hole of the RRH ground terminal.

5 Firmly fix the pressure terminal onto the RRH ground terminal using fasteners.

RFV01U-D1A Installation Manual v2.0 59

Copyright © 2017, All Rights Reserved.

Chapter 3 Connecting Cables

Figure 59. Connecting Ground Cable (2)

Confidential

Pressure Terminal

M6 SEMS (Hex. +)

Heat Shrink Tube (Clear)

Ground Cable

Support Bracket

* Install ground cable inside support bracket to have it

bound/installed with power cable

RFV01U-D1A Installation Manual v2.0 60

Copyright © 2017, All Rights Reserved.

Chapter 3 Connecting Cables

A

Power Cabling

The power supply device consists of the following elements:

Figure 60. Power Equipment Elements

Confidential

Commercial

Power

AC Distributor

C DC

Rectifier

System

Since power is applied to the system where the power cable is connected by

manipulating the circuit breaker of the rectifier, be sure to check the rectifier’s

breaker is turned off (open) before connecting the power cable to the power

connector. If the system is installed while the circuit breaker is on, the worker may

be critically injured as soon as the cable is connected in the wrong way.

Handling the power cable incorrectly may damage the rack or cause an electric

short-circuit through the cable. Ensure the power switch on the rectifier or the

system is turned off before handling the power.

The fasteners for power cable must be tightly secured to prevent electrical

accidents.

The heat-resistant temperature of the power cable should be 90°C or more.

Install the power cable to the power port of the system by considering the radius of

curvature of its cable specification and then cut the cable. If operator installs the

cable after cutting, there may be length difference among the core wires at the end

of the cable because of cable curvature. This may result in poor contact after the

cable is connected to the power port.

When using the same DC power source with a device for outdoor, discuss with a

installation engineer of manufacturer to protect a CDU from a residual surge

energy.

When using a DC power cable, it is possible to use up to 30 m for AWG 8.

However, the distance is under the condition that the cable is installed normally.

When the condition changes, the distance changes.

Install a circuit breaker to a rectifier (or power distributor) for the stable power.

The capacity of circuit breaker is 40 A. (Use UL Listed circuit breakers.)

RFV01U-D1A Installation Manual v2.0 61

Copyright © 2017, All Rights Reserved.

Loading...

Loading...